HARNESSING HEAT

THIS OE FIX™ IS THE ONLY REAL FIX.

The oil filter adapter on millions of Chrysler, Dodge, Jeep and Ram V6-powered vehicles often leaks oil when its plastic housing warps from harsh underhood conditions. As the plastic eventually degrades from heat and chemical exposure, it can even crack from simply tightening the oil filter cap during oil changes. When it fails, replacing it with an OEM housing could mean the same issues again in the future.

This patented Dorman OE FIX filter housing is made entirely of aluminum for a more durable replacement of the failure-prone OEM housing to help prevent future leaks. The housing comes complete with mounting and intake manifold gaskets for an effective repair. The kit also includes the oil cooler, oil filter element, and oil filter cap to update the vehicle to the latest design.

Patented design - features high-pressure, die-cast aluminum housing construction to more reliably replace the failure-prone plastic housing on specific 2011 and later Chrysler, Dodge, Jeep and Ram vehicles with Pentastar engines

Smarter solution - includes required gaskets, oil cooler, oil filter element and cap, bringing early fitments to latest generation filter specification; see included instructions on filter cap

Trustworthy quality - engineered in the United States and made with durable materials to precise specifications, including premium seals to further help resist future leaks

STARTERS

04 Online Extras

Straight Talk

10 Learning With the Training Wheels On

Stepping outside of the comfort zone is uncomfortable for most technicians, especially with driveability. But doing so gradually softens the blow and boosts confidence and efficiency.

Brandon Steckler

16 Cracking the Code on Catalyst Efficiency

Understanding switch ratio vs. oxygen storage capacity

Erik Screeden

22 Proper Main and Rod Bearing Oil Clearance

It’s a critical aspect to engine assembly

Mike Mavrigian

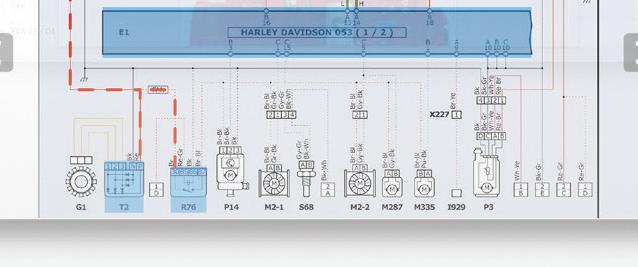

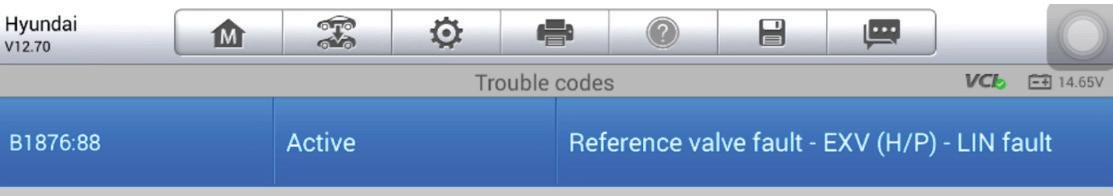

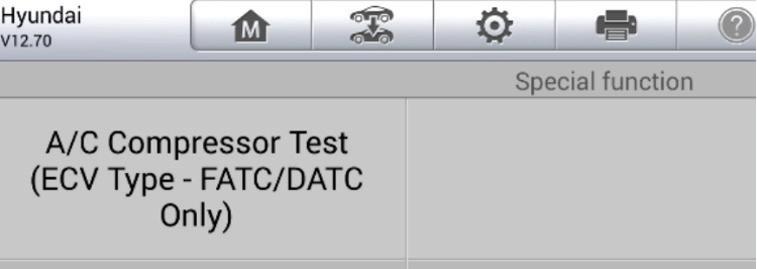

32 Harnessing Heat

Understanding heat pump systems in EVs and hybrids

Jeff Taylor

43 The Bigger Picture

When you can’t see the forest for trees, you tend to miss a lot. My advice? Take a step back and see the bigger picture.

Brandon Steckler

46 Looking Back on 25 Years of EV Technology

The future is getting here quickly, and for many, EVs are a practical alternative to ICE-powered vehicles.

Craig Van Batenburg

66 The Trainer #163

Variable Reluctance Sensors

Brandon Steckler

for any loss or damage caused by errors or omissions in the material herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever. The views and opinions in the articles herein are not to be taken as official expressions of the publishers, unless so stated. The publishers do not warrant either expressly or by implication, the factual accuracy of the articles herein, nor do they so warrant any views or opinions by the authors of said articles.

Endeavor Business Media provides certain customer contact data (such as customers’ names, addresses, phone numbers, and e-mail addresses) to third parties who wish to promote relevant products, services, and other opportunities that may be of interest to you. If you do not want Endeavor Business Media to make your contact information available to third parties for marketing purposes, simply call toll-free 877382-9187 or email MotorAge@omeda.com and a customer service representative will assist you in removing your name from Endeavor Business Media’s lists. Motor Age does not verify any claims or other information appearing in any of the advertisements contained in the publication, and cannot take responsibility for any losses or other damages incurred by readers in reliance of such content. While every precaution is taken to ensure the accuracy of the ad index, its correctness cannot be guaranteed, and the publisher waives all responsibility for errors and omissions

ONLINE

TALK SHOP. ANYTIME.

150,000 AND COUNTING

The Motor Age YouTube channel hit a milestone in July by crossing the threshold of 150,000 subscribers. With nearly 800 videos and more than 16.6 million views, we think these subscribers are on to something! Don’t miss the handson, visual guidance our technical team has been providing to online viewers for the past 15 years. Go to the Motor Age YouTube channel and click that subscribe button!

TAKE OUR QUIZ

Did you know that in addition to reading and watching Motor Age’s technical content, you can also take a stab at solving some of the diagnostic mysteries our writers encounter? Each month when Technical Editor Brandon Steckler presents his Data Doesn’t Lie case study, you can now answer the final diagnostic question online. Look for the quiz at the bottom of those stories, and look for more quizzes to come.

EDITORIAL

GROUP EDITORIAL DIRECTOR

Chris Jones / christopherj@endeavorb2b.com

EDITOR

Mike Mavrigian / mmavrigian@endeavorb2b.com

MANAGING EDITOR

Joy Kopcha / jkopcha@endeavorb2b.com

TECHNICAL AND MULTIMEDIA CONTENT DIRECTOR

Erik Screeden / escreeden@endeavorb2b.com

TECHNICAL EDITOR

Brandon Steckler / bsteckler@endeavorb2b.com

ASSOCIATE EDITOR

Madison (Gehring) Hartline / mgehring@endeavorb2b.com

CONTRIBUTING WRITERS

Jeff Taylor, Craig Van Batenburg

ART AND PRODUCTION

ART DIRECTOR

Emme Osmonson

PRODUCTION MANAGER

Mariah Straub

AD SERVICES MANAGER

Karen Runion

SALES

ASSOCIATE SALES DIRECTOR

Mattie Gorman-Greuel / mgorman@endeavorb2b.com

DIRECTOR OF BUSINESS DEVELOPMENT

Cortni Jones / cjones@endeavorb2b.com

ACCOUNT EXECUTIVES

Kyle Shaw / kshaw@endeavorb2b.com

Marianne Dyal / mdyal@endeavorb2b.com

Annette Planey / aplaney@endeavorb2b.com

Darrell Bruggink / dbruggink@endeavorb2b.com

Sean Thornton / sthornton@endeavorb2b.com

Diane Braden / dbraden@endeavorb2b.com

Lisa Mend / lmend@endeavorb2b.com

Chad Hjellming / chjellming@endeavorb2b.com

ENDEAVOR BUSINESS MEDIA, LLC

CEO Chris Ferrell

COO

Patrick Rains

CRO

Paul Andrews

CDO

Jacquie Niemiec

CALO

Tracy Kane

CMO

Amanda Landsaw

EVP VEHICLE SERVICE/REPAIR GROUP

AND FLEET AND TRAILER GROUP

Chris Messer

BUSINESS STAFF

PUBLISHER

Andrew Johnson

BUSINESS DEVELOPMENT DIRECTOR, MOTOR AGE TRAINING

Michael Willins

CUSTOMER MARKETING MANAGER

Leslie Brown

AUDIENCE DEVELOPMENT MANAGER

Tracy Skallman

SALES COORDINATOR

Jillene Williams

HOW TO REACH US

ENDEAVOR BUSINESS MEDIA LLC.

30 Burton Hills Blvd, Ste. 185, Nashville, TN 37215

Phone: 800-547-7377

CUSTOMER SERVICE

Subscription Customer Service 877-382-9187; 847-559-7598

SUBSCRIBE

MotorAge@omeda.com PO Box 3257 Northbrook, IL 60065-3257

REPRINT SERVICES reprints@endeavorb2b.com

MEMBER OF:

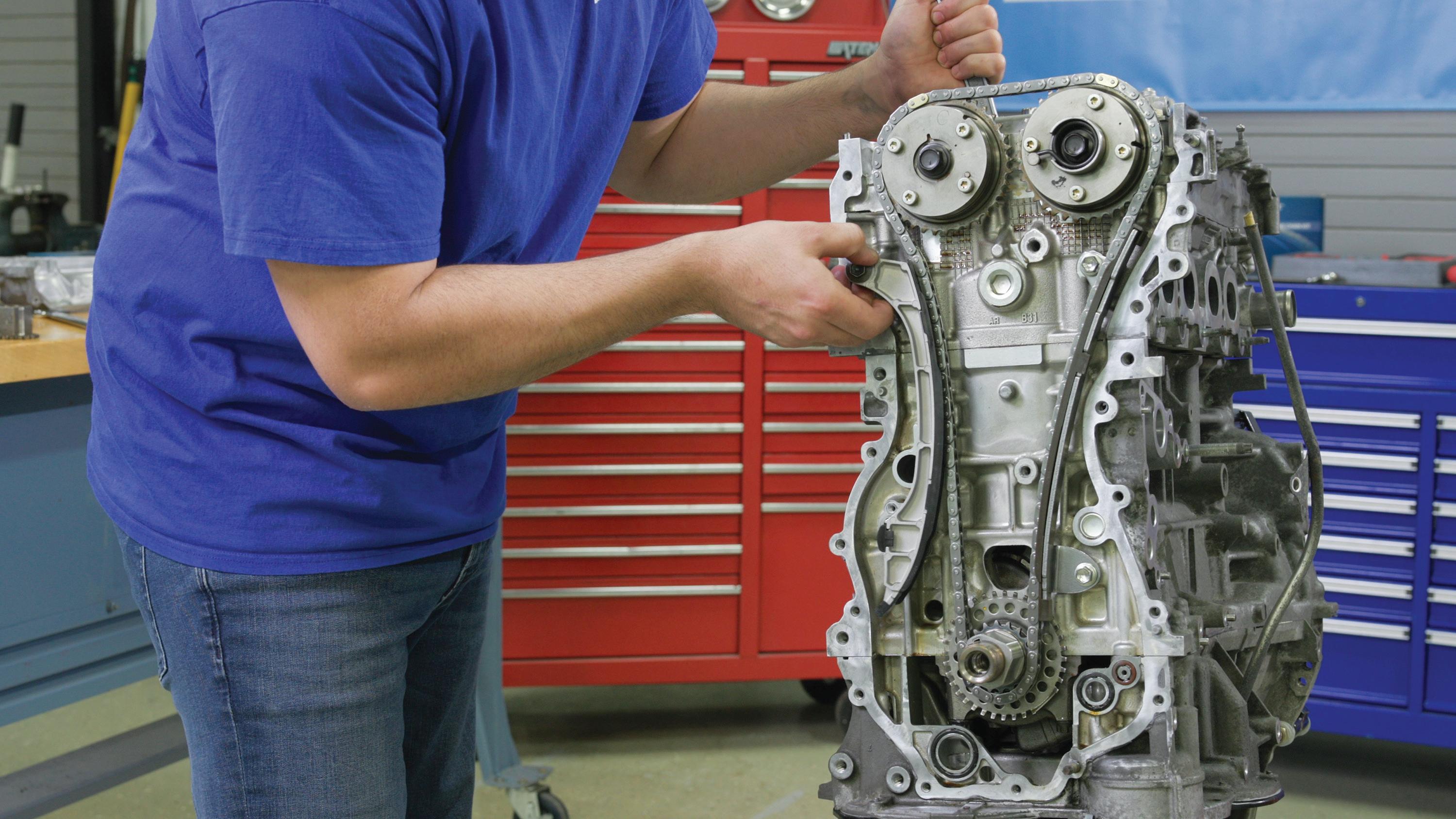

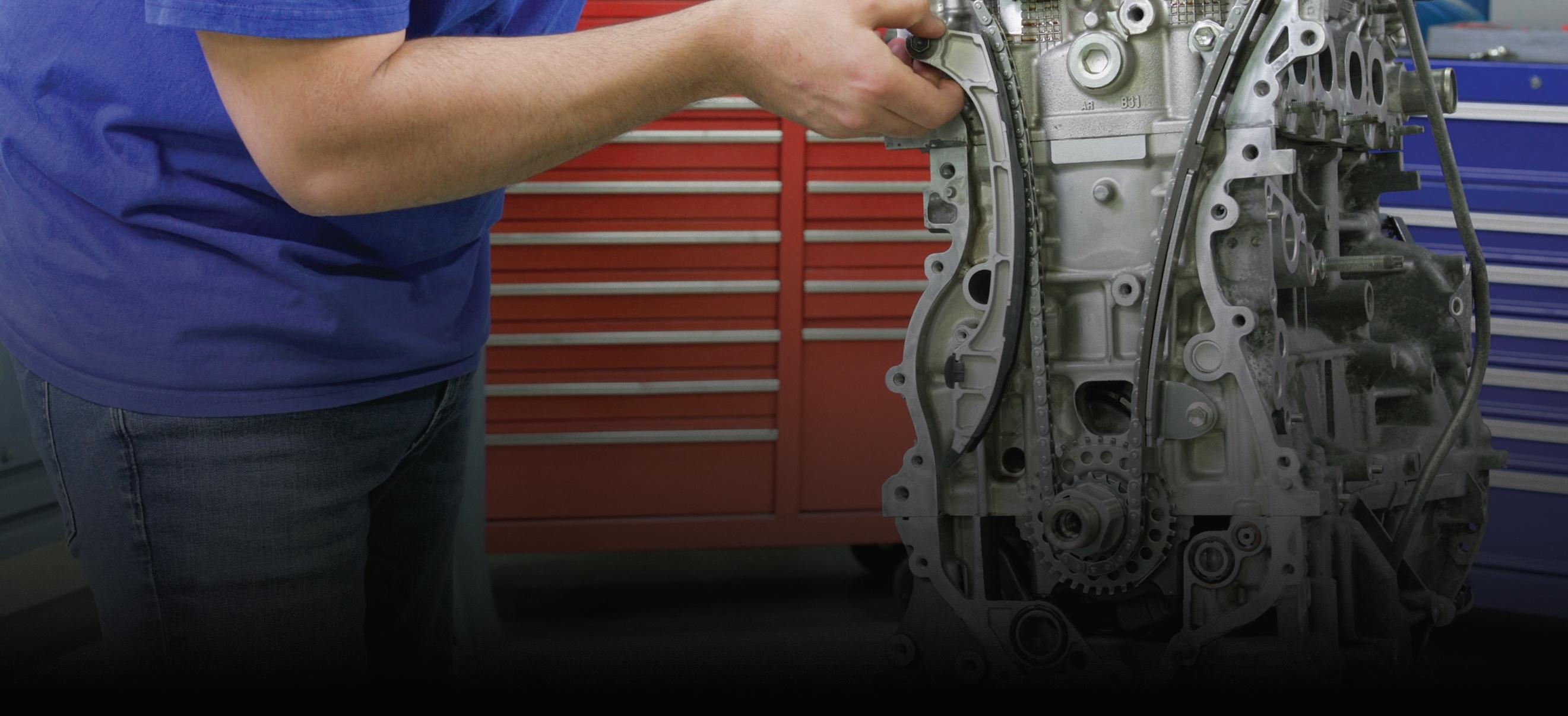

Engine Replacement

What approach is best?

IF A CUSTOMER’S ENGINE has seen better days and needs to be rebuilt or replaced, you have several options. Which option is best? That depends largely on availability and cost. Depending on current engine condition and year/make/model, choices may include rebuilding the engine inhouse, having the engine rebuilt by a local engine machine shop, buying a reclaimed (i.e. salvage yard) engine, buying a new replacement engine from the automaker or buying a remanufactured engine from an independent remanufacturer.

Depending on the specific engine and its current condition, you may opt to perform a rebuild in-house. Of course, this depends on having a tech who is comfortable with this task. In addition, once the engine is torn down, it’s important to verify the condition of key components — block, crankshaft, connecting rods, cylinder heads. This may dictate the need for block deck resurfacing, cylinder over-boring/ honing, cylinder head reconditioning, condition of crankshaft main and rod journals, condition of the connecting rods, etc.

If machine work is needed, since your shop may not be equipped with the necessary equipment, you may need to farm this work out to a local engine shop. Once all machine work has been done, one of your techs may/should be able to reassemble and install the crank, bearings, pistons and rods, cam(s), heads, timing system, oil pump, intake manifold, etc. This approach will take some time, especially considering the local engine machine shop’s lead time. If the customer is comfortable with a potentially long timeframe (which could easily involve as much as a month or so, depending on various factors), this may be a viable option.

Another option is to turn the engine over to a local engine shop and let them handle the entire task (engine disassembly,

cleaning, inspection, reconditioning, and assembly). Once the engine is done, your shop performs the installation to the vehicle. Again, this can result in a lengthy time period, as most of today’s quality engine machine shops/engine builders seem to be slammed with work, so don’t be surprised if you face a lengthy delay.

Buying a used engine from a salvage yard is sometimes viable but this comes with a degree of risk. Depending on circumstance, maybe all you really need is a good shortblock, if you plan to re-use the existing heads, intake, water pump, etc. Or maybe you need a longblock (shortblock with heads). In either case, the condition of the engine is obviously critical. You certainly don’t want to waste your customer’s money and your reputation by installing an engine that is plagued with problems. Low-mileage used engines may seem attractive at first glance, but this is dependent on how the engine was maintained by the previous owner (maybe they never changed the oil). Unless you can obtain a limited “warranty” from the salvage yard as to the engine condition, it’s up to you to pull the heads and the oil pan to perform a cursory inspection. Costwise, buying a salvage engine may be the most attractive price option in the eyes of the vehicle owner, but it’s up to you to make sure that the used engine will be reliable. Depending on the year of the vehicle, a fresh shortblock or longblock may be available from a local automaker’s dealership. This may, again, depending on the automaker, involve a brand new engine or a factory rebuilt engine. I hate to keep using the phrase “depending on,” but there are variables. A “new” engine (short or long block) will likely be a tad on the expensive side, but depending on stock availability, you may be able to obtain the engine in a matter of a few days. A factory reman engine should include a reasonable warranty.

An option to consider is to purchase a remanufactured engine from a reputable engine remanufacturer. Notice that we’re not referring to “rebuilt,” which might involve only a cleanup and replacing a few parts and/or minimal machining. A quality remanufactured engine will provide a product that has been 100% inspected and reconditioned, correcting any issues that retired the original core. As long as an established and reputable remanufacturer does the work, the final product may actually be better than when the engine was when newly made, as any slightly out-of-tolerance issues will likely be corrected. A quality remanufacturer usually provides a limited warranty — maybe one year and 10,000 miles. (This is only an example.)

When a customer has an issue that can’t be solved by parts replacement alone and requires a freshening-up or total replacement, you have choices. No engine replacement will be cheap, but in addition to cost, the vehicle downtime is a major consideration. Obtaining a ready-to-go reman engine is often the best bet.

MIKE MAVRIGIAN MOTOR AGE // EDITOR mmavrigian@endeavorb2b.com

F-150 No Crank

Beware that some 2021-2023 Ford F-150 vehicles may exhibit a no-crank/ no-start condition accompanied by excess battery draw and the A/C clutch engaged at all times. This may be due to an open diode in the A/C clutch field coil, damaging the output driver (field effect transistor/FET) in the body control module (BCM).

Install a battery charger and fully charge the 12V battery. Turn the ignition off, exit the vehicle and shut all doors to allow the vehicle to go into sleep mode for about 15 minutes. Then check for voltage on circuit CH401 (VTWH wires) pin 1 at the A/C compressor clutch connector C100. If voltage is present, disconnect the battery and replace both the BCM and the A/C clutch field coil assembly.

Loud Bang

When Braking

If the owner of a pickup truck complains of a loud bang when stabbing the brakes hard, before you delve into inspecting the chassis or the ABS, check to see if the under-bed spare tire/wheel assembly is properly tightened down. A loose spare may be causing the sudden, loud “bang” noise that at first appears to be coming from the rear axle.

Kill the Stink

An easy way to remove unwanted odors from vehicle interiors is with the use of a portable ozone machine. Ozone is a naturally occurring gas in the atmosphere. These plug-in household-current units generate ozone gas (O3) to eliminate odors and help sanitize the interior, eliminating odors caused by smoke, mold, and other smells. Ozone generation purifies the air and surfaces of the interior without causing any harm to metals, plastics, leather, or fabrics. Place the unit in a

central location as high as practical (on the dash, on a center armrest, etc.) Roll all windows up, leaving one window down about two inches or so. (This provides a bit of air exchange as well as a path for the unit’s power cord.) Allow the unit to run for a required time, perhaps 30 minutes. If the unwanted odor remains, perform a second operation. Note: after running the ozone generator, you may notice a slight “copper/ metallic” taste in the air. This is normal and will subside quickly.

EXAMPLE OF AN OZONE generator in a vehicle interior.

EXAMPLE

Fill the Filter

This is basic information but is sometimes ignored. When performing an engine oil change, always pre-fill the oil filter before installing. Of course, this is dependent on the application. If the filter is installed horizontally or upside-down, this will not be practical, as you’ll spill much of the oil during filter installation. The goal is to add oil to the new filter whenever possible. This allows a faster and more efficient delivery of oil to the bearings. Granted, it will likely take only a few seconds for the system to fully charge, but pre-filling the new filter provides a bit of added protection. Also, before disposing of the old filter, if time permits, it’s a good idea to cut the old filter apart and examine the filter pleats for debris, which will provide an indication of bearing wear/damage. Granted, pre-oiling the filter is not absolutely necessary. After draining oil from the sump, a film of oil remains clinging to vital components such as main and rod bearings. Regardless, pre-filling the new filter remains a good idea. It might not be a deal breaker, but it can’t hurt.

Don’t Hand

Grind the Decks

Before installing original cylinder heads onto the original engine block, it should be obvious that both deck surfaces must be thoroughly clean. However, don’t be tempted to use a handheld grinder or drill equipped with an abrasive disc. This can easily ruin the Ra finish that is so crucial for proper head gasket sealing, and performing the task using a hand-held power tool can also easily create surface waviness that will hinder or ruin the gasket’s ability to seal. Also, avoid using Scotchbrite pads or discs on an assembled short block, as the microfibers that are released can contaminate the oiling system. Using a fast-evaporating solvent and a plastic scraper is a much safer plan.

Learning With the Training Wheels On

Stepping outside of the comfort zone is uncomfortable for most technicians, especially with driveability. But doing so gradually softens the blow and boosts confidence and efficiency.

BY BRANDON STECKLER // Technical Editor

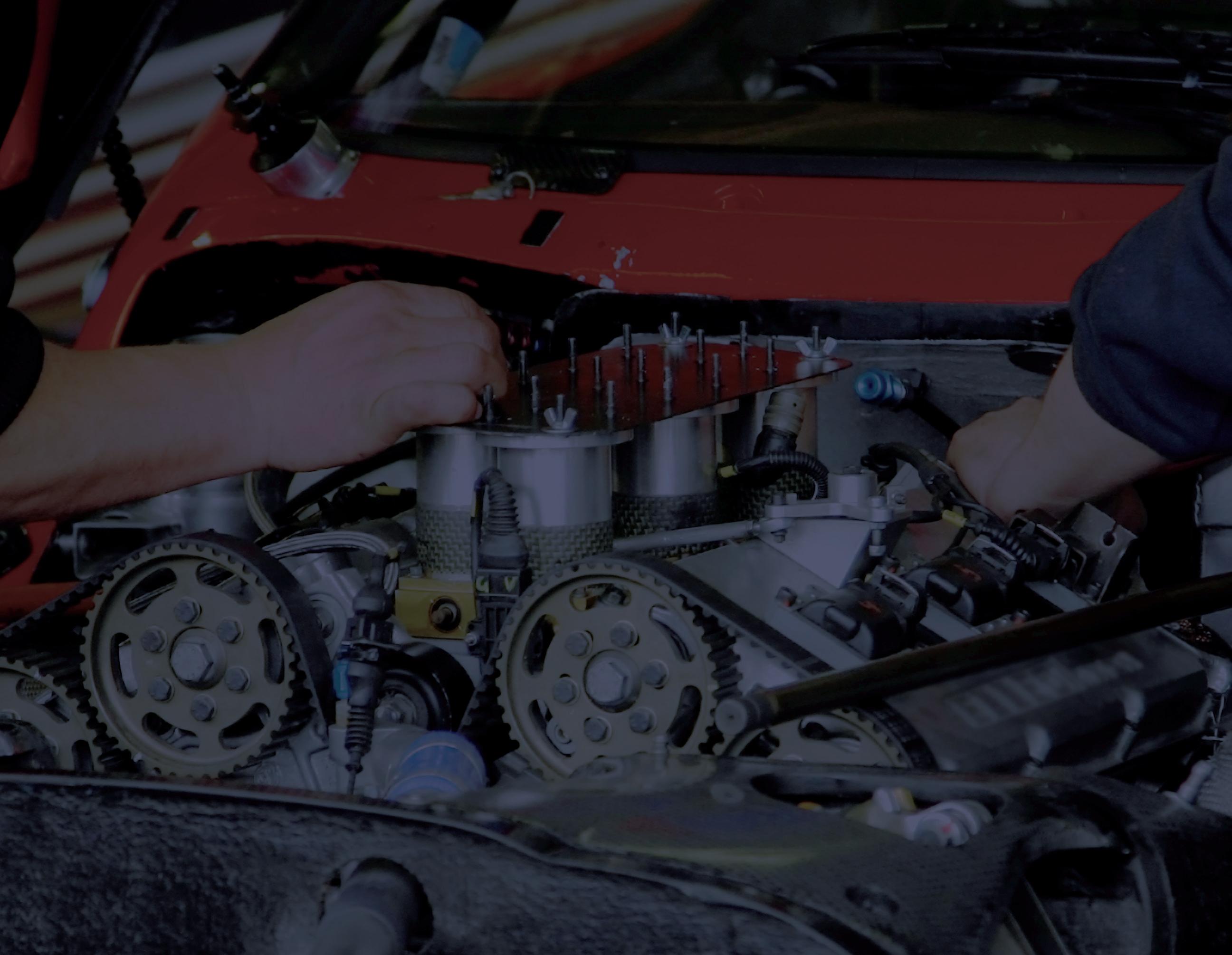

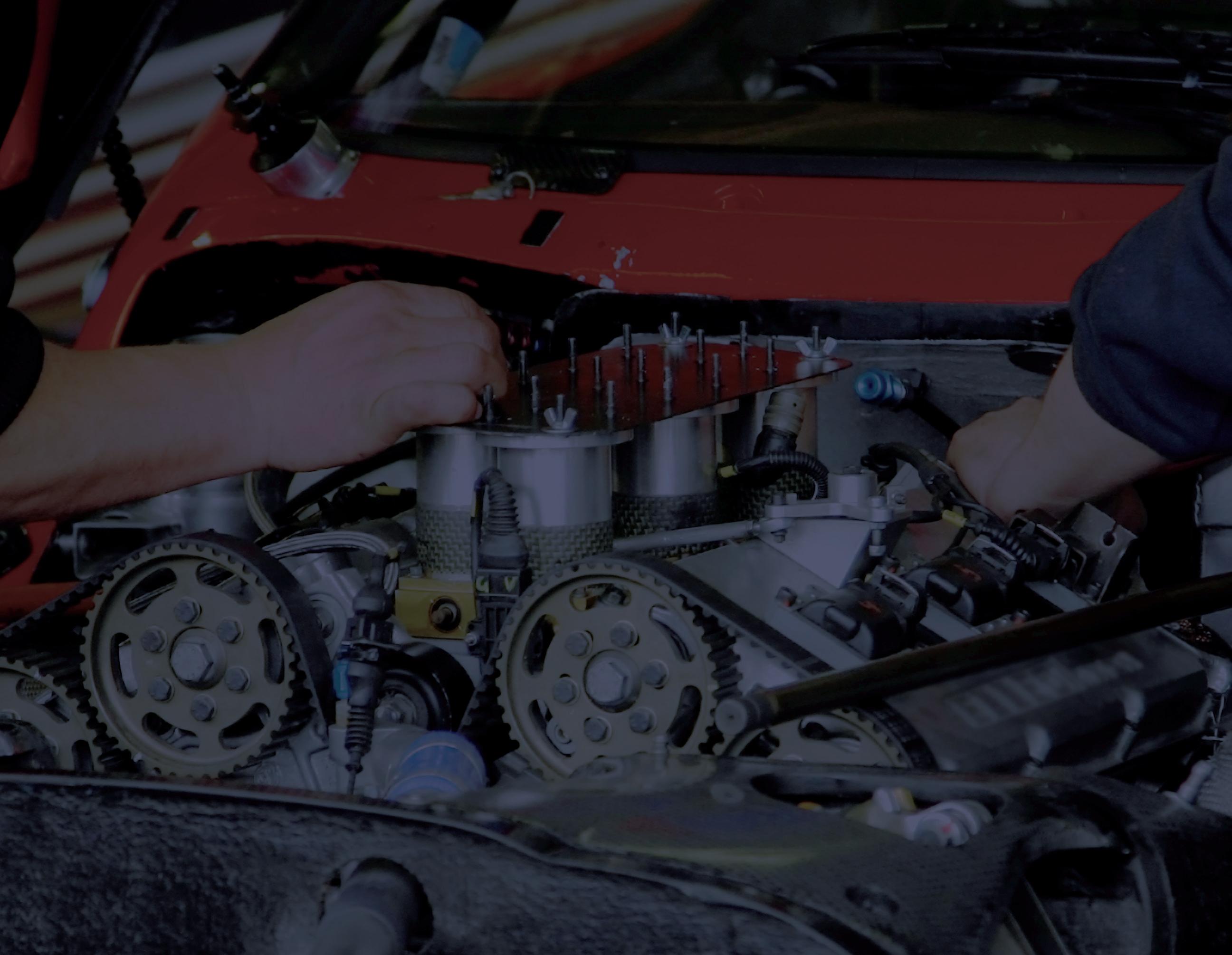

LIKE MANY OF YOU, I began my path towards being a driveability technician learning basic tests that have been around for decades. These tests worked well but the issue I find with these triedand-true tests is that they are becoming

more and more difficult to implement with today’s powertrain configurations. For example, look under the hood of nearly any vehicle using an internal combustion engine and simply imagine removing the spark plugs to perform a

compression test. You’d be hard-pressed to complete that task easily, or in an efficient manner (Figure 1). Component accessibility is not as it used to be and with that, if you want to stay on the forefront of efficiency, your diagnostic tools and testing strategies must adapt as well. The question becomes, “What are you waiting for?”

Engine Failures Like Never Before

But I know what many of you are thinking. And the answer to the question above is typically derived from two different camps.

• “I don’t need that new stuff; my compression gauge hasn’t let me down in 30 years.”

• “I’m not sure how to use those fancy tools. I’m just not good with that sort of stuff.”

Well, I have a valid answer to both because I can speak from experience with each! Let me first state that engines are not nearly as robust as they once were. Sometimes the slightest overheating condition can wreak havoc on an engine — so much so that the entire assembly requires replacement. And the reason makes total sense.

With stringencies of today’s emissions standards on the rise, manufacturers have been forced to drastically increase fuel economy and engine performance output, but at the same time must reduce tailpipe emissions. (This includes carbon dioxide production, typically viewed as an indicator gas for efficiency, a desirable gas; it’s now viewed as a greenhouse gas that contributes to global warming.)

The real kicker is all of this must be derived from smaller power plants. This is the reason we’ve seen many vehicles typically equipped with 8-cylinder platforms drop two of the cylinders.

With all the performance technologies combined this is possible but it requires the engines to be pushed to the brink of destruction. Manufactur-

ers extract every bit of power output from them as possible. At the same time, these engines have become very sensitive, and as a result I have seen more engine-mechanical failures in the last five years than I have in the previous 23 years combined!

So why did I get away from traditional testing, like the mechanical gauge compression test? For one, as mentioned above, accessibility is becoming more of a premium. But more to the point, the compression test only shows a cylinder’s ability to harness and squeeze what’s inside it.

I mention this point because most of the engine failures I see today are with the valvetrain. A simple collapsed intake valve lifter or one that was wiped out with a disintegrating cam lobe drastically reduces valve duration and directly affects the cylinder charge (Figure 2). Even with a perfectly sealed cylinder, compression could be far below specification. The traditional compression test will show you “low-compression” but won’t tell you why. To know more requires disassembly and inspection. Many times, this is an expensive gamble, especially on today’s powertrains.

Advanced Electrical/Electronic Systems

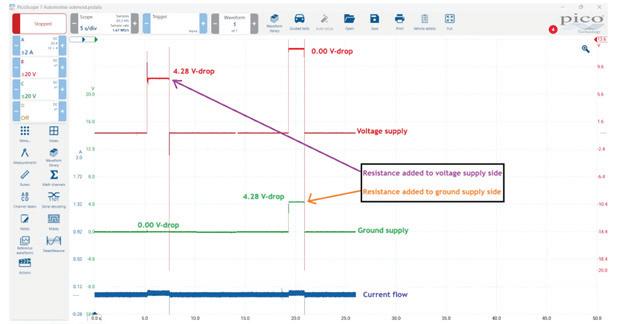

Electricity has been present in automobiles since their inception. For decades, technicians relied on simple devices like test lights and digital volt/ohm meters (DVOMs) to prove out circuit integrity. And, although both of these devices function well, they indeed have limitations (Figure 3)

In years past, the electronics were limited compared to what is found in today’s vehicles. Simple circuits that carried a lot of current (like power window switches) were designed to be in series with the motor itself. This means the entire circuit saw the same current flow as the motor windings. Basic tools like test lights were all that we needed to determine circuit integrity as almost

FIG. 1: It’s engine bay configurations like this Aston Martin V12 that make the tried-and-true tests like the compression test (with a mechanical gauge) a tough pill to swallow. These tests, intended to be easy, could take hours to perform.

PHOTO BY AUTHOR

any change would yield a different brilliance (or none, at all) from the test light, making faults easy to detect.

However, these simple circuits have been replaced with electronic control. Of course, there is still a requirement for the high current flow, but it’s limited to the motor circuit itself — not the switched circuits providing the window request. These switched inputs may be messages from a communication network. These circuits carry minimal current (certainly not enough to illuminate a test light). And it’s the width of the pulses (in different combinations) that determines the message being delivered. Not even a voltmeter could demonstrate that well. Diagnosis is limited to the robustness of the scan tool software, the technician’s understanding of the communication network protocol and most often, a thorough process of elimination, dedicating a lot of time to disassembly.

Pushing Your Boundaries

Above were just a few examples to make my point. Of course, there are many more. But to demonstrate an approach to help you step outside of your comfort zone, I would like you to imagine yourself in my shoes. I do not want you to drop your routine like a bad habit. If you are an experienced diagnostician and you are seeing success and accuracy in your diagnoses, wonderful! Keep doing it!

To broaden your horizons, you are going to have to reach farther than you have before. This can be an almost painless process if you set yourself up for success. My goal for you is to be confident in your venture, and to do so means to have a plan.

Step #1: Begin implementing the tests you are learning on known-good vehicles. My recommendation is to schedule some time each week to stay late after work. Prove to yourself that you can set up and capture the correct data for whichever new test/tool you are implementing. Of course, the data should reflect a healthy functioning component or system (Figure 4)

I make this suggestion because otherwise, when you have hiccups — of course, there will be hiccups along the way, but that is part of the learning process — you’ll surely struggle to distinguish between a true fault of the vehicle and an oversight in the testing process being implemented. If you can do that, you are ready to take the next step.

Step #2: Now it’s time to approach a broken vehicle. What I am requesting you do is add some more work for yourself. Yes, that’s right, do the “new test” (in this case, the relative compression

test). But what I’d like for you to do is simply capture the relative compression data as best you can. Save the scope data captured and do not rely on it as input for diagnosis. Continue to rely on the mechanical gauge compression test because you trust it and it has served you well. When you have a diagnosis present it to your customer (however that occurs in your shop) and assuming the approval for repair is offered, complete the job.

Step #3: Now, when the repair is complete, and before delivering the vehicle to the customer, repeat the relative compression test and again, save the scope data. When the dust settles and the workday is over, take the time to review the pre- and post-repair files for analysis. When success occurs, you will know it because you will recognize the fault in the capture, and it will correlate directly with the tried-and-true mechanical gauge compression testing you have carried out.

Practice Makes Perfect

Let’s try another example. Go back to an intermittent “no-communication” issue, perhaps it’s due to a fault that won’t allow communication on the network. Nowadays, the scan tool software (at least at the OE level) is robust enough to offer some excellent preliminary data

you tools and testing techniques (on known-good vehicles) is not only crucial to growth but also fun! Here, I’m with a group of my mates in the UK, having a great time experimenting on an engine you will likely never see in the United States.

FIG. 2: A worn cam lobe or even a collapsed lifter can drastically affect compression yet yield absolutely no cylinder leakage. Traditional testing would leave inconclusive results.

PHOTO BY AUTHOR

FIG. 3: Simple electrical circuit testing tools like the incandescent test light worked well for decades because the same electrical current used to operate actuators would flow through the switched inputs governing the operation. However, the inputs are now sometimes network messages carrying virtually no current and at incredibly fast speed, far exceding the capabilities of tools like test lights and even DVOMs.

PHOTO BY AUTHOR

FIG. 4: Scheduling time to experiment with new-to-

PHOTO BY AUTHOR

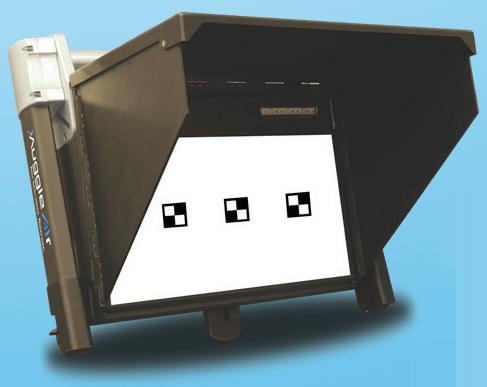

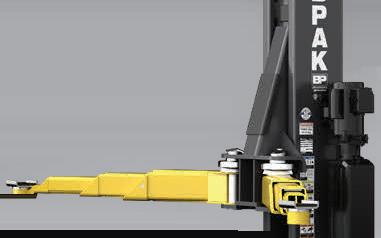

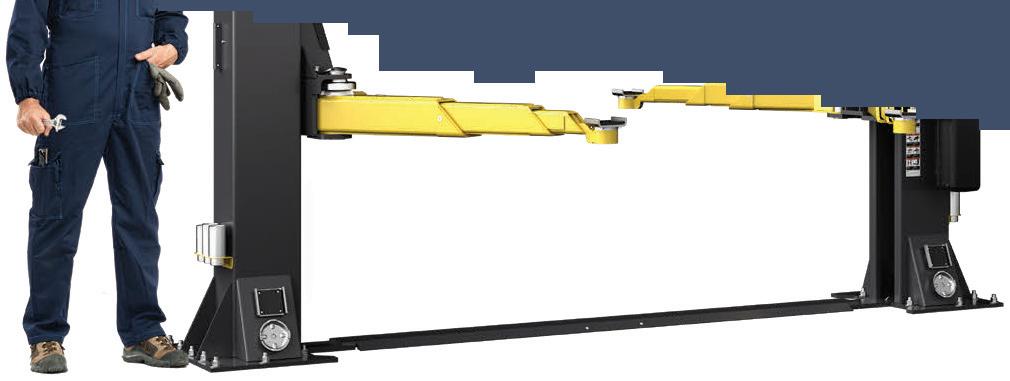

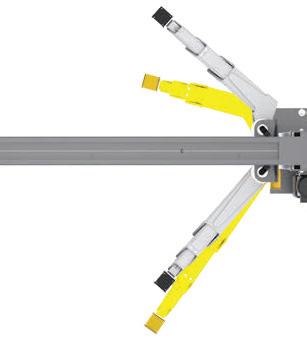

A seamless, full-system solution that guides you from setup through calibration in half the time.

Professional Diagnostic Scan Tools

The next generation of scan tools with the most advanced OE-level vehicle coverage supporting scanning, live data access and complete bi-directional functions.

Heavy Duty Diagnostics

Down time for heavy duty vehicles can cost thousands of dollars. Our solutions help simplify navigating through complex coverage and sophisticated systems to perform ultra-fast and accurate diagnosis.

Tune and Analyze

Test, analyze and diagnose your vehicle electrical and mechanical systems.

to support communication network fault diagnosis. However, even the greatest software won’t come out and point to the faulty component.

With that, the name of the game is “divide and conquer.” In the case of the fault described above, a fault in the wire harness could cause the symptom. Although a process of elimination could eventually render a diagnosis, the potentially dozens of nodes on the network (strewn throughout the vehicle) could also be the cause.

Then again, an output that is controlled by the suspect-ECU could create electrical noise (creating feedback to that ECU) contaminating the entire network. This would make the node look faulty and would lead to unnecessary replacement. The outcome would be very disappointing and potentially expensive. I urge you again to do what you do. Follow the same steps as in the previous example. Before the vehicle is repaired, take the time to implement a new test.

Perhaps you recently attended some training, and learned to implement a lab scope to view CAN bus network activity. Take this time to monitor the network, before a repair attempt is made. Reproduce the fault and capture the CAN bus network activity with the lab scope.

Viewing the data and (for example) seeing that CAN_Hi and CAN_Low both exhibited some high-frequency noise, but only when the headlamps were on, was cause for concern but also led to a visual inspection.

The headlamp bulbs were LED but should’ve been HID. Using this data pointed the technician toward a wiring diagram that showed the body control module (BCM) as the device driving the headlamp circuits.

The transistors operated at a very high frequency because the BCM was not happy with the unexpectedly low current values of the headlamp circuits. This high-frequency switching induced noise on the network (Figure 5)

What’s the point? If not for the lab scope, the noise wouldn’t have been seen. The technician would likely have condemned the BCM for being faulty and would’ve replaced it unnecessarily. What’s more important is there was no need for disassembly, nor process of elimination. The data derived from the scope capture yielded no reason to condemn anything but the aftermarket headlamp bulbs. This never could have been determined with certainty without the scope testing. In fact, it’s unlikely that any tech would’ve found this root

cause fault in any reasonable amount of time, or without many misdiagnoses along the way.

The Leap of Faith

I can promise you several things if you heed my advice. For one, you will feel a sense of frustration as these new and unfamiliar tests will leave you with many failed attempts. But Thomas Edison failed to make the light bulb properly 10,000 times before seeing success. Stick with it!

Secondly, there is a time and place for everything. Please don’t get yourselves into trouble by trying to “learn on the job.” Each one of our work bays is a business within a business. They must be profitable, and this can’t occur if we experiment on the clock. Schedule some time after hours (I suggest once per week) to experiment with knowngood vehicles.

And last, but certainly not least, learn to trust your test results like a pilot of a jet airliner trusts his or her gauges in the clouds. When you practice enough, a sense of confidence builds within you. You’ll certainly find that knowledge begets new knowledge and testing in the described fashion will make you a better, more knowledgeable technician, making you a very powerful diagnostic weapon.

In seemingly no time at all, you will put to rest the time-consuming tests you’ve relied on so heavily for so long. You will begin to replace those tests with the newer, more efficient and less invasive testing you’ve been practicing diligently to implement.

Just like learning to ride a bicycle with the training wheels on, it’s a process. But it’s one worth seeing through as it will serve you well for the remainder of your career. Make tomorrow a new day and take your career as a diagnostician in a very rewarding direction. Learning with the training wheels on is safe and gratifying — you’ll see.

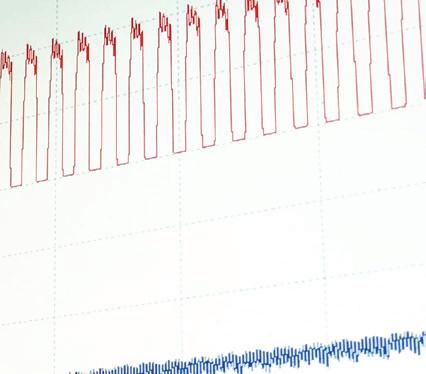

FIG. 5: The high frequency fault seen here (caused by LED headlamp bulbs) could’ve never been seen with tools less capable than the lab scope. Learning to implement tools like this saves hours of diagnostics time, hours more of disassembly, and potentially thousands of dollars in unnecessary component replacement. PHOTO BY AUTHOR

Understanding switch ratio vs. oxygen storage capacity

BY ERIK SCREEDEN

Cracking the Code on Catalyst Efficiency

SPACING OUT rear O2 sensors with spark plug non-foulers has been used with varying effectiveness for years to try and desensitize the downstream sensors by moving them out of the direct exhaust flow. This practice is not only highly illegal but has been made mostly ineffective by some of the more advanced OSC testing procedures in newer vehicle models.

AGE TRAINING AND TST SEMINARS

PHOTO: MOTOR

WITH EVER-TIGHTENING EMISSIONS standards and a continuing increase in average vehicle age, accurate catalytic converter diagnostics are more important than ever. The modern three-way catalytic converter (TWC) is an oxygen storage device that plays a vital role in reducing harmful emissions such as hydrocarbons (HC), carbon monoxide (CO), and nitrogen oxides (NOx). These harmful tailpipe emissions are chemically converted into less harmful substances (nitrogen, carbon dioxide and water) by the catalytic converter,

but its ability to do so depends on that catalyst being in good condition, and the engine maintaining near stoichiometric air-fuel ratio.

How Onboard Diagnostics Track Catalyst Health

To meet emissions standards, OBD-II systems need to monitor the conversion efficiency of the catalyst. Once that efficiency drops below a certain threshold, the system needs to trigger the malfunction indicator lamp, or MIL, off the detected fault, typically the P0420 or P0430 diagnostic trouble code. While specific testing methodology varies greatly by manufacturer and even vehicle model (and needs to be referenced by the technician in service information before any diagnostics begin), there are two main high level strategies employed by vehicle manufacturers to determine catalyst efficiency that technicians need to understand. These are:

• Switch Ratio: Comparing the oxygen sensor cross counts between the upstream and downstream oxygen sensor.

• Oxygen Storage Capacity (OSC): This test is based around the converter’s ability to absorb and release oxygen during changes in air-fuel ratio.

Both of these methods have their advantages and disadvantages, and vehicle manufacturers will base their chosen method of monitoring efficiency based on a variety of factors, including sensor technology. And while more vehicle manufacturers have turned largely to OSC in recent years, it’s important for the technician to understand the two monitoring strategies and their implications for diagnostics and repair.

For a technician to understand how efficiency is tested, it’s vital to understand how a modern TWC functions. The TWC performs three main functions:

• Oxidize carbon monoxide (CO) into carbon dioxide (CO2)

• Oxidize unburned hydrocarbons (HC) into water (H2O) and CO2

• Reduce nitrogen oxides (NOx) into nitrogen (N2) and oxygen (O2)

To accomplish this, the catalytic converter substrate is coated with a washcoat. That washcoat is the carrier of catalyst materials and is used to evenly distribute the elements across the substrate. The washcoat consists of elements typically including platinum (Pt), palladium (Pd), and rhodium (Rh). Rhodium is used as a reduction catalyst, palladium as an oxidation catalyst, and platinum as both a reduction and an oxidation catalyst. The ability of the conversion process to efficiently take place relies on the engine operating at a stoichiometric air-fuel ratio, around 14.7:1 for gasoline engines. It is at this ratio that the right balance of oxygen occurs to support all three chemical reactions. One of the main functions of the TWC is its ability to store oxygen during lean conditions and then release that oxygen during rich conditions to keep the conversion process going, even when the engine AFR wavers slightly.

As the catalyst ages, factors like thermal degradation, contamination, or physical damage can limit the ability of the TWC to store oxygen and perform the needed chemical conversions. When this occurs, the PCM needs to be able to detect this loss, and that is where testing like switch ratio or OSC comes into play.

When it comes to monitoring catalyst efficiency, switch ratio is the oldest and most widely used form of catalyst efficiency monitoring. The process is simple in theory. For vehicles that use narrow-band-O2 sensor technology, the upstream sensors will sweep between approximately 100mv and 900mv in closed-loop operation as the ECM adjusts fueling strategy to keep the engine as near stoichiometric air/fuel ratio as possible. A healthy catalyst will ingest more oxygen when the air/fuel ratio is lean, and release it as the mixture fattens up, buffering those fluctuations,

and leaving consistent voltage feedback from the monitoring rear O2 sensor. The ratio of fluctuation or sweep of the upstream O2 sensor(s) compared to those post converter is your switch ratio. Simply put:

Switch Ratio = (Number of upstream sensor switches) / (Number of downstream sensor switches)

The steadier the downstream O2 sensor voltage output, the better that TWC is performing. Adversely, a downstream sensor that is mimicking the sweeps of the upstream sensor suggests a catalyst that is no longer working efficiently.

Implementation of testing and the conditions needed to run that test will vary from manufacturer to manufacturer and even model to model. But once the predetermined parameters are met, the ECM enters its test mode. When testing, it will begin to monitor the cross counts from the upstream sensors (if equipped with traditional narrow band O2 sensor technology) and compare it to the cross counts from the downstream sensor. If the vehicle utilizes wide range air fuel ratio (WRAF) sensor technology, then the ECM may simulate narrowband behavior by adding and subtracting fuel during the test mode and monitoring downstream O2 sensor response.

Oxygen Storage Capacity (OSC):

Precision Monitoring

We have looked at switch ratio, now let’s take a look at oxygen storage capacity or OSC. This is the point where many people get confused. Switch ratio testing does ultimately test the converter’s ability to store and release oxygen, or its oxygen storage capacity. But the testing strategy of the ECM taking control of the mixture to measure the time-to-capacity is known as OSC testing. The OSC test is a more precise method of looking at catalyst efficiency. As stated earlier, a core function of a healthy TWC is the ability for that converter to store and release oxygen. The

principle behind OSC testing is that a well-functioning TWC will delay changes at the downstream sensor during controlled air-fuel ratio changes. The ECM monitors how quickly the downstream sensor responds as it fluctuates the mixture, rich or lean. The longer the delay in shift of rear oxygen sensor voltage, in theory, the healthier the converter is because of its ability to store oxygen. A reduction in OSC of the catalyst will cause the downstream sensor to respond too quickly, which may trigger a catalyst efficiency DTC.

For a technician, the great benefit of understanding OSC testing is it can be implemented to gain a better understanding of catalyst health, even on systems that do not use it as a native testing strategy. OSC testing gives a comprehensive look into TWC health and performance because it is able to illustrate in graphical form how much oxygen, or “how big of a gulp” that converter can take. By driving the air/ fuel mixture rich, forcing the TWC to deplete its stores of oxygen, and then driving the air/fuel ratio lean and allowing it to fill its lungs, that time base

between when the mixture was driven lean and when the downstream O2 sensor shows a reduction in voltage is a graphical indication of that catalyst’s ability to store oxygen.

OEM implementation of OSC testing as a monitor of catalyst efficiency has slowly grown in favor since the early 2010s. More and more manufacturers, such as Honda, Toyota, BMW, Volkswagen (VAG), Hyundai/Kia, and GM, have come to implement this testing strategy. Newer vehicles with faster and more powerful controllers, and the growing implementation of wide-band air fuel ratio sensor technology, allow manufacturers to emphasize precision and early fault detection. OSC catalyst monitoring also helps keep vehicle owners honest. With a little research, one can quickly learn how to space out the rear sensor and often hide a degraded TWC in a vehicle that uses less precise methods to monitor efficiency. OSC monitoring makes attempting to cheat an emissions test much more difficult.

What Happens When a Test Fails?

With either switch ratio or OSC testing, A SCREENSHOT of graphical O2 sensor voltage data on B1S1 and B1S2 taken from our Launch Throttle V on a 2013 Silverado with just under 100,000 miles. Under varying loads over the course of one minute you can see the switching frequency of the B1S1 voltage as compared to B2S2. While voltage from the downstream sensor will fluctuate a bit, a TWC with good oxygen storage capacity like shown here will not fluctuate with near the frequency nor amplitude like that of the upstream sensor.

PHOTO BY AUTHOR

if a test fails to meet programmed limits the ECM will do the following:

• Store a related DTC, often a P0420 (Bank 1) or a P0430 (Bank 2)

• Turn on the service engine soon light

• Log freeze frame data for the technician to use in diagnosing the problem Often a reduction of conversion efficiency of approximately 50% compared to a new catalyst is enough to trigger the aforementioned series of events. Catalyst monitoring is a non-continuous test, so unlike fuel trim or misfire detections which run continuously, catalyst monitoring only happens under certain operating conditions. These criteria are found in service information, and vary by manufacturer, but often include parameters like:

• Engine is up to operating temperature

• Vehicle is in closed-loop operation

• Idle or stable cruise (depending on test specifications)

• No active trouble codes for things like fuel trim, O2 sensors, or misfires

• Minimum drive time since last test If the criteria are not met, the test will not run. This is why referencing service information is vital for a tech -

nician to verify that a repair is paramount for customer satisfaction. These criteria are strict to ensure that the data gathered is accurate and not influenced by transient operating conditions. Often the test method chosen by vehicle manufacturers depends on fueling control strategy and sensor configuration. This means a technician is far more likely to find a vehicle that uses narrowband sensors to employ switch ratio testing, and one that uses WRAF sensor technology for at least the upstream sensor to employ OSC testing. Some manufacturers, such as GM, have even started implementing a hybrid approach to catalyst efficiency monitoring. These systems will often start with a switch ratio evaluation and then confirm with OSC. This approach of dual testing can help enhance the reliability of the onboard monitoring system and reduce the likelihood of false positive results.

Avoid the Guesswork: Diagnose With Precision

When it comes to chasing down catalyst efficiency problems, this is not the time

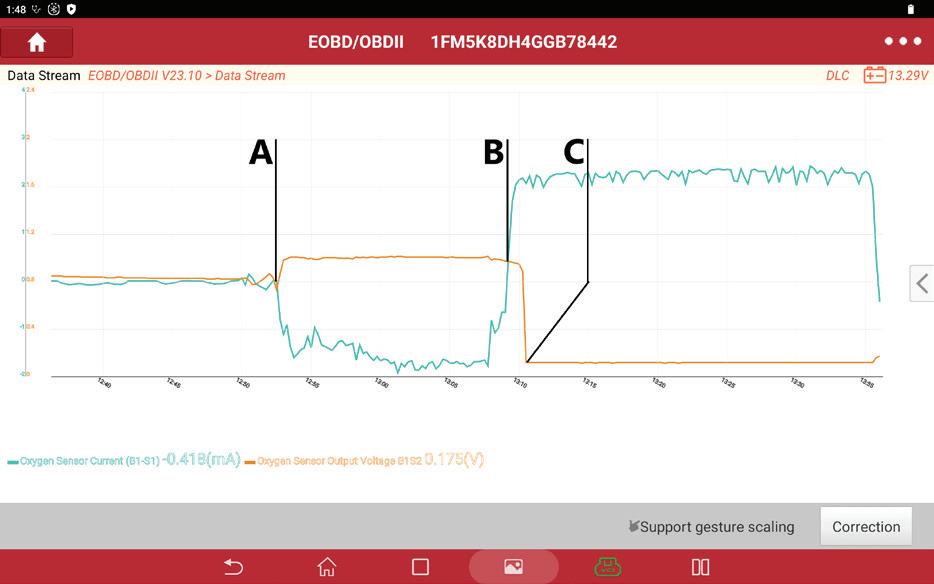

and test driving the vehicle we can illustrate this fact. Point A is where we put the vehicle in power enrichment by going to WOT. Between points A and B the vehicle is at WOT and the TWC has used up its stores of oxygen. Point B is when we close the throttle and put the vehicle in deceleration, fuel cut-off driving the mixture lean and allowing the TWC to “fill its lungs.” Point C is where the TWC reaches its saturation point and the O2 “punches through” the converter. Notice the time base at the bottom of the capture. The O2 punches through in under a second, illustrating poor oxygen storage capacity by this TWC, which is not surprising considering this vehicle has over 200,000 miles.

PHOTO BY AUTHOR

that a technician wants to start throwing parts at a vehicle in hopes that tossing that 50/50 ball yields a positive result. As I often tell my kids, it’s the painful and expensive lessons that tend to stick with you the most. Get me in a sports book in Vegas, and I’ll throw down on a juicy parlay, but I don’t want to gamble when it comes to repairs on a customer’s vehicle, especially with something as expensive as a direct fit catalytic converter assembly. There are many different things that can cause a catalyst efficiency DTC, and often the industry is quick to condemn a converter at the first sign of a P0420 or P0430 DTC without figuring out if the failure is indeed related to a degraded, poisoned or otherwise damaged catalyst. And, if that is the diagnosis, what exactly took the TWC out?

Now remember, a P0420 or P0430 does not always mean the catalyst is at fault. A vehicle has a fairly wide operating range while still being considered in fuel control. The TWC, on the other hand, has a very narrow air/fuel range it can operate within while still being effective. Because of this, a vehicle operating outside of that Lambda range of

EXAMPLE comes from a 2016 2.3L turbo Explorer and our Launch Throttle V. Again, A was the vehicle entering WOT (note the inverse graph due to mapping the sensor current for the upstream and traditional O2 voltage downstream), A to B is WOT operation with the TWC depleting its stores of O2. At B the vehicle again enters deceleration fuel cut-off, and point C is where the TWC is saturated and O2 is able to “punch through.” While this vehicle also has more than 100,000 miles, its ability to store oxygen is measurably higher than that of the previous Envoy. Different years, makes, and models will obviously have different storage capacities in the TWC, but testing like this offers a technician a good general idea in graphical form the condition of the TWC.

PHOTO BY AUTHOR

THIS IS a good example of a degraded oxygen storage capacity of the TWC. By graphing B1S1 and B1S2 O2 voltage on our Launch Throttle V

THIS

0.995 – 1.005 can trigger a catalyst efficiency DTC. Exhaust leaks caused by things like broken manifold bolts or a broken flex pipe upstream of the TWC, or even something like a split resonator, can cause problems if close enough (generally within 15 or so inches) to the downstream sensor.

Even if you do find the converter at fault, typically, something contributed to its demise. Poisoning from coolant and heavy oil deposits can degrade the life of a TWC significantly. And though rare anymore, lead and ZDDP poisoning are still possibilities as well. Prolonged and significant over

PHOTO BY AUTHOR

fueling can cause the converter’s ceramic substrate to start to plug, and even heat shielding that has corroded away can cause the catalyst to not maintain the correct operating temperature. Shotgunning a converter on a vehicle without performing root cause diagnostics is just inviting a comeback.

Smart Strategy = Successful Repair

Regardless of testing type, it is imperative that a technician trying to diagnose a catalyst efficiency problem research service information to determine which system they are working on, and the conditions needed to set the DTC they are chasing down to help set up their diagnostic approach. If the vehicle uses a switch ratio strategy, the technician then knows to focus on things like sensor switching activity (for narrowband O2 sensors) and O2 sensor waveform analysis (upstream versus downstream) to get a good picture of that switch ratio. For OSC, look at things like fuel trim behavior, upstream WRAF accuracy (sensor drift), and rear sensor response time. Catalyst efficiency diagnostics demand more than a surface-level understanding of DTCs and sensor data. As we’ve seen, both switch ratio and oxygen storage capacity testing have distinct applications depending on sensor technology and manufacturer strategy. The key takeaway for any technician is this: don’t guess. Proper diagnosis requires an understanding of how the system is designed to work, what conditions must be met for testing to occur, and how to interpret the results accurately. Whether it’s a failing sensor, an air/fuel imbalance, or a truly degraded converter, identifying the root cause is essential to avoid unnecessary repairs and costly comebacks. With the right knowledge and approach, technicians can not only fix the problem but also prevent it from happening again.

MODE $06 can be a valuable resource for technicians that is often underutilized. Found on the Global OBDII side of the tool, it offers the user a glimpse of diagnostic testing thresholds set by the manufacturer, and more importantly, how well the system is performing in that test. Some tools display this data as hexadecimal units (as seen here from our Throttle V) but that can be easily converted. This allows the technician to not only see system health but also help with after repair verification.

WHILE NOT containing any moving parts, the modern TWC is an important and complex piece of a vehicle ’s emissions control system. In order to perform its role optimally, it relies on multiple other systems in the vehicle to be intact and operating efficiently and correctly.

PHOTO: CLOUD-WALKER / SHUTTERSTOCK

Exhaust gases

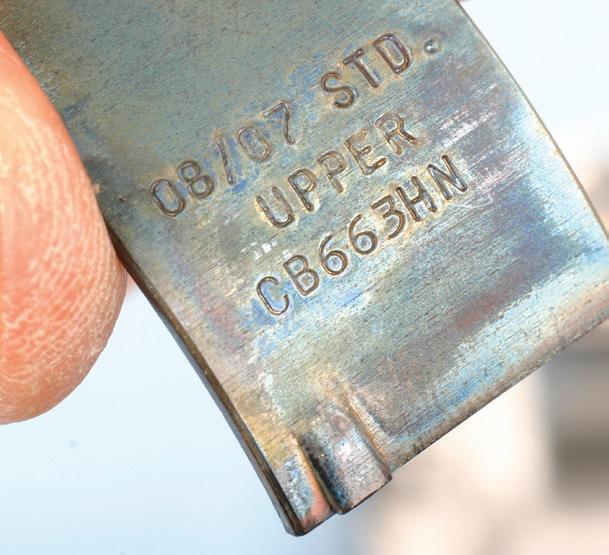

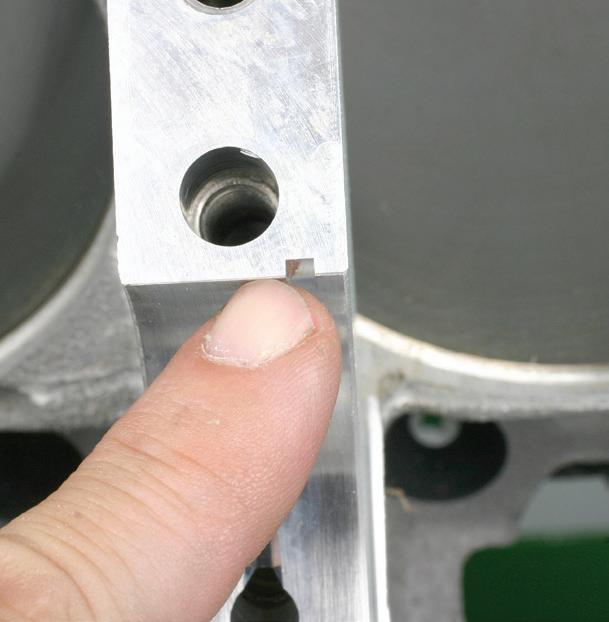

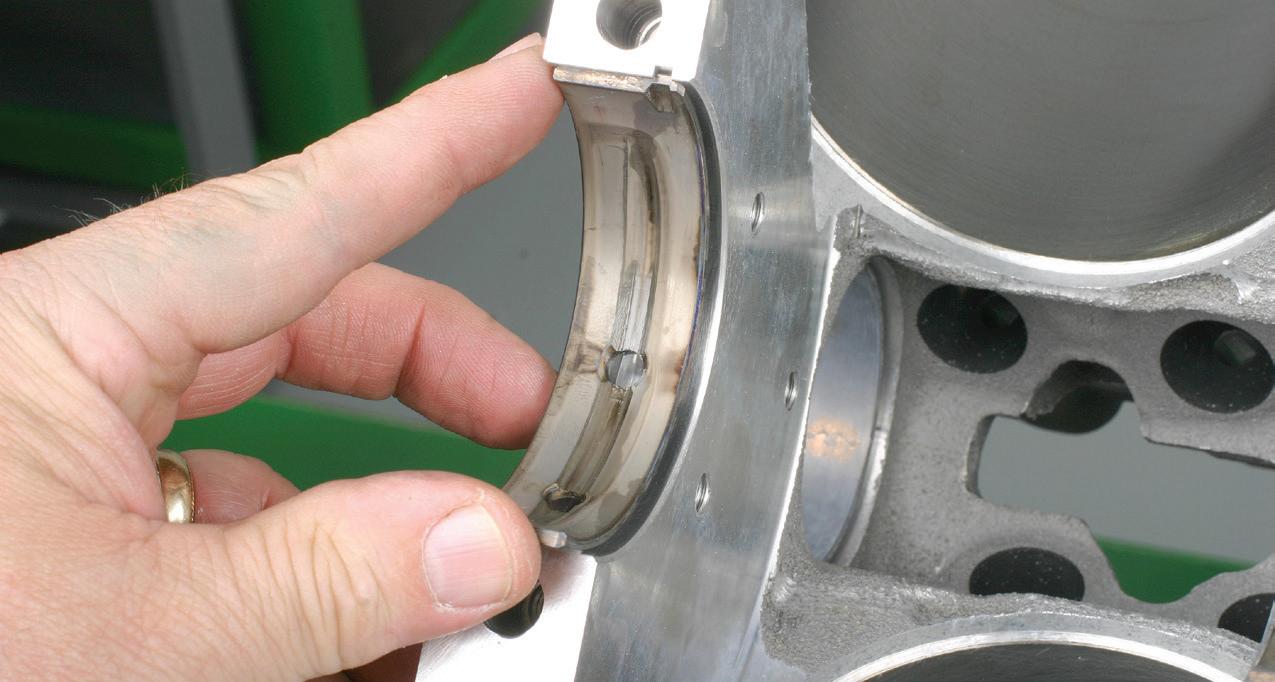

PROPER MAIN AND ROD BEARING OIL CLEARANCE

It’s a critical aspect to engine assembly

BY MIKE MAVRIGIAN

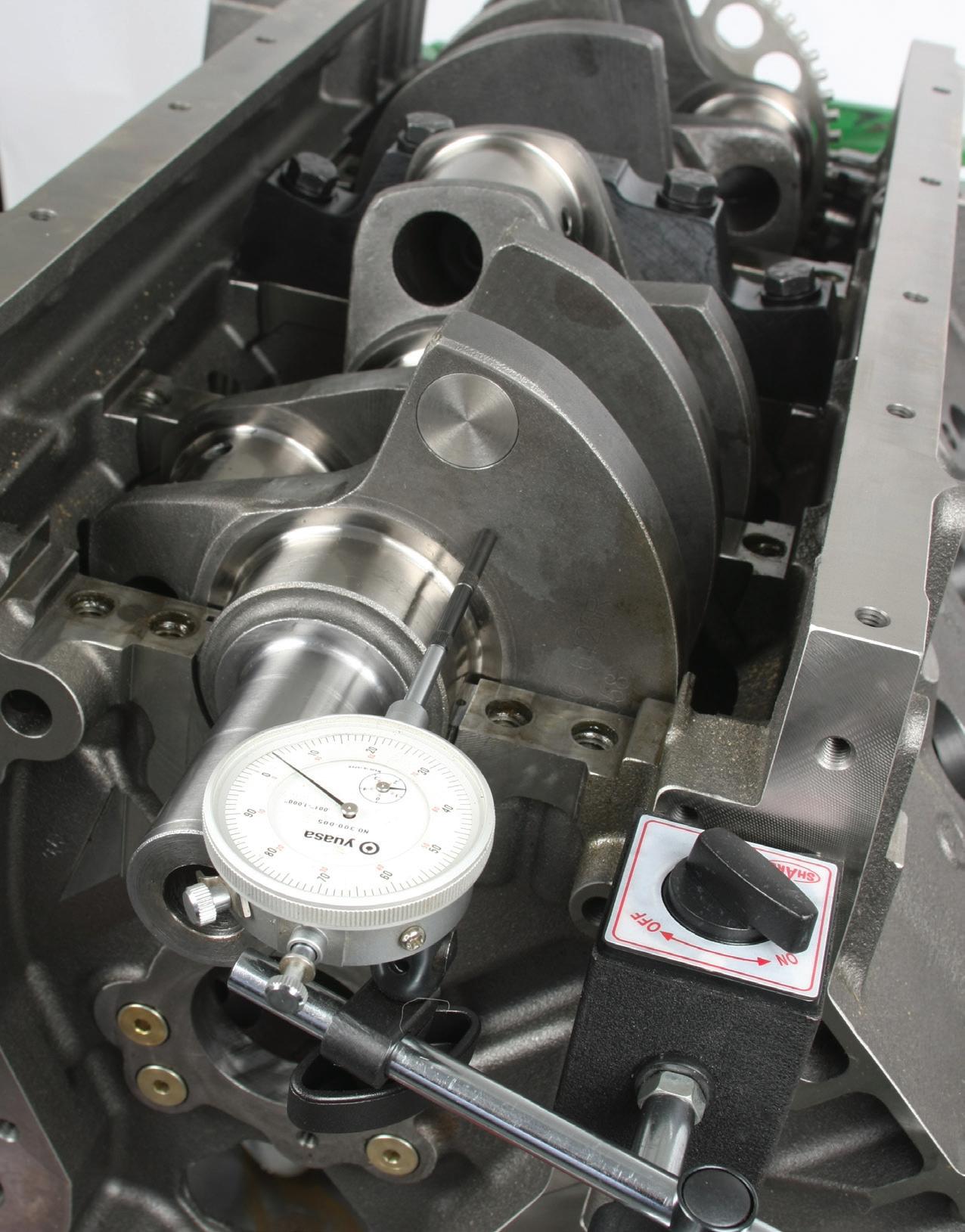

WITH MAIN bearings and main caps fully installed, the bore gauge is used to measure installed bearing inside diameter. The difference in the reading indicates oil clearance. Take the reading at 12 and 6 o’clock positions. Do not measure near/at the parting line.

PHOTO BY AUTHOR

THE IMPORTANCE OF OBTAINING proper oil clearance between bearings and rotating main and rod journal surfaces cannot be over-emphasized. Insufficient oil clearance reduces or eliminates the crucial oil wedge that the journals need during operation and excessive clearance can reduce oil pressure and can cause cavitation that creates aeration that can damage bearings. Crankshaft main and rod journals should never come into direct contact with their respective bearings. Rather, an oil wedge must be generated as the crank turns, allowing the journals to always ride on a supportive film of oil.

When checking for bearing oil clearance on main and rod bearing locations, do not blindly assume that “standard” replacement bearings will suffice. Due to potential stack-up tolerances between main bores, crankshaft journals and connecting rod big ends, do not blindly assume that “standard” thickness bearings will always suffice. Also the crankshaft journals may have been previously re-ground to recondition the crank (if the crank has been re-ground, the front face of the front counterweight should be stamped accordingly — i.e. 0.010, 0.020, etc., indicating journals have been ground to an undersize. If both main and rod journals have been reground, the first number should refer to main journals, with the second number referring to rod journals.)

Replacement bearings are offered in a range of thicknesses to allow the builder to achieve proper oil clearance. The crankshaft’s main and rod journals must be measured first, as these journals may or may not precisely meet the OE specifications.

In addition, the block’s main bore should be checked for size and alignment. If the engine has been rebuilt at some point, it is possible that the main caps have been ground to produce an out of round condition, followed by main bore align honing to return to the specified OE diameter. If the align honing process was performed poorly, you may have a main bore that is a tad too tight or too loose.

A potential stack-up of tolerances (main bore size and crank journal size) can easily result in inadequate oil clearance or excessive clearance. The same concern involves connecting rod big ends. Check rod big ends for out-of-round and for assembled diameter, especially if the rods have previously been resized. By merely assuming that main and rod bores and crank journals are correct, simply ob -

taining “standard” size bearings may lead to serious issues. Always measure first. In general terms, main bearing oil clearance should be 0.001-inch for every 1-inch of main journal diameter. For instance, if the main journals measure 2-inch in diameter, bearing oil clearance should be 0.002”. If main journals measure 2.749”, bearing clearance should be in the 0.00275” range. However, specific

AS CRANK rotation begins, the oil film is generated, creating a hydro-pressure ramp, which lifts the crank main journals into a concentric path. The same applies to the rod bearings, as the pressure of the oil film keeps the rod bearings from rubbing against the crank’s rod journals.

PHOTO BY MAHLE-CLEVITE

WITH THE cap installed, this exerts radial pressure, forcing the back (outside) of the bearing outward against its bore. Bearing crush is critical to hold the bearing in place and to create the proper bearing profile.

PHOTO BY MAHLE-CLEVITE

recommended clearances may vary depending on engine type and application. Engines intended for performance/racing use will typically require slightly greater oil clearance due to higher engine speed and load. Speaking in very general terms, a high performance engine’s main bearing clearance requirement might require an additional 0.0005” of clearance (for a 2” main journal, clearance would be approximately 0.0025”).

Again, depending on the engine application, main bearing oil clearance may vary from about 0.0017” to 0.0025”,

with the tighter clearance sometimes specified for many late model engine designs. Even though crankshaft rod journals are smaller than the mains, rod bearing oil clearance is generally in the 0.002” to 0.0025” range. It bears repeating: always refer to the specific engine maker’s specifications.

Keep in mind that today’s passenger vehicle engines typically run thinner viscosity oils and tighter tolerances.

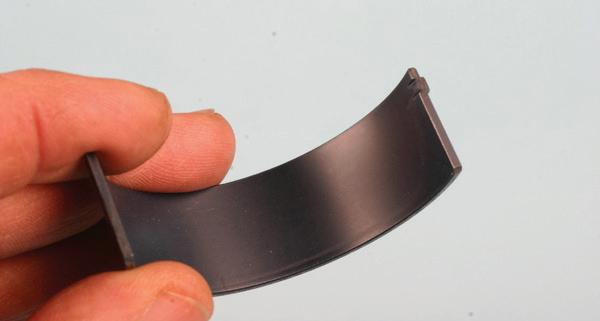

In some cases, in order to achieve proper rod bearing oil clearance, upper and lower bearing shells of different thick-

OF an upper bearing marked with a “1X”. This indicates that the bearing shell is thinner than standard. If both upper and lower bearing 1X shells are installed, this gains an additional 0.001” of oil clearance. If you only need an additional 0.0005” clearance, use a combination of a standard and a 1X.

ness may be paired. This is a common practice among performance or race engine builders. This allows you to “fine tune” oil clearance to gain or lose, for example, a 0.0005” clearance loss or gain (depending if the different thickness bearing set is for an oversized or undersized application). For instance, if your rod bearing clearance is 0.0020” but you want 0.0025”, in addition to a standard-size bearing set, you would purchase a set of 1X rod bearings. If you use the 1X bearings at upper and lower positions, you would gain 0.001” of clearance. But if you use a standard bearing at the lower (cap) location and a 1X bearing shell at the upper (rod saddle) location, you gain an additional 0.0005”. If rod bearing halves are mixed in order to achieve desired oil clearance, traditional school of thought is to install the thicker bearing half in the upper location, with the thinner half in the rod cap. Installing the thicker (for instance “standard”) in the upper location is better suited to handle the higher loading side. On the other hand, many builders feel that this is not necessary, as long as the orientation of thicker/ thinner bearing halves are installed consistently from rod to rod (for example, thicker upper and thinner lower on all rods, or thinner upper and thicker lower on all rods). Caution: Never mix bearings with more than 0.001” thickness difference.

CLOSELY INSPECT the bearing tang notches in the block saddles and main caps. Make sure that the notch is clean and free of burrs. Any debris/irregularities can affect oil clearance. PHOTO BY AUTHOR

NOTE THE small tang on this main bearing. All main and rod bearings will feature a locating tang. This is designed to simply position the bearing in its saddle during assembly. Locating tangs do not prevent bearing shell rotation. Bearings “lock” in place as a result of bearing crush when the upper and lower shells mate during cap installation.

PHOTO BY AUTHOR

DEPENDING ON application, rod bearings may or may not be labeled for position, but be sure to check. Shown here is an upper rod bearing featuring standard thickness (note absence of marking 1X). Upper/ lower bearing inserts may feature slightly different profiles, so don’t mix them up.

PHOTO BY AUTHOR

EXAMPLE

PHOTO BY AUTHOR

When checking for bearing clearance, perform test fitting to confirm clearances prior to final assembly. Do not install the crankshaft at this time. For main bearings, install an upper main bearing shells in the block’s upper saddles. Make sure that the saddles are clean and dry. Install the upper bearings. Do not apply any lubrication to the bearings at this time. Install the lower bearings to the main caps and install the main caps. Tighten all main cap bolts to specification and follow the correct tightening sequence outlined in the service manual. Using a micrometer, measure the crankshaft main journal diameters. (Measure each main journal and record the results.)

Set up a bore gauge to match the crank journal size and zero the gauge. Then use the bore gauge to check the inside diameter of the installed main bearings. The difference observed on the gauge indicates the amount of clearance. Perform the check at the 12 o’clock and 6 o’clock bearing locations. Do not measure at or near the bearing parting lines. Bearing shells feature a slight taper approaching the parting lines, which aids in allowing the creation of the all-important hydrodynamic oil wedge required for supporting the journals to avoid direct bearing-to-journal contact.

Perform the same check on connecting rods. Install new bearings to the rod upper saddle and the rod cap. Install the rod cap and tighten the bolts to specification while the rod is clamped to a dedicated rod vise. Use a micrometer to measure the crankshaft’s rod journals and set up a bore gauge to that size and zero the gauge dial. Use the bore gauge to measure the installed rod bearings (again, at the 12 o’clock and 6 o’clock positions) and record the measurement. The difference between the measured rod journal and installed bearings indicates the amount of oil clearance. Once checks have been performed, place the rod in the rod vise and remove the rod cap.

Tighter oil clearance is generally

ALWAYS INSTALL main and rod bearings dry to the block, rods, and caps. There must be NO particles, oils, or anything else between the back of the bearing and its saddle. Lube is only applied to the exposed bearing faces prior to final assembly.

PHOTO BY AUTHOR

POSITION EACH main bearing in the block saddles with the bearing ends protruding by the same amount at each end, and verify that the oil holes in the bearings align with the oil feed holes in the saddles. If a slight misalignment is found, you can carefully elongate the hole in the bearing, being careful to remove any burrs.

PHOTO BY AUTHOR

INSTALL ROD bearings by aligning the bearing tang with the locating notch and press each end down with your fingers. Each end of the bearing shell should protrude by the same amount at each end.

PHOTO BY AUTHOR

required for small crankshaft journals, the use of lower viscosity oil, near-perfect crank and block geometry, higher engine operating temperatures and perfectly balanced crankshafts. Larger/looser oil clearances accommodate larger crank journals, higher viscosity oil, imperfect crank/block geometry, lower engine operating temperature due to increased oil flow, and weaker housing bores that have a tendency to slightly distort at high engine speeds.

In general, bearings should operate with the least amount of oil clearance as the application permits.

Tighter oil clearance produces less bearing peak loading, reducing the potential for less-than-smooth engine running. Again, pay attention to the engine maker’s clearance specs.

In order to measure individual bearing shell thickness, use a quality micrometer with a ball tip mandrel.

Never use micrometers with flatfaced anvils.

Before measuring, index the micrometer with a standard to insure accuracy and micrometer calibration.

Measure bearing thickness at the mid-point — at the radius, not near the parting line.

Always use the same micrometer for all measurements, as differences in calibration can affect accuracy.

When measuring installed bearing diameter, the rod bolts must be fully torqued to specification (and/or using rod bolt stretch method).

Maintain the same rod bolts per rod, and do not change bolt location.

Maintain the same brand of bearing. Never mix one brand with another.

Both upper and lower bearing halves must be from the same maker, and feature the same surface treatment. Do not mix coated with uncoated halves on the same rod.

Main and rod bearing clearance can be performed with the crankshaft in place, using Plastigage wire. This approach, while commonly used by non-professional

WITH THE crankshaft installed, check crankshaft end-play. Depending on engine design, thicker or thinner main thrust bearings may or may not be available. The thrust/endplay will be specified in the engine maker’s service manual. This may typically be in the range of 0.006 to 0.010”. Perform thrust check without and with main caps/ lower main bearings.

PHOTO BY AUTHOR

MEASURE CRANKSHAFT main journal with a micrometer. This example reads 2.749”. A bore gauge contacts are then adjusted to that journal diameter, and the bore gauge is adjusted to read zero.

PHOTO BY AUTHOR

EXAMPLE OF a bearing shell installed. The mating ends will slightly protrude above the saddle parting line, and each end should protrude by the same amount.

PHOTO BY AUTHOR

Supercharge Your Supply Chain With

Build Estimates In Seconds.

Wit h N expar t Mult i-S el ler you’re c onne cte d to real-t ime inventor y and whole sale pricing from al l o f your par ts suppl iers. Find par ts, t ires, and more Bui ld detai le d est imates fast!

Backe d by t he most c omprehensive catalo g in t he af termarket . You’l l se e more pro ducts, from more suppl iers, g iving you more c ontrol o f your supply chain.

earn points on every parts order Multi-Seller

ROD bearings to the connecting rod big end and tighten the rod bolts to specification with the big end secured in a dedicated rod vise.

SET A bore gauge to match the measured rod journal and zero the gauge reading. Measure installed rod bearing inside diameter. The difference indicates oil clearance.

ANTI-FRICTION COATING is always a good option for main and rod bearings. This coating not only promotes oil cling, but serves as an anti-friction protective layer in order to prevent bearing damage during cold starts and in brief instances of oil starvation. It is not necessary to have a moly coating applied to the front and rear faces of a main thrust bearing’s thrust surfaces, since it’s common for engine builders to sometimes fine-tune thrust clearance by filing a thrust face. An upper main thrust bearing shell is shown here.

engine builders, is a viable alternative but is much less accurate. Plastigage is a compressible plastic wire. Install the upper main bearings into the block’s saddles (dry). Place the crankshaft onto the upper bearings.

Lay a short piece of Plastigage onto the exposed journal, with the wire placed parallel to the crank (wire ends face front and rear). Simply lay the wire onto the journal — do not press down on the wire. Install a lower bearing to the main cap and apply a very light smear of oil to the center of the lower bearing (this prevents the crushed Plastigage from sticking to the lower bearing and pulling off of the journal). Install the main cap and tighten bolts to spec. Do not rotate the crank at any time during this check. Carefully remove the main cap. Using the Plastigage packing slip (which features a series of measuring width markings), compare the markings to the now-crushed Plastigage wire. The

APPLY OIL or assembly lube to the exposed bearing surfaces once bearings have been final-installed, just prior to engine assembly.

closest match indicates approximate oil clearance. Perform the same task with each installed connecting rod. Prior to each individual check, rotate the crank to place the rod journal at bottom-dead center. (With the block upside down, bring the rod journal up, closest to you, for easy access.) Record each clearance in an organized manner, and record your findings. Once done, clean the Plastigage from the journals. Your findings will dictate the use of standard bearings, or will indicate the need for slightly under- or over-sized bearings. Again, the use of Plastigage, while better than nothing, may provide an approximate measurement, but for highest accuracy, performing your measurements with a micrometer and bore gauge is always preferred.

Bearing Design Insight

A variety of bearing designs (and dimensions) have been developed to properly

BEARINGS are subjected to both rotational and reciprocal forces. Anti-friction coatings prevent potential bearing wear during cold startup and for potential intermittent poor oil delivery. Since the coating is of minimal thickness, no compensation is required in terms of installed bearing clearance.

you have discovered slight deviations where thinner/thicker bearings are required.

ROD

PHOTO BY AUTHOR

ONCE BEARING oil clearances have been checked and established, keep all bearings organized in their respective locations. This is especially important if

PHOTO BY AUTHOR

PHOTO BY AUTHOR

PHOTO BY AUTHOR

PHOTO BY AUTHOR

USING A micrometer, measure rod journal diameter.

PHOTO BY AUTHOR

INSTALL

PHOTO BY AUTHOR

THE HEART OF LONGER RUNNING VEHICLES

Continental heavy duty aftermarket air springs, belts, hoses, hydraulics, and tensioners keep your business operating in good health. Our precision-engineered parts are built to last and extend fleet life without skipping a beat. Continental, your first choice for premium aftermarket products.

RUN STRONGER , LONGER

suit any specific engine application. Before we delve into selecting and installing main and rod bearings, we first need to understand bearing design.

out-of-round in the horizontal plane or the vertical plane.

Main and rod bearings’ geometry provides an interference fit, or “crush.” Each bearing shell (upper and lower) is made with a length that results in slightly more than a true half-circle. The ends of the bearing shell, when installed into a housing, protrude slightly beyond the parting line of the housing. When the cap is installed and the cap bolts are tightened, these protruding ends of the bearing shells squeeze against each other and push the bearings against the housing, compressing together like a spring. The outward force of the bearings, as they squeeze into place, causes a slight change in the size and shape of the housing. This is referred to as bore distortion. As you might expect, different housing materials (such as steel vs. aluminum) provide different levels of bore distortion.

Many engine assemblers may not be aware that bore distortion may occur during assembly. Compensating for this bore distortion is the tricky part, since a multitude of variables can directly affect housing bore shape (main bores and connecting rod big ends).

One of the variables directly relates to the shape of the bearing housing mass. Blocks and rods feature irregular shapes that surround the housing bore. For example, connecting rods feature a beam at the top of the bore, notches for bolt heads and/or nuts at each side of the hosing bore, thin or thick ribs at the bottom of the cap, etc.

In addition, dynamic loads (when the engine runs at various speeds and loads) change in both magnitude and direction. All of these factors (design shape and reinforcement of the housing and dynamic loading) combine to cause the bearing housings to realize an out-of-round state under various operating conditions. Depending on the surrounding metal shape and mass, some housings will go

Bearings are not simply perfectly round liners that take up space between the housings and the crank journals. Bearing design is a very complex issue, a factor which most engine assemblers don’t fully appreciate.

Because of bore shape variables, the most desirable bearing shape is provided with a slightly oval bearing inside diameter. As a result, bearings are manufactured with an eccentric wall. In most cases, the bearing wall thickness is greatest at the top and bottom (90 degrees from the parting line). The bearing ID tapers slightly at the parting line area.

Connecting rods are especially subjected to high inertia loads at the top of the exhaust stroke, when the weight of the piston, rings, wrist pin and rod small end effectively pulls at the rod big end, in an attempt to stretch the rod. This dynamic force also tries to pull the rod big end out-of-round, which will cause the bearing housing bore to become tighter at the parting line area. In order to address this, a slight eccentricity is designed into the bearings, with the bearings thinner at the parting line area. This prevents the bearing from contacting the crank journal when bore distortion occurs.

MIKE MAVRIGIAN has written thousands of automotive technical magazine articles involving a variety of specialties, from engine building to wheel alignment, and has authored more than a dozen books that crisscross the automotive spectrum. Mike operates Birchwood Automotive, an Ohio shop that builds custom engines and performs vintage vehicle restorations. The shop also features a professional photo studio to document projects and to create images for articles and books.

Harnessing Heat

Understanding heat pump systems in EVs and hybrids

BY JEFF TAYLOR

WHILE OFTEN OVERLOOKED by consumers, heat pump systems have become one of the most influential technologies in modern EV and hybrid vehicles. They provide energy-efficient heating and cooling while preserving precious battery range.

As electric and hybrid vehicles increasingly replace traditional internal combustion engine (ICE) models, automakers have had to re-imagine nearly every vehicle system. One of the most critical challenges has been managing cabin heating, especially in cold climates where traditional methods either aren’t available or do not perform efficiently. In ICE vehicles, waste engine heat is plentiful and was used to heat the interior of the vehicle for years. In electric vehicles (EVs), however, that luxury does not exist. Many EVs and hybrid vehicles relied on Positive Temperature Coefficient (PTC) resistive heaters to provide the needed heat to the passenger compartment. But even with the simple, dependable fast warm up that the PTC heater provided; they are power-hungry devices that can significantly reduce EV range in cold weather.

Fortunately, most of these vehicles were already equipped with air conditioning systems and relied on an air conditioning compressor to provide cooling to the passenger cabin. This made it easier for manufacturers to transition to reversible heat pump designs, as they could build on existing components and infrastructure. The automotive heat pump system achieved both: a more efficient heating solution and the preservation of its full cooling capabilities.

In this article, we’ll examine what automotive heat pumps are, how they work, and examine some manufacturer highlights. We’ll also look at concerns technicians need to be aware of when diagnosing them, what problems have surfaced in real-world use, and how this technology is likely to evolve. By the end, you’ll understand why heat pumps are at the center of EV/hybrid thermal management and why mastering them is essential for today’s automotive professionals.

What Is a Heat Pump and Why Does It Matter in EVs and Hybrids?

Essentially, a heat pump is a thermodynamic system designed to move heat. It typically works by taking heat from a lower temperature source and releasing it at a higher temperature. In the case of EVs/hybrids, the system extracts heat from the ambient environment and delivers it to the cabin or to vehicle systems such as the battery pack. In warm weather, it can reverse its function, acting like a traditional air conditioning unit to cool the vehicle’s interior or remove heat from the high-voltage battery and other heat producing equipment.

The importance of this system in EVs/ hybrids cannot be overstated. Earlier EVs/hybrid vehicles relied solely on resistive PTC-type heaters, which use electric current to create heat — a method that is simple but extremely inefficient. When cabin heating is needed in cold weather, resistive heaters consume a large amount of energy, sometimes reducing driving range by 30 percent or more. Heat pumps,

by contrast, use a small amount of energy to move existing heat rather than generate it, delivering the same cabin comfort with far less battery drain. This improved thermal efficiency translates directly to extended driving range and better winter usability.

How Heat Pump Systems

Work in Vehicles

In today’s heat pump-equipped vehicles, the HVAC system is designed to reverse the flow of refrigerant to either heat or cool the cabin using a single, flexible system. During heating mode, the system functions similarly to an air conditioner in reverse. Refrigerant first passes through the outside heat exchanger (normally the condenser in cooling mode), which now acts as an evaporator. As cold outside air flows over this component, the refrigerant absorbs heat energy, even in low ambient temperatures and evaporates into a low-pressure vapor.

This vapor then flows to the electric compressor, which compresses it into a high-pressure, high-temperature gas. The hot refrigerant then moves into what would typically be called the evaporator, located inside the cabin, but in heating mode it functions as a condenser. There, the refrigerant releases its heat into the cabin air or to a coolant loop, warming the interior.

In cooling mode, the system returns to a traditional A/C cycle. The cabin heat exchanger reverts to being the evaporator, pulling heat from inside the vehicle, while the front heat exchanger resumes its role as the condenser, releasing that heat into the outside air.

This reversible refrigerant flow is made possible using valves and flow control components, such as a reversing valve or multi-port expansion valves, which direct the refrigerant through different pathways depending on whether the system is heating or cooling. Some systems also include a vapor-injected scroll compressor for improved performance in extremely cold conditions.

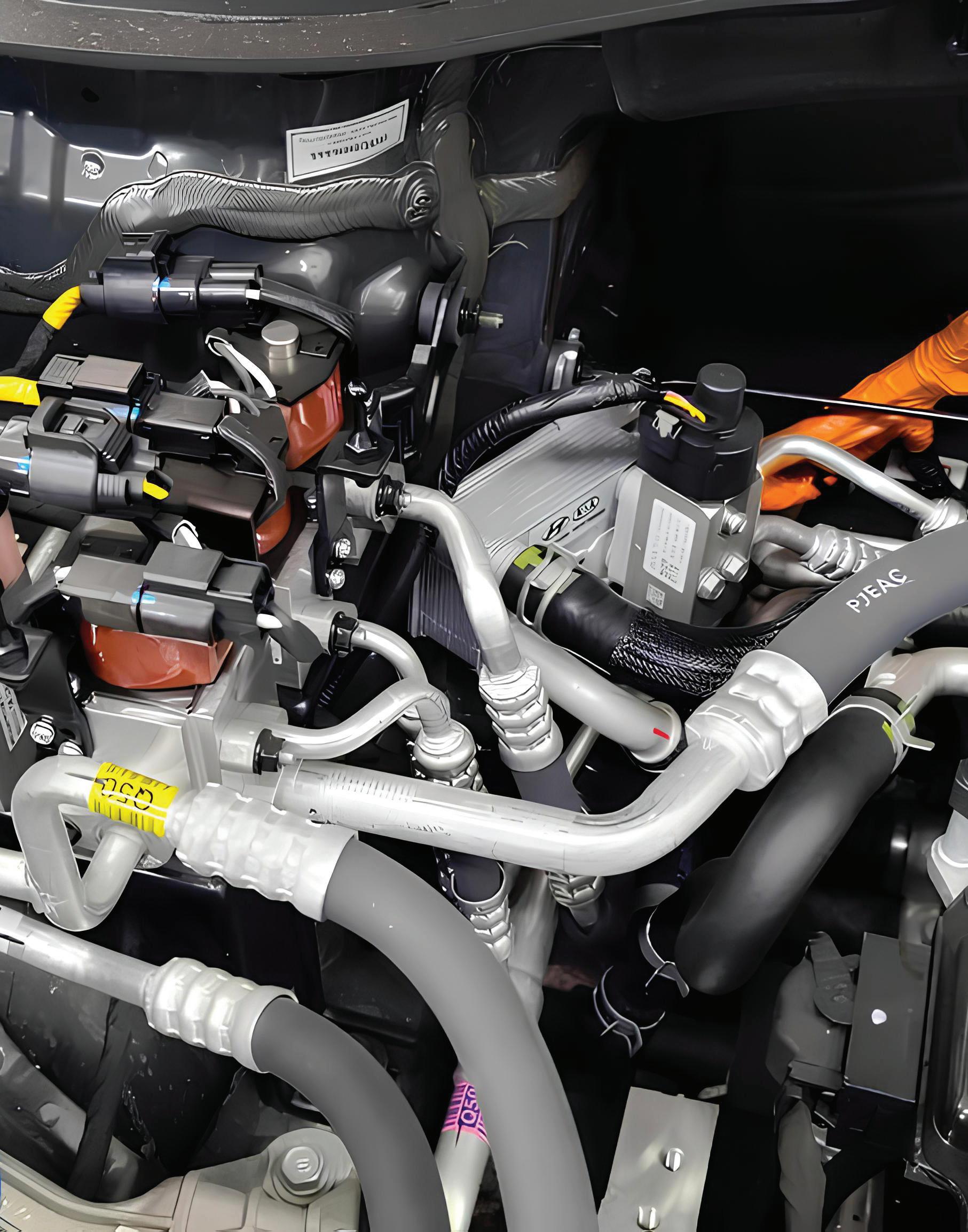

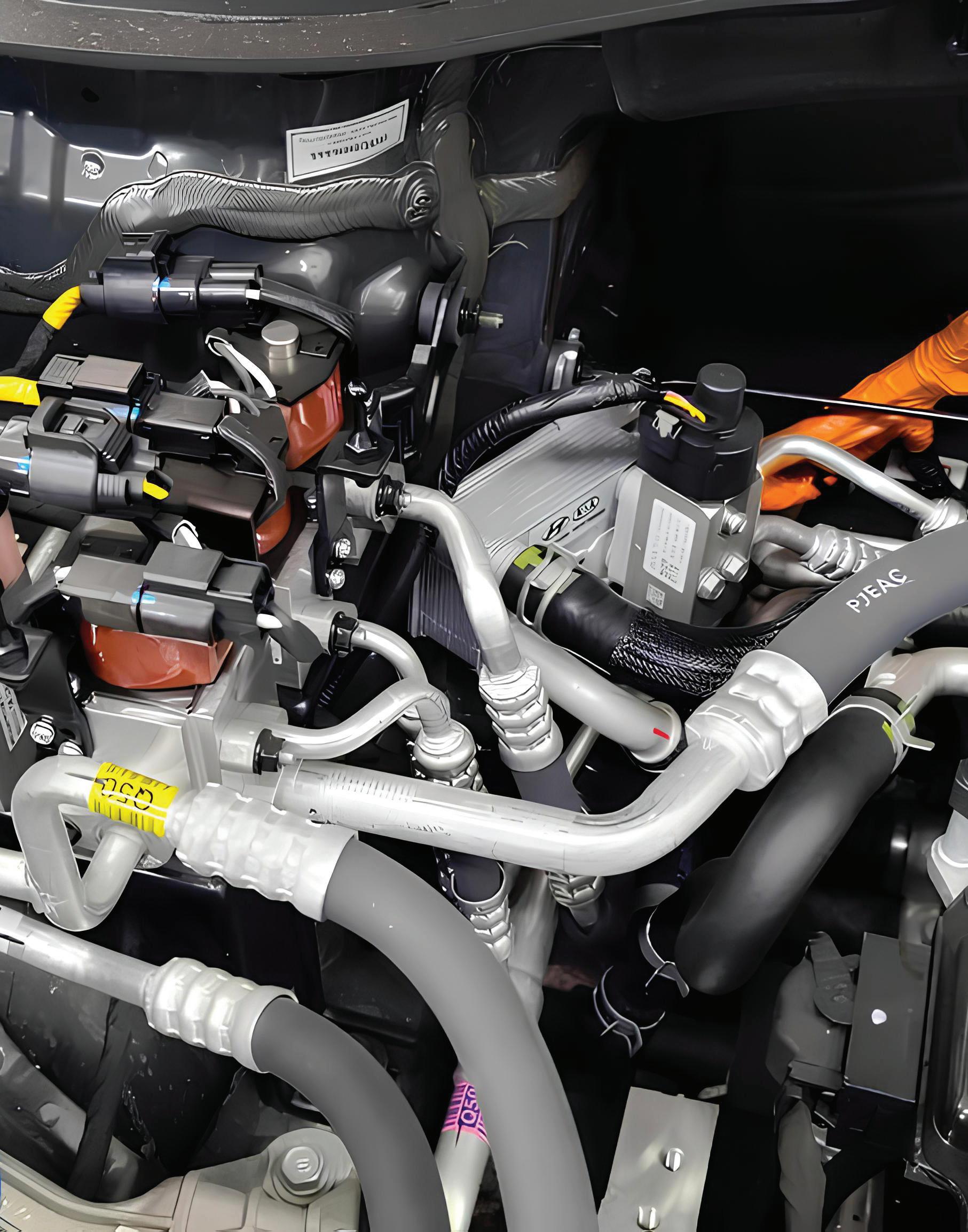

THIS PHOTO shows the complex valving and controls of the refrigerant on a 2022 Hyundai IONIQ, that is equipped with a heat pump system. PHOTOS BY AUTHOR

Vapor-Injected Scroll Compressors

One of the innovations that has allowed automotive heat pumps to function effectively in cold climates is the vapor-injected scroll compressor. This compressor design is a major upgrade over standard compressors, particularly in sub-zero conditions. The vapor injection technique involves splitting the refrigerant flow. A portion is routed through a secondary circuit, where it is expanded and evaporated to form a cool vapor. This vapor is then injected midway into the scroll compressor. By doing so, the system increases mass flow and compression efficiency, improving heating capacity even when the ambient temperature is below minus 4 degrees Fahrenheit (minus 20 degrees Celsius). The vapor injection system also reduces the temperature difference across the compressor, helping to prevent overheating and improving long-term durability.

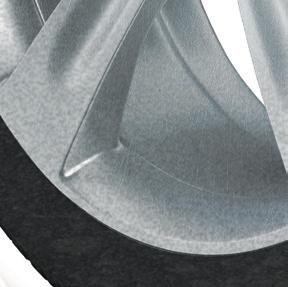

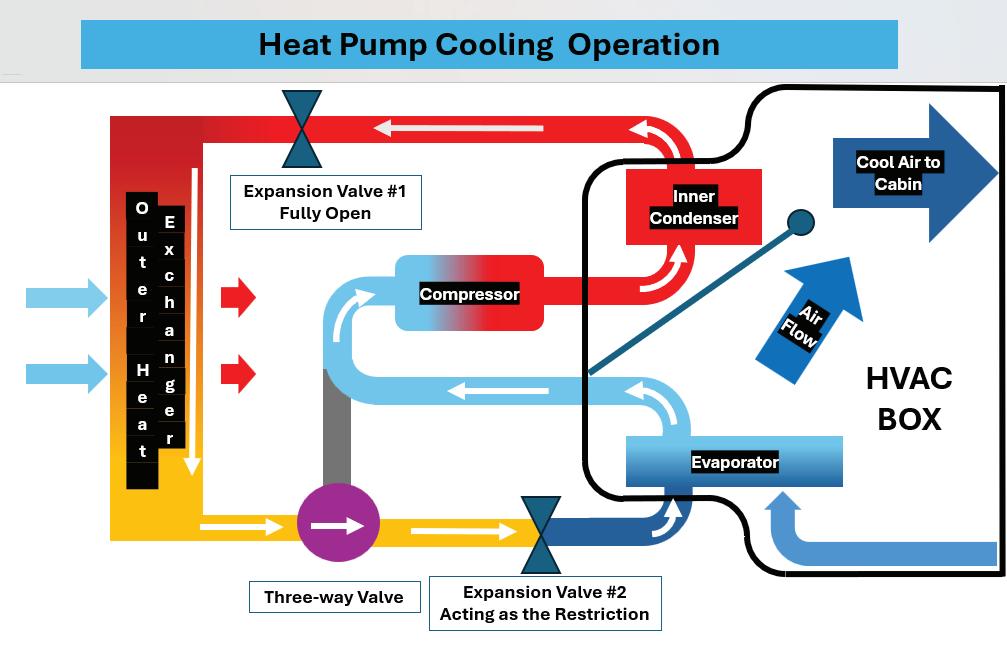

THIS DIAGRAM shows a simple heat pump system that is operating in cooling or AC mode. Starting at the compressor, the refrigerant leaves as a high-pressure gas, that flows through the inner condenser and then passes through the full open expansion valve #1. The refrigerant then is condensed to a liquid in the outer heat exchanger. This liquid then flows through the three-way valve that directs the flow toward expansion valve #2, that is in the restriction or operational mode. Once the refrigerant flows through expansion valve #2 it evaporates in the evaporator and then returns to the compressor to start the process over again. This cooling cycle is like the regular refrigerant cycle that we are familiar with.

PHOTOS BY AUTHOR

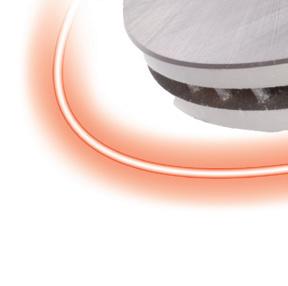

THIS DIAGRAM shows a simple heat pump system that is operating in the heating mode. Starting at the compressor, the refrigerant leaves as a high-pressure gas that flows into the inner condenser, but instead of flowing right through it is forced to condense, because expansion valve #1 is in restriction or operational mode. As the refrigerant is condensed the blower motor blows air over it, removing the heat of compression and warming the interior of the vehicle. After the refrigerant has been condensed, it flows through the restriction of expansion valve #1 and into the outer heat exchanger, that will now act as an evaporator. As the refrigerant evaporates it returns to a gas form and then flows through the three-way valve that will now direct the refrigerant flow back towards the compressor for the cycle to be repeated, because expansion valve #2 is now fully closed.

This compressor design is now featured in vehicles such as the Tesla Model Y, Ford F-150 Lightning, Hyundai Ioniq 5, and others. It has become the gold standard for coldweather heat pump performance in EVs.

Real-World Benefits and Range Preservation

Heat pumps provide quantifiable benefits to EV/hybrid drivers, especially in colder climates. Numerous real-world tests and independent studies have shown that vehicles equipped with heat pumps keep a higher percentage of their normal range in winter conditions compared to those using resistive heaters.

For example, Tesla vehicles equipped with their octovalve heat pump system have demonstrated winter range retention as high as 85 to 90 percent under sub-freezing conditions. Hyundai’s Ioniq 5 and EV6 models perform similarly, with

winter range drops of less than 10 percent. In contrast, early-generation Nissan Leaf vehicles without heat pumps often saw winter range drops of 30 percent or more. GM’s Cadillac Lyriq and Chevrolet Blazer EV, while equipped with heat pumps, still switch to resistive heating below minus 13 degrees Fahrenheit (minus 25 degrees Celsius), leading to slightly lower winter performance.

This difference in efficiency matters not only for range anxiety but also for occupant comfort. Heat pumps provide quicker warm-up times and better temperature stability, all while consuming less energy.

Manufacturers and Their Approaches

Tesla: Intelligent Thermal Management

Tesla’s heat pump system, introduced in the 2021 Model Y, features a vapor-injected scroll compressor and a unique part called the super manifold. The super manifold is a compact assembly housing multiple thermal management components like the octovalve, heat exchangers, sensors, and connections for coolant and refrigerant lines. The super manifold routes coolant and refrigerant between the cabin, battery, and powertrain components based on thermal demands. Tesla even uses the heat from the blower motor to aid in the warming of the passenger cabin. Combined with sophisticated software logic, the system ensures that heat is always used or stored optimally.

The Tesla system operates effectively down to minus 22 degrees Fahrenheit (minus 30 degrees Celsius) and uses overthe-air (OTA) updates to fine-tune its behavior over time. In effect, it’s a dynamic and intelligent system that adapts to environmental conditions and driver behavior, significantly improving winter performance.

GM: Ultium Energy Recovery

General Motors has integrated heat pumps across its Ultium-based EV lineup, including the Cadillac Lyriq, Chevy Equinox EV, Blazer EV, and Hummer EV. These systems include a patented energy recovery func-