Power Play

Power over Ethernet (PoE) enables new lighting options — and new competition from low-voltage contractors.

Read more on pg. 28

CELEBRATING A CENTURY OF UNISTRUT

The year is 1924, the first round-the-world telegram is sent, and Charles Attwood forms the company that would become the leader in metal framing, From our early days as the first adjustable frame system in electrical power stations, to becoming an integral component in global construction projects, Unistrut continues to evolve through innovation.

Award-Winning Performance, Meet Everyday Convenience

Simplify Schedules with Our Retrofit-Friendly Wi-Fi Control

Simplify lighting and load schedules with the ETW Series 365-Day Programmable Wi-Fi Timer. This versatile smart control combines robust scheduling features with everyday convenience, including smart control via the Intermatic Connect app. Available in two or three-circuit models, the ETW Series allows for seamless scheduling of outdoor lighting, indoor lighting, motors, pumps, and more.

Features & Benefits

• Flexible Programming

• Remote Access

• Intuitive Naming

• Adjustable Scheduling

• Remote Override

• Visual Cues

• Service Mode

Manholes And Vaults

The BNT Nonmetallic Cable Support For Power

Underground Devices

BNT Nonmetallic Cable Supports:

High Load Capacity

Arms Can be Used With Nonmetallic or Steel Stanchions

Will Not Rust or Corrode

Insulators Not Required

Excellent Dielectric Properties

Multiple Stanchion Lengths Available

Arms Available in Multiple Lengths With Integrated Saddles or a Flat Surface

Molded from UL Listed

Glass Reinforced Polymer

BNT Saddle Arms Installed in a Nonmetallic Stanchion

With its exclusive online content, ecmweb.com is a valuable source of industry insight for electrical professionals. Here’s a sample of what you can find on our site right now:

MOVING VIOLATIONS VIDEO NO. 307: RMC SECURING AND SUPPORTING DISASTER

Video In this episode, Russ spotted a luminaire without the proper securing and supporting required by the Code. ecmweb.com/21284977

REDUCING RELIANCE ON PPE Safety Electrical Expert Mike Lamendola discusses why you shouldn’t make PPE carry more of the safety burden than it should. ecmweb.com/55002009

MISSOURI BILL CALLS FOR ESTABLISHING A STATE BUILDING CODE

National Electrical Code A push emerges in Missouri for uniformity across NEC and other building codes. ecmweb.com/55000900

Editorial Group Editorial Director - Buildings & Construction: Michael Eby, meby@endeavorb2b.com

Editor-in-Chief: Ellen Parson, eparson@endeavorb2b.com

Managing Editor: Ellie Coggins, ecoggins@endeavorb2b.com

Editor: Michael Morris, mmorris@endeavorb2b.com

Art Director: David Eckhart, deckhart@endeavorb2b.com

Consultants and Contributors

NEC Consultant: Mike Holt, mike@mikeholt.com

NEC Consultant: Russ LeBlanc, russ@russleblanc.net

Sales and Marketing

Vice President: Mike Hellmann, mhellmann@endeavorb2b.com

Regional/Territory Account Manager: David Sevin, dsevin@endeavorb2b.com

Regional/Territory Account Manager: Jay Thompson, jthompson@endeavorb2b.com

Media Account Executive – Classifieds/Inside Sales: Steve Suarez, ssuarez@endeavorb2b.com

Production and Circulation

Production Manager: Brenda Wiley, bwiley@endeavorb2b.com

Ad Services Manager: Deanna O’Byrne, dobyrne@endeavorb2b.com

User Marketing Manager: James Marinaccio, jmarinaccio@endeavorb2b.com

Classified Ad Coordinator: Terry Gann, tgann@endeavorb2b.com

Endeavor Business Media, LLC

CEO: Chris Ferrell President: June Griffin COO: Patrick Rains

CRO: Paul Andrews Chief Digital Officer: Jacquie Niemiec

Chief Administrative and Legal Officer: Tracy Kane EVP, Group Publisher – Buildings/Lighting/Digital

Lighting & Control Market Poised for Transformation

By Ellen Parson, Editor-in-Chief

Every April, we dedicate the majority of our content to lighting & control topics. With LightFair now on a biennial schedule (2024 being an off year), the LEDucation Trade Show & Conference took center stage this year for our in-person lighting coverage. Representing our electrical group, Jim Lucy, editor-in-chief of ewweb.com, was on site reporting from the show floor. Held March 19-20 at the New York Hilton Hotel, Jim described this year’s event as having a “distinctly New York City feel” — with many aisles in the four exhibition halls jammed to the point of gridlock. Organized by the Designers Lighting Forum New York, LEDucation delivered recordbreaking attendance, drawing nearly 11,000 attendees from all segments of the lighting industry. For the latest trends in lighting & control as well as highlights from this year’s event, read Jim’s in-depth show report on page 24.

With this type of active participation and engagement at LEDucation, the demand for and interest in lighting & control products continues to grow. In addition to the fixture miniaturization trend Jim identified at LEDucation, several buzzwords continue to dominate the lighting space, including connected lighting, smart lighting, and lighting-as-aservice (LaaS) — and let’s not forget about the ways in which artificial intelligence could transform this market in the future. According to sister publication LEDs Magazine, “AI systems can analyze vast amounts of data in real time, adjusting lighting settings based on factors such as occupancy, ambient light, and energy consumption.” For more information on how AI is poised to rewrite the lighting controls value proposition, read the full article at ledsmagazine.com/14296266.

It’s no surprise that all of the leading lighting manufacturers are devising new, creative ways to harness the power of AI and rolling those features out in new product introductions. It will definitely be exciting to see how quickly and extensively this trend develops in the next few years. I actually just saw a press release for a ground-breaking technology a few days ago from Lepro. Touted by the company as a “first of-its-kind Generative Pretrain Model for Lighting,” these smart lights adapt to end-users’ commands and emotions, offering the power to interact with intuitive controls that align with their moods and leveraging AI algorithms for a personalized lighting experience. No doubt this trend will evolve moving forward.

In addition to the LEDucation report, we’ve put together an outstanding lineup of articles in this issue that addresses the latest developments, trends, and best practices in the world of lighting & control. Starting with the latest trends in commercial lighting rebates in 2024, turn to page 18 to get the scoop from Randy Young of BriteSwitch on how to navigate the latest updates this year’s for rebates.

How does illumination stack up against other Power over Ethernet (PoE) building applications? Find out in the cover story, starting on page 28. Written by Freelancer Tim Kridel, this piece explains new lighting options made possible by PoE as well as potential competition for electrical contractors from low-voltage contractors.

When it comes to lighting applications, codes and standards are always top of mind. Since different states and municipalities adhere to different versions of IECC and ASHRAE 90.1, find out why it’s critical for electrical contractors to understand what’s required and how to apply the requirements in the field in the piece on page 36, written by Mike Lehman and Joe Briscoe of Leviton.

On page 42, Bob Tortorello of Optec LED Lighting provides best practices for effective lighting projects. In this piece, Bob maintains design engineers and electrical contractors play an integral role with their clients, serving as an unbiased, honest broker. Read this article for detailed guidance on how to implement the most effective lighting projects.

And what type of lighting coverage would be complete without the latest new products introduced to market? Turn to page 46 for a lighting-focused product showcase.

I can’t wait to see what transpires in the next trip around the sun in the lighting & control space — until next year.

As a small business owner, you can’t escape your to-do list. That’s why Progressive makes it easy to save with a commercial auto quote, so you can take on all your other to-dos. Get a quote in as little as 7 minutes at ProgressiveCommercial.com

Diagnosing Your Electrical Safety Protocols

Do you know how to discover and correct defects in your personal safety system?

By Mark Lamendola, Electrical ConsultantYour safety system is only as good as the procedures, training, attitudes, and decisions that comprise it. As with any system, a defect can lead to a malfunction — and a malfunction may produce an adverse safety event, something we call an accident even though it’s nearly always the result of deliberate actions and/or inactions.

If you can detect and correct defects in this system, you can largely prevent adverse safety events. But you must do that deliberately, it won’t happen by accident.

Here are seven common defects along with insight into what to do about them.

LOW COMPLIANCE WITH SPECIFIC SAFETY REQUIREMENTS OR PRACTICES

Not just supervisors, but also coworkers, need to be on the lookout for this. Then dig in to determine the underlying cause.

For example, why does everyone skip Step 3 of a particular procedure? To figure this out, ask each electrician for honest, even brutally honest, feedback. Maybe that step is unrealistic due to (removable) barriers to compliance.

Sometimes it’s a lack of understanding. For example, a confined entry permit is specific to time and personnel. Someone too poorly trained to understand this might try to use someone else’s confined entry permit when serving as that person’s relief (and a poorly trained operator might allow that).

UNSAFE CONDITIONS UNRESOLVED BEFORE PROCEEDING

Sometimes, an employee notices an unsafe condition and reports it to a supervisor who then promises to investigate it. The employee then “carefully” works with that condition present. This greatly raises the odds that someone will get hurt. The supervisor must respond to the complaint immediately, not after other things are out of the way. Safety is the top priority; other concerns can wait. One way to handle an unsafe condition is to empower the affected employee to “own it” until resolution has occurred. But that’s not always feasible. The employee may not have the time,

expertise, organizational authority, or other resources to solve the problem.

So the supervisor must assess the safety issue and reach a decision that doesn’t count on “being careful” (luck). That could mean, for example, roping off the area and reassigning the employee. Resolution doesn’t necessarily mean removing the hazard. Resolution might mean reducing the hazard to a level where correctly chosen and used personal protective equipment (PPE) ensures the employee is protected (e.g., a hot work permit).

UNSAFE ACTS

Employees typically commit unsafe acts for the sake of convenience. For

example, standing on the top rung of a ladder is more convenient than getting a taller ladder — and “it will take just a minute” (famous last words). It is more convenient to string two lanyards together due to lack of a proper attachment point in the needed location than it is to stop work and resolve that issue — and it’s a good way to break your back.

You don’t solve the unsafe acts problem by having supervisors write people up if they catch them committing an unsafe act. That method results in a game of “don’t get caught” rather than a mindset of “work safely.” A proven approach is to empower all employees (including, of course, supervisors) to stop someone who is committing an unsafe act. Then a short discussion ensues as to why that act is unsafe and how to perform the task safely. This system works when employees are genuinely concerned about their safety and that of their coworkers. It’s a coaching relationship.

Not everyone is amenable to coaching. In such cases, the supervisor may use progressive discipline up to and including termination. In some cases, termination is immediate because of the seriousness of the safety infraction (such infractions are normally spelled out in an employee manual or similar document).

INATTENTION

One way that screen addiction reduces safety is the distraction effect. Some people try to multi-task while interacting with their screens. Multi-tasking is an illusion, the reality is your attention switches between tasks, and there is blank-out time during the switches. If you’ve had one of those phone “conversations” with someone who is texting or checking e-mail, you’ve witnessed this effect. Those texts or e-mails are similarly subpar because that person was talking on the phone while writing.

The consequences of inattention when performing electrical work can be

Ultimate G series brackets

Efficient brackets make prefab easy!

Easily mount any box and mud ring to studs or our new open center bracket! Ultimate G series brackets maximize flexibility, saving time and labor. The gangable design that lets you simply add boxes on either side, reducing SKUs. Plus, it holds the box for hands-free installation.

Perfect for prefab—RACO’s ProReady™ solutions drive installation simplicity and efficiency! Ultimate G series brackets are available individually or with built-in STAB-iT® boxes or Hinged Adjustable Mud Rings.

much more severe than a nonsensical message or a confusing conversation. If you’re a manager, make it clear that people must focus on their work and not have distractions. Safety, work quality, and efficiency all require this.

If you’re a worker, find ways to clear your head of distractions. There are plenty of books on the topic. Or try focus training. You practice focusing for five minutes at a time until doing so is easy. Then increase the time to 10 minutes. No texts, no casual conversations, no thinking about what you’ll be doing after work. Focus intently for just a few minutes until such focus becomes a habit, then increase your focus time as you build your “focus muscle.”

INCORRECT USE OF PPE

This includes such things as clipping a lanyard to a raceway instead of an anchor, relying on a dust mask to protect against gases, relying on work gloves for shock protection, etc. It’s sometimes said

SAFETY CORNER

that “some PPE is better than no PPE,” but the reality is that inadequate PPE or incorrectly used PPE is still unsafe. Ensure everyone is trained in PPE usage, and that all procedures identify the PPE required for the given task.

INCORRECT USE OF LADDERS, LIFTS, AND OTHER EQUIPMENT FOR WORKING AT ELEVATION

The two main contributing factors are insufficient training and insufficient equipment. Training can be insufficient if it’s too infrequent, too much at once (like drinking from a fire hose), or not enough. Training must be followed up with observing how people put it into practice.

If people make do with what they have because they don’t have what they need, you have an insufficient equipment problem. Identify the working height and equipment types needed during the project proposal stage (if a contractor) or based on the specific jobs people do in the facility (if maintenance).

INCORRECT USE OF TEST EQUIPMENT

A common error, especially with digital multimeters (DMMs), is that of holding a test lead in each hand and moving them toward their respective measuring points at the same time. This can result in some communication between the leads in the form of an ionization trail, and that sets the stage for an arc flash.

Other errors include using the wrong CAT rating of equipment, not properly connecting the “ground” of equipment with a “ground” connection, using a DMM to directly measure amps on service, feeder, or branch circuits (it’s protected by a 2A fuse and whatever physical distance is in the meter between that post and another post), performing a “circuit must be de-energized” test on a circuit that hasn’t been deenergized, and using damaged test leads.

If people make do with what they have because they don’t have what they need, you have an insufficient equipment problem.

The most common reason for these errors is insufficient training. People must not only be trained in how to perform specific tests with specific test equipment but also on what not to do with specific test equipment. They must know where it can be used within the power distribution system and where it cannot be used within the power distribution system.

A good general “fix it” for the CAT problem in industrial facilities is to ensure that all test leads and equipment are rated CAT IV where practicable. Where it is not practicable, then equipment not so rated should be unmistakably identified (e.g., affix a “lab only” sticker and maybe paint a red stripe around it). Keep such equipment under controlled distribution with checkout available only to technicians/electricians who are certified on that equipment. This kind of setup will keep lab equipment out of the field, while still making it available for laboratory/shop use.

GOING BEYOND THE BARE MINIMUM

Don’t stop at the seven preceding defects alone; they are just examples. Your firm or plant may have many others that aren’t on that list. So how do you find them? A good way to do that is to train everyone — not just supervisors — to look for unsafe acts. People can then report these in the regular safety meetings. It isn’t necessary to identify who did what, only to identify what was done (or not done).

This then becomes feedback for identifying gaps in training, problems in procedures, and deficiencies in equipment. If standing too high on step ladders is a frequent problem, you most likely don’t have enough step ladders of the correct size. It may not be practical to have an array of many sizes of step ladders, and a solution to that problem is to replace the shorter ones with multi-mode or multi-position ladders. If people are “repairing” test leads with phasing tape, an obvious solution is to make new test leads readily available.

Electricians routinely diagnose and repair problems with wiring and equipment, and they are typically very good at doing so. Use the same talent to diagnose and repair problems in your safety system.

Mark Lamendola is an electrical consultant based in Merriam, Kan. He can be reached at mark@mindconnection.com.

NO BURN-THROUGH CHAMPION DUCT® SOLVES UTILITIES CHALLENGES

No burn-through eliminates elbow repairs

Lower material and installation costs

DOWNLOAD FIBERGLASS VS GRC COMPARISON

Fault resistance makes repairing cables easy

Durable and corrosion-resistant for project longevity

BIM/REVIT

©2016 Champion Fiberglass, Inc. Champion Fiberglass® ElbowsHow to Ensure Departmental Efficiency in Electrical Estimating

Know the difference between productivity and production — and how they relate.

By Don Kiper, Estimating 101

Every electrical contractor must look closely at not only their estimating department’s production, but also their productivity.

Production is defined as the act or process of producing. In estimating, production is measured by the total volume or value of estimates produced. Some contractors will track their production monthly, quarterly, and annually. The wise contractor will know the production of each estimator on the team.

Meanwhile, productivity is defined as the rate at which goods or services are produced, especially output per unit of labor. In estimating, productivity is measured by the amount of time required to produce an estimate. Productivity in

estimating is also measured by organization, detail, time, and accuracy of the estimate.

AN EXAMPLE OF PRODUCTIVITY VS. PRODUCTION

Electrician A and Electrician B both installed 100 ft of 3/4-in. EMT conduit. Electrician A installed the conduit in 4 hours and Electrician B in 6 hours. Their production was the same, but Electrician A’s productivity was 33% more efficient.

The level of productivity in production is determined by the efficiency of the work. The higher the productivity of the firm, the greater the earning capacity. This is true both for estimating and project management.

Productivity is often misconstrued with production, but there is a difference in the sense that production indicates the volume of output whereas productivity is the output generated from the resources employed by the company in relation to time.

FACTORS INFLUENCING LOW PRODUCTIVITY

I have observed some contractors who think getting employees to work longer hours is a way to increase production. However, contractors must focus on productivity first and production second. The wise contractor will provide their estimating department with the proper tools and procedures that provide for the greatest productivity.

Expecting employees to work longer hours less efficiently is not the answer. By focusing on productivity, production is automatically increased.

First, consider a few reasons why employees have low productivity:

Multitasking. In reality, an employee can only give their time and attention to one thing at a time. With increased tasks and responsibilities, productivity is decreased because an employee is switching back and forth between tasks, which will break their momentum. Some contractors require their employees to function as an estimator and a project manager. This can be challenging for some.

Workplace stress. It is well known that stress at work affects job performance, morale, and even an employee’s personal life. A great company culture is vital to building a great company. Employees must enjoy their jobs and workplace to be productive.

Lack of sense of belonging. A strong team is necessary for the greatest level of productivity. When an employee feels isolated from the core members of a team, their sense of contributing is diminished.

Lack of recognition. Most employees are dedicated to their positions. Many work hard and seek advancement in their career path. Compensation is important. Employees also excel when their dedication and hard work are recognized by management.

Toxic workplace behavior. Professionalism should be paramount in

the office environment. Inappropriate comments and innuendos create an unhealthy workplace environment.

Poor management. Employees function most efficiently when job descriptions and responsibilities are well defined. No employee can meet expectations unless they are given clear instructions on job performance.

The level of productivity in production is determined by the efficiency of the work. The higher the productivity of the firm, the greater the earning capacity.

BEST PRACTICES FOR INCREASED PRODUCTIVITY

The following should be considered to increase the productivity rate of your estimating department:

Quality estimating software. Software that offers efficient takeoffs, organized breakdowns, multiple bid summaries/users, and detailed reports provides great efficiency to the contractor. No one would learn to type on a manual typewriter before learning a word processing program. Therefore, estimating with pencil and paper is detrimental to efficiency.

Onscreen takeoff. Most leading brands of electrical estimating software provide this valuable tool. Both money and time are saved when drawings do not have to be printed.

Departmental procedures. A weekly estimator’s meeting will provide the opportunity to utilize the collective knowledge of all team members. This meeting will provide for the most efficient post-project

reviews and proper handoff to project management.

Follow an estimating sequence. Consistent procedures produce consistent results. This sequence should provide the estimator with the proper order in which the estimating tasks are to be performed. Just as a pilot has a pre-flight checklist that is followed in a logical sequence for a safe flight, the estimator must do the same.

Single-role estimator. Some contractors have employees who function as an estimator and a project manager. This arrangement should not be considered multitasking. The employee is either estimating or project managing; both cannot be done at the same time — and switching between responsibilities breaks momentum and negatively affects productivity. This decision will vary depending on the size of the contractor. As a company grows, I believe that the single-role model provides the greatest efficiency and profitability for the contractor.

Quality training. The electrical industry spends an enormous amount of money and resources training apprentices to become journeymen wiremen. Sometimes, however, office employee training is overlooked. Proper training empowers employees and increases productivity. Being a good electrician is no guarantee that they will be a good estimator any more than being a good football player makes someone a good coach. Employees function best when they are provided with quality training to function in their positions.

When a company and an estimator have better processes and systems in place, productivity is increased. When companies provide the best tools and detailed procedures for their estimators, more work can be completed in less time.

In conclusion, focus on productivity first, and then increased production will follow. Increasing productivity will increase profits both in the office and field — so don’t be busy; be productive.

Don Kiper is an independent electrical estimating trainer and consultant based in Niagara Falls, N.Y. He can be reached at don@electricalestimating101.com.

AROUND THE CIRCUIT

Electrical Supply Chain Challenges and Solutions

Best practices for electrical contractors and their manufacturer partners

By Eric Nimer, P.E., RMF EngineeringOver the past three years, the global supply chain has been fraught with challenges, particularly within the architecture, engineering, and construction industry. Disruptions, such as manufacturing delays, material scarcities, shipping interruptions, workforce gaps, and regulatory obstacles, have all contributed to an increasingly complex and unpredictable building landscape. While some of these challenges have gradually begun to subside over time, the industry still faces significant hurdles when it comes to electrical equipment — switchgear and generator packages, in particular.

The scramble for materials and resources, reminiscent of the early days of the COVID-19 pandemic when even essentials were scarce, has seeped further into the availability of these pieces of equipment. The associated low-voltage power circuit breakers are now seeing the longest delays, often surpassing a year from the time a purchase order is issued. Reliance on these integrated circuits — primarily supplied by manufacturing centers in Taiwan and China — has set a cascading series of at-home challenges into motion. As a result, professionals from across the AEC industry have had to become increasingly creative with their solutions to keep necessary infrastructure online and improvement projects on track.

THE BURDEN OF SUPPLY CHAIN DISRUPTIONS

The significance of the impact of electrical equipment backlogs cannot be understated. Essentials such as

generator packages and switchgear lineups, which once had a standard lead time of approximately 15 weeks, are now taking more than 92 weeks to deliver. The extensive delays are impossible to accommodate within today’s tight construction timeline expectations and are far too costly to even consider. Consequently, owners, decision-makers, and engineers are forced to problem-solve even earlier in the design process — where information is extremely limited, and changes are inevitable.

Shifts in project specifications can be substantial as a concept moves through the design, development, and documentation phases — further complicating the process of accurately sizing critical

pieces of equipment. Moreover, resizing that equipment can add considerably to the project timeline; every hurdle in the equipment sizing process during the mechanical engineers’ work leads to a delay or “re-do” of the electrical engineer’s sizing. When program changes occur further up the pipeline, such as from the owner or architect, the resulting domino effect sends every engineer back to the drawing board once again.

To solve for these potential setbacks and keep projects moving forward despite the “stop-rework-and-go” model, being employed out of necessity, project teams have begun procuring oversized generators and switchgear to account for the uncertainties. While prudent now,

this strategy can introduce additional delays in project timelines, increased costs, and operational inefficiencies. Oversized equipment is always going to be more expensive than the right-size solution — both upfront and in terms of the ongoing energy prices and maintenance budgets.

Oversizing also raises questions about environmental responsibility that owners will have to grapple with longterm. Operating oversized equipment contributes significantly to energy inefficiencies and a larger carbon footprint, which will translate to broader sustainability questions down the line.

The far-reaching implications of this intermediate solution underscore the urgency of rectifying the challenges within the supply chain. Navigating this landscape demands creative problemsolving and unwavering dedication from engineers and decision-makers. With strategic collaboration and a little creativity, the industry can pave the way

sales@alliedmoulded.com

222 North Union Street

Bryan, Ohio 43506

Ph: 800-722-2679

•

•

AROUND THE CIRCUIT

The University of Maryland Baltimore experienced a phased campus-wide replacement of its electrical power system.

for a more efficient and robust supply chain, thus reducing the environmental footprint of its operations.

WORKING TOGETHER TOWARD BETTER SOLUTIONS

Owners, architects, and engineers must work together to strike a balance between mitigating uncertainties and avoiding unwarranted costs. Proactive planning is key to creating a stopgap for disruptions, and close collaboration is essential to staying ahead of volatility. Particularly for owners who may not be as familiar with the project dynamics as the on-the-ground team, this proactivity recognizes the unintentional role owners may play in overlooking how urgent decisions must be made to stay on track.

Additionally, by ensuring electrical and mechanical teams are kept in the loop on changes in real-time, the entire project team will be able to pivot strategies much faster. Equipment re-selections can be made more quickly, and the downstream processes can be expedited. In this dance, engineers can and should take the lead in advocating for what’s needed to successfully deliver a project that is both budget-friendly and quality-conscious.

When new equipment still is not a viable option, however, used generators have emerged as an effective solution. Most generators are built to support a lifespan of around 20 to 30 years. Inevitably, there will be some variability based on how well the equipment has been maintained and how often it was made to operate beyond its manufactured capacity or output. More often, the largely dependable grid infrastructure in many parts of the United States will have limited the need for generator use to power entire facilities. Many generators are only used during their mandatory testing periods and have many years left of useful life.

It is important to note, however, that while used generators represent a resourceful option that can alleviate the need for last-minute changes and can be a good place to source spare parts in a time crunch, this option becomes less feasible when paralleling switchgear is in place. Fortunately, there are other ways to strategize equipment selections that don’t require a “solve-for-this-scenario” line of thinking.

LEANING ON MANUFACTURER PARTNERSHIPS

While the lead time on larger pieces of equipment can stretch from 52 to 92 weeks, smaller units often have much faster manufacturing turnarounds. By working closely with the architect team, engineers can determine if the square footage needed for a two-part solution is available and pivot to the procurement of two smaller units that fulfill the same capacity initially needed from a larger, single unit. This approach also necessitates ongoing dialogue with the equipment manufacturers themselves; they know best what is available, what has the fastest lead times, what is delayed, and what the alternatives may be.

In the electrical construction and maintenance fields, the relationship between an engineer and the product and equipment manufacturers is not merely transactional; it’s a partnership,. The manufacturer will bring a discerning eye to an engineer’s designs and assist in providing equipment solutions to achieve the architect’s vision. By fostering ongoing, open dialogue, this process is as agile and adaptable as its upstream counterparts — mitigating the impact of last-minute modifications and ensuring the project stays on track the entire time.

These partnerships are also essential in better equipping the manufacturers to equip the engineers. As new products and solutions are introduced to the market and alternatives are tested and workshopped, those open lines of communication can allow for a more robust feedback loop on opportunities to improve or gaps to be filled. This is powerful data for the manufacturer to have — empowering them to evolve their development process in accordance. The benefit of that process is integral to the success of the engineer on a project, whose whole solution hinges on the manufacturer’s ability to respond. Together, this symbiotic relationship bridges the gap between what’s not working and what’s needed, helping to overcome disruptions and deliver innovative strategies efficiently.

Ultimately, each partner on the project team has an equally vested interest in its success. Engineers, in particular, play an important role in bridging vision with reality. This presents a significant opportunity to shape the trajectory of the industry and its expectations of supply chain challenges to produce

more effective and efficient outcomes. By embracing open communication, advocating for collaboration, and balancing financial acumen with agile decision-making, engineers can steer projects through the complex, volatile landscape. What’s more, by better understanding and navigating the maze of shipping timelines, delivery delays, and parts shortages, engineers can help build a more sustainable future for all stakeholders involved.

As technology advances and innovation accelerates, engineers must remain adaptable and open to new solutions, further solidifying their role as pioneers in the ever-evolving landscape of industry and sustainability.

Eric Nimer is an electrical engineer and Georgia Buildings Team Lead for RMF Engineering with experience primarily in health care, higher education, and governmental projects. He also holds a master electrician license (unrestricted).

New Universal Stud-mount Brackets

Maximize your jobsite flexibility, save time and labor!

Easily mount any RACO 4” or 4-11/16” box to metal studs or our new open center bracket and add a mud ring. Just snap the Universal Stud-mount Bracket to the stud for hands-free installation.

The rigid design eliminates the need for far-side support. Install vertical or horizontal. Even gang multiple brackets together. These cost-effective brackets save time and effort.

Available as a flat bracket, raised mud rings, and adjustable mud rings.

Try RACO universal stud-mount brackets for yourself! Scan to request a sample.

Commercial Lighting Rebate Trends for 2024

Check out the latest trends for commercial lighting rebates in 2024.

By Randy Young, BriteSwitchAccording to BriteSwitch, a firm specializing in capturing local, utility, state, and federal rebates/incentives for businesses, the past couple of months have seen a flurry of activity as organizations updated their rebate programs for 2024. Each year, these incentives, which have been instrumental in driving energy efficiency since the mid-80s, continue to evolve to reflect the changing industry and market dynamics. Now, the dust has settled, and most of the new programs have launched, and it’s very favorable for those in the lighting industry.

Here are the rebate trends for commercial lighting and control rebates in 2024.

MOST OF U.S. HAS A COMMERCIAL LIGHTING REBATE PROGRAM AVAILABLE

Over the last 15 years, the availability of commercial lighting rebate programs across the United States has been subject to fluctuations. In that time, the portion

This year, 78% of the country boasts access to such a program (see Map on page 20). It’s the fourth year in a row we’ve seen this coverage level, a good sign for dis-

The Northeast and Northwest remain the best areas with the strongest incentives and good coverage. States like North Dakota and Kansas remain holdouts with no commercial lighting programs at all.

of the country covered by a lighting incentive varied between 42% to 79%. However, recent years have seen a welcome trend towards stability.

tributors and contractors who rely on these rebate programs to help close business.

However, that doesn’t mean everything stayed the same. For example,

some utilities in Ohio debuted new programs in mid-2023. Until that point, the state had no rebate opportunity due to legislation that stopped the energy efficiency rebate programs in Ohio in 2020.

Generally speaking, the Northeast and Northwest remain the best areas with the strongest incentives and good coverage. States like North Dakota and Kansas remain holdouts with no commercial lighting programs at all. The states with the highest populations, California, Florida, and Texas, still have some of the worst rebate opportunities with very few programs which are usually very complex.

REBATE AMOUNTS FOR LEDS STILL STRONG

When LEDs were first introduced in rebate programs, the amounts were very

LIGHTING & CONTROL

Average Prescriptive Rebates in North America Retrofit Lamps/Tubes

$15

Source: BriteSwitch RebatePro for Lighting 2/2024

$10

$5

$0 Fixtures

2015 2016 2017 2018 2019 2020 2021 2022 2023 2024

high, but quickly, a pattern emerged where the rebate amounts declined every year by 10% to 20%. It was a disturbing trend that had many wondering if it was a race to the bottom.

In 2021, that all turned around. Between the soft market, due to a lack of demand for projects and cost increases, the rebate decline slowed down. The incentives started to level out, and over the past few years, we’ve noticed relative stability (Fig. 1).

In fact, rebate amounts for 2024 are up 2% on average for LEDs and 5% for controls. For most LED products, the average rebate across North America is near the highest recorded levels.

The best rebates are still for LED fixtures replacing HID fixtures like high bays and pole lights. It makes sense since these fixtures typically cost the most and also offer the highest energy savings (Fig. 2 on page 22).

With the changes from EISA that went into effect in July 2023, it was expected that the rebate amounts for A19s, PARs, and downlights would decrease significantly, but to everyone’s surprise, they increased. While many programs like Duke Energy’s Smart Saver Program, Energizing Connecticut’s Instant Lighting Program, and the state-wide MassSave program discontinued rebates for these types of lamps, many other programs still continue to include them in their offerings at a higher average dollar amount.

$150

Source: BriteSwitch RebatePro for Lighting 2/2024

$100

$50

$0

2015 2016 2017 2018 2019 2020 2021 2022 2023 2024

Commercial Lighting Rebate Coverage 2024

Percentage of state covered by a lighting rebate

Source: BriteSwitch RebatePro for Lighting 2/2024

In 2024, 78% of the United States has access to commercial lighting rebate programs.

PROGRAM FUNDING STRETCHES FURTHER

The volatility of commercial lighting rebate programs makes it more challenging for contractors, manufacturers, and lighting distributors to take advantage of. Historically, one of the big issues has been programs running out of funding before the program year is over. According to RebatePro for Lighting, 10% to 25% of programs would traditionally run out of funding before the year ended.

However, recent trends indicate a shift toward sustained funding. In 2023, less than 5% of programs ran out of funding before year end. In the late fall, when programs would typically announce their lack of funding, the announcements instead focused on bonus programs. These limited-time spiffs offered increases of 10% to100% for some of the most common upgrades. By the end of 2023, 22% of the programs provided some type of bonus.

Fast, easy installation!

Extra-wide flanges prevent water and air intrusion... Eliminate the need for gaskets and caulking!

Designed for new construction, Arlington’s non-metallic FR series device and fixture boxes mount directly to a flat surface without the need to cut an opening in the substrate. They feature interchangeable backs and extension rings so ONE box works with almost any cladding system – including engineered foam/stucco systems.

Extra-wide flanges prevent water and air-intrusion, helping to meet the International Energy Conservation Code, and eliminating the need for gaskets or caulking.

• FR series boxes ship ready for use with 1-3/8” finish or cladding thickness Depth can be set for custom depth finishes or cladding materials up to 1-7/8"

• Install before or after the weather barrier house wrap - Installation of box before the house wrap at right

• 20 cu inch volume

Patented

LIGHTING & CONTROL

2024 Average Rebate Amounts in North America

Based on prescriptive and midstream rebates as reported in BriteSwitch RebatePro for Lighting 2/2024

Fig. 2. As of 2024, the best rebates are still for LEDs replacing HID luminaires, such as high bays and pole lights.

Type of NLC Rebate Programs

Source:

Some of these bonus programs have even continued into 2024. Right now, more than 30 different bonus or trade ally programs are running, which is quite uncommon to see in the first quarter. One example is Georgia Power’s program, which is is offering a 50% bonus on all standard rebates through June 30.

These changes are most likely not because of increased overall funding levels but decreased participation. With the lighting retrofit market slowing down — and most of the easy targets already having upgraded to efficient lighting, the remaining holdouts will take more convincing. At the same time, contractors and distributors are turning their attention to other opportunities, looking at more attractive and rapidly growing markets like EV chargers and battery storage/ backup. Higher incentives are needed if

Source:

programs are going to meet their annual energy savings goals.

NETWORKED LIGHTING CONTROL (NRC) REBATES GET A BIT STRONGER

There’s been a lot of talk in the lighting industry about the savings potential of networked lighting controls (NLCs). While lighting has become more efficient over the years, turning it off altogether — or offering just the right amount of light when needed — offers even more energy savings. But NLC’s extra cost and complexity make them a tougher sell for many contractors and distributors. Thankfully, this year sees some improvement in the structure, availability and amounts of NLC incentives.

In 2024, 8% more utilities are offering a rebate specifically for NLCs. That means a majority of rebate programs in the United States have now written these controls specifically into their programs. For the other programs, NLC projects will typically qualify under a performance or custom program.

The type of NLC rebate has also shifted, with 53% of rebates being prescriptive — up from 44% last year (Fig. 3). Additionally, standardization of NLC incentives has increased. This year, 70% of the NLC rebates are now paid per fixture, rather than the more complex calculations like kilowatt-hour saved, square feet, or connected watt (Fig. 4).

In terms of dollar amounts, the average NLC rebate amount increased by 4% over 2023.

DON’T OVERLOOK COMMERCIAL LIGHTING REBATES THIS YEAR

With a softer market for commercial lighting retrofits and many in the channel looking to diversify their interests in other markets, rebates are increasingly important. Incentive programs are more stable than ever — with near record-high dollar amounts. Millions of dollars in incentives are out there and available. For every project, you should look into the potential rebates and see how they will impact the payback of the upgrade.

Randy Young is the director of marketing and data solutions at BriteSwitch, a company that specializes in finding and capturing rebates for businesses. He can be reached at randy.young@briteswitch.com.

LEDucation 2024 Smashes Attendance Record

The aisles were packed at LEDucation with more than 10,000 lighting pros looking for the latest design options and networking with industry buddies.

By Jim Lucy, Electrical Wholesaling

LEDucation built on its growing reputation as a national lighting show with estimated attendance of nearly 11,000 and an as-yet undetermined final count of participants in virtual training sessions at the New York Hilton Hotel on March 19-20.

Well over 400 booths and 48 educational sessions attracted members of the lighting community from across the United States. For the 475 exhibitors, a major attraction of the event was that all booths were restricted in size, trimming the comparatively large investment of a booth at LightFair. According to a report

at inside.lighting.com, each individual booth was limited to 224 cubic feet, with standard dimensions of 7 ft in width, 4 ft, in depth and 8 ft in height. Many exhibitors used the smaller footprint to focus on a tightly targeted selection of product launches — often less than five new products.

Although it has evolved into a national show, LEDucation has a distinctly New York City feel. On the first day of the event, some of the aisles in the four exhibition halls were jammed to the point of gridlock. It almost seemed like the event was a victim of its own success,

with some aisles at times almost completely blocked by attendees visiting with vendors and chatting with business associates. Printer glitches on Day 1 at the registration kiosks added to the general atmosphere of controlled mayhem. On Day 2, the show aisles on the trade show floor were much easier to navigate, and registration seemed to be a breeze.

A surprising number of lighting vendors were exhibiting tape lighting at LEDucation, which has become popular because of the broad array of colors LEDs now offer and the customization/ flexibility the products provide. At the

SHOW

Tivoli Lighting booth, Larry Lin differentiated his company’s tape light by demonstrating available color temperatures and other technical characteristics in a notebook with “live lighting.”

The trend toward fixture miniaturization was also evident, with many fixtures of less than 2 in. on display that provide better lighting than the PAR lamp options available a few years ago. WAC Lighting has launched many smaller track luminaires with impressive lighting specs over the past few years, and this design trend was also evident in its new Colorscaping landscape lighting products. They use conventional two-wire landscape lighting to provide tunable white light from 2,700K to 6,500K. Fixture beam spreads are adjustable on site, and the lighting scenes can be controlled via an intuitive app.

Edison Price’s Loom track lighting system also uses smaller fixtures that pack a punch. Loom allows lighting pros to quickly adjust fixture placement along a sliding rail system. The product was one of the Edison Report’s “Top 10 Must See Products” at LEDucation.

Innerscene had a particularly busy booth during both days of the show. Innerscene’s Virtual Sun is a skylight that mimics the light of the sun or as it tracks across the sky with simulated circadian rhythms.

A big part of the LEDucation experience is the event’s impressive offering of on-site and virtual training. Leviton’s Joe

Brisco, technical sales specialist, and ConTech’s Mike Lehman, general manager, helped a packed room of lighting designers and other show attendees understand the nuances of the many code updates for IECC and ASHRAE 90.1 lighting and control requirements. States and cities have adopted different versions of these building and design codes, so it’s important to check with your local inspectors on what version your market area is following.

In the “POE Past-Present-Future” panel discussion, Mitchell Bloomberg, International Lights; Lilian Fu, WSP; Farukh Aslam, Sinclair Holdings; and

Michael Baudo, Zumtobel, updated the audience on the use of DC power in Power over Ethernet (PoE) lighting and other building applications. At Sinclair Holdings, Aslam has been using DC power in hotels and several other large commercial applications and is a big believer in its potential to provide dependable power at a much lower installation cost than traditional wiring because of the use of smaller wire and cable — and the fact that it can be installed without conduit.

LEDucation continues to resonate with lighting professionals for several reasons. It’s an event managed by New York’s lighting designers and lighting reps, so it has a “by the people, for the people” feel.

The continuing march of lighting technology continues to fuel interest in the event, too. It’s getting tough to squeeze additional energy savings out of LED lighting systems because of the revolutionary R&D we have seen with LED technology, and the dramatic savings over the past two decades LEDs have been on the scene. But with fixture miniaturization and other innovative new fixture form factors, advancements in appbased and wireless lighting control, and the potential of PoE lighting, there’s still plenty of new products in the pipeline.

The next generation of LED lighting systems will be on display at LEDucation 2025, which will be back at the New York Hilton on March 18–19, 2025.

Power over Ethernet (PoE) enables new lighting options — and new competition from low-voltage contractors. How does illumination stack up against other PoE applications?

Lighting is a lightning rod for Power over Ethernet (PoE). With publication of the IEEE 802.3bt standard in September 2018, PoE gained the ability to support up to 90W. That made it a good fit for lighting applications that traditionally required an AC outlet. But in the process, 802.3bt opened the door for non-electricians to install lighting, such as audio-video (AV) integrators, security firms, and other contractors who specialize in low-voltage applications. That prompted the electrical industry to lobby for state building code changes to stave off new competition by moving the high-voltage/low-voltage demarcation line. One example from Utah was lowering Class 2 wiring voltage from 100V to 50V.

“The controversial technology is LED lighting,” Chuck Wilson, executive director of the National Systems Contractors Association (NSCA), told EC&M in 2019. “One of the concerns electricians have right now is lighting is going low voltage.”

Five years later, PoE lighting is a relatively niche application, regardless of who’s installing it. In early 2024, the Ethernet Alliance surveyed companies

that design and install PoE equipment, as well as those that own and manage it, such as enterprise IT departments. Only 19% of respondents said they use it for lighting, making it No. 8 on the list of most common PoE applications (Fig. 1) on page 30).

“Right now we are seeing PoE mostly with networked lighting control systems in commercial settings,” says Collin Weiner, president of CalEnergy Corp., which specializes in California Title 24 energy compliance. “PoE is increasingly used in lighting systems for its ability to power and control LED luminaires, either utilizing integrated fixture controls, distributed control systems, or centralized. In addition to being more cost-effective by cutting down on labor and material costs, PoE systems allow for a more flexible and energy-efficient lighting solution. This is especially true in commercial buildings where additions, alterations, and tenant improvements of spaces are common.”

In some cases, PoE is complementing rather than replacing AC.

“We were seeing a push for PoE in the lighting world,” says Eric Hoge, vice president of engineering at Des Moines, Iowa-based Commonwealth Electric

Company of the Midwest. “However, we have had a couple of clients move away from PoE because of issues with the product and Ethernet switches. We are seeing a bigger move toward networking the controls system but using line voltage at the fixtures. The drive for these types of systems is the ability to control either zones or individual lights using Wi-Fi.”

Commonwealth used wireless for recent projects such as the Nebraska Medicine Fred & Pamela Buffett Cancer Center.

“The application is not PoE in a strict sense since the lights are powered by line voltage,” Hoge says. “However, these systems are still controllable at a granular level like PoE fixtures are. The

drawback is that each zone or fixture to be controlled will require a switching mechanism such as a relay that is controlled by the devices.”

Hoge is bullish about PoE lighting over the long term.

“Our biggest challenge is just the technology itself,” he says. “It has come a long way over the past 10 years, but there are still improvements that need to be made to gain widespread acceptance. I think it is like LED 15 years ago. Compact fluorescent was the fixture of choice over incandescent for energy savings. LEDs were in the market, but the technology had not been refined, and the fixtures were not cost-effective.”

Today, Hoge says LED technology is the primary choice on all of our projects.

“I have zero doubt that PoE is the next step for energy efficiency in every facility,” he says. “The ability to measure and manage our energy use will be huge.”

LESS IS MORE

One aspect of PoE’s future is certain: It’s unlikely to get another wattage boost.

“We wrote 802.3bt with the idea that it was the last multipair PoE standard because once you go past 100W, the rules change around installation practices both in the U.S. and Europe,” says Chad Jones, an Ethernet Alliance member and chair of the IEEE P802.3bt task force.

Currently, most market demand is for products well below the 90W maximum.

“The next largest sales point is the Class 6 power source equipment,” says

David Tremblay, Ethernet Alliance PoE subcommittee chair. “That’s up to 60W capability. Marketing research shows that there’s a growing opportunity for Class 8, but we just aren’t seeing that take over the Class 4 and Class 6 demand.”

Energy efficiency is another marketplace factor. Although 90W PoE enabled more lighting applications and competitors, LED efficiency also is key. This trend is playing out with other devices, which highlights potential business opportunities for electrical contractors.

For example, some commercial video displays are now so energy efficient that PoE can provide both their power and data. In the 2024 Ethernet Alliance survey, 39% of respondents said they’re using PoE for displays, making them the

No. 4 most common device. Electrical contractors might see all that as a reason to expand into the digital signage market with design and installation services instead of just pulling power cables as a sub to AV integrators.

“Absolutely contractors will expand, and it’s very exciting,” says Weiner, whose NECA 2023 presentation focused on “How Lighting Controls Can Revolutionize Service and Maintenance.” “The trends of increasing energy efficiency in connected devices and the growing power capabilities of PoE are indeed expanding the range of applications where it can be the sole source of power and data. The combination of these trends along with the introduction of Class 4 fault-managed power opens up new possibilities and opportunities in various sectors.”

CUTTING THE CORD

Some electrical contractors are leveraging PoE to expand into the indoor wireless market. Wi-Fi access points (APs) were the most common PoE device in the 2024 Ethernet Alliance survey.

“One of the challenges we occasionally come across with a client is trying to communicate what is truly required to create a strong, stable network,” says Heath Eastman of Kingston, N.H.-based Eaton & Eastman Electric. “While they may understand the need for good Wi-Fi coverage, it can be difficult to convey how critical the complete system with all of the necessary components truly is. A solid network has become a necessary foundation to ensure proper communication and operation of the equipment that is being utilized in today’s homes and businesses. PoE helps us with the ease of installation as well as a cleaner finished look for the client.”

Another wireless opportunity is indoor cellular “small cells,” which look like Wi-Fi APs but provide 4G and 5G connectivity in malls, airports, and other public places. Some small cell products are available in AC and PoE versions, with technology that helps automate network design aspects, such as site surveys, to identify the ideal installation locations. But as with Wi-Fi, digital signage, and other non-lighting applications, electrical contractors need to acquire some cellular skills to be successful and compete with telecom specialists.

Survey Participants

“Certainly electrical contractors are free to go learn that skill and advertise it and do the job,” says Ethernet Alliance’s Jones. “But it’s not something that your typical electrical contractor will know how to do, and it’s not something you learn in a day.”

Small cells and Wi-Fi APs also can create upsell opportunities for electrical contractors. For example, the client might initially want Wi-Fi for broadband access but then be receptive to other applications that use it for connectivity, such as Internet of Things (IoT)

THE EASY, ECONOMICAL WAY TO SLEEVE THROUGH CONCRETE POURS!

Arlington’s Concrete Pipe Sleeves are the economical way to sleeve through concrete pours in tilt-up construction WALLS – and FLOORS allowing cable and conduit to run easily from one floor to the next.

No costly core drilling – No cutting holes in the form. Plus, you can position the hole prior to pouring the concrete.

• Attaches to form with nails or screws

• Stackable up to 23" h for extra deep pours

• Vents keep wet pipe sleeves from sticking together

• Multiple hole sizes: 1-1/2" • 2" • 3" • 4" • 5" • 6"

After concrete sets, cut sleeve flush with surface. Insert conduit into sleeve.

sensors and controllers for smart home/ smart building systems.

“As IoT continues to grow, PoE becomes a convenient and efficient way to power and connect a variety of IoT devices, such as smart lighting systems, security systems, HVAC systems, and distributed energy resources,” Weiner says. “I predict this will eventually contribute to the development of a smart building under one converged system, replacing the structured cabling system and effectively siloing the different building systems, which is the current practice.”

ALL TOGETHER NOW

There’s no shortage of PoE devices and manufacturers to choose from, but some contractors prefer to stick with one brand to ensure that everything just works.

“We typically install new systems with matching components from the manufacturer to help ensure the ease of installation and solid communication between the equipment,” says Eastman,

who also serves as This Old House master electrician.

However, many PoE installations are multivendor environments because they’re an expansion of the client’s existing system or because no single manufacturer can meet all of the project’s requirements. In those cases, vendor interoperability and technology generations are important considerations. 802.3bt is designed to be backward compatible with 802.3af and 802.3at products, but there’s no guarantee that it will support PoE++ devices because that’s a proprietary version — read more on PoE++ and its potential drawbacks at ecmweb.com/20904845..

Older power source equipment (PSE) might not be able to adequately support newer devices. For example, if a legacy 802.3af Class 3 PSE connects to a newer 802.3bt Class 6 device, the latter will be “power demoted.” This process occurs when the device and PSE initially connect and exchange information about

their capabilities. The device will then start disabling features to ensure it doesn’t draw more power than the PSE can provide.

The Ethernet Alliance’s PoE Certification Program helps electricians quickly identify power levels via logo marks that vendors put on products and in documentation. For instance, if the PSE logo number is greater than or equal to the device’s logo number, then the latter won’t be power demoted.

That’s also an example of how the certification program aims to address some of the problems that were flagged in the 2024 Ethernet Alliance survey. For instance, 15% said “power/operation unreliable” is a major problem (Fig. 2 on page 34).

The program also can help with multi-vendor installations.

“This was one of the main reasons for the certification program: to reduce interop issues,” Jones says. “Something that has an Ethernet Alliance certification is exceedingly less likely to have interop issues.”

NICE WORK — IF YOU CAN GET IT

Understanding these kinds of nuances and caveats goes a long way toward ensuring competitiveness and profitability in the PoE market.

“The largest challenge I see for electrical contractors, low voltage, or AV integrators looking to be successful in this space will be high-level education and training for their team,” Weiner says. “Staying updated on the evolving PoE standards, technologies, and manufacturer best practices requires ongoing education and training. Contractors need to invest in keeping their teams knowledgeable about the latest advancements in PoE to provide optimal solutions for clients. Training programs offered by the Ethernet Alliance and the PoE Consortium will be a valuable resource to keep your team a step ahead.”

In the Ethernet Alliance survey, video surveillance and access control were the second and fifth most common applications, respectively. But successfully targeting those markets doesn’t necessarily mean adding or training employees. It could be faster, cheaper, and less risky to partner with firms that specialize in those applications. Their brand recognition also can help open doors, such as with the IT departments responsible for all Ethernet-based applications.

“By leveraging each other’s strengths, sharing expertise, and staying abreast of technological advancements, they can collectively provide optimal solutions for clients in the evolving landscape of PoE systems, Class 4 fault-managed power, and converged smart building systems,” Weiner says.

This strategy also can be a way to turn competitors into partners.

“As the technology continues to emerge and become more powerful, electrical contractors without a limited energy/low-voltage group are going to be faced with losing a part of their market share,” Hoge says. “These systems can be installed quickly without the necessity of conduit installed by electricians. Technicians are going to be qualified to complete the work.

“Even for contractors with low-voltage teams, there is a steep learning curve to be able to compete as an integrator.

PoE Device Installation Challenges

Learn more at ethernetalliance.org/poecert

That means design and programming expertise will be required at the contractor level. To take the discussion just a little further, does that put the electrical contractor in the same arena as the mechanical contractor for supplying control systems? It certainly is going to

be fun watching how the market changes over the next few years.”

Kridel is an independent analyst and freelance writer with experience in covering technology, telecommunications, and more. He can be reached at tim@timkridel.com.

Build a two- or three-gang concrete floor box by simply locking single gang boxes together!

Then buy the UL LISTED single, two- or three-gang cover/frame kit, with devices included, in PLASTIC, FIVE COLORS – or in economical diecast zinc with a brass or nickel finish. Fast, easy installation.

Cover installs with hinge on either side.

Demystifying IECC and ANSI/ASHRAE/IES Lighting and Control Requirements

Since different states and municipalities adhere to different versions of IECC and ASHRAE 90.1, it’s critical for contractors to understand what’s required and how to apply the requirements in the field.

NBy Mike Lehman and Joe Briscoe, Leviton

NBy Mike Lehman and Joe Briscoe, Leviton

avigating evolving building energy codes and standards is a task that electrical contractors, engineers, designers, and building professionals face daily. Understanding the difference between the International Energy Conservation Code (IECC) and the standards set by the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) and the Illuminating Engineering Society (IES) is critical to ensuring code compliance and optimizing lighting efficiency in various building spaces.

DIFFERENTIATING BETWEEN CODES AND STANDARDS

It’s important to recognize the fundamental difference between codes and standards. The IECC, developed by the International Code Council (ICC),

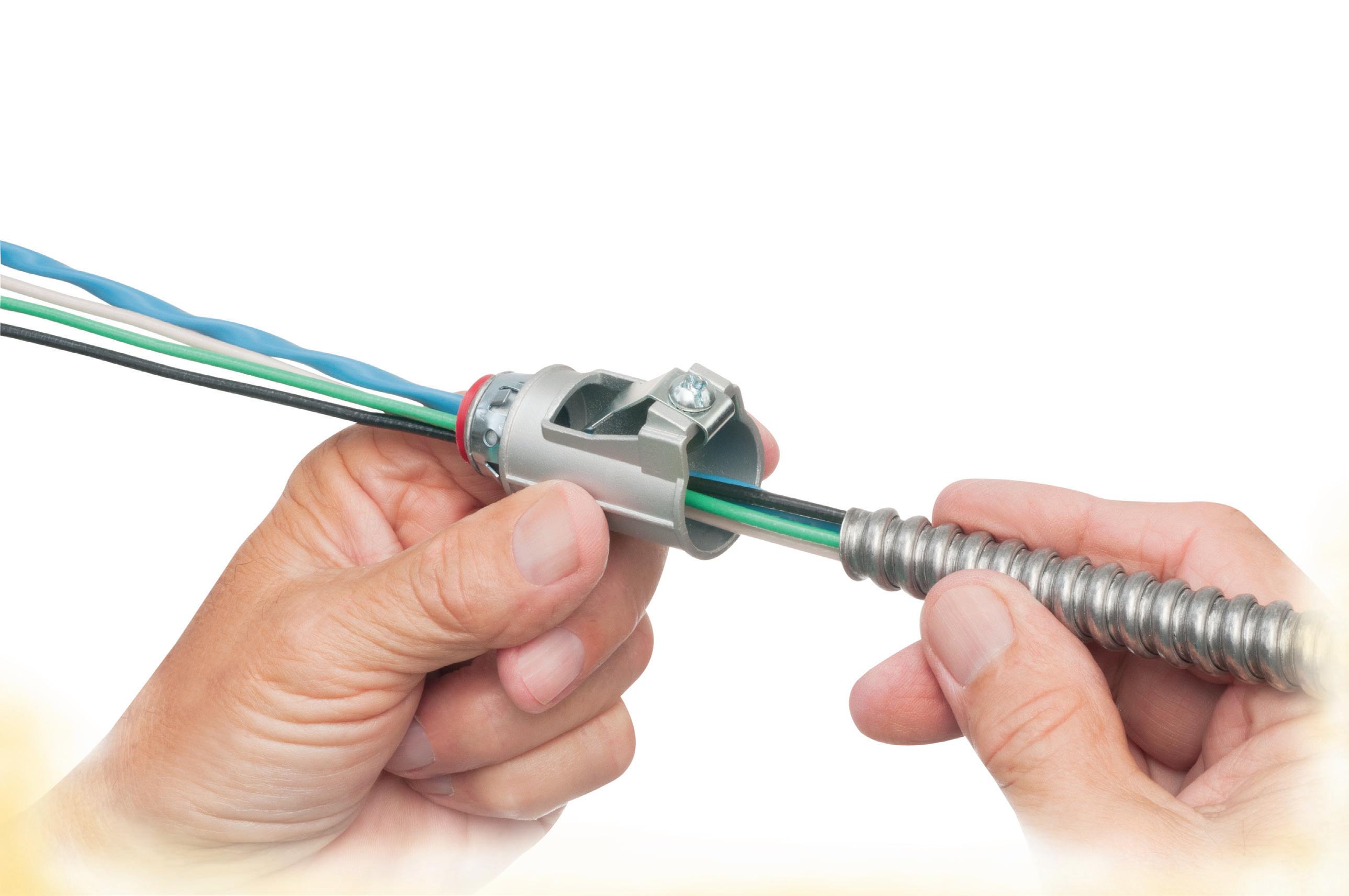

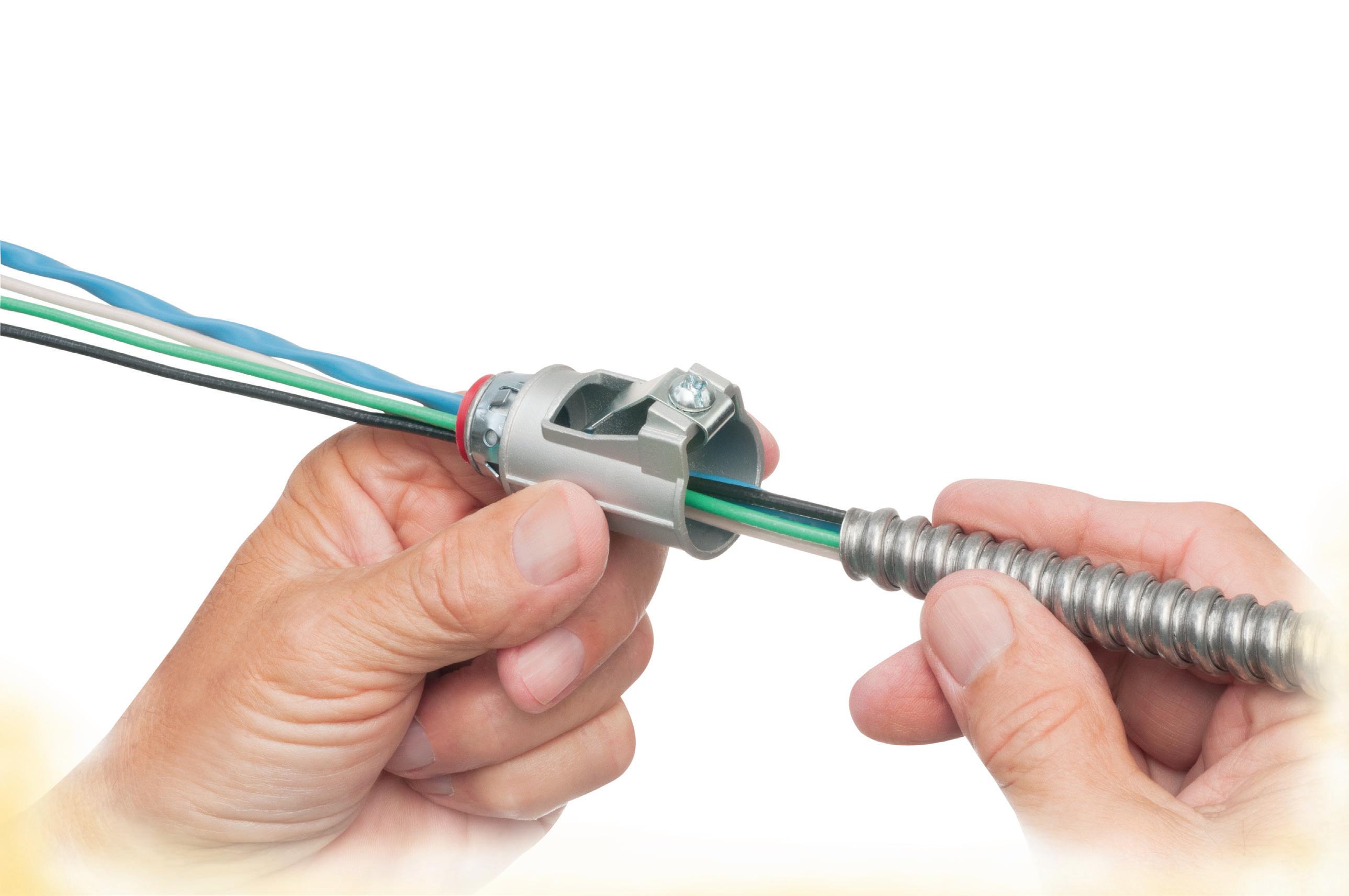

Fully assembled, SNAP2IT® fittings handle the widest variety of MC cable AND THE NEW MC-PCS cables.

Compared to fittings with a locknut and screw, you can’t beat these snap in connectors for time-savings!

• Fast, secure snap-on installation

• Easy to remove, reusable connector

From cable Loosen screw on top. Remove connector from cable. From box Slip screwdriver under notch in Snap-Tite® Remove connector.

establishes minimum requirements for energy efficiency in buildings. It develops codes, which serve as a regulatory framework adopted by states and municipalities to enforce energy conservation measures in construction and renovation projects.

ASHRAE (and partner organizations) establish technical standards and guidelines for the design, construction, and operation of building systems. ASHRAE publishes various standards and guidelines, including ASHRAE 90.1, which specifies energy efficiency requirements that are referenced in codes and rating systems.

VARIED LANDSCAPES OF BUILDING CODE REQUIREMENTS

The challenge is understanding which lighting and control codes/standards apply to your designs and spaces. Some states and municipalities adhere to the IECC; others adopt ASHRAE 90.1. These codes and standards are typically updated every three years — with inconsistent adoption across states and municipalities. Recognizing the differences between the current codes and standards (and their recent updates) is critical for meeting

regulatory requirements and delivering high-performing buildings.

UNDERSTANDING IECC-2021

The 2021 IECC specifies changes aimed at reducing lighting energy consumption in commercial and residential buildings. The most significant change is a reduction in lighting power allowance (Sec. C405.3.2) for most building types. For example, the hospital lumen power density (LPD) dropped minimally from 1.05W/ft2 to 0.96W/ft2, while museums dropped significantly from 1.06W/ft2 to 0.55W/ft2, as shown in Photo 1

Another change in IECC-2021 is a reduction in lighting power of at least 10% compared to the lighting power allowance (Sec. C406.3.1). This change requires the total interior lighting power load calculated with the equation method (Sec. C405.3.1) to be less than 90% of the total lighting power allowance in Sec. C405.3.2 (Building Area Method or Space-By-Space Method).

Lighting efficacy was increased in IECC-2021 and harmonized between the commercial (C406.3.3) and residential sections (R202). As a result of advancing LED technology, lamps must now have an efficacy of at least 65

lumens per watt, and luminaires must have an efficacy of at least 45 lumens per watt. Efficacy is no longer tiered based on wattage consumption.

HOW TO ADDRESS LIGHTING POWER REDUCTION

There are three methods to address lighting power requirements in the IECC. The first entails utilizing the Equation Method, which is calculation-based. The other two ways are the Building Area Method and the Space-By-Space Method. These popular methods are chart-based and deliver quicker results than the Equation Method. The allowances for the same space may differ between the two methods though, with the Space-By-Space Method typically resulting in a greater allowance.

For instance, a 20,000-square-foot library, comprised of 5,000 square feet of a reading area and 15,000 square feet of a stack area will have an allowance of 16,600W using the Building Area Method because of the 0.83 allowance. The Space-By-Space Method, however, results in a greater allowance of 22,500W because the reading area and the stack area are calculated separately using allowances of 0.96 and 1.18, respectively.

When designing lighting, it is important to consider each unique space as well as the required light levels to ensure the occupants are safe and productive. Select luminaires that address the light levels to individual space needs while ensuring the overall power allowance complies with building code requirements.

ADDITIONS TO IECC-2021

In the 2021 IECC, areas where occupancy sensors are required have been expanded to include corridors (Photo 2). This is to reduce the lighting power to no more than 50% of full power within 20 minutes of being unoccupied. Light reduction controls require manual control, allowing the occupant to reduce the light by no less than 50% using dimming, step dimming, or switching. Daylight-responsive controls now include secondary side-lit zones with more than 300W of general lighting within the zones. Daylight controls also cannot exceed an occupancy sensor’s pre-programmed unoccupied light level in the same spaces.

IECC-2021 includes a section for specific applications and requirements for task lighting for medical and dental applications. A manual control must be

provided that is separate from the general lighting, and all lighting and switch receptacles must turn off within 20 minutes of occupants leaving the space.

The 2021 IECC also notes that 50% of all receptacles are to be controlled automatically in a variety of spaces, including private offices, conference rooms, individual workstations, and classrooms. Either split-controlled (topcontrolled) or controlled receptacles must be marked per NFPA 70, National Electrical Code (NEC), located within 12 in. of each uncontrolled receptacle — and controlled by a schedule, occupancy sensor, or signal from another control or alarm system.

Exterior lighting control is typically controlled using a time switch. A new addition requires occupancy sensors to automatically reduce the lighting serving outdoor parking areas by 50% when no activity has been detected for 15 minutes. New parking garage requirements mandate a 30% reduction in lighting power when no activity has been detected for 20 minutes. Additionally lighting for covered vehicle entrances must decrease by 50% from sunset to sunrise to accommodate

drivers’ vision adjustments. Daylight controls are also specified for parking garage luminaires within 20 feet of any perimeter wall structure.

ENERGY MONITORING NOW REQUIRED IN IECC-2021

Energy monitoring requirements have been in the ASHRAE 90.1 Standard since 2013. The 2021 IECC now requires similar energy monitoring requirements for new buildings 25,000 square feet and larger for interior lighting, exterior lighting, plug loads, HVAC systems, process loads, building operations, and other miscellaneous loads. Energy usage must be automatically communicated to a data acquisition system with data stored for a minimum of 36 months and graphical data provided for each end-use category for every hour, day, month, and year for the previous 36 months.

Mike Lehman is general manager at ConTech Lighting, a Leviton Company. He can be reached at mike.lehman@leviton.com.

Joe Briscoe is a technical sales specialist at Leviton. He can be reached at joe.briscoe@leviton.com.

the cable into the connector and rotate the connector clockwise.

Available in 3/8" trade size, both connectors install into a 1/2" knockout, and are Listed for steel and aluminum AC, HCF, MCI and MCI-A cable.

The tinted 40STS has more room inside for easier cable insertion.

for use with AC90 and ACG90 cable.

• Tested to UL 514B and Listed to meet UL ground fault requirements

• Removable Unscrew the connector counterclockwise to remove it from the cable. Remove the connector from the box using a flat blade screw driver. Release the snap tangs from the inside of the box while pulling the connector out of the knockout.

• Packed in heavy-duty, 200-piece boxes

Best Practices for Effective Lighting Projects

Early collaboration and an honest broker are invaluable.

There are three main purposes for exterior lighting: to increase safety and visibility; create the right impression and atmosphere; and enhance security. Understanding the many important considerations and best practices that need to be implemented is key to achieving these goals and having effective lighting projects.

GOOD LIGHTING DISTRIBUTION ENHANCES SECURITY AND SAFETY

When it comes to proper outdoor safety, one of the primary concerns is visibility. Poor lighting conditions can make it difficult to navigate walkways, parking lots, parking structures, and other outdoor spaces. Well-designed exterior lighting increases the feeling of security for facilities’ employees and patrons, helps ensure that people don’t trip and fall, and plays a critical role in the prevention and deterrence of crime.

Since insufficient light can compromise safety, designs often focus on light output. While light levels are critical, poor distribution can create too much lighting in some areas and dark patches in others. In fact, according to Eric Richman, senior research engineer at the Department of Energy, “the conventional wisdom is that more light is better, but from a security standpoint, too much of the wrong kind of light, aimed in the wrong direction, can cause glare. Moreover, security camera function depends on various lighting factors including

uniformity/contrast, light color, color rendition (CRI), and intensity.”

The Illuminating Engineering Society (IES) outlines the most important considerations for effective safety and security lighting:

• Horizontal illuminance is the standard for assessing effective lighting because many tasks are horizontal in nature.

• Vertical illuminance is critical for security issues because identifying objects and their movement is best done by viewing their vertical surfaces.

• Uniformity is important for avoiding dark areas and enhancing the effectiveness of security cameras.

POLE PLACEMENTS

Light poles are needed to mount luminaires for illuminating large, exterior projects, such as parking lots or outside tennis courts. One critical factor is the space between the poles. The goal is to have illumination bright enough that is suitable for the application and meets lighting requirements. Additionally,

the light needs to be uniform across the area so that there aren’t sections that are dimmer or brighter than others across the same space. Replacing light poles is expensive, so while a retrofit project may include new luminaires, many times the pole spacing remains the same.

The poles’ height is also a factor to ensure best practices. Larger parking lots require taller poles spaced farther apart. Taller poles also need higher output luminaires.

If it’s a new construction project, getting involved early is ideal to recommend the pole heights, placement, and beam angles for the layout to ensure optimum light coverage.

OUT WITH THE OLD

While contractors and facility managers may be looking for a quick, easy, and inexpensive upgrade to their lighting system, there are downsides to consider when installing replacement LED lamps in existing fixtures. A replacement lamp may not offer the same light distribution. As outlined above, light distribution is a major consideration for commercial lighting best practices.

On the other hand, there comes a time when old luminaires just need to be replaced. Outdated or malfunctioning luminaires can hinder productivity, waste energy, and increase maintenance expenses. The impetus for this is often the inability to buy replacement parts, or the luminaires are so corroded that they can’t even be opened for repairs.

To get the best light uniformity, a photometric layout was used for Milwaukee Mitchell International Airport’s new lighting upgrade. Remote Lot A now includes LED luminaires that replaced high-pressure sodium luminaires.

Fortunately, there are many benefits of an updated lighting system. Upgraded LED luminaires dramatically reduce power consumption from 50% to 75% compared to older technology. The new luminaires may also support broader sustainability and environmental, social, and governance (ESG) goals such as a smaller carbon footprint. Many facility managers are surprised to learn lighting upgrades often have a short return on investment.

PHOTOMETRIC LAYOUT

Another important lighting best practice is to have a photometric