CUSTOMER-CENTRIC SERVICE

HOW TO MITIGATE SHOP FIRE RISK

DESIGN YOUR SHOP FOR EFFICIENT WORKFLOW

QUALITY CONTROL AS PART OF YOUR LEAN PROCESS

FENDERBENDER.COM / MAY 2024

PAGE 28

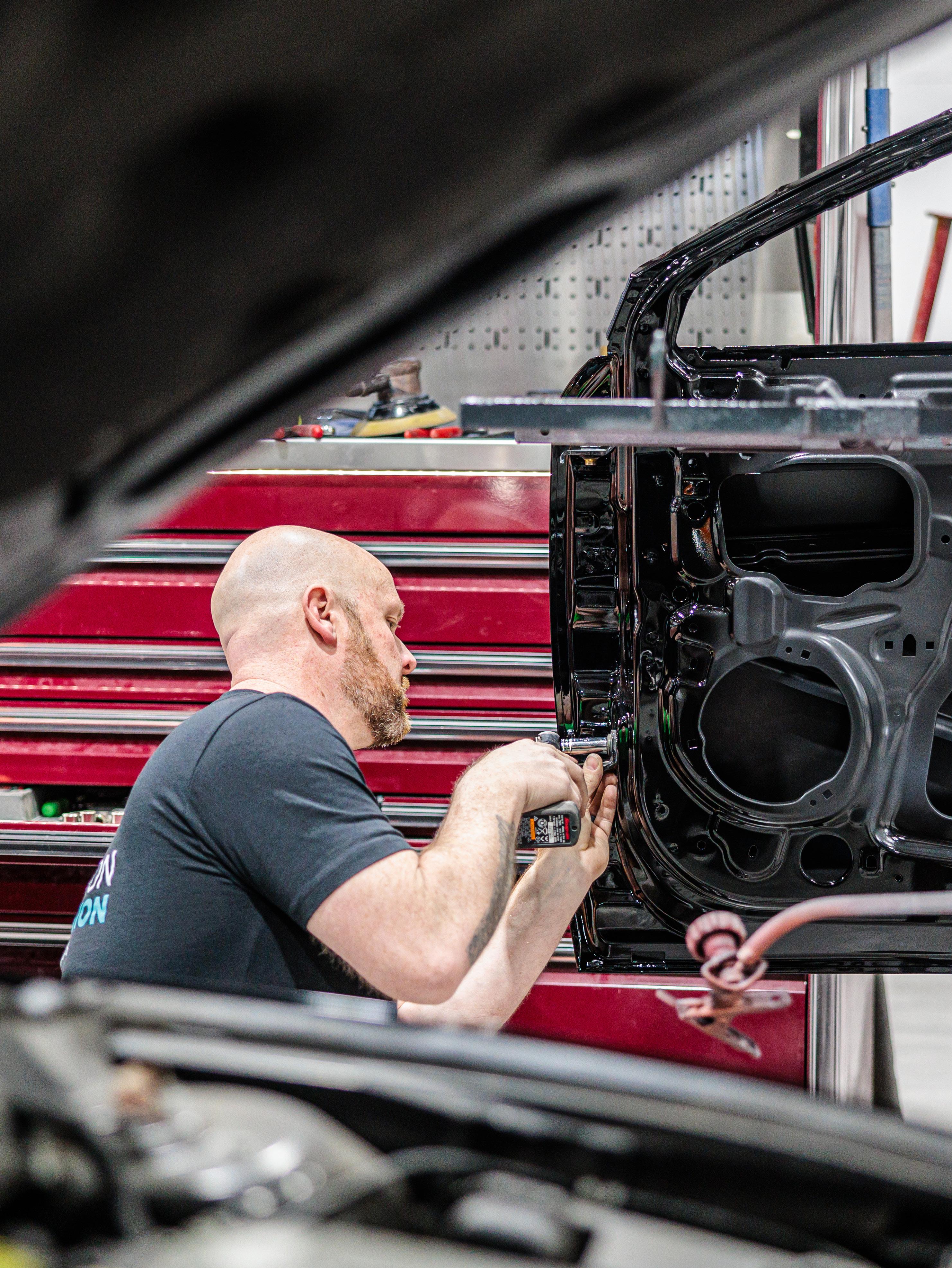

TURNING A SIDE BUSINESS INTO A THRIVING FULL-TIME BODY SHOP

PAGE 22

PAGE 35

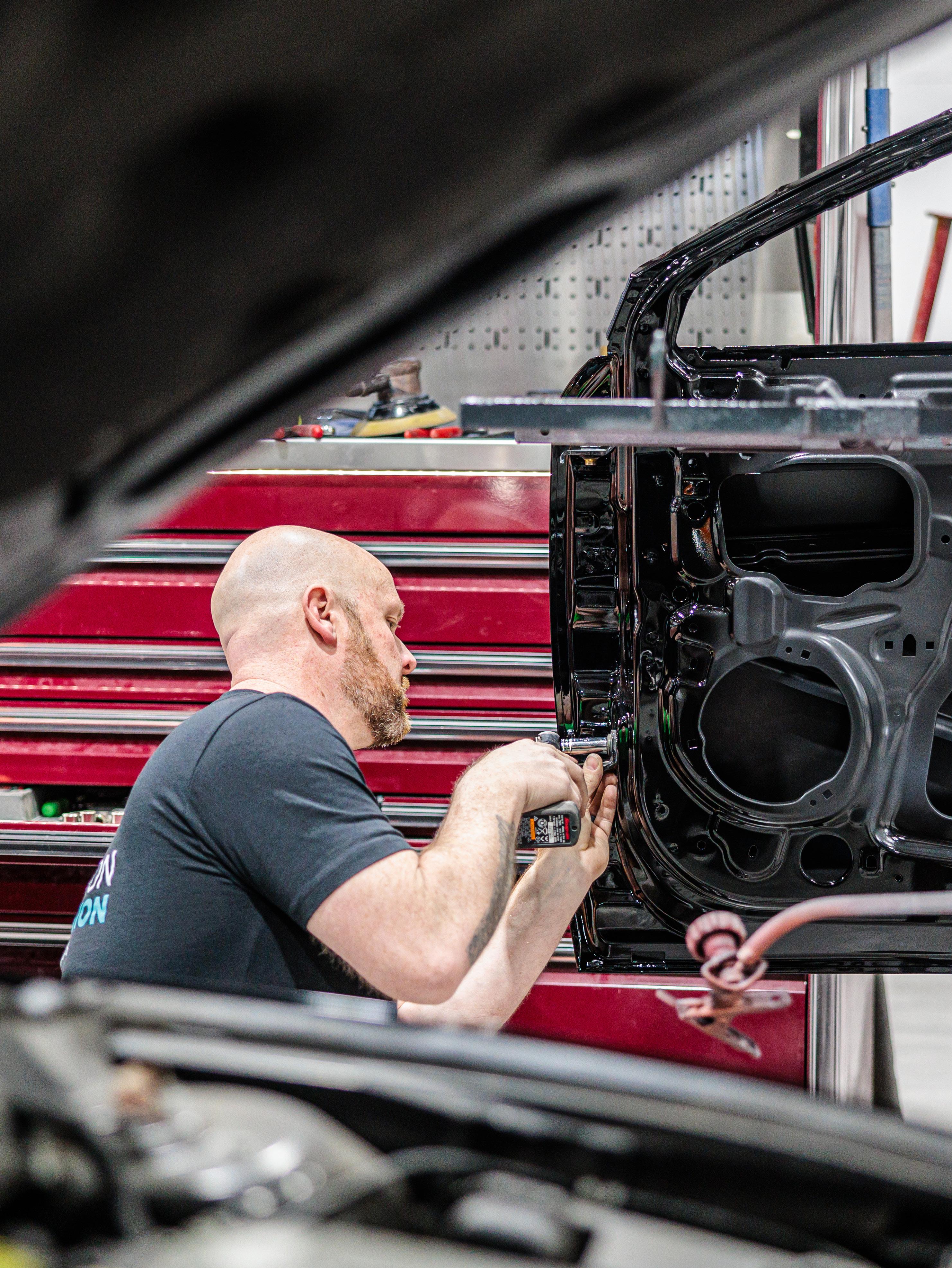

PAGE 40 Early Success Two years in, Darryl and Cecile Liechti already plan to expand Collision Correction in the next 18-24 months.

⁄⁄⁄⁄⁄⁄⁄⁄⁄ ⁄⁄

⁄O⁄⁄⁄⁄⁄⁄⁄P

⁄⁄⁄FF⁄ ⁄O ⁄H⁄

Y⁄⁄F⁄⁄ , ⁄⁄P⁄⁄B , ⁄⁄⁄

⁄⁄B⁄⁄⁄⁄PP⁄

71R07/562P RAER ERAPS

71R07/562P

AUTO DATA LABELS IS CELEBRATING OUR

FOURTEENTH R T Birthday

Thank you to all our loyal customers for your continued support.

Graciously accepting all new customers. Please come join the celebration!

DEAIRBAG ONFLABLELATÉRAL

•⁄o notlean againstthedoor⁄

•⁄o not use seat coversthat block side airbagdeployment⁄

⁄ee owner’s manualfor moreinformation⁄PO⁄⁄É⁄⁄⁄⁄⁄⁄⁄⁄B⁄⁄⁄⁄⁄⁄⁄⁄ G⁄⁄⁄⁄⁄O⁄⁄O⁄⁄⁄⁄⁄⁄⁄⁄

•⁄e vousappuyez pascontrelaporte⁄

•⁄’utilizez pas un couvre siège qui peutbloquerledéploiementducoussingonflablelatéral

⁄oirle manueldu conducteur pour deplusamplesrenseignements⁄ AVERTISSEMENT Order Labels From Our

Californiaclass/stds: PC/ULEVqualified Group: FGMXV01.80111.2L

Evap: FGMXR0095805SFI/HO2S/TWC, OBD:II

Easy To Use App New and Improved ADL App Now Available!

SE

TIREANDLOADINGINFORMATIO

TOTAL 4 FRONT

APACITY

COLDTIREPRESSURE

THISVEHICLECONFORMSTOALLAPPLICABLEFEDERALMOTOR

STANDARDSIN

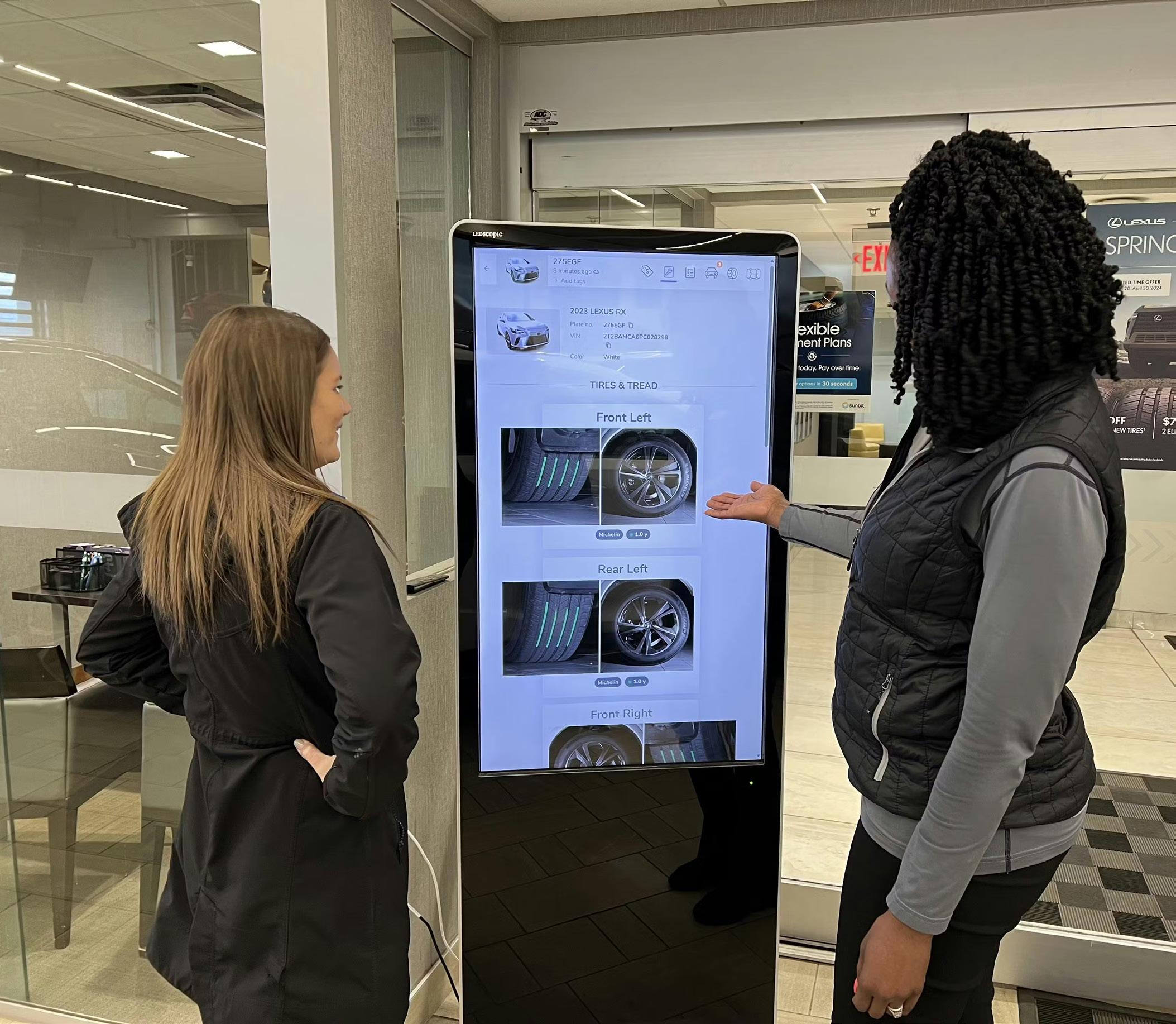

THEDATEOF MANUFACTURE SHOWNABOVE.

Thecombinedweightofoccupants shouldneverexceed SEEOWNERSALFOR

.A.S.UNI.OCROTOMDROFYB ROTOMLAREDEFELBACILPPALLAOTSMROFN NISDRADNATS FOE ERUTCAFUNAM .EVOBANWOHS 00000 B TA 0 042 53/aPk :RWAGRAER BL5233 GK8051 LS61R07/532P J0.7X61 :RWVG GK7662/BL0885 HTIWSERITSMIR ISP DLOC HTIWSERITSMIR ISP DLOC 5800F3810T

00000 ⁄⁄⁄⁄H⁄⁄ ⁄F⁄ ⁄YB⁄ ⁄⁄OYO⁄

⁄W⁄G B⁄⁄⁄⁄⁄ ⁄ ⁄W⁄G ⁄ ⁄F ⁄ B⁄866⁄ ⁄ ⁄⁄ B⁄866⁄ ⁄⁄H⁄ ⁄⁄⁄⁄H⁄⁄

O⁄ ⁄⁄⁄

⁄O⁄O⁄ G⁄⁄⁄⁄⁄⁄⁄F⁄⁄⁄⁄ ,

⁄⁄⁄OF⁄O⁄

⁄⁄⁄⁄⁄⁄F ⁄O⁄O⁄ ⁄⁄⁄⁄H⁄⁄

⁄F⁄H⁄

⁄⁄⁄⁄ FO ⁄⁄⁄⁄⁄⁄F⁄⁄⁄⁄ ⁄WOH⁄ ⁄⁄OB⁄ ⁄ ⁄⁄⁄P ⁄ ⁄⁄⁄ ⁄⁄⁄ ⁄ ⁄⁄⁄⁄ ⁄⁄⁄⁄⁄⁄ ⁄KGP⁄⁄⁄⁄ ⁄ ⁄⁄⁄⁄⁄ ⁄⁄⁄⁄ ⁄⁄ ⁄ ⁄⁄ ⁄⁄ ⁄ ⁄7⁄8⁄ ⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄ YK⁄⁄⁄⁄⁄K , ⁄⁄⁄ ⁄ ⁄⁄ ⁄ ⁄⁄

EXTPNT: RC: DS0: WB BRK INTTR TP/PS R AXLE TR SPR 4 4 GP K 45 V DB F05 UTC

VEHICLESAFETY

EFFECTON

VIN:TYPE: 00000000000000000 MPV AT 205 kPa UA 13 3U51B VEHICLEEMISSION CONTROLINFORMATION toregulations: 2015 Fuel: Gasoline ds: LDV/TIER2C/ULEVqualified NG ⁄⁄ ⁄⁄ ⁄ ⁄⁄⁄ ⁄ ⁄⁄⁄⁄ ⁄⁄⁄⁄⁄⁄ ⁄ ⁄ ⁄⁄⁄ ⁄⁄⁄⁄⁄ ⁄ ⁄⁄⁄⁄⁄ ⁄⁄⁄⁄ ⁄⁄ ⁄ ⁄⁄ ⁄⁄ VEH EMISSIONCONTROLINFORMATION egulations: 2016 MY Not for sale es with California e ns standards. TWC/HO2S/WR-HO2S/CAC/TC/DFI T2B4 LDV L Group:GFMXV02.3VJW Evap MXR0125NBV No adjustments neede ABZ

N ERS I EH re a: C HO2S/WR B Auto Data Labels To Visit Our Website SCAN HERE FOR ADDITIONAL INFORMATION ABOUT AUTO DATA LABELS: visit our website at www.AutoDataLabels.com email us at labels@AutoDataLabels.com or call us at (631) 667-2382 Gro MXR A ACITY sh ul EE UALFOR URE 4 EASY WAYS TO ORDER LABELS! Contact Us : Contact your LKQ/Keystone Local Sales Rep Upload your photos to the Website: www.AutoDataLabels.com Email your photos: Labels@AutoDataLabels.com Use the App: Download the ADL App And Upload your Photos I LEEM

3 May 2024 fenderbender.com MAY CONTENTS 28 FROM SIDE HUSTLE TO THRIVING BUSINESS Darryl Liechti’s shop is growing rapidly, thanks to his focus on customer-centric, honest operations. BY LINDSEY GAINER 22 HOW TO MITIGATE COLLISION REPAIR SHOP FIRE RISK Identify these shop hazards to increase safety and aid regulation compliance. BY JAY SICHT FEATURE PROFILE 05.24 | VOLUME 26 | NUMBER 05 FenderBender (USPS Permit 25614), (ISSN 1937-7150 print) is published monthly by Endeavor Business Media, LLC. 201 N Main St 5th Floor Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI, and additional mailing offices. POSTMASTER: Send address changes to FenderBender, PO Box 3257, Northbrook, IL 60065-3257. SUBSCRIPTIONS: Publisher reserves the right to reject non-qualified subscriptions. Subscription prices: U.S. ($90 per year). All subscriptions are payable in U.S. funds. Send subscription inquiries to FenderBender, PO Box 3257, Northbrook, IL 60065-3257. Customer service can be reached toll-free at 877-382-9187 or at fenderbender@omeda.com for magazine subscription assistance or questions. Printed in the USA. Copyright 2024 Endeavor Business Media, LLC. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopies, recordings, or any information storage or retrieval system without permission from the publisher. Endeavor Business Media, LLC does not assume and hereby disclaims any liability to any person or company for any loss or damage caused by errors or omissions in the material herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever. The views and opinions in the articles herein are not to be taken as official expressions of the publishers, unless so stated. The publishers do not warrant either expressly or by implication, the factual accuracy of the articles herein, nor do they so warrant any views or opinions by the authors of said articles.

07

DRIVER’S SEAT

I-CAR’s RTS App

Should be in Your Technicians’ Toolbox

08

PAST THE PAGE

I-CAR Leads

Forward as it Celebrates its 45th Year

11 BREAKDOWN

Caliber’s apprenticeship program helps combat the technician shortage

16

NUMBERS How ADAS is affecting vehicle repairs

14

LIGHT HITS

The latest stories from around the industry

18 Q&A

When’s the right time to jump into EV repairs?

32

32 THE SOP

How digital marketing can be an effective tool

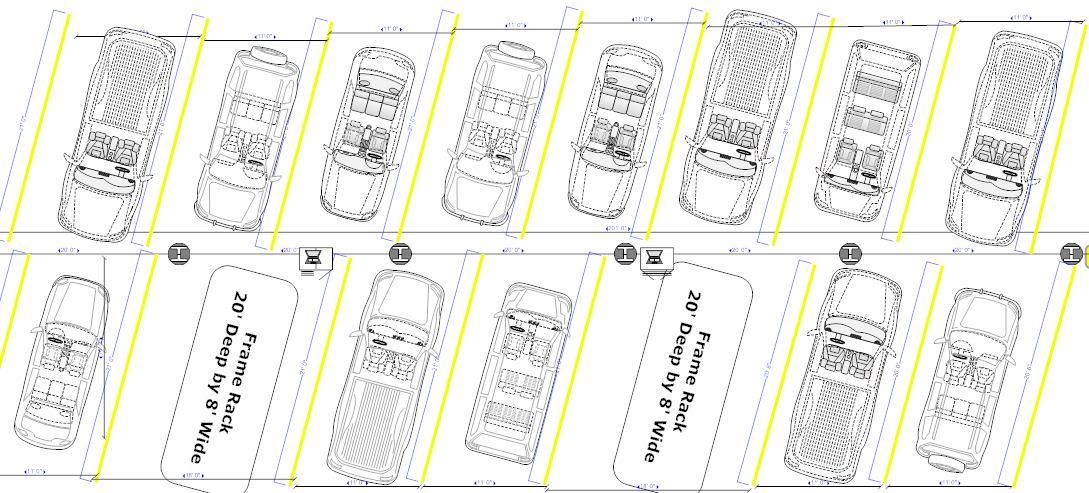

35 OPERATIONS

Design your shop for efficient workflow COLUMNS 20

38 CASE STUDY

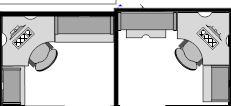

‘Drive-through MRI’ Spots Hidden Damage

40 OPERATIONS Implement a quality assurance process for lean

STEVE TRAPP

SHOP PROFITS

With time and strategic planning, you can manage your shop from afar BY

42 COLLISION COURSE

Are your customers’ vehicles vulnerable to hacking and ransomware?

44

DUE PROCESS

Strategies to cultivate loyalty and retain talent in a private equity era

4 May 2024 fenderbender.com QUICK FIX

STARTER

14

CONTENTS MAY

LOBSIGER

GREG

BY TIFFANY MENEFEE

DREW BRYANT STRATEGY

BY

BY

MOBILE AND REMOTE DIAGNOSTIC SERVICES! ELITEK IS THE PREMIER SUBLET PROVIDER FOR OVER 97% SUCCESS RATE FOR REMOTE AND 97% SUCCESS RATE ON FIRST MOBILE VISIT. FOR SUCCESS! ASK US ABOUT OUR SPECIAL PRICING! 888-8-Elitek | (888) 835-4835 ElitekAuto.com MOBILE FEATURES REMOTE FEATURES •OEM Tools / Best Equipment •Best In Class Experienced Technicians •Complete ADAS, Mechanical Services, Advanced Diagnostics And Wire Repair •Over 86 Service Areas And Growing! •Reduce Cycle Time •No Appointment Needed With Response Time Of 2-4 Minutes Via Easy Ticket Creation •Live Chat With The Master Certified Technician Working On Your Vehicle •Branded OEM Reports •Easy To Use App

EDITORIAL

Matt Hudson Group Editorial Director

Jay Sicht Editor-in-Chief

Abdulla Gaafarelkhalifa Associate Editor

Kacey Frederick Assistant Editor

Emily Kline Special Projects Editor

Leah Marxhausen Special Projects Editor

Drew Bryant Contributing Writer

Tiffany Menefee Contributing Writer

Greg Lobsiger Contributing Writer

Noah Brown Contributing Writer

Lindsey Gainer Contributing Writer

Todd Kortemeier Contributing Writer

Steve Trapp Contributing Writer

EDITORIAL ADVISORY BOARD

Jordan Beshears Steve’s Auto Body

Sheryl Driggers Collision Advice

Frank Rinaudo Industry Consultant

Jason Mundy Mundy’s Collision Center

Stan Medina Certified Collision Works

SALES

Andrew Johnson Associate Publisher ajohnson@endeavorb2b.com

Mattie Gorman-Greuel Associate Sales Director

Cortni Jones Director of Business Development

Diane Braden Account Executive (National Accounts) dbraden@endeavorb2b.com

Marianne Dyal Account Executive (National Accounts) mdyal@endeavorb2b.com

Chad Hjellming Account Executive (National Accounts) chjellming@endeavorb2b.com

Lisa Mend Account Executive (National Accounts) lmend@endeavorb2b.com

Martha Severson Account Executive (National Accounts) mseverson@endeavorb2b.com

Kyle Shaw Account Executive (National Accounts) kshaw@endeavorb2b.com

Sean Thornton Account Executive (National Accounts) sthornton@endeavorb2b.com

Ryan McCanna Administrative Assistant

ART AND PRODUCTION

Mariah Straub Production Manager

Jen George Ad Services Manager

Mitch Bradford Art Director

ENDEAVOR BUSINESS MEDIA, LLC

CEO Chris Ferrell

President June Griffin

COO Patrick Rains

CRO Paul Andrews

Chief Digital Officer Jacquie Niemiec

Chief Administrative and Legal Officer Tracy Kane

EVP Endeavor Business Intelligence Paul Mattioli EVP Transportation Kylie Hirko

VP and Group Publisher Chris Messer

HOW TO REACH US

Endeavor Business Media, LLC

571 Snelling Ave N Saint Paul, MN 55104 tel 651.224.6207 fax 651.224.6212

The annual subscription rate is $90 (U.S.A. only) for companies not qualified to receive complimentary copies of FenderBender.

LETTERS TO THE EDITOR editor@fenderbender.com

Opinions expressed in FenderBender are not necessarily those of Endeavor Business Media, and Endeavor Business Media does not accept responsibility for advertising content.

6 May 2024 fenderbender.com CLICK ON THE LOGO BELOW FOR PRODUCT INFORMATION CONTENTS ONLINE EXTRAS ProColor Collision USA LKQ Corporation PPG Industries CARSTAR

Axalta Coating Systems

AUTEL Motor Age Training Auto Data Labels Elitek Vehicle Services SATA USA Inc.

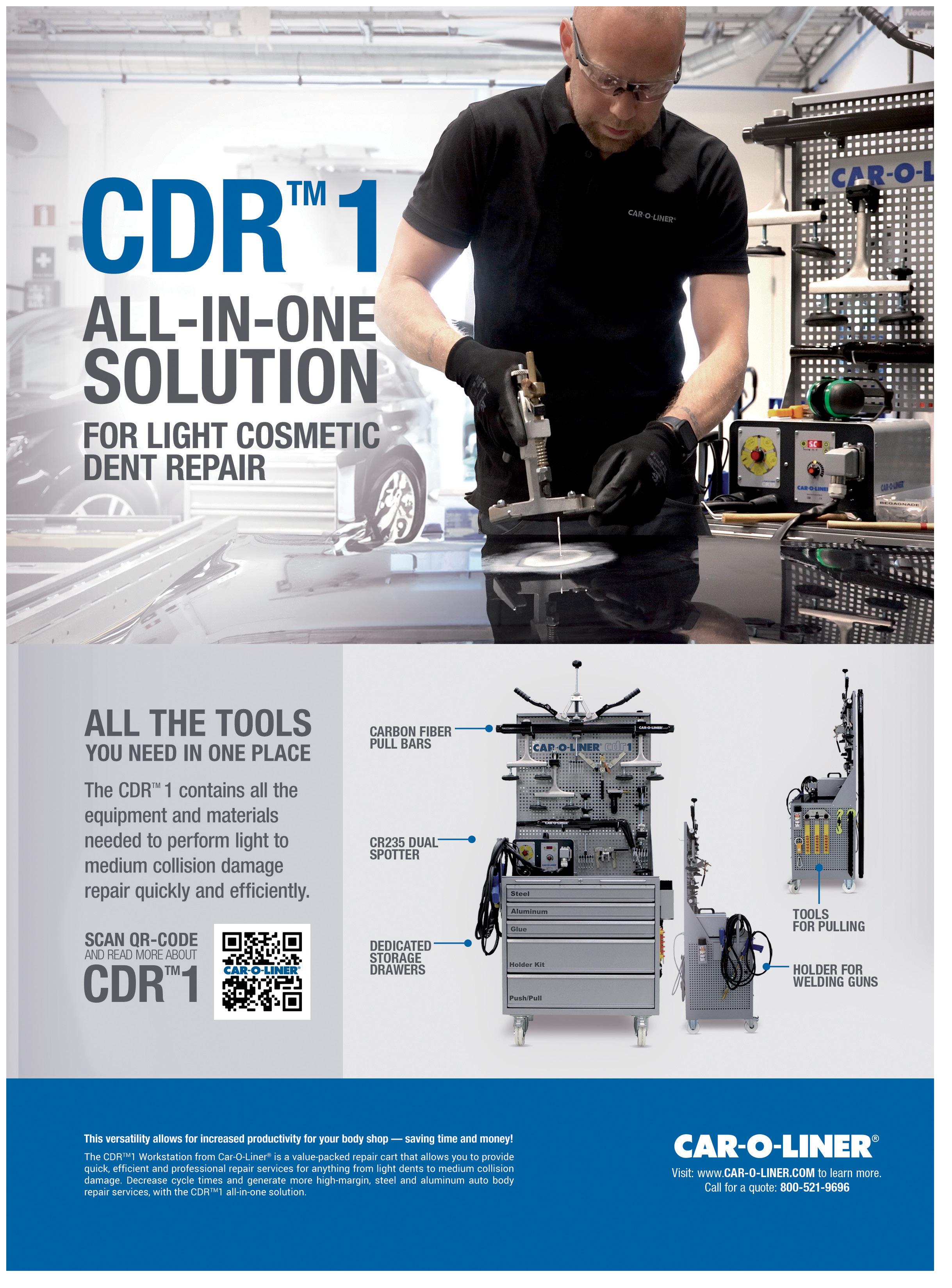

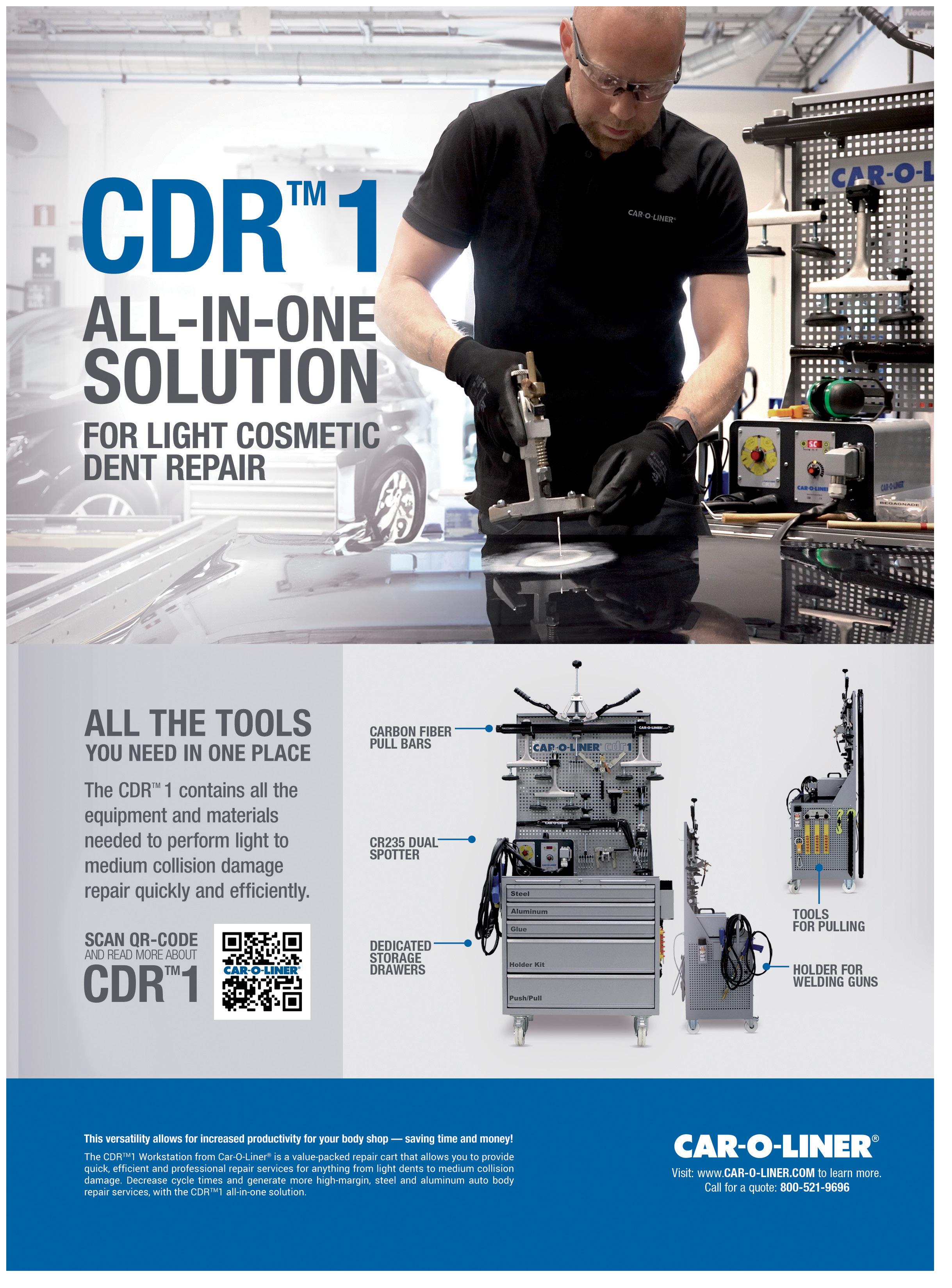

Car-O-Liner

READY ACCESS TO THE CORRECT REPAIR INFORMATION

I-CAR’s RTS App Should be in Your Technicians’ Toolbox

WITH INCREASED VEHICLE COMPLEXITY, the need to access and follow OEM repair information has never been more critical to be able to perform complete, safe and quality repairs. It's part of what FenderBender has promoted in our inaugural Best Repair Planner/Estimator Award. At the beginning of April, I-CAR rolled out its Repairability Technical Support (RTS) Portal mobile app for technicians, available for Android and Apple products at Google Play or the App Store, respectively. It's enhanced the desktop version of RTS, which has been around for about 10 years and was first offered for free to the industry as part of I-CAR's COVID-19 Industry Relief Program before the complimentary access was extended in perpetuity.

This is important because many technicians and other production staff may not have ready access to a computer, but they do have a cell phone in their pocket. The app is easy to navigate and includes features such as access to short technical articles and OEM information such as requirements for calibration, partial part replacement, restraints system part replacement, hybrid and electric vehicle disable procedures, glass replacement, and general best practices.

Users can search "Ask I-CAR" for the most common inquiries for specific collision repair information, and can submit a new question, if needed. The app is only beginning, says Scott VanHulle, manager of Repairability Technical Support (RTS) and OEM technical relations, with additional

functionality to come. As an example, the app currently allows the user to take photos of collision repair work with the mobile device and save them to the app. In the works is the ability to scan the VIN instead of typing in each digit.

For more information or for a download link, go to rts.i-car.com.

7 May 2024 fenderbender.com DRIVER’S SEAT JAY SICHT EDITOR-IN-CHIEF jsicht@endeavorb2b.com

I-CAR LEADS FORWARD AT NATIONAL MEETING

AS THE ENERGETIC Alan Parsons Project “Sirius” (also the Chicago Bulls’ theme song) played through the speakers, the Inter-Industry Conference on Auto Collision Repair (I-CAR) opened its 45th anniversary National Meeting Friday evening general session with its “Leading Forward” theme at the Lincolnshire Marriott in the Chicago suburb of Lincolnshire, Illinois, April 5-6.

I-CAR CEO and President John Van Alstyne said I-CAR’s mission statement has been refined since he began with I-CAR 14 years ago to include all stakeholders in the ecosystem, such as glass installers and ADAS service providers, which also include dealerships that perform ADAS calibrations.

The organization has a number of short-term and long-term goals, he said, but “Leading Forward” reflects its number-one goal and strategy to “establish I-CAR as the recognized leader and industry subject matter expert on vehicle repair, technology and educational programming.”

It includes focusing on providing more technical advisory services to the industry including but not limited to providing expertise on subjects such as planning for investments for equipment and facilities and insights into emerging technologies. It could also potentially mean working with OEMs on designing for repair.

Van Alstyne, who in the same speech announced his retirement at the end of 2025, said the organization will continue to change along with the market and technology.

“We need to be nimble, flexible, and innovative as we think about how we work,” he said.

“The operating infrastructure at I-CAR has really evolved over the past 14 years that I’ve been here. It doesn’t matter if it’s IT platforms or HR processing or financial systems, or how we deliver training, how we schedule training, everything is fresh in the I-CAR world today, and working, I think, a lot better than it ever has.”

Got Techs? Recruiting and Retaining Talent

Dara Goroff, I-CAR vice president of planning and industry talent programming, spoke in Saturday morning’s general session.

In its survey of nearly 840 collision repair technicians conducted with the Society of Collision Repair Specialists with Ducker Carlisle late last year, job satisfaction was found to be derived not so much from pay as much as it is being acknowledged of superior job performance and otherwise appreciated by one’s employer.

“And not only that, they want to grow you because they see your great potential,” she said. “That is when you create retention.”

Arianna Sherlock, senior director of marketing, spoke about the Collision Careers marketing initiative, which she compared to the successful ‘90s “got milk?” ad campaign.

“We are trying to do for you what the California Milk Processor Board did for the milk industry,” she said. “Nobody sees our campaigns and comes to I-CAR, right? They’re coming to your schools, to your shops, and that is exactly why we are investing in this and why we’re in this game.”

Similar to that campaign, Collision Careers is consumer-focused to reach an audience “that we’ve never really been after before.”

The collision repair industry has “an awareness problem,” she said.

Not only are students making decisions about careers before high school, she said; they don’t make them in isolation.

“You have to have his parents on board; you have to have a teacher or a counselor who’s introducing the concept and encouraging them.”

Putting RTS in the Technician’s Hand

The Repairability Technical Support was brought to life in 2014, Van Alstyne said, to make sure the industry had access to the repair information that is critical to fixing cars correctly. RTS access is complimentary, and the next development of that is the new RTS mobile app for technicians.

Scott VanHulle, manager of Repairability Technical Support (RTS) and OEM technical relations, noted that technicians often don’t have ready access to a computer during the workday, but they do have a cell phone. The app allows access to technical information and articles, and it can save the technician’s role to speed access to, for example, that information relevant to a structural repair technician.

“We couldn’t really reach the technicians who often need that information at their fingertips because they’re working on the car today and they have a question. These are the people we need to help get that information out to as quickly as possible, because if the repair planner did a great job, that’s one thing. But also if they run into something that was missed or they didn’t understand and they have a question today, we can help answer that.”

fenderbender.com/linkedin fenderbender.com

8 May 2024 fenderbender.com PAST THE PAGE

VIDEOS | PODCASTS | WEBINARS | NEWS Visit FenderBender.com/news for daily updates from around the collision repair industry. @fenderbendermag

Efficient. Silent. X-nozzle system.

SATAjet X 5500

State-of-the-art paint systems and the latest application recommendations open up new possibilities, but also pose new challenges for professional painters.

The SATAjet X 5500 featuring the new X-nozzle system defines a completely new application standard for the future.

Revolutionary: The X-nozzles are taking atomization to a whole new level

Noticeably quieter: reduced noise level in the relevant sound frequency ranges due to optimized flow geometry of the whispering nozzle

Individual: Matches any application requirement, such as specific characteristics of the paint system, climatic conditions and application method (application speed/control)

Precise: Optimized material distribution for enhanced spraying uniformity and atomization with both spray fan shapes

Low maintenance: No air distribution ring required, which ensures a much easier and faster cleaning process

Efficient: The optimized atomization concept allows for considerable material savings

Phone: 800-533-8016

E-mail: satajet@satausa.com

INFO www.sata.com/x5500

SATA USA Inc. 1 Sata Drive • PO Box 46 Spring

MN 55975

Valley,

www.satausa.com

BREAKDOWN

COMBATING THE TECH SHORTAGE VIA APPRENTICESHIP

Caliber Collision’s Eddie Hightower talks about the TAP program and how it can help attract more trained technicians across the country.

By ABDULLA GAAFARELKHALIFA

ACCORDING TO A 2023 TechForce Foundation report, there are over 30,000 unfilled collision repair technician positions.

This tech shortage is significant enough that industry leaders, such as Caliber Collision, are taking action to combat it and in unique ways, including through its Technician Apprenticeship Program

“We started to see a fall-off of people starting to go to technical training schools,” said Eddie Hightower, the senior vice president of sustainability and social responsibility at Caliber Collision. Hightower said this shortage made it difficult not only for Caliber but the entire collision repair industry to hire new technicians.

No Country for Young Men

According to a 2019 research study by Education Next, between 1990 and 2009 as the average number of academic credits high-school students earned increased, the number of vocational credits dropped by 14 percent, or roughly two thirds of a year of vocational studies.

Donna Wagner, assistant vice president of the ASE Education Foundation, added to this topic with FenderBender. “Some of that is fueled by the belief that you need a four-year college degree to be successful,” she said. Hightower added that interest in other career fields has also been partially responsible in the last few decades. Accord-

ing to the Visual Capitalist, the number of completed bachelor’s degrees for computer and information science jumped by 144 percent from the 2010-11 academic year to the 2020-2021 academic year.

Demographic changes are among the other factors leading to the tech shortage, Hightower pointed out. According to the U.S Census Bureau, there has been a significant rise in the population aged 65 and above. This age group, which accounted for 13 percent of the total population in 2010, increased to almost 17 percent in 2020, marking the highest percentage increase for this age group in the country’s history. This indicates a decline in birth rate, meaning fewer people are entering vocational programs.

These demographic shifts are also shown in the collision repair industry. According to data gathered by Zippa last updated in July 2023, 63 percent of collision repairers in the U.S. are 40 years or older. The remaining 37 percent are under 40. The data from Zippa also shows, unsurprisingly to many, that the field is heavily male-dominated, with 95 percent being male.

Wagner added that because repairers are much older in this field, there’s more overall reluctance to be educated more on changes in the auto industry, particularly when it comes to ADAS or EVs.

Blueprinting For Shortage Solution

Part of Hightower’s role at Caliber is to oversee the expansion of the Technician Apprenticeship Program (TAP), which started in 2021.

TAP is a free, hands-on auto body technician training program that pairs a potential apprentice with an experienced technician in a Caliber Collision center to take their skills to the next level — while also getting paid.

“We are the largest multi-shop operator for collision repair centers in the United States,” Hightower said on why Caliber started TAP. “We have about 1,700 locations across 41 states in the United States. We now employ over 31,000 people in those communities across the United States. We knew that our position as leaders in this space is that we not only needed to do something, but we could also do something.”

Hightower described TAP as a competency-based program that lasts a year. He also added that it’s not just targeted at high school or post-high school aged students, they also welcome people of all age groups and backgrounds, especially those who want to make a career change.

What might be seen as the most attractive aspect of TAP is that apprentices are treated just like employees. Not only are they paid, but they also get the same benefits, such as PTO or a 401(k).

11 May 2024 fenderbender.com QUICK FIX NEWS | IDEAS | PEOPLE | TRENDS

“At the end of it, they get a high-paying career,” Hightower said of TAP. “Really, the sky is the limit.”

Although the TAP is open to people of all age groups, Hightower is particularly interested in encouraging younger people to enter the program because younger folks are typically more tech-savvy. “Cars these days are really just computers wrapped in metal.”

It’s not just the vehicles themselves that are more computerized, but the way to obtain the knowledge to fix a particular vehicle is computerized.

“As late as 10 or 15 years ago, when you had a repair procedure you needed to use, you needed to pull down a book, and you were looking up a physical book for a procedure for a particular make and model for a vehicle,” Hightower explained. “Now

you’re doing all of that via computer, and on a tablet mostly in the back of our shops.”

“It really isn’t the car repair provider that you would think of sometimes,” he said. “Sometimes you think of the grungy, greasy, oil-stained, dust-everywhere things of the past. No! These are really tech-savvy, tech-forward places where we’re working with computerized technology-loaded vehicles of today. Technology is really an attractor for people entering our TAP program.”

The other reason why the program is attractive to younger people, particularly Generation Z/Zoomers, those people born in the late ‘90s to early 2000s, is that a background in collision repair gives those who have it more control over what they do with their career. Those in TAP are not limited to working in Caliber Collision centers after they complete the one-year apprenticeship.

Hightower also points out that Zoomers, a much more environmentally cautious generation, might stick around with Caliber because they learn about Caliber’s commitment to sustainability. “Just last year, we completed a 100-percent LED lighting retrofit in all of our centers,” Hightower said.

Caliber’s efforts aren’t just focused on getting new technicians, but also retaining older and experienced technicians because “they’re the lifeblood of our apprenticeship program,” he said.

As of February, Hightower reported, Caliber Collision invested more than $65 million into the program, and they’ve graduated more than 1,000 techs out of the program since it started. Soon, they hope to see that number double every year as TAP continues.

12 May 2024 fenderbender.com QUICK FIX

WE’RE SOCIAL CONNECT WITH US ON YOUR FAVORITE SOCIAL MEDIA SITES WWW.FENDERBENDER.COM

Senators and Congressmen

Throughout the Land Hightower said that Caliber has been campaigning for more government support for TAP in the form of grants through the Department of Labor.

“We hope to become a grantee this year,” he said.

“When [apprentices] come out of this training program, we’re able to demonstrate to [politicians] what the technicians’ earning potential is over time, and they get it,” Hightower said. “They understand the impact on the economy.”

“We’ve talked to conservative members of Congress, progressive members of Congress, independent members of Congress, and everyone has just been so supportive of this program. There’s a lot of support from Capitol Hill because this issue is apolitical.”

13 May 2024 fenderbender.com

Julio Ruales , a technician at Caliber Collision, stands behind Polyvance’s 8202 Nitro-Fuzer, flanked by TAP apprentices Jessica Dailey (left) and Emily Alberghini (right).

Copyright © 2023 Axalta Coating Systems, LLC and all affiliates. All rights reserved. AN AXALTA COATING SYSTEMS BRAND Get more from your finish. Nason ®XL is an affordable, easy to use refinish system available in thousands of collision-quality colors. Deliver a long-lasting finish with Nason ®XL. VALUE THAT LASTS nasonxl.us 2405FB_Axalta.indd 1 3/26/24 1:43 PM

PHOTOS COURTESY CALIBER COLLISION

LIGHT HITS

ON TIKTOK: BODY SHOP SENDS CAR TO SALVAGE AUCTION BY ACCIDENT

An insurance claims adjuster, who is also a TikTok influencer, found out a body shop mistook her customer’s Cadillac Escalade for a Ford Explorer and accidentally sent their car to a Copart salvage auction facility.

“How did you confuse an Escalade with a Ford Explorer?” she asked while retelling her account with the body shop. “Have you called the customer and told them how you lost their car? And that you towed it to Copart, the salvage yard?”

The video has been viewed over 3.5 million times.

LARGEST COLLISION CENTER IN THE NORTHEAST NOW OPEN

Last week, McGovern Auto Group (MAG) announced the grand opening of the MAG Collision Center, McGovern’s new flagship body shop and the largest body shop in the Northeast. This center promises to reshape collision repair services across Massachusetts and beyond, according to a news release.

The facility, located in Shrewsbury, is a 75,000 square foot and the auto group’s third collision center in Massachusetts, according to their website.

The center’s 40 repair bays can accommodate any passenger or commercial vehicle. Specialized zones cater to the intricate requirements of body repairs, paint prep, paint mixing, detailing, and refinishing. The facility also houses four downdraft-enabled paint booths and a separate paint system for fleet and commercial vehicles.

The MAG Collision Center represents a multimillion-dollar investment in McGovern’s depth in auto repair in the Northeast. Beyond resources, McGovern has furnished the facility with next-generation equipment, materials, and processes to truly optimize and modernize collision services.

For fleet customers, the MAG Collision

Center offers a dedicated 60-foot truck paint booth and prep deck to cater to heavy truck, emergency vehicles, tractor trailers, dump trucks, or equipment repair needs. This capability underpins the shop’s readiness to serve commercial customers across a diverse range of industries while positioning itself as the foremost collision service provider for municipalities in Massachusetts.

The MAG Collision Center will also be home to McGovern’s transport and vehicle mobility division, McGovern Transport, housing its fleet of 14 trucks. With significant regional growth planned for McGovern’s vehicle transportation services, MAG Collision will play an integral role in keeping the division’s trucks meticulously maintained while recruiting top CDL driving talent.

“We are actively looking to grow our talented 30-person team by nearly 50%, with 10 open roles for experienced auto body technicians, paint technicians, estimators, and customer service representatives,” said Brian D’Alesio, general manager of the MAG Collision Center. “I encourage any qualified candidates looking to advance their careers with a growing, dynamic company to inquire about openings.”

The major launch follows a milestone year for McGovern Auto Group, having expanded to 29 dealerships across

Massachusetts, New York, and New Hampshire while amassing over $2.2 billion in annual revenues.

VETERAN AND SINGLE MOTHER ARE GIFTED WITH REFURBISHED CARS

A veteran and a single mother in Port Charlotte, Florida, were both presented a vehicle thanks to the National Auto Body Council Recycled Rides program along with car donor Allstate and repair partner Toyota of Richardson, according to a news release.

NABC, Allstate, and Toyota of Richardson, a Berkshire Hathaway Automotive company, presented a fully refurbished 2019 Jeep Cherokee to Nathan Burrow.

Burrow and his family are always eager to go out of their way to put others above themselves. A decorated veteran, Burrow was injured while serving as a medic in the army in Iraq. Burrow is an alumnus of the nine-week Redefine program of the Adaptive Training Foundation, the organization that nominated him for the car donation. The vehicle will help in his efforts to train other disabled veterans suffering from similar impairments.

“What this means to me is just beyond belief,” said Burrow, reacting to the donation. “I hope that there is a time that we can do it somehow for someone else.”

14 May 2024 fenderbender.com QUICK FIX

MCGOVERN AUTO GROUP

NABC, Allstate, and Toyota of Richardson also presented a fully refurbished 2017 Toyota Camry to Wainesha Stevenson.

Stevenson and her daughters have shown resilience through tough times. All three have juggled work, education, and the demands of everyday life with an indomitable spirit. The young women have finished high school and are embarking on higher education and career goals and a brighter life ahead. The donated car will help them all continue on their journeys. Family Promise of Irving nominated Stevenson for NABC Recycled Rides.

Stevenson was elated to receive the renewed vehicle.

“2024 has started out with a little sunshine,” she said at the presentation. “This is a way to get back and forth to work to earn a living for my family. I am here to be a provider and protector for my girls, and this will enable me to do that.”

Tom Wolf, director of strategic accounts, U.S. and Canada for PPG, said of the presentations: “As we look back on the impact of the PPG MVP Conference, I want to express my sincere gratitude to the PPG Business Solutions team and all who contributed. Collaborating with the NABC and Berkshire Hathaway Automotive to gift two NABC recycled rides to deserving families in need exemplifies the power of partnership and generosity. Thank you for your dedication and commitment to making a tangible difference in people’s lives.”

THE LEGACY OF DON HENTHORN, BENDPAK FOUNDER

Don Henthorn, owner and founder of BendPak Inc., peacefully passed away at home Thursday, March 28, at the age of 85. Under his leadership, BendPak has grown from a small machine shop to one of the world’s leading manufacturers of car lifts and automotive service equipment. Management and operations of the privately owned company are unchanged.

Henthorn transitioned day-to-day management to the current leadership team in 2022 as part of an established succession plan. Serving as chairman emeritus, he continued to coach the team, coming to the office six days a week.

Henthorn enlisted in the U.S. Army at 19 years old. He was stationed at a Nike Ajax missile site in Connecticut. While there, he met Virginia Ann “Ginger” Eib, and they married two days after he was discharged in 1959. Three days after that, they moved to California, where he went to work in the burgeoning aerospace industry. After learning all he could, he started Quality Machine & Associates (QMA) in Simi Valley, California. This premier job shop specialized in precision machine work for aerospace and defense giants like Rocketdyne, Rockwell, and Hughes Aircraft.

Not content with the “feast or famine” workload of a job shop, Henthorn labored after hours to develop and patent specialty tools QMA could market itself. The most successful of these included the 5ivePak, a portable combination coil spring compressor, U-joint press and gear-puller; a MacPherson strut spring-compressor; and a portable exhaust pipe expander.

By the 1970s, Henthorn was increasingly focused on building equipment for the then-bustling muffler shop industry. In 1977, he oversaw construction of the company’s first new building, a 20,000-square-foot manufacturing facility in Moorpark, California. Two years later, QMA introduced a hydraulic tubing bender for muffler shops, and Henthorn was inspired to change the company name to match.

“BendPak” was born. In 1983, responding to customer requests, Henthorn introduced BendPak’s first four-post lift and entered the vehicle lift market.

Over the ensuing decades, BendPak continued to grow. Today, the company has manufacturing and distribution facilities around the world and employs

more than 275 people. In 2023, BendPak moved its global headquarters into a LEED PlatinumTM certified administrative building in Agoura Hills, California. Work is underway on the BendPak Industrial Complex, a huge light industrial space being developed in Mobile County, Alabama, near the company’s recently expanded East Coast campus.

Never one to seek awards or accolades, Henthorn was a believer in hard work. Motivated by the fear of failure and the desire to expand his mind and his business, he pushed the company to continuously improve and grow. For decades, he was the first person in the door every day, starting between 5 and 6 a.m., Monday through Saturday. When asked the secret to BendPak’s success, he would answer simply, “We outwork everybody.”

Henthorn took his responsibility for the safety of millions of mechanics around the world very seriously and was committed to ensuring that BendPak produced superior products.

“We at BendPak wholeheartedly hold the philosophy that only going above and beyond on every product, for every customer, will keep us growing in this business,” he wrote in a letter to customers on BendPak.com. “When BendPak started, I was the sole name and voice attached to the company’s product development and operations. Today, BendPak exists beyond the control of just a few sharp minds. The hundreds of employees we hold dear are heard from and appreciated on a daily basis, which is why people continue to want to work here, and it’s why we’ll continue to thrive for generations to come.”

Henthorn could often be found out in the shop tinkering and inventing things. He also enjoyed golfing and sharing memories with friends, family, and colleagues.

Henthorn is survived by his wife, Ginger, daughter, Susan, and grandchildren Annika, Reagan, Carson, and Kennedy. He was preceded in death by his son, Gary.

15 May 2024 fenderbender.com

HOW ADAS IS AFFECTING VEHICLE REPAIRS

IT’S PROBABLY NO SURPRISE that each new model year brings with it an increasing number of advanced driver assistance system (ADAS) components requiring replacement and/or calibration.

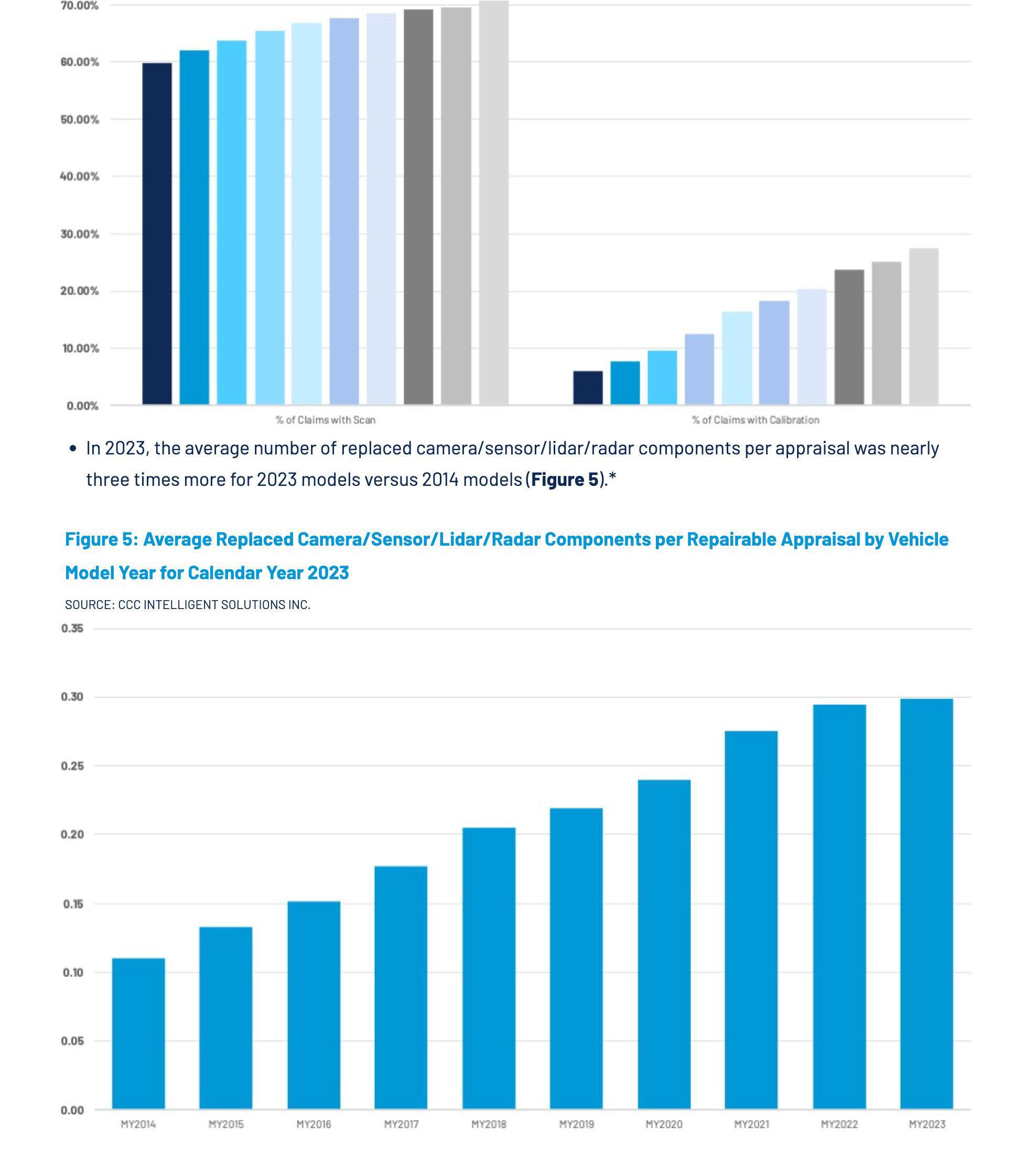

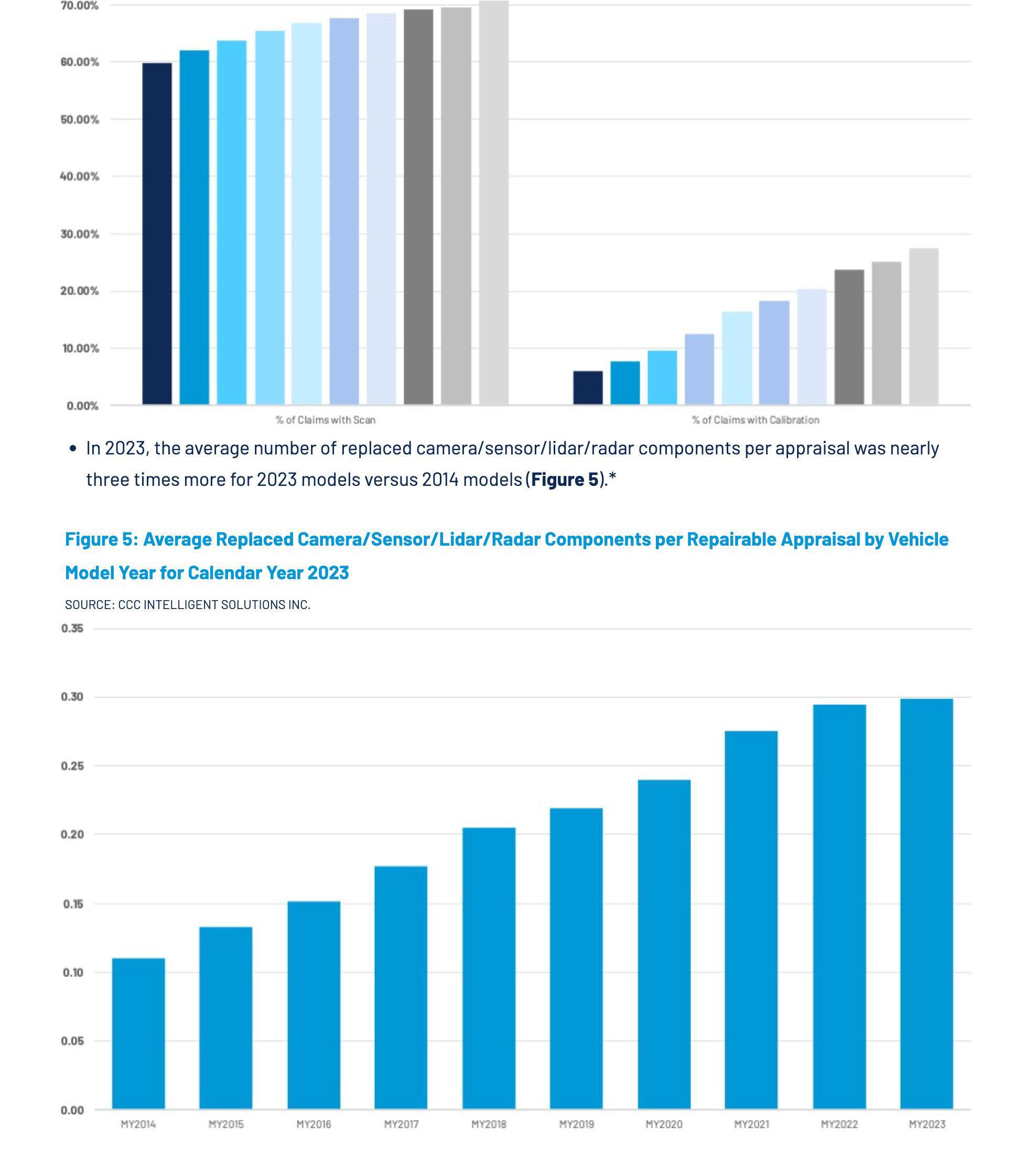

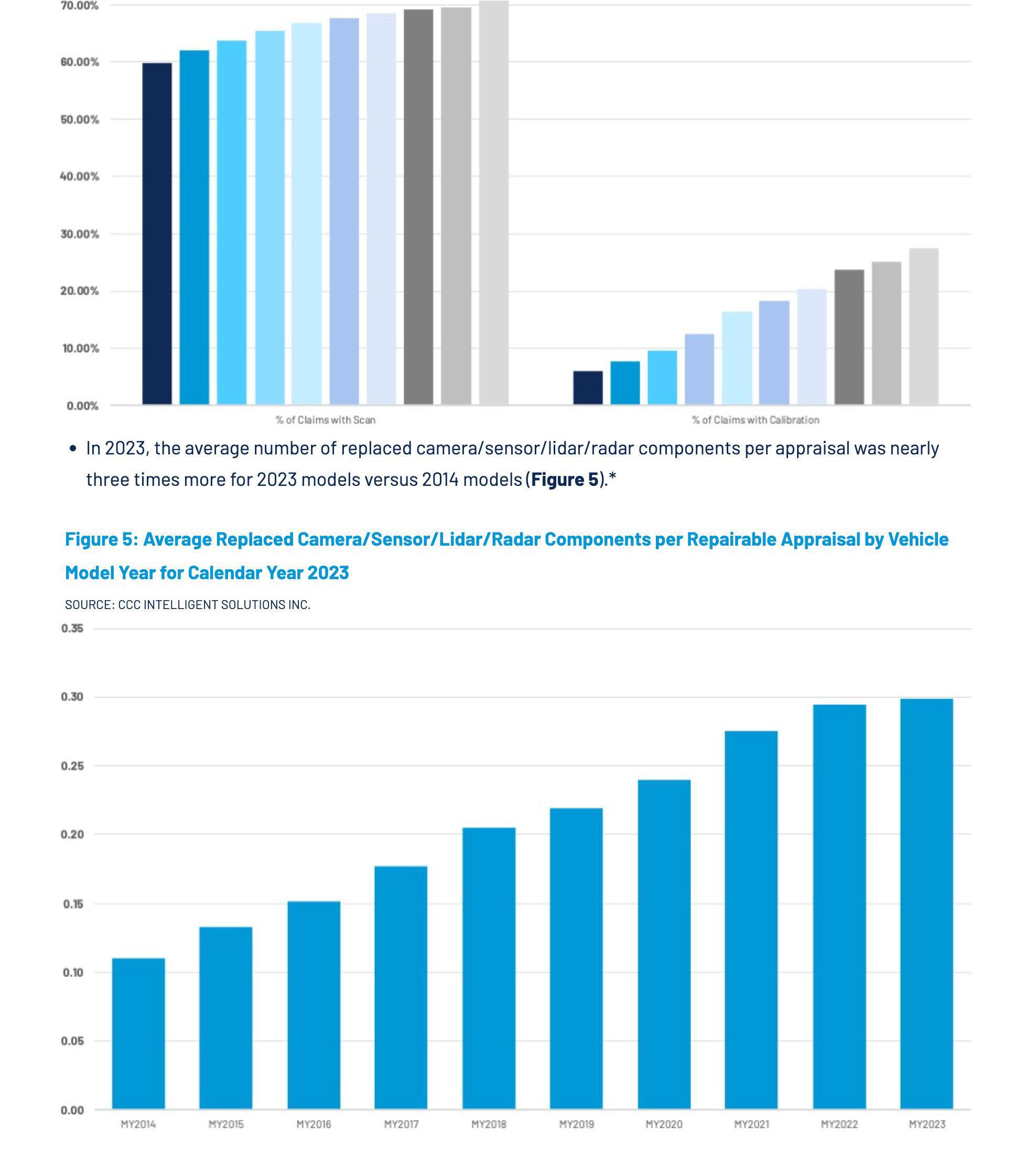

According to CCC Intelligent Solutions’ Crash Course Report (www.cccis.com), nearly 60% of repairable appraisals in 2023 of vehicles made in 2014 included a scan, and only 6% included calibration. For vehicles manufactured in 2023, slightly more appraisals, just over 70%, included a scan, but 27.6% required a calibration.

And last year, 2023 models required nearly three times as many replacements of cameras, sensors, lidar, and radar components per appraisal vs. 2014 models.

The report notes that ADAS is unlikely to end collisions. And in fact, according to NHTSA’s July 2023 data, speeding-related fatalities actually increased by 19% between 2019 and 2021. The reasons include some drivers over-relying on ADAS technology, misusing or disregarding its use, and human error or the complexity of modern traffic environments.

In 2023, the average number of replaced camera/ sensor/lidar/radar components per appraisal was nearly three times more for 2023 models versus 2014 models (Figure 5). *

May 2024 fenderbender.com

NUMBERS

QUICK FIX

Figure 4: Percent of Repairable Appraisals with Scan and Calibration Operations by Vehicle Model Year for Calendar Year 2023

Figure 5: Average Replaced Camera/Sensor/Lidar/Radar Components per Repairable Appraisal by Vehicle Model Year for Calendar Year 2023

SOURCE: CCC INTELLIGENT SOLUTIONS INC.

SAME SYSTEM. SAME GREAT RESULTS. MORE FLEXIBILITY.

Efficiency, sustainability, and ease of use – these are just three of the reasons why PPG’s Envirobase High Performance waterborne paint system is the trusted choice for more than 40,000 body shops around the globe.

But the benefits don’t stop there. The Envirobase High Performance paint system supports fully digitalized repair processes and is compatible with every tool in the PPG LINQ™ digital ecosystem, making it the perfect solution for modern collision centers.

The refinish industry is always evolving. Our PPG experts continue to develop new products that enhance the core Envirobase High Performance waterborne system and help body shops meet changing demands and challenges.

For

PPG ENVIROBASE® HIGH PERFORMANCE

more

envirobase.com The PPG Logo and Envirobase are registered trademarks and PPG LINQ is a trademark of PPG Industries Ohio, Inc. © 2024 PPG Industries, Inc. All rights reserved.

information visit

EV COLLISION REPAIR COSTS AND TRENDS

Kevin FitzPatrick of Opus IVS explains why EVs are so expensive to repair and how to evaluate when is the right time to get certified.

If something is expensive to buy, it’s probably more expensive to repair. As of late, this certainly applies to EVs. According to a 2023 yearly review by Mitchell, the average U.S. repairable EV severity was $6,018, compared to their ICE counterpart, it’s $4,696.

The topic of repair costs for EVs was highlighted in an extreme anecdotal example where Tesla-centric YouTuber, Ryan Shaw, says a fender-bender that damaged his rear bumper resulted in a bill of over $8,700. In a second rear-end collision, his Tesla was so severely damaged that it could not drive away. The cost of completely repairing the car came close to $24,000.

Why are the costs so high? Will it get cheaper at some point? Is it difficult to get certified?

We spoke with Kevin FitzPatrick, Opus IVS senior vice president of North America operations, to learn more.

Why is EV repair so expensive?

“Number one, it’s the [limited] number of facilities repairing EVs. I think that’s one of the biggest factors,” FitzPatrick said. “The other factor is the number of recycled parts that are available to repair these vehicles and the [low availability] of aftermarket parts. Those are the three main factors if we’re going into the costs.”

He emphasized that there’s a lack of options for parts manufacturers given how new EVs still are.

“Tesla, for example, is the manufacturer for most of the parts which leads to longer cycle times in most cases. Anything involving the battery is an instant total.”

FitzPatrick also shared that that

18 May 2024 fenderbender.com QUICK FIX

B y ABDULLA GAAFARELKHALIFA Q&A

ISTOCK / GETTY IMAGES PLUS

repairers often sublet the disarming of the car to a professional to make the EV safe to repair. “In other words, fuses are actually pulled, and the car is brought to a condition where other technicians can put their hands on the vehicle.”

How is the market responding to the high cost of EV repairs?

“Getting more technicians, getting more training,” he said.

He also emphasized the need to increase in the number of qualified and certified technicians so consumers will have more options, therefore boosting competition.

Later, he said that there has been a notable increase in collision repair centers that cater to EVs, but only by a

few percentage points. The reason why there was a slow increase, according to FitzPatrick, is because the demand for EVs by consumers is not growing as fast as many expected.

He also said more vehicle manufacturers are making their presence in the market known, which should eventually increase overall competition in the EV market and drive EV repair costs downward.

If consumer demand is a factor, then why is it so low in the U.S.?

“Unfortunately, the reality in the United States is that the infrastructure needed to support these vehicles didn’t grow as expected,” he said.

“The populace didn’t adopt them in the way the government wanted them to. Younger drivers are certainly adopting them at a much higher rate than older traditional folks such as myself.”

He also recalled the recent ‘deep freeze’ that swept across parts of the country, which exacerbated EV charging problems for owners and drivers.

Aside from the mechanical issues that would occur from meteorological events, the day-to-day ownership of an EV is not what people expected.

Things that FitzPatrick listed as other reasons that will deter those from adopting EVs include:

The cost to charge an EV at public fast chargers can be high.

The short shelf life of an EV tire.

EVs tend to lose more resale value as a percentage compared to an ICE vehicle.

“There are still considerations to be had when adopting EVs as your main mode of transportation.”

Is it easy to get certified?

“Technicians have to take time out of their shop to get training and certified on the repair of these vehicles,” FitzPatrick said. He also emphasizes the safety aspect, which leads to the subletting.

“It’s not a tremendous amount of time. Most of the training takes 30 to 40 hours.”

Is there a projected growth as to how many ev certified collision repair centers will come up or be open considering the demand being lower than what was projected?

“I think all the manufacturers in the U.S. have throttled back on their build projections and I would expect a lot of our larger MSOs to follow suit on what their projections were.”

Despite the low consumer demand, is it still a good idea to get certified and get training?

“I think so,” FitzPatrick said. “It’s a growing vehicle population in any state.”

“I think you have to look at the ballpark for your particular business. If you’re in a metropolitan area, this is something you need to address. Obviously, you should have addressed it already. If you’re in the Midwest or in a rural area, you probably have a little more time.”

“It’s something that every collision repair business owner is going to have to consider soon.”

19 May 2024 fenderbender.com

The Four Stages to Freedom

With time and strategic planning, you can reach the point of managing your shop from afar. But you must learn from folks smarter than you

For many of us who were former technicians who became shop owners or are currently doing both roles, here are the four stages to freedom from our businesses.

Stage 1

The owner is working on cars, answering the phone, ordering parts, writing estimates, dealing with insurers & customers, handling bookkeeping, dispatching work if there are any other employees, maintaining the equipment & building, marketing the business, and more. Some live this life for decades working 70+ hours per week and feel there is no way out. Finding someone to take your spot working on cars in the back is the ONLY way out. Once you search for and hire someone to take your place, you must suck it up and take your tools home!

Stage 2

Now you go to the front, and your new job is to be the manager. You will do everything you did in stage 1, but you can’t work on cars. While managing the front, start documenting everything you do and writing up your tasks as work standards (a clear set of instructions). Now focus on fully training, say, two body techs and one painter.

Stage 3

Now with at least this three-man team in place, your shop should be able to produce $1,200,000 to $1,400,000 in gross sales. Let’s say you are currently taking wages of $100k. You should have an additional $150-250k in net profit. Now it’s time to find that person to replace you in the front! Don’t give me that “There isn’t anyone to hire” garbage, either. I won’t hire any admin folks from the collision repair industry. It’s not that they’re bad people, but they are just corrupted and nearly impossible to retrain. The “greener the better” is what I look for. A person with a good attitude, strong work ethic and a baseline of at least average or above average intelligence can be taught almost anything. You could find this person at your church, or maybe it’s someone who waits on you at a restaurant or even at the Home Depot. Always keep a business card in your pocket; you just never know where you will find them. My two managers came from a John Deere dealership. Once this person is hired, pull out the work standards you created in stage 2 and get them trained!

Stage 4

Once your new manager can do most of your role, you need to get out of the front. Now, move your office home or even build an office in the attic of your shop. No matter what, you must get out of sight of customers and the day-to-day. It’s not that you don’t care about your customers, but it’s amazing now for me how my customers ask for my front admin folks by name and have no idea who I am. Here is your new job:

A. Market the business

B. Go to the Gemba (where the work takes place) to help the employees with processes to make the work easier for them

C. Monitor the finances and business profitability.

D. Within six months or so of hiring a manager, you may need to add a customer service representative, back-end estimator, detailer, parts person, bookkeeper, or other staff. It gets very interesting at this point. How can you leave for vacation and never get a text, call, or email from anyone from your business? You must let go and empower your employees to make decisions. Are they going to make mistakes? Of course! If you scold them for a bad decision or micromanage, you will never get freedom from your business, as they will be fearful to make ANY decisions.They will continue to seek you out for even the smallest things like, “Which sandpaper should I order?”

To get to stage 4, you must seek out folks smarter than you to learn from. These folks can be found in 20 groups from paint companies and independent groups or even individual consultants. A fellow shop owner who is very successful outside of your market can make a great mentor. You must visit their shop and be a sponge. Don’t be afraid to get on an airplane. And you can’t let pride be a barrier, or you will never get out of stages 1-3, let alone see any sight of stage 4. Remember: you must venture out to find these folks; they won’t find you. I would also recommend reading “The E-Myth Revisited” by Michael Gerber. He discusses how we should be building a “franchise prototype.” Another book is “Rocket Fuel” by Gino Wickman, in which he discusses “visionary and the integrator.” In stage 4, the owner can come and go as they please, even add additional shops, and with the right knowledge, achieve a 20%+ NET PROFIT.

GREG LOBSIGER

Greg Lobsiger has owned Loren’s Body Shop in Bluffton, Indiana, for over 23 years. He has been a member of Mike Anderson’s groups for ten years and had extensive lean manufacturing training.

EMAIL: greg@lorensbodyshop.com

ARCHIVE: fenderbender.com/lobsiger

20 May 2024 fenderbender.com

JOSIE SMITH PHOTOGRAPHY

COLUMNS SHOP PROFITS

A proven business model for 20 years, ProColor Collision is growing! Independent body shop owners driving their business forward are choosing ProColor. Standardized operations, management tools and consolidated technology solutions improve performance. The ProColor team of industry professionals are dedicated to performance excellence offering the sales, operational and marketing support needed to take business to the next level. ProColor Collision is committed to helping shop owners grow their business locally while leveraging established relationships with global insurers, suppliers, and fleet companies. The ProColor PROcess is a winning formula. ProColor Collision USA LLC, 650 Pelham Blvd, Suite 100, St. Paul, MN 55114 ® Registered Trademark of MONDOFIX INC. We train the best. You are the PRO. Find out more at procolor.com

How to Mitigate Collision Repair Fire Risk

Identify These Shop Hazards To Increase Safety And Aid Regulation Compliance

By JAY SICHT / Photos Courtesy of GMG ENVIROSAFE

Mitigate Collision Repair Shop Risk

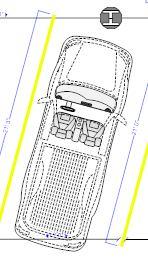

ment distributor. As I was taking inventory in the mixing room and updating the color library on the computer at the shop of one of our customers, one of the technicians in the adjacent building yelled for me to come quickly. As I turned to the walk door connecting the two buildings, I was shocked to see flames shooting up from the GMT 800-platform Chevy pickup on the frame rack several feet high. As he frantically removed the fire extinguisher from the bracket, a column of black smoke rose to the ceiling and rapidly descended to the floor. The little 10-lb. extinguisher had no visible effect on beating back the flames; it was time to evacuate and call 911.

The shop owner had been welding in new rocker panels as part of a rust repair on the pickup. The owner had put down the MIG welding torch and stepped outside to see the latest specials on the tool truck that had just shown up. What he didn’t realize was there was some noise/ vibration/harshness-reducing foam that had ignited from welding and had begun smoldering and then flared up in his absence. The sole technician who’d remained in the shop and yelled for my help was working on a car with his back turned to the scene 30 feet away, and by

the time he saw the flames, the truck was engulfed. It was a total loss, and other non-driveable works in process were also totaled from smoke damage. The damage throughout the post-frame shop was mostly smoke-related, although the fire burned through the sheet metal ceiling to the bottom chords of the trusses. Thankfully, there were no injuries, and after four to six weeks, the shop was back in business.

Identifying Common Problem Areas

GMG Envirosafe has been helping body shops avoid fires and stay compliant with environmental and safety regulations since 1989. In talking with Kevin Dwyer, product manager about some common violations his company representatives see on site visits, many of the violations may seem like common sense. At the same time, they are also frequent enough that this article can serve as a quick reminder of areas of concern that should be addressed.

The paint department is where most violations occur, Dwyer says. Beginning with the basics, having a paint mixing room with explosion-proof wiring is essential.

“I’d say probably 80 percent of the shops do, but I do run into shops that don’t have one. You need it, because that’s where you’re supposed to be storing all your flammables, such as paint and thinners.”

It should also have a 4” sill at the bottom of the mixing room door to be able to contain all the flammable liquid stored in the room so it doesn’t end up in a drain.

A metal trash can with a metal lid is the only acceptable receptacle for solid waste, as if a fire starts in a plastic trash can, the fire will consume the can and spread.

“If it’s a metal trash can, the fire will stay contained to the can and then it can be put out by putting the lid on top of it, choking any oxygen in there,” he says.

Masking materials with uncured primer and paint material overspray, as

well as disposable paint cups that still contain solvent-borne paint residue, are the biggest sources of flammable material, Dwyer says.

“You’re supposed to drain that residue into the waste drum, but a lot don’t do that; they just chuck it. That can be an issue if it’s solvent paint waste.”

Drums of waste paint and virgin thinner require a ground cable and clamp to be attached to them, a quick step that is often overlooked at the time they are switched. Funnels used for waste paint should have a self-closing lid, and if they’re used with polyethylene drums, they should also include a flame arrestor.

Another violation noted by GMG Envirosafe’s inspectors is missing faceplates for electrical outlets in older shops. Electrical extension cords must have intact ground terminals, can’t be frayed, and cannot be “daisy-chained” (interconnected).

Compressed-gas Cylinder Storage

“One of the most dangerous things is compressed gas cylinders,” Dwyer says, noting spare cylinders must be stored upright and secured with a chain or some other method.

“When we go to the shops, one of the first things we check—and this violation is a big fine from OSHA—when they’re in storage, oxygen and acetylene bottles need to be separated by at least 20 feet. When they’re on a cart and being used for work, they’re fine. They need to be stored away from high-traffic areas and exits as well.”

Oily rags must be disposed of—or stored—in a metal container, such as a flammable-materials metal step can, to avoid a source of spontaneous combustion.

Fire Suppression

Shops must also have some kind of fire suppression in the paint booth, whether it’s a wet system through the building’s sprin-

24 May 2024 fenderbender.com

kler system or a dry system with tanks outside the booth. A dry system must be serviced every six months, and sprinkler heads must remain unobstructed. And don’t forget “No Smoking” signs on the paint booth and in the mixing room.

All fire extinguishers must be solidly mounted with signage above them, have ready access, be fully charged (indicator arrow showing in the green), and serviced each year.

“Once a month, someone in-house is supposed to be checking every single extinguisher. There's a tag on the extinguishers from the company that serviced them. And on the back of the tag, there are 12 boxes, one for each month of the year to initial.”

Although fires in neglected paint booth exhaust stacks are possible, Dwyer says the shops they visit are good about changing their filters.

“We give them changeout logs so they can initial and date every time they change the booth filter.”

EV Safety Training

A growing area of expertise for the company is in EV safety training, Dwyer says.

“That is a huge fire risk as well because once those batteries start burning, they don't go out. The fire department needs to put water on them for hours.”

To minimize the fire risk, Dwyer recommends that shops use an intake process just for EVs.

“That’s an issue, because shops don’t realize that. They’re kind of just bringing them in like they do with normal cars. But when you get an EV, you need to identify it and put a placard on it saying it’s an electric vehicle or use some kind of communication system so that everyone in the shop knows this is an EV.”

Before the vehicle is brought into the shop, the battery pack should be assessed for its integrity.

Mixing room violations

This paint mix room shows a couple violations: the plastic trash can needs to be a metal one with a closed metal lid, and the liquid solvent paint-waste container needs to be grounded and include a waste-paint label.

Out of the zone

This fire extinguisher is out of service, as evidenced by the arrow not in the green. It also needs to be mounted, not loose on a table. It is also missing a fire extinguisher sign above it and needs to be tagged by the servicing company to indicate when it was last serviced.

25 May 2024 fenderbender.com

“You could use an infrared camera to look for hotspots. You need to take an initial reading, and then wait 10 or 15 minutes and come back to take another one just to make sure the battery is not heating up. If it’s heating up, there’s a chance it could be going into

As Dwyer notes, that means damage to one cell of hundreds or thousands (depending on the design of the battery pack) ignites the damaged cell, and then ignition and fire continue to spread in adjacent cells in a sort -of domino effect.

“If you bring that into the shop and the car goes into thermal runaway, there’s a good chance the shop’s going to burn down. Someone’s going to get hurt. So you really need a good intake process to make sure [thermal runaway] is not happening.”

The company will tailor a written plan for EV safety, including personal protective equipment (PPE), and training for technicians and administrative staff.

“We try to make it so it’s not as technical for the admin people, to make it easy on them.”

The company has also been doing “EV Wednesdays” on LinkedIn for a little over a year, including topics such as job hazard assessments, hazard communication programs, and PPE requirements. Although some fear working on EVs, Dwyer said much of the fear is unfounded.

“There is a lot of hype around EVs, but the cars are built to be safe. If you just do what you’re supposed to, you’ll be fine. If you wear your PPE and you follow the repair process, there's nothing to it, you'll be fine. Once you deenergize the vehicle, it's just a regular vehicle. There's just so much hype behind electricity it freaks people out. I often talk to techs in the shop, who say, ‘I'm never gonna work on those. But, it's pretty simple. It's about a 20-minute de-energization process.”

Site Plan

A site plan, which serves as an emergency evacuation plan, is sometimes required by the fire marshal. But the company creates one for each of its customers, with copies of

it posted at all exit locations and in each department plus the break room or area. It’s also available on a mobile device.

“I’ve seen it happen where the shop manager will be outside with the fire department, and they can look at his phone for the site plan.”

Offering Peace-of-mind

“There are a lot of different ways with safety to keep the government off your back. But if something happens, you don’t need to worry about it. You can just give us a call, and we’ll come take care of it. We manage compliance for the shops. Shop owners have a lot that keeps them up at night, so that’s something we want to try to give them peace of mind so they don’t have to worry about so much.”

The company offers assistance with compliance for OSHA, EPA, and where applicable, the DOT.

“We’re boots on the ground; we’re in your shop working with you. Most of these other companies are just doing online training. We do offer online training, too, but a lot of the older technicians don’t like using computers. We do bilingual training in-person and online. We cover every state, and we are in Canada as well.”

26 May 2024 fenderbender.com

Managing compliance

A GMG Envirosafe compliance coordinator conducts a shop assessment.

Motor Age Training offers the most complete and extensive collection of B-Series Collision Repair training guides available anywhere!

B2 - Paint & Refnishing Certifcation B3 - Non-Structural Analysis & Damage Repair B4 - Structural Analysis & Damage Repair B5 - Mechanical & Electrical Components Certifcation B6 - Damage Analysis & Estimating Certifcation *training guides available in a variety of formats PASSTHEASE.COM PREPARE FOR AND PASS YOUR ASE CERTIFICATION EXAM GUARANTEED! THANKS

TRAINING SUPPORTERS

TO OUR

Darryl Liechti’s shop is growing rapidly, thanks to his focus on customercentric, honest operations

By LINDSEY GAINER

28 May 2024 fenderbender.com PROFILE

MELANIE HEIGES/PHOTOGRAPHY BY MELANIE

DARRYL LIECHTI HAS A PROBLEM.

His shop — Collision Correction in Williamsburg, Virginia — has grown so fast that he will likely need to expand beyond his current 10,000 sq. ft. space in the next 18 to 24 months, only two years after taking the business full-time and establishing himself in his current location.

It’s certainly a good “problem” to have, concedes Liechti, who spent eight years building Collision Correction as a side job, fixing friends and family member’s cars out of storage units and rented garage space while working full-time for other shops. By 2022, he’d gotten so busy that it was time to make a decision: take Collision Correction to the next level, or scale back and continue with the safe, steady job he had, letting the dream of shop ownership die in the process.

As you may have guessed, he chose to take the leap into ownership…and he hasn’t looked back since.

Chasing the Dream

Liechti is the first to admit that the journey to owner/operator hasn’t been without its difficulties — there’s been plenty of moments of frustration and overwhelm, especially around the leasing and permitting needed to establish the current shop. But, like he always has, Liechti dug in and taught himself what he needed to know to make it happen.

When you hear his story, it’s obvious that this determination and perseverance runs deep, and it’s a big reason why he’s arrived where he is today.

After graduating from Universal Technical Institute’s collision repair program in Houston in 2005, Liechti moved back to Williamsburg and dove into work as a body man’s assistant, moving up to standalone tech three years later and team leader shortly after that. He seized every opportunity to learn about the business, even asking a previous manager to let him work in the front office when a workplace injury rendered him unable to work the floor, so he could see that side of operations firsthand.

By the time Collision Correction was born, Liechti had gained enough experience to know that he wanted to be an owner someday. Seeing struggles with the front offices and customer experiences at other shops really motivated him to want to open his own business, he says.

“I wanted the ability to control the customer experience from start to finish. You can do excellent work in the back, but if your customer has a poor experience, that reflects on the business as a whole.”

Customer-Centric Service

Liechti is incredibly proud of the fact that — first and foremost — Collision Correction is a “customer-centric” repair shop that always operates with honesty and integrity.

It certainly hasn’t happened by accident, though (no pun intended). Liechti has spent countless hours creating standardized processes that ensure every customer gets the same excellent experience day in and day out. Even before he opened his doors, he’d run scenarios with mock customers to hone the process and determine what could be done better.

“If you can find a way to mitigate with the customer, if you can be proactive instead of being reactive, they’re going to have an excellent experience, for sure.”

Communication is key, he says, as is being upfront and honest no matter how difficult the conversation. Empathy goes a long way, too. Liechti and his team never lose sight of the fact that accidents are traumatic events for customers, and they treat them as such.

He also makes it a priority to educate people about their repair and stay in touch throughout the process, often using automated text updates that both save his staff time and provide the customer with necessary information in a quick, efficient way.

“I would say a good 90% of our customers, if not more, prefer text messages. It’s a win-win — they don't really want to be burdened with a phone call, so they're able to see at a quick glance what’s happening, and everything is documented. It's an easy

reference point.”

Things like virtual estimates and contact-free service are additional ways he goes above and beyond to meet the needs of his customers. And the team strictly adheres to OEM procedures throughout the repair process, to ensure the car is fixed in a safe manner, he adds. The shop is I-CAR Gold Class-recognized, and all the technicians are individual Platinum-recognized on top of having multiple manufacturerspecific certifications.

Collision Correction isn’t part of any direct repair programs (DRPs), either, something Liechti says allows him to operate and repair vehicles as he sees fit without any outside interference.

“The customer is our customer, not the insurance company. We are a DRP-free shop. We do not have any insurance relationships; we’re strictly independent. Because of that, we’re able to provide a level of customer service and quality that, in my opinion, is unmatched in our area.”

It’s obvious his customers agree. Liechti has “never advertised a day in his life” — his entire business has been built through word-of-mouth referrals, a testament to the strong reputation he’s earned in the community.

“Honest and highly professional.”

“Darryl and his team are outstanding.”

“The absolute best.”

These are just a few of the ways customers describe the shop in their reviews.

“We love the customer service and community aspect,” he says. “Williamsburg is a very small, business-oriented town. Every chance that we have to get involved in a local program or give back, we absolutely jump at it.”

The shop recently partnered with GEICO and Enterprise Rent-A-Car, for example, to complete the repairs on a Transit van that will be used to pick up and deliver bikes to the less fortunate. And Liechti is interested in creating a program soon for local high school drivers to teach them what to do in the event of an accident.

Not only that, but the team also makes it

29 May 2024 fenderbender.com

a priority to invest in other area businesses — every Friday they all leave the shop for an hour and go have lunch at a non-chain establishment, something they’ve done together for years to bolster the local economy.

“We certainly appreciate our community and the love that they show us. We feel like it's our obligation to give back.”

More Than a Team, a Family

Liechti currently has a staff of eight: two collision techs, one painter, one shop helper, one CSR, one estimator/production manager, and himself and his wife, Cecile.

It’s clear that the camaraderie he shares with his team is a big reason for his success, and it’s something he never takes for granted.

“I'm very fortunate that all of the guys who work for me, we have been together for the last 15 years. We worked together at a few different shops on team-based systems.”

When it came time to take Collision Correction full time, Liechti couldn’t imagine doing it with anyone but his friends.

“I am forever grateful that they trusted the dream enough to come work with me and be the lifeblood of the business,” he says. “I'm very appreciative of the staff we have. We're a family; that's just what it boils down to.”

Liechti says he knows exactly what he’ll get from each of his teammates dayto-day, and them from him. The mutual trust and respect that exist ease his job as a manager, and knowing the strength of each technician means work flows through the shop seamlessly.

“Our technicians are true craftsmen who value continued training and new repair technologies. They’re 100% flat rate, so from a business standpoint, I know what work I can give this guy because he’s extremely efficient at it, and I know what this guy's extremely efficient at. They, in turn, make more money on a flatrate pay scale, and the shop is more productive.”

And speaking of family, Liechti calls Cecile his “rock” and the key to his success on a personal level. Not only does she handle the accounting and invoicing for the business, she’s also been Liechti’s number-one supporter from day one.

“Even back in the days when I was renting storage units to repair friends and family’s vehicles, she would bring me dinner or lunch while I was doing that, understanding the sacrifice of missing out on time with her, or date nights, or things that got canceled because of the work. She understood the dream and stood beside me every

step of the way to make it happen. I'm very blessed and thankful for my wife.”

Keeping the Focus on Quality Long Term

As of now, Liechti says he doesn’t have any ambitions to become a multi-shop operator — he wants to keep a tight rein on quality control and remain customer-centric. When he does grow, he wants to “add value to the team, as opposed to just bodies.”

He’s currently partnering with a local trade school — New Horizons — to provide an internship to one of their students. Liechti has learned a lot from mentors over the years, he says, and he wants to give back in the same way. He also hopes he’s training the next member of his staff in the process.

“It’s really the best situation for us, because of our tight-knit group and the quality that we all expect out of each other daily. Raising someone up in our system who understands those core values, the honesty and the integrity, is ideal.”

As for his advice for other shop owners?

“Stay focused, keep an open mind, research the industry, try to stay on top of industry trends and convey that information and knowledge to customers, and always stay customer-centric.”

30 May 2024 fenderbender.com

PROFILE

31 May 2024 fenderbender.com

HOW TO LEVERAGE DIGITAL MARKETING

It can be the most effective tool to stay on top of your customer’s mind

YOU’VE PROBABLY HEARD the phrase “targeted digital marketing” before — but what does it mean? And how can it help keep your shop at the forefront of potential customers’ minds?

32 May 2024 fenderbender.com

STRATEGY THE SOP SIRAANAMWONG / ISTOCK / GETTY IMAGES PLUS

Targeted digital marketing is essentially a way to make sure that the people most likely to visit your shop see your ads online. People are “targeted” using data they’re putting out into the world — perhaps the wording they choose to perform a search, or the location they perform that search from. Google Adwords, for example, can be targeted to appear to people carrying out Google searches in certain geographic locations — near your shop, or even people in your competitor’s lobby — when they’re searching for certain keywords or phrases, things like “collision shop near me” or “collision shop in [your ZIP code or city].”

Instead of relying on someone remembering your shop from something they may have seen a long time ago — like an ad on TV or the radio — you’re actively meeting people in their moment of need, when they’re searching for your service.

For this reason, Megan Fulkerson, partner and digital strategist at 3P Marketing, believes targeted digital marketing is the most effective tool a collision shop owner can utilize to stay top-of-mind and bring new customers through the door.

Here’s why.

As told to LINDSEY GAINER

Precision Matters

The newest way we are utilizing data to keep a shop top-of-mind is by targeting specific brand owners. For instance, if a shop is certified to repair BMW, Honda and Nissan, we build out campaigns to target owners of those specific brands in a radius around the body shop. By only targeting brand owners, we can tailor the ads to reflect the type of vehicle they drive and inform them that your body shop is certified to repair their vehicle. We can then track if that person ever steps foot in a client’s shop by utilizing cell phone location data (this data is anonymous, so we can’t ever provide a name, only a ZIP code that someone came from).

We utilize software to build out the best possible campaign to ensure we are showing up online regardless of where a potential

customer may be – Googling, browsing online, using social media, streaming television, or visiting your website. Your website is the employee that is working 24 hours a day, seven days a week to keep your shop at the forefront of people’s minds.

Capitalize on Your Value-Adds

The most important things to highlight in your ads (or on your social media accounts) are your value propositions — what do you offer that sets you apart from the competition? Do you offer pick up or delivery, online estimates, a free detail with repair? Highlighting what will make the customer’s inconvenient situation a little easier goes a long way. Equally important is highlighting any brand-specific training your shop has. If a BMW owner learns that you are BMWcertified and why that is so important, it can help ensure you get the repair.

Staying active on social media channels — like Instagram, Facebook, X (formerly Twitter) and YouTube — is another important way to keep your shop top-of-mind with potential customers. It lets you show the world who you are, and why you can be trusted. It’s a great tool to highlight employees, give a “behind-thescenes” look into what’s going on in the shop, and showcase cool, fun or unique repairs.

Social media isn’t the best way to get new customers in the door — that’s the job of targeted digital ads…but it certainly can help you build brand awareness and develop a following of potential customers. Social media is also free — so for shops who may not have the budget right now for ads, it’s a great way to put your value-adds out into the world so people can get a feel for your offerings.

Having your customer service reps push customers to fill out a review is also a great thing to do, because many people will take reviews into account if they are unsure of which shop to go to.

There’s Still An (Important) Place for Community Involvement

Community involvement is not only a great way to support your neighbors and build awareness for your business; it’s also a great

team-bonding activity. During my time at Lefler Collision, we put a large emphasis on community involvement. We did everything from car care clinics for women, to “little lady” days for Girl Scouts, grilling hot dogs at the public pools on Saturdays, passing out water at races, and more! I always had our crew wearing a logoed t-shirt, and it was always fun to give back to the community. Working out in the community provides great content for social media as well and can also be an important factor when someone is looking at your organization as a potential employer.

Should You Manage Advertising In-House or Outsource?

While social media is best managed by someone within the shop, a professional within the marketing agency world is typically needed to place digital ads or streaming commercial spots.

Many tools are not available to the public and have large minimums, which is why it is necessary to use an agency. The biggest positive to using a marketing expert is that you get access to an entire team managing and optimizing the campaign for you, to ensure it’s targeted exactly as it needs to be.

Rome was not built in a day, however, and it’s important to keep that in mind when starting any type of advertising campaign. Utilize data to show what type of traction you are getting. If you do not have Google Analytics set up already, that is a great free tool to help see where traffic is coming from.

The Bottom Line

People are spending more time than ever online — on their phones, laptops, tablets, and other smart devices — and they’re utilizing search engines to find services in their moment of need. Ensuring they see an ad for your shop at that precise moment is the most effective way to bring new customers into your shop, and ensure you remain topof-mind with the people who need your services most. Utilizing social media channels and getting involved in your community will further compound your brand recognition and build a strong foundation upon which your digital marketing can stand.

33 May 2024 fenderbender.com LEARN | GROW | WORK SMARTER

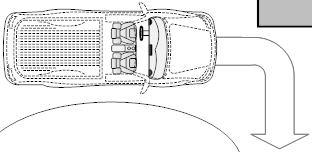

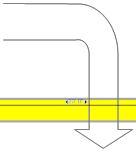

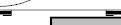

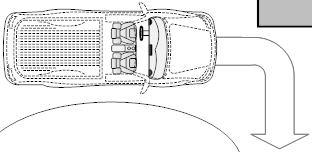

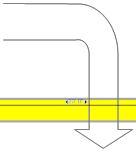

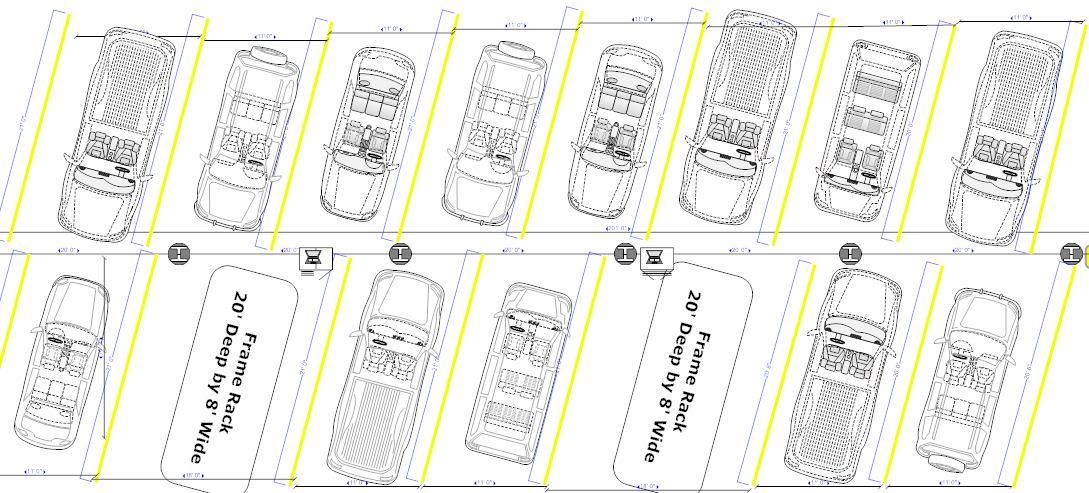

SHOP WORKFLOW IS PART PLANNING, PART PROCESS

A well-designed shop will only run as efficiently as the processes guiding it.

By TODD KORTEMEIER

IT’S IMPOSSIBLE TO consume any media these days without navigating a myriad of shoehorned-in Taylor Swift references, but please excuse one more: When it comes to laying out a collision repair shop, there’s no

35 May 2024 fenderbender.com

STRATEGY

FINANCE+OPERATIONS PHOTOS: RUDZHAN NAGIEV / ISTOCK / GETTY IMAGES PLUS

better starting point than a “blank space.”

But blank spaces have a way of filling up swiftly (sorry). It may seem like that wideopen 20,000-square-foot floor will fit everything your shop needs and then some. But once you start placing equipment, it can be easy to forget things, and suddenly, that wide-open floor isn’t so open.

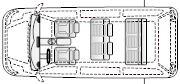

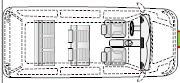

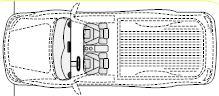

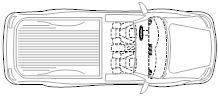

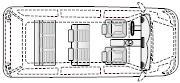

“A lot of times, initial layouts and drawings are done, and the idea for workflow doesn’t necessarily match how they actually do it with their particular people and skill sets,” says Lance Getz, co-owner of Quincy Auto Supply, a PPG Platinum Distributor and auto parts store in Quincy, Illinois, and who was a PPG territory manager and later business development manager from 2004 to 2017. “… So how you do it and how you lay it out also really is impacted by what your team of people looks like, and your skill sets, and your ability to hire people for that.”

How you choose to physically lay out a shop is important, but so, too, is the process that moves cars through that layout.

People and process

Shops build new spaces or renovate existing ones for a reason. Something about the old space wasn’t working. And if the space wasn’t working, it’s also the perfect opportunity to look at all aspects of how you do business.