NAPA SMART SIGN PRO

PROimage Co-Branding Program

4-Star

PROimage Co-Branding Program

4-Star

TRAINING THAT PAYS OFF: INSIDE THE STRATEGIES TOP SHOP OWNERS USE TO KEEP THEIR TEAMS SHARP, LOYAL, AND READY FOR THE TECHNOLOGY OF TOMORROW

Investing in your shop’s future goes beyond tools and technology—it’s about investing in your people. From in-house sessions and gamified micro-learning to national training conferences, leading shop owners share how they’re building stronger teams, improving diagnostic efficiency, and creating workplaces where technicians want to stay and grow.

BY CHRISTINE SCHAFFRAN

New columns focus on using AI in accounting as well as building customer trust with effective conversations. Plus: Robin Reneau lets down her hair to reveal what makes her so successful as Rob the Blonde Mechanic in a podcast episode.

EVs dominate the headlines —but not the driveway

Allocating a budget for tools and equipment

J.M. Auto Service gears up for winter in Northern Minnesota

The ROI of giving back KATHLEEN CALLAHAN

How to handle employee

Surviving the ongoing shift in auto repair DUTCH SILVERSTEIN

Level Up Your Shop Through Training and Profitability

Through hands-on, in-store training with BG Representatives and Field Trainers, plus our award-winning digital courses, we provide the tools and support your techs need to perform at their best.

Power Up Your Shop With BG Training

BROSKI: Building Customer Trust: The Key to Effective Service Advisor Calls

Building rapport or trust isn’t a cookie-cutter operation where you just plug in the script and the stories. There are many types of customers: the car guy, the retired guy, the single mom with one or two kids, the attorney, etc. Victor Broski says once you find common ground and make a connection, everything becomes easier.

HAYES: AI in Auto Repair: The Back Office Race to $100+ Million

When most shop owners think about scaling, their minds go to bays, technicians, and car count. But Todd Hayes says the future of the industry will be won or lost in the back office. Finance and accounting must move as fast as the front of house to compete at the $100+ million level and beyond.

PODCAST: Who is Rob the Blonde Mechanic?

Once a single mom who didn’t know how to check a dipstick, Robin Reneau went through three broken-down cars in four years. Fast forward to today: She’s the first Black woman mechanic to own an independent repair shop in Georgia, running Rob the Blonde Mechanic, LLC. Robin’s journey from high school dropout to shop owner and community leader is all about resilience, representation, and proving what’s possible when you refuse to shrink yourself.

RATCHET+WRENCH

Strategies and inspiration for auto care success.

EDITORIAL

EDITORIAL DIRECTOR

Chris Jones

EDITOR-IN-CHIEF

Christine Schaffran

ASSISTANT EDITOR

Kacey Frederick

CONTRIBUTING WRITERS

Tess Owings, Leona Scott, Alison Johnson

EDITORIAL ADVISORY BOARD

Tara Topel, Topel’s Towing and Repair

Andrew Marcotte, American Pride Automotive

J.J. Mont, J.J.’s Auto Service

Rachel Spencer, Spencer’s Auto Repair

Tonnika Haynes, Brown’s Automotive

Lucas Underwood, L&N Performance Auto Repair

SALES

PUBLISHER

Andrew Johnson / ajohnson@endeavorb2b.com

ASSOCIATE SALES DIRECTOR

Mattie Gorman-Greuel / mgorman@endeavorb2b.com

DIRECTOR OF BUSINESS DEVELOPMENT

Cortni Jones / cjones@endeavorb2b.com

ACCOUNT EXECUTIVES

(NATIONAL ACCOUNTS)

Diane Braden / dbraden@endeavorb2b.com

Darrell Bruggink / dbruggink@endeavorb2b.com

Marianne Dyal / mdyal@endeavorb2b.com

Chad Hjellming / chjellming@endeavorb2b.com

Lisa Mend / lmend@endeavorb2b.com

Kyle Shaw / kshaw@endeavorb2b.com

Sean Thornton / sthornton@endeavorb2b.com

ART AND PRODUCTION

ART DIRECTOR

Emme Osmonson

PRODUCTION MANAGER

Mariah Straub

AD SERVICES MANAGER

Jen George

ENDEAVOR BUSINESS MEDIA, LLC

CEO

Chris Ferrell

COO

Patrick Rains

CRO

Paul Andrews

CDO

Jacquie Niemiec

CALO

Tracy Kane

CMO

Amanda Landsaw

EVP TRANSPORTATION GROUP

Chris Messer

EVP ENDEAVOR BUSINESS INTELLIGENCE

Paul Mattioli

VP OF CONTENT STRATEGY, TRANSPORTATION GROUP

Josh Fisher

SUBSCRIPTIONS

Send address changes and subscription inquiries to:

Ratchet+Wrench PO Box 3257 Northbrook, IL 60065-3257

SUBSCRIPTION CUSTOMER SERVICE: 877-382-9187 ratchetwrench@omeda.com

LETTERS TO THE EDITOR

editor@ratchetandwrench.com

Opinions expressed in Ratchet+Wrench are not necessarily those of Endeavor Business Media, and Endeavor Business Media does not accept responsibility for advertising content.

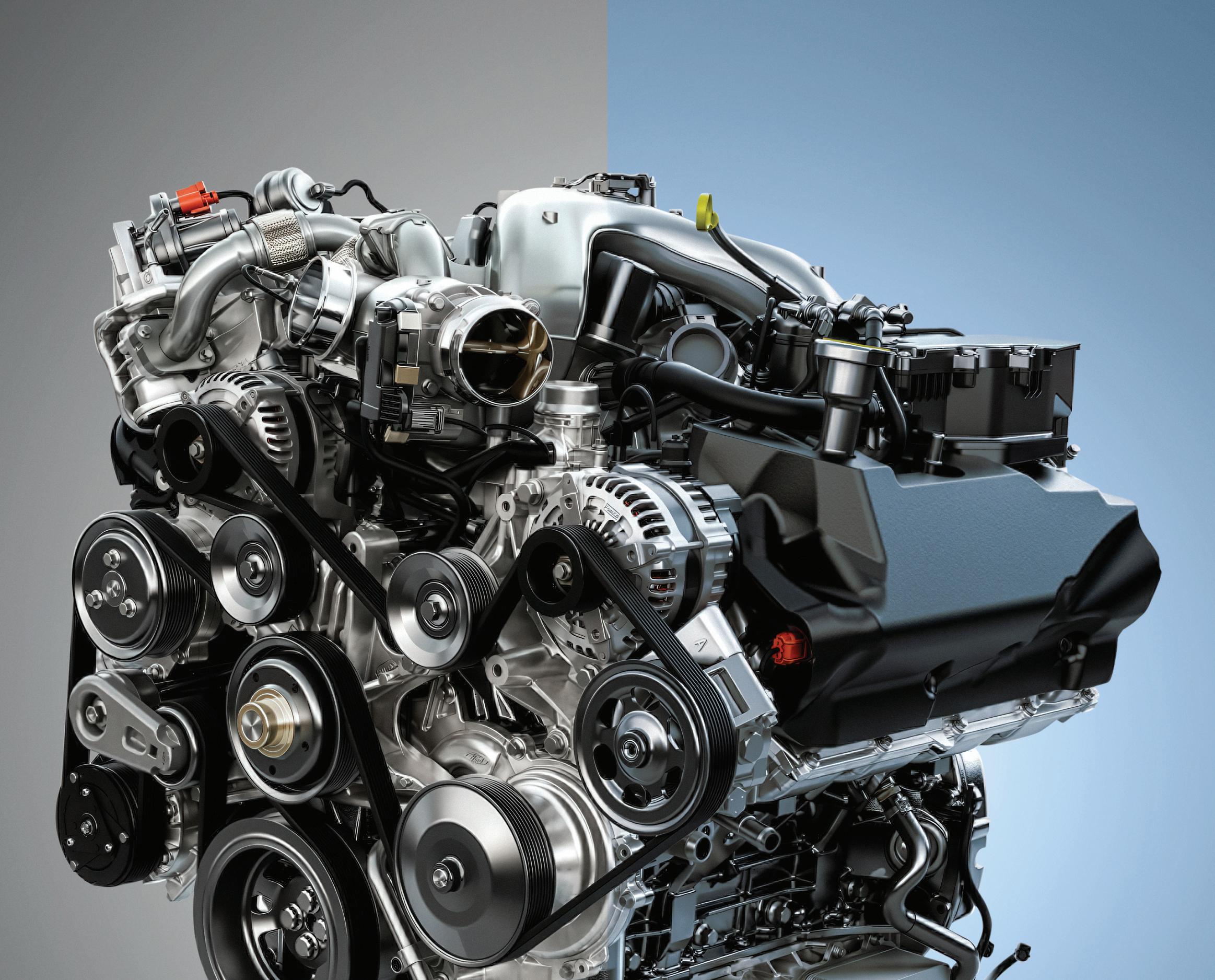

Precision-crafted Ford and Motorcraft® powertrain assemblies are built to all quality standards and OE specifications. They’re specifically engineered to fit and deliver consistently reliable performance and peace of mind: New and remanufactured transmissions and gas engines are covered for three years with unlimited miles, including labor, while diesel engines are supported by a two-year/unlimited-mile warranty (including labor). Plus, there are no exceptions for commercial vehicles. And with our no-risk core return policy, you don’t have to worry about extra charges if your engine or transmission core are damaged.*

Ford and Motorcraft make all the difference — for your customers and your business.

China is racing ahead in electric vehicle adoption while U.S. consumers remain cautious

BY CHRISTINE SCHAFFRAN

Electric vehicles seem to have stolen the spotlight in the world of automotive technology, but that doesn’t mean they are the most popular choice among consumers right now, according to the 2025 Joint Powertrain Trends and Outlook Forecast presented by the Auto Care Association, in partnership with MEMA Aftermarket Suppliers.

Key findings were revealed at the Automotive Aftermarket Products Expo in

November, where strategists of PwC Strategy& unveiled some of the most significant factors driving the U.S. and Chinese markets in 2025 and beyond.

Akshay Singh, a partner in PwC’s U.S. Automotive Advisory practice, noted that while China sits at 30% market penetration

in the EV market, the U.S. lags behind at only 7%. He attributes the stark contrast to vehicle economics and the total cost of ownership, including:

• Government regulations as they relate to certain vehicles

• Whether there are enough models for consumers to choose from

• Whether consumers are willing to wait for a vehicle to charge

• Whether enough charging infrastructure is available.

“If you don’t have the charging infrastructure availability, then you’ll probably see a low adoption rate,” he points out. “These are the different factors we look at and see how each of the factors are trending.”

For instance, he notes, EVs are still about 20% more expensive in the U.S. compared to their counterparts with internal combustible engines. To break it down further, he points out that 33% of EVs cost more than $80,000 in the U.S., which only serves about 2% of the market. Meanwhile in China, 50% of the EV models are less than $25,000, which clearly serves a wider client base.

“It’s essentially giving more prospective EV buyers an affordable entry point,” Singh says. “It’s not just limited to a luxury segment. So, that’s a big reason that EVs are growing in China is because of affordability and hybrid EV models.”

And while the majority of the industry seems to be hyper focused on EVs, hybrids such as Battery Electric Vehicles appear to be climbing in popularity at a higher rate,

says Keshav Chaudhary, Senior Manager for PwC Strategy&.

“When it comes down to the residual value of these hybrids … they’re actually holding their value much better than their ICE counterparts, and we feel one of the reasons this is happening is all the BEVs coming to market, the consumers are much more accepting of having a battery in their car,” Chaudhary explains. Years ago, there was a lot of uncertainty around how the battery life of these BEVs were going to turn out, but now, most of them have credibly shown batteries are lasting eight to 10 years with minimal degradation. So, consumers are very open to having batteries and buying used hybrids as well. And on an overall cost basis, hybrids make a lot of sense.”

Singh noted that battery costs have gone down almost by 20% in the last year and predicted that prices will continue to “go down substantially in the next three or

four years.” He adds that China’s willingness to embrace this technology is putting them ahead in the race for more affordable vehicle ownership.

“Right now, there’s a lot of policy support in China across the value chain, and it’s boosting EV adoption,” he noted. “There’s some policy shift in China, but there’s a lot of incentives that are available. There are lot of regulations in China that are available. There are local electrification policies. But again, it is helping with the growth. But the number-one reason that the costs have come down substantially, is the growth of EV infrastructure, whereas in the U.S., as you know, there are some regulatory headwinds.”

While some sources cite an infiltration of hybrids encompassing around 50% of the market, PwC Strategy& team members estimated it to weigh in more like 24% of the market by 2030.

The National Institute of Automotive Service Excellence was joined by the U.S. Secret Service at their exhibit at the Automotive Aftermarket Products Expo, Nov. 4 to 6, according to a press release.

The purpose of the exhibition was to drive awareness of the wide range of career opportunities available to auto technicians, including with the Secret Service. Since mobility is a key line of operation within protective services, the Secret Service has an array of specialized vehicles to help them securely move leaders from place to place. The organization requires ASE-certified technicians to help keep those vehicles operating safely.

Two specially outfitted Secret Service Chevrolet Suburbans were on display in a co-branded booth with ASE.

“That the Secret Service needs ASEcertified auto technicians underscores the range of career opportunities in this industry,” said Dave Johnson, president and CEO of ASE. “It’s a technical career that requires far more than turning a wrench—modern vehicles are effectively ‘rolling robots’ with unprecedented levels of autonomous capabilities driven by hundreds of sensors and actuators that are controlled by more lines of code than a modern fighter jet.”

AutoVitals has released a new feature allowing for appointments to be written back into Tekmetric’s calendar, according to a recent press release.

The new integration means that shops using AutoVitals Appointment Scheduler will not have to manually enter appointment details into Tekmetric.

However, the AutoVitals Scheduler does not yet read live availability from Tekmetric, meaning customers are still requesting a booking time that must be confirmed by the shop. Additionally, once an appointment is transferred to Tekmetric, any changes made within Tekmetric will not automatically update in AutoVitals’ Conversation Center or Scheduler. To use this feature, shops must enable exact appointment time selection in their AutoVitals settings.

The new feature is available now to

AutoVitals customers on Tekmetric’s shop management system who use the AutoVitals Appointment Scheduler widget on their website. The new capability is the latest in a series of planned integration enhancements designed in direct response to shop feedback.

The U.S. government will be extending current tariff relief programs for automobile and auto parts tariffs, reports NBC News.

The move comes after an executive order was signed in April to keep automobile and auto parts tariffs from stacking on top of one another, as well as providing relief from separate tariffs on steel and aluminum.

With the most recent announcement, the existing tariff offset program has been extended from two years to five.

Automotive manufacturers have strongly urged for such relief, which comes as plans for trade policy restructuring continue to be revised by the government.

“We see there’s a lot of upside depending on how the negotiation goes with the administration,” Ford CEO Jim Farley said in July. “We’re in daily contact with them and, at this point, I would say they’re very productive conversations.”

Ford Recalls 10R80 Automatic Transmissions Used in 2017-21 Model Year

Ford has issued a recall for select 10R80 re-manufactured automatic transmissions due to a rollaway risk, according to Ford Authority.

The transmissions—manufactured between May 30, 2020, and June 13, 2025—were used as service repair parts for 2017 to 2021 Ford and Lincoln vehicles.

The T10 bearing may have been incorrectly installed in affected transmissions, which prevents the transmission from shifting into park and potentially causes the vehicle to roll away.

An estimated 34,481 vehicles are impacted by the recall. Ford will begin communication with vehicle owners on Dec. 1, 2025. For vehicles with 8,000 miles or less, dealers will inspect the transmission for the T10 transmission bearing and replace the transmission if necessary.

The National Highway Traffic Safety Administration is escalating its investigation into General Motors’ 6.2-liter L87 V8 engines, according to AutoGuide.

In April, GM recalled 721,000 vehicles produced between 2021 and 2024 over reports of engine bearing failures. But NHTSA has received an additional 1,157 complaints related to the problem that have prompted it to expand its investigation to another 286,051 vehicles from model years 2019 to 2021, as well as some 2024 vehicles not originally included.

NHTSA will carry out an engineering analysis to determine whether GM’s original recall should be expanded to include Chevrolet Silverado and GMC Sierra 1500, Chevy Suburban and Tahoe, GMC Yukon/ Yukon XL, and Cadillac Escalade models built between 2019 and 2024.

GM has not commented on the new investigation but has pointed to supplier manufacturing and quality issues as reasons in the past.

Several auto repair brands made it onto this year’s Franchise Times Top 400 list, which was recently released. The annual list ranks the largest U.S.-based franchise systems by global systemwide sales, following a fivemonth research and reporting phase.

Midas put out a press release highlighting their spot at no. 46 on the list, moving up five spots from last year and marking a breakthrough to the top 50. It also topped the auto repair category of the list.

Christian Brothers Automotive followed at no. 92, moving up from no. 98 last year. It’s joined on the list by other general automotive repair brands including Meineke Car Care Centers at no. 113, Precision Tune Auto Care at no. 239, and Mr. Transmission at no. 386.

In addition, Franchise Times outlined the top five fastest-growing sectors in a press release. The automotive industry rose to third place this year, seeing +7.1% points, coming after personal services (+8.8%) in second, and health & medical (+12.7%) in first.

President Donald Trump revealed plans to implement new tariffs on imports from China, as shared in a report from WardsAuto.

According to a social media post from Trump, 100% levies were implemented as of Nov. 1, and will stack on the combined duties that Chinese imports are already subject to.

The move comes in response to China placing export restrictions on rare-earthrelated goods and technology, which took effect Nov. 8. Though trade negotiations between China and the U.S. had relaxed in recent months, these events have prompted tension to rise again.

“I was to meet President Xi in two weeks, at APEC, in South Korea, but now there seems to be no reason to do so,” Trump posted on Truth Social.

Ford has issued three separate recalls covering a total of nearly 750,000 vehicles for issues including camera display, steering, and seatbelt defects, reports CBS News.

Certain 2020-2022 F-250 SD, F-350 SD, and F-450 SD vehicles were recalled for potentially not displaying rearview image displays correctly in certain lighting conditions. Over 290,000 vehicles are impacted by the recall.

The issue stems from the image processing module software, which dealers have been instructed to perform an update on to remedy the issue.

Another 115,539 vehicles were recalled for potential loss of steering, comprising the 2020-2021 F-250 SD, F-350 SD, and F-450 SD models from Ford’s Super Duty truck lineup. This issue stems from the steering column upper shaft potentially coming loose from the steering column.

“Dealers will inspect the steering column, and repair or replace the upper shaft as necessary, free of charge,” said the recall notice.

Finally, 332,778 of 2015-2017 Ford Mustang vehicles have been recalled for an issue impacting seatbelt performance. Specifically, the vehicles are prone to corroded

cables breaking, which would prevent the seatbelt from restraining a passenger in the event of a crash.

Factors such as water and road salt can contribute to cables corroding. Dealers will be inspecting and replacing cables as needed, with recall letters to be sent in January, when a final solution is expected to be reached.

Auto Care Plus, a Straightaway brand, announced the acquisition of Ronnie’s Car Care in Tewksbury, Massachusetts, in a recent press release.

Auto Care Plus emphasized the role the acquisition will play in expanding its presence in the northern Massachusetts market.

“This acquisition is another exciting step forward for Auto Care Plus,” said John Manelas, brand president of Auto Care Plus. “We are thrilled to welcome the Ronnie’s Car Care team into the Auto Care Plus family. With additional resources and support, we know this team will continue delivering the best-in-class service customers have trusted for years.”

“For decades, our customers have trusted us to keep them on the road, and I’m confident Auto Care Plus will carry that same legacy forward,” said Ronnie McNulty, owner of Ronnie’s Car Care. “They’re not only keeping our team intact but also investing in renovations to provide an even better experience for the Tewksbury community.”

An auto repair shop in Woonsocket, Rhode Island, recently partnered with a local organization to donate vehicles to veterans in need, reports The Valley Breeze.

The annual Veteran Car Giveaway is now in its seventh year. The initiative, which comes from New Englanders Helping Our Veterans, grew from a single car giveaway in 2019 to now having as many as six vehicles given away this year.

Vehicles are donated by community members and are refurbished by Henri’s Auto Repair, which inspects and repairs each vehicle at no cost to the recipient.

“All of these people could have very easily traded those cars in for new ones,” said Bill Gately, co-owner of Henri’s Auto Repair. “But instead of getting the measly $1,000 or $1,500, they’d rather see it be used by a veteran that’s in need.”

Other local automotive businesses help with the process as well. New parts are donated by Raps Auto Supply (NAPA), while used parts are donated from Woonsocket Auto Salvage, and Larry’s Towing of Burrillville helps with moving vehicles.

Winners of the giveaway were drawn live on air on WOON Radio on Nov. 17, with a giveaway presentation held Nov. 22. Names were drawn at random by local figures including the mayor or Sen. Melissa Murray.

“This whole thing is just little people doing a little bit each,” said Gately. “And in the end, we come out with something big.”

Victory Tire & Auto Celebrates Store Rebranding in Fridley, Minnesota

Victory Tire & Auto recently celebrated the rebranding of one of its stores in Fridley, Minnesota, as shared in a press release.

Formerly known as Victory Auto Service & Glass, the Fridley shop is the first of Victory’s 25 Minnesota locations that will be undergoing a rebrand. Each shop will continue rolling out updates over the coming months.

With the rebrand came upgrades to the store, such as 24-hour key drop and pick-up options and enhanced waiting area amenities. Additionally, the shop’s website now offers online scheduling, automated service reminders and confirmations, and real-time text and email updates.

To celebrate the rebrand, Victory hosted a community event featuring tire-themed mini-Bundt cakes, a fully stocked beverage counter, and prize drawings, including one year’s worth of oil changes. Attendees also participated in a food drive supporting HOPE 4 Youth, a local nonprofit organization dedicated to providing pathways to end youth homelessness. Victory contributed a $1,000 donation, and customers added more than 60 pounds of food and supplies.

“I couldn’t believe the number of longtime customers who came by to celebrate,” said shop founder Jeff Matt. “It was a reminder of the deep relationships we’ve built in this community over nearly three decades.”

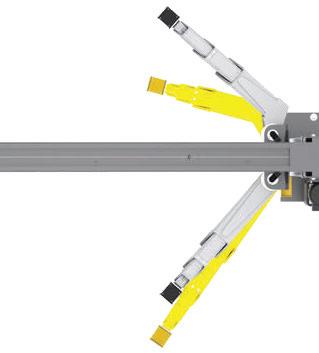

The BendPak 12AP-SRT short-rise two-post lift cost-effectively improves tire shop productivity and efficiency while mitigating risk. With 12,000 pounds rated capacity, massive wingspan that reaches most OEM lifting points, and BI-METRIC™ arms to suit virtually every vehicle lifting requirement – symmetric or asymmetric. The 12AP-SRT can raise 99 percent of cars, SUVs, and trucks to a comfortable working height much faster (and easier) than a set of jacks. Its single-point safety lock system, super-strong automatic arm restraints, and limited max lifting height of 47 inches deliver superior peace of mind. The short 93.5inch columns offer lower product, installation, and maintenance costs, plus a cleaner floorplan. Check out the full line of BendPak lifts at bendpak.com or call us at 1-800-253-2363

Auto shop owners are increasingly recognizing the importance of technology, yet many still allocate minimal funds

It takes a sharp skillset and a deep toolbox to keep customers’ wheels spinning. But just how much of the budget should be dedicated to technology and tools? While 27% of auto shop owners estimate allocating 1 to 5% of the budget to these costs, 28% admit they have no specific budget for equipment. As technology becomes more critical in diagnosing vehicle issues, the amount of your budget that you dedicate to these line items may rise. For now, here’s a look at the numbers dedicated to technology, tools, and equipment as reported in the Ratchet+Wrench 2025 Industry Survey.

With winter on the horizon in northern Minnesota, J.M. Auto Service provides a warm haven to prepare for anything the snow may bring

BY KACEY FREDERICK

Based in the small town of Eveleth with a population of just over 3,400 residents, J.M. Auto Service is a general repair shop preparing residents for all seasons. The shop’s snowplow business is in demand year-round, and with the winter season approaching, they’re ready to lend a helping hand when drivers need it.

From the shop’s warm interior to the friendly faces welcoming customers, Owner Kevin Bird walks through some of the details that make his shop a staple in the community.

J.M. Auto Service is housed in a beige Morton building with a large sign

brandishing the shop’s logo and advertising its snowplow services, which are a must-have for many drivers in Minnesota. Western Defender snowplows are on full display in the business’ front lawn for passersby to see.

“To me, they’re the Cadillac of snowplows; that kind of real high-end snowplow,” says Bird. “We put them on everything, from side-by-sides to front-end loaders. It’s a very seasonal business, but there isn’t a month that we don’t put a snowplow on. So, in the middle of July, it’ll be 80 degrees in northern Minnesota, and we’re still putting a snowplow on.”

Moving inside, the cozy atmosphere immediately welcomes guests with warm beige and brown tones, wood accents, and a fireplace flanked by houseplants. The space comes equipped with Wi-Fi and refreshments, such as snacks and coffee.

“We wanted to go for more of a living room feel versus a waiting room feel—or at the very least an automotive feel,” explains Bird.

Meanwhile, the shop service advisors are up front near the waiting area, ready to assist any customer that walks in. A large window not only frames the space and allows customers to peek inside at the shop floor, but it creates the illusion of a larger space.

Owner: Kevin Bird

Location: Eveleth, Minnesota

Staff Size: 12

Shop Size: 13,200 square feet

Number of Lifts/Bays: 9 lifts/12 bays

Average Monthly Car Count: 311 Annual Revenue: $3.1M

The shop floor features nine bays and angled Mohawk lifts, with bay doors on both sides of the shop. While they try to conserve warm air in the winter, they often leave both sides open in the summer for cars to breeze in and out.

A BG flush machine is in the shop for transmission and coolant flushes, as well as a Hunter Hawkeye Elite alignment machine and rack.

“We really pride ourselves on being a clean shop. I would have to say we’re probably the cleanest shop in the area,” says Bird. “You can look directly into the shop and see the guys working on your vehicles, which means we’ve got to be on our A-game—keeping everything up to spec and not leaving grease stains and things laying around. Cleanliness is very important to us.”

BY KATHLEEN CALLAHAN

Auto repair shops are more than just places where cars get fixed. We’re a part of the neighborhoods we serve, and how we show up for our community says just as much about us as how we show up for our clients. At Xpertech, I can honestly say some of our strongest connections and client loyalty haven’t come from a repair order; they’ve come from the way we engage with our community.

When a business invests in its community, people notice. It builds trust, visibility, and a sense of shared purpose. Clients don’t just see you as “the shop I take my car to.” They see you as a partner, a neighbor, and someone who cares about the same things they do. And let’s be honest—people want to support businesses that support them.

Over the years, our involvement has taken on many forms, including food drives for a local food pantry, annual blood drives at the shop, and fundraising efforts for causes like St. Jude, Dollars for Mammograms, and Spread Spencer’s Sparkle. Each of these efforts gave our team a chance to connect with the community in ways that go beyond oil changes and brake jobs. Some of the most rewarding moments have come from teaming up with other local businesses, like salons and spas or local coffee shops. Something as simple as teaming up for a Mother’s Day giveaway brought us closer—not just to our clients but also to another local entrepreneur trying to make a difference. And let’s not forget sports. Whether it’s supporting local youth leagues or celebrating our men’s senior softball team, showing up for the community is another way we give back and stay connected.

There’s no one-size-fits-all approach to community involvement. Choose causes that align with your values and

your team’s passions. Ask your team to choose a charity or cause and figure out a way for everyone to get involved. The support feels genuine when it’s something you believe in. And remember, engagement doesn’t have to mean writing the biggest check. Showing up, lending your space, or organizing a small drive can have an even bigger impact.

Here are some tips on how to make it work for your shop:

• Get your team involved . Let them help pick the causes. They’ll take more ownership and pride in the effort.

• Promote the event . Use your newsletter, social media, and even waiting room conversations to spread the word.

• Show up . Don’t just sponsor, participate. Be there. Shake hands, cheer, and volunteer.

• Measure impact . It’s not just about dollars raised. Look at the connections you’ve built, the clients who mention it, and the morale boost for your team.

At the end of the day, community engagement isn’t about gimmicks or marketing stunts. It’s about being present, being supportive, and being part of something bigger than your own business. The payoff goes far beyond the bottom line.

Because here’s the truth: When you invest in your community, you’re not just helping others—you’re fueling your business, your team, and yourself.

After two years, this is my final column. Thank you SO much for reading each month and providing me with feedback. I’ve gotten to meet so many of you over the last couple of years and I hope to meet more in the future.

Kathleen Callahan has owned Florida’s Xpertech Auto Repair for 20 years. In 2020, she joined Repair Shop of Tomorrow as a coach to pursue her passion for developing people and creating thriving shop cultures. Callahan is the 2018 Women in Auto Care Shop Owner of the Year, nationally recognized by AAA for three consecutive years, testified for Right to Repair on Capitol Hill, and is vice chair of Women in Auto Care.

kathleencallahanfl@gmail.com

Inside the strategies top shop owners use to keep their teams sharp, loyal, and ready for the technology of tomorrow

BY CHRISTINE SCHAFFRAN

Investing in tools and technology to propel your shop forward is as essential as having technicians to work in the bays. But how much are you investing back into those employees to stay on top of the latest technology and certifications to perform at an optimal level?

According to the 2025 Ratchet+ Wrench Industry Survey, 32% of shop owners send their techs to training quarterly while 30% commit to annual education sessions. What’s more, 62% of shop owners agree to pay for ASE training, 58% pay for education via industry associations, and 56% pay out of pocket for their techs to attend training conducted by a parts or equipment supplier.

Those who prioritize technician training not only gain the loyalty of their employees but increase their confidence in being able to deliver quality work.

“Obviously, all training pays off,” says Seth Thorson, president of Eurotech Auto Service. “It’s going to shorten some diagnostic times. It generally keeps people focused and engaged. And these cars are getting so advanced that if you’re not fully up to date with everything, you’re going to run into trouble working on these vehicles.”

When it comes to balancing how much time to dedicate and how much to invest in employees, options run from daily, bite-sized micro-learning sessions via phone apps to in-house gatherings to week-long conferences that immerse attendees in hours-long courses. Combining different types of training will send a message to your technicians that you’re serious about helping them to be successful in their careers.

Here’s a look at some of the options that will help deliver a well-balanced training module to technicians while ensuring your shop thrives.

When it comes to in-house training at Thorson’s five shops in Minnesota and Wisconsin that specialize in European automobiles, such as Audi, BMW, and Mercedes, he has found the most success in offering paid training during the day.

“Every tech tells me they want training until you ask them to go to training on their own hours,” he explains. “They don’t want to go on night and weekend training.”

Instead, Thorson brings in trainers once a quarter to address issues specific to the brands they service. Instructors typically remain on-site for two days to ensure all technicians receive training while guaranteeing the shop remains productive.

“So, they’re teaching the same class generally two days in a row, which means my shops are operating at half capacity, but I’m getting half my guys one day and half my guys another day,” Thorson asserts. “Some instructors will teach an intermediate and an advanced class, depending on how we break our technicians up. But, with most classes that trainers have nowadays, everybody’s going to get a little something out of it.”

Meanwhile, Thorson estimates six to eight hours are dedicated to Lunch-andLearns that invite vendors to teach while staff members eat lunch provided by the shop. Coupled with a 5- to 10-minute training app on their phones and a brief Monday morning technical meeting with the shop foreman, Thorson says he allocates approximately 40 hours of training per technician per year.

He adds he is currently focused on hiring a full-time technical director to conduct in-house training and hone in on some of the topics where a need for training has been identified. Across the country in Colorado, tech to tech training at Pro Auto Care involves lead technicians and shop foremen discussing diagnostics, drivability, or other complicated subjects in which they’re well-versed and breaking them down to a room full of technicians quarterly for half-day or two-hour sessions. The reason—President Al Oramas says—is because car care is constantly changing and shop owners must stay on top of the most recent innovations.

“Every year, the manufacturers make a change either because they have found an

believes asking employees to attend training goes a long way instead of telling them they must attend. It enforces that management believes in open communication and creating a place where employees are heard.

sends a message that you believe in their skillset, and you want them around for the long haul.

issue with a vehicle or they found a way to improve it. Being a dealership technician, we would get TSBs, or technical service bulletins, that would be fixed in the next model year. That car was changed. When you go to go test stuff, you’ve got to know what are the changes and what are the problems,” Oramas notes. “So, you have to familiarize yourself with a product that is evolving and changing, and you have to be aware of those changes.”

To stay on top of the ever-changing landscape, Tim Suggs of Turbo Tim’s Anything Automotive in Minneapolis, Minnesota, opts to gather as many of his 59 employees from his four stores on Saturdays for in-house training taught by one of the shop foremen. Topics focus mostly on diagnosing problems and making sure the sessions are fun and interactive.

In the same vein, ASE Trivia Night encourages technicians to showcase what they’ve learned utilizing their skill-building phone app that quizzes them for three to five minutes a day.

“It’s gamified and competitive and there’s teambuilding in that,” points out Suggs, whose shops service all makes and models from 2005 and newer. “But it’s making it fun and not feel like work. And it’s not set where the smartest person wins every week. It’s really like who’s consistently doing their classes and learning and getting better?”

Breaking it down further, Suggs says, technicians are permitted to attend 40 hours of training locally in their first year of employment. After the first year, they are free to roam about the country to outof-town training.

“Conferences are a huge part of technicians’ learning. When you go to a class that’s eight hours, you’re going to get way more in depth than a class that’s after work that’s two hours because you just can’t really get into the nitty gritty in two hours,” Suggs explains. “I see the techs when they come back and they’ve been in a day class, and they’re actually using the tools that they’ve learned.”

He adds that the classes are so effective that it doesn’t take any convincing on his behalf for technicians to want to go out of town for training.

“When a technician comes back from training and he’s excited, and all the other

technicians see that, it kind of sells itself,” he admits. “We have to have a lottery for who goes to training because some of these trainings, more people want to sign up than we’re able to take, so they end up selling it to each other.”

Oramas says he not only encourages out-of-town training, but he also incentivizes it. As an ASE Blue Seal of Excellence shop, 75% of front and back staff members are required to be ASE certified to qualify for this distinction. And to be certified, one must commit their own time and resources to pass multiple tests.

“So, part of that is we incentivize our people. We pay for their test if they pass it and we give a pay raise,” Oramas explains. “So those people that are doing the testing and certifying themselves are always at the top of the list (to go out of town) because if you’re willing to take time out of your schedule to study and then go test, you’re likely to go to an event and learn.”

At EuroTech, Thorson says, conferences and trade shows are reserved for shop foremen for a variety of reasons, including the ability to send them to more advanced classes as well as their pay and leadership level.

“It’s going to benefit them more to go to those events, and they have a much higher buy-in, and those people have shown the desire to really want to learn and grow,” Thorson notes. “So, those are the ones that generally are going to go to that type of event.”

With shops in Denver and Littleton, Colorado, Oramas believes creating a culture where employees feel seen and heard should come long before the request for training.

“When you’re asking technicians to do training, you’re either going to tell them or you’re going to ask them,” Oramas notes. “Asking goes a long way. And if you’ve got agreement because people feel very involved in the shop and understand that this is not just another chore, that is where you start. Start by connecting with people.”

Oramas adds informal huddles where technicians can ask questions and make suggestions is not only a morale booster, but a place where team members can have a voice—and sometimes even a say—in shop matters.

Once those connections take root,

technicians are willing to put in the work to retain the skills needed to do a good job and to be rewarded for their efforts. In addition to giving travel priority to those who are willing to better themselves with ASE certification, those who complete apprenticeships are rewarded with a set of tools paid for by Pro Auto Care.

Oramas stresses the name of the game is creating buy-in and a place where employees feel there is value in furthering their knowledge.

“We’ve had multiple people come work for us that are friends with technicians in our shop because they told them this is one of the best places to work,” Oramas says.

When it comes to knowing what subjects to train for, shop owners have their own theories on where to focus their efforts.

At Turbo Tim’s, they’re just breaking into using data from technology, like a popular phone app, to tell them where their technicians would benefit most from training based on their score results to small tests.

“If you ask the technician what they

want to learn, I think a lot of them are going to say ADAS and the truth is that’s like maybe 1% of the work I get,” Suggs notes. “It’s the most cutting-edge thing, but we’re not there yet where it’s like we’re using it every day.”

And although computer skills will inevitably be needed to crack the code on maintaining vehicles, there is still something to be said for old-school skills that require a technician to dig in and get dirty.

“A technician might not know how to do a broken bolt,” Thorson says. “You have to teach them how to drill out a bolt. That’s not going to be done in a class; that is a hands-on skill that has to be taught in the shop.”

To get ahead of the learning curve on electric vehicles, Oramas is not waiting around for manufacturers to hand them the keys to their learning toolbox. Instead, he bought a Tesla Model 3 for technicians to experiment with.

“We have a shop vehicle that we can connect to the computer, look at the diagnostics, look at how to take it apart, understand what’s under the hood, if you will, which is a funny term for a Tesla, cause there is no under the hood, it’s more

LEARN THE AUTO SHOP CONCEPT THAT WILL CHANGE YOUR LIFE

KEY TO KEY TO CALLBACKS

We have not just enhanced, but mastered, the concept of car repair. With monthly revenue figures over $1 million, our system guarantees exceptional customer service and unprecedented sales numbers.

Transform Your Business with Advanced Automotive Training SCAN TO REGISTER FOR THE

JANUARY 17-18

FEBRUARY 21-22

MARCH 21-22

A full day of learning the new AI tools being used in our shops. Spend the day in a deep dive with the industry’s best teachers of AI. This class will elevate your shop to new heights!

ACCOUNTING FIRST & FRAUD PREVENTION

“If you’re not counting your money, someone else is.”

Financial / P&L Statements Budgeting, Projections & Forecasting

Inventory Management Fraud & Embezzlement Plus so much more!

under the car,” he quips. “But the challenges going forward with the new technology, we have to be exposed. You can read all you want, you can watch videos, but when you can do a hands-on, that’s a game changer.”

Although the answers to why technicians need training may seem obvious, the costs associated with these sessions may be difficult to justify for those who are just starting out or shops that are struggling to turn a profit.

However, consider the hidden benefits not only for your shop, but also for your workforce in an industry where shortages abound, Thorson says.

“These cars are getting more and more complicated, and training is the only way you’re going to get better. You either have to steal the most highly trained people from your competition, or you have to train your own,” he advises. “And the only way to get better is to be doing constant training. It’s absolutely critical. Shop owners spend a ton of money with coaches and trainers and coaching and training at conferences and events, but they tend

to spend very little on training their technicians in the technical aspects of fixing the car.”

He adds technicians need to learn to think on their feet and apply the theory behind training to properly diagnose a problem in a vehicle.

“The biggest thing we concentrate on is theory. You have to understand how a system works. If you don’t understand how it works, we can’t make diagnostic steps or diagnostic processes,” he asserts. “Generally, technicians are in the field because they’re good at thinking, but if they don’t know how it works, there’s no way they can use their talents to figure out what the problem is.”

Meanwhile, Suggs points out that training pays for itself when it comes to continuity in production.

“You can grow a B Tech to an A Tech,” he explains. “Because there’s such a shortage of really highly skilled technicians in today’s world, we have to grow them. We can’t just hire them. They’re not out there. They have to be grown.”

To encourage industry growth, Oramas is hoping to someday implement in-house training that invites trainers to

lead sessions and other nearby shops’ employees to attend in a collaborative spirit.

“It’s been a vision of mine for a long time to bring in people from other shops. It breaks down barriers where people kind of look at each other and go, ‘We’re competition’,” Oramas explains. “If we raise the bar for ourselves and we raise others at the same time, the industry is affected by it. So, essentially when the tide comes in, the little boats and the big boats all go up together. We need to work together to improve the industry and ourselves.”

No matter which route you choose for your technicians, your effort in giving them the best learning curve is noticed and appreciated. Whether in-house, independent learning, or out-of-town trade shows and conferences, each session puts them in touch with information that they can store in their educational toolbox.

“Almost everything they bring back is going to have some kind of impact,” Thorson notes. “It’s going to trickle down and become the tribal knowledge for the rest of the team.”

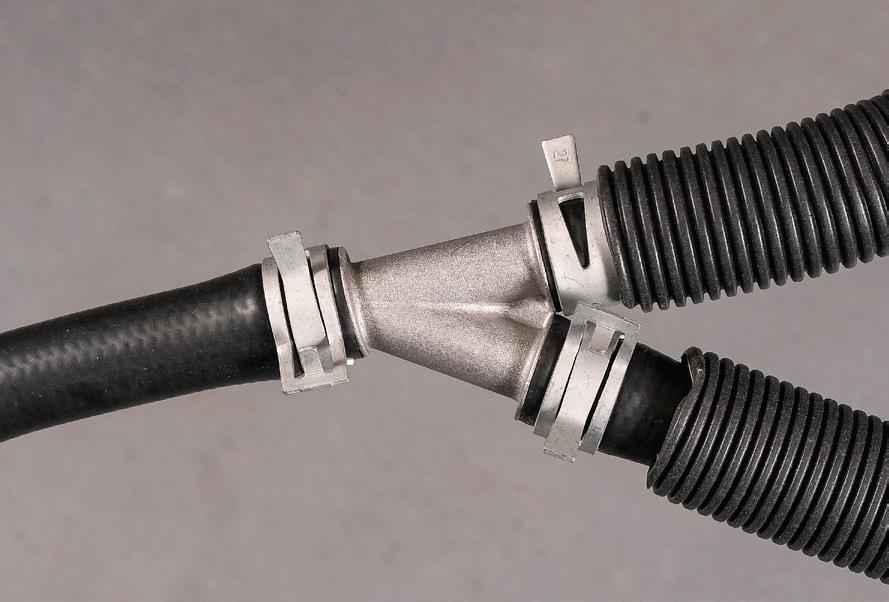

Dorman gives repair professionals and vehicle owners greater freedom to fix motor vehicles. For over 100 years, we have been driving new solutions for the aftermarket, releasing tens of thousands of replacement products engineered to save time and money, and increase convenience and reliability. Founded and headquartered in the United States, we are a pioneering global organization offering an always evolving catalog of parts, covering products for cars, trucks and specialty vehicles, from chassis to body, from underhood to undercarriage and from hardware to complex electronics.

When you see a Dorman product marked OE FIX®, that means it’s designed to offer a better repair solution than the OEM. Dorman is dedicated to these innovative products, which are in turn dedicated to the hardworking men and women of the auto repair industry. Scan to learn more or visit

Tips and tricks for keeping your staff engaged during check-ins

BY TESS OWINGS

We’ve all been there. Another Google Meeting invite rolls in and we’re immediately annoyed. Rather than being able to tackle projects that have been hanging over our heads, we’re forced to sit through another pointless meeting. Research has shown that 90% of employees feel meetings are unproductive. A disdain for team meetings may be the one thing that people from all industries have in common. Many employees greet meeting invitations with an eye roll and a groan and see them as a time to space out and count the minutes until they can get back to their real work.

But, what if they’re actually done right? What if instead of treating them like a requirement for a job they’re used for the common good of a company? Rob Choisser, owner of two locations of Choisser Automotive Services in Maryland, knows the importance of executing meetings the right way.

“Why are we taking time away from our day? Because everyone recognizes

that time is the big equalizer. If we’re doing this just to have a meeting, that’s a waste, but if we create a positive effect or recognition for a job well done, then people will come in with an open mind and you won’t get pushback,” Choisser says.

In other words, be intentional with your meetings. Choisser and Dr. Dana Ñkaña, Director of Autoshop Coaching, share their do’s—and maybe more importantly—don’ts, of running an effective and engaging team meeting.

people make when calling a meeting is going into it without a desired outcome. He adds that even if someone does have a desired outcome, it’s pointless if that outcome is not shared with the team. The reason for a meeting needs to be clear to everyone involved. Without a clear goal, it’s easy to get off task and go down any number of rabbit holes.

Choisser says one of the biggest mistakes

Dr. Ñkaña says that owners and operators need to practice what they preach and give the same attention that they expect from their staff. Too many times, a shop owner is on their phone during a meeting, which doesn’t exactly send a message of importance to the staff. If you need to have that meeting, Dr. Ñkaña says, you need to give your undivided attention. Don’t expect your staff to care if your body language is showing that you don’t.

It can get monotonous listening to the same person all the time. Dr. Ñkaña says that shop owners should ask others on their team to lead meetings on occasion, especially if the person is not participating. Not everyone is a public speaker, he says, but start with a small group and you’ll be surprised how quickly they rise to the occasion. It’s also a great way to get other points of view on how everything is running in the shop and may highlight an issue that you didn’t even

know was there. A fresh perspective is good for everyone.

staff engaged and it’s also a good way to make sure that your message is not getting lost.

white boards and laminated papers that are passed through the group; having visuals helps keep people engaged.

Don’t: Let One Bad Apple

Ruin the Whole Bunch

Dr. Ñkaña and Choisser agree that the right people can make or break everything in your business—including meetings. You can be doing everything right, but there are certain people that will always be negative. Do not let a bad hire bring down the rest of your group. If they are not on board with your shop’s values and culture, let them go.

“Hire likable people; you don’t want someone that walks into the business and it’s like you disrupt their day,” Dr. Ñkaña says.

If someone is coming into your meetings with a bad attitude constantly and you’re following all the do’s and don’ts on the list, the issue is more likely with the person than the meeting. Speak with them about it but if the behavior does not change, it may be time to reconsider if he or she is someone you want on the team.

Don’t: Let the Message Get Lost

One of the biggest mistakes leaders make when holding a meeting is not having a purpose and a desired outcome. When you start a meeting, you need to know exactly what you want to accomplish. Ask yourself what you’re trying to convey.

“As a leader, you can get up there and deliver a message and think it was received and the worst thing is to take the time and pour your heart into something and the message is not received,” Choisser says.

It can be difficult to gauge whether or not the message is received. Time will tell if the activity that you’re looking to change is changing, but if time after time you’re having to discuss the same issue, it’s probably because you’re not delivering the message clearly during the meeting.

Rather than always focus on the behaviors that need to change, showcase something that your team is doing really well, Dr. Ñkaña says. Walk into your shop and show your people that you appreciate them. Give kudos and recognition.

“You pump one person up, the rest will want to get pumped up,” Dr. Ñkaña says. Do this, and less people will dread meetings and may even look forward to them. If it’s always doom and gloom, nobody will want to attend, but throwing in some positive reinforcement can make a world of difference.

Do: Check in with Your Team

One of Choisser’s most used phrases during his meetings is, “Does that make sense?” He laughs that he had no idea how often he used it until it was pointed out to him, but it’s important to check in with your staff and make sure they understand what you’re saying. It keeps the

Choisser always gives his staff an agenda before a meeting so there’s a clear purpose and the whole team is able to look at it and hold it. He explains that having the handouts really enforces the message that’s being delivered and it’s a way to ask your team for engagement. He also utilizes

Choisser says that everything needs to tie back to the “why.” Why are you holding this meeting? Why are you taking time from everyone’s day—including your own? What is the purpose? What is it that you’re trying to change? How do you plan on doing that? Ask yourself questions before calling a meeting both to make sure it’s worthwhile and to ensure your team is engaged. Afterward, follow up with employees to see how the message was received and whether the delivery was successful.

So, before you call another meeting, ask yourself if it’s really necessary. If it is, follow these tips and tricks to make it as effective and engaging as possible.

INDEPENDENT REPAIR SHOPS run on tight schedules and even tighter margins. That’s why eXtra was designed to reward the work you already do—no hoops, no hassles.

It’s a free, multi-brand loyalty program created exclusively for independent automotive service centers. Think of it like airline miles: enroll once, keep buying the brands you trust, and watch your points (XP) grow automatically. Learn more at www.extra-awards.com

Getting started is easy. Register your shop at www.extra-awards.com, select your participating distributors, and continue ordering as usual.

Eligible purchases from program partners are automatically credited to your eXtra account every month so there’s nothing new to scan or submit. Just buy parts, repair vehicles, and watch your rewards build.

A complete list of participating distributors can be found online.

Earn on the Brands You Trust

eXtra partners with industry leaders Bosch,

Bilstein, Steer, and LIQUI MOLY so your everyday mix of parts can work even harder for you.

Your purchases from these trusted brands help your shop earn faster.

Redemption is where eXtra shines. The online catalog features millions of rewards—from cutting-edge electronics and small appliances to sporting goods, travel experiences, event tickets, and gift cards. Use your points to reward employees, upgrade shop equipment, or enjoy a personal treat after a busy season. Prefer a personal touch? eXtra customer service is available 24 hours a day, seven days a week to assist with questions or redemptions.

“It’s really the easiest program to work with. Through the years they’ve really perfected it…It’s a program that’s simple and easy to use.”

—

Bob S. Lombard, IL

eXtra continues to expand, now with more than 21,000 participating shop owners across the U.S. and Canada. Backed by

powerhouse partners—Bosch, Bilstein, Liqui Moly, and Steer—this momentum fuels even more promotions, giveaways, and valuable product education.

All designed to help your technicians stay current, motivated, and productive.

Throughout the year, members can boost their points with limited-time promotions, bonus quizzes, and interactive games that deliver extra XP and prizes.

Whether it’s through seasonal campaigns or partner promotions, eXtra keeps the rewards flowing.

Register and Start Earning in Minutes

1. Visit www.extra-awards.com and click “Register.”

2. Select your country and enter your shop details.

3. Choose your existing distributors and link your customer numbers.

4. Start earning automatically and track your balance anytime—online or through the eXtra mobile app for iOS and Android.

“If you are an independent repair shop, there is no reason why you shouldn’t sign up today. You’re selling the product, get the points.”

— Mike B. Palatine, IL

“I have a trip to Mexico, I have a flat-screen, I have a Dyson vacuum. I mean, there is so much stuff in here! It’s like the Rolls Royce of rewards programs.”

— Jaime H. South Elgin, IL

You’re already doing the hard work—now get rewarded for it. Join eXtra today and turn everyday parts purchases into real, tangible value for your business and your team. Register now at www.extra-awards.com

It’s a sensitive topic that should always be handled with care. Darlene Canfield, human resources executive for Dynamic Automotive, lays out the best plan of action

BY KACEY FREDERICK

While going over inventory, you realize there’s a growing pile of inconsistencies between what you should have and what’s there, with no idea why that could be. If your mind jumps to theft, back up—you’ll need a lot more than a gut feeling before making that assumption. While not something every

business experiences, employee theft is far from unheard of. As a business owner or manager, you have to handle the situation calmly, with a strategy that takes all factors into consideration.

This month, we’re looking at the telltale signs of employee theft, how to responsibly carry out an

investigation, and measures shops can take to prevent it from happening.

BACKSTORY:

Darlene Canfield is the human resources executive at Dynamic Automotive in Frederick, Maryland. Being in the field for 18 years and certified by the Society for Human Resource Management, she has both the experience and training to handle tough situations in the workplace.

PROBLEM:

Discrepancies between actual stock and system records is often where signs of theft begin. The most common and most accessible items taken from an auto repair shop will include inventory stock, along with tools. If a shop is experiencing this, it could potentially be employee theft, but there must be a thorough investigation before jumping to conclusions.

“You should be taking inventory regularly to make sure you have what your inventory says you have in stock. And if not, then that could be a sign— or it could be a sign that somebody’s not entering things into the system correctly,” Canfield explains.

There are many steps shops can take if they’re concerned about potential internal theft. Assuming a complete review of inventory documentation has taken place, in which items sold versus received are compared, then the next step is to confidentially question other team members. Ask them if they’ve noticed anything or if they are aware of anything that’s occurred with the shop’s inventory.

“Gather any type of documentation that may show where inventory is going in and out, and see if there are any trends that make sense.”

And having documentation of everything you discover is essential. It helps keep track of what you’ve found and will help back up any conclusion you arrive at. Additionally,

any shop surveillance footage should be looked over and kept as well.

“Being in the HR realm, documentation is everything. If you don’t document, it didn’t happen. If you ever have to go to court or something, your documentation is what’s going to support you,” Canfield says.

In the event you’ve gathered enough information that points to a particular employee, find a time to pull them aside privately and share everything you’ve found. Avoid making any sort of accusation unless you have solid evidence. Handle the conversation with great sensitivity, and give them an opportunity to explain themselves. Depending on the reason, it may be possible to find a solution with the employee, but it could also be in your best interest to end the relationship.

If you’ve faced employee theft, you already know identifying who did it is just the beginning. An overhaul of your shop’s internal processes should be conducted, especially with regard to hiring.

“I think they would need to rethink their hiring process,” Canfield says. “A lot of that could go back to asking the proper questions during the interview, getting into character questions, doing their due diligence and gaining feedback from previous employers, and conducting background checks.”

If a shop doesn’t have a surveillance system already, that should be a priority—either before an incident takes place and especially if employee theft is suspected.

Employee theft can culminate in a number of ways, but there are many preventative measures shops can take—such as setting up security equipment and staying connected with employees. It’s also important to have a standard operating procedure in place if any inventory disputes do arise to go through the proper channels to resolve the issue. While no one wants to think about an employee stealing from them, the reality is that it does happen, so it’s better to be proactive instead of reactive to protect your assets.

BY

THE 35,000-FOOT VIEW

The importance of embracing innovation and expertise to survive the ongoing shift in auto repair

BY R. “DUTCH” SILVERSTEIN

When I began turning wrenches in the 1970s, the auto repair business model looked very different. Much of the business centered around hard-line engine and mechanical repairs that required an individual with a specific skill set. As time progressed, so did changes in technology. Unfortunately, increased reliability had a downside for the business of auto repair and fewer breakdowns translated to less revenue. The increase in reliability of some components combined with an increased availability of cheaper imported assemblies like alternators and starters prompted a desperate need for a change in the business model.

A lot of shop owners are about to relive a paradigm shift without even knowing it. By definition, a paradigm shift is “a fundamental change in approach or underlying assumptions.” Perhaps the lessons we must learn begin with a very famous paradigm shift in an industry that is not that different in many ways than our own: watchmaking. Back in the 1970s and ’80s, the Swiss watchmaking industry was a powerhouse, built on a centuriesold tradition of intricate, handcrafted mechanical movements. Their business model was rooted in precision, utilizing highly skilled labor and the predictable need for a service on a fairly routine basis (sound familiar?). Then in December 1969, a company called Seiko dropped a bomb with the first mass-produced quartz watch. This wasn’t just a new product; it was a technological and economic tidal wave. This game-changer was cheap to produce, more accurate than any mechanical watch, and required nothing more than an occasional battery swap. By every objective measure of function, it made the mechanical watch obsolete.

Similarly, mechanics who were experts at rebuilding carbs and tuning engines for performance weren’t needed or valued as the industry shifted its focus and embraced the automotive mainte-

nance business model. The best and the brightest weren’t necessary because the maintenance model relied on scalability which required only mediocre to average personnel who were capable of being trained to a minimum standard. This reliance on “average” talent meant that one of the biggest corporate expenses (labor) could be kept low to help the bottom line. Additionally, aftermarket equipment manufacturers rushed to make it easy for services to be performed that were seldom recommended by the vehicle manufacturer. This quest to achieve scale and keep profits high while maintaining low labor expenses begat what is frequently known in our trade as wallet flushing. Nearly every fluid on a vehicle was ripe for a “fluid exchange” under the guise of increasing reliability or component longevity. There was no evidence to support these arguments. For more than two decades, this business model flourished because cars were generally built better than their predecessors. But embracing technology can bring unintended consequences. As newer vehicles and their systems increased in complexity, many of the opportunities that were present to make a fast buck through fluid flushing began to decline. It’s tough to flush power steering fluid when the vehicle isn’t equipped with it. Even “standard repairs” like brake service occur less frequently on hybrid powered vehicles due to regenerative braking.

Then what is failing? The current wave of technological “advances.” Cars have now become less reliable and less repairable all while simultaneously becoming less affordable. If history teaches us anything about human nature, there are going to be shop owners who will scoff at the idea that the current maintenance model is becoming a little less viable with each passing day. That’s okay, the Swiss watch industry scoffed, too, until the Japanese made them irrelevant. They will likely claim that all machines, no matter how

well engineered or assembled, will require maintenance, and they will be right except the scalable, minimally skilled employee won’t be able to perform the work, and those that possess the talent that can, will certainly command higher wages than most are currently being paid. The future of our trade is about diagnostics, specialization, and high-tech repair. So gear up, train up, or get left behind.

R. “Dutch” Silverstein, who earned his Accredited Automotive Manager Certificate from AMI, owns and operates A&M Auto Service, a seven bay, eight lift shop in Pineville, North Carolina. Dutch was a captain for a major airline earning type ratings in a variety of aircraft including the Boeing 767/757, 737, 200, 300 and 400 series, Airbus 319/320/321, McDonnell Douglas MD80/DC9 and Fokker FK-28 mk 4000 and 1000. After medically retiring, he transitioned his parttime auto repair business into a full-time occupation.

dutch@dutchsgarage.com