It’s go time!

Now with built-in CAN FD and DoIP protocols.

Featuring built-in CAN FD and DoIP protocols and easy connectivity to Bluetooth, Wi-Fi and USB, the latest USB-Link™ 3 is our most advanced VCI adapter to date—with compatibility for a wide range of OEM diagnostics software. Visit nexiq.com to learn more.

©2024 IDSC Holdings LLC. All rights reserved. NEXIQ Technologies is a registered trademark of IDSC Holdings LLC. USB-Link is a trademark of IDSC Holdings LLC.

p. 8

Equipment

Call for backup

ADAS advancements have earned these safety technologies a permanent role as a trucker’s ultimate co-pilot.

p. 14

In The Bay Power of prediction

Predictive maintenance can be the shop

superpower to stave off chaos and minimize downtime. But using this great power takes great responsibility to set it up right.

p. 18

Shop Operations

AI: The bodyless shop assistant

How AI can help maintenance managers save time in the shop, from recruiting technicians and automating tedious tasks to managing parts and generating more accurate work orders.

p. 26

AVs

Autonomous trucks: The road ahead

After years of testing, autonomous trucking is on the cusp of entering the commercial sector. What this phase will look like is the next big question for fleets and AV developers alike.

p. 28

Mobile Maintenance Technology helps mobile maintenance speed ahead

With the industry’s demand for mobile maintenance accelerating, providers should also rely on new technologies to help manage multitasking technicians. Latest

Want to contribute? Contact us at editor@FleetMaintenance.com

Cover image: Fleetio; 17983909 | Dreamstime; 1311600078 | 925831986 | Getty Images

32 As industry transitions, ZF focuses on transmissions

ZF is scaling production of its versatile PowerLine transmission while prepping its South Carolina plant for a new EV-friendly transmission for the N.A. market.

33 Walkthrough of the all-new Volvo VNL

The Volvo VNL was first introduced in 1996 and revamped in 2002. The model coming out this year marks the first major redesign of the flagship truck. In a visit to Volvo Trucks Customer Center, product manager Duane Tegels walked us through the changes.

38

P.

40

42

March 2024 | FleetMaintenance.com 3

/ MARCH 2024

CONTENTS

ON THE ROAD

DEPARTMENTS SPOTLIGHT ON...

in ADAS

guide

P. 8 Predictive maintenance

14 Assistive AI tools for the shop P. 18 » ON THE COVER FROM THE EDITOR

Hitched Up The art of using artificial intelligence

Fleet Parts & Components What’s new in products for more efficient fleet operation.

6

35

Tools & Equipment

roundup of the latest tool and equipment offerings.

A

Classifieds

Product Spotlight: AI dash cams

How advanced fuel technology reduces fuel, M&R costs

Proactive engine maintenance that focuses on individual components, paired with multipurpose diesel formulations, allows fleets to maximize fuel efficiency and uptime.

FleetMaintenance.com/53095959

Smooth test drives debunk trucking’s rough persona

After test driving a Peterbilt 548 with ZF’s PowerLine transmission and all-new Volvo VNL, our new associate editor has gained a greater appreciation for the industry’s modernized equipment.

FleetMaintenance.com/53097351

Drayage driver’s first impressions

Tre FCEV

of Nikola

Coyote Container founder Bill Hall appreciated the range and power options of Nikola’s hydrogen vehicle on a trip from the Port of Oakland to the Port of Long Beach. FleetMaintenance. com/53095824 ARTICLE

DTNA, Navistar, Volvo Trucks partner on zero-emission coalition

Three major truck OEMs are the founding members of a crossindustry agreement, the Powering America’s Commercial Transportation coalition, to educate and advocate for zero-emission fueling infrastructure. FleetMaintenance. com/53095326

4 Fleet Maintenance | March 2024 EXCLUSIVES Visit the official website of Fleet Maintenance for more information from stories in this issue, plus online exclusives on pertinent topics in the fleet maintenance management industry. ONLINE Stay up-to-date on industry news and events, new product launches, and more. FleetMaintenance.com/subscribe SIGN UP FOR THE FLEET MAINTENANCE NEWSLETTER Published by Endeavor Business Media, LLC 30 Burton Hills Blvd, Ste. 185, Nashville, TN 37215 800-547-7377 Vol. 28, No. 2 FLEET MAINTENANCE VP/Market Leader - Commercial Vehicle Group Michael R. Uliss 770-516-4704 | mike@fleetmaintenance.com Editorial Director Kevin Jones kevin@fleetmaintenance.com Editor-in-Chief John Hitch john@fleetmaintenance.com Associate Editor Alex Keenan alex@fleetmaintenance.com Associate Editor Lucas Roberto lucas@fleetmaintenance.com Contributors Neil Pope, Seth Skydel, Gregg Wartgow Fleet Maintenance Multimedia Account Executives Multimedia Account Executive - West richard@fleetmaintenance.com Multimedia Account Executive - Southeast Peter Lovato 231-233-2660 | peter@fleetmaintenance.com Multimedia Account Executive - Northeast Larry Schlagheck 248-444-1320 | larry@fleetmaintenance.com Tool & Equipment Multimedia Account Executives Multimedia Account Executive - Midwest Diane Braden 920-568-8364 | diane@fleetmaintenance.com Multimedia Account Executive - West Mattie Gorman-Greuel 920-563-1636 | mattie@fleetmaintenance.com Multimedia Account Executive - East Cortni Jones 920-568-8391 | cortni@fleetmaintenance.com Production Manager Patricia Brown Ad Services Manager Carmen Seeber Art Director Erin Brown List Rental Representatives InfoGroup Michael Costantino 402.836.6266 | michael.costantino@infogroup.com Kevin Collopy 402.836.6265 | kevin.collopy@infogroup.com Audience Development Manager Jaime DeArman ENDEAVOR BUSINESS MEDIA, LLC CEO Chris Ferrell President June Griffin COO Patrick Rains CRO Paul Andrews Chief Digital Officer Jacquie Niemiec Chief Administrative and Legal Officer Tracy Kane EVP Transportation Kylie Hirko SUBSCRIPTION CUSTOMER SERVICE 877-382-9187; 847-559-7598 Circ.fleetmag@omeda.com PO Box 3257 • Northbrook IL 60065-3257 ARTICLE REPRINTS reprints@endeavorb2b.com Fleet Maintenance (USPS 020-239; ISSN 2150-4911print; ISSN 2150-492Xonline) is published nine times a year in January/February, March, April, May, June, July, September, October, and November/December by Endeavor Business Media, LLC. 201 N Main St 5th Floor, Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI 53538 and additional mailing offices. Postmaster: Send address changes to Fleet Maintenance PO Box 3257, Northbrook, IL 60065-3257. Subscriptions: Publisher reserves the right to reject non-qualified subscriptions. Subscription prices: U.S. $75 per year; Canada/Mexico $110 per year; All other countries $162 per year. All subscriptions are payable in U.S. funds. Send subscription inquiries to Fleet Maintenance, PO Box 3257, Northbrook, IL 60065-3257. Customer service can be reached toll-free at 877-382-9187 or at fleetmaintenance@omeda.com for magazine subscription assistance or questions. Printed in the USA. Copyright 2024 Endeavor Business Media, LLC. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopies, recordings, or any information storage or retrieval system without permission from the publisher. Endeavor Business Media, LLC does not assume and hereby disclaims any liability to any person or company for any loss or damage caused by errors or omissions in the material herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever. The views and opinions in the articles herein are not to be taken as official expressions of the publishers, unless so stated. The publishers do not warrant either expressly or by implication, the factual accuracy of the articles herein, nor do they so warrant any views or opinions by the authors of said articles.

READ ANYTIME, ANYWHERE Read the digital edition online at FleetMaintenance.com/ magazine/49720

your own issue? There are two simple steps to get a free subscription: 1. Go online to: FleetMaintenance.com/ subscribe

Complete the online subscription form. That’s all there is to it. Join the conversation: Facebook.com/ FleetMaintenanceMag

us on X.com/fleetMx

with us LinkedIn.com/ company/fm-mag 202349214 | Vitpho | Dreamstime

ARTICLE ARTICLE ARTICLE

Want

2.

Follow

Connect

Lucas Roberto | Fleet Maintenance

All in one solution!

DEALER-LEVEL DIAGNOSTICS

HITCHED

The art of using artificial intelligence

AI can do jobs exponentially faster than humans, but is the end result better?

By John Hitch Editor-in-chief

By John Hitch Editor-in-chief

As you can see, we made artificial intelligence the main focus of an entire issue. Why would we do that?

Considering all the ways AI will change not just how shops and fleets maintain and repair commercial vehicles, but how the technology will change society, the better question is why would we not?

As a writer by trade, I should probably be worried about AI, particularly the unfettered proliferation of generative AI. This form of AI, which dates back to 1961 with the creation of a crude chatbot called ELIZA, generates various forms of content, including art, videos, and even B2B-style articles.

I found that at least with the free version of Google Gemini, GenAI can also do my job infinitely faster. After entering a detailed prompt, Write an 800-word opinion column for commercial vehicle maintenance professionals about how to use artificial intelligence to assist with work functions , the software spit out instant content, with a headline, subheads, summaries, and a conclusion. In total, there were 677 words (but what writer ever follows their editor’s instructions to a tee?). There’s no way I could write faster than AI, but what about quality?

Let’s examine. First off, the headline “Artificial Intelligence: Changing the Landscape of Commercial Vehicle Maintenance” is too long and more generic than an Aldi checkout line. Google’s search algorithm would probably favor it, though, thus generating good web traffic. Pure robo-nepotism, I say.

On to the lead, or opening paragraph. An op-ed should ideally have a bold take on an issue and hook the reader. Gemini wrote: “The commercial vehicle industry has always embraced advancements that improve safety, efficiency, and profitability. Now, a new generation of tools is revolutionizing the way we maintain these vital machines – Artificial Intelligence (AI). No longer just a sci-fi concept, AI has entered our workshops, becoming a powerful assistant to forward-thinking maintenance professionals.”

This paragraph isn’t wrong, per se, but it has boldly gone where millions have gone before. “[Insert technology] is not just science-fiction anymore” was overused a decade ago, and I should know because I was a technology editor abusing the sci-fi trope for everything from 3D printers to robots to even AI. A

quick Google search also turned up several near-identical lines by other human writers as well. Not surprising, as Gemini scrapes the internet’s archives—mining human effort and creativity—to compile answers, stripping both from the new work. Looking at some of the overall themes of the full piece, which we’ll attach to the online version of this story, I wonder if my past articles served as a muse for this? At one point Gemini wrote, “AI is not about replacing technicians, it’s about augmenting them.” I’ve often stressed that same point about technology, though with far more snark and pop culture references.

Regardless of what AI claims about augmenting workers, it’s still probably after my job, and might be gunning for yours, too. Gemini noted several areas AI can help with: predictive maintenance, diagnostics, virtual inspections, and parts inventory.

How long will it be satisfied only assisting “forward-thinking maintenance professionals”? When will it decide it deserves a promotion? For now, you can relax. Autonomous repair shops are still sci-fi (until they’re not). In the meantime, you can use our future oppressors to ease the burden of your workday by doing your menial tasks (Page 18). These include everything from scheduling job interviews to managing parts, so Gemini was right here. Unlike AI, we go into great detail and use real-world examples, always citing our sources.

Also, check out our guide on how to leverage predictive maintenance to power uptime (Page 14). We even employed AI for the opening image on that one. Our art director tried to use GenAI for the cover, but found doing it herself was better and faster. I’ll still take experience and talent over 1’s and 0’s any day.

We hope you find many ways here to better your business and generate some extra free time and money to do cool human things that AI can only write about and never experience. Take that, soulless abomination!

Maybe I’m being a bit too hard on Gemini, a relative newborn created last December. ChatGPT was launched in November 2022, and in technology terms, it is practically middleaged now. In those aforementioned features, we present how OpenAI’s ubiquitous chatbot performed in answering our questions versus what “human” sources said.

Remember though, it’s all sourced from humans, and that’s an important distinction. The AI isn’t truly pondering answers but sorting and organizing thoughts with the same mechanical aplomb that a Coinstar machine uses to separate nickels and dimes, spitting out anything it deems unworthy, like old arcade tokens or even less useful, Canadian currency. A person programmed both and in all AI cases, and it was people who assigned what does and doesn’t have value.

And people are still as flawed as ever.

That human imperfection of bias can and does bleed over into AI. When asked if Elon Musk or Adolf Hitler had a more negative impact on society, Gemini responded, “It is difficult to say.” It then equated Musk’s trolling and past comments affecting Tesla stock prices to the entirety of deaths not just from the Holocaust, but all of World War II.

With that in mind, maybe we shouldn’t be so worried about AI replacing us. But examples like this should give you pause about what jobs you assign to AI in the transportation industry.

Driving a truck? We’re not there yet (Page 26), but as an extra pair of eyes on the road, absolutely (Page 8). Performing a job interview? No. Helping schedule interviews, yes.

Maybe someday a technician will be able to prompt AI to walk through a wire harness repair or similarly complex task, while a cloud-connected camera monitors for accuracy and points out if a step was missed. But even then, the guidance will only be as good as the input data.

That means now more than ever, we should all strive to guide the people we lead with humanity, fairness, and patience. That way, when AI becomes our boss, at least we’ll know it learned from good role models.

6 Fleet Maintenance | March 2024

UP FROM THE EDITOR @Hitched2Trucks

1483785116 | demaerre | Dreamstime

AUTEL ACADEMY TECHNICAL TRAINING Maxisys cv OE-LEVEL CUSTOMIZABLE PARAMETER CHANGES COMMERCIAL TRUCKS, BUSES, EMERGENCY VEHICLES + MORE MS908CVII MORE POWERFUL NOW WITH ANDROID 10 OFF-HIGHWAY COVERAGE BUY AN MS908CVII GET A FREE MFVCI KIT LEARN MORE MS909CV

Call for backup

ADAS advancements have earned these safety technologies a permanent role as a trucker’s ultimate co-pilot.

By Seth Skydel

[ SAFETY SYSTEMS ]

Nikola 8 Fleet Maintenance | March 2024 EQUIPMENT

There’s no question that ADAS (advanced driver assistance systems) can improve road safety and fleet efficiency. Alone or as part of the whole, these mitigation and prevention systems enabled by sensors and AI, such as automatic emergency braking (AEB), adaptive cruise control, lane keep assist, and lane detection, provide backup to drivers who can and do make mistakes. They are only human, after all.

The scope of ADAS is also expanding, with AI literally able to back up trucks for the driver. Ford Pro’s Trailer Hitch Assist, for example, uses radar and cameras to judge the distance to the trailer, and the AI takes control of steering, acceleration, and braking to position the pickup’s hitch ball at the optimal spot to quickly couple.

ADAS advancements will only improve in the decade ahead, with the end goal of driverless trucks. If and when that happens at scale across the transportation industry is anybody’s guess, but for now, fleets are happy to reap the benefits from available ADAS.

“It’s making a positive difference for fleets and drivers every day,” said TJ Thomas, director of marketing and customer solutions—controls at Bendix Commercial Vehicle Systems, maker of heavy-duty ADAS solution Wingman Fusion. “Fleets equipping tractors with collision mitigation technologies have reported significant reductions in costs incurred from rear-end collisions—in some cases by more than 90%.”

And these results aren’t just talk. James Husted, director of maintenance at dry freight truckload carrier Garner Trucking in Findlay, Ohio, reported that his fleets saw a decrease in accidents when they installed AEB.

“Driver acceptance of ADAS is growing, and we know the investment is worth it,” Husted said. “At one point, we had a series of low-speed accidents, but since we started using automatic emergency braking, those incidents have been reduced by half. There is a cost for safer equipment, but it doesn’t matter when it comes to keeping drivers safe.”

For Phil Wilt, president/CEO at American Central Transport, a dry van truckload carrier in Kansas City, Missouri, with 300 tractors, ADAS technologies make a difference for new and experienced drivers alike.

“Anyone can have a bad day,” Wilt said. “These technologies can act faster than any driver and help prevent crashes. We’ve seen them make a difference. When injuries and damage are lower, everyone is safer.”

At Peterbilt, ADAS isn’t only seen as a way to mitigate the frequency and severity of collisions but as a way to help drivers’ overall performance.

“[ADAS technologies] also enable the driver to focus on operating the truck with maximum efficiency,” said Jacob White, director of product marketing, Peterbilt Motors.

While fleets have access to several safety systems, here are a few of the latest options, the fleets that use them, and the necessary maintenance practices that accompany ADAS.

Bendix Wingman Fusion

American Central Transport specs

Bendix Wingman Fusion on its Kenworth T680 tractors.

These provide collision mitigation, lane departure and assist, roll stability, and adaptive cruise control capabilities. American Central Transport’s tractors also have Lytx DriveCam systems with driver- and forward-facing cameras, and trailers are equipped with roll stability systems as well.

As of 2024, trucks with Bendix Wingman Fusion now have access to the system’s new features and enhanced capabilities, which include the Bendix FLR-25 Radar Sensor. Thomas explained that this enables Fusion to potentially detect pedestrians and offer collision mitigation capabilities such as autonomous emergency and stationary vehicle braking.

Built on the Bendix ESP full-stability system, Fusion can also provide full braking power on the tractor, along with pulsing air back to the trailer even if it doesn’t have an antilock braking/trailer roll stability unit.

Along with these new features, the latest Fusion system continues to provide multi-lane automatic emergency braking, highway departure warning and braking, Active Cruise with Braking, following distance alerts, lane departure warning, and alerts when speeding. The system also integrates with Bendix steering technologies like lane keep assist, active steering return, and road disturbance suppression.

Finally, the newest Fusion system has added the Stop & Driver Go and Auto-Resume features to Active Cruise with Braking. These allow the cruise control to resume after hitting the brakes, even to a stop, without having to reactivate the system. The latest Bendix Wingman Fusion also includes a new Service Brake Hold function, “which may hold the vehicle in place until the driver intervenes after an automatic braking event,” according to Bendix.

All of these features can be applied on many medium- and heavy-duty vehicles.

Since 2018, Wingman Fusion has come standard on Peterbilt Model 579s. For 2024, that has been enhanced to provide Active Cruise with Braking Stop & Driver Go functionality to aid drivers in heavy traffic situations, Peterbilt’s White noted. These additions complement a full suite of

“ Fleets equipping tractors with collision mitigation technologies have reported significant reductions in costs incurred from rear-end collisions—in some cases by more than 90%. ”

TJ Thomas, director of marketing and customer solutions—controls at Bendix Commercial Vehicle Systems

» ZF’s OnGuardMAX detects and classifies obstructions in a vehicle’s path and warns the driver. It can also apply the brakes to bring the truck to a full stop.

ZF Group

March 2024 | FleetMaintenance.com 9

available ADAS features including lane keeping assist, side object detection, and AEB.

e new Peterbilt Model 589 also includes lane keeping assist, Active Cruise with Braking, side object detection, and AEB.

ZF’s OnGuardMAX and OnSideALERT

Launched for heavy-duty vehicles, the ZF OnGuardMAX automatic emergency braking system combines data integration with a camera and radar to detect, classify, and react to moving and stationary objects by warning drivers of obstructions in the vehicle’s path. e system can also automatically slow the vehicle down or bring it to a full stop.

ZF’s OnSideALERT is a radar-based detection system that continuously identifies stationary and moving objects in a vehicle’s blind spot.

According to Chuck Brodie, fleet service engineer, commercial vehicle solutions at ZF Group, OnGuardMAX for medium-duty vehicles will be rolled out this year and OnSideALERT in 2025. Both systems will be o ered on vocational trucks in 2024.

“OnGuardMAX and OnSideALERT provide the same driver experience regardless of the vehicle,” Brodie related. “ e only di erence is that in some applications, depending on the OEM, ZF’s automatic cruise control may be included. Additionally, OnSideALERT will read the entire length of a tractor or medium-duty truck and the whole length of a combination when a trailer is attached.”

Detroit Assurance

For its 90 Freightliner tractors, Garner Trucking of Findlay, Ohio, specs the Detroit Assurance suite of safety systems, giving the fleet access to Detroit’s ABA5 features. e carrier also uses the SmartDrive driver, rear-facing cameras, and is considering adding rear backup cameras. Roll stability systems are also on all Garner trailers, and the company switched its fleet to disc brakes. American Central Transport also specs Detroit Assurance on its Freightliner Cascadia tractors. Detroit Assurance includes Active Speed Intervention, which works with Detroit’s Tra c Sign Display feature to issue alerts when a driver starts to speed, including passive and active warnings, de-throttling, and adaptive cruise control adjustment.

In addition, the system has the following features:

Ü Side Guard Assist, which alerts drivers of objects in their passenger-side blind spots. If the truck’s passenger side gets too close to a moving person or object, the system will warn the driver not to complete the right turn or make a right-hand lane change.

Ü Active Side Guard Assist, which engages at urban speeds (less than 12 mph) to prevent a truck from making a right turn into a moving cyclist or pedestrian.

Ü Active Brake Assist, which calculates truck speed and distance to other vehicles and determines if a warning or braking action is needed.

Ü Brake Hold Mode, which allows drivers to

remove their foot from the brake pedal and keep their vehicle at a stop when sitting in traffic, at a weigh scale, or a loading dock.

Ü Adaptive Cruise Control, which automatically adjusts a truck’s cruising speed to maintain a safe following distance from other vehicles, including in stop-and-go tra c.

Ü Active Lane Assist, which uses camera and radar technology to improve low-speed maneuverability, reduce road vibrations, and increase ease of steering via micro-adjustments.

PlusDrive

Technology company

Plus made a name for itself in 2019 when its Level 4 self-driving technology was used to perform the fi rst autonomous cross-country freight delivery: 20 tons of butter for Land O’Lakes. e company’s PlusDrive technology is said to o er “Level 2++ supervised autonomy” and is the ADAS of choice for Nikola, which is expected to use the system on its Tre FCEVs (fuel cell electric vehicles) starting this year.

Typical features include advanced lane centering, collision avoidance, and blind spot detection, though PlusDrive o ers more sophisticated features as well, such as:

Nudging: If the AI detects a large vehicle passing or one stopped on the shoulder, it will nudge the vehicle it controls away to avoid an accident.

Tra c Jam Assist: is is the gridlock version of adaptive cruise control and matches other vehicles’ speeds and stops when needed in stopand-go tra c.

Driver Initiated/Suggested Lane Change: If a disabled or slow-moving vehicle is ahead, PlusDrive can suggest and make lane changes upon the driver’s request.

Predictive Fuel Optimization: Manages braking

» Ford Pro Trailer Hitch Assist autonomously reverses a pickup right to the trailer connection.

Ford Pro

and throttling based on road gradient and tra c to increase fuel/range e ciency by at least 10%.

Ford Pro ADAS

In addition to the usual ADAS features, Ford’s pickup drivers can also employ several assistive features to make work safer and easier. e Trailer Hitch Assist we previously mentioned comes in handy, especially when a user needs to swap out trailers several times in one day. Having the truck automatically get to the right spot to hitch up means they can spend more time on the actual job.

Ford also o ers the Pro Trailer Backup Assist system to help maneuver vehicles into tight areas. e rear view appears on the infotainment screen, and the driver controls the vehicle’s movement using a dial on the dash to perform adjustments.

e manufacturer also has a Tailgate Down Camera and Rear Park Aid Sensors to provide a rear view when backing up.

Managers can also activate in-cab coaching that detects harsh accelerating and speeding. Ford said the coaching had reduced harsh driving events by 80% and speeding by 75%.

Maintenance considerations

Like all other systems on a commercial vehicle, ADAS technologies must be properly maintained to operate e ectively.

“Improperly maintained systems run the risk of being unavailable or not operating to their fullest capacity,” said Brian Screeton, manager, technical training & service at Bendix. “A system not

10 Fleet Maintenance | March 2024

NOW WE HAVE A 90,000-MILE OIL DRAIN INTERVAL.” “ D T O C H A N G E O Y 2 4 , 0 0 0 M I L E S . - Foodliner VP of Maintenance, Kyle Neumann And we can do the same for you. LET US PROVE IT.

performing to expectations can also contribute to driver frustration when behind the wheel, hindering acceptance of the technology.

“ADAS are built on the foundation of antilock braking systems (ABS) and electronic stability control (ESC) technologies,” Screeton added. “A fault with the ABS or ESC system means that the ADAS may not be available.”

One ABS concern that Screeton noted centers on wheel-speed sensors, which can be susceptible to chassis harness issues such as rubs and chafing, as well as issues occurring when service is done at the wheel-end. The sensor may then become nonfunctional if it’s not close enough to the tone ring or a wire is severed.

For stability control, an issue that Screeton advised may arise can be the steering angle sensor falling out of calibration. This can sometimes happen after an alignment, so it’s important to calibrate the sensor after any work is done on the front end.

“Camera issues may tie to camera placement, blindness, or the chassis wiring harness,” Screeton related. “Radar issues can be caused by sensor misalignment, vehicle wiring, or active diagnostic

A World of Comfort

“ Radar issues can be caused by sensor misalignment, vehicle wiring, or active diagnostic trouble codes in other components of the vehicle, like the engine. All radar issues should be evaluated by a trained professional to ensure that the system is functioning properly. ”

Screeton, manager, technical training & service at Bendix Commercial Vehicle Systems

trouble codes in other components of the vehicle, like the engine. All radar issues should be evaluated by a trained professional to ensure that the system is functioning properly.”

Chuck Brodie pointed out two other things a fleet maintenance operation should consider.

“First, ADAS rely heavily on the vehicle’s electrical and CAN systems,” he said. “Technicians

with a strong background in those areas will have an easier time working on them. They will also need to be equipped with diagnostic software and system-specific maintenance manuals.”

Many telematics and video systems can report data on ADAS performance to streamline repairs, Brodie also pointed out. Maintenance operations may find it worthwhile to use that data when

up to 5,000 operating hours

12 Fleet Maintenance | March 2024

AIRTRONIC AIR HEATERS Our exterior-mounted Airtronic air heaters quickly heat and distribute air in trucks through individual outlets, making them ideal for quiet and efficient cab heating. Automatic altitude adjustment up to 5,500 m* Flexible installation angled 90° to both sides possible Stepless performance control for quiet operation | MORE AT EBERSPAECHER-TRUCKS.COM 1-800-387-4800 X2298 FAST, QUIET WITH CAPACITY TO SPARE Optimized heating air flow through enhanced convector Lifespan of

2403FMS_Eberspaecher.indd 1 2/20/24 1:43 PM ©2024 IDSC Holdings LLC. All rights reserved. NEXIQ Technologies is a registered trademark of IDSC Holdings LLC. Blue-Link and First-Link are trademarks of IDSC Holdings LLC. Designed to communicate with your iOS or Android device and supporting CAN FD, the Blue-Link TM 2 vehicle interface, combined with the First-Link TM app, provides quick diagnostics for truck drivers on the road and service writers at a repair facility. Visit nexiq.com to learn more. Mobile intelligence. Heavy-duty truck diagnostics simplified. First-Link TM Get it at the App Store and Google Play 2403FMS_Nexiq-HalfIsland.indd 1 2/19/24 10:27 AM

Brian

addressing issues and specific driver concerns.

“When it comes to ADAS technologies, there are calibration and repair procedures which may be required when replacing components such as cameras or sensors,” said Connor McCann, ADAS strategy and planning director at Ford. “There are also important procedures for ADAS which may be required following collision repairs, windshield replacements, etc., to ensure proper system and feature performance.”

Peterbilt’s White also noted that ADAS technologies typically require a calibration process as part of repair procedures in the event of a collision to ensure the systems operate properly.

“ADAS relies on cameras and radar, which require regular checks and cleaning to ensure accurate functionality,” said Pedro Garcia, global head of product development at Nikola. “Dirt, snow, or even minor damage can impair their performance.

“Any repair or replacement, especially involving windshields, bumpers, or side skirts where sensors are located, typically requires recalibration of the ADAS,” Garcia added. “This is crucial for maintaining system accuracy.”

The time of year can make recalibrating more difficult.

“Winter weather can have a serious impact on the accuracy and precision of dynamic ADAS recalibrations,” Duane “Doc” Watson, technical trainer at Bosch Automotive Aftermarket, noted in an article on sibling brand VehicleServicePros. com. “Snowfall, ice, and accumulation on roads can all play major roles in visibility, vehicle stability and more.”

Watson advised that technicians monitor forecasts to determine the best time to drive the vehicle that requires calibration, as well as check that the tires are not overly worn or full of snow. That could cause slipping, which impacts accuracy. He added that cold weather can also diminish the accuracy of recalibration tools.

While these ADAS maintenance needs may sound intimidating, early adopters have found maintaining these systems to be relatively smooth.

“For the most part, these systems are fairly trouble-free,” Garner Trucking’s Husted said. “Any issues we had early on are gone, as the technologies have been upgraded and improved.”

Other than some early issues with ABS tone rings, which have been addressed, the main service needs for ADAS technologies at

Garner are to make sure radar system covers are not cracked and to have cameras realigned if a windshield is replaced.

Ultimately, regardless of which ADAS a fleet chooses and how this technology improves over the years, road safety still lies with the driver.

“It’s always important to keep in mind that safety technologies complement safe driving practices,” Bendix’ Thomas noted. “No commer -

cial vehicle safety technology replaces a skilled, alert driver exercising safe driving techniques. Responsibility for the safe operation of the vehicle always remains with the driver.”

But with a job as demanding as driving a truck, it’s nice to have a little backup.

For related content go to FleetMaintenance.com/equipment

March 2024 | FleetMaintenance.com 13

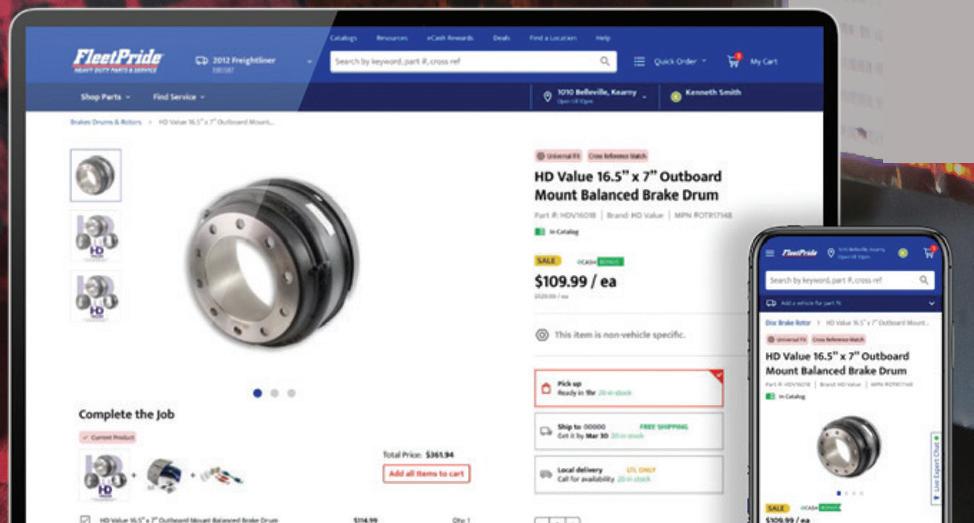

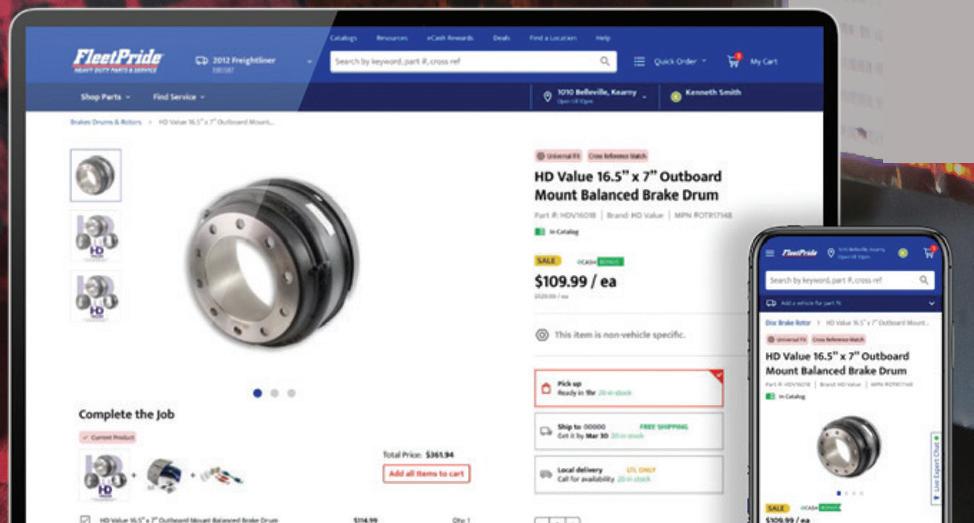

HEAVY DUTY PROS LOVE FLEETPRIDE.COM – THAT’S WHY THEY KEEP COMING BACK FOR MORE. NOW YOU CAN EXPERIENCE IT FOR YOURSELF WHEN YOU REGISTER ON FLEETPRIDE.COM, AND AS A NEW CUSTOMER, WE’LL GIVE YOU 20% OFF YOUR FIRST ONLINE ORDER .* FleetPride.com is fast, easy, and packed with features you’ll love, like real-time 24/7 access to nationwide inventory, millions of cross references, fleet data storage, quick order, live chat and so much more. Order from over a million heavy duty truck and trailer parts – for same-day pickup or shipping straight to your door. FleetPride.com is

Click

Heavy Duty™

SHOP ONLINE. SAVE BIG. NEW CUSTOMERS

*Offer valid for new FleetPride customers only. Use Promo Code FIRST20 at checkout for discount. Exclusions apply. See details at FleetPride.com. 5137 03/24 ©2024 FleetPride, Inc. | 800.967.6206 |

the First

In

and the last online ordering tool you’ll ever need.

SAVE 20%

FleetPride.com

Predictive maintenance can be the shop superpower to stave o chaos and minimize downtime. But using this great power takes great responsibility to set it up right.

By Neil Pope

14 Fleet Maintenance | March 2024

IN THE BAY

[ DATA ] Image: Erin Brown / Generated by Shutterstock; 124601334| 90813514 Dreamstime; 1097138130| Getty Images

hen you have a superpower and don’t use it, the consequences can be dire. A er getting his powers, Spider-Man let a robber slip by uncontested and his poor Uncle Ben paid the price. e wallcrawler famously learned the hard way that “with great power comes great responsibility.” Fleets now also have access to a great power, one that foresees their assets’ impending doom: predictive maintenance (PdX). And they have a responsibility to use this newfound “spidey sense” wisely to fight the pervasive menace of unplanned downtime. is cutting-edge approach to vehicle maintenance ingests telematics and vehicle data , and then employs advanced analytics and machine learning to look for anomalies. If one or more are detected, the system can alert the fleet to intervene. Ideally, the maintenance team has enough time to swing in to make a fi x, preventing a costly vehicle breakdown that tarnishes your relationship with both your driver and customer.

e question, though, is if and how you can responsibly implement this precognitive power into your operations. You don’t want to be so focused on preventing future problems that might happen that you lose sight of the problems right in front of you. is requires a bit of pre-planning to ensure this new tool adds value, not disruptions. e following guide should help you weave a good action plan, transforming you into a bona fide maintenance superhero.

Step 1: Figure out benefits

Predictive maintenance provides foresight far beyond the limitation of present vehicle diagnostics. Unlike waiting for a DTC to flag an issue, this prognostic method utilizes real-time and historical vehicle data with algorithms to identify and accurately predict a component failure. How accurate? One developer, Intangles, reported its predictions have a 95% success rate.

Exactly how does predictive maintenance manage to do all of this? e process begins with the continuous collection of data from a vehicle through sensors and other monitoring devices. Machine learning and statistical models then identify patterns and anomalies in the data indicative of potential issues or future failures.

rough real-time condition monitoring, deviations from normal operating parameters trigger an immediate alert, enabling early intervention. e perks of predictive maintenance extend past simply mitigating vehicle breakdowns and the subsequent fi nancial burden of a sidelined truck, according to Vedant Khattar, CTO at Pitstop.

“ e primary advantages our customers are seeing revolve around reducing vehicle downtime and lowering vehicle maintenance costs,” he said. Other benefits include fewer repeat shop visits and less troubleshooting/diagnostic time.

Another big advantage is consolidating several streams of data in one place, saving users additional time.

“We’ve eliminated the need, for instance, to go to another website to check the troubleshooting guide,” Khattar said.

Pitstop’s primary focus is on integrating data from various sources, particularly in handling the overwhelming influx of fault codes encoun-

tered daily by most fleets. e platform includes a diagnostic module that provides extensive information, including historical data and troubleshooting guides.

“We’ve enhanced desktop functionalities to include additional metadata and explanations, ensuring users have all necessary information at their fi ngertips,” Khattar explained. “So they see their trouble code, the priority level, and all the historical timeline in one table.”

DVIR integrations can also give fleet managers easy access to vehicle history, reported issues, and even remote viewing of real-time sensor data.

In one example, Khattar said that by using this consolidated approach to vehicle data, Pitstop was able to identify a problem with a truck one full day before the driver even noticed an issue. By the time the driver logged the problem, the sensor data had already been noted on that vehicle’s health report and was forwarded to the maintenance team.

Vehicle alerts can be delivered in real-time or as a daily summary and categorized according to severity level. For time-pressed fleet managers keen on streamlining operations, a work order can be generated automatically, factoring in alert severity and vehicle availability. is level of automation ensures diagnostic data is available to technicians even before the vehicle reaches the shop, allowing for proactive measures like advanced parts ordering.

When it comes to the transportation industry, success stories with tangible and impactful results are the ultimate litmus test. PdX provider Uptake shared a compelling narrative of realworld outcomes for one of their client’s fleets in the context of engine-related breakdowns. e implementation reduced engine-related breakdowns by 30-50% year-over-year, Uptake said. e consequential e ects extend beyond statistical improvements, manifesting in a noticeable decrease in days spent in the shop and a streamlined turnaround time for releasing trucks.

In another example, Intangles helped conserve a waste management fleet’s bottom line. Previously, the fleet kept a reserve fleet of five waste trucks because of frequent breakdowns; however, a er adopting the AI-enabled soware, the refuse fleet saw a substantial increase in uptime, explained Alan McMillan, president of Intangles. is allowed them to sell o three out of their five reserve vehicles.

“What’s the ROI on that?” McMillan asked. “ ose trucks were running more e ciently with fewer breakdowns. Customer satisfaction goes up, and their asset availability increases.”

Step 2: Overcome hesitancy

Despite its potential, predictive maintenance, still fi rmly planted in its ‘early-adopter’ phase, hasn’t attracted as much customer interest as expected. Uptake President James Rice acknowledged that fleets have displayed a measured and cautionary pace when adding PdX to existing workflows. “ ere’s consistent growth in this area year-over-year, though not at the desired rate,” Rice explained. “Predictive maintenance lacks a deep history and widespread prior experience,

VETTING AI’S ADVICE ON PREDICTIVE MAINTENANCE

Can AI help us understand AI? We asked the free version of ChatGPT some predictive maintenance questions and vetted those answers with some human experts to find out.

What indicators should a fleet manager look for to determine the readiness of their company for integrating predictive maintenance components?

ChatGPT:

Fleet managers should scrutinize key indicators such as ensuring effectiveness in the current preventive maintenance process, considering fleet characteristics such as age and mileage, and evaluating engagement with telematics providers for dynamic solutions. Collaboration and customization play a pivotal role, aligning implementation plans with fleet goals. Integration into existing workflows, addressing education gaps, and prioritizing technician training are essential. Additionally, the company’s capability to handle data influx and prevent overload should be considered. By comprehensively examining these factors, fleet managers can determine the preparedness of their company for the seamless integration of predictive maintenance components.

PERSON:

Andrew Bartholomew, associate product marketing manager, Fleetio:

It’s not that complicated. An ideal indicator for us would be when an increasing proportion of downtime or repair spend is resulting from repairs that couldn’t be avoided with a comprehensive preventive maintenance system. Essentially, if a fleet’s preventive maintenance process is in order, it’s easier to think ahead; there aren’t going to be as many unexpected issues popping up and taking all of the focus.

March 2024 | FleetMaintenance.com 15

and people often struggle to grasp the nuances as it’s more than just collecting fault data.”

Dave Walters, a senior software engineer at Trimble with more than 40 years of industry experience, attributed the lethargic growth to “a lot of confusion between preventive maintenance and predictive maintenance—and what we can and can’t do today with software.”

Intangles’ McMillan agreed that some in the industry incorrectly conflate the two and suggested this was due to inconsistent marketing language.

“A lot of OEMs are confusing the market by calling Diagnostic Trouble Codes predictive, and they’re not,” he said. “DTCs only emerge once the ECU has recorded an issue that’s already occurred. By that time, that unit has been traveling down the

How can a predictive maintenance algorithm and software adapt to changes in how a fleet operates or how they grow over time?

ChatGPT:

A predictive maintenance algorithm and software can adapt to changes in a fleet’s operations and growth by being dynamic and scalable. These systems can accommodate new vehicles, changes in regulatory compliance, energy transitions, and even the integration of autonomous vehicles. Telematics providers, who often offer these solutions, collaborate closely with fleets to custom-tailor implementation plans, ensuring flexibility. The algorithms incorporate advanced AI techniques to process and prioritize fault codes. This adaptability allows the system to remain effective as the fleet undergoes operational shifts or experiences growth, ensuring that predictive maintenance continues to deliver meaningful insights and benefits over time.

PERSON:

James Rice, president, Uptake:

In the last six to eight months, I’d say our models and process with the algorithms have actually even gotten down to the asset level. We’re taking a little bit more into account at the asset level as opposed to component or fleetwide data that says all 2,000 of my Freightliners should all act the same. The ones in California aren’t going to act the same as the ones in New York. When you have the baseline foundation of what it should be but if you’re in an extreme weather event or extreme temperature, we’re not gonna automatically say that there’s a problem here.

We’ll look and determine if there’s an anomaly and if it’s sustainable. Is it a weird thing for the day, or is it really outside the normal operating measure? That has been how this product is evolving and as data scales, we will continue to build out the power of these algorithms.

highway losing money and causing more issues to happen.”

Because terms aren’t clearly defined, fleets that integrate predictive maintenance can run into problems when dealing with an outside maintenance provider that does not have access to predictive data.

“That shop does a normal diagnostic on it and doesn’t see a trouble code, so that could be a challenge,” McMillan said. “That shop doesn’t see anything because their diagnostic equipment is not telling them.”

Confusion exists, in part, because both preventive and predictive maintenance involve analyzing sensor data for irregularities, such as fluctuating oil temperature, to identify and provide insights on potential issues. A temperature irregularity may not be enough to trigger a DTC, though it could be enough to signal to the PdX system that something isn’t right. This is because the AI compares the new data against historical oil temperatures, putting into context if current operations are normal or abnormal.

PdX also has the ability to detect patterns and learn, enabling algorithms to spot issues faster and more accurately over time. That’s the conceit, anyway. For small fleets (that are typically late adopters) to truly overcome hesitancy, it will take time. As PdX ingests more data and becomes wiser with how to help fleets operate more efficiently, tales of its power will likely spread, and higher take rates will follow.

Step 3: Implement data

Once an operation decides PdX can and should be adopted, management should embrace it wholeheartedly, Rice advised.

“Don’t be resistant to change,” he said. “Consider the shift from manual to automatic transmissions or paper logs to ELDs—initially challenging, but now indispensable. Do you want to continue to receive thousands of fault codes a day, or would you rather have a more streamlined and organized approach?”

In this respect, fleets must remember that with any computing system, even AI, “garbage in/ garbage out” still applies. You want a large sample size of data to empower your PdX, but it has to be the right data.

Utilizing Vehicle Maintenance Reporting Standards (VMRS) codes, created by the Technology & Maintenance Council in 1970, could be just what PdX needs.

“It’s been the ‘universal’ maintenance language for more than 50 years and continues to prove to be flexible and adaptable,” reasoned Jack Poster, TMC’s VMRS guru, who added “there needs to be an agreed-upon method of interpreting and implementing the received [DTC] data, and many believe VMRS is the perfect method.”

A new initiative, spearheaded by Brian Mulshine, now a senior director of product management at Trimble, aims to use VMRS to standardize common language and maintenance alerts and communication between the back office and vehicle to better coordinate service. A new code key would need to be created and would help separate future service events into past due, due

soon, and needs replacement soon.

“The codes can be used across all vehicle/ engine OEMs and component suppliers to digitally communicate predictive and prognostic maintenance and repair requirements,” Poster said.

Step 4: Train technicians

Andrew Bartholomew, assistant product marketing manager from CMMS provider Fleetio, explained that training technicians to effectively leverage PdX can further empower the technology.

“Basic training might consist of comprehensive programs exploring how to use the technology to interpret vehicle data and troubleshoot,” he said. “New technicians should have a structured onboarding process that includes dedicated training on predictive maintenance.”

Bartholomew added that mentorship from more experienced techs, continued professional development, and documentation “knowledge hubs” will help acclimate all techs in the bay to using this powerful tool every day.

Such training is not only foundational but also extends to structured onboarding, fostering a culture of continuous learning.

McMillan echoed the importance of such initiatives by addressing the pressing issue of hiring less-experienced technicians. He said that many fleet customers have asked for Intangle’s help in this area.

“Experienced technicians are increasingly scarce due to the growing complexity of vehicles and limited hands-on experience for new students. Consequently, technicians rely heavily on technology for problem diagnosis,” McMillan explained.

“Intangles assists technicians by preemptively flagging potential issues and offering predictive alerts, detailed symptom and cause lists, severity assessments, and recommended repair paths. This empowers less-experienced technicians to efficiently address problems using our intuitive platform,” he said.

By providing real-time insights and predictive analytics on each vehicle’s performance, it ensures technicians have access to comprehensive diagnostic data and a clear repair path to swiftly resolve issues, regardless of their skill level.

To prevent unnecessary downtime, technicians must be able to rely on accurate diagnostic data. Intangles addresses this by achieving 95% accuracy when forecasting component-level failures in real-world scenarios. This degree of accuracy is attained by blending physics-based models and AI prognostic methods, leveraging machine learning and data analysis to identify patterns and trends. Physics-based models meticulously analyze vehicle component behavior, offering precise insights into degradation and potential failure modes. However, they require in-depth knowledge of system behavior.

To complement this, Intangles utilizes AI techniques to extract structured information from vast datasets collected from over 150,000 vehicles. With approximately six billion sensor parameters processed daily, layered machine learning algorithms continually update the physics-based model with real-time data. This hybrid approach ensures accurate predictions under various envi-

16 Fleet Maintenance | March 2024

ronmental and stress conditions, similar to realworld operating environments.

Step 5: Evaluate preparedness

Fleets contemplating the integration of predictive maintenance into their telematics face the critical task of assessing their readiness. Establishing KPIs will enable this, Bartholomew noted.

“An ideal indicator would be when an increasing proportion of downtime or repair spend is resulting from repairs that couldn’t be avoided with a comprehensive preventive maintenance system,” he said. “If a fleet’s preventive maintenance process is in order, it’s easier to think ahead; there aren’t going to be as many unexpected issues popping up and taking all of the focus.”

One of Fleetio’s customers operating in the construction space estimated that his mechanics historically spent around 30% of their time doing PMs and the rest reacting to vehicle issues as they surfaced. After implementing Fleetio, the proportion of time spent on PMs roughly doubled, showcasing a proactive shift in their approach. This brought annual repair spending down by 30% and showcased a prime instance of fleet readiness for integrating predictive maintenance.

McMillan said that for fleets operating older and/or high-mileage trucks, the need for predictive maintenance becomes more pronounced.

“Typically, if you’re running a little bit older fleet like two to four years, it’s got enough miles to start having issues around the powertrain, and you want to be able to be notified before that engine blows,” McMillan explained. “If somebody has 100% all brand-new trucks and they’re all under warranty, they may be less interested in having an AI prediction because the odds of having an issue are far less.”

McMillan noted some fleets may still want predictive technology to ensure the asset is working properly.

In evaluating your fleet’s preparedness, engaging with your telematics provider is a recommended first step as they offer dynamic and scalable predictive maintenance solutions that can adapt to evolving business requirements.

Hieu Bui, VP of product at Platform Science, a leading telematics technology provider, emphasized that because every fleet is different, customization and collaboration are crucial.

“We always work with our partners to tailor an implementation plan,” he said. “All of our partners in our marketplace are really hands-on with developing a plan, so we partner with them to learn about the fleet, what their goals are, and what matters to them.”

This can include the acquisition of new vehicles, changes in regulatory compliance, electrification, and even autonomous vehicles, Bui noted.

What challenges would you advise people to be mindful of during the integration of a predictive maintenance solution?

ChatGPT:

The answer would depend on the insights and experiences of individuals involved in the integration of predictive maintenance solutions. They might discuss challenges related to technology adoption, data management, technician training, or overcoming hesitancy in embracing new approaches to fleet management.

PERSON:

Vedant Khattar, CTO, Pitstop:

Don’t think it will just start working out of the box. Each company has a different threshold of what is critical and what is minor, so you have to give it at least two to three months because every model takes some time to calibrate. You really need patience, so don’t get frustrated if the system says something is a critical issue but when you check, it was only a minor issue. Those incidents will happen. If it’s reported and then happens again, then it is a problem. But if it happens one time and the computer has learned and improves, it’s only going to get better from there.

At what level of sophistication should fleets commence their implementation of an AI-driven predictive maintenance component?

ChatGPT:

It depends on various factors, such as the fleet’s size, operational complexity, and existing technological infrastructure. It’s recommended for fleets to conduct a thorough assessment of their specific needs, considering factors like the age of their vehicles, maintenance history, and the desired level of automation. Starting with a phased approach, integrating AI gradually and scaling based on successful outcomes can be a strategic way to ensure effective implementation without overwhelming the existing operations.

PERSON:

Alan McMillan, president, Intangles:

No, it’s really straightforward. We plug into their CANBUS through their OBD port. Even if they have something in the OBD port, we just put a pigtail in. In almost all of our installations, there’s already a GPS device or an ELD device running in that vehicle. It’s no problem to run alongside that and frankly the truck driver doesn’t even know we’re pulling all that information back to command center. It’s all done through the cloud and naturally, we’re also doing things like driver behavior. We do all sorts of predictions around that.

Step 6: Mitigate data overload

For fleet managers, the specter of data overload casts a formidable shadow. As vehicles evolve into smarter and more connected entities, the constant influx of data raises a pertinent question: How genuine is the risk of predictive data overload?

Any abundance of information holds the potential to overwhelm, making it difficult to extract meaningful insights. The surge of data being generated has become a double-edged sword, often leading to breakdowns rather than preventing them.

“The amount of data coming off the truck and the number of sensors in the trucks is growing exponentially,” Bui said. “So what we’re seeing is if you don’t treat that data right and do the right things with it, it becomes a negative. If I’m flooded with all of this data and I can’t make sense of it, I’m going to make the wrong decisions.”

The phenomenon of “data numbness” finds support in psychological circles, aligning with the well-known concept in psychology called “decision fatigue.” This term signifies a noticeable decline in decision-making quality after prolonged exposure to a substantial volume of information.

Rice elaborated on the concept of data overload, highlighting its potential to induce another psychological phenomenon termed ‘inattentional blindness.’ This phenomenon occurs when individuals focus on a specific aspect they are familiar with, consequently overlooking other significant details.

Rice explains that “with an increasing number of codes being generated by trucks, there’s a tendency to overlook the sheer volume of data. Instead, attention is often directed only to a select few high-value or high-impact codes. This reactive

approach persists, leading to a cycle of diagnosing problems after they’ve occurred.”

Companies at the forefront of predictive maintenance are actively contributing to alleviating data overload. They achieve this by employing advanced AI algorithms to sort and prioritize fault codes, consolidating them based on specific criteria such as timeframe, frequency, and density. Applied against historical operating parameters, this strategic approach allows for an intelligent assessment of cumulative impact and helps determine whether attention is warranted before sending out an alert.

By embracing the entirety of a truck’s diagnostic data, PdX companies believe they have plotted a clear path between information abundance and strategic discernment and will take the guesswork out of decision-making.

The ultimate goal of PdX is to aid fleet managers in the planning and allocation of resources based on the AI’s recommendations. And the power of predicting maintenance issues well in advance will likely enhance the entire fleet’s performance, allowing for better technician scheduling, parts ordering, and overall utilization.

Fleets should keep in mind that even superheroes with a spider-sense for danger sometimes fail, and mastery of any power takes hard work and contemplation. Building and sticking to a plan, and training maintenance teams to execute it, will determine if you are able to only predict a negative future—or prevent it altogether.

For related content go to FleetMaintenance.com/in-the-bay

March 2024 | FleetMaintenance.com 17

CHATGPT VS. TRUCKING EXPERTS

AI-driven, natural language processing (NLP) tools such as ChatGPT from OpenAI and Google Bard are enabling humans to have normal conversations with computers. While AI tools like these are capable of doing many things, using them as a research assistant is a common way to dip your toe into the AI pool.

Many of these NLP tools build their language models by using publicly available information. For instance, OpenAI relies on three sources of information: what’s available on the internet, information licenses from third parties, and information their users and human trainers provide. This “training process” not only supplies the AI tool with lots of information, but also allows it to pick up on language patterns so it can become a more proficient communicator.

At times, the response you get from an AI tool is not only impressively fast, but also dead-on accurate. At other times, the response can be a little off. That’s why tools like ChatGPT and Bard recommend fact-checking “important” information. But doesn’t that defeat the purpose of using an AI tool in the first place, where one of the primary benefits is reducing time to insight?

“With our asset management software, and even a lot of shop management software that’s out there, the assumptions are controlled,” said Brian Antonellis, senior vice president of fleet operations at Fleet Advantage, an asset management and data analytics firm. “We are taking industry-accepted norms and introducing them to an algorithm, so a fleet can have confidence in the assumptions that are being made.

“While we do get excited about what AI means, we’re also cautious about putting the right data into the system,” Antonellis continued. “Even today, you don’t really know what data and information is in something like ChatGPT. A lot of it is coming from the internet, and that information can be as much as two years old if you’re using the free version. So you have to be cautious. The last thing you want to do is pull a query on the wrong data. And I would be really careful about leaning in too strongly on anything technical, unless you have a verified data source and are comfortable with the assumptions being made, and are able to vet them through your OEM.”

We asked the free version of ChatGPT a handful of questions a fleet maintenance manager might have, and then compared the responses to what a human expert in the trucking industry had to say. In most cases, ChatGPT’s responses were somewhat general, whereas the human industry expert came back with a more refined answer.

Take a look and decide who you’d trust:

Explain how...

To expand what these pocket assistants can do for fleets, last summer Geotab began beta testing a new AI-driven solution, referred to as Project G, with fleet customers. During the first stage of testing, the AI was only trained on a specific subset of data from Geotab’s Data Connector tool, including asset utilization, fuel economy, and idling.

But fleets were asking the AI a lot of questions that required data beyond what Data Connector could provide. Now Geotab has begun incorporating additional telematics data from the vehicle—such as remaining useful oil life, battery condition, and DPF condition—to help maintenance managers gain further insights and improve maintenance scheduling.

This is still like a souped-up predictive maintenance use case. The considerable IQ of available AI solutions can be used for so much more in the shop, really only limited by the users’ creativity and imagination. The problem for most managers, though, is finding time to step away to let their imaginations run wild. Fortunately, the AI that exists right now can perform several tedious tasks to help free your mind.

Technician support

Many jobs will be drastically changed, and some replaced, as AI becomes increasingly embedded in the workforce and is able to do more jobs. In the hands-on vehicle maintenance sector, AI can’t replace brakes or change oil, but it can serve as an extra helping hand in the shop. And asking for that help is getting easier.

“The big revolution we’re talking about is a shop manager having the ability to interact with an AI machine-learning model by simply typing out a sentence,” said Jacob Findlay, co-founder and executive chairman of Fullbay, a heavy-duty repair shop management platform. “And think about a technician having the ability to talk to an AI-powered software to have it create a work order, all while that technician is under a truck.”

With onboard components getting more intelligent, and the supply of human labor getting more scarce, this help should be a welcome addition.

“In an industry where there are more trucks on the road but fewer technicians to repair them, we need this type of technology,” Findlay noted.

The Fullbay founder tends to get a little excited when talking about the realm of possibilities AI brings to the table. The Fullbay platform’s current software functionality ranges from generating estimates and invoices to preventive maintenance tracking and parts inventory management. It also allows shops to generate various reports to help track things like technician efficiency and vehicle cost of ownership. When you think about all of that functionality, there are numerous tasks that could be automated by AI. Additionally, many tasks could be simplified by allowing a welltrained AI tool to retrieve and analyze data. And make no mistake—Fullbay is full of data.

“This puts us in a really good spot to leverage AI [at some point],” Findlay said. “With the vast amount of highly detailed work order and repair information data that’s entered into our system, we’re in a position to do specialized AI training that is proprietary.”

How often should I clean the DPF on my Kenworth truck?

ChatGPT:

Cleaning the Diesel Particulate Filter (DPF) in a Kenworth truck depends on various factors like driving conditions, mileage, and manufacturer recommendations. Typically, it’s recommended to inspect and potentially clean the DPF every 150,000 to 300,000 miles, but this can vary based on your specific truck model and usage patterns. It’s advisable to consult your truck’s manual or the manufacturer’s guidelines for precise maintenance schedules tailored to your vehicle.

PERSON:

Steve Hoke, president of Diesel Emissions Service : That response is spot on from a manufacturer’s point of view. But realworld results would prefer that a DPF be cleaned in the 100K-150K range for the best longevity of the DPF.

“ The big revolution we’re talking about is a shop manager having the ability to interact with an AI machine learning model by simply typing out a sentence.”

Jacob Findlay, co-founder and executive chairman of Fullbay

As a hypothetical example, Fullbay’s repair history data shows that it’s common for a technician to simply swap out a sensor when it’s giving them problems, but that doesn’t solve the root cause of the problem. Now let’s say a technician working in a shop 1,000 miles away does solve the root cause. With AI scanning and analyzing all the repair orders that have gone through the platform, the next technician to encounter this same sensor issue could ask the AI tool what some possible causes are. The AI could suggest what that disparate technician already figured out.

“No human being could ever consume all of that information,” Findlay pointed out. “So from that standpoint, AI could end up becoming the best diagnostic tech in a shop.”

Until that day comes, a shop manager can already take advantage of several “generic” AI tools to assist them in various aspects of their jobs, such as to quickly research certain information, analyze data, create charts and graphs, write emails, or automate scheduling.

20 Fleet Maintenance | March 2024

BENDPAK LIFTS BRING ANY JOB DOWN TO SIZE

Bendpak is the name that fleet operators rely on because they’re the toughest lifts on earth. And nowhere is that strength more impressive than on our PCL-18B series portable column lifts. With a lifting capacity of 18,000 pounds for each column and paired configurations ready to accommodate two, four, six or eight axle vehicles, the PCL-18B is ready to service trucks as heavy as 144,000 pounds. From school buses and fire engines, to agricultural vehicles and utility trucks, bendpak continues to make today’s tough challenges yesterday’s problems. To learn more or to shop now, visit bendpak.com or call us at 1-800-253-2363.

BENDPAK.COM ©2024 BendPak Inc. All rights reserved. BendPak Model PCL-18B-6 Portable Column Lift Certified to meet the standards of ANSI/ALI ALCTV: 2017 FULL MOBILITY SIMPLE OPERATION ADJUSTABLE WHEEL FORKS PCL-18B

1-800-253-2363 •

DOW O

AI: THE DIGITAL OFFICE ASSISTANT

Sometimes we all could use help phrasing things with the right balance of cold calculation and empathy, especially when breaking bad news to a customer. We wanted to see if the free version of ChatGPT was up to the task and asked the following question:

Can you write an email telling my customer that their truck repair will be done Thursday afternoon once a backordered part comes in?

Here’s what ChatGPT produced:

New message Subject Update on Your Truck Repair

Dear [Customer's Name],

I hope this email finds you well. We appreciate your patience and understanding as we work on repairing your truck. We wanted to provide you with an update on the status of the repair.

Currently, everything is progressing smoothly, and our team is diligently working on resolving the issues with your truck. However, we have encountered a slight delay due to a backordered part that is essential for the completion of the repair.

Scheduling and parts inventory

“Maintenance professionals o en rely on their mobile devices to perform day-to-day tasks and reporting,” said Evan Welbourne, head of AI and data at Samsara, provider of the Connected Operations Cloud platform that harnesses IoT (internet of things) data to develop actionable insights for fleets. “AI can be used to streamline and simplify these processes by automating particular tasks and surfacing curated workflows for specific employees, cutting out the noise and only providing them with the information they need for a given task, at a given time.”

Employee scheduling is another management function where AI tools already exist. A so ware company called Celayix uses AI machine learning to study past schedules and various rules the user has set up to automatically schedule shi s that meet certain requirements and operational needs.

We want to assure you that we are actively monitoring the situation, and the backordered part is expected to arrive by Thursday morning. As soon as we receive the part, our technicians will immediately proceed with the repair work.

Our goal is to have your truck fully repaired and ready for pickup by Thursday afternoon. We understand the importance of having your vehicle back in a timely manner, and we sincerely apologize for any inconvenience this delay may have caused.

If you have any questions or concerns, please feel free to reach out to us at [Your Contact Information]. We truly appreciate your understanding and cooperation in this matter.

Thank you for choosing our services. We look forward to completing the repair and returning your truck to you in top-notch condition.

Best regards,

Send

Parts management is another area where AI can play a beneficial role. Yes, there are already plenty of shop so ware platforms out there that possess the functionality to track inventory levels and even set reorder points. But AI can more deeply analyze historical usage data along with additional external factors in real-time (i.e., price, supply, and demand) to help determine what the optimum min/max and reorder levels should be at various points throughout the year.

rough image recognition and machine learning, AI can also help maintenance professionals look up parts faster. e user just takes a photo of the part, uploads it to the so ware, and AI searches for a match. At a point in time when the fleet maintenance industry is losing a lot of tribal knowledge due to an aging workforce, this type of technology will become essential.

In addition to the general types of AI tools just described, there are also some industry-specific

What is the best oil filter for a Detroit DD15 engine?

ChatGPT:

The choice of the best oil filter for a Detroit DD15 engine may vary based on factors like specific model requirements and personal preferences. However, reputable brands such as Fleetguard, Baldwin, and Donaldson are often recommended for DD15 engines due to their quality and compatibility. It’s crucial to consult your engine’s manual or manufacturer recommendations to ensure you choose an oil filter that meets the required specifications for optimal performance and engine protection.

that

PERSON:

Len Copeland, product marketing manager for Detroit Components: While we acknowledge that AI has become influential technology, we still recommend our own branded oil filters for our engines. All of the recommendations are on our publicly accessible Techlit webpage at dtnatechlit.com/portal-public/ (search for “Supplemental Oil Filters”).

22 Fleet Maintenance

|

To

[Your Full Name] [Your Position] [Your Company Name] [Your Contact Information]

examples of AI being put into action. This is an important development. The real potential of AI lies in industry-specific tools trained on specific data that a maintenance manager can feel comfortable in trusting.

Automatic VMRS encoding

The TMC’s Vehicle Maintenance Reporting Standard (VMRS) codes have been developed to keep dealers, repair shops, and fleets on the same page when a vehicle is being serviced. The challenge is that technicians often fail to assign a VMRS code when servicing a vehicle. That makes it harder for a fleet to understand what’s happening in the service bay so it can accurately measure things like M&R costs and TCO.

“We’ve begun using AI in the VMRS encoding of operations,” said Nick Pittinger, director of data services at Decisiv, whose Service Relationship Management (SRM) Ecosystem has more than 7 million assets in operation, along with 5,000 dealers and service providers, and more than 74,000 fleets and asset owners. Needless to say, the Decisiv SRM Ecosystem sees a tsunami of service orders, around 300,000 per month. All of that data is used to develop AI algorithms and machine learning to recognize certain information defined during a service operation, and then encode it with the appropriate VMRS code.

Currently, Decisiv’s AI is automating the encoding of the VMRS system-level code (Code Key 31). That enables people downstream of the repair to gain better maintenance insights, and even perform tasks like warranty claim submission. Pittinger said they’ve been seeing 80-85% accuracy on hundreds of thousands of repair operations per month. That’s a huge improvement considering how VMRS codes were only being provided on 5-10% of the repairs when a technician did it manually.

Given this initial success, Pittinger’s data team is looking into the automation of additional VMRS codes. A logical next step would be the assembly-level Code Key 32. From there, Decisiv’s fleet customers have been asking about things like Code Key 14 “reason for repair” and Code Key 15 “work accomplished.”

Inorganic human resources

Recruiting new technicians has always been a time-consuming

endeavor. It gets even harder when there’s a shortage of talent. A company called Whiterail Recruits is finding that a balance of human and artificial intelligence can work in tandem to help solve this problem. It can also make a maintenance manager’s life a lot easier.

“A good diesel technician is gold these days,” said David Ostrov, head of operations at Whiterail Recruits, a marketing services company that

leverages a unique advertising algorithm and generative AI to more efficiently recruit drivers and technicians. “You need to know how to talk to technicians to really court them.”

This is where Whiterail’s experience in digital advertising comes into play. Their human talent creates compelling, highly targeted, smartphone-friendly ads for websites, social media, and apps that the typical diesel technician tends

How can I improve efficiency in my truck repair shop?

ChatGPT:

There are several things you can do:

• Streamline the repair process

• Employee training

• Utilize technology

• Regularly maintain your repair equipment

• Clear communication

• Set standard operating procedures

• Customer service focus

• Performance monitoring

PERSON:

Jacob Findlay, Fullbay founder and chairman: The best thing a shop can do is grab a pencil and blank sheet of paper, and draw out what the repair workflow is today. Identify the areas where time and/or cost tend to get out of control, and find ways to do things more efficiently. Also, be sure to measure technician efficiency, which is invoiced hours divided by total hours worked. Publish the results so the Hawthorne Effect can play out (which says people change behavior when behavior is being evaluated). Once the key metrics and processes are laid out, set some goals and continuously monitor them.

PERSON:

Nick Pittinger, director of data services at Decisiv: Streamlining communication between the fleet, shop, and suppliers is one of the best ways to improve efficiency. When communication is consistent and clear, the repair event typically goes much smoother and faster. Leveraging standardized operations will also improve efficiency, and is much better than leaving each technician to figure things out for themselves. Improving workflows by automatically assigning tasks through a software platform will also help save time. Finally, shops should find ways to measure performance, analyze that data to identify bottlenecks, and use it to get a little bit better and faster.

to use. But even here, Whiterail’s human talent will o en use various AI tools to ask for advice on what the ad should say and to create imagery.

AI starts playing a bigger role when a person clicks on one of those ads. e person is sent to an AI-driven, chat-based hiring platform on a Whiterail recruitment webpage. is is where the automation kicks in.