Work truck updates

Transmission repair tips

Fleet and shop leaders share how they accommodated growth by moving into new facilities or renovating existing ones.

Page 20

Equipment

Vocational Innovations

Across the board, manufacturers of commercial vans, pickups, and work trucks are loading up their newest models with the latest technologies.

In The Bay

Gearing up for smoother transmission troubleshooting

Transmission troubles are a quick ticket to unwanted downtime, but is the transmission even the issue? We had some experts discuss their tips for improving the troubleshooting process as vehicle powertrains continue to evolve.

Shop Operations

Shop expansion: Plans to grow out and glow up

Whether you’re building, renovating, or moving into a different facility, success comes down to proper planning, proven partners, and a concept built around both efficiency and technician morale.

p. 26

Brakes

Tightening up slack adjuster maintenance

How to inspect, diagnose, and replace automatic slack adjusters.

p. 28

Oscilloscopes

Waveform of the future

An oscilloscope can see certain things a scan tool can’t, making it a valuable addition to a fleet’s diagnostic toolbox.

30 Management Shop culture’s impact on hiring and retention

Alex Keenan ASSOCIATE EDITOR

32 Guest Editorial Using EVIRs to avoid out-of-service violations

Visit the official website of Fleet Maintenance for more information from stories in this issue, plus online exclusives on pertinent topics in the fleet maintenance management industry.

Stay up-to-date on industry news and events, new product launches, and more. FleetMaintenance.com/subscribe

TruckWings

TA’s emergency roadside trucks now equipped with HAAS alert system

The initiative will alert oncoming drivers of roadside technicians via vehicle infotainment centers and navigation apps, the companies stated.

FleetMaintenance.com/55018780

READ ANYTIME, ANYWHERE

Read the digital edition online at FleetMaintenance.com/ magazine/76215

Want your own issue? There are two simple steps to get a free subscription:

With the latest National Highway Traffic Safety Administration report showing that large truck crash fatalities have increased, the call for more government intervention has also risen. FleetMaintenance. com/55010932

Join the conversation: Facebook.com/ FleetMaintenanceMag

Fleet Maintenance is proud to announce nominations are open for the 2nd annual Overachiever of the Year Awards.

By John Hitch Editor-in-chief

By John Hitch Editor-in-chief

Call me a sucker, but I still believe there’s honor in putting in an honest day’s work. It just feels right to show up on time and do quality work until quitting time. And once upon a time, this lunch pail mentality was portrayed as the true engine of American productivity, shared by those who built our cities and roads, cultivated our crops, and made our goods.

I’d argue that the trades, particularly the transportation industry, still attract this type of person, someone who wants to build and fi x, maintain and improve. at’s pretty much the baseline across the board; a technician who doesn’t have a passion for caring for and repairing vehicles or a driver with little regard for safety or e ciency ain’t lasting for long. en there are the overachieving outliers.

ose are the folks who make us all look bad and lazy by comparison. ey show up to work earlier than most and leave even later, working hard and always putting up a good fight against fatigue and distractions. ey have a way of setting the pace, making the walkers jog, the joggers run, and runners sprint. Considering the pace in which the transportation sector is changing and evolving, we’d be pretty screwed if not for them. And they don’t even rub it in.

You know the type: insu erably proficient and annoyingly humble about it, too. If you’ve read this magazine for a while, you may be familiar with former editor Erica Schueller. She’s totally one of ‘em. While doing this job at an extremely high level, she also completed a ten-week course to earn her CDL. Meanwhile, I have to double check if it’s a Commercial Driver License or Commercial Driver’s License. (It’s one of those, I’m pretty sure.) It’s because of the standard she set that I can barely slack o at all. Fortunately, our overachieving art director Erin Brown is still here to pull it all together and make me at least appear competent.

See

Even with that paradigm of quality set, some trucking lingo still doesn’t come quite naturally, and I’ll likely need sources to “dumb things down” for me while writing more technically focused stories for the foreseeable future. But I can recognize greatness when I see it.

And greatness deserves to be recognized, especially when the status quo so o en veers to mediocrity in today’s society. at’s why we launched the Fleet Maintenance Overachiever of the Year Awards last year, and why it’s my pleasure to announce we are running it again this year.

Like last time, we need you to nominate someone you work with that goes above and beyond, that pacesetter who pushes everyone else to try a little harder, to learn a little more every day. Our panel of judges will review all submissions and pick the six winners.

We have six distinct categories:

• Shop Technician

• Mobile Technician

• Supervisor/Manager

• Trainer

• Shop Owner/ Executive

• Support Sta

Keep in mind that we are looking for commercial vehicle professionals who demonstrate Outstanding Achievement in the Field of Maintenance. is means a nominee for the support sta category could work in the parts department or shop o ce, but not in dispatch. And if you work on both consumer and any commercial vehicles, you are eligible.

I’m also a big believer in continuous improvement, so we’re making things easier this year. One criticism from last year was the short nomination period (about a month). We’re giving you all until Sept. 1, 2024.

Also, instead of just emailing us, we’ve created a formal application to guide you through the nomination process. Just head on over to FleetMaintenance.com/2024-awards and follow the instructions. It shouldn’t take long to fill out.

e glory, however, could be eternal. at’s because winners will receive an individual profi le published in our December issue.

ey’ll also receive trophies, customized apparel, and a prize package loaded with tools and swag donated by our generous sponsors. We are accepting sponsors until Aug. 1, so email editor@fleetmaintenance.com for more details.

Whatever prizes we can muster, though, won’t likely have as much impact as the simple act of being nominated.

Dewey Bishop, technical trainer at Ozark Motor Lines, who was a winner of one of our inaugural awards, told me, “ e jacket and other items were nice, but not necessary” and “Award or not, at the end of the day, I am just trying to help our technicians.”

But the outpouring of support from his colleagues did mean something, as did the recognition by the man who nominated him, Wayne Skinner, Ozark’s VP of fleet maintenance.

“I feel greatly appreciated at work; a er receiving the award many co-workers told me it was well deserved,” Bishop said. “I am also greatly appreciative that Wayne took the time to nominate me. It reassures me that working hard to help others does not go unrecognized.”

And the award allowed Skinner to also take a victory lap. He noted he “certainly bragged on [Bishop] to our CFO and my peer VPs at one of our leadership sta meetings.”

If you know someone who fits the bill of Fleet Maintenance Overachiever, I encourage you to think about what makes them great and nominate them today.

OE-LEVEL CUSTOMIZABLE PARAMETER CHANGES

COMMERCIAL TRUCKS, BUSES, EMERGENCY VEHICLES + MORE

Across the board, manufacturers of commercial vans, pickups, and work trucks are loading up their newest models with the latest technologies.

By Seth Skydel [ 2024 VEHICLES ]

By Seth Skydel [ 2024 VEHICLES ]

Today’s work trucks and vans are getting packed by OEMs with more technology than ever before, all in the name of improving safety, productivity, e ciency, and driver comfort. Streamlining maintenance is a cost-saving goal as well.

Manufacturers have also made significant upgrades to vehicle exteriors and interiors, focusing on body integration and upfitter friendliness to allow easier customizations for the work truck sector, where vehicles are asked to perform countless jobs in nearly every industry. The variations from one vocational truck to another are endless. Likewise, the stream

of new innovations from manufacturers, OEs, and suppliers never seems to stop, either.

ese innovations present both a challenge for manufacturers and an opportunity for commercial vehicle users. e OEMs say they are fi rmly focused on customer success and partnering with other companies who can bring the best technologies, products, systems, and solutions to the table. Only time and road miles will prove which are the best, but here we can at least provide what to expect in the coming year in respect to the latest vans, pickups, trucks, and chassis cabs.

» Fleets can manage Sprinter maintenance and track vehicle data via the Mercedes me connect app.

Last-mile delivery has proven that electrification works now, especially due to last-mile delivery vehicles’ daily routes, which are amenable to EV battery capacities and returning home for charging at night. According to CALSTART’s Zeroing in on ZETs (Zero-emission trucks) 2024 update, electric cargo vans account for 80% of the 17,500 ZETs deployed. That’s a 0.39% market share, but OEMs have made electric vans a point of focus.

Ford Pro developments include 26% more range on electric E-Transit low-roof vans and 32% more on high-roof models, according to Kevin Lieberum, Ford Pro commercial truck brand manager. New dual onboard chargers for the vans are available on 2024 models as well.

“The additional range and faster charging create new opportunities for more industries and vocations to use the electric vans,” Lieberum said. “Faster charging and additional range support covering longer distances and unlock solutions for new use cases, like refrigerated delivery.”

Additionally, the Pro Power Onboard system that is now available across the E-Transit van lineup provides 2.4 kW of power and is operable while the vehicle is in motion and while charging, enabling users to plug in a laptop, tools, or other equipment on the go or at the jobsite.

With the commercial vehicle space accounting for so much of Stellantis global revenue—one-third—the OEM has, like Ford with Ford Pro, created its own dedicated business, Stellantis Pro One. At NTEA’s Work Truck Week in March, Stellantis also announced the creation of a North American business unit called Ram Professional to take on the light commercial vehicle leader Ford, while also competing more in the medium-duty space, where it has less than 7% market share.

“We’ve implemented changes designed to increase uptime, both in terms of how the vehicle operates and the data and insights that can be gathered,” said Ford Pro’s Kevin Lieberum, commercial truck brand manager. “For example, the Ford Pro Telematics dashboard features fleet manager and driver views to help manage service intervals.”

With enhanced digital services, customers can monitor their vehicle maintenance requirements, noted Iain Forsyth, director of product management and marketing at Mercedes-Benz Vans USA. “The ‘Mercedes me connect’ Portal serves as an entry point for activating available digital services and for commercial fleets to contact their dealers,” he said.

“Diagnosing issues is much easier with on-board diagnostics

Jeff Kommer, the new Ram Professional commercial sales SVP, said his bosses gave him one clear mission: “Go and crush Ford Motor Company, and let’s become the No. 1 LCV machine on the planet.”

As part of this plan, Ram Professional plans to spend nearly $32 billion by 2025 on electrification and associated software, unveiling the Ram ProMaster EV, which offers a targeted range of up to 162 miles in city driving. The cargo version features a 1.5 ton payload and the delivery version will have a little over 1 ton. The conventional 2024 ProMaster offers 4,680 lbs. of payload and can tow 6,910 lbs.

The 200-kw electric drive powertrain can supply 268 hp and 302 ft.-lb. of torque. The cargo model will have 159-in. wheelbases, and customers can choose 12-ft. or 13-ft. cargo lengths. Available for order now, the new van also includes driver comfort and safety features such as a heated steering wheel and heated windshield.

Technological advancements for Mercedes-Benz Sprinter vans include Parking Package with 360-degree cameras, a Digital Rear View Mirror, Blind Spot Assist including Rear Cross Traffic Alert, and an improved Active Brake Assist system, reported Iain Forsyth, director of product management and marketing at Mercedes-Benz Vans USA. The new Class 3 vans also feature the Moving-Off Information Assist with 360-degree 3D Surround View cameras.

“Our new Anti-Theft Protection Package provides comprehensive protection for the vehicle and cargo,” Forsyth said. “Additionally, digital enhancements through Mercedes me connect, such as geofencing and a vehicle locator, provide vehicle monitoring and fleet security for customers.”

The Anti-Theft Protection Package on Sprinter vans includes a Security Alarm, Interior Motion System, and Tow-Away Protection. The system is armed automatically when the radio remote control is operated, and its battery-powered horn is not accessible from outside of the vehicle and is independent of the on-board power supply.

At General Motors, the Chevy Express and GMC Savana are expected to be discontinued after 2025, with an electric van taking their place in 2026.

In the pickups space, GM is rolling out the Chevy Silverado EV 4WT, which the OEM says has the best range in its segment at 450 miles, with a towing capacity of 10,000 lbs. The Ford F-150 Lightning offers up to 320 miles per full charge and up to 10,000 lbs. with the Max Trailer Tow Package (for Flash and Lariat trims). The work truck version of the Silverado EV also has an estimated 600 ft.-lb. of torque and 515 hp in tow/haul mode.

and fault codes,” said Bruce Vasbinder, director, medium duty marketing at International.

“For example, an operator may choose to have one button activation for required daily vehicle checks, or fleets may elect to prohibit enabling drive unless certain conditions are met.”

Ram Professional has also rolled out the Dedicated Ram BusinessLink dealer network, which provides fleet customers with all their maintenance needs along with additional benefits to improve uptime. For example, BusinessLink customers can jump to the front of the line for diagnostics, get upfitting advice, and receive loaner vehicles to ensure work doesn’t stop when the truck is in the shop. The dealer network will provide maintenance for all makes and models, not just Stellantis vehicles.

Market leader Ford has scaled back production of the Lightning, so it’s fair fleets still want the typical gas- and diesel-powered pickups to serve as fleet work horses. As such, Ford has carried over Super Duty 2023 model year technology and powertrain updates to the manufacturer’s chassis cabs. Included are Pro Trailer Hitch Assist, Smart Hitch, and Pro Trailer Backup Assist systems, a standard PTO provision, and 7.3L V8 gas engine.

Lieberum also pointed out that the Ford Super Duty chassis cab’s standard power locks can be integrated with service body sub-compartment locks via the Vehicle Integration System 2.0, making it easier to ensure all the truck’s doors and cabinets are secure. Available as well are under-seat lockable storage on crew cabs and accessories such as the Vehicle Safe by Console Vault.

“Our customers get both physical and intelligence-based security solutions, and an intelligent layer of security with a camera to monitor the interior,” Lieberum said. “With Ford Pro Telematics services, customers can monitor their trucks for unauthorized activities like door openings.”

At Stellantis, the latest Ram 2500 pickup is offered with two exclusive rear suspensions: a five-link coil system and an air suspension system, reported Trevor Dorchies at Ram Professional.

“The Ram 3500 continues to utilize the rear Hotchkiss leaf spring system or can be specified with a supplemental air suspension system,” he said.

High-resolution backup cameras with dynamic grid lines now come standard to improve visibility around the vehicle, Dorchies added.

“The available digital rearview mirror displays video in real time in all driving modes from the rear-facing camera and can be turned off to revert to a traditional reflective mirror,” he explained. “The digital rearview mirror provides an unobstructed view that enhances safety and reduces downtime. Ram is also offering the Uconnect 5 with 12-in. touchscreen infotainment system that brings ease of use with the ability to integrate your cell phone.”

Brian Tabel, assistant VP of at Isuzu, reported that for the 2025 model year the company is offering a new Class 5 N-Series NRR EV with a completely new cab. The N-Series Diesel will also share some features with the EV.

The new Isuzu models feature ADAS enhancements (standard on the EV and optional on the diesel) that include:

Ü Distance Alert System when a vehicle ahead is within a certain range

Ü Forward Vehicle Start Notification when a vehicle ahead has moved

Ü Mis-Acceleration Mitigation that restricts engine output when an object in front is detected and the accelerator is depressed more than necessary

Ü Full-Range Adaptive Cruise Control that operates until the vehicle stops

Ü Lane Departure Warning System when the vehicle approaches a lane boundary

Ü Advanced Emergency Braking System that notifies the driver with visual and audible alerts and, if necessary, automatically applies braking force to reduce speed

For added security, reported Isuzu’s Tabel, the new Isuzu EV comes with standard keyless entry and starting if the driver has a key fob. Additionally, both the EV and the manufacturer’s diesel trucks have an electrical architecture that powers all safety and vehicle systems along with providing cybersecurity features. There are also a series of exterior design updates to

Manufacturers are also working to make their work trucks more upfitter friendly. Among their offerings are detailed documentation and dedicated teams of experts who work with customers, upfitters, and body and equipment suppliers to ensure proper fit and function.

“Our chassis are designed to be easily integrated by having standard electrical connections, which eliminate the need for cab and wire cutting during the upfit process by leveraging a plug-and-play electrical architecture,” said Johannes Kuhn, vocational and medium-duty product marketing manager, Freightliner. “The M2 106 Plus also has clear back-of-cab packaging to allow the seamless integration of any body. By rerouting aftertreatment systems, batteries, and other components, we can avoid interference or complications for upfitters during the installation process.”

“We work with body integrators to enhance integrations and safety via our Diamond Logic Electrical System,” said Bruce Vasbinder, director, of MD marketing at International. “Customizing includes specifying one of several dozen factory features or creating custom logic to meet each customer’s needs. Our application engineering department also maintains chassis layouts, body builder manuals, and other documentation.”

Vasbinder also pointed out that International has expanded body builder integration capabilities on its eMV electric model with integrated features like ePTO and ePower, which enable a body builder to utilize the batteries to power refrigeration, mobile shredders, bucket trucks, and other applications.

“Battery electric vehicles in general provide unique challenges

for body integrators,” Vasbinder added. “They must learn how to integrate a body safely and effectively on a BEV chassis. That includes lock out/tag out procedures, mounting around new electrical components, and new ways to power bodies which have been traditionally powered by a conventional PTO.”

At Mercedes-Benz Vans USA, the eXpertUpfitter program grants highly qualified upfitters access to 3D engineering data, technical updates, and detailed technical seminars. Additionally, users gain access to VIP technical support services.

Specific benefits for eXpertUpfitters from the manufacturer include:

A Delayed Start Warranty for a maximum of 24 months from the vehicle production date to allow for the upfit build time.

Opting into a Ship-To program that allows vehicles to be delivered directly to their facility.

Priority Technical Support for access to technical information, including 3D CAD data and vehicle specifications.

“We’ve prioritized the ways our customers need to customize their vehicles,” said Ford Pro’s Kevin Lieberum. “We have a dedicated team, and our Body Builder Advisory Service, which actively works with customers on installing equipment or modifying our trucks for the work they need to do.

“That team’s work to get solutions into vehicles also lets us see how we can benefit future model years,” Lieberum added.

“In addition, we maintain partnerships with many major upfitters, and we solicit their feedback to make sure we build vehicles with our commercial customers’ needs in mind.”

» The Isuzu NRR Diesel (pictured) and EV feature enhanced safety features such as Mis-Acceleration Mitigation to slow the vehicle down when an object ahead is too close.

Isuzu

electric

and the addition of LED headlamps, and the front bumper now has a headlamp washer. The interior design includes an updated dash and storage area, auto headlamps, new windshield wiper functions, and updated HVAC controls. The trucks also have a redesigned steering wheel, an instrument panel meter, a multi-information display, and driver and front outboard passenger airbags.

For the Mack MD Series Class 6 model, noted Tim Wrinkle, senior product manager for vocational and medium duty, an Allison 3000 RDS automatic was recently added to enable higher GCWR ratings. The transmission also provides a live Power Takeoff so the vehicle can move and use the PTO at the same time

“We added LED headlights that should last longer than halogen lights as an option on the Mack MD Series,” Wrinkle added. “There is also a connected GEOTAB device in every MD.”

Interior features of Peterbilt medium-duty trucks have been upgraded, too. Included are dual RP 1226 connectors for easier installation of aftermarket components, switch locations that are optimized for easier reach and visibility, a digital display, and an optional multi-function steering wheel to allow drivers to access information without taking their hands off the wheel.

Bendix Fusion collision mitigation is also fully integrated with the digital display in the Peterbilt models. In addition, there is a flex panel that can be configured with additional storage, SmartNav, or additional analog gauges, and a center console with USB and power plugs.

Exterior features on the OEM’s medium-duty trucks include painted and chrome bumper options, LED fog lights, halogen headlights, and a stainless-steel grille to protect the engine and cooling module. On the Model 536 a front engine PTO became available.

Freightliner’s Kuhn reported that the M2 106 Plus has undergone a major redesign where several features were modified or added to the overall structure of the vehicle. “The primary updates include an upgrade to the electrical architecture, integration of Detroit safety systems, and premium insulation to improve fit and finish,” he said.

“In early 2024, a factory-installed Backup Alert System was launched for the M2 106 Plus to provide an additional layer of safety by giving the operator more visibility to blind spots, and to eliminate the need to upfit a third-party solution,” Kuhn added.

Enhancements to the MV Series from International Trucks were related by Vasbinder. “The changes complement and improve safety,” he said.

“They include ADAS, a back-up camera, an automatically dimming full video display rearview mirror, Bendix Intellipark, an option which will automatically set the chassis air parking brake when a driver leaves the vehicle, and Bendix Wingman Fusion with improved adaptive cruise control and options for customizing various features.

“We are also incorporating customer requests,” Vasbinder continued.

Innovation is the most important factor for improved performance in new vehicle design, noted Iain Forsyth, director of product management, Mercedes-Benz Vans USA. “With innovations, we can offer customers the highest functionality, perfected ergonomics, and intelligent concepts that make everyday work as easy and as intuitive as possible,” he said.

“For the future, the focus will continue to be on innovation for a seamless user experience and simple and efficient processes,” Forsyth added. “In this way, customers will have new opportunities to improve the performance of their businesses.”

For 2024, Bollinger Motors is preparing to launch its all-electric Class 4 B4 truck. “The core element of the B4 is a custom chassis that has been engineered and built for Classes 4-6 EV truck applications,” said Jim Connelly, chief revenue officer. “For example, it is 40 inches wide versus the traditional 34 inches to allow the batteries and all componentry to be housed between the frame rails for a safer and more stable platform.”

Connelly also noted that the Bollinger B4 has flat frame rails, making it easier for upfitters to attach products with limited or no modifications. In addition, with low, centered batteries and components, the truck has enhanced driving dynamics, and the placement creates an environment for easier maintenance.

“For example, heated LED headlamps are needed in environments where ice and snow pack the headlamp surface. We also created an option to omit the rear window for applications like work trucks, and ambulance, fire, and rescue vehicles.” For related content go to FleetMaintenance.com/equipment

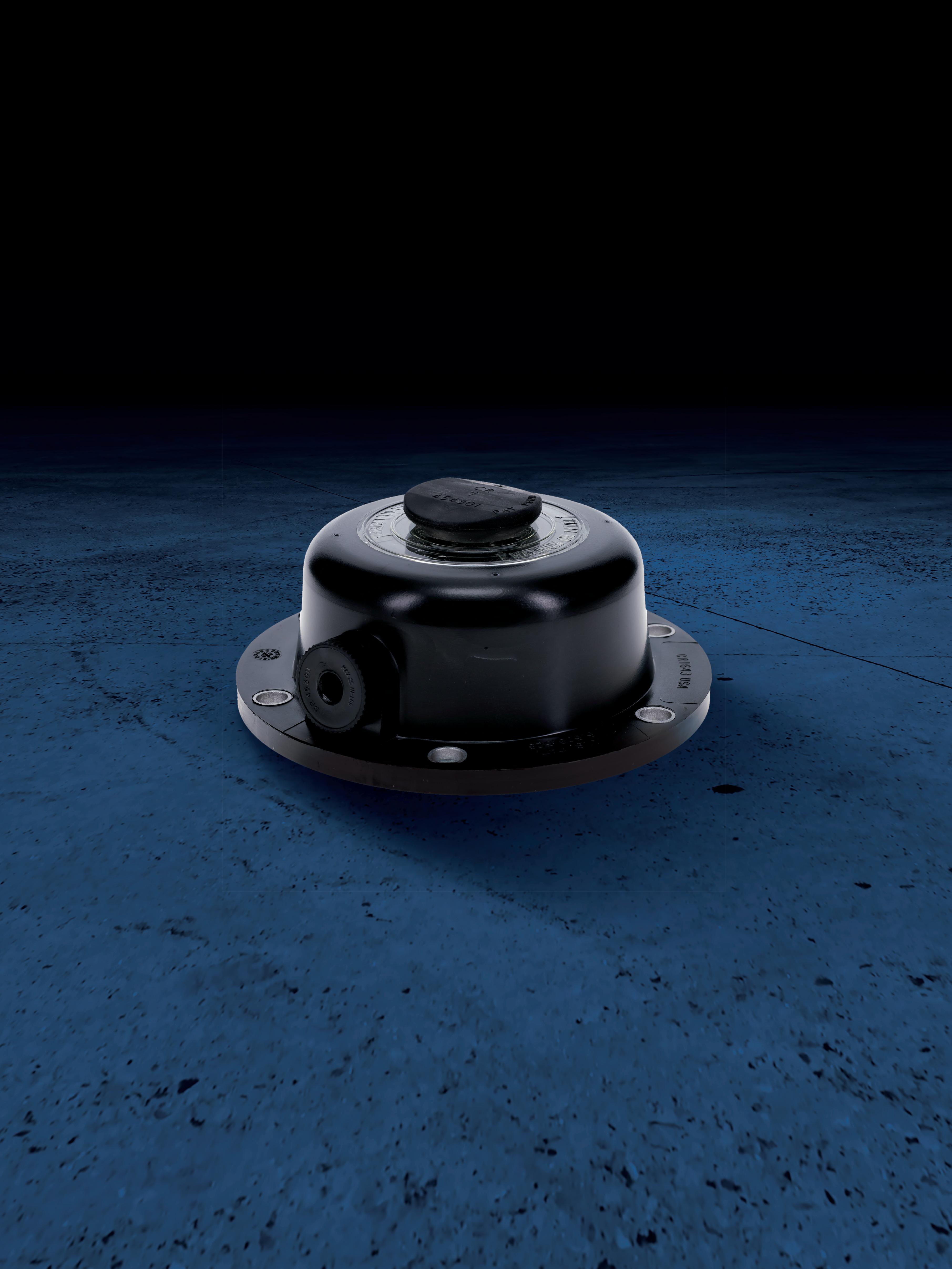

For over a hundred years, SKF has been at the forefront of innovation in the industry. Our commitment to quality and precision has earned us the trust of customers worldwide. With the Oil Fill Hubcap 1643 , SKF continues to push the boundaries of excellence, providing OE vehicle manufacturers and customers with cutting-edge solutions that redefine industry standards and ensures reliability.

For technical support and insights, visit: https://vehicleaftermarket.skf.com/us/en or scan the QR code to know more about the SKF products.

Transmission troubles are a quick ticket to unwanted downtime, but is the transmission even the issue? We had some experts discuss their tips for improving the troubleshooting process as vehicle powertrains continue to evolve.By Lucas Roberto

As transmissions have become more electronically entangled with the engine, fleets have reaped several rewards in terms of performance and efficiency. But with more ECUs come more diagnostic trouble codes.

According to Gary Pfister, Eaton’s N.A. technical services manager, the Eaton Cummins Endurant transmission can produce in excess of 300 fault code variations. “In our older products, we had maybe 75 fault codes,” he said.

Understanding what these mean, and if and how these faults can impact the truck, are critical to keeping performance at a maximum and unplanned downtime to a minimum.

For instance, with the Endurant, a fault code in the 100 series indicates a problem in the chassis, such as a wiring or air issue, while a 200 or 300 series “is more than likely something on our side of the world that we need to address,” Pfister explained.

Addressing those hasn’t been easy, though.

“There’s a number of uphill battles, especially with the newer technologies,” Pfister noted. The last decade has been more difficult in terms of transmissions, as the industry has “leapfrogged technology.”

“And we’re still catching up; we’re learning every day,” Pfister said.

To help maintenance teams catch up and ensure that transmission issues can be detected and resolved in a timely manner, we caught up with some transmission experts who offered several tips to improve the troubleshooting process.

When it comes to unexpected transmission issues, a few are more common than others.

The number-one transmission problem is electrical, Pfister relayed. “It can be a number of things—anything from OEM chassis wiring, to a bad component, to routing of wires, things of that nature.”

Electrical issues require meticulous troubleshooting and diagnosing, or a technician runs the risk of overlooking the root cause of a problem that could be causing multiple fault codes. And with modern powertrains becoming increasingly interconnected, tiptoeing around electrical problems is not an option.

Pfister mentioned that another common problem is with the air system. Some newer transmis-

sions have a pneumatically operated mechatronic transmission module on them, which combines the sensors and solenoids into a single unit to reduce the size of the transmission without sacrificing efficiency.

“Those are much more sensitive, because a mechatronic module uses solenoids and spool valves to select the gears,” he said. “If you get contamination, then that module can stick those spool valves, so now you get an issue where the truck won’t shift.”

A whole host of other transmission problems can come as a result of incorrect maintenance practices. For example, using incorrect fluid or non-genuine parts during maintenance can lead to poor performance and durability in the long term, said Greg King, head of North American Transmission Service at ZF Group.

“The components used in the transmission are designed to specific tolerances and of precise material specification,” King said, “so the use of non-genuine replacement parts might not match the materials and specifications of original OEM components, resulting in reduced performance and product life.”

This sentiment is echoed by Gary Burns, Allison Transmission’s director of customer support and channel development for North America. He emphasized that proper maintenance practices include not only “the use of proper fluid and filters but also maintaining driveline and other powertrain components in accordance with vehicle manufacturer guidelines.”

• Gather complete details of the incident from the driver, including any external factors that could have impacted vehicle performance.

Conduct a visual inspection of the transmission and surrounding components, and test drive to replicate the problem if possible.

Connect the OEM recommended diagnostic tool to read fault codes.

• Verify fault codes or reported issues (i.e., vibrations) do not originate from another system or component in the driveline or elsewhere.

Conduct the repair as per OEM guidelines, using OEM recommended replacement parts and taking care not to skip any steps of the process.

While straying from OEM recommendations to purchase aftermarket and off-brand parts can seem like an easy way to save a few dollars here and there, cutting corners never pays off when it comes to the long-term health of your fleet.

“Modern commercial vehicle transmissions are equipped with mechatronics, transmission control units, and sensors which can identify when there is an issue in the transmission that requires maintenance or when performance is not optimal,” King explained

When a fault is detected due to these situations, the check-light on the dash alerts the driver that intervention may be required. Pfister notes that while every OEM has these dash indicators, what trips them could vary.

And beware taking DTCs at face value when they roll into the shop. It’s also crucial for technicians to distinguish between a DTC generated by a transmission issue and similar-looking malfunctions from a different system.

“It is not always obvious to the vehicle operator,” King explained. “For instance, with modern electronics that communicate over a vehicle network, errors in that communication can appear to be a transmission fault but are elsewhere in the vehicle.”

This piece of the puzzle was also pointed out by Joe Scarnecchia, powertrain sales manager for Mack Trucks. He said “the first thing to remember is that the issue may not be mechanical. It could be an electronic, programming, or software issue.”

This highlights the importance of careful troubleshooting, especially if the only indication of an issue is a dash light instead of a noticeable drop in powertrain performance. Beginning a repair on the transmission itself would be a waste of time and resources if the root cause is actually just an error in the vehicle’s electronic network.

King offered an example: “Many vehicles have inclinometers to know if the vehicle is climbing or descending a hill. The engine and transmission use that information to adjust operating parameters that affect performance,” he continued. “If that sensor is faulty for any reason, it impacts the powertrain performance and could easily cause misleading faults in the other components.”

Identifying transmission problems versus issues with other parts of the drivetrain isn’t

always so straightforward either, said Alex Reid, vocational marketing manager at Kenworth.

“Mechanical damage to other components of the powertrain may create similar symptoms that require further investigation,” he said, but “shift issues are usually obvious.”

Scarnecchia noted that an indicator like noise coming from the transmission would usually be a sign of an internal problem, but something like vibration, for example, could be more ambiguous. This could be indicative of a problem relating to the transmission, driveline, or rear axle.

Allison’s Burns similarly explained that “an impending transmission issue may be indicated by a noticeable difference in operation, such as ‘slipping,’” among other items, but that an issue that initially seems like a transmission malfunction can actually stem from poor maintenance, “which can result in lack of lubrication, cooling issues, or torsional activity,” he said.

Knowing that transmission issues can manifest in different ways, the first step a technician should take before the customer even leaves the shop is to gather as much information as possible regarding the problem, along with any external factors that could have had an impact on the vehicle’s performance.

You want “complete details of the incident,” ZF’s King explained, “including noises heard, vehicle reactions, driving conditions, route conditions, smells, etc.”

Featuring a new grille that’s more aerodynamic, an all-new headlamp assembly, LED lighting inside and out, steering wheel mounted controls, a new 7-inch color Multi-Information Display, electronic climate control, a driver’s seat equipped with an armrest, a new bumper design that reduces repair costs, and the convenience of four cupholders, plus much more.

See your authorized Isuzu dealer for more information.

Even things that may seem inconsequential can impact the performance of transmission components and might be relevant information for a tech to find out before beginning troubleshooting. For example, driving in extreme weather conditions, temperatures, elevations, or terrains can put additional stress on transmission components, leading to malfunctions or accelerated wear that wouldn’t have occurred otherwise.

Technicians should also inquire about the specifics of when the driver noticed a problem, as that could impact the severity or cause of the issue.

Burns explained that “it’s helpful for the driver to note specific operating conditions, including if the vehicle is loaded or unloaded, operating at full throttle or part throttle, if the vehicle is at the beginning of the drive cycle or after some amount of drivetime, traveling at high speed or low speed, etc.”

Scarnecchia also mentioned that it’s important to inquire about any work that may have been done on the truck before the issue started.

Knowing that there’s a long list of potential factors that can contribute to a transmission problem means that any detective work a tech can do before the customer leaves the shop is going to help them locate the problem once they get handson with the vehicle. Including a standard set of questions or a checklist in the intake process is a great way to ensure that techs are getting as much relevant information as possible before troubleshooting.

“ Every product has a diagnostic tool associated with it. Learn it, understand how that tool works ...That tool can be your friend or your foe. ”

Gary Pfister, Eaton’s N.A. technical services manager

When the customer leaves the shop, that’s when the real work begins. Before actively troubleshooting a transmission, most would suggest doing your research. Pfister said that understanding what you’re working with is half the battle, so if you’re not positive, take a moment to figure it out. He suggested taking advantage of online material, like the manufacturer website, among other options.

“Every product has a diagnostic tool associated with it. Learn it, understand how that tool works,” he said. “That tool can be your friend or your foe, so it’s really important for the technician to understand what tools [are in their] toolbox.”

In discussing Allison’s troubleshooting processes, Burns stressed that adhering to OEM recommendations is always the best course of action.

“A lot of time and effort is poured into the development and refinement of Allison’s troubleshooting processes,” he said. “Avoid skipping steps in the process or making assumptions. This can cause you to miss key details or clues that will help identify an issue.”

A basic understanding of the transmission you’re working with and any brand specifics is a good place to start, and checking the transmission controller for any fault codes is the next logical step, according to Reid.

“The brand of the transmission will determine which specific tool to use, but the process is the same,” he explained.

» The Eaton Cummins Endurant can have more than 300 different fault code variations.

“An external visual inspection of the transmission system and surrounding components may also provide useful diagnostic information.”

King seconded this step, stating that the “OEM diagnostic tool must be connected to read trouble codes and enable the use of the OEM troubleshooting trees.”

He also mentioned that if the vehicle is drivable, a test drive is necessary to try to replicate the issue. This can allow an experienced tech to better understand what’s happening and where to start when it comes to identifying the root cause.

King concluded by highlighting the importance of taking it slow when it comes to the troubleshooting process. “Modern electronic systems are very complex, and while they expedite troubleshooting, they can also create complex errors in the vehicle systems,” he said. “The previous inclinometer example illustrates how complexity can impact engines and transmissions; there are many sensors in the vehicle the technicians must keep in mind during the troubleshooting process.”

Ongoing training is going to be a key aspect in ensuring that techs are informed and able to handle whatever comes through the bay doors, especially considering the technological evolution set to come in the following years. The complexity of modern electric systems is already an obstacle for newer techs, and it seems as though fleet vehicles, equipment, and the tools used to service them will only get more convoluted as impending emissions regulations mandate new fuel types, and the corresponding technology advances to accommodate them.

Many newer transmissions may also offer “different drive modes that will give you a selection of engine torque and how the transmission shifts. These different options may affect how the engine and transmission performs,” Mack’s Scarnecchia explained. “Make sure to review the chassis specs, features, and options. The bottom

line is to make sure that you actually have an issue before going into in-depth troubleshooting, because the engine and transmission may be working as they were engineered.”

Not all transmission problems can be prevented ahead of time, as is the nature of unexpected issues, but there are some steps that can be taken to protect your fleet.

For fleet managers, encouraging and enforcing good driving habits and behaviors can go a long way toward keeping your vehicles’ transmission components in better shape for a longer period of time.

King discussed the importance of driver education and training to prevent component abuse, highlighting reckless driving, off-highway use with an on-highway application, and exceeding the vehicle load capacity as some specific practices that can negatively impact transmission health (not to mention fuel efficiency).

Manual transmissions are especially susceptible to “issues from abusive operation, and see a larger variation from driver to driver,” according to Reid. The skill level of the operator when it comes to shifting, and the precision required to do so, can leave a much larger window for things to go wrong than with automatic or even AMTs.

Staying on top of OEM recommended maintenance practices and scheduling periodic inspections can also be instrumental in warding off potential issues, or discovering them before they take your truck out of commission.

Reid explained that on the driver side, it’s crucial to know how your vehicle is supposed to behave and what phenomena could indicate a problem.

“Some transmission behavior is intentional for performance or fuel economy reasons,” he said, offering neutral coast as an example. “Read and understand the operator information to stay up to date on what is normal and what isn’t.”

All this being said, it’s evident that the best way to avoid the majority of transmission issues and the unplanned downtime that comes with them is a collaborative effort between fleets, OEMs, and techs.

Troubleshooting specifics and best practices will undoubtedly continue to evolve with transmission technology in the years to come, but the basics remain. Take your time, know what tools you have at your disposal, and consider all the possibilities that could be at the root of transmission problems.

Pfister concluded with one main piece of advice for technicians: “Get to know the prod-

uct.” Troubleshooting guides, driver’s guides, and service manuals are all out there and at a technician’s disposal. “You’ve got to want to read it and understand it,” he said. “If you want to move forward with whatever you’re doing, you have to be educated about it before you do it.”

For related content go to FleetMaintenance.com/in-the-bay

AT GRAY MANUFACTURING, WE DON’T JUST BUILD JACKS AND TRUCK LIFTS, we build solutions that equip you for more efficient repairs and maintenance. From the exceptional quality of our products to our focus on assisting customers after the sale, every part of our business is designed to serve you. That’s what makes Gray Manufacturing products the best in the industry.

You might find that you pay a little more for our products, but they’re safe, dependable and long-lasting. Is it worth it? Our customers say it is.

We have several Gray Products. When making purchasing decisions, I pay close attention to service life versus cost. I can’t figure replacement cost for Gray because, for over ten years, I haven’t replaced anything.”

- Ryan K.

Gray Manufacturing is the only truck lift system I truly considered. The customer service is second to none, and the quality of their products is what you would expect from a U.S. manufacturer!”

- Mike D.

Whether you’re building, renovating, or moving into a di erent facility, success comes down to proper planning, proven partners, and a concept built around both e ciency and technician morale.

By Gregg WartgowFACILITIES ]

When Austin White and his partners decided to buy a heavy-duty repair shop in 2019, they wanted to put a modern spin on things and grow the business. A er purchasing a truck and trailer repair shop called JECO in Denver, ownership rehabbed how personnel were managed. ey started an apprentice program, hired a full-time trainer, and installed technician incentives. en they worked on branding, changing the shop name to Iron Bu alo Truck & Trailer Repair.

With their initial mission accomplished, a new problem emerged. ose successful changes led to more business, and Iron Bu alo had outgrown its space. is is a good problem to have, but one that needs solving nonetheless. With the transportation industry in a historic time of change, where the needs of both vehicles and technicians will be very di erent in the next decade versus the previous one, shops’ plans for expanding or refreshing existing facilities and adding new ones also need to be reevaluated.

» Pitt Ohio recently refreshed its Baltimore shop with LED lighting and a brighter paint job, as well as improving the break area.

» Pitt Ohio recently refreshed its Baltimore shop with LED lighting and a brighter paint job, as well as improving the break area.

Iron Bu alo intended to fi nd a property they could get a decent deal on and purchase. Unfortunately, the hot commercial real estate market around Denver was making that rather difficult. Eventually, White found a suitable building the repairer could lease. Operations moved into that building late last year, e ectively doubling their square footage to 40,000.

While that expansion was coming together, the opportunity to open a second shop came about. White’s general manager in Denver had informed him she was moving roughly 1,000 miles away to Kalispell, Montana—and would have to resign. White had a di erent idea.

“I did some research and discovered that Kalispell was a much smaller market, but also an underserved market,” White said. “So I asked our general manager if she would be interested in helping us open a shop there. She agreed. We started o just doing mobile repairs to help get our name out. I think it’s going to work out pretty well.”

White said in just a few months, the new shop surpassed its eight-month goal.

“Now we’re moving into a brand-new building that we’ll also be leasing,” he said. “We’re excited about the potential up there.”

Iron Bu alo’s expansion into Montana happened somewhat unexpectedly. It also came together rather seamlessly. Switching locations in Denver took a little more work, but White said he learned some valuable lessons about leasing property.

“Make sure you do your own homework,” White said. is is particularly important when dealing with an absentee landlord. “I never thought we’d have to help a building owner navigate local build-

ing codes. But some of these investment fi rms are so big and own so many properties that they just don’t know sometimes.”

Shortly before the lease papers were signed, the building owner told White he wouldn’t be able to store hazardous materials on site. is puzzled White because the previous tenant had also operated a repair shop. He immediately got in touch with local zoning o cials to explain what he was looking to do with the building. “ ankfully, everything turned out to be fi ne,” White said.

Recognizing this red tape red flag, White proactively scheduled a meeting with the water department to make sure nothing was being missed there. It’s a good thing he did.

“We found out we needed secondary containment on every bulk fluid in the building,” White said. “It sounded scary at fi rst. But once we sat down with the water department o cials to see how we could go about doing this, we realized they were more than willing to help us.”

Ironing things out with local zoning o cials can be an even bigger undertaking when building a new shop from the ground up. “Getting all the necessary permits and approvals can take longer than building the actual building,” said Joe Gonzales, president and co-owner of Guzman Automotive, an automotive service company that provides fleet services for vehicles up to Class 6.

Guzman Automotive’s fl agship location in Taylor, Texas, was built less than a year ago.

“When it comes to planning and zoning red tape, it’s best to let the professionals handle it,” Gonzales said in reference to working with an experienced builder, with emphasis on the word experienced.

“ ey do this kind of thing all the time and know just what to do.”

Inspired by the success they’ve had in Taylor, Guzman Automotive is now looking to build two

A Pyle-ized shop features a white ceiling and walls, aside from the bottom five feet, which is a lighter gray. Iron Buffalo has also switched to white, a stark contrast from the gray and blue that covered the walls when they moved into their new Denver facility.

Pitt Ohio recently refreshed its maintenance shop in Baltimore. Along with a brighter paint job and new LED lighting, Darakos said the facilities team worked to bring in as much natural light as possible. “The feedback has been very positive,” Darakos said. “I’ve even had some technicians jokingly tell me it’s almost too bright.”

At Pitt Ohio’s Baltimore shop, the facilities team took advantage of a spacious mezzanine to put in a table and comfortable seating, along with a fridge and microwave.

Pyle’s walled-off breakrooms also include kitchenettes with a fridge, microwave, and sink area. Windows provide natural lighting.

A flat-screen TV broadcasts “Pyle TV” all day, giving technicians a chance to get caught up on maintenance bulletins and company news while they relax.

more shops over the next year or two. Gonzales is narrowing his hunt for properties based on several criteria. First, a two-acre lot would be ideal to build a sizable shop and provide ample parking for the types of vehicles they service. Secondly, Gonzales wants to pick locations where the business can thrive.

“I make it a point to speak with county and local o cials to see if a certain property we’re looking at is in a high-tra c area, or expected to become one in the future,” Gonzales said. He’s also assessing the current level of auto services in the area. One location he’s evaluating is in the midst of an industrial boom, which could lead to an opportunity to establish a shop that is more skewed toward fleet services.

To secure funding for the expansion, Gonzales reached out to a local bank. His family had previously owned another repair business that it sold for a nice profit. “We’re not using any of that cash to help with this expansion,” Gonzales pointed out. “But I am leveraging it in working with the bank. I can point to that and say, ‘Look at what we’re capable of accomplishing.’ When the bank considered that while looking at the business plan I’d created, along with the growth potential of the areas we are looking to build our new shops in, they were very supportive.”

When the time comes to build Guzman Automotive’s two new shops, they will be patterned a er the flagship location. ey’ll be built by the same contractor, too, who already understands how to bring that concept to life. Gonzales said they initially chose that builder because he had a long resume of designing and building dealership service centers.

Pitt Ohio and Pyle have both been putting in radiant heated floors. Additionally, Pyle’s shop floors are now ground smooth, as opposed to the more traditional porous concrete. A smooth floor won’t absorb chemicals and doesn’t need a sealer.

Pyle is also looking to add air conditioning to more of its shops, starting with those in southern markets. Their shop in Richmond, Virginia, which was built in 2022, is the first to have A/C.

“You’re going to start seeing more heavy-duty shops with air conditioning,” Carrano said. “A/C has been common in automotive shops for a while. It’s becoming necessary in our industry, too, in order to attract technicians with the skills needed to work on today’s heavy-duty vehicles.”

Also in response to today’s workforce realities, Darakos said Pitt Ohio has begun adding showers to bathrooms when feasible. Employees have been appreciative of this simple amenity when they have to scurry off to a personal event immediately after work.

» Remodeling a shop isn’t just to increase layout efficiency. It’s also to help recruit and retain technicians by giving them a place they want to work in.

When Guzman Automotive built its shop less than a year ago, ideas on how to make things more efficient were welcomed from everybody.

“We’d originally wanted power outlets on columns toward the back of the shop,” Gonzales said. “But after hearing from our technicians, we realized it would be more efficient to run power outlets closer to each lift. Our builder agreed and said it wouldn’t be much of an expense, either.”

Guzman Automotive’s builder also came up with the idea to place all bulk fluid tanks outside. Fluids are pneumatically pumped into the shop through labeled faucets on the wall. Gonzales said this makes it easy for technicians, and also helps with fire code compliance because flammable liquids are stored away from any welding or grinding that’s taking place in the shop.

A new consideration for repair shops is EV charging infrastructure.

“For shops that are new to EVs, they might think of EV charging as just electricity and a bunch of plugs,” said Ryan Kennedy, founder of Atom Power, a provider of EV charging hardware and software solutions. “We look at EV infrastructure like an iceberg. The plug is just the tip of that iceberg you can see. Most of that iceberg, however, is under the water.”

To that point, the EV charging hardware itself typically represents just 20% of the total EV charging construction cost, according to Kennedy. While investing in good, reliable hardware is obviously important, partnering with a good, reliable provider is even more critical.

A good provider will become heavily engaged in the planning process early on, helping a shop ensure that it has the power availability necessary to have a reliable system installed. They will also possess both the internal capabilities and external partnerships to ensure a timely, quality installation and ongoing support. This kind of holistic approach, Kennedy said, is why Atom Power has been able to achieve a 99.6% uptime rating, which is far above the national average.

Taki Darakos, VP of vehicle maintenance and fleet services at Pitt Ohio, a less-than-truckload carrier, said expansions are much easier when you have strong relationships with contractors and other partners who can help refine the concept in a practical way.

“Pitt Ohio has developed relationships with general, electrical, and construction contractors, along with appropriate engineering firm support,” Darakos said. “Over time, you come to understand how each other works and what is needed from the get-go. It’s important to develop that working rhythm.”

Pitt Ohio, which provides transportation services in 14 states throughout the Northeast, Mid-Atlantic, and Midwest, typically has multiple renovation projects underway at once. When refreshing a maintenance facility, concept creation requires coordination across several groups, including vehicle maintenance, operations, IT, safety, finance, and C-level executives.

“Everything starts with a site drawing and goes from there,” Darakos said. “Not everything makes it to the finish line, but we work together to come up with the best fit. The tight coordination is so critical that we have a weekly recap call to try and minimize anything slipping through the cracks.”

The goal of a facility refresh is to improve efficiency, as well as technician recruiting and retention.

“It’s all about work environment nowadays,” said Dan Carrano, VP of maintenance at A. Duie Pyle, an LTL carrier with 29 service centers throughout the Northeast, 23 of which have maintenance facilities. “Your shop has to be a place technicians want to go when they wake up in the morning.”

A. Duie Pyle has seen every version of the good, bad, and ugly over its 100 years in business. Now it has taken the best of the best to establish a gold standard that’s being applied to its maintenance facilities. Carrano refers to it as “Pyle-izing” shops. There is quite a bit of Pyle-izing going on these days. Pyle acquired five Yellow properties in West Virginia, Pennsylvania, and New York late last year. “Any time you take over properties from a company that has filed bankruptcy, you know they have likely been neglected,” Carrano said. Pyle’s facility maintenance department is in charge of getting the shell of a facility up to standard. Shops are professionally cleaned, repainted, and relit with LED lighting. HVAC systems are evaluated and updated as needed. Then Carrano and his maintenance team start to get involved.

“We put new air movement and oil systems in,” Carrano said. “We put in double-wall oil tanks, because we never trust existing tanks. Then we put in new tooling (i.e. lifts, jacks, alignment equipment, diagnostic tools, etc.). With those Yellow facilities we’ve acquired, we decided against bidding on the tooling because we like to go with standardized tooling across all our shops.”

Carrano has also developed some preferences to help improve the work environment. “We want a workplace that is clean and inviting,” Carrano said. “We don’t want our technicians to feel like they’re working in a cave.”

third person to work with them,” White said. “We also hired four temporary employees through a labor agency.”

“ With those Yellow facilities we’ve acquired, we decided against bidding on the tooling because we like to go with standardized tooling across all our shops. ”

Dan Carrano, VP of maintenance, A. Duie Pyle

Something that can’t be overlooked when moving into a new facility is the logistical coordination of the move. It was quite the undertaking when Iron Buffalo switched Denver facilities over a weekend. The biggest key to pulling it off was establishing a point person.

“We had our general manager take over some of our service manager’s responsibilities so our service manager could completely focus on the coordination of our move,” White said. A second employee was assigned to function as the point person’s assistant. “Then we hired a

The point person planned what would happen each day of the move. The “moving team” was then responsible for loading trucks with equipment, parts, uniforms, and supplies to get it over to the new building. A specific time was arranged to transfer the technicians’ personal toolboxes, and each technician was responsible for loading and unloading (with assistance) their own toolbox.

A lot of prep work took place in the weeks leading up to the move. The shop interior got a brighter paint job. New office furniture purchased from an auction house was put in place. New shelving was installed and labeled. A week before the move, White had one of his technicians set up the lube system.

When the time came to actually move, White planned for a downtick in shop production and prepared his fleet customers accordingly. He said everyone was very understanding and, in most cases, very supportive. One customer even lent White four of their trailers.

After that brief production disruption, Iron Buffalo’s Denver team has been feeling the positive effects of the new facility and additional workspace. Now, the team in Kalispell is getting ready to start feeling those same positive effects in their new facility. It’s a considerably smaller shop, but it’s also a considerably smaller market. Regardless, the goals and expectations are the same.

“If you take good care of your technicians and help them become more efficient, they’ll take care of you,” White said.

For related content go to FleetMaintenance. com/shop-operations

18,000 LBS. CAPACITY PER COLUMN

BendPak is the name that fleet operators rely on because they’re the toughest lifts on earth. And nowhere is that strength more impressive than on our PCL-18B series portable column lifts. With a lifting capacity of 18,000 pounds for each column and paired configurations ready to accommodate from two, three, & four axle positions, the PCL-18B is ready to service trucks as heavy as 144,000 pounds. From charter buses and fire engines, to agricultural vehicles and utility trucks, BendPaks’ portable column lifts deliver mammoth lifting capability, right to where your heavy work is. To learn more or to shop now, visit bendpak.com or call us at 1-800-253-2363.

Even seemingly minor issues in the brake system can have a big impact on uptime. During 2023’s International Roadcheck, an annual safety and enforcement initiative held by the Commercial Vehicle Safety Alliance (CVSA), more than 4,400 OOS violations were issued due to brakes in North America. It was the top vehicle system o ender during the inspection period, with 25% of OOS violations.

is year CVSA announced that brakes will be under even more scrutiny, with missing camsha bushings added to the 20% criteria for drum and air brakes, increasing the likelihood of a brake OOS violation. Undermaintained automatic slack adjusters were one of the potential OOS indicators that Bendix Commercial Vehicle Systems warned against. “You can spot adjustment issues if you notice slack adjusters that are extended at di erent angles on the same axle,” said Mark Holley, Bendix director of marketing and customer solutions, Wheel-End.

In the U.S., out-of-adjustment brakes and defective automatic slack adjusters were the two most common brake violations, with 5,727 violations and 3,475 violations, respectively. “If you have two brakes out of adjustment on a tractor-trailer total, they won’t let you go,” said Kevin Pfost, product specialist at Bendix. “Your truck is now out of service.”

No one wants that, nor do they want trucks with anything other than perfectly operating brake systems, so here’s a quick guide to tighten up your slack adjuster maintenance.

Slack adjusters actuate a vehicle’s brakes by turning the lateral movement of the pushrod from the air chamber into torque that turns the camsha , which in turn pushes the brake shoes outward against the brake drum to slow the truck. As brake shoes wear out, slack adjusters also compensate for the wear by adjusting the brake stroke, or distance between the shoe and the drum, to stay within regulation.

Older vehicles might still have manual slack adjusters, which perform the same function but require manual adjustment for optimal brake performance. However, they’re less common now. Most modern trucks with air brakes are equipped with ASAs, as they reduce the need for manual adjustments by maintaining the distance between the brake drum and lining, said Gerry Mead, maintenance consultant and former fleet executive.

Drivers can experience uneven braking if a slack adjuster isn’t adjusting enough, whether manual or automatic. But overadjusted ASAs leads to dragging brakes, which Bendix noted can lead to a 1.5% increase in fuel consumption.

Fleets with dragging brakes “have premature wear” and “they’re using up fuel,” Mead noted. “ ey’re just not getting the life out of their brake system.”

And, of course, there’s always the DOT to consider.

“If the adjuster is not operating properly, it may not be self-adjusting, so now your brake will be out of adjustment, and that’s when the DOT will give you a ticket,” Pfost noted. And these tickets can range from $500-$1,848 per count, plus a $500 administration fee.

Drivers may be the fi rst to realize that there’s an issue with a brake, particularly if they experience a ‘so brake’ or ‘brake fade,’ noted Chris Christiansen, warranty and technical services coordinator at Accuride. Encouraging them to log lagging brake performance on their driver vehicle inspection reports is a great way to detect potential adjustment issues.

Technicians should also check for symptoms of brake drag, Mead said. Check for cracked shoes, discolored or cracked drums, and ensure the wheel turns freely.

Photo: Bendix Commercial Vehicle Systems » Make sure the boot is properly seated at the top and bottom and is not loose. This boot is incorrectly seated at the top. » Wipe off the grease valve in the adjuster boot before you purge. Old grease will come out of the valve, ensuring the adjuster is greased. Photos: Bendix Commercial Vehicle Systems » Tap the brake drum to ensure the lining is against the drum (you’re looking for a dull clang, not a ringing sound), and measure how far your mark has traveled. Photos: Point Spring & Driveshaft » To check brake stroke, fill your air reservoir to 90-100 psi, mark your pushrod where it exits the chamber, and apply the brake. 1. 2.If that’s the case, the Bendix Service Guide recommends checking that the ASA can move freely when fully released, as well as inspecting the yoke/clevis and link pins.

“If they’re not paying attention or maintaining it properly, the hole where the pin goes through [the clevis] will get bigger,” Pfost warned. “Now you’ve got the movement of the clevis but not the slack adjuster.”

e pushrod jam nut should also be tight against the yoke adapter, and techs should check the boot for damage. Make sure the pushrod is not bent, broken, or loose, and sits at a 90-degree angle with the camsha , said Mike Gerrick, former heavy-duty fleet training specialist at Point Spring & Drive Sha , a heavy-duty parts and service supplier.

Greasing the ASA is also key, with Accuride’s Christiansen recommending techs grease the adjuster every six months or 50,000 miles. Make sure the new grease is compatible with the manufacturers, or you can risk wearing out the clutch teeth and other internal components of the ASA.

“Be sure to use greases that are compatible with the manufacturers’, otherwise it may have a negative impact on the internal components,” Christiansen noted.

If there’s a problem with the ASA, do not manually adjust it. Each maintenance expert and the CVSA a rmed that techs should only adjust the ASA at installation or when replacing the brake pad lining.

“Every time you adjust the brake and back [the adjuster] o , there are clutches that keep it from backing o on its own,” Bendix’s Pfost explained. “If you’re adjusting the brake once a month, you could damage the slack adjuster.”

Instead, begin your troubleshooting with a free stroke check, Mead advised. Free stroke is the clearance between the shoe and the drum when the brakes are at rest. To fi nd the free stroke, adjust the shoes so that they touch the drum, then back up the adjuster by turning the adjuster hex one full revolution counterclockwise. Without the brakes engaged, use a pry bar to pull the pushrod out and measure how far the actuator travels, specifically between the chamber face and the center of the large pin.

Generally, the free stroke should be between 3/8-5/8”, but Mead explained that this value is o en di erent from OEM to OEM.

Next, check the brake stroke. e brake stroke is the amount the pushrod moves when the ASA is activated. Depending on your brake chamber size, the pushrod’s required maximum stroke will vary. If the push stroke exceeds this requirement, your vehicle will be put out of service.

Perform an ASA function test to make sure the internal mechanisms are working. First, back the adjuster up a half turn with a wrench. If you feel no resistance or hear a grinding noise when backing up the adjuster, that’s an indication that the ASA is bad, Mead cautioned.

Now leave the wrench on the hex or mark a line on the nut and on the body of the slack adjuster, and cycle the brake pedal a few times at about 30 psi, which should cause the wrench or mark on the nut to turn clockwise as the ASA moves the shoes back toward the drum.

If the ASA passes the function test but does not meet the stroke limit, check the foundation brake for worn cam bushings, and make sure the clevis and clevis pins are not seizing or broken.

To avoid mistakes when installing slack adjusters, techs must verify if they’re working with a vehicle that has a clevis welded to the pushrod (the adjuster won’t come with a clevis) or not. Accuride’s Christiansen also noted that techs should always follow OEM installation instructions. Don’t skip installation steps or try to reuse old ASA components with the new one.

“[Techs] want to leave the old clevis on, so they just remove the body of the adjuster. en they take the new clevis o of the one that they just purchased, which is throwing money away in my opinion,” Christiansen argued. He also noted that techs shouldn’t use any impact on the adjusting hex, such as an air gun, because it could damage the clutch internally. Use a 7/16” socket wrench long enough to turn the adjuster hex counterclockwise.

To adjust the ASA a er installation, rotate the adjustment hex clockwise until the lining is against the drum. De-adjust the brake by rotating the hex one-half to one revolution counterclockwise, listening for the normal ratcheting noise.

» Remove the original ASA and clevis. Do not remove the jam nut. Make sure the clevis style is appropriate, then apply antiseize to the chamber pushrod threads and camshaft splines.

» Push the collar nut against the jam nut on the brake pushrod, then add the hex nut.

» Install the slack on the camshaft using the original mounting hardware. Use at least one inner washer. Use washers on the outside of the slack too, with room for the snap ring on the camshaft.

» With a 7/16” wrench, adjust the slack so the collar nut aligns with the clevis. Before connecting, make sure the pushrod is engaged with the hex nut.

» Thread the collar nut onto the clevis, insert clevis pins, and use a template to ensure the pins align with the center of the camshaft. Tighten the collar nut to the clevis, and the jam nut against the collar nut.

» Perform the initial brake adjustment. Double-check the free stroke and stroke length for CVSA regulations.

1. 4. 2. 5. 3. 6.

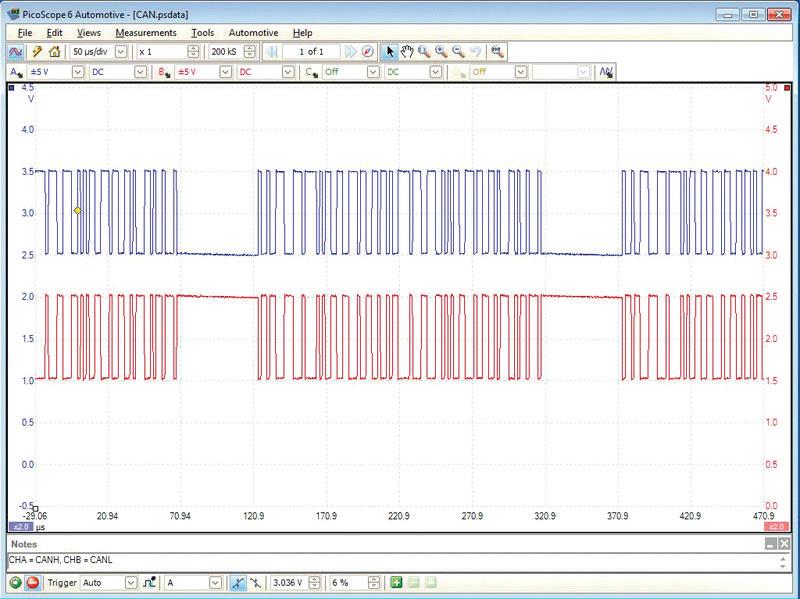

An oscilloscope can see certain things a scan tool can’t, making it a valuable addition to a fleet’s diagnostic toolbox.By Gregg Wartgow

There is no substitute for a great diagnostic scan tool, but an oscilloscope can be a great complement, helping pinpoint the root causes of issues a scan tool merely alerts you to. In some cases, an o-scope will help discover failures a scan tool can’t even see.

Automotive oscilloscopes read voltage over time, something multimeters can’t do, making them powerful tools to test electrical system components for intermittent issues. ey can also perform pressure tests and other diagnostic checks. ese devices read and convert voltage data into a waveform presented on a screen as well, enabling technicians to look for irregularities that suggest a likely problem.

“An oscilloscope is really just a fast volt meter,” explained Mike Eilbracht, a diesel training instructor at Diesel Laptops, a provider of diag-

» Hickock Waekon’s Auto Wave II is more of an entry-level oscilloscope. It’s a standalone handheld unit offering two channels, which keeps things simple for inexperienced techs. That said, two channels are all techs need to perform common waveform diagnostic tests like cam and crank and to simultaneously view high- and lowspeed CAN protocols to verify communication.

Hickock Waekonnostic tools, repair and parts information, and technician training and support. “I guess you could say it’s a voltmeter on roids.”

Eilbracht noted that while these diagnostic tools have many benefits, learning how to use them takes patience.

“Whenever I talk to a technician who is new to oscilloscopes, I remind them that they will need to invest some time in order to get really good at it,” he said. “But I also remind them that they should not be intimidated.”

ere are several types of oscilloscopes out there, each o ering something di erent to the user. Some are standalone handheld units. Others are scan tool add-ons or devices that connect directly to computers. ey may have just one or two channels, or sometimes eight or more. Prices range from several hundred dollars to several thousand.

You’ll get what you pay for, of course, although that doesn’t mean a lower-cost scope would be a bad investment. ROI largely comes down to what you’re looking to do with a scope, as well as the experience level of the technicians who’ll be using it.

“You could always start with a more basic scope, and then go to a bigger system once your skills and knowledge further develop,” said Tom Bauman, director of sales, marketing, and new product development at Hickock Waekon, a manufacturer of oscilloscopes and other diagnostic tools for automotive and midsize truck technicians. It also depends on what type of vehicles are being serviced in the shop.

“I believe a fleet would want at least four channels so technicians could test four circuits at once,” said John Forro, technical training specialist at Autel, a developer of intelligent diagnostics, detection, and analysis systems for automotive and commercial vehicles. “Four channels are o en needed when determining timing-related signals and many other issues.”

Whichever scope a shop goes with, training and support are key.

“Hooking up the scope to the vehicle is the easier part,” said Travis McDonald, service manager at Diesel & O Road Technologies in Soddy-Daisy, Tennessee. “Seeing and understanding what the waveforms actually mean is more challenging.” at said, a good oscilloscope provider will provide training resources for both.

Good oscilloscope providers have also developed product features that make scope diagnostics easier for technicians to perform.

For example, Hickock Waekon’s Auto Wave II handheld oscilloscope has a feature called Auto-

Set, which automatically sets the voltage and time scale based on what the scope is seeing. According to Bauman, this allows novice scope users to quickly begin performing waveform diagnostics.

Premade, guided tests will also prove to be a valuable feature. Guided tests set up the scope for the technician, explain how to connect to a vehicle, perform the test, and evaluate the waveforms. Pico Technology, a leader in PC-based oscilloscopes, has more than 150 guided tests and 6,000 sample waveforms in its so ware library. On top of that, Diesel Laptops has developed dozens of guided tests specific to medium- and heavy-duty vehicles, along with hundreds of sample waveforms.

Diesel Laptops actually leverages Pico’s 4425A PicoScope in its oscilloscope kit. McDonald, who has been using Diesel Laptops’ four-channel scope for nearly two years, likes the tab at the top of the screen that allows a technician to see what a certain waveform should actually look like. at allows for a real-time comparison as a technician is checking waveforms from a vehicle.

Oscilloscopes have been fairly prevalent in automotive repair for many years, but not so much in fleet maintenance shops. at has started to change over the past few years, which is why diagnostics providers like Diesel Laptops continue developing oscilloscope tools and resources specifically geared toward mediumand heavy-duty vehicles.

Navistar is one truck manufacturer that has recognized the potential of scopes in the heavy-duty world. e International truck maker assembled a group of dealership technicians in 2022 to begin testing an automotive oscilloscope from Pico Technology. Missy Albin, a senior lead technician at Taylor & Lloyd Inc. in Bedford, Massachusetts, was one of those technicians. She’s been a heavy-duty tech for 20 years and currently focuses on diagnostics and electrical work. e Pico pilot project represented her fi rst encounter with an oscilloscope.

Albin has been using Pico’s four-channel 4425A Master Diagnostic Kit in combination with PicoScope 7 so ware on her laptop. As someone new to oscilloscopes, Albin said she has benefited from Pico’s guided diagnostic tests. One of those tests is cam and crank synchronization, which utilizes two channels.

“I was able to hook into the two sensors, run my crank session, and take both of those waveforms and overlap them on the computer,” Albin explained. “ en I could count the signals to see if I had an out-of-timed engine. I was actually able to diagnose a spun cam gear by one, two, or three teeth from those waveforms. Without the oscilloscope, I would have had to take the entire front of the engine apart. e scope makes it a much quicker diagnosis. e oscilloscope almost gives you see-through vision to what is actually happening mechanically.”

Another example of where a two-channel scope could come in handy is intermittent or inoperative windshield wipers and interior lighting. Say a technician connects a scan tool to attempt commu-

nication with the BCM (body control module) but is unsuccessful. Should the module simply be deemed faulty and replaced? Not so fast.

“With an oscilloscope, a technician could look at the schematic for that module and identify the CAN bus wires,” Hickok-Waekon’s Bauman said. “ en they could safely back-probe those wires to see if there is any voltage or communication going on. If communication is coming into the module but the scan tool can’t communicate with it, the technician knows the module isn’t working. But if no communication is coming in, the root cause may be the wire itself or somewhere in the wiring harness.”

McDonald said his shop is using its four-channel Diesel Laptops scope at least a couple of times a month. “We typically use it on those weird issues a scan tool can’t pick up on,” he said.

One of those “weird issues” occurred on a Chevrolet truck with a Duramax diesel engine. “It wasn’t reading park or neutral or anything on the dash, and our scan tool couldn’t communicate with the PCM at all,” McDonald said. In fact, the PCM, TCM, and ABS modules were all o ine. McDonald decided to put the scope in the Datalink connectors to read CAN high and CAN low. A er turning the ignition on, the waveform looked jagged and all over the place. A good waveform, in this instance, should look fairly square.