INSIDE THE INFRASTRUCTURE FUNDING GRIDLOCK

The rollout of IIJA and IRA dollars has faced uneven progress since 2021 with political and bureaucratic hurdles slowing key electrical projects. Read more on pg. 30

A Single-Source Supplier for Electricians

Stop chasing parts all over town and half the internet. When jobs call for electrical, plumbing, and HVAC parts, place one order and knock out your next job from start to finish with SupplyHouse.

ECMWEB.COM

With its exclusive online content, ecmweb.com is a valuable source of industry insight for electrical professionals. Here’s a sample of what you can find on our site right now:

THE EVERYDAY ELECTRICIAN: PRODUCTS FROM NECA 2025 NECA Show Coverage Check out some of the products The Everyday Electrician looked at during NECA 2025 in Chicago.

ecmweb.com/55316464

HOW TO DETERMINE THE RIGHT AMOUNT OF ELECTRICAL SAFETY

Safety Unnecessary warnings can actually undermine safety efforts, so ensure that your safety strategy includes practices to streamline procedures and enhance both safety and productivity. ecmweb.com/55321015

ELECTRICAL TESTING QUIZ: CIRCUIT BREAKERS

Quiz It’s time to test your knowledge on circuit breakers! ecmweb.com/55319408

Editorial

Editor-in-Chief: Ellen Parson, eparson@endeavorb2b.com

Managing Editor: Ellie Coggins, ecoggins@endeavorb2b.com

Editor: Michael Morris, mmorris@endeavorb2b.com

Art Director: David Eckhart, deckhart@endeavorb2b.com

Consultants and Contributors

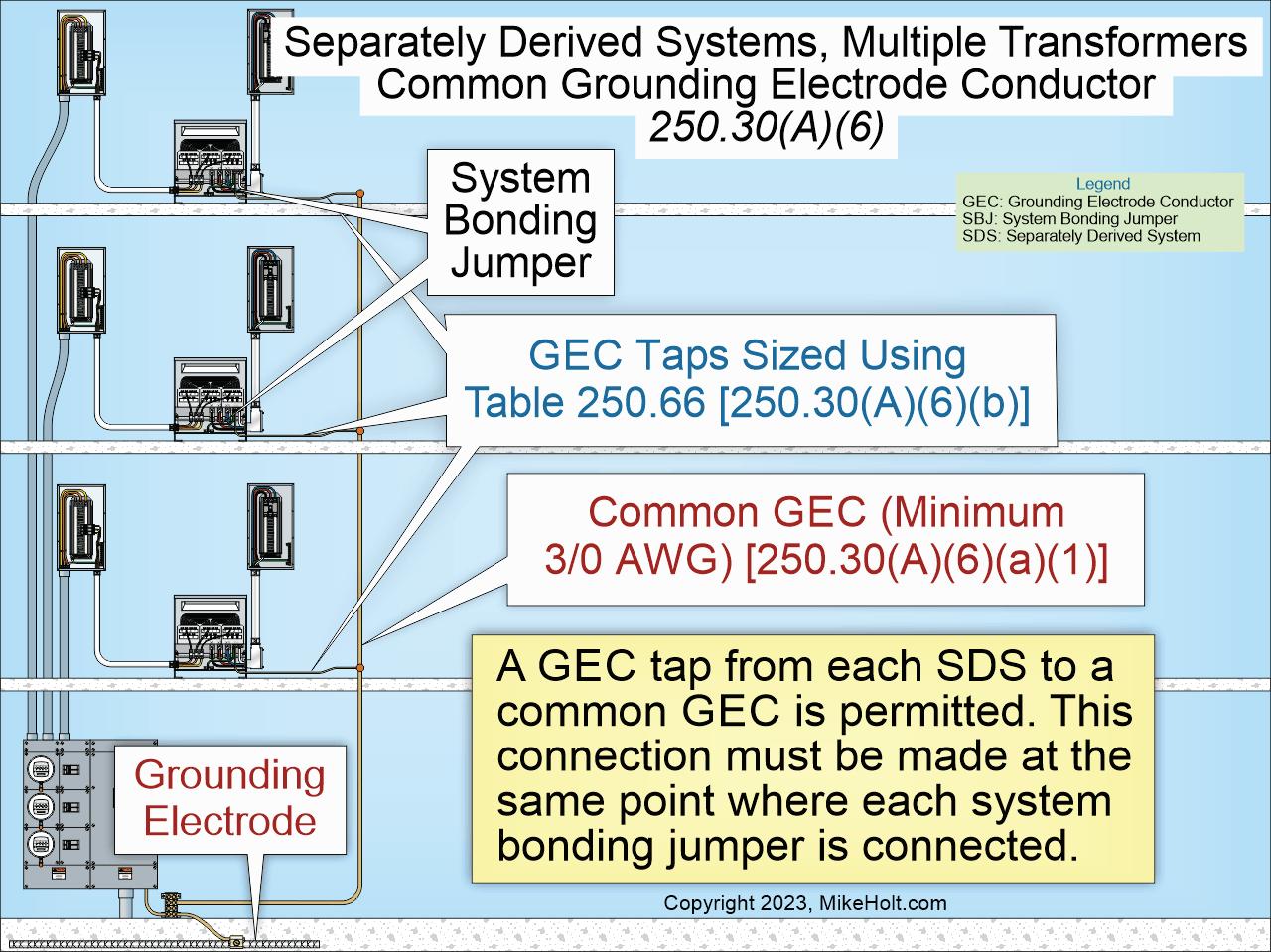

NEC Consultant: Mike Holt, mike@mikeholt.com

NEC Consultant: Russ LeBlanc, russ@russleblanc.net

Sales and Marketing

VP/Market Leader - Buildings & Construction: Mike Hellmann, mhellmann@endeavorb2b.com

Regional/Territory Account Manager: David Sevin, dsevin@endeavorb2b.com

Regional/Territory Account Manager: Jay Thompson, jthompson@endeavorb2b.com

Regional/Territory Key Account Manager: Ellyn Fishman, efishman@endeavorb2b.com

Account Manager: Steve Suarez, ssuarez@endeavorb2b.com

Production and Circulation

Production Manager: Josh Troutman, jtroutman@endeavorb2b.com

Ad Services Manager: Deanna O’Byrne, dobyrne@endeavorb2b.com

User Marketing Manager: James Marinaccio, jmarinaccio@endeavorb2b.com

Endeavor Business Media, LLC

CEO: Chris Ferrell COO: Patrick Rains CRO: Paul Andrews

CDO: Jacquie Niemiec CMO: Amanda Landsaw CALO: Tracy Kane

EVP Building & Construction Group: Chris Perrino

VP of Content Strategy: Mike Eby

Electrical Construction & Maintenance (USPS Permit 499-790, ISSN 1082-295X print, ISSN 2771-6384 online) is published monthly by Endeavor Business Media, LLC. 201 N. Main St 5th Floor, Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI, and additional mailing offices. POSTMASTER: Send address changes to Electrical Construction & Maintenance, PO Box 3257, Northbrook, IL 60065-3257. SUBSCRIPTIONS: Publisher reserves the right to reject non-qualified subscriptions. Subscription prices: U.S. ($68.75 year); Canada/Mexico ($ 112.50); All other countries ($162.50). All subscriptions are payable in U.S. funds. Send subscription inquiries to Electrical Construction & Maintenance, PO Box 3257, Northbrook, IL 60065-3257. Customer service can be reached toll-free at 877-382-9187 or at electricalconstmaint@omeda.com for magazine subscription assistance or questions.

Printed in the USA. Copyright 2025 Endeavor Business Media, LLC. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopies, recordings, or any information storage or retrieval system without permission from the publisher. Endeavor Business Media, LLC does not assume and hereby disclaims any liability to any person or company for any loss or damage caused by errors or omissions in the material herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever. The views and opinions in the articles herein are not to be taken as official expressions of the publishers, unless so stated. The publishers do not warrant either expressly or by implication, the factual accuracy of the articles herein, nor do they so warrant any views or opinions by the authors of said articles.

Reprints: Contact reprints@endeavorb2b.com to purchase custom reprints or e-prints of articles appearing in this publication.

Photocopies: Authorization to photocopy articles for internal corporate, personal, or instructional use may be obtained from the Copyright Clearance Center (CCC) at (978) 750-8400. Obtain further information at www.copyright.com.

Archives and Microform: This magazine is available for research and retrieval of selected archived articles from leading electronic databases and online search services, including Factiva, LexisNexis, and ProQuest.

Privacy Policy: Your privacy is a priority to us. For a detailed policy statement about privacy and information dissemination practices related to Endeavor Business Media products, please visit our website at www.endeavorbusinessmedia.com.

Please Note: The designations “National Electrical Code,” “NE Code,” and “NEC” refer to the National Electrical Code®, which is a registered trademark of the National Fire

Assemble Conduit Above TrenchNo Workers BelowPrevents Injuries and Deaths. Also Allows Digging a Narrower Trench for Less: Excavation, Concrete, Slurry, Backfill & Shoring.

Federal Infrastructure Funding Still Partly in Flux

By Ellen Parson, Editor-in-Chief

Based on EC&M’s annual proprietary survey results from our Top 40 Electrical Design Firms and Top 50 Electrical Contractors, the nation’s top electrical firms are thriving on private-sector demand, but their confidence in federal infrastructure funding may be waning. Delivering strong backlogs and record revenues from leading players in electrical design and electrical contracting in 2024 (the full year in which both survey results are based on), the 2025 data also revealed a clear skepticism regarding infrastructure funding. Overall, few respondents expect that the Infrastructure Investment and Jobs Act (IIJA) or Inflation Reduction Act (IRA), which authorized approximately $1.2 trillion for transportation and infrastructure spending from 2022 through 2026, will meaningfully move the needle anytime soon.

When asked how they thought the executive order President Trump signed in January 2025 (dubbed “Unleashing American Energy”), which halted federal agencies from disbursing IIJA and IRA funding (including monies Congress had already authorized and earmarked for EV charging infrastructure, broadband/telecom, roads and bridges, rail buses, airports, shipping ports, electric grid updates, renewables, and water/wastewater work — many of which were already underway), would affect federal construction projects in 2025 and 2026, respondents seemed to be on the same page.

Among Top 40 Design Firms, only 3% expect the IIJA to have a significant impact on their 2025 projects (down sharply from 12% a year earlier) while nearly 75% foresee minor to moderate negative effects. The Top 50 Contractors echo the theme of unease. Slightly more than half say a freeze or disruption in IIJA/IRA funding will negatively affect federal construction projects through 2026. Only 16% are confident that repeal of the legislation is completely off the table, while about 65% project a gain of no more than 5% in new-project revenue tied to federal infrastructure funds.

As Freelance Writer Tom Zind details in the cover story, “Inside the Infrastructure Funding Gridlock” on page 26, the slowdown is real. The IIJA and IRA were built to modernize power systems, expand EV charging, and boost grid resilience. But by mid-2025, implementation had stalled under political shifts, agency turnover, and a flurry of executive orders and reviews. This article does an excellent job of summarizing key takeaways on the current state of federal infrastructure dollars and what the future may hold for disbursement of funds in specific markets.

Take the Department of Transportation’s National Electric Vehicle Infrastructure (NEVI) program as an example, which allocated $7.5 billion to seed a national charging network. Yet a July 2025 report titled “Electric Vehicle Infrastructure: Improved Performance Management Needs to Be Part of Any Related Federal Efforts” from the U.S. Government Accountability Office (GAO) found that, as of April, only 384 federally funded chargers were open to the public. While the DOT has since issued new guidance to release the 84% of funds still unobligated, electrical contractors active in this market are rightfully wary. The Department of Energy has been even slower to deliver. Out of roughly $43 billion in IIJA funds available through FY 2025, only 11% has been obligated and 1% expended, according to GAO data. Zind noted that the DOE’s programs — particularly those related to “green” energy — have been entangled in executive reviews that prioritize fossil fuel development. This could result in developers, engineers, and contractors getting caught up in potential cancellations.

As of press time in mid-October, IIJA and IRA funds seem to be no longer “entirely” frozen, but they’re not exactly free flowing either. According to reports from Utility Dive online, many programs and awards that were already obligated or executed have resumed disbursements after legal pushback forced the Administration to reinstate previously withheld funds. Still, new awards, especially ones tied to green energy projects, remain under higher scrutiny, are subject to pause, or may receive slower approval. With IIJA and IRA funding still at least partly in flux, EC&M will continue to track this evolving situation and report on any significant developments.

As Sure as the Sun Comes Up

New Options to Support the Transition to LED

Converting traditional light fixtures to LED provides lasting energy savings and lower operating costs. However, if LED fixtures are paired with thermal photocontrols, that costsavings is quickly lost due to premature failures and unplanned maintenance needs.

Choose high-performance NIGHTFOX Electronic Photocontrols to ensure the long-term success of LED conversion projects. Our new fixed mount electronic photocontrols are designed for LED and can accommodate projects of all budgets and sizes.

Learn more today at

The Electrical Market By the Numbers — 3Q 2025 Update

See what 15 key economic indicators have to say about the overall slow growth of the electrical construction market.

By Jim Lucy, Electrical Wholesaling

Electrical Wholesaling’s new Electrical Market By the Numbers analysis for the third quarter of 2025 (3Q 2025) seems to reflect many of the economists’ prognostications you hear right now about the U.S. economy. In a word, it’s “meh” — rather uninspiring and unexceptional — nothing pointing toward great growth far into the future, but no flashing red lights signaling an imminent downturn or recession.

Sara Martin, the associate director for forecasting at Dodge Construction Network, provided a clear summary of the state of nonresidential construction market in the company’s recent analysis of August 2025 construction spending. “Construction activity continues to present a mixed picture,” she said in a press release. “August growth was concentrated in a few key sectors, while single-family and commercial projects experienced broad declines. Large-scale

megaprojects continue to support overall activity, but with mounting signs of economic softness, the pace of growth is beginning to moderate.”

In general, the 15 key economic indicators in the table on page 12 point to a slow-growth scenario in the electrical construction market outside of the booming data center market, and do not indicate any type of major slowdown in the near future. They cover electrical market and construction forecasts, electrical product pricing trends, electrical contractor and industrial employment data, electrical manufacturers’ shipments, and single-family activity.

ELECTRICAL MARKET & CONSTRUCTION FORECASTS

There is a real mix of indicators in these forecasts. The least-bullish of them is the Architecture Billings Index (ABI) published monthly by the American Institute

of Architects (AIA) and Deltek, which surveys architects to predict nonresidential construction activity nine-to-12 months out. This index is showing declining demand for architects’ services on both a month-over-month and yearover-year basis. For August, it stands at 47.2 points, which is under the 50-point mark indicating growth.

But for every sour statistical story in this month’s data, you can find some reasons to cheer. The National Electrical Manufacturers Association (NEMA) publishes its monthly ElectroIndustry Business Confidence Index (EBCI), a monthly survey of senior managers at electrical manufacturers. While the EBCI’s future conditions component was down in August on both a month-to-month and year-overyear basis, it’s still comfortably above the 50-point mark indicating improving business conditions.

Another positive indicator is the Dodge Momentum Index (DMI), a monthly measure of the value of nonresidential building projects entering the planning stage shown to lead construction spending for nonresidential buildings by a full year. It was up +20.8% in July.

ELECTRICAL PRICING DATA

If you are freaked out by an Electrical Price Index EPI that’s currently riding quite a bit over its historical averages on a monthly (+0.2% monthly average) and annual (+2.6% annual average ), you can find reason for concern , Electrical Marketing’s Electrical Price Index’s continues to log large increases year-over-year pricing trends in many key categories,

ID 7507349 © Cornelius20 | Dreamstime.com

MARKET WATCH

THE ELECTRICAL MARKET BY THE NUMBERS

EMPLOYMENT DATA

HOUSING CONSTRUCTION

NAHB/Wells Fargo Housing Market Index (HMI) 32 points Unchanged Down 9 points

Sources: Electrical Markets & Construction Forecasts: AIA Architecture Billings Index - American Institute of Architects; Dodge Momentum Index - Dodge Construction Network; EBCI - National Electrical Manufacturer Association’s ElectroIndustry Business Confidence Index - NEMA monthly survey); EW/VRP Quarterly Survey - Electrical Wholesaling & Vertical Research Partners; Construction Backlog Indicator - Associated Builders & Contractors; Electrical Pricing Data: Electrical Marketing. EW/VRP quarterly survey and Comex; Employment - U.S. Bureau of Labor Statistics; Electrical Manufacturers sales & shipmentsU.S. Census Bureau; Housing - U.S. Census Bureau; and National Association of Home Builders (NAHB)/Wells Fargo.

including building wire and power cable, panelboards, and switchboards.

The double-digit YOY increase in building wire and cable and the +7.1% increase in power cable in the EPI are due in part to the wild swings in the copper prices, which were up 42 cents per pound in early October over early September.

The Electrical Price Index is published each month by Electrical Marketing newsletter and is available as part of a $99 annual subscription. Go to www.electricalmarketing.com for details.

EMPLOYMENT DATA

While electrical contractor data was down fractionally in the most recent data, it’s still on a historic run by registering another month over 1 million employees. It hasn’t been below this mark since January 2022, according to data from the U.S. Bureau of Labor Statistics.

SINGLE-FAMILY HOUSING CONSTRUCTION

While the challenges homebuilders are facing with high interest rates, a smaller cohort of first-time home buyers because of demographic realities and issues with local building restrictions are well known, the latest housing start data swung down again in August with a -7% decline from July to 890,000. That’s also -11.7% below the August 2024 data.

Despite the slowdown in residential construction activity, building permits are still a reliable indicator of future residential and light-commercial building. Home builders typically don’t purchase building permits unless they are serious about breaking ground, and once new housing developments go in, light-commercial construction follows.

SUMMARY

Although the 15 business indicators covered here paint a mixed picture for the electrical construction industry, the slow-but-steady scenario they sketch out to a large degree mirror the business conditions in the U.S. economy as a whole. If the U.S. economy is still growing at the +3.8% pace for national GDP (gross domestic product), it was through 2Q 2025, according to the U.S. Bureau of Economic Analysis, business conditions in the electrical market should remain tolerable. And if the U.S. Federal Reserve cuts the federal funds rate as expected over the next few months, lower rates could juice up construction lending and investment and cut residential mortgage rates, giving homebuilders and the contractors that work on their housing developments reason to cheer.

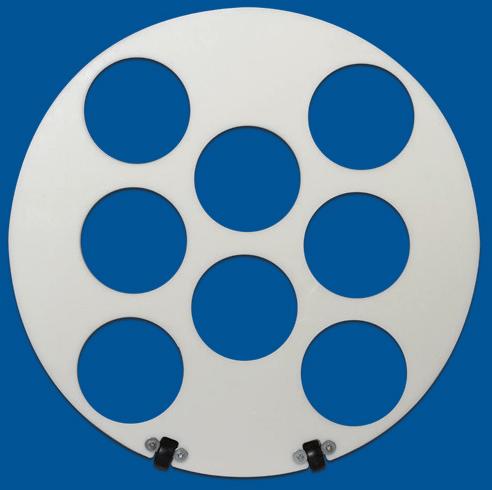

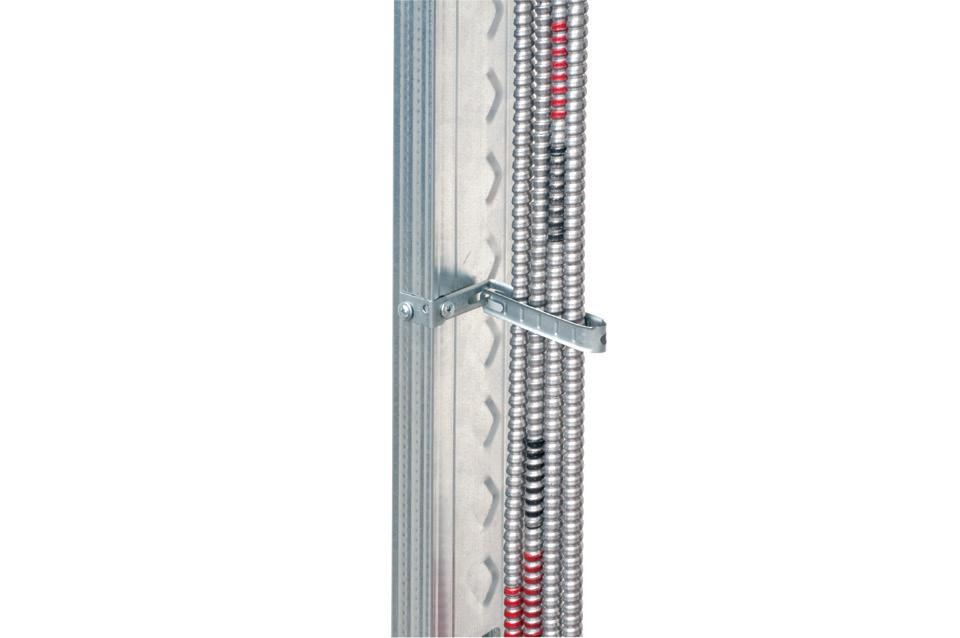

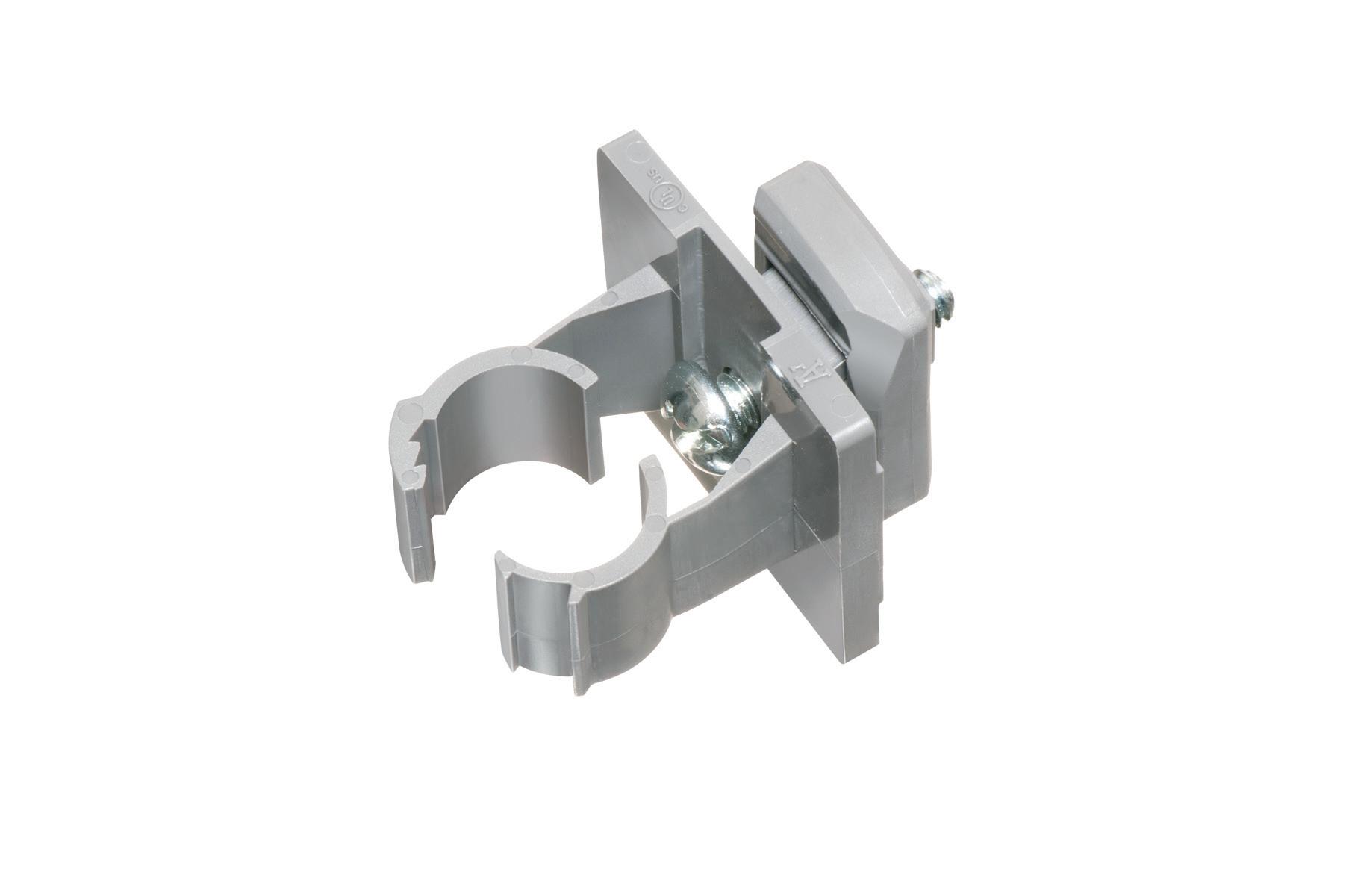

Time-saving non-metallic CableAble® Support Brackets are the ONE BRACKET for support of EMT or flexible metal conduit, power MC and NM cables, and low voltage cables, in commercial or residential work, with plenum or non-plenum ceilings.

Four- and eight-hole CableAble mounts horizontally or vertically to studs or unistrut. And horizontally to all thread and beam clamps.

Lowers total installed cost • Minimizes space required for support –Reduces ceiling congestion • Plenum applications per NEC 300.22(c)

CA8 Eight, 1-1/4" T Bracket

CA8L Eight, 1-1/4” L Bracket CA4 Four, 1-1/4" T Bracket

CA4L Four, 1-1/4” L Bracket

All styles available in bulk 50 packs. To order, add “X” suffix to item number.

Streamlining Construction Procurement: Strategies for Effective Material Management

Design a process of procurement (PoP) that allows your construction org to effectively plan work, manage labor, procure materials, and more.

By Jennifer Daneshgari and Dr. Heather Moore, MCA, Inc.

Wouldn’t you love to have a secret decoder ring for the process of procurement (PoP)? It’s much more than simply purchasing material. It spans across management and the project team as well as the full project. Having a system within your company that easily incorporates digitalization, commonization, and interconnection of information across your project reminds you of your next steps and deadlines, and monitors/ highlights cash management activities. The steps in the PoP, as shown in the Figure on page 16, are:

• Having a procurement plan

• Building a procurement schedule

• Job delivery

• Job material movement and management

• Returns

• Lessons learned and post-mortem Running a project requires planning the work, managing the labor, procuring materials, managing subcontractors, and confirming you have the right equipment and tools while negotiating between other trades and typically working with the general contractor or construction manager to negotiate the schedule and hit the dates required. Like a full project schedule, it’s important to build your own procurement schedule with links to the deadlines for when you must do submittals, get releases, and plan for lead times and deliveries to the job site. While this accounts for much of the spend on your projects, managing

labor and how they spend their time is another large component of your profitability. In the space between procuring the material and doing the actual installation, there is the material management phase of the project.

MATERIAL HANDLING: WHAT IS IT, AND WHO IS DOING IT?

Material handling is much more than simply ordering and receiving. Material handling, by definition, based on a study done by MCA, Inc. for Electri International, formerly Electri21, can be as much as 40% of an electrician’s time. Recognizing all the items involved in material handling that impact your labor productivity and your project’s profitability is shown in Table on page 16. This includes:

• Ordering (whether it’s a call to your inside sales, done by the project team, or the prefab shop, done online, with a material request form). Are you doing it daily or weekly?

• Receiving (at the job site, at the warehouse, in the office, etc.). Planning this is a large portion of Step 3 of the PoP.

• Waiting (for someone to answer your call or the delivery truck to come).

• Unloading (think of how many people it takes to unload the truck and what happens if you have to pull your crew off to do this).

• Sorting (through the delivery that likely has many items mixed in boxes or individual boxes needing to be opened to confirm everything is there).

• Moving to accommodate job site (you have your location on the job site

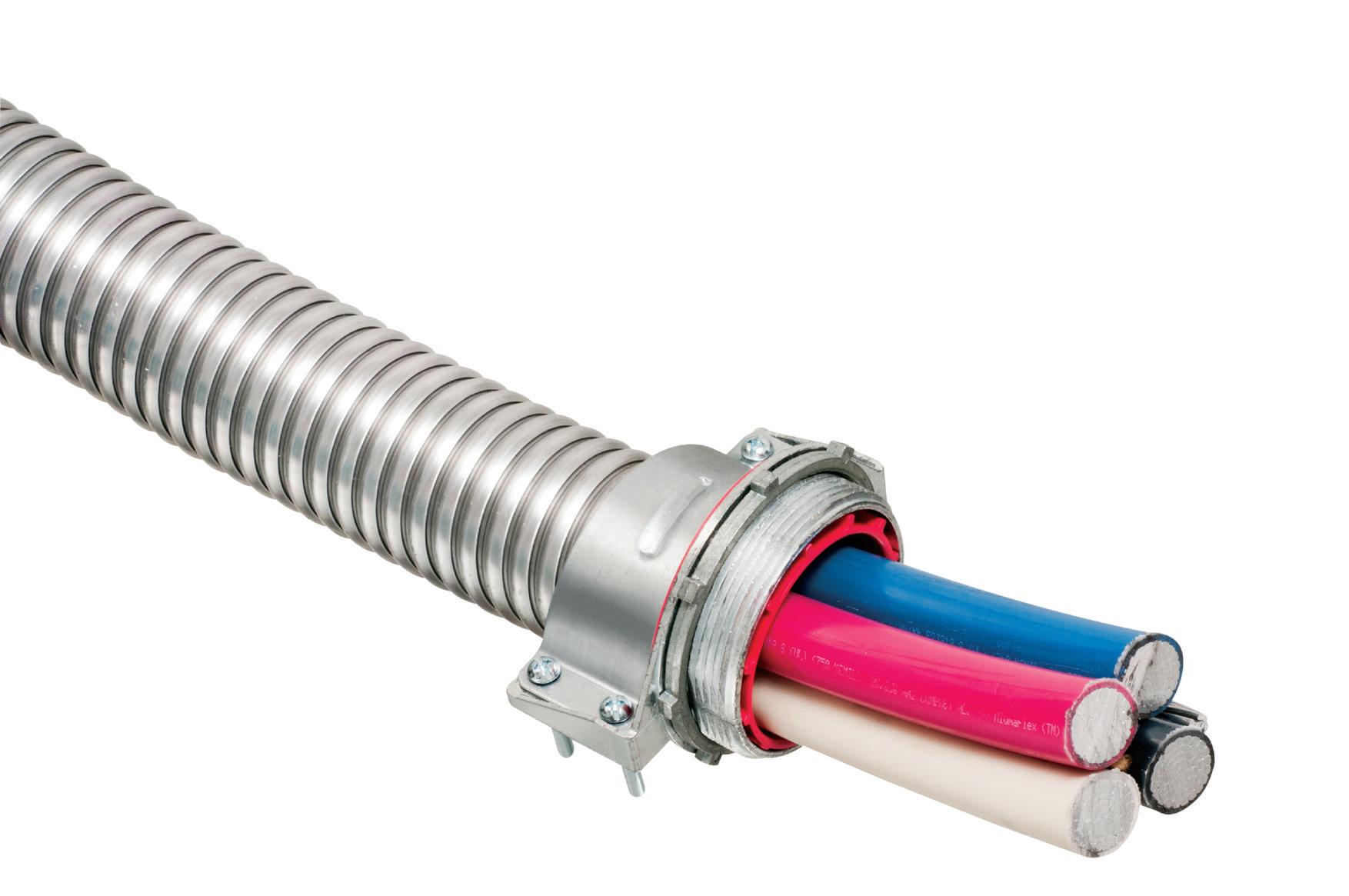

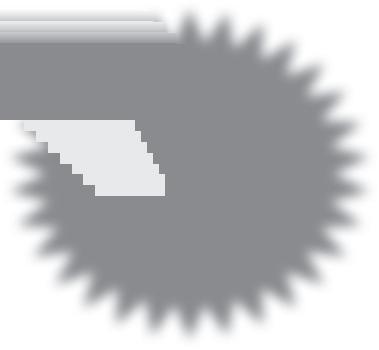

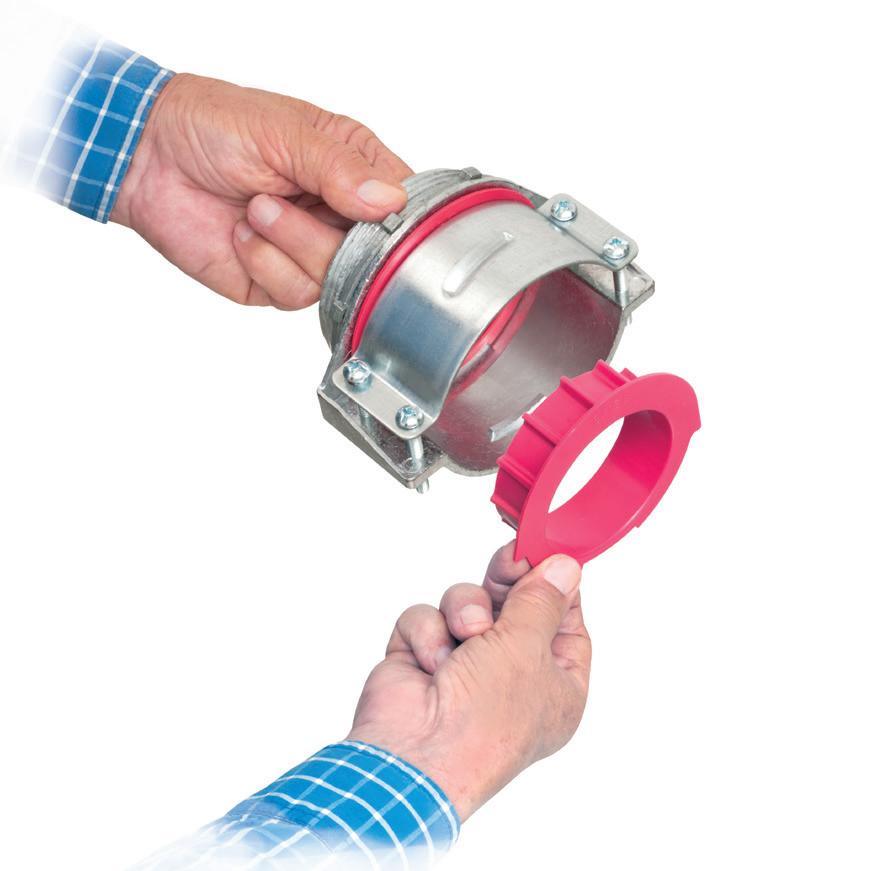

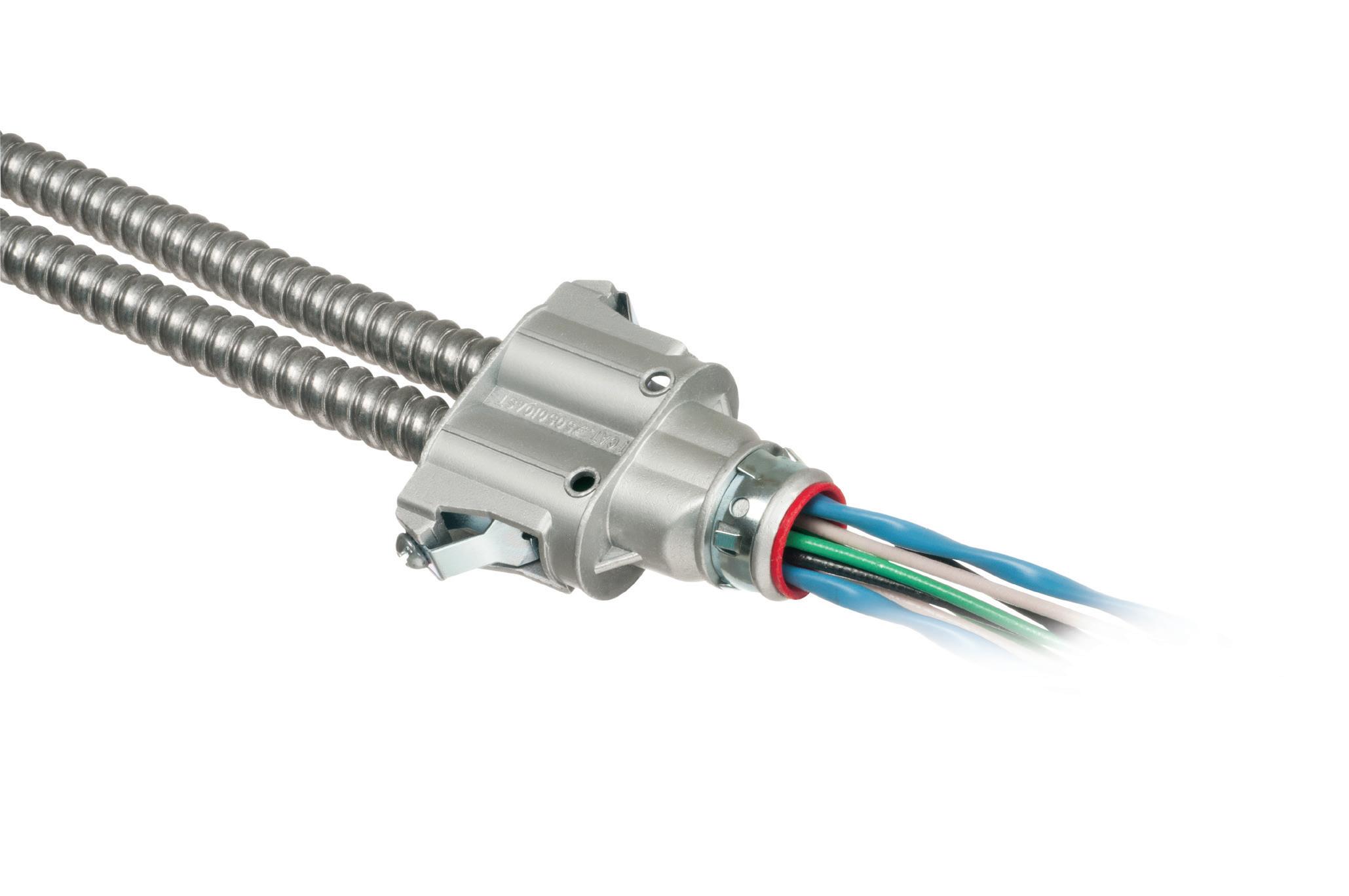

MC CABLE FITTINGS

ONE FITTING FITS MULTIPLE CABLE/CONDUIT TYPES & SIZES

* Aluminum & Steel Flexible Metal Conduits

ONE trade size fits SEVERAL cable types and sizes, plus flexible metal conduit for super convenience and cost-savings! Reduces inventory and material handling too.

Patented

Conductor Size CSA TECK90 Conductor Size # of Conductors* # of Conductors* (AWG/KCMIL) (AWG/KCMIL/ACWU) 6/3, 6/4, 4-3, 4-4, 8/3, 8/4, 6/3

2-3, 2-4, 1-3

2-3, 2-4, 1-3, 1-4, 6/3, 6/4, 4/3, 4/4, 3/3, 1/0-3, 1/0-4, 2/0-3, 3/4, 2/3, 2/4

2/0-4, 3/0-3

2/0-4, 3/0-3, 3/0-4, 2/4, 1/3, 1/4, 1/0-3 4/0-3, 4/0-4, 250-3, 250-4 1/0-4, 2/0-3 250-4, 300-4, 350-3, 2/0-3, 2/0-4, 3/0-3, 3/0-4, 350-4, 500-3 4/0-3, 4/0-4, 250-3 500-3, 500-4, 600-3 4/0-4, 250-3, 250-4, 300-3 600-4, 750-3 300-4, 350-3, 350-4, 500-3 600-4, 750-3, 750-4 350-4, 500-3, 500-4 750-3, 750-4, 1000-4 750-3, 750-4, 1000-3

Concrete tight when taped

JOB-SITE INTELLIGENCE

Process of Procurement

Management Planning Functions

Procurement Plan

• Identify risks

—Business risks

—Integration risk

—Technology risk

• Selection of partner

• Kickoff meeting

—Superintendent

—Contract Mgr. —Purchasing —Vendor —Tools —Safety

• Material management meeting

—Bill of materials

—Special handling

Procurement Schedule

Project Team Planning Functions

• Get overall schedule Completeness Changers

• Develop job strategy Communication with GC/owner

• Factor in lead time for materials —Completeness —Changes

Project Team Management Functions

Job Delivery Returns

• Understand dates and times

• Specific delivery location understanding

• Appropriate vehicle and equip. notification

• Proper notice of delivery

• Proper ID of what is delivered

• Backorders or undeliverables immediately communicated to field

• Field notification of obstacles or site changes to vendor

• Weekly feedback or critique of both what went right and wrong

There are eight steps in the process of procurement.

where you’re storing things, but you have to move to the installation location, or move your laydown area when the job progresses).

• Returns (MCA, Inc.’s research shows that the main reason for returns is overordering, which can be caused by finding/moving material on the job site).

• Delivery mistakes (no one’s perfect).

• Dealing with damages (items ordered early that get shuffled or actual issues with damage from the manufacturer, vendor, or distributor).

• Storing material that will be used later (linked to moving to accommodate the job site, early ordering can cause issues like noted above, such frequent movement or issues with the elements).

Recognizing what’s involved in material management will allow your team to

Job Material Movement and Management

• Assume the “how it gets delivered is correct”

• Prepare the location for transport

• Be specific — communicate needs

• Be realistic based on site conditions

• Make sure vendor is properly equipped 1 vs. 2 people Racks, pallet jacks Lift gates, open trucks

Risks:

• How to deal with delays

• Changing site conditions

• Emergency orders

work on tasks where they can excel. Per Step 1 in the PoP, it’s also important to consider asking your vendor partners to support you. The key isn’t in the labor rate; it’s in the productive installation hours of the highly skilled employee. Both employees will work all day and will work hard; however, you’ll gain minimal revenue and billing from a lesser-skilled person moving material in contrast to what you can achieve by having the highly skilled electrician complete installation tasks. Highly trained and highly experienced electricians don’t want to spend their days moving material; they want to be doing electrical work. Build on/accelerate the support of your highly skilled labor doing what they’re best at, love to do, and are trained for! Keeping your teams working on installation is key.

• Sort/count

• Document (in standard form)— inform PM

• Field schedules pick-up

• Vendor schedule appropriate manpower

• Communicate credit amount to PM

• Verification of credit from vendor (terms of return)

Risks:

• Who is responsible for sorting?

• When/how should returns happen?

Lessons Learned and Post-Mortem

• Must be continuous and ongoing communication

• Supervision peer groups

• How well did the plan work? Pluses and minuses

• Increased trust to encourage feedback and learning

• Share on organization level

SHOULD WE BUY MORE OFTEN?

The simple answer is no! To reduce material management/handling on job sites, focus on ordering materials that you need now. While electrical distributors are happy to take your order and are likely to even deliver it to you daily, this isn’t the most efficient process for specialty trade contractors. MCA’s research shows that about three days’ worth of material on the job site is the “right” amount. Frequent deliveries can slow you down. They create constant disruptions from unloading, sorting, checking, and staging.

Why? Because, as you know, job sites and job progress are constantly changing in the construction industry. No matter how hard we try, we can’t always do everything that we plan each day,

© Dr. Perry Daneshgari and MCA, Inc.

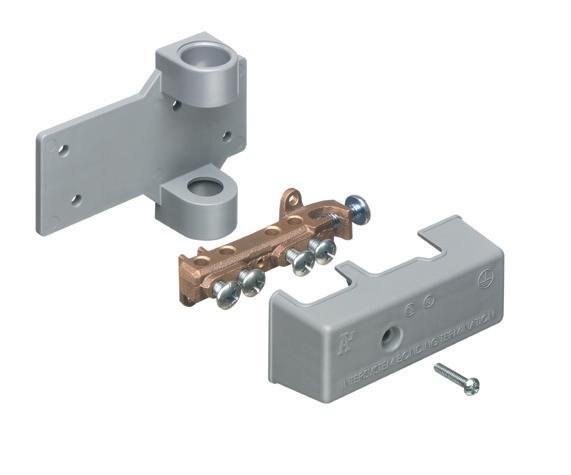

GROUNDING BRIDGE

MULTIPLE ZINC & BRONZE STYLES MEET NEC GROUND

Arlington’s heavy-duty Grounding Bridges provide reliable intersystem bonding between power and communication grounding systems. And handle multiple hookups of communications systems: telephone, CATV and satellite.

Our new GB5T comes with a Combination Threaded and Set-Screw hub for Threaded Rigid – or EMT Conduit.

Arlington’s zinc and bronze grounding bridges...

• Four termination points; more than required by the NEC

• Meet 2020 NEC bonding requirements for 250.94

• Fast, simple installation indoors or outside

• Textured, paintable plastic cover (except GB5NC)

• Easy access for inspections

JOB-SITE INTELLIGENCE

Safety Matters

This twice-a-month e-newsletter delivers the latest trends and information on electrical safety, reports on specific accidents in the field, and provides tutorials and evergreen safety content that can be used for reference and training.

Topics covered include:

• Best practices for safely working on electrical equipment

• Accidents and investigations

• Arc flash

• PPE

• Shock and electrocution

• Fire and security

• Safety audits

Subscribe Today

See all of our EC&M e-newsletters at www.ecmweb.com

not for the whole job and not even for a week or two in advance. In fact, MCA’s research has shown that having less than three days’ material available for installation leaves you with no ability to adjust to changes in today’s conditions.

If you have too little material, then simple redirection starves the labor and reduces productivity. Having material on site too early equates to having too much inventory on the job site. Too much inventory needs to be moved, counted, monitored, and often repaired or replaced. The answer is three days, because three days is about as far ahead as the job conditions are predictable.

Years ago, “just-in-time inventory” was a big craze. The principles and concepts are still with us today, and continue to expand to provide more cost-effective and productivity-supporting material management and logistics practices. The concept is simple; it’s based on the Toyota Production System, translated to construction, that to work, you need to have the materials required, when and where the installation is to occur, but not more than that — not more and not less. Not way before and not after you need it. MCA Inc’s previous EC&M article (November 2024) Logistics – What/ Where/When/How is a great reference with a material ordering checklist and some thoughts around getting material from your vendors.

CAN PREFABRICATION IMPACT MATERIAL MANAGEMENT?

You could use kitted prefab solutions, so everything shows up exactly when and how you need it, ready to install with no extra steps. Additionally, you could work with a partner to provide procurement assistance to enhance productivity, ensuring that materials are ordered and delivered in the most efficient manner possible.

It’s important to be more expansive and think beyond prefabrication. This could lead to benefits such as:

• Increased safety, reliability, and predictability

• Controlled environment

• Buffer for labor allocation (can do things in parallel vs. in series on the job site)

• Can reduce project duration.

• Get more work in the long run.

Material Handling is:

1. Ordering

2. Receiving

3. Waiting

4. Unloading

5. Sorting

6. Moving to accomodate job site

7. Returns

8. Delivery mistakes

9. Dealing damages

10. Storage to be used later © Dr. Perry Daneshgari and MCA, Inc. There are 10 steps when it comes to material handling.

Using the eight steps in the PoP in Fig. 1 and interconnecting informa tion within your company with an easy system allows you to reduce risk and keep your employees focused on labor productivity. As discussed at the start, it requires planning the work, managing the labor, procuring materials, manag ing subcontractors, and confirming you have the right equipment and tools while negotiating between other trades and typically working with the general contractor or construction manager to negotiate the schedule and hit the dates required. To reduce time and cost spent on material management/handling, it’s important to:

• Segregate the on-site electrical work based on experience.

• Optimize orders and deliveries to every three days.

• Use a checklist to get your mate rial as you need it by working with your vendor partners.

• Externalize work as much as possible.

It’s really about making a plan and working with your team and the supply chain to have the right people doing what they do best.

Jennifer Daneshgari is the vice president of financial services at MCA, Inc. She can be reached at jennifer@mca.net.

Dr. Heather Moore is vice president for customer care and support at MCA, Inc. She can be reached at hmoore@mca.net.

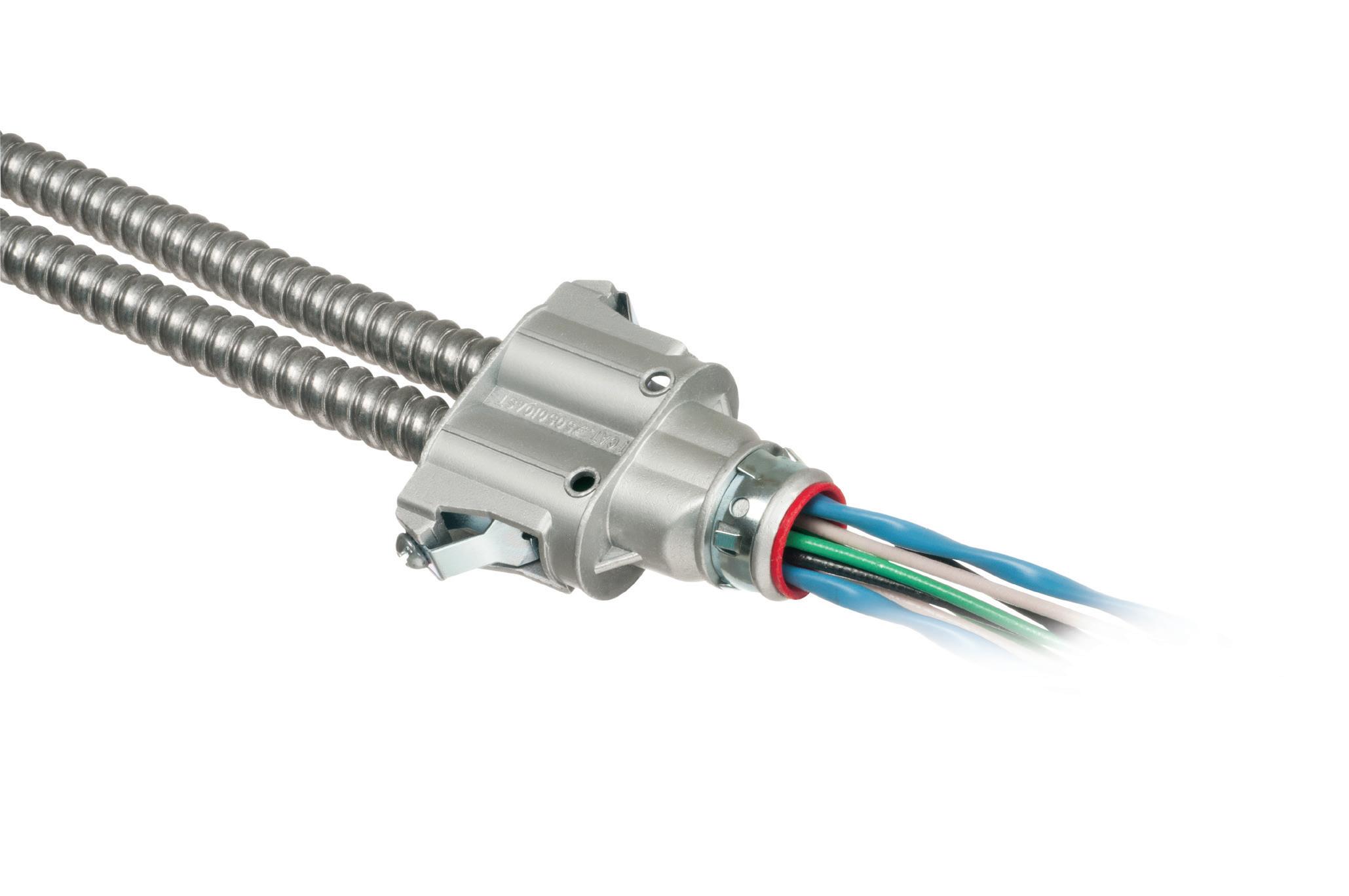

SNAP2IT® CONNECTORS

17SAVE seconds

Fully assembled, SNAP2IT® fittings handle the widest variety of MC cable AND THE NEW MC-PCS cables.

Compared to fittings with a locknut and screw, you can’t beat these snap in connectors for time-savings!

LISTED SNAP2IT ® CONNECTORS FOR NEW MC-PCS CABLE ...lighting & low voltage circuits in the same cable

• Fits widest range and variety of MC cable 14/2 to 3/3

AC, MC, HCF, MC continuous corrugated aluminum cable and MCI-A cables (steel and aluminum)...including the new MC-PCS cable that combines power and low voltage in the same MC cable

ANY Snap2It Connectors LISTED for MC cable are also LISTED for MC-PCS cable! These products offer the greatest time-savings.

• Fast, secure snap-on installation

• Easy to remove, reusable connector From cable Loosen screw on top. Remove connector from cable. From box Slip screwdriver under notch in Snap-Tite® Remove connector.

Easy to Snap into Box!

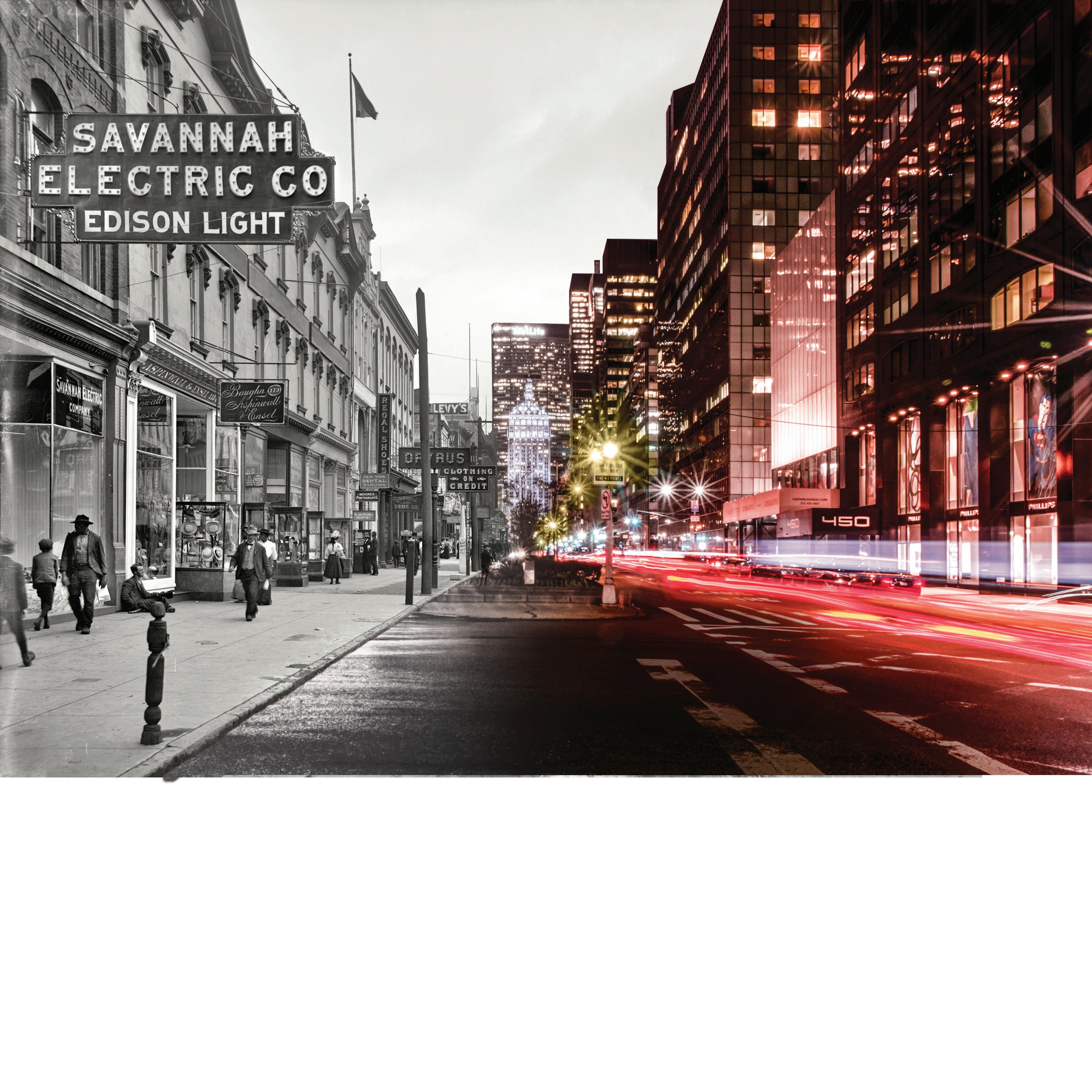

Overcoming Parking Lot Installation Challenges for Electric Vehicle Chargers

Electrical contractors face certain issues when installing EV chargers in parking lots, but there are many options to help navigate them.

By Bill Fowler, Southwire

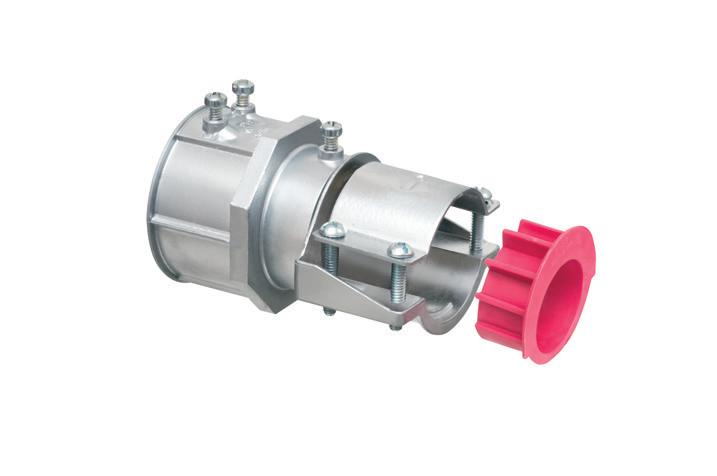

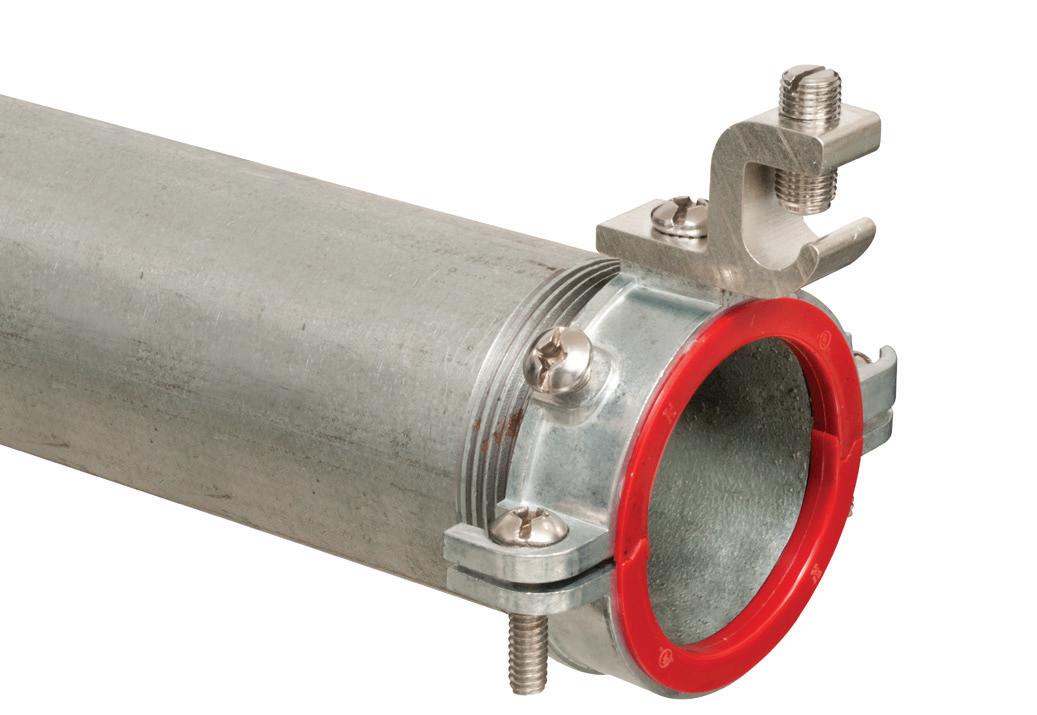

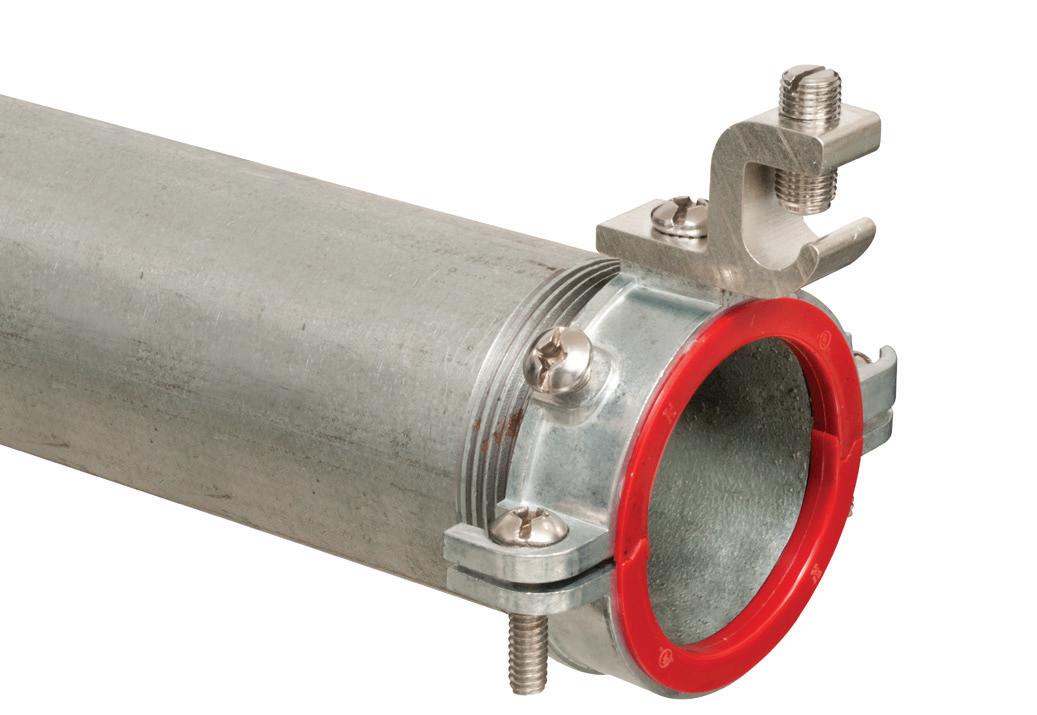

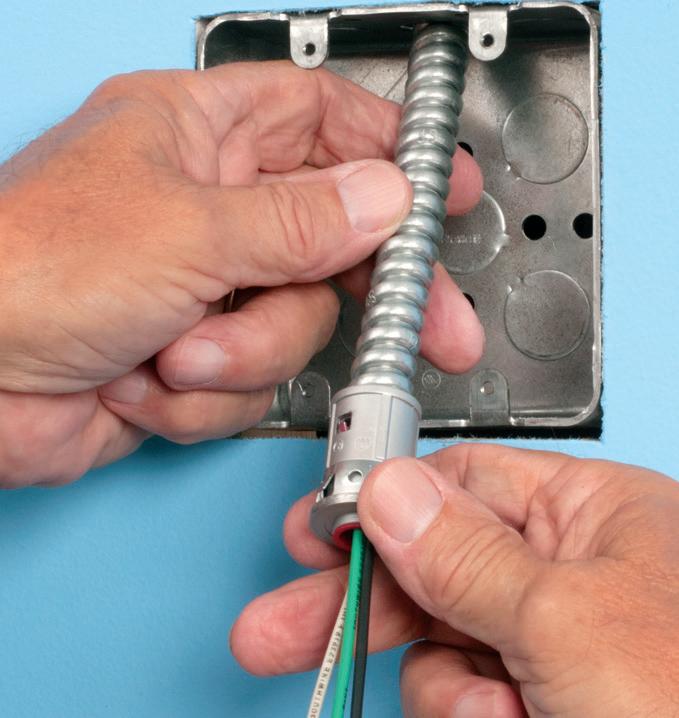

Cable-in-conduit (CIC) is a solution that helps prevent cable being damanged in route to the job site or during installation, as it can be installed in three different methods.

When it comes to installing electric vehicle (EV) charging stations, most business owners want to avoid having their property dug up. Digging in a parking lot can severely disrupt business and cause aggravation among employees. This concern forces contractors to work on set hour schedules so they can minimize the disruption to

daily business activities. Additionally, repairs to the pavement don’t always match the existing asphalt, which leads to future potholes that the business will have to repair.

COMMON ISSUES WITH PARKING LOT WORK

There are a lot of unknowns that can arise when digging into parking lots

to install conduit, cables, and charging equipment. Land records only go back so far, and many big manufacturers have uncovered grave sites, artifacts, and other related items below their property. Discovery of these items can stop a project in its tracks or lead to long delays.

For example, when it comes to grave sites, it is required that you notify the next of kin to get permission to move the grave. This can be a very long process depending on the age of the grave, and some U.S. states also require special permitting if you disturb more than 5,000 cubic feet of dirt.

One manufacturer has created a new department specifically to deal with issues they uncover during installations while digging a trench for conduits. Europe is facing the same issues as companies are trying to install these chargers in historic districts where special permits are required to remove sidewalks.

How can we resolve these issues? The following trends can help move these installations forward.

TRANSPORTATION-RELATED DAMAGE

One common issue that can happen is the cable getting damaged as it’s being transported to the project site or damaged during its installation. This situation stops all work until new cable is ordered and delivered. One option to

Courtesy of Southwire

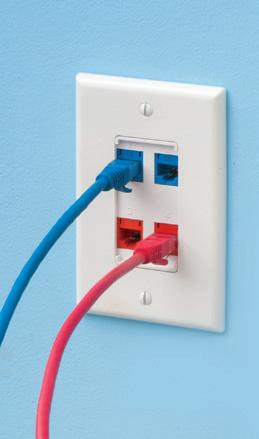

SPLIT WALL PLATES

Arlington’s non-metallic Split Wall Plates provide a simple and effective way to accommodate pre-connectorized low voltage cable(s) of varying size and quantity or pre-existing low voltage cables.

Multiple split grommets are provided with our single- and two-gang wall plates for increased versatility in effectively sizing and covering the hole/opening.

Use as shipped, or with one of the supplied bushings to alter the size of the opening.

• Single-gang CESP1 w/ 1-1/2" opening, bushings for .312" • .500" • 1" openings

•

•

bushings for .750" • 1.250" openings

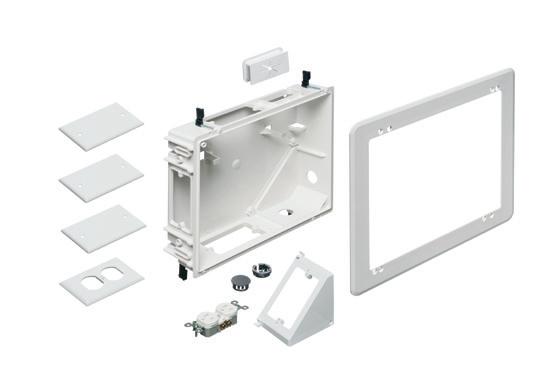

Arlington’s 8X10 TV Box® with a

• Brackets for neater cables, with a 1-1/2" knockout for ENT and other low voltage wiring

Large Volume FURRED WALL BOX

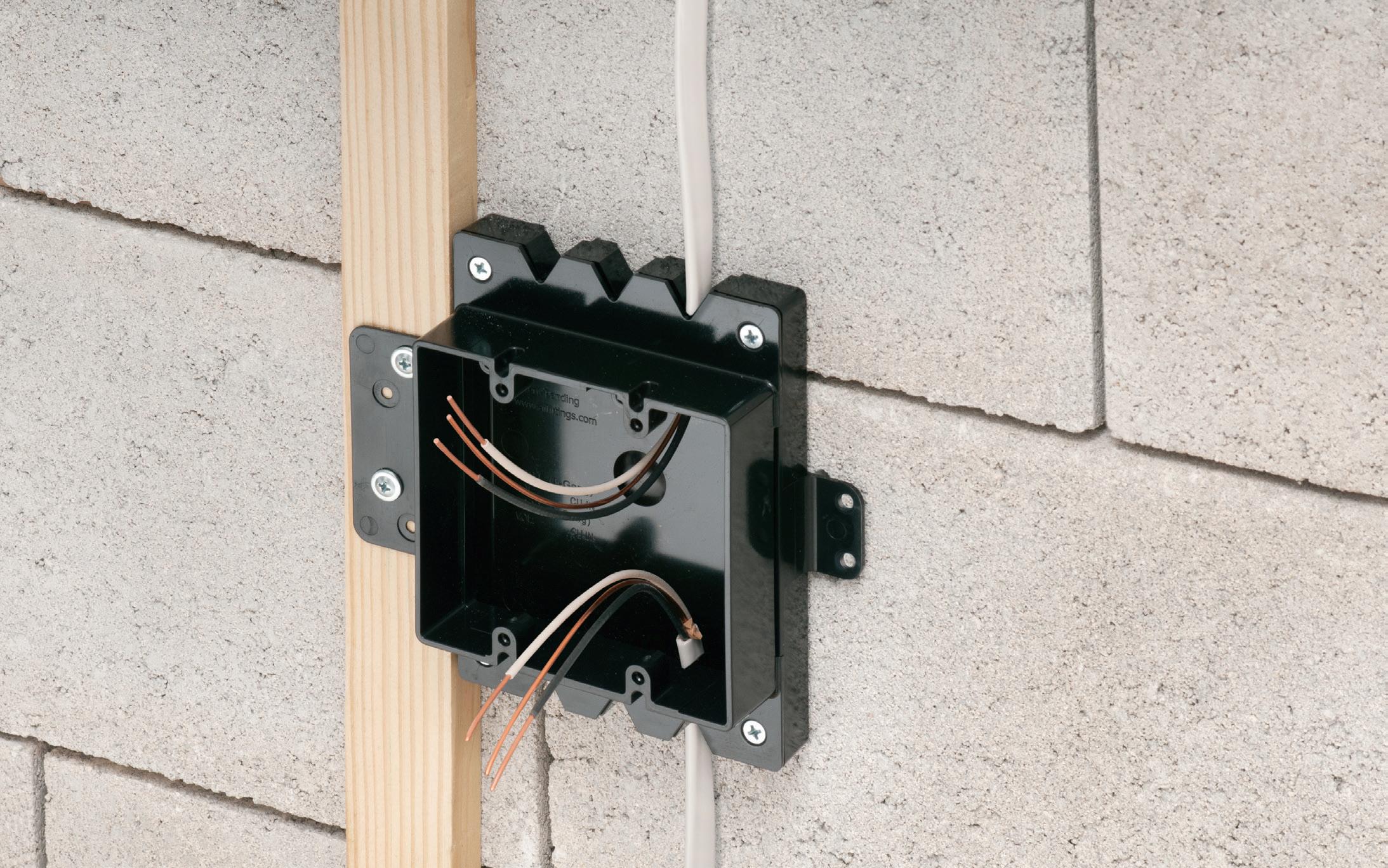

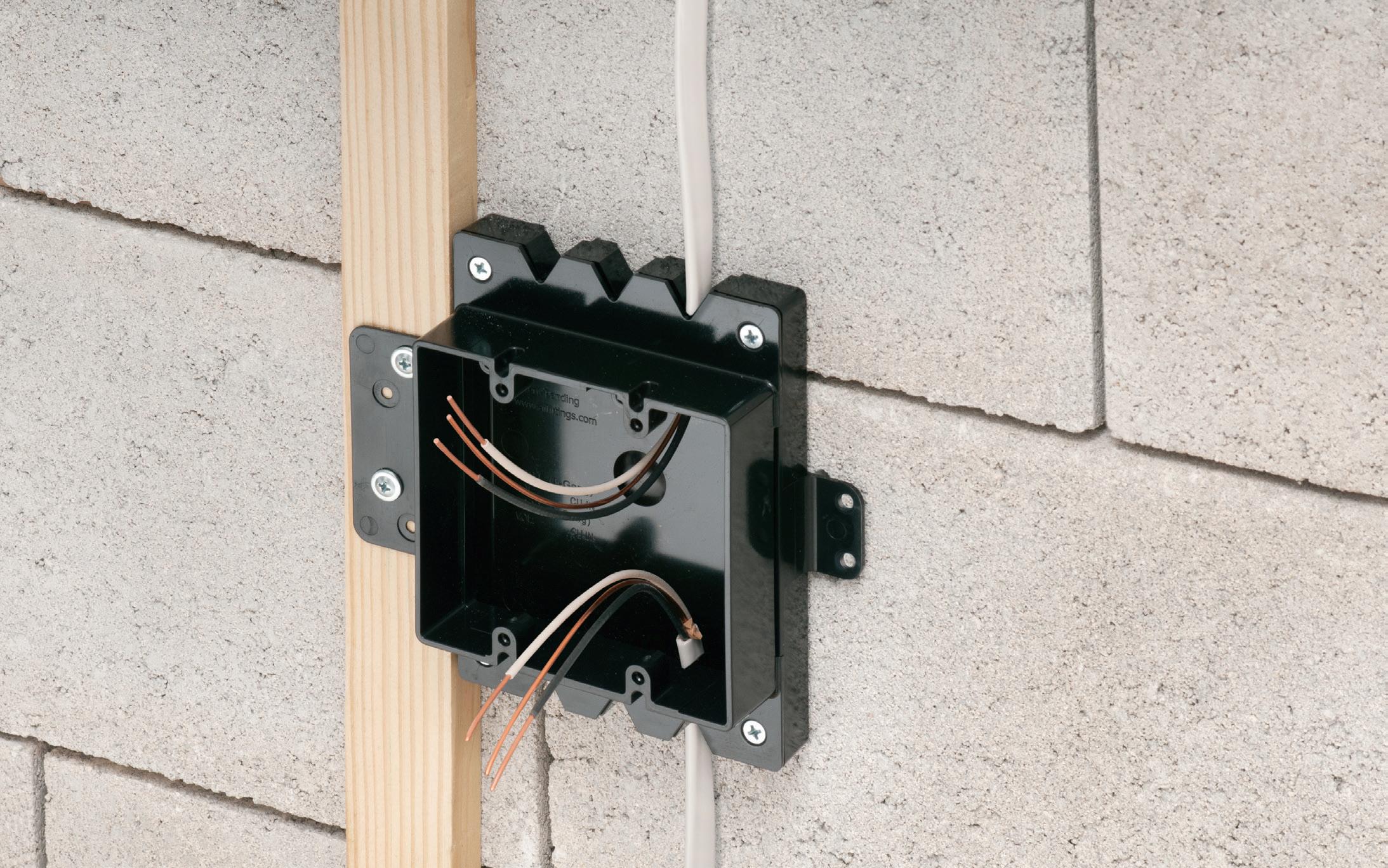

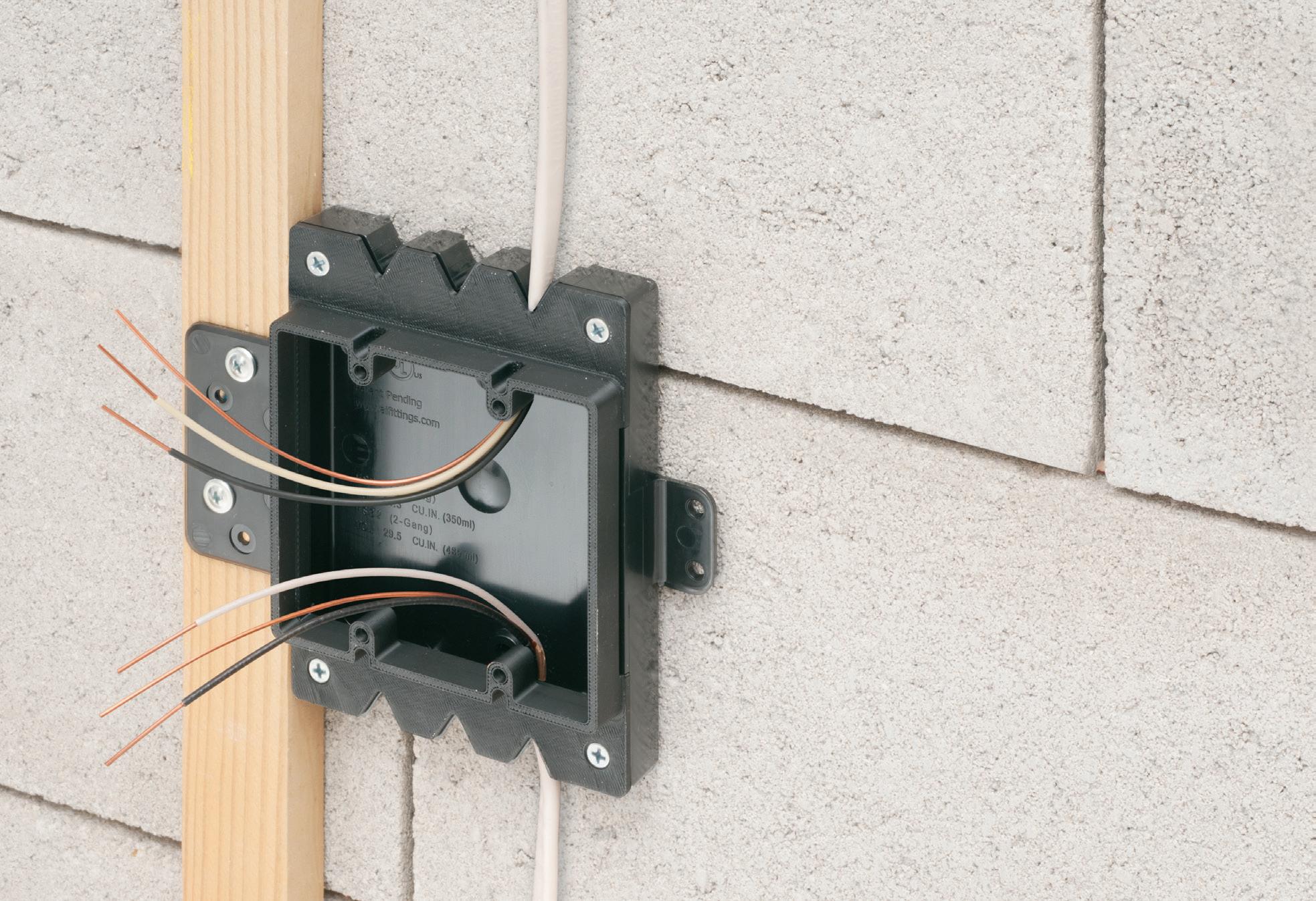

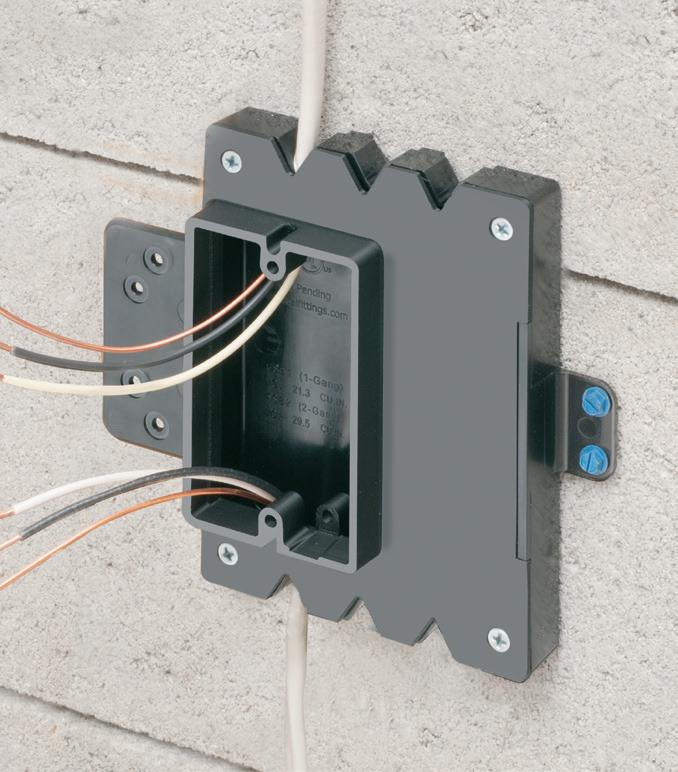

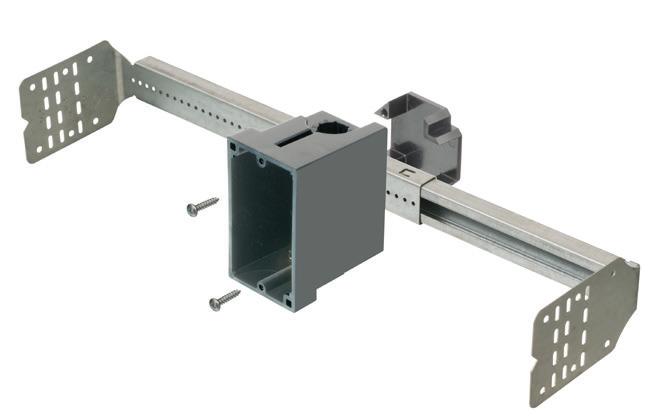

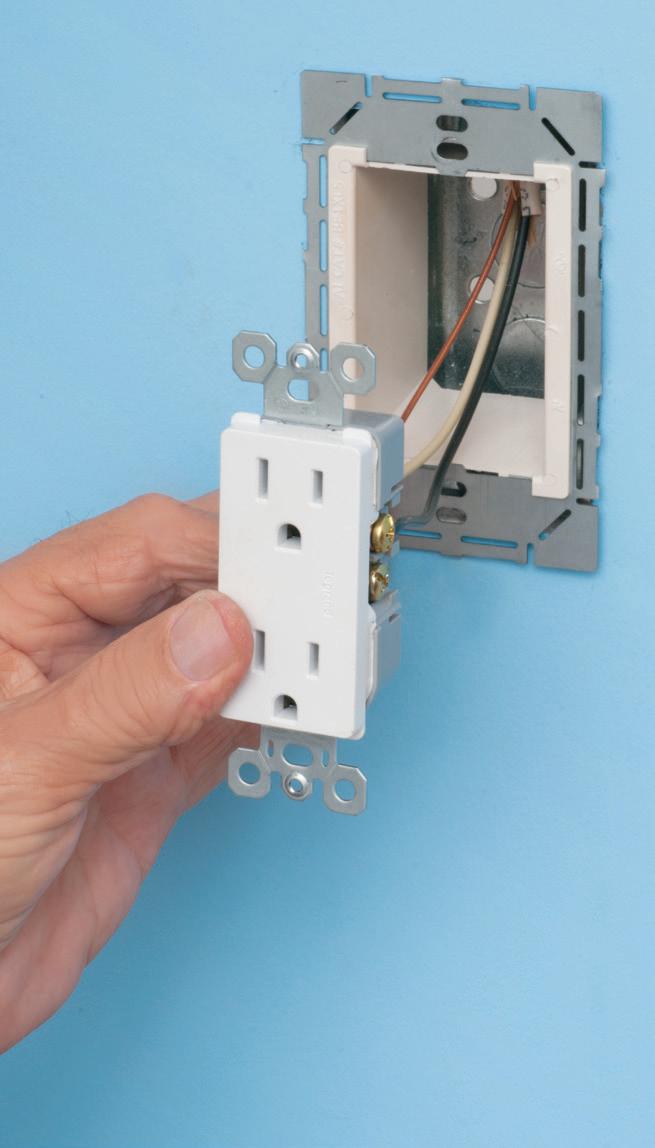

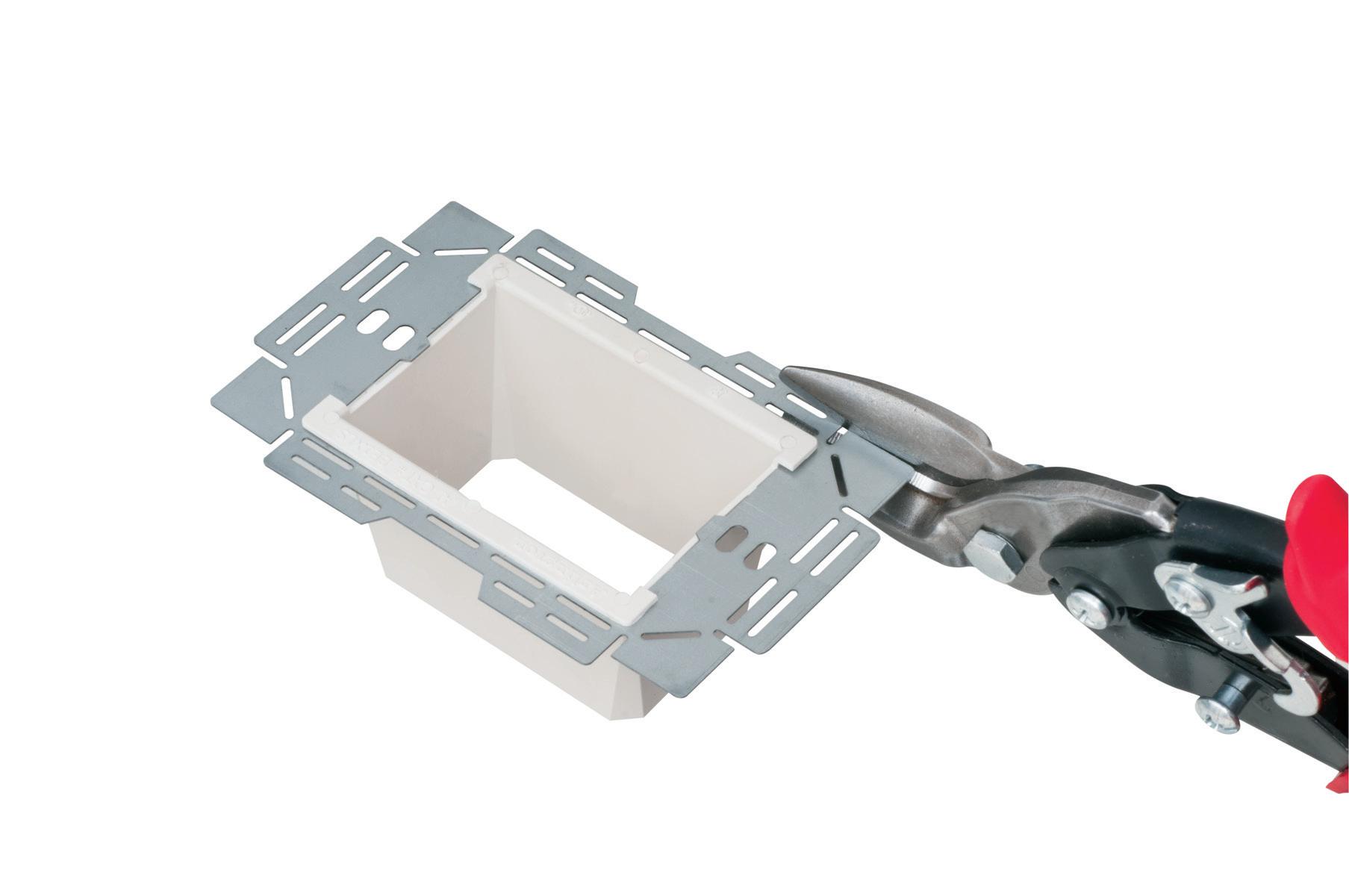

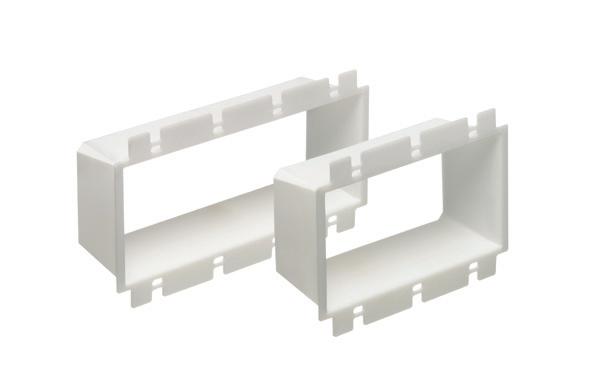

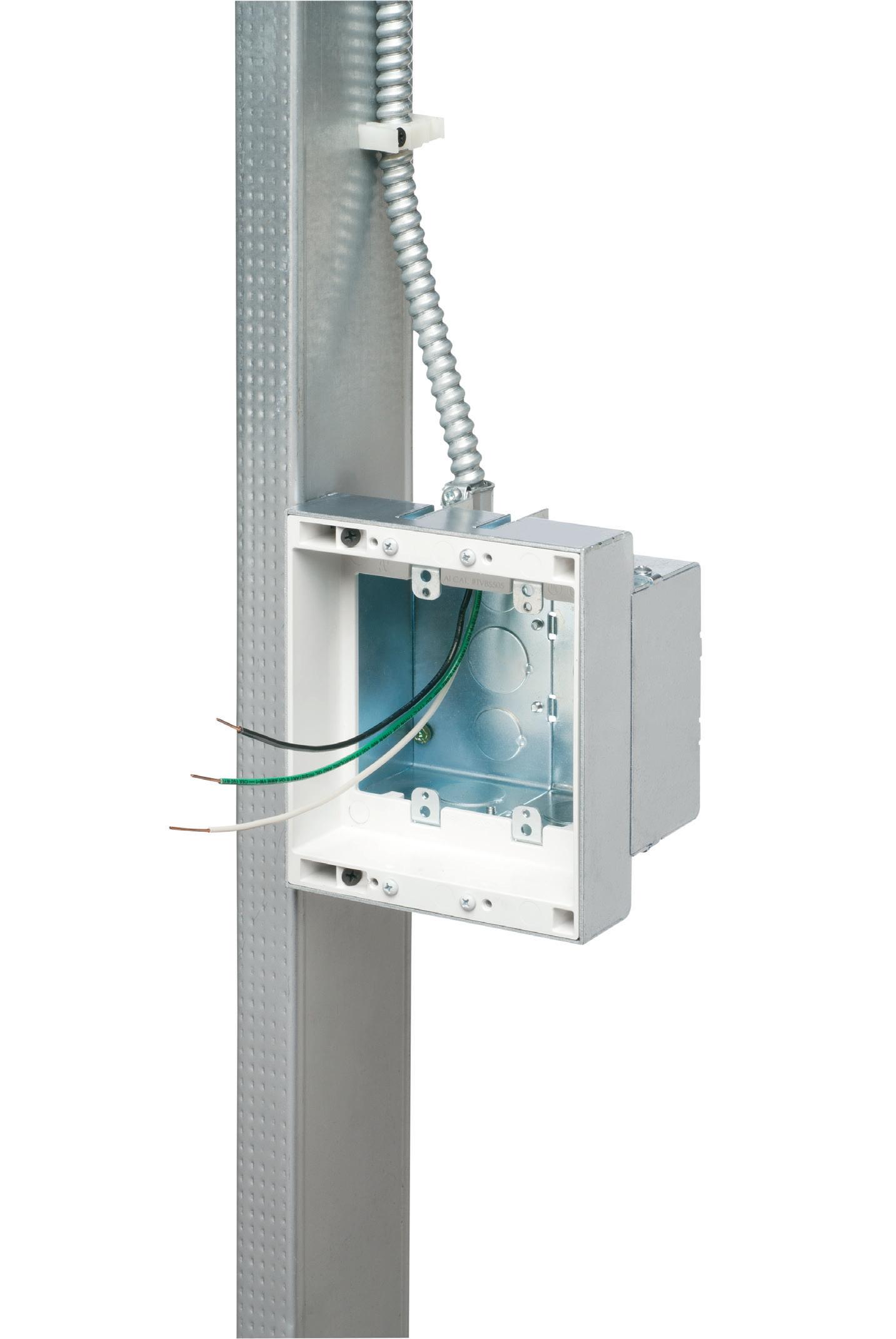

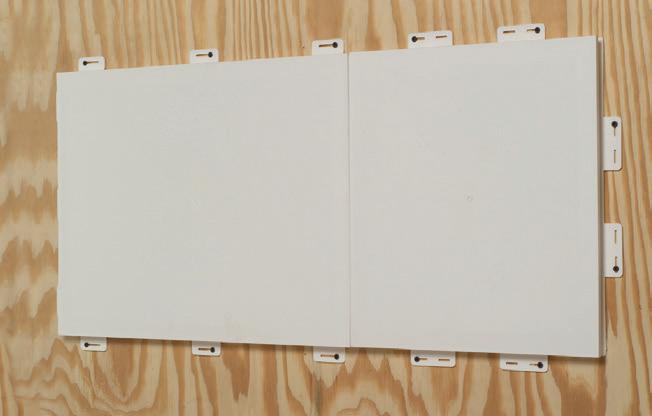

Arlington’s new Furred Wall Box® kit makes challenging outlet box installations fast and easy!

Versatile mounting options Our high strength FSB series outlet box kits are designed for use with existing 1x2 drywall furring strips – but can also be mounted directly to a concrete block wall between furring strips. Place the box or outlet where it’s needed.

Integral cable securement – No pullout! Accommodates GFCI and USB receptacles. Convenient kits simplify ordering of FSB1 and FSB2.

High-strength No breakage in cold weather

Integral Mounting Flanges

FSB2

FSB2

on Drywall furring strip

FSB1 Single gang on Block Wall

Low Profile

NEW FSB12 * FSB22

ADD OUR BOX EXTENDERS to BROADEN APPLICATION and USE

Furring strip flange Mounting Bracket

Base

Assemblies for 1/2" Wall Thickness & Standard Depth

Install on 1x2 Furring Strips or Block Wall with 1/2" Drywall

One-gang FSB12

Block wall flange Mounting

Our NEW Low Profile single and two-gang Furred Wall Box® base assemblies have 1/2" raised ring for use with standard wall plates.

They combine with Arlington’s Box Extenders to deliver installation solutions for wall thicknesses from 1/2" to 1-1/2" and varying device depths

• Integral cable securement – No pullout!

• For standard and GFCI devicesUses standard wall plates

• Single gang FSB12 - 17.0 cu. in. Two-gang FSB22 - 20.5 cu. in.

Add our BOX EXTENDERS for these specific conditions...

1 if Total Wall Layer Thickness is GREATER than 1/2" (up to 1-1/2") Add BE1 or BE2

if Using a Deep Depth Device with 1/2" Wall Thickness Add BES1 or BES2

or Dimmer

Bracket

EV UPDATE

avoid these problems is to use cable-inconduit (CIC), as shown in the Photo on page 20. This type of product can be installed in one of three ways — plowed, trenched, or directionally bored. The use of CIC can avoid digging up the ground and uncovering items that could be an issue related to permitting.

PRE-MADE SKIDS WITH INSTALLED CHARGERS

power up and over where vehicles have to travel in a parking lot, and then guide wires are used between the poles to sup port the power cables. This is similar to an electric utility power line configura tion. Directional boring of conduit is used similarly, but the wires run under neath the parking lot.

This twice-a-month e-newsletter tracks the development, design, installation, and safe operation of electric vehicle supply equipment and systems.

Topics covered include:

• Applying NEC requirements

• Industry news and trends

• New products

• Federal investment allocation

• National EV charging infrastructure buildout development

EV Infrastructure Subscribe Today

See all of our EC&M e-newsletters at www.ecmweb.com

Pre-made skids with chargers installed on them are another great option for avoiding excavation on a job site. The skids allow a pre-made structure to sit on the ground rather than digging a foundation for the equipment. This technique makes system expansion easier, too. With everything above ground, it is more convenient to add or reconfigure the system, if necessary. Since most commercial space is leased, customers do not want to leave a big dollar investment behind if they have to move buildings. If their equipment is on a skid, they can easily disconnect the cables and take the equipment with them.

PRE-LUBED CABLES

Pre-lubed cables are another great option as they do not require installers to apply lube during installation. These cables can also be easily removed if the charging equipment is upgraded or removed. This solution has proven to be helpful when customers eventually upgrade or replace their cable.

AVOIDING CONDUIT

On- or under-the-ground wire raceway systems eliminate the need for conduit. One advantage of this installation technique is that, in most cases, it has 100% allowable fill by the National Electrical Code compared to 40% for conduit. This contributes to less of a support structure needed by the contractor. Similar to the pre-made skids, a wire raceway also adds to the flexibility to easily change or modify the system. However, one issue with over-ground raceway systems is that they do not currently have a driveover raceway that can cross between islands in a parking lot. This is where power poles or directional boring come into play. Power poles are needed to take

CABLE TRAYS AND OTHER OVERHEAD WIRE INSTALLATIONS

Overhead wire installations, like cable trays, are now being used in parking decks as well as some parking lots. With sheds over the cars, this not only pro tects the vehicles from the weather, but it also makes it more convenient to install cables for the charging equipment.

ABOVE-GROUND CONCRETE DIVIDERS

Lastly, above-ground concrete dividers with special channels for wire can be used to get the cables from one point to another. This is seen more with stan dard concrete barriers used for road work, like most people see on the inter state highways. They’re typically known as Jersey Barriers.

Channels are installed on top of the dividers and are placed in the middle of parking lot islands. This acts not only as a cable pathway but also as a barrier required by the Authority Having Juris diction (AHJ) to protect the charging equipment. Cable trays, conduit, and charging equipment are also being placed on these dividers to help protect and add mobility to the system. The most common application appears to be used for school bus charging stations. Some school bus storage space is leased or rented, so school systems need the option to move the system, if necessary.

These are just some of the many new techniques and innovations being deployed to keep construction workers from having to continuously restart projects or uncover hidden disasters that could halt a project entirely.

Bill Fowler is the Director, Business Development-eMobility Infrastructure Solutions, at Southwire. He can be reached at EVSolutions@southwire.com.

Perfect for data center remote power panel feeds, panels, equipment feeds and EV Chargers in parking garages, Arlington’s Listed CableStop® Transition Fittings deliver the efficient, cost-effective way to transition feeder cables to 1.25", 2.5", 3" and 3.5" EMT, IMC and RMC conduit in protective drops, risers and feeds to panels and equipment. Our new CableStop fittings integrate our patented, versatile and SKU-reducing 8412 series cable fittings, with Arlington conduit fittings, allowing for easy transitions to larger knockout sizes.

Available with set-screw or compression connections into 1.25", 2.5", 3" and 3.5" conduit, they ship with multiple end stop bushings that vary the size of the opening – along with a free template select the right bushing for the cable.

EYE ON SAFETY

When and How to Select the Proper Hearing Protection

Workers must wear hearing protection when exposed to loud sounds, including earmuffs and earplugs. Find out when and how to select this equipment based on the task at hand.

By Rick Pedley, PK Safety

Construction and maintenance activities can produce loud noises that may harm workers’ hearing. Even brief exposure to extremely loud sounds can cause permanent hearing damage. Buzzing, grinding, drilling, and other mechanical equipment can all be a cause for concern.

Electrical contractors and their crews need a hearing protection program when working around loud and excessive noises. This includes testing the work site for noise levels to assess risk, reducing the sound of ambient noise, and providing electricians with hearing protection equipment when noise levels surpass the permissible threshold — but not all hearing protection is created equal.

WHEN TO USE HEARING PROTECTION EQUIPMENT

Companies must implement a hearing protection program when noise exposure reaches or exceeds 85 decibels averaged over eight working hours — or an eight-hour time-weighted average (TWA) — according to OSHA.

Job sites with loud noises require monitoring to assess whether hearing protection equipment is necessary. Monitoring can be done with a sound meter. The sounds in the workplace should be recorded throughout the entire shift to calculate the eight-hour TWA. Some sounds may vary in intensity throughout the day, which can affect the TWA. The sound meter should record noise levels in roughly the same spot the workers will be in to increase the accuracy of the findings.

It’s also worth considering hearing screening tests for new employees. It can serve as a defensive way to prevent later claims of work-induced hearing loss or tinnitus.

Once the sound levels have been recorded, the electrical contractor can look for ways to reduce ambient sound levels through substitution. For example, use quieter equipment or materials, move the crew further away from the source of the noise, limit the amount of time each crew member can remain on site while these noises are present, and install sound-reducing barriers to reduce exposure. Some sounds happen by accident. The contractor should take

safeguards to prevent equipment and materials from falling or banging into each other to prevent these sounds.

The sound levels should be tested again after these changes have been implemented to see if further action is needed.

HOW TO SELECT HEARING PROTECTION EQUIPMENT

If workers are still exposed to loud noises at or above the 85-decibel threshold over an eight-hour TWA, everyone must wear hearing protection equipment to reduce exposure.

There are generally two options for hearing protection: earmuffs and earplugs. Earmuffs are reusable and fit over the person’s head. They fit a range of different

ID 39155763 © Pabkov | Dreamstime.com

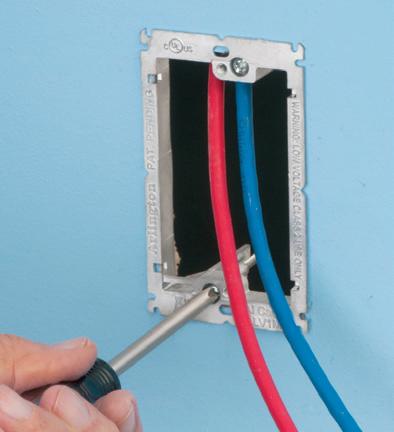

• 2-Hour

• Low voltage side has a combo 1/2" and 3/4" KO for

• Includes NM cable connector (power side)

EYE ON SAFETY

head sizes and can usually be adjusted to wrap around the person’s ears.

Safety Matters

This twice-a-month e-newsletter delivers the latest trends and information on electrical safety, reports on specific accidents in the field, and provides tutorials and evergreen safety content that can be used for reference and training.

Topics covered include:

• Best practices for safely working on electrical equipment

• Accidents and investigations

• Arc flash

• PPE

• Shock and electrocution

• Fire and security

• Safety audits

Subscribe Today

See all of our EC&M e-newsletters at www.ecmweb.com

Earplugs can be disposable or reusable. The plugs slide into the person’s ears to block loud sounds from reaching the eardrum. They are usually made of foam or molded silicone that adheres to the shape of their ear canal. If the plugs are reusable, the material reverts to its original shape and is available for the next shift. Disposable plugs should retain their shape after they’ve been inserted into the ear canal. It’s not recommended to reuse them. They’re a good option if you don’t want to keep track of your earplugs between shifts.

Choosing between earplugs and earmuffs depends on several factors. Earmuffs can interfere with other types of safety equipment, including hard hats, goggles, and other electrical safety gear. In this situation, earplugs are the best choice because they fit inside the person’s ears.

Earplugs are also easier to carry around than earmuffs. They can fit inside a person’s pocket or tool bag without weighing them down in the field. This makes it easy for workers to put on their hearing protection equipment as needed throughout the day.

Earmuffs may be more effective if workers need to wear this equipment for the duration of their shift. Some workers also prefer the feel of earmuffs to earplugs because they may be more comfortable. However, they may also feel warm over time.

A contractor must also decide whether to utilize reusable or disposable hearing protection. Disposable earplugs are less expensive upfront and don’t have to be maintained over time. However, reusing equipment is more sustainable and can eventually save the company money if workers regularly clean and reuse them.

INSPECTING, USING, AND CLEANING HEARING PROTECTION EQUIPMENT

Equipment should be inspected and cleaned before and after every use. Earmuffs are typically easier to maintain than earplugs because they don’t collect as much earwax. Wearing dirty earplugs can lead to infection. These items should

be kept in a clean, airtight container to limit contamination.

All industrial hearing protection equipment will have a noise reduction rating (NRR), which shows by how many decibels the ambient sound will be reduced. Many items come with an NRR of 25 decibels or less. For example, if the noise level is below 100 decibels over an eight-hour TWA, an NRR of 25 decibels would in general be enough to bring the person under the 85-decibel threshold.

However, double hearing protection is required if the noise levels reach or exceed 100 decibels over an eight-hour TWA. This can be done by wearing earplugs underneath the earmuffs. Doubling up on hearing protection increases the NRR by 5 decibels.

The contractor must also train their crews on how and when to use this equipment. If loud noises are always present, workers should don this gear at all times. The work site should have signs posted reminding workers to wear their hearing protection equipment. If the noises are infrequent or only occur during certain times of the day, the company should alert the workers when it’s time to put on their earplugs or earmuffs.

Contractors should document their hearing conservation program for compliance purposes, including data on noise levels, how or if these sounds have been reduced, the types of equipment used, and information about the people using it. Workers who are regularly around loud sounds should have their hearing tested regularly to see if the program is successful.

Some sounds are unavoidable in the workplace. It’s the contractor’s responsibility to ensure its workers aren’t putting their hearing at risk. These tips are designed to help everyone in the industry protect their hearing. Keep it on hand and in mind when surveying potential hazards.

Rick Pedley, PK Safety’s president and CEO, joined the family business in 1979. PK Safety, a supplier of occupational safety and personal protective equipment, has been operating since 1947 and takes OSHA, ANSI, PPE, and CSA work safety equipment seriously. For more information, visit www.pksafety.com.

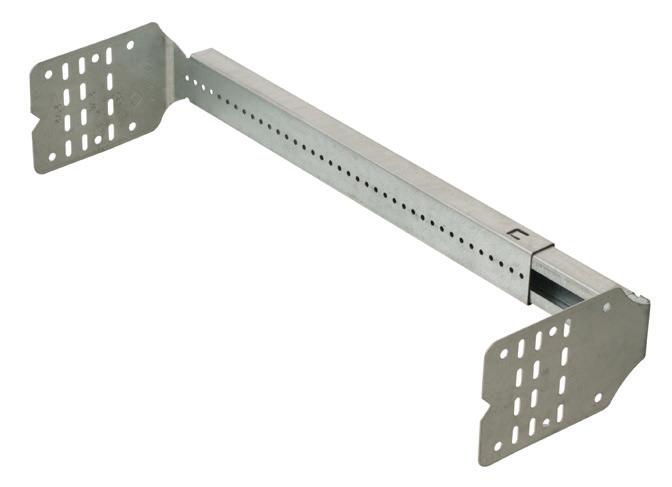

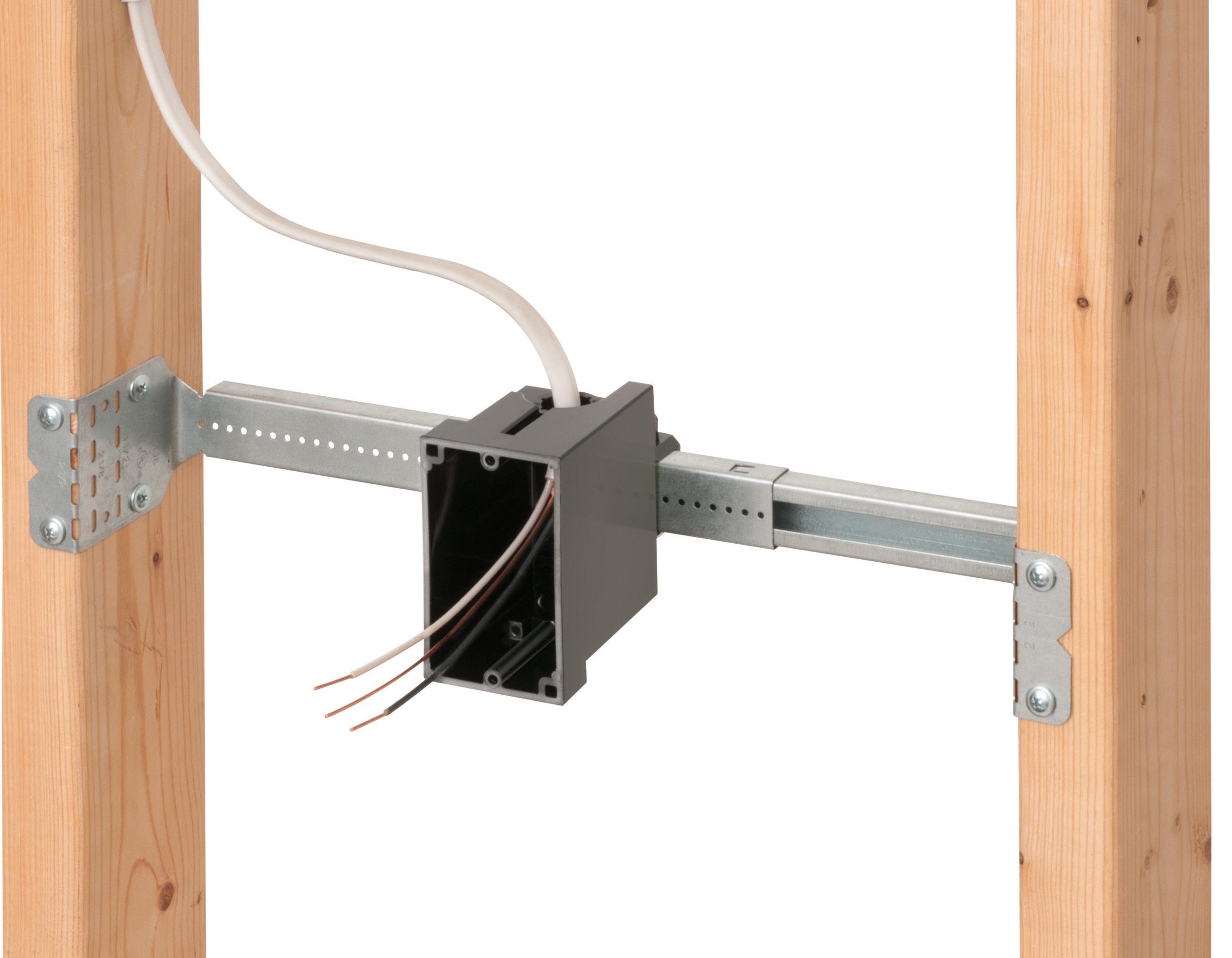

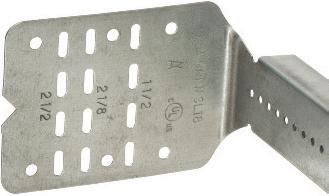

Arlington’s steel SliderBar® offers the easy, NEAT way to mount single or two-gang boxes between wood or metal studs with non-standard stud cavities.

No more cutting, nailing and fitting extra 2x4s to fill the space! SliderBar saves about 20 minutes per box. Designed for studs spaced 12” to 18” apart, SL18 allows positioning of one or more boxes anywhere in the stud cavity.

• Bending guides on bracket assure proper positioning on studs

• Interlocking tab stop prevents accidental disassembly

• Pre-punched pilot holes on BOTH sides of S for easy attachment of one or two boxes

Inside the Infrastructure Funding Gridlock

The rollout of IIJA and IRA dollars has faced uneven progress since 2021 with political and bureaucratic hurdles slowing key electrical projects.

By Tom Zind, Freelance Writer

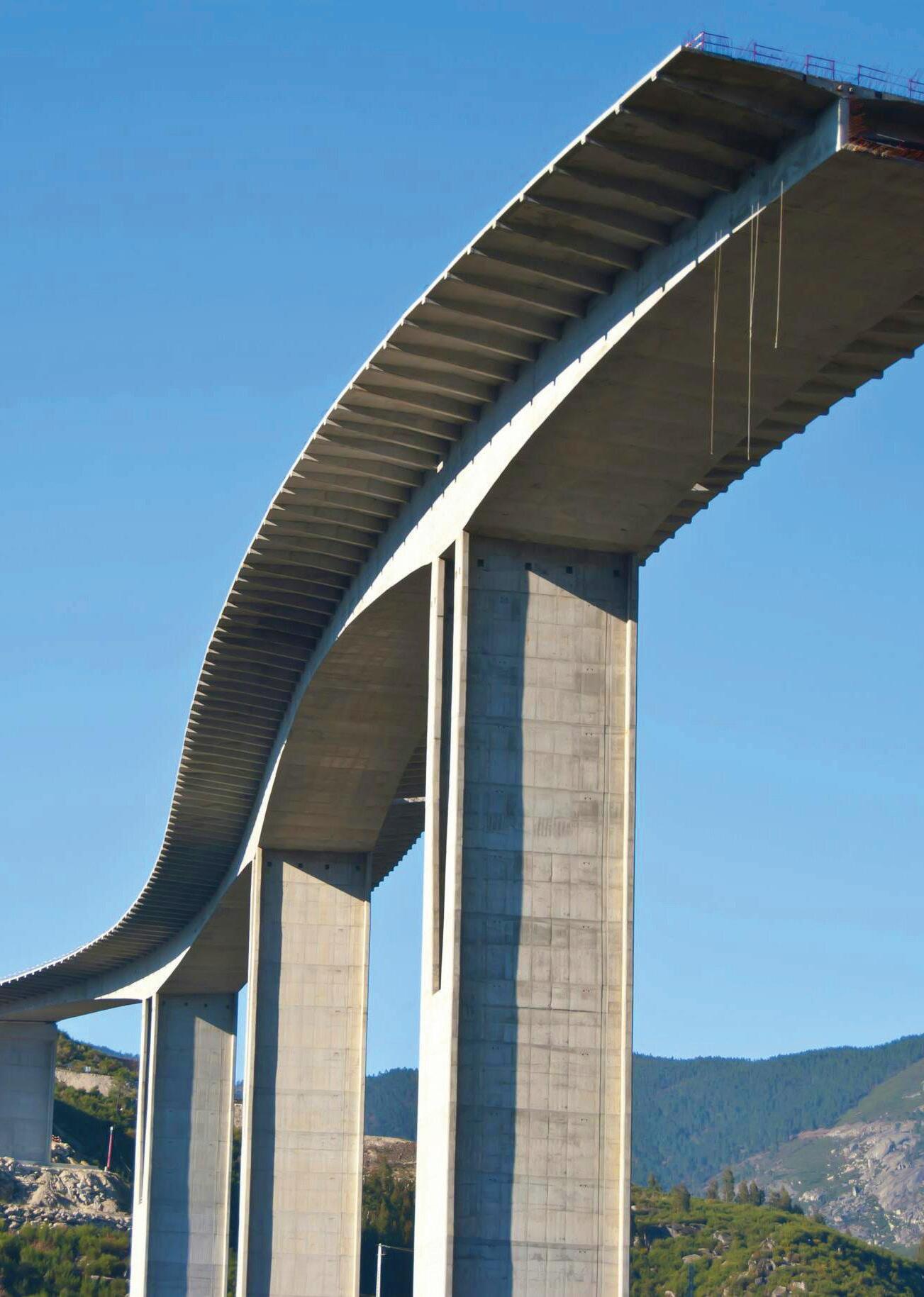

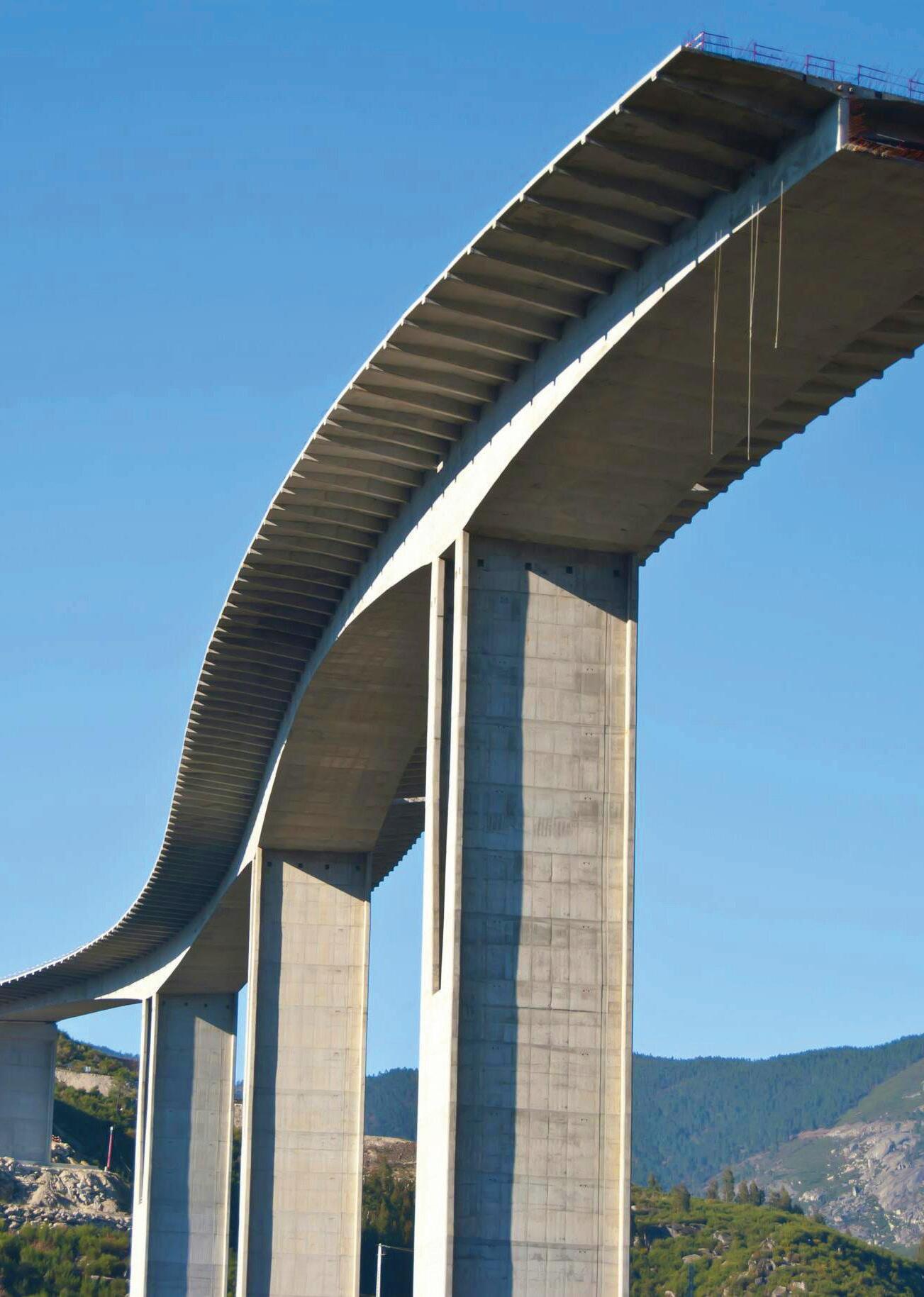

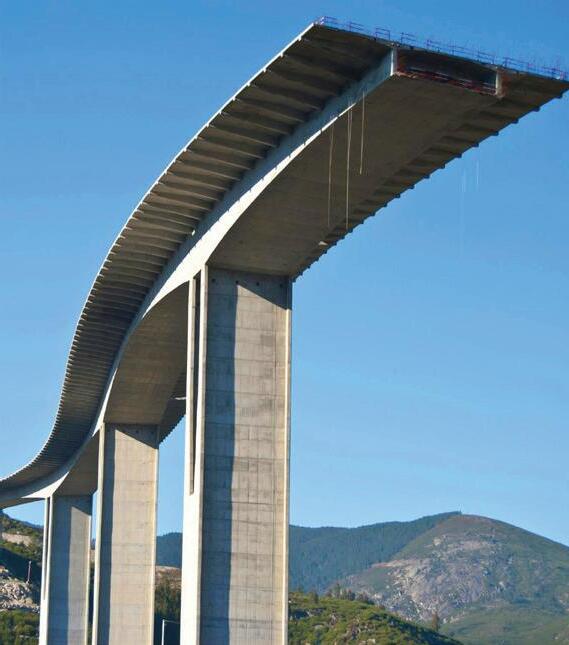

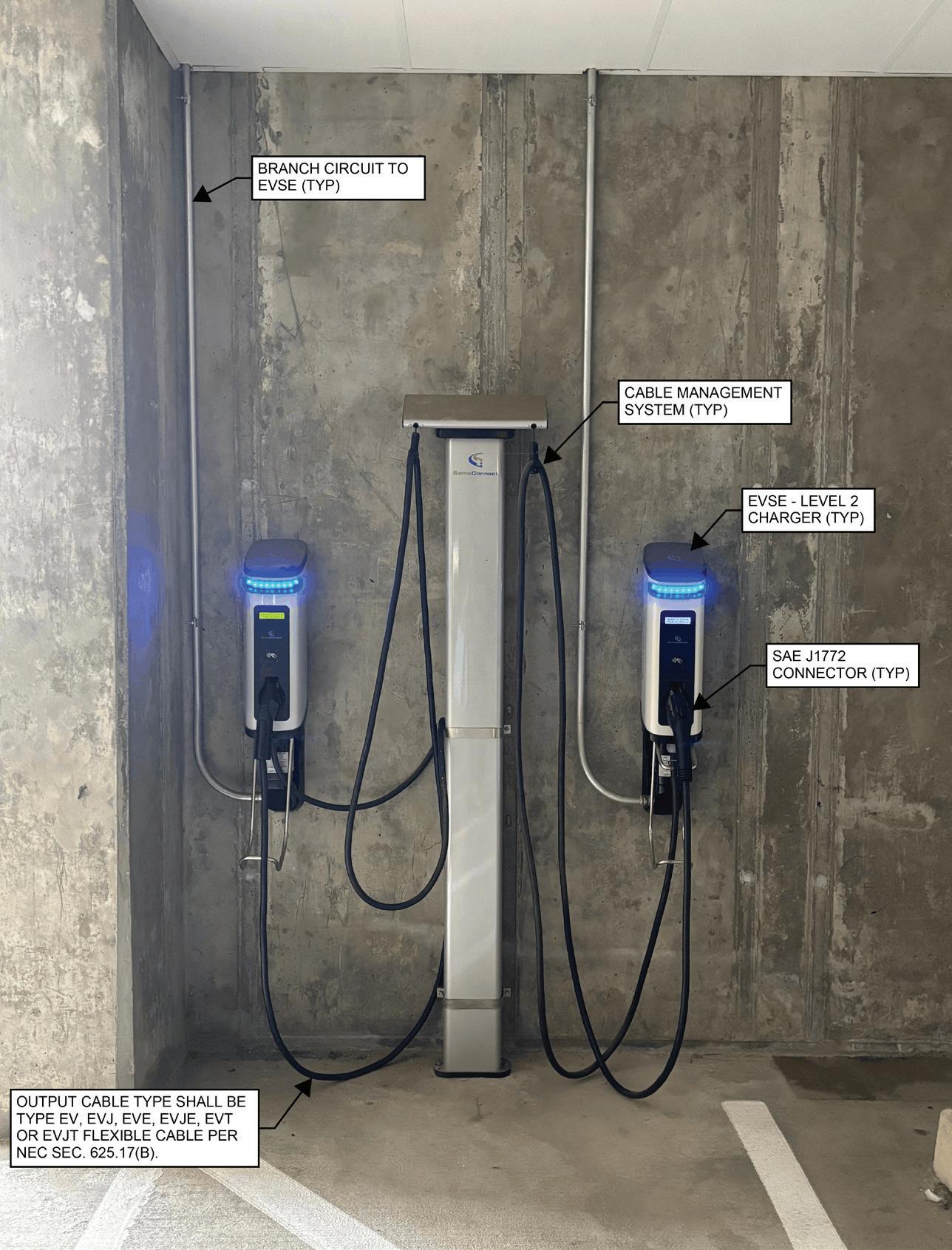

Persistent worries about the state of the nation’s infrastructure now have another wrinkle: mounting debate about what’s worthy of taxpayer support and concerns over how fast that money is getting out the door. Under the new Trump administration, the Infrastructure Investment and Jobs Act (IIJA), passed in 2021 to direct more than $700 billion in grants to fund a wide array of infrastructure programs over five years (Fig. 1 on page 32), has come under some scrutiny. Likewise, parts of the Inflation Reduction Act (IRA), which in 2022 put a similar amount toward infrastructure over time, are being looked at.

Included in the crosshairs of administration actions — executive orders, agency rulings, and Congressional committee oversight seeking to pause outlays in targeted programs pending review — is infrastructure spending that the electrical contracting and design engineering industry covets. This includes projects related to electric

vehicle charging, renewable energy generation, broadband deployment, energy resilience, and virtually anything related to climate change remediation.

Independent of the Trump-induced speed bump, a slow rollout of other IIJA and IRA spending through the Departments of Energy (DOE) and Transportation (DOT), such as that for power transmission and distribution, water, and airports, for example, continues to impact firms and their hopes for an infrastructure spending windfall.

A HALTING ROLLOUT

Ken Simonson, chief economist for Associated General Contractors (AGC), calls the IIJA a “mixed bag” in terms of fulfilling its promise. Contractors are reaping comparatively more benefits from spending on hard infrastructure like water systems, airports, and roads, he says, some of the top “new investment” targets identified by the American Society of Civil Engineers (ASCE), as shown in Fig. 2 on page 32. But others that breed more controversy

(like broadband expansion and energy) are lagging.

“‘Unclear’ is the best adjective when it comes to the IIJA,” he says. “There have been a lot of announcements of things stopped, but it’s not clear how many of them continue to be under review or have been cancelled.”

There’s evidence that worry over the fate of funding has been growing. The most recent quarterly business sentiment survey, conducted by the American Council of Engineering Companies (ACEC) through its members, shows 41% think a slow rollout of the

IIJA will be a contributor to negative economic sentiment a year from now. It doesn’t rank high on the list of potentially impactful factors, but the share has grown steadily since the third quarter of 2024 (when it stood at 26%).

A new round of delays in getting funding out the door is a legitimate worry, says Matt Reiffer, vice president of infrastructure programs for ACEC. While noting new administrations with different priorities typically cause hiccups in programs, he acknowledges that “the pace and scale of change in 2025 has been unprecedented, adding,

“executive orders and agency directives have changed areas of emphasis and prioritization, impacting grant criteria and project selection.”

The result, he says, is that his membership, while confident that markets boosted by federal infrastructure dollars will ultimately deliver, must prepare itself for changes that the spending reviews could spawn.

“The potential disruption from changes in prioritization, particularly in the energy sector and projects related to climate adaptation and resilience, should prompt firms to review and

consider diversifying their business plans,” he says.

EV CHARGING WHIPSAW

Firms in the electrical services space that were counting on the IIJA to deliver opportunity in the buildout of electric vehicle charging infrastructure have had a front row seat to the shifting winds of policy formulation and execution.

The IIJA authorized and appropriated $7.5 billion for programs to support the deployment of public EV charging infrastructure. One was the DOT’s National Electrical Vehicle

Agency Reported Infrastructure Investment and Jobs Act Appropriations for Grant Funding Available to Tribes, States, Localities, and Territories

Department of Transportation

Environmental Protection Agency

Department of Energy

Department of Commerce

Department of the Interior

Department of Homeland Security

Department of Agriculture

Appalachian Regional Commission

Department of Health and Human Services

Delta Regional Authority

Northern Border Regional Commission

Federal Communications Commission

Denali Commission

Southeast Crescent Regional Commission

Southwest Border Regional Commission

$5.0

$1.3

$49.6

$54.7

Source: GAO analysis of Public Law 117-58 and federal agency data | GAO-25-107243

Fig. 1. Five federal agencies are responsible for allocating almost $712 billion in IIJA funds. (Source: GAO Report, April 29, 2025: Infrastructure Grants: Status of Funding to Tribes, States, Localities, and Territories as of December 31, 2024)

Infrastructure (NEVI) Formula program, given $1 billion annually through 2026 to assist states in that effort.

NEVI was slow out of the blocks, however, and has not picked up speed. A July 2025 Government Accountability Office (GAO) report to Congress on EV infrastructure stated that, as of April 2025, only 384 chargers funded through NEVI and another IIJA program were open to the public. While not passing judgement on that number, GAO noted its report was motivated by concerns Congress had expressed “over the pace at which charging ports have been built under the NEVI and CFI (Charging and Fueling Infrastructure Discretionary Grant Program).”

Already struggling, the programs took another hit in January, when Trump issued an executive order halting the disbursement of a broad swath of IIJA funding tied to alternative energy development. Both were affected, leading the Federal Highway Administration (FHWA) to begin a review of them to ensure they aligned with administration policies and priorities. Soon after, FHWA informed states that it was rescinding current and prior versions of its program guidance. The GAO report noted, too, that the administration’s FY 2026 budget was cancelling $6 billion in funds for EV charger programs.

New Infrastructure Spending for 2022-2026

Surface Transportation ($455 billion)

Energy ($42 billion)

Drinking Water, Wastewater, and Stormwater ($46 billion)

Airports ($25 billion)

Ports and Inland Waterways

Source: American Society of Civil Engineers’ Report Card for America’s Infrastructure

Fig. 2. Infrastructure considered more “traditional,” such as roads, bridges, and the like, will dominate future spending.

Now, though, the programs are back up. In mid-August, DOT said following a review, it was unveiling revised guidance aimed at freeing up the 84% of IIJA funding that remains unobligated. That will be achieved by giving states more flexibility, cutting red tape, and updating streamlined applications. In line with the administration’s priorities, the guidance moves the program away from tying funding to the promotion of diversity/equity/ inclusion (DEI), which the administration opposes. DOT says the overhaul will “ensure charging stations are

actually built, and federal funding is spent effectively and efficiently.”

Such administration fine-tuning of IIJA programs could still be in the early stages. Many agencies are still getting their footing and are dealing with reduced staffing levels and changes in priorities fostered in part by actions of the Department of Government Efficiency, and that could affect whether and how fast money gets out the door.

Additionally, the Republican-controlled Congress is expected to enter the fray, taking up legislative responsibilities relating to IIJA reauthorization

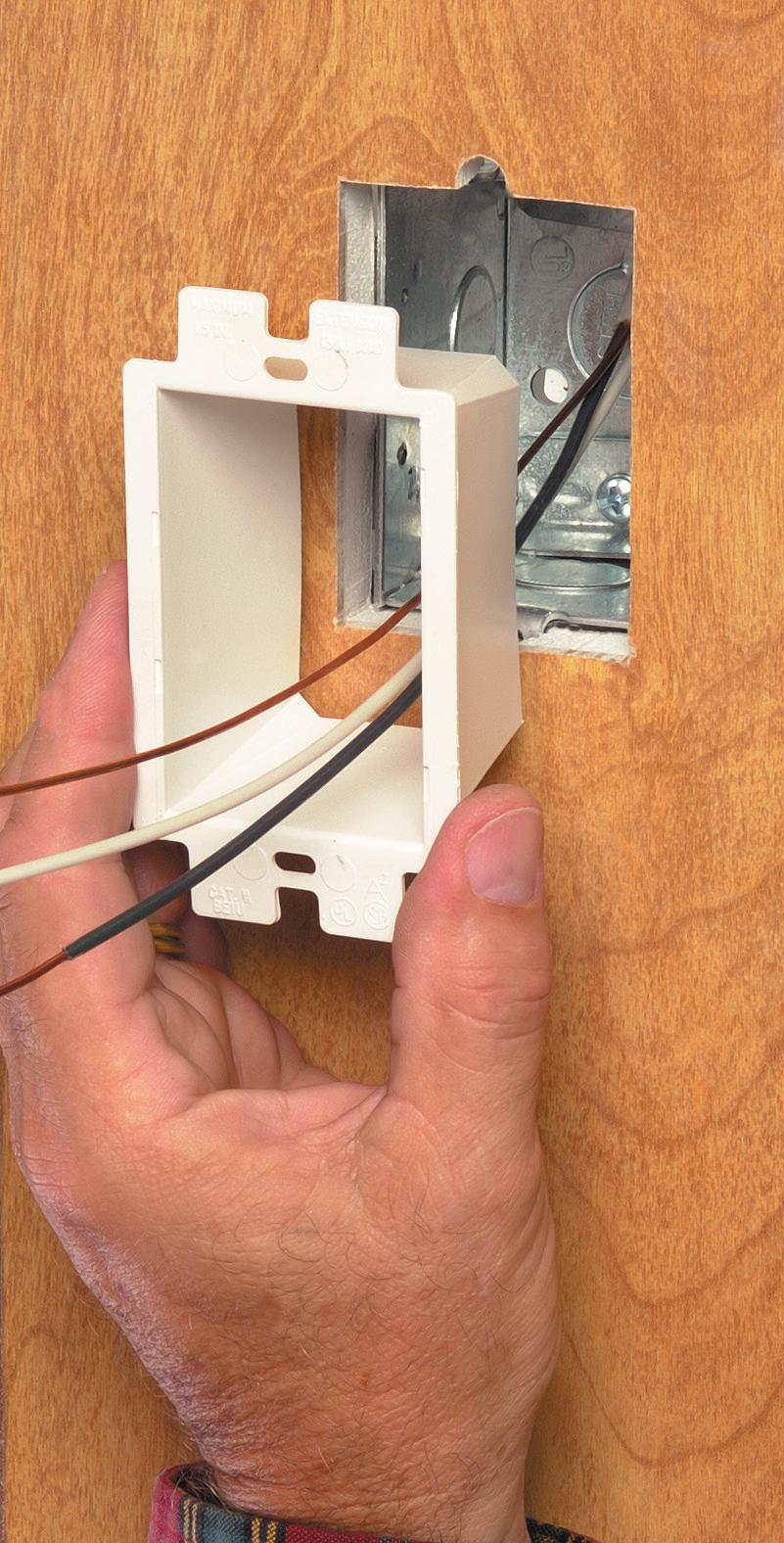

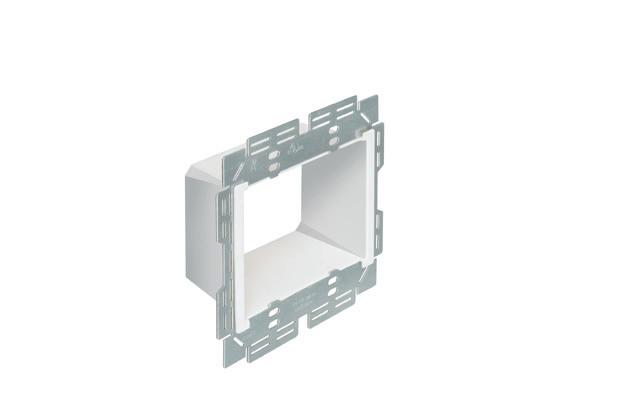

LISTED BOX EXTENDERS

Arlington’s variety of cULus Listed Box Extenders extend set back electrical boxes up to 1-1/2".

Made of heavy-duty, 105°C continuous use 94V0 rated, flame retardant plastic, they level and support wiring devices, while protecting wires against damage and stripping.

Choose the one that’s right for you!

BE1, BE2, BE3, BE4...Single-, two-, three- and four-gang, and BE1R for round or octagonal boxes...

Box Extenders

device support in oversized or mis-cut wall openings, available in single-, two-, three- and four-gang, (patented BE1X, BE2X, BE3X, BE4X.)

Our new heavy duty, COMMERCIAL-GRADE steel support plate! As shipped, single and two-gang BE1XLS and BE2XLS work with maxi cover plates, but they’re and standard plates. Convenient. Saves time. Great for poorly cut drywall.

For all standard devices, switches and GFCIs, our box extenders comply with NEC Article 314.20 for set back boxes.

and proposals to alter the mechanics of the funding. Of some potential consequence, Reiffer says, are appropriations bills that could “redirect some portions of advanced funding under the IIJA into regular agency program budgets, essentially eliminating the supplemental nature of the funding.”

GAO LIFTS THE HOOD

Whether actions by the administration will slow or speed up IIJA funding, the pace is already slow by some measures in many agencies. In an April report to Congress, GAO said that as of year-end 2024, $275 billion of the $581 billion (82% of the total $712 billion authorized) made available to federal agencies for infrastructure projects through fiscal year 2025 had been obligated. Outlays, the amount actually handed over, totaled just $119 billion or 21% (see Table on page 36).

At DOT, by far the largest single recipient of IIJA funding, obligated funding as of July 31 totaled $305 billion, 71% of its $432 billion budget authority. But the total outlay at that date was $169 billion or 39%. Money for roads, bridges, tunnels, etc., has been obligated and outlaid at the quickest pace, around 80% and 50% to 60%, respectively, across agencies like the Federal Highway Administration and the Federal Motor Carrier Safety Administration.

Other DOT sub-agencies are lagging. Federal Aviation Administration dollars, for projects that may impact electrical design and contracting firms more than others under DOT, are

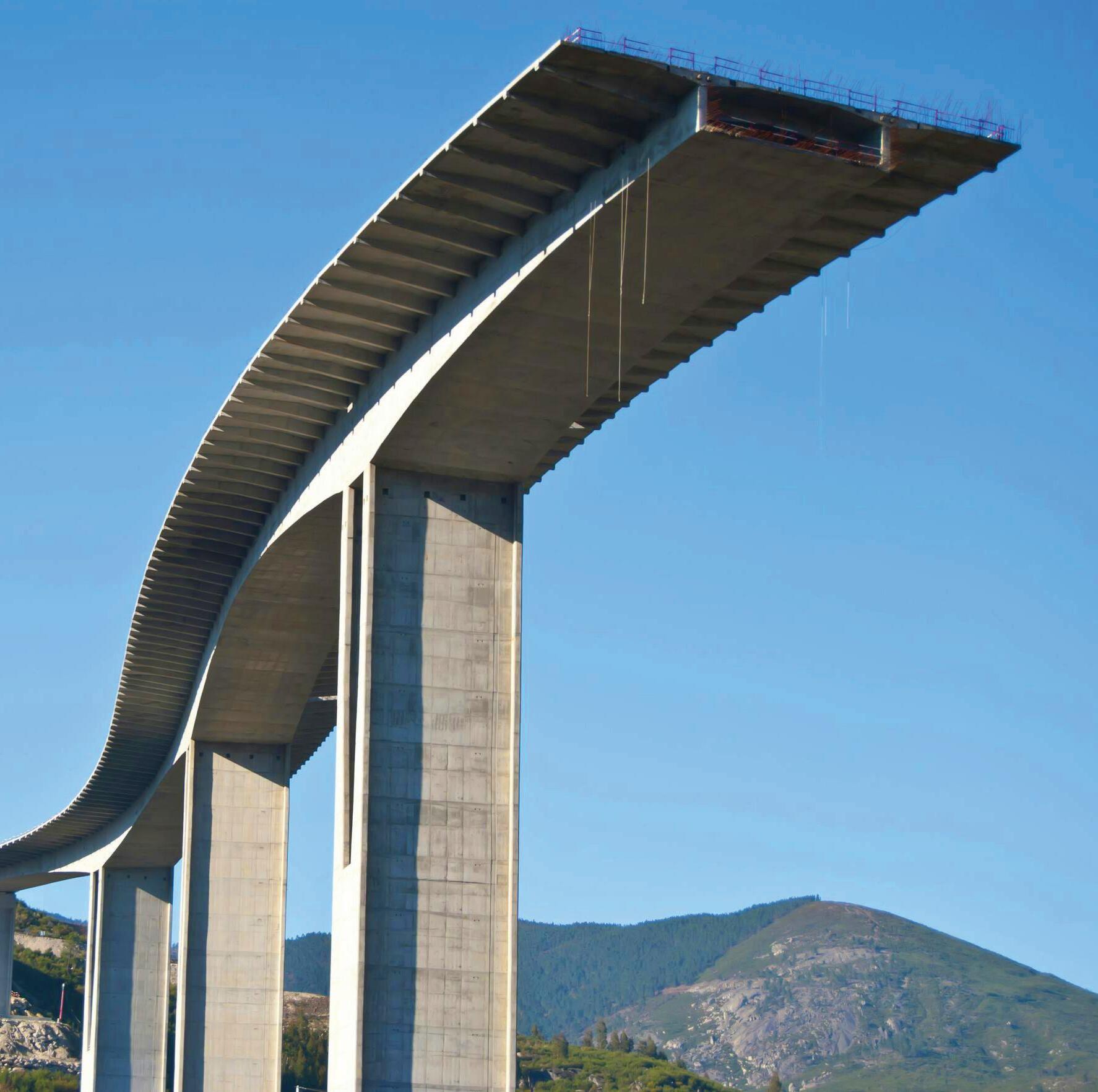

Solar and wind power were prioritized in federal infrastructure spending but could be on the chopping block.

going out more slowly. Of its $20 billion authority, 51% had been obligated and 27% outlayed as of late July. Federal Railroad Administration projects, which can also incorporate heavy electrical, are slow as well. IIJA funding authority was $53 billion, 65% of which was obligated, and only 8% outlayed.

GAO issued a report in July urging DOT to address delays in getting funding to discretionary grant awardees. The sources of the delays include inflationlinked cost increases; conforming to the Build America, Buy America Act; National Environmental Policy Act reviews; and defining project budget and scheduling. These interrelated challenges, GAO said, “create risks for

awardees, including that funding will expire or no longer be available to the awardee,” adding “awardee challenges need to be addressed as it makes deci sions about delivering the remaining billions in IIJA funding.”

At DOE, the agency shepherding IIJA projects with the most potential for the electrical sector, obligations and outlays as a percentage of total author ity is the lowest of some 15 agencies. Of almost $43 billion in funds available for obligation for FY 2022-2025, the agency obligated 11% and outlayed just 1% as of year-end 2024. The lagging performance may be due in part, GAO says, to the agency being one of three that have never drafted an IIJA implementation plan. DOE attributed it partly to decentralized management plans that never developed cohesive implementation guidance.

TARGETING “GREEN”

Prospects for DOE quickening the pace have dimmed. With executive orders and agency directives, the administration has put a bullseye on energy projects that smack of “green,” a significant component of IIJA’s energy infrastructure focus. Trump’s “Unleashing American Energy” executive order (prioritizing traditional energy sources) froze non-conforming IIJA outlays. Though quickly narrowed in scope by the Office of Management and Budget, and subsequently partly reversed by a U.S. District Court judge, the order may be casting a pall over

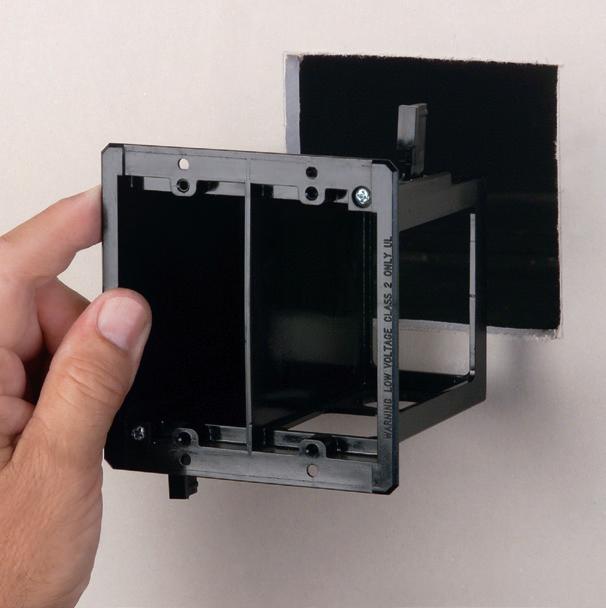

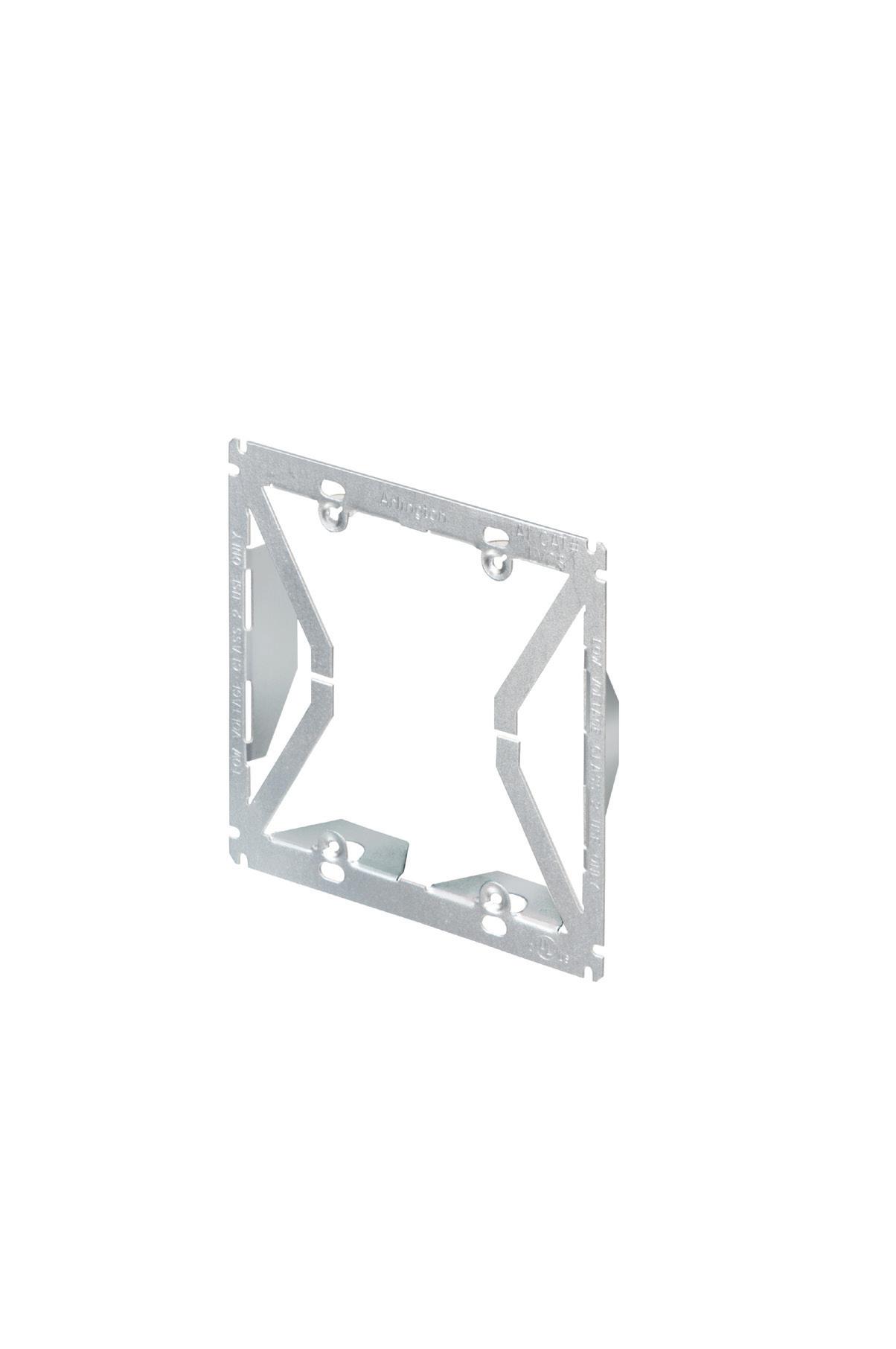

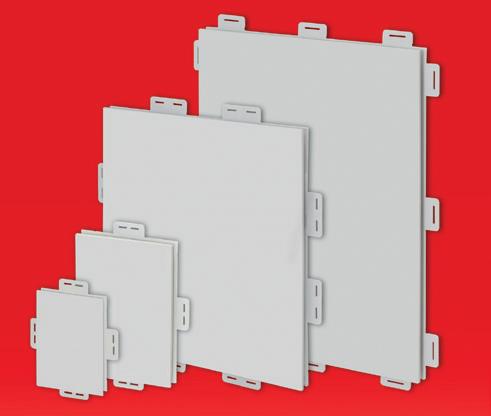

Arlington’s Low Voltage Mounting Brackets are the solution for fast and easy cut-in installation and mounting of Class 2 communications, computer and cable TV wiring and connections.

Introducing METAL low voltage mounting brackets for EXISTING or RETROFIT construction...

LV1M and LV2M COMMERCIAL GRADE

• Extra rigidity and stability where performance and visibility are important or critical

• Threaded holes for easy, fast device installation

• Adjustable bracket for 1/4" to 1" wall board thicknesses

Our LV1S and LV2S PLATED STEEL bracket design, provide excellent stability and secure installation of low voltage devices in 1/4" to 1-1/4" walls - without an electrical box.

Source: GAO analysis of agency data and USAspending.gov obligation and outlay data | GAO-25-107243

Actual outlays of IIJA monies were a small percentage of those authorized as of year-end 2024, according to USAspending.gov.

IIJA funding that goes through the DOE to many energy projects, meaning the funding backlog could remain slow to clear.

Even though Trump’s executive orders have been reversed on challenge, some of which were appealed by agencies, they did prompt lawsuits questioning the executive branch’s authority to block Congressionally approved funding. Their outcome, Reiffer says, could have some bearing on the fate of energy project loans through IIJA and grantees awarded funds that were paused or withdrawn. Overall, “we don’t expect a significant impact on most programs” from the suits; Congress, he added, will also “have a significant role in defining how funds are allocated and overseeing how they are spent.”

The fog of uncertainty surrounding the IIJA is enveloping organizations with a financial stake in prospective spending. Centre Law & Consulting, Tysons, Va., is representing developers, contractors, and others that have made financial and contractual commitments to possibly ill-fated IIJA projects. Business has been predictably brisk, says Managing Partner Barbara Kinosky, because the level of exposure to financial harm from possibly billions of dollars of yanked or slowed funding is high.

Many of Centre Law’s clients find themselves in a fix. Many have spent heavily on proposals, staff, equipment, or other resources to deliver on signed or prospective contracts for IIJA-funded projects. With uncertainty swirling, Kinosky says, they can be in a quandary about whether to pull the plug and seek compensation for cancelled contracts through litigation or negotiation — or wait to see if projects under review ultimately receive funding and move forward.

“We had one client that made a decision to get out, and then two weeks later the termination was rescinded,” she says. “You end up not knowing whether to go full bore or not.”

THE INFRASTRUCTURE GAP

A lack of clarity on individual project funding, administration commitment to spending appropriated money, and the continuation of comprehensive infrastructure legislation come at what may be a critical juncture.

The nation’s infrastructure, says the ASCE in its newest Report Card for America’s Infrastructure, faces a “substantial investment gap.” Over the next decade, $9.1 trillion will have to be spent if 18 categories of infrastructure are to reach a “state of good repair.” But it puts public and private investment at

$5.4 trillion, assuming current funding levels are maintained, leaving a gap of $3.7 trillion. And that gap would grow “significantly if Congress were to snap back investment levels in place prior to recent increases in federal spending.”

The report card, which gives the nation’s infrastructure a grade of “C,” (mediocre/requires attention) up from a “C-” in 2021, credits the IIJA and the IRA with helping to boost that grade. But the true power in that legislation will come from its continuation in some meaningful form.

“The IIJA and Inflation Reduction Act’s $580 billion in new investment has provided an initial and consequential step in bridging the funding gap between the nation’s infrastructure needs and preexisting support,” ASCE says. “We must sustain, or in many cases, increase, infrastructure funding and financing options across all levels of government and the private sector,” and “Congress should maintain investment levels provided by the IIJA when the law expires in 2026 and fully fund authorized programs during the annual appropriations process.”

Tom Zind is a freelance writer based in Lee’s Summit, Mo. He can be reached at tomzind@att.net.

Electrifying the EV Charging Market with Solar and Storage Integration

Electrical contractors and solar companies are integrating EV charging systems with renewables and energy storage to improve resiliency and sustainability for their customers.

By Amy Fischbach, Freelance Writer

As the demand for electric vehicles (EVs) worldwide continues to rise, electrical contractors are plugging into a new business opportunity in the EV charging market. Today, EV sales in the United States have increased to 1.6 million, and globally, to more than 17 million, according to IEA’s 2025 Global EV Charging Outlook.

For example, Trout Electric, a Riverside, Calif.-based electrical contractor, opened its doors in 2008 and dove into the EV charging installation market three years later. Electrification now accounts for 80% of its business between residential and commercial markets.

“Once we saw the potential for the EV market, we fully invested in it,” said Matt Trout, president of Trout Electric, which has four offices in Southern California and Nevada. “We made sure we were on top of all new products and trained our technicians to the fullest extent possible.”

As the EV charging market continues to heat up, contractors are also exploring how to integrate EV charging with on-site renewable energy and storage. With this

Courtesy of Trout Electric

The GM bi-directional system with battery storage powers a 10,000-sq-ft home.

FAN FIXTURE BOX

Arlington’s heavy-duty, plated steel fan/ fixture box has an adjustable bracket that mounts securely between joists spaced 16" to 24" o.c.

Flush ceiling installations

FBRS415 is designed for ceilings up to 1-1/4" thick. For 1/2" ceilings, use the pre-bent positioning tab. For other ceiling thicknesses, bend along the appropriate score line.

• 15.6 cu. inch box ships with captive screws, mud cover, installed NM cable connector

or metal stud, and position the cables. Next bend the strap at the foldline (centerline). Fold the strap over the cables and insert the locking tab in the opening as shown to hold

approach, they can help their customers to reduce demand charges, improve resilience, and support sustainability goals.

“We’re starting to see more customers realize that investing in a combined system delivers greater value than the sum of its parts,” said Kristina Zagame, senior researcher, Electrification, for EnergySage, which connects certified, pre-screened installers with homeowners. “They’re not just saving on energy bills; they’re creating an efficient and resilient energy system for their property and vehicles.”

Case in point: Charging an EV at home is three times less expensive compared to using a DC fast charger — and, with home solar, that cost can drop to virtually zero, she said.

“While it’s not universal yet, adoption is growing, especially in states like California and Texas,” Zagame said. “We expect more homeowners and businesses to start connecting these technologies as they look for ways to save money, reduce reliance on utilities, and improve resilience.”

EMBRACING OPPORTUNITIES

Systems that integrate EV charging, storage, and solar are still emerging, but the market is growing rapidly, said Tom McCalmont, co-founder and CEO of Paired Power, which specializes in solar microgrid charging systems for EVs and EV fleets. In fact, analyst reports predict

that the market for integrated chargers will nearly double from 2021 to 2031, he said.

“Outside of a major expansion of the U.S. grid, integrating solar, battery energy storage systems, and EV charging is the most realistic way to expand EV charging infrastructure to meet demand,” said McCalmont, who co-founded the solar engineering firm McCalmont Engineering, and has 25 years of solar, storage, and EV charging experience. “With the push for transportation electrification combined with data center growth due to AI, there is huge demand for grid expansion that our integrated solar and EV charging system can mitigate.”

An integrated EV charging system can ensure that grid power is managed to reduce or eliminate demand spikes during the day, can time-shift solar power to offset peak time energy costs, or can bank solar power during the day for charging vehicles at night, he said. The storage and solar components of the system can also act semi-independently of the grid, providing a resilient energy source during blackouts or brownouts.

Electrical contractors who understand renewables and EV charging can embrace a huge opportunity, Zagame said.

“This isn’t just wiring a new outlet — it’s knowing when a panel upgrade is needed, how to balance loads when you’re adding multiple systems, and how to properly design for future additions like a battery or more solar,” she said.

For example, the recently released “Marketplace Report” from EnergySage

Integrating Systems: Step

by Step

Before kicking off a project integrating EV charging, solar, and storage, planning is critical, said Matt Trout, president of Trout Electric in California. Here are six steps to keep in mind during a project.

1. Understand the main service capability.

2. Determine the load calculation.

3. Estimate how much renewable energy you will need.

4. Decide on a kind of backup capability.

5. Make sure everything is done to Code following the installation.

6. Understand what maintenance is needed for each product installed, as different products require different maintenance intervals.

Trout Electric installed these three Tesla Powerwalls for a residential application.

Courtesy of Trout Electric

Arlington’s recessed STEEL combination power/low voltage TV BOX® is the best way to mount an LED or Hi-Def TV flush against a wall.

TV BOX provides power and/or low voltage in one or more of the openings. Plugs and connectors stay inside the box, without extending past the wall.

Designed for use in new or retrofit commercial construction where metal raceway is used, we have a STEEL TV BOX for almost any application!

• Steel box; non-metallic paintable white trim plate

• Easy, secure installation

• Optional covers

Arlington’s Concrete Pipe Sleeves are the economical way to sleeve through concrete pours in tilt-up construction WALLS – and FLOORS allowing cable and conduit to run easily from one floor to the next.

No costly core drilling – No cutting holes in the form. Plus, you can position the hole prior to pouring the concrete.

• Attaches to form with nails or screws

• Stackable up to 23" h for extra deep pours

• Vents keep wet pipe sleeves from sticking together

• Multiple hole sizes: 1-1/2"

shows solar contractors are already moving into whole-home electrification services, with storage installed alongside 33% of solar projects, energy monitoring systems with 25%, and panel upgrades with 11%. But adding other electrification products at the same time as solar (like EV chargers and heat pumps) is still minimal, even though they represent a massive market opportunity, she said.

“Contractors that expand beyond single-trade solar or EV charging into full-home electrification can build multiple revenue streams, form stronger customer relationships, and better position themselves as the industry evolves,” she said. “The electrical contractors who invest in this expertise now will capture the largest share of this growing market and be resilient to future changes.”

While some consumers may think they must buy everything at once, they can start with solar, add an EV charger later, and then install a battery when it makes sense.

“It’s typically easier and cheaper to install all at once, but as long as the system is designed to be expandable, you can move toward full electrification step by step,” she said.

Looking ahead, she said these technologies won’t be treated as separate, either in how contractors build their businesses or what consumers expect.

“We’re moving toward a future where a typical home will have solar, storage, and EV charging designed to work together from day one, with smart controls that optimize energy use,” she said. “On the commercial side, the same integration will help businesses cut operational costs and meet sustainability goals. Integration isn’t a nice-to-have anymore; it’s quickly becoming the standard.”

How to Break into the Market

Electricians are crucial to the entire process of installing and integrating EV chargers, serving as the primary professionals responsible for the technical and safety-critical aspects of the job.

“Whether it be performing an initial assessment of the existing electrical system, wiring and circuit installation, testing, or maintaining the systems in working order, electrical contractors are there every step of the way,” said Tom McMalmot, CEO of Paired Power.

Electricians who are working in this sector must be familiar with the National Electrical Code (NEC) as well as local building and electrical codes, which have specific provisions for EV chargers. Electrical contractors should also be aware of the different levels of EV charging (Level 1, Level 2, and DC fast charging) as each has different voltage and amperage requirements.

Electrical contractors looking to help expand EV charging infrastructure can start by getting their Electric Vehicle Infrastructure Training Program (EVITP) certification. The national training and certification program assures that electrical contractors can correctly design and install EV charger electrical systems.

REDUCING CHARGES

When solar, storage, and charging are integrated, customers can significantly lower demand charges using battery storage to flatten their peak electrical draw from the grid. Integrated systems can charge batteries during off-peak hours and discharge them when EV charging would spike grid consumption.

“Instead of solar power flowing back to the grid during the day and then drawing grid power to charge EVs at night, integrated systems store that clean energy and use it directly,” she said. “For many customers, this creates a closed loop where their transportation and home energy needs are met almost entirely by renewable sources.”

When EV chargers are paired with storage and solar, they create microgrids that can keep critical loads running during outages, said Malcolm Proudfit, CEO of Good Energy Solutions in Lawrence, Kan.

“For businesses, this translates to uninterrupted operations and reduced risk exposure,” Proudfit said.

GETTING INTO THE MARKET