Next Generation Advanced Conductor.

TS Conductor’s patented Aluminum Encapsulated Carbon Core (AECC) design eliminates the problems of first-generation advanced conductors. It is fully compatible with ACSR/ACSS installation and maintenance practices.

UTILITIES PROJECT SOLUTIONS FROM CHAMPION FIBERGLASS®

No burn-through eliminates elbow repairs

Lower material and installation costs

Mechanical strength protects conductors

Low coefficient of friction for smooth pulls

Height adjustable utility risers

Operable in temperatures of -40° to +230°F

AI and data centers are rapidly increasing

By JEFF POSTELWAIT, Managing Editor

Strategic budgeting approaches prioritize innovation while maintaining fiscal responsibility.

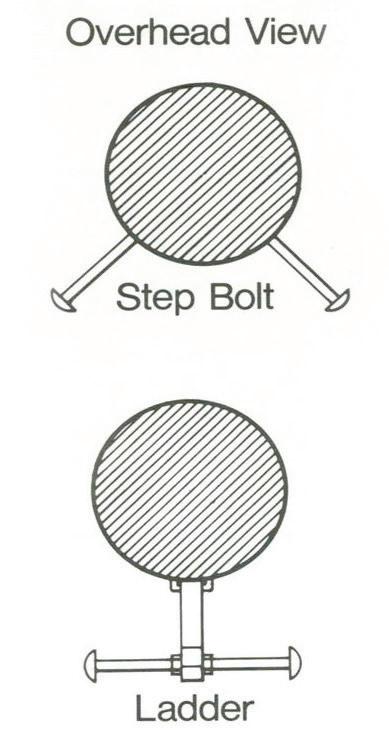

Maintaining safety while unlacing lattice towers during repair and strengthening efforts.

By JASON KILGORE, ELLIOTT THAXTON, Mesa Associates Inc.

The 41st International Lineman’s Rodeo experienced explosive growth with more than 5,000 in attendance.

The utility shares its blueprint for layering AI onto millions of smart meter data points and how it translated those insights into improvements.

Prepay

By CHAD LYNCH, Ocala Electric Utility and, DAVID CONN, Exceleron

Is it time for standards to replace fragmented and inconsistent practices?

PRASAD YENUMULA, Duke Energy

Designing the largest transmission line in U.S. history.

By JILLIAN EDWARDS, AARON WHITE, DAVID GELDER, Invenergy

As structures get larger, ensuring quality foundations gets more challenging!

GEORGE

PISCSALKO, Pile Dynamics, Inc.

on page 6

Group Editorial Director Nikki Chandler nchandler@endeavorb2b.com

Managing Editor Jeff Postelwait jpostelwait@endeavorb2b.com

Senior Editor Christina Marsh cmarsh@endeavorb2b.com

Art Director Julie Whitty jwhitty@endeavorb2b.com

Field Editor Amy Fischbach EOUeditor@endeavorb2b.com

Technical Writer Gene Wolf GW_Engr@msn.com

Senior Editor-at-Large Geert de Lombaerde gdelombaerde@endeavorb2b.com

VP, Customer Marketing Angie Gates agates@endeavorb2b.com

Senior Production Operations Manager Greg Araujo garaujo@endeavorb2b.com

Ad Services Manager Shirley Gamboa sgamboa@endeavorb2b.com

Audience Marketing Manager Sonja Trent strent@endeavorb2b.com

Audience Development Manager James Marinaccio jmarinaccio@endeavorb2b.com

Endeavor Business Media, LLC

CEO: Chris Ferrell

COO: Patrick Rains

CRO: Paul Andrews

CDO: Jacquie Niemiec

CALO: Tracy Kane

CMO: Amanda Landsaw

EVP Endeavor Business Intelligence: Paul Mattioli

EVP Water & Energy Group Diana Smith

VP of Content Strategy, Water & Energy Group Bob Crossen

T&D World (USPS Permit 795-660, ISSN 1087-0849 print, ISSN 2771-6651 online) is published 10 times a year (January to June, August to October and December) by Endeavor Business Media, LLC. 201 N Main St, 5th Floor, Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI, and additional mailing offices. Canadian GST #R126431964.

POSTMASTER: Send address changes to T&D World, PO Box 3257, Northbrook, IL 60065-3257.

SUBSCRIPTIONS: Publisher reserves the right to reject non-qualified subscriptions. Subscription prices: U.S. ($137.50); Canada/Mexico ($170.00); All other countries ($210.00). All subscriptions are payable in U.S. funds.

Send subscription inquiries to T&DWorld, PO Box 3257, Northbrook, IL 600653257. Customer service can be reached toll-free at 877-382-9187 or at tdworld@ omeda.com for magazine subscription assistance or questions.

REPRINTS: To purchase custom reprints or e-prints of articles appearing in this publication, contact Reprints@endeavorb2b.com

PHOTOCOPIES: Authorization to photocopy articles for internal corporate, personal or instructional use may be obtained from the Copyright Clearance Center (CCC) at 978-750-8400. Obtain further information at copyright.com

PRIVACY POLICY: Your privacy is a priority to us. For a detailed policy statement about privacy and information dissemination practices related to Endeavor products, please visit our website at www.endeavorbusinessmedia.com

CORPORATE OFFICE: Endeavor Business Media, LLC, 30 Burton Hills Blvd, Ste. 185, Nashville, TN 37215, U.S.; www.endeavorbusinessmedia.com.

© Copyright 2025 Endeavor Business Media, LLC. All rights reserved. Printed in the USA.

When AI Meets the Grid

My husband is a bit concerned that our college-age kids won’t have the careers they are dreaming of because artificial intelligence will take over. I tell him that AI won’t be able to take all our jobs any time soon because there isn’t enough electricity for that yet.

We are probably both being a bit dramatic or hyperbolic, but in this exchange lies a few lingering questions. And this is one of the biggest topics of discussion everywhere I go now: the consumer media, the industry conferences and our kitchen tables.

On one hand, I’m thrilled that electric utilities are seeing more demand than ever in some regions; this bodes well for the business. On the other hand, I am concerned that they won’t be able to meet the increasing demand for electricity, thereby threatening the security, resiliency and reliability of power. But maybe this is one way we balance how fast our future is coming.

In our November issue, Managing Editor Jeff Postelwait wrote on rising electricity prices. Because there had been such a recent furor over new data centers causing rates to rise, he decided to dig in and find out if this was completely true and to take a look at the bigger picture. Rate setting is complicated in our industry (at least I think so), so the answer, to me, is simply: it’s not that simple. Jeff asked this question in that story: Could AI hit a wall? Improvements in hardware efficiency can cut AI’s power demand, and researchers expect these improvements to continue to net savings in electricity consumption, but the overarching expansion of AI activity means overall demand is likely to continue — perhaps even resulting in the industry hitting a predicted “wall” imposed by power generation limits, he wrote.

Working on that report led Jeff to write our cover story for this month: “Could AI Find Its Limit in the Power Grid?” This turned into a good overview of how utilities are working with big tech to figure all this out (or not). We know AI’s growing energy appetite is reshaping load forecasts and challenging every stakeholder in the industry. And big tech and utilities operate on different timelines, which slows down everything. I don’t want to say “time will tell” in answering anything, as I have confidence in this industry and I know we will make a way forward. It is a challenge, for sure, but we have some bright and energetic people working on this. Just come to any industry conference!

Rodeo Wrap-Up

We also celebrate another segment of our industry this month with our coverage of the 41st International Lineman’s Rodeo that happened in mid-October. This is one year, thank

goodness, that we didn’t have teams out on hurricane duty. It was a record-setting year for attendance, and we enjoyed seeing even more lineworkers bring their families, from babies to grandparents, to cheer them on in the competition. As usual you can catch our photos from the safety conference, exhibition and competition at tdworld.com/ electric-utility-operations.

Despite forecasts of rain, clear skies and early morning fog set the stage for competition day, where nearly 300 teams and more than 350 apprentices competed. Duke Energy and Sturgeon Electric/IBEW Local 47 teams claimed top honors in the journeyman divisions, while Flint Energies’ Hunter Walton swept the apprentice category. See Field Editor Amy Fischbach’s “2025 Rodeo Rewind” story on page 26, along with her story “Living and Loving the Line Life” on page 48.

Structures from ASCE

One of my favorite supplements of the year is included in this issue: the American Society of Civil Engineers’ Structures supplement. It includes four in-depth technical articles that have been presented in sessions at the ASCE Electrical Transmission & Substation Structures Conference, and the content is core to the T&D World audience.

We published our first “lines and structures” supplement in 2011, and in 2015, ASCE partnered with us to provide the articles and distribute it at the ETS conference every three years. This year you will see articles on maintaining safety while unlacing lattice towers during repair and strengthening efforts; on standards contributed by Duke Energy; the construction of the Grain Belt Express; and ensuring quality foundations.

2026 Buyers Guide

December is also the month that we publish our annual print Buyers’ Guide. This is our 57th issue, which provides a comprehensive directory and reference guideto help utilities plan their purchasing needs for the upcoming year. You will find it bagged with the December issue. For a continously updated version, you can go online at https://www.tdworld.com/directory. The online version also features product stories, so check in out.

Every issue we put together reminds me how much this industry is built on people: those solving tomorrow’s grid challenges and those climbing poles in the early morning fog. Technology will keep evolving, but our resilience, ingenuity, and shared purpose remain constant.

So while we may not have all the answers about AI or future demand, I’m confident that, as always, this community will figure it out together.

Keeping Up with Technology is Worth It

Have you noticed how complicated the newest tech-toys have gotten lately? Today’s keyboards and mice have advanced features like programmable buttons, customizable micros and personalized settings. My wireless, ergonomic mouse looks like it would be more at home on the bridge of the Starship Enterprise than sitting at my desk! My mouse came with a 40-page searchable PDF user manual, and we will not talk about my keyboard and its enhanced capabilities, but that’s what users want.

Back in October I wrote about needing to replace my old computer with a new one compatible with upgrading to Windows 11. After a couple of months with the upgrade, I can say it was worth the effort. It’s taking some adjustment getting comfortable with the increasing sophistication of the upgraded software.

those long, drawn-out emails, and it’s proving to be worthwhile.

One last thing about the upgrade, some ancillary devices were not compatible with the new operating system like my webcam. Still, that led to converting to a 4K webcam with better video, improved low-light performance and some other interesting features. There are other devices, but that’s enough for now. The remote office will definitely benefit from this type of advancing technology, but what about the power grid?

Verbally Questioning Management Systems

It hasn’t been left behind. Everyday my inbox is full of press releases about the latest digital technologies for the power grid. The suppliers are focused on the increasing use of AI in the power grid’s

The experts say it’s driven by consumer demand. That might be true, or it could be the normal technological advancement.

Learning about all of the new updates to my software after moving to Windows 11 has been intriguing. There’s no way I would go back to that old video conferencing app. My updated app includes an AI attribute that provides a transcript immediately following the session. It’s a godsend to anyone taking notes for minutes of a meeting or a journalist like me for interviews with experts. Another feature I wasn’t sure of at first was the revision of the email app. It’s AI feature summarizes

applications. One of the most intriguing of these applications isn’t really trending yet, but it’s just may have an enormous positive impact. It comes from the DOE’s PNNL (Pacific Northwest National Laboratory) and it’s called ChatGrid. According to the news releases, it’s a generative AI tool utilizing a natural language interface, which is why it caught my attention.

ChatGrid provides an interactive experience for grid operators using a question-and-answer format, which makes it easier and faster for them to understand complex grid data. Users can ask spoken language questions about power flow,

voltage characteristics, generation, etc. ChatGrid answers them in real-time with visual and textbased answers. It’s currently in the testing and development stages, but it’s showing real promise for helping operators’ decision making.

It’s not a big jump to see this approach being applied to other systems like energy storage, dynamic line rating equipment, smart meters, or grid control equipment. The potential of this conversational approach is staggering because it complements other technologies and human operators rather than replacing them. It’s an important concept. After all, how many science fiction shows do we see the humans engage in question-and-answer conversations with their computers?

Emerging Careers

Somewhat related was an interview with an executive from LinkedIn I found researching ChatGrid. It started off with him discussing trending digital technologies and their impact on businesses. I got hooked when he started talking about people being upset with AI taking jobs. He didn’t agree and defended his position nicely. One point he made struck a chord. He said that 1 in 5 of today’s professional jobs didn’t exist in 2000. To put that in a power grid perspective, the smart grid, renewable energy, data science, grid analytics, etc. are producing jobs/careers that didn’t exist or were slowly emerging in 2000.

I can relate to what he said. When I graduated from engineering school FACTS (flexible AC transmission systems) technology didn’t exist. As a substation engineer, I joined IEEE and became fascinated by power electronics. I started reading everything published about the subject. I attended all the sessions associated with it and was able to move into the field as it developed, which provided a rewarding career. Today there are even more opportunities with trending technologies, but we have to keep up with technologies to take advantage of them!

Is the Grid Going Tech-Agnostic?

Imagine adding megawatts without adding transmission or powerplants!

Have you noticed how many technologies utilities use and depend on daily to keep the lights on? These applications manage assets, support operations, and assist in a wide variety of tasks that were once busy-work eating up resources. It’s an ever-changing world of technology and innovative approaches that keeps pushing the envelope as well as us. There’s an approach that’s been getting mixed reviews for some time now, but that’s been changing lately. Are you familiar with the term “technology agnosticism” or tech-agnostic for short?

There’s been an uptick in interest when it comes to interoperability and the open-source aspect of the digital technologies, which has been good for the proponents of tech-agnostic applications. So what is tech-agnostic anyway? It’s biggest selling point is it blends numerous systems, platforms, and elements without needing to modify any of them. Tech-agnostic, if you will, is a strategy that’s not tied to any single technology, platform or vendor. In other words, it’s users are not locked into a vendor or technology.

That may sound a little like interoperability, but it’s not. Interoperability is the ability for systems and/or applications from multiple vendors to communicate, share data, and work together effectively. Tech-agnostic is an approach that’s neutral to the specific technology, platform or vendor being used. Interoperability works by complying with shared standards and using common data formats. Tech-agnostic, however, use open standards and APIs (Application Programming Interfaces) for flexibility and adaptability.

It’s All About Standards

Instead of continuing to discuss tech-agnostic in generalized terms, let’s look specifically at a segment of the power grid like distributed energy resource (DER) technologies. DER applications are ideal for the integration of tech-agnostic standards.

Authorities have said DERs are non-wire alternatives for addressing the growing demand for electricity we are witnessing lately, which also adds timeliness to this discussion. There are, however, a great deal of DERs already installed on the grid that for the most part, are not tech-agnostic, but can be included in our discussion.

Our discussion emphasizes DERs that are part of this techagnostic movement. One of the keys for DERs to join the techagnostic category is standards. That brings us to standards produced by IEC and IEEE. They focus on the technical specifications developed for the interconnection itself rather than the specific DER technology. IEC TS 62786-1, for example, addresses general requirements, performance and testing of a variety of DERs. IEEE 1547 series cover tech-agnostic standards outlining mandatory performance criteria for how DERs are interconnected with the power grid. Both organizations have comprehensive websites for more detailed information.

One final standard, IEEE 2030 series contain communication protocols for enabling communications between DERs and distributed energy resource management systems (DERMS). DERMS platforms are an important part of structuring DERs into utility-scale power assets. Open protocols like the IEEE 2030 series standardize the communication language that allow all manufactures’ DERs to communicate and interoperate smoothly through management systems. The emphasis is shifted to utility methodologies that focus on ancillary services. The tech-agnostic approach also makes compatibility a non-issue within the technologies.

It’s Getting Complicated

Envision the impact these DER technologies will have once they no longer have the traditional restrictions related to combining them into older vintage technologies. That’s a win for utilities,

CHARGING AHEAD

grid operators and the owners of the DERs. It also provides yet another approach for adding more power and ancillary services to the grid. AI (artificial intelligence) is being integrated into tech-agnostic DER and DERMS platforms. That’s leading to some unconventional approaches. It’s proving worthwhile for utilizing the best technological approaches rather than accepting what’s the easiest way, but it’s a subject for later.

Getting figures concerning the amount of power being provided to the grid by DERs is complicated due to the decentralized nature of this technology. A quick “AI Overview” query revealed that the DERs capacity in the U.S. was estimated at being over 100 gigawatts in early 2025. Still, the power grid is a mixture of tech-agnostic and technology-specific DERs with the majority being the former, but it has to start somewhere. And don’t forget, the technology-specific assets are capable of being aggregated. It’s just that they have a plethora of criteria and conditions.

With the grid facing load growth of over 2% annually for the next 25 years, we can’t be picky. Regrettably, there’s also steadily increasing pressure from governmental sources for the power delivery system to utilize expensive coal and gas generation over efficient renewables. Adding to the complexity is the fact that both coal and gas facilities are not exactly trouble free.

Coal-fired generation can be extremely finicky as witnessed at Sandy Creek a single unit 932-megawatt powerplant. It’s the newest large coal-fired powerplant in the U.S. and it’s already had two major failures since going online. The latest happening was this year, and it’s not expected to be in-service until sometime in 2027. Gas turbines are said to be a fast-fix for generation shortages, but delivery timelines for new gas turbines are five years or more. In addition, permitting and development are also becoming issues at state and local levels.

Streamling Aggregation

Getting back to the DER conversation, both the tech-agnostic and technology-specific DER applications are benefiting from the growth and advancement of DERMS platforms. As more tech-agnostic DERs come online, DERMS will streamline the process of managing their growing numbers. These small-scale energy sources are available, but it’s challenging turning them into utility-scale assets, which is where DERMS platforms come to play. They can aggregate both the DER assets and the real-time data they produce. That gives the utility’s grid operators the ability to see real-time demand and apply the energy resources where they’re needed the most.

This trending technology is necessary for the energy landscape as it becomes more the dynamic and requires faster reaction times. Some authorities are calling these DERMS platforms the central nervous system the modern electric utility. Others see them as the digital brain connecting the utility with its diverse resources. It may be a combination of both, but it’s needed for ensuring grid stability in an unstable world. Whichever it is, it’s starting to trend and that’s what we’re interested in.

A press release from the Business Research Company reported that “the DERMS market size has grown rapidly in recent years.” They are expecting that market to reach US$1.1 billion

in 2025. They are also expecting it will grow to US$1.95 billion in 2029 at a compound annual growth rate of 15.4%. They attribute rising energy demand and the need for energy efficiency as major reasons for this expansion.

A Tech Neutral Framework

Last June, NREL (National Renewable Energy Laboratory) published a narrative titled “FAST-DERMS: An Architecture to Control the Grid of the Future.” Summarizing, NREL said their FAST-DERMS program is a lab tested architecture using a tech-agnostic DERMS solution. It’s a federated approach to grid management for higher levels of customer-owned energy sources. NREL said, “It does not rely on direct utility control over all DERs; rather, they can be managed either directly by the distribution utility, or indirectly through aggregators or a transactive market.”

Recently, the Electric Power Research Institute (EPRI) launched their FLEXIT initiative to standardize and simplify the integration of aggregated DER technologies into utility operations. According to their press release, FLEXIT is designed to increase grid flexibility as electricity demand increases. EPRI said the initiative has more than two dozen utility members representing about 45% of the U.S. electricity customers. EPRI also has more than 40 technology providers including DER aggregators, manufacturers, and DERMS providers.

This tech-agnostic approach is focusing on a standardized, interoperable framework that offers scalability, enhanced resilience, and a greater market participation. The release continued saying, “Under FLEXIT, EPRI is facilitating a working group to understand all perspectives and develop consensus in support of its workstreams. By harmonizing existing standard services, communication protocols, and cybersecurity requirements, findings can enable stakeholders to leverage and integrate reliable, accurate, timely, and actionable DER services into grid operations without compromising safety or security.”

It’s Challenging

If all the studies, surveys, and analyses are correct, the benefits of tech-agnostic applications far outweigh the effort associated with applying them. Tech-agnostic DERs and DERMS applications were picked as discussion topics because they’re important to the power grid, but other technology branches face similar challenges. They have aging infrastructures with a mixture of technological systems too. Everyone can benefit from techagnostic approaches.

Tech-agnostic acceptance is challenged with outdated regulatory frameworks, regulatory understanding, security issues, data privacy, and there is always the reluctance to try newfangled technologies. Diversity also introduces significant challenges. Some see tech-agnostic as being unpredictable and uncomfortable. On the flip side, they offer cost savings, greater flexibility, and more resilience to users. They also defer infrastructure upgrades and in most cases they’re already on the power grid. Overall, the benefits outweigh the drawbacks and those using them will have a huge advantage over non-users at keeping the lights on!

QUICK CLIPS

Xcel Energy Plans First-of-Its-Kind Distributed Capacity Procurement in Minnesota

Xcel Energy has proposed a program to build a distributed battery storage network across Minnesota to help meet growing electricity demand and improve grid operations.

Under the Capacity Connect plan, Xcel Energy would install up to 200 megawatts of battery storage at strategically selected locations by 2028. Working in partnership with Sparkfund, these distributed energy resources are intended to support efficient use of existing infrastructure, maintain reliable service, and contribute to local employment.

“We’re focused on supporting economic growth and the needs of our communities by building out and modernizing our energy grid,” said Ryan Long, president of Xcel Energy–Minnesota, North Dakota and South Dakota. “We believe distributed energy resources are an important part of that strategy. They will complement our current plans for additional renewable and firm dispatchable generating resources to meet our customers’ needs.”

Xcel Energy will integrate the battery storage into its system operations by charging when energy is less expensive and dispatching energy during peak periods, aiming to optimize grid performance. The company plans to choose customer sites — such as commercial, industrial, or nonprofit

hosts — including in environmental justice communities. Each host would receive payments for participation. Typical battery installations would range from one to three megawatts per site (about the size of a shipping container).

“By storing energy when it’s cheap, delivering it when it’s needed most and placing assets where they maximize grid value, Xcel Energy is delivering reliable energy to customers today and building a grid that is ready for tomorrow,” said Pier LaFarge, CEO of Sparkfund.

“Sparkfund will help Xcel Energy deploy distributed energy resources to meet growing customer energy needs, support economic growth in Minnesota and unlock the full value of the U.S. electric grid.”

This distributed capacity procurement is intended to contribute toward Minnesota’s energy storage goals.

Xcel Energy’s Upper Midwest Energy Plan, recently approved, calls for installing 600 megawatts of energy storage by the end of 2030, and the proposed program would advance that effort.

Xcel Energy and Sparkfund plan to monitor performance, costs, and customer experience as the

deployment scales, to ensure the approach remains cost-effective while contributing to a reliable, safe, and clean grid.

Western Farmers Electric Cooperative (WFEC) seeks to identify possible contractors for future Emergency Electric Power Restoration and Debris Removal Services in 2026. Work could be performed across the State of Oklahoma, as well in portions of Texas and Kansas. More information about our service territory can be found at www.wfec.com.

Please submit your contact information via email to bids@wfec.com or send a letter to Procurement Services, 3000 S. Telephone Road, Moore, OK 73160.

Small Businesses, Minority-Owned Businesses,

Woman-Owned Businesses, and Labor Surplus Area Firms are especially encouraged to submit their information. WFEC accepts new contractors throughout the year; however, to establish an agreement for 2026, please submit your information by December 31st, 2025.

Entergy Arkansas Powers Google’s $4 Billion Data Center Investment in Arkansas

Entergy Arkansas announced it will supply power for Google’s planned $4 billion technology investment in Arkansas. The investment includes a new data center in West Memphis — Google’s first facility in the state — focused on cloud and artificial intelligence infrastructure. The company also announced a $25 million Energy Impact Fund to support energy affordability efforts in Crittenden County and nearby communities. The fund will target home weatherization, energy efficiency technologies, and workforce development.

Entergy Arkansas President and CEO Laura Landreaux said, “Google’s $4 billion investment in its new facility, its $25 million Energy Impact Fund, and its investment in the future of our students demonstrates what lasting community impacts a project of this magnitude can have,”

Google will pay the full energy costs of operating the facility. Entergy Arkansas said the agreement will generate more

than $1.1 billion in net benefits over the life of the contract and could help reduce electricity rates for all customers by spreading fixed costs across a larger base.

The new facility will draw from Entergy Arkansas’s existing generation portfolio and transmission network, which will be expanded by a proposed 600-MW solar project paired with a 350-MW battery system in Jefferson County. Entergy has filed the resource for approval with the Arkansas Public Service Commission, saying it will enhance grid reliability, resiliency, and affordability.

“Large industrial and technology companies are increasingly looking at our state because we offer reliable power at affordable rates, and we plan to keep it that way,” Landreaux said. “Large customers, such as Google, help support investments in infrastructure additions that not only help power their facilities but also result in improved grid reliability that benefit all customers.”

Potomac Edison’s New Substation to Reduce Power Outages for 1,900 Customers

Potomac Edison, a FirstEnergy electric company, has introduced a new substation in Morgan County, West Virginia, bringing improved power reliability for nearly 2,000 residents and businesses served by the

and new technology. While construction on the project started in summer 2025, the substation began serving customers in September.

The new substation in Great Cacapon has replaced an older facility, which was dependent on a six-mile-long power line. The substation, located on a 20-acre site owned by Potomac Edison, is served by a safer, easily reachable power line less susceptible to service interruptions.

Completion of the work will serve nearly 1,600 customers in the Great Cacapon

The new substation is equipped with smart grid technology, including automated devices that:

• Detect and isolate problems automatically.

• Restore service remotely without dispatching a crew.

• Pinpoint outage locations to speed up repairs.

The upgrades will help deliver fewer, shorter and less widespread outages for customers. The substation project is part of Energize365, FirstEnergy’s $28 billion investment program across its five-state footprint to modernize the electric grid between 2025 and 2029.

FirstEnergy

Entergy Arkansas

Georgia Power Deploys Advanced Phase Balancing Device to Improve Power Quality

A new grid technology has been installed in Macon, Georgia, as utilities explore options to increase the capacity of existing power lines and improve reliability. Switched Source has deployed its Phase-EQ device in partnership with Georgia Power, a subsidiary of Southern Company, with support from the U.S. Department of Energy’s Advanced Research Projects Agency-Energy (ARPA-E).

The Phase-EQ is designed to increase usable capacity from existing lines by up to 20% by balancing electricity flow across phases. Georgia Power provided site access, engineering input, and operational data for the demonstration, which is being evaluated under real-world conditions.

Southern Company’s research and development group worked with Switched Source to refine and test the technology before installation. Early data indicates the device is operating smoothly, with initial modeling suggesting the potential to reduce

Utility and project partners recently visited the Macon site to see the Phase-EQ installation firsthand.

load imbalance by half and voltage imbalance by more than 30%. Georgia Power is continuing to collect substation-level performance data to assess the device’s effectiveness.

“This deployment represents Georgia Power’s continued efforts to partner with industry and use new technologies to improve grid performance while reducing costs for our customers,” said Robin Lanier, director of grid strategy and solutions at Georgia Power.

Switched Source was founded in 2016 and has focused on technologies that help utilities manage reliability and capacity on the distribution grid. The Phase-EQ functions as a controllable gateway, dynamically balancing power between phases to ease congestion and improve power quality. The project is part of ARPA-E’s SCALEUP program, which provided funding for the company’s early technology development.

Switched Source

AI and data centers are rapidly increasing electricity demand, straining existing power grids and highlighting the need for infrastructure upgrades, collaboration, and accurate forecasting to ensure reliability.

By JEFF POSTELWAIT, Managing Editor

Artificial intelligence is touted as the answer for every inefficiency in business, every work- or liferelated headache, and the friend to every parent who can’t think of what to do with the two pounds of boneless chicken breasts they thawed out earlier in the day. The technology is supposed to also make an absolute ton of money. So far, it appears to be costing a lot of money. But here in the electricity realm, the big question with AI seems to be how quickly is Big Tech going to need all those data centers they are planning on building, and how are they going to power them?

Electricity peak demand and energy growth forecasts over the 10-year assessment period continue to climb higher than at any point in the past two decades, according to the North American Electric Reliability Corporation’s (NERC) 2024 Long-Term Reliability Assessment. The energy demand picture, in short, has been rather boring for the past few decades. Now, business is starting to pick up, leading some in the industry to wonder how quickly things can pivot.

Growing large commercial and industrial loads, electrification of household appliances and increasing electric vehicle

they may outpace the data centers in the long run. However, a small but growing slice of the pie is represented by the emerging large load of data centers, particularly those involved with cryptocurrency mining and artificial intelligence. These, according to NERC, present challenges to forecasting and planning for increased demand.

“The overall speed and magnitude of the growth in and of itself is causing strain on the existing resources. But there’s this additional component, which is the uncertainty of forecasting the demand growth and how it affects your assessments and the certainty of your demand forecasts,” said Evan Mickelson, Power Systems Modeling and Analysis Engineer at NERC.

In a July 24, 2025 webinar, Mickelson drew from a NERC report titled “Characteristics and Risks of Emerging Large Loads,” saying the speed and volatility of these large loads coming online can exhaust reserve margins.

“When utilities have a large interconnection queue for their really large loads, they have to assume that some of them aren’t going to materialize. The assumptions there are really, really important. The increased uncertainty is one of the big drivers of the risks to your resource

Shared Goals, Different Timelines

Big Tech and the power grid share a similar problem: if either the internet or the electricity get knocked down, people start complaining quickly. Both need to maintain reliable, uninterrupted service around the clock. However, things tend to move a lot more quickly in Silicon Valley than they ever do for people who maintain the power grid.

“The scale and speed with which the tech industry operates is on a different time spectrum than the electricity ecosystem. And so, what we’re faced with is what I like to call a growing pain between where our tech companies need to be to serve our customers and to serve this demand and what we’re really capable of doing as an electric industry,” Briana Kobor, Head of Energy Market Innovation at Google, said in a June 18, 2025 EPRI Current podcast episode posted by the Electric Power Research Institute.

Kobor identified aging infrastructure, the need to build increased long-haul transmission and clogged power generation queues as issues hyperscalers such as Google need those who operate in the power sector to solve, adding that collaboration between Big Tech and power engi-

“We are seeing scaled increase in demand from data centers and other parts of the industry,” Kobor said, adding that data centers and the products that they deliver to people have become central to people’s personal lives and businesses. “I like to think of data centers as the backbone of our modern economy.”

A Growing Energy Hunger

An EPRI study found that data centers could consume up to 9% of US power generation by 2030 — more than double the amount currently used.

Data centers are already having issues securing enough power generation to meet their growing demands. Load growth from data centers is placing strain on regional power grids and more than 100 GW of new data center projects could come online over the next decade in the U.S., said James Russell, a principal in Charles River Associates’ Energy Practice.

“Any system headroom that was available prior to 2023 is likely allocated to new projects – meaning that each incremental MW of load requires an incremental MW of generation and transmission capacity,” Russell said. “Years-long load queues are present in most Tier 1 data center markets with adjacent markets becoming congested as well. Utilities and independent system operators (ISOs) need to ensure a permissible rate of load growth that can be matched by new grid infrastructure such that new load doesn’t infringe on system reliability and affordability.”

The limits that exist on how many power plants and power lines can be available in a particular area is already imposing a limit on the growth of AI and the data centers that fuel it, he said.

“The limiting factor for most data center projects is the ability to secure interconnection and power supply. Cumulative load queues across the country currently exceed 400 GW with U.S. peak electricity demand around 760 GW – this scale of load growth is driving delays across all aspects of supporting supply chains,” he said.

Underscoring the disconnect in time scale between the two industries, a 500 MW data center can be up and running in 1-3 years, while the transmission and generation infrastructure it would need

A Google data center in Hamina, Finland.

Workers servicing the power grid in Johannesburg, South Africa.

cogeneration power plant at Berlin-Wilmersdorf.

to function could take 5-10 years, or perhaps longer.

Big Tech: A New Power Partner?

In response to this mismatch, Big Tech is getting more involved in the power sector, and that involvement may deepen in the future.

When asked if we might get to a point where tech companies take more of an interest in power grid infrastructure and maybe even invest in it, Matt DeCourcey, vice president in Charles River Associates’ Energy Practice, said we are already there.

“In most cases, connecting a new data center now requires new generation or transmission capacity to be built specifically to serve that load. The mechanics vary: some are structured through PPAs, others through service contracts with minimum-take provisions, and in some cases through direct ownership. But the principle is the same: the data center is making a long-term, binding financial commitment to cover the cost of the resource and the infrastructure needed to deliver it,” DeCourcey said.

This leaves planners and regulators with two options: Do they wait to determine how much G&T resources will be needed for a particular data center project before one is allowed to connect, or do they let data centers connect while requiring that they be interruptible. The former method is favored in Nevada,

Arizona and other states. The latter is being applied in Texas, Utah and elsewhere, DeCourcey said.

Tony Tewlis, Senior Vice President of T&D Operations for Arizona Public Service (APS), said during T&D World Live 2025 that dealing with the power demand from data centers was among his top challenges.

“With data centers and Big Tech, meter sets are now much larger. 500 MW is the average size of the request for one of these customers, which is comparable in size to a large Walmart,” Tewlis said, going on to add that his utility will need an estimated $6.25 billion in extra capital expenditures over the next decade to serve this load growth.

Tewlis said his utility is exploring new rate structures that are based on how much demand a particular customer class is causing, so data centers might be more responsible for load growth than residential customers.

“Even though a customer may demand something that is impossible, we have to be realistic on what we can do,” Tewlis said, adding that he has had to learn more about data centers in the past 12 months than he ever imagined he would need to.

“On the community side, the dynamic is more complex. Data centers can be both an opportunity and speculation. They bring construction jobs, tax base, and investment in local infrastructure,

but they can also strain local systems. The most successful projects are the ones where developers engage early and transparently: partnering with local governments on siting and permitting, investing in transmission or water reuse infrastructure, and clearly communi cating the broader economic benefits,” DeCourcey said.

hyperscalers and utilities deal with one another, said Anant Kumar, vice presi dent of Charles River Associates’ Energy Practice.

utilities like any other large customer, re questing service and waiting for the utility to deliver capacity. That model doesn’t work anymore. The scale and timing of today’s data center growth, often hun dreds of megawatts at a time, are forcing much closer coordination,” Kumar said.

ers are trying to co-plan years in advance, Kumar said.

sites with available transmission capac ity, co-developing new substations or generation, and exploring long-term power agreements that blend reliabili ty, sustainability and flexibility,” he said. “We’ve witnessed this firsthand with sev eral data center developers we work with. They identify community relations as a key point of differentiation.”

Clouded Forecasts

A question remains: How quickly will these data centers be built and ramped up to their full electricity demand? The fact that nobody knows for sure engenders much

uncertainty in an industry that must submit regular reports on resource adequacy and demand forecasts.

There is a crisis of confidence in load forecasts, particularly the further out you look.

“Grid operators, regulators, and stakeholders are becoming concerned about the accuracy of load forecasts that project a significant amount of data center load growth. These load forecasts are increasingly regarded as highly uncertain,” said Oliver Stover, associate principal in Charles River Associates’ Energy Practice.

Regulators, ratepayer advocates and others are concerned that inaccurate load forecasts can needlessly increase costs to existing electric customers by increasing planning reserve requirements and driving infrastructure investments that won’t ultimately be needed, Stover said.

Stakeholders want utilities and grid operators to increase the accuracy and transparency of their load forecasts. In September 2025, FERC Chairman David Roser requested information about load forecasting from RTOs/ISOs, asking them how they coordinate with utilities, whether the individual utility load forecasts within their RTO/ISO are developed consistently, and whether they share best practices and ensure large load interconnection

OneLiner

ENGINEERING SOFTWARE

Short circuit, relay coordination and breaker rating for transmission networks.

Power Flow

Full-featured power flow for transmission systems.

DistriView

Fault simulation, relay and fuse coordination, voltage drop, harmonic analysis, and reliability calculation for distribution networks.

Relay Database

Customizable database for relays and related equipment.

Line Database

Customizable database for overhead lines and underground cables with built-in electrical parameters calculation engine.

EDX Module

Customizable platform for collaborative OneLiner/Power Flow model building and database-driven model data management.

LEFT: High voltage lines near Phoenix, Ariz., connecting the Palo Verde Nuclear Generating Station to Tonopah.

RIGHT: Steam rising from cooling mechanisms at Palo Verde Nuclear Generating Station, west of Phoenix, Ariz.

ID 212509193 © Steven Cukrov | Dreamstime.com

requests aren’t double counted across utility service areas.

An extra factor in sharpening the forecast is asking what can materially be built. Instead of assuming every data center that has financial backing and motivated stakeholders, supply chain and other restrictions on construction are also being considered in forecasts.

Constraints on computer chips, transformers, labor, available interconnections and capital are each real potential bottlenecks to getting data centers built. These considerations make nearer-term forecasts more reliable than those further out.

Getting Along

With data centers asking so much of power producers, it is understandable to wonder whether power utilities are truly that thrilled to have them as customers. Certainly, some may see opportunities as well as challenges, but some of the predicted spikes in load growth are truly daunting. How well the two get along will differ on a case-by-case basis.

“When a data center and a utility are engaged in discussions about whether the data center should interconnect and become a utility customer, the two parties are partners or counterparties. The degree to which they collaborate closely and get along well varies from case to case,” Kumar said.

If the data center gets interconnected, it is now a utility customer and each party has obligations. Usually, that includes the utility providing a reliable energy supply and the data center operating within certain parameters and paying the utility for that service.

Some utilities are actively seeking new data center entries, while others are more reluctant, DeCourcey said.

“We have found that the regulatory regime where the utility does business has a strong effect on the utility’s enthusiasm for data centers. Many of the strategies to attract data centers are oriented towards shortening timelines to having the project online, including timelines for interconnections, study periods, regulatory

approvals, etc.” DeCourcey said.

The idea of offering discounted rates to data centers, while initially popular for those wanting to attract data center developers, has fallen by the wayside in favor of redesigning rate structures and other solutions.

“Several states have tax incentives to attract data centers. Although data centers consider several factors when deciding where to locate, such as electricity costs and land values, state tax incentives have played a role in where data centers locate. For example, Georgia, Illinois, and Virginia offer relatively generous tax incentives to data centers, and vertically integrated utilities in these states plan to build a significant amount of electric generation capacity to serve new data centers. The retail electric rate designs, not the tax breaks, garner the most attention from ratepayer advocates, who have been active data center tariff proceedings before state public utility commissions,” said Emma Nicholson, energy economist with Charles River Associates.

THE SAFEST WAY

POLE

UTILITY ANALYTICS

HighNoon® Herbicide: A Powerful New Option for Weed Control

If you’ve ever felt like you’re playing whack-a-mole with invasive and undesirable vegetation, you know how important it is to have effective, easy-to-use options for weed and brush control. With its recently expanded label for nationwide use in vegetation management applications, HighNoon® herbicide from Corteva Agriscience gives you and your contractors that option. HighNoon herbicide combines two powerful active ingredients, Rinskor® and aminopyralid, to provide selective activity that helps maintain desirable grasses and forbs while controlling some of your most troublesome weeds like annual and biannual thistles, poison hemlock and wild parsnip. But simply controlling weeds and undesirables is only one of the benefits of an integrated vegetation management (IVM) program using HighNoon herbicide. One Result. Countless Benefits. Used as part of a larger IVM program, HighNoon herbicide can allow native grasses and forbs to become established in rights-of-way. In turn, this helps:

1. Improve biological control. Native ground covers that are allowed to flourish can quickly grow to crowd out invasive or undesirable vegetation species, reducing stem counts over the long term with no additional labor required. HighNoon herbicide controls over 140 broadleaf weeds and annual grasses, and provides a valuable tank-mix partner for enhanced control of woody species like salt cedar and Russian olive, all while allowing valuable native grasses and ground covers to become established.

2. Reduce fuel for fire. Annual and invasive grasses that don’t germinate don’t contribute fuel for potential wildfires. An IVM program using HighNoon herbicide offers highly selective control of some of the most dangerous annual grasses, reducing the overall fuel load and helping mitigate the risk and spread of fire

3. Improve habitat, with less danger to native species. Use of selective herbicides such as HighNoon preserves the vegetation that serves as habitat for birds, pollinators and other species. In addition, control with herbicides means less mowing — and that means less risk to groundnesting birds and other wildlife.

4. Reduce regrowth and spreading. If the weed seed never germinates in the first place, it obviously can’t regrow, and it can’t go to seed later in the year. HighNoon herbicide offers extended residual control, helping prevent regrowth of broadleaf weeds and annual grasses.

Easy-To-Use, Reduced-Risk Control

Along with effective control of broadleaf weeds, HighNoon also gives vegetation managers an easy-touse liquid formulation that mixes well, offers low use rates and low odor, can be used up to water’s edge and, for those who spray sites close to pastures, carries no grazing restrictions. Add the fact that the proprietary Rinskor® active ingredient earned the Green Chemistry Challenge Award from the American Chemical Society’s Green Chemistry Institute, and you have a product that gives the industry a powerful, reduced-risk option for control of brush and weeds.

For more information on the benefits of HighNoon herbicide as a foundation component of an IVM program, reach out to your Corteva Vegetation Management Specialist, or visit HighNoonHerbicide.com.

Now approved across the country, HighNoon® herbicide targets over 140 broadleaf weeds and annual grasses—including poison hemlock, wild parsnip, and thistles—while protecting native vegetation.

As part of an Integrated Vegetation Management program, HighNoon helps:

> Simplify application — Low odor, easy mixing, and flexible use

> Protect habitat — Support pollinators and wildlife

> Block regrowth — Long-lasting residual keeps weeds from returning quickly

Learn more at HighNoonHerbicide.com or get in touch with your Corteva Vegetation Specialist.

Find your Specialist at VegetationMGMT.com/Specialist.

The 41st International Lineman’s Rodeo experienced explosive growth with more than 5,000 in attendance.

By AMY FISCHBACH, Field Editor

The Rodeo grounds disappeared into a fog during the morning of the competition.

ith a storm in the forecast for the 41st International Lineman’s Rodeo, the competitors and spectators arrived prepared to navigate the muddy terrain. Instead, the early morning began bright and warm followed by a fog that rolled into the Rodeo grounds, making the competition virtually disappear into a cloud.

For more than four decades, the International Lineman’s Rodeo has given lineworkers the opportunity to compete and their families a way to connect. From the start, it has focused on safety, tradition and the craftmanship of the line trade.

“Safety is important to everyone, and everything about this Rodeo is safety,” said Dale Warman, cochairman of the International Lineman’s Rodeo Association (ILRA) and one of the founders of the International Lineman’s Rodeo back in 1984. “If you’re a lineman and you’re going to climb in this Rodeo, you’re going to work safe, and when you go back, you’re going to work safe. There are bold linemen and there are old linemen, but there’s no bold old linemen.”

This year, 290 teams and 364 apprentices competed to be the best of the best by engaging in a pole climb, hurtman rescue and mystery events designed to showcase their skills in line work. While the lineworkers were competing in the events, their families were cheering on the sidelines, taking a ride in the bucket truck or participating in the second annual International Kids Lineman Rodeo.

To keep the competitors safe on the Rodeo grounds, the ILRA continued to require full fall protection on all the 40-ft wood poles, a change that was made a few years ago. Michael Stremel, Chief of Safety for the 2025 International Lineman’s Rodeo, said he and his safety committee members were responsible for keeping everyone safe on the Rodeo grounds and responding to incidents if needed.

“I’ve been involved with the Rodeo for a number of years,” said Stremel, who retired from Midwest Energy and now volunteers with the ILRA. “It’s a little foggy and hazy out, but there’s no wind and no rain, and the crews look like they are getting after it.”

Apprentices in Action

As in past years, the apprentice lineworkers competed solo and took their written test at the Overland Park Convention Center the day before the competition. Hunter Walton of Flint Energies swept the apprentice division with 499 event points and a total time of 15:43:00, followed by two PG&E apprentices: Dennis Spars and Austin Prendez.

Walton, who also placed first in the written test event with 99 event points, said he prepared for the International Lineman’s Rodeo by studying the Lineman’s & Cableman’s Handbook every single day.

“I took notes and would go over them anytime I could,” he said. “My coach made questions over the book’s content, which helped even more.”

To practice for the hands-on events, he put in time after work or on his days off to run known events and perform different tasks, which could be part of the mystery events. Flint Energies also gave the competitors working days to dedicate to Rodeo practice, which he said was very helpful. He said his strategies for success were to stay calm and trust the work he put into practice.

“Nerves will get the best of you sometimes, so it’s better to remain calm during pressure situations,” Walton said. “I tried to watch the other competitors who went before me and pick up on tricks that could speed my time up in the event. Although it is important for me to show up and win, I try and remember to have fun. Sometimes I can put too much pressure on myself causing me to get in my head and then it’s a negative impact on my performance.”

Walton said he was honored to achieve such success, especially at the level of the International Lineman’s Rodeo.

“I have been dreaming of walking across that stage and receiving that belt buckle for four years now,” Walton said. “To realize that all my hard

Hunter Walton of Flint Energies topped the apprentice division by scoring the highest number of points in the lowest total event time.

work has paid off, and I am able to bring home the trophy to my company and fellow linemen who helped me over the years is very rewarding. However, I am humbled. I truly believe God gave me this opportunity and guided my hands and feet on competition day. I give all the credit and glory to Him.”

On the day of the Rodeo, the apprentices also had to compete in two mystery events, which were unknown to the participants until the International Lineman’s Rodeo Week. During the first mystery event titled, “My Mistake, Wrong Wire,” the apprentices had up to 15 minutes to swap all the connections and hardware simulating the wrong wire was made the phase wire.

The ILRA provided each competitor with a grunt sack, spare bugs, a spare Fargo or one bolt and a throw line. Apprentices could earn two-point deduction for infractions such as not making proper connections, dropping tools or material, making an incorrect bowline knot or failing to attach the grunt sack to the wire or structure. Ryne Syra, an apprentice for CenterPoint Energy, walked away with a victory with a perfect score of 100 event points and a time of 02:29:90.

During the second mystery event, “How low can you go?,” the apprentices had to climb to the neutral, remove the installed wire brush from one side of the pole and brush the other side of the neutral. Jacob Fintelman, an apprentice for Hydro. One Canada, edged out the competition with a score of 100 event points at a time of 00:21:12.

Team Tradition

While the apprentices compete on their own, the journeymen lineworkers must work together in teams of three to complete four events — the pole climb, hurtman rescue and two mystery events. The IBEW Local 47/Southern California Edison team of Fabian Gutierrez, Jose Leon and Fernando Valenzuela placed 13th out of 290 teams. While the team said they practice the skills of the line trade every day, the International Lineman’s Rodeo gives them the opportunity to incorporate everything they’ve learned into the events and have fun doing it.

“We love it,” Guiterrez said. “We start in May and practice day in and day out. We look forward to it every year to try to make it out to the international championships. We try to enjoy every minute of it.”

Like the other journeymen teams, they didn’t know what they would be doing for the mystery events until they arrived in Kansas City for the 2025 Lineman’s Rodeo Week. For this year’s first mystery event, the trios had to untie and replace the downhill side of the double buck crossarm. Supplied with two new PLP double support ties, the teams had up to 13 minutes to complete the event.

While two journeymen scaled the 40-ft pole, the groundman was responsible for raising and lowering the crossarm. By working as a team, they tried to finish the event on time and avoid any infractions such as failure to wear PPE, cutting out on the pole or failing to use the new tie. The overall winning team was the Front Line Power Construction trio of Jerimy Matheny, Michael Luksch and Rodney Greims, who had a perfect score of 100 event points and the fastest time of 04:03:50.

For the second mystery event, “Flashed Bells Changeout,” both climbers had to work as a team to apply the required cover, install a crossarm link stick and change out the bells. Because it was a simulated energized 4 kV event, they had to wear Class 2 rubber gloves and use other protective cover such as three hoses and one split and one solid blanket. To change out both poly bells, they were provided with a Chance Ribbon hoist, Klein grip, Poly Bells and Crossarm Link Stick.

Duke Energy’s International Lineman’s Rodeo competitors, who could not attend in 2024 due to back-to-back hurricanes, finished strong in the journeyman division at the 2025 Rodeo. Case in point: the Duke Energy team of Tyler Manick, Joshua Buckner and Tyler Nickols, finished first in not only this event, but also in the entire IOU division with a total time of 13:03:44. With 400 total event points, this team also came in third overall in the journeymen best of the best category.

Duke Energy’s journeyman team of Jay Tipton, Keith Griffin and Sandy Barnhill, who were featured on the T&D World Line

This NV Energy journeyman team worked together to showcase their skills at the 2025 International Lineman’s Rodeo.

This journeyman team of Fabian Gutierrez, Jose Leon and Fernando Valenzuela finished 13th out of 290 teams.

Life Podcast after the last time they won the senior division, won it again in 2025 with the time of 18:33:93.

Top Rodeo Champions

The competition may have grown to hit its highest numbers yet, but the events still started on time and wrapped up ahead

of schedule. Before the winners were honored on stage, Dennis Kerr, scholarship chair for the ILRA recognized the scholarship winners and a new annual $10,000 scholarship for an aspiring lineworker in honor of Warman for his dedication to the International Lineman’s Rodeo. Stremel and Doug Fllck also recognized the winner of their fourth annual gun raffle,

Very Low Frequency AC Technology • Cable Diagnostic TD & PD Testing • Cable Fault Locating with Controlled Energy • AC & DC Hipots, Aerial Lift Testers, Oil Testers • Ω-CHECK® Concentric Neutral Testing • Custom Engineered & Fabricated Van Pkgs.

The Sturgeon Electric California/IBEW Local 47 team of Dan Jameson, Enoc Verdin and Joe Maynes won the championship title in the journeyman division at the 2025 International Lineman’s Rodeo.

The top competitors won a championship belt and a trophy at the International Lineman’s Rodeo awards ceremony.

which benefits the ILRA scholarship fund to support students in technical training programs for the line trade.

In addition, the International Lineman’s Hall of Fame honored the inductees for 2024: Andy Batty, owner of Buckingham Manufacturing; Mike Benton of Georgia EMC; George Brooks, former president of IBEW Local 77 and owner of Brooks Hooks; Danny Raines of Raines Utility Safety Solutions; Melvin Tipsord, founder of Tips Tools; and Willie Warren of PG&E.

During the annual awards banquet, the ILRA also revealed the total donation amount of $83,484 for the 2025 Climbin4kids fundraiser, which benefits St. Jude Children’s Research Hospital. Next, the Missouri Valley JATC brought the top winners of its second annual Lineman’s Kids Rodeo up on stage. The organizers awarded championship belts to Adda Thomas in the 1st Step Apprentice (ages 8 to 10) category; Logan Meyers in the Future Lineman (ages 11-13) category and Parker Schleiden for Fastest Overall Aerial Rescue.

After the future lineworkers were honored, the announcer moved the spotlight to the adult competitors. Following the day of competition, the apprentices and

journeyman lineworkers donned everything from flannels and jeans to cowboy hats and boots and matching two-piece suits for their stroll on the red carpet and across the awards stage. As their names and companies flashed across the screen,

their families, friends, teammates and colleagues roared in the crowd to show support and celebrate their victory.

The journeyman team from Sturgeon Electric/IBEW Local 47 of Dan Jameson, Enoc Verdin and Joe Maynes were honored on stage at the end of the awards banquet as the champions of the 2025 International Lineman’s Rodeo with 400 total event points and a time of 12:19:39. This team also climbed to the top of the Contractor Division ahead of 50 other journeyman teams.

During the awards presentation, Kerr congratulated all the competitors and the winners of the 41st International Lineman’s Rodeo, which was the biggest event in its history.

“We put together a great event, the grounds were perfection and everyone had a great time,” he said.

Editor’s Note: For more 2025 International Lineman’s Rodeo coverage, stay tuned to the Line Life Podcast at linelife.podbean.com and check out videos, photo galleries, stories and more at tdworld.com/electric-utility-operations.

AMY FISCHBACH (amyfischbach@gmail.com) is the Field Editor for T&D World magazine and the host of the Line Life Podcast.

The winner of the 1st Step Apprentice division in the Kids Lineman Rodeo was Adda Thomas, who earned a championship belt during the awards banquet.

The International Lineman’s Rodeo finished earlier than scheduled, even with the most competitors in the history of the event.

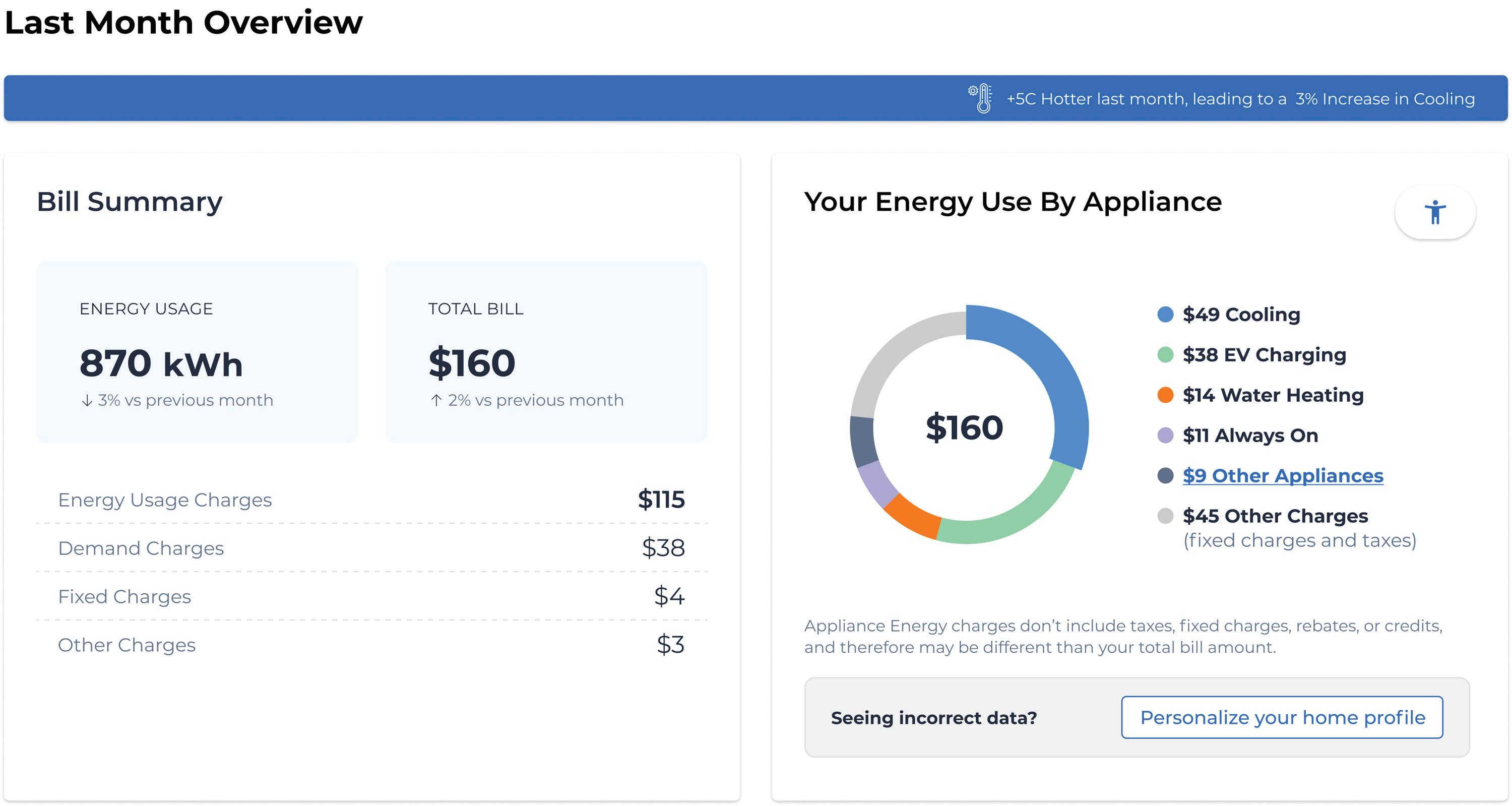

Inside Avista’s AI-Driven Customer Revolution

The utility shares its blueprint for layering AI onto millions of smart meter data points and how it translated those insights into improvements.

By ANDREW BARRINGTON, Avista Corp., and GAUTAM AGGARWAL, Bidgely

For most people, flipping a power switch is an unconscious act, yet it takes calculated effort by utilities to provide reliable power for millions of diverse energy habits and needs. This balance is only growing more complicated, and utilities are faced with making thousands of critical decisions across multiple teams and systems every day.

To achieve faster, more precise decision-making, utilities are increasingly relying on data to better understand each customer as an individual contributor to the grid.

For most utilities today, data sources include a combination of smart and non-smart meters, supervisory control and data

acquisition (SCADA) systems, historical and real-time weather records, and even distributed energy resources. But what does using data really look like? In its raw and unprocessed form, much of this data is a vast, uncontextualized stream of numerical entries.

For Avista Utilities, an electric and natural gas provider with 30,000 sq miles (77,700 sq km) of service territory across three states, this question ignited a multiyear exploration into what is possible when layering AI onto smart meter data. Embracing a mindset where innovation begets innovation, Avista explored the potential power of granular customer insights hidden within millions of data points and how those learnings could be applied

across three core business pillars: customers, workforce and the grid.

High Bill Inquiries

Oftentimes, customer engagement and workforce enablement go hand in hand. Thanks largely to nonintrusive load monitoring (a sophisticated combination of advanced algorithms and machine learning to dissect a home’s total energy usage), AI analytics give utility employees and customers new appliancelevel consumption insight into individual homes.

Traditional data analytics is applied to aggregate energy consumption. AI, however, identifies the unique fingerprints of individual appliances to recognize subtle on/off changes and accurately determine what is in use, how much energy it is consuming and when. This information enables utilities to build detailed usage profiles for everything from refrigerators to washing machines, revealing not just energy consumption and cost but also typical usage patterns and even anomalies that could signal a faulty appliance.

For Avista, this new intelligence unlocked an opportunity to address a critical priority: reducing the volume of high bill inquiries to its call centers.

While some high bill questions start and end with a customer service representative (CSR) conversation, Avista — like other utilities — often dispatches a crew for costly, resource-intensive on-site meter tests to investigate further. Typically, the meter functions properly, revealing customers’ limited awareness of their energy consumption. It is not that customers fail to grasp the link between usage and cost; the problem is that a monthly

total kilowatt-hour (kWh) reading offers no relatable insight. By equipping CSRs with one-click access to appliance-level consumption insights for every home, Avista’s service teams achieved faster call resolution times and significantly improved satisfaction among customers. High bill investigation truck rolls decreased by nearly 27% in 2020 alone.

For example, the CSR can look at a breakdown of the customer’s consumption and see if a specific appliance was acting up or if weather conditions were a factor. If the spike was due to increased cooling usage during a recent heat wave, the CSR can recommend specific thermostat adjustments or an insulation upgrade program.

Direct To Customers

This success gave Avista the confidence to extend these capabilities directly to its customers, with the overarching goal now to reduce high bill situations altogether. The utility made the following resources available to customers on its web portal:

• Bill itemization reports, detailing energy consumption each month by appliance (cooling, heating, laundry, dishwashing, lighting and even electric vehicle charging, if applicable).

• Month-after-month and year-over-year usage comparisons, overlaid with localized temperature history.

• Bill comparison tool, analyzing customers’ top five highest-use appliances in any given month with detailed financial and usage breakdowns for each.

These accessible, easy-to-digest communications empowered customers to self-serve their energy data for a deeper

understanding of their consumption and the ability to make smarter energy decisions independently. By tracking typical usage patterns and detecting anomalies, Avista has been able to resolve issues related to appliance inefficiencies. For example, one customer noticed a dramatic spike in energy costs, jumping from US$77 to $287 between consecutive

months with an alarming $600 projected bill for the upcoming cycle. Leveraging AI energy insights to investigate the appliance usage, Avista detected a faulty heat pump where a fused relay caused both the heat pump and air conditioner to run concurrently. These immediate, data-driven insights enabled Avista to pinpoint the problem quickly and save the customer from an exorbitant and ongoing financial burden.

Underserved Communities

But this is not where enhanced customer support ends. In fact, it opens doors to better serve all customers, including traditionally underserved or harder-to-reach customer communities.

As part of its partnership with SNAP, a local nonprofit aiding vulnerable neighbors, Avista was made aware of a customer with unusually high energy usage (over 38,000 kWh in 12 months) for a 1700-sq ft (158-sq m) house.

While previous meter inspections had not identified any issues, this time Avista used its AI-powered energy insights to identify inefficient heater usage and an unknown “envelope” issue. A subsequent home inspection confirmed the attic had insufficient insulation, below building codes. After installing additional insulation in the attic and to the water heater, the home’s overall energy bill was cut nearly in half, reducing heating costs from $424 to $163. In the three months following the bill reduction, energy consumption decreased by 6500 kWh, saving approximately $700 compared to the previous year.

The Energy Insights chart displays the breakdown of a customer’s energy charges by appliances across the selected timeframe.

Avista began using Bidgely AI in 2019, leading to an immediate drop in high bill calls. A notable spike in 2022-2023, driven by record-low winter temperatures, highlights customers' persistent challenge in understanding the direct impact of increased heating on their energy bills.

Segmentation and Targeting

By fostering greater energy literacy and empowering both CSRs and customers to make informed, data-driven decisions, Avista learned that addressing an immediate challenge — like high bill inquiries — could be the path to preventing them in the future.

Beyond reactive customer support, AI is empowering Avista to explore proactive grid strategies that improve load management and energy efficiency through more precise customer segmentation and targeting.

By gaining deeper insight into individual customers’ usage patterns, Avista optimized its outreach through new program initiatives, including a home energy audit offer aimed at households with above-average consumption (11,500 kWh annually). Filtering by key characteristics such as home age and square footage, the utility successfully narrowed a pool of 210,000 customers to 75,000 with the greatest po tential to benefit. These customers then received more targeted, personalized messaging.

The audits also identified 22,000 homes served by a constrained feeder. The utility sends personalized energy-efficiency tips and recommendations to these customers in the hopes of reducing significant strain.

Avista was even able to detect differences in average winter home energy usage, discerning between homes with efficient shells (good insulation, windows, roof, etc.) and those with poor thermal performance or equipment degradation.

Avista also launched a bill assistance program offering discounts of up to 90% to eligible households to support its most vulnerable customers. While Avista

always knew these customers existed, AI analytics now allows it to more accurately pinpoint and connect with those who need help the most.

This targeted approach proved highly effective. By identifying

Avista successfully used AI analytics data in its email campaigns to more accurately target customers who could benefit from a bill assistance program.

Personalized Bill Itemization allows customers to understand how each appliance category contributes to their monthly energy bill.

Avista customer service agents are able to use AI analytics to detect and resolve appliance inefficiencies. In this example, an agent detected abnormal spikes and worked with a customer to perform various tests to determine their air conditioner was drawing the extra power. The agent then was able to recommend that an HVAC technician come out to inspect the unit.

the right recipients, Avista achieved a 4.8% click-through rate on program emails (significantly higher than the 1.8% industry average) — proving that meaningful data can yield tangible, positive outcomes.

The Potential of GenAI

When it comes to empowering a utility’s workforce to deliver superior service and operate with stronger decision-making, AI has already proven exceptionally capable. Now, generative AI (GenAI) is emerging to further enhance these capabilities with a new dimension of operational efficiency and insight.

Shifting from traditional analytics to a more conversational interface, GenAI

empowers employees to easily access complex information and generate actionable recommendations by asking their own questions to the data — without needing to be a data analyst. This capability promises to streamline workflows, lighten staff’s cognitive burden and cultivate a more agile, responsive workforce prepared for the increasingly complex demands of modern energy management.

Building on its existing AI-powered CSR tools, Avista is now piloting GenAI implementation to further reduce call times and ultimately prevent repeat calls from the same customers.

Through what the utility is calling a GenAI energy assistant proof of concept (POC), Avista’s CSRs have a GenAI copilot during customer interactions. This assistant instantly compiles all relevant

OUR WUNPEECE TRANSMISSION SPACERS REDEFINE THE INDUSTRY STANDARD FOR UNDERGROUND POWER TRANSMISSION INSTALLATIONS. WITH PRECISION ENGINEERING AND UNMATCHED QUALITY,

information into a single high-bill-analyzer report, eliminating the need for CSRs to jump between multiple platforms for meter reads, billing history and appliance-level data. It also prompts the CSR with relevant questions and handles the heavy data lifting (that is, breaking down usage by previous month or year and clarifying what percentage or dollar amount is due to consumption vs. factors

like taxes or kilowatt-hour rate changes) rather than requiring the CSR’s manual computation.

These days, Avista’s CSRs using the GenAI assistance gladly welcome high bill calls because they are now some of the easier calls to manage.

Future of Data-Driven Utilities

As the grid continues to grow more

complex in the years ahead, the ability to make critical decisions with data-driven confidence will be invaluable. By exploring the possibilities of AI, Avista is paving a path to potentially save time and build efficiencies organization-wide. Learning to work within AI parameters and observing the iterative evolution of these tools will be integral parts of an ongoing journey, but one worth taking to create a more intelligent, customer-centric energy ecosystem.

ANDREW BARRINGTON is director of customer service at Avista Corp., where he leads strategic initiatives to enhance customer experience and operational efficiency. With a focus on innovation and team development, he drives service excellence across the organization.

GAUTAM AGGARWAL is chief revenue officer at Bidgely, where he spearheads the company’s mission to accelerate the adoption of a clean energy future with energy data and AI — empowering global utilities and energy providers with smart energy decisions and delivering a reliable, sustainable and resilient grid.

Ocala Electric Helps Customers Beat Back Bills with Prepay

Prepay allows customers to pay into a credit balance.

By CHAD LYNCH, Ocala Electric Utility and DAVID CONN, Exceleron

The City of Ocala, Florida is almost in the dead center of the state, about an hour and a half drive northwest of the town with the big theme parks. About 64,000 people live there — up almost 13% since the last census. The poverty rate is substantially higher than the national average, and in Florida generally residents saw electric rates rise 10% in the past year.

Ocala, and its municipal utility, Ocala Electric Utility (OEU), care about the cost of the vital services they provide. In 2010,

ID 183617188 © Popa Sorin | Dreamstime.com

379404065 © Swathi Chirra | Dreamstime.com

city leadership heard about the voluntary prepay service and decided they wanted it for their customers.