6,000

NAPA Auto Parts stores in the U.S. supported by a nationwide network of distribution centers

Access to an in-house APPRENTICE PROGRAM at no additional cost

NAPA is proud to have America’s largest network of parts and care.

With nearly 6,000 Auto Parts stores and over 17,000 Auto Care centers, from coast to coast, we are one NAPA.

95%

consumer recognition when you co-brand with NAPA Auto Care

NATIONWIDE PEACE OF MIND WARRANTY for your customers, and local labor coverage for you

NAPA Auto Care centers are featured in the national marketing campaign PRIORITY PARTS DELIVERY SERVICE

from your servicing NAPA store

Interested in becoming a NAPA Auto Care center? Scan this QR code to be contacted by a local NAPA sales representative.

Ratchet+Wrench sat down with two of the top females in the auto repair industry in order to understand the road that has led them to the industry, and how they see our sector going forward.

BY IVAN RIOJA-SCOTT

Through determination, training, and the support of her family, Victoria Carl managed to open her own shop at just 21 years old and has been thriving since

KACEY FREDERICK

Making your impact: Go Green Auto Care’s journey to sustainable repair

The rise of electric and hybrid vehicles

Do you really need a coach?

You never get a second chance to make a great first impression KATHLEEN CALLAHAN

A shop owner shares his secret to determining this critical number

Whether you’re a seasoned technician or just starting in the industry, our Gold video library has everything you need to stay ahead of the curve.

Unlock over 60 hours of advanced, in-depth automotive training with our Gold video library. Featuring recorded webinars led by industry experts, this comprehensive library covers cutting-edge diagnostics, complex repair techniques and the latest innovations in automotive technology. With new content added monthly, you’ll stay up-to-date on emerging trends and tools, ensuring your skills remain at the forefront of the industry.

Learn from industry experts through our extensive library of recorded webinars covering essential topics—from advanced diagnostics to the latest automotive technologies. With flexible subscription options, you can access top-tier content when it works best for you.

Subscription benefits

Access to our Free video library

Access to our Gold video library

Webinar handouts

Discounts for live events, including our DTC Annual Event

Swag and other giveaway items Sign up now

BY IVAN RIOJA-SCOTT

I was recently speaking with an accomplished shop owner and he mentioned something that stuck with me for days after our conversation. He said: “This isn’t typically an empathetic industry.” In the true nature of our business, we often deal with the unpleasant, unplanned, and unexpected car repair. A customer that wasn’t expecting his car to break down or a DVI that finds a safety hazard in their vehicle that needs immediate attention. Not only do they face inconvenience, but all too often, the unplanned expense. And it’s our duty to inform them of that scenario that they face. I believe the industry does an acceptable job of showing empathy in these cases, but even though it’s shown, how much can really be done in this situation?

When we delve a little deeper into understanding empathy in the business world, and in our niche of that pie, we quickly realize that empathy isn’t only something to apply to our customers, but to our employees, suppliers, peers, and colleagues. This sounds kind of obvious, but is it really ? When an employee has a personal problem, are we really putting ourselves in their shoes and understanding where they are coming from without applying our frame of mind to that scenario? I’d say it’s hard to have a yes or no answer to any of these questions.

Empathy can appear to be a doubleedge sword, it can be interpreted as being soft or easy to take advantage of, and that’s a fine line to play when you are a shop owner. Now let’s be clear here, empathy is not charity, and while charity can be a gesture into the realm of empathy, one should not be confused with the other.

Ernst & Young’s second Empathy in Business Report states the following: “Empathy in the workplace drives psychological safety and fosters an experiential culture that allows for experimental failure to generate learning

and new ideas.” I find this a very enlightening concept, as when it comes to the workplace, the fear of experimental failure often holds back new ideas and concepts from being fully developed. We might wonder why this happens, and I believe it happens when empathy is not applied from the top down. When employees are afraid to fail, they will not try new concepts. The fear of losing a source of income far outweighs the potential gains of innovation. And lets be honest, nobody likes to live in fear of not having their job and being able to provide for their families.

Developing empathy from the topdown fosters a culture of understanding, growth, learning, and innovation. This might be seen as corporate jargon, but from a pragmatic standpoint, implementing this culture is much easier with smaller companies, auto repair shops, for example.

EDITORIAL

EDITORIAL DIRECTOR

Chris Jones

EDITOR-IN-CHIEF

Ivan Rioja-Scott

ASSISTANT EDITOR

Kacey Frederick

CONTRIBUTING WRITERS

Tess Owings, Leona Scott

EDITORIAL ADVISORY BOARD

Tara Topel, Topel’s Towing and Repair

Andrew Marcotte, American Pride Automotive

J.J. Mont, J.J.’s Auto Service

Rachel Spencer, Spencer’s Auto Repair

Tonnika Haynes, Brown’s Automotive

Lucas Underwood, L&N Performance Auto Repair

SALES

ASSOCIATE PUBLISHER

Andrew Johnson / ajohnson@endeavorb2b.com

ASSOCIATE SALES DIRECTOR

Mattie Gorman-Greuel / mgorman@endeavorb2b.com

DIRECTOR OF BUSINESS DEVELOPMENT

Cortni Jones / cjones@endeavorb2b.com

ACCOUNT EXECUTIVES

(NATIONAL ACCOUNTS)

Diane Braden / dbraden@endeavorb2b.com

Darrell Bruggink / dbruggink@endeavorb2b.com

Marianne Dyal / mdyal@endeavorb2b.com

Chad Hjellming / chjellming@endeavorb2b.com

Lisa Mend / lmend@endeavorb2b.com

Annette Planey / aplaney@endeavorb2b.com

Kyle Shaw / kshaw@endeavorb2b.com

Sean Thornton / sthornton@endeavorb2b.com

ADMINISTRATIVE ASSISTANT

Ryan McCanna

ART AND PRODUCTION

ART DIRECTOR

Emme Osmonson

PRODUCTION MANAGER

Mariah Straub

AD SERVICES MANAGER

Jen George

ENDEAVOR BUSINESS MEDIA, LLC

CEO

Chris Ferrell

COO

Patrick Rains

CRO

Paul Andrews

CDO

Jacquie Niemiec

CALO

Tracy Kane

CMO

Amanda Landsaw

EVP TRANSPORTATION

Kylie Hirko

EVP ENDEAVOR BUSINESS INTELLIGENCE

Paul Mattioli

VICE PRESIDENT - VEHICLE REPAIR GROUP

Chris Messer

SUBSCRIPTIONS

Send address changes and subscription inquiries to:

Ratchet+Wrench PO Box 3257 Northbrook, IL 60065-3257

SUBSCRIPTION CUSTOMER SERVICE: 877-382-9187 ratchetwrench@omeda.com

LETTERS TO THE EDITOR

editor@ratchetandwrench.com

Opinions expressed in Ratchet+Wrench are not necessarily those of Endeavor Business Media, and Endeavor Business Media does not accept responsibility for advertising content.

RIOJA-SCOTT, EDITOR

BY KACEY FREDERICK

Cleanliness is a virtue among most auto repair shops—but for Go Green Auto Care of Newport News, Virginia, they ensure that every aspect of their practice doesn’t just look clean, but is actively making the environment around them cleaner.

The business’ eco-friendly foundation comes from Leslie Jarvis, co-owner alongside her husband, Tyrone Jarvis. They do things a little differently from most shops, but it’s earned them a loyal customer base, more affordable operations, and even allow-

ing them to change statewide legislation paving the way for other small businesses to adopt sustainable practices.

Sustainability has always been at the heart of Go Green Auto Care since it was first founded in 2010, but Leslie’s passion for the topic goes back much further. When she first became a vegetarian in the ‘90s, it was not nearly as mainstream as it is now. She found

support through a community of others like her, which led to learning about environmental conservation and sustainability.

Only a year after opening, the shop was already making an impact, winning the Virginia Clean Business Award for early sustainability efforts, including thorough recycling and the use of non-toxic cleaners and lubricants. It wasn’t until 2015 that the shop met pushback, when it began harvesting rainwater.

The installation of Go Green’s rainwater harvesting system was prompted by a plumbing leak under the foundation of their building, which they were told had to be solved by fixing a pipe under the foundation. Having ownership of the building, Leslie and Tyrone have always had the freedom to do what they want with it, and started thinking of sustainable solutions to their new problem.

That’s when they found a manual on rainwater harvesting, published around 20 years ago by an environmentalist in Roanoke, Virginia. Leslie knew they had found their answer.

“We purchased 500 to 250 gallon tanks, set up the first flush, as well as all the purifying and the filters and everything we needed to get it done. We put out a press release letting everybody know that this was our new initiative,” tells Leslie.

It was a brilliant move to use resources naturally provided to them—not only helping the environment but relieving strain on the city’s supply, while also saving them money.

There were no problems until local officials pushed back, due to a law that mandated connection to the municipal water supply. Otherwise, a building would be considered unfit for habitation. “Even though we had beautiful, clean, potable standards—water fit for human consumption on site—they came in to shut us down,” tells Leslie.

That didn’t stop Leslie, though. She and Tyrone made contact with who their state delegate was at the time, David Yancey, and worked with him to draft legislation that would make it legal for businesses like Go Green Auto Care to harvest rainwater.

As of 2024, that legislation has been signed into law, and Leslie has continued

to advocate for businesses pursuing sustainable practices.

Originally a high school dropout with a GED, last year she graduated from Virginia Commonwealth University with a Bachelor’s in Interdisciplinary Studies, focusing on Environmental Law. She’s now working on another piece of legislation, SB851, which would protect individuals and businesses who invest in rainwater harvesting from local municipalities attempting to restrict or penalize them.

Go Green Auto Care has not only set a precedent for shops to adopt sustainable standards, but has shown how important it is for small businesses to stand up for their values, and how real change can happen with a little planning.

Though not all shops may be able to invest in something like rainwater harvesting or solar power right away, there are small, easy ways to incorporate sustainable practices into a repair shop’s practices.

Leslie suggests for shops to hone in on a

few select things that can be optimized, and slowly expand from there. As one example: instead of throwing kitty litter on oil spills and throwing it out, Go Green uses a squeegee and a dust pan to dispose of the oil, and cleans the floors with non-toxic soap.

Production selection is a simple, yet important change, too—particularly using lubricants and degreasers that are biodegradable and eco-friendly. Another huge aspect of Go Green’s operations is its waste oil

heater, which recycles used motor oil to heat the entire shop. Not only does this cut down on waste, but can drastically cut a facility’s energy bill.

Not only do these practices help the local environment and have potential cost benefits, but have a tremendous impact on the customer experience. Go Green’s clients are always wowed by how spic-and-span the facility is, and that is largely because of the great care the entire team has for maintaining it.

Nearly half the cars on the road in the US are Japanese, and a vast majority of those come from the factory with Idemitsu engine oils, transmission fluids, or PAG oils. For 110 years, Idemitsu has been the go-to source for the most technically advanced, high-performance fluids on the market. Give your customers the OE performance and quality of Idemitsu lubricants.

“I feel a great sense of pride when people come into the shop, and they’re like, ‘Oh my god, this is like my living room!’ It’s not a dirty, oily, greasy dungeon like a lot of shops are,” says Leslie.

Sustainability is a concern for a growing number of people, but it isn’t something many repair shops are openly addressing. Adopting sustainable practices is not just something that will benefit your wallet, but is a way of showing that you are doing your part to keep your community clean, healthy, and safe.

That’s why Leslie hopes that the change Go Green has brought about—making it easier for small businesses to seek alternative, sustainable solutions without being penalized—will make it easier for more shops to feel confident in making such a change themselves.

“There’s cost savings that come with being green, and there’s also customer loyalty that comes with being green and implementing sustainable practices,” says Leslie. “There are people out there that want ethical repair—they want you to be sustainable.”

Idemitsu is the official OE supplier of engine oils and transmission fluids to leading Japanese vehicle manufacturers such as:

We have not just enhanced, but mastered, the

In

Following several reports of issues with General Motors’ 6.2-liter L87 V8 engine, the National Highway Transport Safety Administration has launched an investigation into affected models, according to Car Buzz.

Drivers began saying that they experienced engine failure on lowmileage vehicles—many of them not reaching even 10,000 miles—leading to an engine transplant having to be performed.

The number of complainants grew to 39 before NHTSA had heard enough, launching its own investigation on January 16, 2025. No recall has been issued, but the agency did share what models are being examined:

• 2019-2024 Chevrolet Silverado 1500

• 2021-2024 Chevrolet Tahoe

• 2021-2024 Chevrolet Suburban

• 2019-2024 GMC Sierra 1500

• 2021-2024 GMC Yukon and Yukon XL

• 2021-2024 Cadillac Escalade and Escalade ESV

NHTSA has estimated that a total of 877,710 vehicles are at risk of experiencing complete engine failure.

GM is working with the agency to discover the root cause, though there are some details available on what leads up to the engine failure. It begins with a bearing failure inside the engine, leading to the connecting rod detaching from the crankshaft. This could be followed by either the engine completely seizing, or the rod colliding through the engine block. Drivers are given little time to react, if they receive any warning at all, before the engine fails.

The number of drivers impacted has been so large that GM has been struggling to provide engine replacements, with owners experiencing wait times of up to several weeks.

Renault is licensing its own patented

technology to combat electric vehicle battery fires to the rest of the auto industry for free, reports The Drive.

The automaker’s “Fireman Access” system makes it so that firefighters can easily flood the battery compartment with water. This is achieved through an adhesive disc covering a hole in the battery pack, that’s just weak enough to be broken through with a fire hose.

While EV battery fires typically take hours to extinguish, Renault has claimed its system allows fires to be taken care of in just minutes, and requires 10 times less water.

Currently, the Fireman Access can be found in all current Renault, Alpine, and Dacia EVs and plug-in hybrids— but Renault is offering the patent for other automakers to use at no cost, in a similar move to what Volvo did with the three-point seatbelt.

“Today, I’m delighted to be making this innovation freely available, because when it comes to a subject like safety, we need to break down all the barriers,” Renault Group CEO Luca de Meo said in a press release. “This move is also in keeping with the commitment made alongside the United Nations, to make mobility safer all over the world.”

Opus IVS has partnered with Elitek Vehicle Services to release ADAS MAP, a tool to help shops properly diagnose, calibrate, and repair Advanced Driver Assistance Systems, according to a press release.

Powered by technology from Opus, the ADAS MAP allows shops to easily generate records of each calibration, programming, and scanning event, with clear documentation on what was done and why, based on original equipment manufacturer specifications. It also provides simple documentation on what work is completed in the shop and how long it took.

“We are excited to partner with

Elitek, leveraging our leading-edge technology to enhance repair accuracy while fostering greater trust and collaboration across the industry,” said Opus IVS CEO Brian Herron.

ASA, SCRS, Alliance for Automotive Innovation Propose “SAFE Repair Act”

The Automotive Service Association, the Society of Collision Repair Specialists, and the Alliance for Automotive Innovation have proposed legislation addressing vehicle repair data access, according to a news release.

In a letter to Congress, the groups outlined their proposal for the Safety as First Emphasis—or SAFE—Repair Act, which is meant to build upon a 2014 national agreement that independent repairers may have access to the same data made available to dealers. The agreement was recently affirmed by the coalition in 2023.

The REPAIR Act failed to adequately address safety, said the recent ASA release, arguing that while the REPAIR Act mandated access to repair data, it said nothing about a consumer’s right to ensure it’s being used to restore a vehicle’s safety systems or structure to full functionality.

Some features of the bill include an extension of the same recall and safety protections for OEM parts to customers using non-OEM parts; requiring disclosure of prior alterations or repairs on a used vehicle; and support for periodic safety inspection and post-collision inspection programs.

“While existing frameworks have created a thriving and competitive repair marketplace, we understand the desire for a federal legislative solution that addresses evolving consumer expectations and technological advancements,” wrote the coalition in its letter. “That’s why our three organizations have come together to propose a new path forward–one that builds on existing protections while introducing additional measures to prioritize consumer safety and choice.”

Whether in the repair shop, office, or lobby, you can now look up and order parts wherever you are, from any mobile device. Simply search for O’Reilly Pro in your app store!

• Full parts catalog

• Available in English and Spanish

• Ability to place orders from your mobile device

• License plate scan to VIN

• VIN Scan

• Send quotes via SMS or Email

• Connects to OReillyPro.com for transitions from mobile to desktop

• Search functionality

• Real time product availability

SCAN HERE to download for both IOS & Android

DOWNLOAD O'REILLY PRO

IN THE APP STORE TODAY

BY OUR PARTNER, EBI/IMR

As electric and hybrid vehicles gain traction in the automotive market, repair shops are taking steps to prepare for the shift. While battery electric vehicles currently make up just 4.5% of the vehicles serviced, and hybrids account for 7.2%, the demand for maintenance and repair on these vehicles is rising. In fact, 93% of shops report an increase in BEVs coming in for service over the past two years, while 92% have seen a rise in hybrid repairs.

This growing trend is pushing many repair shops to adapt. More than half (57%) of shops now actively market their ability to service electric and hybrid vehicles, recognizing the opportunity to compete with new car dealers for their share of the business. However, prepara-

tion goes beyond marketing. About 43% of shops have invested in specialized tools and equipment designed for electric and hybrid vehicle repairs, ensuring they have the necessary resources to handle the unique challenges these vehicles present.

Training is another crucial component of this shift. With electric drivetrains, high-voltage systems, and advanced battery technology, servicing BEVs and hybrids requires specialized knowledge. Currently, 42% of shops have invested in training programs to equip their technicians with the skills needed to safely and effectively work on these vehicles.

Staying up to date with industry trends is also key. A majority (59%) of repair shops rely on their first-call sup -

pliers or program groups to provide insights into the latest developments in electric and hybrid vehicle maintenance. This ensures they are aware of emerging technologies, best practices, and potential service challenges.

While electric and hybrid vehicles still make up a small percentage of overall service traffic, the data clearly shows that their presence is growing. Forward-thinking repair shops are making strategic investments in marketing, equipment, and training to position themselves for the evolving automotive landscape. As the shift toward electrification continues, these preparations will be essential for staying competitive and meeting the needs of an increasingly electric future.

your shop intentionally market or advertise that you can service Electric or Hybrid vehicles?

BY TONNIKA HAYNES

Tonnika Haynes, owner of Brown’s Automotive in Chapel Hill, North Carolina, has joined the Ratchet+Wrench Editorial Advisory Board as the newest member.

Having first opened in 1980, Haynes is the second-generation owner of the 4,000-square-foot, family-operated shop. Having grown up in her family business, Haynes is trained in not only automotive repair, but expertly handling customers as well. Haynes is a UNC-Greensboro graduate, now serving on the NC Automotive Service and Tire Alliance board. She’s vocal about the need to prevent burnout among business owners, promoting practices to help those operating shops manage their stress.

What do you need help with? Do you even know? Sometimes, we don’t know what we don’t know—and that’s exactly where a coach can be valuable. Other times, we do know, but we’re too busy, too stubborn, or too unsure of where to start.

A coach can push us, keep us accountable, and challenge our thinking. But not all coaches are created equal, and not every business owner needs the same thing at the same time. In my career, I’ve worked with three different coaching companies, and each one had a different scope and approach—sometimes with some hard love.

I didn’t set out to go through multiple coaching programs, but as my business evolved, so did my needs. As shops grow, the market changes, legislation changes, and many other unknown aspects surrounding business can change,

and sometimes coaches cannot evolve with the business.

If the first experience isn’t great, don’t be discouraged, mine was not. It wasn’t a scam—it just wasn’t the right fit. I got some decent information, but it felt like a generic, one-size-fits-all system. And we all know that one size does not fit all in this industry. Even though my first attempt at hiring a coach hadn’t really delivered the outcomes I desired, I kept searching for the correct coach. There are many factors that can influence the selection of the right coach, but you should have a clear idea of the results you wish to achieve through the coaching process. In my case it was the second coach that changed everything.

It made me take a hard look at how I was running my shop. And I had to face an uncomfortable truth: some of my biggest struggles were self-inflicted. I wasn’t leading—I was micromanaging. I was working in my business, not on it. I had built something that couldn’t function without me, which meant I didn’t have a real business—I had a glorified job. That realization stung. But once I made changes—delegating, stepping into leadership, and setting my shop up to run without me—I grew. When I hit a point where I felt that I had achieved everything I could with this coach, I knew it was time to move on.

Understanding that coaches may not tell you everything that you want to hear and may drastically change how you run your business, and even adjust some ways you interact with people and staff, is not uncommon. But it’s not simple. Keeping your mind open and trusting the process

will help you achieve your goals.

Coaching covers many areas of business, and one of the most important is the financials. I used to think, we made a million dollars—that’s great! But was it profitable? Could I tell you exactly where every penny went? Nope. And that’s not OK. So now, I’m learning a whole new level of business ownership because that’s the thing about coaching—there are levels to this. What works for your shop today may not be enough for where you want to go next. So ask yourself, do you really need a coach? Maybe, or maybe not. A coach can be incredibly valuable if you’re stuck, need structure, or want to grow but aren’t sure how. They help you see what you’re missing, keep you accountable, and push you outside your comfort zone.

But here’s the thing—coaching isn’t a magic fix. You can’t just hire a coach and expect them to transform your business overnight. Show owners must be willing to put in the work. Just like hiring a technician, you need the right fit. The best coach in the world won’t help you if their style, approach, or expertise doesn’t align with your needs.

IF YOU’RE THINKING ABOUT HIRING A COACH, ASK YOURSELF:

• What do I need help with?

(Not just “to grow,” but specifically— is it leadership, financials, marketing, operations?)

• Am I open to feedback and willing to make changes?

(If you just want validation, you’re wasting your money.)

• Do I have the time and energy to fully commit?

(Coaching only works if you apply what you learn.) If the answer is yes, a coach can be a great investment.

Talk to other shop owners. Find out who they’ve worked with, what they liked, what they didn’t. Get the real, unfiltered experiences—not just the polished testimonials on a website. Don’t just rely on word-of-mouth—do your own research. If a coach is as good as they claim to be, they should have plenty of free content out there. Think of it like a restaurant offering samples—before you commit to the full meal (and the price tag), you should be able to get a taste of what they offer.

Check their website—do they have free resources, blog posts, case studies … If they don’t share knowledge freely, that’s a red flag. Listen to their podcasts or webinars—many coaching companies put out free content. This will give you a feel for their style and whether their approach makes sense for your shop and situation. Join industry groups—shop owner forums, Facebook groups, and trade associations are great places to find recommendations (and warnings). Ask questions! If you get a referral, don’t just take it at face value. Ask why someone recommends a coach. What did they actually do for their business? The goal isn’t just to find a coach—it’s to find the right coach for where you are in your business. So be picky, be thorough, and make sure they can actually help you move forward.

A coach can be a game-changer, but only if it’s the right fit and the right time. If you’re considering coaching, don’t just jump in because someone else says you should. Be clear on what you need, find the right person, and be ready to do the work. If you’re not at that point yet, focus on learning in other ways— through mentors, networking, and selfeducation.

The most important thing? Don’t stay stuck. Keep learning, keep improving, and keep pushing forward—whether that’s with a coach, a mentor, or just through trial and error. So, what’s your next step? Coaching, mentorship, or just rolling up your sleeves and figuring it out? Whatever it is, don’t stand still— your business won’t grow that way.

Tonnika

Haynes Owner of Brown’s Automotive

IF YOU CAN’T AFFORD TO HIRE A COACH, ALL HOPE IS NOT LOST

1.

Start with free resources

Many coaching companies offer blogs, webinars, and online tools for free. Take advantage of what’s already out there.

2.

Lean on industry connections

Networking with other shop owners can be just as valuable as formal coaching. Join industry groups, go to events, or just reach out to people you respect.

3.

Sometimes, the best advice comes from someone who’s been where you are. A mentor doesn’t have to be a paid consultant—it can be another shop owner willing to share their experiences.

The point is, if you’re serious about growth, there are always ways to keep learning.

BY KATHLEEN CALLAHAN

Continuing the theme of delivering excellent client service, we are going to focus on professionalism. Our industry has historically had a less-than-stellar reputation for being professional–we are often seen as being dirty, greasy, and messy. The need for professionalism has also increased with the increase of technology in vehicles. The public perception of our staff is more critical today than ever! Let’s dig into some things you can do to increase your professionalism, client confidence, and your bottom line.

Most of the time, our first contact with a client is via the phone. That is why phone etiquette and training are critical pieces of your service to focus on.

• First impressions make a huge difference–every staff member who answers the phone should use the exact same greeting–and always with a smile. Smiles can be perceived through the phone, creating a positive and welcoming impression.

• When you use a clear and slowerpaced greeting when answering the phone, it sets the tone for the call and lets the person on the other end know that your focus is on them and that they are important to you. One-word greetings or mumbling through the “greeting” gives the impression that you are too busy to care about a client’s concern and begin the conversation on a sour note.

• Ensure you introduce yourself and ask the caller what their name is as well. Using their name throughout the conversation is also a great way to show you are paying attention and actively listening.

• Do your absolute best to minimize hold times. If you anticipate a

hold time, ask for their contact information and call them back. Be honest and tell them you must research their request or that the person they need to speak with is unavailable, but ensure you call them back!

• Be prepared when you call a client. Ensure you have all the information for the conversation about their vehicle. You know they will have questions, and being as ready for them as possible will add to the feeling that they are valued.

In addition to the items above for phone calls, making eye contact and smiling at clients when they enter your facility is a high priority for every staff member. Making eye contact and smiling, even when on the phone, ensures the client feels acknowledged and valued.

• Every staff member should practice good hygiene and wear clean clothing free of rips and wrinkles.

• Even with a near-zero budget, having your staff in uniform conveys professionalism. A uniform could be as simple as solid color t-shirts the color of your logo or as sophisticated as dress shirts and slacks for frontof-house and branded uniforms for the back-of-house staff.

• Name tags or name patches are a plus! Clients being able to identify which staff member they are speaking to adds to the relationship you are building with them.

Finally, whether on the phone or in person, never end a conversation with a client without asking if they have any questions. You always want your clients to feel heard and educated.

Knowing these things is great but training your staff and ensuring they follow them are essential. I recommend taking it further and writing a company policy on this. Some of these things may seem unimportant, but the devil is in the details!

Kathleen Callahan has owned Florida’s Xpertech Auto Repair for 20 years. In 2020, she joined Repair Shop of Tomorrow as a coach to pursue her passion for developing people and creating thriving shop cultures. Callahan is the 2018 Women in Auto Care Shop Owner of the Year, nationally recognized by AAA for three consecutive years, testified for Right to Repair on Capitol Hill, and is vice chair of Women in Auto Care.

kathleencallahanfl@gmail.com

Ratchet+Wrench sat down with two of the top females in the auto repair industry in order to understand the road that has led them to the industry, and how they see our sector going forward.

It’s well-known the auto repair industry has been a male-dominated industry for many years. Many women are starting to emerge as strong and successful industry players. They bring a different mindset, higher understanding for the younger consumers, and a more attentive approach to the new generation of customers—many of which are women.

The field remains male-dominated, though the balance has improved over time. According to the Bureau of Labor Statistics, women make up only 12.1% of automotive repair and maintenance roles, 15.1% of jobs at automotive parts and tire stores, and 21.8% of positions at automobile dealers. Additionally, women account for just 29.3% of all manufacturing jobs, many of which are vital to the production and maintenance of vehicles nationwide.

BY IVAN RIOJA-SCOTT

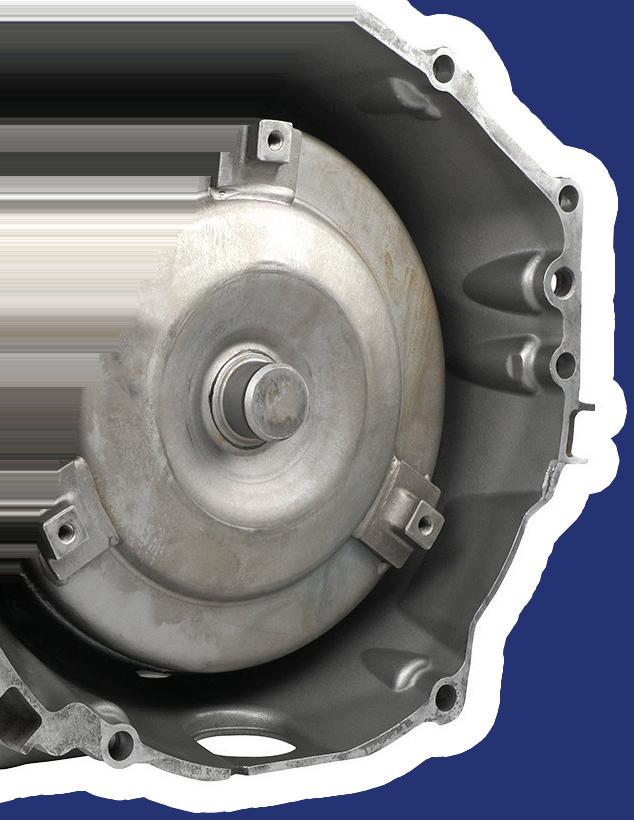

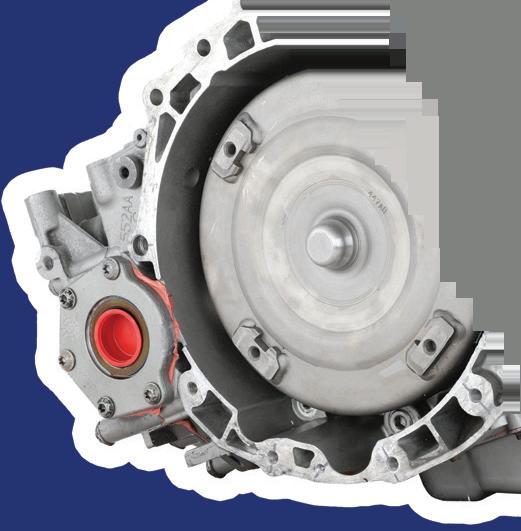

Maryann Croce has co-owned a transmission shop with her husband since 1999. In 2018, she became 90 Day Year certified through personal and professional training. Croce brings a wealth of knowledge, expertise and experience to her seminars and coaching, having held management roles in various industries. Croce is also the owner and lead coach of

Small Biz Vantage, a training and business performance coaching company serving automotive and skilled-trade business owners and their teams. As a shop owner herself, she is well-equipped to address the current needs and challenges that owners face.

An industry speaker, Croce has contributed to numerous automotive and business publications and podcasts. She finds serving on industry boards, school advisory boards and chamber committees to be a rewarding way to help the industry thrive.

Croce recognizes the issues in the industry with finding and attracting talent. She’s taken a very grass-roots approach and believes in starting at the most basic level.

“As a shop owner or someone in the industry, it’s important to get involved in career days or career nights at local schools. This allows you to connect with the next generation and understand what they’re looking for in a career. Gone are the days when a technician would simply clean up or work their way up— today’s vehicles are incredibly advanced, and providing proper training for your team is essential if you want to attract and develop top talent,” states Croce.

Creating a culture that supports growth and development is key. Shops can offer training and other opportunities, but it’s important to remember that this will only be effective if you attract the right type of person—someone who wants that kind of support and development.

“For example, getting involved with career days or career nights at local schools on multiple levels can help the next generation understand the industry and what it has to offer. Engaging with students, understanding their interests, and showing them the diverse career opportunities available is key,” says Croce.

The old way of thinking—that a technician is just there to clean up and work their way up, or that an owner will teach them, is outdated. Today’s workforce requires a different approach. Training is essential, given the advanced technology in vehicles. Providing training opportunities for employees, whether to develop top talent internally or attract the best external talent, is critical.

When Croce first joined the shop she had some doubts about what her role would be. Although she had management experience and handled the financial and customer service aspects of the business, she initially questioned herself as to whether she had the necessary technical expertise in the industry.

“However, I soon realized that my strength lay in focusing on our processes and how best to serve our customers, rather than needing to be the one fixing the vehicles directly. It was a shift in my thinking –I didn’t have to be the technical expert, but rather ensure we had the right systems and approach to effectively meet our clients’ needs,” says Croce.

Croce recognizes that the industry has an outdated perception that needs to be addressed. As shop owners and industry professionals, she understands the responsibility to reposition the industry in a more accurate light lies within. She advocates for each person that’s part of the industry to their share.

“Overall, we need to take an active role in reshaping the industry’s perception and highlighting the rewarding career paths it can provide. By getting involved in the community and prioritizing training and development, we can position the industry for success.”

Croce and her husband have been in business for 25 years. She has immense pride for the team she has built at her shop, and having transitioned into semi off-site ownership, her focus is more on giving back.

“With my shop running smoothly, I’m able to dedicate time to giving back to the industry. I sit on industry boards as well as boards outside the industry, where I can learn from every meeting. This is important to me because the industry has been so good to us, and I’ve had many great mentors, both within and outside the field,” says Croce.

“The fact that I don’t have to be in the shop every day is thanks to my amazing team. I’m grateful to be in a position where I can focus on paying it forward.”

Taylor Mitchell, the CTO of GreatWater Garages, started her career in the auto repair industry at the Auto Care Association, despite her prior experience being in the technology space. This unique background has given Mitchell valuable know-how when it comes to implementing technology to improve businesses.

GreatWater 360 Auto Care is a network of local, full-service auto care shops found in many different communities under various names. However, all GreatWater 360 Auto Care shops share a commitment to delivering the highest level of auto care and customer service to every person who walks through their doors.

“I came over to help build this organization, working with a team to focus on establishing local repair shops. As the CTO, my passion lies in the technology, people, and processes that bring value to our organization,” Mitchell states.

The organization focuses on integrating those local shops into their network, providing the necessary back-end resources. Mitchell works with her team daily to support the local shops in continuing to service their communities.

The industry continues to face the challenge

of finding the right personnel. But Mitchell sees a wealth of opportunity, especially as cars become more technologically advanced. The actual job of a technician is changing and becoming more focused on technology rather than just “turning wrenches.” This evolution in vehicles can help attract a younger generation. Providing career training opportunities and impacting culture development is important for all auto repair shops. “Our company has made employee development a top priority. We recognize it as a core part of our business and company culture. To that end, we’ve dedicated a team member to spearhead our efforts in this area,” says Mitchell.

At GreatWater, employees are provided with training and learning opportunities. This includes daily team huddles, as well as resources and content that are shared with them. The goal is to foster a culture that values continuous learning and growth. “We believe this approach serves two key purposes. First, it helps us attract candidates who share this value. Second, it encourages our employees, especially younger team members, to invest in their own professional development,” states Mitchell.

The company sets the expectation that employees should invest in themselves, just as the company invests in its employees. There are dedicated resources to support and drive these professional development programs forward. While it may seem like an easy problem to solve, it takes effort from all sides.

“Career path is a crucial part of meeting this need. When people have this clarity, it provides them with a clear sense of expectations and a roadmap for growth. It lays out the ‘why’ behind their work and the opportunities for continued development,” states Mitchell.

Auto repair shops have suffered over the years from a bad reputation. Much of this comes from poor communication with customers, and a lack of transparency in regard to the issues that some vehicles may have.

Mitchell emphasizes that educating customers is a critical part of the business. “We use a variety of methods to inform them about vehicle issues, including digital vehicle inspections. Overall, our goal is to clearly communicate vehicle needs and empower customers through transparent information,” states Mitchell.

Younger customers are more technologically adept and often prefer communicating via devices instead of traditional phone calls. Implementing systems that can provide this channel of communication is important for catering to newer customers. “These tools bring transparency to the customer. It’s a communication tool that benefits both us and our customers. It’s an important tool that provides clarity,” says Mitchell.

Independent auto shops often prioritize customer service and quality work above all else. As one shop owner put it, “The bottom line is, just be nice and fix cars.” This sentiment seems pervasive across the industry, with many people advising to take your vehicle to the local shop rather than a larger dealership.

It was the technical project manager role dealing with industry standards that appealed to Mitchell at GreatWater. Although she lacked direct automotive experience, she was drawn to the software development space and the prospect of taking on a new challenge in standards compliance.

The company was seeking someone to help on the standards side of the business, which was a new position for them. While she considers herself to have been an unconventional choice, the automotive industry has a way of pulling people in, as it fosters a close-knit community dedicated to solving interesting problems.

“Though I was met with some initial skepticism, I was confident I could thrive in this role and contribute to the great group of people I would be working with. The chance to be part of an industry network tackling diverse challenges was an exciting prospect,” says Mitchell.

20 Grand Prize Winners and their guest win a driving experience weekend out in Chandler, AZ at the Radford Racing Performance Driving School. Grand Prize Winners will have two full days of high-octane driving on the legendary performance training track!

BY KACEY

For many who enter the automotive repair field, they come with dreams of one day opening a shop of their own. For Victoria Carl, she didn’t think it would come so soon for her—but through being born into the industry, and a determination to build upon the foundation her family gave her, she put herself in a position of owning her own repair shop in Voorheesville, New York, at the age of 25.

For five years now, she’s run Carl’s Advanced Automotive & Truck Repair Center alongside her mother, and neighbors her brother’s own detailing shop across the street. In a time when so many in the industry are looking to recruit talent and formulate succession plans, Carl’s story is evidence that young people entering the field can find success in an environment where their determination and talent is encouraged.

Carl was born into the industry, growing up around the Saab dealership that her grandfather owned. Much of her infancy was spent in a car seat on the parts counter, being passed back and forth among family members at work.

Carl’s father also grew up in the automotive industry, with training specifically in body work. He would leave the dealership and go on to work with brands including Maaco, Bosch, and NAPA, delving into the world of aftermarket scanners and diagnostic tools.

As such, Carl was surrounded by automotive enthusiasts throughout the entirety of her upbringing, and it showed. “I grew up on the tool truck in the summer when I was not in school,” remembers Carl. “We raced go karts. We would purchase trucks that I wanted to drive when I was 16 and restore them.”

From the moment she entered high school, Carl knew she liked hands-on work and wanted to be a technician. When she was a junior, the opportunity came for her to enroll in a heavy-duty diesel class with the BOCES program— but she was met with resistance.

“My guidance counselor was like, ‘No, you’re not going to take the diesel class. Why would you do that? There’s nursing, there’s cosmetology; you should go get a degree in college for something else.’ So that was a little bit of a hurdle, and that just honestly fueled my fire,” shares Carl.

The further ahead Carl pushed, the more she began to realize this was something she truly was skilled at, and could forge a meaningful career in. “Once I put my head down and worked hard ... I started to realize that I really was good at it, and this was something I was doing for myself, and this is something I love,” says Carl.

After graduation, Carl would go to the University of Northwestern Ohio and gained associate’s degrees in both diesel technology and agricultural diesel technology. Through fast tracking her degree, she was able to graduate in a year and a half. She loved what she was studying, but was eager to come back home.

Upon her return to New York in 2019, Carl took on work as a preventative maintenance service technician for semi-trucks, and continued to find her enjoyment in her career choice only grew. Little did she know, an even bigger opportunity would soon fall in her lap.

While Carl was studying in college, her brother was pursuing his own career in automotive, helping out at a local repair shop. When they met him, and learned he had a talented sister as well,

they kept bringing up the idea of them potentially taking on the shop one day.

“They always just joked, ‘Oh, well, you and your brother are going to own the shop someday. You and your sister are going to be the owners,’ and it was funny...and then it wasn’t funny, they were serious,” tells Carl. “So, it was kind of an ‘Oh, well; why not?’ kind of moment.”

With Carl’s brother being still only 17 at the time and looking forward to college, she became business partners with her mother and took over the shop five years ago. Though the experience of becoming a shop owner was entirely new for Carl—who at the time was just 21—she gained guidance from the shop’s previous owners, who stayed around to aid with the transition. Having already established a loyal customer base, the former owner helped introduce Carl to customers. Carl has enacted many operational improvements to the shop, such as

transitioning to being almost entirely paperless. All schedules are now digital; vehicle inspections are now done digitally instead of on paper; and the shop now communicates with customers through text, which has been a convenience for those who may be at work and can’t pick up the phone.

These days, Carl is much more active back in the shop, while her mother works full-time managing the front desk. Her

passion ultimately lies with being able to educate others on how vehicles work— whether that be customers, or aspiring technicians seeking guidance.

“I have an intern right now who is 16 years old and wants to be an auto mechanic, and her mom found me and reached out to me,” tells Carl.

While Carl serves as an inspiration for young women entering the field, she couldn’t have got where she is without a supportive community. With her brother’s auto detailing business

just across the street growing alongside her repair shop, her whole family have been pillars of support for one another throughout the entire journey.

“You have to find people around you that you trust. You literally can’t do it all,” Carl says. “You have to find your village. Whether it’s your mom or your brother, it’s gotta be somebody. You need somebody that you can trust, who understands the way you’re thinking, and somebody you can have as a sounding board.”

Implementing measures and educating employees regarding cyber security will help your keep your shop’s data safe.

BY LEONA SCOTT

In today’s digital world, auto repair shops are increasingly vulnerable to cyber threats. From phishing scams to data breaches, cybercriminals target businesses of all sizes, including independent repair shops. With customer data, payment information and business records stored digitally, implementing strong cybersecurity practices is more critical than ever. Ratchet+Wrench talked to Taylor Fuqua, Tekmetric’s chief technology officer, about his recommendations.

Taking a proactive approach to cybersecurity not only protects customer data but also builds trust, enhances operational efficiency, and ensures long-term success in an increasingly digital industry. Here are seven essential steps every auto repair shop can take to protect their data and customers.

1. Enforce Strong Password Policies

Weak passwords are a significant security risk. According to Fuqua, he says, “The

best advice is to use strong passwords with at least 12 characters.” Shops should implement policies requiring long, complex passwords and encourage employees to use a password manager to securely store them.

Multi-factor authentication (MFA) adds another layer of security by requiring a second verification step, such as a text message code or biometric scan. This extra step makes it significantly harder for hackers to gain unauthorized access.

Employees are often the first line of defense against cyber threats. Regular training on cybersecurity best practices, such as recognizing phishing emails, is crucial.

Fuqua recalls a common scam: “An employee receives an email offering free airline miles, but clicking the link compromises their credentials.” Educating staff on these tactics can prevent costly mistakes. Cybersecurity should be part of employee onboarding and included in an updated employee handbook.

Immediately revoking departing employees’ access to shop systems should be a standard part of the exit process, according to Fuqua.

Shops should ensure their network security is up to date. A secure firewall is essential for blocking malicious traffic. Additionally, shops should separate their business Wi-Fi from guest Wi-Fi, ensuring customers cannot access sensitive business data.

When employees leave, immediately revoking their access to shop systems is another crucial step. “Disengaging access should be a standard part of the exit process,” Fuqua advises.

Handling customer payments securely is critical. To secure credit card transactions, shops must comply with the Payment Card Industry Data Security Standard (PCI DSS).

Fuqua advises against collecting credit card information over the phone. Instead, shops should use secure digital payment options such as text-to-pay. Tekmetric partners with Stripe to maintain PCI compliance, ensuring that payment processing meets the highest security standards.

Systems Updated

Cyber threats evolve constantly, and outdated software can leave businesses vulnerable. Shops should schedule security updates at least twice a year, or opt for systems that automatically push updates.

“Updating software protections regularly is one of the most effective

ways to prevent cyberattacks,” Fuqua emphasizes. Continuous audits, such as those required for ISO 27001 certification, ensure that businesses follow best practices for security.

As more shops transition to digital solutions, cybersecurity will continue to be a top priority. Investing in modern security measures not only protects customer data but also builds trust and credibility with customers.

By following these seven best practices–enforcing strong passwords, educating employees, securing networks, using cloud-based systems, implementing rolebased permissions, ensuring payment security, and keeping software updated–auto repair shops can significantly reduce their cybersecurity risks.

For shop owners seeking to strengthen their security posture, partnering with trusted providers like Tekmetric can offer expert guidance and advanced security solutions, keeping their business ahead of evolving cyber threats.

Tekmetric partners with Stripe to maintain PCI compliance, ensuring that

payment processing meets the highest security standards.

4.

One of the largest security risks for small businesses is storing customer and business data on local computers. Moving to a cloud-based shop management system like Tekmetric provides built-in security measures, including automatic backups and encrypted storage.

“In 2024, Tekmetric maintained 99.9% uptime and continues to push updates daily, ensuring security protections are always up to date,” Fuqua says. Unlike traditional systems, cloud-based solutions remove the risk of data loss from hardware failures or cyberattacks.

5.

Not every employee needs access to all shop data. Using role-based permissions ensures that staff members only see the information relevant to their job.

Tekmetric tracks logins and suspicious activity, allowing shop owners to monitor who is accessing data. This helps prevent unauthorized users from accessing sensitive customer information and strengthens overall security.

BY TESS OWINGS

When Edward Caswell returned from VISION for the first time in 2020, he was in a terrible mood. “I’m failing, I don’t know what my numbers are,” Caswell says was his mentality after he attended the conference.

Caswell started his shop with very little knowledge of how to run a business. The passion and dedication to service was there, but the business mindset wasn’t. For almost four years, Caswell says he ran the business blind while making enough to pay the bills with a net profit of 2.7%.

“How do you know what good looks like if you’ve never seen it?” Caswell says of his early days as an owner. After attending VISION with some of the best shop owners in the county, Caswell realized he could be doing better and that included setting an effective labor rate.

Three years after attending that

eye-opening VISION, Caswell returned to the conference with his head held high and the confidence of a top shop owner who knew what he should be charging for labor and how and when to adjust.

Caswell admits he wasn’t the best student growing up. He struggled in school with ADHD and dyslexia but always found fulfillment in repair work and it became a passion of his.

From 2003-2014, Caswell worked as a teacher but maintained his love of repair work by doing side gigs out of his garage. In 2014, he decided to pursue his love of repair and opened Full Throttle Automotive in Evansville, Indiana, with his wife, Brandi.

With very little business knowledge,

Caswell didn’t know what to charge for the labor rate. So, they called around other shops in the area to see what they were charging and decided to be cheaper. “That was a horrible approach,” Caswell laughs.

For the first few years, Caswell and his team were making enough to pay the bills but after attending that first VISION, he realized that it was possible to do better than just scraping by.

What’s the secret to setting an effective labor rate? Caswell says his approach is different from what others might tell you. For him it’s all about setting the right culture and being as efficient and productive as possible.

Sure, you have to have a solid understanding of your numbers and what your overhead is, Caswell says,

but effectiveness and productivity are key. In order to master that, you need to have buy-in with your team.

By creating an upbeat culture that fosters growth, Caswell says his productivity is high, which allows them to turn a profit without constantly raising prices. Caswell’s technician productivity at his shop is consistently between 115% and 120% (including oil changes), which is far above the industry standard of 80%.

The labor rate is something that is reassessed every quarter with a solid understanding of the numbers. When setting the rate, Caswell and his team look at a P&L sheet and get a solid understanding of exactly how the shop is doing. What’s the overhead cost per hour? What are the tech hours that are being produced? What’s the tech cost? What’s the net profit per hour? All of those numbers–and more–go into setting the labor rate. For example, if the team isn’t turning the amount of hours needed to cover overhead, they need to charge more for labor.

There’s so much that goes into setting a labor rate and it’s an everchanging number, but Caswell’s culture-first approach is a sure-fire way to create a team that’s willing to turn as many hours as possible,

which will help keep labor rate low enough to attract customers and justify the labor rate being high enough to get the kind of customers you’re looking for.

Caswell gets buy-in from his team by taking the team to events like VISION and SEMA, so they can understand the why behind his push for productivity.

Currently, Caswell says his labor rate starts at $130 and can go as high as $170, depending on the job. For example, if someone has a custom car and they bring in their own part, the team needs to charge more labor rate to make up for the part cost.

When asked how he explains that to customers that may call asking for an exact labor rate, he says his team is trained to sell the job rather than the labor rate. He also laughs and says that if the customer is calling asking for the exact labor rate, they may not be the type of customer that he’s looking for.

“We don’t want customers that are price shopping.”

With this rate and the focus on efficiency and productivity, the shop is currently seeing a net profit of 20.74% and $5.3 million in annual revenue.

TAKEAWAY:

In order to set the best labor rate for your shop you need to know your numbers, Caswell says. Get a legitimate P&L done and invest in software that can help you determine effectiveness and productivity. You need to determine how many dollars you need to make to beat overhead and how many hours you will need to turn to make that happen, Caswell explains. Then, you need to work on the culture of your shop in order to encourage your team to turn the number of hours you need so you don’t have a crazy high labor rate.

“You need to set your business up to encourage your team to be efficient,” Caswell says.

The average labor rate varies from shop to shop and that’s due to a number of factors. For Edward Caswell, owner of Full Throttle Automotive in Evansville, Indiana, culture is key, but there are other things to consider before setting your rate. Here are a few factors to consider, courtesy of Auto Leap.

BY LOLA SCHMIDT

Once upon a lifetime ago, I had a mentor that would say, “Kid, you’re either a buyer or a seller in this world. What will you be today?” That question always stuck with me as I traveled thru my careers, because even though I’m an avid consumer, I am most certainly a seller in the scheme of life. As you personally ponder that question, I bet you think, as an owner of an auto shop, you’re a seller, and selling car repair. Which yes, on the surface you are, but right under the surface, in the subconscious where people make their biggest purchasing decisions, you are selling so much more than repairs to your guest. You are selling peace of mind and a guarantee to make things better for their future. You are the cultivators of security, trust, convenience, and care.

Like many of you, I own an auto shop. I have cars at my access on any given day, but if something happens to my daily driver, I am anxious and distraught. In my brain, I know I can get in another car, but it’s not my car. It’s not set to my perfect seat settings, and it doesn’t have all the gadgets I like, and it doesn’t ride the same. I like it, and I’m very unhappy to be without it. So, imagine how your guests must feel handing you their keys. For many of them, this is their only vehicle, they don’t have another car to hop in, and their life is still happening all around them. Their mind is spiraling out of control on how they keep going with no car. That’s a key moment you can make things easier for them.

Many of our guests are military moms with little kids. Every time we told a momma she needed lengthy work, we lost her. You could see the anxiety rise quickly. She knew she needed the work done, she wanted the work done, but she didn’t want to stay at the shop with the kids. And I get it. As a mom, I know the feeling of not wanting to be stuck places with a tiny child. You want to get home. Our service team recognized this issue, and started talking about how we could move over this mountain. Once we worked

through logistics, we launched curbside service to help people get around without their car. Our team will come get your car, drop it off for you, or take you to a local coffee shop if you have a quick service scheduled for the day.

Once word got out about curbside service, it took off. It was something tangible people could utilize, and it helped reduce the level of anxiety they felt about leaving their car at the shop. It was a point of difference that other shops weren’t offering, so curbside service gained us several new faces. But my favorite benefit to curbside service, that we didn’t even consider, was the opportunity to talk to our guests as we drove them around. We got to know them better and deepen relationships in so many great ways. It was a huge hero moment for us to roll this out, and the community loved it. Our service team made it easy to do car care with us. And the payoff was we saw our closing ratio rise and glowing google reviews come in.

Shortly after launching curbside service, we added one loaner car to the shop. We are a shop that does a significant amount of larger work, and sometimes it’s several days since we have our guest’s car. This sometimes would cause push back due to work schedules and family needs. Just as our service team recognized the mom issue, they saw the trend with long jobs being delayed. Our service manager requested we add additional loaner cars to the shop so he could offer them to more people with longer jobs. We have two loaners now and will add another this year. Pair that with a smooth-running curbside service, and we get to make car care easier for people several times a week.

I’m not saying you must start up curbside service or add loaner cars to your shop, but I am encouraging you to identify customer-facing issues you may have and use that issue as an opportunity to create a hero moment for your guests. The quicker you recognize and remove your public’s pain points of doing business with you, the quicker you have more keys

in hand, and the quicker word of mouth spreads that you are more than just car care. And you are so much more than car care. You are a community helper, a family advocate, and a trusted professional. The Yes is much easier to gain when the ease of business is there. Make it easy.

Lauralee Schmidt burst onto the Auto Care scene in 2016. You may know her as Lola, the queen of branding. Cosmetics and Fashion is the industry that Schmidt hails from, so she brings a certain flair and perspective to the marketing side of the auto industry that is both fresh and interesting. When Lola joined her husband at Schmidt Auto Care in 2016, she was terrified to leave all she knew inside a safe and lucrative cosmetic career. But she found a sweet spot inside of branding and education when she stepped onto the shop floor. And from that moment, growth, creativity and business development have been at the forefront of her focus, not only her shop, but for other shops as well.

Lauralee proudly spends her time not only homeschooling their child but heading up the marketing and HR side of their family business. She also sits on the Board of Directors at the Springboro Chamber of Commerce and runs a women’s business group called Women In Power. And after all this is said and done, you may find her at a conference speaking on branding or business development or catch an article she wrote to lift your mood or make you think a little deeper about your business. She will tell you, “All things creative create all things beautiful, so think creatively to live beautifully.”

lauralee@schmidtautocare.com