Greenheck’s air source heat pump dedicated outdoor air system delivers optimal comfort and efficiency while minimizing your environmental impact. Our advanced technology provides reliable heating and cooling for commercial buildings, even in challenging climates. Experience the future of commercial HVAC solutions while reducing your carbon footprint with Greenheck's air source heat pump.

Specify with Confidence. Specify Greenheck.

Energy efficiency is essential to reaching net zero. It’s one of the easiest and most impactful ways to reduce carbon emissions – especially in buildings, which account for a big part of global energy use. With Grundfos smart pumps, you get the best of both worlds: advanced HVAC and water systems that deliver superior energy efficiency without compromising on comfort or performance. Our smart pumps collect and analyze data to optimize performance, uncover hidden energy savings, and reduce lifecycle costs. By automatically adjusting to real-time needs, you can significantly cut energy use and carbon emissions while ensuring reliability and comfort. Start your journey toward net zero with solutions designed to elevate your building’s efficiency.

Discover Grundfos solutions that suppor t the journey towards net zero at grundfos.com/CBS

Even zero emissions may be achievable, according to simulations run

Robbie Svidron

Our industry’s biggest trade show is descending on the Sunshine State to deliver the latest in HVACR technology, innovation and education.

By Steve Spaulding

Letters to the Editor: Four Takes on ‘Divided Nation’ Editorial

Our November/December Editor’s Notes column drew a ‘divided’ response from our readers.

27 32 18

Editor’s Notes Will 2025 Be the Year of A.I.?

By Rob McManamy

Clark’s Remarks

Photovoltaics Are Everywhere! Have You Noticed?

By Larry Clark

HPAC Engineering (USPS Permit 464-930, ISSN 0039-0895 print, ISSN 1930-8957 online) is published 6x a year (Jan/Feb, Mar/Apr, May/Jun, Jul/ Aug, Sep/Oct, Nov/Dec) by Endeavor Business Media, LLC. 201 N Main St 5th Floor, Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI, and additional mailing offices. POSTMASTER: Send address changes to HPAC Engineering, PO Box 3257, Northbrook, IL 60065-3257. SUBSCRIPTIONS: Publisher reserves the right to reject non-qualified subscriptions. Subscription prices: U.S. ($111.25); Canada/Mexico ($123.75); All other countries ($148.75). All subscriptions are payable in U.S. funds. Send subscription inquiries to HPAC Engineering, PO Box 3257, Northbrook, IL 60065-3257. Customer service can be reached toll-free at 877-382-9187 or at HPACengineering@omeda.com for magazine subscription assistance or questions.

Printed in the USA. Copyright 2025 Endeavor Business Media, LLC. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopies, recordings, or any information storage or retrieval system without permission from the publisher. Endeavor Business Media, LLC does not assume and hereby disclaims any liability to any person or company for any loss or damage caused by errors or omissions in the material herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever. The views and opinions in the articles herein are not to be taken as official expressions of the publishers, unless so stated. The publishers do not warrant either expressly or by implication, the factual accuracy of the articles herein, nor do they so warrant any views or opinions by the authors of said articles.

R-32 IS ALREADY USED IN OVER 130 COUNTRIES, INSTALLED IN OVER 230 MILLION SYSTEMS, AND BY MORE THAN 50 MANUFACTURERS WORLDWIDE. FACT

Finding Meaning and Purpose, with ASHRAE’s Dennis Knight

*NEW PODCAST* The 2024-25 president describes how youth and new technology are enhancing the Society’s global mission. www.hpac.com/55246540

and Air Cleaners, Keys to

NOW ON DEMAND: Recorded 11/18, IAQ expert Dr. Bill Bahnfleth explains this revolutionary concept, redefining standards with new air cleaning technologies. www.hpac.com/55236601

NEW eBOOK: The Best of Ken Elovitz, P.E.

An Engineer’s Notebook, 2021-2024. Dive into this collection of useful professional advice, laced with helpful legal acumen. www.hpac.com/55020330

HPAC 2025: Our January Quiz!

Start the new year with a brisk refresher from engineer Ken Elovitz, PE, Esq., on heaters, chillers, piping, water pressure, and more.... www.hpac.com/55250930

EDITORIAL OFFICE

8001 Lincoln Ave. • Suite 720 Skokie, IL 60077 www.hpac.com

EXECUTIVE TEAM

CEO: CHRIS FERRELL

COO: PATRICK RAINS

CRO: PAUL ANDREWS

CDO: JACQUIE NIEMIEC

CALO: TRACY KANE

CMO: AMANDA LANDSAW

EVP, GROUP PUBLISHER –BUILDINGS, ENERGY & WATER: MIKE CHRISTIAN

EDITORIAL CONTACTS

MIKE EBY

Group Editorial Director meby@endeavorb2b.com

ROB MCMANAMY Editor-in-Chief rmcmanamy@endeavorb2b.com

DAVID ECKHART Art Director deckhart@endeavorb2b.com

SALES CONTACTS

MIDWEST BILL BOYADJIS 973-829-0648 bboyadjis@endeavorb2b.com

SOUTH & WEST

RANDY JETER 512-263-7280 • Fax: 913-514-6628 rjeter@endeavorb2b.com

EAST BRIAN SACK 732-629-1949 bsack@endeavorb2b.com

WEST ELLYN FISHMAN 949-239-6030 efishman@endeavorb2b.com

CLASSIFIEDS/INSIDE SALES

STEVE SUAREZ 816-588-7372 ssuarez@endeavorb2b.com

DIRECTOR OF SALES JOE AGRON 941-200-4778 jagron@endeavorb2b.com LIST RENTAL SMART REACH sr-assets@endeavorb2b.com effective PRODUCTION AND CIRCULATION

RITA FITZGERALD

Senior Production Manager rfitzgerald@endeavorb2b.com

MELISSA MENG Ad Services Manager mmeng@endeavorb2b.com

JAMES MARINACCIO

Audience Marketing Manager jmarinaccio@endeavorb2b.com

Residential or commercial. Tank or tankless. Electric or gas. Bradford White offers exceptional performance and exclusive innovations such as Microban® antimicrobial technology inside all tank-type water heaters.

ROB MCMANAMY, EDITOR-IN-CHIEF

As we enter 2025 with many questions and more than a little anxiety, it is hard not to be encouraged and reassured by this industry’s pervasive optimism and resilience.

For all that we have been through these last five years, there is nevertheless an undeniable sense of confidence and progress propelling this industry forward into the new year. In particular, the promise of new technology seems greater than ever right now, despite concerns about possible pitfalls.

In particular, a growing number in our industry now seem to feel artificial intelligence is on the verge of making a major impact on how building projects are designed, built, operated and maintained.

Just this January, in fact, Associated General Contractors of America (AGC) released the results of an expansive 2025 outlook survey with responses from more than 1,000 members. The feedback was undeniably upbeat. For instance, 69% of firms were expecting to add to their headcounts this year, and 77% were having difficulty filling open positions. In fact, their biggest concerns heading into this new year were labor costs and an insufficient supply of qualified workers. Fear of an economic recession only placed fifth on the group’s list of worries.

Two other results, in particular, stood out and they are related. Roughly 1,000 firms said that the construction segment that they expect to see grow the most this year is the already booming market for data centers. So what is the technology in which they plan to make their biggest investment increase over 2024? Artificial intelligence.

So, get ready. Our world is changing.

On the December episode of HPAC On The Air, ASHRAE President M. Dennis Knight, P.E., had this to say about A.I.:

“Artificial intelligence is one of those topics that seems to come up a lot at just about every meeting I go to here in the States and around the world. Specifically, its potential applications in building automation, energy management, and design optimization.

We now have an A.I. multidisciplinary task group that is working to harmonize and

coordinate anything that our technical committees or handbook subcommittees might be working on. They are looking to find any applications for A.I. that would help on the technical side of developing an HVAC system design process.

We’re also exploring how A.I. can enhance ASHRAE’s own member services website, particularly looking to provide more efficient access to our handbooks and standards for our practitioners. Our staff is talking with several vendors now about creating some small language application models -- not large language models like ChatGPT -- that can use A.I. and machine learning to create some local small language models that would help our members with reserach of our standards and handbooks and project documentation.

That could really revolutionize how they use ASHRAE’s 130-year-old knowledge base.”

Smart buildings are already part of that revolution. Check out this seminar description from the ASHRAE Winter Conference this February in Orlando. The event has its own program track for Artificial Intelligence, Building Automation and Controls

Controls with Instant ROI

BAS control systems are often inundated with alarms that go unnoticed, leading to potential issues going unaddressed. Staff may overlook the thousands of alarms that accumulate week after week, but what are the consequences of inaction? Are the same 10 alarms triggering repeatedly, every few hours? This is where artificial intelligence comes into play, offering a powerful solution to this pervasive problem. With today’s AI technology, managing recurring alarms can be streamlined, providing immediate insights and solutions. This seminar explores the potential of AI in transforming BAS alarm management, showcasing successful AI-driven solutions to tackle these challenges head-on.

Indeed, ROI is the key. As our industry becomes more open to the concept of A.I. delivering a tangible return on investment, and not just an expensive novelty, none of us should be surprised to see it join our project teams both sooner and later.

William P. Bahnfleth, PhD, PE

The Pennsylvania State University

Glenn Barrett, PE DC Engineering

David W. Bearg, PE Life Energy Associates

Lawrence (Larry) Clark, QCxP, GGP, LEED AP+ Sustainable Performance Solutions LLC

Kenneth M. Elovitz, PE, Esq. Energy Economics Inc.

Charles E. Gulledge III, PE, HBDP, LEED AP, FASHRAE Environmental Air Systems LLC

Elise Kiland, PE, YEA Critchfield Mechanical Inc.

Nancy Kohout, PE, LEED AP SmithGroup

Valentine A. Lehr, PE, FASHRAE Lehr Consultants International

Ginger Scoggins, PE, CEM, CxA, LEED AP, FASHRAE Engineered Designs Inc.

James P. Waltz, PE, CEM, ACFE Energy Resource Associates Inc.

Michael K. West, PhD, PE Advantek Consulting

Ron Wilkinson, PE, LEED AP Wilkinson Commissioning Management

Gerald J. Williams, PE, LEED AP 8760 Engineering LLC

March 19-20, 2025

Modesto Centre Plaza

Modesto, CA

April 16-17, 2025

Anaheim Convention Center Anaheim, CA

May 14-15, 2025

Oregon Convention Center Portland, OR

August 20-21, 2025

Grand Sierra Resort & Casino Reno, NV

Our industry’s biggest trade show is descending on the Sunshine State to deliver the latest in HVACR technology, innovation and education.

By STEVE SPAULDING, CONTRACTOR, with press releases

The 2025 Air Conditioning, Heating and Refrigeration Expo (AHR) will take place February 10-12 at the Orange County Convention Center in Orlando, FL. This year, the Expo will welcome more than 1,800 exhibitors, 350 speakers, and 50,000 attendees.

Professionals from every sector of the industry will be in attendance including contractors, manufacturers, engineers, system design professionals, facility managers, architects, wholesalers, distributors and more. While the focus of the show is HVAC/R, almost all aspects of the built environment

are represented, including plumbing, piping, hydronics, heating, cooling, controls, tools and software.

What follows is a brief overview of what’s on tap at the show specifically for plumbing, hydronic and mechanical systems professionals. To learn more and customize your show experience, visit the Expo website at www. ahrexpo.com, or download the show app at the Google Play Store.

The Expo floor opens at 10:00 AM on Monday, Tuesday and Wednesday, closing at 6:00 PM on Monday and Tuesday, and 4:00 PM on Wednesday.

ASHRAE’s Winter Conference co-locates with the Expo. Important events for the conference include:

Monday, February 10

President’s Luncheon 12:15 PM – 2:00 PM Honors & Awards Ceremony 2:30 PM – 4:00 PM

Tuesday, February 11

Members Council Meeting 8:15 AM – 12:00 PM Life Members Club Luncheon 12:00 PM – 1:30 PM

Wednesday, February 12

Board of Directors Meeting 2:00 PM – 6:00 PM

This year’s education program will feature more than 250 sessions, including free industry seminars, a robust

panel series lineup, new product presentations and more. “Educating our current and future workforce is an area of dedicated attention and effort across most industry conversations,” says Show Manager Mark Stevens “Over the years, the AHR education program has grown into an important complementary asset to the show floor experience, lending an opportunity for deeper understanding of what’s happening within the industry, how to apply skill and knowledge, and how to prepare for shifts.”

Adds Director of Education Kim Pires, “AHR Expo is a unique opportunity to pair session learning with application practice due to the complementary aspect of our education programming and the exhibition floor. Taking learning one step further, attendees can apply what they’ve just learned in a classroom to products, technology, or conversations on the show floor—creating a valuable opportunity that’s hard to find elsewhere in the industry.”

Education opportunities include panel sessions, free industry seminars and for-credit sessions. Those offer Continuing Education Units (CEUs), Professional Development Hours (PDHs) and American Institute of Architects Learning Units (LUs), but which typically charge a fee.

Other educational opportunities can be found at the New Product Theaters, four of which (A, B, C and D) will host more than 150 rapid-fire, 20-minute presentations from manufacturers on their latest offerings. Attendees are invited to follow up presentations with a visit to the respective booths for more in-depth explanations and 1:1 interactions with products and representatives. No fee or individual session registration is required.

For plumbing professionals, some can’t-miss sessions include:

Artificial Intelligence (AI) and Plumbing: How Smart Applications Can Lead to Smooth Waters Ahead

Presented by John Mullen, RPA Technical Liaison at IAPMO and Susan Frew, PHCC.

Learn how AI and other applied smart technologies can transform the way we think about plumbing. We’ll discuss trends in AI and how they can be applied to the plumbing and mechanical field.

Monday, February, 10th, 11:00 AM to 12:00 PM, W314.

Presented by John Mesenbrink, Editor-at-Large for CONTRACTOR, and Tim Ward PHCC Pros.

The chat digs deep into the building trades industry, and features interviews with industry professionals and a variety of irrelevant, fun stuff.

Monday, February 10, 4:00 PM to 4:50 PM, Podcast Pavilion 1.

The Connected Contractor: Strategies for Building a Digital Footprint Featuring Becca Stamey , Social Media Strategy Expert, Carson

Brown, Chief Marketing Officer at Surge, Danny Braught, LMH Agency, Hanna Egg, Media Marketing at Egg Geo LLC, and IAPMO’s John Mullen. This panel session offers a deep dive into the transformative power of digital strategies for this industry.

Wednesday, February 12, 9:00 AM to 10:00 AM, W331G.

Unfortunately, all trade shows face the threat of unauthorized companies targeting exhibitors with fraudulent offers and the AHR Expo is no exception. If you encounter any offer that seems too good to be true or is off in any way, the first line of defense is to verify the company is on the approved vendor list.

AHR Expo’s registration company is the only authorized source for attendee lists. If anyone else reaches out with list offers, be aware that these are not legitimate offers and do not participate.

onPeak is the only hotel provider endorsed by the AHR Expo. If you are contacted by other third-party

companies offering hotel assistance, please be aware that they are not endorsed by the AHR Expo. If you have received fraudulent emails or phone calls soliciting you to purchase attendee lists, book hotel rooms, or other products/services, file a report. Go to Federal Trade Commission at ReportFraud.ftc.gov.

Make a plan and stick to it: use the show app or your own calendar to set up a schedule. Be selective about the booths you want to visit, the sessions you want to

attend, and the time you want to commit to events. If you want to spend time wandering the expo floor, budget that time and stick to your budget—with so much going on, it’s easy to wander aimlessly and not get the most out of the show.

Hydration and nutrition: if you don’t bring a water bottle, make time to visit the drinking fountains. Concessions at the convention center can be expensive and lines can be long—pack some trail mix or a few power bars in case of emergency.

Wear comfortable shoes: you don’t need to wear sneakers with your suit,

but make sure whatever footwear you’re bringing to the show is broken in and comfortable.

Don’t be a disease vector: if you’re sick, stay at your hotel. If you think you might be sick, mask up and social distance. Wash your hands frequently and well.

Visit us! CONTRACTOR Magazine, HPAC Engineering, and Contracting Business all will be attending the show. Drop by our booth in the West Building, #2261.

Safe travels, and we’ll see you in Orlando!

Our November/December Editor’s Notes column drew a ‘divided’ response from our readers...

Dear Editor,

I enjoyed reading your article, Divided Nation, Focused Industry. The references to Lincoln were especially appreciated. As you wrote, “…it is an opportunity to recommit ourselves to our core values.” Now is the time to unify, give thanks, and move forward.

David Shore, Senior Scientist Environmental Health & Engineering, Inc. Newton, MA DShore@eheinc.com

cases, thinking people can agree that our electoral and political systems are broken. We need campaign finance reform, term limits, and to reestablish the separation of church and state, among other fixes. But the powers that be have no desire for that to happen. What will it take for that to happen?

Barry Campbell, Communications specialist Sandpoint, ID campbell@it-host.com

Dear Editor,

Having just read your Editor’s Note from the HPAC Engineering Nov/Dec 2024 edition — I want to commend you on a thoughtful, spot-on piece. Your perspective makes an excellent welcome for the year ahead. I also enjoyed reading about the generational election judge volunteers; what a fitting anecdote for a year filled with division, misinformation and too many tribal tendencies. Hats off to your writing.

Mark Klein, Founder, Mark Klein Content Houston TX mark@markrklein.com

Dear Editor,

Questioning why you chose to push the “division” narrative and stoke the fires of civil discourse with your HPAC article title? Isn’t every election divided? Isn’t that what makes a free and fair democratic election?

Vincent Grassi, PE, BCxP Woodard & Curran Portland, ME vgrassi@woodardcurran.com

Dear Editor,

I enjoyed your Editor’s Notes regarding the election. While we seem to be a nation torn in two, I find it’s often possible to find common ground with folks who have views other than mine as long as the conversation remains civil. In many

HPAC Responds:

Dear Mr. Grassi,

Thank you for feedback. As you acknowledge, we are a “divided” nation after this election, like most elections. That’s why I chose to emphasize the areas that unite us, especially in this industry.

Regards, Rob McManamy, Editor-in-Chief HPAC Engineering

To add your own comments, write to rmcmanamy@ endeavorb2b.com.

The all-new Laars E-Therm™ commercial heat pump water heater and storage tank solution delivers next-level efficiency in any environment. Build a high-performance, high-volume system that’s cold-climate ready and future-proof:

Laars E-Therm™ Commercial Heat Pump

Water Heater:

• Nominal heating capacity of 325,000 BTU/hr.

• R744 (CO2) natural refrigerant

• Precharged and ready to run

• 180°F hot water generation down to 0°F incoming air temperatures

Laars Heat Pump Ready Stratified

Storage Tanks:

• ASME Sec IV HLW

• Stainless diffuser tubes ensure proper stratification

• Exterior R-16 insulation with topcoat for indoor or outdoor use

• Piping connections and thermal wells located to optimize installed efficiency

Our annual roundup of insights finds great expectations for IAQ upgrades, more manufacturing work and continued decarbonization focus.

By ROB MCMANAMY, Editor-in-Chief

In keeping with tradition and in preparation for the new year, we asked members of the HPAC Engineering Editorial Advisory Board and recent guests on our HPAC On The Air podcast for their views on what they expect to see from our industry in 2025.

What follows are their edited responses...

William P. Bahnfleth, PhD, PE, FASHRAE ASHRAE past president; former chair, ASHRAE Epidemic Task Force; Professor, Architectural Engineering, Penn State

Although there is much uncer tainty in the world as 2025 begins, I think positive developments are possible. The two key questions for the HVACR community are whether energy conservation and decarbonization efforts will con tinue to move forward aggressively and whether the heightened inter est in indoor air quality that have been driven by the Covid pandemic and wildfire smoke incidents will lead to significant change.

emissions have been fairly resilient to shifting political winds. I believe that the same is possible for IAQ now, based on the level of public interest and the number of active state and municipal initiatives, not to mention several bills being considered by the federal legislature in the U.S. that are intended to raise the bar for IAQ.

So I am optimistic that some of these efforts will be successful during the coming year, with or without federal support. As is often the case, our determination to reach our goals is likely to be the key factor.

Jim Pauley, President and CEO

National

We have already seen in recent years that industryled and individual efforts related to energy and carbon

Fire Protection Association (NFPA)

The devastating wildfires in South ern California are a stark reminder that fire safety must remain a pri ority in the face of growing risks. From disasters to advancing tech nologies, our world faces increas ingly complex challenges, making it more critical than ever to uphold rigorous safety standards.

Unfortunately, efforts to bypass time-tested fire codes and standards are threatening the safeguards that protect lives and property. When safety measures are compromised—whether by neglect, costcutting, or insufficient oversight—the consequences are tragic.

At NFPA, we advocate for a collective commitment to safety through the NFPA Fire and Life Safety Ecosystem™. By fostering collaboration between fire safety professionals, lawmakers, and communities, we can ensure that lessons from past tragedies guide us toward a safer future.

Safety comes at a cost, but the cost of inaction is far greater. Together, we must defend and prioritize safety, protecting people and property in 2025 and beyond.

Ginger

Scoggins,

PE, LEED AP, FASHRAE ASHRAE immediate past president; Founder, Engineered Designs Inc.

I expect to see more companies focused on lowering their carbon footprint in 2025. The year 2030 is rapidly approaching, and if companies don’t start working on their impact to the environment this year, they might have issues hitting their goals for lower carbon emissions. So I would think that consulting firms like mine will be receiving more requests for carbon calculating efforts, as well as energy modeling efforts.

We have to reduce the impact of the built environment on global greenhouse carbon emissions. To do so, we have a very large job ahead of us and we must get moving on it. Not just in large cities, but in medium-size cities and rural areas, as well. To date, the larger cities have been leading this charge, but this effort needs to trickle down to smaller firms and areas so that we are all working toward the same goal of reducing the impact of our buildings on our environment.

in play. We are seeing strong demand for very clean clean rooms; large clean & bone dry manufacturing space with low dew points down to -35 F; significant steam systems with robust condensate recovery and flash application; significant compressed air plants, low dew point, waste heat energy recovery; and high-spec water systems.

The food & beverage market is still rocking, with hygienic design needs galore. And the life sciences & pharma markets just don’t stop, either. That means laboratories, clean rooms, and manufacturing space can’t be built fast enough.

Regarding commercial refrig eration, the biggest impact is the refrigerant phasedown happening across the country, and more spe cifically for 2025 in California. As of January 1, California CARB reg ulations have banned the sale and distribution of “virgin” refrigerants with a global warming potential (GWP) greater than 2,200.

This ban will affect refrigerants still commonly used in many legacy supermarkets, namely R-404A and R-507. Supermarkets are allowed to continue to use R-404a and R-507 in their existing refrigeration systems. The catch being, only reclaimed refrigerant is allowed to replace leaked refrigerant, of which legacy (older) supermarkets leak 20 to 25% of their refrigerant annually.

Charles E. Gulledge III, PE, LEED AP, FASHRAE

ASHRAE

past

president; Director of Engineering, Environmental Air Systems LLC

My outlook for HVAC is skewed to the larger scale mechanical market, as that is the sandbox we play in. That said, we expect to see signifi cant buildout of mission critical infrastructure. The “cloud” needs servers to thrive, so everything is going to the liquid-to-liquid cool ing of chips. And that will require a hyperscale HVAC response. Reli ability, reliability, reliability!

Meanwhile, advanced manufac turing is expanding fast and many specialties in that area are

So we have the proverbial rock and a hard place. People need food and food needs refrigeration for safe distribution to the public. It is worth noting that many of the legacy stores are in either urban or rural areas where the feasibility is low to replace a legacy refrigeration system with one from the modern age. The economic cost, space and infrastructure of the older supermarkets, and availability of skilled installation and maintenance technicians, make it very difficult to change from R-404a to a modern refrigerant. So, what will stores do when they can’t obtain the refrigerant they need?

Nancy Kohout, PE, LEED AP Senior Principal / Mechanical Discipline Leader, SmithGroup

In 2025, I expect to see engineers continue to embrace heat pump technology as we work towards decarbonization and, in particular, efficient electrification of heating. With the rise of artificial intelligence and the demand for data centers strong, we will be thinking creatively about how

Data centers will remain an enormous growth market in 2025, along with their insatiable hunger for energy.

fund their innovative systems. Grid interactive design will have increasing importance as power demand rises due to electric vehicle charging, electrification of heat, and data center power requirements.

Elise Kiland, PE, Chair, Young Engineers of ASHRAE (YEA), Critchfield Mechanical Inc.

I hope the industry realizes the shortage in talent we are facing and focuses on workforce development more in 2025. There is high demand specifically for skilled technicians which will require enhanced training programs and

initiatives to attract new human

On the technology front, I expect 2025 to continue the tran sition towards low GWP refrig erants to meet environmental regulations and sustainability goals. This will also require the need to develop advanced leak detection systems and train tech nicians on how to handle these

Sustainable Performance Solutions LLC

Clark

Even as DC changes, I don’t anticiHPAC Engineering’s audience. It’s unlikely that the more environmentally-friendly refrigerants, now commonplace, are going to be affected. And I’m fairly certain that we are not going to return to the days of R-12. Equipment manufacturers will continue to design and build more efficient machines (yes, A.I. will help), regardless of government mandates, because it’s just good business to save customers money and to help protect the environment.

The same can be said for my business, one of the first South Florida-based engineering firms with its practice limited

Beardsley

APRIL 8-9, 2025

HILTON COLUMBUS-POLARIS COLUMBUS, OH

ABMA is excited to engage the next generation of boiler leaders by launching the ABMA Boiler Industry Leaders of Tomorrow (BILT) interest group, which will host the inaugural Emerging Leaders Forum (ELF) taking place April 8-9 in Columbus, OH.

The ELF will have a robust agenda focusing on professional and personal development to expand knowledge, enhance skills and prepare our up-and-comers for the next steps in their boiler career.

❱ Peer-to-peer presentations

❱ CEO Q&As

❱ Emotional intelligence workshop

❱ Tours of National Board’s (NBBI) boiler room, pressure relief and boiler testing laboratory

❱ Facilitated networking

❱ Fun social activities and much, much more.

Don’t miss out on this oneof-a-kind event and be a part of shaping the future of the boiler industry! Registration opens January 2025.

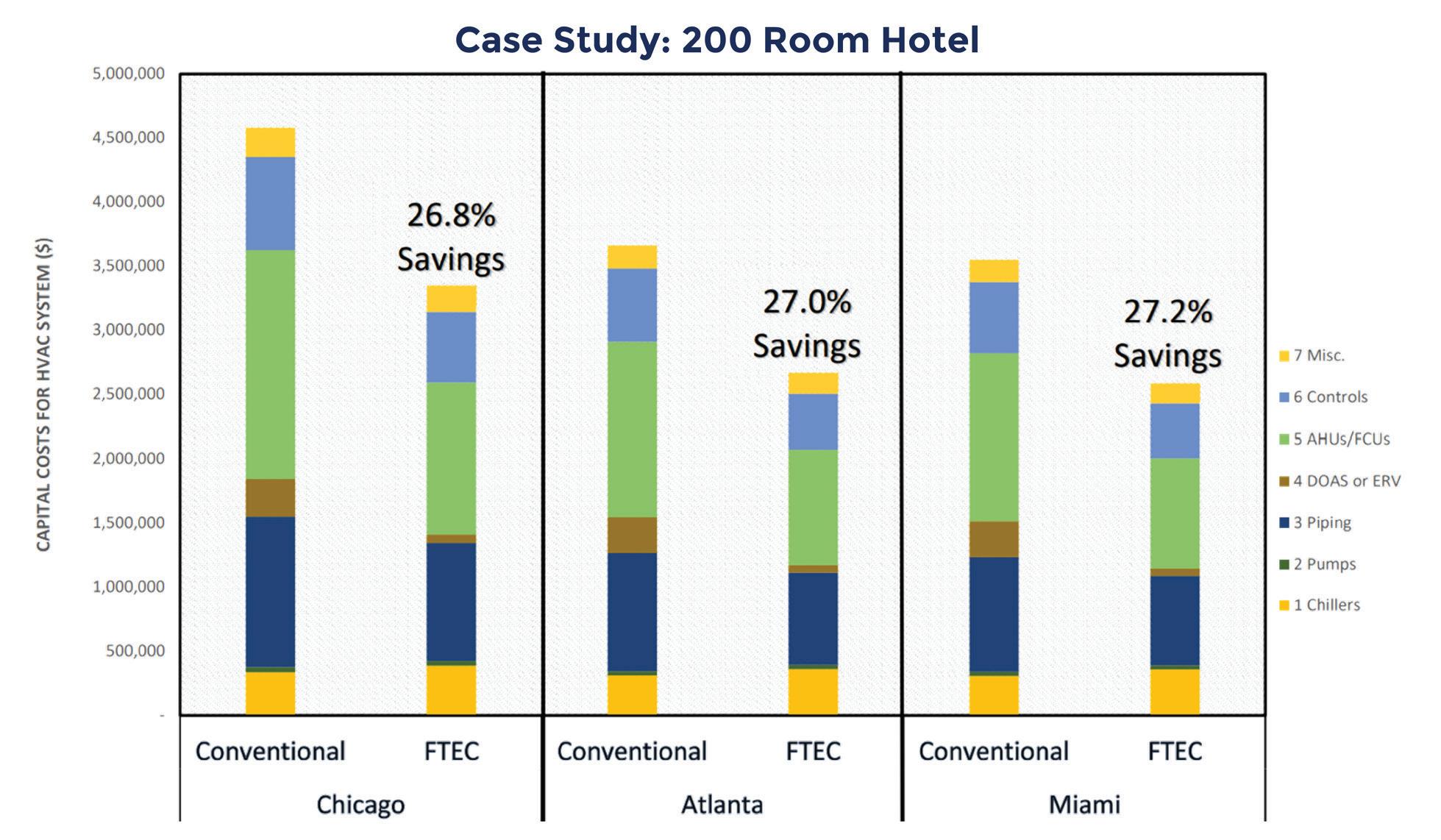

Even zero emissions may be achievable, according to simulations run on a 200-room hotel in multiple cities.

By RICHARD C. FURMAN and ZACHARY M. THOMAS, PhD, FT Energy Controls, LLC

There are significant capital and energy cost savings that can be achieved with an improved chilled water HVAC systems design. A

new approach is presented here that can provide a capital cost savings of 27% and an annual energy cost savings of 36% compared to the conventional system costs.

Using conventional sources, the energy savings also result in a 34% reduction in CO2 emissions.

This analysis assumes the use of an electric heat pump chiller for cooling and a natural gas boiler for heating. The system could be made all electric by substituting electric heat pump heaters for the boiler. When this HVAC system is provided with 100% renewable electricity, it will provide

Richard Furman is CEO and cofounder of FT Energy Controls, LLC. As part of his consulting work, which now spans four decades, he played a role in completing the first commercial demonstration of an HVAC system using both DOAS and ACBs in a U.S. hotel. Furman holds a Master’s degree in chemical engineering from MIT.

Dr. Zachary M. Thomas is COO and cofounder of FT Energy Controls, LLC. He holds both Masters and PhD degrees in electrical engineering from MIT, as well as a JD from Suffolk University.

zero emissions and will still provide significant energy savings over an all-electric, conventional system and require significantly less renewable capacity to be built.

These savings are made possible primarily by transitioning from fan coil unit (FCU) or air handling unit (AHU) piping packages, that modulate only water flow rate, to a new piping package that controls both water flow rate and water temperature. Controlling flow rate and temperature at the FCU can eliminate the need for air reheat, allowing a single FCU coil to be used for both heating and cooling.

Since each FCU utilizes a single coil for both heating and cooling only one piping package is needed per FCU.

The ability to modulate water temperature at the FCU allows the chiller to be operated at a lower temperature. Our study assumed a 38°F chilled water temperature compared to 45°F for the conventional system.

The lower water temperature is used to increase delta T at the FCU permitting a substantially smaller flow rate from the chiller, and consequently

the use of smaller diameter pipes and smaller pumps throughout the chilled water distribution system.

The lower temperature water available at each FCU permits the FCUs to provide substantially more latent cooling. This increased capacity is used to eliminate the need for a dedicated outdoor air system (DOAS).

Outdoor air is brought in using an energy recovery ventilator (ERV) which is about 20% of the capital cost of a DOAS and requires much less fan energy to operate due to the fewer stages. While the ERV is only able to provide about two-thirds of the conditioning needed to bring outdoor air to room neutral conditions, the remaining conditioning can be achieved at the FCUs and AHUs with the additional cooling capacity provided by the availability of lower temperature chilled water.

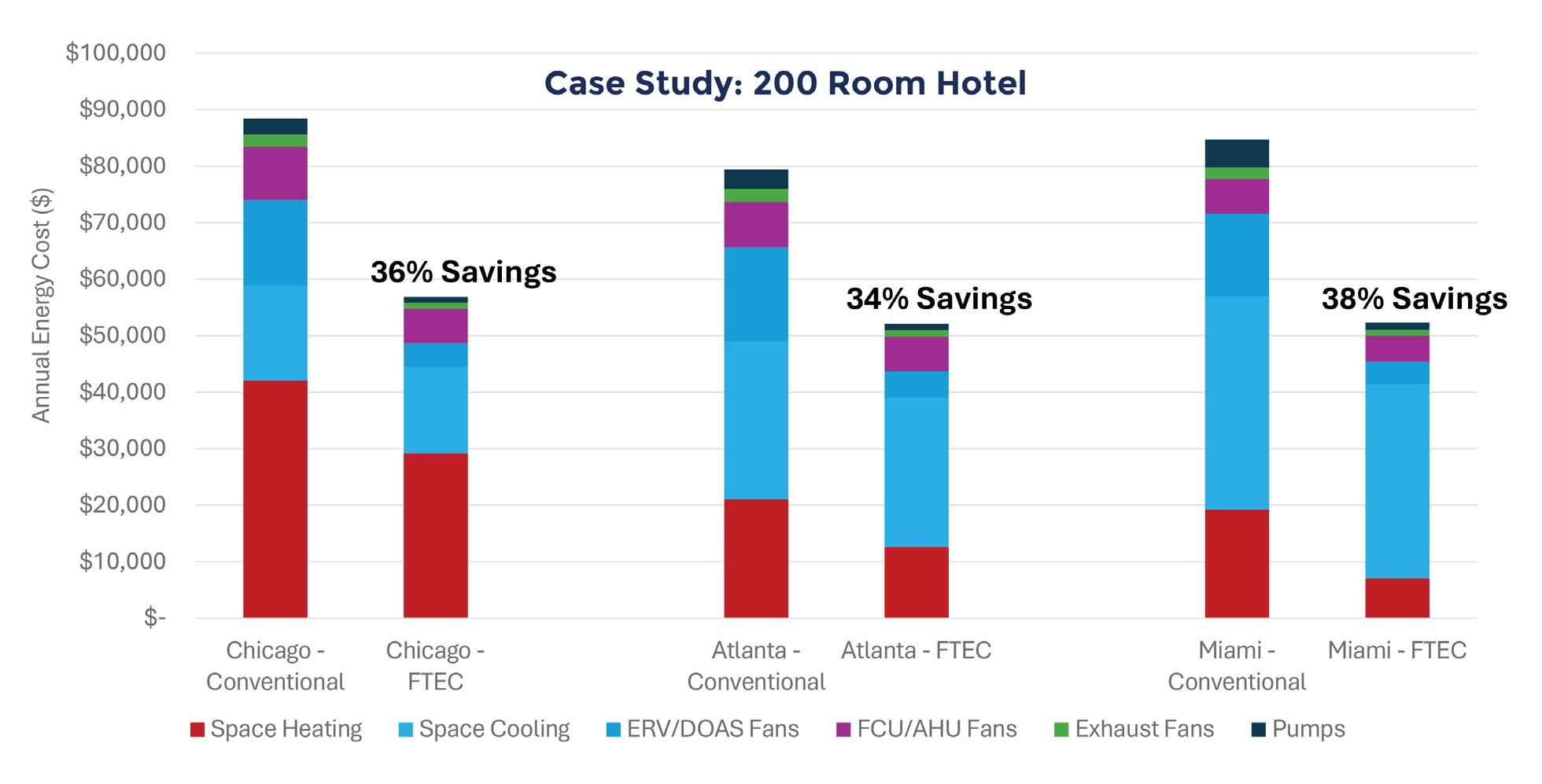

To estimate the energy efficiency and performance of the proposed system, an energy simulation was performed by Syska Hennessy Group, Inc., using an IES VE model for a new 200-room hotel as a case study. Both

a conventional chilled water HVAC system and the new approach were simulated for Chicago, Atlanta, and Miami with 36%, 34%, and 38% energy savings respectively.

A capital cost estimate for the two systems was provided in each city by Gardiner & Theobald. In each case the new approach provided a 27% reduction in capital costs.

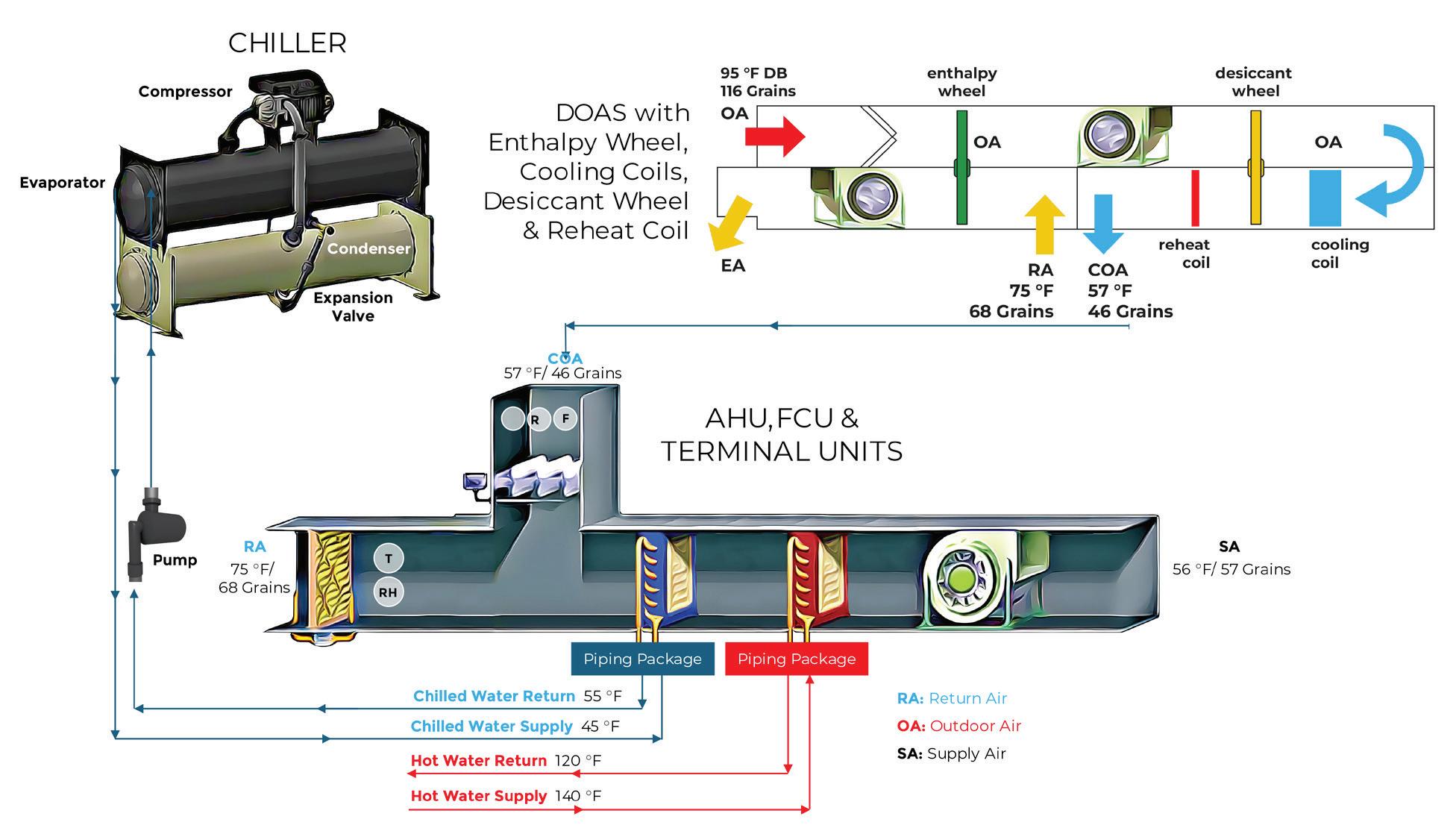

Performance comparisons are made to the conventional chilled water HVAC system shown in Figure 1. This system is intended to be representative of that used for large commercial buildings and industrial plants.

The conventional system consists of chillers that provide 45°F chilled water, DOAS that provide 45°F dewpoint air and FCUs that are designed for a 10°F delta T across the cooling coils. In terms of energy efficiencies and capital costs, there are three major problems with this conventional system.

The first problem is the low delta T of only 10°F, which results in the

need for large pipes, as well as in high pumping energy costs.

The second problem is the high capital cost for the DOAS and its high fan energy costs created to overcome the pressure drops across the enthalpy wheel, desiccant wheel, cooling coil and reheat coil.

And finally, the third problem is the energy penalties of having to reheat the air in the DOAS and FCU and the additional capital cost of having two coils and piping packages in the FCUs.

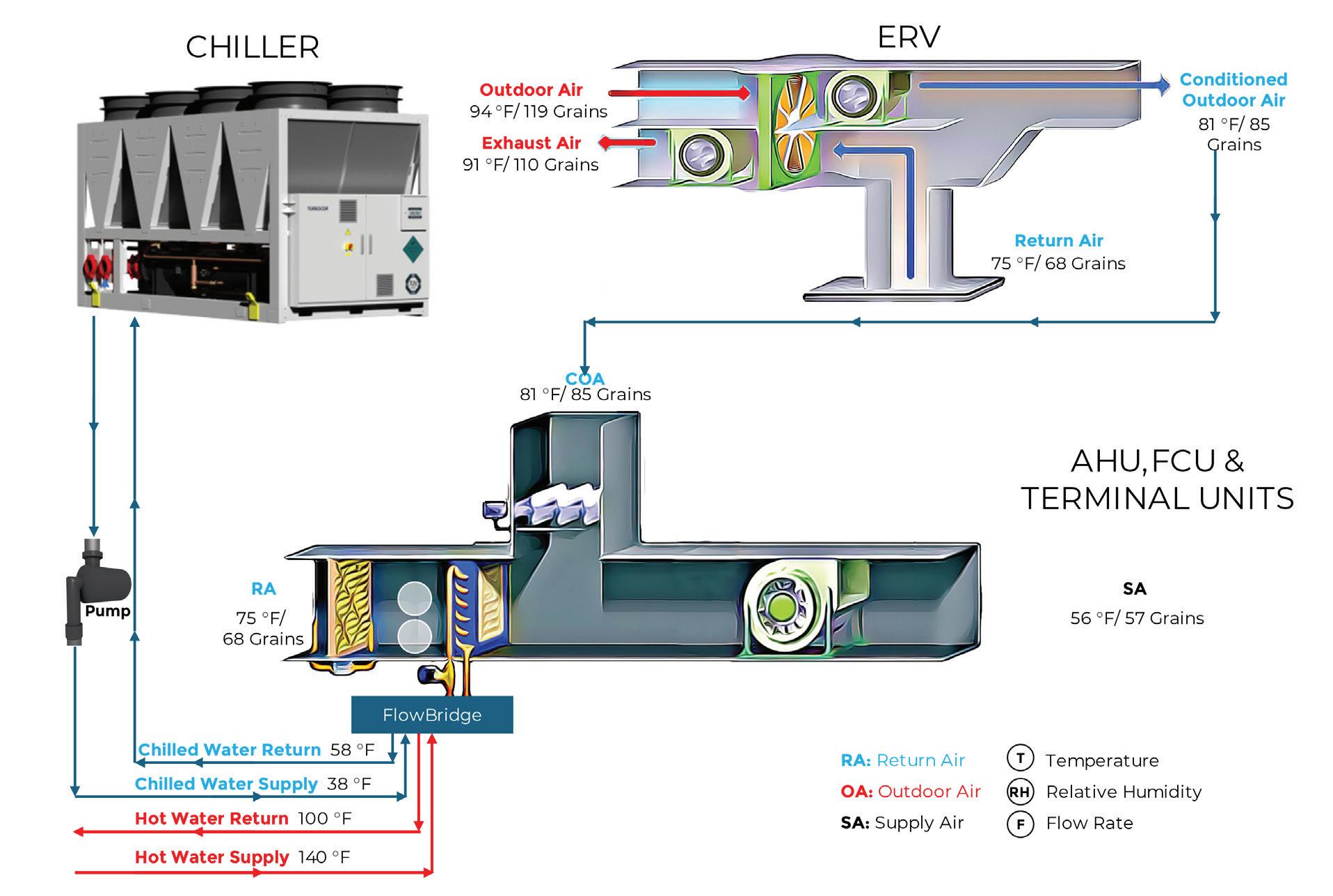

The proposed chilled water HVAC system shown in Figure 2 (above) overcomes each of the identified problems with the conventional system. The new system substitutes an ERV for the DOAS, eliminates one coil from the FCUs and replaces the two piping packages with a single temperature control piping package.

The chiller provides 38°F chilled water, allowing the FCUs to condense more moisture from the air and to reduce the moisture removal needs from the ERV. Delta T is increased to 20°F which reduces the piping costs and the pumping energy costs. The ERVs utilize highefficiency enthalpy wheels which can exchange both moisture and temperature between the conditioned air being exhausted from the building and the outdoor air being added to the building.

A high-efficiency enthalpy wheel can make use of the 75°F return air with 68 grains of moisture to reduce the outdoor air from 94°F and 119 grains of moisture to 81°F and 85 grains of moisture before being introduced into the FCU. This provides twothirds of the temperature reduction and moisture removal needed to get to the room neutral conditions, 75°F and 68 grains (50% RH).

The temperature control piping package enables the use of a single coil for both cooling and heating and

can be controlled so that the need for reheat is avoided.

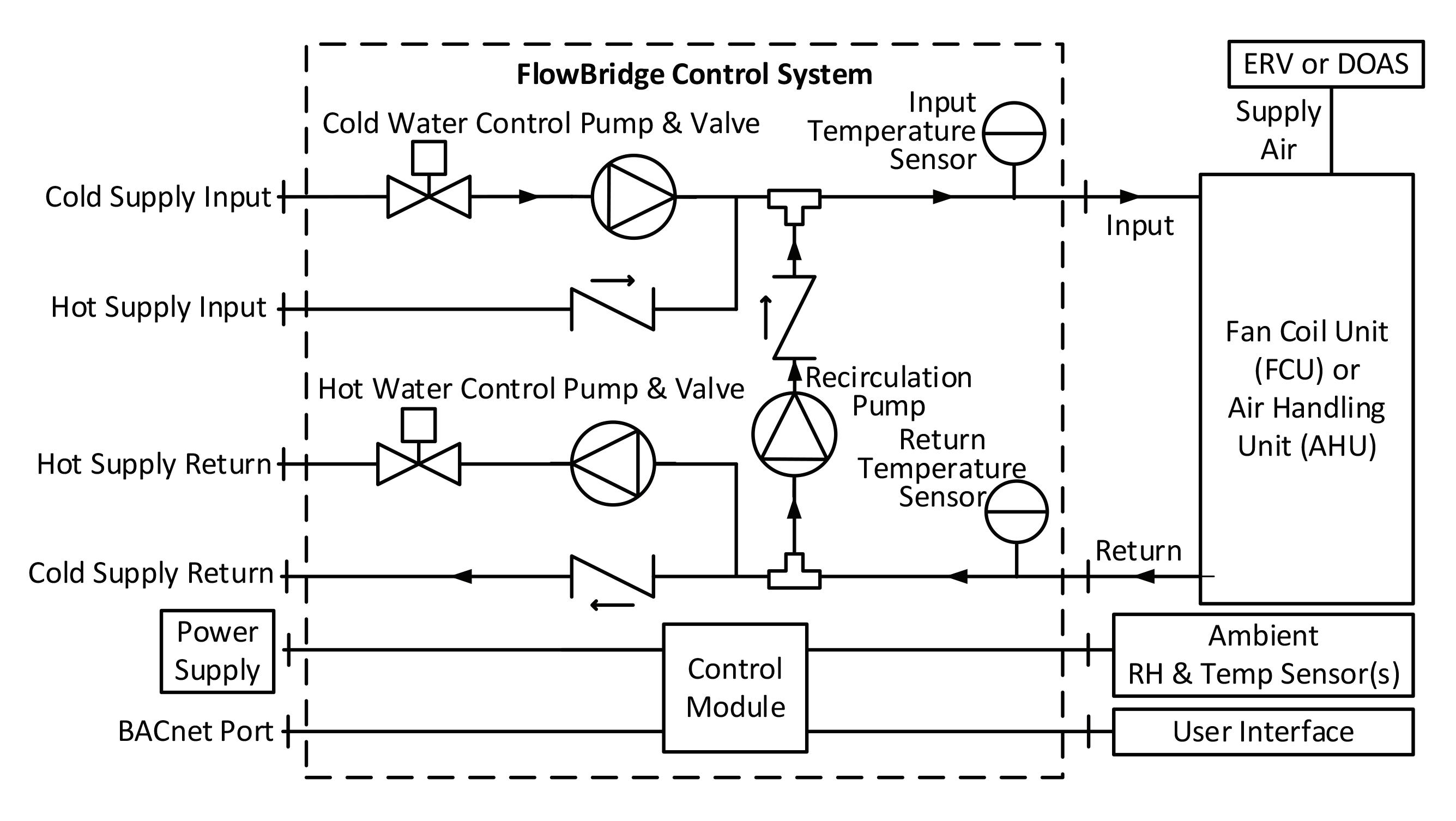

Figure 3 shows a schematic of the temperature and flow rate control piping package. This design connects to a fourpipe system at left and to a single cooling coil at right. A variable-speed recirculation pump is used to mix return water with supply water. A variable-speed supply pump is used to control the ratio of chilled water supply to recirculated return water in the cooling mode.

A variable-speed return pump is used to control the ratio of hot water supply to recirculated water in heating mode. This configuration enables the control of both flow rates and temperatures to each coil. Each FCU and AHU can then respond to the changing loads of latent, sensible, and outdoor air required for each space.

Figure 4 shows a comparison of the energy consumption for the two systems as modeled by engineer Syska

of annual energy costs for conventional versus new system in Chicago (36% savings), Atlanta (34% savings), and Miami (38% savings).

Hennessy. The largest contributor to energy savings is the elimination of reheat during cooling.

The conventional system has dedicated heating coils in both the DOAS and the FCUs, all of which are

eliminated by the new solution (without compromising indoor air conditions). Eliminating reheat also reduces the load on the chillers by about 22%.

The second largest contributor to energy savings is reduced fan energy

consumption. The conventional system must overcome pressure drops across an enthalpy wheel, desiccant wheel, and cooling and reheat coils in the DOAS which is much greater than the pressure drop across the enthalpy

wheel in the ERV (72% savings). The single coil FCUs also require less fan energy than the conventional two coil FCUs (29% savings). Finally, pumping energy was reduced by about 61%.

Figure 5 shows the capital cost savings calculated by Gardiner & Theobald for the new 200-room hotel example. The new system resulted in a capital cost savings of about 27%.

While the chillers are slightly more expensive, the savings was more than offset by savings in pumps, piping, ERV, FCUs and controls. The capital cost for the chillers that produce 38°F chilled water for the new system is about 16% more than the cost for the chillers that produce 45°F chilled water for the conventional system. The cost for the pumps for the new system is about 6% less than the cost for the conventional system because less chilled water is needed to be pumped with a 20°F delta T.

The cost for the ERV in the new system is about 80% less than the cost for the DOAS in the conventional system. The ERV is a simpler system that only requires an enthalpy wheel while the DOAS requires an enthalpy wheel, a desiccant wheel, cooling coils and reheat coils. The cost for the piping for the new system is about 22% less than the cost of the piping system for the conventional system because the new system requires less volume of chilled water than the conventional system.

The cost for the FCUs and AHUs for the new system is about 34% less than the cost for the conventional system because the new system uses the same coil for both cooling and heating while the conventional system requires a cooling coil and a separate heating/ reheat coil.

The proposed new approach to chilled water HVAC systems promises to provide significant capital cost savings,

energy cost savings and a path to eliminate CO2 emissions. The solution is made possible primarily by a new piping package and controller.

FT Energy Controls LLC, which has patented and is commercializing the piping package/controller is actively seeking opportunities for pilot testing of the proposed piping package with the proposed new chilled water HVAC

system. Additional studies are being performed to analyze other types and locations of buildings, and how best to retrofit existing systems to implement the proposed approach.

Those interested in participating in such pilot tests should contact Richard Furman at richard@ftenergycontrols. com or Zachary Thomas at zach@ftenergycontrols.com.

Tankless design, advanced sizing methodologies, and hybrid systems offer the potential for greater efficiency, sustainability and savings.

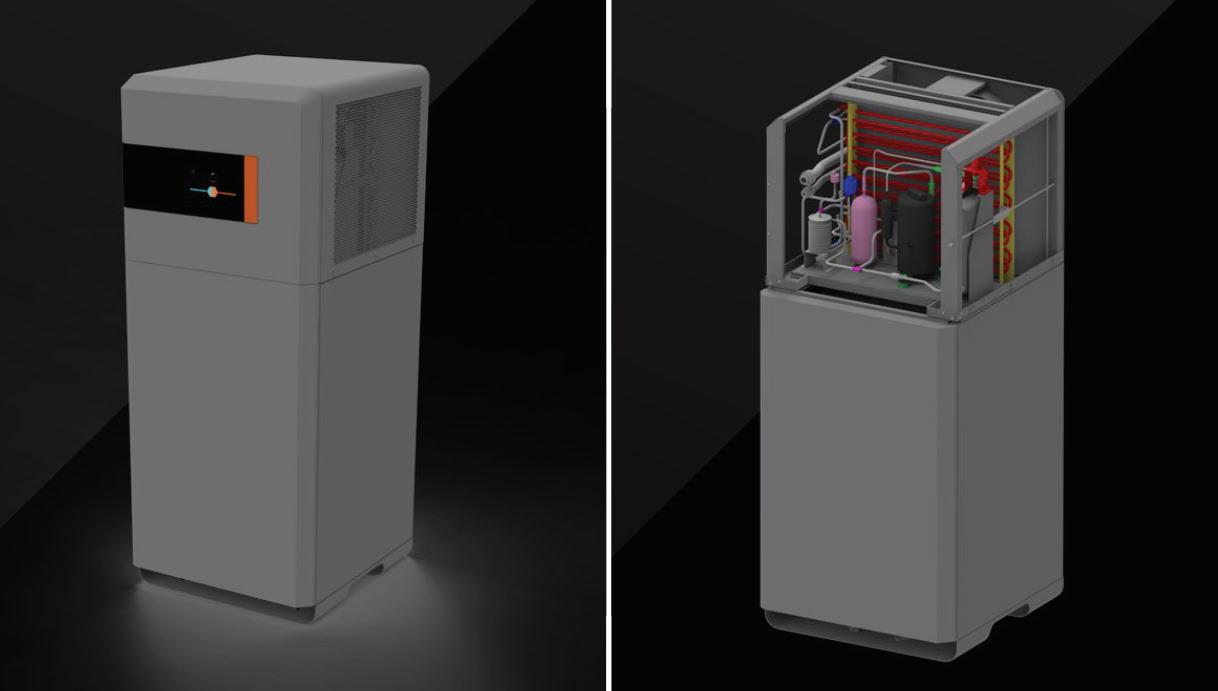

By ROBBIE SVIDRON, Engineering Education Manager, Intellihot Inc.

Heat pump water heaters have cemented their position as the most viable future-proof technology for decarbonizing water heating systems. With several states banning the use of natural gas in commercial buildings, businesses like restaurants, hotels, and multifamily properties have continued to assess heat pump water heaters for their facilities. Apart from favoring sustainability, the technology promises exceptional efficiency, providing the opportunity to realize significant OpEx savings as a result.

However, the implementation of heat pump water heating technology appears riddled with challenges. Addressing these challenges holds the key to unlocking the full potential of heat pump water heaters.

Engineers have found it difficult to assess the true on-field performance of existing heat pump water heaters. Constantly-changing environmental factors like ambient temperature and hot water loads directly impact the performance of heat pump water heaters. Hence, commercial properties find it

difficult to assess how much heat pump water heating equipment they need to reliably meet their hot water demand. Plus, while heat pumps are very efficient at moving heat, they do so at a much slower rate than a conventional gas-fired boiler.

Uncertainty in performance leads to a cost barrier for commercial properties. Being unsure of the right amount of heat pump water heating equipment needed could lead to businesses erring on the side of oversizing. Assuming the need for more heat pump water heating equipment drives up the upfront cost. The fact that heat pumps move heat slower than conventional gasfired boilers increases this tendency to oversize.

Additionally, heat pump water heaters demand a thorough audit of building infrastructure to ensure that there is sufficient electrical infrastructure, space, and ability to meet hot water loads in cold weather. These considerations, in turn, lead to larger upfront costs for the end-user as equipment costs can double or triple that of a conventional boiler system.

Cost is not the only downside to oversizing due to performance uncertainties. More heat pump water heating equipment results in significantly higher space consumption. This scenario is especially true when businesses try to counter performance uncertainties by increasing potable hot water storage to have peace of mind. Higher

Based in the Chicago area, the author holds a mechanical engineering degree from Bradley University, and currently serves as Intellihot’s sales engineering and education manager. Formerly a mechanical systems and applications engineer, Svidron has extensive field knowledge and expertise in multiple water heating systems for a variety of different geographies.

space consumption is a huge barrier for heat pump implementation, especially for facilities like restaurants.

Fortunately, there are three factors that can help alleviate these challenges and speed up heat pump water heater implementation: an on-demand design, advanced sizing methodologies, and in some cases, hybrid systems.

How does tankless technology work in a heat pump water heater? Currently, tankless heat pump water heaters employ a thermal battery to store the heat captured from ambient air.

Use of thermal batteries cut space needs by 40% over traditional heat pump technology, while doubling available hot water, allowing these heat pumps to fit in existing mechanical rooms. Potable water is pulled through a heat exchanger suspended in the thermal battery discharging the stored energy on demand.

This thermal battery design allows the heat pump water heater to decouple energy storage from the potable water used at the fixtures, thus acting like a traditional tankless water heater. The thermal battery can be integrated with the heat pump unit in a combined design, or housed in a separate unit.

Tankless heat pump water heating results in various benefits that can alleviate the aforementioned challenges.

• A tankless approach offers design simplicity. Without the need to rely on storage tanks or mixing valves, on-demand heat pump water heating makes implementation much less complex overall;

• The lack of such external components also negates the need for complex controls;

• With fewer components prone to failure, this approach increases reliability, as well;

• A tankless approach saves a large amount of space by eliminating bulky storage tanks;

• With no potable water storage, an on-demand heat pump water heater also mitigates the risk of Legionella.

Next, advanced sizing methodologies can help counter the performance uncertainties of heat pumps. Some manufacturers have developed simulation-based, multi-dimensional sizing tools that can incorporate advanced modeling techniques to consider dynamic factors like ambient temperature.

A reliable sizing tool will take several factors into consideration. It should be able to incorporate geographic parameters like seasonal and hourly temperature changes. A reliable sizing tool would also be able to predict hot water demand for each commercial property type based on flow rate data from other properties of a similar type in a similar geographic location. Identifying tools that guarantee their sizing results can help ease the uncertainty of choosing the right amount of heat pump water heating equipment.

With accurate sizing, properties can avoid oversizing while being able to meet their hot water demand reliably. This can help properties reduce upfront cost as well as space and electric power needs, essentially making the barrier to implementation smaller.

Finally, challenges with heat pump water heating have sparked interest in hybrid DHW systems that combine the fast delivery rate of high-efficiency gas with the sustainability and performance of heat pumps.

In regions where natural gas is still permitted, pairing a HPWH with a gas-fired water heater can help alleviate high upfront costs. Hybrid systems can open the door to electrification, allowing commercial properties to move towards complete decarbonization in small, feasible steps.

These “hybrid” water heating systems mirror their counterparts in the

automotive industry, where electricity is used wherever possible, with the ability to rely on gas power as a backup when conditions call for it. Commercial on-demand systems work best for such hybrid systems: mitigating Legionella growth, while also reducing standby losses and purging losses in the case of gas-fired equipment.

These hybrid systems can be configured in many ways. Here are three examples:

• Heat pump water heater for primary load, gas water heater for recirculation;

• Heat pump and gas units staged in parallel;

• Heat pump water heater receives incoming water first with a series connection to the gas-fired unit acting as a booster.

Approach #3 can be considered the best option from the above as it maximizes heat pump usage: keeping operational expenses low, while helping cut down upfront costs.

When compared with a heat pumponly system, hybrid systems can significantly reduce the difference in upfront cost. In return, the hybrid system has the potential to substantially reduce operating costs and electrical consumption, boasting a quick payback to recoup costs. Utilizing an advanced sizing tool with the ability to run multiple simulations (as described earlier) can help engineers design a hybrid system reliably.

In conclusion, heat pump water heating technology brings in a fresh set of opportunities and challenges. While heat pumps promise decarbonization and energy efficiency, their implementation can be marred by performance uncertainties, high upfront costs, and high space needs.

However, unique solutions like a tankless design, advanced sizing methodologies, and hybrid systems can help alleviate these challenges. By doing so, they can open the door to complete electrification slowly, allowing commercial properties to aim for zero reliance on natural gas in small, manageable steps.

New group, Boiler Industry Leaders of Tomorrow, aims to grow more next-generation talent into the ranks of management.

By Shaunica Jayson, Vice President, ABMA

Ratcheting up its next-generation focus even further, the American Boiler Manufacturers Association (ABMA) will hold its first Emerging Leaders Forum on April 8-9 in Columbus OH. It will mark the first event in the new Boiler Industry Leaders of Tomorrow (BILT) initiative, a program designed to nurture young professionals at member companies.

“We want to offer these up-and-comers a resource to enhance their knowledge and to expand their network,” explains ABMA President & CEO Scott Lynch. In fact, the original idea for BILT stems from member feedback, where many firms expressed interest in doing more to develop their own young talent.

“They come to the boiler industry from various backgrounds, and all have a variety of roles within their companies,” notes Jordan Croson, ABMA’s new Education Coordinator who heads

the committee planning the event. Made up of emerging leaders, the committee includes Samantha Jarrell, of Valley Boiler; Ryan Poznanczyk, of Applied Heat Recovery; Alex Taylor, of WARE Inc.; and Clayton Viskup, of Victory Energy.

To fine-tune its program, ABMA met with several related industry groups to see how they have fostered their own respective pipelines of young leaders. “We said, ‘tell us about your program, what works, what doesn’t work,’” recalls Croson. Feedback was consistent – offer participants many diverse opportunities to engage and facilitate both networking and learning.

Based on that insightful input, ABMA will be incorporating peer-topeer presentations, CEO Q&As, group networking and education sessions into its April program. Of note, renowned relationships expert Dr. Rick Marks will conduct a workshop on emotional intelligence in the business setting, incorporating interactive elements.

“It’s really great to have someone at the apex of a prominent career come in to talk,” says Croson. “It’s really relatable and nice to have a peer explain some things that everyone is experiencing.”

With the event taking place in Columbus, ABMA will also be partnering with locally based National Board of Boiler and Pressure Vessel Inspectors (NBBI). “This location was specifically chosen so our attendees can visit NBBI. Attendees will see their boiler room, boiler testing facility and pressure relief lab,” notes Croson.

The event will also focus on personal branding. On that note, Croson emphasizes the importance of teaching employees how to present themselves professionally while representing their companies effectively.

“In the beginning of the event, our networking is going to be a little bit more facilitated, where we will have some interactive activities,” Croson said. “And then hopefully, towards the end, we’ve provided you with enough content to go up to someone you’ve engaged with before, remember something about them, or spark some type of connection or engagement.”

Looking ahead, Croson emphasizes the program’s long-term vision.

“Taking an active role in your future is really important,” she adds. “We expect this program to spark engagement that leads to many more interactions with this cohort in the months and years to come.”

For more details on BILT and the Emerging Leaders Forum, contact Croson at jordan@abma.com or visit the ABMA website at www.abma.com.

The American Boiler Manufacturers Association (ABMA) is excited to announce the Women in the Boiler Industry (WIBI) “Rising Star Award” and its inaugural recipient: Carrie Murakami, national inside sales assistant manager at manufacturer Miura America Company.

ABMA has created this new opportunity for the WIBI professional community to facilitate more exposure for up-and-coming women in our industry. As a result, they may attend ABMA events and WIBI functions to network with industry leaders, gain professional growth and insights into the latest developments in the boiler industry, and contribute to the advancement of our field.

Murakami will be a guest of honor at the ABMA 2025 Annual Meeting and WIBI event. She becomes the first woman ever chosen for this prestigious honor, shining a spotlight on the vital contributions of women in a field that has long been predominantly male. Her dedication to empowering others and fostering collaboration aligns seamlessly with the goals of ABMA’s initiative.

With nearly a decade of experience at Miura America, her career exemplifies resilience, leadership, and innovation.

She began her career in quality assurance as an administrative assistant and advanced through roles in safety, general affairs, and business development before becoming a key figure in inside sales. Along the way, Murakami has earned recognition for her commitment to delivering exceptional results, including being named Employee of the Month in both 2017 and again in 2023.

One of Murakami’s stand-out qualities is her ability to deliver meaningful customer experiences, including outstanding factory tours that leave a lasting impression. Her attention to detail, ability to connect with people, and dedication to showcasing Miura’s expertise have been instrumental in fostering strong relationships with customers and Miura’s Representative Partners alike.

Murakami’s recognition is testament to her determination to break down barriers and elevate the visibility of women in the industry. Her journey underscores the importance of diverse voices in shaping the future of this vital field. Her leadership and perseverance serve as an inspiration for women across the industry, and we look forward to seeing her continued impact.

For more details about WIBI and other association initiatives, please visit www.ABMA.com.

E-1510X smart pumps from Xylem/Bell & Gossett, powered by the hydrovar X Smart Motor, offer customizable pumping solutions. Built-in application software makes the drive one of the easiest to commission, program and operate, enabling virtually any configuration of pumps. Advanced system controls (up to 8 pumps) are customizable for various applications. Each unit is fitted with the optimyze sensor to monitor the health of the pump. The integrated pump and hydrovar X motor design eliminate the need for additional wiring, labor and associated costs.

Xylem/Bell & Gossett

The WQ-AS commercial water quality solution from Lync by Watts is a complete, fully engineered, multibarrier solution that optimizes a system’s water quality. It provides facility managers and building owners with three new models (40, 70 and 100 gpm), an upgraded UV disinfection system, increased treatment capacity, greater installation flexibility and more control options. It mitigates scale buildup without the use of salt or harsh chemicals. This anti-scale approach, combined with sediment filtration and UV disinfection, provides protection against contaminants.

Lync by Watts

Lochinvar unveils the Lectrus light commercial electric boiler that can be installed indoors without losing performance—even in below-freezing ambient conditions. Available from 15 kW to 150 kW, it is ideal for almost any application requiring sustainable alternatives to natural gas or propane models. Depending on an application’s needs, up to eight units of varying sizes can be cascaded; it can also be installed alongside other boilers to optimize performance and reduce carbon emissions. The SMART SYSTEM LCD operating control allows for modulation and staging of the elements to operate within the full kilowatt range of the boiler.

Lochinvar

Self-closing pipe clamps from Oatey offer a streamlined solution for securing pipe quickly and reliably. Their push-to-install mechanism allows pipe to be easily secured by simply pushing into the clamp, reducing installation effort. The clamps feature an interlocking design that combines with the dual wall bracket accessory to enable the precise spacing of hot and cold water lines for multiple-pipe installations. Designed for versatility, they are compatible with wood or metal studs, sliding wall brackets and struts. For use with copper, steel, PEX and CPVC pipe. Made of corrosionfree polyamide and resistant to UV, aging, oil and gasoline. Oatey

Emerson launches its AVENTICS DS1 dew point sensor that monitors dew point, temperature, humidity levels and quality of compressed air and other noncorrosive gases in real time from one device. It can help industrial operators detect and mitigate excess moisture in its early stages and prevent moisture-related equipment damage. The sensor element is condensation-resistant and provides long-term, drift-proof performance. Measurement values include pressure dew point, temperature, relative humidity, absolute humidity, moisture content, moisture content V/V, water vapor partial pressure and atmospheric dew point. Also suitable for other noncorrosive gases including nitrogen, oxygen, argon, helium and sulfur hexafluoride.

Emerson

HEMCO HEPA and carbon filtration packs are designed to be mounted inline in the exhaust ducting from a fume hood or contaminant source up to 1,500 cfm. The filter pack includes a galvanized steel housing with a hinged and gasketed access door for filter change-out and molded composite resin inlet and outlet plenums with duct connection collars sized to meet specifications. Both filters include a 30% pleated prefilter and can be paired together for applications that require particulate and fume removal.

HEMCO

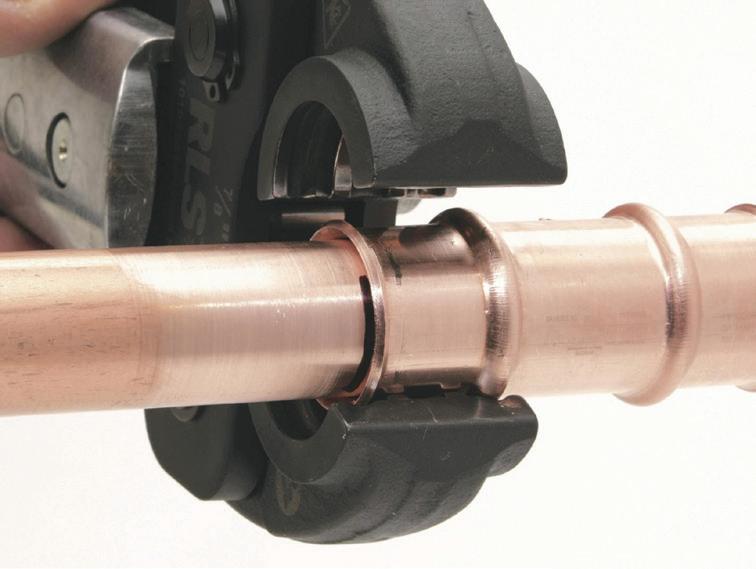

Rapid Locking System introduces A2L-compliant press fittings— couplings, elbows, reducers, tees, caps, bushings and SAE flares—that provide a more sustainable and environmentally friendly solution to the market. Attaining A2L compliance required the manufacturer to ensure that the fittings adhere to updated industry code and standard requirements by participating in a testing and screening process across multiple third-party testing labs.

Rapid Locking System

Diversified Heat Transfer launches the SPC liquid-to-liquid cooling heat exchanger to be used for cooling MRI machines, CT and PET scanners, electron microscopes and linear accelerators, as well as for industrial and HVAC cooling needs. The high-efficiency, brazed-plate packaged cooling system can efficiently produce up to 90 gpm of chilled liquid, depending upon operating temperatures,. With a maximum 150 psig water pressure and an adjustable temperature control set point, the unit uses real-time load tracking and responsive controls to maintain accurate cooling temperatures under various load patterns. Units can be coupled with all major medium-, normal- and low-temperature condensing boiler water to achieve high efficiency in an optimal space.

Diversified Heat Transfer

Johnson Controls launches the YORK YK-CP centrifugal chiller is designed and optimized specifically for the use of the ultra-low GWP refrigerant R-1234ze(E) without requiring a larger chiller footprint or sacrificing efficiency. It can be equipped with an optional variable-speed drive for optimal utilization at both full and part loads, as well as under design and off-design conditions at varying ambient temperatures. It offers realworld efficiencies as low as 0.15 kW/ton (23.4 COP). features the OptiViewM Control Panel with updated software, making it easier to streamline operations by providing operators with the information they need in a clear, accessible format while increasing efficiency and minimizing errors.

Johnson Controls

The Pista Pro-Pak from Smith & Loveless is built with a retractable fiberglass enclosure that provides essential freeze and environmental protection, enhancing reliable grit pumping performance in even the harshest climates. For additional resilience in extreme weather, an optional heater is available to safeguard operations. The durable steel base supports the factoryassembled grit chamber drive assembly, priming system and controls, all of which come prewired to expedite installation and reduce on-site labor costs. This solution meets the evolving needs of municipal and industrial wastewater treatment facilities.

Smith & Loveless

SmartFlex BK360 gloves from Brass Knuckle are designed to keep hands warm and protected all day, no matter how low the temperature drops. It starts with a layered 13-gauge nylon shell augmented with a 7-gauge napped acrylic lower liner. Next, a seamless and stretchable full-knit wrist helps prevent dirt, debris and cold air from getting inside the glove. Foam latex coating on full fingers, palm and 3/4 inches deep on the back remains soft in cold conditions. The sponge-like foam coating is an excellent dry gripping surface and, when surfaces are wet, it draws liquids away from the gripping surface, improving slip resistance.

Brass Knuckle

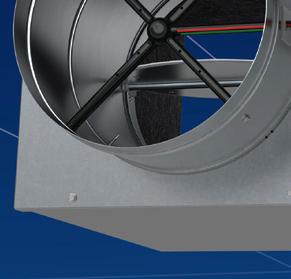

Greenheck's comprehensive line of Air Terminal Units (ATUs) provide an

Single duct, fan powered, dual duct, and retrofit ATU models are available.

Specify with Confidence. Specify Greenheck.

Solar PV is now ubiquitous. So where else can renewable energy enter our lives?

Larry Clark

A regular contributor to HPAC Engineering and a member of its editorial advisory board since 2012, the author is a principal at Sustainable Performance Solutions LLC, a south Florida-based engineering firm focusing on energy and sustainability. Email him at larry@ sustainflorida.com.

Photovoltaics became ubiquitous while we weren’t looking!

Solar PV is more than the commonplace residential and commercial rooftop arrays that continue to multiply, especially in states like California where, according to Forbes Home, more than 38% of homes are now solar-powered; in Nevada, where more than 42% of the homes have PV; and Arizona and Utah, each of which boast 18% of its homes with solar PV.

Although rooftop PV arrays – including PV roof tiles and building-integrated PVs and ground-mounted arrays are the most common for primary or ancillary electric power for residential and commercial buildings, there are numerous other applications, both indoor and outdoor, that we may not even notice.

For example, how many of us can even remember when and where we got our first PV calculator, capable of being powered by ambient indoor lighting? Now they are common giveaways at trade shows.

In my own experience, I’ve had literally dozens of PV-powered devices that I took for granted, ranging from the PV/battery backup fence charger that protected our horse pasture in Pennsylvania in the late 1990s, to my first hybrid car (a Prius) that had PV on the roof to power air circulation when the car was parked in the sun, to the PV-powered/ hand-crank backup emergency radio that we now rely on in Florida, especially during hurricane season.

These extremely small PV systems, often referred to as pico PV can, in addition to radios, power such devices as flashlights and lanterns, MP3 players, watches, phone chargers, and even small fans. Then there is PV-powered landscape and pathway lighting, street lighting, traffic calming and information signage (Yes, I know I’m speeding! Thanks!), bus stop lighting, and the PV-powered E-bikes and scooters that are rampant here in South Florida.

Of course, electric vehicle charging is another common application for PV, and not just cars and trucks (although solar-powered

EV charging stations are prevalent in Europe and their numbers are increasing in the U.S.). Solar cells have been part of every U.S. spacecraft since the launch of the first Vanguard 1 satellite in 1958. Solar PV panels on boats are also a common sight here in South Florida.

During a recent stay in Key Largo, I had the opportunity to do a boat trip to Molasses Reef, a coral reef located within the Florida Keys National Marine Sanctuary, approximately 5.5 nautical miles offshore. During the ride out to open water, I counted nearly half of the sailboats moored in the canals with solar panels installed.

Incidentally, Molasses Reef, which is a designated “Sanctuary Preservation Area”, is wellknown for its exciting diving and snorkeling,

with more than 600 possible species of marine life. It shouldn’t be a surprise that sailors living there would promote sustainability by using renewable energy on their boats. When they’re under sail and charging their batteries with PV, there are no carbon emissions.

And by the way, none of this is being mandated by any government at any level. It’s just well-intentioned citizens trying to make a difference. Which begs the question:

How can the rest of us use more renewable energy, even in some little things, to reduce our carbon footprint?

Energy efficiency is essential to reaching net zero. It’s one of the easiest and most impactful ways to reduce carbon emissions – especially in buildings, which account for a big part of global energy use. With Grundfos smart pumps, you get the best of both worlds: advanced HVAC and water systems that deliver superior energy efficiency without compromising on comfort or performance. Our smart pumps collect and analyze data to optimize performance, uncover hidden energy savings, and reduce lifecycle costs. By automatically adjusting to real-time needs, you can significantly cut energy use and carbon emissions while ensuring reliability and comfort. Start your journey toward net zero with solutions designed to elevate your building’s efficiency.

Discover Grundfos solutions that suppor t the journey towards net zero at grundfos.com/CBS

Designed for fresh air.

AAON Delta Class has been dedicated from the beginning. AAON is always innovating. Learn more about our dedicated outdoor air systems (DOAS).