IN COLLISION REPAIR

For 45 years at I-CAR,® we’ve been the go-to for training that keeps pace with collision repair technology. We’re helping to keep technical skills more current than ever, with specialized courses in EVs and ADAS. This helps you complete the quality repairs that get drivers safely back on the road.

OUR ALL-INCLUSIVE, CUSTOMIZED TRAINING PACKAGE ENABLES YOUR SHOP TO ACHIEVE GOLD CLASS® RECOGNITION IN ONE YEAR OR LESS

Get to Gold Class is the most direct and affordable way for your shop to get started on its training journey that contributes to complete, safe and quality repairs.

A customized package gives your shop:

• A discount on Gold Class required training

• Turnover protection*

• An In-Shop Knowledge Assessment™

• Flexible monthly or pay-in-full payment options

*Exclusions apply.

I-CAR.com/GTGC

Gold Class achievement demonstrates to your customers, your staff and the industry that your shop is committed to the highest standards of education, professionalism and training in collision repair.

MARKETING TO INSURERS

VR TRAINING IN COLLISION REPAIR

ALWAYS EVOLVING

This Illinois shop has an expert strategy to use multiple buildings and segment repair work.

THE MODERN COLLISION SHOP

FRONTGAWR: 2735LB AT

REARGAWR: 3325LB 1508KG P235/70R16SL 16X7.0J

WITHTIRESRIMS

PSI

240 kPa/35 1240KG P235/70R16SL 16X7.0J

AT 205 kPa/30

01/03 00000000000000000

VEHICLESAFETY STANDARDSIN EFFECTON THEDATEOF MANUFACTURE SHOWNABOVE.

NISSAN ROLLS OUT REBATE PROGRAM FOR NISSAN AND INFINITI PARTS PURCHASED THROUGH OPSTRAX

The OEM says the initiative will assist in driving better relationships and increase safety

By JAY SICHTCOLLISION REPAIRERS LOOKING TO increase their use of OEM parts just got a boost in the form of a new rebate program by Nissan. The Trax Rebate program applies to all Nissan and Infiniti parts ordered as part of a complete repair estimate through the online parts procurement tool OPSTrax.

“Nissan understands that our customers’ safety comes first, and we know the safest repair is one with 100% OEM parts with trained technicians and the right tools,” said Daniel Dent, manager of Wholesale-Collision, Certified Repair Network for Nissan, Group of the Americas. “The program has been in development for years, and we know it gives the independent shop operator an opportunity to take another step toward ensuring they install the parts they feel more confident in.”

The amount of the rebates progressively increases based on the percentage of Nissan or Infiniti OEM parts purchases, with steps at 65 to 74.99%, 75 to 84.99%, and over 85%. For an example repair that requires $3,200 in parts, Dent said, a non-Nissan-certified or nonInfiniti-certified shop using RepairLogic that buys up to 85% ($2,720,

in this example) of the parts requirement as Nissan OEM parts would receive a rebate of $48. At the other end of the spectrum, an Infiniticertified or Nissan-certified shop purchasing 100% Infiniti or Nissan OEM parts on the repair estimate would receive a $153.60 rebate.

“The shop will get a rebate direct via ACH to their chosen business account,” Dent says. “They can use that rebate to cover any expense or improvement they choose.”

There is no “catch” or parts that are ineligible, Dent says, although there is a 5% administrative fee off the total rebate, which the shop pays monthly.

“Nissan and Infiniti are striving to provide more value and benefits to our collision center customers,” he says. “We will continue to listen to the owners and operators to positively impact their business and people at the grassroots level. We strongly feel this new initiative assists in driving better relationships with our dealers, customers and owners of our vehicles. We are proud to partner with businesses and individuals who care about the customer experience and providing the absolute safest repair possible.”

GEARED DUAL- ACTION POLISHER

EDITORIAL

Matt Hudson Content Director

Jay Sicht Editor-in-Chief

Hanna Bubser Associate Editor

Kacey Frederick Assistant Editor

Leah Marxhausen Special Projects Editor

Drew Bryant Contributing Writer

Tiffany Menefee Contributing Writer

Greg Lobsiger Contributing Writer

Lindsey Gainer Contributing Writer

Noah Brown Contributing Writer

Nolan O’Hara Contributing Writer

EDITORIAL ADVISORY BOARD

Jordan Beshears Steve’s Auto Body

Sheryl Driggers Universal Collision

Frank Rinaudo Frank’s Accurate Body Shop

Jason Mundy Mundy’s Collision Center Stan Medina Certified Collision Works

SALES

Andrew Johnson Associate Publisher ajohnson@endeavorb2b.com

Mattie Gorman-Greuel Associate Sales Director

Cortni Jones Director of Business Development

Diane Braden Account Executive (National Accounts) dbraden@endeavorb2b.com

Marianne Dyal Account Executive (National Accounts) mdyal@endeavorb2b.com

–

Cuts like a rotary, finishes like a DA!

– Lightweight, low profile, precision balanced design for superior control.

WE LISTEN. WE OBSERVE. WE INNOVATE.

FASTENERS GRAPHICS WINDSHIELDS

Chad Hjellming Account Executive (National Accounts) chjellming@endeavorb2b.com

Lisa Mend Account Executive (National Accounts) lmend@endeavorb2b.com

Michael Parra Account Executive (National Accounts) mparra@endeavorb2b.com

Martha Severson Account Executive (National Accounts) mseverson@endeavorb2b.com

Kyle Shaw Account Executive (National Accounts) kshaw@endeavorb2b.com

Sean Thornton Account Executive (National Accounts) sthornton@endeavorb2b.com

Ryan McCanna Administrative Assistant

ART AND PRODUCTION

Mariah Straub Production Manager Jen George Ad Services Manager Mitch Bradford Art Director

ENDEAVOR BUSINESS MEDIA, LLC

CEO Chris Ferrell President June Griffin

CFO Mark Zadell

COO Patrick Rains

CRO Reggie Lawrence

Chief Digital Officer Jacquie Niemiec

Chief Administrative and Legal Officer Tracy Kane

EVP Endeavor Business Intelligence Paul Mattioli

EVP Transportation Kylie Hirko

VP and Group Publisher Chris Messer

HOW TO REACH US Endeavor Business Media, LLC

571 Snelling Ave N Saint Paul, MN 55104 tel 651.224.6207 fax 651.224.6212

The annual subscription rate is $90 (U.S.A. only) for companies not qualified to receive complimentary copies of FenderBender.

LETTERS TO THE EDITOR editor@fenderbender.com

Opinions expressed in FenderBender are not necessarily those of Endeavor Business Media, and Endeavor Business Media does not accept responsibility for advertising content.

MEET ME IN LAS VEGAS

The SEMA Show is a collision repairer’s destination

IF YOU’VE EVER WATCHED a pair of Top Fuel dragsters or nitro Funny Cars launch off the starting line, you know nothing compares to the ground-pounding staccato of each cylinder firing and pushing out 1,500 hp per cylinder as they hit 100 mph in less than a second, the air filled with the acrid fumes of nitromethane and tire smoke. For a new attendee, it’s difficult for even a lifelong motorsports enthusiast to grasp just how the event assaults the senses…but in a good way. It’s a phenomenon often called a “baptism by nitro,” and there are many clips on social media catching fans unaware of just how loud these missiles are until they streak by. I’ve delighted in introducing the spectacle to friends, family, and coworkers over the years.

I attended my first SEMA Show in 2000, and just like drag racing, I’ve tried to prepare newcomers. I show them a map with the exhibitors’ floor plan, pointing out the tiniest square on the map is 10’x10’. But you just have to experience it to appreciate its scale, sights, and sounds. From the driving events and hundreds of vehicles on display outdoors, to every type of car celebrity (and even movie star car buffs) you can think of, unveilings of high-caliber car builds, and the associated receptions about town, there’s no shortage of excitement to be had without ever spending a quarter in a casino. Be sure to check out our SEMA Preview on page 51 to see what you can look forward to.

The Collision Repair & Refinish segment of the show has capitalized on that nearby excitement, and now, owners, managers, and technicians can check

out the latest tools and equipment, mostly consolidated since 2021 in the Upper South Hall for easier access and a bit of breathing room. It’s a week to network at events, including the MSO Symposium on Monday and the Collision Industry Conference (CIC) Tuesday as well as get caught up on training from I-CAR and SCRS. An attendee can take away as much as he or she desires for which he or she budgets time. The joke at the show among colleagues is we’re “working only halfdays.” The joke, of course, is the day often begins with a 7 a.m. breakfast presentation and ends at 10 p.m. with an awards reception, with any “free” time occupied with uploading articles and photo galleries. It’s not an easy week, but I wouldn’t have it any other way. It’s an annual shotin-the-arm reminder of the enormity and importance of our industry. If you’re in the area, check out our SEMA Show booth (#41078). Thank you for your continued support of FenderBender, and I hope to see you in Vegas.

JAY SICHT EDITOR-IN-CHIEF jsicht@endeavorb2b.com

• WORkS ON 2 POST LIFTS

Latest technology capabilities of monitoring and adjusting wheel measurements while vehicle jacked on 2 post lift.

• COMPAtIBLE WITH ALL OtHER TyPES OF LIFTS

• PRE ADAS CALIBRAtION ALIGNMENT READINGS

• MOBILE ALIGNER, SPACE SavER

• SEAMLESS SOFTWARE

• INTEGRAtED OE DAtABASE

• INStANT vIN DECODING

BREAKDOWN

ZOOMERS ON THE ROAD

How shops can capture the attention of the younger generation

By KACEY FREDERICKAS VEHICLES CONTINUE to age and change, so do people. Staying in touch with trends among younger demographics and learning how it will relate to your business’s advertising is something every successful business is conscious of.

Sara Fraser of Haas Performance Consulting is not only familiar with how to market for independent shops, but how to make that marketing appeal to all age demographics. She’s shared her insights on what shops can do (and not do) to capture the attention of Generation Z and beyond.

Making Your Virtual Mark

The biggest way to reach younger audiences is online, and investing in online advertising is a simple and effective way to make your business seen. The best platforms to focus on are typically Instagram and TikTok, as data has shown that most users on these platforms range from 18 to 34.

An online advertisement will stick with most younger people if it seems genuine, and a shop can achieve this by portraying themselves as transparently as possible. Using photos taken of the actual shop and its employees in advertisements as opposed to stock photos is a good way to communicate that sentiment.

“They’re really looking for honesty, transparency, upfront information, they want the facts–like they are going to do their research, they’re going to read reviews–that kind of stuff,” Fraser says. “So [avoid] anything that’s kind of gimmicky, or just not transparent and truthful.”

Indeed, most young people are proficient with the Internet and like to do research before paying money for a product or service. A shop that has its information easily accessible is more likely to capture the attention of the young Internet researcher–especially in an automotive emergency.

If they must click through several tabs to find basic information, such as the shop’s address or services offered, many will simply go to the next shop on their list rather than scour through the website. One way to keep this from happening is to create an FAQ page.

Another key step to focus on is setting up your shop’s Google profile. This is commonly overlooked but can in fact lose the attention of many prospective clients.

A Google profile contains information that will be used to direct related searches toward your business. If a shop hasn’t looked over its Google profile and included what services it provides, it may affect how often it shows up in online search results. And when marketing to the young generation of Internet researchers, having that Google profile set up to include you in as many search results as possible is crucial in gaining their business.

Miles of Road Ahead

A decline in the demand for automotive work doesn’t seem to be likely with the incoming generation.

Though rideshare services have become more common, most younger people still plan on owning their own vehicle. Having a personal vehicle makes life easier in many ways, but it can also serve as a source of income for many, especially young people trying to get by.

Shops can not only gain clients from understanding how to connect with the younger generation, but also attract people in that demographic that are looking for a career.

As the industry faces a shortage of technicians, it’s important to learn how to market not only your services to potential customers, but your workplace to potential talent. Fraser has assisted many shops with the hiring and interview process and has found the most important thing for those entering the field is having a job that provides security.

“I always ask in an interview, you know, ‘what are the three most important things for you in your next job?’ And in this age group, it tends to be that safety is always in one of those top three,” Fraser

says. “So they’re looking for a safe environment–and that’s physically safe, and also mentally safe, they want to know that they’re not going to have to deal with harassment and bullying at work.”

This can be achieved by expressing sentiments in job ads about the company

culture and showing that your staff are team players that take care of one another and have a good work-life balance.

Hosting outings or lunches with the shop staff is also a great way to build a genuine bond that can appeal to that demographic of young people first entering a field.

With the entirety of Generation Z soon being able to own and drive their own vehicles, it’s certainly not a group of people the auto industry should ignore.

Many strategies for attracting younger demographics, such as increasing your business’ presence in search

results, will yield successful results, but being aware of Generation Z’s role as the informed customer and their specific concerns will help attract potential lifelong relationships, if not the beginning of a successful career in the automotive aftermarket.

LIGHT HITS BOGI LATEINER SPEAKS AT ASE INSTRUCTOR’S CONFERENCE

The ASE Education Foundation enlisted automotive expert and ASE spokesperson Bogi Lateiner to speak at its recent instructor’s conference, according to a press release.

The presentation, titled “Revving up the Diversity: Shaping an Inclusive Future in Auto Repair High School and College Shop Programs,” started with a scenario of a female student who is repeatedly discouraged by her instructor to join an automotive course.

Lateiner then discussed how instructors can create an encouraging environment, such as treating both men and women the same. Women should be receiving the same expectations in regard to their work, without any assumptions being made about their intelligence or capabilities based on their gender.

Lateiner warned to not make men and women feel as if they are competing with each other. Refrain from making comments about how men are being “shown up” by women or similar remarks, as this only further divides colleagues and places unreasonable expectations on women.

For much of the presentation, Lateiner described the automotive industry as a club that no one wants to be a part of, and this must change if the technician shortage is to be addressed.

“Often viewed as being sensitive, the younger generation is not necessarily sensitive, but asks for what they want

and need,” Lateiner said. “In this hiring environment, employees have more power. Asking to be treated with respect, to be trained and provided with a career path while working in a collaborative environment isn’t being sensitive. It’s what every employee should have.”

NEW STANDARDS AND ACCREDITATION FOR ASE

The ASE Education Foundation has announced updates to its collision repair and refinish standards as well as the creation of a new area of accreditation, according to a press release.

These changes were the result of a workshop conducted by the ASE Education Foundation, which reviewed the methods used by ASE-accredited collision repair and refinish programs in high schools and colleges.

Those that reviewed the changes were a committee consisting of vehicle manufacturers, collision repair and refinish shop owners and technicians, instructors and industry trainers, and equipment and parts suppliers.

The new accreditation is titled “Collision Repair and Refinish Fundamentals” and includes 121 distinct skills/tasks a required minimum of 300 hours in combined classroom and lab instruction.

Using existing areas of accreditation as its template, the new accreditation centers on five core skill areas that employers are most concerned

with: damaged vehicle disassembly, reassembly, small dent repair, plastic repair, and prep for refinish.

Updates were also made to collision repair and refinish standards, which included new hybrid and electric vehicle safety tasks that are now required for all students in ASE-accredited collision repair and refinish programs.

Additionally, two new task sections were added to the mechanical and electrical components for Advanced Driver Assistance Systems and hybrid and electric vehicle service procedures.

DODGE MUSCLE CARS AGAIN AT TOP OF LIST FOR MOST-STOLEN VEHICLES

The Highway Loss Data Institute (HLDI) has released its list of the most stolen vehicles for model years 2020-22, which the Dodge Charger SRT Hellcat and Dodge Charger HEMI have again made the top of, according to a press release.

Rather than reporting on raw numbers of thefts, HLDI examines claims per insured vehicle year to evaluate the relative risk of each vehicle and includes stolen vehicle parts or for items taken from a vehicle.

The Charger SRT Hellcat experienced theft claims that were over 60 times more frequent than the average for all 2020-22 models. The Charger HEMI experienced claims that were over 20 times higher than average.

Since model year 2011, Charger and Challenger models have made the list of most stolen vehicles, though it’s become more common since then.

2020-22 Charger SRT Hellcat models experienced 25 whole-vehicle theft claims per 1,000 insured vehicle years–an increase from 18 claims for 2019-21 models. For comparison, the 2017-19 model of the Infiniti Q60, had only 2 thefts per 1,000 insured vehicle years.

Other 2020-22 models that were frequently stolen includes luxury vehicles made by BMW, Infiniti, and Land Rover, and three large pickups with powerful engines, as well as some inexpensive models from Honda, Kia, and Nissan. Hyundai and Kia models have also experienced a dramatic increase in thefts in recent years after a viral video exposed many models for lacking electronic immobilizers.

FLORIDA VETERAN RECEIVES ‘RECYCLED RIDE’

The National Auto Body Council’s Recycled Rides program donated a vehicle to a veteran in Daytona Beach, Florida, according to a press release.

With the help of car donor GEICO and collision repair partner Daytona Toyota – Certified Collision Center, a 2015 Ford Escape was given to Nilsson Garcia during an August 26 presentation.

Garcia served in the U.S. Army from 1991 through 1995 and has been without a vehicle since losing his job at the beginning of the COVID-19 pandemic and having to let his car go.

Last year, Garcia began volunteering with charity partner Soldiers’ Angels and was eventually recruited as an intern. He has had to either borrow vehicles or utilize public transportation to get to places he needs to be.

Along with the vehicle, Garcia received a pass to attend a driving school from NASCAR Racing Experience, as did his mentor from Soldier’s Angels as well as the team at GEICO—a NASCAR Premier Partner—and Daytona Toyota, who is an official Daytona International Speedway partner.

Over 3,200 vehicles have been donated by the NABC. This giveaway marks Daytona Toyota – Certified Collision Center’s fifth giveaway they have been involved with.

“We want to be good community partners and give back to those in need,” said Todd Sindel, collision center

manager at Daytona Toyota. “To help a veteran like Nilsson get back on the road with reliable transportation and give back to other veterans is our goal.”

CAR ADAS SOLUTIONS GAINS INDIANA LICENSEE

Car ADAS Solutions has announced Midwest ADAS as its newest licensee, according to a press release.

Located in Merrillville, Indiana, Midwest ADAS is owned by Andy Tylka–who owns body shops in three different regions of Indiana and Illinois–and his brother, Geoff Beckett. The facility will serve body shops in Indiana and Illinois.

Midwest ADAS was first established in February 2023 and received support from Car ADAS Solutions with setting up the facility, such as planning the layout for the lighting and electrical, measuring the concrete, and ensuring they were meeting OEM specifications. The extra help resulted in Midwest ADAS opening within 50 days of securing a location.

Tylka felt the facility was needed due to the prevalence of improper ADAS calibrations present in the industry, which became apparent to him after meeting Car ADAS Solutions CEO Greg Peeters at an AkzoNobel ACOAT Selected North American Performance Group event.

Prior to opening, Car ADAS Solutions also offered Tylka and Beckett the opportunity to attend a week-long training program in Salt Lake City, Utah, as well as training opportunities for their employees.

An open house was held by Midwest ADAS on July 12 for a group of 45 guests that included estimators and technicians from 11 body shops. Attendees were impressed with the quality of the facility, with some telling Tylka it was the best they had ever seen.

Tylka is passionate about ensuring the industry as a whole has the tools and knowledge needed to perform proper ADAS calibrations and is even in the process of creating educational material to share with collision repair facilities.

“As the first standalone facility in Indiana to do this the right way, we’re trying to set the bar in the industry,” stated Tylka. “I feel like we have the responsibility of educating Indiana and the industry on the need for calibration.”

FIX AUTO USA OPENS FIRST TEXAS LOCATION

Fix Auto USA has announced the opening of its first Texas location, Franchise Update Media has reported.

Fix Auto Houston is located at 9350 Cypress Creek Parkway, Houston, Texas, and marks the brand’s entry into the Lone Star state. The facility holds I-CAR Gold certification as well as Automotive Service Excellence certification.

The location’s owner, Kevin Taylor, brings 18 years of experience as an owner-operator, having previously led a team of nearly thirty employees.

Taylor is a second-generation shop owner and grew up supporting his family’s business. Though he first expected to start a career in capital finance, after assisting his father with his business and causing sales to double, he realized he wanted to work in the automotive industry.

Throughout his career, Taylor has won awards such as the Maaco Cup, awarded to the top franchisee in North America. He has also served on various industry councils and holds I-CAR Platinum certification.

“With his gift for the business, tireless innovation and expert leadership, Kevin Taylor is a true exemplifier of what it means to make an impact and buck the system,” said Fix Auto USA COO for U.S. collision Damien Reyna.

CRASH CHAMPIONS ACQUIRES TWO NEW JERSEY LOCATIONS

Crash Champions has announced the acquisition of two locations in New Jersey, according to a press release.

The acquisition of Terry’s Auto Body in Whippany and Towne Auto Restoration in Randolph was finalized on August 25.

With the addition of the two stores, Crash Champions has expanded its total number of locations in the state to six.

“After more than 50 years of serving customers in Morris County, this is a proud step for both collision centers,” stated Michael Melillo, owner of Terry’s Auto Body and Towne Auto Restoration. “We are certainly proud of the hardearned reputation that we built by providing personal and trusted service to the local community.”

DO YOU PERFORM ADAS CALIBRATIONS IN-HOUSE?

THIS MONTH, you will read about how the industry continues to adapt to new challenges. There is an ever-present need to adapt for new tools and equipment, including the need to calibrate ADAS.

The 2022 FenderBender Industry Survey marked a big jump from 2021, with 8% more shop owners reporting their shops are equipped to perform ADAS calibrations in their shop to deal with an increasingly complex vehicle population. That increased another 2% for the 2023 survey.

Is

Yes: 31%

No: 69%

Yes: 29%

No: 71%

NEWELL’S AUTO BODY

1. ALWAYS EVOLVING

Newell’s Auto Body started in 1958, but it has been constantly evolving. In 2023, the shop had just undergone some expansion work.

“That was just completed earlier this year,” says Amanda Anderson, the third-generation co-owner. “It’s been fantastic. So much easier. We’ve got our parts manager in there, and we have tape on the floor for all the parts carts to be organized out of our production building.”

The Newell’s shop is more like a campus, with multiple buildings and segments and specialties. The expansion work comes with some logistical puzzles to put all the right pieces in the correct place so that jobs can flow easily between segments but also have enough room to grow and work on their own.

2. LAY OF THE LAND

The Newell’s campus includes the “lower building,” which is the original shop space. Today, that includes the detail department, as well as mechanical work like alignments, tires, and suspension work as repair jobs require. The lower building includes a fast lane as well, which can tackle smaller jobs like bumpers, mirrors, and dents.

“Back in ‘98 we completed our production building, which is still our main production building now. That is about 12,000 square feet,” Anderson says.

The production building is where much of the collision repair work is done, including disassembly and paint. A third building on the grounds is planned to accommodate an expansion of mechanical work. All the segmentation and planning helps staff focus on big and small jobs separately.

Submit Your Shop

Proud of your shop and want to show it off to your peers? Tell us about it at NEWS@FENDERBENDER.COM

“More helpful now than ever, because he can fly through this smaller stuff,” Anderson says. “We hate making cars wait so long to get the car repaired. Even though it’s a smaller job, it’s great to tell a customer that it will be two weeks.”

3. FOCUSED ON EFFICIENCY

Anderson and husband Art are co-owners of Newell’s. Anderson’s father, Todd, retired in early 2022, and he had run the store after taking over for Anderson’s grandfather. Anderson says it was her father who started the segmentation strategy in the ‘90s.

“A few years after that, they got away from the combo tech thing and made it specialized,” she says.

Recently, Newell’s added bigger drivethru paint booths with embedded mixing rooms. The big plan in the near future will be to expand capabilities in mechanical work. They’re starting to move a technician and large equipment, like an alignment machine, into the “third building.” It’s a logistical challenge, but Anderson says the team has been great.

“I think our biggest strength is our crew, from the managers to the detail,” she says. “Everybody has a lot of buy-in and it is a family business. Not that we’re large, but when you start getting bigger, you focus on efficiency and some stuff that might sound like big business, it can be easy to lose that feeling.”

5 Ways to Combat Rising Paint Costs

Here are a handful of steps you can take to help get your paint and materials gross profit to the benchmark goal of 50% gross profit

Whether we like it or not, it sure looks like the inflation we have seen since Covid started in March 2020 is here to stay. Since then, paint costs have increased approximately 40%. Most insurers in my market in 2020 were paying $36 with the archaic calculation of a dollar amount for materials times each refinish hour per estimate. If we do the math, the current materials rate for my market would be $50.40. Most every shop in the USA has not seen anything close to a 40% increase from insurers since then. Here are a few things we can do to combat this wrongdoing, as the benchmark goal is a 50% gross profit for paint and materials.

1. Paint discounts: National MSOs are receiving approximately 65-72% off list price at the corporate level from paint manufacturers. Otherwise, MSOs’ costs range from 28-35%. Independent shops collectively still hold more market share than the MSOs. So, the paint manufacturers still need us, even though individually we don’t need the truckloads of paint one national MSO may need. The best way to start negotiations is just to pick up the phone and talk with your local jobber. I just went through our negotiation process, and it was well worth the effort. Competition is fierce between jobbers, and don’t be afraid to shop around. I am not in favor of upfront dollars by signing a contract, but in some cases it may be worthwhile. Just be aware of the income tax ramifications in the future and if you sell your shop or switch paint lines mid-contract, you will have to buy your way out. A fair discount with no contract is usually the ideal scenario. I have even seen independent shops create a co-op and approach different quality paint lines for the best service and discounts as an organized group of shops as would an MSO.

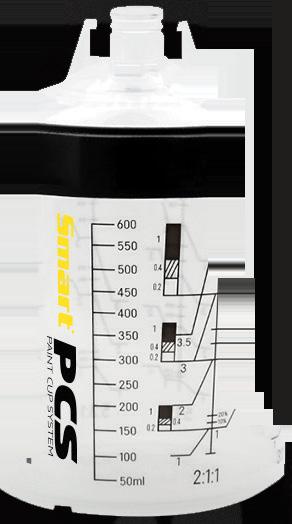

2. Efficient painters: As a rule, if we are spraying waterborne basecoat, we shouldn’t need to mix more than 2 ounces per refinish hour on an estimate. For solvent basecoat, its 2.5 ounces per refinish hour. For clear, we should be able to stay within 2 ounces per refinish hour. Also, some jobs will take more, and some will take less. Example: For a bumper-only tri-coat replacement, it can be nearly impossible to get enough coverage at, say, 5.3 refinish hours, or 10.6 ounces of color vs., say, a mailbox down the side of car. Be sure your mix-

ing scale is tied directly to your estimating system so your painters know how much paint they must work with when they enter the RO. AGAIN, this is just a rule or average, and it’s best to just reach out to your specific paint company for clarification of their recommended usage. Lastly, estimate quality can make or break these formulas!

3. Lack of proper estimating knowledge: This is one of the biggest problems in the industry for overall business profitability. I am still shocked when I am working with some shops on just how pitiful their estimates are. We must write on average of at least 10 refinish hours per estimate. Most management systems will tell us our average, but if not, just track your RO’s every month in Excel and make a graph to see what you’re averaging and trending going forward. As an industry, we love to point fingers at insurers on why we struggle with profitability. Well, that can be a valid point, but many shops owners simply do NOT understand their numbers. Most paint manufacturers offer estimating training, so if you need help, reach out to them. I see different shops working on the same cars and their average refinish hours per estimate can range from 7.5 to 15.5 refinish hours. For the 7.5-hour shops, don’t expect even a “Thank You” card from an insurer.

4. Materials rates and invoicing: If your shop uses Open Shop in CCC or downloads an estimate, the insurer has already put in its rates. Be sure to change the rates to your rates each time. Make them change them back, it’s your shop, not theirs. Never, ever, stop pushing daily for higher rates. So many shop owners just get mired in the dayto-day by working in their business and not on their business. When it comes to P&M calculators, obviously they can be an anecdote to insurer paint caps. They can also be helpful for invoicing on specific estimates. But be very careful not to let this be a Band-Aid for poor estimating. In those cases, we lose the refinish labor that should have been on those estimates.

5. Profit & loss statement: Many times, I will ask a shop if they are making money on P&M. Most always they say, “Yes.” Then when I see their P&L, their first line says, “Gross Sales” and no details of sales/COGs categories. These shops are just running blind and operating off their checkbook. If this is your case, reach out to me and I will.

EMAIL: greg@lorensbodyshop.com

ARCHIVE: fenderbender.com/lobsiger

Evolving Expectations

By Noah Brown Shops are being asked to take on more than ever before. Focusing on three key areas of your shop can help you stay ahead.

Evolving Expectations

Collision repair has faced an incredibly turbulent last half decade. There continues to be growth and new opportunities, but even that presents a new set of challenges that needs to be addressed.

Data from a CCC Intelligent Solutions report published at the end of last year shows repair volume continues to return to pre-pandemic levels, but that also means shops have to keep producing amid technician shortages, still ongoing supply chain troubles and increasing expectations from customers.

Almost all of the challenges that collision repair as a whole faces can be traced back to overarching theme that is summarized best by the 2023 FenderBender Industry Survey: People don’t realize how advanced and adaptable the industry is.

“The world as a whole, including the consumer and insurance companies, believe that we are still fixing cars like we did 30 years ago, or even 10 years ago,” the report says. “An updated

mindset on cost to complete repairs and the necessary procedures required to do so is vital to this industry moving forward successfully.”

Most of the challenges that the industry faces today aren’t new. I-CAR President and CEO John Van Alstyne says many of the “new” technologies that are present in cars today, such as different ADAS systems, have been around in some form for 20 years or so. Instead, the difficulty comes from the fact those technologies are now reaching a critical mass and have become prevalent in everyday repairs. In order to fix cars, shops have to fix those devices.

“There's been an acceleration of change,” Van Alstyne says. “The scale is getting to a point where decisions have to be made as to how we really deal with these technologies effectively because it's impacting virtually every repair today.”

Addressing the key areas of tools, your technicians and expectations can set your shop up for success, both now and in the future.

The Evolving Vehicle

Miles Driven

In the top-10 U.S. cities by population, miles driven are up 4% from pre-pandemic levels.

+4%

Drivers on the Road

An all-time high of 231.6 million drivers took the road in 2020—projections show 243.3 million in 2023

Cars on the Road 284 million in 2022

284,000,000

Length of Rental 18.2 days in 2022, an increase of three days over 2021

3+ Days

Complexity of Vehicles

45% of all vehicle systems are expected to be powered by semiconductor-based chips by 2030

45%

Weight of Vehicles

The average passenger vehicle in the U.S. weighed 4,200 pounds in 2021, an increase of 1,100 pounds from 1981.

231,600,000 +1,100 lbs

Technicians

Auto shops across the country face a plethora of challenges, but the tech shortage remains at the top of the list.

Data from the 2023 FenderBender Survey shows the industry will need 113,000 new technicians by 2026, but it’s not likely that number will be met. In 2022, there were 4,487 new techs entering the field to fill 35,239 open positions.

Across all regions surveyed in the survey, around 42 percent of respondents said the tech shortage was their No. 1 concern, an 8 percent increase from last year and the second year in a row that the shortage ranked first.

According to Steve Wurtz, owner of Blue Ash Auto Body in Cincinnati, Ohio, the shortage isn’t necessarily about the lack of an opportunity for prospective technicians. In fact, he says it’s quite the opposite.

“They get an opportunity that is unbelievable,” Wurtz says. “Within five years of being out of vocational school, they can be making $100,000 a year or better. And they have the knowledge to where, as the indus-

try grows and more and more shops are coming on board, they can be the ones going into a shop and leading it in the future.”

In order to maximize that opportunity, though, Wurtz says shops need to make continual investments in their employees. Van Alstyne agrees and says that shops need to stop comparing their own job openings against just other shops' – instead, they need to really focus on making their shop an attractive workplace regardless of industry.

“The general public has too many options before them in terms of where they want to spend their life journey working.

There are a lot of benefits to collision repair, but not everybody sees that,” Van Alstyne says. “For the individual business owner, it's about stepping up your game. Make those strategic investments that help in the development and the retention of employees.”

One of the most sustainable ways to do that is through industry trainings. Investing time and resources into your technicians both shows that your employees are

valuable to your business and helps your shop stay up to date on new OEM requirements, trends and other technologies.

Data from the 2023 FenderBender survey shows that 56 percent of respondents attend industry-specific trainings at least once a year, and nearly 64 percent of respondents say at least one member of their team attends trainings at least once annually.

On the other side of that coin, though, 11 percent of respondents says no one from their shop ever attends industry-specific technical training, and for 14 percent, their shop doesn’t pay for any training.

Shops need to do what they can to invest in their employees in order to be an attractive employer for prospective employees out on the job market.

“It's incumbent on businesses to figure out how to stay abreast of the developments in the industry,” Van Alstyne says. “That includes repair methods and technology, but it also boils down to being able to retain people.”

Tools

Wurtz has been the owner of his shop since 1976. Over the last 50 years, he’s expanded his shop several times to account for the growing needs of his business. Even now in his 70s, he’s still investing in the shop’s technology.

Right now, he’s looking into different options for an ADAS calibration setup.

“My kids are like, ‘Dad, when are you going to retire? Are you done?’” Wurtz asks. “And here I'm taking a mortgage for another million dollars to find another building.”

Though his shop has expanded significantly, ADAS is still something that his shop has to subcontract out to other shops.

“Call me a control freak or whatever,” he says. “I'm not comfortable with that.”

Shops across the country are also placing more emphasis on being able to do ADAS repair in-house. Thirty-one percent of respondents to the industry survey say their shop is equipped to perform ADAS calibrations, a 10 percent increase from just two years ago.

It’s not just ADAS, either. Scan tools are also quickly becoming essential as more

OEMs start requiring them to be certified to perform repairs on their vehicles. The survey shows that the number of shops that own two or more scan tools has risen steadily over the last couple of years, now sitting at 46 percent. Slightly less than twothirds of respondents say they use a thirdparty service such as asTech for scans.

Almost every part of the business, from the actual repair work to how you communicate with customers, is undergoing a massive technological revolution. Wurtz says investing in the tools necessary to perform at a high level is no longer optional.

“It is time to get serious and invest in your business,” he says. “Put your profits back into the business.”

Tech & Tools

Insights from the 2023 FenderBender Industry Survey Report

As vehicles become more advanced, tech and tool considerations become more important than ever. Whether it is bespoke tools required from OEMs or equipment necessitated to perform ADAS calibrations, survey respondents were asked to evaluate how they plan and budget for technology and tools.

Budgeting

Asked what percentage of their annual revenue is reserved for technology, tool, and equipment purchases, a majority said they created a budget:

58% Yes

42% No

ADAS Calibrations

The 2022 FenderBender Industry Survey recorded a sharp jump in this area as 8% more shop owners said their shops were set up to perform ADAS calibrations in comparison to 2021. That number rose again slightly in 2023 as more shops deal with the reality of more “computers on wheels” rolling across their floors.

Is your shop equipped to perform ADAS calibrations? 2022

29% Yes

2023

31% Yes

Scan Tools

In another area of advancing vehicle technology, shops are making investments in owning OEM scan tools . The number of shops that reported owning just one dropped by six percentage points in 2022 compared to the 2021 FenderBender Industry Survey, and dropped again in 2023 while there were increases in shops that owned three or more.

How much does your shop charge for diagnostic scans?

53% One full labor hour

21% Less than one full labor hour

26% More than one full labor hour

How many OEM scan tools does your business own?

21% Zero

33% One

Does your shop utilize a third-party service for scanning services?

(e.g., asTech, dealership outsourcing, etc.)

Does your business have challenges being reimbursed for diagnostic scans? There was a big shift here as 52% of shops answered yes to this question in 2022.

63% Yes

37% No

41% Yes

59% No

EXPECTATIONS

Other Technology

While year-over-year trends are mostly flat, the five-year look for tech and tool trends shows a big shift in the industry’s adoption of certain capabilities. The number of shops able to repair aluminum components has jumped by nearly 20% while carbon fiber is up 6%.

Does your business have the capability and equipment to repair aluminum components?

80% Yes

15% No

5% No, but plan to be aluminum-capable soon

Does your business have the capability and equipment to repair advanced structural composites or carbon fiber components?

Which of the following does your business utilize?

Electronic management system

72% No

18% Yes 10% No, but plan to be equipped for advanced composites soon

Electronic estimating system

97%

Customer satisfaction (CSI) software

42%

Customer relationship management (CRM) software

16%

Key performance indicator (KPI) tracking software

40%

Electronic parts procurement software/program 64%

Accounting software such as QuickBooks

60% 70% 0 10 20 30 40 50

*Respondents were asked to select all that apply

Technology Trends

Does your business use an OEMapproved refinishing system?

95% Yes

5% No

What type of paint is used in your shop(s)?

41% Solvent-based

28% Waterborne

10% Both

Expectations

There are more cars on the road than ever before in the U.S., hitting 284 million in 2022. These vehicles are more complex than ever, too – data from the industry survey shows just under half of all vehicle systems are expected to be powered by semiconductor chips by the end of the decade.

Despite all of that and how highly skilled collision shops need to be, the perception of what goes into a repair has remained dreadfully archaic.

“One of the biggest misconceptions is that the repair process is simple,” the survey says. “Many people think that we are just fixing some dents and putting some paint on their vehicle. Repairs are increasingly complex.”

Consumer behavior has been forever changed in a major way post-pandemic. People are increasingly impatient and requiring more accommodations and updates throughout a repair process despite being aware of still-ongoing labor and supply shortages.

And if that weren’t enough, insurance companies are becoming increasingly stubborn in negotiations, sometimes flatout refusing to pay for OEM-required repairs because they deem it too expensive. New estimating technologies that rely on AI are exacerbating the problem, too.

“Everything they're doing to try to make it easier on the insurance industry is not making it easier on us,” Wurtz says. “Estimating companies are now coming out with virtual reality where you take a photograph of the vehicle and then you’ve got an estimate. It’s going to save theinsurance companies a lot of time and money, but that doesn't mean you’re going to get an actual blueprint on how that car has to be repaired.”

All of the expectations facing a modern repair shop can be overwhelming, and

Wurtz says the state of the industry has gotten to a point where having a dedicated team approach is no longer optional. Shop owners have to change their own expectations.

“People are going to have to realize they can't do it on their own,” Wurtz says. “You have to develop a team to work with within your facility and be able to rely on them, trust them and let them run with the ball.”

Data from the survey shows at least 68 percent of respondents had some form of team approach when repairing individual vehicles, but Wurtz says that team mentality approach needs to be taken to the macro level management of the entire shop.

Having team members delegated to handling important tasks — such as documenting procedures and steps taken during a repair to have a hard paper trail when preparing to negotiate with insurance or making sure customers are getting updates on their vehicles in a timely manner — is crucial to make sure your shop is meeting the growing expectations of your customers, insurance and other stakeholders.

Looking Ahead

Collision repair is an incredibly resilient industry, and that resilience is being tested. More than ever, industry professionals need to keep up to date with new trends, tools and technologies to remain relevant. Though it may seem daunting, Van Alstyne says the bottom line for the industry is the same.

“The collision repair industry is in the business of fixing cars, right? And if you're in the business of anything, businesses continuously evolve and change. You have to continue to make adjustments as you go into the future with any business,” Van Alstyne says. “It’s not just one magic silver bullet. It's just stepping up

our game collectively as an industry and as individual business owners.”

Collision repair will always be necessary, and Wurtz says there will always be opportunities for those that invest. That investment is just no longer optional.

“There are opportunities out here that are just enormous,” he says. “You have to be paying attention to what's going on in the future.”

exclusive seller for Dynacoat, the perfect match. But that’s not all — our dedicated team also provides the brands, training and reliable delivery you need to serve your customers.

FenderBender’s

Show Preview

The 2022 SEMA Show brought an impressive 30% increase in exhibit space and 35% increase in the number of exhibitors from 2021’s soft return after canceling the 2020 event for the COVID-19 pandemic. Each year, the Specialty Equipment Manufacturers Association (SEMA) Show draws thousands of exhibitors, collision repair shop owners, technicians, hot rodders, and enthusiasts.

Where else can collision repairer shop owners, managers, and technicians check out the latest high-level custom car reveals from their favorite builders, catch up on the latest education, and attend co located events such as the MSO Symposium on Monday or the Collision Industry Conference on Tuesday? Get a first look at the cutting-edge technology in action on the show floor.

The SEMA Show floor is massive, so FenderBender is here to guide you through this year’s highlights. The 2023 SEMA Preview highlights available educational seminars and featured vendors. All show information is subject to change, so please visit semashow. com for all updates and information.

FOLLOW US AT THE SEMA SHOW

How to stay updated on everything SEMA through social media and online

Can’t make it to SEMA this year, or want to be in too many places at once during the show? In order to give everyone an opportunity to see what is going on, FenderBender will cover the SEMA Show all week long. The coverage will include news items throughout the week, product releases, award winners, event information, and other SEMA happenings. For a behind-the-scenes look at what it’s really like to attend the show, follow FenderBender’s website and social media accounts.

SEND US YOUR COVERAGE

At the show and snapped a great picture or took a video you want to share with @FenderBender? Tag us on Facebook with what you got @FenderBenderMag.

@FenderBenderMag

The top stop for almost every bit of coverage throughout the week. Like and follow “FenderBenderMag” on Facebook for daily photo albums, events, and news

@FenderBenderMag

Photos from the week will be posted during the show for a behind-thescenes look at everything SEMA.

BY THE NUMBERS

A closer look at the statistics that comprise SEMA

70,000 buyers at the show 85%

2,000+ exhibits

Percentage of people in a Forbes Insight study who reported they build stronger, more meaningful business relationships during in-person meetings and conferences

The Upper South Hall is 464,658 square feet and is approximately 1,690 feet end-to-end

3,300 media representatives representing online digital and print publications

NEW PRODUCTS SHOWCASE MOVES TO NORTH HALL

Visit the New Products Showcase, relocated this year to 30,000 square feet in the North Hall, to check out thousands of the latest products in one location.

Use the SEMA Show mobile app’s “Product Scanner” feature to scan and download product photos and exhibitor information that will remain on your SEMA Show app long after the 2023 show has ended.

HOW IT WORKS

Browse Products

Take a look around the showcase to view products you have heard of but never seen, and discover products new to you.

Scan Products

Either scan products using the SEMA Show’s app or a provided scanner to acquire information.

Capture Product Information

Access production descriptions, images and exhibitor booth numbers through the app or through printouts.

For more information on what exhibitors and products will be showcased, visit semashow.com

SEMA SHOW PREVIEW: Q&A

TOM GATTUSO SEMA Vice President of Events

There are always big features being added to the jam-packed programming at the SEMA Show. Tom Gattuso, vice president of events for SEMA, lays out the landscape for those in the collision repair business and what you can look forward to at this year's event.

FenderBender: Can you speak to the size and strength of the show in these past few years?

Tom Gattuso: We’re very pleased with the progression that the show has made since we had to cancel for COVID. In 2021, the show was the highest-attended trade event in the country. And it looks like we’re on that path again for 2022, but for 2023, we’re seeing really strong support.

Our registration numbers right now and participation levels are stronger than they’ve been since the pre-COVID timeframe. That’s really a testament to the strength of the industry right now and the support from the industry so they can all gather and really start to chart the course of what the future can look like.

FB: What new attractions or events can you highlight for this 2023 SEMA Show?

TG: The show is always changing, and i think that’s one of the most exciting parts of producing it. We’re going to see all new activations in the front of the show. We’re going to showcase companies who haven’t been there in the past, and they’re going to be doing some vehicle displays.

Literally, when you step on the grounds on the Convention Center, you’ll be able to hear and see and smell and really feel the industry at work, and it really does get you geared up for an incredible four days of doing business.

That said, the show will start with the kickoff breakfast. We’ve got new entertainment for that, a new motivational message there. At the same time, it’s where we award all the new products winners for the year. That’s a not-to-miss event, because it starts the show off on a really positive note by showcasing the innovation and having a really strong message of perseverance and progression for the industry.

And then, we’ve got a great new products showcase in the works. That’s going to have displays in almost 30,000 square feet, which is bigger than it was last year. We enjoy that because it really is a great place for attendees to be able to come to the show and see a lot of innovation in one place, and they can start to schedule the exhibitors and companies they want to see from there.

We also have a really strong education program. We're featuring a main stage

experience that’s going to have some really notable speakers, Tim Tebow being one of those, who are going to share some best practices and really motivate small business owners on how they can tackle challenges.

We have some really great education tracks that are applicable to the collision repair industry. one of the tracks is “Inside the Shop,” which is really designed for aspiring technicians and shop owners to create some education around what’s going to be happening in the future. We’ve got a track for aftermarket updates and future trends. There's one for small business strategy. There’s a track for vehicle technology and electric vehicles—I think electric vehicle are really a focus right now for the collision repair industry because they come with a brand new set of requirements and challenges, and you’ll be able to get up-todate information on that.

And for the small business owner, we do have a legislative and regulatory track that’s going to really speak to the latest developments in emissions compliance and certifications, so you’ll be able to know the latest trends and advocate for change in the industry.

We’ve got a Future Tech Studio, which is a cool area that’s an evolution of what we’ve done in the past with SEMA electrification. We’ve gathered new alternative fuel sources and really, our goal is to show people all of the options that you have for propulsion and give people a glimpse of what the next five or 10 years might look like for vehicles on the road.

Our SEMA Garage will have an area where we’ll focus on ADAS and how you can calibrate vehicles to get them either back to factory spec, or if you’ve done modification, what you can do to lift a truck and have all the safety equipment still work. That’s an emerging thing we’re really focused on. They’re also going to showcase some of the emissions progress we’ve made and new trends there, as well as featuring the product development center that the SEMA Garage represents.

It’s going to be in the same hall as our tools and equipment and collision repair sections. So it will be an area where you’ll be able to spend some time in the Upper South Hall and really get some benefit from the show.

FB: More broadly at the show, are there any other highlights?

TG: One of the benefits of a face-to-face event is the ability to network with the industry that you’re in, and we’re seeing tremendous support from the collision repair part of our industry. When you come to the show, you want to have a plan to meet with some colleagues, not just from a buyer-seller relationship, but really peer-to-peer and share some best practices that way.

And we’ve got things set up for that, like our kickoff breakfast or Thursday banquet or some of the education events that SCRS and I-CAR are doing. There’s also an opportunity to go to our collision repair stage, and that’s kind of a joint effort between I-CAR and SCRS, and we’ll share some collision repair trends there as well.

I’d say that really embracing the industry that you’re in and finding other like-minded people to share some of the challenges and innovation that everyone is coming up with together, because that type of thing really propels the industry. We’re honored as The SEMA Show to be able to showcase the things that can gather people so they can have that networking and have that interaction, and go out and propel the industry forward.

FB: Seeing the presentations of vehicle on the show floor is great, and of course the companies that use them as a way to showcase products.

TG: It’s funny, because a lot of times people will think of SEMA as a car show. And really, the cars are the canvas on which our industry paints. It’s the perfect place to be able to showcase your products and services that you provide. While you’re looking at a beautiful piece of artwork on a vehicle, you start to notice the things that really resonate with your section of the industry. You look really closely at how welds are made, where most people at a car show would look at it differently.

We’ve got some of the best builds in the world, but the amount of heavily focused innovation that’s going on there and to watch people interact with the vehicles on display is really fun to watch.

Answers have been lightly edited for clarity.

SEMA FEST IS AN EXCITING TWO-DAY FESTIVAL CELEBRATING CAR CULTURE

In previous years, the SEMA Show opened its doors to the general public for fun and features on Friday of the event week.

In 2023, SEMA Show organizers are bringing more to the public for an all-encompassing experience known as SEMA Week. This includes a brand-new event called SEMA FEST, which is a two-day festival with music, food, and of course, automotive enthusiast fun.

SEMA Fest takes place at the Las Vegas Festival Grounds, which is adjacent to the Convention Center, where the SEMA Show happens. The inaugural SEMA Fest has musical acts including Imagine Dragons, Wiz Khalifa, and Ludacris.

In addition to music, SEMA Fest promises "ride-and-drive" features, a consumer marketplace, drifting displays, and more. The event is Nov. 3 and 4.

3:00 PM 4:00 PM 5:00 PM 6:00 PM

Educational Sessions

During the SEMA Show, there are numerous offerings that attendees should be sure to take advantage of. Here’s a look at some of the seminars that are available. Sessions and times are subject to change, please visit semashow.com for current information and to learn about more seminars and events.

MONDAY — 10/30

TUESDAY — 10/31

WEDNESDAY

12:00–1:30 PM

Death of the Estimator Role

12:30–1:30 PM

Marketing Jedi Training: All Levels Welcome - From Padawan to Master

12:30–1:30 PM

EV: Pulling Together the Critical Puzzle Pieces

1:00–4:00 PM

1:00–4:00 PM

2:30–4:00 PM

Phone Etiquette and the Power of Mystery Shopping

2:30–4:00 PM

Honey, You Shrank the Dents! Smaller Dents, Bigger Dollars with “Pull to Paint” Approach

2:30–4:00 PM

Doing More with Less: Operationally Addressing Workforce Shortages and Growing Backlogs

3:00–5:00 PM

Further Opportunities to Grow

The SEMA Show holds many other educational sessions. Below are some other tracks of seminars available during the week. Further information on the sessions within the tracks can be found on the SEMA Show website.

Aftermarket

for Today, Presented by Dale Carnegie

Legislative and Regulatory

Main Stage Experience

Sales and Marketing

Small-Business Strategy

TIA

Vehicle Technology and

Accudraft Paint Booths

Booth #33071

accudraftpaintbooths.com

This year at the 2023 SEMA show, Accudraft will display several of our products for the automotive repair industry. The showcase piece being our TITAN booth, perfect for any refinishing that your shop will do. Coming standard with 15HP motors, the ability to move 20,000 CFM, as well as produce 1.5 million BTU of heat through its direct fire AMU. Also on display is the newest additions to the booth; Vetrino glass doors and FOCUS control panel. The new doors and control panel comes standard on the Titan but are available as an upgrade on our premium booths**. Also being showcased is our cloud-based Accudraft LIVE program, which is a must have for any shop owner. Measuring real time analytics of the booth’s performance, giving the owner actual cost breakdowns per booth, per location. Driven by the 15”color touch screen FOCUS panel, live also gives the shop the ability for remote diagnostics and much more. At Accudraft, we specialize in the design and manufacturing of high quality paint booths across a multitude of industries. From automotive, truck, aerospace/defense, we offer a diverse range of standard and customizable solutions for any application. We pair the latest in booth technology and innovative solutions with quality manufacturing and service to help drive your business for the future. At Accudraft, we firmly stand behind saying “we have a solution for every industry”.

Stop by our booth to find out what it means to #goaccudraft!

Fuji Spray Auto

Booth #34199 fujisprayauto.com

Building on a foundation of 35+ years of spray expertise, Fuji Spray Auto features compressor spray guns that align with the Fuji Spray legacy of excellence, while offering the collision repair and car-refinishing industries high-performance and versatility at a competitive price.

Fuji Spray Auto is committed to delivering spray professionals the optimal combination of comfort and efficiency, reducing time per job in the booth and maximizing material savings.

Fuji Spray Auto is a division of Fuji Spray, a Canadian-based designer and manufacturer of exceptional spray equipment used around the world. Fuji Spray’s best-in-class spray equipment delivers a perfect finish every time for a wide range of finishing industries, including automotive, woodworking, resurfacing and sunless tanning. This diverse experience is backed by unparalleled customer service, which has made Fuji Spray a leader in the global spray equipment industry.

The Perfect Finish Starts With Fuji Spray®

At Fuji Spray, we care about the finish, and we start by focusing on the customer experience.

We care about making top-of-the-line, easy to use spray system that deliver a perfect finish every time. Our products are used for a wide range of finishing industries, including woodworking, automotive refinishing, marine, bathtub & kitchen resurfacing, and sunless tanning.

We care about your total satisfaction - in our products and our customer service. We provide training, product support and helpful insights that will help you achieve the best results with our equipment.

You’re part of the Fuji Spray family and we want to help you finish strong.

Hunter Engineering Co.

Booth #42017 Hunter.com

At SEMA 2023, Hunter Engineering Co. will once again exhibit a wide range of innovative, high-tech wheel and tire service equipment, designed and built in the U.S.

Additionally, SEMA 2023 will feature the introduction of a major new Hunter product designed to meet a critical need, now and in the future: Ultimate ADAS™️.

“We named it Ultimate for a reason,” says Ryan Gerber, ADAS product specialist. “It’s the fastest and most precise ADAS calibration system available.”

The Ultimate ADAS™️ system is an innovative method of eliminating error-prone manual layouts common to static ADAS calibrations.

“Ultimate ADAS™️ combines Hunter alignment technology with an efficient and easy-to-use guided target placement system for around-thevehicle coverage,” Gerber says. Gimbal-mounted lasers are the key component, replacing the inexact guesswork of strings, plumb bobs and tape measures to cut setup time by 70 percent for some procedures.

The gimbals and onscreen guidance make target placement much more precise by automatically compensating for non-level floors, monitoring for placement errors, and confirming accuracy with laser measurements each step of the way. Easily decipherable paper and digital confirmation of targets and placement is included and available via the HunterNet®️2 customer portal.

“Calibrations aren’t necessarily difficult, but setting up can be very time-consuming, because it absolutely has to be accurate,” Gerber says. “With this new system, techs won’t need to learn geometry on the fly with strings and plumb bobs, since the lasers will locate the precise spots almost instantly.”

Ultimate ADAS™️ is currently exclusive to Honda and Acura dealers. To see the future of ADAS in action, please visit Hunter Engineering in booth #42017.

KECO Body Repair Products

Booth: #32201

kecotabs.com

KECO Body Repair Products is a distinguished name in the auto collision repair industry, specializing in Glue Pull Repair (GPR) and Paintless Dent Repair (PDR) tools and components. At the heart of KECO’s mission lies a fervent passion for advancing the art of auto collision repair. KECO excels in tools, techniques, and training, all revolutionizing the repair process with the least invasive methods available. Celebrating 60 years of manufacturing expertise, unrivaled postpurchase support, and advanced in-house training options, KECO ensures your success and stands by your pursuit of the highest quality repair for your customer.

KECO Body Repair Products is returning to SEMA 2023 with added GPR product innovations designed to help technicians and body shops make clean and efficient repairs. The L2E GPR Collision System is the flagship work cell built on the foundation of KECO’s 2021 New Product of the year winner in collision & refinish. KECO’s L2E will be complimented by a complete lineup of GPR systems and tools designed to meet the needs of those looking to correct damage from roughout to a flat finish.

Auto body professionals are invited to experience KECO’s innovative solutions firsthand at SEMA Booth #32201, where they can engage with experts, try GPR techniques, and gain insights into implementing the least invasive repair methods in the collision industry.

To explore KECO’s comprehensive range of GPR tools, tabs, glue, and accessories, visit their official website at kecotabs.com. For inquiries, personalized demonstrations, or technical support, the friendly and knowledgeable customer service team can be reached at 888.532.6822 or sales@keco.com.

Polyvance

Booth #34087 polyvance.com

Polyvance will be bringing a brand-new product to SEMA this year! Visit booth 34087 to see plastic welding demonstrations with the industry-leading Nitro-Fuzer nitrogen plastic welders, as well as the new 6180 Mini-Fuzer. The Mini-Fuzer is Polyvance’s first consumer grade hot air plastic welder, filling the price gap between their airless plastic welders and Nitro-Fuzer nitrogen plastic welders. Most professional collision repair shops see the benefits of using a nitrogen plastic welder, but not all of them can afford one. The Mini-Fuzer allows these shops to make stronger, faster repairs than airless welding or two-part adhesives can offer. Polyvance’s plastic welders and variety of welding rod give the user the ability to repair virtually any damaged plastic part.

Since its founding in 1981, Polyvance has been exclusively focused on plastic repair and refinishing. As a result, the company has created a line of products to help shops refinish plastics, including cleaners, adhesion promoters, primersurfacers, and specialty coatings. Their Bumper & Cladding Coat Adhesion Primer is one of the industry’s most popular adhesion coatings, helping paint stick to raw polypropylene OEM replacement bumper covers since 2003.

Polyvance leads the industry in plastic repair training with hundreds of online videos as well as instructor-led, hands-on training courses. The Polyvance University portal offers online, self-paced training. Combining this online training with some hands-on experience and repetition using one of Polyvance’s welders will enable practically anyone to repair damaged automotive plastics. Polyvance has the equipment, products, and knowledge for shops looking to repair more plastic.

ProColor Collision

Booth #32255

Collision Repair & Refinish – South Hall Upper procolor.com

At this year’s SEMA show, ProColor Collision, along with NOVUS Glass, will showcase its leadership in the collision repair and automotive glass industries. Also, at the same booth, one can experience NOVUS Glass’ superior glass repair and replacement advantage!

Since 2001, ProColor Collision has been disrupting the North American collision repair industry with its strong focus on training, technology, and talent. We offer independent body shops the opportunity to join one of the largest and fastest growing automotive aftermarket networks in the world. We leverage established national and global partnerships with insurers, fleets and suppliers to help drive business to our franchisees.

Stop by our booth to witness firsthand how ProColor Collision is supporting its franchisees in reinventing their operations from their traditional format so that their teams remain on top of new automotive technologies and operational strategies.

At our booth, you will also witness the latest innovations in glass repair and replacement as NOVUS Glass showcases the opportunities of this rewarding aftermarket business. Also, learn more about the fully equipped NOVUS Glass mobile van, which allows franchisees and their teams to repair or replace automotive glass wherever their customers are located.

For more information or for franchising opportunities, please visit procolor.com or novusglass.com.

*ProColor & NOVUS are part of Fix Network World, the leading global automotive aftermarket services network. Our family of brands spans over 2,000 points of service internationally. In the United States, Mondofix, Inc. has granted an exclusive license to 79411 USA LLC to the FIX AUTO brand.

asTech®️ Driven by Repairify™️

Booth #34193 astech.com

asTech®️, based in Plano, Texas, is the leading global provider of comprehensive remote and local diagnostic, calibration, and programming repair solutions to the automotive aftermarket. asTech®️ provides cutting-edge, certified and AI driven repair solutions using OEM and OEM Compatible tools to ensure safe and accurate repairs based on OEM data driven procedures. Through its’ patented Rules Engine and proprietary software tools, asTech®️ provides virtual ASE-Certified Master Technician warrantied services direct to its’ customers in 44 countries in addition to exclusively managing the Launch Tech and Autel remote service offerings. The asTech®️ virtual ASECertified Master Technicians provide repair solutions for vehicle trouble codes remotely along with real-time assistance to shop technicians at the vehicle when needed. With the asTech®️ All-In-One, asTech®️ has developed and delivered the most comprehensive single device solution for remote and car side diagnostics, calibrations, and programming in the global aftermarket.

SATA by Dan-Am Company

Booth #31017 satausa.com

This spray gun is a universe unto itself SATA, presents a special edition of its wellknown premium spray gun: The SATAjet X 5500 universe.

Talk about being on the pulse of time: instead of a “normal” present as a bonus, every painter who owns a SATAjet X 5500 universe gets access to a new SATA universe. This specially designed online world is regularly fed with new content and promotions. Members can take part in competitions and receive exclusive news and information. You’ll be the first to find out about new products – just look under “Sneak Previews”.

This online experience is exclusive to anyone who owns a SATAjet X 5500 universe and has secured a place on the website using their SAL number (SATA Authentification Label). This SAL number is a special SATA feature: Usually, the buyer of a product can check online whether they have purchased an original SATA product. In case of this new special edition, the number also opens the door to the SATA universe – and can only be used once to register a user.

Jari Pfander, Head of Marketing & Communication at SATA, explains: “We want to give something back to our painting specialists. Something that goes beyond a simple “thank you for your loyalty”. Anybody who registers for the SATA universe may well feel part of something special. And they are indeed privileged, for example when it comes to first insights of upcoming products.”

SUN Collision Repair Information

Booth #32017 (Snap-on) suncollision.com

SUN ®️ Collision Repair Information provides complete, accurate data that auto body shops can trust to repair any vehicle, in any condition, with maximum efficiency. The software delivers both collision and mechanical repair information together through a single login, helping technicians fix cars faster with more confidence.

Driven by its powerful search engine, 1Search Plus, SUN Collision provides on-demand access to current OEM repair specifications and procedures for all makes on a user-friendly, card-based dashboard. The software provides essential repair information for body and frame, paint and finish, materials, and more. Plus, it simplifies repairs involving complex electronics and Advanced Driver Assistance Systems (ADAS). Through the software’s ADAS Quick Link button, technicians can quickly find vehicle-specific ADAS information needed to diagnose, repair and calibrate damaged components, including sensors, cameras and radar systems.

To speed electrical diagnostics and repairs, SUN Collision’s award-winning interactive wiring diagrams feature trace-to-trace capabilities and exact diagram jumps that make it easy to locate and troubleshoot specific wires. Technicians can navigate directly to specific component information without a secondary lookup.

SUN Collision’s latest innovation is the exclusive Repair Package, which significantly expedites the blueprint process for body shop estimators. It eliminates the tedious manual research needed for estimates, instantly generating a comprehensive package with repair procedures, illustrations, diagrams, and associated OEM part numbers. It integrates with estimating platforms, uses CIECA standards for efficient data transfer, and supports customization.

SUN ®️ is a brand of Snap-on®️ Incorporated and headquartered in San Diego, California. For more information, call 877-840-1973 or visit suncollision.com.

US Autocure

Booth: N/A usautocure.com

Speed. Efficiency. Quality. Profitability. US Autocure engineers infrared curing systems designed to meet the needs of many industries, including automotive collision repair. US Autocure systems are designed by a team of engineers and autobody specialists who understand the need for quality and efficiency.

US Autocure systems are designed to allow autonomous operation, semi-autonomous, or manual control. Operational control is maintained through the interface and can be programmed by the operator or recalled as a previously defined recipe. The user has manual control over surface temperature, panel angles, tracking speed, and optimum surface temperature.

Speed and light exposure are controlled by either values programmed manually by the operator, or by the pattern and formulations for the given application. As the carriage moves across the substrate, laser IR sensors record the temperature of the material. The carriage speed is automatically controlled to maintain the optimum temperature. Optimum temperature for the substrate is approximately 205 degrees Fahrenheit, but optimum exposure to IR will be dependent on the paint selected. IR exposure will be measured in a relative scale to the sensor used.

US Autocure systems are fully-compliant to US Fire Prevention Standards and have earned Class 1, Div 2 certifications. Compliant US Autocure systems do not require enclosures and can be retrofitted to a wide range of existing spray booths and environments.

Proudly offering American design, build, installation and support, US Autocure will provide industries with cost effective, efficient, profitable solutions through manufacturing of the world’s highest quality automated curing solutions.

RESOURCE GUIDE

Accudraft

Booth #33071 accudraftpaintbooths.com

asTech (Repairify™️)

Booth #34193 astech.com

Fuji Spray Auto Booth #34199 fujisprayauto.com

Hunter Engineering Co. Booth #42017 Hunter.com

KECO Body Repair Products

Booth: #32201 kecotabs.com

Polyvance

Booth #34087 polyvance.com

ProColor Collision

Booth #32255 procolor.com

SATA

Booth #31017 satausa.com

SUN Collision

Booth #32017 suncollision.com

US Autocure

Booth: N/A usautocure.com

MAINTAINING STRONG RELATIONSHIPS WITH INSURERS

Whether or not you’re in the DRP world, insurer relationships are key to good business

RYAN DEMARCO, vice president of All County Collision in Eustis, Florida, knows a thing or two about direct repair programs (DRPs).