NOAH BROWN

DRIVER’S SEAT

Reader’s Choice recognizes exceptional OEM parts dealers

ON THE SCENE

AkzoNobel builds Momentum at Anaheim Event

Elite Estimatics brings remote expertise to shops 18 LIGHT HITS

The latest stories from around the industry

19 NUMBERS

Growing insurer influence now the no. 1 concern in Industry Survey 20 SNAP SHOP

Windham Body Shop prioritizes what’s best for its customers 40 FINANCE+ OPERATIONS

Optimize Paint and Material and Sublet Gross Profit

Quality photography helps tell the repair story and improve your bottom line

48 FENDERBENDER READER’S CHOICE

Communication between you and your OEM parts supplier is vital to your success

62 CASE STUDY

Increase efficiency with remote scanning

Take time to fine-tune your

Each year, the FenderBender Reader’s Choice recognizes the best of the best.

WITH ALL THE CHALLENGES to meet the demands for increasing repair speed and accuracy — whether from customers or insurance company KPIs — the role of your OEM dealer parts departments can't be denied. It's those dedicated wholesalers who go the extra mile in ensuring the right parts are delivered on time that FenderBender recognizes each year with the Reader's Choice. This designation is reserved for the best in the collision repair wholesale parts industry.

The parts department is the backbone of the dealership, and high performance is critical to its success, even if the sales or service department often get the accolades. Each year, FenderBender readers are surveyed on who the best, preferred, and most trusted wholesalers are in their market, allowing us to recognize these deserving teams.

In this month’s special section, learn from industry pros how enhancing communication across the collision repair OEM wholesale parts ecosystem benefits all participants. Thin margins make profitability challenging, which Collision Advice Owner Mike Anderson says is causing more wholesalers looking to exit the wholesale business. Shops can better work to keep their wholesale partner profitable by, for example, limiting returns and return delays.

“You think you had cycle time challenges during COVID?” Anderson asked. “Well, if more wholesalers leave the business, cycle times will increase. Whether you're a shop or you're an OEM, I think we must stop and say, ‘What am I doing that could be contributing to the demise of a wholesale parts vendor?’ Because that's not good for anybody.”

JAY SICHT EDITOR-IN-CHIEF jsicht@endeavorb2b.com

Chris Jones VSRG Editorial Director

Jay Sicht Editor-in-Chief

Peter Spotts Associate Editor

Kacey Frederick Assistant Editor

Emily Kline Special Projects Editor

Leah Marxhausen Special Projects Editor

Drew Bryant Contributing Writer

Tiffany Menefee Contributing Writer

Greg Lobsiger Contributing Writer

Noah Brown Contributing Writer

Lindsey Gainer Contributing Writer

Todd Kortemeier Contributing Writer

Steve Trapp Contributing Writer

Jordan Beshears Steve’s Auto Body

Sheryl Driggers Collision Advice

Frank Rinaudo Industry Consultant

Jason Mundy Mundy’s Collision Center

Stan Medina Certified Collision Works

Andrew Johnson Publisher ajohnson@endeavorb2b.com

Mattie Gorman-Greuel Associate Sales Director

Cortni Jones Director of Business Development

Diane Braden Account Executive (National Accounts) dbraden@endeavorb2b.com

Marianne Dyal Account Executive (National Accounts) mdyal@endeavorb2b.com

Chad Hjellming Account Executive (National Accounts) chjellming@endeavorb2b.com

Lisa Mend Account Executive (National Accounts) lmend@endeavorb2b.com

Annette Planey Account Executive (National Accounts) aplaney@endeavorb2b.com

Kyle Shaw Account Executive (National Accounts) kshaw@endeavorb2b.com

Sean Thornton Account Executive (National Accounts) sthornton@endeavorb2b.com

Ryan McCanna Administrative Assistant

ART AND PRODUCTION

Mariah Straub Production Manager

Jen George Ad Services Manager

Mitch Bradford Art Director

ENDEAVOR BUSINESS MEDIA, LLC

CEO Chris Ferrell

COO Patrick Rains

CRO Paul Andrews

Chief Digital Officer Jacquie Niemiec

Chief Administrative and Legal Officer Tracy Kane

EVP Endeavor Business Intelligence Paul Mattioli

EVP Vehicle Service/Repair Group and Fleet and Trailer Group

Chris Messer

HOW TO REACH US

Endeavor Business Media, LLC

571 Snelling Ave N Saint Paul, MN 55104 tel 651.224.6207 fax 651.224.6212

The annual subscription rate is $90 (U.S.A. only) for companies not qualified to receive complimentary copies of FenderBender.

LETTERS TO THE EDITOR editor@fenderbender.com

Opinions expressed in FenderBender are not necessarily those of Endeavor Business Media, and Endeavor Business Media does not accept responsibility for advertising content.

Valorem is the know-how and service of LKQ; the legacy of innovation and quality that is AkzoNobel. Valorem is a premium product line with built-in profitability and no compromise in quality, performance, color match, or warranty. The Valorem system provides reliable color match using industry-leading digital color tools, helping increase a collision shop’s profitability with faster process times. With Valorem what you see is what you get. – a premium, complete refinish system and the technical support behind it.

Valorem is power, performance, promise. Valorem is changing the way you buy paint.

The July 9-10 event showed shops how to build momentum for success in the second half of the year.

By PETER SPOTTS

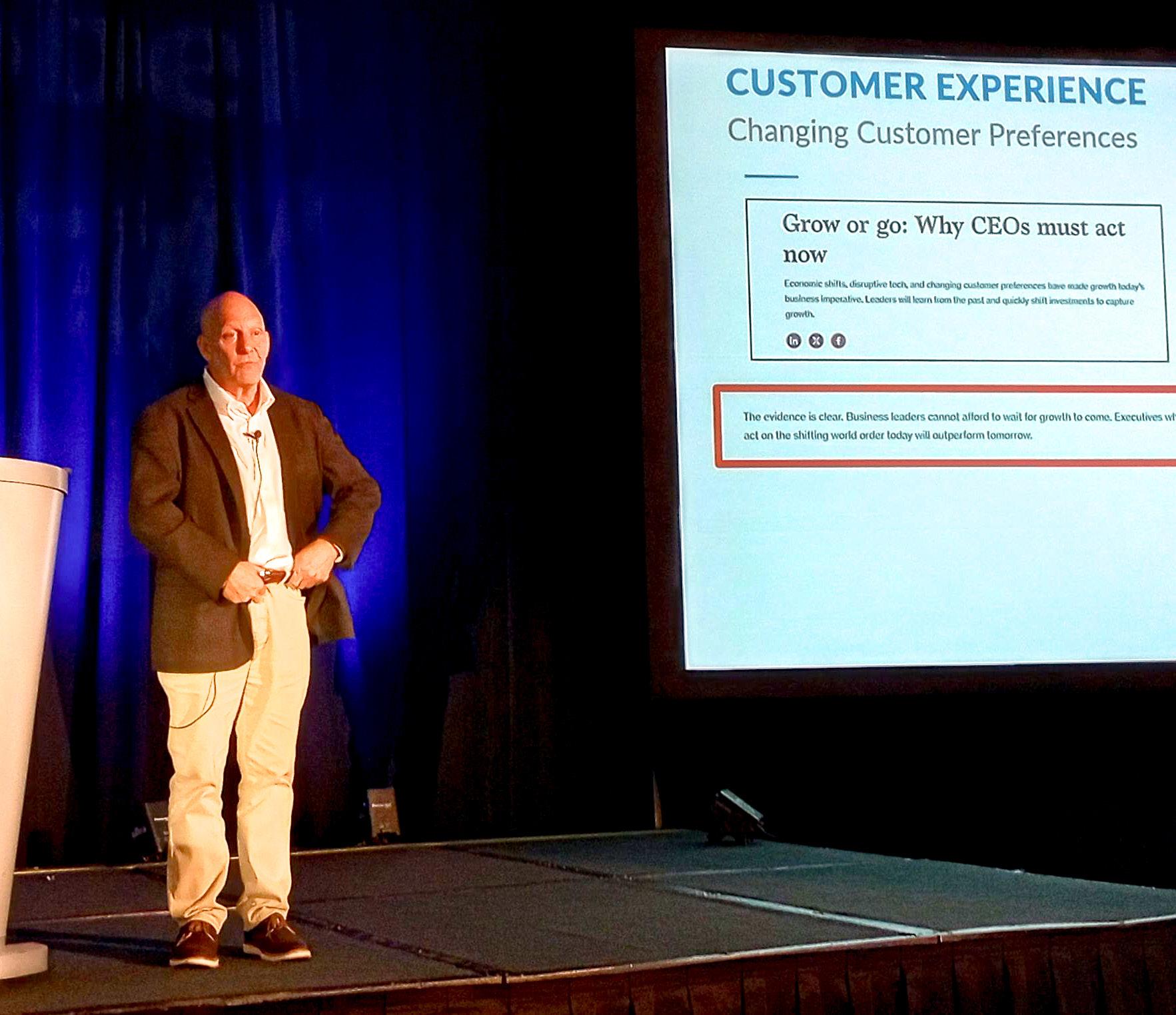

AKZONOBEL’S 2025 Collision Industry Experts Event gathered more than 360 industry professionals together to focus on one message for the remainder of the year – building Momentum.

Dan Carranza, AkzoNobel’s national sales director, Vehicle Refinishes USAMexico, got the Collision Industry Experts event, Momentum, rolling on Wednesday, July 9, at the Hotel Fera Anaheim in Orange, California. He called attention to the struggles the industry

faced over the first two quarters of the year. The pressure shops are under currently also provide opportunities for a comeback.

“The people who are losing are the people that are sitting idle, doing nothing,” he said. “We can’t control the market, but

we can control what happens in Q3 and Q4 to set us up for 2026.”

David Roberts, founder and managing director at Focus Advisors, provided industry insights and highlighted the importance of speed and cycle time, which he feels will be the most important metric for shops going forward.

“The fast are eating the slow,” he said. “We believe the fastest cycle times will succeed.”

Mike Anderson of Collision Advice backed up Roberts’ claim during the final session of the conference, reinforcing that cycle time will be the number one key performance indicator shops should look at.

“Every insurance carrier I’ve been talking to has been telling me cycle time is the number one KPI,” he said. “Anyone remember the GEICO ARX days where they wanted you to fix cars in four days or less? I’m telling you, that’s what we’re going back to.”

Anderson emphasized that faster cycle time will lead to more work for shops because “if you fix the car fast for an insurance company, they will reward you with more work.”

Shops will need quick communication to complement faster cycle times. Ryan

Taylor’s presentation on the applications for AI in body shops highlighted how missing a potential customer’s phone call or text message and not responding within 5 minutes has a 90% defect rate.

Additionally, 47% of customers want to do business after business hours. AI messaging systems can reduce the time it takes a shop to respond to a customer and provide responses to inquiries received after hours. Taylor used a fishing analogy for shops to reel in customers.

“How are you going to be responsive when that customer gives you a little nibble? If you need work right now and that customer is reaching out to you, are you setting the hook?” Taylor said. “The faster you set the hook the more likely you are to get that customer.”

AI also plays a role in insurance coverage for repair procedures. AkzoNobel

‘Tighten your belt’ Mike Anderson “tightens his belt” while discussing the state of the industry and what shop owners must do to navigate current economic challenges.

Senior Services Consultant Tim Ronak hosted a session on negotiation strategies and warned attendees about how insurance companies employ AI to deny and push back on repair procedures that have historically been covered. They use AI to scrub the internet for any marketing materials to identify inconsistencies or information that could help them deny a claim.

“What we’re finding is AI is being used to deny and pushback repair procedures that historically they paid without any question,” he said. “The level of scrutiny and pushback is about to increase.” Ronak’s session was titled “Win-Win Negotiation in Estimating,” but that’s not exactly how negotiations go.

“You win. They lose. That’s how I’m going to negotiate,” he said. “We’re just trying to get paid for what you need to do get that car back to pre-loss.”

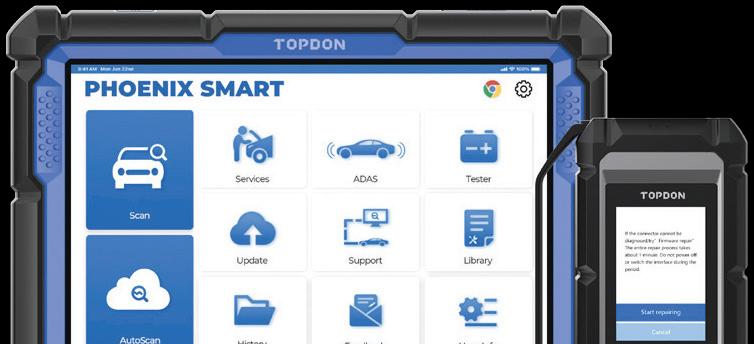

Cody Rinaudo provides shops estimating services when they need it, and without breaking the budget.

By PETER SPOTTS

ADMINISTRATIVE DUTIES are a constant struggle for collision repair shops. Increasing amounts of paperwork and estimating duties stretch staff responsibilities and take away time from the most important part of the shop – fixing the customer’s vehicle.

Cody Rinaudo experienced these issues firsthand working in his parents’ body shop for 15 years and launched his remote estimating company, Elite Estimatics, to solve them.

“Administration was always difficult. You always either had too much or not enough,” Rinaudo says. “You always had varying levels of workload and the admin staff always had to either be really slow or really busy. You didn’t want to hire

somebody in an interim and it was just difficult to manage.”

Another factor driving his business venture is the current economic state of the industry. As repair shops across the country see reduced car counts, they’re looking for places to cut costs and administration is one of the first areas they look at.

“So, everybody is seeing reduced car count and unfortunately that leads to potential

layoffs in certain aspects trying to cut costs where the revenue isn’t there to substantiate it,” he says. “Part of my clients, I’m seeing a need for remote estimates so they can keep their production staff maintained and producing repairs. Alternatively, I’ve got some shops that have some individuals that need assistance and training.”

Elite Estimatics provides remote admin work, consulting, auditing, and remote repair plans for shops looking to grow but can’t afford or justify a full-time staff member at this time.

In a typical case, the shop performs 100% disassembly of the vehicle and sends comprehensive photos of all the damage to Rinaudo. More complex repairs might require a video to show insurance damages that are difficult to see in photos. He reviews the damage, researches all the relevant OEM procedures relevant to the repair, gathers other documentation from CCC Intelligent Solutions, the Database Enhancement Gateway, motor guides, and anything else necessary to support and justify the repair. Time to complete a job depends on the type of vehicle and the complexity of the repair.

“Typically, my goal is to have it back to you within 24 hours depending on my workload at that point in time. How much it takes me to do that file depends on the size of the repair,” Rinaudo says. “If it’s just a bumper/ fender, that might be an [hour to an] hour and a half, where if it’s a structural on a higher end Mercedes, BMW, or Porsche, that could be four or five hours of work with the research required for those as well.”

As a remote estimator, the success of Rinaudo’s work depends on getting accurate information from the shop.

“Honestly, there’s a risk of that doing it in person if you don’t know what to look for, but ultimately, yes, I’m relying on

someone else on the other end to give me the proper information to have the necessary output,” he says.

Rinaudo offers on-site training for shops. He can review standard operating procedures, identify workflow problems, and provide suggestions for improvement. The most common problem Rinaudo said he finds with shop SOPs is that many shops don’t have SOPs in place. He also offers repair training for shops that want to learn how to do the estimating work in-house.

“I can come in and do repair plan training; work with the staff, the estimator and technician together, on a process to complete 100% disassembly and to write a proper repair plan,” he says. “I can do just estimatics training where I’m teaching how to navigate OEM systems to pull the necessary information from the service manual to capture everything necessary, [or] negotiation training to communicate with the insurer and advocate for the needed repair.”

Rinaudo offers four remote service estimate plans that range from $60-$1,200. The four plans offer varying levels based on the type of car and how much detailed information the client wants. Plans cover standard, exotic, OEM-certified, restricted, and EV vehicles. The cheapest plan does not include procedures or additional documentation from CCC and the DEG.

He also offers three tiers of auditing services: full file review for $325, estimatics review for $225, and OEM procedure review for $175.

On-site services include SOP development for $2,000/day, one-on-one individual training for $3,000/day, repair plan training for $4,500/day, and negotiation training for $3,000/day.

For customers that want to routinely use repair plans or auditing services, Rinaudo

offers three subscription models. The White Glove Repair Planning service covers 15 repair plans per month, and costs $3,750-7,500/ month based on shop certifications and needs.

The White Glove Auditing service covers 25 audits per calendar month, and costs $5,000/month.

The third tier, Platinum Concierge Full Service, includes all remote services provided by Elite Estimatics and has no

monthly limit on services. Platinum member jobs have priority when they come in. It costs $11,000/month.

While a website is a work in progress, a full breakdown of a full breakdown of Rinaudo’s service and price offerings is available on the Facebook page Elite Estimatics. Anyone interested in contacting Elite Estimatics can email eliteestimatics@gmail. com or call 985-788-0914.

Continental Cooling Fan Assemblies are exact replacements for the original fan in fit, form, and function, right down to the electronic module.

They restore the original cooling performance and feature OE mounting locations and plug-and-play electrical connections for quick, easy installation, right out of the box. Continental Cooling Fan Assemblies –OE quality with plug-and-play installation.

Find the right part at: www.continentalaftermarket.com

Of the nearly 100 repair procedures covered in the “Who Pays for What?” collision repair surveys throughout the year, destructive testing of welds is one of the “Top 3 most important,” to shop consultant Mike Anderson of Collision Advice, who conducts the surveys with CRASH Network.

“This step is so critical to ensure safe and proper repairs,” Anderson said. “A proper weld involves so many factors that it is nearly impossible to tell if the settings are correct without first performing a destructive weld test. And it needs to be performed for every type of weld being made on the vehicle.”

Looking at the survey data over time, the news is generally good. A decade ago, more

than 80% of shops had never sought to be paid for the destructive testing procedure. Anderson raised concerns about whether it was something most shops were doing. That has continued to fall over time, with 32% of shops this year acknowledging they had never sought to be paid for destructive testing of welds.

The percentage of shops that somehow believe that the eight large national insurers asked about in the surveys will never pay for the procedure also has fallen over time, from nearly 80% in 2015 to half that today.

But this year’s survey findings include some troubling data, Anderson said. The percentage of shops reporting they are paid “always” or “most of the time” by the eight largest insurers for the labor involved in destructive testing of welds – though still significantly higher than what it was a decade ago – dropped 9% in the survey conducted in April compared to the prior year.

“I won’t be satisfied until I’m convinced, most importantly, that this critical step is being performed 100% of the time,” Anderson said. “But the lack of reimbursement for it causes me great concern as well. This is a non-negotiable procedure. Every OEM states that we need to do this. Shops need to do this, and insurers should be paying them for this not-included procedure.”

New teardown requirements for automotive repair dealers are in effect as of July 1. These changes are part of the Bureau of Automotive Repair’s approved regulatory action to update Title 16 of the California Code sections 3303, 3352, and 3353. The regulatory changes include:

• Adds and amends definitions, including “teardown,” “third-party payor,” and “specific job”

• Clarifies what must be included in a tear down estimate, such as time and cost to reassemble

• Outlines requirements for preparing an estimate based on one provided by a third-party payor

• Requires disclosure of third-party payor amounts on the estimate, or a notice if the amount is unknown

• Requires towing service fees to be provided to the customer and authorized separately from the repair estimate

To view the final regulatory text and materials, visit BAR’s website at bar.ca.gov/ regulatory-actions.

In a departure from responses in previous years, 2025 FenderBender Industry Survey respondents no longer report the technician shortage is their largest concern, replaced by the insurers' influence on the repair process. In fact, the tech shortage now ranks third in two regions. Below is the

breakdown of response percentages by region, sorted from highest to lowest for each region. For those selecting "other" for their responses, fill-in answers, although worded differently, included a number-one common concern of getting paid properly by insurers for all work done.

Insurer influence on the repair process A shortage of qualified technicians Rising cost of doing business Other Inconsistent repair standards Low labor rates Vehicle design advancements Technology and tool/equipment needs Parts choices (OEM vs. aftermarket)

By Peter Spotts

LOCATION: NEW ALBANY, MISSISSIPPI

OWNER: ROBBIE WINDHAM

SIZE: 10,500 SQUARE FEET

REPAIRING VEHICLES ISN’T A JOB for Robbie Windham; it’s a lifestyle. Every customer who enters Windham BodyShop can expect to receive clear, transparent communication about what their car needs and know the team will work to deliver the best quality repair possible for their vehicle.

“The transparency is the big bit. Quality is the other thing. We try to explain to our customers you get what you get with the insurance company,” Windham said. “With Windham Body Shop, if you would like to have a higher quality repair, we offer that service as well.”

Windham grew up working on vehicles in his parents’ garage and helping out with the family business, Windham Appliances, which is the oldest business in town with 54 years of service. In high school, he knew collision repair was exactly what he wanted his future career to be and, after graduating, went straight to community college to take courses.

In 2009, Windham made the tough decision to build his own shop in New Albany, Mississippi. He didn’t have everything he needed to start fresh, but it was his goal.

“I didn’t really owe a lot of money on what I had, but I didn’t have the equipment I needed to do things. As the cars evolve, the equipment evolve and training evolves,” he said. “It was a hard decision because I didn’t know if it would work or not…I just kind of took a leap of faith, you might say.”

After 15 years of successful service in the community, it was time to expand. The shop underwent massive renovations last year, doubling the size of the production floor, investing in new equipment, and increasing staff size to include a full-time repair planner/ blueprinter, an in-house bookkeeper, and two part-time front-end estimators.

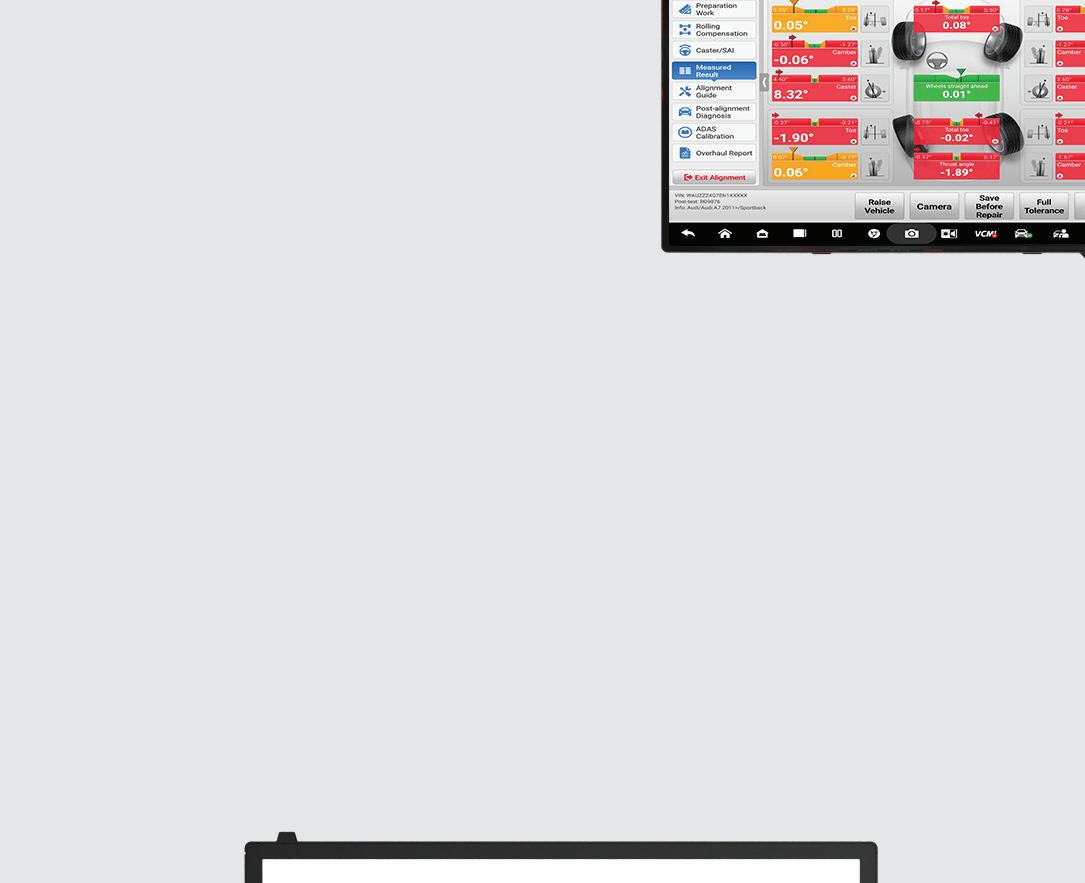

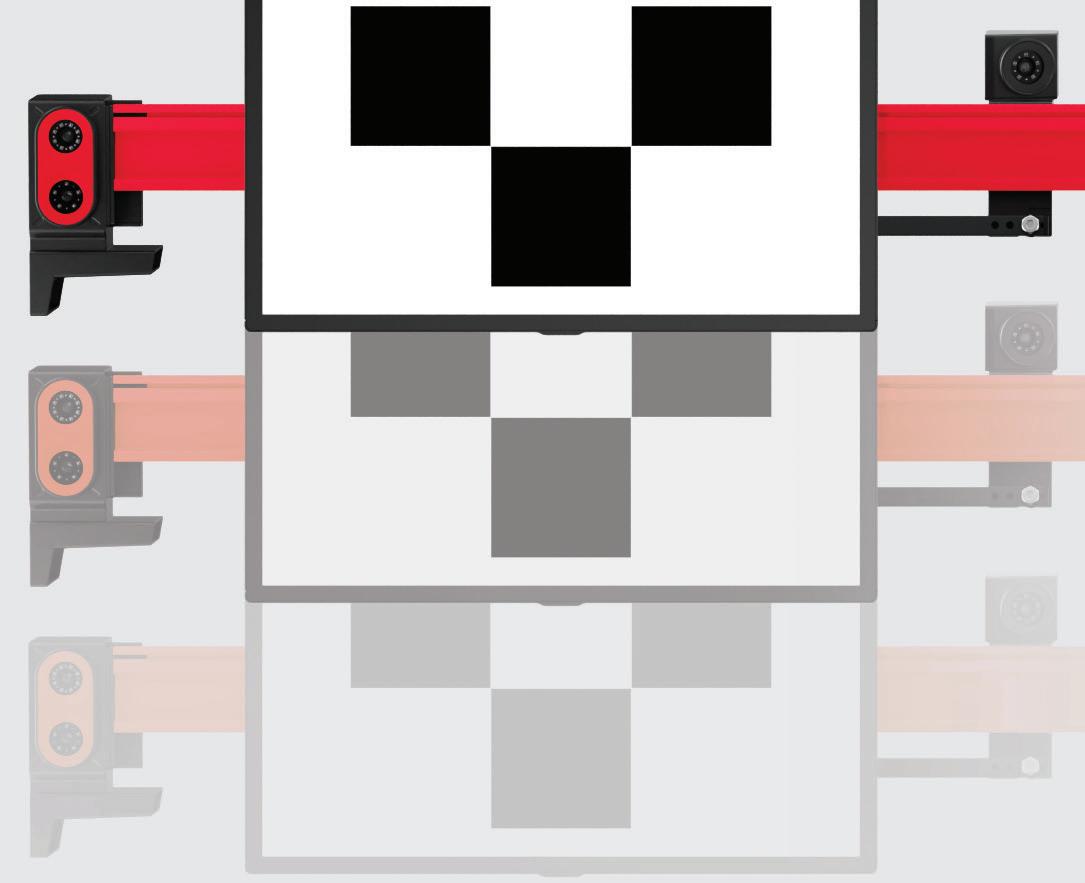

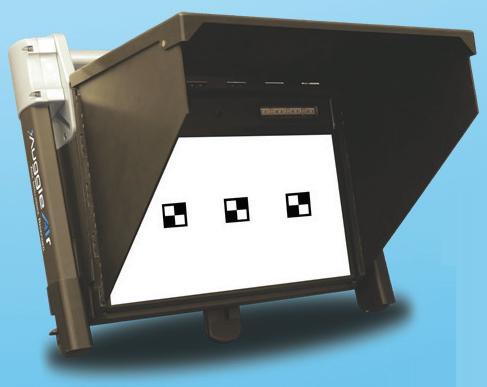

The expanded production floor has a bay for the structural repair equipment and a dedicated place for ADAS calibrations.

“It’s kind of a dual-purpose spot because we’re not constantly doing ADAS; I’ve built an equipment closet so all of our equipment goes into that closet,” Windham said. “We have an aluminum cleanroom that’s on the opposite side of it, so when you draw those curtains, you can use one side for the aluminum clean room and it blocks everything off for the ADAS.”

Across from the ADAS space are two paint booths. Windham set them up endto-end so jobs can go in one end and out the other.

“We do disassembly, try to take anything off the car to do the refinish,” he said. “We do that, so we can do multiple jobs in the booth at one time.”

Equipment additions from Car-O-Liner include a CTR9 resistant spot welder; VAS draw aligner; CMI 300 triple torch welder for steel, aluminum and silcon bronze welding; aluminum dust extractor; 5500 BenchRack; 3X 3D measuring systems; and the EV01 and EV02 clamping systems.

Windham also uses 3M sealer and bonding equipment, Bosch ADAS calibration system, KECO and Cam Auto glue pull repair equipment, Pro Spot suction post for GPR, BETAG Flatliner, BETAG T-Hotboxes, BETAG PDR light, Snap-on aluminum dent repair system and air conditioning refrigerant recovery/ recycle/recharge machines, and a Chief PNP90 self-piercing rivet gun for aluminum. The AC machines provide a significant upgrade to the daily work experience for his technicians.

Windham will continue to improve the shop as he continues working on his goal of providing the best possible repairs for his customers as the industry continues to evolve.

“This is an industry that's ever changing,” he said. “We'll add other stuff, but I don’t know how quickly it’ll be. There’s always more to come.”

The owner’s responsibility is ultimately to make sure the business is healthy, with good profitability and cash flow.

For most of my adult life, I have never had the respect for medical doctors that I should have. Now that one of our kids is nearly through medical school, I have had a change of heart. As the bible says it best, “I am fearfully and wonderfully made." Medical students spend hours upon hours and months on end, studying and memorizing material. Then they must pass several eight-hour long milestone tests to keep moving forward. After graduation comes three years of residency while making $65-70k per year working 60 to 70+ hours per week. Get this, then to specialize to become, say, a cardiologist, that’s an additional three years of fellowship. That’s 27 years of schooling from kindergarten to, say, age 32... minimum!

What does becoming a doctor have to do with collision repair, you’re wondering? When it comes to profitability for our shops, a lot! Do we spend at least one to two hours per month studying our Profit & Loss statement? Some may be saying to themselves, “Greg, you don’t understand. I just don’t have the time.” Well, the answer to more time is literally in the palm of our hands. Get this, the average American spends five hours per day on their phone. That’s over 150 hours, or six 24hour days per month. Shut that baby off!

So, now that we have just found all that time to study our P&L, it must make sense, and we must have clean numbers. There are many ways to look at our P&L. That can be Month to Date, Year to Date, by Quarter, this YTD compared to Last YTD, Trailing Twelve Months etc. When it comes to comparison to a prior period, I like to look at mine by the quarter to level out any paint bulk buys or monster jobs that finally leave, once a year bills, etc. We need to study each passing month, of course and be looking for errors. These errors can be in many forms, for example: Not seeing an electric bill for July, but June shows double the normal coding errors for, say, a Towing bill under Scanning etc.

I unfortunately need to mention this one. We all want to trust people, but we must be smart at the same time. Several years ago, I had a bookkeeper who had stolen from me. Fortunately, I

know where every penny goes in my business, and it didn’t take long for me to realize her vehicle repairs at the local dealership were being paid by my shop! She was quickly fired and reimbursed me the next day. Point being, owners MUST be aware of where every penny goes. I know owners who have been the victim of embezzlement of six figures, and it took years for them to discover it. Ronald Reagan said it the best, “Trust, but verify.” Sometimes, it is not an integrity issue, but rather a lack of knowledge or complacency. I know of a shop that had the U.S. government show up and chain their front doors together, as the bookkeeper wasn’t paying payroll taxes.

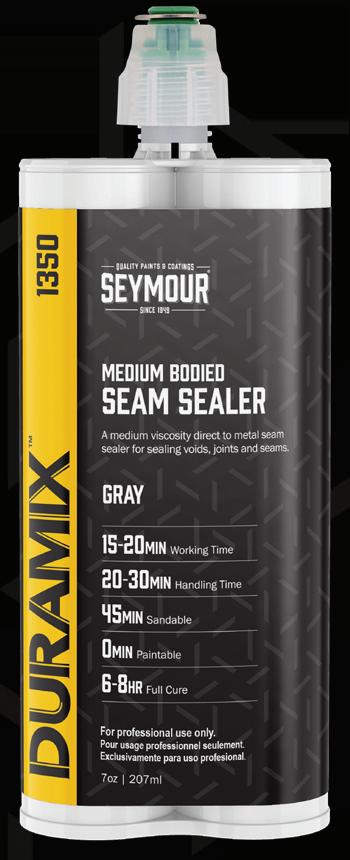

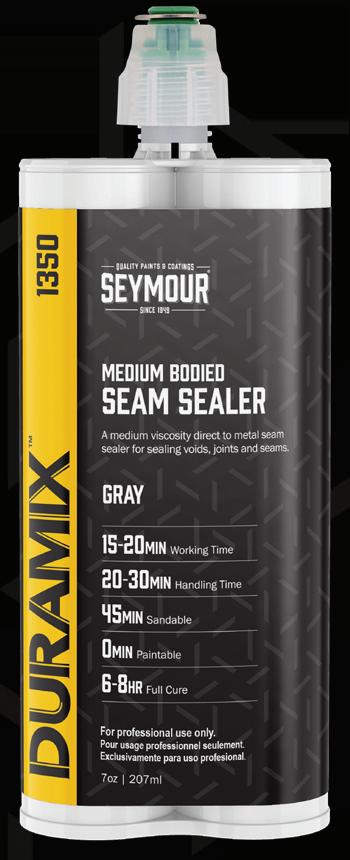

The owner’s responsibility is ultimately to make sure the business is healthy with good profitability and cash flow. As an example, our Paint & Materials profitability was 50% GP JanMar 2025 and then was 42% Apr-Jun 2025. That’s an 8% drop, right? We need to go on a discovery process and ask these questions. 1. Was there a paint price increase? 2. Did we get a new painter? 3. Did we get a new estimator who needs more training in writing for proper refinish hours? 4. Did we switch paint lines? You get my point here, as we must be detectives to discover the problem. Recently, I was reviewing my P&L and discovered our Stock Parts Gross Profit was lower than normal. We then met as an entire shop and reviewed what all is included in stock parts and coding was correct for: 1. Clips & Fasteners. 2. Seam Sealers. 3. Freon. 4. Antifreeze. 5. Doublesided tape. 6. Adhesives and application tips 7. Drill bits. 8. Sanding belts. 9. Alu. welding studs, etc. I explained that even down to the Stock Parts Gross Profit level can determine whether all get a bonus or not. Let’s say a shop does 750 cars per year and misses $30 of stock parts on every job — that’s a loss of $22,500 per year.

I never signed up to be a medical doctor, but I did sign up to be a body shop owner. We must take time every month to close our office door, shut off our phones and study our P&L. For most of us, we are bringing in millions of dollars every year. Are we at least keeping $20 (20% net profit) of every $100 from leaving?

GREG LOBSIGER

Greg Lobsiger has owned Loren’s Body Shop in Bluffton, Indiana, for over 23 years. He has been a member of Mike Anderson’s groups for ten years and had extensive lean manufacturing training.

EMAIL: greg@lorensbodyshop.com

ARCHIVE: fenderbender.com/lobsiger

With a waterborne basecoat that’s easy to mix, match and apply and that uses the same coat flash application you’ve already perfected, Cromax® EZ makes an exceptional finish feel effortless. Discover how easy an outstanding finish can be.

axalta.us/ez

Training isn’t always fun, but it’s essential to your shop’s growth. Learn how to get your employees more engaged.

By NOAH BROWN / Photos courtesy of COLLISIONRIGHT AND LEADING EDGE

The long weeks in August are often referred to as the dog days of summer. They’re hot, unforgiving, and they seem to drag on indefinitely.

During NFL training camp, which is actively underway, players are expected to learn the basics of their teams’ playbooks and practice the fundamentals that will lay the groundwork for a successful season.

It’s vital work, but to put it mildly, it’s less than enjoyable work: Repetitive drills for eight hours a day in the hot sun, frustrating learning curves and thankless work day in and day out for weeks on end, with the only thanks or reward being the possibility of making the roster for kickoff weekend.

It’s grueling, and many players would prefer not to do it if they didn’t have to. Fast forward to January when playoffs start, however, and more often than not, it’s the teams that are the most fundamentally sound that are left standing. Those hard weeks and months before the season end up paying off with a chance at football immortality, and players on those teams will usually say that their success started all the way back in training camp.

Unfortunately, there aren’t any rings or trophies to be won in the collision industry like there are in sports, but the analogy still holds strong – training, thankless as it may be, is essential to a successful business, and a dedication to

continual learning can help set your shop apart from the competition.

In largely the same way a head coach has to find ways to motivate his players through the slog of training camp, you may find that you, too, have to figure how to get employees energized and willing to participate.

Adan Ibarra has owned Leading Edge Collision in Houston, Texas, for five years and managed the shop for 11 years before that. In an industry that is constantly evolving and is laser-focused on KPIs and efficiency, building a culture of continuous education is an investment that will pay off in the long run.

“I think we as an industry have always looked at our priorities wrong. Get the cars out, make money, you know, how many cars do we do and what’s our cycle time and things like that, right? Those typically seem to be what the priorities are,” Ibarra says. “In my opinion, if you put the training as the number-one priority, then the cars go out quicker because everybody’s a little bit more trained and they tend to be more efficient.”

Building that culture and enthusiasm for training is easier said than done, but Makenzie Tedder, safety training and compliance coordinator for CollisionRight, says it’s possible.

“Obviously, mandatory training is not the most fun thing in the world,” Tedder says. “I don’t think anybody’s lining up to do mandatory training classes just because it’s fun. But there are ways to make it more engaging and more enjoyable.”

Ibarra says he understands that it’s not easy to get everyone in your shop into a trainingfirst mindset – with the number of tasks each employee has to take care of on a daily basis, it’s easy for a certification course or an online training module to get buried on the to-do list.

In his shop, Ibarra gives every employee, regardless of position, one hour a week to complete training courses. He says this helps establish an expectation that training isn’t optional in his shop.

“A lot of people in our industry can relate that it’s just so hard to put training first,” he says. “But ultimately, if we’re not putting training first, we’re jeopardizing the quality and safety that our customers expect when they give us their keys.”

To help manage that expectation, Ibarra says he’s put his office manager in charge of keeping track of trainings for everyone in the shop. At the start of a week, he’ll check in to see how the previous week’s trainings went. His office manager will provide a quick run down of who completed what training or, more importantly, if someone didn’t complete a required module.

“When I get that feedback, it’s easy for me to go to an employee and just have a conversation like, ‘Hey, I noticed you missed one or two weeks of training this month. What happened?’” Ibarra says. “Just having that conversation, holding that accountability,

Creating enthusiasm It takes time and effort, but CollisionRight’s Tedder says it is possible to make mandatory training more engaging.

tends to help fix those little problems and gets everybody engaged doing what’s expected of them.”

That expectation doesn’t have to change even your operation is bigger than one shop, too. Tedder manages the training for all 125 CollisionRight locations across the country, and she says there is a clear and consistent expectation that training is prioritized at each location.

“I think safety should be approached the same way regardless of the size. It should always be something that’s important and should always be something that is a priority,” Tedder says. “Our number one goal at CollisionRight is to have all of our shops at I-CAR Gold status within six months of acquisition if they’re not already. We take a lot of pride in knowing that we want to continue the education for our employees.”

It will take a clear, concerted effort from your shop’s leadership, but making it known that training is an expectation and not an option is an essential first step.

Tedder acknowledges that just because CollisionRight has a consistent expectation for training, a one-size-fits-all approach isn’t going to be the most productive use of time.

“Not everybody learns the same way; not everybody teaches the same way,” Tedder says. “We try to give our employees all the knowledge that is necessary without dragging it out too long, and we try to make it very individualized to that person.”

As training coordinator, Tedder says she spends a lot of time trying to find the most up-to-date and engaging training modules that she can. She says I-CAR has a vast catalog of cutting-edge training that is more than just a presenter running through a slideshow.

Additionally, having more frequent and regularly scheduled training will make it easier to keep each module shorter, saving more time and having a better chance of keeping technicians and other employees engaged.

“We make them short, sweet and to the point,” Tedder says, “but we make sure that

Giving them a boost Many technicians are self-motivated, and tying training to their ability to progress further in their careers can give them a boost.

our employees are getting what they need from the trainings.”

In an effort to keep their staff more engaged, Tedder says she has an open-door policy with all her team members. They can ask her questions about the training offered and provide feedback on what’s working and what they wish would be a little different.

Whether someone prefers to learn behind a computer or by going to an in-person class in another state, she says CollisionRight tries to be as accommodating as possible.

“I have no problem getting in my car and driving to your shop and helping you do whatever you need to do,” Tedder says. “The relationship I have with our managers and employees allows me to let them know

that I’m here for them. However I can make this better for them, if it’s in my power to make it happen, I’ll make it happen.”

Ibarra says a culture of engagement with training and getting employees on board starts with you. When he first took over as owner of Leading Edge, he said he had a difficult time getting techs to take more than the bare minimum for training.

“One of my mentors always talked about non-negotiables. What are your non-negotiables?” Ibarra says. “I turned training into one of my non-negotiables.”

In addition to giving each employee an hour a week to do training, he put his shop’s mission statement on a banner and hung it up in the back of the shop. He held a meeting under that banner and connected the importance of always getting better to that mission statement. And the only way his team gets better, he says, is through training.

“I’m not going to be pulling teeth,” Ibarra says. “This is something that is just required. It has to happen.”

To help incentivize participation, Ibarra says he and his office manager would provide an occasional reward – such as a $25 gift card or something else small – to people who didn’t have to be reminded to do their training. From there, he says, word spreads pretty quickly, and soon more and more of his techs began to do the training.

Though the extra incentive helped, Ibarra says the most powerful thing he did to help lead that shift was to keep connecting the training back to their mission statement and remind his technicians about how their engagement will be a benefit to them over the course of their career.

“It’s a constant conversation,” Ibarra says. “Knowledge is power, and nobody can take that away from them. Whatever happens in their career, whether it’s with my shop or if they move somewhere else, this is only going to help them succeed.”

Ibarra says a lot of his employees, like a lot of people in the industry, take an immense amount of pride in their work and are generally self-motivated. By tying education and training to that pride, you can show a tangible connection between training and future opportunity.

That, he says, is when you know you have a culture of continuous education.

“I tell my team, whenever you’re wearing a Leading Edge shirt, it’s not just a uniform. It’s something we stand for,” Ibarra says. “If you don’t have pride in what you do, then what are you standing for?”

Results-driven Tedder says each CollisionRight shop (bottom) needs to be at I-CAR Gold recognition in six months, a standard that helps put an emphasis on training.

STRATEGIES & INSPIRATION FOR MSO SUCCESS

Armenian American Tigran “Ty” Safaryan put in the work—and it’s certainly paying off.

By LINDSEY GAINER | Photography B y NICK HEMPHILL

That’s the single best piece of advice Tigran “Ty” Safaryan, owner of Fine Line Auto Body in Columbus, Ohio, has received in his life, he says — and he’s living proof that it’s true.

After moving to America from Armenia in 1994 at just 19 years old — and with little more than a love for cars and a dream of owning his own repair shop — his operation is now the largest family-owned and operated collision MSO in Columbus, Ohio, in addition to owning numerous other partner businesses.

Safaryan says that when he first moved to the U.S., the language barrier was by far the biggest challenge he faced. Coming from a family with an auto body repair business in Armenia, he had a solid foundation of auto repair skills — but his English wasn’t strong at first. He didn’t let that slow him down.

“I always wanted to be in the business, just like my family. I’m a car guy,” he says.

And so, Safaryan got to work…teaching himself English, attending college, and working for free at a local shop to build on his existing knowledge.

“Adjusting to a new country, new systems, and a different way of doing business — all while learning a new language — pushed me to grow quickly both personally and professionally,” he reminisced.

Within just two years of coming to the United States, in 1996 Safaryan opened the first of what would grow to become a network of 12 Fine Line Auto Body shops across Columbus.

“In the beginning, Ty was truly a oneman show,” says Fine Line’s Regional Office Manager Vanessa Flannery. “He did it all: answering phones, paying the bills, writing estimates and supplements, performing body work, and even painting vehicles himself. Every aspect of the business ran through Ty’s

hands, laying the foundation for what Fine Line is today.”

By 1998, Safaryan had outgrown the original two-bay garage and opened his second location, the company’s West Broad Street shop. And expansion just continued to snowball from there.

“Growing to multiple locations was always part of the vision,” added Flannery. “That goal fueled every decision, with each new shop bringing them closer to building a recognizable, trusted name across the region.”

Now operating 11 shops — with the 12th in the works — Safaryan is well and truly on his way to building an empire.

When asked how many more shops he’d like to open in the future, his answer came quickly.

“As many as I can — the sky is the limit! The next ten years will be full of surprises.” After all, he says, Columbus is a large city, and he wants to capture as much of the market as possible.

Safaryan’s ability to expand the way he has certainly reflects the trust customers

place in Fine Line for reliable collision repair, adds Flannery.

“Through all of Fine Line’s growth, Ty has remained true to his original values: hard work, treating people well, and always striving for the highest quality.”

Every new Fine Line shop is built to emulate the others that have come before it — there’s a “look” to all the shops, says Safaryan, so customers immediately recognize them.

In addition to large overhead doors in front, each shop is exceptionally clean — from the perfectly manicured landscapes outside down to the offices and shop floors within. And there’s an “open” feel to them, he adds.

Safaryan also prefers to build his shops from the ground up to ensure consistency — something he’s done with the last eight of his eleven locations. The first three were brownfields; none were acquisitions. He’s now undertaken so many greenfield projects, he says, that he has the permitting and build

Coworkers, Not Employees

Fine Line currently has just over 100 employees across all locations, but Safaryan prefers “coworkers,” he says, and he makes every effort to treat them like family.

time down to a science — it takes him about six months to get the proper permits, and between 8–12 months to complete construction.

The shops have also continually grown in size to accommodate the thriving business. While many of the shops average around 10,000 sq. ft., the newest location in Hilliard boasts around 12,000 sq. ft. and 17 overhead doors, with a capacity for 45 cars inside.

To ensure that every location operates smoothly and mirrors the others’ operations, Safaryan employs two regional shop managers who visit all the shops almost every day. There’s also an office manager at each location, with Flannery overseeing the entire network of offices. Weekly managerial meetings and daily staff meetings keep everyone on the same page, too.

Fine Line currently has just over 100 employees across all locations, but that’s not the term Safaryan prefers to use when referring to

them — they’re his coworkers, he says, and he makes every effort to treat every single one of them like family.

“I spend more time with them than many of my own family members, so I mean it when I say they really are like another family to me,” he emphasized.

Flannery, who’s worked for Safaryan for eight years, is quick to agree.

“He creates a close-knit, supportive environment that really reflects his core values.”

There’s also plenty of opportunity to grow with the business — it’s what Flannery appreciates most about her employer, she says. She started in one of the local offices and worked her way up to regional manager.

“They value my input and allow me to contribute ideas that we use in our day-today operations,” she adds, something else she and her fellow coworkers love about working for Safaryan.

Not surprisingly, given the way he runs his businesses, Safaryan is also a very charitable person, supporting the

Every new Fine Line shop is built to emulate the others that have come before it to ensure consistency and increase customer recognition.

community through his church, helping families both in the U.S. and Armenia, and actively taking part in charity work that “brings people together.”

Fine Line has made it a goal to acquire most major manufacturer certifications over the years, to offer customers the highest quality repairs possible. Safaryan likens it to seeing the right medical specialist for a health concern, knowing that practitioner is the expert in their field.

“You wouldn’t go to a dentist and ask them about your heart, right?” he mused. “It’s the same with certifications. We want customers

to know we’re specifically equipped with the knowledge and tooling to handle their particular vehicle.”

The shops’ first efforts towards certification began around 12 years ago, added Flannery, when advanced technology started becoming standard in vehicles.

“We realized we needed to meet strict manufacturer requirements to deliver the highest quality repairs. At the time, we already held our long-standing I-CAR recognition but quickly discovered there was much more involved. Our first OEM certification was secured in 2014, and since then, we’ve added most major manufacturers. The motivation has always been to ensure top-tier work for our customers, and we’ve definitely seen a return on that investment. We’re always open to adding more and plan to complete the full lineup in the coming years.”

In addition to high-quality repairs, what is it, in Safaryan’s estimation, that keeps customers continually coming back to Fine Line over competitors?

“The personality of our employees. Our positive energy. And our excellent customer service,” he says.

That’s certainly backed up by the nearly 6,000 (yes, you read that right!) mainly five-star Google reviews that the shops have amassed between them, where people repeatedly tout their excellent experiences and the impressive quality of work the shops put out. Their reputation is certainly something Safaryan and all his employees are incredibly proud of, as they should be. Coupled with their longstanding presence in the community, they’ve become a household name all over the region.

“We ask customers how they hear about us,” says Safaryan, “and many indicate they’ve just always known, the same way you know there’s a McDonald’s nearby.”

On top of Safaryan’s successful collision repair businesses, he also owns numerous partner businesses that allow him to

provide comprehensive service to his customers. From towing and rental cars to glass repair, dealerships, and an insurance company, his network is continually growing.

His portfolio of businesses includes Twins Buick GMC Discount Auto Glass, Solid Insurance, Bobb Automotive, Speedy Car Rental, Liberty Towing, and Gray Gables Realty The glass company, in particular, has really taken off, with 14 installers doing work across Columbus, including for many of the dealerships in the city. Safaryan estimates around 80% of the local franchise dealerships use their services, and they’re likely the second largest installer in the city.

“All the businesses benefit from each other,” he says, and allow him to provide customers with an experience uniquely tailored to meet their needs.

It’s a culmination of decades of hard work, and Safaryan’s success is truly proof that hard work does indeed pay off.

“Stay committed, put in the effort, and the results will follow,” he says.

The most digital SATA of all time

It comes with a completely new nozzle concept.

Features a basic or digital options with an unprecedented range of functions.

jet X BASIC - analogue version

jet X DIGITAL ready - optimally prepared for digitization

jet X DIGITAL - with adam X's various digital functions

jet X DIGITAL pro - with adam X pro's full range of digital functions

Packed with features that make the difference.

We did this for one reason alone: to make it easier for you to be better.

www.sata.com/jetx

www.satausa.com

Repairers are the repair experts and should stand up to unfair or unreasonable pricing demands.

By DARRELL AMBERSON

IT WAS NEARLY A YEAR AGO that GEICO announced an agreement with Repairify — specifically their brand asTech — that included standardized pricing, particularly for their direct repair program (DRP) shops. It was stated at the time that the plan was to “reduce friction.” Later, State Farm rolled out a new agreement with Opus for their Select Service DRP shops. It’s been getting a lot of attention in recent months. This arrangement also has pricing terms. I have been told that there are other insurers forming relationships and pricing structures who are waiting to see what happens with the GEICO and State Farm programs before rolling theirs out.

Based on what I see in shops, read in the trade press, and hear at industry conferences, there appears to be less clarity, and there is certainly more friction than before.

Let’s look at a few aspects of the State Farm agreement. A statement from their Select Service Program Administration says, “State Farm will require the use of ADAS MAP, an ADAS calibration software system for vehicles requiring calibration. The Opus IVS software scrubs estimates and/or repair orders and identifies VIN-specific ADAS systems, necessary calibrations and provides OE repair procedures.”

(Do you remember when State Farm respected the ability of shops to make their own choices, often called “open platform”, on things such as estimating systems, parts procurement systems, and CSI vendors? How times have changed!) This statement in State Farm’s document is misleading, as the system will identify most of those items, perhaps even almost all. But by the admission of this vendor — as well as oth-

er vendors with a similar product — these systems are not all-encompassing and may not provide all the information needed regarding build data, nor all the necessary required operations or repair procedures. While these systems are a great aid, one must still review the original equipment manufacturer (OEM) repair procedures to get ALL the necessary repair information. Interestingly, to reinforce my points and to illustrate the conflicting information, the Opus MAP Agreement Portal states, “….it is possible that the Software may not always have full coverage for a vehicle, and it is possible for errors in results. You further acknowledge and agree that you shall be fully liable for any and all decisions and actions you make as a result of using the Software and Support Services under this Agreement, and that any results from using the Software should be checked against the OEM factory information if such results are used to determine the functionality of safety equipment on a motor vehicle.”

The State Farm statement also says, “……. the amount billed for calibrations should not exceed the price State Farm would have paid per the part code table. State Farm has also identified local mobile/car side providers that work in the area on the Opus landing page.”

One could question why a mobile ADAS business should be associated with the pricing standard. Their cost of operation is obviously lower than that of a calibration center. And the calibration center would more likely be in compliance with OEM repair procedures regarding necessary floor levels and controlled lighting without interference. While checking, I found a few local vendors on the Opus page. I suspect it varies in different markets. At least one of the vendors listed is part of a large collision consolidator with

close DRP ties to State Farm. One of the others is part of a glass business. Whatever each represents, this arrangement is rife with concerns over a lack of credibility and conflicts of interest. Many collision repairers would be reluctant to deal with an ADAS company that is part of a competing business. Our local State Farm people are indicating that all shops have to comply with their pricing model because this handful of shops agreed to. I’ve read that in some markets, State Farm people have stated that this program is still a test and may change. Yet I know in at least a few markets that non-Select Service shops are not being paid any more for their ADAS operations than what is in the parts code table. Still, there are reports of pricing flexibility in some markets. And in at least one market, State Farm is refusing to cover the costs of transporting vehicles to calibration centers because their statement implies the viability of mobile calibrations. Of course, those don’t require transporting vehicles. And again, based on OEM repair procedures, we know many mobile calibrations are not proper and potentially cause erratic/unsafe function . Supposedly, there is at least one mobile vendor in my local area with a calibration center who will transport vehicles without charge. We haven’t seen evidence of that yet. And again, because a small number of vendors elect to do something to appease an insurer, that shouldn’t necessarily become the standard among many vendors or repairers.

When we talk about OEM repair procedures, we also should bring up other OEM statements. These could include job aids, technical service bulletins, and position statements. There have been some insurers who publicly

acknowledge the importance of repair procedures but cast doubt on these other statements. Some say they should only be taken on a case-by-case basis, or subject to interpretation or discussion. Do they think only the competent OEM people write the repair procedures and incompetent ones write the others? The truth is that they come from the same manufacturer’s staff who have respon-

sibilities to their company and to the public with whom they share this information. And many of these statements, aids, etc., are of immense value to provide clarity on how ADAS work should be performed. It is up to us as repairers to find OEM repair information and use it. Remember, there is only one repair standard; it is the standard set by the manufacturer. I-CAR, which provides great training

and direction, has acknowledged from their beginning that the OEM procedures (information) are THE standard.

These pricing matrices are an issue unto themselves. There is a lot of discussion about some being formed that have different tiers for different operations for different brands. I understand the concerns of insurers that some shops have

abused the ADAS situation by charging exorbitant fees. But that shouldn’t mean that the majority of shops have to accept pricing on the lower end of the range. As an industry and as individual businesses, we need to establish fair pricing that accommodates a reasonable profit in a wellrun business. And in the ADAS business, we should not use the typical old philosophy that all education and equipment and site expense is simply a business expense, and that we only charge for labor based on the time spent by a tech. A calibration center has huge equipment purchases with expensive and time-consuming updates. Much of our equipment quickly becomes outdated. And our training costs are huge and increasing with changing technologies. Simplistic pricing models are preferable to minimize friction.

The GEICO arrangement shares some of these aspects causing friction and lack of clarity, particularly regarding the pricing model, questions on tooling (such as aftermarket versus OEM scan tools), approved services vendors, procedures, and liability.

Over the years, especially when there is a significant change in the collision repair industry, there have been many cases where a vendor elects to form a relationship with an insurer in an effort to gain market share. Usually, these relationships rely on the vendor offering lower cost solutions. Unfortunately, sometimes the cost reduction comes from cutting corners by deviating from OEM repair procedures. Often the end result is that competing vendors cut their pricing to protect their market share. At the end of the exercise, there isn’t necessarily a big shift in market share and instead all the vendors end up doing about the same thing as before except that all are performing the work for less, often the standards are “watered down” (compromised), and the insurers laugh all the way to the bank. And the consumer is at risk of receiving poorer quality with a chance of compromised safety.

The blurred line between recommendation and requirement

I reached out to Revv, a software company that provides ADAS repair information similar to some of the other providers. But Revv has not elected to partner with an insurer as some of the others have.

“The only consistent requirement we’ve seen within certain DRP programs is alignment with established calibration pricing guidelines,” explains Joel Adcock, director of partnerships at Revv.

This distinction matters significantly as shops nationwide report pressure to:

• Adopt specific third-party ADAS identification platforms

• Utilize designated calibration providers from restricted lists

• Compromise on OEM procedures when they exceed reimbursement thresholds

“The line between recommendation and requirement has become dangerously blurred,” Adcock notes. “We’ve heard firsthand from our customers and the ADAS community the confusion and anxiety shops are experiencing, potentially compromising the repair integrity shops work hard to maintain.”

As a comprehensive, tool-agnostic ADAS solution, Revv delivers OEM documentation, audit-ready invoicing, and compliance support in a single platform. Revv is encouraging shops to ask a different kind of question:

Are we following procedures because we must? Or is it because we’ve been led to believe we have no other option?

For repair facilities navigating these waters, Revv recommends:

• Requesting written documentation of any purported requirements

• Consulting directly with insurer representatives about actual network obligations

• Maintaining records of OEM-compliant procedures regardless of reimbursement challenges

“We stand with repairers who want to do the right thing,” Adcock adds. “And sometimes, the first step to doing the right thing is simply asking: What’s really required here?”

Obviously, our industry is in a state of uncertainty on this topic, and in many ways, these insurer programs are adding to the lack of clarity as well as causing increased friction. That’s despite the claims of some of those behind these insurer/software relationships that part of their goal is to drive more acceptance of performing ADAS work. I don’t doubt that there may be some noble intent. But whenever collision businesses have specific repair vendors and pricing structures forced upon them, especially with structures that seem to favor insurers financially and alienate some vendors, there is cause for concern and apprehension. As Joel Adcock said, I believe we as repairers should focus on doing the right thing. We are the repair experts. We should continue to educate ourselves and rely on facts for our repair decisions and pricing negotiations. We should repair vehicles properly, based on OEM repair information, proper tooling, and price our work accordingly, standing up against any unfair or unreasonable pricing demands. Our industry is typically slow to adjust to new technologies and pricing structures. We as repairers need to make sure that our voices are heard and that we have our appropriate influence within our industry.

was president of operations for LaMettry’s Collision, a 10-location multi-shop operator in the Minneapolis area purchased by Quality Collision Group in November 2024.

ARCHIVE: fenderbender.com/Amberson

EMAIL: d.amberson@frontier.com

Together, Paint and Material and Sublet make up as much as 19% of sales. Here are process areas of improvement on which to concentrate.

By STEVE TRAPP

HAVING RUN HUNDREDS of performance groups over the past 40 years, I was challenged by FenderBender to recap the key learnings on the main topics the groups discuss. This is the third part of the series.

This article will share processes implemented by the performance group members who achieve the highest paint and material gross profit percentage. Paint and Material represents anywhere from 7.8-9.8% of various shops’ sales mix, and depending upon their circumstances, shops can expect to earn between 20 and 70% gross profit. As most of you know, it’s either a sales issue, cost issue or both. Let’s explore the processes which optimize performance

As Paint and Material reimbursement is largely tied to the Paint Labor sales, we find that the industry’s inexperienced estimators rely too much on merely selecting the exterior painted parts and not looking deeper. Missed labor time on weld burn panels, second or third , color tinting, and masking time often is vastly underestimated. The most profitable repairers, estimators, and repair planners are constantly reviewing the updates to the database procedure pages, attending estimating courses, and calibrating against one another to ensure times are optimized.

Additional materials beyond paint labor hours are often driven by getting paid to cover the car, for hazardous waste removal and extra materials needed. Many paint companies will warn the estimators if the LIST cost (never mark up beyond that) of the products mixed have exceeded the estimated allowance to trigger the estimator to review their assessment of paint times to see if additional panels or processes were required (again photos of vehicle in prep really help in justifying.)

This is an age-old category that has recently been enhanced with tools such as 3M Repair Stack, which tracks the body materials (seam sealers, caulk, etc.) as “kits” which have been measured out with the 3M rope to justify the amount estimated. Any additional paint and material reimbursement

here will help offset the obvious costs for these products consumed.

Much like we reviewed last month with parts, selection of the paint and non-paint supplier should be a balance between achieving a fair discount and the aftersale service and support that distributor/ paint supplier can provide. The target is to get your paint cost as close to 3-4% as you can and then hold your non-paint cost to 1.2-1.5% so your overall cost is 4.2 to 5.5. With 8-10% sales, you should hit a pretty solid paint and material gross profit %. Before we get too deeply into analyzing costs, let’s ensure we have purified or accurate cost data.

Coding: Be sure your paint distributor creates five or more accounts to enable allocating the costs to the appropriate department.

1. Paint or Liquid Costs

2. Non-paint or Allied Costs

3. Aftermarket Parts (if you code seam sealers and caulks as aftermarket parts)

4. Shop Supplies and

5. Small Tools and more as needed.

Verify invoices periodically to ensure the appropriate costs/expenses are applied to each category.

Inventory: Instead of counting ending inventory at the end of each month, most repairers ask that the suppliers use their historical consumption report to generate a minimum inventory level. Heavy-use toners on the mix machine should be noted with a green dot on the mix machine, medium yellow dot and red for limited-use toners. You can then visually look at the mix machine to see if there is any over/ understocking. For the non-paint items, the best practice is for them to restock the shelves back to the minimum at the end of the month so that what has been purchased is VERY close to what was consumed. The goal is to have enough inventory to never

run out, but not too much (more than two to three weeks of stock).

You should NEVER use the WIP paint and material cost, as the management system makes up an assumed cost the moment the R.O. is created. Using this will lead to nothing but inaccuracies and frustration.

Total Effective Discount (TED): A final thing to consider when evaluating your paint and material costs is to consider how your paint deal is structured. If 100% of the discount offered is shown on the invoice, this is not a concern. Most distributors and repairers prefer to have 20-35% discount shown on the invoice, then provide a monthly (preferred for cash flow) or quarterly rebate. If the distributor or supplier provided a pre-bate or investment up front, that needs to be converted to a discount and applied. How to calculate TED: Invoice discount (25%) + Monthly Rebate (10%) + Pre-bate Amortized Monthly for term ($100K/%1M Purchase obligation = 10%) = 45% Total Effective Discount. Finally, if your income statement under P and M costs shows only the invoice discount of 25%, you need to take an additional 20% off and then analyze your paint & material GP%. Often, the additional 20% is reflected as an income in the non-operating expense category. Before digging deeply in the shop paint and material handling processes, you should purify the data and then review the remaining costs.

Overmix: The bulk of the paint-related waste can be found in this category. It is visually obvious because of excess paint left in the gun cup liner after the liquid coatings are applied. To minimize the overmix, encourage your painters to agree to a gradient per paint hour which closely yields a mix quantity to allow the vehicle to be fully painted.

Primer: If you keep small damage small and do a great job refining dents before applying filler and use a 3” DA when you can, you can reduce primer use to .81

ounces per hour or even less with a UV primer which has NO waste, as it is not activated like traditional 2K primer and thus has no potlife.

Base: The base is the costliest coating to mix. When mixing base, the top performers try to limit mixing more than 2.0 ounces for waterborne paint or 2.4 ounces per hour for solvent-based paints. Base is generally applied with a 70% overlap, and if the system is wet-on-wet, it can be covered in 1.5 - 2 coats. If you see overmix on the paint bench, weigh the waste and multiply the ounces by the per ounce cost and explain to them that this is $60 worth of paint in this cup.

Clear: Clear is the final coating and must generally be applied to the entire painted panel. Clear often can be applied in 1.5 to 2.0 coats. So, mixing 1.8 ounces of this solvent-based product should be enough. Never plan on adding an additional coat “in case” you need to buff, instead eliminate buffing’s root cause and prevent the waste. Overall liquid per panel should be limited to 4.6 to 5.5 total ounces (all the above added together) mixed per paint hour.

Overapplication – Air Pressure / Number of Coats: A common correction for the painters who started to paint with waterborne paint was to raise the air pressure up to as high as 28 psi at the tip. Over the years the paint companies have worked to reduce that need and now have suggested 22-22 psi and their scale formulas and spray out cards are being updated to reflect that method. For every 1 psi you can reduce pressure, you will consume 6% less paint –as it doesn’t get lost in the air.

Color/Texture Match : Another error is to not invest enough time in colormatch up front and then to need to rescuff and paint a surface or surfaces. If you must fully repaint the exterior color and clear on a vehicle, you often end up applying 5 ounces of paint up to nearly 9 total ounces, nearly 80% more than need-

ed. If you make 40%, that means you are painting that and the next two jobs for no gross profit to just break even on paint and materials.

How do we get a better color match? Use the spectrophotometer on all jobs during advanced inspections or enhanced repair planning and then render it and proof the color on the screen or perform a sprayout to verify the color. If the color needs to be tinted and you get a “hit,” then train the camera (which is tied to AI) by taking an additional set of images of the “hit on a hit,” and this will teach the paint company database and build a “special color library” in your company’s mixing databases. NEVER attempt to match the color when the vehicle is in the booth; you tie up the booth, while you rush the above process.

Technical Errors: Rework or buffing due to preppers or painters not following the paint company’s technical data sheets is certainly preventable. But you need to build a positive relationship with the paint representative or distributor technical expert and encourage the painters to listen to them intently and follow their documented and tested processes. As they wrap up a visit, ask them to ALWAYS meet with you (and the paint team) to debrief you on their findings. Review any tips they suggest and follow up on past tips to ensure they have adhered to them. Benchtop chemistry has no place in 2025, where mistakes cost expensive rework and negative NPS/CSI scores from customers.

Underuse: Frankly, the biggest waste of sandpaper is from underuse. The sanding discs still have 70-90% of life left after a small to medium repair is completed. As technicians switch from 80 to 180 to 250 to 500 grit, they often dispose of the discs. Instead, store the unused discs on the cart for later use. Look at masking procedures; with 2” tape and urethane-grade plastic sheeting, there is almost no need for

masking paper use.

A similar thing happens to seam sealers and caulks. Using 1/3 to 1/2 of a tube and not having a bin for unused bins to share with others results in waste.

A form of overeruse is found with gun cup liners. When the painter selects a much larger liner than is needed, this adds costs when a smaller liner would have worked just as well.

Waste: This loss of profits drives managers crazy. Examples might be leaving tape on the vehicle and moving it outside and it gets rained on or falls off and gets driven over. The obvious signs of waste are frustrating, but they don’t add up to as much as the wastes above.

Prior to ADAS repairs, sublet represents 2.8-6% of a shop’s sales mix, now it ranges anywhere from 5-16% depending on how the shop chooses to address ADAS and Mechanical Repairs. Historically sublet GP was 2022% and now it varies from 17-35%.

Mark-up should be 33% to make 25% on things such as glass mechanical, stripe, etc., but many repairers have accepted a 25% mark-up and therefore only make 20%. Remember, if you can source the parts for the sublet provider do that and send it with the vehicle so you can make the profit on the part and only mark-up their labor.

One profit center can really add income to offset parking lot property taxes, insurance and lot maintenance expense because 100% of storage goes to reduce expenses and help with profitability. So, since most insurers won’t pay storage until an estimate is generated, immediately upon arrival, run an AI estimate for the repair to start the clock running until they decide to pick it up.

An obvious drain on sublet margin is if you collect rental car or towing fees and cannot mark them up. If you collect for it,

get a mark-up or otherwise let them pay them directly.

If you do all the above steps, reconciling the monthly vendor statement should be a breeze. Receiving distributor invoices should be easy if they limit costs/expenses to the categories you required, then merely ensuring the accurate discount was applied to all invoices.

All of the paint distributors want to get

paid in a timely manner, therefore be a smart operator and budget cash flow to be able to fully pay these vendors in the “X” day window they require to earn an additional percentage (often 2%) for paying promptly. This only enhances the discount and thus the final margin on the monthly profit and loss statement.

With paint and materials being nearly 10% of sales and sublet also nearing 10%, these two categories of expenses are significant potential contributors to overall shop net

profit. Paint cost control involves time invested in color matching, proper measurement, and proper application skills to apply it to avoid rework. Cost control for nonpaint is also significant as those costs can equal 30-33% of the total materials bill, so limiting waste, under use, or other controls can assure there is less waste here. Finally, when it comes to sublet, a savvy operator keeps a close eye on mark-up versus discount, getting estimates written quickly to begin collection storage, and they don’t collect money for rental or towing without making the markup.

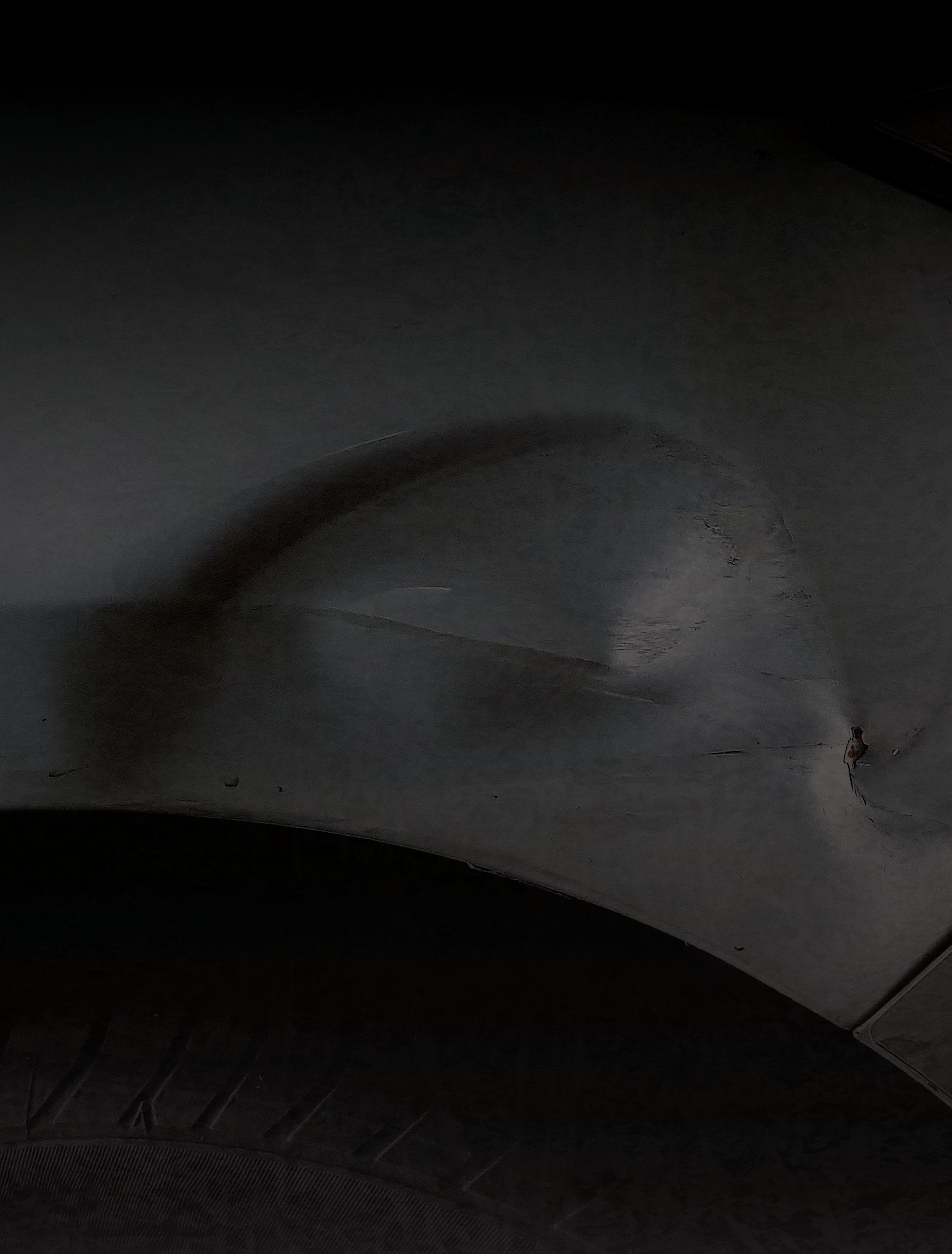

High-quality photos can affect your shop’s bottom line in more ways than one.

By TODD KORTEMEIER

IT IS SUCH A CLICHÉ that it is practically the standard by which all other clichés are judged—a picture is worth a thousand words. And well-worn as it is, it’s a phrase that has never been more apt for the collision repair industry. Every shop takes photos at multiple steps of the estimating and repair process, maybe even at every step. But not all photos are created equal. Making sure those photos capture what they need to is vital to protecting your bottom line.

With the increasing cost of repairs due to necessary procedures like scanning and calibrations, insurers are seeking to reduce labor hours by reducing severity. And it makes it really easy to knock a few hours off an estimate if it’s not clear how severe the damage is. Shop owners should view photos less as a documentation and more like an illustration — making clear to anyone viewing it what needs to happen.

“The photos are really important because they’ve got to tell the story,” says Anthony McNee, winner of the 2024 FenderBender Best Repair Planner/Estimator Award and blueprinter at Ultimate Collision Repair in Edison, New Jersey. “So, if I’m looking at the car later on, or somebody else is looking at the car, you can tell exactly what happened with the car.”

Award-winning blueprinter or not, anyone can see the difference a photo can make. Photo quality isn’t so much of an issue anymore — most shop employees today are walking around with cameras in their smartphones which not so long ago would’ve qualified as high-end professional cameras.

The camera is only a tool, however. A paint gun also isn’t very useful if the person wielding it doesn’t know what they’re doing. The person taking that photo needs to ensure that it’s capturing the subject properly and showing what the photo needs to show.

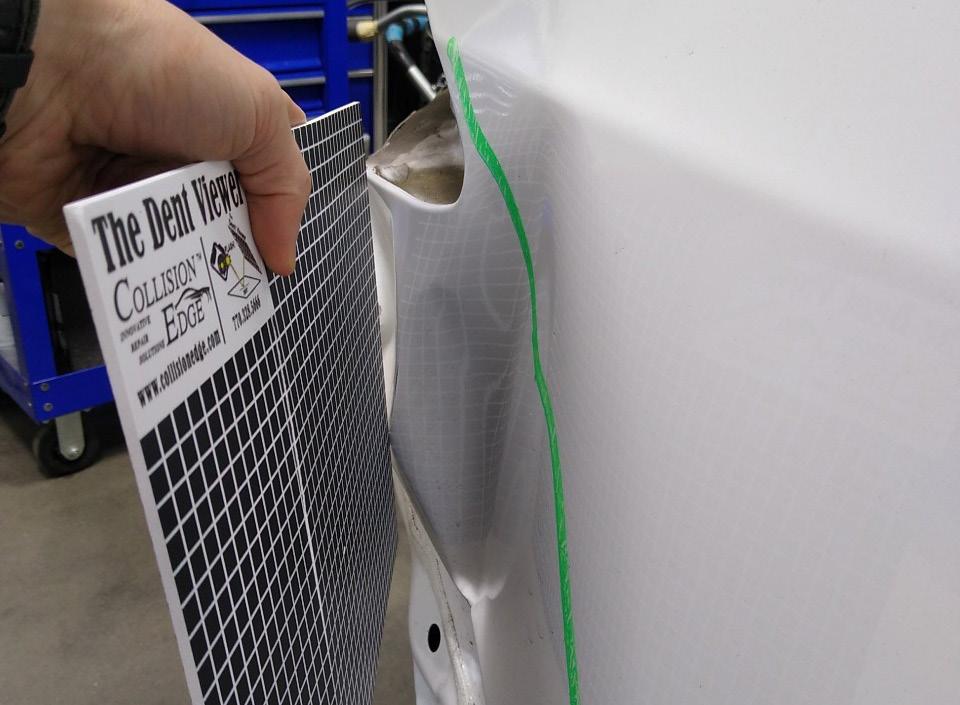

“The reality is, when you upload photos to an insurance company, they look at them, and maybe I’ve invoiced for six hours, [but] the insurance company says, ‘Well, we don’t really see six hours. We see three hours,’” says Keith Egan, performance director with BETAG North America. “I think part of that is, we’re uploading photos that aren’t quality photos, enough to outline why it’s actually a six-hour dent.”

Lighting makes a huge difference in showing damage properly. No different than in any other photo, lighting adds depth and shows detail. In addition to offering lighting equipment for sale, BETAG includes education on proper utilization of light as part of its estimator training.

Quality of light is certainly important, but it’s just as important to have light properly positioned, showing the full depth of the damage and not casting any distracting shadows. Without the proper lighting, Egan says, sometimes damage can even be missed entirely.

“You know, a body man will finish a car and send it to the paint department, and they’ll paint it, and then all of a sudden, there’s a dent in the door that was missed,” Egan says. “And the body man says, ‘Well, it wasn’t there when you sent it over.’ But in reality, it probably was, and it was missed in the estimating process.”

Egan emphasizes that BETAG’s estimator training is unlike some other, more traditional, training out there. It places importance on assessing damage, taking good photos, and using the right light to take those photos. That helps to “tie together” estimators and technicians, increasing efficiency and making sure everyone has what they need to do the job and with the proper time to do it.

“If I write something for eight hours, and I accept four hours after negotiating, now what’s happening is I’m going to my technician and saying, ‘OK, we got paid four hours,” says Egan. “And automatically in that technician’s mind, for efficiency, especially in a dealership group, he’s thinking, well now I have to fix it in two hours to make money?”

McNee knows as much about estimating and repair planning as anyone, and taking good photos has become an increasingly important part of that process. And it’s about more than just the estimator; it’s team-wide. As part of using photos to tell the story, “You have to look at it from somebody else’s point of view,” McNee says.

As opposed to, say, the technician, the estimator knows where the part came from on the car, where it was broken off. Someone else may not know that, so the photos need to reflect that part of the story.

“Maybe put the part next to where you took it off the car and take the photo,” McNee says. “Try to make it as simple as you can. Try to make your photos kind of like one after another.”

McNee says his shop also utilizes tools and visual aids of sorts to help illustrate

damage. Dent boards offer a comparison of scale for dents, making them instantly clearer in photos. They also use color-coded pointer sticks that indicate where something needs to be repaired or where something needs to be replaced.

“Anybody looking at the photos can tell exactly what we’re looking at and even point to the damage,” says McNee. “... So if I’m looking at the car later on, or somebody else is looking at the car, you can tell exactly what happened with the car, whether we replace the part, repair the part, paint the part, you have to be able to tell exactly what happened with the repair of the car.”

Another tool in McNee’s arsenal is an app called Carmic. While the app doesn’t help take better quality photos, per se, it helps organize photos and make them even more useful. Drawing heavily on AI technology, Carmic allows users to categorize not only photos but also documents for each stage of the repair. Photos are even searchable, as AI can detect whether it’s looking at a wheel or a bumper. It’s an app that can go on every employee’s phone so everyone is working off the same information.

Sergio Palma is the creator of Carmic, and solving the problem of how collision repair shops organize and take photos is one he’s been working on for roughly two decades. “It’s ‘No photo, no pay,’” says Palma, who has worked closely with the team at Ultimate Collision to ensure the platform meets their needs.

“The estimators, they have 200, 300, maybe 400 pictures at times,” Palma says. “My platform really helps facilitate getting those pictures in, but they might not all go to the insurance company, and many don’t. A lot just stay internal; it’s basically liability or just maybe understanding a process, because maybe a tech is working on a car they don’t usually work on, and they want to do some before and after, just so they can remember how to put something back together.”