6,000

NAPA Auto Parts stores in the U.S. supported by a nationwide network of distribution centers

Access to an in-house APPRENTICE PROGRAM at no additional cost

NAPA is proud to have America’s largest network of parts and care.

With nearly 6,000 Auto Parts stores and over 17,000 Auto Care centers, from coast to coast, we are one NAPA.

95%

consumer recognition when you co-brand with NAPA Auto Care

NATIONWIDE PEACE OF MIND WARRANTY for your customers, and local labor coverage for you

NAPA Auto Care centers are featured in the national marketing campaign PRIORITY PARTS DELIVERY SERVICE

from your servicing NAPA store

Interested in becoming a NAPA Auto Care center? Scan this QR code to be contacted by a local NAPA sales representative.

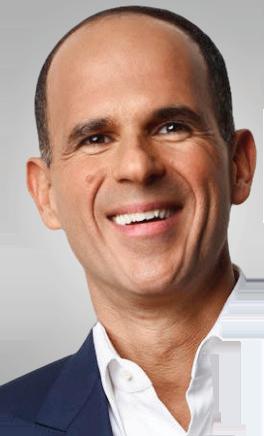

KACEY FREDERICK

On Select Genuine Nissan and Value Advantage® Shocks & Struts, Radiators, A/C Condensers, Belts & Tensioners, Cooling Hoses, Alternators & Starters, Sensors & Switches.

Qualifying enrollees are also eligible to earn up to 3% back 2 on a wide range of select Genuine Nissan and Value Advantage® mechanical parts. There is no cost or purchase obligation to participate. Sign up at NissanUSAPartsRewards.com.

by Ivan Rioja-Scott

There’s a clear difference between listening and hearing. We often use these terms indifferently, and in my opinion, that’s a huge mistake. And it’s a mistake that I am also culpable of from time to time. Active listening is defined by six main skills: paying attention, withholding judgement, clarification, sharing, summarizing, and reflecting. These six additional skills also require development individually and represent a continuous challenge and learning process. When we factor in the inevitable noise that exists around us, the process of developing our active listening skills becomes even more difficult. Over time listening behaviors like nodding or repeating what has been said word-per-word are antiquated forms of making the other communicator understand that we are in fact listening to them. The reality is that those learned habits may actually be mechanisms of deflection and dismissal, the exact opposite of active listening.

Our industry has a large number of diverse actors, all of which have inputs, thoughts, ideas, and opinions that matter. It’s up to us to decide how much importance or weight we give to each of these actors, and how we allow their ideas to shape our decision-making process on a day-to-day basis. Being a shop owner requires listening to many voices, often at the same time, and being able to decipher the depth of meaning of those voices, how their circumstances influence those opinions and thoughts, and after all that, applying a critical thinking process to make the best decision possible. Critical thinking is maybe the most difficult part of the process. It requires that we question our belief system, or time-tested pragmatic approach to doing business, and most

importantly, it mandates an evolutionary mindset. However, applying the principles of active listening will almost always simplify the steps that are required after. Simon Sinek, a renowned English-born author, in one of his many public appearances stated, “listening is not the act of hearing the words spoken, it is the art of understanding the meaning behind those words.”

Listening is a trust-building exercise. When the people we interact with feel heard comprehended, as humans, it brings us closer to each other. Understanding different points of view enriches our own, it helps us learn about new ideas of how we can approach our businesses, our personal relationships, and how we see and interact with the world. But we may just be missing out on all of this if we don’t listen, actively.

EDITORIAL

EDITORIAL DIRECTOR

Chris Jones

EDITOR-IN-CHIEF

Ivan Rioja-Scott

ASSISTANT EDITOR

Kacey Frederick

CONTRIBUTING WRITERS

Tess Owings, Leona Scott

EDITORIAL ADVISORY BOARD

Tara Topel, Topel’s Towing and Repair

Andrew Marcotte, American Pride Automotive

J.J. Mont, J.J.’s Auto Service

Rachel Spencer, Spencer’s Auto Repair

Bruce Howes, Atlantic Motorcar

Lucas Underwood, L&N Performance Auto Repair

SALES

ASSOCIATE PUBLISHER

Andrew Johnson / ajohnson@endeavorb2b.com

ASSOCIATE SALES DIRECTOR

Mattie Gorman-Greuel / mgorman@endeavorb2b.com

DIRECTOR OF BUSINESS DEVELOPMENT

Cortni Jones / cjones@endeavorb2b.com

ACCOUNT EXECUTIVES

(NATIONAL ACCOUNTS)

Diane Braden / dbraden@endeavorb2b.com

Darrell Bruggink / dbruggink@endeavorb2b.com

Marianne Dyal / mdyal@endeavorb2b.com

Chad Hjellming / chjellming@endeavorb2b.com

Lisa Mend / lmend@endeavorb2b.com

Annette Planey / aplaney@endeavorb2b.com

Kyle Shaw / kshaw@endeavorb2b.com

Sean Thornton / sthornton@endeavorb2b.com

ADMINISTRATIVE ASSISTANT

Ryan McCanna

ART AND PRODUCTION

ART DIRECTOR

Emme Osmonson

PRODUCTION MANAGER

Mariah Straub

AD SERVICES MANAGER

Jen George

ENDEAVOR BUSINESS MEDIA, LLC

CEO Chris Ferrell

COO

Patrick Rains

CRO

Paul Andrews

CDO

Jacquie Niemiec

CALO

Tracy Kane

CMO

Amanda Landsaw

EVP TRANSPORTATION

Kylie Hirko

EVP ENDEAVOR BUSINESS INTELLIGENCE

Paul Mattioli

VICE PRESIDENT - VEHICLE REPAIR GROUP

Chris Messer

SUBSCRIPTIONS

Send address changes and subscription inquiries to: Ratchet+Wrench PO Box 3257 Northbrook, IL 60065-3257

SUBSCRIPTION CUSTOMER SERVICE: 877-382-9187 ratchetwrench@omeda.com

LETTERS TO THE EDITOR editor@ratchetandwrench.com

Opinions expressed in Ratchet+Wrench are not necessarily those of Endeavor Business Media, and Endeavor Business Media does not accept responsibility for advertising content.

IVAN RIOJA-SCOTT, EDITOR

Shops That Perform 40% Maintenance Are More Profitable

Don’t let your shop get stuck doing only repair work. Balance the mix with BG Automotive Maintenance Services. Independent shops are most profitable when their business includes maintenance work. Maximize productivity and increase profitability–get in touch with your BG Distributor today!

Right to Repair can be a polarizing topic, and while most of the industry is in agreement, the pragmatic application and approval is still in the air

BY KACEY FREDERICK

The discussion surrounding high-tech vehicle data access has only grown more relevant in the auto repair industry—but not everyone has the same stance on how to best handle the issue. While Right to Repair has gained incredible traction, some shop owners in the industry have concerns with how it may ultimately impact their day-to-day operations.

So, what exactly is the REPAIR Act calling for? Ratchet+Wrench sat down with Scott Benavidez, owner of Mr. B’s Paint and Body Shop Inc. in Albuquerque, New Mexico, and chairman of the Automotive Service Association’s board of directors, to hear some of the valid concerns he has as an independent shop owner.

In turn, Lisa Foshee, senior vice president of the Auto Care Association’s Government Affairs and General Counsel, offered some insight into how some of these concerns are being addressed by the Right to Repair movement.

Different shops have different experiences with being able to access data. For Benavidez, his shop has seen little issue with communicating directly with OEMs for the data they need to repair vehicles.

But this process can look different for mechanical repair shops, as opposed to collision repair businesses, Foshee counters. It’s true that data access is typically not a huge roadblock for collision shops: these vehicles are often still under warranty, making it the automakers’ best interest to be compliant with collision shops. For mechanical repair and service shops, it’s more likely they’ll be seeing mostly cars that have aged out of their warranties.

Foshee cites a recent ACA survey in which 63% of respondents reported diffi-

culty accessing repair data either daily or weekly. Additionally, 51% reported having to send up to five vehicles to a dealer each month due to data access restrictions.

R2R opponents have their reasons for being skeptical of the legislation as an answer, though; particularly, how government involvement will impact the operations of smaller shops.

“I think our biggest concerns were having the government regulate shops and regulate that kind of information,” explains Benavidez. “They do not have the capacity to do it. They do not have the people

in place to do it. It was better to be able to problem-solve it ourselves, with direct contact with the OEMs.”

This relationship between shops and OEMs is what was outlined in a Memorandum of Understanding between ASA, the Society of Collision Repair Specialists, and many different automakers. The MOU has been a central talking point in the debate surrounding R2R, with many questioning if further action is needed.

Many have dismissed the MOU as a solution, though, as it provides no consequences for automakers not providing

someone repair data. Nothing about the MOU is legally binding or compels an automaker to do anything. This is where the fear for many shops lies: not having an enforceable promise that the repair data will be there for them when they need it.

In addition, Foshee points out that the MOU applies only to data gained through a scan tool plugged into the OBD-II port, not everything that is transmitted wirelessly and stored virtually.

The way this data is wirelessly collected and stored was confirmed by automakers themselves in a statement to the United States Bureau of Industry and Security.

“Generally speaking, auto manufacturers maintain control of any vehicle-generated data that is transmitted to them,” the statement read. “For the data to be shared with other entities, the auto manufacturer would have to proactively share that data with a third party or authorize access to that data by a third party.”

The topic of data access brings up another

crucial point, though: is it fair to force OEMs to hand over repair data to shops for free? As Benavidez points out, it isn’t practical to force companies that have invested money researching and developing this data to simply hand it over, when even dealerships usually must pay for that same data.

However, the REPAIR Act doesn’t call for this data being given away for free. The language of the bill only asks that it is offered at the same price it is for dealerships.

“The REPAIR Act in no way asks for the data to be provided for free. That is not on the table,” explains Foshee. “If you charge the dealership $1,000 a month, then that’s what you should charge the aftermarket. But at no point has the aftermarket asked for the data for free.”

With shops already having to compete on a plethora of aspects like customer service and trustworthiness, Foshee contends that the REPAIR Act will offer a level playing field for both dealerships and independent shops.

The idea of a level playing field is a dominant force behind the push for R2R. In

that same vein, the bill also emphasizes the importance of aftermarket parts—something some opponents have questioned the motives of. But R2R proponents counter that it isn’t conducive to fair competition for OE parts to be the only ones propped up as a solution.

While ASA is not opposed to any kind of legislation promoting data access, Benavidez says that it’s important to try and make the process outlined in the MOU work before jumping to sweeping federal regulations as a solution.

The push for R2R comes from an anxiety many mechanical shops are feeling— small, independent shops, who may not have the relationship with auto manufacturers that others do—that they feel the MOU has not addressed.

Concerns from both sides of the aisle are valid. But the over 60% of repair shops surveyed by the ACA, who report having trouble accessing data, are still looking for solutions that they have yet to find.

We have not just enhanced, but mastered, the concept of car

With monthly revenue figures over $1 million, our system guarantees exceptional

In 15 minutes every car gets a full comprehensive inspection on the speed rack. Pictures and videos capture the problems to be presented to the customer.

“If you’re not counting your money, someone else is.”

Financial / P&L Statements

Budgeting, Projections & Forecasting Inventory Management Fraud & Embezzlement Plus so much more!

General Motors shared what its course of action would be in the event of environmental regulations on new vehicles being relaxed, reports The Detroit Free Press.

While GM will still look to pursue EV production long-term, its shortterm plans may adjust depending on what the incoming presidential administration will do.

“In a world where compliance is eased, you could see where you don’t necessarily need as much plug-in, you might not need as much (battery electric vehicles) as well. But we’ll cross that bridge,” said GM CFO Paul Jacobson at the UBS Global Industrials and Transportation Conference in Manalapan, Florida, this past Wednesday.

Jacobson added that GM will still aim to offer an all-electric lineup within the next decade as part of its long-term plans. The company is currently on track to meet its shortterm goals and achieve variable profitability for its current EVs, with the next step being to attain pretax profitability.

“That’s going to be a function of where the adoption rates are, and obviously there’s a lot of uncertainty as to administrative priorities as we see turnover in the White House,” explained Jacobson.

In the event that regulations are rolled back, GM will have to adapt by cutting the cost it takes to make EVs faster, produce less EVs, and not take advantage of some economies of scale. Jacobson described these moves as tweaks as opposed to a full-blown pivot, with the company being conscience to not over-correct itself.

The National Highway Traffic Safety Administration will not be seeking an immediate recall of ARC Automotive and Delphi Automotive airbags,

instead opting to investigate further, reports Reuters.

In Oct. 2023, the agency argued that the airbag inflators should be recalled due to the risk they posed of sending metal shrapnel flying upon deployment.

Automakers including General Motors, Toyota, and Volkswagen voiced opposition to NHTSA’s decision, and the agency has since not made a decision.

“NHTSA is specifically looking to gather more information on the technical and engineering differences between the inflators as installed into the manufacturers’ respective vehicles, as well as differences in processes among the relevant factories and manufacturing lines,” NHTSA said in a statement.

A group of U.S. senators recently sent a letter to the CEOs of the top auto manufacturers urging them to step down from their opposition to Right to Repair, reports The Verge.

Composed by Elizabeth Warren (D-MA), Jeff Merkley (D-OR), and Josh Hawley (R-MO), the letter accuses automakers of fighting Right to Repair legislation for profit-driven interests, in an effort to monopolize automotive repair and maintenance.

The senators pointed out that, while automakers frequently cite cybersecurity as the cause for concern for Right to Repair, they themselves have been found to not comply with this. Earlier this year, we shared how General Motors shared customer driving data with insurance companies without clear disclosure.

Additionally, the letter cited a Federal Trade Commission study that found no evidence of independent shops being any more likely to mishandle vehicle data than a dealership.

“As the gatekeepers of vehicle parts, equipment, and data, automobile manufacturers have the power to place restrictions on the necessary tools and information for repairs,

particularly as cars increasingly incorporate electronic components,” wrote the senators. “This often leaves car owners with no other option than to have their vehicles serviced by official dealerships, entrenching auto manufacturers’ dominance and eliminating competition from independent repair shops.”

Signs of waning interest in the Tesla Cybertruck is potentially leading to more of the vehicles landing in used car lots, according to Inside EVs.

The second quarter of 2024 saw the Cybertruck become the best-selling electric pickup in America, after being the third-best-selling EV in the country in Q3—however, the vehicle has been showing less impressive numbers lately.

After Cybertruck assembly line workers were told to stay home for three days earlier this month, Reuters has now reported that Cybertrucks are now taking up to 75 days to sell, compared to what was 27 days this past May.

According to data from CarGurus, the price of a Cybertruck has seen a 3.19% drop over the last 30 days, sitting now at $106,845. It’s also a 10% price drop from the last 90 days.

Though sales of the Cybertruck were nearly equivalent to the combined sales of all other electric trucks this past July, analysts have argued that this is due to Tesla filling out a backlog of older orders.

The longer these Cybertrucks sit in lots, the easier it will likely be for a consumer to find a used one for a much lower price, as explained by Inside EVs. As of now, the cheapest used Cybertruck listed on CarGurus is selling for $82,995. It has 17,400 miles, a dual-motor, and has already been through two previous owners.

“The number of days they’re sitting is getting longer and the price is coming down, and I can tell you the sales volume has come down,” said Kevin Roberts, director of economic and market intelligence at CarGurus.

By Spiro Morogiannis, BG Training Manager and BGU Instructor

As you enter the new year, it’s time to review what worked in 2024, but also implement changes needed to drive continued growth through the new year. Adopting a mindset of constant improvement will yield positive results. While each shop faces unique challenges—like employee retention, high tooling and diagnostics costs, and inconsistent labor times—simply refining existing shop processes can make a significant difference in shop profitability in 2025. Setting strategic goals focused on financial success, staff development, customer engagement, and process efficiency is crucial. Investing in training, goal incentives, and process conformity will foster growth, as a committed team will in turn invest in your success.

1. Assess 2024 Performance

Review your 2024 KPIs (Key Performance Indicators). If you’re not using a quality shop management system, consider investing in one—it can elevate your business from “getting by” to thriving. Key metrics like labor efficiency, job GP%, and bay turnaround are areas that can quickly boost profits.

2. Establish New Targets

Set revenue targets but focus on labor efficiency (productivity %). Jobs like quick-turn suspension repairs or preventive maintenance with high labor efficiency can drive profitability more than laborintensive heavy line jobs.

3. Manage Expenses

Be mindful of expenses without sacrificing quality. I follow the rule: “Get the best quality you can afford,” as it pays off in the long run, whether it’s for parts, fluids, or tools.

4. Invest in Technology

Technology is crucial. From shop management systems to diagnostic equipment, look for upgrades that yield high ROI. Focus on cost-effective improvements that generate quick returns, helping you fund bigger investments for future growth.

1. Hiring and Retaining Skilled Employees

What sets your shop apart? Focus on training and setting individual goals to drive employee retention. Many techs leave because they aren’t offered training or opportunities to grow. Make development a key part of your shop’s operations to stand out.

2. Training and Upskilling

“Invest in your people and they’ll invest in you.” Continuous training not only improves skills but also enhances retention. A well-trained team is your shop’s success!

3. Leadership Development

Your team leads are the backbone of your business. Invest in leadership training and encourage personal growth so they can take on more responsibility. Developing leaders improves your entire operation.

4. Team Morale and Engagement

Employees need more than just expectations; they need purpose. Incentives, clear processes, and owner accountability fosters engagement. Lead by example, explain why things are done, and create a workplace where employees feel valued and motivated to contribute.

1. Build Stronger Customer Relationships

Start with retention. What sets you apart? Effective communication, managing customer expectations, offering options, and having a solid MPI process will build trust. Remember, you are their trusted automotive professional—never breach that trust.

2. Marketing and Outreach

Effective marketing isn’t only about coupons or discounts. Use social media to share success stories, reward loyal customers unexpectedly, and ask for referrals. Remind customers why they choose your shop over others. Additionally, email marketing can keep customers engaged with special offers, maintenance reminders, and updates about your services.

3. Create an Outstanding Customer Experience

You’re in the people business, not just car repair. Show you care through timely communication, clear options, and a process that keeps customers informed about their vehicle’s needs today and in the future. Exceptional customer service is rare— make it your shop’s hallmark.

4. Develop Partnerships

Forming partnerships within 20 groups, coaching services, and parts suppliers is crucial for growth. Don’t try to do it alone—these connections provide essential resources and support for your success.

1. Break Down Goals into Actionable Steps

Start with the “low-hanging fruit”—process management, quality control, and thorough work that reduces comebacks and downtime. These basics fix many other areas of your business. For example, implement a 100% MPI process with a clear system for marking vehicles red, yellow, or green. Whether paper or digital, this step protects and drives your shop forward. Invest in highROI areas first to free up time and resources for additional goals.

2. Track Progress and Adjust Goals

It’s okay to adjust goals as long as you’re maintaining momentum. Set clear expectations, track progress with charts, and regularly review goals with your team. Consistent meetings help visualize where you are and where you’re headed.

3. Hold Yourself and Your Team Responsible Accountability starts with you—the owner or manager. Lead by example, as you’re setting the standard for your team. Without accountability, goals won’t be achieved. You must embody the work ethic and standards you expect from your team.

Having a plan for your shop is half the battle, as it’s easy to get sidetracked by the daily grind of automotive repair and maintenance. Goal setting isn’t a one-time event—it’s a continuous process of self-accountability, implementing and revising systems, and setting high standards. As you work toward your goals, many things will naturally fall into place, and it’s crucial to regularly assess what’s working and adjust what’s not.

With 2025 here, now is the perfect time to take the next steps for your shop. In a market where people are holding on to older or used cars and new vehicles are less affordable, you have a prime opportunity to grow customer retention and capture business. The industry’s trends are in your favor—now’s the time to play your hand.

Spiro Morogiannis serves as BG Training Manager and BGU Instructor. He has 8 years of experience with BG and 15 years in the automotive industry, specializing in independent automotive shops. With a deep understanding of maintenance and repair operations, Spiro brings valuable insights into best practices and industry trends.

Measuring your annual revenue and different profit margins can help you make financial decisions

BY IVAN RIOJA-SCOTT

Within the tracking KPI section of the 2024 Ratchet+Wrench Industry Survey Report, shop owners were asked about their annual revenue, overall gross profit margin, and overall net profit margin. Understanding the overall financials of shops allows shop owners to make datadriven decisions.

Based on insight from the 2024 Ratchet+Wrench Industry Survey Report, over 50% of surveyed shops have an annual revenue of over $1,000,000, and at the same time, over 50% of shops reported a gross profit margin of over 50%.

Developing a solid working relationship with your mobile technician can lead to more efficient operations

BY IVAN RIOJA-SCOTT

The mobile mechanic business has experienced tremendous growth since 2016, with especially pronounced growth in 2020 and 2021 due to the COVID-19 pandemic. According to AutoMonkey, which provides mobile mechanic services in 34 states, the mobile technician market grew 15% in 2024, and similar growth is projected for 2025. Over the past decade mobile technicians have been able to offer expanded services, shorter wait times, and more specific technological services. It’s expected that in 2025 the service portfolio of some mobile mechanics expand into ADAS calibrations and EV battery replacements.

Mobile technicians offer service and expertise that many shops don’t have in-house. Developing a system for collaborating with them is key to being more efficient, and ultimately, offering a better service to your customers.

Over the past few years mobile technicians have become more prominent. Their availability, expertise, and ease of door-to-door service has allowed shops to avoid sending cars to dealerships, therefore becoming more cost-effective. However, developing a strong and reliable working relationship can be challenging. Matt Skundrich, owner of Mad Programming

in the greater Orlando, Florida area, takes a personal and somewhat “oldfashioned” approach to his service: “I like to talk to people and work with shop’s technicians. I’m very relational.” The exchange of information between the shop and the mobile technician is one of the most important parts of a job. For both parties maximizing billing time and hours is an integral part of the process. Performing the repair in the least amount of time allows both parties to maximize their profits. In the world of information that we live in, it’s ever-so-relevant for the shop to share with the technician, in the initial request for service, as much and detailed as possible. “Sometimes simple information as a cylinder misfire can help me understand what the vehicle needs before I even reach the shop,” says Skundrich. Mobile technicians are often called upon when there’s a problem that cannot be addressed with the shop’s own resources, or even when the shop has already tried to fix the issue. Skundrich, a seasoned mobile technician, always prefers to have the full, undisclosed information prior to on-site arrival, even when the shop preempts the problem. “Some shops will call me before addressing the problem and ordering new parts and ask me to come visit them beforehand,” notes Skundrich. While this may require more than one visit, which is not common, it can ultimately help find the solution faster.

Providing t he mobile technician with the largest amount of information upon the request for his service will almost always expedite his visit to the shop. Skundrich emphasizes the importance of principal information such as the year, make and model of the vehicle in question. In the case of a programming service request, the module information, what type of fix has already been performed or attempted, as well as the provenance of the replacement parts supplied, is necessary information.

Time is money, and in the case of auto repair shops, both mobile and on-site,

that’s a truth well told. While a mobile technician’s service is requested to perform repairs that the shop has not been able to do, or attempted to do, there are small aspects that can facilitate the visit of a mobile technician. Overlooked in many cases, having the battery of the car charged, having a minimum amount of gasoline in the car, or creating a safe place for the technician to work, are all fundamental in making the repair faster and easier for everyone. “Treat your mobile technician in the same way you treat your customer. Anything that makes my visit easier makes me want to come and service your shop faster and more often,” says Skundrich.

Most experienced mobile technicians have a network of peers that they can rely on when they face a challenging repair. This network of informational exchange often allows them to share scenarios, experience, and potential solutions for problems. “I have a big network of mobile colleagues and when I run into something there’s always a plethora of potential solutions to pull from,” notes Skundrich. When a shop hires the service of mobile technicians, they’re benefiting from the network that they have, and a wealth of additional experience that comes with them. Dealerships offer solutions, but sometimes lack more detailed aspects of coding and programming. As Skundrich says: “Noting is 100%, but when a shop calls me with a known issue, I tell them that I can solve 80% of the problems.”

Most auto repair shops cannot offer 100% of the services that their clients may require for their vehicles. Sometimes this has to do with the cost of the required equipment and the ROI figures that would make a high-value equipment purchases valid for the amount of potential work that shops can generate. In other cases, mobile services can offer additional services such as key cutting and programming that will ultimately allow your shop to offer a complete customer experience.

Matthew Skundrich Owner of Mobile Advanced Diagnostics and Programming

Over the past 18 years, Matthew Skundrich has been diagnosing and fixing automobiles. While repairing vehicles, he also attended Universal Technical Institute, he finished student of the course in several courses and maintained perfect attendance. For the past 9 years, he has owned and operated Mobile Advanced Diagnostics and Programming. Providing the local area with dealer services at their door. The services provided to shops are module programming, key cutting, diagnostics, and advanced divers assistance system calibrations.

Learning from both the OEM and aftermarket about the latest systems in vehicles has prepared him for fixing any vehicle that someone could call about. Using the training he has passed both ASE and I-Car certification tests. His spare time is spent helping people hone their skills in the automotive world. Someone as simple as writing an article for a magazine, creating a class that he sees as a need, or helping a tech understand how I came to my diagnostic conclusion. Using my daily work as examples has lead to having the students and techs enjoy a unique class.

matt@madprogram.com

BY KATHLEEN CALLAHAN

Starting back up in January is hard, and before we know it, we’re in February, which means that Hallmark tells us that it’s Valentine’s month. And while most people think about Valentine’s Day and their significant other, I want you to think about it in relation to your significant family—your clients.

What are you doing to make sure your clients feel special? I am talking about every month of the year, not only one month a year. Here’s a nice opportunity to think about what you are doing and what more you could do.

Here are some things to ask yourself:

• Do you have a clean and comfortable waiting area?

• Do you offer Wi-Fi, coffee, water, soda, or snacks?

• Do you have first time clients complete a “new client info sheet” so you can learn more about them, their car, and their concerns? (If not, reach out to me, and I can send you mine as a sample)

• Do you offer loaner cars or a shuttle service?

If you said no to any of these questions, perhaps take a moment to evaluate the possibilities of implementing some of this in your shop because many of us out here take that even further. Building relationships beyond vehicle maintenance and repair is a critical part of keeping your clients your clients and not losing them to the cheap oil change offer down the road. Some things I do to remind my clients how special they are:

1. Sending a monthly newsletter with engaging things, including a puzzle, a recipe, fun dates for the month, some silly jokes, and a personalized message from me or a staff member about happenings around town, events we participate in, hobbies, kids, and more. I also express grati-

tude to those who referred new clients our way, and we share some of our glowing reviews. People want to know they are doing business with people, not a faceless company. Of course, I have some help with this through my coaching and marketing company, so it doesn’t feel overwhelming every month.

2. We give small gifts to clients with each service. I set an average budget of $2 per car and set out to find unique items to gift monthly. In 2024, we gave notepads with our logo, Valentine candy hearts, cookies, umbrellas, sunglasses, tote bags, calendars, and the “famous” spice rub clients rave about! We also teamed up with a local coffee shop to purchase insulated tumblers with both our logos, which give you a discount at her shop every time you visit.

3. Along with emails, we send handaddressed cards a few days after our clients have been in, thanking them for choosing us. I include my business card in case they have any challenges or praise to share. Our envelopes are bright pink, so they don’t get lost in the junk mail.

4. We give out “Xpertech Bucks” to clients who refer someone to our shop as a little token of appreciation. We also send them out on our clients’ birthdays if they share them on our info sheet—so they know their special day is important to us! (This is an excellent opportunity for your staff to jot down notes during client conversations and add them to their file in your shop management software. This could include anniversary dates, beloved pets, or special dates for their kids/grandkids. Anything that shows them they are more than a transaction to you.)

5. We have a whiteboard that welcomes our scheduled clients each day—so they feel welcomed and special when they walk in.

I know this can feel overwhelming, but I promise it isn’t. Start with one or two things—you’ll see the difference immediately and want to do more! And make sure to tell me about your successes (or challenges) when you see me at the Women in Auto Care Leadership Conference or Ratchet + Wrench Management Conference 2025!

Kathleen Callahan has owned Florida’s Xpertech Auto Repair for 20 years. In 2020, she joined Repair Shop of Tomorrow as a coach to pursue her passion for developing people and creating thriving shop cultures. Callahan is the 2018 Women in Auto Care Shop Owner of the Year, nationally recognized by AAA for three consecutive years, testified for Right to Repair on Capitol Hill, and is vice chair of Women in Auto Care.

kathleencallahanfl@gmail.com

Understanding the core strengths of your shop allows you maximize profit and reduce down time

BY

BECKY WITT

eorge Witt Service opened its doors back in 2002. The idea behind the shop was to specialize in two Japanese brands, Toyota and Honda, and while the area in which is stands today was not in the desired location, it did have the right amount of space and parking.

Becky Witt, the founder, started the shop with a wealth of experience as service manager at different dealerships. While working at these dealerships she had shown her skill at implementing several measures to improve efficiency both with time management and with costeffectiveness. As she recalls: “When I was working at local Honda and Acura dealership, we had a lot across the street which required the technicians to spend time moving cars back and forth. When I realized how much billing time was wasted by technicians, I created a plan to hire a driver and proposed it to my manager. When it was implemented, we were able to bill $5,000 more per month.”

Understanding the monetary value of time has driven George Witt Service to focus on the efficiency of billing hours, delving into the calculation of the cost of operation per minute. As Witt states: “We take all of our costs, salaries, overhead, parts, rent, electricity, and we calculate how much we need to make per minute to cover these costs.”

The Method and the System

In order to be able to achieve the given revenue goal per minute, George Witt Automotive has developed a series of systems that make the cost per minute achievable. As Witt says: “The two main timewasters are late customers and empty working bays.” To address these issues, especially the latter, the shop loads up the early morning appointments, not allowing for many more later on in the day, and if availability is limited, the customers are scheduled for the following day.

Once the appointments are made there are two actions that the staff at George Witt Service perform, the ticket (estimate) is written up when the appointment is set, and the expected parts are pulled from the shelf, labeled, and prepared for the technician to start the work immediately. In Witt’s experience, customers will have more time to discuss the issues or problems with their vehicles when they call to make an appointment than when they drop off their vehicles for service or repair. This allows the shop to have a deeper understanding of what each vehicle will require prior to the actual visit. Keeping the correct amount of regularuse parts in stock requires a finite balance of understanding the needs of your customers, making sure your shop is not overstocking and therefore potentially wasting money, and assuring you have the required space and inventory system to accommodate the parts. At George Witt Automotive there’s a policy of carrying more stock parts than those required. The shop can support obsolete stock in exchange for not wasting time waiting for parts to arrive, “We carry thousands of parts in our regular inventory, even if some become obsolete. We build that into our cost structure," says Witt. For Witt the cost of stocking parts is not the problem, it’s the cost of not having parts immediately available and the wait time incurred when this situation occurs.

The expertise and know-how George Witt Service has in regard to the makes that they work with is a fundamental step in achieving the desired cost per minute benchmark. At George Witt Service the inspection process starts with the call for the appointment. While Witt assures that DVI’s are

not required, and waste time, the shop’s process for the cost of inspection is built-in to the cost of the annual service. As Witt states: “The first thing we do is take a road test with the car. We then bring the car in, look under the hood, put in the air and pull the wheels, check suspension and actually measure all eight brake pads.”

Witt believes that proper factory maintenance with OEM fluids and parts is the best way to optimize billable hours. Becky Witt began Witt’s optimization by researching oils that could last up to 8,000 miles or one year. This way, her customers only need to come in one time per year. This single visit, which has the oil change as the main component, has additional service items included, all following proper factory schedules. Therefore, the once-ayear visit has now become an annual maintenance visit. As she says: “We do exactly factory-scheduled maintenance, nothing more. We don’t any “wallet flushes” or additional non-scheduled services.” By following the principle of scheduled maintenance, the shop has managed to make 80% of their business regular maintenance, and only 20% repair visits. As Witt confirms: “Doing it the way we are doing it, the cars are well maintained.”

At George Witt Automotive the office staff starts 30 minutes before the technicians do. Prior to this, customer cars have been scheduled in short increments, and when the technicians arrive, there are already cars in the bays ready to be worked on.

When Becky Witt started George Witt Service back in 2002, she had a clear idea of wanting to find work life balance for herself and her employees. The first measure she implemented was deciding to open just five days per week—most shops at that time were open six days per week. Witt has always looked at the business by the numbers and she soon realized that over any given Monday, the shop would receive, on average, 47 phone calls for appointments. The number of appointment requests would gradually decrease as the days of the week passed, and by Friday, there would be almost no appointments at all. “We’ve thrived on receiving cars early in the morning and having them out of the shop that same days," Witt states. It was soon clear to Witt that Friday afternoon was not productive enough to stay open, so she decided to close Friday at midday, and sales did not drop. As time progressed, the shop evolved into a 4-day week—removing Friday from the schedule completely—and again, sales did not decrease. At this point, Witt had also decided to work “by appointment” only on Thursdays, but she knew that she needed the right personnel to be able to shorten the schedule even more. After some creative hiring practices based on the hiring teachings of Bill Haas, she was able to secure the right technicians for this type of schedule. As Witt says: “We bill out 1.6 hours of labor per one hour of actual labor.” This effective labor rate is what has allowed George Witt Service to open, as of the past two years, from Monday morning to Wednesday at noon.

Not all money is good money, and not all jobs are good jobs. Understanding your real cost structure allows shop owners to evaluate what types of jobs are profitable and which ones are not. Many shop owners struggle turning down customers with the fear of developing a bad reputation or losing that customer for future business. Becky Witt’s cost per minute approach helps clarify why some jobs are not worth it. As she states: “You can’t fix it all. There are certain jobs that you either need to price accordingly or just say no.” In her 40-plus year career, she’s been able to narrow down her business model by optimizing and specializing. George Witt Service works with Honda and Toyota (plus Lexus and Acura). Over time and dedicated work, the know-how of her technicians and front office staff has allowed the shop to preempt the service and wear items that most vehicles will require, allowing maximum profitability, and turning down jobs that don’t produce the desired cost per minute. As Witt states: you have to have really good techs, you have narrow down what you do, you have to say no to the bad stuff, and you have to focus on the stuff you make money on.”

Becoming an off-site owner is the goal for many shop owners but the process that gets them to that point is challenging and often comes in unexpected forms

BY IVAN RIOJA-SCOTT

PHOTOS CONTRIBUTED

Like many independent auto repair shops, Beachside Tire & Auto Repair opened its doors in Hilton Head, South Carolina, during the mid-80’s as a family-run business. Sam Johnson, son of the founder, grew up close to the family business and after attending college he returned home to take an active role in the shop. After the unfortunate passing of his father in 2012, he suddenly was forced to take over the business. As he recalls: “I went from being a service advisor on a Saturday to running the entire operation on a Monday.”

It’s not uncommon for businesses to be passed down to the next generation, but the abruptness with which it happened at Beachside set Johnson onto a journey of learning, ending in becoming a successful off-site owner.

After four years as an owner, Johnson saw an opportunity to open a second location in Bluffton, South Carolina. As he admits: “A building became available and even though we weren’t really prepared for it, we seized the opportunity.” Beachside’s second location went through a process of slower growth. The addition of a second location and a new business partner afforded Johnson the opportunity to grow his father’s business while covering both the Hilton Head and Bluffton Markets. Johnson mainly focused his time and effort in the Hilton Head location until the year 2020, when the building where it was located was declared condemned.

Upon an initial disappointment and obvious loss of profits and potential loss of valuable customers, this scenario represented a turning point for Johnson. During the time that the new location in Bluffton had been set up and running, it

was his business partner that had mainly managed and run the new store. Johnson soon realized that his work had now become redundant, thus allowing him to take on the role of an off-site owner. With the passing of his father, he has always prioritized time with his family, and this new situation was going to allow him to prioritize that over the day-to-day running of the business.

Back when Beachside started in Hilton Head, South Carolina, Johnson’s father focused on the customer experience, on building the relationships with his customers. “We try to exceed expectations with every customer,” Johnson says. Creating that customer experience comes both from implementing the right systems and hiring and training the right personnel. Beachside implements training programs for all employees, and some have remained in the business even after the passing of Johnson’s father. He encourages his employees to take note of customer service ideas and concepts that they experience at other businesses, even those that are non-automotive. “It’s important that we listen to our employees and implement their suggestions,” Johnson states. For Johnson’s shop, that has over 1,100 Google reviews and 4.9 rating, transparency and communication are fundamentals in regard to customer service. Even before DVI

software was available the shop’s technicians would use digital cameras and images placed into digital documents that would be sent to customers for their evaluation.

A successful business doesn’t always come through innovation. It’s much more common to see shops achieve success through focus. Beachside stopped working on European vehicles approximately two years ago. Understanding that these vehicles were not producing the desired profitability versus the cost of systems, training, and time, made Johnson decide on this measure. He admits that he has lost a few customers, especially those households with a mix of both American and European vehicles, but after the stated period it has resulted in a smoother shop running process.

This question is one that many shop owners ask themselves at certain points of their career. There’s no simple answer, and the complexity of each particular situation is equal to the real-life doubts that arise from the myriad of factors that play into this decision. Most shop owners that face this dilemma have achieved a certain level of success—in some occasions the goal was from the start— and taking the next step can be the one that instates the most fear. Shop owners tend to agree that you can’t really completely walk away from the business. Coaching, opening up a different shop, a completely different business, and even developing hobbies or ways to occupy time, can make the next step easier. These are all solutions for the

AUTO AND TIRE REPAIR

Located in Bluffton, SC

aftermath but implementing the correct systems to have this work properly and deciding what the role of the off-site owner will be, is the most challenging.

In a recent Ratchet+Wrench Radio Podcast Brian Moak defined the scenario of working yourself out of a job as “leveling up.” This point of view holds meaning and value. Being able to create a business that is mostly self-sufficient should be a sign that something has been done correctly. It means that solid systems have been put in place, that operational procedures are working efficiently, financial goals and objectives are being met, and most importantly, that time is now available for those shop owners that have reached this milestone.

Understanding what each of your technicians prioritizes is key for creating long-term employees

BY LEONA SCOTT

In the competitive world of automotive repair, which deals with a shortage of skilled workers, talented technicians are prized and valued. Losing a key team member to another shop can feel like a personal and professional blow. However, it can also be an opportunity to reflect, adapt and grow as a leader. Here are three strategies to respond effectively when another shop recruits one of your technicians without getting into a bidding war.

1. Build a Culture of Retention

The foundation of any great team is a workplace culture that fosters loyalty. Erich Schmidt, owner of Schmidt Auto Care, a 14-bay facility in Springboro, Ohio, emphasizes creating an environment where technicians feel valued and motivated. His shop offers a four-day workweek, PTO, health, dental, and vision insurance, and even shuts down for a week at Christmas. Schmidt Auto Care

stays warm during frigid winter temps and offers A/C in the summer so technicians have a safe and comfortable environment in which to do their jobs well. Schmidt says, “Know your employees. Understand what motivates them.” For some, it’s money, but for others, it might be work-life balance, opportunities for growth, or access to the latest technology. By maintaining open communication and tailoring incentives to individual needs, you reduce the likelihood of your

team members being swayed by a higher paycheck elsewhere.

Actionable Tips:

1. Conduct regular one-on-one meetings to understand your employees’ goals and concerns.

2. Offer consistent, structured opportunities for professional development, such as requiring 40 hours of training annually, which Schmidt demands.

3. Celebrate successes, whether mastering a new skill or achieving a personal milestone.

2. Handle Departures with Grace

When a technician decides to leave, your reaction can have lasting repercussions. Schmidt recalls the first time a tech left his shop: “The tech gave two weeks’ notice after being offered more money elsewhere. It was easy to let him go because there was some toxicity.” Not burning bridges paid off; that technician eventually purchased the shop he moved to.

A professional approach ensures that your reputation remains intact—with the departing employee and your current team. “Our industry isn’t as professional as other industries,” Schmidt

says. “We need to change that.” By handling exits professionally, you set a standard of respect that resonates across your business.

1. Always conduct an exit interview to understand the reasons behind the departure.

2. Express gratitude for the employee’s contributions and wish them well.

3. Keep communication lines open; you never know when a former employee might become an ally or return.

3. Reflect and Reinforce

A departure is also an opportunity to evaluate your business practices. Schmidt shares, “It’s harder to decide to leave us because we offer a better workplace for everybody.” Reflecting on why an employee left can help you identify areas for improvement.

In addition to providing competitive benefits, Schmidt ensures his shop stays ahead with state-of-the-art technology, from full ADAS capabilities to cutting-edge diagnostic tools. “My shop foreman has permission to purchase subscriptions and technology,” Schmidt

“We don’t just talk about staying current; we act on it.”

- Erich Schmidt, Owner of Schmidt Auto Care

says. “We don’t just talk about staying current; we act on it.”

Reinforcing your commitment to your team and investing in your shop sends a clear message: you value your employees and are willing to evolve to meet their needs.

1. Survey your team regularly to gather feedback on workplace satisfaction.

2. Invest in technology and facilities to ensure a comfortable, efficient workspace.

3. Partner with a business coach or mentor to maintain accountability and focus on long-term goals.

While losing a technician to another shop is never easy, the experience can catalyze growth. You can turn a potential setback into an opportunity by building a culture of retention, handling departures professionally, and using the experience to strengthen your business. As Schmidt wisely notes, “Make sure you’re fully communicating. Open communication makes it less likely for employees to be poached.” Ultimately, the best defense is a strong, engaged team that sees your shop as the place to grow and thrive.

Proper geographical planning, smart spending, and the right partners can help you succeed. BY TESS

OWINGS

Between December of 2008 and December of 2010, 1.8 million small businesses closed their doors, according to an article by Investopedia, “Great Recession: What It Was and What Caused It.”

Andy Emery not only got the keys to his repair shop–Antero Automotive & Truck Services–the same month that the market crashed, he made just shy of $1 million his first year in business. Emery defied all of the odds and opened a brand-new business during an extremely problematic time for most and excelled. So, how was he able to succeed when so many were forced out of business? He was smart with his money, and he made sure to go above and beyond for his customers. On top

of that, he found a clever way to pay for his largest equipment expense.

Emery began his career in automotive working in a full-service two-bay gas station with his stepfather. He says his stepfather’s shop did huge numbers for such a small location and had an impressive customer base that included many of Colorado’s professional athletes, including those from the Denver Nuggets and Broncos. During his time working with his stepfather, he met coaches, players and other local celebrities. “Customer service was paramount,” Emery says of his stepfather’s work ethic.

Emery went on to work for a corporate auto repair company where he learned the ins and outs of running a high-efficiency, high volume shop. He was with the company for four years and ran a few of their locations during that time. There, he learned the back end of running a shop. He also learned that his values did not align with theirs. “I was raised to take care of people,” Emery says.

Emery credits the experience with teaching him many valuable lessons about running a business–including what he wasn’t going to do. He took a few months off and then a building in Greenwood Village, Colorado–the same area his stepfather’s shop was located in–opened up. Being very

familiar with the area, Emery felt it was meant to be and decided to open up his shop in 2008. Then, the market crashed.

Emery’s biggest concern was the same as all small business owners–getting people in the door. The location wasn’t ideal for foot traffic. It’s not on a busy street and you really have to look for it, Emery explained. That presented a huge problem for him as a new business owner. On top of that, Emery wasn’t a marketing guru. His stepfather didn’t do any marketing and he was never a part of the marketing when he worked for the large corporation. Emery wasn’t discouraged. He had a family to feed and believed that if he took care of his customers the money would come. He was right, but first, he needed to find a way to bring these customers in.

Emery’s strategy was less about how to market and more who to market to. He used his knowledge of the area to reach out to customers that he knew from working with his stepfather, which helped tremendously. On top of that, he knew that he needed to justify the cost of his $80,000 tire alignment machine so he decided to find a way to bring in plenty of jobs for that by partnering with businesses that needed that work done.

Discount Tire was his target and, although they were already working with someone, he found out that they were unhappy with their service. “I saw that as my window,” Emery says. He found any opportunity he could to sell his business to Discount Tire. He told the employees and the manager that they would get special pricing for their own vehicles, sent them lunch and schmoozed them until they decided to switch to Antero for their tire alignments. The partnership is great because it’s guaranteed work for Emery’s shop and it’s also great word-of-mouth marketing because they will spread the word about Antero to their customers for him. In addition, Antero also partners with a few body shops in the area that need tire alignments done.

The first year in business, the shop made $940,000 and Emery was able to take home a salary for himself. He started the shop with one other employee and quickly hired another. This year, he has 10 employees that work for him and the shop billed $3.9 million.

“Research the area you’re looking at.” Emery knew the area extremely well from working at his stepfather’s shop, however, he says that there are so many tools available for getting information on demographics, that there’s no excuse for not being well-

informed on the area you decide to open a shop in. It also helps to have a solid financial plan. On top of that, he says that his biggest piece of advice would be to align yourself with one or two people that have the same values, mindset, and excitement levels as you do. That, he says, will accelerate your success.

Oh, and being involved with coaches and groups never hurts. Emery says he went 10 years without becoming involved and now that he’s a part of a coaching group he has things that he would have done differently had he known. “I went at it by myself for a long time and had a lot of missed opportunities,” Emery says.

35,000-FOOT VIEW

BY R. “DUTCH” SILVERSTEIN

Have you ever read something or heard a speaker say something that made you question everything you thought you knew about a subject? It happened to me when I read “The E-Myth Revisited” by Michael Gerber, over 20 years ago. It was the beginning of a love-hate relationship with the ideas presented in the book and with a gnawing disgust of an increasing percentage of auto repair businesses that have adopted many of his concepts.

If you haven’t read the book, especially if you are a technician turned shop owner, I can’t recommend this book highly enough. While that may seem like a contradiction to the previous paragraph, bear with me and I’ll explain. Mr. Gerber is better able to describe the sense of frustration and despair that often comes with shop ownership in those cases where a technician decides to go out on his own and start his own business. He attributes this to a few core reasons, the main reason being what he calls “The Fatal Assumption”, which is: “if you understand the technical work of a business, you understand a business that does technical work.” He proves this assumption as false and highlights the conflicts within the parts of the shop owner that he labels as an entrepreneur, manager, and technician. He continues: “The real tragedy is when the technician falls prey to the fatal assumption, the business that was supposed to free him from the limitations of working for someone else actually enslaves him.” This was indeed a revelation. When I read the chapter discussing these difficulties it felt as if he wrote that chapter just for me. I was very comfortable in my role as technician, but dealing with the public and keeping up with paperwork made me miserable. To say that I was ready for a change would be an understatement. I was eager to learn his solutions.

The first step was defining what an “Entrepreneurial Business Model” actually is. This model has less to do with what’s done in a business and more to do with how it’s done. The commodity isn’t what’s important—the way it’s delivered is what matters. This idea troubles me. Auto repair isn’t a commodity in my view, it’s a service. The product that is

delivered can differ wildly in quality. Gerber sums it up this way, “to the entrepreneur, the business is the product.” This emphasizes not on the quality of the core products or services provided, but the business itself, and runs against everything that I had ever heard or read. An adage frequently attributed to Ralph Waldo Emerson is: “If a man can write a better book, preach a better sermon, or make a better mouse-trap than his neighbor, tho he build his house in the woods, the world will make a beaten path to his door.” Quality is everything.

The mechanism to deliver this superior business is the franchise business model, which Gerber refers to as the “Turnkey Business”. He cites the absolute need for standardization of policies and procedures to account for nearly all situations. The role of each employee is to be clearly defined in writing and the manner in which they dress is to be standardized for each of these roles. The business has to be perfectly predictable in all of its composing parts, and if it were to be easily duplicated, it has to have scalability. Taking advantage of this concept of leveraging the efforts of many to produce a product or service is hardly new, but the acceptance of not producing a good product but one that is—just good enough—galls me. Never is this more evident than in the examples that Gerber cites of business “successes”. One of his favorites is McDonalds. There are over 41,000 McDonalds locations worldwide. By many barometers this is an extremely successful business, but let’s be honest; when you think of a good hamburger; thick, flavorful, juicy and satisfying, you’re probably not thinking of McDonalds. The experience is what is being truly sold, not superior taste or quality of the food.

This attitude of “just good enough” transfers to the quality of employees as well. He states: “The model will be operated by people with the lowest possible level of skill”. He continues, “because if your model depends on highly skilled people, it’s going to be impossible to replicate”. In short, you don’t want or need superstars, you just want to make those who are just barely competent feel like they are superstars.

Let me be blunt here … We don’t test for proficiency in our field, nor do we don’t require any form of meaningful standardized testing. There’s very little aside from observation to differentiate between those that are good from those that are barely competent. Consequently, many of the technicians currently employed by franchises are underqualified and not given the proper training. But their work is profitable and now that’s all that matters.

While producing a lower quality product packaged with ribbons and bows for the unsuspecting consumer, our trade is diminished with each new auto repair franchise business model that opens.

R. “Dutch” Silverstein, who earned his Accredited Automotive Manager Certificate from AMI, owns and operates A&M Auto Service, a seven bay, eight lift shop in Pineville, North Carolina. Dutch was a captain for a major airline earning type ratings in a variety of aircraft including the Boeing 767/757, 737, 200, 300 and 400 series, Airbus 319/320/321, McDonnell Douglas MD80/DC9 and Fokker FK-28 mk 4000 and 1000. After medically retiring, he transitioned his parttime auto repair business into a full-time occupation.

dutch@dutchsgarage.com

Depending on whom you listen to, you might think effective filtration is all about maximum filter efficiency. That just isn’t the case. With 85 years of experience, WIX® understands the best filters optimize engine protection and performance.

To strike the right balance, WIX considers all key performance benchmarks—not only contaminant removal. When you choose WIX filters, you’re choosing the optimal levels of efficiency, capacity and pressure drop for long-term, reliable filtration and maximum engine protection.