Caution: supply-chain bumps ahead

Strategies for controls engineers to mitigate supply-chain disruptions in machine building

Strategies for controls engineers to mitigate supply-chain disruptions in machine building

Get way ahead with adaptive automation

Levitating planar movers

Scalable payload kg

Individual product transport

6D motion

Velocities up to 2 m/s

Free system layout

Elevate your automation game with XPlanar. Developed in-house by Beckhoff, this mechatronic system makes your production literally fly with magnetically levitating movers and base tiles that you can arrange to fit your unique applications – assembly and packaging, pharma and food, entertainment and beyond. So, what will you do with XPlanar?

Processing with up to 6 degrees of freedom

Transport and processing in one system

Wear-free, hygienic and easy to clean

Multi-mover control enables parallel and individual product handling

Fully integrated into the powerful and standardized PC-based Beckhoff control system

(TwinCAT, PLC IEC 61131, Motion, Measurement, Machine Learning, Vision, Communication, HMI)

www.vega.com/vegabar

256 colors

Individually selectable:

Measurement in progress

Sensor switching Process malfunction

cover story

Caution: supply-chain bumps ahead

Strategies for controls engineers to mitigate supply-chain disruptions in machine building

Nick Fryer, Sheer Logistics

machine input

Industrial robot applications expand Industry supports robot integration into work cells, aided by open-source control architectures

Mike Bacidore, editor-in-chief

product roundup

Find the right control PLCs, PACs, IPCs and more controller options for machine builders

ACOPOS 6D allows you to move products freely through an open manufacturing space – unbound by the limits of one-dimensional production flow. Magnetic levitation provides six degrees of freedom for unprecedented processing density on a fraction of the floorspace.

No contact, no noise, no wear

Micron-precise positioning

11 shuttle sizes

Widest payload range

Most advanced planar software platform on the market

br-automation.com

CEO

Endeavor Business Media, LLC

30 Burton Hills Blvd, Ste. 185, Nashville, TN 37215 800-547-7377

Chris Ferrell

COO

Patrick Rains

CRO

Paul Andrews

CDO

Jacquie Niemiec

CALO

Tracy Kane

CMO

Amanda Landsaw

EVP Group Publisher

Tracy Smith

VP/Market Leader - Engineering Design & Automation Group

Keith Larson

editorial team

editor in chief

Mike Bacidore mbacidore@endeavorb2b.com

managing editor

Anna Townshend atownshend@endeavorb2b.com

digital editor

Madison Ratcliff mratcliff@endeavorb2b.com

contributing editor

Rick Rice

rcrice.us@gmail.com contributing editor

Joey Stubbs contributing editor Tobey Strauch tobeylstrauch@gmail.com

contributing editor

Charles Palmer charles101143@gmail.com

columnist Jeremy Pollard jpollard@tsuonline.com

design/production

production manager

Rita Fitzgerald rfitzgerald@endeavorb2b.com ad services manager

Jennifer George jgeorge@endeavorb2b.com art director

Derek Chamberlain

subscriptions

Local: 847-559-7598 • Toll free: 877-382-9187 email: ControlDesign@omeda.com

sales team

Account Manager

Greg Zamin gzamin@endeavorb2b.com 704/256-5433 Fax: 704/256-5434

Account Manager

Jeff Mylin jmylin@endeavorb2b.com 847/516-5879 Fax: 630/625-1124

Account Manager

Kurt Belisle kbelisle@endeavorb2b.com 815/549-1034

9 editor’s page AI and low-code pair well, survey shows

Mike Bacidore, editor in chief 10 embedded intelligence How to achieve speed control with VFDs

Jeremy Pollard, CET

12 technology trends I/O innovations changed system design

Rick Rice, contributing editor

16 component considerations Intrinsic safety for hazardous areas

Tobey Strauch, contributing editor 17 automation basics How to consider safety in system design

Charles Palmer, contributing editor

50 live wire Presence sensors for harsh environments

Joey Stubbs, contributing editor

The quality of Yaskawa products is second to none, but Yaskawa Quality goes beyond that. It’s the total experience of purchasing Yaskawa products and working with people.

ü Global Expertise

ü Proven Quality Management

ü MTBF of up to 28 Years

ü Award Winning Customer Service

ü Product Lifetime Training

ü Free 24/7/365 Technical Support

Want to have that working for you? Contact Yaskawa today.

Mike Bacidore editor in chief mbacidore@endeavorb2b.com

THE APPLICATIONS OF artificial intelligence (AI) continue to expand, but it’s no surprise that low-code/no-code programming is at the forefront.

“Combining AI with low-code/no-code development accelerates digital transformation by enabling faster prototyping, broader accessibility and reducing the need for specialized coding skills,” says Lucas Oliveira, global account manager. downstream and chemicals, at Radix Engineering and Software. Oliveira co-presented on navigating the hype around industrial AI with with Celanese’s Ibrahim Al Syed at the 29th Annual ARC Industry Leadership Forum in Orlando, Florida. “Integrating AI models into these platforms allows businesses to automate complex decisions, enhance user interactions with natural language processing and optimize workflows with intelligent recommendations.”

With essential data locked in legacy systems for many manufacturing organizations, application development that digitizes operations is a valuable approach for the industry. Whether that’s improving quality control, streamlining processes, increasing customer satisfaction or improving employee safety, accelerating digital transformation is high on the agenda, with 52% of manufacturing IT leaders ranking digital transformation as their leading low-code use case.

“The Low-Code Perspective: Insights from Enterprise IT leaders” report provides an overview of the key trends shaping the low-code market among 2,000 global enterprise tech C-suite executives and senior IT decision-makers in the United States, Germany, United Kingdom, Japan Belgium, Netherlands and Luxembourg.

69 % have concerns regarding the governance around AI-assisted coding.

Research from Mendix, a Siemens business, found that lowcode platforms have become a strategic enabler supporting digital transformation at an organizational level. Siemens was a global sponsor of the ARC event.

“We have always believed that low-code had the potential to be much more than a tool to automate manual processes,” says Raymond Kok, CEO of Mendix. “This survey shows that the market agrees. Used wisely, low-code is about rethinking entire business processes from the ground up. In turn, this enables the other critical benefit of low-code: innovation. Enterprises will be able to speed up digital transformation cycles and innovate at scale. Low-code also opens new avenues for fusion teams to think bigger when it comes to using tech to transform their organization for the future, as long as they are prioritizing upskilling users to maximize the potential of low-code for their unique use cases. Low-code continues to be closely aligned to today’s market’s needs, while also offering a springboard for future innovation.”

According to the report:

• 99% of manufacturing organizations surveyed are using low-code as part of their development process. Low-code is now a mainstream technology. For the majority of respondents (75%), low-code improves the organization’s ability to innovate at scale.

• 77% of respondents identify the C-suite as the driving force for low-code adoption. Low-code is seen as a strategic enterprise technology used to facilitate digital transformation and enhance operational efficiency. Long-term organization investment means the entire C-suite is now involved in lowcode decision-making.

• A definitive 84% of manufacturing IT leaders surveyed say combining artificial intelligence and low-code would help the organization innovate faster, more than any other sector surveyed. Yet 69 % have concerns regarding the governance around AI-assisted coding. Survey results indicate that IT leaders want to invest in low-code and AI, but they acknowledge that functional implementation requires upskilling for both developers and non-technical users alike.

Jeremy Pollard jpollard@tsuonline.com

AS TECHNOLOGY HAS MOVED forward, ac/dc drive control, while initially expensive, has proven to be the evolution of reduced voltage starting.

Using ac variable-frequency drives (VFDs) on even smaller motors has created reduced mechanical stress on the components used in the process. In across-the-line starting of motors, a flex rotational coupling would often be used to soften the blow to the system, which is not required when using a VFD.

Using this softened startup speed curve has many benefits for the process materials and components. Blowers and fans benefit from this approach in many applications. Pumps also benefit with a controlled startup of flow, which would also benefit the control valves, should they be present.

precision is a bit in question. If a blower or fan is rotating at 900 rpm or 895 rpm, it isn’t a really big deal. A pump for flow, however, may be critical enough to employ a different control method.

This method of speed control could be scalar or vector. One of the advantages of this method of control is that multiple motors can be controlled with the same drive output to maintain a similar speed for all motors. Speed regulation methods should be employed in the case of multi-motor control, which is application-dependent.

Energy savings is an unintended benefit of reduced starting speed applications.

The use of ac motor and drive technology, even in lowspeed applications, has allowed control-system designers to build more robust systems with a better maintenance record. Arguably, dc motor control is rarely used in modern system designs.

Energy savings is an unintended benefit of reduced starting speed applications. In fan/pump applications, a reduced percentage of speed results in horsepower reduction of greater proportions.

One of the most complex systems I was involved with, from afar, was a printing-press application. Synchronized drive systems allowed for the line to start up as one, and the drives had a common speed signal and tach/resolver following control to make sure the drives started up and ran at the same speed.

With 2025 drive technology, this can be done over a network; however, having a hardwired solution may be better served. Network non-deterministic characteristics may play havoc with motor speed timing.

Alternating-current drives can come in low-voltage to medium-voltage applications. The mining industry would have medium-voltage hoist drives for skip control and ball mills, for example.

There are varying technological drive properties. Volts/ Hertz is a standard method of speed control; however, the

For a more precise speed control profile, most applications would choose a pulse-widthmodulated (PWM) VFD. Using speed feedback for error compensation allows for very precise speed control, should the application require it.

Sometimes it comes down to motor selection, as well. Using an ac servo motor gives the application a better torque profile than a standard induction motor. Positioning applications would normally utilize a servo motor, while typical rotational applications can use a standard ac induction motor.

For high-torque or quick-acceleration movement profiles, a servo motor would better suit that application.

Vector-controlled motors use a VFD, which typically employs a closed-loop controller for precise speed control. This also means that a feedback device, such as an encoder or resolver, needs to be used to attain this tight control. Pulsewidth modulation is used for speed control rather than V/Hz.

Over my career, spanning more than 45 years, I have witnessed the rise of VFDs for energy control, electricity bill reduction and creating a more precise manufacturing environment. The advent of high-powered insulated-gate bipolar transistor (IGBT) has allowed for VFD development in highercurrent applications, as well as power conversion. Common silicon-controlled rectifiers (SCRs) and triodes for alternating current (TRIACs) have been phased out in favor of IGBTs.

JEREMY POLLARD, CET, has been writing about technology and software issues for many years. Pollard has been involved in control system programming and training for more than 25 years.

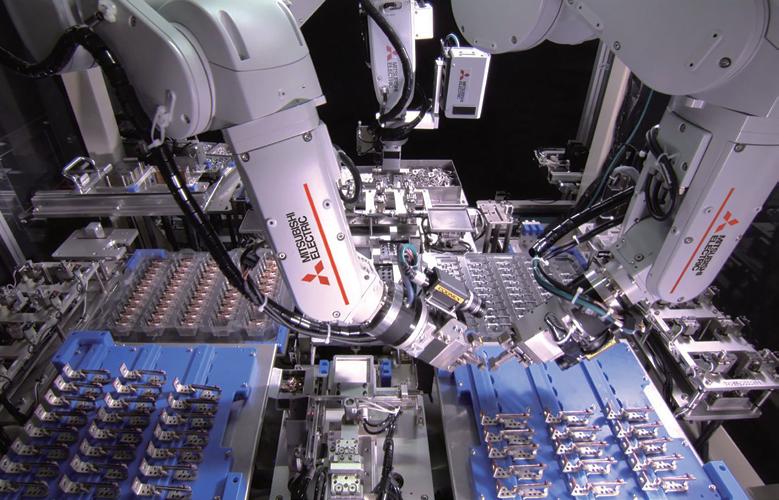

Mitsubishi Electric Automation delivers quality, performance, and compatibility that exceeds your expectations, making your job, and your life, easier. When products are built better, last longer, and work seamlessly with current and future applications, you not only reduce downtime and expenses…you also reduce energy usage, electronic waste in landfills, and scrap. That helps you achieve your productivity and sustainability goals.

Rick Rice contributing editor rcrice.us@gmail.com

WHEN SETTING OUT to design a control system, the logical path tends to start at the brains of the operation and end at the fingers and toes. The controller choice comes first, then the major devices and, finally, the input and output devices that make it all come together.

While this is the traditional way to design a control system, innovation on the input/output (I/O) end of the system has changed the way we might approach our designs. In the early days of programmable logic controllers (PLCs), we would approach a design by listing all of the devices that make up the machine or process, splitting it into inputs and outputs and then splitting that list up into analog and digital devices. From this list, we could determine how many logic modules were needed to talk to all of the field devices.

Each slot didn’t have to contain a physical module, but the memory allocation would match the size of the rack since these early PLCs assigned blocks of memory based on the size of the rack in which it was mounted. For example, a base rack might have four slots in it, so memory was allocated based on potential of four I/O modules in the four slots of the rack.

A remote rack might have seven or 10 slots, and the assigned memory of that rack would be based on the potential of all seven or 10 slots being filled with I/O modules.

Innovation on the input/output (I/O) has changed the way we might approach our designs.

The next generation of PLC, sometimes called a programmable automation controller (PAC) used the same rack-based I/O system with two notable differences. The physical size of the racks was much smaller, about one-third of the size, and the controllers were tag-based instead of memory-based.

That module count would determine the size of the chassis needed to mount the I/O modules. In some cases, there were more modules than the base controller rack, or chassis, could contain, and we would split the modules up into base and child/subracks. A communications protocol that was native to the main processor would be used to have the base rack talk to the child racks.

In those early days, the base rack and the child racks needed to be in the same physical control panel, and the method of communications had distance limitations. As the years passed, the development of additional communications protocols would make it possible to mount the child rack in a remote location and the term “remote I/O” came into use. Depending on the communications protocol, the distance from base rack to remote rack could be as little as a few feet and as much as several hundred feet.

Base and remote I/O originally had the same mounting base or backplane. The base chassis, or rack, would have a processor in the first position/slot with I/O modules filling out the rest of the positions in the backplane, while the remote chassis would have a communications module in the first slot with the same type of I/O modules filling out the rest of the slots in the rack.

In a memory-based system, the controller had a series of base pre-configured memory files. The base types were bit, integer, floating-point, timer and counter.

The size—how many elements of the defined type—could be expanded or reduced based on the needs of the program. Additional files could be added to the base memory system to further define the program needs but had to be of the same type as the base memory files.

In a tag-based system, tags are user-definable, meaning they are given a text name and can be of any file type. Like the memory-based system, the tag space can be as big as the program needs. However, for both systems, the size of the memory space plus the program itself determines the model of controller that needs to be used for the system.

The latest generation of controllers no longer use a fixed chassis and can contain as many modules as the model of controller permits. The size of the base memory also comes with a defined number of communication nodes that can talk directly to the controller. The more memory, the more communication nodes are available, and the cost of the controller goes up in a relative manner.

All of this innovation has opened up possibilities when it comes to the architecture of our control system. Variablefrequency drives (VFDs) and servo drives now connect to

our controller on a standard communications protocol, which is determined by the make of controller, and appear as nodes on the communications channel.

The same is true for other output devices such as linear drives. The remote I/O racks don’t have to be of the same I/O type as the base controller and can be quite small. This makes them more appropriate for mounting remotely on a process or machine.

Some remote I/O racks can be mounted directly on the machine frame, without the need to locate them inside a junction box. The machine-mounted devices are robust and resistant to environmental conditions that traditional I/O racks could not be exposed to.

While all of this innovation has happened to the “brains” side of the control system, a quiet revolution has happened on the “fingers and toes” end of the design. Traditional I/O would come in digital or analog versions. The device would wire to a digital or analog I/O module, which would, in turn, talk to the controller in the system.

Methods of wiring have made it much easier to deploy I/O. This has enhanced control designs because it isn’t so much trouble to get additional signals back to the controller.

The machine-mounted I/O module mentioned previously now comes in versions where the module itself is a node on the communications network. Most machine-mounted modules are capable of up to eight or 16 points of I/O, but, even better, those modules can be daisy-chained together to provide even more machine-mounted I/O points but on the same node on the communications network.

Machine-mounted I/O can be user-configurable, meaning that individual points can be assigned as an input or output and since each of the eight points of physical ports can be split into two separate points, there can be 16 points of either input or output, on a point-by-point basis, chosen by the designer/programmer.

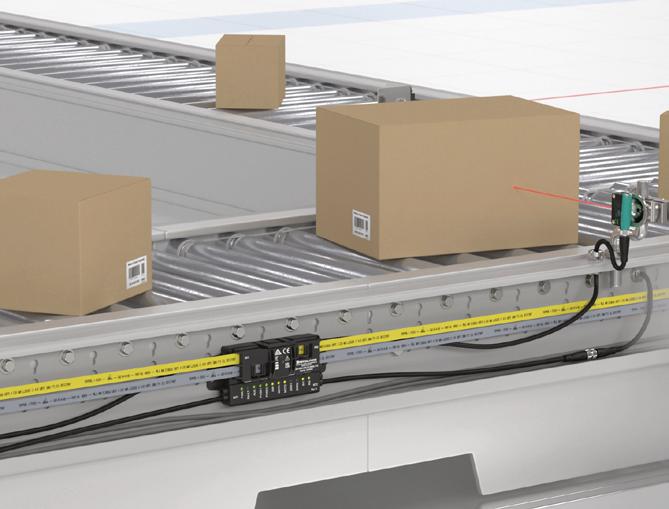

Gaining traction over the past couple of years, IO-Link is a game changer in the world of I/O. Using the same physical connections as a traditional M12 I/O point, I/O devices can provide more than just the analog or digital signal back to the control system. IO-Link devices essentially become nodes where additional information like model number and signal strength/health can be read from the device, but user configurations can be downloaded to the device, as well.

The machine-based module changes—instead of traditional I/O, it is now an IO-Link master or slave—and the

usual four wires now become two wires for power and the other two wires are for communications.

The best part about the advent of IO-Link is many of your favorite I/O devices are already capable of IO-Link. There is no need to move away from what you are comfortable using.

One example of where IO-Link provides an advantage is the ability to monitor signal strength. A traditional digital sensor would only be able to signal a change of state to indi cate the presence of an object. With IO-Link, the processor can receive a 1 or 0 to indicate the presence or absence of the object. But it can also read the quality of the signal.

This can be used by the programmer to set up a message to indicate the demise of a signal. This would suggest that the sensor has accumulated debris that is inhibiting the ability of the sensor to properly function.

A message could be then displayed on the operator station to prompt the operator to clean off the sensor or an nounce impending failure, so that maintenance can plan to replace it as a planned event.

The concept of IO-Link has even migrated to safetyrelated systems. The safety relay becomes a master, and the individual devices on the safety channel become nodes on a safety network. The devices can be door switches, light curtains, safety mats or locking gate latches.

The programmer defines the order of the devices on the network and downloads the configuration to the safety relay. If the definition doesn’t match the actual order of the devices on the network, an error occurs, and the definition must be corrected before the function can take place.

Like the base devices on IO-Link, these safety link systems can indicate not only make-or-break status but additional information like pending failure of dual chan nels of operation.

Door latch devices provide tags to not only indicate status of the door switch but tags to command the door latch to lock or unlock. All of this in a single tag structure in the memory map of the safety relay with one tag for each node on the network.

A control system relies on the inputs and outputs to make everything happen, and every new innovation makes that system easier to design and implement.

RICK RICE is a controls engineer at Crest Foods (www.crestfoods.com), a dry-foods manufacturing and packaging company in Ashton, Illinois.

Tobey Strauch contributing editor tobeylstrauch@gmail.com

INTRINSIC SAFETY IS A design technique that incorporates limiting the amount of energy available for ignition in a hazardous area. The kind of applications calling for intrinsic safety are boilers, power houses, fuel stations, fuel cell testing, chemical transaction areas, mines, kilns, fluid beds or any applications that could be susceptible to ignition due to gases, fumes, dust or fibers.

For instance, certain metals may be flammable, and, if you pile shavings from making airplane parts and then provide an ignition source, a fire could be started that is not put out by water. Temperature plays a huge role in the processing of certain flammable materials, and so does water.

Occupational Safety and Health Administration (OSHA) has similar standards for installing machines in hazardous areas, which require specific wiring methods, classified locations and air flow. These standards reference the National Electric Code (NEC) and National Fire Protection Agency (NFPA).

The idea of intrinsic safety is to prevent explosion, or threat of contamination, explosion or spark.

Fire engineering studies the fire triangle, and results are used to warn firefighters on how to treat certain types of fires. How do engineers deter a fire or combat or isolate a fire?

Some fires are not extinguishable with water. Other materials must burn themselves out. Dismissing the pillars of intrinsic safety could be devastating.

Engineers comply by building machines with low-energy signaling—24 V— in hazardous areas. Intrinsic safety is designed to protect low-energy systems or signals.

Create safety barriers that limit the times of transmissions and reduce heat, dust or any kind of combination that could cause an explosion. Purchase cards and equipment that meet International Electrotechnical Commission Explosive (IECEx) certification, the European Union’s Atmosphères Explosibles (ATEX) directive and explosion-proof environment standards. In short, these are governing bodies that provide legal and regulatory frameworks to create electronics usable in a potentially explosive environment.

ATEX certification shows a machine to be compliant with European Union directives for proving safety in specific environments and explosive atmospheres. Products complying with these standards will be labeled.

Machine builders wanting to meet European standards will be required to certify their builds, much like Underwriters Laboratories (UL) builders do.

There are physical requirements and electrical requirements, as well as wiring measures that reduce sparks or threat of ignition. For instance, electrical boxes need to prevent dust entry in a hazardous environment. OSHA also has marking standards that include the area classification, symbols, type of protection designations, gas classification group, if required, and temperature classification.

Class I, II and III are noted by NFPA 70 and then divided into two divisions and then up to four groups. These classifications are based on gases or vapors, combustible dust and ignitable fibers. How do we fight the potential for combustion in these categories? Engineers set up boundaries, use air flow and reduce flammability reactions based on wiring, conduits and ductwork.

Software-wise, alarms are set up to protect an area and to shut down faulted equipment and turn on air flow to evacuate the area of combustibles. If the machine is in an area that houses many of these machines, then the machines are daisy-chained so that, if one machine faults, they all shut down due to the flammability in the area.

This adheres to machine zoning and the control of the process. Zoning hazardous areas is critical due to having controlled entry and controlled actions such as no smoking, no cell phones and no naked lights. Automation engineers can deploy safety gating and regulate zones with badges or keys or operator-control-room interface and request-to-enter gates.

This is the first of a two-part article. For Part II, visit www. controldesign.com to read, “Intrinsic safety for PLCs and HMIs in hazardous areas.”

Tobey Strauch is an independent principal industrial controls engineer.

Charles Palmer contributing editor

DESIGNING A SAFETY-CERTIFIED industrial system involves complying with various legal requirements to ensure the systems under design will operate safely and reliably. The first and most important point is to understand the applicable standards and regulations. These are clearly spelt out in international publications, such as the International Organization for Standardization (ISO) 13849, International Electrotechnical Commission (IEC) 61508, IEC 62061 or others, depending on your industry.

Downloading and familiarizing oneself with these is the first of many steps, as they determine design parameters and actual application must-haves.

Should the design be within the requirements, it will be certified, allowing construction/fabrication to commence.

1. Documentation and traceability: Maintain detailed documentation throughout the design and development process. This includes design specifications, safety manuals and other relevant documents to demonstrate compliance with safety standards.

2. Verification and validation: Perform verification and validation activities to ensure that the implemented safety features and systems meet the specified requirements. This includes testing and simulation to validate the safety functions.

Consider redundancy, diversity and other safety principles in the design process.

The next step is to conduct a comprehensive risk assessment to identify potential hazards associated with the industrial system under design consideration. Use methodologies such as hazard and operability (HazOp) analysis or failure modes and effects analysis (FMEA) to evaluate risks. Once the level of risk has been established, determine the safety integrity level (SIL). This is necessary in terms of compliance with standards like IEC 61508.

One needs to develop a functional safety plan that outlines the safety goals, requirements and strategies to achieve and maintain functional safety throughout the system’s lifecycle.

Where is the equipment to be installed? Will it be in an intrinsically safe area or in a hazardous area? If applicable, classify and designate hazardous areas within the industrial facility according to relevant standards, such as those specified in the European Union’s Atmosphères Explosibles (ATEX) directive for potentially explosive atmospheres.

Now that the framework and legal compliances have been achieved, it is time for the actual design and architecture. Consider redundancy, diversity and other safety principles in the design process. To optimize the overall safety target, bearing in mind that the weakest link in any chain is its potential failure, it will, in all likelihood, be necessary to implement safety instrumented systems to mitigate specific risks. Ensure that these systems comply with relevant standards and are designed to achieve the specified SIL.

3. Third-party assessment: Engage a third-party certification body or expert to assess and certify the safety integrity of the industrial system. This step is crucial for obtaining official safety certification.

4. Compliance with local regulations: Ensure compliance with local safety and industrial regulations. This may involve obtaining permits, approvals or certifications from relevant regulatory bodies.

5. Installation and commissioning: Follow safe installation practices and procedures. Commission the industrial system in accordance with safety guidelines and standards.

6. Maintenance and periodic assessment: Establish a maintenance plan that includes periodic assessments of the safety-critical components and systems to ensure ongoing compliance with safety standards.

7. Recordkeeping and reporting: Maintain accurate records of safety-related activities, assessments and any modifications made to the industrial system. Be prepared to report safety incidents or compliance-related information as required by regulations.

Always consult with legal and safety experts familiar with the specific standards and regulations applicable to your industry and location to ensure full compliance.

Charles Palmer is a process control specialist and lecturer at Charles Palmer Consulting (CPC). Contact him at charles101143@gmail.com.

Strategies for controls engineers to mitigate supply-chain disruptions in machine building

by Nick Fryer, Sheer Logistics

INDUSTRIAL SUPPLY-CHAIN managers have been faced with a multitude of challenges in recent years. From the COVID-19 pandemic to geopolitical tumult, military conflicts and extreme weather events. While some of these issues may subside in 2025, new challenges, such as the impact of expected tariffs on supply chains, threaten additional disruption.

As the adage goes, change is the only constant. That’s why embracing strategies that can build supply chain resilience has never been more important.

Supply chains face some key risks in the machine-building sector, but there are ways to mitigate them. Greater supply chain visibility, more collaborative and diversified supplier relationships and leaner manufacturing are paving the way for fewer disruptions, but their efficacy relies on more businesses embracing innovative technologies.

Assessing and managing risks in machine-building supply chains

Assessing and managing risks in any supply chain can usually be divided into five phases, as V.M. Rao Tummula and Tobias Schoenherr prescribed in their white paper, “Assessing and Managing Risks: Using the Supply Chain Risk Management Process (SCRMP),” on ResearchGate:

• risk identification

• risk measurement and assessment

• risk evaluation

• risk mitigation and contingency plans

• risk control monitoring.

What underpins each of these is the need for accurate data and data systems that allow logistics and supplychain leaders to not only see what’s on the supply-chain horizon, but to monitor exactly where intervention can be performed at any given moment.

The job of supply-chain risk management and trying to avoid supply-chain disruptions is further complicated by the fact that strategies need to include a look at both internal production processes and external risks.

Machine breakdowns are as important to keep an eye on as the potential impact of climate change and increased natural disasters. Controls engineers know better than anyone that the secret to withstanding such pressures is less about the actions taken in response to each crisis and more about the systems in place that ensure that manufacturing rolls along regardless.

Enhancing supply-chain visibility and control through technology

Machine-building supply chains are complex beasts. Tracking risks from all sides and being nimble enough to respond to them requires embracing technology that creates more visible and data-driven supply chains.

Real-time transportation visibility platforms (RTTVPs) are one of the most important innovations driving the new era of supply-chain visibility and control. These platforms rely on a mix of the global positioning system (GPS) and telematics to track shipments and provide live updates

on both the location and status of goods in transit. Used as part of a transportation management system (TMS), they can be an integral part of optimized route planning and transportation.

Also in the realm of tracking technology are Internet-of-Things (IoT) devices and radio-frequency identification (RFID) tags. IoT sensors play a crucial role in supply chain visibility, thanks to their ability to collect data on everything from location to temperature and send out automated alerts if conditions change or hit concerning thresholds. RFID tags use radio frequencies to help businesses to keep track of inventory.

What all this technology does when used together is provide decision makers with the data and insight that they need to maintain manufacturing systems and schedules. Scheduling systems powered by artificial intelligence (AI) can even be integrated to automate some of this work and further streamline supply-chain control.

The benefit of accurate tracking technology and the data it collects is that it’s far easier to see which suppliers are consistent and which have become mired in disruption. This then allows for better strategizing on where diversification in the machine-building supply chain needs to occur.

Diversification and the flexibility it offers is a fundamental part of supply chain resilience, but so is collaboration, at least from a data

perspective. As Deloitte pointed out in its Business Operations Room blog post titled, “Harnessing the power of supply chain collaboration: Supply chain resilience and risk management,” collaborating and sharing information on capacities and capabilities builds trust and allows all those within that network to detect risks far earlier and respond to them more quickly, too.

It allows supply-chain managers to more accurately balance the external risks mentioned earlier, alongside internal ones, so that more informed manufacturing decisions can be made if it looks like a certain part will be delayed.

Lean manufacturing is an umbrella term that covers varied approaches that all aim to do the same thing: cut back production activities that don’t add value, while prioritizing quality

and meeting customer demand. One of the most effective of these measures is just-in-time (JIT) production.

The risk with leaner approaches such as JIT is the potential for stockouts and disruptions. The solution, however, isn’t to abandon these highly efficient measures but to revamp them, as ManMohan S. Sodhi and Thomas Y. Choi suggest in their Harvard Business Review article, “Don’t Abandon Your Just-In-Time Supply Chain, Revamp It.”

This includes identifying priority parts and stockpiling those if data suggests they’re vulnerable, investing in tracking technology and buffers, such as more collaborative relationships with suppliers.

In an increasingly unpredictable global landscape, supply chain managers in the machine-building sector must proactively address challenges with resilience-focused strategies.

By leveraging advanced technologies for real-time visibility, fostering diversified and collaborative supplier relationships, and by embracing lean manufacturing with adaptive safeguards, they can mitigate disruptions and maintain operational continuity.

The key lies in combining innovative tools with data-driven decisionmaking to ensure that production systems remain agile and efficient, regardless of external pressures. With these strategies, manufacturers are well-equipped to navigate the evolving complexities of supply chain management and drive sustainable success.

Sheer Logistics Vice President Nick Fryer has more than a decade of experience in the logistics industry, spanning marketing, public relations, sales enablement, mergers and acquisitions. Contact him at nick.fryer@sheerlogistics.com.

supports robot integration into work cells, aided by open-source control architectures

by Mike Bacidore, editor-in-chief

SEVEN PANELISTS answered questions about robotics integration. Chris Savoia is regional head of UR+, Americas, at Universal Robots. He answered some pertinent questions about robotic integration.Kristian Hulgard is general manager, Americas division, at OnRobot.Fredrik Ryden is CEO of Olis Robotics. Kenneth Bruun Henriksen is the global head of MiR Go Ecosystem and a board member of Aim Robotics. He shared his thoughts on robot integration. Mark Collins is senior automation electrical engineering coordinator at Mazak in Florence, Kentucky. He holds a bachelor of science in electro-mechanical engineering from Miami University in Ohio. With more than 25 years of experience in a variety of roles in the manufacturing and machine tool industry, Collins has acquired a breadth of experience in robotic automation, machining process, industrial networking and security. He is looking forward to seeing how artificial intelligence, big data and the continued move toward a more connected manufacturing industry will affect the future of manufacturing. Misa Ilkhechi is co-founder and vice president of sales at Formic. He leads the product vision, strategy and roadmap for a flexible and affordable robot-as-a-service offering that democratizes access to automation for factories of any size. With more than 10 years of experience in automation, robotics and business development, he answered our questions about the

future of robotic integration. David A. Bruce is engineering manager, general industry & automotive segment, at FANUC America. He answered our questions about robotic integration.

As industrial robot installations continue to rise, they continue to be integrated into work cells for palletizing, machine tending, welding and other industrial applications. What innovative or efficient robot-integration applications have you seen or been involved with?

Chris Savoia, regional head of UR+, Americas, Universal Robots : An example of this is with

Righthand Robotics, which has an incredible end effector that looks a bit like it is from the movie “Alien.” It has three grasping claws and a suction cup that extends to grab packaged goods from bins, performing millions and millions of picks mainly within the logistics industry. Another example is Translas, who manufactures a welding torch that embeds fume extraction at the tip without comprising weld puddle dynamics or quality (Figure 1). Another recent application is from Versabuilt, which has a patented system that cuts down retooling time for CNC mill machinetending automation applications. It doubles down as the cobot fingertips can also be the work holding in the machine tool, meaning you cut design in half when changing work orders.

Kristian Hulgard, general manager, Americas division, OnRobot : Right now, end-of-line automation is very popular. Palletizing is especially hot for a variety of reasons. It’s physically demanding work. It’s increasingly difficult to find and retain workers for manual positions like palletizing. And palletizing is well understood in terms of automation.

In terms of efficient robot integration, I have fully installed a collaborative palletizing application in less than day. This covers the entire deployment process from arriving at the facility with the hardware, setting it in place and running our software. There was a blank space in the factory the day before, but, seven hours later, the company had a fully functional automated palletizing cell. This type of efficiency just hasn’t been possible before. It’s innovative on both the hardware and the software side, and it’s extremely efficient in terms of robot integration.

Fredrik Ryden, CEO, Olis Robotics: We have deployed our remote monitoring and controls software on everything from palletizing cells to highly customized cells used for handling radioactive samples. The common thread across these deployments is that a continuously monitored cell is faster to deploy and easier to operate and maintain (Figure 2).

Kenneth Bruun Henriksen, global head of MiR Go Ecosystem: The integration into other work cells is a key feature of autonomous mobile robots (AMRs). Common integration areas are to connect directly to the work cell and pick up parts with, for example, conveyor top modules. But moreover end-of-line palletizing where the AMRs connect to the palletizers is also a use case that’s increasing.

In the electronics sector especially, there’s also an increased focus on integrating mobile manipulators, with

a mobile robot and a collaborative mobile arm. Collaborative mobile robots have been used for machine tending for some years now, but they can become more productive and versatile by adding mobility.

Mark Collins, senior automation electrical engineering coordinator, Mazak : We’ve been involved in several innovative robot integration applications, including dynamic work cells for real-time adaptive machining, automated inspection and quality control using vision systems and intricate machine-tending scenarios. One notable project included integration of a shop-floor coordinate measuring machine (CMM), an industrial robot and top-of-the-line optical measurement system to provide an automated machining cell with 100% part inspection for a leading supplier in the defense industry.

Misa Ilkhechi, co-founder and vice president of sales, Formic : As the momentum of robotic integration accelerates, we at Formic have been deeply involved in optimizing robot cell configurations. Our approach has been rooted in the principles of standardization and modularization of robot cell designs, facilitating rapid deployment across various industrial applications. By embracing the latest software methodologies, we’ve been able to enhance the configurability and management of these cells, streamlining recipe creation through a user-centric graphical user interface (GUI). This not only expedites the setup process, but also empowers users, even those new to automation, to tweak and manage cell operations with precision.

To further support this, we’ve compiled a rich library of video-based documentation, providing clear, step-by-step technical guidance on troubleshooting and optimization. Our focus remains steadfast: to ensure fast, simple integration of robot cells, driven by technical excellence and user accessibility.

David A. Bruce, engineering manager, general industry & automotive segment, FANUC America: In my role in the general industry and automotive segment supporting all our intelligent options, I get the chance to work on proof-ofconcept systems for large potential applications. One that I worked on back in 2020 has turned into a multiplesystem order for one of the largest logistics companies on the planet.

The application is flat sorting or sometimes called package induction where in a logistics facility several packages that are mostly flat, but not always, need to be singulated into a highly automated sorting system at over 1,000 parts per hour.

The challenge with this application involves not only very good machine vision to identify the best pick point and type of package, but also efficient and intelligent path planning to ensure the absolute maximum accelerations possible are used because too much acceleration will result in the package being ripped off the tooling, and too low acceleration will put the system behinds its goal rate.

This application is almost completely manual today and is one of the top applications that companies are looking to automate, and with the right technology and integration it is a perfect fit for vision-guided robotics.

Robot duty is also a large concern for these types of systems where the robot will be working as fast as it can and with a different path each cycle.

The specific model of robot and its precise placement in the work cell will ensure that the robot will perform and last several years, and this is where an offline simulation tool is able to provide very accurate estimates for duty and motion speeds and allows our team to identify the best robot model and position for it in the system.

What have been the biggest improvements to robot integration and interoperability with other robots or components in work cells in the past five years?

Kristian Hulgard, general manager, Americas division, OnRobot : One of the biggest improvements has been the transition to fully electric and software-controlled end-of-arm tooling (EOAT). The adaptable,

intelligent EOAT can replace traditional pneumatic- or hydraulic-powered hardware across many material-handling applications (Figure 3). Electric EOAT is not just more intelligent than its traditional counterparts; it’s also easier to integrate with your industrial robot arm.

Most manufacturers of automation hardware aim for easy interoperability in an effort to lower the barriers to automation adoption. Not all achieve this goal. Those that do are manufacturers that make it easy for end users to get all the components in the work cell communicating and working together.

Fredrik Ryden, CEO, Olis Robotics : There is a growing awareness that communication on the plant floor doesn’t need to be real-time, except at the lowest levels of the technology stack. This greatly simplifies software and hardware interfaces since standard PC hardware can be used in combination with well-supported open protocols, such

as representational state transfer (ReST) application programming interfaces (APIs).

The ability to operate using standard hardware and software means access to a complete ecosystem of software tools and people. In turn, this increases the chance of a successful initial deployment and enhances the likelihood of a quick resolution should any problems arise.

Kenneth Bruun Henriksen, global head of MiR Go Ecosystem : The biggest improvements have been driven by advancements in standardized communication protocols, which can help facilitate seamless data exchange and coordination between different robots, components and communications systems such as enterprise-resource-planning (ERP) and warehouse-management-system (WMS) software.

Additionally, the rise of collaborative robots and AMRs have also prompted the integration, as these are made not just to collaborate with humans but also by nature being flexible and easy to deploy into other systems (Figure 4). This has opened up the idea of using robots in areas where it has been impossible until a few years ago.

Chris Savoia, regional head of UR+, Americas, Universal Robots : The robot operating system (ROS) has been a great boon for the industry. Admittedly, ROS is oftentimes more complex and requires more experienced programming skills than is ideal, since it requires the use of a Linux terminal. But ROS has allowed very sophisticated robot systems to be deployed without needing a Ph.D. in robotics, especially since ROS2 has launched, which fixes a lot of the architectural problems of ROS1. Universal Robots maintains an active ROS2 driver that can be used by startups, researchers and other developers to build reliable, innovative products from our platform.

Misa Ilkhechi; co-founder and vice president of sales, Formic : Over the past five years, the realm of robotic integration has witnessed transformative advancements, particularly in the domain of interoperability. Companies like Ready Robotics and Vention have been at the vanguard of this evolution, pioneering the development of cohesive programming interfaces that bridge the gap between distinct robotic systems and actuators. These unified interfaces play a pivotal role in streamlining integration processes and ensuring seamless communi-

cation between robots and other cell components. Additionally, there’s been a noticeable surge in the development and adoption of robot-operating-system (ROS) libraries. This open-source approach promotes a collaborative ecosystem, allowing for the rapid exchange of innovations and ensuring that robotic systems can operate harmoniously within diverse work cell configurations.

David A. Bruce, engineering manager, general industry & automotive segment, FANUC America : All major industrial robots have some form of safety-rated software to limit the areas where the robot can be at any given time. This type of software has allowed the work cell footprints to shrink dramatically, which greatly reduces the required real estate within a facility for a robotic-based automation system.

FANUC’s version of this is dual-check safety, and it allows a user to specify various zones, in cartesian or joint space, where the robot cannot be or has to be based on safety-rated signals from other devices in the work cell.

It is called dual-check because two sperate processors are constantly monitoring the user-specified requirements and the robot’s position and current speed vector, and if ever both processors disagree there will be a fault stopping the robot.

Mark Collins , senior automation electrical engineering coordinator, Mazak : Over the past several years, the industry has witnessed significant improvements in standardization and communication protocols. The adoption of open standards such as OPC UA and

MTConnect has greatly enhanced interoperability between robots and other components in work cells. Additionally, advancements in Industrial-Internet-of-Things (IIoT) technologies have allowed for seamless data exchange and real-time monitoring, leading to more efficient and synchronized work-cell operations.

Can you explain how software or open-source control architectures have changed robotic integration?

Fredrik Ryden, CEO, Olis Robotics : Although not immediately obvious, open-source software is built into many of the devices that operate on a production floor. Note that much of this software was not explicitly developed for the manufacturing realm, such as Linux, but other software, such as Robot Operating System (ROS), were developed with automation in mind.

Open-source software plays three important roles. First, it is neutral, which makes it easier for competing vendors to rally behind it. Second, it is auditable, so anyone can see how it was written, which can increase trust. And, third, it is easily accessible and often free of charge, which supercharges innovation. All of this results in software and hardware that is easier to integrate on the production floor.

Chris Savoia, regional head of UR+, Americas, Universal Robots: Open-sourced architectures are not embraced by everyone in the community. Many traditional industrial robots manufactured have very hidden and proprietary systems that stifle innovation. Other more modern robot systems, while still patented and reliable, are built off open-source ideals. Most important is the enablement of the free flow of information. Companies that publish information in developer communities foster innovation, which ultimately leads to a larger general adoption of robots by society.

G20 ZPA Motor Control Module

For more information, visit www.pepperl-fuchs.com/pr-g20zpa

■ Smooth processes with zero pressure accumulation control module for 24 V DC motorized drive rollers

■ Integrated logic enables simple plug-and-play commissioning

■ Simple integration—all required connection cables are integrated into the module

Misa Ilkhechi, co-founder and vice president of sales, Formic : Over the past decade, the rise of software-centric and opensource control architectures has fundamentally reshaped the landscape of robotic integration. Traditional proprietary systems, while effective, often posed challenges in terms of flexibility and adaptability. Open-source control architectures, on the other hand, have ushered in an era of unprecedented collaboration and innovation.

With platforms like ROS leading the charge, developers and engineers across the globe have been able to contribute to and leverage a collective pool of knowledge. This collaborative approach has accelerated the development of sophisticated algorithms, sensor integrations and motion-planning techniques.

Moreover, these open architectures promote modularity. This means that robotic systems can be more easily customized to suit specific applications or integrated with new technologies as they emerge. The transparency of open source also ensures that any issues or vulnerabilities are quickly identified and addressed by the community, leading to more robust and reliable robotic solutions.

Lastly, from a software perspective, the shift toward more intuitive graphical interfaces and simulationbased environments has democratized access. Even individuals with minimal coding experience can now design, test and deploy robotic workflows with relative ease, thereby expanding the potential for robotic applications across various industries.

Mark Collins, senior automation electrical engineering coordinator, Mazak : The evolution of software and open-source control architectures has revolutionized robotic integration. Open-source platforms provide greater flexibility, allowing for easier customization and adaptation to specific manufacturing needs. This has led to more streamlined programming, faster implementation and improved collaboration between different robotic systems within a work cell. The use of common software platforms also facilitates smoother communication and integration with other industrial machinery. As the machine-tool industry continues to develop standards like MTConnect to create a normalized semantic vocabulary and information model that doesn’t vary by manufacturer, integration will continue to become easier.

Kristian Hulgard, general manager, Americas division, OnRobot : The emergence of no-programming-required deployment software is a game-changer for automation because it cuts the cost and complexity traditionally associated with setting up robot cells. This type of software not only handles the integration between different components in the cell, but it also enables easy application setup, as well as monitoring and remote analytics. As it develops, software like this will solve many integration problems. As the need for automation rises, so does the need for engineering human resources, but there’s already a shortage of robot integrators. By exploring software-enabled alternatives we can enable robotics integrators to do more.

However, for that to happen, we need artificial intelligence (AI), we need more advanced software solutions, and we need to incorporate tools that minimize the deployment time on each application.

As manufacturers and warehouses/distribution centers push toward autonomous operations, what is the benefit of collaborative robots (cobots) and their ability to work alongside humans?

Kenneth Bruun Henriksen, global head of MiR Go Ecosystem : Cobots and AMRs offer many valuable contributions: cobots and AMRs work alongside human employees, increasing overall productivity by handling repetitive tasks and assisting with material transport, allowing humans to focus on more complex activities. These robots are easy to program and adaptable to changing tasks and environments, making them ideal for dynamic operations. Compared to traditional robot systems, cobots and AMRs are cost-efficient. Integrating AMRs and cobots requires less infrastructure and setup time, even when connecting to other existing systems.

At the same time, they improve workplace safety and create more attractive workplaces. Cobots and AMRs are equipped with advanced safety features, ensuring they can work safely near humans, reducing the risk of accidents and injuries. Moreover, they handle physically demanding tasks, reducing the physical strain on human workers and de -

creasing the risk of workplace-related injuries and fatigue.

By complementing human skills, the robots enhance productivity without replacing workers. Studies show that implementing AMRs not only makes a more productive workplace that allows the company to actually hire more people, but also makes the workplace more attractive because people at any level would like to work with robots, which in today’s labor market is a valuable asset.

Fredrik Ryden, CEO, Olis Robotics : Cobots are the most impactful technology in industrial automation over the past decade, but there is still some way to go to make industrial automation easier to use anywhere and by anyone.

It’s important to understand the strengths and weaknesses of collaborative automation. Cobots have been amazing at lowering the barrier to adoption of industrial automation, making industry-grade automation available to companies of all sizes, even those with no prior robotics experience.

One of the key benefits of cobots is the ability to physically grab and move the robot around as part of the programming process. This hand-guiding method or programming is extremely intuitive and ideal for many applications. In welding applications for example, a welder that has never used a robot before, but knows where the end-effector should be positioned to complete the task, can easily hand-guide a cobot through a welding process, instead of spending hours programming via traditional programming pendants.

However, cobots have their limits. There are some applications that

require higher-speed or higherpayload capabilities. Traditional industrial automation is well-suited

to these applications, especially in low-mix/high-volume production environments.

One axis or fifty.

Servo hydraulic or servo electric. Position, velocity, or force control. Direct connection or through EtherCAT.

Delta RMC Motion Controllers and graphical RMCTools software make complex motion easier, smoother, and more precise.

Drive over to deltamotion.com or call 1-360-254-8688

Get your next project moving forward more quickly than you thought possible!

Kristian Hulgard, general manager, Americas division, OnRobot : My somewhat controversial answer here is that in the next 10 to 15 years there simply won’t be that much of a difference between a standard industrial robot and a collaborative robot.

From speed and payload capabilities to usability and safety, all of these features are being introduced in both industrial robots and collaborative robots. You could question the value of using a safe, collaborative robot if you are not planning to have people around the robot. But there are so many other factors that determine the type of robot you’re going to use, from small footprint to ease of use. Fifteen years down the road, as the lines between collaborative and traditional industrial automation continue to blur, I don’t think the distinction between the two will matter that much, if it exists at all.

David A. Bruce, engineering manager, general industry & automotive segment, FANUC America : While the flexibility and shorter engineering time of a

collaborative robot–based system is attractive, the fact is collaborative robots are slower than regular industrial robots, which means in applications where the throughput requirement is very high they are just not an option. That being said, there are many applications that are prototyped using a cobot just because they are much easier and safer to deal with in the lab than regular industrial robots. Not having to separate a cobot from its environment is certainly a cost savings in terms of material and engineering time, and the user interfaces for most cobots are generally much easier to navigate than those for traditional industrial robots. And this makes setup and execution of a simple robotic system much easier, provided the cobot is able to achieve the required throughput.

Chris Savoia, regional head of UR+, Americas, Universal Robots : Universal Robots is good at human-scale automation, especially for tasks that take about the same physical space and run at about the same rate as a human operator (Figure 5). Along the same lines, the cobots tend to fit better alongside human operators, without as much extensive re-engineering of the workspace. Oftentimes, cobot work cells can even be set up to have the cobot be removable and easily wheeled away so a human can step in to retool machines and set up new jobs. Safety is an important factor here; new innovations in

reliably sensing humans present in the work cell means cobots can get closer to human and still have a high safety performance level and thus a solid risk assessment.

Mark Collins, senior automation electrical engineering coordinator, Mazak : Collaborative robots, or cobots, play a pivotal role in the move toward autonomous operations. Their inherent safety features and ability to work alongside humans without the need for extensive safety barriers make them ideal for tasks that require close collaboration. This not only enhances operational efficiency, but also contributes to a more flexible and responsive manufacturing environment, where humans and robots can complement each other’s strengths. As this technology develops, it will be important for manufacturers to perform in-depth risk assessments to ensure a safe work environment.

Misa Ilkhechi, co-founder and vice president of sales, Formic: Collaborative robots, or cobots, represent a paradigm shift in the robotics domain, particularly with the growing emphasis on autonomous operations in the manufacturing and distribution sectors. One of the primary advantages of cobots is their intrinsic design philosophy, which emphasizes human-robot collaboration (Figure 6).

Unlike traditional industrial robots, cobots are engineered with advanced sensors and safety features that allow them to operate in close proximity to humans without posing risks. This facilitates a symbiotic workspace where humans and robots can complement each other’s strengths.

Moreover, their lightweight design and compact footprint render cobots uniquely suited for mobile applications. This mobility advantage means they can be rapidly deployed across different zones within a facility, offering unprecedented flexibility. Whether it’s adapting to changing production schedules, addressing bottlenecks or being redeployed for varied tasks, cobots stand out as agile and versatile assets in modern production environments.

In essence, cobots not only bridge the gap between fully manual and fully automated processes, but also usher in an era where the agility of human ingenuity and the precision of robotics converge for unparalleled operational efficiency.

B&R Industrial Automation

Beckhoff Automation

Beijer Electronics

DigiKey

KEB America

Mitsubishi Electric Automation

Novotechnik US

Pepperl + Fuchs , Inc Process Automation Division

SEW-Eurodrive

SMC Corporation of America

VEGA Americas

Yaskawa America

Together with ABB, we are the only company to offer a complete portfolio of robotics, automation and software. As part of ABB, we continue to be guided by the same values: Creating more productive and sustainable manufacturing solutions with our customers. We share our automation expertise through training and collaboration.

B&R is an innovative automation company with headquarters in Austria and offices all around the world. On July 6, 2017, B&R became a business unit of the ABB Group. As a global leader in industrial automation, B&R combines state-of-the-art technology with advanced engineering to provide customers in virtually every industry with complete solutions for machine and factory automation, motion control, HMI and integrated safety technology. With Industrial IoT communication standards like OPC UA, POWERLINK and openSAFETY as well as the powerful Automation Studio software development environment, B&R is constantly redefining the future of automation engineering. The innovative spirit that keeps B&R at the forefront of industrial automation is driven by a commitment to simplifying processes and exceeding customer expectations.

At Beckhoff, automation is our calling. We empower engineers to differentiate and succeed as industry leaders – to harness new technologies, embrace open standards and solve the world’s most complex problems.

Founded and led by engineers, we organically create advanced controls, communication, IoT and motion technologies that become unique tools for your one-of-a-kind challenges in an age of digital transformation. As a global partner with U.S. headquarters in Minneapolis, we remain committed to sustainability, inclusivity and support for the people behind the automation. So whether you’re powering the EV revolution, dazzling on Broadway, launching satellites or harnessing the wind – you can reach new heights for your business, industry and humankind.

We connect people and technology through innovative industrial automation solutions that enable businesses to digitalize, optimize, and transform their operations. Our goal is to empower our customers with user-friendly interfaces, smart automation systems, and digital solutions that effectively bridge the gap between human expertise and technological advancements.

Beijer Electronics Group is a global technology company specializing in industrial automation, digital solutions, and human-machine interface (HMI) products. Founded in 1981 in Sweden, Beijer Electronics has grown to become a global leader in industrial digitalization.

Beijer Electronics specializes in three key industries across marine, rugged, and manufacturing industries:

• Advanced HMI Solutions: Innovative, user-friendly HMI systems designed for rugged environments, simplifying processes, improving efficiency, and enhancing user experience through real-time data visualization, control, and analysis in industrial settings.

• Cloud-Based Solutions: Utilizing the cloud, users can securely collect, analyze, and access data remotely. These solutions enhance scalability, operational flexibility, and enable more informed, efficient decision-making.

• Web Based Software: WebIQ: Completely built on the open standards HTML5, CSS and JavaScript. WebIQ is the 100% web technology-based web HMI system with extensive design features to create breathtaking professional and performant web HMIs that allows you to distinguish your HMI.

Beijer is dedicated to driving innovation and delivering tailored solutions, making us a trusted partner for businesses evolving toward smarter, more efficient processes.

DigiKey is a global leader in the cutting-edge commerce distribution of electronic components and automation products. We provide an industry-leading breadth and depth of product in stock and available for immediate shipment while supporting engineers and buyers with a wealth of digital tools and resources to make their jobs more efficient.

DigiKey is a leader and continuous innovator in the worldwide high-service distribution of electronic components and automation products. The global distributor offers more than 15.9 million electronic and automation products from over 3,000 quality namebrand manufacturers. The company’s reputation extends worldwide as the original industry pioneer and provider of more than 1.9 million in-stock parts ready for immediate shipment. With products available in both design and production quantities, DigiKey is the best resource for designers and buyers alike.

Through digital tools, industry-leading supplier partnerships, and an unrivaled breadth of products, DigiKey paves the way as a one-stop shop to serve customers in a unique automation landscape. DigiKey is the preferred supplier for industrial automation, control and safety products, carrying a broad portfolio of products, including advanced controls like PLCs, HMIs, motion, safety and robotics.

In addition to its core stock, DigiKey offers more than 3.6 million additional parts from more than 1,400 suppliers through the DigiKey Marketplace, augmenting the types of products they don’t currently have in their in-stock inventory.

DigiKey provides detailed technical resources and robust search functionality to help customers find the exact parts they need. It also offers a range of digital tools, an on-demand multimedia library, a comprehensive article library, community forums and more.

DigiKey’s 3+ million square feet of product distribution space in Thief River Falls, Minn., allows it to more efficiently meet and exceed customers’ expectations. They provide top technology components to leading and up-and-coming companies in 180+ companies worldwide.

From prototype to production, DigiKey has the resources and products to take your design to the next level. Learn more at www.digikey.com/automation.

For over 50 years, KEB has delivered German-engineered automation solutions, ensuring machines run reliably and efficiently. Our VFDs, controls, geared motors, brakes, and clutches boost performance and productivity. With world-class engineering, tailored solutions, and local support for North American OEMs, we’re ready to elevate your automation capabilities.

KEB America is a North American manufacturer of industrial automation products for applications in the packaging, plastics, metalworking, and material handling industries. The company manufactures, assembles, and supports its German-engineered controls, drives, motors, brakes, and clutches at its ISO 9001:2015 certified, 150,000-square-foot facility in Shakopee, Minnesota.

Machine builders utilize KEB’s motion control and automation solutions due to their performance, safety, reliability, and energy efficiency. The product lineup includes: precise motor control through variable frequency drives (VFDs) and servo motors; efficient power transmission via gearboxes and geared motors; reliable braking and clutch systems for stopping and starting; and seamless system integration and control through automation software and human-machine interfaces (HMIs).

Complementing these core offerings, KEB provides dedicated safety products, including FSoE in its drives, safety PLCs and safety I/O modules, designed to meet stringent safety standards like IEC 61508 SIL 3 and DIN EN ISO 13849-1 PLe. These safety components ensure reliable monitoring and control of safety functions, integrating seamlessly with KEB’s automation ecosystem to provide a comprehensive and safe solution for industrial applications.

KEB America is a wholly owned subsidiary of KEB Automation KG, a global provider of complete automation system solutions headquartered in Barntrup, Germany. KEB Automation KG has four global production sites, 14 international offices, and 1,500+ employees worldwide.

MISUMI is a leading manufacturer and distributor of configurable components and off-the-shelf products. With a vast selection of over 80 sextillion standard and customized parts, we serve as a one-stop shop for engineering solutions to meet customer specifications. MISUMI is committed to empowering customers to achieve high-precision design work incredibly fast.

With over 20 million products globally for automation, press die, and plastic mold applications, MISUMI serves as a trusted resource across various industries, including automotive, medical equipment, consumer packaging, semiconductor, and warehouse automation.

MISUMI is one of the largest distributors of Japanese electronic brands while offering an extensive selection of top US and EU brands. These include Mitsubishi Electric, Fuji Electric, Patlite, IDEC, Murrelektronik, Nitto Kogyo, Takachi, and Eaton.

Our comprehensive range of electrical, wiring, and control components includes:

• Power Supplies: Reliable, versatile solutions for industrial applications.

• Power Distribution: Components to enhance system performance.

• Electromechanical Controls: Products to automate machinery.

• Configurable Enclosures: Designed to fit and protect your equipment.

• Cordsets and Connectors: Seamlessly integrated for optimal performance.

MISUMI simplifies the sourcing process by providing an intuitive online platform and detailed catalogs that make it easy to find, configure, and order even the hardest-to-find products. Value-added services, such as cut-to-length cabling, configurable cordsets, and configurable enclosures, help you save time and money.

Why Choose MISUMI?

• High-Quality Products

• Competitive Pricing

• Streamlined Ordering

• Fast Shipping

• Low or No Minimum Order Quantities

Discover how MISUMI’s electrical components can streamline your projects at MISUMI.INFO/ELECTRICAL.

Mitsubishi Electric will contribute to the realization of a vibrant and sustainable society through continuous technological innovation and ceaseless creativity.

We are committed to making the world a better place. We help organizations innovate their manufacturing and processes, accelerate digital transformation, and improve energy efficiency and sustainability by leveraging the quality, performance, and compatibility built into our intelligent automation solutions. Our solutions include robots, programmable logic controllers, human-machine interfaces, variable frequency drives, servo amplifiers and motors, motion controllers, computer numerical controls, and custom engineered solutions. Mitsubishi Electric Automation has a great depth of knowledge from working with a wide range of industries.

Novotechnik introduced the potentiometer into the general machine engineering sector in the 1950s. Since then, the company developed technology used in position transducers and rotary and linear potentiometers that set the standard with outstanding linearity and reliability over an extended operating life.

Today, Novotechnik has developed new technologies that are raising the standard, bringing a new level of linearity and reliability to non-contacting applications.

An international sensor and transducer manufacturing company, Novotechnik’s US operations are headquartered in Southborough, Massachusetts. Contelec and Novotechnik are divisions of the Siedle Group.

The company develops and produces a wide variety of rotary, and linear position sensors using contacting and non-contacting technologies for a wide range of motion control applications in the automotive, machine engineering, plastics, medical equipment, hydraulic, pneumatic, medical products and control industries.

Novotechnik is world wide certified as one of the first companies to achieve the ISO/TS 16949 certification. This complies with the requirements of the automobile industry - VDA 6.1, QS9000, EAQF, AVSQ - regarding quality management systems. ISO 9001 Certified.

For decades, Pepperl+Fuchs has been developing and distributing industrial sensors, sensor systems, and electrical explosion protection with the highest quality standards for use in automation technology. Our diverse product portfolio provides sensors for standard applications as well as customized solutions, so our customers always receive the ideal sensor system for their specific requirements. Our product portfolio of industrial sensors for factory automation is characterized by a high degree of innovation. It consists of inductive, photoelectric, capacitive, magnetic, and ultrasonic sensors. Additionally, we offer powerful components such as rotary encoders, positioning and identification systems (RFID, Data Matrix, barcode), AS-Interface, as well as suitable accessories. Industrial vision systems and sensors—one of the key sensor technologies of the future—are also part of our portfolio.

Our full range of IO-Link sensors rounds off the comprehensive product range and paves the way for Industry 4.0 technology. State-of-theart technologies and a global sales and production network make Pepperl+Fuchs the ideal partner for a wide variety of global industries. These include markets such as automotive, material handling, packaging, print and paper, doors, gates, and elevator construction, process equipment, mobile equipment, and renewable energy.

The extent of our portfolio is backed by the product quality we offer. Our worldwide manufacturing sites are certified to ISO 14001, ISO 80079-34, or ISO 9001 through third-party certification bodies. We continuously optimize our processes to supply you with stateof-the-art technology and high-end products you can count on.

Pepperl+Fuchs started its business in 1945 and from then on has grown continuously. Now we offer global support in virtually every area of the world with more than 40 subsidiaries on 6 continents.

Known around the world as a pioneer and innovator in sensor technology and electrical explosion protection, your individual requirements are at the heart of everything we do: with a passion for automation and groundbreaking technology, we understand the demands of your markets—developing specific solutions and integrating them into your processes.