HOW TO BECOME REFERRAL PARTNERS WITH COMPETITORS

WHY

WHY

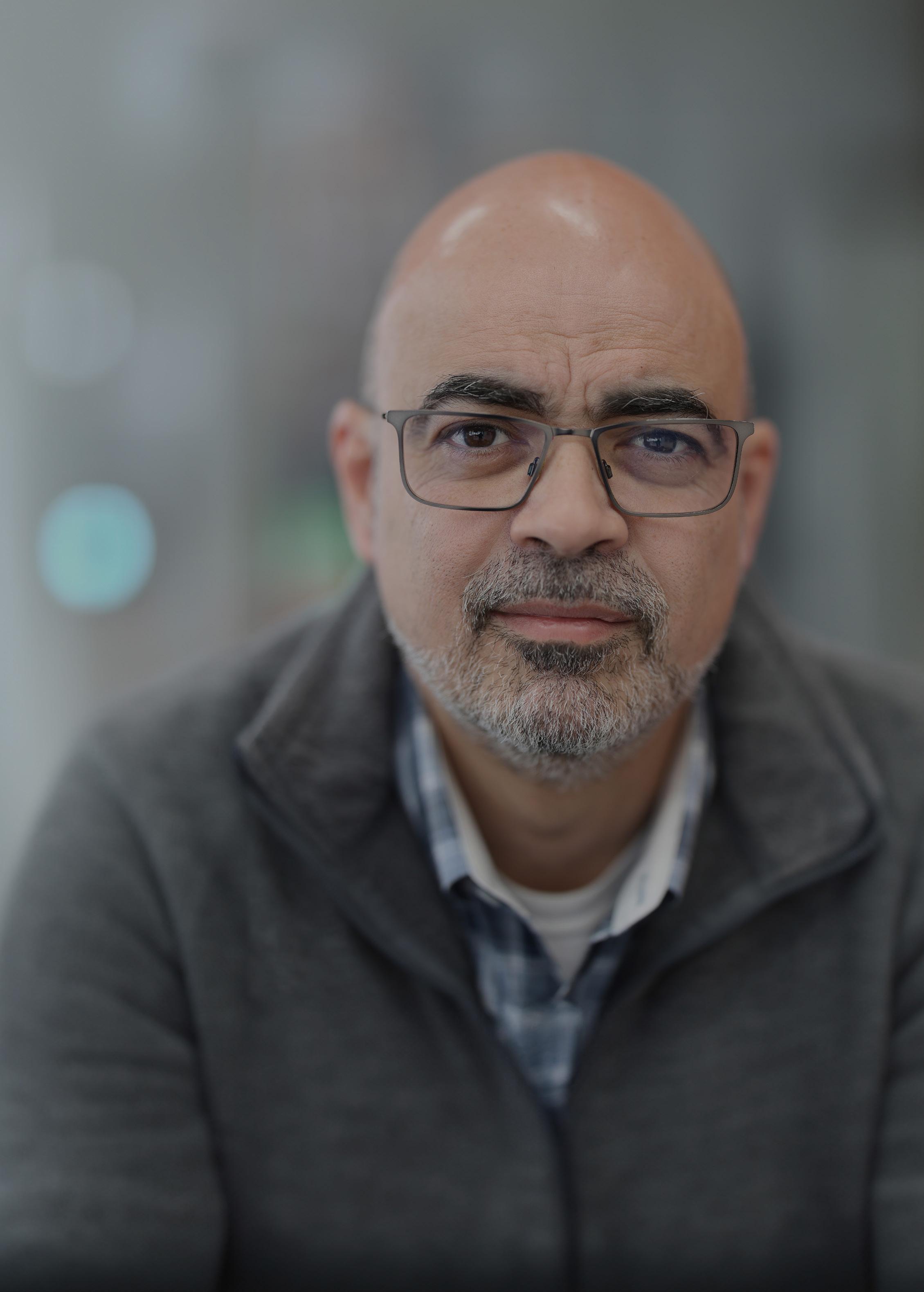

KARIM MORSLI WENT FROM AN INFORMATION TECHNOLOGY CAREER TO OWNING AN AUTO REPAIR SHOP PAGE 24

SERVANT LEADER Karim Morsli wants to help those inside his shop and beyond to find the tools necessary to grow and be successful.

Three auto repair shop coaches talk about why shop owners need to adopt the mindset that the future is now and operate their businesses accordingly.

BY ALISON JOHNSONHow Karim Morsli’s

06

Are you in the right game?

09 BREAKDOWN

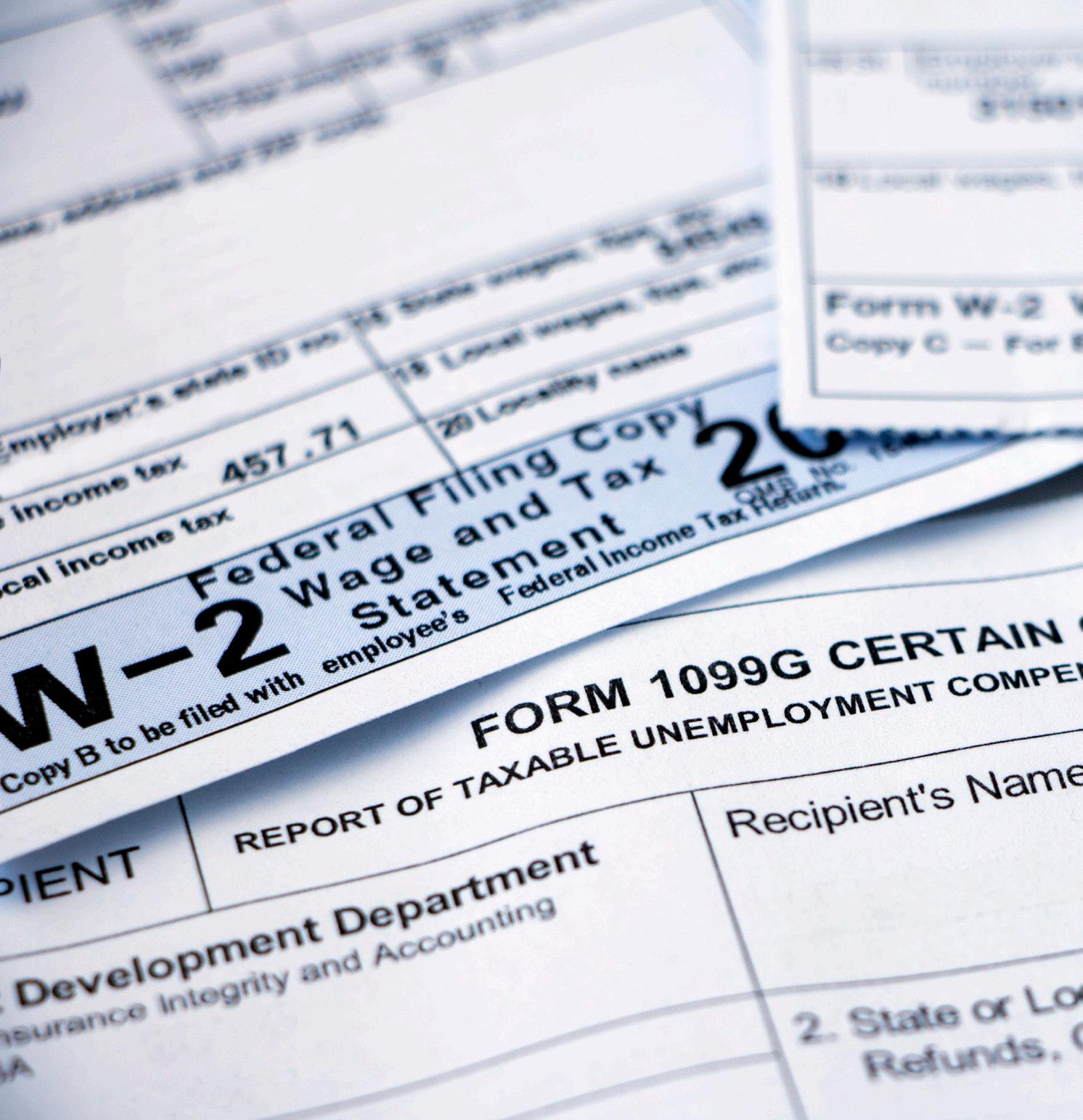

What to do when the government has questions about your money

16 THE SOP

How to prevent techs from burning out

18

Going

KATHLEEN

27

29

32

How

ONLINE

EDITORIAL

EDITORIAL DIRECTOR

Matt Hudson

EDITOR

Chris Jones

ASSISTANT EDITOR

Kacey Frederick

CONTRIBUTING WRITERS

Tess Owings, Alison Johnson, Nolan O’Hara

EDITORIAL ADVISORY BOARD

Tara Topel, Topel’s Towing and Repair

Andrew Marcotte, American Pride Automotive

J.J. Mont, J.J.’s Auto Service

Rachel Spencer, Spencer’s Auto Repair

Bruce Howes, Atlantic Motorcar

Lucas Underwood, L&N Performance Auto Repair

SALES

ASSOCIATE PUBLISHER

Andrew Johnson / ajohnson@endeavorb2b.com

ASSOCIATE SALES DIRECTOR

Mattie Gorman-Greuel / mgorman@endeavorb2b.com

DIRECTOR OF BUSINESS DEVELOPMENT

Cortni Jones / cjones@endeavorb2b.com

ACCOUNT EXECUTIVES

(NATIONAL ACCOUNTS)

Diane Braden / dbraden@endeavorb2b.com

Darrell Bruggink / dbruggink@endeavorb2b.com

Marianne Dyal / mdyal@endeavorb2b.com

Chad Hjellming / chjellming@endeavorb2b.com

Lisa Mend / lmend@endeavorb2b.com

Martha Severson / mseverson@endeavorb2b.com

Kyle Shaw / kshaw@endeavorb2b.com

Sean Thornton / sthornton@endeavorb2b.com

ADMINISTRATIVE ASSISTANT

Ryan McCanna

ART AND PRODUCTION

ART DIRECTOR

Emme Osmonson

PRODUCTION MANAGER

Mariah Straub

AD SERVICES MANAGER

Jen George

ENDEAVOR BUSINESS MEDIA, LLC

CEO

Chris Ferrell PRESIDENT

June Griffin

COO

Patrick Rains

CRO

Paul Andrews

CHIEF DIGITAL OFFICER

Jacquie Niemiec

CHIEF ADMINISTRATIVE AND LEGAL OFFICER

Tracy Kane

EVP ENDEAVOR BUSINESS INTELLIGENCE

Paul Mattioli

EVP TRANSPORTATION

Kylie Hirko

VICE PRESIDENT - VEHICLE REPAIR GROUP

Chris Messer

HOW TO REACH US

ENDEAVOR BUSINESS MEDIA

571 Snelling Avenue North, St. Paul, MN 55104 tel 651.224.6207 fax 651.224.6212

web endeavorbusinessmedia.com

LETTERS TO THE EDITOR editor@ratchetandwrench.com

Opinions expressed in Ratchet+Wrench are not necessarily those of Endeavor Business Media, and Endeavor Business Media does not accept responsibility for advertising content.

HOW ATI SHOPS PERFORM*

5 % GROSS PROFIT MARGIN

6 % LABOR MARGIN

5 % PARTS MARGIN

5 O

→ The trusted leader in coaching and consulting for independent auto repair shop owners.

→ Over 25-year track record elevating 10,000+ members across the U.S. and Canada.

→ The most comprehensive program and support network, backed by ROI results guarantee.

Do you know the difference between a finite game and an infinite game? Of course, context clues lead us to the conclusion that a finite game has an end while an infinite game does not. Captain Obvious, right?

I watched Simon Sinek explain this concept recently on a YouTube video. It was about what winning companies understand that their competitors do not. He said when games are governed by finite rules, like football, both teams know there is a beginning and an end and to win you must have more points than your opponent when the clock rests on all zeroes.

In infinite games, like Risk, the game has an undefined end and players play until one’s resources are exhausted leaving one player remaining.

Business is an infinite game. As Sinek pointed out, sometimes you’re ahead of your competitor, and sometimes you’re behind. Sometimes you’re the innovator, sometimes you’re the laggard. But in every situation, if done right, your top competitor becomes your biggest source of motivation—your worthy rival.

But you have to make sure you’re in the game, first.

For auto repair shop owners, the electric future game is happening right now. The point of watching and waiting has passed and it’s now about preparing and training. You’ll either get the necessary tools, equipment and education to compete, or you’ll drop out of the game at some point. It may not be this year or next, but like Blockbuster, you will meet your Netflix—that shop that’s on the cutting edge taking your market share.

In this month’s feature, “The Automotive Future is Here. Are You Ready?” (p. 20), auto repair shop coaches Vic Terasik, Bill Haas, and Rick White want to avoid obscurity. They talk about the importance of shop owners moving deliberately and urgently in these rapidly changing times in the automotive aftermarket.

I challenge you to think about your business as an infinite entity. Find a worthy rival that keeps you innovating on a service and performance level. And remember, the future isn’t coming—it’s here.

CHRIS JONES, EDITOR CHRISTOPHERJ@ENDEAVORB2B.COM

CHRIS JONES, EDITOR CHRISTOPHERJ@ENDEAVORB2B.COM

Dependability: the most important of all our batteries’ abilities.

O.E.-backed, extended-life performance with wide coverage and a large, available inventory.

Be a one-stop power shop. bproauto® long-lasting batteries offer majority coverage for most vehicles. Competitively priced, corrosion resistant and tested to O.E. standards. Backed by our limited warranty, our battery lineup offers 30 part numbers to cover more than 91% of the total North American market. Over 40 part types. Over 20,000 part numbers.

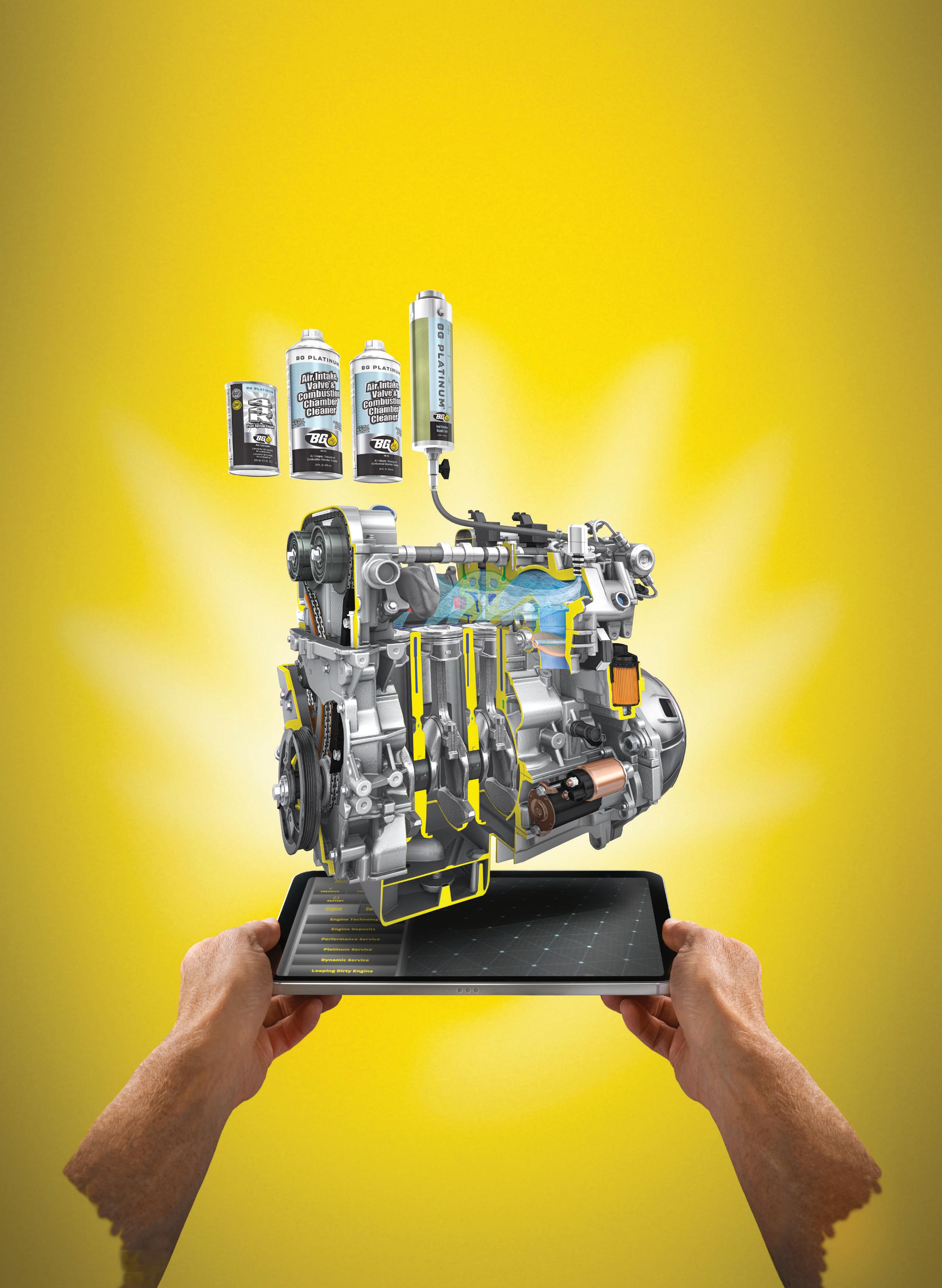

Take a look inside today’s engine technology with the BG Experience™ App. An award-winning, industry-leading maintenance education tool for automotive technicians and service advisors.

By placing virtual 3D engines in your shop, the app visually demonstrates drivability issues common with today’s engines and educates shop staff how BG services can prevent these challenges.

Having the government in your business isn’t fun, but the process might not be as scary as you thinkBY NOLAN O’HARA

If you’re a shop owner worried about being audited, you’re probably not alone.

Nancy Williamson, a veteran certified public accountant and CEO and founder of Williamson Advisors in Austin, Texas, says she finds that business owners often have a lot of fear about being audited, but the chances of it actually happening are incredibly low.

In fact, the chances of a small business owner being audited are just 2.5%, according to Rocket Lawyer.

But if you do happen to be among the unlucky 2.5%, undergoing an audit isn’t necessarily as scary as you might think, Williamson says. And if you do find yourself in that unfortunate position, here are some tips that can help you navigate the process of an audit.

The first thing you should do if you find yourself being audited, Williamson says, is to hire a professional to guide you

through the audit, specifically someone who has experience dealing with the Internal Revenue Service.

That can be a certified public accountant or an enrolled agent. You’re probably familiar with a CPA, and it’s most common for those undergoing an audit to hire a CPA. But you may not be familiar with EAs, which are another excellent option who can help guide you through the process of an audit.

While CPAs cover a broader range of

services, EAs are solely focused on tax compliance. And many EAs have previously worked as an IRS agent. With their experience being specifically tailored to tax preparation and compliance, they can be a great resource for anyone looking for help being guided through an audit.

“Looking for an EA to represent you might be a cheaper and more effective solution,” Williamson says.

Whether you hire a CPA or an EA, the first step in working your way through the audit is to hire someone with experience dealing with tax compliance so you’re not handling the audit on your own.

Getting the necessary materials organized to deal with the audit is the next step. In fact, having all your tax documents organized is the best way to avoid an audit all together.

“The way to audit-proof yourself is to have good books and records,” Williamson says.

Having your tax documents, books

and records organized is key to going through an audit as quickly and painlessly as possible. That starts with best practices throughout the year, like not mixing personal and business payments when using bank accounts or credit cards. And it looks like keeping track of tax documents, spending, and receipts.

“Keeping your books in QuickBooks, not having a box of receipts in an Excel spreadsheet, all of that’s the first step in making sure that if you get audited, you’re prepared,” Williamson says.

If you are being audited and you haven’t kept track of spendings, receipts, etc., you need to track down those documents as quickly as possible. Williamson says you should call your banks, credit card companies and gather all the information necessary for going through the audit.

If there’s a bright side to being audited, it’s that the IRS isn’t going to ask for every conceivable receipt, W2, 1099, or

other document. They’ll only ask for the information that doesn’t line up with the information they have on their end.

Williamson says the most common type of audit is a desk audit, which are triggered automatically if certain information doesn’t line up. For example, if the dollar amounts on a W2 or 1099 don’t line up with the dollar amounts the IRS has, that could trigger an audit.

So, you’ll only need to provide the information that doesn’t match with what the IRS has. If it’s one specific item, prove that item. If there are several forms or receipts needed, provide those. Whatever materials the IRS requests, provide them exactly what they ask.

“Get representation, provide the information that they request as simply and easily as possible and then don’t volunteer additional information,” Williamson says.

If you’re reading this and don’t know that you’d be prepared for an audit, it might

just be time to make sure your ducks are in a row. Even if you start being more organized now, that could help you in the future should you be unlucky enough to be subjected to an audit.

“It’s going to be October of (2024) for maybe (2022’s) tax return, so there’s always going to be a pretty good time gap between it,” Williamson says.

Williamson also says it’s important to remember everything with the IRS is negotiable.

“Do the best you can and then prepare to negotiate,” Williamson says. “There’s payment plans with the IRS. There’s structured settlements with the IRS. They are not as omnipotent and scary as people think they are. They want to work with you.”

This tip should go without saying, but if you’re getting mail from the IRS, don’t ignore it. “I can guarantee if your bank account got levied, you’ve gotten 5,000 pieces of mail that you’ve ignored,” Williamson says. So don’t ignore any notices and respond to and address them once you’ve received them.

Lawmakers in Maine have voted to make some drastic changes to the recently passed right-to-repair legislation, reports the Portland Press Herald.

Having gone into effect in January, the bill is currently only requiring automakers to make their repair data accessible. The second phase of its rollout would begin in 2025 with the creation of a standardized data platform, in which all repair data from automakers is stored. An independent entity would then be appointed to oversee how the data is handled.

On Feb. 13, lawmakers voted 7-1 in approval of an amendment that would do away with the bill’s second phase, eliminating the creation of a standardized data platform and a group overseeing it. Now, it will proceed to the House and Senate to be voted on there.

Reasons for lawmakers’ concern have been attributed to potential cyber security risks associated with creating what would be the first standardized platform for auto telematics. Members of an independent entity abusing their positions to promote personal financial gain has also been cited as a cause for worry.

Following the move, supporters of the original bill have voiced criticism. Rep. Daniel Sayre, D-Kennebunk, who casted the only “no vote,” argued that the amendment is a dramatic change from what 84% of Maine residents voted for in November.

“The Legislature should not be usurping the power of the people. That’s just wrong,” said Dan Brooks, owner of an independent shop in Augusta, prior to Tuesday’s vote. “My customers know and trust me. They voted for this.”

The ASE Education Foundation has named Virginia Oden as its newest assistant vice president, according to a press release.

Oden carries experience as a recruiter in the automotive and healthcare industries. Prior to coming on as assistant vice president, she was a transportation program specialist with the Oklahoma Department of Career and Technology Education,

where she established relationships both in the private sector and with educational organizations.

Throughout her career, Oden has worked with instructors and industry professionals to develop strategies for recruitment and training. She has collaborated with local, state, and national organizations to provide employment opportunities for Oklahoma schools and students.

As the Foundation’s assistant vice president, Oden will be highly involved in working alongside the organization’s field managers, industry partners, state and national educators, and career and technical education (CTE) organizations.

“Virginia brings an extensive background in recruiting and retention with her, and she will play an instrumental role as we continue to expand our program offerings and address the industry’s need for more entry-level technicians,” said ASE Education Foundation President Mike Coley.

Stellantis to Begin Using Tesla’s EV Ports in 2025, Cementing it as Industry Standard

Stellantis will be implementing Tesla’s North American Charging System (NACS) charging plug in all of its electric vehicles beginning in 2025, making it the final major automaker to make the move, reports Kelley Blue Book.

The most commonly used charging port other than NACS is the Combined Charging System (CCS), but the disparity between the number of functional charging stations compatible with CSS compared with Tesla’s coverage of chargers made auto manufacturers consider teaming up with the EV pioneer.

It began with Ford, who reached an agreement with Tesla allowing them to use NACS ports on their own EVs. They were shortly followed by General Motors, and soon thereafter NACS was endorsed by SAE (formerly known as the Society of Automotive Engineers) to be made an industry standard.

Most automakers have slowly joined Ford and GM in implementing NACS, with Stellantis being the final one to climb aboard. Now, nearly every EV manufactured from 2025 onward will be equipped with NACS charging ports.

Northwood University President Approved for

Northwood University President Kent MacDonald will be continuing his role for another six years, according to a press release.

MacDonald first became president in the summer of 2019. Since then, Northwood has received renewed accreditation by the Higher Learning Commission, increased its enrollment, expanded its number of scholarship offerings, and invested in expanding living and learning facilities for students and staff.

Upon the Northwood University Board of Trustees approving a six-year contract with MacDonald on Feb. 2, chairperson Dr. Jennifer Panning expressed optimism for what the next six years will bring. William S. Stavropoulos, former CEO and chairman of The Dow Chemical Company, added that he was incredibly pleased with Northwood’s decision to reinstate MacDonald.

For his second term, MacDonald highlighted two goals he has set: to raise the total value of Northwood’s scholarship offerings and to increase the number of endowed professorships.

“These are the future free enterprise leaders who will drive global social and economic progress!” stated Dr. Panning. “Our students—as well as our staff, faculty and trustees—hold Kent and his wife, MaryEllen, in the highest regard, and we are all excited about the next six years together!”

Accel Auto Parts has recently become a member of TruStar, according to an Automotive Parts Associates (APA) press release.

Launched this past December, Accel Auto Parts Owner Jamie Sites has been working in the automotive industry since the age of 16. The company was founded to provide auto parts to its sister company, Accel Automotive, Tire, & Towing. It also offers parts and services in Vandalia, Ohio, and to its surrounding areas.

Sites said that the decision to join TruStar was immediate, having been impressed with the benefits offered by the group.

“We think that Accel Auto Parts will

be a great addition to TruStar,” said APA President Steve Tucker. “We believe that Accel’s future is bright and are excited to grow with them.”

The National Highway Traffic Safety Administration (NHTSA) has closed an investigation into potential risk of engine fires in Hyundai and Kia vehicles, determining no further action will be needed, Reuters reports.

The agency first launched its investigation of the problem in 2019, with the effort escalating in 2021 after receiving reports of 161 fires caused by engine failures. This investigation is separate from the probe NHTSA opened in November, related to oil leaks in 6.4 million Kia and Hyundai vehicles posing fire risks.

Kia and Hyundai have issued a total of eight recalls for engine fire risks. During its investigation, NHTSA found that those who received the recall fixes experienced fewer incidents related to engine fires than those who failed to receive the repairs.

The automakers said that they have extended their limited engine warranties and are utilizing an engine control software modification that will detect potential engine failure, limit engine power, and warn the driver.

Hyundai will be reminding drivers affected by the recalls to receive repairs for the next three years. Kia will send reminders out every eight months for the next three years as well.

The Advance Auto Parts Foundation (AAPF) has continued its support for nonprofit organizations supporting veterans with a total of $1.75 million in donations, according to a press release.

Donations from over 100 Advance Auto Parts supplier partners will go towards supporting Hire Heroes USA of Alpharetta, Georgia, Building Homes for Heroes of Island Park, New York, and Stop Soldier

Suicide based in Durham, North Carolina. This is AAPF’s second year of fundraising and has brought a total of $3.75 million in donations between the three organizations.

Using earlier contributions from AAPF, Hire Heroes USA was able to establish its Women Veterans Program, which provided over 2,000 women veterans with access to career services, transition specialists, and support staff last year. This year’s donations from AAPF will help to continue the program.

Funds gifted to AAPF partner Building Homes for Heroes will be put towards the Advance Auto Parts Foundation Rapid Response Program, a group that supplies financial support to veterans in need. Last year, 130 veterans received assistance from the program.

Stop Soldier Suicide will use its received donations to build upon its wellness team, which was expanded last year thanks to previous AAPF donations, allowing the organization to provide support to over 300 veterans at no cost to them.

“The military veteran community is one of the Advance Auto Parts Foundation’s three focus areas, and we are proud to partner with our suppliers to support critical needs within that community,” said Advance Auto Parts Foundation President Elisabeth Eisleben. “Our veterans have earned the opportunity for meaningful employment, appropriate housing and mental health care, all of which are fundamental to their wellbeing.”

J.D. Power’s latest Vehicle Dependability Survey revealed what issues are causing drivers the most grief with their vehicles, according to a news release.

The 2024 U.S. Vehicle Dependability Study is based on responses from 30,595 original owners of 2021 model-year vehicles. The survey was conducted from August through November 2023.

An industry average of 190 problems per 100 vehicles marks a four-digit increase from 2023’s findings. Between 90 days and three years of ownership, the problems drivers are experiencing have increased from 12% in 2023 to 17% this year.

Following the results of the survey,

some problems in particular stuck out. The most frequent complaints were related to infotainment systems, with drivers experiencing difficulty in connecting to things like Android Auto or Apple CarPlay.

The dissatisfaction with infotainment systems was nearly double that of the next-highest source of discontent: driver assistance alerts. This category includes lane departure warnings, lane-keeping assistance, forward collision warnings, and automatic emergency braking. Rather than becoming more used to the presence of these alerts, drivers grow increasingly bothered by them, and have reported an increase in problems between 90 days and three years of ownership.

With electric vehicles still going through growing pains, the majority of complaints made were from owners of battery electric vehicles (BEVs) and plug-in hybrid electric vehicles (PHEVs) as opposed to gaspowered and hybrid owners, with BEVs taking the cake for most trouble.

After three years of ownership, 39% of BEV drivers had their tires replaced within the past 12 months. Having scored 19% higher than gas-powered drivers, the difference marks a unique problem faced by EV owners.

“Historically, VDS model results mirror the results of the respective model year in the J.D. Power Initial Quality Study, so a deterioration of vehicle dependability is unusual,” remarked Frank Hanley, senior director of auto benchmarking at J.D. Power. “This can likely be attributed to the tumultuous time during which these vehicles were built, and owners are keeping their vehicles for much longer.”

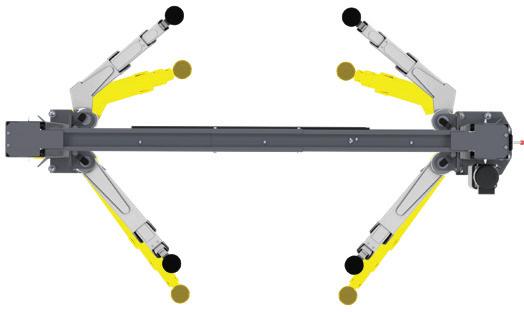

Our 10AP Series offers the convenience of wide or narrow installation wrapped up into one configurable package. This durable, safe, and reliable car lift features an expandable top beam and BI-METRIC™ arms to suit virtually every vehicle lifting requirement – symmetric or asymmetric. The 2-in-1 design gives operators the option of loading vehicles either symmetrically (centerline of vehicle at column) or asymmetrically (centerline of vehicle behind column). The simple, yet highly sophisticated is sure to keep operating costs low and productivity high. Check out the full line of 10AP lift series at bendpak.com or call us at 1-800-253-2363.

How long does the average repair take at an auto shop?

BY CHRIS JONESEfficient shops are profitable shops. As reported by 2023 Ratchet+Wrench Industry Survey Report respondents, nearly half of auto repair shops hit an efficiency between 80%-100% and 41% hit productivity in the same range. But what about under the hood? How long is the average repair?

Auto repair is hard work. For some techs, losing the passion boils down to a lack of appreciation and decreased learning opportunities. Jeff Compton, auto technician and host of The Jaded Mechanic Podcast, explains.

When I talk to techs, most of them burn out because they get stagnant with the pace of a shop. Most of the time, it also goes along with feeling not compensated at the level they feel they deserve financially, or not feeling appreciated. But most techs don’t quit (over money). That ranks closer to about the fifth reason. Most feel like they’re not recognized as vital to the (shop’s) success.

Remember:

Your Techs are the Product

A lot of techs aren’t challenged with repairs. Most enjoy learning new things, and the work can just feel mundane and routine. They lose that fire. If you want to push your techs to stay on the cutting edge, they need training, destination events, and technical training that renews their vigor for this industry. It boils down to your culture—for your technicians, especially. They’re the product you sell when you’re in this line of work; the people vital for making the repairs, and you have to see them as such. The way a salesman loves the type of car they sell, you should have that same enthusiasm for your technicians. You can’t look at them as an expense. You have to see them for what they are—the product. Don’t let the day-to-day routine or lack of appreciation cause dread for your techs. Thank them often as they are the reason your shop stays in business.

Don’t

In a perfect world, we’d all want five techs who could fill each other shoes at any given point, but we all have different strengths and weaknesses. Pigeonholing happens because he or she becomes your go-to diagnostic tech, your go-to interior work tech, or your go-to suspension tech. That’s when burnout can happen. They want to learn new things and that comes back to training. You have to give them exposure. A lot of times, I see shops with (a tech who) can diagnose in half an hour and you have another tech who may get the same result, but it might take 90 minutes. (Shop owners) fall into the trap of giving that work to (the tech) who can knock it out in 30 minutes. What that sets you up for is a precarious situation because that tech then becomes efficient, and the other techs do not develop their skills. That tech becomes so vital that if you lose them, how do you succeed him? You want to avoid that in the aftermarket. Every one of your techs should be able to navigate most of the scan tools that are in the shop; they should be able to learn how

a basic circuit can be diagnosed properly. Efficiency grows with time and opportunity. Don’t burn your techs out by overrelying on their skill set.

Don’t just focus on just the bottom line, which is the effective labor rate. That’s an important factor and I’m not trying to disregard it. If you want to see that vigor and fire and confidence a tech gets when they take a challenge that’s out of their wheelhouse and knock it out of the park by actually getting to the end result, then don’t look at the bottom line like, “Ah, I missed out on X amount of dollars because I didn’t dispatch to my strongest player.” Play long ball. You want to see that tech develop to become an even better tech a year from now, two years from now. You want all-star players; that’s the end goal. You’re not going to get there if you keep them doing what they’re strong at. You have to challenge them. And it’s up to the leader, the manager, to challenge them in a way that doesn’t punish them financially. There’s a mentorship (opportunity) involved in your strongest guy being able to guide them through and show them the processes. I’m big on processes. If you have a process on how to do a repair, or how to do a diagnostic, that process can be shared with somebody else. If you don’t have a process, you’re completely at the whim of how that technician decides to attack that job. Most shops will have a really good working front office and have a lot of processes that are documented in place. It has to be the same in the back. That must become your shop’s culture.

Lastly, this is a really hard industry physically, and that can lead to burnout too. Most techs reach a point where no matter the love for the job there are certain things that they are going to say, “I don’t want to do that.” Get past the idea that when techs say that it’s about pay or frustration. Sometimes, it can be physical pain.

Jeff Compton

Auto technician and host of The Jaded Mechanic Podcast

Jeff Compton is an automotive technician who has worked at dealerships and independent auto repair shops since 1996. He’s also the host of The Jaded Mechanic Podcast where he is known for his candor as one not shy about discussing the challenging issues facing the auto care industry.

jeffsmopar@yahoo.ca

Years ago, every January, I would talk about this being the year I would be a million-dollar shop. Then, I would be disappointed each December that I didn’t make it. The definition of crazy is doing the same thing repeatedly and expecting different results. One day, I heard two quotes that have stuck with me:

“An idea is just a dream until you write it down.” —Anonymous

“A goal without a plan is just a wish.” —Antoine de Saint-Exupery

I had never written down that goal, much less made a plan to achieve it! How did I expect to do big things, without setting intention and focusing?

It isn’t too late if you didn’t set goals for sales and profit for 2024. Written goals are critical to your ability to meet or exceed them. Then you have to check your progress often.

As we prepare to close out the first quarter of 2024, now is a great time to check in on how we are doing on our goals for the year and to set our focus on the next steps for a successful second quarter. Although I monitor where I am with daily, weekly, and monthly goals, I believe checking in quarterly is also critical in case my area of focus needs a significant shift.

Perhaps you’ve heard about setting SMART goals. A dear friend shared with me about using SMARTER goals. What in the world does that mean?

Specific. Make your goal crystal clear. Instead of saying “I want to be busier,” say “I want to increase gross sales by 10% over last year, which is $934,500.”

Measurable. Your goal should have a way to check if you’re making progress. You cannot manage what you do not measure.

Achievable. Your goal should be something you can do. If you don’t have enough bays or technicians to have $3 million in sales, that might be too aggressive. Start with a goal that’s challenging but doable.

Relevant. Your goal should make sense and be important to you. Don’t set a goal just because someone else thinks you should. Pick something that matters to you. Would you prefer to focus on net profit instead of gross sales? Fantastic! It’s your goal.

Time-bound. Set a deadline for your goal. Instead of saying, “I want to improve and bring in more cars,” say, “I want to increase weekly car count by the end of June 2024.”

Evaluate. Check in on your goal regularly. Look at your email capture rate and see if it is getting better. If not, you might need to check that your process for obtaining those addresses is being followed by everyone in the shop.

Revise. If things aren’t going as planned, don’t give up. You can adjust your goal or how you’re working toward it.

Remember, SMARTER goals are about making your goals clear, doable, and focused so you can succeed!

The constant dance of shop ownership is the balance between getting the front and back-of-house operating efficiently. Setting and checking your goals regularly will help you achieve more and more success.

Kathleen Callahan has owned Florida’s Xpertech Auto Repair for 20 years. In 2020, she joined Repair Shop of Tomorrow as a coach to pursue her passion for developing people and creating thriving shop cultures. Callahan is the 2018 Women in Auto Care Shop Owner of the Year, nationally recognized by AAA for three consecutive years, testified for Right to Repair on Capitol Hill, and is vice chair of Women in Auto Care.

kathleencallahanfl@gmail.com

Rick White helps auto repair shop owners get unstuck in their businesses by introducing processes that help them become competitive using relevant technology.

The industry is vastly different than it was 20 years ago. Are you doing the things you need to make sure your shop is still here 20 years from now?

BY NOAH BROWN PHOTOS CONTRIBUTEDOften, when trying to make a point about how far technology has advanced, it’s tempting to compare today’s world to that of the one decades ago. Twenty-year lookbacks are incredibly common, and for good reason–the world is vastly different now than it was in 2004.

Back then, MySpace was in its infancy (as was the whole concept of social media), iPods and DVDs were the primary media to listen to music and watch movies, and Apple was three years away from unveiling the iPhone.

The same is true for the automotive sector. In 2004, the Toyota Prius accounted for more than half of all hybrid vehicle sales with nearly 54,000, and Tesla was still four years away from delivering its first vehicle.

While those comparisons can prove insightful at times, however, they can gloss over just how quickly an industry, and the world, can change. Think about all the changes you’ve seen in your shop in just the past two to five years.

The National Highway Traffic Safety Administration only began requiring vehicles under 10,000 pounds to have a backup camera in 2018. Most advancements in higher levels of ADAS have only really made noticeable strides in the last three years. Electric vehicle manufacturers have only had a serious presence in the industry for two or three years, Tesla notwithstanding.

So much can–and has–changed since the turn of the decade in the automo-

tive repair industry. But everyone knows that. Hearing someone making a big deal about the industry changing is cliché at this point, so why even bring it up?

Rick White, president of business management consulting firm 180BIZ, says that it’s a point that a lot of people in the industry are missing, whether they know it or not. He says a notable number of shops he’s worked with are stuck in the past, either through ignorance or arrogance, and are still running things the way they have for the last 20 years.

“There are still some shops out there that are handwriting repair orders. Look at today’s vehicles, the number of computers and components in them, that’s not going away,” White says. “If you’re a shop that’s working on cars that are 20 years old or older, is that a choice, or is it because you don’t have the proper equipment and the training? Technology is not a one-off. It should be a part of a plan.”

Vic Tarasik, founder and managing

partner of Shop Owner Coach, says that some shops are taking the advances in technology for granted and are operating under the assumption that business will continue to just roll in because it always has, regardless of the ability of the shop.

“They look at technology just being in the bays,” Tarasik says. “Technology is not a boogeyman–the main purpose of technology is to increase efficiency and productivity. It’s crucial to the survival of the business. You can’t have a shop today and not adopt technology and expect to thrive.”

Adopting a technology mindset is not only an attainable goal for any shop, regardless of their starting point, but also a necessity to stay in business for the next 20 years and beyond.

Though it may feel like it at times, your shop doesn’t have to buy its way into a tech mindset. White says sometimes buying too many new tools or other technology can be a detriment if you and your team don’t have a plan for it.

“Some of us feel like whoever has the most tools wins, but that’s not the case,” White says. “I love to see a shop invest in technology, but you have to make sure

there’s a market for it and that you’re not going into debt to acquire it.”

A technology mindset starts with planning and some good, old-fashioned research. Getting even the most basic understanding of what technologies are coming into your shop and what customers might need can help form a plan for your shop’s technology needs.

“Do your homework before you invest in the technology. To spend thousands of dollars on training for EVs when less than 1% of vehicles on the road are EVs, it’s not sustainable,” White says. “ADAS is a solid investment, and as we get to copilot and driverless technology, it becomes even more important. Do your homework. Make sure you have a market.”

And this doesn’t just apply to EVs. White says this research into what services you provide and what additional services your customers may need can help guide many decisions when planning out what technology to invest in.

“Let’s say there’s a shop that isn’t doing alignments that wants to get a $90,000 lift. How many alignments do you have to do to make that worth it?” White asks. “And you can’t just take all the money that you make and put it toward the cost of the machine. There’s a lot of other stuff to it.”

Staying in the know about the needs of your customers will help identify the tools your shop should invest in. And, if investing in that equipment makes sense for your shop, there are also smart ways to make those purchases more affordable. White recommends putting a small amount–say 3% to 5%–of sales into an account designated specifically for technology and tooling purchases. If you do it regularly, your shop might feel it for a little bit, but after a while, it becomes second nature. And, pretty soon, your shop will be able to buy new tools outright without having to scramble to find money.

“How cool would it be to be able to cover something upfront instead of having to get a monthly payment?” White says. “The problem is we all want it now. If we can give ourselves the gift of patience and start a budget, it helps.”

And though you may ultimately be the one writing the check to purchase new technology or tools, you don’t have to be the only one making the decision.

White says the easiest way to get team buy-in on major investments is to let them help make the decision. Your technicians will know what your shop needs the most and where improvements can be made.

“When I’m buying new equipment, my team is totally involved,” White says. “Get the team involved, figure out where they’re struggling the most, and develop a plan from there.”

Whether your shop is in a good position or it’s playing catch-up to get up-to-date on the latest technology, it can be daunting to lead the charge. When you invest in new technology, tools, or training, you know it’s not just your livelihood that’s on the line. Your whole team is dependent on that decision to work.

Tarasik says that pressure can lead people to make less-than-ideal and sometimes desperate decisions when they don’t need to. He encourages shop owners to contact other shops in their area to see what they’re doing and how they’ve handled certain challenges. The first step in dealing with that pressure, he says, is to remember that you don’t have to do this by yourself.

“Don’t feel like you’re the tip of the spear. Spend time with someone who has already been down that road. Surround yourself with good people from different training organizations, Facebook groups, trade shows, and other places. Spend time with someone else and walk in their shoes.”

White says getting up close and personal with new equipment and technology is crucial. Industry trade shows and other events are prime places to start to get an understanding of what technology is out there and what might be useful for your shop.

“You can start to see some of this technology, and then from there, make sure you know how the system works and what the return is,” White says.

An owner or manager can only do so much to establish a culture of technological learning on their own. Bill Haas, owner of Haas Performance Consulting, says there isn’t enough time in the day for one person to be able to effectively develop and implement a technology strategy for a shop.

“Unfortunately for the people that are making the decisions, they’re so busy in the business that they can’t spend their time on the business,” Haas says. “(They aren’t) able to do the research and evaluate what direction they need to go in. They don’t have the time to do it well.”

Haas says you need a good team in place with a good support system to help attract new talent and establish a strong working environment that can not only adapt to new changes in the industry but to thrive while doing so.

“You have to be a shop that’s willing to invest in your people. You have to pay them well. You have to give them a great benefits package. That has to happen first. When it does, you’ll have plenty of people who are excited to work in this industry.”

Training and development need to be a part of your shop’s offer to technicians and other employees. The only way that your shop will be able to retain highquality talent and keep up with growing technological trends is if your team is eager to take on those challenges.

“Find people on your team who are curious about certain aspects of the technology in these cars. Then, make them the people who go to trainings and trade shows,” Haas says. “Let them get as much information as they can, and then as a team you can collaborate and figure out which way to go.”

A technology mindset comes down to two crucial things–understanding the needs of your customers and the strengths of your team. If your shop can invest in tools that you know your cus-

tomers need while maintaining a staff of techs who are eager to learn, you’ll be in a good position to take on any new technology that might come your way.

Adopting new technologies, Haas says, is no longer an option.

“We have to get out of the mindset of fixing broken cars. We are in the technology business. Technology is integrated into every part of the car now. There’s a computer that manages every function of the car,” Haas says. “How are we not a technology business?”

Karim Morsli on his leadership philosophy and how he transitioned from IT company owner to the it guy of Winkler AutomotiveBY KACEY FREDERICK PHOTOS BY ROBERT SNIP

Each shop owner has their own story of how they got to where they are now. For some, the automotive industry is all they’ve ever known, offering them a level of familiarity–but those who enter from other fields offer unique perspectives that may not be apparent to those already in the game.

When Karim Morsli decided to transition from IT (information technology) into being the owner of Winkler Automotive in Gaithersburg, Maryland. He saw vast opportunities for improvement: both in the industry and himself, as he adapted to and learned to thrive in a new field.

Morsli first came to the Gaithersburg area as a teenager in 1981. His family immigrated from Algeria after his father, a successful engineer, gained a position with the World Bank.

Morsli went on to study engineering himself in Canada and afterward went to Europe to study business, earning an MBA before spending some time working as a field engineer in the oil fields of Africa.

After returning to Maryland, starting a family, and running his own IT (information technology) company for a while, Morsli began to reflect on what legacy he would be setting with work.

“I knew I needed to do something different,” he remembers. “Right around that time my mother passed away, and my father had passed away a few years before; it was a very big turning point for me. I was questioning a lot of the things that I

was doing, and what I was leaving behind, and so on.”

Throughout his life, Morsli always had a fascination with cars. Back in the late ‘90s, Morsli installed a touchscreen computer into his car, a 1997 BMW 3 Series. Everyone who saw his car was shocked to learn that it wasn’t a stock part, but that Morsli had supplied and installed it all himself.

Being involved with engineering and technology, his interest was in the increase of technology he saw blossoming in the automotive industry through the late 1990s to early 2000s, which was similar to what he was handling in IT.

Entering the world of automotive work was not an impulsive decision, however, Morsli challenged himself on whether this was just a hobby or something leading to a fulfilling career.

“I had been warned that you can’t mix pleasure and business. So, I took it in stride, and I studied it for quite a few years before I thought, ‘Yeah, I think I’m cut out for it–I’m gonna give it a try,’” says Morsli.

Once he was prepared, he reached out to a longtime friend who owned a shop. Though he was surprised that Morsli wanted to transition from IT into automotive, he was prepared to help him hone his vision for what kind of shop he would run.

Morsli was put in touch with George Winkler, owner of Winkler Automotive for over three decades. Winkler was ready to retire, and it was a successful business that Morsli felt he could elevate to another level.

In December 2015, Morsli officially took the reins at Winkler Automotive and soon began implementing several improvements to the business’ operations, using his knowledge of IT as the foundation.

“When you want to improve an industry, you also have to really leave the door open to be able to look at what’s going on in other industries because the disruptive ideas that are going to bring about amazing change are not necessarily in our industry, otherwise we’d be doing them,” Morsli explains.

When Morsli took over, one of the first new tools he introduced to his staff was digital vehicle inspections–something only a small number of shops were

doing at the time. It digitized the typical maintenance checklist technicians would use while inspecting a vehicle and made it easier to share with the customer.

His shop was also an early adopter of cloud-based technology, storing invoice scans in Google Drive and using optical character recognition technology to find documents by simply entering a keyword in a search bar.

Digitizing these aspects of the work being done was part of Morsli’s vision to make everything run smoothly as well as more transparent for clients. Though the shop’s technicians initially weren’t sure about the change, they started to see how it was helping and embraced it.

Ultimately, providing his technicians with all the tools they need to succeed is a huge part of what Morsli views as his job. Many of them weren’t used to working with bosses who felt that way, but he sees his success as being dependent on theirs.

“I practice servant leadership; I’ve always practiced it. That’s how I was raised with my father,” says Morsli. “My father would always tell me, ‘Blue collar, white collar–it doesn’t matter one bit. At the end of the day, we’re all human beings, and we’re all entitled to dignity.’ And so that’s always stuck with me.”

The response he’s received from his

staff has raised some concerns he has about how the industry is training and treating its technicians, and he hopes his shop will help raise the standard. With every job offer he gives, he puts everything that was agreed upon during the interview in writing–something that has taken some new hires by surprise.

Seeing professional workplaces where employees are respected and make a decent living is what attracts potential entry-level technicians. This is something many other industries realize and make a point to advertise to those entering the workforce.

“The amount of technicians that we’re losing at the high school level just simply because they think they can do better as IT techs–or HVAC techs, or electric, etechs–is quite scary.”

Only a quality business can attract quality employees. Morsli credits the success of his shop to the dedication of his entire team, and as a shop owner, he knows it’s his responsibility to provide them with every opportunity to succeed.

“What does treating your employees right mean? Respect them, honor your agreements with them, provide them training opportunities, help them grow by evaluating them frequently and giving them constructive feedback, and be a mentor to them and a leader,” Morsli says. “And that’s, I think, what needs to happen more and more in our industry.”

About four years ago, John Miller bought 12 dozen bagels and began taking them to auto shops, tire shops, and used car lots around him.

Miller, director of business development for Fifth Gear Automotive, delivered an innovative pitch with those treats: If you ever have a job you can’t handle, please refer that customer to us rather than to a dealership.

Today, referrals account for 40% of total revenue for Fifth Gear, a Texas-based, family-owned and operated company with five locations in the Dallas-Fort Worth area. The program helped the business weather the COVID-19 pandemic and has fueled the addition of three new shops in the past two years.

Fifth Gear’s three-member Outside Business Development Team has built a portfolio of about 1,400 shops that know they can pass along the company’s business cards if a job seems too big or complicated.

“I understand it sounds bizarre,” says Ceasar Cordon, who heads the Outside Business Development Team. “I get asked often, ‘Why would I send you cars? You’re my competitor.’ But we’re really not. We’re not there to poach anything from anyone. We want to take unwanted work off their plates and help the entire network of independent local auto shops succeed.”

Cordon and his fellow team members, Connie Clover, and Scott Luce, visit about 900 to 1,200 shops in any given month—basically, anything that has a lift on site. Between them, they rack up 5,000 to 7,000 miles and run through an average of 4,000 business cards monthly.

Established in 2004, Fifth Gear began in a humble three-car garage at the side of an old Texaco station. The full-service company accepts all makes and models of vehicles, with an emphasis on European cars and heavy repairs.

“Many cars that come to us are very broken,” Cordon notes. “If we can’t fix them, they’re likely going to the junkyard. That’s why we can tell another shop that focuses more on maintenance or lighter repairs: ‘Send your headaches to us, and then we can give that vehicle or that customer right back to you for jobs you can or want to do.”

Referral programs, then, can also support other shops’ strengths: a tire shop meant to handle small, rapid jobs that doesn’t want to tie up a rack for hours or days, for instance, or a used car dealer that needs help with certain models or mechanical issues as they prepare cars for sale.

Here are more of Cordon’s tips on creating an effective referral program: Just do it. The only way to start is to simply get on the road. Make as many visits as possible to other area shops, even if it might feel a bit uncomfortable initially.

Be reassuring. Immediately explain that you’re not there to hurt anyone else’s business, only to offer an alternative to dealerships for unwanted jobs. If you construct the conversation right, you’ll likely be surprised at how many shops welcome having that option.

Don’t bring money ... Referral programs should never involve kickbacks or bribery. They’re not about lining anyone’s pocket.

… but do bring food. Bagels, cookies, muffins, or other snacks are great tools to open doors–and possibly minds–in the middle of a long workday. Businesses that provide regular referrals or send over a particularly lucrative job could get extra, perhaps even a lunch delivery.

Leave when asked … If managers or available team members are not receptive to your idea, thank them for their time and head out. Don’t press.

… but don’t give up on that site. Due to high turnover in the auto industry, a

shop’s leadership or staff might look very different in six months to a year. Go back and see if interest has changed, too. Fifth Gear, for one, has a four- to five-week cycle between most visits.

Emphasize brand awareness. Drive cars with a company logo and leave business cards wherever you can. Become a walking, talking billboard.

Don’t totally overlook dealerships. Used car departments often buy cars at auction, sight unseen, and might not have the time, knowledge, or correct tools for repairs. Instead, they might outsource work without an eventual buyer ever knowing it had left the lot.

Be a good partner. Be available to help other businesses at times, whether that’s lending tools, giving advice, or directing customers to them for jobs in their specialty areas.

Meet with anyone who will talk to you. You don’t necessarily have to score a sitdown with a shop owner or manager. Just

getting your name out there with technicians and other employees is valuable.

Join local business groups. Fifth Gear is a member of 13 different Chambers of Commerce and sends representatives to meetings, ribbon cuttings, and other events. Aim to become engrained, recognized, and trusted in your community.

Push your boundaries. Last year, Clover began crossing over the Texas state line to visit shops in Oklahoma, about an hour south of Fifth Gear’s main location. Within a week, cars were coming back over the border as referrals.

Always look at the big picture. Good referral programs can benefit the entire automotive industry, Cordon believes–one community at a time.

“There are more than enough cars and trucks out there for everyone,” he says. “We should work together to get rid of negative connotations that people unfortunately have of our industry. We can help make each other better.”

“Onboarding is your opportunity to explain the rules of the game and make no mistake, this is a game,” Bill Greeno, owner of Quality Automotive Servicing in Truckee, California, says.

Think about it, would you bowl with a blindfold on? Not knowing where the ball was going or how many pins you knocked down? Doesn’t sound fun, does it? That’s the comparison Greeno uses to describe hiring an employee without proper onboarding. If you don’t onboard your employees, you’re leaving them to guess and make up their own rules, which they will do. Employees, much like athletes playing a game, need to know exactly what the rules are and what penalties are to be expected if they break those rules. That’s where a well-thought-out onboarding process comes into play.

BACKSTORY:

Greeno has been onboarding employees for decades. In the ‘90s, for example, Greeno traveled from college to college, recruiting and interviewing students for various positions at a ski resort. He would conduct an average of 30 interviews per day so he developed a system and process for getting the most qualified people possible. Greeno says that his onboarding process started back then and has continued to evolve with him.

Greeno is a coach in the industry and says that he’s been lucky enough to learn from horror stories that his peers have told him about what he describes as “ruining employees.”

“We will go into a facility where some -

one has not been onboarded properly and they have all of these bad habits,” Greeno says. “This person is beyond help, you have ruined them. With employees, we need them not to guess.”

Greeno says onboarding is the solution to “ruining employees.” It helps set clear expectations for what exactly the person who is hired should be doing and what they can expect if they are not performing the duties expected of them. Greeno details his onboarding process below.

Onboarding starts before the employee is hired, Greeno explains.

“The interview process is your first opportunity to communicate with an

individual about the company in its entirety,” Greeno says.

From the big picture stuff to the nuts and bolts, this is your time to tell potential hires what they can expect if they are hired. This helps weed out people who will not be a good fit.

“The training begins the moment you talk to them,” Greeno says. “You’re setting the foundation for everything else.”

Greeno’s interview process includes speaking to them on the phone, having candidates take the CliftonStrengths Assessment, and a group interview.

The first day the employee comes in, Greeno goes over the handbook with them. The handbook is 57 pages long, and it’s extremely detailed. This is your opportunity to explain to your hire what their responsibilities are outside of their everyday opportunities. What exactly does that mean? Greeno says a common gripe he hears amongst his peers is their people are always on their phones. Well, onboarding is your chance to set those expectations and you can spell that out in the handbook. Greeno has pages in his employee handbook about the use of electronic media, what his social media policy is, and even information about bathroom usage. This part of onboarding takes roughly two hours, Greeno says.

No matter what position they are hired for, everyone in Greeno’s company gets phone training. Why? Well, that’s precisely the question that he asks his employees after the training. Talking on the phone translates to talking to people in person, and he wants everyone on his team to understand the importance of customer service.

The length and details of this step vary based on the candidate, but it’s the part of the onboarding where the candidate sees how to do the actual job that they have been hired for. Greeno strongly suggests that even if they are extremely qualified, they don’t touch a car or write any tickets on the first day.

Greeno’s onboarding process comes full circle as his last step is bringing in an outside coach to break down the new hire’s CliftonStrengths assessment results from their interview process.

“You need to understand your strengths and how to work with other people’s strengths,” Greeno says.

If you come to work at Greeno’s shop, you know what to expect. You’re not guessing at what his policies are and what will happen if you bend the rules.

That being said, turnover is unavoidable and if an employee needs to be fired, they need to be fired, Greeno

explains. Having a solid onboarding process in place helps make letting an employee go easier because you know the hiring process will go smoothly. Having this onboarding process in place has been extremely helpful for Greeno in staffing his new shop.

Proper onboarding will save you a lot of headaches down the road. Set your employees up for success in the beginning. If you don’t have a solid onboarding process in place right now, Greeno suggests starting by writing down three to five things that are needed to onboard an employee successfully and develop the process from there. Every time you think of something new, add it to the list.

The auto repair industry has a checkered reputation—and for good reason. If it’s going to change, it begins with awareness

It really shouldn’t come as a surprise that our industry continues to suffer under a penumbra of dishonesty and distrust. While some may argue that public sentiment is shifting to a more positive perception, a cursory Google search of the question “Are Auto Repair Shops Trustworthy?” reveals overwhelming contradictory results. Articles entitled “How to Choose an Auto Mechanic You Can Trust” or similar titles abound. Social media personalities frequently tout what’s wrong with the auto repair business. Identifying problems in the industry is easy. In the words of some friends who are combat veterans, the sheer volume of what is wrong represents “a target-rich environment.”

What is the genesis of this reputation that yokes us to public skepticism and cynicism? What attitudes and business practices do many shops employ in their daily operations that reinforce this negative stereotype that runs counter to the interest of those whom they profess to serve? I am not referring to deliberate dishonesty (e.g., recommending a service with the intent of making money absent legitimate need). Although we know that this type of activity exists, it is the exception to the rule. Yet this perception of selling that which is not believed to be needed is common in the public sphere. What I am referring to is both common and harmful. It’s called self-interest in polite circles, but I’ll just call it what it is—greed, in the guise of accepted business practice.

The answers to the above questions require a shop owner to identify their core philosophy regarding the very nature of the business and their motivation to become an owner. How a business owner views the role his business plays in the community and the responsibility they bear to those served (including employees). In my experience, owners can generally be divided into two distinctly different groups: servicedriven customer-centric owners (SDCC) and money-motivated sales-centric owners (MMSC). Make no mistake though, owners who are the latter are the problem.

Both SDCC owners and MMSC owners have three things in common: the need to be profitable, the need to provide service (although they frequently define and measure service differently), and the need for growth. What differs is the hierarchy of importance each assigns to these needed components and how they measure success.

The goals for a customer service-driven business can be best illustrated by envisioning a Venn diagram comprised of sales, community service, and corporate culture with customer advocacy as its core. The SDCC shop owner acknowledges that they have a moral obligation to be a trusted, unbiased source of sound automotive information irrespective of the profit potential. They acknowledge and accept the mantle of moral responsibility that comes with their position. They realize that their role is akin to that of a fiduciary whose job is to “manage the person’s money and property for their customers’ benefit, not their own.” They believe that by being of service to meet their customers’ needs, sales will follow. They and their employees are first and foremost advocates and educators for their clients, not commissioned salespeople hoping to achieve often arbitrary sales goals.

Let’s speak of the MMSD owner. Imagine a dartboard with its nested concentric circles. The ‘bullseye’ for a money-motivated sales-centric owner will be sales. In the next adjacent ring is service. Sales first, service second. The focus is foremost on making the sale and any other concentric ring is subordinate to sales and that, sadly, includes the customer. Any benefit to the community or to employees must be thought of strictly in terms of return on investment. The sales-centric owner disavows any responsibility or moral obligation to their customers aside from remaining within acceptable legal business practices. Their myopia allows them to view their business solely as a profit-producing machine focused on car count and average repair order. They consider employees nothing more than components in that machine. In the words of one

well-known industry coach: “You’re building a business, not a family.” Technician names and billed hours will be posted for all to see with the hopes of ‘spurring competition’ (code words for finding more things to sell). The sales-centric owner employs salespeople as service advisors. These salespeople need not be knowledgeable about automobiles; what they need to know is how to sell. And it’s this focus on sales to the exclusion of all else that’s at the heart of our lousy reputation with customers as an industry.

R. “Dutch” Silverstein, who earned his Accredited Automotive Manager Certificate from AMI, owns and operates A&M Auto Service, a seven bay, eight lift shop in Pineville, North Carolina. Dutch was a captain for a major airline earning type ratings in a variety of aircraft including the Boeing 767/757, 737, 200, 300 and 400 series, Airbus 319/320/321, McDonnell Douglas MD80/DC9 and Fokker FK-28 mk 4000 and 1000. After medically retiring, he transitioned his parttime auto repair business into a full-time occupation.

dutch@dutchsgarage.com