DYNAMIC DUO

MEETING MODERN CUSTOMER EXPECTATIONS

Still Tinkering Swayzi Giles grew up helping her dad Cole in their home garage. Now they’re both professionals.

FATHER AND DAUGHTER WORK SIDE BY SIDE IN UTAH PAGE 28

PAG E 24

PA G E 32

BECOMING A DESTINATION SHOP

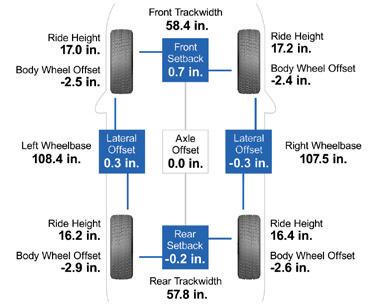

TRACKING THE LITTLE DETAILS

PA G E 34 FENDERBENDER.COM / FEBRUARY 2023

VEHICLEMFD.BYFORDMOTORCO.INU.S.A.

FRONTGAWR: 2735LB AT

REARGAWR: 3325LB 1508KG P235/70R16SL

1240KG P235/70R16SL

16X7.0J

GVWR: 5880LB/2667KG WITHTIRESRIMS PSI COLD

16X7.0J

240 kPa/35

DATE: THISVEHICLECONFORMSTOALLAPPLICABLEFEDERALMOTOR VEHICLESAFETY STANDARDSIN EFFECTON THEDATEOF MANUFACTURE SHOWNABOVE.

01/03 00000000000000000

AT 205 kPa/30

WITHTIRESRIMS PSI COLD F0085T0183

P265/70R17 REAR SPARE⁄⁄H⁄⁄⁄⁄⁄⁄F⁄⁄BY⁄⁄⁄OYO⁄⁄⁄⁄O⁄O⁄⁄⁄⁄⁄⁄F⁄⁄⁄⁄⁄⁄⁄⁄, ⁄⁄W⁄⁄⁄⁄⁄⁄⁄⁄B⁄⁄⁄⁄W⁄⁄⁄⁄F⁄⁄⁄⁄668⁄B⁄⁄⁄⁄⁄⁄⁄668⁄B ⁄H⁄⁄⁄⁄⁄⁄H⁄⁄⁄⁄⁄⁄⁄O⁄FO⁄⁄⁄⁄⁄⁄O⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄B⁄⁄ F⁄⁄⁄⁄⁄⁄⁄⁄⁄O⁄O⁄⁄⁄⁄⁄H⁄⁄⁄⁄⁄⁄⁄⁄F⁄⁄Y ,⁄B⁄⁄⁄⁄⁄⁄,⁄⁄⁄⁄

⁄H⁄F⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄O⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄FF⁄⁄⁄⁄⁄O⁄ ⁄H⁄⁄ ⁄⁄⁄⁄ ⁄OF⁄⁄⁄⁄⁄⁄F⁄⁄⁄⁄⁄⁄⁄⁄⁄HOW⁄⁄⁄⁄BO⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄

⁄ ⁄⁄⁄⁄⁄⁄⁄⁄ ⁄ ⁄⁄⁄⁄⁄⁄⁄

⁄’utilizez⁄pas⁄un⁄couvre⁄siège qui⁄peut⁄bloquer⁄le⁄déploiement⁄du coussin⁄gonflable⁄latéral⁄ ⁄oir⁄le⁄manuel⁄du⁄conducteur⁄pour de⁄plus⁄amples⁄renseignements⁄

⁄⁄⁄⁄⁄⁄ ⁄⁄⁄⁄⁄⁄⁄⁄ ⁄ ⁄⁄⁄⁄ ⁄⁄⁄⁄⁄⁄⁄ ⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄8⁄7⁄ ⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄Y,⁄⁄⁄⁄⁄⁄⁄⁄ ⁄ ⁄⁄ STK VEHICLE TY STANDF MANU 000 ⁄ ⁄⁄⁄⁄⁄⁄⁄ WE’VE HEARD YOU DOWNLOAD OUR NEW FREE APP AND START ORDERING YOUR LABELS TODAY! To Visit Our Website SCAN HERE FOR ADDITIONAL INFORMATION ABOUT AUTO DATA LABELS: visit our website at www.AutoDataLabels.com email us at labels@AutoDataLabels.com or call us at (631) 667-2382 Vin Labels AC Labels Caution Labels Emission Labels Tire Pressure Labels Paint Code Labels SRS SIDE AIRBAG COUSSIN GONFLABLE LATÉRAL (SRS) ⁄O⁄⁄⁄O⁄⁄⁄⁄⁄⁄⁄O⁄⁄⁄⁄⁄J⁄⁄Y⁄O⁄⁄⁄⁄⁄⁄H⁄ ⁄o⁄not⁄lean⁄against⁄the⁄door⁄ ⁄o⁄not⁄use⁄seat⁄covers⁄that ⁄block⁄side⁄air⁄bag⁄deployment⁄ ⁄ee⁄owner’s⁄manual⁄for more⁄information⁄ ⁄O⁄⁄⁄É⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄B⁄⁄⁄⁄⁄⁄⁄⁄ ⁄⁄⁄⁄⁄⁄⁄O⁄⁄⁄O⁄⁄⁄⁄⁄⁄⁄⁄ ⁄e⁄vous⁄appuyez⁄pas⁄contre⁄la⁄porte⁄

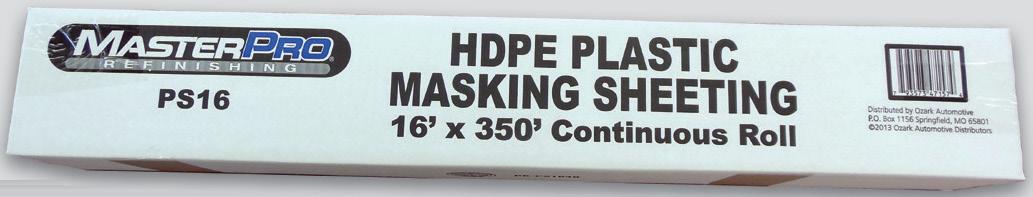

WARNING AVERTISSEMENT TIRE AND LOADING INFORMATION TIRE SIZE COLD TIRE PRESSURE 303kpa 44psi 303kpa 44psi 303kpa 44psi The combined weight of occupants and cargo should never exceed 505 Kg or 1114 Lbs. P265/70R17 P265/70R17 P265/70R17 FRONT REAR SPARE SEE OWNERS MANUAL FOR ADDITIONAL INFORMATION SEATING CAPACITY TOTAL 3FRONT 3REAR 0 VEHICLE EMISSION CONTROL INFORMATION Conforms to regulations: 2016 MY California: Not for sale in states with California emissions standards. TWC/HO2S/WR-HO2S/CAC/TC/DFI U.S. EPA: T2B4 LDV 2.3L-Group: GFMXV02.3VJW Evap: GFMXR0125NBV No adjustments needed. FED OBD II Fuel: Gasoline ABZ VEHICLE MFD. BY FORD MOTOR CO. IN U.S.A. DATE: EXT PNT: RC: DS0: WB BRK INT TR TP/ PS AXLE TR SPR 114 4 GP K 45 V DB F05 UTC THIS VEHICLE CONFORMS TO ALL APPLICABLE FEDERAL MOTOR VEHICLE SAFETY STANDARDS IN EFFECT ON THE DATE OF MANUFACTURE SHOWN ABOVE. 01/03 VIN: TYPE: 00000000000000000 MPV FRONT GAWR: 2735LB AT AT 205 kPa 30 240 kPa 35 1240KG P235 /70R16SL 16X7.0J REAR GAWR: 3325LB 1508KG P235 /70R16SL 16X7.0J GVWR: 5880LB/ 2667KG WITH IRES RIMS PSI COLD WITH IRES RIMS PSI COLD F0085 T0183 UA 13 3U51B DELIVERY IN 1-3 DAYS! Auto Data Labels NEW SIMPLIFIED ORDERING PROCESS : TAKE A PHOTO IN OUR APP & SEND IT WITH YOUR ORDER! New! ADL App Now Available! ORDER YOUR LABELS TODAY! APPLE STOREGOOGLE PLAY

TWICE AS NICE

THE ONLY FRAME TO PERFORM ADAS CALIBRATIONS & WHEEL ALIGNMENTS

INTELLIGENT ADAS IA900WA SYSTEM

The Next Step In ADAS Calibration Now Includes Wheel Alignment Technology. One Frame To Perform 4-Wheel Alignment & ADAS Calibration.

IMPROVE SHOP EFFICIENCY & PROFITABILITY

• PRECISE OPTICAL MEASUREMENT WITH 6 HIGH RESOLUTION CAMERAS

• SELF CALIBRATING CAMERAS, ALWAYS ACCURATE, EVERY TIME

• CAMERAS AUTOMATICALLY TRACK VEHICLE HEIGHT ON LIFT

• MAXISYS INTERFACE FOR WHEEL ALIGNMENT

ADAS CALIBRATION SELF-CALIBRATING AUTO HEIGHT TRACKING 6 HI-RES CAMERAS WHEEL ALIGNMENT

WEB: AUTEL.COM | SUPPORT: 1.855.288.3587 EMAIL: USSUPPORT@AUTEL.COM FOLLOW US @AUTELTOOLS

How Do We Get Started?

Gas-catalytic, medium-wave infrared curing is adaptable to a broad range of applications.

To determine how US Autocure systems can help you, we start with 3 simple steps: 3

1 PAINT: Our chemist will review a list of the coatings products and other technologies you use and their response to infrared curing.

2

PROFITABILITY: We’ll work with you to determine the areas of savings and gains that infrared curing can provide.

BOOTH: Some basic spray booth information is all that is needed to help us determine the best system for you.

There are no costs associated with these steps and we will not share this information with anyone but you. These activities can be completed quickly, but we won’t rush you.

We believe in our technology.

We want you to be comfortable that it’s right for you.

480.268.9703

USAutocure.com Get Started DISTRIBUTED EXCLUSIVELY BY

5 February 2023 fenderbender.com FEBRUARY CONTENTS 28 FATHER/DAUGHTER POWER Cole and Swayzi GIles love working side by side at their Utah shop. BY TODD

24 SHOPS OF CHOICE What some shops are doing to attract top techs BY TODD KORTEMEIER FEATURE PROFILE 02.23 | VOLUME 26 | NUMBER 02 FenderBender (USPS Permit 25614), (ISSN 1937-7150 print) is published monthly by Endeavor Business Media, LLC. 1233 Janesville Ave., Fort Atkinson, WI 53538. Periodical postage paid at Fort Atkinson, WI, and additional mailing offices. POSTMASTER: Send address changes to FenderBender, PO Box 3257, Northbrook, IL 60065-3257. SUBSCRIPTIONS: Publisher reserves the right to reject non-qualified subscriptions. Subscription prices: U.S. ($90 per year). All subscriptions are payable in U.S. funds. Send subscription inquiries to FenderBender, 571 Snelling Ave N, St Paul, MN 55104. Customer service can be reached toll-free at 800-260-0562 or at subscriptions@fenderbender.com for magazine subscription assistance or questions. Printed in the USA. Copyright 2023 Endeavor Business Media, LLC. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopies, recordings, or any information storage or retrieval system without permission from the publisher. Endeavor Business Media, LLC does not assume and hereby disclaims any liability to any person or company for any loss or damage caused by errors or omissions in the material herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever. The views and opinions in the articles herein are not to be taken as official expressions of the publishers, unless so stated. The publishers do not warrant either expressly or by implication, the factual accuracy of the articles herein, nor do they so warrant any views or opinions by the authors of said articles.

KORTEMEIER

QUICK FIX 10 PAST THE PAGE A deserving Recycled Rides winner 11 DRIVERS SEAT Seeing the world 13 BREAKDOWN The future of scanning? 17 NUMBERS Best laid future plans 19 LIGHT HITS A legend retires, and much more 20 SNAP SHOP Out of the elements 20 CONTENTS FEBRUARY

and Dry Customers and employees don’t have to brave the North Dakota weather at this shop.

Warm

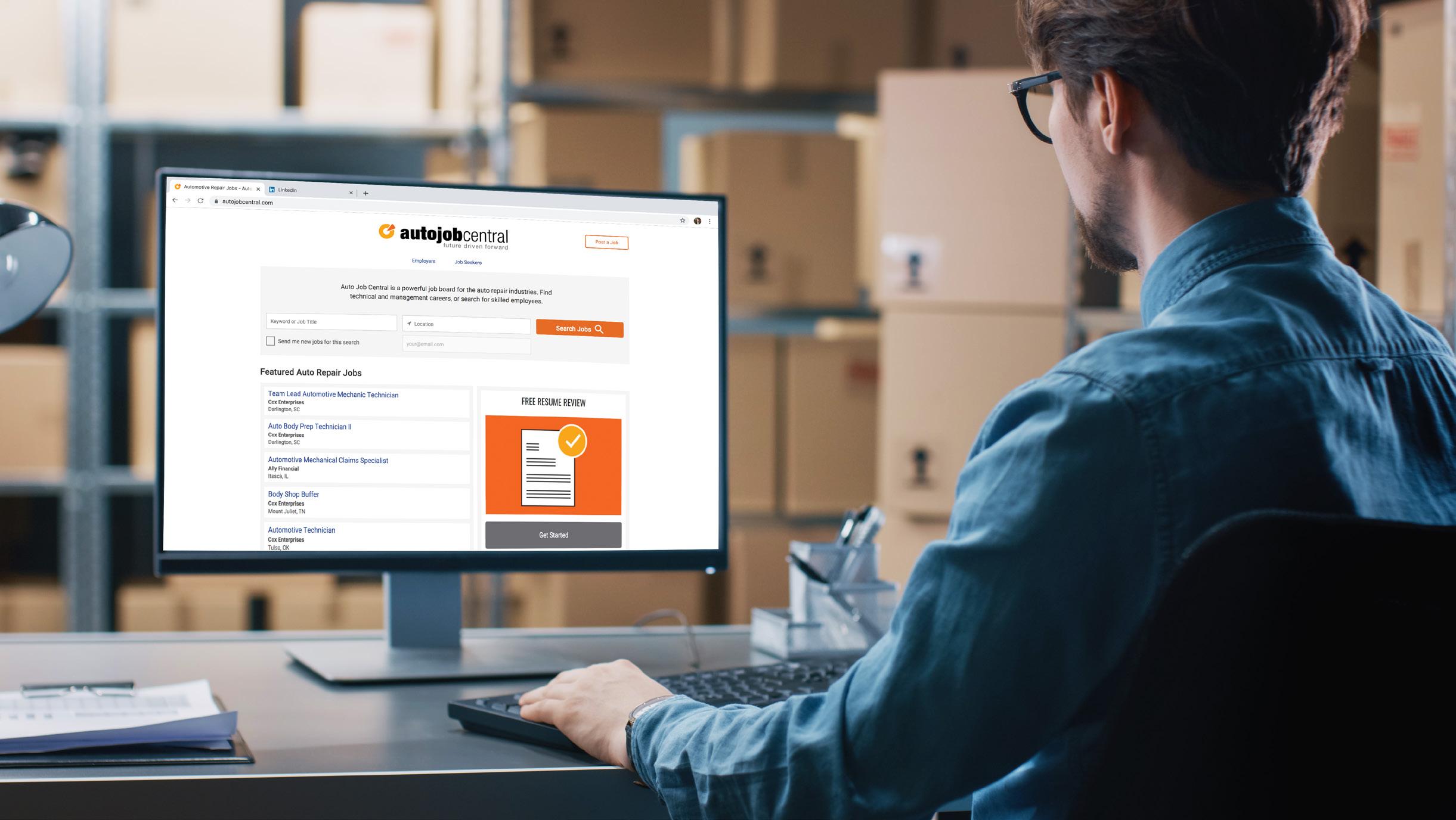

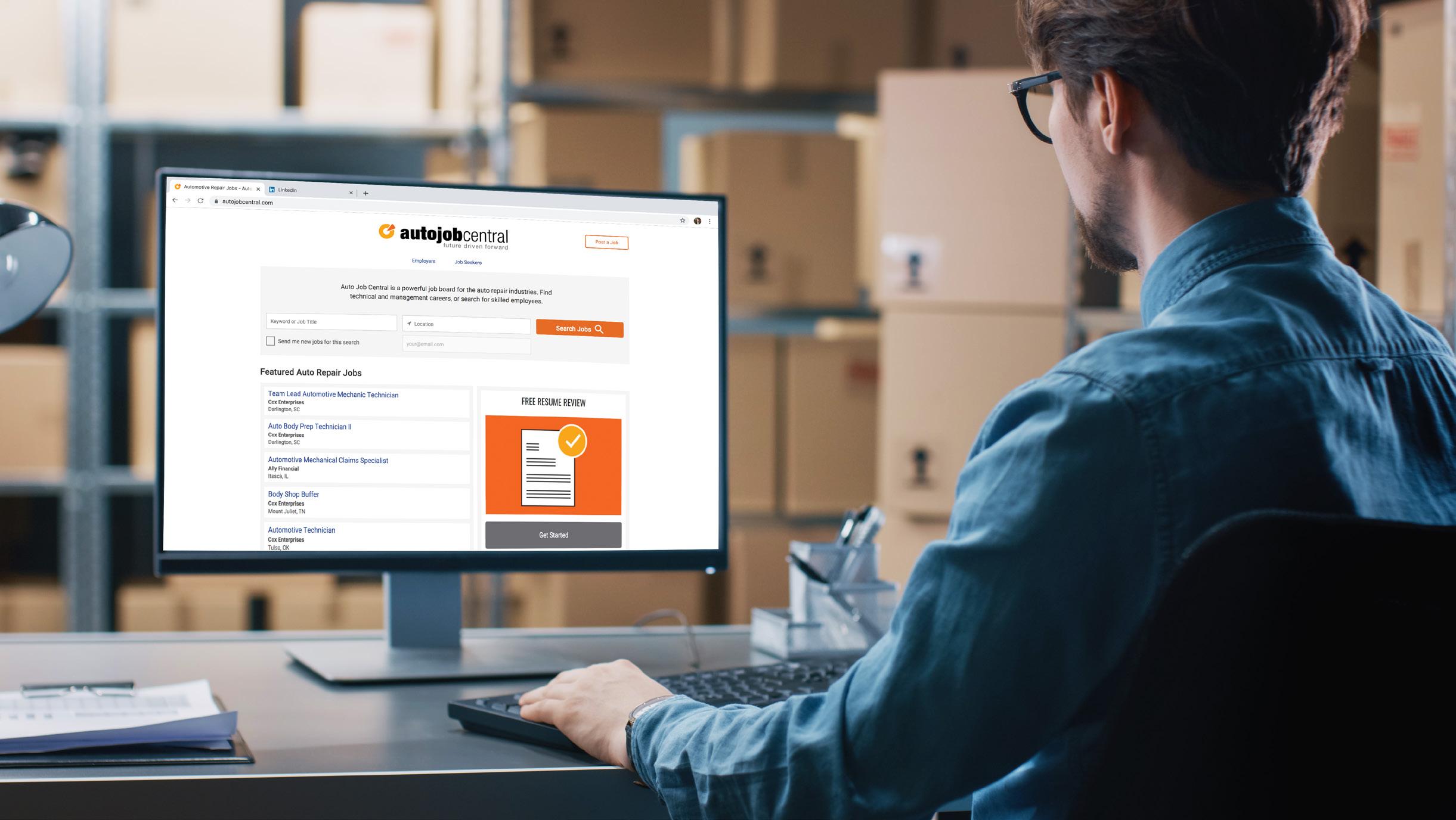

7 February 2023 fenderbender.com 2302FB_ARSLoaner.indd 1 1/23/23 9:35 AM STRATEGY COLUMNS 32 THE SOP Don’t forget the little things 34 CUSTOMER SERVICE Making collision repair more like Amazon 36 CASE STUDY Succession isn’t always a success 23 SHOP PROFITS What’s hiding in the details BY GREG LOBSIGER 47 COLLISION COURSE Learning to ask BY TIFFANY MENEFEE 48 DUE PROCESS Getting on schedule BY DREW BRYANT 32 38 ADAPT Innovation wanted in EV batteries 40 EDUCATION + TRAINING Researching repair procedures

8 February 2023 fenderbender.com

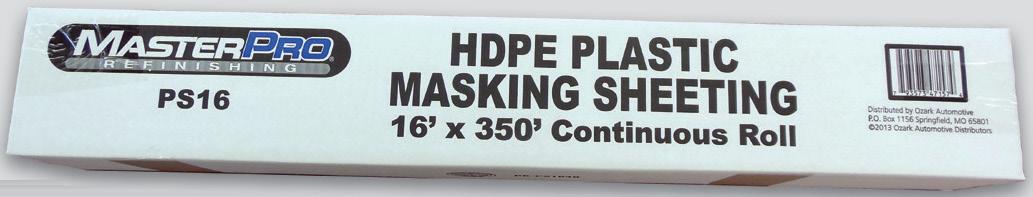

CONTENTS ONLINE EXTRAS SATA/Dan-Am Company Mitsubishi Hunter Engineering O’Reilly Auto Parts Industrial Finishes Spanesi Americas Polyvance ProColor Collision AUTEL Auto Data Labels Auto Job Central AutoZone ARSLoaner Axalta Coating Systems Accudraft

CLICK ON THE LOGO BELOW FOR PRODUCT INFORMATION

EDITORIAL

Matt Hudson Content Director

Todd Kortemeier Editor

Hanna Bubser Associate Editor

Leah Marxhausen Special Projects Editor

Drew Bryant Contributing Writer

Kimanzi Constable Contributing Writer

Tiffany Menefee Contributing Writer

Greg Lobsiger Contributing Writer

Lindsey Gainer Contributing Writer

EDITORIAL ADVISORY BOARD

Jordan Beshears Steve’s Auto Body

Sheryl Driggers Universal Collision

Greg Lobsiger Loren’s Body Shop

John Magowan Ernie’s Auto Body

Stan Medina Certified Collision Works

ART AND PRODUCTION

Jonathan Ricketts Senior Art Director

Mitch Bradford Art Director

Morgan Glisczinski Graphic Designer

Emme Osmonson Graphic Designer

Hana LeBrew Print Production Assistant

SALES

Chris Messer Vice President and Publisher

651.846.9462 / cmesser@endeavorb2b.com

Andrew Johnson Associate Publisher

651.846.9459 / ajohnson@endeavorb2b.com

Marianne Dyal Marketing Strategist (National Accounts)

706.344.1388 / mdyal@endeavorb2b.com

Chad Hjellming Marketing Strategist (National Accounts)

651.846.9463 / chjellming@endeavorb2b.com

Bob Marinez Marketing Strategist (National Accounts)

216.533.8747 / bmarinez@endeavorb2b.com

Martha Severson Marketing Strategist (National Accounts)

651.846.9452 / mseverson@endeavorb2b.com

Kyle Shaw Marketing Strategist (National Accounts)

651.846.8480 / kshaw@endeavorb2b.com

Dan Thornton Marketing Strategist (National Accounts)

734.676.9135 / dthornton@endeavorb2b.com

Sean Thornton Marketing Strategist (National Accounts)

269.449.0257 / sthornton@endeavorb2b.com

Kenzie Verschoor

Associate Marketing Strategist (National Accounts)

651.846.9472 / kverschoor@endeavorb2b.com

Matt Harper Regional Sales Manager

651.846.9551 / mharper@endeavorb2b.com

Melody Todd Senior Marketing Strategist (Regional Accounts)

651.846.9468 / mtodd@endeavorb2b.com

Tim Hill Marketing Strategist (Regional Accounts)

651.846.9454 / thill@endeavorb2b.com

Autumn Morey Customer Success Representative

651.846.9460 / amorey@endeavorb2b.com

Jen George Client Service Specialist

651.846.9465 / jgeorge@endeavorb2b.com

FENDERBENDER

Mariah Straub General Manager and Production Manager

Meghann Moore Bookkeeper and Client Service Specialist

Tiffany Fowler Senior Digital Media Strategist

Karley Betzler Administrative Assistant

HOW TO REACH US

571 Snelling Avenue North, St. Paul, MN 55104

tel 651.224.6207 fax 651.224.6212

The annual subscription rate is $90 (U.S.A. only) for companies not qualified to receive complimentary copies of FenderBender

BACK ISSUES

Past issue single copies are $8. Go to fenderbender.com/backissues

LETTERS TO THE EDITOR editor@fenderbender.com

ARTICLE REPRINTS

For high-quality reprints or e-prints of articles in this issue call 651.846.9488 or email reprints@fenderbender.com. Opinions expressed in FenderBender are not necessarily those of Endeavor Business Media, and Endeavor Business Media does not accept responsibility for advertising content.

READ WHAT THE PROS READ

9 February 2023 fenderbender.com

TO SUBSCRIBE OR RENEW AT FENDERBENDER.COM/SUBSCRIBE

“The opportunity to read about ways to improve your business from credible owners and manufacturers is priceless.”

—Stan Medina, Owner, Certified Collision Works, Corpus Christi, Texas

‘BUD’ EARNS RECYCLED RIDE

JUST IN TIME FOR THE HOLIDAYS, a Sun Prairie, Wisconsin, charity worker received a bit of a reward for years of hard work in the form of a Recycled Ride from the National Auto Body Council, the organization announced in a press release.

Proud new owner Simmie “Bud” Bryant took possession of a 2021 Kia K5 donated by Allstate and refurbished by Gerber Collision & Glass of Sun Prairie. The Bank of Sun Prairie sponsored the event. The presentation to Bryant was held at The Sunshine Place, a local charity where Bryant works as a handyman performing maintenance work for the building. Bryant was expected to use the new vehicle to spend more time with his grandchildren and also move into safer housing, which he was unable to do previously as he had no way to commute to work.

“Bud is someone we depend on to keep Sunshine Place looking

good,” said Ann Maastricht, executive director for The Sunshine Place, via the press release. “He has always been willing to do whatever is asked of him, including working nights and weekends, particularly when it comes to snow removal. Being able to work with Allstate, Gerber Collision, Bank of Sun Prairie and the National Auto Body Council to make all it possible to present him with a vehicle is incredible. He gives so much and we are honored to be able to give back to him.”

Bryant became one among more than 3,000 Recycled Rides recipients who have been gifted with reliable transportation since the program began in 2007. The total value of the vehicles awarded is estimated at $42 million.

Visit FenderBender.com/news for daily updates from around the collision repair industry.

@fenderbendermag @fenderbendermag

@fenderbendermag fenderbender.com/linkedin fenderbender.com

10 February 2023 fenderbender.com

PAST THE PAGE

COURTESY GERBER COLLISION & GLASS OF SUN PRAIRIE

WINDOWS ON THE COLLISION REPAIR WORLD

On opening up other perspectives in the pages of FenderBender

HERE AT FENDERBENDER, WE TRY NOT to give information in terms of what shop owners should or shouldn’t do. I’ve learned a thing or two about collision repair, but the lot of you have forgotten more about this industry than I’ll ever know. I deal with words, not wrenches.

If you were able to be dropped into a shop across the country and find out what they were doing differently than you, you’d probably be happy to take in that info. But probably not all of that information would be relevant to your shop. That shop has its own unique market that might be radically different from yours. However, maybe there’s one little strategy you could pick up. Or maybe there’s one little strategy that doesn’t fit but that makes you think of something else. Carrying that information back to your shop instantly would be like magic.

At its best, I like to think of FenderBender as your teleportation device into those other shops. It’s a marketplace of ideas, some that may not apply but a majority that at least get you thinking. I think this issue is particularly geared toward that goal.

Every shop today is facing the same challenge and there is no singular solution. But shop owners are continuing to innovate and do what they can to do right by their customers and their employees. In this month’s feature story (p. 24) you’ll read about what shops are doing to cope with the technician shortage, but from a different perspective. They’re asking what can they do to be a place technicians want to work at in the first place.

We’re also looking at what shops can offer to a customer base that has changed

rapidly (p. 34). Customers today are used to instant results thanks to online retailers. Body shops will never offer instant doorto-door repairs, but there are some ways to bridge the gap of customer expectations.

Whether or not you adopt these strategies is up to you. We’ll be back next month with more windows into more shops. Thank you for your continued support of FenderBender.

TODD KORTEMEIER EDITOR tkortemeier@endeavorb2b.com

11 February 2023 fenderbender.com DRIVER’S SEAT

VIDEOS | PODCASTS | WEBINARS | NEWS

Measure Your Success. Right Down To The Millimeter. 224-SPANESI (224-772-6374) www.spanesi-americas.com facebook.com/spanesiamericas Spanesi Americas, Inc. 123 Ambassador Dr. STE 107 Naperville, IL 60540 Live Measuring, Vehicle Frame and Structural Items, Mechanical Parts, User Added Points With Photos, Suspension Parts, Comparative Measurements Scan For More Information ACCESS CHALLENGING MEASUREMENT POINTS Multiple Probe And Extensions Included ACCURATE Exact Measuring INTUITIVE USER EXPERIENCE Exclusive WinTouch Software MEASURING IN MINUTES Fast Measuring Setup UNIVERSAL Measuring Any Vehicle On Any Bench, Rack Or Lift Touch Electronic Measuring System

ANALYSIS

PROTECH’S ID 3 COULD BE THE FUTURE OF MACHINE LEARNING IN DIAGNOSTICS

The software uses AI and machine learning to identify needed calibrations in a repair By TODD KORTEMEIER

THE IDEA THAT many points of data are better than one is not new. It is in fact among the oldest ideas in Western philosophy. Aristotle wrote in Politics that the many, when together, can have abilities far beyond even the most excellent individual.

13 February 2023 fenderbender.com QUICK FIX GETTY NEWS | IDEAS | PEOPLE | TRENDS

While probably not the sort of thing Aristotle had in mind, the value of that pooled information is the principle behind Protech Automotive Solutions’ ID3 calibration identification solution. Unveiled at the 2022 SEMA Show, ID3— pronounced “ID cubed”—uses artificial intelligence (AI) and machine learning to identify calibration needs in a repair. While that service exists in many forms today, Protech Vice President of Product Development Don Mikrut says that the key difference with ID3 is that instead of merely returning what kind of calibrations might be needed, ID3 is able to use its knowledge base to deliver more accurate assessments quickly.

“We start to triangulate all that data through the algorithms and the machine learning that we’ve developed, to come back and say, based on your pre-scan, and the estimated damages, and the OE procedures and knowledge base, we’ve been able to triangulate this,” says Mikrut, hinting at the source of the three in ID3’s name. “Every line of that estimate comes back and tells you this is what needs to be calibrated on this vehicle based on the damages.”

To know that this process happens in milliseconds is to partially understand the genesis of this project and its need in the marketplace. With the advent of ADAS systems, shop owners were needing to devote time to a manual research process to know what systems needed to be calibrated on a vehicle for any given repair. A diagnostic scan could reveal what systems were present but not necessarily which ones were impacted by damage. That leaves a process open to interpretation and judgment calls.

This is what Protech was hearing from its collision customers. A research and development team led by Vice President, Protech Technology Innovation Chris Gutierrez was tasked with solving this problem and the result was ID3, which had been rolled out in approximately 1,200 locations by the end of 2022. The team leaned on “30-plus years of building a knowledge base,” according to Mik-

rut, that encompasses Protech’s acquired expertise as well as data from OEs for ID3 to draw on.

“ADAS ID3 builds on our expertise and history in the vehicle diagnostic industry by revolutionizing the identification of calibration and repair needs, thus saving our technicians and partners time and money,” said Gutierrez at the time of the product’s release. “Protech’s focus is to fix vehicles the right way the first time.”

And ID3 isn’t just a one-time search. It continues to work as a vehicle goes through the repair process and is equipped to handle any contingency.

“Your estimate can be five lines, it could be 100 lines,” says Mikrut. “And so our algorithm, the way we do it is that we triangulate every one of those lines to make sure that we’ve cross-referenced everything in that estimate. And not only from the preliminary estimate … as that estimate evolves to the full repair plan, and the finalized repair bill, we run it through that algorithm again so our machine learning continues to go through if there is a chance that as they tear the car out and find additional damages that our algorithm will come back and give them an additional calibration that may

14 February 2023 fenderbender.com

QUICK FIX

be necessary on more internal damages found as the car continues through the repair plan.”

The difference that thoroughness makes is evident in the performance ID3 customers are seeing as the tool rolls out.

According to CCC’s Crash Course report prepared by industry analyst Susanna Gotsch, in the third quarter of 2021 7.1% of all appraisals included a calibration event. The results Protech is seeing from ID3 report that more than 30% of vehicles report a needed calibration.

Bridging that gap is vital to completing safe, quality repairs. It’s

simply unknown what the nature of those missed calibrations is. It may appear that the systems are working but not working as intended.

“What it means is that they’re not within the tolerances of where the OEM needs them to be,” explains Mikrut. “So they may function, but not function exactly as they were designed. They may be late to notify you of lane departure. Are they emergency braking, because it’s not at the right angle?”

To get ID3 working in the hands of customers, Protech has partnered with diagnostic tool providers Autel and Bosch

for a seamless integration with those devices. How it works is the diagnostic information is sent to ID3, which goes through the triangulation process Mikrut outlined, and then returns a report either in an email or PDF format to the customer.

ID3 is one among an array of solutions Protech offers to its customers. The company also offers mobile diagnostics and calibrations, static calibration centers, virtual support and more. Protech realizes that continued innovation is essential to survive as the pace of vehicle development is not going backwards.

“It’s not only telling you what needs to be calibrated, we tell you how it needs to be calibrated,” says Mikrut. “And we’re advancing that as the vehicle advances so that they understand it. Because the last thing people need to know is, ‘Hey, look, I tried to do a dynamic, it failed. Oh, no, I can’t do it dynamic. What do I do?’ That’s where our information will come back and say, well, now you have no choice but to do static.”

Even with the swift advancement of vehicles, a platform like ID3 is in theory inherently equipped to deal with the changes. The more vehicles that get scanned the more data there is and the more machine learning that takes place. Every year that gets added onto Protech’s 30-plus years of experience means more knowledge for the base.

“We’re always doing the research on the newest and latest vehicles,” says Mikrut. “So, because we have great relationships with OEMs and what we do with getting access to their repair procedures, their information, we’re constantly looking at the [2023 vehicle models] before they come out. So as soon as that information was there, we’re building the database, right? Because we need that information because, in a collision space, we can see a car that’s brand new, say he just drove off the lot and someone hit him, we’ve got to make sure that we’re always on the cutting edge. And so we’ve got a team of researchers that are doing that on a regular basis.”

15 February 2023 fenderbender.com

GETTY

aleinmont@email.com Tel: (H) 491-555-9876 Reason for alignment: ADAS COLLISION CENTERS OTTO BOT’S 12345 Repair Rd. Cambertown, TN 38467 Tel: (491) 555-3020 Before Measurements Additional Measurements Advanced Measurements Technician Notes Te 491-555-9876 Reason for ADAS Calibration Toyota : RAV4 : 2016-18 Addit onal echn cian R012345 04/19/16 3:11 PM Al Leinmont 4321 Main St. Cambertown, TN 38467 aleinmont@email.com Tel: (H) 491-555-9876 Reason for alignment: ADAS Calibration COLLISION CENTERS OTTO BOT’S 12345 Repair Rd. Cambertown, TN 38467 Tel: (491) 555-3020 Toyota : RAV4 : 2016-18 Before Measurements Additional Measurements Advanced Measurements Technician Notes Find damage before it fi nds you Uncover hidden collision issues with Hunter’s unique blueprinting workflow. Scan or visit www.hunter.com/collision

NUMBERS

A PLAN TO SUCCEED

THIS MONTH’S CASE STUDY COVERS succession planning, and how those plans can go awry when life and business have other ideas. To what extent are owners planning for the future? The 2022 FenderBender Industry Survey reports that just under half of the 506 respondents plan to retire in the near future. But just about a third of all respondents said they have no succession plan in place.

Sell to consolidator:

Transfer ownership to staff: 9%

7%

No succession plan:

32%

Other:

12%

Percentage of all survey respondents

Sell to private buyer: 15%

Leave it to family or business partner:

25%

17 February 2023 fenderbender.com

QUICK FIX

A proven business model for 20 years, ProColor Collision is growing! Independent body shop owners driving their business forward are choosing ProColor. Standardized operations, management tools and consolidated technology solutions improve performance. The ProColor team of industry professionals are dedicated to performance excellence offering the sales, operational and marketing support needed to take business to the next level. ProColor Collision is committed to helping shop owners grow their business locally while leveraging established relationships with global insurers, suppliers, and fleet companies. The ProColor PROcess is a winning formula. Find out more at procolor.com This advertisement is not an offering. An offering can only be made by a prospectus filed first with the Department of Law of the State of New York. Such filing does not constitute approval by the Department of Law. ProColor Collision USA LLC, 650 Pelham Blvd, Suite 100, St. Paul, MN 55114 ® Registered Trademark of MONDOFIX INC. PROSPER WITH THE

s

CCC’S SUSANNA GOTSCH RETIRES AFTER 30 YEARS

CCC Intelligent Solutions Inc. Senior Director Industry Analytics Susanna Gotsch retired after three decades with the company at the conclusion of 2022.

According to a press release, Gotsch started with CCC in 1992 working in product development and management before moving into her role as industry analyst for the company in 2000. Among her notable achievements are starting CCC’s Crash Course publication in 1995 and earning a Most Influential Women in the Collision Repair Industry award in 2011. She has also served on the board of the Women’s Industry Network and represented CCC at numerous industry conferences.

“Susanna is exemplary in every way and her retirement, while bittersweet, is extremely well-earned,” said CCC Chairman and CEO Githesh Ramamurthy, via the press release. “From her early days helping to build what has become a world-class analytics team, to becoming among the most valued and trusted voices in the industry, Susanna’s contributions have been significant within CCC and beyond. She has been generous with her time and knowledge and leaves behind a strong team to carry forward the important work of equipping customers with information and insights to help them manage their business. We wish Susanna the very best as she transitions into retirement.”

CCC’s trends and insights team dedicated to industry analysis will continue to be led by Vice President, Product Marketing Jason Verlen. That team has expanded to include Kyle Krumlauf, focusing on auto physical damage, and Erik Bahnsen in casualty. Ramamurthy said that expanding this team is expected to scale the analysis the company is known for, which Gotsch played a key role in developing.

“CCC has been my home away from home for 30 years and I will miss working

side-by-side with my amazing coworkers and so many wonderful people in this special industry,” said Gotsch. “I’ve had a front row seat as the industry has been transforming from analog to digital to AI-powered. I have thoroughly enjoyed my role in bringing CCC’s passion for helping customers use data-driven insights to inform their business. I’m excited to spend more time with family and pursue my other interests, and I wish to thank Githesh, the CCC team, and the industry for an amazing run.”

I-CAR OFFERS NEW COURSE ON VEHICLE TRENDS FOR 2023

With new vehicles and associated technology on the way in 2023, I-CAR rolled out a new course identifying vehicle technology and trends of note in the new year.

According to a press release, I-CAR’s Vehicle Technology and Trends 2023 course is a one-hour lesson led by I-CAR technical experts. Topics covered include ADAS features, unique features and technologies of 2023 model year vehicles and beyond and all the related considerations applicable to collision repair. The I-CAR Subscription Training Program includes the course, or it is available for a one-off purchase to any collision repair professional not already a subscriber to the program.

“With automakers (OEMs) introducing more than 100 vehicle changes each model year, the speed with which new technologies are introduced into vehicle applications is unprecedented,” said I-CAR Vice President, Sales and Marketing Nick Notte, in the press release. “As the collision repair ecosystem continues to be redefined, this course is another intentionally-designed resource to help collision repair professionals prepare for the road ahead.”

Vehicle Technology and Trends is an annual offering from I-CAR, presented as part

of its Vehicle and Technology and Specific Training family of courses. Enrollment is open now through the I-CAR website.

I-CAR AND CREF HONOR JEFF SILVER WITH MEMORIAL SCHOLARSHIP

I-CAR and CREF are honoring the legacy of one of their most influential members with the creation of the Jeff Silver Memorial Scholarship.

According to a press release, the scholarship will first be awarded this year to a collision repair student in a fitting tribute to Silver, who passed away in September 2022 at the age of 80. Silver spent much of his five decades in collision repair helping create opportunities for students to enter the industry, working with I-CAR since its founding and helping start CREF in 1991. Silver served as I-CAR executive vice president for 11 years beginning in 1986 and played a key role in the development of I-CAR Gold Class certification. After leaving I-CAR he and his wife Jeanne ran Butterfield Bodyworks CARSTAR in suburban Chicago for 25 years.

“Jeff was passionate about helping collision school programs and their students, which is why he had an active role in establishing the Collision Repair Education Foundation back in 1991,” said Jeanne, via the press release. “This memorial scholarship will allow his vision to carry on in supporting these students. Thank you in advance for considering helping honor Jeff’s legacy by supporting this scholarship!”

This is not the first honor named for Silver. The Jeff Silver Award has been presented each year since 2009 to an I-CAR Platinum member who has worked to enhance a positive image of the collision repair industry. Applications for students interested in the scholarship opened in January; anyone interested in making a donation to the scholarship fund may do so at collisioneducationfoundation.org/ donate-now.

19 February 2023 fenderbender.com

LIGHT HITS QUICK FIX

5-STAR COLLISION & GLASS CENTER

B y TODD KORTEMEIER

Photos by RUSSELL HONS PHOTOGRAPHY

LOCATION: GRAND FORKS, ND

OWNER: CRAIG AMIOT

SIZE: 7,000 SQUARE FEET

STAFF: 7

AVERAGE MONTHLY CAR COUNT: 107

AVERAGE REPAIR ORDER: $1,600

ANNUAL REVENUE: $2,050,000

When winter comes, the wind is known to howl across the plains of North Dakota, sometimes carrying blinding snow or stinging sleet. Grand Forks locals in need of collision repair have enough to worry about with a damaged vehicle without taking the weather into account, and that’s where the drive-in estimate bay at 5-Star Collision & Glass Center comes in real handy. Customers love it, but employees love it too, since it offers bright, consistent lighting in addition to the consistent climate.

“It’s nice,” says shop manager Bob Arnold. “I mean, even just the lighting, even when it’s nice outside, sometimes it’s better to get inside and get better pictures and see things a little better without that sun glaring on you. When it’s raining, wintertime, especially, it’s a game changer, not run outside with a hat and gloves on trying to get as many pictures as you can, as fast as you can to get back inside. So it’s really nice in that aspect for sure.”

Submit Your Shop

Proud of your shop and want to show it off to your peers? Tell us about it at SUBMISSIONS@10MISSIONS.COM

Other customer comforts include a lounge with coffee and tea, and the shop does also offer pickup and delivery for the ultimate comfort and convenience. Photo estimates are available as well, though the shop always prefers to do physical estimates for accuracy.

20 February 2023 fenderbender.com

SNAP SHOP QUICK FIX 1

1. GIMME SHELTER

2

2. PEOPLE AND PROCESS

In business since 2001, 5-Star moved to its current location in 2014. The shop is equipped to do dynamic calibrations in house with plans to expand to add static calibrations in the new year. More space for glass work is in the works as well. The shop prides itself on its process, clearly communicated to customers in five stages of what to expect.

“We really focus on that customer experience for the customers,” says Arnold. “It’s a pretty easy process for us, because we do it every day. But it’s a pretty emotional and high stress process for the customers that aren’t doing this every day.”

3. A CLEAN FINISH

When that process is completed, 5-Star likes to send customers off with a thorough cleaning that the shop says sets it apart in the market. Calling it a “borderline detailing” just with no carpet shampooing, waxing and the like, Arnold says the shop will clean down into the nooks and crannies like ash trays and door jambs to leave customers feeling great about their repair.

“That’s probably one of the biggest things we hear back from our customers, just how clean it is,” says Arnold. “You know, a lot of people don’t even notice the dent or how well it was fixed. We pride ourselves on the quality of our work, but what they see is a nice clean interior when they pick it up. That seems to make a big difference.”

21 February 2023 fenderbender.com

3

AUTOZONE PARTS AVAILABLE IN CCC ONE® Easier, faster ordering with 24/7 access and leading stock coverage Access OE-quality mechanical parts from Tier 1 manufacturers Improved accuracy for more efficient repairs ©2022 AutoZone, Inc. All rights reserved. AutoZone, Duralast are registered marks of AutoZone IP, LLC or ones of It’s affiliates. All other marks are property of their respective owners. All photographic, clerical, typographical, and printing errors are subject to correction. CCC and CCC ONE are registered trademarks of CCC Intelligent Solutions Inc. For more information visit AutoZonePro.com/Collision

Estimating for Higher Gross Profits

Your profit could be hiding itself in the details

It’s interesting when I ask a shop owner if they know what their gross profit is. Many will say, “Sure do.” Then after some conversation the truth surfaces and unfortunately, many have no idea.

Our gross profit is what is left over after all the work we have completed less our Cost of Goods Sold (COGS). COGS equals all our costs associated to repair the cars: Paying out for technician labor, parts, repair materials, paints, and any sublets. We should be striving for a 50% gross profit as a rule, but unfortunately many shops are in the 40% to 42% range. Here is the trouble with the latter: If these shops have an overhead expense in the 35% range, that means there will only be a 5% to 7% net profit left over at the bottom! We will discuss how to lower overhead as a percentage of gross sales in the coming months.

How can shops move their gross profit closer to the 45% to 50% range? The easiest and the most effective way is with better estimating. I have reviewed quite a few different shops’ estimates in the past twelve months. It just blows my mind how many shop owners don’t understand what good estimating looks like. They pay for estimating software and just think clicking on parts to repair or replace is all they can charge for. I heard a statement some years back that I will never forget: “I don’t mind going home tired or I don’t mind going home hungry, but I will not go home both tired and hungry.”

There are so many shops that do countless operations for free and never take the time to document and charge for them. I can hear what some of you are saying right now, “Greg, it’s all good and nice to add stuff to our estimates, but then we have to get the insurer to pay for them!” Well for starters, if you don’t ask for something you for sure won’t get a call from the insurer stating, “You missed clean and retape of the door side molding and I added it to your supplement.”

Let’s just look at a quarter panel only replacement. For decades prior to proper estimating knowledge, my uncles and I did a ton of work for free by not charging for it. We would just accept the insurer’s quarter panel replacement estimate for approximately 40 to 45 hours. After gaining

knowledge of how to properly charge for all the not included operations, my staff now understands anything less the 75 to 80 hours to install a new quarter panel is an utter failure.

Here are just a few things that are NOT included in an LH quarter panel replacement with a fuel door: Research and print OE procedures; Safety inspections per procedures; Disconnect & reconnect electrical components; Reset electrical components; R&I LF & LR door; Make sleeves if recommended by OE; Destructive test welds; Pre & post scans; Seam sealer; Cavity wax; Structural foam removal & replacement; Structural adhesive; Expansion foam; Panel bond adhesive; R&I wheel; Torque wheel to specs; R&I rear seat belt; Color tint; Protect interior for welding; Roll back carpet; Dress welds; Feather/prime/block; Remove stone guard; R&I rocker molding; R&I trunk interior including carpet; Remove old urethane from rear glass and quarter glass R&I; R&I headliner; R&I LH roof airbag; R&I quarter vent; Multiple test fits; R&I fuel door; R&I fuel filler pipe; R&I exhaust shield; R&I spare tire & jack; R&I rear rebar for rear body panel refinish; Setback wiring harness for tail lamp & dogleg interior area; Setup/measure/body pull; Repair and refinish of pinch welds; R&I trunk lid; R&I trunk & door opening weatherstrips; Repair & refinish for each of these components due spotweld removal and welding: inner rocker, outer wheelhouse, inner wheelhouse, trunk gutter, tail lamp pocket, rear body panel, floor extension and fuel pocket; Detrim and blend of trunklid and LR Door; Refinish of entire LH aperture and new quarter backside; Mask door, back glass and trunk openings, hinges, labels and striker; Denib and buff. This is NOT an exhaustive list, but maybe something here will make us think the next time we need to replace a welded-on panel. Please understand, you can’t just add these not included operations and expect to get paid from an insurer. We must do them along with adding great photos (over 50% of shops need training on how to take good quality photos), material invoices, OE documentation and line notes for each one! We are in full control of our profitability.

GREG LOBSIGER

Greg Lobsiger has owned Loren’s Body Shop in Bluffton, Indiana, for over 23 years. He has been a member of Mike Anderson’s groups for ten years and had extensive lean manufacturing training.

EMAIL: greg@lorensbodyshop.com

ARCHIVE: fenderbender.com/lobsiger

23 February 2023 fenderbender.com

JOSIE SMITH PHOTOGRAPHY

COLUMNS SHOP

PROFITS

BECOMING A DESTINATION

The

By TODD KORTEMEIER

24 February 2023 fenderbender.com Topical

things employers can do to attract the best talent and retain it in a difficult market

IT’S A QUESTION every shop is asking: How can we recruit qualified technicians, and how do we keep the talented techs we have? These questions have a myriad of answers and none of them provide an easy solution.

Shops aren’t going to stop asking those questions anytime soon. But there’s another question they can ask that might be an answer of its own: How can we become a place that techs want to work at in the first place? Rather than react, what can shops do to be proactive in solving their labor woes?

Speaking at the 2022 FenderBender Management Conference, Mike Anderson got right to the point. To grow your business, you have to grow your people. And Anderson didn’t ignore the facts, pointing out the reality that the industry is going to need 80,000 new technicians by 2024, according to the TechForce Foundation. Whether or not that target is achievable is up for debate, but the drive for new techs is on and they’re looking for work.

Today’s employees expect different things than workers even a few years ago. Higher salaries, better benefits and flexible working schedules are how employers are differentiating themselves in the current labor market. While not all of these benefits are feasible in collision repair, the shops that can offer the most can become destination shops in the eyes of prospective employees.

For Nick Edwards, owner of four-shop Car Center out of Michigan, if you’re not starting with an established culture then it’s difficult to be attractive to the employees you’re seeking. It’s one thing for a manager to tell a prospective employee what they’re going to get out of working at a given shop. It’s another for them to hear it from their future colleagues.

“I know we’re successful when I can tell that person, go call six different people that work for us and ask them how it is,” says Edwards. “And so I feel like that I can say that confidently, I don't prep my team. I'm not like, ‘Hey, Jim's calling, say a good word for me, he wants to come work here,’ my hope is that they can naturally call the team members that currently work here. And they say, ‘Yeah, you got to get on board. It's awesome.’”

For Edwards, that’s part of one of his business’ guiding principles. At a lot of shops, and a lot of businesses in general, the customer comes first. That’s true in a sense

for Car Center, but Edwards says that his team of employees comes first. Team members are the first customer. And that in turn benefits the customers, who will be receiving great service from happy, satisfied and skilled professionals.

That well-rounded approach is key for Car Center’s goal of offering more than just a job. That means offering a place where a tech can grow a career in the collision repair industry, not just make a stop on the way to something else. And that means offering a place where an employee’s entire well-being is cared for, and they’re not just there to collect a paycheck.

“There's a lot of people that are money driven, and lots of people are driven by different things. But I think one of the things in our generation today or the workforce today, that we're seeing more than ever, is that people want to be a part of something bigger than themselves,” says Edwards.

Car Center employees are empowered to play a role in the shop’s broader, long-term success. Playing a key role in maintaining that inclusive culture is Megan Bridinger, culture ambassador for the company. Brid-

inger cited the company’s open door policy for employees to offer feedback or suggestions as well as regular opportunities to contribute.

“We actually do these things called the start, stop, keep meeting,” says Bridinger, “And this is basically an opportunity for each of our locations to kind of get together. And it says in the name, what we should start doing, what we should stop doing and what we should keep doing. And especially this is really beneficial to everybody sitting in one room having a conversation.”

Edwards adds that in addition to the start, stop and keep meetings, which are geared around technicians, there also are “L10” meetings at the leadership level and at the store level, where general managers and estimators can get together and talk process. Employees also receive regular reviews, not only to monitor their performance but also get insight into the employee’s goals.

“There's four questions that we ask all the time,” says Edwards. “Do you have the tools and resources to do your job? What have I done to support you and help you do your job better? And what have I done to

25 February 2023 fenderbender.com

PEOPLE WANT TO BE A PART OF SOMETHING BIGGER THAN THEMSELVES.”

—Nick Edwards, owner, Car Center

hinder your job? What goals do you want? So, asking for their feedback and how we can improve as well.”

Like Car Center, the crew at Pro Tech Collision Center in Houston believes strongly in the relationship between happy employees and happy customers. Skilled employees make quality repairs, leading to even happier customers. That’s why Pro Tech owner Adria Gonzales makes sure her employees get the training they need and want to enhance their career.

“Being an independent, you have to strategically look at how you're going to grow and leverage an independent shop for the future,” said Gonzales, whose shop received a 2022 FenderBender Best Workplaces Award. “And given the EV trends, that is something that I have asked our team, ‘Are you interested in this,’ and they are so excited that we're working on plans to get them up to speed so that we can start advertising that we have the certifications to work on the EV and hybrid vehicles out there.”

In addition to I-CAR and technical training, Gonzales says she’s always interested in any training that can help employees work better together. Open communication is a priority at Pro Tech and helps make a positive environment.

“Walking the shop, as the owner, I have a team that they know what their responsibilities are,” says Gonzales. “And they know that if they do their part, I'm also going to ensure that I have their back. I think in this world of

people, people are definitely trying to make sure that they can have a sustainable, happy, balanced life. And that's something that I want my employees to have as well.”

That means a manageable schedule for employees, no six- or seven-day work weeks if it can be avoided. Techs have the option of extra hours in busy periods if they need it, but otherwise Gonzales trusts employees to budget their time during business hours. The shop offers paid holidays if they fall during the week, and also offers a week of paternity leave for new fathers.

“We’re trying to bring in a younger generation to help fill the gaps of those that are also retiring out of this industry, and try and bridge that gap and share the knowledge across the board,” says Gonzales.

One of the ways Gonzales is dealing with the projected tech shortage is by thinking creatively. Maybe a prospective employee doesn’t have the collision repair experience that’s ideal in that position. But Gonzales says she’s learned to look at a person’s abilities, and not necessarily what they have done.

She cited an example of an employee in her office with a teaching background who has the outgoing personality to work with customers and also the organizational skills to keep track of several different tasks at once. She also has an employee who was a welding instructor, possessing mechanical knowledge while

also being able to convey that information well to a customer.

“I really look at each person's strong suits and see what skill sets each person contributes,” says Gonzales. “And by doing that, it may, if we're trying to find a role to fill, it may not be through the traditional aspects of finding someone who's already established a career in the collision repair industry. Only because we do have a shortage of resources.”

Naturally, the shops that do the best at becoming destination shops don’t have to flex those muscles often as they’ll have fewer positions to fill. That was the case for both Pro Tech, which is just a few years old, and Car Center, which has employees who have been with the company for nearly 20 years. More are literally waiting to get in.

“We have people that are, potentially waiting in the wings to join our team, just because they want to be a part of it,” says Edwards. “And they like the leadership that we have in place. And so that's a pretty rare thing I think in our industry right now.”

Both owners say they would like to do more. Gonzales hopes to be able to offer retirement plans, and also find solutions to common employee complaints such as the strain that supply chain woes put on their efficiency. Edwards was proud the company was able to recently offer short term disability benefits and he hopes to add life insurance benefits in the near future. These are some tweaks that add to what has already been a successful environment for both attracting and retaining employees.

“Everything always comes back to a set of core values,” says Edwards. “And that is the driving force of everything we do every one of our conversations.”

Gonzales reminds that while each shop is of course looking to bring in the best employees, it’s ultimately the customer who will benefit in the end.

“Find what you want to be able to create in creating the cultu re,” says Gonzales. “Because that is the thing that I look at is that this a customer who has a wrecked vehicle, who has to bring it in for repair, that’s stressful, and we want to make their experience less stressful and not add any more stress to the fact that they’re having to have a vehicle repaired and take the burden off of them and provide them kind of a one stop experience.”

26 February 2023 fenderbender.com Topical

FIND WHAT YOU WANT TO BE ABLE TO CREATE IN CREATING THE CULTURE.”

—Adria Gonzales, owner, Pro Tech Collision

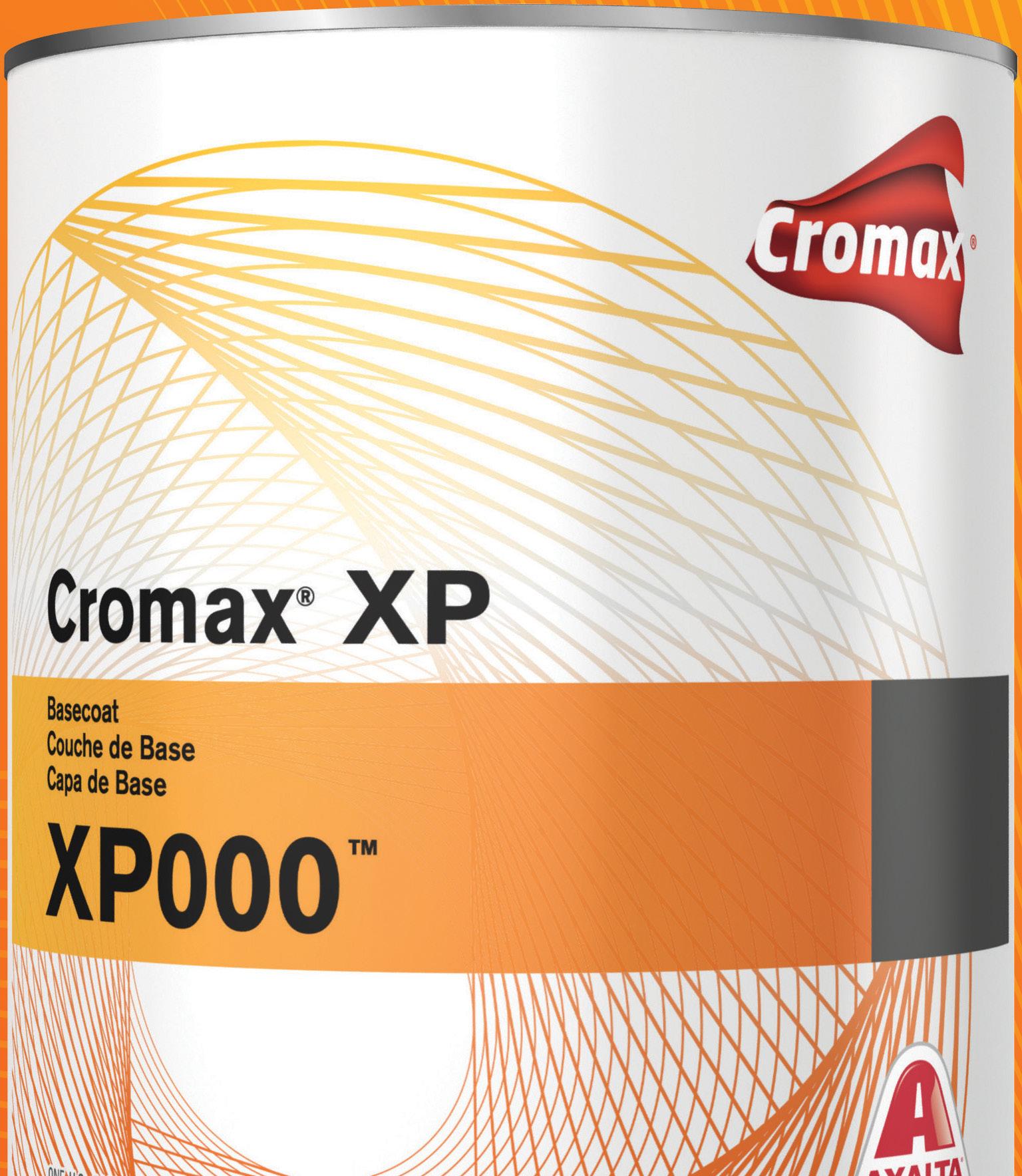

More coverage in every can.

Unlike other basecoats that can require up to six coats, Cromax® XP delivers full coverage in as few as two coats. It’s easy to learn, use, and even repair—if ever needed. Cromax® XP is the ideal solventborne system for those who value quality and simplicity.

Experience the difference. axalta.us/xp

AXALTA COATING SYSTEMS Copyright © 2022 Axalta Coating Systems, LLC and all affiliates. All rights reserved.

One Shop’s Strongest Bond:

Father-daughter team Cole and Swayzi Giles work side by side at their Utah shop.

By TODD KORTEMEIER / Photography by SAMUEL GONZALES PHOTOGRAPHY

Cole Giles never went to school for collision repair. Those programs existed, but as a hobbyist already interested in cars and automotive repair, the shop that first hired him had no concerns that they could teach him everything he needed to know and how they wanted it done. And Giles is still at Cascades Collision in Utah, now a disassembly manager after 17 years pounding fenders.

“Seventeen years of this body work, just goes by fast, that’s all I can say,” says Giles.

While Giles received his share of on-thejob training, he came in with some acquired knowledge as well. Giles’ wife Heidi relays a story about how her husband got into collision repair in the first place. It was a chance meeting at Walmart with a shop owner who was also a fireman with Cole’s father. Cole expressed an interest in doing bodywork, and Heidi was able to confirm she knew her

husband would have a knack for it. She’d seen him fix a dent in the family truck using just a two-by-four and a hammer.

Even with that seemingly natural talent, collision repair wasn’t necessarily Plan A for him. Giles had hoped to do more restoration work, or fabrication, working on hot rods and such. But he saw collision repair as a great place to start. It was his foot in the door and the start of his education.

Plus, he was able to keep up his other automotive interests on the side. He always had some kind of project car going at his home garage. Any free time he had, he’d be out there working on it. And perhaps accidentally, he provided the inspiration and pathway to collision repair for his future co-worker, his daughter Swayzi.

All the Giles girls enjoyed tinkering and working alongside their dad on projects, learning all about vehicle repair and main-

tenance along the way. But it was Swayzi that took to it the most, offering a helping hand at home, and, eventually, into the body shop.

“Ever since I was a little girl, my dad’s always had a project car out front working on it any chance he got, he’d always go into work early, so he could come home earlier than usual so he could work on his new toy that’s out front,” recalls Swayzi. “And I’d always come out, and I’m a little bit of a daddy’s girl, so I always wanted to hang out with my dad and see what he’s doing.”

From the time she was about 6, she recalls, Swayzi has spent time at Cascades with her dad. It started with going with her mom to meet him for lunch. Heidi recalls a fair amount of good-natured mischief, with Swayzi swiping the occasional stray marker to write on car windows. Even from that early age she became something of a fixture at the shop.

28 February 2023 fenderbender.com

PROFILE

29 February 2023 fenderbender.com

“I always was known in the shop, just a cute little girl just running through the shop, everyone’s picking on her,” says Swayzi. “And I’ve always just grown up around cars. So my passion came from just seeing my dad work on them. And then building bonds with guys that still work here to this day.”

After all those years spending time around the shop, Swayzi decided to seriously pursue collision repair as a career in high school. In her senior year she did an internship at the shop, receiving school credit for it to boot. It was two class periods every other day that she got to have handson experience inside the shop. It was also a brush with the disbelief that sometimes comes from being a woman in a male-dominated industry.

“My teacher didn’t believe that I was in the body side, interning, she thought I was interning with the office ladies up front,” says Swayzi. “Like, no, I’m actually around back. I’m currently tearing off the bedside

off of this truck. And she came back there. And she’s like, ‘Oh my goodness, you are.’ So that was pretty funny. It’s funny when people don’t believe that I’m, you know, in this kind of industry.”

The reaction within the shop has been much different. Swayzi says her co-workers, many of whom she’s known most of her life, think it’s pretty cool what she’s doing and treat her just like another employee. But there was a bit of adjustment in her going from that little girl running the shop getting teased to a full-fledged member of the team. With her dad a senior employee and having been in the industry for so long, they weren’t sure how far to take the typical ribbing that goes on in a body shop.

“They don’t want to, you know, cause waves, but they think it’s super cool,” says Swayzi. “And we like to give each other crap all the time, they always make fun of me because I’m short, or I haven’t learned everything yet. But, you know, we all still

have so much fun. And I think everyone so far that has learned that I work beside my dad, and I do this type of stuff, they think it’s super cool.”

Swayzi began working at Cascades in February of 2022, and at the time of this reporting she had been working side-byside with her dad in disassembly for about three months. She started out in the detail bay just to get her foot in the door. She isn’t certain exactly where she wants to take her collision repair career but was currently training to be a disassembly technician and that was a suitable challenge for the time being. As she noted, being somewhat vertically challenged can make it hard to work around bigger vehicles but given the right training she’s excited about doing just about anything in the industry.

For Cole, his own career suddenly has a new burst of motivation in getting to work alongside Swayzi. She had recently just moved out from the family home, so they get

30 February 2023 fenderbender.com PROFILE

to see each other at work instead. They make a good team with contrasting styles; Heidi notes Cole is more of a quiet, head-down, getit-done kind of worker while Swayzi can be “full of so much sass” and energy.

A father of all daughters, Cole didn’t want to discourage any of his girls from getting into the industry, But he also wanted to be realistic with them about what they might be getting into. It wasn’t an easy career.

“I told her not to,” Cole says. “It’s kind of wear and tear on your body, stuff like that. But that’s how she wants it, she liked working on cars. And I couldn’t stop her. I told my other kids like, go to school, do something different, you know. But yeah, I’m excited to see her following in my footsteps.”

Only one of the other girls expressed an interest in getting into collision repair, and Cole gave her the same talk. She listened, he said.

“I’m the one daughter that didn’t listen,” says Swayzi.

31 February 2023 fenderbender.com

Like the Old Days Swayzi Giles grew up helping her dad Cole in the family garage and now she does it for a career.

KEEPING TRACK OF THE LITTLE THINGS

It can be hard to make time for tasks that aren’t a part of fixing cars.

“IT’S THE LITTLE DETAILS THAT ARE VITAL. LITTLE THINGS MAKE BIG THINGS HAPPEN.”

– John Wooden, NCAA coach

That statement holds a lot of truth for a business owner, doesn’t it?

32 February 2023 fenderbender.com

STRATEGY

THE SOP GETTY

LEARN | GROW | WORK SMARTER

When you sit down and think through all the little details and responsibilities that go into running a successful collision repair shop, it’s easy to see how it’s those little things that compound on one another to make the big thing—the business—happen.

For Steve Wolfe and his partners at Diversified Body and Paint in Henderson, Colorado, the little things are seemingly endless … and, as an independently owned and operated shop, Wolfe and team had to implement their own system to manage it all from the ground up.

How do they do it? Everyone has a role to play, and no detail is overlooked—from making the coffee in the morning and ensuring there’s bottled water waiting for customers to keeping the shop clean, the social media pages updated, and making sure the employees all have what they need—it’s imperative that everyone does their part so nothing falls through the cracks.

As told to LINDSEY GAINER

FINDING A SYSTEM THAT WORKS

There are lots and lots of small details to be successful in today’s business, on top of the most important job of all—taking care of your people and the things that keep them moving, like estimates, payroll, parts, etc. Take care of your employees and they, in turn, will take care of your customers. Details that affect the customer are always our priority, big or small.

Everybody in the shop has things they’re responsible for, but we’re not a corporate store—we’re independent.

So, as owners, we’ve carried a lot of these little roles on our own for a long, long time. In a car shop where you’ve got 20-plus corporate-owned stores, for example, it’s very cookie cutter. You walk in the door and the receptionist makes the coffee and this and that. But in our world, because we’re independent, we wear a lot more hats. We have lots of checks and balances along the way to make sure nothing is missed, and we have to regularly assess responsibilities and workflows to ensure everything that needs to get done is being handled.

MAKE A LIST…AND CHECK IT TWICE

Ron Kuehn—president of Collision Business Solutions and the leader of one of the 20 Groups I’m a member of— gave us all a sheet of paper (actually, it was three pages!) to write down in detail who does what in the business. All of the owners filled them out, and it was eye opening to see how much we all do day to day. As we went down through our lists, it was crazy what we discovered! We’ve delegated a lot, but seeing how many of the “little things” we still handle was really insightful. His challenge to us now is to work on giving more away, to continue to work on delegating.

I’d recommend every owner take the time to write out a list like this, both for themselves and their employees, to track what’s being done in the shop and by whom. Not only is it important to know who does what and hold people accountable for their responsibilities, you need to make sure nothing is slipping through the cracks

and have a contingency plan in place for when an employee needs time off. When that person is away, who’s responsible for stepping in to handle their work?

No task is too small to include, either. Making the morning coffee may seem like a relatively unimportant thing, but the reality is that the little things really do matter. You can be the best of the best at what you do, but if you let the little details slide it can really affect your business in the long run. People notice those kinds of things. Customers’ expectations are high, and we always try to put out a product to match. A big part of that is not neglecting the little things!

We’re big into checks and balances in our shop, too. Our estimators carry the job from cradle to grave, making sure no detail is missed. Checks and balances are set up for each and every department for accountability—sign-off sheets with supervisor approvals and spot checking are a daily occurrence. It’s all about quality control. We live by the rule, “pass no defects,” meaning you always double check your work before passing it onto the next person in line.

A FINAL WORD OF ADVICE

If I could give a new shop owner—or any owner for that matter—one piece of advice, it’d be to join a 20 Group or something similar, to share business benchmarks and ideas among your peers. You’ll be amazed at how beneficial the collaboration is in figuring out the best ways to run your business—in the big and small ways alike.

33 February 2023 fenderbender.com

CUSTOMER SERVICE

THE AMAZONIFICATION OF COLLISION REPAIR

How businesses can help meet the demands of the modern consumer

By KIMANZI CONSTABLE

WHEN YOU NEED TO BUY something for your home or life, you’ll likely check Amazon first. The company offers an easy-to-use website and app, great prices, quick delivery and a smooth customer experience. You know what you’ll get when you do business with Amazon.

34 February 2023 fenderbender.com

STRATEGY

GETTY

Amazon is one of the largest companies in the world, with net estimated sales of $127.1 billion in the third quarter of 2022, according to data from Statista. They’ve grown into a large and profitable business through the modernization of its operations.

The seamless experience a retailer like Amazon has created is something that customers have grown accustomed to when doing business. While collision repair shops aren’t able to deliver door-to-door repairs in two days, they can mimic some of the benefits users experience with a modern company like Amazon. That experience can help build a modern collision repair shop.

“When it comes down to it, customers want the ability to know and control what’s going on with their vehicle. They want a smooth shop repair experience,” says Ryan Marrinan, now an application engineer with 3M’s aftermarket auto division who is a former collision repair specialist with 20 years of experience working in two auto body shops in Minnesota. “The way the world is going requires a more modern approach for shops. We must realize the last eight years have become much more accelerated, moving toward an online experience. If shops don’t evolve and modernize, they’ll be left behind. The customer is different, and cars are more advanced; it’s up to shops to keep up, and using an ‘Amazonification’ approach could help.”

Customers today are used to instant results based on the offerings of online retailers, and you can offer services to help meet current expectations. Here are a few places to start.

SET UP AND USE 24/7 ONLINE SCHEDULING

Having to call a shop to schedule an appointment is one more point of irritation for your customer. The good news is that today’s online software makes the process easier and creates a better customer experience.

You can eliminate some of the “human” elements of this process by setting up online scheduling. Many shop software providers offer this kind of functionality.

With scheduling software, customers can conveniently go online and schedule or change appointments. Your customer service team can go online and see what activity is happening with appointments.

You can customize this software to whatever makes the most sense for your shop. You can add automated appointment

reminders through text and email so customers always know what’s happening.

Your customers don’t want to call to check, change, or get updates about their appointments—setting up online scheduling software is a relatively easy way to provide an Amazon-type experience.

HAVE EXTENDED HOURS WHEN IT MAKES SENSE

Amazon is extensive with its ability to deliver to its customers worldwide and do so quickly. Online retailers are obviously open at all hours, able to cater to a customer at any time.

Today, your customers have a busy life. They have work, family, businesses and more. Your customer would love to be able to schedule an appointment and/or drop off their vehicle during regular hours, but that’s not always possible. Offering extended hours where it makes sense can capture more of these customers. You could elect to extend hours during the holiday season, the summer or when you expect the shop to be busier than other times.

You don’t have to offer 24/7 hours all the time, but if you did a time audit, you’d probably find opportunities to offer extended hours and make your customers happier.

PROVIDE PHOTO UPDATES

There’s something to be said about building trust with your customers. One way to build trust is by demonstrating to the customer your efficiency in a way they understand. People are visual in nature, and providing photo updates is an incredible way to build trust.

Showing your customers what repairs are needed and why through photos builds trust. There’s clarity for the customer, and the extra touch of having photos separates your shop from others.

People purchase on Amazon at an accelerated rate because of the visualness of the platform. Customers can not only see multiple photos of items but can even see photo reviews from customers. It’s built trust and is a strategy shop owners can add to the processes.

“The visual appeal is what customers today are looking for. Auto body repair is still a visual business, and customers want to see what’s going on,” says Marrinan.

SET UP AUTOMATED COMMUNICATION

Communication makes or breaks a business. The way and frequency at which your shop

communicates will make all the difference and determine whether you have lifelong customers. Just like customers are able to track packages to their doorstep, they might like to track their vehicle through its repair process as well.

“Some customers like to have daily updates,” says Marrinan. “How you communicate is important. You need a system and software that’s open to communicating with the customers as they expect. Communication is often more important than speed. Communicating that with customers will go a longer way than you getting their vehicle back quicker.”

Marrinan notes that his own vehicle was in a repair shop recently, and the text and email communication the shop provided made him want to recommend the shop to others. He says it was a great customer experience.

You can create a better communication experience using automated systems and software. The ability to schedule appointments is one part of a good communication strategy, but it’s more than that.

Customers want updates on where their vehicle is in the process, any unexpected circumstances that add more time, any unique situations that arise during repair, changes in charges, and anything else they’d like to know. All of this communication could be set up and managed with software.

“It’s not rocket science; communication with your customers is crucial. Take a look at the reviews on our site, and you’ll see how and why we prioritize good communication,” says Ron Perretta, owner of Professionals Auto Body. “It’s ridiculous for a customer to have to call the business that they are spending money with just to find out the status of their car. Sadly, that’s what’s typical in our industry.”

MODERNIZE YOUR SHOP

“Some other ways worth mentioning include proper training for shop staff, management of the overall repair process and billable materials, and having the products required to repair vehicles per OEM recommendations,” says Marrinan.

The bottom line is that using Amazon’s customer experience principles can help collision repair shops build stronger businesses. Your customers will have a better experience, making them become word-ofmouth marketing for your shop.

See which of these strategies you can implement in your shop, and it will improve efficiency.

35 February 2023 fenderbender.com

CASE STUDY

THINKING ABOUT THE FUTURE

One operator’s non-linear path to forming a succession plan.

By LINDSEY GAINER

SUCCESSION PLANNING—MUCH like life insurance, wills, and other future-oriented activities—can be hard to prioritize. As a business owner with a to-do list a mile long, it can be hard to find time to do what needs to be done now, let alone carve out time to plan for the future.

36 February 2023 fenderbender.com

STRATEGY GETTY

But if there’s one thing that every longstanding business has in common it’s this: they’re all the result of a successful transition (or sometimes multiple transitions) of ownership. Such transitions require a solid, strategic plan that can take years to build and execute—which is why it’s never too early to start the planning process for what will come next. And even the best-laid plans hardly ever play out exactly as anticipated, as Kathy Mello—owner of TGIF Body Shop in Fremont, California—learned firsthand.

THE PROBLEM

Life is unpredictable, and succession is a long, complicated process.

Before COVID entered the scene in 2020, Mello was well on her way to passing leadership responsibilities over to her son, Jason Cocco, who is staged to take over the business upon her retirement. But the past several years have presented unforeseen challenges for Mello, as they have for many shop owners throughout the country.

“Our progress has been stunted by several circumstances,” explained Mello. “First it was the cancer journey of my husband, which required my presence and care. Then, it was all the uncertainty presented by COVID and the shutdown, which we have managed through. My life was put on hold by a life-threatening hospital stay after contracting COVID early in the pandemic as well, and that required an extended recovery. Now, COVID-related regrowth is stunted by the technician crisis. I know that we are not alone in having to schedule out as a result.”

But, despite the hardships she’s faced both personally and professionally, Mello continues to look to the future with hope and determination. The succession plan will continue to move forward, albeit more slowly than initially anticipated.

THE SOLUTION

Start earlier than you think you need to, and get help putting a strategic plan in place. No matter what stage your business is in, it’s important to consider what will come next. For Mello and her husband, that meant evaluating the interest—or disinterest—of each of their four children in taking over the shop.

“Whether you’re selling a business or succeeding to others it requires a great deal of focus and a lot of crossing of t’s and dotting of i’s,” says Mello. “I recommend that the sooner you start the process the better, because, as we have found, life can get in the way of progress. I believe that attention needs to be given to both the personal/ family side of things as well as seeking the guidance of professionals who have vast experience with such transactions.”

From the start, Mello has utilized the expertise of professionals well-versed in succession planning, and she recommends other shop owners do the same. Having someone to guide you through the process is invaluable. Accountants, lawyers, and other owners who have completed their own successions can all be hugely helpful resources.

As a first step, Mello hired an independent party to interview each of her and her husband’s four children to explore whether any of them had an interest in succession … and if so, how they wanted to be involved. From there, they were able to start formulating a plan.

“Only one of them—aside from Jason, who has been running the day-to-day—is still in the industry and works and lives several hours away,” says Mello. “They have all expressed autonomy yet support for the family-founded business, and the opportunity for more involvement in the future will remain a possibility at the discretion of Jason, once the torch is passed.”

THE AFTERMATH

Prepare to be flexible and make adjustments as needed.

For the time being, Mello’s succession plan has been placed on the back burner while more urgent matters are addressed … namely, the technician shortage.

“The focus at the moment is to launch a technician training program sanctioned by the department of apprenticeship in California,” says Mello. “It’s an earn-while-you-learn program and should open up a pipeline of talent. Once that is rolling, we will return to the focus of business succession.”

In the meantime, Jason holds sweat equity shares in the business until the “fullblown” plan for financial succession is complete. When the time comes to financially complete succession, Mello says she will once again seek professional guidance on how to best proceed.

THE TAKEAWAY

Don’t let the future sneak up on you…start planning NOW!

As business author Alan Lakein once said, “Planning is bringing the future into the present so that you can do something about it now.” Succession planning is the ultimate example of that!

Even if you’re years away from wanting to retire, it’s important to start thinking about that next chapter now, well ahead of time. Planning for succession involves extensive legal, financial, and operational considerations that require a great deal of forethought and counsel, regardless of whether you’re planning to sell your business or pass it on to someone. Life will happen and priorities will shift, but a solid foundational plan is essential for your business to thrive for years to come.

37 February 2023 fenderbender.com

EV BATTERY RECYCLING NEEDS INNOVATION

The current infrastructure set and technologies used for EV battery recycling will not be sufficient if demand for the vehicles continues to spike, as industry experts suggest it will

By NOAH BROWN

BETWEEN FULL BATTERY-ELECTRIC and hybrid plug-in variations, there were around 7.2 million electric vehicles on the road globally in 2019, up from a measly 20,000 in 2010, according to the International Energy Agency, with the U.S. accounting for around 1.5 million.

38 February 2023 fenderbender.com

STRATEGY

ADAPT

GETTY

Electric vehicles have become increasingly popular in large part due to significantly reduced impact on the environment; a report from the International Council of Clean Transportation shows that electric vehicles in Europe produce, on average, 50 percent fewer life-cycle greenhouse gases over the first 100,000 compared to internal combustion engine-powered vehicles.

EVs aren’t totally green from the getgo, though. The batteries that power electric vehicles are significantly larger than those found in ICE-powered cars and require extensive mining for materials such as cobalt and lithium, which produces a large amount of pollution.

Battery materials are only going to get harder to come by, too: The IEA projects there will be upward of 145 million EVs on the world’s roads by 2030, meaning demand for batteries will only grow exponentially in the coming years.

And the challenge facing battery producers doesn’t end once a battery is placed inside a vehicle.

Extensive battery recycling will need to become much more prevalent than it already is for EV adoption to become less of a fad and more of a long-term, viable solution for the industry.

COMPLEX RECYCLING

Per a report from Reuters, researchers in Britain and the United States have found several ways to recycle EV batteries “that can drastically cut costs and carbon emissions” while also bulking up global supplies “for an expected surge in demand.”

With materials such as cobalt and nickel, which are expensive to mine, being able to retrieve those materials from a battery would save a lot of time, money and greenhouse gas emissions.

“We can’t recycle complex products like batteries the way we recycle other metals. Shredding, mixing up the components of a battery and pyrometallurgy destroy value,” Gavin Harper, a research fellow at the government-backed Faraday Institution in Britain, said.

Pyrometallurgy is the practice of retrieving metals from a substance using blast furnaces. Between that and other current methods, which include “shredding the batteries into very small pieces” and processing those shavings into necessary

material, current recycling practices aren’t able to adequately recover a large amount of materials from current EV batteries.

According to Reuters, though, Researchers from several British universities working through the Faraday Institution, Britain’s state-sponsored research lab, have “found a way to use ultrasonic waves to recycle the cathode and anode” in an EV battery without the need for shredding.

The tech recovers cobalt, nickel and manganese from the cathode powder of a battery, and it recovers graphite from the anode powder. One of the researchers working on the project says the process of separation via ultrasonic waves could save as much as 60 percent on materials when compared to the cost of “virgin material.”