THE

Strategies & Inspiration for Collision Repair Success Acquired Knowledge Shop owners like Brian Davies look to those who’ve come before to lead their shops today.

Strategies & Inspiration for Collision Repair Success Acquired Knowledge Shop owners like Brian Davies look to those who’ve come before to lead their shops today.

Strategies & Inspiration for Collision Repair Success Acquired Knowledge Shop owners like Brian Davies look to those who’ve come before to lead their shops today.

Strategies & Inspiration for Collision Repair Success Acquired Knowledge Shop owners like Brian Davies look to those who’ve come before to lead their shops today.

BY JASON BOGGS

BY JASON BOGGS

TIFFANY

TIFFANY

Matt Hudson Content Director

Todd Kortemeier Editor

Hanna Bubser Digital Reporter

Leah Marxhausen Special Projects Editor

Jason Boggs Contributing Writer

Lindsey Gainer Contributing Writer

Tiffany Menefee Contributing Writer

Kevin

Writer

Jordan Beshears Steve’s Auto Body

Sheryl Driggers Universal Collision

Greg Lobsiger Loren’s Body Shop

John Magowan Ernie’s Auto Body

Stan Medina Certified Collision Works

Zach Pate Creative Services Director

Jonathan Ricketts Art Director

Olivia Curti Graphic Designer

Morgan Glisczinski Graphic Designer

Emme Osmonson Graphic Designer

Hana LeBrew Print Production Assistant

Chris Messer Vice President and Publisher 651.846.9462 / cmesser@10missions.com

Andrew Johnson Associate Publisher 651.846.9459 / ajohnson@10missions.com

Marianne Dyal Marketing Strategist (National Accounts) 706.344.1388 / mdyal@10missions.com

Chad Hjellming Marketing Strategist (National Accounts) 651.846.9463 / chjellming@10missions.com

Bob Marinez Marketing Strategist (National Accounts) 216.533.8747 / bmarinez@10missions.com

Martha Severson Marketing Strategist (National Accounts) 651.846.9452 / mseverson@10missions.com

Kyle Shaw Marketing Strategist (National Accounts) 651.846.8480 / kshaw@10missions.com

Dan Thornton Marketing Strategist (National Accounts) 734.676.9135 / dthornton@10missions.com

Sean Thornton Marketing Strategist (National Accounts) 269.449.0257 / sthornton@10missions.com

Kenzie Verschoor Associate Marketing Strategist (National Accounts) 651.846.9472 / kverschoor@10missions.com

Matt Harper Regional Sales Manager 651.846.9551 / mharper@10missions.com

Melody Todd Senior Marketing Strategist (Regional Accounts) 651.846.9468 / mtodd@10missions.com

Autumn Morey Customer Success Representative 651.846.9460 / amorey@10missions.com

Jen George Client Service Specialist 651.846.9465 / jgeorge@10missions.com

Mariah

For

TO SUBSCRIBE OR RENEW AT FENDERBENDER.COM/SUBSCRIBE

“The opportunity to read about ways to improve your business from credible owners and manufacturers is priceless.”

—Stan Medina, Owner, Certified Collision Works, Corpus Christi, Texas

IN THE SEPTEMBER ISSUE, FenderBender brought you the story of Mike Schoonover, and why he was the choice for the 2022 FenderBender Award. Mike officially received his award in September at the 2022 FenderBender Management Conference in Arlington, Texas, along with his wife Gayle, who is a co-owner of Schoonover Bodyworks & Glass in Shoreview, Minnesota.

Schoonover was also one of many professional speakers from around the industry offering sessions on a wide range of topics for attendees. Schoonover took to the stage later the same day after receiving his award to present a session entitled, “How I Did It: The FenderBender Award Winner’s Guide to Success.” Schoonover

talked through the philosophies and processes that have helped make Schoonover Bodyworks the award-winning shop that it is with a focus on quality.

Other presentations included “Determining the ‘Sweet Spot’ for Your Shop” by Drew Bryant of DB Orlando Collision and “The Secret to Successful Insurer Negotiations” from Pronto Body Shop owner and FenderBender columnist Tiffany Menefee. Planning is already underway for the 2023 FenderBender Management Conference in Denver next year.

Visit FenderBender.com/news for daily updates from around the collision repair industry.

Sometimes the best resource for shop owners is each other

IN LATE SEPTEMBER I had the privilege of attending our FenderBender Management Conference. If you weren’t able to join us— well, first I hope you join us in Denver next year—this annual event brings shop lead ers together from around the country for a few days of education, networking and a little bit of fun as well. Attendees had the privilege of learning from peers and other industry professionals through speaker sessions that ran through three days. These topics ranged from the niche to subjects that could apply to all body shops.

On the first day of the conference, I was in line for coffee with a shop owner. As we both reached for the half & half, I deferred and said to go ahead, that we’re all friends here. That was true, this shop owner re plied, that there was a community effect wherever this many shop owners were gathered. If one owner were to discuss a problem he or she has had, then odds were almost certain that another shop owner had experienced that exact same problem. There was power in that, we agreed.

The lessons owners could learn from the speakers at the conference were invaluable. But so too were those networking opportu nities where owners could learn from each other. Even thinking beyond the confines of a conference, there are opportunities each day for owners to help each other out, wheth er that’s a 20 Group, a regional association or simply staying in touch with the shops in your area fighting the same battles.

I like to think of FenderBender as a place where you can read about those other perspectives, whether similar or differ ent to yours. In this month’s feature story (p. 24) we bring you three different op

erators to discuss the ways they lead their shops in 2022. Hopefully you find some thing in there to think about, or confirm something you’re already doing. In the rest of the issue you’ll find other perspectives, such as how to market OEM certifications, if you have them (p. 34). And in something that affects all shops, there’s a guide to un derstanding shop liability (p. 40). Thanks for doing what you can to work together to raise up this industry.

TODD KORTEMEIER EDITOR tkortemeier@endeavorb2b.com

Family values go beyond the literal meaning at Xtreme Collision, impacting everything from daily operations to technician recruitment

By HANNA BUBSERIT’S ONE THING TO SAY that a work place treats team members like family. It’s another thing to have a workplace that liter ally is family. At Xtreme Collision Center in Morristown, Vermont, owner Adam Grant knows about this distinction firsthand.

Adam and his wife Amy have a blended family of four kids. That family dynamic has come to play a critical role in the daily operations of the body shop, which opened in 2004. But starting the shop didn’t come without its challenges.

Within one year’s time, the father of Amy’s twins from her previous relationship tragically passed away in a four-wheeler ac cident, and then Adam and Amy discovered that they were expecting their youngest son. It was a lot of change at once and open ing a body shop on top of everything else added another layer.

“When people talk about adversity and starting a business,” Adam says. “It’s defi nitely not for the weak at heart.”

But through familial support and de termination, Xtreme Collision has found a great home in Morristown.

“We moved into a shop that had been a body shop before for a number of years, which was great for us,” Adam says. “It started out with me writing estimates dur ing the day and painting cars at night and getting little to no sleep, and Amy com ing in in the morning and putting our son down on her desk on a little pad for naps. Our first year, I think we did about $450,000 or $500,000 and currently today we’re at about $2.4 million.”

The numbers speak for themselves, but it goes beyond that. Xtreme has truly estab lished itself as a stand-out shop in the im mediate area and beyond.

“We’re a small-town family run opera tion,” Adam says. “We’ve got a lot of DRP re lationships … our closest competitor that’s a big DRP shop is about an hour away in all directions. We’ve got a nice little spot here and we’ve worked hard for [about] 20 years.”

Since the beginning, the family compo nent of Xtreme Collision has grown along side the shop, and over time more and more family members have joined the team.

Adam’s wife, Amy, handles the financial side of the business, which includes work ing with insurance companies. Twin sons Tucker and Dayne work in the shop as well, as does son Cole.

“Both Tucker and Cole started in the

wash bay,” Adam says. “They came in there and then slowly progressed along to the me chanical side and then to being body men.”

About four years ago, Xtreme Collision had rented out the space next door to run a mechanical garage. Tucker originally wanted to pursue mechanical repair but found his way into auto body work when a

spot opened on the Xtreme Collision team. It’s been a great fit ever since.

Cole participated in a local automotive program at a technical school, and he also had his aim set on becoming a mechanical repair technician. Adam says that when they ran the mechanical garage and things got slow, he’d enlist the help of Cole to pull

a bumper cover off or do other body work. Now he’s working alongside other skilled body technicians in the collision shop, which is now Xtreme’s sole focus.

“We took two people that didn’t have any experience in a body shop and we’re turn ing them into real well-rounded body men,” Adam says.

Dayne went to school to become a chef and worked in that career field prior to join ing the Xtreme team. After working count less late nights, holidays and weekends, he wanted a change of pace. Xtreme had an opening for a parts person and wash bay technician. Dayne took the opportunity, and it paid off.

“He does all the pre- and post-scanning and the pre- and-post washing,” Adam says. “He also checks in parts, receives parts and stores parts—all the parts manager duties.”

In addition to his family, Adam says there are three other technicians at the shop as well as someone in the office. Hav ing a work environment that is rooted in family values has lent itself well to other GETTY

aspects of running the shop. One such area that Xtreme has focused on includes the concept of “growing your own” technicians.

“We’ve taken people that have had an interest and put their feet to the fire,” says Adam. “It’s really about taking a person with an interest and letting them run with it.”

This strategy has involved an invest ment of extra time and effort, but it has worked out well for the shop. It has allowed Xtreme to employ and develop quality tech nicians from the ground up.

“Initially, it’s time consuming. Stuff happens, but in the next breath, they’ve all turned into great technicians,” Adam says.

Adam says that when the interest to do the work is present, the motivation to learn and execute the job correctly comes along with it. He details the success story of one technician who didn’t come from a body re pair background.

“One of our technicians was an auto de tailer,” Adam says. “He put in a lot of accesso ries on vehicles, but never was a body man. Now, he’s tearing vehicles apart and putting

stuff back together. He’s doing a great job. He had that interest, and it’s been well worth it.”

But the work doesn’t end once the tech nicians are trained. Adam also understands the value of retention and keeping those quality technicians on his team. Adam says that maintaining an effective team, includ ing those in his family and beyond, comes from understanding what they value.

“Obviously pay is a huge thing, but [find] out what’s important to the technician,” Adam says. “Maybe it’s time off, maybe it’s money, maybe it’s being in a different place in the shop. But you’ve really got to find out what the employee’s ‘go’ button is and what they’re motivated by.”

It hasn’t always been easy for Xtreme, though. Adam acknowledges that although he puts time and effort into keeping the best of the best on his team, he has also felt the impact of the technician and talent shortage.

“We went through a spell where we lost a lot of technicians. But I always look at things like that, like a blessing in disguise,” Adam says. “I don’t think we would be in

as good a place as we are right now if those people were here so keeping the right tech nicians, I think is a big challenge.”

Regardless, the family oriented Xtreme approach has proven positive for Adam and his team. With his family at the helm, they have been able to establish an envi ronment that invests in technicians and therefore establishes a consistent promise of quality to customers.

Adam is proud of the foundation that he and his family have created. Naturally, succession is a topic that comes to mind with all his family members working to gether so closely.

Adam says that the presence of his fam ily does not necessarily make planning for succession any easier, but at the same time it doesn’t make it any more difficult.

“At this point, with this much family in volved in it, I’m not sure what’s going to hap pen,” Adam says. “If one of them wants to step up and take it over, then by all means. If they all don’t, that’s fine. If they all do, that’s great too.”

The new world of collision repair needs technicians, estimators, and managers who are proficient with plastic repair. Set your shop above the competition by enrolling in a self-paced plastic repair course at Polyvance University. Polyvance University’s classes adapt to your schedule and training needs.

THE NUMBERS FROM THE 2022 FenderBender Industry survey make it clear: Training is a point of focus for shop leaders and their employees alike. Only 12% of the 506 survey respondents said that they never attend industry training, while 54% said they attend at least once a year if not more frequently.

But what about the rest of the shop? Survey says that other employees are training just as frequently. When asked how often other members of their team attend training, respondents said:

the help of

from

The Collision Repair Education Foundation has announced two new members to its board of trustees.

According to a press release, Keith Bell of Axalta Coating Systems and Mark

Managing Director Brandon Eckenrode via the press release. “There’s no doubt that they will be an integral part of our efforts moving forward to achieve CREF’s vision and goals!”

with the shop have been working there for decades.

“Rich was very good at making sure a car looked the best it could when it left the shop. Like my husband, I enjoy making people happy,” said Connie Kepner, Kepner’s owner and CEO, via the press

with the

Use TechForce

for

future,

with other

Don’t let the name “Ye Old Station” fool you. Sure, the shop has been in business for 60 years, though its current building is much newer, but there’s nothing old about how this Cheshire, Connecticut, shop goes about its business. It’s a goal of the shop to remain on the cutting edge of technology.

“We evolve with the technological world,” the shop website proudly states, “evermore so than yesterday.”

At the time Director of Operations Russell Sharnick spoke to FenderBender, the shop was just taking delivery of equipment to work on Rivian EVs, one of just 70 shops in the country set up to do so and one of only three in Connecticut. It was still all in boxes though as they didn’t even yet have the tools to set up the equipment, such is the newness of the vehicles. It’s a $350,000 investment, Sharnick says, but one the shop believes is worth it to stay up to date.

“Rivian is going to be a goal that we’re going to trust in,” says Sharnick. “I could work on the other manufacturers like Tesla, and there’s newer car companies, but there’s other people that do that professionally, and they know it. So we’re just being diversified, and just doing what we’re gonna want to do to grow this business with the tools that we have in Rivian, we’re going to put our money in and trust. And I think it’s going to pay off.”

Space-age EV tech aside, the shop also takes pride in serving all manner of vehicles, from standard passenger cars to tractor trailers to fleet vehicles, which has been an emerging part of the growing business. The shop has a 50foot long paint booth to handle anything that might come its way. The shop boasts mostly 5-star reviews on Google, and owner John Mazzella has worked to make a comfortable environment for customers.

“It’s a sharp looking shop,” says Sharnick. “It’s a country atmosphere out this way. So I mean, the office itself, it’s [John’s] personality, I’m looking at a set of the little table and chairs that you could see maybe at a cafe, but it’s a stick shift that [moves the seat] up and down.”

The original shop, opened more than 60 years ago, still stands in town, and Mazzella still owns it. He’s even thought of re-opening it, but doesn’t have the manpower at the moment. For now, the shop will stay firmly planted in the present and future.

“This magazine has been a key component to our organization in keeping us up to date with new vehicle trends and technologies in our forever evolving industry.”

—Jonathon Best, Vice President, Fender Mender Collision, Charleston, S.C.

TO SUBSCRIBE OR RENEW AT

TO SUBSCRIBE OR RENEW AT

Vince Lombardi, famed football coach of the Green Bay Packers, once opened season training with the now famous quote, “Gentlemen, this is a football.” The team had a devastating loss that ended the prior season. The team gathered for training camp expecting to pick up where they left off. They likely came ready to learn new plays to build on the previous year and complex strate gies for beating teams that beat them the year be fore. Instead, Lombardi opened training camp by going all the way back to the beginning: “Gentle men, this is a football.” From there he had them open their playbooks to page one. These profes sional athletes, who were at the top of their game and the height of their careers were learning ba sic blocking, tackling and catching.

With all the technology and new tools of mar keting, it can be easy to forget what helped us suc ceed in the first place: Taking care of customers one at a time. It’s easy to get sucked into the vortex of social media, search engine optimization, geo fencing, email marketing … and the list goes on, growing every year with new tools, new apps and new tactics.

However, the core function of sales is sim ply creating customers. If you can get people to “know, like, trust” and refer you, your business will never want for customers. Word of mouth is still the king of all tactics. By the way, the “know, like and trust” framework is from John Jantsch, my Vince Lombardi.

What do people experience when they interact with your shop? Are the people who care for your customers truly caring? I’m talking about the customer service representatives, the ones who answer the phones, the ones who take payment at the end of the repair. Are they warm, energetic, empathetic and great at listening to the individu al needs of each customer?

Let’s take a quick, closer look at each of those.

Warmth is mostly communicated through body language and eye contact. Genuine caring comes through when we stop a conversation we’re having to attend to the needs of a potential custom er in front of us. Or if we’re on the phone we can at least make eye contact and mouth the words, “Be

right with you.” That simple acknowledgement puts people at ease. I had the opposite experience at a restaurant recently. I stood waiting to be seated for a very uncomfortable 10 minutes. Ten minutes! In silence. To make it even more awkward there was someone washing dishes that would peek around the corner at me and when we made eye contact would divert their eyes back to the task at hand. And there was a waitress who was likely dou bling as the hostess who clearly saw me but stayed at the table she was serving, having a conversation. Not taking an order. Not fielding a concern. Talk ing as if they were her friends. I double checked the sign and internet to make sure they were still open, and it was at least an hour before closing time. I eventually left feeling awkward and slightly em barrassed that I wasted 10 minutes of my life that I will never get back.

Energy, also expressed by body language and words carries a sense of positivity, and confidence that we can help. And we’re ready to do so!

Empathy, often perceived as a natural gift, is actually a skill that can be learned. Some may have a higher capacity than others, but anyone can learn through practice how to be more empa thetic. It starts by simply noticing people. Which is pretty much the opposite of what I encountered at that restaurant.

Listening. The customer isn’t there to hear about your weekend. They don’t care about your personal problems or even your entertaining stories. They are there because they have a problem, a need, and they think you can help. Prove them right.

If you want to find out if your front line is exhib iting these qualities, all you have to do is observe them in action. You can get fancy and hire secret shoppers but really observing their interactions with a few customers will tell you all you need to know. Use the items above like a checklist and just walk into your shop and observe your team inter acting with customers. It won’t take long, and if you find a teachable moment, you may just be setting your shop up for great success. In some ways, it’s sad that good customer service has become a dif ferentiator, but with the bar so low, this is your chance to shine.

After 18 years in the industry, Kevin Rains sold his network of shops. He now coaches body shop owners and leaders and is the author of the upcoming book Launch to Legacy: The Small Business Roadmap to Success and Significance. You can reach Kevin at kevinrains@gmail.com

EMAIL: kevinrains@gmail.com

ARCHIVE: fenderbender.com/rains

Photos by MICHAEL CUTHBERTSON Illustration by OLIVIA CURTI

Photos by MICHAEL CUTHBERTSON Illustration by OLIVIA CURTI

AT FIRST GLANCE, the results of the 2022 FenderBender Industry Survey might look a little strange when it comes to forecasting the future. The 506 survey respondents cited numerous serious challenges facing the industry, from the runaway technical advancements in vehicles (2%) to a shortage of qualified technicians (34%). But on the other hand, 72% of this industry cross-section said they expected their sales to go nothing but up over the next five years.

“I see a growth every year since I've been in business, there has always been an increase in business,” says J. Mark Smith, owner of J. Mark Smith Body Shop in Decaturville, Tennessee. “The United States, this whole country is just gonna keep getting bigger and bigger is my thought, you know, as far as the amount of people we have, [and] the amount of cars that's gonna be on the road.”

As Smith points out, some of the future optimism can be chalked up to a numbers game. There are of course going to be more cars, more drivers. And what’s driving even bigger numbers is the nature of the cars themselves. Cars are increasingly technical, increasingly complicated. That drives up repair costs and average orders.

But this is where a bit of trepidation steps in alongside the optimism. Some of the industry’s long time leaders are seeing collision repair changing rapidly. Change can be exciting, but also nerve-wracking.

“I don't know exactly what the electric market is going to do to us,” continues Smith. “... I don't really know what the future is going to hold as far as electric cars are going to work. What's going to be the life of that electric car? How many years are we going to be working on that electric car? Cars nowadays, you know, I live in a rural area. And you know, there's lots of cars on the highway [that are] 20 years old, electric cars [when they’re] 20 years old, are they going to still be on the road?”

Every shop owner wonders about where their shop is and where it’s headed. And they all have different ways of pulling those levers. FenderBender spoke to three of these leaders about how they keep things moving forward in 2022.

Unlike a majority of survey respondents who reported they don’t have a higher education degree, a majority of the shop leaders FenderBender spoke to had college degrees: John Baker of Wallace Collision Center in Bristol, Tennessee, and Brian Da vies of Body Works Plus in Charlotte, North Carolina. But while Baker’s industrial en gineering degree and Davies’ mechanical engineering degree have certainly helped enhance their technical knowledge as they made their way in collision repair, they like Smith all learned the business the same

way. It was working in their family shops from a young age.

“I worked for my dad from the time I was a small kid and I grew up as a little boy beat ing on fenders and trying to learn how to fix cars like the other guys were doing that worked for him,” says Smith, 62. “And then as I grew older, I just decided that was the profession I was going to go into.”

Davies was 11 or 12 by his estimation when he started working in a shop his fa ther invested in. But it wasn’t a linear path from there to owning the Charlotte shop he’s helmed for 22 years. An engineering

career followed college, designing and en gineering bearings for large automakers, but an office job just wasn’t the right fit. It was his dad who helped him get back into the business, co-signing on a note for a building while Davies cashed out his 401(k) to make it happen.

Baker’s father and grandfather started an Oldsmobile dealership in 1961, which spawned a collision shop in the 1970s. Baker spent time in high school and college working at the shop, and like Davies worked in engineering after college before decid ing to get back into collision repair. In the end he was able to marry both careers, as instead of hiring a consultant to institute lean processes, Baker’s father hired him and he’s gone on to run the collision end of things for the last four years.

While all three of these operators grew up in the industry to varying degrees, 69% of survey respondents said they do not have a parent who is or was involved in collision repair. Smith says his children don’t have any interest in getting into the industry, but he has a grandson who’s soon graduat ing with a business degree and plans to get into collision repair.

Smith recalls when he was that age there wasn’t much in the way of formal education expected when working at a body shop. But with the modern industry complicated by new technologies and pro cesses, there’s definitely some advantages to having a wide range of skills.

“I've stressed for him to try to get that [degree], to where he would be able to maybe know a little bit more about the op erations in the office than I've known since I had no education in that,” Smith says. “But everything that I've got I just picked up from my dad who taught me back years ago, as I've grown through the business I've tried to stay up to date.”

The survey respondents this year are at a variety of different stages in their careers. But whether they’re in the first few years of operating a shop or ready to retire, a 45% majority of respondents said that manage ment training for themselves is something they do at least once a year. Another 34% said they’ve been through training at least once in the past five years.

For Baker, Davies and Smith, training is also a key component in how they stay

said they have never undergone training

up to date with everything in the indus try. While Davies has now operated Body Works Plus for 22 years, his experience upon first becoming an owner is instruc tive for anyone else starting out. He sought out some of the most experienced voices, both within the industry and on topics of leadership in general.

The Davies family circa 2000 wasn’t taking its vacations at Disney World or the like, instead it was north to Washington, D.C., where Davies sought to learn as much as he could. While the rest of the fam ily was still asleep, Davies would rise early

Regional associations can serve as a meeting of the minds to share problems and solutions encountered by multiple owners.

and meet a fellow early riser, well-known industry expert Mike Anderson, at his Beltway-area shop. At that time Davies had just bought his shop in an emerging part of downtown Charlotte and could take many lessons from Anderson.

“Mike Anderson was a legend really back then,” Davies says. “And I wanted to really kind of model myself [after him] because his shop was between Alexandria and D.C. And it was a little similar, it was kind of like … in the rough side of town, and it was a small footprint, I think he had, like, 10,000 square feet back then. And he prob ably had 20 employees. So, I called him and met him. And he was kind enough to let me come visit his shop. And he showed me the whole deal.”

That was just the beginning of Davies’ education in leadership. He convened with another Mike, Mike Jones of Discover Lead ership Training, a program with indus

try clients such as the National Auto Body Council. It was working with Jones that inspired Davies to start the North Carolina Association of Collision and Repair (NCA CAR) with some colleagues in 2016. Now a part of a united Carolina’s Collision Asso ciation, NCACAR formed a network of allies and mentors for area shops.

All three operators spoke about the importance of learning from others. All are active in their respective regional associations. Smith is the president of the Tennessee Collision Repairers Associa tion, of which Baker is a member at large. The opportunity to share knowledge and experience is something all three of them took seriously.

“You get this many shop owners to gether, there's some problem that someone else has had,” says Smith. “... And most of the time, there's someone that's already been down that road. After we have a meet

of survey respondents said they’re involved in their regional association

ing, anybody there that night should have something they can take back to their shop the next day and use it to make the shop more profitable.”

And there’s more to running a shop than just industry knowledge. Davies has enrolled in a program designed for en

trepreneurs called Strategic Coach out of Chicago, traveling to the Windy City once a quarter for three years at his own expense. Davies also is an avid reader of industry and general business topics, as is Baker.

“I probably read too much to be hon est with you,” Baker says. “But I really think that's one of the reasons why we are trying to lead and at the forefront of gathering the new stuff that's coming out because that's really what in my opinion is what's really important.”

A majority of survey respondents—40 percent—reported they have no specific budget for training. This can be taken in one of two ways, either that you can’t put a price on how much is too much for train ing, or shop owners aren’t being judicious enough in allocating the proper amount of funds for training. Viewed in concert with the second-highest percentage of response, 33% said they budget just 1-5% for train ing, it seems that most shops tend towards the latter. The message from the operators FenderBender spoke to was clear: when it

comes to training, they would do whatever it takes.

“[Training is] something that I think is really important, and sure we should keep a close eye on what we spend on training, but I think my personal opinion is the training pays for itself,” says Baker.

Baker cites an example of glass work, which his shop formerly sublet out. But after growing tired of being on someone else’s schedule, he sent one of his techs to Auto Glass University in Wisconsin to bring that in house. That was a direct ex ample of a net gain resulting from train ing, But whether it’s OEM training, paint supplier training or something else, all en hance the quality of repairs and thus the shop’s reputation and revenue.

All three men invest in training even beyond I-CAR, and all the shops are I-CAR Gold certified, something that tracks with the majority 55% of survey respondents who hold the same status. I-CAR is also the training survey takers invest in the most, at 79%. Only 23% of shops invest in manage ment or career development training, and Davies is one of them.

FenderBender spoke to; all invest in varying degrees of it for themselves and their employees.

form of training taken by respondents was paint company training at 65%, followed by OEMspecific training at 50%

Body Works Plus owner Brian Davies shares a few books that have been influential in his life and career:

“The E-Myth: Why Most Businesses Don't Work and What to Do About It” by Michael E. Gerber

A step-by-step guide for the new entrepreneur taking a business from its infancy to leading it through growth and all the pitfalls along the way.

“Built to Last: Successful Habits of Visionary Companies” by Jim Collins and Jerry I. Porras

A research-based examination of the history of some of the world’s most successful companies and the steps they took to stay on top.

“Good to Great: Why Some Companies Make the Leap & Others Don’t” by Jim Collins

Following up on the findings of “Built to Last,” a study of what makes companies successful and how they separate themselves from the rest.

“The ones that have been interested, I'd like to get them all to go, but the ones that have been interested we've sent them to Discover Leadership,” Davies says. “And I think that's a really good way to build a team and the philosophies there.”

More than half of survey respondents reported having no OEM certifications. In an era when collision repair is becoming less and less universal, that’s a number that could look far different in the 2023 survey. But these three operators are all ahead of the curve as they hold multiple certs and make OEM training a priority.

“Schooling is a required operation to run a business nowadays, because cars change so much every year, something is different,” says Smith. “So all of our guys have training each year. Costs money to send guys to school, but we want cars re paired the correct way. We're not a hack shop; we want everything to be done as OEMs want it to be done.”

Baker says that his shop can’t afford to send techs to training for every class they wish to take, but they’ve managed to sup port the 22 certifications his shop holds. He likens it to the construction of a house where there are many different speciali ties on a job site from framers to roofers. A house doesn’t get built without everyone, and a shop doesn’t do quality repairs with out a qualified person for each job.

Proper training doesn’t just up the quality of a shop. It can also be an indicator of qual ity to technicians if a shop offers a full slate of training opportunities to further their careers. And those are shops that will be most attractive to new employees and help keep employees long term.

“Training is a really good retention tool for the technicians because your shop is of fering opportunities that other collision re pairers in your marketplace probably don't offer,” says Baker. “I think it's been a really good way to keep our staff engaged and continuing to learn the newer technology because, you and I both know it, it contin ues to replace itself pretty quickly.”

Shop owners can’t afford to overlook any tool that might help retain and/or re cruit talent in a time when a majority 34% of survey respondents said a shortage of quality technicians was the single biggest challenge facing the industry. Smith con

curs, saying he has gotten involved at the educational level by serving on the board at the local Tennessee College of Applied Technology (TCAT) campus. He’s hired a pair of young techs directly out of the colli sion repair program.

Other concerns from Baker and Davies included keeping up with the latest tech nology and knowledge to complete repairs properly. That leads back into training, and making sure their techs have the tools they need for the modern industry. Employ ees today expect and respond to different things. All three of these shop leaders have learned those lessons over the years.

“In the beginning, I thought that people knew what they should be doing all the time,” Baker says. “And I quickly realized that it's really a lack of my leadership that was causing failures, if you will. I mean, if there is an issue, the leader, that falls on your plate.”

Baker stresses the importance of stan dardized processes, as sometimes em ployees simply might not know that what they’re doing is wrong since there is no standard. Establishing those standards is a priority for Smith when thinking about his leadership style. Employees are empowered to self-evaluate the work they have done.

“I tell my guys, fix that car like it's your own car, and, like myself, if you're hard to please, if you feel like it's going to please you it's going to please anybody else,” Smith says. “That's always been my thought. If that car will please me when I get done working on it, then it's going to please them because I'm picky at what I do, and I want it to be done like it's supposed to be done.”

An owner sets the tone for the shop, and that’s as true today as it was a century ago. But what it takes to lead a shop has changed. It’s not as much setting rigorous standards and demanding employees follow them. It’s keeping an eye on the future of the industry and what it means for the shop. It means do ing all you can to bring in the most talented employees and ensuring they have incen tive to stay there.

“There's the carrot and the whip,” says Davies. “And I just don't think that works nowadays anymore. I just don't think the younger people are getting it and even older people, they're just not tolerating it. So, my style is just trying to pay people well and re ward them for, you know, job well done.”

Global recession may have hit several industry sectors but is the aftermarket industry immune? Steve Leal looks at the situation and recommends how shops can insulate themselves against any uncertainty arising from the disruptions.

For quite some time, the global aftermarket industry has been resilient to all that has been happening around the world. We have seen it all – the industry survived the twoyear pandemic, we continue to cope with staffing shortages, we are keeping up with the changing automotive technology, and, together, we have addressed all challenges for the greater good of the industry.

Even as we adjust to the “new normal”, the information coming out of media channels these days is not very encouraging. The world is headed into its worst recession, the supply chain disruptions have impacted the automotive industry, and global disruptions have affected the procurement of critical automotive parts. I am hoping that the devastating effects of all these challenges do not impact our industry significantly.

Almost all industry leaders who I have spoken to in recent times seem to agree that the industry will be able to survive the latest recessional trends. Historically speaking, the aftermarket industry is large, fragmented and recession-proof. I would like to share that optimism, except that I believe being prepared and nimble should be the mantra for all those who have a stake in the automotive and aftermarket business.

Though the situation is volatile and hard to predict, recessions are not new to our industry. They have a certain life cycle and typically take place once every eight or 10 years. During that time, the most robust businesses survive, while those who haven’t kept up with the changes around them get purged. We have witnessed

some industry mammoths downing their shutters during seemingly minor recessions, while new names thrive from unexpected opportunities.

In all this drama taking place, there may be some good news and bad for the aftermarket industry. In the past, whenever recession struck, customers increasingly choose the lower-cost option of repairing their current vehicles instead of buying new ones. As per current global trends, demand for new and used vehicles are high and wait periods are typically between 5 to 10 months, forcing consumers to hold on to their old vehicles for much longer than before. Such customers prefer to have their vehicles repaired and making them last longer.

While we are yet to see any major impact of recession on our industry, my advice to shops is to consider the recession as a temporary setback (just like we did for the pandemic) and be ready to modify your operations every time, to keep yourselves ahead of the curve. Here are my Top Five recommendations to insulate your business from the ongoing economic uncertainty.

Develop a “Playbook”: Many smart entrepreneurs begin by taking a real, hard look at their operations to identify near and immediate risks to their business. Their “Playbook” recognizes impending challenges and is flexible to fine-tuning and change as they go along. They determine what’s required for the business, implement cost-efficient operations, and look for longer-term gains. Remember – those important decisions you make during this critical time may make or break your company.

Consolidate your business: Shops are increasingly keen to put their customers back on the road in the quickest time possible. This means, they are always looking to consolidate associated aftermarket services –collision repair, glass repair and mechanical services –under one roof. Doing so

allows them better control over the repair process and prevention of unnecessary operational costs, time and effort.

Joining a franchise network: There has never been a better time to align your business with an established aftermarket franchise network. At Fix Network, we have many inspiring success stories of shop owners who have benefitted from being a part of our family. Joining a franchise network opens a world of advantages –your teams learn from the finest minds in international repair and customer service, you have access to insurance partnerships and parts manufacturers, you have established KPIs for business success, and your shop receives 24x7 marketing, operational and technical support from the network’s team.

Training and Certification: I will always be a lifelong advocate of continuous training and certification. During this time, when business is slow, it would be a good time to invest in training your teams to repair the most complex vehicles. As an example, at our training centres, I am witnessing a greater demand from our shops to learn how to service and repair electric vehicles. Certification gives customers the peace of mind that their vehicles are being looked after by trusted hands and are being repaired safely.

Not everyone likes too many disruptions but adapting and adjusting accordingly will go a long way to protect your business from conditions beyond our control. Fingers crossed, this too shall pass!

Steve Leal is the President & CEO of Fix Network World, the leading global automotive aftermarket services network which includes ProColor Collision. The family of brands spans more than 2,000 points of service internationally.

Staying calm, flexible and managing expectations is key when there’s a sudden influx of work

IF YOU LIVE IN a state that experiences snow or ice storms—or lucky you, both— then you’re likely no stranger to the dreaded surprise winter storm that loves to sneak up out of nowhere.

Whether it’s an inch of snow or a foot, the outcome is often the same for a collision repair shop … lots and lots

of work pouring in from accidents that happen as a result of the hazardous driving conditions.

While it’s great to have people knocking down your door, it also presents plenty of challenges—how do you make room in your schedule for these unexpected additions? Will you have enough staff to cover the amount of work pouring in? How will you set customer expectations around wait times?

Jerald Stiele, owner of Collision Center 1 in Hopkins, Golden Valley, and Prior Lake, Minnesota, is no stranger to this kind of situation, and acknowledged that sudden influxes of work can be “a big challenge for shops.” These are his best tips for how to handle the situation should you ever find yourself in the midst of this kind of storm.

As told to LINDSEY GAINEROver the past couple of years, we have not been affected as much by “the big win ter storm” like we used to be … it seems the big storms with heavy snowfall are detected early enough now that people are better prepared. I think a lot of folks also have the ability to work from home now, and a heavy snow day gives them a good excuse to do so. What seems to give

us a sudden, large influx of work is the “sneaky” 1-inch snowfall or sleet that peo ple are not prepared for. After these types of winter events we can find ourselves overwhelmed with calls for tows or dropoffs of non-drivable vehicles.

The most important thing we can do in these situations is manage the cus tomer’s expectations. We only have the capacity to produce so much work and we need to make sure that our “in-process” inventory stays manageable. So, as diffi cult as it is, we sometimes get to the point where we can no longer accept additional tow-ins or non-drive drop-offs. Again, being a business owner, this is very diffi cult to do. We like to think that we should never turn work away or say no. In some situations, however, it is best for our busi ness and our customers. We want to help everyone and profit from as many jobs as possible, but by accepting more work than we can efficiently handle we are set ting ourselves up to disappoint our cus tomers and overstress our staff. No one wins in that scenario.

We try to continually evaluate what we have scheduled to come in and what we can efficiently produce and make de cisions from there.

Leave room in the schedule for the unexpected and communicate honestly. We try to proactively leave spots open

in our schedule for this type of influx of work. These days we are scheduled out far enough that we can pull jobs in ahead of schedule if we don’t get the sudden winter storm. We have a sched uling system that an outside consultant helped us build based on our historical repair output. We categorize jobs into the different classes: Level 1, Level 2 and Level 3 size repairs. We take in a set number of each of these per day know ing that will maximize our efficiency.

We do not completely turn a po tential customer away when an influx hits—instead, we share honestly when we would realistically be able to start and complete their repair. We are very upfront about when our next Level 3 spot is available and, at times, that could be eight or more weeks out. We want to build life-long customers and ambassadors through honesty.

Finally, don’t neglect to show appreciation to your staff.

So much is demanded of us as a shop to day—strictly adhering to ever-changing repair procedures, parts and supply shortages, staff shortages, increasing demands from insurance companies … I could go on and on. We have to truly val ue our entire team that is fighting these battles every day. We try our best to keep things fun and light at times and show appreciation, winter storm or not.

Certifications can be both a marketing tool and an indicator of quality for your shop

By TODD KORTEMEIERDESPITE HAVING one of his two loca tions just a short drive up the 101 from the birthplace of Tesla, and in the heart of the EV giant’s tech-savvy customer base, San Francisco Bay Area shop own er Jason Wong avoided being an early adopter of the company’s certification program for years.

But his longtime customers were be coming increasingly environmentally conscious and swapping their Subarus for Teslas. When they had the misfortune of being involved in a collision, they’d call. And in response Wong was happy to

provide a list of shops who would be more than happy to do the repair. But the calls and emails continued, asking him to re consider. Finally he called a Tesla rep.

“I said, ‘Hey, I’m calling you because I think this is the right thing to do, and I’d like to get in your certification pro gram,’” says Wong, who operates shops in San Francisco and San Jose and was the 2022 CARSTAR Franchisee of the Year. “And I remember his answer to me was, ‘Jason you don’t have to get in our program to fix our cars.’ And I told him, ‘I’m not going to fix your cars unless I’m on the program, unless you give me ac cess to the literature.’”

For Wong, the 10-plus OEM certifica tions he holds in addition to Tesla aren’t so much a marketing tool as a safety and quality tool. To do repairs right and to do them safely, he wanted to have that cert. Step into the lobby of his San Francisco store and you won’t find a sign for Tesla, Volkswagen, Infiniti or anyone else.

The shop does, however, make use of its online presence with ads on Yelp and Google to try and capture custom ers looking for certified shops. Adjacent to Silicon Valley, Bay Area customers are very much digital-first. “They don’t even want to talk to us,” Wong quips. Custom ers may or may not know going in that they’re getting a certified repair, but Wong believes the quality of that repair speaks for itself.

“I don’t really look at the certifications to drive business,” Wong says, “I look at the certifications as like we actually re ally need the repair procedures to repair your car correctly to be safe on the road.”

Halfway across the country on an other peninsula, that of the state of Michigan, the folks at Riverbend Body Shop in Grand Rapids are a little more out front with their certifications. You’ll find the logos of everything from Buick to Subaru on the shop’s website and Ser vice Writer Zach DeGroot says the shop has invested money optimizing its site to be SEO-friendly when customers Google things like “Subaru certified body shop.” They’ve also made partnerships with lo cal dealerships, with business cards on the desks of the local Honda dealer’s ser vice department.

The shop was the first one in the state

of Michigan to earn Honda/Acura certi fication, DeGroot says. It was also one of the first in the region to get certified for Subaru. However customers find them, as soon as they call to make an appointment, the shop is happy to inform them of the wise decision they’ve made.

“Our CSRs are trained,” says DeGroot, whose father Jim is the third-generation owner of the business founded more than 75 years ago. “Once they determine the year, make and model of the vehicle the customer calls in, if it’s a vehicle that falls into one of our certifications, that is one of the first work tracks that they’re using is that our shop is certified from the manufacturer of their vehicle which means that our technicians achieved spe cial training, we have specialized tools specific to their vehicles.”

The shop educates the customer on even more aspects of the certification, such as there may be actual represen tatives of Subaru popping in to ensure repairs are being done to certification. Anecdotally, results speak for them selves, as DeGroot was able to relay ex amples of customers coming from hours away and even other states because they were seeking a certified shop. The re sults are there statistically, too, as the shop boasts 4.9 stars on Google with more than 600 reviews.

As in Wong’s shops, DeGroot has no ticed that the quality of an OEM-certi fied repair is evident to the customer in the final product, whether they realize it or not.

“We have an extremely strong pres ence in our market with our reputation for our repair quality,” DeGroot says. “I think our OEM certifications have actu ally fueled that reputation. Reason being is because we are focused on proper, safe, OEM specific repairs, with OEM parts. Our overall quality is evident to the cus tomer when they pick up the vehicle.”

As the certifications support perform ing quality repairs, they in a way market themselves. Satisfied customers fuel re peat business and positive word of mouth for the shop. Both Wong and DeGroot agreed that while dollars are dollars, the ROI can’t exactly be measured in the cost of the cert vs. the revenue it directly brings in. There’s an intrinsic value that

both men found to be a net positive.

“As an owner,” Wong says, “a lot of peo ple will look at it as like, hey, they’re al ways looking on a return on investment, which is very logical. I stopped looking at it that way many years ago.”

The question that Wong asks instead, of himself and his staff, is though the shop may be having success right now, what is the biggest potential for crisis? The answer, Wong says, is if the shop compromises on a repair and somebody gets hurt, or worse.

“At that point it doesn’t really matter how much the certification cost anymore because it would never amount to what would end up happening if it’s not done properly,” Wong says.

DeGroot concurs, especially in light of how he sees the industry changing. In creasingly complex vehicles are leaving customers in the middle, trying to under stand the issues facing their repair.

“Some shops might think they do great work and have great body work and refinish,” says DeGroot. “But at the end of the day if certain parts aren’t uti lized in that vehicle, the biggest thing for us in the marketing standpoint is basically just trying to reassure cus tomers that we know how to fix their vehicle and that everything we do is geared with that mentality that that ve hicle, the safety features, basically ev erything about that vehicle even though it was in an accident are not going to be compromised for that customer driving that vehicle forward.”

With an industry that’s changing, both DeGroot and Wong believe OEM cer tifications will continue to play an impor tant role in a shop’s business and recom mend owners stay informed and aware of current events to make the best decisions for their shops.

“I think the biggest thing is just kind of making sure that customer feels com fortable with the repairs being done to their vehicle, so I think it’s just an impor tant thing in my opinion to kind of keep a pulse on where the industry’s going,” DeGroot says. “Do the research on what OEM certifications, what that means, from what it can do for your facility and just trying to basically align yourself with the best, safest repairs.”

How to offer a little something extra to employees who don’t get full-time benefits

By MATT HUDSONIN GENERAL, THE MENAGERIE OF benefits offered to full-time employees is well-known. If a company is able, it typically offers some combination of healthcare, vision, dental, and maybe a 401(k) plan in exchange for 40 hours of work each week.

But in automotive repair, full-time employment might not cover everyone.

Part-time labor is a great way for shops to give younger workers a start, keep employee schedules flexible, and manage costs. But in an increasingly competitive hiring environment, employers might want to add a little incentive to part-timers— something a little extra for their time.

And while traditional healthcare benefits are still sought after, they aren’t as standard as they once were. Penny Yountz, an HR business partner for Employer’s Advantage, says that online healthcare marketplaces and subsidized plans helped all kinds of employees get competitive plans.

“Now, they have an available method of getting coverage on their own and not needing that employee coverage,” Yountz says. “It really gave a lot of small employers the opportunity for that not to be the biggest need.”

If operators aren’t yet ready to offer health benefits to their part-timers, there are more creative options for employee perks.

Part-time workers, especially younger ones, are serious about saving for the future. Yountz says that a little help from employ ers in this area could be a great way to round out support for employees.

“That is what a lot of folks right now are looking for,” Yountz says. “It is putting money aside for the future. And the young er generation is really looking for that.”

This could be a 401(k) or IRA setup, and the message to the employee is that your business wants to help them set up finan cial security for the future.

Yountz says that 40 percent of high school graduates are looking for positions that have growth opportunities, whether that’s related to their income or job title. For relatively small shops with little movement among tech positions, that might be tough to offer. But a savings plan helps to put that growth mindset into the compensation.

Plus, employers have the opportunity to sweeten the pot and contribute to one of those plans.

“It’s not that big of an investment as it would be contributing to a traditional med ical plan,” Yountz says.

The health reimbursement arrangement

is an account that’s paid into by an employ er, and the employee can use that money for qualified, health-related activities. The benefit of enrolling in an HRA instead of a basic healthcare stipend is that the money is tax-free, and in some cases, the money can be rolled over from year to year.

“There are some that are doing it on a post tax basis,” Yountz says. “But if you’re going to do it, you might as well do it right.”

According to the federal government, many kinds of HRAs require the employee to be enrolled in a healthcare plan before getting the HRA. They may be able to use the HRA money toward a healthcare pre mium, however.

When investing in various benefit pro grams for employees, check to see if the vendor offers any additional perks to busi nesses. Yountz says that, for example, the company that manages business retire ment accounts might have a financial edu cation seminar program that could visit your shop.

Those kinds of sessions could offer valuable information that some employees might not get elsewhere.

“Like helping employees understand why it’s important for them to have a will,” Yountz says. “And putting money aside in case something happens to them.”

Companies also offer sessions on homebuying or renting. For the automotive enthu siast, vehicle purchasing and maintenance could be another session topic. Those ad ditional perks could help you decide which vendor to use.

The Employee Assistance Program, or EAP, could offer a number of different ser vices for employees. Those services are typically geared toward employee wellbeing and could include counseling, crisis intervention, substance abuse, elder care, and others.

Yountz says that employees are en couraged by employers who are striv ing to promote mental health among the workforce.

“Another big key topic right now from an HR standpoint is burnout and mental health awareness,” she says.

EAPs are structured in different ways.

Some are created by an employer, while others are grouped and sold as a service package by a third party. For many employ ers, the cost can be surprisingly affordable for impactful services.

“Most of the EAPs that I am familiar with are anywhere between $2 an $4 per month as the investment that an employer makes,” Yountz says.

There are some newer vendors that pack age a bunch of smaller fringe benefits to offer. One such vendor, with which Yountz is familiar, is set up so that an employer can award employees “points.” The em ployee is then able to redeem those points for a number of everyday uses, like toward a streaming subscription, to help pay for food or grocery delivery, or a number of other things.

“With the points, we go online and select what we want,” Yountz says. “If I’m a Netflix person, I can use it to pay for my Netflix sub scription. If I’m a foodie, I can pay for certain food boxes or a coffee-of-the-month club.”

Yountz recalls a company that said it was spending to provide a whole bunch of ben efits but had a low participation rate. It took some time before the company real ized that the benefits weren’t applicable to the age bracket of the employees.

Companies provide benefits so that their employees can get use of them. Yountz suggests a quick survey to find out what matters most to your people.

“Give the employees a voice,” she says. “If you haven’t done it before, then kick it off by looking at some benefits options, saying, ‘We want to know what’s important to you.’”

Different benefits might be beneficial to different age brackets, people who live in different areas, or even employees at different times of the year. Much like the nature of part-time employment, business owners can be nimble with their benefit choices to adapt to changing times. For example, if someone in your small busi ness recently adopted a boisterous dog, maybe a dog-sitting stipend is the benefit for your operation. Employees will notice the effort.

“There are a lot of different things you can do to increase retention,” Yountz says.

A WELL-INFORMED TECHNICIAN is a pow erful technician. Information access is what fuels modern vehicle repair. Understanding how to equip technicians with the resources that they need to succeed can mean the dif ference between a shop that is prepared for the future and a shop that is not.

Repairing electric vehicles and ve hicles with ADAS components is still a newer shift for shops in the industry, but it shouldn’t be ignored. As time goes on, more and more of these types of repairs will be showing up at shops. Proper train ing and education are key.

Darrell Amberson is the president of operations at LaMettry’s Collision in Min nesota, and Jason Zeise is the mechanical operations manager at LaMettry’s. Both agree that a thoughtful and well-in formed approach is the best approach to have when it comes to these repairs.

“Every year, a higher percentage of vehicles that we work on have ADAS on them,” Amberson says.

An influx of highly technical repairs means extra attention must be paid to each situation. Zeise explains that expe rienced technicians can fall into a habit of not looking up repairs for tasks that they’ve done many times before. But with ADAS components, it’s important to dou ble check.

“I use this analogy all the time: you have a body technician that can remove a bumper without looking up procedures. As an ASE Master Mechanic, I’ve done thousands of wheel alignments,” Zeise says. “I don’t need to look up how to do that wheel alignment. But without looking that up, at the last line of that wheel alignment it says, ‘You must calibrate a camera.’”

LaMettry’s prioritizes training and staffing that allows them to approach these unknowns with confidence. The

new equipment available to learn and implement these types of repairs is cru cial to the process as well, says Amberson.

“In terms of the ADAS work that we’re doing, there’s been a little bit more equip ment that’s been released and more is coming,” Amberson says. “So, we’ve had the opportunity to look at some of that. We’ve got more choices now.”

Regardless of the amount of initial ef fort put in to prepare for high-tech repairs, Amberson and Zeise acknowledge the risks involved as well. One area that is especially tricky to navigate is customer data.

“The first thing that comes to mind is the customer’s personal information, and that is a huge challenge for our industry,” Amberson says.

Amberson explains that automated systems can transmit data to unknown places. For example, he says an accident report could show up with a third party and diminish the value of the vehicle and it isn’t exactly known how the third party gets access to that information. Amber son says that this risk can be easier for a customer to overlook.

“[When you] get into Bluetooth and things like that, there can be a lot of cus tomer data in there. I know not many peo ple think about it in a total loss situation or a vehicle trade in,” Amberson says. “A customer should have a lot of that erased before turning the car to somebody else, otherwise they have access to a lot of per sonal information.”

Customer data is not to be taken lightly, as Amberson and Zeise note. As vehicle technology continues to inno vate, unknowns are bound to happen. But as with many tasks in this industry, finding the right place to start makes all the difference.

In terms of electric vehicle repair, Zeise

says that it’s all in the procedural approach. Zeise says that safety is a necessity.

“So, if you get an electric vehicle that’s been damaged or disabled or has issues, the first thing that you need to do is look up, ‘How is it safe to work on this vehicle? Are there any concerns off-hand before I work on this vehicle? How do I disconnect the high voltage system?’” Zeise says.

Zeise also recommends using re sources such as the I-CAR Repairability Technical Support service. It’s a system that grants access to a wide variety of repair information that could ordinarily take hours to research.

Regardless of how you access the in formation, Zeise says that it is important to do your research and do it thoroughly.

“You have to research, find out what you’re working on, what are the hazards involved, and make sure that you follow those procedures to the letter,” Zeise says.

High-tech repairs and unique shop so lutions are some of the topics that Amber son and Zeise helped tackle at the ADAPT: Automotive Technology Summit in Sep tember. Both Amberson and Zeise were speakers at the Summit.

“We’re at a crossroads [in] our industry. Many of us are attending industry events and are talking a lot about vehicle sophis tication, safety issues, [and] elevating the stature of our industry … and then there is another side of the industry that’s not do ing that so much,” Amberson says.

Amberson says that it is important to be prepared for what comes next. Events such as the ADAPT Summit can help stimulate conversations about the ad vances in vehicle technology that impact everyone across the industry.

“I think [that] one has to make a deci sion,” Amberson says. “Are you going to be a player in the future or not?”

WHETHER WE’RE TALKING ABOUT fenders or fences, bumpers or basket balls, there is a constant to every indus try—change. The best and brightest in any given industry are the ones who stay ahead of the curve, even when they as an individual may be falling behind. Attor ney William Ferreira relayed one such story from his law school days.

“I’ll never forget, my mentor, when I

With more complicated repairs, shops face more potential liability issues than ever

was in law school, I would come in, and he would hand me these research projects or whatever else,” says Ferreira, whose firm Automotive Defense Specialists is tailored toward the automotive repair in dustry. “And he’d say, ‘Listen, when I went to law school, we didn’t have the comput ers, we didn’t have the internet, we didn’t have all these resources available to us. And yes, I know how to use some of them. But the newest graduates are on the cut ting edge of technology. And they know how to access things that I don’t know how to access or get to as quickly and as efficiently as you new kids.’”

The analogy here to collision repair is that there is more for owners to stay up to date on than ever. From OEM procedures to how to handle EVs, shops are dealing with a lot. Staying current isn’t only im portant for completing quality repairs, it’s absolutely vital for keeping your shop from being exposed to liability. There’s more of that than ever, too.

“There’s nobody banging on your door to say, ‘Hey, man, you got to get educated on this,’ you’ve got to be proactive with it, do it on your own and take initiative,” says Justin Fisher, who operates multiple CAR STAR shops in the Chicagoland area. “... If you’re not aware that you are liable for that, then that’s already an issue or prob lem, right? So step one would be being aware, self awareness, knowing that you are liable for it. And then, all right, how do we implement a process or procedure to make sure we’re doing this correctly? And are you going far enough?”

Many liability issues for shops are obvious. If a repair isn’t completed prop erly and that vehicle gets in another ac cident, that shop has opened itself up to liability. Then there are other things that are not so obvious. As shops take on more and more jobs, some are more inclined to sublet work, such as calibrations, as is the case in Fisher’s shops.

But even if a shop employee isn’t the one completing the work, the shop can still be held liable if something goes

wrong. And with calibrations, the stakes are high. Fisher cited an example of a bumper loaded with blind spot sensors, which if it was just a few degrees off could equate to 15 feet out of alignment out on the road.

“That’s one particular area that I tell my body shops, I know you got to sublet work, I know you can’t do everything,” says Ferreira. “Nobody’s master of all trades. But when you do sublet the work, you want to build a relationship with the shop and you want to ensure that they’re insured, you know that they have some type of policy should something happen, or one of their mechanics is negligent in some way and it comes down to it, that there’s a policy that’s going to cover the damages because you don’t want to be put out of business or be bankrupt by a sublet auto repair shop that did shoddy work.”

There are other factors, of course, that present roadblocks for shops doing their best to complete safe and quality repairs. Shops need access to the latest OE proce dures and how to find them, as Ferreira noted. Shops also have to negotiate the repair process with insurers, something that can cause delays and put pressure on all parties.

And if a shop feels pressured to com plete repairs on anything but its own timeline, that opens the door for mistakes to be made. The antidote to this, in Fer reira’s opinion, is a combination of thor oughness, patience and resolve. Shops simply have to take the time to research repairs thoroughly. They have to have the patience to say to insurers that either they will do the repair correctly or they won’t do it at all. And they have to have the resolve to stick to that message.

“The insurance company is going to come in and give you a terrible first es timate, you’re gonna say, ‘OK, I see what they’re saying, I’m gonna go do my own research and see what I need to do to re pair this vehicle,’” Ferreira says. “And you’re going to take pictures, you’re going to print out copies of the manufacturer

specific repairs, where it says you need to repair this, like this, and you’re going to put it all together in an estimate, and you’re going to send it to the adjuster and the insurance company.”

Ferreira acknowledges pushback is possible, if not likely. But he advises shops to do all they can to avoid anything that opens them up to liability. And that’s especially true when there are more and more exposures.

There are the aforementioned cali brations and the infrastructure require ments that come with it. There are the strict temperature requirements for stor ing EVs. There are the special procedures for safely handling their high voltage systems. There are the environmental re quirements for working with aluminum, and so on.

“It sounds super fun. It’s going to be great,” says Fisher, laughing. “So when it was just mechanical vehicles, just a gas operated vehicle, those have been around for so long, everybody can be an expert on repairing those. The EV vehicles are so new, everybody’s going to have some thing different out on that, I think in terms of the OEs. So I’m curious to see how that evolution takes place.”

That raises the stakes for the insurers as they’re forced into more complicated and more expensive repairs. And just like shops have to do their due diligence to stay current, so do adjusters. Adjusters may not yet have the education they need to make an informed estimate, and that’s again where the shop comes in.

“That is certainly on the shop,” says Ferreira, “or at least the shop foreman, or the lead estimate writer or the teardown specialist, to make sure they keep up on their training, make sure they go to as many classes as possible, and making sure they go to I-CAR, updates, and cer tifications, and they learn these new sys tems, and they learn what repairs are go ing to be necessary to return the vehicle to pre accident condition, because that’s what the policy allows for.”

Enhanced rules engine provides shops with more control over OEM and aftermarket tools

asTech, a Repairify company, recently announced industryrevolutionizing changes and expanded offerings that will dramatically streamline shop workflow with one-stop access to diagnostics, ADAS insights, calibrations, and programming for a shorter repair cycle and a more profitable shop.

asTech is the leading provider of remote diagnostic solutions and services to the collision industry. asTech provides cuttingedge, expert diagnostics using OEM and OEM-compatible tools to provide safe and accurate repairs.

The company provides remote diagnostics using its patented device and access to ASE and I-CAR Certified Technicians, who service many trouble codes remotely and provide real-time assistance to shop technicians at the vehicle when needed. asTech also offers ADAS insights via adasThink, mobile repair, key replacement, and calibration services.

The asTech® device is unique because it offers a choice of two diagnostic scan types: remote OEM or OEM-compatible, which is an aftermarket scan that has been tested and validated by Repairify to perform as accurately as the OEM scan tool.

One of asTech’s most notable new features is its patented diagnostic Rules Engine, now enhanced with the ability to customize. The new ‘shop rules’ feature is especially useful for collision centers certified by a specific OEM that has scan tool requirements, or shops participating in insurance direct repair programs, which may also have influence on repair procedures.

Interested in more information? Visit us online at astech.com/our-solutions, reach out to info@astech.com or call customer service at 1-888-486-1166.

The exponential growth in the number of vehicles with Advanced Drive Assistance Systems (ADAS) such as Blind Spot Monitoring, Automatic Emergency Braking and Lane Keep Assist should act as a catalyst for shops that perform calibrations to develop a process that enables them to perform them as efficiently and as accurately as possible. Calibration systems innovation has taken the tedium out of the most-time consuming segment of ADAS calibration— setup, and vehicle to target positioning—and provided technicians with a calibration process that is both efficient and precise.

The Autel Intelligent ADAS IA900WA wheel alignment and ADAS calibration unit simplifies the complexity of the calibration process into a guided, straightforward process. The IA900WA is an industry first offering 4-wheel alignment and ADAS calibration all-in-one system. The design of the IA900WA itself is elegant and efficient. It features a folding crossbar, six high-resolution positioning, and tracking cameras in the frame that automatically monitors vehicle height on the shop lift. Robotic frame movement for efficient use and alignment reading accuracy to 0.02 degrees for precise alignments. Alignment coverage is for U.S., Asian and

European vehicles, 1996 and newer and the user is guided in the complete process with illustrated alignment instructions, live readings, required tools, and adjustment locations display on included 24” touchscreen screen.

The IA900WA system is offered in various packages including an All Systems ADAS package which Includes targets, patterns, and calibration components to calibrate cameras, RADAR, LiDAR, and night vision units.

As vehicle manufacturers continue to share their safety systems throughout the entire lines, and more and more vehicles with these systems enter shops, solutions that provide technicians with a repeatable, efficient process to calibrate these input devices have become essential.

Designed to repair of small to medium autobody damage, the CDR1 Cosmetic Dent Repair Workstation from Car-O-Liner ® is a value-packed repair cart that allows technicians to quickly and efficiently complete professional repairs of light cosmetic damage on aluminum and steel. These quick cosmetic collision repairs generate good margins, faster cycle times and decreased need for expensive, heavy equipment investments. The wide range of color-coded tools is neatly arranged in the workstation to roll around the workshop easily.

• Dedicated Storage Drawers ensure tools are separated and organized, keeping them ready for use and easy to locate.

• Carbon Fiber Pull Bars are lightweight and three times stronger than steel for ease of use; 50, 100 & 160cm.

• WorkShop Solutions™ tool boards provide excellent equipment storage; pulling bars, hand-pullers (steel and aluminum), four 6-finger claws, and much more.

• CR235 Dual Spotter, switch quickly between two dedicated guns, meets aluminum and steel welding needs, no need for extra equipment.

• Meets OEM demands for smart, quick repair solutions.

BASIC: includes equipment on tool boards and in the drawers for the repair of steel and aluminum ADVANCED: includes Basic plus a drawer for repair with glue MASTER: includes Advanced plus drawers for a Holder Kit and PushPull tools

Offer more solutions to your current customers and gain new ones by providing quick, efficient, professional repair of minor collision damage.

Visit car-o-liner.com for more information.

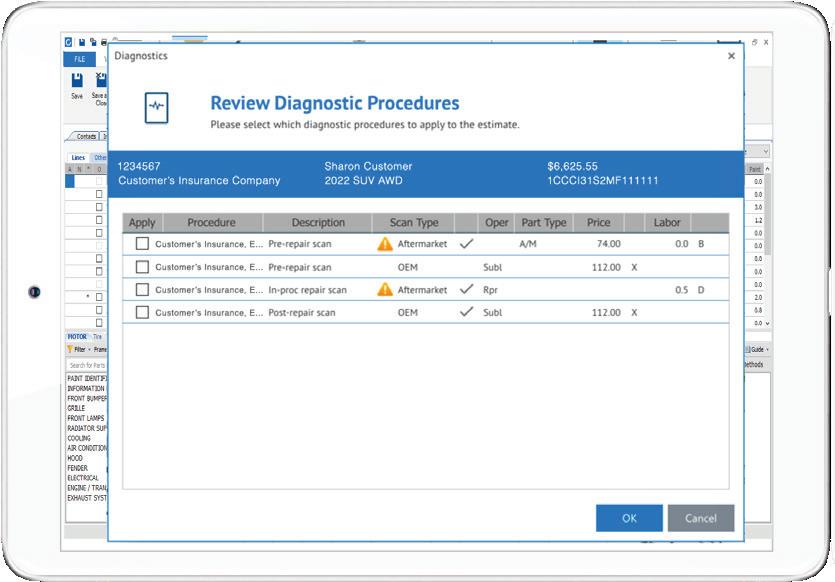

With CCC ® Diagnostics, shops configure their CCC ONE® software to inform users what type of scan should be performed at each stage of a vehicle’s repair. Repairers can more efficiently and consistently document OEM or aftermarket scans on preliminary estimates to reduce the need for timeconsuming supplements.