SUBSCRIBE FOR FREE

SUBSCRIBE FOR FREE

THE CHALLENGES INVOLVED IN DESIGNING TYRES FOR EVs

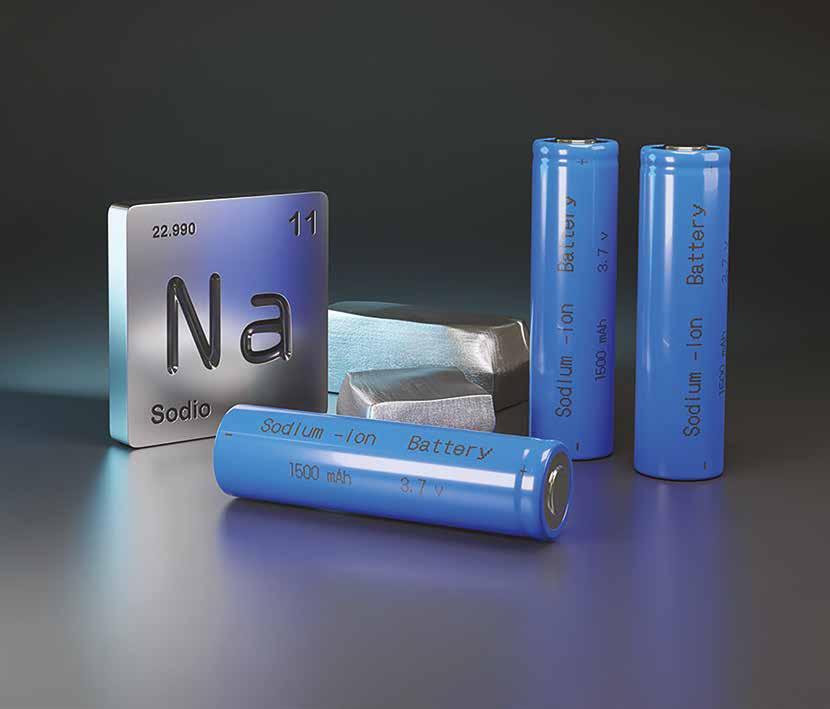

SUPERCHARGING SODIUM-ION

Could sodium-ion batteries outpace lithium-ion charging?

HYDROGEN PROPULSION

How 3D printing is rewriting hydrogen intake design

ADVANCING TOWARDS AUTONOMY

The latest developments in autonomous technologies

ASC INERTIAL SENSORS

Innovative sensor technology made in Germany –solving complex automotive challenges across the world:

■ Fast: diverse, ready portfolio meeting your needs

■ Flexible: individual customization and support

■ First: speedy development and delivery

■ Reliable: robust to prevail extreme testing conditions

We partner for your success. Let’s talk about it: www.asc-sensors.de

Welcome to this issue, where the pace of change across the transport sector feels faster than ever. Electrification, automation and digital intelligence are no longer future concepts; they are reshaping vehicle design, infrastructure planning and operational strategy in real time.

E-powertrain development continues to move at speed (page 8), with compact drive units and advanced power electronics delivering longer range and improved performance (page 10).

Battery technology remains at the heart of this transition, and solidstate batteries are edging closer to commercial reality (page 20).

Promising higher energy density, faster charging and improved safety, solid-state solutions could remove some of the key constraints still facing electric transport.

Alongside electrification, autonomous driving technologies are steadily advancing. Incremental gains in sensor capability, AIdriven perception and vehicleto-everything connectivity are enabling higher levels of automation in controlled environments (page 28). In logistics hubs, depots and fixed-route operations, autonomy is already delivering efficiency and safety benefits (page 30), with wider applications now firmly in sight.

As these trends converge, the challenge for the industry is integration - aligning vehicles, infrastructure, regulation and skills. In this issue, we explore how manufacturers, operators and suppliers are navigating that complexity and positioning themselves for the next phase of transport transformation.

Hayley Everett Editor

16

HYDROGEN PROPULSION

TREADING A NEW PATH

The challenges involved in designing tyres for EVs, and how to tackle them

8

10

DESIGN FLUX

How recent breakthroughs are redefining electric powertrain performance

HYBRID EFFICIENCY

Taking a closer look at KGM Motors’ new dual tech hybrid powertrain

13 SUPERCHARGING SODIUM-ION

Could sodium-ion batteries outpace lithium-ion charging?

18

How 3D printing is rewriting hydrogen intake design

COMPOSITE CONSTRUCTION

The role of composites in minimising weight in electric buses

20 NEXT STEP FOR SOLID-STATE

Exploring the latest developments moving solidstate batteries closer to commercial reality 22 AFFORDABLE AUTOMATION

Ford’s newly-announced eyesoff EV driving roadmap

32 ZERO-CARBON COMBUSTION

A new hydrogen ICE test facility aims to accelerate zero-carbon combustion technology

How supply chain transformation is set to be a cornerstone of sustainable aviation

How AI and smart monitoring are improving safety and efficiency in the rail sector

ADVANCING TOWARDS AUTONOMY

Assessing the latest developments in autonomous transport technologies

30

AUTOMATING ASSETS

Highlighting the inertial sensor innovations facilitating high-speed transportation of people and goods

PUBLISHER

Jerry Ramsdale

EDITOR

Hayley Everett heverett@setform.com

DESIGN – Dan Bennett, Jill Harris

HEAD OF PRODUCTION

Luke Wikner production@setform.com

HEAD OF SALES & PARTNERSHIPS

David Pattison

ACCOUNT DIRECTORS

John Abey | Peter King

SENIOR ACCOUNT MANAGERS

John Davis | Darren Ringer | Roy Glasspool

ACCOUNT MANAGERS

Paul Maher | Iain Fletcher | Marina Grant

e advertising@setform.com

CONTACT US...

t +44 (0) 207 253 2545

e mail@setform.com

New ultra-rugged edge AI systems for mission-critical applications from Bressner Technology

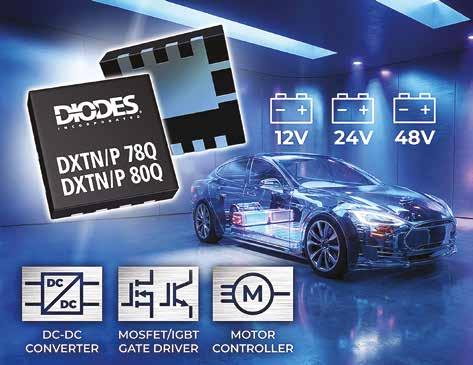

Diodes Incorporated expands its automotive bipolar transistor portfolio

WORKFORCE REFORM

Summarising the latest skills, training and workforce updates from across the transport sector

40CONNECTING THE COMPOSITES COMMUNITY

JEC World 2026 returns to Paris

ADDRESSING TRANSPORT’S TECHNICAL RESILIENCE

CIHT’s National Conference takes place in London

EXPLORE THE BATTERY REVOLUTION

The Battery Tech Expo UK returns to Silverstone

Setform’s international magazine for transport is published twice quarterly and distributed to senior engineers throughout the world. Other titles in the company portfolio focus on Process, Design, Energy, Oil and Gas, Mining and Power.

The publishers do not sponsor or otherwise support any substance or service advertised or mentioned in this book; nor is the publisher responsible for the accuracy of any statement in this publication. ©2026. The entire content of this publication is protected by copyright, full details of which are available from the publishers. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior permission of the copyright owner.

The challenges involved in designing tyres for EVs

• -45 °C to +150 °C

• Efficient Heating and cooling

• Flow & pressure control

• Single/multiple fluid circuits

• Automated drain & refill

• Integrated pressure overlay

• Heat exchange pump option

The Unimotive range is specially designed for applications in the automotive industry. Typical applications include temperature simulations as well as material testing and temperature-dependent stress and load tests for automotive parts and functional components.

www.huber-online.com

The rapid growth of the electric vehicle (EV) market means that automotive manufacturers across the entire supply chain are having to rethink their R&D approach to reflect this new normal. Tyre technology is a prime example of this scenario, with traditional suppliers having to deliver new innovations that will enable their products to be successfully deployed on EVs.

And as Jaap Leendertse, general manager PCR/SUV tyre development at Sumitomo Rubber Europe observes, the successful players here will be the companies that recognise the importance of offering customers products that are purpose-designed for EVs. “Battery electric vehicle (BEV) and plug-in hybrid electric vehicle (PHEV) numbers are only going to increase, and we want to maintain our reputation for taking care of the environment by offering a tailored product for these vehicles, so the users can extract the

A tyre development specialist tells Louise Davis what the challenges involved in designing tyres for EVs are – and how they can best be tackled

Jaap Leendertse, general manager PCRSUV tyre development, Sumitomo Rubber Europe

most from switching to this category. The technology used in EV tyres is still relatively new, and it’s something that will be incredibly important for the future,” Leendertse comments.

So, how do tyres that are suitable for EVs differ from those designed for internal combustion engine (ICE) vehicles? “Many of the characteristics are shared and we are looking for very similar attributes, but there are some specifics for this segment,” explains Leendertse. “BEV tyres are designed to meet the higher loads exerted by this category of vehicle. There is an increased focus on reducing rolling resistance to maximise range whilst also coping with the faster acceleration and higher torque found in EVs. Finally, there are design features such as seamless, continuous sipe edge contact and offset tread grooves to improve refinement as EVs are typically quieter.”

The structural considerations associated with tyres for EVs mean that suppliers such as Falken, one

of Sumitomo’s brands in Europe, are having to prioritise different features than those for their ICE vehicle ranges. “For example, due to the higher loads exerted on BEV tyres, we add reinforcing materials in the carcass and structure,” confirms Leendertse.

Noise, vibration and harshness (NVH) also influence the design of EV tyres in a different way to ICE tyres. Leendertse notes: “Internal noise and comfort are very important and, because BEVs have less noise emission, any external noise needs to meet regulations. We have created specific design changes such as the seamless sipe edges and the use of our proprietary Silent Core (specialised noise-absorbing sponges) to achieve this.”

The tyre development expert says that testing is one area that is comparable to traditional ICE tyre development work. “Aside from

Falken’s parent company Sumitomo Rubber has developed a simulation technique called Tyre Aerodynamic Simulation, which is used in the process of tyre development. On this, Leendertse comments: “To reduce the electricity consumption of EVs, it is very important to minimise tyre rolling resistance as well as air resistance around the tyre. Sumitomo will pursue the development of a tyre shape that optimises aerodynamic performance by visualising the airflow around the tyre of a running vehicle through our own simulation using AI, thereby aiming to develop a tyre that further contributes to lowering the electricity consumption of an EV in a next-generation EV tyre to be launched in 2027.”

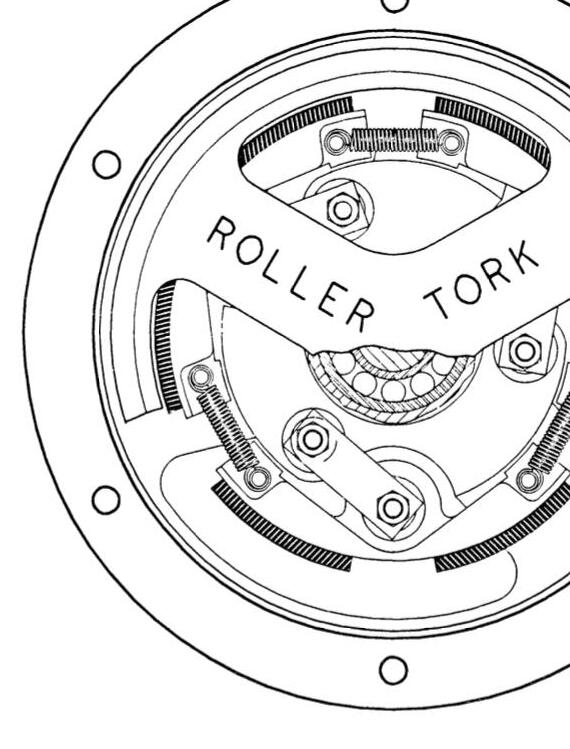

Falken adds reinforcing materials to the tyre carcass and structure to accommodate the higher loads exerted on BEV tyres

Q6 e-tron

taking into consideration any specific requirements from car manufacturers, in general, testing is similar to ICE vehicles with the exception of the wear test – because we cannot achieve the same mileage in a day.”

Naturally, much of Falken’s R&D work is focused on materials. What compounds and mixtures of materials does Leendertse believe are more beneficial for the demands of EVs?

“New tailored synthetic rubber –developed in close cooperation with the chemical industry – is key for mileage and rolling resistance, whilst specific profiles and patterns are important as well,” he states. “These are all designed to meet the demands of BEVs as well as offer lower noise levels. For example, we use the Silent Core sponges in our e.ZIEX pattern and this tyre also contains up to 29% of sustainable and recycled raw materials,” he adds.

The e. ZIEX tyre that Leendertse

highlights has been something of a success story for Falken since its 2024 launch. He details: “Its asymmetric tread pattern, developed using our Advanced 4D NANO Design technology, features optimised tread edges that prevent pressure peaks by distributing pressure from the tyre smoothly. The tread pattern is also optimised at the contour of the tyre shoulder, lowering its rolling resistance.”

A notable design achievement can be found in the tyre’s smart approach to tackling noise. “Drivers are placing greater importance on vehicle refinement and comfort. Between ICE vehicles and EVs, the difference in cabin noise can be stark, yet the e. ZIEX tyres are engineered to enhance refinement for both powertrains,” reports Leendertse.

Durability was another focus of the e.ZIEX’s development work. EVs typically deliver far greater levels of torque than ICE vehicles, thanks to their instant power delivery

capabilities. Applying this increased performance to the road is achieved via the tyres, resulting in more aggressive wear compared with an ICE vehicle. Leendertse points out that tyres must also accommodate the increased weight of EVs – usually 20-30% more than a typical ICE vehicle. “We have worked extensively to optimise the construction of the e. ZIEX tyre, using new materials and construction techniques to ensure it is lighter than a conventional tyre. The tread has been designed to wear evenly to maintain consistent grip throughout its life, enhancing safety and providing budget-friendly longevity,” the expert reveals. He also mentions that the e. ZIEX tyres are available in the size range of 17-21in and a width of 215-255mm, “to accommodate for the larger brakes usually fitted to EVs to counteract any losses in braking performance associated with increased vehicle weight.”

Electric powertrain technology continues to evolve at pace, with recent developments in axial flux motor design demonstrating step changes in power density, torque delivery and packaging efficiency. Among the most significant advances is YASA’s latest prototype electric motor, which has set a new unofficial benchmark for power density and highlights how alternative motor topologies are moving from niche applications into mainstream high-performance automotive powertrains.

In October 2025, YASA announced that it had surpassed its own earlier achievements by recording a shortterm peak output of 750kW from a motor weighing just 12.7kg. This equates to an unofficial power density of 59kW/kg, a 40% increase over results achieved only months earlier, when a 13.1kg prototype delivered 550kW, corresponding to 42kW/kg. While the headline figures focus on peak output, YASA also estimates

continuous power capability for the new motor in the range of 350kW to 400kW, underlining its relevance for sustained vehicle operation rather than brief laboratory demonstrations.

Designed and developed at YASA’s Oxford Innovation Centre, the prototype is a fully functioning unit undergoing extensive dynamometer testing. The company emphasises that the results are derived from physical hardware rather than simulation alone, with performance gains achieved through precision engineering, advanced thermal management and optimised packaging, rather than exotic materials. Support for the programme has been provided by the UK’s Advanced Propulsion Centre.

Simon Odling, YASA’s chief of new technology, added: “The early results are extremely encouraging. The motor’s performance on the dyno has exceeded even our most optimistic simulations.

As well as its incredible peak power and overall power density, we estimate this new motor will be able to deliver all-important continuous power in the region of 350kW-400kW. This is real hardware, in real life, delivering real data – and it’s performing beautifully.”

Axial flux motors differ fundamentally from the radial flux machines that dominate today’s electric vehicle market. Radial motors, which trace their origins back several decades, generate torque through magnetic flux flowing radially from the rotor to the stator. In contrast, axial flux machines use magnetic flux oriented parallel to the axis of rotation, allowing a larger effective rotor radius within a compact axial length. This geometry offers inherent advantages in torque production and power density, but has historically been constrained by manufacturing complexity and cooling challenges.

YASA’s approach addresses these limitations through a yokeless and segmented armature design that removes the stator yoke and significantly reduces iron mass. According to the company, this can cut stator iron content by up to 80%, contributing to motors that are two to three times more power dense than non-axial alternatives. Shorter copper windings and direct oil cooling further enhance thermal performance, enabling higher continuous output compared with equivalently rated radial machines.

Thermal management remains a critical factor in electric powertrain design, particularly for highperformance and commercial transport applications where repeatable output is essential. YASA contrasts the behaviour of conventional radial motors, which may be limited to around 50% of peak power under continuous operation due to heat build-up, with its axial flux motors, which can sustain a significantly higher proportion of peak output. The company cites a 200kW axial flux motor capable of delivering approximately 150kW continuously, supported by high thermal contact oil cooling.

Beyond raw performance, packaging efficiency is another area of focus. Axial flux motors typically have a much shorter axial length than radial designs, and YASA states that its motors can occupy around 50% less volumetric space while also being up to 50% lighter. For vehicle designers, this can translate into greater freedom in drivetrain layout, opportunities for lower vehicle mass, and secondary benefits such as smaller braking systems and reduced battery capacity for a given range target.

The latest prototype builds on more than a decade of development following YASA’s foundation in 2009 as a spin-out from Oxford University. The company’s origins lie in research undertaken by founder and chief technology officer Dr Tim Woolmer, who explored axial flux concepts as an alternative to conventional motor architectures. Over time, YASA developed manufacturing processes

based on soft magnetic composite materials and segmented pole pieces, overcoming many of the production barriers that had previously limited axial flux adoption.

YASA’s motors have already seen deployment in a range of high-profile applications, from concept vehicles and motorsport to limited-series production cars. In recent years, adoption has accelerated following the company’s acquisition by MercedesBenz Group in 2021, with YASA becoming a wholly owned subsidiary tasked with developing electric motors for the AMG.EA electric-only platform. Partnerships with premium manufacturers have followed, including Ferrari and Lamborghini, where axial flux motors form part of advanced hybrid powertrains.

Commenting on the latest test results, Dr Woolmer said: “On behalf of the entire YASA team, I’m proud and excited to so quickly follow up on the already remarkable results of our initial testing with this incredible result. To achieve a 750kW short-term peak rating and a density of 59kW/ kg is a major validation of our nextgeneration axial flux technology. It’s proof of what focused engineering innovation can achieve. And this isn’t a concept on a screen — it’s running, right now, on the dynos. We’ve built an

electric motor that’s significantly more power-dense than anything before it – all with scalable materials and processes. This motor will bring gamechanging technology to the highperformance automotive sector.”

According to YASA’s CEO Joerg Miska, “This record demonstrates what makes YASA unique. With three times the performance density of today’s leading radial flux motors, YASA continues to redefine the boundaries of what’s possible in electric motor design – turning pure innovation into tangible engineering progress. Our technology is delivering measurable results today, while paving the way for a new generation of lightweight, efficient electric propulsion systems.”

As electrification expands across passenger vehicles, performance cars and increasingly into heavier transport segments, advances in motor technology will play a decisive role in improving efficiency, reducing mass and enabling new vehicle architectures. YASA’s latest axial flux prototype illustrates how rethinking core components of the electric powertrain can unlock substantial gains, suggesting that the next phase of electrification may be driven as much by motor innovation as by advances in batteries and power electronics.

KGM Motors UK has launched its next-generation Dual Tech Hybrid powertrain, marking a significant technical step in the company’s electrification strategy for the UK market. Debuting in the new Torres Hybrid and Actyon Hybrid, the system is designed to deliver high real-world efficiency and a driving experience closely aligned with that of a full electric vehicle (EV), while retaining the long-range capability and towing robustness expected from KGM’s SUV portfolio.

Developed in collaboration with BYD, the Dual Tech Hybrid System is a series-parallel architecture that combines a newly designed 1.5-litre turbocharged petrol engine with an e-DHT (electrified Dual Hybrid Transmission) and dual electric motors. By actively managing how and when each component contributes power, the system is intended to maximise efficiency across a wide range of driving conditions, from urban stop-start traffic to sustained motorway cruising.

“The new Dual Tech Hybrid powertrain in Torres Hybrid and Actyon Hybrid shows exactly where KGM is heading in the UK,” says Kevin Griffin, managing director of KGM Motors UK. “It gives our customers the

smooth, near-silent feel they associate with electric vehicles, but with the range, robustness and everyday usability they expect from a KGM. This technology is the foundation for our next generation of powertrains, as we bring more practical, real-world electrified options to the market.”

The hybrid transmission is based on Korea’s first P1 + P3 dual-motor architecture, adapted from BYD’s plug-in hybrid technology for full hybrid use. A 130kW P3 drive motor is mounted close to the driveshaft, enabling immediate response to throttle inputs. This motor delivers up to 177ps and 300Nm of torque, supporting strong acceleration and linear power delivery characteristic of electrified drivetrains.

Supporting the powertrain is a class-leading 1.83kWh hybrid battery, the largest in its segment, paired with a lightweight 12V LFP low-voltage system. The e-DHT enables a wide range of operating strategies, including electric-only EV mode, series hybrid operation, parallel hybrid operation, and direct engine drive. In total, the system can automatically switch between nine different driving modes, optimising

power flow without driver intervention. All-electric driving is possible at speeds of up to 62mph, enabling near-silent operation with instant torque in urban and suburban conditions.

Energy management is further enhanced by an adjustable regenerative braking system with three selectable levels. Drivers can choose between a more conventional braking feel or stronger regeneration to maximise energy recovery. When Smart Regenerative Braking is enabled, the system automatically adjusts deceleration based on traffic conditions ahead, improving smoothness in stop-start driving while increasing recuperation efficiency.

Noise, vibration and harshness have also been addressed through extensive sound insulation and the use of smart frequency dampers within the suspension system. These measures are designed to maintain a quiet cabin environment even when the engine is operating, while improving ride stability across varied road surfaces.

Both the Torres Hybrid and the Actyon Hybrid form part of KGM’s broader plan to expand its electrified line-up, supported by ongoing investment in hybrid and electric vehicle production at its manufacturing facilities in Korea.

Detailed experimental analysis reveals the decisive mechanisms governing ion kinetics at hard carbon negative electrodes

Experimental evidence suggests sodium-ion batteries can outpace lithium-ion charging

As the transport and energy sectors accelerate toward electrification, demand is increasing not only for higher energy density batteries, but also for systems that can charge rapidly, operate reliably, and rely on materials with secure global supply chains. While lithium-ion batteries (LIBs) remain the dominant technology today, growing attention is being paid to sodium-ion batteries (SIBs) as a complementary or alternative solution.

New experimental research published in Chemical Science by Tokyo University of Science, provides quantitative evidence that SIBs can achieve faster charging rates than

LIBs under the right conditions, offering potential advantages for high-power transport and infrastructure applications.

Sodium-ion batteries have long been attractive due to the abundance and low cost of sodium compared with lithium. However, questions have remained over whether SIBs can match or exceed the electrochemical performance of LIBs, particularly in demanding use cases. A research team led by Professor Shinichi Komaba at Tokyo University of Science has now addressed a critical part of this debate by directly

comparing the intrinsic charging kinetics of sodium and lithium ions at hard carbon (HC) negative electrodes. Hard carbon (HC) is a lowcrystallinity, porous carbon material widely regarded as the most promising anode material for SIBs. It can store large quantities of sodium and enables energy densities comparable to commercial LIBs. Although HC has been considered a fast-charging material, conventional battery testing methods often obscure its true rate capability. In composite electrodes, dense packing of active material can lead to concentration overvoltage during rapid charging, where ion transport through the electrolyte becomes the limiting factor. This

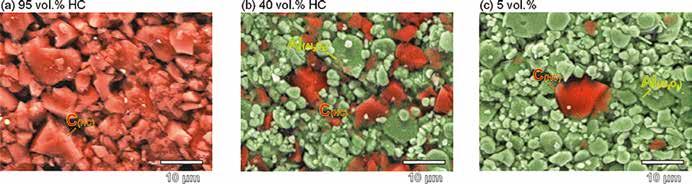

Electrodes with different ratios of hard carbon (red) to Al2O3 (green), the latter of which is electrochemically inert. Using the more diluted versions of the electrode, certain rate-limiting phenomena can be avoided, enabling scientists to more accurately measure ion kinetics in hard carbon. Image via Professor Shinichi

creates what the researchers describe as effective “ion traffic jams,” preventing accurate measurement of the material’s intrinsic kinetics.

To overcome this limitation, the research team employed an innovative experimental approach known as the diluted electrode method. In this technique, HC particles are mixed with an electrochemically inactive material, aluminium oxide (Al2O3), in carefully controlled ratios. By sufficiently diluting the active material, each HC particle is surrounded by an ample supply of ions, minimising electrolyte transport limitations and allowing the fundamental reaction rates to be measured directly.

Using this method, the team compared sodiation (sodium insertion), lithiation (lithium insertion), and lithium intercalation behaviour in hard carbon and graphite electrodes. The results showed that sodiation in diluted HC electrodes exhibited rate capability comparable to lithium intercalation in diluted graphite electrodes, already a benchmark for fast-charging anodes in LIBs. More significantly, detailed electrochemical analysis demonstrated that sodium insertion into hard carbon is intrinsically faster than lithium insertion in the same material.

The researchers applied cyclic voltammetry, electrochemical impedance spectroscopy, and potentialstep chronoamperometry to quantify ion transport behaviour. From these measurements, they calculated apparent diffusion coefficients, which describe

how quickly ions move within the electrode material. Across a wide range of conditions, the apparent diffusion coefficients for sodium were generally higher than those for lithium. As Komaba states: “Our results quantitatively demonstrate that the charging speed of an SIB using an HC anode can attain faster rates than that of an LIB.”

Beyond confirming faster sodium kinetics, the study also identified the key mechanism that ultimately limits charging speed. Hard carbon stores ions through a multi-step process. Initial adsorption and intercalation at defect sites and between graphene layers occur rapidly for both sodium and lithium. However, the final stage involves a pore-filling mechanism, where ions aggregate to form pseudometallic clusters inside nanoscale pores within the hard carbon structure. The researchers found that this pore-filling step is the rate-determining process for overall charging.

Through detailed kinetic and thermodynamic analysis, the team showed that sodium requires less activation energy than lithium to form these clusters. This lower energy barrier explains why sodium insertion proceeds more rapidly during the pore-filling stage. Komaba highlighted the design implications of this finding: “A key point of focus for developing improved HC materials for fast-chargeable SIBs is to attain faster kinetics of the pore-filling process so that they can be accessed at high charging rates. Also, our results suggest that sodium insertion is less

sensitive to temperature, based on the consideration of smaller activation energy than lithiation.”

This reduced temperature sensitivity is particularly relevant for transport applications, where batteries must operate reliably across a wide range of climates and duty cycles. Faster intrinsic kinetics and lower activation energy could enable more consistent performance during cold starts or highpower operation, areas where LIBs can face limitations.

The findings suggest that sodium-ion batteries should not be viewed solely as a lower-cost or resource-secure alternative to lithium-ion technology. Instead, they may offer genuine performance advantages in charging speed, especially for applications requiring frequent fast charging or high-power throughput. For transport sectors such as buses, commercial vehicles, rail auxiliaries, and stationary systems supporting charging infrastructure, these characteristics could prove highly valuable.

While further development is required to optimise HC structures and full-cell designs, this work provides a clear experimental foundation. By isolating and quantifying the fundamental kinetic processes at the negative electrode, the study offers actionable guidance for materials engineering and cell optimisation. As electrified transport expands, such advances indicate that sodium-ion batteries could play a significant role alongside lithium-ion systems in building more resilient and sustainable energy storage solutions.

The rise of hydrogen propulsion places unprecedented demands on materials, sealing, thermal stability and system integration. Lightweight structures must withstand pressure, vibration and thermal cycling while maintaining absolute dimensional integrity. Against this backdrop, Alpine’s Alpenglow Hy6 offers a compelling case study of how advanced composites and hybrid manufacturing can redefine what is technically feasible in hydrogen powertrain design.

At the centre of the project is a fully monolithic intake plenum and manifold system 3D printed by CRP Technology on behalf of Alpine. Manufactured in carbon fibre–reinforced thermoplastic Windform SP

using Selective Laser Sintering (SLS) and refined through CNC machining, the system demonstrates how additive manufacturing can move beyond prototyping into structurally critical engine components.

The Alpenglow Hy6 embodies Alpine’s vision of hydrogen-powered performance. As in any hydrogen combustion architecture, the intake system quickly emerged as a critical bottleneck; it must handle elevated pressures, temperature gradients and continuous vibration while preserving perfect sealing.

In the initial setup, the plenum and

manifolds were already 3D printed, but aluminium flanges were bonded to the parts to interface with the engine. During bench testing, Alpine engineers identified leakage and sealing issues at the glued joints, driven by the different thermal expansion coefficients of aluminium and the polymer composite, further aggravated by vibration and high thermal loads.

To address the challenge, Alpine engaged CRP Technology for a fast, robust solution capable of maintaining structural integrity under extreme conditions. CRP – also the manufacturer of the original components – proposed

a fully monolithic intake system produced again by SLS, using a single material throughout. Windform SP was selected once more for its high stiffness, mechanical strength and thermal resistance – key properties that made a monolithic architecture both feasible and reliable.

Only minor design adjustments were needed. The final system comprises three single-body components – one plenum and two manifolds – with flanges integrated directly into the Windform SP structure, eliminating aluminium parts. This redesign simplified assembly and ensured uniform material behaviour, delivering dimensional stability and consistent sealing performance even under high turbocharged pressure.

“Transforming the intake into a fully monolithic structure allowed us to stabilise the entire air-path architecture and remove the weak points inherent in multimaterial assemblies,” explains Franco Cevolini, CEO and CTO of CRP Technology and CRP Meccanica.

“With Windform SP and SLS, engineers can design around the behaviour of a single, predictable material – an essential advantage when dealing with the pressure pulses and thermal gradients of a hydrogen engine.”

The project also highlights the role of hybrid manufacturing workflows in next-generation powertrains.

After SLS manufacturing, the parts underwent vapor smoothing at CRP Technology, reducing surface porosity and improving the aerodynamic quality of internal channels, critical for optimising airflow. CRP Meccanica then carried out CNC finishing on the coupling interfaces, leveraging its high precision machining expertise within the CRP Group.

This additive-plus-subtractive workflow delivered tight dimensional accuracy and precise assembly fit, enabling the components to withstand repeated pressure cycles up to 5 bar during turbocharged operation. The result is a set of lightweight, geometrically complex components capable of operating reliably under the thermal and vibrational stresses typical

Final version of the two intake manifolds manufactured by CRP Technology using SLS in carbon fibre–filled composite Windform SP, with flanges directly integrated into the structure and monolithically 3D printed

of high-performance environments –without tooling, and with the agility needed for rapid iteration.

The monolithic intake was first validated on the engine dyno, where it demonstrated excellent sealing and mechanical stability under demanding thermal and pressure cycles. It was then installed on the Alpenglow Hy6 for on-track testing, confirming durability, resistance to pressure and heat, and overall performance.

From a development standpoint, the elimination of tooling significantly shortened the design-to-part cycle. “For experimental hydrogen programmes, the ability to iterate quickly without manufacturing constraints is crucial,” notes Cevolini. “That flexibility translates directly into faster development and more robust engineering decisions.”

Although developed for a highperformance concept, the lessons

Alpenglow Hy6. Image via Alpine Design

extend well beyond motorsport. As manufacturers evaluate hydrogen within broader e-powertrain strategies, components must address thermal management, sealing, weight reduction and packaging efficiency.

Additive manufacturing with advanced composites enables design driven by function rather than manufacturing constraints. The geometric freedom of SLS allows channels, mounting features and reinforcements to be integrated directly into a single component, reducing assembly complexity and eliminating weak interfaces. Windform SP is central to this shift: its fibre-reinforced structure delivers a balanced combination of stiffness, strength and thermal resistance, while compatibility with vapor smoothing and CNC machining ensures that additively manufactured parts meet the tight tolerances required in powertrain systems.

www.crptechnology.com

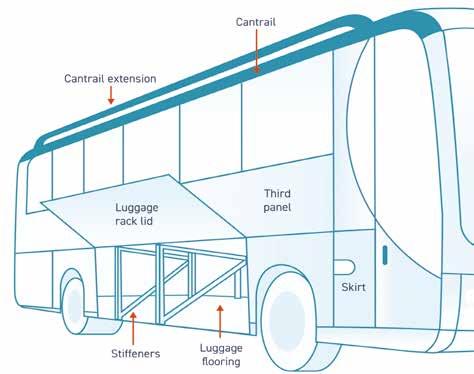

Exel Composite’s Patrick Loock discusses the role composite materials play in minimising weight and maximising fuel efficiency in electric buses

Government policies and investments are speeding up the evolution of zero-emission public transport. China, the world leader in electric bus adoption, has supported the deployment of more than 500,000 e-buses through a combination of subsidies, local manufacturing incentives, and stringent emissions targets.

Financial incentives and pricing strategies are also encouraging greater public transport use. In the United States, New York’s Metropolitan Transportation Authority (MTA) has introduced the OMNY contactless payment system, which automatically caps weekly fares after a certain number of trips. This system has made public transit more affordable and predictable for riders, while supporting efforts to expand zero-emission bus fleets in major US cities. Continued government support will be key to ensuring this trend is sustained.

Early electric buses performed poorly in terms of range, only offering 100-170km per charge, while diesel buses ran for 575km. However, advancements in battery technology, including improvements in energy density and charging speed, along with innovations in materials like composites, have improved operational efficiency. In September 2023, VDL Bus & Coach’s new-generation electric ‘Citea’ traveled 310 miles in 24 hours in the “MaxiMile Challenge.”

Composites play a crucial role in the construction of modern electric buses, whether it’s the roofs, body panels, side walls, skirt profiles, or luggage racks. Their durability and performance reduce maintenance requirements and add longevity to the overall vehicle lifetime. They can provide up to three times the tensile strength per unit weight, have low thermal conductivity, and a coefficient of thermal expansion

Composites play a crucial role in the construction of modern electric buses

of 0.1–0.5 x 10-6/°C, ensuring minimal dimensional change.

The ability to mould composites into complex shapes makes them ideal for bus construction. Advanced manufacturing techniques like pultrusion and continuous lamination enable the production of seamless parts. Composites side panel assembly, for example, is simplified by eliminating the need to join multiple metal panels.

Weight reduction plays a crucial role in e-bus design, as battery packs alone can add 1,350–2,300kg to a vehicle’s weight. Composites are key to achieving this without compromising strength and resilience. For example, fiberglass strikes a balance between durability, lifespan, and structural integrity, with some products offering up to 20% weight reduction compared to aluminium. Carbon fibre, with up to 40% weight reduction, is preferred for load-bearing applications, though it comes at a premium. Meanwhile, hybrid composites combining different types of fibre offer a cost-effective alternative, reducing weight by 20-40% while providing aluminium-like stiffness.

Aside from weight savings, composite materials are extremely corrosionresistant compared to metals. Unlike steel, which requires coatings like hot-dip galvanizing, composites eliminate the need for these kinds of treatments, reducing production costs. They are thus ideal for public transport, where longevity and affordability are essential. Composites reduce maintenance and downtime, improving service availability.

Composite materials used in electric bus manufacturing improve efficiency, extend the lifespan of vehicles, and facilitate sustainability. As demand for zero-emission public transport grows, the future of urban mobility will be shaped further by innovation in long-lasting, lightweight composites.

“Composites UK has been really important to us as a company over the last few years. It provides access to industry specific advice that an SME like us would struggle to source otherwise. Additionally, the networking opportunities give us a place to keep upto-date with industry developments.”

Lyndon Sanders, Director, Far-UK

Composites UK is the Trade Association for the UK composites industry.

Across the UK each member of Composites UK receives the opportunity to:

• Save money

• Save time

• Boost their impact

• Expand their network

• Secure their future

Capitalise on the growth of the Global composites market and join the expanding list of Composites UK member companies today.

“Our visibility across the composites community has not only increased since becoming members but also continues to allow us to deepen our knowledge about this innovative sector by working with our industry peers and specialists. Everyone at Composites UK is a pleasure to work with and we are looking forward to what is next in store.”

Julia Loeser, Sales and Marketing, DK Holdings

Donut Lab’s SSB announced at CES 2026

Solid-state batteries continue to be widely regarded as a critical next step in energy storage for electric vehicles and transport applications, promising higher energy density, improved safety and faster charging compared with today’s lithium-ion technology. While large-scale commercialisation remains challenging, a series of recent announcements from Europe, the UK and global OEMs indicate tangible progress across materials development, pilot manufacturing and early vehicle deployment.

A major European milestone was announced in January 2026 with the launch of Argylium, a new company formed by Syensqo and Axens to accelerate the industrialisation of advanced solid-state battery materials. Based on Syensqo’s pilotscale work, Argylium will focus on scaling next-generation sulfide solid electrolytes for all-solid-state batteries (ASSB), strengthening Europe’s position in a field currently dominated by Asian manufacturers.

The new venture builds on Syensqo’s successful solid-state battery pilot line in La Rochelle and more than a decade of research conducted at its Aubervilliers laboratory near Paris. Axens brings industrial process design and large-scale manufacturing expertise, while IFP Energies nouvelles (IFPEN) contributes specialist knowledge in inorganic chemistry and divided materials from its Lyon research centre.

“The creation of Argylium represents an important step forward in bringing solid-state battery materials to market readiness,” says Thomas Canova, head of R&I at Syensqo. “By joining forces with Axens and IFPEN, we are enhancing the chances of successfully scaling up Syensqo’s pilot innovations and contributing to advance Europe’s electrification and energy storage ambitions.”

Axens frames the partnership as part of a broader industrial strategy. Fabrice Bertoncini, Axens Group’s executive vice president in new development and transformation, says: “With over 50 years experience

in scaling up technologies to the commercial levels, in partnership with IFPEN and aligned with our strategy to develop industrial assets in Europe for the production of advanced battery materials for cathodes (CAM) and recycling of Black Mass, our association with Syensqo aims to lay the groundwork and build a robust ecosystem for the commercialization of solid electrolytes by 2030.”

Alongside materials development, progress is also being made at the cell level. UK-based solid-state battery developer Ilika has begun shipping 10Ah solid-state battery prototypes to automotive and industrial customers, representing a five-fold increase in capacity compared with its earlier 2Ah P1 cells delivered in mid-2024. The new Goliath cells are produced on an automated pilot line completed in October 2025 and incorporate a proprietary oxide coating designed to improve safety.

According to analysis by automotive consultancy Balance Batteries, Ilika’s technology could reduce

EV battery pack weight by 20% and cut manufacturing costs by approximately £2,500 per vehicle. Early manufacturing results from the pilot line are encouraging, with a 93% yield rate achieved in the initial production batch.

“We are excited that our new automated pilot line is now producing high-quality, consistent battery prototypes for our partners to evaluate,” says Graeme Purdy, CEO of Ilika. “This achievement is a significant milestone toward bringing our technology to market, further opening the window for licensing discussions with manufacturers.”

Ilika has also produced early samples of larger 50Ah P2 cells for internal testing, with customer shipments expected to follow once feedback from the current prototypes is received during 2026. Industry interest appears strong, with a senior battery development executive at a major UK automotive supplier stating: “Here in the UK and more broadly in Europe, there is significant interest in developing technical solutions that are differentiated from the offerings available from established cell manufacturers,” adds Purdy. “We look forward to evaluating these 10Ah prototypes from Ilika, which demonstrate the company’s sustained capability to improve and mature their product for commercial roll-out.”

Beyond Europe, solid-state batteries are beginning to appear in real-world transport applications. At CES 2026, Donut Lab revealed an all-solid-state battery designed for EVs, claiming an energy density of 400Wh/kg, the

Ilika’s Goliath SSB

ability to recharge to full capacity in five minutes, and minimal capacity fade over a tested lifetime of 100,000 cycles across temperatures ranging from –30°C to above 100°C.

The first production application will be in Verge Motorcycles’ TS Pro and TS Ultra models, which are scheduled to reach customers in the first quarter of 2026. Donut Lab CEO Marko Lehtimäki says: “Our answer on solid-state batteries being ready for use in OEM production vehicles is now, today, not later. Donut Lab has engineered a new high performance solid-state Donut Battery that can be scaled to major production volumes and seen now in real world use in the Verge Motorcycles bikes out on the road in Q1.”

While all-solid-state batteries remain rare in production vehicles, semi-solid-state technologies are already entering the market, particularly in China. Manufacturers

Argylium builds on Syensqo’s successful solid-state battery pilot line

including Nio, SAIC-owned IM Motors, MG Motor and Dongfeng are deploying batteries with gellike electrolytes that bridge the gap between conventional lithium-ion and fully solid-state designs. These systems offer higher energy density and faster charging, albeit without the full safety and durability benefits of true solid electrolytes.

Western OEMs are also advancing pilot and demonstration programmes. Stellantis and Mercedes-Benz are testing semi-solid-state cells supplied by Factorial Energy, while BMW has begun evaluating all-solid-state prismatic cells from Solid Power. Toyota, Honda, Nissan, Volkswagen Group and Hyundai-Kia all maintain active solidstate development programs, with most targeting limited production toward the end of the decade.

Despite the growing momentum, large-scale deployment will take time. BloombergNEF projects that solidstate batteries will account for around 10% of global EV and stationary storage demand by 2035, with early adoption concentrated in premium or performance-focused vehicles. Nevertheless, recent developments - from European electrolyte scaleup and UK pilot manufacturing to motorcycles using all-solid-state packs - suggest that solid-state batteries are steadily transitioning from laboratory promise to transportready technology.

Ford has outlined a significant technology roadmap that links affordable electric vehicles with higher levels of automated driving, artificial intelligence integration and a new centralised electronic architecture. Announced at CES 2026, the strategy centres on the company’s forthcoming Universal Electric Vehicle (UEV) platform, which is set to debut in a $30,000 electric pickup truck and later support eyes-off highway driving by 2028.

The most notable development is Ford’s plan to evolve its existing BlueCruise system from hands-free to eyes-off operation. Today, BlueCruise enables hands-free driving on more than 130,000 miles of mapped highways, provided the driver remains attentive and ready to intervene. The next-generation version is intended to meet SAE Level 3 criteria in defined conditions, allowing drivers to disengage visual attention while the system manages the driving task.

Crucially for the transport sector, Ford is positioning this capability not as a premium feature limited to high-end vehicles, but as part of a mass-market EV strategy. The UEV platform has been designed from a clean sheet to reduce cost and complexity, enabling advanced driver-assistance features to be deployed on lower-priced vehicles. This contrasts with several competitors, whose Level 3-capable systems are currently restricted to luxury models with price points well above six figures.

Ford has not yet disclosed technical details about the sensor suite that will underpin eyes-off BlueCruise. It remains unclear whether lidar will be incorporated alongside cameras and radar, although the company has indicated that its ownership of the end-to-end sensing and software stack provides flexibility as the technology evolves. Advances in lidar cost and packaging may influence

Ford announced a new strategy for its UEV platform at CES 2026

future system configurations, particularly as regulatory frameworks for Level 3 automation mature in the United States and other markets.

The push toward higher automation aligns Ford with a broader industry trend. Mercedes-Benz currently offers a limited Level 3 system in the US, while several Chinese manufacturers have announced similar timelines targeting 2028. Ford’s approach differs primarily in its emphasis on affordability and scale, leveraging a unified vehicle platform to spread development costs across high-volume models.

Beyond automated driving, the UEV platform introduces a new in-housedeveloped electronic architecture built around a High Performance Computer Centre. This zonal architecture consolidates infotainment, automated driving functions, audio and connectivity into a single, compact computing unit. By reducing the number of discrete control modules, Ford aims to lower production costs, simplify software updates and improve long-term system reliability. For commercial and fleet operators, this could translate into vehicles that gain functionality over time through software improvements rather than

hardware changes.

Artificial intelligence also plays a growing role in Ford’s vehicle ecosystem. The company is integrating AI-driven assistants into both its vehicles and mobile applications, allowing functionality to move seamlessly between the driver’s phone and the vehicle. Unlike generalpurpose AI tools, Ford’s system is designed to use vehicle-specific data, enabling practical use cases such as load and cargo-fit assessment for pickup trucks.

While detailed specifications of the $30,000 electric truck have yet to be released, Ford has positioned it as a cornerstone product for competing with fast-moving Chinese EV manufacturers on cost, software capability and development speed. The combination of a low-cost EV platform, centralised computing and a clear path to Level 3 automation underscores Ford’s effort to redefine value in electric and automated vehicles.

As regulatory, technical and infrastructure challenges remain, Ford’s announcements suggest a long-term commitment to integrating advanced powertrain, computing and automation technologies into mainstream transport vehicles rather than reserving them for niche or luxury segments.

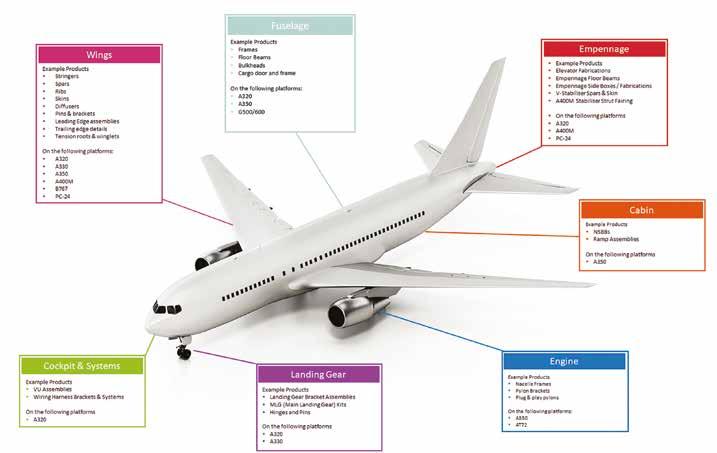

With parts flying on nearly every major commercial aircraft, Gardner’s operations span Europe and Asia and support all major OEM platforms

Philipp Visotschnig, CEO at Gardner Aerospace

Gardner Aerospace’s Philipp Visotschnig discusses supply chain transformation as a cornerstone of sustainable aviation

Addressing a professional audience from across the transport and aerospace sectors at Advanced Engineering, Philipp Visotschnig, CEO at Gardner Aerospace, set out a supplier-led perspective on aviation’s sustainability challenge, arguing that the next phase of aviation’s evolution will be determined as much by manufacturing, materials and data as by aircraft and engines.

“We don’t build the aircraft. We build the parts that make flight possible with precision, reliability and partnership,” Visotschnig said,

positioning Gardner Aerospace as a representative example of the deeply embedded global supply chain that underpins commercial aviation.

With parts flying on nearly every major commercial aircraft, Gardner’s operations span Europe and Asia and support all major OEM platforms.

Visotschnig framed aviation’s development as four historic phases.

“Since the Wright Brothers made their first flight in 1903 there have been four great steps in history of aviation,” he said, moving from making aircraft fly, to making them safe, then accessible, and now sustainable. “Now

we are entering step four, perhaps the most demanding of all, make flight sustainable.”

Today’s aviation supply chain is vast and highly interconnected. Nearly five billion passengers fly annually on around 25,000 commercial aircraft operated by more than 100 airlines. Manufacturing is concentrated around Airbus and Boeing, supported by a small number of engine and systems suppliers and more than 1,000 parts and service suppliers. “An aircraft is one of the most complex

products ever built,” Visotschnig said, highlighting the fragility of a system where a single out-of-tolerance component can disrupt an entire production line.

While aviation delivers undeniable economic and social benefits, it is also energy and material-intensive. Visotschnig emphasised that, “emissions are the problem, not aviation itself,” and argued that sustainability efforts must focus on improving the system rather than constraining it. Although the majority of lifecycle emissions occur during aircraft operation, the supply chain typically accounts for between 2% and 5% of total emissions. With more than 1,000 large commercial aircraft produced each year, this represents millions of tonnes of CO2 annually.

Gardner Aerospace’s own scale illustrates both the challenge and the opportunity. The company employs around 2,000 people across nine sites, producing more than 20,000 part numbers and delivering over two million parts per year. Visotschnig described an ongoing digital and operational transformation, stating: “For us, sustainability is not a project beside the business. It is how we run the business.”

The aviation industry’s commitment to net zero by 2050 relies on three primary levers: more efficient aircraft, large-scale adoption of sustainable aviation fuel, and lighter, more efficient materials. Suppliers play a direct role in all three. Gardner Aerospace is supporting Airbus’s “Wing of Tomorrow” programme by manufacturing prototype components for next-generation lightweight wing structures. “It’s a concrete example of how suppliers, even suppliers beyond the tier one level, can play a role in advancing sustainability,” Visotschnig said.

He noted a broader shift in industry expectations. “Sustainability used to be a box ticking exercises, another audit, another report, that mindset is obsolete,” he said. Environmental performance is now a competitive metric, embedded in tenders and long-term agreements alongside cost, quality and delivery.

Gardner Aerospace structures its sustainability strategy around three pillars: cleaner operations, smarter products and digitalised processes, and collaboration across the value chain. Energy use is the largest contributor to operational emissions. Four of the company’s nine sites are already largely solar powered, with a rollout plan for the remainder. Smart energy management systems automatically power down idle equipment. “Despite a major production ramp up over the past few years, we have reduced our overall energy consumption by about 15%,” Visotschnig said.

Material efficiency is another focus. Aerospace machining typically removes large volumes of material, but Gardner’s aluminium recycling rate exceeds 98%. The company is now working with Airbus to create a closed-loop recycling system where scrap is remelted and recertified for aerospace use, delivering up to 95% carbon savings compared with primary aluminium production. “That’s circularity in action, and it’s happening today,” Visotschnig said.

Surface treatments are also evolving. Gardner has transitioned serial production to chromate-free processes, reducing chromate usage by 80% over the past decade. While technically complex, Visotschnig described the transition as irreversible.

Digitalisation underpins the second pillar. “You can’t manage what you

don’t measure,” he said. By linking planning, machining, inspection and logistics, Gardner is creating a digital thread for every part, capturing process data and energy footprint. Future ambitions include verified carbon labels on individual components and real-time monitoring of sustainability metrics alongside traditional manufacturing KPIs.

The third pillar is collaboration. “Sustainability will only work if we align our flight path, not compete for altitude,” Visotschnig said, calling for standardised metrics, harmonised reporting and aligned incentives across OEMs, suppliers and regulators. He warned that administrative burdens risk slowing progress, particularly for smaller suppliers. Finally, Visotschnig emphasised the human dimension. “No machine saves energy on its own. No process reduces waste without human insight and action,” he said. Gardner is embedding sustainability into training at all levels, empowering shop floor operators to drive continuous improvement. “That’s how sustainability evolves from compliance to culture, and culture is what keeps progress alive long after the project ends.”

Looking ahead to 2035, Visotschnig outlined a vision of fully renewablepowered sites, closed-loop materials, low-carbon logistics and a workforce proud of its environmental stewardship. “That’s not a dream. It’s perfectly achievable,” he concluded, framing sustainability as the defining challenge of aviation’s fourth great era.

Petards Rail discusses how AI and smart monitoring are improving safety and efficiency in the rail sector

The UK rail industry is experiencing a technological transformation as artificial intelligence and smart monitoring systems deliver measurable improvements in safety, efficiency and passenger experience. Network Rail’s Intelligent Infrastructure programme, which collects data from over 30,000 sensors across the network, has addressed a critical challenge that historically cost the sector 341 days of delays per year between 2019 and 2023 due to track issues alone.

“Up to maybe five years ago, the only way we could prevent track failures was by foot inspections,” explains Nick Kotsis, chief data & analytics officer at Network Rail. “Engineers had to walk on the track to identify possible cracks and defects.”

Today, high-definition cameras, LiDAR scanners and vibration monitors feed data into AI systems that identify degradation in tracks, signalling and electrical systems, sometimes generating alerts up to 365 days before a fault develops. Petards Rail, a leader in intelligent train technology, has released a new whitepaper looking at how AI and smart monitoring are impacting the rail sector.

The economic and environmental benefits are substantial. Predictive maintenance systems have enabled some European rail operators to achieve 25% cost savings through reduced downtime, whilst AIoptimised driving advice has delivered energy savings of 10-15%.

“Innovation has always been critically important in the rail industry. And now more than ever, it’s key to addressing the challenges ahead, from climate change to increased demand,” says David Muse, chief technical architect at Petards Rail, a leader in

intelligent train technology.

The technology is also enhancing safety, with onboard obstacle detection systems using thermal cameras and machine learning identifying hazards such as fallen trees or vehicles on tracks up to 1,000 metres away.

At London Waterloo, LiDAR and AI crowd-monitoring systems have been trialled to detect congestion and alert staff before safety risks emerge. Meanwhile, automatic passenger counting systems achieving 98% accuracy are helping operators tailor timetables and provide realtime information to manage busy schedules.

The UK government has invested £58 million in AI and rail innovations through programmes including First of a Kind, funding 179 projects covering AI-based crowd monitoring, predictive maintenance and energy optimisation. Industry estimates suggest AI-based predictive maintenance could reduce train breakdowns by 30%, whilst AI optimisation of ticketing and pricing could boost revenues by 3-8%.

David Muse, chief technical architect at Petards

Across the EU, Europe’s Rail Joint Undertaking is funding projects including DAYDREAMS, My-TRAC and SMART, which demonstrate AI’s benefits in predictive maintenance, passenger engagement and safety. According to the whitepaper, there are three key benefits of getting a digitalised railway system in place:

• Digital transformation will improve the passenger experience across the network

• Digital transformation will increase how efficient the sector is

• Digital transformation will modernise and optimise rail operations

“AI is not replacing rail professionals, it’s empowering them with better tools to deliver safer, more reliable and more efficient services,” adds Muse.

As rail networks face growing pressure from rising passenger volumes and evolving safety expectations, AI and smart monitoring are positioning the sector to meet these challenges whilst delivering improved service reliability and reduced operational costs. Further information can be found in Petard’s whitepaper.

Assessing the latest developments in autonomous transport technologies

Autonomous transport technologies moved decisively from concept to implementation at CES 2026, as vehicle manufacturers, technology suppliers and mobility providers showcased systems already operating in real-world environments. Announcements from Karsan, Texas Instruments (TI) and the Volkswagen Group illustrated how autonomy is advancing simultaneously at the vehicle, semiconductor and data ecosystem levels, with a shared emphasis on safety, scalability and regulatory readiness.

Public transport specialist Karsan used CES 2026 to underline that autonomous mobility is no longer confined to pilot projects. The company presented next-generation autonomous vehicles already operating in live service and formally introduced its Karsan AI (Autonomous Intelligence) vision.

Defining this approach, Karsan CEO Okan Baş said: “Karsan AI is positioned as a mobility intelligence that perceives, makes instant decisions

and continuously learns. The future is not only electric, but also intelligent. This approach reveals Karsan’s vision of not only producing zero-emission vehicles, but also designing the future of cities through autonomous and intelligent transportation solutions.”

Karsan positioned its autonomy strategy as a natural evolution from electrification to smart mobility, emphasising end-to-end system integration and long-term partnerships. According to Baş, “The secret to Karsan’s autonomous success lies in strong partnerships and an endto-end solution approach.”

Operational pressures are accelerating adoption. “The difficulty of finding drivers and increasing operational costs worldwide are pushing cities towards autonomous solutions,” Baş said. He added that Karsan’s focus remains on regulationaligned deployment: “We are managing this transformation in a manner that is compliant with regulations, safe and sustainable. Our goal is to implement truly driverless public transport systems where the safety driver is completely eliminated, in parallel with the development of regulations.”

Karsan used CES to reinforce its broader message that autonomy must deliver tangible benefits. “The mobility of the future will not only be electric; it

will also be intelligent, autonomous and add real value to human life,” Baş said.

At the component level, Texas Instruments highlighted how advances in automotive semiconductors are enabling more capable autonomous systems across a wider range of vehicles. TI introduced new high-performance computing system-on-chip (SoC) devices, radar sensors and in-vehicle networking technologies designed to support up to SAE Level 3 autonomy.

“The automotive industry is moving toward a future where driving doesn’t require hands on the wheel,” said Mark Ng, director of automotive systems at TI. “Semiconductors are at the heart of bringing this vision of safer, smarter and more autonomous driving experiences to every vehicle.”

Central to this strategy is TI’s scalable TDA5 SoC family, delivering AI performance from 10 to 1200 TOPS with power efficiency beyond 24 TOPS/W. The devices integrate the latest generation C7 neural processing unit and Arm Cortex-A720AE cores, supporting sensor fusion, AI decisionmaking and cross-domain integration within a single chip. According to TI, this architecture reduces system complexity while helping automakers meet Automotive Safety Integrity Level D requirements.

Radar capability was another focus, with the launch of the AWR2188 eight-by-eight 4D imaging radar transceiver. By integrating eight transmitters and eight receivers on a single chip, the device simplifies high-resolution radar design while improving detection performance. TI stated that the transceiver enables object detection beyond 350 metres and supports advanced use cases such as identifying closely spaced vehicles and detecting lost cargo.

Vehicle networking is also evolving to support autonomy. TI’s DP83TD555J-Q1 10BASE-T1S Ethernet PHY extends Ethernet to vehicle edge nodes, enabling unified, timesynchronised data exchange with reduced wiring complexity. Together, TI described these technologies as an end-to-end system approach supporting higher automation levels

across entry-level to premium vehicles.

While hardware and vehicle platforms advance, data-driven learning is becoming increasingly central to autonomous system performance. The Volkswagen Group announced plans to expand its use of anonymised sensor and image data from customer vehicles across around 40 European countries starting in January 2026.

The objective is to continuously optimise driver assistance systems and automated driving functions using real traffic scenarios rather than simulations alone. According to the Group, customers will benefit through software updates that enhance comfort and safety, with customer consent described as a “fundamental prerequisite” and data use governed by national and European regulations.

Volkswagen’s existing fleet already contributes to safety improvements through anonymised swarm data used to generate high-resolution maps, enabling lane guidance on roads without markings and refined hazard alerts. Engineers now aim to deepen this approach by analysing specific scenarios where assistance systems are most critical, such as interactions with pedestrians and cyclists or complex parking environments.

Data transmission is event-based rather than continuous and can be triggered by emergency braking, full manual braking or sudden evasive manoeuvres. Relevant inputs include camera images, sensor detection results, vehicle dynamics data and environmental conditions. The Group emphasised that individual identification of people is not relevant and that consent can be revoked at any time.

Taken together, the announcements at CES 2026 demonstrate how autonomous transport is progressing through parallel developments in vehicles, electronics and data ecosystems. The technology’s deployable capability is increasing, built on proven technology, regulatory alignment and continuous learning from real traffic conditions.

To ensure and expand sustainable mobility solutions, the transport of passengers and cargo requires high-performing, seamlessly integrated monitoring and control systems. High-capacity transportation assets can be maximised through automated 24/7 sensor supervision, real-time analyses and predictive maintenance alerts and actions.

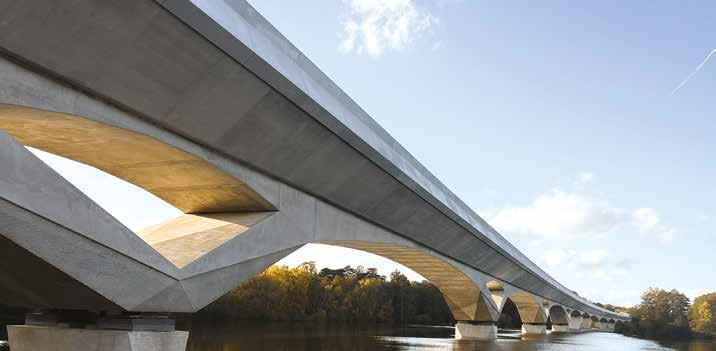

One such example is a large rail viaduct in the UK that was just completed to form a critical component of the new HS2 highspeed rail programme. To help ensure its smooth, safe and stable operation, ASC supplied specially configured servo-balanced quartz accelerometers for integration in the bridge. Specially developed and evaluated for this industry partnership, the ASC QBA series is now available for broad application. It helps infrastructure operators strengthen the safety and proactive maintenance of critical infrastructure while achieving gains in traffic volumes, efficiencies and cost savings for railway companies.

The 2.1 mile, gently curving viaduct was built in an area of diverse landscapes. It stretches over a series of lakes, waterways and reservoirs, open green spaces and parks – an intensely frequented public area. As part of a high-speed rail line putting considerable strain on the structure, therefore, precision instrumentation and constant monitoring are of essence. To that end, the bridge operator decided to integrate highperformance, servo-balanced quartz accelerometers at defined measuring points in the deck segments and noise barriers of the bridge to ensure seamless, safe operation under extreme stress loads.

“When StrainSense Limited, our distribution partner for the UK and Ireland, received the request to

provide high-precision sensors based on quartz technology, they spoke to us,” says Renate Bay, managing director of ASC Sensors. “To meet the brief, our team immediately went about customising our quartz-based accelerometers to provide effective help in the structure’s monitoring and sound barrier deflection. In mid-2025, we delivered the first batch of sensors for the project.”

Close collaboration between the two sensor specialists and the customer drove technical excellence. What

resulted was the customisable ASC QBA series: uniaxial quartz accelerometers specially designed for highest precision in structural health monitoring, configured to the needs of rail infrastructure operators and civil engineering at large.

ASC QBA series accelerometers are now readily available in verticalmounted, uniaxial VX, VY or VZ sensitive directions. Based on proven, high-performance servo-balanced quartz sensing elements, they feature a measurement range of ±30g. A resolution of better than 1μg enables the detection of even the smallest vibrations. They offer outstanding long-term stability of the scale

The ASC QBA series accelerometer

from close customer

factor (K1: 1200ppm) and bias (K0: 1200μg), too. On demand, biaxial and triaxial accelerometers as well as smaller measuring ranges down to ±1g are available.

ASC’s robust QBA series can be adapted to fit application-specific housing of protection class IP67. The upgraded electronic circuitry utilises flexible power supply of 9-36VDC and a 4-20mA analogue current output for reliable data transmission. The sensors have been developed to provide high accuracy and long-term stability in applications across the world. At operating temperatures from -40°C to +70°C, they can be leveraged from the arctic circles to the world’s deserts almost without exception.

Like most of its flexible range of inertial sensors, ASC can adapt its QBA sensors to include tailormade biaxial and triaxial accelerometers. Also feasible, on demand, are even smaller measuring ranges of up to ±1g as well as an optional voltage output signal. They can be equipped with a customer-specific connecting cable.

Beyond bridge monitoring and civil engineering, ASC QBA accelerometers can help solve a wide range of further high-end measurement, monitoring and navigation challenges. These include train vibration and tilt control

applications, conveying systems, seismic detection, automotive testing or navigation systems in the aviation and aerospace industries.

“We’re proud to be supporting highspeed railway, a key step towards a sustainable future of transport and mobility,” Bay says. “As with the UK high-speed rail infrastructure operator, we’ll collaborate closely with you to adapt our cutting-edge sensor technology to unique specs and business needs.”

“At ASC, leapfrog sensor innovation typically comes from close customer collaboration,” Bay adds. “The best ideas usually emerge from bringing diverse perspectives to a tough problem – often something no one ever tried solving before.” ASC will then tailor a solution. However, it is even better when those innovations become accessible to others in the market, too. “Our rapidly growing world needs strong transport and mobility options. The ASC team partners with pioneering organisations and businesses around the globe to create those.”

Johnson Matthey (JM) has officially opened its first dedicated hydrogen internal combustion engine (H2ICE) testing facility, marking a significant milestone in the development of low- and zero-carbon propulsion technologies for medium- and heavyduty transport. The new centre of excellence, located at JM’s existing Gothenburg site in Sweden, is designed to evaluate advanced emission control and after-treatment systems for hydrogen-fuelled internal combustion engines operating at full scale.

H2ICE technology uses zero-carbon hydrogen fuel in conventional internal combustion engine architectures, offering a pragmatic decarbonisation pathway for applications such as trucks, buses and off-highway vehicles where energy density, durability and refuelling speed remain critical. By combining familiar engine platforms with hydrogen combustion, the technology enables manufacturers and fleet operators to leverage existing supply chains while reducing lifecycle carbon emissions.

The Gothenburg facility was first announced in July 2025 and has now been completed on time and on budget following a £2.5 million investment spread over three years. The official opening was performed by Damien Sotty, JM R&D director, Daniel Sandqvist, Gothenburg test centre manager, and Jonas Edvardsson, managing director JM Gothenburg. The investment significantly expands JM’s heavy-duty testing capability by enabling full-engine H2ICE testing for the first time, rather than componentlevel evaluation alone.

This expanded capability supports the rapid evolution of both global regulatory frameworks and customer demand for cleaner transport solutions.

It also reflects growing industry interest in hydrogen combustion as a complementary technology to fuel cells and battery-electric powertrains, particularly in high-power and longduty-cycle applications.

“This investment shows JM is backing H2ICE as a ready-to-go technology that will enable mobility partners to meet their decarbonisation and climate goals,” says Tauseef Salma, JM chief technology officer in clean air. “Our state-of-the-art Gothenburg facility positions JM as a world leader in sustainable technology solutions, transforming energy and reducing carbon emissions.”

The new installation is capable of supporting hydrogen internal combustion engines rated up to 600kW (800hp). Testing will focus on catalyst performance within complete exhaust after-treatment and engine control systems, generating data critical to improving efficiency, emissions compliance and durability. The Gothenburg site already hosts medium- and heavy-duty diesel engine test cells, allowing direct comparison between conventional and hydrogenfuelled combustion technologies.

The facility includes an on-site hydrogen supply and storage area equipped with a compressor and intermediate storage tank, with hydrogen storage capability up to 413 bar. It is also fitted with hydrogen flow meters and analysers, comprehensive exhaust measurement instrumentation,

and the full range of control, sensing and safety systems required for highpressure hydrogen operation.

The H2ICE investment builds on JM’s earlier collaboration with Cummins and technology partners PHINIA and Zircotec through Project Brunel. Launched in November 2021 and successfully concluded in March 2025, the project delivered proof points demonstrating significant improvements in hydrogen engine performance and durability, helping to de-risk the technology for commercial deployment.

Salma adds: “For more than two centuries, JM has helped tackle some of the world’s biggest challenges. We continue to do so today because it’s in our DNA. The opening of this new testing facility shows our commitment to strategic partnerships to drive innovation, strengthening the potential of H2ICE as a net zero pathway for commercial vehicles.”

Beyond its own R&D activities, JM is also a founding member of the Global Hydrogen Mobility Alliance, which brings together more than 30 automotive, energy and technology companies. The alliance is actively urging EU policymakers to recognise hydrogen mobility, including hydrogen internal combustion engines, as a core pillar of Europe’s transport decarbonisation and industrial strategy.

•

•

•

•

Bressner Technology introduces new ultra-rugged edge AI systems for mission-critical applications

The SEMIL-2200 and SEMIL-2200GC series edge AI computers

Bressner Technology, a system integrator and value-added distributor of industrial hardware solutions, has announced the availability of the new SEMIL-2200 and SEMIL-2200GC series from its long-term partner Neousys Technology. Designed for the most demanding defense and security environments, the fully sealed MIL-

STD-certified edge AI computers combine high computing performance with uncompromising reliability and durability under extreme conditions.

The new SEMIL series sets a benchmark in rugged edge computing. Both systems are certified to MIL-STD-461G, MIL-

STD-1275D, and MIL-STD-810H, ensuring dependable operation across land, sea, and vehicle-based deployments.

• MIL-STD-461G: Electromagnetic compatibility for ground applications

• MIL-STD-1275D: Reliable power regulation for vehicle and mobile use

• MIL-STD-810H: Proven resistance to shock, vibration, and extreme temperatures

With

the introduction of the SEMIL-2200 and SEMIL-2200GC, Bressner Technology expands its rugged computing portfolio for customers operating in mission-critical environments

The computers feature a fanless, fully sealed IP69K-rated enclosure, capable of continuous 24/7 operation even under high-pressure cleaning or heavy dust exposure. A patented thermal design enables wide-temperature operation from −40°C to +70°C, with sustained GPU performance up to 58 °C before thermal throttling.