Tips for Getting the Most Out of Your DMM

these practical steps to get correct readings from your digital multimeter every time. Read more on pg. 34

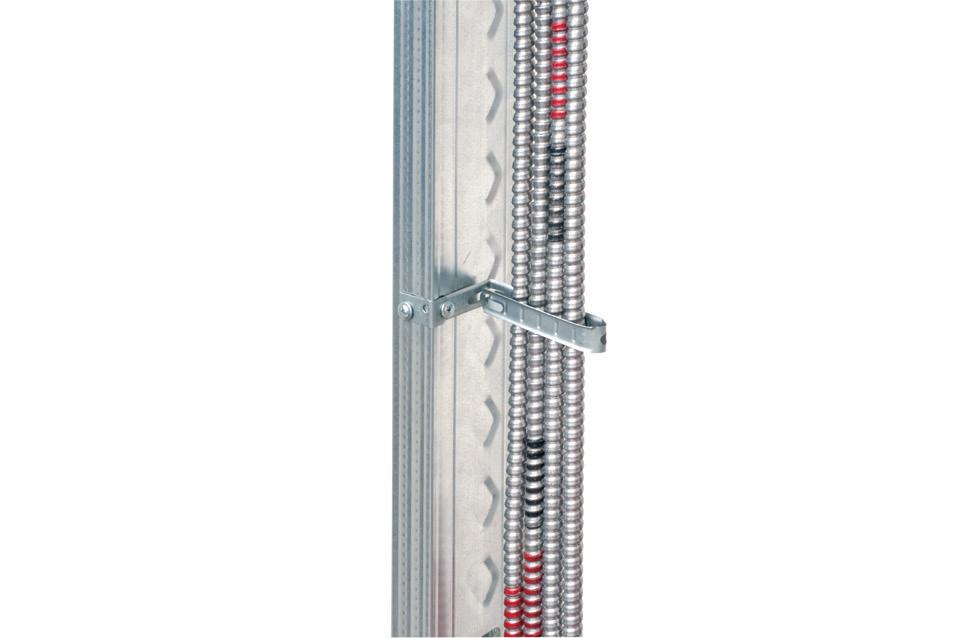

FLEX YOUR SAVINGS with Liquid-Tuff™ Custom Cuts

Discover the ultimate solution for your repetitive job needs with Liquid-Tuff™ Custom Cuts from Atkore. Factory-cut and deburred conduits that simplify installation, reduce time spent on each job, and maximize schedule certainty, especially for large repetitive quantities of 500 pieces or more.

From homes to prison cells, the modular and panelized construction market is booming. Here’s how it differs in building design, job-site workflow, and

ECMWEB.COM

With its exclusive online content, ecmweb.com is a valuable source of industry insight for electrical professionals. Here’s a sample of what you can find on our site right now:

SHOULD NOT ABANDON NATIONAL ELECTRICAL SAFETY REQUIREMENTS

National Electrical Code Todd Sims from NEMA explains why the path to making new homes more affordable should not come at the expense of eliminating electrical safety requirements. ecmweb.com/55270514

EC&M ON AIR — THE MOST MEMORABLE EC&M CONTENT OF 2024 WITH THE EC&M EDITORS

Podcast The EC&M editors discuss our readers’ most popular articles, videos, podcasts, and social media posts from last year. ecmweb.com/55270396

FEDERAL PROJECT LABOR AGREEMENT MANDATE AT RISK Construction In this Members Only article, Tom Zind looks at a recent court ruling that telegraphs an end to the year-old project labor agreement (PLA) requirement. ecmweb.com/55270123

Editorial

Group Editorial Director - Buildings & Construction: Michael Eby, meby@endeavorb2b.com

Editor-in-Chief: Ellen Parson, eparson@endeavorb2b.com

Managing Editor: Ellie Coggins, ecoggins@endeavorb2b.com

Editor: Michael Morris, mmorris@endeavorb2b.com

Art Director: David Eckhart, deckhart@endeavorb2b.com

Consultants and Contributors

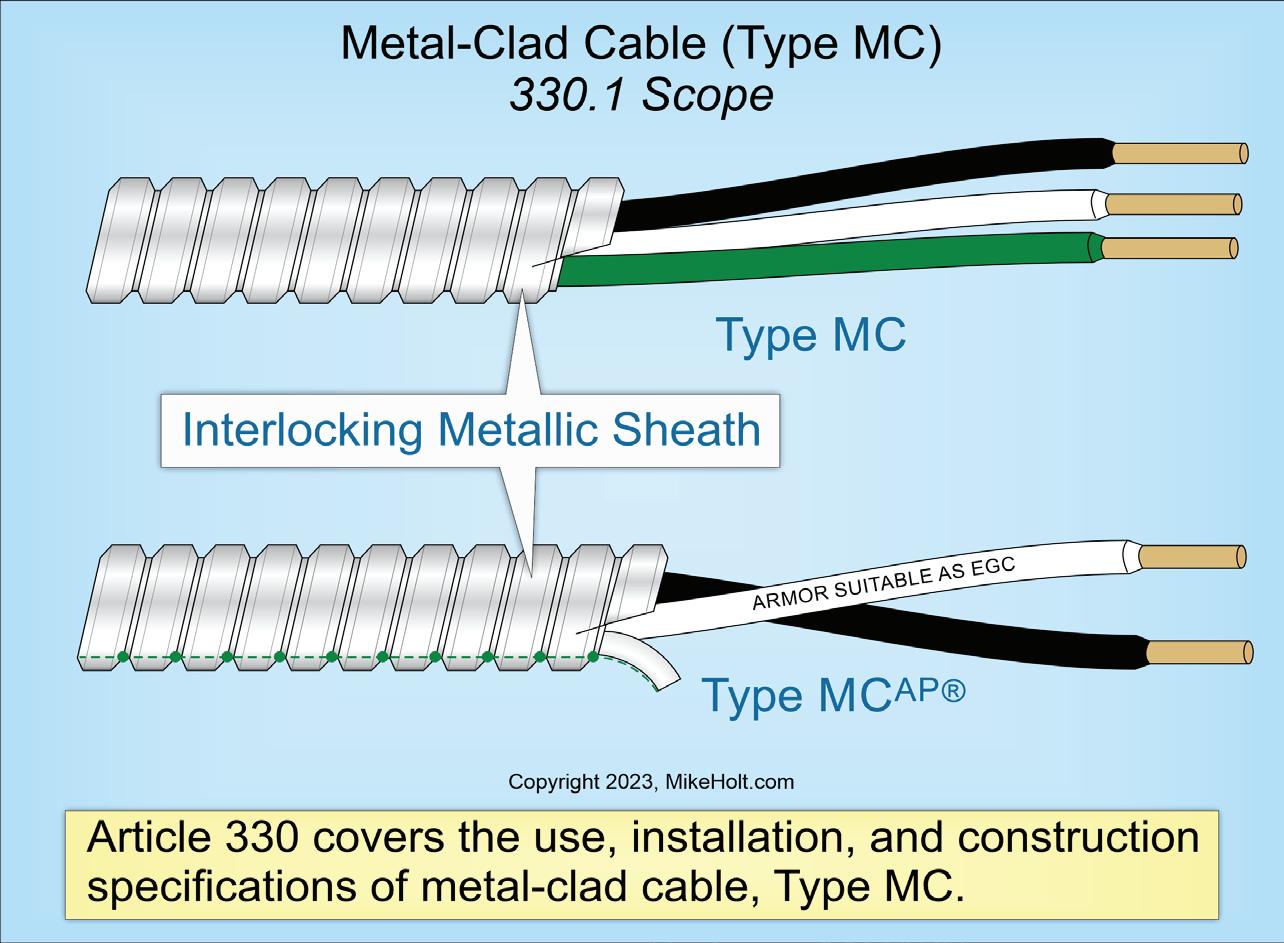

NEC Consultant: Mike Holt, mike@mikeholt.com

NEC Consultant: Russ LeBlanc, russ@russleblanc.net

Sales and Marketing

VP/Market Leader - Buildings & Construction: Mike Hellmann, mhellmann@endeavorb2b.com

Regional/Territory Account Manager: David Sevin, dsevin@endeavorb2b.com

Regional/Territory Account Manager: Jay Thompson, jthompson@endeavorb2b.com

Regional/Territory Key Account Manager: Ellyn Fishman, efishman@endeavorb2b.com

Media Account Executive – Classifieds/Inside Sales: Steve Suarez, ssuarez@endeavorb2b.com

Production and Circulation

Production Manager: Josh Troutman, jtroutman@endeavorb2b.com

Ad Services Manager: Deanna O’Byrne, dobyrne@endeavorb2b.com

User Marketing Manager: James Marinaccio, jmarinaccio@endeavorb2b.com

Endeavor Business Media, LLC

CEO: Chris Ferrell

CDO: Jacquie Niemiec

COO: Patrick Rains CRO: Paul Andrews

CMO: Amanda Landsaw CALO: Tracy Kane

EVP, Group Publisher – Buildings, Energy & Water: Mike Christian

Electrical Construction & Maintenance (USPS Permit 499-790, ISSN 1082-295X print, ISSN 2771-6384 online) is published monthly by Endeavor Business Media, LLC. 201 N. Main St 5th Floor, Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI, and additional mailing offices. POSTMASTER: Send address changes to Electrical Construction & Maintenance, PO Box 3257, Northbrook, IL 60065-3257. SUBSCRIPTIONS: Publisher reserves the right to reject non-qualified subscriptions. Subscription prices: U.S. ($68.75 year); Canada/Mexico ($ 112.50); All other countries ($162.50). All subscriptions are payable in U.S. funds. Send subscription inquiries to Electrical Construction & Maintenance, PO Box 3257, Northbrook, IL 60065-3257. Customer service can be reached toll-free at 877-382-9187 or at electricalconstmaint@omeda.com for magazine subscription assistance or questions.

Printed in the USA. Copyright 2025 Endeavor Business Media, LLC. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopies, recordings, or any information storage or retrieval system without permission from the publisher. Endeavor Business Media, LLC does not assume and hereby disclaims any liability to any person or company for any loss or damage caused by errors or omissions in the material herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever. The views and opinions in the articles herein are not to be taken as official expressions of the publishers, unless so stated. The publishers do not warrant either expressly or by implication, the factual accuracy of the articles herein, nor do they so warrant any views or opinions by the authors of said articles.

Reprints: Contact reprints@endeavorb2b.com to purchase custom reprints or e-prints of articles appearing in this publication.

Photocopies: Authorization to photocopy articles for internal corporate, personal, or instructional use may be obtained from the Copyright Clearance Center (CCC) at (978) 750-8400. Obtain further information at www.copyright.com.

Archives and Microform: This magazine is available for research and retrieval of selected archived articles from leading electronic databases and online search services, including Factiva, LexisNexis, and ProQuest.

Privacy Policy: Your privacy is a priority to us. For a detailed policy statement about privacy and information dissemination practices related to Endeavor Business Media products, please visit our website at www.endeavorbusinessmedia.com.

Please Note: The designations “National Electrical Code,” “NE Code,” and “NEC” refer to the National Electrical Code®, which is a registered trademark of the National Fire Protection Association.

Corporate Office: Endeavor Business Media,

ID

© Valiantsin Suprunovich | Dreamstime

ID 109058947 © Ratmaner | Dreamstime

Assemble Conduit Above TrenchNo Workers BelowPrevents Injuries and Deaths. Also Allows Digging a Narrower Trench for Less: Excavation, Concrete, Slurry, Backfill & Shoring.

Electrical Industry Braces Amid Tariff Whiplash

By Ellen Parson, Editor-in-Chief

As I sat down to write this month’s viewpoint, I had several ideas floating around in my head. However, given the fact that this date coincided with the March 4 deadline for President Trump’s tariffs to go into effect on Mexico, Canada, and China, I couldn’t think of a more timely topic to cover in this editorial. Since the Trump Administration took office, this continues to be a fluid situation. Nevertheless, I think it’s important to ponder what these tariffs may mean for the electrical industry. Implemented on March 4 by President Trump as a measure to address national security concerns/combat drug trafficking and trade imbalances (in an effort to revitalize U.S. manufacturing and reduce trade deficits), the United States imposed a 25% tariff on most goods from Mexico and Canada (with energy exports from Canada facing a 10% tariff), and the existing 10% tariff on Chinese goods increased to 20%. Reciprocal tariffs on other countries will kick in on April 2. To set the stage for what many are calling a “trade war,” global tensions are definitely heating up because goods from China, Mexico, and Canada accounted for more than 40% of imports into the United States in 2024; these three countries are also the top three export markets for our country. What does all of this mean? I’m certainly no economist, but, depending on what source you’re citing, you’ll find the situation characterized as everything from a necessary means to safeguard American interests and level the playing field, revitalize domestic industries, and protect American jobs to economic suicide that will inevitably lead to increased inflation, higher interest rates, a risk of recession, increased consumer costs, and ongoing market volatility. According to a piece by Reuters (https://bit.ly/41RqZnP), “CEOs and economists say Trump’s tariffs on Canada and Mexico, covering more than $900 billion worth of annual U.S. imports, will deal a serious setback to the highly integrated North American economy.” Whether that will happen — and to what extent — is yet to be seen. How will the new trade policies affect the electrical construction market in terms of material prices (such as copper wiring and availability of electrical equipment like electrical panels, switchgear, and transformers to name a few), equipment lead time, and supply chain issues? The National Electrical Contractors Association (NECA) sent out an alert to its membership in early February, summarizing the immediate risks such tariffs could pose as well as offering strategies stakeholders should adopt to mitigate risks at ecmweb.com/55267362. The National Electrical Manufacturers Association (NEMA) issued a statement on March 5 from Debra Phillips, president and CEO, encouraging a long-term deal that strengthens trade across North America. “As the second largest U.S. exporter and second largest U.S. importer of manufactured goods, electrical manufacturers play a pivotal role in securing American energy independence and ensuring a secure and resilient grid — investing tens of billions of dollars in U.S. manufacturing and creating thousands of new jobs for American workers across the country,” she said in the statement (https://bit.ly/41sKJwl). “New trade policies must provide predictability and certainty for future domestic investments, allowing for a reasonable transition period for new large-scale manufacturing to come online and for supply chains to move.” As of press time (a few days after President Trump’s speech to Congress in which he admitted the tariffs may cause “a little disturbance”), the President had granted automakers a one-month exemption from the 25% tariffs on Mexico and Canada (as of March 5) on vehicles that comply with the United States-MexicoCanada Agreement (USMCA) free trade treaty. On March 6, he also announced a one-month tariff delay on all products from Mexico and Canada covered under the USMCA until April 2. Considering how many times the tariffs have changed in the last three days alone, by the time this print issue hits readers’ hands or the digital edition drops online, things could have changed many more times. After experiencing the whiplash of covering this breaking news story, I can’t help but wonder if this is truly about tariffs. Whatever agreement is ultimately reached on exact percentages of duties collected, deadline extensions, exemptions, or specific goods, the overall chaos and instability this atmosphere is creating — not to mention uncertainty in many of the vertical markets our audience serves — must, at least to some degree, be affecting electrical professionals when it comes to business planning, economic forecasting, and supply chain strategies. As this story continues to unfold, you can bet EC&M will bring you the latest updates and analysis.

WHERE FACILITY CHALLENGES FIND SOLUTIONS

CENTRAL VALLEY

March 19-20, 2025

Modesto Centre Plaza

Modesto, CA

SOUTHERN CALIFORNIA

April 16-17, 2025

Anaheim Convention Center Anaheim, CA

NORTHWEST

May 14-15, 2025

Oregon Convention Center Portland, OR

RENO

August 20-21, 2025

Grand Sierra Resort & Casino Reno, NV

15- or 20-amp, TR & TR/WR $6.00 each/$300 per case of 50 Purchase in bulk to receive additional

10 cases = 5% off 20 cases = 10% off 30 cases = 15% off 40 cases = 20% off 50 cases = 25% off

Vist

Warehouse Pick Up Price $19.55

Warehouse Pick Up Price $27.57

Price $32.57 2X4FT Panel

Product Features:

• Backlit technology that offers even lighting distribution without shadowing.

• Color selectability allows for changing between 3500K, 4000K or 5000K.

• Wattage/Lumen selectable versions: three different lumen outputs in the same product.

• Emergency battery back up optional.

• The range input voltage 120-277V.

• 125 lumens per watt -CRI>80

• DLC Premium/DLC Standard

Areas of Application

The backlit Panels are the high efficiency solution for offices, schools, hospitality and retail areas.

ELECTRICAL TESTING EDUCATION

Online Partial Discharge Detection and Location

How to determine the reliability of underground cables/ terminations and identify PD to prevent costly downtime

By Bharat Nandula, Qualitrol

Power cables are important assets in electric utility transmission networks for the reliable operation of power systems. To prevent catastrophic failures in underground cables and terminations, it is important to know how to leverage the various types of available sensors that can detect partial discharge (PD) and locate the source so that appropriate action can be taken to avoid in-service failures. This article answers questions about how technology can help identify partial discharge in underground cables without expensive shutdown time.

Power cable systems consist of the cables themselves and their accessories — joints and terminations. In recent years, the use of high-voltage (HV) power cables has increased due to more densely

populated urban areas and new power cables being installed in old networks.

New synthetic polymer materials have boosted the birth of extruded XLPE power cables, and the use of XLPE

insulation in HV cables is increasing due to its advantages: low dielectric losses, suitability for high operating temperatures, and relatively easy and low-cost manufacturing.

Electrical Testing Education articles are provided by the InterNational Electrical Testing Association (NETA), www. NETAworld.org. NETA was formed in 1972 to establish uniform testing procedures for electrical equipment and systems. Today the association accredits electrical testing companies; certifies electrical testing technicians; publishes the ANSI/NETA Standards for Acceptance Testing, Maintenance Testing, Commissioning, and the Certification of Electrical Test Technicians; and provides training through its annual conferences (PowerTest and EPIC — Electrical Power Innovations Conference) and its expansive library of educational resources.

Sparking at the termination point was visible, which could eventually break down the bushing connected to the cable.

ELECTRICAL TESTING EDUCATION

Online PD Measurement Sensors

A combination of HFCTs and TEV makes it possible to separate the signals that are coming from the switchgear panel, terminations, and cables.

Let’s address some key questions that arise around the topic of PD testing.

Q: How can you ensure the reliability and availability of cables that experience transients, lightning, or switching surges and fault voltages?

Electrical diagnostic tests have played a role, though this often involves expensive shutdowns and other cost implications. Most dielectric failures in HV XLPE cables are associated with defects in joints and terminations that develop over the lifetime of a cable system. To detect such changes at an early stage, detailed information on insulation condition is necessary. As an alternative to traditional diagnostic methods, this information can be achieved by PD monitoring during the operation of the equipment.

The most effective tool to detect local damage, defects, and/or localized aging processes in extruded cable systems is measuring PD. On-line PD measurements are most suitable

for detecting problems in cable terminations and joints. Harmful levels of PD can be detected well before a breakdown.

With continuous measurement, reliable estimations about insulation condition can be made.

Possible applications for online PD measurements are:

• Quality assurance of installed cables

• Continuous cable monitoring

• Location of problematic joints and terminations

• Prioritizing cable replacements

Q: What are the advantages of online PD monitoring over offline PD measurement?

Using PD technology has proven to be an excellent method to identify problems in insulation. IEC 60270, High-Voltage Test Techniques — Partial Discharge Measurements, details the most adaptive and conventional method of measuring PD. However, this method is most suitable for offline diagnostics in environments with less

electromagnetic interference. Since aging of the insulation of in-service HV components is ongoing, on-site PD testing and diagnosis have attracted increased interest for use in condition monitoring. Since conventional PD measuring systems used in a controlled factory environment are not generally suitable for on-site application, specialized PD detection and measurement methods have been introduced.

PD signals can be detected by unconventional PD measuring methods and systems that use the physical characteristics and properties of the PD processes. These methods have gained significant popularity as they can be applied while equipment is operating. For example, unconventional PD coupling methods based on inductive or capacitive sensors have led to increased sensitivity at the accessories (joints) compared to conventional PD detection at the cable end. One promising approach is the use of inductive PD sensors at terminations and cross-bonding the links of long HV cable systems.

Fig. 1.

SNAP2IT® CONNECTORS

Snap connector onto installed MC cable.

Arlington’s new one-piece RETROFIT SNAP2IT® fittings are easy to use in an OLD WORK installation, and handle the widest variety of cables! They’re ideal for adding additional circuits to a load center. And you get the same labor-savings in a retrofit installation!

Easy snap-in installation - NO TOOLS. Install connector into the knockout in an existing box, pulling cable/conduit through the knockout. Slip the fitting onto the cable, then snap the assembly into the box. That’s it... a secure installation with no pullout

Widest total cable ranges 14/2 to 10/3

Widest variety of cables AC, MC, HCF, MC continuous corrugated aluminum cable, MCI-A cables (steel and aluminum), AC90,

Arlington’s non-metallic Split Wall Plates provide a simple and effective way to accommodate pre-connectorized low voltage cable(s) of varying size and quantity or pre-existing low voltage cables.

Multiple split grommets are provided with our single- and two-gang wall plates for increased versatility in effectively sizing and covering the hole/opening.

Use as shipped, or with one of the supplied bushings to alter the size of the opening.

• Single-gang CESP1 w/ 1-1/2" opening, bushings for .312" • .500" • 1" openings

• Two-gang CESP2 w/ 2" opening, bushings for .750" • 1.250" openings 1-1/

ELECTRICAL TESTING EDUCATION

MRO Insider

This e-newsletter, published monthly, serves electrical engineers, plant managers, maintenance engineers, facility and energy managers, maintenance supervisors, electricians, and technicians who work in industrial, commercial, and institutional facilities.

Topics covered include:

• Maintenance, repair, and operations

• National Electrical Code on the production floor

• Safety procedures and programs

Subscribe Today

See all of our EC&M e-newsletters at www.ecmweb.com

Cable PD Portable System

USB link to laptop to acquire data, analyze and generate reports

Transponder receives small PD pulses from one HFCT and injects a high magnitude pulse back into the cable

Several advanced software techniques and hardware solutions are useful for discriminating between actual PDs and noise interferences.

Q: What type of sensors or sensing techniques are used in online PD testing?

To detect PD activity online, nonintrusive sensors must be used. For online PD detection, high-frequency current transformers (HFCTs) are used to detect current pulses from PD in the cables and switchgear. Transient earth voltage sensors (TEVs) are used to detect electromagnetic radiation from PD activity from terminations and switchgear. By using a combination of sensors, sensitivity to various types of PD can be obtained, and the measurements from different sensors can be correlated to aid in the diagnosis. A combination of HFCTs and TEV (Fig. 1 on page 14) makes it possible to separate the signals that are coming

Time (ns)

from the switchgear panel, terminations, and cables.

HFCT

The most suitable sensors for underground cable PD measurement are inductive-type HFCTs. These sensors can be installed when the cables are in use (i.e., energized). Typically, HFCTs are mounted on the ground straps of the MV or HV cable at the connection boxes. To design and select appropriate HFCTs for these applications, the lower and higher cut-off frequencies, polarity, and saturation characteristics must be considered. A lower cut-off frequency is an essential parameter for HFCTs. It’s a compromise between the ability to detect dispersed signals from long cables and tolerating noise pickup from mains. Most of the HFCTs on the market for lower

Fig. 3. Partial discharges were clearly evident during the testing cycle.

TEV sensor to detect external discharges

HFCT sensor to detect cable internal discharges

Other 2 HFCTs AC Supply

Long length of power cable

Plastic & Steel 8X10 TV BOX

Arlington’s 8X10 TV Box™ with a Plastic or Steel Box offers the ultimate in versatility for installing TVs in new and retrofit projects. There's more room in the box for wires and it installs horizontally or vertically to properly position low voltage connections behind the TV.

• Ideal for home theater systems: multiple connections for sound systems, satellite TV, CATV, DVRs

• Brackets for neater cables, with a 1-1/2" knockout for ENT and other low voltage wiring

• Box mounts to stud in new work; for retrofit, mounting wing screws secure

ROOF TOPPER® supports raise conduit/raceway 4" or more off the roof surface, allowing contractors to comply with the 2017 NEC® for temperature adjustment for circular conduit.

The heavy-duty base, made of 100% recycled material, sits on the roof deck. There’s no need to mount ROOF TOPPER to the surface with mechanical fasteners.

Offered in a variety of sizes and configurations, ROOF TOPPER supports up to 2000 lbs, and stands up to extreme rooftop conditions protecting and elevating conduit or raceway above the roof deck.

ELECTRICAL TESTING EDUCATION

cut-off frequencies operate in a range from 50 kHz to 150 kHz. For special applications where no dispersed signals need to be captured, much higherfrequency ranges can be used with the benefit of obtaining lower noise levels.

Higher cut-off frequencies — the maximum frequency at which an HFCT needs to respond — depend on the application. A high-frequency HFCT cut-off is generally 10 MHz or higher based on the application. The HFCT should be clearly marked in terms of its polarity relationship (e.g., an arrow pointing toward the grounding point of the cable or earthing strap). The orientation doesn’t seem to matter, but if more than one HFCT is used in a test and the polarity of the signals needs to be compared, a clear and common definition is needed.

TEV

Another type of sensor widely used in medium-voltage (MV) switchgear employs the transient earth voltage (TEV) phenomenon, which has been more widely exploited for condition monitoring and asset management of MV switchgear. Transient earth voltage sensors make use of the skin effect to measure electromagnetic radiation

due to internal partial discharge. This is an attractive sensing option because measurements are inherently safe and can be made without any physical intrusion or modification to the switchgear. The benefits of TEV measurement derive from the ability to

install sensors non-intrusively on inservice equipment.

Q: What are the possible approaches for monitoring PD? Two approaches can be used to perform online PD testing on cables: periodic

Fig. 4. Phase C clearly showed PD signals during testing.

Fig. 5. Observing Phase C and TEV activity in the time domain, it was clear that the PD activity was located at the termination end of the cable.

LISTED BOX EXTENDERS

Arlington’s variety of cULus Listed Box Extenders extend set back electrical boxes up to 1-1/2”.

Made of heavy-duty, 105°C continuous use 94V0 rated, flame retardant plastic, they level and support wiring devices, while protecting wires against damage and stripping.

Choose the one that’s right for you!

BE1, BE2, BE3, BE4...Single-, two-, three- and four-gang, and BE1R for round or octagonal boxes...

Box Extenders

device support in oversized or mis-cut wall openings, available in single-, two-, three- and four-gang, (patented BE1X, BE2X, BE3X, BE4X.)

Our new heavy duty, COMMERCIAL-GRADE steel support plate! As shipped, single and two-gang BE1XLS and BE2XLS work with maxi cover plates, but they’re and standard plates. Convenient. Saves time. Great for poorly cut drywall.

For all standard devices, switches and GFCIs, our box extenders comply with NEC Article 314.20 for set back boxes.

ELECTRICAL TESTING EDUCATION

Illumination Insider

This e-newsletter tracks the research, development, design, installation and operation of all types of lighting and control products.

This twice-a-month product is geared toward professionals working in the industrial, commercial, retail, residential, institutional, health care, government, and utility market sectors.

Subscribe Today

See all of our EC&M e-newsletters at www.ecmweb.com

monitoring and continuous monitoring. Periodic monitoring is reasonably immediate to deploy, with tests between a few minutes and a few hours per circuit.

Continuous online monitoring provides 24/7 monitoring and the ability to do trending. By trending this summary data, changes in PD activity during the monitoring session can be observed. For example, increases in PD magnitude indicate the defect is getting larger, and increases in PD count indicate defects are discharging more rapidly. When the activity meets pre-set event criteria, discharge magnitude levels, and discharge rate, the system can generate alarms.

Q: What is the greatest challenge in performing online PD measurement?

The greatest challenge in online PD measurement is distinguishing between actual PD signals and noise from various sources such as electromagnetic (EM) interferences, adjacent circuits, and corona when cables are connected to overhead lines. Several advanced software techniques and hardware solutions (Fig. 2 on page 16) are useful for discriminating between actual PDs and noise interferences.

In the following case study, capturing 50 non-consecutive cycles and all pulses in the time domain — while at the same time capturing the phase-resolved PD data — showed the data in different dimensions.

CASE STUDY

Periodic online monitoring was conducted on 3-phase, 268-m, single-core 33kV cables terminated to switchgear. The remote ends were terminated to a transformer. The PD monitoring system used HFCTs, TEV, and a portable measuring instrument. PD recording was performed at an MV metal-clad switchgear cable termination box. HFCTs were clamped around individual earth shields of power cables, and TEV sensors were attached to the inner walls of the switchgear cable termination enclosure.

Fifty non-consecutive cycles were recorded. With the help of software and algorithms like artificial intelligence (AI) and pulse shape analysis, the data was

divided into PD and non-PD categories, as shown in 4 on page 18.

The investigation further consid ered data including phase activity, pulse shapes, and phase-resolved PD com pared with TEV and HFCT graphs. Note that phase graphs were phase consistent, and pulse-shape graphs confirmed the PD source from Phase C.

The next task is to determine the loca tion of the partial discharges. Comparing the HFCT and TEV data indicated the same activity from both sensors. As this software and monitoring device can cap ture individual pulses, we further looked at data in the time domain. The same activity was observed in pulse-shape analysis graphs from the HFCT, which was installed on phase C, and the TEV sensor, which was placed on the panel.

Observing Phase C and TEV activity in the time domain ( was clear that the PD activity was located at the termination end. You can see that HFCT and TEV activity was occurring at the same time at a high magnitude.

When the terminations were opened a few months later, it was clear that there was sparking at the termination, which could eventually break down the bush ing connected to the cable (see on page 12).

CONCLUSION

Online PD measurement is an important technique for use on power cables and switchgear during routine inspection and after installation to assess the condition of equipment and prevent catastrophic failures. Implementing online periodic monitoring is an effective solution to avoid catastrophic failures. The case study explained how important it is to have time-domain measurements. Time-domain characteristics can be used to classify the signals, and the method of separation based on time characteristics and AI allows noise pulses and PD to be isolated.

Bharat Nandula is a technical application specialist at Qualitrol, where he serves as a technical resource on GIS, transformers, and high-voltage cable monitoring solutions for the company’s sales and product managers and end users.

MC CABLE FITTINGS

each fitting also comes with end stop bushings that accommodate different size cable bundles. ONE trade size fits SEVERAL cable types and sizes, plus flexible metal conduit for super convenience and cost-savings! Reduces inventory and material handling too.

Refer to spec sheet for specific end stop sizes Listed for FMC

6/3, 6/4, 4-3, 4-4, 8/3, 8/4, 6/3

2-3, 2-4, 1-3

2-3, 2-4, 1-3, 1-4, 6/3, 6/4, 4/3, 4/4, 3/3, 1/0-3, 1/0-4, 2/0-3, 3/4, 2/3, 2/4

2/0-4, 3/0-3

2/0-4, 3/0-3, 3/0-4, 2/4, 1/3, 1/4, 1/0-3

4/0-3, 4/0-4, 250-3, 250-4 1/0-4, 2/0-3

250-4, 300-4, 350-3, 2/0-3, 2/0-4, 3/0-3, 3/0-4, 350-4, 500-3 4/0-3, 4/0-4, 250-3

500-3, 500-4, 600-3 4/0-4, 250-3, 250-4, 300-3 600-4, 750-3 300-4, 350-3, 350-4, 500-3

600-4, 750-3, 750-4 350-4, 500-3, 500-4 750-3, 750-4, 1000-4 750-3, 750-4, 1000-3

MOTOR FACTS

Get to Know Your Electric Motors

Basic tips and information about electric motors to keep on hand

By Mike Howell, PE, EASA

Electric motors are critical assets in many applications, so access to nameplate ratings and terminal markings can save time and money as a motor is moved in and out of service for storage, maintenance, repair, or replacement. While there are many types of electric machines, this piece will focus on standard, 3-phase, squirrel cage induction machines. Most of these are built to NEMA or IEC standards, and most of their nameplate information is standardized.

NAMEPLATE INFORMATION

NEMA and IEC standards mandate that motor nameplates provide such details as the manufacturer’s name,

motor type, and frame designation. Manufacturers assign unique types to identify motor applications and specifications. Frame designations define standardized dimensions critical for mounting and coupling motors to driven equipment. This information is available in NEMA Std. MG 1 and IEC Std. 60072-1.

Motor nameplates generally include the rated power, base speed, voltage, frequency, and full-load current. This basic information is often documented by the end user either on schematics or in asset management systems. Other important characteristics like insulation class, ambient temperature, and duty type are often overlooked but the

two characteristics we’ll focus on here relate to starting current and accelerating torque.

STARTING CURRENT

The starting current, also known as locked-rotor current (LRA), may appear on the nameplate of NEMA motors, but usually, a NEMA code letter indicates a permissible range. IEC Std. 60034-12 limits locked rotor apparent power using design letters. When end-users procure replacement motors without considering this starting characteristic, starting problems often arise.

Newer machines built to higher efficiency standards generally have low-resistance rotor cages, which means

FLOOR BOX

(3) FLBC8500 boxes

a two-gang box. Add another for three-gang! FLBC8500 Single gang box

Single gang

FLBC8510BR Brown

FLBC8510BL Black

FLBC8510GY Gray

FLBC8510CA Caramel

FLBC8510LA Lt Almond

Two-gang

FLBC8520BR Brown

FLBC8520BL Black

FLBC8520GY Gray

FLBC8520CA Caramel

FLBC8520LA Lt Almond

Three-gang

FLBC8530BR Brown

FLBC8530BL Black

FLBC8530GY Gray

FLBC8530CA Caramel

FLBC8530LA Lt Almond

Build a two- or three-gang concrete floor box by simply locking single gang boxes together!

Then buy the UL LISTED single, two- or three-gang cover/frame kit, with devices included, in PLASTIC, FIVE COLORS – or in economical diecast zinc with a brass or nickel finish. Fast, easy installation.

Cover installs with hinge on either side.

Two-gang FLBC8520MB

Three-gang FLBC8530MB

(1) FLBC8530BL Black plastic cover/frame kit

FLBC8530MB

MOTOR FACTS

higher starting current. So, replacing an older kVA code G motor with a new kVA code J model could increase the starting current by as much as 43%. To some extent, this situation is unavoidable, but it can be anticipated, which helps when planning.

ACCELERATING TORQUE

The NEMA design letter specifies the torque profile as the motor accelerates to full speed direct-on-line at rated voltage and frequency (see Figure at right). Design B machines (the most common) are used in applications like pumps, fans, and blowers. Design C machines are usually found in applications like conveyors and crushers. High-inertia load applications like punch presses use Design D machines, often with a flywheel in the system. The rotor cage design determines the speed-torque curve profile, so a stator winding redesign cannot facilitate a design letter change. Trying to replace a Design C or Design D motor with a Design B motor because of availability is a common error that almost always results in rapid failure. IEC Std. 60034-12 defines the common IEC design letters N and H. The nameplate may indicate the motor’s design characteristics. Keeping a photo of each nameplate on file is useful when repairs or replacements are needed.

TERMINAL MARKINGS

NEMA Std. MG-1 and IEC Std. 60034-8 provide standardized terminal markings for 3-phase machines. It is important to retain documentation for the number of motor leads and how they are marked. A

C or H

A, B or N

NEMA speed-torque curves.

or part-winding. Machines designed for multiple speeds at power frequency by changing the external connection may have more than one winding as well. Service centers have reliable procedures for identifying and marking the leads of 6- and 9-lead machines, but they’re not trivial and can require special equipment not always available to the end-user. For this reason, the ser-

The bottom line: Having procedures in place to document and preserve the external connections can save time and prevent mistakes when motor repair or replacement is necessary.

3-lead machine is simple to connect to the power supply. It gets more complicated with 6-, 9- or 12-lead machines that may have several design configurations, including multiple voltages, multiple speeds, and special starters like wye-delta

vice center usually sends personnel to the site or transports the motor to the service center. It is difficult to identify and mark 12-lead machines without disassembly if most (or all) of the markings are gone.

The bottom line: Having procedures in place to document and preserve the external connections can save time and prevent mistakes when motor repair or replacement is necessary. If a service center rewinds a motor and changes the number of leads, be sure the change is well documented.

SUMMING IT UP

Including complete motor nameplate data and terminal marking information in your asset management system and ensuring that procedures are in place to preserve terminal markings on the motor are very simple ways to reduce downtime and streamline replacement should a machine need to be removed from service for repair or replacement.

Mike Howell is a technical support specialist at EASA in St. Louis. EASA is an international trade association of more than 1,700 electromechanical sales and service and repair firms in nearly 70 countries. Visit www.easa.org for more information.

Design B

Design

Design

EASYTHUMB SCREW ADJUSTMENT

Here’s reliable hanging support for fixtures, fixture boxes, cable tray, high bay light fixtures and other static loads requiring drop wire support! Better than traditional wire-hanging methods, costs much less than competitive products.

• Screw engages six points of contact on wire – no internal spring

ONE Wire Grabber holds a static load up to 75 lbs;

• Easy length adjustment with thumb screw – no special tool

• Works in dry or wet locations; unaffected by oil or grease

• Connector ships fully assembled

Wire Grabber Kits

(Bulk wire available)

SINGLE LOOPED END

CATALOG WIRE NUMBER LENGTH

DWB0805 5'

DWB0812 10'

DWB0815 15'

DWB0820 20'

DWB0830 30'

”Y” w HOOKS ”Y” w TOGGLES

CATALOG WIRE NUMBER LENGTH

DWYH0805 5'

DWYH0810 10'

DWY2H0810 2 PK* 10'

DWYH0815 15'

DWYH0820 20'

DWYH0830 30'

CATALOG WIRE NUMBER LENGTH DWYT0805 5' DWYT0810 10'

DWY2T0810 2 PK* 10'

DWYT0815 15'

DWYT0820 20'

DWYT0830 30'

How to Make Safety Training Stick

It’s easy for details to get lost and concepts to be forgotten — so how can you fix this?

By Mark Lamendola, Electrical Consultant

The learning retention rate for safety training varies between abysmal and outstanding. This wide range means that in many organizations — and for many individuals — there is an excellent opportunity for improvement.

The less that is retained, the higher the risk of injury or death. It’s much better to be at or near the “outstanding” end of the spectrum rather than at the other end. So how do you get there?

TYPES OF RETENTION

With any kind of training, students experience two kinds of retention:

1. Immediate retention. Instruction is given. What does the student remember at its conclusion?

2. Retention over time. Knowledge degrades over time, so what you remember days or months after training is almost certainly going to be less than what you remember right after training.

If immediate retention is low, then retention over time will also be low. So one key to retention over time is to start with more that you can lose. Suppose in your organization the average loss after six months is 10%.

• If students retain 30% of the training at its conclusion, six months later they will retain 27%.

• If students retain 90% of the training at its conclusion, six months later they will retain 81%.

BOOSTING IMMEDIATE RETENTION

Here are some reasons immediate retention can suffer, and what to do for each one:

• Students are disengaged. This could be because the training is boring and/or the value of it has not been properly communicated. Start by emphasizing why the particular training matters. You can use visual aids such as injury photographs, or even have a guest speaker who suffered injury. For example, a Chicago-based electric utility had a lineman who had lost both arms speak on electrical safety, and those in attendance were fully engaged.

• Too much distraction. Have people shut off their phones. Make it clear they need to focus on the training. Reward them for this focus by keeping the training fairly short. Keeping it short

also helps them stay focused, because for most people, the “focus muscle” tires out after about 20 minutes.

• It’s treated as an afterthought. Is the training held after a long work day when people are tired with no real preparation? Schedule it at a time and in a place conducive to learning. Prepare for the session as if someone’s life counts on it (because that may very well be the case). Refuse to engage in “death by PowerPoint.”

• The material is poorly arranged. When training is divided topically — perhaps into modules — a student can more easily focus, more easily build on one point to understand another

Arlington’s steel SliderBar™ offers the easy, NEAT way to mount single or two-gang boxes between wood or metal studs with non-standard stud cavities.

No more cutting, nailing and fitting extra 2x4s to fill the space! SliderBar saves about 20 minutes per box. Designed for studs spaced 12” to 18” apart, SL18 allows positioning of one or more boxes anywhere in the stud cavity.

• Bending guides on bracket assure proper positioning on studs

• Interlocking tab stop prevents accidental disassembly

• Pre-punched pilot holes on BOTH sides of S for easy attachment of one or two boxes

SAFETY CORNER

point, and more easily remember information because (in a given session) it’s related.

• Too much detail at once. Break it down into digestible chunks. Focus a given session on one or two major concepts. Use as many sessions as you need rather than rushing to check off the box. Break the more complex topics into multiple sessions and revisit already covered topics (in brief) as you go through the series of sessions. It is better to sip from a glass than try to drink from a fire hose.

• The training is a boring lecture People learn best when they are interacting with the instructor. Get them involved by asking them questions, giving them problems or challenges to work out, and calling on individuals to ask questions or give comments on what was just said.

• Where applicable, require practical demonstrations. A practical demonstration allows the student to move understanding from the abstract to the real world. In the real world, the student’s other senses will also be brought to bear, and that is yet another way that learning sticks.

Reasons for low immediate retention can vary by subject, location, instructor, and individual. Identify the existence of low retention by giving a short quiz and/ or asking for a practical demonstration. Find the reason for low retention by asking students and instructors for their input. Use the input to improve the training. Then rinse and repeat with each subsequent session. Do this process with a teamwork attitude rather than an attitude of blaming someone. The idea is you work together to bring training retention as close to 100% as you can — regardless of who needs to make what adjustment or change.

BOOSTING RETENTION OVER TIME

One obvious way to boost retention over time is to conduct training more frequently. A word incorrectly used for this technique is “retraining,” but retraining means you repeat the training — and it does not connote frequency. Using a combination of both will yield superior results, especially if the retraining

is done with the idea you will cover the material but not aim it at the uninitiated. The way you retrain a previously trained person should differ from how you train a completely new person. The person being retrained already understands the concepts and principles but may have grown a bit fuzzy on the details.

Retraining on lockout/tagout, for example, doesn’t need as much time on concepts such as why lockout/tagout is important or on principles such as “always verify.” It doesn’t need as many examples to illustrate the typical workflow. Retraining might, however, entail new information (such as how to handle an atypical workflow based on something that actually happened in the plant).

Some other ways to boost retention over time:

• Hold to the standards. If people are trained to do things a certain way but in practice see them done to a lower standard, then that is the standard to which they will most likely drop. If you teach that a fall harness must be inspected before each use and people are not doing that, the training will not stick.

• Make people responsible for each other’s safety. This is a common practice in diving, climbing, and other dangerous endeavors. If you are charged with keeping your buddy safe, and it’s part of the way things are done, then you will be mentally rehearsing your safety training on a routine basis.

• Give people authority. It isn’t enough that every worker must have the authority to stop work if something or someone is not safe. They must have that authority if something just doesn’t seem safe. There’s often a reason for those prickly neck hairs or that nagging “I can’t put my finger on it” doubt. When those arise, the worker must have the authority to stop work and the responsibility to methodically address the issue. Maybe it’s nothing. Maybe it’s something. They can’t know until they check it out. As they check it out, that training kicks in and gets reinforced in their memory.

• Do random spot checks. For example, Mike and Jeff are performing a

lockout/tagout. So stop Mike and ask a question such as, “Once this breaker is locked out, I will know the circuit is dead, right?” Mike should respond in the negative, and then tell you that you don’t know it’s de-energized until you use a three-step verification process with a meter. If you get any other kind of response, rephrase the question.

• Address near misses. Why do near misses happen? It is not because people properly executed the work in the way they were trained to do it safely and they just had bad luck. It is because they made one or more safety mistakes and escaped injury due to good luck. It’s those mistakes that need to be identified. It’s unlikely a supervisor will witness a mistake as it happens, so how can this valuable information be shared and learned from? Establish a penaltyfree safety mistake reporting system. It can be an anonymous system similar to a suggestion box, or whatever people are comfortable with. But get that information to people so they learn from mistakes rather than die from them. Update both initial training and retraining accordingly.

BE SPECIFIC

While general safety awareness is never a bad idea, it is not sufficient for retaining the specific safety information that workers must use to perform their work. It’s often easier for managers and supervisors to rely on passive means because they never have to confront someone “who wasn’t doing anything wrong, he just forgot.” But when someone forgets, the consequences can be tragic.

Carl might be able to recite “Safety is no accident” due to having read it on the shop entry floor mat several times a day, but that’s not going to help him remember the correct way to do a voltage check versus another method that creates an ionization trail. If Carl’s workmate Julie sees him start to perform the voltage check the wrong way, she must have the authority and responsibility to stop Carl, address the problem, and report the near miss.

Mark Lamendola is an electrical consultant based in Merriam, Kan. He can be reached at mark@mindconnection.com.

Super-secure installation!

Our

L-shaped fan/fixture box mounts to single or double joists with a captive center screw. No loose parts!

screws ship captive, ready to install box and bracket. For

• Locator posts assure proper positioning of fan/fixture bracket

This convenient combo box has power and low voltage openings in the same box for a neat, time-saving installation.

The box adjusts to fit wall thicknesses from 1/4" to 1-1/2". Mounting wing screws hold it securely in place.

• 2-Hour Fire Rating

• Low voltage side has a combo 1/2" and 3/4" KO for raceway

• Includes NM cable connector (power side)

Designed for new work, Arlington’s non-metallic 20 cu inch FR series device and fixture boxes mount to a flat surface with NO NEED to cut an opening in the substrate.

Interchangeable backs and extension rings allow ONE box to work with almost any cladding system, including engineered foam and stucco systems.

Extra-wide flanges prevent water and air-intrusion, helping to meet the International Energy Conservation Code, and eliminating the need for gaskets or caulking.

Boxes install before or after the weather barrier house wrap. And ship ready for use with 1-3/8” finish/cladding thickness. Adjustable up to 1-7/8" for CUSTOM depths.

Troubleshooting Voltage Sags and Swells

Best practices for field technicians investigating power quality problems

By Jason Axelson, Fluke

Asteady supply of voltage is important in industrial and commercial applications to maintain equipment performance, product quality, and safety, while also minimizing downtime. Voltage sags (where the expected voltage dips 10% below the expected range) or swells (where voltage jumps 10% above the expected range) can cause problems throughout facilities. In this article, we’ll discuss steps to effectively troubleshoot voltage sags and swells.

WHAT ARE SYMPTOMS OF VOLTAGE SAGS OR SWELLS?

Voltage sags and swells manifest in many ways. Lighting circuits can be impacted, which workers may notice as annoying flickering or even lighting levels dropping to unsafe levels. Equipment with electronic power supplies may reset, and

processes requiring use of motors could fail or experience production errors due to loss in motor torque.

THE IMPACT OF VOLTAGE SAGS AND SWELLS ON PROCESSES AND COMPONENTS

Sensitive electronics operate using electronic power supplies that require peak voltages to be within an optimal range to operate properly. Voltages that are either too low or too high can damage power supplies or cause equipment to shut down, restart, or operate at reduced performance levels. While events of short duration tend to have less impact on system performance, longer events can impact power supply performance and prevent equipment from operating.

If problems with sags and swells aren’t addressed, out of warranty repairs could become common, decreasing

Courtesy of Fluke

GROUNDING BRIDGE

MULTIPLE ZINC

Arlington’s heavy-duty Grounding Bridges provide reliable intersystem bonding between power and communication grounding systems. And handle multiple hookups of communications systems: telephone, CATV and satellite.

Our new GB5T is THREADED for threaded conduit or another GB5T – with a SET SCREW for use on EMT or PVC.

Arlington’s zinc and bronze grounding bridges...

• Four termination points; more than required by the NEC

• Meet 2020 NEC bonding requirements for 250.94

• Fast, simple installation indoors or outside

• Textured, paintable plastic cover (except GB5NC)

• Easy access for inspections

INSIDE PQ

PQ Newsbeat

If you’re an engineer, commercial or industrial facility manager, or electric utility employee concerned about the quality and reliability of power delivery, this e-newsletter (sent out monthly) is for you.

Topics covered include:

• Power quality

• Voltage sags & swells

• Transients

• Harmonics

• Power factor

• Test & measurement techniques

Subscribe Today

See all of our EC&M e-newsletters at www.ecmweb.com

available capital for other products. Motors could also suffer reduced torque, decreasing energy efficiency and increasing utility costs.

WHAT CAUSES VOLTAGE SAGS AND SWELLS?

The most common causes of voltage sags are loads turning on. Voltage sags can also happen due to impedance problems, such as loose wiring or improper cable sizes for the load requirements.

Swells in voltage can be caused by loads on the system being turned off as well as by switches being activated or line to ground faults causing voltage swells.

HOW TO IDENTIFY VOLTAGE IRREGULARITIES

1. Interview all the stakeholders in the environment to document and understand the problems each individual is experiencing. This process helps avoid unnecessary investigation into the origin of the problem and helps determine if the problems are isolated to one particular area of the plant.

2. Once the location or locations of possible electrical problems have been identified, inspect the electrical panel for loose connections — either by using a thermal imager, visually, or by de-energizing and securing the panel to check proper torque. Correct any loose connections found.

3. Take simple meter measurements with an appropriately rated multimeter at panels and subpanels to confirm proper voltages.

4. If supply voltages are normal — and dips and swells are still occurring even after loose wires have been corrected — connect a power analyzer with recording capabilities to better understand what is going on with the electrical systems at all times of the day. Ideally, record for at least a week.

Power analyzers capture the ongoing voltage and current to help determine the cause or source of the problem. If both the current and voltage drop at the same time during a voltage sag, the cause of the voltage sag was most likely internal. If the current remains constant, the most likely cause of the sag is external.

While voltage swells occur less frequently, the power analyzer can still

help identify the source of the problem. Look for line-to-ground faults on single-phase lines, which can cause the voltage to suddenly swell on the two non-faulted phases.

HOW TO RESOLVE VOLTAGE IRREGULARITIES

1. Correct any loose connections and ensure proper grounding.

2. If voltage irregularities are still occurring, other mitigation options include installing suppressors, filters, isolation transformers, voltage regulators, or power line conditioners. An uninterruptible power supply (UPS) system is another option that employs different technologies to improve power. However, it comes at a higher capital cost.

3. After mitigation solutions are employed, ask operators and other stakeholders to keep a log to report any continuing problems. You can also continue using a power analyzer after fixes are in place to ensure power stability has been achieved.

CONCLUSION

Voltage sags and swells can cause prob lems in the short term as assets reset unexpectedly or production slows down. The long-term implications, including damage to assets and increased utility costs, can be even more costly.

Finding and correcting the root causes of voltage sags and swells is an important part of ensuring quality power supply in your facility. Address ing these issues reduces overall costs and increases uptime. Even if your plant isn’t currently experiencing symptoms of voltage sags or swells, performing power quality studies from time to time can help identify potential cor rective actions that not only improve equipment performance but also reduce energy consumption.

Jason Axelson is a product application specialist for Fluke. He has more than 15 years of experience helping custom ers and partners find solutions for power quality, scope meters, and battery testers. He also conducts application training to help diagnose and resolve both technical and product inquiries.

STEEL

SNAP2IT® CONNECTORS

TINTED 40STS

the cable into the connector and rotate it clockwise.

Available in 3/8" trade size, both connectors install into a 1/2" knockout, and are listed for steel and aluminum AC, HCF, MCI and MCI-A cable. The tinted 40STS has more room inside for easier cable insertion.

In Canada both connectors are Listed for use with AC90 and ACG90 cable.

• Tested to UL 514B and Listed to meet UL ground fault requirements

• Removable Unscrew the connector counterclockwise to remove it from the cable. Remove the connector from the box using a flat blade screwdriver. Release the snap tangs from the inside of the box while pulling the connector out of the knockout.

• Packed in heavy-duty, 200 piece boxes

CATALOG NUMBER CABLE RANGES STEEL Snap2It® connectors

38STS AC, HCF, MCI, MC!-A 14/2 w ground, 14/3, 14/2 12/2 w ground, 12/3, 12/2 • 10/2 w ground, 10/3, 10/2 .405” Dia. Minimum to .605” Dia. Maximum

40STS AC, HCF, MCI, MC!-A

Tinted 12/2 w ground, 12/3, 12/2 • 10/2 w ground, 10/3, 10/2 .480” Dia. Minimum to .605” Dia. Maximum

120A

38STS

By Randy Barnett, NTT Training

Tips for Getting the Most Out of Your DMM

Follow these practical steps to get correct readings every time.

Modern digital multimeters (DMMs) are user-friendly, accurate, and safe — when used correctly! Reading voltage is simple, but measurements must be properly interpreted. With a clamp-on DMM, accurate current flow readings are obtained if you follow the tricks of the trade. Resistance measurements are easy if you know what you are measuring

(see “Make Sure Your DMM Does What You Need It to Do,” below). Following are tips for measuring voltage, current, and resistance for safe and effective DMM use.

TIPS TO INTERPRET THE VOLTAGE MEASUREMENT

Follow all safety precautions, set up the DMM, and place the test leads on the test points. The number appearing on the meter face is the voltage difference

Make Sure Your DMM Does What You Need It to Do

Here’s a handy checklist to follow when using a digital multimeter (DMM).

Inspect the DMM, leads, and any accessories before each use.

Replace DMM batteries before use if a low battery indication is obtained.

Use a logging DMM to record data for later analysis and spot trends/sporadic problems.

For safety and convenience, use a wireless DMM to obtain measurements remotely from the equipment.

Consider a DMM with temperature, frequency, capacitance, milliamp, microamp, and other measurement capabilities if needed.

Use the diode test function rather than the resistance function to test the operability of electronic components with P-N junctions such as diodes, transistors, and LEDs.

Use the relative mode (REL) feature to indicate the difference between a stored value and the current value.

Use the min/max setting to capture events that occur in microseconds and would otherwise be lost.

Use intrinsically safe DMMs in hazardous locations.

between those two points. However, that number may not be what you think it is.

Set the DMM for the correct voltage.

A simple error is failing to set the meter function switch to the appropriate voltage type (AC or DC). Experienced techs will quickly catch their mistake and change to the switch. New technicians, while learning to use their meter, may just be confused and proceed in the wrong direction. Make sure you know whether the circuit is AC or DC, and set the meter accordingly.

Use a true-rms DMM (when applicable).

Reading voltage values in electronic circuits, such as variable-frequency drives (VFDs), uninterruptible power supply (UPS) systems, battery chargers, and any distribution system supplying significant electronic loads, requires the use of a “true-rms” meter rather than an “average-responding” DMM. An average responding meter reads the root mean square value (rms) of a pure sine wave. Due to the countless electronic devices in distribution systems today, many such systems are made up of distorted sine waves. These distorted waves can produce voltage readings as much as 40% low and high on average responding DMMs. Electronic loads produce high-frequency noise and harmonics that distort the non-sinusoidal readings. Low-pass filters are designed into DMMs to block high-frequency noise. Use the correct type of DMM on these circuits, or expect inaccurate readings (Photo 1 on page 36).

Be aware of voltage drop.

When measuring voltage values in distribution systems, do not expect to read nominal system voltage — the

voltage found on the transformer nameplate. Voltage drops due to long conductor runs and equipment operations occur. Intermittent problems and overheating may occur. If a coil in a relay or motor starter drops to approximately 70% to 80% of the rated voltage, the relay will continually drop and pick back up creating a chattering sound. Motors will tend to draw more current at lower voltages, creating overheating problems. Understand the concept and effects of voltage drop to effectively troubleshoot your system.

Watch for DMM loading in electronic circuits.

DMMs have high input impedance when set to voltage, thus preventing the meter from acting as a load on the circuit. While not a problem when reading distribution system voltages, measuring values in electronic circuits can be different. Modern DMMs generally have sufficient input impedance, preventing any appreciable amount of current flow through the DMM. Ensure the meter

meets the proper specifications when working with electronics.

TIPS FOR CLAMP-ON AMMETER USE

The clamp on the clamp-on DMM senses the strength of the magnetic field around a conductor created by current flow. Increasing current flow increases the strength of this field and thus an increased amperage reading on the meter. Grasping this basic concept helps us understand the tips for using the clamp-on DMM.

Clamp around only one wire.

The direction of the electromagnetic field developed around a conductor depends upon the direction of the current flow through the wire. The clamp on the DMM (whether a part of the meter design or an accessory for the meter) senses this magnetic field developed around the wire. As current flows through one conductor of a circuit, it returns on an opposite conductor. Thus, the magnetic fields developed around each of these conductors would be in

opposite directions. If both conductors are placed inside the clamp at the same time, the magnetic fields will cancel each other, and the field sensed by the clamp will be zero, thus the DMM would indicate zero amperes when, in fact, there is current flow through the circuit (Photo 2 on page 36).

Three-phase motor circuits can be tricky as well. If the current is flowing out to the source on one ungrounded conductor, then it is flowing back on the other two phase conductors at the same time. Since the three conductors are out of phase with each other, clamping around two of the three phases will provide a very inaccurate and useless reading. Clamping around all three of the phases would show zero amperes on the DMM once again. Clamping around more than one wire in a single-phase or a 3-phase circuit rather than just one will most likely produce an incorrect reading. Keep the wire in the right spot. Many technicians are not aware of the two parallel lines found on the clamp of

the DMM (Photo 3 on page 38). In fact, many refer to this as a “negative sign.” The parallel lines indicate the “sensing zone” for the clamp. The conductors under test must be placed at or below these parallel lines for an accurate reading.

In addition to the true vs. average responding meter discussion previously, using an average-responding clamp-on meter can give erroneous readings as well. Know your DMM and what you are measuring.

Be safe — probing can be dangerous.

Probing around in a live panel with the DMM clamp to try and clamp around only one wire can result in unwanted contact with live parts. You might even knock a loose wire out of its terminal. As with all DMM usage, follow safety procedures, and never attempt to measure current with test leads inserted in the input jacks.

TIPS FOR ACCURATE RESISTANCE MEASUREMENTS

To measure resistance with the DMM, a small amount of current flow leaves a battery from within the meter, flows out the test lead, through the component under test, returns through the opposite

readings on a non-sinusoidal sine wave. Both

average-responding

test leads

same point on a variable-frequency drive output (non-sinusoidal). The drive is set at 208VAC. Notice the average-responding DMM on the left reads 298.8VAC — approximately 30% higher than the true-rms DMM on the right.

test lead, through meter circuitry, and back to the battery. The amount of current flow is converted to ohms of resistance, and thus the reading on the meter face. Not paying attention to this

simple circuit is where the problems arise with measuring resistance. Do not touch the tips of both test leads while attempting a resistance reading.

Photo 1. These readings show the difference in true-rms and

DMM voltage

DMMs’

are at the

Photo 2. In this single-phase, 240V example, Photos 2(a) and 2(b) show approximately the same amperage in each ungrounded conductor. Photo 2(c) shows what happens if the clamp is placed around both conductors. The magnetic fields around each other are equal and opposite — and cancel out the voltage that would be induced into the clamp. The DMM now reads “zero.”

Arlington’s new Furred Wall Box™ kit makes challenging outlet box installations fast and easy!

Versatile mounting options Our high strength FSB series outlet box kits are designed for use with existing 1x2 drywall furring strips – but can also be mounted directly to a concrete block wall between furring strips – so installers can place the box or outlet where it’s needed.

No cable pullout! Accommodates GFCI and USB receptacles. Convenient kits simplify ordering.

Large, pancake-style box with cover

High-strength No breakage in cold weather

Integral Mounting Flanges

FSB2

Current will flow through any path possible to return to the source. Of course, the DMM does not know what path the current flow has taken — only that a certain amount flows back to the meter.

Photo 4 illustrates this error as the worker places fingertips on the test leads while testing a motor starter. Holding onto the tips of both leads will cause the DMM to attempt to measure resistance across the worker’s body, and the actual desired measurement will not be obtained. Always be sure at least one end (if not both ends) of the meter leads is making contact only with the circuit under test; otherwise, a parallel path for meter current flow can be created through the technician’s body.

Disconnect one portion of the circuit (if required).

Another example of parallel resistance is reading through multiple components when troubleshooting. Even the savviest troubleshooter can be caught off guard by this one. This especially applies when reading resistance in control circuits. There will be many parallel paths for current flow in the typical control circuit. Make sure the component under test is isolated from the remainder of the circuit.

Measure resistance only on de-energized circuits.

Do not rely on the DMM for protection. Understanding how the meter works to read resistance is also key to safety. Imagine placing a couple of AA batteries across an energized 120V, 240V, or even a 480V circuit. Not only would the meter most likely be destroyed, but the worker could also receive serious injury. Fortunately, most DMMs will have built-in protective circuitry to protect both the worker and the meter. If set to read resistance and placed on a live circuit, the DMM may emit an audible sound, a flashing LED, or simply fail to read a value depending upon the DMM. This is just another good reason to use quality test equipment and know that DMM before you use it.

SUMMARY

Don’t be fooled by the user-friendliness of the modern DMM. A quality device used correctly can tell the electrical worker the specifics of a circuit that

3. Most clamp DMMs will have some method to indicate where the conductor is to be placed within the clamp for the most accurate reading. Photo 3(a) shows two parallel lines, which is typical, and the conductor must be placed at or below these parallel lines. Photo 3(b) shows an example of placing the conductor near the top of the clamp. This is the circuit from Photo 2 and should read 17A. The reading now is considerably inaccurate.

Photo 4. Testing motor starter contacts is a good example of how an inaccurate resistance reading can be obtained. With the black test lead on L1 and the red test lead on T1, see Photo 4(a), the DMM should indicate “0L” (open circuit) since the starter contacts are open. In Photo 4(b) the technician is using their fingers to hold the test leads in place. The parallel path created as DMM current flows across the worker's body from one hand to the other gives the erroneous reading of 14.16 megohms, indicating faulty contacts.

would be impossible to know otherwise. However, if certain key aspects of measurement techniques are not closely adhered to, inaccurate measurements can result — sometimes grossly inaccurate measurements. Be sure to know your meter and its nuances before you first apply it to a circuit. Understand how your DMM works and its limitations. Follow the manufacturer’s instructions for use,

and apply the DMM tips provided to get the most out of your DMM.

Randy Barnett is an NFPA certified electrical safety professional, a long-time journeyman electrician, instructor and author with expertise in industrial electrical construction and maintenance. He is Electrical Codes & Safety Manager for NTT Training.

Photo

CableStop™ TRANSITION FITTINGS

• TRAY CABLE

• FMC

• MC & PVC MC

• AC90 & ACWU

• TECK Cable

Perfect for data center remote power panel feeds, panels, equipment feeds and EV Chargers in parking garages, Arlington’s Listed CableStop™ Transition Fittings deliver the efficient, cost-effective way to transition feeder cables to 2.5", 3" and 3.5" EMT, IMC and RMC conduit in protective drops, risers and feeds to panels and equipment.

Available with set-screw or compression connections into 2.5", 3" and 3.5" conduit, they ship with multiple end stop bushings that vary the size of the opening – along with a free template select the right bushing for the cable. FROM

Our new CableStop fittings integrate our patented, versatile and SKU-reducing 8412 series cable fittings, with Arlington conduit fittings, allowing for easy transitions to larger knockout sizes.

Ensuring Accuracy in Demand Factors with the NEC

How to dispel common misconceptions when it comes to demand factors and the Code.

By Jennifer Kuether, P.E., Syska Hennessy Group

Engineers often include demand factors in panel schedules and/or load cal culations when preparing an electrical design. It is important to include these as permitted by the Code so that equipment is properly sized and correctly shown on drawings, resulting in an accurate determination of spare capacity. NFPA 70, National Electrical Code (NEC), allows engineers to take into account demand factors for various scenarios in electrical designs. By carefully following the NEC, engineers can avoid several negative scenarios and ensure the success of their projects.

The NEC defines a demand factor as a ratio of the maximum demand to the total connected load; this is in reference to a system or a part of a system that is under consideration.

AREAS OF OVERSIGHT

Two common errors often emerge in electrical designs:

1. Using 125% as a demand factor for continuous loads, and 2. Approaching demand factors as a grey area and therefore devising demand calculations based on the engineer’s generalizations.

17SAVE seconds

Fully assembled, SNAP2IT® fittings handle the widest variety of MC cable AND THE NEW MC-PCS cables.

Compared to fittings with a locknut and screw, you can’t beat these snap in connectors for time-savings!

LISTED SNAP2IT ® CONNECTORS FOR NEW MC-PCS CABLE ...lighting & low voltage circuits in the same cable

• Fits widest range and variety of MC cable 14/2 to 3/3

AC, MC, HCF, MC continuous corrugated aluminum cable and MCI-A cables (steel and aluminum)...including the new MC-PCS cable that combines power and low voltage in the same MC cable

ANY Snap2It Connectors LISTED for MC cable are also LISTED for MC-PCS cable! These products offer the greatest time-savings.

• Fast, secure snap-on installation

• Easy to remove, reusable connector From cable Loosen screw on top. Remove connector from cable. From box Slip screwdriver under notch in Snap-Tite® Remove connector.

Easy to Snap into Box!

Table 1. Correct demand factor applied.

The NEC requires that branchcircuit conductors and overcurrent protection (as well as feeder overcurrent protection) shall be sized at 125% for continuous loads. See related requirements in Secs. 210.19(A)(1), 210.20(A), and 215.3. This requirement is sometimes misinterpreted. Consequently, the engineer applies a 125% demand factor for loads in a panel schedule and/or a load calculation. However, the 125% has already been applied at the branch and feeder level, so applying a second time to determine the load on the distribution equipment is neither necessary nor correct. Demand factors also are never more

than 100%; the demand load should not exceed the connected load.

Refer to NEC Table 220.45 for lighting-load demand factors. This table outlines demand factors that may be used for lighting different occupancy types; demand factors range from 25% to 100% in this table.

CASES IN POINT

Consider the hypothetical panel schedules in Table 1 (incorrect) and Table 2 (correct). These are both representative of the same fictional small commercial office project. The project scope for the examples includes circuiting for a few receptacles and some luminaires. Since

lighting is a continuous load, some engineers mistakenly apply a 125% demand factor for lighting; this is shown in Table 1. One can see that the demand load exceeds the connected load in this panel schedule, which should never be the case. Per NEC Table 220.45, office lighting falls into the “other” category, and the associated demand factor should be 100%. Refer to the panel schedule in Table 2 for the correct version for this project scenario; in this case, all loads are factored at 100% and demand load equals connected load.

NEC AREAS OF EMPHASIS

Aside from the 125% misconception, engineers also sometimes may make

Table 2. Incorrect demand factor applied.

CABLE SUPPORT

Arlington’s economical CUS6 galvanized steel Cable Support holds cable secure and centered on a metal or wood stud.

It’s perfect for fastening and individual metal clad cables –or six NM cables on a 2x4. to a wood or metal stud, and position the cables. Next bend the strap at the foldline (centerline). Fold the strap over the cables and insert the locking tab in the opening as shown to hold

Arlington’s Concrete Pipe Sleeves are the economical way to sleeve through concrete pours in tilt-up construction WALLS – and FLOORS allowing cable and conduit to run easily from one floor to the next.

No costly core drilling – No cutting holes in the form. Plus, you can position the hole prior to pouring the concrete.

• Attaches to form with nails or screws

• Stackable up to 23" h for extra deep pours

• Vents keep wet pipe sleeves from sticking together

• Multiple hole sizes: 1-1/2"

the mistake of assuming that they can determine demand factors on their own. Instead, they should follow the NEC guidelines closely. Below are some especially useful sections to focus on.

Refer to Sec. 220.40 regarding the calculated load of a feeder or service. This Section of the Code indicates that the load for a feeder or service shall not be less than the sum of the associated branch circuits after any applicable permissible demand factors are applied. The NEC does allow demand factors for less than 100% for several scenarios.

It can be reasonably assumed not all occupants in dwelling units will use loads at the same time; therefore, the NEC has several allowances for a reduction of demand load when calculating the service size for a dwelling unit. Per Sec. 220.41, the minimum unit load, which includes most of the receptacles and lights, should not be less than 3VA/SF. This can then be reduced as applicable per Table 220.45.

The demand for motors and fixed heating should be 100% unless there is an exception that satisfies Sec. 220.51 and/or Sec. 430.26, and the AHJ has granted permission for this. An example of a possible application of Sec. 220.51 and/or Sec. 430.26 is electric heaters and/or motors that do not all operate at the same time. In this case, the AHJ may grant permission to use the largest of the non-coincidental loads for consideration.

Another exception cited within Sec. 430.26 is the ability to use historical data from an existing facility when factoring in motor loads for a new facility that is similar to the existing facility. Appliance loads in a dwelling unit may have a 75% demand factor applied for the situation of four or more appliances, per Sec. 220.53.

Table 220.54 shall be used for applying demand factors for electric clothes dryers. This demand factor is more applicable when considering several dwelling units as the demand factor for one to four electric clothes dryers is 100%.

Section IV of Art. 220 also offers an alternative approach for sizing service and feeders for dwelling units; this Section is entitled “The Optional Feeder and Service Load Calculations.” This approach allows for a more bulk-type demand factor, which can be applied for general receptacle/lighting loads,

appliances, and motors; however, there are certain requirements that the engineer should take note of before choosing the optional calculation method. Some examples of these requirements are that multifamily units must have electric cooking and that dwelling units are equipped with electric space heating, air conditioning, or both. Table 220.84(B) can be referenced for the optional load demand factors related to three or more multifamily dwelling units.

For multiple elevators served by the same feeder, there is a demand factor that can be used in Table 620.14. These demand factors are based on a 50% duty cycle — meaning half time on, half time off.