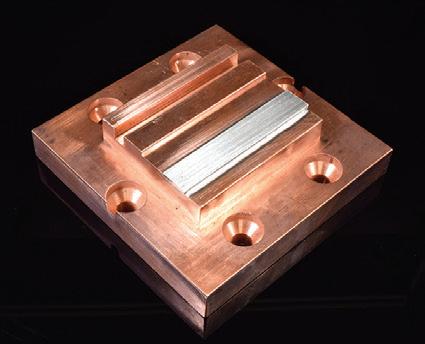

The reliability, resiliency and efficiency of the Electric Power Grid depend on a network of optical infrastructure and innovative substation and conductor accessories. AFL has been providing aluminum, copper and fiber optic solutions to electric utilities for more than 100 years. Let AFL help you improve the reliability of your electrical and optical infrastructure.

Visit AFL at booth # 6608 during IEEE PES T&D Conference and Exposition 2024.

One technology company offers innovative line-powered monitoring systems and shares some breathtaking images from its equipment in this gallery. Images shared here include scenes from Norway, Iceland and Turkey.... https://tdworld.com/21283270

The Biden Administration and the Department of Energy recently announced billions of dollars in funding to strengthen the resilience of the North American power grid.... https://tdworld.com/21282600

FERC’s Order No. 2023 requirements involve accelerating interconnection studies to mitigate project backlogs that have reached historic levels.... https://tdworld.com/21281962

Executive Editor Nikki Chandler nchandler@endeavorb2b.com

Senior Editor Jeff Postelwait jpostelwait@endeavorb2b.com

Associate Editor Ryan Baker rbaker@endeavorb2b.com

Art Director Susan Lakin slakin@endeavorb2b.com

Field Editor Amy Fischbach EOUeditor@endeavorb2b.com

Technical Writer Gene Wolf GW_Engr@msn.com

Community Editor Rich Maxwell tdwmediapartners@gmail.com

Senior Editor-at-Large Geert de Lombaerde gdelombaerde@endeavorb2b.com

VP, Market Leader, Energy Mark Johnson mjohnson@endeavorb2b.com

Director, Business Development Steve Lach slach@endeavorb2b.com

Director of Marketing Angie Gates agates@endeavorb2b.com

Senior Production Operations Manager Greg Araujo garaujo@endeavorb2b.com

Ad Services Manager Shirley Gamboa sgamboa@endeavorb2b.com

Classified Production Designer Terry Gann tgann@endeavorb2b.com

Audience Marketing Manager Sonja Trent strent@endeavorb2b.com

Audience Development Manager James Marinaccio jmarinaccio@endeavorb2b.com

CEO: Chris Ferrell

President: June Griffin

COO: Patrick Rains

CRO: Paul Andrews

Chief Digital Officer: Jacquie Niemiec

Chief Administrative and Legal Officer Tracy Kane

EVP Endeavor Business Intelligence: Paul Mattioli

EVP Industrial and Energy Group: Mike Christian

VP, Accounting: Angela Mitchell

VP, Digital Business Development: Paul Andrews

VP, Content: Travis Hessman

VP, Customer Marketing: Angie Gates

VP, Digital & Data Innovation: Ryan Malec

VP, Digital Finance: Jessica Klug

VP, Production Operations: Curt Pordes

VP, Sales Operations: Missy Zingsheim

VP, Technology: Glen Scheithauer

T&D World (USPS Permit 795-660, ISSN 1087-0849 print, ISSN 2771-6651 online) is published monthly by Endeavor Business Media, LLC. 201 N Main St 5th Floor, Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI, and additional mailing offices. Canadian GST #R126431964.

POSTMASTER: Send address changes to T&D World, PO Box 3257, Northbrook, IL 60065-3257.

SUBSCRIPTIONS: Publisher reserves the right to reject non-qualified subscriptions. Subscription prices: U.S. ($137.50); Canada/Mexico ($170.00); All other countries ($210.00). All subscriptions are payable in U.S. funds.

Send subscription inquiries to T&DWorld, PO Box 3257, Northbrook, IL 60065-3257. Customer service can be reached toll-free at 877-382-9187 or at tdworld@omeda. com for magazine subscription assistance or questions.

REPRINTS: To purchase custom reprints or e-prints of articles appearing in this publication, contact Reprints@endeavorb2b.com

PHOTOCOPIES: Authorization to photocopy articles for internal corporate, personal or instructional use may be obtained from the Copyright Clearance Center (CCC) at 978-750-8400. Obtain further information at copyright.com

PRIVACY POLICY: Your privacy is a priority to us. For a detailed policy statement about privacy and information dissemination practices related to Endeavor products, please visit our website at www.endeavorbusinessmedia.com

CORPORATE OFFICE: Endeavor Business Media, LLC, 30 Burton Hills Blvd, Ste. 185., Nashville, TN 37215, U.S.; www.endeavorbusinessmedia.com.

© Copyright 2024 Endeavor Business Media, LLC. All rights reserved. Printed in the USA.

DELIVERING SMARTER AND DATA-DRIVEN DIGITAL SOLUTIONS TO CONTINUOUSLY REFINE AND OPTIMIZE YOUR VEGETATION MANAGEMENT AND INFRASTRUCTURE PROGRAMS FOR MAXIMUM IMPACT.

FROM STRATEGY TO EXECUTION LEARN MORE AT THE ALL NEW ASPLUNDH.COM

DIGITAL@ASPLUNDH.COM 1.800.248.TREE

BY NIKKI CHANDLER, EXECUTIVE EDITOR

To solve a problem — especially if it’s pervasive, painful, and ongoing — you must face it head on. You have to dive into it and feel the pain so that you can come up with the solution, get past it, and move forward in a better state. That problem for our industry is the transition to a decarbonized state. I know this “problem” stems from a problem — climate change, or in other terms, if you like: the need for good environmental stewardship — so I guess you could say in trying to solve one problem, we are creating another problem.

I wish it were simpler than that; that we could just decarbonize and be done. Our industry has been working on it for years. I always tell friends and family to not underestimate the utility industry’s motives and action in decreasing carbon emissions. Greenhouse gas emissions from electric power production have decreased by about 15% since 1990, according to the Environmental Protection Agency.

But people also shouldn’t underestimate the electric utility industry’s drive to ensure reliability, which is crucial all the time. I also like the term energy security because electricity really is a necessity now. As you know, these concepts are bumping up against one another at the moment.

Midcontinent Independent System Operator CEO John Bear, in a letter introducing the update to the MISO Reliability Imperative, did not hold back in naming and claiming the problems our industry is facing. “There are immediate and serious challenges to the reliability of our region’s electric grid,” he wrote.

He acknowledged that we could get to that decarbonized end state. In fact, studies conducted by MISO and other entities indicate it is possible to reliably operate an electric system that has far fewer conventional power plants and far more zero-carbon resources than we have today. But we aren’t there yet, and getting there is “posing material, adverse challenges to electric reliability.”

Bear isn’t the first person to raise the red flag. As more rules are proposed, industry associations speak up. When the EPA proposed to essentially eliminate carbon dioxide emissions from power plants by 2035 this past August, Edison Electric Institute and the National Rural Electric Cooperative Association sounded

the warning bell. Fellow regional transmission operators PJM Interconnection, Electric Reliability Council of Texas and the Southwest Power Pool joined MISO in filed comments responding to the draft rule. For these groups, the EPA’s intention may be altruistic, but the timing and means doesn’t necessarily work.

Bear went on to call out the prevailing investment criteria for financing new energy projects. We “will continue to need dispatchable resources for reliability” during this transition. Other challenges he identified include extreme weather events, supply chain and permitting issues, large single-site load additions (data centers, for example), incremental load growth (electrification) and neighboring grid systems becoming more interdependent. It’s enough to make you want to go home, crawl into bed and pull the covers up. But take heart, our industry has always had the most intelligent, creative, and driven people who rise to these challenges. It started with Edison and Tesla.

MISO is a great example to consider. It first published its Reliability Imperative in 2020, a framework to address the urgent and complex challenges facing the grid. “The region’s 45 million people are counting on MISO and its utility and state partners to get it right,” Bear wrote in his message.

The imperative is a living document, according to MISO, which was just updated in February. It’s a good plan, with an overview identifying challenges and key initiatives addressing those challenges. Within that, MISO is working on releasing actual playbooks to make action easier, such as the “Attributes Roadmap,” to address system adequacy, flexibility, and system stability.

Since I am a word person at heart, I noticed the action words included in MISOs’ key initiatives summary: ensure, develop, modernize, prepare, enhance, and fortify. See the MISO’s Imperative for more detail.

This past December, Jim Robb, president and CEO of the North American Electric Reliability Corp., described the “hyper-complex risk environment” the utility industry faces. The environment entails reliability, resilience and security concerns such as fuel uncertainties; loss of key essential reliability services; need for investment in infrastructure; and cyberattacks. He presented the three-legged stool for resilient utilities: access and affordability, reliability and security and environmental sustainability. That’s where we need to be; and I think we will get there. It will be fun, maybe sometimes painful, and we will come out in a much better place because of it.

●

The T&D World Live expert advisory board is instrumental in selecting the topics, presentations and speakers for our program. One of our members shares his varied experiences, concerns for the utility industry and thoughts about T&D World Live here.

David Treichler is director of Strategy and Technology for Oncor Electric Delivery, responsible for strategic analysis supporting the growth of the enterprise. His focus on how technology is changing the nature of human relationships extends to his work as a futurist and widely published novelist.

Q: How did you get into the utility industry? Is this something that you always know you had wanted to do?

A: I was working for Raytheon Company in classified intelligence and battlefield simulation training systems when I became aware of an opportunity with Oncor. I was selected to lead Transmission development outside ERCOT in a joint venture with what was then Westar and Berkshire Hathaway utilities. This was when FERC 1000 was expected to open transmission development.

Q: Is there anything from your past that really pointed you to where you are now in your career?

A: I have worked in a number of different industries and organizations. That has provided an ability to look at questions and issues from a variety of perspectives. I seldom see a problem from just one side. It also permits me to see opportunities that others are not considering.

Q: Have you had a particular person or mentor that has helped you along the way and how did they do that?

A: So many have influenced my career(s) that the list is long and distinguished. Every person I talk with I learn something from. I hope I am able to share insights as well.

Q: What is one of the biggest obstacles you have faced in your life or career and how did you get past it?

A: My biggest obstacle also enabled my strength. I grew up in a small town where there were more cows than people. But there was a library, which gave my imagination wings. I started creating stories to share with others as my mind tried to comprehend the world. Ever since I read as much as possible and write three to four novels each year. The novels help me solve the problems I cannot in reality.

Q: What do you enjoy most about your job now?

A: Gathering data, drawing insights and working with others to develop effective strategies to grow the enterprise.

Q: What is one of the more exciting things that has happened to you in your career?

A: Enabling a U.S. Army squad fight in a virtual environment with a U.S. Marine squad that was physically 139 miles away in another simulation system and changing the combat terrain and environment throughout the exercise.

Q: From your corner of the industry, what are the major problems do you see that need to be addressed?

A: The biggest challenge we are working through in Texas is how to manage the rapid growth of intermittent generation resources while maintaining reliability and resilience in a rapidly growing service area.

Q: Any ideas on what can help those problems?

A: It will take an all of the above, all-hands-on-deck approach, with smart analysis, constant communications amongst all parties, and the cooperation of nature to manage the transition.

Q: What do you think has been one of the most exciting technologies or events that has happened in our industry in your lifetime?

A: Our industry is so dynamic at the moment that it is the confluence of a range of technologies, enabling tools and insight delivering systems, incredibly bright and dedicated people, along with rapid customer and load growth in our service area, that brings me to the office eager for the day.

Q: What did you enjoy about last year’s T&D World Live event?

A: T&D World Live has been an opportunity to work with colleagues from across the industry and the industries that are attempting to learn how to integrate into our grid, in presenting information and insights that will enable and accelerate that integration.

Q: What are you looking forward to this year at T&D World Live?

A: I am looking forward to having time to chat with my colleagues about what they have learned in the past year, what they are seeing as the next challenges to engage, and how they plan to approach those challenges utilizing new tools and products we may first learn about at the T&D World Conference.

Q: Besides T&D World Live, what other events do you attend or participate in?

A: This year I am keeping closer to home than in the past. I have been in Austin for conferences on the ERCOT market, thermal generation considerations, and an academic conference on the future of electrification just in the month of February.

Q: Anything else you would like to add?

A : The pandemic changed the way we learn with another webinar available nearly every day. In my experience if that is the only opportunity to learn you are limited to information. A face-to-face environment permits gleaning of insights, and a renewal of relationships essential for effective leadership. T&D World Conference is a great place for such contestations.

Last month’s issue of T&D World featured the upcoming May IEEE PES T&D Conference & Exposition being held at the Anaheim Convention Center. I have been to many PES T&D Expos, but it all started in Anaheim many years ago. Friends had told me about the PES Expo and I decided that if possible I’d go. Getting permission wasn’t easy. There was never enough money in the budget for training or travel. I asked for approval, but was told no. It turned out, however, there was a loophole, Corporate loved positive publicity.

profession? More importantly, it’s an opportunity to make first contact with new colleagues and open doors to lifelong friendships, which is invaluable. I know it because it happen to me many times.

Presenting that paper at that panel session introduced me to some of the world’s leading HVDC experts who were also on the panel. We first met at the author’s breakfast the morning of the session. Many of us decided we wanted to meet again for dinner to discuss HVDC technology. That introduced me to another important feature of attending the PES conference: networking. After all, the Expo is a gathering place for the industry’s top professionals.

I had been the project engineer on an HVDC (high-voltage direct current) back-to-back converter station project my company had built. I found out there was going to be a panel session discussing the latest HVDC projects and they were calling for papers to be submitted by prospective panelists. I sent in an abstract and the paper was accepted. I was an accepted panelist and the next thing I knew I was in Anaheim.

Thinking back, I must have really wanted to go. I had no experience writing technical papers, and I had never been on a stage making a presentation in front of hundreds of people. I was way out of my comfort zone, but it was worth the effort and as a learning experience, it was beyond expectations.

Funny, Disneyland was a short distance down the street, but for a utility engineer like me, the exhibits on that exposition floor surpassed anything at Disneyland. There was so much happening it was hard to decide what to explore.

If you have ever gone to a PES Expo you know what I mean. Where else can you see and interact with the latest power grid tech-toys? Where else can you have coffee with experts and pickup tips to improve your skills? Where else can you informally trade tricks to perform more efficiently in your

By the end of the conference, I had made some friends and been invited to join the HVDC subcommittee and several of its working groups. They wanted me to help write standards, guidelines, and recommended practices, but luckily I didn’t realize that at the time. These publications define the equipment of the power delivery system — talk about looking behind the curtain. When I got back to my office, once again I asked for permission to join these groups, but the answer was still no. As luck would have it our converter station developed a problem that impacted its reliability. It was a real brain-twister and had everyone’s attention, including the manufacturer. Several HVDC utility engineers I had met in Anaheim said to call them if I ever had an interesting problem. I called and true to their word, they helped, and the problem was fixed. This proved the value of being connected to the HVDC community and I received approval to join the working groups and attend general PES meetings.

From a 30-plus-year perspective, I started out my PES career as a confused working group volunteer and ended up the chairman of the T&D Committee. There were many other offices and work in between. I’d like to go into more details, but there isn’t space for that. If there was, I could tell you about the quirky guy I met at a PES general meeting in NYC. He was standing right behind me in the line for discount Broadway tickets in Times Square.

He told me he was the editor-in-chief for Transmission & Distribution, the predecessor of T&D World, and his name was Rick Bush, hmmm. It was a strange day and again I wish I had space to tell the full story. Years later he’s one of my best friends and I’m an engineer/journalist with the monthly column you’re reading. You never know where attending a PES Expo will lead you!

OUR TEAM HAS THE WORKFORCE AND EXPERTISE TO SOLVE ALL YOUR T&D CHALLENGES

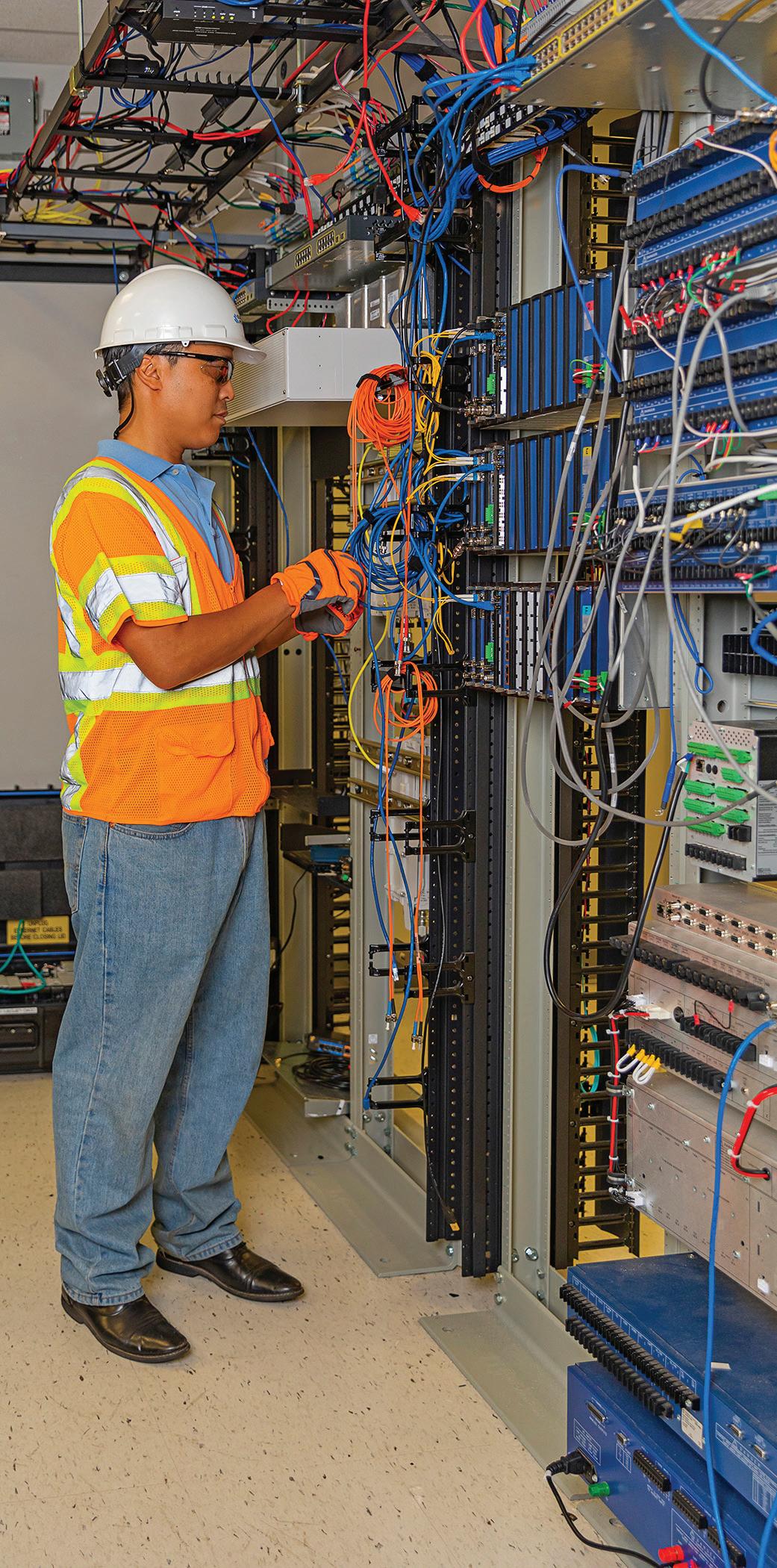

When it comes to trending technologies it’s pretty hard to beat what is going on with digital substations. This technology is providing modernization across the board when it comes to substations. From new substation facilities to antiquated conventional substations they’re all benefiting. It helps that the technology saves money and increases the efficiency of our substations. It also improves personnel safety and increases cybersecurity along with reducing maintenance outages while keeping the equipment healthy and many other budget friendly considerations.

For years the electrical substation has been thought of as the hub or the heart of the power grid, but there has always been something missing — intelligence. It’s been a vulnerable point. There is very little feedback on what is taking place in conventional substations, except when personnel are sent to the facility. Digital substation technology has proven to be the answer. It places intelligence exactly where it’s needed — at the hub of the power interactions. By digitalizing the substation, it’s becoming the brain of the power grid, but it’s been a slow process.

Digitalization began in the control building by replacing the old-school analog control and protection systems with digital processors. Then it moved into the yard by integrating sensors, intelligent electronic devices (IEDs), and other digital technologies directly into the substation’s outdoor equipment. It wasn’t long until manufacturers developed a digitalization strategy for the entire substation, but there was a problem, those early platforms were proprietary systems.

Proprietary devices don’t work with other manufacturer’s equipment and propriety systems have always been an issue for utilities. They want open architecture with plug-andplay practicality. It took a while, but the International Electrotechnical Commission (IEC) addressed the issue with their IEC-61850 standard. It’s the communication standard

for electrical substation automation systems, which defines interoperability between products from multiple suppliers. In a short time, IEC-61850 has matured into a series of protocols addressing areas required for advancing digital substation technologies.

This series of standards includes the primary processes along with secondary and auxiliary equipment in the substation. The technology is still expanding, and we haven’t reached its full potential. The Business Research Company published its “Digital Substation Global Market Report” in early 2024. It estimated the digital substation market “will grow from US$ 7.3 billion in 2023 to US$ 8.03 billion in 2024 at a compound annual growth rate (CAGR) of 11.7%.” They attribute this growth “to grid decentralizing, electrification of transportation, standardization and interoperability, rapid urbanization and electrification.” Business Research Company also project that the digital substation technology to grow to US$ 12.51 billion in 2028 at a CAGR of 11.7%.

Part of that growing market is represented by retrofitting existing conventional substations, which is an enormous market. In North America alone, it’s estimated there are over 79,000 substations in service, with an average age of these substations of around 40 years. That means the technologies in these substations can span from antique status to state-of-the-art facilities. It also means that removal and replacement of these existing substations is economically unfeasible, but retrofitting these substations with cutting-edge digital technology is a viable option.

Manufacturers offer utilities a variety of choices when it comes to retrofitting an existing substation that starts off by replacing aging analog components with digital applications. There is also the option available that includes installing a process bus out in the substation’s yard with the equipment. This retrofit enables the monitoring and control of power flow in near real-time. It also allows for faster diagnostics that can

resolve potential issues before they become serious problems, but it’s getting complicated. So let’s talk with an expert in this area.

“Charging Ahead” connected with Thomas Werner, senior global product manager at Hitachi Energy to discuss the subject of digital substation technologies. Werner began the chat saying, “There are many factors associated with designing and building a new digital substation. Topping the list are high performance and increased flexibility. There are also cost savings linked to the reduction of copper control cable, which is typically estimated at about 60-80% compared to a conventional substation. That savings is multiplied by the reduction in labor required to install the cable from the yard equipment to the control building with its marshaling cabinets and control and protection equipment racks. This is all replaced by point-to-point fiber optic cable. There are also savings associated with less equipment installed in the station, which allows for the digital substation’s smaller footprint. There is an alternative to building a new digital substation facility for those wishing to explore the available technologies. Utilities can upgrade an existing conventional substation and achieve substantial benefits while gaining experience.”

Werner continued, “Upgrading conventional substations with digital components improves reliability, allows real-time monitoring and control of the power flow, which provides better asset management. It enables component health checks, diagnostics, and automated problem solving. We have found

that some utilities are high on the learning curve when it comes to retrofitting digital devices to their substations. They may elect to upgrade the entire facility. Other utilities may feel uncomfortable taking on that much at one time and decide to only implement one or two feeders. That is the advantage of utilizing a technology like Hitachi Energy’s SAM600 3.0 process interface unit. The utility is able to proceed at a pace that fits the user’s scope.”

Werner explained, “The SAM600 3.0 is designed to let the user configure it as a merging unit, a switchgear control unit, or a combination of both. It supports many different installation approaches. By combining the three units into a single device the pace of the retrofit is faster because design, installation, and testing are more efficient. The SAM600 3.0 interfaces directly with outdoor equipment like circuit breakers, disconnect switches, and other devices and it includes built-in conversion of analog-to-digital signals. It also gives users access to advanced automation and communications applications and can easily be expanded for future requirements.”

These conventional substations contain large amounts of digital technologies, but they’re not being used as an intelligent link. That’s where digital substation technology comes into play. It takes full advantage of informational technology and operational technology connectivity (IT/OT). It enables yard devices to share data with the control and protection schemes

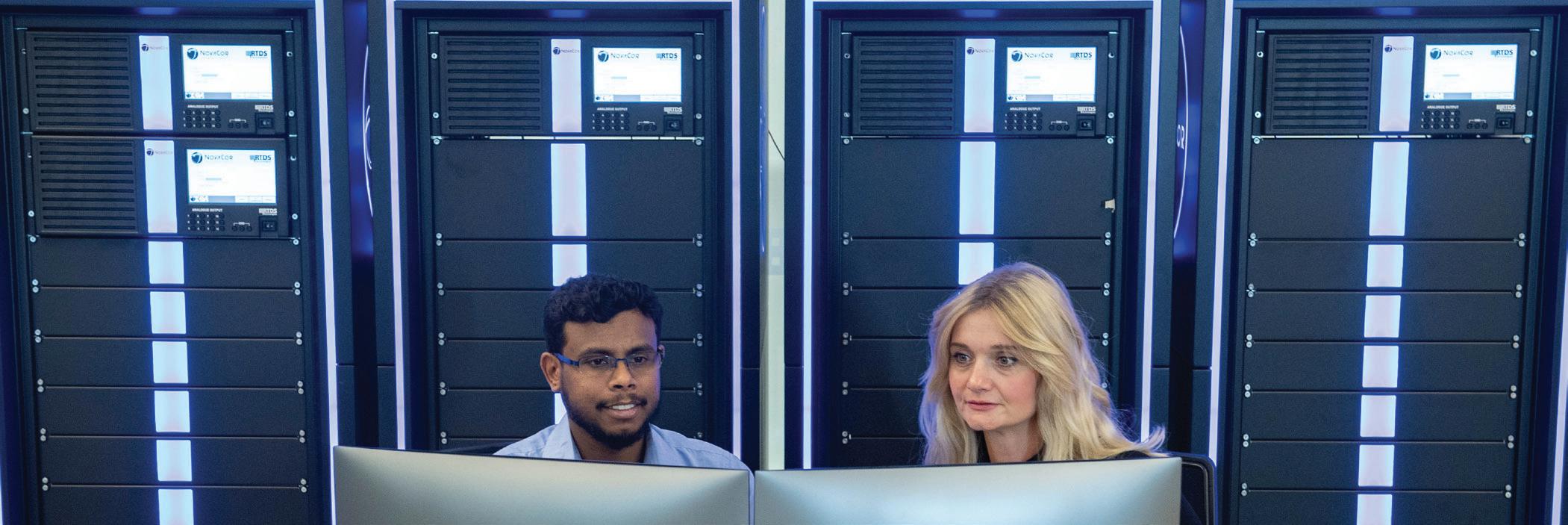

The RTDS® Simulator is the world standard for real-time power system simulation and hardware-inthe-loop testing of control and protection equipment. It’s at the heart of power system innovation laboratories around the world, supporting efforts to de-risk novel technologies for a secure energy transition. Explore case studies and free webinars at our website to learn more.

and other digital substations in real-time for faster response times. A network of digital substations using IT/OT shares and compares this data, which increases the efficient utilization of assets, not to mention faster response time to external events that can impact the power grid.

Installing new digital substations and/or retrofitting existing conventional substations with digital technologies will make IT/OT networking happen and that is exactly what is needed for the demands being placed on our power delivery system. Upgrading conventional substations is simpler and quicker than replacing them, which is much less costly. This type of interconnectivity can improve reaction times to extreme climate change weather related events fueled by global warming, which increases resiliency. Advanced asset management is moved to the next level as IT/OT enhanced digital substation networking is integrated with AI, cloud computing, and other advanced technologies. Predictive models with proscriptive analytics are only two examples of applications making digital substation technology more intelligent. It also gives digital substations a giant leap with self-monitoring, full automation, real-time data acquisition and many additional features. The total package gives a utility a dynamic view of their power system along with the tools for making faster decisions.

That is exactly what has been needed for quick reaction to our rapidly changing environment. Digital substation technologies are slowly bring accepted, but that is changing as

the technology becomes more commonplace. Last year the Nepal Electric Authority awarded GE Renewable Energy’s Grid Solutions a contract to modernize 39 of their substations. The project will retrofit existing substations with digital technologies in relay panels and electrical devices to enable real-time monitoring of power transmitted through these substations.

Recently One Energy Enterprises, an industrial power solutions company, announced they had energized a fully digital, plug-and-play digital substation. The 30 megawatt (MW) substation is expandable to 150 MW and was built using Schweitzer Engineering Laboratories’ TiDL system connecting the monitoring and controls of a Hitachi Energy circuit breaker and power transformer by fiber optic cable. A few years ago, SP Energy Network, a United Kingdom (UK) transmission and distribution network operator, and Hitachi Energy announced their project to retrofit two bays of the existing Wishaw 275 kilovolt substation in Scotland with digital substation components. The retrofit provided valuable experience upgrading a conventional substation.

It has been hard enough keeping up with the advancements and improvements of digital technologies, and now digital substation technology has complicated it more. It gives us the ability to modernize portions or entire conventional substations. It’s the equivalent of a digital fountain of youth for these facilities, but there’s a steep learning curve to harnessing this technology!

The Infrastructure Investment and Jobs Act represents a monumental leap toward the creation of an expansive network of 500,000 EV charging stations across the United States by the year 2030. This initiative is recognized as an unprecedented advancement in the realm of EV charging infrastructure, setting the stage for an EV charging experience that is universally accessible, cost-effective, dependable, and equitable.

Central to this visionary endeavor is the $5 billion investment in the National Electric Vehicle Infrastructure (NEVI) Formula Program. This program is meticulously designed to aid states in the establishment and maintenance of an EV charging infrastructure that promises to redefine the American travel landscape, steering it towards more environmentally friendly and sustainable transportation modalities.

Beyond the foundational NEVI program, the push towards electrification encompasses a broader vision for the United States — a seamless and robust network that not only supports the logistical demands of electric vehicles but also enhances the overall travel experience. This includes the integration of state-of-the-art charging solutions that cater to a variety of settings, from urban centers to remote locations, ensuring that EV drivers have access to charging facilities wherever their journeys may take them.

Implementing such an extensive infrastructure comes with its set of challenges.

States are diligently working to navigate these complexities, from selecting optimal locations for charging stations that are easily accessible from major highways to ensuring the infrastructure meets the necessary power output standards. This phase is crucial in laying the groundwork for a future where electric vehicles are a mainstream mode of transportation.

With states like California leading the charge in enhancing existing EV infrastructure, and others quickly mobilizing to expand their charging capabilities, the nation is witnessing significant strides towards the realization of this grand vision. Ohio’s groundbreaking on the first NEVI project in October 2023 symbolizes a collective movement towards a sustainable and electrified future.

The shift towards electric vehicles is not confined to the NEVI program alone. Oldcastle Infrastructure is at the forefront of this transition, offering a spectrum of EV charging infrastructure solutions tailored to meet the diverse needs of the modern EV market. By laying the foundational infrastructure essential

for electric vehicle ecosystems to scale, and offering solutions designed for rapid deployment, Oldcastle Infrastructure’s innovations are crucial in facilitating the widespread embrace of electric vehicles, ensuring a smoother transition to a sustainable automotive future. n

Sources: driveelectric.gov; fhwa.dot.gov

Find out how you can partner with Oldcastle Infrastructure in your EV charging journey.

Supply chain issues, new construction and demand outpacing manufacturing capacity are several factors behind the shortage of electrical transformers, a critical power grid component.

The Department of Energy is placing a bet on more advanced transformer designs that it hopes will alleviate the long lead times for new transformers, which many in the industry say are hampering outage restoration, renewable energy projects and power grid upgrades.

Up to nine participants can draw from an $18 million funding opportunity for developing, testing and piloting new “flexible innovative transformer technologies,” according to a release from the DOE.

Last year, utilities told T&D World that the shortage has caused lead times in excess of three years in some cases. The impact is felt by utilities all over North America.

DOE’s funding is intended to boost development of new transformer designs with a wide range of transmission and distribution uses. “More flexible and adaptable grid components will increase grid resilience at lower cost and reduce supply chain challenges facing the utility sector,” said Gene Rodrigues, Assistant Secretary for Electricity.

Transformer manufacturers say labor shortages, hard-to-source materials and worldwide shipping delays are among the culprits for the supply shortage.

The funding opportunity will be co-funded by the DOE Office of Electricity as well as the Office of Cybersecurity, Energy Security,

and Emergency Response.

The two areas of interest named by the DOE are to research and develop advanced distribution transformers (flexible, modular, scalable, hybrid or solid state) as well as to demonstrate activities for advanced distribution transformers across a range of transmission-scale duties. Applicants must demonstrate a process for evaluating the prototype performance and extrapolating results to the targeted power and voltage ratings of the final design. Prototypes must also demonstrate high efficiency, variable/controllable impedance, and the ability to accommodate a range of high-side and low-side voltages.

DOE said it expects to announce the selectees in late summer.

The directors of American Electric Power Co. have removed Julie Sloat from her roles of chairman, president and CEO and elected a former Xcel Energy Inc. leader to take her place during the search for a successor.

Sloat had moved into the top spot at AEP just 14 months ago after working as the company’s CFO and senior vice president of treasury and risk as well as president and CEO of its Ohio utility. She had been with the company, which serves 5.6 million customers in 11 states, since 1999. Taking her place is Ben Fowke, who led Xcel from 2011 until the summer of 2021 and was elected to AEP’s board a few months later.

Speaking to analysts on a Feb. 27 conference call that accompanied AEP’s fourth-quarter results — net income of $336 million, down from $384 million in late 2022, on revenues of about $4.6 billion—Fowke said Sloat’s dismissal was not the result of any disagreement about operations or policies or related to any ethics or compliance issues. He added that he expects the CEO search will take at least six months but not more than a year.

“The strategy’s great,” Fowke said. “We just have to execute

and that’s what we’re focused on.”

The CEO change comes after AEP has since December had to digest adverse regulatory rulings in Texas, West Virginia and with the Federal Energy Regulatory Commission. Fowke said he intends “get very much involved” in regulatory strategy, which is being led by Executive Vice President Peggy Simmons.

Sloat’s exit also comes two weeks after AEP’s board announced it had reached an agreement with investment firm Icahn Enterprises to have the latter fill two new board seats and appoint a non-voting board observer. Veteran investor and activist Carl Icahn said then his team was looking forward to working with Sloat and AEP’s board “to optimize the value and performance” of AEP’s businesses. Those operations will continue to include several divisions that had been on or appeared to be headed to the auction block: Fowke said the board has decided to retain the Transource Energy competitive transmission subsidiary as well as investments in the Pioneer and Prairie Wind transmission joint ventures. (AEP’s leaders are close to wrapping the divestiture of the company’s AEP

Energy retail and AEP OnSite Partners distributed resources units.) Combined, AEP has invested about $550 million in Transource and the JVs and Sloat said last summer that selling those assets would let the company further narrow its focus on its regulated businesses.

“We think it’s a great asset,” Fowke said on the conference call about Transource. “Given the various changes that FERC is looking at, I think it gives us a lot of optionality.”

In looking to build further in the competitive transmission market, AEP joins NextEra Energy Inc., where leaders a month ago said they will invest nearly $2 billion in three projects over the next four years. Other utility leaders have in recent months also been talking up the need for more investment in transmission capacity to help meet growing demand from commercial and industrial customers. —Geert de Lombaerde

The Midcontinent Independent System Operator’s (MISO) Board of Directors has approved the 2023 MISO Transmission Expansion Plan (MTEP23). MTEP23 underscores MISO’s commitment to ensuring reliability for our footprint as the grid evolves.

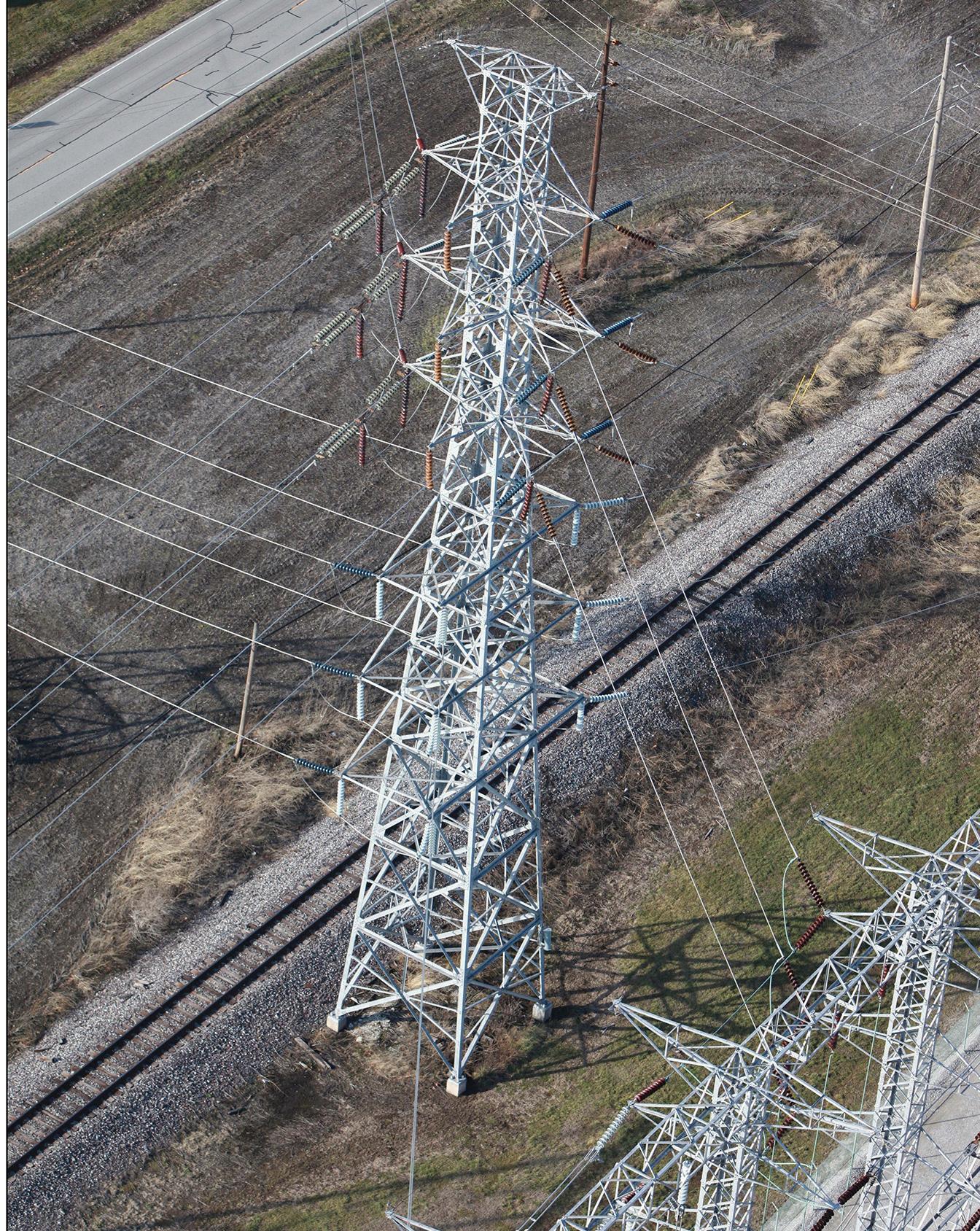

MTEP23 is the largest in MISO’s history both by volume and investment (excluding the two years of accounted Multi-Value Projects/Long Range Transmission Planning (LRTP) portfolios). The groundbreaking $9 billion in transmission enhancements will fund 572 projects addressing aging infrastructure, new load and added generation due to retiring traditional resources. These projects total over 700 miles of new or upgraded lines.

“I am extremely proud of the commitment and quality of work my team members and others throughout the organization did to make MTEP23 possible. It took extensive stakeholder processes and significant modeling and analysis over the past year,” said Aubrey Johnson, MISO’s vice president of System Planning & Competitive Transmission.

Unlike typical MTEP cycles in which investment is spread across the region, $3.9 billion (or 43% of the total investment) is planned for projects in Louisiana and Texas. This is largely in response to an increase in generation retirements and load associated with economic development.

The changing resource mix continues to add complexity to both MTEP and LRTP planning. In response, our planning tools and processes must also evolve to sustain their role as key initiatives of the Reliability Imperative’s Transmission Evolution pillar.

The North American Electric Reliability Corp. took a look at electric vehicle adoption and issued some suggestions on how industry and regulators can come together on making sure EVs get charged without adversely affecting the bulk power grid.

In NERC’s “Potential Bulk Power System Impact of Vehicle Chargers,” the corporation called for cross-sector work to address the existing knowledge gap between what utilities are expecting EV users to do and what they may actually do — the latter being something NERC’s white paper admits nobody is quite sure of and calls for more research.

According to NERC, there are big gaps in technical understanding, planning and modeling for EV charging readiness programs. Neither EV users as a group nor electric utilities and grid operators have reliable charging models, sufficient standardization of charging devices, or studies into the impact on the bulk power grid.

NERC also finds that there is only a single, broad electrical model for EV charging, and grid operators and planners have to build better models that can make accurate predictions on EV user behavior.

“The growing penetrations of EVs necessitate a study of the real or anticipated risks that the EVs with their charging requirements bring to the electric grid,” according to the white paper.

Also, EV charging systems need to be united under a common control and performance standard. If you charge two EVs from different automakers at the same charging station, the vehicles may not draw on the power grid in the same way, according to NERC.

“This lack of standardization makes grid planning difficult. Efforts are under way within the electric industry to address this issue,” according to the white paper.

Finally, NERC says, EVs and their charging systems’ impact on the power grid have not been sufficiently studied. To combat this, NERC performed a study based on the lone model available at the moment to examine this EV chargerpower grid interaction. The corporation found EV chargers can adversely affect the bulk power delivery system’s reliability depending on how they draw current.

EV chargers are currently designed only for user convenience and not for overall grid stability. This needs to change, according to NERC’s directions, and could conceivably come about through collaboration between manufacturers and the utility industry.

NERC recommends EV and charging manufacturers reach out to utilities and develop standards and performance guidelines to promote what NERC calls grid-friendly charging. In the absence of industry collaboration, the federal government and regulators may need to step in.

—Jeff PostelwaitThe leaders of Exelon Corp. are trimming the distribution capital spending plans at their Commonwealth Edison Co. unit — which is by far the company’s largest — by $1.25 billion over the next three years in response to a December decision by Illinois regulators to deny a multi-year grid plan.

That Exelon President and CEO Calvin Butler and his team are cutting ComEd’s capex goals isn’t a surprise. They said on the heels of the Illinois Commerce Commission decision that they’d need to re-evaluate their investment plans. But the scale of the cuts is significant: Executives’ plans had called for ComEd to spend a little more than $2 billion on distribution projects this year and then grow that number to more than $2.35 billion in 2025 and $2.45 billion in 2026. The retreat from those targets constitutes a haircut of more than 60% — although overall capex at ComEd will fall by less than that figure because of larger transmission investments.

“Our job is to align with what they are requesting,” Butler said on a conference call following Exelon’s fourth-quarter earnings report, which showed net income of $617 million on operating revenues of $5.37 billion. “We are building a plan to achieve those goals and we will continue to talk with those stakeholders. But […] we are ready to pivot if required.”

The Illinois regulators’ decision also has forced the Exelon

executive team to lower their longer-term forecasts for growth in operating earnings and dividend growth by a percentage point to a range of 5% to 7%. This year will likely see growth come in below that range with 2025 being better in that regard, they said.

The ICC’s decision wasn’t the end of this story for ComEd, however. The company has appealed the ruling and an order on revenue requirement increases from that rehearing process is due in June. ComEd officials also have filed with an appeals court seeking a new review of questions around its planned return on equity, capital structure and possible returns on its pension assets.

Despite the ComEd stumble, the capex budget for Exelon as a whole will grow slightly this year to $7.4 billion as transmission projects scale up. Through 2027, Butler and his team plan to put to work $34.5 billion, which is an increase of $3.2 billion from their previous four-year plan spanning 2023 to 2026. Exelon’s rate base is forecast to grow an average of 7.5% annually to $73.9 billion from $55.4 billion last year.

Shares of Exelon (Ticker: EXC) rose more than 4% to $36.21 on the heels of the earnings report and outlook. They are, however, still down about 10% over the past six months, trimming the company’s market capitalization to about $36 billion. —Geert de Lombaerde

The New York State Public Service Commission approved the joint proposal of Orange and Rockland Utilities, and New York State governing bodies and regulators for undergrounding a portion of a transmission line.

The New York State Departments of Public Service, Environmental Conservation, Transportation, Agriculture and Markets, as well as the County of Rockland and the Town of Clarkstown presented the project with the utility.

The $57.8 million electric transmission project is a new 138 kilovolt underground transmission line, primarily within the public roadway rights-of-way, for a total distance of about five-and-one-half miles between the Burns substation and the West Nyack Substation in the Town of Clarkstown, Rockland County.

“This new transmission project is good news for the region and its customers,” said Commission Chair Rory M. Christian. “It will help improve reliability and reduce the chances of power outages due to an over-stressed electric grid.”

According to the joint proposal, the new power line is needed

to relieve potential overloading of O&R’s existing 138 kV overhead Line 702 between its Burns and Oak Street substations.

Recent summer studies indicate that the power flow on the existing line will exceed its capacity if an outage occurs on another 138 kV line serving the region. Additional anticipated loads from proposed data centers in the Orangetown area will increase the potential for overloading under the same contingency.

Should such overloads occur, load transfers to adjacent substations will be needed and, if the overloading persists, load shedding will occur to prevent damage to the existing conductors. Once completed, the project will immediately alleviate loads on the existing line, improving the regional transmission network’s overall resiliency and power source reliability to southern Rockland County, while using existing ROW without visual impacts.

Two public statement hearings were held on May 25, 2022 at the Rockland County Seat, New City, to receive public comment. No party is challenging the joint proposal or the project.

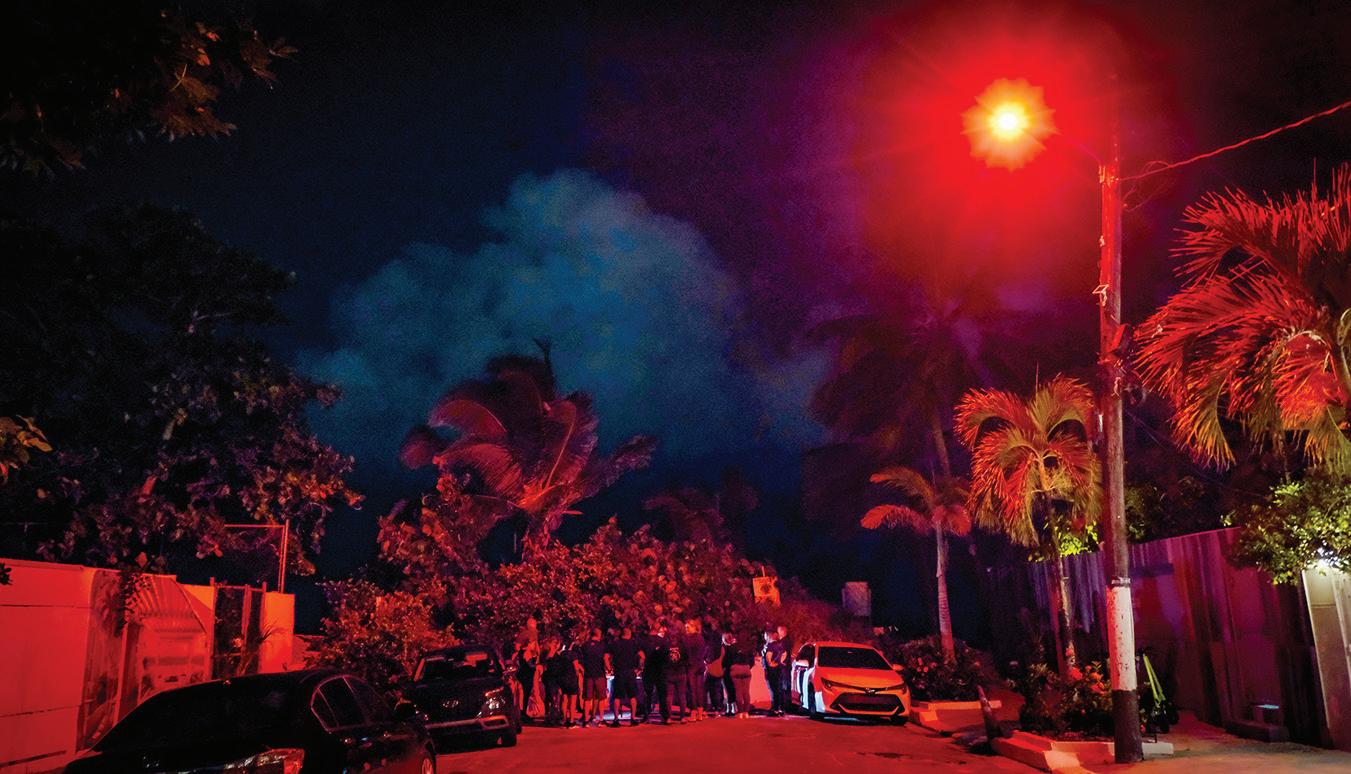

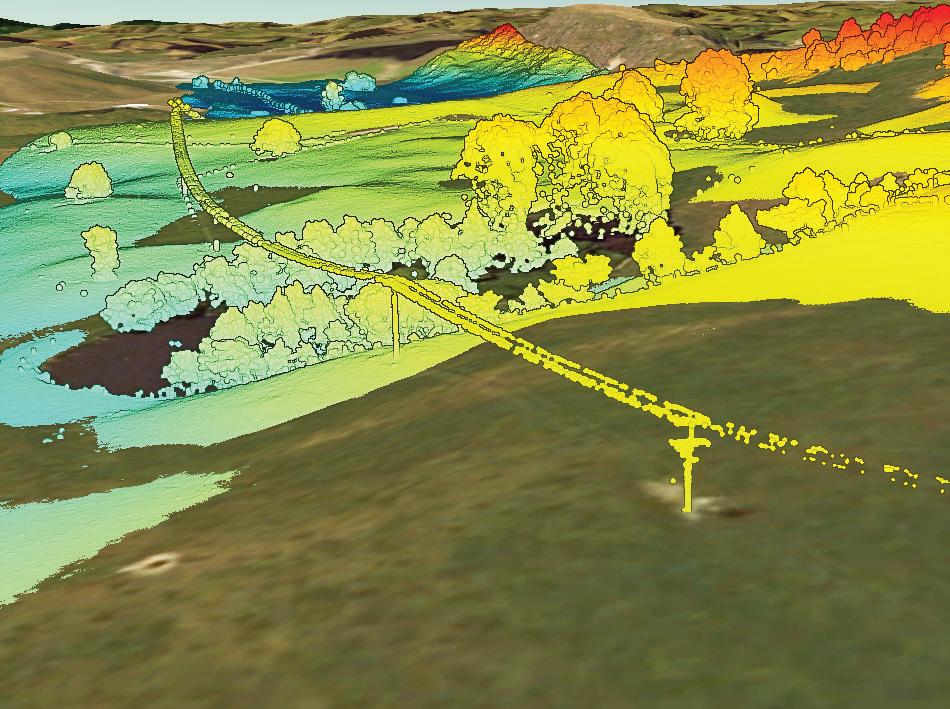

With Puerto Rico’s climate zones and year-round growing season, overgrown vegetation is responsible for more than half of LUMA Energy’s outages to its 1.5 million customers on the island. The utility has cleared 3,900 miles of power lines since June 2021, and by the end of 2026, it expects to clear 16,000 miles of power lines — achieving a 35 to 45% reduction in outages.

To take a proactive approach to grid resiliency and reliability, LUMA is zoning in on vegetation clearance as part of its “Building a Better Energy Future” island-wide work plan. The federally-funded projects are mainly focusing on three key areas — vegetation clearing, automation devices and substation modernization.

“Nothing is more important for LUMA than continuing to improve reliability and the service that we provide to our customers. These combined initiatives, designed to build a better energy future, represent billions of dollars of investment into

Puerto Rico’s electric system and are focused on improving overall reliability, as well as providing new ways to communicate and serve our customers in every municipality,” said Juan Saca, president and chief executive officer of LUMA.

LUMA recently launched its vegetation clearing initiative, a one-time, multi-year effort to clear overgrowth and vegetation across critical electric infrastructure. The plan will focus on a full remediation of all transmission and distribution rights of way (ROW), substations, and telecommunications sites. As part of its vegetation clearing initiative, LUMA is leveraging federal funding to clear transmission and distribution power lines and establish new ROWs on the island to improve service reliability. FEMA recognized that a vegetation reset is an eligible expense, and the work is also recognized under the Section 406 Hazard Mitigation Fund.

“Vegetation is a big part of our plan, and we are very excited we are beginning a historic project,” said Dr. Shay Bahramirad, senior vice president T&D, Strategy and Sustainability. “This one-time reset will allow us to improve the reliability significantly.”

As part of LUMA’s Island-Wide Work Plan, the utility is planning projects to improve reliability and better serve its customers.

Reliability Improvement Initiatives

• Grid Automation

• Vegetation Clearing Initiative

• Substation Modernization and Rebuilds

• Pole Repairs and Replacements

• Advanced Metering Infrastructure (AMI)

Customer Service Initiatives

• Improved Outage Communications

• Financial Support and Flexible Billing

• Energy Savings Customer Programs

• Community Streetlight Initiative

LUMA has been partnering with the Central Office of Recovery, Reconstruction and Resilience (COR3), the governor of Puerto Rico and the Energy Bureau on the initiative. Each shares a collective commitment to executing the project, and together with the federal government, is making the necessary reviews, she said.

“This is a historic opportunity for Puerto Rico to not only improve the reliability and resiliency of the system but make it possible to rebuild the whole grid to provide enhanced levels of service,” Bahramirad said. “We are incredibly thankful to our local and federal government partners for their continued support in making this possible for the communities in Puerto Rico.”

During the first year of the plan in 2024, the vegetation clearing crews will clear 5,700 miles, and the second year in 2025, they will clear 6,900 miles. The third year, they will clear the remaining lines in the system.

“After the first year of the program, we are going to reduce the frequency of outages by 15 percent,” Bahramirad said.

“This will have a significant impact on customer outages.”

Along with the sheer scope of the work, LUMA is also committed to comply with environmental laws and regulations related to vegetation, Bahramirad said. For example, the utility must comply with regulations set forth by the USDA, Forest Services, Puerto Rico Department of Natural and Environmental Services, U.S. Fish and Wildlife Services and others.

“Complying with environmental laws and regulation, protecting endangered species and environmental stewardship are LUMA priorities,” Bahramirad said.

In addition, many of the ROWs haven’t been touched or cleared per industry standards for many years, which creates additional obstacles for access. In addition, LUMA must take outages in certain cases to perform the work safely on the line.

“Because of the state of the grid and the extreme heat that everybody around the world is experiencing these days, it needs to be done very methodically,” she added. “These are a few of the challenges that we have to overcome, but we are committed to moving this project forward because of the significant implication to our customers.”

LUMA is focusing on creating improved access to the power lines to not only improve reliability, but also help to expedite the grid modernization projects.

“It’s going to help us to move forward with the construction and transformation of the grid faster because it takes less time to get to the structure, for instance, to change a pole on top of a mountain.”

During the vegetation clearing reset, LUMA is installing sensors and leveraging LiDAR technology to keep track of the progress, create a proper database and perform analytics moving forward. For example, LUMA’s team is taking LiDAR images of the ROWs to be able to establish the proper ROWs and understand the type and intensity of vegetation in different areas.

“We made a commitment to the federal government that we are going to ensure that moving forward after we cleared one time, we’re going to maintain it properly per industry standards,”

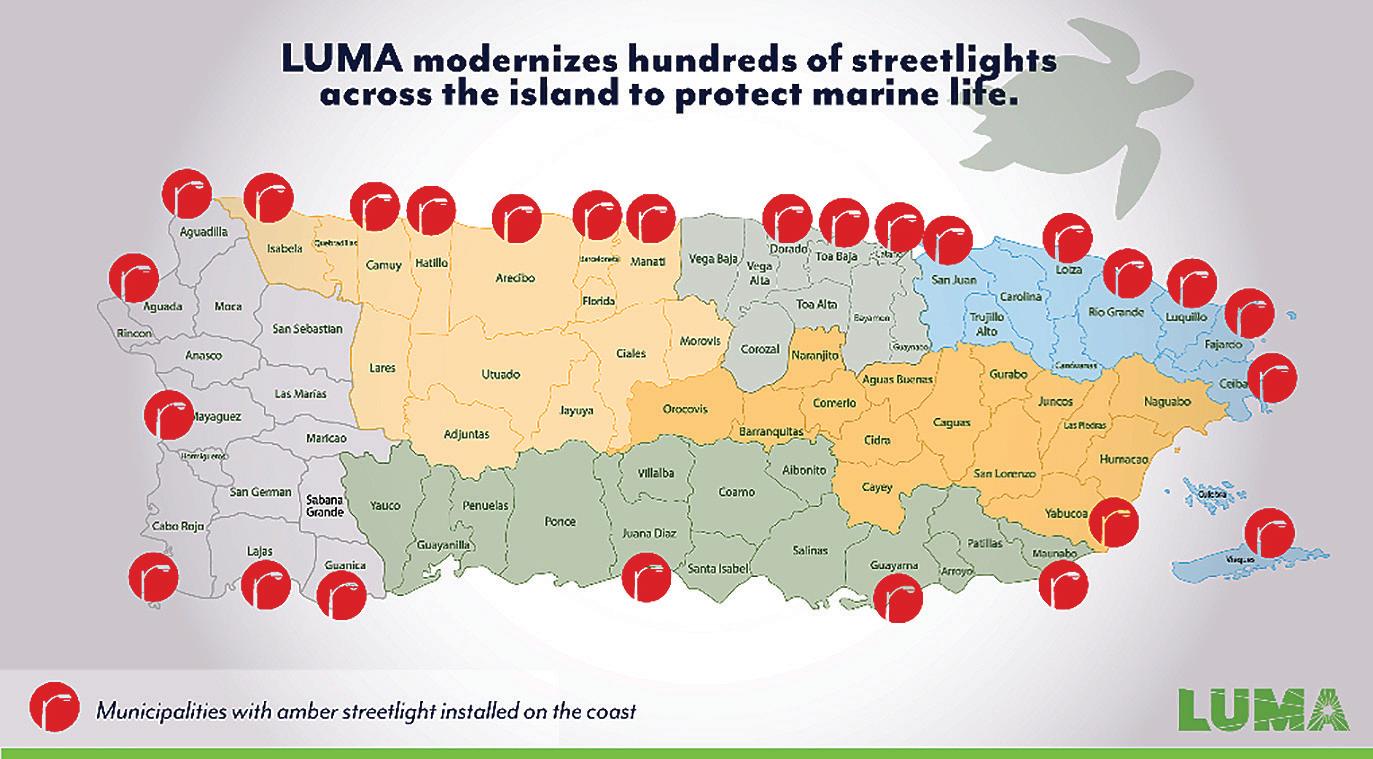

As part of its Building a Better Energy Future island-wide work plan, LUMA is upgrading its electrical system. At the same time, it’s changing the way its communities are illuminated by installing new streetlights featuring LED technology. Through the FEMA-funded Community Street Lighting Initiative, LUMA’s line crews are installing streetlights that consume about 65% less energy and last up to four times longer than conventional sodium and mercury lights and have an added benefit of protecting the local marine life.

“We have installed streetlights that comply with all applicable laws and contribute to the conservation of endangered species,” said Heriberto González Méndez, director of LUMA’s Community Street Lighting Initiative.

“This initiative brings significant improvements to public safety and energy efficiency in communities across Puerto Rico.”

To date, the utility has modernized hundreds of streetlights across the island, including those in sea turtle nesting areas. LUMA is coordinating with turtle conservation groups like 7 Quillas to ensure a safer environment for the reproduction and survival of the endangered species.

“Light pollution is very harmful to turtles because it confuses them and leads them away from the coast,” said Karen Schneck Malaret, education coordinator for 7 Quillas.

See the map below to see where the new streetlights have been installed on the island.

Bahramirad said. The analytics and data gathering will help us to establish a condition-based system.”

To ensure that it is using the best academic practices and talent as part

of this initiative, LUMA is in dialogue with the University of Puerto Rico and two other universities in Puerto Rico. The utility has hired 200 recent graduates from six universities in Puerto Rico.

An additional 1,300 to 1,500 new jobs will also be created to remove hazardous vegetation from across the island.

“This young, energetic talent is going to help us do vegetation clearance Steel

As an expert in the world of IEC 61850, I know how important testing the SAS and SCADA is. StationScout provides a really simple and clear overview of the communication within automation and control. Both the behavior of IEDs and all signals transmitted are visualized transparently. The dedicated powerful test set establishes a cybersafe connection to the station network. StationScout is the ideal tool during the entire lifecycle of IEC 61850 systems.

www.omicronenergy.com/StationScout

going forward, do proper analytics and make sure we keep it the way it has to be,” Bahramirad said.

Because Puerto Rico has various climate zones, it has different types of vegetation on the island, compounding the challenge of vegetation clearing. “The southern part of the island is drier compared to the middle, which has a mountainous area,” Bahramirad said. “This does create different challenges for the execution of the work as well as for the maintenance.”

By partnering with the University of Puerto Rico, LUMA is striving to understand the locality of plants and vegetation and learn how to use environmentally friendly treatment. “We are looking potentially into planting different types of vegetation under the ROWs,” she said. “For sure, it will not be a type of plan that creates an invasion, but it’s one of the scopes of collaboration with the University of Puerto Rico.”

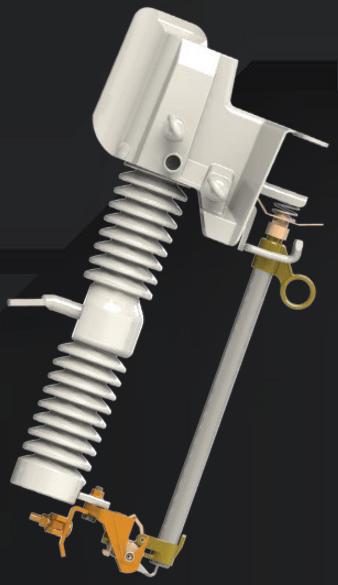

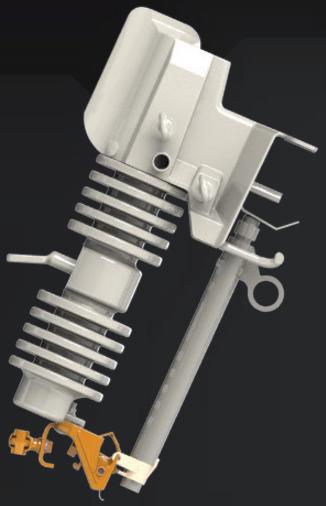

Beyond vegetation clearing, LUMA is also installing smart meters and grid automation devices. As part of the utility’s $876 million Meter Modernization Initiative, LUMA will install more than 1.5 million smart meters over the next three years. The smart meter technology will expedite response and service restoration through improved, remote outage detection technology.

To further help increase visibility into its transmission system, LUMA has installed sensors on different structures so when a fault occurs in the system, the field workforce can quickly identify its location.

“This type of data is going to help us to do the work analytically and more intelligently,” Bahramirad said. “We are trying to tackle improving the frequency and duration of outages from many different fronts, and one of the most important components is automation devices. They will help us to isolate the fault and impact a fewer number of customers so we can replace them faster and send our crews to the right place.”

In the past two years, the utility has installed 3,500 automation devices, and it plans to install 5,000 automation devices this year and next year. In five years, the utility plans to have 35,000 automation

devices varying from three-phase reclosers to single-phase reclosers to cutouts and fault current indicators.

Another important benefit of this work is that it will help with integration of renewables and require less truck rollout, which means less carbon footprint. To determine where to install the devices, LUMA has been receiving technical assistance from six national labs and the Department of Energy.

“We look into different parameters such

as the number of customers and historical reliability data,” Bahramirad said.

To increase the resiliency of its system, LUMA is also focusing on both modernization and the rebuild of infrastructure damaged by hurricanes. In addition, the utility is upgrading obsolete equipment past its life expectancy and providing operational flexibility and station redundancy.

“A proper planning hasn’t ever been done in Puerto Rico,” Bahramirad said. “We have been doing area planning and doing studies for both the transmission and distribution to identify the locations to eliminate the single point of failure.”

LUMA has seven new greenfield substations and is also replacing several high-voltage breakers and transformers to improve the resiliency of the system and reduce the likelihood of blackouts. For example, as part of its FEMA-funded Substation Modernization Initiative, the utility completed critical upgrades and improvements to the Sabana Llana substation in early December 2023, resulting in improved reliability across the island and optimizing distribution operations for customers served by other nearby substations.

At the Sabana Llana Substation, workers replaced breakers and an outdated transformer with industry-standard modern equipment. Crews also performed thermal imaging inspections and conducted necessary repairs at the substation and cleared vegetation. LUMA’s

employees also protected crews and critical infrastructure by replacing 1200 ft of fencing and installing a secondary grounding area.

“The Sabana Llana substation is a critical part of achieving our goal to improve system reliability and help reduce the risk of future outages for our customers,” Saca said. “Work like this will help us achieve what we know the people of Puerto Rico expect and deserve — a more reliable energy service with fewer outages.”

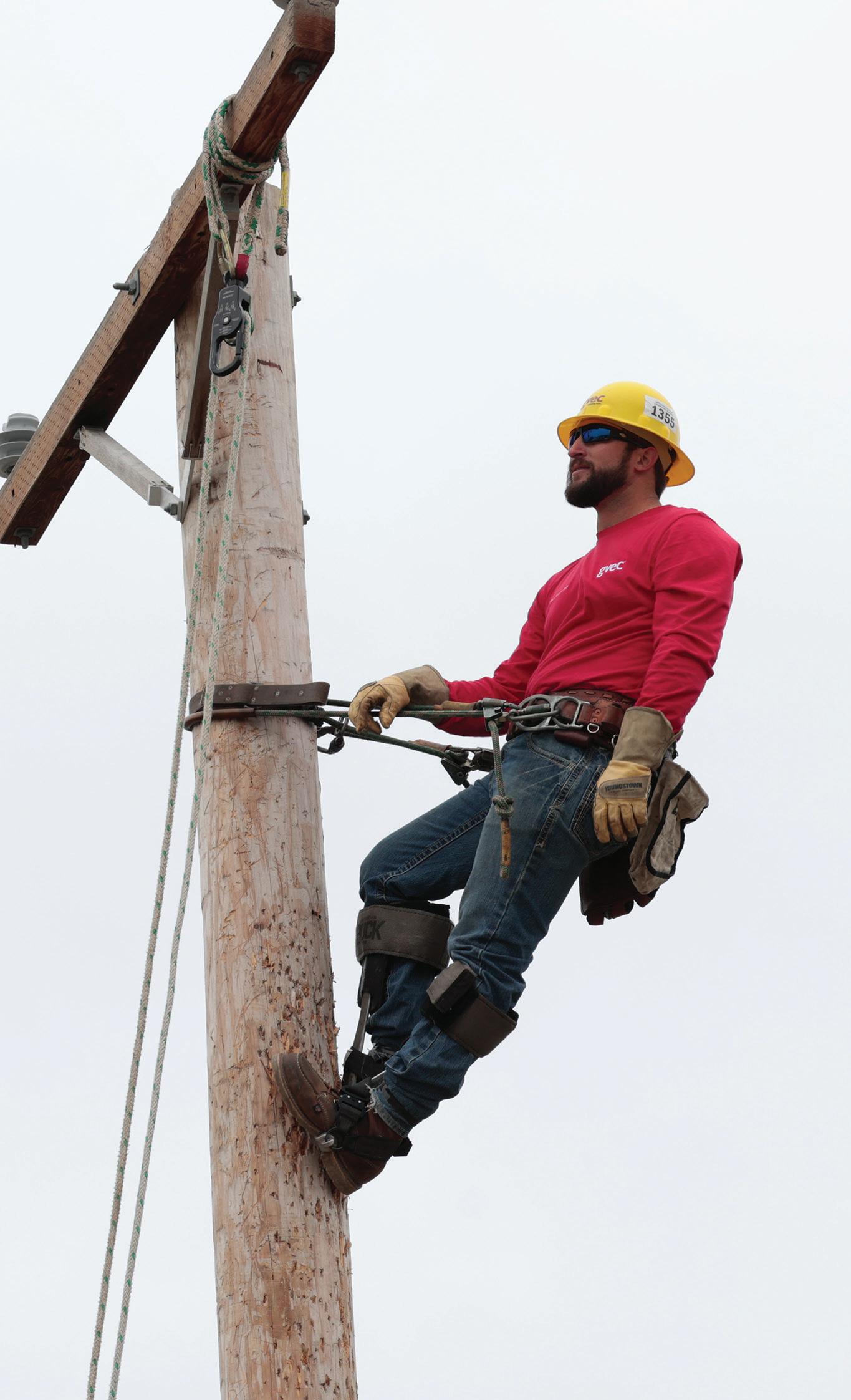

LUMA is not only modernizing substations, but also upgrading its electrical system to improve reliability. Line workers have installed more than 10,400 poles as part of the utility’s commitment to build the overhead system to withstand 160 mph winds. LUMA plans to replace a significant number of the poles on the island in the next five years.

Due to the environmental conditions, some of the poles are constructed of concrete or fiberglass, while others will be made from steel. The line workers are also installing wider fiberglass crossarms, which aren’t as susceptible to corrosion

due to saltwater exposure. The utility is keeping track of the assets in the system so as they move forward with modernization, it can do condition-based maintenance, ensuring that the assets have a longer lifespan.

Significant progress has been made in improving reliability, improving customer service and integrating more renewables than the past decade, but Bahramirad said there’s still a long way to go.

“We empathize with our customers that they have to experience outages, and we are working very hard to make sure that we design and modernize the grid, not only for the next two or three years, but for the next three generations of Puerto Rico,” she said.

AMY FISCHBACH (amyfischbach@gmail.com) is the field editor for T&D World magazine.

Editor’s Note: The statistical data in this story are accurate as of press time. To listen to Dr. Shay Bahramirad talk about LUMA’s island-wide work plan, tune into the Line Life Podcast by going to linelife.podbean.com.

Texas has emerged from two winter storms in the three years since Uri with no major issues, but recommended reliability plans are still not fully implemented.

By RYAN BAKER, Associate EditorSince the fatal effects of Winter Storm Uri struck Texas three years ago, two other major, named storms, hit the region and neither caused the power grid to fail the way it did in 2021.

It remains an open question how much Texas’ energy sector – famously deregulated and operating in some ways as an island unto itself – will fare during future winter storms, as well as summer heat waves and severe weather.

In January, Winter Storm Heather entered the U.S. in Oregon, caking Portland in ice before hopping the Rockies and sweeping through the South. Snow blanketed the area from Tulsa to Dallas and ice choked roads in Houston and San Antonio. There were some scattered, local outages, but the bulk power delivery system stayed on its feet, despite an even higher peak power surge than during Uri (78,138 MW during Heather versus 69,812 MW for Uri).

During Christmas 2022, Winter Storm Elliott caused outages for millions of Americans in the Eastern half of the country. According to a joint study into the storm’s impact by FERC and NERC, there were 3,565 unplanned outages in the Eastern Interconnection, largely resulting in 90,500 MW worth of power

units that were offline unexpectedly. The commissions compared this impact to Uri’s impact on Texas, adding that this storm showed infrastructure east of the Mississippi is still vulnerable to extremely cold weather.

Texas was on the outside edge of Elliott’s impact, with the impact falling hardest on the South, Mid-South and Appalachian states. Both storms could be called glancing blows compared with Uri’s direct hit.

During Elliot, north of 80% of outages were the fault of temperatures being outside of historical data – whether the cause was a power plant shutting down, a natural gas wellhead freezing or some other temperature-related cause.

FERC Chairman Willie Phillips said the cause of wide-spanning, long-lasting outages, severe weather, is not going to go away.

“It shouldn’t take five winter storms in 11 years to show us the gravity of the situation we find ourselves in,” Phillips said in September 2023, adding that some recommendations from his commission’s 2021 Uri report are still not implemented.

We are now three years removed from at least 240 and perhaps as many as 700 lives lost and 10 million plus people losing

power and there are still doubts on whether Texas can stand up to another large-scale event.

The main issue is being able to implement regulations and practices for events that are statistically low to happen – at least historically.

When the Electric Reliability Coun-cil of Texas, the operator for most of Texas’ power grid, instructed utilities to minimize power demand or risk more damage to the grid during the winter storm in February 2021, transmission companies were forced to cut off power to portions of the natural gas delivery system. Freezing wellheads and offline processing facilities made natural gas producers unable to supply adequate fuel to power plants, exacerbating the problem in a state where natural gas is the No. 1 source of electricity at more than 41%.

The new leadership at regulatory bodies is quick to point out that positive change has taken place. New weatherization regulations for energy facilities were adopted in May 2021. The Texas Public Utility Commission was tasked with creating and enforcing criteria for power plants, while the powerful Railroad Commission of Texas, which regulates oil and gas extraction, gas utilities, coal mining and other aspects of fuel and power production, set new requirements for natural gas facilities.

A raft of new state laws required officials and industry players to create a plan to ensure that important natural gas facilities continue to get power even if rolling blackouts were ordered. Other laws mandate winterization for power plants – a big

item in FERC and NERC’s recommendations for Texas that went unheeded for years – and stiff fines for noncompliance from regulators.

ERCOT also implemented several management and grid operation modifications. They included requiring extra thermal

Building on over 130 years of experience, GE Vernova is now an independent, publicly traded company on the NYSE. Together, with our customers, we continue our mission to electrify and decarbonize the world.

gevernova.com

power generation to be retained in reserve if power facilities went offline unexpectedly, or demand exceeded predictions.

Since the detriment to the grid in Feb. of 2021, there have been multiple cases of energy companies either issuing warnings for cold temperatures or requests to minimize the use of power in households.

During Elliot, Texas saw temperatures drop down to the low teens. Electricity demand skyrocketed, reaching levels close to that of the storm in 2021.

Despite these challenges, ERCOT did not have to reduce load during the cold snap since electricity generation and reserves were sufficient. Rolling blackouts were used by several other significant regional grids around the country due to a higher frequency of thermal plant failures brought on by cooler temperatures and precipitation.

A few other recently anticipated cold fronts forced ERCOT, the PUCT, and utilities like Austin Energy to release weather watches and to recommend lower electricity usage.

• Jan. 15, 2024 from PUCT

• Jan. 10, 2024 from ERCOT

• Dec. 4, 2023 from Austin Energy

• Aug. 24-30, 2023 from ERCOT

• June 20, 2023 from PUCT and ERCOT

Texas’ power grid is still vulnerable to extreme cold and heat as well as severe weather from thunderstorms to hurricanes. It’s safe to say alerts such as these, as well as the weather preparations that accompany them will be necessary in the future.

Investigations and controversies launched quickly after Uri, and many energy leaders changed roles in Texas. There continues to be turnaround in lead roles.

Texas S.B. 2154, signed by Abbot in 2021, increased the size of the PUCT board of commissioners from three to five after Uri, but as of press time only four commissioners are appointed, and none of the current commissioners have been on the job since before

April 2021 (the three in charge during Uri were compelled to step down).

The new law also did away with the requirement that every PUCT commissioner must “be well informed and qualified in the field of public utilities and utility regulation,” but added requirements that they be Texas residents. Some of Texas’ energy regulators were criticized after Uri for living outside the state.

Commissioners Will McAdams and Peter Lake, appointed in April 2021, both stepped down in 2023 before their terms were up. PUCT commissioners serve six-year, staggered terms.

Around the time he resigned, Lake said the Texas power grid had been in crisis when he took over but was now more reliable than ever thanks to the PUCT and ERCOT’s reforms. Lake favored a plan of economic incentives to keep power plants in service and build new ones, but the state legislature preferred laws to pay direct bonuses for bringing new gas plants online and encouraging new plants through loans.

For his part, McAdams said he needed to spend more time with his family, adding the PUCT had a lot of new hires that should keep making progress on shoring up the power grid. In February 2024, he announced he’d be taking a lobbying position.

Thomas Gleeson was appointed chair of PUCT in January 2024. Gov. Greg Abbott, who picked Gleeson, pointed to his long record with the commission.

“Thomas Gleeson’s longtime service at PUCT and wealth of knowledge make him the ideal choice for Chair of the Commission,” Abbott said. “As a seasoned leader with over 15 years of experience at the agency, including serving as executive director and chief operating officer, Thomas will help ensure Texans and Texas communities have the utility services they need.”

Changes have also been in store at ERCOT. Jayapal Parakkuth was named the senior vice president and chief information officer. Venkat Tirupati was promoted to vice president, DevOps and Grid Transformation. Taylor taking on the role of senior vice president, chief financial officer and chief risk officer. Finally, Adam Martinez was given the role of vice president of Enterprise Risk and Strategy.

Anyone in a new job will need time to adjust to the learning curve, however the ERCOT leadership remains upbeat.

“Our responsibility to all Texans is to ensure we continue to maintain a reliable and resilient grid now and in the future. These organizational changes will support ERCOT’s continued mission to implement solutions for the challenges our industry faces and position us to meet this responsibility,” said ERCOT President Pablo Vegas, who took over in 2022.

Vegas’ predecessor, Brad Jones, died in November 2023 after serving as interim president and CEO at ERCOT from May 2021 to November 2022.

Vegas told a press conference before Winter Storm Heather that ERCOT performed hundreds of winterization checks through 2023. After the storm’s impact, the Texas power plant fleet saw roughly half the unit outages as during Uri. Also during the storm, Texas’ solar power sources provided nearly a fifth of generation at the peak of Heather’s impact, setting a record. The state’s powerful wind energy assets contributed up to 30% of power generation during Heather.

ERCOT is looking into another potential source of emergency power: the Pattern Energy Southern Spirit Transmission line, which has been under development for some 10 years – not an unusual span of time for these sorts of projects. In this proposal, Texas would be linked to an extra 3000 MW of power via about 320 miles of new transmission. The line will not be energized until at least 2029, and the states providing that power, Louisiana and Mississippi, have yet to approve the

project. However, Southern Spirit would more than double the capacity of Texas’ present interconnections, according to project developers.

The ERCOT grid currently gets about 820 MW via the Southwest Power Pool and about 400 MW from a pair of lines linking it with the grid managed by Mexico’s Comisión Federal de Electricidad. The Texas Interconnection, managed by ERCOT, continues to operate separately from the Eastern and Western interconnections as a way of sidestepping oversight from federal organizations such as FERC.

The Texas grid has gotten by the cold spells of the past, but they have yet to face anything close to the cold temperatures and outages seen back in 2021.

What’s most concerning is, even though temperatures were about 10 degrees warmer, power demand during the most recent incident almost surpassed levels from Uri. The day before the cold front came, ERCOT’s own demand estimate was off by 12,000 MW due to changing factors such as home heating electrification and population growth.

Grid reliability is becoming more and more dependent on an aging fleet of coal and gas facilities as energy demand rises. In periods of extreme heat or cold, these facilities are less effective at counteracting projected dips in intermittent power sources like wind or solar. Building new power plants is such an expensive prospect for companies that it is difficult to

imagine a few incentives passed by the state legislature moving the needle much.

Regulators are assessing potential improvements to the electricity market. However, in the interim, until additional capacity is brought online under a better market structure, ERCOT will face difficulties in maintaining balances between supply and demand throughout extreme weather events due to the increasing discrepancy between the increasing renewable capacity and completely transportable resources.

Texas sits roughly in the middle of the class on energy efficiency – tied for 29th place in the American Council for an Energy Efficient Economy (ACEEE) rankings, which consider state laws, energy codes and utility programs, among other things.

The Lone Star State requires its utilities to cut down peak demand by 0.4%, a regulation unchanged since 2011, according to ACEEE. The state also lacks a demand response program that could compensate ratepayers for using less electricity at peak, which could help.

Local utilities and retail companies are doing what they can on a piecemeal basis with their own programs, but overall, it seems easier to save electricity than it would be to build a fleet of new power plants.

Troublingly, Texas has also become a haven for cryptocurrency miners, attracted by lax regulations and cheaper energy. Bitcoin miners eat up some 2100 MW in Texas, according to the Texas Blockchain Council, a trade group. The legislature reacted by putting tax breaks for miners on the chopping block.

ERCOT has said crypto miners applied to them to use as much as 20 GW, which is a staggering figure to consider when 7.5 GW is what ERCOT found itself needing to shed three years ago to prevent the complete collapse of the Texas grid.

Crypto traders point out that ERCOT can strike deals to pay miners to switch off their energy-hungry rigs when power supplies are tight, but the cost of that gets passed on to ordinary ratepayers. Texas consumers still remember getting stuck with record-high utility bills during Uri thanks to regulations intended to encourage energy production during times of high demand. Texas courts are still weighing the question of whether this should have been done at a time when millions of people were in a blackout. Wood Mackenzie and the New York Times estimated the demand from crypto mines have led to utility bills rising about $1.8 billion.

Texas remains an oddity in the power sector. Its mostly deregulated status combined with its vast capacity to produce its own energy and its pride in both has led to a several energy panics, including during Uri. We are mostly concerned with power grid stability here, and that is only achieved with long-term reliability. Three years is not long enough to determine whether we are there yet.

Some of Texas’ new regulations have teeth enough to be an improvement, but continued changes will be needed as temperature extremes continue to be the rule rather than the exception.

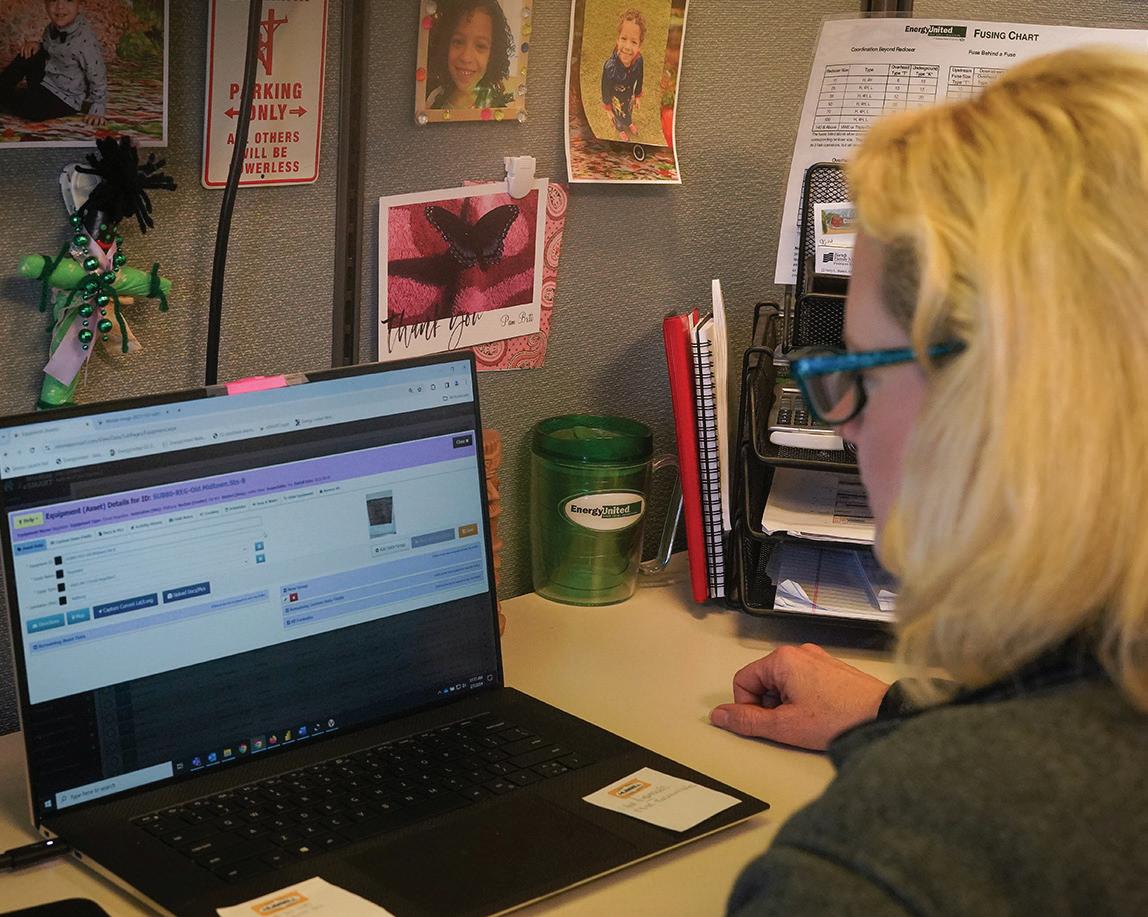

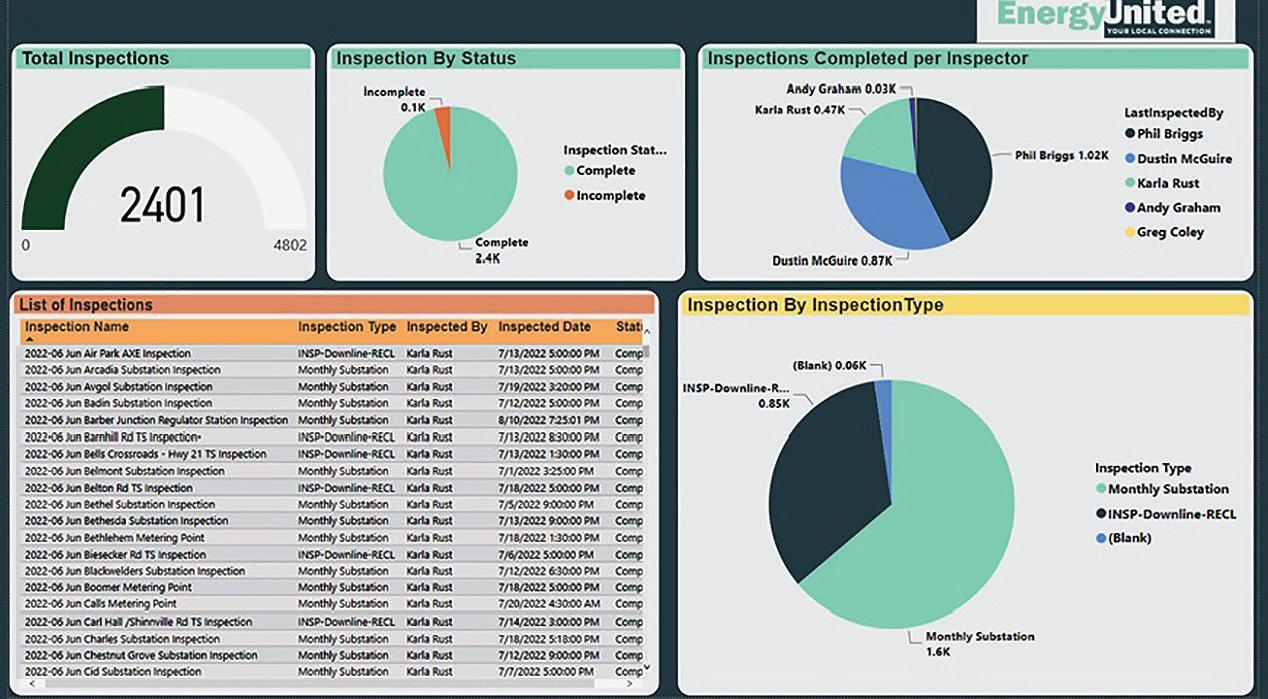

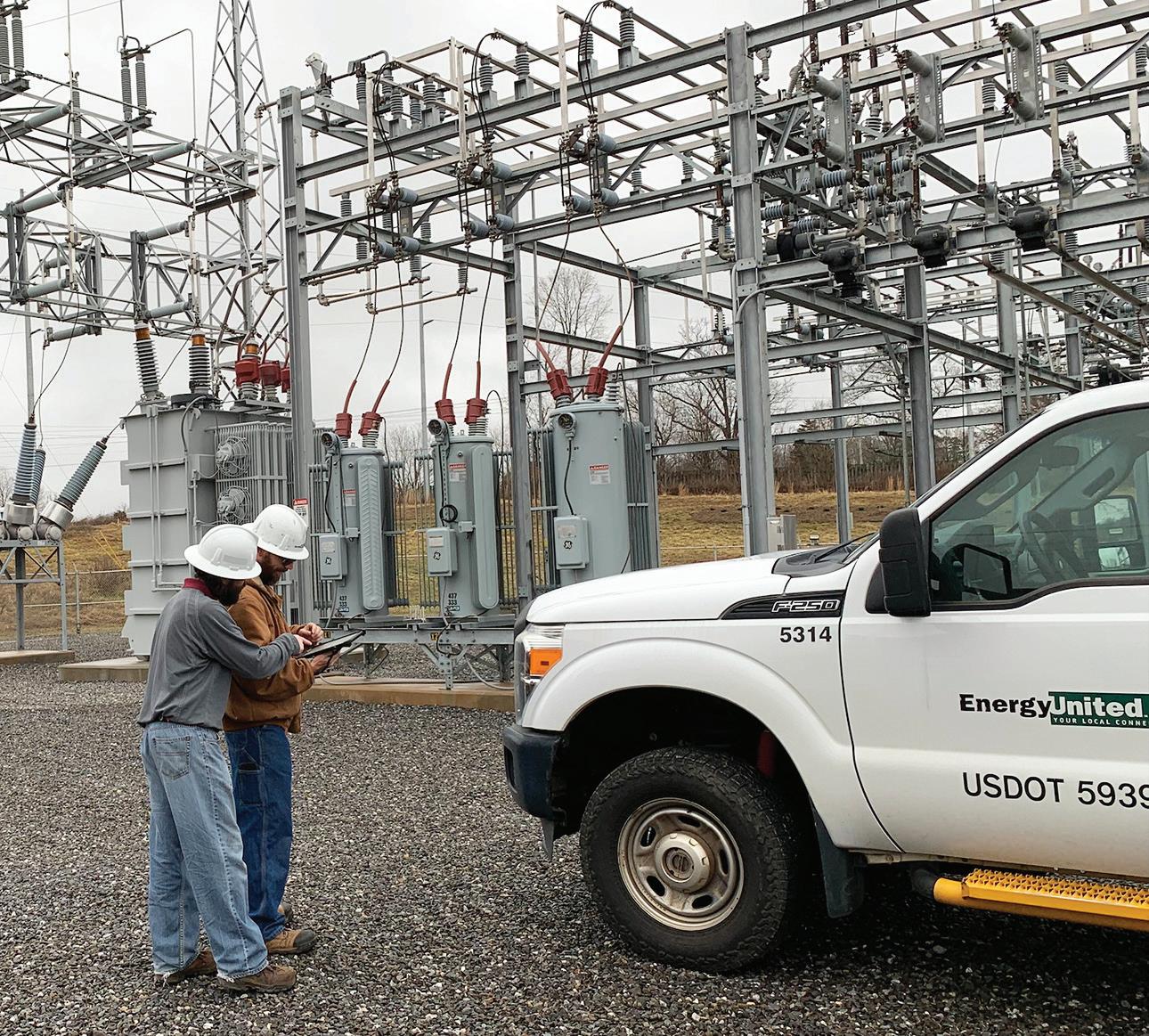

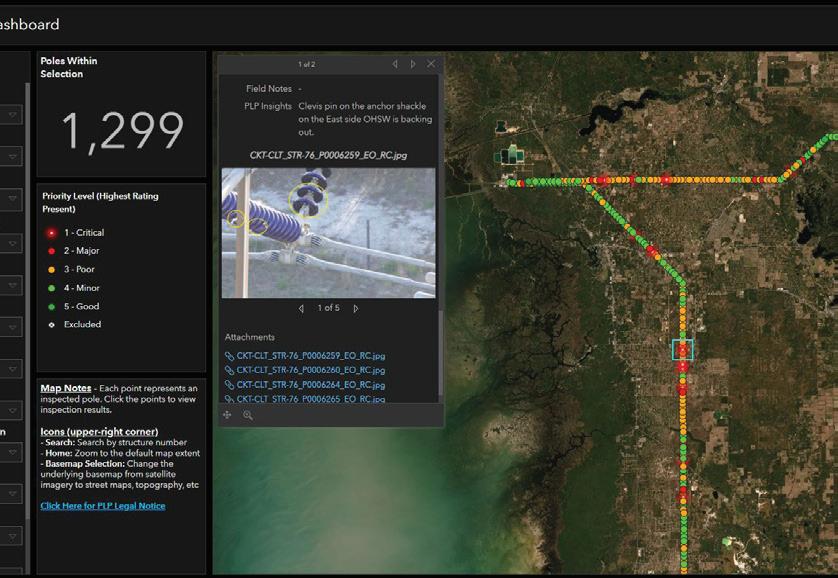

Despite a bumpy start, EnergyUnited overcomes substation inspection hurdles to transform its processes, maximize talent and improve efficiency.

By KARLA RUST, EnergyUnitedTechnology is often hailed as the great arbiter for working smarter instead of harder. But for EnergyUnited’s technical services team, the paperless system that used to be in place delivered the opposite effect — creating more work, not less. The technology was not bad, per se, but ultimately — having been adapted from another solution — it did not deliver as expected or needed. The result was a laborious, inefficient process.

So, when the cooperative decided to abandon the previously implemented technology used for substation inspections in favor of its old paper-driven processes, it became clear help was needed.

Its return to paper processes was not a case of the coop being technologically averse. With roots back to the late 1930s, EnergyUnited differs from the coop it used to be. Formed in 1998 following the merger of Crescent Electric Membership Corp. and Davidson Electric Membership Corp., EnergyUnited’s footprint in North Carolina now stretches across the state, serving 19 counties.

While still primarily rural, the coop has experienced increased suburban growth and is the largest of the 26 electric coops in North Carolina, with over 12,000 miles (19,312 km) of distribution overhead and underground lines, 199 miles (320 km) of transmission lines, 71 substations and 11 12.5-kV delivery points.

The challenges EnergyUnited faced with its original paperless system had little to do with using technology and everything to do with having the right technology. An initial paperless process that should have streamlined substation inspection reporting instead created organizational challenges that, in the words of author Aldous Huxley, felt like this: “Technological progress has merely provided…a more efficient means for going backward.”

EnergyUnited’s technical services team oversees the construction, maintenance and repair of substations and downline

equipment as well as maintains inspection sheets and equipment information generated from substation inspections. Unfortunately, problems with extracting and reporting data emerged shortly after initial attempts to incorporate paperless substation inspection forms began. The primary issues were threefold:

• Platform failures led to inspection data loss. Inspection data, completed offline on tablets and then uploaded once technicians returned to the office, often was lost to upload failures. Once uploads began, the paperless platform automatically deleted data sheets from the system, regardless of whether an upload was successful. Upload failures resulted in data loss and, because the information was unrecoverable, a technician could lose an entire day’s work.