Itissaid that intelligence is the most fairlydistributed good in the world: Everyone thinks theyhaveenough of it.Isn’t that nice? (Almost)everyone is satisfied with their lot, and no one feels shortchanged. Whereelseistheresuchunity in an increasingly divided and polarized world? However, no matter howlittle deficiency one mayrecognizeinoneself,the neediness of others seemsglaringlyobvious. Theysimplydo not want to acknowledge that they have not thought enough or—between us—perhaps simplylack the tools for adeeper understandingofthe matter, don’t they?

Isn’t it great that we can nowsupplement “natural stupidity” with artificial intelligence? As achild, Iwouldhavebeen overjoyed to have such athinking servant at my beckand call: Just image writing thank-you postcards to grandparents after Christmas or a birthdayor quicklydelivering that unwanted school essaysoone can finallygo out and play. And of course the possibility to produce an endless of stream funnypictures …You canread on page 16 howthis might look in plant engineering.Onpage 8, you’ll find Merck’s visions on the topic!

However, the AI itself often produces—lets say—surprising results. Besides the widelyrecognized hallucinations,morally questionable answers and ageneral indifference on matters of opinion, thereare also,shall we say, unusual outcomes. Let’saddress the elephant in theroom:GrabanAI image generator and writeapromptlike“Generateanimage that showsaroom without elephants in it.”You willbeamazed at howmanypachyderms the AI triestosneak intothe picture. Someofthem mighthavetwo or even three trunks, but the origin is easytorecognize Sigh. Athinking machine that has supposedlyabknowledge of mankind cannot imagfree room?Too stupidindeed!

DominikStephan Editor

IbrahimKar/MichaelBerz

Version1.0

ISBN:978-3-8343-2424-5 149.00EUR

Whenplanningprojectsfortheprocess industry,itisrecommendabletocarry outthe estimation of costsinone of theearlierprojectstages.Thisway,itis easiertogaincompetitiveadvantagesin aglobalmarketwithrisingrawmaterial pricesandincreasingengineeringand assemblycosts

Thetemplates area practicaltoolfor costestimatorswho need to prepare theaccompanyingdocumentsforacost estimation.Theyarefullyeditableand canbeadaptedtotheproject-specific requirementsatanytime.Furthermore, asamplecalculationwithanaccuracyof ±30%ismadeavailableasanExcelfile

Furtherinformationandpurchaseat https://vogel-fachbuch.de/en

In this together:Strategicpartnershipsare front and center of FetteCompacting's service portfolio for the pharmaceuticaland nutrition industries. Discover, howcooperation likethese help to develop products and processes “from lab to production”. Page 32

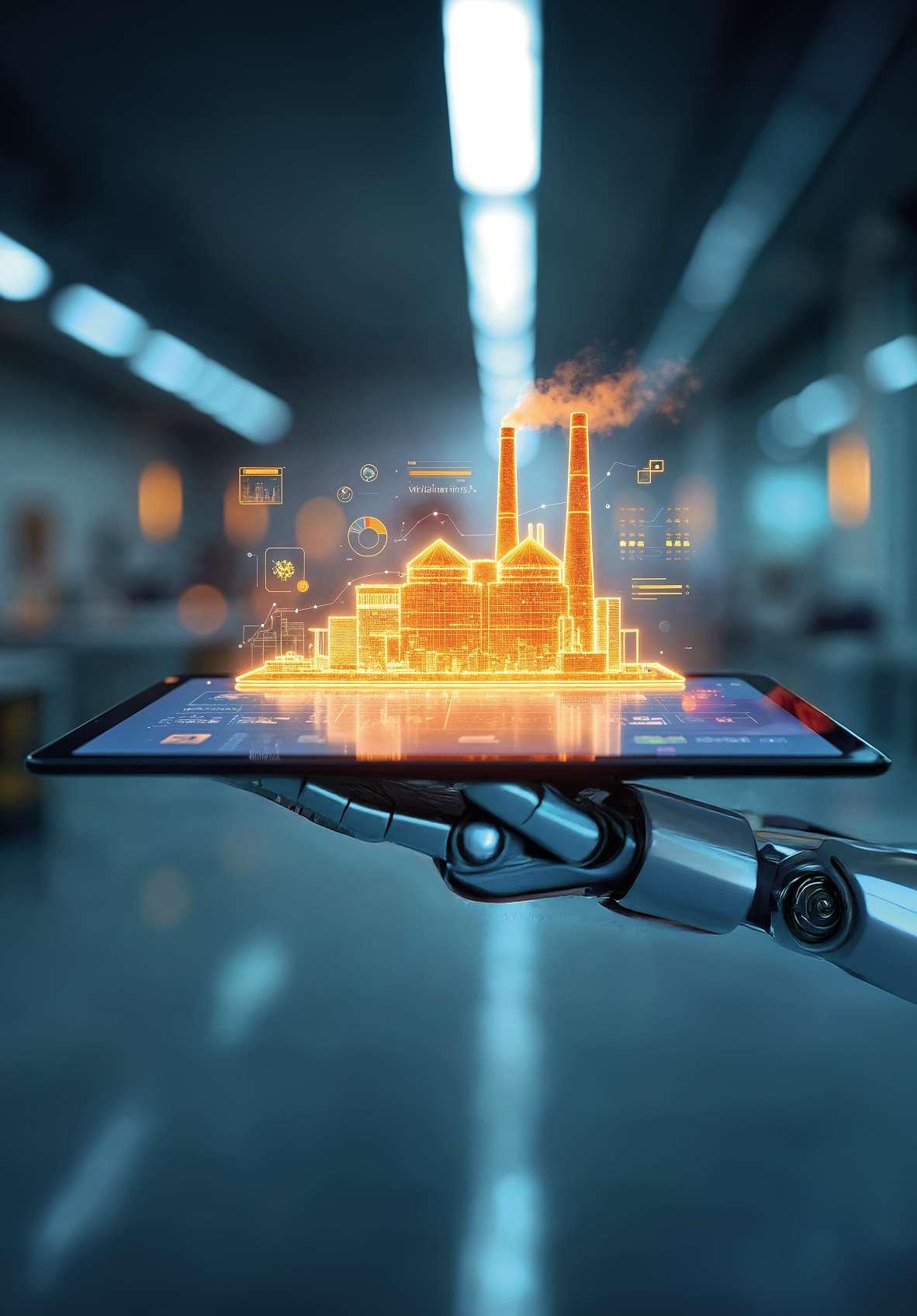

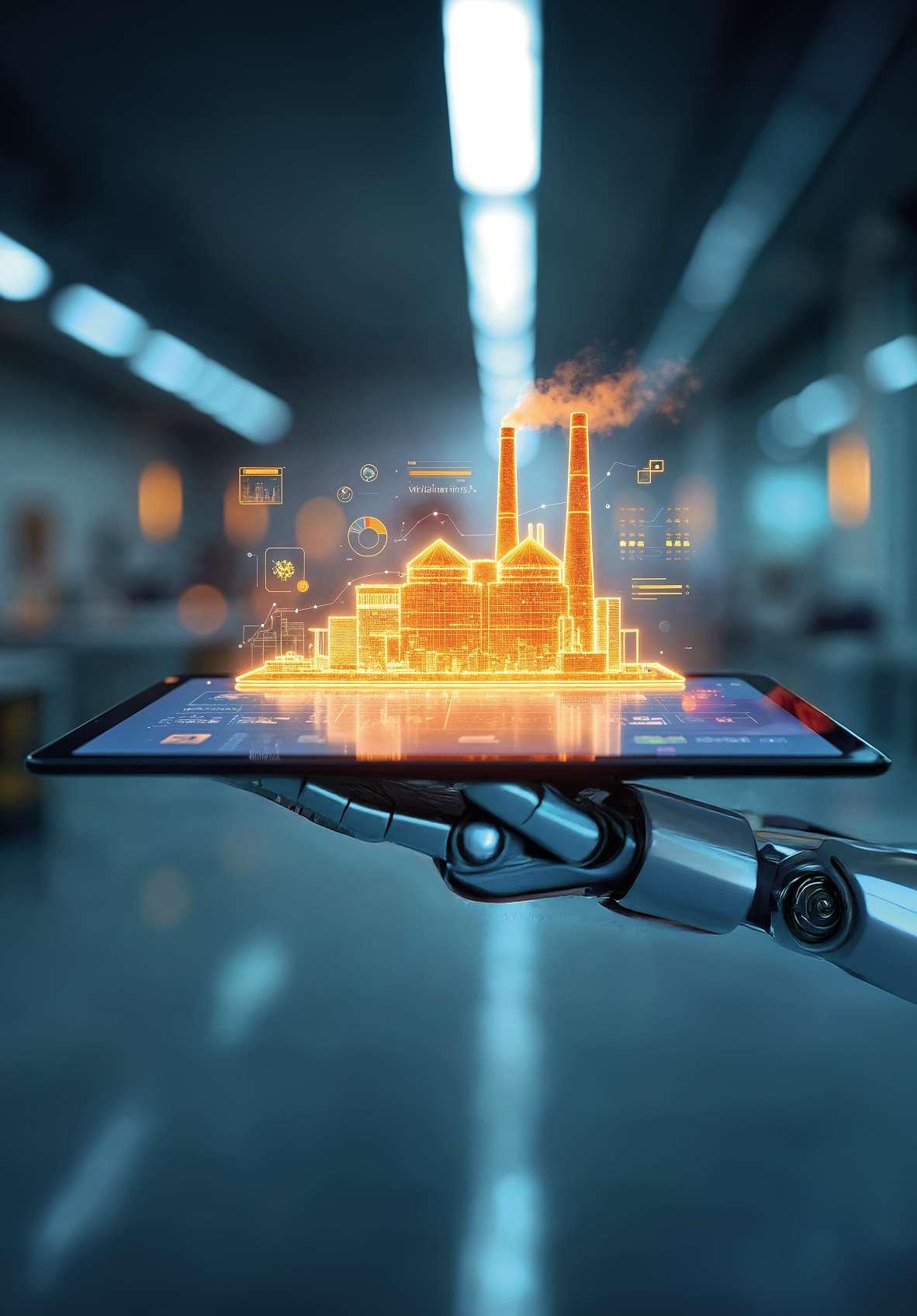

The perfectproduction process made to order couldbe just afew clicks away:Smart technologies such asartificial intelligence and generative AI have the potential to revolutionise industrial operations and engineering alike, ourtopstory shows. Page 16

1.7BILLION DOLLAR PROJECT

Hong Namkoong,President and CEO of Samsung E&A(left)and MashalSaoud Al-Kindi, CEOof Ta’ziz arehappy to announce the large-scalemethanol plant projectinthe UAE.

The UAEbecomes amethanol producer: Abu Dhabi Chemicals DerivativesCompany RSC Ta’ziz has awarded a1.7-billion-dollar EPC contract to Samsung E&Afor developingoneoftheworld’slargestgastomethanol plants in the Al Ruwais Industrial City,Al

Dutch chemical companyLyondell Basell has plans to develop anew propylene production plant at its Channelview Complex near Houston, Texas/USA.Oncompletion, the project is expected to have an annual production capacity of approximately400 thousandmetrictons.Groundbreakingand construction areexpected to begin in the thirdquarter of 2025, with aprojected startupinlate2028.Thenewmetathesisunitwill convert ethylene intopropylene for use in theproductionofpolypropyleneandpropylene oxide. End-use-related product lines include food packaging,medical devices, automotive components, aircraftdeicing fluid, building insulation, cushions for homefurnishingsandtelecommunications equipment. (wer)

Dhafraregion, Abu Dhabi. The project is a keymilestone in thecompany’s mission to advancetheUAE’seconomicdiversification by unlocking newdomestic chemicalvalue chains, spokespersons said. The 1.8 million tonsperannum(mtpa)plantwillbethefirst

MEGA–MERGER

methanolproductionfacilityinthecountry and shall be poweredbyclean energy Ta'ziz comprises of three industrialzones, thefirstbeinganIndustrialChemicalsZone that willhost chemicals production. The second is the Light Industrial Zone, which will be home to downstream conversion industries and finallyanIndustrial Services Zone.Inaninitialphase,Ta'zizwillproduce 4.7 mtpa of chemicals by 2028, including methanol, low-carbon ammonia, polyvinyl chloride (PVC), ethylene dichloride, vinyl chloride monomer,and caustic soda. Several of these chemicals will be produced for the first time in the UAE, reinforcing the company’sstrategicgoaltoexpandthelocal chemicals value chain. (wer)

AdnocandOMVtoEstablishNew60+ Billion-DollarGlobalPolyolefinsChampion

AdnocandOMVhaveplanstocombinetheir BorougeandBorealisbusinessestoestablish anew firm, the Borouge Group International. The newlyformed companyisthen expected to acquireNovaChemicals for 13.4 billion dollars, thus establishingthe world’s fourth-largest polyolefins player. The acquisition, together with the recontribution of Borouge-4, would createa new60+ billion-dollar global champion, set to operate theworld’sfourthlargestbynameplatepolyolefins production capacity.The groupis intended to be headquartered in Austria, with regional headquarters in the UAE. In addition,itwillretaincorporatehubsinCalgary,Pittsburgh and Singapore. It will be listedontheAbuDhabiSecuritiesExchange (ADX),subject to approval by theUAE SecuritiesandCommoditiesAuthority(SCA)and

ADX. Under the terms of the Agreement, Adnoc and OMV will hold equal stakes of 46.94percentinBorouge,withjointcontrol and equal partnership,with the remaining 6.12 percent in free float. (wer)

Adnoc has also entered intoa sharepurchase agreement with Nova Chemicals Holdings for 100 %ofNovaChemicals Corporation

BASF is investing amid-double-digit millioneuroamount in anew alcoholates plant.

BASF is investing amid-double-digit million-euroamountinanewalcoholatesplant at its main siteinLudwigshafen, Germany. The plant will produce sodium methylate

and potassium methylate, twochemicals used forthe production of biodiesel and pharmaceutical and agricultural applications. Utilizing state-of-the-art technology, the newsitewill replaceanexisting productionfacilityinLudwigshafenandisexpected to start up in the second half of 2027.BASF is aleading supplier of alcoholates for various applications. The newplant complementsBASF’sexpansionofitssodiummethylateproduction in Guaratinguetá, Brazil. Among other uses, alcoholates serveascatalysts and reactants in various industries, mainlyfor biodiesel and in pharma or agricultural applications. Thus,the investment supportsthegrowingmarketforlifescience productsandthedemandforbiodiesel.(dst)

As part of areviewinitiated by Air Products’ newly-elected BoardofDirectors and CEO, the Companydecided to exit three projects in the U.S. As aresult, Air Products expects to recorda pre-taxchargenot to exceed 3.1billion dollars in its fiscal 2025 second quarter,primarilytowritedownassets and terminatecontractual commitments. Among these areaSustainable Aviation Fuel expansion project with World Energy in Paramount,California.Further,AirProducts hascancelleditsplanstoconstructa35metricton per dayfacility to produce green

liquid hydrogen in Massena, NewYork, and relatedliquidhydrogendistributionanddispensingoperations. Thedecisiontocancel this project is basedonrecent regulatory developmentsrenderingexistinghydroelectric powersupplyineligible for the Clean Hydrogen Production TaxCredit (45V)as wellasslowerthanexpecteddevelopmentof ahydrogen mobility market in the region. CarbonmonoxideprojectinTexas:AirProductshasterminatedaprojectinTexasforthe production of carbon monoxide duetounfavorable project economics (dst)

Theenergy companyaims to producebiomethane from agricultural and livestock waste.

Moeve has recentlyannounced an ambitious 600-million-euroinvestment plan for the constructionofupto30new biomethane plants by 2030 throughout Spain, with Andalusia, Catalonia, and Galicia being among the regions with the greatest potential for its deployment. This investment is part of the company’splans to promotethe circular economyand lead the energy transition, in the framework of itstransformation strategy Positive Motion. The energy companyaimstoproducebiomethanefrom agriculturalandlivestockwasteandmanage aprojectportfolioof4TWhby2030.Theuse of this renewable gas, instead of fossil fuels, will allowMoeve to reduce CO2 emissions from its energy parks, chemical plants, its industrial clients and partners, as well as providingacomplementaryvectorforgreen hydrogen production and promoting sustainable mobility (dst)

Artificialintelligenceisbecoming agame changer in the fields of healthcare, life sciences, and electronics —and Merck in Darmstadt wants to be at theforefrontofthisrevolution.“Thejourney has only justbegun,” says CEO Belen Garijo.Here’swhere Merckisalreadyusing AI and whatplans the companyhas.

Artificial intelligence (AI) isno longer atrend; it has seamlesslyintegrated into manyaspects of our lives, such as cars and smartphone cameras. Thanks to the media coverage of ChatGPT,eventhose lessfamiliarwithtechnologyarenowawareoftheterm generative AI.

But howisartificial intelligenceutilizedacross the chemical andpharmaceuticalindustries? Thesignificance of AI at Merck, achemical and pharmaceutical companybased in Darmstadt, Germany, wasevident during an event held in earlyDecember last year

Merck's CEO Belen Garijo emphasized the strategic importanceofthesetechnologiesandtheimpactthatAI

WRITTEN BY AnkeGeipel-Kern SeniorEditor PROCESS Worldwide

could have on the processindustry and beyond: “Artificial intelligence is morethan ahype.Itisa transformative force that changes the waywework and communicate,”she stated.

ChiefTechnologyOfficerLauraMatz,whohasbeenin hernewlycreatedrolesinceJuly2021,isalsofocusingon AI-driveninnovations. She supports thecompany's Smartfacturing program, whichaimstoleverage synergies among the three business areas of Merck:Electronics, Health Care and Life Science. The goal is to createa moreefficient and flexible production environment through automation, data analysis, AI and IoT, Matz explains.

MerckhasinitiatedatransformativeprocesswhereAI playsacentralrole.Thisprocessaimsaddresstheuseof AI within the companyso that Merck canremain at the technological forefront, while also providing AI-supported tools that help customers solve their problems Thecompanyispursuingadualapproach:Creatingecosystems for securedata exchange amongcustomers, scientists,institutesandauthorities,whilealsooffering AI-supported tools that help customers address their challenges.

This includes the launch of AI-poweredsoftware like Catalexis, which assists customers in developing new syntheses by significantlyreducing the number of required experiments fromseveral hundredtojust 23. Basedonthe data from atest kitwith23catalysts, the algorithm suggests 20 selected catalysts for thedesired reaction.

The companyseesitself on agood path,yet therestill remains work to be done: To leverage thefull potential ofartificialintelligence,Merckneedstodevelopa“Data CultureVision”andequipallemployeeswiththeknowledge andtools to use data and AI effectively,explains Whalid Mehanna, who has served as ChiefData& AI Officer since 2023. Mehanna oversees MDAO,the data andAIorganizationwithinthecompany(MerckData& AI Organization), which aims to drive the combined strategy for digital innovation.

Mehanna loks back on over 25 years of experiencewith big data, havingpreviouslyled the Data &Analytics team at Mercedes Benz. Now, he wants to motivate the 63,000employeesatMercktoleveragethepossibilities of AI and to focus on data quality in their dailywork. It isasignificanttaskthatrequiresasolidfoundationand fundamentalwork,heemphasizes.Mehannaillustrates thiswithapyramid,wherethepeakrepresentsadvanced AIsettotransformthemanydifferentbusinessprocesses and models below.

“Byequippingeveryemployeewiththeknowledgeand toolstousedataandAI,wecancreatethefoundationfor sustainablegrowthandsetthestagetochangethegame,” Mehanna explains. Aspecific example of internal AI application is my GPT, an in-house Chat GPTdevelopment introduced in 2023.Ithas processed over three million queriessince itslaunchand hasbeen well-received, with approximately18,000 users. The system nowcontainsfeaturesforcollaboration,websurfing,and accessing companysystems

ForMerck,AIisnotnew.Thecompanyhasbeenworking with the data analysis companyPalantir since 2017, aimingtocreatedataecosystems.Thetwopartnershave since formed twojoint ventures:

PhilippHarbach, GlobalHead of Group DigitalInnovation, expains how the AI-optimised Catalysis selectionworks with Catalexis.

The joint ventureSyntropy by partner companies Merck and Palantir aims to help aggregateand utilizescientific data from cancer research moreefficiently. Theidea is simple: Scientists, institutes and health authorities among others, canupload raw datasets intothe databaseand makethem accessible to thewhole scientific community.The AI solution integrated intothe Syntropyplatform enables users to search for data, extractinformation, analyzeitand even visualizeit.

The idea of the data analysis platform Athinia is similar.However,itfocuses on material data for semiconductormanufacturing.Athinia is designed to allowmanufacturers and material suppliers to exchange, aggregate, and analyzedata, therebyimproving the understanding of interactions between materials and processes in semiconductor manufacturing.CTO LauraMatz has made the partnership a priority,also serving as CEO of Athinia.

Furthermore,arevolutionindrugdevelopmentisonthe horizon, drivensignificantlybyAshwini Ghogare, the HeadofAIandAutomationforDrugDiscoveryatMerck. Ghogare, whoholds aPhD in chemistry,isalso the drivingforcebehindAidisson— shortforAI-enabledDrug DIscoverySolutiON,anAI-basedmodelingplatformthat aimstoidentifypromisingmoleculesfornewdrugsfaster and moreaccurately.

“Every shot ahit,”explains Ghogare, illustrating the goal behind Aidisson. This could save alot of timeand money. After all, in thelifecycle of adrug from development to marketlaunch, the design of the active ingredient accounts for 40 percent of the timeand consumes over twobillion US dollars.

The keytothisdevelopment is thevast amounts of experimental data that flowintothe modeling process. “30yearsofdataandexperienceindrugdevelopmentare embedded in the software,”explains Ghogare.Importantly,italsoincludesinsightsonmoleculesthatdonot meet expectations. These negative data areparticularly importantindevelopinggenerativeAImodelstoprevent the AI from hallucinating and producing inaccurate models, emphasizes Ghogare.

ThegenerativeAImodelsnotonlyoptimizebutalsogeneratede-novovirtualmoleculemodelswiththedesired chemical properties, thedevelopers explain. Newmoleculesarecreatedbasedonnovelty,drug-likeness(follow-

“Byequippingeveryemployeewiththeknowledge andtoolstoleveragedataandAI,wearelaying thefoundationforsustainablegrowthand settingthestagetochangethegame.”

Chief Data & AI Officer

ingaqualitativeassessmentofacompound'ssuitability as adrug) and similarity to achemical target structure. Theyalso evaluatethe generated molecules basedon their ability to be synthesized. This represents asignificant advancement, the digitization expertexplains.

Manypromisingdrugs fail due to the lack of feasible or overlycomplex synthesis routes. Synthia, as thenew software is called, enables chemists to determine the most suitable synthesis routefor their drug candidates and also provides alist of essential components and reagents needed for drug production.

Merck is nowmarketing the originallyinternal tool globallytoexternalpharmaceuticalcompanies.Smaller teams,whichrarelyhaveaccesstolargeinternaldatasets to develop their ownmodels, could particularlybenefit from Aidisson, thecompanystates.

ItisafactthatAIwillevolveintothemostcrucialtoolin drugresearchinthefuture.Merckexpertsagreeonthis withtheircompetitorsinthemarket.Nopharmaceutical companyunderestimatesthesignificanceofAI,hoping forefficiency gains and timesavings. Despite theseadvancements,Merck'sexpertsagreethatAI —nomatter howsophisticated —alone is insufficient. Human expertise is essential for identifying the idealmolecules.

AI-assisted molecular designcan enhancemolecules to minimizethe number of required “design-make-test” cycles for optimizing drug candidates. StuBailey,the HeadofClinicalMeasurementSciencesatMerckHealthcare, notes a25-50 percent acceleration in theprocess,

alongwithreducedmaterialandlabtesting.Inonecase, Merck assessed 46,000 theoretical molecules using AI, resulting in the synthesis of 35, over half of which were promising candidates.This represents asignificant improvementcomparedtoapurelyexperimentalapproach, wherethe average success rate is belowone percent.

As amid-sized pharmaceutical company,Merck has a broad focus, including vaccines, therapeutic proteins, antibody-drug conjugates,monoclonal antibodies, and smallmoleculesinthefieldsof“Neurology&Immunology,” “Oncology,”“Fertility,” and “Cardiovascular,Metabolic &Endocrine Disorders.”

“Artificialintelligenceis morethanjustahype.Itisa transformativeforcethat changesthewaywework andcommunicate.”

BelenGarijo,CEO

RegardingtheuseofAIindrugdevelopment,thecompanyfollows a“modalities-agnostic research strategy.” Thisstrategyaimstoleverageinsightsfromallclassesof drugssothatthe developmentofbiologics, ADCs, and thediscovery of small molecules can mutuallybenefit one another.Specifically, researchers utilizethe prediction model Alpha-Fold for AI-assisted protein design and modeling,which predicts the3Dstructureofa protein based on linear amino acid sequences.

AI, as demonstrated by Merck, is not apassing fad. When usedthoughtfully, it can address complex challengesandelevatetheanalysisoflargedatasetstoanew level. (agk)

At NEXTEN,weare reimaginingthe pharmaceutical landscape. This is more than just an event; it is acelebration of tabletinginnovation. Join IMAActivefor tworemarkabledays with technicalsessionsthatwillguide theIndustrytowards anew eraofpossibilities

27-28 October,2025 VillaErba, LakeComo, Italy

Secureyour placetoday Register now at: ima.it/pharma/ima-active-nexten-event or scan here

Cancarboncaptureand AI safe the world?Wetalkedwith Celanese’s GlobalSustainabilityDirector forAcetyls,Kevin Norfleet, about the company’smegaCCU project and the central role thatgenerativeAI technologies playinthe futureofchemicalproduction.

Mr.Norfleet, the chemicalindustry is ahard-toabatesector.How canCelanese help industry playerstoachievetheirnetzeroemissiontargets?

KevinNorfleet:Decarbonizationisabigchallengeforthe hard-to-abatesector and thereare no silverbullets. We thinkourCCUproject—oneoftheworld’slargestcarbon captureutilization facilities in Texas, USA—is astep towards building awareness of CCUasanoption,both

forchemicalproducersanddownstreammanufacturers whocould use materials made from CCUtomeet their owngoals. CCUhas thepotential to be very compelling for certain products, particularlymethanol derived chemistries.

Asmentionedabove,Celanesehasdevelopedoneof the world’slargestcarboncapture utilizationfacilities at its Texassiteinthe USA. What is the total carboncapturecapacityofthisunit?Andwhatisthe uniquefeatureaboutthisproject?

Our CCUproject sits within our Fairway Methanol joint ventureand our close partnership with Mitsui &Co. helped makethispossible. The project launched in January2024andaimstotake180,000tonsofCO2 peryear andconvertitinto130,000tonsofmethanol.OurCO2 is fromindustrialemissionswithmorethan80percentof thoseemissionsactuallycomingfromthird-partysources. We essentiallytakeCO2 emissions, purifyand compress them, and then injectthem into our methanol reactor along with alow-carbon intensity hydrogen. Abig advantage is that we leverage alot of existing scaleandassetstobeabletodoaprojectofthissizeina

PROFILE

Kevin Norfleet, GlobalSustainabilityDirectorfor AcetylsatCelanese, ispioneering one of the world’slargest CCUprojects,aimed at converting 180,000 metric tons of CO2.He also promotes the integrationofGenerative AI in plant operations, enhancing efficiency and maintenance.

waythat also makes economic sense. Once we have the CCUmethanol,ourintegrationisuniquelyabletotransform it into awiderange of products thatcan impact countless markets likebuilding and construction,packaging,toys, automotive and personal care products.

Howhas the establishmentofthis facility helped thefirmtocontributetowardslow-carbonsolutions andacirculareconomy?

TheCCUprojectisthebasisofourEco-CCofferingacross abroadrangeofproductstoachievebothalowercarbon footprintaswell as circular content usingthe mass-balanceapproach.WhatthatmeansiswecanoffertheEcoCC option on products likeacetic acid,vinyl acetate, POMpolymer,EVA polymer,ethyl acetate andmany other materials that arechemically identical buthave the benefits of CCUallocated intothe product carbon footprint and circular content percentage.ThatEco-CC offering has been well receivedbycustomersina wide range of industries lookingtomakeprogresstowards sustainabilitygoals.Forexample,we’veannouncedpublicpartnershipswithHenkelinadhesivesandCloverdale Paint in architectural coatingstobring CCUintodownstream products. Our ultimategoal is to continue to build amarket for CCU-based materials across arange of applications and partner withmorecompanies.

Inyouropinion,whatisthecurrentmarketscenario forCCU?

There’scurrentlyalotofinterestinCCUbutstillnotmanyoperationalprojects.Someofthatisrelatedtoawarenessand marketability.Most of the time, when people hear aboutcarbon capture, it’sreferring to carbon captureandsequestration,whereCO2 isstoredintheground versusutilizedtomakeproducts.Itcanalsobechallengingfor brands to make claims with CCUasitdoesnot always fitcleanly into thebio-based or recyclecontent categories thatmanypeople think of whenconsidering sustainable content options.

Asaresult,alotofourworkisfocusedoncreatingthe foundationforCCUtoberecognizedandaccepted.CCU offers great advantages and opportunities and hasthe potential to createaself-sustaining market forCO2

Gen AI (ArtificialIntelligence) is currently beingexploredfor plant operationsand maintenance. Can thesmarttechnologyalsobeappliedtoCCUplants inordertooptimizeoperations?Pleasementionthe benefitsofaGenAI-basedCCUunit.

Celanesehasembarkedonanaccelerateddigitalization journeytodevelop manufacturing ‘Plantsofthe Future’ that transformthe entire enterprise into aseriesofautonomous,integrated,yetuniqueandoptimizeddigital manufacturingplants.Thisincludesdevelopmentofthe CCUPlantoftheFuture,whereeachphysicalassetofthe plant is replicated as adigital twin with aunified, integrated data platform that can be visualized Atthecoreofthisevolutionisthestrategicintegration of AI and generative AI, epitomized by JO.AI, agenerative AI-poweredcoreunique to Celanese.JO.AI is anatural languagebot that efficientlyretrievesinformation; offers analysis, predictions andcontrol;and generates insights and actionsfor manufacturing operations.It seamlesslyintegrates intoworkflows,providing real-time suggestions, explanations and feedback during industrial processes while troubleshootingguidance to

operators and acting as an assistant to quicklyresolve issues beforemajor upsets or failures occur.

Whatare the challenges of incorporatingthe CCU technologyinchemicalplants?

Alot of different processes makeCCU work. It first requiressourcesofCO2 thataresuitableforutilization.You need aproduct (e.g., methanol) that canbemade from CO2 and in manyinstances, hydrogen to completethe process. These elements then must be combined economicallyand efficiently. Akey partofthis is ensuring the chemical industry has flexibilityonallocating the benefits of CCUinaway that makes economic sense; whileanalyzingthefullpicturecarefullysothebenefits of the project arenot double counted.

As themarketand demand forCCU-based materials grows, CCUwill become moreviable andthe rangeof projectsitsupportswillcontinuetoexpandaswell.(dst)

WRITTEN BY

AhlamRais

FreelanceEditor

PROCESS Worldwide

“Celanesehasembarkedonanaccelerated digitalizationjourneytodevelop manufacturing‘PlantsoftheFuture’, includingtheCCUPlantoftheFuture, whereeachphysicalassetoftheplantis replicatedasadigitaltwin.”

Kevin

Norfleet,Celanese Acetyls

CharlieTan, CEOofGlobalImpact Coalitionshares detailed insights about the objectiveofthe coalition, projectsinitiatedbythe consortium inthe past,upcomingopportunitiesfor clean technologies as well as the challenges faced by thechemical industry.

WRITTEN BY AhlamRais

The‘GlobalImpact Coalition’ wasestablished in 2023. Whatwas the objectivebehind forming acoalition focusedonreducing emissions in the chemicalsector and whydid it spin-off from the World EconomicForum?

Charlie Tan: We areworking to reduceemissions in the chemicalsector because it is acritical sectoratthe base ofover95percentoftheproductsusedbysociety.Atthe sametime,itisresponsibleforaroundtwobilliontonnes or five percent of global greenhouse gas(GHG)emissions. Whilemuch of the focus has been on reducing emissions from the energysector, the chemical sector emissions continue to rise, especiallyconsidering the growing global demand.

Recognizingthechallengesfacingthechemicalindustry,theWorldEconomicForum(WEF)convenedagroup

ofCEOsfromleadingglobalchemicalcompaniestowork collectively to reduce emissions. This platform was called the Low-Carbon Emitting Technologies (LCET) initiative.Itprovedasuccessfulmodelwiththepotential to grow even further as an autonomous organization. Hence, in November 2023, we spun-out of the WEF and emergedastheGlobalImpactCoalition,anindependent entity dedicated to accelerating the development and scale-up of newtechnologies and innovative business models to reduce emissions across the chemical industry.Byfosteringcollaborationandimplementingrobust governance structures and operational frameworks, we arepoisedtocatalyzeinnovation,scaleprovensolutions and drive meaningful reductions in emissions.

At the COP29Summit in Baku, UN Secretary-General António Guterres stated “I urge every party to step-up,pick-up the pace, and deliver.The need is urgent. Thetime is short.”How can the ‘GlobalImpactCoalition’helptocutemissionsintheindustry? ThiscalltoactionresonateswiththemissionoftheGlobal Impact Coalition, which is dedicated to drivingsystemicchangeinthechemicalindustrytoachievenet-zero emissions. Thechemical sector’scurrent production modelsandoil-basedvaluechainshavebeenoptimized

Charlie Tanservesasthe ChiefExecutive Officerofthe GlobalImpact Coalition(GIC), an organizationbornfromthe WorldEconomic Forum. With over tenyears of experienceinthe energy sector,Tan previously built start-ups, including asuccessful waste oil collectionbusiness. At the helm of GIC sinceNovember 2023, he collaborateswith adedicatedCEO advisory boardtofoster partnershipsamong majorchemicalcompaniestocut emissions in the sector

over decades, making them deeplyentrenched.Achieving net-zeroemissions requires afulltransformation, one that can’t be achievedbyindividual companies working in siloes. Manyofthe technologies needed alreadyexist,butscalingthemupdemandsnewapproaches to collaboration, funding,and innovation. The transformation requires rethinkinghow companies work together.New circular business models and innovativewaysofintegratingexistingtechnologiesare critical,asarealignmentongoals,fundingmechanisms, andofftakeagreementstoderiskandacceleratethetransition.Historically, companies havebeen hesitant to sharetheirR&Dorbusinessstrategies,butthismindset must evolve.This is wherethe Global Impact Coalition comesin. Acting as an incubation platform, we bring together leading companies to co-createand co-build newventures, scale transformative technologies, and develop integrated solutions. By pooling resourcesfor R&D,streamliningsupplychains,andaddressingshared challenges likewastereduction, companiescan drive progress far moreeffectively than theycould alone.

TheGIC has completed oneyear sinceits establishment. Which projects have beeninitiated by the consortiumduringthispastyear?

Wehaveestablishedasolidstructureandpipeline,going from over 25 projectideas coming outoffourideation sessions to five working groups withthree initiatives quicklyprogressingintoa second phase:

The GIC Automotive Plastics Circularity project is advancing towardsapilot launch in early2025. The project aims to increase the lowrecyclingrate(less than 20 percent)ofEnd-of-Life Vehicle (ELV) plastics. This project has the potential to captureand valorize over 800 million metric tons of ELV plastic.

The GIC Direct Conversion project is advancing research intoprocesses that convert wasteintoC2+ compounds for use in thechemical industry.This approach could offer alow-energy,low-emission, andcost-efficientroutefor waste-to-chemicals.

The GIC SustainableOlefins project is exploring new low-emissions routes to olefins through conversion from sustainable methanol sources.

Industry leaders in Germany statethatitisnot possible forthe chemicalindustry to achieve net zero emissions without CarbonCaptureand Storage. Whatareyourthoughtsonthis?

Capturingcarbonwillundoubtedlyplayacriticalrolein achieving net-zeroemissions. However,within the chemicalindustry, the focus extends beyond Carbon Captureand Storage (CCS)toinclude Carbon Capture andUsage (CCU). Thegoalisn’t just to storecaptured carbonbuttoutilizeitasafeedstockforproducingvaluable chemicals likemethanol. At the Global Impact Coalition, we’reactively exploring sustainable routes to methanol, and one promising pathwayinvolvesusing capturedcarbonasarawmaterial.Ultimately,abalanced approachincorporatingCCS,CCU,andotherinnovations will be essentialtomeet the industry’s climate targets.

Whataretheupcomingopportunitiesforcleantechnologies such as green hydrogen, and e-crackers in thenearfuture?

Cleantechnologieslikegreen hydrogenand e-crackers holdtransformativepotentialforthechemicalindustry

“Capturingcarbonwillundoubtedly

playacriticalroleinachievingnet-zero emissions.Thegoalisn’tjusttostore capturedcarbonbuttoutilizeitasa feedstockforproducingvaluable chemicalslikemethanol.”

Charlie Tan, GIC

Green hydrogen can serveasazero-emission energy source and feedstock, replacing fossil-based gas. Its application in processes like ammonia production or as fuel fore-crackers can drasticallylower emissions. E-crackers, poweredbyrenewable electricity,represent another game-changing innovation. Forexample, acollaboration between GIC members BASF and Sabic, together with Linde is currentlyconstructing theworld’s first demonstration plant for large-scale electrically heatedsteamcrackerfurnaces.Byusingelectricityfrom renewable sources instead of natural gas, this technologycouldreducecarbonemissionsfromoneofthemost energy-intensive production processes in the chemical industry by at least 90 percent.

Whatare the challenges faced by the chemical industry in order to achieve net zero emissions by 2050?Howcanitbeovercome?

Achieving net-zeroemissions by 2050presents significant challenges forthe chemical industry, including:

High energy demand: Manychemicalprocesses are energy-intensive and rely on fossil fuels.Transitioning to renewable energy sources at the necessary scale is amonumental task.

Technological maturity:While innovative solutions likegreen hydrogen, e-crackers, and CCUare promising,manyare still in earlystages of development.

Economic feasibility:Decarbonization requires massive investment, and the transition mayraise costs, impacting competitiveness.

Regulatory hurdles: Inconsistent global policies and lack of standardized frameworks slow progress To overcomethese challenges, amulti-pronged strategy is essential. Collaborative innovation is key, as partnerships across sectors canacceleratethe development anddeploymentoftechnologies.Atthesametime,governmentsmustprovidepolicysupportbyimplementing clear regulations and offering subsidies for clean technologies to foster their adoption. Investmentininfrastructureisequallycritical, particularlyinbuilding renewable energy networks and supporting the transformation toward recycling systems and low-emissions technologies.Ultimately,industryleadershipwillplaya pivotal role, with companies setting bold targets,adopting sustainable practices, and committing to invest in long-term solutions. Thisisprecisely what we areworking to support at the Global ImpactCoalition, bringing together companies to collaborate, co-invest and lead theway towardamoresustainable future. (dst)

PROCESSTIP

Read more about the world'sfirst full-scale carboncapturefacility on ww.process-worldwide. com(search for'Decarbonization').

Smart technologiessuch as artificialintelligenceand generative artificial intelligenceare in vogue. Its manybenefits have encouragedindustrial players, especially in the chemicaland oil& gassector,toexplore the technologies and even incorporate it into their industrialplants.

WRITTEN BY

AhlamRais

FreelanceEditor

PROCESS Worldwide

AChinese start-up stunned the AI (Artificial Intelligence)industry when it introduced its free AI-poweredchatbot in January 2025. Claimed to bedevelopedatacostofjust6milliondollarsandatimeline oftwo months, the chatbot seemed to challenge majorUSAIandtechfirmsthatinvestedheftyamounts in billions of dollars to establish asimilar platform. As moreand morecompanies enterthe AI market space, newand innovative ideas will keep on emerging.This also goes ontoshowhow farAIasatechnologyhas evolvedoverthe years.

AI is all about smart machines or systemsthat arecapableofcarrying out tasks which areusuallydoneby

human intelligence. Gen AI (Generative Artificial Intelligence)ontheotherhandisatypeofAItechnologythat produces newand original text by identifying different patternsandstructuresinanexistingdataset.Theabove Chinese start-up is an example of this. Today, we live in anagewherebothAIandGenAIcannotbeignoredand industrial players arewell awareofthis fact too.

Industrial plants have manyprocesses and AI can be used to improveand optimizemostofthese processes

Industries such as the chemicaland oil &gas industry have ahardtime replacing their highly knowledgeable and skilled employees, this is where AI and Gen AI come in

by analyzing existing data sets withrespect to rawmaterials, temperature, pressureetc.The adoption of this technology also helps to minimize resource consumption such as energy,raw materials as well as costsfor industrial units. Thus,offering highly-efficient processes.AIalsohelpstopredictequipmentfailureviasensors andmonitoring systems well in advance so that appropriatemaintenance measurescan be undertakenina timelymanner and downtimecan be minimized

“AIand Generative AI aretransformingindustrial plantsbyofferingdistinctyetcomplementaryadvantages,”shares Dr.Steffen Lamparter,HeadofResearch Group Industrial ArtificialIntelligence, Siemens.“Traditional industrial AI excels in structuredoperational tasks:analyzingsensordataforpredictivemaintenance, monitoring equipment health, and optimizingprocess parameters through advanced analytics. This helps plants reduce downtime, extend equipmentlife, and maintain consistent product quality.Generative AI brings additional capabilities by makingmaintenance moreconversational and intuitive.”

“The chemicaland oil &gas sectors areincreasingly embracing AI and Gen AI for plant maintenance and operations,”mentions AlainHermans, Process Industries Manager at RockwellAutomation. “The potential for improved efficiency,reduced downtime, andenhancedsafetyisdrivingadoption.Companiesrecognize thevalueproposition of these technologiesinoptimizing processes and achieving operationalexcellence. Whileinitialhesitationexisted,industryleadersarenow actively exploring and implementing AI solutions, paving the wayfor wider adoption.”

Lamparterelaboratesthatmajorchemicalcompanies areincreasinglyimplementingAI-drivensolutions,particularlyinareas likepredictive maintenance, process optimization,andoperationalefficiency.“Theadoption trendisparticularlyevident among industry leaders, withmajor global oil and gasproducers havingalready developed comprehensive AI strategiesacross their operations. However, adoption ratescontinue to vary significantly by region and companysize, with larger organizations typicallyleading theway in implementing these technologies,”hecontinues.

Industries such as the chemical and oil &gas industry have ahardtime replacing their highlyknowledgeable andskilledemployees,thisiswhereAIandGenAIcome in.“Asexperiencedemployeesretireandnewhirestake timetoreachthesamelevelofexpertise,companiesare searchingforwaystobridgetheknowledgegap,”shares Lamparter. “AIand Gen AI can help in this regard.By integratingAI-powereddecisionsupportsystems,plant operators can rely on real-time recommendations to fine-tune processes without needing decadesofhandson experience.”

HecontinuestosaythatindustrialCopilotsareemerging as aparticularlyeffective solution to this challenge. Gen AI-empoweredsystems can act as adigital knowledge repository,allowing workers to instantlyretrieve best practices, troubleshoot issues, or even generate reports and documentation in seconds.

“AIand Gen AI can mitigate the challenge of limited skilledpersonnelinthechemicalandoil&gasindustry,”

explains Hermans. “AI-poweredsystems can automate routine tasks, freeing up experienced workers for more complexproblem-solving.GenAIcancreateinteractive training simulations, providing realistic scenarios for skill development and knowledge transfer.” All these advantages makethesetechnologies worth exploring

Whiletheadoptionratesforthesenext-gentechnologies aresteadilyincreasing,there arestill concerns among industry playersregarding thesafetyoftheir sensitive data.“AI adoption doesn’thavetomean sacrificingsecurity,” opines Lamparter.“Siemens has built its IndustrialAIandGenAIsolutionswithdataprotectionattheir core.Onekeyapproachison-premiseandedgecomputing,which ensures that sensitive data remains within a company’sinfrastructurerather than being transferred toexternalcloudenvironments.Thisallowsbusinesses to harnessAI-driveninsightswithout exposing critical information to unnecessary risks.”

“AIandGenAIcanmitigatethe challengeoflimitedskilledpersonnelin thechemicalandoil&gasindustry.”

Alain

Hermans, Process Industries Manager at Rockwell Automation

He adds that security alsodepends on strong encryption, strict access controls, and transparent AI governance. By followingglobal cybersecurity standards like IEC 62443, Siemens helps industrial players implement AI in away that aligns with industry bestpractices. “For companies looking to integrateAIwhile keeping their data secure,the keyisdeploying AI in controlledenvironments, enforcing robust data governance, and continuouslymonitoring AI systems for vulnerabilities,” explains Lamparter.

“Rockwell Automation prioritizes data protection throughamulti-layeredapproach,”elaboratesHermans. “Weemployrobust cybersecurity measures, including dataencryption,accesscontrol,andintrusiondetection systems. Additionally, we offer solutions with on-premisesdatastorage,ensuringdataremainswithinthecompany'scontrol.Bypartneringwithtrustedprovidersand implementing industry best practices, we ensuredata security.”ThisshowsthatleadingindustrialAIandGen AI players have meticulously developed theirsolutions and areprepared and all set for the long term.

Withtheintroductionofnewtechnologies,companies arebound to be worried about itsdownside but to educateoneselfontheseinnovationsandtakeadvantageof these technologies in atimely manner will help organizationstostaycompetitive,especiallyatthegloballevel, or else theywill be left out. (wüh)

Fluoropolymers meet requirements thatare often unattainablewith other materials. The eliminationofPFAS-based high-performance materials would have drastic consequences formanyindustries.

Regulatory authorities areconsidering acomprehensive ban on per-and polyfluoroalkyl substances(PFAS). What does this mean forthe industry?AnEU-wide ban on these high-tech materialswouldhaveserious consequences—but arethereany alternatives? How arecompaniesdealingwith this challenge?

Thegroupofsubstancesknownasper-andpolyfluoroalkyl compounds (PFAS)isinthe coshhair of the authorities: In the USA, aPFASreporting obligation will takeeffectin2025, while in Europe a cross-industry ban is being discussed. Getting rid of these substances howeverwill not be an easytask:The versatile and extremelydurablealkyl compounds are ubiquitousinhigh-performancematerials,coatings,and even medical technology.Pans coatedwithPTFE, commonlyknown by the brand name Teflon, can be found in nearly everyhousehold.The industry also uses fluoropolymers in hoses, pipes, seals, fittings, valves, and membranes, ofwhich there areover10,000 variants. Consequently,thesealingindustry,whichreliesonthese polymers as essentialmaterials, would be particularly affectedbya ban.

ButwhatwouldapotentialPFASbanmeaninconcrete terms? Fluoropolymers and perfluoropolyethers (PFPE)

arethe first choice in numerous industrial applications due to their temperature, pressure, and chemical resistance—especiallywhen asealing material must meet multiplerequirements,suchasexcellenthigh-temperatureresistance and compatibility with lubricants. However,fluoropolymers arealso expensive materialsthat aretypicallyused onlywhentheirperformance cannot be matched by other,cheaper polymers.

It is preciselythis durability that has drawncriticism towardsthese materials: The substances, colloquially known as “forever chemicals”,donot break down naturally. Theyaccumulateinthe environment andwater bodies,aretakenupbylivingorganisms,andthusenter the food chain. Some of thesechemicals arealso suspected of being carcinogenic

Therefore, the European Chemicals Agency (ECHA) publishedaproposalinFebruary2023foracomprehensive PFAS ban in the European Economic Area, which would effectively remove more than 10,000 per-and polyfluoroalkyl substances from the market.Following asix-month consultation period during whichcompanies couldsubmit concerns and exemption requests, a decisionbytheEUCommissionisexpectedin2025.Over 4,400stakeholderstooktheopportunitytosubmitmore than5,600comments.Concurrently,theEuropeanFood Safety Authority (EFSA) loweredthe limits for certain PFAS in food again in 2023

However, it’snot that simple: Whileceramic-coated potsandpansaremarketedashotalternativestoTeflon in thekitchen, the removalofthese high-performance materials in industry would have drastic consequences—after all, these substances meet requirementsthat areoften unattainable with other materials.

The sealing industry, for instance, findsitdifficultto part with PFAS:Acompletereplacement of PFAS as a material for elastomer sealsisnot feasiblewithoutsignificantlossesinmaterialpropertiesandlifespan—this conclusion is supported by arecent study fromthe Fraunhofer Institutefor Mechanics of Materials(IWM) Giventhe multitude of over 10,000PFAScompounds, theauthors advocatefor adifferentiated,fact-baseddiscussion regarding their regulation.

The mechanical seal specialist EagleBurgmann, part of theFreudenbergGroup,also calls for abalancedapproach instead of ablanket PFAS ban: “Wesupport the goals ofthe European Green Deal and the Chemicals Strategy for Sustainability,but we demanda differentiated,risk-basedapproachtochemicalregulation as plannedfor PFAS,” emphasizes ThomasBöhm, Senior Expert Digital Engineering &Standards.However,this requires investments in safe production anddisposal

processes.Onlythencansealingtechnologycontinueto fulfill its role in industry and society

Dr.RaimundJaeger,anadvisorinthefieldoftribology at Fraunhofer IWM, explains: “Fromour perspective, consideringthelifecycleoffluoropolymersclassifiedas ‘polymers of lowconcern’isa plausiblemethod to realisticallyassess potential hazards to human health and the environment. Allinvolvedstakeholders agreethat safeproductionanddisposalofpolymericPFASisessential. As long as we carefullyavoid harmful environmentalimpacts,theuseoffluoropolymersinindustryshould remain possible.”

“Weadvocateforadifferentiated, risk-basedapproachtochemical regulationasplannedforPFAS.”

Thomas Böhm, EagleBurgmann

Abinding timeline for the implementation of aEuropean PFAS regulation is still pending.Nevertheless, the industry is alreadypreparing for possible changes. At Freudenberg, thesearch for alternative materials is underway despitethe current indispensability of fluoropolymers: “Wehaveunique expertise in developing polymericmaterialssuchaselastomersandthermoplastics for industrial high-performance requirements. Our materials have enabled numerous newtechnologies in the past, and our material experts arehighlymotivated to continue developing innovative solutionsfor future challenges,”saysBöhm APFASban without suitable alternativesposessignificantrisksfortheprocessindustry.Adifferentiated,riskbasedregulatoryapproachthatallowscontrolledusage would be abetter path. (dst)

Rising energy andraw material prices, supplychain risks, increasing regulation and digital change areputting pressureonthe chemicalindustryand customer sectors. Operatorsmust rely on their components—can the valveindustrydeliver the necessary effective, sustainable andsafesolutions?

The chemical industry is clearlyfeeling theeffects of energy and rawmaterial prices, supplychain risks, sustainability,increasing regulation and digitalisation.Manyfactors have to be addressedatthe same time, and when it comes to this,dependable partnersareindispensable.Evenseeminglysimpleelements likefittings, valves and drivesare essential. Efficiency, sustainability and digital enhancements should never compromise utility

Chemicalcompaniesarefindingdependablepartners in the valves industry.This is becausethe sector is con-

Hydrogen tightness tests ensurethatthe limits are adhered to and volatile emissions areminimized.

stantlyinvesting in thedevelopment of newproducts andsolutionsforthechemicalindustry.Andalsoinnew employees wheneverappropriate. Forexample, HartmannValves:thechemicalindustryisahighpriorityfor this company, which is also reflected in its investments.

“In recent years, we have expanded our team in the area ofvalvesforthechemicalandpetrochemicalindustries,” explainsHartmannValves.TheirResearchandDevelopmentdepartmentisincreasinglyfocussingonsolutions suchasaballvalve with an integrated heating jacket. Basically, theaim is “toachieve increased safety for our

customerswith our metallic gas-tightballvalve,especially in moredemanding applicationsorthose with special functions”.Inthe future, theywanttocontinue to develop new, innovative solutions togetherwith customers in the chemical industry,and to invest in these products.

The digitalisation of valves in the chemicalsectoris steadilygaininginimportance—itisakeyplayerinthe shifttowardssustainabilityandefficiency.Inadditionto aspects such as digital type plates, digitalisation is playing an increasinglyimportantrole, especiallyin theautomation of valves. “Automated data readoutisindemand here,”according to Hartmann Valves

Similarly, valvespecialist Samson notes thattheseinnovations facilitateremotecontrol and real-time monitoring,therebysignificantlyenhancing operational efficiency.Their unique predictive maintenancesolution SAMDigitalstrivestodeliveracomprehensiveportfolio of solutions, including the smartfitting management system,SAMValveManagement.Thissystemoptimizes the control and regulation of chemical processing and transportation within plants.

Especiallyinhazardousareas,automationhasbecome astandardpractice.“Indifficult-to-accessorlarge,complexinstallations,thissavesworkingtime,”emphasizes Armaturen Vertrieb Alms (AVA). Remote control enhances safety for operating personnel, particularlyin explosive environments or when handling hazardous materials. “Asour valves aremostlyusedinsafety-relevant applications,weprimarilyinstall actuators that immediatelyreturntoapredefinedsafetypositioninthe event of apower failure.”Itiscrucial to have asafety system in place that safelyinterrupts the process in the event of adropincontrolpressureorloss of electrical powersupply.Forexample,theprocessoffillingaboiler or reactor can be stopped automatically—“closed”safetyposition—orapressurereliefcanbetriggered—“open” safety position. Richter Chemie-Technik introduces a linedsafety valveinthe KSE 3.0 series, optimizingflow streams and simplifying the installation process. “This valveenhancesefficiencyandcost-effectivenessinplant operations,”states Richter

Theshift toward platform-based product solutions is vitalintheprocessindustry.Byimplementingstandardized interfaces and harmonizedmodules, plant operatorscanbettermeetcustomerrequirements.Thisadaptability allows operatorstoadjust quicklytodynamic market conditionswhile optimizing productivity withoutcompromisingquality.Akeyaspectofthisapproach is individual customization. Users canmodifyvalve internal assemblies to align with their specific process conditionsandleveragemanufacturingtechniqueslike 3D printing to createtailored solutions. This reduces manufacturingeffortandensurescompliancewithcomplexregulations.Thisflexibilitynotonlyboostscustomer satisfaction but also strengthens relationships between manufacturers and clients.

Modularity provides significant benefits. Awellthought-outproductarchitectureandextensivecomponent kits increase variety and shorten development

times. Manufacturers gain from reusable modules, which simplifyprocurement and production processes. Moreover, solutions designed with modularity in mind can easilyincorporatenew functions and product variants. The integration of artificial intelligence and digitizedautomationaimstoenhanceproductionprocesses, adaptingtoshiftingmarketdemands.Suchinnovations positiontheprocessindustrytotacklefuturechallenges and maintain its status as an innovation leader

To securecompetitiveness, the chemical sector increasinglyturns to green gasand chemical recycling Hydrogen serves not onlyasacrucial rawmaterial but also as an energy carrier.However,building the necessary infrastructurefor hydrogen transport will require significant investment in pipeline construction.Efficient and safe fittings areessential for chemical plants and pipelines. Thefittings industry plays avital role in addressing the sustainability goals and challenges currentlyfacing the chemical sector and strategicallyimplementing solutions

As the chemical industry navigatesthe challenges of todayand tomorrow,itfinds areliable partner in the fittings industry.Through ongoing innovations, digitization,and automation,suppliers significantlyenhance thesafetyandefficiencyofchemicalprocesses,ensuring long-term competitiveness in an evolvingmarket. (dst)

These automated valves (from Emerson) have been designed forcryogenic use. They areintended to provide safe, leak-free shut-off during demanding unloading operations in the oil and gas industry

Thetrendtowardsconnectedfittings withintelligentsensorsremains

unbroken:digitizationenablesremote control,predictivemaintenance,and real-timemonitoring,increasing efficiency.

Utilizing wastecookingoil as akey rawmaterial,atop biodiesel producerfacedthe challenge of maintainingefficiencywhile preventing clogging in their centrifugalseparators. To tacklethis, they adopted an automatic self-cleaningstrainer.This has helped to rationalise theproductionprocess and improve the efficiencyofthe plant.

BSource:Eaton

EatonMCS500 automatic self-cleaning strainers aredesigned with durable stainless-steel screens from 15 micronsto¼-inch (6.35 mm) perforations to handle awide range of particle sizes and types.

iodieselcanbeproducedfromvarious feedstocks including vegetable oils, animal fats or recycled such as used cooking oils (UCO) whole biodiesel manufacturing ocess encompasses five keystages: feedstock purification, transesterification reaction, separation, distillation, and quality testing

The feedstock purification stage is particularlychallenging when using UCO, which often contains a complex and unpredictable contaminant mixture including food particles and burnt residues. These impuritiesare removedusing acentrifugal separator thatisnotablychallengingto maintain.

The separator must operateat veimpuritieswithoutbecoming largeparticles.Anycompromise lead to frequentmaintenance, seprocessefficiency ep,therefore,becomesindispensthe centrifugal separator.This typrainersorfilterstoremovelarger oil enters the separator. However, electing andmaintaining theapstem that can handlethe highly load. Inadequatefiltration can gerparticles,whichcandamage einternal components. On the equent filter changes and mainteoperational costs.

esel producer with an annual pro250,000 tons searched fora manufilters, prioritizing those with a

proven track recordofaddressing similar process challenges and the capability to fulfill demonstration trial requests.Aftercarefulevaluation,thecompanyselected Eaton’sFiltration Division to engineer an effective solution.

Eatonproposedastate-of-the-artautomaticfiltration system chosen for its strong performance in managing high levels of suspended solids (SS)aswell as its capacitytofunctioninharshconditions.Thissolutioninvolved thedeployment of twokey products:

MCS-500: This automaticself-cleaningstrainer is designed to handle up to 500 PPM of inletSS, makingitideal forthe high-contaminantloadfoundin UCO.

DCF-800: Used for field testing,this mechanically cleaned filter allowedfor real-time adjustmentand optimization during the initial trial phase

“The implementationstarted with an extensive threemonthfieldtest,duringwhichDCF-800filterswerestrategicallyinstalled at keypoints along thebiodieselproduction line, especiallybeforethe centrifugalseparators,”saysUlrich Latz, Global IndustrialFiltration ProductManageratEaton.“Thissetupenabledthecompany to directlyobservefiltration efficiency throughoutthe trial.Followingthis,ourengineersrefinedtheoperating conditionsusingtheinsightsgained,supplyingourcustomer with optimized calculations for thedisc stroke and purge cycles.”

Latzalsoexplainedhowtheavailabilityofvariousfilter elementsfor testing facilitated solution finding.The company’spreviousfilterelementhada25-μmretention efficiency;however,testing of variousEaton filter elements determined that a75-μmslotted wedge wire screenwouldmeettheprocessrequirementsmosteffectively.Thisphasewascriticalindemonstratingfiltration capabilitiesontheactualproductionline,thusensuring thesolutionwastailoredtomeetthecompany’sprecise needs.

Ultimately,thecompanyinstalledthreeMCS-500strainers at the front end of the centrifugal separator. By fine-tuning the purge cycle and disc strokecycle,this solution can adapt flexiblyto varying particle levels, ensuring optimal filtration. Additionally, as oilpasses through the filter,itforms an oil film, which cancause fluctuationsinflowsimilartoacoatingeffect.TheMCS500 strainer effectively addresses this by mechanically removingtheoilfilmfromthefilterelementduringthe disc work process.

Anothersignificantenhancementistheabilityforoperatorstosetupandinitiatethefilterpurgingcyclewithout interrupting manufacturing,contributing to a smoother,continuous workflow.

“While exact savings areconfidential,our customer has confirmed that theROI period is under oneyear, ” says Product Manager Latz. “Additionally, although maintenance guidelines suggest changingthe filter elementsannually,thecompanyhasnotneededtoreplace them since their initial installation. This highlights the effectiveness of the MCS-500 solution in this application.”

:E at on

Encouragedbytheproject’ssuccess,thecompanyisnow investigating filtration challenges in other intensive applications likemarine and aviation fuel production, anticipating continuedpurchases of Eaton products to support their expansion and progress.

“Our customer is very satisfied and appreciatesthat technicalmanualswereprovidedinmultiplelanguages, which improves comprehension globally,”saysLatz “Theyfound our on-sitedemo to be thesafest approach to minimizing risks associated with newequipment installation,andit'snowroutineforthemtocontactusfirst for anyfiltration issues.”The biodiesel producer alsois recommendingthemechanicalcleaningfilterproducts to similar installation operators he adds (dpo)

“Whileexactsavingsareconfidential, ourcustomerhasconfirmedthatthe ROIperiodisunderoneyear.”

Ulrich Latz, GlobalIndustrialFiltrationProduct Manager, Eaton

Everyonewants hydrogen -but isn't itdangerous? After all, the gasisnon-toxic but highlyflammableand ahigh levelofsafetyawareness iskey to safe operationthat protects the environment, personnel and infrastructure- so it'shigh time to take a look at whatneeds to be considered whenhandlinghydrogen. Whattechnologyis needed to detect the colorless H2 flames?

CemilÇaylı

Renewable hydrogen is set to playacrucialrole in the energy transition. European states areexperimentingwiththispromisingenergycarrier,and theyaretestinghowtheycanrepurposeexistingnatural gasdistribution networks to bring it to the consumer Hydrogenisahighlyflammablegas.Thatiswhytechnical staffwill need to be trained for safety. Theywill also need to be equipped with theright tools to detect gasleaks and see hydrogen flames.One suchtool is the thermalimaging camera.

Althoughhydrogenisseenasacleanenergycarrier,itis not always producedinaclean way. Gray hydrogen is produced from fossil methane through aprocess called steam reforming and results in the emission of carbon dioxide(CO2).Bluehydrogenalsoreliesonthisprinciple, although80to90percentoftheemittedCO2 iscaptured and stored underground.

As the name suggests, greenhydrogen is the mostenvironmentallyfriendly: It is produced via electrolysis, using renewable electricity to split waterintohydrogen

and oxygen.Whenproduced at times when solar and windenergy resourcesare abundantlyavailable, renewable“greenhydrogen”cansupporttheworld’selectricity needs,providinglong-termandlarge-scalestorage.The storage potential of hydrogen is particularlybeneficial for powergrids, because it allows for renewableenergy tobekeptnotinlargequantitiesandforlongperiodsof time.

Withallitspotential,thequestionremainshowhydrogen, once produced,can be efficientlydelivered to the consumerortothepointofuseinlargequantities.Until now,themarkethasbeendiscouragedbythesubstantial expensesthatareassociatedwithestablishingadedicated hydrogen pipeline or delivery infrastructure

Anotheroptionthathasbeengainingmoreattention inrecentyearsisconvertingtheexistingnaturalgasdistributionnetworkforthepassageofhydrogen.Obviously,hydrogen and natural gashavedifferent characteristics—forexampleintermsofflammability,density,and ease of dispersion—but with theinfrastructurefor natural gasalreadyinplace, aconversion forhydrogen distribution could be economicallyinteresting.Several demonstrationprojects and proofs of concept have

demonstratedthat with afew adjustments, hydrogen canbeinjected intoexisting naturalgas pipelines and delivered to awide range of end-point applications.

In 2020,apilot hydrogen project went operational in the UK.The HyDeploydemonstration showedthat it waspossible to blend up to 20percent of hydrogen with normal gassupplyintoKeeleUniversity’s private gasnetwork, which serves 17 faculty buildings and 100 domestic properties.

Also in the UK,afeasibility study—the H21 Leeds City Gatereport—was carried out, confirming that conversionofthe UK gasnetwork to 100percent hydrogen wasboth technicallypossible and could be deliveredata realisticcost.

Another pilot project started in 2022, in Lochem’s Berkeloorddistrict (the Netherlands).There,twelve homes areheated using hydrogen transported over the natural gasgrid.

In Hoogeveen, the Netherlands, the development of the world’s first hydrogen district is planned. Atthetimeofwriting,manymoredemonstrationand pilotprojectsarebeingdeveloped,showingthegrowing interest in the development of hydrogennetworks.

Oneofthedifficultieswhen workingwithhydrogenisthat ahydrogenflameisnot alwaysvisible.Hydrogenis alsoverylightsothatworkers alwaysneedtobeonguardfor unexpectedflamemovements duetowindbursts.

Nowweknowthat existing infrastructurecan be used: Howcanexistinggasdistributionpipelinesbesafelydecommissioned as anatural gaspipeline and commissioned as ahydrogen pipeline during theconversion to ahydrogen network? From apractical standpoint, the distribution pipes will need to be purged. Natural gas will need be let out and hydrogen gaswill need to be let in. Research has shown that hydrogen can beused to displacenaturalgasfromexistingnaturalgaspipelines, andthatanaturalgasdistributionpipelinecanimmediatelyberecommissioned as ahydrogen distribution pipeline after the natural gashas been displaced. Onefrequentlyusedtechniquewhenpurgingpipesis flaring.This is asafety measure often employed in industrial settings wherehydrogen is used.The process involves burning off excess hydrogen in acontrolled manner.Hydrogenflaringistypicallydoneduringmaintenance,leakdetection,orothersituationswherethere is excess hydrogen that cannot be safelystoredordisposed of in acontrolled way.

Althoughhydrogenisnottoxic,therearespecifichazards associated withworkingwith hydrogen gas, and flaring it posescertain risks. Just likemanyother gases,

IbrahimKar/MichaelBerz CostEstimationin

PlantConstruction

ISBNHardcover:978-3-8343-3436-7 ISBNE-Book:978-3-8343-6251-3 1st edition2020,180pages 119.80EUR

Thebookpresentsthebasicsofcost estimationinthedesign,procurement of materialsand construction of plants.Theprocedureisillustrated withanexampleprojectthatexplains with varyingdegrees of accuracy. Important templatesand supportingdocuments areprovidedinthe appendix.

IbrahimKar/MichaelBerz Templates: CostEstimationin

PlantConstruction

ISBN:978-3-8343-2424-5 Version1.02020 149.00EUR

Theeditabletemplatessupportthe cost estimatorwithchecklistsand formsinthecreationoftherequired accompanyingdocumentsofacost estimation.Thetemplatescanbefully adaptedtothe individual project requirements.

Furtherinformationandpurchaseat

www.vogel-fachbuch.de/en

Depending on how it is produced, adistinctionismade between conventional“gray” hydrogen from naturalgas, “blue”hydrogen, in which the resulting CO2is captured and deposited, and “green”electrolysis hydrogen

PROCESSTIP

www.process-worldiwde comfeaturesaforecast of thegloballow0carbon hydrogen supplyfor 2030

PROCESSINFO

hydrogen is highlyflammable and canigniterapidlyin thepresence of oxygen. Maintenance workers should thereforewear protective clothing that can withstand theheatandbeawareoftemperatureconditionstoavoid burns. Maintenance workers should alsouse tools that areintrinsicallysafe to avoid spark discharge accidents

Tosafelyworkwithhydrogen,technicalstaffneedstobe trained and theyneed to use the appropriatetools.One of the difficulties when working with hydrogen during flaringactivities is that ahydrogen flame is not always visible.Hydrogenisalsoverylightand—sinceflaringis done in open air—technical workers always need to be onguardforunexpectedflamemovementsduetowind bursts.Toensuresafety,technicalstaffneedabetterview of theflame during flaring works. Some of themostfrequentlyused technologies to monitor hydrogen flares arethermocouples,ultraviolet(UV)sensorsandinfrared (IR)sensors.Sometimes,certaincontaminantslikewater or dust are added to the hydrogen, which makes the flame morevisible.

Hydrogen (H) is agaseoussubstancethatisthe simplest member of the family of chemicalelements. Underordinary conditions, hydrogen gasisaloose aggregationof hydrogen molecules, each consisting of apair of atoms, adiatomic molecule,H2.

Availability:Hydrogenisthe most abundant element in theuniverse but only makesuponlyabout0.14percent of Earth’s crust by weight.

Diffusivity:Hydrogen’s greatest advantage, in terms of safety,is its ability to diffuse throughthe air muchfaster than other gaseous fuels, making it less likelytoaccumulate.

Toxicity:colorless,odorless, tasteless,and non-toxic

Flammability:Hydrogenisahighly flammablegas.Its broad flammability limits and low ignitionenergy increaserisk.

Visibility:Unlikemethane and gasoline fires, hydrogen burns with anearlyinvisible flameindaylight. However,contaminants in the aircan create some visibility.

Although all above-mentioned technologies arevaluable to detect hydrogen fast and accurately, theyare missingone essential feature: they do not allowtoactuallysee ahydrogen flame. That is whythermalimaging cameras arethe ideal complementary tool. Although hydrogen flamesare invisible during daylight, they do emit thermal radiation. Thermal cameras can detect these temperaturechanges, allowing technical staff to visualize the exact movement of the flames and safely approach ahydrogen flame. Thermal imaging cameras areanindispensable tool for anyone working on hydrogenpipelinesormonitoringhydrogenflares.Here’swhy:

Improved situational awareness:Thermal imaging cameras provide avisual representation of the entire scene, including thehydrogen flareinstallation. This offers improved situational awareness, which can be particularlyuseful in industrial settings with multiple processes.

Improved staff safety:Thermal cameras allowtechnical staff to monitor flames from asafedistance. Theydon’t have to approachthe flame closely, and the detection sensors insideathermal cameradonot need to makephysical contact with the flame.

Multiple uses: Thermal imaging cameras have a broad range of applications,beyond flame detection. Theycan be used for electricalinspections, mechanical inspections, and more. Thisversatility makes them avery economicaltool for arange of maintenance and safety tasks

Seeing temperaturedifferences:Thermal imaging cameras enable maintenanceworkers to visualize subtle temperaturedifferences.Thisenables them to detect not onlyflames, but alsohotspots, overheating problems, and other potential issues related to possible equipment malfunctions

Fewerfalse alarms: Unlikeflame detectors in certain environments, thermal imaging cameras areless prone to false alarms caused by non-flame sources such as sunlight, welding arcs,orhot surfaces. ThermalandacousticcamerasfromFlirsupporttechnical maintenanceprofessionals in safelyworking in hydrogenenvironments.Flircamerasprovideuserswith detail-richthermal images in avariety of thermalcolor palettes enabling greater situational awareness and understanding (dst)

FetteCompactingpresentsitselfconfidently as astrategic partnerfor thepharmaceuticaland nutritionindustries. Thebroad serviceportfolio ranges from formulationdevelopment to production support.

Thepharmaceuticalpackagingindustry facesthe challengeofgrowing sustainability.Patient-centered innovations and sustainable materials whereamong the highlights at Pharmapack Europe 2025,promising environmental advancements andenhanced patientexperiences.

Industrymarketreportshavepredictedasignificant increase in the growth of the globalpharma packaging industry in the next tenyears.Whatare your thoughtsonthis?

Sherma Ellis-Daal:The short answerisyes …and this alsochimes with everything we sawatPharmapack Europe(whichwasheldfromJanuary22ndto23rd,2025in Paris, France).If youonlytakethe findings in our own Pharmapack report, thereisbig th potential not onlyi -

Sherma Ellis-Daal is theBrand Director of Pharmapack Europe, a leading event in the pharmaceuticalpackaging andmedication dispensing industry.Inher role, she provides insights intoindustry trends and developments in pharmaceutical packaging.

options, but also,incontract packaging and filling.The latter hasbecome especiallytopical with the great volume of GLP-1 drugs (Glucagon-likePeptides medications that help lowerblood sugar levels and promote weight loss)wehaveseen in the lastfew years, and this willonlyaccelerateasgenerics come to market.

Theencouragingaspect,andagainyouseethiswithin ourPharmapackAwards,isthattheneedforconnected devicesandimprovedpatientexperienceandoutcomes is nowbeing matched with aligned innovations in sustainability…and youonlyneed to go back ayear to see howthesetwoequallyimportanttrendswereoftencomingintoconflict—soit’sgreattestamenttotheindustry

“Thereisbig growth potentialinnewer types of packaging innovations”,says Sherma Ellis-Daal, Brand Director at Pharmapack.

andespeciallythesmallerinnovatorsthatweareseeing thesetrendsalign.

Which country leads the global pharma packaging industry aththe moment? And wheredoes Europe fitin?

TheUSAstilldominatesthesectorbothintermsofoverallinnovationcontributions and, of course,interms of reimbursement of pharmaceutical products. It’sa marketthat is allowing morecomplex devicestobedeveloped and commercialized.

However, Iwould sayintermsofearly-stage innovations, the market is potentiallyhotter in Europe for sustainability technologies and devices andwe’re seeing manyregional hotspots acrossthe Old World for packagingand device innovation.Infact, bothSwitzerland andParisfinished well clear of all other locationsinthe recent Pharmapack device innovation and manufacturingindex

Please mentionthe latest solution(s)thatfocused onsustainabilityatPharmapackEurope2025.

We had one recent participant in the Start-Up Market—the Bioenzymatic Fuel Cells companyBefc—that has invented anew biofuel (essentiallyfunctioningsimilartoanelectricalbattery)andpapercircuitboard.The massive benefit of this isthat inpharmawetransport hugeamounts of temperaturesensitive biopharmaceuticals(likee.g.vaccines)andwestillhavetousebatteries and trackers to monitor these in transit—which areobviouslybad forthe environment when disposedof.

With this newtechnology,wecan see everythingthat happenedintransportbutatamuchlowercostofgoods. Andthen, rather the worry about the mountingwaste,

Allkeytopicsaroundyourjobonyourfavouritedevice Readnews,articlesandwhitepaperthewayyoulikeit. www.process-worldwide.com

Smart technologies likenon-electronic labels capable of monitoring time and temperatureare revolutionizingsupplychains and productmonitoring.

Thenext Pharmapack will be held on January 21st to 22nd 2026 in Paris, France.

literallyeverythingisbecomingincreasinglybiodegradable. It’sinnovations likethese that have kept Pharmapacksocentralandimportantfortheindustrytrends anditiswhybiggercompaniescomeheretoaccesscompletelyrevolutionary approaches. It is at meetings like this that novelapproaches go from pilot to commercialized technologies.

Whatwerethelatestindustrytrendsthatwerewitnessedatthetradefair?

PharmapackEurope2025highlightedseveralkeytrends thatarecurrentlyshapingthefutureofpharmaceutical packaging: One of the most prominent trends wasthe focusondevice and packaging innovation, explored in sessionssuchasthekeynotebyLionelJeanninfromNovartis Pharma, which provided global insights intothe emerging trends andmarketdevelopments, including regulatory shifts.

Large volume and high viscosity drug delivery was another significant trend, emphasizing patient-centric devices and self-administration of complexformulations.AsmitaKhanolkarfromSMCaddressedthisinher keynoteand examined whether newdevices or formulations better meet the needs of patients with chronic diseases.

Lightning talks in this track also discussedclinical trials, pain management as well as thereadiness of the market for newdevice withdrawals, thus providinga comprehensiveviewofthechallengesandopportunities in this space.

“Largevolumeandhighviscositydrug

deliveryareasignificanttrend,

emphasizingpatient-centricdevicesand self-administrationofcomplex formulations.”

Sherma Ellis-Daal, Pharmapack

Breakthroughs in materialscience,suchasmulti-layered vials and recyclable high-barrier papers, areenabling new applications forprecisionmedicineand biologics.

Sustainability also remains atransformative trend within thepharma packaging sector.Sessions at the trade fair addressed both the challenges and solutions in this space. Thekeynotesession, “Rethinking Sustainability”,explored howcompanies canviewsustainability initiativesaslong-term investments.

TimKeuler and Radek Paruszewski from Kloeckner Pentaplastdiscussedthetransitiontosustainableblister packaging,whileNovoNordisk’sBaijiaHuanghighlighted strategies to minimizeenvironmental impact through sustainable plastics. Apaneldiscussion featuring supplychain stakeholders also provided aholistic viewofachieving sustainability across the industry

Whatarethepotentialopportunitiesforthepharma packaging sector in Europeinthe next five to ten years?

Thepharmaceuticalpackagingsectorispoisedfortransformative growth over the next decade, drivenbykey trends in sustainability,patient-centric innovation or material science, as well as smart technologies, and talent inclusivity

The industry is increasingly prioritizing eco-conscious solutions, with recent advancements in recyclable materials and bio-based polymers addressingenvironmentalconcernsand regulatory demandsalike. At the same time, patient-focused designs arereshaping drug delivery and packaging.Theyemphasize intuitive use, enhanced safety as well as improved adherence to treatment.

At thesame time, breakthroughsinmaterial science, such as multi-layeredvials and recyclable high-barrier papers, areenabling newcompletelyapplications for precision medicine and biologics, while smart technologies likenon-electronic labels capable ofmonitoring timeandtemperaturearerevolutionizingsupplychains and product monitoring

In addition, also the emphasis on fostering emerging talent and promoting inclusivity is fuelinginnovation, ensuring that fresh perspectivesand diverse contributions can help to shape the futureofthe industry.Together,these trends highlight adynamic sector shift towardsamoresustainable, efficient, and patient-centeredapproach in pharmaceutical packaging and drug delivery (dst)

FindmoreinformationonPharma&Foodonline!

Stayuptodateandfindsolutionsforyoureverydayworkinthe bigfieldofPharmaandFoodon www.process-worldwide.com/pharma-and-food

Working together in partnership is at the centreofFetteCompacting’snew direction: Together —fromlab to production

FetteCompacting isonasuccessful path and presents itself confidently asa strategic partner forthe pharmaceuticaland nutritionindustries. We inquired intohow the companyembodiesits neworientation: “Together —fromlab to production.”

After its appearance at Achema2024, the company’smessageshouldbewell-receivedinthemarket: FetteCompactinghas positioned itself as a processpartnerforpharmaceuticalproductionandhas shiftedawayfromthe image of merelyamachinery manufacturer.This strategic process began twoyears ago, and since the beginning of this year,ithas alsobecome visible in the company’sleadership structure. Alongside CEO Joachim Dittrich and CFO Anke Fischer, Dr.MartenKlukkertnowcompletesthetrioasChiefCustomer Officer

At FetteCompacting,with tenyears of service,hecan alreadyberegarded as aveteran. Forthe pasttwo years, hehasbeenresponsibleasVicePresidentoftheCustomerDevelopmentCenterforthefiveCompetenceCentres locatedinGermany,the USA, Brazil, India,and China, andhehas been closer to pharmaceuticalcustomers than anyone else in the company.

His newrole as a“customer communication expert” isthustailor-madeforhim—ontopofthis,henowalso

carries asignificant amount of strategicresponsibility: embedding customerorientation intothe DNAofthe company, further developing the range of services and process partnerships, and implementingthe corresponding structures

NowtheTransformationisAlsoVisibleat theC-Level

Customer orientation is abuzzword that manycompaniesproudlyboast—machinerymanufacturersalsolike to presentthemselvesassolution providers. However, FetteCompactinghasbeenpursuingthisinitiativewith great determinationfor thepast twoyears,including a culturalshift within the company. The newlycreated positionofCCOnowunderscoreshowseriouslytheleadership trio takes the transition from atablet pressmanufacturer to astrategic partner of the pharmaceutical industry.“Ourcustomersnowdemandmorethanjusta technicallyperfect machine from us; they expect func-

FetteCompacting’s service portfolio: from labtoproduction

tioning processes,”explains Klukkert. He hasobserved this market development for years,and the mottopresentedatAchema,“Together—fromlabtoproduction”, represents the ambitionthat FetteCompacting has workedoutforitself.Thisentailssupportthroughoutthe entirelifecycleoftheOSD fromformulationandprocess development to scale-up,production, and later process optimisation. As afirst necessity,the FetteCompactingteamhas beenbuildingforthepasttwoyearsandhasestablished newstructures. Of course, the sales department is still theapointofcontactforcustomers,butthepurelycommercialmindsetisbeingreplacedbyafocusonthecore challengesofthecustomerandtheoverallsolutionthat should emerge later.Specifically, this means breaking down the traditional concept of functional areasand moving away from puremachinery sales. “Weengage with pharmaceutical customers as an interdisciplinary, content-driventeam and discussthe bestprocess solution,”emphasisestheCCO.Itiscrucialtoinitiatediscussionswith the pharmaceuticalpartneratatime when everythingisstillopenfromatechnologicalperspective

Dr.AnnaNovikova, Head of Process Consultancy