If you only think of Greenheck as a fan company, think again. We engineer and manufacture the industry’s most comprehensive line of air movement, control, conditioning, and distribution products for commercial, industrial, and institutional buildings. Our energy-efficient products keep occupants comfortable, productive, and safe while supporting sustainability. Let us help with your next project.

A

With ProCoreTM high corrosion-resistant technology, the battle against leaks has changed forever

Tired of replacing leaky coils? ProCoreTM copper tubing provides the solution. Even in the most severe environments, tubing with ProCoreTM technology maintains refrigeration system integrity with no reduction in capacity. Install with confidence, and bring longer-lasting comfort to your customers.

• Dramatically inhibits pitting & corrosion

• Maximizes reliability of the heat transfer system

• Enabled a drastic reduction in replacement coils over the last 5 years

• Stronger and more resilient than standard & oxygen-free copper

20 ASHRAE’s Next Generation, with YEA’s Top Leaders

The challenges facing young engineers today may be more complex than ever, but our guests this month reassure us that the energy, skills, and organization are coming together to meet them head on.

By Rob McManamy

25 Calculating Boiler Efficiency via Stack Loss Method

New ABMA White Paper explores best practices for defining boiler efficiency.

By M.W.

Valentino

8 AIA Mid-Year Consensus Forecast Sees 7% Rise

July updates to eight industry forecasts foresee construction spending finishing 2024 strongly, but then slowing in 2025. For now, data center projects are leading the way.

By the American Institute of Architects

The chair of ASHRAE’s new Center of Excellence for Building Decarbonization offers an urgent path forward, supported by recent case studies.

By KENT W. PETERSON, P.E., FASHRAE

HPAC Engineering (USPS Permit 464-930, ISSN 0039-0895 print, ISSN 1930-8957 online) is published 6x a year (Jan/Feb,,Mar/Apr , May/Jun, Jul/ Aug, Sep/Oct, Nov/Dec) by Endeavor Business Media, LLC. 201 N Main St 5th Floor, Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI, and additional mailing offices. POSTMASTER: Send address changes to HPAC Engineering, PO Box 3257, Northbrook, IL 60065-3257. SUBSCRIPTIONS: Publisher reserves the right to reject non-qualified subscriptions. Subscription prices: U.S. ($ 111.25); Canada/Mexico ($ 123.75); All other countries ($148.75). All subscriptions are payable in U.S. funds. Send subscription inquiries to HPAC Engineering, PO Box 3257, Northbrook, IL 60065-3257. Customer service can be reached toll-free at 877-382-9187 or at HPACengineering@omeda.com for magazine subscription assistance or questions.

Printed in the USA. Copyright 2024 Endeavor Business Media, LLC. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopies, recordings, or any information storage or retrieval system without permission from the publisher. Endeavor Business Media, LLC does not assume and hereby disclaims any liability to any person or company for any loss or damage caused by errors or omissions in the material herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever. The views and opinions in the articles herein are not to be taken as official expressions of the publishers, unless so stated. The publishers do not warrant either expressly or by implication, the factual accuracy of the articles herein, nor do they so warrant any views or opinions by the authors of said articles.

From the world’s #1 air conditioning company, discover the cloud connected benefits of VRV EMERION provided by Daikin’s HERO Cloud Services.

HPAC ‘On The Air’: Women Marching Forward, with ASHRAE’s Nancy Kohout

*NEW PODCAST* This month, we chat with the event chair of the upcoming ‘Women in ASHRAE Leadership Symposium’, set for Chicago this fall. www.hpac.com/55055767

WEBINAR: A.I., Drones, Digital Twins and You!

ICYMI *NOW ON DEMAND* Recorded May 9, this Oracle Industry Lab presentation takes a deep dive into the technologies transforming our jobsites! Sign in & watch! www.hpac.com/21285224

NEW eBOOK: The Best of Ken Elovitz, P.E.

An Engineer’s Notebook, 2021-2024. Dive into this collection of useful professional advice, laced with helpful legal acumen. www.hpac.com/55020330

HPAC 2024: Our July Quiz!

*CENTURY OF PROGRESS* Our 95th anniversary journey continues with a deeper dive into HVACR history. Take the quiz! Win prizes! www.hpac.com/55090790

EDITORIAL OFFICE

8001 Lincoln Ave. • Suite 720 Skokie, IL 60077 www.hpac.com

EXECUTIVE TEAM

CEO: CHRIS FERRELL

PRESIDENT: JUNE GRIFFIN

COO: PATRICK RAINS

CRO: PAUL ANDREWS

CHIEF DIGITAL OFFICER: JACQUIE NIEMIEC CHIEF ADMINISTRATIVE AND LEGAL OFFICER: TRACY KANE EVP, GROUP PUBLISHER –BUILDINGS/LIGHTING/DIGITAL INFRASTRUCTURE: TRACY SMITH

EDITORIAL CONTACTS

MIKE EBY Group Editorial Director meby@endeavorb2b.com

ROB MCMANAMY Editor-in-Chief rmcmanamy@endeavorb2b.com

DAVID ECKHART Art Director deckhart@endeavorb2b.com

SALES CONTACTS

MIDWEST BILL BOYADJIS 973-829-0648 bboyadjis@endeavorb2b.com

SOUTH & WEST

RANDY JETER 512-263-7280 • Fax: 913-514-6628 rjeter@endeavorb2b.com

EAST BRIAN SACK 732-629-1949 bsack@endeavorb2b.com WEST ELLYN FISHMAN 949-239-6030 efishman@endeavorb2b.com

CLASSIFIEDS/INSIDE SALES STEVE SUAREZ 816-588-7372 ssuarez@endeavorb2b.com

DIRECTOR OF SALES JOE AGRON 941-200-4778 jagron@endeavorb2b.com LIST RENTAL SMART REACH sr-assets@endeavorb2b.com effective PRODUCTION AND CIRCULATION

RITA FITZGERALD Senior Production Manager rfitzgerald@endeavorb2b.com

MELISSA MENG Ad Services Manager mmeng@endeavorb2b.com

JAMES MARINACCIO Audience Marketing Manager jmarinaccio@endeavorb2b.com

• NeoTherm® XTR (399-1500 MBH; 10:1 turndown) our newest boiler and water heater –common vent for up to 8 units.

• MagnaTherm® (20:1 turndown; 95+ thermal efficiency) industry-leading fire-tube or water-tube boiler technology including Tru Trac® real-time O2 trim and Laars Linc® intuitive touchscreen control.

• FT Series Commercial Boiler (301 or 399 MBH; 10:1 turndown) our newest commercial boiler converts from wall to floor with optional stand.

Get all the technical details, specification and submittals information you need for Laars commercial condensing boilers for your next projects.

ROB MCMANAMY, EDITOR-IN-CHIEF

Truth be told, I rarely know what these essays will be about until the last minute. I often have my topic chosen weeks in advance, but current events invariably upend my best laid plans. This month, it happened again.

On June 28, the U.S. Supreme Court issued a monumental 6-3 decision that shocked legal scholars. The landmark ruling, Loper Bright v. Raimondo, effectively upended the rule-making authority of the U.S. Environmental Protection Agency, putting at risk some 18,000 lower court decisions that now may have to be re-litigated!

Surely, I thought, the massive implications of that ruling, alone, would overwhelm this space and fill my summer editorial.

But then, on Monday, July 15, a new topic literally came roaring down the street outside my house, as my wife and dog and I huddled in our basement stairwell. Shortly before 10 p.m., one of more than two dozen EF-1 tornadoes blew through my neighborhood in south suburban Chicago, uprooting trees, ripping solar panels and attached shingles off roofs, and flinging debris everywhere. Miraculously, not a soul in our community was killed or seriously injured. But many of us lost power for 24 to 72 hours, and all of our lives had a new focus.

have broken poles. These types of outages take awhile to restore.”

But our industry delivered. Local contractors and MEP engineers pitched in 24/7, helping in the summer heat to keep IAQ high and cool air flowing in hospitals, senior centers and grocery stores. Indeed, we became one of those hard-hit communities you always see on the nightly news, but the mood here was not despair. It was relief that we were still here, gratitude for all the help received, and resolve to pay it forward.

One friend from the next block pointed to the sign in front of my neighbor’s house and said, “That’s what it’s all about on this street.” #HelpEachOther

That’s when I realized that my new editorial topic had arrived. The EPA could wait. Indeed, red, blue or purple states, urban, suburban, rural... at the end of the day, we are all neighbors. Just as we are all Americans. This fall, as this wild race for the White House barrels toward its dramatic climax, I pray that we all remember that.

Just as the HVACR industry continues to prove just how important it is to our daily lives, whether we are in crisis, or dealing with worsening effects of climate change, events like this also remind the rest of us how we are all part of a community.

EDITORIAL ADVISORY BOARD:

William G. Acker Acker & Associates

William P. Bahnfleth, PhD, PE The Pennsylvania State University

David W. Bearg, PE Life Energy Associates

Don Beaty, PE, FASHRAE DLB Associates Consulting Engineers

Lawrence (Larry) Clark, QCxP, GGP, LEED AP+ Sustainable Performance Solutions LLC

Peter D’Antonio, PE, CEM, LEED AP PCD Engineering Inc.

Kenneth M. Elovitz, PE, Esq. Energy Economics Inc.

Thomas Hartman, PE The Hartman Co.

Asif Kadiani, PE, CEM Murphy Co.

John H. Klote, PE, DSc

Valentine A. Lehr, PE, FASHRAE Lehr Consultants International

Mark S. Lentz, PE Lentz Engineering Associates Inc.

Joel N. Orr, PhD Orr Associates International

When the day after dawned, however, an extraordinary thing happened.

Neighbors were up and out all up and down the street, helping each other. Talking, hugging, surveying the damage, clearing debris, offering to refrigerate perishables for those without power. Soon, public works crews and utility trucks rolled in to help. And within 24 hours, we had workers from as far away as California and Georgia. ComEd brought in 1,000 workers from other utilities, including 300 from Canada.

“They’re facing downed trees, branches all over,” said ComEd spokesperson Neena Hemmady. “They have downed lines. They

In that spirit, I plan to serve as an election judge again this fall, and I urge all of you, in one way or another, to find your own path to civic duty. Public service is a concept that we hear so little about in these contentious times. But I know the instinct is still there and it remains strong. In fact, I have seen it on the very street where I live.

P.S.

I could also recount here my high-speed blowout while driving back from ASHRAE in Indy. But I will save that for another day. Of note, the #HelpEachOther theme plays a key role in that story, too.

J. Jay Santos, PE Facility Dynamics Engineering

Andrew J. Streifel, MPH University of Minnesota

James P. Waltz, PE, CEM, ACFE Energy Resource Assoc. Inc.

Michael K. West, PhD, PE Advantek Consulting

Ron Wilkinson, PE, LEED AP Wilkinson Commissioning Management

Gerald J. Williams, PE, LEED AP 8760 Engineering LLC

3–10HP ECM-powered pumps, plus SelfSensing VFD’s, optimizing system efficiency and savings Most Efficient Design > 84% of the time*

Standard NEMA-frame motors offering easier serviceability and shorter lead times

Taco Tags providing vital product information, right at your fingertips

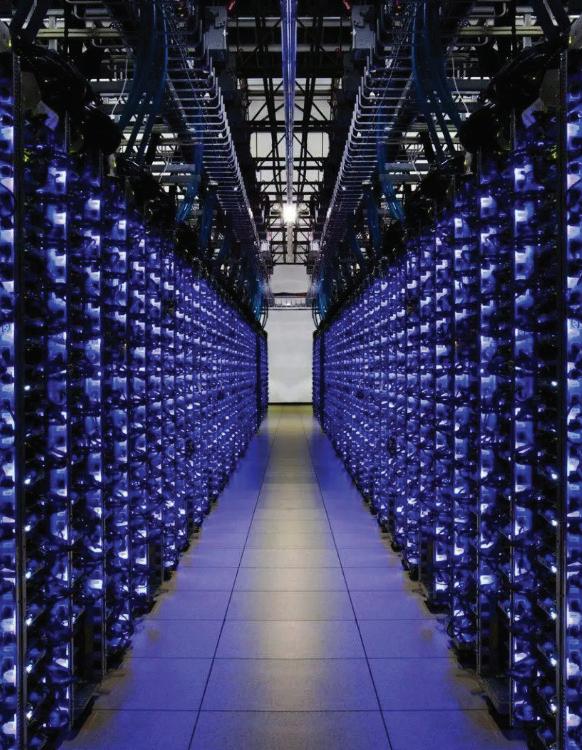

July updates to eight industry forecasts foresee construction spending finishing 2024 strongly, but then slowing in 2025. For now, data center projects are leading the way.

Spending on nonresidential buildings is projected to increase more than 7% this year, according to The American Institute of Architects mid-year Consensus Construction Forecast. The spending will slow to only 2% in 2025 as market challenges continue to impact the pace of growth.

Construction spending, while continuing to increase, has seen the pace of growth slow so far this year, and this slowdown is expected to continue into 2025. The challenging lending market for construction projects, continued weakness in commercial property values, and ongoing softness in billings at architecture firms contribute to the slowdown.

The Consensus Construction Forecast panelists, a group comprised of the leading construction forecasters from across the country, report sector conditions diverging with performance varying greatly sector by sector:

• Commercial facilities activity effectively will be flat this year and next;

• Manufacturing projects will increase almost 14% this year before stabilizing in 2025;

• Institutional work will gain more than 10% this year before slowing to 4% in 2025.

“The disparity in sector performance highlights the uneven economic conditions and ongoing market uncertainties,” noted AIA Chief Economist Kermit Baker, PhD, FAIA. “Despite the challenges, specific sectors like manufacturing construction are showing strong ongoing activity from the surge in projects that started during the pandemic, while most institutional sectors are seeing reasonably healthy gains, fueled by the education market.”

These are key conclusions from the mid-year update by the AIA Consensus Construction Forecast panelists, a group comprised of the leading construction forecasters from across the

country. This survey evaluates how this year is likely to shape up from the midyear vantage point, and projects how these trends are expected to play out as we move through the coming year. The figures presented here are in nominal terms, meaning that they are not adjusted for inflation.

While the overall nonresidential building market is seeing reasonably healthy growth this year, its performance has varied greatly by sector. The commercial sector has seen declines year-to-date as compared to the same period a year ago, while spending on manufacturing facilities has seen strong growth and most institutional sectors have seen reasonably healthy gains.

On the commercial/industrial side, a few key sectors have been generating strong growth while others are stagnating.

For example, manufacturing construction currently accounts for well over a quarter of all spending in the

nonresidential building sector, a share that has doubled since 2019. Embedded in the generally weak retail and other commercial sector is warehouses, which account for over 9% of spending in the broader nonresidential building category. Its share has increased from just over 6% in 2019.

Finally, data centers are categorized within the broader office sector. While traditional office spending has been declining, spending on data centers has been rapidly increasing. Commerce Department figures peg data center spending as accounting for over 3% of the overall nonresidential building market, and its share has doubled since 2019.

In total, these three niche commercial/industrial construction sectors currently account for over 40% of the nonresidential building market, up modestly from their 39% share last year. In 2019, these three sectors accounted for less than 23% of overall nonresidential building activity.

As a result, these construction sectors that typically have a different design focus, materials composition, and contractor specialization now account for much of the gain that the industry has seen recently. That would suggest that some segments of the industry have benefited from the strong growth in these sectors, while others have been passed over.

Construction spending, while continuing to increase, has seen the pace of growth slow so far this year, and this slowdown is expected to continue through this year and into 2025. Indications of a continued slowdown include a challenging lending market for construction projects, continued weakness in commercial property values, and ongoing softness in billings at architecture firms.

• Challenging lending market — Yields on 10-year treasury bills, typically used as a proxy for construction financing costs, are currently running between 4.25% and 4.5%. While not

dramatically different from levels of the past few decades, they have risen significantly from levels seen in recent years. During the summer of 2020, yields hit a low for this cycle at just over 0.5%. They stayed below 1% through early 2021, and below 2% through early 2022. Currently, lending rates are significantly changing the calculations of project feasibility.

The Federal Reserve Board’s survey of senior loan officers documents the tighter lending standards for commercial real estate lending. According to their recent report, “a significant net share of banks reported tightening standards for all types of CRE loans.

Meanwhile, a moderate net share of banks reported weaker demand for construction and land development loans, while significant net shares of banks reported weaker demand for loans secured by nonfarm nonresidential and multifamily residential properties. The most cited reasons for tightening credit policies on CRE loans were less favorable or more uncertain outlooks for CRE market rents, vacancy rates, and property prices.

Additionally, major net shares of other banks cited a reduced tolerance for risk, increased concerns about the effects of regulatory changes or supervisory actions, and a less favorable or

more uncertain outlook for delinquency rates on mortgages backed by CRE properties.”

• Continued weakness in commercial property values – A tighter financing environment coupled with weaker demand for most categories of commercial properties continues to put downward pressure on property values. MSCI’s Commercial Property Price Index indicates a 13.5% overall decline in commercial property values since its most recent high in midyear 2022. Offices have seen the steepest decline of over 26% over this period, while apartment values have declined by 21%. Retail facilities have seen a more modest decline of 10%, while industrial property values have continued to increase, tacking on about 5% in value gains over this period. Price declines for apartments and retail facilities are beginning to moderate, but continue to fall quite sharply for offices, particularly in downtown areas;

• Billings at architecture firms –Architecture firm revenue is a very accurate leading indicator of construction spending with a 9-to-12-month lead. Quarterly billings at architecture firms have been declining since the fourth quarter of 2022, according to the AIA/Deltek Architecture Billings Index (ABI).

However, the pace of that decline – though volatile— has begun to accelerate over the past 10 months. Firms that specialize in the multifamily residential market have seen the steepest downturn in billings, followed by those specializing in commercial/industrial activity. Firms with an institutional specialization have generally seen revenue levels hold steady, although there has been emerging weakness in recent months. Given that both new design contracts and project inquiries at such firms have been about as weak as billings, prospects for a turnaround in design activity do not appear imminent.

Outside of a few niche sectors, such as manufacturing and data centers, the commercial/industrial outlook is poised at best for very modest growth or more likely declines in spending levels moving forward. The AIA Consensus Construction Forecast is calling for essentially no growth this year and next overall in the commercial markets. For industrial facilities, current project activity is expected to produce healthy double-digit spending growth this year, but then stabilize for 2025.

Most of the institutional sectors offer more potential in terms of growth in the near term according to the AIA Consensus Forecast panelists.

The overall sector is projected to increase almost 11% this year, and then record another 4% increase next year. Health care construction, a significant institutional sector, has seen growth throughout the pandemic, and is poised for a 7% gain this year, and an additional 4% next. Amusement and recreation, a sector that understandably saw little activity during the pandemic, is now poised for a double-digit percentage rebound this year, and an additional 4% increase in 2025.

However, expectations are that much of the projected growth in the overall institutional sector will be generated by the education market. Education is the largest institutional component, and

accounts for almost one in every five dollars spent on nonresidential building construction. Longer-term, spending on educational facilities is largely driven by demographics, namely the increase in the under age 25 population. There were over 100 million persons under age 25 in the U.S. in 2020. This group is expected to increase by almost two million by 2030.

The greatest increases are expected to come from the under age 10 population, as the number of 10-19-year-olds is expected to decline between 2020 and 2030, while the 20-24-year-old group is expected to increase only modestly.

But these estimates may turn out to be too low if immigration numbers were to increase. This decade, the increase in net immigration is expected to outpace the natural increase in our population (defined as the number of births minus the number of deaths), and historically, children have comprised a large segment of the immigrant population. Additionally, many educational construction and reconstruction projects were put on hold during the pandemic with the increase in remote education, so pent-up demand will push up construction activity levels.

One final consideration that will impact the construction outlook moving forward is the growing importance of reconstruction activity as a share of overall construction spending. Surveys conducted by the AIA have discovered that about 50% of billings at architecture firms come from work on existing buildings, including additions to existing facilities.

The current economic environment of declining values of existing buildings coupled with the elevated cost of building new facilities often tilts the scales toward reconstruction over new construction. The expectation is that the reconstruction share of total construction activity will continue to increase in the years ahead.

For more, go to www.aia.org.

The chair of ASHRAE’s new Center of Excellence for Building Decarbonization offers an urgent path forward, supported by recent case studies.

By KENT W. PETERSON, P.E., FASHRAE, Chairman, ASHRAE Center of Excellence for Building Decarbonization (CEBD)

Addressing climate change is more pressing than ever, and the built environment plays a significant role in this global challenge. Buildings are responsible for a substantial portion of global carbon emissions, making it imperative for the construction industry to innovate and adopt new strategies for decarbonization.

This article explores how emerging technologies can revolutionize building design, construction, and operation, propelling us toward a sustainable and decarbonized future.

Nature, exemplified by the forest ecosystem, operates on principles of sustainability and efficiency, with no concept of waste. Every element contributes to the cycle of life, creating a balanced and self-sustaining system. This natural model inspires the concept

of the circular economy, where waste is minimized, and materials are continuously reused and recycled. By emulating nature, we can create efficient and environmentally friendly buildings.

The forest serves as a metaphor for the ideal built environment. In a forest, fallen leaves decompose and enrich the soil, supporting new plant growth and maintaining a balanced ecosystem. This cycle of life is sustainable and efficient, highlighting the importance of designing buildings that operate with similar principles. By integrating natural processes into building design, we

The author is chair of ASHRAE’s new Center of Excellence for Building Decarbonization (CEBD), formerly the Task Force on Building Decarbonization (TFBD). An ASHRAE past president, Peterson is co-founder and COO of consulting engineer P2S Inc., a Legence Company based in Long Beach CA.

can reduce waste, improve resource efficiency, and create spaces in harmony with the environment.

Unlike natural systems, human activities often lead to significant waste and inefficiency. Landfills accumulate materials that could be recycled or reused, highlighting missed opportunities for more sustainable resource management. Similarly, energy consumption is often wasteful. As we continue to improve our quality of life through technology, we must address the environmental impact and ensure that future generations inherit a sustainable world.

Current waste management methods, particularly landfills, exemplify the inefficiency of human systems. Many materials in landfills could be recycled or repurposed, reducing the strain on natural resources and minimizing environmental impact. In the same vein, energy consumption in buildings is frequently characterized by inefficiencies that result in unnecessary carbon emissions. Addressing these issues requires a comprehensive waste and energy management approach, incorporating advanced technologies and innovative practices.

Building decarbonization involves reducing greenhouse gas (GHG) emissions throughout a building’s lifecycle. This journey aims to achieve nearnet-zero emissions from buildings by 2050. GHG emissions from buildings are categorized into operational and embodied carbon.

Operational carbon includes emissions from energy used to heat, cool, and power buildings, while embodied carbon encompasses emissions from the materials and construction processes.

In 2022, according to industry estimates, buildings accounted for 38% of energy-related CO2 emissions, underscoring the critical need for decarbonization.

Addressing both operational and embodied carbon is essential to

creating a sustainable future. Operational carbon emissions are generated during a building’s use phase, primarily from heating, cooling, lighting, and powering various systems. In contrast, embodied carbon emissions arise from the production, transportation, and installation of building materials and construction activities.

Achieving decarbonization requires a holistic approach that considers a building’s entire lifecycle. From the initial design phase to construction, operation, and eventual demolition, each stage presents opportunities to reduce carbon emissions. This lifecycle perspective ensures that decarbonization efforts are comprehensive and effective, addressing immediate and long-term environmental impacts.

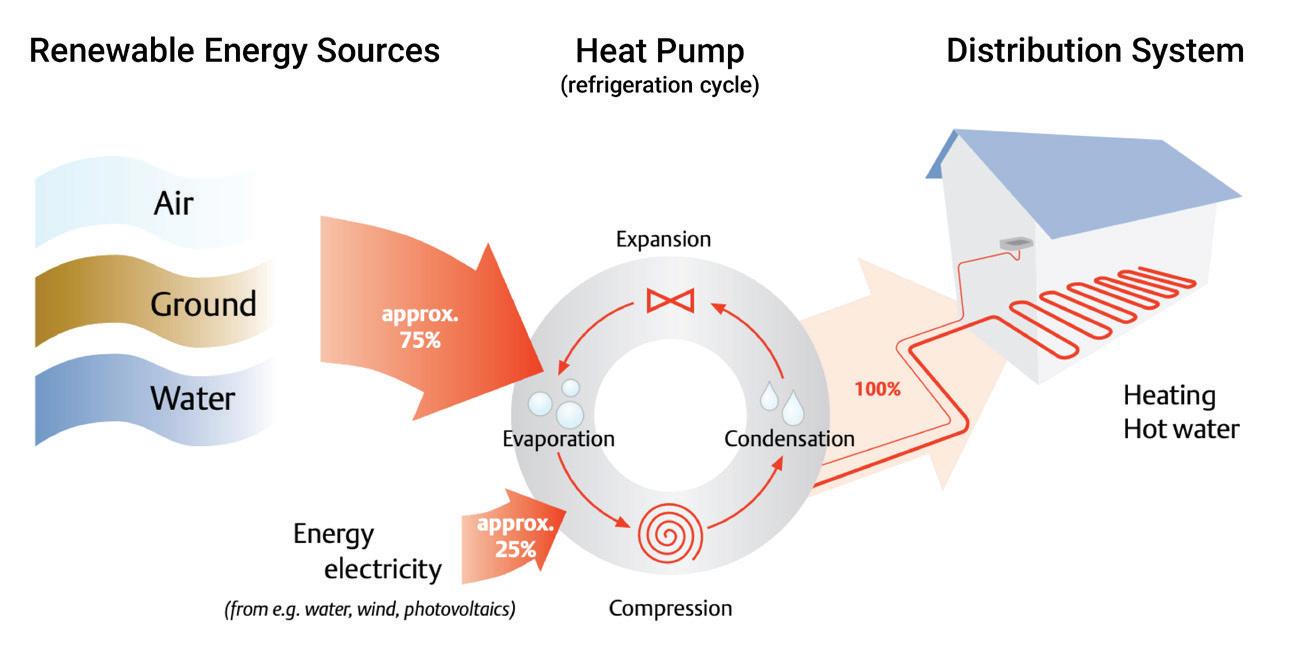

Heat pumps are a cornerstone of decarbonization efforts in building design. They can achieve high-efficiency levels and significantly reduce energy consumption by transferring heat rather than generating it. This technology is particularly effective in regions with moderate climates, where the temperature difference between the heat source and the heat sink is relatively small. Advanced heat pump systems can still provide substantial energy savings in colder climates by leveraging geothermal or water sources.

Replacing fossil fuel use with electricity can reduce overall emissions and improve building efficiency. As electricity’s carbon intensity contin-

The most sustainable energy is the energy we don’t use. Reducing energy consumption through efficiency and conservation is more effective than generating new energy, even from renewable sources.

Heat pumps, for instance, provide efficient heating and cooling solutions, significantly reducing carbon emissions. These systems can operate using various energy sources, including air, water, and ground, and achieve 200550% efficiencies through the refrigeration cycle.

ues to decline, strategic electrification becomes a viable pathway to decarbonization. Beneficial electrification involves the intentional shift from direct fossil fuel use to electricity in applications when it reduces overall emissions and enhances efficiency.

Transitioning to electric heating and cooling systems is key to beneficial electrification. Electric systems, particularly when powered by renewable energy sources, offer significant environmental benefits over traditional fossil fuel-based systems. However, the success of this transition depends on the availability of low-carbon electricity. As the grid increasingly incorporates renewable energy, the carbon intensity of

electricity will continue to decrease, making electrification an even more attractive option.

BIM optimizes energy efficiency, reduces waste, and facilitates collaboration throughout the building lifecycle. By leveraging BIM, the construction industry can sustainably design, construct, and operate buildings. BIM fosters collaboration among architects, engineers, contractors, and facility managers by providing a common platform for sharing information. This integrated approach ensures that sustainability and decarbonization goals are considered at every stage of the building lifecycle.

BIM enables detailed simulations and analyses that can optimize building performance. By modeling various design scenarios, stakeholders can identify the most energy-efficient and sustainable options. BIM also supports integrating renewable energy systems, advanced HVAC technologies, and other sustainable features into building designs. This holistic approach not only improves building performance but also reduces costs while enhancing the project’s overall value.

AI enhances the integration of decarbonized buildings into the smart grid, optimizing energy use and facilitating seamless interaction between buildings

and the grid. AI can predict energy consumption patterns, optimize battery storage, and improve building performance. It facilitates the interaction between buildings and the grid by optimizing when to feed excess renewable energy back into the grid or to draw energy from it.

AI-driven energy management systems can significantly reduce energy consumption and emissions. AI can make precise adjustments to HVAC, lighting, and other building systems by analyzing historical data and real-time conditions. These adjustments can optimize energy use, reduce peak demand, and improve occupant comfort. AI also plays a critical role in demand response programs, enabling buildings to respond dynamically to energy supply and demand changes.

The following projects demonstrate impressive uses of these technologies and concepts. They each represent viable pathways that different sectors of the built environment can take to achieve decarbonization goals.

The retrofit of New York City’s landmark Empire State Building, including advanced Energy Management Systems (EMS), led to a 38% reduction in energy use and $4.4 million in annual energy savings. This highlights the potential for substantial energy and cost savings in existing buildings through intelligent retrofits.

The retrofit here involved upgrading the building’s insulation, windows, and HVAC systems, as well as implementing a comprehensive energy monitoring and control system. New controls were implemented at the zone level, allowing facility operators to have granular control of the building and adjust for the requirements of different sections or tenants.

Constructed in 1931 and once the world’s tallest office tower, the iconic Art Deco-style building was part of the first generation of skyscrapers. These latest improvements have set a new standard for energy efficiency in older skyscrapers and demonstrated the feasibility of large-scale retrofits. The Empire State Building’s owners are now moving

forward with a second phase of EMS upgrades, where they hope to increase energy savings by up to 70% by retrocommissioning and optimizing controls for existing systems to eliminate waste energy, increase automation, and improve part load efficiencies.

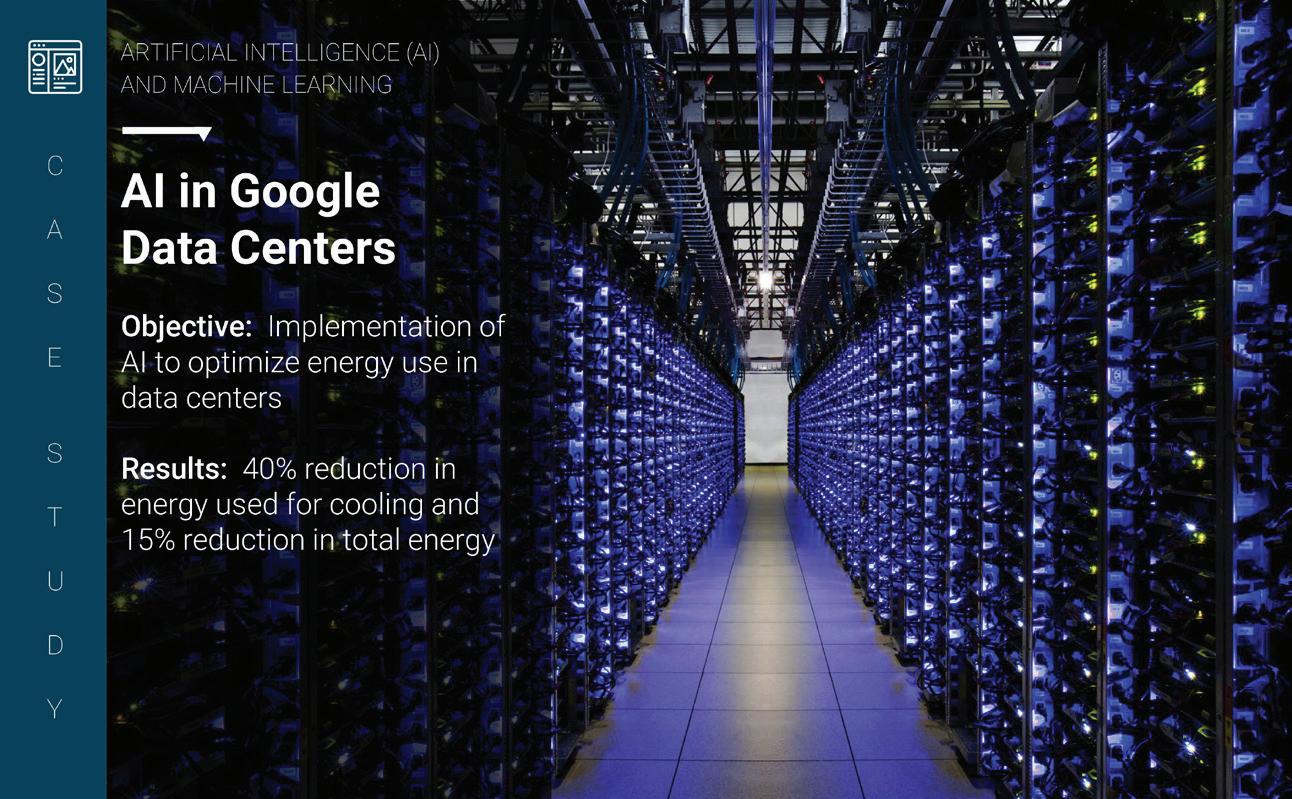

Google used DeepMind AI and machine learning to optimize the energy consumption of its data centers, resulting in a 40% reduction in energy used for cooling and a 15% reduction in total energy consumption. Google accomplished these reductions by using AI to analyze historical data and adjust cooling systems to minimize energy consumption.

This showcases the potential of AI to significantly reduce carbon footprints in even the most energyintensive environments. By leveraging machine learning algorithms, Google’s AI system can predict cooling needs and make real-time adjustments to optimize efficiency. That not only reduces energy consumption but also enhances the overall reliability and performance of the data centers.

This zero-carbon building in Trondheim incorporates 3,000-sq-m of solar panels and a natural refrigerant heat pump, achieving energy positivity across its lifecycle, including energy consumed in producing and transporting building materials, on-site construction, and end-of-life deconstruction. It demonstrates the feasibility of smart, energy-efficient building designs in challenging environments, as the eightstory office building is located 63° north of the equator.

At this latitude, sunlight varies greatly between the seasons, and so the project presented a unique opportunity to explore how to harvest and store solar energy under challenging conditions. The building’s design integrates passive and active measures to maximize energy efficiency and minimize carbon emissions. Occupant-adaptive HVAC

and lighting systems and a high-performance building envelope contribute to the building’s exceptional performance.

The Edge is a smart office building in Amsterdam that utilizes over 28,000 IoT sensors to monitor and manage its various building systems. Sensors monitor lighting, temperature, and occupancy in real-time, allowing adaptive control. Automated adjustments to lighting and HVAC systems based on occupancy and environmental conditions optimize energy use throughout the building.

The automated adaptive controls and sensors significantly improved occupant productivity and comfort. The Edge has achieved a 70% reduction in energy consumption compared to traditional office buildings, setting a benchmark for innovative, sustainable design.

The Wavehouse data center is Europe’s largest 3D-printed building and is described as the first of its kind in the global industrial and data center sectors. This unprecedented building achieved a 55% reduction in embodied carbon. The building’s structure was completed using 450 tons of recyclable printing concrete, significantly reducing construction waste and emissions.

Its innovative approach demonstrates the potential of additive manufacturing in creating sustainable building solutions. 3D printing can significantly reduce embodied carbon and resource consumption by minimizing material use and optimizing construction processes.

Decarbonizing the building sector requires a holistic approach, integrating new technologies and rethinking traditional practices. As we strive toward net-zero emissions, measuring operational and embodied carbon is essential, ensuring our efforts lead to genuine sustainability. Whole-life carbon assessments provide a comprehensive understanding of a building’s environmental impact, from material extraction to end-of-life disposal.

Our greatest advances will come from applying technological innovations to benefit humanity. We must be willing to explore the possibilities and embrace innovation. If we do, there are no limits to the impact on the greater good of humanity and the well-being of individuals and industries alike.

Collectively, we can build a better tomorrow with sustainable and innovative solutions. Let us minimize our industry’s environmental impact and deliver high-performing, low-carbon buildings for future generations.

And let us not delay.

Choosing the ideal tankless gas water heater for the job is easy with Bradford White. Our Infiniti® GS and GR models are ready for anything with a robust and flexible design that specifiers love.

• Residential and Commercial applications (Indoor/Outdoor)

• Robust stainless steel heat exchanger for longer life

• Cascade and common venting between standard and recirculation models

• ENERGY STAR® certified and Certified Green Product™ by the Green Restaurant Association

The facilities expo team is excited to announce that the Facilities Expo is coming to Reno, Nevada on August 21-22, 2024! It was decided to expand the facilities expo to Reno, NV due to the increasing demand in the growing market and the positive feedback received from existing exhibitors. The decision was made to tap into the potential of the Reno area and provide a platform for businesses to showcase their products and services in this thriving region.

AUGUST 21-22, 2024

The Facilities Expo provides valuable FREE learning and networking opportunities in a unique format serving the Northern Nevada and Tahoe region. The Reno Facilities Expo attracts a diverse audience of facilities managers, maintenance managers, and energy managers from a wide variety of industries including education, entertainment, fi nancial services, government, healthcare, hospitality, logistics, manufacturing, technology, utilities, and others.

Here’s what you can expect at the Reno Facilities Expo:

• Exhibits: Explore a wide range of exhibits featuring the latest products, technologies, and services in facility management. Discover solutions to enhance productivity, sustainability, safety, and efficiency in your organization.

• Educational Seminars: Attend thought-provoking seminars and workshops led by industry experts. Gain knowledge and valuable insights on important topics such as energy management, predictive maintenance, safety codes and regulations, and more.

• Networking Opportunities: Connect with fellow professionals, exhibitors, and industry leaders. Exchange ideas, collaborate, and expand your professional network throughout the expo.

• Product Demonstrations: Witness live demonstrations of innovative facility management solutions. Get hands-on experience with state-of-the-art equipment and technologies and learn firsthand how they can benefit your organization.

Don’t miss out on this exceptional opportunity to stay ahead of the curve in facility management. Join the facilities team at the Facilities Expo in Reno, Nevada on August 21-22, 2024.

The challenges facing young engineers today may be more complex than ever, but our guests reassure us that the energy, skills, and organization are coming together.

This month, HPAC On The Air sets its sights firmly on the future of our industry. With that in mind, we spoke with the top three leaders of Young Engineers in ASHRAE (YEA), the committee for members aged 35 and under.

Started in 2007, the group is led by YEA’s new Chair, Bruno Martinez ; Immediate Past Chair Baki Cvijetinovic; and Elise Kiland, Vice Chair. Through our chat, we learned more about each of our guests, as well as the group’s history, growth and accelerating mission in recruiting new engineers to be leaders in solving the next generation of industry problems.

Ranging from decarbonization and next-wave technology to international collaboration and diversity, equity and inclusion efforts, our conversation was both wide-ranging and inspiring...

HPAC: Welcome everyone to this focus on the next generation of our profession. Our guests are three of the top leaders of YEA who will update us on the many forwardlooking efforts the group currently has underway, and what it means for the future not just of our industry, but for the planet as well. With that, please tell our audience a bit about each of you. Baki, let’s start with you, and Elise and Bruno, please take your turn...

Baki Cvijetinovic: Thanks for having us, Rob. My name is Baki Cvijetinovic and I am based out of Vancouver, British Columbia. I am the Immediate Past Chair of YEA and I’m a mechanical engineering lead in the Vancouver office of AtkinsRéalis.

Kiland: I am Elise Kiland and I’m based in the San Francisco Bay Area of California. I am vice chair of the YEA Committee and I’m a project manager for a design-build contractor.

Bruno Martinez: My name is Bruno Martinez, and I am the new chair of YEA. I’m based in Brazil, right now in Curitiba, but sometimes in São Paulo, as well. I am a mechanical engineer and I work for a green company called GreenYellow do Brasil, where I am the head of energy efficiency.

HPAC: Thanks so much to all of you for joining us. Could you please give us a bit of history about the Young Engineers in ASHRAE, and its current makeup?

Baki: So we actually became a standing committee of members council on July 1st, 2007. Functioned as a subcommittee of the Membership Promotion committee. Our goal generally is to enhance our member benefits for

young engineers in ASHRAE by identifying, creating and supporting activities focused on their specific needs. And our primary focus is attracting and developing YEA members for future membership and leadership within ASHRA and the HVAC industry. We’re about 20% of overall ASHRAE membership.

HPAC: YEA was particularly involved with the Decarbonization Challenge that (former) ASHRAE President Ginger Scoggins had launched. Where do we go from here now that the initial grants were announced at the winter conference?

Elise: At the 2023 winter conference in Atlanta, Ginger’s presidential advisory committee came to us and said, “We want you guys to administer this Decarbonization Challenge fund, and we want to announce it by the 2023 annual conference in Tampa, and then we want it done by the 2024 annual conference in Indianapolis. Our reaction

was like, Say what? But if you need something done, have it have YEA do it, I guess. So we built a team led by Zach Alderman and Madison Schultz, and we were able to design this program in about five months so that it could be announced at the annual conference in Tampa. We opened applications in November, received 43 applicants and were able to award over $65,000 of funding to nine project teams from five continents. They’re projected to save at least 2.3 million kilograms of carbon with completion of the projects, and they have the potential to save millions more over the lifetime of the projects.

ASHRAE also received $84,000 in matching funds, which more than doubled our impact. And all of the projects were completed in time for the annual conference in Indianapolis in June. We’re hopeful that other chapters, regions, societies will be inspired.

HPAC: Aside from decarbonization, so much change is happening, particularly with transformative technology of all sorts. Undoubtedly, the young engineers are already at the forefront of that transition, and I’m sure older engineers are seeking your guidance. But just tell us what YEA members are most excited about now?

Bruno: Our members are most excited about sustainability, in general, and everything that is involved with sustainability. I work with energy efficiency and see a lot of ASHRAE members working with LEED certifications, redesign, and usually they are gravitating around these areas. Of course, A.I. is something that is very interesting and everybody’s trying to understand how they can use it and maybe increase the energy efficiency of a system or a building. And of course, YEA members are very

Membership

excited about all these technologies. We know that ASHRAE has these technical committees and that the young engineers usually are most interested about energy efficiency, like the TC that works with ASHRAE 90.1. And it depends a lot on where your career is driving you and we are seeing a lot of YEA members working every part of the HVAC industry. Many young engineers are very excited about exhaust systems, for example. So it really depends on where you are working right now.

HPAC: What is it about exhaust systems that is exciting YEA members?

Bruno: Well, you use a lot of controls for that and there are a lot of regulations. For some people, that is boring because you have to be very specific in the regulations. But if you work with this, it’s something that you are passionate about it. It doesn’t matter if you are young or old, you’re going to do a lot of nice things in this field.

HPAC: YEA has considerable international input. Please talk to us about that a bit.

Elise: Were’re focused on increasing membership internationally. I think most of our members are from America and Canada, but there’s so much research that shows that when you bring in more diverse opinions and insights, you produce better work more efficiently, so on and so forth.

So we host one of our YEA leadership weekends internationally every year. That rotates among 13 to 14 regions and regions at large... So we’re really excited about that, just bringing new voices in the room. Baki touched on earlier, I think. One of our main goals is building up the Society’s future leadership. So I think the more people we can bring into the room and have feel welcomed into ASHRAE from a younger age, the better future our society has moving forward.

HPAC: How does YEA determine the programs that it will offer members to get them more involved?

Baki: I think there’s a lot to say in terms of the programs that we offer and how we’re really trying to reach out to our members. We’re really trying to engage and get them more active in their involvement in ASHRAE. The three of us are good examples of what you can do in your ASHRAE career and I think we’ve all seen quite a bit of value in our own careers in terms of growth. So we want to really extend that to our membership, as well, in terms of how we really want to drive that. We do have these programs, like Elise mentioned, where we have these leadership weekends. They try to bridge the gap between the engineer and the leader, supervisor, manager and really push our membership towards those goals if they have them.

We’re also looking at expanding more involvement on technical side in such a large technical organization, there’s kind of like a technical arm that’s much larger than the governance arm that there’s a lot of work happening through technical committees through attending and speaking at conferences. And there’s a lot more than the winter and annual conference that exists within ashtray. There’s a lot of these topical conferences. So we’re trying to bring awareness. We’re trying to encourage members and make it a lot more exciting and a lot less scary to get involved in these types of things. We’re trying to engage them through scholarships and grants to attend events, as well. And that really is helping us on the diversity front, too, by bringing in individuals from more difficult economic backgrounds.

Finally, I think we’re really also trying to engage more employers as well. What we’ve seen is particularly young engineers and young members of ASHRAE, the ones that are most involved are typically the ones where they have their leaders, mentors, employers all saying, “Hey, there is actually a lot of benefit to what happens over here. Try joining. We’ll help you out, maybe even fund a portion of your involvement.”

And that does really help.

HPAC: If a member is turning 36 and aging out of YEA, are they required to have a replacement before they leave?

Elise: We’re constantly going through membership of the committee, so we’re pretty good at (recruiting). But if you’re talking about YEA overall, we have been kind of on a growth curve as far as back as I can remember. I think there was a slight dip during the pandemic, but there is a lot of interest in what we do, not just from the younger group, but also from the older group. In terms of mentorship, we’ve been trying to figure that out for a while, especially with the ASHRAE College of Fellows. We really want to

get this right and get our membership involved with some mentors for their ASHRAE experience and for their own career. But it’s a volunteer organization so it does require some time and commitment.

ASHRAE has created CEBD, its first-ever center of excellence to bolster efforts to reduce greenhouse gas emissions in buildings.

ASHRAE has strengthened its commitment reducing of greenhouse gas (GHG) emissions in the built environment by establishing of its first ever center of excellence.

The ASHRAE Center of Excellence for Building Decarbonization (CEBD) will drive the adoption of climate change mitigation policies and reinforce ASHRAE’s goal to achieving net zero GHG emissions in operation for all new buildings by 2030.

The CEBD’s primary activities are focused on:

• Strategy – Guide ASHRAE’s building decarbonization efforts and integrate relevant goals into the Society’s strategic plan. Develop, lead, and collaborate on strategic initiatives with partner organizations to accelerate and advance global building decarbonization;

• Thought Leadership – Track emerging issues and trends to showcase ASHRAE’s leadership position;

• Collaboration – Coordinate joint initiatives, events and projects with U.S. and international organizations that compliment ASHRAE’s building decarbonization efforts;

• Public Advocacy – Provide reliable technical info on decarbonization to policymakers, media, and the public.

“Our decision to establish the ASHRAE Center of Excellence for Building Decarbonization represents a strategic move towards amplifying our impact on climate change mitigation in the built environment,” said 2024-25 ASHRAE President Dennis Knight, P.E., Fellow Life Member. “By making building decarbonization a focal point of our technical resources and advocacy, we are broadening our capacity to drive systemic change. CEBD signifies ASHRAE’s dedication to empowering stakeholders with essential resources and educational opportunities and underscores our pivotal role in shaping a more sustainable future.”

The CEBD is releasing two new technical guides:

• Decarbonizing Hospital Buildings – Available now, this guide assists hospital facility managers, planners, architectural and engineering teams, and other stakeholders in reducing GHG emissions;

• Decarbonizing Building Thermal Systems: A How-To Guide for Heat Pump Systems and Beyond – Coming soon, this guide supports design engineers and building operators in decarbonization efforts, covering application, sizing, system configuration, refrigerants, electrical requirements, and control strategies.

To see the full roster of CEBD members and learn more about all the Society’s building decarbonization initiatives, visit ashrae.org/decarb.

New

ABMA White Paper explores best practices for defining boiler efficiency.

By M.W. VALENTINO, President, Boiler Room Consulting, LLC

In the boiler-burner industry, the term “efficiency” is used by manufacturers, engineers, trade organizations, and governmental agencies to publicize and differentiate the effectiveness of products at converting available energy to produce hot water and steam.

Typically, application of the term efficiency will fall into one of four categories: (1) Combustion Efficiency, (2) Boiler Efficiency, (3) Thermal Efficiency, (4) Fuel-to-Steam Efficiency.

Here’s a basic description of each:

1. Combustion Efficiency is a measurement as to how well a burner converts the energy provided by a fuel into usable heat. However, it should be noted that Combustion Efficiency is often used to mean boiler Stack Loss Efficiency without consideration to Radiation & Convection (R&C) losses from the boiler external surfaces;

2. Boiler Efficiency is a general term requiring further definition as to what is intended or included in its meaning. For example, are R&C heat losses from external surfaces included?

3. Thermal Efficiency is a measurement as to how effectively the heat exchanger transfers the available heat from the fuel to the product being heated, i.e., to steam or hot water;

4. Fuel-to-Steam Efficiency is basically a measurement of the overall efficiency of the boiler, including heat losses associated with boiler surfaces R&C losses to the environment.

The American Society of Mechanical Engineers Power Test Code PTC 4 defines two methods for determining Fuel-to-Steam Efficiency, namely: The Input-Output Method and the Stack Loss or Indirect Method.

Theoretically, when boiler surfaces R&C losses are accounted for, the Stack Loss Method used in determining boiler efficiency yields equivalent results to the Input Output Method. While the Input-Output method is simpler in concept, it is generally less accurate in predicting boiler efficiency. This is due to potential large errors associated with fuel and steam flow measurements.

Whereas, the Stack Loss Method relies essentially on temperature measurements and not flow measurements, knowledge of the fuel characteristics and flue gas makeup are also required.

This white paper addresses the Stack Loss or Heat Loss efficiency method in

defining boiler efficiency. Note that the terms “stack loss” and “heat loss” can be used interchangeably.

This is an indirect method for determining boiler efficiency. It applies equally well to steam and hot water boilers fired by any fossil fuel. In fact, it applies to other types of heating equipment, such as thermal fluid heaters.

The Fuel HHV, or higher heating value, is typically furnished upon request and can be obtained from the fuel supplier or via an independent testing laboratory, such as with fuel oils.

Calculation of the stack heat losses requires a fuel analysis listing the composition of the fuel. This information may also be obtained from the fuel supplier, such as in the case of a natural gas supplier, or may require a fuel analysis performed by an independent testing laboratory.

Once the analysis of fuel composition has been done, plus a few key temperature measurements including ambient air humidity, the stack heat losses can be calculated. These calculations will include:

• Heat lost to the dry flue gases (Ldg), on a Btu per pound fuel basis;

• Heat lost to conversion of hydrogen in the fuel to water vapor (Lm), on a Btu/lb fuel basis;

• Heat lost due to humidity of the air (Lh), on a Btu/lb fuel basis;

• Heat lost due to unaccounted sources (Lu), such as carbon and carbon monoxide remaining in the flue

Based in Monroe WI, the author has been president of Boiler Room Consulting, LLC, since 2017.

15% Excess Air

21% Excess Air

36% Excess Air

55% Excess Air

gas and other minor sources. Often in gas combustion, these sources are ignored.

Where,

HHV = higher heating value of the fuel in Btu per lb;

Wg = weight of flue gas pounds per lb of fuel burned;

Wh = weight of moisture in air / lbs per lb of fuel burned;

Tg = temperature of stack or flue gas leaving the system in degrees F;

Ta = temperature of the ambient air in degrees Fahrenheit;

Cp = mean specific heat of gas between Tg and Ta in But/lb-F. Often, a value of 0.24 is used;

H2 = percent hydrogen in fuel by weight;

M = percentage of moisture in fuel by weight;

Hs = enthalpy of steam at Tg and 1 psia;

ha = enthalpy of water at Ta in Btu per lb.

It is important to note that the aforementioned calculation routine does not fully apply to condensing boilers, specifically hot water condensing boilers.

Boiler efficiency holds different meanings to people within our industry. Terms such as boiler efficiency, combustion efficiency, and thermal efficiency are often used interchangeably without specification as to what they truly mean.

ASME PTC 4 recognizes two approaches to determining boiler efficiency, namely, the Input-Output Method and the indirect Stack Loss (or Heat Loss) Method. When performed correctly and accounting for test instrumentation errors is made, both the Input-Output and Stack Loss

Assumes:

• Natural Gas

• 80 F Air Temperature

• 0.5% Radiation & Convection Losses

approaches to determining boiler efficiency should yield very similar identical results.

Stack temperature and excess air level have a significant impact on efficiency. Rules of Thumb which are often employed to yield “ballpark” estimates of efficiency change include:

• For every 1% additional oxygen if the flue gas, efficiency is reduced by roughly 0.5%;

• For every 40 degrees Fahrenheit increase in stack temperature, efficiency is reduced by roughly 1%.

Besides reducing excess air levels to improve efficiency, incorporating a Stack Economizer with the boiler can provide significant improvement in improving boiler efficiency. A 1% to 3% improvement in efficiency is typical for a relatively low capital investment.

While the penalties associated with higher excess air levels, elevated stack temperatures, or not including a stack economizer with the boiler may seem trivial in magnitude, it is not uncommon for larger boilers to yield annual fuel bills in the millions of dollars range.

Likewise, poorly insulated and maintained boilers can yield elevated stack and surface temperatures over time. For example, scaled water-side and sooted fireside surfaces impede heat transfer and yield elevated stack gas temperatures.

Just 1/16th of an inch of scale or soot can reduce boiler efficiency by 3% of more. To achieve optimal performance, proper water chemistry, proper tuning, and taking advantage of ancillary efficiency enhancing equipment such as stack economizers can go a long way toward reducing annual operating costs and extending boiler life.

For the rest of this white paper, including much more data, please go to: abma.com/abma-publications.

Danfoss launches the 6-cylinder semi-hermetic BOCK HGX56 CO2 T reciprocating compressor, ideal for large-capacity heat pumps. It achieves water temperatures up to 90° C/194° F and offers an efficient alternative to ammonia and synthetic refrigerants. The unit reduces cost, system complexity and the number of compressors required for large industrial heat pumps, refrigeration and district heating systems.

Danfoss

Rensa Filtration introduces its high-performance SuperFlo HEPA filters that use advanced mini-pleat technology to achieve high dust loading and low resistance to airflow at 250 FPM, 500 FPM and 600 FPM compared to aluminum separator-style HEPA filters. This filter design provides HEPA level filtration with lower pressure drop, which leads to energy savings and lower cost of ownership. The SuperFlo Deep Pleat HEPA (pictured) offer high efficiency and cost-effective replacement for separator-style HEPA filters. The SuperFlo V-Bank HEPA is designed to perform in adverse, critical and sensitive conditions.

Rensa Filtration

Bosch Home Comfort releases its Air Series Purifiers that remove more than 99% of air impurities with an all-in-one pre-filter, activated carbon filter and HEPA layer. They come in three sizes to fit the space: the compact Bosch Air 2000, mid-size Bosch Air 4000 and large Bosch Air 6000 (includes additional anti-bacterial layer). Each Energy Star-certified model features easy-to-use controls such as an LED light ring to indicate air quality, a built-in timer and three levels of ventilation regulations; quiet mode operation; and smart sensors to detect dust and automatically adapt to the air quality and room size.

Bosch Home Comfort

The hybrid electric heat pump water heater from Noritz consumes up to one-third of the electricity required by a standard residential electric water heater with a resistive element, yet maintains the same level of hot-water delivery. The hybrid designation denotes the inclusion of dual 4.5-kW electric elements positioned at the top and bottom of the tank to provide backup water heating or accelerate recovery times when necessary. Handling hot water temperatures ranging from 50° F to 160° F, the product will be available in four sizes: NHP50, NHP65, NHP80, and NHP120.

Noritz America

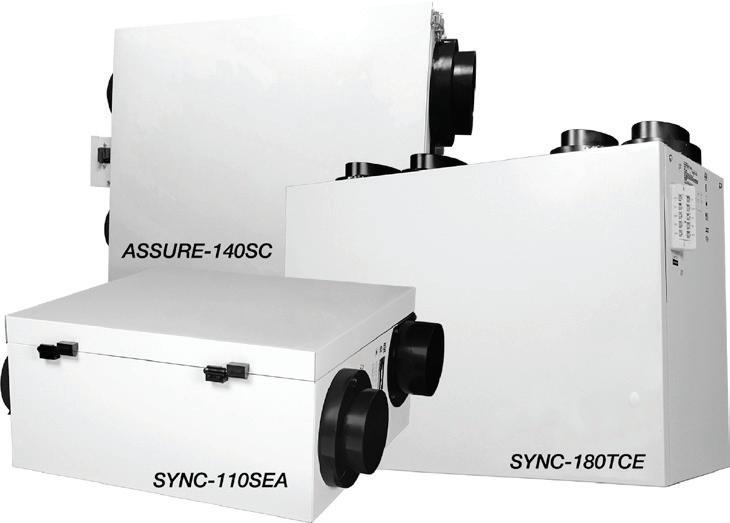

Greenheck Fan Corp. adds three new models to its line of high-performance residential energy recovery ventilators (ERVs). The ASSURE-140SC is a cold weather-certified ERV with a 30 to 160 cfm operational range, available in hardwired and mirrored configurations. The SYNC-110SEA features precision balancing to dial in precise airflow when paired with the PrecisionSYNC controller; available in hardwired and mirrored configurations. The most compact ERV offering at 9.75” in height, the SYNC-110SEA is ideal for bulkheads and drop ceilings. The SYNC-180TCE, a top-port ERV featuring a 75 to 200 cfm operational range, offers precision balancing when paired with the PrecisionSYNC controller and 77% sensible recovery efficiency.

Greenheck Fan Corp.

HYDRO•X Power flush valves and faucets from Zurn combined with EZ Gear technology offers sustainable power, reliable operation, water efficiency and ADA compliance. Hydro•X Power technology delivers renewable, uninterrupted hydropower designed to last the life expectancy of a commercial restroom. Gear-driven ceramic cartridges drive both flush valves and faucets for maximum reliability, while minimizing maintenance and unplanned downtime. They are less susceptible to debris and buildup and outlast and outperform solenoids. Compatible with the Bluetooth app, plumbPRO.

Zurn

McDonnell & Miller updates its GuardDog RB-24SE low water cut-off with an exclusive, patented self-cleaning probe that minimizes scale build-up and protects users from potential boiler shutdowns or water overfill. It also features a leak-free, metal-to-metal seal and a push-to-test button that quickly confirms proper operation, enabling low water cut-off protection to be verified without draining any part of the system. Its compact size fits high-efficiency boilers, and the optimized design ensures reduced footprint, making it the ideal choice for space-conscious installations. The universal wiring harness fits most of today’s hot water boilers.

McDonnell & Miller/Xylem

The L54120+ Lorawan wireless water meter from H2O Degree is ideal for tenant water submetering for billing as well as leak detection and alarming. The device is equipped with LoRaWAN secure wireless 915 MHz technology, offering state-of-theart wireless signal strength, industry-standard open protocol and security. With its long-range wireless connectivity, the meter can operate within a 1,000-foot radius of the gateway. This capability simplifies submetering installations by eliminating the need for repeaters. Measures cumulative water flow in gallons and records the number and duration of water usage events, such as toilet flushes.

H2O Degree

2402HPAC_AAON_MKPL.indd 1 1/17/24 10:25 AM

AeroTherm® Series Heat Pump Water Heaters provide the advanced efficiency, comfort and control you and your customers demand.

See all the features.

*Rebates vary by region. Microban® antimicrobial product protection helps prevent the growth of bacteria, mold and mildew that may affect the product. The built-in antimicrobial properties do not protect users or others from disease-causing organisms. Microban® is a registered trademark of Microban Products Company. ©2024, Bradford White Corporation. All

BWHPEN0724

• 399 MBH and 301 MBH sizes

. Small compact size . Fits in tight areas . Quiet performance . Upper and lower inlets . Attractive appliance-style design

• Up to 10:1 turndown and 95%+ thermal efficiency

• Converts from wall to floor with optional stand

• DHW Smart PriorityTM

Greenheck's comprehensive line of Air Terminal Units (ATUs) provide an energy-efficient way to regulate airflow for maximum occupant comfort.

Single duct, fan powered, dual duct, and retrofit ATU models are available.

Specify with Confidence. Specify Greenheck.

The first industrial-scale solar fuel plant, now open in Switzerland, is adding to the evidence that alternative fuels could play a key role in meeting long-term goals.

Larry Clark

A regular contributor to HPAC Engineering and a member of its editorial advisory board since 2012, the author is a principal at Sustainable Performance Solutions LLC, a south Florida-based engineering firm focusing on energy and sustainability. Email him at larry@ sustainflorida.com.

Solutions to climate change generally fall into two categories: adaptation and mitigation.

Adaptation is taking measures to live with and minimize the damage resulting from climate change. Make no mistake, we have no choice but to adapt as best we can to the effects of climate change that have already occurred, such as rising sea levels and more intense and frequent storms.

Mitigation solutions proactively try to reduce the greenhouse gas (GHG) emissions that are responsible for climate change. Decarbonization has advanced as a key element of mitigation, and there has been much emphasis by lawmakers and scientists to significantly reduce the use of fossil fuels.

Unfortunately, we are not yet at a point where we can depend entirely on renewable energy as our only sources of power, and one of the activities most affected by eliminating fossil fuels is transportation. Our cars (in spite of the push for EVs), trucks, buses, trains, ships, and planes all depend on fossil fuels, and even so-called “clean” fossil fuels emit significant amounts of GHG.

all considerations allows for a more holistic approach in assessing the energy landscape: Synthetic fuels are fuels produced via chemical or biological reactions…”

There are many synthetic fuels: biofuels like biodiesel, bioethanol, and biogas, produced from biological materials like vegetable oils and animal fats; hydrogen-based fuels; powerto-liquid (PtL) fuels, produced using renewal electric power sources; and gas-to-liquid (GtL) fuels that typically use natural gas as feedstock. The latter, of course, is still relying on a fossil fuel energy source.

Synthetic fuels have long been advanced as an alternative to fossil fuels. However, there is a lot of confusion about what actually constitutes synthetic fuels.

In Current Opinion in Biotechnology, Vol. 81, June 2023 (#102919), the authors’ definition of synthetic fuels “does not depend on a particular consideration in the use of fuels, such as fuel scarcity, independence from foreign oil, carbon dependency, or climate change. Further, synthetic fuels can be contrasted to fuels produced via fractionation of crude oil. Creating a definition instead that encompasses

Now Synhelion, a spin-off of the Federal Institute of Technology Zürich (ZTH Zürich), a public research university in Switzerland, has launched the first industrial-scale solar fuel plant. Designated Plant DAWN, Synthelion claims that it will produce several thousands of liters of synthetic fuel per year, beginning this year, and demonstrate the viability of commercial production. The plant relies on a 20-m (66-ft) tall solar tower, containing a solar receiver, thermochemical reactor, and thermal energy storage for 24/7 production. Concentrated sunlight is directed to the tower by heliostats, and solar energy provides all of the heat required for production. The synthetic crude oil produced by DAWN is subsequently processed into certified solar kerosene for aviation and solar diesel and gasoline for road and marine transportation.

Although the primary focus is initially on aviation – partners include Lufthansa, Swiss International Airlines, Zürich Airport, and Pilatus Aircraft – solar diesel and gasoline products could conceivably allow us to use our internal combustion engines for a while longer.

Our monthly Podcast series offers unique and compelling industry insights for engineers in the HVACR market. Each month, we talk with engaging thought leaders and practitioners like ASHRAE’s Bill Bahnfleth and Legionella expert Dr. Janet Stout. Produced by HPAC Engineering magazine and hosted by Editor-in-Chief Rob McManamy, this series is just one of several exciting Members Only features, designed to enhance your HPAC multimedia experience.

Change is in the air.