Properly managing override and selective control

Integrating mobile robots in plants

Prepare for scarce chemical engineering graduates

Properly managing override and selective control

Integrating mobile robots in plants

Prepare for scarce chemical engineering graduates

It’s time to construct the infrastructures that hydrogen economies, net-zero emission targets and other sustainability goals will require

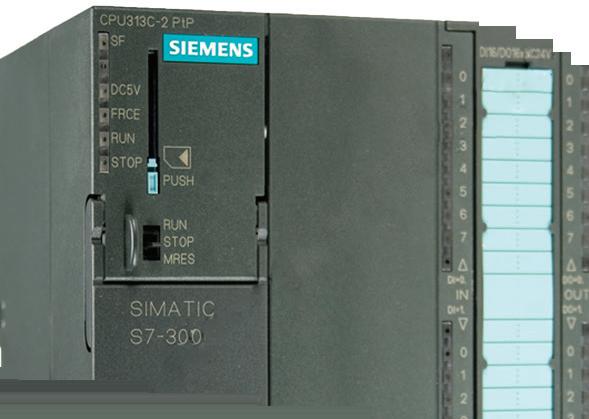

Process improvement is like a trapeze act. You need a trusted partner who lends a hand at the right moment.

Just as athletes rely on their teammates, we know that partnering with our customers brings the same level of support and dependability in the area of manufacturing productivity. Together, we can overcome challenges and achieve a shared goal, optimizing processes with regards to economic efficiency, safety, and environmental protection. Let’s improve together.

20 COVER STORY

It's time to construct the infrastructure that hydrogen economies, net-zero emissions targets and other sustainability goals will require by Jim Montague

28 ANALYZERS

Saudi Aramco's field test shows dielectric measurement results in a liquid hydrocarbon process by Ali S. Aldossary

31 DEVELOP YOUR POTENTIAL

Prepare for scarce chemical engineering graduates

How to put your company at a hiring advantage by R. Russell Rhinehart

CONTROL (USPS 4853, ISSN 1049-5541) is published 10x annually (monthly, with combined Jan/Feb and Nov/Dec) by Endeavor Business Media, LLC. 201 N. Main Street, Fifth Floor, Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI, and additional mailing offices. POSTMASTER: Send address changes to CONTROL, PO Box 3257, Northbrook, IL 60065-3257. SUBSCRIPTIONS: Publisher reserves the right to reject non-qualified subscriptions. Subscription prices: U.S. ($120 per year); Canada/M exico ($250 per year); All other countries ($250 per year). All subscriptions are payable in U.S. funds.

Ready for the drone show?

Drones and robots might seem scary, but they have growing value for us

Navigating sustainability complexity

The objective is more than the biggest return on investment

A little cyber-insurance goes a long way

Are you certain your cybersecurity is up to the task?

WITHOUT WIRES

The benefits of the extra 'I'

Industrial Internet of Things (IIoT) devices are critical to operations, so what provides the right stuff?

Integrating mobile robots in plants

Exchanging real-time data with robots on missions

HUG tackles energy, cybersecurity and AI Honeywell User Group 2024 draws 1,100 attendees to Madrid

Factors to determine the cost of ownership of SCADA systems

Complicated costs stem from a wide range of features and licensing models

Growing Li-ion battery market needs dynamic process control

Ways to speed time to market and ensure reliable project execution

Ins

Control's

Controlling two variables with one valve

How to properly manage override and selective control

Enclosures corral the help they need

New sizes, mountings, subpanels, support arms and accessories let housings surpass their capabilities

Deep dive into distillation control

Examining the tug-of-war between reboiler and reflux actions

Get uncomfortable

Do we have what it takes to suceed at sustainability?

Don't bet on it.

Endeavor Business Media, LLC

30 Burton Hills Blvd, Ste. 185, Nashville, TN 37215

800-547-7377

EXECUTIVE TEAM

CEO Chris Ferrell

President July Griffin

COO

Patrick Rains

CRO

Paul Andrews

Chief Digital Officer

Jacquie Niemiec

Chief Administrative and Legal Officer

Tracy Kane

EVP/Group Publisher

Mike Christian

EDITORIAL TEAM

Editor in Chief Len Vermillion, lvermillion@endeavorb2b.com

Executive Editor

Jim Montague, jmontague@endeavorb2b.com

Digital Editor Madison Ratcliff, mratcliff@endeavorb2b.com

Contributing Editor

John Rezabek

Columnists

Béla Lipták, Greg McMillan, Ian Verhappen

DESIGN & PRODUCTION TEAM

Art Director

Derek Chamberlain, dchamberlain@endeavorb2b.com

Production Manager

Rita Fitzgerald, rfitzgerald@endeavorb2b.com

Ad Services Manager

Jennifer George, jgeorge@endeavorb2b.com

Operations Manager / Subscription requests Lori Goldberg, lgoldberg@endeavorb2b.com

PUBLISHING TEAM

Group Publisher

Keith Larson

630-625-1129, klarson@endeavorb2b.com

Group Sales Director

Amy Loria

352-873-4288, aloria@endeavorb2b.com

Account Manager

Greg Zamin

704-256-5433, gzamin@endeavorb2b.com

Account Manager

Kurt Belisle

815-549-1034, kbelisle@endeavorb2b.com

Account Manager

Jeff Mylin

847-533-9789, jmylin@endeavorb2b.com

Subscriptions

Local: 847-559-7598

Toll free: 877-382-9187 Control@omeda.com

Jesse H. Neal

Award Winner & Three Time Finalist

Two Time ASBPE Magazine of the Year Finalist

Dozens of ASBPE Excellence in Graphics and Editorial Excellence Awards

Four Time Winner Ozzie Awards for Graphics Excellence

Drones and robots might seem scary, but they have growing value for us

HAVE you seen a good drone show lately? Summertime means the skies usually light up with traditional fireworks for various celebrations, but those noisy pyrotechnics are giving way to aerial drones coordinated in intricate displays. For some, they’ve upped “ooh-ahh” factor considerably.

Of course, drones—the mobile kind you see on plant floors—sometimes invoke a different kind of emotion. Instead of canines feeling terror, humans may feel terrorized, or at least worried about being replaced. The oohs and aahs sometimes become much different types of exclamations.

Drones and robots are part of automation growth and, like it or not, they're increasing in value for process operators because safety, efficiency and sustainability are paramount. As pointed out by our newest columnist, Penny Chen, senior technology strategist at Yokogawa, process operators favorably compare the time and costs associated with robot deployments to preparing human workers with personal protective equipment such as fire suits (p. 14).

Chen adds mobile drones and robots often do the “dirty and dangerous” work, freeing humans to perform much bigger, collaborative tasks. So, while fears understandably arise that humans will be replaced in plants like fireworks are being replaced at Independence Day celebrations, rest assured the technology is available to augment digitalized process control, not dominate it.

And there’s also the reality that there aren’t as many workers to replace. It’s no secret that next-generation process control engineers are hard to find. As Russ Rhinehart shows in his feature on scarce engineering graduates (p. 31), the downward trend in interest in the discipline will soon make hiring entry-level employees very competitive. Having automated processes at the ready means those new hires can be used for more thought-provoking and collaborative ideation. It may actually be a more interesting and exciting way to begin their careers.

This discussion isn't new. The convergence of humans and automation is a debate happening in all walks of life. We’ll continue to explore how we’ll adapt to the influx of robots and drones in our lives, but it behooves us to remember that just as the drones in the sky aren’t destroying our summer nights, they aren’t destroying our work either.

LEN VERMILLION Editor-in-Chief lvermillion@endeavorb2b.com

"Drones and robots are part of automation growth and, like it or not, they're increasing in value to process operators because safety, efficiency and sustainability are paramount."

VP of industry programs and alliances

For sustainability projects, the objective is more than gaining the biggest return on investment

CONSIDER a common situation in a refinery or chemical plant: an old, natural gas-fired heater is the focus of a possible upgrade, replacing its combustion control system and burners. The new equipment promises to reduce fuel consumption by 15%. Traditionally, the decision to make such a change would hinge on the cost of buying the new hardware and installing it compared to the fuel cost saved. There might be some additional benefits if nitrogen oxide (NOx) emissions are tightly regulated, but it’s probably a minor factor.

These days, sustainability questions likely enter the discussion, too. Let’s say the facility has a reliable supply of natural gas at a good price, but the new equipment is expensive. Yes, it will achieve the promised gas consumption reduction, but it will take 10 years or more to realize the full payoff. Based strictly on a cost/benefit analysis, such a project likely gets passed over in favor of something with a more aggressive return on investment (ROI). Sustainability considerations can change this picture.

The traditional question is, “How much money can we make or save from a project against the cost?” Now, an added question is, “How much carbon emissions can we eliminate against the cost?” This question has its own analytical tool and representation: the marginal abatement cost curve graph (MACC), which helps rank projects based on the amount of carbon dioxide (CO2) or equivalent (CO2e) avoided or reduced against the cost (net present value) per ton. Looking at the graph, let’s think about what it illustrates (Figure 1).

Each rectangle on the graph represents a project. The width of the rectangle indicates the amount of CO2e reduction. The height is the cost per ton. For example, carbon capture and storage (CCS) by large process furnaces can eliminate a large amount of CO2e at a relatively low cost. On the other hand,

electrification of large recycle compressors has a small reduction effect, but a high cost.

Digging deeper into the analysis by looking at the left end of the graph, some projects (blue rectangles) more than pay for themselves, while also reducing emissions, though, the reduction for most is modest. Nonetheless, since they offer positive capital effects, they merit serious examination. At the opposite end of the graph (green rectangles), deciding to start producing green hydrogen has a high cost and results in limited CO2e reduction.

For most facilities, looking at projects close to where the green rectangles first break north of the horizontal axis is inexpensive and practical, although with limited effectiveness in terms of emissions reduction. Examples shown include:

• Tank heater and heat tracing electrification (replacing steam);

• Column reboiler electrification (replacing steam and conventional fired heaters);

• Process modifications for increased heat integration and recovery (improving overall efficiency);

• Flare gas recovery (reducing energy waste);

• High-efficiency lighting (reducing energy waste).

CCS projects that typically pump carbon dioxide into the ground rather than release it to atmosphere have a modest cost, but provide a sizeable reduction, and may be practical for further study.

The challenge for companies when implementing a sustainability initiative is to look at individual projects that improve resource use, reduce energy consumption, expand use of green energy, and reduce carbon emissions. Compiling a potential project list related to carbon emissions starts with brainstorming sessions involving operations management, operators, process engineers, information

Green Hydrogen

Electric Process Heaters - Crude, Vacuum Unit

Electric Steam Boilers

Large Recycle Compressors Electrification Blue Hydrogen

Large Process Furnaces CCS

Renewable power substitution for existing power usage

FCC Regenerator Flue Gas CCS

Utility Plant CCS

Hydrogen Plant CCS

Tank Heaters and Heat Tracing Electrification

Column Reboiler Electrification Process Modifications for increased Heat Integration and Recovery Flare gas recovery High Efficiency Lighting

Condensate/cooling twr avail/eff Unit Advanced Control

Emissions Monitoring & Control Process Heater Automation Upgr Site Energy Mgmt and RTO Producing SAF Producing Renewable Diesel

Figure 1: A typical MACC graph shows project cost per ton of CO2e (y axis) against the amount of emission reduction (x axis). The CO2e offset credit line represents what might typically be available as a public subsidy or tax credit to offset the project cost. Source: Emerson

technology, production planning and reliability representatives, with guidance from industry subject matter experts. Participants must consider all associated effects for improving operational efficiency, reliability, yields, energy efficiency, waste, off-spec product reduction, flaring, regulated emissions control, electrification and other areas. Ideas should be consolidated and ranked based on cost, impact, difficulty and timeframe. The result is an extensive project list that serves as the input to the next step in the process—project analysis.

Ultimately, projects can be placed on the MACC graph to compare their effect in the larger picture of the facility. In many cases, a project that improves energy usage, yields, production or reliability can be justified on its own merits, and has a positive net present value. In some cases, projects won’t show a positive net present value, but are justified based on CO2e emissions reductions. A CCS project is a prime example since it doesn’t affect production—positively or negatively—because its cost solely reduces emissions.

An analytical tool is only as good as the data it’s evaluating, and estimating the CO2e reduction of some projects is more challenging than others. Projects that reduce fuel or steam consumption, and CCS implementations, are relatively easy to quantify. However, electrifying fuel-burning equipment requires a plant model to estimate new steam and fuel balances, develop project cost estimates, and gauge the impact on CO2e emissions. There’s also the potential to move pollution somewhere else if the utility serving a facility is generating electricity by burning natural gas, or worse, coal. Reducing CO2e at the facility by increasing coal consumption somewhere else is false sustainability.

We define net-zero as complete elimination of fossil fuel use. The concept really isn’t practical for a facility of any size or complexity because it requires the use of technologies and green-power sources that aren’t available in sufficient quantities in most areas. Greater investments in wind farms and solar power to support net-zero plant sites will be necessary throughout the world. Such projects need time to consider approvals, permitting, engineering and building before they’ll make significant contributions. Many such projects are underway, but their full effect is some time away.

In the meantime, adding a CCS system to a furnace exhaust, for example, can still make major sustainability contributions. Implementation must begin with sophisticated engineering analysis to define their cost and design parameters. At the same time, projects shown on the MACC graph at the cost break line, such as flare gas recovery, energy management systems, high-efficiency lighting and combustion optimization, can be self-financing and implemented in the short term.

While the MACC graph is an excellent tool for defining and prioritizing likely projects, it ignores many factors, including:

• Prioritization of multiple projects across a multi-year timeframe;

• Risks associated with various technology options;

• Capital budget constraints, competition among multiple projects, approval snags and other obstacles; and

• Cooperation of third-parties, such as utilities, to provide additional green-power options. Clearly, more sophisticated evaluation tools are needed.

Marcelo Carugo is VP of industry programs and alliances at Emerson, working with downstream manufacturers on digital transformation through automation technologies. Pete Sharpe is a principal consultant with Emerson’s industrial software business, focusing on the petrochemical and chemical industries.

Are you certain your cybersecurity is up to the task?

THE investor analysts questioned the executive board about their cyber-exploits, “Can you please assess your capabilities to repel or recover from a cybersecurity breach?” It’s a valid inquiry, especially when stories (and non-stories) of utilities and manufacturing enterprises being halted by cyberattacks are now routine (https://on.wsj.com/4cpm2VG).

Less-than-brilliant hackers in their parents’ basements might take offense. There are ransomware exploits for sale on the dark web, which intruders can use to lock up your PCs until you pay them off. They’re competitively priced and ready to be deployed by any novice. Why wouldn’t CEOs turn to their CSOs or CISOs, and say, “Tell me we’re protected from this trash.” Perhaps, they might even use some profanity to describe their concerns.

Managed barriers—firewalls, for example— have been in place for years at the edges of our business networks, where they interact with the larger Internet. Still, exploits sneak through, unbeknownst to employees, who connect a phone to a company laptop for charging, or insert a USB drive for transferring a file via “sneaker net.” Emails are filtered for all manner of might-be spam. It’s a bettersafe-than-sorry philosophy for email delivery, especially because we get the chance to review blocked messages. Among the spam are phishing exploits that give attackers possible routes around cyber-barriers. Process control networks are largely isolated from the deranged and decadent free-for-all of today’s World Wide Web, at least we hope they are. One of the first things an auditor tests is whether you can “ping Google” from your distributed control system (DCS). For a few decades, we took comfort in the air gap that separates us from criminal exploits on the web.

However, Windows-based PCs and serverbased operating systems run most operator workstations, engineering consoles, historians

and database servers. Windows boxes have USB ports just like their business network kin, so unsuspecting end users can insert their diseased dongles or charge their infected iPhones. We block them, either with Group Policy Object (GPO) software in the Active Directory or with mechanical, USB port blockers. One vendor’s remedy for deploying group policy had the undocumented feature of also disabling USB ports serving mice and keyboards. This rendered useless an operator workstation—an essential tool for running a chemical plant. We spent hours into the weekend uninstalling the software, after which the affected workstations had to be reconstructed (bare metal install) from scratch.

Ethernet switches must have their unused ports physically blocked, and many of us have invested a few thousand dollars each to replace unmanaged switches with managed switches, which can lock down all their ports through firmware. This sounds great until the firmware has a hiccup and blocks a legit connection, or you swap out a workstation or a controller, and discover it has no connection to its kin on the process control network. Oops, forgot to unlock the ports. Issues such as these exemplify the core question of this essential tool of operations: is the cure worse than the disease?

The ideal control system is an uninterrupted connection to the (ideal) operator’s mind. They see flows, levels, pressures and their connections to the process, not numbers and graphics. It will not be a happy day when their workstations lock up, not because of ransomware, but because the latest unseen whitelisting update blocked an OPC connection or slowed their console to a crawl.

Thankfully, our system vendors vet the software to protect the OT domain. There’s hope that unknown features will be dispatched before the ladies and men at the console have an unfortunate experience.

JOHN REZABEK Contributing Editor JRezabek@ashland.com

" Process control networks are largely isolated from the deranged and decadent free-for-all of today’s World Wide Web, at least we hope they are."

IAN VERHAPPEN

Solutions Architect

Willowglen Systems

Ian.Verhappen@ willowglensystems.com

"IIoT devices are widely distributed, so they’re not always in a secure environment."

Industrial Internet of Things (IIoT) devices are critical to operations, so what provides the right stuff?

CONTINUING a discussion from my last column (June ’24, www.controlglobal.com/IOTproliferation) on the Industrial Internet of Things (IIoT), let’s move into the process industry realm where I believe there are “fewer fools” because control professionals understand the basic requirements for configuration and testing. That’s not to say we don’t make mistakes, but we have standard change management and related procedures to circumvent accidents. We’re also aware of the potential consequences of mistakes and act accordingly.

So, other than IIoT devices being more critical than IoT devices such as your doorbell, what does the extra “I” really mean?

• IIoT devices are widely distributed, so they’re not always in a secure environment. And there are additional endpoints, so they’re more vulnerable than traditional field devices.

• Provisioning associated with connecting a device to the control system must be part of the security and architecture design.

• Automation with limited or no human intervention allows a system to fail gracefully, and recover from service interruptions.

• Integration with sensors and actuators connects the control system in multiple ways, including to cloud-computing services.

• Most industrial installations deploy hundreds or thousands of devices over wide areas and different applications to support reliable operations and asset management.

• Higher levels of accuracy are available, not only for measurements, but also to handle latency and response times because automated, high-speed machinery is synchronized down to milliseconds.

• Flexibility to be programmed or configured to meet specific applications. One sensor can measure multiple ranges over its life, depending on where and how it’s deployed.

• Industrial products are designed to operate for 20-30 years before a scale replacement is performed. Plus, they must run with high

availability and reliability since poor data from I/O reduces model accuracy.

• IIoT devices are often deployed in harsh environments that are regularly subjected to extreme cold, heat, vibration, pressure and hazardous/flammable (gas/dust) conditions.

• System architectures must be resilient and always complete their processes, so they don’t negatively impact operations.

• IIoT devices must be serviceable to sustain levels of performance required over anticipated lifecycles.

• Advanced analytics are crucial to extract actionable insights, including self-diagnostics, from machine-generated data that drives major operational improvements.

We take this list for granted because that’s what control systems do. Though an IoT sensor may provide the right signal, it may not be able to do it for the multiple years required by industrial settings. Masking an IoT device in another shell to make it look like an IIoT device, or worse, fake, forged or knock-off units that look the same right down to the packaging is another challenge.

One possible way to reduce the likelihood of a fake or forged unit is with digital nameplates or electronic labels that are directly linked to the manufacturer to provide original certificates, user manuals, software updates, etc. Unfortunately, electronic labeling has too many global variations by country, industry or even manufacturer. The recently completed IEC 63365 committee’s work on a digital nameplate standard, known as IEC SC65E WG2, is one such standard for process transmitters, but there are similar standards for medical devices and others. To help with the interoperability of these electronic labels, NEMA has started an initiative analogous to the unique identifier (UID) used in asset management to define a baseline for all intelligent labels regardless of industry or application. Time will tell if they’re successful.

PENNY

CHEN senior technology strategist, Yokogawa penny.chen@yokogawa.com

"By performing lower value tasks, robots enable people to focus on strategic efforts that can't be automated."

Ideally, process control systems can seamlessly exchange real-time data with robots on missions

MANY industrial process operations deploy mobile robots for a variety of purposes. A “mission,” during which a robot travels to one or more specified locations in the plant, can be for visual inspection, sound detection, emissions or leak detection, thermographic inspections, a mapping survey, or routine surveillance that simulates an operator’s round.

Mobile robots can incorporate human-like capabilities, such as hearing, sight, smell and touch, which enable them to read gauges, record sound signatures, detect hot and cold spots, pinpoint leaks, determine valve positions, and detect abnormal objects.

In today’s era of staffing shortages, prospective users no longer need to wrestle with the idea of replacing human workers with machines. By performing lower value tasks, robots enable people to focus on strategic efforts that can’t be automated.

Mobile robots increase safety by reducing risks to the workforce. The “dirty and dangerous” assignments they perform keep people out of harm’s way. By venturing into hazardous areas, robots not only increase workforce safety, but they also increase productivity. Process operators have favorably compared the time and costs associated with robot deployments to preparing human workers with personal protective equipment (PPE) such as fire suits. This is particularly effective during night shifts. On missions such as operator rounds, robots have proven they can reduce errors and rework.

If we expand the definition of mobile robots to include drones, the benefits extend to include coverage of difficult-to-access locations. Most human workers are happy to forego climbing ladders on antennas, elevated water tanks, smokestacks and wind turbines.

For predictive and prescriptive management purposes, drones and mobile robots typically use artificial intelligence (AI) or machine learning to enable data analysis and fusion based on inputs from their payloads.

While many industrial process operations deploy or test them, use cases are still limited. Some users say one issue related to incorporating them into their standard operating procedures is time. The user experience, training, maintenance and proofs-of-concept (and value) have been very positive.

One of the primary challenges is that no one robot can do everything necessary. While the digital platforms in today’s drones and mobile robots are generally excellent, there are incompatibilities among models.

For an industry experiencing digital transformation, this creates the potential for more silos. Each robot has its own proprietary interface and type of data storage, on premise or in the cloud. A large data volume can be collected—but good data orchestration and analysis are necessary for predictive and actionable knowledge.

Questions remain about how robot data can be used by all the entities in the enterprise’s database such as the process control system. Ideally, the process control system could seamlessly exchange data with robots in realtime during missions.

Fortunately, a solution is available. Using a software platform for robot fleet management, the direction and data collection from multiple types of robots can be performed in a unified manner. In addition to asset performance management, robot-supplied data can be associated with control/safety systems and used for operational purposes.

By unifying data from all robots, this platform gives users a comprehensive visualization on one web browser. A dedicated viewer isn’t required. Media data collected by the robot, such as photos and audio, can be viewed live.

Regardless of the robot model, there is one, unified environment for user experience and enterprise data. This enables, not only digital transformation with mobile robots, but also autonomous operations.

Honeywell User Group 2024 draws 1,100 attendees to Madrid

TO keep its customers ahead of today's looming challenges, Honeywell Process Solutions (process.honeywell.com) provided its usual host of solutions and expert advice to more than 1,100 visitors from 54 countries at its 47th annual Honeywell User Group 2024 on June 10-13 in Madrid, Spain. The event was the first of two this year because HUG Americas is scheduled for Oct. 1-3 in Dallas, Texas.

Pramesh Maheshwari, president of Honeywell Process Solutions, reported that HUG 2024’s agenda focused on three development efforts that are key to industrial progress—energy transition, cybersecurity and artificial intelligence (AI).

“Digital transformation, especially facilitated by AI, plays a central role in advancing key business objectives, but implementation can keep you up at night,” said Maheshwari. “How do you ensure that AI systems are integrated consistently, scalably and holistically?”

Maheshwari also stressed AI’s importance in training and retaining next-generation workforces. “AI facilitates training by augmenting human capabilities,” he said. “Imagine predictive abilities that allow workers to envision future developments and intervene proactively. This technology holds the potential to revolutionize the productivity and effectiveness of workers whether they're in maintenance, operations or engineering roles.”

Maheshwari added that many AI capabilities are already available in Honeywell’s products. However, as AI and digital transformation increase automation and network

connections, risks of cyber-intrusions and cyber-attacks also increase. “We’re bringing AI to other core capabilities to make plants run better and more safely and for organizations to respond more quickly,” he explained. “Cybersecurity isn’t just an IT issue. It’s a core business priority.”

On the energy transition front, Maheshwari reported that Honeywell is actively seeking to reduce emissions. “And not through monthly estimates, but in real-time, with detection, measurement, monitoring and reporting. We’re also investing in battery storage technology to facilitate industrial energy transitions.”

Jason Urso, CTO for industrial automation at Honeywell, added, “Digitalization is changing the ways all plants operate, and we’re keeping them ahead of the curve with capital project executions in less time and with lower risk. This is done by automating digital twins during commissioning to improve reliability; continuous evolution to achieve new benefits while protecting decades of existing investments; and superior operations that let every user work like a 30-year expert and make every day their best day of production.”

Users can achieve these unprecedented gains by implementing the Experion PKS Highly Integrated Virtual Environment (HIVE), which is now faster, simpler, lower risk, less costly, more reliable, and uses new software tools to streamline migration projects. Urso reported that mass standardization can be achieved by using Honeywell’s Universal I/O modules and marshalling along with its Universal Process Cabinet (UPC) products, which simplify engineering due to standard wiring and controls that reduce or eliminate many traditional tasks. Likewise, they can interact with their Experion PKS Control HIVE and I/O HIVE counterparts in production areas to eliminate engineering efforts. Beyond its gains with Universal I/O and marshalling, Experion PKS HIVE has also been buoyed by the recent release of the Control Network (CN) 100 module for Series C I/O HIVE, OneWireless access points, and other new CN modules.

“Control HIVE delivers comprehensive flexibility by allowing any module to communicate with any controller,” explained Urso. “It also reduces project risk with a digital twin, allowing users to better manage operational flows, reduce factory acceptance test (FAT) times, and reduce alarm rationalizations and control-tuning tasks.”

For full coverage, visit www.controlglobal.com/sponsored-content/article/55059252/live-from-honeywell-users-group-2024

• Schneider Electric (www.se.com) released a report June 25 that estimates electrification of U.S. industries will increase by half from 30% at present to 45% by 2030, a 50-percentage-point increase. The report, compiled by Schneider's Sustainability Research Institute, also recognizes the potential for a corresponding 25% reduction in fossil fuel demand over the same period. It’s available at www.se.com/ ww/en/insights/post/the-untold-potential-and-rationale-ofindustrial-electrification-in-the-united-states

• Co-owners of the Process Automation Device Information Model (PA-DIM), FDT Group (www.fdtgroup.org/pa-dim), FieldComm Group (www.fieldcommgroup.org/pa-dim), ISA 100 WCI, NAMUR, ODVA (www.odva.org/pa-dim), OPC Foundation (www.opcfoundation.org/pa-dim), Profibus and Profinet International (www. profibus.com/pa-dim), VDMA and ZVEI, released PA-DIM Version 1.1 specification on June 11. It includes expanded device type support for process analyzers and an enhanced basic hierarchy structure with new extensions to benefit users and suppliers.

• INEOS Olefins & Polymers USA (www.ineos-op.com) and NextEra Energy Resources LLC (www.nexteraenergyresources.com) broke ground June 20 on INEOS Hickerson Solar, a new 310-MW solar project in Bosque County, Texas. Expected to produce 730,000 MWh of clean energy annually, the project will reduce greenhouse gas emissions by approximately 310,000 tons per year. The output of INEOS Hickerson Solar aims to cover the net purchased electricity load for all 14 of INEOS O&P USA’s manufacturing, fractionation and storage facilities.

• FieldComm Group (www.fieldcommgroup.org) reported June 27 that it’s successfully approved physical layer conformity of ABB’s (www.abb.com) first vortex flowmeter (VortexMaster FSV400) and swirl flowmeter (SwirlMaster FSS400) with Ethernet Advanced Physical Layer (Ethernet-APL) communication interfaces, following a series of tests. Ethernet-APL (IEEE 802.3gc or 10Base-TL1) is a new member of the family of Ethernet standards, providing full Ethernet and TCP/IP connectivity in hazardous environments at 10Mbit/s for field instruments over fieldbus Type A cables.

Control Amplified offers in-depth interviews and discussions with industry experts about important topics in the process control and automation field, going beyond Control's print and online coverage to explore underlying issues affecting users, system integrators, suppliers and others in the process industries.

Check out some of the latest episodes, including:

Coriolis technology tackling green hydrogen extremes

FEATURING EMERSON'S GENNY FULTZ AND MARC BUTTLER

Ultrasonic technology takes on hydrogen, natural gas blends

FEATURING SICK SENSOR INTELLIGENCE'S DUANE HARRIS

Asset-specific insights to transform service workflows

FEATURING EMERSON'S BRIAN FRETSCHEL

Analytics enabling next-generation OEE

FEATURING SEEQ'S JOE RECKAMP

BARRY BAKER

Vice President, Trihedral Engineering Limited

THE classic economic definition of the total cost of ownership (TCO) is the purchase price of an asset plus its operating costs over the asset’s lifespan. While this may be relatively easy to calculate for hard goods like a piece of machinery, the cost factors for soft goods, such as SCADA software, are more complicated to ascertain due to their wide range of features and licensing models. Control talked with Barry Baker, vice president of Trihedral Engineering Limited, to gain some insights from his more than 30 years of SCADA systems experience in many diverse industries.

Q: What factors would be considered in determining the TCO of a SCADA System?

A: Most SCADA systems will be required to operate for a decade or more before any major disruptive changes in an OT environment, so the TCO calculation can be divided into three distinct phases: build, operate and maintain. They can be performed by different users and both analog and digital factors are used in the calculation of TCO.

Q: What are analog and digital factors?

A: Costs that can be calculated, such as the purchase price or I/O capacity per license, are analog in nature. A digital consideration is something such as reliability, which translates to a question of the cost of failure to the purchaser. For most in our industry, pricing in failure is simply a no-go, so it becomes digital, either meeting the reliability threshold or not. One customer evaluating SCADA software products had an option to get free SCADA software included from a potential hardware vendor. While the purchasing department liked the price, the project owner noted the free software could cost a lot if it failed in the monitoring of their billion-dollar asset portfolio. You can guess that they determined free, with uncertain reliability, was not really an option.

Q: How is this different from the TCO calculation for an IT system?

A: While OT and IT systems are both software, most IT systems tend to follow the major release cycles in OS platforms, such as the three-to-five-year schedule of major releases of Microsoft Windows or associated IT hardware, which responds to changes in processors, network types or compatibility with other IT hardware. In contrast, most OT systems focus on industrial control hardware for a particular process that's required to have high availability disrupted with weekly updates. In some OT operations there are stringent change controls to minimize risks to critical infrastructure because there's a possibility of unintended consequences when performing updates. In other industries, OT system engineering may be subject to laws regarding professional engineering practices due to their legislated liabilities relating to serving the public.

Q: What considerations are there for initial purchase price?

A: The purchase price translates into the license cost because software is conveyed by its license vs. physical transfer of hard goods. The license agreement determines how the software operates and under what restrictions. The common forms of operation are perpetual licenses that never terminate, or time-limited software-as-a-service (SaaS) licenses that are common in cloud-based systems. In a SaaS agreement, the purchaser is required to periodically pay a license fee for the software to continue to operate, whereas perpetual is a one-time initial charge.

When evaluating both, there is the analog consideration of the time-value of money over the expected lifetime of use coupled with a possible yearly price escalation on SaaS because most systems are not immune from inflation. In a digital consideration, the

purchaser must “guesstimate” the expected lifespan of the SaaS and determine their upset cost if it's discontinued. When it comes to impact from license restrictions, the purchaser must evaluate potential costs of any obligations to the software licensor, such as purchaser being required to indemnify the software supplier for certain activities or license breaches. The software license may have a stated limitation of use that can expose the purchaser to liability for selecting the wrong product if a failure later occurred. Finally, there is the determination of how much software is needed and/or if any additional components are required to meet the application needs. An example is determining the number of I/O to be monitored. Are you forced to pay for the maximum product size, or can you reduce costs by sizing it to what you need? This should not be confused with what the license agreement allows, as “unlimited I/O license” means it can monitor an infinite amount of I/O, which isn’t practical since computers have processing limitations.

Q: What are build-phase considerations?

A: Systems which come with integrated functionality will have a lower build cost vs. having to write code to achieve the same. The argument that writing code allows flexibility overlooks the hidden costs to maintain that code over the lifespan of the system. The timeframe includes product, OS, and personnel changes that impact how a particular script performs, and is called technical debt. There are other considerations as computer languages can fall out of favor in support, or be blocked by security concerns or changes to licensing models, such as VBA and JAVA.

Also, a user must consider ease of configuration. Are there any separate sub-components that must be configured to achieve system functionality? Is the database ready to use or are there license costs and administration time to be considered? If so, the complexity in the solution will result in more build time and costs.

Q: What are operate-phase cost considerations?

A: The purchaser must determine if the product is intuitive and easy to learn. Operators will change over the system lifespan, so what is the cost to train new people? Can it be self-taught or easily learned with on-the-job teaching from other operators?

Also, does the product include tools that aid the operator, such as ISA 18.2 alarm management, easy navigation, operator notes, and the ability to trend and analyze suspect I/O without requiring additional engineering work?

Finally, how easy is it to recover from errors? Software with integrated features allows for fast recovery, and results in lower operational costs. These features are sometimes available as third-party products but require additional integration time. User workflow enforcement ensures use vs. the “always-on” availability of integrated product solutions.

Q: What are maintenance cost considerations?

A: The first is how easy it is to update and maintain product concurrency. We want to avoid the Windows XP trap, where the OS was provided with patches for many years but otherwise abandoned with regards to product evolution. In the end, when Microsoft terminated support, users were forced to make major changes with disruptions to their businesses. Products that provide an easy evolution path by maintaining backward compatibility are less costly to maintain vs. purchasing a major product version and undergoing rework of the application on a periodic basis.

For more information, visit VTScada.com

It’s time to construct the infrastructures that hydrogen economies, net-zero emission targets and other sustainability goals will require

by Jim Montague

ONCE we decide where to go, we start looking for the shortest path. The same goes for pursuing net-zero carbon emissions and other sustainability goals. Once we muster the will to take the first step, we pack what we think we’ll need for the trip, and begin seeking ways to smooth and straighten the road to going green.

Because net-zero targets and sustainability are almost impossible to approach as one big goal, most overall efforts are broken up into smaller programs and projects. For instance, the Greenhouse Gas Protocol (ghgprotocol.org) classifies a company’s GHG emissions as direct emissions from its owned or controlled sources (Scope 1), indirect emissions from generating purchased energy (Scope 2), and indirect emissions, not included in Scopes 1 and 2, which occur in the value chain of the reporting company (Scope 3), including upstream emissions by its contractors and suppliers, and downstream emissions by its clients and customers.

One of the hottest topics in sustainability today is using hydrogen to store power. However, what makes it even more attractive to net-zero supporters is using the excess capacity of renewable energy sources like solar and wind to electrolyze water into green hydrogen, which can be consumed, emissions-free at a later time.

“Because green hydrogen uses renewable energy like solar and wind, and could decarbonize many industries, it’s been a focus of ours for some time,” says Justin Ryan, director of technology and energy transition at Avid Solutions Inc. (avidsolutionsinc.com), a system integrator and certified member of the Control System Integrators Association (www.controlsys.org). “Green hydrogen can be used when alternative energy sources aren’t feasible, when electrification and batteries aren’t viable, or where carbon-intensive hydrogen is used in manufacturing.”

Ryan reports that Avid was the system integrator for the largest proton exchange membrane (PEM) electrolyzer facility in the U.S., which started production in January 2024. The Plug (www.plugpower.com) plant is located in Woodbine, Ga., and produces up to 15-tons per day of liquid hydrogen. Plug produces hydrogen that’s used by its fleet of fuel cells or sold to customers.

“Fuel cells require hydrogen to produce power. As a result, Plug steadily acquired companies and technologies to produce green hydrogen themselves. Leveraging their PEM electrolyzer technology, Plug built its first

industrial-scale production facility. Its electrolyzer and overall, balance-of-plant (BOP) controls were designed and deployed by Avid. These controls were based on Rockwell Automation’s PlantPAx process automation system. This includes the controls of all BOP applications, including pure water for electrolysis, plant air, cooling systems, purge gas, power distribution and rectifier integration, and storage and shipping terminals. In addition to the BOP controls, we integrated unit controls for the main process consisting of electrolysis, gas drying, puregas filtering and liquification,” explains Ryan. “For example, liquefaction uses a cryogenic process to compress and cool hydrogen for storage and shipment at -423 °F based on Chart Industries technology. All of these assets were designed to be integrated and work together.”

The facility also has FM-listed, fire-and-gas system (FGS) protection and a safety instrumented systems (SIS) provided by Avid. These act as independent layers of protection. The FGS was designed with detector placement based on a provided gas dispersion analysis. The provided detectors monitor for leaks, flame and gas concentration above a safe, lower explosive limit (LEL).

Liquid, green hydrogen from the Woodbine plant is shipped via cryogenic storage trucks to clients with large warehouses, such as Amazon, Wal-Mart and Home Depot, which use it in their hydrogen-powered forklifts. These retailers can refill a forklift with hydrogen in about five minutes, compared to needing 15 hours to recharge a battery-powered forklift. “The U.S. Dept. of Energy (DoE) estimates that demand for hydrogen in the U.S. will reach 10 million metric tons per year (MMT/ yr) by 2030 and 50 MMT/yr by 2050,” says Ryan. “To achieve this goal, tax breaks are available for switching to renewable energy sources or using them in infrastructure projects. To demonstrate some of this capability, Caterpillar and Microsoft use hydrogen fuel cells for data center backup power as a replacement for a fossil-fuel solution.”

One of the earliest commitments to sustainability in the process industries was made in 2017 by Yokogawa (www.yokogawa.com), which pledged to achieve net-zero emissions by 2050 and transition worldwide to a circular economy by the same year, along with maintaining the well-being of its employees, customers and communities.

“I’ve been at Yokogawa for more than 30 years, so I know we’ve been involved in the energy sector for a

long time. However, we’re now developing new energy sectors that are very different from our usual refining and petrochemical processes,” says Gou Iwata, head of business strategy and water business development at Yokogawa’s Energy and Sustainability division. “These projects aren’t just photovoltaics and wind, which are getting bigger and bigger They’re mostly smaller than our usual pumps and compressors. In either case, they need suitable process automation and controls, which can also meet Scope 1, 2 and 3 goals for reducing CO2 emissions and help save energy, too.”

For example, Gou reports that Yokogawa Australia recently provided an energy management system (EMS) for a 10-MW electrolyzer, 18-MW solar plant, and 8 MWh battery energy storage system (BESS) at the Yuri Green Hydrogen Project (arena.gov.au/ projects/yuri-renewable-hydrogen-toammonia-project) in the Pilbara region of Western Australia. The project is a joint venture between Mitsui and Engie Renewables Australia Pty., Ltd., with engineering, procurement, construction and commissioning (EPCC) services provided by Technip Energies and Monford Group Pty., Ltd.

The Yuri facility will use solar power to produce up to 640 tons per year of green hydrogen, which will be used as a feedstock to produce green ammonia by 2030 at an adjacent ammonia plant operated by Yara Pilbara Fertiliser (YPF) Pty., Ltd., which is a subsidiary of Yara International ASA, one of the world's largest producers of nitrogen-based, mineral fertilizers. Yokogawa’s subsidiary, PXiSE Energy Solutions (pxise.com), is developing the EMS for the solar power plant, BESS and electrolyzer. It will be combined with an integrated control system (ICS) centering on a Collaborative Information (CI) Server that Yokogawa will also provide as part of the project’s first phase. The EMS will manage the Yuri facility’s inverter and batteries,

while the ICS and related PLCs will manage its RTUs, SCADA system and PXiSE software. Once these systems are installed and integrated, the plant's renewable energy production will be managed autonomously to ensure consistent stability and power quality based on the ammonia plant’s operating requirements, local weather and other factors (Figure 1).

“We’ve already spent about a year integrating Yuri’s control systems, including PXiSE’s EMS, which is especially important because this greenhydrogen process requires consistent, high-quality electricity to produce high-quality hydrogen,” explains Gou. “This can be difficult for a solar plant due to clouds and other factors. This is where battery storage comes in to cover gaps and maintain a steady power supply, while BESS relies on PXiSE’s high-speed controls.”

“Because sustainability depends on who you are and what you’re doing, we ask potential users if they’re aware of the energy they’re using to make their products,” says Gou. “Many users aren’t measuring energy parameters as closely as needed. They may know their overall energy consumption, but they aren’t measuring per machine or unit produced. So, we suggest they consider digitalizing, getting more granular, and measuring the electricity, water, steam and/or compressed air used per unit, so they can compare production lines. We do the same for Yokogawa’s manufacturing areas, and each department has energy budgets and sustainability goals.”

Gou reports these efforts are aided by Yokogawa’s newly launched OpreX Carbon Footprint Tracer software, which gathers and analyzes sensor data. “We looked at one of our production lines that was supposedly shut down during lunch, and found that it was still using lots of power. We evaluated its performance with our software, pinpointed leaks in its compressed air lines, and found it was

also leaking water elsewhere. Any user can track and optimize parameters like this, and deal with leaks or other issues, beginning with easy items and then moving on to harder ones. Many users traditionally leave equipment running for perceived quality or safety issues, but there’s proof that they don’t need to. Likewise, many plants turn on heating equipment too early in the day, when they could use timers instead.”

Gou adds that sustainability can also be achieved by considering how process applications and facilities are designed, and applying system integration to balance production with some added requirements. “Many users have dealt with peaks in electricity availability before, but with solar power, that peak may shift to 2-3 p.m., and they may need battery coverage to shift it,” says Gou. “PXiSE is good at high-speed frequency and voltage control, and making adjustments in five minutes, which is similar to using model-predictive control and digital twins. Yokogawa comes from the operations technology (OT) side, so we’re all about collecting and using measurements for optimizing operations. Sustainability also uses measurements, and communicates them for the future of our planet.”

While many process industry professionals increase sustainability via the familiar efficiency improvements they’ve pursued all along, reducing CO2 emissions also means going in some unfamiliar directions. This is another reason why net-zero initiatives are broken up into Scope 1, 2 and 3 categories, which Emerson (www.emerson.com) adapts into three pillars:

• “Greening of Emerson” for improving its own sustainability;

• “Greening by Emerson” for supporting the sustainability efforts of its customers with process automation and related technologies; and

Figure 1: The plan for a 10-MW electrolyzer, 18-MW solar plant and 8 MWh battery energy storage system (BESS) at the Yuri Green Hydrogen Project in the Pilbara region of Western Australia specifies it will use an energy management system (EMS) from Yokogawa’s PXiSE Energy Solutions and an integrated control system (ICS) centering on a Collaborative Information Server that Yokogawa will also provide. The EMS will manage the facility’s inverter and batteries, while the ICS and related PLCs will manage its RTUs, SCADA system and PXiSE software. The Yuri facility will use solar power to produce up to 640 tons per year of green hydrogen, which will be used as a feedstock to produce green ammonia at an adjacent ammonia plant by 2030. Source: Yokogawa

• “Greening with Emerson” for working with other partners, larger communities and governments to drive future sustainability innovations.

While it’s been developing the technologies needed to support power generation of blended natural gas with hydrogen for several years, Emerson also explores how to automate generation and storage of hydrogen produced from renewable energy sources. Supporters expect this green hydrogen will enable the creation of a circular economy with little or no waste or negative environmental impact.

“Using excess renewable energy capacity to make green hydrogen turns it into a storage media because that hydrogen can be used later in gas turbines or other applications,” says James Fraser, global renewable power VP at Emerson’s Power and Water Solutions business. “These efforts are further enabled by our Ovation Green

renewable power portfolio of solutions, which can manage I/O for power generation, safety controls, software for managed assets and optimization technologies. All of our tools can pull more details from assets, which means they can be deployed, maintained and scheduled more efficiently. They’re also using more advanced control algorithms to predict performance, which can help with renewable energy production and storage decisions, too.”

To develop more renewable energy applications that might eventually support green hydrogen production and storage, Emerson was recently enlisted by Lodestone Energy (lodestoneenergy.co.nz) to automate New Zealand’s first large-scale, solarphotovoltaic (PV) project at two 25MW sites at Kaitaia and Edgecumbe. However, efficient generation and distribution of solar PV requires precise

coordination of multiple, third-party devices and controls that can give operators complete visibility, intuitive capabilities and grid stability. Consequently, the utility is implementing Emerson’s Ovation Green solar platform, using an Ovation DCS and OCR3000 controllers to provide comprehensive control that will minimize the impact of solar PV’s variability and intermittent performance (Figure 2).

"New Zealand’s goal of achieving carbon neutrality by 2050 is an ambitious endeavor that will require many renewable, power-generation sources to be safely and rapidly brought online,” says Peter Apperley, engineering GM at Lodestone. “Emerson’s expertise in automation software for power generation and sustainability will help us build a world-class facility more quickly, while also integrating more seamlessly with the national grid to drive successful, efficient operations over the lifecycle of the plant."

Lodestone’s solar PV project requires multiple interfaces to thirdparty systems, including inverters, high-voltage switchboards, weather stations, security systems and grid-authorized RTUs. The Ovation platform will act as a process orchestration tool to seamlessly connect these devices to provide fast and intuitive visibility for operators. Ovation automation technologies and OCR300 controllers will also make it easier for the utility’s operators to quickly respond to grid-frequency events, while Ovation’s enterprise data solutions will provide secure monitoring of solar PV operations at the control room or on mobile devices by measuring, monitoring and reporting key performance indicators. Finally, the Ovation platform and green-solar solution is suited to supporting compliance with New Zealand’s energy participation code.

“There are some easy sustainability wins and ROI in power generation and process applications by optimizing existing assets, which can move

Net-zero pledges and other sustainability efforts have multiplied in different professions and regions, and produced guidance that shares common suggestions but also expresses key differences. Here’s an updated list of the notable organizations and links:

• American Chemical Society's 12 principles of green engineering (www.acs.org/content/acs/en/greenchemistry/principles/12design-principles-of-green-engineering.html)

• AIChE's Institute for Sustainability (www.aiche.org/ifs)

• Carbon Disclosure Project and Leadership Index (www.cdp.net)

• Climate Group’s (www.theclimategroup.org) EP100 Initiative

• The Carbon Trust (www.carbontrust.com)

• EcoVadis Sustainability Ratings (ecovadis.com/suppliers)

• Environmental Defense Fund’s Pathways to net-zero: a guide for business (business.edf.org/wp-content/blogs.dir/90/files/ Pathways-to-Net-Zero.pdf)

• Environmental Protection Agency's (EPA) E3 sustainability tools (www.epa.gov/e3/e3-sustainability-tools)

• European Union's “Sustainability guide” (sustainabilityguide.eu)

• Investopedia's Environmental, social and governance (ESG) criteria (www.investopedia.com/terms/e/environmental-socialand-governance-esg-criteria.asp)

• ISO’s Embracing net-zero and guidelines (www.iso.org/climatechange/embracing-net-zero and www.iso.org/netzero)

• NIST’s Manufacturing Extension Partnerships (www.nist.gov/ mep/manufacturing-reports/sustainability)

• UL's “Sustainability and environment solutions” (www.ul.com/ services/solutions/sustainability-and-environment-solutions)

• U.N.’s Net-Zero Coalition (www.un.org/en/climatechange/netzero-coalition) and U.N.'s 17 sustainable development goals (sdgs.un.org/goals)

• University of Oxford’s “Net-zero principles” (netzeroclimate.org/ policies-for-net-zero/net-zero-principles)

• World Economic Forum’s “Industrial sector turning net-zero goals into practice” (www.weforum.org/agenda/2024/06/industrial-sector-turning-net-zero-goals-into-practice)

them closer to their setpoints, and reduce costs and CO2 emissions,” adds Fraser. “However, users also need a larger, overall vision for sustainability that they can work back from. Hitting net-zero targets and achieving sustainability can’t be random. Making electricity with renewables and storing energy as hydrogen improves carbon footprints, but automation, software and more data can add more small wins that will eventually become big wins.”

To keep its 2018 promise of reducing its Scope 1 and 2 emissions by 40% by 2030, Vinci Energies (www.vincienergies.com) in Nanterre, France, nearby Paris, organizes its sustainability efforts into three pillars: acting for the climate, working towards a circular economy, and preserving natural environments. These directives extend to the seven system integration companies it operates in North America, including Actemium industrial automation brand, Axians information and communication brand, and newly acquired Premier Automation LLC.

“Even though some companies were acquired more recently than 2018, we performed back calculations to establish baselines for each. Next, we record quarterly energy-use numbers due to electricity, natural gas and water consumed, and waste produced,” says Phillip Meyer, director of quality, health, safety, environment and IT at Vinci Energies North America. “This determines our Scope 1 and 2 performances for what we use as a company, and helps us begin to approach Scope 3 for what’s going on upstream, downstream and over applicable lifecycles.”

Meyer reports that Vinci Energies’ internal sustainability efforts let it carry over the same principles to projects for its clients. Some of its Actemium projects include:

• Actemium Avanceon is working on three antiquated chillers at a plant in New Jersey, which used to run its third chiller continuously and 100% manually based on operator “feel”—and just experienced it’s third hot-standby incident. Automating all the chillers into one optimized control system allows them to operate more judiciously, and is expected to reduce their peak energy use, earn rebates, and save $300,000 per year.

• Actemium Atlantic Canada is implementing Real-Time Coefficient of Performance (RtCOP), an AI based software it developed to automate refrigeration systems. RtCOP analyzes system capacities and theoretical power consumption, continuously and in real-time, for every combination of equipment that could run in a facility. The AI application takes advantage of existing temperatures, pressures, flows and compressor curves. It’s then linked seamlessly with the existing control system using a custom PlantPAX addon instruction. RtCOP selects equipment with the lowest calculated consumption, and optimizes setpoints to meet

provide comprehensive control that will minimize the impact of solar PV’s variability and intermittent performance. The Ovation platform will act as a process orchestration tool to seamlessly connect third-party systems, including inverters, high-voltage switchboards, weather stations, security systems and grid-authorized RTUs. Source: Emerson

plant requirements with the least energy consumption. It does this 24/7 and reduces kilowatt hours (kWh) by up to 26% per year. For example, a frozen food processor in Canada implemented RtCOP, and cut its annual electricity use by almost 2.6 million kWh, which is equivalent to approximately 455 metric tons of CO2 emissions.

• Actemium Toronto created a Data Management System (DMS) for a process that produces cement-free, carbonnegative concrete. The system pulls information from more than 200 data points from Rockwell PLCs managing temperature sensors, humidity sensors, drying timers, cooling timers and other devices. These are combined with more than 100 manually entered values and more than 100 calculated values to give the client information from dashboards to trend graphs to alarm status. The system gives the client the information required to verify the amount of carbon sequestered in the concrete it produces.

“Our leadership is committed to reducing our Scope 1 and 2 emissions by 40% based on 2018 figures, but sustainability also represents big efficiencies and savings in materials, power and logistics,” explains Meyer. “Many clients want to get in on those savings, too.”

Just as it’s crucial to include control strategies, cybersecurity and other performance attributes into automation projects before they’re designed and developed, Meyer stresses that sustainability must be on the same list.

“Vinci Energies’ Axians brand has created software for assessing the estimated carbon footprint of a given project, which must be provided in much of Europe,” says Meyer. “It also points out details, including potential CO2 savings. For example, instead of shipping infrastructure servers and switches for a light-rail project in Toronto from New Jersey to Italy for factory acceptance testing (FAT), it shows approximately how much CO2 and revenue can be saved by sending the equipment directly from New Jersey to Toronto, and performing the FAT remotely at the client’s site.”

Meyer adds that savings calculations like these will become increasingly important for evaluating future sustainability plans and projects. This is because he reports that green business activity is expected to multiply four to 10 times by 2030, and participants need some way to assess and compare which proposals will be the most beneficial.

“All of these projects will require automation to be efficient, but they’ll also need to determine which controls will be the most useful because many PLCs and other devices are becoming obsolete,” adds Meyer. “As usual, buy-in and investment from leadership will be vital to reaching net-zero targets. However, it will be just as crucial for managers to give their people chances to exercise their creativity when developing and applying sustainability solutions. There are many young people who are very interested in this, and they must be encouraged and given time to see what they can do with software and other tools that can reduce CO2 emissions and save money at the same time.”

KENNY MARKS

Lithium and Battery

Business Development Manager

Emerson

LITHIUM-ION (Li-ion) batteries are becoming more prevalent as electrification takes hold of energy and transportation sectors. The manufacturing of these batteries requires a production and distribution process model that can keep up with the growing demand. Control spoke with Kenny Marks, Lithium and Battery Business Development Manager at Emerson, to get a sense of the challenges that customers encounter and innovative automation solutions that can help increase speed to market and help ensure reliable project execution.

Q: What trends drive the Li-ion market?

A: It's good to look at it from both the demand and supply sides because there's a lot happening in this space. There's been a big increase in the adoption and growth of electric vehicles.

As more renewable energy is used, it increases the need for energy storage systems. This, combined with traditional uses of Li-ion batteries like consumer electronics, results in an increased demand for batteries across the globe.

Shifting to supply, there are policies in place around supply chains and incentives for startups, joint ventures, partnerships and vertical integration that result in a massive amount of new investment globally, as well.

Q: What challenges face this industry?

A: The Li-ion value chain has complex processes to get to the battery in EVs driving on the street, whether it’s the upstream extraction or processing piece, building the battery itself, or the recycling of the battery when at endof-life. All of these verticals face unique challenges, but regardless of where in the value chain or the project customers may be, we see some common challenges.

A lot of customers wonder how to shorten project timelines without dramatically increasing risk. One thing happening is the use of

pilot projects to learn quickly what works and what doesn’t at a smaller scale. The challenge becomes how to leverage those learnings and scale up for production.

Once up and running, quality is incredibly important. The question becomes how to ensure that the most effective control strategies are in place.

Also, no matter what industry you're in, sustainability is a big topic. For example, how to build facilities and operate plants more efficiently and effectively when it comes to water and energy usage. There is also a lot of investment and innovation around making a more circular supply chain. That includes reclaiming minerals from end-of-life batteries and reintroducing them into the value chain.

Q: How does Emerson address the challenges customers face?

A : We're engaged and partnering with customers of all types—from startups to new joint ventures and partnerships to companies that have been in this space for a while and are growing or vertically integrating.

A s we talk to each customer, it's important for us to engage early and understand their unique challenges. Every project has different goals and complexities.

We address those challenges through a combination of things. One is our background and experience in process control and automation. We've built an innovative, easy-to-use DeltaV™ distributed control system that has been relied upon by customers across the globe in all major industries. And our knowledge of how to apply this comprehensive suite of technologies has helped ensure customers meet their business needs today, and in the future. Also, our global teams and consistent execution process help ensure that, no matter where the execution is happening, it is done effectively and efficiently.

Q: How do you help businesses get to market quickly?

A: Normally, when you try to do things faster there's a tradeoff when you eliminate steps. You can do things differently, but you're probably adding risk in another phase of the project. It might be shifting risk from project execution to startup, for instance.

We look at how we can make it less of a tradeoff by using new processes enabled by new technology and tools, so that when we shorten and eliminate steps in the project execution, we're not adding risk at another phase. For example, Emerson's Remote Virtual Offi ce (RVO) can do cloud engineering, so no matter where the project teams are, they can work together and collaborate across disciplines of the project. By leveraging Emerson's confi gure to order (CTO) cabinets, we can eliminate hardware FAT requirements and do FATs entirely virtually, within that RVO environment. And then, using Smart Commissioning in DeltaV and AMS Device Manager, we can further shorten project execution by eliminating tasks and performing hardware and software confi guration in parallel. This highly-automated device commissioning software not only reduces steps, it also eliminates risk.

the lithium value chain and helps optimize the value chain from the mine to the gigafactory.

Whether they're working on one project in one part of the value chain, or they're working on a multiphase project that's vertically integrated and touching multiple parts of the value chain, they know that they are working with an automation partner that has the technology and solutions to support them. Again, you think about risk, having that one partner really helps from a communication standpoint and eliminates touchpoints.

How can Emerson continue to meet customer demands while delivering high quality and compliance?

A: We've already touched on scalability. To expand a bit, the key is the ability to scale without impacting operations. The ability for customers to scale and grow seamlessly from pilot to production, and then add functionality online when they want to—with no impact to their operations—is a core benefit.

Q: Companies probably have automation software on their minds. How can you help?

A : It’s a top-of-mind conversation with a lot of customers. O ur DeltaV portfolio addresses key challenges throughout

FIND OUT MORE:

Hear more about DeltaV and lithium-ion batteries on the Control Amplified podcast at www.controlglobal.com/podcasts.

The big challenge typically with bad quality is poor control leading to high variability, and that's true here as well. There's complex, multi-input, multi-output processes we see in this industry that benefit from advanced control technology in addition to traditional PID control. Using the combined Emerson and AspenTech portfolio, customers can bring in Aspen DMC3™, a model predictive control platform, and enhance their quality

Then there’s artifi cial intelligence (AI) and analytics, and I think we're just seeing the beginning of how that technology can be used for multiple applications including quality. However, having good data is the key foundation to be able to leverage AI to improve your business decisions, improve your control, and learn about how different actions impact your operations. Again, regardless of where our customers are at in their journey to commercialized production and beyond, Emerson and our broad portfolio of austomation solutions can help.

Saudi Aramco offers field test results for a dielectric constant water cut meter with internal environmental and process temperature compensation in a liquid hydrocarbon process

by Ali S. Aldossary

THE petroleum industry typlically uses water cut meters to measure and monitor the volume percent (V%) of water in a liquid hydrocarbon product flowing from a well, produced from a separator, transfered in pipelines, or stored in loading tankers. There are several technologies used for such measurements with the main being dielectric measurements using radio or microwave frequency and near-infrared (NIR) measurements. Gamma ray-based instruments are also used, but they’re less common.

These measurements are important because excessive sour water carryover throughout the crude oil supply chain results in higher corrosion rates in pipelines, offspec crude oil supplies, and more water-to-evaporation ponds at terminals. One major challenge is finding a reliable, low-maintenance, accurate analyzer to measure low (0 - 0.2 V%) water cut at the outlets of gas-oil separation plants (GOSP). In additon, the analyzer needs the following features to measure correctly:

• Installing an inline, static mixer to homogenize the oil and water mixture;

• Installing sample probes to provide a representative sample for the analyzer;

• Installing a lab-sample, take-off point within 1 m of the analyzer probe; and

• Correct sample point location to obtain a representative sample.

One such analyzer, an electronic, dielectric-constant type measurement device, uses temperature and dielectric tables to compensate for temperature-induced dielectric changes from the process and the environment. It enables the analyzer to avoid drift after its first field calibration. The water cut meter is an insertive device with no analyzer shelter, and it requires a three-sided sunshade.

The analyzer has a built-in static mixer and lab-sample, take-off point, ensuring accurate measurement and validation. The water cut meter is a tested device with more than 16 years in the field, and it has a user list including international oil companies. It’s manufactured in flexible user ranges, which cover most upstream and downstream applications.

The advantages of this water cut include minimal maintenance, low operating expenditures (OPEX) and capital expenditures (CAPEX), and suitability for harsh weather conditions. It was piloted in the outlet of a desalter at an Aramco GOSP, and was monitored for more than a year. During that time, the water cut meter’s readings were found to be accurate when compared to lab analyses, and it had high online availability (>95%) and was shown to be robust. It also demonstrated an excellent response to process changes during field tests.

The tested, dielectric-constant type, water-in-oil monitor is a full-bore, inline and online device designed to continuously

monitor water content in flowing, hydrocarbon media (oil). It’s inline because it can fit into an existing pipeline, and it’s online because it can continuously monitor and transmit values to a remote location.

The unit is designed so the fluid mixture fl ows through a fi xed electrode assembly (Figure 1). This enables the dielectric constant of the mixture to be measured as a variable capacitance, which in turn produces an analog or digital output. This solution utilizes smart-sensor, data-analytics technologies in lieu of commonly used measurement techniques, and leverages built-in, artifi cial intelligence (AI) models. The accuracy is ±0.05% in the range from 0 - 1%. The analyzer is rated for an ambient temperature of 60 °C.

Advantages and limitations

The dielectric-constant analyzer offers distinct advantages because no frequent-field calibration is required. Once the analyzer is calibrated at the commissioning period, there’s no need for repeat calibrations, so safety is improved because operations personnel aren’t exposed to H2S gas.

It also offers easy installation with less space requirements. It’s robust and rugged construction is suitable for harsh

industrial environments and hazardous area installation. Only minimal maintenance is required with no consumables. In addition, it has a faster response time, which helps realize the full potential of advanced process control (APC) schemes. However, the meter is unable to measure water cut in multiphase stream compositions.

Saudi Aramco’s field test was conducted by creating upsets in the process and observing the response of the analyzer. Lab samples were taken before and after creating the upsets to compare with analyzer readings. The lab method used was ASTM D4007 (centrifuge method).

The pilot success was measured by the following criteria:

• The water cut monitor reading value must be within ±0.05% water of the actual value determined by lab-sample analysis;

• The monitor must operate successfully within the upper environmental temperature limits listed in the monitor manufacturer’s specifications during summer’s ambient air temperatures and radiant heat conditions;

• The monitor must not show physical degradation or probe damage related to normal or abnormal operating conditions (provided the abnormal operating conditions don’t exceed the design conditions of the monitor);

• The monitor must not show signs of signal or measurement interference due to process background changes that may occur during normal or abnormal operating conditions (provided the abnormal operating conditions don’t exceed the design conditions of the monitor); and

• The monitor must operate reliably during the pilot period upon commissioning, and must attain a 95% or greater online availability under normal and abnormal operating conditions (provided the abnormal operating conditions don’t exceed the design conditions of the monitor).