Dr. Kishor Khankari cooks

Greenheck’s eCAPS® Bridge for Revit® plugin provides access to the most complete catalog of HVAC LOD 200 and 300 product content - without leaving Revit®

Dr. Kishor Khankari cooks

Greenheck’s eCAPS® Bridge for Revit® plugin provides access to the most complete catalog of HVAC LOD 200 and 300 product content - without leaving Revit®

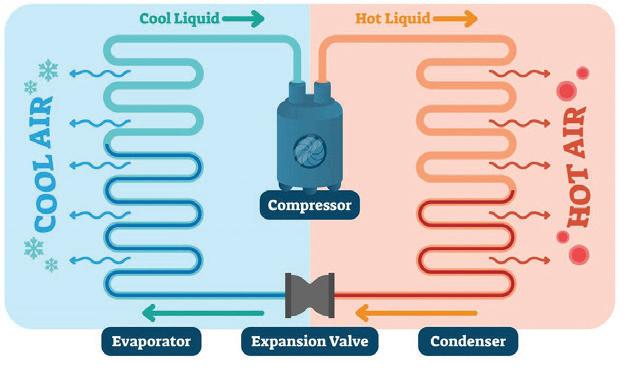

The Daikin MEGA-Q system provides an all-electric, inverter driven hot water solution, making it an ideal choice for commercial buildings with large volume.

INDOOR COMPONENTS

OUTDOOR COMPONENTS

The impact of exhaust flow rate on the dispersion of NO2 in a multiunit residential kitchen was evaluated, using new metrics developed by the author to ensure proper IAQ levels for occupants.

By Kishor Khankari, PhD

23 Optimizing the Chemistry Behind Closed-Loop Heating Systems

As heating networks become more complex, water treatment programs need to evolve beyond traditional inhibitor dosing and flushing cycles.

By Michael Warady

District Heating Must Pivot To Energy Efficiency

Advanced electrode boilers can replace outdated fuel-burning equipment and still meet ambitious decarbonization goals.

By Del Williams

The first-ever woman to lead the American Boiler Manufacturers Association is also its first international member in that role. She’s excited for the future of this industry.

By Rob McManamy

Held concurrently with AHR Expo, the engineering meeting drew 3,800 attendees to Orlando

Editor’s Notes As EPA Resets, Engineers Remain Focused on Mission By Rob

McManamy

Today’s polarized politics betray the popular consensus that existed in 1970.

By Larry Clark

HPAC Engineering (USPS Permit 464-930, ISSN 0039-0895 print, ISSN 1930-8957 online) is published 6x a year (Jan/Feb, Mar/Apr, May/Jun, Jul/ Aug, Sep/Oct, Nov/Dec) by Endeavor Business Media, LLC. 201 N Main St 5th Floor, Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI, and additional mailing offices. POSTMASTER: Send address changes to HPAC Engineering, PO Box 3257, Northbrook, IL 60065-3257. SUBSCRIPTIONS: Publisher reserves the right to reject non-qualified subscriptions. Subscription prices: U.S. ($111.25); Canada/Mexico ($123.75); All other countries ($148.75). All subscriptions are payable in U.S. funds. Send subscription inquiries to HPAC Engineering, PO Box 3257, Northbrook, IL 60065-3257. Customer service can be reached toll-free at 877-382-9187 or at HPACengineering@omeda.com for magazine subscription assistance or questions.

Printed in the USA. Copyright 2025 Endeavor Business Media, LLC. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopies, recordings, or any information storage or retrieval system without permission from the publisher. Endeavor Business Media, LLC does not assume and hereby disclaims any liability to any person or company for any loss or damage caused by errors or omissions in the material herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever. The views and opinions in the articles herein are not to be taken as official expressions of the publishers, unless so stated. The publishers do not warrant either expressly or by implication, the factual accuracy of the articles herein, nor do they so warrant any views or opinions by the authors of said articles.

BLUETOOTH CONNECTIVITY FOR 54% FASTER INSTALLATION

We created the Rheem® Endeavor® Line in response to tougher Department of Energy regulations that went into effect in 2023. Rather than simply making our products larger to achieve increased efficiencies, we redesigned them from the ground up to create our most energy-efficient, dependable, capable and sustainable lineup yet. And now, many models utilize low global warming potential refrigerant— meeting the EPA’s new standards. Rheem.com/Endeavor

NOTE

Breaking Barriers, Listening to Customers, with ABMA’s Nancy Simoneau

*PODCAST* We chat with the first-ever woman to lead the American Boiler Manufacturers Association, as well as the first international member to fill that role. www.hpac.com/55271779

Clean Airflow and Air Cleaners, Keys to

EDITORIAL OFFICE

8001 Lincoln Ave. • Suite 720 Skokie, IL 60077 www.hpac.com

EXECUTIVE TEAM

CEO: CHRIS FERRELL

COO: PATRICK RAINS

CRO: PAUL ANDREWS

CDO: JACQUIE NIEMIEC

CALO: TRACY KANE

NOW ON DEMAND: Recorded 11/18, IAQ expert Dr. Bill Bahnfleth explains this revolutionary concept, redefining standards with new air cleaning technologies. www.hpac.com/55236601

Engineering eBOOK: The Best of Ken Elovitz, P.E.

An Engineer’s Notebook, 2021-2024. Dive into this collection of useful professional advice, laced with helpful legal acumen. www.hpac.com/55020330

CMO: AMANDA LANDSAW

EVP, GROUP PUBLISHER –BUILDINGS, ENERGY & WATER: MIKE CHRISTIAN

EDITORIAL CONTACTS

MIKE EBY

Group Editorial Director meby@endeavorb2b.com

ROB MCMANAMY Editor-in-Chief rmcmanamy@endeavorb2b.com

DAVID ECKHART Art Director deckhart@endeavorb2b.com

SALES CONTACTS

MIDWEST BILL BOYADJIS 973-829-0648 bboyadjis@endeavorb2b.com

SOUTH & WEST RANDY JETER 512-263-7280 • Fax: 913-514-6628 rjeter@endeavorb2b.com

HPAC 2025: Our March Quiz!

*SPRING TRAINING* As our climatecontrolled world shifts from heating to cooling this month, we review some basics. Take the quiz! Win prizes! www.hpac.com/55270806

Follow us on Twitter at @HPACEng, as well as our sister publications, @Contractormag, and @ContractingBiz. Retweet our up-to-date content, send comments, questions. Expand your world of engagement with us, at no extra charge!

EAST BRIAN SACK 732-629-1949 bsack@endeavorb2b.com WEST ELLYN FISHMAN 949-239-6030 efishman@endeavorb2b.com

CLASSIFIEDS/INSIDE SALES

STEVE SUAREZ 816-588-7372 ssuarez@endeavorb2b.com

DIRECTOR OF SALES JOE AGRON 941-200-4778 jagron@endeavorb2b.com LIST RENTAL SMART REACH sr-assets@endeavorb2b.com effective

PRODUCTION AND CIRCULATION

RITA FITZGERALD

Senior Production Manager rfitzgerald@endeavorb2b.com

MELISSA MENG Ad Services Manager mmeng@endeavorb2b.com

JAMES MARINACCIO

Audience Marketing Manager jmarinaccio@endeavorb2b.com

HEAT TRANSFER FLUIDS FOR ANY APPLICATION

PROVIDING GLYCOL-BASED HEAT TRANSFER FLUID TO KEEP YOUR HVAC SYSTEMS AND PROJECTS RUNNING SMOOTHLY.

Thermal Charge® offers application-specific heat transfer fluids, innovative inhibitor technology, and industry-leading service and fulfillment so you can power through every challenge, need, and demand.

Visit thermalcharge.com to find the right heat transfer fluid for your application.

BY ROB MCMANAMY, EDITOR-IN-CHIEF

On March 12th, new EPA Administrator Lee Zeldin announced that the federal agency was undertaking 31 actions to roll back several regulations and reconsider many others, including rules requiring the reporting and tracking of greenhouse gas emissions, and others affecting the ongoing refrigerant transition.

Not surprisingly, the announcement caused concern among the mechanical engineering community, as it signaled a dramatic change in federal environmental policy. With that in mind, to gauge reaction among engineers, I reached out to HPAC Engineering’s Editorial Advisory Board, as well as Kent Peterson, P.E., chair of ASHRAE’s Center of Excellence for Building Decarbonization (CEBD).

An ASHRAE Past President (2007-2008) and founder of P2S Inc., an engineering and consulting firm based in Long Beach CA, Peterson authored our cover story on decarbonization technology last summer and has been a guest on the ‘HPAC On The Air’ podcast. His firm response surprised me.

“It has zero impact on what we’re doing,” said Peterson. “It doesn’t really impact our work at the state level, either. And to be honest, I haven’t seen anybody backing off on anything yet this year. Remember, most of these announcements are ‘reconsiderations’ of rules, so we are a long way away from anything concrete. I think we all should just take a deep breath and see where we are in six months.”

Sound advice from an experienced industry practitioner. Noted Peterson, “The industry is already well down this road,” suggesting that many manufacturers and facility owners have already come too far to turn back now.

“Captains of industry are not going to change complex and important standards based on politics,” added Ron Wilkinson, P.E., LEED AP, a longtime member of HPAC Engineering’s Editorial Advisory Board and the creator of the popularJohnny Tundra: Cold-Weather Engineer series. Wilkinson is an expert in building commissioning practices.

“To this point, we have not seen our clients back away from their long-term plans to transition out of the current technologies into the next,” said fellow Advisory Board member Glenn Barrett, engineering manager at DC Engineering in Spokane WA. In 2022, Barrett presented a webinar for HPAC Engineering, ‘Refrigerants Reckoning,’ to help readers prepare for the national transition that is now upon us.

“While this Administration now is working to roll back (EPA) requirements in the name of being competitive and cost effective, we don’t know what the next Administration will do, or the one after that, or the one after that. So, many of our clients are looking at the long game in this regard.”

It is the uncertainty of the moment that is creating the most angst.

“Historically, we have seen that when federal regulations back away from requirements, then the state level increases to compensate,” added Barrett. “At the moment, though, we honestly don’t know how this will play out. On one hand, we certainly appreciate the significant cost and hardship to facility owners whenever a complete equipment replacement is required. But on the other hand, manufacturers have also spent millions on R&D, new product development, and listings preparing for this.”

So, for now, the mindset among HVACR engineers appears to be one of just putting their heads down and pushing forward. Said Peterson, “There was a lot of discussion at our winter meeting in Orlando about where things were headed, but ASHRAE Secretary Jeff Littleton just reassured everyone, ‘We’re staying true to our mission.’”

For the last three years, for Peterson and members of CEBD (formerly ASHRAE’s Task Force on Decarbonization), that mission has involved 90-minute meetings every other week, “and the agenda is always full,” he noted. As an international society, (ASHRAE) “needs to be out in front on climate change. So we are committed to the science. And as a technical organization, that’s the way it should be.”

Steady as she goes, for now.

William P. Bahnfleth, PhD, PE The Pennsylvania State University

Glenn Barrett, PE DC Engineering

David W. Bearg, PE Life Energy Associates

Lawrence (Larry) Clark, QCxP, GGP, LEED AP+ Sustainable Performance Solutions LLC

Kenneth M. Elovitz, PE, Esq. Energy Economics Inc.

Charles E. Gulledge III, PE, HBDP, LEED AP, FASHRAE Environmental Air Systems LLC

Elise Kiland, PE, YEA Cambio.ai

Nancy Kohout, PE, LEED AP SmithGroup

Valentine A. Lehr, PE, FASHRAE Lehr Consultants International

Ginger Scoggins, PE, CEM, CxA, LEED AP, FASHRAE Engineered Designs Inc.

James P. Waltz, PE, CEM, ACFE Energy Resource Associates Inc.

Michael K. West, PhD, PE Advantek Consulting

Ron Wilkinson, PE, LEED AP Wilkinson Commissioning Management

Gerald J. Williams, PE, LEED AP 8760 Engineering LLC

Held concurrently with AHR Expo, the engineering meeting drew 3,800 attendees to Orlando

ASHRAE recognized donors to its Research Promotion campaign in Orlando. For a full list of donors, visit ashrae.org/rp.

The 2025 ASHRAE Winter Conference brought together HVACR industry leaders, experts and professionals for an engaging and impactful event focused on key topics such as artificial intelligence, emerging technologies and workforce development.

Taking place February 8-12 in Orlando FL, the conference attracted close to 3,800 attendees and featured more than 400 committee meetings, 111 technical sessions and numerous networking events. Running concurrently, the AHR Expo occupied the Orange County Convention Center, hosting more than 1,800 exhibitors, showcasing the latest HVACR technologies, products and services to an estimated 50,000 attendees over three days.

Among the most well-attended in-person sessions were:

• Seminar 13: Low and Ultra-low GWP Refrigerants and Equipment to comply with Current and Future Decarbonization Efforts;

• Seminar 8: Earth, Heat and Ice: Expanding the Effectiveness of Geothermal Systems Using Ice Storage;

• Seminar 42: The Wonderful World of Dedicated Outdoor Air Systems and Energy Recovery Equipment;

• Seminar 25: Energy Storage Solutions to Enhance Building and Grid Resilience;

• Seminar 11: Advances in AI Technologies for the Buildings Industry.

The most popular livestreamed session was Seminar 36: Interdisciplinary Dimensions of Occupant Behavior, Indoor Environmental Quality for Building Health.

In his State of the Society Address, 2024-25 ASHRAE President M. Dennis Knight provided updates on the current Society Year theme: Empowering Our Workforce, Building a Sustainable Future

“As we look to the future, I call upon each of you to continue to be passionate ambassadors for our industry,” said Knight. “Share your stories, engage in conversations, and inspire the next generation of professionals. We need to demonstrate to the world what we do and the profound impact our industry is making today. And the even greater potential it holds is in the future to address indoor environmental quality, sustainable development and resiliency,” he added.

Knight highlighted progress on key initiatives, including a newly-released workforce development roadmap which outlines strategies for attracting, engaging and retaining talent to the HVACR industry. Knight’s full State of the Society address manuscript and presentation can be found at ashrae.org/president.

During the conference, President Knight announced the winners of the 2024-25 ASHRAE Decarbonization Challenge, a grant program supporting ASHRAE chapters in implementing local projects focused on energy efficiency and emissions reduction. The challenge, led by the Young Engineers in ASHRAE (YEA) committee, received 14 project submissions, awarding seven projects with grants ranging from $2,970 to $10,000, totaling $59,970.

Further reinforcing its commitment to industry innovation, ASHRAE announced the establishment of the $1 million Gordon Holness Presidential Fund. Created through an endowment, this fund will provide an annual $50,000 grant in perpetuity to support ASHRAE chapters in developing and executing creative solutions to some of the industry’s most pressing building challenges. Holness, who served as ASHRAE President in 2009-10, joined Knight at the 2025 Winter Conference to announce the fund’s launch.

ASHRAE honored the outstanding contributions of its members during its Honors and Awards Program. Additionally, ASHRAE Executive Vice President and Secretary Jeff Littleton provided updates on the Society’s progress in advancing the built environment in his report.

“ASHRAE remains steadfast in its mission to serve the built environment through research, education, and the development of industry-leading standards and guidelines,” said Littleton. “As we navigate the evolving challenges and opportunities within our field, our commitment to innovation, knowledgesharing and workforce development is stronger than ever.”

Through collaboration with its global network of chapters and industry partners, the Society will continue to drive

meaningful advancements that shape the future of HVACR, he added. “ASHRAE is not just adapting to change—we are leading it.”

Our commitment to innovation, knowledge-sharing and workforce development is stronger than ever.

—ASHRAE Secretary Jeff Littleton

In addition, the ASHRAE Learning Institute (ALI) also provided valuable educational opportunities in Orlando, offering 20 courses during the conference. Among the most popular were:

• Changing Environments and Loads for Data Center (High Density, Liquid Cooling, Edge Computing);

• Guideline 36: Best of Class HVAC Control Sequences;

• V in HVAC – Health and Energy Improvements Using Indoor Air Quality Procedures.

All registered attendees, both in-person and virtual, will have access to the virtual conference platform during the conference and 12 months post-conference.

The 2025 ASHRAE Annual Conference will take place June 21-25 in Phoenix, AZ. The 2026 Winter Conference is set for January 31-February 4, 2026, and the AHR Expo, February 2-4, 2026, will be in Las Vegas, NV.

AtmosZero cofounder Ashwin Salvi stopped by to update HPAC on his firm’s long-awaited debut this spring of its modular electrified heat pump boiler for client New Belgium Brewing in Colorado.

Armstrong Fluid Technology’s Steve Lane was excited to introduce five new products being released this year, including the Design Envelope Energy Transfer Station, expected to hit the market this fall.

Nearly 1,900 companies exhbited at the show, including more than 560 based outside the U.S., representing 37 countries.

Nick Agopian of ReviveAire LLC describes his firm's new Aireshield plasma technology, which improves IAQ by controlling a wide range of RNA and DNA-based pathogens, including viruses, bacteria, and airborne mold spores. Compliant with ASHRAE 241 standards.

Did you know EVERY Bradford White tank-type water heater comes with an extra level of protection? Vitraglas® is the only tank lining in the industry featuring Microban® antimicrobial technology to help prevent the growth of bacteria, mold and mildew on the surface of the tank lining.

The impact of exhaust flow rate on the dispersion of NO2 in a multiunit residential kitchen was evaluated, using new metrics developed by the author to ensure proper IAQ levels for occupants.

By KISHOR KHANKARI, PhD, ASHRAE Fellow

Proper ventilation in the kitchens of multi-family housing units is key to reducing exposure to pollutants from cooking and gas stove burners. Mechanical kitchen ventilation with range hoods or overthe-range microwaves (OTR) can potentially reduce occupant exposure to cooking-related indoor pollutants. Several factors related to the exhaust hoods and user behavior can affect ventilation performance. The flow rate and physical characteristics of the exhaust fan used during cooking were the most important determinants of integrated exposures after cooking.1

However, the actual usage of the kitchen ventilation during cooking is low. Occupants often do not use their range hood due to the lack of awareness of the benefits. A large survey of Canadian homes showed that only 30% of households reported regularly using their range hood.2 The inadequate use of ventilation during cooking highlights the need for educational programs on cooking exposures and ventilation strategies.

A field study of nine homes in California showed wide variations in pollutant concentrations both across and within homes.3 Four of the nine homes had kitchen levels that exceeded the national ambient air quality standard threshold of 100 ppb NO2 over 1h4.

Field measurements of exhaust flow rates have shown a wide range.

For example, one study found rates ranging from 76 to 309 cfm (36 to 146 L/s), with actual flow rates 12–31 percent lower than those specified in product literature.⁴ Another study found airflow rates varying from 92 to 275 cfm (43 to 130 L/s) for different over-the-range microwaves (OTR) and range hoods.⁵ ASHRAE 62.2 requires range hoods to move at least 100 cfm (47 L/s) of airflow with a downstream duct static pressure of 62.5 Pa6.

In addition to the exhaust flow rates, the airflow patterns in the kitchen play a key role in determining the flow path of pollutants and its distribution in the space. Therefore,

Based in Ann Arbor MI, the author is an ASHRAE Fellow and President of AnSight LLC, his own consulting engineering practice specializing in computational fluid design (CFD) for building HVAC and data centers. Contact: kishork@ansight.com.

understanding these airflow patterns and flow paths is crucial for determining the level of pollutant exposure for people in the space.

The dispersion of pollutants and their flow paths can be influenced by a variety of factors. They include exhaust flow rates, the design of the exhaust hood, size and location of make-up air openings, the location and capacity of the cooking burners, cooking practices, and user behavior when operating the kitchen ventilation system.

Conducting physical tests on all these factors under controlled conditions for various operating conditions can be time-consuming and laborintensive, if not impossible. Computational Fluid Dynamics (CFD) analysis offers a practical alternative for systematically evaluating all these parameters.

What is Computational Fluid Dynamics (CFD)?

CFD is a science that deals with simulation and analysis of fluid flow, heat transfer, mass transfer, and transport processes. CFD analyses are based on laws of physics, such as the conservation of mass, momentum, and energy.

The science employs numerical methods to solve the underlying transport equations. It thus predicts temporal and spatial variations of governing entities such as velocity, pressure, temperature, chemical concentrations, etc., without requiring the assumption of well-mixed conditions. CFD simulations yield a wealth of information related to timevarying three-dimensional distributions of these entities that are difficult to obtain through prototyping or physical testing.

There are numerous examples of CFD use for various applications that aim to meet specific design goals. For example, designing smoke exhaust systems for fire scenarios, predicting the transient time-temperature history of chilled water in thermal storage tanks, analyzing stratified ventilation systems such as traditional displacement ventilation (TDV) and underfloor air distribution (UFAD), as well as optimizing the cooling performance of data centers, cleanrooms, and laboratory ventilation systems. Additionally, these tools can be used for predicting plume dispersion from exhaust stacks and equipment yards of large data centers, among other applications.

This study utilizes CFD simulations to examine the effectiveness of residential kitchen ventilation for various exhaust flow rates. It assesses the transient dispersion of nitrogen dioxide (NO2) and temperature distribution using an identical setup and release rate of NO2.

The study also introduces two new measures, Spread Index (SI)TC and Purge Time (PT)TC, to evaluate the effectiveness of kitchen ventilation. The main goal of this CFD study is to demonstrate relative spread of pollutants in the kitchen due to the indoor airflow patterns.

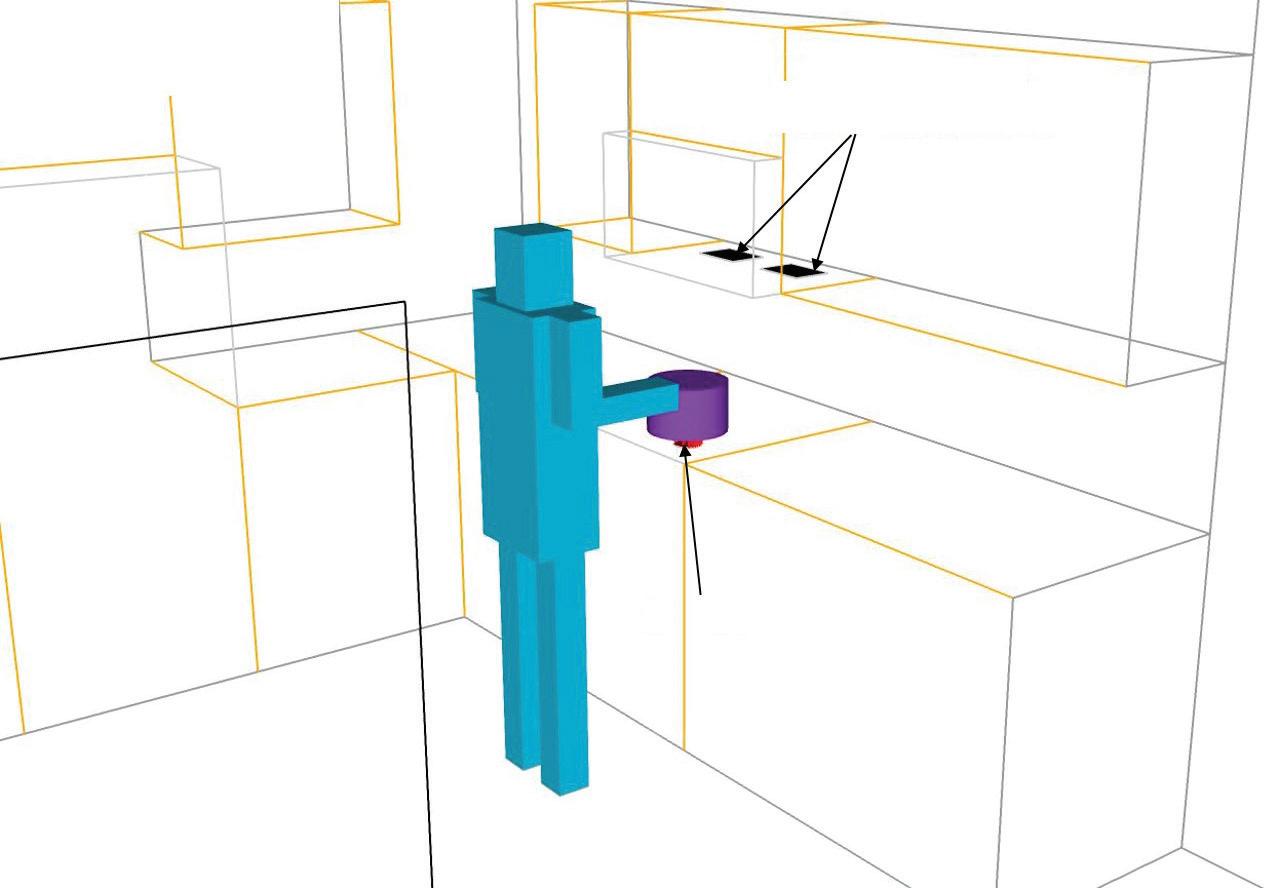

A three-dimensional, transient, nonisothermal CFD model of a kitchen and the adjacent living room in a multi-family housing unit was developed for this study. The total floor area of the model space is 375 sq. ft. (35 m2) (15 x 25 feet, 4.6 x 7.6 m) with a 9-foot (2.7 m) ceiling height. The kitchen floor area is 143 sq. ft. (13 m2) (11 x 13 ft, 3.3 x 4 m).

As shown in Figure 1, the kitchen has cabinets, a nook, a refrigerator, and an occupant standing in front of the

Time: 15.0 (min)

cooking range. The door between the living room and the kitchen is assumed to be open. Additionally, a large nook opening (9.75 x 4 feet, 3 x 1.2 m) is placed between the kitchen and the living room. The kitchen is equipped with an over-the-range microwave with an integrated exhaust fan. The exhaust air is vented outdoors through two exhaust grilles placed under the microwave. The outside air is supplied through a door undercut of the main door in the living room.

This model setup represents typical operating conditions of a kitchen during the winter season in a cold climate region with closed doors and windows. In such situations, the leakages through door undercut remain the major source for the makeup air.

The transient (time varying) analysis was performed for a total duration of 30 minutes with exhaust flow rates of 75, 150, and 300 cfm (35, 70, and 140 L/s). The flow rates correspond to the air change rates of 1.3, 2.6, and 5.2 1/h, respectively, for the entire space. Whereas for the kitchen space, these flow rates correspond to the air change rates of 3.5, 7, and 14 1/h, respectively.

The front burner located on the right side of the cooktop is assumed

Time: 15.0 (min) Time: 15.0 (min)

to be ‘ON’ for the first 15 minutes. The heat release rate from the burner is assumed to be 17000 Btu/h (5 kW), of which 80 percent is to be consumed by the cooking process. The rest is dissipated to the surrounding area.

Nitrogen Dioxide (NO2) was considered as the main contaminant generated from the gas burner during the natural gas combustion process. A constant generation rate of NO2 was assumed to be 3.307E-06 lb/min (1.5E06 ng/min).⁶ The NO2 generation rate was assumed to be constant and the same for all analyses. The ambient concentration of NO2 is assumed to be zero. The previous study showed significantly lower levels of ambient NO2 concentrations relative to those generated from the indoor emissions.

A virtual sensor was placed in the model in front of the occupant’s face, as well as in the two exhaust grilles, to monitor time-varying concentrations at each location. With the help of this data, the exposure (dose) for the occupant was computed by the cumulative product of the NO2 concentration (ppb) and the duration of the exposure (min). The standard k-e turbulence model was employed to compute the turbulent viscosity of

the air. A computational mesh of 1.2 million hexahedral mesh was created by placing fine mesh near strategic locations.

Spread Index (SI) TC is a CFDbased metric developed to analyze and quantify the spread of pollutants in a given space. It is computed as the ratio of the volume occupied by the pollutant level above a certain acceptable concentration (TC) to the total volume of the space. The goal of the kitchen ventilation systems is to minimize the contaminant concentrations below acceptable concentration throughout the space and to limit the spread of pollutants. Spread Index (SI)TC is a metric of ventilation effectiveness that helps quantify the spread of pollutants in a three-dimensional space.

In an ideal scenario, the concentration levels should always remain below the acceptable target, indicating a (SI)TC close to zero during and after cooking. It’s important to note that the safe concentration levels depend on various risk factors, such as the type and quantity of pollutants released during the cooking process. Higher (SI)TC values can indicate the spread and accumulation of pollutants above acceptable concentration levels.

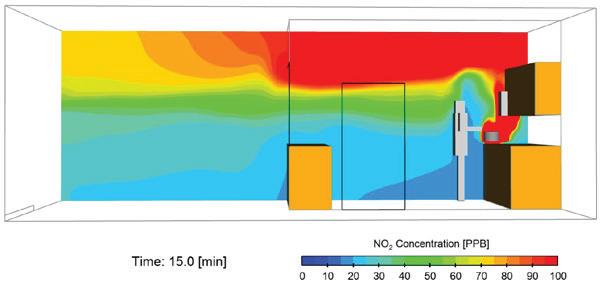

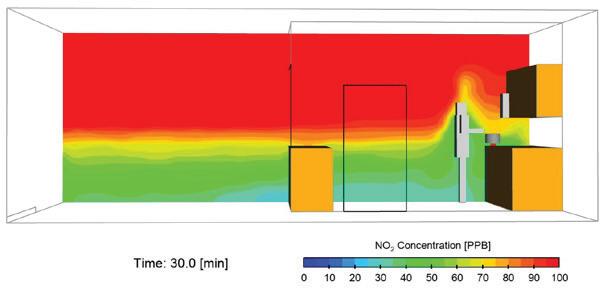

Figure 4: Distribution of NO2 concentration at the end of 15 and 30 minutes for three exhaust flow rates showing thermal plume displacing the pollutants away from the breathing zone of the occupant.

The design of a ventilation system as well as the resulting airflow patterns and pollutant flow path play a crucial role in determining the (SI)TC levels in the space.⁷ For the demonstration purposes, the target concentration of NO2 was assumed to be 100 ppb, which is an EPA-acceptable concentration level for 1h.

Purge Time (PT)TC: It is the amount of time required for a kitchen ventilation system to reduce the Spread Index (SI)TC from its highest value to zero. Essentially (PT)TC measures how well the ventilation system clears the space and reduces the pollutant concentration to a safe level (target concentration). (PT)TC can provide valuable guidance in estimating the decay rate of pollutants after the burners are turned ‘OFF.’

In this study, the impact of exhaust flow rates was analyzed by evaluating the (PT)100ppb values.

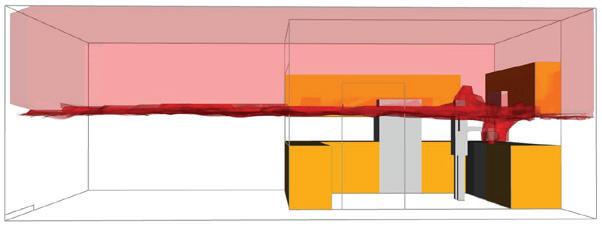

Figure 2 shows the airflow patterns in the kitchen for the make-up air entering into the kitchen through an open door between the kitchen and the adjacent space. The airflow path lines are colored by the air temperature. As shown in this figure, the make-up air is drawn towards the exhaust grilles located under the microwave oven. The hot air that is released around the burner rises upward towards the ceiling in front of the person. It also shows the air from the kitchen escapes into the adjacent living room.

As mentioned before, the make-up air enters the space through the gap under the main door in the living room (not shown in Figure 2). Three-dimensional airflow patterns in the entire space are quite complex and have a large impact on the spread and distribution of pollutants in the space.

Figure 3 shows temperature distribution on a vertical plane passing through the burner and the person after 15 and 30

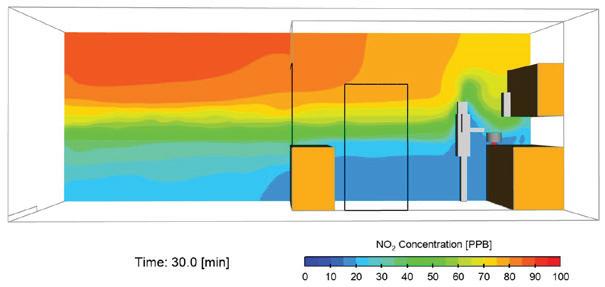

Figure 5: Spread Index (SI)100ppb at the end 15 and 30 minutes for three exhaust flow rates showing part of the kitchen with NO2 concentration at or above 100 ppb.

minutes for the three exhaust airflow rates. These figures indicate thermal stratification in the space for all flow rates during the first 15 minutes when the burner is ‘ON’ and

even after the burner is ‘OFF’. The hot air rises towards the ceiling and then moves along the ceiling into the adjacent space. In the cases of 75 and 150 cfm exhaust flow rates, the temperature distribution in the kitchen space shows a little difference.

However, in the case of 300 cfm exhaust flow rate, the hot air is drawn into the exhaust grilles during the first 15 minutes and the purge of hot air is complete at the end of 30 minutes. Note a thermal plume rising from the person is visible in the figure for the temperature distribution at the end of 30 minutes for a 300 cfm exhaust.

Figure 4 illustrates the distribution of NO2 concentration on a vertical plane passing through the burner and the person at 15 and 30 minutes for all three exhaust airflow rates. These figures show that there is a higher concentration of NO2 in the upper section of the kitchen, which can be due to thermal stratification.

Similar to the temperature distribution, there is little difference in the NO2 concentration in the space for the 75 and 150 cfm exhaust flow rates. However, during the purge phase after the burner is turned ‘OFF’ (at 30 minutes), the thermal plume plays a crucial role in maintaining low concentration levels in front of the person. The displacement of hot air can draw the surrounding clean air around a person, as well.

For the same reasons, in the case of a 300 cfm exhaust flow rate during the first 15 minutes, concentration levels of NO2 in front of the person are at their lowest, and by the end of the purge phase (30 minutes), the concentration levels are further reduced.

Figure 5 shows the Spread Index (SI)100ppb plots for all three exhaust flow rates at the end of 15 and 30 minutes. The Spread Index plots show the areas with NO2 concentration levels at or above 100 ppb. As depicted in the figure, at the end of 15 minutes, increasing the exhaust flow rate from 75 to 300 cfm resulted in an 82 percent reduction in the Spread Index from 60.1 to 10.8 percent.

On the other hand, increasing the flow rate from 75 to 150 cfm only led to a 14.8 percent reduction. At the end of 30 minutes, with a 75 cfm exhaust flow rate, the (SI)100ppb reduced by only 19 percent. However, in the cases of 150 and 300 cfm, the (SI)100ppb fell to zero, indicating that the entire space had NO2 concentration levels lower than 100 ppb.

The exhaust flow rate of 300 cfm keeps the contaminated air with NO2 confined to the kitchen and prevents it from spreading into the adjacent living room. It’s interesting to see a dark cloud forming over the person’s head, indicating a pocket of low NO2 concentration (less than 100 ppb) due to the thermal plume. This can act as a “protective shield,” displacing pollutants away and reducing exposure.

Thermal stratification causes pollutants to accumulate and move along the ceiling, above the breathing zone of occupants. It suggests that running a bathroom exhaust fan near the kitchen could help remove the contaminated air near the ceiling, although this was not explored in this study.

Figure 6 shows the variation of the Spread Index (SI)100ppb with time for all three exhaust flow rates. As shown in the case of 75 cfm exhaust flow rate, the (SI)100ppb never reaches zero value, which indicates that the 75 cfm exhaust flow rate is inadequate to purge NO2 level below the acceptable value. Whereas in the cases of 150 and 300 cfm exhaust flow rates, the Purge Time (PT)100ppb is 26 and 16 minutes, respectively. This indicate the time required to lower the NO2 concentration level below 100 ppb.

In all the cases, the (SI)100ppb reaches peak values at 15 minutes, at which time the burner is turned off and the generation of NO2 stops. Thereafter, with increasing air change rates, the rate of decay also increases. This figure shows the impact of both the dilution due to increased airflow rate and the rate of removal due to increased ACH. Increasing the exhaust airflow rate from 75 to 150 cfm shows will impact the purge rate and Purge Time (PT)100ppb.

It should be noted that for a 300 cfm exhaust flow rate due to high air change rates, the (SI)100ppb reaches its peak sooner and remains at a steady level for 7 minutes.

Figure 7 shows variations of NO2 concentration in front of the person’s face as detected by the virtual sensor and the associated cumulative exposure with time. As shown in this figure the NO2 concentration levels for all three flow rates (except for the 75 cfm) remain below 100 ppb, resulting in significantly lower exposure level than the EPA-acceptable limit of 100 ppb-hr.

The peak cumulative exposure value is 30 ppb-hr for the case of 75 cfm exhaust flow rate for 30 minutes. This is consistent with the previous studies indicating that even moderately effective venting range hoods will dramatically reduce the pollutant concentration levels.

Also note that during the first 15 minutes, when the burner is ‘ON’, the cumulative exposure levels remain below 10 ppb-hr. Further, the cumulative exposure increases

7: Variation of NO2 concentration and cumulative exposure with time for three exhaust flow rates indicating lower exposure than acceptable values.

during the purge phase when the burner is ‘OFF’ (no NO2 generation). Such exposure can be realized only when the occupants stay near the stove even after the cooking is over, which can happen on rare occasions.

Such low exposure can be attributed to the thermal stratification in the space which displaces the contaminated air above the breathing zone.

In this CFD study, a three-dimensional, transient, nonisothermal CFD model was developed to study the transient temperature distribution and the dispersion of NO2 in the kitchen and the adjacent living room. The effectiveness of the kitchen ventilation was evaluated using newly developed metrics of Spread Index and Purge Time.

The study analyzed the conditions with closed windows and doors which is most common during the winter in cold climates. It was found that an exhaust flow rate of 75 cfm is inadequate for effectively removing pollutants from a kitchen space.

Increasing the exhaust flow rate was shown to reduce the spread of high-concentration zones of pollutants into adjacent spaces, as indicated by the Spread Index analysis. Additionally, increasing the exhaust flow rate reduces the Purge Time and helps in the effective removal of residual pollutants after cooking when the burner is turned ‘OFF’.

The analyses also suggest that the thermal plume from occupants and the buoyancy of hot gases can help reduce the cumulative NO2 exposure. While occupant NO2 exposure levels remained significantly low during the first few minutes of cooking when the burner is ‘ON’, the exposure level starts increasing during the purge phase when the burner is turned ‘OFF’.

However, an increase in the exhaust flow rate significantly reduces cumulative NO2 exposure levels. It is important to note that for all exhaust flow rates analyzed in the study,

the cumulative NO2 exposure levels remained significantly below the EPA-acceptable level of 100 ppb-hr for short-term exposure. The analyses also indicate that thermal stratification causes pollutants to accumulate and migrate along the ceiling above the breathing zone of occupants.

Furthermore, the thermal plume from an occupant can form a “protective shield” to help reduce pollutant exposure. This study suggests that CFD can be a valuable tool in analyzing these parameters cost-effectively and optimizing the performance of kitchen ventilation systems.

1. Nina A. Dobbin, Sun L., Wallace L., Kulka R., You H., Shin T., Aubin D., St-Jean M., Singer B.C. 2018 The benefit of kitchen exhaust fan use after cooking - An experimental assessment. Building and Environment 135 (286–296).

2. Sun L., Singer B.C. Cooking methods and kitchen ventilation availability, usage, perceived performance and potential in Canadian homes. 2023 Journal of Expo Sci Environ Epidemiol 33, 439–447.

3. Brett C. Singer, Delp W., Lorenzetti D.M. Maddalena R. L 2016. Pollutant Concentrations and Emission Rates from Scripted Natural Gas Cooking Burner Use in Nine Northern California Homes. Ernest Orlando Lawrence Berkeley National Laboratory Report.

4. US EPA (2016) Integrated Science Assessment for Oxides of Nitrogen - Health Criteria (2016 Final Report), Washington DC, U.S. Environmental Protection Agency.

5. Zhao, Haoran, Delp W., Chan W., Walker I., Singer B.C. 2020. Measured Performance of Over the Range Microwave Range Hoods. Lawrence Berkeley National Laboratory Report.

6. ANSI/ASHRAE. 2022. Ventilation and Indoor Air Quality in Residential Buildings, Standard 62.2-2022.

7. Khankari, Kishor. 2016. Analysis of Contaminant Flow Path and Laboratory Ventilation Effectiveness. ASHRAE Conference Paper for ASHRAE Annual Conference. St. Louis, MO.

As heating networks become more complex, water treatment programs need to evolve beyond traditional inhibitor dosing and flushing cycles.

By MICHAEL WARADY, CEO, EAI Water

Aclosed-loop heating system should, in theory, be one of the most stable components of a building or facility’s infrastructure. It operates in isolation, doesn’t evaporate water like an open cooling system, and shouldn’t be exposed to outside contaminants.

Yet, despite these advantages, many closed-loop networks quietly degrade over time, losing efficiency and developing costly mechanical issues that are

often misdiagnosed as routine wear and tear.

Years ago, at a client’s Central Utility Plant, system operators had noticed subtle but persistent issues—pumps working harder than usual, fluctuating differential pressures, and gradual declines in heat transfer efficiency. No major leaks had been detected, and on paper, the system had been running as expected. But when they pulled a water sample, the issue became clear.

Corrosion debris was circulating through the network, pH levels had drifted outside the ideal range, and

biofilm had begun forming in low-flow sections of the system.

So the problem wasn’t mechanical—it was chemical.

Despite following a standard inhibitor treatment program, the system’s water chemistry had never been fully optimized. Over time, the facility did several rounds of retrofits and additions to the system – inadvertently leading to dead legs, open valves leading to contamination, and unchecked microbial activity that slowly degraded internal piping and heat exchangers. The system was doing exactly what it had been designed to

Author Michael Warady is CEO of Economic Alternatives, Inc. (www.eaiwater.com), a total water solutions provider out of Southern California. A graduate of Duke University with two masters degrees from Yale University, he is also president and co-founder of Sylmar Group.

do—circulate water efficiently—but the chemistry behind that water had been slowly working against it.

This isn’t an isolated case. Across commercial and industrial heating networks, the misconception that closed loops are low maintenance has led to widespread failures that could be avoided with a more precise approach to water chemistry.

There’s a reason so many facility teams assume closed-loop systems are setand-forget infrastructure. Unlike open cooling towers, they don’t evaporate water, don’t require frequent blowdown cycles, and aren’t constantly exposed to fresh contaminants.

And oftentimes consulting engineers describe these systems as such. But that assumption ignores the reality of internal chemical degradation, slow water loss, and minor oxygen ingress— all of which gradually destabilize system conditions over time.

One of the most common and underestimated issues is oxygen infiltration. Even in a well-sealed system, air can enter through leaks, valve adjustments and turning, or pressure fluctuations. Once inside, oxygen reacts with system metals, producing corrosion byproducts that circulate through the network, potentially clogging strainers, reducing pump efficiency, and fouling heat exchangers.

Another issue that often goes unnoticed is pH instability.

Many closed-loop systems experience gradual shifts in alkalinity due to chemical mismanagement, makeup water additions, or internal reactions with system materials. If pH drops too low, acidic conditions accelerate metal degradation. If pH drifts too high, scale forms on heat transfer surfaces, reducing efficiency and forcing the system to work harder to maintain setpoints.

Microbiological fouling is also a factor, though it’s rarely addressed in closed-loop treatment programs. Low-flow sections, stagnant backup

piping, and underutilized loops create ideal environments for biofilm to develop. Once biofilm forms, it acts as an insulator, reducing heat exchanger efficiency while creating pockets of localized under-deposit corrosion.

A district heating system in a commercial development recently encountered these exact issues. Over time, the facility managers had begun noticing higher energy consumption, flow imbalances, and declining pump efficiency. When they finally investigated, they found a combination of oxygeninduced corrosion, unbalanced pH, and microbial growth—factors that had gone undetected for years because standard water treatment protocols weren’t addressing the real problem.

A well-maintained closed-loop system isn’t just one that’s flushed periodically and dosed with inhibitors—it’s one where water chemistry is actively managed to prevent long-term degradation. The difference between a system that operates efficiently for decades and one that develops premature failures often comes down to how well pH, corrosion control, and microbial activity are balanced.

Facilities that take a proactive approach to closed-loop water chemistry focus on stabilizing pH, controlling oxygen levels, using tailored corrosion inhibitors that match the system’s metallurgy, and working with a licensed water treatment professional to help support and provide best practices to facility managers.

Rather than relying on scheduled flushes and reactive chemical dosing, these systems are monitored dynamically, with adjustments made in response to real-time conditions rather than predetermined maintenance intervals.

A commercial high-rise in Southern California that brought EAI on board saw immediate improvements in system performance. By optimizing pH, fine-tuning corrosion inhibitor dosing,

installing corrosion coupon racks, and addressing minor leaks that had been allowing oxygen ingress, they extended heat exchanger lifespan, reduced pumping energy, and stabilized temperature fluctuations across the network.

Despite the clear advantages of proactive water chemistry management, many facility teams continue operating under the assumption that closed-loop systems don’t require ongoing oversight. The result? Accelerated corrosion, biofilm formation, and efficiency loss that could have been prevented with a more precise approach to water treatment.

While chemical optimization is essential for closed-loop system performance, equally important is having the right expertise to manage these complex chemical interactions. A licensed, certified water treatment professional (preferably someone with a CWT certification) brings more than just chemical knowledge – they provide the experience, technical understanding, and systematic approach needed to maintain long-term system stability.

A large-scale district heating provider discovered this firsthand when they switched from an in-house maintenance approach to partnering with a CWT. For years, their closed-loop network had suffered from gradual circulation inefficiencies and unexplained corrosion issues. Despite following standard chemical treatment protocols, they couldn’t achieve stable system performance. The missing element wasn’t better chemicals – it was the expertise of having experienced professionals diagnosing, and solving these issues in the past.

Licensed water treatment professionals bring several crucial advantages to closed-loop system management. First, they understand the intricate relationship between system metallurgy, operational conditions, and chemical treatment programs. This allows them to develop tailored

solutions that account for specific system characteristics rather than applying a one-size-fits-all approach.

Second, certified professionals have extensive experience identifying early warning signs of system degradation. They can spot subtle indicators that might go unnoticed by general maintenance staff. This early detection capability often prevents small issues from developing into costly system failures.

Third, professional water treaters are required to maintain current knowledge of industry best practices, emerging technologies, and evolving treatment methods. As regulations change and new treatment options become available, they ensure that facility system partners remain both compliant and efficient. Their ongoing education and certification requirements mean they’re continuously updating their expertise to match industry advancements.

Perhaps most importantly, licensed professionals understand that effective water treatment isn’t just about adding chemicals – it’s about developing comprehensive management strategies with their clients. With that in mind, they help establish monitoring protocols, implement preventive maintenance schedules, and create documentation systems that ensure consistent system performance over time. Their systematic approach transforms water

treatment from a periodic maintenance task into a cornerstone of facility operations.

At an East Coast university campus, the transition to professional water treatment management led to immediate improvements in their heating network efficiency. The water treater identified oxygen ingress points that had been overlooked, implemented a more precise chemical monitoring program, and established clear protocols for system baselining and tracking. Within months, they saw reduced energy consumption, improved heat transfer efficiency, and more stable system operation.

As heating networks become more complex and energy efficiency remains a top priority, water treatment programs will need to evolve beyond traditional inhibitor dosing and occasionalflushing cycles. The next generation of closed-loop systems will be designed with water chemistry management as an integral component, rather than a reactive maintenance function.

Some commercial developments are already adopting real-time chemical monitoring, ensuring that corrosion inhibitors, pH stabilizers, and oxygen scavengers are continuously optimized.

Instead of relying on manual testing, these systems provide dynamic feedback, allowing facility managers to make real-time adjustments to maintain ideal conditions.

In some high-performance heating networks, advanced filtration and side-stream separation technologies are being integrated to remove corrosion byproducts before they accumulate and foul system components. This shift from passive treatment to active water management is setting the standard for the next generation of facility operations.

As regulations tighten and energy efficiency expectations grow, buildings that fail to implement proactive closedloop water treatment strategies will face rising operational costs, shortened equipment lifespans, and increasing compliance challenges. The cost of inaction is not just higher maintenance—it’s premature system failure and long-term infrastructure degradation.

The facilities that invest in quality chemical selection and continuous, professional oversight will operate at higher efficiency for years to come and protect the initial investment into this infrastructure.

Those that continue relying on outdated assumptions about closedloop stability will face the consequences of slow but inevitable system decline.

Advanced electrode boilers can replace outdated fuel-burning equipment and still meet ambitious decarbonization goals.

By DEL WILLIAMS, Technical writer

District heating – the generation of heat in a central location and distribution of it to local customers at greater economies of scale than individual heating systems – plays an important role in helping the transition to clean energy.

The challenge, however, is that district heating, used to provide hot water and heat to buildings through an insulated pipe system, must soon pivot from burning fossil fuels.

“District heating networks offer great potential for efficient, costeffective, and flexible, large-scale use of low-carbon energy for heating,” says the International Energy Agency (IEA), a Paris-based intergovernmental group that provides policy recommendations and data for the global energy sector. “However, the decarbonization potential of district heating is largely untapped, as 90% of the heat supplied in district networks is produced from fossil fuels.”

IEA’s 31 member countries and 13 associate members represent 75% of global energy demand. Aligning with the IEA’s Net Zero Emissions by 2050 Scenario requires significant effort to rapidly improve the energy efficiency of existing networks, switch to renewable heat, integrate secondary heat sources, and develop new highefficiency infrastructure.

Fortunately, innovation in the form of the latest, high-voltage, immersed electrode or jet-type electrode boilers makes district heating much greener,

particularly when the electricity comes from renewable sources.

Municipalities and businesses relying on district heating are already pivoting from inefficient equipment that produces excess carbon emissions to economical electrode boilers that can quickly rival the output of large gas or oil-fired boilers in a smaller footprint.

Also, the advanced electrode boilers do not have a high minimum operating level to make them immediately available. So they offer much faster start-up and shut down time while being safely and easily maintained.

District heating systems offer substantial potential for improving energy efficiency, reducing greenhouse gas emissions, and integrating renewable

and waste heat sources, particularly within urban centers.

In this effort, an increasing number of district heating plants are turning to high-voltage, electrode boilers to absorb excess power production, quickly provide grid service, and costeffectively balance out fluctuations. A growing number of municipalities are also installing new or retrofit high voltage electrode boilers that are compact, economical, and produce no emissions.

The upgrades often entail retrofitting or replacing boilers with cleaner, more efficient electric alternatives, along with the heat distribution network. Electrode boilers use the conductive and resistive properties of water to carry electric current and generate steam with greater responsiveness and efficiency.

“An AC current flows from an electrode of one phase to ground using the water as a conductor,” says Robert Presser, VP of Acme Engineering, a Montreal-based manufacturer of industrial and commercial boilers. “Since chemicals in the water provide conductivity, the current flow generates heat directly in the water itself. The more current (amps) that flows, the more heat (BTUs) is generated, and the more steam produced for use in district heating.”

When supplying district heating, electrode boilers are much more responsive and flexible than fossil fuel burning units. “With electrode boilers, the energy input and adjustment are very precise and virtually immediate. In contrast, increasing or decreasing the temperature in a gas-fired boiler is a slower process because it takes time for the heat in the boiler to rise or dissipate before reaching the targeted output,” adds Presser.

Advanced, high-voltage electrode steam boilers like the CEJS also have a 100% turndown ratio, the ratio between a boiler’s maximum and minimum output. Most gas boilers have a ratio of 10:1 or 5:1, which means the units take a significant time to reach full capacity. Both the CEJW and CEJS immersed electrode hot water and steam boilers have a minimum output level of 7-8% of rated capacity, still far better than a modern gas-fired boiler.

“With a 100% turndown ratio, you can leave the boiler in standby at low pressure and bring it to full capacity in about 90 seconds as needed, which no other boiler type can achieve today,” says Presser. “Communities and businesses utilizing district heating also appreciate the eco-friendly nature of electrode boilers. Without combustion, these boilers are clean and emissionfree. The design also eliminates many environmental issues associated with fuel burning such as fumes, fly ash, and large obtrusive exhaust stacks,” he adds.

The energy efficiency of electrode boiler technology, however, is one of its most remarkable characteristics.

“For district heating, the extraordinarily efficient power-to-heat generation capability of electrode boilers, in which almost 100% of the electrical energy is converted into heat with no stack or heat transfer losses, combined with an ability to use and balance intermittent renewable energy, makes the technology crucial today,” says Presser.

As an example of energy and design efficiency, the CEJS electrode steam boiler produces maximum amounts of steam in minimal floor space, with boiler capacity from 6MW to 68MW. The electrode boiler operates at existing distribution voltages, 4.16 to 25 KV, and is up to 99.9% efficient at converting energy into heat.

The boiler can produce steam in capacities up to 270,000 pounds per hour, with pressure ratings from 75 PSIG to 500 PSIG. All CEJS boilers are designed to ASME Code or EU Pressure Vessels Directive and are certified, registered pressure vessels. Electrical standards meet CSA, UL, or CE requirements.

According to Presser, there are additional reasons for municipalities and businesses to use high voltage, jet type electrode boilers for district heating. “Electrode boilers can match the heating output of fuel burning boilers while converting almost all the energy to heat. Electrode boilers also are much smaller than fossil fuel burning boilers so are easier to use in smaller structures,” he says.

For residential or commercial property owners, electrode boilers also lower costs for installation, operation, and maintenance. Gas-fired boilers require fuel lines, storage and handling equipment, economizers, and emission control equipment. Advanced jet type electrode boilers have a minimal number of components and electrical controls, with fewer parts. Under normal operation, the absence of excessive temperatures and electrode burnout also assures long operating life.

In addition, the units further lower operating costs with automatic controls that reduce the need for operating personnel. The most advanced types of these boilers, such as CEJS or CEJW, also offer greater safety than traditional fuel-burning models.

“With the electrode boilers, there are no combustion hazards because there are no flames, fumes, fuel lines or storage tanks. There are no problems with heat buildup or electrode burnout even if scaling should occur, and thermal shock is eliminated. Also, there is no low water danger since the current cannot flow without water,” Presser explains.

Unlike fossil fuel burning boilers, electric boilers require minimal maintenance since there is no burner, no material burned, no soot created, no chimney, and no wearing mechanical parts. With fewer parts than more complex fossil fuel burning units, electrical boilers are also more compact and simpler to install than conventional systems, he adds.

Finally, the electric units are exceptionally quiet compared to fuel-fired boilers. Unlike gas-powered burners that throttle like turbine engines almost continually, electric boilers keep operational noise levels down.

With all the advantages of high output, jet-type electrode boilers, in addition to their value in balancing out the use of intermittent renewable energy in the power grid, it is evident why a growing number of communities and businesses are selecting them for district heating.

As the effects of climate change become more severe, the urgency of switching to clean energy and decarbonizing the energy sector will only increase across the globe. In this effort, district heating paired with electrode boilers will be a vital part of the solution, as member countries strive to meet IEA decarbonization goals.

For more, email rpresser@acmeprod. com; or visit: https://www.acmeprod. com/jet-type-steam-boiler.

The first-ever woman to lead the American Boiler Manufacturers Association is also its first international member in that role. She’s excited for the future of this industry.

This spring, HPAC On The Air spoke to Nancy Simoneau, president of Groupe Simoneau, a 40-year-old Canadian boiler manufacturer based in Quebec, and the new Board Chair of the American Boiler Manufacturers Association (ABMA).

In January, Ms. Simoneau became the first woman ever to attain that title with the 137-year-old trade group, as well as the first non-U.S.-based member to fill that role.

Here, she discusses the unique perspective and infectious energy, focused on both internal and external customers, that will help to define the theme of her two-year term.

HPAC : Nancy, thanks so much for joining us on HPAC On The Air. First, please tell our listeners a bit about Groupe Simoneau and your journey into this industry.

Nancy Simoneau: Well, I’m an accountant by trade. So I finished my accounting degree in 1992. At that time, it was a very difficult time for the economy and I couldn’t find a job. So my dad, René Simoneau, had started in 1984, a service company for boilers. He was a boiler maker and high-pressure welder, and I was working a bit for him while I was a student. But after that, I said, well, if you want me to join you, then I will start the manufacturing arm of this company if you allow me to do so. He said, yes, because I was one of the first persons in the family to get a university degree. So he was probably thinking that I knew everything and I was great at everything. So he put his confidence in me and I started

Simoneau, left, and VP Shaunica Jayson are leading ABMA’s outreach to women.

to manufacture boilers at that time. And I fell in love with this trade and the people within the trade. I’ve been in this market for almost 38 years now.

HPAC: I noticed there’s a very nice quote from your father on the company website. He said, “I’m sure you’ll do a better job than me. If you succeed, all the better. If you don’t, I will always be your father, and I will always love you.” Can you talk about that a bit?

Simoneau: Yes, that’s what he said to me when he left the company. He was quite young, 53, when he left, and that was soon after the second tower fell in New York City on Sept. 11. He just got overwhelmed, I guess, by all the things that were happening. And he said, “Well, Nancy, I’m out of here.” I think, first of all, we can’t be two leaders like we were in the same place. And he said, “If I want to enjoy my life, I need to take time now.” He said, “You do whatever you can with

the company and if you put it in the drain, I will still love you, my dear.”

So that was a big source of stress for me because I knew I was bearing his assets every morning on my shoulders when I was coming in to work. That’s the reason why I wanted to buy the company from him. I said, well, at least if I buy the company, he’s going to be secured. His money’s going to be out of reach. And that’s how I bought it back from him and started my own journey as an entrepreneur.

HPAC: As both the first woman and the first international member to lead such an established association, what does your appointment say about ABMA now?

Simoneau: Well, first of all, it’s an honor to be appointed as the chair of the ABMA. I remember when I started in this trade, ABMA was the authority in this business. So I had a very high appreciation of the association because

we were always referring to it to make sure that we were doing our stuff properly and according to their recommendations for safety and efficiency, etc. So I think my appointment also is showing the evolution of this association and the openness of all the members to embrace where we’re going and how we all have to play together to serve an industry that is mission critical for our customers.

HPAC: On an ABMA podcast a year ago, heralding the launch of the new Women In the Boiler Industry group, aka WIBI, you said that “Women bring something different to this industry.” Could you please elaborate a bit more on that here?

Simoneau: It’s been fantastic the level of interest that we are seeing with WIBI. I think women, what most of the time bring to the table is a little bit more empathy and sensitivity. And our industry is particularly driven by engineers because it’s quite regulated. With a boiler, you burn gas, you have pressure. So it needs to be well-designed, well-built and the safety of the people surrounding the equipment is always the first thing we think about. But by having a lot of engineers in our industry, sometimes we lose a bit of the sensitivity and empathy we need to capture all 360 degrees of the situation so that we can care for our customers. So I think we bring that. We also have a lot of precision. I mean, we stick to our stuff. And I’m not saying that men don’t have that. I don’t want to look like it’s us versus them. It’s us together. And much of the time, we bring a little bit more of a customercentric focus, making sure what we care for is bigger than us.

HPAC: Overall, what are you most excited about for your term as ABMA Chair?

Simoneau: I want to put a little touch of my vision into the ABMA. So my mantra for my two years is “every member matters; ears open; heart engaged; and ready to serve.” So I want everybody in our association to make sure they get what they want out of it. If all of us, including the staff at ABMA, live through those values for the next two years, then I think it’s going to make a difference on how our members feel. They will feel welcomed, valued, understood and listened to. No matter who you are, you are a member of ABMA. And that’s important for me.

HPAC: Given this unusual political moment in U.S.-Canada relations, do you anticipate the issue of tariffs playing any role at all for you or your firm this year? What about sustainability issues or energy-efficiency goals?

Simoneau: It’s quite stressful in a way because I think we at ABMA have this vision of including Canada. We have many people from Europe, as well as members from

The American Boiler Manufacturers Association (ABMA) is expanding its Board of Directors to address the group’s significant membership growth and continuing evolution.

Over the last five years, ABMA has increased membership by more than 30% and created a new category for companies representing manufacturer members. Overall, ABMA now has more than 170 companies in the boiler sector.

With that in mind, ABMA will now add up to three additional board seats, with one designated for a Manufacturer Representative member. These changes will enable ABMA to expand the diversity of products and services across its leadership.

ABMA Board Chair Nancy Simoneau stated, “Our leadership will be stronger with the new board seats along with additional diversity and perspectives in the ABMA Boardroom.”

Mexico. Our industry is quite integrated, so it will impact all of us if we have tariffs because we have many Americans sending equipment into Canada and the opposite, too. Boilers, burners and other equipment. So, for sure, it will put pressure on our industry if we have that. What I dread, though, is I don’t want our relationships to be impacted. We are dear friends. We’re collaborators and we’ve been together for many years. We don’t have power and control over the policy and we don’t want to become politicians.

And as much as I’m a Canadian, we have to keep our heads cold and work with our logic and our business sense. So I think resilience is key, and agility. Sometimes maybe I trust too much life, but I have a tendency to see my glass of water full and there’s going to be opportunities. There’s going to be maybe collaboration, getting more involved between some manufacturing companies. We don’t know how it’s going to unfold, but I know it’s going to be a tough period. In the end, I really think it’s going to be for the best for everybody. So I put my confidence in life. My mom was saying to me when I was young: “Trust life, trust life, Nancy.”

It’s going to unfold properly, but we have to make sure that we keep our employees secure. I mean, there’s a lot of uncertainties and insecurities, I think, on both sides of the border right now. So we have to calm down the play and make sure that we keep our head cold and our logic first before we put our heart on the table.

To listen to all previous ‘HPAC On The Air’ podcasts, visit our Members Only page at www.hpac.com.

Infinitum introduces the Aircore Heavy Duty motor has an integrated variable-frequency drive that facilitates CDU, vertical in-line pump, HVAC and other heavy-duty applications, reducing overall energy usage. Its reduced size and weight unlock infinite design potential, making any machine lighter, quieter and more efficient. Configurable, with analog and digital inputs for pressure sensors, flow switches, etc. Meets the highest efficiency standards at a wide range of load conditions.

Infinitum Electric

The Webstone Hydro-Core Press Manifold from NIBCO is a redesign of the Hydro-Core double ball drain. It now features fully integrated press end connections for fewer potential leak paths and less brass. It retains the original manifold’s core functionality in a compact new body. The forged brass assembly includes closely spaced tees for hydraulic separation and drain valves for isolation and future service. Designed for use with water, oil or glycol mix in residential or light commercial heating systems, the manifold is available in sizes 1 in. and 1 1/4 in., including reducing branch options.

NIBCO

ClearDrain PVC from RectorSeal effectively eliminates major contributors to clogged HVACR condensate drains. Its polymer surface is electrostatically repulsive, offers low surface energy and protects against bacteria, viruses, molds, biofilm and other microorganisms with its hydrophobic properties.

RectorSeal

The Series 250 butterfly valve from Victaulic is designed for domestic water, technical cooling and HVAC systems. Made to last at least twice as long as competitive valves, it delivers UL-certified reliability, improved flow characteristics, new disinfectant-resistant gasket formulations and multi-material compatibility. Engineers and contractors will find the Series 250 reduces installation complexity and streamlines system maintenance, says the company.

Victaulic

The EWX Series electric boiler from Sussman Electric Boilers sets a new standard for sustainable heating in commercial and industrial HVAC applications by delivering zero emissions and significantly reducing carbon footprints. The ultra-compact design enables all models to fit seamlessly through a standard 36-in.-wide doorway. With 32 different models ranging from 270 kW to 1200 kW, the unit is perfect for retrofitting aging systems or transitioning to fully electric hydronic designs, meeting the growing global demand for decarbonized solutions.

Sussman Electric Boilers/DHT

Constant-speed vertical-in-line fire pumps from Armstrong Fluid Technology feature a maximum 500 gpm flow for both 60hz and 50hz markets and new high-pressure ratings of up to 160 psi. They eliminate the need for offset piping and motor realignment. Other features include smaller motors than comparable pumps at the same duty point and smaller environmental footprints than standard diesel pumps.

Armstrong Fluid Technology

The CMK-224 floor-standing commercial rack system from Noritz provides even more powerful hot water delivery by racking four NCC199CDV tankless units installed back to back, while also delivering greater space savings for businesses and commercial facilities.

Noritz America

RIDGID’s RP 251 Press Tool features an endless 360-degree head swivel to reach tight spaces from practically every angle, an ergonomic design with a forward-positioned trigger, and an in-line SlimGrip handle for easy, overhead one-handed use. It also comes equipped with a brushless motor capable of more than 60,000 press cycles, requiring no scheduled maintenance for maximized jobsite performance. An improved 360-degree LED light ring provides bright visibility in dark conditions for enhanced execution. Compatible with all RIDGID compact series jaws, rings and actuators. It can press up to 1 1/4 in. on copper and stainless steel, up to 1 1/2 in. on PEX tubing, up to 1 in. on carbon steel, and up to 1 3/8 in. on copper tubing in refrigeration.

RIDGID

Powered by Xylem’s hydrovar X Smart Motor, Bell & Gossett’s Series e-80X (close-coupled) and e-80SCX (split-coupled) Smart Pumps offer customizable pumping solutions. They reduce electricity consumption, improve overall system performance and lower life cycle costs. Designed for horizontal and vertical in-line mounting, they are ideal for hydronic heating and cooling systems, light industrial processes and general service. Built-in application software makes the drive one of the easiest to commission, program and operate, enabling virtually any configuration of pumps. Advanced system controls (up to eight pumps) are customizable for a wide range of applications.

Bell & Gossett

End suction pumps from Armstrong Fluid Technology now include three larger sizes with permanent magnet motors up to 50hp that eliminate the need for an inertia base (4200h pictured). Featuring Design Envelope technology with integrated intelligent controls, they can save up to 65% in energy over comparable traditional constant-speed or variable-frequency-operated pump installations. Also, because of the factory-aligned rigid coupling, there is no need for coupling realignment during the installation process.

Armstrong Fluid Technology

Hitachi unveils the air365 Max all-inclusive HVAC system, a cost-efficient and adaptable VRF technology that offers energy efficiency and seamless comfort for users. SmoothDrive 2.0 precisely controls the compressor speed and measures the gap in room vs. set temperature. This reduces wear and tear on the compressor by reducing start/ stop events, improves temperature stability and reduces energy consumption at part load. Includes proprietary sigma-shaped heat exchanger that features a new three-way path structure to expand the heat-transfer area. The gas injection scroll compressor is driven by a DC inverter motor and can operate in tiny increments of 0.1Hz.

Hitachi

HEMCO’s Back Draft Fume Hoods are designed to remove hazardous fumes and odors, using back draft technology. The vented hoods are perfect for laboratories with limited space or when multiple hoods are needed. A full selection of accessories and components includes work surfaces, base cabinets, plumbing and electrical services. Acrylic viewing shroud is optional. They are shipped completely assembled and equipped, ready for operation.

HEMCO Corp.

Today’s polarized politics betray the popular consensus that existed in 1970.

Larry Clark

A regular contributor to HPAC Engineering and a member of its editorial advisory board since 2012, the author is a principal at Sustainable Performance Solutions LLC, a south Florida-based engineering firm focusing on energy and sustainability. Email him at larry@ sustainflorida.com.

On January 28, 1969, at the same time that I was in school receiving birthday wishes from friends, Union Oil’s Platform A started spilling oil off the coast of Santa Barbara, CA. It wasn’t until years later, when I moved to Pierpont Beach in Ventura, that I fully realized the true significance of that accident.

That was the beginning of what, at the time, would become the largest oil spill in U.S. history. Today, it still ranks third, behind the Exxon Valdez and Deepwater Horizon disasters. Many attribute the Santa Barbara spill as being the direct catalyst for the first Earth Day in 1970.

Although there is no doubt that it helped to inspired that first Earth Day celebration, many others (including me), believe that the original inspiration for Earth Day came from the 1962 publication of Rachel Carlson’s Silent Spring. Carson’s best-selling book exposed the hazards of pesticides, particularly DDT, and for the first time, it aroused widespread environmental consciousness among the general public. In addition to helping inspire the creation of Earth Day, it ultimately led to the creation of the U.S. Environmental Protection Agency (signed into law by Republican President Richard Nixon) and the banning of DDT, as well as the regulation of other pesticides.

For those readers not familiar with the history of Earth Day, here’s a brief synopsis:

In 1969, the Vietnam War had been raging for at least six years, and millions of Americans were protesting continued U.S. involvement. Anti-war demonstrations, especially on college campuses, represented the largest public protests in U.S. history. An early opponent of the war, former Wisconsin governor and then U.S. senator, Democrat Gaylord Nelson, was best known for his environmental advocacy.

Shrewdly taking a page from the student activism of the time, Sen. Nelson proposed an environmental teach-in on college campuses and was able to partner with California Republican Rep. Pete McCloskey, Jr. as his co-chair. A key activist they recruited of was Harvard

graduate student Denis Hayes, the former student body president at Stanford University.

Nelson asked Hayes to organize and coordinate the first Earth Day. He selected April 22, 1970, for the event. It was the Tuesday between Spring Break and final exams, so most students would be on their campuses that day, Hayes reasoned. The event was celebrated on some 2,000 college campuses and in hundreds of communities across the country, and April 22 has been recognized as Earth Day ever since.

During the next 10 years, leading up to Earth Day 1980, a vast array of significant environmental legislation was passed by Congress, including the Endangered Species Act, the Marine Mammal Protection Act, the Superfund Act, the Toxics Substances Control Act, the Resource Conservation and Recovery Act, the Clean Air Act, and the Clean Water Act. By that Earth Day, in fact, DDT and leaded gasoline were no longer in use in the U.S.

By 1990, Earth Day was a global event, with more than 140 countries participating. Twenty years later, in 2010, on the 40th anniversary of Earth Day, nearly one billion people joined more than 200 government leaders in more than 39 countries to advocate for sustainable green economies. In 2016, the UN chose Earth Day for the signing of the Paris Agreement.

Of course, on Earth Day 2020, the 50th Anniversary, the pandemic forced many of the planned activities online. Even so, It is estimated that 1 billion people worldwide participated in some type of Earth Day activity, and more than 100 million streamed a three-day ‘Earth Day Live’ event.

In April 2024, the EPA finalized rules that dramatically reduce the number of people facing elevated cancer risks because of their exposure to air pollution. It also finalized the first drinking water standard for PFAS “forever chemicals” because of their link to increased risks of cancer and other medical disorders.

Today, even as EPA steps back, my hope is that Earth Day can still show all of us what is possible when we work together.

April 16-17, 2025

Anaheim Convention Center Anaheim, CA

May 14-15, 2025

Oregon Convention Center Portland, OR

August 20-21, 2025

Grand Sierra Resort & Casino Reno, NV

Designed for fresh air.

AAON Delta Class has been dedicated from the beginning. AAON is always innovating. Learn more about our dedicated outdoor air systems (DOAS).