Use these seven tips to ensure you’re up to date on structural repairs.

As the types of features and devices advance, are you keeping up with your equipment and training?

24

Avoid comebacks and improve quality and durability by selecting the proper products and following standard procedures.

As the types of features and devices advance, are you keeping up with your equipment and training? BY

JOHN ANELLO

Use these seven tips to ensure you’re up to date on structural repairs.

BY TIM SRAMCIK

Avoid comebacks and improve quality and durability by selecting the proper products and following standard procedures.

BY JOSH AVELLO

COLLISION WINNERS AND RUNNERSUP AT THE SEMA SHOW BY ABDULLA GAAFARELKHALIFA // Associate Editor

AIRPRO LAUNCHING MARKET STUDY ON DIAGNOSTICS, ADAS CALIBRATIONS

TURNING PASSION INTO IMPACT: PAINTING RAISES $8K FOR CYSTIC

Endeavor Business Media, LLC

30 Burton Hills Blvd, Ste. 185, Nashville, TN 37215 Phone: 800-547-7377

EDITORIAL STAFF

CHRIS JONES

GROUP EDITORIAL DIRECTOR cjones@endeavorb2b.com

JAY SICHT

EDITOR-IN-CHIEF jsicht@endeavorb2b.com

ABDULLA GAAFARELKHALIFA ASSOCIATE EDITOR agaafarelkhalifa@endeavorb2b.com

RHONDA COUSIN ART DIRECTOR

CONTRIBUTORS

JOHN ANELLO

JOSH AVELLO

TIM SRAMCIK

ENDEAVOR BUSINESS MEDIA

CEO CHRIS FERRELL

PRESIDENT JUNE GRIFFIN

COO — PATRICK RAINS

CHIEF REVENUE OFFICER PAUL ANDREWS

CHIEF DIGITAL OFFICER JACQUIE NIEMIEC

SALES STAFF

ANDREW JOHNSON PUBLISHER ajohnson@endeavorb2b.com

MATTIE GORMAN-GREUEL SALES DIRECTOR mgorman@endeavorb2b.com

CORTNI JONES DIRECTOR OF BUSINESS DEVELOPMENT cjones@endeavorb2b.com

Account Executives:

DIANE BRADEN dbraden@endeavorb2b.com

MARIANNE DYAL mdyal@endeavorb2b.com

CHAD HJELLMING chjellming@endeavorb2b.com

LISA MEND lmend@endeavorb2b.com

MARTHA SEVERSON mseverson@endeavorb2b.com

KYLE SHAW kshaw@endeavorb2b.com

SEAN THORNTON sthornton@endeavorb2b.com

CHIEF ADMINISTRATIVE AND LEGAL OFFICER TRACY KANE

CHIEF MARKETING OFFICER AMANDA LANDSAW EVP, TRANSPORTATION KYLIE HIRKO

JAMES HWANG Inside Sales & Brand Manager, ASE Study Guides jhwang@endeavorb2b.com

Check out some of the new products we saw at the 2024 SEMA Show, including the latest from SATA, Sun Collision, and Hunter Engineering! FENDERBENDER.COM/55243343

BUSINESS STAFF

CHRIS MESSER VP/GROUP PUBLISHER

MICHAEL WILLINS BUSINESS DEVELOPMENT DIRECTOR, MOTOR AGE TRAINING

LESLIE BROWN CUSTOMER MARKETING MANAGER

MARIAH STRAUB PRODUCTION MANAGER

JENNIFER GEORGE AD SERVICES MANAGER

TRACY SKALLMAN AUDIENCE DEVELOPMENT MANAGER

JILLENE WILLIAMS SALES COORDINATOR

REPRINT SERVICES reprints@endeavorb2b.com.

CUSTOMER SERVICE Subscription Customer Service 877-382-9187; 847-559-7598

ABRN@omeda.com PO Box 3257 Northbrook IL 60065-3257

ABRN is published 4 times yearly (March, June, October, December) by Endeavor Business Media, LLC. 30 Burton Hills Blvd, Ste. 185, Nashville, TN 37215. Customer service can be reached toll-free at 877-382-9187 or at ABRN@omeda.com for magazine subscription assistance or questions.

Printed in the USA. Copyright 2024 Endeavor Business Media, LLC. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopies, recordings, or any information storage or retrieval system without permission from the publisher. Endeavor Business Media, LLC does not assume and hereby disclaims any liability to any person or company for any loss or damage caused by errors or omissions in the material herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever. The views and opinions in the articles herein are not to be taken as official expressions of the publishers, unless so stated. The publishers do not warrant either expressly or by implication, the factual accuracy of the articles herein, nor do they so warrant any views or opinions by the authors of said articles.

Endeavor Business Media provides certain customer contact data (such as customers’ names, addresses, phone numbers, and e-mail addresses) to third parties who wish to promote relevant products, services, and other opportunities that may be of interest to you. If you do not want Endeavor Business Media to make your contact information available to third parties for marketing purposes, simply call toll-free 877-382-9187 or email ABRN@omeda.com and a customer service representative will assist you in removing your name from Endeavor Business Media’s lists. ABRN does not verify any claims or other information appearing in any of the advertisements contained in the publication, and cannot take responsibility for any losses or other damages incurred by readers in reliance of such content. ABRN welcomes unsolicited articles manuscripts, photographs, illustrations and other materials but cannot be held responsible for their safekeeping or return.

BY ABDULLA GAAFARELKHALIFA // Associate Editor

During the 2024 SEMA Show, SEMA announced the winners of its Best New Products Awards. ese accolades are given to the most innovative and cutting-edge products that will be available in 2025.

Here’s look at those winners and runners-up who contributed directly to the field of collision repair.

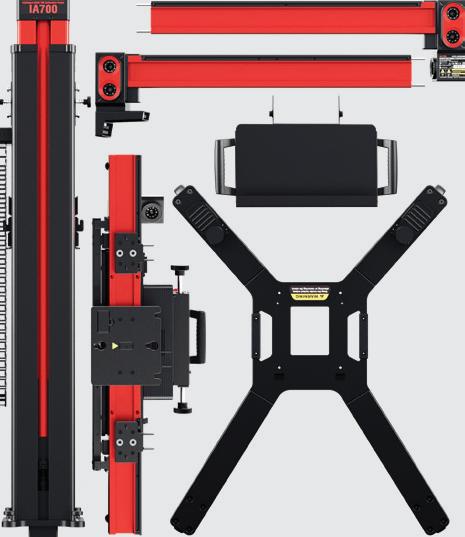

RUNNERUP: Revv ADAS Mechanical (Revv ADAS)- Revv ADAS Mechanical is tailored for the mechanical repair sector, integrating Revv’s ADAS research platform with diagnostic and calibration systems like the Autel IA900. is solution allows repair shops to o er comprehensive ADAS diagnostic services within standard repair packages, enhancing consumer safety and boosting revenue. It provides detailed reports that guide technicians through the necessary calibrations and repairs, ensuring all ADAS features are restored to OEM speci cations.

RUNNERUP: Solar Wireless Driving Assistant (Vision Automobile Electronics Industrial)- e Solar Wireless Driving Assistant is a hands-free driving system that uses solar power to operate. It includes features like adaptive cruise control, lanekeeping assistance, and collision avoidance. e system is designed to enhance driving safety and convenience by automating routine driving tasks and providing real-time feedback to the driver. It is particularly bene cial for long-distance driving and in heavy tra c conditions.

WINNER: Revv ADAS Plus (Revv ADAS)-

MIKE FITCH, vice president of revenue for Revv ADAS, holds the trophy for Best ADAS Product after the SEMA Best New Products Awards.

Revv ADAS Plus is an AI-powered ADAS calibration reporting tool designed for repair and calibration shops. It automates the identi cation of ADAS calibrations in real-time, scrubbing estimates from major estimating systems like CCC, Mitchell, and Audatex while referencing OEM repair procedures. is tool helps shops capture additional revenue by identifying every billable ADAS procedure, potentially adding an average of $1,250 per job. It also integrates seamlessly with various estimating platforms, allowing for e cient work ow management and custom invoicing.

RUNNERUP: SagolaSpray (Sagola by Elcometer)- SagolaSpray is a virtual reality training tool for spray painting. Developed by professional spray painters, it provides a realistic spray painting experience without the need for actual paint or materials. e VR environment allows users to practice spray techniques repeatedly, receive instant feedback, and improve their skills. It is bene cial for students, training centers, and professionals looking to enhance their spray painting precision and e ciency.

RUNNERUP: RTS App (I-CAR)- e RTS

App by I-CAR is a mobile application designed to support collision repair professionals. It provides access to a wealth of resources, including repair procedures, technical articles, and training materials. e app helps technicians stay updated with the latest industry standards and best practices, ensuring high-quality and safe repairs. It also includes features for managing class rosters, tracking student progress, and accessing teaching materials.

SCOTT VANHULLE (left), manager of Repairability Technical Support and OEM technical relations, and Jeff Peevy, vice president of industry relations, stand in front of the I-CAR exhibit at the SEMA Show.

WINNER: I-CAR Academy (I-CAR)- I-CAR Academy o ers a comprehensive curriculum for collision repair education, aimed at both schools and shops. e program includes foundational knowledge in collision repair, disassembly and reassembly, plastic repair, aluminum and steel small dent removal, and preparation for re nish. It combines online learning with hands-on skills training, ensuring students are wellprepared for entry-level technician roles. e curriculum is designed to maximize student retention and includes industryrecognized badges upon completion.

The company seeks collaboration from all industry stakeholders to benefit motorist and public safety.

AirPro Diagnostics Chief Global Development Officer Michael Quinn provided a statement to FenderBender following his announcement at the Collision Industry Conference Tuesday, Nov. 5, that it is launching a formal study into market trends in diagnostics and ADAS calibrations, with a note that a more formal press release will follow.

“Recently, we all have been exposed to a significant amount of misinformation about diagnostics and ADAS services in our industry,” the statement reads. “This has included solutions that allegedly simplify the processes but do not account for the complexities of properly diagnosing

and repairing a vehicle equipped with ADAS features.

“Repairers have shared they are being told that critical steps — such as sequential pre- or in-process scans — are unnecessary, that automaker recommendations and software are irrelevant, and we are seeking to provide clarity.

“This type of misinformation jeopardizes both vehicle safety and the integrity of repair practices, and we believe it’s crucial to provide clarity.

“We will be seeking collaboration from all industry stakeholders, including this body, in an effort to benefit motorist and public safety. For more information or

to join as a partner, please contact us at: study@airprodiag.com.”

LKQ Corporation’s Refinish Division has launched a new privatelabel line, FinishMaster by LKQ, which in a news release it said combines the strengths of Keystone Platinum Refinish and FinishMaster Smart products.

This new brand aims to deliver superior collision refinishing products at great value, with over 650 SKUs available to more than 40,000 customers across North America.

“We partner with top vendors to ensure our products meet high-quality standards and provide innovative solutions for your success,” said Sarah Collins, director of product management. “Each partner is selected for their commitment to quality and sustainability. With LKQ Refinish, you have a dedicated partner to help you thrive in a competitive industry,

delivering the performance you need for your collision refinishing projects.

We’re with you every step of the way!”

“To successfully develop your own brand in any industry, it’s crucial to meet customer expectations for top product performance and quality at great prices,” said Ed Pietrzak, vice president of specialty sales. “With years of experience from both LKQ and FinishMaster, we

have established ourselves as a trusted provider of high-quality, cost-effective refinish products across North America.

FinishMaster by LKQ continues this legacy, offering a comprehensive range of high-performance products designed specifically for collision centers, ensuring our customers receive exceptional value without compromising on quality.”

Troy Buck, owner of Fix Auto Avondale, transformed his passion for art and automotive painting into a thriving hobby that has made a significant impact on cystic fibrosis research, according to a news release. After a career as a police officer, Buck uncovered his talent for auto painting when a friend requested his help in painting a truck. With no prior experience, that first project ignited a lifelong passion that seamlessly blended his work in collision repair with his auto painting passion. Buck has cultivated a successful business at Fix Auto Avondale, allowing him to step back and focus on his true passion for art. With a stable team in place, he has dedicated time to connect with his community through painting, showcasing how art can bridge gaps and foster relationships. After dedicating over

100 hours to the painting, Buck added the finishing touch when NASCAR legend, Jeff Gordon, personally autographed it at Hendrick Motorsports in Charlotte, NC. This project combined Buck’s expertise in auto repair with his artistic vision, utilizing automotive paint for an authentic finish. In the release, Driven Brands thanks Axalta for supplying the paint, coordinating the images, and facilitating Buck’s trip to Charlotte. The painting sold for $8,000 at the Limitless 2024 Conference auction on October 10, 2024,

with all proceeds benefiting cystic fibrosis research and advocacy. “Art has always been a way for me to express myself and connect with others,” said Buck. “Being able to mix my passion for auto painting with my work in collision repair has been incredibly fulfilling.” By combining his artistic talents with his expertise in collision repair, Buck demonstrates that franchisees can make a significant impact beyond automotive repair, inspiring others to blend their passions with purpose for a meaningful cause. “Troy’s remarkable journey is a testament to the power of passion and creativity,” said Damien Reyna, US COO, Driven Brands Collision. “His dedication not only elevates our brand but also makes a profound difference in the fight against cystic fibrosis, inspiring others to use their talents for a greater purpose.”

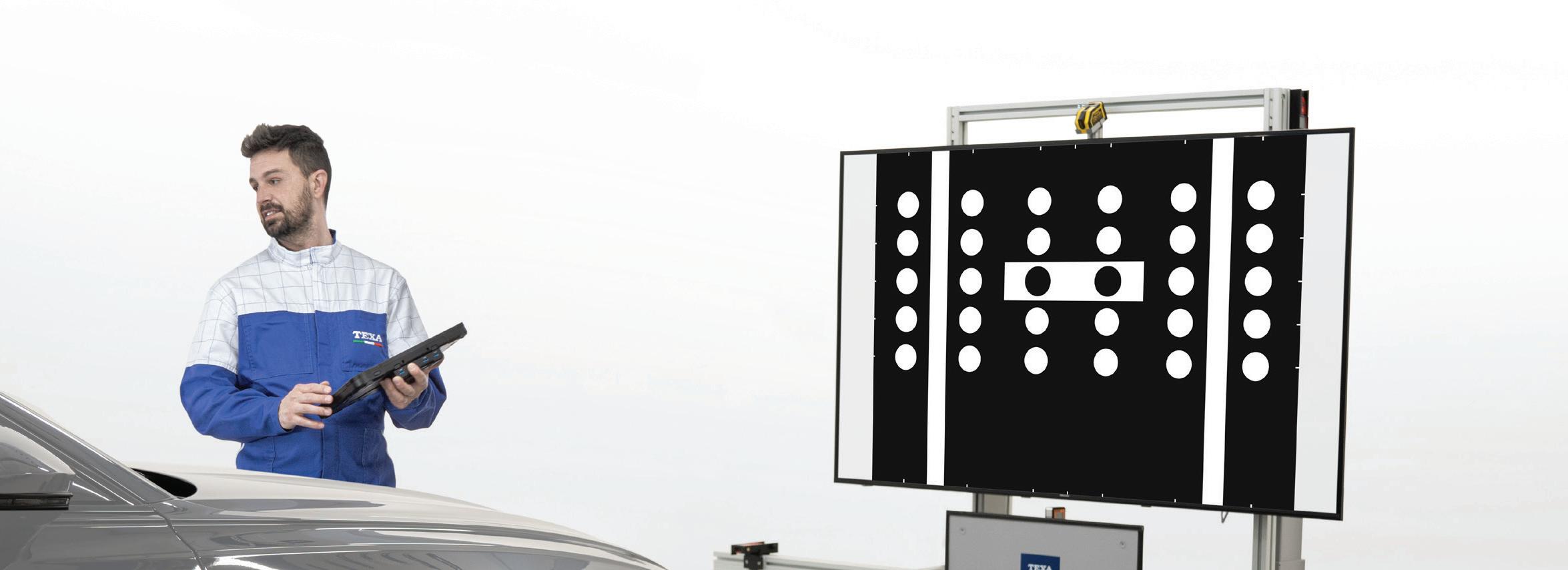

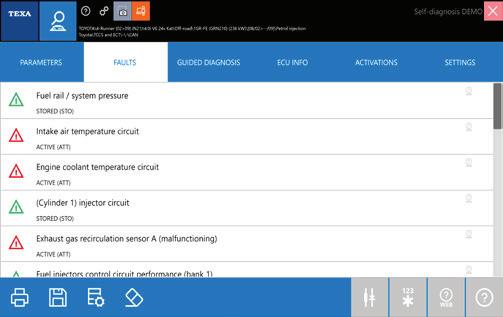

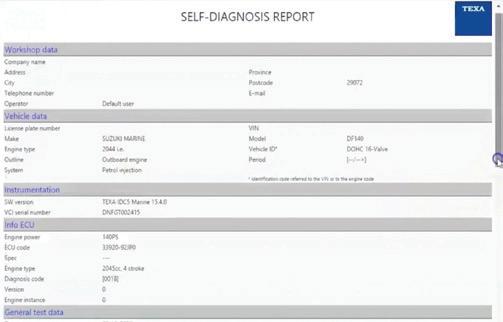

BY JOHN ANELLO

As the owner/operator of a mobile diagnostic business for 33 years, I have always strived to keep on top of technology with the latest equipment as well as to keep myself educated with any new advances in the automotive industry. The only way to survive is to keep moving forward, or you will find yourself falling behind with antiquated equipment. My experience has taught me to retool my business every three years and

keep all my equipment up to date with the latest software every month because our industry as a whole just moves too quickly with the advancement in technology. I just recently had to upgrade my service vehicle with a Starlink satellite dish on the roof to increase my software download services without interruption because my air card could no longer handle higher demand download speeds, and I had to overcome constant outages of cellular service. The demand for

KEEPING UP WITH YOUR EQUIPMENT AND TRAINING?

reprogramming has never been so high in my business, and I needed to keep on the cutting edge of technology (Figure 1).

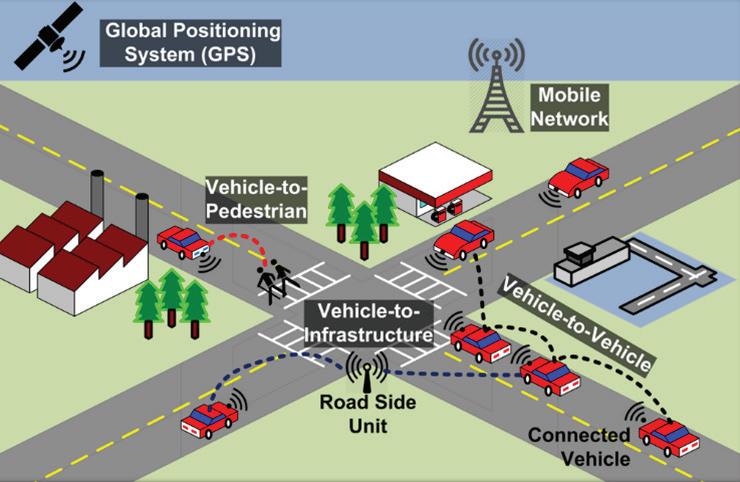

Over the past five years, I have seen so many new changes to enhance and improve the advanced driver assistance systems. There are so many security changes that had to be addressed to protect the onboard computer systems from

being hacked by the environment around the vehicle. This all started with the introduction of the SPY Car Study Act of 2017, which set new standards for onboard cybersecurity. This involved encryption of CAN bus networks and placing a firewall system within the network to protect the powertrain and ADAS systems from entertainment systems that were tied to mobile phones or satellite services. Chrysler was one of the first manufacturers in 2018 to install a gateway

computer in front of the OBD2 connector to prevent aftermarket scan tools from performing bidirectional controls without security access (Figure 2). This would soon be followed by other manufacturers as we got close to 2023 and I’m guessing that by 2025 most all manufacturers will be going this route.

Currently, Chrysler, Nissan, Mercedes, Volvo and Tesla are the manufacturers I’m seeing who have jumped on the bandwagon. The good news is that a company, AutoAuth, was launched for the aftermarket industry where you can register your shop, Wi-Fi enabled scan tools, and shop technicians to get access to unlock these vehicles (Figure 3). They will charge you a yearly fee to unlock Chrysler and Nissan vehicles for now, and I’m sure there will be many more manufacturers joining their service as time goes on. But for now, the only way

without interruption. My air card could no longer handle higher demand download speeds, and I had to overcome constant outages

FIGURE 3: With an annual fee, AutoAuth allows registered shops, Wi-Fi enabled scan tools, and shop technicians to unlock Chrysler and Nissan vehicles.

4: Newer radar systems have advanced to locate multiple moving or approaching objects.

to unlock the other manufacturers is with their factory scan tools with a yearly subscription that can be very costly. These networks on these vehicles have to be unlocked before you can perform any ADAS functions with your ADAS software.

There have been so many advances with the onboard ADAS software and networks, but there has also been advancement in component hardware where it’s just not about plug & play. These parts have gotten more advanced in technology and require more set up procedures prior to an ADAS calibration. They may need to be unlocked by the manufacturers, configured for the vehicle, programmed with software and even be sold as right and left pairs if their firmware has been updated. So now it’s a constant battle to keep

up with the many changes. A lot of the newer radar systems have become more advanced to achieve a wider spectrum to locate multiple moving or approaching objects in front of the vehicle. So the smaller targets once used a few years ago have even tripled in size (Figure 4).

The windshield lane camera system has also reached an advancement in technology. Now, they’re not only looking for lines on the highway to keep the vehicle in the lane but are also calculating objects in the roadway to enhance the radar systems. Subaru has now moved to a mono camera system for 2024 to detect bicycles and pedestrians and coupled this with their dual EyeSight camera system (Figure 5). This now actually doubles the work needed to calibrate a windshield on a Subaru because it requires two different target setup procedures. This is all to increase the sensor fusion activity between the radar and camera system for more precise control of Level 2 ADAS vehicles where both braking and steering are involved.

These Level 2 vehicles are able to brake, accelerate, and steer the vehicle, but they still are not driverless cars. They require the driver to be the redundancy of the system to take over the brake and gas pedals or steering wheel when necessary. Tesla will actually give you a warning on the dash after so many minutes to put your hands back on the steering wheel if it doesn’t sense your hands on the steering wheel by the use of a torque sensor within the steering system (Figure 6). If your hands do not return to the steering wheel, the system will come out of self-driving mode. Then there is always that

6: Tesla will display a warning on the dash after so many minutes for the driver to place his or her hands back on the steering wheel if it doesn’t sense the driver’s hands on the steering wheel. This is possible by using a torque sensor within the steering system.

smart person who tries to override the system by shoving two water bottles in the steering wheel (Figure 7) as counterweights to fool the system…but this is a dangerous thing to do, so please use the vehicle as intended.

It has gotten to the point where I have already come across shops that tell me where a few customers have tried to blame their cars for the initial accident and claimed that the vehicle did not stop for them. As a precautionary measure, I had to add a disclaimer at the base of my invoice that reads as follows: “ALL camera and radar calibrations are performed to put vehicles back to specification to enhance driver assist for Level 1 and Level 2 ADAS Vehicles. These systems are NOT set up for driverless vehicles and require eyes on the road and hands on the steering wheel at ALL times. Drivers must ALWAYS be prepared for a handoff of vehicle operations such as steering and braking at ANY given moment.” This is a disclaimer that you should also be putting on your invoices to protect yourself when performing ADAS calibrations.

There are Level 3 vehicles out there where the vehicle will actually drive itself, but there is still a redundancy requirement to take over operations if the vehicle has issues to maintain its task of driving the vehicle for you. This driverless technology is just getting more advanced as time goes on, but we still have a way to go. I see the future with more advanced ADAS components becoming standard in the vehicles as they become more cheaper to install, such as night vision using thermal cameras because they can do a more precise recognition of pedestrians and bicycles in what will

then be standard camera and radar systems. Then you also have the 3D area mapping using lidar laser light technology that can’t be fooled by shadows, bright sunlight, or oncoming headlights that camera systems are exposed to.

The final stage to take driverless vehicles to the next level would be to build an advanced roadway infrastructure to interact with ADAS vehicles (Figure 8). This would include smart signal lights that could warn vehicles of the status of their operation prior to reaching an intersection or even a roadside unit to warn vehicles about accidents and road conditions. This could even be coupled with Vehicle-to-Vehicle (V2V) communications. The possibility of these things happening is not too farfetched, but just be prepared when we get there. So, keep tooling and keep current on the latest technologies. Don’t fall behind, or technology will pass you up.

JOHN ANELLO is the owner and operator of Auto Tech on Wheels, established in 1991 in northern New Jersey. He provides technical assistance and remote reprogramming with 21 factory PC-based scan tools. Driven by a passion for cars, John’s business now services roughly 1,700 shops.

SCAN THE QR CODE TO SHARE THIS ARTICLE AND READ RELATED ARTICLES ONLINE

• Bi-Metric™ Lifting

• Automatic Swing Arm Restraint System (ASARS)

• Expandable Top Beam

• Padded Overhead Safety

• Single-Point Safety Release

• Safety Locks in Each Column

• Dual Hydraulic Direct-Drive Cylinders

• Low-Pro Triple-Telescoping Swing Arms

• Heavy-Duty Aircraft-Quality Equalizer Cables

USE THESE SEVEN TIPS TO ENSURE YOU’RE UP TO DATE ON STRUCTURAL REPAIRS.

BY TIM SRAMCIK

Time ies. In the collision repair industry, it seems to move especially fast. It seems like just yesterday that shops were rst dealing with issues like how to repair high-strength steel (HSS) and ultra-high-strength steel (UHSS) structural parts.

OEM information was tough to come by, and repairers struggled with problems such as sectioning these parts or doing full replacements, which was followed by the inevitable debate with insurers over the best choice. Just as these issues were being worked out, the in ux of sensors throughout vehicle bodies shined a new light on the necessity to ensure every structural repair was performed accurately the rst time to keep safety systems working properly. ese days, the challenge continues as shops must keep up with the steady river of new repair information and the need to replace old equipment with new.

Fortunately, you’re not alone on your structural journey. I-CAR, vendors, your fellow repairers, and others are there to help. With them, here are seven structural repair tips from experts designed to keep you on track.

You’re probably on the right track, so stay there!

Keeping up with constantly evolving technology is a chore, but overall, the repair industry is on the right track. “Shops are getting better with staying informed and performing proper repairs,” says Robert Hornedo, president of Pacific Collision Equipment Company in Signal Hill, California.

Hornedo says that one of the biggest changes he’s seen in the automotive industry over the past three decades is the precision in the manufacturing process, which requires repairers to be much more aware of the consequences of an inadequate or insufficient repair. Vehicles now have between one and one and a half millimeter tolerances, so there’s a very slim margin for error. Hornedo notes, “I’m really happy to see so many shops being aware and more

WITH VEHICLE tolerances often below 2 mm, it’s critical to use the right procedures and equipment to repair vehicles.

conscientious of the quality of the repair. They know what the consequences could be, and I think as shops continue to pursue OEM certification, more will reach the same realization.”

Still, there’s also plenty of work to be done since he also notes that within a radius of just a few miles of his business, he’s familiar with 20 shops struggling with being fully professional businesses. But they’re trying. That attitude is significant, since Hornedo says it demonstrates that many shops recognize there’s an opportunity to make money and be successful if they continue to invest in quality work.

Accurate structural repairs start with professional damage analysis.

A truly thorough (professional) analysis involves measuring with a 3D measuring system. Structural damage, even if it’s significant, may not be detected simply by sight or may appear to be light to moderate. Buckles and bends might not appear.

Hornedo and Bret Runyon, territory manager for Spanesi Americas, explain that HSS and UHSS structural components are designed to absorb or transfer energy. Shops must then examine these energy transfer points, which are located throughout the whole frame rail. Moreover, components of that frame rail, especially hydroformed steel, may feature multiplelayers of different kinds of steel. “After a collision, if you didn’t measure the vehicle, you’d never noticed that the rail is three, four millimeters back since, structurally, the whole thing moves,” Hornedo says. “You might end up buying a new hood, a new bumper, a grille, and fender, and after installing them, discover things still don’t line up.” Then you’re stuck writing up supplements, gaining insurer approvals, and trying to explain to frustrated customers why they’re getting their vehicles back later than expected.

Without measuring during damage analysis, you’ve opened the door to creating a mess. Finding your mistakes then, or by waiting until measuring until after the work is complete is a recipe for

costly mistakes. Put your 3D measuring equipment to work before the estimate is written.

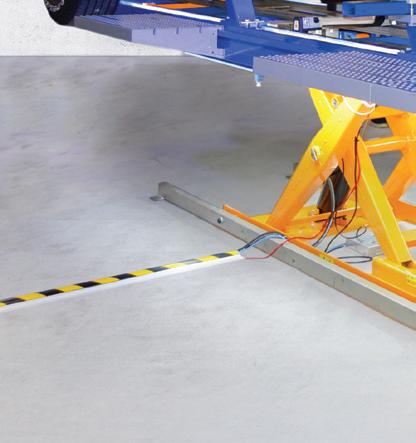

Rid your shop of older, problematic equipment

While you need to consistently use your measuring tools, your shop would be well served if you removed (or sidelined) older equipment that can cause you problems. For structural repairs, you should know by now that pinch weld clamps no longer have a place. Runyon recommends mothballing any tie-down chain and binder, along with no longer using full-frame clamps.

Hornedo says shops need to abandon frame machines. “By that, I mean those frame machines that are not machinemilled benches, because there’s a definition between the two,” he explains. “Those are totally inaccurate and crooked and even from the factory when they’re brand new, they’re crooked. When you have a vehicle that’s manufactured with two-millimeter tolerances or less and you put it on top of a crooked frame machine, you end up with a crooked vehicle.”

Couple that with an inadequate measuring system that just averages numbers (more equipment you need to remove), and you’ll be sending out a steady stream of structurally compromised vehicles.

Understand what goes on in the factory. Knowing how to repair something often begins with understanding how it was originally assembled. This is particularly true with structural automotive repairs. Consider that modern automobiles are largely assembled by robots that perform precise, exacting work. Your repairs need to be performed with

the same dedication to precision. This isn’t simply true for luxury or high-end models. Hornedo notes that even the least expensive vehicles. “The integrity of the build of all the vehicles is without question, so the integrity of the repair must be the same.

Invest the time necessary to find the correct repair procedures.

Long gone are the days when shops struggled for access to OEM repairs and information. Repairers can still face challenges locating procedures for up to date, thorough structural work. Runyon says there is so much information available, shops need to find ways to navigate through it. Further, the folks doing the navigation aren’t always “body guys.” Faced with these challenges and believing they have time to dig through new information, shops will return to handling repairs they always have, he adds. In addition, negotiating with insurers to pay for research time can be defeating. If that weren’t enough, Runyon says shops sometimes find the need to juggle OEM repair subscriptions. He says some will get a three-day subscription to ensure insurers reimburse them while forgoing an annual subscription that might not be.

Though these challenges can prevent shops from accessing the critical procedure they need, both Runyon and Hornedo say these difficulties must be overcome. The consequences are too serious to ignore. Shops, therefore, would do well to set up a process to access this information, whether that means putting a staff member in charge of this work, keeping techs well trained in structural repairs, and/ or ensuring estimators are trained as well. ALL PROPER structural repairs begin with using 3D-measuring systems during damage analysis.

Don’t hesitate to ask for help.

With all the challenges you face in the collision repair industry, remember that you’re never alone. If you’re looking for help to ei -

ther keep your structural repairs on the right path or to get them there, assistance is readily available. Runyon says shops can turn to their local state associations, many of whom are holding structural repair educational days, and the Society of Collision Repair Specialists. Companies such as Spanesi and Car-O-Liner also have plenty to offer, including product support for their structural

SUPPLIERS CAN offer vital training and guidance for structural repair programs.

Sand, mask, prep and paint

Openings in covers can be painted from the front and back to assure complete coverage STC35800

18” in with bi-directional access

Efficiently remove fender flares, rocker moldings, and interior door panel clips STC21710

Original SeamBuster Allows you to easily separate spot welded or bonded panels.

Install or remove door springs

Securely holds doors and deck lids open during automotive repairs

STC21910

For Body Shop Paint & Repairs

Securely holds doors and deck lids open during automotive repairs

STC20015

3 Nylon Head Shapes with Arbers

Air hammer driven set of three, self lubricating Nylon reinforced heads

STC20046

Includes additional wedge for gentle and non-damaging removal of moldings and trims

Hold Disc Brake Rotors in Place 12mm (Green) & 14mm (Red) Wheel Bearing Studded Hubs Hold-A-Rotor

STC71000

equipment and training in areas such as 3D measuring and damage analysis.

Just as important, they can offer guidance on how to best assemble and finance your structural repair equipment. “To do this work, you need a smart spot welder, a repeatable, reliable electronic measuring system, and an OEM-certified bench. Those are things you have to have, but if you can’t afford to do them all in one shot, what do you do?” Hornedo says. “We can give you help like suggesting you prioritize. Ask yourself, ‘What comes first? What’s going to help me in my business the fastest, the quickest, best return on investment so that I can go to the next step?’”

Stay focused on the customer.

If you still need a “glue” to bind you — and every part of the industry— to keeping up with evolving structural work, look no further than doing what’s best for vehicle owners. “ Stay focused on the customer, and everybody will win - insurance companies included,” Hornedo says. “The more educated the shops are, the faster they’re able to repair cars, which will reduce labor, rental, and other costs.”

He and Runyon agree that education of shops, their estimators and techs, and insurance companies is the key. “We all want the same thing,” Hornedo says. “We want to make a living, and that always starts with doing the right thing for customers. We all have to give customers what they deserve, and we do that by agreeing and understanding what the best repair is and sticking by that.”

TIM SRAMCIK began writing for ABRN over 20 years ago. He has produced numerous news, technical and feature articles covering virtually every aspect of the collision repair market. In 2004, the American Society of Business Publication Editors recognized his work with two awards. Sramcik also has written extensively for Motor Age and Aftermarket Business. Connect with Sramcik on LinkedIn and see more of his work on Muck Rack.

SCAN THE QR CODE TO SHARE THIS ARTICLE AND READ RELATED ARTICLES ONLINE

BY JOSH AVELLO

It’s a product for the foundation of painting and part of the body repairs, but the term “primer” is vague once you consider all the “primers.” In simple terms, it’s meant to promote adhesion of additional products and provide a ground coat foundation. It’s also typically an identi able medium to dark gray color, but it can also be found in other colors. Most body technicians think of primer surfacer when referring to the subject. Painters may think of primer sealer, and these barely cover what primer is in the whole automotive body repair process after the OEM builds the car. Along with their limitations are on the repair end and what is overlooked by just grouping all these primers together.

Primers: the foundation and for corrosion protection

From the factory level when the OEM builds its cars, the whole body of the car may be dipped in a solution of wash primer that is essentially various acids and a metal conversion coating to protect the vehicle from rusting. This is followed by additional coatings such as e-coat primer, along with the rest of the coatings to give the car color. When we repair it and it’s down to bare metal from the accident or repair process, we have exposed bare metal that must be protected against corrosion. This is not limited to the obvious rusting steel can do, as even aluminum will corrode, albeit in

a different way, as it oxidizes and can cause material failure that at its worst could compromise safety. So we have some primer category products options we must apply to restore corrosion protect to not cause failure:

While these may be called “wash,” “acid,” “etch,” or “acid etch,” these primers all work similarly from one paint company to the next. They try to mimic the early coatings process at the factory when the whole car was submerged in a solution to convert the metal surfaces. Some of these products are 1K,

PRIMER SURFACER applied after body repairs. While you want to reduce spreading the repair area to reduce color matching problems and overspray, don’t tape and mask off too close to the repair area intended to be covered as pictured. This can cause hard lines from the overspray or even running out of room to spray the surfaces leaving even harder lines. These will be hard to sand and block out risking showing up later in the painting process.

meaning they’re not mixed with another chemical, so there is not a reaction needed for them to cure. That’s why you often saw these in a dedicated paint gun hanging up in the mixing room ready to spray until the next job that needed protected. Some issues arise from these products being misused and the technical data sheet (TDS) not being read. The most common is body technicians doing their metal repairs and ending with body filler and applying primer to the whole repair area because of the exposed metal. This must be avoided, as the acids will react with the body fillers. A similar situation is the paint department first applies an etch primer to large metal areas exposed, then the body department applies body filler on top of it. This is a situation with incompatible products. These acid primers must be separated with a different layer of a different type of primer such as primer sealer (more on that below) to not cause a failure of products.

Some companies, such as AkzoNobel, have even developed wipes that resemble a household cleaning disinfectant wipe. These can be easily used on cut-through metal areas or large areas to convert the metal surface for corrosion protection. They are great for last-minute catches in the booth when you miss seeing some exposed metal areas and are ready to do the rest of the priming so you can quickly protect the metal.

This is viewed by many to be the true high-quality choice in restorations to protect metal from corrosion, and some OEMs even require this to warranty the repair before topcoating with any body repair or paint materials. But there can be a tradeoff in productivity, as epoxies can sometimes take a while to dry. So even when mixing a small amount to apply to, say, new spot welds prior to seam-sealing, the long curing time is sometimes a complaint. The payoff is this will not react with repair materials under or above such as body filler, and it can combine the steps of corrosion protection and sealing repairs from additional repair layers.

While not typical, some of the more common primers in a shop, surfacers and sealers, are sometimes manufactured to be combined to act and spray the same way but have the chemical properties of an epoxy to also provide corrosion protection.

Making “e-coat” and other 1K primer products

Some primers we may have at our disposal in a shop or want to use are 1K aerosols. The 1K means one part, with no hard-

SEALER spot repair preparing for a color blend with Sikkens Colorbuild Plus primer mixed as a sealer.

ener or activator mixed in the can. But there actually are 2k aerosols that are the exact same as what you’d mix for your paint gun but in an aerosol form. These 1K primers may not be that durable in general, but especially if used over bare metal they have absolutely no corrosion protection. Any additional body repair materials or paint coatings are at risk of failing from the bottom up, and it’s not as durable of a repair. Consequently, it will not live up to attempting to replicate to pre-accident condition. They should not be relied on if attempting to protect the metal only. Some products are colormatched to the factory e-coat. While they are a convenient way to match colors, again they do not restore corrosion protection of what wasn’t already achieved. They also need to be topcoated with clearcoat to protect from elements, especially UV rays if exposed. Technicians think they’re recreating the “e-coat,” which is not possible at the repair level. True e-coat, electrodeposition coating, is made with a negative electrical charge on the part and a positive electrical charge on the chemical coating being applied, ensuring even application to nooks and crannies. This is performed with the whole body or individual parts submerged using specialty equipment that isn’t available at the repair shop level. These aerosol products’ function are only to quickly match the factory e-coat’s appearance.

As previously noted, surfacer is the product most commonly associated with the word primer, particularly for body department repairs. Its main job is to help transition the dent and surface coatings that are scratched from sanding, welding, and other body repairs in preparation for additional paint coatings. It is not meant to fill. Most of these products, even when applied to the highest ACCEPTABLE mil thickness by the manufacturer’s technical data sheet (TDS), are not enough to truly “fill.” Typically, this product has zero corrosion protection and is meant to only help transition the

WHEN APPLYING primers on plastic bumpers, make sure to apply appropriate adhesion promoter that may be needed before spraying the primers of choice. Along with any flexible additives if not already included. (Note again, caution on masking off so close to intended primer coverage area to reduce hard lines in material).

Why do so many shops choose Cromax® XP? Maybe it’s because they can achieve a premium finish in as few as two coats. Or that it’s easy to mix, match, and apply. It could also be having access to the most innovative digital color match tools. But we’d like to think it’s all of it.

See what sets Cromax® XP apart from the competition. axalta.us/xp

various repair spots. So, covering raw metal from the body repair process needs to be addressed with one of the anticorrosion primers. Even though the metal, body filler, and other products will need to be straight, after applying this over all those transitions it will still need a final blocking to ensure straightness of the whole repair area.

Seal the deal: Primer sealer and ready for color

This is the other common “primer” people think of. This is meant for closing up many repair situations that are ready for true painting of colors. These do not have much material mil thickness build and are meant for separating or assisting with color evenness. Some examples are sealing off products from each other, such as acid primers from other repair materials, basecoat color repairs, and covering anything else needed to continue with color coatings. These are available in different colors, including white, gray, black, and shaded in between, to a range of colors to help with easier hiding of the topcoat. It is also sometimes required for very unique or difficult colors, as prescribed within the paint manufacturer’s formula, or you’ll never get the proper look for the color. These usually do not have any corrosion protection ability unless they are a hybrid.

Waterborne primers and UV primers

While most primers, particularly the surfacers and sealers we commonly use in a shop, are hardened by the chemical reaction of mixing products, there are some that use other

I also interviewed Bob Chapman, technical instructor for AkzoNobel’s training center in the Chicago area for some examples of issues of things that can go wrong with primers. Here is a summary of that interview.

ABRN: What are three of the most common problems you’ve seen when it comes to primers?

Chapman: One, I would say, is overapplication of primer, putting the primer on too thick or too many coats. A lot of that is from a misunderstanding of the solvent. Overapplication can trap it between layers, not allowing for proper flash times. The solvents will eventually come out and make the appearance of shrinkage of the repair area, [be sunken in or causing a halo showing it] when in reality it is still the same physical amount of primer applied, it was just too much solvents overapplied and trapped.

Number two would be the tip size for the spray gun, such as selecting one that’s too small for proper build, or too big, leading to overapplication.

ABRN: I especially see that happening a lot from no one reading the TDS on their products.

Chapman: Yes, and another one is sanding before fully cured. You get, for example, a lot of people priming something by the end of the workday to cure overnight. The temperature of the shop of the shop drops overnight, even worse in winter, and then you get someone sanding it the next morning. It could sand badly by gumming up the sandpaper if it’s not still fully cured. Or even if it sands OK but hasn’t fully cured and solvents are not completely out of that, when they paint over the top of that and when the solvents finally release, the primer shrinks.

ABRN: What do you feel like you want people to know most or think of the most when you hear the word “primer,” as that is such an ambiguous term?

Chapman: Primer is mainly used as a surfacer and is NOT to fill dents or bad bodywork and is meant to level the repair area substrate up to the existing finish that may be 4-5 mils from the factory finish, and we’re basically putting about that with primer same or a little bit more to level up with the featheredged repair.

Additionally, final thoughts on troubles can stem from a purchasing or use mindset similar to what you may encounter at, say, your local home improvement store. Just because it’s available and for sale, it doesn’t mean the product fits your needs or even is of quality. Understand the product’s limitations and proper use, especially in comparison to what liability you’re willing to take on in the sake of saving money for yourself, the customer, or standing by the repair whether by your shop’s reputation or an actual warranty.

When it comes to custom paint jobs it’s hard to beat the complexity of a lowrider, typically they are elaborately painted and decorated with murals, colorful candy paint jobs, and pinstriping as an expression of the car and owner.

The conversion of standard production vehicles into mobile canvases that are long, low and sleek “low and slow” is a cultural phenomenon. www.sata.com/lowrider

X 5500 Lowrider

methods for additional speed or, in some areas, environmental regulations. Ultraviolet (UV) primers can cure only by using special UV lights ranging from handheld to large lights. Sometimes, if allowed by the TDS, they can even be set by the sun’s UV rays by putting the repair part or car in the sun. They rapidly set – almost instantly – by the UV rays instead of waiting for a chemical curing process. The downside can be ensuring that the primer actually is cured by the UV method of choice by the technician. If it’s not, it will never cure and it can fail if all the layers aren’t cured. So this can have limitations if you can’t get the light in all the areas you spray. There are also primers that use waterborne technology, similar to that ofsome basecoat systems as the carrier of the liquid, instead of solvent chemicals. They evaporate the liquid out over time or through forced air equipment, helping to reduce VOCs that can be regulated in some areas or simply desirable for those trying to reduce chemical exposure to benefit employees’ health.

Additional additives or prep

There are additives we can use in some manufacturers’ primers or sealers to achieve different repair durability or

USING SILCO’S 2K aerosol primer surfacer, 7300 M30 Superfast Primer. This is the same two-part primer that is mixed and sprayed in a gun but in an aerosol. Because it’s a two-part (2K), this provides the same durability and sanding capabilities, which is not common for aerosol primers that are usually 1K (one part).

characteristics. A common one is a flex agent for plastic parts such as bumpers to meet the demands for flexibility, expansion/contraction, and general abuse, such as stone impacts on the front of a car. Another use is for underpanel areas such as underhood or an inner bedside. These help give not only a factory-like matte inner panel color to replicate the e-coat appearance, for example, but also to help harden and seal the primer from the elements. Primers typically don’t have long-term durability without this additive if you’re not doing additional topcoating steps like color and clearcoat that is not always needed in such as in underhood or inner structures, which saves material and steps. An adhesion promoter may first need to be sprayed on plastics to help adhere the same primer (or sealer) you would use elsewhere.

Tear down to the “foundation”?

With so many types of primers, many of the problems come from not understanding their uses in different areas and stages of the repair. We also may misuse the product by not following the product manufacturers’ TDS’ step-by-step requirements for the products’ proper selection, mix ratio, and application. Develop shop SOPs to refresh everyone

currently using the products and as employees shift to different roles in the shop or new employees are hired.

Simply put, let’s get back to basics on a few things regardless of if you’ve been spraying the products for years to decades or all the large number of products rolling through our shops by doing a few steps.

JOSH AVELLO’S career has spanned across various positions, including as a technician on both the body and paint sides, working for equipment sales companies, and as an instructor in welding certification and other auto body courses. He has presented various topics of technical and business auto body courses to leading industry companies and events across the country. He is now a sales representative and new business development for Performance Auto Color, an automotive paint and supply distributor of many product lines for auto body shops in Missouri and Illinois.

SCAN THE QR CODE TO SHARE THIS ARTICLE AND READ RELATED ARTICLES ONLINE

Motor Age Training offers the most complete and extensive collection of B-Series Collision Repair training guides available anywhere!

B2 - Paint & Refinishing Certification

B3 - Non-Structural Analysis & Damage Repair

B4 - Structural Analysis & Damage Repair

B6 - Damage Analysis & Estimating Certification

B5 - Mechanical & Electrical Components Certification

*training guides available in a variety of formats THANKS

Norton Premium

SATA USA Inc.’s special edition for this year is the SATAjet X 5500 Lowrider, available by Dec. 6. It is a great design that pays tribute to the builders and the paint work that is done on cars, trucks and motorcycles in the Lowrider custom world culture. There will be a limited run available in a total of 408 guns available between HVLP and RP models: I-nozzle 1.2I RP 1220946, 1.3I RP 1220962, 1.3I HVLP 1220988, and 1.4I HVLP 1221004; and the O-nozzle 1.2O RP 1220954; 1.3O RP 1220970; 1.3O HVLP 1220996, and 1.4O 1221012.

FENDERBENDER.COM/55243259 SPONSORED

Automotive Masking Tape is designed for the paint masking process, delivering sharp paint lines and protection in collision repair applications, including spray-paint preparation and high-temperature painting. It features a rubber-based adhesive for surfaces such as painted metal, rubber, and glass that enables clean removal after bake cycles of up to 248 F. Its flexible crepe paper backing enhances visibility and conformability to curves and contours without tearing, making the application process easier. It’s suitable for waterborne and solvent-based paints and is resistant to UV exposure for up to three days.

FENDERBENDER.COM/55166345

The BendPak Octa-Flex Series offers the functionality of a traditional two-post lift with the added versatility of a second set of powered assist arms for lifting and maneuvering large or heavy vehicle components such as EV battery packs. The overall size of the lift has been reduced without affecting drive-through clearance and lifting height, and the series now uses direct drive for faster and smoother assist arm use. The Octa-Flex series also has a single power unit and controller for better efficiency and maintenance.

FENDERBENDER.COM/55343323

Smarter. Faster. Cleaner. A clean shop can mean less rework, better cycle times, and the peace of mind that you are doing what you can to improve the shop environment. For you, your technicians and your customers. The 3M Clean Sanding System is a complete sanding solution for efficiently moving through your essential surface preparation and finishing work. The system includes a dust extractor, pneumatic and/or electric random orbital sanders, mobile workstation, wide selection of quality abrasives, and personal protective equipment.

FENDERBENDER.COM/55243251

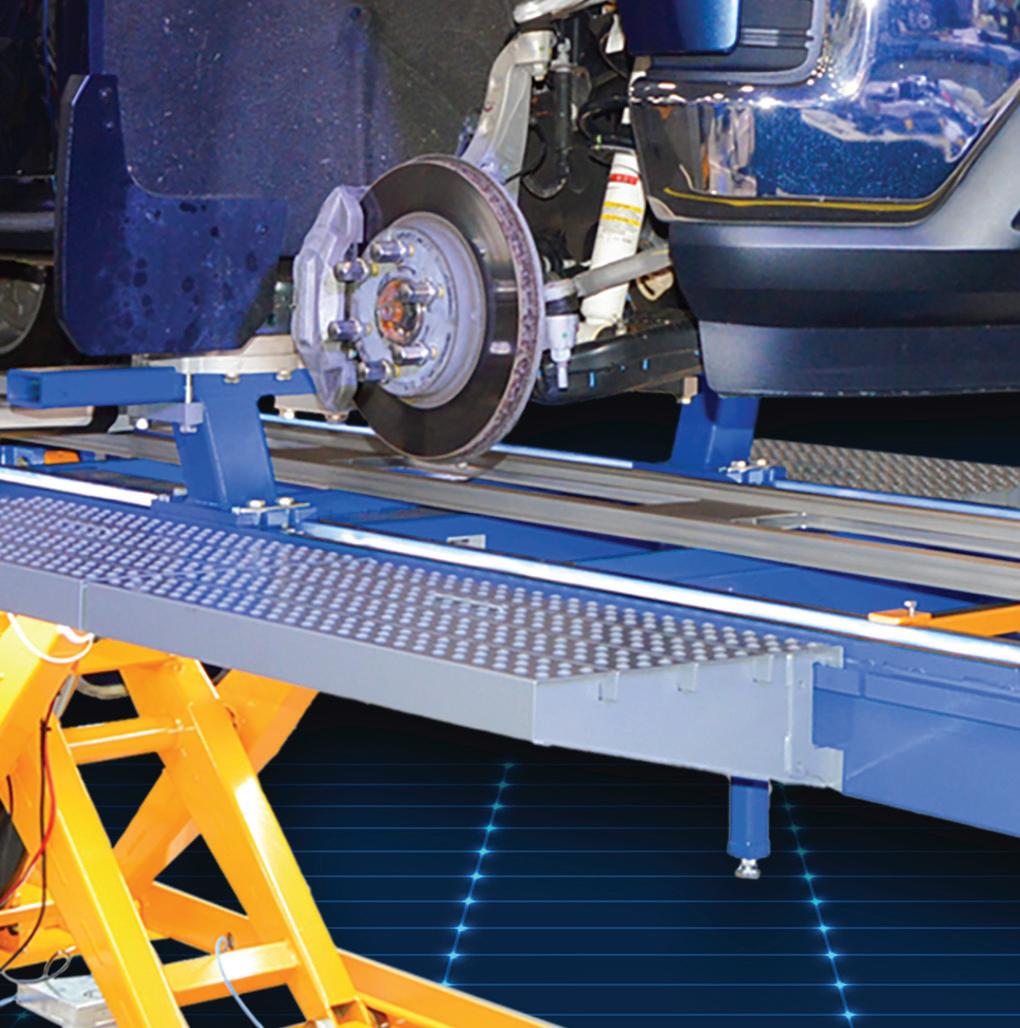

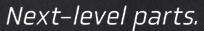

The new Car-O-Liner BenchRack Versa features low-profile, high-strength, lightweight steel and aluminum ramps that facilitate quick and proper vehicle lifting, providing full access for immediate work. The new short ramps enable lifting by the wheels, allowing technicians to quickly and securely position vehicles at an optimal working height. The BenchRack Versa features an increased lifting capacity up to 10,000 lbs, and there’s no need for rubber blocks when lifting vehicles, ensuring OEM compliance, especially for electric vehicles (EVs). The Quick Clamping Q63 arms allow users to achieve faster clamping with less effort.

FENDERBENDER.COM/55243277 SPONSORED

Mohawk Lifts’ SLT-2500 is an upgraded version of its scissor lifting table. This new model increases the lifting capacity from 2,000 to 2,500 lbs, making it ideal for transmission, differential, and EV battery service. The SLT-2500 is designed to provide enhanced performance and reliability for various automotive service needs.

FENDERBENDER.COM/55240135

The Cartec Headlight Tester, No. 433-HA, is crafted from a robust alloy material and suited for advanced lighting systems. The tester’s column is lightweight, easy to adjust, and rigid for long-lasting performance. The column can rotate +/- 5 degrees for fine-tuned adjustments. Equipped with scales in both inches and millimeters, the column provides measurement options that comply with international standards. The base is equipped with three wheels for mobility, and knurled knobs that simplify the level adjustment. Additional features include a 5.7” touchscreen display with 180-degree rotation, an onboard printer, a dust cover, a cross laser for correct centering of the beam source, and more.

FENDERBENDER.COM/55243374

The BendPak Ergochair Ergo-Jet, No. 5160112, features TPR wheels that provide shock absorption, cushioning, floor protection, and quiet rolling. The wheels are also resistant to chemicals, acids, alcohol, and water and easily roll over rough surfaces thanks to their width. The chair has a thick-padded seat and backrest with heavy duty non-slip textured marine-grade vinyl. It features an adjustable air spring, locking casters, adjustable footrests for more leverage, and horizontal and vertical arm adjustment. The Ergo-Jet also includes an easily accessible tool tray below the seat.

FENDERBENDER.COM/55243336

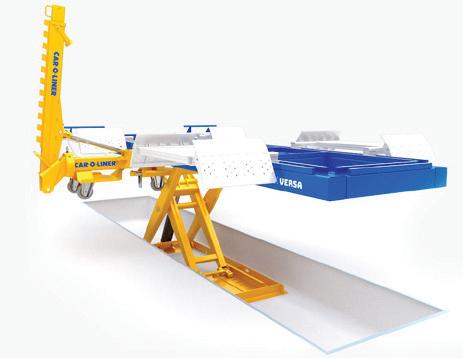

SEM Performance Abrasives, from PPG Refinish, are designed for every stage of the repair process. The product line incorporates precision grain technology, which delivers fast cutting, longevity, and consistency for a wide range of repairs and substrates, according to the company. SEM abrasives provide durability, excellent edgewear, and an even cutting surface, allowing technicians to achieve exceptional feather-edging. Another feature is the multi-hole design, engineered for dust-free sanding. This extends the product’s lifespan and creates a cleaner work environment, reducing the need for frequent cleanups and enhancing overall efficiency.

FENDERBENDER.COM/55166342

The Aircat 3/8” Orbit Low Vibration Lube Free Orbital Palm Sander, Nos. 67006-338 and 67000-6-338CV, feature a double-sealed, lubrication-free motor that prevents dust contamination of the air motor and eliminates the need for oiling. To ensure user comfort, the sanders use a smooth-design throttle lever, ergonomic housing, and an anti-vibration motor that reduces vibration levels to 0.8m/sec2. The orbital sander weighs in at 2 lbs with a 4.3” profile, while the geared sander weighs in at 3.4 lbs with a 4.5” profile.

FENDERBENDER.COM/55243371

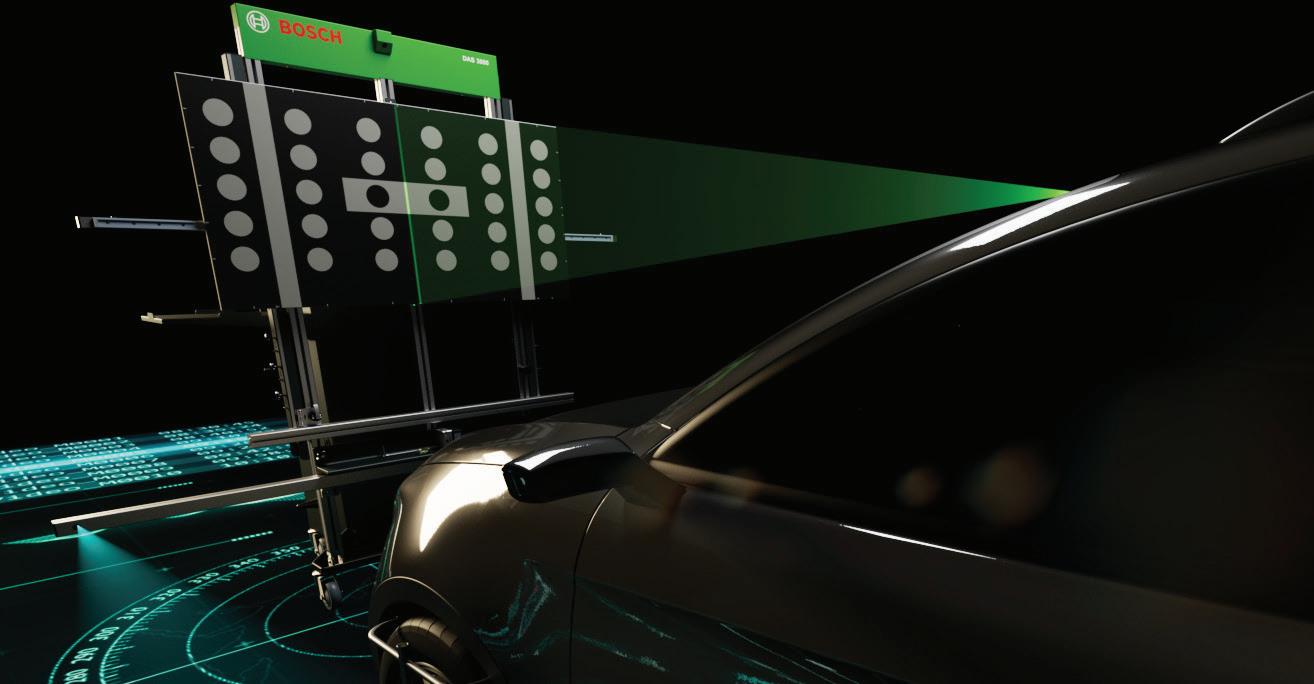

A commonized set-up approach based on OEM specifications provides an easy to follow setup without sacrificing accuracy and precision

Future-proof your investment with the confidence that your calibrations are completed to the tightest tolerances and the the first time.

Guided interactive workflow. Step-by-step instructions and consistent user interface across all makes and models.

Modular and future-proof: Designed to work with new targets and the next generation of ADAS technologies

Integrated storage and maneuverability keep your equipment clean and serviceable and ready to use at a moment’s notice

Fast and efficient placement using digital vision positioning which automatically measures vehicle distances and angles to ensure precise calibration

Bosch DAS 3000

The calibration solution for fast, reliable and precise calibrations on a wide range of advanced driver assistance systems.

Get more information about the DAS 3000