Refrigerants in Transition

Commercial buildings are making the switch. Are you ready for the new A2Ls?

See pg. 16.

Commercial buildings are making the switch. Are you ready for the new A2Ls?

See pg. 16.

HEAT TRANSFER FLUIDS FOR ANY APPLICATION

PROVIDING GLYCOL-BASED HEAT TRANSFER FLUID TO KEEP YOUR HVAC SYSTEMS AND PROJECTS RUNNING SMOOTHLY.

Thermal Charge® offers application-specific heat transfer fluids, innovative inhibitor technology, and industry-leading service and fulfillment so you can power through every challenge, need, and demand.

Visit thermalcharge.com to find the right heat transfer fluid for your application.

Engineers must overcome the potential threat of waterborne pathogens, the risks associated with extreme water temperatures, and the need to maintain both organizational and regulatory compliance.

By Brian Armstrong

As the global refrigerants market churns with change, one VRF expert suggests how best to handle the impact of the

Achieving occupant comfort can be tricky, so psychrometric principles must be applied to find that proper mix of space temperature and humidity control.

By David Schurck

ABMA will host its third bi-annual event next spring as players from across the entire boiler supply chain descend on Nashville.

By Shaunica Jayson

HPAC Engineering (USPS Permit 464-930, ISSN 0039-0895 print, ISSN 1930-8957 online) is published 6x a year (Jan/Feb,,Mar/Apr , May/Jun, Jul/Aug, Sep/Oct, Nov/Dec) by Endeavor Business Media, LLC. 201 N Main St 5th Floor, Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI, and additional mailing offices. POSTMASTER: Send address changes to HPAC Engineering, PO Box 3257, Northbrook, IL 60065-3257. SUBSCRIPTIONS: Publisher reserves the right to reject non-qualified subscriptions. Subscription prices: U.S. ($ 111.25); Canada/ Mexico ($123.75); All other countries ($148.75). All subscriptions are payable in U.S. funds. Send subscription inquiries to HPAC Engineering, PO Box 3257, Northbrook, IL 60065-3257. Customer service can be reached toll-free at 877-382-9187 or at HPACengineering@omeda.com for magazine subscription assistance or questions.

Printed in the USA. Copyright 2025 Endeavor Business Media, LLC. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopies, recordings, or any information storage or retrieval system without permission from the publisher. Endeavor Business Media, LLC does not assume and hereby disclaims any liability to any person or company for any loss or damage caused by errors or omissions in the material herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever. The views and opinions in the articles herein are not to be taken as official expressions of the publishers, unless so stated. The publishers do not warrant either expressly or by implication, the factual accuracy of the articles herein, nor do they so warrant any views or opinions by the authors of said articles.

Engineers, plumbing groups, sign expanded Memorandum of Understanding for future

Legionella and Beyond, with Engineer-Microbiologist

Dr. Abe Cullom

“PODCAST* After outbreaks in NYC and Iowa, we chat with the Special Pathogens Laboratory water safety director. www.hpac.com/55316807

EDITORIAL OFFICE

8001 Lincoln Ave. • Suite 720

Engineering eBOOK: The Best of Ken Elovitz, P.E.

An Engineer’s Notebook, 2021-2024. Dive into this collection of useful professional advice, laced with helpful legal acumen. www.hpac.com/55020330

HPAC 2025: Our September Quiz!

*BACK-TO-SCHOOL!* Schools everywhere have been reopening in recent weeks. Let’s dust off the books to test your HVACR knowledge. Take the quiz! Win prizes! www.hpac.com/55312891

BRIAN SACK 732-629-1949

bsack@endeavorb2b.com WEST ELLYN FISHMAN 949-239-6030 efishman@endeavorb2b.com

CLASSIFIEDS/INSIDE SALES

STEVE SUAREZ 816-588-7372 ssuarez@endeavorb2b.com

DIRECTOR OF SALES JOE AGRON 941-200-4778

jagron@endeavorb2b.com LIST RENTAL SMART REACH sr-assets@endeavorb2b.com effective PRODUCTION AND CIRCULATION

RITA FITZGERALD Senior Production Manager rfitzgerald@endeavorb2b.com

MELISSA MENG Ad Services Manager mmeng@endeavorb2b.com

JAMES MARINACCIO Audience Marketing Manager jmarinaccio@endeavorb2b.com

for your nex t big high ef f iciency commercial heating application

Cascade up to 32 units and common vent up to 4 units for a wide range of heating outputs.

Patented Navien designed and built ASME-Certified “H” stamped stainless steel fire tube heat exchanger.

Intuitive 7" touch screen control for easy set up and diagnostics.

Built-in hardware for boiler pump, 3 heating zones or indirect tank control.

To learn more about all the big things happening at Navien, visit Navieninc.com.

BY ROB MCMANAMY,

It’s no secret that our industry is still considered one of the most litigious of all the business arenas. The pressurized mix of design changes, competing trades schedules, materials deliveries, weather delays, worker shortages, accidents, etc., all under tight deadlines, has long kept lawyers at full employment in and around engineering and construction.

When I was in law school 35 years ago, the joke then about this industry was that “every project has three phases: design, construction... and litigation.”

But one thing that remains lesser known since then is that our industry also has been one of the most proactive and forwardthinking about alternative dispute resolution (ADR) methods. From arbitration to mediation to med-arb to project neutrals to dispute review boards to partnering, etc., many attorneys representing engineers, architects, contractors, subcontractors and owners, both public and private, have been striving for decades to find a better way to ensure that inevitable disagreements do not derail critical projects.

One such construction attorney is my longtime friend, Jim Groton , 97, a retired partner at the Atlanta law firm of Eversheds Sutherland and perhaps the AEC industry’s best-known and most respected evangelist for dispute prevention and ADR. With that in mind, Jim earlier this year sent me a copy of the latest book he had just co-authored for the American Bar Association (ABA), entitled Preventing The Dispute Before It Begins: Proven Mechanisms for Fostering Better Business Relationships (www.americanbar. org/products/inv/book/448840293/).

Since the 1960s, Groton and others in the ABA construction bar have been pushing for a better way to foster non-adversarial relationships across project teams. By anticipating project pain points and discussing ahead of time how they can and should be dealt with when they arrive, the parties can prevent most disputes from happening and facilitate successful project delivery, he says. The new book offers several key tools to help make that a reality.

In an online interview from 2021 with future co-author Allen Waxman, then CEO of the International Institute for Conflict Prevention and Resolution (CPR), Groton explained, “I’m in favor of getting into problems at the moment they come up, and not letting them ever escalate into disputes with a capital ‘D’... Dispute prevention means not just keeping people out of litigation, or out of arbitration, or out of mediation. It’s keeping them out of Disputes that involve lawyers, adversarial relationships, arguments, etc.”

In short, it’s all about preserving the relationships between good faith parties, including the project owner, so that they can all work together again down the road, if they so desire.

“There are ADR mechanisms to avoid litigation and set up a dispute resolution process; these include arbitration and mediation,” says Carlos Hernandez, former CEO of engineering giant Fluor Corp., as quoted in the book. “But we should begin the dispute prevention process before we get to those stages. The processes should focus from the inception on the contractual relationship. We’ll all benefit from putting in place means to solve disagreements before they become full-fledged disputes.”

With that in mind, Hernandez urges all industry stakeholders to adopt the new CPR Dispute Prevention Pledge for Business Relationships. To read the pledge and see why firms like Microsoft, Visa, and General Motors have signed on, go to: https://www. cpradr.org/dispute-prevention-pledge-forbusiness-relationships.

For Groton, as complicated as the many massive construction projects are that he has worked on over the last 60 years, one simple lesson from childhood has stuck with him about how parties should treat each other. “Long ago, as a schoolboy in boarding school, each table would be served pie after dinner every Saturday,” he told Waxman with a smile. “But the boy chosen to slice the pie could only keep the last piece for himself. So he had to be fair to everyone else along the way.”

That’s a credo that still applies well beyond the dinner table today.

William P. Bahnfleth, PhD, PE The Pennsylvania State University Glenn Barrett, PE DC Engineering

David W. Bearg, PE Life Energy Associates

Lawrence (Larry) Clark, QCxP, GGP, LEED AP+ Sustainable Performance Solutions LLC

Kenneth M. Elovitz, PE, Esq. Energy Economics Inc.

Charles E. Gulledge III, PE, HBDP, LEED AP, FASHRAE Environmental Air Systems LLC

Elise Kiland, PE, YEA Cambio.ai

Nancy Kohout, PE, LEED AP SmithGroup

Valentine A. Lehr, PE, FASHRAE Lehr Consultants International

Ginger Scoggins, PE, CEM, CxA, LEED AP, FASHRAE Engineered Designs Inc.

James P. Waltz, PE, CEM, ACFE Energy Resource Associates Inc.

Michael K. West, PhD, PE Advantek Consulting

Ron Wilkinson, PE, LEED AP Wilkinson Commissioning Management

Gerald J. Williams, PE, LEED AP 8760 Engineering LLC

Grinder Systems

Solids-Handling Systems

Effluent Systems

Simplex

Duplex

Triplex

Quadplex

Order a Liberty EPS and you’ll get the assurance of the complete system arriving to the job-site with factory matched components – pump, panel, basin, internal piping, guide rails, floatsall from one source. With an almost unlimited number of basin and panel options - we can customize a system for your specific application. Need it fast?

Specify a pre-designed system from Liberty! Pre-designed systems are available and ready to ship in 24 hours. Consult factory for more information on our pre-designed packages.

Explosion-proof models available for hazardous locations!

Engineers, plumbing groups, sign expanded Memorandum of Understanding for future collaboration.

The American Society of Plumbing Engineers (ASPE) and IAPMO® have renewed a Memorandum of Understanding (MoU), now incorporating ASSE International and ARCSA International, to jointly advance and promote the mutual interests of education, regulations, design, specifications, installation, and inspection of plumbing systems, as well as training, testing and certifying qualified professionals to perform design work responsive to the need to conserve and protect water supplies, and reduce energy use connected to delivery and use of water.

Initially created in 2010, through this updated MoU, the member organizations pledge continued cooperation in achieving such mutually beneficial objectives as:

• Collaborating to advance safe, sustainable, and resilient plumbing systems through open communication, consensus standards development, and promotion of public health, welfare and safety, and environmental protection — both nationally and globally;

• Jointly promoting and developing beneficial products, services, and marketing initiatives by leveraging each organization’s strengths to support members, cross-market offerings, and explore sustainability opportunities within the plumbing industry;

• Collective promotion and co-hosting of educational programs, events, publications, and standards, with designated staff regularly reviewing offerings to identify mutually beneficial opportunities for both memberships;

• Maintaining timely collaboration at all levels to support a professional

plumbing industry through joint promotion, standards development, education, and public recognition of the partnership;

• Collaborating on shared goals by exchanging chapter information, encouraging joint meetings, technical committee participation, and leveraging each organization’s expertise to enhance education, communication, and industry engagement;

• Improving resource efficiency and strengthening the partnership through regular staff collaboration, mutual membership incentives, shared news and activities, and support for stronger enforcement of plumbing and mechanical codes and standards;

• Collaborating on the development, revision, and promotion of green plumbing and alternate water source certification programs and standards, with ASPE providing design certification and training, and ASSE and ARCSA leading installation and inspection certification efforts.

“We are thrilled to reaffirm and expand our partnership with IAPMO, ASSE International, and ARCSA International,” said ASPE Executive Director/CEO Billy Smith, FASPE. “By combining our strengths and expertise, we are advancing the science of plumbing engineering, resilient plumbing systems, innovative education, and vital standards development to protect

public health, welfare and safety, and our shared water resources for communities everywhere.”

Added IAPMO CEO Dave Viola, “This renewed Memorandum of Understanding reflects the strength and unity of our industry’s leading organizations working together to help ensure safe, sustainable, and innovative plumbing systems. By bringing ASSE International and ARCSA International into the conversation alongside our longstanding work with ASPE, we’re expanding the impact of our collective expertise to better protect public health, conserve water, and promote energy efficiency worldwide. Collaboration like this is essential to building a stronger, more resilient future.”

Founded in 1964, ASPE is a professional organization dedicated to advancing the science and practice of plumbing engineering. ASPE provides its members with access to technical education, professional development, industry standards, and a global network of plumbing engineering professionals committed to protecting public health, safety, and welfare through innovative plumbing system design.

IAPMO, founded in 1926, is a global nonprofit organization that develops and promotes comprehensive plumbing, mechanical, and building codes and standards to protect public health, safety, and the environment. Through education, product certification, code

development, and industry collaboration, IAPMO supports sustainable practices and innovation in the built environment worldwide.

ASSE International is a 119-yearold ANSI-accredited standards developer and certification body dedicated to protecting public health and safety through the development of performance standards, professional certifications, and educational programs for the plumbing and mechanical industries.

Founded in 1994, ARCSA International is a nonprofit organization dedicated to promoting sustainable rainwater and stormwater harvesting practices through education, standards development, and advocacy worldwide.

The 2025 ASHRAE Building Decarbonization Conference, Oct. 22-24, will be the hub for engineers focused on how to accelerate building decarbonization strategies.

“Decarbonization is not just about technology. It’s about rethinking how we design, operate, and value our buildings,” said 2025-26 ASHRAE President Bill McQuade , P.E., CDP, Fellow ASHRAE, LEED AP. “This conference is about equipping

building professionals with the strategies, partnerships and tools needed to make measurable progress.”

The two-and-a-half-day program will feature 21 seminars, 14 panels, five technical tours and three keynotes across four tracks: Scaling Decarbonization, Innovator’s Showcase, Blueprints for Change, and Beyond Decarbonization. Sessions will deliver both visionary perspectives and practical solutions that attendees can apply immediately

To date, registrants seem most eager for these highly anticipated sessions:

Demystifying Existing Building Decarbonization: New Tools for Strategic Decarbonization Planning: This panel discussion introduces attendees to the strategic decarbonization planning process, presents three tools, and provides examples of plans that have been developed and successfully implemented in real buildings.

Innovating to Zero: Developer Arriving at Net Positive, Operator Electrifying a Community Including Shared EVs and Designer Outthinking AI in “Human Versus AI”:

This seminar features three leading projects in climate action. The trio includes a fully net-zero campus building at the University of Illinois, an all-electric Canadian development with shared EV mobility, and a bold “human versus AI” competition exploring low-carbon design at scale. Together, they reveal how developers, operators, and designers are rethinking what’s truly possible now.

This session explores how new data centers can transform waste heat into a valuable resource for heating buildings and supporting sustainable urban development. Case studies demonstrate integrated design strategies and emerging metrics that are reshaping the future of data center efficiency.

The Art of Decarbonization:

The Museum of Modern Art’s multiphase strategy to meet New York City’s Local Law 97 targets while safeguarding irreplaceable artwork and improving operations is examined. Speakers will share how energy upgrades, carbon reduction measures, and real-time

analytics are helping to meet sustainability goals and enhance resilience.

Decarbonizing at Scale: Using AI to Move Fast (and Accurately) for Large Real Estate Portfolios

This session presents how one organization is leveraging AI-driven analytics to accelerate the decarbonization of a large real estate portfolio. Presenters will explore legislative and financial drivers, tradeoffs between traditional engineering and AI approaches, and lessons learned on using technology to achieve emissions goals at scale.

ASHRAE’s New IBC Framework:

An Interactive Discussion

This interactive session introduces

ASHRAE’s global code framework designed to help countries implement building energy codes by 2030. Participants will preview assessment tools and technical guidance, then take part in a mini stakeholder workshop to experience how this framework can advance decarbonization collaboration worldwide.

In-person registration to attend the 2025 ASHRAE Building Decarbonization Conference is $750 for ASHRAE members ($800 for non-members). Additional options are available.

For the full technical program, registration and additional info for the 2025 Building Decarbonization Conference, visit ashrae.org/2025decarb.

In response to production of new low-global warming potential (GWP) refrigerants that have not yet had the benefit of independent evaluation, the Air-Conditioning, Heating, and Refrigeration Institute (AHRI) is launching an industry-wide cooperative research program to identify and evaluate promising alternative refrigerants having a GWP of less than 300 for major product categories, such as air conditioners, heat pumps, chillers, and heat pump water heaters.

The program, called the LowerGWP Alternative Refrigerants Evaluation Program, or Lower-GWP AREP, is of interest to AHRI members companies seeking to assess refrigerants that might be appropriate for future HVACR applications, while avoiding duplicative work. This is the third iteration of the program: AHRI successfully managed the original R-22 AREP in the 1990s and oversaw the work of AREP-2 in the 2010s in response to environmental concerns related to high-GWP refrigerants.

As with previous efforts, AHRI will provide the leadership to coordinate

and manage this industry-driven research and work closely with experts from its member companies.

“The objective of this program is to help the industry identify and evaluate the most promising refrigerants, as well as to understand the technical challenges of enabling their use,” said AHRI Vice President of Research Xudong Wang. “The program will not rank these alternatives, but will instead focus on identifying potential replacements for current refrigerants that will allow the industry to meet and comply with future regulatory activities in the United States and abroad.”

To begin, the Lower-GWP AREP will survey chemical producers to create a list of candidate refrigerants. Those that are selected will undergo comprehensive testing, including

compressor calorimeter testing, system drop-in testing (if applicable), and soft-optimized system testing. Refrigerant stability and compatibility with lubricants and other common materials will also be tested, if necessary.

Tests are expected to be performed at participating companies’ laboratories, using their own resources, and paid at their own expense.

The program will be overseen by a Technical Committee consisting of experts from AHRI member firms, operating under the AHRI Research and Technology Committee. The Technical Committee will be responsible for developing detailed test protocols prior to the start of the program, prioritizing tasks if refrigerant samples have limited availability, and ensuring the quality of the results to be published.

Once the Technical Committee roster is finalized, an open solicitation will be made to both U.S. and foreign manufacturers to participate in the testing program. Testing is expected to begin in January 2026.

Contact: Xudong Wang, VP Research, xwang@ahrinet.org.

MagnaTherm® HTD Volume Water Heater

• 20:1 Turndown

• Outstanding 95% Thermal Efficiency

• Field-proven, durable stainless steel heat exchanger

• 6 Sizes: 1600-4000 MBH

• Also available as a condensing boiler

Storage Tanks

• Tank sizes from 80 to 6000 gallons

• Glass lined, epoxy lined, or stainless steel

• Bare, rigid foam, or jacketed and insulated

• Standard or custom built to your specifications

H 75% MORE EFFICIENT*

H ULTRA QUIET OPERATION

H MULTILINGUAL SMART CONTROL

H EXCLUSIVE LED DIGITAL DISPLAY

• Up to 4.20 UEF** – ENERGY STAR® Certified

• Built-in Bradford White WaveTM Connectivity for easy diagnostics and remote-control access via mobile app

• Zero clearance requirements on sides & rear

• English, Spanish, and French languages

• Exclusive Vitraglas® tank lining with Microban® antimicrobial technology LEARN MORE

As the global refrigerants market churns with change, one VRF expert suggests how best to handle the impact of the new A2L’s.

By JOSEPH GUERIN, VRF Specialist, Trane Technologies

Last spring, my colleague Laura Michel and I presented an HPAC Engineering webinar entitled,“What Engineers Need to Know about The Impact of A2L Refrigerants on VRF Systems.” It was an overview of the upcoming changes to variable refrigerant flow (VRF) system designs, and

it was very well-received by HPAC’s online audience.

Attendees tuned in from all 50 U.S. states and 13 other countries. The high attendance and numerous questions submitted highlighted the importance of this discussion and the industry’s desire for more information on this compelling topic. In fact, the number of questions would have required several hours to answer had we addressed them all on the day of the presentation.

With that in mind, we decided to present the information here, as well, incorporating some more recent significant changes to the ASHRAE® 15 safety standard that could have important ramifications for VRF and Ductless projects.

As an industry, we have had over a century to discuss, understand, and agree on the application of air conditioning. Other countries have been using A2L refrigerants for more than

Based in Maryland, the author is now in his 11th year with Trane. Today, he is Trane Technologies’ Mid-Atlantic VRF Ductless Sales Specialist. In his current role, Guerin is responsible for overseeing and supporting the design and application of commercial VRF projects in the region. As an active ASHRAE member, he has taken a keen interest in the 2022 update of the ASHRAE 15 Safety Standard, exploring its implications for VRF and Ductless system designs. Email: Joseph.Guerin@Trane.com.

Import Deadline

≤ 65k btu/h Mini-split Multizone

Installation Deadline Mini-split

Mitsubishi Electric Warranty Parts availability

Import Deadline ≤ 65k btu/h

Heat Recovery VRF

Multizone Heat Pump VRF

Installation Deadline VRF

The EPA outlined different timelines for Mini-Splits and VRF equipment. VRF must be manufactured or imported by the end of this year, and it must be installed and charged for operation by the end of 2026.

a decade, but here in the U.S., we have only been discussing them for VRF and Ductless applications over the last few

Other countries have been using A2L refrigerants for more than 10 years, but the U.S. has only recently been discussing them for VRF and Ductless applications.

years. So, suffice it to say, our collective understanding of the entire topic is still in its infancy.

So let me start with the good.

While some geographies may be hesitant to use A2L refrigerants in certain equipment, the demand for Ductless/Mini-Split products is still 7.8% higher than last year, according to the latest Air-Conditioning, Heating and Refrigeration Institute (AHRI)

ASHRAE 34 Classifications for Refrigerant Toxicity and Flammability. ASHRAE 34 added Flammability Class 2L in the 2010 version since these refrigerants exhibited a distinctly lower flammability than the Class 2 refrigerants.

market data through July of this year. Overall, this shows that our industry did not pull back when Ductless products transitioned to R-454B. Rather, it surged forward with the adoption of the new refrigerants. If this is any indication of where VRF is headed, it

would be expected for VRF to continue its powerful growth in the industry as a very efficient and sustainable system.

A side benefit to VRF equipment using A2L refrigerants is the addition of leak

detection and safety shut-off valves. To be perfectly blunt, if VRF does not have these items, the projects where it can satisfy the ASHRAE 15 safety standard are very few and far between.

Multitudes of engineers and contractors in our industry have been requesting these features for years. So, many are now thrilled to see them included as standard in this next generation of VRF equipment. Primarily, these new features will keep occupants safer and will give building owners greater peace of mind, just knowing that they are in place.

But they also assist with troubleshooting if something does go wrong. For instance, now that we have detectors, we can locate a refrigerant leak much faster and more easily. Better yet, the system only needs to isolate the units that detect refrigerant, allowing the remainder of the system to continue operation (Interpretation IC 15-2022-7).

One of the other major changes since last spring’s webinar that most deem as “good” is Addendum ‘A’ to ASHRAE 15-2024. This addendum added an additional exemption to the shaft enclosure requirement, saying that if the piping was tested in accordance with Section 9.13, it is exempt from requiring a shaft. However, if that piping is placed into a shaft enclosure anyway, it will still require ventilation for A2L refrigerants. While the ventilation requirement remains, this is still a welcome relief that allows VRF and Ductless designs considerably more leeway.

As the safety standard continues to evolve, code compliance is another conversation the industry is now having. The International Mechanical Code (IMC) and ASHRAE 15 have conflicting information in a few areas, leaving engineers and contractors to wonder whether they should follow the latest national safety standard, or follow their local code.

Thankfully, this conversation has made its way to the local level, where some jurisdictions are modifying their

Refrigerant pipe shaft requirements are one of the most discussed aspects of ASHRAE 15, with multiple addenda posting to both the safety standard and the code. Engineers and contractors should continue to follow this topic closely as more proposed changes are still under review.

Multitudes of engineers and contractors have been requesting leak detectors and shut-off valves for decades.

VRF equipment using A2L refrigerants finally has them.

own regulations to provide a more harmonized standard for local use. For example, the North Central Texas Council of Governments (NCTCOG) approved regional amendments to the 2024 IMC, explicitly incorporating

ASHRAE 15-2022 verbiage. To see the document, go to hpac.com.

In a similar fashion, the Board of Building Regulations and Standards (BBRS) in Massachusetts issued an advisory stating that systems compliant with the updated ASHRAE 15-2022 standard are also compliant with the 10th-Edition Massachusetts building code, effectively bridging the gap with IMC 2021 and enabling projects to move ahead without costly restrictions. To see the document, go to hpac.com

For jurisdictions not taking this approach, the industry has still another avenue for code compliance.

Engineers and contractors are allowed to file for a variance citing future codes. The publication of ASHRAE 15-2024 came one year earlier than usual and was relatively unnoticed compared to the publication

of the 2022 version. But this was quite significant because it establishes a new three-year cycle that coincides with the model code cycle.

The ASHRAE 15-2024 standard can now be submitted in public comments to the code councils for incorporation into the IMC 2027 code. Orchestrating the safety standard and code in this way will give the industry a cohesive guideline moving forward. In fact, we’re already witnessing that come to pass. As just one example, Section 1109.2.5 will be modified so that Exception 2 to pipe shafts recognizes A1 as well as A2L refrigerants.

While these changes are positive for VRF and Ductless applications, it would not be responsible if we didn’t also discuss the sticky issues that remain.

As already mentioned, if a pipe shaft is used, regardless of whether it is not required, that shaft must be ventilated. An addendum to remove this requirement for A2L refrigerants is still under review, and its acceptance is not a foregone conclusion, despite the broad support it would likely garner in our industry.

The ASHRAE 15-2024 standard can now be submitted in public comments to the code councils for incorporation into the IMC 2027 code.

Another stickier topic that still has many scratching their heads is unoccupied, energy-dense spaces in buildings, i.e. IT closets, server rooms, etc.

The requirement to evaluate occupied AND unoccupied spaces for A2L refrigerants is proving quite difficult in these situations because of the high capacity-to-volume ratio these spaces

The

location and testing of VRF refrigerant piping will require additional focus from engineers and contractors as they begin working with A2L refrigerants soon.

see. It remains to be seen whether the safety standard will give any leniency to these unoccupied spaces. But for now reducing system charge, increasing effective dispersal volume, or using mitigation controls are the only levers we can pull at this time.

Lastly, ASHRAE recently cleared up the question on how VRF Branch Controllers should be evaluated. The safety standard does not specifically mention the terms “Branch Controller,” “Refrigerant Distribution Box,” or anything similar, so until recently, the best understanding was to treat a Branch Controller as part of the refrigerant piping and, therefore, exempt under Section 7.2.3.1.1.

But Interpretation IC 15-2022-12 now establishes a Branch Controller as separate from refrigerant pipe, therefore requiring its own effective dispersal volume calculation. Reducing system sizes and increasing dispersal volume are still options, but given the large refrigerant charges in VRF systems, this could still prove difficult for certain projects.

Thankfully, another option exists which is a ventilated enclosure. ASHRAE defines this as “a type of equipment enclosure that includes an integral ventilation system that will prevent refrigerant leaked inside the equipment enclosure from escaping into the space surrounding the equipment enclosure.”

It remains to be seen how each manufacturer decides to handle this, but with the A2L transition date on the horizon, we should know very soon.

If the webinar presented in April didn’t address all your concerns, I hope these updates offer additional clarity and reassurance. ASHRAE is not increasing the burden on VRF design and installation but rather recognizing and providing the framework to design smarter and safer systems.

With thorough testing, strategic code citation, and local expertise, you should find that these new standards and regulations pave the way for greater innovation and efficiency in VRF and Ductless systems.

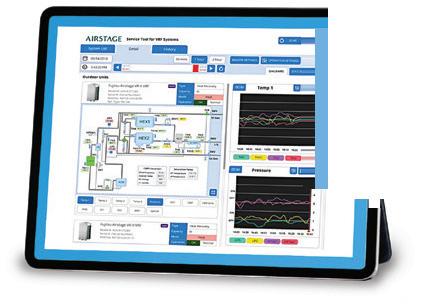

Now, cost doesn’t have to be the biggest elephant in the room when choosing a BMS.

Experience the benefits of an innovative virtual Building Management System with Fujitsu AIRSTAGE Cloud.

Don’t let a ton of upfront costs keep you from optimizing your facilities’ energy costs. Fujitsu’s innovative AIRSTAGE Cloud BMS, coupled with AIRSTAGE VRF products, allows facilities managers to install, control, troubleshoot, and reduce energy costs – all from a simple online platform. This new, virtual private BMS produces a strong ROI in months, not years! Plus, our full line of AIRSTAGE VRF solutions is backed by 45 years of HVAC expertise and delivers more flexibility, power and comfort in less space. Say goodbye to the elephant in the room – and hello to a smarter, more cost-effective BMS solution…Fujitsu AIRSTAGE Cloud.

Charlotte Pipe and Foundry’s Edge HP Iron pipe and fittings are designed for aggressive DWV applications. This specially coated cast iron provides enhanced protection for environments such as hospitals, commercial kitchens, soda fountains, casinos, and more. The electrocoating process prevents delamination, delivering cutting-edge performance every time.

Engineers must overcome the potential threat of waterborne pathogens, the risks associated with extreme water temperatures, and the need to maintain both organizational and regulatory compliance.

By BRIAN ARMSTRONG, Director, Hot Water Group, Armstrong International

Designing a best-in-class hot water system that meets a building’s hot water requirements while ensuring the health and safety of its occupants is not a simple task.

Engineers are faced with the potential threat of waterborne pathogens like Legionella, the risk associated with extreme water temperatures, and the need to maintain organizational and regulatory compliance.

While there’s no one-size-fits-all solution to achieve a healthy hot water system, engineers can build in lasting safeguards and efficiencies by focusing on core design and operational principles, emphasizing four key pillars: infection control, scald protection, compliance and sustainability.

In some organizations, these priorities may also be governed by the requirements of a Water Management Plan (WMP)—a facility-specific strategy typically overseen by the facility manager or safety team, with input from consultants and engineers, and guided by standards such as ASHRAE 188-2021 and Guideline 12-2020.

Ultimately, when system design reflects these four key pillars, and aligns with an established WMP where applicable, engineers help ensure hot water delivery that is safe,

reliable and efficient. Let’s take a closer look at each pillar.

Waterborne pathogens, especially Legionella, require a thoughtful risk management strategy. But because water quality and system design vary widely across the U.S., and because Legionella can thrive under many environmental conditions, there’s no universal solution. Instead, specialists use the concept of barriers: combinations of processes, tools, and procedures that help control the spread of infection.

The most essential barrier is water temperature. All parts of the hot water infrastructure should be maintained above the Legionella growth range high limit of 122°F (50°C), and initially heated to or periodically elevated to 140°F (60°C) or above, which kills the bacteria within 32 minutes.

The age of the water also matters. Areas such as pipe runs leading to low-use fixtures can allow water to stagnate and drop into the 95°F–115°F (35°C–46°C) range, which is ideal for Legionella growth. To mitigate this, engineers can reduce those distances

Based in Kalamazoo MI, the author is part of Armstrong International’s 5th generation family ownership. He serves as the firm’s director of hot water, managing sales, marketing, and service operations for the company’s hot water system solutions.

using appropriate piping technologies, fittings and design recommendations. Likewise, periodic fixture flushing is an additional infection control measure.

A discussion about infection control isn’t complete without addressing biofilm, the organic slime that builds up inside hot water systems. Left unchecked, it provides a nutrient-rich environment for bacteria.

A 2024 study by the Montana State University Biofilm Engineering Dept. found that scale buildup in pipes provides a scaffold for biofilm. ASPE affirmed this in its 2022 publication, Engineering Methodologies to Reduce the Risk of Legionella in Premise Plumbing Systems, finding scale contributes to flow restriction, water heater inefficiencies and pathogen development. Historically, removing scale required ongoing maintenance. Today, nanobubble technology offers a chemical-free, automated solution. Installed as a static side-stream, the system creates microscopic bubbles that remove scale and prevent future deposits. This improves system hygiene and performance without introducing additives, making it ideal for both new builds and retrofits.

Scald prevention is another important pillar, so developing a methodology for optimizing against scald risk is an absolute must—both for the safety of users and operators.

Today’s digital mixing valves maintain a high degree of set point accuracy. They provide precise temperature control, resist temperature creep, and can communicate with building automation systems to enhance user safety. These valves typically hold temperatures within 2° of the setpoint and can issue alerts or default to cold water/ return water only, as needed.

Temperature creep—a gradual increase in system temperature during zero fixture demand—can result when return water isn’t properly

This illustration shows the technology used at six different points in the hot water system: 1. Heat pump; 2. Digital water heater; 3. Nanobubble generator (scale remover); 4. Digital recirculating valve; 5. Thermal utility management system (for monitoring and reporting); 6. Hands-free digital water temp controls.

proportioned. High-performance digital mixing valves offer multiple integral thermistors to help reduce this risk.

In high-temperature systems, those calling for 140°F/60°C or above, pointof-use protection becomes even more important. Thermostatic shower valves and under-sink thermostatic mixing valves (TMV) offer basic scald protection, but their performance depends heavily on proper setting and maintenance. The most protective feature is the hot stop, which limits maximum temperature, but it requires seasonal adjustment and must be reset after servicing. A misadjusted hot stop can expose users to scalding temperatures.

For simplified protection, a lowertemperature recirculating hot water system with a digital mixing valve set point of 123°F/51°C – 125°F/52°C, served by a >140°F/60°C water heater, can reduce the need for thermostatic point-of-use temperature control. In these systems, pressure balance shower

valves (PBV) offer added protection by compensating for supply pressure changes and shutting off flow entirely during pressure failure.

At lavatories, the scald risk is lower since users can typically withdraw hands quickly. While special consideration may be needed for infants, the elderly, and individuals with physical limitations, for general use, a mechanical valve with an integral hot stop set to 110°F (43°C)— installed ahead of the faucet and supplied by 122–125°F (50–52°C) water from a digitally controlled recirculating system—offers a simple and effective solution.

Modern technologies make it easier to maintain infection control barriers, especially temperature-based strategies that inhibit Legionella growth. For example, digital recirculation valves, whether installed at the point of source

or zoned throughout the building, can keep system water within 2° of the setpoint. High-performance models with a 1° inlet-to-outlet differential are particularly effective. This precision allows systems to maintain minimum temperatures without setting the mixing valve at a dangerously high outlet temperature.

Primary or secondary hot water temperature control at the point of use has been an accepted practice but plumbing designs that specify pointof-use TMVs bring challenges. TMVs often contain rubber seals and narrow passages, which can foster bacterial growth. By design, they also restrict high-temperature disinfection unless manually overridden and reset.

It is also important to operate the circulation pumps continuously. Thermostatic and digital master mixing valves, which require an aquastat to shut the pump off for over-temperature protection, may compound the risk of pathogen growth in stagnant, warm water. Codes and regulations that require pumps to shut off as an energy-saving measure should be challenged accordingly.

A healthy hot water system must also align with the applicable Standards of Care, including:

• OSHA Technical Manual;

• Joint Commission Environment of Care;

• ASHRAE 188-2021;

• ASHRAE Guideline 12-2020;

• VA Directive 1061.

These documents offer guidance on temperature control limits, monitoring, documentation and response protocols. A properly implemented WMP is key to meeting these standards.

Compliance is especially critical in healthcare. In 2017, the U.S. Centers for Medicare & Medicaid Services (CMS) issued a directive requiring hospitals and long-term care facilities to implement policies that reduce microbial growth in building water systems. Since CMS controls Medicare and Medicaid reimbursement, loss of certification can have

serious financial consequences. Certification can be done either by a state inspection, or by Joint Commission (a CMS certification subcontractor).

The CMS directive (which used ASHRAE 188 as a guideline) marked the most significant change in how facilities were required to manage and prevent the spread of Legionella since the bacteria was identified in 1976 in Philadelphia.

Finally, all products used in a hot water system must be certified and comply with the relevant standards for hot water systems by the International Association of Plumbing & Mechanical Officials (IAPMO) and the American Society of Sanitary Engineering (ASSE).

The way we heat water is changing. Many states and cities are adopting electrification policies to reduce dependence on fossil fuels. CO₂-based air source heat pumps are being heavily promoted for commercial applications, thanks to their strong efficiency performance, low environmental impact, and suitability for domestic single-pass water heating. However, they are not well-suited for recirculating hot water systems. These systems require multiple tanks, including swing tanks, that often hold water in a temperature range that promotes Legionella growth, making them incompatible with ASHRAE 188 and Guideline 12.

New, high-temperature watersource heat pumps, however, are a strong option that can recover waste heat from chillers, exhaust fans or sewer systems. Still, energy efficiency improvements can also be made without switching to electric. An ongoing study with Pacific Gas & Electric examined a simulated 44-unit apartment environment at its San Ramon, CA, test lab. The study has shown that using pointof-source water temperature control (central master mixing valve) yields energy savings between 10% and 18% above point-of-use controls.

This was attributed to reduced system heat loss at higher recirculation temperatures, along with reduced

tank stratification. These findings were further validated in real-world installations of digital mixing valves at hotels and medical facilities, and they will be used as evidence to propose plumbing code changes in California.

Condensing water heaters, while not new, have become highly efficient in recent years, generating 99 cents worth of hot water for every dollar spent on fuel. While the goal is to eliminate fossil-fuel use eventually, the abundance of low-cost, relatively clean-burning natural gas in North America makes it a compelling option. Until we move completely away from fossil fuels, a logical interim solution would be to adopt a hybrid system that uses a water-source heat pump for baseline load and a gas-fired heater for peak demand— ensuring a reduction in fuel use while maintaining performance.

On-demand water heaters are another efficient option. These systems avoid standby heat loss, deliver up to 99.8% operating efficiency, and can heat water to disinfection temperature before blending it down with onboard digital controls for recirculation.

Finally, as noted, nanobubble technology also supports sustainability by removing scale, improving heat transfer, and reducing energy use.

Each hot water system has a unique profile, shaped by variables like building type, usage patterns, fixture layout, geographic location, seasonal water temperature shifts, and water chemistry.

But regardless of those differences, the foundation for a healthy system must prioritize infection control, scald protection, compliance, and sustainability. By anchoring to these four pillars, and implementing a thoughtful WMP, engineers can deliver systems that are safer, more efficient, and better equipped to meet the demands of today’s buildings.

In doing so, this will not only protect users and operators in the present but also build resilient infrastructure that stands the test of time.

Stay ahead in HVACR through hands-on learning experiences at the AHR Expo. Build valuable networking connections with cross-disciplinary peers and industry leaders and discover solutions for current and future projects. AHR is your place to thrive in engineering planning and design.

FEB 2 -4 2026

Achieving occupant comfort can be tricky, so psychrometric principles must be applied to find that proper mix of space temperature and humidity control.

By DAVID SCHURK, DES, CEM, LEED AP, CDSM, SFP

HVACD engineers face the complex task of designing systems that deliver comfort, productivity, and occupant satisfaction across all building types. This is a formidable task, and one that can be best achieved when certain psychrometric principles are understood and applied. Temperature alone does not guarantee comfort, and it is only through the proper combination of space (sensible) temperature and (latent) humidity control that indoor environments are created that achieve optimized results.

Warm blooded animals (like us) maintain an internal temperature higher than the ambient temperature surrounding us, so heat flows from our body to the environment. Humans constantly regulate heat through a balance of heat production (metabolism) and heat loss, exchanging heat with the environment in order to regulate temperature. Temperature regulation attempts to maintain core body temperature near 98.6°F (37°C), despite varying conditions and activity levels.

At rest, the body loses heat through conduction (~3%), convection (~27%), radiation (~40%), and evaporation through the skin (~30%). For HVACD engineers, understanding these physiological mechanisms is key to designing spaces that align with how the body actually sheds heat.

The rate at which we deliver metabolic heat outward depends on several factors.

Sensible heat loss from the skin is regulated by the thermal insulating value of clothing, the ambient temperature, and the heat coefficient of air at the skin surface. Evaporative heat loss from the skin depends on the wetness of the skin, the vapor pressure (humidity) in the ambient air, the evaporative heat transfer coefficient, and the vapor permeance of clothing. With mean radiant temperature being another crucial factor, these govern rates of heat loss between the body and the external environment.

If the rate of bodily heat production exceeds that of total heat loss, heat storage occurs, and deep body temperature rises. It must then be dissipated to the external environment to prevent overheating, with heat illness occurring if the body is unable to maintain a balance between heat generation and core body temperature. If taken further, heat stroke happens when core body temperature reaches ~104°F (40°C).

Once environmental temperature rises and heat loss is impaired, sweat evaporation becomes the body’s primary cooling method. Sweat evaporation is the vaporization and subsequent diffusion of moisture from the skin surface, and the thermal energy needed to vaporize sweat (the latent heat of evaporation), is drawn from the skin and therefore cools it.

Values for latent heat of evaporation of human sweat are suggested to be

similar to the latent heat of evaporation of pure water, giving a value of ~1,050 Btu/lb (~2,445 kJ/kg) at 72°F (22.2°C).

Of the primary heat-loss mechanisms noted, it is the impact that evaporative cooling has on our body that is often overlooked or misunderstood.

While occupants may prefer cooler indoor temperatures for comfort, particularly in the summer, building code and standards (e.g., ASHRAE 55, 62.1, or 170) may dictate humidity conditions for compliance. It is the two, simultane-

Temperature alone does not guarantee comfort, and it is only through the proper combination of space temperature and humidity control that indoor environments can achieve optimized results.

ously, that truly determine how well any indoor environment is received.

Unfortunately, many HVACD systems cannot obtain the combined temperature and humidity that garners environmental success, and unfortunately a lack of attention to this important psychrometric prerequisite many times results in less than desired results.

While dry-bulb temperature often dominates discussions of comfort, humidity, and more specifically vapor pressure, plays an equally critical role.

Vapor pressure is the force exerted by water vapor. It is defined as the pressure at which vapor, and liquid can exist in equilibrium at a given temperature.

In psychrometrics, the value of vapor pressure is calculated from other properties such as humidity ratio or dew-point temperature (absolute moisture). Each water molecule exerts pressure on the surrounding environment. Water vapor diffuses (moves) from high to low vapor pressure and can move independently of airflow.

Simply stated, it is the displacement of molecules of a fluid within another fluid, such as water vapor in air. Measured in inches of mercury (inHg), vapor pressure helps explain sweat evaporation.

When attempting to remove and evaporate sweat from the body, moisture must typically travel through clothing. Perspiration which is driven through clothing must then be exposed to convective air currents which assist in evaporation and its cooling effect.

Evaporative cooling depends on vapor pressure gradients between skin and ambient air, which are strongly influenced by local psychrometric conditions. These conditions determine how quickly any vapor transmission occurs by molecular diffusion and evaporation, and what immediate cooling effect it may have on a building occupant. Without creating space conditions to accomplish this task, people can feel wet, clammy, and too warm regardless of the dry-bulb temperature.

In fact, colder air in a too-humid environment may aggravate an already unpleasant situation. Many times, we do not need cooler ambient air, we need drier ambient air.

Figure 2 shows the vapor pressure gradients between a saturated skin surface at 92°F (33.3°C) and the surrounding air at 72°F drybulb (22.2°C), with varying relative

David N. Schurk, DES, CEM, LEED-AP, CDSM, CWEP, SFP, CIAQM, is the “Dehumidification Jedi” at Innovative Air Technologies in Covington, GA. He is an ASHRAE Distinguished Lecturer and has over 40-years of experience in the design and analysis of heating, ventilating, and air-conditioning systems for a variety of market sectors, with a special focus on aerospace and healthcare facilities. Schurk can be reached at 920-530-7677, or david@dehumidifiers.com.

72°F

humidities. It is evident that lower space vapor pressures can drive higher vapor pressure differentials which assist in moisture diffusion, positively impacting our body’s evaporation efficiency.

As a caveat, while vapor pressure is typically expressed in inHg, inches of water column (inH2O) may be a more intuitive measurement for HVACD professionals who compare it with fan static pressure. This requires multi-

If the rate of bodily heat production exceeds that of total heat loss, heat storage occurs, and deep body temperature rises.

plying inHg by ~13.60 to achieve a comparable number. Viewed this way, it is immediately recognizable that vapor pressure can create a considerable driving force for moisture in the air.

Engineers should consider designing indoor environments which can achieve the necessary vapor pressure gradients between the occupant’s skin and the surrounding ambient to assist in wicking perspiration quickly, through layers of outer clothing. How large this indoor vapor pressure gradient needs to be is ambiguous, and subjective to seasonal weather conditions, the occupant’s activity level,

the amount of outer clothing worn, along with other influencing factors. More industry guidance is needed in this area, but regardless it is important to understand and take into consideration.

As an example, orthopedic surgeons heavily gowned and performing stressfully under high intensity lighting may demand their operating suites be both cold and dry, perhaps conditioned to 60°F DB (15.6°C) at 40% RH and ~36°F (2.2°C) dewpoint temperature at 0.20 inHg. Without aggressive dehumidification strategies, these conditions cannot be achieved with conventional cold coil-based cooling systems.

Elderly individuals in senior care facilities may prefer surroundings closer to 78°F (25.6°C) at 50% RH and ~58°F (14.4°C) dew-point at 0.48 inHg to provide warmer temperature with a surrounding humidity that limits the evaporative cooling effect from their body, see Figure 3

Too high of vapor pressure differential, coupled with cold interior building surfaces, is also a possibility of why people located in wintry northern climates may feel “chilled” even with elevated indoor sensible temperatures when relative humidity drops below ~30% due to drier outdoor conditions. This may create too much evaporative cooling of an occupant’s skin surface.

It also illustrates why a one-size-fits-all approach to humidity control cannot meet the physiological needs of diverse populations. Indoor skin-to-air vapor pressure differentials of 1.12 to 1.20 inHg may be warranted in the summertime, while wintertime differentials of 1.04 to 1.12 inHg may be more favorable.

Existing practices applied in HVACD system design often fail to achieve satisfactory indoor conditions when considering both temperature and humidity. Most systems take a traditional approach to dehumidification which is based on the removal of moisture through condensation.

This occurs when air is chilled below its dew-point temperature through contact with a cold surface such as a cooling coil supplied with refrigerant or chilled water. As warm, humid air passes over the coil’s tubes and fins, its sensible temperature is reduced, and depending on the leaving temperature of the air, latent heat may also be

removed through formation of liquid condensate, which lowers the moisture content of the air.

Many systems like this cannot reach a low enough coil temperature to meet psychrometric requirements for comfort based on indoor humidity and the resulting vapor pressure gradients between skin and ambient air which enhances the evaporative cooling effect.

In applications requiring humidity control beyond the limits of cooling coils, solid desiccant dehumidification provides a proven alternative. This technology can remove moisture from the air by means of a desiccant, a substance that “adsorbs” water in its vapor state (molecularly), without requiring moisture to condense on a cold surface.

Solid desiccant dehumidification can easily maintain a space at 60°FDB (15.5°C) and 40% RH for a hospital operating room environment, or

garner dew-point temperatures as low as -80°F (-62°F C) for lithium battery manufacturing and other critically stringent applications.

The engineer’s role then become one of achieving a balanced design which

applied chilled-water with reheat) to maintain optimal humidity conditions and applicable skin-to-air vapor pressure differentials is imperative. Comfort is not a thermostat setting, it’s a psychrometric balance. By designing for both temperature and vapor pressure control, engineers

Engineers can design indoor environments which can achieve the necessary vapor pressure gradients between the occupant’s skin and the surrounding ambient to assist in wicking perspiration quickly.

controls latent loads as aggressively as sensible loads and does not rely solely on space temperature control to produce satisfactory results. Considering dedicated dehumidification strategies (e.g., active solid desiccant, DOAS,

can deliver environments that build upon, and go beyond, the guidance of ASHRAE Standard 55 on thermal comfort, truly optimizing human comfort, performance, and wellbeing.

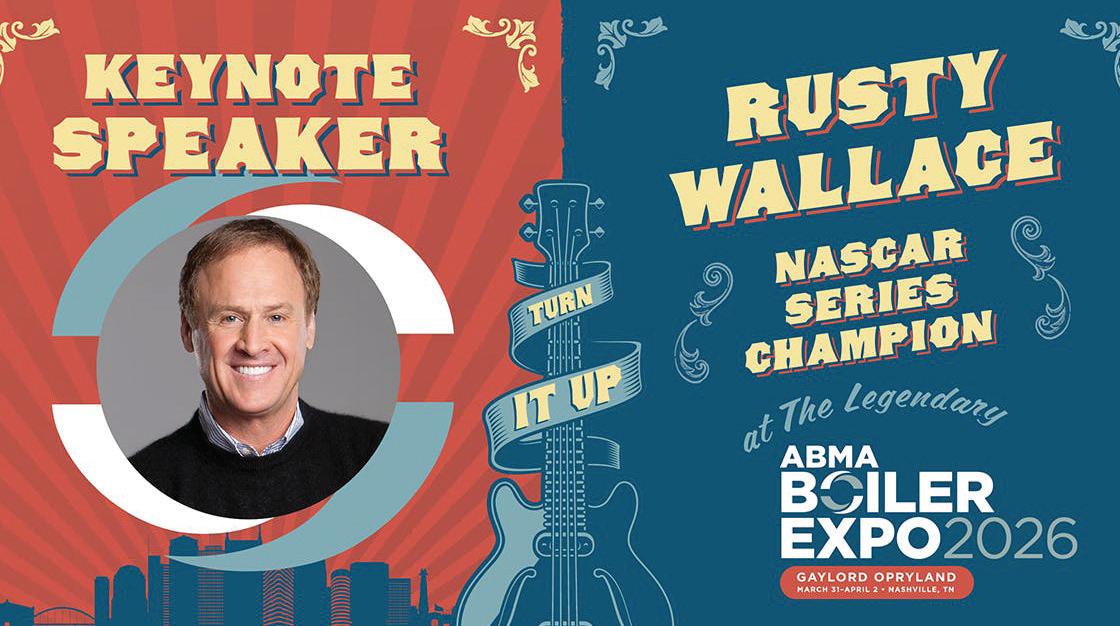

ABMA will host its third bi-annual event next spring as players from across the entire boiler supply chain descend on Nashville.

By SHAUNICA JAYSON, VP, American Boiler Manufacturers Association

The American Boiler Manufacturers Association (ABMA) has unveiled an exciting and revitalized educational program for the 2026 BOILER Expo, taking place next spring at the iconic Gaylord Opryland in Nashville, TN.

This highly anticipated event will expand our educational offerings from previous expos and feature over 20 breakout sessions across four key educational tracks. In addition, next year’s event will feature new handson boiler training opportunities, and expanded pre-conference workshops, ensuring an enriching experience for all attendees.

As the only industry event dedicated exclusively to the entire boiler supply chain, the ABMA BOILER Expo serves as a vital platform for networking, learning, and discovering the latest innovations in boiler technology. Scott Lynch, ABMA President & CEO, states, “In collaboration with the BOILER Expo Advisory Committee, we are meticulously curating a lineup of high-impact content that meets the pressing needs of end-users, engineers, consultants, operators, and boiler professionals.”

Educational tracks will focus on:

• Fundamentals & Essentials: Attendees will gain crucial insights into boiler selection, effective operation,

proper maintenance, and strategies to maximize efficiency. This foundational knowledge is designed for both newcomers and seasoned professionals looking to hone their skills;

• Safety & Compliance: Ensuring the highest level of boiler safety is paramount. Participants will delve into effective project readiness, understanding the significance of boiler safety, and staying compliant with ever-evolving codes and regulations that govern the industry;

• Technology & Innovation: The industry is evolving rapidly, and our sessions will cover the latest advancements in technology. Learn how innovative solutions are being developed to meet and exceed customer needs, helping to foster a more efficient and sustainable boiler room environment;

• Emerging Trends & What’s Next: Explore how the boiler industry is shaping its future through hybrid systems and alternative fuel sources.

Attendees will be introduced to new trends that are redefining the boiler landscape and paving the way for tomorrow’s boiler room.

Additional event highlights include:

• Two Pre-Conference Workshops;

• 10 Dedicated Expo Hours;

• Over 100 Top Boiler Industry Companies will be exhibiting;

• NEW Expo Hall Interactive Hub;

• Mobile Equipment Pavilion;

• NEW Hands-on Boiler Training & Tours in the Gaylord’s Boiler Room;

• And more! For updates, visit abmaboilerexpo.com.

“As we gear up for the 2026 ABMA BOILER Expo, I invite everyone to come together to enhance our knowledge and experience the innovation in our industry,” adds Dustin Divinia, President of Vector Systems & Chair of the BOILER Expo Advisory

Committee. “The exciting enhancements to our educational program promise to deliver invaluable insights and foster collaboration. We are looking forward to the opportunity to elevate boiler expertise and propel the boiler industry forward!”

We expect over 1,500 attendees for this unparalleled experience tailored for everyone in the boiler industry. General Registration opens this fall. So take advantage of this prime opportunity to be part of this memorable gathering in Nashville. To obtain more

information on ABMA and stay up to date on the BOILER Expo, please sign up to receive ABMA’s Boiler Weekly by visiting ABMA.com/news

Since our founding in 1888, the American Boiler Manufacturers Association (ABMA) has advocated for the safe production and operation of boilers, facilitated advances in energy efficiency, and provided solutions for our member companies. Throughout our history, the boiler industry and our member base have relied on the ABMA to lead the industry as it tackles challenges and embraces opportunities in our constantly evolving sector. Through participation with ABMA, our members are better informed, connected, and positioned to thrive in today’s global boiler industry. To learn more, please visit ABMA.com.

NASCAR legend named to kick off ABMA event next spring in Nashville.

The American Boiler Manufacturers Association (ABMA) is thrilled to announce that racing legend and NASCAR Series Champion Rusty Wallace will be the keynote speaker for the 2026 BOILER Expo, taking place at the stunning Gaylord Opryland in Nashville. With nearly 40 years of thrilling racing history, Wallace is not just a champion on the track; he is a trailblazer, a motivator, and an inspiring figure whose impact on the sport of NASCAR has shaped its very identity. The 1989 NASCAR Cup Series Champion, Wallace commanded the racing circuit with remarkable

drive, achieving 55 career wins and a legendary 16 consecutive seasons in the sport.

“Rusty’s unparalleled success and charismatic persona make him an exceptional speaker who will

captivate and inspire our audience,” said ABMA President Scott Lynch . “His stories of determination and resilience resonate far beyond the race track and into every aspect of business and life.”

Rusty’s legacy goes beyond his accolades as a driver. He transitioned from the driver’s seat to a leading voice in racing as the Lead Auto Racing Analyst for ABC and ESPN, and currently serves as the Lead Analyst for MRN Radio, reaching listeners across the nation. His extensive knowledge of racing, passion for the industry, and commitment to

philanthropy through The NASCAR Foundation exemplify his dedication to enriching the community.

Attendees of the 2026 BOILER Expo can expect to gain valuable insights as Rusty shares his experiences and lessons learned throughout his illustrious career. From navigating challenges on and off the track to inspiring teams to achieve peak performance, Rusty will undoubtedly motivate our industry to “Turn it Up, and Amplify Boilers!”

The BOILER Expo is the premier event dedicated to the boiler supply

chain, showcasing leading boiler manufacturers and providing exceptional networking opportunities for those engaged in the purchasing, operation, and maintenance of boilers.

Don’t miss this extraordinary opportunity to hear from Rusty Wallace, a true icon of resilience and a testament to the power of passion and perseverance. General registration for the 2026 BOILER Expo opens this fall.

For more information about the event and to stay updated on all BOILER Expo announcements, visit ABMABOILEREXPO.com.

Industry veteran also leaves his role as chief inspector for Texas.

For medical reasons, Rob Troutt has resigned as chair of the board of trustees for the National Board of Boiler and Pressure Vessel Inspectors (NBBI), effective Aug. 31. He also stepped down as chief boiler inspector for the State of Texas.

“We are grateful for his leadership, dedication, and many contributions during his time as chair,” said NBBI Executive Director Joel Amato. “Under his guidance, we have made significant progress. We thank him for his service.”

In accordance with NBBI bylaws, 1st Vice Chair Eben Creaser, chief inspector for the province of New Brunswick, will serve as interim chair. An election will be held during the Members’ Meeting on Oct. 7 to fill the position for the remainder of Troutt’s term, which concludes May 31, 2026.

Troutt was first elected to the Board of Trustees in 2017 as a Member at Large and became Chair in 2021. He had been chief since 2013.

Creaser, who has served as chief since 2009, was first elected to the Board of Trustees in 2016.

A National Board member and chief inspector since 2013, Troutt had joined the Texas Department of Licensing and Regulation in 2008 as a boiler inspector team leader for ASME and National Board joint reviews.

Troutt served on the National Board Inspection Code (NBIC) Main Committee and the NBIC Subcommittee on Repairs and Alterations. He also had served on several ASME committees, including Section IV Main Committee, Section IV Welded Boilers, and Section VI.

Carrier releases the high-efficiency AquaSnap® 30RQM Modular AirSourced Reversible Heat Pump with a compact footprint and scalable design. It can be tailored to the size and demands of a client’s building, with reliable performance at low ambient temperatures to reduce the need for traditional boiler systems. The heat pump can generate up to 140° F hot water and operate at ambient temperatures below 0° F. It is designed to use lower GWP R-454B. The modular design allows for greater flexibility for individual building needs, with the ability to link up to 16 units for a total capacity of 320 tons of cooling capacity or 4,222 MBH of heating capacity.

Carrier

Johnson Controls launched PENN® System 550 C550A web-enabled control modules, designed to streamline the transition from analog to digital temperature, humidity or pressure-sensing within commercial HVACR equipment. The C550ACN control module features two relay outputs and is a functional replacement for System 350 control modules with a relay output. The C550ACN control module features two relay outputs and is a functional replacement for System 350 control modules with a relay output. The C550AQN control module features two analog outputs and is a functional replacement for System 350 control modules with an analog output.

Johnson Controls

Aspen Mfg. introduces its new Versa Pro convertible coils and air handler systems, which can be converted to use either R-32 or R-454B refrigerant. The dual-refrigerant capability delivers flexibility for both new and retrofit installations. They can be factory- or field-convertible to use either refrigerant, coupled with a proper metering device and a refrigerant detection system, providing outstanding installation flexibility. Aspen Mfg.

AERCO adds to its SmartPlate EV indirect water heater line with high-flow models capable of supporting domestic hot water loads up to 140 gal. per minute. Designed to pair with condensing and electric boilers, the new models offer greater performance flexibility, ideal for both new construction and retrofit projects. They feature compact designs, simple integration and stainless steel potable water components. The line is specifically engineered to complement lowtemperature hydronic systems. By using boiler water temperatures as little as 5 degrees above the required DHW set point, the units reduce radiation losses and drive overall system efficiency. AERCO

Baltimore Aircoil Co. launches its QuickCross replacement fill kits, a new option for crossflow cooling towers. They offer a fast alternative for situations where rapid fill replacement is critical, and budget constraints are a priority. Designed for expedited installation, these kits minimize downtime, allowing customers to quickly restore operations with fill kits for select Series 3000 cooling towers, available with one-week shipping.

Baltimore Aircoil Co.

General Pipe Cleaners’ JM-1000 X Mini-Jet is an upgrade to the toolbox jetter, offering a more efficient motor and a new balanced design. At 23 lb., it provides 1,500 psi of cleaning power. Ideal for clearing clogged sinks, tubs and laundry drains, it clears grease, sand and ice from 1 1/2-in. to 3-in. lines up to 50 ft. long. The pump and motor assembly are safely contained in a rugged, metal diamondplate case. The unit includes a Super-Flex high-pressure jet hose, four-piece nozzle set and water supply hose.

General Pipe Cleaners

AERCO adds a new 2,000 MBH model to its CFR condensing boiler line. Patented StackGuard technology enables CFR to operate as a high-efficiency boiler while maintaining dry flue gas, making it safe for Category I vent systems. Engineers can now select from three CFR sizes to best match building loads. Each CFR unit features a durable 439 stainless steel fire-tube heat exchanger. Thermal efficiency is up to 87.1%, with a 4:1 turndown ratio (dependent on capacity). Boiler sequencing technology allows up to 16 boilers to operate in harmony, each at part load, for optimal efficiency and redundancy.

AERCO

HS Series horizontal split case pumps from Taco feature a short shaft design, extending their operational life and reducing maintenance requirements. The heavy-duty cast and ductile iron casing ensures exceptional strength and longevity, making them an ideal choice for demanding environments. Their extra-heavy construction enhances durability, providing long-lasting performance in even the most rigorous applications. They are built with a mechanical seal and bearings that are easily accessed without disturbing the top casing, making maintenance fast and hassle-free. Each pump comes equipped with Taco Tags, QR code technology that provides instant access to essential product information.

Taco Comfort Solutions

NAVAC’s NEXUS digital manifold gauges are now compatible with the measureQuick app, a widely used diagnostics and performance analytics platform that consolidates data from smart HVAC tools. Technicians can view, log and analyze live system data — such as temperature, pressure, subcooling and superheating — directly within the measureQuick ecosystem. This streamlined workflow reduces manual data entry, improves diagnostic accuracy and helps HVAC professionals troubleshoot faster and more effectively.

NAVAC

Series 94 stainless-steel butterfly valves from Mueller Steam Specialty are engineered to deliver precise flow control and durability across a range of demanding industrial applications. These double offset butterfly valves are designed to optimize system performance while minimizing turbulence, making them ideal for use in chilled and technical water loops, particularly in data center environments. They feature a stainless-steel body and trim for superior corrosion resistance, and a double offset disc design that reduces friction and seat wear, extending service life. A bidirectional, zero-leakage RPTFE seat with a patented retainer ring ensures tight shutoff and reliable performance at temperatures up to 500° F.

Mueller Steam Specialty

Quest Controls enhances its Model 600 lead/lag controller with built-in Ethernet connectivity. Users can monitor and adjust system settings remotely via a password-protected web interface or Modbus TCP, reducing the need for onsite service calls and enabling smarter environmental control from anywhere. Flexible architecture enables centralized management and coordinated operation across multiple HVAC zones. It leverages the patented economizer control algorithm to reduce compressor runtime and maximize free cooling. A web-browser interface allows for simplified configuration and monitoring as well as an intuitive display and keypad.

Quest Controls

Fujitsu General America introduces the AIRSTAGE J-7s line of VRF heat pumps. The line includes two-, three- and four-ton models designed for commercial and light commercial applications. Certified energy efficiency ratings reach up to 15.7 for EER2, 22.2 for SEER2, 11.3 for HSPF2 and 4.64 for COP2. Optimized for a wide range of climates, they operate reliably in outdoor temperatures from -15° F to 70° F in heating mode, and 23° F to 122° F in cooling mode. They feature a 16% smaller footprint than earlier models, reducing mechanical space constraints. Most models are Energy Star and Energy Star Cold Climate-certified.

Fujitsu

General America

Dart Controls introduces the 65E, a high-performance pulse width modulation controller for 12 through 48-volt battery-powered equipment. Now available with reversing option. Rated for 10 to 20 amps continuous current, it features adjustable maximum speed, minimum speed, current limit, I.R. compensation and acceleration, plus a quiet operating frequency of 18kHz. Compact and efficient, it is ideal for portable equipment and solar-powered applications. The updated design includes 12-48 VDC operating range in the same control (jumper selected), supply voltage and current limit status LEDs, and current limit shutdown and output. Available in open chassis and NEMA 4X enclosed models. Dart Controls

Weil-McLain introduces the Simplicity combi boiler. Engineered for high efficiency and dependable performance, this residential gas boiler is designed to deliver reliable comfort and convenience. Available in 110, 150 and 199 MBH. With a 95% AFUE for reduced energy consumption and costs. Suitable for combi or heat-only applications. Stainless-steel, fire-tube heat exchanger ensures long-lasting performance. Ready for integration with heat pumps. Intuitive touchscreen display for easy navigation. Connect via smartphone with Bluetooth.

Weil-McLain

EVAPCO introduces the Titan closed-circuit dry cooler, part of its ecoAir series. The unit’s air-cooled heat exchangers are ideally suited for large-scale heat rejection duty, including use at battery plants, data centers, industrial processing and power generation facilities. It uses the latest heat transfer technology to cool circulated water or glycol by deploying high-efficiency fans up to 36 ft. in diameter. Its V-configured fin/tube bundles are elevated to permit optimal air flow, allowing substantial reduction in plot area; noise emissions and power consumption are also reduced. Because natural refrigerants can be used, including ammonia and carbon dioxide, the cooler can also operate on the condensing side of a refrigerant system. EVAPCO

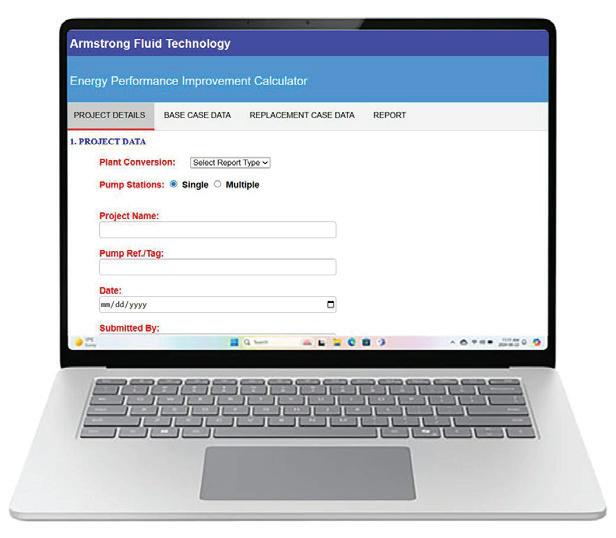

Armstrong Fluid Technology introduces the Energy Analyzer, a new cloud-based tool that generates clear audit reports showing potential energy and water savings for central air conditioning plants that use water-cooled chillers and cooling towers. Drawing on detailed information about the building — including a profile of wet-bulb temperatures, building load percentages, setpoints, minimums and capacities — the tool provides detailed calculations of the savings available with upgraded control and optimization solutions. Armstrong Fluid Technology

Complete Mailing Address of Headquarters or General Business Office of Publisher (Not Printer): Endeavor

Media, LLC,30 Burton

Blvd., Ste. 185., Nashville, TN 37215 Full Names and Complete Mailing Addresses of Publisher, Editor, and Managing Editor - Publisher: EVP/ PUBLISHER NAME Chris Perrino, ADDRESS 30 Burton Hills Blvd, Ste 185, Nashville, TN 3721; Editor: Mike Eby, 30 Burton Hills Blvd, Ste 185, Nashville, TN 37215; Managing Editor: Rob McManamy, 30 Burton Hills Blvd, Ste 185, Nashville, TN 37215

Owner - Full name and complete mailing address: Endeavor Media Holdings I, LLC, 905 Tower Place, Nashville, TN 37204; Endeavor Media Holdings II, LLC, 905 Tower Place, Nashville, TN 37204;Resolute Capital Partners Fund IV, LP, 20 Burton Hills Blvd, Suite 430, Nashville, TN 37215;RCP Endeavor, Inc, 20 Burton Hills Blvd, Suite 430, ,Nashville, TN 37215;Northcreek Mezzanine Fund II, LP,312 Walnut Street, Suite 2310,Cincinnati, OH 45202;Invegarry Holdings, LP,44235 Hillsboro Pike,Nashville, TN 37215;Everside Fund II, LP,155 East 44th St, Suite 2101 - 10 Grand Central,New York, NY 10017Everside Endeavor

F1 Blocker, LLC, 155 East 44th St, Suite 2101 - 10 Grand Central, New York, NY 10017;Everside Endeavor International Blocker, LLC, 155 East 44th St, Suite 2101 - 10 Grand Central, New York, NY 10017;Everside Founders Fund, LP, 155 East 44th St, Suite 2101 - 10 Grand Central, ,New York, NY 10017;Suncap Endeavor Blocker, LLC,155 East 44th St, Suite 2101 - 10 Grand Central,New York, NY 10017; Known Bondholders, Mortgagees, and Other Security Holders Owning or Holding 1 Percent or More of

14. Issue Date for Circulation Data: September/October 2025

a. Total Number of Copies (Net press run)