CLINICAL INTELLIGENCE FOR THE HEALTHCARE ECOSYSTEM MAY 2024 | VOL. 48, NO. 5 Laboratory Supply Strategies ...6 Reusable vs. Single-Use ... 14 Surgical Device Pre-Treatment ... 18 Recycling, Sustainability ... 28 WWW.HPNONLINE.COM CRITICAL CARE Operations Worth Watching ... 10

VISIT US AT APIC 24 #917

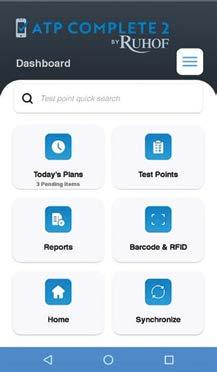

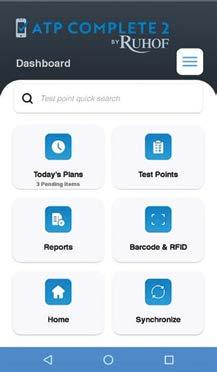

CLEAN CONFIDENTLY with The Next Generation of Contamination Monitoring Technology

• SMART HANDHELD MOBILE PLATFORM

• CLOUD-BASED

• WI-FI CONNECTIVITY

• INFINITE USERS & TEST POINTS

• CUSTOMIZABLE DASHBOARD

• RFID READER/BARCODE READER

• USER FRIENDLY INTERFACE

PREPZYME FOREVER WET

Enzymatic pretreatment humectant spray designed to keep instruments and rigid scopes moist for up to 72 hours.

• EARN CE CREDITS

• VIEW PRODUCT DEMONSTRATIONS

ENDOZIME TRIPLE PLUS WITH APA

Multi-tiered enzymatic detergent with advanced proteolytic action & rust inhibitors for the effective decontamination of surgical instruments and endoscopes

• PICK UP GENEROUS FREE SAMPLES

• RECEIVE A LIMITED-EDITION GIFT

• www.ruhof.com

(800)

1

537-8463

AD-077 Rev0 013124

2 | May 2024 | Healthcare Purchasing News Sourcing & Logistics 6 > Improving Lab Supply Strategies Requires Better Communication JANETTE WIDER 32 > AI and Healthcare: Matchmaking and Translation KAREN CONWAY Surgical/Critical Care 10 > This Critical Care Operation is Worth Watching JANETTE WIDER Infection Prevention 14 > Reprocessing Single-Use Devices Helps Orgs Achieve Cost Savings, Sustainability JANETTE WIDER Sterile Processing 18 > Tips for Point of Use (POU) Pre-Treatment Success KARA NADEAU 22 > From Novel to Established, a Journey of VHP Sterilization ARTHUR HENDERSON 26 > Qualities of Strong, Effective, QualityFocused SPD Leaders DAVID TAYLOR 27 > Bone Cement and Black Light Detection - Part 2 STEPHEN M. KOVACH Special Report 28 > The Way Forward for Sustainability in Healthcare MATT MACKENZIE Departments 4 > Good Things Come to Those Who Wait 5 > What’s on the Web, Advertiser Index 10 6 18 14 28 CONTENTS > MAY 2024

Good Things Come to Those Who Wait

BY JANETTE WIDER, EDITOR-IN-CHIEF

This month we covered a “critical care operation worth watching.”

When I’m not wearing my Editor-inChief hat for Healthcare Purchasing News, you will often find me watching a television series or a movie. And, of course, in true modern-day fashion, I’m obsessively looking up information on the next season or what other projects the actors are working on now.

Sometimes, I feel impatient waiting for certain media to drop (I’m looking at you, James Cameron and the Avatar films). Nevertheless, I’m always looking for updates online about the next big movie from certain actors or if a series I love has been renewed.

In my role at HPN, I’m doing something similar. I’m keeping tabs on different departments at hospitals across the country via press releases, articles, podcasts, and videos to see what new and innovative things they are implementing. Yet, in healthcare, I tend to be more patient.

On page 10, Columbus, Ga.-based Piedmont Columbus Regional is featured in a Q&A with HPN about its expansion plans for its ICU and the impact it will have on the community. Founded in 1836, Piedmont Columbus Regional is a healthcare provider in west Georgia serving the Columbus, Ga. area with a network of health and

medical services through its two hospital campuses. Piedmont Columbus Regional joined the Piedmont system on March 1, 2018.

During COVID, it became apparent to leaders at the organization that more space was needed, and they took action. The project will be completed in two years’ time and will now be able to provide the community with the most up-to-date ICU environment.

HPN plans to feature more stories like this one moving forward so our readership can learn from their peers and see what is happening in hospitals across the U.S.

We have one more exciting an nounce ment for the brand this month. HPN is launching its podcast, Healthcare Hodgepodge, later this month. The podcast will feature interviews with industry experts and article reads across our many verticals. Hosts of the podcast will include Janette Wider, Editor-in-Chief; Matt MacKenzie, Associate Editor; and Chris Driscoll, Publisher. Healthcare Hodgepodge will be available on your favorite podcasting app—subscribe today so you don’t miss the first episode!

Finally, if your department is doing something that is “worth watching,” reach out to me at jwider@hpnonline. com or connect with me on LinkedIn.

EDITOR’S NOTE 4 | May 2024 | Healthcare Purchasing News Connect with us: facebook.com/hpnonline twitter.com/hpn_online linkedin.com/company/healthcare-purchasing-news/ Group Publisher Chris Driscoll cdriscoll@endeavorb2b.com | 978-880-8345 Editor-in-Chief Janette Wider jwider@hpnonline.com Associate Editor Matt MacKenzie mmackenzie@endeavorb2b.com Senior Contributing Editor Kara Nadeau knadeau@hpnonline.com Advertising Sales East & West Coast Kristen Hoffman khoffman@endeavorb2b.com | 603-891-9122 Midwest & Central April Bruffy abruffy@hpnonline.com | 713-992-0381 Strategic Accounts Sales Chris Driscoll cdriscoll@endeavorb2b.com | 978-880-8345 Advertising & Art Production Production Manager | Ed Bartlett Art Director | Tracy Arendt Advertising Services Karen Runion | krunion@endeavorb2b.com Audience Development Laura Moulton | lmoulton@endeavorb2b.com Endeavor Business Media, LLC CEO Chris Ferrell | President June Griffin COO Patrick Rains CRO Paul Andrews Chief Digital Officer Jacquie Niemiec Chief Administrative & Legal Officer Tracy Kane EVP Medical & Healthcare Technology Kylie Hirko EVP Endeavor Business Intelligence Paul Mattioli Healthcare Purchasing News USPS Permit 362710, ISSN 1098-3716 print, ISSN 2771-6716 online is published 11 times annually with an additional issue in November - Jan, Feb, Mar, Apr, June, Jun, Jul, Aug, Sep, Oct, Nov, Nov IBG, by Endeavor Business Media, LLC. 201 N Main St 5th Floor, Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI, and additional mailing offices. POSTMASTER: Send address changes to Healthcare Purchasing News, PO Box 3257, Northbrook, IL 60065-3257. SUBSCRIPTIONS: Publisher reserves the right to reject non-qualified subscriptions. Subscription prices: U.S. $160.00 per year; Canada/Mexico $193.75 per year; All other countries $276.25 per year. All subscriptions are payable in U.S. funds. Send subscription inquiries to Healthcare Purchasing News, PO Box 3257, Northbrook, IL 60065-3257. Customer service can be reached toll-free at 877-382-9187 or at HPN@omeda.com for magazine subscription assistance or questions. Printed in the USA. Copyright 2024 Endeavor Business Media, LLC. All rights reserved. No part of this publication June be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopies, recordings, or any information storage or retrieval system without permission from the publisher. Endeavor Business Media, LLC does not assume and hereby disclaims any liability to any person or company for any loss or damage caused by errors or omissions in the material herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever. The views and opinions in the articles herein are not to be taken as official expressions of the publishers, unless so stated. The publishers do not warrant either expressly or by implication, the factual accuracy of the articles herein, nor do they so warrant any views or opinions by the authors of said articles.

Jimmy Chung, MD, MBA, FACS, FABQAURP, CMRP, Chief Medical Officer, Advantus Health Partners and Bon Secours Mercy Health, Cincinnati, OH

Joe Colonna, Chief Supply Chain and Project Management Officer, Piedmont Healthcare, Atlanta, GA; Karen Conway, Vice President, Healthcare Value, GHX, Louisville, CO

Dee Donatelli, RN, BSN, MBA, Senior Director Spend symplr and Principal Dee Donatelli Consulting LLC, Austin, TX

J. Hudson Garrett Jr., PhD, FNAP, FSHEA, FIDSA, Adjunct Assistant Professor of Medicine, Infectious Diseases, University of Louisville School of Medicine

Melanie Miller, RN, CVAHP, CNOR, CSPDM, Value Analysis Consultant, Healthcare Value Management Experts Inc. (HVME) Los Angeles, CA

Dennis Orthman, Consulting, Braintree, MA

Janet Pate, Nurse Consultant and Educator, Ruhof Corp.

Richard Perrin, CEO, Active Innovations LLC, Annapolis, MD

Jean Sargent, CMRP, FAHRMM, FCS, Principal, Sargent Healthcare Strategies, Port Charlotte, FL

Richard W. Schule, MBA, BS, FAST, CST, FCS, CRCST, CHMMC, CIS, CHL, AGTS, Senior Director Enterprise Reprocessing, Cleveland Clinic, Cleveland, OH

Barbara Strain, MA, CVAHP, Principal, Barbara Strain Consulting LLC, Charlottesville, VA

Deborah Petretich

Templeton, RPh, MHA,Chief Administrative Officer (Ret.), System Support Services, Geisinger Health, Danville, PA

Ray Taurasi, Principal, Healthcare CS Solutions, Washington, DC

What’s on the Web

Human Case of H5N1 Bird Flu Reported in Texas

A person in Texas has tested positive for highly pathogenic avian influenza (HPAI) A(H5N1) virus (“H5N1 bird flu”) a er exposure to dairy ca le in Texas presumably infected with the viruses. CDC continues to consider the human health risk assessment for H5N1 bird flu in the U.S. general public to be low, but they urge that people with “close or prolonged, unprotected exposures to infected birds or other animals (including livestock), or to environments contaminated by infected birds or other animals, are at greater risk of infection.”

Read on: hpnonline.com/55001503

HHS Publishes White Paper on Supply Chain

The U.S. Department of Health and Human Services (HHS) announced via a press release that it has released a white paper highlighting steps HHS has taken to prevent and mitigate drug shortages and proposing additional solutions for policymakers to consider. Drug shortages have occurred in the nation’s healthcare system for several decades, largely due to market failures and misaligned incentives. The paper suggests solutions and says that HHS is prepared to work with Congress on this issue so patients do not go without needed meds.

Read on: hpnonline.com/53072187

Coming Soon: HPN’s New Podcast, Healthcare Hodgepodge

Healthcare Purchasing News is pleased to announce the launch of Healthcare Hodgepodge, a podcast featuring interviews with industry experts and article reads of our topical content across HPN’s many verticals including supply chain, infection prevention, surgical/critical care, sterile processing, healthcare IT and more. Healthcare Hodgepodge will be available on your favorite podcasting app in late May.

hpnonline.com | May 2024 | 5

Editorial Advisory Board 679764821 © MARIA_LH | STOCK.ADOBE.COM

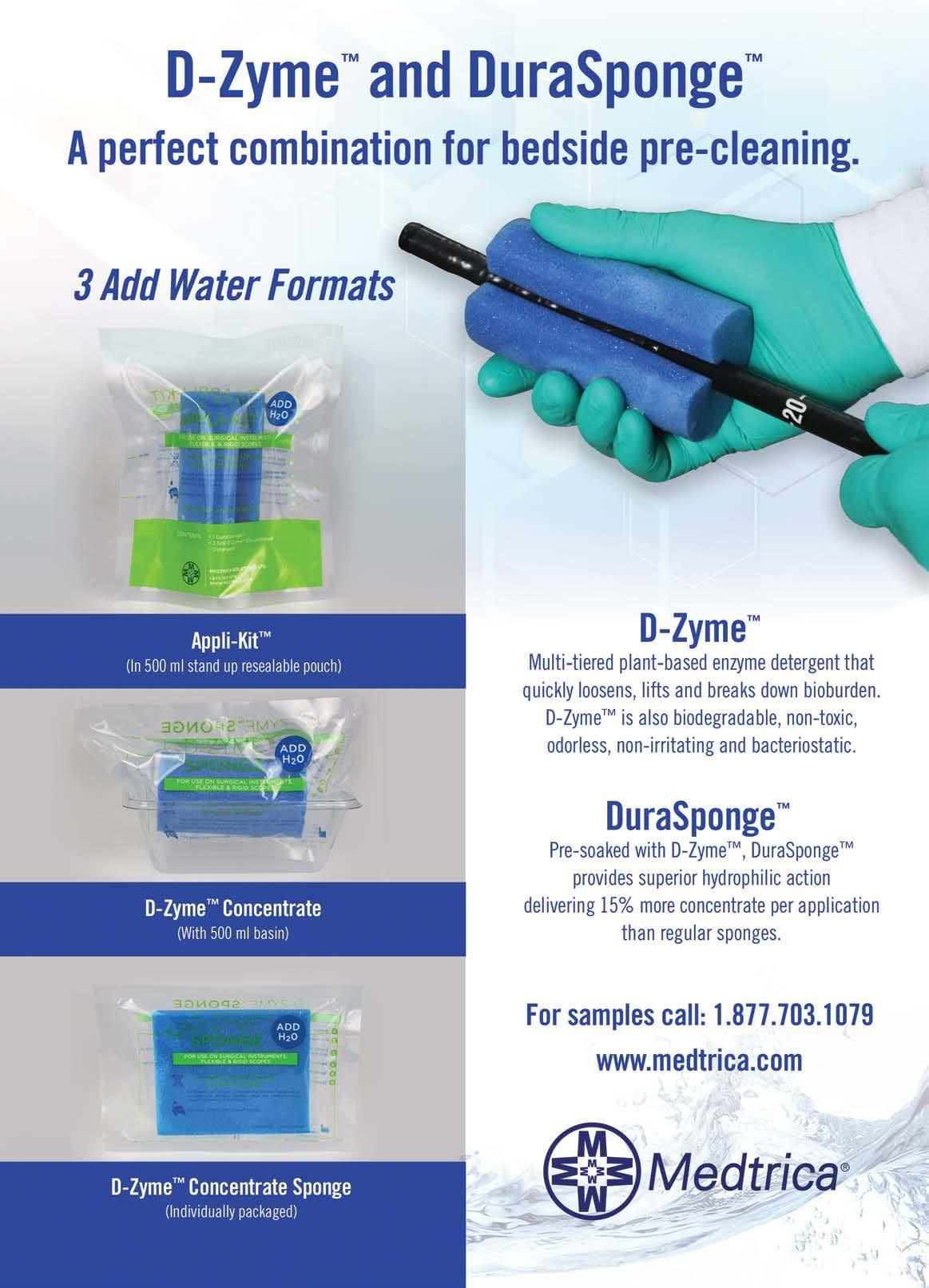

This index is provided as a service. The publisher does not assume liability for errors or omissions. Index of Advertisers Aesculap ................................. 17 aesculapusa.com/aicon Cygnus Medical 13 cygnusmedical.com Dale Medical Products C4 dalemed.com/samples DETECTO 11 detecto.com Healthmark Industries ....... C3 hmark.com Medtrica 3 medtrica.com Ruhof Corporation C2 ruhof.com Uline 9 uline.com

Improving Lab Supply Strategies Requires Better Communication

BY JANETTE WIDER, EDITOR-IN-CHIEF

Laboratory services are imperative to the healthcare ecosystem. Laboratory procedures aid clinicians in diagnosing, managing, and treating patients—yet when an organization does not have successful laboratory supply chain strategies, patient care can become delayed, lost revenue can occur, and there can be extra burdens and stress on staff to keep up with demand.

Healthcare Purchasing News spoke with two industry experts in this space. Kevin Dunwoody, vice president laboratory national field sales, Medline, and Barbara Strain, MA, SM (ASCP), CVAHP, principal, Barbara Strain

Consulting LLC, formerly director of Value Management at University of Virginia Health System, and current member of HPN ’s Editorial Advisory Board.

When asked how lab supply strategies differ from other supply strategies, Dunwoody said, “For maximum lab efficiency and effectiveness, lab supply strategies should closely mirror other service line supply strategies in healthcare settings. Healthcare settings—including clinical labs— have processes and protocols that are very well defined. Lab team members know exactly what they need to run tests and which lab supplies need to be readily available. Most lab supply strategies could—and should—align with the strategies for everything purchased in volume

SOURCING + LOGISTICS 6 | May 2024 | Healthcare Purchasing News

throughout that hospital or healthcare system—whether it’s office supplies, maintenance repair and operations (MRO), or IT.”

He continued, “Minimally, healthcare and lab supply strategies should:

• Effectively standardize your product list to the degree possible

• Rationalize and consolidate a SKU list to decrease variability

• Deliver the right mix and quantity of products to match your demand profile and available storage

• Make shipments as full and infrequent as possible to minimize workflow disruption.”

Further, Dunwoody added, “At the end of the day, while accounting for the variety of required hazardous or temperature-controlled product storage solutions that address specific lab product attributes, there is not much justification for running a clinical lab supply chain that is not in sync with other supply chains in a hospital or healthcare setting.”

“Hospitals and health systems operate more efficiently and effectively when they align lab supply chain strategies

with other supply strategies within their hospitals or networks,” he said.

Dunwoody also commented on the biggest concern today when it comes to lab supplies. He said, “One of the biggest concerns for labs today is that many equipment and instrumentation manufacturers are requiring specific consumables, reagents, chemicals, etc. brands to be used with their products without demonstrating significant improvements to outcomes. This makes it more challenging for health systems and their labs to realize available efficiencies, particularly across service lines.”

“Labs are also in a unique and sometimes challenging position as they often cannot use a sub or move to another item if presented with a national backorder issue,” he continued. “Unlike medsurg, commodities and consumables where a robust auto sub program can help end users navigate through supply chain issues and backorders, labs often need to validate and update certain SOPs when looking at a new item. This only enforces the need for and importance of upstream data and proactive communication on inventory and supplies to the lab buyers and end users. Working

hpnonline.com | May 2024 | 7

Kevin Dunwoody

259896072 © GORODENKOFF | STOCK.ADOBE.COM, 55363932 © ARROW | DREAMSTIME.COM

Barbara Strain

together to plan and prepare for possible supply chain disruptions through data and communication will allow lab professionals more time to focus more on patient care and less on inventory management.”

Value analysis and the lab

When asked about the relationship between the laboratory and value analysis teams, Strain said, “It’s an interesting relationship.” She went on to explain that there are meetings where key members of the laboratory gather and speak, for example, about new methodologies. The team generally equates this to value analysis—looking at what the value of continuing a current methodology is or adopting a new one. Then, Strain said, it stops short of all the rest of the value.

Strain added, “What can help is when there is a topdown approach, where it becomes a strategic initiative in a hospital organization to look at how the best value can be provided to patients as well as to the organization. Then it becomes more evident and easier in a way that everyone is on board, whether they are in the laboratory, radiology, imaging, or nursing so that there is a process, and that is where value analysis, along with leaders, develops programs.”

“And then these teams are formed,” Strain commented. “You have to have folks that understand enough about the laboratory or any other area in a way that makes it meaningful to everyone. Right now, I think there’s a little bit more of a trend that there are value analysis teams for the laboratory.”

Current challenges

As for the biggest challenges for those responsible for lab supplies, Medline’s Dunwoody stated, “One of the biggest challenges is that healthcare space is at a premium. You walk into most labs and they are jammed with people, products, samples moving through. Often, you won’t see cohesive storage strategy. Hospitals and health systems are looking for ways to consolidate and store products being used for the variety of lab work—chemistry, biology, pathology, etc.—without negatively impacting the workflow or the samples coming through the space. Lab leaders are constantly looking to more effectively manage consumption of lab supplies in the given space.”

“Ideally, labs should be able to map out the areas where items are being used and disposed of along with best places to store those items to optimize workflow,” he added. “But that’s easier said than done.”

As for a possible solution, Dunwoody said, “Whether it’s creating more or re-engineering lab testing space, find costsavings or improving processes, bring in your lab teams and other stakeholders to identify what needs to be addressed and make a plan to act. Consult with distributors or business partners who have expertise in healthcare supply chain optimization, like Medline, who are committed to solving your bigger supply chain challenges with you, and can provide insight into how other clinical labs or healthcare systems have overcome similar challenges.”

Strain also added her two cents on current challenges. She said, “They [the lab] still won’t get what they need when they need it.”

Strain went on to say that there are often communication issues. For example, the lab often needs certain items—like test trips or reagents—by a certain time and things just don’t show up. So much depends on the laboratory; for example, if they don’t get a result out to someone in the emergency room or the operating room in a timely manner, it can mean the difference between the patient being helped effectively and the patient getting worse, or even dying.

Strain then commented on the importance of value analysis teams in regard to the laboratory when it comes to solving challenges. She said, “Value analysis listens to managers or leaders from, say, immunology or chemistry or hematology, and what they’re really planning, and then we help to look for their GPO contracts. What issues have

SOURCING + LOGISTICS 8 | May 2024 | Healthcare Purchasing News

eNews Print Digital Edition Industry-leading coverage of Supply Chain, Infection Prevention, Surgical/Critical Care and Sterile Processing products, services and practices SUBSCRIBE hpnonline.com/hpn-subscribe 2401HPN_HouseAd_Subscribe_14sq.indd 1 12/1/23 3:12 PM

you had with your current supplier? Can we help intervene there and figure out what we can negotiate to help make that better?”

Speaking from personal experience, Strain added, “And we actually then brought different divisions from the same manufacturer together that were siloed in different lab divisions so that they understood that we could work together for a common contract rather than all these individuals with all these different sort of rules and guidelines and things that they wanted to do. We were very helpful in bringing a lot of different people together, including end users of the lab services as well as the manufacturers that were providing them and other parts of the lab and some physicians on some cases and things like that to talk through. We’d understand what was happening with results and what was happening in the lab and how we could come together.”

“So, there’s some very good synergies for the laboratory with value analysis,” she asserted. “On the other hand, on the supply chain side, they would come in very early on with some inventory solutions and so labs can have full lean, exercises and assessments done and [learn] how to organize their supply rooms and how to do other types of inventory systems to make it easier. I remember going into one lab’s storeroom where they had things and we also had to understand what the Joint Commission and DNV and other inspection agencies’ guidelines were about putting boxes directly on the floor and things like that. So, we would get different types of shelving and different things for them so they could all be in compliance. It’s a very synergistic relationship when you put it all together.”

AI and the future

Medline’s Dunwoody then commented on what seems to be today’s million-dollar question in every sector of the healthcare industry right now: What is the deal with artificial intelligence (AI)?

“Our customers are definitely asking about AI solutions in lab supply chain to help identify and remove nonvalue added activities from lab processes,” he stated. “Currently, the more interesting lab AI solutions work with camera-based inputs and electronic IDs in storage areas. But, as with the rest of the healthcare industry, there are hurdles around patient privacy and security that are curbing the advancement of AI in lab supply chain at this time.”

And as for the future of this space, Dunwoody said, “Technology advancements and further investments into automation will have a big impact on the future landscape of clinical labs. Staffing shortages coupled with increased testing demands due to an aging population will continue to cause issues with time management for

lab professionals. Automation and new advanced testing platforms will not only allow labs to become more efficient and streamline a lot of their processes, but it also presents exciting opportunities in the form of early detection and better care of their patient population. 70% of all medical decisions are made and based on testing done within a clinical lab setting. This means investing not only in new technology but also people and future education and awareness on the importance of a lab professional is crucial and extremely impactful to the future of healthcare.”

“In addition, real estate in health systems and hospitals is becoming too valuable to do non-revenue generating, non-value added activities,” he added. “Every inch of a hospital or health system is being used to provide better service to patients, improve patient outcomes, and operate more effectively and efficiently.”

Dunwoody concluded by saying that, “More health systems are taking these non-value added services out of expensive health system real estate and are establishing multi-use central service centers designed to provide support operations and functions. More health systems will be using or operating consolidated service centers in 5-10 years.” HPN

hpnonline.com | May 2024 | 9 1-800-295-5510 uline.com ORDER BY 6 PM FOR SAME DAY SHIPPING π OUR SELECTION STACKS UP 2405HPN_Uline.indd 1 3/28/24 1:48 PM

This Critical Care Operation is Worth Watching

BY JANETTE WIDER, EDITOR-IN-CHIEF

Founded in 1836, Piedmont Columbus Regional is a healthcare provider in west Georgia serving the Columbus, Ga. area with a network of health and medical services through its two hospital campuses. Piedmont Columbus Regional joined the Piedmont system on March 1, 2018.

Located in Columbus, Georgia and serving patients from 21 surrounding counties, the Midtown Campus is a 583-bed tertiary care hospital providing an array of services to meet the

medical needs of the diverse community, including oncology services at the John B. Amos Cancer Center and the Family Medicine Residency Program at Midtown which was the first of its kind in Georgia in 1972 and is one of the first in the southeastern United States.

According to a March 14, 2023, press release, Piedmont Columbus Regional announced its Midtown Campus will undergo a renovation and expansion over the next two years to increase its ICU capacity.

The press release states that “The 99,038 square foot project, which was designed by Earl Swensson Associates and is being built by Brasfield & Gorrie, will include 43 new ICU beds along with a renovated 15-bed nursing unit. Construction is tentatively set to be completed in March 2026.”

Healthcare Purchasing News had the opportunity to speak with chief medical officer Christopher Edwards, M.D., critical care director Cindy Kinney, and Piedmont Fayette CEO Steve Porter about this massive project,

SURGICAL/CRITICAL CARE 30517931 © DANIL RUDENKO | DREAMSTIME.COM 91156500 © MARTIN BARRAUD | GETTYIMAGES.COM 10 May 2024 Healthcare Purchasing News

QUALITY WHERE CHOICE MEETS

DETECTO manufactures more unique models for each clinical product category than any other medical scale company. Giving you better choices means you never have to settle for a product that isn’t the right fit for your application.

DETECTO: A true vertically-integrated medical scale manufacturer – family owned and privately held – with factory and headquarters in Webb City, MO.

DETECTO | 102 East Daugherty St. | Webb City, MO 64870 | (800) 641-2008 | detecto@cardet.com | www.Detecto.com

MORE

The Best Choice is the One That Gives You

Choices

LEARN MORE

other initiatives, and the future of Piedmont Columbus Regional.

Are there any current initiatives (other than the expansion) in critical care that Piedmont Columbus Regional is working on?

Edwards: In Columbus, we are working on our new free standing pediatric facility, the Bill and Olivia Amos Children’s Hospital. This will include pediatric critical care beds staffed by pediatric intensive care specialist physicians.

In general, what are the biggest challenges in the critical care space? How are organizations solving these challenges?

Edwards : As in all areas of healthcare, there are challenges with staffi ng. Critical care requires specialized training for physicians, nurses, and other levels of staff

as the patients are the sickest of the sick with complicated medical problems. Fortunately, we are rebounding from the critical staffing challenges that were the result of the COVID pandemic.

Regarding the expansion, can you please share with us how this project came to be? I see there was a need to increase ICU capacity. Can you expand on that?

Edwards: It became apparent during COVID that we needed more ICU space in order to manage surges during crises like the pandemic. But even during “normal” times our ICU at Piedmont Columbus Regional Midtown is typically full, and at times we are holding ICU patients in the Emergency Department. We needed to do what we could to eliminate the need to hold our admitted

critical care patients in the ED. We feel this expansion of ICU beds will accomplish this goal.

I see there will be a renovation as well as an expansion. What is being renovated?

Edwards: The entire ICU will be renovated; we are not just adding beds. At the end of the project, every ICU room will have been increased in size and completely redone. From a size standpoint, each room will be 2.5 times larger than the current rooms which will allow for a better space for patients, family, and staff. In addition, we are renovating and adding additional medical/surgical beds.

How will this new project benefit the community?

Edwards: The project will ensure that our community will have the most up-to-date ICU environment in the event of a critical care need. And by adding beds, we are helping to ensure we have the capacity to provide critical care locally at all times.

Are you using any new technologies in this space right now?

Kinney : The Real-Time Locating System (RTLS) is one of our newest technologies. Because our ICUs are currently located on three different floors, fi nding ICU equipment can be a challenge. The RTLS system allows us to tag our ICU devices and track

SURGICAL/CRITICAL CARE

12 | May 2024 | Healthcare Purchasing News

Headwall Footwall

PCR Midtown ICU

their locations using the RTLS webbased software. It’s a quick and efficient way to locate equipment.

What is in store for Piedmont Columbus Regional over the next 5-10 years?

Edwards: We are focused on patient safety and quality of care. If we provide the highest quality and safest care, our system will continue to thrive. Our goal is zero harm by 2026. We also want to provide the best access and patient experience for our communities. So for the next 5 to 10 years, we will focus on continuous improvement in these areas.

Anything else you’d like to share about critical care in your organization/the renovation and expansion?

Kinney : Because the physical design of the unit heavily impacts staff workflow, accessibility to equipment and supplies, and communication practices, feedback was sought from members of the ICU team early in the construction process. Their involvement helped to ensure that highly frequented areas like the storage, medication, and supply rooms were appropriately located and that telephones, computers, and the telemetry monitoring stations could be easily accessed by the staff. In the patient rooms, they provided input on the bed-ventilator-IV pump locations, configuration of the headwall, room lighting, and the type of patient lift system that would fit our needs. Our goal was to provide our staff and patients with the best ICU environment possible.

I recently saw that the American Association of Critical-Care Nurses recognized the Critical Care Unit at Piedmont Fayette with the silver-level Beacon Award for Excellence. Any comments on this achievement?

Porter : Earning the silver level Beacon Award for the second time demonstrates Piedmont’s commitment to consistently providing quality care. Our patients and our community can be confident in our critical care teams when they are needed the most. HPN

Cindy Kinney Christopher Edwards

Cindy Kinney Christopher Edwards

Reprocessing Single-Use Devices Helps Orgs Achieve Cost Savings, Sustainability

BY JANETTE WIDER, EDITOR-IN-CHIEF

When costs are top of mind for every department in a hospital, the choice of single-use devices or reusable devices is an important one. Healthcare professionals today are not only understaffed but under constant pressure to keep costs low. Reprocessed single-use medical devices have been around for quite some time and many professionals

are taking a closer look at what their organization is doing in terms of reprocessing single-use devices. Not only can reprocessing single-use devices be cost effective, but it has environmental benefits as well.

Editor’s Note: Our special feature this month is about sustainability in the healthcare system, see page 28.

According to an article from APIC, “Increasing healthcare costs,

environmental concerns, and recognition of finite resources have prompted healthcare facilities to consider reprocessing devices labeled as single-use devices. At the same time, concerns over the safety of reprocessed single-use devices led the U.S. Food and Drug Administration to develop and publish regulations for this practice. Under these regulations, reprocessors, hospital-based or third party, must

INFECTION PREVENTION 14 | May 2024 | Healthcare Purchasing News 196942895 © PORAMATE CHEEWAPAT, 154742208 © POP NUKOONRAT | DREAMSTIME.COM

meet the same standards as the original manufacturer.”

The article adds that “For several decades, hospitals and private healthcare establishments have reprocessed various single-use devices (SUDs). The practice of using SUDs was promoted as labor-saving and cost-efficient. By 1982, at least two-thirds of all sterile devices used carried a label saying, ‘for single use only.’”

Further, “Concerns about healthcare costs, changes in the reimbursement system, and concerns about the environmental impact of disposing of these devices prompted healthcare facilities to evaluate the feasibility of reusing such devices. The U.S. Public Health Service approval of the practice of reusing hemodialysis filters led the way for current activity.”

“Manufacturers choose whether or not to label a device ‘single use,’ and they are not required to provide evidence to support their designation,” the article added. “Many manufacturers attach the single-use label to devices they previously marketed as reusable or currently market them as reusable outside the United States. At the same time, the U.S. Food and Drug Administration’s (FDA) Medical Device Reporting system has documented few adverse events associated with the reuse of SUDs.”

Healthcare Purchasing News had the opportunity to speak with Maureen Spencer, M.Ed, BSN, RN, CIC, FAPIC, infection preventionist consultant and Lars Thording, VP, marketing & public affairs, Innovative Health about their views on single use vs. reusable devices.

Regarding her background, Spencer says, “So my consulting experience is really more with companies. One of the things we focus on is bringing new vendors into infection prevention (IP) to try to help them navigate the world of IP and some things we’ve found useful to navigate that world.”

Instructions for use

As for best practices and guidelines, she said, “APIC has some guidelines and then of course we have the instructions for use (IFU) from the manufacturers when they’re going to label it single use, like harmonic scalpels or disposable blood pressure cuffs. Additionally, they’re now pushing endoscopy equipment that’s disposable but it’s very expensive.”

Spencer added, “We follow the IFUs, and some people are very strict about it. They don’t want any legal responsibility. Some hospitals say if it says disposable, single use then that is what we do. Then other hospitals have decided to look at various equipment from these companies that offer sustainability systems and have had success in reprocessing certain equipment like harmonic scalpels. The problem is they’re pushing disposable, like in the endoscopy area, because they can make a lot of money and they’re saying, ‘Well, then we won’t have these outbreaks.’”

She comments that, on endoscopes, there is data available on how to clean out, for example, crevices where rubber starts to crack after a period of time. “I would push for something like that rather than disposable endoscopes, because I think it is just too cost prohibitive for companies,” she added.

Going green

What about the environmental impact of reusing instruments or devices? Thording said, “There is a lot of interest in hospitals in becoming greener, but unfortunately road

maps and handbooks are few and far between. A couple of government agencies recently have tried to launch some toolboxes, but I would say in general, frankly, it’s been very hard for hospitals to adopt things like environmentally preferred purchasing.”

Thording added, “Meaning that in our consideration for what products to purchase and use in the hospital, we will favor products that are environmentally favorable. Because almost all purchasing decisions in healthcare are based on something else—costs. So, that is a major barrier.”

Best practices

“As for best practices in hospitals, I would say number one is creating tools so that everyone from physicians to administrators to technologists are aware of the environmental impact of what the hospital does,” Thording commented. “Transparency is a part of the solution itself. I think to some extent when physicians don’t take the environmentally preferred device, it’s probably because they’re not aware.”

Thording noted that best practice number two is to make environmental considerations a part of the purchasing decision making. And that’s something that easily fits within the purview of the Value Analysis Committee. The Value Analysis Committee gathers people from many different functional areas to make decisions about what products to adopt.

Thording stated, “Number three is the background. The vast majority of a hospital’s carbon emission footprint does not come from what the hospital does. It comes from what? The hospital buys so that means that most of the carbon emissions are coming from what is called scope 3 emissions. That is from the products and stuff that the hospital buys. So ask your suppliers to provide accounting of carbon emissions footprints of the

hpnonline.com | May 2024 | 15

Maureen Spencer Lars Thording

devices that they’re selling. It’s difficult to do, but it’s becoming more and more normal to be able to provide that kind of accounting and it really should be standard practice to demand that as a supply chain because it is a supply chain that is responsible for most of the waste and most of the carbon emissions.”

“And number four is that when there is a choice between reusable and single use devices to favor the reusable one, but in many cases, the fact is that that choice is not there,” he said. “That type of device is simply just single use or that type of device is not reusable. This not only relates to the infection preventionists, but it relates to OR directors, as well. If it involves surgical instruments like the harmonic scalpels of the trocars, they probably have a surgeon that

does that kind of surgery approve and give their input into it. This does involve teamwork: it involves a group of people together working with the vendor on what the vendor can do, and the process of collecting everything in those green bins to get those back to the loading dock and on the trucks that bring them to this facility. And then they reprocess them and get them back into stock. There are some surgeons when they see it’s a reprocessed harmonic scalpel, for instance, might reject it and say, ‘I don’t want use one that’s reprocessed. I want one that’s brand new.’ Sometimes that’s the influence of a vendor.”

Recycling

Thording also mentions a barrier to reprocessed single-use devices. “Now, when the purchasing department is

willing to look at environmental considerations, they get a conflicting message from leadership of the hospital: You need to reduce your costs and you need to pick the more environmentally friendly option,” he said. “The problem is that in most cases, environmentally friendly solutions are more expensive than the cheapest product in the market. So that’s definitely a barrier.”

Thording concluded by saying “Recycling is a big barrier to reprocessing. I just put the devices over here and somebody takes them, and it gets recycled. But the fact is now it’s out of circulation. So now it can’t be reused, which is expensive for the hospital and recycling usually does not yield really even close to the carbon emission results as reprocessing does.” HPN

INFECTION PREVENTION 16 | May 2024 | Healthcare Purchasing News

WEBSITE hpnonline.com MAGAZINE hpnonline.com/subscribe NEWSLETTERS Sign up for monthly updates FACEBOOK hpnonline HPN_Online LINKEDIN healthcare-purchasing-news Scan Here to Subscribe to our FREE Magazine COMPLIMENTARY MAGAZINE SUBSCRIPTION 12 Issues — Including the Annual Reference and Buyers Guide Reporting the information, solutions and stories about supply chain management 2405HPN_HouseAd_Subscription_12h.indd 1 4/3/24 2:46 PM

AESCULAP Aicon™ Sterile Container System

Unwrap the future of sterile supply management. With features that help streamline processes and reduce the possibility of wet sets, Aesculap’s next generation rigid container is everything you’d expect from the market leader.

Visit aesculapusa.com/aicon to learn more about how this breakthrough technology can help your SPD Operate With Greater Precision.

OPERATE

PRECISION

WITH GREATER

Meet our newest STERILIZATION POWERHOUSE.

Aesculap, Inc. - a B. Braun company M e e t o u r n e w e s t

Tips for Point of Use (POU) Pre-Treatment Success

BY KARA NADEAU, SENIOR CONTRIBUTING EDITOR

It is well known that surgical/device pre-treatment is a point of contention between many sterile processing (SP) and operating room (OR) teams. When post-procedure pre-treatment isn’t performed correctly (or at all), SP teams are stuck with having to remove hardened biological/organic material, adding extra work, prolonging the reprocessing cycle, and jeopardizing patient safety (e.g., retained bioburden, instrument/ device damage).

Healthcare Purchasing News (HPN ) reached out to SP leaders, consultants and solutions vendors to solicit their opinions on why point of use (POU) pre-treatment is such a challenge and proven methods they have employed to improve compliance.

The battle with biofilms

Let’s start by getting back to the basics with biofilm. Preventing the formation of biofilms, defined as “surface-attached communities of

bacteria embedded in an extracellular matrix,” is a relentless battle in healthcare environments with the constant contamination of environment surfaces and objects.1

So-called “build-up biofilm” that forms on reusable medical devices “represents a great challenge for healthcare-associated infection control and prevention,” as noted by the editors of a Hygiene journal special edition on the topic.2 They go on to state:

STERILE PROCESSING 18 | May 2024 | Healthcare Purchasing News 516399284 © VZMAZE | GETTYIMAGES.COM

“Evidence-based strategies and practices to prevent biofilm formation and the chemical fi xation of existing biofilms, as well as to remove biofilms from environmental surfaces and reusable medical devices, are required to minimize pathogen transmission and, therefore, to deliver safer care to the patients.”

Performing cleaning and decontamination as soon as possible after an item has been used – at the point of use - is an evidence-based practice recognized throughout the healthcare industry (CDC, AORN, AAMI, APIC, etc.).

If POU pre-treatment of contaminated instruments and devices in the OR is a proven strategy to help prevent biofi lm formation, why isn’t compliance 100% across the board?

Challenges to compliance

Researchers from the Graduate School of Nursing, Uniformed Services University of the Health Sciences, in Bethesda, Md., conducted a literature review on POU treatment compliance and published their findings in the January 2024 issue of the journal Military Medicine. An interesting aspect of this research was the extrapolation of POU treatment noncompliance implications for Military Health System policies and future considerations.

If poor pre-treatment compliance makes decontamination more difficult when the OR and SPD are housed together in a stable, well-equipped hospital environment, just imagine the impact when compliance failures take place during “large-scale combat operations.”

With studies indicating “that drying times beyond 15 minutes significantly reduce the effect of subsequent cleaning to remove protein residues, including prions,” time is of the essence whether the surgical procedures are taking place in a hospital or on the battlefield.3 As the researchers

stated, “Completing POU treatment is critical to a successful surgical mission in both the hospital and austere environment.”

Based on their literature review, the researchers identified these barriers to POU treatment compliance: “complex POU processes, intricately designed surgical instruments and endoscopes, lack of healthcare worker (HCW) knowledge and competency, and inadequate or ambiguously written policies.” They pointed to “Training, competency assessments, and clearly written policies and procedures” as “cost-effective, evidence-based, and feasible solutions.”4

Turning back to the civilian healthcare delivery environment, contributors to this article commented:

“It can be difficult for any sterile processing department to achieve 100% compliance with all that we are responsible for,” said Randalyn Harreld, CRCST, CIS, CER, CHL, CSPDT, CASSPT, BLS, AAS, clinical education, manager, U.S., Belimed. “The amount of ‘best’ practices that have come into play, the variations in instructions and the entities providing guidelines and standards can be difficult to follow 100% of the time.”

“I believe POU pre-treatment is such an issue because people often will not prioritize a process change until it is mandated or a hospital is written up for noncompliance,” said Ascendco Health Co-Founder & CEO Brian Reed. “And they are getting written up.”

“When I perform audits, point of use treatment (POUT) failure is usually one of the top things that

is a compliance issue,” said David Jagrosse, CRCST, CHL, President, David Jagrosse Consulting. “To be clear, it is in the IFUs and AAMI standards but from a technical standpoint, it is not that we can’t process instruments without pre-treatment having been performed, but rather, it makes it almost impossible and much more challenging and very time-consuming.”

“OR staff may not understand the critical importance of immediate postprocedure pre-treatment of instruments,” said Joan Melendez, president & CEO, Xcelrate UDI. “Failure in this area risks patient safety, damages instruments, and delays processes.”

Explain the “why”

Explaining to the OR why their part in pre-treatment is important and benefits their workflows, and ultimately their patients, is key to gaining support.

“It’s like what Tom Cruise said in Jerry Maguire: ‘Help me help you,’” said Jagrosse. “The OR wants instruments turned over. They need them back for the second, third and fourth cases of the day. If they don’t do this pretreatment, it makes it almost impossible to turn these instruments over in a timely and efficient manner.”

Harreld refers to “obedience, accountability, and the inevitable ‘that’s not my job’ mentality.”

“Sometimes things don’t happen because people don’t want them to happen,” said Harreld. “More times than I’d like to admit I’ve seen many disregard point of use care, stating that it simply isn’t their job, they don’t

hpnonline.com | May 2024 | 19

David Jagrosse

Joan Melendez Brian Reed

Randalyn Harreld

have time, the spray is too much, too tedious, etc.”

“If the team understands ‘why’ something is being asked of them, and not just being asked to do it, usually the compliance rate will go up, and even better ideas can come into play all while increasing morale and outcomes,” she added.

Ongoing education and training are critical to long-term POU pre-treatment compliance success. Melendez recommends that hospitals “Prioritize joint sessions for the OR and SPD staff on correct sterilization techniques, regulatory updates, including FDA guidelines, and ISO 13485 standards. This approach ensures high-quality patient care through adherence to compliance, fostering a culture of excellence and continuous improvement,” she explained.

Understand the challenges

“As Sterile Processing professionals we should consider how we can help the OR reach pre-treatment goals,” said Jagrosse. “For example, one hospital purchased 4 oz spray bottles for pre-treatment application that the sterile processing team supplies on the case carts.”

“Have the right products and workflow that fit the need of your unique inventory,” said Harreld. “Make sure a point of use product process and workflow are set up. Many times, it might not work spraying liquid in the OR when the patient is still there, and no core is available or soiled utility space to complete the job. Maybe your workflow doesn’t allow for this to happen. Make sure we set our teams up for success to make POU pre-treatment mandatory and possible.”

Engage in collaboration

Harreld recommends SP teams partner with all areas responsible for POU pre-treatment and set a game plan together. She stated:

“Create a committee and let infection control be the driver of the safety component while a chief surgeon can also be the facilitator in the OR to help push the task. Implement a policy that addresses the process and include SPD during the education portion of this. Be consistent and hold the line when or if people start to push back.”

“Keep a team approach and mentality during this whole process and make sure to work together, as it’s the collective duty to take part in this important practice,” she added. “The procedure areas, clinics, operating room personnel, infection control reps, and doctors all need to collaborate with sterile processing to make this joint effort realistic and achievable.”

Melendez recommends strengthening communication between SP and OR teams through regular meetings and feedback sessions to facilitate a collaborative approach to address pretreatment issues.

Eddie Conklin, CRCST, CHL empha sized the vital roles of surgical technicians and decontamination technicians and the workflows that link them, stating:

“Being at the point of use, a surgical tech sees each individual instrument being used and knows the extent of bioburden, especially on complex or difficult instruments. Their AST standard addresses this; if the instrument is not precleaned at a minimum it should be separated for the decontam tech. Decontam techs’ workflows are large volume, and they work in batches to cover several ORs.”

“The instruments should be counted, the count sheet validated, and the instruments placed back in their original containers,” Conklin continued. “Extra items, such as peels, should be separated to avoid missing instruments at assembly and to improve first pass yields, quality, and efficiency. Indicators, pan locks, white arrows, tags, and labels should be removed.”

Back it with documentation

As Harreld pointed out, “Almost all recommendations, including guidelines from AST, AAMI and AORN, mention the importance of point of use care, so it is everyone’s responsibility. We need to be setting expectations and holding our teams to them to ensure they understand how it helps the longevity of the instruments and makes the cleaning process safer and more effective.”

Manufacturers’ instructions for use (IFU) are a vital resource for both the OR and SP teams to understand their roles in instrument cleaning and maintenance. Melendez recommends ensuring all OR team members have access to and understand manufacturers’ IFUs.

“Additionally, implement tray worksheets to accompany each instrument tray, serving as a checklist to ensure adherence to SOPs and IFUs,” she added.

Capture and measure compliance

According to Jagrosse, most hospitals will establish key performance indicators (KPI) for POUT. Then the question becomes, how do they set a baseline, measure compliance, and track improvements?

“Some organizations measure POUT compliance in decontamination on paper but departments with instrument tracking systems will have the ability to scan a case cart and scan a barcode to document deviations. Because if you don’t measure it or have a handle on it, it doesn’t exist.”

Address issues in a timely manner

Jagrosse pointed out that access to real-time data on POUT compliance enables timeliness of response, stating:

“Some places will collect the data and wait until the monthly meeting saying, ‘we had 72 instances of

STERILE PROCESSING 20 | May 2024 | Healthcare Purchasing News

non-compliance,’ but that means nothing when speaking in a crowd setting. In other instances, an SPD team will identify a deviation, attempt to address it with the OR team at the end of the day, which is again too late, and they may often answer ‘It wasn’t me, I was relieved for lunch,’ so now there is no ownership of the deviation.”

“There must be accountability and the best way to do that is in real time and not daily or monthly,” Jagrosse continued. “There are tracking systems that allow us to immediately identify deviations and even send text alerts to key leaders. If you get those real time notifications and directly address an issue with the corresponding OR team, then you will be able to engage with the team responsible for the deviation.”

According to Reed, Ascendco Health applies analytics to the

events captured and recommends to the hospital when and where they should perform audits (e.g., on certain trays, staff members, times of day).

“When hospitals are recording events and performing audits, they have seen an over 95% reduction in events,” said Reed. “It’s important to note that the tracking and auditing goes both ways. With our system, the OR team uses a dedicated smart phone or tablet to record events on trays coming from the SPD, such as missing/damaged instruments, holes in sterile wrap, etc. We didn’t invent event recording, but we made it easier to record events as it becomes part of the SPD and OR workflows.”

Keep patient safety as the focus

“The more hospitals push their care teams to attend to more patients and

increase surgical volumes, we must calculate more time for these additional responsibilities to take place and avoid the awful habits of taking shortcuts,” said Harreld. “This comes into play with priority sets and turnovers, inventory issues, etc. OR minutes equals money, but we also have safety to always consider.” HPN

References:

1. Biofilms on medical instruments and surfaces: Do they interfere with instrument reprocessing and surface disinfection, American Journal of Infection Control (AJIC), November 2023, https://www.ajicjournal.org/article/S01966553(23)00314-0/fulltext

2. The Impact of Biofilms on Cleaning, Disinfection of Surfaces and Reprocessing of Reusable Medical Devices, Hygiene, https://www.mdpi.com/journal/hygiene/special_issues/biofilm_cleaning

3. Rubak P, Lorenzen J, Ripadal K, Christensen AE, Aaen D, Nielsen HL, Bundgaard K. Can a humid storage environment of surgical instruments before reprocessing increase patient safety and durability of instruments? J Hosp Infect. 2022 Apr;122:64-71. doi: 10.1016/j.jhin.2022.01.012. Epub 2022 Jan 22. PMID: 35077808.

4. Eberhardt GL, Atwood BI, Smith JD. Point of Use Treatment for Medical Devices: From Bedside to Battlefield. Mil Med. 2024 Jan 9:usad499. doi: 10.1093/milmed/usad499. Epub ahead of print. PMID: 38198220.

hpnonline.com | May 2024 | 21

CONNECT WITH CLINICAL INTELLIGENCE FOR THE HEALTHCARE ECOSYSTEM Like us Follow us Link up eNews hpnonline.com Print 2405HPN_HouseAd_Connect_12h.indd 1 4/3/24 2:43 PM

From Novel to Established, a Journey of VHP Sterilization

BY ARTHUR HENDERSON, RN, SENIOR CLINICAL EDUCATION SPECIALIST, STERIS CORPORATION

For over 30 years, healthcare facilities have relied on vaporized hydrogen peroxide (VHP) to sterilize temperature sensitive medical devices. From its origins as a novel technology, VHP has gained the trust of healthcare, regulatory bodies, and standards organizations. With the release and Food and Drug Administration (FDA) recognition of a low temperature vaporized hydrogen peroxide standard (ISO 22441), the FDA classified vaporized hydrogen peroxide sterilization as an “Established Category A method of sterilization for products labeled sterile.”4 This is good news for manufacturers of sterile products looking to move away from Ethylene oxide (EO) as this puts VHP sterilization on equal terms with EO and steam sterilization processes.

FDA’s classification of VHP sterilization is part of a broader initiative to reduce the use of EO sterilization applications. This change is expected to increase adoption of VHP sterilization over the more environmentally hazardous EO sterilization applications used to sterilize products today. This leaves many healthcare facilities asking, “What does this mean to healthcare’s medical device processing?” The answer, increased adoption of VHP sterilization as a choice for reusable device sterilization.

Evolving to address sterile processing challenges

1993 to 2009 VHP Sterilization focus to replace EO

EO sterilization began as means to sterilize temperature sensitive materials incompatible with steam

sterilization. It has sterilized single use sterile items, reusable medical devices, and non-medical items like spices for many years. However, some of these materials easily absorb EO requiring extensive aeration times to remove the chemical from those materials. Sterilization cycle times ranged between 8 to 12 hours to complete mostly due to aeration needs. The long cycle times created bottle necks and required excess inventory to accommodate sterile processing needs. Additionally, EO’s carcinogenic and mutagenic nature created concerns and stricter regulation of its use. In 1993 the first VHP sterilizer was made available to healthcare facilities with the goal to provide a low temperature alternative to EO sterilization.

At that time, vaporized hydrogen peroxide sterilization was a novel

CONTINUING EDUCATION 22 | 2024 | Healthcare Purchasing News PHOTO COURTESY STERIS Contributed by:

Define what is meant by “established sterilization process”

List key breakthroughs in VHP sterilization development

Pair medical devices with the VHP sterilization cycle type

Figure 1: Sterile Processing Technician preparing to sterilize a 3D printed surgical guide

Learning Objectives 1.

2.

3.

sterilization method. It had proven safety and effectiveness but was a new form of sterilization with no established standard to define its use. Its popularity grew as manufacturers of rigid and small flexible endoscopes, batteries, and specialty surgical instrumentation began to include VHP sterilization in their instructions for use. By 2008, VHP sterilization was no longer ‘novel’ but ‘non-traditional’ as FDA had evaluated sterilizer data as part of a quality systems regulation evaluation and determined the methods to be adequate.

2011 to 2015 VHP Sterilization used to preserve device integrity

Medical devices continued to evolve as did their cost, increasing repair and replacement budgets. Facilities sought methods to preserve their medical device investment, one of which was VHP sterilization. Its low temperature process offered a broad range of material compatibility. Combined with a lesser vacuum, as compared with steam sterilization, it preserved the integrity of instrument adhesives and delicate optics. The demand to use VHP sterilization for a wide variety of rigid endoscopes brought a need to sterilize longer stainless-steel channels with smaller diameters.

Batteries previously sterilized through an immediate use steam sterilization cycle to limit exposure to high temperatures were sterilized through a low temperature, terminal VHP sterilization cycle preserving the battery’s life.

VHP sterilization is limited by the total number of channels within a load; the length and diameter of a channel; and the number of channels within a single device. Several new claims came during this time including multiple channel devices and narrow lumens typical of urology and pediatric devices.

2016 to 2018 Fast terminal cycle to help reduce immediateuse steam sterilization

The year 2013 defined the term Immediate-use Steam Sterilization (IUSS) and brought new policies intended to reduce its use. Quick turn processes and loaned equipment vendor policies met some success. However, late loaned trays and back-to-back cases continued. Added delays came from waiting for quick turn steam sterilized items to cool.

VHP sterilization responded to the need for speed by increasing load weights up to fifty pounds. With no need to cool sets after sterilization, sets return to use immediately after cycle completion. VHP sterilization also addressed the need for quick turns of terminally sterilized single items. For the time needed to run an IUSS cycle, VHP sterilization could complete and release a terminally sterilized instrument. By the end of 2018, VHP sterilization was a common sterilization method processing many of the same types of instrumentation as steam sterilization.

2023 First FDA cleared sterilization application for 3D printed medical models

Continued addition of instrumentation claims led to a major advancement outside the category of medical instrumentation. In 2023, a VHP sterilization platform became the first sterilizer with FDA cleared claims to sterilize 3D printed anatomical models and patient specific guides. Anatomical models allow visualization of surgical site anatomy. Patient specific surgical guides help surgeons precisely position cutting instruments for accurate osteotomies or pin and screw placement. Up until this point, facilities would have to develop and validate sterilization cycles for these items. Most healthcare facilities were not equipped to perform sterilization validation, toxic residual analysis,

Lesson:

From Novel to Established, a Journey of VHP Sterilization

April 2024

This lesson was developed by STERIS. Lessons are administered by Endeavor Business Media.

Earn CEUs

After careful study of the lesson, complete the examination online at educationhub.hpnonline.com. You must have a passing score of 80% or higher to receive a certificate of completion.

Certification

The Certification Board for Sterile Processing and Distribution has pre-approved this in-service unit for one (1) contact hour for a period of five (5) years from the date of original publication. Successful completion of the lesson and post-test must be documented by facility management and those records maintained by the individual until recertification is required. DO NOT SEND LESSON OR TEST TO CBSPD. www.cbspd.net

Healthcare Sterile Processing Association, myhspa.org, has pre-approved this in-service for 1.0 Continuing Education Credits for a period of three years, until March 22, 2027.

For more information, direct any questions to Healthcare Purchasing News editor@hpnonline.com.

hpnonline.com | 2024 | 23

Quiz Answers: 1. B, 2. E, 3. A, 4. B, 5. A, 6. D, 7. A, 8. D, 9. C, 10. B

cytotoxicity, and material analyses. Using an FDA cleared cycle saves facilities both time and money while supplying assurance of the sterilization process.

Given the long history of safety and effectiveness coupled with its growth and evolution, it is easy to see why this once novel sterilization process is now seen as established.

Established yet different when sterilizing medical devices

VHP sterilization joined steam and EO as established sterilization platforms, but it is different from them in many ways. The obvious differences include the sterilant, exposure time, and aeration requirements. The not so obvious difference is the determination of which devices to process within the sterilization platform.

Steam and EO sterilizers have defined sterilization cycle parameters that have been validated using a specified load configuration. The load configuration is defined within standards and guidelines and does not include specific instrumentation characteristics. Steam, for example, defines the worst-case load based on the weight of the metal mass included within the sterilizer using wrapped trays and a total load capacity. It does not include testing of lumen lengths, diameters, or instrumentation itself. This requires each device manufacturer to select the steam sterilization cycle best suited for their instruments and validate that the sterilization cycle parameters previously cleared by the FDA for the sterilizer are right for their instrument. The instrument vendor must provide this information to the user as part of the instrument’s instructions for use (IFU). If a steam or EO sterilization cycle is not listed in the IFU, it cannot be used for that device. VHP sterilizers are different. These sterilizers define the instrument characteristics and packaging for each

sterilization cycle as well as the largest load configurations for each cycle. Instruments that have the specified characteristics are tested and validated by the sterilizer manufacturer. Any instrument that falls within the defined instrument characteristics for the sterilization cycle validated by the VHP sterilizer manufacturer can be sterilized within it. The device manufacturer does not have to test and validate the instrument in the VHP sterilizer for a user to be able to use the VHP sterilizer cycle. The user must confirm that the instrument meets the cycle’s requirements and is compatible. The critical instrument characteristics to review include:

• Length and diameter of lumens and channels

• Number of lumens and channels in the instrument

• Compatibility of the instrument’s materials

• The type of sterile packaging

Obtaining this information from the device manufacturer can be challenging. To help, VHP sterilizer manufacturers have worked with device manufacturers to create searchable lists of instrumentation that can be sterilized within their respective sterilizers.

What can be sterilized?

VHP sterilizers provide sterile processing departments flexibility when managing workloads and workflow. Requiring only electricity and sterilant, VHP sterilizers can serve as a backup sterilization process when steam sterilizers go down such as during a boil alert, flood, or other emergency event. Understanding what can be sterilized within a VHP application is critical when planning for general workflow and emergency situations. VHP sterilizers have various sterilization cycles based upon the types of devices. The cycles and cycle claims will vary between sterilizer manufacturers. Refer to your sterilizer

operator’s manual for the types of devices that can be sterilized in any given cycle.

The general instrumentation cycle is the first type of cycle. This cycle sterilizes instrumentation with diffusion restricted spaces, such as hinges and box locks but not with lumens. “Non Lumen” and “Express” cycle are common names. Instrumentation can be composed of a variety of materials compatible with VHP. Forceps, light cords, cameras, and da Vinci endoscopes are some of the devices that are sterilized in general cycles.

The second cycle type sterilizes instruments with stainless steel lumens. This cycle type has a wide variety of names including “Lumen” and “Standard” cycle. The length and diameter of the lumen is important and not every cycle can sterilize the same lumens. These cycles typically allow mix loads of lumened and non-lumened instrumentation. Some sterilizer cycles are FDA cleared to sterilize stainless steel instruments that have two or three channels. Typical instrumentation includes rigid cystoscopes, orthopedic drills, trocar sheaths and some eye instrumentation.

Flexible endoscope cycles are the third type of sterilization cycle. As the name suggests, these cycles sterilize a variety flexible endoscopes. Typically cycle names include “Flexible” and “Flex” cycle. The lumen lengths within endoscopes play an important part in deciding if an endoscope can be sterilized within a cycle. Typical flexible endoscopes include bronchoscopes and surgical flexible endoscopes. Large flexible endoscopes, such as choledochoscopes and colonoscopes, contain a dry lubricant within the interstitial space of the endoscope that is incompatible with VHP sterilization.

The fifth and last cycle type is a specialty cycle designed to sterilize anatomical models and patient

CONTINUING EDUCATION 24 | 2024 | Healthcare Purchasing News

specific guides that were 3D printed within the hospital. It is important that the material used to construct the model is compatible with the system and that any lumens within the model meet the diameter and length requirements specified for the special cycle.

VHP sterilizer and device manufacturers often give sterilization information based on a single device but rarely is a device sterilized alone. Building sets for VHP sterilization will require knowledge of the

requirements of all the instrumentation within the set, the tray or container used to hold the instrumentation and all accessories including wraps, instrument organizers, and items used to protect wraps from punctures and tears. The set, in its entirety, should be compatible and packaging materials validated for VHP sterilization. Packs that hold items that can be sterilized in different sterilization cycles should be reconciled to the cycle that is common between all items within the set.

VHP sterilization into the future

Vaporized hydrogen peroxide has rapidly advanced over its short thirty plus years of use as a healthcare sterilization choice. Its continued application and new advancements in 3D printed models and guides is just the fi rst of many new sterilization applications to come in this established sterilization process’s future. HPN

References online at hpnonline.com/55001566.

From Novel to Established, a Journey of VHP Sterilization - Practice Quiz

1. What is an “established sterilization process”?

A. A 510(k) cleared sterilization cycle

B. A sterilization process listed in an Instructions for Use

C. A category of sterilization cycles listed by the FDA

D. A sterilizer sold in the United States

2. What were the challenges of EO sterilization addressed by VHP sterilization?

A. Compatibility issues with EO sterilization

B. Long cycle times

C. Chemical hazards of EO

D. All of the above

E. B and C

3. Why is the low temperature, lesser vacuum of VHP sterilization cycle preferable for rigid endoscopes?

A. Preserves the integrity of instrument adhesives and optics

B. Creates shorter sterilization cycles

C. Allows sterilization of more than one channel

D. Reduces dependence on aeration

4. How many stainless-steel lumens in single device can some cycles sterilize?

A. 1

B. 2-3

C. 4-5

D. 6

5. Which sterilization process does not require time to cool instruments prior to use?

A. VHP Sterilization

B. Steam Sterilization

C. Dry Heat Sterilization

D. Steam Formaldehyde Sterilization

6. How do healthcare facilities benefit from using VHP sterilization to sterilize 3D printed medical models?

A. There is no benefit

B. Cycle times are faster

C. The 3D printer runs faster

D. Save money on costly validations

7. Healthcare facilities can choose to sterilize a device in VHP sterilization cycle based on the device’s characteristics and sterilization packaging.

A. True

B. False

All CEU quizzes must be taken online at: educationhub.hpnonline.com.

The cost to take the quiz is $10.

8. What is considered when deciding a medical device’s ability to be sterilized in a VHP sterilization cycle?

A. Lumen length and diameter

B. Compatibility the instrument

C. Sterilizer manufacturer’s device matrix

D. All of the above

9. Which VHP sterilization cycle type can be used to sterilize a bronchoscope?

A. General cycle type

B. Stainless-steel Lumen cycle type

C. Flexible cycle type

D. Specility cycle type

10. When building a set, which sterilization cycle should be used?

A. The cycle most recommended

B. The cycle common to all instruments

C. The shortest cycle time

D. The longest cycle time

hpnonline.com | 2024 | 25

PURC HASI NG NE WS Healthcare ™ EDUCATION HUB

Qualities of Strong, Effective, QualityFocused SPD Leaders

BY DAVID L. TAYLOR, MSN, RN, CNOR, PRINCIPAL, RESOLUTE ADVISORY GROUP LLC

Sterile Processing (SP) leaders, like business leaders in other segments, must possess many skills—and know how to apply them consistently and effectively to be successful. Strong leaders not only strive to inspire and motivate their teams, but they also oversee considerable production cycles and critical safety requirements to ensure safe, high-quality, and well-functioning devices and exceptional service are delivered to their many healthcare customers within the organization.

Certainly, all leaders are not created equally. Although there are both great and poor leaders, virtually any dedicated, quality-focused SP professional can step up as a leader in their own unique way. They can become a Certified Instrument Specialist, for example, an unofficial mentor for fellow technicians, or serve as a liaison between the Sterile Processing department (SPD) and Operating Room (OR). Even the most experienced leaders should aim to continually broaden and improve their leadership skills to support their team and customers. Any departmental or business leader can make or break an organization, either promoting good outcomes or contributing to avoidable risks. This is why organizations must make hiring and developing excellent leaders (and mentoring and supporting future ones) a top priority.

Core priorities for effective SP leaders

SP leadership priorities are vast and will vary slightly from one facility to the next; however, some fundamentals should always be emphasized. These can include:

• Building dedicated teams of trained and certified staff that proactively solve problems in real time, while planning for incidents before they arise (and potential mitigation strategies).

• Improving or maintaining staff engagement by creating a positive and supportive culture where employees receive ongoing education and training and are proud of the work they do each day.

• Emphasizing safety and quality practices and empowering staff to raise issues or concerns that may affect the quality of their work and compromise patient care.

• Assessing instrument set inventories and streamlining same-day instrumentation turnaround, while also reducing error rates for surgical and procedural instruments.

• Being prepared to adapt to changes, tackle unexpected challenges, and seize on emerging opportunities.

Successful leaders also possess certain essential qualities, including integrity, accountability, and empathy. They hold high moral and ethical standards, are honest, and foster trust within their team. They take responsibility for their actions and their team’s performance, whether good or bad, and are supportive and encouraging, bringing out the best in their employees. They are also compassionate, respectful, and know how to connect with others, regardless of their backgrounds and differences.

Further, excellent leaders are experts at cultivating interdisciplinary relationships and collaboration, including with departmental and facility executives. They are competent at managing departmental and interdepartmental conflict and understand the need to partner for quality and safety. The best SP leaders are also confident in their knowledge and skillsets and know how to bring about the best in their teams and colleagues. They understand how their interdisciplinary colleagues work within the interconnected, broader healthcare ecosystem and lean on effective communication skills to clearly and concisely address problems, seek and adopt solutions, and foster compliance, motivation, and engagement.

Finally, effective SP leaders have good vision and strategic foresight. They plan effectively, stay current with industry, regulatory, or standard changes, set clear goals that will benefit their teams, customers, and organization, and keep a finger on the pulse of technological changes and innovations that will impact SP operations now and in the future.

Conclusion

Becoming a strong leader is always an ongoing journey, and any dedicated employee can become a leader, even informally. Effective leaders, regardless of their official title, are dedicated to sharing their knowledge with others, lending valuable support and collaborating for improved quality, safety, and efficiency. HPN

ASSOCIATION: HSPA 26 | May 2024 | Healthcare Purchasing News

Bone Cement and Black Light Detection - Part 2

BY STEPHEN M KOVACH, BS, CFER, CLINICAL EDUCATOR EMERITUS, HEALTHMARK, A GETINGE COMPANY

QThe original question from last month: “Recently, I read some posting on the Internet that one can use black lights to detect residual bone cement. Is that true,1 and can our department use a black light for this purpose?”

A“Now, the rest of the story…”2

My basic research has led me to consider the following:

• Some “bone cements” have phosphates {calcium, magnesium, beta tri-calcium, etc.} and other materials like barium sulfate in their design.3

• Users should know the type of bone cement used at their facility.

• Can staff perform their own testing on devices to find an acceptable level for detection?

• What type of “black light” ultraviolet (UV) light can be used?

• Does the IFU of the purchased black light state the device can be used for detecting medical bone cement?

• What does the literature say about using the black light method for the purpose they want?4,5,6 (Note: I have not found any peer-review literature supporting this practice.)

• Why are professionals using a black light without real data to support their practice?

Again, the question is: What does the black light pick up (show/glow) if a department is using it as an inspection tool? Because we do know that “Proteinaceous materials emit fluorescence when illuminated by UV light.”5

We all know the use of black light technology is helpful in hand hygiene. Some companies even say it can be used on a hard surface to help determine whether proper cleaning was performed.4 This technology requires not only a black light but a specific gel or powder to be used to show how effective your hand washing process is or how thoroughly a hard surface has been cleaned.4,7 I did not find anything related to using this process on medical devices. As I asked in April, “Could a black light pick [up] residual bone cement if left on the medical device?” That is, residual bone cements the natural eye cannot perceive. I would find answers to at least the questions I raised (you might have more) using this black light as an

inspection/detection tool. Once they are all answered, I would then make a policy on how to use this tool within my department for inspection purposes—if the research called for such a policy