A DEEP DIVE INTO GM’S TRAILER BRAKES

VehicleServicePros.com APRIL 2024

PAGE 26

PAGE 40 GETTING CREATIVE

PAGE 10 Oil selection is becoming more complex. PAGE 18

SWITCHING YOUR BRAINS TO EVS

WITH A/C DIAGNOSTICS

ENGINE OIL

Dorman OE FIX TM parts are designed to improve reliability or simplify service.

AutoZone and Dorman put repair professionals and vehicle owners first. Whenever an OEM doesn’t offer the service solution you deserve, Dorman develops a better solution—an OE FIX™ solution.

AutoZone® carries thousands of Dorman OE FIX™ parts that come in countless varieties, featuring:

Upgraded materials to increase reliability

Time-saving designs, such as multi-piece and flexible features, separately serviceable components, etc

Smarter electronics, featuring plug-and-play modules, included programmer tools, faster processors, etc

Serviceable components to simplify future maintenance

Scan to learn more or visit DormanProducts.com/AZ

Including patented OE FIX™ oil filter adapters for Pentastar engines with upgraded aluminum designs

TM

©2024 AutoZone, Inc./Dorman Products, Inc. All Rights reserved. AutoZone and AutoZone & Design are registered marks of AutoZone IP C or one of its affiliates. Dorman & Design, D Design, OE FIX, and OE FIX & Design are trademarks of Dorman Products, Inc. or one of its affiliates. All other marks are property of their respective owners. Expanded Availability, Delivered Fast

4 Online

6 Straight Talk

8 Tech Tips

10 Getting Creative With A/C Diagnostics

Understanding the specific system is critical.

Brandon Steckler

18 The Ins and Outs of Engine Oil Oil selection is becoming more complex.

Mike Mavrigian

26 A Deep Dive Into GM’s Trailer Brake Technology

Understanding how the pickup truck systems work and what issues may occur.

Jeff Taylor

35 The Universal Language of Drivability

Diagnosing engine power loss from more than 1,500 miles away.

Brandon Steckler

40 Switching Your Brains to EVs How to train your drivability mind for the electric vehicle world.

Craig Van Batenburg

58 The Trainer #147

The key to efficient drivability diagnostics

Brandon Steckler

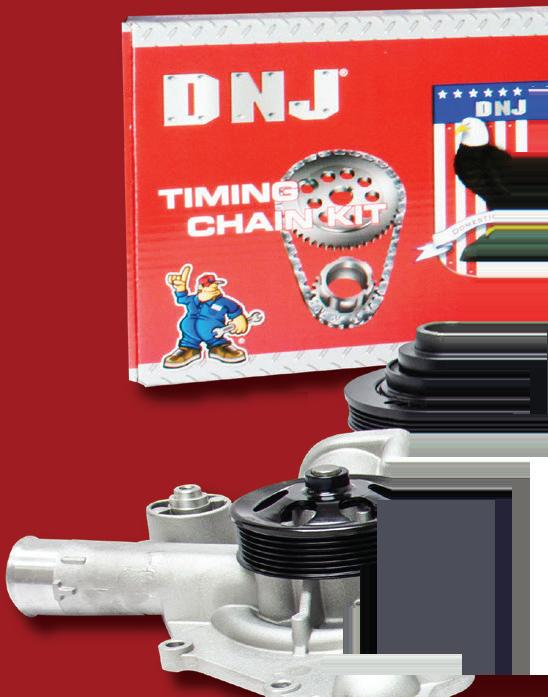

49 Automotive Product Guide

53 Technical Service

53

articles.

Endeavor Business Media provides certain customer contact data (such as customers’ names, addresses, phone numbers, and e-mail addresses) to third parties who wish to promote relevant products, services, and other opportunities that may be of interest to you. If you do not want Endeavor Business Media to make your contact information available to third parties for marketing purposes, simply call toll-free 877382-9187 or email MotorAge@omeda.com and a customer service representative will assist you in removing your name from Endeavor Business Media’s lists.

Motor Age does not verify any claims or other information appearing in any of the advertisements contained in the publication, and cannot take responsibility for any losses or other damages incurred by readers in reliance of such content. While every precaution is taken to ensure the accuracy of the ad index, its correctness cannot be guaranteed, and the publisher waives all responsibility for errors and omissions

AD DEADLINES: Insertion orders–1st of month preceding issue date. Ad materials–5th of month preceding issue date.

VEHICLESERVICEPROS.COM 3 MOTOR AGE

STARTERS

TECHNICAL

TOOLBOX

Bulletins

18 10 40 26 CONTENTS April 2024 / Vol. 143 #2 Motor Age is published 6 times yearly (February, April, June, August, October, December) by Endeavor Business Media, LLC. 201 N Main St 5th Floor, Fort Atkinson, WI 53538. Customer service can be reached toll-free at 877-382-9187 or at MotorAge@omeda.com for magazine subscription assistance or questions. Printed in the USA. Copyright 2024 Endeavor Business Media, LLC. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopies, recordings, or any information storage or retrieval system without permission from the publisher. Endeavor Business Media, LLC does not assume and hereby disclaims any liability to any person or company for any loss or damage caused by errors or omissions in the material herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever. The views and opinions in the articles herein are not to be taken as official expressions of the publishers, unless so stated. The publishers do not warrant either expressly or by implication, the factual accuracy of the articles herein, nor do they so warrant any views or opinions by the authors of said

Ad Index

ONLINE

TALK SHOP. ANYTIME.

VIDEO

NEW SERIES

Motor Age Technical Editor Brandon Steckler has launched a new monthly video series. Wrench Tales takes a deep dive into perplexing repair stories with other technicians across the country. The guest technician shares the story of a particularly difficult repair project, and also walks through the diagnostic steps he or she followed to analyze the codes in the problematic system. And of course they talk about all of the surprises found along the way. Catch up with the initial episodes featuring technicians Chris Martino and Rick Urso on Motor Age’s YouTube channel.

CHECK OUT OUR NEWEST VIDEO SERIES: WRENCH TALES

AWARDS

BEST YOUNG TECH

Motor Age is kicking off the fourth year of the Best Young Tech Award in April. The contest honors one exceptional technician who is making strides to move the service repair industry forward. This award is designed for technicians 35 and younger who are excelling in their current role and passionate about their work and the industry. The winner will be honored during a special award presentation during the 2024 SEMA Show.

EDITORIAL

GROUP EDITORIAL DIRECTOR

Matt Hudson / mhudson@endeavorb2b.com

EDITOR

Mike Mavrigian / mmavrigian@endeavorb2b.com

MANAGING EDITOR

Joy Kopcha / jkopcha@endeavorb2b.com

TECHNICAL EDITOR

Brandon Steckler / bsteckler@endeavorb2b.com

ASSOCIATE EDITOR

Madison Gehring / mgehring@endeavorb2b.com

CONTRIBUTING WRITERS

Jeff Taylor, Craig Van Batenburg

ART AND PRODUCTION

ART DIRECTOR

Rhonda Cousin

PRODUCTION MANAGER

Mariah Straub

AD SERVICES MANAGER

Melissa Meng

SALES

ASSOCIATE SALES DIRECTOR

Mattie Gorman-Greuel / mgorman@endeavorb2b.com

DIRECTOR OF BUSINESS DEVELOPMENT

Cortni Jones / cjones@endeavorb2b.com

ACCOUNT EXECUTIVES

Kyle Shaw / kshaw@endeavorb2b.com

Marianne Dyal / mdyal@endeavorb2b.com

Martha Severson / mseverson@endeavorb2b.com

Darrell Bruggink / dbruggink@endeavorb2b.com

Sean Thornton / sthornton@endeavorb2b.com

Diane Braden / dbraden@endeavorb2b.com

Lisa Mend / lmend@endeavorb2b.com

Chad Hjellming / chjellming@endeavorb2b.com

ENDEAVOR BUSINESS MEDIA, LLC

CEO

Chris Ferrell

PRESIDENT

June Griffin

COO

Patrick Rains

CRO

Paul Andrews

CHIEF DIGITAL OFFICER

Jacquie Niemiec

CHIEF ADMINISTRATIVE AND LEGAL OFFICER

Tracy Kane

EVP TRANSPORTATION

Kylie Hirko

BUSINESS STAFF

VP/GROUP PUBLISHER

Chris Messer

ASSOCIATE PUBLISHER

Andrew Johnson

BUSINESS DEVELOPMENT DIRECTOR,

MOTOR AGE TRAINING

Michael Willins

CUSTOMER MARKETING MANAGER

Leslie Brown

AUDIENCE DEVELOPMENT MANAGER

Tracy Skallman

SALES COORDINATOR

Jillene Williams

HOW TO REACH US

EXCLUSIVE

TOP PRODUCTS

Are you on the hunt for a new scope, or planning to invest in updated lifts for your shop in the near future? Check out the most popular products other technicians, shop owners and tool distributors have researched lately with our monthly roundups of the most-read products on VehicleServicePros.com.

ENDEAVOR BUSINESS MEDIA LLC.

30 Burton Hills Blvd, Ste. 185, Nashville, TN 37215

Phone: 800-547-7377

CUSTOMER SERVICE

Subscription Customer Service 877-382-9187; 847-559-7598

MotorAge@omeda.com

PO Box 3257 Northbrook, IL 60065-3257

REPRINT SERVICES

reprints@endeavorb2b.com

MEMBER OF:

VEHICLESERVICEPROS.COM 4 APRIL 2024 CELEBRATING 125 YEARS

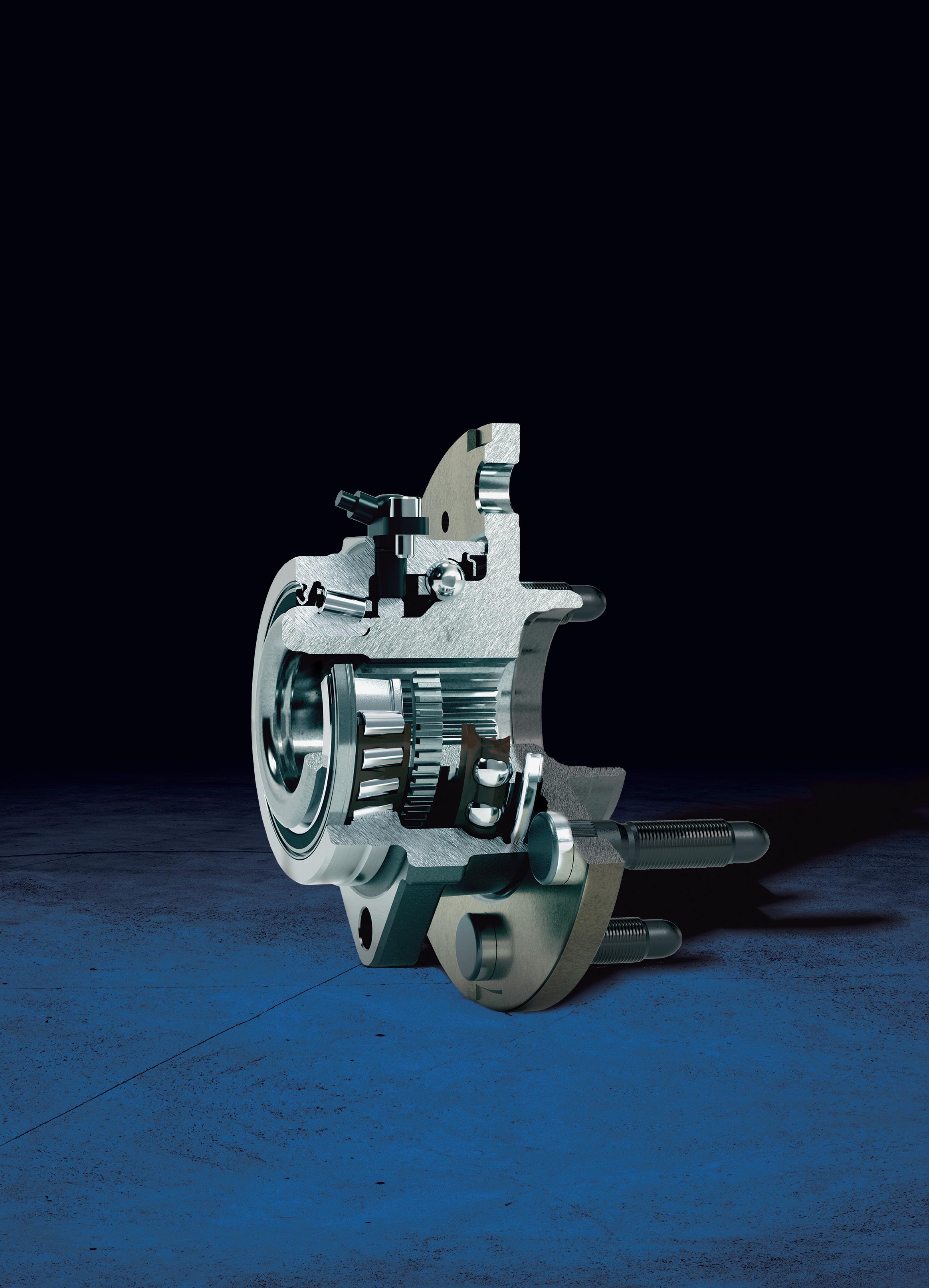

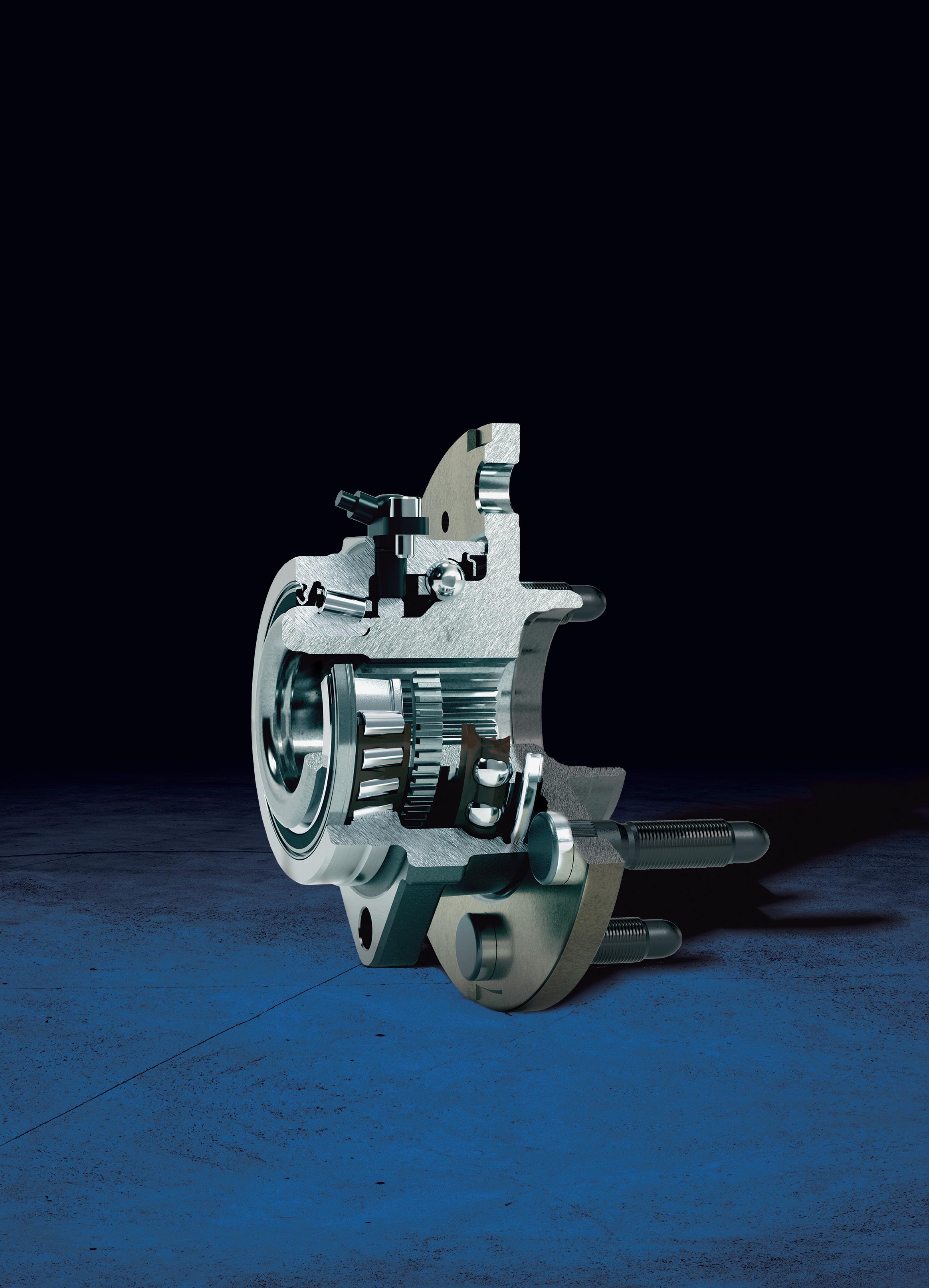

O.E.-backed

application-specific assemblies with premium components.

Tested and proven, bproauto® complete strut assemblies are designed to install easily, are available for most makes and models, and are among the most competitively priced strut assemblies in the market – even with their premium components, including a best-in-class strut. Backed by our 24 months/unlimited miles warranty.

Over 40 part types. Over 20,000 part numbers.

©2024 Stellantis Auto SAS. All Rights Reserved. bproauto is a registered trademark of Stellantis Auto SAS.

Aftermarket strut technology that’ll help smooth things over with your customers.

Search our catalog at bproautoparts.com

complete

The Importance of Understanding NVH

Customers complaining about noises, vibrations, clunks or bangs can open up a can of worms from a diagnostics standpoint.

YOU’VE PROBABLY ALREADY HEARD THE joke wherein a customer brings a vehicle into a shop and complains, “My car keeps making these awful noises.” The technician replies by saying, “Have you considered removing the Taylor Swift CD?”

Yep, that’s funny, but customers complaining about noises, vibrations, clunks, bangs or other abnormal conditions can certainly open up a can of worms from a diagnostics standpoint. The noise might be traced to the suspension (knocking or ticking noise when the vehicle is turned to the right, or when the vehicle runs over bumps in the road). The cause might be strut bearings or a worn CV joint or loose/worn shock. Maybe a whistling noise is heard at a certain vehicle speed, which might be caused by an air leak at a door seal or a dislodged undercar belly cover.

A ticking/rattling noise might be heard on cold startup or whenever the engine is idling, and the engine running rough is possibly caused by a stuck lifter or malfunctioning cam phaser. A hissing noise accompanied by a rough idle might be traced to an engine vacuum leak. A screeching noise might be due to a worn or misaligned drive belt. An undercar thumping noise might involve a loose/missing exhaust pipe hanger or a worn/damaged watts link at the rear suspension. A squeak, screech or

grinding noise under braking might be caused by worn brake pads where the wear indicator is scraping the rotor. A chirp/tick noise upon startup might simply be an electric fuel pump cycling up. A worn or improperly installed clutch may cause a shudder effect.

We could go on and on, but you get the drift. In addition to being knowledgeable about the various systems — brakes, suspension, body, exhaust, fuel system, engine mechanicals, etc. — we need to understand the over-riding area of NVH (noise, vibration, harshness). The study of NVH deals with concerns involving unusual noises, vibrations, shimmy, banging, etc.

A variety of noise and vibration levels exist in the normal operation of any vehicle. When noises and/or vibrations are perceived by the customer, the vehicle ends up in your shop, and it’s up to you to determine the cause and repair. NVH is the industry-wide term used when discussing these conditions.

If the cause of the customer complaint is not obvious or easily determined, understanding the theory and practice of NVH diagnostics can guide you through logical steps to determine the root cause.

Of course, all auto manufacturers offer training materials and service manuals to support your efforts. But are you aware of the automakers’ training

materials specific to NVH? Chances are, each manufacturer offers this material. Toyota, as but one example, produced an extremely in-depth training manual on this subject. While a manual that discusses NVH in depth will not be specific to a year/make/model, it offers overall knowledge that is applicable to all vehicles.

Few of us have the luxury of plenty of free time during the workday, but studying one of these manuals, even bit by bit, over the course of time, will definitely increase your understanding and will enable you to more skillfully address these customer concerns.

MIKE MAVRIGIAN MOTOR AGE // EDITOR mmavrigian@endeavorb2b.com

MIKE MAVRIGIAN MOTOR AGE // EDITOR mmavrigian@endeavorb2b.com

STRAIGHT TALK VEHICLESERVICEPROS.COM 6 APRIL 2024

Oil Reminder

Never assume that a new or reman engine or transmission is ready to install and use. New and reman engines are usually shipped without oil to avoid potential leaks during shipping. If you’re replacing an engine or transmission, always check fluid level and add as needed per factory specifications, and be sure to use only the type, viscosity and volume of lubricant specified by the automaker. The need to be aware of this should be obvious, but it only takes one bad assump-

If a customer has a 2017-2018

Bolt EV and says that the

8 APRIL 2024

Chevy Bolt Tip

brake, SCAN TO READ MORE ARTICLES LIKE THIS VehicleServicePros.com Follow Us On INSTAGRAM @motor_age MA-4103.indd 1 11/15/23 2:03 PM VehicleServicePros.com Follow Us On INSTAGRAM @motor_age MA-4103.indd 1 11/15/23 2:03 PM

Chevy

Remember to Check Park Brake

Let’s face it — far too many drivers tend to ignore the parking brake system, especially those who drive vehicles equipped with an automatic transmission. They toss it into Park and never give the park brake a second thought. As a result, in many cases the parking brake system may be “frozen” (stuck) if and when they do attempt to use it. The result can be either the park brake does not function at all, or it engages and will not release. Of course, if it won’t release, the customer will likely need to have the vehicle towed to a repair shop.

When any vehicle is on your lift, and especially when you’re doing a brake job, remember to inspect the system for condition and operation. If the system is currently working (or now working after you repaired), advise the customer to occasionally use the Park brake (give it some exercise) to prevent it from seizing or becoming inoperative in the future. This is especially important for vehicles driven in winter conditions where salt/brine is used to keep roads de-iced.

After Engine Replacement

If you have a customer whose late model vehicle required an engine replacement (new or reman), advise them that it may take one, two or even more fuel tank trips for the adaptive learning system to settle down (fuel mpg reading, idle quality, etc.). We recently replaced a 5.0L engine in a 2020 Ford F150 and the customer kept complaining of an intermittent rough idle and other anomalies. After driving the vehicle for about 700 miles, everything went back to “normal.”

Squeaky Mazda

Some 2017-2020 Mazda6 vehicles equipped with a 2.5T engine may exhibit a squeaking noise from the exhaust manifold when idle speed drops from fast idle to normal idle during a cold start. This is caused by a variable valve being stuck in the closed position. When returning from fast to normal idle, the stuck valve suddenly opens due to thermal change, resulting in the noise. Mazda has updated the exhaust manifold. If the customer wants to eliminate the noise, replace the manifold with new P/N PY8V-13-450K.

9 MOTOR AGE VEHICLESERVICEPROS.COM

Trust us to be your partner in repairs — be Delphi Driven. Delphi aftermarket steering and suspension parts undergo rigorous dimension, material, durability and performance tests. Our engineers are driven to ensure that our parts meet OE form, fit and function specifications so you can install them with confidence. Contact your Delphi Rep to learn more. Premium Steering and Suspension delphiaermarket.com 2404MA_DelphiTechnologies.indd 1 3/13/24 10:12

Getting Creative With Getting Creative With

AC DIAGNOSTICS

AC DIAGNOSTICS

BY BRANDON STECKLER // Technical Editor

BY BRANDON STECKLER // Technical Editor

A/C DIAGNOSTICS 10 APRIL 2024

the specific system

Understanding

is critical.

WHEN MULTIPLE PROBLEMS exist in an inoperative refrigerant loop, the stride for accuracy becomes even more of a challenge.

When it comes to A/C diagnostics, it’s pretty straightforward. Like addressing any other system in the vehicle, having the right tools for the job, adequate service information, and the know-how to approach the system in question is always the right approach.

But, what happens when the system in question has more than one issue? How do we alert the customer accurately, the first time? Sometimes we can’t.

This same scenario drives techs insane — and typically is the cause of much frustration and lost revenue.

The initial approach

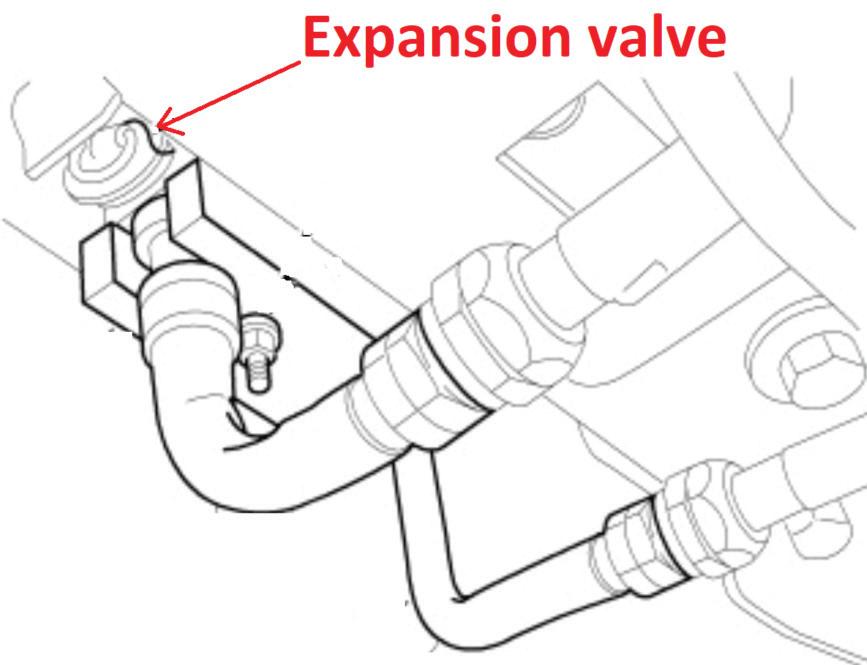

My good friend, Rick, faced this very same challenge not too long ago. The subject vehicle was a 2015 Chrysler Town and Country van with 185,000 miles on the odometer and the complaint was that the automatic A/C wasn’t performing correctly (Figure 1). Like many minivans of today, this one was also equipped with rear zone A/C.

The initial approach was typical. The system was evaluated preliminarily, and the A/C compressor was found to be inoperative. This led to a system pressure test proving the refrigerant charge was significantly low.

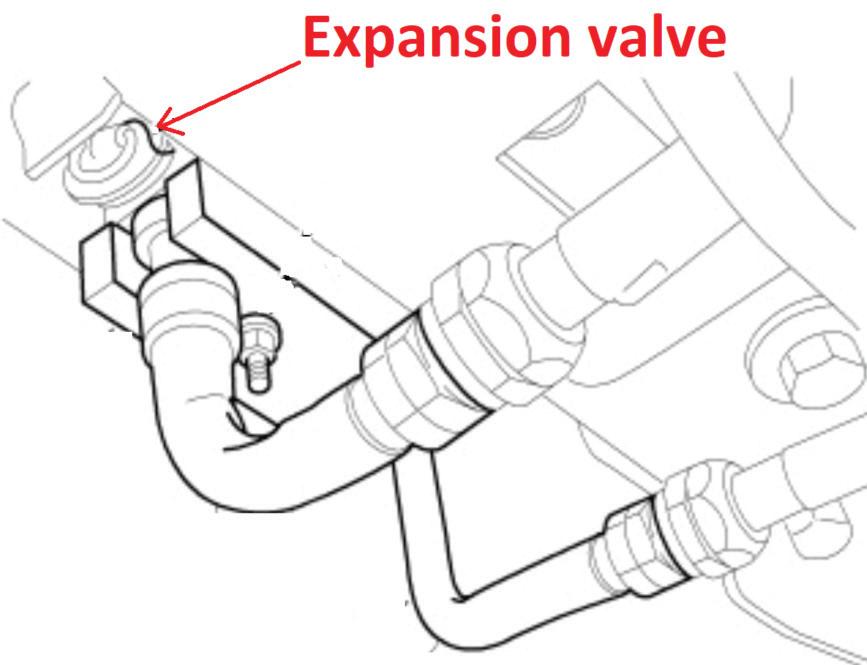

Further investigation found a leaking rear expansion valve at the rear evaporator core. After consulting with the customer about the suggestion to include the replacement of the rear evaporator core, the customer concurred, and both components were replaced (Figure 2). The compressor oil was balanced, and the system was evacuated and charged to specification.

VEHICLESERVICEPROS.COM 11 MOTOR AGE

PHOTO CREDIT: BANCHA SINGCHAI | #1373304788

ISTOCK � GETTY IMAGES PLUS

FIGURE 1: THE SUBJECT vehicle, a 2015 Chrysler Town and Country with a tri-zone automatic climate-controlled HVAC system, has a complaint of poor A/C performance.

FIGURE 2: THE LOCATION of the rear expansion valve made it prudent to also recommend the replacementof the rear evaporator core as the vehicle is eight years old with 185,000 miles on it.

PHOTO BY BRANDON STECKLER

PHOTO BY BRANDON STECKLER

However, upon delivery of the vehicle, the compressor had become very noisy. Further analysis pointed to a faulty compressor clutch pulley bearing. Due to the cost of clutch assembly replacement and the age of the original compressor, Rick installed a replacement compressor as an assembly.

A shot at redemption

This is where things start to go awry. With the replacement of the fixed displacement A/C compressor assembly and rebalancing of the oil, Rick followed up with a generic A/C system performance test. Meaning, he evaluated the pressures at idle, vent temperatures, and factored in the ambient conditions.

The results of the test at idle are as follows:

• Ambient temperature: 82 F

• Outlet temperature: 78 F

• Low-side pressure: 80 psi

• High-side pressure: 150 psi

This is the point when Rick reached out to me for input because he wasn’t happy with the outlet temperatures at the vents. After hearing of the saga, I told Rick that I agreed the outlet temperatures were subpar and there is definitely an issue that must be addressed. I suggested that he reference and follow the published A/C performance test in service information for this vehicle specifically (Figure 3) As can be seen, it appears the new A/C compressor is not pumping refrigerant efficiently. But is it the fault of the compressor or is there an underlying cause?

Every vehicle has specific test criteria and for good reason. For one, we must always factor in the current ambient conditions. Temperature, sun load, heat load and humidity all affect the performance of the A/C system. Also, a smaller vehicle has less mass than a larger one. This means the larger vehicle holds more heat energy. Although some tests are more stringent/accurate than

others, following the vehicle-specific A/C performance test takes all those factors into account and levels the playing field to obtain more accurate test results. Besides, they typically offer a correlation chart that compares pressure/temperature and make suggestions toward likely failed components or areas of malfunction in any area of the HVAC system (Figure 4)

According to the chart, there are a few possibilities:

• A slipping belt would prevent the compressor from working efficiently.

• A faulty expansion valve would not modulate/throttle the refrigerant properly.

• The new compressor could be faulty/ low displacement.

• A restriction in the refrigerant lines could create a pressure drop and performance issue.

Each one of the above bullet points could be very likely, especially due to the age of the vehicle and the previous failures/replaced components. The question I posed to Rick is what test could we do to help eliminate one or more of the possibilities above?

Hindsight is always 20/20

Although Rick was a victim of circumstance — meaning, he did nothing wrong — this was his shot at redemption. In hindsight, Rick could have charged the original leaking system to specification and upon conducting the performance test he likely would have witnessed the symptoms and test results he was currently experiencing. Then again, the vehicle did leave the shop with a properly performing A/C system, so all bets are off.

What I was alluding to above when I questioned Rick about a different approach to eliminate possibilities, the “touch test” came to mind. Because the refrigerant loop operates off principles that dictate how temperature and pressure relate, with a topological layout of the refrigerant loop’s configuration we can anticipate the temperature of the components at any given spot in the loop.

A/C DIAGNOSTICS 12 APRIL 2024

Ambient Air Temperature (Apparent) 21° C 27° C 32° C 38° C 43°C (70° F) (80° F) (90° F) (100° F) (110° F) Maximum Allowable Air Temperature 9° C 9° C 12° C 15° C 24°C at Center Panel Outlet (48° F) (48° F) (54° F) (59° F) (75° F) Maximum Allowable Air Temperature 10° C 13° C 15° C 17° C 24°C at Drive Side 2nd Row Headliner Outlet (50° F) (55° F) (59° F) (63° F) (75° F) Suction Pressure at Service Port 138 to 310 kPa 138 to 345 kPa 207 to 365 kPa 207 to 414 kPa 241 to 448 kPa (Low Side) (20 to 45 psi) (20 to 50 psi) (30 to 55 psi) (30 to 60 psi) (35 to 65 psi) Discharge Pressure at Service Port 1034 to 1724 kPa 1379 to 2068 kPa 1551 to 2241 kPa 1724 to 2413 kPa 2068 to 2758 kPa (High Side) (150 to 250 psi) (175 to 300 psi) (175 to 325 psi) (250 to 350 psi) (300 to 475 psi)

FIGURE 4: FOLLOWING THE A/C performance test is a guide describing the link between test results andpossible faults. It’s a great way to gain insight into the nature of the fault and how to develop a diagnostic game plan.

BY

BY

FIGURE 3: THE VEHICLE-SPECIFIC A/C performance test is documented in service and repair information. It is recommended to help guide you toward the root cause of a fault. It takes the opinion out of the analysis. PHOTO

BRANDON STECKLER PHOTO

BRANDON STECKLER

With that, if an issue like a restriction existed, the correlating pressure drop of the circulating refrigerant would yield a temperature drop across that restriction. There would be a significant temperature change and it would be easily sensed by hand, through the touch test (Figure 5).

As demonstrated by the colors blue and red, these colors truly represent pressure zones but also the temperature we should anticipate during the touch test.

(Red is hot and blue represents cold.) This diagram reflects the configuration of this vehicle’s system topology.

Starting to the left of the compressor is the outlet. The compressor outputs a hot, high-pressure gas into the discharge hose and then travels through the condenser. As it does so, heat energy radiates from the hot gas allowing it to condense into a liquid. The hot, liquid refrigerant leaves the condenser in the liquid line and travels through the receiver/dryer which acts like a reservoir for the liquid refrigerant. After that, the expansion valve serves as a restriction and creates the necessary pressure drop allowing two things to occur. The hot,

high-pressure liquid refrigerant becomes a cold low-pressure liquid.

As the cold liquid refrigerant makes its way through the evaporator core, which is located in the cabin, it absorbs heat from the cabin and boils off into a gaseous state once again. As this occurs the refrigerant absorbs the heat energy from the cabin and allows the cabin to cool. The compressor will draw the cold gas in and pressurize it to repeat the cycle.

Putting the game plan into action

Rick ran the system and began his touch test. Almost immediately Rick found his issue as he burned his hand when placing it on the discharge hose — between the compressor outlet and the condenser inlet. This is indicated by the yellow star in the diagram.

The question then becomes, “If there is a restriction on the high side of the

A/C DIAGNOSTICS 14 APRIL 2024 2404MA_ETEReman_ATSG.indd 1 3/11/24 11:24 AM

C O N D E N S E R R C V R E V A P EXP VALUE COMPRESSOR HIGH PRESSURE LOW PRESSURE HIGH TEST PORT RESTRICTION LOW TEST PORT PHOTO BY BRANDON STECKLER

FIGURE 5: A TOPOLOGICAL layout of the refrigerant loop can aid in the diagnosis, taking into consideration the test port locations, particularly.

HIGHLY EFFICIENT SYNTHETIC MEDIA MAX TESTED FOR QUALITY & PERFORMANCE PRE-LUBED GASKET FOR EASY INSTALLS 30%MORE 100% LESS TheNEW Mighty MAX Oil Filters protect engines 10K miles or more between service intervals. Unique red M-Pleat design has more media for higher dust-holding capacity and 30% longer life. Silicone Anti-Drainback Valve provides extended protection against dry engine starts. Bold red can screams performance. Visit MightyAutoParts.com/MightyMAX

system, why is the high-side pressure not extremely elevated?” This is where system configuration comes into play. But we will first prove the location of the restriction using a thermal imager. This will offer something visible to show the customer and to document on the repair order.

The combination/Siamese discharge hose and liquid line are shown. The bright white area in the image indicates the location of the restriction in the discharge hose (Figures 6 and 7). The picture is worth a thousand words. We know the hose isn’t physically damaged on the outside, so it has either internally collapsed or there is debris in the hose. The reason high-side pressure is not very elevated can be seen in the topology diagram. The high-side test port is downstream of the restriction. If it was upstream of the restriction, the diagnosis would’ve been swift and simple. These simple observations are frequently overlooked by technicians, and they tend to assume every high-side restriction will cause a pressure increase. It truly depends on the location of the restriction relative to the test port location.

Removal of the hose allowed Rick an opportunity to push shop-regulated

air through the hose. He captured metal shavings from the hose that likely came from the compressor. But was it the original compressor or the replacement compressor that dumped the metal shavings into the system?

At this point, I will give you my opinion. Experience tells me that metal is very difficult to get out of a refrigerant loop. With that, I would recommend a total system replacement. I am being ignorant of cost and simply stating that is the safest way to properly repair the vehicle. Rick has a few other points to factor in though.

For one, he warranted the new compressor with another replacement. Two, he replaced the condenser along with the Siamese refrigerant line (as there is no way to guarantee no metal resides inside it). Three, he replaced the receiver/dryer (containing the sack responsible for removing/trapping moisture from the refrigerant) as the metal particles tend to cling to it.

Again, I will state that it is a gamble because any remaining metal can circulate in the repaired system and wreak havoc. But it doesn’t mean it’s an improper or incomplete repair. Even if Rick recommended full component replacement, the choice is up to the customer. After repair, a subsequent A/C performance test proved the system functioned as designed and the gamble paid off. Here are the results:

• Ambient temperature: 82 F

• Outlet temperature: 48 F

• Suction pressure: 42 psi

• Discharge pressure: 181 psi

Automotive Autopsy

After disassembly, Rick noticed that the first replacement compressor had a bit of drag to it as he manipulated it by hand. This was likely the culprit that dumped the metal into the system. Reflecting on our A/C system performance test, even if Rick replaced the restricted hose, a repeat test likely would have failed. The metal shaving from the compressor would reduce its ability to pump refrigerant and

the symptoms of low displacement would have been exhibited. (High suction pressure/low discharge pressure).

My point is that even following procedure can still lead to tough roads ahead. But being creative with the tools you have, your knowledge of how the components of the system function, and what to expect from the derived test results can serve as a supplement to good service information. The combination of the three serves as the three legs of a stool to keep you upright in almost any situation. Persistence pays off!

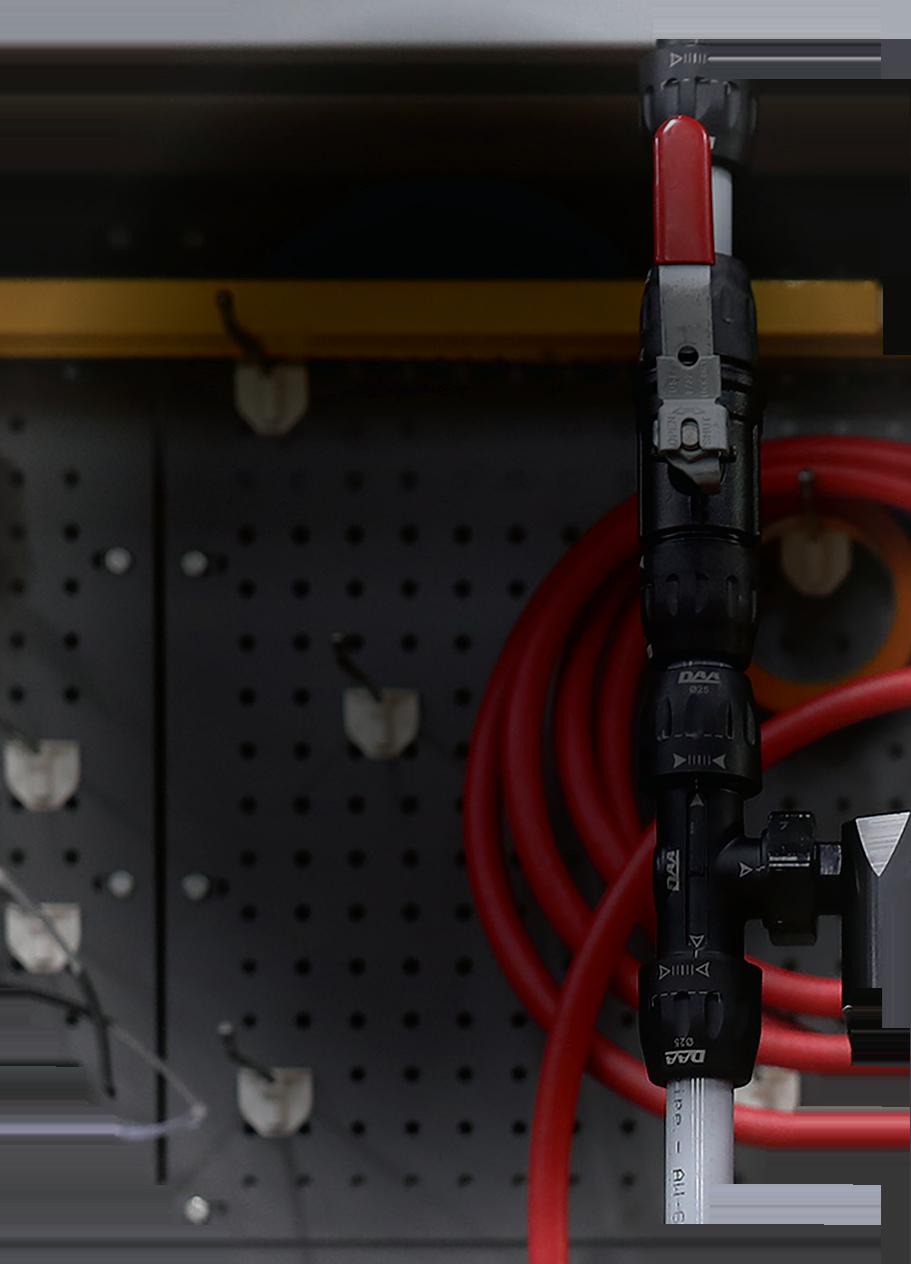

Get creative with tools like the thermal imager. The thermal imager detects infrared heat energy. Any object that is warmer than absolute zero emits infrared radiation. The further from absolute zero the surface temperature of the measured object is, the more infrared heat energy it will emit. Capitalize on this and use it to your advantage when possible.

Reference service information and determine the system’s topological layout before troubleshooting issues via a performance test. Not only will the test results make better sense to you, but you will have a greater understanding of how the individual components work together as a system.

All of these skills and techniques come together and will help you become a better technician overall.

SCAN TO READ MORE ARTICLES LIKE THIS

BRANDON STECKLER is the technical editor of Motor Age magazine. He holds multiple ASE certifications. He is an active instructor and provides telephone and live technical support, as well as private training, for technicians all across the world.

A/C DIAGNOSTICS 16 APRIL 2024

FIGURE 6: THE SNAP-ON Diagnostic Thermal Imager was used to locate a restriction on the high side of the refrigerant loop.

FIGURE 7: THE SNAP-ON Diagnostic Thermal Imager offers dual views of the image being targeted. A raw photo and one indicating the intensity of Infrared radiation (heat signature).

PHOTO BY BRANDON STECKLER

PHOTO BY BRANDON STECKLER

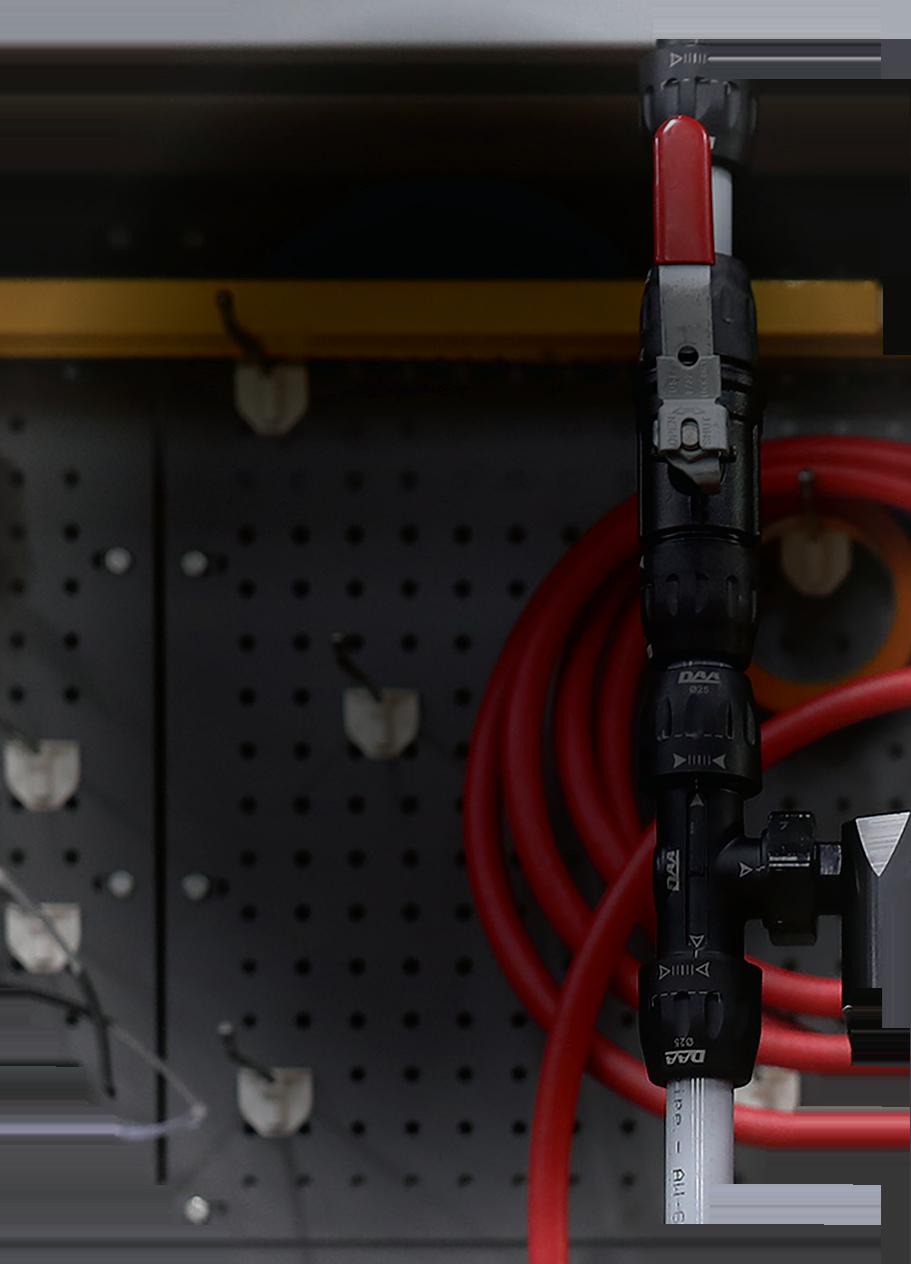

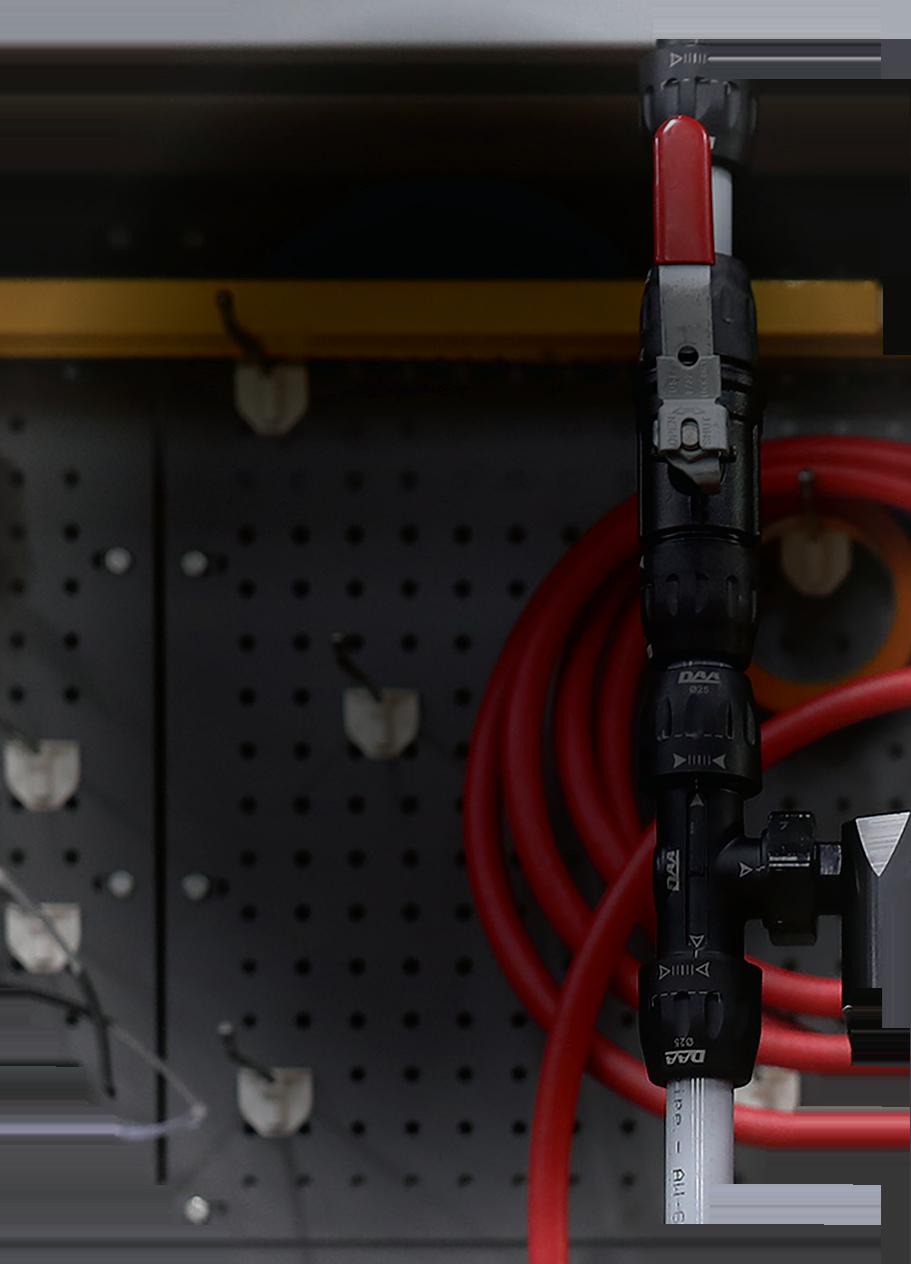

Professional aluminum ComPressed air PiPing system Measure and Cut ➤ Push to Connect Call for a FREE quote Use for new installation, or to expand or modify your current system. SATA USA Inc. 1 Sata Drive • PO Box 46 Spring Valley, MN 55975 Phone: 800-533-8016 E-mail: satajet@satausa.com www.satausa.com • ENERGY EFFICIENT • EASY TO INSTALL • Modular design • Corrosion Resistant • Leak-free guarantee • Removable and reusable • Push-to-connect technology • Immediate pressurization • Full bore design • 1/2” to 6” pipe sizes • Save Money

Oil selection is becoming more complex.

BY MIKE MAVRIGIAN

The Ins and Outs of Engine Oil

UNFORTUNATELY, TODAY’S DRIVERS do not tend to check engine oil levels manually, as they instead rely on instrument panel displays to remind them of the next oil change interval. Some of today’s engines don’t have dipsticks but there is a dash reading and procedure to verify the proper level.

In addition, some vehicle owners don’t pay attention to the type and/or viscosity requirements, potentially assuming that

if oil is at the correct level, it doesn’t matter. This attitude is a recipe for long-term disaster. Choosing the correct type and viscosity is critical in terms of engine longevity, engine power output, fuel economy and emissions.

The engine oil of choice must prevent engine component wear, limit timing chain wear, and prevent sludge, varnish, and oil deposits. It must control deposits in the turbocharger, on the engine’s pistons

ENGINE OIL 18 APRIL 2024

GETTY IMAGES | #1340648083 SCAN TO READ MORE ARTICLES LIKE THIS

and prevent low-speed pre-ignition (LSPI). LSPI is a potentially catastrophic engine problem that occurs when tiny particles of fuel and oil self-ignite in the combustion chamber. Turbocharged gasoline direct-injection engines in particular are prone to LSPI. Rods, pistons, piston rings, cylinder walls and spark plugs can all be damaged by severe LSPI conditions.

Adhering to the manufacturer’s recommended engine oil ensures that the oil will feature the required oil additives to prevent LSPI, limit oil volatility, wear, deposits, sludge, foaming, and still supply the critical cleaning and lubricating protection.

The manufacturer is going to be specific on the type of oil (conventional, semi-synthetic or full synthetic), the oil grade (SJ-SP, GF-6A, GF6B), any other specific specifications and the engine oil viscosity. All these pieces of information must be known before adding new oil into any customer’s engine.

Once the engine manufacturer specifications for engine oil are known, don’t select an oil simply based on the viscosity rating. Examine the oil bottle/container or bulk oil information package and ensure that the chosen oil meets the needed specifications.

The engine oil container’s label must provide the oil type, viscosity, OEM specific performance specifications and display one or a combination of the following symbols.

The American Petroleum Institute (API) Service Symbol “Donut”: The API provides a license to apply the “Donut” symbol to ensure consumers buying that engine oil that it meets API’s engine oil standards.

The American Petroleum Institute “Starburst”: The API “Starburst” is another symbol to look for on the package or specification sheet of the engine oil you are installing. This symbol signifies that the oil meets the most up-to-date specification provided by the International Lubricant Specification Advisory Committee

and the engine oil will meet the additional fuel economy and emission system protection requirements.

As of May 1, 2021, all oil products displaying the “Starburst” must meet the API SP/Resource conserving specs.

International Lubricant Specification Advisory Committee (ILSAC) “Shield”: The “Starburst” certification will remain on legacy products (0W-20, 5W-20, 0W-30, 5W-30, 10W-30), but the “Shield” is the new identification mark for the ILSAC SAE 0W-16 viscosity engine oil. ILSAC GF-6 oil specifications are now broken into two separate standards, ILSAC GF-6A for legacy viscosity grades and ILSAC GF-6B for SAE 0W-16. ILSAC GF-6A and its legacy grades will be backwards compatible, but the ILSAC GF-6A is not.

Oil Type

There are three common types of engine oil used today. Conventional engine oil is a base mineral oil, derived from crude oil-based products. Synthetic engine oil is a manufactured chemical compound that is engineered to provide enhanced lubrication properties and supply significant benefits. Synthetic engine oils provide superior low temperature performance, higher thermal stability, lower volatility, better shear performance and other enhancements over conventional engine oils. Semi-synthetic engine oil is a combination of conventional oil and synthetic oil. There is no classification as to how much synthetic oil is blended with conventional engine oil to create a semi-synthetic engine oil blend.

VEHICLESERVICEPROS.COM 19 MOTOR AGE

SELECTING THE proper engine oil is more critical today due to ever-evolving automaker specifications.

IT’S BEST to follow the engine oil fill cap or owner’s manual for viscosity selection. 0W-20 shown here. EXAMPLE OF Ford 5.0L cap indicating 5W-20.

PHOTO BY JEFF TAYLOR

PHOTO BY MIKE MAVRIGAN

PHOTO BY MIKE MAVRIGAN

Viscosity

It should be obvious that engine oil needs to be thin enough to provide lubrication upon cold startup in order to provide critical lubricating oil film to all components, yet be “thick” enough to provide lubrication and heat transfer when the engine is at operating temperature. While specific engines may call for 0W, 5W, 10W or 15W for “cold” operation, the “hot” viscosity rating of 20 or 30 will provide the needed lubrication.

In very broad and generic terms, as engine oil passages/orifices/paths become tighter, thinner cold viscosities may be needed. As temperatures and operating conditions (cylinder bore expansion, higher engine speeds, etc.) change, thicker formulations may be needed. Of course, in this article, we’re primarily focusing on street-driven and un-modified engines. For racing/heavy duty applications, “thicker” hot viscosity ratings may need to increase.

The viscosity numbers refer to the oil’s viscosity or thickness. The oil viscosity number that precedes the “W” for winter, stands for the oil’s thickness at zero degrees Fahrenheit (or minus 17.8 Celsius). The lower the number the thinner the oil at that temperature. The oil viscosity number after the W refers to the oil’s viscosity at 212 Fahrenheit (100 Celsius), indicating the oil’s resistance to thinning when hot.

Oil viscosity ranges have, in recent years, evolved according to the specifications required by the automakers, based on specific engine designs in order to deliver the required lubrication to ever-advancing internal combustion engine designs. Adherence to the specified viscosity ranges has become increasingly important and is not to be ignored.

You should be aware by now that the trend in oil viscosity has been moving to lower-than-traditional levels. As a for-instance, 0W-16 is now common in Toyota and Honda engines. Interestingly, 0W-8 has been specified in Japan-based Hondas for some time now. Cold viscosity numbers

ENGINE OIL 20 APRIL 2024

CRITICAL WEAR-RELATED components such as cylinder bores, piston rings, piston skirts, lifters, rockers, camshafts, cam chains, variable valve systems, cam actuators, etc. rely on the correct type/viscosity/formulation. This has become increasingly important with modern engines due to tighter clearances and performance, emissions and fuel economy goals.

PHOTO BY MIKE MAVRIGAN

PHOTO BY MIKE MAVRIGAN

THE USE of roller lifters reduces friction between cam lobes and lifters, allowing the use of thinner viscosity oil for cold startup. This also reduces the need for certain friction modifiers that would otherwise be needed as part of the oil’s makeup for flat-tappet cams.

like that may sound scary, but we need to bear in mind that the automakers have reasons to specify such levels based on their research and development.

Low viscosity oils considerably lower the energy losses that are attributed to engine oil and its viscosity causing friction (main/rod/cam bearing friction, piston to bore friction) but these low viscosity oils can have a negative effect and may increase friction on other parts of the engines such as the camshaft and lifters/followers.

Most of today’s engines are fitted with electronically controlled variable displacement oil pumps. These oil pumps will easily supply the needed engine lubrication at the desired pressure and volume to fully compensate for the oil’s thin viscosity. Also, as compared to older flat-tappet lifters and friction-inducing rockers, the trend towards using roller lifters and roller rockers significantly reduce friction, allowing the use of thinner viscosity oil.

Today’s engines feature much tighter tolerances and clearances, requiring a thinner oil to be delivered upon cold startup. Also, tiny orifices featured in oil activated and controlled variable valve timing actuators depend on the engine oil’s low viscosity for proper functionality especially when the engine is cold. Oil that is too “thick” under startup conditions can starve critical components until temperatures rise and sufficient oil flow is obtained. The wrong viscosity oil can easily cause drivability concerns, hesitation, performance issues and even possibly the MIL being illuminated if the wrong viscosity engine oil is installed. In a nutshell, the oil must be “thin” enough under startup and initial warmup to lubricate, stabilize and become more viscous to properly lubricate components once the engine reaches full operating temperature. It’s not as easy task to provide the proper balance.

Low viscosity oil reduces engine warmup times, improves cold weather starts

An oil manufacturer weighs in ExxonMobil Product Solutions provided some insights on the latest trends in engine oil, including why automakers have made the switch to synthetic oils, and the next oil specification that’s already in the pipeline.

What’s new in engine oil technologies?

What are the latest trends on oil viscosities?

ILSAC GF-7 is the new engine oil specification planned for introduction in the first quarter of 2025. It is designed around improved low speed pre-ignition protection, increased fuel economy benefit, and better deposit control. Additionally, additive technology has advanced to lower levels of sulfated ash, which is also part of the draft ILSAC GF-7 specification, for protection of emission aftertreatment devices. New detergents have been developed to protect against higher boost pressures and compression ratios. The trend towards lower oil viscosities continues as evidenced by the addition of SAE 0W-8 and 0W-12 viscosity grades into the API SP Resourcing Conserving category, which drives the use of higher quality, lower viscosity base stocks to enable these lower viscosity grade motor oils.

Why have automakers moved to synthetics?

Automakers continue to be challenged to meet the consumer demands for improved engine performance, including better fuel economy and longer engine life. To meet these challenges, automakers have turned towards full synthetic lubricants, which typically offer better performance and protection than synthetic blend and conventional motor oils, even at the same nominal oil performance level. As a result of the use of synthetic lubricants, automakers can design their engines to take advantage of the better performance from synthetic lubricants to provide overall better engine performance to the consumer.

Why is it important to adhere to oil type and viscosity ranges specified by the automakers?

The oil plays an integral part in engine performance, serving multiple functions including wear protection and engine cooling. Automakers design their engines to operate at peak performance with oils of specific viscosity grades and performance levels. As a result, using the specified viscosity grade and oil performance level can ensure owners of optimum performance over the lifetime of their vehicle.

VEHICLESERVICEPROS.COM 21 MOTOR AGE

and increases fuel economy. Changing from the old familiar 5W-30 to 0W-16 represents a 2% increase in engine fuel economy and the use of the ultra-low viscosity oils such as the 0W-8 could further improve engine fuel economy by another 0.6 to 1.1%.

Many automakers tend to establish their own proprietary engine oil specifications to meet the specific designs and requirements of their engines, emission systems and the engine operating systems. These proprietary formulations often have modified additive packages and can pass specific chemical and physical oil tests that may not be included in the standardized oil testing procedures. GM’s dexos Gen2 for example, supplies extra protection against LSPI, uses a new oil performance test that GM developed to protect turbochargers and a newer oil aeration test.

As another example, Ford 5.0L engines featured in the F-150 lineup are specified for either 5W-20 or 5W-30 oil, which can be confusing for do-it-yourselfers and some professional techs. The safest way to decide on which range to use is to refer to the owner’s manual and also pay attention to the markings on the oil fill cap, which will clearly indicate what viscosity range to use. Possible yearly design improvements in valvetrain, cam timing actuators and piston cooling nozzles may have prompted the automakers to alter the viscosity range for specific engines. Other examples of manufacturer-specific specification are dexosD, FCA Material Standard MS-6395, VW 508.00, BMW LL-04 and Ford WSS-M2C962-A1. This is something that we need to pay specific attention to when providing an oil change.

Does this mean that you must use only the automaker’s brand of oil? Of course

not. As long as the oil meets (or exceeds) the automaker’s formulation specs, you’re good to go.

Keep in mind that automakers don’t

ENGINE OIL 22 APRIL 2024 2404MA_PicoTechnology.indd 1 3/12/24 3:46 PM

PHOTO BY MIKE MAVRIGAN

EXAMPLE OF Mobil 1 oil 5W-20 specified for 2020 Ford F-150 5.0L.

arbitrarily change oil specs for the fun of it. There are many variables that prompt them to decide on oil viscosity and formulation in an effort to enhance engine longevity, performance, emissions and fuel economy. The automakers aren’t playing with oil requirements just to make our lives more difficult.

One of the areas easy to overlook involves the use of start-stop technology, wherein the hydrodynamic oil film may momentarily collapse between the stop function and the re-start function. This concern may require special oil properties and unique bearing materials to be used to prevent wear. Also, consider that hybrid engines that are not running can allow moisture to form on pistons and cylinder walls that will need to be dealt with by the engine oil and its additive package when the engine starts running again and the moisture is deposited in the oil pan.

Adding the incorrect oil to an engine will not result in immediate engine damage. However, even though an engine doesn’t completely seize up from using the “wrong” engine oil, that doesn’t mean damage doesn’t occur. For instance, if a Corvette LT4 engine was given starburst oil because someone didn’t read to know

IGNORING OIL change intervals can certainly result in issues such as sludge buildup, but this can also result from using the incorrect oil formulation.

it needed a special oil, there wouldn’t be immediate failure. But over time, problems would likely develop. Oil viscosity and formulation is critically important in turbocharged engines, due to the extreme heat and turbine speed that the oil must deal with to prevent coking and turbo failure.

VEHICLESERVICEPROS.COM 23 MOTOR AGE Free Part Smart Training Honda Starter Issues with Nelson Davis On Thursday May 23, 2024 1 PM - 1:30 PM EDT Scan the QR code to register · MIL illuminated after Starter replacement. · 2 Essential tests for slow cranking complaints · Honda TSB/PCM Reflash 2404MA_MotorcarPartsofAmerica_REV.indd 1 3/13/24 9:00 AM

PHOTO BY MIKE MAVRIGAN

The correct/specified oil will feature the required balance of base oil and additives for a given engine. If an oil lacks the right components or the right balance, bad things may happen. Depending on which additive is missing, over time this may result in metal-on-metal contact in the valve train. An engine oil lacking certain antioxidants could see heat damage since

local hot spots in the engine spike to 400600 degrees Fahrenheit. Over time this buildup of varnish can keep parts from moving properly. Using an oil that does not meet the automaker’s specs can lead to varnish and sludge buildup, even if oil change intervals are conducted within/ near the OE interval recommendations.

We simply cannot take engine oil for

CYLINDER LEAKAGE TESTER WITH 2 GAUGES

Measures the ability of an engine cylinder to hold compressed air using shop air pressure; supplements a compression tester

Includes a precision regulator, an M14 standard reach adapter on a 26-inch hose assembly and an M14 long reach solid adapter

M68 special gauge has one multicolored band for measuring low, moderate and high leakage, and a scale range from 0-100%

WWW.LANGTOOLS.COM

granted, tossing in whatever oil is handy or available at the lowest price. Today’s ever-evolving engine designs present specific lubrication demands that require the use of specific thickness ranges and friction-modifying formulations.

ROCKER ARMS increasingly feature roller pivot axles. A full-roller rocker design will also feature roller tips that glide (as opposed to rub) on the valve stem tips.

MIKE MAVRIGIAN has written thousands of automotive technical magazine articles involving a variety of specialties, from engine building to wheel alignment, and has authored more than a dozen books that crisscross the automotive spectrum. Mike operates Birchwood Automotive, an Ohio shop that builds custom engines and performs vintage vehicle restorations. The shop also features a professional photo studio to document projects and to create images for articles and books.

ENGINE OIL 24 APRIL 2024

HELPS TO DETECT COMMON ENGINE FAULTS

2404MA_A&EHandTools.indd 1 3/11/24 12:44 PM

#CLT-2

PHOTO BY MIKE MAVRIGAN

REV UP YOUR SAVINGS! ALL-IN-1 SHOPPING ! Tools & Equipment | Shop Essentials © 2024 Wrenchers LLC. All Rights Reserved. 1-800-261-7729 Call Now for a FREE catalog! Ask about our price match guarantee. WE WILL NOT BE UNDERSOLD!

out duty cycled signal commands via the dedicated LIN bus to the TBPM for trailer brake application. The GM Trailer Sway Control uses the ESC system to identify instances of trailer instability and uses differential braking to mitigate trailer oscillation and instability. To reduce or cut the back-and-forth motions of the trailer, GM’s Trailer Sway Control can detect the unique vehicle dynamics associated with sway and, if needed, apply the brakes, and reduce engine torque.

The BSCM can activate the trailer brakes to slow down and stabilize the vehicle when a sway condition is encountered. The Trailer Sway Control system can detect and identify instances of recurring instability in the trailer, and then send a warning signal to the instrument display to alert the driver about the unsafe configuration of the trailer.

The TBPM is mounted above the spare tire of the truck. It receives the BSCM’s commands and then provides the trailer brake output voltage, triggering the trailer brake operation. But that is not the TBPM’s only task. It also helps to identify the type of trailer brakes being used and provides diagnostic information on the trailer brake circuit. The TBPM continuously sends test voltage pulses out through the trailer brake output circuit looking for a trailer. When a trailer is attached and plugged in, it will continue to send out these test pulses to identify the type of trailer brakes, and as a diagnostic feature of the trailer brake circuit and its connections.

When a trailer is initially plugged into the truck’s trailer plug, the test pulses sent from the TBPM on the trailer brake output circuit will be altered by the type of trailer brake system and its components and circuitry. The TBPM will report to the CCM and BSCM the way that the test pulse reacted/changed when the trailer plug was attached to the truck and the trailer brake output circuit. The CCM/BSCM will use that information to decide the type of trailer brakes being used.

Note on some wiring diagrams the TBPM may be shown as the CCM or the CCMA — it depends on the year/model and equipment level of the truck.

Electric Trailer Brakes

This system uses the familiar electromagnet/lever arm assembly that is activated by a controlled electrical output signal from the truck, which in turn directly activates the brake mechanism. The light duty GM system can accommodate up to eight trailer brake electromagnets on a four-axle trailer. This trailer brake system will be displayed as “Electromagnetic Brakes” when using the scan tool.

Electric Over Hydraulic (EOH) Trailer Brakes

This trailer brake system utilizes the trailer’s dedicated electric hydraulic brake system and controls the EOH system by an electrical output signal from the towing vehicle. The EOH braking system

uses hydraulic pressure to activate the trailer brakes, but instead of the familiar surge brake hydraulic actuator on the trailer tongue, there is now an electrohydraulic actuator supplying the needed brake pressure to activate the trailer brakes. This system cuts the braking lag time that surge brakes encounter and provides much higher hydraulic braking pressure: 1000-1500 psi vs. 400-800 psi that the surge brake actuator could provide. This system allows for the use of trailers with disc brakes. The brake system will be displayed as “Electrohydraulic Brakes” when using the scan tool.

EOH brakes have some unique operating conditions. Most EOH systems require a 20-30% duty cycle to activate the pump motor, and if the trailer gain is set too low, and the brake pedal pressure is light, the pump motor may not function. This is normal. The operator should follow the owner’s manual to ensure that the proper gain setting is set. If the truck has detected EOH and the vehicle is fully stopped, there will be no trailer brake output. This is also normal. Certain EOH systems require a special adapter module to be installed on the trailer for the truck to recognize the trailer and provide the proper trailer brake function. Certain EOH manufacturers have made these adapters available.

Note: If a trailer brake system that is not compatible is connected, the ability to brake the trailer may be partially or entirely disabled. An increased stopping distance or trailer instability

GM TRAILER BRAKE TECHNOLOGY 28 APRIL 2024

PHOTOS BY AUTHOR

GM HAS had some issues with the truck’s seven-way connector door spring and cable security tab, which can lead to a loose trailer seven-way plug and possibly cause the “Check Trailer Wiring” warning message. New revised parts are available to fix the issue.

may result in personal injury or damage to the vehicle, trailer or other property. An aftermarket controller is necessary for trailers equipped with air or surge trailer brake systems.

Once the CCM/CCMA or BSCM has determined the type of trailer that is plugged in, the TCBM continues to send test pulses, checking the trailer brake circuitry. If an issue is detected on the trailer brake circuit, the driver will be notified with the proper warning message on the instrument cluster and a DTC may be recorded to aid in diagnostics. There can be three distinct warning messages displayed on the instrument cluster:

1. “Check Trailer Wiring” comes up as a warning on the dash, even when there isn’t a DTC. If the trailer brake output circuit detects an open or high resistance during the current ignition cycle, this message will be shown.

This is normal when unhooking the trailer or removing the plug from the trailer’s wiring while the ignition is turned on. This is also a common concern that will intermittently appear on the instrument cluster while towing, then the message goes away. This typically indicates a poor/loose connection on the seven-way trailer plug, (more on this later).

2. “Check Trailer Wiring” comes up as a warning on the dash supplemented with the C1114 DTC, but not the “Service Trailer Brake Message.” The problem is likely due to a short to ground in the trailer brake output circuit.

3. A “Service Trailer Brake System” message will be accompanied with the C1114 DTC. A poor trailer ground circuit or a short to power on the trailer’s brake output circuit could be to blame for this problem.

Evaluating the Trailer Brake System

Trailer brake issues usually stem from wiring or brake issues on the trailer and often have nothing to do with the truck’s electrical system. Wiring, connectors, splices and routing in most trailers aren’t comparable with the quality and protection that

you will find on the factory installed wiring harnesses and connections of today’s vehicles.

Many times, push/block/snap connectors, pouch connectors and wire taps are used during the trailer manufacturing process. As a result, the CCM/BSCM may detect issues and defects that are difficult to identify as being specific to either the truck or the trailer.

GM does build a seven-way trailer brake module tester and trailer simulator (EL-52641) that will attach to the truck’s trailer connector. It will simulate the electromagnetic trailer brakes, display that on the scan tool and allow for the checking of the other circuits at the seven-way trailer plug. But this tool does not simulate the load that the electromagnet of the trailer would produce.

GM recommends that techs build a tester with known good functional trailer brake magnets as the quickest and most straightforward method of testing issues in the brake output circuit on trailers with electromagnetic trailer brakes. This tester will apply the correct loads to the truck’s electrical system, similar to what a trailer does without requiring the entire trailer. This test rig also makes use of real trailer braking magnets.

When building the brake circuit tester, construct a tester in which the number of trailer brakes can be adjusted by adding

GM TRAILER BRAKE TECHNOLOGY 30 APRIL 2024

THIS DASH warning message will show up if the truck detects an issue in the trailer brake electrical circuit of the truck or the trailer. It is a normal condition when the trailer is unplugged, with the ignition on when disconnecting the trailer, but not when towing down the road. This warning only shows an issue with the trailer brake electrical circuit.

CORROSION INSIDE the truck’s seven-way connection or the trailer plug itself can cause dash warning messages and trailer brake issues.

BY AUTHOR

PHOTOS

BY AUTHOR PHOTO

or removing pairs of magnets to match the quantity on the customer’s trailer.

The test harness can be built using up to eight trailer brake magnets (four axles and the maximum number of trailer brake magnets the system is designed to accept).

Connecting the test harness to the truck’s seven-way connector should cause the instrument cluster to indicate “Trailer Connected” and the scan tool to show “Electro-magnetic brakes” in the CCM/BSCM data parameter “Trailer Brake Type.” Also, it is recommended to install the trailer brake magnet harness in the truck bed and ensure that the harness is sufficiently long to fit into the vehicle’s seven-way connector. This will enable the driver to use the truck as though the trailer was hitched.

If when driving the truck with this test harness installed and you don’t see any dash warning messages or DTCs, the truck is not likely the issue, and you will need to look closely at the trailer wiring, the trailer brakes themselves and the seven-way connector and cable.

Common Issues

Weak or poor connections at the seven-way trailer plug connector are the most typical problems with this system. This issue commonly causes the “Check Trailer Wiring” message to flash on the dash while driving. Certain 2014-2018 trucks have suffered from an issue involving a weak spring-loaded door of the seven-way connector. This door spring not only holds out moisture and debris when the seven-way connector isn’t being used, but it helps hold the trailer plug firmly in the connection. GM has an updated truck-side trailer connector available (PN. 23404450). There have been other updates to the truck side seven-way connector, socket and receptacle on various years or GM trucks, so be sure to check for part updates.

Issues can arise from excessive length trailer harnesses, looping or wrapping the harness under sway bars or sway bar connections causing the connections to be pulled or stressed. Corrosion, improper seven-way plug trailer repairs and poorly made replacement seven-way connector parts (both truck and trailer side) can result in the trailer brakes not functioning and

warning messages on the dash. The location of the TBPM above the spare tire exposes the module and its connectors to corrosion and moisture intrusion. There have also been concerns about the TBCS failing, which results in inoperative trailer brakes and sets a C1117 DTC. Evaluating the switch starts by looking at 5-volt reference and ground and then watching the switch control parameters on the scan tool.

Some trailers are factory equipped with electronic sway control, while others may have had this system added later. These systems will apply the trailer’s brakes independently of the towing vehicle to control trailer sway. Be aware that these devices can affect the truck’s ability to decide what type of trailer brake system is on the trailer and can cause dash warning messages and DTCs. There have also been concerns about aftermarket modules installed on trailers with EOH brake systems. These modules will allow a truck that only has electric trailer brake ability to tow an EOH trailer, but they can affect the way the GM system detects the type of trailer that is being attached to the truck.

The innovative trailer brake system used on the Chevrolet and GMC line of light-duty pickup trucks ensures a safe and controlled towing experience for drivers. The integrated features of the system not only adjust trailer braking force and stability control but also utilize advanced technologies such as ESC and Trailer Sway Control to mitigate trailer oscillation and instability.

However, like any complex technology, the GM trailer brake system is not immune to occasional issues. Loose connections, corrosion and other factors can impact its performance. Regular maintenance and adherence to proper procedures are essential to ensure the system operates at its best.

JEFF TAYLOR is a seasoned professional at CARS Inc. in Oshawa with 40 years in the automotive industry. As a skilled technical writer and training developer, he holds licenses in both automotive and heavy-duty vehicle repair. Jeff excels in TAC support, technical training, troubleshooting, and shaping the future of automotive expertise.

GM TRAILER BRAKE TECHNOLOGY 32 APRIL 2024

THIS SCREEN from the scan tool shows that the trailer brake control data and testing is in the Chassis Control Module Auxiliary on this 2017 GMC Sierra. The location of the trailer brake control will depend on the level, types of options and year and model of a light duty GM pickup.

THIS SCREEN shows that the Chassis Control Module Auxiliary has identified the type of trailer brakes being used on the trailer that is attached to the truck. The trailer brake control module is constantly testing the trailer brake control output circuit and is showing its test results as OK.

www.rangerproducts.com *Free shipping to direct shipping points within the 48 contiguous United States only. © 2024 BendPak Inc. Ranger Products is a registered trademark of BendPak. Ranger tire changers are packed with more features, power, and torque, and they’re backed up with an industry-leading warranty; all without straining your budget. If you’re seeking a departure from the ordinary, consider the innovation, efficiency, and satisfaction that come with Ranger – brought to you by BendPak. Connect with us at 1-800-253-2363 or explore further at www.bendpak.com. 24 Month Warranty OEM Approved Max Performance Free Shipping* Shop Now Say hello to more. Model: R80EX Dual Tower Assist SPEED RimGuardTM Wheel Clamps Turboblast™ Bead Seating Bead Handling Tools Bead Handling Tools Tilt-Back Tower Dual-Flange Bead Loosener Durable Forged Steel Foot Pedals Foot-Controlled Tire Inflator Shown With Optional Leverless Bead Lifter

The Universal Language of Drivability

Diagnosing engine power loss from more than 2,500 miles away.

BY BRANDON STECKLER // Technical Editor

THE DATA DOESN’T LIE

TO

OF THE 7,139 languages spoken worldwide, it never ceases to amaze me that “drivability” is one language I can speak everywhere I go.

Just recently I had an interesting but difficult conversation with Rayo, a bright young tech from Guadalajara, Mexico. My lack of fluent Spanish and his broken English made conversing a bit of a challenge. Rayo was faced with a strange concern.

A 2015 Toyota Land Cruiser, with a 5.7L V8 engine was experiencing what he described as a strange loss of power output. According to Rayo, the engine began to

struggle under acceleration between 4,000-5,000 rpm. The issue seems straight forward but I was faced with educating the young tech on how to obtain the appropriate data (and in the appropriate fashion) to allow for analysis. He was using Toyota’s factory scan tool for this era of vehicle, the Toyota Techstream.

Preliminary Data

After further discussion, he described the loss of power output to be more of an “engine cut-out.” I first viewed the data

he sent me to get an idea of what he saw (Figure 1). As you can see, I configured the data PIDs in a customized list from the left of the screen capture in graphical format to see how they correlated with one another. I refer to this as action/reaction comparative measure. I do this to only see the data I need to see. This tells a drivability story. These include:

• MAF

• RPM

• Throttle position

• Lambda 1

• Lambda 2

• Total trim 1

• Total trim 2

If one multiplies the engine displacement (in liters) by a factor of 37, it will reflect expected grams per second MAF values at 5,000 rpm/full-throttle.

FIGURE 1: THIS TOYOTA Techstream capture exhibits data right from the driver’s seat.

From this data it can be seen that the engine can breathe properly, is fueled properly and the PCM is not working very hard to maintain fuel control.

35 MOTOR AGE TECH CORNER

WELCOME BACK

ANOTHER EDITION OF “THE DATA DOESNT LIE,” A REGULAR FEATURE, WHERE I POSE A PUZZLING CASE STUDY.

PHOTO BY AUTHOR

According to the data, the engine appears to be breathing correctly under heavy

acceleration (219 grams per second). This is good news because from over

2,500 miles away, I can tell for sure that the exhaust isn’t restricted, and the engine has no timing issues.

I can also see that the fuel system is up for the task. The lambda values on both banks indicate the engine is fueled correctly (nearly 20% richer than stoichiometry) and the PCM can carry out that task with no corrective factor (as indicated by nearly zero fuel trim on either bank).

However, something strange occurs about 20 seconds afterward (Figure 2). Although the operating conditions remained unchanged, the data indicates the lambda values (both banks) exceed 1.23 (over 23% lean of stoichiometry). I would’ve expected the fuel trim to attempt compensation but as can be seen, they both remain at zero. Viewing the data from the MAF as well as engine speed shows no variation at all. Any time you see straight lines on graphed data, it typically indicates a state of default, as in, the data isn’t true.

Weighing the Possibilities

Just a moment past the cursor (Red arrows), the vehicle comes back to life and the data begins to update again. This is the symptom Rayo has been experiencing and at this point, I’m growing suspicious

36 APRIL 2024 TECH CORNER Home of the Original Mini-Ductor www.theinductor.com 877-688-9633

NUTS &

AUTO GLASS Available through your local tool distributor.

Inductor® Pro-Max uses high frequency magnetic fields to generate Invisible Heat® in metallic car parts without the collateral damage of an ope flame to nearby parts. Quickly and easily remove vinyl graphics, moldings, auto glass, windshields, mechanical and suspension parts. 2404MA_InductionInnovations.indd 1 3/14/24 1:31 PM

GRAPHICS

BOLTS

The

FIGURE 2: THIS PORTION of the same capture shows the PCM exhibiting erroneous data. A common sign of trouble with the PCM entering a stare of default or reset.

BY AUTHOR

PHOTO

of a computer issue. I believe the PCM is resetting for some reason. A few common causes for this scenario are:

• High-energy discharge from an inductive device (like brain damage)

• Loss of PCM voltage, ground or ignition feed

• Loss of 5V reference circuit or (internal PCM fault or external circuit fault).

My advice at this point was to determine which of the three bullet points above was occurring. I advised Rayo to first measure the CKP/CMP signals on a digital storage oscilloscope along with their reference voltage and ground supply circuits. Unfortunately all I can show you is the picture Rayo took with his cell phone (Figure 3).

According to the scope capture, both the CKP and the CMP signals fail at the time the vehicle’s symptom presents. However, the 5V reference voltage that feeds both sensors (allowing them to operate) is dropping out simultaneously.

The Data Doesn’t Lie

With all the information in front of us, and the desired information not yet obtained, we are faced with deciding how to proceed. Here are some bullet points of what we know to be factual, and I will ask all of you, diligent readers, for your input:

• Vehicle loses power under acceleration.

• The engine breathes correctly.

• The engine is properly fueled.

• The PCM appears to be resetting.

Given this information, what would you do next?

• Replace PCM for erratic internally shorted 5V reference.

• Monitor 5V reference circuit at PCM with amp probe.

• Rewire all of the 5V reference circuit feeds on the vehicle.

• Replace CKP/CMP sensors for intermittent 5V ref short to ground.

VEHICLESERVICEPROS.COM 37 MOTOR AGE 2404MA_Topdon.indd 1 3/11/24 12:46 PM

FIGURE 3: THIS LAB scope capture demonstrates the CKP and CMP sensor signals failing. Definitely a cause of a PCM reset. However, it’s the 5V reference circuit feeding the sensors that is the root cause fault. This must be pursued to locate the cause of the PCM reset concern.

SCAN TO READ MORE ARTICLES LIKE THIS

Solved: 2015 Ford Transit, misfire under heavy load

From March 2024, VehicleServicePros.com

BY BRANDON STECKLER // Technical Editor

What would you recommend doing next, given the data bullet points in last month’s challenge?

Given this information, what would you do next?

1 | Replace all six fuel injectors to be sure.

2 | Replace the No. 6 fuel injector only.

3 | Evaluate the performance of the injector circuit.

4 | Perform and injector system cleaning service.

For those of you who chose answer No. 3, congratulations. The amperage

waveform is frequently one reflected upon to determine if/how the work is being performed. It will be clear to see if the injector is not functioning properly but also determine if the circuit is functioning correctly. Although the test was conducted the injector drive circuits were all identical, eliminating the circuitry and PCM as the fault.

The next logical thing to do might be to perform an injection/induction system cleaning service but results vary so I won’t say answer No. 4 is incorrect. Although it

may be cost-effective to replace only the faulted injector, the labor is very similar to replacing all six. Even If we educate the customer about the fact that the other five injectors are of the same age and operated under the same conditions, it will be up to them how they wish to proceed in that fashion. This customer agreed to replace all six injectors and the drivability fault was rectified (Figure 4).

Be sure to read the next Motor Age issue for the answer to this month’s challenge and what was discovered!

BRANDON STECKLER is the technical editor of Motor Age magazine. He holds multiple ASE certifications. He is an active instructor and provides telephone and live technical support, as well as private training, for technicians all across the

38 APRIL 2024

TECH CORNER

BRANDON STECKLER TACKLES A NEW VEHICLE EACH MONTH. FOLLOW ALONG HERE IN MOTOR AGE, AND ON VEHICLESERVICEPROS.COM!

world.

A REPEAT OF A failed test (once the repair has been completed) is always a great idea. This No. 6 injector cancellation exhaust gas test proves the fault has been repaired, with the replacement of the GDI injectors.

PHOTO

BY AUTHOR

NAPA SOLUTIONS IS NOW DORMAN SAME QUALITY PARTS. ONE BRAND NAME. We’ve made it easier to enhance your competitive edge by expanding your inventory of innovative Dorman products. Instead of searching for a NAPA Solutions box, find what you need under the Dorman label. Find what you need at Pro.NAPAPROLink.com or speak to a sales rep to learn more © 2024 National Automotive Parts Association LLC. MAN

Switching your brain to EVs

How to train your drivability mind for the electric vehicle world.

BY CRAIG VAN BATENBURG

BY CRAIG VAN BATENBURG

40 APRIL 2024 TRAINING FOR EVS PHOTO CREDIT: SERRNOVIK #1331185449 ISTOCK � GETTY IMAGES PLUS

I WAS TEACHING a class in Montreal, Canada, that worried me as I was preparing the material. I have a lot of confidence in my abilities and also enough self-awareness on what I should stay away from. My apprehension wasn’t the subject manner. It was...is there enough to teach given this was a three-day class? I had been at this college before and knew most of the faculty.

The department head wanted a class on pure electric cars. This was some time in 2013. Once the fee was established and the date sent, I went to work writing an out-

line for the class. In no particular order, I listed all the components used in an EV that were similar in a hybrid vehicle. As this was my third visit, I had a good idea of what they knew.

One by one, I added the EV side that related to the hybrid’s DC-DC converter, inverter, drive motor or motors, high voltage cables, detection systems for high voltage leaks, electric air conditioning compressors, li-ion cells, modules, cooling systems and more. I had never before been asked for a class that excluded the internal combustion engine (ICE).

VEHICLESERVICEPROS.COM 41 MOTOR AGE

NISSAN LEAF that will not charge on a Level II EVSE.

PHOTO BY ACDC

AUTHOR CRAIG Van Batenburg teaching an EV class to a full house.

In 2013 hybrids were the dominant technology. I started my high voltage training company, ACDC, in the year 2000. A lone Honda Insight was the subject matter. As I made sense of this transition, I said in the classroom, “ACDC will make sure your 12-volt brain is well developed. Then we will create a high voltage brain to use along with it. Where the two brains match up, the learning is easy, but sometimes ACDC will break the connection between the two, so your 12-volt brain is not used on a high voltage system.”

We still use that thinking today.

It is 2024 and the ICE is no longer needed, if a person, school, city or company wants to change fuel sources. In 2013, that possibility was very limited. Change was happening then but ever so slowly, from all ICE, to hybrids and now pure electric vehicles.

In a technician’s lifetime, that change

OFFICE:

EMAIL: CRAIG@FIXHYBRID.COM

HOURS: 9-5 EST MON - THURS

TRAINING CENTER LOCATED IN WORCESTER, MASSACHUSETTS

was fast. As a result we must change our diagnostic approach.

As the class in Montreal was getting closer, I removed all references in my handouts to hybrids.

What was taken out? Nickel Metal Hydride chemistry, belt-driven anything (water pumps, A/C compressors), typical

ICE cabin heating, all ICE and transmission lessons, and more.

What was added to make it an EV? Cells in parallel called groups, group balancing, SAE J1772 charging standard plugs, DC fast charging, more advanced cooling and heating systems for the battery packs, heating for the passengers,

TRAINING FOR EVS 42 APRIL 2024 We Train Technicians in Hybrid and EV Service and Repair www.FIXHYBRID.com

508-826-4546

• HV Safety Certification • 450 Page Technical Book written in House • Service Advisor Training • Hybrid EV Tools and Equipment • ASE Preperation Class For L3 • Live and Recorded Online Training • Hands-On-Classes • Consulting 2404MA_VanBatenburgsGarage.indd 1 2/29/24 11:28 AM

THE EMVS you need to know — the Volt, Leaf and Bolt.

battery removal equipment, estimating range, the onboard charger, a gateway for high voltage distribution, water tight battery packs, module replacement at the pack level, and more.

Let us take a “no start” in a typical ICE-powered modern car or truck. In this

case, the car gets towed in and the customer is not with the vehicle. This may be a new customer that does little preventive maintenance. You have no service records and the service advisor sold one hour of diagnostics. You are already in a tough position. The work order has only “No Start”

written on it. This is the way the shop operates. It is not technician centered.

What do you do? If it is not snowing, raining or you don’t see a tornado heading your way, you grab four tools. In your bag you add a scan tool and a 12-volt jump box, best if it is your own (that way you know

VEHICLESERVICEPROS.COM 43 MOTOR AGE QUALITY BOXES ORDER BY 6 PM FOR SAME DAY SHIPPING π SHIPPING SUPPLY SPECIALISTS COMPLETE CATALOG 1-800-295-5510 2404MA_Uline.indd 1 3/5/24 10:06 AM

CHECKING A Nissan Leaf at a DC charging station. ACDC ACDC A NISSAN Leaf at a technician class.

they are both charged up). The other tools are an OBDII break-out-box and a DVOM. You get in and plug in your break-out-box into the DLC with the meter connected to pin 16 and 4. Before you try to crank the car over (KOEO), you check the voltage of the 12-volt battery. It reads 10.7 volts. No need to add more codes, so you locate the 12-volt battery. If you are lucky, once you open the hood, it is in plain sight. Attach the jumper box and get back in and gather any codes. Make a PDF of the codes. Now you try to crank over the engine. It cranks over and will not start.