Factories and plants look to machine builders for more energy-ef cient equipment

SEAMLESS eCAD TRANSDUCER TRANSLATION VENDOR INTEROPERABILITY APRIL 2024

Made in America Save 10-40% Over C-more CM5 & EA9, w/ 5-20% Bigger Display Same day Ship if Ordered by 6 p.m. CST Say No to CHINA & Invest in American Jobs EZAutomation.net Introducing Latest in EZTouch HMIs EZ5 Series HMIs 4" - $299 7" - $399 8" - $599 10" - $699 12" - $899 15" - $1299 Programming so simple that even your CEO can do it in minutes! Let's Compare HEAD-TO-HEAD to C-more CM5 & EA9 Save 10-30% over CM5 Starting at $299 Features EZAutomation EZ5 - $299 AutomationDirect CM5 AutomationDirect EA9 Price 4" - $299, 7" - $399 8" - $599, 10" - $699 12" - $899, 15" - $1299 4" - $340, 7" - $479 8" - N/A, 10" - $769 12" - $1029, 15" - $1609 4" - N/A, 7" - $794 8" - $1383, 10" - $1778 12" - $1545, 15" - $2803 Display Screen Size All EZ5 are standard screen sizes & not wide screen displays. 10"19.5%, 12" - 6.3%, 15"-4.9% bigger All wide angle displays, 5 to 20% smaller than standard size displays Standard size displays HMI On-line edit to change program without shutting down the HMI or the machine. Patented Online Edit Feature Not Available Feature Not Available LED back lighting 400 NITS, 75K Hrs @ 55°C 310 NITS, 50K Hrs @ 25°C310 NITS, 50K Hrs @ 25°C Touchscreen Rugged 0.090" thick anti-glare touchscreen Paper Thin Touchscreen Paper Thin Touchscreen Logic expressions to save PLC code Scripting / Expressions No Scripting / Expressions No Scripting / Expressions Program/Edit HMI screens from 50 ft away without a programming cable EZ-WiFi Programming Not Available Not Available Remotely monitor the Panel Yes, with real-time data loggingNo real-time data logging No real-time data logging 24 Hr. Burn-in Yes No No Made in America to create and sustain American jobs Made in America, Free of Tariffs Made in China, Constant threat of Tarrifs Made in China, Constant threat of Tarrifs FREE Legendary Programming Software Call 1-877-774-3279 for Application Assistance or visit www.EZAutomation.net/ez5 * All product names, and trademarks are the property of their respective manufacturers. EZAutomation disclaims any proprietary interest in the marks or names of others.

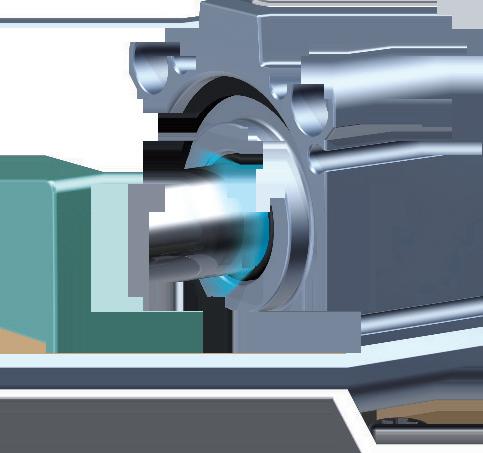

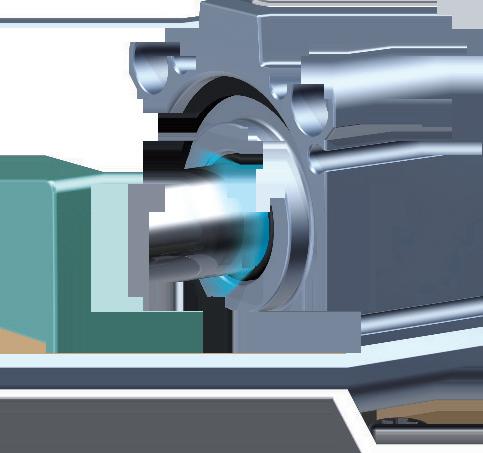

ACOPOS P3

Big impact, small footprint

With the ACOPOS P3, B&R is setting new standards for motion control. This 3-axis servo drive offers a power density of 4 amps per liter, making it one of the most efficient servo drives with integrated safety functions on the market. It also offers unrivaled dynamics and precision, with a sampling time of just 50 µs for the entire controller cascade.

•69% smaller footprint with highest power density

•No additional fans in the control cabinet

•The right solution for every machine

br-automation.com

B&R | A member of the ABB Group

Inside the cabinet? Outside? You choose with our powerful, ultra-compact IPCs

Small enclosures. Harsh environments. Evolving requirements. As engineers, we know these factors must be addressed constantly. Every new machine presents unique challenges and opportunities to innovate. So our ultra-compact Industrial PC series gives you freedom to choose the perfect controller for every machine. Maybe it’s the C6015 with dimensions of just 82 x 82 x 40 mm and outstanding installation flexibility. Or maybe your machine calls for the IP65/67-rated C7015 for cabinet-free installation. All IPCs in this series deliver powerful control to simultaneously run automation, HMI, edge computing/IoT and other communication – all on one controller. They make ideal gateways to the cloud and support flexible I/O system expansions – inside or outside of the cabinet. The choice is yours

Scan to discover all the IPC installation and application possibilities

| PC51USA

PLC system controls solar thermal power Control system optimizes energy harvesting, storage and distribution

cover story Standards and regulations fuel the green machine Factories and plants look to machine builders for more energy-efficient equipment Anna Townshend, managing editor 16 PLCs Open architectures impact PLC longevity How universal automation extends IEC 61131-3 Tobey Strauch, independent controls engineer 27 sensors How to verify transducer readings Machines rely on accurate analog-todigital conversion of 4-20 mA signals Larry Stepniak, Flint Group 29 product roundup Network links, gateways and switches Industrial networking devices keep data moving and systems connected 31 table of contents Volume 28, No. 2 ControlDesign.com / April 2024 / 5 CONTROL DESIGN (USPS 17792, ISSN 1094-3366) is published 6x annually or bi-monthly by Endeavor Business Media, LLC. 201 N. Main Street, Fifth Floor, Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI, and additional mailing offices. POSTMASTER: Send address changes to CONTROL DESIGN, PO Box 3257, Northbrook, IL 60065-3257. SUBSCRIPTIONS: Publisher reserves the right to reject non-qualified subscriptions. Subscription prices: U.S. ($120 per year); Canada/Mexico ($250 per year); All other countries ($250 per year). All subscriptions are payable in U.S. funds. Printed in the USA. Copyright 2024 Endeavor Business Media, LLC. All rights reserved. No part of this publication can be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopies, recordings, or any information storage or retrieval system without permission from the publisher. Endeavor Business Media, LLC does not assume and hereby disclaims any liability to any person or company for any loss or damage caused by errors or omissions in the material herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever. The views and opinions in the articles herein are not to be taken as official expressions of the publishers, unless so stated. The publishers do not warrant either expressly or by implication, the factual accuracy of the articles herein, nor do they so warrant any views or opinions by the authors of said articles.

23 CREDIT: DEREK CHAMBERLAIN, GENERATED WITH SHUTTERSTOCK AI

PLCs

Flemming Jørgensen, Jorgensen Thermal Solutions

9 editor’s page Vision system increases energy efficiency Mike Bacidore, editor in chief 10 embedded intelligence The evolution of HMI Jeremy Pollard, CET 11 technology trends Pneumatic devices bring the I/O Rick Rice, contributing editor 14 component considerations Supercharge your workflow with eCAD Shawn Cox, contributing editor 15 automation basics Top robotic applications for sensor data Charles Palmer, contributing editor 34 real answers Do vendor-agnostic devices make sense? Anna Townshend, managing editor 42 live wire What’s old and new with machine safety? Joey Stubbs, contributing editor

Altech 6 B&R Industrial Automation .............................................3 Beckhoff Automation 4 Contemporary Control Systems 33 DigiKey 44 EZAutomation 2 Hammond ............................................................................ 28 icotek North America 41 Novotechnik 13 SMC 8

index ControlDesign.com / April 2024 / 7 table of contents Volume 28, No. 2 Endeavor Business Media, LLC 30 Burton Hills Blvd, Ste. 185, Nashville, TN 37215 800-547-7377 CEO Chris Ferrell President June Griffin COO Patrick Rains CRO Paul Andrews Chief Digital Officer Jacquie Niemiec Chief Administrative and Legal Officer Tracy Kane EVP Industrial Group Mike Christian VP / Group Publisher Keith Larson editorial team editor in chief Mike Bacidore mbacidore@endeavorb2b.com managing editor Anna Townshend atownshend@endeavorb2b.com digital editor Madison Ratcliff mratcliff@endeavorb2b.com contributing editor Rick Rice rcrice.us@gmail.com contributing editor Joey Stubbs contributing editor Shawn Cox brianshawncox@gmail.com contributing editor Charles Palmer charles101143@gmail.com columnist Jeremy Pollard jpollard@tsuonline.com design/production production manager Anetta Gauthier agauthier@endeavorb2b.com ad services manager Rita Fitzgerald rfitzgerald@endeavorb2b.com art director Derek Chamberlain subscriptions Local: 847-559-7598 • Toll free: 877-382-9187 email: ControlDesign@omeda.com circulation requests / classifieds Lori Goldberg lgoldberg@endeavorb2b.com sales team Account Manager Greg Zamin gzamin@endeavorb2b.com 704/256-5433 Fax: 704/256-5434 Account Manager Jeff Mylin jmylin@endeavorb2b.com 847/516-5879 Fax: 630/625-1124 Account Manager Kurt Belisle kbelisle@endeavorb2b.com 815/549-1034

COLUMNS

ad

Mike Bacidore editor in chief mbacidore@endeavorb2b.com

Mike Bacidore editor in chief mbacidore@endeavorb2b.com

Vision system increases energy efficiency

CONVENTIONAL SILICON ARCHITECTURE has taken computer vision a long way, but Purdue University researchers are developing an alternative path, taking a cue from nature, that they say is the foundation of an artificial retina. Like our own visual system, the device is geared to sense change and designed to be more efficient.

“Our long-term goal is to use biomimicry to tackle the challenge of dynamic imaging with less data processing,” says Jianguo Mei, the Richard and Judith Wien Professor of Chemistry in Purdue’s College of Science. “By mimicking our retina in terms of light perception, our system can be potentially much less data-intensive.”

Mei and his team drew their inspiration from light perception in retinal cells. As in nature, light triggers an electrochemical reaction in the prototype device they have built. The reaction strengthens steadily and incrementally with repeated exposure to light and dissipates slowly when light is withdrawn, creating what is effectively a memory of the light information the device received. That memory could potentially be used to reduce the amount of data that must be processed to understand a moving scene.

will let the machine make the decision faster with less data and fewer data requirements also means there will be a decrease in power requirements, making that machine more energy-efficient, explains Tutt. “I am interested to see where this evolution of computerized vision systems will go,” he says. “As this technology is modeled and a digital twin of the eye is created to generate a computer vision system, I think it could be implemented within the next five to 10 years.”

In industrial systems or machinery, there is typically a sensor with a computer behind it.

The team calls the device an organic electrochemical photonic synapse and says it more closely mimics how the human visual system works and has greater potential as the foundation of a device for human-machine interfaces (HMIs).

“I can definitely foresee this technology becoming a part of vision systems,” says Dale Tutt, vice president, industry strategy, at Siemens Digital Industries Software. “In the studies they are doing at Purdue University, researchers are able to mimic the results of the human eye in a way that requires less data requirements. That is intriguing to me.”

When you think about the various applications that have vision systems, the promise of collecting information that

In industrial systems or machinery, there is typically a sensor with a computer behind it, and the computer is doing the calculations and work, explains Tutt. “It appears that sensor could easily be replaced with more efficient optical sensors, which would lead to different algorithms that require less computing power to do the calculations and analysis of what the vision sensor is capturing,” he says. “In theory, many of the sensors could be replaced with this newer or evolutionary technology. I might even go so far as to say it has the potential be revolutionary technology, especially if we can combine it with artificial intelligence (AI) to truly mimic not only the vision powers of a human, but also the ability to problemsolve and make decisions the way a human does.”

Mei’s vision system, like human vision, is relatively lowresolution but is well-suited to sensing movement. Human eyes have a resolution in the neighborhood of 15 microns. The prototype device, which houses 18,000 transistors on a 10-centimeter square chip, has a resolution of a few hundred microns, and Mei says the technology could be improved by lowering resolution to about 10 microns.

“When we look at industrial vision applications, the first implementation that comes to mind is robotics in a factory or other similar situations that currently leverage computer vision systems,” says Tutt.

ControlDesign.com / April 2024 / 9

editor’s page

Jeremy Pollard jpollard@tsuonline.com

The evolution of HMI

A HUMAN-MACHINE INTERFACE (HMI) can come in various forms and had its genesis in hardware and firmware. I remember Steve Rubin, founder of Intellution, which is now iFix, telling the story of burning programmable read-only memory (PROM) on his kitchen table as a system update. The core of an early HMI has always been software/firmware that interfaces with specific hardware in the same space.

The video cards were normal, and there was a DOS interface to the video memory to draw the primitives—lights, buttons—and then a communication driver poached data from the system controller, typically a programmable logic controller (PLC) to animate these primitives.

tools and add-ons such as OPC UA for communication, so the screen and back-end processes can access multiple devices on the same platform, which typically would use Ethernet for connectivity. Again, software plug-ins would be used to integrate data from certain supplier devices into one HMI application.

A methodology that is thrown around a lot is edge computing, and the HMI is at the edge. What does this really mean?

A typical HMI hardware platform is an industrial, or commercial, PC mounted in or on the control panel.

Enter 1990 and Windows 3.0. A small company called Wonderware was working with Microsoft and developed Network DDE so they were intimate with the operating system (OS). The PC had been out for eight years using DOS as its OS, and HMI software was being developed under DOS, which Intellution migrated to and was the de facto leader in the space until.

Under Windows, Wonderware created a whole new ball game. Using standard interfaces such as video drivers and serial card/utility card drivers, a new HMI era was born. And we have never looked back.

The HMI provides the same level of interface as always—pump on/off and alarming, for example. But it has so much more capability in this age of networking, wireless and edge computing.

HMI is typically located at the machine level and is strictly software-based using standard PC-based hardware and systems. Some can support different programming languages, and most support template-based configuration of screens that the operator interfaces with.

A typical HMI hardware platform is an industrial, or commercial, PC mounted in or on the control panel, but, of course, the visualization can be a mobile device such as a smart phone or tablet. Connecting wirelessly is an option here.

In recent years, HMI software has become mainstream in the fact that it can and does use commercially available

An edge device is at the end of a network and has computing capabilities. In a previous life, the HMI would read data from the PLC, which would have been formatted by the PLC and displayed. This data would be recorded on a clipboard and sneaker-netted into an office for data entry.

Now, no clipboard should be implemented. The HMI can take the raw data from the PLC, format and put the data through algorithms created by scripting to produce a result that means something to someone or something like a database.

It’s where the database is located that is the game-changer. It can be located locally, but more often it is located in a server room in the plant. In recent years, data was mirrored from the server to the cloud, which is offsite to be made available for remote users.

Now, an HMI with Internet connectivity can use protocols reserved for server-based applications directly to send data to the cloud and to the third-party applications that use this data for a variety of decision-making instances.

HMI software is no longer a simple machine interface to an operator. It can interface to local back-end programs, such as a computerized maintenance management system (CMMS) or enterprise resource planning (ERP) system, and cloud-based third party applications directly and can provide remote access for monitoring and control, if needed.

JEREMY POLLARD, CET, has been writing about technology and software issues for many years. Pollard has been involved in control system programming and training for more than 25 years.

10 / April 2024 / ControlDesign.com

embedded intelligence

Rick Rice contributing editor rcrice.us@gmail.com

Rick Rice contributing editor rcrice.us@gmail.com

Pneumatic devices bring the I/O

ONE OF MY PRIMARY responsibilities is identifying older equipment that is at risk of failure due to obsolete hardware in the control system and building new controls to replace them. Much of my target equipment started life in the 1980s. It is a tribute to the designers of this equipment that it has survived 40 or more years of daily use and still performs the job it was designed to do.

What is interesting is the comparison of what were industry-leading techniques and technology back in 1980 compared to where we are. A recent controls upgrade project provided a reminder of the importance of choosing the right components for pneumatic operations.

an actuator. In each position, the spool, or valve station, directs flow from the pressure port while the other actuator port exhausts to atmosphere. For a three-position valve, two solenoids are required to shift the spool. In the de-energized state, springs on each end of the valve spool keep the valve in the center position. This is normally all ports blocked and exhaust. To operate an actuator, the desired direction must remain powered on. Removing power returns the valve to the center/blocked position.

Pneumatic vendors thought to combine the remote I/O with the manifold directly.

Any deep dive into the journey that technology has taken over the past 40 years should start with the statement that, at its base, the principles of operation remain the same.

Pneumatic valves come in three primary types—two-way, three-way and four-way.

Two-way two-position valves can be normally open or normally closed. They are direct acting valves where a single solenoid initiates a shift in the valve to the opposite state, and a spring returns the valve to the normal position after power is removed from the solenoid.

These valves pressure and exhaust one outlet port. The outlet either has pressure or it is blocked, depending on the position of the valve. A good example of use would be a blast of air to blow a product off a conveyor.

Three-way two-position valves can be normally open or normally closed. They are direct acting valves where a single solenoid initiates a shift in the valve to the opposite state, and a spring returns the valve to the normal position after power is removed from the solenoid. These valves pressure and exhaust one outlet port. The outlet either has pressure or it is clear to exhaust, depending on the position of the valve. A good example of use would be an actuator that would energize to extend and de-energize to retract to the original position.

Four-way two-position valves typically have four or five ports and two or three positions. For each position, there are two distinct flow paths for extending and retracting

These basic principles of pneumatic and hydraulic valves have not changed. Another key principle or rule of thumb is to keep the length of hose from valve to actuator as short as possible. This keeps the action as responsive and quick as possible.

Air is compressible, so the longer the length of hose, the more air must be applied to cause an action at the actuator. For dual port valves, keeping the hoses the same length is important to keep the extend and retract actions the same.

Flow controls have a considerable impact on the actions of pneumatic devices. When used on an actuator, the flow control limits the release of air on the opposite side of the actuator and is used to control the speed of the action.

Further, end cushions in cylinders create, as the name suggests, a cushion of air right near the end stroke of the actuator. This allows for a speedy main movement, depending on the flow control setting, and then a final deceleration, as it were, of the actuator when it meets up with the cushioned part at the end of stroke. These two functions can be compared to controlling the speed and deceleration of a variable-frequency drive to control the motion of a motor-driven device.

None of the preceding details changed much over the years. Individual manufacturers continue to tweak an already good and long-standing product to further improve the function. For example, the inner chambers and paths in both valves and actuators are worked on to improve the flow of air to optimize performance.

One manufacture I work with has come up with a new valve body that uses the same physical size but a signifi-

ControlDesign.com / April 2024 / 11

technology trends

technology trends

cantly improved volume of airflow. This increases speed of shifting and, by association, greater speed of the actuator.

For a designer, understanding how pneumatic devices behave is a very important part of coming up with a good controls package. For example, due to the use of flow controls and end cushions, some movements that are physically longer would benefit from sensors to indicate the position of the actuator.

We cannot rely on time because that can vary, depending on the settings for flow or end cushion. In critical movements where paths might cross with other actuators, assuming that an actuator is out of the way, based on time, will likely result in a collision.

The biggest development in pneumatic control likely came out of the understanding that the distance from a valve to an actuator is critical. In larger machines or process applications, the distance from the control cabinet to the field device might be quite long. The solution to that was to mount the manifold or a smaller version of it on the machine, close to the devices.

Traditionally, machine wiring would carry signals to that machine-mounted manifold, which added some latency to the actions due to inherent lag associated with sending signals over long distances, but it kept the actuator connections as close to the valve manifold as possible. Thankfully, the fieldbus entered the picture. A fieldbus does just that, moves the originator of the signals from the main control panel to the field-mounted device using communications.

Communications, even in the earlier days of this technology, was much faster than the physical wires strung on the machine. Instead of a multiconductor cable strung along the frame of the machine, the communications cable consisted of a few conductors, as few as two or five plus a shield, in its own protected jacket.

The first versions of this technology involved mounting field, or remote, I/O stations at strategic locations on the machine or process and then controlling the pneumatic devices from that close proximity. Power plus communications cables were the only wires needed to get from the main cabinet to the remote station.

The real innovation came from these original concepts. Pneumatic vendors thought to combine the remote I/O with the manifold directly, in one bundle that could be mounted right there on the side of the machine.

Contained in the manifold block is a communications module talking in whatever version of fieldbus the designer chooses to use. The control of the manifold is direct terminations that happen from the communications module to the backplane of the manifold—neat, clean and protected.

We now have the ultimate version of this concept. If you have pneumatic devices, you likely also have inputs and outputs in the immediate vicinity. Instead of mounting a separate remote I/O station, why not have modules that connect directly to the valve manifold and use that same backplane connection to talk to the embedded communication module?

The number of additional I/O modules is only restricted by the fieldbus protocol and the capabilities of the communications module.

The use of fieldbus technology is changing the way we design and build machines and processes. It drastically cuts down on wiring and puts specialty function modules on a machine where they once were restricted to the main processor rack in a control cabinet.

Where we once had to put such equipment in a protective enclosure on a machine, many of the fieldbus on-machine devices can live right there in the harsh environment, again reducing design and build costs. Since these devices are usually field-configurable, the ability to add or subtract manifold stations and input/output stations at a time after design makes them all the more attractive.

Adapting to change can be hard. As humans, we seem bound to resist such changes, and that can hold us back at times. Challenges can exist, for example, when upgrading a system that didn’t have a proper safety circuit in it. By adding that safety circuit and the necessary means to cut off power to field devices, we created an issue where a dust control valve that needed to stay open for cleaning was closing when we hit the e-stop.

Using technology and knowledge, we were able to change the control at the device to use a double-ended valve that would stay in the last position if we pressed an e-stop to drop power. Using the new technology in our upgrade saved the day for us because we already had additional control points in the manifold and simply changed out the valve.

RICK RICE is a controls engineer at Crest Foods (www.crestfoods.com), a dry-foods manufacturing and packaging company in Ashton, Illinois.

12 / April 2024 / ControlDesign.com

component considerations

Shawn Cox contributing editor brianshawncox@gmail.com

Supercharge your workflow with eCAD

ELECTRONIC COMPUTER-AIDED DESIGN (ECAD) represents a suite of specialized digital tools meticulously crafted to cater to the intricate demands of electrical design. With its robust features and tailored functionalities, eCAD software empowers engineers and designers to seamlessly craft intricate schematics, to meticulously plan panel layouts and to map out wiring diagrams with unparalleled precision.

One of the key strengths of eCAD lies in its ability to enhance efficiency across the design workflow. By automating repetitive tasks and providing intuitive design aids, it accelerates the pace of development, allowing teams to meet deadlines with confidence. Moreover, eCAD software minimizes the risk of errors inherent in manual design processes, thereby bolstering the reliability and integrity of the final product.

workflows, enabling technicians to access critical components for inspection or repair.

Cable and wire harness design represents another aspect of electrical system engineering, involving the systematic arrangement and interconnection of cables and wires. Through planning and organization, cable and wire harness designs optimize signal transmission, minimize electromagnetic interference and bolster overall system reliability.

The software fosters seamless collaboration among design teams.

The software fosters seamless collaboration among design teams, irrespective of geographical boundaries. Through features like real-time collaboration and version control, it ensures that all stakeholders are on the same page, promoting synergy and cohesion throughout the design lifecycle.

Electrical schematics serve as indispensable visual guides, detailing the intricate arrangement and interconnection of electrical components within a system. These schematics are akin to blueprints, providing a clear roadmap for technicians and engineers to follow during installation, troubleshooting and maintenance tasks.

By illustrating the precise wiring connections and component configurations, electrical schematics facilitate the swift identification and resolution of potential issues, thereby enhancing operational efficiency and minimizing downtime.

Panel layouts, on the other hand, are vital blueprints that present the strategic positioning of electrical components within control panels or cabinets. These layouts are crafted with attention to detail, ensuring not only efficient organization, but also proper spacing and accessibility for maintenance and troubleshooting.

By adhering to standardized design principles and ergonomic considerations, panel layouts streamline operational

By adhering to best practices in cable management and routing, such as implementing shielding techniques and employing appropriate cable dressings, engineers can mitigate the risk of signal degradation or cross-talk, thereby ensuring the functionality of the electrical system. Enhance design accuracy and efficiency by utilizing advanced tools and methodologies. Streamline processes, reduce errors and achieve superior results through precise planning, effective collaboration and continuous improvement in design practices. Facilitate seamless collaboration among design teams with integrated communication tools and shared platforms.

By providing a comprehensive suite of digital tools tailored specifically to the needs of control design, eCAD accelerates the prototyping process, allowing engineers to iterate and refine their designs with ease. Through advanced simulation capabilities and virtual testing environments, eCAD software enables designers to anticipate potential issues and optimize performance before a single component is fabricated, significantly reducing time to market and enhancing product quality.

Moreover, eCAD simplifies troubleshooting by providing engineers with detailed insights into the functionality of their designs, facilitating rapid diagnosis and resolution of issues. Whether it’s identifying faulty components or optimizing wiring configurations, eCAD empowers engineers.

SHAWN COX is a licensed master electrician/PLC programmer. He was co-owner/operator of Bobby Cox Electric for 15 years and is currently employed by BMW Manufacturing as an ESA.

14 / April 2024 / ControlDesign.com

Charles Palmer contributing editor

Charles Palmer contributing editor

Top robotic applications for sensor data

AS WE MOVE INTO a digitalized world filled with new technologies, the movement toward smart sensors—those that can and do talk to the Internet, the cloud and the edge—is gaining popularity almost exponentially.

Remember that applications for these also include “dumb” or analog devices.

Position sensors play a crucial role in robotics by providing information about the location, orientation and movement of robotic components.

These sensors are used to enable robots to navigate, manipulate objects and interact with their environments. Here are several ways that position sensors are used in robotic applications:

Feedback from the sensors is used to continuously adjust and control the robot’s movements, ensuring accuracy and stability. Closed-loop systems correct errors and deviations from the desired position.

Robotics application 5 — collision detection

For this we use force or torque sensors. Force/torque sensors on robot arms can detect unexpected contact with objects or obstacles. This information is crucial for implementing safety measures, preventing damage to the robot or its surroundings and enabling collaborative-robot (cobot) applications.

Wheel encoders and IMUs help estimate the robot’s position and orientation as it moves.

Robotics application 1 — Joint position sensing

For these applications, rotary or linear encoders, potentiometers, resolvers are used. Robots have joints that move in various ways, such as rotational or linear motion. Position sensors attached to these joints provide feedback on the angles or positions of the joints. This information is essential for precise control of the robot’s movements.

Robotics application 2 — end-effector positioning

Here we use force/torque sensors, six-degrees-of-freedom (6DOF) sensors, vision systems. In terms of how these are applied, position sensors on the end effector—the tool or hand of the robot—help to determine its position and orientation in three-dimensional space. This is critical for tasks like pick-and-place operations, assembly and other applications requiring precise manipulation.

Robotics application 3 — absolute and relative positioning

In this application, absolute encoders or relative encoders are employed. Absolute encoders provide the precise position of a robotic component, while relative encoders measure changes in position. Both types are used in robotics for tasks ranging from navigating within a workspace to controlling specific joint movements.

Robotics application 4 — closed-loop control systems

A closed-loop control system uses feedback from a measurement device, a sensor. Position sensors are integral to closed-loop control systems.

Robotics application 6 — navigation

For navigation and odometry, wheel encoders or inertial measurement units (IMUs) are generally used. For mobile robots or autonomous vehicles, wheel encoders and IMUs help estimate the robot’s position and orientation as it moves through space. This information is essential for navigation and mapping tasks.

Robotics application 7 — sensor feedback signals for control algorithms

These can be various types of encoders or sensors. To move under control, the robot has position sensors which provide feedback to control algorithms, allowing robots to adapt their movements based on external stimuli or changes in the environment. This adaptive capability is crucial for tasks like obstacle avoidance and responding to dynamic environments.

Robotics application 8 — orientation

Orientation control or dynamic balancing is achieved through the installation of inertial measurement units. These devices are used in balancing robots and humanoid robots to maintain stability by constantly measuring and adjusting the robot’s orientation. This is particularly important for applications such as walking, climbing stairs or traversing uneven terrain.

Charles Palmer is a process control specialist and lecturer at Charles Palmer Consulting (CPC). Contact him at charles101143@gmail.com.

ControlDesign.com / April 2024 / 15

automation basics

BY ANNA TOWNSHEND, MANAGING EDITOR

BY ANNA TOWNSHEND, MANAGING EDITOR

16 / April 2024 / ControlDesign.com cover story

MANY DIFFERENT

ENVIRONMENTAL regulations are affecting manufacturing, namely driven by U.S. commitment to the 2015 Paris Agreement or Paris Climate Accords, which pledges to achieving net zero greenhouse gas (GHS) emissions by 2050. This will be an immense challenge for industry, driving sustainable options to become more standard in machinery. But first, to improve sustainability, manufacturers must measure energy usage and standardize energy management data.

Many machines depend on pneumatic power as much as they do on electric power, and compressed-air conservation will also play a large role in making machines more sustainable.

Manufacturing operations are already supporting these efforts in many ways with communication protocols for energy metering, strong supervisory control and data acquisition (SCADA) foundations and fieldbus connectivity that brings data to the device level.

One truth to measurement

To improve sustainability, it’s imperative to first measure the machine’s energy usage. Tracking usage opens the door to being able to identify areas of waste and opportunities to reduce usage of limited resources, such as through turning off unneeded equipment automatically, says Steve Fales, director of marketing for ODVA. There is a significant opportunity to make achieving sustainability not only possible, but profitable, he says.

To support these efforts, ODVA is participating in a joint consortium to standardize power consumption management and develop a new OPC UA interface standard to acquire energy

consumption data in industrial manufacturing. The joint effort is being co-developed by ODVA, the OPC Foundation, PI North America and VDMA. The initiative is designed to optimize energy usage and thereby reduce the detrimental impact on the environment from waste, explains Fales.

“The Power Consumption Management collaboration will help ensure end users have a highly standardized and interoperable means to reach their environmental, social and corporate governance (ESG) goals,” Fales says. Work began in 2022, and the group is actively working to develop the specification.

of energy information or dynamic demand-response,” says Fales.

“CIP Energy allows systems to monitor energy usage and manage energy for efficient energy consumption through dynamic control of energy state and analysis of energy information,” Fales says. Repeatability, consistency and simplicity are the key factors to making this protocol scalable, he adds. CIP Energy identifies the key energy usage attributes that are consistent across EtherNet/IP devices, and the information is stored in energy objects for easy access, management and reporting.

“The idea is to be able to use devices fully when they are needed as a part of the process and to be able to reduce power usage when they are not. Additionally, understanding power usage across a process can allow for identification of areas where waste can be reduced,” Fales says.

Standardization of energy usage data will enable greater adoption across automation industries. “Having data labelled in the same way and measured in the same scale will allow for greater benchmarking and comparison across industries as well,” he adds.

ODVA is also working to contribute to sustainability efforts in industrial automation through CIP Energy, a network extension for EtherNet/IP. “CIP Energy provides a family of objects and services for the optimization of energy usage (OEU) and allows scalability of implementation within the device from basic energy awareness to more advanced functions for control of energy, aggregation and reporting

“Protocol-neutral energy attributes allow for flexibility in the propagation of energy information via multiple protocols to facilitate an e-business model, such as capturing energy requirements as a line item on production bills of material or to implement demand-response mechanisms for dynamic energy transactions,” he adds.

This is supported by the work done by the Power Management Consumption consortium and the developing OPC UA interface standard. “Business reporting will be much easier knowing that energy data from multiple communication protocols will be formatted in a consistent way with the same labelling and scaling. CIP Energy is one of the existing standards that will contribute to the new OPC UA interface standard,” Fales adds.

ControlDesign.com / April 2024 / 17 cover story

7 TRENDS CRAFTING MORE EFFICIENT MACHINES

More sustainable machines and the processes they drive will be a key part of many industrial strategies, and they are already influencing machine design and operation. In many cases, these same practices are already used in the name of efficiency, cost savings and profitability.

1

Sustainability will soon be an equal player in that arena, leaning into the efficiencies industry has already capitalized on and bringing in new opportunities.

More flexible and open machine design will support the data infrastructure and accumulation needed for more

LITHIUM BATTERIES FOR MOBILE POWER

When a pet-food manufacturer wanted a more efficient method for sampling products in various parts of the plant, it went to Gray Solutions, a system integrator, based in Lexington, Kentucky. The legacy solution was a pneumatic carrier tube system, but Gray Solutions recommended an autonomous mobile robot to move materials to and from production lines with operators. “This solution was much cheaper overall but also had a significant impact on energy usage,” says Greg Powers, vice president of cool stuff at Gray Solutions.

AMRs and automated guided vehicles (AGVs) use lithium batteries, which are more efficient than motors to run conveyor belts. “Rechargeable batteries are much more efficient than long conveyors with many motors,” he adds. The AMR solution was also cheaper overall than replacing the old system of pneumatic tubing and vacuum motors.

Overall, Gray Solutions has many customers asking about energy usage monitoring for their automation projects, including the sensors and devices used to capture the needed data. “In addition, since we are heavily involved in building manufacturing facilities, reduction in emissions and greenhouse gases is always a consideration in adopting these technologies or processes for greenfields,” Powers says.

2

WIDE-BANDGAP MATERIALS IN SEMICONDUCTORS

Silicon has been dominant in semiconductors for many years but is reaching its performance limits. New materials for semiconductors have the potential to make significant impacts on energy consumption. Wide-bandgap (WBG) semiconductor materials can make electric components smaller, faster and more efficient than silicon-based counterparts.

“New technologies, such as wide-bandgap technologies— silicon carbide (SiC) and gallium nitride (GaN)—apply to power conversion and inversion, and motor drives and control,” says Alex Wood, global senior marketing director at Avnet Embedded. “Power conversion and inversion involves high-voltage switching. DC and ac motors require conversion and inversion. The speed of switching and how easily these devices can be controlled directly impacts overall efficiency and losses.” WBG materials switch faster and with fewer losses than incumbent

efficiency gains. Likewise, technology advances in batteries, semiconductor materials, electric control, pneumatic actuation and design advances for more flexible and open communication and data sharing will provide the next level of efficiency standards.

solutions, such as insulated-gate bipolar transistors (IGBTs) and metal-oxide-semiconductor field-effect transistors (MOSFETs), explains Wood. “Although WBG devices are currently more expensive than their IGBT and MOSFET counterparts, the price difference is moving in the right direction, while the gains in terms of energy efficiency are already here,” he says.

In industrial machine design, Wood says that moving motor drives toward the use of WBG is probably slower than in new markets, such as electric vehicles (EVs) and EV charging, where WBGs are used for power conversion and inversion. However, he also says that the leading semiconductor vendors in this area have a very clear objective to enable the industrial market to benefit from the gains offered by WBG.

3

TIGHT, PRECISE CONTROL

Jim Larsen, focus industry manager of food and beverage at Burkert USA says both large and small companies are increasingly investing in monitoring and traceability technology for resources like energy, water and compressed air.

“Further, companies are taking a serious look at equipment that can deliver precise control,” he says. “The motivation here is there is efficiency and resource savings in precision. Devices that control to a tighter tolerance utilize fewer utilities. Additionally, devices that simply take less energy to operate are obvious targets.”

More compact systems and components are also a part of sustainability. Block-style manifolds and complex piping flow paths allow for more accurate and efficient control of applications like process heating and cooling, clean-in-place (CIP) cycles and faster switching between media, Larsen says. “There is a blended approach to using electric control and pneumatic actuation in the same process control loop, based on which is more effective to provide the desired results,” he explains. “Precise control of critical process systems is a means to optimize system efficiency. For example, when looking to control a heating or cooling process, the faster that system can be stabilized and the more tightly it can be maintained, the more efficient it is overall. When precision capability is combined with lower energy consumption by the devices themselves, there is a direct and very desirable impact to not only sustainability initiatives, but return on investment/total cost of ownership as well.”

18 / April 2024 / ControlDesign.com cover story

With dynamic demand response, a machine device could go into low power when not needed. On a larger scale, demand response can balance energy generation, distribution and usage through planning, analytics and utilities/end-user cooperation. “Power generation and distribution utilities are looking to predict a stable amount of energy usage over time to be able to deliver power when and where it is needed efficiently. End users are trying to minimize energy usage to the extent possible, while also working with utilities to use a consistent amount of power at given times per contractual agreements and pricing incentives. The combination of pricing incentives and agreements also works to reduce grid usage at peak operating times. Additionally, utilities work to make sure that they are delivering power optimally by delivering intermittent power loads when and where they are needed the most to ensure that the grid is stable and end users don’t see disruptions in critical processes. End users having devices that can optimize power either based on usage or time can aid in cooperating with utilities on energy usage,” Fales says.

Under pressure

Pneumatic systems are among the biggest energy wasters, and the inherent inefficiency of compressed air also makes it expensive.

“Monitoring is key to all sustainability efforts,” says Jon Jensen, energy efficiency team manager at SMC. “At the machine level, we see trends toward monitoring the pressure, flow, temperature and dewpoint of compressed air, allowing for data-driven decisions. There is also a growing importance for sensors that use little power, are

easy to install and can even communicate wirelessly. Machine builders and system integrators are asking us to produce components that use less energy to operate, both electrically and in their compressed-air consumption. There is specific interest in innovative technologies that use less compressed air than traditional components. Additionally, these customers are asking for more advanced monitoring systems to identify opportunities for even more energy savings.”

Jensen says increasing sustainability standards are driving industrial machine design to be more automated or semi-autonomous. “Automated machinery will soon be expected to have the monitoring necessary to reduce air consumption whenever and wherever by controlling pressure and flow,” Jensen says. “Machines will also be expected to have capabilities for self-diagnosis. For example, continuous monitoring of flow can be used to predict the failure of pneumatic components; an increase in flow can be attributed to a leak, which is a sign of wear. Mapping the flow profile against the motion profile of a machine can isolate the location of a leaking component to a specific circuit.”

With the motion profile already in the machine’s sequence of operations, software can compare the flow profile—peaks and valleys—and correlate to actions in production. “For example, let us say that the flow 20 seconds into the machine’s cycle is normally 10 standard cubic feet per minute (SCFM). After some time goes by, the software notices that the flow at that timestamp is now 15 SCFM. If we also have the machine’s sequence of operations, it could be determined that Cylinder 3 is retracting at that point, which

narrows the problem down to just a few components in that part of the circuit—the cylinder rod seal, a fitting or flow control and the tubing between the directional control valve and the cylinder,” Jensen says.

Ultimately, a focus on sustainability will involve designing systems to enhance operator interaction and engagement with energy management. “Real-time monitoring will provide insights and data that empower individuals to make energy-efficient decisions; it will bridge the gap between emerging technologies, artificial intelligence, sensors and regulatory procedures, emphasizing the importance of human resources in future energy management,” Jensen says.

Strong SCADA

Mitsubishi Electric also sees strong end user interest in SCADA systems for better monitoring capabilities on the overall industrial process, individual machines and components. “SCADA also becomes the foundation for other data analysis by creating historical stores of data to be mined by layered artificial intelligence (AI) applications,” says Patrick Varley, product marketing manager at Mitsubishi Electric.

While many are embracing sustainability, some still have investment cost and profitability concerns.

Part of a well-designed system means selecting the most suitable equipment, without over-specifying. “Often, there is a tendency to select more powerful motors, robots and controllers than needed. This means that companies may be overpaying and underutilizing their equipment, leading to energy inefficiencies and unnecessary costs,” Varley adds.

ControlDesign.com / April 2024 / 19 cover story

ELECTRIC VS. PNEUMATIC

“More critical thought is given to engineering choices, starting with the decision whether to go primarily with electric or pneumatic automation for the machine,” says Frank Langro, director of product market management, pneumatic automation at Festo. “This decision comes down to the application as well as cost. When the choice is to use pneumatics, OEMs are more interested today in optimum sizing than they have in the past, as proper sizing not only saves energy, it also saves on cost of components and contributes to overall equipment effectiveness.” OEMs use Festo pneumatic sizing tools much more frequently, says Langro. “This is in contrast to engineers selecting a valve based on the cylinder’s port size. Now it is sizing for optimum performance,” he explains.

The automotive industry has been trying to move away from pneumatics and go all-electric with their production lines for years, Langro says. “It was a result of energy costs, the cost of generating pneumatic compressed air was seen as more expensive than running electric for electric servo drives and steppers,” he adds. However, certain applications demand the forces needed from pneumatics, or space constraints demand compressed air.

The packaging industry, Langro says, is also embracing electric where possible, with many machine builders producing all-electric versions of, for example, a case packer or box erector. There also may be instances where machines require electric and pneumatic power, because of space or cost concerns. “We see both approaches being used in the market,” Langro says.

Typically, the component cost for a new electric system will be more expensive than pneumatic. “Pneumatic is a low-cost technology. But there is an overhead that goes with pneumatics in terms of having a compressed air system in your facility,” Langro says. Likewise, in a brand-new facility with no installed infrastructure, the pneumatic system would cost more from the ground up. “If you’re going into an existing facility that already has a pneumatic system and infrastructure in place, there’s minimal add-on cost,” Langro says.

5

SOFT STARTERS AND VFDS

“OEMs are increasingly more conscious of energy consumption than ever before,” says Jason Demicoli, product line manager, switches, Americas, at Carlo Gavazzi. “We started getting more requests for products that do not just switch the loads on/off but also help in reducing energy consumption.” Variable-frequency drives (VFDs) are one solution, when used properly, that can reduce energy costs in motor-control applications.

“In applications where the motors run at full speed, the soft starter is more efficient than a VFD as it has lower losses during operation,” Demicoli adds.

6

CONTROL FLEXIBILITY

Flexible and reconfigurable machines support the scale-up of new operations and help facilities more easily upgrade legacy equipment to match market needs. “Controls technologies can support sustainability efforts in several ways,” says Patrick Varley, product marketing manager at Mitsubishi Electric. “First, as they have become more versatile and easier to use, they help make sure that equipment remains serviceable, optimizing uptime. In addition, it is easier to repurpose controllers and monitoring systems to suit different projects as companies progress forward in their digitalization and sustainability roadmaps.”

As with most manufacturing technologies, increasing the flexibility to accommodate future automation requirements is important, adds Varley. This enables users to add to I/O to control more machines or utilize different communications protocols, which may be required if a new device needs to be added to the machine, he stresses.

Machine designs that offer greater availability to monitoring capabilities, through integration with supervisory control and data acquisition (SCADA) systems, support the flexibility needed to meet sustainability and profitability and operation standards, Varley adds.

7

OPEN ARCHITECTURE AND SHARED DATA

Upgrading legacy systems with monitoring capabilities to support more efficient operations will be a big challenge for many older facilities, but they can start by establishing open network architecture that will help future integration. Clean data collection and modeling will also be a key foundation to optimizing for energy efficiency.

“Soft starters are also a technology that may result in energy savings by reducing peak demand from motor loads,” Demicoli says. In heat-pump applications, this can require less over-sizing of generators and off-grid inverters.

“Machine builders are also developing energy-ready machines for seamless integration into end users’ energy management systems,” says Corinne Pellish, sustainability partnership and program manager at Rockwell Automation. “These machines are engineered to connect with nearby equipment and operate in an energy-efficient manner. A crucial design approach involves establishing a network infrastructure using an open, unified network architecture. Additionally, to facilitate seamless integration, manufacturers are designing an object-based data model that enables shared data across the system, library management at the automation layer and automatic discovery by the information layer. In terms of energy-ready machines, OEMs can create the common data model around water, air, gas, electric and steam data.” 4

20 / April 2024 / ControlDesign.com cover story

Sizing a motor, for example, will depend greatly on the application and specific motor manufacturer’s specifications. “One significant area of energy reduction will be supported by the use of an inverter to drive the motor. Inverters offer the ability to drive a motor with just the energy needed for the application,” Varley says.

As they operate non-stop for years at a time to support production lines, the impact of reducing the energy consumption of drives, controls, robots and other factory automation devices, even by a fraction, can be significant, says Varley. “Extending their lifecycle can help cut waste of materials that cannot be recycled or repurposed. In both cases, companies can benefit from reduced total cost of ownership, which, in turn minimizes CAPEX and OPEX,” Varley adds. “By designing the production machines with enough flexibility to be able to be modified for the needs of future iterations of the end product, you can extend the life of the equipment used on the manufacturing floor.”

Fieldbus connectivity

More original equipment manufacturers (OEMs) are looking for monitoring capabilities with fieldbus connectivity, says Jason Demicoli, product line manager switches for the Americas at Carlo Gavazzi. “With Industry 4.0 mentality, it’s not just expected that field devices switch the load, but the need for more data down to the field devices is becoming almost a default,” he says. In more complex machines, such as plastic extruders, injection, thermoforming or semiconductor equipment, programmable logic controllers (PLCs) must manage sometimes hundreds of components, says Demicoli. “If we can interconnect all field devices back to

Fieldbus connectivity down to the component level is an important controls step for sustainability efforts and the need to measure, monitor and adjust.

the main brain, then the possibilities of increasing the machine capabilities are endless,” he adds.

Fieldbus connectivity down to the component level is an important controls step for sustainability efforts and the need to measure, monitor and adjust, explains Demicoli. “Supervisory controls/monitoring can give you a general understanding of the machine behavior, but, in the era of the Industrial Internet of Things (IIoT), more detailed data is required,” Demicoli says. “When analyzed properly, this detailed data can help machine builders have a better process control but also can help them improve future designs. Data collected from field applications can start becoming an asset to monetize since different models for machine learning can be created.”

It is also important to be compatible with the different industrial protocols, such as EtherNet/IP, EtherCAT, Profinet, Modbus TCP, IO-Link, he says.

Heating elements and more in plastic injection machines

Carlo Gavazzi’s NRG Smart Solid State Relay with built-in monitoring and fieldbus communication is used in plastic injection machines to measure energy consumption. “In sensitive heating processes, such as plastic injection machinery, the monitoring of heating elements is critical to ensure a consistent process that yields a highquality product and make sure that, if a heater breaks, countermeasures are taken instantly to avoid costly damages to screw feeders, as well as

the high scrap cost,” Demicoli says. “Additionally, variations in the heating element resistance, especially in an open-loop system may also result in high energy consumption.”

In order to maintain a precise temperature in the mold zones, the plastic injection machines can benefit from fast switching of the heating elements via the solid-state technology, says Demicoli. Electro-mechanical contactors and relays could also do this, but frequent switching leads to frequent field replacement, he adds.

“This is more a lifecycle cost issue. A solid-state relay’s lifetime is measured in millions of cycles, which means less scrap, lower lifecycle cost and less need to throw away faulty components when they reach their lifetime,” Demicoli says.

Blown film extrusion processes use infrared heaters strategically along the extrusion line, to maintain the required temperature for proper melting and processing of the plastic material. “Through a soft-start function, the inrush current of the heaters is eliminated thereby avoiding temperature shocks to the heaters but also avoiding possible temperature overshoots,” he adds.

Demicoli also says that monitoring energy consumption (kwH) between equivalent machines in a production facility can also identify areas for implementing energy-saving initiatives.

Voltage sags can also greatly affect open-loop processes and are typically related to the power network quality and/or a fault on the power network.

ControlDesign.com / April 2024 / 21 cover story

Voltage compensation features can automatically correct the output power to compensate for voltage sags. “In the case of a process involving openloop heater control, voltage compensation mimics the functionality of the PID loop with an instantaneous reaction,” Demicoli says.

Energy-management communication protocols

Sustainable practices for each manufacturer may also extend beyond its shop floor, up and down the supply chain, and more end users may soon be asking for data about the environmental impact of materials and processes.

“Standards are also coming into play as we evaluate the carbon footprint of our manufacturing supply chain and supply our customers with the data they need to evaluate us as part of their supply chain. We are already starting to publish data about the product environmental footprint (PEF) of our products such that customers can complete this evaluation,” says Lou Grice, vice president of digitalization and government relations at Phoenix Contact.

“In B2B environments, companies should consider that their downstream customers may require some statement of the environmental impact made by their suppliers,” Grice says. “In general, this means that data provided by suppliers about products and services should be expanded to include data linked to sustainability concerns like PEF. Depending upon the product, the PEF will account for various value chain items, including materials and manufacturing process used to make the product as well as product distribution, use and end-of-life,” he adds.

With at least one control cabinet and available space, monitoring meters can be installed on machines with minimal considerations.

As example, the PEF for a Phoenix Contact feed-through terminal block shows the material composition, environmental considerations for product manufacturing, customer distribution, use phase and end of life. Emissions data and calculations from general databases and emission reports from its suppliers were used to calculate the product environmental footprint.

Phoenix Contact also uses green energy, such as solar power, wind generation, energy storage and hydrogen gas, and its EMpro energy monitor supports sustainability efforts at its manufacturing facilities. “When we have a need to monitor multiple circuits with mixed voltage levels, we use a solution with our PLCnext controller and our Axioline power measurement modules,” says Russell Kolacek, building automation engineer at Phoenix Contact. “For data collection, we use common data manipulation protocols such as representational state transfer (REST) application programming interface (API) and message queuing telemetry transport (MQTT) to gather and share data. We store meter readings in a time-based database, which we can review and analyze later.”

He says REST API was used because the energy meter was supporting direct polling of live values. The meter’s implementation was also well-documented, which allowed the backend programming to be created.

“Using both REST API and MQTT as open communication protocols means

our internal application can have long lifecycle, as it is not dependent on a proprietary protocol or communication that is burdened by a license. We can maintain and adapt this code base as necessary. It is also lightweight and well supported by many IIoT frameworks,” Kolacek adds.

Time-based databases are efficient when working with energy data, Kolacek adds. “We are concerned here with the efficiency of storage both in the speed of read/write of the data and in the amount of storage it occupies,” he says.

Phoenix Contact is working with machine builders to design the power meter into the main cabinet of machines.

For a time, many machines will need to be retrofitted with energy monitoring solutions. With at least one control cabinet and available space, monitoring meters can be installed on machines with minimal considerations, Kolacek says. For installation, consider the power distribution layout for the machine and the available space needed for the energy meter.

“Installing in the field requires an additional electrical enclosure and planning for a machine power outage. We typically will locate the energy meter at the delivery point of power for the machine, so we must find space to locate this additional panel. Using a machine built with energy monitoring included, we simply have to bring data monitoring to the machine, making installation much simpler,” Kolacek says.

22 / April 2024 / ControlDesign.com cover story

PLC system controls solar thermal power

Control system optimizes energy harvesting, storage and distribution

by Flemming Jørgensen, Jorgensen Thermal Solutions

SOLAR THERMAL IS a highly effective method for large-scale energy production in geographies with high levels of direct sunlight. For industrial operations with signi cant heat consumption, solar thermal is often more cost-effective than fossil fuels, and it also results in lower carbon-dioxide emissions. Solar thermal is especially attractive in situations where land is plentiful and readily available.

At a remote mining facility in northern Mexico, heat accounts for an important amount of energy consumption at the plant. This is due in part to the heavy use of electrowinning, also known as electroextraction, a process used to obtain metals from ore. Electrowinning can require a tremendous amount of heat energy, and most copper mines using the electrowinning process rely on boilers to support this

process. Because of the abundant access to land and nearly 3,000 sunshine hours available per year, solar thermal was an obvious choice for this site.

Jorgensen, a large-scale solar heating equipment and system provider, needed to develop a control system that not only maximized the solar heat production, but also ef ciently managed and distributed heat to support a variety of processes.

ControlDesign.com / April 2024 / 23 PLCs

Figure 1: The sun heats a fluid in the solar collectors, which is then pumped through a heat exchanger to transfer energy for storage and usage elsewhere. (Source: Jorgensen Thermal Solutions)

From sun to process heat

Solar thermal plants generate process heat by harnessing heat from sunlight using flat plate collectors. Unlike photovoltaic (PV) systems that require semiconductors in arrays of solar cells to generate electric current, solar thermal plants use groupings of solar collectors to capture energy from the sun (Figure 1).

The solar energy is used to heat a fluid—in this case a mixture of water and glycol—circulated through the solar collectors. The heated fluid is then pumped to a heat exchanger, transferring the heat to plain water which is used for heat storage. The heated water in this storage tank is then distributed to various processes and heat consumers throughout the facility.

Forward-looking control

Jorgensen developed a control system specifically tailored for large-scale solar thermal plants. The S200 system controls the solar heat production, backup electric heat generation, and distribution to heat consumers throughout the facility. Consisting of a primary programmable logic controller (PLC), multiple remote input/ output (I/O) units, and a humanmachine interface (HMI), the system is highly flexible and reactive to the dynamic needs of the facility.

While programming for the electric backup and consumption systems is relatively straightforward, the solar thermal system introduces complexities due to its reliance on sunlight. The solar collectors are capable of

heating the fluid to temperatures up to 95 °C; however the generated temperature for any project is based on the needs of the client and for optimizing the overall efficiency of the installation. Off-peak conditions, weather, and of course nighttime hours also need to be addressed.

For this reason, feedforward control principles are used to anticipate the system needs on cloudy days and optimize the output. For the solar thermal system, feedforward entails using the control logic to simulate conditions based on solar radiation, ambient temperature and the solar collector profile. Without utilizing these advanced calculations, the system would not react quickly enough to changing atmospheric and limited sunlight conditions.

Based on a history of proven performance and application advancements over the years, Jorgensen selected the AutomationDirect Productivity2000 micro-modular PLC, a powerful yet cost-effective solution that is equipped to handle the combination of feedback and feedforward controls (Figure 2).

Despite the advanced programming required for the application, the team found the free Productivity PLC development software platform intuitive and easy to use.

Night shift challenges: continuous operation

With mining operations running 24/7, the automation system faces the challenge of functioning continuously under widely varying conditions, even at night when the solar collectors are not generating heat. The electrowinning process requires the electrolyte be heated to 50 °C for metal extraction. To maintain a constant

24 / April 2024 / ControlDesign.com PLCs

Figure 2: The micro-modular PLC supports traditional automation logic and closed-loop feedback control for the backup electricity and consumption systems, as well as the advanced programming of feedforward principles used for the solar thermal system at the facility.

(Source: Jorgensen Thermal Solutions)

electrolyte temperature throughout the process, an automated consumption system is employed.

The consumption system supports not just the electrowinning process, but also the production of hot water for the copper cathode rinsing. Much like a typical commercial or consumer building, or even some cities, this method of district heating or “heat networks” is designed to distribute heated water to clients and processes throughout the site. At any given time, the number and volume of users can change dramatically.

To guarantee uninterrupted operations, an insulated water tank stores hot water generated by the solar collectors so it can be distributed as needed. The storage tank is fitted with a variety of temperature, pressure and fluid level sensors that communicate status through remote I/O back to the primary PLC. Similarly, the solar heat production incorporates some flow meters used for metering the energy production. Various Ethernet remote I/O is distributed tens and hundreds of meters throughout the facility where needed, supporting seamless integra-

tion of field sensors with the control system (Figure 3).

As demand for heated water fluctuates, the consumption control system relies on a proportional-integralderivative (PID) control feedback loop. The distribution manifold water differential pressure is the process variable, and the controlled output operates a series of pumps using variable-frequency drives (VFDs). More water users cause the pressure to drop, which requires the pumps to speed up. The opposite happens as there are fewer water users.

ControlDesign.com / April 2024 / 25 PLCs

Figure 3: Ethernet-based remote I/O was distributed tens and hundreds of meters apart throughout the facility where needed, to minimize the amount of local field wiring.

(Source: Jorgensen Thermal Solution)

This arrangement allows the logic to closely regulate water differential pressure to the desired setpoint, because the controls responsively operate the pumps. In this case, the pump VFDs are advanced devices themselves, and a Modbus RTU serial connection is used for communication between the PLC and each VFD.

Monitoring critical systems

For any mining application, reliability is paramount, especially in harsh, dusty and remote environments. The Jorgensen S200 system incorporates data logging to support quick issue troubleshooting and alarm resolution. In addition, operators can monitor process status in the main control room using the AutomationDirect C-More 15-inch touchscreen HMI (Figure 4).

Designed for user-friendly operation, the touchscreen interface plays a crucial role in maintaining operational visibility. Users can tell at a glance how the system is running or if there are any alarms, and with the proper security credentials they can configure operational parameters.

DIY inventory check

During the design phase, challenges often emerge. For this solar thermal project, the global supply chain crisis created complications. A shortage of microchips led to extended delivery times on some components, and in this case one of the affected components was the remote I/O adapter. Rather than delay the solar thermal project, Jorgenson worked directly with AutomationDirect technical support during the development phase to find an alternative solution. The solution was to use a secondary PLC in a remote location for handling the

remote I/O there, even though it was still controlled by the primary PLC.

One of the unique attributes of AutomationDirect is its consumerfacing website featuring transparent information about stocking levels. When Jorgenson identified the remote I/O delivery date as a risk, it was able to view real-time inventory levels on the website and select components that had the best availability for their project timeline. This resulted in swapping the remote I/O adapter with a second PLC that was affordable, was readily available and met the functional requirements and schedule needs.

AutomationDirect’s support extends globally, facilitating ordering through the website without delays for quotes and proposals. This proved beneficial for Jorgensen, a global operator based

in Denmark, but placing orders with delivery to Mexico. The AutomationDirect technical support team delivered a positive experience, highlighting the importance of collaboration and quick issue resolution in complex projects.

Flemming Jørgensen is the director at Jorgensen Thermal Solutions, operating in Denmark and Mexico. With more than two decades of solar energy experience, Flemming helps companies to use less energy through energy optimization and by generating economical, green and reliable thermal energy without burning fuel. He has a manufacturing engineering degree from the Technical University of Denmark.

26 / April 2024 / ControlDesign.com

PLCs

Figure 4: The touchscreen HMI provides plenty of space for clean and streamlined graphics developed with an emphasis on intuitive and easy use by the many operators throughout the facility. (Source: Jorgensen Thermal Solutions)

Open architectures impact PLC longevity

by Tobey Strauch, independent principal industrial controls engineer

READING ABOUT NAMESPACES, programming organization units (POUs) and function blocks is a bit like a kid learning English by spooning up letters from alphabet soup. Many people ask about the effects of the Industrial Internet of Things (IIOT) and Industry 4.0 on industrial automation, and they reference open programmable logic controllers (PLCs), and they talk about IO-Link, protocol converters, cloud interfaces and single-pair Ethernet (SPE).

It’s easy to look at what we can touch and feel and leave out the behind-thescenes stuff: software. Software has its own changes related to Industry 4.0.

This year, Phoenix Contact will have interfaces set up with universal automation products built by Schneider Electric. Debuted in 2020, EcoStruxure was designed for the development and management of control systems. This was the beginning of changing IEC 61131-3 and extending it with IEC 61499.

There is a push for plug-and-play components in industrial automation. For an industry that is slow to change, it will be uphill in some instances.

Why? Industry still has 30-year-old GE systems requiring memory mirroring to allow for new systems to be put into place so that inputs and outputs can be converted in blocks.

This allows production to take short downtime periods for integration movements from old to new. However, this is the tenacious way of converting 1990s software control systems to new.

FP POU is not bound to any namespace

(POU is a member of the global namespace).

Labeling: no prefix character before block type.

FP POU is a member of a namespace.

The calling POU is not pasrt of the same namespace.

Labeling: hash (#) character before block type.

FP POU is a member of a namespace.

The calling POU is not pasrt of the same namespace or the namespace is added to the ‘Usings’ list of the calling POU.

Labeling: asterisk (*) character before block type.

Figure 2: The robot function block can be the same but used differently, making software development easier because the person who is setting up the program tree and flow may not be working the robot code. But that person can use the robot interface based on knowing how the function block inputs and outputs work and where, when and how to call the robot function block.

(Source: Phoenix Contact)

ControlDesign.com / April 2024 / 27 PLCs

How universal automation extends IEC 61131-3

Figure 1: A generic robot interface might look like this. (Source: Phoenix Contact)

BLOCK SYMBOL RobotFB1 RobotFB RobotRange RobotX AddArm RobotY RobotZ RobotFB1 #.RobotFB RobotRange RobotX AddArm RobotY RobotZ RobotFB1 *.RobotFB RobotRange RobotX

RobotY RobotZ MEANING

AddArm

This type of integration would also not be possible without software ideas to work around proprietary protocols and closed PLC platforms.

It is also a reason to think about PLCs and architectures. If POUs, namespaces and function blocks are utilized in architectures, then integrators have the capacity to program modularly.

Modular programming allows repeatability and reuse. This makes porting code between processors easier and development of multiple lines faster. Open PLC hardware would mean the software could go anywhere, regardless of platform. It also makes the data interfaces simpler. The push is to change architecture so that automation can focus on “speed, agility,

flexibility and efficiency,” according to “The Road to Universal Automation,” by ARC Advisory Group’s Harry Forbes.

For example, Phoenix Contact’s PLCnext utilizes namespace assignments, and a generic robot interface might look like Figure 1. And Phoenix Contact already has UniversalAutomation.org (UAO) blocks for PLCnext.

The RobotFB can be the same but used differently (Figure 2). This makes software development easier because the person who is setting up the program tree and flow may not be working