What owners need to know when considering an expansion

What owners need to know when considering an expansion

Unlike other basecoats that can require up to six coats, Cromax® XP delivers full coverage in as few as two coats. It’s easy to learn, use, and even repair—if ever needed. Cromax® XP is the ideal solventborne system for those who value quality and simplicity.

Experience the difference. axalta.us/xp

REVOLUTIONARY: The X-nozzles are taking atomization to a whole new level

NOTICEABLY QUIETER: Whispering nozzle™ due to optimized air flow geometry

INDIVIDUAL: Matches any application requirement, climatic conditions and application method

PRECISE: Optimized material distribution

LOW MAINTENANCE: No air distribution insert required

CONSISTENT: Constant fan size across the entire nozzle spectrum

EFFICIENT: The optimized atomization concept enables to realize considerable material savings

SATAjet X 5500 video

www.sata.com/x5500io

CLEAN: The cup can be easily, cleanly and safely separated from the spray gun

SAFE: Firm connection between lid and cup (thread)

REFILLABLE: The cups can be easily refilled

BENDABLE: The SATA RPS cup can be safely tilted* by up to 45° forward, right and left

www.sata.com/rps

EDITORIAL

Matt Hudson Content Director

Todd Kortemeier Editor

Hanna Bubser Associate Editor

Drew Bryant Contributing Writer

Tiffany Menefee Contributing Writer

Greg Lobsiger Contributing Writer

Lindsey Gainer Contributing Writer

Noah Brown Contributing Writer

Emily Markham Contributing Writer

Jordan Beshears Steve’s Auto Body

Sheryl Driggers Universal Collision

Frank Rinaudo Frank’s Accurate Body Shop

Stan Medina Certified Collision Works

ART

Mariah Straub Production Manager

Jen George Ad Services Manager

Mitch Bradford Art Director

Emme Osmonson Graphic Designer

Hana LeBrew Print Production Assistant

CEO Chris Ferrell President June Griffin

CFO Mark Zadell

COO Patrick Rains

CRO Reggie Lawrence

Chief Digital Officer Jacquie Niemiec

Chief Administrative and Legal Officer Tracy Kane

EVP Endeavor Business Intelligence Paul Mattioli

SALES

Chris Messer Vice President and Publisher

651.846.9462 / cmesser@endeavorb2b.com

Andrew Johnson Associate Publisher

651.846.9459 / ajohnson@endeavorb2b.com

Marianne Dyal Marketing Strategist (National Accounts)

706.344.1388 / mdyal@endeavorb2b.com

Chad Hjellming Marketing Strategist (National Accounts)

651.846.9463 / chjellming@endeavorb2b.com

Bob Marinez Marketing Strategist (National Accounts)

216.533.8747 / bmarinez@endeavorb2b.com

Martha Severson Marketing Strategist (National Accounts)

651.846.9452 / mseverson@endeavorb2b.com

Kyle Shaw Marketing Strategist (National Accounts)

651.846.8480 / kshaw@endeavorb2b.com

Dan Thornton Marketing Strategist (National Accounts)

734.676.9135 / dthornton@endeavorb2b.com

Sean Thornton Marketing Strategist (National Accounts)

269.449.0257 / sthornton@endeavorb2b.com

Kenzie Verschoor AssociateMarketingStrategist(NationalAccounts)

651.846.9472 / kverschoor@endeavorb2b.com

Matt Harper Regional Sales Manager

651.846.9551 / mharper@endeavorb2b.com

Melody Todd Senior Marketing Strategist (Regional Accounts)

651.846.9468 / mtodd@endeavorb2b.com

Tim Appelgate Marketing Strategist (Regional Accounts)

651.846.9458 / tappelgate@endeavorb2b.com

Autumn Morey Customer Success Representative

651.846.9460 / amorey@endeavorb2b.com

Ryan McCanna Administrative Assistant

HOW TO REACH US

Endeavor Business Media, LLC 30 Burton Hills Blvd, Ste. 185, Nashville, TN 37215 tel 800.547.7377 fax 651.224.6212

The annual subscription rate is $90 (U.S.A. only) for companies not qualified to receive complimentary copies of FenderBender.

LETTERS TO THE EDITOR editor@fenderbender.com

Opinions expressed in FenderBender are not necessarily those of Endeavor Business Media, and Endeavor Business Media does not accept responsibility for advertising content.

WE TALK ABOUT IT all the time in FenderBender. You’ve no doubt heard it from other sources, as well. Be it a 20 Group, a regional association, a conference or something else, there is power in learning from others and discussing shared experiences.

I was chatting recently with FenderBender columnist Greg Lobsiger, who is a longtime member of Mike Anderson’s groups and had just attended one of their quarterly meetings. Perhaps not coincidentally, Greg’s edition of “Shop Profits” (p. 23) this month covers the importance of seeking out quality, professional advice. Not every source of information out there is going to be wellestablished within the industry like Greg and his long-time associates. Others may have their own agenda they are trying to implement, or just don’t yet have the knowledge to be instructive.

It got me thinking how that’s an important message not just for collision repair, not just for business, but for nearly every aspect of our lives these days. We have access to more information than ever, but what percentage of it can be reliably pegged as authoritative? Misinformation and disinformation have bigger platforms, and more of them, than ever. It’s incumbent upon all of us to interrogate where we’re getting our information from.

I’m including FenderBender in this. We always strive to bring you the advice of top experts from around the world of collision repair, but always consider if their message makes sense for your business. If there’s something we might be missing, you can find my email at the bottom of this page.

And speaking of pages, in addition to Greg’s column I wanted to highlight Tiffany Menefee’s column (p. 45) with some practical advice on how you can help retain your top employees. And Drew Bryant’s column

(p. 46) offers an interesting angle on how you can better understand those team members and more seamlessly integrate new processes. Our columnists do an outstanding job offering advice to improve different areas of a business, and I think this month’s pieces are particularly strong.

Elsewhere, our main feature story (p. 24) is about expansion and every consideration that goes into it. If expansion isn’t in your future, I think you’ll enjoy the story of Sean Guthrie (p. 30) and how he’s helped expand his family’s business and set it up for the future. From our crowd to yours, thank you for your continued support of FenderBender.

TODD KORTEMEIER EDITOR tkortemeier@endeavorb2b.com

TODD KORTEMEIER EDITOR tkortemeier@endeavorb2b.com

GEORGE AVERY, the program manager of NABC’s First Responder Emergency Extrication (F.R.E.E.) program that teaches first responders to save lives, recently helped save a life himself after witnessing an accident, according to the NABC.

While driving home one evening in Dallas on his way home from an NABC Board of Directors meeting, he witnessed a vehicle hit a motorcyclist, pounding the rider and their bike into a barrier.

Avery “swerved into traffic” and positioned his vehicle to protect the motorist before cutting him loose from his helmet, which was causing him to choke.

Avery remained with the injured man until help arrived. The individual suffered “a broken hip and shoulder and other injuries,” but survived the incident. @fenderbendermag

As someone who helps train first responders through the F.R.E.E. program, Avery had knowledge of what to do in such an accident. The program helps first responders and firefighters to know what actions to take in accidents, focusing on those involving “late model vehicles with lighter weight, high strength steels, sophisticated electronics and multiple airbag systems.” The program provides practice situations with materials donated by partners.

ANALYSIS

Nashville played host to the 2023 American edition of IBIS

By TODD KORTEMEIERNASHVILLE— The International Bodyshop Industry Symposium (IBIS) returned to the United States in April in downtown Nashville as it hosted a conference centered around the theme of “Sustainable Secrets for Success.” A wide cross-section

of perspectives from inside and outside the collision repair industry was presented, with insurers, repairers, educators, vendors and more all on hand. Attendees heard from University of Tennessee professor Chad Autry about how the issues impacting the global supply chain impact collision repair. They heard from industry veteran and consultant Harold Sears about how the future of parts shortages could involve 3D printers. There was also shop owner and leadership coach Claudia Morgillo, who helped explain how brain

chemistry can affect how employees do their jobs.

One particularly enlightening session was entitled “Trends and Innovation in the Claims and Collision Market.” When talking about new technology or processes in collision repair, the discussion is often framed with a warning that these new things are coming and to prepare yourself and your shop accordingly. But in many cases, those things that have been talked about as being on the horizon for years are starting to take up more of the collision

repair sky. Allcat Claims Inc. COO Ramon Lopez outlined how technology has the power to interconnect all segments of the collision repair process to the point that an automated crash detection can connect to labor hours and parts prices to produce an estimate in mere seconds.

“So I’m here to tell you all that that happened,” Lopez said. “But that’s not going to happen. It’s not years to come. An automated estimate, using machine learning, artificial intelligence, and collaborate with other parts distributors, labor hours, markets,

that was created. And so from that space, like, everything is changing right now.”

While IBIS is based out of the U.K., holds conferences all over the world, and the attendees to the invitation-only event came from across the U.S. and Canada, there was a decidedly Music City feel to the event. Former country musician and shop owner turned business coach Dave Luehr pulled double duty on Thursday, speaking on a panel about prioritizing people and then just hours later closing out the day with his guitar and a couple songs.

“I’M HERE TO TELL YOU ALL THAT THAT HAPPENED, BUT THAT’S NOT GOING TO HAPPEN, IT’S NOT YEARS TO COME ... EVERYTHING IS CHANGING RIGHT NOW.”

—Ramon Lopez, COO, Allcat Claims Inc.A Taste of the Music City Dave Luehr serenades the crowd with some of Nashville’s favorite tunes.

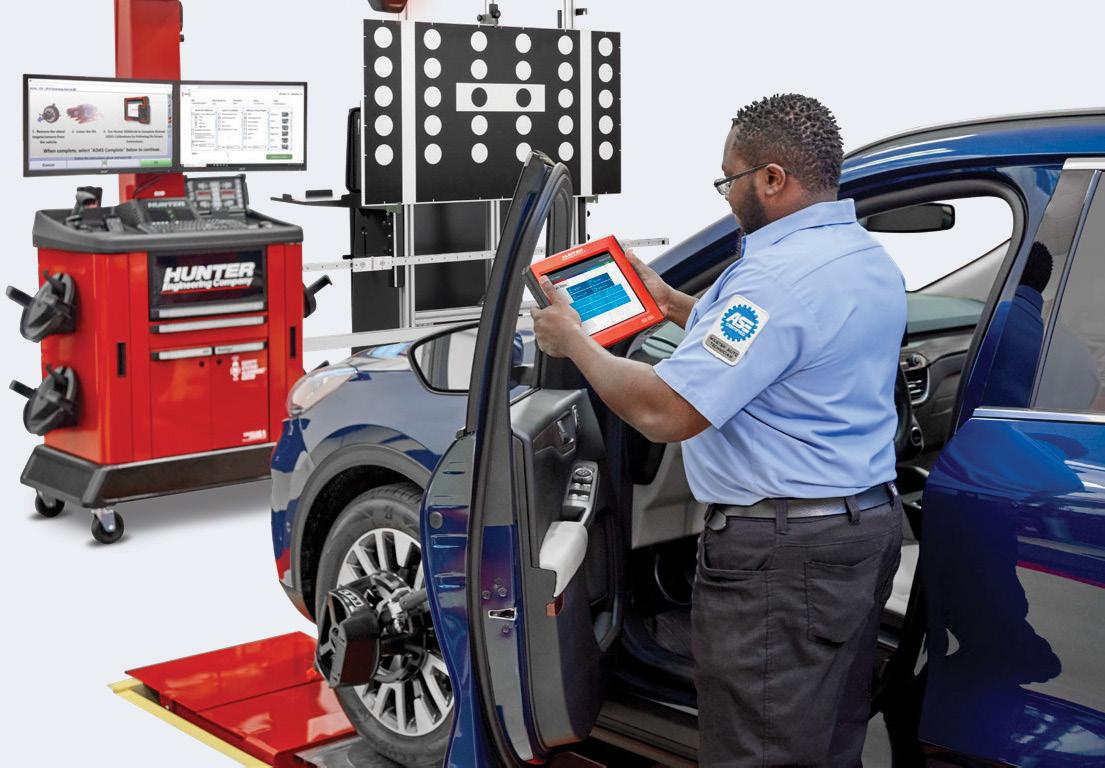

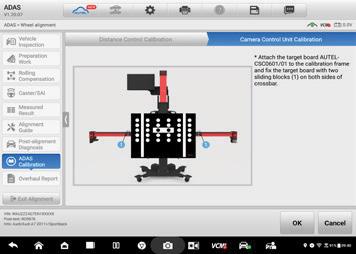

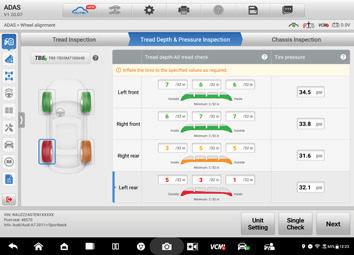

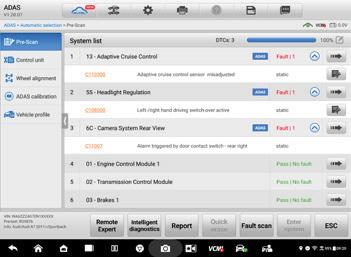

Clear, onscreen step-by-step instructions make the ADASLink® diagnostic scan tool your gateway to ADAS calibrations.

Onscreen direction walks techs through calibrations for millions of vehicles

Comprehensive pre- and post-scans of installed systems and codes

Full diagnostic capabilities reveal trouble codes and other vehicle information

Secure gateway and gap coverage

Code/pair new parts to the vehicle after installation

Follow guided processes to calibrate required systems after a collision

NUMBERS

THIS MONTH’S feature story breaks down all the considerations that go into planning and financing an expansion, which is an issue that a sizable portion of FenderBender readers are thinking about. We asked in our 2023 FenderBender Industry Survey if shop owners out there were either planning an expansion or looking at adding new locations down the road.

Shops Planning to expand

39%

Shops NOT Planning to expand

61%

The most recent “Who Pays for What” survey revealed an increase in the number of shops that utilize “an invoicing system to bill for materials,” according to a press release.

A previous similar survey in 2021 reported “about half” of shops using “the multiplier method (a flat dollar amount per refinish hour) to bill for materials,” with only about 19% using “a materials calculator or invoicing system.”

Now, results for those that use an invoice system “remains essentially unchanged,” but the survey found that over 40% of shops now use both invoicing and other methods. This marks a 32% increase from 2021.

Mike Anderson of Collision Advice carries out the surveys with the help of CRASH Network. He believes that the price of paints increasing is what resulted in this change.

“I really think the large change we are seeing is due to the multiple increases in paint prices virtually all shops experienced since we last did this survey in January of 2022,” Anderson stated. “More shops are beginning to charge for paint and materials with a detailed invoice that shows exactly what was used on the vehicle.”

A collision repair shop in Savannah, Georgia, is accused of taking customers’ vehicles and money but failing to complete any repairs, WTOC11 reports.

Hernandez Collision Center has been the root of several complaints from locals who claim they took their cars to stay in what many are referring to as “car jail.” The shop took their vehicles to have them sit in a lot, never being worked on.

Heather Hurst took her Toyota 4-Runner to the body shop after someone rear-ended her. Every collision repair shop she contacted told her it would be months before they could fit her in–except

Hernandez Collision Center, who took her vehicle that same day.

According to documents obtained by WTOC11, Hurst’s car sat in the lot “for six weeks, unrepaired and racking up fees.” When Hurst decided to retrieve her car and take it to another shop, Hernandez Collision billed her for nearly $6,000.

The shop then sued Hurst, as well as another unnamed woman, for violating arbitration agreements contained in documents they were asked to sign by “seeking extra-judicial remedies.”

The store has been involved in over 120 lawsuits, most of them involving them suing “customers for abandoning their cars,” and the arbitration agreement makes it incredibly difficult for anyone to sue the store.

1Collision has announced the addition of Art City Auto Body in Springville, Utah, to its network, according to a press release.

The shop was opened in 1995, and as of two years ago, is owned by Daniel Arce, who purchased the business from William Rathigan. Springville is known for having a strong community in the arts, earning it the label Art City, where the shop’s name is derived from.

Arce had worked in the shop when he was a teenager, eventually going from sweeping floors to learning how to do bodywork. After working as an estimator for different shops for several years, he became a facility manager.

After purchasing the shop, Arce enlisted the help of his two younger brothers: Ben Arce, who is an estimator that runs production, and John Arce, who manages the parts department.

Since the new ownership, the shop and its 20 employees have “quadrupled business.” They’ve had so much business that the shop is backlogged, and currently adding another building to triple its size.

“Daniel is fairly new in the industry; however, in a short period of time, he has made his business flourish like owners

that have been in the industry a long time,” stated John Hollingsworth, 1Collision’s director of new location development.

Kyle Murray’s family operates several CARSTAR locations in and surrounding Seattle, but he had the idea to start one location dedicated to EVs, according to a press release.

Murray’s grandfather, Bj Bjorneby, originally founded Bjorneby’s Auto Rebuild around 50 years ago. Since then, Murray’s parents and uncles have run several locations with CARSTAR, such as CARSTAR Murray’s, CARSTAR Port Orchard, Bob Bjorneby’s CARSTAR Federal Way Collision, and CARSTAR at 272nd.

In early 2022, Murray noticed the number of electric vehicles appearing on the road and within his family’s shops and realized he would most likely only see more. He started researching the possibility of EVs and ICEs being worked on in the same facility and decided to take on the task of making CARSTAR Murray’s Des Moines into a shop solely for EVs.

Murray started by focusing on three areas: “team training, facility improvements and process changes.” First, he trained the shop’s team on OEM and I-CAR training to learn the ins and outs of Teslas and other EVs.

The facility originally opened in 2002 and also needed a revamp, so stronger power resources and storage accommodation was built. Murray also devised a system of taking inventory on in-demand parts and ensuring there was enough on hand so that backorder delays wouldn’t be a problem.

“We [are] definitely seeing an increase in our profitability, thanks to the improved efficiency of just repairing one type of vehicle, the higher standard labor rates for EVs and motivation and productivity of our repair professionals,” Murray stated. “…We see customers coming from four to five hours away for service, and we’re already booked out for the next four to five months on repairs.”

Classic Collision has announced the acquisition of Suburban Auto Body located in Little Canada, Minnesota, according to a press release.

Suburban Auto Body has served the area for 40 years and has been able to operate on newer vehicles with the use of “advanced materials and technology” and knowledgeable technicians.

“I have built this company with a focus on making our customers happy and know that Classic Collision too takes passion in customer satisfaction,” stated former owner Dennis O’Connell.

Classic Collision CEO Toan Nguyen said that Suburban Auto Body was “a high performer in the Twin Cities” and is welcomed to the Classic Collision network as the company looks to further expand in the state.

ProColor Collision has announced the opening of its newest location in North Hollywood, California, according to a press release.

The 17,000-square-foot shop at 6872 Lankershim Blvd aims to provide collision repair to the greater Los Angeles area. It has also recently been given I-CAR Gold certification.

The store will be owned and operated by Pargev Adamyan, who has more than 20 years in the collision repair industry.

“We offer the best customer service with 50 years of shop and insurance experience as we strive to do a better and cleaner job every time,” Adamyan stated.

Adamyan wishes to continue in the footsteps of his father, who worked in the collision repair industry for 30 years. Adamyan made the decision to join ProColor Collision to have access to resources such as “the most up-to-date technology, strong history and proven network support.”

ProColor Collision’s Western United States General Manager Peter Polito said the company has many owners similar to Adamyan working with them.

“ProColor Collision includes many inspired owners, such as Pargev, who understand the significance of representing an established global network and are dedicated to investing in superior efficiency and continuous education to achieve great success,” Polito stated.

Quality Collision Group (QCG) has completed an acquisition of Schaefer Autobody Centers, Business Wire reports.

Schaefer Autobody is based in St. Louis and has been in business since 1985. They have 14 locations that began the process of being shifted to the QCG network “immediately.”

QCG CEO Jerod Guerin was compelled to approach owner Scott Schaefer because of the company’s “leadership position in the market” and saw a potential growth opportunity.

Following the merger, Schaefer will be joining QCG’s executive team, and plans for Schaefer Autobody to keep its identity.

“The Schaefer way of doing things isn’t going away; it’s only getting better,” Schaefer stated. “Joining Quality Collision Group allows us to expand and deliver the best results for our customers and clients.”

As Schaefer moves to his new executive role, Schaefer Autobody’s head of human resources Jaime Matthews will fill the vice president role of Schaefer Autobody Centers.

Fix Auto USA has announced the opening of a new location in Ogden, Utah, according to a press release.

Fix Auto Ogden is owned by Efrain Perez, who operates the store alongside his wife, Rebeca Perez. Efrain is from Colombia, where he got his start in the industry by helping his dad with work around his body shop. His family moved

to the United States and Efrain soon started his own small body shop.

While Rebeca is new to the automotive industry, the same drive that motivated her background in healthcare working as a nurse helps her to connect and communicate with customers.

The 10,500-square-foot facility will employ eight individuals. Efrain said he is “optimistic about taking this location to the next level,” with it set to gain I-CAR Gold certification soon and plans to earn more OEM certifications sometime this year.

“Growth can often be difficult to manage but is always a good thing when it has empowered individuals like the Perez family leading the charge,” Driven Brands’ COO of U.S. collision, Damien Reyna, stated.

The Society of Collision Repair Specialists (SCRS) board has elected two new members and one incumbent to its membership, according to a press release.

Chosen by SCRS board members on April 11 during an election, Michael Giarrizzo Jr., Andrew Batenhorst, and Tony Adams were elected to the board.

Adams is an AkzoNobel business services consultant and has served one term, which consists of three years. He has served previously as vice president of the Kansas Auto Body Association, an SCRS affiliate.

Batenhorst is the body shop manager at Pacific BMW Collision Center in Glendale, California. He is passionate about “giving back” to the industry and wants to help others see the potential in taking advantage of what’s changing in collision repair. In the past, he has been a member of the Collision Industry Conference Estimating Committee and the California Autobody Association.

Giarrizzo is the president and CEO of DCR Systems and has been in the industry since 1984 in his family’s shop. After the business was acquired, he helped it expand to 64 locations before becoming a COO and later forming DCR Systems, with seven locations currently.

LOCATION: NEW CASTLE, PA

OWNER:

SHANE CALDARARO

SIZE: 30,000 SQUARE FEET

STAFF: 20

AVERAGE MONTHLY CAR COUNT: 120

ANNUAL REVENUE: $5.2 MILLION

B y TODD KORTEMEIER Photos by CLARK’S STUDIO Submit

Every shop owner strives to make continual improvements to his or her business. But after more than six decades and eight additions and expansions to Nick’s Auto Body in New Castle, Pennsylvania, third-generation owner Shane Caldararo has said that’s enough. There’s not really anywhere else to go anyway, unless it’s across the street.

“That’s the original building (from 1958), so it was on one parcel, and now it sits on six. We took over the whole block,” Caldararo says with a laugh.

What was a one-bay shop when Shane’s grandfather Nick started the business now has 30 bays. The original New Castle location is the flagship of a Nick’s Auto Body network that includes shops in Clarion and Sharon as well as a truck and trailer shop and estimating facility elsewhere in New Castle. While the business continues to grow, the expansion of the original shop is at an end.

“If I expand more, I’m going to need more employees,” says Caldararo. “And that’s getting more difficult. So, we are focusing on proficiency, making sure cars get out faster.”

The presence of the estimating facility up the road is a big boon for customers. They can drop off their vehicle and get into their rental without having to leave the facility. So that lets the New Castle shop focus solely on doing body work.

“We do the full teardown and blueprinting, which I feel makes the cars go through, well I don’t feel, I know, makes the cars go through a lot faster,” says Caldararo. “So we can get the job done a lot quicker for the customer.”

There are three frame machines, two paint booths and four hydraulic lifts. The shop is I-CAR Gold and ASE certified. Caldararo notes that environmental responsibility is a priority at the shop. As a “green” body shop, Nick’s uses filtration systems and water-based paint, something they’ve done since 2010.

The shop stakes its reputation on quality repairs and outstanding customer service, which Caldararo is still involved in on a day-to-day basis. There is also a full-time employee dedicated to customer communications. Caldararo’s father is also still involved with the business after passing control to his son in 2020—”My dad is still in every day, he does all our deposits. And I like to say he causes problems and then leaves,” Caldararo jokes.

Caldararo’s brother is also an estimator at the truck and trailer location. Caldararo owns all the businesses and while things are set for the time being, he’s always keeping an eye on the future as far as new locations.

“Do we want to expand? Of course we do,” he says. “But it’s not a dire need, we kind of just play by ear. It seems like we find shops just at a whim, someone calls you and you look at it, and you like it. You always say you’re going to stop, but you never do.”

Absolutely reach out for help, but consider sources carefully

In Proverbs it says, “Plans fail for lack of counsel, but with many advisers they succeed.” It’s interesting to observe which shop owners run highly profitable shops and those who don’t. These two groups have very different characteristics.

The first group contains shop owners who are just stuck in their own world. They have a mindset that the collision repair business is just a very hard business, they work very long hours and hope there is enough money at the end of each month to pay bills. Many times, this group will have a high level of pride, which can be a huge barrier to their success and some even have a victim mindset. When I worked with my uncles from 1985–2000, we fit this group to a T. The cost of too much pride is incalculable.

The second group contains the shop owners who have been willing to suppress their pride and have become open to learning from others. There are many folks out there to learn from. One of the best ways is to consider joining a 20 Group. These groups are made up of approximately 20 shops from all over the country and are not competitors of our local markets. They usually meet at a different location every quarter someplace in the country. Most meetings last for two days and travel on each end. Time is spent just diving into the profit & loss statements of each shop, discussing industry issues, employee issues, etc., and often having guest speakers. Some of the shops are extremely successful and some are just learning how to improve their businesses. There are independent groups, and some paint companies have 20 Groups. For me, I have been a member of Mike Anderson’s groups for the last 12 years and the ROI has multiplied many times.

With most of these 20 Groups, you can go to the first meeting as a guest for free plus travel costs, just to see if it might be a good fit for you. Getting away from our shops to work on our business and not in our business is one of the best things we can ever do to improve. Many might be saying, “Greg, there is no way I can ever leave my shop for three to four days.” Well, it’s kind of like prayer. When we say we don’t have time to pray, that is when we need to pray the

most! Your shop will still be there when you get back, and when you return after a day or two, it will seem like you never left, trust me!

One thing for sure to consider: If you have never attended the annual FenderBender Management Conference, I would highly recommend it. Outside of COVID, I have gone the last five years and even above hearing some great speakers, I have made some very close friends. Another group to consider learning from are specialty coaches. There are coaches who specialize in Lean thinking, better estimating/negotiations and even coaches who help us with the proper mindset with personal development. Most would be surprised at the number of professionals, whether that be business owners, world class athletes, wealthy investors, etc., who are ALWAYS trying to improve their game in certain areas by using specialty coaches. I personally have invested nearly six figures in Lean coaching and this investment alone continues to compound on an annual basis. I even have a buddy who has invested in coaching on learning how to sell (in a good way). Selling goes far beyond just scheduling a customer to have their car fixed. It can help with dealing with insurers, vendors, our employees and even our families at home. Of course, investing in selling coaches is now on my bucket list!

When it comes to mentors, coaches, and fellow shop owners we network with, we must be VERY careful. Picking the wrong ones can have a very adverse effect on our businesses. I have even seen some shop owners on many of the social media pages pushing their ideas, but after pulling back the curtain, it could just be a bunch of smoke and mirrors. At the end of the day, we must vet anyone we try and learn from. It’s kind of like hiring a Certified Financial Advisor (CFA). We find a person who talks a good game, and they present us with their products that will (possibly) be worth X in the future. They may even drive a new BMW, live in a big house and have an appearance of richness. The question lies in, do they have true wealth, and should we entrust our money with them? CFAs can be like some shop owners we may try to follow; one of the best litmus tests is to ask first for a copy of their financial statement.

EMAIL:

What owners need to know when thinking about expanding

Knowing when he was ready to expand was the easy part for DB Orlando Collision owner Drew Bryant.

“When we were parking on top of the sidewalks out front of the building,” Bryant says. “There simply wasn’t enough parking.”

An overflowing lot is a good problem to have. But a problem is a problem nonetheless, and a business expansion can be a challenge for any owner to deal with for the first time. There are banks to deal with, business plans to draw up, research to do and, as in Bryant’s case, real estate to look for.

Matt’s Automotive owner Matt Lachowitzer is a veteran of many expansions in his mechanical and collision repair business. No two expansions are alike; it may involve renting vs. owning, adding on vs. building anew, and myriad financing options. Lachowitzer has only been in business since 2009 but has seen the financing environment change in numerous ways.

“Interest rates are today, much, much higher,” says Lachowitzer, who owns shops across Minnesota and North Dakota. “Banks are a little tighter than they used to be, need a lot more information. There’s a lot of regulation and making sure you have all your ducks in a row, financials, projections. My first building compared to the stuff we buy now, they’re a lot larger dollar amounts. Real estate values have gone up exponentially.”

Those “tighter” banks mean a little bit more scrutiny on an owner’s expansion plans. That’s where a business consultant like Nina Ross may come in handy. Ross has been a consultant since 2017 and also

hosts a YouTube channel offering guidance on specific topics. At the time of this reporting, Ross was nearing the end of an expansion process with a client of hers, Brian Finger, who ran a remote diagnostics business in Houston.

FenderBender spoke to the shop owners and Ross about getting started in the expansion process and some potential pitfalls along the way. While a business consultant like Ross can certainly help move this process along, at the end of the day it’s on the owner to make the right moves for his or her business.

“The bank wants to know that you have 100% knowledge of your business,” says Ross. “Because if you can’t talk about it, you don’t know it. And if you don’t know it, they don’t believe that you can further the growth and development of a business.”

As in Bryant’s case, knowing you’re ready for an expansion can seem like the easy part. Too much business and not enough space is simple math. But Lachowitzer also offers a

word of caution that sometimes an owner’s existing space could be underutilized.

Before making a jump, owners should explore if there are any ways to increase their shop’s efficiency. That could look like longer days, double shifts, and swapping out crews, Lachowitzer says. And once a shop does decide to expand, it’s important to know there is enough staffing in place to support that.

“It may take time to fill these spots that you’re going to create by expanding,” says Lachowitzer. “So start working on having a bench filled before you start a construction project, make sure you have a pipeline of people that you can bring in or bring in knowledge to get trained up for when that expansion is done.”

Once an owner decides to move forward with an expansion plan, everything is on the table. Ross says that one thing that often surprises owners is that a bank is going to evaluate personal credit as well as the financials of the business. If any issues need to be addressed in an owner’s credit, it should be done before moving forward.

“Your entire financial picture will be looked at,” says Ross. “If a client came to me and said that their personal credit was kind of shady, I would stop the process there. Because then you’re wasting your time. It’s either they may get a portion of what they want, or they will get some of what they want at a super high interest because of the personal.”

As for business financials, Ross says there is no magic number of growth or revenue a bank wants to see but they certainly want to see solid, sustainable growth. Shops that are “barely making it” may want to put the expansion on hold. Growth of 20% is a good estimate, Ross says.

Solid financials need to be backed by a solid business plan. The more ambitious the plan, the more it may face scrutiny. In deciding to purchase a new space, Bryant settled on a former medical college. Obviously not already optimized as a collision repair facility, the building needed multiple floors torn down and

office space demolished and turned into warehouse space.

“The bank thought I was out of my mind and essentially said, ‘This is not going to happen,’” Bryant says.

But Bryant was able to walk through why the facility would make sense and why his shop was ready to make such a move. He had KPIs to show how efficiently the shop operated and why the space would help maximize its earning potential. Those are the kind of things best answered by owners intimately familiar with the business.

While Ross’ diagnostics client gave her all the credit for developing his winning business plan, Ross herself says that a particularly savvy owner would be able to put one together on their own. She recommends doing some online research for a template, then filling in what you can, focusing on making sure the numbers are correct. If the bank can see the money in and money out, that’s a start.

“As a business leader, no, I would not go out right away and spend $15,000 on a business plan,” says Ross. “I will see if I could

The ability to prove with data the success of the business is key when speaking to a bank.

Costs of a new space can skyrocket easily, and it isn’t easy to go back to the bank again. Drew Bryant reminds owners that if they think they have enough, they probably don’t.

“If you think you're going to need 500, figure out how to get a million,” Bryant says. “If you think you're going to need a million, figure out how to put 5 million in there.”

write it myself, and then maybe find someone who can finish it off for you.”

Ross says that in the actual meeting with the bank, she had to say very little. They wanted to hear from the business owner about why the plan was viable. Ross’ client, for example, is heavily into ADAS work which she says is a relatively unexplored market in Houston. That helped secure the financing.

“Before you go to the bank, before you do anything, have all your financials and your projections and your acquisition costs of equipment and all the other pieces that are going into equipping this building, and marketing, and everything that you’re going to need to fill that extra space,” says Lachowitzer. “Really have a plan together when you go to the bank.”

Every situation is unique, and there may be more back and forth between bank and business, Ross says. Once the funds are delivered then the rest of the project can proceed, whether that’s adding onto a building or looking for a new space. Bryant was able to find his new space in an unusual way.

A member of Bryant’s 20 Group gave him the advice that when he went out to dinner with his wife, to eschew a table for the

bar and have conversations with the other patrons about what business they were in. After three weekly attempts, Bryant lucked into a meeting with someone in commercial real estate, and suddenly he had access to all sorts of options his realtor wasn’t finding.

“It was amazing at how many more of those relationships kind of kept coming back up,” Bryant says, adding that other people he’d met were helpful in other areas such as someone in site development. Sharing info and building relationships can be a big help in what can be a frustrating and long-term process.

And once the financing is done does not mean the easy part is over. Ross gives an example that a site her client fell in love with turned out to have a future highway expansion planned to run right over it within five years. Think long-term; patience and due diligence can help ensure owners don’t make a permanent mistake.

The waiting for the job to be done can be long, and owners handle it in different ways. Lachowitzer says he’s not the kind of owner who can be on a construction site each day. Bryant says the opposite. He even had a blueprint he hung up in his shower to look at and plan each morning. If the preparation was all in order, the payoff will be worth the trouble.

By TODD KORTEMEIER

By TODD KORTEMEIER

Growth has come quickly, but measuredly, for Sean GuthriePhotos Courtesy SEAN GUTHRIE

The Guthrie family doesn’t do anything slowly. Whether it is in motorsports or in business, Car Crafters founder Jim Guthrie and his son and Chief Operating Officer Sean only know how to push the limit. Jim founded Car Crafters in Albuquerque, New Mexico, in 1982, and even from humble beginnings in his parents’ house, he was always on the edge.

“My grandma got tired of him leaving the hot water heater off, because he turned it off so that the pilot light wouldn’t blow the house to smithereens when he was painting cars,” recalls Sean. “So they gave him the ultimatum: Stop it, or do it professionally.”

While steadily growing the business into an established member of the Albuquerque community, Jim also pursued a life-long passion for going fast. He got his big break in racing in 1997, running a partial schedule in the Indy Racing League (IRL) that included starting in the second row of the Indianapolis 500 and scoring a shock win at Phoenix. Jim went on to win Rookie of the Year honors that season and raced on and off in IRL for the next few years before injuries and the mounting costs of racing led him to hang up his helmet as a professional driver for good in 2001.

It was just a few years later that Sean was fresh out of high school and making his way up the racing ladder in the developmental Indy Lights series on a team Jim owned. As Jim knew well, racing didn’t always work out as a full-time career, and Sean looked to keep his options open. He tried college; his grades were good but he missed too much school while racing. He also kept working at Car Crafters, where he’d started working summers in high school.

Sean’s tasks progressed from sweeping shop floors to throwing himself into learning all he could from the shop technicians—he says now it was like having “10 dads” to show him the ropes and watch out for him. Being a body tech seemed to suit him best, he recalls, and he told his father that’s ultimately what he

wanted to do. But Jim already had a fast track in mind.

“Well, son, I’m glad you have passion for the industry. I’m glad that you’re working hard,” Sean recalls his dad saying. “You’re not going to be a body guy. No, I’ve got bigger plans for you.”

Sean was about to get a real-world advanced degree in all aspects of running a body shop, working his way up through different roles like parts manager, estimator and production manager. By 2015, Car Crafters had long outgrown the Guthrie family garage but was still just a single location. That was about to change, and Sean was at the forefront of it, re-shaping the nature of the business in expanding from one to six locations in the span of 18 months.

“We doubled in size, and revenue doubled in size as far as employee count, and went from one to six stores, in just 18

months,” Sean says. “I got to meet a lot of new people and really understand how you have to earn respect when people don’t know who you are.”

Having only worked at Car Crafters with his “10 dads,” going into these newly-acquired businesses was a difficult challenge Guthrie had to overcome. All they knew was that he was the owner’s son and perhaps misjudged the knowledge and experience he’d worked hard to collect.

“It was a very difficult point in my career,” Guthrie says. “It was a huge building and learning experience. And I think that that has kind of prepped me for the venture we’re taking on now.”

The growth hasn’t stopped, though Car Crafters remains at six locations around Albuquerque. Car Crafters, however, is now just part of a larger business known as Open Road Collision that operates shops across New Mexico and Texas. Car

Crafters eventually got to the point where there were no new markets to explore in Albuquerque. And, coming out on the other side of COVID-19 with the business still intact, it was time for a new strategy.

“If you’re not growing, you’re dying,” says Guthrie. “… We weren’t done doing the growth on our own and taking our culture and our love for our people to greater levels.”

When Guthrie says “our” he means his dad, who is still involved in day-to-day operations, his mom, the shop’s lead accountant, and their team of employees that continue to guide the direction of the business. And that direction is always full throttle, eyes far down the road.

How much more the business will expand, Guthrie isn’t sure. But for now the focus is on how to make the locations they presently have more efficient and more successful. Just as the Car Crafters

name means something in Albuquerque, Open Road Collision has left intact the names of its acquisitions relevant to their local markets, such as Drury Moss Collision in Amarillo, Texas.

“We only change what has to be changed,” says Guthrie. “And we maintain as much as we can, and we learn from our partners. Yes, we’re going to put in a few processes and procedures that we know to be successful. But we’ve also picked up processes and procedures from all of our acquisitions, and learn from them. Because that’s how we’re going to get better.

“Doing what you always have done will get what you always have got. We want to get more than what we’ve always got. We want to learn and grow.”

Guthrie says that there have been two constants at Car Crafters—always taking care of people first and always changing. To the first point, Guthrie has

overseen the partnership with a national insurance and benefits provider to serve all the new, far-flung employees. That was a top priority in being able to meet the basic needs of new team members upon acquisition.

To the second point, the business is changing with the times in terms of embracing new technology and processes. In a conversation earlier in the year on CollisionCast, Guthrie shared the company’s strategies around embracing ADAS calibrations, and they now are a licensee of a calibration facility through Car ADAS Solutions. To Guthrie, the ability to change with the times and taking care of people are directly and intrinsically linked.

“Having a culture that puts our people first allows us to have a culture that’s willing to change,” Guthrie says. “They’re willing to take a gamble on something new, because they know that it either is

The Car Crafters team focuses on constant improvement, which has fueled the business’ growth. going to work, or it’s not and we’re going to go backwards, but no matter what they’re going to be taken care of.”

A racer’s mindset is to always push the envelope and keep shaving seconds off lap times. A zero second lap is impossible—but that doesn’t mean it’s not something to keep striving for. The Guthrie family business has some ambitious goals, too, such as reaching the No. 5 spot of biggest MSOs, behind the four “behemoths” as Guthrie calls them.

“I don’t know that we can get there, I won’t say we won’t get there,” says Guthrie. “But I think I think reaching kind of the top five is, is a good goal for us just to set something ambitious, but not out of touch today.”

Jim Guthrie was never big on setting goals, says Sean. He believed that if you set a goal you might get complacent once you hit it, and he wanted the shop to always be striving for a little extra.

“It was just, let’s be better tomorrow than we were today,” says Sean. “And now look where we are because of that, we’re growing. And we continue to grow.”

The two generations of Guthries have plenty of years of running the business ahead of them with no plans to slow down anytime soon. Sean has two sons who enjoy running around the shop just like their dad used to do. As far as the future of the business, it will continue to be guided by the people with their hands on the steering wheel.

“It truly does come down to the people,” says Sean. “I don’t care if you’ve got one employee or 1000 employees, they’re who make the business and if you take care of them, they will take care of you. And then if you want to grow, you can grow with them.

“If you think you can do it on your own, it’s not going to happen. I don’t care if you’re small or big. This industry is too complex and too difficult for one person to grow it.”

Building positive buzz around your business in its community

YOU WANT PEOPLE TALKING ABOUT your shop. But how do you make sure the word around town is positive? What can you do to encourage the kind of buzz that brings new customers to your shop, and keeps previous customers coming back time and time again?

As Told To LINDSEY GAINER

So much of how body shops get their customers comes down to three things: insurance referrals (if they are a direct repair program), digital marketing efforts to pull in new customers, and the work that you do and the reputation that you build one customer at a time—i.e. word of mouth. How many times in your day-to-day do you either ask a friend for “who was that X that you recommended?” or “does anybody know a good X?” In a business based on customer service, reputation, the quality of your work, your customer focus, even your ideal type of work (such as OEM-specific repairs) get conveyed and shared by word of mouth. While you can’t necessarily tie word of mouth directly back to your ROI like you can with marketing or advertising initiatives, it’s extremely important. Asking the question “how did you hear about us?” is a great way to track as best you can, though.

People are usually happy to share about excellent customer service if you ask them to, especially when you make it a point to let them know how important it is for your business. To ensure you’re getting the best feedback possible:

• Do exceptional work.

• Always provide top notch customer service.

• Communication, as with any relationship, is vital—don’t leave your customers waiting for updates, delays or changes. Most of the time if you read a bad review on a body shop’s Google My Business page, it’s due to bad communication … the shop was difficult to reach, they missed deadlines or didn’t provide updates, or there was a general lack of understanding on the customer’s part due to a lack of communication.

• Treat each customer like it’s your first and only customer—even if they are not returning the same courtesy.

Always ask your customers for reviews— like I said before, most everyone checks reviews before they select a service provider these days. Right now, Google My Business reviews are the most valuable. Maybe in the future Bing or some other AI-powered search engine could replace Google, but until then Google is still where everybody goes to check reviews.

A couple things to keep in mind:

• Google specifically states that you cannot solicit reviews in bulk (but does not define what “bulk” is), and says you cannot financially incentivize or “buy” reviews. So, don’t run contests in exchange for reviews.

Another supposed red flag is getting a bunch of reviews from your own IP address (via your Wi-Fi), so avoid asking people to leave a review on the spot.

Instead, encourage customers to leave a review after the fact by sending a followup email with a link to your Google listing, adding a postcard requesting a review to paperwork at pick up, or adding signage to your lobby or front desk.

Once you have the reviews, you can use them as social media posts on your shop’s Facebook page, too. Sharing one or two reviews a week is a great way to leverage the feedback you’re getting for marketing. Also, anything that can drive people to your Google My Business page (like paid advertising) is going to get more people to see those reviews.

Lastly, make sure you respond to all reviews—good or bad—right away. This shows people you care about their experience. Thank people for good reviews, and offer up the opportunity to contact the shop to discuss a negative review or issue further. Most of the time bad reviews are a result of poor communication. You have to really butcher a car to get a bad quality review. But if you don’t clearly define how long the repairs will take or how estimates or the final bill is calculated, parts delays, etc., those will get you a bad review much faster than an issue with a repair. People remember how they were treated above all.

ADAS IS A UBIQUITOUS term for a ubiquitous facet of the automotive repair industry.

The all-encompassing acronym covers every component in a vehicle that uses some sort of advanced technology such as cameras or sensors to help keep the driver safe in some way. Adaptive cruise control, auto lane keep assist, emergency crash detection and other features all fall under the ADAS banner.

ADAS as an industry is booming, and it’s only becoming more prominent. Data from AAA shows that at least 90 percent of new vehicles sold over the past couple of years are equipped with at least one ADAS feature. Adding on top of that, data gathered by global research firm Counterpoint shows just under 50 percent of new vehicles sold in the first half of 2022 reached Level 2 of autonomy classification.

“ADAS systems are complex and repairing and calibrating an ADAS-equipped vehicle requires very specific knowledge, skills and equipment,” says Bud Center, technical products and curriculum director for I-CAR. “We can’t stress enough the importance of proper ADAS repairs and calibrations to ensure these systems are performing as designed when the vehicle is returned to the customer.”

These systems are only going to become more prevalent as time marches on, and knowing how to calibrate and repair them will be a critical part of a collision repair shop’s ability to fully and completely repair vehicles.

If your shop is new to the ADAS realm, finding out where to get started can be a little overwhelming.

Tyler Peartree is the manager for the flagship location of Silver Lake Auto, a fourshop MSO just west of Milwaukee, Wisconsin. As Silver Lake was looking to enter the ADAS space about five years ago, Peartree says one member from his team took an inperson class from Autel that helped them get started.

“It was eye-opening in terms of what needed to be done,” he says.

Classes provided by organizations such as I-CAR or Autel are excellent starting points. Center says I-CAR’s listing of courses covers everything from tools and equipment needed to step-by-step calibration guides.

Most organizations will have a combination of online and in-person training options as well as dedicated staff who are there to help guide you through the early phases. I-CAR’s recently opened Chicago Technical Center also features handson courses using tools and equipment required by OEMs.

“There is always someone at I-CAR who is eager to help you get started,” Center says. “We’re just a click or phone call away depending on how you want to start that conversation.”

Peartree also says the courses that his team member took played a pivotal role in helping his shop get on board. Though they were already inclined to do so, the ownership group of Silver Lake Auto listened to what their technologist learned and what he recommended they pursue.

“It was all education. Once we sent our technologist to that class, he came back and educated the owners on the importance on it, and it was a pretty quick conversation after that,” he says. “It’s just that next steppingstone to stay ahead of the curve as the industry progresses.”

There are varying levels to which your

shop can service ADAS-equipped vehicles. Not all shops will see the same number of ADAS equipped vehicles, and those that see higher numbers will still see a variation in which systems they are working on.

There are around 284 million registered vehicles in the U.S. at the end of 2022, and the average age of a vehicle on American roadways is north of 12 years old. A majority of cars still don’t have ADAS features, and that can play a big role in determining what kinds of equipment your shop might need.

“Shops can start by analyzing their business to understand the vehicle years, makes and models they are most commonly repairing in their location and available in their metro area,” Center says. “With this information the shop can determine the tools and equipment that best fits their business needs.”

In some cases, it might not make sense to invest thousands of dollars into ADAS calibration equipment if it’s not something that will benefit your shop in the immediate to mid-term future. In that case, finding a third-party source to outsource your ADAS work to might make more sense. Even then, though, Center says it’s important to have an understanding of ADAS repairs to check your vendor’s work.

“It is also important to note, even if your decision is to use a third-party vendor to perform your ADAS repairs and calibrations, it is critical for the shop’s staff to be educated on ADAS so they are able to verify your vendor has calibrated the vehicle properly, documented the repair and calibration process appropriately, and the systems are performing as designed when the vehicle is returned to the customer,” he says.

In addition to knowledge and demand, Center says shops should take into account the physical space they have to work with. ADAS calibration and repair require space and specific conditions to make sure components are functioning properly. New lighting, non-reflective wall and floor coatings, level floors and more are all necessary features in a space that is used for ADAS work. If the demand is there and your shop has the space, jumping into ADAS work could be a boon for your business.

Silver Lake Auto purchased its ADAS equipment right around the same time their technologist came back from taking ADAS repair classes. They also happened

to have an old dent repair building on the grounds of their flagship store that was under-utilized, which provided the perfect space to build an ADAS-specific calibration and work area.

“We did a lot of research in the beginning to make sure the building was adequate before we bought all the equipment,” Peartree says.

Their technology center has been running for about a year, and it acts as a onestop shop for everything related to ADAS repair—techs in the center can perform calibration, modular reprogramming, sensor installation and more.

Even if your shop has the space and demand, Peartree says it will take some time to get everything up and running.

“You’re going to be in about six months of getting everything set up, get the equipment and getting your people educated,” Peartree says.

Despite the hefty up-front investment, Peartree says the commitment to ADAS has been worth every penny.

“Not only as a revenue stream, but knowing that the vehicles we repair are safe and that we’re protecting our customers’ investments and themselves,” he says. “These are collision avoidance systems. If the calibration is off, the outcome isn’t just a check engine light. The outcome could be the vehicle isn’t going to avoid an accident.“

Center says using resources such as I-CAR’s trainings and course offerings, it provides them with a huge advantage over other shops that aren’t.

“They’re demonstrating their commitment to stay current with the latest repair and calibration techniques, which can increase their credibility as a leader in collision repair with customers, OEM networks and direct repair programs,” he says.

ADAS is rapidly expanding, and it’s only going to continue to be a big player in the automotive sector. Learning how to effectively repair and work with ADAS equipment is quickly becoming more than an extra service shops use to draw in customers—soon, it’s going to be an absolute necessity.

“Get into it, don’t be afraid of it and get educated on it,” Peartree says. “Jump into it as quickly as you can so you don’t get left behind.”

By LINDSEY GAINER

By LINDSEY GAINER

MORE THAN EVER BEFORE, accurate record keeping is essential to the success of a collision repair shop. Not only do shops need detailed records for maximum insurance reimbursement, the new generation of ADAS-capable cars carries a level of liability in repair that their predecessors never did. And good records lead to good customer service, says Cecil Bullard, owner and CEO of The Institute for Automotive Business Excellence.

“Bad record keeping will cost you,” says Bullard, “in just about every way possible.”

“It’s about the customer, really, and the customer needs to have a good understanding of what happened with their vehicle,” he says.

But having a process for spelling out what happened, why you did what you did, and what the ultimate solution was isn’t only important for the customer, he adds—it’s important for the success of your business, too.

“You want to make sure that if you have to look back at this later,” says Bullard. “Let’s say 14 months goes by and there’s some kind of an issue with the vehicle—you want to be able to easily and quickly go back and find

out what you did, why you did it, how you did it and what the outcome was. It is super important, especially for the collision industry, because we do so much business with insurance companies.”

Collision repair shops have always kept records, but the process by which those records are kept has changed drastically over the years. Gone are the days when a shop could operate effectively with paper records and a filing cabinet, says Bullard. These days, if you’re not using the latest management software, you’re losing out on potential profit.

“Being accurate and organized and having a really good description of what happened and why it happened is essential to getting paid,” says Bullard. “The way to make money in the collision industry is to make sure that you’re literally charging everything that you can legitimately charge the insurance company. If you don’t document properly—the way the insurance companies want it documented—you’re either not going to get paid or you’re going to get paid a lot less.”

The level of detail this necessitates is impossible to achieve without the help of management software, in Bullard’s opinion. Without it, he says, you’re going to have a hard time painting an accurate picture, not only for the insurance company but for your customers, too.

There’s also the matter of warranty issues—if you can’t quickly find the answer to what was done on the car in the past, you could spend hours trying to figure out what happened.

“It’s all about time and money in the collision industry,” Bullard says. “It’s about efficiency and making sure that you’re billing for everything that’s fixed. If you’re not keeping records, you’ll go broke, plain and simple.”

Another big issue, says Bullard, is liability. Cars today have highly advanced ADAS components that must be calibrated with razor precision to avoid a malfunction that could result in another accident. And the exact fix needs to be documented with as much detail as possible, to protect you and your shop from litigation.

“I really don’t think most shops under -

stand the amount of liability they have with modern vehicles,” Bullard warns. “If you have to go to court or if there is some question as to what was done and how it was done … if you have a good description on a repair that was fixed correctly, it protects you from litigation. If you don’t, you’re in trouble.”

“Also, I might have to prove to the IRS how much money I made, and how and why I made it so that I don’t get audited,” he adds. “There’s multiple ways that having really good record keeping and a great story is beneficial to the business itself.”

The best solution? A record-keeping software system designed specifically for collision shops.

“If you don’t have this kind of system,” Bullard says, “it will drive you out of business. I’m not trying to sell management systems … I just think that business is so much more complicated today than it was even ten years ago, and there’s just no way to run your business properly without it.”

Once upon a time, he says, you could purchase a management system for your shop and use it indefinitely. But those days have come to an end. Technology is changing so quickly that it’s impossible for the older systems to keep up, and shops need a system that can be updated regularly so it doesn’t become outdated.

“A system that was written in the last five years is, in my opinion, exceptionally better than a system that was written 15 years ago. I’ve seen a lot of people try to limp their older systems along and it results in a lot of headaches and wasted time.”

To find the best solution for your shop, Bullard suggests asking for recommendations in online collision groups, or doing a quick Google search. Take note of which systems keep popping up.

Once you’ve narrowed it down, compare what they offer for training, and pick the one with the most robust support.

“Whenever you’re going to implement a system like this it’s a big deal,” cautions Bullard. “There’s a three to six-month learning curve. It’s disruptive, and you just have to plan for the disruption. But

Bullard says many companies have online training built into their program, but make sure you verify exactly what kind of training and support resources the system has in place before making a decision. Proper training is essential for a successful transition.

“In my opinion, it’s usually worth spending the money to bring somebody in to work with your staff, kind of hand in hand over some period of time,” Bullard says. “Because again, if you’re not doing it right, especially in the collision industry, you can lose tens of thousands of dollars over a couple of months in billing. And so, you’ve got to make sure that not only do you know how to use the system, but you know how to use it to write the story that needs to be told for the insurance company.”

Bullard is also of the mindset that there’s no better way to learn than to dive in headfirst. Get the training, he says, then go live and “fight your way through it.” Don’t spend any more time than you have to straddling two different record-keeping systems.

“You need two things to be successful in anything—one is knowledge,” says Bullard. “You can get the knowledge through training. Some systems have online training, some of them don’t. Some of them will send somebody out or you send your people to them. Most today have something online. I see a lot of shops that are afraid to dive in the deep end though, so to speak, and fully immerse themselves in the transition. At some point you have to just get in the pool and swim, because experience is the second key to success. Knowledge can only take you so far. Experience drives you the rest of the way.”

The bottom line? Good record keeping is good business.

Keeping accurate records not only allows you to better communicate with your customers and provide better customer service, it gives you the information you need to receive maximum insurance reimbursement and protects you from liability.

Ask yourself “what’s the complaint of the customer?” and “what’s the cause and what was the cure?” If you have a way to document that in detail, in a system that’s easy to search and refer back to, you’re golden.

AS SHOPS GRAPPLE with vehicles changing and becoming more electric, finding technicians who are equipped to work on EVs becomes essential in a pool of talent that is already limited.

FenderBender sat down with Troy Lachance, an instructor in the automotive program at White Mountains Community College in Berlin, New Hampshire, to talk about what technicians entering the workforce need to know and what is needed in the industry from the next generation.

Lachance graduated in 1993 from the program he currently teaches and then went on to work as a full-time world-class General Motors technician until 2013.

Lachance never intended to become a teacher, but in 2011, he was approached by

a former teacher who encouraged him to apply for a vacant position at the school.

“I just happen to get a visit from him one day saying, ‘Hey, one of the other instructors is retiring. I think you’ve got a good personality and would be a good fit,’” Lachance recounts. “And I applied for the job and the rest is history. So you just never know where life is going take you right?”

Since then, Lachance has run his own repair shop from his home and pushed for the automotive program at WMCC to create classes dedicated to electric vehicles.

The school offers students a 15-week EV course in the traditional automotive program, or a one-year accelerated electric vehicle program, which Lachance had a part in helping create.

There’s much that students need to learn before they are able to build an EV successfully, but the biggest point Lachance hammers home for them is attention to safety.

“It’s no different than a lineman working out on the pole, you know, [on] your street corner, there’s a lot of safety protocol that has to happen,” Lachance says. “And we by far focus on that not only first but spend the most time with safety. And with that safety component comes the understanding of how things work.”

Students listen to lessons as well as perform hands-on work. In the one-year EV program students have the chance to build an EV in the class shop. It’s a great opportunity for students to work on something new without potentially endangering anybody.

Lachance encounters many students that aren’t interested in learning about EVs. He asserts that regardless of anyone’s feelings on the existence of EVs, as long as they exist, technicians will have to know how to deal with them.

“You don’t have to like EVs,” Lachance states. “… I’m neutral. But you’d be silly if you didn’t recognize the increased popularity and the fact that you can make a bunch of money fixing them.”

With nearly every manufacturer having an electric or hybrid option now, technicians who are qualified to work on EVs present themselves as an asset to any shop.

“The EV techs are short; there’s not many of them out there. So you can work wherever you want–more or less name

your price, as long as you are, you know, asking reasonable wages and, you know, you’ll be in high demand,” Lachance says.

Shops looking to attract talent that can work with this emerging technology must show that they can have a fulfilling career. If students see that they can make a comfortable living working in the industry, the industry will draw in intuitive minds.

“We need intelligent, intellectual people to work on vehicles,” he asserts. “… Younger people need to understand that there’s a lot that emulates what they already know, right? Whether it’s video games, and computers and cell phones … there’s a lot of modern electronics and computerized components

that require the interest and expertise of the younger generation.”

Technicians aware of and willing to adapt to the changes in the coming years, such as battery technology changing and improving, can help shops navigating oncoming changes.

Regardless of the direction the industry and the future of EVs go, Lachance’s goal is to prepare his students to have the best opportunities and to keep drivers safe with the work they do.

Though he doubts many proposed EV transition goals will be met, EVs are nonetheless established in the industry and will only become more prominent. As shops look for talent to build their teams, they need to be sure their technicians can handle what is becoming an established market in the industry.

EVERY COMPANY HAS a business culture—what makes up that culture depends on a variety of factors. At an AAPEX session titled “Building a Culture that Employees Embrace,” Sara Fraser, creative director at Haas Performance Consulting, defines a business culture as the company’s personality.

“[Employees are] not just looking for a place to go during the day to come home with a paycheck; they want a lot more than that,” Fraser says. “They want purpose and growth and recognition and connection and belonging and benefits and perks.”

It’s all these little pieces coming together to create a workplace that employees want to come into each day. To create a business culture that embraces employees shop owners need to access their businesses while considering these five questions—what is the “ideal” boss, what are employees looking for in a job, how do you show the company’s culture, are you hiring for that culture and why do employees leave?

The “Ideal” BossFor starters, are you approachable? Will your employees come to you with problems, concerns, or feedback? They should want to interact with you.

“Nobody should ever be afraid of their boss, right?” Haas says. “To me, that’s where self-examination is such an important piece of them—stopping long enough to review themselves and understand, ‘Maybe I’m part of the problem.’”

Adding to that, Fraser notes that in an internal job satisfaction survey she read, it stated that 75 percent of people found their boss to be the most stressful part of their job.

“That’s a problem,” Fraser says.

Fraser lists these traits as what employees are looking for in their bosses:

• Approachable

• Honest

• Trustworthy

• Positive

• Personable

• Understanding

• Calm/patient

• Organized

• Consistent

• Contributing

As a leader at your shop, you must first understand what your employees are looking for and then provide them with that.

What Employees are Looking for in a Job

Fraser discusses a class she taught a while back about how employees want to be thanked for coming into work and doing

their jobs, and how during a break, one of the attendees texted his employees and thanked them and that his employees’ reaction was to ask, ‘Are you OK?’

“That shouldn’t be the reaction. It shouldn’t be that out of place to say thank you to your employees,” Fraser says. “Recognition is saying thank you.”

Apart from recognition, employees are also looking for their job to challenge them and give them the opportunity to grow, and with that also comes their desire for clear, honest, and consistent communication.

Employees want to know what’s coming next for them. Is there a possibility for a promotion or a raise? When? What steps does the employee need to take to get there? Be sure there is open dialogue about these topics with your employees.

Employees are also looking for positive and uplifting environments with a clear goal or mission to work towards.

“You have to spend time with your people, and you have to listen. You can’t be the one doing all the talking,” Haas says. “Because once you know what your people need, then it’s your job to make sure they get it.”

Showing your business’ culture to those outside your company is just as important as creating that atmosphere within it. If you have a job opening and potential employees are researching your company, what will they find? Utilize your website and social media pages to show off what your company is all about.

Fraser and Haas suggest, posting pictures of company outings, fundraisers, community involvement, etc. Just be sure your posts are authentic and present your company’s personality.

It is also important to share your culture with your customers. If people believe your company isn’t taking care of its employees, then people may not want to spend money with you.

“People want to do business with people that take care of their employees,” Fraser says.

Another part of showing your culture involves how you respond to online reviews. Respond as promptly as you are able and be respectful of your customers’ opinions. If there’s a question or complaint, do your best to quickly resolve the situation.

Selecting the “right” people for your

business can be tricky, but Fraser and Haas break the hiring process down into these simple steps:

• Employment ad/job description

• Resume/application

• Pre-employment assessments

• Interview

Having a process like this in place is very important, Haas notes, without it you may end up hiring in desperation, just taking the “best of what was available,” but not hiring to fit your business culture. To start, you need an employment ad. People need to know that there’s an opportunity at your company, and they need a way to communicate with you.

Next, you’ll need to provide a job description. Applicants need to know what’s expected of them—what are the responsibilities and tasks required of them for this job? In the job description, Haas advises to also write about what kind of environment your shop is and the kinds of things you go out and do as a team—that’s your competitive edge.

“[You’ve] got to demonstrate that to people,” Haas says. “This is the difference between us and the rest of the shops—you’ll enjoy working here. We’ll enjoy having you here, and we’re going to have fun while we’re here. We’re going to work, but we’re going to enjoy it while we do our work.”

Once the employment ads and the job description are out there, you’ll need to monitor them, and watch for incoming resumes/ applications. After these start coming in, the review process begins. Not only are you going to want to look over the resume/application, but you’ll also want to call some of the references and check around on social media. This will give a better feel for what kind of person the applicant is overall.

When you’ve found an applicant you think may be a good fit, then it’s time to schedule an interview. To prepare for this interview, you’ll want to create a list of questions to ask. Fraser and Haas list a few sample questions you can ask:

• Tell me something your resume doesn’t.

• What are your hobbies?

• Describe your most difficult diagnosis or customer. How did you handle it?

• What is your most valuable tool?

• What is the best job you ever had? Why?

When asking questions, it’s important they be open-ended like the examples above. You should also try to ask some questions that don’t have to do with the job.

“Be interested in who they are as a person,” Fraser says.

This will not only show them that you see them as more than just another cog in their machine, but that you care. It will also give you a better idea of how they may fit into the environment at your business.

Employees leave for a multitude of reasons—some reasons are outside your control, but many you have the power of changing. Fraser and Haas look at seven questions employees are asking themselves about how satisfied they are with their job. These questions include:

• Do you know me?

• Do you understand what is important to me?

• What can you do to help develop my skills?

• When do you think I am worth a raise?

• Do you care about what I think?

• Can you appreciate my effort?

• Am I respected?

Communication is a huge part of helping your employees answer those questions. If you’re saying thank you to your employees, they know they’re appreciated. If you do reviews with your employees and talk about training to continue developing their skills or discuss when/what they need to do to earn a raise, then they know you’re invested in keeping them around, Fraser notes.

Haas explains that what makes these questions so important is that “if they don’t know the answer to those questions, then where do they find the answers or what assumptions might they make? Maybe they feel like, ‘I guess I’m not appreciated here. It’s time for me to start looking for a place I’ll be appreciated.’”

A good rule of thumb for understanding if your employees are happy is just to observe them, Fraser notes. You can see a lot in a person’s mood. Are they interested in their work? Do they seem happy? Or frustrated and stressed out? Are they openly talking with you? Know how to spot the warning signs an employee may be unhappy and could be looking for work elsewhere.