Technology that constantly monitors and refreshes building systems is feeding a ‘zero-engineering’ concept.. Read more on pg. 16

Technology that constantly monitors and refreshes building systems is feeding a ‘zero-engineering’ concept.. Read more on pg. 16

If you only think of Greenheck as a fan company, think again. We engineer and manufacture the industry’s most comprehensive line of air movement, control, and conditioning products for commercial, industrial, and institutional buildings. Our energy-efficient products keep occupants comfortable, productive, and safe while supporting sustainability. Let us help with your next project.

Don’t stick your neck out on an

Experience the benefits of an innovative virtual Building Management System with Fujitsu AIRSTAGE Cloud.

Don’t let upfront costs stretch your budget to the max. Fujitsu’s innovative AIRSTAGE Cloud virtual BMS, coupled with AIRSTAGE VRF products, allows facilities managers to install, control, troubleshoot, and reduce energy costs – all from a simple online platform. With an ROI in months, not years, you’ll see immediate benefits. Moreover, our full line of AIRSTAGE VRF solutions - backed by 45 years of HVAC expertise - delivers more flexibility, power and comfort in less space. Reach new heights of performance and efficiency without sticking your neck out…Fujitsu AIRSTAGE Cloud.

20 Can Smart Facades Sustainably Heat and Cool Buildings?

A promising research project looks at the potential for thermoelectric systems to thermally condition buildings. By

Mahsa Farid Mohajer

22 Backflow Technology Comes of Age

A look at how smart technologies are transforming water safety and system management in today’s interconnected buildings. By

Nadeem Mirza

28 ABMA Sets Lineup for First WIBI Symposium

Set for October in Minneapolis, inaugural Women in Boiler Industry Symposium takes shape, breaks new ground. By

Shaunica Jayson

10 ‘Gimme Shelter’: ASHRAE Wraps Annual Meeting, Launches New Strategic Plan Focused on IEQ

In a city eternally grateful for HVACR, the Society drew 2,000 engineers to Phoenix from all over the world. Its new leadership then unveiled an ambitious roadmap thru 2028.

Rob McManamy

A life-cycle approach can unleash the potential of BAS systems and move smart buildings closer to a zero-engineering concept.

By Kaishi Zhang

8 Editor’sNotes

Engineering as Unifying Language By Rob

McManamy

30 New Products

34 Clark’s Remarks

Game Changer for Coastal Erosion Mitigation? By Larry

Clark

HPAC Engineering (USPS Permit 464-930, ISSN 0039-0895 print, ISSN 1930-8957 online) is published 6x a year (Jan/Feb, Mar/Apr, May/Jun, Jul/ Aug, Sep/Oct, Nov/Dec) by Endeavor Business Media, LLC. 201 N Main St 5th Floor, Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI, and additional mailing offices. POSTMASTER: Send address changes to HPAC Engineering, PO Box 3257, Northbrook, IL 60065-3257. SUBSCRIPTIONS:

Publisher reserves the right to reject non-qualified subscriptions. Subscription prices: U.S. ($ 111.25); Canada/Mexico ($ 123.75); All other countries ($148.75). All subscriptions are payable in U.S. funds. Send subscription inquiries to HPAC Engineering, PO Box 3257, Northbrook, IL 60065-3257. Customer service can be reached toll-free at 877-382-9187 or at HPACengineering@omeda.com for magazine subscription assistance or questions.

Printed in the USA. Copyright 2025 Endeavor Business Media, LLC. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopies, recordings, or any information storage or retrieval system without permission from the publisher. Endeavor Business Media, LLC does not assume and hereby disclaims any liability to any person or company for any loss or damage caused by errors or omissions in the material herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever. The views and opinions in the articles herein are not to be taken as official expressions of the publishers, unless so stated. The publishers do not warrant either expressly or by implication, the factual accuracy of the articles herein, nor do they so warrant any views or opinions by the authors of said articles.

The Daikin MEGA-Q system provides an all-electric hot water solution, making it an ideal choice for commercial buildings with large volume, non-potable hot water needs.

Engineering ‘Lightning Poll’ Results, with ACEC’s Daphne Bryant

*NEW PODCAST* The ACEC Research Institute’s executive director walks us through some encouraging recent data from the American Council of Engineering Companies. www.hpac.com/55300492

and Air Cleaners, Keys to

NOW ON DEMAND: Recorded 11/18, IAQ expert Dr. Bill Bahnfleth explains this revolutionary concept, redefining standards with new air cleaning technologies. www.hpac.com/55236601

Engineering eBOOK: The Best of Ken Elovitz, P.E.

An Engineer’s Notebook, 2021-2024. Dive into this collection of useful professional advice, laced with helpful legal acumen. www.hpac.com/55020330

HPAC 2025: Our July Quiz!

*KEEPING COOL* As summer’s record heat wave sizzles on, dive into some history of air-conditioning and refrigeration. Answer 5 questions for a chance to win $25! www.hpac.com/55299816

Follow us on Twitter at @HPACEng, as well as our sister publications, @Contractormag, and @ContractingBiz. Retweet our up-to-date content, send comments, questions. Expand your world of engagement with us, at no extra charge!

EDITORIAL OFFICE

8001 Lincoln Ave. • Suite 720 Skokie, IL 60077 www.hpac.com

EXECUTIVE TEAM

CEO: CHRIS FERRELL

COO: PATRICK RAINS

CRO: PAUL ANDREWS

CDO: JACQUIE NIEMIEC

CALO: TRACY KANE

CMO: AMANDA LANDSAW

EVP, BUILDING & CONSTRUCTION GROUP: CHRIS PERRINO

EDITORIAL CONTACTS

MIKE EBY VP of Content Strategy, Building & Construction Group meby@endeavorb2b.com

ROB MCMANAMY Editor-in-Chief rmcmanamy@endeavorb2b.com

DAVID ECKHART Art Director deckhart@endeavorb2b.com

SALES CONTACTS

MIDWEST BILL BOYADJIS 973-829-0648 bboyadjis@endeavorb2b.com

SOUTH & WEST

RANDY JETER 512-263-7280 • Fax: 913-514-6628 rjeter@endeavorb2b.com EAST BRIAN SACK

732-629-1949 bsack@endeavorb2b.com WEST ELLYN FISHMAN 949-239-6030 efishman@endeavorb2b.com

CLASSIFIEDS/INSIDE SALES

STEVE SUAREZ 816-588-7372 ssuarez@endeavorb2b.com

DIRECTOR OF SALES

JOE AGRON 941-200-4778 jagron@endeavorb2b.com

LIST RENTAL SMART REACH sr-assets@endeavorb2b.com effective PRODUCTION AND CIRCULATION

RITA FITZGERALD Senior Production Manager rfitzgerald@endeavorb2b.com

MELISSA MENG Ad Services Manager mmeng@endeavorb2b.com

JAMES MARINACCIO Audience Marketing Manager jmarinaccio@endeavorb2b.com

80% of the buildings that will exist in 2050 are already built*. That means the potential to drive change is already in place – hidden in the water systems we use every day. Yet, most of these systems in commercial buildings aren’t optimized. They run at full capacity even when demand fluctuates – wasting energy and driving up costs.

Grundfos helps you unlock the hidden potential.

Our smart, energy-efficient, and reliable solutions adapt in real time to improve flow, reduce consumption and enhance performance across the board – without compromising comfort. From heating and cooling to pressure boosting, reuse and wastewater, every part of the system can perform better – if it flows smarter.

Whether it’s a hotel, hospital, office building or airport, Grundfos helps you unlock your building’s capabilities and take a confident step toward your sustainability ambitions. Let water flow smart

Discover the smart way forward at grundfos.com/US/CBS

ROB MCMANAMY,

At some point during ASHRAE’s lively annual meeting in broiling Phoenix this June, it hit me... There were roughly 2,000 attendees from all over the world on hand, but they were all speaking one language: Engineering.

Indeed, engineers from Asia, Africa, Europe, North and South America, the Middle East, Australia, all had converged in the Southwestern U.S. to meet in person, share stories, present solutions and ask questions about issues, both practical and pressing, related to heating, refrigeration and air conditioning. An international Society both hardened and reenergized by

meeting to collaborate and to use their collective learning and hard-won skills to help solve complex problems for the benefit of humankind. And all their diligent efforts and shared best practices were framed in the language of “engineering.”

Think about that.

In this divisive moment of surging international friction and political hostility, doesn’t that sound like a refreshing way to approach things? By leaning into the math? When times get tough, maybe we should actually just let the engineers lead.

the recent Coronavirus pandemic and its inherent call on the group’s vital indoor air quality expertise, attendees now arguably seemed even more bonded to each other than before Covid.

As I watched the global mix around me, I recalled the iconic Old Testament story of the Tower of Babel, where humans were said to get “too prideful” and schemed to build a soaring edifice that would reach to Heaven. To teach humans a lesson, the Almighty then supposedly introduced different languages to sew discord and to prevent designers and builders from different lands from reaching their towering goal. Or so the Bible story goes.

But in Phoenix, that dynamic had been reversed. Seemingly humble engineers from all four corners of the Earth, with varying levels of experience, were cheerfully

“We have answered the call in the past and helped to solve difficult problems in times of great need,” said new ASHRAE President Bill McQuade, PE, in Phoenix. “It is a new day and time for another ‘good turn.’ We can build on a half-century of progress in the energy performance of buildings and now focus the same effort on the indoor climate and environment.”

Emphasing that theme in his first Presidential speech, McQuade reminded attendees of how important their roles are in today’s world. “Providing safe, stable, and sustainable shelter is not just a basic human need; it is a fundamental pillar of societal advancement,” he said.

Thank goodness such vital global work is still in the hands of responsible problem solvers who speak the same language.

EDITORIAL ADVISORY BOARD:

William P. Bahnfleth, PhD, PE The Pennsylvania State University

Glenn Barrett, PE DC Engineering

David W. Bearg, PE Life Energy Associates

Lawrence (Larry) Clark, QCxP, GGP, LEED AP+ Sustainable Performance Solutions LLC

Kenneth M. Elovitz, PE, Esq. Energy Economics Inc.

Charles E. Gulledge III, PE, HBDP, LEED AP, FASHRAE Environmental Air Systems LLC

Elise Kiland, PE, YEA Cambio.ai

Nancy Kohout, PE, LEED AP SmithGroup

Valentine A. Lehr, PE, FASHRAE Lehr Consultants International

Ginger Scoggins, PE, CEM, CxA, LEED AP, FASHRAE Engineered Designs Inc.

James P. Waltz, PE, CEM, ACFE Energy Resource Associates Inc.

8760 Engineering LLC ID 340124554

Michael K. West, PhD, PE Advantek Consulting

Ron Wilkinson, PE, LEED AP Wilkinson Commissioning Management

Gerald J. Williams, PE, LEED AP

ROB MCMANAMY,

In a city eternally grateful for HVACR, the Society drew 2,000 engineers to Phoenix from all over the world. Its new leadership then unveiled an ambitious roadmap thru 2028.

As the new ASHRAE President Bill McQuade, P.E., CDP, LEED AP, left the stage after his inaugural address in Phoenix on June 23rd, it was no accident that the public address system started blaring the iconic strains of the Rolling Stones’ 1969 tune, “Gimme Shelter”.

Indeed, that title echoed the focus of McQuade’s speech, which set the theme for the Society Year of his presidency: “Healthy Buildings: Designing for Life.” In it, he called on ASHRAE members to champion indoor spaces that support occupant health, greater productivity and better quality of life.

“Shelter is one of the most fundamental human needs, essential for survival, safety, and well-being,” said McQuade, who had changed into hiking gear for his talk. “Throughout history, humans have sought shelter to

protect themselves from the elements, including extreme weather, predators, and environmental hazards. In its simplest form, shelter provides physical protection, ensuring that individuals are shielded from rain, cold, heat, and wind. However, its significance extends beyond physical safety. It plays a vital role in providing emotional and psychological security, which fosters a sense of stability and comfort.”

From that background, McQuade went on to emphasize the subject’s urgency for his engineering audience.

“Today, shelter is more than just a roof over one’s head,” he added. “Shelter encompasses the hospitals we are born in, the homes where we find comfort, the schools where we learn, and the buildings we work in. A welldesigned shelter prioritizes indoor environmental quality (IEQ), ensuring good air quality, proper lighting,

thermal comfort, acoustics, and access to safe water, all essential for health and comfort. Providing safe, stable, and sustainable shelter is not just a basic human need; it is a fundamental pillar of societal advancement and long-term development.”

All told, ASHRAE’s four-day annual conference drew 1,990 registered HVACR and building science professionals from around the world to discuss decarbonization, heat pumps, refrigerants, thermal energy storage, workforce development, professional ethics, and new technology. Attendees engaged in over 80 technical sessions spanning eight tracks. The most highly attended sessions included:

• Using Artificial Intelligence to Make You Irreplaceable;

• Generative AI applications in HVAC: Tools, Techniques, Best Practices;

HEAT TRANSFER FLUIDS FOR ANY APPLICATION

PROVIDING GLYCOL-BASED HEAT TRANSFER FLUID TO KEEP YOUR HVAC SYSTEMS AND PROJECTS RUNNING SMOOTHLY.

Thermal Charge® offers application-specific heat transfer fluids, innovative inhibitor technology, and industry-leading service and fulfillment so you can power through every challenge, need, and demand.

Visit thermalcharge.com to find the right heat transfer fluid for your application.

• Hot! Hot! Hot! Best Practices and Challenges of Heat Recovery from Data Centers.

One undercurrent apparent in Phoenix was concern over the ongoing federal withdrawal from some areas ASHRAE has been very invested in, such as decarbonization and reducing greenhouse gas emissions.

“We are all so proud of the work that ASHRAE has done to protect our climate and outdoor environment by improving energy efficiency, eliminating ozone depleting refrigerants, conserving resources, and decarbonizing buildings,” said McQuade. “We have answered the call in the past and helped

to solve the difficult problems in times of great need. It is a new day and time for another ‘good turn.’ We can build on a half-century of progress in the energy performance of buildings and now focus the same effort on the indoor climate and environment. We need to become healthy indoor environmentalists.”

Referencing ASHRAE’s recent prominent role in advising government on IAQ practices during the pandemic, one emotional session attendee asked, “If we can’t rely on government guidance anymore, and info has been removed from websites, will ASHRAE be more proactive in promoting itself as a reliable area for guidance?”

Panelists answered in the affirmative, noting that 12 Public Policy and Issues Briefs (PPIBs) are now available at ashrae.org/about/government-affairs/ policy-positions-and-issues#briefs While that does not fully replace all of the scientific and technical data that may now be missing, “ASHRAE is working on making more free information available to the public intended for non-specialists,” said one speaker.

That said, all attendees have access to all sessions online through next June. The 2026 ASHRAE Winter Conference will take place January 31 – February 4, 2026 in Las Vegas. The AHR Expo will be held February 2-4, 2026.

MISSION:

To serve humanity by advancing the arts and sciences of heating, ventilation, air conditioning, refrigeration and their allied fields.

VISION:

A healthy and sustainable built environment for all.

c. Develop resources based on member needs and industry trends. 1 2 3

Position ASHRAE as the global leader in advanced solutions to improve indoor environmental quality (IEQ) and address climate change.

a. Lead the development of widely adopted standards to support indoor environmental quality, decarbonization, and resilience.

b. Develop alliances and diverse working groups that position ASHRAE to lead and collaborate globally in identifying challenges, defining solutions, and developing approaches to address them.

Pursue impact-focused engagement by targeting stakeholders to support a strong workforce and maximize utilization, adherence, and trust of ASHRAE’s global expert resources.

a. Tailor and target engagement and resources to ASHRAE members and defined key stakeholders.

b. Provide guidance to targeted stakeholders on impactful ways to maximize the positive downstream effect of their engagement on the built environment.

c. Empower professionals in their journey to maximize industry impact in support of ASHRAE’s mission and vision.

d. Pursue partnerships to amplify the impact of ASHRAE’s mission and support the HVAC&R and built environment workforce.

Increase the accessibility of ASHRAE content, resources, and member opportunities.

a. Identify and address structural, content, and financial barriers to access.

b. Align communication and delivery methods and formats to enhance accessibility and effectiveness of content, resources, and volunteer opportunities.

c. Strengthen communication channels with and through chapters and regions to empower contribution to the Society as thought partners in adapting resources to local context and needs.

On July 1, ASHRAE released its 2025–2028 Strategic Plan, “developed to accelerate the transformation to a more sustainable built environment through global leadership in IEQ, decarbonization and workforce development.”

The plan centers on three goals:

• Lead globally in IEQ, decarbonization and resilience through widely adopted standards, alliances and member-driven technical resources;

• Deliver engagement by tailoring outreach to key stakeholders, empowering professionals and forging partnerships that strengthen the HVAC&R and built-environment workforce;

• Expand access to ASHRAE’s knowledge and opportunities by removing structural, financial and communication barriers and elevating the role of chapters and regions.

Four Strategic Initiatives

• Healthy, Sustainable and Resilient Communities: Accelerate the development and adoption of standards, best practices and technical guidance that enhance IEQ, reduce GHG emissions and improve the resilience of buildings and communities.

• Empowered Workforce: ASHRAE will grow its education and professional development efforts to help close the global skills gap.

• Organizational Agility: ASHRAE will invest in digital transformation and streamlined communication platforms to improve the speed and clarity of information sharing between chapters, regions, committees, etc.

• Emerging Technologies: The Society will actively identify, evaluate and promote emerging innovations, including AI-powered systems and smart building technologies, that support integrated solutions for energy efficiency, occupant health and operational performance.

For more on the new Strategic Plan and Initiatives, see the tables below and on the previous page.

:

value of ASHRAE’s resources is grounded in unbiased data, developed through rigorous research methods. AI: The use of AI enables ASHRAE to improve data collection, automate internal operations, and promote agility. Global Network: ASHRAE’s global network convenes the industry to generate unparalleled knowledge and content.

Healthy, Sustainable and Resilient Communities

Providing a healthy, productive and resilient indoor environment, while minimizing greenhouse gas emissions, is critical to today’s built environment. Further, global stakeholders’ leveraging of ASHRAE’s standards and technical resources presents an opportunity for ASHRAE to solidify global leadership in supporting healthy, sustainable and resilient communities. ASHRAE prioritizes timely identification of industry trends, expedient content development, and forges key partnerships to advocate and collaborate with industry.

The development of a skilled, competent, and solutions-oriented workforce is critical to addressing the challenges facing the built environment and the HVAC&R industry, today and in the future. ASHRAE continues to provide educational and professional development resources. Our members and industry partners need these tools to implement key initiatives such as decarbonization, resiliency, and indoor environmental quality goals and policies. ASHRAE, with the support of our chapters and regions, partners with key industry stakeholders in tackling the unique workforce challenges facing the industry globally.

ASHRAE’s ability to serve communities, the industry, the current and future workforce, and provide value to its volunteer members, is dependent on forward-looking products, services, and solutions. ASHRAE will use emerging technologies to support the development of resources and knowledge flow between ASHRAE’s chapters, regions, technical bodies, and the industry, harnessing organizational and operational efficiencies.

In today’s rapidly evolving landscape, emerging technologies are revolutionizing the built environment and HVAC&R industry, expanding numerous career opportunities. By combining technological advancements such as AI with human creativity, both seasoned professionals and new talent can collaborate to drive industry-wide progress. Advanced automation and AI-enabled systems propel energy efficiency and smart buildings, enhance comfort and IEQ, improve operations and maintenance, and deliver holistic and sustainable solutions for industry professionals. ASHRAE engages in a thoughtful process to evaluate and prioritize opportunities to leverage new technologies.

ASHRAE’s member and volunteer base maximizes the organization’s reach, foresight, leadership position, and organizational knowledge. A broad group of stakeholders leverage ASHRAE’s resources to make decisions and meet objectives that positively affect the environment. A viable, thriving industry makes a positive global impact.

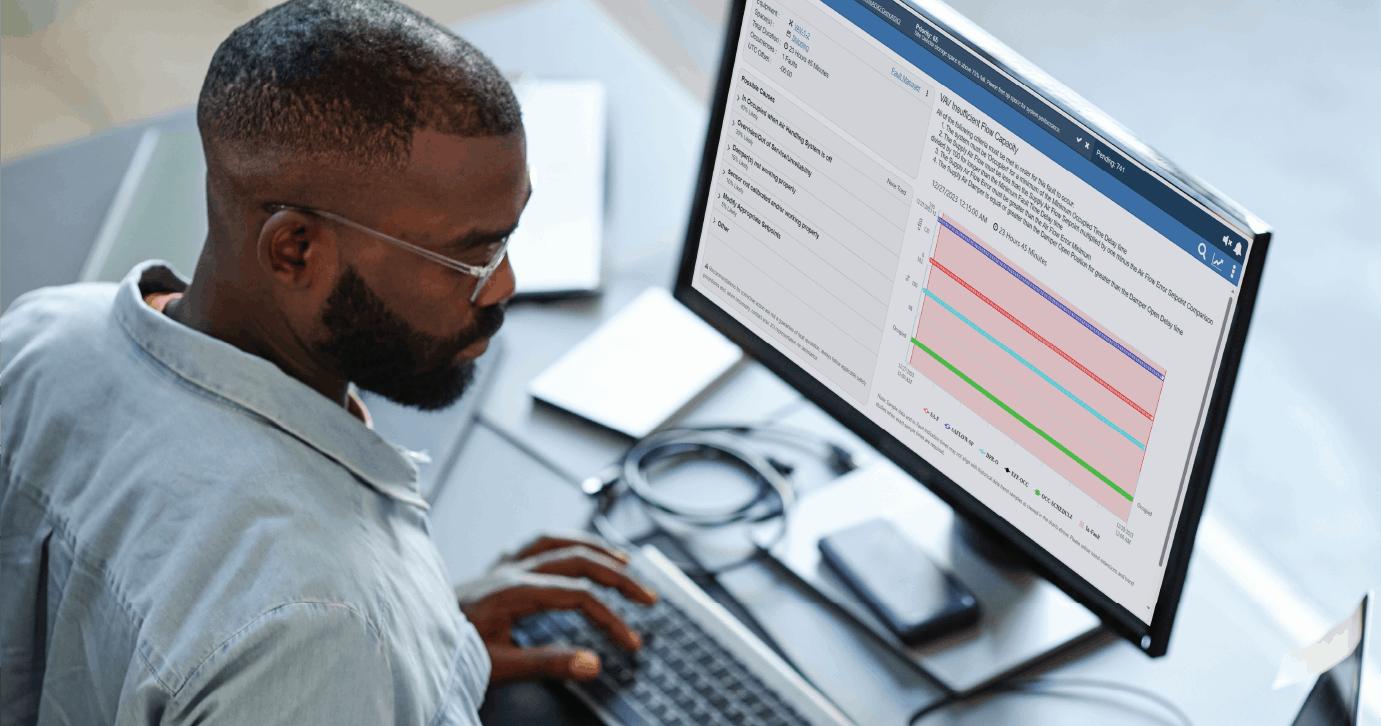

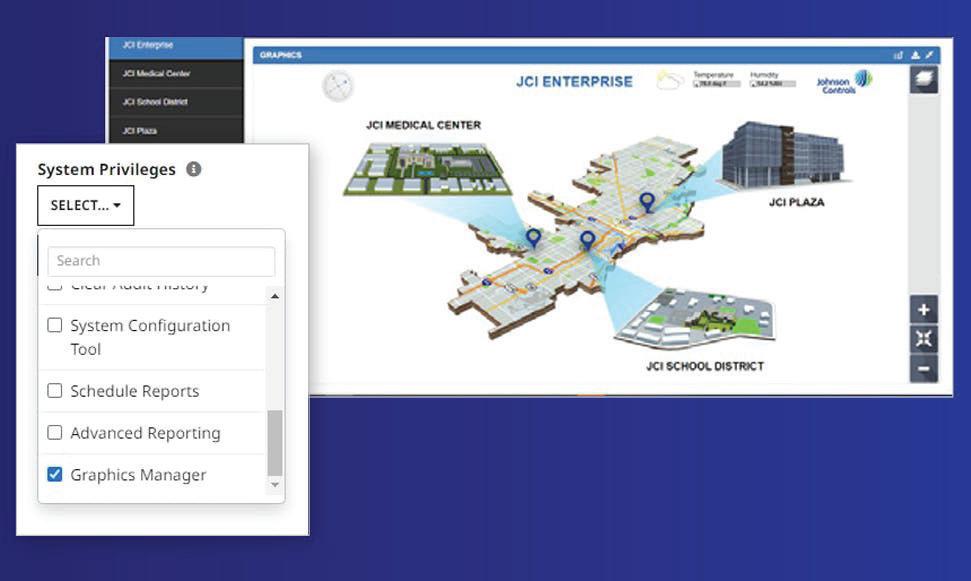

A life-cycle approach can unleash the potential of BAS systems and move smart buildings closer to a zero-engineering concept.

By KAISHI ZHANG, Vice President, Global Product Managament, Building Automation Systems and Control, Johnson Controls

An effective building system is the result of many factors, including energy reduction, regulatory compliance and facility management simplification. However, building systems are often designed and updated based on a piecemeal approach that focuses on a single stage of a building’s life cycle or area of operation. By making updates in isolation or based solely on immediate needs, this approach can limit progress and overlook valuable opportunities to maximize performance.

Fortunately, there’s another way that building owners and facility managers can make buildings smarter, more comfortable, more energy efficient and easier to operate: the life-cycle approach. Imagine this approach as a constant circle in which technology continually monitors building systems and is constantly refreshed with the latest functionality. In this way, the technology can help deliver optimal outcomes from the building’s initial design and build to commissioning and operation and any potential service or retrofit upgrades as the building ages.

An intelligent building automation system (BAS), which connects commercial HVAC, lighting, security and protection systems on a single platform, can make the life-cycle

approach possible. Facility teams can use BAS technology to monitor assets in real time, automate processes and

Imagine a circle in which technology continually monitors building systems and is constantly refreshed with the latest functionality.

gain access to data and analytics that help them enhance building efficiency, occupant comfort, safety and more.

Although hardware and devices in these systems may not last for the duration of a building’s lifespan, specific capabilities in dynamic BAS software can help building owners and facility managers ensure that their systems evolve to meet operational and sustainability goals across the full building life cycle.

Many currently available building automation systems require specialized expertise to install, program and commission. Because of skilled labor shortages, service providers are using the life cycle approach and implementing plug-and-play BAS technologies and factory-connected assets. This is

Based in Boston, the author has extensive global experience in smart building, industrial automation, and related controls and software. Now in his third year with Johnson Controls, he had previously spent eight-plus years with Schneider Electric, developing and promoting its next-generation industrial automation platform.

helping to move the industry closer to the ‘zero-engineering’ concept.

Zero engineering reduces BAS tool complexity and relies on artificial intelligence (AI) and machine learning (ML) to make processes simpler and more efficient. One way to reduce engineering is by avoiding time-consuming and costly, customized control sequences in favor of standardized ones.

For instance, using proven control sequences according to ASHRAE Guideline 36, High-Performance Sequences of Operation for HVAC Systems (G36) helps to maximize HVAC control stability and provide insights through realtime fault detection and diagnostics.

From factory-connected, plugand-play assets to zero-engineering BAS technologies, contractors and technicians can reduce the learning curve associated with BAS programming and installation. Instead, they can use their time to focus on value-added services and maximize an organization’s capital expenditure (CAPEX) investment.

Following BAS installation and programming, the next step is deployment and commissioning, a process that often requires specialized, on-site

personnel, such as a dedicated commissioning agent. This specialist ensures the wiring aligns from both a control and electrical engineering perspective and that the system operates as designed – a process that’s critical to operational success.

In tandem with zero engineering, the industry is shifting toward continuous commissioning.

Using a life cycle approach, engineers and technicians can use connected controls to remotely and

continuously commission building automation systems by leveraging the power of the digital thread from the engineering phase to reducing the engineering effort and the need for on-site specialists, as well as to help minimize human error.

Leading service providers with dedicated BAS experts can remotely support local technicians while leveraging software to diagnose commissioning issues and faults. Some service providers have developed workflow tools to guide local technicians with clear, standard processes. This helps ensure that technicians of any skill level can effectively program and commission the system, ensuring systems are ready for use on time and within budget. The first step toward zero commissioning starts with this collaboration between remote experts and local technicians.

After BAS commissioning and integration with smart building equipment and systems, the facility team assumes day-to-day operation and monitoring. Through connected controls, teams can remotely monitor and manage a building’s smart assets.

With this enhanced visibility and control, teams can get more value from a BAS which, in turn, optimizes

building performance, maximizes operational expenditures (OPEX) and helps achieve positive outcomes. For example, this approach helps:

• Save energy and meet decarbonization goals;

• Accelerate return on investment (ROI);

• Advance operational efficiency and enhance reliability;

• Maximize system performance;

• Simplify building management;

• Maintain regulatory compliance;

• Strengthen cybersecurity;

• Improve occupant productivity, comfort and well-being.

Because BAS can be so feature rich, understanding a system’s full capabilities to deliver these outcomes can be a challenge for facility teams. Many teams take advantage of just a fraction of what their BAS can do.

Facility teams and local technicians can get support from the same BAS experts that support programming and commissioning. Using remote capabilities, these experts can connect to a building’s BAS. This allows them to view and assess analytics in relation to outcomes so they can prioritize how to align the system with an organization’s goals and adjust remotely. If needed, BAS experts can also provide remote support to on-site technicians.

Remote assessment can be especially useful for maintenance.

In the current service approach, when there is an issue, a technician must make an on-site visit to determine what is needed. This trial-anderror process can waste time and require multiple visits, potentially extending downtime and impacting comfort, performance and efficiency.

With the life-cycle approach, facility managers can leverage BAS data, digital capabilities and remote BAS experts to streamline diagnostics. In some cases, remote experts may be able to address the issue immediately. If a local technician is required, they are able to understand the issue before they arrive, helping them work more

efficiently, reducing costs and maximizing the visit’s value.

A future-proof BAS is one in which the software application life cycle is

Zero engineering reduces BAS tool complexity and relies on AI and ML to simplify processes.

decoupled from the hardware life cycle. The service provider continuously upgrades software over time and, when the hardware approaches the end of life, it only takes a few clicks to move the software to a new hardware platform, reducing system downtime. Separating the software life cycle from that of the hardware allows the system to seamlessly upgrade, expand and evolve while it helps reduce costs for building owners and facility managers.

Advanced BAS technologies offer software applications that upgrade within a few clicks. As in the concept of continuous commissioning, some BAS software employs a continuous

release model to seamlessly update system functionality, as needed.

A continual release model lets operators access new capabilities and features as they are developed, rather than on a periodic release schedule. This approach gives organizations more control over system functionality, since they can choose which updates and features to implement. As a result, facility teams can be better equipped to respond to new and emerging challenges while achieving their goals.

Building owners and facility managers can get the most out of a BAS by considering a life-cycle approach that optimizes value and achieves better long-term outcomes. By partnering with a building technology supplier with a complete ecosystem of connected technologies, expertise and services, organizations can drive results across the full building life cycle.

Intelligent building automation systems deliver a powerful combination of technology, software, data analytics, remote support and the expertise of local specialists. With these solutions, building teams are well positioned to maximize the potential of their facility and to build a future that’s smarter, healthier and more sustainable.

A promising research project looks at the potential for thermoelectric systems to thermally condition buildings.

By MAHSA FARID MOHAJER, PhD, Sustainable Building Analyst, Stantec

What if we could design buildings that could heat and cool themselves? What if we do this by repurposing existing technology? And what if we could seamlessly integrate this technology into a building’s walls?

The building industry has made great progress in reducing its operational carbon. But humans still consume a huge amount of global energy cooling and heating our buildings. We need new ways to get to net zero.

As a doctorate student at University of Massachusetts, Amherst, I was part of an ongoing research effort looking into the potential uses for thermoelectric (TE) materials in buildings. Several departments contributed to the project.

Ajla Aksamija and Zlatan Aksamija, professors at UMass Amherst at the project’s onset, invented this patentpending technology.

What are Thermoelectric Materials?

Thermoelectric materials are “smart” materials. TEs can convert temperature differences (or heat flux) into electrical energy. The behavior of TE materials has been known for years, but researchers have mostly focused on new classes of TE modules (TEMs). Or they have experimented with applications such as thermoelectric generators

Roosevelt University in Chicago provides the ongoing research opportunity.

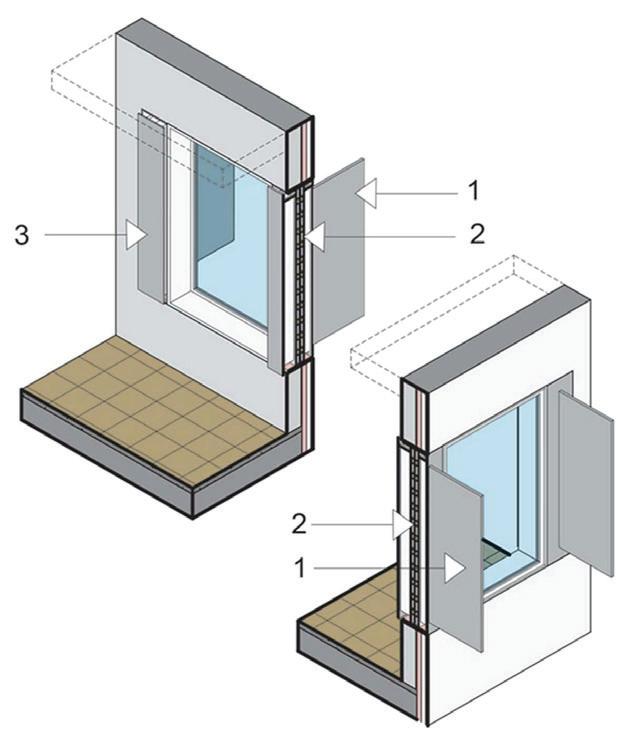

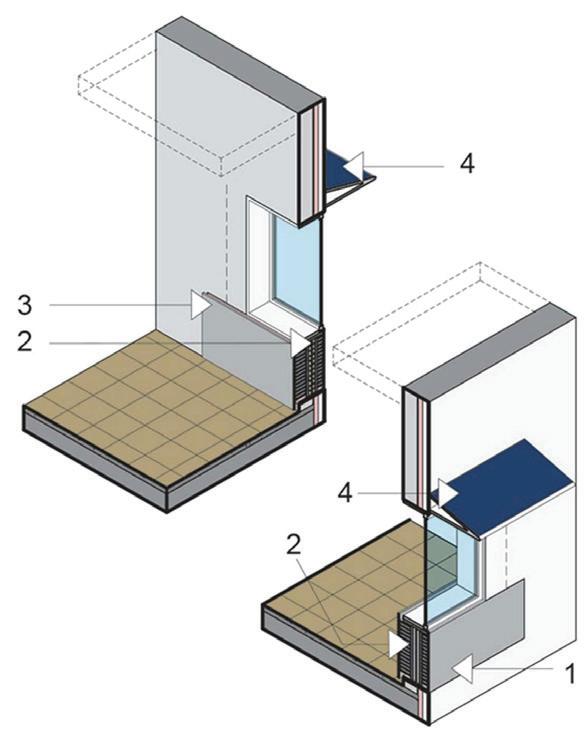

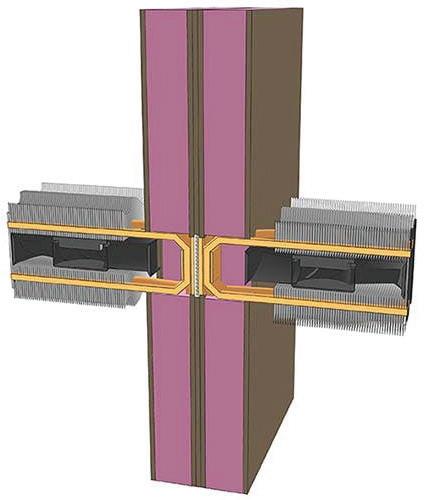

Opaque facade with window and vertical shading (left) and with horizontal shading (right). The elements include: (1) exterior heat sink, (2) interior radiant panel, (3) TEM components, and (4) photovoltaic panel.

to make cars more efficient. There has been little research on their use in the building industry.

Could we implement TE devices in building facades to use the temperature difference between inside

Based in Raleigh NC, the author has been a Sustainable Building Analyst at Stantec since the fall of 2022. A graduate of the University of Massachusetts at Amherst, she is is driven by the belief that the built environment can and should coexist harmoniously with nature. She can be reached at mahsa.faridmohajer@stantec.com.

and outside to generate electrical energy? We attempted to answer that question in our research. If we could, we hypothesized that we could use that electricity to heat and cool perimeter spaces in buildings without relying on a conventional HVAC (heating, ventilation, air conditioning) system. And we could even generate electricity when the spaces are not occupied.

Potentially, we could retrofit existing buildings by integrating TEMs in their facades. And, once available, the industry could use these systems in new construction.

What makes the idea of using TEs in building exteriors so exciting? By applying TE technology in buildings, we could potentially cut their carbon appetites and energy bills. But that’s not all.

Thermoelectric facades are modular. They don’t need to be connected to a conventional HVAC system, fuel source, or air ducts. They use radiant heating and cooling. TEMs are compact, reliable, and stable. They do not contain any moving parts, which reduces maintenance costs compared with conventional HVACs. These systems can store energy locally, operate quietly, and eliminate the need for refrigerants.

Potentially, we could retrofit existing buildings by integrating TEMs in their facades. And, once available, the industry could use these systems in new construction, potentially meeting most of the heating and cooling needs of the perimeter spaces in commercial buildings. In both cases, we would reduce buildings’ energy appetite from the grid. But first, we needed to find out if the technology worked.

The team researched TEMs integrated into facades to see if theory could be reality. In the initial phase, we built simple prototypes to test our hypothesis of TE’s heating and cooling ability. Preliminary results were promising, indicating potential.

In the next phase, we studied the integration of TEMs as stand-alone elements in the facade and combined with heat sinks in facade assemblies. We used a thermal chamber to simulate various exterior environmental conditions from 0° to 90°F. And we measured the temperature of the internal heat sinks both in heating and cooling modes. Our results showed that facades with integrated TEMs and heat sinks should operate well in heating and cooling modes under varying exterior environmental conditions.

For the next phase, the team created energy models based on our initial findings. We tested a single office space with a TEM facade and a large commercial building with a perimeter TEM facade. We compared performance with a conventional system in various climate zones and weather systems. Once again, the results exceeded our expectations.

A prototype facade with TEM at center and heat sinks on either side. Tests so far have shown them working well.

Our models showed the facade panels worked best when the temperature difference was high, as this is when they delivered more energy.

We began to look at optimizing the system. Computational fluid dynamics (CFD) helped us determine that about 15% of the facade should be devoted to TEMs for optimal performance. Next, the team designed various facade assemblies with appropriate architectural details. To gain acceptance in the industry, these smart facades will need to have a variety of materials and styles, with window options. The team also incorporated shading and photovoltaic panels in the facade systems. (There’s no reason that a facade that heats and cools can’t look good, too.)

Researchers built two full-scale working prototypes. But they have yet to test them under real-world conditions. We have published various articles and research papers on our project. Examples include: “Novel Active Facade Systems and Their Energy Performance in Commercial Buildings” and “Thermoelectric Materials in Exterior Walls: Experimental Study on Using Smart Facades for Heating and Cooling in High-Performance Buildings.”

The team’s research indicates that this technology has great potential. So, what’s next for facades with integrated TEMs?

The inventors are pursuing a patent and seeking manufacturing partners to bring these products to the marketplace. They are excited about the possibility of smart facades in the next generation of low-carbon buildings.

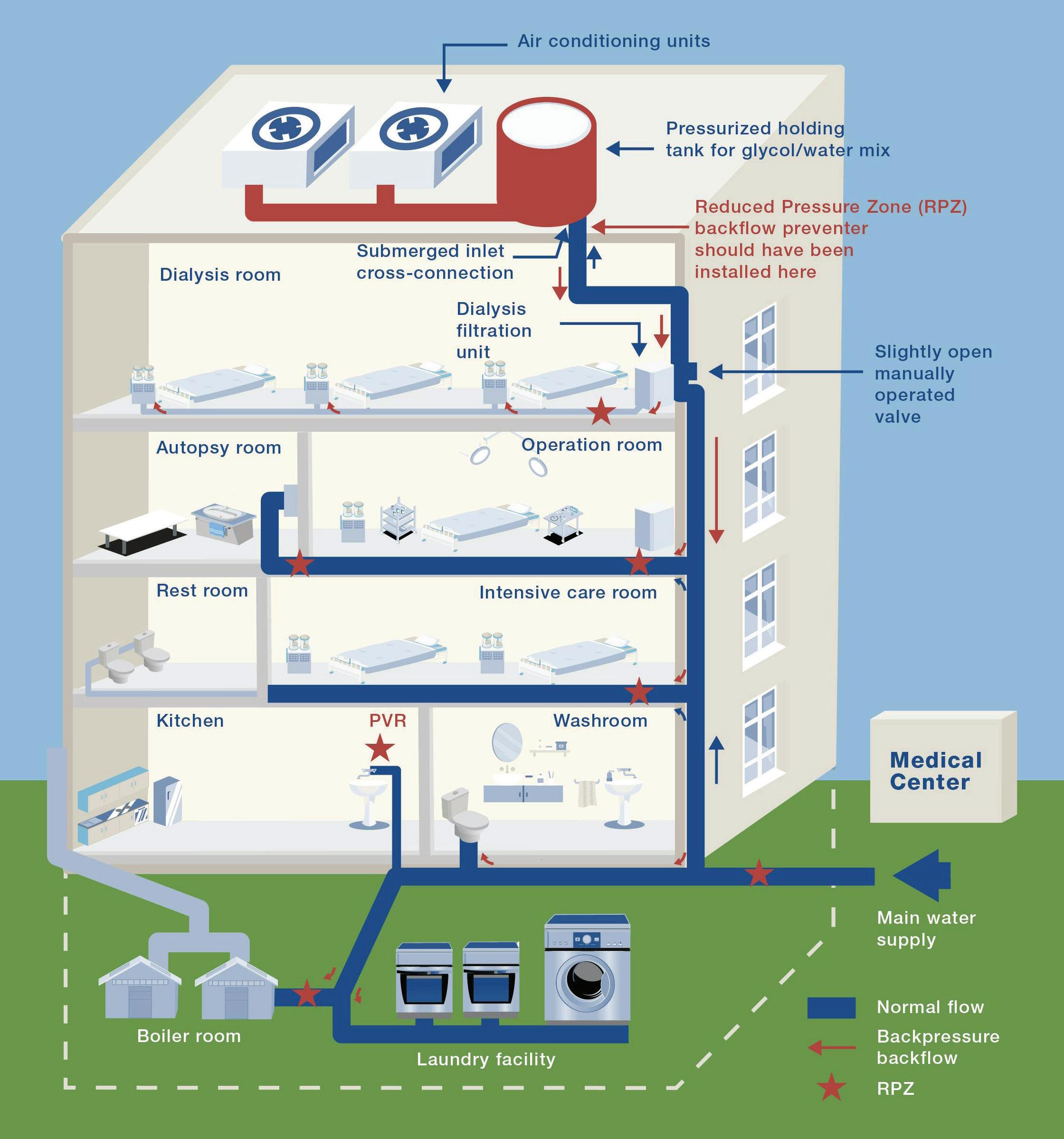

A look at how smart technologies are transforming water safety and system management in today’s interconnected buildings.

By NADEEM MIRZA, Senior Product Manager, Watts

Backflow prevention assemblies, while fundamental components in safeguarding potable water supplies, have not – in the minds of most trade professionals – been at the forefront of technological innovation.

Yet, mirroring rapid advancement seen across the broad spectrum of the plumbing and mechanical industry, this critical sector is surpassing expectation. The “world of backflow” now

embraces sophisticated technologies that are fundamentally changing how we protect water sources and manage building systems.

For those in the design and engineering field and those they serve –among them, installing contractors, and facility managers – staying ahead of these developments is essential for maintaining competitiveness, system reliability and all facets of the safety equation for connected water systems.

A wealth of greatly more capable and intelligent technology is now entering the backflow prevention

universe. These innovations extend beyond the basic function of preventing reverse flow, incorporating features such as easy connectivity to Building Management Systems (BMS), continuous monitoring of device performance and system conditions, and integrated safety functionalities like flood and freeze protection.

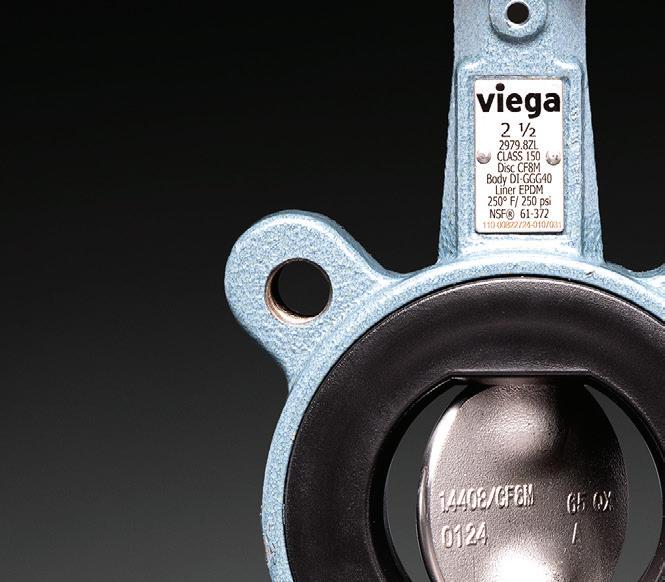

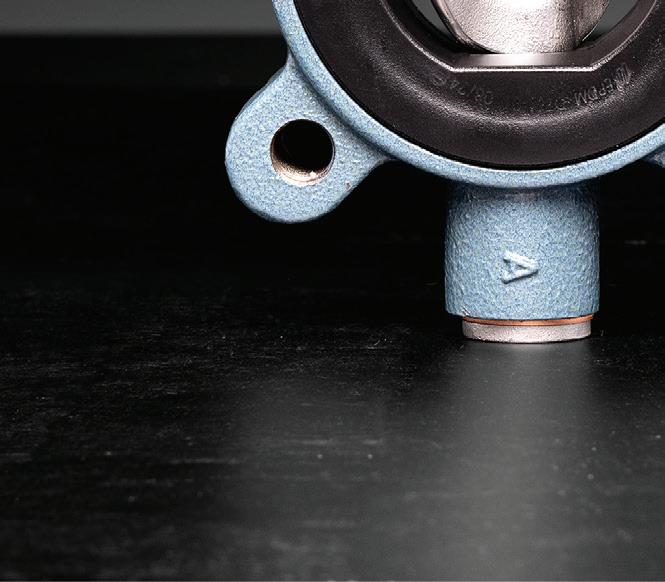

One of the most common and effective types of mechanical backflow preventers is the Reduced Pressure Zone (RPZ)

Nadeem Mirza is Watts’ Senior Product Manager, Backflow and Risers. He has overall responsibility for the strategy, new product development, and product management of Watts, Ames Fire & Waterworks, and FEBCO brand backflow and riser solutions.

COP efficiency of 4.0

R744 (CO2) natural refrigerant

Pre-charged and ready to run

Laars E-ThermTM is a new commercial heat pump water heater with a nominal heating capacity of 325,000 BTU/hr. It’s cold-climate equipped and ready for the era of electrification.

Build a Complete Commercial Domestic Hot Water Heat Pump Solution:

• Laars E-ThermTM Heat Pump

• Stratified Storage Tanks

• Temperature Maintenance “Swing” Tanks

• Full Tankless Electric Back-Up

assembly. RPZ backflow preventers are designed for highhazard applications, meaning they protect against situations where a backflow event could cause serious illness or death. Their design incorporates two independently operating check valves and, critically, a hydraulically operated differential pressure relief valve located between the two check valves to provide a third line of defense, and redundancy.

The relief valve in an RPZ assembly constantly senses the pressure differential across the first check valve. In normal operation, the pressure between the two check

valves (the reduced pressure zone) is maintained at least 2 psi lower than the supply pressure. This pressure differential ensures that if the second check valve is compromised, any backpressure will push water towards the relief valve, where it can be safely discharged, rather than pushing it back into the potable supply through the first check valve.

A key function of the relief valve is to provide diversion of water in the event a check valve fails, acting in essence as an informant. If the first check valve fouls or fails, allowing

Leak Detection

Performance Monitoring

Smart Freeze Monitoring

Backflow Integrated Tamper Switches

RPZ Backflows (inddor or outdoor). Some backflows have built in sensor.

Sensitive backflows where 24/7 water pressure fluctuations may be required

Any water carrying vessels that could be at risk freeze (valves, pipes ...)

Ensure water flow in fire sprinkler application. Provides alert when someone tries to shutoff.

• Building management systems

• Cellular network

• Wi-Fi connectivity

Building Management Systems. Some backflows have built in pressure sensors.

• Built in Wi-Fi (no app required)

• Building or Irrigation Management Systems

• Hardwire to Fire Panel

• Auxiliary alert to local alarm/lights

pressure in the reduced pressure zone to rise too close to the supply pressure (typically within 2 psi), the relief valve is designed to open.

While visible discharge is a vital safety feature, it also presents a practical challenge. Backflow preventers are often installed in areas not frequently monitored – often in outof-the-way locations, typically out of sight. This means relief valve discharge may go unnoticed for extended periods.

Addressing the risk of undetected relief valve discharge has led to the first major wave of digital technology integration into backflow preventers: flood detection and protection. These smart devices are engineered to sense the presence of water from relief valve discharge in the immediate vicinity of the backflow preventer. Upon detecting water, the system triggers an immediate alert to designated personnel.

These alerts can be delivered through multiple channels, including text messages, emails, and automated phone calls, leveraging connectivity options such as integration with existing Building Management Systems (BMS), dedicated cellular gateways, or Wi-Fi networks. The ability to receive instant notifications provides building owners, facility managers, and maintenance staff with precious time to investigate the cause of the discharge and take corrective action before the situation escalates into a major flood event.

Some non-critical water supply systems can be configured to permit automatic shut off of the water supply based on duration and magnitude of relief valve discharge/flood condition.

Water damage is the number one cause of property damage in the USA, exceeding both fire and theft in terms of financial losses. On average, commercial water damage from a minor flood event costs between $11,000 to $24,000.

Provides prevention against flooding ($$) and saves water (sustainability) when installed outdoor backflow.

Pressure fluctuation monitoring could help with other parts of plumbing systems such as pumps.

Low-cost solution that can provide alerts 24/7 from less visited/forgotten/location

A cost-effective way to reduce field installation using a pre-calibrated switch.

Overall, water and mold damages cost $2.5B to insurance companies every year. Plus, there’s high risk of black mold in humid climates.

The integration of smart technology extends beyond just flood detection. Modern connected backflow assemblies can also incorporate sensors for other critical conditions, such as freezing temperatures.

Freeze alerts provide valuable redundancy, even in mechanical rooms that are typically heated. Unexpected HVAC failures or extreme external temperatures could still expose backflow preventers, especially those near exterior walls, to freezing conditions, potentially damaging the assembly and compromising its function. An automated freeze alert allows staff to take preventative measures, such as adding supplemental heating or insulating the device, before damage occurs.

The integration of connectivity and smart features in backflow prevention assemblies offers distinct advantages for engineers during the system design phase.

• Simplified specifications: Features like integrated tamper switches streamline the specification process. Instead of specifying a standard backflow preventer and a separate fire tamper switch with its own wiring requirements, engineers can specify a single unit with integrated monitoring capabilities;

• Enhanced system reliability and resilience: Incorporating flood protection connectivity directly into the design provides an inherent layer of defense against water damage. Engineers can design systems knowing there is an automated mechanism to alert facility staff to potential issues originating from the backflow preventer, reducing the risk profile of the building;

• Improved freeze protection design: While mechanical rooms typically have heating, incorporating freeze alerts adds a valuable redundancy. Engineers can specify these features to provide an extra safeguard, particularly for assemblies located in potentially colder zones or buildings where consistent heating cannot be absolutely guaranteed during off-hours or power outages.

By leveraging connected technologies, engineers can design more sophisticated, reliable, and safer plumbing systems to address potential hazards and simplify ongoing management for building operators.

For facility managers, smart and connected backflow prevention technology represents a significant leap forward. It offers...

• Remote monitoring: In today’s complex buildings, backflow prevention assemblies are often located in remote mechanical areas. Visual inspection as the primary monitoring method is simply not viable for ensuring timely detection of issues like relief valve discharge or tampering. Connected technology provides remote visibility into the status of critical equipment, including fire line backflows, flood sensors, and freeze condition alerts;

• Proactive alerting: Automated alerts for flood, freeze, or tamper events allow facility managers to respond proactively. Instead of discovering a problem hours or days later (or worse, after a flood has caused significant damage), notifications are immediate. This enables rapid

dispatch of maintenance personnel, minimizing downtime and damage;

• Streamlined maintenance planning: While not yet offering predictive failure data for all parameters, the current generation of smart backflow preventers provides valuable operational data and alerts.

Connected technology transforms backflow prevention from a passive installed component into an actively monitored system, providing facility managers with the tools needed to enhance safety, reduce operational risks, and improve maintenance efficiency.

Integrating connected backflow preventers into a building’s infrastructure involves various connectivity options, each with its own implications for design and security. Common methods include direct integration with the BMS, wi-fi connectivity, and cellular gateways.

Watts technology, as an example, supports both BMS integration and independent operation via cellular gateways. Cellular gateways offer a valuable alternative when connecting directly to the building’s IT network presents security challenges or is prohibited by IT policies. By utilizing an independent cellular connection, the backflow preventer’s smart module can transmit alerts without accessing the secure building network.

When considering Wi-Fi or cellular connectivity, network security is paramount. Data transmitted from the device, even if it’s just alert data, should be encrypted. Cellular connections often provide a higher level of inherent security by operating independently of the local network infrastructure. If integrating with a BMS, collaboration with the building’s IT department is essential to ensure secure network integration and data handling protocols are followed.

Specifying connected valves requires adherence to relevant industry standards, guidelines, and certifications to ensure proper function, reliability, and compliance with regulatory requirements. Engineers should reference standards from organizations such as the University of Southern California (USC) Foundation for Cross-Connection Control and Hydraulic Research, the American Society of Sanitary Engineering (ASSE), and local plumbing codes. These standards dictate the type of backflow preventer required for different hazard levels and applications, testing and maintenance protocols.

The types of data generated by connected backflow valves are primarily focused on alerts rather than raw performance data. Smart modules within the devices process

sensor inputs (like pressure differential, water presence, temperature), triggering alerts when conditions deviate from normal parameters. While the modules are gathering data internally to make these determinations, raw data is typically not transmitted externally.

This approach is often taken to address data integrity and security concerns. Transmitting large volumes of raw performance data could create cybersecurity vulnerabilities.

The evolution of valve connectivity over the next 3-5 years is poised to move toward more sophisticated performance monitoring and, potentially, predictive maintenance capabilities.

Future systems could potentially monitor subtle changes in performance parameters over time – such as slight variations in pressure differentials under specific flow conditions, the frequency and duration of relief valve opening events (even minor ones), or changes in check valve sealing behavior.

This shift towards predictive maintenance, powered by enhanced connectivity and data analytics, represents a significant advancement in the ongoing effort to ensure the safety and reliability of our water systems.

Set for October in Minneapolis, inaugural Women in Boiler Industry Symposium takes shape, breaks new ground.

By SHAUNICA JAYSON, Vice President, ABMA

The American Boiler Manufacturers Association is excited to host its inaugural Women in the Boiler Industry (WIBI) Symposium this October 15-17 in Minneapolis. This dynamic two-day event has been designed to empower and connect individuals who support the advancement of women throughout the boiler industry.

With that in mind, four featured speakers have now been confirmed for the event: Catherine Tojaga, PE, President of CT Mechanical & Hemingway Chimney; Howard Berny, Chief Boiler Inspector, State of Minnesota; Colleen Keyworth, VP of Sales & Marketing, Online Access, Inc.; and Ruth King,

renowned profit and wealth guru for the HVACR industry.

“WIBI is about celebrating the talent, vision, and leadership of women in our industry,” said ABMA Board Chair Nancy Simoneau. “This symposium gives us a space to share our stories, build meaningful connections, and inspire the next generation.”

Simoneau, president of Quebecbased Groupe Simoneau, in January became the first woman ever to lead the 137-year-old trade group, as well as the first non-U.S.-based member to fill that role.

• Educational Sessions : Dive deep into the critical topics shaping our industry. From confidence building and leadership development to understanding the evolving business

landscape, our expert-led sessions will equip you with the tools to excel.

• Confirmed Topics:

• AI & Marketing Tools;

• Business & Personal P&L’s, Balance Sheets, & KPI’s;

• Boiler Room Hazards, Maintenance & Safety;

• Negotiation Strategies with Confidence;

• Technical NBIC Boiler Inspection Code & Changes.

• Fireside Chats & Leadership Panels: Engage in thought-provoking discussions with industry leaders. Explore current trends and tackle key career challenges as we shine a light on the unique experiences women face within the industry.

• Keynote on Emotional Intelligence: Discover the importance of emotional intelligence in leadership and team dynamics through an inspiring keynote that will leave you feeling empowered and motivated.

• Networking Breaks & Receptions: Connect with fellow attendees in a relaxed setting. Share experiences, exchange ideas, and forge meaningful professional relationships that can support and uplift you throughout your career.

• Boiler Room and Energy Plant Tours: Experience firsthand the heart of our industry. Get a behind-thescenes look at the Ever-Green Energy St. Paul Cogeneration Biomass Combined Heat and Power Plant, Abbott Northwestern Hospital Central Utility Plant, and Karl Dungs

Manufacturing Facility , offering insight into key industry operations.

WIBI Symposium Key Topics to Explore:

• Building Confidence in a MaleDominated Industry;

• Leadership Development Strategies;

• Navigating Career Progression and Development;

• Understanding the Changing Business Landscape;

• Effective Communication and Negotiation Skills;

• Work-Life Balance Strategies;

• Mentorship and Sponsorship: Finding Your Advocates.

Early Registration: $525 Begins July 10th and ends August 5th

Regular Registration: $625 Begins August 6th and ends September 16th

Late Registration & Non-ABMA Member Access: $725 Begins September 17th and ends October 15th

**Please Note: Registrants must have a profile with ABMA prior to registration. If you need a profile, are unsure if you have one, or have any other questions, please contact Yasmin Rowe at yasmin@abma.com.

Non-ABMA member registration will open in September if space permits. For more details about WIBI and ABMA, please visit www.ABMA.com/ WIBI. To connect with current WIBI members and stay up to date, please join our LinkedIn professional group!

The inaugural event is made possible through the leadership of the WIBI Advisory Committee: Nancy Simoneau, Tricia Staible, Shaunica Jayson, Yasmin Rowe, Jordan Croson, Jihan Shogan, Carrie Murakami, Chelsey Ryker, Christa Rogers, Colleen Keyworth, Dustin Divinia, Jennifer Guerrero, and Tricia Fredrick.

Your journey to forging broader networks, fueling knowledge, and igniting new opportunities starts at the WIBI Symposium. Be part of a still-growing community at ABMA that champions women and professional allies in the boiler industry. Together, we will inspire, learn, and grow as we shape the future of our field. This event welcomes men and women who support progress in our industry!

Next-generation zone controls from Taco feature easy-to-read diagnostic lights for all outputs, including zones, boilers and auxiliary connections, ensuring quick troubleshooting with minimal downtime; simple wiring and grounding options that streamline installation, reduce setup time and make the process hassle-free for installers; Smart Plus Logic for DHW recirculation optimizes hot water delivery with advanced logic that improves both efficiency and comfort; and post-purge and pump exercise functions that ensure the system operates at peak performance while extending its lifespan.

Taco Comfort Solutions

Weil-McLain introduces the Simplicity combi boiler. Engineered for high efficiency and dependable performance, this residential gas boiler is designed to deliver reliable comfort and convenience. Available in 110, 150 and 199 MBH. With a 95% AFUE for reduced energy consumption and costs. Suitable for combi or heat-only applications. Stainless-steel, fire-tube heat exchanger ensures long-lasting performance. Ready for integration with heat pumps. Intuitive touchscreen display for easy navigation. Connect via smartphone with Bluetooth.

Weil-McLain

NIBCO announces new Webstone G-Series products with interchangeable end connections and accessories to customize installation. The PP-RCT G-Union fittings are available in sizes 1/2 in. through 2 in. and are compatible with PP-R and PP-RCT piping systems. The new FTG G-Union fittings feature a type K copper tailpiece and are available in 1/2 in. through 2 in., including reducing sizes. The horizontal mount air separator is now available with G-Thread ends, which are compatible with a wide assortment of G-Series fittings and accessories for a custom installation. All products are suitable for plumbing and heating applications. NIBCO

Conquest condensing commercial water heaters from PVI feature a submerged combustion chamber and a heat exchanger with a dimpled array of fire tubes fabricated entirely from durable, corrosion-resistant AquaPLEX duplex stainless-steel alloy. The upgraded straight, fire-tube heat exchanger design increases thermal efficiency to 98% across all inputs. The pump is now strategically positioned at the front and side of the water heaters for easier access and improved reliability. Available in a range of inputs from 399 MBH to 1200 MBH, with natural gas and propane options, and indoor and outdoor configurations.

PVI

Noritz America’s upgraded NCC199CDV pro condensing tankless water heater offers a Uniform Energy Factor of 0.98. Bluetooth connectivity delivers greater control over water heater functionality, including timers and temperature control. Models include a display built into the bottom of the front panel, showing the water heater’s current temperature, operational status and error codes. Up to six units can be connected as a single system. Up to 12 units in a single application can be common-vented. Natural gas is the default fuel type; however, each unit is shipped with a gas conversion kit to facilitate quick switching to liquid propane on the jobsite. Energy Star-rated. Noritz America

Did you know EVERY Bradford White tank-type water heater comes with an extra level of protection?

Vitraglas® is the only tank lining in the industry featuring Microban® antimicrobial technology to help prevent the growth of bacteria, mold and mildew on the surface of the tank lining.

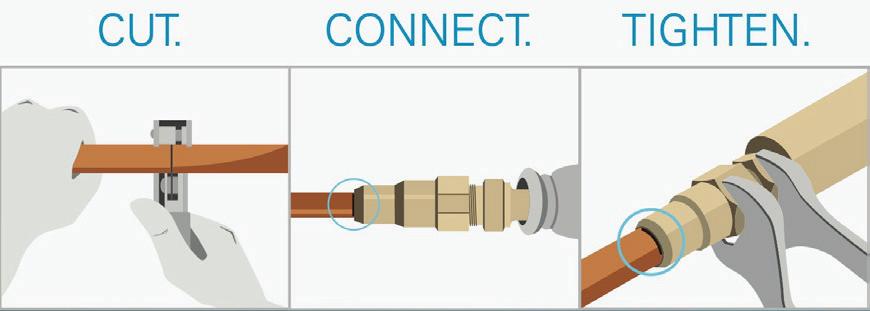

Daikin OTERRA single-zone heat pumps are now available in convenient 115V models, featuring the new SIGNA flareless adapter for faster, easier installation compared to traditional flared connections. They are designed for ease of both installation and maintenance, while providing excellent efficiencies. Powered by Daikin inverter technology, these compact, lightweight heat pumps handle a wide range of outside temperatures, cooling from 50° F to 115° F, heating from 5° F to 65° F. The SIGNA flareless adaptor allows for simple and fast copper pipe connections, while a 15A circuit breaker occupies only one slot in the main breaker. Available in 0.75 to 1 ton with 9,000 to 12,000 BTU/hr. heating capacities, the systems come pre-charged to support up to 50 ft. of refrigerant piping.

Daikin Comfort

Gripple’s TecLoc Conduit Claw for seismic stiffening within building service applications is a fast and secure, IAPMO-approved seismic rod stiffening clip, designed to be quickly installed using pipe or conduit to secure suspended services and prevent buckling in seismic conditions in a variety of building service applications. Its universal compatibility with 1-in EMT, 1-in. Schedule 40 Pipe, and 3/8-in., 1/2-in., and 5/8-in. rod sizes eliminates the need for multiple SKUs. The clip prevents rod buckling under seismic conditions, maintaining structural integrity and supporting code compliance in critical infrastructure, such as hospitals, data centers, and commercial buildings.

Gripple

Robroy Industries launches the Rocket Rack Configurator, allowing users to create precise 3D renderings of Rocket Rack assemblies in just minutes, eliminating the need for complex 3D CAD modeling or specialized design skills. This drastically reduces the time spent on raceway design, allowing engineers and designers to move projects forward quickly and confidently. Users can choose from various mounting configurations to tailor their designs to meet specific project needs. Configuration options include trapeze, wall mount, single or double post, or inline multiple post assemblies. The configurator is designed to recognize real-world interferences with design, ensuring that assemblies fit seamlessly within existing structures and eliminating costly design errors.

Robroy Industries

A Northwestern University researcher has found a novel way to ‘cement’ the seabed beneath sea walls, removing the need for sand replenishment.

Larry Clark

A regular contributor to HPAC Engineering and a member of its editorial advisory board since 2012, the author is a principal at Sustainable Performance Solutions LLC, a south Florida-based engineering firm focusing on energy and sustainability. Email him at larry@ sustainflorida.com.

Sea level rise has been a recurring topic in Clark’s Remarks, but coastline erosion has not been specifically addressed. Let’s remedy that.

Here in South Florida, including Broward County where I live, we try to prevent tidal flooding and coastline erosion through the use of tidal flood barriers such as banks, berms, green-grey infrastructure (a combination of engineered and natural features), upland stem walls and, of course, seawalls. Virtually every property – private and public – on the beach, the Intracoastal Waterway, or on one of the 18 canals just in Broward County, has a seawall.

In 2010, before climate change was widely discussed in the mainstream media, four southern counties formed the Southeast Florida Regional Climate Change Compact. One of the Compact’s early goals was to develop a uniform plan and strategy for seawalls.

While seawalls are critical to preventing tidal flooding, they are themselves vulnerable to water intrusion and have limited life spans. Many are 40 or 50 years old and, absent a uniform code or standard, were not properly constructed or installed when new.

structures, a Northwestern University researcher, Prof. Rotta Loria (who works at the intersection of the fields of Mechanics of Materials, Energy, and Electrochemistry), has found an innovative way to strengthen the seabed beneath sea walls.

His process can also stabilize sand to prevent beach erosion, eliminating the need for sand replenishment, where lost sand lost is replaced from another source. The downside to beach replenishment is, of course, the fact that it’s only a temporary solution, since the added sand may well disappear with the next storm.

Prof. Loria calls the process, recently published in Communications Earth & Environment , “Electrodeposition of calcareous

South Florida soils are mostly limestone, not bedrock, so seawalls are always at risk of failing over time. Extreme high tides, which occur 6-8 times per year, can breach the seawalls, which can cause them to collapse and, because there is no water pressure during extreme low tides to help anchor them, those low tides can also collapse them.

In any case, although seawalls are not as friendly to the coastal ecology as are natural shorelines such as littoral zones (the shallow water close to shore, hosting aquatic plants and animals), they are for now a necessary evil.

In an effort to improve coastal protection without the use of costly and unreliable

cement from seawater in marine silica sands.” That’s a long name for applying mild electrical stimulations to the seawater to precipitate its solid mineral binders – primarily magnesium hydroxide and calcium carbonate –thus “cementing” the sand without the use of cement.

This process mimics the manner in which marine organisms use metabolic energy to grow their shells from the minerals in seawater. Since the electric charge is very low, it poses no threat to marine life or beachgoers, and the resulting sand is as strong as a seawall. That could be really good news for the 40% of the world’s population that the United Nations estimates lives within 100 km (62 miles) of a coast.

August 20-21, 2025

Grand Sierra Resort & Casino

Reno, NV

September 30-October 1, 2025

Santa Clara Convention Center

Santa Clara, CA

October 29-30, 2025

Irving Convention Center

Irving, TX

AAON Delta Class delivers comfortable, clean air in exceptional environments — like yours.

AAON is always innovating. Learn more about our dedicated outdoor air systems (DOAS).