Conformstoregulations: 2015

Fuel: Gasoline EPAclass/stds: LDV/TIER2 ss/stds: PC/ULEVqualified 01112L

• e vousappuyez pascontrelaporte

•⁄’utilizez pas un couvre siège qui peutbloquerledéploiementducoussingonflablelatéral⁄⁄oirle manueldu conducteur pour deplusamplesrenseignements⁄

EHICLEEMISSIONCO

U.S. EPA:T2B4 LDV :GF X 02.3VJW NBV Noadjustmentsneeded. FEDOBD II Fuel: Gasoline

n orms to regulations: 2016 MY California: Not for sale in states with California emissions standards. WC/HO2S/WR-HO2S/CAC/TC/DFI

BY LINDSEY GAINER

BY JAY SICHT

Chris Jones VSRG Editorial Director

Jay Sicht Editor-in-Chief

Peter Spotts Associate Editor

Kacey Frederick Assistant Editor

Emily Kline Special Projects Editor

Leah Marxhausen Special Projects Editor

Drew Bryant Contributing Writer

Tiffany Menefee Contributing Writer

Greg Lobsiger Contributing Writer

Noah Brown Contributing Writer

Lindsey Gainer Contributing Writer

Carol Badaracco Padgett Contributing Writer

Steve Trapp Contributing Writer

Jordan Beshears Steve’s Auto Body

Sheryl Driggers Collision Advice

Frank Rinaudo Industry Consultant

Jason Mundy Mundy’s Collision Center

Stan Medina Certified Collision Works

Andrew Johnson Publisher ajohnson@endeavorb2b.com

Mattie Gorman-Greuel Associate Sales Director

Cortni Jones Director of Business Development

Diane Braden Account Executive (National Accounts) dbraden@endeavorb2b.com

Marianne Dyal Account Executive (National Accounts) mdyal@endeavorb2b.com

Chad Hjellming Account Executive (National Accounts) chjellming@endeavorb2b.com

Lisa Mend Account Executive (National Accounts) lmend@endeavorb2b.com

Kyle Shaw Account Executive (National Accounts) kshaw@endeavorb2b.com

Sean Thornton Account Executive (National Accounts) sthornton@endeavorb2b.com

Mariah Straub Production Manager

Jen George Ad Services Manager

Mitch Bradford Art Director

CEO Chris Ferrell

COO Patrick Rains

CRO Paul Andrews

CDO Jacquie Niemiec

CALO Tracy Kane

CMO Amanda Landsaw

EVP Transportation Chris Messer

EVP Endeavor Business Intelligence Paul Mattioli VP of Content Strategy, Transportation Group Josh Fisher

HOW TO REACH US

Endeavor Business Media, LLC

571 Snelling Ave N Saint Paul, MN 55104 tel 651.224.6207 fax 651.224.6212

The annual subscription rate is $90 (U.S.A. only) for companies not qualified to receive complimentary copies of FenderBender.

LETTERS TO THE EDITOR editor@fenderbender.com

Opinions expressed in FenderBender are not necessarily those of Endeavor Business Media, and Endeavor Business Media does not accept responsibility for advertising content.

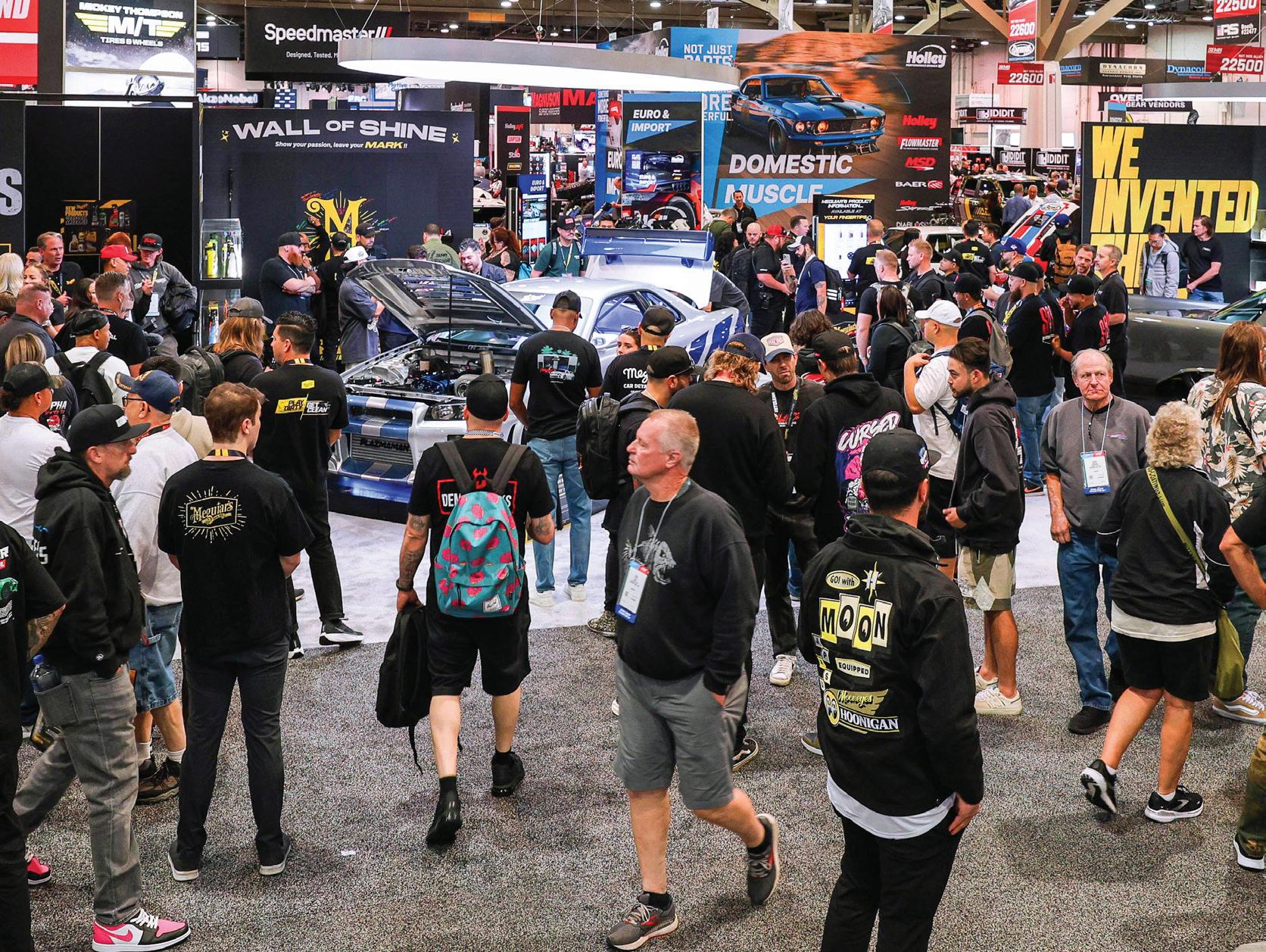

CAN YOU BELIEVE IT? At the time of this writing, the SEMA Show is less than seven weeks away.Since I first attended in 2000, the Las Vegas Convention Center has grown to total 4.6 million square feet.

The renovation of the North and South Halls is now finished, part of a total $600 million refresh for the expansive complex that is scheduled for a December completion. Most of the collision repair-oriented training events and exhibits are centrally located in the upper South Hall.

Maximize your time and travel investment at the show with a bit of planning and strategy. Pre-run the show by referring to our SEMA Show guide within this issue, which includes a training schedule for I-CAR and SCRS Repairer Driven Education sessions. I’ve spotlighted some of the latest collision repair tool and equipment offerings in this month’s feature. Also, check out the semashow.com website, where you can map out the vendors you want to visit and their locations. Although paper maps are available at the show, the mobile app is a useful guide to help you navigate the expansive halls and outdoor exhibits. You can scan products in the New Products Showcase (which has moved this year to the South Lower Hall) for more information and to find those manufacturers’ booths.

It’s common to walk seven miles a day, so pack two pairs of comfortable and broken-in shoes and alternate them

each day. It’s the desert, so don’t forget saline nasal spray and lip balm. It’s noisy inside the halls, so don’t forget mints or chewing gum. (There will be a lot of “close-talking!”) One notable change this year: the Collision Industry Conference and the Collision Industry Red Carpet Awards, Nov. 4, move to a new venue, Resorts World. I look forward to honoring our 2025 FenderBender Award and Best Repair Planner/ Estimator there.

I hope to get the chance to say hello to many of you there. Rest up, and see you soon!

JAY SICHT EDITOR-IN-CHIEF jsicht@endeavorb2b.com

By PETER SPOTTS

THE NEWGATE SCHOOL celebrated 50 years of providing tuition-free education to future collision repair professionals on August 2. The festivities included a car show, music, food trucks, and the community that makes the school’s existence possible.

Over the past five decades, more than 800 students have come through Newgate’s doors in Minneapolis and learned collision repair skills that become a foundation for their career pursuits.

“It’s something we’re really proud of; to hit this milestone is really big and we’re really excited for the next 50 years,” said Tyla Pream, office manager at Newgate. “Since we get public vehicle donations — being able to be sustained through that system of donated vehicles and selling those vehicles to fund everything — it’s very special to us to know we’re supported by the community.”

The celebration drew more than 150 people and 54 vehicles. The diverse setup included a 1960s Bel Air, Ford F-150s, Monte Carlos, Hondas, Corvettes, a Toyota MR2, and more. Face painting, artistry, food trucks, and music provided plenty of family-friendly fun. Vendor partners of the school, including PPG, were on hand to celebrate as well.

The school’s education is built on community buy-in and relies on donated vehicles from individuals and businesses to provide hands-on learning opportunities for its students, who pay no tuition or fees. Students work on the vehicles, fix them up, and then the school can sell the vehicles. They also have the “Wheels for Women” program, which provides the better-quality donated cars at no cost to single moms transitioning into school, work, and self-sufficiency.

Pream said most donations come from individuals. They call the school or find it online and bring their cars in. Others see technicians out in the shops working on their car.

“They’re seeing firsthand that their mechanic out in the world went to Newgate. Most of our donations come from referrals, so someone they know,” she said.

Donations have dropped in the past eight years. In 2017, the school received

about 3,600 vehicles. In 2024, the school received just over 1,800 vehicle donations. Despite the decline in donations, it has not diminished the schools ability to continue developing its students. They learn the technical skills, work ethic, and confidence they’ll need to succeed, and become certified auto technicians in 12-18 months.

The school currently has 24 students enrolled – 12 autobody and 12 mechanical. Pream said the time it takes a student to complete the curriculum depends on what skills they have when they come to the school and how quickly they pick up what they’re taught.

“We help with them getting that toolkit and getting a job when they’re done,” Pream said. “We’re able to do a lot with just the vehicles that are donated.”

Ron Severson founded the school in the early 1970s in partnership with the University of Minnesota to help young adults in the area build better lives for themselves and

their families through collision repair career opportunities. In 1975, the school was incorporated as a separate non-profit.

In 1979, Newgate purchased a garage in St. Paul and established the Auto Body Training Center, primarily serving young adults who had dropped out of school or were not succeeding in a traditional classroom setting.

Newgate pioneered its use of donated vehicles to fund school operations in 1981. In 1993, Newgate purchased its current property at 2900 East Hennepin Avenue in Minneapolis. The increased space enabled the school to add the auto mechanics program and more than double its student roster. The “Wheels for Women” campaign launched in 1996.

With the support of the community, Newgate School looks forward to another 50 years of tuition-free collision repair education.

“It’s a great little community that we have that people are willing to talk to us and donate their vehicle to us,” Pream said.

Mitchell’s Q2 2025 Plugged-In: EV Collisions Insights Report examines the decrease in collision claims frequency for repairable battery electric vehicles in the U.S. and increase in mild hybrid electric vehicle claims across North America. It also explores how changes to government incentive programs are impacting consumer adoption of BEVs on both sides of the border.

Claims frequency for repairable, collision-damaged BEVs fell significantly for the first time in the U.S.— dropping to 2.92% last quarter, a decrease of 7%, said Ryan Mandell, vice president of strategy and market intelligence at Mitchell. This decline coincided with a 6.3% reduction in new BEV purchases compared to Q2 2024 despite record-breaking sales earlier in the year.

Even with the declines, there are more BEVs on the road today than ever before and many organizations are still betting on the long-term growth of electric propulsion. Panasonic recently opened a $4 billion lithium-ion battery plant in De Soto, Kansas and plans to employ 4,000 workers by the end of 2026. The company also began mass production of 2170 cells at a second North American facility with the goal of establishing annual production capacity of nearly 32 GWh in the future.

Unlike all-electric counterparts, sales and claims frequency of mild hybrids are increasing. Repairable mild hybrids rely on a small electric motor to assist the gasoline engine. In Q2 2025, it rose to 4.62% in the U.S. and 4.33% in Canada, a jump of 2% and 9% respectively over the previous quarter.

For collision repairers and auto insurers, the steady growth represents an opportunity to focus on vehicles that combine cost advantages like automobiles with an internal combustion engine and less specialized training than is necessary for BEVs. Without the dramatic policy fluctuations affecting all-electric options, mild hybrids also present a more predictable and financially stable segment for carrier underwriting models.

The full report is available at www.mitchell.com/plugged-in.

As auto loan delinquency rates continue to decline nationwide between Q1 and Q2 of 2025, the personal-finance company WalletHub released an updated report highlighting the Cities Where Auto Loan Delinquency Is Decreasing the Most.

The report aims to spotlight areas where residents face a lower risk of credit score damage and vehicle repossession.

“It’s encouraging to see that many cities had significant decreases in the auto loan delinquency rate between Q1 and Q2 2025,” said Chip Lupo, WalletHub analyst. “This demonstrates either that economic conditions are improving or that people are prioritizing getting current with payments on secured debt like auto loans so they don’t get their property repossessed. Whatever the root cause of reduced delinquency rates, it’s good news for consumers and the economy overall.”

To determine the rankings, WalletHub analyzed proprietary consumer data across 100 of the largest U.S. cities, focusing on changes in auto loan delinquency rates between Q1 and Q2 of 2025.

For the full report and to see where your city ranks, visit https://wallethub.com/edu/ cities-auto-loan-delinquency/139821.

Insurify projects the national average cost of full-coverage car insurance will increase 4% by year’s end from $2,313 to $2,402 and up to 7% if prolonged tariffs lead to significant insurer losses.

Two motivating factors behind increases are tariffs and extreme weather, according to the Insurify’s latest report. Since April 1, inflation increased and several rounds of tariffs increased the cost of repairs. For insurers, that means the same volume of claims now costs more money to cover. The report said car insurance companies could raise premiums to align their rates with this additional financial risk.

Natural disasters affect significant swaths of the country. Los Angeles County fires in January destroyed as many as 6,300 vehicles, according to estimates. In 2024, Florida hurricanes led to more than 100,000 auto insurance claims. Hail, prevalent in the

Midwest, accounts for about 12% of comprehensive car insurance claims.

Insurify analysts said tariffs could prove less burdensome than expected, claim volume could fall, and regulators could push back on rate increases, resulting in more modest pricing. Some insurers are already easing rate hikes and lowering premiums, but premiums could also rise higher than expected if the U.S. implements new tariffs.

Without tariffs affecting rates further, Insurify analysis suggests rates would rise about 4% by the end of 2025, based on systemic factors such as inflation and how much money insurers are paying out in claims. If insurers still need to account for tariffs in rate setting, Insurify projects that the increase could rise to 7% as insurers covering repair claims pay more to replace foreign-sourced car parts.

Read the full report at https://insurify. com/car-insurance/report.

PPG completed the 3,000th global installation of its PPG MoonWalk automated paint mixing system at Wren’s Collision Group’s facility in Auburn, Alabama, according to a news release.

Since its launch in 2019, the PPG MoonWalk system helped deliver accuracy, traceability, and productivity across the automotive repair process in body shops.

“We are proud to be a part of this innovation in the automotive industry with the installation of the 3,000th PPG MoonWalk system at our newest body shop,” said James Wren, owner of Wren’s Collision Group. “With our new Auburn facility, we are looking forward to continuing to drive productivity, efficiency, and profit throughout the 19 body shops we own. We are excited to be a part of this milestone for PPG as a long-standing partner.”

Leading collision centers in more than 60 countries use the PPG MoonWalk system, recognizing it for its innovation, sustainability benefits and ease of use.

Key benefits of the PPG MoonWalk system include:

• Precision and accuracy: Delivers consistent paint mixing for accurate color matches, reducing costly rework.

• Time savings: Automates mixing to

streamline prep time and allow technicians to focus on repairs and spraying.

• Reduced waste: Minimizes over-pouring and materials usage to lower costs, and improve sustainability.

• Digital integration: Connects seamlessly with the PPG LINQ digital ecosystem for efficient workflows, real-time data, and inventory management.

“Wren’s Collision is embracing the future of collision repair with the installation of the PPG MoonWalk system at its newest location,” said Rodolfo Ramirez, PPG vice president, Automotive Refinish, Americas. “They’re advancing efficiency, accuracy, and consistent quality, and we’re honored to support forward-thinking custo

TOPDON USA is partnering with the transportation, skilled trades, electrical, and energy education division of Universal Technical Institute, Inc, according to a news release. The collaboration reflects a shared commitment to preparing students for the future of transportation and addressing the growing need for skilled electric vehicle technicians.

Through this effort, TOPDON is equipping UTI campuses in California, Texas, and Pennsylvania with advanced automotive diagnostic tools that support handson training in modern EV servicing and battery management. These include the Phoenix Max diagnostic scanner and the Tornado120000 smart programming power supply. Students can get experience with voltage stabilization and diagnostics on today’s 12V systems.

“We’re excited to advance into the next phase of our partnership with UTI,” said Chad Schnitz, vice president of TOPDON USA. “According to Q1 2025 reports, electrified vehicle sales in the U.S. continue to climb year-over-year. As these vehicles age, we’ll need a skilled workforce to service and repair them. By supporting UTI’s EV training efforts, we’re helping prepare the next generation of automotive technicians to meet that demand.”

As part of the broader partnership, new brand installations have also been completed at UTI’s campuses in Rancho Cucamon -

ga and Sacramento, California. Featuring TOPDON’s signature blue color and “Fix Like a Pro” tagline, the displays help familiarize students with industry-standard tools and employers they might one day work alongside, reinforcing the connection between classroom training and career readiness.

The TOP-UP program first launched in 2022. The initiative supports trade schools, community colleges, and technical institutions nationwide by equipping them with modern tools and resources designed to strengthen the talent pipeline entering the automotive service industry.

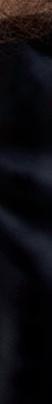

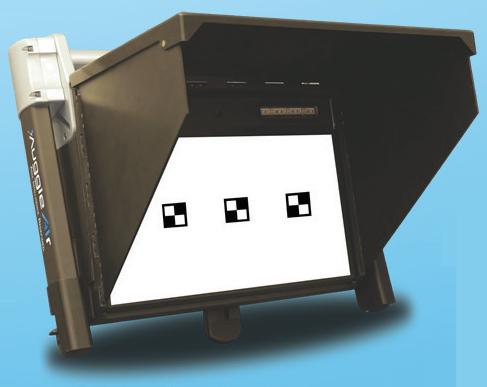

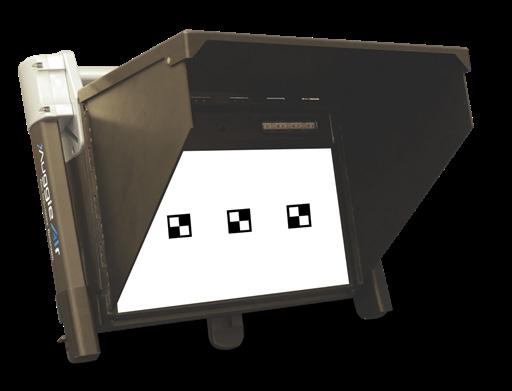

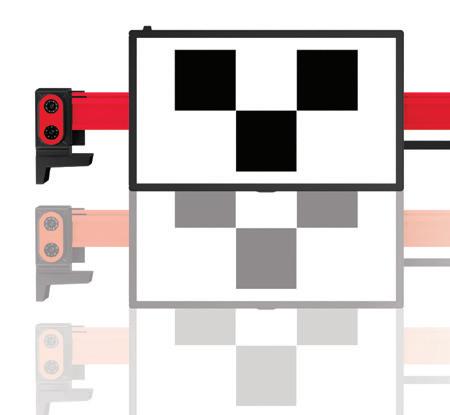

AS MORE VEHICLES come equipped with ADAS features, the need for ADAS calibrations continues to grow. The number of shop owners and operators responding to this year's FenderBender Industry Survey reported a marked increase from those in 2023 and 2024, jumping from an average of 30% to now nearly half reporting they perform in-house ADAS calibrations.

In this year’s survey, the majority (35%) of those surveyed who said they don't complete all calibrations in-house use a mobile service for ADAS calibrations, followed by OEM dealers (25%) and onsite third-party calibration services (24%).

Future-proof your investment with the confidence that your calibrations are completed to the tightest tolerances and the strictest standards correctly, the first time.

Fast and efficient placement using digital vision positioning which automatically measures vehicle distances and angles to ensure precise calibration.

Modular and future-proof: Designed to work with new targets and the next generation of ADAS technologies.

Integrated storage and maneuverability keep your equipment clean and serviceable and ready to use at a moment’s notice.

By PETER SPOTTS

AUTO BODY

MIKE

SIZE: 15,000 SQUARE FEET STAFF: 18 WHEN FULLY STAFFED, CURRENTLY 9 AVERAGE REPAIR ORDER: $6,000

SHOP LAYOUT IS CRUCIAL to creating smooth, organized workflows that efficiently move vehicles through the facility for quick repairs. Steve’s Auto Body used the contruction of its third facility as an opportunity to design the entire building around the specific repair processes that drive the success of its other shops.

Steve’s Auto Body opened its third location in the St. Louis area in June following a soft opening in May. Vice President Jordan Beshears, who is also a FenderBender Advisory Board member, says eight years ago they went through PPG Green Belt training and started a lean process journey. The facility intakes the vehicles, disassembles them, and moves them through the repair process in a straight line.

“Everything in the shop has a certain place where it needs to be and then when

you get into our paint shop, it becomes a complete closed-loop pull system,” Beshear said. “So, once a vehicle’s in there, it cannot be moved. It has to get fixed in a certain order and then it just goes right out from prep to mask to paint to reassembly to detail. There’s no jumping cars around and a lot of wasted movement.”

The new shop design is based off Steve’s Auto Body’s O’Fallon, Illinois, location, the first shop. They are also building a calibration facility. It will be standalone business on a different property from the shop.

“We essentially built the process and then built this shop around our process,” he says.

“So, there are only a few minor tweaks that allow for cars to flow through the facility better compared to O’Fallon.”

One layout change from the O’Fallon shop gives the new shop a slightly more open floor plan. When a vehicle enters, it goes through “X-ray disassembly.” In that process, the blueprinter and disassembly technician disassemble the car for repair. The shop orders the parts the needed parts and once they arrive, the vehicle goes through structural repair, painting, and reassembly.

“We do have our higher-level techs come in and help with reassembly, but we have designated reassembly techs as well,” Beshears says. “And then it just pulls forward one stall into the detail area and then it’ll go off for any sublet calibrations, wheel alignments, all that stuff to finish the process.”

Over his 18 years at the business, Beshears says they have locked in on the brands and products that serve their operations well. The shop uses Pro

Spot for welding and, with many positive experiences, uses it for most other equipment as well. The paint shop has been and continues to be a loyal PPG customer, using Envirobase High Performance waterborne paint.

“Moving forward, everything will be Pro Spot welders at all our facilities,” he says. “We have Car-O-Liner benches at all our facilities. So, the same went in here and then Global Finishing Solutions prep decks and paint booths, which have served us extremely well in our other facilities. So, essentially, Global for all paint booths, Car-O-Liner for frame machines, and Pro Spot for essentially everything else.”

The shop currently has nine staff members, scaling up to 18 when it’s fully staffed. Beshears says they started with a smaller crew that trained at their other two facilities and will continue to build up to full staffing as volume increases.

The shop is located next to a GMC dealership. Beshears anticipates it will be a great partner for the business, and they will work on getting GMC certification for this location. Beshears says they will wait a bit to see the volume and types of cars they get before they decide which OEM certifications to target. Due to its location and design to optimize repair processes, Beshears anticipates the new facility will have a higher volume than the other two shops once it’s fully online.

“It is in a better area, but it’s more because of the throughput with some minor changes that we made to allow cars to flow through the shop better,” he says. “So, we’ll just be able to get more done out of this footprint than we will the other footprints just because of spacing.”

Tight accounts receivable control and daily oversight are crucial to stop cash from slipping through the cracks and jeopardizing profitability.

It is interesting how different businesses work. Let’s say I go to Walmart to buy $150 worth of items. Then after filling my cart, I head to the checkout lane and ask the clerk, “Could you just send me a bill?” I am sure we would get back a snicker at first and then an abrupt, “No, we can’t send you a bill, and you can’t leave the store with those items without paying.” We would get the same response from the gas station clerk, home improvement center, restaurant and most every other retail business. Now, let’s look at a bank. What if I met with the loan officer and said, “I need to borrow $50,000 for 30-90 days, but you can’t charge me any interest.” I bet it wouldn’t take long to be escorted to the entry door and asked to leave.

The unfortunate truth is, about 90% of the body shops in the US do extend credit to vehicle owners. We allow them to pick up their vehicle without being paid in full. The worst part about extending this credit is we don’t even collect one dime of interest! What a lousy bank we make, right?

Back in March of 2023, I wrote a column for FenderBender called “The Cashflow Fix,” based on the book Profit First. If you have not read the column, I encourage you to find it in the FB archives. Since I manage every incoming dollar for my shop based on Profit First, it is a driver for me to keep my accounts receivable (AR) as low as possible. AR is just a black hole. And on top of that, it’s taxed as ordinary income with accrual accounting.

Obviously, the reason shops allow AR is for our customers’ repair experience. Most shops that have, say, a $15,000 repair and have been paid $13,000 will probably let the car go while still waiting on the check from the insurer for $2,000. Even if we have proof of payment from the insurer, it could take 7-10 days for the payment to arrive. It’s hard to grow a business when we hold cars for an extra 7-10 days. Granted, we can force the insurer to pay overnight by FedEx etc. Don’ t forget the basics of having your shop set up for EFT as much as possible with insurers. Along with this, always track down initial photo estimate payments at drop-off and supplement payments while the car is in process.

First, let’s establish what is a reasonable amount of AR for “ABC Auto” Body that does $3,000,000 in yearly gross sales or $250K per month. For this size shop, the amount of AR would preferably be $25K - $37.5K (10-15% of monthly revenue). I know some of you are thinking, “Greg, we often have jobs over $25,000!” Trust me, I get it. But I am talking about on AVERAGE.

So, how does ABC Auto Body allow their AR to get to $50K+ (20%+ monthly revenue)? For starters, the owner needs a kick in the pants. Granted, ABC could have some fleet accounts etc., that have credit terms established. I get that, but I am talking everyday average retail vehicle owners here.

When it comes to AR, someone needs to be monitoring it every day, not once per week or even every other day. Whether it’s the shop owner, bookkeeper/controller etc. that oversees AR, we must be contacting the paying party (insurer, vehicle owner etc.) prior to the 31-60 days overdue. I am talking even by the ten day or twoweeks mark here. Make sure notes are left in the RO of who was emailed/called etc. Some shop owners may be saying, “Well, I don’t want to put too much pressure on my bookkeeper.” If that is your case, then you must allow your body techs to send pinholes to paint or let the painters shoot the wrong color plus runs. We pay people to do a job, and therefore they must do it. I do have some fellow shop owners’ friends who incentivize bookkeepers to keep a low AR. It’s not for me, but it works for them. Either way, if you have a bookkeeper, you should be getting weekly AR aging reports from them.Another major reason for high AR is not processing supplements after blueprint or not pre-closing jobs before vehicles leave. It just blows my mind how some shops that produce, say, 15 cars per week and have 30 cars in “Delivered Not Closed” buckets. I get dry heaves if I see mine over 6-7!!! The longer you let those jobs just sit there before sending in the supplement, the less likely you will ever get them collected, or at least, paid in full.

Greg Lobsiger has owned Loren’s Body Shop in Bluffton, Indiana, for over 23 years. He has been a member of Mike Anderson’s groups for ten years and had extensive lean manufacturing training.

EMAIL: greg@lorensbodyshop.com

ARCHIVE: fenderbender.com/lobsiger

With a waterborne basecoat that’s easy to mix, match and apply and that uses the same coat flash application you’ve already perfected, Cromax® EZ makes an exceptional finish feel effortless. Discover how easy an outstanding finish can be.

axalta.us/ez

Check out what some of this year’s exhibitors have in store for you.

By JAY SICHT

part of your strategy for visiting the SEMA Show, be sure you also check out our SEMA Show Preview in this issue for the featured companies and information on the educational programs offered by I-CAR and SCRS. We asked SEMA Show exhibitors to give us a sneak peek at what they will be highlighting at this year’s show.

“The 3M booth [No. 30125] at this year’s SEMA Show will be featuring some exciting new products and experiences,” says Becky Miller, vice president, portfolio, 3M Automotive Aftermarket Division. “Expect

to see 3M’s latest and greatest innovations, including the recently launched 3M Performance Spray Gun 2 and Fine Finishing Nozzles . We consulted with painters to get their input on the improvements they wanted to see reflected in the next generation of our popular spray gun, and the result is a new, state-of-the-art product that combines painters’ insights with 3M innovation.”

Miller shared that other new 3M products being showcased will be the new 3M Hookit Flexible Foam Abrasives , which “help deliver greater uniformity, conformability and consistency across paint preparation procedures and give you greater sanding confidence and peace of mind in your working environment. Additionally, this year 3M is celebrating 100 years since Richard G. Drew’s invention of automotive masking tape transformed the industry. Our booth space will include a fun and interactive component that will commemorate this significant milestone, so make sure you swing by.”

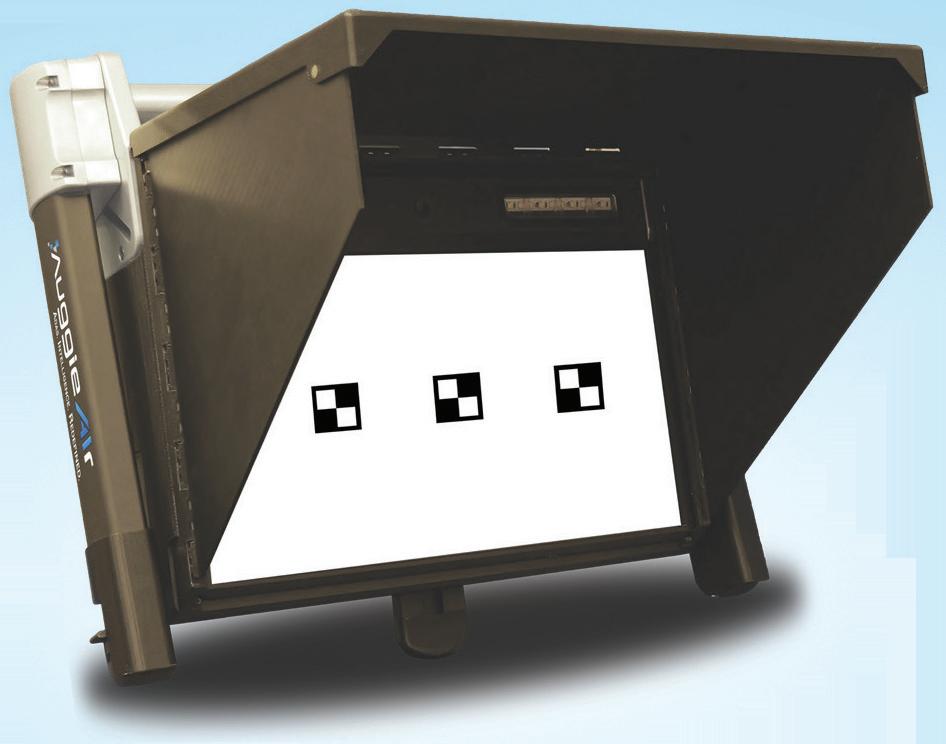

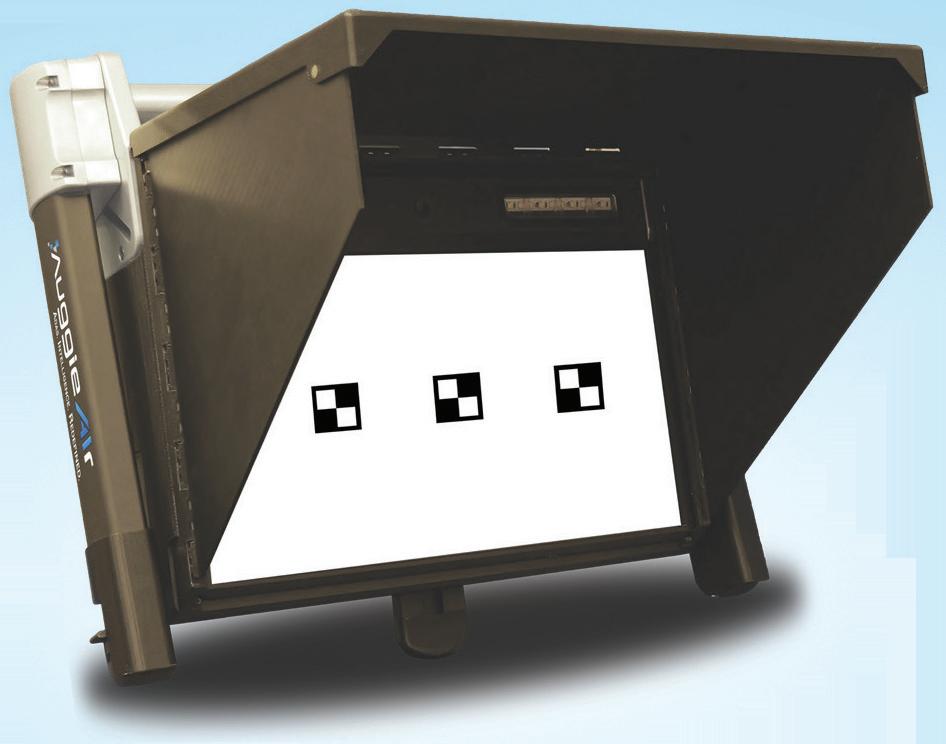

As in years past, AirPro Diagnostics (booth No. 33211) will be highlighting its Auggie Air mobile calibration tool, says Marketing Manager Thomas Mulgrew.

“With Auggie Air, we’ve raised the bar on the already impressive Auggie mobile forward-facing camera calibration tool. It combines enhanced portability, smarter battery management, and a much more intuitive interface — speeding up workflows while maintaining accuracy. Add global compatibility and a compact design to the mix, and it’s a game-changer for shops wanting faster cycle times, increased capacity, and higher customer confidence.”

If you have spent much time at the outdoor exhibits, you know BendPak’s outdoor booth in the Silver Lot (No. 81210) is hard to miss, full of stacks of classic and custom vehicles. It’s complemented by an equipment-packed booth upstairs in the South Hall Tools & Equipment Section (booth No. 36131).

“There are new products for collision repair shop owners and techs at both locations,” says Sean Price, BendPak director of product development. “Outside, be sure to check out the latest QuickJack portable car lifts. The new QuickJack 6000TL and 6000TLX models are rated for 6,000 lbs., while the 8000TL and 8000TLX can handle up to 8,000 lbs. — the most powerful QuickJack units to date. For shops with low ceilings or that never need to go under a vehicle, we’re showing off the latest in our AP Series of lifts, the 12AP-SRT. It has all the safety and reliability features of a full-size BendPak AP Series lift with shorter columns and a lower lifting height. Of course, we’ll also have the latest Cool Boss evaporative cooler models, Ergochair ergonomic work seats and must-have accessories like JackPak portable power solutions, Litestix work lights, GoAir Mini air compressor, and more.

“Inside, you’ll find the one-of-a-kind eight-armed Octa-Flex two-post lift. A lift like no other, it was specifically designed to facilitate cab-off work, EV battery removal, and other tasks that used to require multiple technicians and additional equipment. And just in case you can’t make it to both loca-

The eight-armed Octa-Flex two-post lift allows for cab-off work, EV battery removal, and other tasks that used to require multiple technicians and additional equipment.

tions, this booth also features the latest from Cool Boss and a full line of accessory equipment. We’re also planning to give sneak peeks of a couple of new products in each booth. Come and tell us what you think!”

Car-O-Liner shows off new technology for performance and precision

Car-O-Liner (booth No. 32017) will be showcasing systems such as the BenchRack Versa, CTR9, and Car-O-Tronic Vision2 , which Lara Jones, content writer for Car-OLiner parent company Snap-on Equipment, says are designed to elevate your shop’s performance, precision and reputation.

“The BenchRack Versa redefines flexibility and ergonomics in frame straightening,” she says. “With full 360° access and compatibility with both unibody and full-frame vehicles, it’s engineered for speed and accuracy. Whether pit-mounted or fixed, Versa integrates seamlessly into any workshop. Paired with the CarO-Tronic Vision2 measuring system, it delivers real-time diagnostics and pinpoint precision, ensuring factory-spec repairs every time.”

The CTR9 spot welder brings “transformative power and agility into your hands” for “unmatched maneuverability,” she says, with Its lightweight welding gun, 355° swivel handle and telescopic arm.

Unmatched

Maneuverability

The Car-O-Liner CTR9 spot welder offers a lightweight welding gun, 355° swivel handle and telescopic arm. The Vision2 system is backed by a database of more than 18,000 vehicles.

8,000-LB. Capacity

The new BendPak QuickJack 8000TL and 8000TLX can handle up to 8,000 lbs.

“With 16,000 amps and CAN bus communication, every weld is strong, safe and OEMcompliant. New for 2025, the fully automatic, water-cooled AW-Tong enhances precision and efficiency with advanced thickness measurement and ergonomic design. Optional WeldLogger software adds traceability, making documentation effortless.

“At the heart of precision lies the Car-OTronic Vision2 system. Wireless and lightningfast, it’s backed by a database of more than 18,000 vehicles, making it easier to uncover hidden damage. Vision2 software guides technicians through each step, enhancing workflow and reducing the risk of rework.”

Jones says OEM approvals set the systems apart.

“Trusted by leading vehicle manufacturers, Car-O-Liner solutions meet rigorous standards for safety, accuracy and performance. These endorsements aren’t just badges, they’re proof of reliability, giving customers confidence and shops a competitive edge. Experience the power of OEM-approved technology and discover how Car-O-Liner transforms collision repair into a smarter, faster and more trusted process.”

New to the Global Finishing Solutions booth (No. 31055) this year will be an expanded

Clean And Bright

GFS’ Booth Shield protective wall coating and PIG

Grippy Mat brighten up a paint booth.

selection of paint booth accessories, with exclusive discounts for SEMA Show attendees and free shipping to your facility, says Mick Ramis, vice president of Auto Refinish and Aftermarket Sales.

Accessories include the new and improved Grate Lifting Tool for replacing exhaust filters in a downdraft paint booth. The tool does the heavy lifting for the technician, picking up exhaust pit grates so filters can be quickly changed without straining one’s back or pinching fingers between grates.

Also featured will be booth protection products, such as the Booth Shield protective wall coating and PIG Grippy Mat protective floor covering to help keep the paint booth clean and bright. SEMA Show attendees can also get an up-close look at GFS’ magnetic accessories — units for storing and organizing your spray guns, tape, tack cloth, tools, razor blades and other items, conveniently mounted onto your paint booth’s walls.

“GFS is dedicated to helping businesses improve the efficiency of their paint operation,” Ramis says. “We invite you to come see in person how our high-quality, proven paint booth accessories can help your business improve productivity and increase profit.”

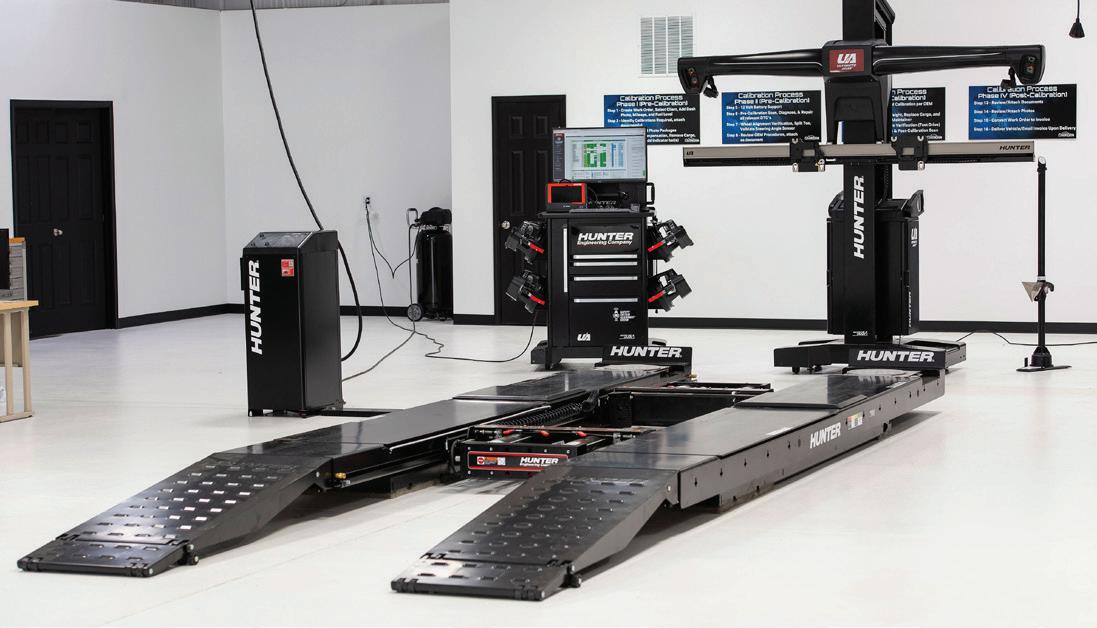

Hunter Engineering (booth No. 42017) will be highlighting four major product introductions at SEMA 2025, adding to the wide range of high-tech wheel and tire service equipment traditionally on display in the Hunter booth, says Pete Liebetreu, vice president of product management and marketing.

“Hunter loves coming to SEMA and showcasing innovations. It’s fun and exciting, but sometimes the core message gets lost in the bling. Hunter brings new products to the market to solve real-world problems. We want to save time, make the technician’s job easier, and improve outcomes for the motoring public. All

‘Xpandable’ for ADAS

The HawkEye Elite Xpandable from Hunter Engineering allows shops to scale alignment, dianostics, and ADAS calibration.

our new introductions — and we aren’t telling you all of them ahead of time — will raise the bar on productivity in the workshop.”

The focus at the booth will be on the fol lowing four product introductions:

The HawkEye Elite X configuration offers shops the opportunity to future-proof their businesses by investing in a scalable align ment, diagnostics and ADAS solution. The new configuration comes standard with standardsetting WinAlign software and specs database, the ADASLink diagnostic scan tool with secure gateway ability for dynamic calibrations, preand post-scans, and steering system resets.

HawkEye Elite X provides a seamless upgrade to Hunter’s Ultimate ADAS static calibration system that cuts target setup time by up to 70 percent via laser-guided precision.

The new Maverick Pro center-clamp tire changer builds upon the original Maverick with two important enhancements. The first is a new ergonomic pick-and-place wheel lift capable of lifting and tilting heavy assemblies and 19.5inch wheel-and-tire assemblies up to 175 pounds in one smooth motion. The lift holds its position while elevated and then lowers automatically.

Additionally, the Maverick Pro features an under-wheel light that illuminates the lower roller and bottom bead during the mount/demount process.

Hunter’s Quick Check autonomous inspection systems now feature the new Inspection Live cloud-based software, allowing two lanes to be run from a single console, over-the-air updates on a weekly or monthly basis, and more.

The new Road Force WalkAway wheel balancer now features Hunter’s WalkAway inflation system, designed for a time savings of up to 15 minutes on a typical four-tire changeover.

John Bean brings adaptable ‘real-world’

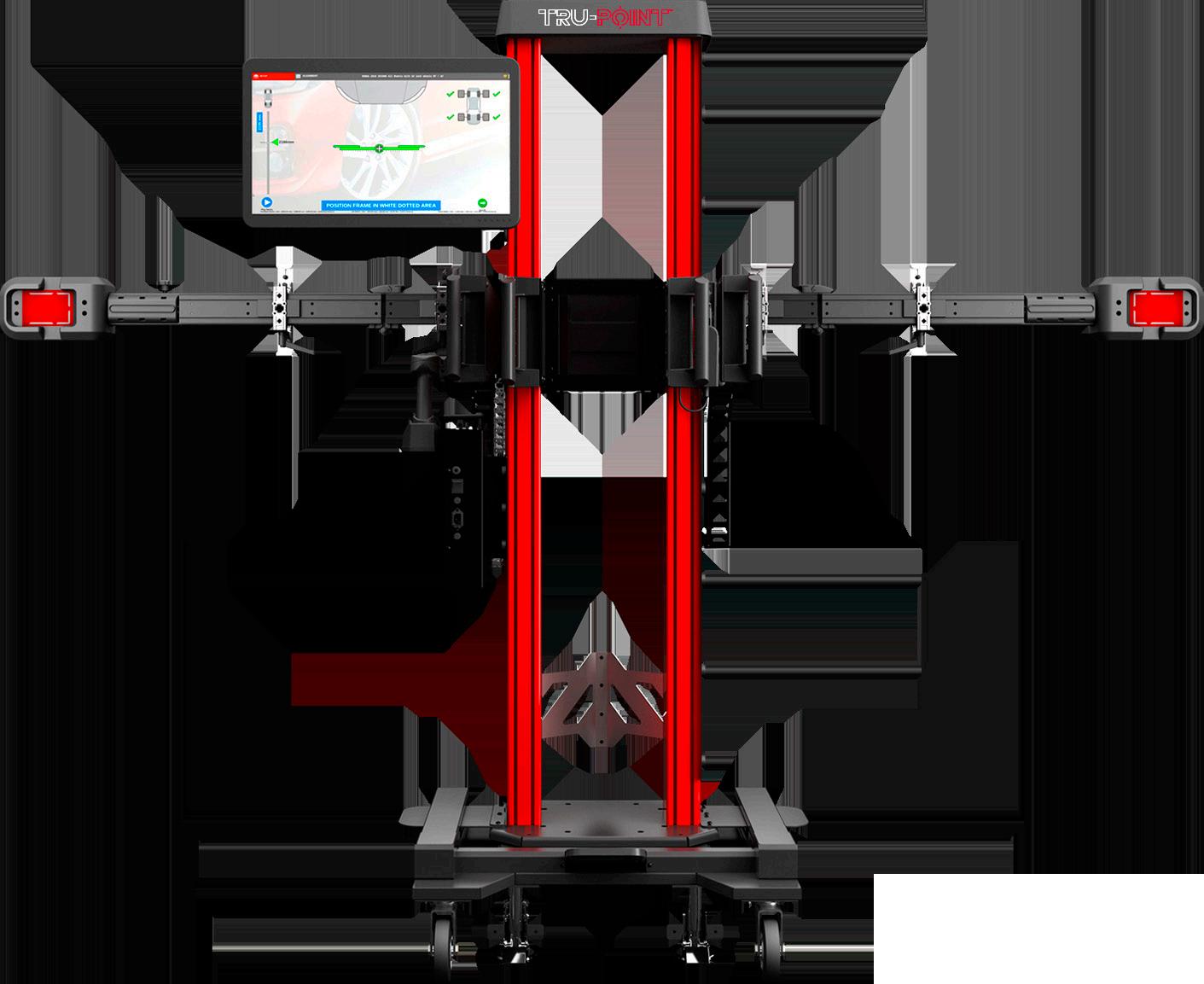

Another Snap-On brand, John Bean, will showcase its Tru-Point ADAS calibration equipment at booth 32017.

“Shops today are challenged to keep pace with rapidly advancing vehicle technologies,” Jones notes, pointing out that because ADAS is now standard on most vehicles, proper calibration after repair is critical for safety.

“Restoring a vehicle now extends beyond structural damage — it demands safety systems function precisely as designed. What

once required complex setups and extensive training can now be streamlined into an efficient, profitable process with Tru-Point.”

By using its advanced camera technology, she says, the system creates a live 3D model of the vehicle and floor to guide technicians through each step. And a color-coded interface ensures targets are placed correctly, reducing errors and rework.

“John Bean has been a leader in alignment technology for nearly a century, and TruPoint continues that legacy, offering shops a smarter way to manage ADAS calibration.”

The Tru-Point system adapts to real-world shop conditions by accounting for uneven flooring. Jones says that allows it to deliver accurate results whether working on a lift or on the shop floor. Vehicle movement between calibrations is not an issue, and every calibration includes a detailed report as proof of accuracy.

Jones says this is how Tru-Point boosts shop performance:

• Checks alignment before every calibration

• Simplifies training with guided workflows and live camera prompts

• Grows profits through alignment and ADAS services

• Provides verification reports as proof of accuracy

“As buyers seek to add services without a heavy upfront investment, Tru-Point makes it easy for shops to expand into ADAS calibration profitably. When paired with a John Bean aligner, the system creates two revenue opportunities: correcting alignment issues and completing OEM-accurate ADAS calibrations. This seamless workflow enhances efficiency, builds trust and maximizes long-term profitability. As a result, shops can handle today’s ADAS challenges while preparing for even more complex systems tomorrow.”

Precision And Strength

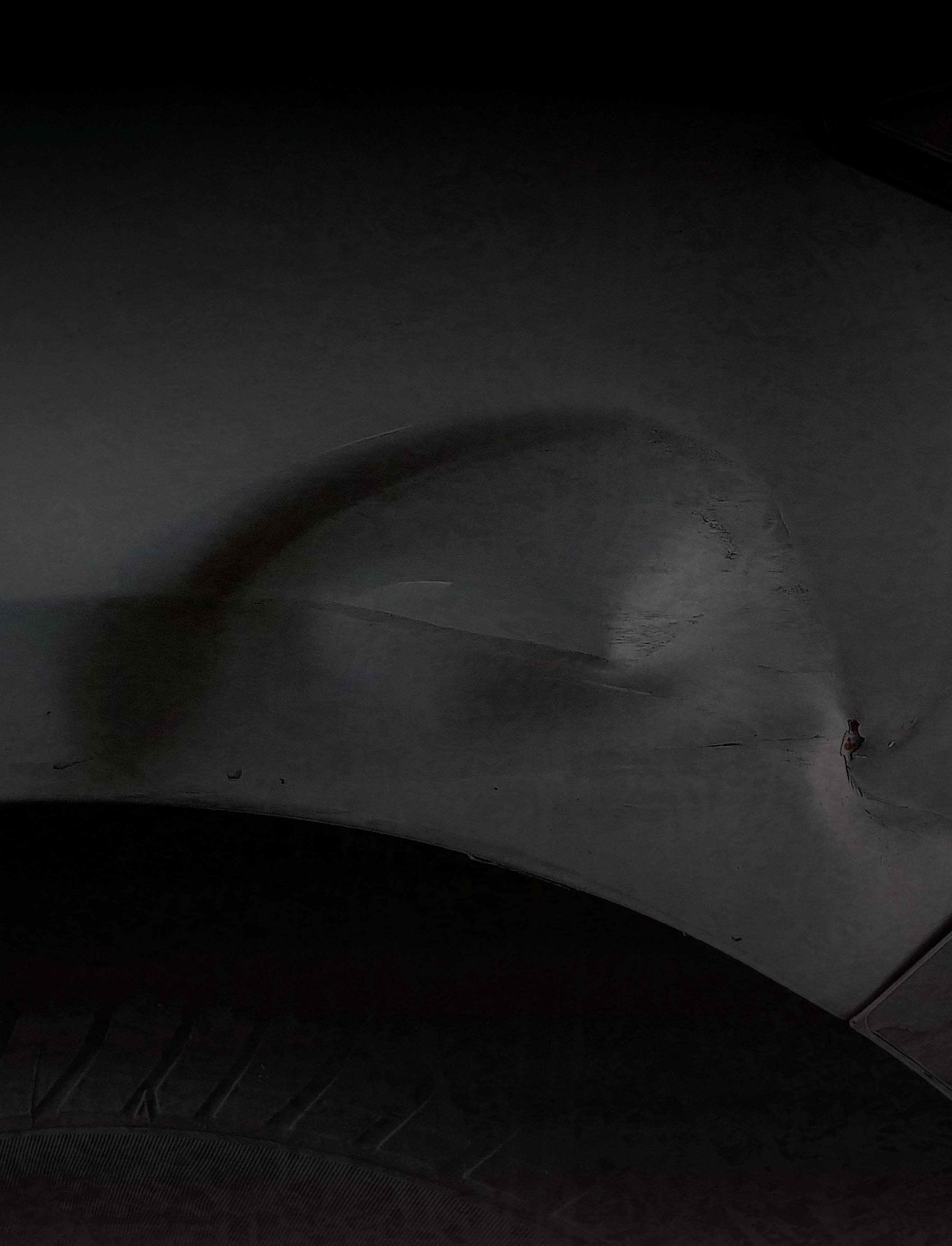

KECO’s Premium Collision System can help unlock repairability to keep panels on the car.

combines precision control with high strength pulls for challenging collision damage

KECO Body Repair Products (booth 32213) will show its Premium Collision System in action with live glue pull repair demonstrations on a vehicle in the booth.

“The Premium Collision System is the most complete solution available for collision shops, designed to give technicians every tool they need to unlock repairability and keep panels on the car,” says Product Manager Benjamin Staton.

As part of the demo, visitors will see how the system integrates advanced tools like the K-Power Lateral Tension Tool and the KTower, which Staton says combines “precision control with the strength needed to correct even the most challenging collision damage.”

“By watching real repairs unfold, attendees can experience how the Premium System reduces the need for invasive methods such as stud welding and replacement, while improving cycle times and preserving OEM integrity. The booth is built to feel like a working repair environment, giving technicians, shop owners, and industry leaders the opportunity to step close, ask questions, and see firsthand how the Premium Collision System is reshaping collision repair. This isn’t just a display of tools – it’s a demonstration of how Glue Pull Repair can raise the standard of quality, efficiency, and repairability in the industry.”

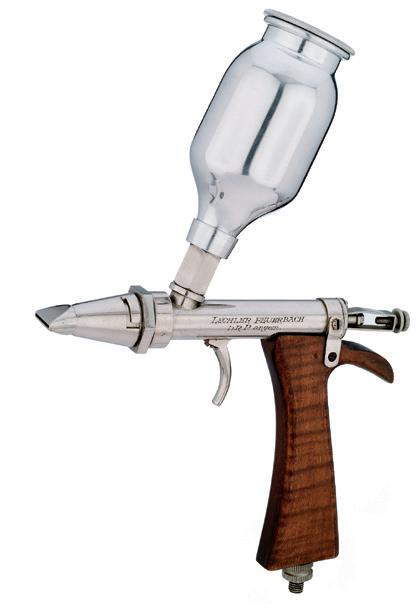

If you’ve been a longtime SEMA Show at tendee, you know SATA’s booth, regardless of where the Collision Repair & Refinish section has been located, is one of the first exhibitors most see when they set foot on the floor. This year, the company — origi nally known as Sanitaria — celebrates 100 years of producing its first spray gun at booth 31017.

At the show, the company celebrates that milestone with the launch of three limited production anniversary spray guns.

The jet X 100 Years Edition is a spe cial edition of its current top model. The design proudly features the original tech nical drawing of the “No. 1” spray gun from 1925. It’s available exclusively through au thorized SATA distributors while supplies last and is “a unique blend of top-tier performance and rich heritage,” according to the company.

Marking 100 Years

The SATA jet X 100 Years Edition celebrates the company’s “No. 1” spray gun from 1925.

The SATAminijet 4400 B and SATAjet 100 B 100 Years Editions are also available with the same striking anniversary design.

Whatever your collision repair tool and equipment needs are, the SEMA Show is likely to have it. And don’t forget to check out the New Products Showcase in the Lower South Hall for an efficient look at many vendors’ latest and greatest offerings.

By LINDSEY GAINER | Photography By JOHN PAYNE/PAYNE PRODUCTIONS

Collision Advice’s Mike Anderson’s Spartan 20 Group has become synonymous with excellence. Comprised of 196 highperforming shop owners bound by the common goal of achieving the safest possible repairs, it’s an elite group; and one that’s aptly named.

A Spartan, according to the dictionary, is, “a person of great courage and self-discipline,” referencing the people of Sparta, an ancient Greek military civilization known for these very characteristics.

It certainly takes both to run a collision business to the standards the Spartan Group requires — just ask the Speck family, winners of the 2024 Spartan of the Year award, and owners of K-ceps, based in Granville, Ohio.

Once a DRP-heavy repair facility with no OEM certifications, the family, with partners and brothers Adam and Chris Speck leading the charge, completely transformed their business model under Anderson’s mentorship. They’ve fully embraced the Spartan mentality — and, they say, there’s no looking back.

“We’re not perfect, but we work toward being better every single day,” Adam says. “We have a saying here,” Chris adds, “that ‘If it’s not broken, break it.’ We don’t want to get comfortable. We’re constantly evolving.”

Walk into K-ceps Auto Body (which, in case you’re wondering, is Speck spelled backwards) on any given day and you’ll find an

immaculate 80,000 sq. ft. shop with highend, EVs, European, and exotic cars lining the shop floor as far as the eye can see.

Their impressive OEM certification portfolio includes heavy-hitters: Audi, Bentley, GM, GM EV, GM C8, GM Cadillac, Jaguar, Land Rover, Lamborghini, Lucid, Maserati, Mercedes-Benz, Mercedes-Benz EQ, MercedesBenz Sprinter, Porsche, Rivian/Rivian Fleet, Subaru, Volkswagen, and Volvo, and they have dealer partnerships with nearly every single manufacturer.

“We’ve found great success in partnering with great dealers,” Adam says. “We share a common goal of taking care of our mutual client, and it just works. We have each other’s backs.”

“We’re really passionate about the brands we partner with, and it’s something we don’t ever take for granted, that’s for sure,” Chris says. “We get to work on some really cool cars and meet some incredible people.”

Just recently, for example, they had about 40 Lamborghinis in the shop for a club event…a true testament to just how esteemed and clean the shop really is.

The facility wasn’t always this version of itself, however.

Started by Adam and Chris’ father and mother, Ray and Susie, in 1993, K-ceps was a one-man operation in the beginning.

“My dad came up through the industry,” Adam says. “After working in dealerships for a while, he decided to go out on his own. He did every job in the shop while my mom took care of the financial side of things, and it grew rapidly.”

Chris, Adam, and their brother Jeff all eventually joined the business, which now also includes two stand-alone service centers and a towing company in addition to their two collision shops.

“Some people say it’s hard to work with your family,” Adam muses, “but we’re the exception — we spend all week together and we still have Sunday dinner every week. We truly love what we do, and we love doing it as a family.”

Chris echoes the sentiment wholeheartedly. Each member of the family is an integral part of the team, he says, and they all use their strengths for the good of the business.

“It works well because we’ve each found what we’re really good at, and we do it; there’s not a lot of overlap. Adam is really strong on the operational side of things, whereas I’m strong on the analytical/financial side. Jeff, he’s our ‘Swiss Army’ knife — with mechanical, body shop, and towing experience, he flexes wherever he’s needed. My mom still works on the financial side with me, and my dad does a little bit of everything…he’s here, there, and everywhere.”

And when it comes to role models, Chris says, they couldn’t have had two better ones than their parents. Running a business with honesty and the utmost integrity, striving for excellence, never settling, and keeping the customer at the forefront, always, were all direct hand-me-downs, he shares.

“We all truly, sincerely feel we’re in the business of people, we just happen to fix cars,” he adds.

Everything the family does is in pursuit of serving their customers better — including the transformation the shop has undergone.

It all started back in 2017, says Adam, after the family attended one of Mike Anderson’s seminars.

“We knew about Mike for a long time; he’s always been someone we look up to,” says Chris. “He’s a personal hero of ours.”

“He was pushing OEM certifications, and we didn’t really know much about them,” continued Adam. “But the more that we started to investigate and partner with the vehicle manufacturers, the more success we achieved.”

“Once we started getting into the OEM certifications and training — and adopting Mike’s principles — we never looked back,” Chris says. “Performing complex OEM repairs using only OEM parts is not always easy, but it’s always satisfying…and that’s what makes it worth it.”

A rigorous overhaul of their books, processes, and operations followed, which included consolidating their original shop in Johnstown and their second location in

Striving For Perfection

“We have a saying here,” Chris Speck says., “’If it’s not broken, break it.’ We don’t want to get comfortable. We’re constantly evolving.”

An Emphasis On OEM Certifications

any

Granville into one mega-facility (their existing 80,000 sq. ft. Granville shop, which they purchased in 2018) at Anderson’s recommendation. They also transitioned to a “cell” repair system that operates as independent teams within the larger unit.

“We have three cells right now in Granville, with a goal of expanding to five eventually,” explained Adam. “Each cell is essentially like a micro body shop with its own assigned customer service rep, back-end estimator, and four technicians (one is a master technician, two B-level techs and a C-level tech). They work as a group, together, and they always process their cars as a team.”

Not only does this model increase efficiency in the shop, but it also makes growth easier.

“When you’re working with a cell system, it’s very ‘plug and play.’”

They’re currently putting that theory to the test in Cincinnati, where they’ve just acquired a new facility. Although they’ve been in the city for a year fixing Rivians, this move to a new, larger shop — around 15,000 sq. ft. — will allow them to clone Granville’s operations and work on a wider variety of cars. They’ll operate with one repair cell to start and expand to more as business picks up.

“The way we do things now, it just feels like the right thing to do for our clients,” Adam says. “Every time my dad sees Mike [Anderson], he praises him for what he’s helped push us to do, and just the way he’s helped us change the landscape of K-ceps and the future of K-ceps.”

The brothers joined Anderson’s Spartan 20 Group upon its inception in 2021 as well, which, they say, is an honor to be a part of in and of itself.

“You can’t help but get better just by being surrounded by people that do what you do at a very high level,” Chris says. “You see your shop with the same eyes every day.

When you can bring fresh eyes to it, even if you don’t necessarily always like what you hear, that’s where the biggest opportunities are found. You have to listen with the intent to be influenced.”

Listening to your team is imperative, too, Chris says. “Some of the best ideas come from our teammates.”

The brothers strive to remain “coachable” at all times, and they expect the same in return.

“You can’t teach attitude and desire,” Chris says, which is why the business always looks for employees who are eager to learn and willing to flex with the everchanging repair landscape to carry the shops into the future.

K-ceps never uses aftermarket or recycled parts, and the team researches repair instructions on every single job. They do things by the book 100% of the time.

“It doesn’t matter if we just fixed the same model or issue last week — the engineers could have changed a procedure since then,” Adam explains. “It takes longer to do it that way, but we just feel that it’s the right way to repair a vehicle. We’re the type of people who won’t even take generic drugs. I tell people that all the time. I’m like, ‘I won’t even go to the drug store and buy aftermarket.’”

Chris recalls the moment a tech they trained — who’s never worked anywhere else — saw an aftermarket sticker on a car he was disassembling and had no idea what it was.

“It was a foreign concept to him because he has never put on an aftermarket part in his entire career here. That’s something I’m really proud of.”

The team also invests a significant amount of time at the beginning of the repair process “triaging” cars and engaging in open, honest communication to educate clients — flipping the triangle upside down, as Anderson would say — to minimize bottlenecks and frustration down the line.

It’s this kind of commitment to excellence that earned the shop Spartan of the Year …and the brothers come by it honestly. Their dad, says Chris, “is the person that, in the best possible way, is never satisfied. He is always pushing for the next thing…he’s never been one to shy away

from change. He’s just as gung-ho for these certifications as we are, and he’s allowed us to completely change course and really ramp up the way we do business over the last few years.”

In addition to the quality of their repairs and strict adherence to OEM procedures, parts, and scan tools, Anderson says that parts storage procedures, facility cleanliness, and guest experience ratings (like CCC Carwise and Google), among other criteria, all played into the decision.

“Collision Advice is honored to recognize K-ceps as our Spartan of the Year,” Anderson says.

And the feeling certainly goes both ways. The brothers say they were equally “honored and humbled” to receive the award, and in true people-first fashion, were quick to credit their team for the win.

“Our entire team is just really, really proud of it. It was really incredible to go back to the shop and bring everyone together, our entire team, and say, ‘Hey, we’ve got some awesome news. We won shop of the year!’ Every single person was

thrilled. We had a party. Adam and I got to take the credit — we got to pick up the trophy, and we get to do interviews and such — but really it’s the entire team that made this happen. It’s the entire team that does this on a daily basis, and we’re so proud of them. We told them that this isn’t our award…it’s theirs. We couldn’t do any of this without our team.”

“We want to be a regional MSO, but do it right,” Adam says. “We never want to lose focus of our core values, of taking care of our clients and fixing cars properly and safely — the rest will come if we’re doing those things.”

They’re eager, adds Chris, to “take the show on the road,” and replicate their successful model in Granville wherever it’s needed.

Winning Spartan of the Year isn’t the finish line, he says…just the opposite, in fact.

“It’s given us some great momentum. Now that we’ve achieved this, it’s like, ‘Okay, well, what’s next?’ This isn’t the finish line. It’s the starting line.”

Precision alignment takes extra time—and deserves extra pay. New technology requires new tools, and precision work means you can add manual labor.

With the CJP-907, manually add up to 6 hours of labor to measure blind spot sensors before sending the vehicle for ADAS recalibration.

at our

The amount of work caused by a wrong decision and the associated high costs of repainting the area leave no room for compromise when it comes to choosing the light quality.

In order to ensure that the correct color variant is selected during refinishing and the associated color shade can be determined, a light source that reproduces the entire color spectrum of visible light (daylight) as far as possible must be used. The specially developed SATA trueSun facilitates professional color retrieval and identification, even inside the bodyshop.

Best possible close to daylight reproduction of different color shades

Homogeneous light distribution across the entire illuminated area

Approx. 70 minutes at full light intensity

Uniform light intensity - independent from the battery's level of charge

Charging cycle time of only 50 minutes

Infinitely adjustable light intensity

Can’t make it to SEMA this year, or want to be in too many places at once during the show? In order to give everyone an opportunity to see what is going on, FenderBender will cover the SEMA Show all week long. The coverage will include news items throughout the week, product releases, award winners, event information, and other SEMA happenings. For a behind-the-scenes look at what it’s really like to attend the show, follow FenderBender’s website and social media accounts. @FenderBenderMag

SEND US YOUR COVERAGE

At the show and snapped a great picture or took a video you want to share with @FenderBender? Tag us on Facebook with what you got @FenderBenderMag.

The top stop for almost every bit of coverage throughout the week. Like and follow “FenderBenderMag” on Facebook for daily photo albums, events, and news @FenderBenderMag

Photos from the week will be posted during the show for a behind-the-scenes look at everything SEMA.

The SEMA Show New Products Showcase, which is moving to the Lower South Hall, is the world’s largest display of new automotive aftermarket products. It is the top buyer and media destination at the show, featuring thousands of the hottest products in the industry.

The Upper South Hall is 464,658 square feet and is approximately 1,690 feet end-to-end

Take a look around the showcase to view products you have heard of but never seen, and discover products new to you.

Either scan products using the SEMA Show’s app or a provided scanner to acquire information.

Access production descriptions, images and exhibitor booth numbers through the app or through printouts.

Use the SEMA Show mobile app’s “Product Scanner” feature to scan and download product photos and exhibitor information that will remain on your SEMA Show app long after the 2025 show has ended. For more information on what exhibitors and products will be showcased, visit semashow.com

The SEMA Show is ready for 2025 with an expanded layout, expanded live stream, and improved SEMA Fest. Tom Gattuso, vice president of events for SEMA, discusses what changes they’ve made to this year’s show to make it the biggest one yet.

FB: Last year, it was ADAS everywhere. Do you expect that trend to continue or do you think a new trend or technology will pop up and that will be the new big thing at SEMA this year?

TG: I think the ADAS trend will continue and the way I see the industry, I have a little bit unique perspective where we’re close to the collision repair industry, just as an example. They were, in my opinion, years ahead on ADAS from some of the performance parts of the industry. So that’s continuing to get more refined and, as technology continues to advance, we’ll just see a lot more adaptation for that into the individual tire shops and collision shops, as well as the performance shops. What I like about that topic, as an example, is you’ve got people who’ve been dealing with it for a couple of years ahead of people in trying to get a car back to factory specifications. There was this need to reset ADAS features. Then you have this performance industry that’s making modifications to cars and now they’re starting to share notes. I think that’s

really a healthy thing to have happen and it’s great to see that networking and sharing of ideas happen.

The other thing we did…we’ve moved our new products showcase to the Lower South Hall. That brings this hub of new products to the hall. I like having it in Lower South Hall because it gives you this two-way traffic and it will provide energy and momentum to that hall. We moved registration to the east side of that hall. Last year we had people show up early, so it gives them some time to walk through the new product showcase.

FB: Is there anything else new that you’re trying out this year?

TG: We’ve expanded a little bit into Westgate with an international pavilion we created. That gave us some room on the show floor to introduce some of the features. One of the examples of that is our Battle of the Builders showcase… that’s been in different places and it’s that way because it’s very popular. That’s

likely to go from outside to inside. We’re going to move our SEMA Live from one hall to another because it’s a feature of cars and the energy that’s happening at the show. It was a big hurdle to jump over in its first year when you think about all the work that needs to go into a 31-hour straight broadcasted event. If you look down the road for what we’re trying to do…we feel like it sends our message out and gives people a glimpse of what happens at the SEMA Show to a much wider audience…We start when the show opens and end it when the show closes every day. We broadcast it on our YouTube channel. We found it is giving us a wider impression base than traditional television did.

FB: What does SEMA Fest look like this year?

TG: This year we will have three bands perform and will have some motorsports activities and cars on display. We caught up on technology where we’ve now got some lighting options where we’ll be able to almost turn the lights on and off on that lot. In the past, if you turned the lights off it took 10-15 minutes to turn them back on. That’s going to allow people to migrate between watching music and watching motorsports.

The cool thing about SEMA Fest, for me, is we noticed a change of the pipeline between our manufacturer exhibitors and their end users…When you have manufacturers going direct to their end user more than they had, it creates something where they want that same thing on their trade show floor. They

want that interaction with their end user. We created this Friday experience open to the public opportunity – the general public is able to buy a ticket to the show and that’s partnered with our SEMA Fest event so you can go to either or both. It gives us this really unique ability to have our companies in our industry have B2B conversations and some segment of consumer or enthusiast conversations.

FB: A big part of SEMA is networking and making connections. What other opportunities for networking can attendees expect to participate in at the show this year?

TG: We have structured and unstructured. When we talk about structured, we have things like our kickoff breakfast, which is also paired with our new product showcase winners for the week. That’s a great start for the SEMA show because it’s an opportunity to celebrate the innovation, but also we have somebody that will give a keynote and motivate people for the week of business that’s ahead. We also have our councils and networks that do events throughout the week. That gives people an opportunity to lock into a segment of the industry.

A lot of learning and networking happens on the show floor. There are people who come to the SEMA show that have friends they’ve been associated with for 30 or 40 years that they met on the show floor. I always tell people your next best seller is right around the corner, but be careful who you talk to because you may know them for the next 30 years.

FB: What do you hope the public takes away from this year’s SEMA Show?

TG: For me, it’s a trend observation type of thing. We’re sort of famous for the “hot roddiest” hot rods and the most “lifty” lifted trucks, right? In a lot of these, when you look at what we do, we’re an incubator for ideas. Not all ideas are good, and not all ideas are bad, but we come together as an industry and say, “Here’s this cool thing.” I remember the first time I saw a

20-inch wheel and it was at the SEMA Show. I couldn’t fathom anything that big. How would it fit on a truck or a car? What is the future of that? Now they’ve incorporated a 20-inch wheel where it’s almost commonplace when you associate it with performance. It’s things like that that I think an enthusiast coming to the show will notice. It’s the vehicle builds; the cars people are featuring in their booths that are there to showcase the products. I like that part of it.

The SEMA schedule is packed with learning opportunities for the hottest industry topics. Here are the offerings from I-CAR and SCRS, which cover electric vehicles, ADAS, welding, auto claims, AI, and more. Session times and locations are subject to change, so make sure to check semashow. com for the latest information about these seminars and other events.

All times in Pacific Time (PT)

The SEMA Show holds many other educational sessions in addition to the I-CAR and SCRS seminars. Below are some of the other topics that have sessions during the week. Check the SEMA Show website for the full schedule and session information.

OEM Certifications: The Business and Tooling of Yesterday, Today, and Tomorrow

From Boomers to Zoomers: Communicating Across Generations, Presented by Dale Carnegie

Five Ways to Make Your Small Business More Successful

Trends and Directions: Key Factors Impacting the Automotive Aftermarket

The SEMA Women’s Leadership Symposium: Leading for Success, Powered by SBN

Attracting and Retaining Young Talent in the Automotive Industry, Powered by FLN

Tuesday, Nov. 4

9:30am — 11:00am Creating Harmony in the

Repair Process Through Collaboration 9:30am — 11:00am A Consumer’s Guide to Getting Fully Reimbursed for Automobile Claims

9:30am — 11:00am

Take Control: How Bringing Auto Glass In-House Can Boost Profit and Procedural Compliance

12:00pm — 1:30pm Financial Fundamentals for Collision Repair Centers

12:00pm — 1:30pm Are You Offering Jobs, or Careers?

1:00pm — 2:00pm

Wednesday, Nov. 5

9:00am — 10:00am ADAS Diagnostics –When Calibration Fails

9:00am — 10:00am MIG Welding Basics

11:00am — 12:00pm Damage Discovery for ADAS Sensor Mounting Locations

9:30am — 11:00am

Shaping the Future of ADAS in Collision Repair: A CommunityDriven Approach

9:30am — 11:00am Winning Leadership: Influence, Impact, and Driving Results in Collision Repair

9:30am — 11:00am Automotive Advertising: The Road Map to Building a Successful Online Presence

Thursday, Nov. 6

9:00am — 10:00am Understanding High Voltage Safety

9:00am — 10:00am MIG Welding Basics

1:00pm — 2:00pm Understanding High Voltage Safety

1:00pm — 2:00pm ADAS Diagnostics –When Calibration Fails

12:00pm — 1:30pm The Body Shop Business Trifecta: A Roadmap to Build Generational Wealth

12:00pm — 1:30pm Accuracy Unlocked: Empower Your Team with Data, Tools, and a Clear Plan to Develop their Best Blueprints

12:00pm — 1:30pm The Unseen Effect of Bonus Plans in Your Shop

11:00am — 12:00pm Introduction to Electric Vehicle Considerations

11:00am — 12:00pm MIG Welding Advanced Features

3:00pm — 4:00pm Introduction to Electric Vehicle Considerations

11:00am — 12:00pm Damage Discovery for ADAS Sensor Mounting Locations

3:30pm — 4:30pm OEM Summit Session III 12:30pm — 1:30pm OEM Summit Session I 2:00pm — 3:00pm OEM Summit Session II 2:30pm — 4:00pm The IDEAS Collide Showcase

1:00pm — 2:00pm Understanding High Voltage Safety 1:00pm — 2:00pm ADAS Diagnostics –When Calibration Fails

11:00am — 12:00pm MIG Advanced Welding Features 3:00pm — 4:00pm Introduction to Electric Vehicle Considerations

11:00am — 12:00pm Damage Discovery for ADAS Sensor Mounting Locations

Booth 30125

3m.com/3M/en_US/ collision-repair-us/

At 3M, the art and science of automotive collision repair is a crucial part of our longstanding connection to our customers. For decades we have crafted abrasives, adhesives, and coatings to solve the latest auto body repair demands. Some of these products include our groundbreaking 3M™ Cubitron™ II and Trizact™ abrasives, 3M™ Platinum™ body fillers and our premium 3M™ Perfect-It™ compounds, polishes, and pads. Our 3M™ Performance Spray Gun, together with our 3M™ PPS™ 2.0 Paint Preparation System, delivers new levels of efficiency in paint and coating application and material savings. Every 3M product, every solution, is backed by our expert technical team to help guide you and your body shop every step of the way.

As digital technologies continue to transform the world and the way we work, 3M is at the forefront of driving tools that enable this transformation. Operational efficiency is an area where 3M is working especially hard to simplify the process and transform the way work gets done in body shops. We do this not only by promoting training and standardized repair processes, but now with a new customized, connected digital solution to aid in the most critical information flow to help drive performance, timing, and material usage. 3M’s tools empower the connected body shop and help you to unlock opportunities for profit and growth.

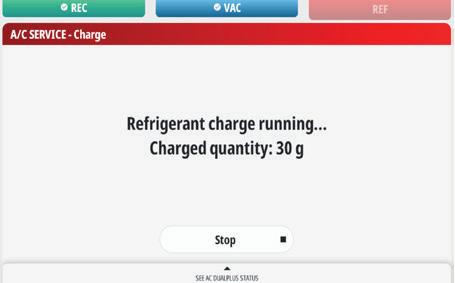

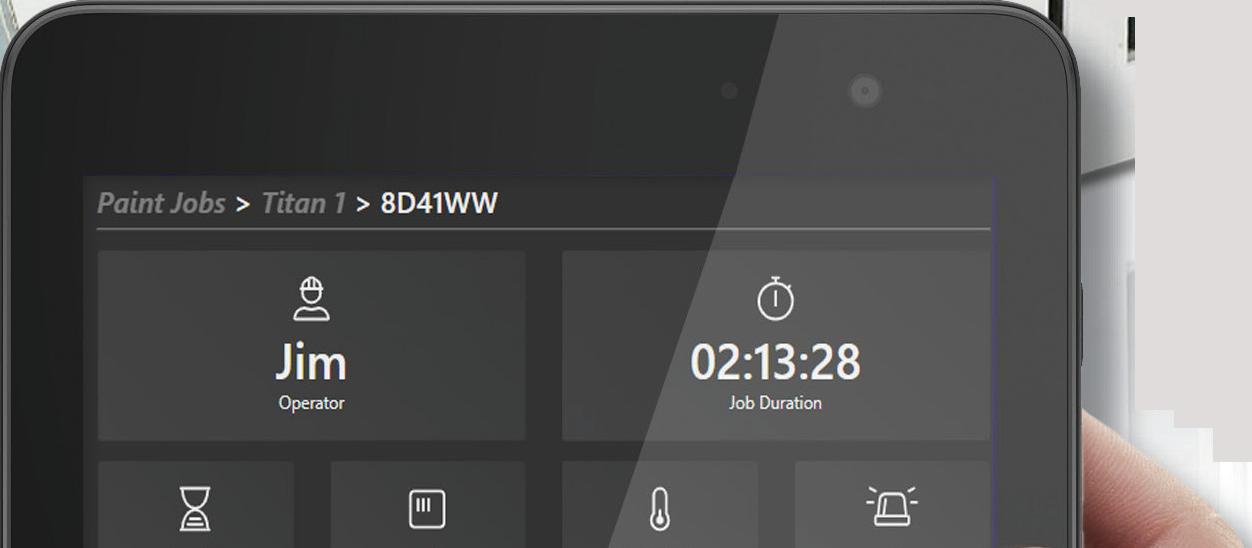

Accudraft LIVE™ is an interconnected ecosystem designed to optimize every stage of the finishing process by using advanced technology. It provides real-time data and analytics to empower paint shop managers with actionable insights. Accudraft LIVE™ turns a paint booth into an intelligent, data-driven system that helps paint shops achieve high levels of efficiency, quality, and profitability. It offers unmatched control, real-time insights, energy savings, improved safety, and a future-proof design.

Accudraft LIVE™ is available in three tiers:

• Accudraft LIVE™ Core: This is the foundational level, ideal for smaller shops or those new to data-driven management. It provides real-time performance metrics, remote monitoring, maintenance alerts (such as filter monitoring), and technical support.

• Accudraft LIVE™ Select: This tier is for growing shops or those with higher production volumes. It builds on the Core tier with more comprehensive features like advanced data analytics, and unlimited remote diagnostics and technical support. Also, we can build on custom reporting tools, cost analysis reviews and remote training.

• Accudraft LIVE™ Plus: This tier represents the highest level of intelligent paint booth management, providing full access to all features within the Accudraft LIVE™ ecosystem, including all Core and Select functionalities. It includes priority access to dedicated technical support, scheduled quarterly inspections by certified technicians, and a comprehensive filter supply program. The Plus tier also offers an extended or lifetime warranty on key components. This tier is designed for businesses that require the highest level of performance, reliability, and support, essentially future-proofing their investment.

37225

Leading Automotive Refinishing Technology

With years of experience in designing and manufacturing finishing solutions for the automotive refinish industry, DeVilbiss ensures a high-end finish while providing the highest transfer efficiency. We provide sustainable and innovative solutions to help you work faster, creating higher output which in turn leads to higher revenues.

DeVilbiss has years of experience developing professional spray guns and equipment designed to easily integrate into your overall automotive refinishing operation. Our focus is on driving quality, efficiency, and environmental sustainability.

Booth 34183

fujisprayauto.com

Fuji Spray Auto – Trusted Performance for Collision Repair

In the collision repair industry, time, precision, and reliability make all the difference. For over 35 years, Fuji Spray Auto has been a trusted name in advanced spray finishing equipment, proudly serving repair professionals across North America and beyond.

Our reputation is built on delivering equipment that combines affordability with uncompromising quality. We understand that collision centers operate in fast-paced environments where every hour counts. By providing cost-effective solutions without sacrificing performance, we help shops maintain profitability while ensuring superior finishes.

At Fuji Spray Auto, we believe that a strong manufacturer-to-consumer relationship is essential to success. That’s why we work directly with collision repair professionals, listening to their needs and refining our products to maximize throughput, minimize downtime, and reduce frustration. This synergy allows us to deliver equipment that isn’t just built to meet industry standards— it’s crafted to exceed them.

Whether it’s through improved efficiency, enhanced control, or unmatched durability, our spray systems empower repair shops to keep vehicles moving, customers satisfied, and businesses thriving. Choosing Fuji Spray Auto means choosing a partner committed to your success in every detail.

Booth 42017

Hunter.com

Hunter Engineering will be highlighting four major product introductions at SEMA 2025, adding to the wide range of high-tech wheel and tire service equipment traditionally on display in the Hunter booth.

The HawkEye® Elite X configuration offers automotive repair shops the opportunity to future-proof their businesses by investing in a scalable alignment, diagnostics and ADAS solution. The new configuration comes standard with standard-setting WinAlign® software and specs database, the ADASLink® diagnostic scan tool with secure gateway ability for dynamic calibrations, pre- and post-scans, and steering system resets.

Then, HawkEye® Elite X provides a seamless upgrade to Hunter’s award-winning, best-in-class Ultimate ADAS® static calibration system that cuts target setup time by up to 70 percent via laser-guided precision.

The new Maverick® Pro center-clamp tire changer builds upon the original Maverick® with two important enhancements. The first is a new ergonomic pick-and-place wheel lift capable of lifting and tilting heavy assemblies and 19.5s up to 175 pounds in one smooth motion. The lift holds position while elevated and then lowers automatically.

Additionally, the Maverick® Pro features an under-wheel light that illuminates the lower roller and bottom bead during the mount/ demount process.

Hunter’s Quick Check® autonomous inspection systems now feature the new Inspection Live cloud-based software, allowing two lanes to be run from a single console, overthe-air updates on a weekly or monthly basis, and more.

The new Road Force® WalkAway™ wheel balancer now features Hunter’s WalkAway™ inflation system, designed for dramatic time savings of up to 15 minutes on a typical fourtire changeover.

I-CAR at SEMA 2025: Education, Innovation & Hands-On Expertise

I-CAR®, the industry’s trusted leader in training, innovation, and workforce development, returns to the 2025 SEMA. This year, I-CAR reinforces its role as a leader in education with interactive training, technology showcases, and expert-led insights designed to help owners, technicians, and industry professionals stay ahead. Visit I-CAR at booth #33135 in the Upper South Hall!

Innovation in Action:

VR Training & 2026 Sneak Peek

I-CAR’s Virtual Reality (VR) experience lets technicians refine their skills in a simulated, risk-free environment. The demo also offers a preview of I-CAR’s newest immersive learning format, launching in 2026, underscoring the organization’s mission to deliver relevant, accessible, and on-demand training.

Hands-On Demos: Welding in Real Time

At the SEMA Collision Repair & Refinish Stage (#32145), I-CAR experts will deliver live welding demonstrations, giving attendees the chance to see best practices in action.

Expert Insights: Trends & Skills You Can Use

I-CAR specialists and industry partners will lead discussions on collision repair challenges and solutions. These sessions offer practical takeaways and will be available on-demand.

Training That Matters: Practical Courses

I-CAR will host six courses in classrooms S224 & S225, including:

• MIG Welding (two courses, from basics to advanced)

• Electric Vehicles (two courses on high-voltage safety and service)

• ADAS (two courses on calibration and sensor mounting challenges)

Reserve Your Spot

Reserve VR or welding demos at the I-CAR booth or Stage via QR code. Learn more about I-CAR’s SEMA 2025 schedule at I-CAR.com and follow I-CAR on Facebook, Instagram, LinkedIn, and X.

Booth 32213 Kecotabs.com

KECO Body Repair Products is a leading manufacturer and innovator in Glue Pull Repair (GPR) technology, based in Oklahoma City. For decades, collision damage that was once written off as “replace only” can now be repaired thanks to KECO’s commitment to unlocking repairability.

At the center of KECO’s offering is the L2E Premium Collision System - a fully equipped, shop-ready solution that enables collision centers to repair complex damage with confidence. Unlike traditional methods that require grinding, welding, or excessive heat, KECO’s GPR process utilizes precision tools and lateral tension to release locked metal and maintain the unlocked state throughout the repair.

The L2E Premium is designed to streamline workflow. Organized drawers, a shadow board, and advanced tools ranging from rough-out to flat finish, ensure technicians have everything they need - from large pulls to fine knockdown work - without slowing down the repair process.

Training is central to KECO’s mission. Hands-on courses in Oklahoma City and on-site shop training provide technicians with the skills to maximize efficiency, achieve OEM-compliant results, and safely repair modern materials, including aluminum and EVs.

Shops adopting KECO systems report faster throughput, lower material costs, and reduced delays from parts replacement. By giving repairers the tools and process to repair more and replace less, KECO is shaping the future of collision repair.

Booth 31017 jetx.sata.com/100yearsedition

SATA Marks 100 Years with Exclusive Anniversary Spray Guns

Kornwestheim, Germany – Exactly one hundred years ago, SATA — then known as Sanitaria — produced its very first spray gun. Today, the company is celebrating that milestone with the launch of the jet X 100 Years Edition and a strictly limited production of three anniversary spray guns created especially for the occasion.

It all began in 1925 with a chance meeting on a train. One passenger represented Sanitaria AG, the other the Lackfabrik Lechler paint factory. The later was searching for a tool to apply his newly developed sprayable paints. Sanitaria, already experienced in atomizing liquid materials, had the answer. That conversation led to the development of the company’s very first spray gun — and a century of continuous innovation.

This fateful encounter is now being celebrated for the hundredth time. To mark the occasion, SATA is releasing the jet X 100 Years Edition, a special edition of its current top model. The design proudly features the original technical drawing of the “No. 1” spray gun from 1925. Available exclusively through authorized SATA distributors — available late-October - while supplies last— it’s a unique blend of top-tier performance and rich heritage.

SATA enthusiasts can also find the SATAminijet 4400 B and SATAjet 100 B 100 Years Editions available individually, each carrying the same striking anniversary design.