SAFE TEAM

At Asplundh, safety is the starting point. Our “Safety Always” culture, hands-on training and rigorous protocols prepare our people to prevent accidents, so they return home safe and your projects move forward with confidence. Whether it’s managing vegetation, maintaining infrastructure, responding to storms or leveraging digital solutions, one call connects you to a full workforce with the expertise to deliver, all working as one safe team.

RELIABILITY THAT GOES DEEPER.

ABB Installation Products for electrical applications are grid resilient, storm hardened, sustainable, and safety proven — including our Elastimold® solid-dielectric switchgear. ABB is engineered to outrun because there’s no benefit as powerful as reliability. Learn more.

The California utility invented the AWARE system to mitigate outages, expedite restoration and improve productivity for the field workforce.

The California electric utility shares how it is upgrading its substation automation systems on its path to grid modernization.

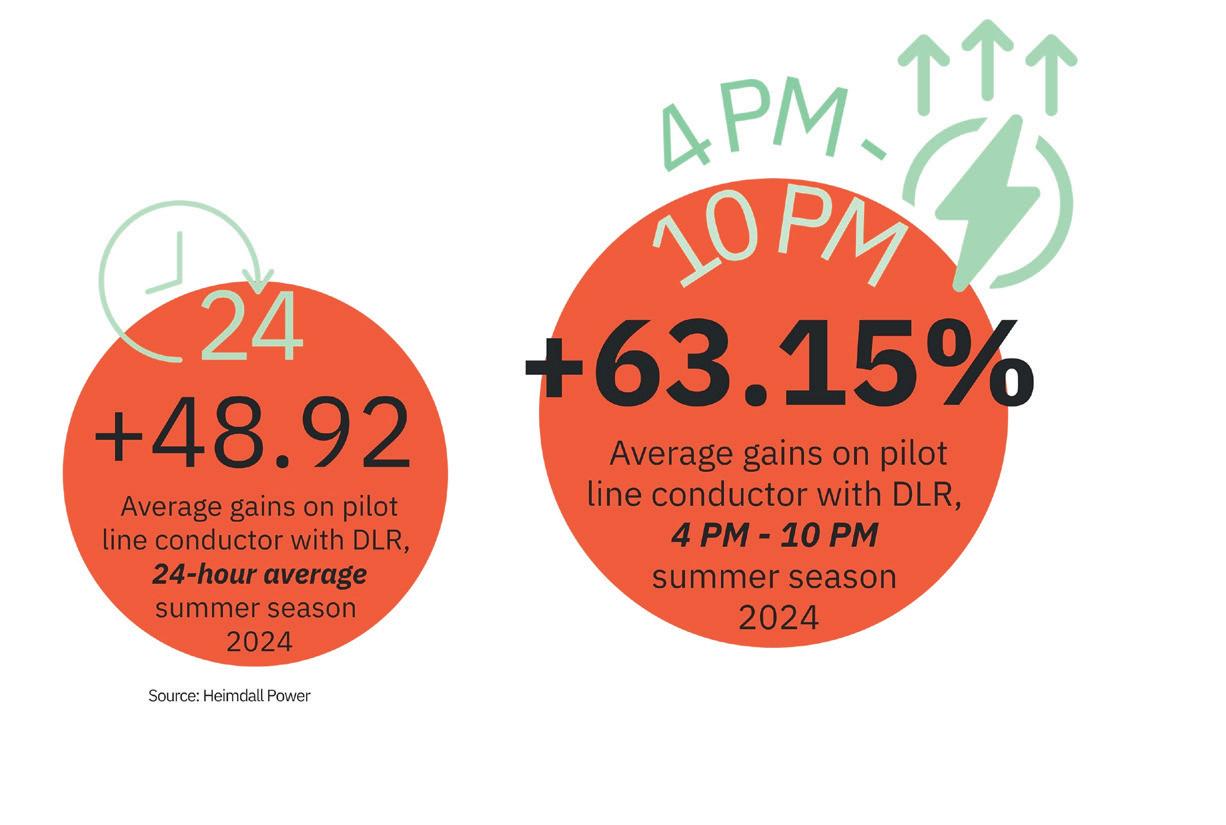

Great River Energy’s implementation of dynamic line rating demonstrated capacity gains, cost savings, and enhanced grid resilience through real-time weather and line condition data.

Courtesy of Southern California Edison

CHAMPION FIBERGLASS® UTILITIES PROJECT SOLUTIONS FROM

No burn-through eliminates elbow repairs

Lower materials and installation costs

Mechanical strength protects conductors

Low coefficient of friction for smooth pulls

Operable in temperatures of -40 degrees to +230 °F

Height adjustable expandable utility risers for easy installation

New on tdworld.com

Visit the website daily for breaking news, videos and photo galleries.

Electric Utility Operations: Transmission Project Gets Regulatory Green Light in Illinois

The 380 miles of high-voltage lines will increase access to energy sources in the Ameren Illinois service territory. https://tdworld.com/55309703

Overhead Transmission: Rethinking Utility Pole Restoration as a Capital Investment

Utilities are shifting from traditional pole replacement to strategic reinforcement, emphasizing regulatory frameworks, cost management, and innovative technologies to enhance grid resilience amid climate threats. https://tdworld.com/55314026 Smart Utility: How Utilities Can Protect Ratepayers from Rising Costs

With increasing frequency and cost of weather disasters, utilities are turning to AI to enhance asset inspection, resource allocation, and decision-making, fostering a more resilient and affordable power grid while maintaining traditional practices. https://tdworld.com/55311219

Group Editorial Director Nikki Chandler nchandler@endeavorb2b.com

Managing Editor Jeff Postelwait jpostelwait@endeavorb2b.com

Senior Editor Christina Marsh cmarsh@endeavorb2b.com

Art Director Julie Whitty jwhitty@endeavorb2b.com

Field Editor Amy Fischbach EOUeditor@endeavorb2b.com

Technical Writer Gene Wolf GW_Engr@msn.com

Community Editor Rich Maxwell tdwmediapartners@gmail.com

Senior Editor-at-Large Geert de Lombaerde gdelombaerde@endeavorb2b.com

Director, Business Development Steve Lach slach@endeavorb2b.com

VP, Customer Marketing Angie Gates agates@endeavorb2b.com

Senior Production Operations Manager Greg Araujo garaujo@endeavorb2b.com

Ad Services Manager Shirley Gamboa sgamboa@endeavorb2b.com

Audience Marketing Manager Sonja Trent strent@endeavorb2b.com

Audience Development Manager James Marinaccio jmarinaccio@endeavorb2b.com

Endeavor Business Media, LLC

CEO: Chris Ferrell

COO: Patrick Rains

CRO: Paul Andrews

CDO: Jacquie Niemiec

CALO: Tracy Kane

CMO: Amanda Landsaw

EVP Endeavor Business Intelligence: Paul Mattioli

EVP Water & Energy Group

Diana Smith

VP of Content Strategy, Water & Energy Group Bob Crossen

T&D World (USPS Permit 795-660, ISSN 1087-0849 print, ISSN 2771-6651 online) is published 10 times a year (January to June, August to October and December) by Endeavor Business Media, LLC. 201 N Main St, 5th Floor, Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI, and additional mailing offices. Canadian GST #R126431964.

POSTMASTER: Send address changes to T&D World, PO Box 3257, Northbrook, IL 60065-3257.

SUBSCRIPTIONS: Publisher reserves the right to reject non-qualified subscriptions. Subscription prices: U.S. ($137.50); Canada/Mexico ($170.00); All other countries ($210.00). All subscriptions are payable in U.S. funds.

Send subscription inquiries to T&DWorld, PO Box 3257, Northbrook, IL 600653257. Customer service can be reached toll-free at 877-382-9187 or at tdworld@ omeda.com for magazine subscription assistance or questions.

REPRINTS: To purchase custom reprints or e-prints of articles appearing in this publication, contact Reprints@endeavorb2b.com

PHOTOCOPIES: Authorization to photocopy articles for internal corporate, personal or instructional use may be obtained from the Copyright Clearance Center (CCC) at 978-750-8400. Obtain further information at copyright.com

PRIVACY POLICY: Your privacy is a priority to us. For a detailed policy statement about privacy and information dissemination practices related to Endeavor products, please visit our website at www.endeavorbusinessmedia.com

CORPORATE OFFICE: Endeavor Business Media, LLC, 30 Burton Hills Blvd, Ste. 185, Nashville, TN 37215, U.S.; www.endeavorbusinessmedia.com.

© Copyright 2025 Endeavor Business Media, LLC. All rights reserved. Printed in the USA.

Sanghwan Kim/iStock/Getty Images Plus

Ameren

ID 6211175 © Traffictax | Dreamstime.com

The Grid’s Check Engine Light

Early warnings have been in use in most aspects of our lives for a long time. Each year, we go to the doctor for checkups where we have our blood taken to monitor for any early warnings of something going wrong with our bodies. In fact, I just walked out of one of my preventive screenings today, having felt relieved for checking that box feeling fortunate to have access to regular preventive care.

We have early warning systems for cars too. A few weeks ago, my daughter’s check engine light started flashing, and before the engine could be permanently damaged due to a leaking gasket seal (among other things), we were able to get the car into the shop and soon she was on the road back to college.

The grid has also had fault detection and location technologies for many years, but these have traditionally only identified problems after a fault had already occurred. In those cases, some damage may have been avoided through faster response, but the fault itself was not predicted in advance.

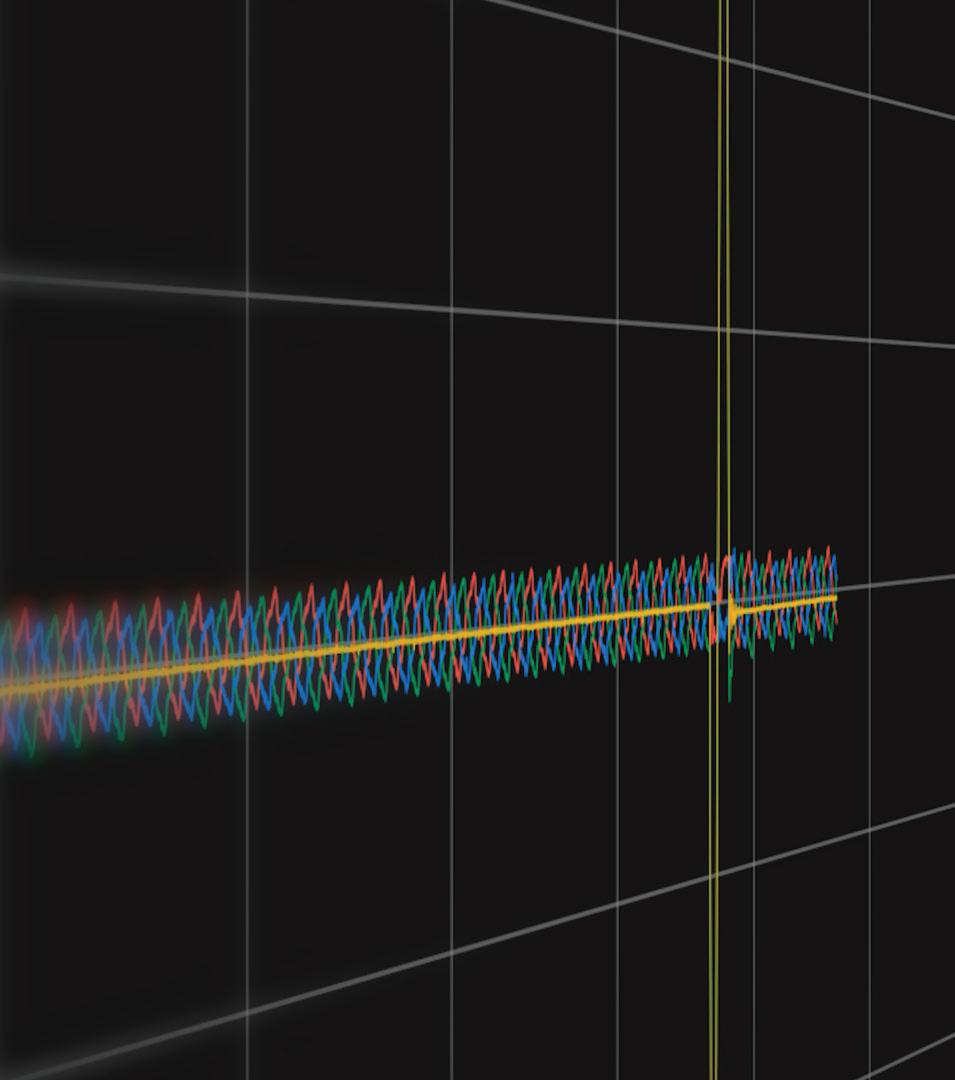

With the advent of machine learning, and more advanced artificial intelligence, which rely on collecting and interpreting vast amounts of operational data, we are seeing amazing potential for all kinds of applications for the grid. In our cover story written by Field Editor Amy Fischbach, we learn about Edison Award winner Southern California Edison’s AWARE system.

What’s new with tools like AWARE (Advanced Waveform Anomaly Recognition) or other AI-driven waveform anomaly detection is that they’re moving closer to pre-fault detection, essentially recognizing subtle waveform distortions or anomalies that may indicate equipment stress before an outright failure happens.

SCE started on this initiative just two years ago. The grid operations team had a vision to be able to shift from reactive response to predictive intelligence, thinking this would help them catch issues sooner and ultimately enable better forecasting and reduce restoration times, which is the essence of resilience. And that is how AWARE came about. Now SCE is actively using the system and working to improve it.

There has been some confusion in the industry about the nature of AI and how it can be used. T&D World Technical Editor Gene Wolf has done a great job of explaining and keeping up to date on the technology; just check out his monthly Charging Ahead section in each issue. His take on SCE’s new system in comparing it to standard protective relays: “AI looks at patterns of events. It doesn’t operate faster than a relay, and it doesn’t need to. AWARE is not replacing the relay; it’s

identifying potential issues that may cause the line to trip before the line trips. AI knows where that event is located, and a crew can be dispatched to fix the issue before it’s an outage. The relay looks for a current spike and AI looks at overall operations. AWARE is going to help SCE and other utilities. AI needs to be used to learn.”

A Favorite Fall Activity

As the weather cools down here in Kansas City and pumpkins appear everywhere, the T&D World staff and the International Lineman’s Rodeo Association are putting the finishing touches on rodeo preparations. I shared in my Global Viewpoint last year some of my favorite memories over the years of this event, as it really has been a tradition with our staff and my family.

If you ever get the chance to see it, don’t pass it up! It really is a celebration and tribute to our lineworkers. T&D World has been honored to partner with IRLA for so many years on this. Watch for our coverage in next month’s issues and online; we cover everything we can about it from the competition (of course), the tools, the families, and the awards.

Appreciation for Service

Speaking of memories, we have had two major retirements at T&D World this year, and I couldn’t resist sending these two individuals a thank you and best wishes. Our art director of more than 30 years, Susan Lakin, retired at the beginning of the year. Susie was one of those few media designers who had a passion for the electricity industry. She read every article that she designed (which, believe it or not is rare), and even pointed out a few typos to us grammar nerds. Her appreciation of the beauty of transmission lines and substations shined through in the pages of T&D World magazine for many years. When you get a chance, check out our 75th Anniversary print/digital edition from last November where you will see one of her most heart-felt designs.

This August, long-time advertising sales representative Steve Lach retired. He had been with the magazine for 36 years, creating enduring relationships with the product and service providers for T&D World. From the time I joined T&D World as an intern in the 90s, Steve made me feel like part of the family. He was a big part of growing the magazine and media brand but was always giving credit and praise to everyone else.

We have been blessed to have such an amazing tradition of dedicated team members bringing T&D World forward, and our current family will continue to serve you with the same dedication and passion for this industry.

The Tech-Landscape Is Changing

“Charging Ahead” has covered remote working and the technologies that make it possible for many years now. Last December we talked about Wi-Fi 7 gaining popularity and how it will improve our workplace’s speed, connectivity, and stability. This month we’re highlighting our PC’s (personal computers) evolving operating systems (OS). It’s October and the 14th is the deadline for migrating from Windows 10 to Windows 11, but what does that entail? Microsoft has been trying to get users to install the Windows 11 OS for several years now, but many of us have been procrastinating.

365 user and I have been ignoring Microsoft’s notices to upgrade my OS since they started showing up in my inbox. Yep, I put off installing Windows 11 because of my desktop’s component limitations and now the deadline is here.

Resistance is Futile

I’d like to be upset at Microsoft, but how can I? After all, they launched Windows 10 back in 2015 and have been trying to get my attention for years. Also, how many other operating systems can you name that have been supported for ten years? I can’t think of any. Heck, if this was my smartphone we were talking about, I would have up -

Windows 11 has some very specific hardware requirements for a PC to install and operate it. Unfortunately, many older PCs can’t be upgraded because of these component constraints. Google’s “AI Overview” reports that there remain potentially millions of Windows PCs worldwide requiring the upgrade to Windows 11, but they’re handicapped by their aging architecture. So, what happens? Well. come October 14th, Microsoft stops supporting Windows 10. They will no longer supply security patches, bug fixes, or technical support.

Taking it a step further, it’s going to limit access to new features and technologies. Imagine, for example, not being able to run a program as commonplace as the Microsoft 365 (formally Office 365). That really caught my attention! I’m a heavy

graded it every two or three years and never thought anything about it. This is the way!

Still, there are options available. Microsoft is offering a free year of Windows 10 security support to those users who qualify. For those who don’t qualify, there’s a one-year program that costs US$30. For the techno type, there’s also the option of moving to another OS like Linux Mint and bypassing the whole issue. In addition, it’s been said there is a franken-computer option by adding parts to their old PC, but that’s a waste of time because it’s not real.

Keeping it simple, it’s a hardware compatibility issue. The CPU (central processing unit), GPU (graphics processing unit), RAM (memory), and other PC resources must meet stringent requirements. Also the PC must include system firmware like

the TPM (trusted platform module)

UEFI (unified extensible firmware interface) and secure boot.

For those wanting more facts, there are excellent websites with extensive details available, but let’s get back to that statement about Windows 10 having limited access to technologies.

The Changing AI Workplace

As you may have noticed, this is a subject that’s important to me. As I said, I have been dragging my feet deciding what to do with the Windows 11 dilemma, but my research changed that. Replacing my PC will allow me to continue exploring the expanding virtual world of artificial intelligence (AI), which would be close to obsolete technology. An upgrade to my favorite graphic suite focused my attention on that with its latest features.

It offered elements that would have seemed like science fiction a few years ago but are a reality today and AI is driving this advancement. Looking through the directory on my PC uncovered many programs and applications that had been revised with advanced features. Revisions that are more complicated, but they also include AI-driven tools, making their complexity extremely user friendly. Just look around and you’ll find AI enhanced software is everywhere. It’s been added to spreadsheet programs, project management suites, PDF software, to name a few applications.

Even routine tasks are becoming AIpowered. When was the last time anyone used a paper map? My smartphone AI assistant provides detailed locational directions to wherever I’m going. My tablet has replaced that old-school clipboard. It can be loaded with records that can be quired by voice for information. Forms can be filled out using only my voice for collecting field data.

The tech-landscape is evolving and without cutting-edge computing we can’t keep up with these technological advancements!

Tapping Into the AI Electric Utility

Isn’t it time to consolidate the smart grid elements that we have available?

Who would have thought when smart grid technology was introduced it would have had the impact it has?

Initially, it was considered more of a hodgepodge of digital technologies than anything approaching a smart grid. Integrating sensors, transducers, and controllers into critical equipment like large power transformers to monitor the essential parameters made sense to many stakeholders. Large transformers are expensive, have long lead times for replacements, and impact a utility’s ability to deliver electricity. Something like a smart electric meter, however, was a different story and acceptance took a while.

The technology improved with features like two-way communications and control, which added to the appeal of the smart grid concept. The availability of real-time data proved valuable for monitoring a wide range of utility assets and bringing self-awareness to both sides of the meter. Smart grid applications got a needed boost with the introduction of UIoT (utility internet of things), a branch of IoT (internet of things) technologies. UIoT dealt specifically with technologies within the utility sector, and it brought attention to their benefits. Several decades later smart grid technology has become so intertwined with the power delivery system that it’s impossible to have one without the other.

The worldwide marketplace has responded favorably to this condition, but it has been the influences of artificial intelligence (AI) that’s getting everyone’s attention. According to an “AI Overview” query, smart grid’s global market has undergone a positive uplift with the integration of AI (artificial intelligence) into its digital-based components. The inquiry indicated that smart grid technologies, particularly those driven by AI, are

experiencing robust growth. It’s expected that this market will reach an estimated US$208.15 billion by 2032.

So What’s Next?

AI-powered digital systems are transforming the power grid’s landscape by providing it with the self-awareness needed for the dynamic environment the power grid finds itself in today. A few months ago we looked at the holistic approach of the end-to-end digitalization the power grid needs to keep up with our rapidly changing landscape. This growing trend is needed to improve the power grid’s performance, which brings us to the next logical step. The AI electric utility is being seen as the most effective approach to consolidate AI and the smart grid.

What is an AI electric utility? Defining that isn’t easy with an undertaking that’s still developing and evolving. Like so many of today’s digital-based applications, the definition is somewhat fluid. Let’s just say it’s the optimal method to combining AIdriven functionality with the smart grid applications. As one group put it, the goal is to upgrade the operations of the existing electric power grid. A DOE (Department of Energy) report points out that advancements in AI are maximizing energy operations while reducing risks.

That’s pretty much the goal of every sophisticated digital platform that’s been deployed by the utilities and grid operators in the past several years, but the AI utility is a bit different. We have a wide selection of advanced technological applications that watch, supervise, and manage everything from vegetation dangers to power flows, and the number is growing. Merging them provides a critical awareness that’s best achieved when these systems are working together rather than continuing as individual elements.

Operating Beyond Old Boundaries

An illustration of this is the asset management system’s (AMS) evolution. AMS has been moving in this direction since its inception. As AMS matured, it produced really big-data that needed AI to turn it into useful information. Basically, that led to asset health modules, which brought about performance modules. Other useful elements came along that had positive influences on other digital systems, which in turn grew in numbers. As the old adage says, “A rising tide lifts all boats.”

Schemes such as distributed energy resource management systems, demand response programs, vegetation risk platforms and others followed this same process. Features were added and functions led to interactions between the various smart configurations and AI became the glue holding it all together. AI-driven functionality linked multiple databases and integrated them with a variety of digital asset technologies. Interestingly, we are just starting to see how the AI electric utility fits into this process and some other more well-known applications.

“Charging Ahead” has featured many of these AI-enhanced tools this year such as the virtual power plant, community microgrids, battery management systems, etc. These unconventional approaches symbolize more than a band-aid for the existing power grid. Each is a piece of the AI Utility’s virtual infrastructure needed by the aging infrastructure to address the growing challenges of climate change and the

grid’s growing power demands. Let’s look at actual advanced AI utility projects

Deploying the Next Generation

A few months ago, the California Independent System Operator (CAISO) and Open Access Technology International (OATI) announced a groundbreaking pilot program that the two have entered. It marks the first time that an ISO is deploying AI technology to streamline operational processes starting with outage management. A press release from OATI said, “It was the world’s first generative and agentic AI platform purpose-built for the energy industry.” CAISO is the balancing authority for 80% of the state of California and parts of Nevada. CASIO is also the operator of the Western Energy Imbalance Market, so this is a major generative AI pilot project.

The release continued saying, “CAISO’s pilot will determine the extent to which its outage management system, which includes structured tables, unstructured text and long review times for system operators, can be made nimbler and more efficient using generative AI.” CAISO stated this program fits perfectly with their ongoing control center modernization program. It was expected that this tool would improve the operators’ situational awareness and free up time for other important tasks that can make a real difference for those operators. Testing is expected to start later this year, which will move the AI utility another step forward.

PD Monitoring Expertise in a Box

With our PARADIMO 100 system, you do not have to be an expert to monitor partial discharge (PD) activity, interpret the data and verify insulation condition in Gas-Insulated Switchgear (GIS) and Gas-Insulated Lines (GIL).

PARADIMO 100 continuously monitors PD activity in GIS and GIL and displays real-time and trend data on a PC or tablet via the convenient Web interface. It automatically detects and classifies PD defects sothat you can easily and reliably assess the risk and take corrective action to prevent failure. With PARADIMO 100, it is like having your own PD expert in a box.

omicronenergy.com/paradimo100

SCAN ME!

Earlier this year, the AI utility received backing from EPRI (Electric Power Research Institute) in the form of its “Open Power AI Consortium.” EPRI’s announcement stated the Consortium membership numbers over 116 industry leaders (at the time of this writing). They consist of electric utilities, technology providers, and researchers from around the world.

EPRI said that the Consortium, “will drive the development and deployment of cutting-edge AI solutions tailored to enhance operational efficiencies, increase resiliency and reliability, deploy emerging and sustainable technologies, and reduce costs while improving the customer experience.” EPRI continued saying the Consortium “aims to evolve the electric sector by leveraging advanced AI technologies to innovate the way electricity is made, moved, and used by customers.”

Also, Duke Energy has released several announcements this year about their plans for deploying AI throughout their operations. It’s said to be a holistic integration of AI-powered technology across the entire organization ranging from business development to maintenance and everything in between. One report said Duke would be using generative AI to reduce interconnections study times from weeks to minutes. Another release said Duke was combining human expertise with AI’s predictive maintenance to improve operations and the health of critical equipment like power transformers. This is tapping into the AI electric utility big-time!

AI Collaborator

These are only a small portion of news releases and announcements coming from utilities and grid operators telling how they are using AI-driven technologies. Overall it appears that AI in general and generative AI in particular are finding their way into the power grid in growing numbers. Surveys are listing percentages of utilities utilizing AI ranging from 30% to over 70%, but it’s the growing interest that’s important.

Overall, some utilities are totally embracing AI, while others are in the initial stages of acceptance. Most users, however, reside in between, which isn’t surprising. The power delivery industry is more risk-averse than other industries because keeping the power flowing is critical to modern society.

Interestingly, there’s a subtle shift that kept popping up in the research for this article. It’s the blending of AI’s abilities with human expertise that was discussed by many utilities in their narrative of deploying AI on their systems. Developers found that humans brought innovative problem solving into the relationship. In addition, humans can identify potential blind spots that AI is unaware of. They recognize a possible problem through critical thinking that the AI applications lack. This shift is beginning to look like a trend, which will be interesting to watch as it progresses. Ultimately AI utility needs people and AI technology working together to be successful!

Leaders in microgrids have something in common

They use the RTDS® Simulator to test their systems.

How do you validate microgrid protection and control systems?

The RTDS® Simulator is the world standard for real-time digital simulation, used worldwide for the closed-loop testing of protection and control systems. Hardware-in-the-loop testing allows users to de-risk the integration of novel systems and optimize performance by connecting real devices to a simulated network. Closed-loop testing with a real-time simulator reduces commissioning delays and increases reliability, resilience, and performance. In the hands of innovators, the RTDS Simulator is changing the grid as we know it.

QUICK CLIPS

BY T&D WORLD STAFF

Report: Worsening Transformer Shortages Amid Rising U.S. Power Demand

The U.S. power sector is facing mounting strain as demand for transformers outpaces supply, according to a new analysis from Wood Mackenzie. The report projects that by 2025, supply shortages could reach 30% for power transformers and 10% for distribution transformers, creating challenges for utilities and delaying new generation projects.

Wood Mackenzie’s study, Untangling the U.S. Transformer Supply Chain Crisis, notes that demand for power transformers has surged 116% since 2019, while distribution transformer demand has grown 41%. Rising electricity consumption — up 7% since 2020 after a decade-long decline — coupled with aging infrastructure and a surge in clean energy projects, has fueled the pressure.

“Domestic manufacturing capacity simply cannot keep pace,” said Ben Boucher, senior analyst for supply chain data and analytics at Wood Mackenzie. “By 2025, imports are expected to make up 80% of U.S. power transformer supply and 50% of distribution transformer supply. This imbalance is raising costs, lengthening lead times, and delaying critical projects.”

The report also highlights policy and trade developments as complicating factors. New tariffs, including a planned 50% tariff on copper in August, are expected to drive up costs for both imported and domestically manufactured transformers. In addition, recent legislation — including President Trump’s “One Big Beautiful Bill” — is projected to alter demand for step-up transformers by scaling back clean energy incentives.

Despite these challenges, manufacturers have announced more than $1.8 billion in new North American capacity investments since 2023. While those projects may provide some relief, Wood Mackenzie cautions that they will not be enough to fully close the supply gap given the pace of demand growth.

“The U.S. transformer market stands at a critical juncture,” Boucher said. “Without coordinated action on standardization, workforce development, raw material supply, and trade policy, extended lead times and elevated costs could become the new normal — with major consequences for grid modernization and clean energy deployment.”

Hitachi Energy Commits $450M+ to New Virginia Transformer Factory

Executives of Hitachi Energy say they’ll spend $457 million to build a new transformer plant next to one of its facilities in Virginia. The new factory, which officials say will be the country’s largest for making large power transformers, is expected to employ 825 people once fully up and running.

The new South Boston plant will crank out transformers to be used in high-voltage transmission and power generation projects as well as in data centers and large-scale industrial sites. Word of Hitachi’s large investment plan comes just a few weeks after executives said they’ll spend $100 million to add to

the latest in a series of investments—by Hitachi as well as manufacturing peers such as GE Vernova, Schneider Electric and Eaton—that aim to increase U.S. manufacturing capacity of critical grid

“Power transformers are a linchpin technology for a robust and reliable electric grid and winning the AI race,” said Andreas Schierenbeck, CEO of Hitachi Energy. “Bringing production of large power transformers to the U.S. is critical to building a strong domestic supply chain for the U.S. economy and reducing production bottlenecks, which is essential as demand for these transformers across the economy is surging.”

Construction work on the second South Boston plant will begin by year’s end and be completed by 2028. New workers will be hired in phases but a spokesperson said the company expects to ramp up production and hiring “fairly quickly.”

Hitachi Energy’s existing plant in South Boston opened its doors nearly 60 years ago.

Hitachi Energy

shaunl/E+/Getty Images

Emergency Order Issued to Secure Grid Reliability in Midwestern Region

The U.S. Secretary of Energy, Chris Wright has issued an emergency order to minimize the risk of power outages and address critical grid security issues in the Midwestern region of the United States.

The order directs the Midcontinent Independent System Operator (MISO), in coordination with Consumers Energy, to ensure that the J.H. Campbell coal-fired power plant in West Olive, Michigan remains available for operation. MISO is also directed to take every step to minimize cost to the American people.

Since DOE’s original order in May 23, the Campbell plant has proven critical to MISO’s operations, operating regularly during periods of high energy demand and low levels of intermittent energy production. The Campbell Plant was scheduled to shut down on May 31, which is 15 years before the end of its scheduled design life.

“The United States continues to face an energy emergency, with some regions experiencing more capacity constraints than others,” said U.S. Secretary of Energy Chris Wright. “This order will help

Trump Names David Rosner Chairman of FERC

President Donald Trump has named David Rosner Chairman of the Federal Energy Regulatory Commission (FERC).

“I am honored to serve as Chairman and excited to continue working with my colleagues on the Commission and FERC’s extraordinary staff to enable reliable, affordable, and abundant energy for all Americans. Energy lights our homes, powers our businesses, and we need it more than ever to grow the innovative industries of the future,” Rosner said.

Rosner has served as a FERC Commissioner since June 2024 and has nearly two decades of experience in energy technologies, market design, and energy policy. Prior to his appointment as Commissioner, he was an energy industry analyst at FERC and spent two years on detail to the U.S. Senate Energy and Natural Resources Committee staff. At FERC, he led efforts related to electric transmission, fuel security, energy storage resources, and natural gas-electric coordination.

His previous roles include senior policy advisor for the U.S. Department of Energy’s Office of Energy Policy and Systems Analysis and associate director at the Bipartisan Policy Center’s energy project.

ensure millions of Americans can continue to access affordable, reliable, and secure baseload power regardless of whether the wind is blowing or the sun is shining.”

According to DOE’s Grid Reliability Evaluation, power outages are expected to increase by 100 times in 2030, if the U.S. continues to take reliable power offline. The emergency conditions that led to the issuance of the original order will be continued.

The order is in effect beginning on August 21, 2025, and will continue until November 19, 2025.

Google, Kairos Power and TVA Collaborate to Deliver Clean Energy

Google, Kairos Power, and the Tennessee Valley Authority (TVA) have collaborated to meet America’s growing energy demand and strengthen the country’s leadership in advanced nuclear energy. Through a new power purchase agreement (PPA) between Kairos Power and TVA, Kairos Power’s Hermes 2 Plant in Oak Ridge, TN, will deliver up to 50 MW of energy to the TVA grid powering Google data centers in Tennessee and Alabama.

TVA will buy electricity from an advanced, GEN IV reactor, and Hermes 2 under Kairos Power’s deal with Google to enable 500 MW of new, advanced nuclear capacity to come online by 2035 in support of Google’s load growth. Kairos Power will increase Hermes 2’s output from 28 MW to 50 MW generated by a single reactor, scheduled to begin operations in 2030, to accelerate the delivery of clean energy to Google.

As part of the agreement, Google will receive the clean energy attributes from the plant through the TVA system to further decarbonize its data center operations in Montgomery County, TN, and Jackson County, AL, and support future growth in the region.

Tennessee Valley Authority

The California utility invented the AWARE system to mitigate outages, expedite restoration and improve productivity for the field workforce.

By AMY FISCHBACH, Field Editor

Imagine having the power to diagnose an illness even before symptoms even appear. While this technology may not yet be widely available with the human body, it is already happening with the electric grid. A new AI tool — the Advanced Waveform Anomaly Recognition (AWARE) system — is capturing the pulse of the grid by installing digital fault recorders (DFRs) at substations to capture distribution voltages and currents.

Two years ago, the Grid Operations team at Southern California Edison (SCE) embarked on the mission to detect grid faults earlier and prevent them from escalating into major outages. By shifting from reactive response to predictive intelligence, the team could catch issues sooner, enable smarter forecasting and reduce restoration times. To accomplish these goals, the AWARE system was born out of necessity.

“We challenged ourselves to move beyond traditional fault-finding techniques and start thinking in patterns,” said Vik Trehan, vice president of Transmission, Substations and Operations at SCE. “Waveforms contain the unique signatures of different failure modes. Learning to interpret those signatures allows us to fundamentally reimagine how we translate raw waveform anomalies into actionable insights.”

The AWARE system is designed to work alongside other monitoring systems by giving a head start in finding and fixing grid issues.

Courtesy of Southern California Edison

sensor data to flag early signs of trouble long before traditional alarms go off. It interprets patterns invisible to the human eye and too subtle for conventional monitoring, converting raw waveform “noise” into meaningful fault signatures.

SCE was inspired to leverage the sensors already in its system and develop a comprehensive solution combining physics, machine learning and human expertise into a unified, proactive solution.

“The breakthrough was recognizing that waveforms are stories,” Trehan said. “Interpreting those stories allowed us to move beyond reacting to grid issues to anticipating them. AWARE gives us that capability, a step toward an AI-native grid — one that’s smarter, more proactive and ultimately, safer.”

By proactively identifying electric system issues, AWARE is making the grid safer and more reliable for the communities served by SCE, said Pedro J. Pizarro, president and CEO of Edison International, parent company of SCE.

“As homes and businesses increasingly rely on clean energy, using advanced technology can help reduce the number and length of outages and repairs,” Pizzaro said. “When we identify and fix problems faster, customers win with more affordable, available, and reliable electricity.”

Proactively Identifying Grid Issues

The AWARE system can detect earlystage and evolving power system faults long before they become visible through

traditional monitoring. It identifies subtle waveform anomalies that correspond to emerging equipment degradation. These faults, left unchecked, can potentially trigger widespread outages or damage infrastructure.

“What sets AWARE apart is its precision: it doesn’t just detect that something is wrong — it identifies what, where and how soon it may fail,” Trehan said. “The system continuously ingests waveform data from existing technologies and applies tailored algorithms to sense meaningful deviation from normal electrical behavior. This enables proactive intervention.”

Instead of waiting for failures to trigger alarms, AWARE reads the warning signs buried in the noise, which makes it possible to isolate risks earlier, prioritize critical assets and guide field response with surgical accuracy. Case in point: in the pilot phase, when smart meter data was captured by AWARE, the locations of issues were accurately identified 80% of the time within the immediate vicinity, sometimes down to a specific piece of equipment.

Diving Into the Technology

At its core, AWARE fuses physics-informed AI/ML with real-time waveform and

The system continuously processes data, and when something deviates — whether it’s a fractured bushing, a failing capacitor, a loose connector or a potential high-impedance fault —AWARE flags the anomaly, assigns a probable fault type, and correlates it with location and equipment metadata.

But AWARE doesn’t just detect; it classifies. Using signal processing and machine learning layered with physics models, it separates nuisance from necessity, reducing false positives while increasing precision. That means field crews get fewer vague alerts and more actionable ones like the right equipment, right location and right cause.

“The value isn’t just in identifying problems — it’s in shortening the time between insight and response and building trust in an AI system that actually earns its place in operations,” Trehan said.

Throughout the project, Trehan personally oversaw each phase of the implementation, translating high-level strategy into a system capable of operating at the intersection of engineering, AI and realworld operations.

“AWARE was born from a bold vision and a clear mandate: to unify grid technologies and engineering systems,

Left: Hamed Valizadehhaghi (left) and Kyle Chang are part of the Grid Operations team that worked on the AI tool two years ago to better address disruptions to the grid. Center: SCE’s AWARE system monitors the health of the grid and alerts crews to early-stage faults. Right: AWARE uses AI and machine learning to predict and identify potential anomalies on the grid that the human eye may overlook.

Photos by Roberto Lazarte

enhance them with AI/ML and shift from reactive outage response to predictive, proactive grid management through disciplined execution,” he said. “The success of this project was driven by the outstanding efforts of the Grid Operations team, whose expertise, innovation and bias for

action turned a moonshot concept into a working solution.”

Every phase reflected a culture of ownership and iteration, he said.

“We didn’t just build a tool; we refined a methodology,” he said. “The team pressure tested ideas against real waveform

data, worked shoulder-to-shoulder with field resources and architected a scalable platform grounded in physics and practicality,” he said. “The result is an AI-powered anomaly detection system that transforms raw data into foresight and field response into precision action.”

AWARE SYSTEM EARNS ELECTRIC POWER INDUSTRY’S HIGHEST HONOR: THE EDISON AWARD

The Edison Electric Institute (EEI) awarded Edison International and Southern California Edison (SCE) with the 97th Edison Award in June 2025 for the AWARE system. A panel of former electric industry executives selects the recipient annually for this award.

“On behalf of EEI and our member companies, I am proud to congratulate Edison International and Southern California Edison for winning this year’s Edison Award,” said Pat VincentCollawn, EEI interim president and CEO. “By developing innovative uses for artificial intelligence to help prevent power outages, Edison International and Southern California Edison are leading by example and showcasing the incredible ingenuity at the heart of our industry’s efforts to enhance the safety, reliability, and resilience of America’s energy grid.”

Trehan said the recognition was deeply humbling and rewarding.

“We’ve created something that can truly make a difference protecting people from getting hurt, preventing outages and reducing the cost of grid maintenance over time,” he said. “Knowing that this innovation came from within our own walls made it even more meaningful. It’s powerful to internalize

Integrating with Other Applications and Systems

The AWARE system is designed to work alongside other monitoring systems by giving a head start in finding and fixing grid issues and improving reliability for customers. While most existing systems are reactive, AWARE shifts the paradigm.

“AWARE offers a sharper signal-to-noise ratio, earlier detection windows and higher specificity in fault typing,” he said. “It doesn’t flood crews with alerts; it arms them with precision. At its core, AWARE flips the script on outage response. Instead of waiting for something to break, we’re using waveform data to see the break coming.”

SCE has taken measures to proactively mitigate faults before they potentially cascade into outages, often before customers or even crews are aware that anything

what this means at the utility level.

When you step back and look at our core metrics — customer satisfaction, affordability, reliability and safety — you realize this system touches all of them. There’s something grounding about

has gone wrong. This shift from reactive troubleshooting to early-stage detection means fewer surprises, less damage and better outcomes across the board.

“These tools can help utilities to make faster, smarter and more informed decisions and ultimately, support a more resilient, efficient and sustainable electric grid.”

“The system estimates fault locations with precision, helping us zero in on high-risk infrastructure quickly and act before failures escalate into safety hazards or customer disruptions,” he said. “Early detection of abnormal conditions enables

seeing your own team’s innovation reflected back through outcomes that matter. It’s a reminder that big ideas don’t always come from outside; they can come from the people who know the grid best.”

proactive remediation in high fire-risk areas, an operational advantage that also reduces liability. Fault type identification enhances situational awareness for crews, reducing windshield time and ensuring faster, safer responses.”

Pinpointing anomalies before they escalate shortens restoration time and improves crew efficiency, particularly in difficult settings like underground networks. Ultimately, less downtime and fewer extended outages translate directly into improved customer satisfaction, he said.

“The real power of AWARE isn’t just in finding faults faster — it’s in making them less likely to occur at all,” Trehan said.

Leveraging the Possibilities of AI

The AWARE system can identify unique waveforms for different types of

Pictured left to right: Pedro J. Pizarro, President and CEO of Edison International; Hamed Valizadehhaghi, senior advisor of Grid Operations; Vik Trehan, Vice President of Transmission, Substations and Operations; Steve Powell, President and CEO of Southern California Edison

equipment. While most systems search for symptoms, AWARE looks for signatures.

“By analyzing real-time electrical waveforms, AWARE detects subtle anomalies, like equipment wear or abnormal voltage drift, before they evolve into visible failures or outages,” he said. “This ability to recognize early warning signs allows for faster, more precise intervention. It not only boosts grid reliability but reduces customer impact.”

Unlike conventional fault detection tools that treat all disturbances as noise or group them into broad categories, AWARE identifies the unique “fingerprint” of each failure type. For example, the waveform signature of an underground cable fault will look entirely different from an overhead conductor arcing due to wildlife. AWARE’s evolving event catalog makes it possible to match these patterns and triage issues proactively.

“It’s the difference between guessing and knowing, reacting and predicting and a late response and none needed at all,” he said.

While most fault detection systems are narrowly scoped, triggered by known patterns and limited by rigid assumptions, AWARE doesn’t just detect what’s expected, Trehan said. Instead, it learns from the unknown.

AWARE works alongside existing grid technologies, but pushes far beyond them by detecting early, subtle signals

RESILIENT STRUCTURES FOR A RELIABLE GRID

As severe weather events intensify around the world, electric power grids are increasingly tested by hurricanes, ice storms and wildfires. In the face of these challenges, more than ever before, we need to stay connected – to the electrical grid and to each other. Resilient Structures composite poles have demonstrated near perfect performance by reliably standing strong in nature’s harshest conditions. Engineered to be resilient, safe and environmentally sound they are the new standard in grid reliability.

AWARE system flags anomalies with increased precision, meaning field crews get more actionable alerts to respond with the right equipment to the

of trouble, whether from equipment degradation, wear or emerging anomalies. What sets it apart is not just the data, it’s how SCE uses it.

By leveraging these core capabilities to handle real-world grid data, AWARE sets a new benchmark for applied AI:

• Custom AI/ML design tailored for grid signals. Instead of forcing grid

The

right location.

Courtesy of Southern California Edison

waveform data into off-the-shelf algorithms, AWARE crafts AI/ML features that capture the essence of fault events, unlocking nuanced relationships and surfacing rare failure modes that would otherwise be missed.

ASPEN

• Physics-aware modeling. Because distribution data can be messy, Trehan said, AWARE uses expert-guided physics models to de-noise and contextualize raw signals, increasing confidence and interpretability.

• Low dependence on pre-labeled

ENGINEERING SOFTWARE

OneLiner

data. Most machine learning in this space is bottlenecked by signature libraries. AWARE’s architecture minimizes that constraint, making it adaptable across circuits and scalable as new equipment is added.

• Interpretability by design. Because trust matters, AWARE’s outputs are not black boxes. Instead, they’re understandable and traceable, enabling crews to act on them with confidence. In short: AWARE doesn’t just improve fault detection — it rewrites what detection means, he said.

Expediting Restoration Times

Having the ability to pinpoint where failures occur in a service territory through the AWARE system can accelerate restoration times for field crews.

“Knowing exactly where a fault is occurring changes everything,” he said. “Instead of driving miles of line to find the issue, crews can go straight to the source. That means less windshield time, faster repairs and quicker service restoration.”

Short circuit, relay coordination and breaker rating for transmission networks.

Power Flow

Full-featured power flow for transmission systems.

DistriView

Fault simulation, relay and fuse coordination, voltage drop, harmonic analysis, and reliability calculation for distribution networks.

Relay Database

Customizable database for relays and related equipment.

Line Database

Customizable database for overhead lines and underground cables with built-in electrical parameters calculation engine.

EDX Module

Customizable platform for collaborative OneLiner/Power Flow model building and database-driven model data management.

The AWARE system helps pinpoint where failures occur, which can accelerate restoration times for field crews.

Courtesy of Southern California Edison

The new AI tool is not just about speed, but it’s also about precision. AWARE’s pinpointing capability improves safety by giving crews critical situational awareness before they even step out of their truck. In high-risk environments, that knowledge can make all the difference.

“Targeted dispatching also reduces labor strain and restoration costs, turning what used to be a needle-in-a-haystack problem into a direct response mission,” he said.

Unlike other types of technology, AWARE doesn’t require new field sensors. New and added sensors can provide more data and be helpful, but the tool uses SCE’s existing infrastructure to analyze voltage and current patterns in real time. When the system spots a deviation from normal electrical behavior, it flags the anomaly and uses AI to classify it against a growing library of fault signatures. SCE also monitors the system through a dedicated interface and email alerts.

While engineers primarily monitor AWARE, its insights are shared with field crews through dashboards and internal

tools. SCE is actively training teams to interpret AWARE data and fold it into daily operations, giving lineworkers better awareness and helping them show up on-site informed and ready to act.

Looking to the Future

In the future, Trehan expects AI and ML to play an increasingly central role in the grid’s future, particularly in predictive maintenance, wildfire mitigation and the integration of distributed energy resources. These tools can help utilities to make faster, smarter and more informed decisions and ultimately, support a more resilient, efficient and sustainable electric grid.

In the meantime, SCE is continuing to build on the success of AWARE by improving how the system predicts and prevents issues.

“It’s already helping us find and resolve problems faster — and we believe other utilities can benefit from this technology, as well,” he said. “AWARE demonstrates how AI and ML can address complex utility challenges while enhancing

operational performance.”

Looking ahead, AWARE also lays the groundwork for a future digital twin, an advanced simulation environment that can model grid behavior under extreme weather, load shifts or fault conditions. This capability could allow utilities to test optimization strategies, improve system protection and adapt to evolving grid demands more proactively.

He said AWARE represents more than a system. Instead, it’s a mindset shift that challenges the industry to think differently about fault detection, by moving from reactive triage to anticipatory action.

“What makes this innovation special is that it wasn’t imported from a vendor,” he said. “It was built in-house by people who know the grid and care about its future. That kind of alignment — between technical excellence, field insight and public safety — is rare. We hope AWARE inspires similar efforts across the utility space, where domain-driven innovation can directly protect people, prevent wildfires and reshape how we define reliability.”

From Aging RTUs to Next-Gen Automation

The California electric utility shares how it is upgrading its substation automation systems on its path to grid modernization.

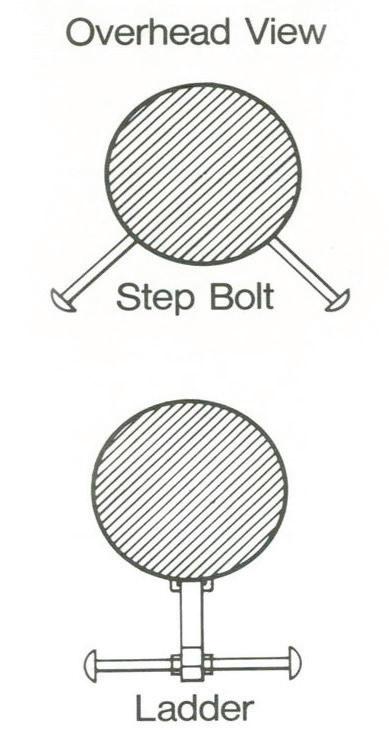

Substation Gateway/ humanmachine (HMI)-based architecture is suitable for Modular Protection Automation & Control (MPAC) enclosures and switchgear.

By MICHAEL ZHANG and FRANKIE AU-YEUNG, Pacific Gas & Electric Company

In the heart of California, Pacific Gas and Electric Company (PG&E) is facing a major challenge — and an exciting opportunity. With thousands of aging Remote Terminal Units (RTUs) installed since the 1990s, PG&E is now working to modernize its substation automation systems to meet the demands of a smarter, more connected energy grid.

But this isn’t just about replacing old equipment. It’s about rethinking how the entire system works — from hardware and software to cybersecurity and future expansion. Here’s how PG&E is tackling this transformation and what it means for the future of energy.

What Are Substation Automation Systems and Why Do They Matter?

Substation automation systems are the brains behind the power grid. They monitor and control the flow of electricity, helping utilities like PG&E deliver reliable energy to millions of homes and businesses.

PG&E uses two main types of automation systems: RTU-based systems and Gateway/HMI-based systems. RTU-based systems rely on RTUs to gather critical data from meters, relays and other substation equipment. RTUs serve as data hubs, collecting information on voltage, current, breaker status and more — then relaying that data back to grid operators.

Gateway/HMI-Based Systems are a more modern approach that uses fast Ethernet networks to manage high volumes of data. These systems are suitable for newer setups like Modular Protection and Automation & Control (MPAC) enclosures, where advanced diagnostics and automation are essential.

The Problem: Aging Equipment and New Demands

manufacturers no longer exist.

• Limited Capacity: These legacy systems struggle to keep up with today’s growing data demands, especially as the grid becomes more decentralized and data intensive. Existing RTUs data processing and handling capability has limitations in hardware and software to handle large volumes of real-time/nonoperational substation data.

• Integration Issues: New technologies such as battery energy storage systems, rooftop solar and microgrids often aren’t compatible with the older RTU models.

• Rising Failure Risk: As with any aging infrastructure, the risk of performance issues or outright failures increases over time.

For PG&E, upgrading these systems is critical to maintaining reliability, especially as more Californians adopt electric vehicles, solar panels and smart appliances that place new demands on the grid.

The “Four Ps” of PG&E’s Upgrade Strategy

To guide this complex modernization efforts, PG&E is using a structured approach — focusing on four key dimensions, known internally as the “Four Ps”: P1. System Function Perspective focuses on how well the entire automation system works as a whole, not just how the individual pieces perform. The goal is to build an integrated system that can reliably collect, analyze and respond to data in real time. That means ensuring the RTUs and gateways have fast, reliable processors capable of handling modern data volumes and run on secure, real-time operating systems that can respond instantly to grid changes.

MPAC Enclosure Panels require high data processing and handling capabilities for the exchange of data and remote access of IEDs (intelligent electronic devices) such as circuit breakers, transformers and capacitor banks. Images courtesy of PG&E

Many of PG&E’s RTUs were installed more than a decade ago, some even in the early 1990s. Today, these units face several challenges:

• Outdated Technology: Some RTUs are now obsolete, and parts are difficult to replace. In some cases, the

In addition, they are designed with modular hardware so they can be easily expanded or updated and offer strong protections against cybersecurity threats. They must also sync accurately with GPS and time servers to ensure data precision across the grid. By modernizing the functional core of its substation systems,

Expenses for training and transition relate to supporting field crews and engineers as they transition to new systems.

The total cost of ownership is evaluating not just upfront expenses, but longterm savings from better performance, reduced outages and lower operating costs. PG&E is also exploring whether existing hardware or configurations can be reused, reducing waste and increasing cost-effectiveness.

PG&E is laying the foundation for faster diagnostics, better fault isolation and more responsive grid operations.

P2. System Application Perspective — focuses on usability, looking at how easy the system is to use and maintain. PG&E wants tools that are intuitive, support multiple communication protocols and help engineers troubleshoot problems quickly. These platforms should offer intuitive graphical user interfaces (GUIs) that simplify troubleshooting and support for multiple communication protocols to ensure compatibility with various devices. They must also have configuration tools that streamline updates and make it easier

to pinpoint problems. Advanced diagnostics and data analysis features can reduce on-site testing and speed up repairs. By reducing complexity in the field, PG&E can save time, lower costs and reduce the risk of outages due to human error.

P3. Company Financial/Investment Perspective — refers to the significant capital investment of upgrading hundreds of RTUs.

PG&E is being strategic in how it allocates resources — comparing the cost of retrofitting existing systems versus fully replacing them.

Key financial considerations include initial costs like hardware, software, licensing and labor for installation. Maintenance costs involve ongoing upkeep, including the ease of sourcing replacement parts.

P4. Future System Expansion Perspective — looks to the grid of tomorrow. The energy landscape, specifically the grid, is evolving fast. PG&E’s upgraded systems must be built for the future, not just today.

That means making sure they can support distributed energy resources (DERs) like rooftop solar and battery storage and microgrids, especially in rural or wildfireprone areas that benefit from local energy resiliency. They must also back renewable energy integration, as California pushes toward 100% clean electricity and artificial intelligence and machine learning tools that help predict grid behavior and optimize performance. Finally, they must encourage the development of digital substations using IEC 61850 and other global standards for next-gen automation and interoperability.

Future-proofing these systems now helps PG&E avoid expensive upgrades

Many RTUs were installed more than a decade ago with distributed hardware I/O connection and intelligent electronic device (IED) serial/network communication data polling in the substation environment.

Some substations have older RTUs with centralized I/O architecture with serial communication data polling to SCADA master stations.

later, and ensures customers benefit from tomorrow’s innovations without delay or additional costs.

Why It Matters: The Bigger Picture

This upgrade project is part of PG&E’s broader commitment to grid modernization. By investing in smarter substation automation, PG&E is enhancing reliability as faster, more accurate data improves response times and outage management. It also supports clean energy because flexible automation systems are essential for managing the variability of renewable energy.

Another important part of the project is its ability to strengthen cybersecurity. Modern platforms provide better protection against growing digital threats. An additional benefit is driving equity. Improved automation helps PG&E better serve remote, underserved and high-risk communities.

Looking Ahead: Building a Smarter Grid

PG&E is not alone in facing the challenge of aging RTUs. Utilities across the United States — and around the world — are grappling with similar questions about how to modernize critical infrastructure while keeping costs manageable and reliability high.

With its “Four Ps” strategy, PG&E is offering a potential blueprint for how to do it right: balancing technical performance with usability, fiscal responsibility and forward-thinking design.

Serving more than 16 million people across a vast and varied service area spanning 70,000 square miles in Northern and Central California, PG&E needs systems that are as dynamic and resilient as the communities we serve.

MICHAEL ZHANG (MQZ1@pge.com) is a principal automation engineer in Pacific Gas and Electric Company (PG&E). Mr. Zhang has more than 34 years of relevant professional experience in electric utility, oil and gas pipeline control and instruments measurement and telecommunication industries. He possesses strong management experience in operation and maintenance of power utility automation systems and instrumentation devices and solid knowledge and experience with SCADA/ RTU and automation equipment, computer systems

The substation gateway functions as data concentrator and connects various intelligent electronic devices (IEDs) via serial/network connection to collect substation data.

and instrumentation. He also has expertise in developing programs, and in solving a broad range of complex technical problems for clients. Mr. Zhang obtained a master’s degree in electrical and computer engineering in 1991 from Xi’an Jiaotong University in China.

FRANKIE AU-YEUNG (FKA1@pge.com) is a principal automation engineer/ MPAC program manager in the Substation Automation Engineering department at Pacific Gas and Electric Company (PG&E). He received his bachelor’s of science degree in electrical

engineering from San Francisco State University in 2000 and his MBA in 2006. He has 25 years of expertise in power system protection and substation automation, including 15 years of managing the Modular Protection Automation and Control program (MPAC). He is responsible to lead and interact closely with cross-functional teams, MPAC contractor/ building vendor and performance metric management, managing the MPAC program/projects, and responsible for the annual Automation T&D Capital Program, Automation Long-Term Planning and SCADA Bundling Initiatives & Unit Cost strategies.

Data Centers as Positive Disruptions to the Grid

Modeling energy growth associated with data centers and smart integration through load flexibility and real-time coordination unlocks a new frontier in grid modernization.

By GIRI IYER, SUPRIYA CHINTHAVALI, and HILLARY K. FISHLER, Oak Ridge National Laboratory

Following decades of steady 1% electric load growth per year, the U.S. electric grid has been forced into action — faced with the sudden reality of the seemingly insatiable energy appetite of data centers across the nation. A traditionally risk-averse, slow-moving industry, electricity providers had considered 1 MW to be a larger-than-usual strain on the grid. Driven primarily by solar and wind generation farms as well as electric vehicles, the Federal Energy Regulation Commission (FERC) issued Order 2222

— to create more distributed energy resource (DER)-based supply-side liquidity — recognizing the need for prosumer participation in decentralized energy generation, alleviation of cost pressures on maintenance and aging T&D networks. Generative artificial intelligence (GenAI) and commercial construction companies are currently investing billions in the rapid buildout of data centers. With few incentives to align with the regulatory frameworks of the North American Electric Reliability Corporation (NERC)

and FERC, many are bypassing the traditional role of electric utilities in generation, transmission, and distribution. As a result, some data centers are pursuing behind-the-meter generation, while others are planning to go fully off-grid in pursuit of energy self-reliance.

Most data centers still rely heavily on the grid, placing significant strain on utility operations, existing infrastructure, and ultimately on energy affordability for customers outside the data center industry. At the same time, states, counties, and utilities

have a regulatory window of opportunity to reframe technology, research, and development to address the rapid load growth driven by AI. Yet regulatory bodies such as public utility commissions remain limited in their ability to match the influence of national utility monopolies in electricity, natural gas, and water. At the core of these challenges are the risks to consumer-level energy affordability and reliability.

In recognition of this complex challenge, Oak Ridge National Laboratory (ORNL) is spearheading the Modeling Energy Growth Associated with Data Centers (MEGA-DC) project. Demonstrating an emerging core capability and providing resilience as a service, ORNL is moving at the speed of the industry, collaborating with states, utilities and sponsors to win the AI wars with global competitors in what is like the Manhattan Project of this era.

Data Center Landscape

Because data center designs vary widely, the MEGA-DC project models facilities

of all types, sizes, and locations. These range from small Bitcoin and edge centers to traditional enterprise sites, collocated GenAI training hubs, and large hyperscalers. Each build differs in its purpose, components, energy and cooling sources, and computing applications, among other factors.

Facing challenges tied to electricity, water, cooling, storage, broadband, and fiber, the data center industry is racing to boost efficiency and reduce dependence on utility infrastructure. Some enterprise facilities are refreshing systems and adopting newer technologies to improve performance and cut interdependencies. GenAI start-up data centers, focused on training and scaling AI agents for cloud infrastructure, are exploring collocation for energy, fiber, and broadband to strengthen security and redundancy. Large hyperscalers are also pursuing collocation, with an emphasis on circularity — testing innovations such as on-chip cooling to improve both power utilization effectiveness (PUE) and water utilization effectiveness (WUE).

Despite rapid innovation and a growing push for circularity, the industry still faces barriers from state energy offices, regulated utilities, adjacent industries, and public stakeholders. Across the country, concerns have been raised about land use, real estate availability and costs, supply chain pressures, and the environmental and noise impacts of data center siting and operations.

To ease the strain of rapid data center growth and its indirect impacts on the grid, ORNL is developing an integrated systems approach to help states, utilities, and other stakeholders transform data centers into grid-orchestrated assets. Through its MEGA-DC initiative, ORNL works with an advisory board and partners to shape scenario-based decision-making frameworks tailored to the needs of states and localities. In examining factors such as economic and market trends, regulatory constraints, energy affordability, and infrastructure resilience, four major scenarios have emerged across the data center landscape:

Want to Learn

More about Ceramic Insulators?

As the grid evolves, so must our understanding. The Insulator Education Initiative equips technical teams with clear, practical knowledge to keep pace with industry change. Through impartial videos, tools, and comparison tables, it empowers smarter insulator decisions — and stronger, more resilient grids.

• Off-grid data centers

• Grid-connected data centers

• Grid-cognizant data centers

• Grid-orchestrated data centers. Each of these scenarios will be modeled in MEGA-DC’s digital twin environment for every state and its counties.

Off-Grid Data Centers

To win the global AI race, competing U.S. innovators must focus on training agents faster on larger data libraries. The desire for speed and intensity of this development, however, greatly outpaces the electric grid industry. But, because limitations exist in areas such as energy price, water availability, real estate availability and cost, broadband and fiber connectivity as well as workforce availability, data centers are gaining momentum in behind-the-meter circularity that are, in turn, at odds with regular energy customers, policymakers and the electrical utilities themselves.

This move by private industry toward off-grid data centers, as seen recently with MARA Holdings’ acquisition of a 114-MW Bitcoin data center and subsequent offgrid transition, is an evolution that may alleviate the electric affordability concerns voiced by regulators.

While the industry’s innovation drives ahead, with the goal of sloughing off the reliance on utilities and other stakeholders for resource provision, market-related conflicts arise for some players. A deeper story emerges when the off-grid data center challenges the constructs and desires of investor-owned utilities (IOUs). Still, for municipalities, member-driven cooperatives and utility districts, unique and granular challenges exist — while service area and community impacts endure across resources, land use and affordability for a data center’s neighbors.

Grid-Connected Data Centers

In MEGA-DC, the grid-connected data center is a paradigm in which the facility itself is an opaque load to the grid — with the existing infrastructure serving as a primary or secondary energy source. Utilities see this as the traditional model where the data center may be subject to powerpurchasing agreements to reduce their energy costs. Even with load-shifting or load-shedding clauses, these agreements

Framework for MEGA-DC, the data center as a grid asset. ORNL

still define the grid-straining data center as a single utility customer.

MEGA-DC considers this data center type as being closely aligned with the electric utility and, therefore, its regulatory construct. Yet, a multitude of concerns and challenges are being forced on the grid and its T&D infrastructure because of data center interconnectedness. States and utilities now are faced with a balancing act between providing for the data center’s energy needs and cascading impacts across service areas, counties and localities.

States such as Ohio, Washington and Indiana have begun to experiment with mitigating effects of data center strain on grid infrastructure and energy consump tion, such as consumer energy affordabil ity. For example, to offset the costs of infra structure improvements, data centers may be subject to things like minimum energy purchase commitments requiring larger payments for their large load. However, regulatory overhaul’s time-consuming nature cannot outpace the industry. Fur thermore, strategic innovation beyond the electrical grid is needed — as highconsumption data centers place strain on other resources, such as water and land. And, while the technology industry’s rapid advancements are reducing data center energy footprints, this progress has been just as quickly offset by the seemingly ex ponential proliferation of data centers across the U.S.

Grid-Cognizant Data Centers

MEGA-DC defines the grid-cognizant data centers as facilities with more predictable energy demands on the grid in perfor mance of AI-based tasks. Even with this predictability, the challenges posed by a grid-cognizant data center become criti cal for those that are either larger in size or even in number. In a state with high data center concentration, conversations shift to a grid-wide network of hurdles to overcome, such as state energy reserves, interconnect queue wait times and transmission-side congestion analysis.

the permitting, development and deployment processes create barriers across state lines and regulatory environments, while impacting large customer populations and stakeholders. At a higher level, oversight from NERC, FERC and the interplay between the balancing authorities (that is, PJM Interconnection, Midcontinent Independent System Operator and Electric Reliability Council of Texas) add another layer of time-consuming coordination,

consensus building and decision-making. Up against the GenAI players whose expediency is unmatched, T&D utilities are falling increasingly behind.

ORNL’s current intellectual property and research on the grid-cognizant data center class is prepared for pilot demonstration, where the upstream benefits of load cognizance to the electric utility can be translated into load-forecasting improvements at a distribution level.

The transmission industry, a focal point of this scenario, is investigating grid-enhancing technologies like advanced conductors, dynamic line rating, grid inertia, series and shunt capacitance devices. Funding for new transmission lines exists, yet

• Overhead/Underground Transmission

Environmental Compliance A Leader in Electric Utility Construction Providing World-Class Services in...

• Overhead/Underground Distribution

• Substations & Switchyards

• In-House Helicopter Operations

Grid-Orchestrated Data Centers

Where traditional data centers operate as passive energy consumers with fixed, opaque load, having limited grid interaction, MEGA-DC’s ultimate vision is to empower states, utilities and customers by enabling the grid-orchestrated data center. Featuring real-time, two-way communication, this data center class would be actively managed as a grid asset, with a flexible, transparent load.

From an energy and load transparency perspective, there is industry precedence in game-changing innovation, such as DERs like solar and wind energy, batteries and vehicle-to-grid electric vehicles. Yet, to date, as data center players are 10-to-100 times bigger than their DER counterparts, with energy needs and consumption profiles to match, there is critical need for rapid research, development and deployment of a stabilizing force for the grid.

By leveraging MEGA-DC and managing large data center loads more flexibly, these facilities could play a vital role in supporting the grid—shifting load, reducing

demand during peak times, and helping maintain balance. This stabilizing force within the GenAI industry could also drive market growth, supported by surplus energy generated through a network

“MEGA-DC’s ultimate vision is to empower states, utilities and customers by enabling the grid-orchestrated data center.”

of collocated facilities across the U.S. Such an oversupply has the potential to reshape energy market dynamics, lower prices, and create new opportunities for improved energy affordability for utility customers.

Collaboration Welcomed

ORNL is accelerating U.S. competitiveness, leveraging existing and emerging core capabilities at the GenAI innovation frontier. To transform data centers into integrated grid assets and ensure reliable grid performance, the MEGA-DC team is

engaged in a holistic approach for siting and leveraging of data centers — analyzing their AI-load profiles and optimizing their load flexibility and planning for transmission capacity — while maintaining resource availability, power provision and affordability for the customer.

Under the guidance and oversight of the MEGA-DC advisory board, ORNL is collaborating with states and industry to develop this multidisciplinary tool for electric grid resilience. As it progresses in its journey, ORNL welcomes new stakeholders and partners to provide feedback, ask questions and join in this exciting collaboration.

GIRI IYER is senior program manager of the critical infrastructure resilience group and PI on the MEGA-DC project at ORNL.

SUPRIYA CHINTHAVALI is group leader of the critical infrastructure resilience group and co-PI on the MEGA-DC project at ORNL.

HILLARY K. FISHLER, Ph.D., is a research associate in the critical infrastructure resilience group at ORNL.

From Paper to Proactive

How UCEMC transformed asset management with a scalable, data-driven approach.

By JOE SKELTON, UCEMC

Working smarter, not harder — it’s a familiar refrain, but one that still resonates, especially among electric cooperatives where rapid growth can strain efficiency and stretch limited resources. At the same time, managing aging infrastructure while preparing for future demand has become an essential priority.

Upper Cumberland Electric Membership Corporation (UCEMC) is an electric power distribution cooperative serving more than 54,000 members across eleven counties in western Tennessee.

Like many electric cooperatives, UCEMC is experiencing both commercial and residential growth in its service area. In 2017, it served roughly 49,800 meters; today, the meter count is 55,000 and growing. Much of that expansion has occurred just during the last couple of years. As a result, staying ahead of maintenance

and inspections has become a growing challenge.

With the Upper Cumberland’s strategic location, strong workforce, and high quality of life, the region has become an increasingly attractive destination for businesses looking to expand or relocate — a trend reflected in the nearly 9,700 new jobs created last year in Tennessee’s rural and suburban counties.

As commercial and residential growth accelerated across its service territory, UCEMC quickly recognized that greater efficiency and enhanced data visibility would be essential to managing this momentum and meeting future demand — and it wasted no time taking action.

The Challenge: Managing Growth with Limited Resources

Like many rural cooperatives, UCEMC operates with a lean team tasked with a

wide range of responsibilities. With only three substation technicians supporting a network of 13 substations and more than 4,775 miles of distribution lines, the organization feels the strain of growth.