Turner Construction Company

Turner provides building services to clients who value diligence, resourcefulness and creativity. Because Turner is a global company based in North America, we are able to offer clients the accessibility and support of a local firm with the stability and resources of a multi-national organization.

$20.8B

13,000 Employees

1,500

Optimizing Projects with a CrossDisciplinary Approach to Construction

Manufacturing facilities and advanced technology are vital to America’s progress and innovation. Our skilled industrialists collaborate to optimize your facility’s design and functionality. This crossdisciplinary “kit of parts” approach streamlines construction, accelerating the process of bringing your production online efficiently and effectively.

OUR SERVICES

Our services include material handling, integration and automation, startup and commissioning, process equipment and systems, facility and

Manufacturing

Automotive, Aerospace, Consumer Products, Semiconductors, Warehouses + Distribution Centers

Battery + EV

Automotive, Electric Vehicles, Battery Cell Plants, Battery Recycling

process integration, structures and cranes, and unique utility and MEP requirements.

DEDICATED MARKET SEGMENTATION

Advanced Manufacturing building requires a higher level of expertise given the process integration component along with complex mechanical and electrical systems, piping, and equipment installation. Turner’s industrial team specializes and focuses on these unique aspects throughout the construction process.

Industrial Process

Food + Beverage, Glass + Plastics, Metals + Composites, Paper + Packaging, Steel Processing

Pharma + BioTech

Bulk Manufacturing, Pilot Plants, R&D, Clinical Development, Individual Therapy Manufacturing, Vivarium

Renewables

Solar Panels, Solar Materials, Wind, Hydrogen

Experience Modification Rate (2023) 0.61

PROJECT SPECIFIC SAFETY PLANNING

Overview: For the Nucor Steel Decatur project, we implemented targeted safety measures and real-time risk management to ensure safe operations during the Meltshop conveyor additions, minimizing downtime and maintaining production efficiency throughout the project.

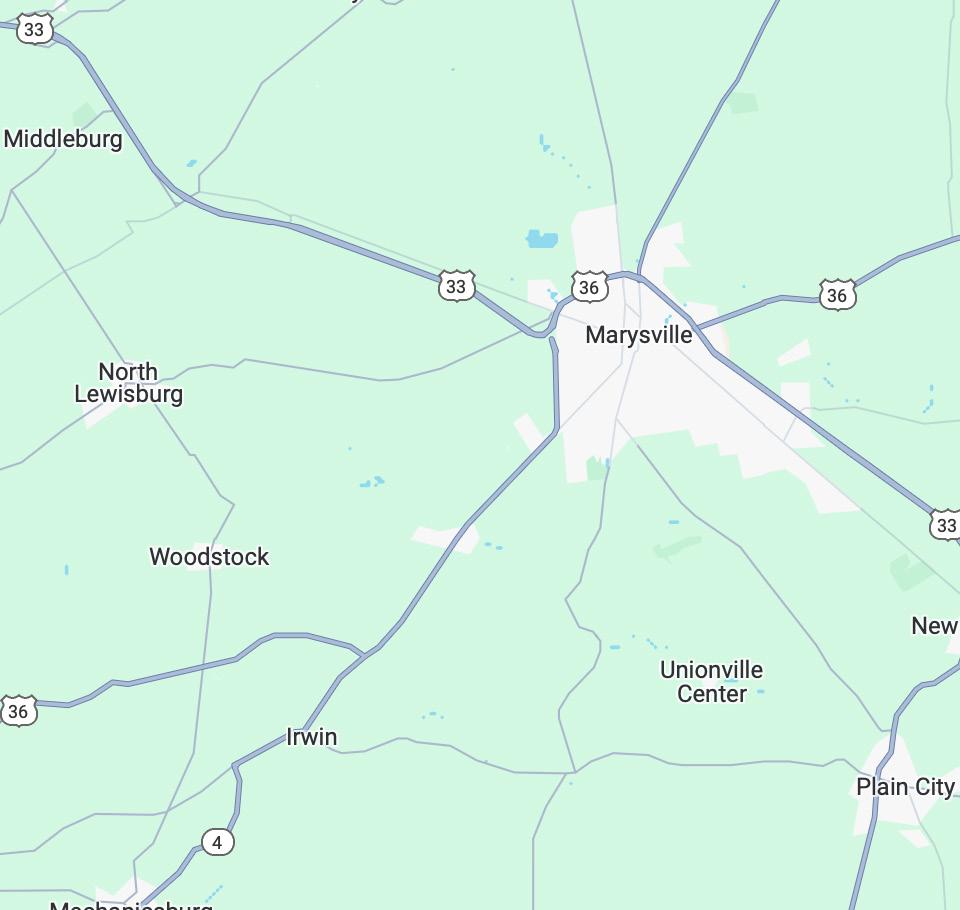

Overview: For the Honda Marysville project, we utilized specialized safety measures and dynamic risk controls to ensure a secure environment during the paint line installation, while also coordinating closely with operations to minimize disruptions and ensure smooth workflow integration.

Overview: For the MS Silicone Burnsville project, Turner used tailored safety measures, including risk assessments and specialized training, to manage hazards in the Process and Hydraulic Piping additions, ensuring compliance with industry standards and reducing potential delays caused by safety incidents..

Nucor Steel Meltshop Conveyor Additions

Honda / TKS Paint Shop

MS Silicone Process + Hydraulic Piping Additions

BENEFITS OF CREATING THE RIGHT ENVIRONMENT:

Reduced Accidents

Improved Efficiency Compliance Risk Management

Turner prioritizes safety with decades of experience, expert partnerships, and strict subcontractor vetting. Our approach includes geotech verification, controlled access, and clear communication for secure and successful projects.

Our safety processes, developed over decades of experience, address specific risks on active sites through integrated owner/engineering/ construction teams, partnering with industry experts, and strict evaluation of subcontractors to eliminate unqualified firms. We ensure thorough verification of geotech, utilities, and site mapping, control excavation and soil testing, and manage spoils and stormwater exposure. Clear demarcation of zones for storage, construction, and staging, along with traffic and material management, ensures smooth operations. Scheduled communication at all levels and coordination with OEMs and Systems Integrators further enhance safety and efficiency.

Turner Construction Company enhances site safety with proven risk mitigation across large industrial projects. Turner ensures secure boundaries, controlled access, and clear communication, prioritizing worker safety and effective risk management in complex environments.

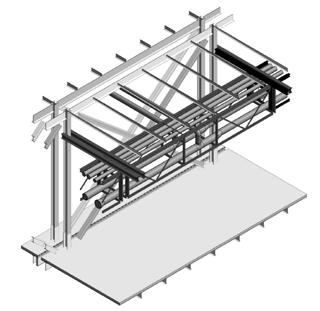

Photographed Offsite at Prefab Mfg. Facility

Building with Precision and Excellence in Industrial and Advanced Manufacturing Projects.

Whatever You Envision, We Can Build It

Turner excels across all industry sectors. Whether your project is straightforward or complex, we have the expertise and resources to deliver exceptional results. From advanced manufacturing facilities and energy projects to high-tech aerospace and automotive plants, we’ve handled it all. Our comprehensive approach ensures that each project is executed with precision and efficiency, meeting the highest standards of quality and performance.

AEROSPACE

AUTOMOTIVE

Aeojet Rockdyne Manufacturing Facility Huntsville, AL

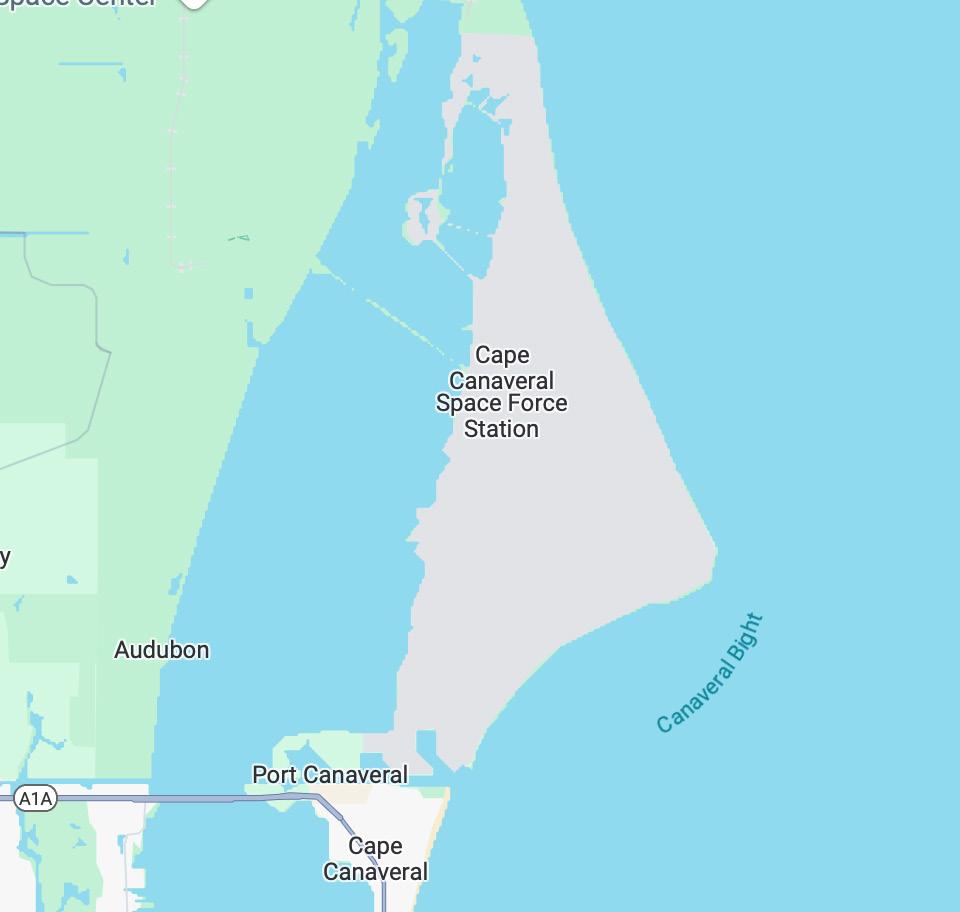

Confidential Space Exploration Company Launch Pad + Support Facility Cape Canaveral, FL

Boeing Charleston Expansion North Charleston, SC

Confidential Space Exploration Company Test Stand Huntsville, AL

Vought Aircraft Manufacturing Facility Charleston, SC

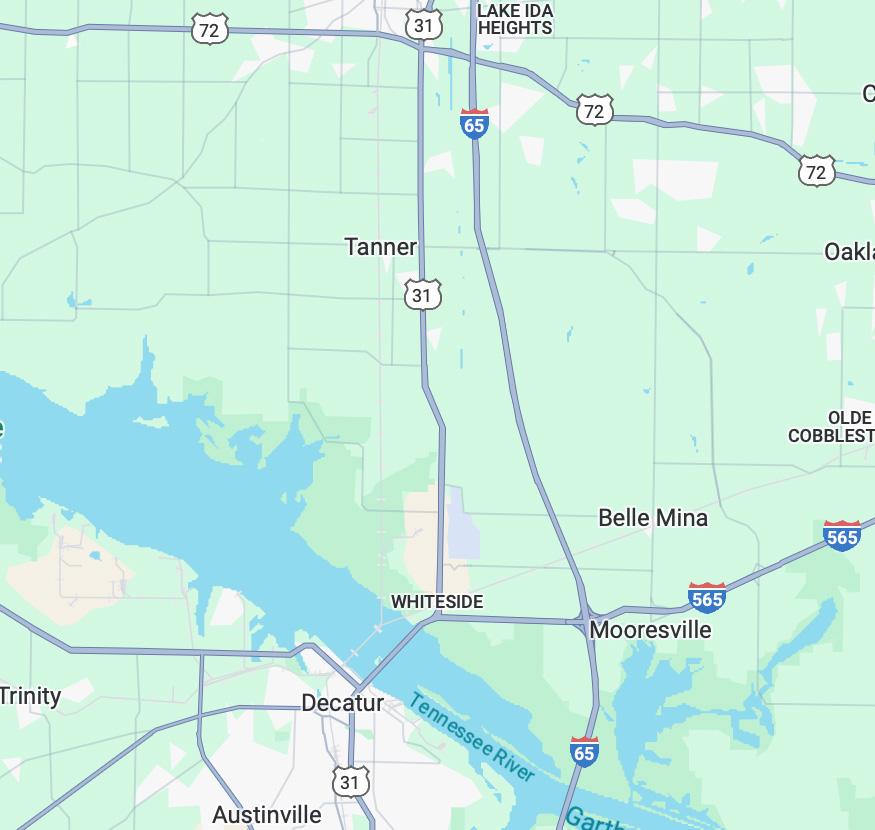

United Launch Alliance Decatur, AL

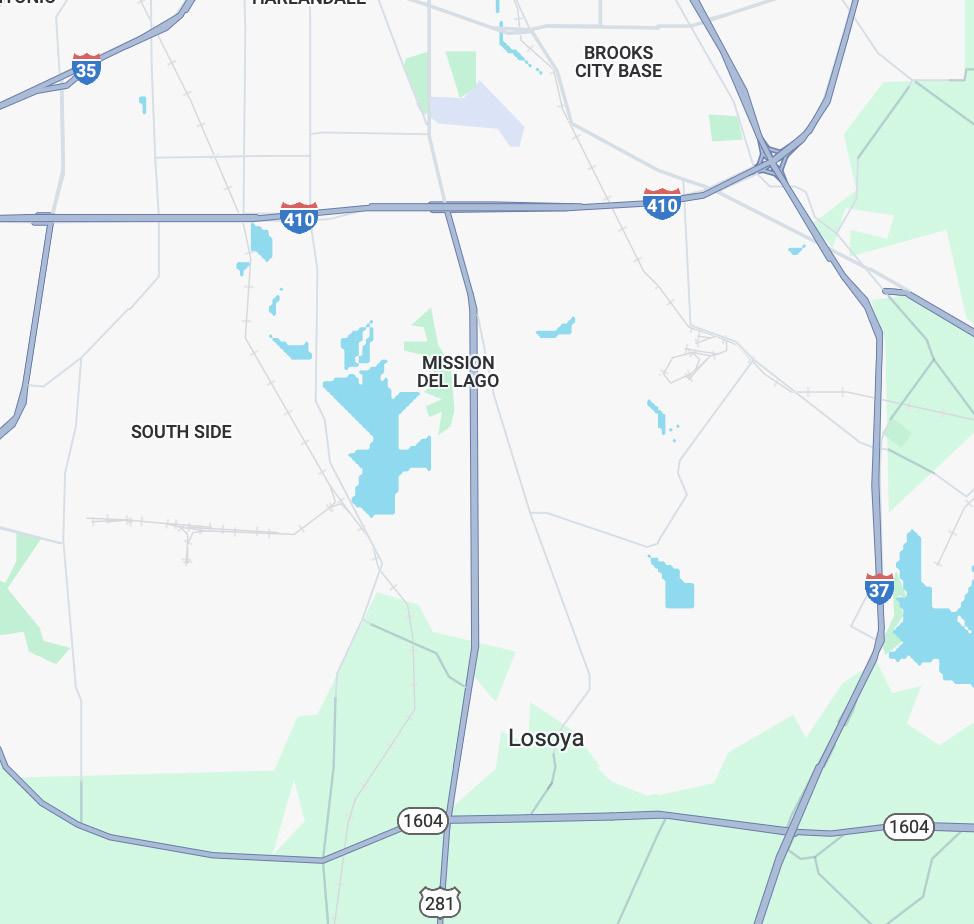

Navistar Truck Assembly Facility San Antonio, TX

Mercedes-Benz Carolstream, IL

Nissan Engine Plant Decherd, TN

Honda of America Manufacturing Paint Shop Marysville, OH

KIA Paint Shop West Point, GA

Body in White Facility* Greer, SC

Amprius Technologies Gigafactory CO

LH Battery Company Lithium-Ion Battery Facility Fayette County, OH

Tesla Panasonic Gigafactory Multiple Projects NV

Ascend Elements Battery Recycling Facility Hopkinsville, KY

Duksan Electera Electrolyte MFG Facility Shelbyville, TN

Redwood Materials Anode Copper Foil + Cathode Plant NV

Solarworld Moduling + Logistics Hillsboro, OR

Evergreen Solar Manufacturing Facility Marlborough, MA

Duke Energy Control Station Multiple Projects Cincinnati, OH + Harrison, OH

Silicon Components Manufacturing Facility OH Semiconductor Manufacturing Facility Saratoga County, NY

Confidential Chip Manufacturing Facility Chandler, AZ

FOOD + BEVERAGE

GENERAL MANUFACTURING

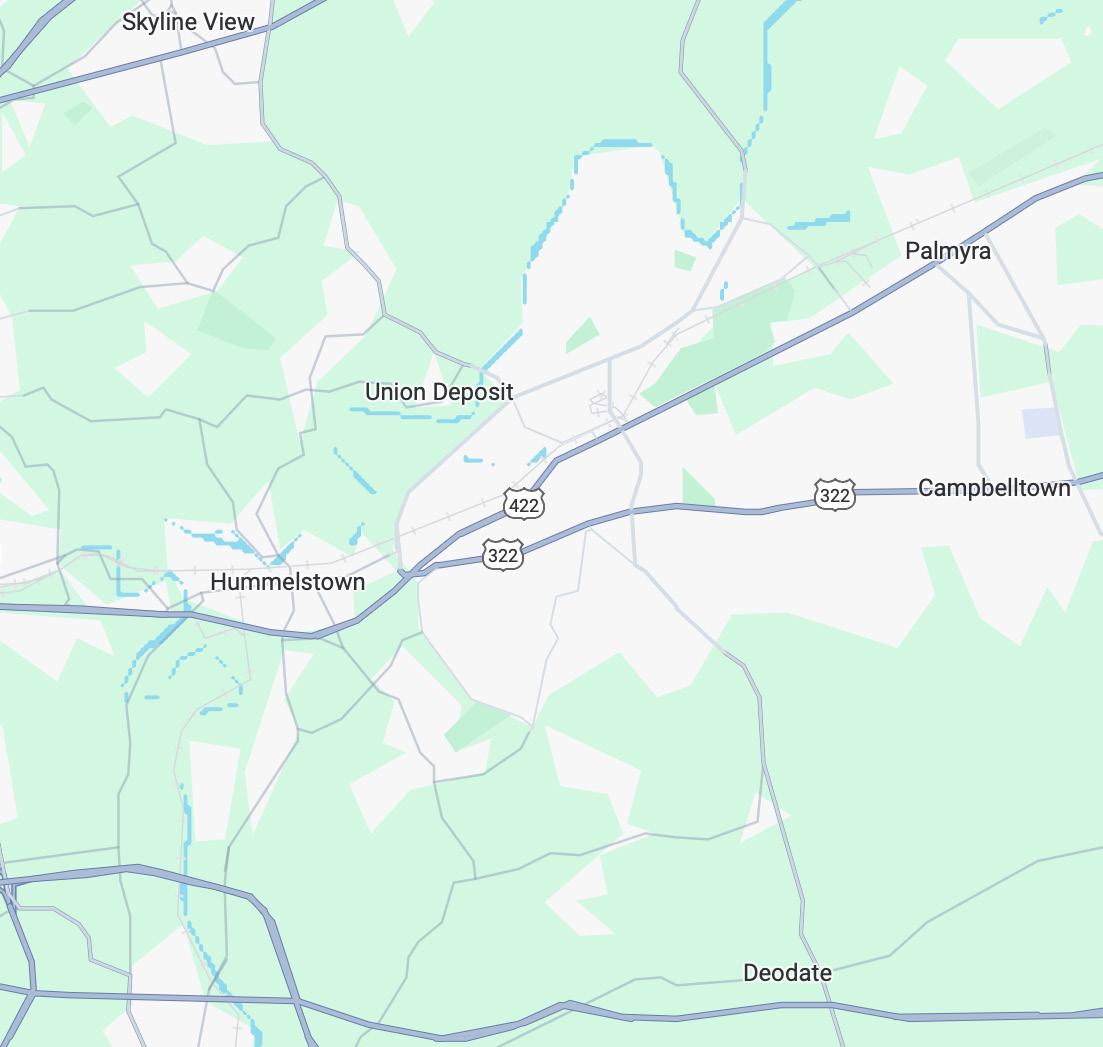

Hershey Company Manufacturing Facility Hershey, PA

New Bakery Facility Rockwall, TX

Nestle Allentown, PA

Sysco Philadelphia Freezer/Cooler Expansion Philadelphia, PA

Mondolez Manufacturing Facility Toronto, CAN Lenature’s Global Beverage System Latrobe, PA

Schwan Cosmetics USA Murfreesboro, TN

Magnus International Painesville TWP, OH

Procter + Gamble Cape Giradeau, MO

Agilent Pharmaceutical Manufacturing Facility Frederick, CO

Mane, Inc. Wayne, NJ

Mitsubishi Heavy Industries Pearland, TX

Inergy Systems New Boston, MI

Sisecam Glass Manufacturing Plant Ankara, Turkey

Sisecam Glass Manufacturing Plant Bursa, Turkey

Owens-Illinois Glass Container Manufacturing Facility Windsor, CO

Sisecam Glass Manufacturing Plant Mersin, Turkey

Guardian Industries Float Glass Facility Dewitt, IA

Carpenter Technology Athens Operations Program Athens, AL

Mississippi Silicon Burnsville, MS

Alcoa/Arconic Tech Center Changes New Kensington, PA

Rolled Alloys Temperance, MI

Chase Brass + Copper Company Montpelier, OH Materion Inc. Reading, PA

Building the Future of Aerospace

Turner’s Industrial Aerospace expertise covers high-tech facilities, delivering advanced solutions for the aerospace sector. With a strong track record in constructing manufacturing plants, R&D centers, and specialized environments, we excel in managing complex projects from start to finish. Our team’s knowledge in precision engineering, safety, and technology ensures facilities enhance productivity and meet aerospace standards. Turner’s commitment to innovation and collaboration fosters successful partnerships in aerospace manufacturing.

Site Logistics + Security FOD + Precision Systems Commodity Panels + Distribution Hydro

FEATURED PROJECT:

BLUE ORIGIN LAUNCH PAD COMPLEX 36 BUILT BY TURNER

Turner used modular construction techniques to assemble major components offsite, minimizing on-site risks. The 934K-pound hydraulic pit structure and launch table were modularized and safely lifted into place.

BLUE ORIGIN LAUNCH PAD COMPLEX 36

CAPE CANAVERAL, FLORIDA

Testing Systems

Overhead Cranes + Heavy Slabs Underground Utility Tunnels Electrical + Control Systems

Hangar Door Systems

High Purity Piping Systems

The project features a 973’ rocket ramp, a 317’ x 100’ launch pad, a flame deflector, and 530’ towers.

Blue Origin aims to make history with New Glenn’s first orbital flight later this year.

Prefab Roof Trusses at the Integration Facility.

Accelerating Automotive Facility Delivery

Turner’s industrial automotive experience encompasses OEM facilities and 1st through 3rd tier vendor plants, addressing all stages from Greenfield projects to renovations and expansions. We manage diverse areas including paint shops, body shops, trim/chassis, stamping, assembly, engine/powertrain, and distribution, as well as equipment foundations. We also specialize in advanced automation systems, quality control areas, and sustainable manufacturing practices, ensuring that facilities are both cuttingedge and efficient.

FEATURED PROJECT:

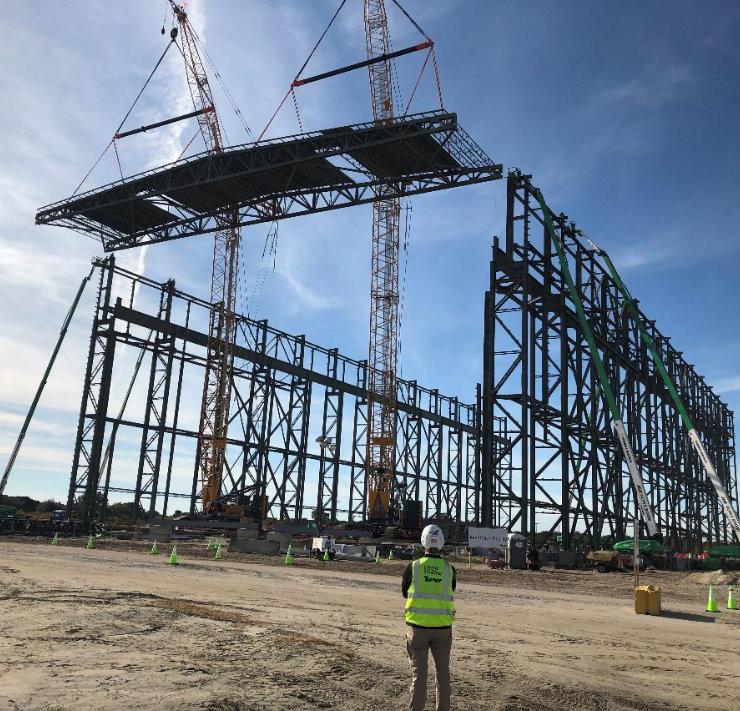

NAVISTAR TRUCK ASSEMBLY FACILITY BUILT BY TURNER + GHAFARI

The project features four buildings: general assembly, logistics, logistics warehouse, paint building, and body shop.

Process Equipment Installation Heavy Pits + Trenches Super Flat Floors + Finishes Fuel + Scrap Handling

Conveyors + Conveyor Tunnels Bridge + Gantry Cranes Elevators

Injection + Blow Molding Logistics Facilities

NAVISTAR TRUCK ASSEMBLY FACILITY

SAN ANTONIO, TEXAS

Achieved ZERO lost time incidents with a Zero Incident Safety Culture.

A state-of-the-art manufacturing line that shows our commitment to efficiency + quality.

Meticulous planning delivered a fully occupiable campus in fourteen months, with savings in mechanical and electrical systems.

Navistar utilized a waste-free paint system that eliminated material waste.

TOTAL SQUARE FOOTAGE 1,000,000 sq. ft.

The unique site grading provides the storm retention ponds reduce and improve storm water runoff quality.

TOTAL MAN HOURS 700,000

Experts in Battery Facility Construction

Turner is a leader in building advanced battery production facilities, specializing in the following items below. We excel in constructing central utility buildings, clean and dry rooms, pack facilities, ESS assembly, battery recycling, and facility renovations. With expertise in utility commissioning and site selection for both green and brownfield sites, we integrate SCADA, ASRS, and AGV systems to enhance efficiency. Leveraging xPL prefabrication and SourceBlue for global equipment sourcing, we expedite projects by reducing lead times and ensuring timely delivery.

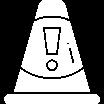

FEATURED PROJECT:

LITHIUM-ION BATTERY PRODUCTION PLANT, BUILT BY TURNER, YATES, + KOKOSING INDUSTRIAL

2,600,000 sq. ft.

Cathode + Annode Production Process Utilities Battery Recycling

LITHIUM-ION BATTERY PRODUCTION PLANT

FAYETTE COUNTY, OH

40-GWh electric vehicle battery plant

Routing 40-inch pipes was streamlined by using prefabricated spine racks.

Prefabricated spine racks not only saved four months on the schedule but also cut costs to $19M, compared to $129M for a traditional stickbuilt approach.

Lowering site elevation saved $100M

TOTAL SQUARE FOOTAGE

4,000,000 sq. ft.

DAILY, WORKFORCE COUNT 2,600

Central Cooling Plant = 27k Tons Total Cooling Capacity; Desiccant Dehmidifier Units = 1.1M CFW Supply Airflow, 12.6 Tons Cooling Capacity, 457 Units of Airside Equipment; 3- 300 HP Boilers; 3 57MVA High Voltage Transformers; High Voltage Switchyard

The length of 78 football fields.

Excellence in Energy Infrastructure

At Turner, we bring extensive experience in energy construction projects, specializing in the development of advanced energy infrastructure. Our expertise encompasses a wide range of facilities, including energy control stations, substations, and power generation plants. We excel in managing complex projects that integrate cutting-edge technology with robust construction practices, ensuring efficient and reliable energy solutions. From initial design through to final implementation, Turner is committed to powering the future with excellence in energy infrastructure.

DUKE ENERGY CONTROL STATION MULTIPLE PROJECTS BUILT BY TURNER

The 25,000 sq. ft. Duke Energy West End Control Station in Cincinnati, OH, manages regional energy distribution with advanced systems, improving grid reliability.

The 40,000 sq. ft. Duke Energy Controls Center in Harrison, OH, uses advanced systems to enhance regional energy reliability and grid management.

OHIO

Supports natural gas operations with advanced systems and sustainable design

Duke Energy’s Kellogg Gas Operations Center in Cincinnati, OH, is a 30,000 SF facility with state-of-the-art equipment.

A new transmission substation in Ashland County, Ohio.

Clean Room + Semiconductor Experience

Through Turner’s history, we have developed a solid understanding of the unique requirements of complex semiconductor projects. Project teams must focus on maximizing construction productivity, minimizing costs, and paying attention to details. Turner’s Lean approach is ideal for executing these projects safely and to the expected quality standards. We have a specialized market segment group that addresses the technical issues and demands of semiconductor manufacturing facilities. This team has extensive experience in the design, installation, and operation of all-class cleanrooms. We offer diverse experience in delivering comprehensive solutions for semiconductor clients with exceptional safety, efficiency, quality, and precision—whether for new construction, expansions, renovations, or tool installations. Below a 5-step process for cleanroom facilities:

FEATURED PROJECT:

ADVANCED TECHNOLOGICAL MANUFACTURING FACILITY BUILT BY TURNER + SSOE GROUP

The project features a 25-ton crane, silicon production facility, 138:12.47kv substation, clean rooms, and systems for bulk gas, chemicals, and waste.

Design + Planning

Design cleanroom concepts, HVAC systems, and sustainable structures.

Classification + Commissioning

Classify and commission cleanroom systems for contamination control.

Process + System Integration

nstall and integrate process, gas, exhaust, and I&C systems, including leak detection.

Airflow, Controls, + Efficiency

Optimize airflow, temperature, and humidity for operational efficiency and functionality.

Utility Systems + Installation

Set up bulk delivery systems, construct central utility buildings, and complete tool installations. 1 2 3 4 5

ADVANCED TECHNOLOGICAL MANUFACTURING FACILITY

SPRINGFIELD, OHIO

Turner provided more than $19,000,000 in approved design-assist savings.

The 138 kV substation, shown in the photo, ensures reliable power for the facility.

BIM prefabricated eight 58,000 lb chiller skids, saving $2M and 8,000 man-hours.

The facility has a 25-ton overhead crane for efficient heavy material handling.

TOTAL SQUARE FOOTAGE

361,000 sq. ft.

TOTAL MAN HOURS

325,000

Advanced Food + Beverage Facilities

Turner’s Food + Beverage expertise covers dairy, meat processing, and snack and beverage production. We manage Greenfield projects and renovations using various delivery methods, ensuring comprehensive cGMP and FMSA compliance. Our careful planning and execution deliver high-performance facilities that enhance efficiency and meet stringent industry standards. By focusing on optimizing workflow, reducing downtime, and implementing innovative solutions, we drive success in the food and beverage sector with reliable, topquality results and sustainable practices.

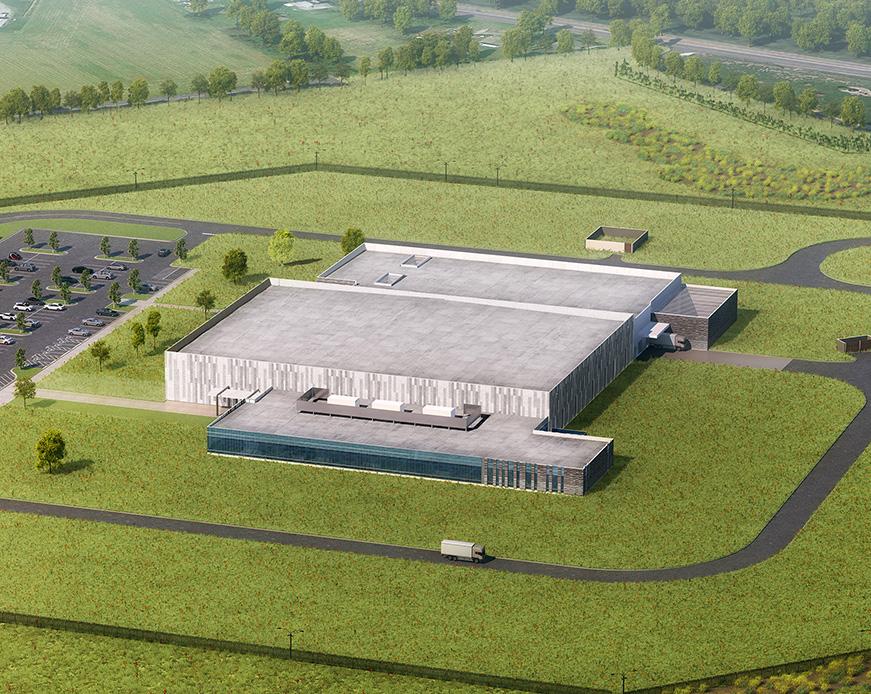

FEATURED PROJECT:

HERSHEY COMPANY MANUFACTURING FACILITY BUILT BY TURNER + NUTECH CORPORATION

The world’s most advanced chocolate plant with state-of-the-art technology and adaptable candymaking equipment.

HERSHEY, PENNSYLVANIA

HERSHEY COMPANY MANUFACTURING FACILITY

Advanced, real-time diagnostics systems for smooth operation.

New high-speed lines produce 2.9 million Hershey’s Kisses per hour, totaling 70 million daily.

Fresh almond roasting plant, stainless steel silos for corn syrup and fresh milk.

TOTAL SQUARE FOOTAGE

340,000 sq. ft.

JOBS CREATED 300+ temp jobs

Building Glass + Plastic Mfg Across Multiple Sites

Turner excels in delivering glass + plastic manufacturing facilities, focusing on safety, quality, and schedule. Leveraging our expertise in precision installation, clean room environments, and advanced production lines, we ensure seamless integration with existing operations, maintaining production throughout construction. Our team emphasizes cost management and advanced technologies to deliver highquality projects. We specialize in constructing complex glass handling systems, automated production facilities, and precise environmental controls to ensure high performance.

FEATURED PROJECT:

GUARDIAN INDUSTRIES MULTIPLE PROJECTS IN NUMEROUS STATES BUILT BY TURNER

This jumbo coater, the latest addition to the plant in Carleton, MI, marks the company’s first installation in North America.

GUARDIAN INDUSTRIES PROJECTS

• Geneva, NY: 700,000 sq. ft. (Float Glass Facility)

• Dewitt, IA: 730,000 sq. ft. (Float Glass Facility)

• Carleton, MI: 44,360 sq. ft. (Science Tech Center)

• Morehead, KY: 380,000 sq. ft. (Automotive Trim Facility)

• Evansville, IN: 54,000 sq. ft. (Automotive Parts Electroplating)

• Ligonier, IN: 396,000 sq. ft. (Automotive Glass Manufacturing)

• Corsicana, TX: 48,000 sq. ft. (Glass Coater Addition)

• Richburg, SC: 120,200 sq. ft. (Glass Coater Addition)

• Kingsburg, CA: 125,000 sq. ft. (Glass Coater Addition)

• Carleton, MI: 27,300 sq. ft. (R&D Facility)

Over 23 years (1991–2014), Turner completed over 2.6M sq. ft. of construction for Guardian Industries.

Our first project for them was the Automotive Glass Manufacturing Facility in Ligonier, IN.

The Guardian Industries Float Glass Facility in Geneva, NY includes deep foundations and batch facilities spanning over 700,000 sq. ft.

The new flat glass meets the top 20% limit in the U.S. GSA’s carbon standard.

Cutting-Edge Construction for Metal Production

Turner’s metals and composites experience spans greenfield manufacturing facilities, renovations, and expansions, delivered through EPC, Design-Build, CMAR, and General Contracting. We specialize in systems for melting, rolling, forging, stamping, die-casting, galvanizing, pickling, slitting, extrusion, foundries, and metallurgical labs, as well as composite manufacturing for aerospace, automotive, and renewable energy sectors. Our expertise includes working with steel, alloys, carbon fiber, fiberglass, and thermoplastics, managing advanced processes like resin infusion, autoclaving, and automated fiber placement to deliver precise, high-quality results.

FEATURED PROJECT:

CARPENTER TECHNOLOGY NEW ALLOYS PRODUCTIONS FACILITY BUILT BY TURNER + BWSC

Processing Equipment Piping Systems

Heavy Hydraulic Systems

Cooling Beds

Bridge + Gantry Cranes Heavy Equipment Foundations

Conveyors + Trenches

Dust + Fume Management

Finishing Processes

Turner delivered EPC and commissioning services for this new design-build alloys production facility for a high-end metals producer.

ATHENS, ALABAMA

CARPENTER TECHNOLOGY NEW ALLOYS PRODUCTIONS FACILITY

The campus supports the smart technology of Carpenter Technology’s advanced Information System

The facility integrates re-melting, forging, and associated finishing and testing capabilities into an ultra-modern facility.

We completed the project in 21 months, six months ahead of the scheduled 27-month duration

At the core of the plant’s operations is the world’s largest radial press.

TOTAL SQUARE FOOTAGE 580,000 sq. ft.

TOTAL MAN HOURS

2,000,000+

Scan the QR code to find our office locations.