technicians for these unique challenges.

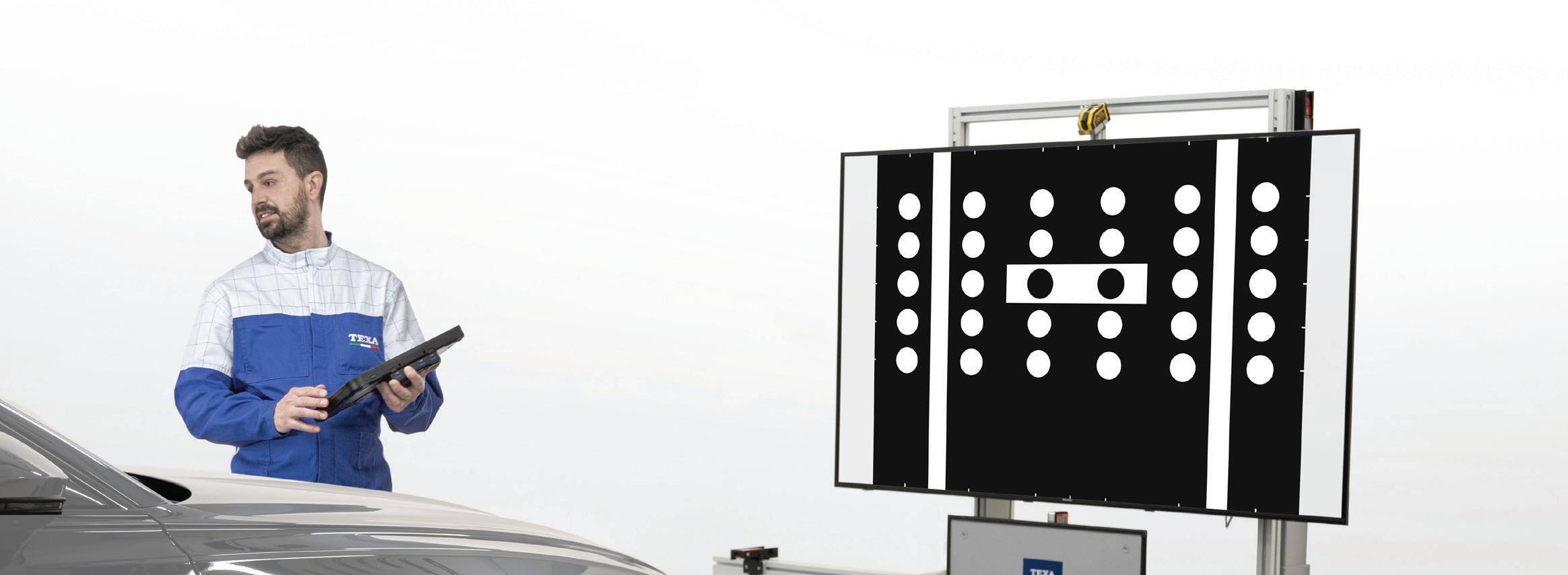

The ADAS calibration environment must include the proper conditions for lighting and background.

Put more dollars in your pocket this year with these hot paint products.

The ADAS calibration environment must include the proper conditions for lighting and background. BY JOHN ANELLO

Advanced training can help prepare technicians for these unique challenges. BY SCOTT KABOOS, JEFF POOLE

Put more dollars in your pocket this year with these hot paint products. BY TIM SRAMCIK

FACEBOOK GROUP CALLS ATTENTION TO HYUNDAI PAINT ISSUES CAR ADAS SOLUTIONS PARTNERS WITH HUNTER ENGINEERING

FLORIDA BODY SHOP MORE THAN DOUBLES SIZE OF FACILITY FOR TESLA REPAIRS

FENDERBENDER . COM

Endeavor Business Media, LLC

30 Burton Hills Blvd, Ste. 185, Nashville, TN 37215 Phone: 800-547-7377

EDITORIAL STAFF

CHRIS JONES GROUP EDITORIAL DIRECTOR cjones@endeavorb2b.com

JAY SICHT EDITOR-IN-CHIEF jsicht@endeavorb2b.com

ABDULLA GAAFARELKHALIFA ASSOCIATE EDITOR agaafarelkhalifa@endeavorb2b.com

JENNIFER DAKAS ART DIRECTOR

CONTRIBUTORS

JOHN ANELLO

SCOTT KABOOS JEFF POOLE

TIM SRAMCIK

ENDEAVOR BUSINESS MEDIA

CEO CHRIS FERRELL

COO — PATRICK RAINS

SALES STAFF

ANDREW JOHNSON PUBLISHER ajohnson@endeavorb2b.com

MATTIE GORMAN-GREUEL SALES DIRECTOR mgorman@endeavorb2b.com

CORTNI JONES DIRECTOR OF BUSINESS DEVELOPMENT cjones@endeavorb2b.com

Account Executives: DIANE BRADEN dbraden@endeavorb2b.com

MARIANNE DYAL mdyal@endeavorb2b.com

CHAD HJELLMING chjellming@endeavorb2b.com

LISA MEND lmend@endeavorb2b.com

ANNETTE PLANEY aplaney@endeavorb2b.com

CRO PAUL ANDREWS

KYLE SHAW kshaw@endeavorb2b.com

CDO JACQUIE NIEMIEC

CALO TRACY KANE

CMO AMANDA LANDSAW

SEAN THORNTON sthornton@endeavorb2b.com

The latest in vehicle infotainment, electric vehicles, and connectivity are just some of the automotive attractions at the annual Consumer Electronics Show (CES), held Jan. 6-9 in Las Vegas.

An Inter-Industry Conference on Auto Collision Repair (I-CAR) group attended CES, and Elizabeth Prosser, senior manager of marketing, shared these photos from the event, taken by Marketing Associate Megan Waltman, as an exclusive to FenderBender and ABRN. FENDERBENDER.COM/55262067

EVP, TRANSPORTATION KYLIE HIRKO

BUSINESS STAFF

CHRIS MESSER VP/GROUP PUBLISHER

MICHAEL WILLINS BUSINESS DEVELOPMENT DIRECTOR, MOTOR AGE TRAINING

LESLIE BROWN CUSTOMER MARKETING MANAGER

MARIAH STRAUB PRODUCTION MANAGER

JENNIFER GEORGE AD SERVICES MANAGER

TRACY SKALLMAN AUDIENCE DEVELOPMENT MANAGER

JILLENE WILLIAMS SALES COORDINATOR

JAMES HWANG Inside Sales & Brand Manager, ASE Study Guides jhwang@endeavorb2b.com

REPRINT SERVICES reprints@endeavorb2b.com.

CUSTOMER SERVICE Subscription Customer Service 877-382-9187; 847-559-7598 ABRN@omeda.com PO Box 3257 Northbrook IL 60065-3257

ABRN is published 4 times yearly (March, June, October, December) by Endeavor Business Media, LLC. 30 Burton Hills Blvd, Ste. 185, Nashville, TN 37215. Customer service can be reached toll-free at 877-382-9187 or at ABRN@omeda.com for magazine subscription assistance or questions.

Printed in the USA. Copyright 2025 Endeavor Business Media, LLC. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopies, recordings, or any information storage or retrieval system without permission from the publisher. Endeavor Business Media, LLC does not assume and hereby disclaims any liability to any person or company for any loss or damage caused by errors or omissions in the material herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever. The views and opinions in the articles herein are not to be taken as official expressions of the publishers, unless so stated. The publishers do not warrant either expressly or by implication, the factual accuracy of the articles herein, nor do they so warrant any views or opinions by the authors of said articles.

Endeavor Business Media provides certain customer contact data (such as customers’ names, addresses, phone numbers, and e-mail addresses) to third parties who wish to promote relevant products, services, and other opportunities that may be of interest to you. If you do not want Endeavor Business Media to make your contact information available to third parties for marketing purposes, simply call toll-free 877-382-9187 or email ABRN@omeda.com and a customer service representative will assist you in removing your name from Endeavor Business Media’s lists. ABRN does not verify any claims or other information appearing in any of the advertisements contained in the publication, and cannot take responsibility for any losses or other damages incurred by readers in reliance of such content. ABRN welcomes unsolicited articles manuscripts, photographs, illustrations and other materials but cannot be held responsible for their safekeeping or return.

Why do so many shops choose Cromax® XP? Maybe it’s because they can achieve a premium finish in as few as two coats. Or that it’s easy to mix, match, and apply. It could also be having access to the most innovative digital color match tools. But we’d like to think it’s all of it.

See what sets Cromax® XP apart from the competition. axalta.us/xp

PREPARE FOR AND PASS YOUR ASE CERTIFICATION

Motor Age Training offers the most complete and extensive collection of B-Series Collision Repair training guides available anywhere!

B2 - Paint & Refinishing Certification

B3 - Non-Structural Analysis & Damage Repair

B4 - Structural Analysis & Damage Repair

THANKS TO OUR TRAINING SUPPORTERS

B5 - Mechanical & Electrical Components Certification

B6 - Damage Analysis & Estimating Certification

*training guides available in a variety of formats

Hyundai Motor America has announced an extension of the warranty coverage for certain 2017 and 2018 model year Elantra, Sonata, and Santa Fe Sport vehicles due to issues with peeling or bubbling white paint.

e a ected areas are most commonly found on or around the hood, fender, and roof.

The complaint has been well-known and often shared unenthusiastically through multiple Facebook groups.

One member of the Facebook Group, “Hyundai Paint Peel/Peeling” wrote in a post on January 14:

“I’ve been in contact with Hyundai corporation for several months now, and all they tell me is it’s my fault it’s peeling, and that it’s out of warranty.”

Another member posted on January 11:

“Yesterday I had a Hyundai .. it was peeling so bad yall on the top and on top of the trunk. They wouldn’t do ANYTHING.. today I got rid of it! Yall can too! Had to take a little bit of an L to get it out of my hands but it’s done

This Facebook group is centered on sharing stories of their paint-peeling problems and the responses they’ve gotten from Hyundai and/or local dealers.

no more paint peeling!! #toyotaforever No more Hyundais ever!”

At https://autoservice.hyundaiusa. com, the VIN can be input to verify extended warranty coverage for the following vehicles:

• 2017 Model Year: Warranty extended to 6 years from the date of original

exhibiting peeling on its fender after she said the dealership fixed the hood as a “one-time courtesy fix.”

retail delivery or date of first use, with unlimited miles.

• 2018 Model Year: Warranty extended to 5 years from the date of original retail delivery or date of first use, with unlimited miles.

Car ADAS Solutions announced a new partnership and collaboration with Hunter Engineering Company.

As part of the partnership, Car ADAS Solutions’ users will have direct access to Hunter’s Ultimate ADAS, other products and training resources. Car ADAS Solutions and Hunter Engineering’s team are also working together to promote safe, efficient ADAS calibrations in the industry.

“This collaboration combines the history of quality, expertise

>> CONTINUED FROM PAGE 7

and OEM approval from Hunter Engineering with the innovative solutions of Car ADAS Solutions,” said Greg Peeters, CEO of Car ADAS Solutions. “The partnership will bring the ADAS calibration industry enhanced services and support, includ-

ing comprehensive partnership training, implementation, technical support and software integrations.”

“Car ADAS Solutions and Hunter Engineering are both leaders in the ADAS Calibration space,” said Kaleb Silver, senior director - systems product

management for Hunter Engineering Company. “Hunter’s goal is to provide Car ADAS’s customers and locations with state-of-the-art, OEM-approved ADAS calibration equipment that ensures the job is done right and documented for future reference.”

Northwest Collision Center in St. Petersburg, Florida, has expanded its facility from 17,000 to 39,000 square feet to accommodate Tesla-certified collision repairs.

The expansion provides Northwest Collision Center with additional capacity to handle a growing customer base and implement cutting-edge technology. The enlarged facility features “state-of-theart” equipment designed specifically for Tesla vehicles.

“Our expanded facility delivers unmatched precision and efficiency, setting a new standard in exceptional auto body repairs, especially for Tesla owners,” said Gregory Descent, owner of Northwest Collision Center.

In addition to specializing in Tesla repairs, Northwest Collision Center continues to provide a full range of services for all makes and models.

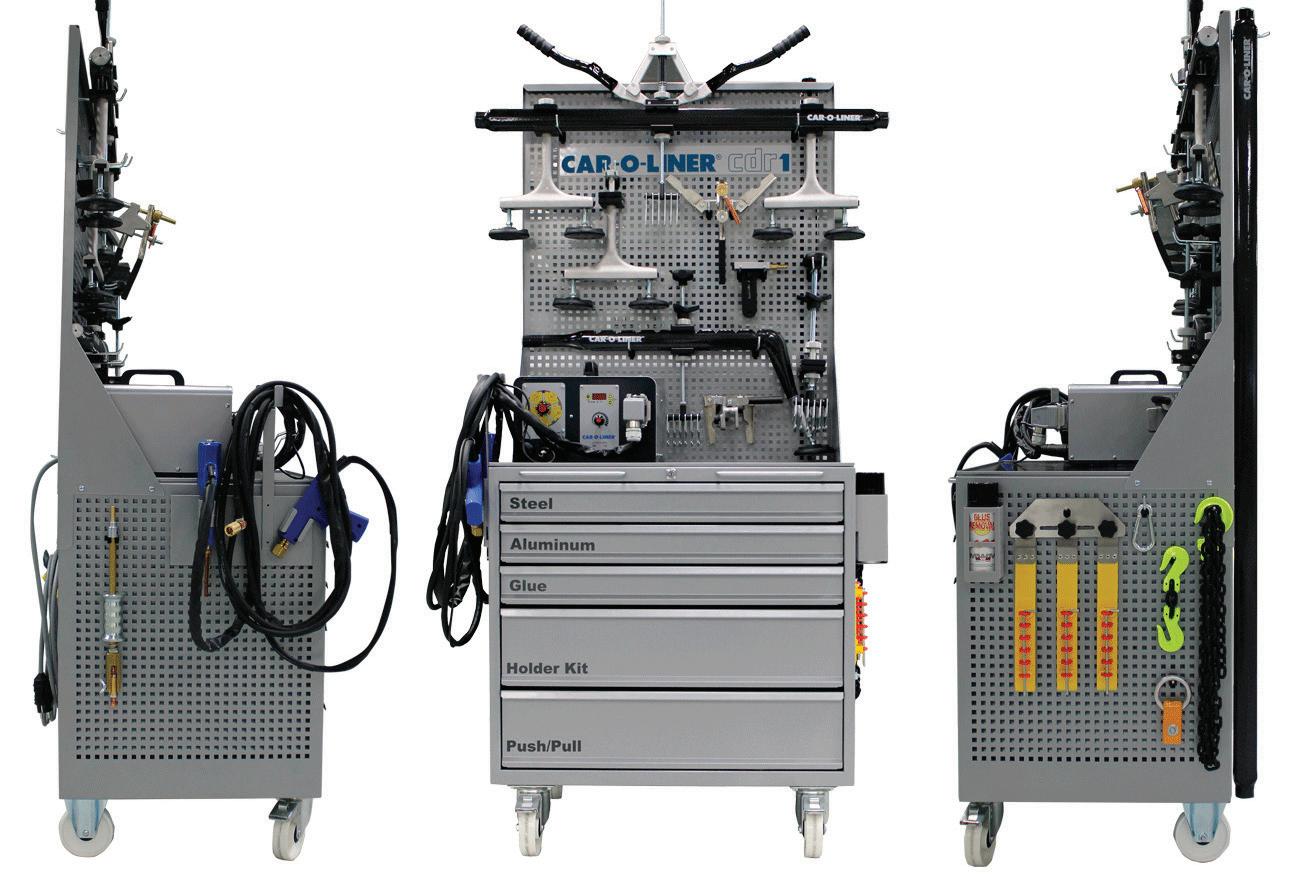

Young Collision, Precision for Collision and Car-O-Liner partnered with the Young Caring for Our Young Foundation to donate a high-end spot welder to Ogden High School, in Ogden, Utah, on January 9.

“This is better than Christmas,” said James Cook, an automotive and collision repair teacher who’s been with the school for 19 years. “It means that we will attract more students into the program because we have the most updated equipment. It will also attract more potential employees and employers so that they can come and potentially hire our students, because they’ll be well trained on this type of equipment.”

Precision for Collision and Car-OLiner set up a new CTR9 resistance spot welder at the school — a product that’s valued at over $42,000. The equipment will allow students to join metal sheets together with more accuracy and efficiency. According to Young Collision Director Chris Hudson, giving students access to this level of machinery while in high school is unprecedented.

“What I love about working for the Young Automotive Group is that we’re

all tasked with giving back to the community,” Hudson said. “I believe that our partners are also looking to do the same. Partners like Car-O-Liner and Precision for Collision are acknowledging the need for recruiting and retention in a career field that has a serious shortage of technicians nationally. By ensuring students have the latest technology and up to date procedures, we are collectively transforming the next generation of the work force and creating opportunities within our communities.”

This effort adds to others Young Collision has been engaged in at Ogden High School. In the past, they’ve worked

with Young Caring for Our Young to donate a waterborne paint mixing system, host training sessions during automotive shop classes, and participate in career day events. In total, their contributions have amounted to over $75,000 in value.

“Our company values opportunities to help that young generation of technicians,” said Mike Hasko, general manager of Precision for Collision. “We’re thankful to work together with partners like Car-O-Liner and Young Automotive who share that ambition, and actively engage in endeavors like this that have a lasting impact on futures.”

The University of the Aftermarket Foundation (UAF) reminds students that March 31 is the deadline to submit applications on its Aftermarket Scholarship Central websites at AutomotiveScholarships.com and HeavyDutyScholarships.com.

Over $800,000 of scholarships will be awarded for the 2025-26 academic year to students enrolled in four-year and two-year colleges as well as ASE/ NATEF certified automotive, collision and heavy-duty/diesel post-secondary programs.

The foundation’s AutomotiveScholarshps.com and HeavyDutyScholarships. com websites are streamlined, mobileready portals with easy navigation and a simplified online application process for students interested in careers in the motor vehicle aftermarket. By completing a single application online, students will

The Alliance of Automotive Service Providers of Minnesota (AASP-MN) will be awarding up to $20,000 in scholarships to select students enrolled in post-secondary automotive (auto service or collision repair) programs. Scholarship awards will range from $500 to $2,500 per student and can be applied towards tuition or tool purchases.

To be eligible, applicants must be enrolled in a Minnesota-based ASEaccredited automotive program in the fall of 2024. Applications will be reviewed by a committee of industry

be considered for multiple scholarships for which they are eligible. The websites allow applicants to view the details of all scholarships available and continue to update their application until the March 31 deadline.

A complete list of scholarships offered by UAF and affiliated organizations is featured on the websites with links to information outlining each organization’s scholarship details, eligibility requirements and awards. To be considered for as many scholarships as possible, UAF urges applicants to read the individual pages thoroughly to ensure they include the proper information required by each organization with their application.

ADOBESTOCK_406617105

representatives, with consideration given to scholastic achievement, education and career goals, financial need, and written recommendations. Applications must be submitted electronically or postmarked no later than March 31. Applications can be downloaded from the Alliance’s website, or submitted online at automotivescholarships.com/scholarships/alliance. Online submissions give students the opportunity to compete for several different awards, including those offered by the University of the Aftermarket Foundation Scholarship Committee and over 40 other automotive aftermarket organizations and companies. Specific requirements for each organization’s awards can be found at www.automotivescholarships.com.

Applications are now being accepted for the Federated Car Care Scholarship, according to a news release.

Administered by the University of the Aftermarket Foundation, several scholarships will be awarded to employees and children of active Federated Car Care Center members.

Eligible applicants include those attending a two- or four-year accredited college, an ASE/NATEF certified postsecondary automotive, heavy-duty or collision technician training program, or any licensed and accredited vocational school. High school seniors graduating in 2025 and heading to any of these postsecondary programs are also eligible.

The Federated Car Care scholarships are funded by Fisher Auto Parts in memory of Art Fisher, founder of Federated Auto Parts and the Federated Car Care program. Qualified candidates should specify “Federated” on their application when applying online by March 31.

“We are proud to once again provide scholarships for the children and employees of Car Care members, helping the recipients continue their education,” said Bo Fisher, chairman and CEO of Fisher Auto Parts. “The University of the Aftermarket Foundation’s platform makes the application process simple and efficient. We encourage all interested applicants to submit their applications now and we look forward to awarding Federated Car Care scholarships to another group of deserving students for the 2025-26 academic year.”

Federated is one of more than 30 organizations awarding scholarships on the foundation’s Automotive Aftermarket Scholarships Central website.

THE ADAS CALIBRATION ENVIRONMENT MUST INCLUDE THE PROPER CONDITIONS FOR LIGHTING AND BACKGROUND.

BY JOHN ANELLO

Iwas called to a shop to calibrate a camera on a 2023 Acura Integra that just had a new windshield replaced (Figure 1). ere were no codes on the vehicle scan report and no warning lights were on the dash. But the shop wanted the calibration done because the camera was dismounted from the old windshield and put into a what I call a “hangman position.” is is a trick many glass guys use to prevent any dash lights from being triggered during their windshield replacement procedure. ey simply remove the camera from the windshield mounting area and let it hang by its wiring without unplugging it so it’s ready to be remounted to the new windshield.

But when remounting the camera, there is no guarantee it will be in the proper position as it was before on the original windshield, especially if the windshield comes with a new mounting pad. If it is an aftermarket windshield,

it may even have a slight difference in pitch than did the factory windshield. There are some shops that may just let the vehicle go because there are no lights on because nothing was disconnected, but it becomes a liability issue. The manufacturer recommends that if a windshield is replaced, the camera must be recalibrated. This could set up a liability issue if the camera system cannot track the roadway properly and deviates slightly to either the right or left of its intended course.

At each shop I go to, I usually have a dedicated bay I use, and many of these bays present different challenges for me. It becomes a personal relationship with these shop bays

to know how to set up the vehicle with that particular bay and what precautions I need to take. This particular shop is a very old shop, and it has many windows throughout the building for good lighting. But that poses issues for me with sunlight that will create a glare on the windshield and compromise the camera’s ability to focus on the target in front of the vehicle. There is one window in this shop that has sunlight glaring into the bay from the right side of the building (Figure 2), but if I go there early enough in the morning it doesn’t pose a problem. It’s like my “window of opportunity,” and if I don’t beat the positioning of the sun, the only solution would be to cover the window with cardboard.

During my setup procedure, I always start by doing an integrity check behind the camera mounting cover (Figure 3). You need to make sure everything is properly plugged in, the camera is seated properly, and the camera heating element is not compromised in any way. I have come across quite a few windshield replacement jobs where cameras were not snapped in properly or the camera heater/camera mounting pad were compromised. The other issue is to make sure that the mounting cover is tightly sealed against the windshield so as not to allow “intruding light” to interfere with the camera’s viewing area. These quick checks will save you a lot of time if your calibration fails after you have followed all the setup procedures with your equipment to properly aim the camera.

When setting up your vehicle, it’s always best to use two laser devices to grid the floor to make sure your ADAS target frame is properly placed in front of the vehicle. I use a low profile four-line laser that will shoot a laser under the vehicle to hit a laser target that I have placed on the floor in the rear center of the vehicle (Figure 4). The laser will direct a laser line toward the front of the vehicle at the same time to create a centerline on my ADAS target frame.

Then with the second laser mounted to the top of my ADAS target frame, I simply shoot a laser line back to the vehicle to overlap the laser line created by the floor laser (Figure 5). This procedure gives me a precise grid on the floor so that I know my ADAS target frame is properly squared with the vehicle.

My second challenge was that the garage door I was facing has windows in it, which created another problem of light glare for the windshield camera. I could have easily turned the car to face the back of the shop, but you need to understand that from my experience I have found the garage door to be the best background for camera calibrations. Most shops usually have so much stuff in the building from vehicle teardowns or just cumulative hoarding that could confuse the camera during its calibration process. It’s very easy for a camera to pick up another black or white object in its path and have trouble focusing on the targets. The fix here was to get an assistant in the shop who was willing to help me by holding two very large cardboard pieces to create a backdrop behind my targets to block the garage door windows (Figure 6). Once the criteria were all met for the camera calibration and the frame was raised to its proper height, I used the scan tool to command the camera to look for the targets that I had placed at equidistant specs from the centerline of the frame machine, and the procedure was successful.

This whole procedure went very well, and as a post procedure I made sure to calibrate the steering angle sensor and the ABS yaw sensor. The ADAS network is a critical system of components, and each player plays a role in the driver assist operations. The ABS is the main arbitrator of the system because it makes the final decision to stop the vehicle. The electronic steering system has the role of steering the vehicle, and it crucial to make sure the sensors within the ADAS network of the vehicle are properly calibrated so that the radar and camera systems on the same network can monitor the vehicle dynamics based on the learned geometry of the vehicle. The engine control system is also on this same network and is the propeller of the system. If any individual

system fails in this network due to an error, then the whole system will default to inoperable and then you will have the “Christmas tree” effect on the dash.

The future of these ADAS systems will only get more complex as the auto industry pushes for Level 4 systems to be standard on vehicles, which means there will be no need for a driver in the driver’s seat. This means more locking down of vehicle networks which will require you to have a manufacturer subscription to allow your scan tool to perform bidirectional command procedures to work on ADAS systems and other body control systems on board. There will be more encryption of data flowing through these vehicles to prevent “cyber vehicle hacking.” There will also be more complex systems that will focus on vehicle-to-vehicle (V2V) communications as well as vehicle-to-infrastructure (V2I) communications. This will be an industry that can only drive you to keep yourself updated with your equipment and invest in the educational courses associated with these systems. You will have to buckle up and remove yourself from your comfort zone, because those who play out of the sand box will be the true blazing technicians to carry the torch into the future.

JOHN ANELLO is the owner and operator of Auto Tech on Wheels, established in 1991 in northern New Jersey. He provides technical assistance and remote reprogramming with 21 factory PC-based scan tools. Driven by a passion for cars, John’s business now services roughly 1,700 shops.

SCAN THE QR CODE TO SHARE THIS ARTICLE AND READ RELATED ARTICLES ONLINE

BY SCOTT KABOOS, JEFF POOLE

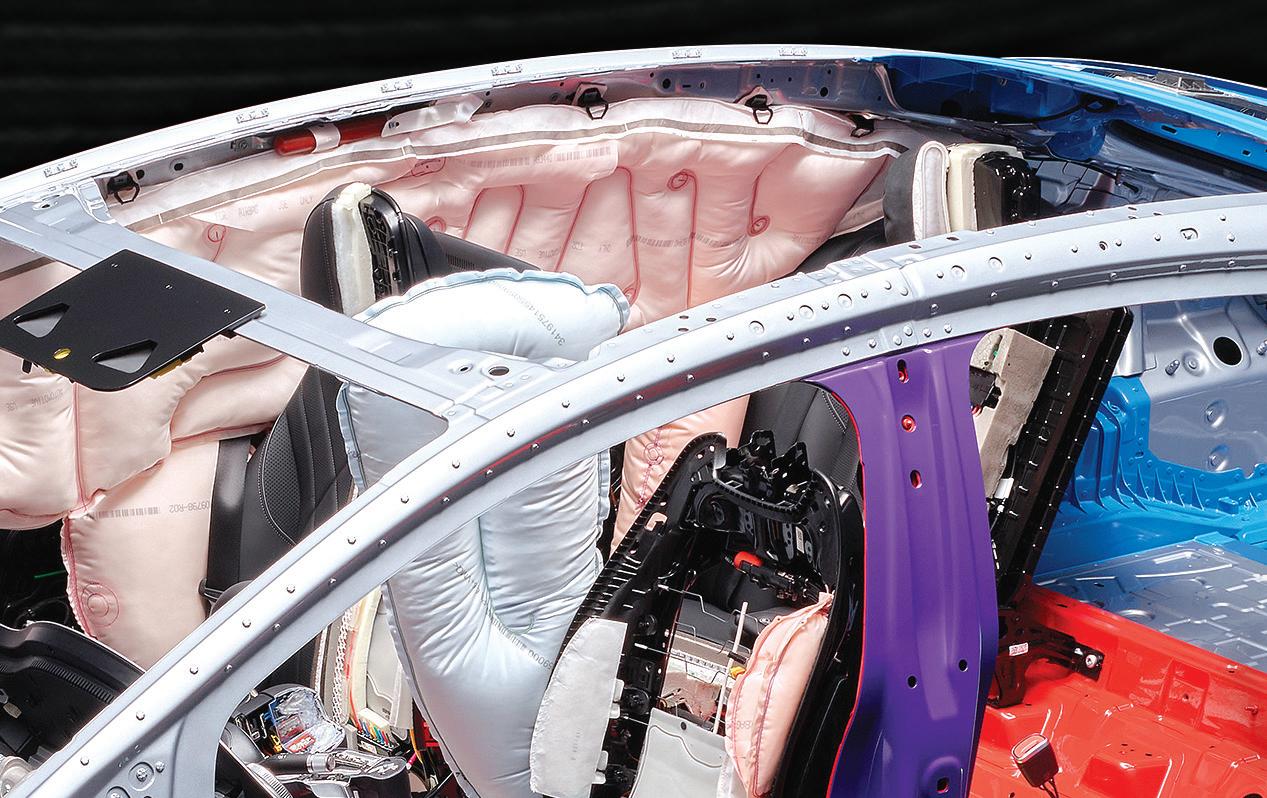

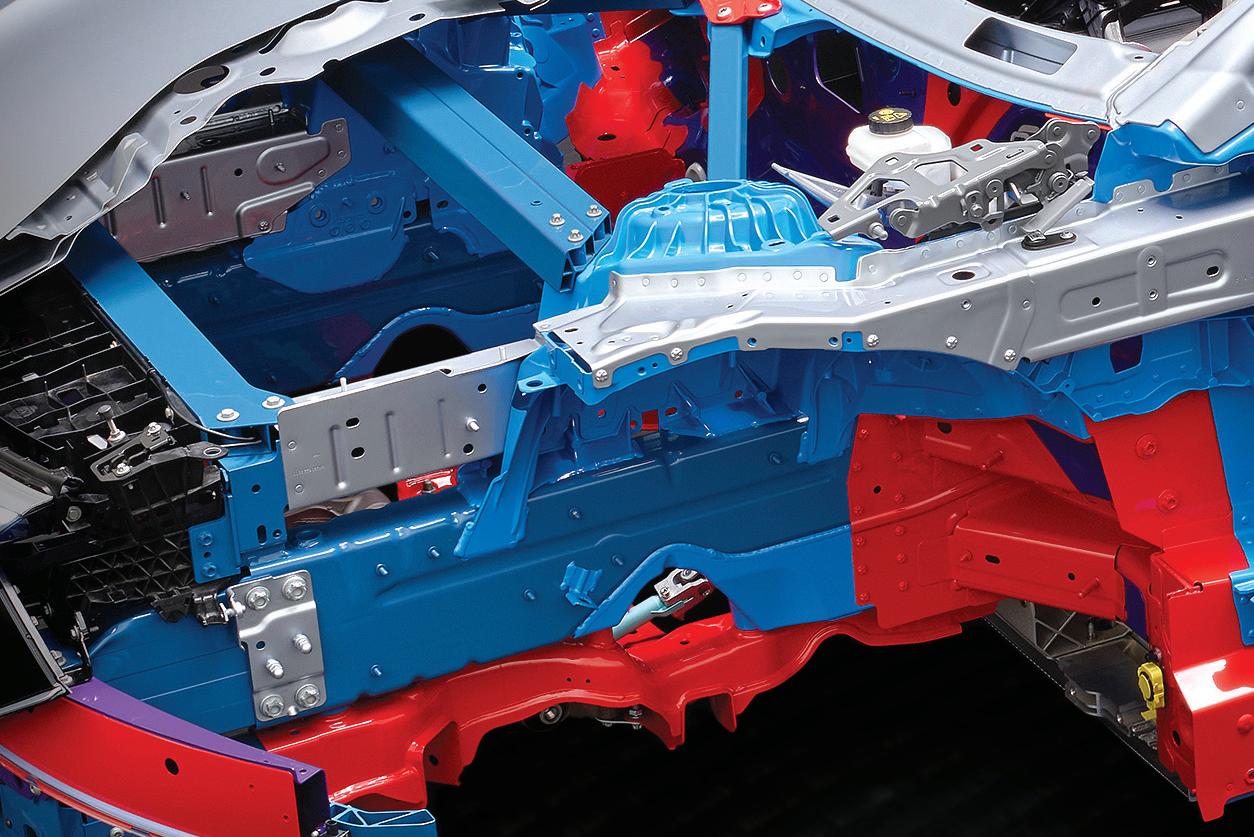

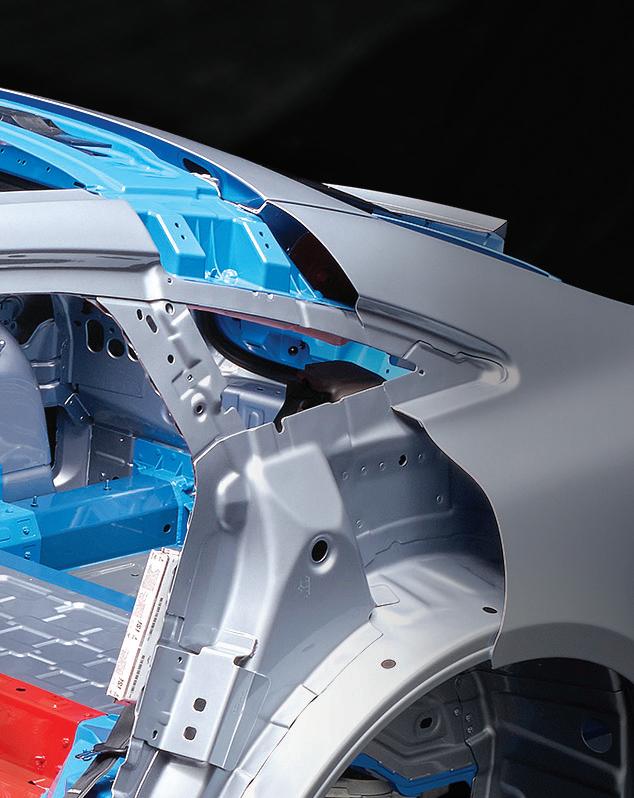

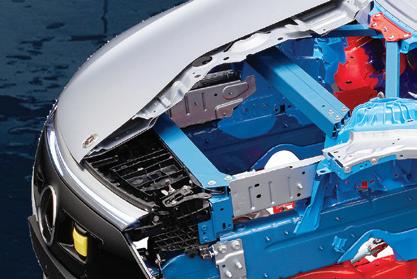

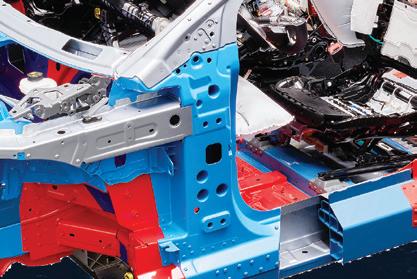

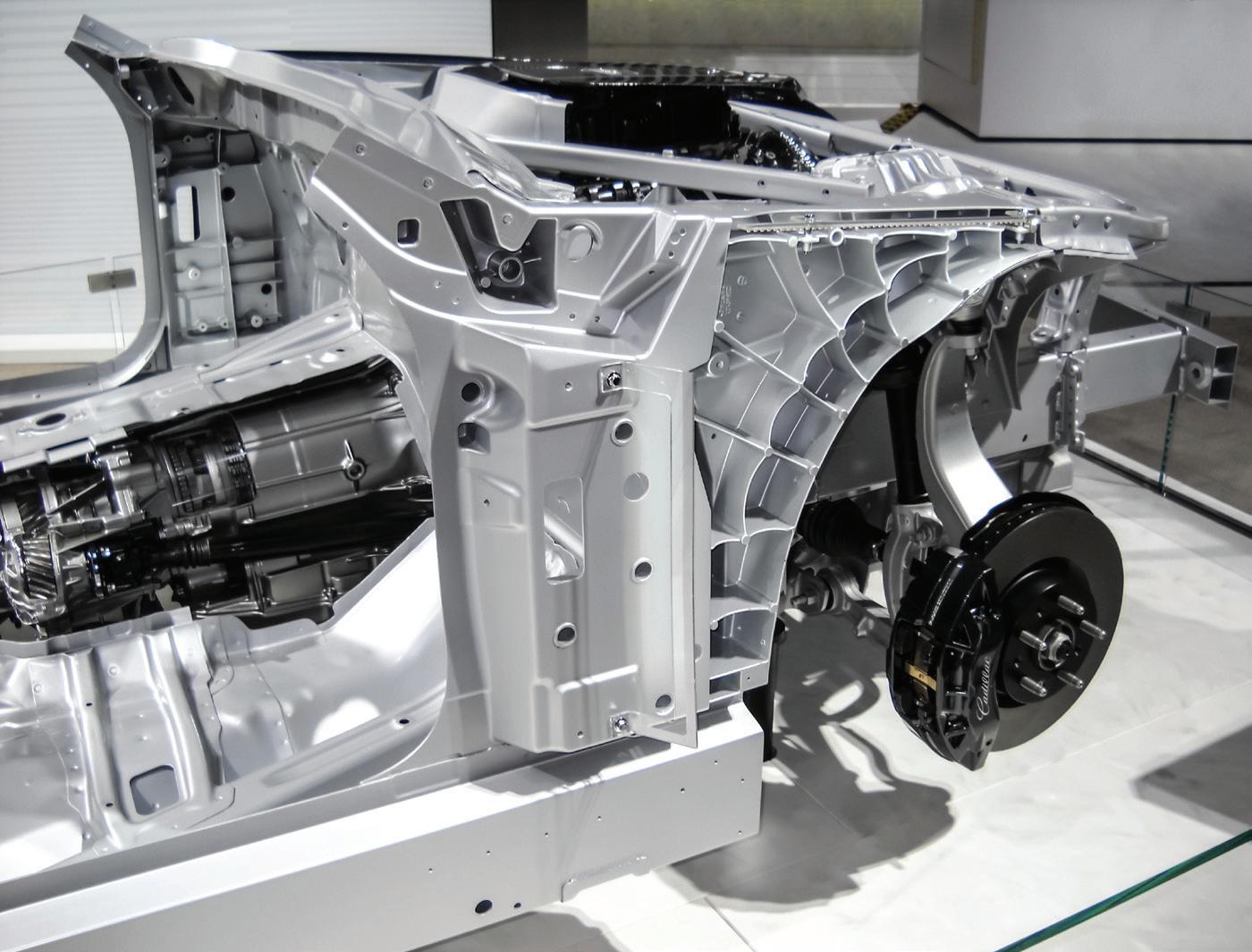

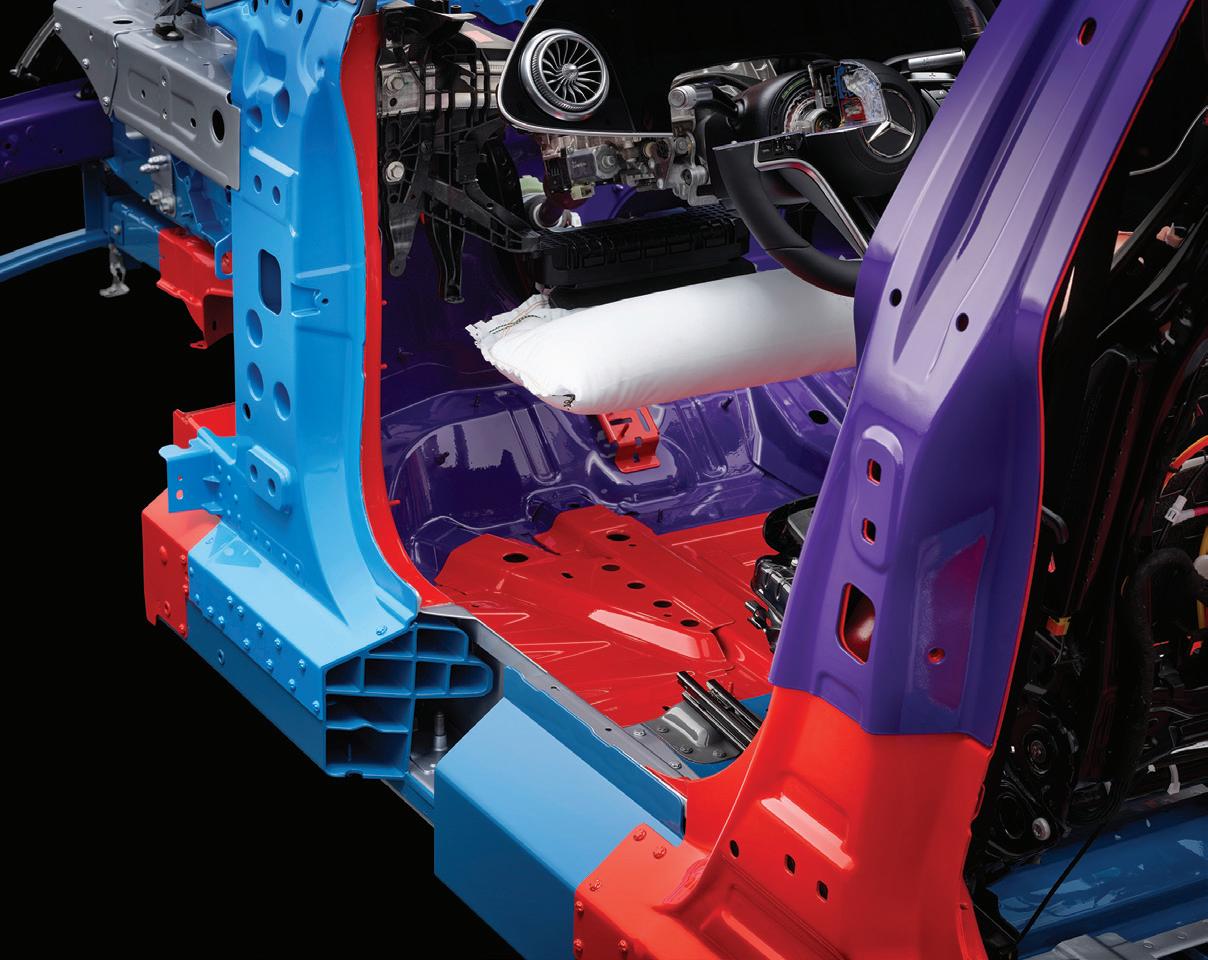

As the automotive industry moves toward lighter and more efficient vehicles, the importance of advanced training for collision repair technicians has never been greater. Both performance and regulatory factors influence the drive for lighter vehicles. For internal combustion engine (ICE) and hybrid vehicles, a lighter weight is essential for meeting increasingly stringent fuel efficiency standards, such as the Corporate Average Fuel Economy (CAFE) standards. For electric vehicles (EVs), lighter weight directly impacts the range of the vehicle, offering a competitive advantage for manufacturers striving to extend battery life and improve performance. Both of these trends are pushing the demand for lightweight materials in vehicle construction, which presents unique challenges for repair technicians.

THE VARYING MATERIALS of the MercedesBenz EQS body shell are shown in different colors and form the outer deformation zones of the vehicle.

MERCEDES-BENZ USA

Technicians and shop owners must recognize the importance of embracing a comprehensive approach to training, which includes both OEM-specific education and broadspectrum foundational programs like I-CAR training. It is highly recommended that technicians, along with engaged shop owners and managers, fully embrace the OEM training available, especially for specialty and high-end vehicles. OEM training provides invaluable insights into vehicle manufacturer service information, service bulletins, and collision repair publications, which are essential for ensuring the accuracy and integrity of repairs.

While I-CAR training offers a strong base of general knowledge — covering topics like attachment methods, structural repair and advanced materials — this foundational training prepares technicians for more specialized OEM programs. I-CAR’s broad training spectrum helps technicians become familiar with key repair concepts and techniques that they will later encounter during more detailed OEM training. By combining both OEM-specific education and

versatile training programs, repair professionals can ensure they are fully equipped to meet the demands of modern vehicle repairs, particularly when dealing with lightweight materials and advanced technologies.

The repair of lightweight materials requires technicians to stay in line with OEM-specific procedures, which differ significantly based on the material in question. On the steel side, advancements like ultra-high-strength steel enable thinner, stronger components, but they also introduce the risk of losing structural integrity if improperly repaired. Technicians must be trained to recognize when sectioning or full part replacement is necessary and follow the manufacturer’s guidelines for attachment methods, whether it’s welding or cold joining methods like rivet bonding.

Aluminum-intensive vehicles, such as the Ford F-150, have further driven the adoption of rivet bonding techniques over traditional welding. While welding is still sometimes required, manufacturers increasingly prefer cold joining

methods to avoid weakening the material. I-CAR’s specialized courses help technicians navigate these changes, ensuring they adhere to correct attachment methods to preserve the integrity of the vehicle.

As lightweight materials like aluminum and high-strength steel become more common, repair processes must adapt. In some cases, repairability may be limited, and part replacement becomes the only option. The complexity of materials, such as layering within a part or integrating different materials (steel, aluminum, and carbon fiber), can make repairs more challenging. I-CAR training prepares technicians for these scenarios by teaching them how to evaluate the repairability of a part, whether sectioning is allowed, and when full part replacement is necessary.

OEM procedures play a critical role in maintaining safety and performance

like aluminum become more common, repair processes must adapt. In some cases, such as with aluminum castings, part replacement is the only option.

standards. For example, using the wrong welding technique on ultra-high-strength steel can weaken the part, compromising the vehicle’s safety. As one expert noted, “It’s not about your ability as a technician — it’s about following the OEM requirements to ensure the vehicle performs as designed.” This highlights the need for ongoing, specialized training to ensure technicians do not inadvertently compromise the vehicle’s structural integrity during repairs.

Repairing lightweight materials requires practical, hands-on training to refine skills. Technicians should practice on scrap materials, particularly in welding and bonding exercises, to ensure they can execute repairs accurately. I-CAR’s hands-on approach allows technicians to simulate realworld scenarios, such as performing repairs on aluminum or high-strength steel, before working on customer vehicles. This practice builds confidence and ensures that repairs are performed with precision. -any photos of hands-on repairs?

Continuous Learning and Adaptation to Emerging Technologies

As part of its Repairability Technical Support (RTS) OEM linking pin activity, I-CAR helps connect the collision repair industry to the vehicle makers. Here is one example, titled Ford Aluminum Vehicle Running Board Mounting Location Repairability, found here: https://rts.i-car.com/crn-1995.html:

“A common question when it comes to the 2015-present Ford F-150 is the repairability of the running board mounting location. Specifically, when the stud is torn out of the inner rocker panel. We reached out to Ford for clarification.

Per our contact at Ford, the following procedure applies to these vehicles:

• 2015-present Ford F-150

• 2018-present Ford Super Duty

• 2018-present Ford Expedition

• 2018-present Lincoln Navigator

Per our contact at Ford: “They can do weld repair to the stud areas. The inner rocker panel can be sectioned where required. The repair facility can order the inner rocker and cut out a plate around the stud and weld it in following the sectioning guidelines outlined in the repair manual. It would be very invasive to replace the inner rocker panel unless there was additional damage to the inner rocker panel beyond the torn-out stud.”

This means there are several repair options to consider when assessing the damage and the extent of the repair to be completed:

• Repair/straighten the stud mounting area and weld any cracks or tears in the immediate stud location.

• Following Ford’s sectioning guidelines, cut a portion from the new inner rocker panel service part and install accordingly.

• Replace the inner rocker panel at factory seams. This requires the outer uniside and the rocker panel reinforcement to be replaced. This should be considered if there is additional unrepairable damage beyond the torn-out stud(s).”

As vehicle technology evolves, so must the skill sets of collision repair technicians. Lightweight materials are not only essential for meeting fuel efficiency and range goals but are also vital for the continued development of electric and autonomous vehicles. Technicians must stay updated on new material types, advanced tools, and the latest repair techniques to ensure they can repair modern vehicles safely and effectively. Whether through I-CAR courses, OEM certifications, or manufacturer-specific training, ongoing education is critical for technicians to stay ahead of industry trends and deliver high-quality repairs.

The push for lighter vehicles, driven by fuel efficiency standards for ICE vehicles and range requirements for EVs, is reshaping the collision repair landscape. Repairing these vehicles requires technicians to possess specialized knowledge and skills, particularly when working with lightweight materials like aluminum, carbon fiber, and high-strength steel. I-CAR training, with its focus on OEM-specific procedures and hands-on experience, ensures that technicians are prepared to meet these challenges head-on. By prioritizing continuous learning and following manufacturer guidelines, the collision repair industry can maintain high standards of safety and repair quality, ensuring that every vehicle remains roadworthy and performs as designed.

ONGOING EDUCATION IS CRITICAL for technicians to stay ahead of industry trends and deliver high-quality repairs.

SCAN THE QR CODE TO SHARE THIS ARTICLE AND READ RELATED ARTICLES ONLINE

Scott spent the first 20 years of his career in the collision industry as a structural repair technician. In that time, he worked for independent, dealership, and MSO shops. In 2014, he began a new chapter as a collision instructor at the High school and college level including becoming the Program Coordinator for the prestigious Fayetteville Technical College, Collision U program where he was recruited by American Honda to develop their collision technical training program. Scott is a 6 category I-CAR platinum individual, 3x Recertified ASE Master Collision technician and has earned AMCE and AMAM designations with AMI. He has also been a part-time welding instructor for I-CAR for the past seven years. In his spare time, Scott enjoys building street rods and restoring antique cars.

Jeff first ventured into a commercial shop in the late ’80s and not long after that was enrolled in some I-CAR classes. Many days in the collision shop repairing vehicles and presenting I-CAR courses in the evenings eventually led to national I-CAR recognition, when Jeff was awarded “Instructor of the Year” for 2005. From repairing vehicles as a technician to helping with the development of training materials for the collision repair industry here in the U.S. and viewed in other countries, with over 35 years in the industry Jeff is a sought-after subject matter expert when it comes to identifying the important aspects of a scenario and how it applies to collision (or other loss type) and vehicle repairs for application in educational resources.

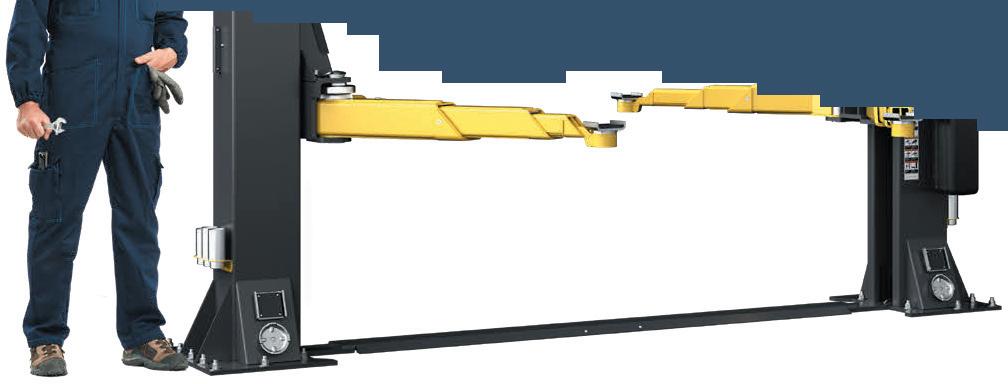

Many body shops use low-rise or mid-rise scissor lifts when they need to raise vehicles for wheel, tire and body work. But while these small lifts can be a great choice for such applications, low- and mid-rise scissor lifts lack the versatility of a two-post lift. eir low rated capacity (less than 10,000 lbs.) and design limitations mean they can only properly pick up about half the vehicles on the road today. Meanwhile, a welldesigned two-post lift can raise most modern cars, SUVs and pickup trucks. Stepping up to two-post lifts can improve body shop productivity and technician ergonomics. But some shop owners worry that two-post lifts come with additional risk.

Here are 5 tips for mitigating risk when using two-post lifts in applications that don’t require standing under the vehicle.

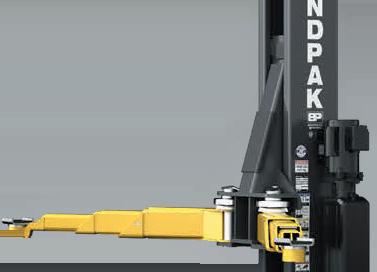

1. Limit how high technicians can raise vehicles. Many national franchise operations limit the height at which their technicians can work. If the techs are only doing wheel, tire or body work, they don’t need to raise a vehicle six feet in the air. Choosing a short-rise two-post lift like the new BendPak 12AP-SRT makes enforcing this limit easy. Its maximum lifting height is 47 inches, so technicians simply can’t raise it any higher. Even with its short stature, the 12AP-SRT offers all the versatility of a 12,000 lbs. capacity two-post lift. Its tripletelescoping Bi-Metric swing arms can reach most OEM lifting points, enabling it to efficiently pick up 99 percent of modern vehicles.

2. Choose ALI Certified lifts. Professional shops deserve professionalgrade equipment. The only way to be sure a lift meets industry safety and

performance standards is to choose one that has been third-party tested and certified by the Automotive Lift Institute (ALI). Look for the ALI Gold Label or check the Directory of Certified Lifts at autolift.org to confirm whether or not a lift is certified.

3. Train technicians. All technicians should be trained on safe lifting practices and how to operate the specific lifts in the shop. This training should include proper spotting, lifting, and lowering procedures.

4. Consider safety features. Safety features vary widely among lifts and lift manufacturers. Look for automatic safety locks in every column, a single-

point lock release, and the strongest possible automatic arm restraints.

5. Regularly inspect and maintain the lifts. Technicians should check their lifts daily. Have every lift professionally inspected by an ALI Certified Lift Inspector annually to ensure it’s in proper working order. Follow the instructions in the lift operator manual for specific maintenance requirements.

New professional short-rise two-post lifts like the BendPak 12AP-SRT offer the versatility, productivity and ergonomics of a full-size two-post lift with lower costs and less risk.

There are a lot of ways to press the gas on your shop earnings in 2025. You can expand, invest in newer equipment, overhaul your operation, or become OEM-certified to grab more business. If those options are a bit too expensive right now, you can always look for ways to cut expenses, especially using input from a consultant (something your vendors can help with). Some of the quickest, least costly ways to punch up revenue could be right in front of you right now in new products available from your paint vendors.

Annually, if not more often, paint manufacturers release new products designed to help you work more efficiently with minimal investment of time and money. Since their success is tied to yours, these companies are on the constant lookout for ways to build efficiencies and increase your throughput. If you haven’t yet this year, call up your paint reps and see what they can offer. In the meantime, here’s a

BY TIM SRAMCIK

look at the latest and greatest products that could be helping you as we speak.

AkzoNobel – “App-etite” for digital power Apps have evolved well beyond being smartphone doorways to social media, email, news, and weather. Today, they have the power to help manage your entire operation. The AkzoNobel Performance Portal (The App) is engineered to do just that by enhancing communication and data-driven decision-making.

The App promises to:

• Streamline operations through standardized workflows that eliminate inefficiencies and reduce variability while maintaining quality and efficiency.

• Cut overhead costs by streamlining middle management

• Optimize inventory, reduce cycle times, and maximize capital utilization

• Offer real-time analytics to provide instant, actionable insights for managers

• Identify inefficiencies before they impact shop bottom line and improve workflow

• Provide teams with clear direction and actionable insights to improve performance.

• Foster a collaborative culture that aligns teams with organizational goals

• Speed up integration and get new shops profitable, and

• Standardize processes for scalability, efficiency, and costeffectiveness.

AkzoNobel says The App offers even greater value for Multi-Shop Operators (MSOs).

As OEMs expand their finish colors options, shops face an unceasing challenge to produce exact color matches. Axalta now offers Irus Scan, its latest spectrophotometer that scientifically measures paint color on a vehicle to provide accurate color matches in waterborne and solvent-borne basecoat technologies.

Axalta explains that Irus Scan leverages an inverse angle to detect hue shifting effect pigments for more precise reading for popular achromatic effect colors. The company declares Irus Scan is the first spectrophotometer with built-in gloss measurement capabilities to ensure accurate surface preparation and clearcoat product usage.

A high definition, RGB camera measures colored sparkle and pairs them with the company’s color formula retrieval system to provide what Axalta says is the single, best color match for vehicles using a newly refreshed database of over two million color formulas. This setup is designed to eliminate time in the color match process, allowing for more vehicles to be processed faster and more efficiently.

Axalta adds that due to its accuracy, Irus Scan reduces the need for spray outs to check color and decreases rework from color match errors, reducing product waste and upgrading environmental sustainability.

Speaking of caring for the environment, BASF has created new finishes, its Glasurit AraClass A-C-24 Eco Balance and R-M Race Finish-R eSense, designed to boost

shop efficiency using a formula engineered to significantly cut CO2 emissions.

Using ChemCycling technology under BASF’s mass balance approach, these clearcoats are manufactured using recycled feedstock.

BASF says the products are driven by its “vision to support a circular economy by reducing the use of fossil raw materials, minimizing waste and cutting CO2 emissions in the value chain.” The recycled feedstock is derived from waste tires, effectively diverting them from landfills or incineration. BASF notes that its Glasurit AraClass A-C-24 Eco Balance and R-M Race Finish-R eSense clearcoats are the first automotive refinish products to utilize this technology.

According to BASF, product benefits include quick drying speeds for fast processing, with the coating drying in 20 minutes at 40 degrees Celsius. By reducing drying time, energy consumption can be significantly lowered, resulting in improved efficiency and reduced environmental impact. The company notes that this feature is particularly advantageous for electric vehicles since it minimizes their exposure to excessive heat.

In addition to these ChemCycling clearcoats, BASF intends to launch another sustainable solution-new mixing clears based on BASF’s biomass balance approach have been added to the waterborne basecoat series of Glasurit 100 Line and R-M Agilis, both of which the company claim already offer the lowest VOC content below 250 g/L in the industry. The new mixing clears are formulated to reduce CO2 emissions by up to 50 percent.

PPG has its own solution for better color matching with its Deltron NXT product line, which offers the latest pigments and effects. Replacing powder pearls are 13 new liquid pearls designed to provide easier, more accurate color matches to OEM colors that promise to be easy to dispense and to improve ready-to-spray settling. Joining them are nine new Xirallic and four Colorstream liquid effects pigments to better match today’s most complex, iridescent colors. Further, new toners also have been added to ensure supply

The App, available from AkzoNobel, places the power to guide your business in your smartphone with feature that use data analytics and other sources to streamline management, optimize inventory, and reduce cycle times.

BY DR. STEVE JOSEPH, CORPORATE SCIENTIST, 3M COLLISION

With the vast majority of professional collision repairers in North America using a disposable paint cup and liner system, it is hard to believe that they didn’t even exist 25 years ago. Before 3M introduced the Paint Preparation System (PPS) to the market in July 2001, permanent plastic or metal cups were the only option.

At 3M, scientists and engineers use science to develop new solutions, new technologies, and sometimes even new industries that solve challenges that people face every day. PPS came to fruition out of a desire to be embedded in the body shop environment and to work with painters to understand their unique

challenges, pain points, and everyday processes. It was clear that the repetitive process of mixing paint in separate containers, pouring the paint through a paper strainer into the spray gun reservoir, and then cleaning up the spray gun and cups afterwards was ripe for a better, more innovative approach.

At the time, the industry was transitioning from siphon-fed to gravity-fed spray guns, driven primarily

sustainability, including Vivid Red Ruby which will work to eliminate the use of tinted clears.

A new “blacker than black” jet black toner is designed to enhance basecoat application, while a new blue black toner can improve the ability to match vehicle colors from around the world.

by the improved transfer efficiency of these spray guns with top mounted cups. Additionally, shop owners were looking for more efficiency and less material waste while concerns over solvent use and disposal were growing.

Countless hours were spent developing concepts and building prototypes before a breakthrough was ultimately reached: why not take the container of mixed paint and place it on the spray gun to eliminate the transfer step? This new cup that doubled as a spray gun reservoir could then be disposed of, and in turn could eliminate much of the solvent associated with spray gun cleaning.

The 3M team field-tested a variety of PPS prototypes with production painters to understand the factors that were most important to them. This guidance led the team to pursue a liner and cup system over a linerless vented cup, as it allowed painters to not only keep the spray gun positioned at 90 degrees to the panel, which optimizes material transfer and reduces waste, but also spray upside down to cover hard-to-reach areas.

It took a number of years to transform the original concept into what would become the world’s first disposable paint cup system. Following its launch, PPS would soon gain acceptance throughout the market and become adopted by painters all over the world.

Today, when compared to the use of conventional spray gun cup systems, PPS users can help reduce solvent consumption by up to 70 percent, material waste by up to 10 percent, and see improvements in overall productivity and cycle time. Achieving greater productivity and efficiency within the paint process is an ongoing commitment for 3M. In 2018, 3M introduced the PPS Series 2.0 Spray Cup System, which was redesigned for even easier and cleaner painting after engaging with painters to understand opportunities to further improve the product.

PPG says the additional introduction of new reducers enhance the painter’s ability to achieve efficient refinish repairs in the full range of operating conditions — from cool and dry to hot and humid. Supporting this effort includes a new reducer selection guide, gun chart and application recommendations.

Paint companies have targeted a number of spots in the refinishing process with upgrades to speed paint work. Sherwin-Williams now offers Collision Core Pronto, a fully automated dispenser for mixing color. This dispenser is fully integrated with its Collision Core Color products and sends multiple mixes to the dispenser, allowing the technician to focus on other, more value-added activities. It’s available with four or six dispensing heads, which SherwinWilliams says gives flexibility for customers operating in high-volume or high-labor cost environments. SherwinWilliams says key features and benefits (based on the fourhead model) include:

• The ability to dispense nearly 200 colors per day. With four high-tech dispensing heads, Pronto can mix up to four colors at the same time. The company declares Pronto is the first solution to offer concurrent multiple mixes.

• Pronto is engineered to be a user-friendly plug-and-play solution that requires no manual mixing, cleaning or calibration, and can be operated by practically anyone, freeing up skilled technicians to focus on application and repairs.

A full host of new refinish products available this year offer every shop the opportunity to add speed, increase quality, and boost revenue.

• Fast mixing times. Initial users have demonstrated a total mix time of five minutes – 50 percent quicker than alternative mixing systems, which can save significant time in busy operations.

• Saves up to 50 percent in labor time. The four-head machine can process 24 mixes an hour, significantly increasing body shop productivity.

• Consistent color precision with reduced product waste. Pronto is fully integrated with Color Retrieval Systems and allows for extreme precision down to 0.01 g. with no dripping or risk of overpouring. This factor can ensure minimal product waste and fewer errors in color formulation.

• Can be used for all job sizes. Pronto can dispense as little as 50 g accurately, amounts Sherwin-Williams says are impossible to achieve with a manual process.

• Low maintenance. Pronto is designed with full product recirculation intended to eliminate the risk of clogging and ensures consistent, error-free operation. The company says the fully automated recirculation system substantially reduces maintenance-related downtime, letting shops focus on core tasks.

Ready to get started with these or other new products? Keep in mind that regardless of shop size, even modest increases in production-even an additional 1-3 jobs per weekcan set you up for a brighter 2025 and put you on the path for an even better 2026.

TIM SRAMCIK began writing for ABRN over 20 years ago. He has produced numerous news, technical and feature articles covering virtually every aspect of the collision repair market. In 2004, the American Society of Business Publication Editors recognized his work with two awards. Srmcik also has written extensively for Motor Age and Aftermarket Business. Connect with Sramcik on LinkedIn and see more of his work on Muck Rack.

SCAN THE QR CODE TO SHARE THIS ARTICLE AND READ RELATED ARTICLES ONLINE

The 3M Clean Sanding System is a complete sanding solution for efficiently moving through your essential surface preparation and finishing work. The system includes 3M’s dust extractor, pneumatic and/or electric random orbital sanders, mobile workstation, wide selection of quality abrasives, and personal protective equipment.

• Designed to reduce dust in the air from sanding for a cleaner workspace.

• Helps shops boost productivity and efficiency by helping to reduce rework and cleanup time.

• Compact and mobile. Designed for easy, flexible use around the shop.

• Compatible with pneumatic and/or electric sanders.

• Tech-friendly design including auto on/off, antistatic hose, rubber wheels, brake locks, and LED indicator lights.

FENDERBENDER.COM/55264835 SPONSORED

The AIRCAT 0.6hp Decal/Pinstripe Removal Tool, No. 6345, offers a free speed of 2,600 rpm with a 0.6hp motor.

The tool includes built-in gear reduction that eliminates stalls and silencing that reduces tool noise to 80 dBA. It uses a 4” rubber eraser wheel that is ideal for decal and pinstripe removal and has a 360-degree adjustable side handle that ensures user control while under load. The tool only weighs 2.15 lbs and includes an air regulator on top of the housing that allows users to adjust the tool speed and output.

FENDERBENDER.COM/55264763

The Killer Tools Deluxe Vacuum Floor Puller, No. ART23DX, features an easy-to-use ratcheting chain that allows for 1,500 lbs of pulling with one-handed operation. The puller enables the user to set up quickly and easily anywhere in the shop, and make sheet metal pulls without having to search for chain pots or wait for a frame rack. The tool includes an additional plate for anchoring the vehicle or for down-pulls, a storage tray and carry handle for easy transport and accessory storage, and a six-finger pulling claw and down-pull pulley.

The High-Voltage Pack Service Tool, No. xPDC-1K, from Midtronics is a flexible platform with capabilities to meet EV battery specifications. The tool is designed to provide safe and efficient charge and/ or discharge of HV packs with

control and monitoring to simplify operation. Additional features include an Android interface with on-screen prompts to perform service with minimal input, and two power level variants to match the user’s needs.

FENDERBENDER.COM/55261712

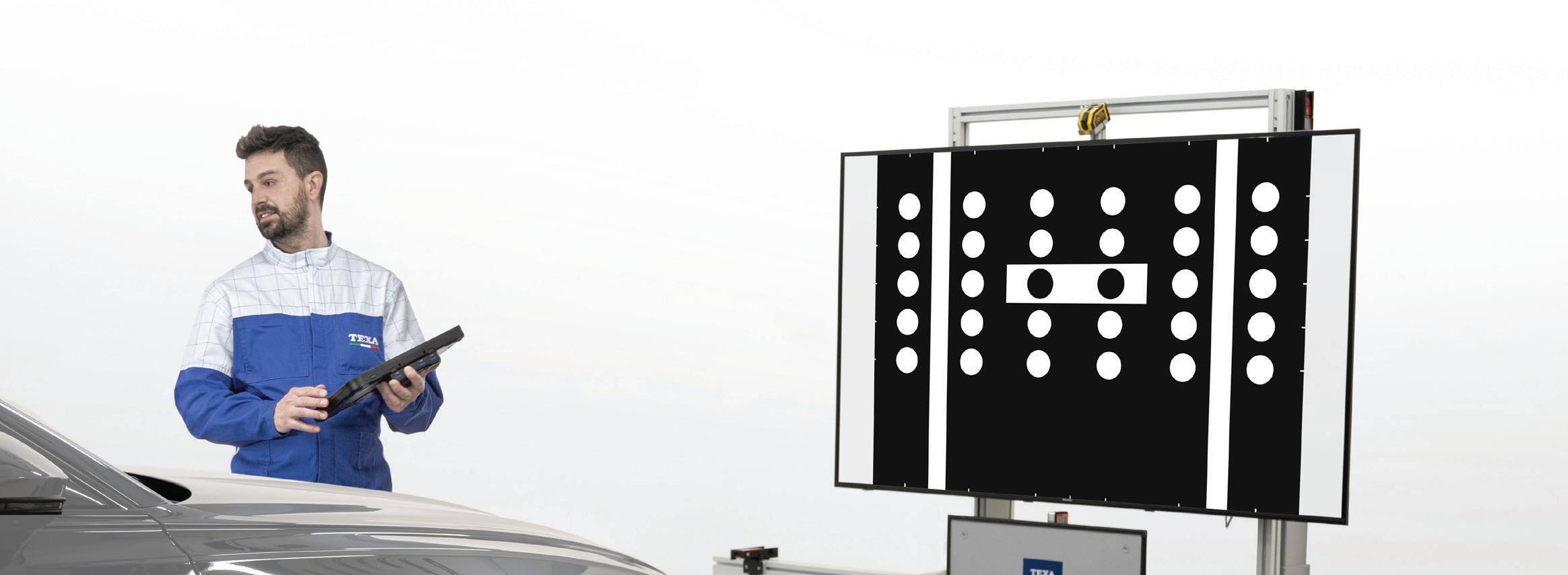

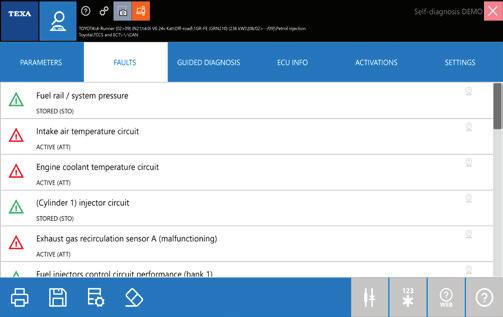

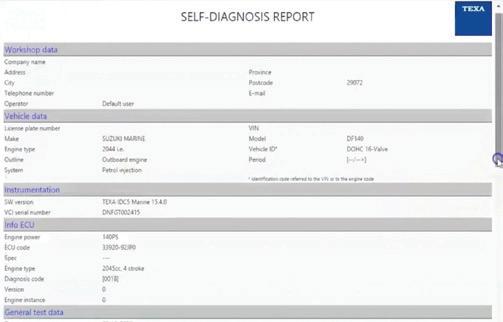

The TEXA IDC6 AI Diagnostic Assistant is designed to provide technicians with the advanced experience and troubleshooting knowledge needed to diagnose repairs quickly and accurately the first time. The IDC6 engine uses relevant and filtered data, validated vehicle records, and code-specific technical service bulletins to identify the correct repair blueprint for all vehicle issues. Two functional steps based on AI support operate IDC6 diagnostic assistance, focusing on autonomous working access. The AI Smart Diagnosis function guides technicians through all diagnostic stages. IDC6 quickly completes the TGS3 control unit scan for automatic vehicle selection, and VIN Scan confirmation, then optimizes malfunction identification and suggests effective troubleshooting and repair or service options.

FENDERBENDER.COM/55264960

FENDERBENDER.COM/55263981

The Cementex Feature Series Arc Flash Protective Clothing PPE is made with FR-treated cotton and meets current ASTM F1506 and F1959/1959M-99 standards. The series includes coats, parkas, bibs, pants, coveralls, and leggings. Each option features specific safety measures, such as FR Velcro closures, quick-disconnect shoulder straps, and knit wrist cuffs, to ensure secure closure, easy access, and rapid removal. The sizes range from small to 5X with a standard inseam of 32”. It is also available in duffle bag, backpack, and hard-sided container kits with hardhats and eye and hearing protection. The clothing is made with USA labor and materials.

FENDERBENDER.COM/55264143

The Ray-Ban Meta Wayfarer Black with Transition Green Lenses, No. RB0RW4006, from Matco Tools, features light-responsive lenses that adapt from being fully clear indoors to fully dark outdoors. The glasses include hands-free technology with voice activation that allows users to get answers from Meta AI, capture photos and videos, make calls, send messages, listen to music, and more.

FENDERBENDER.COM/55264420

The OPUS IVS DrivePro 2 Plus is designed to be a diagnostic platform that the company says offers 100 percent brand coverage. Users can access their own OEM software through MyCarDAQ or pre-existing OEM applications through the tool’s Farsight mode. The DrivePro 2 Plus allows users to access direct communication with brand-specific master technicians as well as integrated AI for instant repair suggestions and troubleshooting. It features up to 16GB of RAM, an Intel Core i3 or i5 processor, and is 5G capable. It comes in a rugged, drop-tested body.

FENDERBENDER.COM/55264436

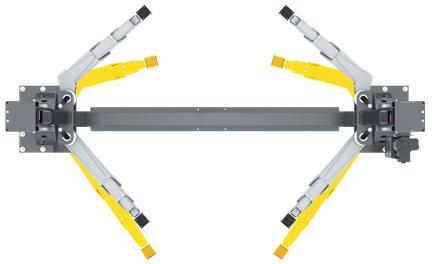

The 16AP and 20AP Series Two-Post Lifts from BendPak feature multi-faced columns for more evenly distributed loads compared to traditional columns and an automatic swing arm restraint system that delivers 360 degrees of grip with more than 2,000 lbs of load-holding force. The arms can retract as short as 35” and extend up to 65” to allow the lifts to service a wide range of vehicles with a variety of lifting points. The 16AP Series has a maximum lifting height of 89.75”, and the 20AP Series has a maximum of 90.25”. The 16AP and 20AP also come in taller versions, the 16AP-192 and 20AP-192, that measure 193” versus the base models’ 169” to service larger vehicles.

FENDERBENDER.COM/55264027

The 250 MP PRO Welder, No. 415, from Forney Industries, features MIG, TIG, and stick welding capabilities, as well as dual-voltage input and generator compatibility. It includes TruSet technology, which simplifies setup by providing optimal settings based on material type and thickness. It also offers Expert Set and Expert Info technology, which offers user-friendly guidance and insights on the LCD display screen, and the Set and Forget despooler design that ensures consistent wire feed performance.

FENDERBENDER.COM/55264796

The new Diagnostic Thermal Imager+ from Snap-on uses infrared technology to reveal heat caused by friction, electrical resistance, pressure changes, and more to help professional technicians track down vehicle faults and find the fix faster, without having to hope or guess that the code was the right one after all. Key features of the Diagnostic Thermal Imager+ include:

• Point at any area of the vehicle for detailed images of the object’s heat signature

• Customized views on screen to assist in diagnosis and pinpointing location

• Image blending, split screen view, picture-in-picture view, and record a 20-second video

• Pull trigger to capture images, then use saved images to create convincing repair orders; save, store, and print

• Detects problems all around the vehicle: brakes, heated seats, misfires, HVAC, worn bearings, belts, emission controls, and more

• Reference images show normal and failed components so technicians know what to look for

When connected to Wi-Fi, every image captured with the Diagnostic Thermal Imager+ is automatically uploaded to the Snap-on Cloud. Technicians can then access the images from their phone or computer whenever they need them, helping to make the next diagnosis and repair faster and more accurate.

FENDERBENDER.COM/55260670

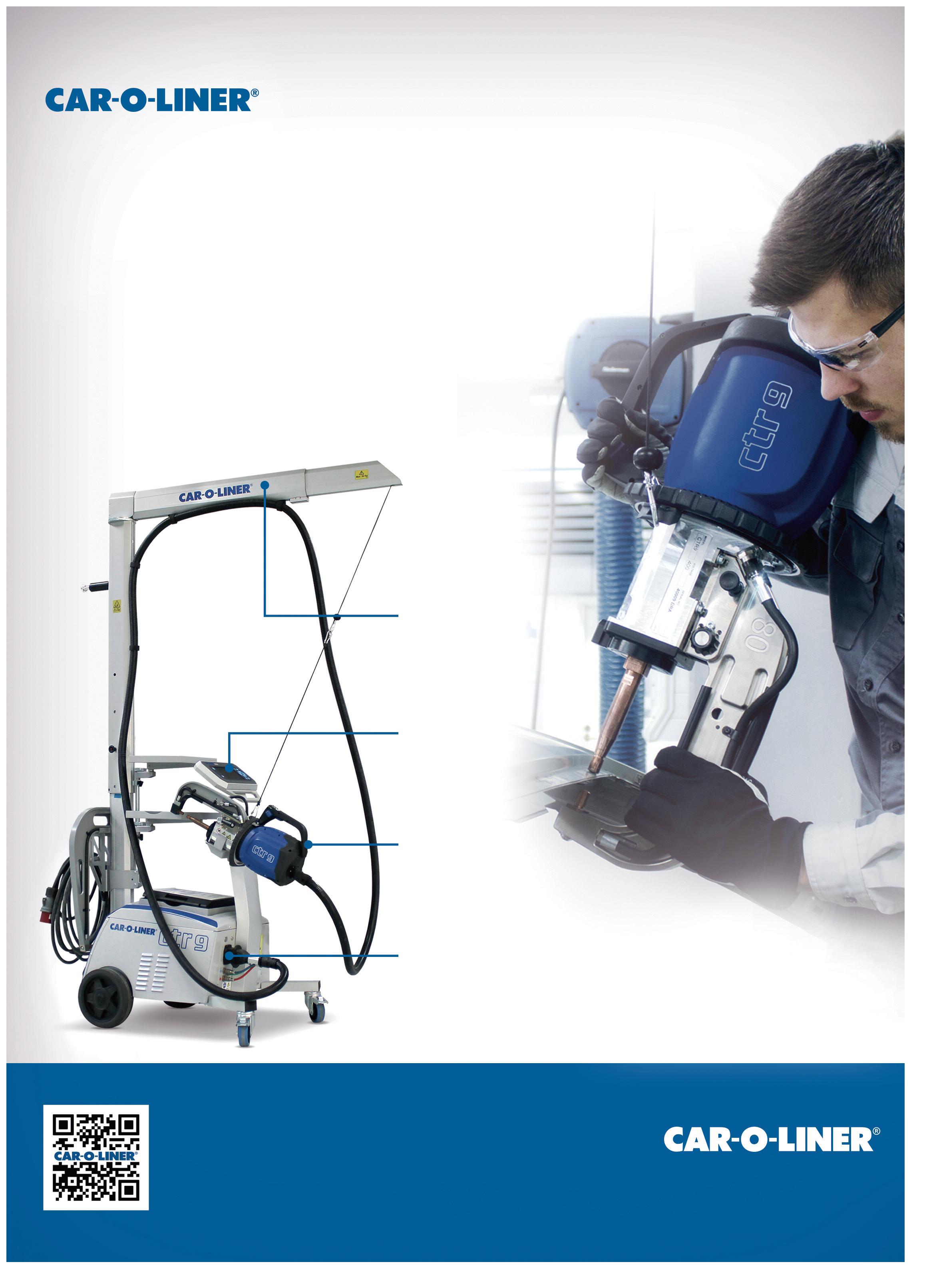

In the fast-paced world of automotive repair, efficiency and precision are paramount. The CTR9 Spot Welder from Car-O-Liner ® stands at the forefront of collision repair technology, offering a fully automatic solution that is now approved by BMW. This endorsement underscores the welder’s superior quality and performance, making it an indispensable tool for any professional workshop.

The CTR9 is engineered with a revolutionary lightweight transformer gun, designed to enhance user comfort and productivity. Its 355° swivel handle and ergo-grip ensure perfect working positions, reducing strain and fatigue during prolonged use. The gun is supported by a telescopic arm crafted from durable, lightweight extruded aluminum, allowing for easy vertical and horizontal adjustments. This design provides maximum freedom of movement, ensuring that technicians can work efficiently in any setting.

At the core of the CTR9 is a compact power unit, featuring a low center of gravity for enhanced mobility and stability. Equipped with a robust 16,000-amp transformer and CANBUS communication, this welder delivers precise, consistent results every time. The power unit’s easy-to-use control panel, complemented by an exclusive LED display, simplifies the welding process, enabling technicians to achieve flawless results with ease.

The CTR9 is designed with accessibility in mind. Its 236-inch cable allows users to reach more parts of the vehicle without the need to reposition equipment, saving valuable time and effort. Additionally, the optional shelf and clip kit

keeps accessories organized and within reach, while the clip kit secures hoses, enhancing safety in the workspace.

The Car-O-Liner commitment to innovation and quality is evident in the CTR9 Spot Welder. This tool not only meets but exceeds industry standards, providing workshops with a reliable, high-performance solution for collision repair. Its OEM approval by BMW is a testament to its exceptional capabilities and trusted performance.

For over fifty years, Car-O-Liner has been a leader in providing technologically advanced collision repair equipment. The CTR9 Spot Welder exemplifies this legacy, combining cutting-edge technology with practical features that meet the

demands of modern workshops. Whether you are a seasoned professional or a newcomer to the industry, the CTR9 offers an unparalleled welding experience.

Invest in the CTR9 Spot Welder and elevate your repair capabilities to new heights. For more information or to request a quote, visit our website or contact your local distributor today. Experience the precision, efficiency, and reliability that only Car-O-Liner can deliver.

CAR-O-LINER

29900 ANTHONY DR #3609 WIXOM, MI 48393 (800) 521-9696 www.car-o-liner.com

AirPro says its Auggie is the automotive industry’s most advanced forward-facing camera (FCC) solution for ADAS calibrations. Auggie utilizes machine learning and vision technology to accurately render ADAS targets and lighting conditions, ensuring precise alignment for proper FCC ADAS calibrations according to vehicle manufacturer specifications. Designed for accuracy and mobility, Auggie delivers precise calibrations in any environment and is compatible with the most sophisticated calibration-capable scan tools. This groundbreaking solution streamlines the ADAS calibration process, allowing your business to operate more efficiently and increase profitably.

FENDERBENDER.COM/55252771

EVO stands out as the ultimate solution designed to optimize your performance and enhance your repair processes. Integrate Car-O-Liner EVO systems into your alignment bench for top-notch flexibility, efficiency, and precision. Combine Quick 42, BenchRack, and Speed benches with Car-O-Tronic systems for real-time control and precise data. Get quick, quality results from diagnosis to documentation. EVO adapts easily to any repair job with three configurations. Say goodbye to pricey gear and meet market needs effortlessly with Vision2 X3. From assessment to delivery, EVO guarantees certified quality. Turn time into cash with its all-in-one solution, compatible with Car-O-Tronic for unbeatable efficiency.

FENDERBENDER.COM/33037028

CarCapsule USA’s PaintProStation, a 26’x14’x10’ professionalgrade mobile inflatable paint station, provides ample space and high-efficiency air movement to ensure a professional-grade outcome. It is completely portable and can be easily set up in minutes with no tools needed. The sturdy 12” air-filled frame is inflated by a powerful inflation pump that automatically turns on when it senses a 1/4 lb. of air loss. As the frame is sealed, it will not collapse if power is lost. This technology differentiates the PaintProStation from competitors’ products. A powerful 4,235 CFM blower with remote control exchanges air within the PaintProStation approximately 70 times per hour. The design features an easy open front drive-in door, and right and left side man-doors for easy access. Convenient hose and electrical ports are located on each side. The unit is very durable and includes heavy-duty zipper pulls and a heavy-duty chemical-resistant reinforced base mat. Maintenance is made easy with removable and replaceable filters and replaceable inner wall panels.

FENDERBENDER.COM/55253116

The EVS Plug-In Device from Elitek Vehicle Services performs pre/post scans and programming and offers live chat with the technician and customer. With a fast response time and faster cycle times, according to the company, the device is designed to aid in repair planning. It is engineered to be easy to use with PC, smartphone, or tablet capabilities. The product features a wired internet option, status LEDs, four CAN busses, and CAN FD and DoIP readiness.

FENDERBENDER.COM/55264988