New CVe Monitors and ProFile v5 help to improve thevisibility andproductivity ofyourinjectionmoulds. Those responsible for afleet of toolingcan benefit from newBluetooth® connectivity:

•Real-time visibility of mould activityand KPIs

•Global asset management fortracking mouldsand dies.

•Make data-based decisionstodrive improved OEE

•Global access withsecure,role-based reporting.

Begin thejourney to better profitability today. Visit us onlineoremail from theQRcode belowtoreceive a proposal that achievesyourvision of progress ahead

For a long time, toolmaking was primarily about one thing: high-precisionmachining Today,thatisnolongerenough.Rising energy prices, global competition and the call for more sustainable processes are forcing the industry to undergo a paradigm shift. It is no longer just perfect individual parts that are in demand, butcomplete,networkedsystems–andwiththem,acompletelynew self-image

Digitalisation and artificial intelligence (AI) are opening up new scope for action here – and they are precisely the focus of K 2025 in Düsseldorf, whose theme of ‘Embracing Digitalisation’ programmatically sums up the change. (Read our trade fair preview report)

What was previously characterised primarily by experience, intuition and structures that had developed over many years is now increasingly data-driven and networked Sensors, cloud applications and IoT interfaces enable the continuous collection and analysis of machine data in real time. On this basis, AI systems can recognise patternsthatremainhiddentothehumaneye–whetherinthethermal ‘fingerprinting’ofmachinesandtools,predictivemaintenanceorthe precise prediction of processing times

But even more crucially, AI makes the implicit knowledge of experiencedspecialistsexplicitandaccessible.Largelanguagemodelsand digitalknowledgeplatformsallowworkinstructions,designdataand empiricalvaluestobelinkedandretrievedinamatterofseconds This securesvaluableknow-how–acrucialfactorinviewoftheincreasing shortage of skilled workers

K 2025 shows what this path could look like. More than 3,000 exhibitors will be presenting their solutions for digitally networked, resource-efficientandAI-supportedplasticsproductioninDüsseldorf. WhetherattheVDMAForumorinthespecialshow‘Plasticsshapethe Future’, it will become clear how data is turned into knowledge – and how knowledg lead to F the t l d uld ki i dustry, this i

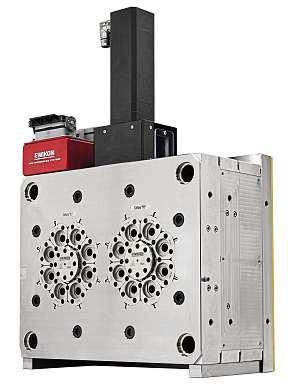

The solution for demanding filter applications

The hole filter with the unique design on the market reduces the shear and thus retains the mechanical properties of the plastic and keeps the pressure loss to a minimum.

•Maximum flow cross section outside the filter element

•More than 1,000 angled holes to keep shear and flow rate in the holes to a minimum

•Pressure loss with the same filter performance

Hot runner solutions for enhanced performance, uptime and ROI p. 18

How Mold-Masters is redefining hot runner performance through Symfill and Multi-Layer Co-injection technologies

Subscribe to our newsletter

▪ etmm-online/newsletter

▪ facebook.com/ETMMMagazine

Events

▪ etmm-online.com/events

Suppliers database

▪ etmm-online.com/suppliers

Photo galleries

▪ etmm-online.com/galleries

Industry news

▪ etmm-online.com

ETMM Media

▪ media.vogel.de/etmm

Symfill Technology is only available on Mold-Masters’ Master-Series hot runner systems.

BY THE NUMBERS

6 World of robots

NEWS STORIES

8 Swiss machine tool giant emerges

9 Mitsubishi Materials merges European units

K 2025

10 K 2025: Where plastics shape the future

12 Exhibitor innovations at K

24 Controller-related approaches for reliable recyclate processing

36 Machining robot bridges gap to machine tools

37 Single robot takes on multiple tasks

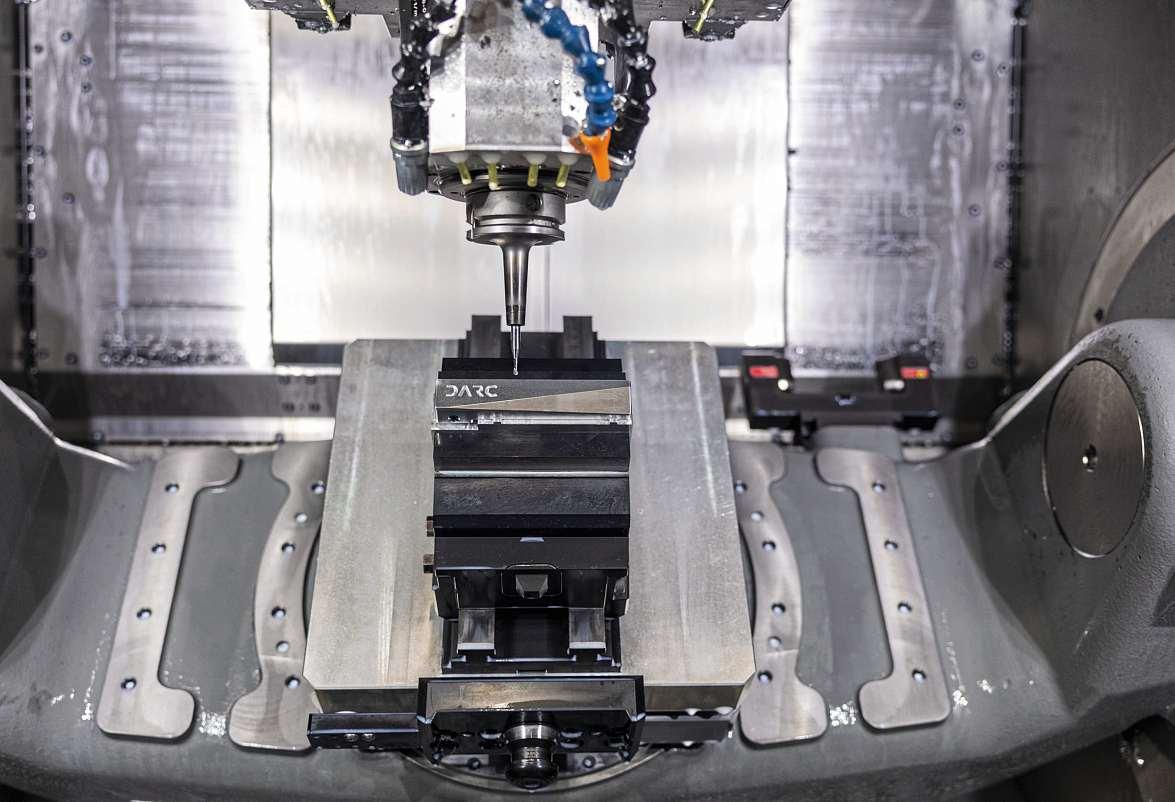

MACHINING ACCESSOIRES

38 Turning single-part production into a 24/7 operation

TOOL & MOULD MATERIALS

40 Faster cycles, stronger moulds with copper alloys

ADDITIVE MANUFACTURING

42 Global AM stage celebrates 10 years of innovation

28 Sustainable style: Bell’s injection moulding upgrade

CUTTING TOOLS

32 Sandvikintroducestheall-rounddrill

MACHINING EQUIPMENT

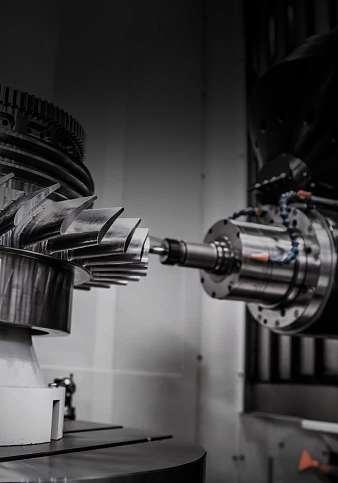

34 Capacities doubled, machining times slashed

Sprint Apex gate seals improve ESCR performance of CSD caps by up to 40 percent.

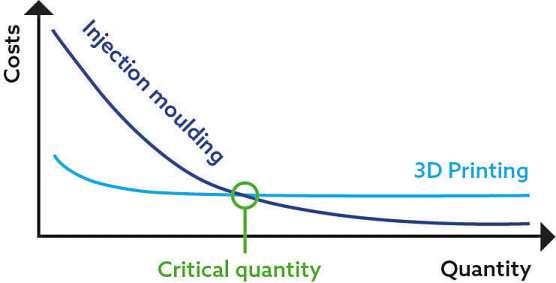

44 Unlocking cost-efficient small series production with MJF

47 Towards defect-free metal 3D printing QUALITY CONTROL

48 How imperfections can improve the quality of polymers

3 Editor’sMessage

49 Masthead 50 ISTMAWorldNews

Ranking September’s most clicked articles on etmm-online.com

Events: 50 startups from eight countries to exhibit at EMO

Cutting tools: Premium tool coating backed by premium service 3. Markets: U.S. tariff expansion poses challenges for plastics industry

Software: Module Works 2025.08 software release now available

Hot Runners: Application-specific hot runner systems

Messe K Düsseldorf 08.10.2025–15.10.2025 Halle 1 – Stand C 13

The global robotics market remained highly concentrated in 2024, with just a handful of countries accounting for the majority of new installations.

Globalindustrialrobotinstallationsdipin2024

Annual installations of industrial robots - World (1,000 units)

Preliminary data from the International Federation of Robotics (IFR), as reported at the World Robotics Conference, indicate that global industrial

Top5robotmarketsintheWorldandtheEU

sunits

The world’s top 5 industrial robot markets in 2023 were China, Japan, the United States, South Korea and Germany. Within the

Germany, Italy, Spain, France and Hungary are the top 5 markets, with Germany being the largest market in Europe.

The Make-to-Order Days are launching as a new trade fair

Make-to-OrderDays,orMTO Daysforshort,isanewevent formatthatwillbelaunched on 9 and 10 June 2026 at the Stuttgart Exhibition Centre. The new buyer’s fair for precision parts, contract manufacturing and machining is aimed specifically at decision-makers and buyers from future-oriented industries. The focus is on order-related precision manufacturing

The MTO Days bring togethersuppliersofprecision manufacturing technology with industrial users from high-growth sectors such as defence and robotics. The new trade fair is positioning itself as a specialised procurement platform for strategic networking, innovation and business development

Inadditiontotheclassicproductshow,theformatoffersadiverse supportingprogramme:aspecialistforumaddressescurrenttopics relating to digitalisation, precision and manufacturing trends and examines them from a practical perspective A central networking areaandseparatemeetingroomscreatetheidealconditionsforpersonal exchange and confidential discussions. (ast)

Korean machine tool manufacturer

DN Solutions acquiresHeller Under the agreement, the German company withahistoryof130 years will continue its long-standing brand. With this step, the partners hope to open up additional opportunities for customers, employees and the entire industry Together,thetwocompanieswillformastrongglobalplayerwithtechnological depth and comprehensive process expertise in machine tool manufacturing

DNSolutionsispartoftheDNAutomotiveGroupandisoneofthe fastest-growingcompaniesintheinternationalmachinetoolindustry With sales of around 2 billion dollars and more than 2,000 employees, DN Solutions is now one of the top three manufacturers worldwide.“BycombiningourstrengthswithHeller’sover130years of expertise in machining centres, this partnership will deliver groundbreaking innovations to the manufacturing industry Furthermore, the two companies will offer unique value to customers,” explains Wonjong Kim, CEO of DN Solutions (ast)

Through the acquisition of the GF Machining Solutions DivisionfromGeorg Fischer, the United GrindingGrouphas created a new heavyweight in the globalmachinetool industry The company now operates under the name United Machining Solutions, headquartered in Bern, Switzerland. With the integration of 15 brands, annual sales of more than 1.5 billion dollars,andover50internationallocations,thegroupcountsamong the world’s leading manufacturers of machine tools.

Under the umbrella of United Machining Solutions, the group is structured into two divisions: United Grinding and United Machining UnitedGrindingencompassesthebrandsMägerle,Blohm,Jung, Studer, Schaudt, Mirkosa, Walter, Ewag and IRPD

The United Machining division integrates the expertise of GF Machining Solutions as a global leader in precision engineering and advanced manufacturing technologies, and expands the portfolio with the brands Agie Charmilles, Charmilles, Mikron Mill, Lichti, Step Tec and System 3R. (ast)

CecimocallsforunifiedEUstrategy

Cecimo’s AM Europe Manifesto forms basis for AM ecosystem in Europe

European machine tool association Cecimo and its partners have released a manifesto outlining a strategic vision to establish the EU as a global leader in additive manufacturing (AM). The document stresses the transformative potential of AM for digitalisation, sustainability, and industrial resilience — but also warns that Europe risks falling behind without coordinated action.

Key challenges include growing global competition, lack of AM awarenessinindustryleadership,technicallimitations,andashortageofskilledpersonnel.DespiteexistingEUinvestments,thesector needsaclearroadmapandstrongerpolicyalignment.Themanifesto highlights AM’s critical role in Europe’s green and digital transitions – enabling lightweight, localised, and resource-efficient productionwhilereducingdependenceoninternationalsupplychains

Signatories include leading industry associations from Germany (VDMA),France(Evolis),Spain(Addimat),andeightothercountries. Cecimo, which represents over 1,500 European manufacturing enterprises, urges policymakers to act now. (ast)

ce : fr ee lic ensed

MMC Hartmetall GmbH and MMC Hardmetal Europe (Holdings) GmbH have officially merged and will now operate under a new name: Mitsubishi Materials Tools Europe GmbH (MMTE) The step consolidates Mitsubishi Materials Corporation’s European operations under one unified identity

Aspartofthemerger,MMCHartmetallGmbH(MHG) hasbeenintegratedintoMMCHardmetalEurope(Holdings) GmbH (MHE). The combined entity has been renamed MMTE, which will act as the central European organisation for Mitsubishi Materials’ Metalworking SolutionsCompany.Themoveisdesignedtostreamline operations,strengthencoordinationacrosssubsidiaries andreinforcethecompany’scommitmenttoinnovation and customer service in Europe. (ast)

According to VDW Executive Director Markus Heering, the first-half momentum came largely from Europe.

OrdersreceivedbytheGermanmachinetoolindustryin the second quarter remained at the same level as in the same period of 2024. Domestic orders fell by 14 percent, while orders from abroad rose by 7 percent. From January to June 2025 orders fell by 5 percent. Domestic demand shrank by 22 percent, while foreign orders were up4percentonthepreviousyear “Themainimpetusin the first half of the year came from Europe, although demand levels have not yet picked up in the domestic German market,” says Dr. Markus Heering, Executive Director of the VDW (German Machine Tool Builders’ Association). The uncertainty caused by the US tariff policy and the many other crises is causing investors to take a wait-and-see approach. While the recently negotiated tariff rate of 15 percent applies, this will increase costsandsignificantlyinhibitGermanexportstotheUS By contrast, the medium term outlook in Germany is brightening The approved increase in spending on defense and infrastructure as well as the recently adopted investment package could noticeably raise consumers’ willingness to make new purchases. (ast)

From 8 to 15 October 2025, K in Düsseldorf will once again be the central stage for the international plastics and rubber industry. Around 3,200 exhibitors from 66 countries will present innovative solutions, forward-looking products and impressive machines in live operation.

With the motto “The Power of Plastics! Green — Smart — Responsible,” K 2025 is setting the agenda for the industry The slogan, say the organisers, mirrors the sector’s values and ambitions whilehighlightingthecentralroleofplasticsasadriver of innovation and progress across multiple industries.

Facts,figuresandinternationalflair

The international appeal of K is apparent: the last event in 2022 was attended by 3,020 exhibitors from 59 naGLOBAL STAGE FOR INNOVATION

At a time of global uncertainty, the Düsseldorf trade fair seeks to reaffirm its position as the world’s leading platform for plastics and rubber Nowhere else, organisers stress, is the entire value chain presented with such breadth and depth. K is both a global showcase for a dynamic and forward-looking industry and a stage for shapingthefuture—whetherthroughpioneeringtechnologies, debate on global challenges, or the launch of cross-border collaborations.

K impresses not only with its dimensions but also with thevarietyofnationsrepresented.Ithasbeencompletely booked up since May 2024. Over 177,000 m2 net exhibitionspaceinthe18exhibitionhallsandontheoutdoor premises provide room for the entire spectrum of the plastics and rubber industry:

Machinery and equipment: Halls 1, 3-4, 8b as well as 9-17

Raw materials and auxiliaries: Halls 5, 6, 7, 7a, 8a, 8b

Semi-finished products, technical parts and products of reinforced plastics: Halls 5, 6, 7, 7a, 8a, 8b

tions and 177,486 visitors from 167 countries. Particularly well represented were the exhibitors from Europe, Asia and the USA and a total of 71 percent of trade visitors hailed from abroad.

In2025,exhibitorsfromEuropeinparticularwillonce againbestronglyrepresented,especiallyfromGermany, Italy, Turkey, Austria, the Netherlands, Switzerland and Spain. At the same time, K shows the changes in the globalmarket:thenumberandexhibitionspaceofcompanies from Asia have remained at a consistently high level for years. The presence of companies from China, IndiaandTaiwanwillbeparticularlycomprehensive In addition, the USA will once again be represented by a larger group of exhibitors.

The high number of innovations as well as the presence of all market leaders are regularly rated with top scores by K visitors (98 percent visitor´s satisfaction) Thisrelatesnotonlytoplasticsandrubberproductmanufacturersbutalsotoindustrialendusersthatregularly visitK Theseincludeexpertsfromthefieldsofautomotive,packaging,electricalengineering,electronics,communications, construction, medical device technology or aviation and aerospace. They all appreciate the trade fair as a source of inspiration for their industries and products as well as a platform to discover pioneering innovations that help them successfully hold their own alongside international competitors.

K 2025 has set itself the task of tackling the key challenges of our time and presenting concrete solutions. Thisisalsoreflectedinthethreeguidingtopics:Shaping theCircularEconomy,EmbracingDigitalisationandCaring about People.

The Specials at K 2025 will once again mirror the trade fair’s key themes, combining well-established formats with fresh initiatives. The official show “Plastics Shape the Future” spans seven themed days featuring discus-

More than 3,200 exhibitors from 66 countries gather in Düsseldorf to highlight the industry’s role in progress and responsibility

Further details on K 2025, including the exhibitor list, specials programme and ticket information, are available on the official trade fair website: www.k-online.com

sions, keynotes, a political panel, Career Day and a startup pitch

TheVDMAForumunderthemotto“ThePowerofPlastics”willhighlighttheroleofmachineryandtechnology in circularity with live demonstrations, workshops and events for young talents. Since 1983, Rubberstreet has been the go-to hub for elastomers and will again showcase the sector’s innovative strength.

TheStart-upZonereturnswithanexpandedplatform for newcomers, while the Science Campus provides insights into cutting-edge research from universities and institutes. New additions include the Young Talents Lounge, which addresses recruitment challenges by introducingstudentstocareeropportunities,andWomen in Plastics, a debut networking event designed to strengthen visibility and exchange for women in the industry (ast)

Mould optimisation through venting of the cavity

High-precision helix geometry ensures reliable function (venting channel depth 0.01 mm)

Interchangeable with standard ejector pins

Wide range of dimensions available from stock AT A GLANCE

Low punctual surface wear increases the service life

VENTING AS STANDARD FOR SHOULDERED EJECTOR PINS Visit us in hall 1, booth C02

Standard parts manufacturer Meusburger willbepresentingitslatestdevelopmentsin plates, mould bases, components and hot runner systems. The company focuses particularly on its current campaign on demouldingandonaspecialareafordesigners. Meusburgerprovidesitscustomerswitha comprehensiverangeofhigh-qualityplates and mould bases. The raw materials that have been heat-treated for stress relief guar-

antee maximum quality and precision. Thankstoahighproportionofin-houseproduction and enormous storage capacities, Meusburger ensures very short lead times. The portfolio also includes high-precision components that are precisely tailored to customerrequirements.Inadditiontoguiding elements and ejectors, there are innovativeslidesystems,locks,andawiderangeof hot runner solutions. Meusburger is contin-

uously expanding its product range and is always on hand to advise customers. The latest campaign on demoulding will also be presentedatthestand.Regardlessofwhethercustomersprefermechanicalorhydraulic components,Meusburgerhastherightsolution.Thenumerousin-housedevelopments, whicharebasedonyearsofexperience,provide customers with practical support for efficient demoulding processes. The standard parts manufacturer offers standard components as well as customised designs and complete solutions to save customers valuable time in planning, designing and mould making

Theexhibitionstandalsooffersanareafor designers, where Meusburger presents the diverse functions of its portal. Numerous new features enable an efficient design process — and that 24/7 in up to 20 languages. Visitorswillgetanoverviewofthetriedand trusted wizards and configurators from Meusburger, which impress with new, clearer functions. Particularly noteworthy is the Meusburger CAD tool, a user-friendly software solution for designers that offers numerous advantages. www.meusburger.com

KraussMaffeiwillfocusitspresentationson the latest developments in injection moulding technology, automation and additive manufacturing,highlightingadvancements aimed at maximising efficiency

The company will be showcasing the new all-electric PX series in combination with thenewLRXPluslinearrobot.TheLRXPlus series offers a wide range of functions for flexible automation and is characterised by a high level of compatibility, both with KraussMaffeiinjectionmouldingmachines andwithsystemsfromothermanufacturers as well as with various automation tasks.

Visitors to the trade fair can experience the efficient combination of PX machine and LRX Plus robot live at the company’s booth. Future-oriented applications for medical technology, technical components and packaging/logistics will be on display.

With the MC7, Krauss Maffei presents a modern, web-based control platform It featuresintuitiveoperation,powerfulsoftware andhardwarearchitectureandhighsecurity standards. The MC7 architecture already includes the upcoming requirements of the CyberResilienceAct(CRA) Thismeansthat the control system is even better protected

againstcyber-attacksandthedistributionof malware The CRA standard also makes it easier to connect machines to the network fordigitaldatausage Anotherfeatureofthe new MC7 control system is the new, webbasedvisualisationconcept,whichfeatures intuitive user guidance, clear display and extended functionality

A further highlight is the new Chopped Fiber Processing (CFP) technology, which enablesthedirectcompoundingofchopped glassfibersandpolypropylene.CFPensures efficientmeltingandhomogeneousmixing, producing high-quality, fiber-reinforced components at lower cost Compatible with standard Krauss Maffei injection moulding machines and easy to retrofit, the process promisesareturnoninvestmentinundera year

The company is also expanding its automation portfolio with a fully automated assembly cell that assembles three plastic partsinrealtime,featuringlaserandoptical inspectionforprecisionandqualitycontrol. In digitalisation, new tools such as the Dataset Manager, AI-based operator assistance, and updated APC Plus functions aim to streamline production.

In additive manufacturing, Krauss Maffei willdebutitsPowerPrintFlexandPrintCore systems,deliveringlarge-format,high-qualityprintingforindustrialapplications,from mould making to functional end-use parts. Live demonstrations will showcase each technology in action. www.kraussmaffei.com

Guill Tool & Engineering will present a range of extrusion tooling solutions. Originally developed for the Guill Bullet tool, a uniqueGuillextrusionheadthateliminates fastening hardware with a fixed center design, multi-port spiral flow and gum space adjustment, Cam-Lock is now available on many of the company’s existing extrusion heads. The design allows quick and easy assembly and disassembly of the crosshead andeliminatestheneedforsocketheadcaps screws.

By rotating the tooling in relation to the material flow, the new rotary head design increases the wall strength of an extrusion, therebyallowingathinnerwallwithlessmaterial.Benefitsincludeonlyrotatingthedie, randomising any gauge bands or thickness variations and, in some cases, improving material properties of the end product. Various sizes of tubing can easily be accommodated with this unique design.

Guill’s Single Point Concentricity extrusion crosshead uses micro-fine adjustment

screwsforpreciseconcentricityadjustment, reaching0.008”orfinerperrevolution.This single point concentricity adjustment is a uniqueGuillinnovationfortheextrusionof thin-walled jacketing and precision ID/OD tubing guill.com

AtK,Syncrowillpresentthetangibleresults ofnearlytwodecadesoftechnologicaldevelopment, introducing a range of advanced systemsdesignedtoenhanceefficiency,precision and sustainability in extrusion and recycling operations.

Among the key innovations is Retrofyt, a complete upgrade for supervisory systems onblownandcastextrusionlines.Basedon a dedicated PLC and a modern touchscreen HMI, the solution is tailored to each plant, optimisingperformancewithadvancedcontrol of temperature, pressure, extruder and haul-off speeds, IBC management, and thickness profiles. Another highlight is Zyroblock,anauxiliarybubblecoolingsystem that lowers film temperature with targeted cold air flows, preventing blocking in the stretching section. Zyrowax, meanwhile, removes monomers generated at the extrusiondieviaatwo-stagesuctionprocess,with installations under the cooling ring and in the bubble cage.

syncro-group.com

Wittmann will present to its visitors at its booth a wide range of smart solutions in the field of injection moulding technology under the motto of “Smart Choices — Smart Savings”

The highlight of this presentation will be the new Macro Power 500/3400 Although the machines of the Macro Power series from Wittmann Battenfeld have always scored by their small footprint and consequently modest space requirements on customers’ production floors, the new Macro Power stands out by even greater compactness

AnothermachinefromtheMacroPowerserieswillbeshownwith multi-component technology This machine, a Macro Power 650/2250H/1330H Combimould with a rotary table 1500 mm in diameter,savesspaceontheproductionfloor,andnotonlyduetothe small footprint, which is a characteristic of all Macro Power machines,butalsoonaccountofitstwohorizontalinjectionaggregates. On this machine, a foldable laundry basket will be manufactured fromPPandTPR,usinga1+1-cavitymouldsuppliedbyATAKalipve Plastik, Turkey www.wittmann-group.com

As a partner for mouldmaking and the plastics-processing industry, HascowillbefocusingatK2025onpractice-relatednewandfurther developments,digitisationinmouldmaking,processreliabilityand energy efficiency. The latest new products will be presented live

The Hasco cooling range has been increased. The extended cooling system Ø5 allows precise cooling of slide bars and small moulds — ideal for complex applications with limited build volume. The portfolio is supplementedbyfurtherchemicalworkingsubstanceswithNSFH1certification, which meet the highest safety standards in food and medical technology

Withanewslideretainer,Hascooffersareliablesolutionforavoidingdamageandmalfunctionswithslideinserts ThenewInsertkey also enables unambiguous coding of inserts

Hasco hot runner will show some new developments in the field ofadditivemanufacturinginhotrunnertechnology,andhowthese can contribute to making mouldmaking fit for the future. www.hasco.com

Oerlikon HRS Flow will showcase its Stargate HRS hot runner technology, which enables precise control of melt injection into the mould cavity through a revolutionary Valve Gate concept. Another new developmentistheGlowHRSsolution,whichallows for the direct injection of aesthetic parts in amorphous materials. Systems from the globalhotrunnerspecialistwillalsorunlive atpartnercompanies,includinganinjection

moulding tool for automotive parts that delivers a flawless surface and minimises secondary operations.

Beyond,visitorscanexpecttoseeinteresting developments in application-specific solutions for multi-cavity systems. These include the Up Nozzle series, which is specificallyengineeredforcompact,tight-space applicationswithlowshotweights,andnew solutions designed for luxury and

eco-friendly parts in the beauty and personal care industry

With a 12-mm nozzle cutout, the series delivers exceptional performance in hardto-reachgateareas.Thesefeaturesmakethe seriesidealforindustriessuchasbeautyand personal care, packaging, beverages, and technical applications.

At their booth, Oerlikon HRS Flow will present crystal-clear, eco-friendly parts produced with dedicated hot runner solutions for luxury cosmetic packaging These componentsbenefitfromadvantagesofthetechnology, including crystal clarity, significant wall thicknesses of up to 12 mm, and high process repeatability

At the Engel booth (Hall 15/B42-C58), a three-dropsystemfromtheGaseriesofOerlikon HRS Flow’s Diamond Lux line of hot runner solutions will be demonstrated for producing a rear light concept application. In this process, a decorative foil is back-injected with Plexiglas 8N from Röhm and thenoverfloodedwithPUR.Thefoilenhancesthevisualdesignofthefinalproduct.This project is a collaboration between the Zechmayer, Leonhard Kurz, Engel and Röhm. www.hrsflow.com

Machine manufacturer Engel will demonstrate how technological innovation, digital intelligence and sustainability can be effectively combined. Their trade fair presentation focuses on industry-specific injection moulding solutions that enable companies to manufacture more efficiently, precisely and flexibly. Engel will showcase its technologies and solutions in practical operation — from the use of artificial intelligence in the runninginjectionmouldingprocesstohighlyintegrated production cells for the automotive, medical, technical moulding and packaging sectors.

For instance, Engel is demonstrating the highly integrated series production of innovative rear-end-lights on a high-performance duo 700 two-platen injection moulding machine with 7,000 kN clamping force. The visible parts, measuring 600 x 240 mm, are manufactured using a combination of decorative foilmelt and functional clearmelt technologies in a vertical rotary tablemould.Inadditiontodesignfreedom,downstream processesareintegratedintotheinjectionmouldingcell, andaseparatehardcoatingprocessisnolongerrequired thankstoclearmelt.Whilethecolourdesignfromadecorative foil is applied to the component on one mould side by back-injection of thermoplastics (foilmelt), the opposite side is overflooded with polyurethane (clearmelt)toformahighlytransparentandrobustprotective layer.Aspace-savingintegratedautomationsystemwith a viper 40 linear robot enables short cycle times within acompactandefficientcell.Thetransferfoilissupplied byLeonhardKurz.Atthepartner’sstand,thecomponent is further processed using an integrated LED function foil. With this application, Engel demonstrates how visiblepartsintheautomotivesectorcanbebothfunctionalised and decorated — economically, with high precision and in a compact production process.

Exhibitsrangefromcompact,automatedcellsforfuel cell seals, lightweight bicycle handlebars and foamed B-pillar trims to fast cell culture plate production. Medical applications include high-speed production of cell culture plates with streamlined validation. Highlights also feature the premiere of an electric tie-bar-less machine for fittings with integrated seals, production of recycled construction blocks with improved strength and thin-walled yoghurt cups using 30 percent rPET www.engelglobal.com

Kistler will be demonstrating how current challenges in plastics manufacturingcanbe mastered. Visitors will find new and optimisedsolutions along the value chain, from cavity pressure sensors, systems andsoftwareforprocessoptimisationandqualitymonitoring Anew assemblysystemandanopticalinspectionmachineforend-of-line inspectionwillalsobeondisplayatthebooth.Thefocusisonapplications in medical technology and electronics production.

HighlightsincludetheupdatedComoneo7.0processmonitoring systemwithenhanceduser-friendliness,thenewMultiflowfunction for precise hot runner control and upgraded hardware ready for futureAIapplications Complementingthis,theAkvisiosoftwareprovidesfastdataanalysisandseamlessdocumentation,whilethenew NCFQ 2166A joining system offers high-speed, sensor-driven precision for sensitive medical and electronic parts Rounding out the portfolio, Kistler’s KVC 821 vision inspection system with AI-based image processing ensures 100 percent quality control. www.kistler.com

BorideEngineeredAbrasivesoffersacomprehensiverangeofmould polishingsolutions.Thecompany’sproductsaretrustedbytooland mould makers in over 50 countries. Boride’s product portfolio includesacomprehensiverangeofmouldpolishingstones,including EDM, ceramic and polishing stones for a variety of tool steels and applications; diamond compounds available in a wide range of micron sizes for precision polishing; dressing sticks trusted worldwide for maintaining grinding wheels and superabrasive tools; and polishing kits offering complete solutions for mould repair and finishing

“Our focus has always been on delivering products that help mould makers achieve the highest standards of surfacefinishandefficiency,”saidLesleyMurphy,MarketingandSales Manager at Boride Engineered Abrasives. “The K-Show audience represents some of the most innovative and quality-driven professionalsinplasticsmanufacturing,andETMMistheperfectplatform to share our latest solutions with them.” www.borideabrasives.com

Withdecadesofexperienceand strong innovative power, Ewikonfocusesonthemedicaland pharmaceutical sectors, electricalengineering,technicalparts andpackaging Foreachofthese industries, the company delivers tailored hot runner systems designedformaximumprocess reliability, efficiency and product quality

In medical and pharmaceutical applications, Ewikon is presentingnewvalvegateandmultiple nozzle concepts for direct side injection, as well as compact micro distributor technology for very small shot weights with excellent temperature control, now also available in a needle valve version. For electrical engineering and technical parts, the company is introducing advanced nozzle tip solutions for demanding applications, energy-efficient nozzles with tailor-made system design and pre-assembled L2X systems that integrate quickly and operate leak-free.

DevelopedandmanufacturedexclusivelyinGermany,allproducts are supported by a global sales and service network across Europe, America and Asia.

www.ewikon.com

At K 2025 in Düsseldorf, Haitian International will present two new machine generations for the packaging industry: the electric Zhafir Zeres F and the servo-hydraulic Haitian MAV/F Pro — both live in Europe for the first time.

ThenewgenerationoftheZhafirZeresFSeriescombineselectrical precisionandanintelligentmachineconceptwithhigh-speed.Technicalhighlightsincludeinjectionspeedsofupto500mm/s,motion sequences of up to 1,300 mm/s, and AI-supported tool monitoring thatdetectsdeviationsof0.01mminlessthan0.05seconds.Anew cylinder heating technology reduces energy consumption by up to 30percent.TheZE-FSeriesachievesanefficiencyofupto95percent.

Live at the trade fair, the ZE-F Series will showcase a 500 ml food containerwitha4cavitymouldincludingafullyintegratedIMLcell, was developed entirely in-house. With the Zhafir Zeres F and the servo-hydraulicHaitianMarsFPro,HaitianInternationaladdresses a wide range of applications in the packaging industry. eu.haitianinter.com

Specifically designed for multi cavitymanifoldsystemsandhot halves, Mastip’s range of MX nozzlesissuitedforsmalltomediumapplicationsinalltypesof markets. With low moulding temperature and pressure, and duetoit’sexcellentthermalconsistencytheMXnozzleisableto process a wide range of plastics. The company announced that thisserieshasbeenexpandedto include the MX09 nozzle range.

TheMX09nozzlehasbeentestedwitharangeofmaterialsandhighinjection pressures,demonstratingenhancedreliability,aconsistenttemperatureprofile, and improved thermal stability through the use of an advanced micro coil heater and thermocouple design. With a minimum pitch of 20 mm, a pocket of 14 mm, a nut diameter of 7 mm and a range of extended tips available, the MX09 can fit into very tight spaces.

Mastip has developed the MX09 nozzle to meet customers’ demands for a small pitch, high value moulding solution for the packaging, caps and closure and medical markets. MX09 is available in H13 Steel (F1), in both front and rear loadingconfigurations,withstandardlengthsvaryingfrom55-175mm.TheMX nozzle range now includes the 09, 13, 16 and 19 series to offer a comprehensive solutionfordifferentindustryrequirements Mastipsolutionsfeatureadvanced thermal technology designed to support high-quality component production and are complemented by a global service and support network. mastip.com

FORCES OF UP TO 6,500 KN

In addition to exhibits from the fields of hollow blow moulding technology and extrusion, Japan Steel Works is presenting three injection moulding machines (SGM) from its Jads series at K — with clamping forces of 800 kN, 2,200 kN and 6,500 kN respectively These machines are fully electric systems, recognised for delivering profitable precision injection moulding across all major industries and plastics processing sectorsworldwide.Expertsfromthecompany’sheadquartersinJapan,itsEuropean injectionmouldingsubsidiaryJSW-PMEbasedinWarsaw,PolandandKT-Sakkas in Germany will be on hand to provide visitors with advice and support.

For example, the fully electric J80ADS injection moulding machine with 800 kNclampingforcewillproduceacoverfromrecycledABSmaterialusingaJSW sample mould. The part is then removed by a Scara and 6-axis robot, inspected byacameracontrolsystem,andtheresultingdataisusedtoautomaticallyadjust the machine’s settings.

The J220ADS will be demonstrated in a 2-component configuration using a FLiP additional unit. Meanwhile, the J650ADS (6,500 kN clamping force) will showcasetheconstructionoflargermodelsintheSGMseries.Here,theproven advantages of the electric design are applied on a large scale, as they have been successfully offered to the market for many years. www.jsw.de

WITHOUT COMPROMISE

From beverage closures to medical vials, Mold-Masters proves that hot runner technology has the power to shape markets — cutting scrap, boosting durability and even enabling the shift from glass to plastic in medical packaging.

Asproductlinesmature,ithasbecomerarertosee thedevelopmentandintroductionofcompletely new products that have a significant impact on the bottom line of plastic part production

Mold-Masters,aleadingdeveloperandsupplierofhot runners,controllers,auxiliaryinjectionandco-injection systems, continues to push the boundaries for what is considered possible by developing technical solutions forveryspecifictechnicalchallenges.Theseapplication specific optimizations have been successful in enhancingpartquality,minimizingscrapandpreventingdowntime where it was previously thought impossible Overcoming application specific challenge has allowed Mold-Masters to continue to optimize application results and break away from the competition

In the world of consumer and medical packaging, Mold-Masters has introduced specific technical solutions that includes their Sprint Apex gate seal, Symfill Technology and Co-injection Multi-Layer Technology

SprintApex:ImproveEnvironmentalStress CrackResistance(ESCR)ofCSDcaps

Achieving and maintaining a proper Environmental StressCrackResistance(ESCR)levelisaKeyPerformance Indicator (KPI) for moulding equipment that produces capsandclosures.Assuch,itmeasuresacarbonatedsoft drink(CSD)cap’sdurabilitywhenitisplacedunderpressure or encounters severe operating conditions. The presenceofinjectionflowlinescanhaveanegativeeffect on ESCR performance in these situations, considering thatifasingleCSDcapfails,theentirebatchmaybesubject to a claim.

Withthatinmind,moulders,capdesignersandbrand ownersareconstantlylookingtoincreasetheirabilityto detect injection flow lines, while also enhancing safety factors,productperformanceandcustomersatisfaction This can be a challenge as light weighting inevitably means a reduction in wall thickness that may compromise the CSD cap’s strength. Also, using recycled and bio-based resins may not have the same strength and durability as conventional resins.

To help moulders overcome these challenges, the Sprint Apex gate seal is designed to significantly minimize the presence of injection flow lines, which can increasetheESCRlevelofCSDcapsbyupto40percent,as determinedandvalidatedthroughthird-partytestingat Dow Pack Studios. Additionally, in-field beta testing of the Sprint Apex on high-cavitation moulding systems determined that stress cracking was significantly reduced on all dimple and non-dimple CSD-cap designs

“The new Sprint Apex Gate Seal is the innovative solutionthatmajorglobalmoldersandconvertershavebeen waiting for,” said Thomas Bechtel, Sr Director, Global R&D for Mold-Masters. “This solution will help eliminate spoilage during the CSD-cap production process, resulting in a more streamlined manufacturing operation that will result in a healthier bottom line for the manufacturer and minimize the risk of bad parts in the box.”

The new Sprint Apex Gate Seal is compatible with Mold-Masters Sprint Hot Runner system as it features industry-standard cut-out and sealing dimensions that make it interchangeable with a standard hot-tip gate Additionally,existingmouldsusingcompetitivehot-runner systems can be retrofitted with a Sprint Hot Runner systemthatincorporatesSprintApexGateSeals.When retrofitting, customers can reuse their existing cavity inserts, making the conversion process more economical and shortening ROI

Mold-MastersSprintApexGateSealgaining marketplacetraction

Since its inception, the Sprint Apex gate seal was designed to serve as the new standard for cap and closure molds. This new solution has already been adopted by

Enables light weighting for cost savings and supports customers’ sustainability initiativ by reducing material usage without sacrifi cing CSD-cap durability

Improves colour-change performance by up to 65 percent when compared to standard gate seals.

Improves the appearance quality of caps that have difficulty hiding flow lines such as transparent decorative caps.

Eliminates the use of insulation caps, a common wear item, for reduced maintenance costs. Sour ce : Mold-Mast ers

severalmolders,whohaveseenmultipleimprovements to overall product quality and cost effectiveness.

A major beverage moulder has designated Apex to become its new standard gate seal after various performance test results.

During testing, which included multiple dimple designs,themouldercomparedApextoatraditional3and 6-holegatesealtipdesignintheproductionof1881CSD caps. Customer test results showed stress crack failures occurredoncapsmouldedwiththetraditionalgateseal design.

Alternatively, Apex eliminated stress cracking on all dimpleandnon-dimpledesigns.Thebeveragemoulder hasalreadyretrofittedexistingmouldsandwillincorporate Apex as the new standard in any new hot runner systems.

Mold-Masters Sprint Apex gate seal significantly minimizes flow lines. This processing benefit also improves theappearancequalityofcapsthathavedifficultyhiding flow lines. While colorant has a major impact on flow lineappearance,Apeximprovescapappearancequality regardless of colorant used. Applications include transparent decorative caps, shampoo caps, detergent caps, and more.

ExampleA:PurpleFlip-TopCap: Inthefirstapplication, a major closure moulder experienced a cloudy appearance on the top of the cap after a resin/colorant change which could not be processed away After conversion to Apex,thecloudingeffectwassignificantlyreducedwithout process adjustments

Example B: Satin Cap: In the second application, a major cosmetic moulder experienced flow lines on the top of a large detergent cap produced in a natural and satin finish. A switch to Apex significantly minimized flow lines,makingthemnolongervisible.Additionally,Apex accommodated a gate detail that matched the customer’s standardized cavity interface.

Apex also provides scrap reduction and helps sustainability initiatives by enhancing colour change performance.Acustomerreportedthatonecolourchangeon acompetitorshotrunnerdesignproducesapproximately 30,000 closures (60 kg) of scrap using their standard gate seal tip With Sprint Apex, they were able to speed up the color change process and reduce their colour changescrapbyabout50percent(15,000closuresor30 kg).

Apex gate seals have also eliminated insulation caps, a wear component common with traditional industry-standard gate seal designs. Generally, these insula-

tioncapsgetfrequentlyreplacedaspartofregularmaintenance. On a high-cavitation hot runner system the annual cost of these spare parts alone is about 10,000 dollarspermould(notaccountingforlabour/downtime). Apex benefits moulders enormously by reducing the ongoing maintenance costs for production companies.

Minimizingbarrelbowtosignificantly enhancepartquality

Mold-Masters’ Symfill Technology significantly minimizescoreshifttoimprovepartquality(straightness)of cylindrical, center injected components having an aggressive L/D ratio It achieves this by allowing the melt to enter the nozzle runner channel from multiple sides as opposed to the single-entry point of traditional designs. The gating method (one center gate) remains unchanged. Even the hot runner nozzle remains ‘as-is’

Examples of such components that would benefit fromthistechnologyincludebloodtubes,needleshields, over caps, packaging and other similar parts from the medical, consumer, cosmetic and stationary industries.

Minimizing barrel bow offers many downstream processing advantages which includes:

Tubes roll concentrically in the labelling machine.

Increases final stage throughput.

Minimizes machine downtime.

Symfill Technology has been valuable on many applicationstodate.Inabloodvialapplication,barrelbowwas reducedbyupto90percent(aslittleas0.15mm)byeliminating core shift.

In a separate consumer packaging application designed to hold tablets, the customer reported that their Symfill enabled hot runner system “delivered the tightestconcentricitytoleranceandperfectgatequalityfrom the first shot”

Symfill Technology is exclusively available with Mold-Masters hot runner systems.

Enablingtheconversionfromglassto plasticinmedicalpackagingapplications

Mold-Masters Co-injection Multi-Layer Technology is enablingtheconversionfromglasstoplasticinmedical packaging applications.

A plastic container is lighter than glass and resists breakage which reduces the risk of losing bio-samples and exposing healthcare personnel to infectious substances. Normally one would assume that switching to plastic is a straightforward application, but because medicalcontainersarerequiredtocarryvarioussamples and cultures for testing, they must also meet the necessarypreservationstandards.Asaresult,plasticcontainersconvertingfromglassmustincorporatehigh-performance gas and moisture barriers.

Mold-Masters Co-injection Multi-Layer Technology allows two different resins to be combined into a single 3-layermeltstreamwithoutanypenaltytocycletimeor productionvolume.Thecompany’ssystemsarecompatible with various High-Performance Barrier materials suitable for a range of medical packaging applications that enable the conversion from glass to plastic.

For example, Mold-Masters Multi-Layer Co-injection technologywasusedtoproducebloodculturecollection bottlesandvialswhichenabledtheswitchfromglassto a plastic alternative The bottles were able to be used by

“Oursystemsarecompatiblewithvarious High-PerformanceBarriermaterials suitableforarangeofmedicalpackaging applications.”

Mold-Masters

healthcare professionals concurrently with glass versionstoaidintheconversionprocess.Theplasticbottles have been validated by all laboratories who stated that there was no difference in organism yield and time to positivity Collectionprocedures,safetyadapters,collection and volumes all remained the same as its glass predecessor

The same technology is being used to Co-Inject recycled resins (PCR) as the core layer up to 50 percent of total part weight. This capability can be applied to a variety of applications, including packaging containers, such as fruit cups to 20 liter pails with weights ranging from 5 g to 950 g

Inconclusion:Trueindustryleadersdeliver morethanjusthardware

Until plastic injection moulding parts can be achieved withabsolutequalityandconsistencywithoutanyscrap, hot runner suppliers will be challenged to develop technical solutions to overcome processing limitations and further optimize production. This will be the deciding factor between hot runner suppliers treated as a commodity and those that are true industry leaders that deliverexceptionalvaluethroughtheiryearsofapplication experienceandaccesstoR&Dresources.Asanindustry leader,Mold-Mastersremainsasoneofthefewthatcan deliver results that no one else can. (ast)

Symfill Technology is only available on Mold-Masters’ Master-Series hot runner systems.

From precision labelling and high-temperature sealing to servo-driven motion systems and rugged connectors — new mould components and industrial solutions demonstrate how innovation is driving efficiency and reliability in tool and mould making.

Precision, durability and efficiency are central to modern tool and mould making Suppliers are respondingwithnewcomponentsolutionsthatsimplify processes, improve product quality and support reliable, cost-effective production Recent innovations fromHasco,Knarr,ServomoldandBindershowhowthe industry is moving forward.

Hasco has introduced its new Z48600/… to Z48645/… marking stamps without height adjustment. These enableclearanddirectlabellingofinjection-mouldedparts withproductiondataorcavitynumbers.Apreciselatchingfunctionensuresconsistentpositioningofthearrow insert,whilerecessedengravingguaranteescleanreproduction, good readability and long-lasting resistance. Theinsertscanbereplacedeasilyfromthepartingplane without dismantling the mould, and the design is suita-

WRITTEN BY AlexanderStark Managing Editor ETMM

ble even for very small installation spaces. Manufacturedfromcorrosion-resistant1.4112stainlesssteel,the marking stamps offer high wear resistance and a long service life, ensuring reliable traceability and quality assurance.

Sealingwithstainlesssteelscrewplug

Knarrhasexpandeditsrangeofsealingsolutionswitha newstainlesssteelversionofitsscrewplug,designedto withstand high temperatures. Equipped with an FKM O-ring, the plug can handle water temperatures up to 180°C and oil up to 200°C, providing a durable and reliable seal without the need for additional sealants. The high-temperature O-ring is also available as a separate sparepartandwillbeintegratedintofuturebrassscrew plug designs.

Asanalternativetotheknownoptions,Knarroffersa Screw plug (70943) equipped with an O-ring Without anyadditionalsealant,itprovidesanextremelyreliable anddurableseal.Thescrewcanbemountedveryquicklyandeasilywithoutanypreparatoryworkandcanalso be reused after disassembly without time-consuming cleaning

For the sealing plug with O-ring (72078) Knarr provides the Torx version. Especially when mounting in hard-to-reachpositions,Torxofferstheclearadvantage thattheplugstaysonthescrewdriverbetterandslipping isavoided.Thisprotectstheinnerprofileandmakeslater dismantling easier The plug is designed for a maximum water temperature of 100°C (oil 180°C).

Servomold has developed the servo linear actuators of thenewSLACompactseries,whichsignificantlyreduce the size while maintaining the same forces as the previousseries,forthelong-termreliable,100percentprecise and powerful execution of linear movements in injection moulds. Powerful, clean and oil-free, they are ideal cleanroom-compatible alternatives to traditional hydraulic and pneumatic cylinders for translatory slide, core or platen movements. They are available at short notice in performance classes from 4 kN to 50 kN, with different motor and spindle configurations and completely in stainless steel.

Hasco expands its range with new non-height-adjustable marking stamps, enabling precise, durable and space-saving product labelling for reliable traceability in injection moulding.

The SLY core pulling systems are designed to guide, center and position slides and cores in the injection mouldwithµmprecision.Servo-electricallydrivenand equipped with minimum quantity lubrication, they meetthebasicrequirementsofmanufacturersofsleeveshaped components such as housings and cartridge holdersforauto-injectionsystems.Themainpartofthe slide guide is integrated into the SLY concept and positioned outside the mould frame. This can reduce the overallmoulddimensionsbyupto45percentcompared toconventionaldesigns.Thespace-savingarrangement of the motor and spindle between the guides also contributes to this The compactness enables the cost-cutting use of smaller injection moulding machines with thesamenumberofcavities,anditreducestheneedfor expensive tool steel while lowering production costs. Precision bores with special fine centering ensure that the slide bodies are positioned with µm accuracy, eliminating the need for time-consuming adjustment work during installation. Assembly time is reduced to just a fewhoursandtheprecisionguaranteedbyServomoldis maintainedevenaftermaintenanceordisassemblywork without the need for readjustment.

With the launch of the latest 813 (T-coded) and 823 (L-coded)seriesfieldattachableM12connectors,Binder is expanding its portfolio with particularly robust solutions. The connectors have a robust stainless steel locking mechanism, have an IP67 degree of protection and an outstanding mechanical service life of over 100 mating cycles. The 813 series offers a pole count of 4, while the823seriesofferspolecountsof4and4+FE.Bothvariants are designed for cable diameters of 6-13 mm. Another advantage is their high temperature resistance: theyaredesignedforanoperatingrangeof-40°Cto+105 °C and are therefore ideal for modern industrial applications (ast)

Discover more innovations in tool and mould components in the Components section of ETMM Online: www etmm-online.com/ components.

REPRODUCIBLE PART QUALITY

Fluctuating material properties in recyclates pose a major challenge in injection moulding. To ensure consistent part quality and process stability, Arburg has developed intelligent control solutions, enabling efficient and reliable processing of PIR, PCR, and regrind materials.

Recyclates are challenging to process because of their non-homogeneous characteristics. The shape and quality of the non-homogeneous material influence the melting process.

ETMM-TIP

Arburg shows how digital control functions stabilise injection moulding with recyclates. Details at www.arburg.com

Reproducibly manufacturing moulded parts out of virgin material from shot to shot and batch to batch at a consistently high part quality is state of the art, but usually places high demands on the controller technology When it comes to processing content such as post-industrial recyclate (PIR), post-consumer recyclate(PCR)andbioplastics,thematerialandprocessing properties can vary considerably. Control concepts that ensure constant mould filling and, ultimately, consistentqualityoftheendproductsarethereforerequired to use recyclates efficiently. For this task, Arburg has developeddigitalpilotfunctionsforitsmachinecontrol-

lersthatkeeptheinjectionmouldingprocessstableduring the injection and holding pressure phase.

From a chemical perspective, recyclates are plastics just like conventional virgin materials, with the differencethattheyhavealreadybeenfinishedproductsthat havehadaperiodofuseandhavethenbeenreprocessed. However, there are still many unanswered questions as towhetherandhowrecyclatescanbeusedaseffectively andreliablyasvirginmaterials Injectionmouldingprocessors have to face a new set of challenges here.

From the machine's point of view, injection moulding involves two large “black boxes” that significantly influence process stability and part quality This is because the machine itself has no knowledge of which material isfedintothehopper,orwhathappensbetweenthetwo mould mounting platens

These are two major challenges when it comes to reliablycontrollingprocessparameterssuchasthetemperature progression of the moulding compound and the temperature progression and pressure profile in the mould. The biggest difference between processing recyclatesandvirginmaterialisthatthematerialproperties and characteristics such as mechanical quality, colour and smell can vary within a delivery or an order over a wider range. Since no clear material specification can currently be assigned to the recycled granules in most recycling processes, no data sheet is available during machine setup, which makes processing more difficult. However, the Gestica and Selogica controllers for Allrounder injection moulding machines have pilot functionsthatcounteractfluctuatingviscositiesinthemelt: “AXW Control Reference Pilot” and “AXW Control Recyclate Pilot” can detect and even out irregularities and actively control the ongoing injection process in order to keep the mould filling as constant as possible and ensure consistent part quality despite major variations.

Meltingprocessasaninfluencingfactor

Ahomogeneousandstablemeltingprocessisanimportant influencing factor in the production of good parts. Itstartswiththematerialbeingfedintotheplasticising

screwasevenlyaspossible.Theshapeandqualityofthe recyclate play an important role here. If the material is intheformofgranules,recycledplasticcangenerallybe processedaswellasvirginmaterialwithouttheneedfor additionalhardware.Thesituationisdifferentforflakes and reground material. Flakes can vary greatly in size andshape.Regroundmaterial,ontheotherhand,which is material from plastic parts that have only been shreddedwithaspruegrinder,consistsoffragmentsofdifferentsizes,ideallyingrainsizesoftwotofivemillimetres. Thesegrainsareusuallyaccompaniedbyfinermaterial, uptoandincludingdust-likematerial Toensureastable melting process, any dust must be removed from the reground material.

For the processing of reground materials and flakes, Arburg offers a retrofittable recyclate package that combines software and hardware features Among the software features are multi-stage start-up parameters and the digital “AXW Control Screw Pilot” assistance function, which ensures precise and stable mould filling. In termsofhardwareequipment,amodifiedcylindermoduleenablesuninterruptedfeedingevenofpoorlyflowing materials. A plasticising screw with a modified, deeper high-compression (HC) geometry ensures homogeneous processing Grooves in the feed zone help the material to be drawn in, despite its irregular shape, and conveyed forward in a stable manner The screw also has a CrNcoatingtoreducetheformationofdepositsandwear caused by unexpected foreign bodies.

Filling the mould cavity in a reproducible manner from cycletocycleisthebasisforconsistentcomponentquality A successful control concept for this is the “AXW Control Screw Pilot” or “position-regulated screw” pilot function, where the filling process is adapted to the requirements of the flow path in several stages by a speed-regulated screw movement. The active acceleration and braking dynamically compensates for disruptive influences, so that a constant amount of melt is fed into the cavity These dynamics have proven to be particularly useful at high injection volume flows, especiallywhenitcomestopreventingpressurepeaksandoverfilling by targeted and rapid braking

The holding pressure phase is also crucial for part quality It is usually executed as a quasi-static, pressure-controlled process, with the optimum parameters previously determined by a machine setup technician No account is taken of short-term influences during ongoingproduction,suchasviscosityvariationsinthemelt (caused by recyclates, lubricants or colour additives), or long-term wear, e.g on the non-return valve and other

Sour ce Arbur g

WRITTEN BY

DrThomas Walther

Director Process Development Arburg

“Fluctuatingmaterialpropertiesmake recyclateprocessingaparticularchallenge ininjectionmoulding.”

Thomas Walther, Director Process Development, Arburg

The reliable processing of recyclates places high demands on the controller technology of injection moulding machines.

mechanicalcomponents.Inthelongterm,thiscanlead tovariationsinthecavitypressureandhencetoirregular part quality

For this reason, as early as 1988, Arburg developed an injection process regulation function that is integrated in the controller and regulates the holding pressure curve in real time via a pressure sensor in the mould. Thissoftwarefunctionhasbeencontinuouslydeveloped andisnowknownas“AXWControlReferencePilot” The Reference Pilot uses the nominal value reference curve of a good part as the basis for active regulation in the holdingpressurephase,wherethecurrentholdingpressure is adjusted according to the internal pressure. A pressure sensor positioned as close as possible to the sprue in the mould is required as the associated hardware The way it works is comparable to autonomous driving:evenwithGPSandaknownroute,avehiclestill needsadditionalactivesensorstobeabletomovesafely in road traffic. This is the only way to detect unforeseen bumps, road works or other road users, for example.

So that it can quickly counteract disruptive influences and actively balance out pressure variations, the software receives signals regarding mould cavity pressure thatarerecordedinrealtimebythesensor Thisenables Reference Pilot to regulate the internal pressure curve from the current actual value to the desired nominal value.WhenReferencePilotisusedforcontrol,thepressureconditionsinthemouldarepreciselyadjustedfrom shottoshottomatchthereference,withtheactualvalue being raised to the nominal value. This results in a constant shot weight and consistently high part quality, without the need for manual intervention during process parameterisation.

To use Reference Pilot, two conditions must be met: The injection moulding machine must be equipped with “AXW Screw Pilot”, which is standard for electric and hybrid Allrounders.

There must be enough space in the mould cavity to install a pressure sensor

Thesensoritselfcausesadditionalexpense;inaddition, expertiseandtimearerequiredtorecalibrateitforeach setup process and to maintain it regularly. This is the only way to ensure that the internal pressure sensor

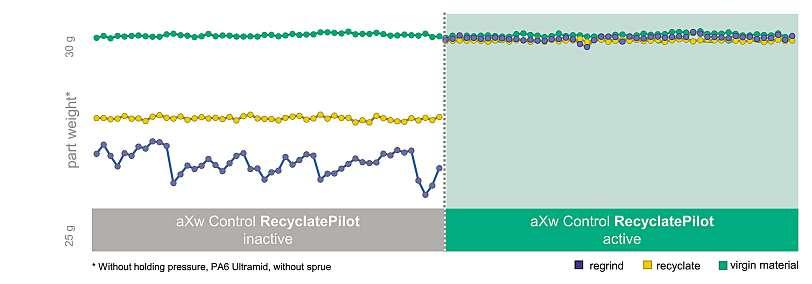

In the “hair comb” example, the mould filling based on part weight shows how values of recyclate granules (yellow line) and reground material (blue line) can be brought up to the level of virgin material (green line) with the Recyclate Pilot (right image).

measuringequipmentisfullyfunctionalanddeliversthe correct signals. If all requirements are met, the injection moulding process can be stabilised quickly and reliably through the interaction of the sensor and the pilot function.

An alternative is the new “AXW Control Recyclate Pilot” function,whichcontrolstheinjectionmouldingprocess directly in the injection or mould filling phase based solelyondatafromthestandardmachinesensorsystem. Compared to Reference Pilot, which receives signals directly from the cavity, the Recyclate Pilot has a longer partial control circuit. Nevertheless, it offers a number of clear advantages:

No need for additional sensors

Pilot function can be activated by pressing a button

Proven sensor system only needs to be calibrated every few years

Pilot function balances out short-term variations

Processcontrolatthepushofabutton

The operator initially optimises the process settings as usual so that the required quality of the good part is achieved. This reference is transferred to the pilot function via a control command. An additional command activates Recyclate Pilot, which then analyses the injectionbehaviour,detectsdistinctivepointsanddeviations in the injection process and ensures that the injected volumeandthereforethemouldfillingremainconstant. Thisisdonebycomparingtheeventpatterninthesame cycle with the reference entered during the injection phase and, if necessary, adjusting the switch-over point at short notice. In addition, correcting the dosage vol-

ume also makes the overall process more stable in the long term and across cycles.

Varying material properties and viscosities in injection moulding become particularly apparent during sprueless production without holding pressure, leading to incomplete mould filling In a “hair comb” case study, PA6 was processed in three variants – virgin material, recyclate granules and reground material.

The virgin comb, produced without holding pressure, was incomplete and served as a reference. Parts made from recyclate granules showed consistent but lower weight, while reground material produced significant weight variations. This changed at the push of a button with active control using Recyclate Pilot. Now the part weight was constant and almost the same for all three variants. This case study shows that the digital pilot function can balance out the resulting variations in mould filling, thereby significantly increasing process reliability and part quality

WiththehelpofdigitalpilotfunctionssuchasRecyclate Pilot and Reference Pilot, process reliability can be significantlyincreasedduringtheprocessingofrecyclates. The injection profile and filling process of the moulded part remain stable and correspond to the specified reference.

Itisimpossibletofullycompensateforthepoormaterial properties of recyclates, so part quality improvements remain limited. User expertise is still key to matching concepts with processes, though AI-based methods may offer added support in the future. (ast)

The Recyclate Pilot balances out material variations, thereby increasing process reliability and part quality — as can be seen from the filling of a hair comb, manufactured in the material variants without holding pressure.

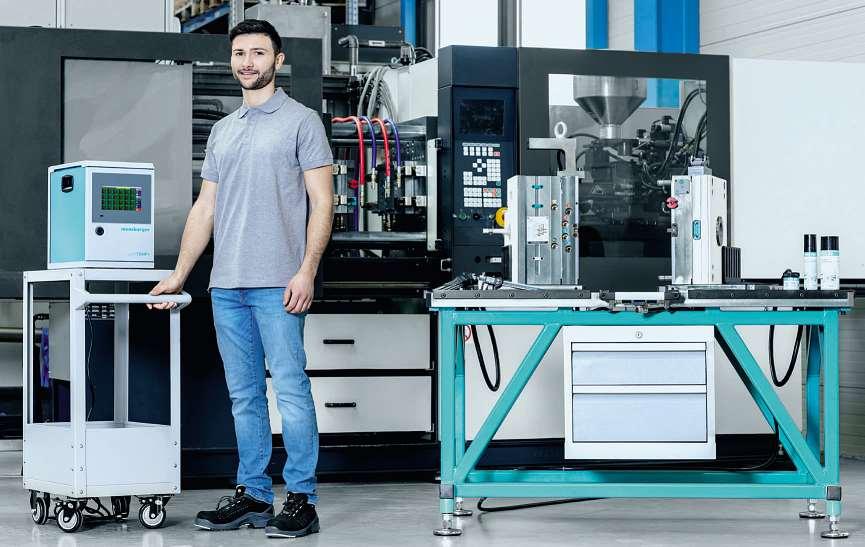

Bell, a Polish cosmetics manufacturer, is integrating energy-efficient injection moulding technology and transparent consumer communication into its production strategy, with a focus on sustainable packaging and operational efficiency.

Transparency is an essential part of Bell’s corporate philosophy, with the main emphasis not so much onthetransparentplasticmaterialswhichtakeup the lion’s share of the company’s production, but rather on transparent communication directed towards consumers. For the Polish cosmetics manufacturer’s commitment to sustainability is setting high standards Only particularly energy-efficient machinery and equipmentareadmittedtothecompany’sinjectionmoulding floor, such as the injection moulding machines, robots and dryers from Wittmann.

BellPPHUKosmetykiislocatedinJózefów,just20kilometers south-east of the Polish capital Warsaw From a window in his office, Production Manager Waldemar Gulakeepsaneyeontheinjectionmouldingfloor,which

at present contains 48 injection moulding machines — all of which have come from the Wittmann Group and are equipped with linear robots from Wittmann. An extension is planned for the next few months, since the demand for cosmetic products from Bell is increasing rapidly.

Everythingstarted35yearsagowiththeproductionof lipsticks. Now Bell covers the entire range of decorative cosmetics and delivers its products to more than 60 countries worldwide.

All primary packaging for make-up, eyeshadow, mascara etc. is produced in-house with a strong focus on sustainability Servo-hydraulicSmartPowerandall-electric Eco Power injection moulding machines dominate thepicture.Thenumberonedecision-makingcriterion

for investments in new injection moulding technology isenergyefficiency “Witheverynewmachine,theenergy efficiency increases even further,” Gula reports “At the beginning of our efficiency boosting program, we wereproducingninemillionpartspermonth.Nowthis has gone up to twenty million, but still our energy consumptionintheinjectionmouldingshophasremained the same.”

Gula attributes this success to the consistent use of injection moulding technology from the Wittmann Group The machines from the Eco Power series come with highly dynamic servo motors to drive the main movements. Thanks to Kers, the deceleration energy of thedrivesisrecoveredandusedwithinthemachine,for example to supply the necessary voltage to the control system, or for barrel heating “Kers stands for Kinetic Energy Recovery System,” explains Bogdan Zabrzewski, Managing Director of the Wittmann subsidiary in Poland.“WithKers,afurtherreductionofenergyconsumption by up to 5 percent is possible.”

The servo-hydraulic Smart Power machines from the Wittmann Group also operate with Kers. In this series, the combination of fast-responding servo motors with powerfulconstantdisplacementpumpsisthestandard For the injection moulding process, this means maximum speed and precision of the machine’s movements with simultaneous minimal energy consumption

On the day of the visit, small, slender bottles produced inside a 16-cavity mould were running off the clock-out belt of an Eco Power 300 injection moulding machine. Anyone unfamiliar with the material would take it for glass.Inreality,itisPET “PETlookslikeglass,butitdoes not break when it falls down,” explains Gula, which is whythismaterialisplayingamoreandmoresignificant part in cosmetics packaging Twelve years ago, Bell was the pioneer in this field. “We were the first cosmetics producer to manufacture bottles for mascara and lip gloss from PET,” says Gula.

Today,primarilyPETGisprocessed,aglycol-modified variant offering a particularly high degree of transparencyandimpactstrength,andsimultaneouslyexcellent processingattributes.Withtheirstandardiseduniversal screws, the Smart Power and Eco Power machines deliverfirst-classinjectionmouldingresults.“Onlythedrying process presents a special challenge for this material,” Gula discloses. While normal PET is dried with temperatures around 160 °C, PETG requires significantly lower temperatures between 60° and 70 °C. “So, we have specially fitted the Wittmann Drymax dryers for our customer Bell with a cooling device,” reports Bogdan Zabrzewski. In this customised solution, it was of special importance for Bell that the cooling can be switched on or off as required. For the dryers are being used flexibly for other materials, too

“TheDrymaxfromWittmannhasabsolutelyconvinced us,” says Gula. “We are reaching a dew point of -67 °C with it. This has not been achieved so far by any other dryermodel.”Zabrzewskiexplainsthehighperformance of the Drymax dryer with the use of two desiccant cartridges.“Thedryersdeliverprocessaircontinuously,and drying air of constant high quality.” Thanks to countercurrent regeneration, the dryer also stands out by its extremely energy-efficient operation.

Machineswithshortdeliverytimes

Bell’s customer base is heterogeneous. In addition to long-standingcustomers,whoplacetheirorderswellin advance and invariably for large quantities, there is a daily inflow of many short-term orders involving relatively small batch sizes. What is more, every national market sets different requirements, all of which has led to a very large number of active moulds and frequent mouldchanges.“Elasticproduction”isthetermusedby WaldemarGulatodescribethisgreatflexibilityrequired from Bell every day.

“We are able to fulfill all packaging wishes Any form and any colour — from transparent and matt-finished right up to high-gloss,” says the Production Manager, and then adds that at present primarily high-gloss surfaces generated inside a mould are increasingly in demand. Here, sustainability is also an issue, since metalising and chrome plating are more and more often dispensed with to protect the environment as well as the

Production inside a 16-cavity mould. All injection moulding machines are equipped with linear robots for parts removal.

“Witheverynewmachine,theenergy efficiencyincreasesevenfurther.”

Waldemar Gula, Production Manager, Bell

staff members. The current trend favours non-coated mono-materialpackaging,becauseitiseasiertorecycle.

“Webearagreatecologicalresponsibility,”emphasises Waldemar Gula. “It is important for us to include the consumers’interestsinallourdecision-making.”Onits website, for example, Bell posts information about sustainable production and instructions for correct disposal of the packaging, so that the plastic materials will be returnedtothecycle.Everypieceofcosmeticpackaging leaving the Bell plant in Józefów is provided with a QR code.Thisgivesconsumersveryeasyaccesstoinformationaboutthepackagingmaterialsusedandthecorrect way of disposal for recycling “This is the only way for a circular economy to function,” states Waldemar Gula, “by integrating the consumers into our network as part of the value chain.” (ast)

Further details on Wittmann’s energy-efficient moulding and drying systems: www wittmann-group.com

To reduce manufacturing costs and boost efficiency, Schaltbau automated the de-flashing of plastic housings at its Bavarian plant using a Rösler wire mesh belt blast machine, cutting personnel needs by 40 percent while ensuring gentle, Atex-compliant processing.

Achieving a competitive edge in the market by cost-efficient production of innovative products. A global leader in the production of electromechanical components for safe and efficient switching operations and the protection of direct current applicationsfollowedthisguidelinebyautomatingthede-flashing of plastic housings at its German location. The companychoseaRöslerwiremeshbeltblastmachine,modelRSAB370-T1+1,compliantwithAtexregulations.This investmenthelpedtopracticallycutthepersonnelcosts in half

The Schaltbau is a globally leading supplier of direct current (DC) solutions. This multi-division company, located in Munich, specialises in electrification products and solutions for many industries. For decades railway

customers have been utilising the comprehensive portfolio of contactors, plug connections, switches and safety components. The trademark Eddicy stands for ultra-modern solutions for safe and reliable switching operations and the protection of direct current applications in the sectors energy and e-vehicles. These innovativeproductsareproducedatseverallocationsinGermany, Europe, the United States and Asia including a plant in Aldersbach, located in Bavaria, Germany.

Reducingmanufacturingcosts

Armin Voggenreiter, Director of Operations at the Aldersbach location of Schaltbau, comments: “To remain competitive at our Aldersbach plant we work hard to

The innovative products from Schaltbau, such as contactors, are — among others — used in the sectors railway, energy and e-vehicles.

identifycostreductionpossibilitiesforpracticallyevery single manufacturing step.” As part of a lean manufacturing project the production of housing components was extensively analysed. These are moulded in a pressing operation utilising melamine/polyester materials. Due to some material overflow in the press unwanted flashes are created, which must be removed to ensure the safe assembly and functionality of the components. To date the flash removal was done manually requiring alotoftimeandpersonnel.Forexample,onepersonwas stationed at each press. Therefore, automating the de-flashing operation offered a substantial cost-saving opportunity

TheprojectmanagersatSchaltbaupresentedthistask to two equipment manufacturers, whose machines are already utilised in other manufacturing areas of the company.ArminVoggenreiterexplains:“Röslerwasone ofthetwosupplierswetalkedto Weknowthiscompany well,becauseithasbeenareliablepartnerofoursinthe field of mass finishing.”

Amajorrequirementfortheselectionoftherightblast machine was that the de-flashing process had to be extremely gentle. For example, the components must not

Oberf lächent echnik

ce : Rö sler

Sour

“Theshotblastmachineallowed ustoreduceourpersonnelcostsby around40percent.”

Armin Voggenreiter, Director of Operations, Schaltbau

tumble over each other during the entire process, and theymustbecompletelyfreeofanyresidualblastmedia when coming out of the machine. “For this challenging task Rösler presented by far the most convincing equipment concept”, remembers the Director of Operations. Rösler offered the highly flexible wire mesh belt blast machine, model RSAB 370-T1+1, as the most suitable solution for the continuous, gentle de-flashing of the housing components The de-flashing trials at Rösler were conducted in a comparable machine. “The excellentresultsoftheprocessingtrialsconvincedusthatthe Rösler equipment concept was by far the best for our purposes,” concludes Voggenreiter

Aftertheyhavebeenpressed,theduroplastcomponents, with dimensions of up to 350 x 215 x 45 mm and weighingupto575g,aremanuallyplacedonthe370mmwide, wear-resistant wire mesh belt. The transport speed through the blast machine, precisely adapted to the respective work pieces and the severity of the flashes, is stored in a processing program, which can be selected by the operator at the control panel. The blast chamber is equipped with two W32 turbines, which were specially developed for the treatment of plastic components. Oneturbineisplacedaboveandtheotherbelowthewire meshbelt.Themeshiswideenoughthattheblastmedia — in the form of polyamide pellets -- reaches the work pieces on all sides so that they can be de-flashed in one single pass through the machine. Any dust created duringtheprocessiscontinuouslyremoved.Moreover,the

ETMM-TIP

Learn more about Rösler’s wire mesh belt blast machines and their applications in plastic component finishing at www.rosler.com

standardblow-offsystemandtheadditionalcompressed air blow-off device ensure that any residual blast media is removed from the de-flashed components. At the machine outlet a chute transfers the finished housingcomponentstoaseparateconveyorbeltsystem in“L”shapedesignforreturningthecomponentstothe loading section, where they are removed by hand. “The shot blast machine allowed us to reduce our personnel costs by around 40 percent,” reports Armin Voggenreiter Tominimisetheoperatingnoise,theentireshotblast machine is placed in a noise absorbing cabin. To offset the resulting shortening of the loading area, Rösler increased the length of the wire mesh belt.

The standard, highly effective blast media cleaning system with vibratory screen and air-wash separator, augmented by the automatic media replenishment system, ensures that the blast media mix in circulation always contains the optimal pellet size distribution. The RSAB 370-T1+1atSchaltbaualsocontainsananti-staticsystem withautomaticcompounddosing.Thispracticallyeliminates the risk of dust and blast media adhering to the de-flashed components The anti-static system and the installation of an Atex compliant dust co of the safety measures required by Atex. (ast)

De-flashing is the process of removing excess material — known as “flash” — that forms along the edges of moulded or pressed components when material overflows the mould cavity. In plastic manufacturing, flash can affect the part’s fit, function, and safety, making its removal a crucial step before assembly. Traditionally carried out by hand, de-flashing can be automated using specialised equipment, such as blast machines, to achieve consistent, gentle, and efficient results while reducing labour requirements.

Sandvik Coromant has noticed that modern drilling requirements demand multi-talented drilling tools.

Sandvik Coromant’s new Corodrill Dura 462 is built for versatility, delivering precision and stability across a wide range of materials. Field tests show productivity gains of up to 110 percent and tool life extensions of more than 36 percent.

In January, the World Economic Forum reported that selectedproductionsitesinitsGlobalLighthouseNetwork are achieving productivity gains of 70 percent. And this was achieved with reduced energy costs and shorter time to market (by 40 percent in each case). But howcansuchefficiencybeachievedwithoutdrivingup costsandwithsuchawidevarietyofmaterials?Sandvik Coromant has the answer! It is a new, flexible drilling tool for multi-material applications

Drillingisanoldprocess,buttodayitisno trivialmatter

Drilling is a fundamental but technically demanding manufacturing process, as the Swedes emphasise One