LASER FOCUS

Daniel Sumner is leading the family business with unwavering determination and dedication.

Blood, Sweat, and Tears

Together with his father, Sumner spent countless hours planning every facet of how 23 Mile Collision’s new shop would look and operate.

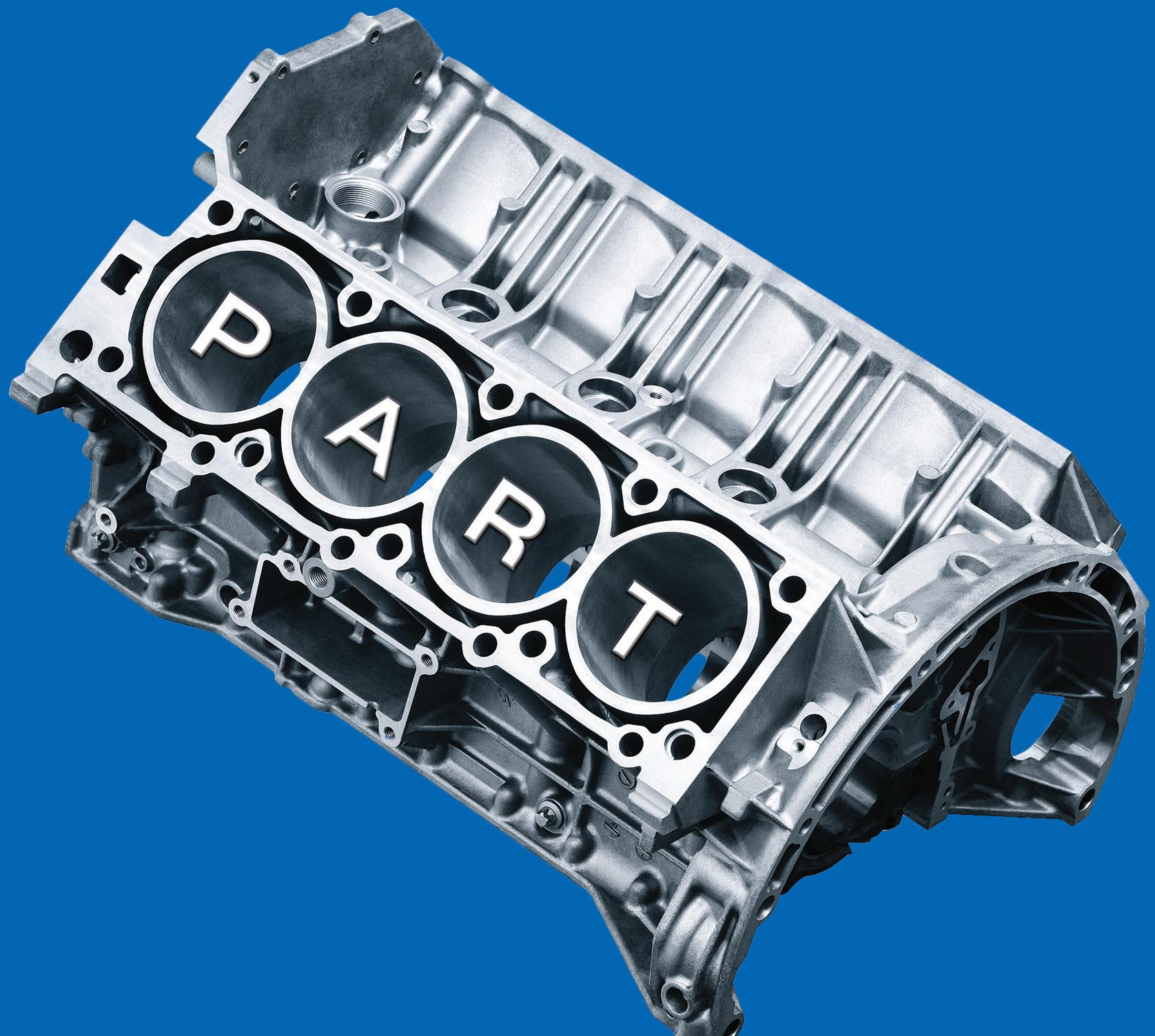

We’re excited to share that the ADL Mobile App and LKQ B2B Web Portal (portal.lkqcorp.com/ login) now use the same login . One password for both platforms — simple, secure, and seamless.

New Dashboard is available on our Website & Mobile App

• Faster, Easier Ordering: Place orders in just a few clicks with our streamlined interface.

• Track Your Orders: Get real-time updates on every order you place.

• Access Shipping Info & Reprint Invoices: All your order and billing details in one place.

• View Credits: Easily see account activity and available credits.

• Order History: Quickly search past purchases and reorders.

Scan the QR Code to get started now!

Improve Shop Estimates and Repair Plans with Front Office Collision Repair Training

Enhance your skills with our 3-day front office training. Gain hands-on context of repair and paint fundamentals to better engage your technician counterparts. Ideal for estimators, adjusters, and managers, this course boosts estimation accuracy and insurance communication, potentially increasing captured lines per estimate.

Register today to enhance your skills.

BY TIM SRAMCIK

Daniel

LINDSEY GAINER

Where

Nearly

WHERE DO WE GO FROM HERE?

Forging ahead with renewed optimism

AT THE TIME OF THIS WRITING, the biggest event of the year for collision repairers, the SEMA Show, is just a few weeks away. And I expect to return to the office exhausted from a full week of travel and running from early morning to late evening. At the same time, after a good night’s rest upon my return, I’m always excited about the possibilities for the industry. Despite the current business slowdown, research firms predict a modest uptick in the next five to seven years. That ranges from .8 (Grand View Research) to 5.9% (Global Market Insights) compounded annual growth rate for the entire market, which includes crash parts, paint, and allied products. It’s at least a positive direction. That said, we’re focused at FenderBender on helping you make money, save money, and work smarter, presenting options for exploring new markets, what to consider for growing your market reach or selling to a consolidator, and more.

In this issue, columnist and shop owner Greg Lobsiger advises implementing a solid marketing strategy and working on operational improvements. Veteran collision repair consultant Steve Trapp gives options how shops can help reverse the total loss trend while fixing vehicles correctly. Representatives from Accudraft and GFS weigh in on what to do to make your existing booth perform to its potential, including while planning for a replacement. And see how two shops

using guidance from Mike Anderson at Collision Advice have maximized their production efficiency.

As always, please reach out to us if you have an idea that can help fellow shop owners and operators, and I’ll leave you with this parting thought from Drew Bryant, owner of DB Orlando Collision, in this month’s column: “When the work gets quiet, it’s not a punishment. It’s an invitation to rebuild stronger, leaner, truer.”

JAY SICHT EDITOR-IN-CHIEF jsicht@endeavorb2b.com

EDITORIAL

Chris Jones VSRG Editorial Director

Jay Sicht Editor-in-Chief

Peter Spotts Associate Editor

Kacey Frederick Assistant Editor

Emily Kline Special Projects Editor

Leah Marxhausen Special Projects Editor

Drew Bryant Contributing Writer

Tiffany Menefee Contributing Writer

Greg Lobsiger Contributing Writer

Lindsey Gainer Contributing Writer

Todd Kortemeier Contributing Writer

Steve Trapp Contributing Writer

Carol Badaracco Padgett Contributing Writer

Tim Sramcik Contributing Writer

EDITORIAL

ADVISORY BOARD

Jordan Beshears Steve’s Auto Body

Sheryl Driggers Collision Advice

Frank Rinaudo Industry Consultant

Jason Mundy Mundy’s Collision Center

Stan Medina Certified Collision Works

SALES

Andrew Johnson Publisher ajohnson@endeavorb2b.com

Mattie Gorman-Greuel Associate Sales Director

Cortni Jones Director of Business Development

Diane Braden Account Executive (National Accounts) dbraden@endeavorb2b.com

Marianne Dyal Account Executive (National Accounts) mdyal@endeavorb2b.com

Chad Hjellming Account Executive (National Accounts) chjellming@endeavorb2b.com

Austin Miller Account Executive (National Accounts) austinm@endeavorb2b.com

Lisa Mend Account Executive (National Accounts) lmend@endeavorb2b.com

Kyle Shaw Account Executive (National Accounts) kshaw@endeavorb2b.com

Sean Thornton Account Executive (National Accounts) sthornton@endeavorb2b.com

ART AND PRODUCTION

Mariah Straub Production Manager

Jen George Ad Services Manager

Mitch Bradford Art Director

ENDEAVOR

BUSINESS MEDIA, LLC

CEO Chris Ferrell

COO Patrick Rains

CDO Jacquie Niemiec

CALO Tracy Kane

CMO Amanda Landsaw

EVP Transportation Chris Messer

EVP Endeavor Business Intelligence Paul Mattioli

VP of Content Strategy, Transportation Group Josh Fisher

HOW TO REACH US

Endeavor Business Media, LLC 571 Snelling Ave N Saint Paul, MN 55104 tel 651.224.6207 fax 651.224.6212

The annual subscription rate is $90 (U.S.A. only) for companies not qualified to receive complimentary copies of FenderBender.

LETTERS TO THE EDITOR editor@fenderbender.com

Opinions expressed in FenderBender are not necessarily those of Endeavor Business Media, and Endeavor Business Media does not accept responsibility for advertising content.

ProColor Collision

Telwin

Collision Repair Systems

Bosch

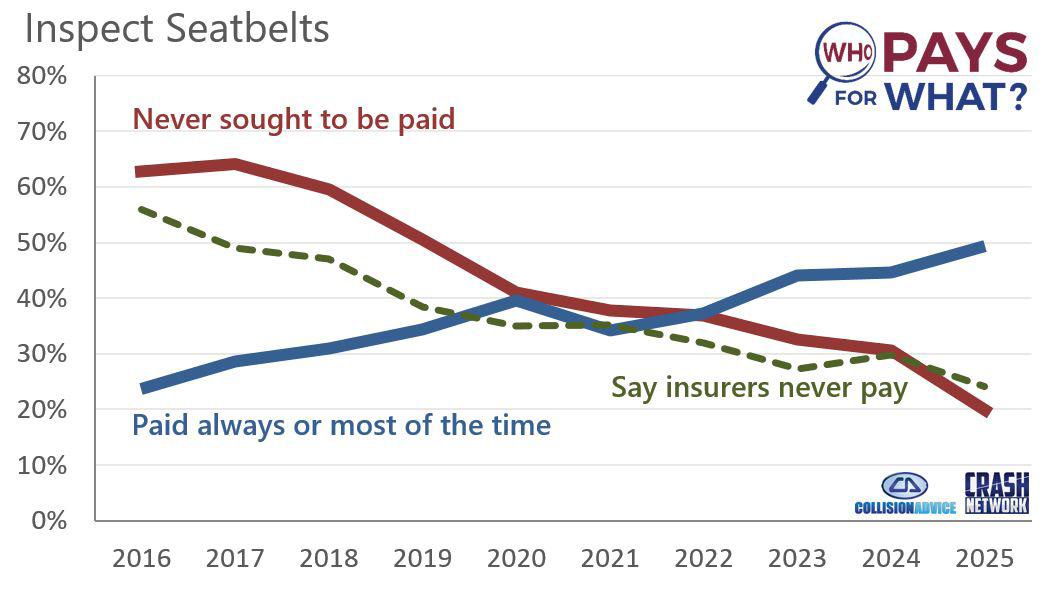

NEARLY 50 PERCENT OF BODY SHOPS GET PAID FOR SEAT BELT INSPECTIONS

NEARLY 50 PERCENT OF SHOPS responding to the most recent “Who Pays for What?” survey now say they are regularly getting paid for the labor involved in inspecting seatbelts by the eight largest national insurers, twice the percentage that said that when the question was first asked in the “Who Pays for What?” survey series back in 2016.

This “not-included” repair operation – for which every OEM has a very specific procedure – is a necessary and required part of a safe collision repair, said Mike Anderson of Collision Advice. He will not be satisfied until 100 percent of shops are performing it.

“As I conduct workshops across the country for automakers and wholesale parts managers, it is concerning to me to hear how few seat belts are being sold,” Anderson said. “This leads me to believe that too many in the industry do not understand how critical this procedure is or aren’t looking at the OEM information on this to know how to properly inspect a seat belt. It’s often more than just a visual inspection.”

The industry appears to be headed in the right direction regarding the procedure. In 2016, 63 percent of shops acknowledged they had never included it on a final invoice. Today, it’s

down to 20 percent. Of those who had it in 2016, 56 percent said that insurers would never pay for it. Today, one in four still believe that insurers won’t pay them for the procedure, even while 49 percent of the shops that do charge for it say they get paid all or most of the time by the eight largest national insurers. Another 26 percent are paid at least sometimes.

“I am glad to see the big improvement, but more is needed,” Anderson said. “As an industry, we must accept responsibility for researching and following the requirements for this on every single vehicle we repair.”

from around the collision repair industry.

BRIDGING GAPS IN PLASTIC REPAIR PRACTICES: A COLLABORATIVE INDUSTRY APPROACH

Plasnomic’s Plastic Repair Council is working with collision repair organizations to create universal best practices.

By PETER SPOTTS

PLASTIC MAKES UP 50-60% of the average claim replacements for pickup beds, headlights, bumpers, or trim for collision repair professionals. However, there are no standards for plastic repairs across the world and Plasnomic, led by its global Plastic Repair Alliance Council, is taking the initiative to rectify the issue.

Established this year, the council will gather the best plastic repair practices from every continent to create a universal standard for plastic repairs. Mario Dimovski, who entered the industry as a plastic repair apprentice at 16, brings three decades of experience to the head of the initiative.

MARIO DIMOVSKI

“It’s not a sprint; it’s a marathon,” Dimovski said. “Collectively, we need to reach the end goal and establish an industry alliance or mutual understanding of what best practice methods are, and what plastic repairs should look like, backed by testing, experience, and process validation.”

One of the major difficulties Plasnomic faces is the variance in advancement between countries. Dimovski explained that his home country, Australia, is fairly advanced, as is the U.S. Other places, such as India and the Middle East, are still developing as technology evolves. The car parcs across the different regions of the world also vary wildly.

“Each region will face different challenges depending on where they are in their growth or expansion strategy for plastic repairs,” he said. “Our council members represent countries at varying stages of plastic repair adoption, which is a great advantage. It allows us to develop tailored solutions as we listen to their input and contributions, helping to shape the plastic repair standardization, adoption, and education journey in a way that’s localized to their specific needs.”

The council represents collision repair organizations across the globe. Members include:

• Anso Jacob, Body Shop Guru, India

• Charles Canning, Halo Group, South Africa

• George Varagic, Industry Exec, Canada

• Graham Threlfall, AkzoNobel, UAE

• John Morrissey, Plastfix, Australia

• Kurt Lammon, Polyvance, U.S.

• Leonardo Gomez, Mirka, Germany

• Meghan Barrera, SEM/PPG, U.S.

• Mario Dimovski, Boyd Group, U.S.

• Peter McAninch, Plastrepair, UK

• Rebecca Miller, 3M, USA

• Robert Snook, IBIS Global, UK

• Ryan Gafford, Caliber Collision, USA

• Okuda Teruyuki, Asia, Japan

• Roberto Sticca, CSN Collision, Italy They must distill the world’s best practices to create a universal standard for collision repairers. Dimovski said it’s not that anyone is

doing it wrong per se, but many are set in doing plastic repairs the way they’ve always done and don’t know that there might be better or more efficient ways out there.

“That’s the only way because we want to make sure we have access to, and knowledge of, the entire collision plastic repair market. There could be an incredible tool, material, or welding machine in a small corner of Italy or South Africa that nobody has even heard of,” Dimovski said. “Just because it’s not on LinkedIn or social media, how would you know about it? That’s the whole purpose of this call to action that has generated so much interest from all pockets of the industry globally.”

The council is currently gathering information from repair providers, trainers, and tool, material, and equipment manufacturers. They’re encouraging as many as possible to join the council to provide their experience and input. They’ve already received responses from across the globe including companies in the U.K., U.S., Brazil, and Turkey.

“The whole objective is to identify and extract any plastic repair solutions currently available around the globe,” Dimovski said. “From there, we can begin to formalize what we have in front of us and determine what we need to adopt and refine in order to create standardized methods and validate specialty supplies.”

The end goal is to have a set of best practices that Plasnomic can present to OEMs. Dimovski said Plasnomic needs to first establish itself as an authority on plastic repairs with best practices backed by test data and thorough due diligence before approaching OEMs.

“We want to be ready with facts on the best, safest, and OEM-compatible ways to repair plastics,” Dimovski said. “We need to go in so well prepared that whatever they ask, want, or need, we already have the answers. For me, there’s still a lot of work to do before we reach that stage; they are the last and final piece of our puzzle.”

Dimovski hopes to create a centralized platform where any collision repair professional or

shop can go to ask a question about plastic repair and get the answers they need. They can contribute and modify the standards as plastic repair continues to evolve.

The council also wants to work with training bodies such as I-CAR to help spread the knowledge to repairers. Dimovski said they’re partnering with world-leading automotive based laboratories to conduct various tests on plastic repair methods, including ADAS components, and how different repair techniques perform across different plastic types.

“The shops will be the clear winners, gaining access to an authority and central platform where they can acquire knowledge, best practices, and support to repair to a unified plastic repair standard,” he said. “Plastic has evolved significantly over the last couple of decades. It used to be a straightforward polypropylene, but today most plastic bumpers, for example, are made from a polypropylene/EPDM blend, which is softer and more rubber-like. These material changes are reshaping how repairs must be approached.”

Dimovski feels humbled to head what he considers to be one of the most dynamic groups he’s ever seen the industry assemble. His responsibility is to absorb everyone’s information, filter ideas, and be a coordinator and mediator. He works full-time for The Boyd Group Services Inc. as well, so he lends his extensive plastic repair expertise and makes sure the council is talking to the right people.

Plasnomic’s initiative represents a unique opportunity for the collision repair world to come together and generate more work for collision repair shops while improving sustainability and customer safety.

“It’s a testament to everyone involved in this council, as well as the partners and those continuing to come on board to contribute,” Dimovski said. “This is exactly what the industry has needed. I truly believe this is a sign of greater things to come as the industry unites to achieve more together.”

Now

It only comes once every 100 years.

SATA celebrates 100 years of spray gun history – with a limited special edition. For the first time ever, we offer three special edition options: The jet X DIGITAL ready, SATAminijet 4400 B or SATAjet 100 B. This 100 Years Edition features the original technical drawing of our very first spray gun from 1925 – a fascinating fusion of tradition and innovation. Don't miss this once-in-a-lifetime opportunity!

Get yours now – at your local SATA dealer.

ON THE SCENE

ASCEND GATHERS DRIVEN BRANDS COLLISION GROUP IN DENVER

The annual Abra, CARSTAR, and Fix Auto USA conference featured education, networking, and more.

By JAY SICHT

DOWNTOWN DENVER’S SHERATON hosted the Driven Brands Collision Group — Abra, CARSTAR, and Fix Auto USA — Sept. 30 –Oct. 3 for its annual conference. Franchisees, industry leaders, vendors, and corporate staff gathered for the three-day Ascend event for education, networking, fundraising, and celebration.

JAY SICHT

Sterling Hawkins, author, investor, and entrepreneur, and Wednesday morning’s keynote speaker, shared how he’d built a $1 billion tech company with his father, only to lose it all when funding collapsed. It forced him to confront failure and rebuild his life. His “No Matter What System” is a five-step framework for embracing discomfort, taking ownership, and reframing problems into opportunities. He concluded his speech by noting that real progress, whether personal or organizational, demands courage, commitment, and the willingness to move through fear, because transformation only happens on the other side of discomfort.

Sean Carey, president of SCG Management Consulting and Thursday’s keynote speaker, predicted that slumping collision

Rides Tuesday afternoon, two cars were given to deserving families, including this one, through the National Auto Body Council’s Recycled Rides program.

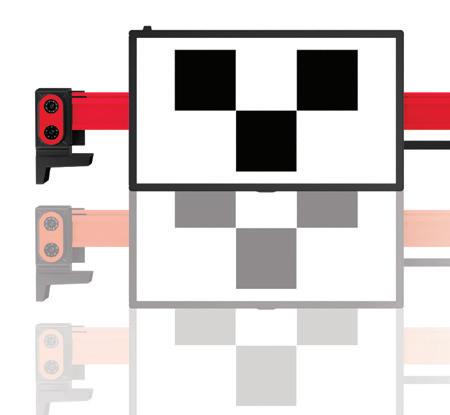

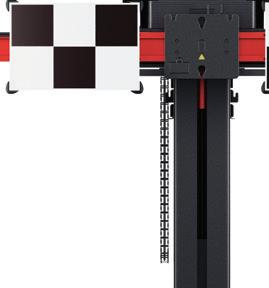

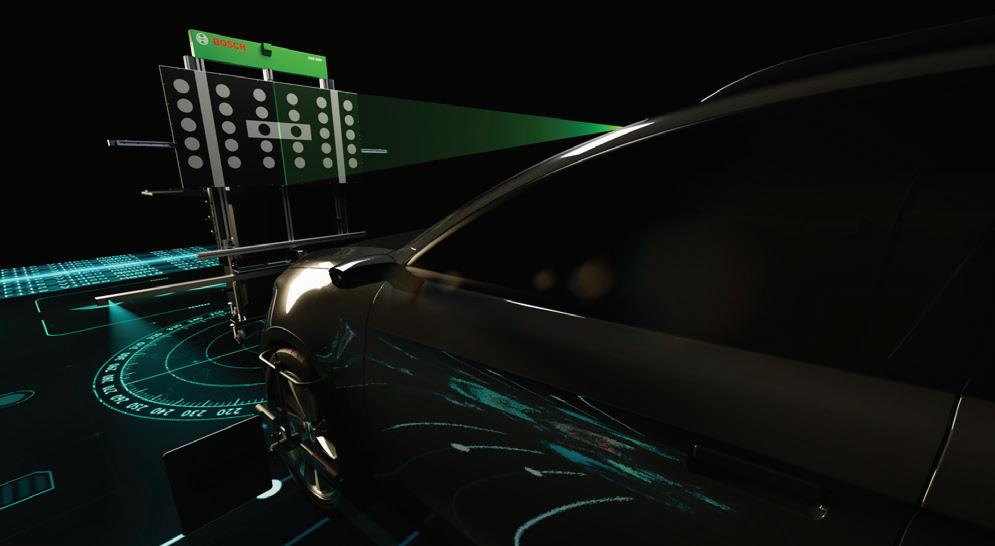

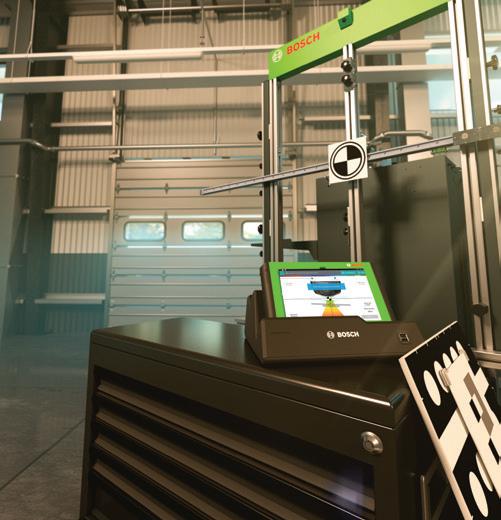

Future-proof your investment with the confidence that your calibrations are completed to the tightest tolerances and the strictest standards correctly, the first time.

Fast and efficient placement using digital vision positioning which automatically measures vehicle distances and angles to ensure precise calibration.

Modular and future-proof: Designed to work with new targets and the next generation of ADAS technologies.

Integrated storage and maneuverability keep your equipment clean and serviceable and ready to use at a moment’s notice.

Recycled

JAY SICHT

repair sales will shift course within the next year. Factors that have contributed to a decline will begin to reverse, he said, citing an aging car parc, which resulted in more total losses, and rising insurance prices causing drivers to carry higher deductibles or drop physical damage coverage altogether.

“And so the consumer backed away from making claims,” he said. “They backed away from having vehicles repaired. If they made a claim and got paid out, they kept the check — and put some tape on the vehicle.”

The supply of used vehicles will be the shortest the industry has ever seen, he predicted, and as their value increases, more will be trading them for new vehicles, which means the used vehicles will need to be prepped for sale.

“So the canary in the coal mine here is going to be dealer refurbish and fleet work — auction, fleet, detail refurbishment. You’ll start to see that coming back because people will change out of their vehicles. They’ve been in them too long, and they’ve got a little bit of a ding or a dent. They don’t want to be in it anymore — they want something new and shiny.”

At the same time, consumer confidence is increasing, if not by the end of the year, by the end of the first quarter of 2026, and toward the end of next year, “We’ll see a small return to normality” with total losses continuing to trend downward and consumer confidence increasing.

Dozens of vendors showcased products and services at the well-attended Wednesday afternoon vendor show. During the

REAR-END COLLISION, ESTIMATING, AND REPAIR:

THE DAMAGE YOU CAN’T SEE OR MEASURE

Precision alignment takes extra time—and deserves extra pay. New technology requires new tools, and precision work means you can add manual labor.

With the CJP-907, manually add up to 6 hours of labor to measure blind spot sensors before sending the vehicle for ADAS recalibration.

See how it works

Taking a MoonWalk Kerry Woodson (r.), co-owner and general manager of Jungerman CARSTAR in St. Peters, Missouri, checks out PPG’s MoonWalk semi-automated paint mixing system at the vendor fair.

COURTESY OF DRIVEN BRANDS/ARANCO PRODUCTIONS

media roundtable, Driven Brands Collision Group President Sabrina Thring noted the group plans to continue growing up to 100 units per year across North America, with the majority of that growth being in the United States, where the group sees opportunities and markets to penetrate. About 60% of that will be independent conversions, with MSOs making up 10 to 15 percent.

“And then we have another strategic lever where we work with our insurance partners to define markets, where they have work and where we need to put stores,” she said. “We have probably three or four levers to our strategy.”

Damien Reyna, COO, Driven Brands Collision Group, said the conference gathering all collision brands coincides with the group’s operational philosophy of taking the best pieces each brand brought to the company through acquisition.

Gala Event

Jesse Weideman, director of franchise operations, Abra; Dennis O’Mahoney, senior VP - brand leader, Fix Auto USA; Scott Paul, VP of U.S. Operations for CARSTAR; Damien Reyna, COO of Driven Brands Collision Group, and Lesa Laird, VP of Franchise Services for Driven Brands Collision Group and emcee for the event, stop for a photo at the Gala.

“We get asked a lot if there is a plan to ever just pull everybody under one banner and call it ‘Driven Brands Collision’ or something to that effect. And our answer remains the same: we won’t do that because of the brand identities and the strong cultures that they’ve built. These are franchisees who have joined a banner, and they specifically chose that banner for one reason or another.”

Reyna added that the group’s performance helps build its insurance relationships, which allows it to build its OEM relationships and to be “good, supportive partners of each.”

Following an awards gala Thursday night, a live charity auction raised funds in support of the Cystic Fibrosis Foundation. In total, the Group raised more than $90,000 throughout the conference for the Cystic Fibrosis Foundation.

COURTESY OF DRIVEN BRANDS/ARANCO PRODUCTIONS

NUMBERS

WHAT TYPE OF PAINT DO YOU USE?

WATERBORNE PAINT CONTINUES to increase in popularity, as reflected in this year's FenderBender Industry Survey in the number of shop owners and operators reporting they use waterborne paint. This year, 75% use waterborne either exclusively or as one of their systems. Last year, only 59% used either waterborne only or both waterborne and solvent-based paint.

DO YOU PREFER

OR WATERBORNE PAINT?

UNLOCKING CAREER SUCCESS WITH I-CAR’S TWO-YEAR APPRENTICESHIP INITIATIVE

Discover how I-CAR’s two-year Registered Apprenticeship Program offers collision repair shops a pathway to develop skilled technicians through paid, structured training recognized by the U.S. Department of Labor, supported by incentives and industry standards.

By PETER SPOTTS

I-CAR’S NATIONAL REGISTERED Apprenticeship Program is the latest development for collision repair industry workforce development, designed to train someone with no foundational knowledge to be a competent professional.

The two-year structured training program delivers a nationally recognized

credential from the U.S. Department of Labor using paid, on-the-job learning and related technical instruction.

Last year, the U.S. Department of Labor designated I-CAR a National Apprenticeship Hub, which enables the organization to provide incentive packages to qualified shops on a first-come first-

served basis. The packages can help shops get the tools they need and cover costs to lessen the financial burden of apprenticeship. Interested shop owners and operators can complete an inquiry form at i-car.com/registered-apprenticeship. Dara Goroff, vice president of planning and industry talent programming at I-CAR,

spoke with FenderBender about what shops would fit the program, how much it costs, and the challenges they might face when taking on an apprenticeship.

Editor’s Note: This interview has been edited for length and clarity.

FB: Is there a typical profile for a type of shop or where this works well and where it wouldn’t?

The ideal shop would be a shop that’s Gold Class already because we know two things if they’re Gold Class: We know that they’ve committed to a lifetime of learning for their employees, and they really believe in employee development. The second thing is we know that they have representatives for all the required roles in the industry. So, they’re likely to be able to convey the right knowledge to somebody who’s entry level.

As long as a shop is Gold Class, they don’t really need to have done anything to prepare for registered apprenticeship. We will want them — and the Department of Labor wants them — to have a one-to-one mentor-to-apprentice relationship. When they’re ready to onboard an apprentice, they will have to have a designated mentor, but we have tools that can help them get there. If they’re interested and they’re Gold Class, my recommendation is for them to reach out to our program administrator or one of our representatives in the industry who will get them to the right place.

FB: Is there a cost or obligation to see if I’m going to be a good candidate?

There is no obligation at all. There’s no cost to talking to Jen, our admin. We will work through not only what you need to do in your shop to get ready for this, but also the Department of Labor’s requirements. None of that is at a cost to the shop. My thought is that we will have shops that are not yet Gold Class, but they’re on the pathway and they’re really close. [They] want to talk to somebody at I-CAR before they truly are ready so that they know as they’re laying the foundation…they can also keep an eye out for who’s a viable mentor and what they have in their shop to help them train in an entry-level technician.

FB: What would be the biggest challenge to a shop owner or operator implementing an apprenticeship program?

You need a program that the industry validates that it brings an apprentice up to the skill levels that are transferable to any employer in that industry. I think one of the reasons it’s kind of hard to start a program is it’s especially hard for an individual employer who’s really focused on fixing cars to go to the Department of Labor and say “I can set an educational standard that other shops would believe in”…The second thing is the administrative work. The Department of Labor wants to make sure that the program that they’re offering as a registered apprenticeship is successful. Any employer participating in a program normally would have to report back to the Department of Labor at regular intervals...I think generally, if you’re not a larger employer, it’s hard to say I’m going to hire somebody who’s just going to administer this program or make sure that my apprentices are hitting the right milestones. We’ve taken away that barrier, too, because our administrator will help with all those things.

FB: What does the program cost?

Well, it’s going to be hard to answer that, not because I’m equivocating. The cost is variable based on what the employer needs. The incentives can cover the cost of the culture assessment, the mentor apprentice-matching, the tools for up to three apprentices at a location, and, once they accept an incentive package, we’re providing the two years of curriculum. The two years of curriculum is variable because if you’re going into a large shop, that’s going to have numerous people going through it. It costs more than if you’re going to a small location. I don’t mean to hide the cost. It’s kind of hard to give a ballpark, but if someone’s interested in us, reach out to us as soon as possible because we do have those incentives available. The Department of Labor has funded quite a few packages, and they are available on a first-come, first-served basis.

FB: You mentioned a two-year timeframe. Is that standard?

That is the standard for the apprenticeship. That is exactly what we offer to cover as far as the curriculum [is concerned]. We know from the Department of Labor data and statistics that they’ve shared with us that employees going in as apprentices have a mindset to more likely to stay with the employer. They see the finish line in front of them. But we also have found…more people are interested in applying because they know it’s a two-year program. They feel like they’re going to be given time to learn and that they’re going to progress to something that truly is meaningful as a profession.

FB: Any final thoughts or comments?

So, this is an important thing to note for employers who have looked and tried to find grants and funding, and they haven’t seen anything available in their state. It’s important to create a relationship that can help you find the things that are available, because the government changes all the time. We’re constantly on the hunt to see what’s available for those running a Department of Labor Registered Apprenticeship program…It isn’t like if you look once, “My state doesn’t have anything for this.” They’re constantly changing for the good of our industry, and I think this country needs to invest in skilled trades. I think, no matter what party is in office, we’re going to see a resurgence of interest in the skill trades.

Dara Goroff, I-CAR vice president of planning and industry talent programming DARA GOROFF/LINKEDIN

Current State vs. Future State

is a crucial time to improve everything we do.

Believe it or not , we have only two months left in 2025. As we look back on the past ten months YTD vs. 2024 YTD, are gross sales up or down? How about net profit — is it up or down? If things are up, then we need to be very thankful for our team and our customers’ loyalty. If our gross sales — and most importantly — net profit, are down, then what are we to do? Well, time to get off our backsides, turn that frown upside, roll up our sleeves and get to work!!! Many may be saying, “What are we to even work on, Greg, as we don’t have the customer demand we had two to three years ago?”

Of course, it is crucial to implement a good marketing strategy in times like these, but this is a crucial time to improve everything we do. Let me start with this. Back in 2013, I had lean collision expert John Sweigart come into my shop over two different weeks to teach me about lean philosophy and fundamentals. As I reflect on that time of great learning, one of the lean tools I learned was value stream mapping.

Basically, a VSM is a visual way of diagramming all our steps from the customer contacting us with, “I just wrecked my car,” to a completed repair and cash going into the bank. In the world of lean, Toyota uses a VSM as a fundamental tool in continuous improvement to identify and eliminate waste. Toyota developed the tool — which it calls a material and information flow diagram — and it is a critical part of the Toyota Production System. A value stream is all the actions (both value-creating and non-value-creating) required from crash to cash for shops. Just FYI: In the last trailing twelve months, Toyota has produced MORE net profit dollars than Mercedes, Ford, GM, Honda and Tesla COMBINED. So, we’d probably better listen to them!

After day two of John’s arrival back in 2013, using some wall space and sticky notes he just started asking questions to the employees who covered each department. The first department was the admin folks and John asked,” What happens when a customer calls saying, “I just wrecked my car?” We then listed out all the steps and processes, from gathering their information to getting the vehicle towed to our shop or driving in for an estimate,

etc. We then spent an entire day just going through every department, noting each step and its processes. This included preordering parts, receiving invoices, vehicle check-ins, looking up procedures, blueprinting a vehicle, ordering more parts, checking in parts, etc. We then included all the downstream departments for Body, Prep, Paint, Build, Detail, QC, Delivery, Customer Closeout, Cash in the Bank. We ended up with around 20 steps and 300 processes. Just FYI: by the time we got to step #6-7, I was physically sick to my stomach, because I could visually see all the dumb things we were doing that no customer would EVER pay for. What a terrible current state we had!!!

Now it was time to fix this. We then went through every step and every process to figure out if it was value to a customer or not and whether we could eliminate it or not. Example: Would a customer pay to have basecoat applied to fender? Of course! Would a customer pay us to receive multiple parts invoices from a vendor that brings parts for the same RO over a 3–4-day period? Of course not! By the time we finished discussing and reviewing everything, we cut 20 steps to 12 and 300 processes down to around 100. This was our new future state system to strive for! We literally cut out 2/3 of our waste. When shops take time to do an event like this, all the departments get to see all the stupid stuff they’re doing and then can fully understand there is a much better way to do the work.

Most recent data show that cycle time for the vehicle owner is around 15 days on average across the country. Fifteen days X 24 hours = 360 hours. Without getting into the weeds with weekends, working hours, tech efficiency, etc., actual touch time for each vehicle is around, say, 18 clock hours on average (depending on in-house ADAS calibrations etc.). Granted, we have insurance approvals and parts we are waiting for. Now, just stop and think about it. What has been happening to the car for the other 342 hours we have the vehicle? Well, nothing, and the customer is still without their car! Even though it’s very hard work, when we strive to achieve a better future state, we will have a culture, customer loyalty and profits like no other shop around us, I guarantee!

GREG LOBSIGER

Greg Lobsiger has owned Loren’s Body Shop in Bluffton, Indiana, for over 23 years. He has been a member of Mike Anderson’s groups for ten years and had extensive lean manufacturing training.

EMAIL: greg@lorensbodyshop.com

ARCHIVE: fenderbender.com/lobsiger

PREPARE FOR AND PASS YOUR ASE CERTIFICATION

Motor Age Training offers the most complete and extensive collection of B-Series Collision Repair training guides available anywhere!

B2 - Paint & Refinishing Certification

B3 - Non-Structural Analysis & Damage Repair

B4 - Structural Analysis & Damage Repair

THANKS TO OUR TRAINING SUPPORTERS

B5 - Mechanical & Electrical Components Certification

B6 - Damage Analysis & Estimating Certification

*training guides available in a variety of formats

Exploring Production Efficiency

Use these five steps to make the most out of your productivity potential.

By TIM SRAMCIK NICOELNINO

Exploring Production Efficiency

There’s a telling irony in the fact that building efficient operations isn’t typically an efficient process. Strictly speaking, business efficiency is an organization’s ability to use resources such as time, labor, and materials to produce maximum output (in terms of services and revenue) with minimal cost and waste. It measures how well a business transforms inputs into profits by streamlining processes, reducing redundancies, and optimizing operations to boost productivity and profitability. That all is easily comprehensible, but turning it into an actual operation is the trick, especially if you’re a collision repair operator already fully invested in just turning a profit and surviving. Moreover, there’s no one model (or even a limited number) that shops can turn to. This leaves most operators tweaking efficiencies where they can instead of implementing a true efficiency vision where they could reap the most benefits. Fortunately, there are solutions available to bring a true vision to life. Help abounds with consultants who can assist you with your business. You can also look at other shops and how they’re turning new approaches to efficiency into lessons that every shop can learn from. Here’s a look at two such shops — Central Florida Body and Paint in Orlando and Wallace Collision Center in Bristol, Tennessee — along with five steps that can guide you into sharing their fresh approach to efficiency.

A word about lean

No idea dominated the collision repair industry during the first 20 years of the new millennium more than lean processing. With insurers holding sway over shop profits with no relief in sight, shop owners turned to lean processing to cut waste and return these lost dollars to their own

Certified Repairs Wallace segments its work by popular models and luxury lines. COURTESY OF WALLACE COLLISION CENTER

COURTESY OF CENTRAL FLORIDA BODY AND PAINT

and speed repair times with measures that ensure all damage is diagnosed initially and OEM repair procedures are always strictly adhered to.

pockets. Operators invested heavily in rethinking the streamlining of their work and reducing, sometimes only by minutes, the time taken to perform various tasks. More available time was supposed to translate into more throughput. Couple that with reclaimed costs and waste, and shops had a surefire path for success. Except it wasn’t that easy. Overhauling a business into a lean operation could be more than some shops and their employees would accept. Some repairers even began pushing back against lean changes they believed offered little or no return on the investment. No, lean isn’t dead, and in fact, far from it. But shops can focus on other areas of efficiency.

Step 1:

Focus on process consistency.

Streamlining your processes is a big part of lean, but both Central Florida Body and Paint and Wallace Collision Center have their own take. Both aim to reduce mistakes

At Central Florida, Managing Partner Nader Akbari explains his shop utilizes a detailed vehicle check-in process outlined as a key to efficiency. Steps include full photogrammetry, decontamination (siliconebased power wash), a thermal interior wash with protectant, followed by diagnostic and factory scans, and suspension measurement to ensure there is no missed damage or other issues that can cause problems downstream. “We want the vehicle touched as little as possible, so we don’t have big problems like redos that really hurt efficiency,” he explains. With that done, blueprinting and then repairs can begin.

Wallace employs similar prep and blueprinting processes, although it separates its work into two sets of certified repairs. The first set is certified work on popular models like Ford and Subaru and the second is on luxury lines. “It’s almost like a businesswithin-a-business structure,” explains Director of Operations John Baker. Further, he notes that repairs are segmented, with designated teams or employees focused on specific repairs. With the shop’s staff dialed into consistent work processes, costly mistakes can be drastically reduced if not eliminated altogether.

COURTESY OF WALLACE

COLLISION CENTER

Step 2:

Build on experience.

Baker says this setup offers further efficiency. Since employees are focused on performing specific work on specific vehicle makes, they become accustomed to the work. They aren’t left having to navigate and train on a number of vehicle makes. Ease of repair through familiarity is built into the operation.

This approach has allowed Wallace to bring in work it once outsourced, such as glasswork. To make this operational model work, the shop puts employees in positions where they best fit (based upon factors such as training and evaluation). While other repairers look for ways to cross-train workers so they can share resources on jobs, Wallace has found that by doubling down on simplicity and consistency, they can reap more benefits. On a side note, the shop employs a safety inspection tech to evaluate all work. At one time, several employees shared this duty. Baker says the business eventually decided to use one dedicated employee to, again, ensure consistency. Even a single role has an important place in a business built on consistency.

Step 3:

Invest in your workforce.

Of course, such an operation relies heavily on a trained workforce that remains in place, a true luxury in an industry where many techs move from shop to shop. Wallace has addressed the situation with an apprenticeship program for which it can draw its own labor pool. The shop works with nearby vocational and tech schools to identify highperforming students and then puts them to work on a blueprinting team to see if they’re right for the shop and if they want to do the work. Currently, four apprentices are working as flat-rate technicians.

Baker points out that his shop’s focus on certification work also has a part in employee retention. “A lot of techs have never really traveled,” he says. “We give them the chance to go somewhere they haven’t visited and stay while they train. It’s a big deal to them.”

Step 4:

Use the available tools.

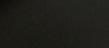

Managing operations based on top-tier consistency is no easy matter. Central Florida makes full use of its 45,000 square feet. Both

By starting every repair with preparation processes such as cleaning and scans, shops can create accurate repair blueprints and mistake-free work.

it and Wallace use a variety of digital tools to manage workflows and ensure accurate OEM repair steps are delivered.

Central Florida makes use of production boards displayed on a large touch screen TV, cloud-based software, RepairLogic for accessing OEM procedures, and a new app they are helping test, Carmic, that documents repairs and uses artificial intelligence to help technicians quickly search through repair procedures using voice commands.

Wallace uses Rome collision management software, which Baker says tracks how many repair orders an estimator or tech is handling, and features a big board showing where a vehicle is in the repair process and who’s working on it.

Both shops note the importance of leveraging technology to ensure consistency and repair accuracy. Technology is at the core of their ability to maintain their processes.

Step 5:

Remove insurers from the equation.

One of the final, if not main, keys for

Process Consistency

shops to institute far-ranging efficiency practices is by taking full control of their businesses. This can be nearly impossible with insurers making their own demands, including approvals for work and supple ments. Central Florida and Wallace have both responded to this problem by keeping insurers at bay. Wallace is not a part of any DRP, preferring instead to found its opera tions on certified repairs. Central Florida has its own unique take.

Akbari says the business begins work ing with customers immediately to clarify what work they will be responsible for. This eliminates the need to negotiate for work permission during the repair. “This is something a lot of shops should and could be doing,” he says. “Shops shouldn’t be afraid to have these conversations with customers or insurers. It really cuts down on any possible interruptions with the work.”

He continues. “You have to do your work the way you want. You can’t have 23 differ ent processes because you work with that many insurers.”

What’s more, the actions Central Flori da and Wallace take to eliminate mistakes similarly reduce supplements and other is sues. “It’s not uncommon to see prolonged back-and-forth with insurance companies over supplements, with some shops doing five to seven supplements on a single job,” Akbari says. “It’s also not uncommon to have cars sit for 20 to 30 days while shops wait for permission for work. That’s no way to work and be efficient.”

Repair information done right

• Current OEM Data

• Simplified Blueprinting

• One-Stop ADAS Resource

• Detailed Procedures

• #1 Wiring Diagrams

• Intuitive Dashboard Navigation

The two shops have used these approach es to significantly improve shop metrics, most notably repair hours. With dedicated efforts

LASER FOCUS

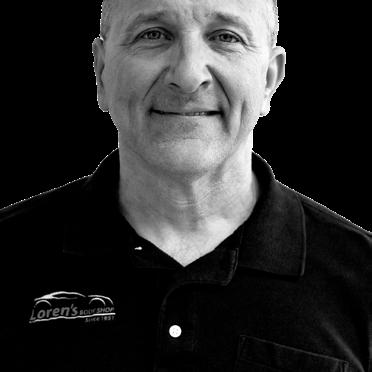

Daniel Sumner is leading the family business with unwavering determination and dedication.

By LINDSEY GAINER

Photography

GROWING UP,

Daniel Sumner watched his dad, Shawn Sumner, pour his blood, sweat, and tears into building 23 Mile Collision in Shelby Township, Michigan.

Now, 25 years later, it’s Daniel’s blood, sweat, and tears that are carrying the shop into the next generation.

“Watching how hard my dad worked, it motivates me to want to work even harder,” Daniel says.

From the time he was a young child, all he ever wanted to do was take over the shop. The fact that he has — while also successfully leading an expansion that doubled their square footage this past year — sometimes feels surreal, he says. And while the journey has tested him in just about every way imaginable, he wouldn’t change it for the world.

“To stand here today and say that I have achieved my goal of bringing 23 Mile Collision to a place it has never been before, it’s nothing short of a dream come true. I want to show everyone that if you work hard enough and truly want to achieve something, anything is possible.”

Baptism by Fire

23 Mile Collision has always been a part of Daniel’s life, almost from day one — his father founded the business just several months after he was born, and he’s been in and around it ever since.

His first official job was working as a porter at age 17. From there, he started learning everything he could from the techs — bumping cars, doing heavy replacements and frame work — and he started painting as well. Learning to write estimates came next, before eventually running the office and working directly with the customers.

“Dealing with customers every day really taught me how to communicate more effectively and learn the skills I’d need to be in charge,” he says.

After he graduated from high school — at his parents’ encouragement — Daniel tried college for a short time, but, within a week, he was skipping classes to work at the shop.

His mother was less than pleased when she found out, he admits, but “she’s on board now,” he chuckles. “She knows this is what I’ve always wanted to do.”

By 2022, Shawn felt it was time to let Daniel spread his wings and run the shop on his own.

“My dad started coming in just a couple of hours every day and had me run the shop the rest of the time. That was his way of teaching me.”

It was a tried-and-true method, given that it’s how Shawn started, too.

Although he’d worked in multiple shops as a tech before setting out on his own, he didn’t have any experience in other aspects of the business — writing estimates, working with customers and insurance companies, etc. So, he taught himself from scratch, running a one-man show in the shop while Daniel’s mother, Sylvia, handled the books.

“It was definitely a big risk to take. A lot of people doubted him, but he proved them all wrong.”

Daniel is determined to do the same thing.

“The journey to get to where I am today definitely has not been easy,” he admits. “I

had to learn how to put out fires and handle tough situations at 22 years old.”

There’s a “long list” of things his parents have taught him over the years, Daniel says, but the value of hard work and dedication tops the list.

“When you are running any business, it’s a lot more stressful than people think. I treat the shop like it is a living, breathing thing. When it needs to eat, you feed it. No matter what. No matter where I am, I’m always thinking about the shop. Even though it is very, very stressful, it will always be what I want to do.”

Shawn is semi-retired now but still comes in from time to time. “He looks over things here and there and just likes to be a part of the shop in any way he can,” Daniel says. And Sylvia still handles bookkeeping on the back end. Both are incredibly proud, they told me, to have Daniel leading 23 Mile Collision into the next generation.

“Watching our son take the reins of the business we built has been one of the greatest joys of our lives,” they said. “His vision, dedication, and integrity make us incredibly proud – not just as parents, but as founders who know the future is in good hands.”

A “living, breathing thing” “When [the shop] needs to eat, you feed it,” says Daniel Sumner. “No matter where I am, I’m always thinking about the shop.”

Moving forward, Daniel wants to keep the values his parents have lived and breathed into the business every day at the forefront of operations.

“Hard work, honesty, and treating every customer like family.”

Those are the Sumner family nonnegotiables.

“We believe in doing the job right the first time and standing behind our work. My dad’s reputation was built not just on skill, but on trust. People know when they come here, they’ll be treated fairly and leave satisfied. As I take the wheel, I’m committed to carrying those values forward. I’ll continue to put quality and integrity above all else, while also bringing in modern tools, technology, and training to keep us competitive in today’s market. My goal is to honor what my dad built, while evolving the shop to meet the needs of the next generation of customers.”

The first step in that evolution was a brand-new shop that the team just moved into in August. At double the size of the original shop, there’s plenty of room for Daniel to grow and build on his dreams.

Passing the Torch

Growing up, Daniel Sumner watched his dad, Shawn, pour his blood, sweat, and tears into building 23 Mile Collision. Now, Daniel is carrying the shop into the next generation.

Eyes on Expansion

Daniel Sumner plans to expand the business again in the future now that he has experience with the process.

Reaching New Heights

Much like he did when he was training Daniel to manage the shop, Shawn stepped aside and let Daniel take charge of the business expansion, allowing him to learn through firsthand experience. “I told my dad that as much as possible, I wanted to handle this expansion alone. I wanted to be able to say I did it. And he was on board.”

Daniel knew he wanted the new shop to stand out from others in the area “not just from the outside, but the inside, too.” But finding the perfect location took some patience. 23 Mile Collision is named for the road it’s located on, so they had to wait for something nearby to become available.

In November 2024, it finally happened. A 17,000 sq. ft. building just 500 ft. down the street from the original shop came up for lease, and it was everything they needed — but, having been used as a spring shop most recently, it took extensive renovations to turn the space into a body shop. The nine months it took to get everything operational were, admittedly, “the most stressful of my life,” Daniel says.

“Going through the inspections and permitting was definitely not easy. From all new electrical to fire suppression systems, mechanical work, and on and on and on… I never could have imagined it’d be so much work to get up and running. I was on the phone 24/7 dealing with the city, contractors, customers, lawyers… something new seemed to pop up every day.”

Together with his father, Daniel spent countless hours planning every facet of how the new shop would look and operate — even down to the logo, which Daniel designed himself.

“We worked together on the signs, office, exterior color of the building, how the back of the shop looked… all of it. I used some of his knowledge of the business and what he thought was necessary, and I used my knowledge from touring other shops, searching shops online, and gaining any ideas that I could to make it state-of-the-art.”

Standing Out Daniel Sumner’s goal was to make the new facility unique among his competition.

Nonnegotiables

All his hard work has certainly paid off — the new shop is not only beautiful; it’s highly functional, too. A great deal of effort was made to streamline production, Daniel says, to ensure smooth workflows. And the shop boasts a brand new Garmat downdraft paint booth, with a plan to acquire more new equipment in the near future.

Daniel also hired two additional employees to accommodate the influx of work they can now handle in the bigger shop, bringing their total employee count to10. He plans to grow the team even further once things settle down as well.

“I have amazing technicians that show true pride in what they do, and the shop wouldn’t be where it is today without the fantastic employees I have. They’re truly more like family to me than coworkers.”

Additional investments in certifications and training are also in the works, Daniel adds, noting that the shop is on track to achieve I-CAR Gold Class status “very soon.”

What Doesn’t Kill You…

Now that the team is officially moved into their new location, there’s (a little) room to breathe and reflect on what an amazing

accomplishment and learning experience this past year has been.

“This whole process made me stronger and taught me so much, which makes me even more grateful to see what we have achieved,” he says. “I put everything I have into this move, and I couldn’t be happier with how it all turned out.”

Daniel plans on expanding the business again in the future and knows next time will be a million times easier now that he knows what to expect.

But no matter what the future holds, one thing is certain. 23 Mile Collision has always been and will always be the same independent, family-owned businesspeople have come to know and trust.

“We’ve been a family-owned business for over 25 years,” and that carries weight in the community, Daniel says. “We’ve developed a great name for ourselves. We care about our customers’ cars more than we care about our own.”

That’s evident, given that once upon a time there was only one other shop within a mile radius of them…now there’s eight, yet 23 Mile Collision is busier than ever, with no plans to slow down any time soon.

“I can’t wait to see what the future holds for 23 Mile Collision.”

Moving forward, Daniel wants to retain his parents’ values of hard work, honesty, and treating every customer like family.

CREATING A CAREER PATH FOR GEN Z TECHS

Be ready to help them learn and grow their skills once they enter your doors.

By CAROL BADARACCO PADGETT

AS A COLLISION REPAIR SHOP OWNER, what do you do when a promising young tech walks through your doors? How can you entice them to want to stay, grow in the field, build up a strong and sustainable career, and then pass down their hard-earned experience to others?

For Ed Kalinowski, owner of Phil’s Collision Center in Schererville, Indiana, he strives to show young techs a solid career path they can get serious about, and then he gives them the tools they need to navigate the journey.

Here’s the formula Kalinowski used to bring in two strong Gen Z techs, Waylon (24) and Brendan (22).

The backstory

Kalinowski was born and raised in Illinois, 10 minutes from his family’s auto body shop. By the time he got to high school, a new vocational technical center had opened with a track for automotive techs.

It was an instant attraction. So Kalinowski studied there and went into the family business after graduation in 1981. Then,

in 2000, his father bought a shop in Florida, and the family moved there for a time. Ed eventually took over the reins of the Florida business from his father.

“By 2014, we’d done well in Florida, but my father wanted to come back to Indiana to see his grandchildren, so we ended up selling the Florida collision shop,” Kalinowski says. Once in Indiana, they found an auto body shop for sale with an excellent reputation for outstanding work, Phil’s Collision Center.

“Phil’s had a reputation for quality, so we took it over,” Kalinowski says. “Today, we’re

ranking No. 1 in Google reviews, as we have a great team with a high level of dedication, and nobody can touch us. In our area here at Phil’s, we’re known for high-quality work and outstanding customer service. I’m proud of the way it took off for us.”

Today, with 45+ years in the business under his belt, Kalinowski knows how much promise a young tech can bring to a business. He learned it firsthand as a young tech himself, fresh out of vocational-technical school, and also by watching his own son’s trajectory in the auto body business.

“Eddie, my son, has been at the shop since he was 5 years old, sweeping floors, and he took a liking to it,” Kalinowski says. “He’s just 28 years old, and he’ll take over eventually.”

Then, Kalinowski, who’s eyeing retirement by 2028, adds, “I told him I’ll always be there to help and guide him.”

The challenge

Every collision repair shop owner, whether or not they have a son waiting in the wings, knows they need fresh blood to learn the ropes and keep the business moving forward. But, as Kalinowski knows too well, attracting Gen Z workers can be difficult.

“They are hard to find,” he admits. “And I’ve found it hard just getting them in the door. Then, for the ones who do come in, it’s difficult finding [young techs] who really want to work and are willing to learn.”

So, when Kalinowski eventually had two promising Gen Z candidates walk through his doors, he was ready to help them learn, grow, and exceed even his own expectations.

The

solution

The same vocational center that trained Kalinowski back in high school is a resource for him today.

“I asked the teacher to send the best of the best, and I interviewed several applicants (Waylon and Brendan among them), and they started building their careers here,” Kalinowski says.

He also has excellent technicians in the shop with I-CAR training, and those seasoned, veteran team members provide hands-on training for his young techs.

“The combined experience between my team is over 150 years, and they’re dedicated, each and every one,” Kalinowski says.

His techs also follow factory recommendations in their body work, and that’s another valuable practice they pass down to trainees.

“We go by manufacturers’ recommendations [in our repairs] and we follow their repair methods,” Kalinowski notes. The result? The highest quality — the kind Kalinowski makes sure that Phil’s Collision Center delivers.

Gen Z-aged Brendan and Waylon are also enrolled in I-CAR training courses, which they began in October 2025.

“I make sure they reach their goals, and I give them incentives. They reach out to the experienced techs when they have questions — and my techs want these questions. Our young guys are guided the whole way through,” Kalinowski says.

In addition, he offers all his employees health insurance that includes dental and vision. And he allows techs to bring in their personal cars and work on them at Phil’s, as well as getting their parts at cost. Older crew members like this perk very much for their family cars.

Waylon and Brendan are big fans of this perk, Kalinowski notes.

“I offer the shop to them every Sunday and they work on their own vehicles. That’s a great perk to these kids, and I have full trust with them [while they’re in the shop],” Kalinowski says.

Naturally, pay and economic prosperity are also powerful incentives for his employees. As Kalinowski reports, “We have a huge payroll, great accounts, and a great relationship with insurance companies.”

The quality of equipment at Phil’s is another excellent incentive for techs young

and old. “I’ve spent a lot of money on our equipment, which is all top of the line,” Kalinowski says. “We have a [Chief] Meridian frame measuring system, for example, with a complete line of Pro Spot welders.”

On Phil’s Collision Center’s two-acre property, Kalinowski is also creating a new addition specifically for his painters — again, with all top-of-the-line equipment.

The aftermath

Brendan and Waylon arrive faithfully for work each day at 7:30 a.m. “Then, they rotate weekends. We’re a six-day-a-week shop, and the business is here to support it,” Kalinowski says. That business, which sits just one mile from the Illinois border, is bolstered by an estimated 80,000 vehicles traveling east and west past it each day.

Circling back around to his commitment to tech training, Kalinowski says it’s ongoing throughout a tech’s career. “All the money I make I invest back into my employees.”

The takeaway

At the end of the day, Kalinowski himself is extremely dedicated to the collision repair industry, and he models this to his techs, young and old.

“I’ve had my life in the industry, and it has been phenomenally good to me,” he says. “I’ve made a lot of money being a shop owner, and this was my reward for the dedication I’ve put into it.”

It’s a privilege, he says, to get to work on people’s cars, which are oftentimes their second biggest investment next to their homes. And once the team at Phil’s Collision Center is finished with a repair, word gets out, and that reflects on the shop and those who work there.

“Somebody will come into the shop and say, ‘You did my uncle’s car, and now I’m here,’” Kalinowski says.

The career path at Phil’s Collision Center is as apparent as a big red stop sign. And that makes young techs inclined to walk through the door.

NAVIGATING THE RISE IN TOTAL LOSSES

By focusing on efficient repairs, strategic discounts, and proactive insurer discussions, shops can capitalize on repair opportunities.

By STEVE TRAPP

REPAIRERS HAVE SEEN a gradual increase in vehicles being declared a total loss from 10-14% just 10 short years ago, to 24-30% in 2025. What has changed — and what could repairers consider — to reverse this trend?

Further background:

The industry has just emerged from an unusual phase post-COVID, where repairs postponed had to be completed, gas prices declined, miles driven were up, and nearly every repairer had a backlog of several weeks. This led to record profits, and the technician shortage was less of an immediate concern.

Interestingly, many shops’ sales grew, but not based on the additional volume of vehicles repaired. Instead, the average RO $ went from $3,200 to nearly $5,000 due to the ADAS system pre and post scans, vehicle calibration, and test drives. This also added to the repair cycle time, as these additional ADAS repairs often occurred after the repairs were completed. So, cycle times and length of rental spiked to nearly 15 days on average, further adding to the cost of the repair.

Underlying this trend was most new vehicles being packed with new accident-avoidance technology to stop rear-end accidents, adaptive cruise and emergency braking, side mirrors marking vehicles in the blind spot, lane-keeping, backup cameras, and so much more technology. As a result, the number of repairable claims per registered vehicle have declined dramatically. Some experts say the various systems reduce types of damage 17-32%! As the car parc of vehicles with this technology grows every year, we have seen fewer and fewer repairable claims.

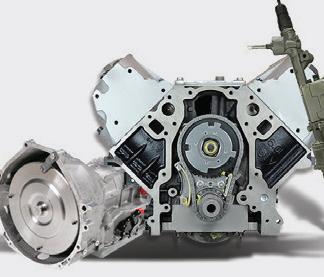

Expansion of total losses of claims

During the explosion of volume post-COVID, when parts were again more readily available, repairers got into a bit of a parts replacement frenzy and stopped repairing parts. The repair vs. replace ratios went from 60:40 to 40:60, and this drove up the average RO $ cost and drove down the repair labor hours per RO. During this period, used and salvage values soared to all-time levels. Repairers, faced with this

seemingly limitless supply of repairs, got a bit lazy and stopped selling and started merely processing claims. And when a vehicle with significant damage was towed in, they merely disassembled it for the teardown fee, charged administrative fees for writing the estimate, and then the vehicle was sent to the salvage yard. The phrase, “Let that one go” was heard all too often, to the point that now we have 24-28% of vehicles being declared a “total loss.”

Having managed various 20 groups over the years, we have seen this trend played out in a few key indicators, such as labor hours per RO and most poignantly in the frame/ structural sales mix, which was 3-5% and is now as low as .2 - .5%. Ultimately, this means we don’t use the expensive frame machine and computer measuring system as often as we used to. We currently see the frame machine being used primarily on vehicles one to three years old, and rarely on vehicles over five years old.

Common total loss scenario

Case: seven-year-old vehicle worth $22,000. With a total loss threshold of 75%, it should total when the estimate exceeds $16,500.

Estimated Repair Cost: $12K based on an AI estimate or an initial assessment. It’s probably $15,000 (or more) after you repair plan/repair the vehicle. The insurer thinks they can sell it as salvage for $14,500, so they are compelled to reduce their risk and total the vehicle.

Potential Gross Profit on Repair: On a $15,000 repair, assuming a 45% gross profit (more repair than replace), you could earn $6,750 (45% of $15,000) on that repair. If labor represents 40% of the repair with 75 labor hours at $80 per hour, that’s roughly $6,000 in labor.

Often, that initial estimate-to-vehicle value of 60-65% now triggers the insurer to total the vehicle without much thought. Therefore, technicians don’t get the opportunity to flag up to 75 labor hours, and the shop forgos $6,750 in gross profit. Therefore, the frame machine, rivet guns, and welders required for OEM programs rarely get used, tying up cash in the equipment and space in the shop.

Break-even with profit matters

With traffic declining, it’s important to know your shop’s financial break-even point considering cash flow (principal on loan or capital leases). Overhead Expenses $: $100,000 and $15,000 profit = $115,000

Divided by Gross Profit Percentage: 45%

Break-even plus profit sales: $255,555

So, if your shop is projecting to be shy of this number, it makes sense to evaluate whether you can prevent a total and add gross profit dollars to cover the overhead expenses and profit target. If a single heavy hit adds $6,750 (see example above), then it would take preventing two to three jobs from being considered a total loss to go from break-even to making a solid profit! Let’s look at ways to reduce the cost of repair to prevent a total.

How do we “prevent totals?”

Underlying assumption: Whatever we do, we ALWAYS provide a “safe and proper repair” following industry-approved resources such as I-CAR and OEM recommendations and never shortcutting.

Labor:

1. Repair all the parts which you can safely repair: sheet metal, nonstructural, plastics (plastic welding and repair techniques), refinishing wheels, etc.

2. Consider having a second body labor rate for a specific insurer to prevent totals and then pay your flat rate using the same percentage as the normal rate. Example: Door rate $80 and flat rate of 36%, or $28.80, and the “preventing a total” rate might be as low as $65 at a flat rate of 40% (higher due to the skill level required); the techs would make $26 per hour on those jobs.

3. You might be able to discount the paint labor rate in the same proportion as the body tech. NOTE: Savings of 70 body and paint hours * $15 per hour = $1,050

How do we get technicians on board with this? The good news is technicians can work at 165-250 percent efficiency, so if they work efficiently on these repairs, they can make up for the slightly lower rate. Not producing these hours means there are not enough hours to achieve their financial goals, so this gives them a chance to produce 42 body and 28 paint hours for this single RO. Even at a lower flat rate, this contributes to achieving their weekly pay goal.

Parts:

1. If a $16,000 repair has 40% parts, then the parts sales will be $6,400 at a 30% margin that would be $1,920 in parts margin.

2. If you profit-match to salvage or aftermarket, then the parts costs can be reduced, and the OEM dealer can supply parts for their costs plus the parts margin of the salvage or OE part. In some cases, dealers with an older lowturn part might be compelled to sell the part for even less to help you prevent the total. Note: Savings of $1,920 * 20% = $384 P & M:

Since we are not reducing paint labor hours, this would remain constant. Body materials and Paint materials could be discounted if your business is currently profitable in this category. Some paint companies offer a discounted paint system which could be used to reduce the base and clear costs to attempt to save money on these repairs:

Note: Savings $100 discount

Sublet:

Talk to your ADAS vendor and tell them you need to have them pre and post and calibrate for $75 less to prevent this from being a total and they may be willing to discount their services for the incremental work.

Note: Savings of $100 due to the additional discount

Why are the thresholds being lowered?

With the average vehicle age being nearly 14 years and designed to last beyond 200,000 miles, there is a huge demand for used engines, transmissions, and main drivetrain components as they fail. And the vehicle itself is still quite useful. This, along with a very lucrative salvage market, means the salvage values of vehicles remain high. As a result, insurers are dropping their thresholds to 55% of the vehicle’s value to declare a total loss. Repairers are losing out on these high-cost repairs where they can use the skills of their staff and the tooling investment they have made.

A call for legislative action

The salvage value has been bid up on totalloss vehicles by offshore buyers, so the insurers claim it’s economically better for them to total the vehicle. One proposal is for CIC, SCRS, ASA, and state associations to call for an “export tax” for the total loss vehicles purchased by offshore buyers. If that tax were added to drive up the price paid per vehicle, the demand

by these offshore buyers would then decline. Salvage values would decline, and it would again be economical to repair these vehicles here in the USA, protecting jobs of estimators, technicians, parts coordinators, and more. This is a long shot, so what can we do now?

Meet with the insurer to prevent a total

So, meeting with the insurer and saying, “If we discounted $1,600 ($1,050+$384+$100+ $100) to $13,400, would you allow us to repair the vehicle and prevent it from being a total loss?”

Besides the repair cost, why would the insurer be willing to choose to have the vehicle repaired?

1. Their policyholder may want to keep the vehicle. They perceive they have taken good care of the vehicle, they like it, they have invested in recent repairs/new tires, etc.

2. The repair center offers them a lifetime warranty and a promise to fix it right!

3. Evaluate damage and assess whether the damage is not safety or drivabilityrelated. Would they allow the customer to accept appearance allowances on wheel scuffs or other non-safety-related items to save the deductible, when the policyholder prefers that?

4. Agree to repair all parts that can be safely repaired, especially plastics (getting customer acceptance)

5. Even more extreme, to mitigate the insurers’ risk, you might consider capping the total cost and agreeing to forgo revenue beyond that amount. Given vehicle complexity, this is a risk if the vehicle has unforeseen damage.

How might repairers convince a customer to allow you to prevent a total loss?

1. To offset part of their deductible (with insurer approval), you could select items that are appearance-related (for an appearance allowance) that they could live with (e.g. a scratch on a rim or trim piece, not safety-related).

2. You may want to buy a few loaners to let the consumer drive for free while you’re completing the repair (up to a limit on the number of days). This eliminates the costs of a rental and provides a consumer convenience.

3. In your glove box kits or brochures where you describe “What to do in case

of an accident,” discourage customers from allowing Copart or another salvage pool to take the vehicle directly to their lot. Suggest they have it towed to a collision repair shop for assessment to keep control in their hands. Heck, just getting their personal effects and removing customizations is a lot easier.

4. Review the benefits of both possibilities, preventing a total vs. allowing it to total.

The benefits to consumers for preventing a total:

1. If the vehicle is well maintained, why would they want to lose control of this vehicle they like?

2. No shopping for a new car

3. No transfer for insurance or license

4. No loss of the accessories they added without adding them to their coverage.

5. The cost of a new vehicle means higher license and insurance costs.

6. No need for a down payment on a new car and possibly a higher payment

Final option: repairables

I hate to go here, but shops could start to buy back total loss vehicles, repair them properly, get them inspected, and sell them. If the vehicle was totaled without a lot of damage, then the shop would make money on the repairs. The repairer’s vehicle sales division could also make a margin on the sale of the vehicle as an additional way to make money.

Conclusion

The trends in industry toward more ADAS equipment have led to a reduced number of vehicles in reported claims. On top of that, we have noted the increase in total losses reducing the number of available repair jobs. With repairers seeing a decline in volume of 8-18%, some repairers may need additional volume to keep their staff and cash flow possible. Therefore, shops may want to consider some of the ideas we shared to try to prevent these total losses from being towed away. After they review the financial benefits to the shop, insurer, and consumer for preventing totals, they may consider these strategies. Ultimately, it’s up to you — the business owner — to decide if you are willing to discount (a bit of a slippery slope) to prevent totals and keep larger heavy hits coming to your repair center to achieve the sales targets to make a profit in the tough months we may face.

CONSIDERING THAT NEW BOOTH BOOST

What can you can do to keep your booth running at its best, and how do you know when it’s time for an upgrade?

By TODD KORTEMEIER

JEREMY WINTERS REMEMBERS the photo — his first appearance in FenderBender, more than nine years ago, back in his days as a painter.

“Pull it up,” says Winters, now a content creator for Accudraft. “You’ll see a picture of me standing in front of a car, pulling the trigger. It’s a cool backlit shot. But look at the ceiling filters behind me. The ceiling filters are dark brown, and those things were way overdue.”

Within six months working in that exact same booth, Winters recalls, he felt the concrete vibrate. It turned out that years of overspray had collected on a fan blade, throwing it out of balance and eventually breaking it. The brown filters could’ve been a clue that an inspection was needed, but instead what followed was new fans, a whole new support structure, and a costly repair.

“It was just one of those things of, ‘Yeah, well, it’s not having any problems right now,’ but that’s something that could be checked and seen just during a regular inspection of the booth.”

A pound of prevention

If you’ve found yourself wondering if it’s time to upgrade your spray booth, then consider yourself lucky. That means you haven’t been forced into it due to some catastrophic failure. Lack of inspections and proper maintenance can doom a spray booth which should last easily 20 years — Winters shares there are Accudraft booth that were installed in the ‘80s but are still going strong.

Business needs sometimes dictate upgrading to a new booth, but if it’s just increased performance and efficiency you’re after, first make sure that you’re optimizing the lifespan of your current booth. Winters preaches the importance of changing filters and keeping a log of when they were changed and at what hour reading for the booth, something that you can monitor through Accudraft Live on Accudraft machines for real-time performance diagnostics.

According to Global Finishing Solutions (GFS), filters should be changed every 100 operating hours, or roughly every three to four weeks. But with so much variance in paint operations, some need changing more quickly. And not all filters are created equal either. High-grade filters will be more efficient and require less frequent changes.

“While you may be saving money now, the cheaper quality of the materials will load with paint more quickly,” says David Smith,

service and preventative maintenance manager for GFS. “This will cause more frequent filter change-outs. Low-cost alternatives also have a lower capture efficiency. That can lead to an even higher expense of replacing other parts, such as fans, motors and ductwork.”

Other maintenance tips from GFS include using protective booth coatings and floor protection to help reduce overspray. Protecting light fixtures, too, can help ensure that vision remains constant. GFS’ Booth Shield product is peelable so that cleanup is easy.

Finally, GFS recommends establishing a regular maintenance schedule, ideally at the interval recommended by your booth’s manufacturer. The action items on this schedule should include both inspection and cleaning procedures, fixing what needs fixing but inspecting every point of wear. Depending on your booth’s usage, some of these items may need daily inspections.

“In addition to protecting your employees and facility, routine cleaning and maintenance of your paint booth will ensure it lasts for many years to come,” Smith says. “A small investment in time now can result in long-term savings of costly repairs or even booth replacement.”

Winters notes that oftentimes business can get in the way of doing maintenance or performing inspections. As in the example with the out-of-balance fan, if something isn’t causing a problem right then, it can be easy to assume that everything is in order. “Kristen Felder has a great saying of, ‘We never have time to do it right the first time, but we always seem to have time to do it right the second time,’” Winters says.

That’s why he recommends scheduling your booth downtime. What causes disruptions in a shop are sudden things. Downtime is downtime, but if everyone knows it’s coming, it makes it that much easier to plan for.

Time for something new

So, you’re keeping up on your maintenance, doing regular inspections, but all good things must come to an end. When do you know enough is enough and it’s time for an upgrade?

Winters says that recurring electrical failures, to the point where the booth is shutting down and needs a repair visit every time, are a sign that the air makeup unit