LUXURY VINYL TILE

Competitive Price Point

Designed to meet a range of project requirements.

Warranty-Backed Performance

Covered by our 15 Year Commercial Limited Warranty, when used in the proper fit for use environment for normal indoor commercial applications.

Superior Durability

ExoGuard+® advanced topical finish technology delivers the highest performance scratch resistance and resists UV light degradation, hand sanitisers, disinfectants and common stains.

Direct Glue or Loose Lay

Our 2.5 mm platform offers direct glue installation, while 5.0 mm has a dual purpose backing construction allowing for direct glue or loose-lay installation for more flexibility to support the needs of the space.

Adhesive Free Installation

5.0 mm can be installed adhesive free using Mag Tabs/Tab IT and 2.5 mm using Uzin Sigan Double-Sided Tapes.

No Transition Needed

5.0 mm LVT can be installed next to most carpet tiles without the need for transition strips.

Indoor Air Quality

This product is Indoor Air Comfort Gold certified for low-emitting products and demonstrates our focus on quality and contribution to a healthy indoor environment.

Low VOC Certified

Certified to rigorous indoor emissions requirements.

Improved Acoustics

Improve sound transmission and sound impact to 20bB when used with suitable acoustic underlay

Slip Resistance

With an R10 rating, the product provides moderate slip resistance.

Non-Ortho-Phthalate

Formulated without ortho-phthalates.

Fire Rating

Classified as fire retardant, achieving a fire rating of Bfl-S1.

PVC-FREE RESILIENT

Features + Benefits

PVC 100% Recyclable

At the end of its useful life, we will reclaim and recycle EcoWorx™ Resilient styles to make more EcoWorx® products.

No PVC

Utilises minimum of 25% recycled content, is optimised for low embodied carbon and is carbon neutral.

Superior Durability

ExoGuard+® advanced topical finish technology delivers the highest performance scratch resistance and resists UV light degradation, hand sanitisers, disinfectants and common stains.

Fire Rating

Classified as fire retardant, achieving a fire rating of Bfl-S1.

Slip Resistance

With an R10 rating, the product provides moderate slip resistance.

Acoustics

Achieves an impact sound reduction of 9bB. By using a suitable acoustic underlay, this increases to a sound insulation of 20dB

Adhesive

Free Installation

Can be installed adhesive free using Uzin Sigan Double-Sided Tapes.

Indoor Air Quality

This product is Indoor Air Comfort Gold certified for low-emitting products and demonstrates our focus on quality and contribution to a healthy indoor environment.

Ease of Installation

Back bevel allows for ease of installation ensuring that planks seamlessly connect reducing the time required for installation.

Warranty-Backed Performance

Covered by our 15 year Commercial Limited Warranty, in conjunction with approved adhesives.

Light & Easy to Handle

EcoWorx™ Resilient is 25% lighter than PVC flooring. Easier to transport to site, easier to handle on site, and quicker to install.

Terms & Information to Know

ExoGuard® Finish

High resistance to scratching is one of the key performance criteria needed to keep a resilient flooring investment looking good over the long term. A top coat is the first line of defense to protect flooring investment against scratching, staining and scuffing. Its primary function is to provide added durability and longevity to the wear layer while increasing cleanability, lightfastness and overall performance. Our ExoGuard® system of top coat finishes, ExoGuard® and ExoGuard+® both offer exceptional durability and protection against stains and abrasions in commercial environments.

Wear Layer

Wear Layer is a PVC film that goes over the print film layer during lamination, measured in mm and mils. There are two different units of measurement, mm is used to communicate overall product thickness and mil to communicate wear layer thickness:

0.3 mm 12 mil wear layer residential / multifamily housing / senior living / light commercial

0.5

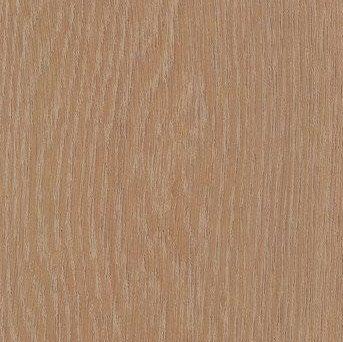

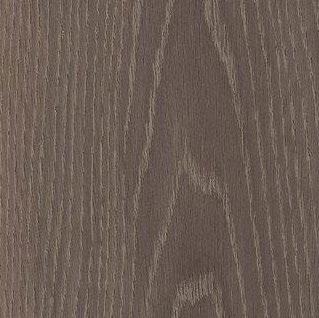

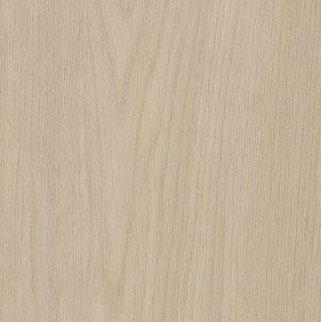

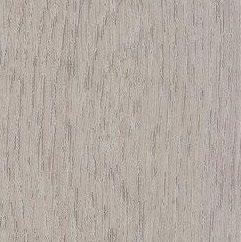

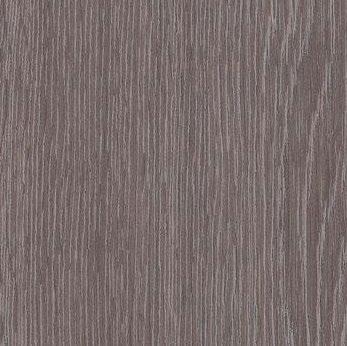

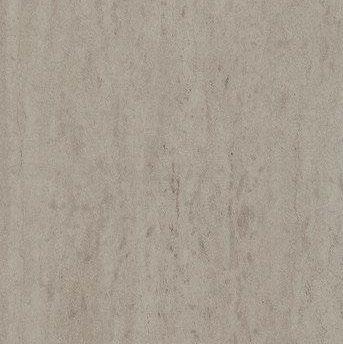

High-Resolution Image

Using the latest print film technology to replicate the natural aesthetics of materials such as wood and stone, featuring realistic variations in colour and visual texture.

Embossing

High-resolution imagery is paired with a subtle embossed surface texture that physically aligns with the visual design it replicates. This process enables users to both see and feel the authentic texture of wood and natural stone, making the surface difficult to distinguish from the real material.

Pattern Repeat

Designs that are heavily populated are shuffled to divide pattern repeat lengths. As a result, the visual pattern shifts from tile to tile, creating a broad range of variations that give each installation a distinct unique appearance rather than a uniform repetitive look.

Slip Resistance

Slip resistance refers to a surface’s ability to prevent slipping by providing sufficient friction between footwear (or bare feet) and the floor. It helps determine how safe a surface is under different conditions such as dry, wet, oily, or contaminated environments.

Shaw Contract resilient floor finishes are designed with a moderate texture to help provide a reliable and acceptable level of slip resistance in both wet and dry conditions. The performance of any resilient floor finish is optimum when they are complemented by good on site housekeeping practices.

Slip Rating

A slip rating is a standardised measure of how slippery a surface is. It indicates the level of traction or grip a floor provides under various conditions—such as dry or wet.

The Pendulum Test is a dynamic test that simulates the heel strike of a person walking, especially on a wet surface. A swinging pendulum arm with a rubber slider makes contact with the floor. The friction it encounters slows the pendulum, and this loss of energy is converted into a Pendulum Test Value (PTV).

What the values mean:

· PTV < 25 → High slip risk

· 25–35 → Moderate slip risk

·

≥ 36 → Low slip risk (commonly accepted minimum for wet areas)

Shod ratings come from the DIN 51130 ramp test. They are intended for people walking with shoes—hence “shod”. A person wearing standardised footwear walks back and forth on a grease-coated ramp. The ramp is gradually tilted until the person begins to slip. The angle at which slipping occurs determines the R-rating.

R-Rating Slip Resistance Typical Use

R9 Lowest slip resistance Dry indoor areas

R10 Moderate slip resistance Lightly wet areas (kitchens, entryways)

R11 High slip resistance Wet commercial spaces

R12 Very high slip resistance Industrial wet/oily areas

R13 Maximum slip resistance Very wet environments (showers, pool decks, heavy industry)

Fire Classification

Fire classification for flooring refers to the system used to classify how a flooring material reacts to fire, including how easily it ignites, how it contributes to flame spread, how much heat it releases, and how much smoke or flaming droplets it produces. This classification helps ensure the material meets safety regulations and is suitable for its intended environment.

Shaw Contract resilient flooring has been independently awarded ‘Bfl-S1’ certification as per the ‘BS EN 13501: 2007+A1: 2009’.

‘Bfl’ rated flooring products have a very limited contribution to fire and that while they will ignite when exposed to enough heat, products that are characterised under this category are designed to resist ignition, and if set alight their composition is intended to resist further burning.

Acoustics

Acoustic performance for flooring refers to how well a flooring system absorbs, reduces, or blocks sound, both within the same room and between adjacent spaces. It describes a floor’s ability to control:

1. Airborne sound (voices, music, HVAC noise) and

2. Structure-borne or impact sound (footsteps, dropped objects, rolling carts).

Flooring materials and their underlying assemblies influence the transmission, absorption, and insulation of sound energy throughout a building.

Understanding the acoustic performance of a floor finish is essential to support occupant wellbeing, ensure compliance with building regulations, and improve the overall functionality and privacy of a commercial indoor setting.

Material Health – VOC’s

Low emission floor finishes help create healthier indoor environments, especially for vulnerable groups like children, senior citizens, and those with allergies or asthma.

Shaw Contract LVT floor finishes are ISO 16000 - Indoor Air Quality compliant and our EcoWorx Resilient Products have been awarded ‘A+ Emission’ certification. All products have been awarded Eurofins Air Comfort Gold.

Direct Glue

An installation method in which the flooring product is glued directly to the floor, subfloor or underlayment.

Loose Lay

Loose lay resilient flooring installation is a method where resilient floor planks or tiles are installed without adhesives, nails, or mechanical locking systems. Instead, the flooring rests directly on the subfloor, staying in place through a combination of:

· Weight and mass of the planks/tiles

· A high-friction or rubberised backing that grips the subfloor

· Tight edge-to-edge fit

This method classifies it as a floating installation, but unlike click-lock, loose lay relies on friction and stability, not interlocking mechanisms. The flooring can be easily lifted, removed, or replaced.