HOW A PARTS STORE SUPPORTS AUTO REPAIR SHOPS

KEEP YOUNG TECHS ENGAGED

HOW A PARTS STORE SUPPORTS AUTO REPAIR SHOPS

KEEP YOUNG TECHS ENGAGED

MARCONI: FOLLOW CUSTOMERS, NOT TRENDS

It’s the unfiltered truth. Motorcraft ® parts are premium replacement parts – designed, engineered and recommended for Ford and Lincoln vehicles. They’re tested to provide performance and long-life reliability. And they’re 20,000 active parts strong, with a deep inventory that includes filters, fluids, brakes, batteries, spark plugs and much more. Let your customers breathe easy. See your Ford Certified Parts Wholesale dealer for more details.

12 SPEED READ

Right to Repair heats up as industry groups debate the latest development

15 NUMBERS

Who’s opening shops in 2023?

17 ADAPT

Does 3D printing have a place in the automotive aftermarket?

18 SHOP VIEW

Rick’s Automotive Inc Springfield, Missouri

21 STRAIGHT TALK

It’s OK to follow trends, but know your customers first. JOE MARCONI

35 LEADERSHIP

Are your top techs and advisors feeling heard?

40 CASE STUDY

A New Jersey shop owner on how learning KPI changed his shop

EDITORIAL

CONTENT DIRECTOR

Matt Hudson

EDITOR

Chris Jones

ASSISTANT EDITOR

Kacey Frederick

CONTRIBUTING WRITERS

Joe Marconi, Aaron Stokes, Tess Owings, Nolan O’Hara

EDITORIAL ADVISORY BOARD

John Miller, Fifth Gear Automotive; Doug Grills, AutoStream Car Care Center; Jimmy Alauria, 3A Automotive Service; Andrew Marcotte, American Pride Automotive; Bruce Howes, Atlantic Motorcar Center; Rob Choisser, Choisser Import Auto Services; Lucas Underwood, L&N Performance Auto Repair; Ryan Hillebrand, Urb’s Garage

SALES

ASSOCIATE PUBLISHER

Andrew Johnson / ajohnson@endeavorb2b.com

ASSOCIATE SALES DIRECTOR

Mattie Gorman / mgorman@endeavorb2b.com

DIRECTOR OF BUSINESS DEVELOPMENT

Cortni Jones / cjones@endeavorb2b.com

ACCOUNT EXECUTIVES

(NATIONAL ACCOUNTS)

Diane Braden / dbraden@endeavorb2b.com

Marianne Dyal / mdyal@endeavorb2b.com

Chad Hjellming / chjellming@endeavorb2b.com

Bob Marinez / rmarinez@endeavorb2b.com

Lisa Mend / lmend@endeavorb2b.com

Michael Parra / mparra@endeavorb2b.com

Martha Severson / mseverson@endeavorb2b.com

Kyle Shaw / kshaw@endeavorb2b.com

Sean Thornton / sthornton@endeavorb2b.com

ADMINISTRATIVE ASSISTANT

Ryan McCanna

ART AND PRODUCTION

ART DIRECTOR

Emme Osmonson

PRODUCTION MANAGER

Mariah Straub

AD SERVICES MANAGER

Jen George

ENDEAVOR BUSINESS MEDIA, LLC

CEO Chris Ferrell PRESIDENT

June Griffin

CFO Mark Zadell

COO Patrick Rains

CRO

Reggie Lawrence

CHIEF DIGITAL OFFICER

Jacquie Niemiec

CHIEF ADMINISTRATIVE AND LEGAL OFFICER

Tracy Kane

EVP ENDEAVOR BUSINESS INTELLIGENCE

Paul Mattioli

EVP TRANSPORTATION

Kylie Hirko

VICE PRESIDENT - VEHICLE REPAIR GROUP

Chris Messer

HOW TO REACH US

ENDEAVOR BUSINESS MEDIA

571 Snelling Avenue North, St. Paul, MN 55104 tel 651.224.6207 fax 651.224.6212 web endeavorbusinessmedia.com

LETTERS TO THE EDITOR editor@ratchetandwrench.com

Opinions expressed in Ratchet+Wrench are not necessarily those of Endeavor Business Media, and Endeavor Business Media does not accept responsibility for advertising content.

I’ve had a love affair with HGTV for some time. The first show I ever watched was “Design on a Dime” in the late ‘90s. I was obsessed with how they could redesign interiors on a low budget. In time, I progressed through the programming going from “Love It or List It” and “Property Brothers” to “Rehab Addict”, “Flip or Flop” and “Home in a Heartbeat.” I also subscribe to HGTV Magazine.

That love of interior design started young when I was 11 or 12 years old. I’d rearrange various rooms within my grandparent’s home a few times a year alongside my aunts. We’d move furniture, change the photos and fixtures on the walls and hang new drapes. There was even a point in my life when I strongly considered majoring in interior design. There’s something about a well-designed and decorated space that’s calming or energizing. And I’m not alone in feeling that way.

In this issue, we have three aesthetically-pleasing shops that are designed to create an atmosphere of calm and comfort for their customers. In our feature story, “Impressive Interiors” (p. 30), you’ll read about Jared McPike of InMotion Auto Care in Lincoln, Nebraska, and Jeana Babcock of Babcock Auto Care in Rochester, Minnesota. These two shop owners (along with their co-owners) went above and beyond to create gorgeous waiting areas in their shops designed to show their customers that a trip to the auto repair shop can be as relaxing and upscale as any hotel lobby or lounge area.

The Shop View this month, Rick’s Automotive in Springfield, Missouri (p. 24), is a sleek and modern-looking shop (it even has a gym!). Guests are also treated to valet parking-like front-door service. I hope the shops you read about and see in this issue inspire you to think about how you’re using your space. Today’s customers want to visit a shop that looks as high-end as the quality of work you provide. It’s a worthy investment.

CHRIS JONES, EDITOR CHRISTOPHERJ@ENDEAVORB2B.COM

BY CHRIS JONES

BY CHRIS JONES

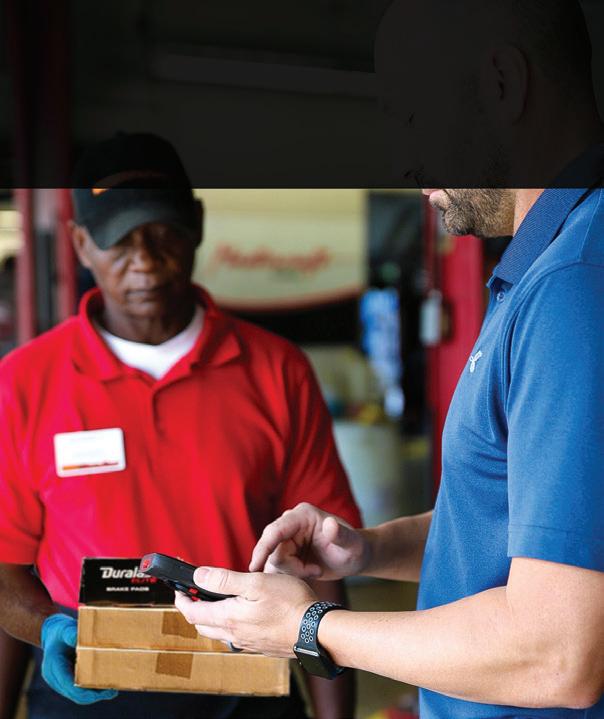

The sun isn’t up long before Trey Magee cracks open the doors at his Carquest Auto Parts store in Toano, Virginia. His family has been in the auto parts business for 42 years—since 1981— when Magee’s grandfather purchased his first Carquest location. His father would eventually join the business a decade later and today, Magee has created tremendous success for himself and his team within this same business—one he never intended to join.

Before taking over the store, Magee worked in law enforcement in Washington, D.C. A chat one day with his father caused him to reconsider the direction of his career. His father explained that Advance Auto Parts was opening the door for them

to acquire more stores, and he was in a unique position to step into the business and scale it up as large as he wanted.

“(My dad) said, I can’t do it. I have no desire to do it. I don’t want to do it. So, if you’re happy being a cop, you stay up there and be a cop and do your thing. No harm, no foul, but if you have any interest at all, come down and listen to (them) and hear them out,” Magee says.

According to Magee, that day, Advance sold him on the dream. He left law enforcement behind to build the family auto parts store. Today, the family has three stores in Virginia—Wakefield, Waverly and Toano—and Magee hopes to have a dozen or so more in the future.

“I hope we have 10, maybe more.

I don’t know, but I don’t want to stop. These opportunities weren’t there for my grandpa and my dad,” Magee says.

Parts shortages have been a recurring storyline in the automotive aftermarket over the past three years. This shortage has left some auto repair shops in a lurch when it comes to rapidly sourcing auto parts. It’s a situation Magee is aware of, and one he works hard to help solve for his customers. As the shop gets calls for parts, he’s able to supply them from his store, but when he cannot, he’s able to tap into a large network of parts distribution centers in and around his immediate area.

“There are just tons of options for getting parts, so it’s utilizing the networks that we have. We have a lot of networks and Advance and Carquest have millions of dollars’ worth of inventory that aren’t in any one particular location of ours to sell but within a couple of hours. We can get it,” Magee says.

He says as a parts store owner, he’s responsible for taking the initiative to know and understand the needs of each of his customers, what they frequently order and the availability of each part. With this information, he and his team can forecast what inventory he needs to have on hand for each customer.

“There are trends of what they buy and the things they use,” Magee says. “We sit down, and we have discussions and forecast, ‘This is what I’ve been using over this amount of time. Well, it’s not available today. Alright, guys, we need to keep our eye on this inventory when it comes available.’ I will have all those things in the store when (they) need them next. Our philosophy is if you’re willing to buy it, I’m willing to keep it. I’m willing to stock it—doesn’t matter what it is.”

Magee says good communication is the catalyst for building trust between

the parts store and independent repair shops. The shops need to know they can depend on the parts store to come through, in the clutch when necessary, and the parts store wants to be the trusted partner the repair shop can count on.

Victory Automotive, one of the newer shops in Magee’s service area, is one such customer. As a new shop, they need to develop trust with their customers immediately. Having an auto parts store that’s reliable makes that possible. Aaron Chadwick, the shop’s owner, has sourced parts from Magee since his shop opened two years ago.

“I’ve known them for a while because I worked at a local (shop) before. As soon as I opened up my own business … I stuck with them. The drivers are great. You can’t ask for better people,” Chadwick says.

Chadwick says his shop’s efficiency also depends on the availability and speed of sourcing parts.

“When it comes to parts, that’s half the battle. If you can’t get car parts quickly, you’re wasting money, you’re wasting time—cars are on a lift and (you’re waiting on) a part. Then lifts are not being used to make more money,” Chadwick says.

Magee adds that one way he supports shops like Victory Automotive is having his driver stock oil and filters on shelves regularly to make them readily available for the technicians, so the parts are an arm’s length away rather than a phone call away.

Hunter McClendon, a technician at Victory Automotive says the relationship they have with Carquest is an important one.

“We got to have parts to fix vehicles. So, it’s a team effort. If we don’t have good quality parts, good parts quickly, we can’t serve our customers. So, when you call, you’re talking to somebody there,” McClendon says. “We have a good relationship.”

At the end of the day, Magee feels like he’s in the right career. He’s learned over time how to allow the people on his team to take leadership within their positions. That translates into customer service people developing relationships with regular do-it-yourself customers from the counter and parts drivers making meaningful connections with auto repair shops—a must for mutual success. A little bit of wisdom from his father was the catalyst for that change. If Magee was going to build something bigger than his predecessors, he needed to do what they didn’t.

“He said, ‘Son, you’ll never be the man if you are the man. I’ve spent all my life in the store at Wakefield. If that phone rang, they wanted to speak to me.’ He said, ‘If you create an environment where when the phone rings, you’re the only person that they want to speak to how are you ever truly going to grow this into something special?’”

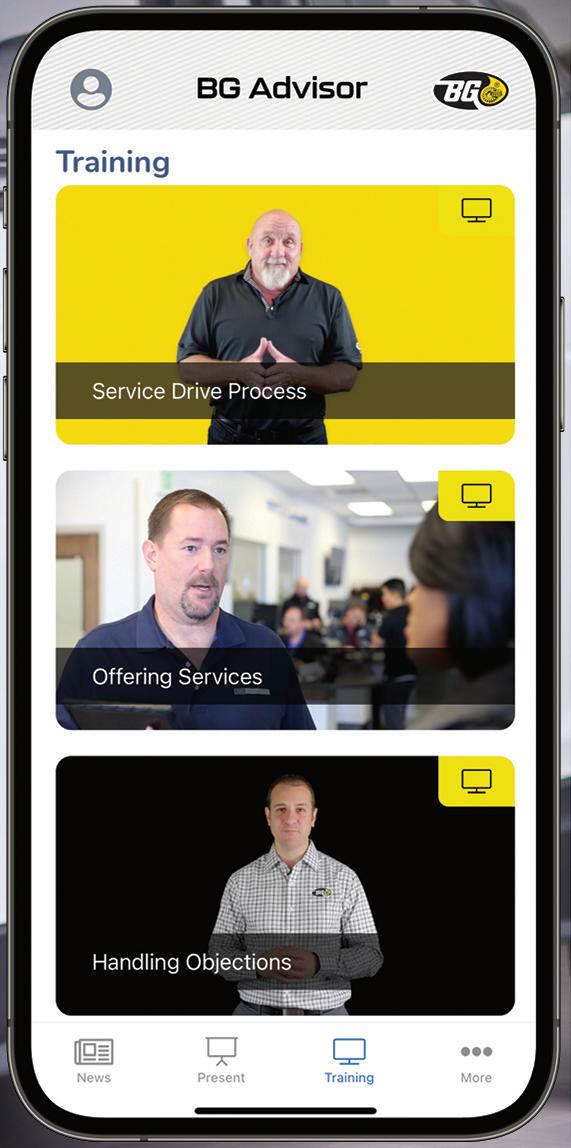

Two keynote speeches for the 2023 Ratchet+Wrench Management Conference will bring expert advice and tons of experience to bookend three days of immersive professional development.

The opening keynote will be given by Brian Moak of Illinois-based Heart Certified Auto Care. Moak is an entrepreneur and family man, as well as the owner of Heart, one of Chicagoland’s top-producing independently owned auto repair facilities. The business has been serving Illinois’ Northshore community for over 40 years. Moak grew up in the business, officially joining the company in 2004 and began running operations in 2009. Through his dedication to leading with authenticity, he has successfully enabled not only his auto repair business but several of his other business ventures to achieve recordbreaking productivity.

Aaron Stokes will deliver the clos -

ing keynote. He has been in the automotive industry since 1999 and owns nine shops (and growing) in the Middle Tennessee Area. He is well known as the founder of Shop Fix Academy, one of the largest coaching organizations in the country that coaches operations reaching $1.2 billion in cumulative auto repair. Stokes’ depth of knowledge can also be found through his monthly column in Ratchet+Wrench magazine, and his high-energy presentations always leave viewers with actionable advice.

The Ratchet+Wrench Management Conference is September 20-23 in Aurora, Colorado, with more than 30 educational sessions. Registration and more information can be found at rwconference.com.

The recent right-to-repair agreement

between three industry organizations made up of automakers and repair shops has drawn criticism from the industry, Jalopnik reports.

A recent letter created by the Automotive Service Association, the Society of Collision Repair Specialists and the Alliance for Automotive Innovation is an agreement on guidelines for right-torepair legislation. However, many have criticized the letter for not doing enough.

As covered by Wired, though the letter promises independent shops access to the data and tools needed to diagnose and repair vehicles, it does not outline how this will be enforced. Additionally, many are still concerned with car owners’ rights to perform work on their vehicles.

The concern particularly lies with smaller, independent businesses, or those who work on vehicles at home, not having access to information from cameras and sensors. This includes data on location, speed, acceleration and the performance status of the vehicle’s software.

I’m replying right now to my 9 most recent reviews, and I’d say it’s excellent at personalizing each one without me having to agonize over it. Super cool!

- Jennifer Ringham, Precision Imports (Milaca, MN)

y 9 most recent e cellent at ut me ha in to r cool! (Milaca, MN)

a onize ove

- Jennifer Precisio

I would like to say how nice the AI feature is.

- Rob, Morrison's Auto-Rite (Boston, MA)

We’ve trained and leveraged new AI tools to create a simple process for you to allow AI to respond to your business reviews for you. It’s simple, straightforward, and puts you on a path to domination for your digital marketing.

Nothing brings the automotive aftermarket community together like AAPEX. It’s the only event where hands-on training meets expert-led business education. Where professionals and industry leaders from around the world gather to make connections, catch the latest demos, and find the perfect products. And it’s where you belong. Secure your spot today.

The 2023 Ratchet+Wrench Industry Survey Report showed a 5% increase in auto repair technicians who have become shop owners since 2022, but the second largest segment came from an unlikely group—porters (up 4%).

No matter how big or small the job, we’ve got you. From starters to struts, and everything in between, our parts are made with quality materials, engineering and testing that we can both proudly stand behind. So the next time you reach for quality, let us hand it to you.

As the repair industry faces supply chain constraints, many are looking for solutions to help overcome these obstacles, such as IBIS Global’s 3D Printing in Auto Repair Task Force.

The task force is dedicated to researching the application of 3D printing in the repair space and how it can be used in the production and repair of parts. Task force lead Harold Sears sat down with Ratchet+Wrench to talk about what he and his team have unearthed about this innovative technology and the ways it can be used to empower the repair industry.

Sears has worked with 3D printing for nearly 30 years, starting during his time at Ford Motor Company while helping them oversee the expansion of 3D printing technology in the company.

Sears was a CAD (computer-aideddesign) application programmer in the early 90’s when his boss volunteered to take over the operations of a rapid prototyping machine installed in their building. The machine created 3D-printed parts for prototypes, adding material one layer at a time, and was put there by the company’s product development group, who had no intention of running it after they finished experimenting with the machine.

The CAD models used as input for

the processes of the machine were hard to come by at the time. With Sears’ intimate knowledge of CAD databases, his boss implemented his help to create solid models as input to the system, marking the beginning of Sears’ involvement with 3D printing technology.

“Little did I know that 30 years ago, the decision that I made was going to impact the rest of my life,” recalls Sears.

Between then and now, Sears has seen great developments in 3D printing technology. While it has initially been used for prototyping under the name “rapid prototyping,” it has evolved into what is called additive manufacturing, which has utilized the capabilities of 3D printing to assist in optimizing design and reducing the weight of the parts and total part count.

Though companies such as Whirlpool and John Deere have implemented 3D printing in the repair of their products, the automotive industry has not been as willing to adopt the new tech. 3D printing materials are not always compatible with vehicles, with many of the processes for 3D printing utilizing UV-sensitive materials.

While UV-sensitive materials pose a risk, there are still opportunities for parts that are located in places blocked from the sun, such as under a vehicle’s hood. Part of what Sears’ task force is doing is working with manufacturers to find out what parts of a vehicle could be 3D printed.

“Another goal of our task force in working with the automotive OEMs is (that) they’re working hard at certifying these materials (and) they’re working hard at pushing the material suppliers to get these materials that they can

certify and use in their applications,” Sears explains.

As many OEMs become more interested in the use of 3D printing in production and work to make it happen, many opportunities are presented for those in the aftermarket industry to save time and money in obtaining and repairing parts.

Instead of tossing a part that has minor damage, with 3D printing, shops could have the option to recreate small pieces of a part to help make it whole again. Not only will this save money, but it also has a positive environmental effect.

“You may have a part that’s perfectly good, and just a little piece is broken off of it that’s not even visible to the customer, and it’s totally repairable,” Sears says. “Why take that off and throw it in the garbage and have it end up in the landfill if you can 3D print that little piece and mend it back together and have the part be safe and functional for the customer?”

3D printing could help with what Sears calls “captive inventories.” Oftentimes, shops are forced to order a minimum number of parts, even if it’s far more than what they need. This not only requires more money being spent but dedicated inventory space for all these extra parts.

Though the technology is still a long way from reaching that point, Sears and his task force are helping both OEMs and providers of 3D printing materials to move towards this change.

“Things are starting to line up in that direction, where it may be possible in the future,” Sears says. “On-demand digital parts anywhere in the world, you know, with reduced turnaround times, and then, you know, less environmental impact from the technologies.”

RICK’S AUTOMOTIVE INC.

Owner: Rick and Karen Hughlett

Location: Springfield, Missouri

Staff Size: 44

Shop Size: 28,000 square feet

Number of Bays: 28

Average Monthly Car Count: 1,400

Annual Revenue: $9.5 million

Rick Hughlett became a shop owner in the most peculiar way in 1980.

“Before he owned it, he was working for a guy; I think it was Lee’s Automotive. The guy took off one day and went to Vegas and was like, ‘Hey, just send my checks to this address,’” says Travis Comfort, vice president or Rick’s Automotive.

Rick took the shop over and turned a two-employee run shop in a 2,800 square foot space into a 28,000-square-foot enterprise comprised of three buildings that services general auto repair and fleet repair, and services two local hospitals.

Rick’s Automotive is custom-built from the ground up with high visibility in mind. It pairs a clean stainless-steel exterior accented with red neon lights that rests on a well-manicured landscape.

“The visibility is beautiful. We have a nice huge display room that faces the street. We have big banners we put in there and we swap them out with different holidays, events, stuff like that,” Comfort says.

The service entrance is covered, similar to that of dealerships, to enable customers to be valet parked. One of four porters then parks the customers’ vehicles and provides any necessary transportation.

“We just tell customers to pull up under the awning, park the car there, come inside the lobby and we’ll take it from there. We don’t want our customers you know searching for a parking spot and or then trying to walk you know, a good distance just to get in,” Comfort says.

Rick’s Automotive has 22 technicians, including tire and lube techs. With the exception of those techs, all of the technicians are ASE certified with most of them at master level. An ASE Blue Seal shop, Rick’s also actively trains apprentices under these veteran technicians to keep the talent pool filled.

“We have a few apprentices working under season techs that have taken a couple of courses. We do require all our technicians to be certified, so if they want to move up, they’ve got to get their ASE certs,” Comfort says.

100% of All Wearable Parts Replaced Special Cleaning and Remanning Process

Remanned 100% In-House

Fully Remanufactured for Proper Fluid Distribution, Pressure and Leak Prevention Every Single Part is Cleaned, Remanned or Replaced

Low High

Knowing your business and your customers safeguard your shop against trends that may not benefit you

BY JOE MARCONIThe year was 1973 and, like many from my era, I started my career working as a technician in a gas station. The typical gas station had two to three bays, and at least two to four gas pumps. Part of my job description was to pump gas if needed. Self-serve was not yet the norm. By the way, we were open seven days a week, with half days on Christmas, New Year’s Day, Easter and Thanksgiving.

The automotive repair industry has changed dramatically over the past few decades. There aren’t many gas station/ repair shop business models these days. Today, there are franchises, tire stores, off-road shops, specialty shops and other niche businesses. In many markets, the independent general auto repair shop model dominates the typical modern-day model. No matter what business type, it seems shop owners crave benchmarks and guidelines. While there is merit to this, there’s no one size that fits all business model. And there shouldn’t be.

The reason why I bring this up is that there are a lot of discussions these days about certain standards that auto repair shops should aspire to. Perhaps the most popular is setting a standard for the right KPIs and profit margins. Also, many industry people are promoting the five-day workweek as the standard, with some saying that a four-day work has benefits that outweigh the five- or six-day work model. Additionally, it’s common to hear that technician production and efficiency standards need to fit into a certain range to determine the overall success of the company.

We all understand the value of benchmarking as a way of analyzing what we are doing compared to other similar businesses. However, auto repair shops are like fingerprints; no two are alike. And from my experience as a former repair shop owner and now a business coach, trying to fit your repair shop into a neatly formed benchmark-based model may be more detrimental than beneficial.

If we look at KPIs and margins, for example, it’s typical for a general repair shop to strive for 70% or better on labor profit and a 50% part margin. But everyone reading this understands that percentages and dollars are not the same. Some shops do not fall into the typical percentage range, but their business model produces remarkable results to their bottom line in terms of “profit dollars.”

Let’s talk about the four and five-day workweek. As I mentioned earlier, back in the ‘70s, the gas station I worked at was open seven days a week, with half days on holidays. When I started my own business in 1980, I was not about to be open seven days a week, and holidays were out of the question altogether. But being open six days a week was something I felt I needed to do. I had to be there for my customers. Through the years we tried to close on Saturdays, but it just didn’t work for us. This is not to say you must be open six days a week or even five days a week, which is the point I’m making. Some point to employee morale and increased production by not working a five- or six-day workweek. This may be true and probably is for many shops. But

can anyone say that this is true for every repair shop, in every area of the country?

Know Your Shop

Here’s the bottom line. While there is a benefit to having standards and benchmarks, every repair shop is different. Learn what others are doing but understand your business model and the KPIs that drive dollars to your bottom line. Then decide for yourself what makes the most sense for your business, not someone else’s.

Joe Marconi has more than four decades of experience in the automotive repair industry. He is the former owner of Osceola Garage in Baldwin Place, N.Y., a business development coach for Elite Worldwide, and co-founder of autoshopowner.com. Reach him at j.marconi@eliteworldwide.com.

Two shops that go the extra mile to creating stunning atmospheres for customers

BY CHRIS JONES | PHOTOS BY DON SHEPARD & KEN KLOTZBACH

BY CHRIS JONES | PHOTOS BY DON SHEPARD & KEN KLOTZBACH

When Jeremy and Jeana Babcock began leasing the Rochester, Minnesota, shop that bears their name in April 2011, they knew they had a full-blown renovation on their hands. The space they moved into, a former Firestone, had been vacant since 2009 and needed more than just a fresh coat of paint.

“It was a mess. It was dirty, dingy, had a bad layout and was was white, red and yellow when we started our reno,” says Jeana Babcock

Their vision was to make Babcock Auto Care feel as comfortable as a modern, upscale home, and a $120,000 investment from their landlord made their goal possible.

Using the capital, Jeremy and Jeana anchored the lobby with a lounge area

complete with a gas fireplace. They added a full coffee bar, installed a children’s play area and set up café style seating with high-top tables for people who want to work while they wait on their vehicles to be repaired. Mood lighting, earth tones, live green plant and an open floor plan add to the ambiance of the shop’s lobby.

“I just wanted people to feel comfortable,” Babcock says. “I wanted to give it a homey feel.”

From the outside in, the Babcocks aimed to portray the shop as classy and professional from its logo to its lobby. Here’s how they achieved it.

Jeana knew she wanted a logo that would be strong, visible and unmistakable. En-

listing the help of Jeremy’s uncle Hal, a Texas-based graphic designer, the couple went through a few iterations of its logo with and without graphics. It finally came together when Jeana sketched her rendition of the logo on a note card and added a visual element from Hal’s design.

“I just said, ‘I want something simple. I want our name and so I literally drew it out on a note card. He had sent us this cool gray ‘B’. So, I said I want you to put that gray ‘B’ in the background. He mocked it up, and it was perfect—then we just backlit it,” Babcock says.

The sun shines approximately 180 days out of the year in Rochester, Minnesota— the national average is 205, in case you’re

wondering—and nearly one-third of the year it sees some form of precipitation.

Understanding Minnesotans need to get the most out of these sunny days, Jeremy and Jeana positioned the café seating near the windows and kept the glass largely unobstructed to allow the maximum amount of natural light to wash the space.

“Natural lighting lifts everyone’s mood … it makes you feel good,” Babcock says. “We have a lot of clouds up here, so even if you get a little bit more light through the window’s when it’s sunny, I think that’s great.”

When purchasing the lighting and furniture, they were patient and creative, shopping around for what fit their vision.

Knowing they wanted high-top tables, Jeana went to a store that specialized in commercial-quality game room furnishings. For the large coffee table in the lounge, she shopped at a furniture store for a dining room coffee table and had Jeremy cut the legs down. As for the couches, nothing but leather would do, and she sourced another store for it.

“I looked around to see who had what I needed,” Babcock says, “I kind of sourced it from all over once I had my vision.”

For Jeremy and Jeana, the time, energy and resources of renovating an existing shop boils down to creating an environment that’s appealing internally and externally. For their team members, there’s a level of pride that goes into working at a shop that’s worthy of an HGTV magazine center spread. For customers, it’s the comfort of being in a place that shows that it cares about the details and the customer experience. While some customers may think premium shop, premium pricing, that’s not the case, says Babcock. It’s about changing the perception of auto care and creating an environment that looks grand and attracts quality talent behind the counter and in the shop.

“I wanted to serve people. I want them to feel comfortable, right? That’s why I did it. When you walk into a dirty shop or a shop that doesn’t give you warm vibes, it’s difficult. I think in this day and age our industry gets a bad rap. So anything we can do, to help people’s guard go down, I think is great,” Babcock says.

Here are a few tips from Jeana Babcock:

• Don’t be afraid to decorate your shop with items you’d include in your home.

• Think aesthetics and harmony when choosing paint colors and furniture.

• Care enough about quality to do it right the first time.

• Décor doesn’t have to be expensive.

• Incorporate green plants for a home-like feel.

• Invest in comfortable and inviting furniture for a pleasant customer experience.

By following these tips, shop owners can create an atmosphere that fosters

trust and comfort, turning auto care into a positive and enjoyable experience for all.

Business partners Jared McPike and Sherri Stock started InMotion Auto Care in Lincoln, Nebraska, in 2012. The pair met while working at a Chrysler dealership—McPike a service advisor and Stock in a managerial role. The two owners built from the ground up on land sold to them by the dealership that once employed them.

Today, InMotion Auto Care is a 10bay, 10,000-square-foot shop custombuilt to fit seamlessly within the neighborhood in which it borders.

Here’s what they did.

One key focus for McPike was making sure the shop wasn’t a large, gaudy eyesore. So when they had it designed, they made sure its color scheme and feel were on par with the community. The shop is so well designed that it fools most people.

“A lot of people say, ‘I didn’t think this was an auto repair shop.’ They (think) it was a different business because of the way it looks from the outside,” McPike says.

A benefit to building a shop is the ability to factor in much-needed parking. While the lot McPike and Stock built on was limited in size, just like when they planned for growth in building a large shop, they also thought about parking as best they could with the space they had. He says he’s glad they carefully planned parking because it would be a challenge today given their volume if space wasn’t available.

“We (placed) the building … in a way that would maximize as much parking up front as possible, and then also have some room in the back. When you open up you’re not going to have a ton of customers coming in but our thought process was, you know, over time, we’re going to probably run out of parking,” McPike says.

If you build it they will come. That’s the lesson from the motion picture “Field of Dreams” and it fits McPike’s story as well. For McPike, having a custom-built

upscale auto repair shop isn’t just about providing his team somewhere nice to work, but attracting high-quality talent. The company recently added a couple of new service advisors whom he’s sure knew the type of look and environment InMotion Auto Care provided.

“You’ve kind of have to put your money where your mouth is, you know? I think it’s helped us out with getting quality technicians and quality service advisors,” McPike says.

And even though the building is now 10 years old, he says they are adamant about cleanliness and upkeep because the shop does attract a certain caliber of customer.

“Your standards go up, you know? I mean, if you’re going to show a customer a nice building a nice interior, nice exterior, they’re going to expect a higher level of service. So, our expectations obviously go up as well as far as our level of service to our employees and to our customers,” McPike says.

Bill and Kaylin Walker do it all at their Brewer, Mainebased, family-owned and operated auto repair shop.

BY TESS COLLINS | PHOTOS BY KAYLIN WALKER

BY TESS COLLINS | PHOTOS BY KAYLIN WALKER

up until about a year ago, he wore all of the hats at Walker’s Garage in Brewer, Maine. You called to set up an appointment? Walker answered the phone. Parts needed ordering? Walker again. Your repair order? Written by Bill. Walker’s Garage was truly a one-man operation. Oh, have we mentioned he also does collision repair?

About a year ago, Walker brought his wife, Kaylin, to do marketing, most of the scheduling, social media and other frontof-the-house tasks, which has helped ease much of the burden for Walker, but when it comes to the 62 car count monthly average, that work falls solely on his shoulders.

Walker says banging out 15-20 hours of work as a technician in a day is no problem for him; it’s the other tasks that slow him down. Walker always has his phone in his pocket so clients can reach him whenever they need to. He describes a typical day of working on a vehicle, having to stop and take his gloves off to answer the phone and then having to go into the office to check on an estimate or call the insurance company or order parts and then calling the client back before heading back to the vehicle to finish what he started. That’s just during the day. After hours is when he has to take care of all of the owner responsibilities, such as analyzing P&L sheets.

“Having to switch all these hats during the day can be exhausting,” Kaylin says of her husband’s workload. “But he succeeds because he’s done every job.”

Walker has worked in parts, detail, body and mechanical repairs. He’s also completed Dupont’s refinishing program, has his State of Maine Inspection License and has even worked as an estimator so he understands the claims process inside and out.

“Having the client-facing skills in his previous jobs, he can relate (to them),” Kaylin adds. “His soft skills have made him able to navigate every scenario that he’s been given.”

A lifelong resident of the area, Walker has been able to build a trusting and loyal

Walker’s Garage opened in October of 2021.”

customer base and fulfill a lifelong dream of opening his own shop.

When Walker told people who he’d known for 15-20 years that he was opening his own business, they were all thrilled that he was fulfilling one of his goals. Walker laughs and says he had no idea he had been talking about it for so long but that COVID was a wake-up call for him and Kaylin.

When COVID hit, Walker started working on vehicles at his home as a side hustle and he began to wonder if he could do it full-time. He looked into it and he wouldn’t be able to do it from his own garage as his home was a residential-only zone, but he began to look at properties and when the perfect fit came along, he and his wife took the leap and went after his self-described “pipe dream.”

“We didn’t want to get to the end of our life and say we wish we would have tried,” Kaylin says of starting the business.

Walker’s Garage opened in October of 2021.

“What’s a sick day?” Walker laughs when asked what he does when he feels under the weather.

It takes a lot to run any business, but when you and your wife are the only employees, it makes it even more so. Walker says on days that he isn’t feeling well, he powers through, for the most part, unless he’s contagious. There have been a few situations, including a family vacation and a trip to VISION, where the shop needed to shut down. In these situations, Kaylin explains that they give customers plenty of notice and schedule a few cushion days on either side in case of travel delays. The few times Walker has been too sick to work, he’s called and explained the situation to his customers and because of the relationship that he’s built, they’ve been extremely understanding.

“People are a lot more flexible than I would have thought,” Walker says.

Another very important task that Walker has as owner is payroll. How exactly do you handle that when you and your wife are the only employees? In the beginning, Walker says he didn’t pay himself and would just take an owner’s draw for the bills that he needed to pay.

Owners: Bill Walker & Kaylin Walker

Location: Brewer, Maine

Staff Size: 2 Shop Size: 1,584 square feet (including both the garage and office)

Number of Bays: 1.5

Average Monthly Car Count: 83

Annual Revenue: $436,876

When Kaylin started, he put her on the payroll and has since added himself as well. He explains that they know what they need to get by and if they need more, they can kick that in with an owner’s draw.

Walker and Kaylin work and raise two kids (Brynn and Billy) together. They’re basically with each other all day, every day. So, what’s that like?

“I love that I get to work with my best friend,” Kaylin says.

Speaking with them, it’s easy to tell that they’re still crazy about each other and that they’ve figured out a way to maintain a successful personal and professional relationship. That doesn’t mean it’s always easy. Before Kaylin came to work at the shop, they had many conversations about how they were going to make it work. Clearly defined boundaries have been key. They each have a “lane” in the business and try as much as they can to stay in it.

“I had to kick her out of the shop because she was vacuuming all of the dirt out of the cracks on the floor,” Walker says of the early days of working together.

“In the beginning, I was trying to understand everything about the industry and it was overwhelming and that was where a lot of frustration for me came,” Kaylin says. “Bill has that knowledge. It’s not realistic for me to understand the technical stuff, my job is to relate to the customers. Bill knows what he’s doing out there.”

They’ve also created a boundary between home life and work. Work talk, for the most part, stays in the shop and during work hours, they try not to discuss their dinner plans or personal matters.

What do the kids think of their parents’ shop?

“They love it,” Kaylin says.

She says that their daughter hands out the shop’s business cards and pens at school to her friends and that they often wear their company t-shirts while out and about. Walker often has to work until late at night but Kaylin and the kids will bring him dinner or dessert at the office so they still get a chance to spend time together as a family.

The Walkers have found true success both personally and professionally and should be an inspiration to others to follow their dreams.

I love that I get to work with my best friend.”

BY CHRIS JONES

BY CHRIS JONES

According to data from management consulting firm McKinsey & Company, 4.4 million people quit their jobs each month last year (2022). A Pew Research poll showed that 57% of people left their jobs because they felt disrespected, 43% left because of insufficient benefits and

39% due to long hours. Overall, 90% of respondents to the Pew survey say they want empathetic leaders—which equates to leaders, people who understand, respect and appreciate the value they bring into the work environment.

Darrin Barney, co-owner Barney Brothers Offroad and Repair and president and CEO of Elite Worldwide, says that if shop owners really want to grow it begins with hiring people better than them in skilled positions. If you’re a shop owner who doesn’t want to end up on the short of the stick from a personnel standpoint should adhere to these steps.

Barney recounted the story of Henry Ford’s now famous court appearance, in which he was placed on the stand to give an account for his lack of education. A man of wit, Ford proved them wrong by showing the court that It wasn’t his personal intelligence that made him a man of education, but the collective intelligence of the personnel he surrounded himself with that did.

“I had to learn to get out of the way and let my people do what I pay them to do,” Barney says.

He added that employees today want to be part of the adventure. They don’t just want to work for you, they want to make meaningful contributions to the workplace. But that starts with shop owners first having a vision.

“If you don’t know where you want to go, superstar employees won’t stay with you. People want to feel like they’re part of something,” Barney says. “You have to inspire your people to where you’re going. You have to take care of your people. They have dreams and goals and if you don’t know that, they’re going to go somewhere else.”

Once you identify your vision, take time alone each day to think about that vision and how you’re moving toward it.

“One of the coolest things about (Nike founder) Phil Knight was he’d sit in a recliner at night thinking about where he wanted his company to go. The successful are always thinkers,” Barney says. “I put a sticky note on my office door so people

know when it’s my think time. You need think time.”

To craft a vision, Barney says to build a mission statement. He added that shop owners need to consider what motivates people—and it’s not just money.

“When you start thinking about your mission statement, your brain will subconsciously help you to figure it out,” he says.

Barney says he has created 12 guiding principles and has one member of his team recite a principle in each team meeting.

“It gives your people something to think about.”

As a shop owner who specializes in modifications, Barney was comfortable not doing auto repairs. His coach told him he needed to do it if he wanted to boost his bottom line and level up his shop. Hesitant, he did and was sold. When he started inspecting the vehicles that came to his customization shop, the business grew. He says the same is true when the inspiration to change trickles down from the shop owner down to the team. Some may push back before they buy in, he warned.

“People don’t like change. People will

fight you on it, but you have to be enthusiastic and sell the vision to them,” he says, reminding the room of the first principle. “People support what they help create. You have to have your team involved before they adopt changes. One of the mistakes I made was not getting people involved. When I did, things changed.”

If you want to be the biggest shop in town, you have to do the work, know your competitors and understand what you have to do to be competitive. He says keeping an open mind and getting your team involved in building the dream is imperative.

“You have to let the team help with the plan. People don’t want a j-o-b, they want a career, and they want to help you,” Barney says.

Write short-term, mid-term and longterm goals for your shop. Goals aren’t set in stone, but they give your subconscious and your people somewhere to go. And work on your job descriptions. Sometimes you won’t know because you find someone special, and you create a place for them. Once, Barney and his manager interviewed a candidate they had no po-

sition for but liked and they brought her on as a bookkeeper. Putting her on the phone one day, they discovered she excelled and has since become a great service advisor.

“You have to think outside the box. I saw something in her,” he says. “It may not always work out, but you have to find people’s strengths and weaknesses and find where they fit. If they don’t fit at one position, their strengths may work in another.”

One employee, who started with him as an advisor but who didn’t work because he didn’t like being on the phone, was moved to shuttle driver, a position with which he has since excelled.

Step 4: Innovate

Barney says shop owners need to know what motivates their people. It’s not all about money for some and they need to learn that quickly. He has one tech who likes extra time off and one who likes recognition (read: words of affirmation if you’re a disciple of “The Five Love Languages”). Johnny, the advisor he reassigned to shuttle driving, likes to have his ideas heard. One thing Barney did was allow Johnny to start listing parts customers didn’t want back after modification jobs on eBay and Barney gives him a cut of the profit.

He also says shop owners need to hire people with personalities unlike their own. These people will provide honest feedback and in doing so help the shop elevate to new levels.

“When you hire someone who intimidates you, that person will take you to the next level. They’ll spot things wrong to help you build your business. And when listening to them, they’ll keep giving you ideas,” Barney says.

Learn to watch and allow things to happen. As long as the ideas and changes don’t fly against the core values, you can permit freedom of thought. When his team implemented a three-inspection policy, he wasn’t there for it, but he allowed it to happen. He also told the story of an employee on his team who was not used to checking the customer key

drop-off box. He allowed it to happen for a few days and eventually reminded them of the need to add that step to their daily routine.

“We get used to doing things a certain way. The subconscious kicks in with muscle memory. We have to change muscle memory. He wasn’t used to checking the key box and had to learn,” Barney says.

There comes a time when you try out things, test systems and processes and they come up short, but not for a lack of effort and readjusting. They simply aren’t a fit for the shop. When ideas don’t work over time, Barney says to not be afraid to blow it up and rebuild.

He recounted a time when he pulled his entire team together to walk through the entire customer experience as a team to help figure out where things were going wrong.

“We didn’t know (what we didn’t know) until we did that. I thought we had it all dialed in, but we didn’t. Don’t be afraid to blow it up and rebuild, but do it the right way,” Barney says.

Leading must be done by example and for better or worse, your team will model the leadership you display in front of them. Once, Barney walked past some trash in the parking lot and his employees saw it. It happened for two days until the third when he picked it up and brought it in to throw away. Upon seeing this, one of his employees mentioned noticing the trash and himself walking over it the same as Barney had done.

“When it comes to nurturing, we have to lead by example. Your people are watching you,” he says. “When you go to your shop, walk through the door and know that you’re going to be the best shop owner you can be. We have to think all of our decisions through.”

In the shop, it’s imperative to get this right because tolerance of the wrong things can be detrimental to the team.

He once hired a technician who had great references, a $150,000 toolbox and looked like a producer. Once in the shop, the tech averaged only 20 hours per week, which was a shock to Barney,

whose minimum is 40 hours per bay. He observed the tech for two more weeks and nothing changed. He worked with him and every adjustment to make it work but at the end of two months, the tech still was unable to turn 40 hours. Barney reassigned him to shipping, hoping he’d fit because he liked his attitude, and he couldn’t continue to pay him as a tech and when that didn’t work, he had to let him go.

“He was a great guy, but he wasn’t a good fit for us. If someone isn’t performing, you owe it to them to help train them. It’s cheaper to keep them. If you don’t think they fit the position, transfer them to a new position. If that doesn’t work, you have to terminate. But the one thing you don’t want to do is tolerate,” Barney says.

On the flip side of that, he once had an excellent mechanic but his attitude was terrible. The tech didn’t show up on time for huddles despite being senior among the techs. The employee said he didn’t care about the huddles and didn’t want to listen to the other techs in the meetings. He became defensive and drew a line in the sand with Barney.

“I let him go because he refused to be there and be there on time. It ended up being one of the best decisions. I didn’t realize how bad he was for the shop. It’s the hardest one, but the right thing to do,” Barney says. “If you tolerate that behavior, what does the rest of the team say?

When Barney let go of the tech with the bad attitude, a new tech with the right attitude tech with better skills showed up and replaced him.

Barney says shop owners have to always be available for their team and provide and receive good feedback. Do hard things, be willing to listen to ideas and make changes to show your team that you value their contribution. A caring shop owner also must be willing to work through things and figure out new ways to get things done. Change takes time. But meet regularly with your team to get temperature checks and to keep them invested.

“People want to be a part of something, and they support what they help create,” Barney concludes.

How learning to track KPI helped Edwin Platt change the trajectory of Platt’s Performance Plus

BY CHRIS JONES

BY CHRIS JONES

Flying blind is an expression derived from the aviation world when World War II pilots who were unable to see the horizon would have to rely on their instincts and instruments to guide their aircraft. Today, it has come to mean anyone who does a job or runs a business solely relying on guesswork with the hope of achieving a successful outcome.

When Edwin Platt, owner of Platt’s Performance Plus, Inc. In Jamesburg, New Jersey, opened his shop in 1988, he was doing just that—piloting without a flight plan.

Backstory:

When Platt opened his shop, he was a solo operator. In those days, sophisticated customer relationship management software hadn’t been invented, so he ran the business on paper.

He had run a few other small businesses in the past, but none as detail-oriented as an auto repair shop. Platt recalls the day-to-day operations as being hectic, even after he did score his first computer.

“I was just by myself. I’d have a headset on at the time turning wrenches, doing the numbers,” he

says. “(I was) looking at the numbers and mostly everything was on paper in the beginning. Then I got my first computer system, but still wasn’t tracking numbers.”

Problem:

Platt’s inexperience with tracking numbers is a common problem many fledgling auto repair shop owners face. Rather than managing by the numbers, it’s an operation based on volume approach that doesn’t take into account external variables that affect the bottom line.

“My friend was my accountant at the time, and he looked at my books every month and told me if I was doing good or bad and gave me the numbers back that way. I really wasn’t looking at the numbers by myself,” Platt says.

And what neither understood was how key performance indicators were the governing data points that auto repair shops relied on for success.

“I didn’t know key performance indicators,” Platt says. “But then I got with ATI—Automotive Training Institute—in Maryland, and they started talking about running your business by the numbers and tracking different benchmarks that you have set up and that’s what really got me on track to running the business; looking at numbers you need to do make money.”

It wasn’t for lack of effort that Platt’s auto repair shop wasn’t as successful as it could have been. He was putting in the work, seeing financial counsel and even hired a management company before switching to ATI. There, he learned about optimizing his website to generate more traffic, discovered the power of participating in 20 groups and ultimately learned to run his business by the numbers— setting course before taking flight.

One area he noticed an immediate change in was when he began to track technician efficiency and its impact on his labor rate. He conducted an exercise by which he clocked how much time his technicians took between cars following a complete repair and that’s when understanding the data clicked.

“We clocked how long it takes to do this and how much time was being wasted ... and studied our time, our patterns, what we do to be more efficient. That was a big time saver to get my labor efficiency up because that’s what I was trying to do. I was looking at why we’re not billing the right hours. It’s because we weren’t working smart,” Platt says.

Aftermath:

Platt continues to be coached and has since gone on to become one of the top performing shops under ATI, being named the Top Shop in the $1-$2 million bracket and his shop has been recognized in the company’s Top 25 and Top 12 shops nationally in the program.

Today, his son is now running more of the day-to-day operations, something Platt attests that wouldn’t have been possible had he not learned to run his business by the numbers. Before understanding his KPI, he was unable to get away from his shop.

“I couldn’t walk away. I was very hard to get away for a meeting,” Platt says.

Takeaway:

In teaching his son the business, he’s stressed the value of operating the shop using benchmarks and data points, something his son has taken to and excelled in doing.

“He’s learned the numbers too and he knows the numbers really well,” Platt says. “He’s doing really well for me. So, it’s helping me be able to step back. I want to retire. I don’t want to be here all my life.”

Last winter, Platt was not only able to walk away for a meeting, but he even left the shop behind to take a Colorado ski vacation. But make no bones about it, he watched the numbers from afar just to be sure.

“I can see everything that’s going on and what my son’s doing. I wasn’t here for half the month and the shop ran great,” Platt says.

that’s what really got me on track to running the business; looking at numbers you need to make moneyPHOTO COURTESY OF EDWIN PLATT

Considering a business coach? You're not alone! The concept of coaching is no longer confined to athletes and performers; it has evolved to cater to anyone seeking personalized solutions and support to unleash their full potential. Surprisingly, this includes a growing number of auto shop owners who are reaping the benefits of coaching.

If you're an auto shop owner grappling with any of the following top 5 challenges, a business coach could be the game-changer you need:

If your income as a shop owner is less than what you could potentially earn working for someone else, it's time to seek guidance.

Are you stuck at the shop from opening to closing time every day because you lack confidence in your employees' ability to handle daily operations? A coach can help you develop a more e icient and independent team.

When was the last time you enjoyed a proper vacation or attended significant family and friends' events? If years have passed, a business coach can assist in creating a work-life balance that ensures personal happiness and success.

You might have no idea about your business's actual value or what would happen to it and your family if you were unable to work. A coach can help you assess the worth of your business and plan for unforeseen circumstances.

Feeling stuck in first gear with no clue how to progress? A business coach can provide valuable insights, reveal blind spots, and equip you with the knowledge to propel your auto shop forward.

So, if you're considering an auto shop coach, take the next step by requesting more information. With the right guidance, you can overcome obstacles, unlock your potential, and steer your auto shop towards greater success and profitability.

Hiring techs fresh out of school can be challenging, and rewarding

BY NOLAN O’HARAWhen Ross Colket made the decision to open Colket Automotive Technical Services in Lansdale, Pennsylvania, back in 2007, he knew exactly who to call. At the time, Colket taught classes at the Carquest Technical Institute (CTI), and he had a student who stood out to him.

“I was very impressed with his mechanical skillset,” Colket says.

So Colket gave him a ring when he opened up his shop, and that student worked for Colket for about two years before taking the leap and diving into shop ownership himself. Since then, Colket has made a habit of hiring and developing young, fresh-out-of-school technicians, with many having gone on to see success throughout their professional careers.

Finding and developing good young techs is vital to the industry as older techs retire and fewer people enter the field, leaving a widespread shortage of technicians. At the same time, it’s just as important for shops to create pathways for fresh techs to develop and reach their personal career goals.

But finding good young techs and establishing pathways for their personal and professional development doesn’t come without its challenges.

Colket has successfully found good, fresh techs fairly regularly—he says he currently has two good younger hires working for him now—but he’s well

aware not every tech who makes it through school is guaranteed to succeed or will be the right fit for his shop.

In reality, he says, really only two out of every 20 students in a graduating class will be poised for success in the industry. There are a couple of reasons why.

When Colket was growing up, he lived on a farm and his family ran a brick manufacturing business. He grew up with a very mechanical background, having worked on cars and farm equipment for the family business and all before he’d entered the auto industry.

But he says nowadays with how complex car repair has become that fewer and fewer people are growing up fixing their own vehicles, and thus have lost that mechanical background. On top of that, there are fewer opportunities for the current generation to gain experience with vehicle repair prior to school.

For many, tech school is their first time under the hood of a car.

“I had conversations with some tech school teachers, and it used to be, you know, they would get into doing quite a bit of repair on a high school level,” Colket says. “Now it’s more lefty, righty … ‘This is a washer; this is a nut.’ They’re

starting on a much more (basic) level.”

Additionally, much of what students are learning in tech schools is outdated, says Jim Cokonis, a longtime industry trainer, teacher and curriculum developer.

“You have a guy who learned and did a great job on an old coach flat-tire changer and a bubble balancer and you put him in a shop with modern equipment, and he doesn’t even know how to run it,” Cokonis says.

That requires shops to retrain young techs after bringing them on.

At Colket Automotive Technical Services, training — or retraining — young techs has become part of what they do. Colket says when they hire a fresh-outof-school tech, they’ll have them shadow a more experienced tech.

When applicable, they take time for collective teaching moments. If the shop is struggling with a diagnostic issue, Colket is on the shop floor helping the crew figure it out. He also takes one-on-one time with young techs, always willing to teach and train. The techs just need to absorb the information and retain it.

It’s all part of the team environment Colket has worked to build. Training isn’t something they do just a couple times a year; rather, as Colket says, “It’s a part of the day-to-day operations” of the shop.

While Colket has had success developing young techs, other shops often struggle to relate to younger generations, Cokonis says. Some who have been working in the industry for some time have the perception that Gen Z doesn’t have a strong desire to work; however, Cokonis has a much different perception.

“Some of the older instructors, bosses, managers they have, even older than Boomers, they have what they call Silent Generation or World War II-era mentality about discipline in the shop, and they wonder why they struggle with young people,” he says. “That’s as honest as I can be in the assessment of what I have watched transpire.”

Cokonis says younger generations, Gen Z in particular, are really working to understand a healthy work-life balance.

“You’ve got them in every Fri-

day night, every Saturday, working six days a week with a day off in the middle of the week. And they have friends and they have recreational activities and things like that,” Cokonis says, “and the job environment isn’t inspiring to them in the long term. So, you’re going to have troubles with retention and attendance.”

Instead, shops can inspire new hires by identifying their goals and creating pathways for their newbies to reach them. Both Colket and Cokonis noted it’s important to have conversations about goals and interests early on.

The purpose of that is twofold: First, if you can put new hires in a position that fits their interests, they’ll automatically be more invested in their work. And second, not every shop will be able to help their staff members reach their end goal. They might be a stepping stone, with both the owner and the employee knowing eventually the latter will move on.

Although, Cokonis says, “You should be willing to invest the time to get that person as far as you can get

within your organization.”

Colket says that at his shop currently, he doesn’t have anyone looking to move on. A big part of that is giving new hires opportunities related to their interests while putting them in positions to succeed. If the shop inspires new hires to reach their goals—whether (that’s) shop ownership, specialty repairs or becoming a service advisor— they’ll be more invested and dedicated to their work.

It’s a win-win for both the shop and the employee.

“You need to be supportive of them in training, identify the training opportunities in your area,” Colket says. “… The biggest thing is support them in it. Pay for the training. Don’t expect them to pay for it. The better they get, the more money they’re going to make.”

And the better off the shop will be. Colket says he had an accident last fall that caused him to take some time off. While he was gone, the shop ran itself. “I was out of work for two-and-half weeks and they handled it top to bottom,” he says.

Columns

StokesYour team will make mistakes. Knowing how and when to intervene makes all the difference.

BY AARON STOKESAs owners, we get frustrated and say, “Man, we’re always screwing this up!” or “Tom, Sally, why does this keep happening over and over.” Instead of digging into the person, we should blame the process. If we blame the process, that allows the person to lower their guard and not feel attacked. That allows us to say, ‘Alright, Sally, we’ve got to stop greeting the customer this way. After you find out about parts availability, we need to call them back. Or maybe you’re calling, but you’re not getting a person on the phone.” (That’s one of the things we teach—always get a hold of somebody and get confirmation they’ve received your message.) As you attack the process, it causes that team member to say, “Hey, I could have done better.” This allows us to sit back and go, “OK, where in this process are we continuing to do the exact same things hoping we’ll get a different result, but aren’t?” We keep getting the negative result. So, if we continue to dig, we will find it. The real key would be to let them continue to make mistakes and let it snowball all the way to the end. In doing this you will see the thing causing the next problem and the ones after that. You’ll think, Holy cow, they’re really messing up! That’s going to cost me money . You don’t want to let it happen; you want to intervene. You need to let it pan out and then say, “Alright, I see what’s going on. I see the issues.” The reason we didn’t before is because when an employee does something wrong, we’re there to fix it before it hits level two or level three. We’ve never seen it at a seven, eight or nine.

There is another mistake that Tom or Sally makes when they get stressed out which causes them to run to the bathroom and hide. When I see it, I’m able to go, “Alright, everybody see what happened? Mrs. Jones got really upset with us. We told her the car would be done at 3 o’clock on a Friday, but the wrong part came in. We left a message she didn’t get. She showed up after we closed at 6, left a scathing voicemail and a negative review and picked up her car on Monday.” They’ll think there’s nothing more we could have done since we called and the message, but as soon as we found out about the part at 11 am, we could have called, waited and called again. We need to call until we get a hold of someone because this is going into a weekend when most people want their car—the stakes are higher. Then the team’s going to say, “OK, that makes sense.” That starts with us all looking inward and saying, “What could we have done differently?”

August is one of the hottest and busiest months of the year. Instead of them focusing on Mrs. Jones being then friction throughout the entire process, we need to be looking at our processes. Seeing where we parked cars that are completed. We need to be looking at how we do our QC process. We need to be looking at how we answer the phone. Examining everything we do—how can we streamline it and make it more efficient? That

aaron@shopfixacademy.com

ratchetandwrench.com/stokes

keeps ego out of it. That keeps defenses down low and keeps everybody willing to work as a team. So instead of just saying the goal is to hit 400 grand, we’re now saying the goal is the best technician quotes we’ve ever done. The goal is we’re going to be better at communicating than we’ve ever been. The goal is we’re going to be better at following sales scripts than we’ve ever followed them before. If we make those small things the goal, the overarching goal of hitting 400 grand will take care of itself—and we’ll get there because of a lack of friction.

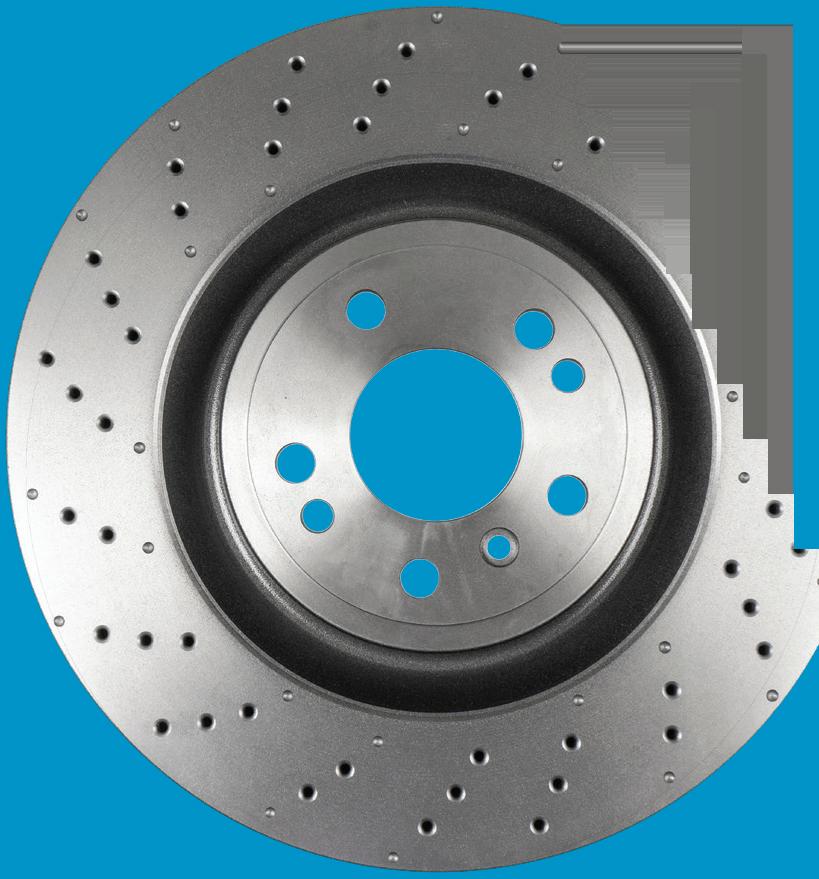

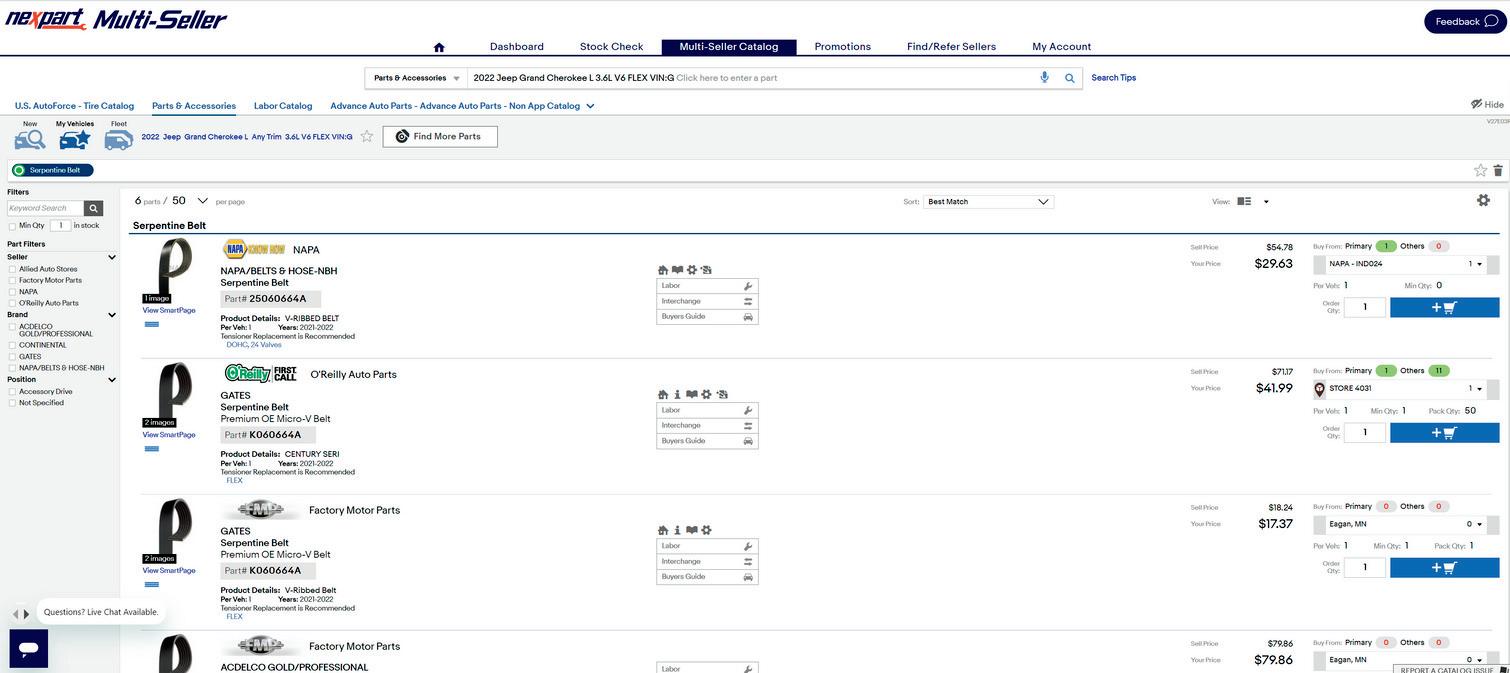

PARTS BUYING INNOVATION GEARED TOWARD YOUR SUCCESS

EASIER PARTS ORDERING

EXPANDED AVAILABILITY & FAST DELIVERY

STREAMLINED ACCOUNT MANAGEMENT

EXCLUSIVE PRICING

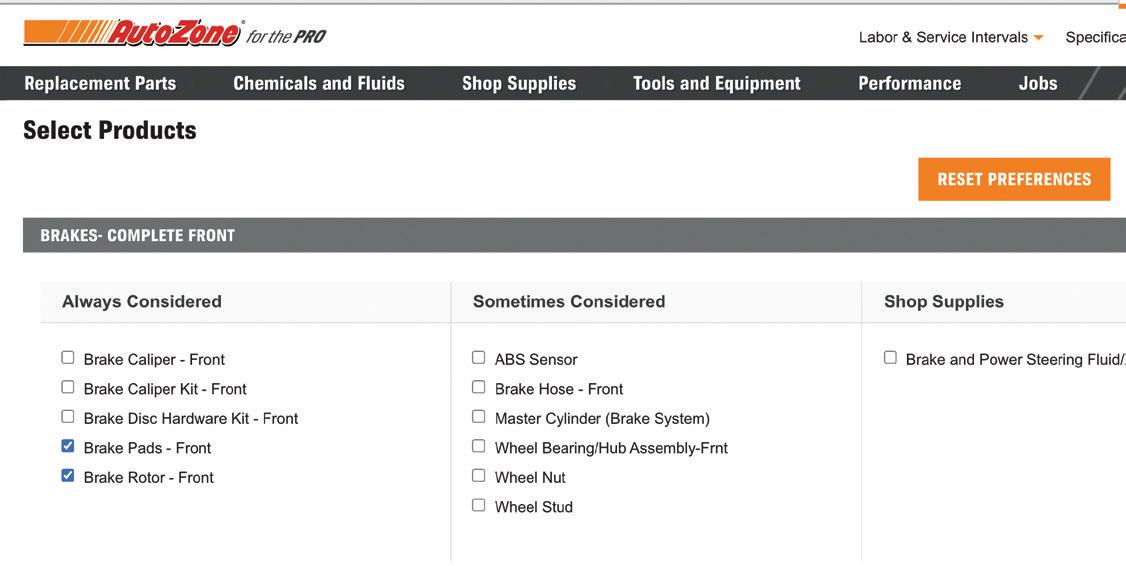

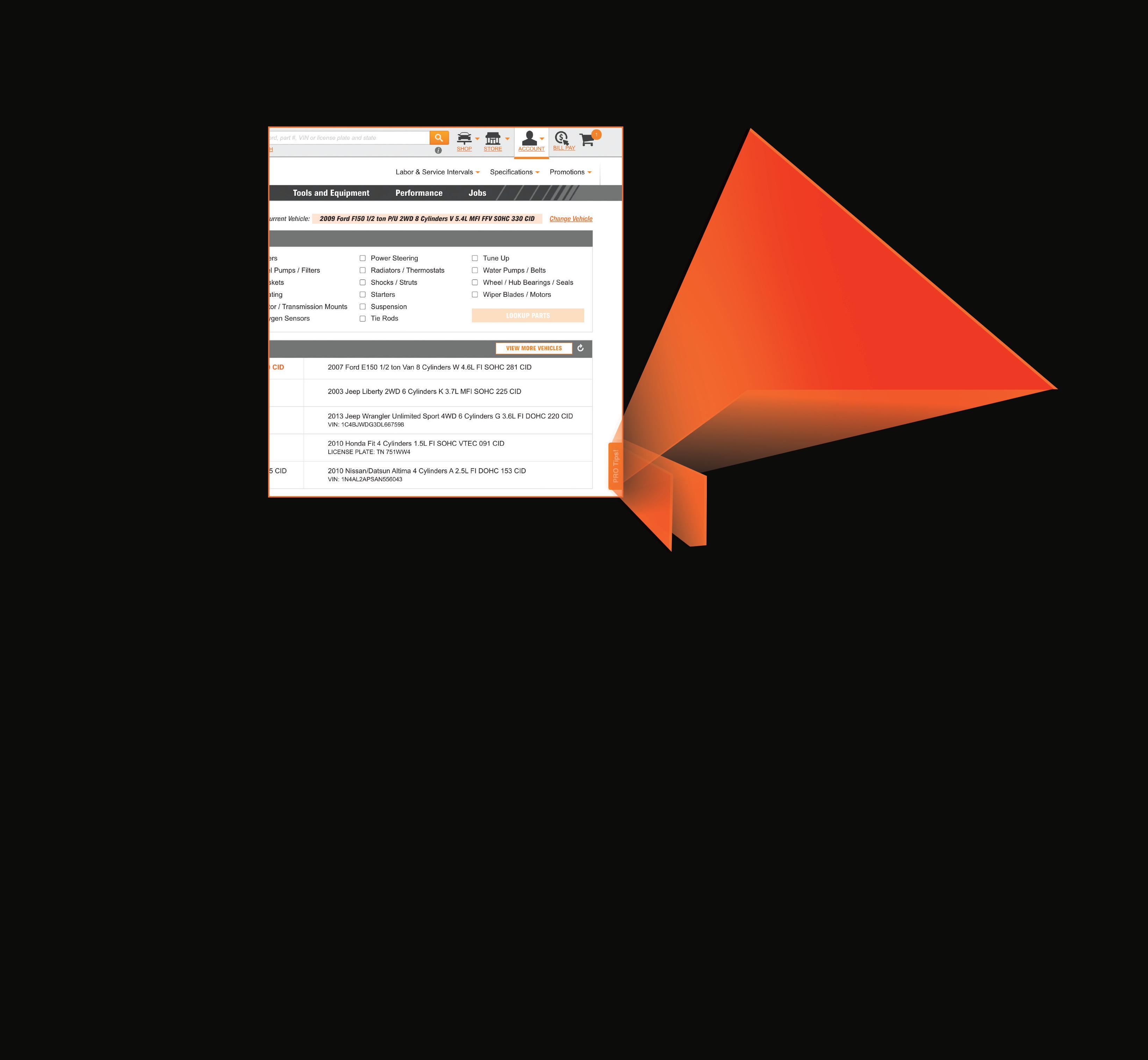

LOGIN > HOME > ENTER TERMS IN SEARCH BAR > SELECT ALL PARTS THAT APPLY > RESULTS DISPLAY

The improved search function allows you to search for more than one part type at a time.

• Search by vehicle and part, keywords, or frequently ordered products

> For example: “06 Camry battery” or “ battery, wipers, front brake pads, rear brake pads, front rotors, and rear rotors”

• Select all the parts you need and click CONTINUE

• Product results show everything you need on one page

Use the FREQUENTLY ORDERED feature on home page for quick and easy part selection on routine items.

To learn more tips on this feature check out Pro Tips! on AutoZonePro.com

PRO Tips!

more accurate

HOME > CLICK ON JOBS > CHOOSE APPLICABLE JOB > SELECT DESIRED PARTS > RESULTS DISPLAY

You can also search by preset jobs. All the necessary parts for the job will be loaded, eliminating the need to search parts one by one. For example, when doing a complete front brake job, you would follow these steps:

> Select from the list of preset jobs Brakes Pads - Front

> Select the parts you need for the job and click CONTINUE

• Product results will display your selected parts on the next page

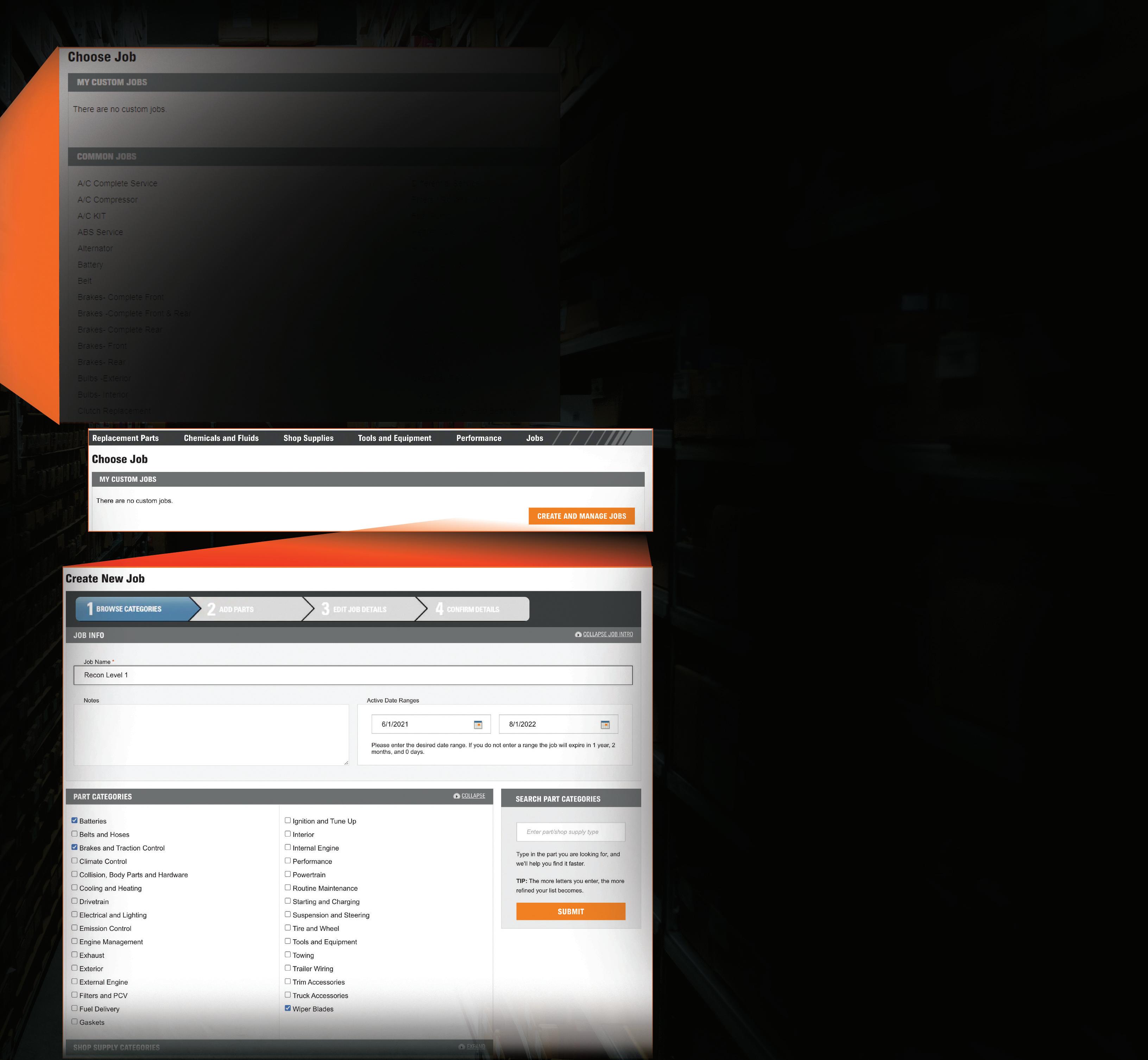

HOME > CLICK ON JOBS > CLICK CREATE AND MANAGE JOBS > CLICK CREATE CUSTOM JOB

Use CUSTOM JOBS to create your own parts list for common jobs, and save for future use.

For example, if you have a common part list used for reconditioning, create a “Recon Level 1” job for faster ordering:

> Click on CREATE CUSTOM JOB and title it “Recon Level 1”

> Select Batteries, Brakes and Traction Control, and Wiper Blades and click CONTINUE

> Under each category, select the parts you need and click CONTINUE

> Choose Always, Sometimes, Shop Supplies or Remove and click CONTINUE

> Confirm details and click SAVE JOB

• All of the required part types will be pulled when you click on your custom job

Access to anything you could need is right at your fingertips from AutoZone’s entire product selection. You can even search non-stocked parts from our Vendor Direct Network (VDP).

• Save the time you would spend looking for hard-to-find parts

• Regardless of the brand, YES! WE’VE GOT IT!

All search results have accurate, multi-view images to verify you get the right part the first time.

Click ENLARGE IMAGE on the bottom right of any picture to view close up

To learn more tips on this feature check out Pro Tips! on AutoZonePro.com

PRO Tips!

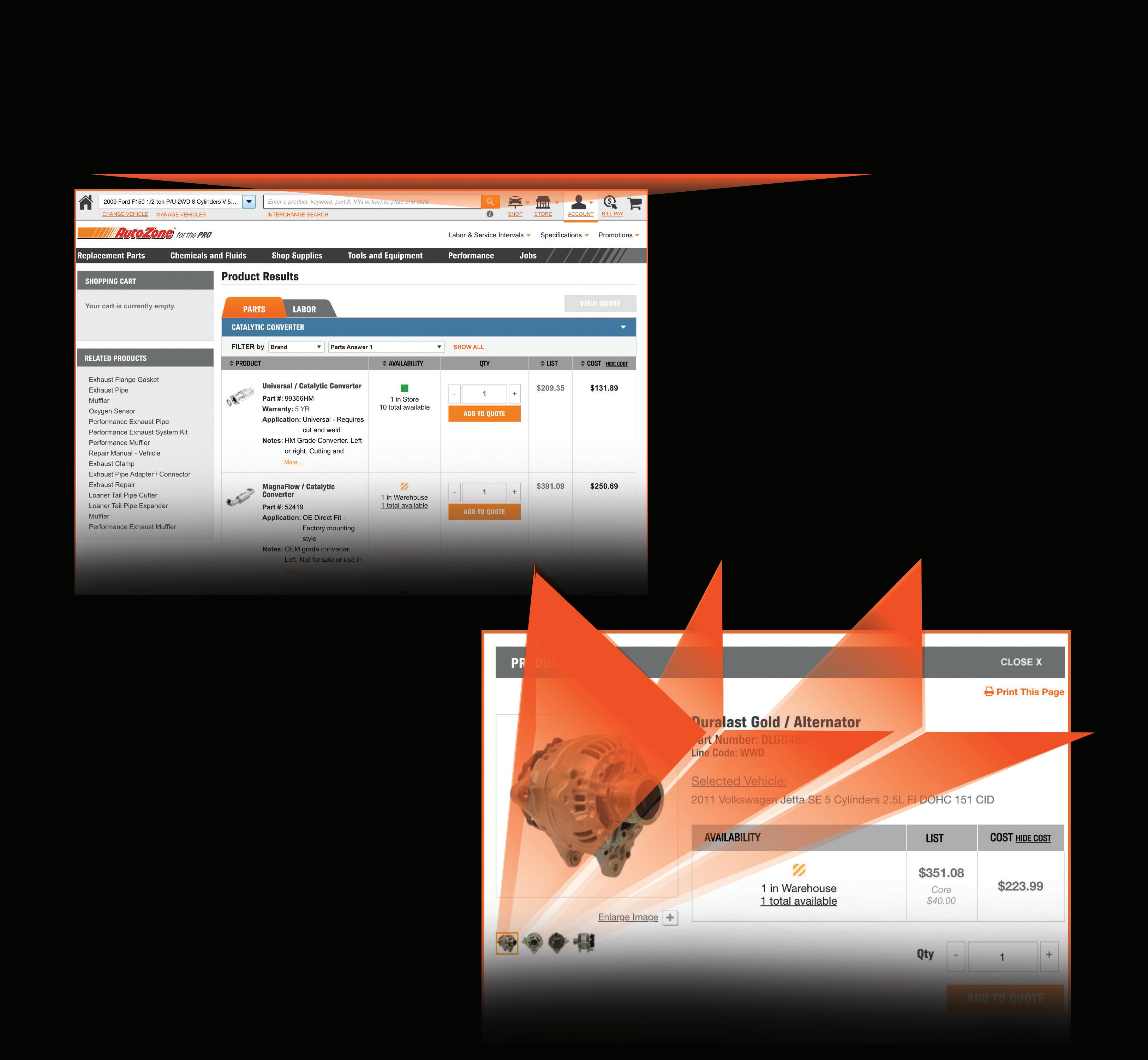

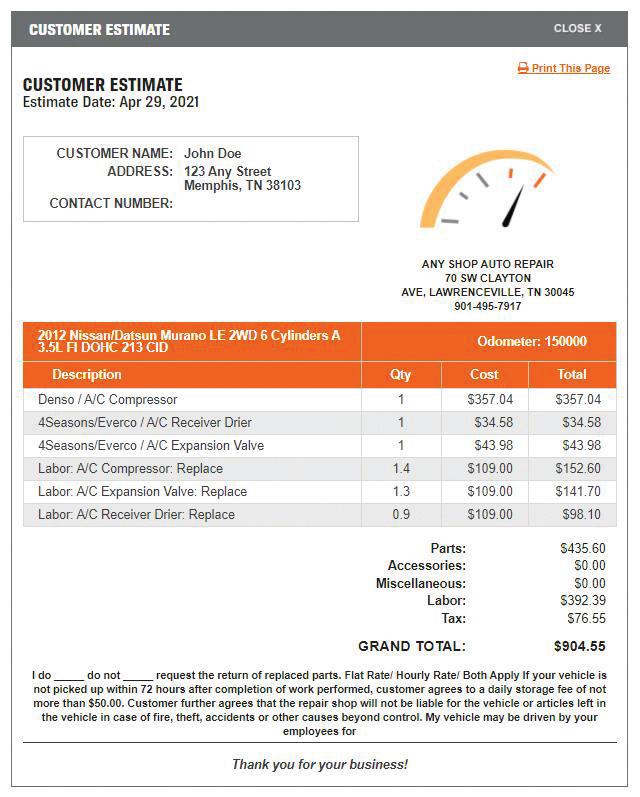

HOME > SEARCH AND SELECT PARTS > FROM PRODUCT RESULTS PAGE CLICK ADD TO QUOTE > CLICK VIEW QUOTE > CLICK CREATE ESTIMATE

Create professional and custom printable estimates right on the website when you’re selecting the parts.

• Allows you to store customer data

• Includes customizable services and terms

• Labor estimates powered by ALLDATA

Control your parts profits by defining your own list rates and managing customized charges.

To learn more tips on this feature check out Pro Tips! on AutoZonePro.com

Look up and order parts anywhere, anytime in the AutoZonePro.com mobile app. Whether you’re in the office, back in the bays, or with a customer, use the app to conveniently search or scan VINs and license plates and find the parts you need at the right price.

• Vehicles searched and parts ordered in the mobile app are automatically updated to your desktop

• Set your language to English or Spanish

• Click “ADD TO QUOTE” to add all applicable parts right from the Product Results page to create an estimate

Maximize your profit potential with the most comprehensive inventory, available around the corner

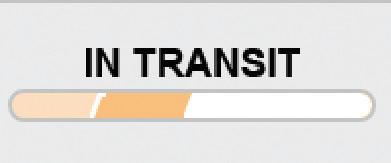

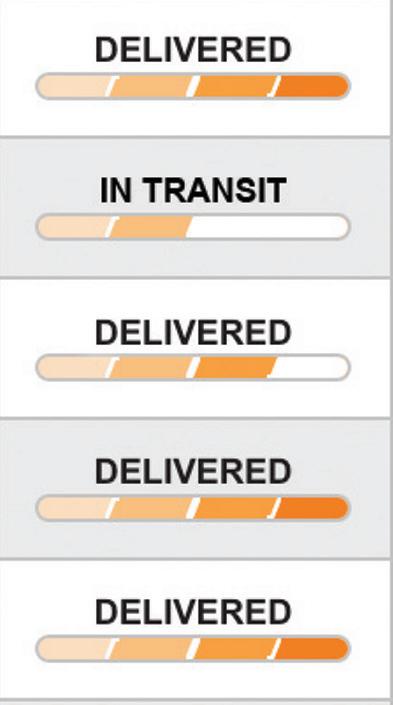

The ability to track your parts order online makes it easy to manage operations and customer expectations with accuracy.

• Track multiple orders at once

Increased store stock of late-model coverage across all product lines provides more availability for even faster delivery.

> Expanded import coverage

> First-to-market on most popular applications

> World-class distribution network

25,000 SKUS covering 2016-2021 vehicles

140,000 SKUS across all categories in stock

GPS technology digitally maps the fastest routes to your shop to ensure shorter, more efficient drive times from our stores or hubs.

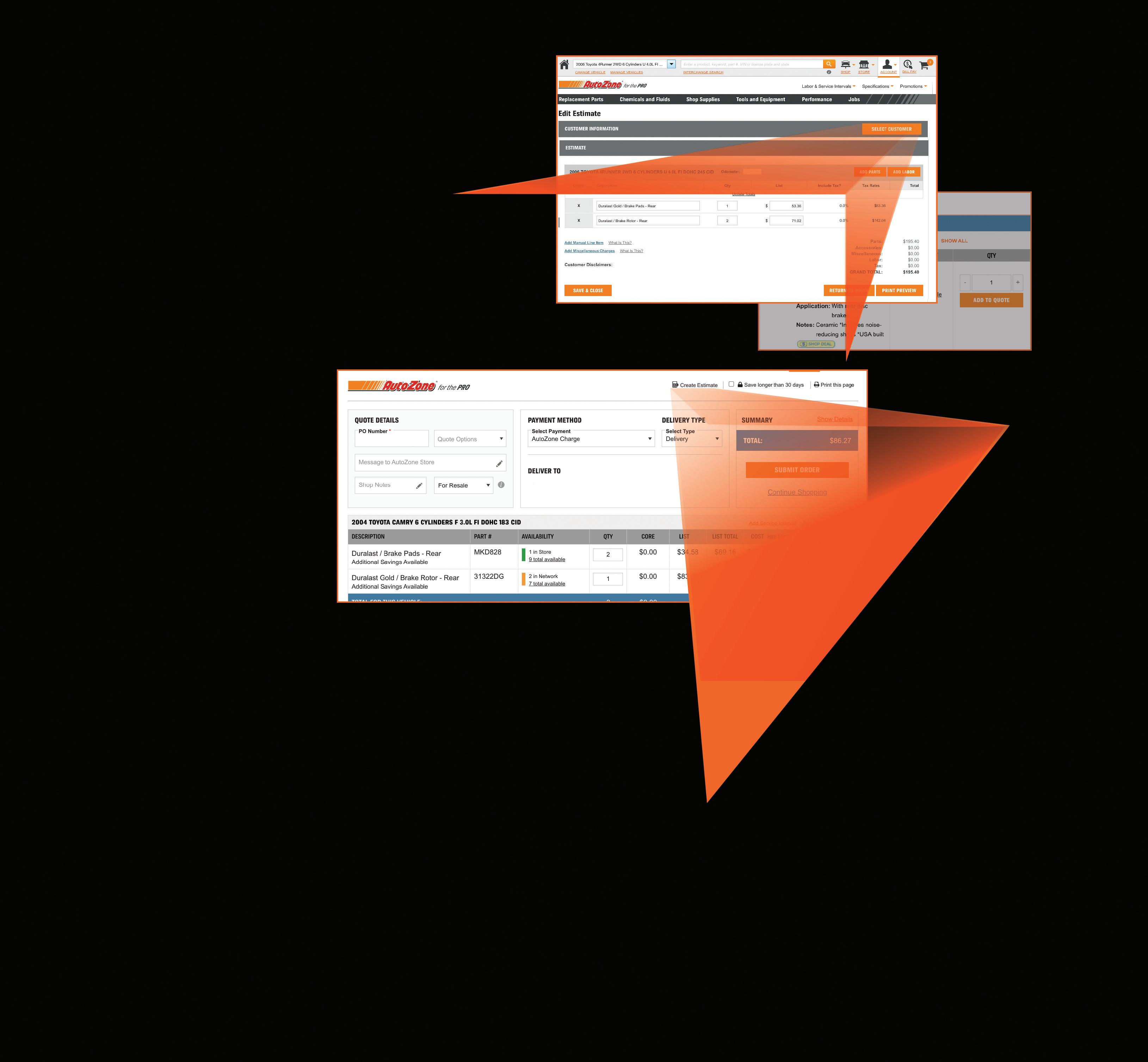

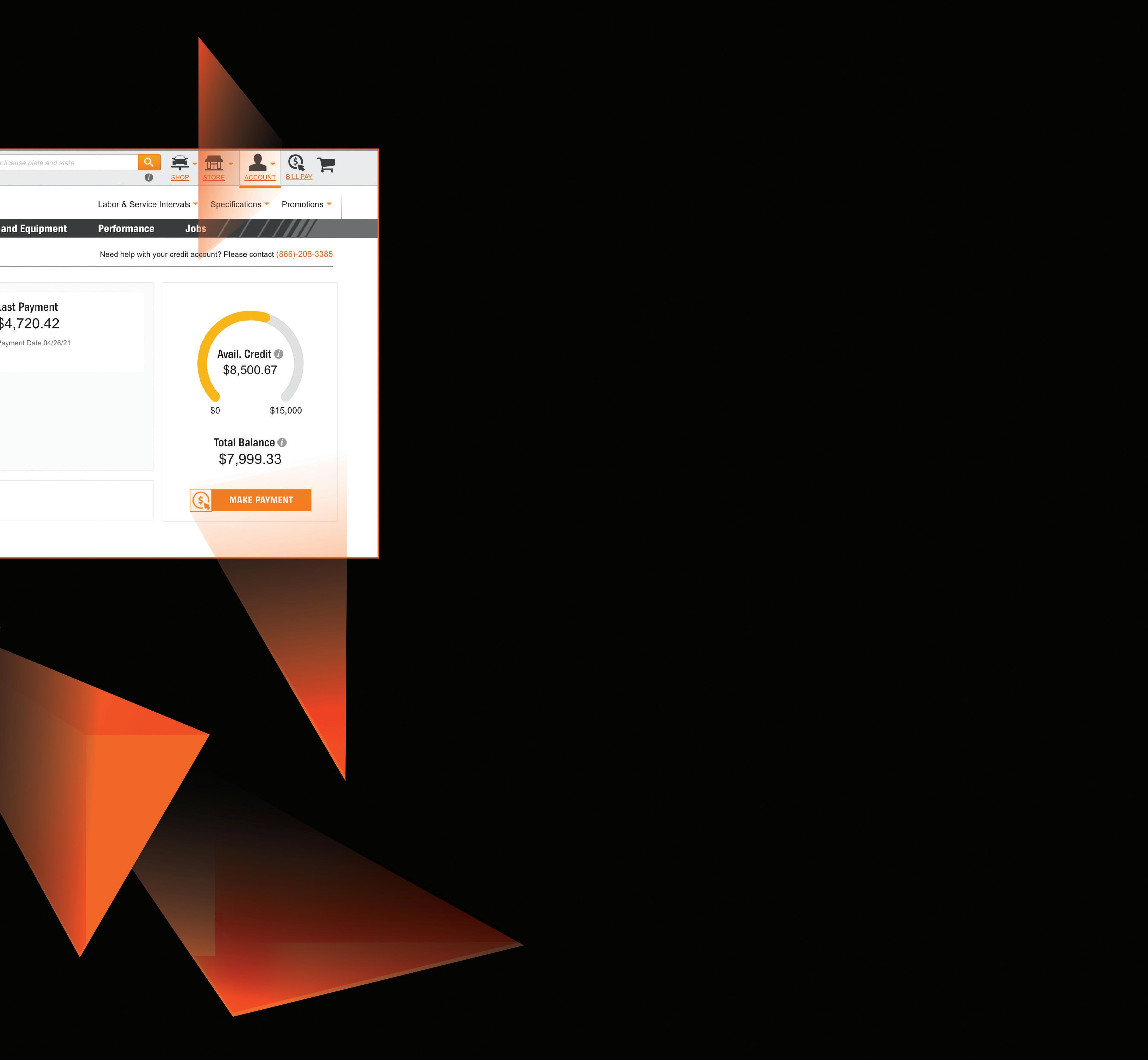

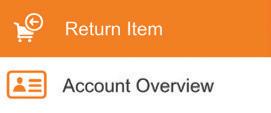

Manage due dates, set payment preferences, view balance, and more with full account management access in one easy-to-use site and one location.

• ACCOUNT OVERVIEW is a quick dashboard to manage all pertinent areas of your account, including credit availability, transaction history, and even bill pay

• Access any transaction history and documentation whenever you need it, even when these transactions were made over the phone

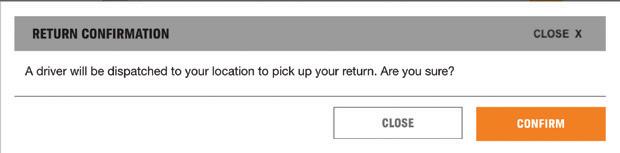

Invoices are immediately available online when you sign for your delivery on the driver’s digital device. Similarly, when a return is received, you’ll be notified by email and your account will be credited in near real time, with documentation available online.

• Conveniently sort by transaction type and date for faster referencing

Intuitive experience that puts all your business needs and activity in one place

Securely save your preferred payment methods for faster, more efficient ordering.

• Your credit limit is adjusted instantly when payments are made to keep your business moving

• Current balance, last payment, and past due information are displayed in real time during the bill pay process for full visibility

The ACCOUNT OVERVIEW dashboard gives a quick, singular look at all your vital account information so you can keep operations moving.

To learn more tips on this feature check out Pro Tips! on AutoZonePro.com

Tips!

We took the hassle out of the mix by looking at your business, along with millions of suppliers and competitors, to price shop for you.

Using multi-sourced intelligence for competitive pricing, specific to your shop’s needs.

Designed to give you profitable pricing on the parts you buy most.

IF YOU NEED MORE HELP, CONTACT OUR SUPPORT DESK AT ELECTRONIC.ORDERING@AUTOZONE.COM OR CALL 866-853-6459

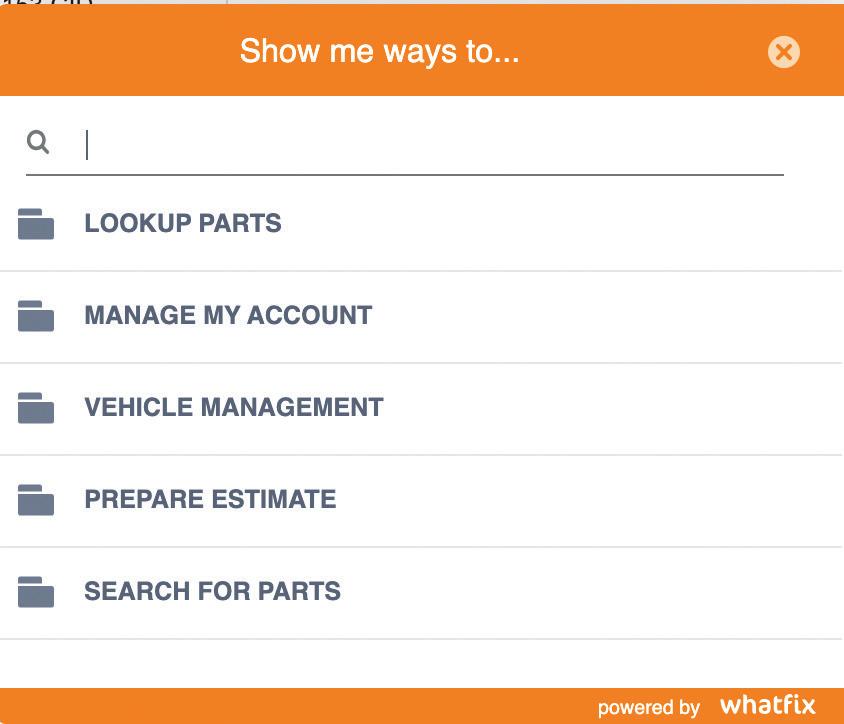

Check out the new PRO TIPS! online help tool. With dozens of help topics available, the Pro Tips! tool walks you through step-bystep instructions visually, so it’s easy to learn how to do something new. Always available on the right side of your AutoZonePro.com window.

Reference the orange boxes that pop-up to find more information.

When your ProTips! subject is listed with a play button icon, click to watch a short instructional video.

Type in the search bar under “Show me ways to...” or click on the relevant folder below

Always available on the right side of your AutoZonePro.com window – or click and drag to reposition it to somewhere that suits you better.