https://jobs.tdworld.com/search

https://jobs.tdworld.com/search

Group Editorial Director Nikki Chandler nchandler@endeavorb2b.com

Managing Editor Jeff Postelwait jpostelwait@endeavorb2b.com

Senior Editor Christina Marsh cmarsh@endeavorb2b.com

Associate Editor Ryan Baker rbaker@endeavorb2b.com

Art Director Susan Lakin slakin@endeavorb2b.com

Field Editor Amy Fischbach EOUeditor@endeavorb2b.com

Technical Writer Gene Wolf GW_Engr@msn.com

Community Editor Rich Maxwell tdwmediapartners@gmail.com

Senior Editor-at-Large Geert de Lombaerde gdelombaerde@endeavorb2b.com

VP, Market Leader, Energy Diana Smith dsmith@endeavorb2b.com

Director, Business Development Steve Lach slach@endeavorb2b.com

VP, Customer Marketing Angie Gates agates@endeavorb2b.com

Senior Production Operations Manager Greg Araujo garaujo@endeavorb2b.com

Ad Services Manager Shirley Gamboa sgamboa@endeavorb2b.com

Audience Marketing Manager Sonja Trent strent@endeavorb2b.com

Audience Development Manager James Marinaccio jmarinaccio@endeavorb2b.com

Endeavor Business Media, LLC

CEO: Chris Ferrell

COO: Patrick Rains

CRO: Paul Andrews

Chief Digital Officer: Jacquie Niemiec

Chief Administrative and Legal Officer: Tracy Kane

Chief Marketing Officer: Amanda Landsaw

EVP Endeavor Business Intelligence: Paul Mattioli

EVP Building, Energy and Water Group: Mike Christian

T&D World (USPS Permit 795-660, ISSN 1087-0849 print, ISSN 2771-6651 online) is published monthly by Endeavor Business Media, LLC. 201 N Main St 5th Floor, Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI, and additional mailing offices. Canadian GST #R126431964.

POSTMASTER: Send address changes to T&D World, PO Box 3257, Northbrook, IL 60065-3257.

SUBSCRIPTIONS: Publisher reserves the right to reject non-qualified subscriptions. Subscription prices: U.S. ($137.50); Canada/Mexico ($170.00); All other countries ($210.00). All subscriptions are payable in U.S. funds.

Send subscription inquiries to T&DWorld, PO Box 3257, Northbrook, IL 60065-3257. Customer service can be reached toll-free at 877-382-9187 or at tdworld@omeda. com for magazine subscription assistance or questions.

REPRINTS: To purchase custom reprints or e-prints of articles appearing in this publication, contact Reprints@endeavorb2b.com

PHOTOCOPIES: Authorization to photocopy articles for internal corporate, personal or instructional use may be obtained from the Copyright Clearance Center (CCC) at 978-750-8400. Obtain further information at copyright.com

PRIVACY POLICY: Your privacy is a priority to us. For a detailed policy statement about privacy and information dissemination practices related to Endeavor products, please visit our website at www.endeavorbusinessmedia.com

CORPORATE OFFICE: Endeavor Business Media, LLC, 30 Burton Hills Blvd, Ste. 185., Nashville, TN 37215, U.S.; www.endeavorbusinessmedia.com.

© Copyright 2024 Endeavor Business Media, LLC. All rights reserved. Printed in the USA.

BY NIKKI CHANDLER, EDITORIAL DIRECTOR

This November, I had the privilege of leading a fireside chat at the Utility Broadband Alliance Summit and Plugfest on how utilities can prepare for the energy surge from data centers, as well as AI, EV and cryptocurrency. As with any open discussion, the conversation took its own shape as the panelists addressed questions on how the stability of the grid may be affected, what engineering challenges are being faced, and how broadband communications plays a role in modernization of the grid (to address the energy transition and that energy surge). I was joined by Jack Janney of Southern California Edison, David Hulinsky from Black & Veatch and Ali Shah of Nokia.

I had been invited to the event more than a year prior when I met with Anterix’s Ryan Gerbrandt, one of the founding members of UBBA, and since it was in Kansas City, where I live, I couldn’t pass it up. But beyond that, T&D World is planning to cover more stories on utility communications in the next year.

It has come full circle for me, as I joined a magazine called Mobile Radio Technology right out of college after interning with Transmission and Distribution World. We covered communications for mission-critical applications, utilities being part of that. Back then, utilities used land mobile radio for day-to-day operations (and many still do). Automation was becoming more widespread for utilities, but we hadn’t yet come into “smart grid;” we were just on the horizon of “big data.” Power-line carrier systems were used, which carried both voice and data. Starting in the 1980s, licensed 900 MHz point-to-multipoint radio systems became popular, especially for small substations. These systems provided cost savings over leased phone lines and were under the complete control of the utility company.

In the 1990s, unlicensed 900 MHz mesh radio systems were installed and added to the communications networks. The industry thought initially that these radio systems provided undetermined communication response times and were not suitable for monitoring and control. However, with proper design and management, these systems came to meet the requirements.

The idea of a smart grid with advanced technology and communication capabilities began to emerge in the early 2000s. Here we are in 2024, and smart grid had turned into grid modernization. And with grid modernization comes more complicated communications needs for utilities. So utilities turned to networks owned by cellular providers such as AT&T and Verizon. This may work for a while, but it leaves utilities subject to outages and limited functionality (and bandwidth). Just this past February, AT&T suffered an outage reportedly affecting public

safety communications. I didn’t find any reports from electric utilities but that drives home the riskiness of using a third-party telecommunications firm.

As I walked into the keynote session at the UBBA event, I heard Burns & McDonnell CEO Leslie Duke mentioning the very topic my session would be covering, as well as the main topic of conversation at events the second half of this year: data center demands. She mentioned that 38 GW is the peak demand growth in electricity that grid planners forecast for the United States through 2028, driven by growth of data centers as well as onshoring more manufacturing, EVs and artificial intelligence.

So how do we meet the demand? We know the answer is multifaceted. There may not be a single answer. One of the ones I hadn’t considered yet is private LTE networks. You must think about what it takes to modernize the grid. And one of those components is the telecommunications system supporting it. Duke stated it simply: “PLTE is a way to achieve goals.”

It has pushed utilities to take charge of their own telecom infrastructure. Big names like San Diego Gas & Electric, Evergy, Ameren, Xcel Energy, Tampa Electric and Southern Company have all moved to private LTE networks. They’re using these networks for their internal communications and to manage the millions of devices in the field—from sensors and smart meters to digital substations. And it’s not just the major investor-owned utilities.

In August, Ericsson announced a landmark collaboration with NRTC, Southern Linc and Anterix to deliver private network solutions to electric cooperatives of all sizes and service terrains across the United States.

My utility, Evergy, as mentioned above, worked with Burns & McDonnell in designing its private network and supporting the build-out management. Evergy is deploying Ericsson’s cloud-native dual-mode 5G Core and private RAN network, which supports both LTE and 5G, allowing for a transition to future 5G services. Ericsson is also supporting Evergy’s ability to rapidly expand PLTE to enable grid modernization applications. Evergy expedited the cell site build plan and launched the first site in May 2022, which was less than two months from the project award.

A 2021 survey conducted by the Utility Broadband Alliance to gather feedback on broadband infrastructure strategies’ challenges and needs revealed a lack of education on the issues as the greatest challenge in supporting a broadband network, as well as a lack of communication network expertise. The report concluded that “Utilities need to prioritize a strategic communications roadmap addressing the opportunities and challenges presented herein.”

Iread many reports, studies, and white papers in the course of researching for this monthly segment on trending digital technologies impacting the power grid. I think of it as a way to increase my digital literacy and keeping up with the transition into the digital era. With the December shopping season, it’s easy to keep track of the latest technological gizmos. My virtual inbox is full plus there are pop-ups from online searches. This month I decided to catchup on Wi-Fi and wireless networking for my virtual office, which meant digging into Wi-Fi 7 (IEEE 802.11be).

Of course I got sidetracked by a study from Dell and the Institute for the Future. As I read the report, one thread caught my eye. It said that 85% of the jobs that will be available in 2030 haven’t been created yet. Wow, given the short timeframe, that doesn’t seem possible, but thinking over the past few years it’s feasible. It wasn’t that long ago when the remote workplace was a niche item. Just a short time ago generativeAI was unheard of, today it’s part of our smartphones along with our cutting-edge software.

53% to 57% of the remainder of workforce are hybrid workers (working on- and off-site). They also noted the virtual office is still defining itself. Also, both sides of the issue are benefiting too much to stop, so the best thing is to stay informed about the technology.

Wi-Fi’s wireless connectivity plays an important element in both our virtual offices and the digital era’s transition. A report from the Wi-Fi Alliance projected that 4.1 billion Wi-Fi devices will ship in 2024 and by the end of the year there will be about 21.1 billion Wi-Fi devices in use. All of those devices used in the digital era transition need standards like IEEE 802.11be. By the way, the folks at IEEE are busy laying the groundwork for 802.11bn, which will probably be known as Wi-Fi 8, but that’s a story in development right now.

The standards and spec-sheets that define Wi-Fi 7 technology show it’s a solid upgrade with significant advancements over its predecessors. Keeping it simple, today’s Wi-Fi 7 is faster and more stable than ever before. It also boosts extremely low latency (the time it takes for data to travel). And it’s ability to manage massive numbers of connected devices is incredible. Its data management abilities are extraordinary with multi-link operation and wider channels, but there are plenty of in-depth reviews if you want more information.

Without realizing it, we have become ensnared in the digital era. Interestingly some have embraced it, others are apprehensive, while many try to ignore it. For those who have come to terms with the digital era, it’s best to stay on the high-side of the learning curve. That’s why improving my digital literacy scores are high on my priority list. It’s also why the quest to understand more about Wi-Fi 7 started. Wi-Fi 7 is enmeshed in the off-site office, but my probe led me to some news stories about employers pushing to end the remote workplace.

More exploration into this complicated issue revealed several studies that determined between 25% to 30% of workforce who can work remotely do. In addition, between about

There is, however, one negative trait of Wi-Fi 7 that has been getting more attention than it deserves. When Wi-Fi 7 was first introduced it was expensive, especially when compared with Wi-Fi 6E devices, but that’s changing. With holiday shopping taking place, the retailers have already started making Wi-Fi 7 routers competitive with Wi-Fi 6E. That’s important because routers are usually the first step in upgrading our wireless networks.

In addition, pricing for Wi-Fi 7 compliant laptops is starting to soften. It’s a good bet that as the December holiday spending heats up, both online retailers and the bricks-and-mortar segment will offer bigger discounts. One of the nice things about technologies like Wi-Fi 7 is they tend not to be disruptive. Rather, they’re quietly advancing the digital era’s transition. It may be redefining everything, but it’s still comfortable.

It’s a good time to be working with emerging digital technologies. We’re constantly learning, relearning, and in some cases unlearning as we work to stay current. Think back, at one time virtual meetings were very uncomfortable, but today they’re part of the tech-landscape. Understanding technologies takes work, but what doesn’t?

Integrated solutions are required for our interconnected power grid.

There’s a transition taking place in the power grid. Actually there are a number of transitions taking place and it’s a normal continuous process. Some are in the foreground while others are in the background, but there are many occupying the middle ground quietly shaping the grid. That takes a lot of time and effort to keep up with it all and stay current. We do have one advantage, these transitions are usually related to each other by the common thread of improving the power delivery system through digital technologies.

Take power electronics for example. It’s one of the longest running and most dominant transitional forces in the power industry with its roots extending back decades. It’s applications are changing the way power grid operates. Essentially it is used for conversion, control, and conditioning of electrical power. This transformation shows no signs of slowing down. Several authorities say that roughly 70% of electrical energy in the U.S. is now processed through power electronics. They don’t see it stopping until that figure increases to 100%, which confirms its influence, but it hasn’t been without some bumps along the way.

Consider the initial deployment of wind and solar generation with their BESS (battery storage systems) backups. These energy sources produce DC (direct voltage) electricity, which needs to be converted to AC (alternating current) for grid use. That requires an inverter, but those available at the time could not handle grid disturbances without tripping. Inverter technology advanced producing grid-forming inverters, which can manage grid disturbances without shutting down.

When increasing numbers of renewables started replacing large coal-fired generators another difficulty was discov -

ered. Grid-inertia was removed with the retirement of the traditional generators, which impacts grid stability. The grid-forming inverter was developed and combined with advanced digital controls to address the grid-inertia issues, but more on that later. There are more examples, but this gives the idea. Power electronics is such a versatile technology that many experts call it the power grid’s equivalent of the Swiss-Army knife.

This might be a good place to look closer at what power electronics is. Basically, power electronics is the utilization of solid-state electronics to change current and voltage levels and shapes. It improves power transfer, enhances reliability, and increase system efficiencies while strengthening grid stability. Two applications of interest to this discussion are HVDC (high-voltage direct current) and FACTS (flexible alternating current transmission systems) controllers.

HVDC transmission has become the technology of choice when it comes to transporting large blocks of power over extreme distances. It’s the evolution of VSC (voltage source converter) based technology that’s of interest. It’s redefining both HVDC and FACTS applications being utilized by the power delivery system. Let’s look at FACTS closer.

FACTS controllers can address and improve localized performance issues like power quality and frequency support. The most common FACTS controllers are TCSC (thyristorcontrolled series capacitor), SVCs (static VAR controller), STATCOMs (static synchronous compensators), and UPFC (unified power flow controller) to name a few. Adding VSCbased technology to the controllers provided faster dynamic response and better regulation.

Prior to FACTS controllers, utilities had few options when it came to voltage support, but that changed as SVCs and STATCOMs became available. The technology quickly advanced with more types of FACTS controllers. These device were able to quickly respond to the fast-changing system conditions found in the power system’s dynamic environment and provided the sophisticated tools operators needed, but it doesn’t stop there.

Power electronics has many other offshoots that are important for a holistic approach to the improvement of the power gird such as the spread of intelligent electronic devices (IEDs). They have integrated every aspect of the power delivery system producing real-time data, which feeds powerful computers using sophisticated software and artificial intelligence improving dynamic monitoring and management systems. This

new outlook confirmed that the power grid and its issues were more interconnected than previously thought.

Traditionally FACTS controllers and VSC-HVDC applications were utilized as more of a localized remedy applied to a limited problem. A better perspective revealed some issues were more far reaching, requiring a coordinated effort to correct. Utilities and grid operators were able to see that an all-inclusive approach has benefits over stepwise applications. With that in mind, it’s once more time to talk with the expert. “Charging Ahead” contacted Inés Romero, vice president of Hitachi Energy’s Product Management and Strategy (Grid Integration).

Ms. Romero began the discussion saying, “The challenges facing the power grid are increasing in both numbers and complexity. We see increasing amounts of renewables being installed on the grid while coal-fired generator are retiring in greater quantities. Lower available inertia can produce variable power flows whose predictability is lessening. There is also a growing need to expand power grids to connect more clean energy and avoid congestion. In addition, the load demand is growing faster than expected requiring more clean generation be quickly connected to the grid. Addressing these issues and others is a growing concern for everyone associated with the global power grids.”

Romero continued, “Hitachi Energy believes that the power industry needs a holistic approach as the power grid

transitions to a more efficient and responsive energy system. Grid-enSure is a fully integrated portfolio based on advanced power electronics managed by cutting-edge control systems that was developed for today’s power grid. It encompasses HVDC, MVDC (medium-voltage direct current), STATCOMs, enhanced STATCOMs, energy storage solutions, and semiconductor technologies. Hitachi Energy designed GridenSure specifically to improve stability, flexibility, and resilience of the power grid. It’s an integrated portfolio designed to strengthen the power delivery system.”

Ms. Romero explained, “It’s all about what utilities require to improve their ability to meet their customers’ demands. If they need to move large blocks of power across extremely long distances, then VSC-HVDC is the technological solution. When backup power is needed there are battery technologies available to provide it. Batteries can also support voltage and to some extent frequency support, but if grid-inertia is the problem then enhanced STATCOMs offer an optimal solution. Enhanced STATCOMs quickly provide synthetic inertia by utilizing supercapacitors controlled by high-power semiconductors. Supercapacitors can store hundreds of megawattseconds of power and release that power within microseconds of a disturbance occurring.”

Romero said, “Inertia has become one of the biggest concerns on the power grid, but Grid-enSure remedies that and many other issues with advanced power electronics

OUR WUNPEECE TRANSMISSION SPACERS REDEFINE THE INDUSTRY STANDARD FOR UNDERGROUND POWER TRANSMISSION INSTALLATIONS. WITH PRECISION ENGINEERING AND UNMATCHED QUALITY,

and state-of-the-art control systems. Whatever the customer needs for their energy system, the Grid-enSure portfolio can provide it.”

Earlier this year, the German TSO (transmission system operator) TransnetBW announced they had signed an order with Hitachi Energy for two enhanced STATCOM facilities. They will be installed in substations at Wendlingen and Oberjettingen, Germany. The installations will provide almost 2 gigawatts of grid inertia from the 2x250 MVAR gridforming enhanced STATCOMs. There will also be a 150 megawatt storage system included. The construction will start in 2025, and the devices will be operational in 2028.

It’s hard to believe that power electronics started out so long ago with the mercury-arc rectifier. From today’s viewpoint, it has been an exciting evolution of power semiconductors moving from kilowatts to gigawatts while reducing their footprint substantially. It’s been a steady progression of innovative technological advancements, with a growing interconnectedness throughout the power grid. By integrating digital technologies massive amounts of big-data have been created. Big-data requires sophisticated dynamic operating and management systems to convert it into useful information. Digital-twin technology creates a virtual model of the grid. The information allows real-time monitoring of its operation and its behavior. It takes the operator to a new level of connectivity and controllability.

On a more tangible side, consider groups of digital substations acting together to address congestion with information supplied by IEDs on the transmission and distribution system. The flow of information drives FACTS controllers working in combination with other controllers and VSC-based HVDC elements to manage power flows, grid stabilization, reduce system losses, and many other functions needed for a resilient power grid.

Some of this may sound like science fiction, but all of the technologies mentioned are off-the-shelf. They are available today and the amazing thing is it’s all still evolving and advancing, which is good because they’re the key to mitigating complex power system problems. Clean energy brings some of the most challeng-

ing power distribution issues, but it’s doubtful that renewable generation or distributed energy resources are going to be declining in the future. Demand for power is not going away and neither is grid congestion.

Remember that old saying, “the whole equals more than the sum of its parts?” It’s true and our 21st century power grid needs holistic systems. By operating power electronics together it’s possible improve the grid while maintaining its system integrity. Those who take advantage of it are going to be glad they did. Those who don’t will be fighting the forces of evolution, which is never good!

The Swedish utility has used lightweight covered conductor, or tree wire, for decades and has developed a budget outline to guide its investment.

By PETER IPSEN, E.ON

Often referred to as tree wire in the U.S., covered conductor is used widely by E.ON in Sweden to ensure power continuity for its customers as well as the safety of its line crews. The technology was developed by Swedish cable company Amokabel in the 1990s in response to heavy winter storms causing trees to fall on lines. It has been improved over the years into the product it is today.

In many cases, covered conductor maintains supply even when a line has been downed. However, E.ON aims to minimize any risk to third parties, so its line crews respond as quickly as possible and prioritize the order in which fallen trees are removed.

This type of lightweight covered conductor system was developed for restringing existing poles. Rather than being bare wire, covered conductor has three protective layers made from modern lightweight polymers. This prevents electrical faults by stopping tree branches and foliage from coming into direct contact with live conductors. It has been deployed widely across E.ON’s 89,000-mile (143,000-km) network, particularly on 20-kV lines running through forested areas.

E.ON has upgraded its entire network with covered conductor, and no longer has any bare wire. Now, its current focus is on increasing grid capacity. Sweden’s electricity demand is forecasted to double by 2045 due to growth in electric vehicles and heat pumps, as well as the connection of distributed renewables and the electrification and decarbonization of industry. Today, E.ON uses conductors with cross-sectional areas of 62 sq mm, 99 sq mm, 159 sq mm and 241 sq mm (122.4 kcmil, 195.4 kcmil, 313.8 kcmil and 475.6 kcmil), depending on loads. The utility foresees upgrading covered conductor lines to higher crosssections and higher voltages — for example, 52 kV — to cope with future demand and allow for spare capacity.

This rolling program has given E.ON extensive experience with covered conductor. The utility has developed a budget outline to guide its investment. The outline uses a typical project cost for three

phases of almost SEK 660,000 per km (approximately US$100,000 per mile).

This assumes a medium to challenging terrain in which a crew can cover 2 km (1.2 miles) per week. However, the timescales and costs can vary depending on the complexity of work, terrain and other site-specific factors. A project factor can be applied to account for more challenging conditions, while simpler projects away from roads are less costly because traffic management is not needed.

The budget accounts for 49 hours of engineering design and project management. This includes analysis of the line to evaluate the terrain and the procurement of materials, such as accessories, additional bracing and other site-specific needs. It also includes establishing a work plan, developing an environmental plan, and securing permissions and consulting with landowners, local authorities and road authorities.

Other costs include arranging permits for traffic closures and securing traffic barriers to protect line crews and members of the public.

When it comes to on-site labor, the budget includes 142 hours for E.ON’s line crews, which are typically three or four strong. Once on-site, they establish and prepare the site and put appropriate traffic management in place. The simplest approach is to have a guard in place during the line-pulling work. Then it is pulled without slack to maintain the line height in the intersection, or a catch line can be set up. In some projects, automated traffic lights might be used.

Electrical work starts with switching to temporary lines. The team checks the status of poles and mounts additional bracing and anchoring, if necessary. Then the team dismantles and restrings the conductor onto the existing poles and adjusts or moves some poles if needed. The next step is to make connections and carry out switching to return the line to live status.

The most cost-effective approach is to assess the condition of existing poles before starting work and beginning the outage. This means any need for pole replacements, repairs or reinforcements is known in advance and can be planned for properly.

E.ON’s policy during line renovations is to replace all end poles and angles as a preventive measure. These are the hardest to replace during a storm and take the most time. The utility believes this standard requirement is worth the additional cost.

When

or four strong.

Another important factor to consider when replace existing poles is — when changing the conductor, for example, from aluminum conductor steel-reinforced (ACSR) 62 to covered conductor 62 — it becomes almost like pulling up ACSR 99 in terms of forces and weight. So, it is important for the poles to

be dimensioned accurately. E.ON learned this the hard way when the covered conductor held up under fallen trees but the poles did not.

The budget outline also allows for materials, machine hire and other costs. The baseline cost is calculated based on restringing

● Nordic’s PSP-151530-MG-CB-FIBER pedestal is the enclosure for a fiber optic enclosure.

●Lockable & Removable lid allows open access foreasytrainingoffiber strands inside the flared base.

●Pedestal’s built-in mounting bracket makes it easy to attach the fiber optic enclosure.

●Large expansive interior cavity for easy fiber enclosure installation.

●Accommodates a variety of fiber enclosures

●The word “FIBER” is imprinted on the top lid.

●*Hand holes available for other fiber applications.

three phases using conductor with a cross-section of 159 sq mm (314 kcmil), one of the larger cross-sections E.ON uses. Accessories also are included for jointing, bracing and anchoring as well as for rerigging or adjusting poles, if needed.

When it comes to installation and handling of covered conductor, E.ON line workers have said it is similar to working with bare wire. In contrast, the alternative approach of undergrounding is similar to laying water mains or gas pipelines.

The type of covered conductor E.ON uses is based on a fully sealed system, which protects the line from water ingress.

This requires the use of connectors that pierce through the insulation to make an electrical connection between conductors, while a mechanical clamp holds the connector in place and seals the joint against moisture. Each connection can be completed within seconds, as there is no need to strip insulation to make connections.

Lightning protection is another important factor for covered conductor because lightning arresters must be installed at key points (equipment poles, covered conductor to bare and underground transitions, and dead-ends).

To ensure crews have the skills and knowledge to tackle any overhead equipment they might face in the field, E.ON has its own training camp for technicians and contractors.

The camp includes every type of equipment a connection technician might encounter on E.ON’s real-world network, including poles, overhead lines, earth cables, cable cabinets, cable terminations and network stations. Every type and configuration of pole on the network is represented, with composite and wood poles, as well as all types of angles and end poles.

A low-height area provides an opportunity for practical demonstrations and hands-on learning without having to work at height. The camp also includes small substation demonstrators for crews to learn about transitioning between underground and overhead lines.

Located in the Swedish town of Alstermo, the training camp has helped to cut development time and improve product quality since covered conductor technology was first developed in the 1990s. It is hosted by Amokabel, which is an immediate neighbor and a manufacturer of covered conductor. The camp gives E.ON’s line crews an opportunity to provide feedback to the manufacturer on their experience working with conductors and accessories.

While covered conductors were developed to protect power continuity for customers during Nordic storms, it also can be used for other applications. For example, it is being used in Australia to cut wildfire risk as it is fully covered to prevent sparking, while being lightweight and resistant to abrasion and ultraviolet rays

PETER IPSEN is a highly experienced Technical Expert at E.ON Energidistribution, Sweden. He specializes in the design, implementation, and optimization of energy distribution networks and is a long-term member of various technical committees, including SEK, the Swedish national standardization body for electrical standards.

Orlando Utilities Commission uses real-time monitoring to pinpoint why a large manufacturing plant was suddenly experiencing outages.

By MELVIN LIWAG, Orlando Utilities Commission; CHARLIE NOBLES and CORY STEWART, Ubicquia

Power quality is a cornerstone of reliable electrical service, particularly for large commercial and industrial customers. Poor power quality can lead to costly disruptions, equipment damage and operational inefficiencies, making it essential for utilities to ensure consistent and clean power delivery. According to the Electric Power Research Institute (EPRI) 2022 Power Quality Tech Newsletter, poor power quality costs U.S. businesses more than US$145 billion annually.

Power quality events can halt entire production processes, often occurring 20 times to 30 times per year, with a 1-second outage costing industrial and digital economy firms $1477 per second. A ResearchGate paper, the Consequences of Poor Power Quality — An Overview, by Sharmistha Bhattacharyya and Sjef Cobben of the Technical University of Eindhoven in The Netherlands, shows 70% of power quality issues occur on the customer side because of equipment operation and wiring, with the utility often shouldering the blame for poor power quality.

The technology to spot power quality problems and their causes — no matter whose side the issue is on — plays an integral

role in preventing future interruptions and outages as well as providing accurate information to forge a solid partnership with the customer.

Orlando Utilities Commission (OUC), the 14th largest municipal utility in the U.S., has long prioritized reliability — serving over 242,000 metered accounts, including 32,000 commercial and industrial clients, in Orlando of Orange County and St. Cloud of Osceola County. OUC’s 418-sq mile (1083-sq km) service territory includes significant installations such as an international airport, nationally recognized tourist attractions, major health care facilities, and large-scale manufacturing and supply chain operations.

For nearly six years, OUC provided uninterrupted power to a large manufacturing plant in Orlando, thanks to infrastructure designed for maximum reliability. The plant was served by three dedicated underground feeders and 10 three-phase transformers, eight of which were 2500-kVA units. These transformers

Network Operations Center (NOC) at Ubicquia headquarters.

were part of an engineered system featuring automation capabilities, such as auto-transfer switches that could switch to backup power sources within two seconds of a disruption. This

setup was critical, as it ensured the manufacturer could operate without interruption — even during hurricanes and daily thunderstorms, common in Central Florida.

You Should Turn to

•Undergrounding Research

•Webinars, White Papers & Presentations

•Reference Library & Helpful Links

•Power Delivery Expertise

As professionals from the North American power industry value chain, PDi2 members work to determine the most viable, reliable, resilient and cost-effective solutions for the installation of transmission and distribution systems. PDi2 educates stakeholders on investment decisions based on data-driven life-cycle cost analysis.

Join the Discussion Today!

For more information, go to pdi2.org, email info@pdi2.org, or call (703) 212-7745.

However, that changed in 2022 when the manufacturer experienced unexpected partial power outages and low-voltage events. These events caught the utility off guard, as the system had previously withstood numerous challenges, including Category 3 and 4 hurricanes such as Irma, Ian and Idalia as well as many tropical storms, without issue.

OUC began a thorough investigation to pinpoint the cause, deploying temporary data loggers and pulling historical data from meters to discover why certain transformers were blowing fuses. While these tools were effective for basic monitoring, the utility needed more detail to diagnose the complex power quality issues. Because two meters were connected to the customer’s 10 transformers, providing data every 15 minutes, and the data loggers only held two weeks of data, OUC installed two power quality meters to gather more precise data.

With access to more data points, the utility discovered that three transformers linked to the outages were overloaded. However, it still required more information to understand the root cause of the issue. Seeking to understand the partial outages better, the utility visited with the plant engineer and discovered the manufacturer had recently installed an 800-hp compressor and an entire process line wired to a fully loaded transformer. Each time the compressor started, it brought the transformer well above its current rating and caused bayonet fuses inside the transformer to blow several times.

OUC continued using its older monitoring equipment and discussed with the customer about transferring loads for better balance. At the same time, the utility discovered a solution that could obtain a real-time view of the customer’s power quality issues, especially the load profile, which could help the utility to be more proactive and prevent problems.

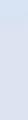

OUC learned from another utility about Ubicquia’s UbiGrid Distribution Transformer Monitor (DTM+) and UbiVu AI-driven asset management platform. During a planned outage, OUC installed UbiGrid DTM+ units on the three overloaded transformers.

The impact was immediate, providing OUC with real-time transformer load monitoring, voltage, internal pressure, temperature, and dozens of other monitoring capabilities upstream, downstream and in the transformer. For example, OUC can now monitor the customer’s load profile and see current spikes when a process starts. The utility can detect sags and harmonics, determine the origin and cause, and address them before outages occur or transformers are damaged.

Shortly after the units were installed, the manufacturer experienced another outage over the Christmas and New Year holidays. This time, OUC was equipped with real-time data, leading to a rapid diagnosis. An engineer was able to access the asset management platform from a laptop at home, pinpoint the cause down to the specific transformer and circuit — a blown bayonet fuse — and coordinate a swift response to restore power.

The information helped to guide the field technician to the right transformer to replace the fuse — without having to waste time inspecting all 10 transformers — and coordinate with the customer to reenergize.

With the real-time monitoring units, OUC can provide valuable insights to the customer. With the ability to see overloading transformers, the utility can provide this information to the customer for better load balancing. In turn, this improves reliability and extends the useful life of assets.

OUC can measure a wide range of grid and transformer health factors by monitoring primary current, secondary current and secondary voltage 7800 times per second to gain a more accurate picture of power quality issues. This enables measuring frequency, power factor, sags, swells, harmonic distortion, transients, and critical transformer health data such as temperature, pressure, load, pole tilt and impact. Health reports are delivered every two minutes, and alerts are sent immediately by text or email.

Ubicquia works closely with OUC’s power quality team, establishing alert thresholds and reports, while keeping the utility updated when new analytics capabilities are released.

Building on the success of the real-time monitoring units at the manufacturing plant, OUC plans to expand the technology to other commercial and industrial customers. Future deployments include applications at a new theme park with rides and hotels, opening in 2025, and possible deployments at a growing number of small satellite emergency room (ER) facilities, where reliable power is critical.

ER facilities require a high level of power quality due to the sensitive nature of imaging equipment. This can be challenging because some facilities must be served with overhead feeders,

UbiGrid DTM+ pad mount installation.

making them susceptible to weather, vegetation and wildlife. With new monitoring and analytics capabilities on distribution transformers, the utility’s power quality team is focused on the feeders to improve reliability.

The journey from a sudden power quality issue to a successful resolution is a testament to OUC’s commitment to reliability and innovation. By embracing advanced monitoring technologies, OUC can ensure its customers receive the reliable service they depend on. As the utility looks forward, it sees the continued expansion of smart monitoring solutions playing a crucial role in maintaining and enhancing the reliability of Orlando’s power grid.

MELVIN LIWAG has dedicated 30 years to the Orlando Utilities Commission, establishing himself as an experienced electrical engineer within the electric utilities industry. With expertise in operations and construction management, Liwag excels in the distribution control center and trouble dispatch environment. He is proficient in smart grid project engineering and management, electric distribution design, reliability engineering, and avian and bald eagle conservation. An accomplished engineering professional, Liwag graduated from the University of Central Florida with a BS in Electrical Engineering.

CHARLIE NOBLES serves as the Vice President of Business Development for Ubicquia’s Smart Grid segment. With a focus on expanding Ubicquia’s market presence, he promotes the company’s innovative smart grid solutions, including the UbiGrid platform. Charlie brings a proven track record of success from his tenure at Progress Energy (now Duke Energy Progress) and Sensus, where he delivered key utility solutions to a diverse set of global utility companies.

CORY STEWART is the Utility Solutions Architect for Ubicquia’s Utilities segment. He supports sales teams as a technical SME for presentations and deployments, both in person and remotely. Cory installs UbiGrid DTM+ units on transformers, sets up customers on the UbiVu network, and designs and administers training on product usage. He advises customers on maximizing the benefits of transformer monitors. Cory has over 15 years of experience in technology consulting, including smart grid consulting and power quality analysis.

RTDS Technologies is celebrating 30 years of the RTDS Simulator – the world standard in realtime simulation and hardware-in-the-loop testing. The RTDS Simulator revolutionized the testing process for control and protection systems when it was introduced to the power industry. Today, the technology is at the heart of innovative laboratories in more than 57 countries around the world. Leading utilities, manufacturers, research and educational institutions, and consultants rely on the RTDS Simulator to de-risk new technologies for a secure energy transition.

The electric utility industry is at the forefront of infrastructure related optimization efforts when it comes to addressing the complexities, cross-industry issues, and regulatory challenges.

By PETER ARVAN MANOS, ARC Advisory Group

For all industries, the T&D World Live Conference in Atlanta, GA had very compelling sessions across five tracks of importance, including: AI and Digitalization, Distributed Energy Resource Integration, Electrification and eMobility, Grid Resiliency and Black Sky Hazards, and the Future Transmission & Distribution Grid.

The electric utility industry is at the forefront of infrastructure related optimization efforts when it comes to addressing the complexities, cross-industry issues, and regulatory challenges associated with clean energy, e.g., for freight transportation,

or for heat to replace fossil fuels in industrial processes, or for clean energy for feedstocks in other applications.

Electric service restoration efforts in response to Hurricane Helene are the largest utility industry mutual aid assistance mobilization in U.S. history. Tens of thousands of utility crews from all over the U.S. have been participating in restoration efforts. The scale and depth of the storm’s destructiveness in some areas of the Southeastern U.S. is requiring a full rebuild, rather than mere repair, for portions of impacted T&D systems. While this reduced utility attendance somewhat at the conference, nonetheless, personnel from utilities and their solution and service provider communities participated in numerous productive meetings and panel sessions.

Heroic utility line workers’ collaborative spirit was praised at the conference. Cross-industry collaborations at the conference are also praiseworthy. Utilities’ long-standing traditions of mutual aid point to key wider trends,

because much greater cross-collaboration was evident at the conference in other ways that span across industries who share risks associated with infrastructure and supply chains, including those associated with energy and with transportation, all of which rely directly and indirectly on electric utility service.

Growth areas are impactful, for example, for the oil & gas, chemical, mining & metals, and diverse manufacturing industries, given the economic value and other benefits associated with electrification and replacement of highly GHG emissive processes with cleaner energy sources ranging from renewable electric power to hydrogen to other sources.

To achieve success, innovations driven by competition are an important factor. But it will be insufficient. We also need greater collaboration, and a vision on the part of industry that can appropriately position policymakers to enable the infrastructure resources we all share.

The integration of wind and solar on the electric grid is an enormous success. At a presentation by the California Independent System Operator (CAISO), the fact that the drop in solar output during a partial eclipse last year was handled routinely amazed this analyst, when noting that the one hour drop in question represents roughly the same amount of electric generating ca pacity required to support the five bor oughs and surrounding suburbs of NYC in Con Edison’s territory on a typical day. Con Edison’s current peak is at around 13,000 MW, and when I worked there as an engineer in the mid 1980’s, it was a big deal when peak demand of 10,000 MW was exceeded for the first time — and now this is just a blip on a cloudy day for CAISO’s dispatch of power to compensate for intermittency of solar power…if such fluctuations can be predicted as reliably as a solar eclipse can be predicted.

The ability to integrate renewables, and, going forward, to integrate electric vehicles of all kinds, both require tremendous im provements in the robustness and real-time capabilities of industrial data fabrics in support of advanced analytics, and in the digitation of the electric grid.

At the conference key challenges came to the forefront, along with great successes in meeting some of industries’ prior big

challenges as exemplified by the integration of solar in California mentioned above.

Many of us have said it is good, in the energy transition, to take an “all of the above” approach, one where we support many different tracks on the path to resilient, economical, and reliable energy supplies. But the challenges that came to the forefront during this conference led me to look at the “all of the above” approach with some newfound skepticism. There are several reasons.

First, the use of certain clean energy solutions needs to be seen in a realistic context where different options are viewed and compared in practical ways. Some technologies are less

viable than some people suggest, when it comes to their capacity to economically be reliable elements for new energy supply to meet all the new electric load coming on board. Second, it is not a question about such sources having sufficient technical feasibility. Instead, it is about their only being able to contribute a small portion of the needed capacity.

Two such examples are the use of farmland to create fuels off of the crops grown on the farmland, and second, the creation of biodiesel from reclaimed cooking oil:

• The energy efficiency of PV solar panels is about ten times higher than the rate at which plants convert sunlight to energy, and the use of farmland for “energy crops” instead of using it for crops in our food supply, should generally be shunned, since such high-cost energy sources also elevate food prices. And while making biodiesel from waste cooking oil is a better use of the waste cooking oil, than disposal of the oil in landfills, it is not going to be an important element of our energy mix.

regarding their positioning around hydrogen going forward.

• While my colleagues at the conference laughed when I pointed it out, they agreed with my suggestion that we would all have to increase our consumption of fried foods ten-fold to a hundred-fold, for biodiesel from cooking oil to be any sort of “pillar” of our clean energy supply. It should not be touted as such, but instead should be viewed, simply, as a better way, from a circular economy point of view, of “disposing” of waste cooking oil.

Three big challenges discussed at the conference included the challenges associated with clean hydrogen, the promise of transportation electrification, and finally the unprecedented growth in electric power demand and T&D build-out associated with the massive new data centers quickly being added to our infrastructure.

The benefits of clean hydrogen, if it could be economically pro -

The various technologies for, and challenges of, clean hydrogen were delved into in detail, including the vulnerability of welds in most of our natural gas utility pipe infrastructure to become embrittled if the amount of natural gas put in the mix exceeds 10%. The depth of industrial dependencies on hydrogen currently was highlighted, as was how small the current production levels were for clean hydrogen vs. the volumes of hydrogen in existing use cases overall.

Electrification of transportation will increase the economic and environmental benefits of clean electrification enormously, but will also require a massive increase in the ability of our infrastructure to utilize real-time data and control systems to run optimally and to create new markets for all participants (including drivers of passenger EVs and operators of EV freight trucking fleets). The complexity includes optimizing battery charging and routing of vehicles with widely varying needs.

A fascinating example of the complexities involved was around the benefits of regenerative braking systems on EV freight trucks, since such brakes not only help to charge the battery, but also help to extend the useful life of the friction brakes. If a truck is going to leave its charging station at a higher elevation than its first destination, its battery should not be charged to 100%, since it will exert undue wear on its brakes while going downhill and will lose an opportunity for some “free” charge off the regenerative brakes. A limiting case example given involved an actual use case of a massive EV truck at a mine at the top of a

hill, which charged itself with regenerative braking while going downhill with a full lode of ore, and which was then able to go, empty, back up the hill “for free” in effect, not needing to have charging infrastructure installed for this use case.

The ability to build new electric infrastructure to charge large truck fleets is key, and is daunting, given timing, costs, and real estate issues involved. Many truck depots are in dense industrial areas where real estate to add new electric substation capacity may not be readily available. Many depots lease their space from landlords who have no interest in building out EV charging infrastructure. Seaports came to the forefront as a growing area where such infrastructure can more often be readily built, and where trucks are often going anyway to pick up cargo. Pilot programs for fast charging capabilities, and even for inductively charging with no physical connection between the charger and the truck, were discussed.

Finally, the other big challenge involved how new data centers are being built rapidly, and are enormous, with some coming in at 1,000 MW per data center (i.e., 10% of NYC’s total electric power demand, per data center!). The plans to build or upgrade needed substations and T&D infrastructure often go on fast tracks with these data center projects, based on the enormous demand for the compute power of these data centers, and the deep pockets of the investors involved. They typically, contractually, are expected to run at near 100% of their rated capacity, 24/7, so there is little or no option for most of them participating in peak demand reduction programs to help keep the grid up and running more reliably and economically — the exception is a smaller subset of data centers that are not dedicated to large language models or other AI-driven use cases, but instead have more flexibility to shift load if it is of economic benefit (e.g. this group includes Bitcoin mining data centers).

The three challenges mentioned above are interconnected and can be recast as opportunities.

While new installations of T&D switchgear can enable the faster control capabilities that are needed for a more dynamic grid to take on massive increases in electric vehicles, the existing infrastructure, including capacitor banks, involves

electro-mechanical relays and control systems that cannot respond fast enough for optimal grid operations. Ironically, the tremendous growth spurts in demand for electricity to support new data centers for AI and cloud-based industrial data fabrics, functionally, will be enablers for the more dynamic grid, since the data center’s support for AI and data fabrics is precisely what is required to run the grid in the new ways it will need to be run — so utilities and their industrial, commercial, and residential end users will be among the key users of the new data center’s offerings.

Words matter, and the word “sustainability” has its place, but “risk reduction” is the better term here, in the context of recommendations for how to address our challenges better. And the risk of not stepping up is too great here, vs. the risk of stepping up, to meet the challenges, if they are seen clearly.

Risk reduction should be a cross-industry cultural mandate, and should ideally become embedded in a new generation of better regulatory and market-building structures. It became clear to me during the conference that we need as stern and strict a set of regulations being imposed on the local, state, and federal policymakers, as on industrial and public interest stakeholders. To meet 2050 goals requires a shared vision.

Enter full lifecycle costing capabilities, of a next-gen character. They should build upon, but go far beyond, what we used to call good old “engineering economics,” and should go hand in hand with build-out of big models to support better decisionand policy- making. In the context of energy transition and

industrial sustainability, ARC recently articulated related trends with regard to a System of Systems (SOS) approach.

The best risk reductions are those that are entered into in a collaborative way, per the utility industry’s mutual aid assistance example. The business model upon which mutual assistance was built has been a great success. But it evolved in response to storm situations of the frequency and scale of the past, and, like other infrastructure and severe weather challenges, requires new refinements and improvements.

As was mentioned during the conference, the increasing frequency of line crews being called away to help in restoration

efforts is starting to have negative impacts on the maintenance of the home utility’s T&D systems. A start related statistic is that there have been as many Category 4 and 5 hurricanes in the US in the last 8 years, as in the prior 56 years — an 8-fold increase. Smarter T&D infrastructure, and better hardened T&D infrastructure, represents a shared resource of the industrial and commercial and residential end users who will be enabled to participate in new value areas of economic benefit to all participants.

If, and when, the new smarter T&D infrastructure gets built out, with the needed more real-time capabilities, there is still a regulatory disconnect that must be addressed, one for which, hopefully, the above-mentioned lifecycle costing, and big models, will be deployed. The utility example here has its counterpart in other industries: T&D infrastructure, and underlying baseload power generation infrastructure, has a 2x to 10x longer useful life, than the assets it is being connected to. Below, to provide context for the above recommendations, some examples are shown.

• If a truck depot electrifies, can the investors or regulators who fund and approve the T&D build-out be guaranteed that the electric capacity to charge the truck fleet will be needed after the (relatively much shorter) useful lives of those electric trucks have passed? What if hydrogen replaces electricity as the best fuel source for the freight trucks of the future?

• What if a regulator approves a microgrid at a location, whose economics were a function of the need for power at the end of a certain line, and the economics are ruined by some non-regulated build-out of power generating capacity from some competitor — what is the responsibility of the regulator to the microgrid owner who got permission to build the first facility?

• Similarly, what if some of new data centers being built this year are replaced at other locations by other data centers in a decade or two, at a point in time when the new T&D and generation infrastructure that was built to serve those data centers is still “young” and largely undepreciated?

PETER ARVAN MANOS is Director of Research, Electric Power and Smart Grids, at ARC Advisory Group. Links to his recent work can

The 2024 competition marked the 40th year of the event with more than 1,000 competitors.

By AMY FISCHBACH, Field Editor

The spirit of the International Lineman’s Rodeo has lived on for 40 years. It’s a legacy and tradition that has connected lineworkers worldwide through competition and camaraderie.

Dale Warman, one of the founders of the Lineman’s Rodeo and a 2019 inductee into the National Lineman’s Hall of Fame, says the idea for the Rodeo was inspired by the cowboys, but is all about the line trade. Every event includes skills that lineworkers routinely perform out in the field — whether it’s scaling a wood pole, working with hot sticks and rubber goods, tying a knot or replacing a blown fuse, tie or cutout.

“When we started this, it was all about one thing — it was by linemen, for linemen and about linemen,” he said. “The whole idea was that linemen and their families could enjoy themselves, get away from work and compete in a friendly competition to show their families what they do. It worked well, and it got bigger and bigger.”

While the event launched with only a dozen journeyman teams in 1984, the event has experienced explosive growth to well over 1,000 competitors. In 2024, 227 three-member journeyman teams and 380 apprentices showcased their skills in the hurtman rescue, pole climb and mystery events on the Rodeo grounds.

One of those journeyman teams consisted of three brothers — Jordan, Keith and Tate King — from Xcel Energy in Colorado. Tate King says it’s awesome to be able to be on the same team with his brothers, not only in real life, but also in the trade.

“My dad was a lineman also, and I think he’s proud of us,” King said. “We work together, we go through practice and try to get ready for the Rodeo.”

Due to back-to-back hurricanes in the Southeast just before the event, not all the competitors were able to travel to Kansas City for the Lineman’s Rodeo Week due to ongoing rebuilding and restoration. Those apprentices and journeymen lineworkers who were able to compete, however, kicked off the competition a little before 7:30 a.m. on an unseasonably warm October morning at the Agricultural Hall of Fame grounds in Bonner Springs, Kansas.

Following the American and Canadian national anthems and moment of silence, the announcer signaled the competitors to head to their first events for a full day of competition. Like last year, all the events had to be conducted in full fall restraint, and no free climbing was allowed.

The competitors could also compete in five different divisions — investor-owned utilities; REA, REC and electric cooperatives; municipals; contractors; and military. Within the journeyman bracket, those competitors aged 50 years old and older could also compete at the senior level on journeyman teams. Throughout all the events, the volunteer judges evaluated the competitors on five

main criteria — safety and safe work practices, neatness and ability, equipment handling, timely completion of the event and the ability to follow all event and general rules.

As such, the competitors had to not only try to complete the events quickly but also safely by following all the rules and regulations. Otherwise, they could lose event points and the opportunity to be honored on the stage at the awards night. By watching other lineworkers in action, it gave the competitors like OG&E’s Jeff Stith the opportunity to learn from others.

“It’s our second time competing together, and my favorite part of the Rodeo is the events and the climbing,” Stith said, who was on a journeyman team with Trent Massey and Todd Munson. “It’s a good time and a family event. The weather is beautiful out here, and it’s fun to see all the different competitors from different locations interact with everyone.”

While the roots of the Rodeo are in the Midwest, teams from all over North America now compete at the Rodeo, which has also attracted interest from visitors from England, Brazil, Jamaica,

Poland, New Zealand and Australia among other countries. Canada often has teams competing on the international level at the event. For example, Manitoba Hydro sent two apprentices and three journeyman teams to compete at the 2024 International Lineman’s Rodeo. Chad Williams, a journeyman powerline technician for IBEW 2034 and Manitoba Hydro, competed as an apprentice eight or nine years ago. For this year’s competition, he was on a journeyman team for the first time with Jared Flaman and Matt Lake. The trio finished in the top quarter of all the journeyman teams.

“I love the Rodeo,” Williams said. “It’s cool to see where people come from and how they do it a little differently.”

In the line trade, lineworkers must work together to keep the power flowing and the lights on. Just as they serve on crews back home, the journeyman teams must also compete in teams of three to finish four different events with the maximum number of points in the minimum time frame. Two journeymen serve as climbers while the third member of the team works as a groundman.

As in years past, the journeyman teams had to compete in a hurtman rescue event on a 40-ft wood pole. All three members of the journeyman teams had to participate in the event simultaneously, with the climbers rescuing the mannequin and the groundman using the extendo to open the switch and then laying the hurtman on the ground. The Habersham EMC team of Tucker Dyer, Dillon Welborn and Robert Morris scored the full event points with a time of 01:27:66, earning the top spot in this event in the journeyman division.

Another traditional event, the pole climb, tasked journeyman teams with climbing and descending

the pole without breaking the raw egg. The climber carefully places the raw egg in a small bucket, scales the pole, drops down an empty bucket at the top of the pole, places the egg in his or her mouth, hangs the new bucket on the hook and then climbs down. Once on solid ground, the competitor must show the egg to the judge, who will inspect it for any cracks, which incurs a 10-point infraction.

Ameren Illinois captured the top three spots in the journeyman division in the pole climb with the team of Jacob Carr, Buck Rodgers and Teddy Brinkoetter coming out on top with a time of 1:09:15.

While the journeyman teams could practice back at home for the hurtman rescue and pole climb events, they didn’t know the ins and outs of the mystery events until they arrived in Kansas City for the Rodeo Week and picked up their packets. For the first mystery event, the teams had a maximum time of 17 minutes to replace a bad C-neck tie. The simulated energized event required the journeymen to use materials including shotgun sticks, hoses, a split blanket and more. The IBEW Local 1245 team of Josh Klinka, Dustin Krieger and John Damas inched out the competition with a 10-second lead and a time of 08:34:04.

For the second mystery event, the journeyman teams had up to 20 minutes to replace a solid blade non-load break cutout serving a single-phase tap line at 4 kV. The PG&E/IBEW Local 1245 and SCE Local 47 team of David Angove, Brandon Gloria and Floppy Hunt climbed up to the top of the event with a time of 06:38:28.

The team that won the grand championship trophy, however, hailed from the Marion Operating Center of Ameren Illinois and included Jason Novak, Clayton Gulley and Austin Lewis. The team, who were crowned the best of the best of the journeyman division, were one of only seven teams with a perfect 400 event points and no deductions, but they accomplished it in the lowest time of 20:05:30. Novak says winning the title, “Best of the Best,” was an amazing feeling.

“We practiced hard, but it takes a special day to win it all against the most elite competitors in the world,” Novak said, who has competed at the International Lineman’s Rodeo for more than 20 years. “We developed a game plan before each event, but anything can happen, and we adjusted on the fly. I couldn’t be prouder of how my teammates performed and how the other Ameren competitors did as well.”

Once apprentices have completed four years of their apprenticeship and meet certain criteria, they can compete on journeyman teams, but until then, they must go solo at the Rodeo.

Zackery Goff, a fourth-year apprentice for Pedernales Electric Cooperative, got a three-peat by winning the apprenticeship division, not once, not twice, but three times in a row. Along with winning first place in the overall apprentice category, he also placed first in the REA division, second in the written test category and fourth in the hurtman rescue. He says when it comes to competition, the nerves still definitely kick in, regardless of any wins in the past.

“I really enjoy competing and seeing what I can push myself to do,” he said. “Paying attention to the details is important, and I like the safety aspects of Rodeo competitions, knowing it’s helping me to become better at my trade. It’s also fun being around other people and meeting folks at International.”

For the written tests, he put in a lot of time studying on his own time to learn the material, and for the hands-on events, he says there are many secrets to success on the apprentice level.

“I think it’s a combination of the hard work and practice I’ve put into it, coupled with the mentorship I’ve had through other people taking the time to teach me and help me along the way,” he said. “I’m grateful for that and all the support.”

For 2025, Goff must compete at the journeyman level once he tops out at PEC.

“It’s bittersweet knowing I finished my last competition as an apprentice, but I’m excited for the next phase of my career and look forward to continuing to learn and grow, and hopefully be back next year competing as a journeyman,” he said.

Like the journeymen lineworkers, they must also compete in two mystery events, the pole climb and the hurtman rescue, but they must also take a written test the day before the Lineman’s Rodeo. The 50-question test, which uses multiple choice and true/false questions, is based on content from the 14th edition of The Lineman’s & Cableman’s Handbook. Aaron Paisley, apprentice for Snohomish County PUD, captured the win in the

written test event with only six deductions, which put him ahead of the pack at 94 points.

Like the journeymen teams, the apprentices also had to showcase their skills on pole climbing, which is often something they practice for hours at a time during their apprenticeships. Jack Fletcher from IBEW Local 42 won this event

with a total time of 00:35: 22 and no deductions.

Because it’s important for not only journeymen, but also apprentices to know what to do in the event of an emergency, the apprentices must also compete in the hurtman rescue. Apprentice Clayton Tanner from Ameren Illinois swept the division with a total time of 01:05:50 and a perfect number of points.

The apprentices also had to compete in two mystery events, but they were completely different than those for the journeymen. For the first mystery event, they had up to 11 minutes to complete a transformer outage restoration. They first had to use a telescopic stick to remove the simulated blown fuse. Once the barrel was down and the stick was collapsed and back on the tarp, they could tool up or replace the blown fuse link. After adjusting their fall protection, they could then climb to the

proper working height to retrieve the 8-ft shotgun and remove the squirrel. After returning the shotgun to its location, they had to climb down the pole, replace the blown fuse link and rehang the fuse barrel. Hunter Walton, an apprentice for Flint Electric Membership Corp., won this event with a time of 03:35:61.

For the final mystery event, apprentices had 15 minutes to finish an obstacle course by completing varying tasks at different spots on the pole. For example, they had to ascend the pole and remove the old tie wire and tie pad from the conductor without using knives. They then had to install the new preformed tie wire and tie pad. They also had to exhibit one of the foundational skills of the line trade—rope tying—by tying the two 10 ft tails together with a square knot. Dwight Diaz from IBEW Local 47 finished the event 16 seconds ahead of the closest competitor with a time of 04:33:56.

Following the day of competition, the lineworkers and their families came together for the final time at the awards banquet. The Overland Park Convention Center exhibit hall was transformed into a banquet venue with thousands of competitors and supporters cheering on the victors.

The ceremony began with a performance by Blane Howard, a Nashville recording artist. He revved up the crowd with his take on country classics by musical groups such as Brooks & Dunn with lyrics focused on the hard-working line trade. Next, the ILRA showcased the 40th anniversary video commemorating the history of the event and looking to the future of the International Lineman’s Rodeo.

At the banquet, Dennis Kerr, the co-chair of the ILRA, also honored the 20 scholarship recipients for 2024, and Andy Price from the International Lineman’s Museum inducted six new

individuals for the 2023 class into the Lineman’s Hall of Fame: Hazel Bush, Chad Dubea, James Bowden, Brady Hansen, Mike Hennesey and Harry Reeves. Jason Novak and Paul Koehler, journeymen lineworkers for Ameren Illinois, also brought their families up on the stage to present a check for $83,484 for St. Jude Children’s Research Hospital as part of the 2024 Climbin4kids fundraising campaign.

Another highlight of the banquet was the recognition ceremony for the first Kids Rodeo, organized by Missouri Valley JATC and sponsored by Buckingham Manufacturing. One of the 11-year-old competitors, whose dad is a lineworker for Evergy, says he had fun rescuing a giant teddy bear off of a tower mounted to the back of a truck for the “Teddy Bear Rescue.” Kessler Hilson won first place in the eight- to 10-year-old age group, “1st Step Apprentices,” and Jake Milhoan won the 11- to 13-year-old age group, “Future Lineman.” Both winners were presented on stage with a child-sized championship belt, just like those worn by the grand champions at the International Lineman’s Rodeo.

After honoring the winners of the Kids Rodeo, the ILRA began announcing the names of the top apprentices and journeymen lineworkers in all the events and across all the divisions at the 2024 International Lineman’s Rodeo. Many of the winners received plaques while the top performers brought home trophies for being the “best of the best” in the line trade.

To learn more about the winners and to see more coverage of International Lineman’s Rodeo Week, stay tuned to the Line Life Podcast at linelife.podbean.com and to our website at www.tdworld.com/electric-utility-operations , where we celebrate the line trade not just during Rodeo Week, but year-round. Also, mark your calendars for the 2025 Rodeo, slated for Oct. 15-18, 2025.

BY AMY FISCHBACH, FIELD EDITOR

Bryce Zahn, who competed at the 2024 International Lineman’s Rodeo, recently returned from storm duty restoring power following Hurricane Helene. To learn more about his experiences with this hurricane restoration, listen to the Line Life Podcast at linelife.podbean.com.

I got my foot into the door as a groundman working on a Vac-Tron truck and various other URD work such as boring and stubbing transformers for line installations. I did not go to boot camp or a line school. I had no previous experience really except for a few years working for Comcast.

Working on power lines and in the electrical field has always been something that interested me for years. It wasn’t until the age of 32 I made the decision to pursue this field. I knew one or two people who were lineworkers but they had never talked about their careers. I made numerous phone calls to the union, MoValley and friends and eventually began working as a groundman for Capital Electric. From there I eventually started my apprenticeship and next year I will top out as a journeyman lineman.

As a seventh-step apprentice, I’m currently on an overhead dock crew learning many different things from switching, reconduct jobs, pole changeouts, maintenance work, even some URD, and many other things. My work day currently runs from 7 a.m. to 3 p.m. I am on a three-person crew and am the only apprentice. Our work focuses on dock work for Evergy. I am trained through the experiences we encounter with the work Evergy gives us each week.

• Is a seventh-step apprentice who recently competed in the apprentice division at the 2024 International Lineman’s Rodeo.

• Enjoys spending time with his wife and four children, eating at Texas Roadhouse and helping others. He also loves to hunt and fish.

• Learning how to use meters, different powered hand tools and digger derricks during his apprenticeship.

• Encourages aspiring apprentices to never stop learning and always look for ways to improve and sharpen their skills.

• In the future, he sees the need for grid infrastructure improvements and expansions.

It is challenging to travel to get the required experience especially when you have a family. It’s also difficult to keep up with the bookwork from the JATC.

I think there are a lot more resources available to apprentices now, and the book work is probably more advanced than in the past.

Working storms for me is the pinnacle moments of what I do. I enjoy them thoroughly. I love to help people. I love the giving spirit and the spirit of unity and gratitude that overcomes everyone involved. The working conditions are tough sometimes with long hours, little sleep and being away from your own family. All of these things are part of storming though. It gives me a great sense of pride to work on storms.

I love being a part of this trade. It’s very rewarding and storming is my favorite part. Turning people’s lights back on in a time of loss and devastation is very rewarding.

It takes a good attitude, a good work ethic and perseverance. I would say my best quality is the work ethic my parents helped develop in me.

To stay safe in the field, you must use safe work methods, proper PPE and fall protection correctly.

I see myself as a journeyman lineman and hopefully a foreman eventually. To reach this goal, I plan to continue working hard and learning everything I can possibly learn.

Editor’s Note: If you would like to nominate an apprentice for Faces of the Future, please email Field Editor Amy Fischbach at amyfischbach@gmail.com. All profiled apprentice lineworkers will receive a tool package from Milwaukee Tool.

Lineworkers and their families come together to learn about safety, swap shirts and explore the Expo.

By AMY FISCHBACH, Field Editor

For the line trade, it’s all about keeping the lights and power on for customers. For one special week each year, however, lineworkers and their loved ones travel to Kansas City for the Lineman’s Rodeo. The event celebrated its 40th year in 2024 with line apprentices and journeymen lineworkers from all over North America and supporters from around the world.

To get the Lineman’s Rodeo Week off to a safe start, the International Lineman’s Rodeo Association (ILRA) partnered with its sponsors — Honeywell Salisbury, NECA, Tempest Energy and IBEW Local 47 and 66 — to present a one-and-a-half-day Safety and Training Conference at the Overland Park Convention Center.

“Hopefully these two days will help you guys and gals to be safer on the job,” Chad Schimpf said, a journeyman lineworker for Ameren Illinois who led this year’s safety conference after sharing his personal injury story two years ago. “That’s what the safety conference is all about.”

About 300 people registered for the conference, which was a good turnout for the 40th anniversary of the Lineman’s Rodeo, says Rustin Owen, a member of the ILRA safety and training committee and safety observer at the International Line -

man’s Rodeo. Along with line apprentices, journeyman lineworkers and supervisors, students from Metropolitan Community College-Kansas City actively participated in the safety discussions. Owen says it’s very important for students to attend and learn more their future careers in the line trade. It also reinforces the importance of safety, not just in the classroom, but also when they move out into the field and start their apprenticeship programs.

Beyond the line students, several journeyman lineworkers from the 249th Engineer Battalion also attended the con ference. Owen, who helped to start the U.S. Army Prime Power training school for lineworkers at Fort Leonard Wood in Missouri, says he appreciated having them in attendance.