The era of rigid, siloed industrial software is over. Start building next-gen control systems with Ignition 8.3.

2025

The era of rigid, siloed industrial software is over. Start building next-gen control systems with Ignition 8.3.

2025

Useful and effective data analytics begin with matching the right tools to the right tasks

With an experienced partner, you can achieve more.

Optimizing processes and maximizing efficiency is important to remain competitive. We are the partner that helps you master yield, quality, and compliance. With real-time inline insights and close monitoring of crucial parameters, we support manufacturers to optimize processes, reduce waste, and increase yield.

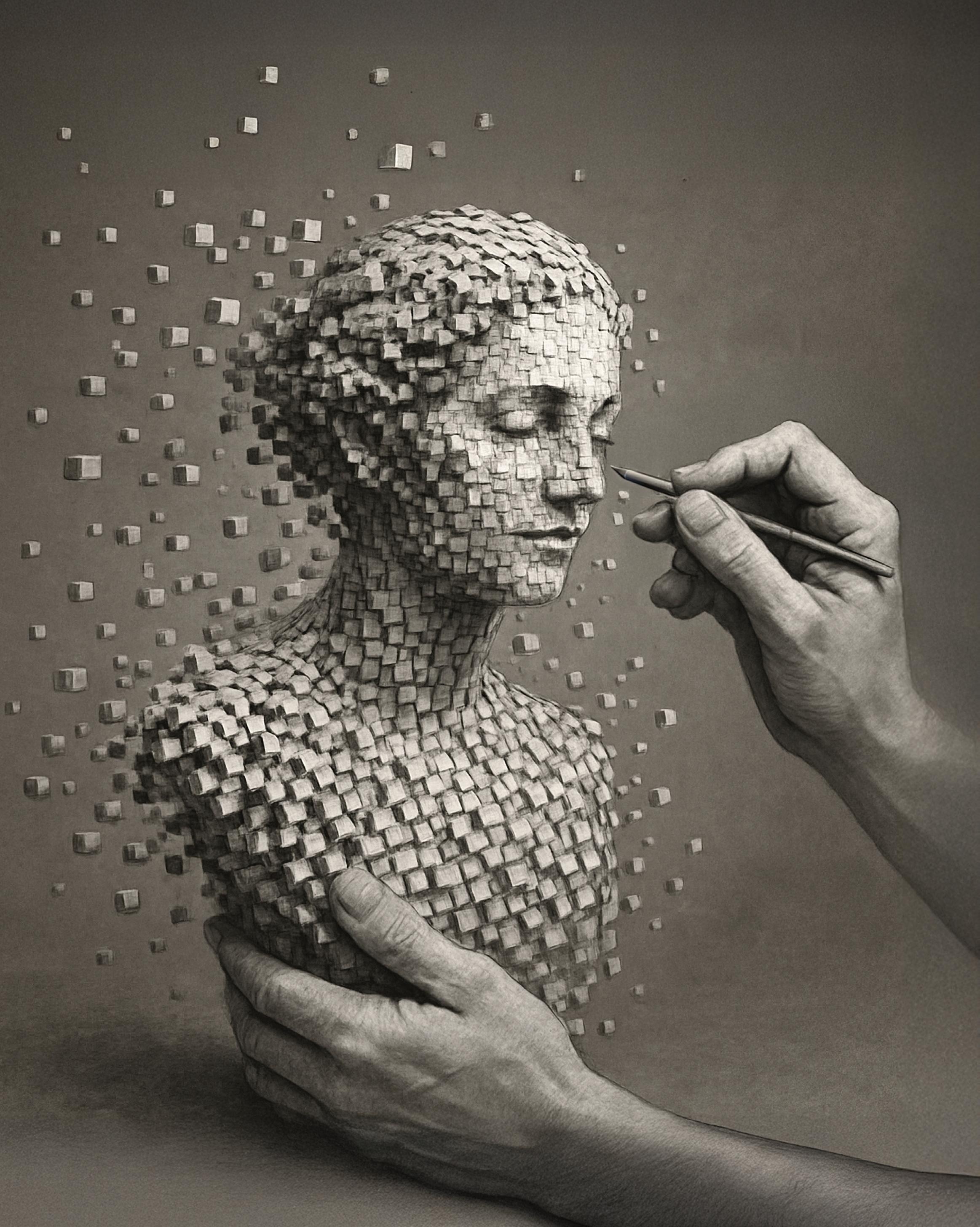

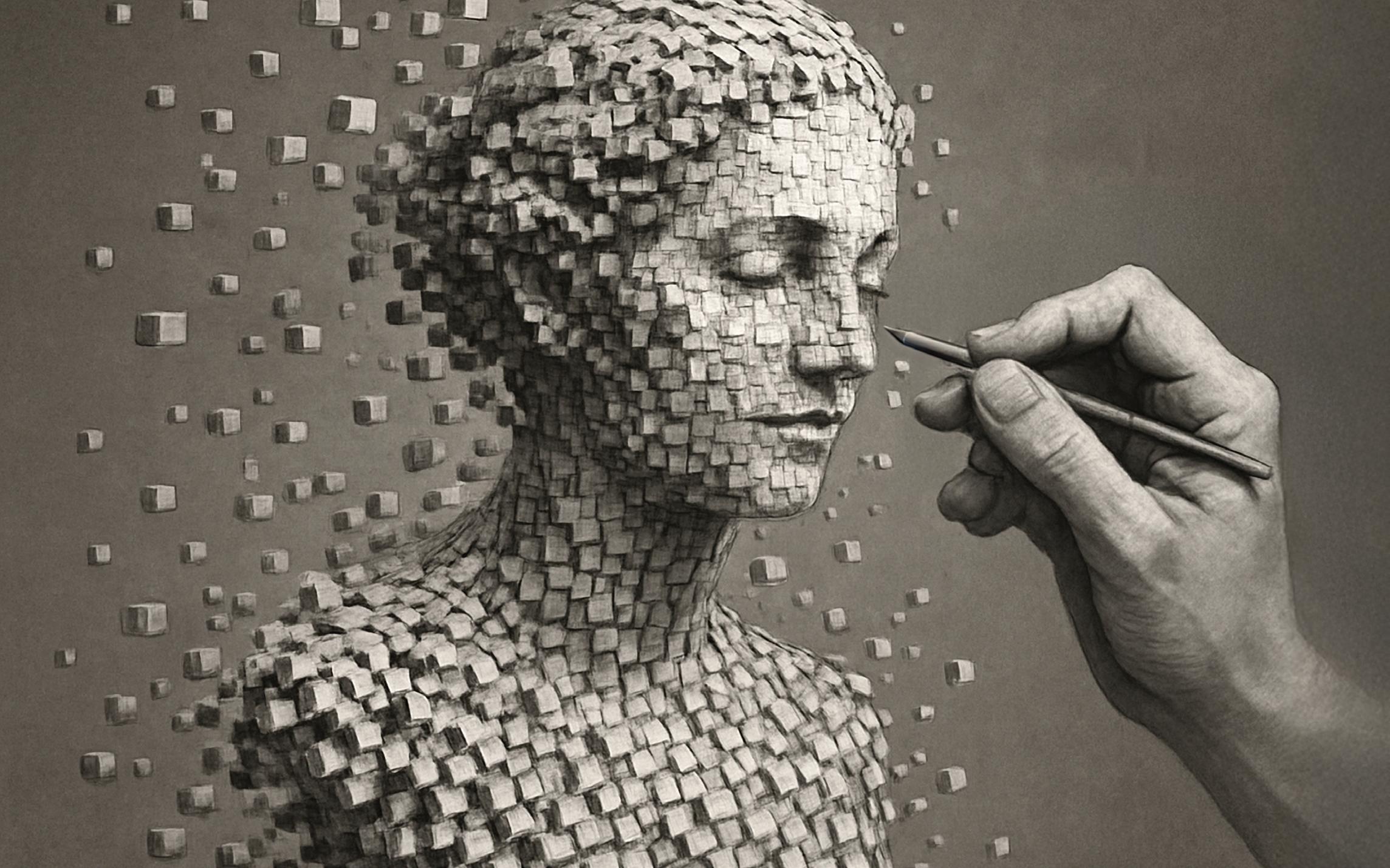

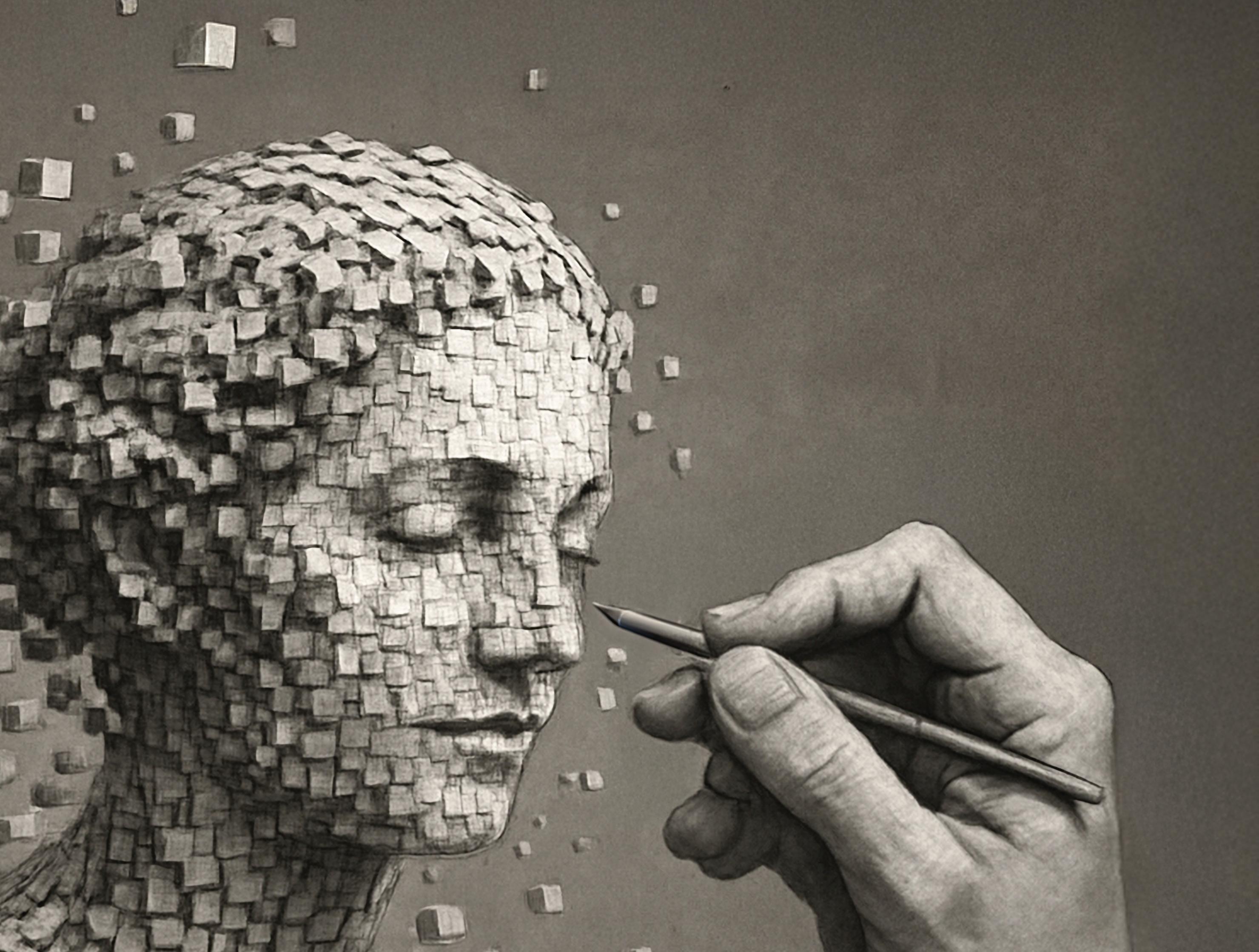

Shaping analytics Useful and effective data analytics begin with matching the right tools to the right tasks by Jim Montague

An expert's journey to implementing best process control via instrumentation, control strategies and PID control by Greg McMillan

YOUR POTENTIAL Remove fear by being prepared What happens when fear makes you protect yourself from the awfulness that might happen? by R.

Russell Rhinehart

Yokogawa’s vision of autonomy is shaped by decades at the frontlines of industrial systems. Autonomy means achieving stable operations unaffected by environmental change. It means reducing human workload, preserving expertise, and optimizing the entire plant, supply chain, and beyond.

By combining our core strengths in measurement, control, and information with deep domain knowledge and best practices, we deliver conviction—assurance born from experience—and innovation driven by advanced technologies.

In doing so, we’re redefining the future of industrial workflows and advancing the sustainability of our partners and society.

We can't let

The role of AI in industrial data management

Artificial intelligence helps industry on its path toward autonomous operations 12 ON THE BUS

The process of backing up

The odds for success improve when control schemes remain operator- and novice-friendly

14 WITHOUT WIRES

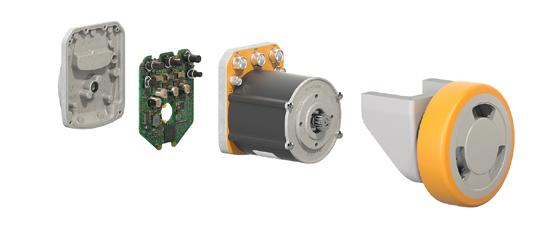

Motors, drives, wireless?

Units enable better condition monitoring and data analysis

16

The Rope Experiment

The Rope Experiment measures the length of the circumference of a circle that yields a rational value

18

Coriolis flowmeters raise the bar in flow measurement

Coriolis flowmeters have become standouts for mass flow measurement, particularly for complex applications

20 IN PROCESS

61% of cyber-pros planning AI adoption

ABB to assist green-power transition at Tata Steel U.K.; Endress+Hauser purchases rest of CodeWrights from Pepperl+Fuchs; Catena-X and OPC enabling data exchange

37 RESOURCES

Cybersecurity made simpler

Control 's monthly resources guide

38 ROUNDUP

Multitasking puts drives in the driver's seat

Motors, drives and accessories combine and integrate capabilities for a more forceful presence

40 CONTROL TALK

Optimizing modern instrumentation maintenance programs

How to get I&C labor focused on tasks that could add considerably more return-on-investment

42 CONTROL REPORT

Who we work for Stay close to rooftop technicians and other infrastructure experts

Endeavor Business Media, LLC

30 Burton Hills Blvd, Ste. 185, Nashville, TN 37215

800-547-7377

EXECUTIVE TEAM

CEO Chris Ferrell

COO

Patrick Rains

CRO

Paul Andrews

CDO

Jacquie Niemiec

CALO

Tracy Kane

CMO

Amanda Landsaw

EVP Manufacturing & Engineering Group

Tracy Smith

VP of Content Strategy, Manufacturing & Engineering Group

Robert Schoenberger

EDITORIAL TEAM

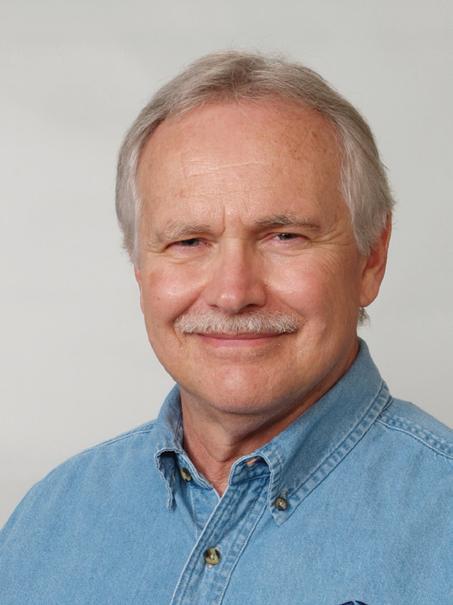

Editor in Chief

Len Vermillion, lvermillion@endeavorb2b.com

Executive Editor

Jim Montague, jmontague@endeavorb2b.com

Digital Editor Madison Ratcliff, mratcliff@endeavorb2b.com

Contributing Editor

John Rezabek

Columnists

Béla Lipták, Greg McMillan, Ian Verhappen

DESIGN & PRODUCTION TEAM

Art Director

Derek Chamberlain, dchamberlain@endeavorb2b.com

Production Manager

Rita Fitzgerald, rfitzgerald@endeavorb2b.com

Ad Services Manager

Jennifer George, jgeorge@endeavorb2b.com

PUBLISHING TEAM

Group Editorial Director

Keith Larson

630-625-1129, klarson@endeavorb2b.com

Group Sales Director

Mitch Brian

208-521-5050, mbrian@endeavorb2b.com

Account Manager

Greg Zamin

704-256-5433, gzamin@endeavorb2b.com

Account Manager

Jeff Mylin

847-533-9789, jmylin@endeavorb2b.com

Subscriptions

Local: 847-559-7598

Toll free: 877-382-9187 Control@omeda.com

Jesse H. Neal Award Winner & Three Time Finalist

Two Time ASBPE Magazine of the Year Finalist

Dozens of ASBPE Excellence in Graphics and Editorial Excellence Awards

Four Time Winner Ozzie Awards for Graphics Excellence

We can't let STEM education resources and access fall by the wayside

ON a recent morning walk with my dog, I was taken aback for a second. As Princess pulled me around a corner, eager to investigate the latest “data” left by other neighborhood pups, I came upon a familiar friend, someone I hadn’t seen in months—our neighborhood school crossing guard. That’s when it hit me that it was the first day of school.

In our neighborhood, many of the children she protects from cars whizzing through the intersection during rush hour were on their way to a local STEAM academy—previously a STEM school, but at some point an “A” for arts was added. I admit, I hadn’t thought about it for a while, but it seems the idea of STEM (science, technology, engineering and math) education was knocked off the front pages, so to speak. Maybe it’s become so popular nowadays that the newness of the idea has worn off? It got me wondering if enrollment in STEM-specific education still increasing. After all, as a person covering engineering and technology for most of my career in one capacity or another, the rise of STEM has been a frequent story and column topic for years.

So, I did what anyone these days might do when curious about such types of facts. I asked AI for help.

Here’s what I got, courtesy of ChatGPT, and the news is still good, though challenges remain to educating the next workforce of control engineers. In broad terms, the STEM K–12 education sector is growing robustly, both in financial terms and overall engagement. However, the gender gap in STEM persists. While boys’ enrollment in STEM programs rebounded to pre-pandemic levels by 2024, girls did not recover, indicating uneven progress in STEM participation.

In the U.S., demand for STEM-focused schools and curricula continues to rise, but institutional capacities and resources limit access. One example ChatGPT showed me is the case of South Brooklyn, N.Y., where a new charter STEM-focused school received 445 applicants for just 125 seats. So, there’s tough competition for limited resources, and that scenario plays out in cities around the U.S.

Continuing to build enough resources to educate students, girls and minorities especially in STEM programs is vital to there being enough control engineers in the future. We can’t afford to let STEM education access fall by the wayside.

LEN VERMILLION Editor-in-Chief lvermillion@endeavorb2b.com

“In broad terms, the STEM K–12 education sector is growing robustly, both in financial terms and overall engagement.”

PENNY CHEN

Senior Technology Strategist Yokogawa penny.chen@yokogawa.com

“Data silos restrict access, reduce interoperability and compromise data integrity.”

Artificial intelligence helps industry on its path toward autonomous operations

THE industrial sector is steadily progressing toward autonomous operations by enhancing existing automation technologies with artificial intelligence (AI). Every organization is working toward this goal, and technology providers across various domains contribute to the transformation. Data plays a dual role in the journey—it’s both fuel and the foundational element. However, we must first understand and manage its context to harness its full potential.

One major hurdle faced by industry is fragmented data. Industrial environments rely on a wide array of systems—DCS, PLC, HMI, SCADA and IoT platforms—that support realtime monitoring, control, trending, etc. These systems manage machine logic, process control and work order execution. Additionally, manufacturing systems manage operations, resource planning, workflow coordination, order tracking, quality reporting, root cause analysis and yield accounting.

Beyond operations, innovation systems analyze historical data, model and optimize processes, support R&D and plan services. Regulatory systems manage risk modeling,

compliance reporting and strategic planning. Enterprise systems focus on business, customer, product, asset and process orchestration. The coexistence of these diverse systems leads to data silos, making integration and utilization difficult.

Industrial operations generate several types of data:

• Structured: reports, transactions, work orders;

• Semi-structured: design and engineering files, digital simulations (2D/3D);

• Unstructured: video and audio recordings;

• Event: typically structured; and

• Geolocation: often semi-structured. Despite the abundance of data—from sensors to control systems to historians—it remains underutilized. For instance, while sensor values with process variables and/or manipulated variables (PV/MV) are sent to a DCS, and diagnostic data goes to asset management systems, sensor performance history may only be accessible to manufacturers. End users often rely on local historian systems, missing valuable insights for predictive analysis.

The diversity of data sources and missions drains resources and complicates collaboration. Data silos restrict access, reduce interoperability and compromise data integrity. Ensuring data is accessible and interoperable across applications, systems, users and suppliers is a significant challenge.

Cybersecurity adds another layer of complexity. Protecting data at its source is a crucial step to prevent manipulation and mitigate threats.

Advances in cloud computing, digital twins and AI enable better data utilization, operational efficiency and decision-making. A key trend is flattening the Purdue Model—integrating levels 2, 3 and sometimes level 4—to break down silos and enhance data management.

Organizations such as CESMII (Smart Manufacturing Institute, cesmii.org), in collaboration with OPC Foundation (opcfoundation.org), VDMA (www.vdma.eu) and the Industrie 4.0 Platform (www.plattformi40.de), are driving standardization

and interoperability to build a collaborative ecosystem.

Effective data management is foundational to autonomous operations. It involves:

• Data cleaning: removing noise and inconsistencies;

• Data classification: organizing data by type and relevance; and

• Data contextualization: understanding relationships and meaning.

Contextualization, often referred to as data fusion, is best achieved through knowledge graphs, which visually represent data relationships. They can be large and complex, or modular with orchestration layers. Once contextualized, data can support applications that provide recommendations based on operational needs, asset conditions, compliance requirements and environmental factors. Clear objectives and guardrails are essential when applying AI technologies.

Achieving autonomous operations is not a solo effort—it requires

collaboration between operational technology (OT) and information technology (IT). OT brings domain expertise, while IT contributes AI methodologies. Building an open ecosystem that leverages the strengths of all players is key. The partnership between Yokogawa and KBC (kbc. global) exemplifies this synergy, combining deep operational knowledge with advanced analytics.

Beyond data management, the next step is leveraging AI to support decision-making, which involves building AI agents using generative AI and agentic AI frameworks. These agents function as building blocks for applications, orchestrating multiple agents to deliver intelligent, autonomous solutions.

The path to autonomous operations involves creating a digital fabric that connects and contextualizes industrial data using AI. By breaking down silos, managing data effectively and fostering collaboration, industry can enhance operational efficiency and empower smarter decision-making.

JOHN REZABEK Contributing Editor

JRezabek@ashland.com

“More complex schemes that are in service routinely can be building blocks for easing acceptance and understanding of other advanced control applications.”

The odds for success improve when control schemes remain operator- and novice-friendly

FRED needed a new vehicle to pull a heavy trailer. He found a new SUV brimming with clever features, including some that were purported to help with towing and trailer backup—something he really needed. But after a year of ownership and numerous trailer towing episodes, he was still struggling to utilize the unfamiliar tech effectively.

Fred could see his surroundings and his vehicle from numerous angles, including a view depicting the SUV from above. But when backing up the trailer, he still stuck his head out of the window, occasionally getting a few shouted suggestions from his spouse.

There are instances where a control professional’s cleverness and creativity can impact usability in a similar way, as Fred discovered when he proposed using a valve position control scheme. He was uncertain about the capabilities of a positioner for a large butterfly valve to operate the valve with enough resolution, accuracy and repeatability, amid concerns about hysteresis and deadband. His scheme aimed to improve the precision of a pressure control scheme that utilized the coarse (large) valve to keep a smaller valve in its optimal control range.

It's especially concerning during uncommon transitions in the process operating state—startups, shutdowns, significant rate changes, or changes in product slate or specification. This doesn’t happen every day, just as Fred wasn’t backing up his trailer daily, not even every weekend. What should one do with setpoints and modes when, suddenly, a downstream unit has a steam outage, and rates must be reduced immediately? Breaking out procedures or training literature at such junctures is akin to Fred reading the manual while blocking traffic, amid horns honking and profanity, as he tries to maneuver his trailer.

Giving operators guidance about what the automation system is doing can be useful, but unfamiliar changes—one individual

memorably struggled to move a valve, while the faceplate was flashing “check target mode”–aren’t guaranteed to register in the operator’s mind, especially under duress. Onstream help may only prove effective when there’s ample time for deliberation and discussion, and checking understanding with those who are more experienced. What will the novice do when the veteran isn’t there to give advice and orders, and the flare’s plume of fire and black soot ensures his manager will be interviewed on the evening news?

Control professionals like Fred increase their odds of success when their control schemes remain operator- and novicefriendly. In some cultures, our peers see themselves as providers of “infrastructure," but when one seeks to fully exploit the computational power and capabilities of modern control systems, it’s important to engage with the real end user—the board operator. More complex schemes that are in service routinely can be building blocks for easing acceptance and understanding of other advanced control applications.

One might make some effort to depict these schemes graphically, revealing what’s under the hood, possibly using custom subpictures or popups that reveal the details in real-time. Those with the time and resources to use a process simulator or a useful digital twin are especially fortunate, and such platforms coupled with regular drills or challenges will improve understanding, as well as suggest improvements for the systems engineer.

While Fred’s trailer struggles may cause a kerfuffle at the campground, underutilized or disabled control schemes can impact the enterprise. Advanced controls improve profitability, reliability and safety, and impact on the environment. Our end-user board operators need to be confident and comfortable to ensure they’re fully utilized—so we don’t find they’ve backed up into manual control.

IAN VERHAPPEN

Solutions Architect

Willowglen Systems

Ian.Verhappen@ willowglensystems.com

“Without analysis, data is a net loss to the organization. It must be turned into actionable activities to improve overall plant performance.”

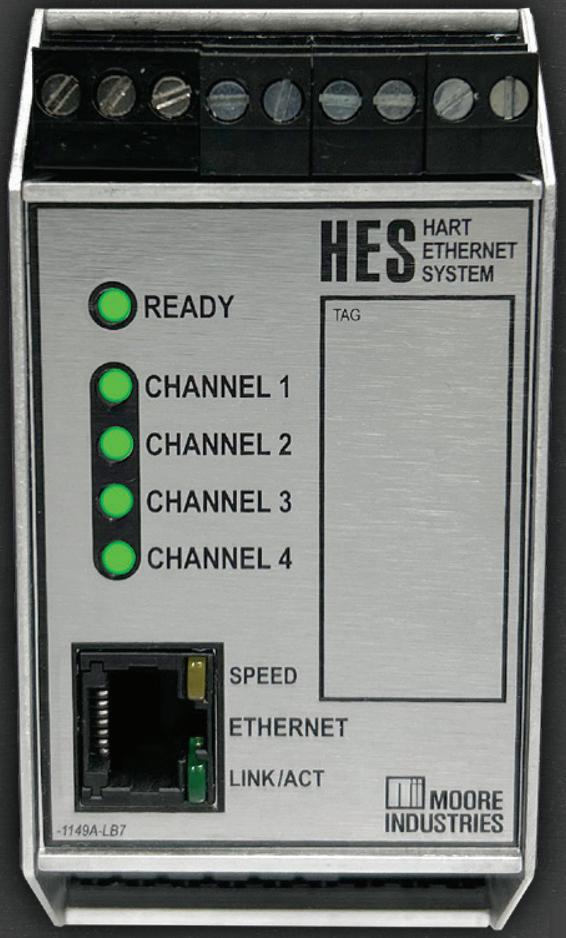

WHAT do motors and drives have to do with wireless? Wireless sensors are diagnostic tools that support condition monitoring of motors and drives. Before you can install your first wireless sensor, you need to create the infrastructure of gateways, backhaul network and data gathering software in the locations of your facility where you plan to install sensors.

The key motor-and-drive parameters that are monitored to provide condition monitoring inputs include vibration, temperature, motor current and electrical “signatures.”

Vibration is one of the most effective methods for detecting mechanical faults, which is why hardwired, dedicated vibration monitoring systems have been installed on large and critical motors and drives for decades.

Wireless sensors, usually accelerometers, make it possible to add vibration analysis to any machine on a permanent or short-term basis. For example, this is when an operator finds a machine is misbehaving, but manual surveys don’t tell the story. Continuous measurement means a sensor will be there whenever the anomaly occurs, and can correlate it with what’s happening in the process at that time, whether a certain part of the operating curve is ramping up or ramping down.

Wireless temperature sensors can be mounted on the motor case or bearings to monitor excessive heat. Overheating, as indicated by abnormally elevated temperatures, is an indicator of impending motor failure.

Motor current signature analysis (MCSA) uses wireless current sensors to analyze the electrical current drawn by a motor. Changes in current frequency can reveal mechanical and electrical faults in the

motor and driven equipment, making MCSA an effective tool for detecting:

• Rotor bar failures affecting current draw and longer ramp-up times, with a corresponding decrease in motor efficiency;

• Stator winding faults, reducing motor torque and in severe cases insufficient starting torque; and

• Eccentricity and air-gap issues, leading to winding damage and, if bad enough, rotorstator damage.

Drives have unique electrical signatures that can indicate potential problems: current signatures show changes such as sidebands, harmonics or noise floor, while voltage signatures can monitor for harmonic distortion, phase imbalance and voltage peaks, which can be analyzed to detect faults in the drive's rectifier or inverter circuits. They can also monitor power quality for harmonic distortion, voltage sags/swells, or other power quality issues that can affect the drive's performance and lifespan with similar impacts for vibration and temperature.

Without analysis, data is a net loss to the organization. It must be turned into actionable activities to improve overall plant performance. Turning diagnostic data into action can be done by local engineering and maintenance teams from their analysis. However, it’s also sent to the manufacturer’s cloud, where it can be anonymized, and added to a data repository for further analysis.

Patterns can be found based on equipment information combined with data from thousands of other machines in similar applications, and enable earlier warnings, so repair/ replacement of a motor or drive can happen when it’s convenient. More data equals better models and results, and wireless enables economically collecting that data full time or as required, so your plant runs better.

Securely Enable OT Data - Send your industrial data seamlessly through a data diode. Data from Modbus, OPC DA/UA, A&E/A&C, MQTT and other sources gets collected into a unified namespace (UNS), mirrored through the diode, and recreated on the insecure side of the network.

JESSE YODER Founder & President Flow Research Inc. jesse@flowresearch.com

“

The ratio of a circle's circumference to its diameter is defined by the length of the circular boundary measured in rational units.

”

The Rope Experiment measures the length of the circumference of a circle that yields a rational value

MOST people are familiar with the formula for measuring the area of a circle: π * r2, where “r” stands for the radius of the circle. Meanwhile, there’s no escaping the need to measure the area of a round pipe when calculating flow.

The formula for measuring volumetric flow is Q = A * v, where “Q” is the volume of flow that passes a specific point in a unit of time. “A” is the cross-section of the inside of the pipe and “v” is the average flow velocity. The cross-section is calculated as Area = π * r2.

The circumference of a circle is determined by 2 * π * r. It's used to find the value of π, which is defined as the ratio of the circumference of a circle to its diameter.

Early Babylonians and Egyptians found it impossible to measure the circumference of a circle as a round area. Instead, they tried approximating its length with polygons and other straight-line shapes that closely resembled the distance around the circle. Eventually, the invention of calculus and infinite series turned the focus to finding a mathematical equivalent to the circumference of the circle. These efforts proved fruitless as well. Once the computer age arrived, the focus turned to calculating π to as many decimals as possible in hopes of finding a set of repeating digits.

The Rope Experiment provides a way to measure the length of the circumference of a circle that yields a rational value.

For example, a circle with a radius (r) of 2 inches and a diameter (d) of 4 inches gives the following value for the circumference of the circle: C = 2 * π * 2. Multiplying this out, it is C = 4 * π

Given that π is approximately 3.1416, this gives a value of 12.5664 inches for the circumference of the circle. However, it can only

be an approximation since we're using an approximate value for π.

Now, take a rope and form it into a circle with a radius of 2 inches—easily be done by measuring in a straight line from the center of the circle to its edge formed by the rope. Lay the rope that forms the circle flat and it becomes a straight line of length C. The straight line has measurable, rational length (you can measure it with a ruler or by counting units). There's no need to use π provide the length of a straight line, so the circumference is a rational number.

Measure the rope with a yardstick or a tape measure. You'll find that the length of the rope is right around 12.5 inches, depending on required precision. Using the approximate value of π as 3.1614 in the formula 2 * π * r, the circumference is 12.5664 inches. Using the formula for the circumference in the equation 2 * p * r, we get an irrational value that can only be approximated because it includes a value (π) with indefinitely many digits that never repeat.

Use a tape measure to get a value for the length of the rope that is just over 12.5 inches. We can carry this out to any desired level of precision, but it depends on our unit of measurement and the precision of our measuring tool.

A rope doesn’t change length when you shape it into a circle. The length of the rope remains constant regardless of its shape. The ratio of a circle's circumference to its diameter is defined by the length of the circular boundary measured in rational units. The result is a rational value, specific to the precision of measurement, not a transcendental abstraction. Given that we have a measurable, rational length for the rope when it's laid flat, this is also the length of the rope when it's shaped into a circle. The problem is not with our measurement of the rope, but our formula for calculating the circumference of a circle.

Everything is possible. With VEGA.

Industry 4.0 sets high standards for the future of sustainable production. Our level and pressure instrumentation is designed to meet these demands, combining the essential features that enhance quality, efficiency, and flexibility in your processes –every single day.

JANA ANDREAS Senior Global Product Manager, Emerson

HIGHLY accurate and versatile, Coriolis flowmeters have become standouts for mass flow measurement, particularly for complex applications in the chemical, energy, life sciences, and oil and gas industries. Control talked with Jana Andreas, Senior Global Product Manager, Emerson, about how Micro Motion™ ELITE™ Coriolis flowmeters are reinvigorating the possibilities for flow measurement in industrial processing.

Q: What makes Micro Motion ELITE Coriolis flowmeters stand out in the world of flow measurement technology?

A: These Coriolis flowmeters are a benchmark in flow measurement. What sets them apart is the ability to deliver unmatched accuracy and reliability across a wide range of applications—from simple fluid measurement to complex, multiphase flows. They're exceptional at measuring gases—even in their dense or supercritical phase.

The meters have been designed to perform in the most demanding environments, including high-temperature, ultra-cryogenic and high-pressure conditions. They’re not just measurement instruments—they’re precision tools that help our customers optimize their operations, reduce waste, and ensure consistent product quality.

Q : What are the meters' advanced measurement precision capabilities, and how do they impact process performance?

A: ELITE flowmeters offer precision in mass flow, density and temperature measurement. This level of accuracy is critical for processes where even small deviations can lead to significant losses—think of any custody transfer application, dosing in pharmaceuticals or blending in chemical manufacturing.

By providing real-time, highly accurate data, these flowmeters enable tighter control over process variables. This means less variability, fewer errors and more consistent outcomes. For customers, it translates into better product quality, reduced rework and compliance with industry standards.

Q: How do ELITE meters maintain accuracy and reliability in harsh or dynamic operating environments?

A: They're engineered for resilience. Their robust construction allows them to operate reliably in extreme conditions—high temperatures up to 800 °F, high-pressure applications up to 6,000 psi, and even in the presence of entrained gases or solids.

Their design minimizes the influence of external factors like vibration or pipe stress, which can often distort readings in less advanced meters. So, our customers can trust the data they’re getting, even in the most challenging environments.

Q: Smart Meter Verification (SMV) is a standout feature. How does it work, and what value does it bring to customers in terms of diagnostics and uptime?

A: SMV is an easy-to-use, inline diagnostics tool that comes standard with any ELITE meter. It lets users confirm the health and performance of the meter without requiring customers to stop their process. It also helps determine the best time for flowmeter calibration, and significantly lowers calibration costs by extending calibration intervals.

This proactive approach and early detection of issues helps reduce unplanned downtime, extends equipment life, and ensures accuracy over time, meaning no shutdowns or manual inspections, and fewer trips to the field.

Q: What industries or applications benefit most from ELITE meters' fluid compatibility and certifications?

A: The versatility of the series is one of its biggest strengths. The meters are compatible with a wide range of fluids, including aggressive, corrosive chemicals, viscous slurries and delicate biopharmaceuticals, making the sensors ideal for the oil and gas industry, chemical manufacturing, life sciences and energy transitions, but the list is really endless. When it comes to certifications, they're approved for use in hazardous and strictly regulated environments like custody transfer applications— some approvals to highlight are NTEP, MID or OIML.

Q: How does the optimized sensor design reduce installation complexity and improve measurement stability?

A : Installation can often be a customer pain point with flowmeters, but these Coriolis meters are designed to make it easy.

The sensor's optimized design minimizes the effects of installation variables like pipe stress, mounting conditions or flow disturbances. There are no straight-pipe requirements. The meters are non-intrusive and allow for bidirectional flow.

LISTEN UP!

You get stable, accurate measurements without needing extensive upfront engineering, saving time during setup and reducing risk of measurement errors down the line. For OEMs and system integrators, ease of installation is a major benefit, helping them deliver reliable solutions efficiently.

Q: How does the ELITE series support digital transformation?

A: It offers enhanced connectivity options that allow seamless integration with control systems and data platforms. Customers can access realtime data, perform remote diagnostics, and predict maintenance needs before issues arise.

By enabling data-driven decisionmaking, the meters help businesses optimize performance, reduce downtime and improve overall operational efficiency. It’s a key enabler for digital transformation, especially in industries looking to modernize their infrastructure and embrace Industry 4.0.

Q: What cost-saving or productivityenhancing benefits can users expect?

A: The financial impact of ELITE flowmeters can be substantial. Accuracy often directly translates into cost savings. The meter's highly precise measurement helps minimize material

To hear more about ELITE flowmeters, listen to Control Amplified featuring Jana Andreas at www.controlglobal.com/podcasts, or wherever you get your podcasts.

waste, rework and the risk of errors, which is important where raw materials are expensive or tightly controlled.

Cost-savings and incremental benefits are more significant when you consider total cost of ownership. Reliability and diagnostic capabilities reduce downtime and maintenance costs. The ease of use means less time spent on training and troubleshooting.

Q: How do the meters help improve safety in highly regulated industries?

A: Compliance and safety are non-negotiable in pharmaceuticals, oil and gas and chemical processing. They come with comprehensive certifications, ensuring they meet international standards for safety, quality and environmental impact.

Their design and smart diagnostics prevent failures that lead to safety incidents or regulatory violations.

Q: How could the meters align with Emerson’s broader strategy for innovation in flow measurement?

A: Emerson offers an extensive product portfolio to address all flow measurement needs. ELITE has always been the leading platform for the most demanding applications. As industries evolve and processes become more complex, accurate, reliable and connected, measurement solutions grow.

ELITE embodies Emerson’s commitment to solving real-world challenges through technology advancements— whether that’s improving efficiency, enabling digital transformation, or supporting sustainability goals.

IN the face of growing cyber-risks, 61% of cybersecurity professionals in manufacturing plan to adopt artificial intelligence (AI) to help manage risks and strengthen protection, according to Rockwell Automation Inc.’s (rockwellautomation.com) 10th annual "State of smart manufacturing” report released on Aug. 13.

Compiling input from more than 1,500 participants from 17 manufacturing nations, the report reveals that cybersecurity is becoming a central business issue. It adds that only economic conditions surpass cybersecurity as the respondents’ top external concern. One third of them report having direct information technology (IT) and operational technology (OT) cybersecurity responsibilities.

"Cybersecurity is no longer just a technology issue. It's a boardroom issue,” says Stephen Ford, VP and CISO at Rockwell. “As IT and OT get more connected, the attack surface is expanding. Our research confirms what we see firsthand—cyber-risk is now one of the greatest threats to manufacturing growth. You can't protect tomorrow's enterprise with yesterday's tools. AI is a critical part of the modern security stack, enabling manufacturers to detect threats in real-time, maintain productivity, and stay ahead in an aggressive cyber-threat landscape."

The report’s primary cybersecurity findings include:

• Cyber-threats are among the most serious external risks. Cybersecurity (30%) is among the top external risks, second only to inflation and economic growth (34%).

• Security teams accelerate AI adoption. 61% of cybersecurity and IT professionals plan AI and machine learning

(ML) adoption to aid security in the next 12 months, outpacing manufacturing by 12 percentage points.

• Cybersecurity tops smart manufacturing use cases. 38% of manufacturers plan to use data collected from current sources to drive protection.

• IT/OT security takes center stage. 48% of cybersecurity professionals identified securing converging architecture as a key to positive outcomes over the next five years, compared to just 37% on average.

• Cyber readiness is a growing talent priority. More than half (53%) of respondents from companies of $30 billion or larger identified cybersecurity practices and standards as extremely important skill sets, compared to 47% of all respondents.

• Workforce development is still a major hurdle. A shortage of skilled talent, training challenges and increasing labor costs remain barriers to competition. As manufacturers recruit the next generation, cybersecurity and analytical skills are also becoming hiring priorities, reinforcing the need to align technical innovation with human development.

"Cybersecurity has become a business enabler," adds Ford. "It's no longer just about preventing threats. It's about empowering transformation with confidence. Forward-thinking manufacturers are proactively using advanced technologies like AI to stay ahead of evolving risks."

The report’s findings are available at: www.rockwellautomation. com/en-us/company/news/blogs/ot-cyber-trends-2026.html

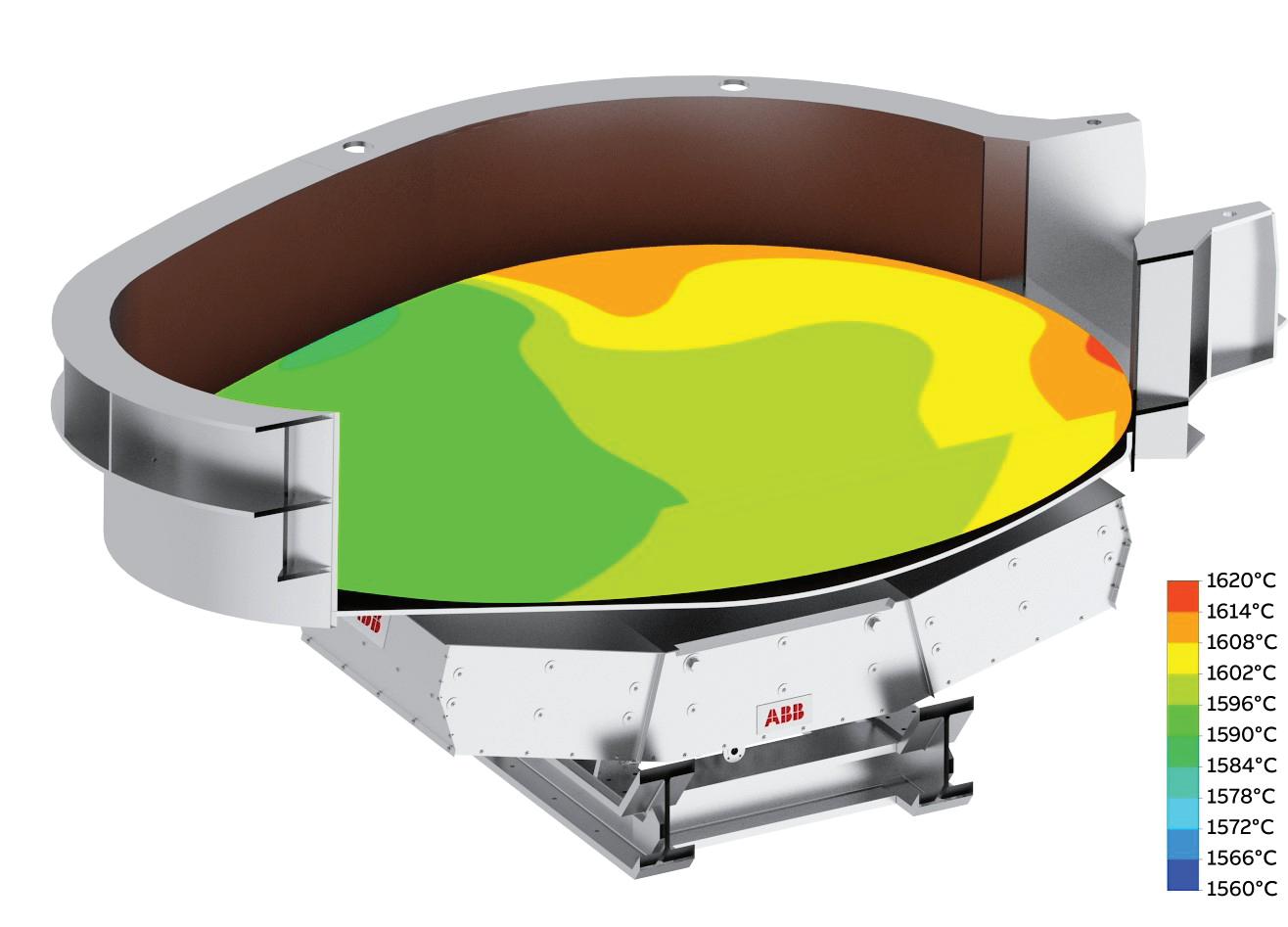

ABB (go.abb/processautomation) reported July 29 that it will provide electrical power supply management/distribution and electromagnetic stirring at Tata Steel’s 125-year-old Port Talbot Steelworks in Wales, U.K. These combined projects will help ensure safe, efficient and optimized operations when the plant's new 320-ton-capacity electric arc furnace (EAF) starts up in 2028 (Figure 1).

Figure 1: The green steelmaking facility at Port Talbot will supply downstream businesses and customers with the high-quality, low CO2 steel products. Source: Tata Steel

Figure 2: ArcSave electromagnetic, stirrer-based, metallurgy technology rapidly homogenizes temperature distribution and chemical composition in the electric arc furnace (EAF) melt while speeding up scrap and ferroa recycling. Source: ABB

Construction work for Tata Steel’s EAF project is set to begin this year. It will mark the start of a transformation in the steelmaking process at the site.

“We’re looking forward to ABB helping us positively impact the transformation at Port Talbot Steelworks, a site undergoing critical change for the future of U.K. steelmaking,” says Rajesh Nair, CEO, Tata Steel U.K. “Their proven technologies and expertise will support our evolving production processes onsite, enabling resource and cost efficiencies for the long-term. We’re looking forward to driving this project forward.”

The global steelmaker is investing more than £1.25 billion at the Welsh plant. The project includes £500 million in U.K. government support, which focuses on energy transition and decarbonizing the steelworks’ operations. The site will shift from running blast furnaces to low-emission steel recycling, and aims to cut CO2 emissions by an estimated 90%. Tata Steel U.K. hopes produce fossil-free steel by 2045, and reduce its CO2 emissions 30% by 2030.

To support these objectives, ABB will be responsible for delivering electrical power distribution equipment, including high- and low-voltage switchgear, power transformers and distribution transformers, connected through a plantwide, power-distribution control system. This will be central to achieving a fully, digitally enabled solution for power management and distribution in line with ABB’s plans to drive progress via leaner, cleaner operations.

As part of the main contract between Tata and Tenova (tenova.com), a provider of sustainable solutions for green transition in the metals industry, ABB will deliver its ArcSave electromagnetic, stirrer-based metallurgy technology (Figure2). This equipment, known as Consteerrer, is jointly developed by ABB and Tenova under an exclusive global partnership agreement, and tailored for continuous-charging EAFs. With more than 165 references worldwide, it provides many advantages, including a 5-7% increase in EAF productivity, 3-5% decrease in energy consumption, and 1% in additional yield.

It’s expected that ABB will commission its technologies by 2027 in time for full operational start-up at Port Talbot.

Endress+Hauser (us.endress.com) reported July 31 that it’s purchased the remaining 33% of CodeWrights GmbH (codewrights.de) from Pepperl+Fuchs (pepperl-fuchs. com), and is now the software and service company’s sole owner. Located in Karlsruhe, Germany, CodeWrights was founded in 2002 as a joint venture between Pepperl+Fuchs and Endress+Hauser, which owned twothirds of its shares. CodeWrights has close to 50 employees, who develop customized software for measurement and automation technology, such as apps and cloudbased applications for industrial automation and embedded software for devices.

“We’re excited to assume full ownership of CodeWrights. At the same time, we’d like to thank Pepperl+Fuchs for more than 20 years of constructive partnership,” says Dr Rolf Birkhofer, managing director of Endress+Hauser’s Digital Solutions division. “We believe strongly in the expertise of the team and the strength of the business model. Together, we look forward to driving further growth and success.”

Lutz Liebers, COO for process automation at Pepperl+Fuchs, adds, “We look back on decades of successful collaboration built on mutual trust and respect, for which we would like to express our genuine appreciation. We’re confident that, with Endress+Hauser as the sole owner, CodeWrights is ideally positioned to drive its strategic development and realize its full potential.”

Thomas Debes, managing director at CodeWrights, reports the acquisition will have no impact on its day-to-day operations. “By transferring the shares, we’re creating a clearer ownership structure and strengthening our company’s strategic ability to act. This decision enables faster coordination and provides new impetus for our shared growth,” adds Debes. “CodeWrights will continue to serve all customers with the same commitment and maintain its established service portfolio. Employees at both CodeWrights and Endress+Hauser can expect continuity in their work and collaboration.”

Catena-X Automotive Network e. V. (catena-x.net) and the OPC Foundation (opcfoundation.org) reported Aug. 19 that they’re collaborating to accelerate standardized, cross-company, data sharing across manufacturing industries. Their partnership focuses on supporting the European Union’s (EU) upcoming regulation requiring a Digital Product Passport (DPP) by 2027, which demands trusted, machine-readable product data across value chains.

Catena-X reports it’s the first open, collaborative data space for the automotive industry, enabling sovereign, standardized data-sharing, based on interoperable infrastructure and semantic templates. By aligning OPC UA’s modelling capabilities with Catena-X’s governance framework and cloudbased infrastructure, the two organizations aim to simplify data integration, reduce reporting errors, and enhance compliance with emerging regulatory demands like DPP.

Catena-X and OPC plan to cooperate in four areas:

• Semantic integration by combining OPC UA’s information modelling and Catena-X’s semantic templates to create a comprehensive repository of interoperable, machine-readable models. This technology backbone will also support automated DPP generation from production data.

1 4/28/25 1:50 PM

• Open-source reference implementation by jointly developing and providing open-source reference implementations for key dataspace and interoperability components, enabling straightforward integration of OPC UA-based systems into Catena-X’s data ecosystem.

• Reference architecture alignment by aligning OPC Foundation’s Cloud Initiative reference architecture with Catena-X’s dataspace architecture to enable streamlined deployment from the plant-floor to the supply chain.

• Industrial ecosystem enablement by empower companies to leverage existing OPC UA tools and infrastructure to meet emerging regulatory requirements, particularly DPP, while reducing integration costs and accelerating time-to-compliance.

“The OPC Foundation provides rich, secure, and proven access to standardized information—an essential foundation for digital transformation," says Oliver Ganser, board chairman at Catena-X. "By linking this data to Catena-X's ecosystem, we turn standardized information into cross-company value. This collaboration benefits both ecosystems, and marks a key step toward end-to-end data chains at scale, and cross-industry solutions, like the DPP.

For more information, download the “OPCF Catena-X” whitepaper at shorturl.at/VsClo or attend a live presentation at 1 p.m.. CET on Oct. 14 by signing up at attendee.gotowebinar. com/register/3937509918021582942

• ABB (go.abb/processautomation) reported Aug. 6 that Greek tissue maker Intertrade Hellas S.A. (intertradehellas.gr) has chosen it to apply its quality control system (QCS) to existing and new tissue machines at the company’s Inofyta facility. The project includes ABB’s Network Platform (NP) 1200-based QCS platform with sensors and controls.

• Honeywell (www.honeywell.com) announced Aug. 20 that it’s expanded its Smart Energy portfolio by acquiring three utility platforms from SparkMeter Inc., a provider of grid management solutions for utilities. The platforms include Praxis data analytics platform, GridScan visibility software, and GridFin financial management application.

• Fortifi Food Processing Solutions (FortifiFoodSolutions. com) in Woodlands, Texas, announced Aug. 18 it’s buying Chicago-based Provisur Technologies (www.provisur. com), a provider of further-processing solutions for the protein industry, including grinding, forming, slicing and tumbling technologies.

• Analytical measurement, analysis and automation supplier Analytik Jena GmbH+Co. KG (www.analytik-jena.com) reported Aug. 20 that it’s launched Analytik Jena Brasil Ltda. to serve Brazil and Latin America’s markets. The new subsidiary is located at Endress+Hauser’s (us.endress.com) campus in Itatiba, São Paulo state.

• Tasi Measurement (tasimeasurement.com), a provider of industrial and commercial monitoring technologies in Largo, Fla,, reported Aug. 12 that it’s acquired DCiii LLC (dc3control.com) in Corpus Christi, Texas, which is a provider of chemical injection automation solutions for the energy and industrial sectors.

• Ondex Automation (www.ondex.ai) announced Aug. 21 that it’s acquired Vision and Control Systems (VCS, visionandcontrolsystems.com). A system integrator in Chicago, this transaction is Ondex’s fourth acquisition since April 2024,

• Hargrove Controls & Automation (hargrove-epc.com) reported Aug. 7 that it’s formed a partnership with ABB (abb. com). As an ABB Channel Partner for process automation solutions, Hargrove will be even better equipped to deploy industrial digitalization solutions for its clients.

by Jim Montague

Useful and effective data analytics begin with matching the right tools to the right tasks

JUST as the most precise instruments and controls can’t make up for badly installed or broken sensors, uncalibrated instruments, out-of-tune signals and other blurry inputs, data analytics can’t be effective if users don’t pick and apply appropriate tools guided by specific problems they want to solve or practical goals they want to achieve.

For instance, most U.S. foundries are still small- to midsized, family- and privately owned companies with less capital to invest, so many still rely on manual data entry and Excel spreadsheets. Conversely, this situation also means a few foundries, such as 50,000-squarefoot Ferroloy Inc. (ferroloyinc.com) in Wichita, Kan., can gain and maintain a competitive edge by upgrading to newer SCADA and

analytics software. The company manufactures ductile iron and gray-iron castings, and reports it needed to find an alternative to its highly manual data collection processes, which were riddled with inaccurate and unused data.

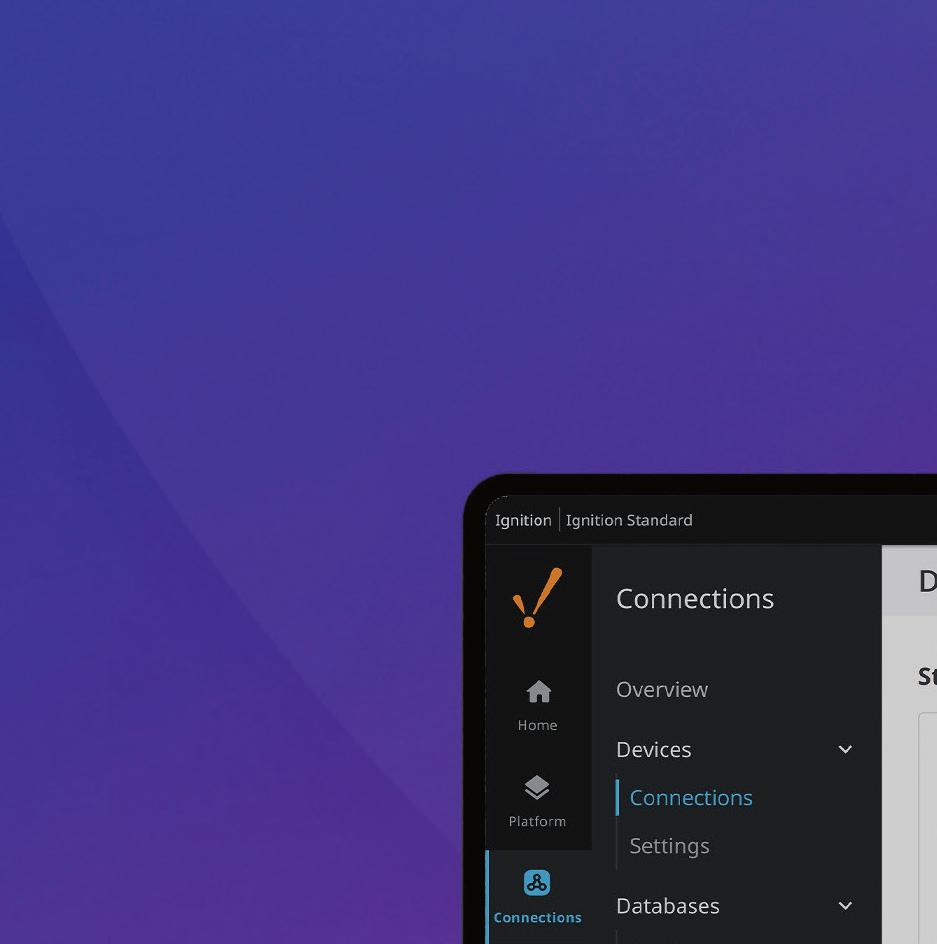

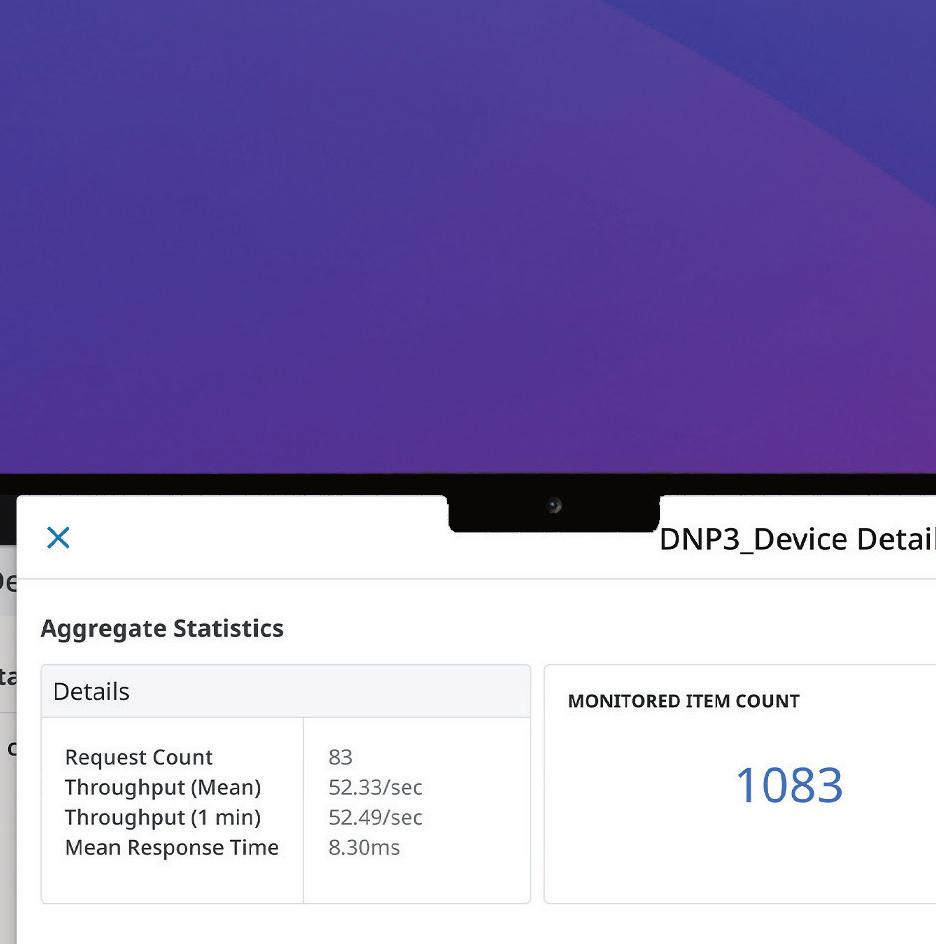

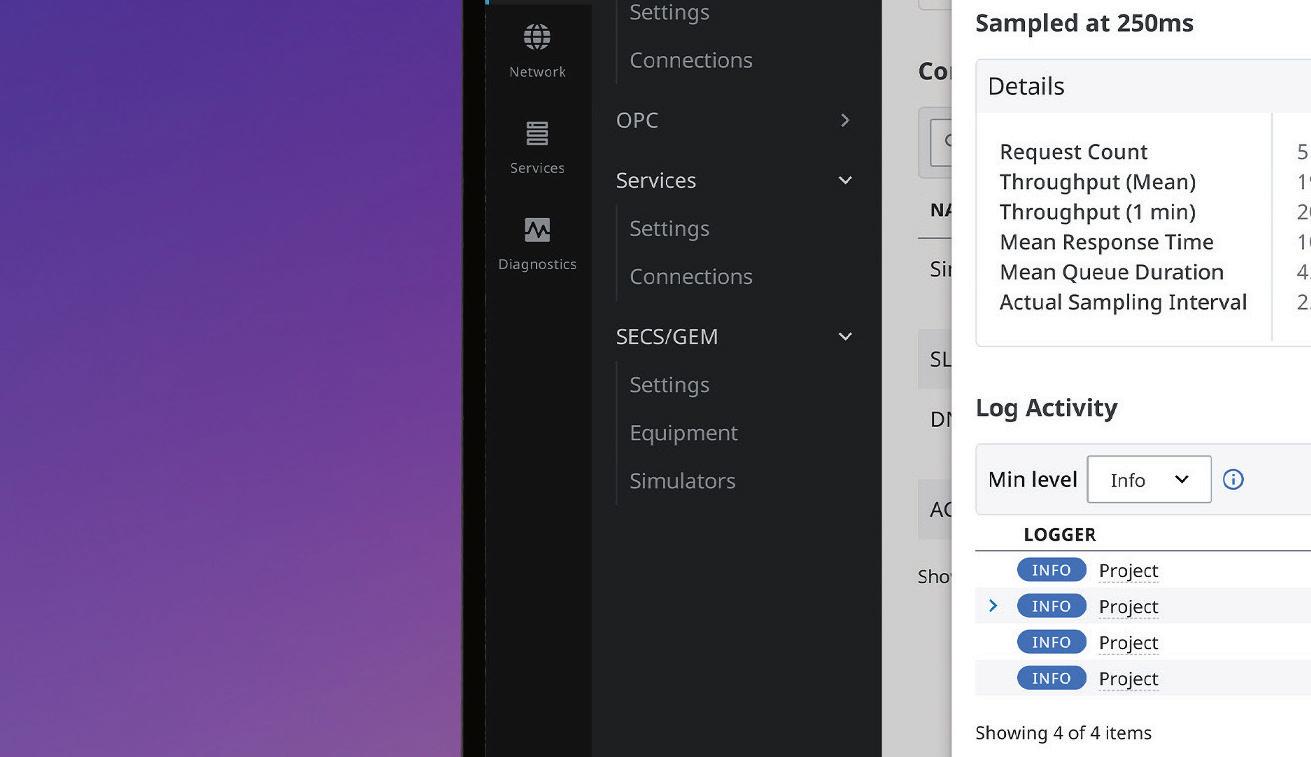

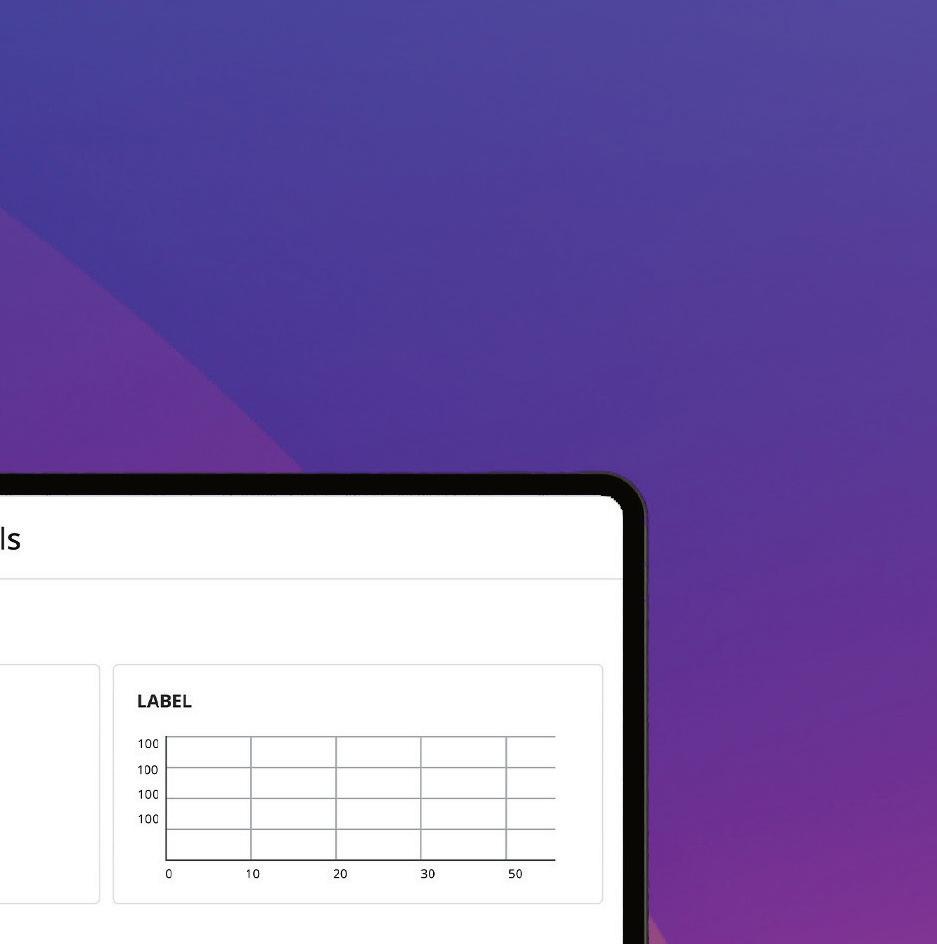

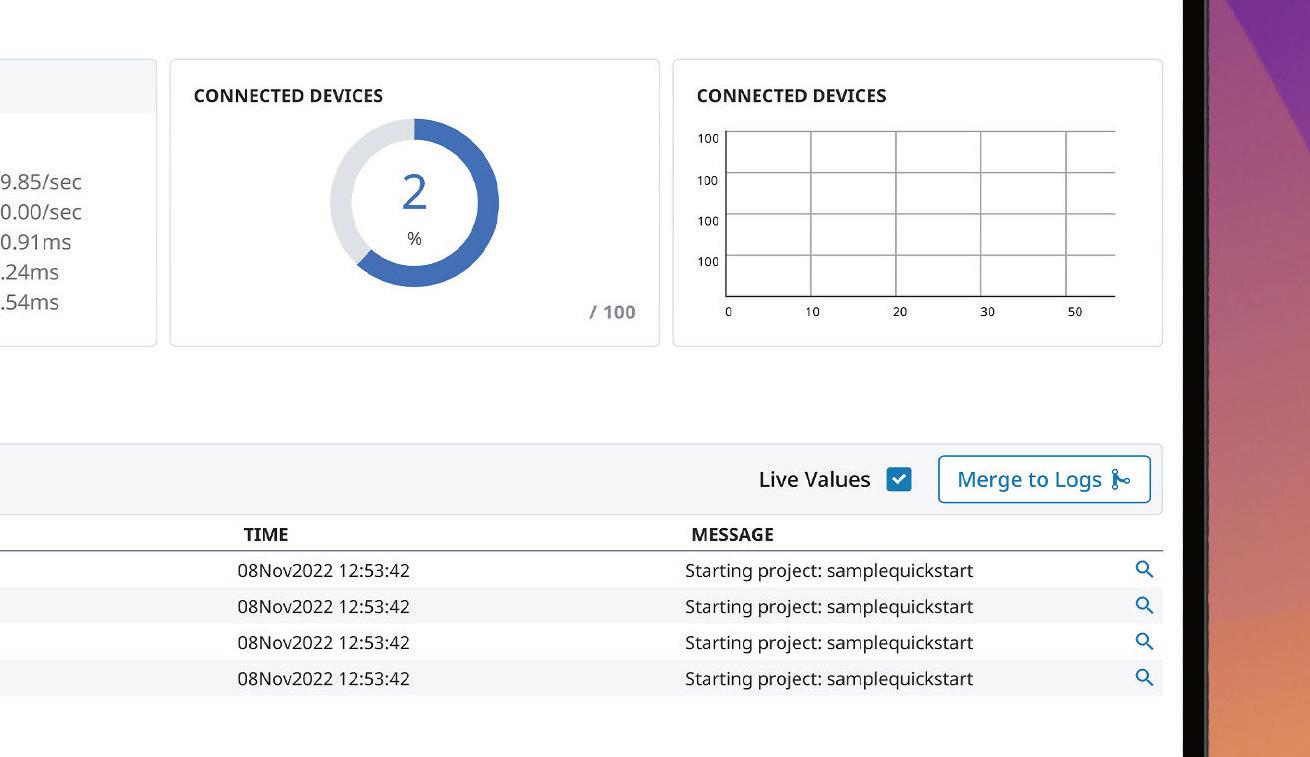

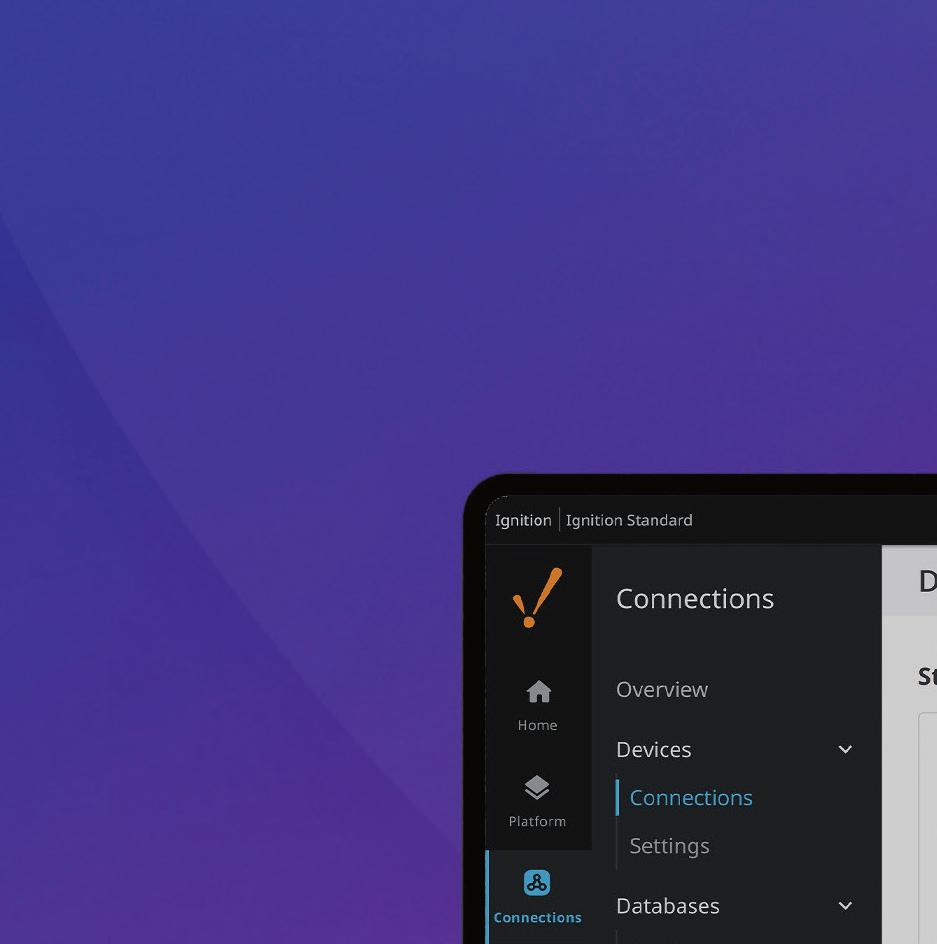

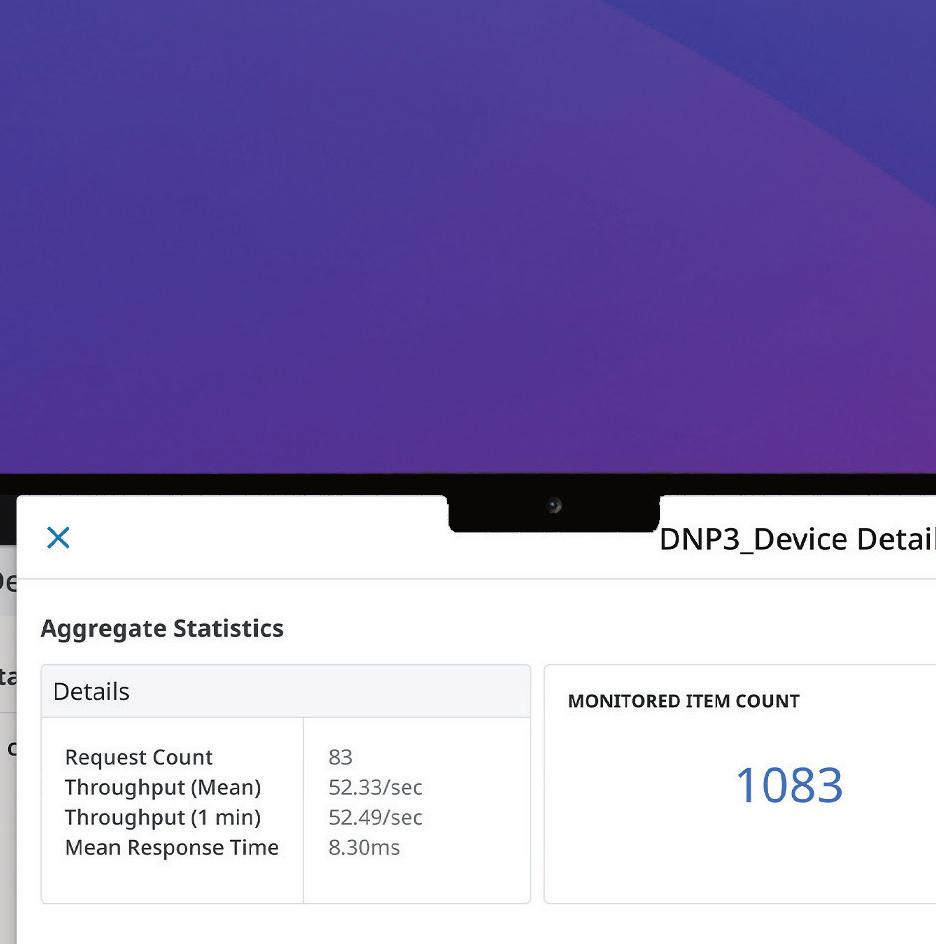

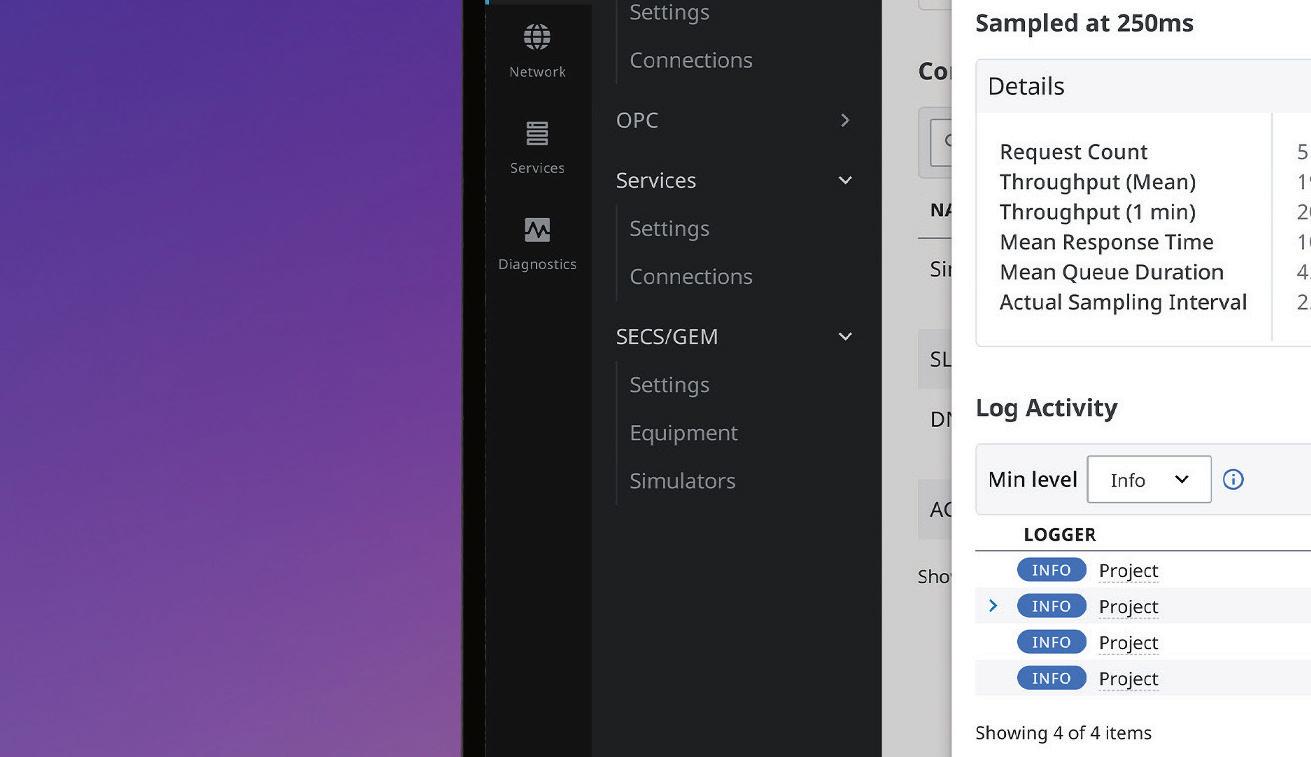

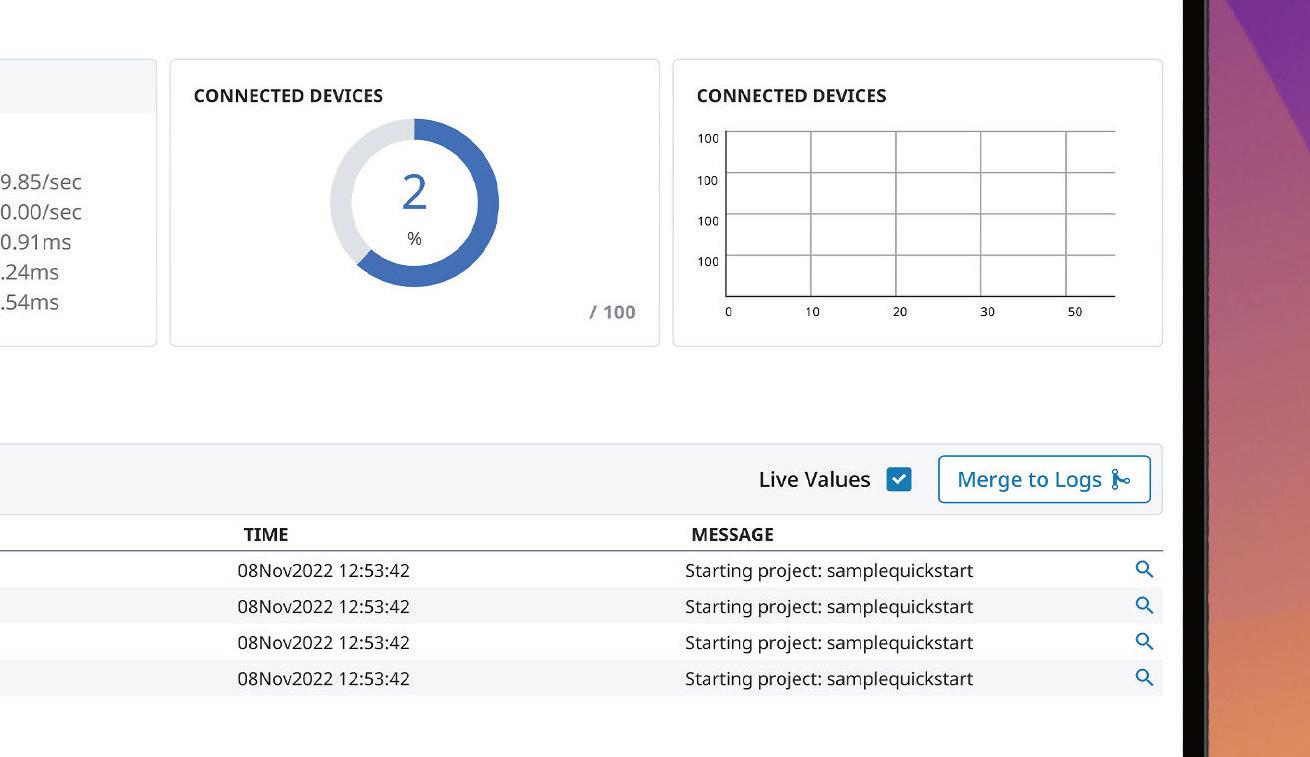

Ferroloy adds it wanted to improve throughput and quality, while reducing unplanned downtime, as well as implement lean manufacturing practices to drive behavioral changes, Consequently, it hired a new process engineer, enlisted Artek Integrated Solutions (artekis.io), a system integrator in Folsom. Calif., adopted Ignition web-based SCADA software from Inductive Automation (inductiveautomation.com), and designed device visualizations using Ignition’s Perspective module.

“We're trying to digitalize an aged process, and gain better visibility to unlock latent potential within the process,” says Clint VenJohn, process engineer at Ferroloy.

Previously, Ferroloy mostly used its available data to solve individual problems, rather than support companywide initiatives. To create a SCADA system beneficial to operators, as well as management, Artek built and configured a MySQL database on Ferroloy’s servers, which was then connected to Ignition’s Tag Historian module, as a centralized repository for maximizing data collection and analytics. This combination created a single source of truth that any user could reference.

“The goal with the Ferroloy project was to digitally transform their disconnected foundry that relied heavily on manual data gathering on paper through more efficient data collection and analysis,” says Jerry Eppler, cofounder and CEO at Artek.

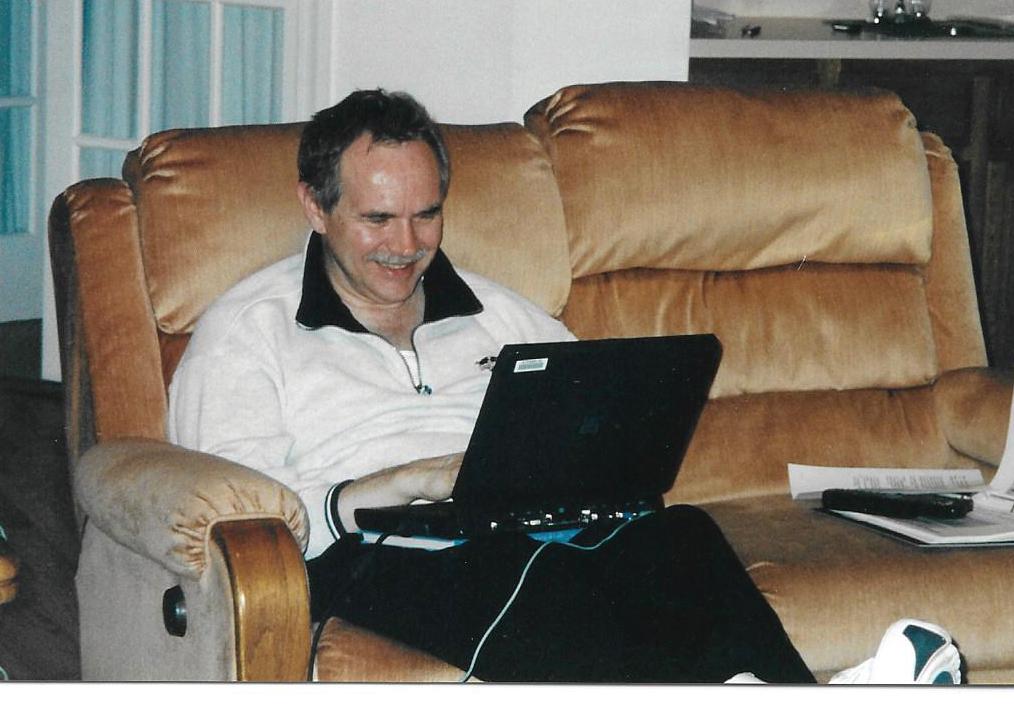

Ferroloy sought to increase its capacity by 25-30%, reduce scrap by 30-35%, but still avoid distracting its operators pouring 2,700 °F, molten iron (Figure 1). Ignition helped Ferroloy progress toward its goals by identifying methods for improving efficiency, backed by quantitative data. “With Ignition, we can see more or less up-to-the-minute production data, while before we’d lag behind by a week or so,” explains Clint VenJohn, process engineer at Ferroloy. “We can identify trends and shift reports almost in real time, which are huge improvements that let us respond to problems more quickly.”

Similarly, Ignition’s device drivers help Ferroloy reach its patchwork of different PLCs and other devices that don’t communicate with them, and connect despite the foundry’s inherently dusty environment that’s typically harsh on electronics. It also using Ignition to reach smart TV monitors that display KPI dashboards for quick reference above the foundry’s six production lines.

“One of Ferroloy’s main problems was the data they were gathering on the plant-floor was siloed from their Hitachi equipment by its software. If you needed that information,

you had to walk there to get it,” adds Jim LePratt, design service engineer at Artek. “Ignition brought the siloed data from their Hitachi and Heraeus equipment directly into screens that could be used on the plant-floor for verification that the product was good at the point it was being used.”

Likewise, Ignition and its Mitsubishi driver software linked to Ferroloy’s Sinto molding machines with Mitsubishi PLCs. This allows their production data to be fed back to B&L’s off-premises Odyssey enterprise resource planning (ERP) software-as-a-service (SaaS) via an application program interface (API) and sync routines. They monitor Odyssey for changes in real-time, and alert Ignition and its users. The driver supports the supplier’s proprietary Mitsubishi Electric Sequence Control (MELSEC) protocol over TCP networking. This establishes a direct connection between the PLCs and ERP system, eliminating the need for added software, and reducing project costs by freeing operators from manually inputting data.

Even though software is the primary driving force of today’s data analytics, it still has to run somewhere, and must take in and relay information to other physical locations. All of these jobs require cables, connectors, sensors, instruments, I/O, PLCs, DCSs, servers and other hardware, and they’ll all require installation, configuration, troubleshooting, maintenance, repair and replacement sooner or later.

Figure 1: Ferroloy iron foundry in Wichita, Kan., worked with system integrator Artek Integrated Solutions to build and configure a server-based MySQL database; link it with Inductive Automation’s web-based Ignition SCADA software and Tag Historian module; establish a centralized repository for maximizing data collection and analytics; and identify trends and shift reports almost in real time. Ignition also helps the foundry secure data from its Hitachi and Heraeus equipment, connect with PLCs on its Sinto molding machines, and directly access its B&L Odyssey ERP system.

For instance, Varland Plating (varland.com) in Cincinatti, Ohio, has been bulk electroplating automotive, aerospace, electrical, firearm components, consumer parts, fasteners and other products for 80 years. Though historically, mostly manual, its barrel-plating process includes: controlling barrel rotation speed and direction with variable-speed drives (VSD); tracking parts moving through the plating lines and their time at each step; maintaining precise vat temperatures, fluid levels and pH conductivity settings; managing automated chemical feeds; and tracking precise electrical currents with a rectifier that facilitates electrolysis.

To perform these tasks efficiently and produce quality products, Varland started automating them in the 1990s, when its engineers adopted Opto 22’s (opto22.com) SNAPLCM4 controllers, mistic racks with G4 single-point I/O, and FactoryFloor flowchart-based programming software. These solutions enabled the company’s objectives for decades, but the limits of its legacy hardware became evident over time.

“Every barrel on our automatic plating lines has a radio frequency identification (RFID) tag, and our hoists use serial RFID readers to help us track jobs through production,” says Toby Varland, technology VP at Varland. “Each SNAP-LCM4 controller supports a maximum of four serial ports. At least one of those ports had to be reserved for I/O, so we were limited to a maximum of three RFID readers per controller.”

This limited number of serial ports required Varland to daisy-chain dozens of I/O racks on individual serial communication ports, and in some cases, expand the architecture to add more processors. This setup led to increased communication latency, potential data collisions, and complicated troubleshooting, ultimately hindering system performance and reliability. Fast forward to today, where Varland reports that one GRV-CSERI-4 serial module on Opto 22’s latest groov EPIC system supports four serial ports, and a single EPIC processor can support up to four of these modules, resulting in 16 individual serial connections in one controller.

“Hooking up RFID readers to serial modules on EPIC lets us condense to a single processor per plating line,” explains Varland, who also noted the shift from serial to Ethernet networking and communications. “We could theoretically keep running SNAP-LCM4 processors. Most of our systems have been running reliably with serial for many years. However, newer groov products have more installation, programming and operator-experience capabilities that make it easier for our staff to do their jobs.”

Likewise, Varland also upgraded several thousand digital and analog I/O points one rack at a time without ripping-andreplacing components, and employed a workaround to avoid a costly shutdown.

It used Opto 22’s Scratch Pad temporary memory storage area to accomplish data exchanges between controllers and I/O processors, which allows users to map EPIC’s I/O channels to internal memory registers that their legacy SNAP-LCM4 controllers can access. Open communication between legacy and new equipment lets them maintain the existing program on legacy hardware, while developing a new one in parallel.

“The control logic on the LCM4 doesn’t change,” adds Varland. “We can start developing a new solution on groov EPIC. For testing, I can flip a switch, do some testing, and then flip back to the old program.”

Help for homegrown historians

Thankfully, upgrading its 30-year-old control infrastructure enabled Varland to make its critical process variables available in a modern, Ethernet-based communications interface. However, this raised a new challenge—limited visibility and no long-term trend analysis. Subsequently, Varland used free resources to develop homegrown historian software. Using Opto 22’s open-source-friendly REST API, Varland deployed a suite of PHP command-line scripts that retrieve I/O and critical data values, and log them into an InfluxDB time-series database.

Figure 2: After updating its controls and I/O to Opto 22's groov EPIC controllers, I/O channels and GRV-CSERI-4 serial modules, Varland Plating in Cincinnati, Ohio, developed DIY historian software with Opto 22’s open-source-friendly REST API, contextualizes data with Grafana’s open-source monitoring platform, and collects data with Ignition web-based SCADA software.

The data is then visualized and contextualized using Grafana, an open-source monitoring platform (Figure 2).

While its DIY historian was a victory, scaling homemade data collection scripts is challenging. Plus, as the system grows, maintaining continuity is risky, especially if the original developer becomes unavailable. Consequently, they needed a scalable platform with professional support and documentation to ensure long-term SCADA reliability.

“Through groov EPIC, we learned about Ignition software, and we feel we can use it to accomplish many SCADA goals we haven’t achieved yet,” says Varland. “We started with an Ignition Edge license on one of our groov EPICs, and I liked it enough that we bought a full Ignition license that we now run on Apple’s Mac Studio server. InfluxDB and Grafana worked really well for long-term storage and trend analysis, but Ignition lets us remove the pain point of custom data collection, and allows us to use Ignition Historian as a passthrough to get data into InfluxDB more reliably and with less work.

“Getting data into a historian platform, where we can be flexible about how we access and study it, has given us new insights into our processes. We reduced downtime, improved our operator experience, and freed our operators to focus on parts and quality. No one doubts the impact, even though it’s hard to measure.”

While data analytics are typically used to track down existing problems, users are logically anxious to employ it to prevent future difficulties from arising in the first place.

To gain more detailed and accurate views into motor performance sooner, Reliance Industries Ltd. (www.ril.com) began developing a two-part rotary equipment performance monitoring (REPM) and early event detection (EED) program in mid-2023 for two asset categories at its 16 refining, petrochemical, plastics and other manufacturing facilities in India. Expected to be completed this past June, the first part of Reliance’s REPM-EED program covers 11 types of critical equipment, including multi-component machines operating at 500 kW or more with no redundance, which have instrumentation and sensors for continuous, online monitoring. EED enhances monitoring with data analytics and failure-detection algorithms. It can recognize potential failures before methods like infrared tomography, vibration and lubricant analyses, and extend users’ response and prevention intervals.

EED begins with standard connections to data, such as sensor tags, historians, events and alarms, and other sources. This information enables runtime analytics and other calculations for a content library of devices, such as pumps, compressors, extruders, turbines, centrifuges and others. These calculations also include attribute models, preprocessing and data cleansing, user-defined calculation,

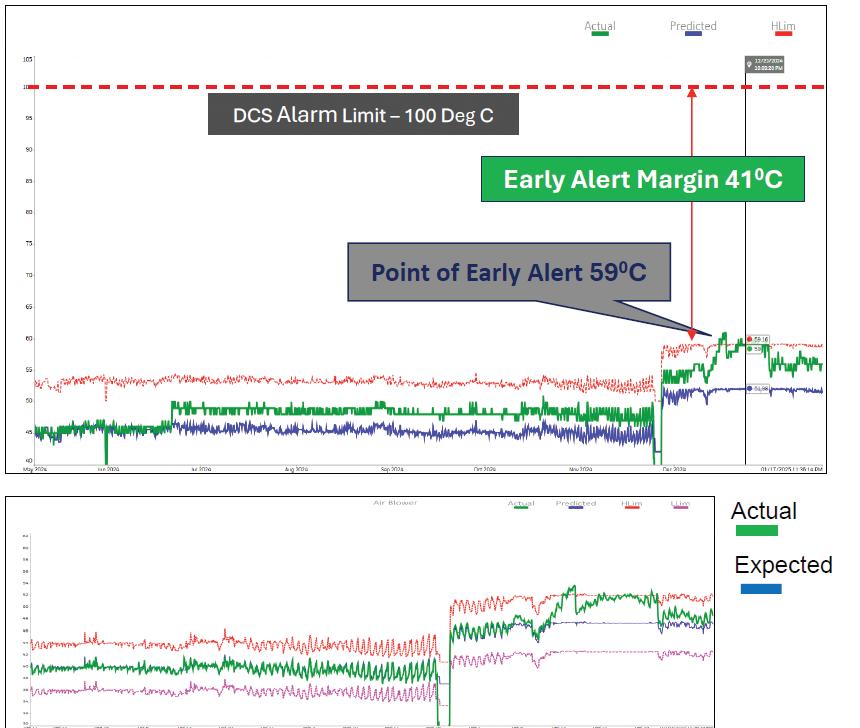

Figure 3: The rotary equipment performance monitoring and early event detection (REPM-EED) program at 10 of Reliance Industries’ refining and other facilities in India has evaluated and modeled 1,095 rotating assets and found 406 faults. For example, it found increasing lube oil (LO) supply and radial bearing temperatures in an compressor’s combustion air blower. Its predicted value was 52.02 °C, but its early-alert high limit was 59 °C, which revealed a valve malfunction in the LO cooling water supply line, and resulted in alternative cooling that prevented a major breakdown.

and first-principle and machine learning (ML) models. Their results let EED detect situations sooner by comparing actual versus predicted conditions using fault models, and prioritizing faults by combining fault severity with asset criticality.

“EED’s integrated model uses vibration and machine health data, as well as pressure and flow parameters, but it can also add upstream and downstream conditions, and ambient environmental conditions. All of these parameters were part of our blueprints for improving rotary device monitoring, management and optimization,” says Swapnil Kharche, digital transformation lead for reliability and maintenance at Reliance. “We built these and other sources into our EED blueprints, so we could lock in all the symptoms for each type of rotating equipment into our software and solution. We also adopted Honeywell’s (process.honeywell.com) Asset Performance Manager (APM) software that can detail 28 different ways that a compressor can fail.”

Even more importantly, Reliance’s EED team also organized three-day workshops for each of the 11 equipment types, and called in engineering personnel to discuss rotary equipment symptoms and failures, develop data models, refine blueprints, and conduct user acceptance tests (UAT).

Rotating gains keep coming Kharche reports it’s been 18 months since the critical-equipment, REPM-EED project was rolled out, started completing

Just as most labor involved in painting a room goes into scraping, patching, sanding and taping before any paint cans are opened, effective data analytics is also mainly identifying problems, goals, information sources and formats, and deciding how to standardize, contextualize and align them before any insights can be produced. The following are some of the primary tasks:

• Identify pain points and business objectives that can guide the quest for the most suitable analytics, and narrow it enough to provide the best chance of becoming reality.

• Find partners who can contribute to the company or organization’s analytics goals, needs, tasks, assignments and timing, such as colleagues, system integrators and suppliers.

• Inventory present data repositories, files, tags, signals, parameters and formats most likely to generate benefit from further examination, including both their content and identifying information. When possible, do the same for new and upcoming sources.

• Evaluate ways that information is collected, documented, managed, networked and housed, whether it’s in onsite components, historian hardware or software, or in remote servers or cloud-computing services.

• Determine whether device-level inputs and content from sensors, instruments and analyzers must be pretreated or organized in some way before being relayed onward. Also, investigate if and how much information reformatting may be needed for communication purposes, and check what software, device or combination should be implemented.

• Examine whether proposed analytics operations or software can communicate, work with and gather data from legacy historians or related devices. If this communicate and exchange isn’t available, decide if an intervening device or software can be implemented to allow it.

• Whether onsite or remote, find the most appropriate place to conduct data analytics. More data processing and prioritizing on the plant-floor or close to the edge may lighten the load on upstream, enterprise-level or cloud-based systems, and may be safer for some time-constrained or mission-critical processes. However, more cloud-based analytics may allow more powerful data processing, and fuel more detailed and sophisticated results and revelations.

• Eliminate or at least reduce communication barriers by assessing current network protocols that relay data from onsite process and production areas to local or remote analysis facilities.

• To rescue isolated information, determine whether existing production-level devices are collecting data, where they’re storing it, if they’re linked to any larger networks, whether they can communicate, and how detailed is the data they can share.

• Develop, test, deploy, tweak and routinely recheck analytics software, devices and systems to gauge if present requirements are satisfied, or if process operations need updated or new analytics or support functions.

its initial models, and began pushing data through ADL. The EED team modeled about 14 assets per month, and so far it’s covered 1,095 rotating assets of the 11 device types, which serve in 492 asset trains at 10 of Reliance’s sites. These assets are also include in 960 projects that have been completed, redeployed and handed back to their site teams. Since the critical-equipment EED program started, Kharche reports that it’s identified 406 faults, including 92 that generated user feedback, and 63 that were identified for potential value capture. Four notable examples at Reliance’s sites include:

• Lube oil (LO) cooling system anomaly and preventing bearing deterioration. Fault reported was a temperature increase in a radial bearing in an integrally geared compressor’s combustion air blower. Its predicted value was 52.02 °C, but its early-alert high limit was 59 °C, and its DCS alarm limit was 100 °C. Diagnosis found that an LO cooling system anomaly was increasing the LO supply temperature and radial bearing temperature. User feedback reported a valve malfunction in the LO cooling water supply line, and that bearing temperature was normalized by using alternative cooling arrangements that didn’t require stopping operations. The benefits and savings included preventing a major breakdown and achieving a huge monetary saving by preventing lost production (Figure 3).

• Bearing failure and shutdown avoidance in a centrifugal pump. Fault reported was increased vibration in a radial bearing in a centrifuge pump. Its predicted value was 5.35 mm/sec, but its early-alert high limit was 6.7 mm/sec, and its DCS alarm limit was 16 mm/sec. Diagnosis found the vibration increase was accompanied by reduced bearing and LO temperatures, which raised suspicions of an anomaly in the LO system. User feedback reported water ingress in the bearing housing due to seal leakage. Water was drained from the LO tank, the seal was secured, and bearing temperature and vibration levels were normalized. A seal failure was avoided.

• Thrust bearing anomaly and preventing production losses. Fault reported was a vibration increase in a radial bearing on a recycle gas compressor. Early-alert high limit was 35µ, while the DCS alarm limit was 75µ. Diagnosis noted a continuous rise in the compressor’s thrust bearing temperature and displacement, indicating a mechanical defect. User feedback reported that an unbalanced situation was found, and added that naphtha injected during an opportunity window normalized the vibrations. Benefits and savings included preventing bearing deterioration and secondary damage, avoiding a major breakdown, and achieving a huge monetary saving by preventing lost production.

• Seal failure avoidance in Sundyne pump. Fault identified was low seal-differential pressure in a dissolver feed pump. Its differential presure setpoint was 6.5 bar and its

Figure 4: To make fluffier Nestlé Quik and Ovaltine, the company’s plant in Waverly, Iowa, recently partnered with Aveva, and transferred production data to its Connect, Historian and Advanced Analytics services to predict quality parameters, recommend optimal setpoints, and subsequently saved 10% on powder. This graph shows the accuracy of AI calculations trained to predict product density compared to actual density found in the company’s lab.

predicted value was 7 bar, but its early-alert low limit was 5.5 bar and there was no low limit available in the DCS. Diagnosis revealed a decrease in seal differential pressure due to a loss of barrier fluid flow. User feedback reported a field control valve (FCV) malfunction was observed during a field inspection, and the FCV was repaired and flow rates returned to normal. The benefit was avoiding a seal failure and downtime.

One emerging force promising to enable analytics is AI and its interactive accessories. However, as usual, it seems like some human understanding and logic is necessary to develop and apply them effectively.

For example, Nestlé (www.nestle. com) recently partnered with Aveva (www.aveva.com) on a lighthouse project to optimize production of its

Nesquik and Ovaltine chocolatepowder products at its plant in Waverly, Iowa. These products undergo an agglomeration process during production that involves wetting and drying the powder until it achieves the right moisture and density, or optimal fl uffi ness. Operators previously ran this agglomeration process manually, but this sometimes caused unwanted variability in the powder’s moisture and density.

Consequently, Nestlé designed a solution that uses real-time production data and advanced analytics to generate setpoint recommendations that keep moisture and density levels within desired limits, and minimize variability to consistently produce lower-density, fluffier chocolate powder. The lighthouse team began by transferring production data from one of Waverly’s agglomeration towers to a cloud-computing service and Aveva’s Connect

data services and historian software, where they could perform advanced analytics with AI and machine learning (ML). Next, Nestlé developed a dashboard in Connect that visualizes predicted moisture and density, along with the setpoint recommendations, which are enabled by Aveva’s Advanced Analytics software. Operators can also view customized dashboards next to SCADA screens that show predicted and actual density and moisture levels (Figure 4). Also, the recommendations screen takes the guesswork out of process control because operators can simply follow Advanced Analytics’ guidance to ensure product consistency. In the future, the team expects to close the loop by feeding Advanced Analytics’ setpoint recommendations directly into Nestlé’s SCADA system to automate adjustments.

In addition, the lighthouse team trained no-code analytics models using historical process and lab data, establishing a correlation between the product’s quality parameters and process variables. These models automatically generate setpoint advice for operators to use in the plant when making equipment adjustments, and subsequently achieved several positive results. During the lighthouse project’s one-shift, eight-hour trial, the team saw more consistent powder produced with optimal moisture and density levels. At the end of the trial, the socks used to catch waste were mostly empty due to reduced fine-powder circulation and waste. Finally, Nestlé uses inline check weighers underneath conveyors to weigh every product as it passes along the line. The team found that powder from the trial had consistently higher moisture and lower density, eliminating the need to overfill jars to reach desired fill levels. In fact, the trial revealed that for every 10 1-kg jars produced, Nestlé saved up to one 1 kg of product—or up to a 10% savings.

An expert’s journey to implementing best process control via instrumentation, control strategies and PID control

BY GREG MCMILLAN

ARE you ready to take a trip down memory lane to learn how to achieve the best process efficiency and capacity for the most important batch and continuous control applications? My journey to find and implement the best process control by realizing the best instrumentation, control strategies and PID control has been a bumpy ride at times, but we learn the most from mistakes.

Electrical and instrument design and construction

I started out in electrical and instrument (E&I) design and construction in 1969. After a 12-week training course and some preliminary plant work helping my mentor, I moved to an onsite position at a plant in West Virginia. It was responsible for installation, calibration, checkout and startup of the E&I systems for a new production unit and control system upgrade of three existing production units. I oversaw E&I construction using union electricians and pipefi tters who, like me, had no previous experience in instrumentation. We learned the hard way.

specialty chemicals plant in Texas. I subsequently moved to the plant construction site, in charge of two newbies with no experience. Fortunately, the Texas plant’s E&I technicians took the lead in instrumentation calibration.

In our water batching application, temperature loops were too slow, and valves didn’t open until PID output was 25% or more. Thermowells had sand in them from being installed with no covers during piping and equipment sandblasting, and valves with a terrible response didn’t have positioners. The contractor followed the prevailing rule that valves in fast loops shouldn’t have positioners, which was based on a theoretical study that didn’t consider bench settings, poor resolution from stiction, lost motion from backlash and shaft windup.

Plant E&I technicians didn’t show up until after the plant was up and running at design specifi cations. The biggest problem I experienced was rotary control valves with rusted piston actuators from outside storage, pulley systems and rudimentary positioners. These valve assemblies provided by an on/off valve supplier were cheap. I replaced the valve assemblies with actuators, direct links and high-gain positioners designed for throttling valves. The startups were tortuous, but successful.

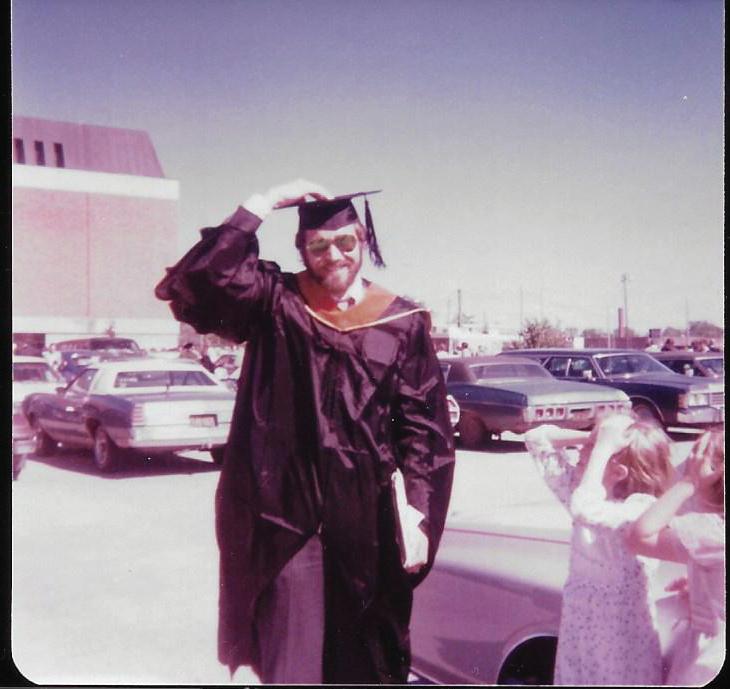

Greg graduated with a master's degree after going to night school, while working for Monsanto in engineering technology.

After we cleaned out the thermowells and installed high-gain pneumatic positioners, the startup quickly and greatly improved. I developed a first-principle dynamic simulation to help understand the challenging objectives of an axial compressor, and the simulation attracted the engineering technology department. I was invited to be a modeling and control engineer in 1977.

I became the company’s representative at a contractor in Massachusetts responsible for designing the world’s largest

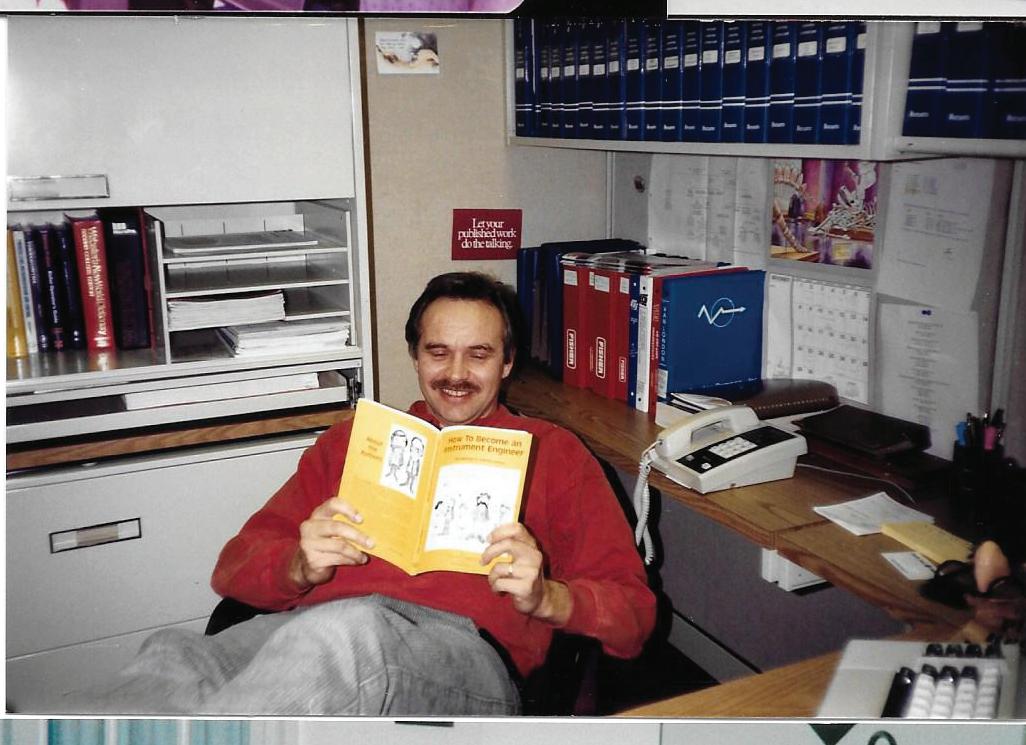

Engineering technology (ET) modeling and control I was incredibly lucky to be working in ET because it featured about 100 of the world’s experts in modeling and control. The department head was University of Texas Professor Emeritus James Fair. We were all given the freedom to advance technologies to improve operations by process modeling and control, and publish results, an incredible opportunity that I doubt exists anywhere today.

I worked on control problems for large axial compressors with steep surge curves, which were prone to more damage than centrifugal compressors. I found one that had a pitot tube in a box for compressor suction flow measurement, which is a key process variable for surge control. A venturi tube replacement made a big improvement in operating point relative to surge point.

I thought I could enable the surge controller to recover from surge by making the surge valves, measurement and controller work faster. However, I learned that, once in surge, the jumps in flow were so large and fast, due to positive feedback in compressor curve to left of surge point, that feedback control was unable to recover. So, I designed an open-loop backup to equip the controller with a surge valve opening large and long enough to recover from surge. I provided some simple additional logic to predict a potential crossing of the surge curve that would later become a future, value-prediction block.

A key to my many more intelligent compressor control applications, including dealing with compressors in series, was the momentum balance showing the compressor installed characteristic to the left of the surge point. This was rarely seen in the literature and seldom described by compressor suppliers that positive feedback could cause jumps in suction flow.

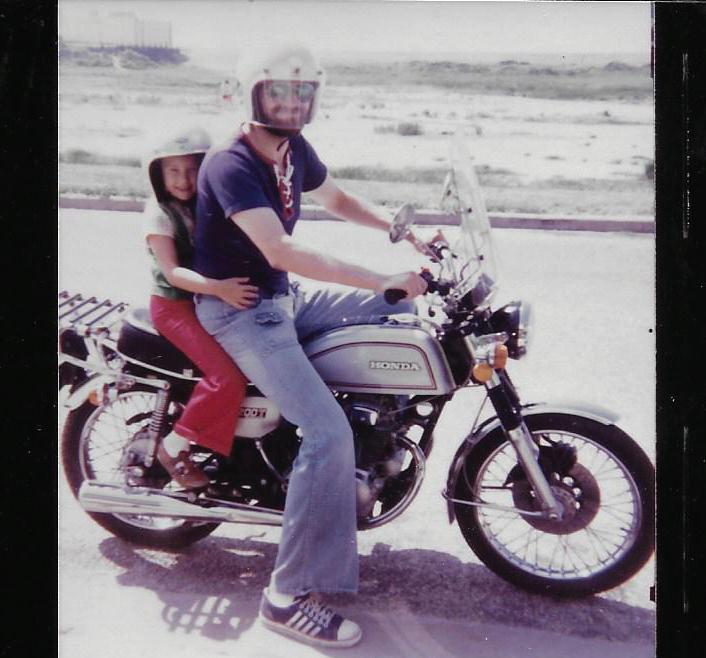

He commuted on a motorcycle from Galveston Island, Texas, to Monsanto's Texas City plant for plant E&I construction and startup.

I tried following the rule of using boosters instead of positioners on fast loops. On startup, the surge valves assigned to be open suddenly slammed shut. An E&I technician showed me that, with a booster and no positioner, he could manually move the diaphragm actuator shaft of a 24inch surge valve. So, I immediately reinstalled the positioner with the booster on its output with a booster bypass valve slightly open to prevent oscillations from the positioner seeing the very small booster volume instead of the large actuator volume. The original theoretical studies that advised replacing positioner with booster didn’t account for the booster’s low inlet-port sensitivity and high outlet-port sensitivity to slight changes in diaphragm actuator volume and pressure from diaphragm flexure leading to positive feedback.

A few years later, when I showed up at supplier’s lab to test the pressure control valve response time for sensitive furnace pressure control in inches of water column, I was surprised to find the 16-inch valves with diaphragm actuators had boosters but no positioners. I showed them how I could manually position the valves by grabbing the shaft. The supplier put positioners on the valves with boosters on the positioner outputs with slightly open bypass valves, and found an article written a decade earlier by their company expert detailing the need for boosters on positioner outputs with a slightly open bypass valve that’s now an integral part of some boosters. The pressure control valves then all worked well with a response time of less than one second.

One plant asked me to help with some new, large valves in the piping spec they bought to improve pressure control. They were inexpensive, large-capacity, tight-shutoff valves. When I went to the plant lab to check out the valves’ response, the person in the lab room looking at the computer results from a smart positioner said the valves were responding to a 0.5% change in signal. I put a travel gauge on the butterfly disc, and found that the valve didn’t respond to signal changes smaller than 8%. The positioners were being lied to due to shaft windup from high-seal friction from tight-shutoff design.

I subsequently found the same problem in another plant installing new piping spec valves. These rotary valves are attractive because they’re cheap, with high capacity and tight shutoff. They’re sometimes referred to as high-performance valves. Often, technicians are clueless because smart positioner readback and diagnostics are lies due to shaft windup from seal friction, stem friction from graph oil packing, lost motion from key lock connections, rack and pinion actuator resolution limitation, and backlash from link-arm and Scotch-yoke connections.

A diffi cult plant compressor startup triggered several trips on startup attempts. The plant was subject to six or more startups each year. When I told operators I’d automate the startup, they said it wasn’t possible because they always experienced trips. To me, this was motivation for startup procedure automation.

I used dynamic simulations to develop and thoroughly test the logic needed. The first and subsequent automated startups were successful. Next, we needed to reduce plant shutdowns because it had been pushed beyond original design capacity due to so many recycle streams. By installing three measurements with middle-signal selection, improving downstream operations, and flow control on key recycle streams to prevent positive feedback, plant trips went from more than six per year to one per decade. Plant production capacity and safety greatly increased.

My colleague didn’t think it was a good idea to automate a hazardous raw material transfer that was extremely difficult for operators. So, he sat in the control room with gas masks on, while I commissioned the procedure automation that was thoroughly tested by a dynamic simulation. It went extremely well. I’ve successfully used procedure automation in difficult plant operations, and used state-based control to proactively deal with abnormal plant operating conditions.

I also found some analog control holdouts. One was a furnace pressure controller that could go off-scale in 0.1 seconds, and the other was a polymer pressure controller. The manipulated variable in each case was an incredibly fast variable speed drive (VSD) set by a fast analog signal. I remember looking at the polymer pressure controller and thinking the fast oscillations were noise, but later finding out they were load disturbances.