Marketanalysis

How

How

Searching the industry to advance the maintenance and profitability of your injection moulds? OEMs and Moulders can now monitor assets with ProFile Bluetooth® connectivity:

• Realtime visibility of mould performance and KPIs

• Make data-based decisions to drive improved OEE

• Global access with secure, role-based reporting

Begin the journey to better tooling productivity today. Visit procomps.com/ProFile or email from the QRC below to receive a proposal and plan that will achieve your vision.

Intheworldofplasticproducts,toolandmouldmakersplayacrucial roleasalinkbetweendesigners,plasticsprocessorsanduserindustries Their expertise and services are invaluable as they enable innovativedesignstobetranslatedintofeasibleandefficientproductionprocesses Thisexpertiseshouldnotonlyberecognised,butalso appropriately rewarded However, the reality is often different

Thepracticeofhavingproductionresourcessuchasmouldsmanufacturedcost-effectivelyincountriessuchasChina,whileatthesame time relying on the highly specialised expertise of European manufacturers for instance for design and prototyping reveals a discrepancyintheappreciationoftheseessentialservices Ontopofthat, large corporations often use their market power to dictate unfair deliveryandpaymenttermsthatpushsmallandmedium-sizedcompaniestotheirfinanciallimits Theironyisthatthesecorporationshave reduced their own capacities to cut costs and are now dependent on the structures of the mould makers to ensure the feasibility of new products in injection moulding.

If the European tool and die industry continues to suffer or even disappear under these conditions, it could lead to a shift in market power, with Chinese manufacturers dictating prices and standards This would not only weaken the European industry, but would also affect the innovative strength and quality ensured by decades of expertise and experience The strategic shift needed involves not just recognisingthecraftsmanshipandinnovationthatEuropeantooland mould makers bring to the table but also understanding the broader implications of manufacturing decisions, e g on sustainability

Itisofstrategicimportancethatcompaniesrecogniseandvaluethe expertise and role of toolmakers as problem solvers and innovators Fair and appropriate remuneration for their services is crucial for the future viability and competitiveness of the European manufacturing industry The aim is to promote a culture of appreciation and respect that forms the basis for a sustainable and innovative production landscape

COVER STORY

AI is transforming the future of manufacturing p. 22

How the manufacturing industry is turning to Artificial Intelligence to spark the next stage of development

Subscribe to our newsletter

▪ etmm-online/newsletter

▪ facebook com/ETMMMagazine

Events

▪ etmm-online com/events

Suppliers database

▪ etmm-online com/suppliers

Photo galleries

▪ etmm-online com/galleries

Industry news

▪ etmm-online com

ETMM Media

▪ media vogel de/etmm

BY THE NUMBERS

6 The US plastics industry in 2023

NEWS STORIES

8 Trumpf partners with space start-up

TRADE FAIRS

10 Plastpol 2024 showcases cutting-edge technologies

12 MTA announces flagship initiative at Mach 2024

14 Mach 2024: Trade fair preview

REPORTS MARKETS

18 How Portugal carves its niche in the global mould making market

MACHINING EQUIPMENT

26 Transforming challenges into opportunities

28 Linear machining for trouble free production

COMPONENTS

30 Mould tracking: smart, wireless and user-friendly

CUTTING TOOLS

32 Resource-saving ultra-fine filtration technology

ADDITIVE MANUFACTURING

38 High-octane storytelling with 3D printing technology

INJECTION MOULDING

40 It's all in the mix: robots take production to a new level

42 Sustainable injection moulding leads the way

CAD/CAM & SOFTWARE

44 Software rapidly simulates elastic press deflection

45 Thyssenkrupp automates CAM programming

QUALITY CONTROL

46 Why Alltrista Plastics adopts advanced metrology systems

48 The sound of quality: Intelligent detection in production

What advantages can AI offer the manufacturing industry? What do you have to watch out for?

EDM EQUIPMENT & SUPPLIES

34 Mitsubishi Wire EMD gives spark of productivity at MJ Toolmakers

36 Excel Precision's smart bet on Sodick drives growth REGULARS

3 Editor’sMessage

49 Masthead

50 ISTMAWorldNews

Ranking

January/February’s most-clicked articles on etmm-online com

1. Markets: The U S plastics industry in 2023 in seven charts

2. Markets: US tool and mould making market on course for growth

3. Components: How wireless connectivity is changing tool and mould management

4. Management: Extensive job cuts loom at Bosch

5. Materials: A very hot item: Thermoplastics for up to 1,200 °C

Assessing the US plastics industry landscape in 2023 reveals a year marked by nuanced shifts across multiple sectors. From fluctuations in production levels and shipments to the complex interplay between labour constraints and export dynamics, the plastics industry faced challenges and opportunities.

FLOATING INSERT

Allows for self-centering in the cavity because of horizontal and vertical movement when the mold closes.

6 INSERT DIMENSIONS & 9 STROKES

• FASTER INSTALLATION & MAINTENACE: Only one screw on the ejection side and two screws on the injection side

• INDIVIDUAL MOLDING INSERT: Easily disassembling for customer to machine.

• APPROPRIATE FOR CLEANROOM: Turcite® wear plate eliminates the need for lubrication.

• SMALL SPACE REQUIRED: Very compact product enables its use in small places.

• OVERALL SAVINGS: Up to 50% less than other slides on the market.

• COOLING CAPABILITIES: Pre-drilled holes to easily customize the cooling channels.

With this acquisition, Krones continues to implement its M&A strategy

Sour c e: fr ee lic ensed

In a press release dated 29 January 2024, Krones, Neutraubling (Germany) announced the imminent acquisition of 100 percent of the shares in Netstal, based in Näfels, Switzerland, from Krauss Maffei. On February 7th, the contracting parties signed the purchase agreement. The purchase is subject to approval by the antitrust authorities. Krones expectsthetransactiontobe finalised in the first half of 2024.

Netstal is a leading supplierofinjectionmouldingmachines to the beverage market (PET preforms and caps) as well as to the medical and thin-wall packaging market. The company is a technological leader in its markets and has already been a strategic partner of Krones in the past. In the 2023 fiscal year, Netstal generated with a workforce of morethan500employeesarevenueofmorethan200millioneuros. TheprofitabilityofthecompanyiscurrentlybelowtheKronesGroup levelbutisexpectedtoclosethisgapoverthecomingyears Netstal will be reported as part of the segment Filling and Packaging Technology (ast)

Sincethebeginning oftheyear,Agathon has been the exclusive distributor of demoulding elements from the Lüdenscheid-based standard parts manufacturer Strack Norma in Switzerland. As an experienced expert in the field of precision parts for injection moulding, Agathon offers on-site advice and technical expertise on all matters relating to latch pullers, slide units and limit switches.

StrackNorma’scooperationwithAgathon,oneoftheleadingmanufacturersofgrindingandlasermachinesaswellasprecisionparts for machine, tool and mould construction, enables the standard partsmanufacturertoofferitscustomersmorecomprehensivesolutions in Switzerland.

“Thisexclusivepartnershipisaclearcommitmentbybothcompanies to offer excellent customer service and high quality products Our modern demoulding elements, combined with the technical expertise of Agathon's sales staff, create synergy effects from which ourcustomerscanbenefitinthelongterm,”explainsSebastianPeter, Sales Manager at Strack Norma. (ast)

The German technology company Trumpf and the European space-travel start-up The Exploration Company are cooperating on the constructionofcore components for spacecrafts for missions in the earth’s orbit and to the moon. As early as spring 2024, the Exploration Company will use 3D printers from the laser specialist to print core components of the Huracán and Mistral engines for the Nyx Earth and Nyx Moon spacecraft in Planegg near Munich. The aim is to make the Huracán engine reusable and refuelable in the orbit with bio-methane and oxygen.

“Ouraimistoofferspacemissionsmorecost-effectivelythanwas previously possible. Our spacecraft can benefit from Trumpf’s manufacturing and application expertise. Trumpf has decades of experienceintheproductionofhigh-precisioncomponents,”saysHélène Huby, CEO of The Exploration Company The start-up plans to send a space capsule to orbit the earth for several months in an initial mission in 2026. Starting in 2028, further missions are planned to go to the moon. (ast)

Orders received by the German machine tool industry in Q4 2023 were 17 percent down on the previous year’s figure. Orders from Germanyfellby20percentwhereas those from abroad dropped by 15 percent. Demand increasedbyelevenpercentin nominal terms in 2023 as a whole. Domestic demand was down 14 percent, while foreign demand was nine percent lower In real terms, there was a 16 percent decline in demand over the year as a whole.

“Our industry is receiving no impetus from the global economyatpresent.Theinternationalpurchasingmanagers’index revealsweakperformanceinthekeymarkets,”saidDr MarkusHeering, Executive Director of the German Machine Tool Builders’ Association (VDW), commenting on the result. The only exceptions which could provide any impetus are India and Mexico Domestic demand is also continuing to suffer from the geopolitical and economic uncertainty as well as from high interest rates and energy prices.ThelackofordershaspromptedtheVDWtoforecastaslight decline in production of three percent for 2024. (ast)

Italian automotive supplier Sapa is expandingintoNorthernandWesternEuropewith the acquisition of 100 percent of the Promens Zevenaar and Rongu plants in the Netherlands and Estonia. The plants were acquired from Berry Global, a world leader in packaging and engineered materials.

The two plants had a combined turnover of 105 million euros for the year ended September 2023, and employ more than 600

Zahoransky has sold the production site for injection moulds.

In the course of the further development of the group of companies,Zahoranskyhassoldthe production site for injection moulds Zahoransky Formenund Werkzeugbau in Rothenkirchen (Germany) to MT Management. As part of a management-buy-out, the long-standing managing director and toolmaking expert Monty Tepper will take over the entrepreneurial responsibility Since 1991,thesitehasbeenproducing injectionmouldsforawidevariety of plastic products in the personal care and consumer products sector in the Vogtland regionofSaxonywitharound70 employees. In the future, the companywilloperateunderthe name Molding Tec Steinberg andwillcontinuetofocusonthe production and sale of moulds and tools. Zahoransky is focusing on its production capacities for injection moulds at its sites in Freiburg and Coimbatore (India) in order to achieve further synergies. (ast)

people.FollowingSapa’srecentacquisitions inSpainandMorocco,thisisaninvestment in expansion into the world of trucks.

The new 12-month pro-forma turnover of the Italian industrial group will exceed 400 million euros. With this acquisition, Sapa strengthensitspresencewithkeycustomers such as Volvo, Scania and Daimler Trucks

Akeyaspectofthisgrowthandexpansion is the introduction of the One-Shot process

tothetrucksector Thecompany’sOne-Shot technologyenablestheproductionofplastic components for commercial vehicles in a single process, improving efficiency, sustainability and quality for both electric and internal combustion vehicles.

According to the company, this acquisitionrepresentsanimportantmilestoneand confirms its steady growth in the sustainable mobility industry (ast)

Meusburger has extended its product range with the single nozzle easyFILL as an approx 30% more cost-effective alternative to the single nozzle smartFILL EH 4000

Characteristics:

› Compatible with the fitting dimensions of the smartFILL series

› Available for the sizes 27 and 37 mm in the lengths 60, 80, 100, and 120 mm

› Recommended for plastics without glass fibre reinforcement and visually undemanding components

Innovations in injection moulding machines used for polyethylene and polypropylene granule processing open new opportunities for manufacturers.

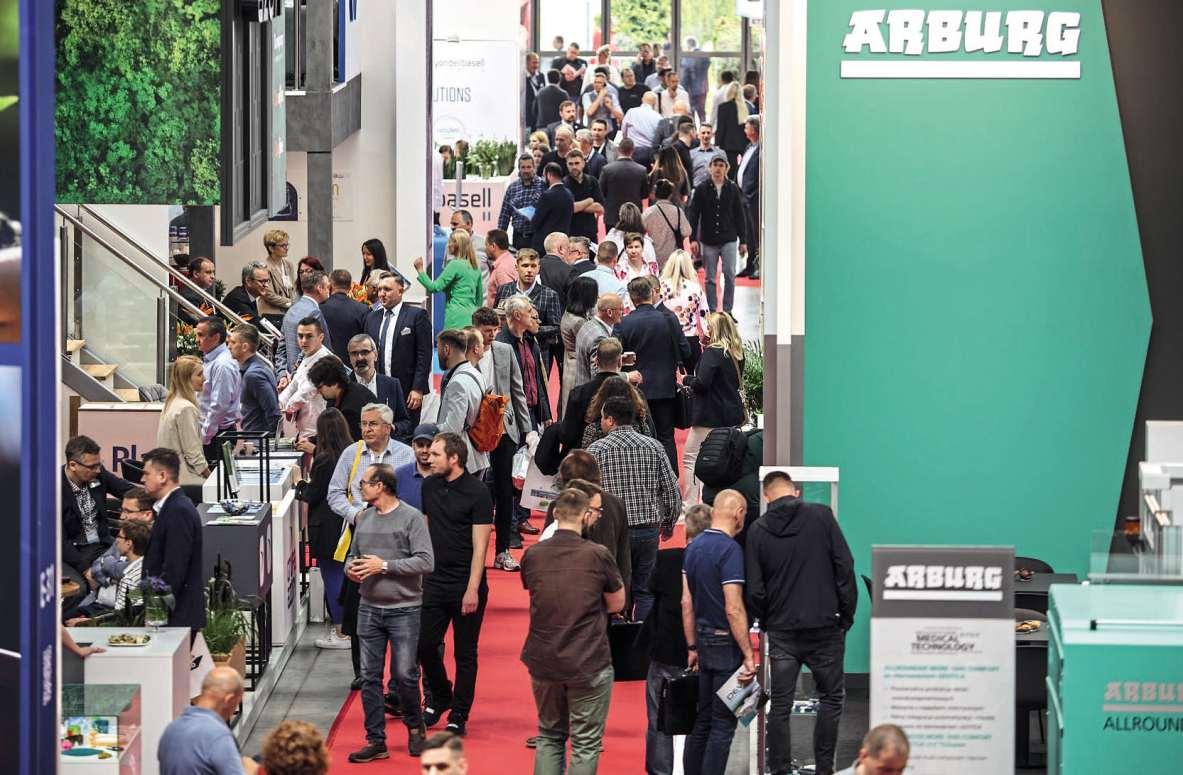

Plastpol, the leading event for the plastics processing industry in Central and Eastern Europe, returns for its 28th edition in Kielce, Poland from May 21-24, 2024. The show will again feature advanced technologies, innovative injection moulding and extrusion machinery.

The world of advanced plastics processing technologies,innovativeinjectionmouldingandextrusion machinesandmodernpolymermaterials;thisand muchmorewillbeondisplayatTargiKielce(Poland)for four days in May 2024. Plastpol welcomes the most importantcompaniesintheindustryfromEuropeandAsia, all coming to Kielce to showcase their latest offerings

According to all indicators, the International Plastics andRubberProcessingFairPlastpolwillonceagainconfirm its position as the largest event for the plastics processing industry in Central and Eastern Europe. For the 28th time, Targi Kielce will bring together the most important companies; the event will take place from May

21–24, 2024. The majority of exhibitors, with whom the organisers have been cooperating for many years, have confirmedtheirparticipation.Therearealsomanyfirsttime exhibitors who appreciate the power of Plastpol in Poland. Companies from many European and Asian countries,includingIndia,China,theRepublicofKorea and Turkey, are taking part in the fair National stands will be hosted by Germany, the Czech Republic and Portugal.KamilPerz,directorofthePlastpolprojectatTargi Kielce says: “We already know that exhibitors will occupy the entire space of our exhibition and congress centre; we are open for the last registrations. There are not many spots available to choose from.”

Plastpol will be held from May 21–24, 2024.

“For27years,theindustryand itscompanieshaveperceived Plastpolastheplacetomeet significantclients,prosperfor newmarketsandestablish keybusinesscontacts”.

Kamil Perz Plastpol Project Director

AtthelasteditionoftheKielcePlasticsProcessingFair in May 2023, 600 companies from 29 countries presentedtheirwiderangeofproducts.Abouthalfoftheexhibitors are foreign companies from Austria, Belgium, the Czech Republic, Denmark, Egypt, France, Spain, the Netherlands, India, Ireland, Israel, Japan, South Korea, Turkey, Italy, Germany, Portugal, Romania, Switzerland, Sweden,Slovakia,Taiwan,Ukraine,theUnitedKingdom, Hungary, Latvia and China.

“Plastpolhasbeendesignedforbusinessanddialogue. The international character of the show is conducive to newsupplychains,itenhancescontractnegotiation,and boosts networking and contact establishment. Leads become contracts”, emphasises Kamil Perz

Machinery and equipment are the foundation of the modern manufacturing industry Innovations in injection moulding machines for polyethylene and polypropylene granulate processing are opening up new opportunities for manufacturers to increase work efficiency and product quality The latest models of injection mouldingmachinesandextrudersthatofferevengreater precision, energy savings and integration with intelligent management systems; this and much more at Plastpolexpo thesegroundbreakingsolutionsarenot only revolutionising the industry, but also contributing to the pursuit of sustainable development.

“The new technologies exhibition is accompanied by conferences meetings with experts and lectures offered by industry specialists are appreciated by our exhibitors and visitors. Such sessions serve their purpose discussion, setting course of actions and new goals”, emphasises Agnieszka Dąbrowska, deputy director of the Plastpol project at Targi Kielce.

Theatmosphereatbusinesstalksisconduciveforthe future. The future is full of changes and challenges for companiesoperatingintheplasticsandrubberprocessingindustry ExcitingdiscussionsaccompaniedtheconferenceorganisedbythePlasticsEuropePolskaFoundation, the representative body of plastics producers in Poland, which has a long-standing tradition of presenting the latest data on the situation of the plastics indus-

try in Poland against the backdrop of Europe. The Plastics and Rubber Processing Fair Plastpol will be the venue of the presentation. According to the experts speakingattheconference,theindustryhasbeendeveloping atanexcellentpaceovertheyears,butthedeclineinthe industry'sgrowthrateafteratemporaryrecoveryfollowing the pandemic is a worrying trend.

Another activity offered to companies related to the plastics processing industry the first Świętokrzyskie Bioeconomic Hackathon Bio Boosters. The event is organised by Targi Kielce and the Polish Foundation for Education and Social Dialogue Pro Civis. The aim is to develop and implement a more economical and ecological solution to be used in the exhibition halls of Targi Kielce.ThefinalwilltakeplaceonApril10-11,2024atthe Kielce Exhibition and Congress Centre.

TheOmniplastcompetitionforexpertsintheplastics andrubberprocessingindustryisanintegralpartofthe exhibition. The aim of the event is to spread and populariseknowledgeofplasticsprocessingandrelatedtechnologies. The competition is open to representatives of companies exhibiting at Plastpol, and the winners can lookforwardtoattractiveprizes.The28thInternational Fair of Plastics and Rubber Processing Plastpol will witness the third and final stage of Omniplast. The event starts at noon on May 21, 2024 at the Kielce exhibition and congress centre. (ast)

Plastpol brings together leading Polish and international companies. They showcase the latest solutions in:

Technologies, machines and devices for plastics processing

Design

Plastics

Rubber processing

Recycling

In 2024, the organisers expect 600 companies from 29 countries as well as 15,000 visitors.

The venue offers 7 expo halls, a modern congress center and 2,400 parking spaces.

7 airports within 180 km radius, direct access via the S7 and 74 expressways ensure quick access for visitors.

The Manufacturing Technologies Association is launching Knowledge Hubs at Mach 2024, a flagship event aimed at helping UK manufacturers improve competitiveness, efficiency and sustainability. The show will provide a perfect platform for possible solutions.

TheManufacturingTechnologiesAssociation(MTA) willuseitsflagshipevent,Mach2024,tolaunchits new initiative to help UK manufacturers become more competitive while improving efficiency and sustainability A series of Knowledge Hubs will feature at the exhibition, taking place at the NEC, Birmingham fromApril15-19,2024,alldesignedtoencourageUKen-

“MachistheUK’sonlylive,national eventshowcasingsustainable, innovativetechnologiesusedacrossthe manufacturingspectrum.”

James Selka, CEO of the MTA

gineering-based manufacturers to adopt new technologyandtechniquestoenablethemtocompetegloballyin a sustainable manner

TheUK’seconomicgrowthiscurrentlyoneoftheslowestoftheG7,characterisedbylowproductivity,lowwages and poor investment. In many cases, global competitors have not just caught up with the UK but have overtaken it in terms of productivity and investment.

Adoptionofnewtechnologyandimplementinglatest techniques in manufacturing processes is one way to boost the UK’s economic output. The MTA’s Knowledge Hubs at Mach 2024 will focus on educating users on when and how to adopt new technologies such as AutomationandRobotics,DataandArtificialIntelligencefor manufacturing,sustainablemanufacturingtowardsnet zeroandtheuseofAdditiveManufacturingtechniques.

TheMTAispartofaunitedfrontbyUKmanufacturing organisations, along with the Manufacturing Technolo-

gy Centre (MTC) and Mach 2024 Headline Sponsor LloydsBank,toincreasetheuptakeoftechnologiessuch as automation and robotics.

The need for this approach was brought sharply into focus following the release of new figures highlighting the UK’s lack of investment in technology and its poor adoption of robotics in the industry The figures show the UK currently languishing in 23rd place in terms of theglobalutilisationofindustrialrobotsinmanufacturing–laggingnotjustbehindtheeconomicsuperpowers, but also the likes of Spain and Finland.

Making the UK more automation & robotics focused is the aim of one of the Knowledge Hubs at Mach 2024. Thehub,supportedbytheMTC,aimstoeducatecompanies on how the technology can be used to automate many processes to improve productivity

Commentingontheinitiative,JamesSelkaDL,CEOof theMTA,whichorganisestheMachexhibitionsaid;“Although industrial robot installations in the UK were up three percent last year, this was just a tenth of what is happening in Germany and also behind the likes of France, Spain and Italy”

“Our Knowledge Hubs at Mach 2024 aim to reverse the decline and enable the UK to re-establish itself as a sovereignmanufacturer Todothatwehavetorecognisethe importance of investing in the latest technologies for improving manufacturing efficiency and optimising productivity OurroleistohelpUKmanufacturersfocus onthenewtechnologyandprovideimpartialadviceand way-findingonwhenandhowtoadopt.MachistheUK’s only live, national event showcasing sustainable, innovativetechnologiesusedacrossthemanufacturingspectrum and is the destination of choice for companies looking to adopt and invest in the digital revolution,” Selka continues.

Another of MTA’s Knowledge Hubs will focus on the adoption of Data and Artificial Intelligence (AI) in manufacturing – latest technology designed to help manufacturing achieve agility through improved production processes while reducing costs and streamlining the supply chain.

Likewise, Additive Manufacturing (AM) is a technologywithhugepotentialtorevolutionisethewaypartsand products are designed and manufactured

“The possibilities offered by AI, married to AM techniques,isatantalisingprospectfortheindustry,”added Selka. “The ability of mass customisation to reshape production processes is revolutionising manufacturing asweknowit.Thenotionofbatchmanufacturehasbeen turnedonitsheadwithshort-runproductioncyclesand prototyping capable of being delivered at minimal cost and to high specification.”

TheMTAhasbeensupportedinitsstancebytheManufacturing Technology Centre (MTC). The centre advocates the adoption of robotics and automation in UK manufacturing as a means to achieve higher productivity, efficiency and quality as well as aid sustainability

MikeWilson,ChiefAutomationOfficer,MTCsaid:“We cannot compete in global markets without addressing our very low adoption of robot solutions Adopting au-

tomation at all levels of manufacturing in the UK is necessaryforustocontinuecompetingeffectivelyasaglobalmanufacturingpowerhouseandcounteringtheongoing labour shortages ”

The MTC’s report, “Robotics and Automation: A New Perspective”, concludes the slow uptake of robotics amongBritishmanufacturers,andareluctancetoinvest in automation, has contributed to the country’s limited improvements in productivity in recent years

However,itstatesthatautomation,alongwithreshoringmanufacturingoperations,canleadtonewopportunities for UK businesses.

The report says it’s not too late to turn the situation aroundbutthepriorityhastobeanimprovementinthe rate of adoption. It calls for a renewed emphasis on the need to improve productivity through the use of automation, with manufacturers, research organisations, equipmentsuppliersandGovernmentworkingtogether to help businesses improve their performance through the intelligent use of automation.

The report also stresses the importance of independent advice to new users, particularly in the SME supply chain. Such advice will be available to those exhibiting andattendingMach’sco-locatedevent,theEngineering Supply Chain Show (ast)

Reversing UK manufacturing’s poor record for adopting new technology will be tackled head on at Mach 2024.

The MTA, which organises the Mach event has been campaigning for greater adoption of new technology for some time. It will expand upon this at Mach 2024, which opens its doors at the NEC in Birmingham on 15th April, with dedicated Knowledge Hubs. These will focus on educating manufacturers on when and how to adopt new technologies:

Automation and Robotics

Data and Artificial Intelligence

Energy Efficiency

Additive Manufacturing

Tooling

Leader Chuck will present the latest innovationsfromits Italian partner, Balance Systems, developed to expand the company’s range of retrofit solutions for grinding and dressing process optimisation. Balance Systems provides customisable and easy-to-integrate solutions to optimise almost every grinding and dressing process

Whether gear, cylindrical, centreless, surface, profile or special-purpose,grindingmachinesareusuallythelaststepinthemanufacturingprocess Theysupportmostprecisegeometriccharacteristicsofthepart:fromdimension,profile,flatness,circularity,cylindricity, conicity, as well as good surface finish This is why it is important to preserve machine qualities and whenever possible increase their performance “Modernisation can increase the profitability of your old grinding machine,” explains Mark Jones, Managing Director, Leader Chuck. “There are three significant reasons to consider ‘retrofitting’ your grinding machines; balancing, touch detection and gauging ” leaderchuck.com

On Stand 320 in Hall 18 at Mach 2024, Starrag will be presenting its latest innovations from across the company’s diverse portfolio of high-performance solution-driven machine tools.FromtheBumotec machine range, Starrag will present its latest turn/mill product lines that can now be viewed in the company’s new virtual showroom.

ThevirtualshowroomisareplicaoftheStarragfacilityinVuadens, Switzerland and it provides manufacturers with an opportunity to investigate a wide range of solution-based innovations that range from the small and compact s128 simultaneous 5-axis machining solutiontothe36-axiss1000/Ctransfermachinewith8machining stations in a single footprint platform.

The virtual showroom enables manufacturers to view videos of individualmachinetools,applicationdemonstrationsandmachine specifications from the comfort of their connected devices. As a systemintegratorofhighlyproductivemanufacturingsolutions,the Bumotec virtual showroom gives engineers a flavour of what is possible when they invest in industry-leading technology www.starrag com

PaulHorn,thesolidcarbidetooling,carbide insert and tool holder manufacturer headquartered in Tübingen, Germany, has supplied more than 200,000 special tooling solutionsovertheyearsandcurrentlyoffers 25,000 standard products, including five due to be introduced to the UK and Irish markets at Mach 2024. Wholly-owned subsidiary Horn Cutting Tools will be on stand 6-210 to explain the reasons behind the launches and will also exhibit a broad cross section of the manufacturer's tooling range

AnadditiontotheHornSuperminiboring, grooving and chamfering system will be announced, a variant with a precision-ground rake face designed for producing ultra-fine bores. The ground cutting edge is free from notches when viewed at a magnification of x200 and the tool can be used to machine componentshavinganinsidediameterfrom just0.3mm.Sharpinsertgeometryensures process reliability, even with very small infeed and cutting feed rates. The specially developed coating is suitable for stainless steels,non-ferrousmetalsandothermetals. The Supermini Type 105 system insert is compatible with over 1,000 insert variants using a single tool holder, facilitated by in-

ternalcoolantsupplyandeasyinsertchanges without removing the holder

Horn has developed a new milling cutter range for efficient machining of stainless steelsandothermaterials.Thecutters,available in DSHPR and DSR types, are designed with specific geometries for both roughing and finishing, including applications in the food, chemical, pharmaceutical, watchmak-

ing, and precision engineering industries. The IG3 coating on these cutters provides high temperature resistance and longevity

A new, high-performance, carbide grade from Horn, the SG3P, presents enhanced possibilities in terms of performance and tool life when whirling medical screws. It enables shorter cycle times for thread production thanks to higher cutting values, including when processing materials that traditionally are difficult to machine In addition, the combination of an ultra-fine-grain carbide powder and a high-temperature-resistantcoatingraisesprocessreliabilityand improvescomponentquality In-housecoatingoftheinsertsenablesfastdeliverytimes andthecarbidegradeisavailableforallstandard Horn thread whirling systems.

Toaddressvibrationissuesinboringoperationswithlongoverhangs,Hornpresentsa boring bar with adjustable damping This featureallowsforpreciseadjustmentstominimise vibrations, leading to improved surface quality and increased insert life. The boringbarsarereadilyavailableinstandard length-to-diameterratios,withhigherratios offered as special tools. www.horn-group com Sour c e: Ho rn

Sandvik Coromant, a leading specialistinglobalmetalcutting, has reaffirmed its commitment to nurturing future talent in engineering by sponsoring the EducationandDevelopment(E&D)

Zone at Mach 2024. The E&D Zone is the educational hub at Mach 2024 and is designed for students keen to explore what engineering-based manufacturing can offer them as a future career

AcrucialpartoftheE&Dzoneisguidedtoursoftheexhibition.Aspartofthese tours, students learn more about the latest manufacturing technologies being developed and deployed in the UK industry and get to learn about potential careerpathsandopportunities evenprovidingguidanceonthemanufacturing and engineering companies that are recruiting UK apprentices

CommentingonSandvikCoromant’sinvolvementwiththeE&DZone,James SelkaDL,CEOattheManufacturingTechnologiesAssociation(MTA),whoown andorganiseMach2024said:“Attractingnewtalentintotheengineering-based manufacturing sector is a key driver for the MTA. The dedicated E&D Zone at Mach continues to be our biggest opportunity to inspire a future generation into engineering as an exciting career ”

Withover3,000studentsinthekeyagerangeofelevento18expectedtoattend the event this year, Mach 2024 promises to provide lots for them to see and experience with interactive activities organised by key contributors www.machexhibition.com/student-zone

Walther Trowal shows a centrifugal disc finishing machine of the model range TT…A/2C for finishing the surfaces of small, mass-produced parts at Mach. The socalled “double-batch” systemallowstheprocessingof one batch, whilst a second batch is passing through a separation system, where the finished parts are separated from the processing media. The simultaneous operation of two separate process stages minimises unproductive idle times and allows high efficiency plus maximum throughput. The TT..A/2C systems are very compact.

The company also presents its CB circular vibrator, which can be integrated into automated manufacturing operations. Optional technical characteristics likethepartsloadingchuteontheoutsideoftheprocessingchannelandtheso called“gateclearing”featuregreatlyfacilitatetheintegrationofthesemachines into automated production processes and guarantees batch integrity

Since most mass finishing processes require the addition of water and liquid processing compounds, the finished parts often undergo a drying operation Therefore,WaltherTrowalalsodisplaysaGdrierthatnotonlydriestheparts,but alsogeneratesalightpolish Themachinecanbecombinedwithupstreammass finishing systems in batch as well as continuous feed operations Additionally, thecompanydemonstratesaZMbasketcentrifugethatallowsthecleaningand recycling of the mass finishing process water in a closed-loop system. wwwwalther-trowal.com

19 – 22.11.2024 FRANKFURT/GERMANY

formnext com

The demands on industrial production are constantly increasing A rising need for complex and individualized parts, even shorter product cycles, a scrutinization of proven supply chains plus a desire for increased sustainability in this transformation – these are the challenges faced by industries worldwide It is also a chance for AM to showcase its expertise and creativity

Formnext 2024 provides the ideal platform to showcase your solutions in Additive Manufacturing or along the entire process chain Actively design the future of production

Register now as an exhibitor at Formnext and request an offer without any obligation

Honorary sponsor

Heller Machine Tools, a German-owned company with a manufacturing facility in Redditch,UK,iscelebratingits50thanniversary in 2024 and will showcase its capabilities at Mach 2024. The machine tool manufacturer provides users with solutions to maximise machine availability and productivity,helpingthemtoproducepartsreliably and at a competitive cost per part in day-today manufacturing The holistic Heller ser-

vice includes time studies which are accurate to ± 5 percent, evaluation of requisite workholding, consideration of automation and unmanned running requirements, built-in chillers for cooling the machine elements if they are required to achieve tolerance, tool life monitoring and broken tool detection.

Although not at the show, to be featured prominently on the stand will be the new F

Renownedasaspecialistinprecisiontoolingandholemakingapplications, Big Kaiser has introduced a plethora of new products over the last twelve months all of which will be on the stand at Mach 2024 in Birmingham

From its portfolio of bore machining products, the expansion of theEWNMonoblockrangewillbeshown.Designedtoimproveproductivity and performance for end users, the system uses Smart Damper technology that reduces chatter and subsequently cycle times,deliveringexceptionalmachiningaccuracyandsurfacefinish quality TheEWNMonoblockfineboringheadshavebeenexpanded with the new CK1 and CK2 products that support the machining of diametersfrom20to36mm and25to47mmrespectively The full EWN Monoblock family of products ranges from the smallest type CK1 to the largest model CK7 which now supports fine boring from 20 mm to over 200 mm diameter

www.bigkaisereu Sour c e: Big K aiser/ I T C

Also, new from the Big Kaiser bore machining stable will be the new MW rough boring bars. Manufactured from carbide, they deliver significantly improved precision levels.

6000 5-axis mill-turn machining centre launched by Heller at the last EMO trade show Ithasbeendesignedfromtheground up following extensive research carried out amongstthemanufacturer'scustomerbase. Highlights of the new generation include newswivellingheadswithintegratedmotor spindles developed in-house and an optional direct-drive torque table for carrying out in-cycle turning operations. A pallet changer is included as standard for first-level automation,enablingeasyintegrationlateron of a rotary or linear pallet storage and retrieval system.

FeaturedatMachwillbeHeller-4-Industry, the group ' s drive towards integration of its machinetoolsandcontrolsintotheIndustry

4 0 environment Within the multi-faceted portfolio is the Heller-4-Services interface, which focuses on transparency of digital manufacturingandmaintenance.Themodule forms the basis for evaluating machine dataandstatisticstoreducedowntimes.Additionally, visualisation of specific informationsuchasstatusdisplaysofaxesandspindles enables a user to predict wear and implement preventive maintenance. www.heller.biz

At Mach 2024, Hurco Europe will showcase its latest advancements in prismatic machiningequipment,with a focus on 5-axis machining and automation for 3-axis and 5-axis vertical machining centres. The display will feature the integration of automation solutions like the Hurco Pro-Cobot Profeeder on a VM20i 3-axis VMC and an Erowa Robot Compact 80 on a VMX30Ui 5-axis model Additionally, Hurco will presentarangeof3-axisVMCs,includingthepopularVM10iandthe entry-level VM One, designed for compact yet powerful machining options for small to medium batch runs

Turningsolutionswillalsobefeatured,withtheintroductionofa new range of driven-tool CNC turning centres, including the TMX10MYSi with a 10-inch chuck, showcasing higher power, speed, and a larger frame with added Y-axis for versatile machining

Furthermore, Hurco continues its partnership with Roeders of Germany,displayingahigh-precision5-axisRoedersmachiningcentre designed for applications requiring fine surface finishes.

www.hurco de

The priority for nearly all manufacturersissustainable production, where output or machine capacity is increased, while minimising costs and maintainingquality In order to achieve this, every step in the process engineering, design, CAM programming and machining shouldbeinspected,verifiedandoptimised VericutCNCSimulation software ensures programs are error free and all operations work togetherasintended,whileoptimisationcapabilitiesofthesoftware ensure the whole process is operating as efficiently and as sustainablyaspossible theresultissignificantsavingsinmanufacturing time, reduced energy consumption and increased profits.

Visitors to the Mach 2024 can get live demonstrations of the features in Vericut 9.4, plus an exclusive preview of what’s to come in version 9.5. Vericut is the renowned global leader in NC code simulation, verification and optimisation. It enables users to link all the machiningoperationsend-to-endtoevaluateandimprovetheentire manufacturing process.

www cgtech.com

One of the highlights at Mazak’s stand will be the HCN-4000 Neo making its UK debut, a high-performance horizontal machining center with high productivity, accuracy and environmental performance. Alongside will beasecondNeomachine, the Variaxis i-800 Neo, a next generation 5-axis machining center for full automatic operation over extended periods. With its high rigidity construction and equipped with a 10,000 rpm spindle as standard, machine users will be investing in accuracy and productivity

MazakwillalsobegivingaUKdebuttotheFSW-460V(seepicture), apurposebuiltmachinedevelopedtoovercomethekeychallenges faced by manufacturers adopting friction stir welding (FSW) technology to join materials. With the FSW, Mazak has created a heavy-duty and highly rigid technology ideal for those requiring a machining and welding capability within the same machining envelope, in line with Mazak’s Done-In-One philosophy, to increase productivity and profitability The machine is ideal for manufacturers working in volume production environments. www.mazakeu.de

Brudererissettohighlightitshigh-speedpresstechnologyatMach 2024,featuringtheBSTL350-88inaliveproductionlineforthefirst time at a major event. This line will demonstrate precision, energy efficiency and the production of miniature components, alongside showcasinganewmodel,theBSTA710-220,knownforitslargebed length and adaptability The BSTL comes into its own for precision and continuity and uses up to 30 percent less energy when compared to older machine models.

A turnkey line will be established, featuring a state-ofthe-art pallet decoiler and winder, with purpose-built ‘Mach’ tooling set to produce commemorative giveaways for visitors to the stand. Experts from Bruderer UK will also be available to talk about the company’s growing range of machines and associated partner technology that is helping its customer base in automotive, aerospace, building products and the rapidly emerging electrification market. The company’s latest press will also utilise Bruderer’s newcontrolsystemthatcanbeaccessedwithdifferentdevicesviaa web browser www.bruderercom

Sour c e: Bruder er

Roemheldissettointroduceitslatestadvancementsinworkholding technologyandintegratedmouldanddiehandlingsystems Forthe first time at a major UK exhibition, Roemheld will demonstrate its recentlyintroduced,mechanicallyoperated,self-centringmachine vice. Manufactured in the group ' s Austrian factory in Rankweil, the new Hilma.UC 125 vice is of modular build and is intended for 3- to 5-axis prismatic machining applications. The design ensures easy toolaccesstotheworkpiecefromallsides,allowingtheuseofshort tools for high precision machining in a single set-up Versatility in operationisensuredbyhavingaseparatevicebaseandtwoindividual jaws that, when a single handle is turned, travel simultaneously inwardstowardsthecentretoclamptheworkpieceandoutagainto release it. The universal clamp, hence UC in the product name, can be adapted to accommodate a wide variety of prismatic and round workpiecegeometriesandsizesinjustafewsteps.Thejawopening can be extended quickly to 600 mm, one of the largest available on the market.

www.roemheld.de

The Portuguese tool and mould industry, with its roots in glass production, has evolved into a global powerhouse of the plastics industry. At the forefront of innovation, it consistently invests in research and development, adopting cutting-edge manufacturing technologies. Explore the landscape of today’s

market in this deep dive.

WRITTEN BY AlexanderStark Managing Editor ETMMThe Portuguese tool and mould industry started whenAníbalHenriquesAbrantesbroughtthefirst injectionmouldingmachinetoMarinhaGrandein 1943 This marked the beginning of a period of significant growth, attracting global investors and increasing the industry’s international presence. Initially focusing on glass moulds, the sector pivoted to plastics postWorldWarII,reducingrelianceonGermanandAustrian imports.

Since then, the Portuguese mould making industry has grown and consolidated its reputation in the internationalmarket,drivenbyexternaldemand,integrated competencesandinnovativesolutionsofferedtoitscustomers. Portuguese mould makers have largely established themselves as one-stop-shops for tooling and moulds,coveringallaspectsfromproductdevelopment and simulation, through mould design and manufacture, to try-out, commissioning and maintenance.

As of 2022, Cefamol reports that the sector includes 478 small to medium enterprises, employing about 9,900 individuals More than half of these companies are located in Marinha Grande (24 percent), Leiria (15 percent), and Oliveira de Azeméis (15 percent).

Oneoftheindustry’sstrengthliesinitsabilitytodesign and manufacture complex moulds, backed by decades of experience and high vertical integration Advanced designtoolsandmetalworkingmachinery,alongwitha skilledworkforce,ensureexceptionalquality Thisexcellence has fostered long-term customer relationships.

Akeysuccessfactoristheindustry’scollaborativespirit and well-organised network. This includes sharing resourceslikeinjectionmouldingmachinesandrecommending partners for complex projects, fostering a synergy that benefits all.

The industry’s infrastructure is supported by the fact thatmanycompaniesowninjectionmouldingmachines of various sizes. These machines are used not only for contractmanufacturing,butalsoforthemanufactureof their own plastic products. This dual use ensures optimum machine utilisation and paves the way for new marketopportunitiesandrevenuestreams.Inparticular, some mould makers are part of larger conglomerates. This integration allows for the maximisation of mould making and injection moulding capacity, combining expertise and flexibility, especially for large projects.

To further increase scale and capacity, some companies have pursued growth through acquisitions. Others areseekingeconomiesofscalethroughstrategicalliances. A notable example is the Mexportools joint venture, whichaimstogrowintheMexicanmarketinparticular This venture, comprising four Portuguese companies withmorethan30years’experienceinthemanufacture of moulds of various sizes, works with Mexican public research centres. This approach not only addresses issues of scale, but also exploits geographical advantages such as proximity to the US

Despite challenges like the Covid-19 pandemic, automotive industry uncertainties, and raw material short-

agesduetoglobalconflicts,thePortuguesemouldmaking sector remains resilient. This is reflected in a significant increase in exports to demanding markets and industries.

Accordingtothelatestdata,thePortuguesemould-makingsectorranks8thintheworldand3rdinEurope,with exports to more than 80 countries. Its success is attributed to adaptability, technological progress and strict quality control. Companies are highly export-oriented, sellingalargeproportionoftheirproductiontocustomers abroad.

In 2022, Europe and North America were the main destinationsfornationalexports.ExportsbyPortuguese toolanddiemakersexceeded500millioneurosin2022. Theyrecordedforeignsalesof505.42millioneuros an increase of 1.4 percent compared to 2021 which not

Portugal’s mouldmaking and tooling industry is known for its collaborative approach. For example, under the umbrella of the Portuguese Engineering & Tooling Cluster, the country’s mouldmakers are promoting the collective brand of their industry on a global scale. This cluster is represented by Pool-Net and includes a wide range of stakeholders from business, science and technology. As a recognised partner in public decision-making in Portugal, PoolNet’s role is to streamline and monitor the implementation of a strategic plan that includes long and medium term visions and strategies.

Pool-Net promotes cooperation, allowing companies to achieve synergies that would be difficult to develop if they worked isolated from other companies working in this field. apptoolingportugal.com/en

Central

onlyrepresentsarecoveryfromthepandemiceffectsof the previous two years, but also symbolises the reversal ofadownwardtrendinthesectorandtheconfirmation of its foreign market-oriented profile.

Europe, especially the EU, and North America, especiallytheUnitedStates,remainedthemaindestinations forPortugueseexports,withsharesof79percentand10 percent respectively

The traditional markets Germany (21 percent), Spain(16percent)andFrance(13percent) continueto dominate, with 51 percent of national exports going to these three countries. The United States continues its upwardtrendinthetopexportmarkets,rankingfourth with the same percentage as the Czech Republic, which completesthetopfive.Portugal’sforeigntradedataconfirmthatcountriessuchasPoland,MexicoandtheUnited Kingdom also remain markets of considerable interest.

The adaptability of the sector to the international environmentandtheabilityofcompaniestoreinventthemselvesduringthepandemicperiod,leadingtothedesign and development of new products with greater value fromthecustomer’spointofview,havebeendrivingfactors in Portuguese production. In 2022, the value of the sector’s production will be around 631 million euros, a calculation based on the fact that the value of exports represents, on average, 80 percent of production.

In 2022, the automotive industry remains the main customer,accountingfor74.8percentofthesector’soutput. Although the automotive sector remains an important customer for Portuguese mould making, a significant trend is emerging Other industries are increasingly turning to the country’s expertise for customised solutions. A prominent example is the medical equipment industry, where precision and high reliability are essentialforsuccess Thisdiversificationisdrivenbythe needtoreducedependenceontheautomotiveindustry

Sour

Many mould makers offer try-outs on their own injection-moulding machines.

and to explore markets with potentially better conditions and profitability

Portuguese mould makers are adapting to the changes in the automotive industry, particularly around electricvehicles,andareconfidentoftheirabilitytomakea significant contribution to this sector R&D is a key strength, with many companies collaborating with universities and participating in research projects. The use of advanced manufacturing technologies such as 3D printing and additive manufacturing is becoming increasingly important, particularly in the production of complex tooling

The packaging industry remained the second largest customer for tooling (8.4 percent). The other sectors weregenerallyinlinewithlastyear’sresults,withhouseholdappliances,electricalgoodsandaerospaceshowing slight increases. Telecommunications, agriculture/irrigation,construction,mobilitywerealsoreportedascustomersectorsformouldmakingcompanies,confirming the trend towards diversification.

The Portuguese mould making industry is characterised by its integrated service offering, commitment to quality, sustainability efforts and technological innovation. Despite challenges such as competition from lowcost markets and the need for economies of scale, the industry has shown remarkable adaptability and strategic foresight. The emphasis on R&D, combined with a global focus and a move towards diversification, positions the country as a leader in both technological advancementandmarketresponsiveness.Astheindustry continues to evolve, its blend of traditional expertise, innovative solutions and strategic partnerships will be crucial in maintaining its competitive edge (ast)

Sour

State-of-the-art machines and spotless shop floors impress even demanding clients.

Automation helps Portuguese mould makers stay productive 24/7.

Automation and digitalisation are indispensable features of modern factories. The manufacturing industry is now turning to Artificial Intelligence to spark its next stage of development. But what will manufacturing look like in the future?

WRITTEN BY DanielSchauber Specialist Journalist On behalf of VDWArtificialIntelligencehasbecomeindispensablein the monitoring and control of machines. Neural networksarenowusedasamatterofcourse,even in highly specialised machine tools.

“Artificial Intelligence in the form of neural networks is often used to monitor machines. The networks are ‘trained’ using large amounts of data from various sensorsinordertopredictsignalpatterns,”saysProf Berend Denkena, head of the Institute of Production Engineering and Machine Tools (IFW) at Leibniz University Hannover, explaining the principle. The staff are informed, and the machine is stopped if there is a discrepancy between the predicted and the actual signal pattern.

AI is evolving rapidly, which means that industry professionals have to contend with a constant barrage of newtrends.AccordingtoDenkena,currentinnovations of special interest include the development of AI assistance systems based on large-scale language models. These model the succession of elements in a sequence. AIassistantssuchastheGithubCopilotarealreadygainingacceptanceinthefieldofsoftwaredevelopment,for example.

The cloud-based tool, developed by Microsoft subsidiary Github and AI specialist OpenAI, helps specialists toprogrambyauto-completingcodes.“AIassistantsalso offer great potential in production where they can sim-

plifymachineoperation,whichiscurrentlyhighlycomplex in some cases, ” says Denkena.

In the industry, AI has already become established in thefieldofpredictivemaintenance.Sensorsandneural networkshelpdetectwhetheramachineisdefectiveand requiresmaintenance.Manufacturingtechnologymanufacturers often partner with researchers and research-oriented startups in order to address this research-intensive field.

The Hamburg-based startup Ai-omatic solutions, for example, specialises in predictive maintenance. Lena Weirauch, CEO and co-founder of Ai-omatic, explains: “AI makes it possible to understand information, recognise patterns, solve problems, and make decisions. The datausedfor‘training’suchAIthereforeplaysaverybig role.”

Thisworksparticularlywellinproductiontechnology, she says, because of the considerable data base which already exists. Predictive maintenance is also so attractive “ because many machines are already equipped withalargenumberofsensorsthatgeneratedatawhich can then be evaluated,” says Weirauch.

According to Weirauch, AI-based processes that have already made the leap from the research lab to industrial practice include image recognition technologies that are used for quality inspection in manufacturing or for autonomousnavigationofrobotsanddrones.Industrial robots and cobots (collaborative robots) are equipped with advanced AI algorithms to perform tasks in manufacturing, logistics and inventory management, she explains.

Such cobots are offered by the robot manufacturer Yaskawa in Kitakyushu, Japan, for example The intelligent machines can pack pallets in a fully automated process They use AI which allows them to do away with protective guards, to work with different types of pallets, and to load different pallet heights.

Robotics specialist Schunk, based in Heuchelheim, Hesse, also equips robots with AI, enabling them to recognise objects and sort them accordingly This allows smallandmedium-sizedcompaniestoautomatesorting tasks, for example, and have their machines work through the night

Laser specialist Trumpf, based in Ditzingen in the southwest of Germany, is also developing the use of AI in production. The company launched an AI-based systemin2020thathelpsemployeessortcomponents.This Sorting Guide is displayed on a screen in their work environment, graphically showing employees which components belongs to which job orders. In addition, the screen also contains all relevant information on the follow-up processes. This should significantly increase productionefficiency,especiallyinthecaseofsheetmetal panels used for a range of different orders, promises Alexander Kunz, head of the Smart Factory unit at Trumpf

“We feed the AI with data until it can recognise new situations faster and make better decisions than a human oraconservativealgorithm,”Kunzexplains.“Onlythen do we refer to this as AI at Trumpf ” Two key use cases

are diagnosis-based process optimisation and preventive prediction.

Trumpf’sActiveSpeedControlsystemforlasercutting, for example, makes use of a camera which takes 40 images per second. “We train the AI to distinguish good cross-sectionalimagesfrombadonesandthentodecide uponappropriateaction.Thisallowsustocontinuously improve the cutting quality,” says Kunz. In the case of preventive prediction, for example, the AI recognises independently if a contour is difficult to produce or whenapartisindangerofjamming “Again,wecantrain thesystemtotakeappropriateactionbyitself Thishelps prevent mistakes before they happen.”

ForArtificialIntelligencetobeabletodevelop,itmust be able to draw on natural intelligence and the experientialknowledgeofhumans.Thismeansthatspecialists must train the AI before it can be used. This is the point at which a merely intelligent machine can turn into a self-learning machine.

This makes AI particularly appealing in the face of the current skills shortages. “In my view, demographic changeismakingthefeedingofdomainknowledgeinto Artificial Intelligence one of the most exciting research topics in production engineering right now, ” explains Prof ChristianBrecher,whoheadstheChairofMachine Tools at the Laboratory for Machine Tools and ProductionEngineeringatRWTHAachenUniversity The“preservationofexpertknowledge,”asBrechercallsthetransfer of knowledge from man to machine, will help to counteracttheseriousshortageofskilledworkersinthe future.

“AImakesitpossibletounderstand information,recognisepatterns, solveproblemsandmakedecisions.”

Lena Weirauch, CEO of Ai-omatic

However, small and medium-sized companies often lack the necessary financial and human resources to integrateAIintotheirproduction.“Onesolutionwould be to collaborate and form partnerships,” says Brecher, who is also a board member of the WGP (German Academic Association for Production Technology), an associationofleadingresearchersinproductionscience.“In Aachen, this is the strategy we are pursuing in our numerous centers and specialist working groups. ”

Furthermore,transferprojectsarehelpingtotakethe knowledge from the research lab into the industry One exampleistheDemonstrationandTransferNetworkAI in Production (Pro-KI), which is being given extensive supportbytheWGP Atotalofeightcentersthroughout Germany are offering training courses and transfer projects to manufacturing companies.

The use of AI in industrial production offers many advantages,butitalsobringsitsownchallenges.Firstofall, AI models need sufficient quantities of high-quality da-

AI’s role in manufacturing extends to predictive maintenance, leveraging sensors and neural networks to foresee machinery defects. Assistance systems and tools are simplifying complex machine operations and programming tasks. AI technologies have also advanced into quality inspection, autonomous navigation and the operation of industrial robots and cobots, facilitating tasks like packing, sorting and inventory management.

However, the integration of AI in production faces hurdles, including financial and resource constraints for small and medium-sized enterprises, the necessity of high-quality data and resistance from employees and executives. Despite these challenges, AI's potential to enhance efficiency, innovation, and competitiveness in manufacturing is undeniable.

ta.ThatiswhyLenaWeirauchofAi-omatichasissueda pragmatic recommendation for companies to “ first createusecasesforwhichdatamayalreadybeavailable.” Integrating AI into existing production processes and machines can also be a complex undertaking which requiresmultipleadjustmentsandinvestments.Thiswhy it makes sense for companies first to use standard tools or existing AI applications instead of developing their own.

Humansaren’talwayseasytoconvinceregardingtheuse of AI either, as the start-up founder notes. “Often, there is an initial antipathy toward AI arising from ignoranceandalackofknowledge,”Weirauchsays.EmployeesneedtobepreparedandgiventraininginAIsystems to ensure they can use them effectively Nonetheless, WeirauchacknowledgesthatAIinmanufacturingraises ethical questions, particularly with regard to the use of autonomous robots and their impact on jobs.

Will skilled workers really become superfluous in factories once their knowledge has been transferred to the AI system? Denkena considers the issue from different angles: “Before all major technological revolutions, the questionwasraisedwhetherthenewtechnologywould make humans obsolete,” he says. “It was difficult to imagine what new role humans would play in factories beforecomputer-controlledmachineswereintroduced. Today, of course, we see computers as tools that we use and not as our rivals. I think we’ll come to see Artificial Intelligence as a tool in the same way in the future.”

Nevertheless,thepeopleworkinginsmartfactorieswill require new skills. “Employees will need software skills and will need to be versatile,” explains Denkena. Artificial Intelligence is set to increase both the number of machinesandtheirdegreeofautomation.Programming the individual machines will become much easier, however employees will be expected to handle a large number of different machines.

IfAIistosucceed,itwillneedtoovercomeadegreeof resistance evenfromtheexecutivesofmanufacturing companies. “Many companies are still very reluctant to sharedata,”saysDenkena.TherearescarcelyanyindustrialproductiondatasetsavailableonlargeAIplatforms like Hugging Face, he says In many other areas, however, open source has been instrumental in ensuring the successofAImodels “Inaddition,thelevelofstandardised communication is still insufficient for the Internet of Things,” warns Denkena. Individual solutions are required for everything, including data acquisition. “The necessary financial investment make it particularly difficult for small and medium-sized companies to get started with AI.”

Meanwhile,AIisclearlyunavoidableifindustrialproductionistoremaininternationallycompetitive.“Given thechallengesfacingGermanandEuropeanindustry,AI willplayanimportantroleinraisingtheefficiencyofour production and business processes, and thus our competitiveness,”saysBrecher Inaddition,AIwillbeadecisive factor in determining a companies’ ability to innovate their products and production processes. (ast)

Sour c e: T oolcr a ft

RJG has introduced a new feature to its CopilotprocesscontrolsystemcalledMAX,the Process Advisor This feature incorporates artificialintelligencetechnologyusingMaster Molder techniques to provide real-time guidance to optimise injection moulding processes.

MAX acts as an intelligent assistant that continuously monitors process parameters and provides troubleshooting suggestions. ThisadditiontotheCopilotsystemispartof RJG’s ongoing efforts to integrate AI into its solutionstoimprovecontrol,efficiencyand quality in the moulding process.

The system is designed to keep injection moulding processes running at optimum performance levels. It addresses the industry’sskillsshortageandfocusesonreducing scrap and downtime, increasing efficiency and improving part quality

MAX has a user-friendly interface and provides step-by-step instructions for process optimisation. This is designed to help operatorsofallexperiencelevelseffectively manageprocessissuesandmakeimmediate improvements.

The company has focused on providing solutionssuchasprocesscontrolconsulting,

c e: RJ

Sour

training and technology to address issues such as skilled labour shortages, downtime andincreasedscraprates.MAX,poweredby artificial intelligence and incorporating RJG’sMasterMolderprocessingexpertise,is designed to improve operational efficiency, reduce downtime and scrap, and support data-driven decision making

The Copilot system, with the addition of MAX, offers several features, including in-

ect, the company’s robotics team played a keyroleinthedevelopmentofa6-axisrobot from Autonox Robotics.

Offline programming using CAM path planning allows the robot cell to be programmedefficientlyandquicklyinasimilar waytoaCNCmachinetoolandalsoenables movement patterns and reachability to be simulated. This means that machine operators who only have experience with traditional machine centres also find it easy to switch to the robot. The application can be extended by adding almost any number of tools, creating a flexible and efficient manufacturing process, since many different toolscanbeprovidedforautomatedrunning periods. A nominal reach of two metres combined with a simultaneously rotating machining table also allows larger components to be machined with just one or very fewclampingsetups.Therotatingtablehas a load-bearing capacity of up to 5,000 kg

The second recent development from Toolcraft is a hybrid robot application that canbeusedforadditiveandsubtractivemachining The laser welding head can machine components using directed energy deposition. This technique coats and adds

jection moulding process monitoring and control, real-time notifications, process troubleshooting advice, alarm setting, shotby-shot data review, part and process auditing, and process automation capabilities.

newcontourstoexistingcomponentsusing selectivematerialdeposition.Damagedand worncomponentscanberepairedbydepositing material where it is required, with the laser-based and intricate welding process transferring little heat into the workpiece.

Besidessavingcosts,repairsusefewermaterials than making new components and allow for combinations of materials that werenotpreviouslypossible.Therobotfrom MabiRobotichasamachiningradiusof2 25 metres,makingitsuitableforbothsmalland largecomponents.Inadditiontotraditional laser-powder deposition welding, EHLA deposition can be used to coat rotationally symmetrical components.

Theadaptivemotorspindleallowscomponents to be pre-machined, welded and post-machined in a single clamping setup within the same robot system. The switch from welding to milling is also fully automated without the need for any manual intervention This allows surfaces to be prepared for the welding process, reference surfaces to be produced during the manufacturing process and surface finishes to be machined in further steps.

As a family-run business, Canterbury Tools has been involved in the design and manufacture of press tools since it was established almost 50 years ago To optimise the production of specialist press tools, the subcontract manufacturer utilises cutting tools supplied by Guhring.

TheWestMidlandsmanufacturerCanterburyTools

specialises in the production of single operation tools, progression tools, transfer tools, as well as components and assemblies for automated and robotic processes in sectors as diverse as the agricultural and construction industries through to the medical, IT, aerospace and automotive sectors. To retain an industry-leading position, the ISO: 9001 manufacturer is always looking for opportunities to accelerate performance and productivity and it is this determination to succeed that led the company to Guhring

At Canterbury Tools, the company utilises a selection of 3-axis machines from small capacity to three meter bedmachinesaswellassimultaneous5-axismachining

Discussingthedailyoperationofthebusiness,JoshBennett, the Operations Team Leader at Canterbury Tools says: “We pride ourselves on manufacturing high-qualitypresstoolingandthisincludeseverythingfromsingle operation to progression tools and small fine blanking worktoautomotivetooling Presstoolscanbequitecomplicated projects, so we use a lot of different machine tools andastechnologyhasadvanced,whatwasonce done on manual machine tools is now moved to CNC machines.”

Thecompanymachinesalotofchallengingmaterials that can rapidly erode tool life and profit margins if the correcttoolsarenotselected.Alludingtothis,Joshsays: “Wetakemassiveprideinwhatweuseintermsofcutting tools, as we have to cut very tough material daily This meansthetoollifedoesmakeadifference Wedonotcut materials like your everyday mild steel and aluminium where you can get away with using the same tools for a longtime.WhenyouarecuttingthingslikeD2toolsteel andrunningintricateformswithahighmaterialremoval rate, you really can burn through tools quite quickly”

AlludingtohowCanterburyToolsfoundeditsrelationshipwithGuhring,Joshcontinues:“Wewereintroduced toGuhringattheMach2022exhibition Wehavealways pridedourselvesonbeingattheforefrontwhenitcomes to cutting tools. It is an ever-evolving industry, so you have to keep up with the technology When we spoke to Guhring at Mach, they made promises that we have heard from many other cutting tool companies in the past. Guhring told us things like ‘We will improve your toollife’,‘We’llcutyourtoolingcosts’and‘We’llimprove yourmaterialremovalrates’ Atthetime,wewereinthe market to improve upon what we were doing and we thought we were already using very good cutters but as always, were open to be proven wrong ”

Discussing the first tool that Canterbury used from Guhring,Joshcontinues:“ThefirstGuhringtoolwasthe DiverSeriesofendmills Guhringtoldusthatitwasthe ideal tool for our applications and everyday use. We trialled the Guhring Diver against the tools we were using at the time. To our surprise, they annihilated the performance of the apparently high-end tooling that we were using at the time.”

“We found a 3X increase in performance compared to what our existing tools were doing This was a massive surprisetoourmanagementteam,theaccountantswho deal with the daily costs of our business and most importantly to the machinists on the shop floor The machinists really saw a difference in what they were doing every single day with the new cutting tools. From this point, we took Guhring seriously and really put their tools through some rigorous testing From the testing, we saw a threefold increase in our tool life when we ran at the same speeds and feeds as our old cutters. With helpfromGuhring,theirNavigatorsystemandtheirengineers,wehonedourskillsetandstartedtousethisskill to push the cutters to within an inch of their lives.”

Commentingonthetooling performance after upskilling the engineers at Canterbury Tools, Josh adds: “We wanted to see exactly what we could get out of the Guhring tools. We were increasing our cuttingdepthsandstepoversby1 to 1.5 times as well as increasingourspeedsandfeedswhile maintaining a much higher tool life than what we were previously getting ”

Discussing the switch to Guhring, Josh adds: “By switching to Guhring, we foundamuchhighermaterial removal rate and this meant thatjobswereonmachinesfor less time. In the world of CNC machining, this is massive. You always want the job to be ‘ on and off’ the machine as quickly as possible. Additionally, not having to change the cutters as often has reduced thedowntimeincurredbytool changeovers.Toremove,reset and replace tools is a process that can take anything from five to 15 minutes the number of these tool changeovers has been drastically reduced.

If you have a tool that you expecttochangeeveryhour,and then you change to a Guhring tool that gives you four hours of tool life, you have cut out three tool changes in just one job cycle. Additionally, you have slashed your tooling costs.”

With regard to the service provided by Guhring, Josh says: “Another main advantage with Guhring is their next-day delivery The service isexcellentandifwearereally stuck, they can often help us with‘sameday’delivery Being abletooffercustomersarapid

“Themachinistsreallysawadifferencein whattheyweredoingeverysingledaywith thenewcuttingtools.”

Josh Bennett, Operations Team Leader Canterbury Tools

turnaround service and adhere to very short lead times is critical to our business and it’s something we can only offer if we have the cutting tools and support available from Guhring for the job ” (ast)

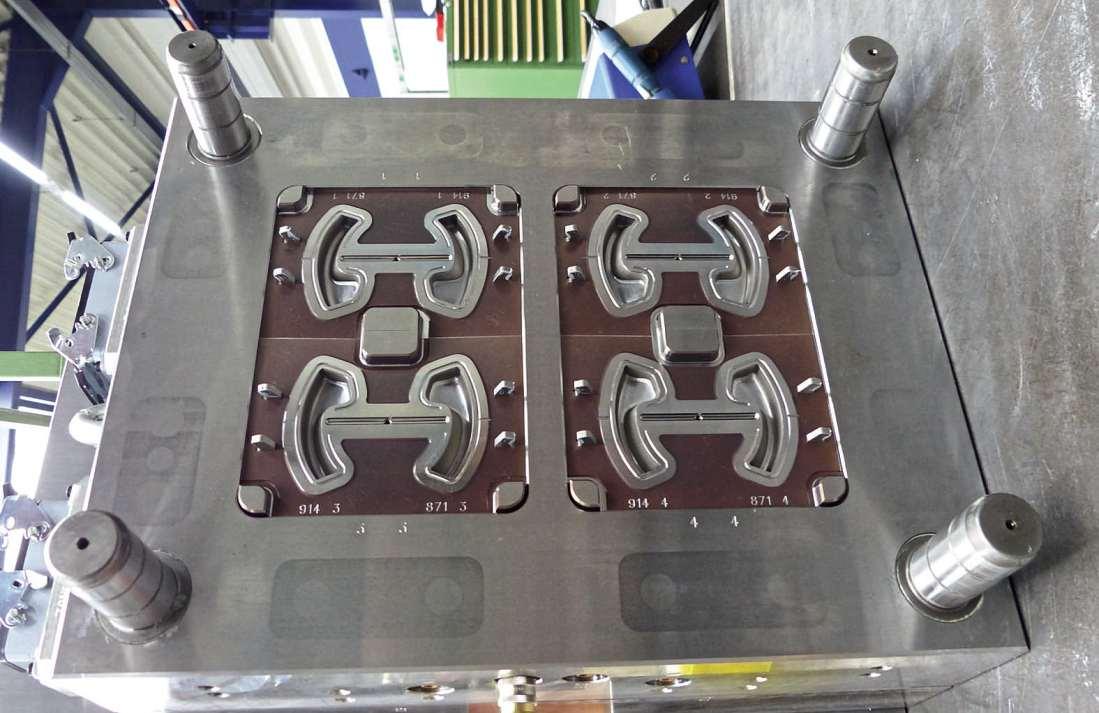

Dohlen & Krott Werkzeugbau elevates its production of complex injection moulded parts to new levels of speed and precision with a linear machining centre from Fehlmann. The company was convinced by its unmatched precision, energy efficiency and compact footprint.

The main focus at Dohlen & Krott Werkzeugbau in Baesweiler, Germany, is on highly complex, predominantly hardened injection moulded parts. Although a fully-fledged 5-axis machine was available formillingthesecomponents,itwasdifficulttoachieve the required precision with it. Therefore, after an intensivebenchmark,thedecisionwasmadeinfavourofthe Versa 645 linear machining centre from Fehlmann, becausethecomponentsinquestioncannowbeproduced much faster and more precisely

The Managing Director of Dohlen & Krott Werkzeugbau,RalfKahlen,didnotmakeiteasyforhimself When the decision was made to invest in a new machining centre,anintensivebenchmarkwasfirstcarriedoutand, among others, the Fehlmann company in Switzerland was visited. The production depth, the quality, the availability of spare parts, the competence of the employees andthewillingnesstoinnovateconvincedhim.Thetendency towards the Versa 645 linear, according to Ralf Kahlen, was already there beforehand: “The Fehlmann

companyhadmentionedtwowell-knowncustomersin Holland to me. I visited these companies and talked to the people in charge about their experience with these machining centres. The workpieces produced on them really impressed me. But also in comparison with the other machine manufacturers, my decision was made quickly Ourspaceisverylimited.Anyothermachining centre would have been too big for the existing product portfolio Irrespectiveofthis,energyefficiencyisalsoan issueforus.Andthen,ofcourse,itwastheprecisionthat could not be achieved with any other machine ”

ThetolerancesinBaesweilerare5µm,thesurfacesRz 0.8, without air conditioning This is one of the reasons why the high-precision package option was chosen A package that Alain Strebel, sales manager at Fehlmann, specifiesasfollows:“Westillscrapethecontactsurfaces ofthelinearguides,haveageometricprecisionprotocol andcheckthepositioningaccuracyinallaxesaccording to ISO 230/2. For both measures, we then set ourselves eventightertolerances.”PeterPotjans,FEsalesengineer for North Rhine-Westphalia at Fehlmann, adds: “We deliberatelymilledthetestcomponentforDohlen&Krott

The employees at Dohlen & Krott are enthusiastic about the Versa 645 linear, not least because of the large screen of the Heidenhain control.

Dohlen & Krott is a medium-sized, owner-managed company that has been producing injection moulds for sophisticated moulded parts for a wide range of industries for over 30 years. A comprehensive after-sales service is offered for these moulds. From spare parts supply to spare parts management and maintenance also within the scope of service contracts to repair and revision. The clientele includes companies from the automotive and electrical and electrical industries, medical technology, cosmetics and packaging In a second business area, Baesweiler concentrates on contract manufacturing. Here, the focus is on single-part and series production.

At Dohlen & Krott, the options of tool changer with chain magazine for 86 tools and the high-precision package were drawn. The Versa 645 linear is considered extremely precise even in the standard version with cooled slide parts and machine structure, the supported X-axis along the entire bed length.

several times without air conditioning With the result thattheresultswerecontinuouslywithinthetolerances of +/- 3 µm. ”

Dohlen&Krottiscommittedtomillinganyway,because 98 percent of the components in the cavity area are polished. An EDM structure is not necessarily seen as an advantage. With the Versa 645 linear, which arrived in October 2022, it is now possible to deliver the components to the polisher with almost the final quality Ralf Kahlen can confirm the advantages that Fehlmann describes for the Versa 645 linear It starts with the work area, which is freely accessible from the front in any arrangementforset-upworkandprocessmonitoring Automation can be connected without any problems.

“Technicaldataareofless interesttome,Ihavetokeep aneyeonourcustomers' products.”

Ralf Kahlen, Managing Director Dohlen & Krott Werkzeugbau

In Baesweiler, the Versa 645 linear machining centre isalreadypreparedforanErowaautomationsystem.AlthoughtheVersa645linearisalsousedforcontractproduction(25to30percent),thefutureautomationwillbe used exclusively for the area of multiple cavities (up to 96 cavities). Now the linear drives also permit high acceleration and dynamics. However, dynamics only play a subordinate role at Dohlen & Krott, because in mould makingtheyarenotlookingforthesecond.RalfKahlen: “If I have a good feeling about such an investment, it is not the second or the price that decides. In the end, I havetohavemycustomers'productsinmind.Andif,as with the Fehlmann, I can produce the precision and quality quickly and without problems, that is also an economic advantage.”

Anothereconomicadvantageiscertainlythefactthat acompleteproductrangehasnowbeentransferredfrom another machine to the Versa 645 linear Process reliability, on the other hand, was a high priority for Dohlen &Krottfromtheverybeginning Especiallysinceawide varietyofmaterialsaremachinedonthemachiningcentre. This starts with M 330, extends to alloy and heavy metals,hardeninguptoHRC62andsoonalsotitanium. For a correspondingly large set of moulds, the machine canrunfortwodays Buteventhen,therehavebeenno problems with precision so far

NowtheproductsinBaesweilerarethesameasbefore the investment. However, the required precision and quality can be produced much faster and without problems.Andnotentirelyunimportantinthiscontextisthe fact that the employees are also enthusiastic about the Versa 645 linear especially since the tolerances are becoming increasingly tighter (ast)

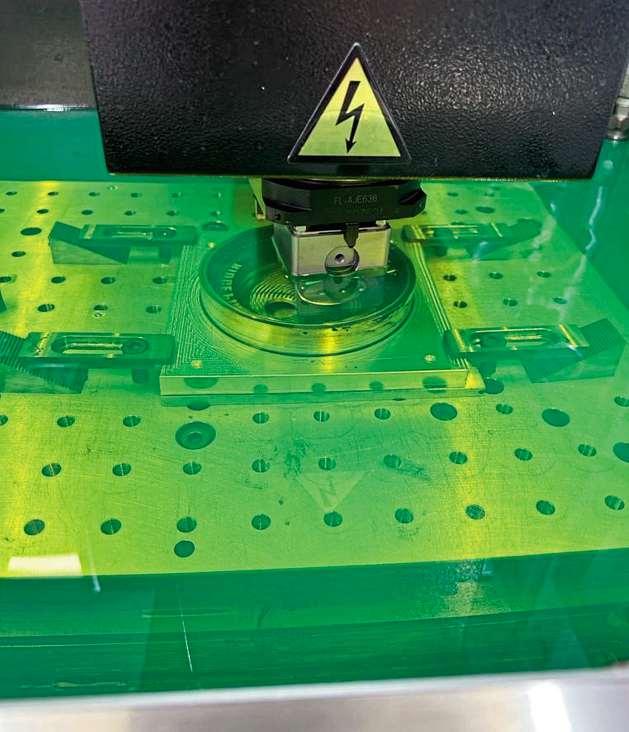

Progressive Components has been a pioneer in mould monitoring since 1994. Its latest innovations further streamline asset management for OEMs, mould makers and tooling companies by transforming tools and moulds into intelligent factory components.

WRITTEN BY AlexanderStark Managing Editor ETMMFor nearly three decades, Progressive Components has been at the forefront of mould monitoring innovation. In 1994, the company was the first in the industry to introduce cycle counters to accurately track mould usage and plan preventive maintenance before more costly problems occur over the life of the mould. Sincethen,Progressive’smonitoringsolutionshavekept pace with the advancing possibilities offered by digitalisation. Naturally, for their tracking and monitoring solutions,connectivityisagiven.Andastheindustryof things moves towards cloud services, Progressive Components has followed suit.

This is reflected in one of their latest developments, Profile v4. This advanced cloud-based asset manage-

mentandreal-timemonitoringsystemistailoredtothe needs of OEMs, mould makers and tooling companies. For OEMs, it provides real-time visibility of global tooling assets, including performance and key metrics. Mouldersbenefitfromtheabilitytotrackdowntimeand scrap, support OEE reporting and manage preventive maintenance work orders and spare parts inventory

Together with hardware components such as CVe Monitors and a Gateway device, it transforms tools and moulds from an analogue asset to components of the smart factory

Profileisaversatiletoolfororganising,maintainingand trackingtoolsandequipmentglobally Itcanbeusedas integrated with Proehensive real-time nic monitors track cycles and time injection moulds. ws downtime and performance weaknesses to identifiedanderrortrends identified. ecentlythecompanyhas the4thiterationof CVe Monitors. “The MonitorRTallowsusers the tool’s cycle count dataonthedevice, Bluetooth access to informationusingtheProfile th additional hardsend real-time data to App in the cloud for ains Carlos Saboga, omponents’ European Techni“TheCVe-RTisthe historyProgressive ems. ” relesslytotransmit data directly from the tool to the gateway and on to thecloud,wherecustomerscanviewtheinformationin the Profile Real-Time Asset Management System. The

systemalsosupportssupplychaindatasharing,enabling connection to existing ERP/MES systems via APIs and integration with reporting platforms for customised reporting

Each device is manufactured with a QR code and uniqueserialisationforassignmenttoaspecifictoolvia the Profile system. This provides a convenient file sharing method for mould makers to share documents, printsandotherinformationwithcustomers,andmould makersandOEMswhowanttoviewKPIsgloballycando so with easier access.