ULTRA SERIES

NEXT GENERATION, HIGH-PERFORMANCE DIAGNOSTICS

1-YEAR FREE

EXCLUSIVE

12 AAPEX/SEMA Editor's Picks

Our editors’ top picks for new products that caught their eye at the 2025 AAPEX and SEMA shows.

24 Top 100

Check out the top 25 most viewed products from 2025.

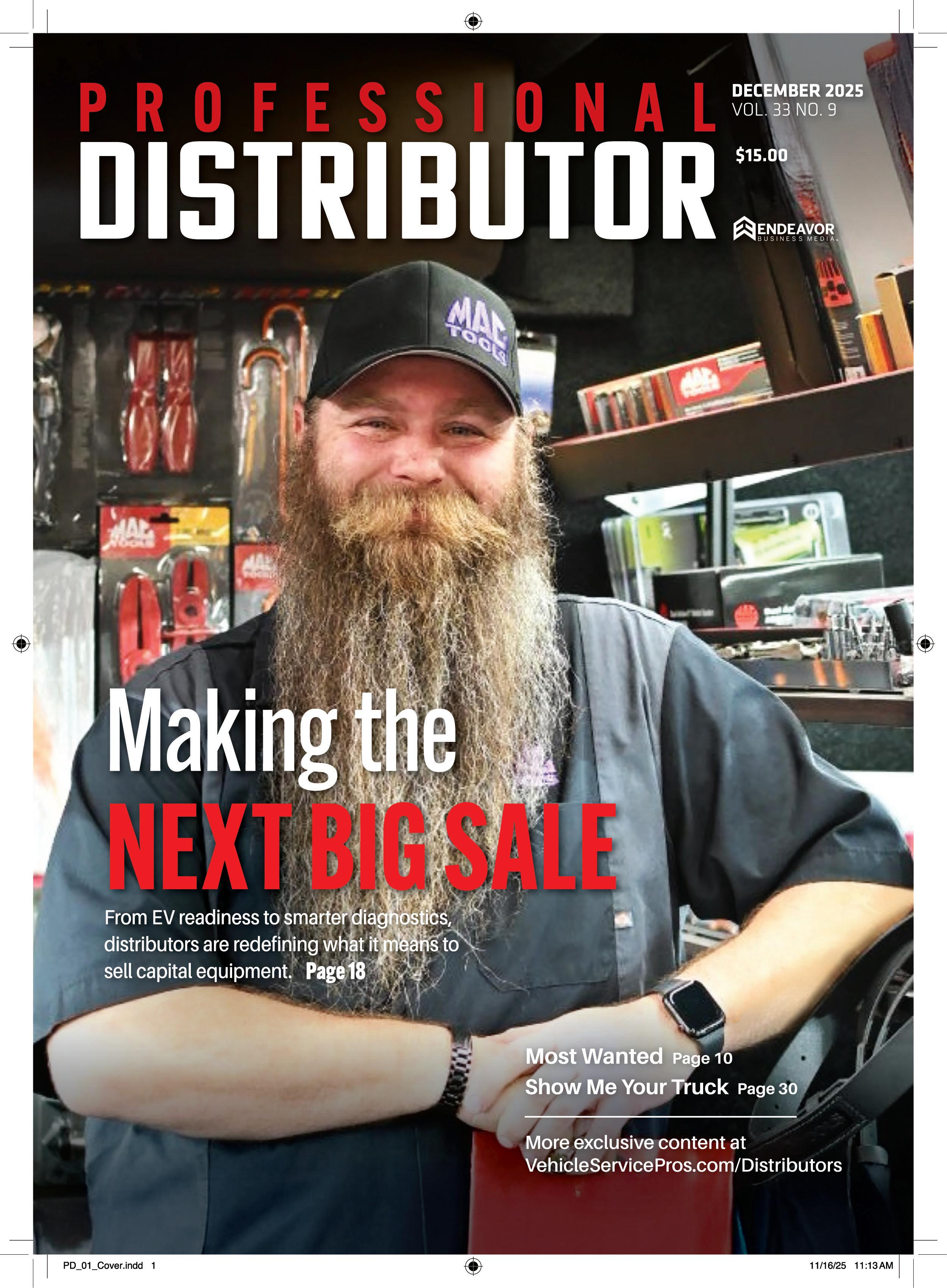

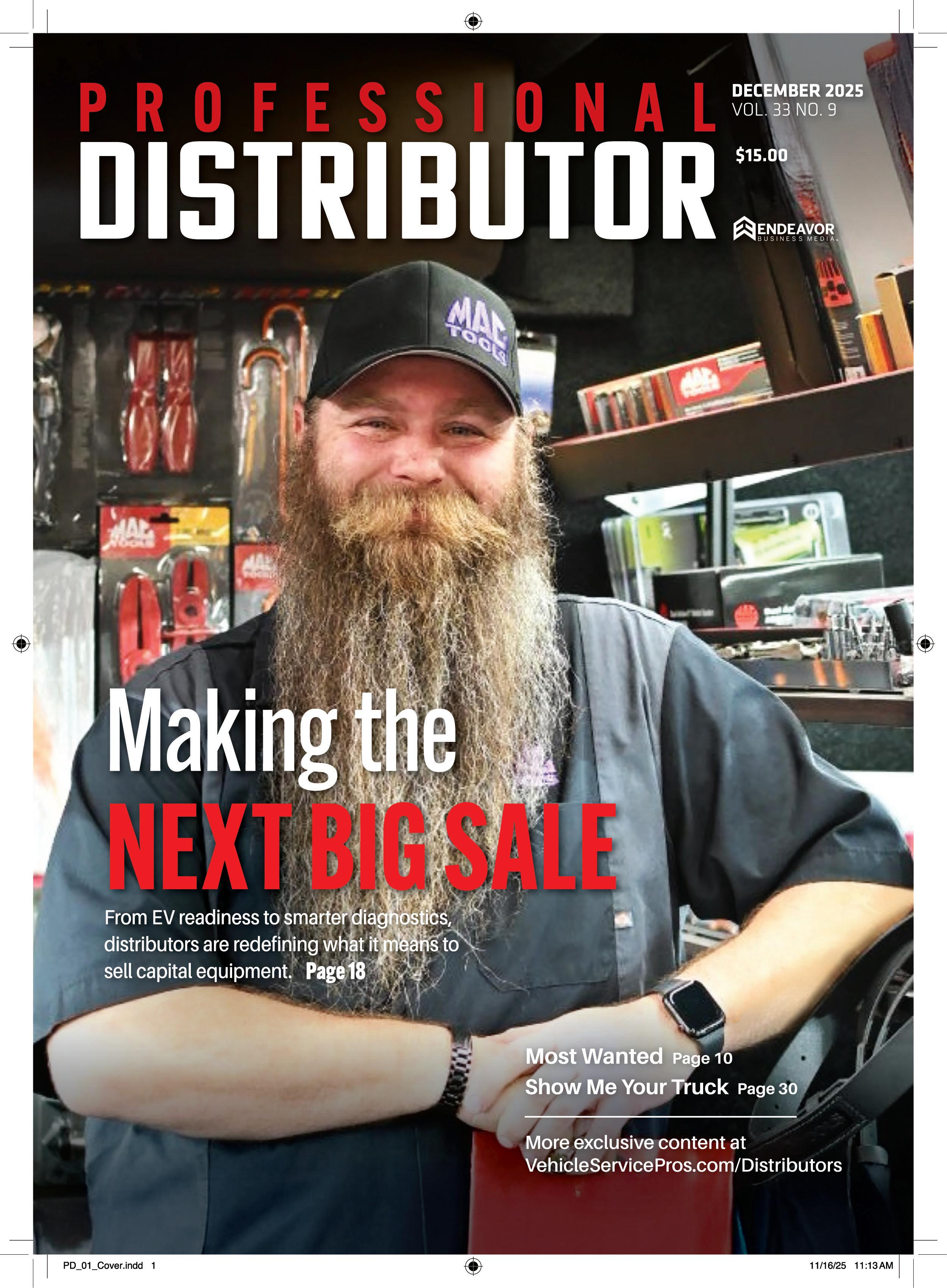

COVER STORY

18 Making the next big sale

From EV readiness to smarter diagnostics, distributors are redefining what it means to sell capital equipment.

DEPARTMENTS

28 The Truck Stop

The LDV team offers their advice on customizing your truck, from keeping comfortability in mind when displaying tools, to organizing based on your route’s needs.

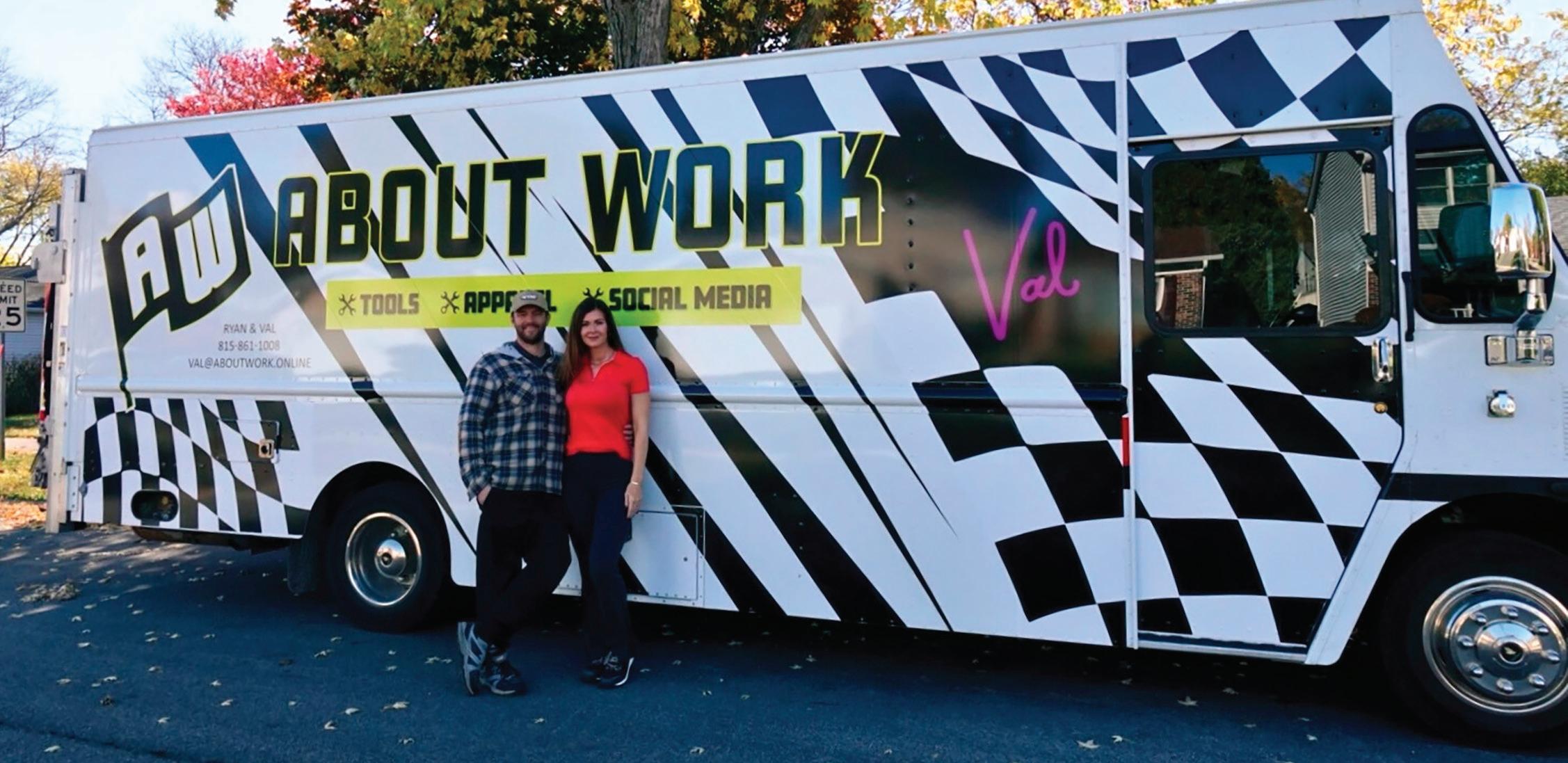

40 Tales from the Road

Independent distributor duo Ryan and Val Visona have come a long way in their time in the industry, and they’re not done yet.

PRODUCTS

6 Sneak Peek

Brand new products from Carlyle Tools, Ken-Tool, asTech, and more.

10 Most Wanted

The top requested products from technicians and shop owners, based on pageviews from VehicleServicePros.com.

14 In Focus

Taking a closer look at products from Streamlight, Mayhew, XTool, and FJC.

SALES

30 Show Me Your Truck

Jay Hashagen, Cornwell Quality Tools

32 Tool Dealer 101

Brian Fahlgren discusses the importance of toting and promoting tools in the shop.

34 Driving Sales

Products that will help your bottom line.

42 Pro Tips

Distributors share advice on what to do with your old truck.

EDITORIAL DIRECTOR Chris Jones 770-625-1526 ChristopherJ@EndeavorB2B.com

EDITOR-IN-CHIEF Nadine Battah 330-808-4298 Nadine@VehicleServicePros.com

EDITOR Emily Markham 920-234-6359 Emily@VehicleServicePros.com

ASSISTANT EDITOR Elli Carder 224-324-8514 Elli@VehicleServicePros.com

ASSOCIATE SALES DIRECTOR Mattie Gorman-Greuel 920-563-1636 MGorman@EndeavorB2B.com

DIRECTOR OF BUSINESS DEVELOPMENT Cortni Jones 920-568-8391 CJones@EndeavorB2B.com

ACCOUNT EXECUTIVE Diane Johnston 920-568-8364 Diane@PTEN.com

ACCOUNT EXECUTIVE Sean Thornton 269-449-0257 SThornton@EndeavorB2B.com

PRODUCTION MANAGER Jane Pothlanski 224-324-8507 JPothlanski@EndeavorB2B.com

AD SERVICES MANAGER Karen Runion 330-736-1291 KRunion@EndeavorB2B.com

ART DIRECTOR Eric Van Egeren

AUDIENCE DEVELOPMENT MANAGER Debbie Dumke

ENDEAVOR BUSINESS MEDIA, LLC

CEO – Chris Ferrell

COO – Patrick Rains

CDO – Jacquie Niemiec

CALO – Tracy Kane

CMO – Amanda Landsaw

EVP – Transportation Group – Chris Messer

VP of Content Strategy – Transportation Group – Josh Fisher

FOUNDER RUDY WOLF

Subscription Customer Service 877-382-9187; 847-559-7598 • Circ.ProfDistmag@omeda.com PO Box 3257 • Northbrook IL 60065-3257 Article reprints reprints@endeavorb2b.com

by any means, electronic or mechanical, including photocopies, recordings, or any information storage or retrieval system without permission from the publisher. Endeavor Business Media, LLC does not assume and hereby disclaims any liability to any person or company for any loss or damage caused by errors or omissions in the

SNEAK PEEK

Welcome to Sneak Peek!

This section features recently introduced automotive tools and equipment. See new products even before automotive technicians read about them in PTEN magazine.

BACKED BY A LIFETIME GUARANTEE

Milwaukee Tool 1/4” Drive

3” Locking Extension, No. 43-249300, offers control and security in tight applications. The extension features the largest knurling surface on the shaft and female drive end, allowing precise control even when working with oily materials. A durable knurled locking collar keeps the socket secure, and a detent hole increases engagement with the ratchet head. The extension is chromeplated for corrosion and rust protection, and it is backed by a lifetime guarantee.

For more information, visit VehicleServicePros.com/55322066

AVAILABLE IN STANDALONE OR TORQUE CHECK CONFIGURATIONS

The Chicago Pneumatic CP89 Series Digital Torque Wrenches offer +/- 2 percent accuracy with a robust gear system that’s accurate up to 25,000 cycles. Each wrench features a soft grip, non-slip handle and a 12 LED progressive light display. The series includes 1/2” drive models that cover a torque range of 20N.m (15 ft/lb) to 340N.m (250 ft/lb), and the wrenches are available in standalone or Torque Check configuration. Models with Torque Check provide torque and angle measurement, P-sets, sequencing, and reporting via the CPLinQ application.

For more information, visit VehicleServicePros.com/55318638

ADJUSTABLE BOX-END HEAD PIVOTS FOR GREATER ACCESS

The 7-pc Flex-Head X-Frame SAE Ratcheting Wrench Set, No. 80090, from SK Tools features an exclusive X-Frame design, engineered for strength, balance, and precision in tight spaces. The wrenches feature a 180-degree flex head rotation, with adjustable box-end head that pivots for additional access in hard-to-reach areas. Additional features include, an ultra-low 1.7-degree arc swing, a dual-pawl engagement ensures constant contact for faster turns, an I-beam handle construction, a SureGrip anti-slip design, and more. This set includes 3/8”, 7/16”, 1/2”, 9/16”, 5/8”, 11/16”, 3/4” sizes.

For more information, visit VehicleServicePros.com/55329677

FEATURES MAGNETIC SOCKET EXTENSION HOLDER

The Carlyle Tools Magnetic Tool Tray features a magnetic socket extension holder with a non-marring design to protect surfaces while keeping sockets organized and within reach. Its low-profile, flexible construction bends easily to fit in tight spots or curls up for compact storage. Designed to magnetically cling to toolboxes, lifts, and even curved or ferrous surfaces. Available in a 4” or 10” option.

For more information, visit

DESIGNED TO MOUNT SEAMLESSLY ON HATS

The Streamlight SL-SideSaddle USB is a compact, unobtrusive lighting system designed to mount onto hats, hard hats, and helmets. It stays clear of essential gear. Dual LEDs offer spot, flood, and combo beam options, while a blue safety taillight boosts visibility from behind. A push-button switch with mode memory remembers your last setting. The light is IPX7-rated and waterproof to 1m for 30 minutes. Spot: 350 lm on high for a 6.25-hour run-time, 100 lm on low for a 12-hour run-time. Flood: 325 lm on high for a 7-hour run-time, 85 lm on low for a 12-hour run-time. Combo: 400 lm on high for a 5-hour run-time, 160 lm on low for a 7-hour run-time.

For more information, visit VehicleServicePros.com/55324273

DESIGNED TO STREAMLINE TPMS SERVICES

The TSAP2 from Launch Tech USA is designed to streamline and simplify TPMS service by offering an intuitive platform with over 10 different TPMS functions. The tool is constantly updating, keeping users equipped with up-to-date vehicle cover-

the Launch LTR TPMS sensors for a more complete solution.

For more information, visit VehicleServicePros.com/55324280

FEATURES 2-HOUR CONTINUOUS RUNTIME

The Wheeler F.A.T. Wrench AutoTorque features an ultra-precise digital torquing sensor to prevent damage and easy torque adjustments between 10-65 in-lbs. It also offers a variable speed with a multi-speed trigger with up to 200 rpm motor speed, a magnetized 1/4” hex drive that securely holds bits, and an easy-to-read digital LCD screen that displays torque settings in 0.1 in-lb increments. The AutoTorque is powered by a 12V detachable battery with a USB-C charge port and a quick-check LED for battery status, capable of providing a continuous runtime of 2 hours on a single charge. It comes with 15 of the most popular bits, including SAE hex and Torx bits.

For more information, visit VehicleServicePros.com/55326608

INCLUDES A 30” DOUBLEEND TIRE SPOON

The Ken-Tool Truck Tire Service Kit, No. PN 35645, is engineered for long-lasting performance in the shop or on the road. The kit includes a T45A Tubeless Tire Iron, a 30” double-end tire spoon, the T11ES BeadBreaking Wedge with Safety Handle, the T35 Heavy Duty Tire Hammer with a 16-1/2” handle with replaceable rubber head, an 8 lb bucket of white tire paste, a Euro-style lube applicator brush, two aluminum C-Lok bead holders, and a leather rim protector to prevent rim scratches and damage.

For more information, visit VehicleServicePros.com/55322038

IDEAL FOR USE ON HARDTO-REACH FIXINGS

The CTA Tools Metric Hex Socket Bit Set w/ Reduced Shank, No. 2244, is a 10-piece set of reduced shank hex bit sockets ideal for use on hard-to-reach fixings. The set includes 5mm, 5.5mm, 6mm, 7mm, 8mm, 10mm, 11mm, 12mm, 13mm, and 14mm hex key bits. The reduced shank diameter allows for additional access in tight areas.

The 1/4” drive socket bits: 5mm, 5.5mm, 6mm, 7mm, and 8mm, are 87mm in length.

The 3/8” drive socket bits: 10mm, 11mm, 12mm, 13mm, and 14mm, are 93mm in length. These sockets are manufactured from robust chrome vanadium steel, with a polished chrome finish. The bits are made from impact-grade S2 steel.

For more information, visit VehicleServicePros.com/55324251

FEATURES THREE RATCHETING LEGS

The Ratcheting Harmonic Balance Puller, No. 38000, from Cal-Van Tools is designed to remove harmonic balancers without the hassle of trying to start bolts or the frustration of positioning multi-jointed puller legs. Three ratcheting legs with puller feet eliminate the need for bolts. There’s no need to remove the radiator or other components with this compact design. The legs quickly adjust and hold their position. The puller has a push turn click design.

For more information, visit VehicleServicePros.com/55329203

ELIMINATES THE PHYSICAL STRAIN OF WHEEL SERVICE

The BendPak RWS-200WL BatteryPowered Wheel Lift eliminates the physical strain of wheel service, protecting technicians while delivering greater uptime. Unlike air-powered models that must stay tethered to an air supply, this rechargeable battery-powered lift is truly mobile for use throughout the shop. With double the power of 12V units, the RWS-200WL delivers faster lift speeds, superior torque, and a 200-lb capacity to easily handle oversized wheels and tires. By reducing technician fatigue and lowering the risk of strainrelated injuries, the RWS-200WL can help reduce workers’ comp claims, support OSHA-compliant safety practices, and even contribute to lower insurance premiums over time.

For more information, visit VehicleServicePros.com/55318803

FEATURES EXPANDED SIDE STORAGE

The Matco Tools 38” x 24” MSCX SIDEKICK Ready Tool Cart is equipped with rails ready for the SIDEKICK modular organizational system, sold separately, that allows users to attach cup holders, phone holders, power tool holders, and more to their cart. It features expanded side storage and a top till cutout that provides a clear view into the top till area and eliminates the need to reach over the cart’s lip. The cart is available in blue, green, black, or gray.

For more information, visit VehicleServicePros.com/55293873

INCLUDES 388 TOOLS SELECTED FOR AUTOMOTIVE WORKSHOPS

The Hazet Assistent 179NXL-8/388 Tool Trolley features eight drawers with five fully stocked soft foam inserts and a total of 388 tools selected for commercial vehicle/ van workshops. The trolley includes a 1/4” bit smart case for delicate interior work, 3/8” and 1/2” fine-tooth reversible ratchets and sockets for engine and body work, and a range of screwdrivers and T-wrenches. A wide range of slogging wrenches, combination wrenches of up to 41mm, and ratcheting combination wrenches up to 32mm are also included. The trolley itself features double-walled, fully welded construction with edge protection and internal damping. The drawers have a load capacity of 40kg and an automatic self-closing function.

For more information, visit

PROVIDES DIAGNOSTIC INSIGHTS AND HARDWARE CAPABILITIES

BlueDriver MAX from is designed to serve the commercial diagnostic needs of dealerships, fleets, and inspection businesses conducting high-volume scans and calibrations. This tool provides enhanced diagnostic insights and offers expanded hardware capabilities. BlueDriver MAX is optimized for cost reduction and revenue generating opportunities, according to the company. It offers administrative controls for oversight into work being conducted in the field and provides opportunities to generate custom reporting.

For more information, visit VehicleServicePros.com/55329583

WALKAWAY INFLATION SYSTEM RELEASES INFLATION CHUCK

The Hunter Engineering Road Force WalkAway Wheel Balancer is capable of reducing door-to-door four-tire changeover times by up to 45 percent. The key component for the timesaving is the WalkAway inflation system, which automatically releases the inflation chuck when inflation is compelete. This allows the machine to perform the balance spin, greatly reducing the time spent inflating assemblies on the tire changer. Additional features include a new two-piece hood that enables the balancer to sit 4.5” closer to the wall, a new hood angle sensor to provide a smooth opening, and updated software.

For more information, visit VehicleServicePros.com/55329797

FITS 6MM AND 7.5MM STEMS

The Lisle Corporation 11-pc Injector Seal Installer Kit, No. 34850, is used for replacing Teflon seals on most Hitachi, Bosch, Continental, and Delphi fuel injectors found on many Ford, GM, and Subaru engines. It also works on many Ford ECO injectors with direct injectors. The pilot cone is placed onto the end of the injector, and the seal is started over the cone. The installer is used to push the seal over the remainder of the cone and into the groove on the injector tip. The sizer is then placed over the seal to compress it back to the correct OD to allow installation into the cylinder head. Applications include: 2010 and later GM engines including 1.4L, 1.5L, 2.0L, 2.4L, 2.5L, 3.0L, 3.6L, 4.3L,5.3L, and 6.2L; 2010-2017 GM 2.0L, 2.5L, 3.6L, 5.3L, and 6.2L engines; 2014-2019 Subaru 2.0L and 2.4L turbo engines; Ford injectors 2011 and newer. Fits 6 and 7.5mm stems.

For more information, visit VehicleServicePros.com/55329569

SUPPORTS BOTH 6V AND 12V SYSTEMS

The RUGGED BY SCHUMACHER Battery Charger and Maintainer Line, Nos. SC1677, SC1678, SC1681, SC1682, and SC1684, from Schumacher Electric Corporation is designed to support both 6V and 12V systems, offering 1A, 2A, 3A, 5A, and 10A charge and maintain rates. Each charger features a low-profile clamp design and patent-pending clamp assembly with Schumacher Flex Eyelet Technology. These clamps are designed to easily convert into ring leads by removing a single screw, offering a low-profile solution for hard-to-reach terminals. Key features include an override mode, advanced multi-stage charging, automatic maintenance mode, and reverse hook-up protection. Each product includes a repair mode for reviving batteries and a service mode for maintaining stable voltage during maintenance.

For more information, visit VehicleServicePros.com/55324590

SUPPORTS UP TO 220 LBS

The Killer Tools Heavy Duty Tire Lift , No. ART47, is engineered for safe and efficient tire handling, enabling technicians to remove and install tires with ease. Its heavy duty, powder-coated steel frame supports tires up to 220 lbs, and the wide stance with locking casters keeps the unit secure. The offset column and built-in lug tray offer convenient access and lug storage. It features precise height adjustment up to 27” with an ACME thread and 1/2” impact drive for precise tire alignment. Adjustable rolling arms and a securing bar fit most tires up to 38”.

For more information, visit VehicleServicePros.com/55329801

MADE OF HIGH-STRENGTH STEEL AND LIGHTWEIGHT ALUMINUM

The 3-Ton Combination Service Jack, No. CSESJ30HN, from Cornwell Tools, is constructed of both high-strength steel and lightweight aluminum to provide a 3-ton lifting capacity while weighing only 65 lbs. Dual-pump pistons quickly reach service height. The jack has an over 4” saddle diameter with 4” minimum saddle height, and an 18.5” maximum lift height with bypass valves to prevent over-extension. Premium seals, hydraulic fluid, and components for a long, dependable service life. Manufactured to comply with the ASME PASE-2019 Safety Standard.

For more information, visit VehicleServicePros.com/55285696

SIZES RANGE FROM 1/16” TO 1/2”

The 29-pc Pyramid Point Drill Bit Set , No. 6629DSA, from Mac Tools is made from durable M35 Cobalt steel for drilling through materials including stainless steel, hardened alloy, grade 8 fasteners, and cast irons. The pyramid point design acts as a self-centering step drill for precision without walking on curved surfaces. The tri-flat shank design on 1/8” and above helps to eliminate slippage. Sizes range from 1/16” to 1/2” to accommodate a wide variety of light and heavy duty applications.

For more information, visit

TEMPERED TO 54 TO 58 HRC

The 12-pc Punch and Chisel Set , No. 9R-400-012, from KNIPEX includes three 8” cold chisels, two center punches, two tapered punches, and five pin punches. The octagonal shape makes the punches easier to grip when striking, and also prevents the tool from rolling away when placed on a surface. The material core design prevents mushrooming of the striking head. Tools are tempered to a hardness of 54 to 58 HRC. Complies with DIN 7255 standard. The chisels feature a hand ground sharpened edge designed to cut and shear cold metal. The striking head is turned and chamfered.

For more information, visit

Thin tips and smooth chrome finish help engage tight clips

Steel construction and different offsets for maximum leverage

Do YOU stock it?

The following products are among the most requested tools and equipment from recent issues of PD 's sister publication, PTEN. Perhaps you've already received requests about some of these items. Take a closer look at stocking them.

A LE Ds indicate charging stages

The CT5 TIME TO GO from CTEK features a series of LED lights that indicate different charging stages, and how long (in hours) the battery needs before it’s charged. The CT5 uses advanced technology giving the user three charging and maintenance programs — normal, AGM charging, and record. The charger is fully automatic, it can be connected directly to the battery indefinitely, if required, and it won’t over or undercharge.

For more information, visit VehicleServicePros.com/55292123

C Mi nimizes noise and vibration levels

The Evergrade RGX Pro 316 Cordless Sander with 3/16” Offset offers the power and performance of a pneumatic sander without the need for an airline, according to the company. The sander is balanced for fine user control without any risk of running off. The tool uses patented technology to provide low noise output and low vibration levels for operator comfort. It is lightweight, weighing only 2.65 lbs, and offers speeds of up to 10,000 rpm. The 3/16” offset is ideal for aggressive sanding.

For more information, visit VehicleServicePros.com/55276793

AB El iminates need for multiple OEM subscriptions

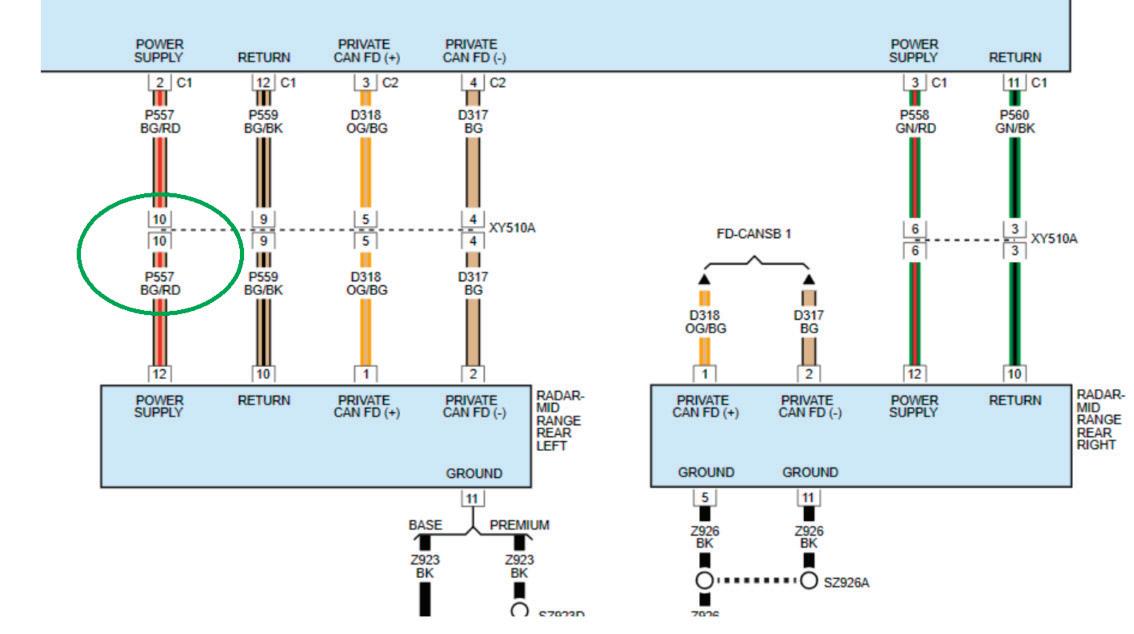

The Bosch HD Diagnostic Solution, No. 3824A, is designed to bring OE-level heavy duty coverage to the shop floor, with an all-in-one subscription that unlocks access to repair information and wiring diagrams for all makes and models — eliminating the need for multiple OEM subscriptions. This device offers a wide range of manufacturer, engine, and system coverage to optimize repairs involving transmissions, brake systems, exhaust treatment, and more. Enhanced bidirectional controls streamline injector coding, forced DPR regen, VGT relearning, special tests, component actuations, and more. The first-year software subscription is free, plus a 30-day Troubleshooting and Repair subscription trial.

For more information, visit VehicleServicePros.com/55291175

D Ta blet weighs less than 1 lb

The Autel MD600CV Heavy Duty Diagnostic Tablet services a wide range of Class 3 to 9 light, medium, and heavy duty vehicles. It offers 38 services, maintenance, and reset tasks, including DPF regen, VGT programming, oil light reset, airbag reset, idle shutoff, brake bleed, injector coding, trailer ABS diagnostics, and more. The MD600CV features an 8-megapixel camera, 64GB of software and data storage capacity, and the Autel MaxiVCI V200, which supports J1708, J1939, J1587, CDL, and PLC protocols. The MD600CV also offers Expert mode, which provides direct access to OE-specific system components. The tool weighs just under 1 lb.

For more information, visit VehicleServicePros.com/55276744

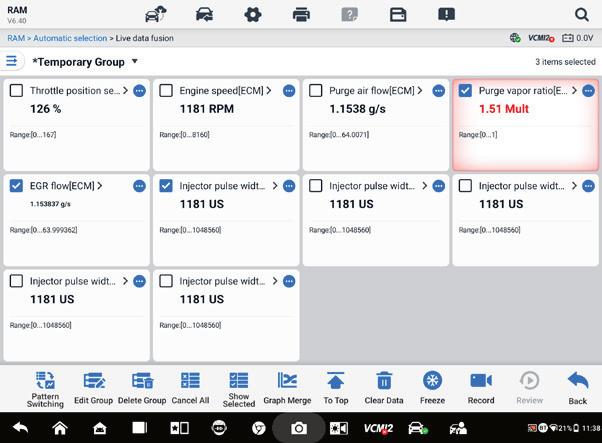

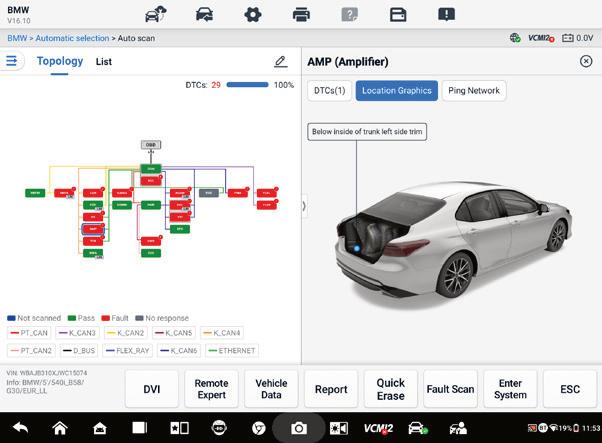

E Fe atures access to Direct-Hit database

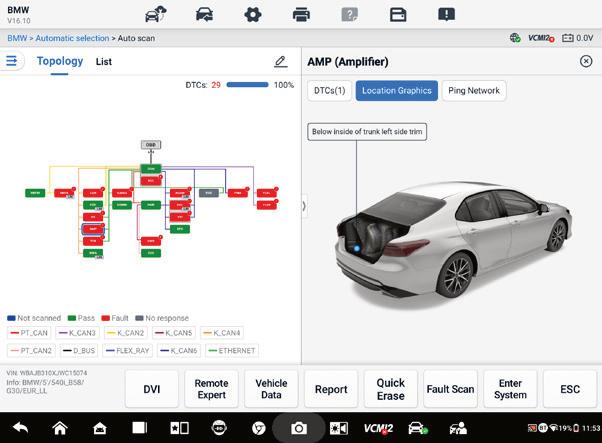

The XTool Prodigy is the company’s new 13” flagship professional bidirectional scan tool featuring extensive vehicle coverage of European, Asian, and domestic vehicles and conforming to the latest new age network protocols, such as CANFD, DoIP, and more. Diagnostics are aided by the direct integration of the Identifix Direct Hit database, which is included for free for one year. The XTool Compass is a smaller 9” version.

For more information, visit VehicleServicePros.com/55289221

F Cr afted with high-performance D2 steel

The Provoke Aluminum Folding Tactical Knife Morphing Karambit, No. CRK4040, from Columbia River Knife & Tool (CRKT), blends ancient design with cutting-edge innovation. Featuring Kinematic technology, it deploys instantly with a simple push of the thumb, ensuring rapid response when needed. Crafted with high-performance D2 blade steel, it offers edge retention for increased cutting power. The aluminum handle provides strength while keeping the knife lightweight for easy handling. Designed for secure carry, its flush-mounted clip ensures discreet and reliable storage. According to the company, the Provoke is the perfect fusion of tradition and futuristic functionality.

I Bu ilt-in power strip with four outlets

The 44” RS Pro 9-Drawer Flip Top Power Service Cart w/ Workstation, No. HOMBL06044090, from Homak Manufacturing, is a heavy duty tool storage unit designed for maximum efficiency, security, and durability. The power tool drawer includes a built-in power strip with four outlets and two USB ports, keeping tools organized and charged. A lockable top till with gas struts offers additional storage and charging for devices like laptops and phones. Built for strength, it features 520-lb capacity casters, a stainless steel worksurface, and a high-security locking system. Nine spacious drawers with 100-lb ball-bearing slides ensure smooth operation, while a UV-protected powder coat finish enhances durability. Backed by a 5-year warranty for peace of mind.

For more information, visit VehicleServicePros.com/55279302

For more information, visit VehicleServicePros.com/55287276

G Re volutionary technology enables 10x faster vehicle scans

Designed and engineered with cutting-edge technology, the X-431 Throttle V from Launch Tech USA delivers a combination of automotive intelligence, quick navigation, and ergonomic handling for optimal efficiency. As the most powerful automotive scan tool in the X-431 family, the X-431 Throttle V provides fast performance for optimal efficiency during diagnostics and vehicle repair. With access to X-431 FIX and CODE ASSIST carline repair information, the diagnostic repair process can effectively and accurately be accelerated with confidence.

For more information, visit VehicleServicePros.com/55019102

H Ma de of oil-hardened vanadium steel

The KNIPEX 8” Long Nose 40-Degree Angled Pliers with Cutter, No. 26 22 200, feature distortion-tolerant, flexible precision tips that are stable even when twisted. The half-round pointed jaws have 61 HRC hardened cutting edges for soft, medium-hard, and hard wire, and the tool is made of oil-hardened vanadium steel. The slim long nose is ideal for working in confined areas, and the pliers feature KNIPEXTEND comfort handles.

For more information, visit VehicleServicePros.com/55289330

J Ru ns bidirectional tests

The i50HD Heavy Duty Diagnostic and Diesel Engine Scanner from Foxwell is compatible with Android 9.0 operating systems for global markets and features wireless connection and one-touch updates. It offers a comprehensive and affordable diagnostic solution for pickups, trucks, and buses like Caterpillar, Paccar, International, Detroit, Hino, Ford, Chrysler, and more. i50HD not only performs general diagnostics like reading code/ erasing code, live data, active test, and ECU information, but also DP regeneration, injector cutoff, and speed limit settings. The i50HD can run bidirectional tests and automatically read VINs.

For more information, visit VehicleServicePros.com/55041057

We saw a number of products introduced at the AAPEX and SEMA shows again this year. Here are some new tools and equipment selected by our editorial staff that piqued our interest.

Midtronics Prevents unintended EV movement

The Midtronics Electric Vehicle Immobilizer, No. xIM-100, can be used in situations where an electric vehicle may appear disabled but is still active. The xIM-100 provides clear, authoritative vehicle-status indication, and where supported, immobilization of BEVs and PHEVs through the universal charge-port interface. The tool helps to prevent unintended EV movement and offers instant visual confirmation of a secure connection — green for immobilized and red for caution. Users will have no direct contact with the highvoltage system, and its universal fit means it works in any charge port. The tool also maintains power for essential vehicle functions such as the windows, seats, and lights.

Editor’s Note: Shop safety is crucial, especially for shops working on electric vehicles. Utilizing this immobilizertool,technicianscanconfidently ensure that an EV has been disabled before they start any repairs.

For more information, visit VehicleServicePros.com/55330262

2025 EDITOR'S PICKS

Ansell

ANSI A9/ISO F-rated

The Ansell HyFlex, No. 11-594, is an ANSI A9/ ISO F-rated glove. The glove features an AEROFIT Coating, which is up to 30 percent thinner than the standard Ansell glove with the same level of protection, for improved tactility and control. It also has an 18-gauge liner providing users comfort in precision handling. According to the company, the gloves are certified skin-friendly and touchscreen compatible to reduce glove removal during work. Editor’sNote:Cuts,chemicalburns,andotherinjuriesawaitatechnician’shands every time they step into the shop. By wearing the proper protective gear, such as these ANSI A9/ISO F-rated gloves, they can prevent these accidents. For more information, visit VehicleServicePros.com/55330268

GripEdge

43 percent shorter than standard hex bit sockets

The GripEdge 6-pc RPT 3/8” Drive Low-Profile SAE Hex Dual Action Driver Set, No. DDHBS6S, is just 1-1/16” long and up to 43 percent shorter than standard bit sockets. Its patented RPT technology delivers up to 50 percent more grip on good fasteners and 400 percent more on damaged ones, according to the company. This set is constructed from single-piece S2 steel for maximum strength. The set includes a 2nd-generation aluminum storage rail.

Editor's Note: A compact, high grip solution like the GripEdge RPT LowProfile Driver Set helps reduce the risk of slipped or rounded fasteners, even in tightspaces.

For more information, visit VehicleServicePros.com/55328574

OTC

Safely remove oil pan drain plugs

The OTC Drain Plug Pro Tool Kit, No. 5961, features an interchangeable design. The kit includes attachments for standard drain plugs, low-profile drain plugs, internal hex drain plugs (17mm), and 1/4” hex bits. It can be used with any 1/4” square drive socket, and helps users safely remove oil pan drain plugs by avoiding contact with hot oil and preventing them from dropping drain plugs and other fasteners. The flexible shank with 1/4” square drive helps remove or thread smaller fasteners even in hard-to-reach places. Contained on a handy socket rail for hanging or tool drawer storage.

Editor’s Note: Utilizing OTC’s Drain Plug Pro Tool Kit technicians can save time and money by avoiding dropping or losing drain plugs. For more information, visit VehicleServicePros.com/55330266

asTech

Sends automatic calibration alerts

An enhancement to asTech’s adasThink, Connected Calibrations, is integrated into the repair order submission process. Connected Calibrations automatically flags required calibrations in a real-time dashboard so estimators at collision repair facilities can track them from initial bid to completion. Built-in notifications alert shops when a calibration is not ordered. This ensures that calibrations are not missed during the repair process and enables shops to capture more revenue opportunities.

Editor's Note:ADAS, and the repair work that comes with it, is still pretty new to many technicians, and having technology like Connected Calibrations can help prevent more inexperienced technicians from missing crucial calibrations. For more information, visit VehicleServicePros.com/55330259

SP Tools USA

Bolt-busting torque of 1,600 ft-lbs

The SP Tools USA 18V 1/2” SX Drive High-Torque Impact Wrench Kit, No. SP83130US, is designed with a highpower brushless motor to ensure efficiency and longevity, a variable speed switch with a brake for precise control during any application, and a nextgen battery cell with INR chemistry for high safety, low resistance, and improved energy capacity. It features a bolt-busting torque of 1,600 ft-lbs and a working torque of 900 ft-lbs. The RPM ranges from 0 to 1,400, and the BPM ranges from 0 to 1,950. Without the battery, the tool weighs 7 lbs. Battery charging takes 1 hour with an auto cut-off. The kit comes with the 18V 1/2” Drive Impact Wrench, two 18V 6Ah Li-ion battery packs, and an 18V battery charger.

Editor's Note: SP Tools' 18V HighTorque Impact Wrench gives technicians the confidence to tackle demandingjobswithitsstrongperformanceandcontrolledpowerdelivery.

For more information, visit VehicleServicePros.com/55330352

Autel Uses Nitrogen for pressure leak test

The Autel MaxiHVAC AC909 is a 4-port manifold system designed to bring skill, understanding, and precision to HVAC diagnostics. The system provides step-by-step guided instructions for equipment hookup and the entire repair workflow. It also features a vehicle-specific overview of A/C specifications and locations, including compressor and refrigerant types. The tool introduces the use of Nitrogen for a pressure leak test, “system tightness test,” and purge procedures for faster evacuation. According to the company, this is the first A/C manifold gauge tool that decouples from the A/C lines while still monitoring low and high pressures.

NextLED

5 color temperatures with memory function

The NextLED Rechargeable Color Matching Light, No. NT-6692M, is a CRI 96+ rated light with five color temperatures (2,700K, 3,500K, 4,500K, 5,500K, and 6,500K) for critical color matching and identi-

Editor’s Note: With its step-by-step workflow, vehicle-specific data, and innovative ability to monitor pressures even after disconnecting from the lines, the AC909 supports more accurate,confidentrepairsinarapidly changing service landscape.

For more information, visit VehicleServicePros.com/55330343

Editor’s Note: Tools like the NEXTLED Color Matching Light help reduce guesswork by offering precisecolortemps,adiffusertocut glare,andflexiblemounting,giving technicians clearer visibility.

For more information, visit VehicleServicePros.com/55330328

PRODUCT IN FOCUS

MAYHEW TOOLS

Dominator Pro 34” Heavy Duty Pry Bar

Built from hardened and tempered alloy steel with a full-tang handle for durability.

APPLICATION

The Dominator Pro 34” Heavy Duty Pry Bar, No. 14126GN, from Mayhew Tools, is made for prying, lifting, and separating tasks where extra strength is needed in tight quarters. A few common applications include:

• Separating suspension components in wheel wells

• Aligning drive components in wheel wells

• Separating drivetrain components

• Lifting drivetrain components into position

ORIGIN

Mayhew already produces what they consider to be the toughest pry bar on the market — the Big Stick, which is 54” long and made from tough 7/8” square steel stock. The length on that bar can make tight-quarter tasks that need extra muscle difficult, like working in wheel wells and underneath cars. This bar was designed to provide a heavy duty pry bar option in a shorter length while still maintaining its strength.

STORAGE AND DISPLAY

The item is shipped as a unit of one in a box. Mayhew suggests hanging the bar up in your truck.

SELLING POINTS

• Made from heavy duty steel, which is ideal for any prying or lifting tasks. They are designed to be struck without damaging the handle, which also serves as a shock absorber, reducing hand fatigue. The patented two-composite handle is ergonomically designed to provide superior comfort and grip.

• The bar is made from 7/8” square steel stock and features an extra-large handle, allowing it to shine on the toughest jobs where you might need to use both hands (and some extra elbow grease).

MANUFACTURING SPECS

The tool is manufactured in Turners Falls, Massachusetts. The bar is made of 7/8” chrome vanadium steel using proprietary in-house treatment techniques, and the handle, also produced in Massachusetts, is a patented two-composite handle made of high-impact glass-filled polypropylene with an impact-resistant high durometer TPE overmold. The product weighs about 7.5 lbs. The bar is tested and proven to exceed ASME standards, including torture testing with a 15-lb sledgehammer and bend testing with 250 ft-lbs of torque. The handle is tested to withstand over 1,000 lbs of pull-off force.

FEATURES AND BENEFITS

This bar is part of an expansion of Mayhew’s Dominator Pro Pry Bar color line. Mayhew is nicknaming this bar the “Big Stick Junior” as it is modeled after their 54” heavy duty pry bar, but in a shorter length. It is meant for tough jobs where the bigger bar might be too large to fit the application.

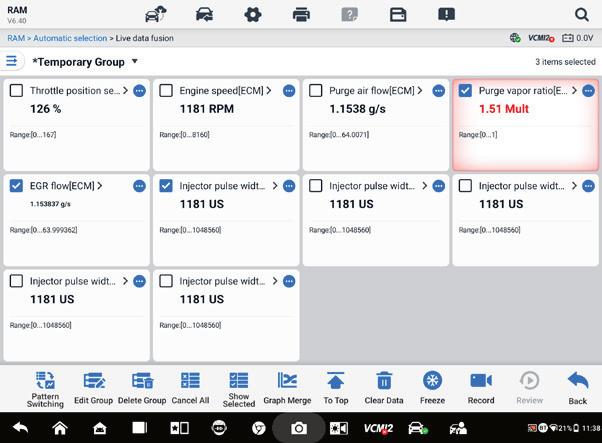

XTOOL HDGURU

Performs Cummins HD (Class 4-8) maintenance functions, including special functions, feature activations, and more.

APPLICATION

The HDGURU from XTool performs over 60 bidirectional tests, 35+ Cummins dedicated functions, and advanced feature and parameter programming for Cummins Class 4-8 HD Trucks.

FEATURES AND BENEFITS

In the Class 4-8 HD sector, Cummins engine applications are close to 40 percent of the fleets of HD vehicles on the road today in the continental U.S. The HDGURU is a scan tool that supports Cummins engine diagnostics with a multitude of functionality. This product’s price point sits 50 percent lower than equivalent HD scan tool solutions on the market.

SELLING POINTS

• HD scan tool for Cummins engine applications, which constitute 40 percent of the Class 4-8 segment

• 60 bidirectional tests

• 35+ Cummins engine applications dedicated functions

• Attainable price point (under $1,000 MSRP)

• Fleet focused - No equivalent HD scan tool product on the market, according to XTool

ORIGIN

There was a lack of options for HD scan tools in the market, and the scan tools that are available are at a much higher price point. This was the reason to release the HDGURU. Furthermore, Cummins engines account for 40 percent of the fleet HD market.

MANUFACTURING SPECS

Scan tool tablet manufactured by XTool in Shenzhen, China.

STORAGE AND DISPLAY

This product is fairly lightweight and weighs less than 10 lbs. It ships in a box.

SUGGESTED RETAIL PRICE

$550

Visit XTool’s website to learn more about the HDGURU: xtooltech. us/collections/car-diagnostics/ products/hdguru

PRODUCT IN FOCUS

FJC Heater for Electric Blower

Converts compatible air blowers into a space heater for fast, supplemental heat in garages and work areas.

APPLICATION

Converts your compatible air blower into a space heater for fast, effective supplemental heat in garages and work areas.

FEATURES AND BENEFITS

• Warming work areas: Adds quick supplemental heat to garages, workshops, or bays during cold weather so technicians can work comfortably.

• Seasonal shop comfort: Helps maintain a productive environment in winter months without heating an entire building.

• Drying and curing: Speeds up drying of vehicle interiors, painted surfaces, or other components when combined with airflow.

• Targeted heating: Provides focused heat for specific work areas, such as under a vehicle or inside a compartment, without wasting energy heating the whole space.

• Improving technician efficiency: Keeps work environments warm, reducing downtime caused by discomfort or coldsensitive tools and materials.

STORAGE AND DISPLAY

One per box. To store the Heater for Electric Blowers efficiently on a truck, you’d want to stack the boxes carefully, keeping heavier ones on the bottom and limiting stacks to a safe height to avoid crushing. Position them near the door if they’re high-turnover items and consider using shelving or racks to keep them organized and easy to access. If you have many units, palletizing with shrink wrap can make loading and unloading easier, while straps or cargo nets help prevent shifting during transport. Clear labeling will also make finding and handling them much smoother.

SELLING POINTS

• Seasonal demand and versatility: Ideal for cold-weather months, making it a timely upsell for technicians who need warmth in their workspace.

• Adds value to existing products: Converts an air blower into a heater, giving customers more functionality without purchasing a separate unit.

• Easy to use and install: Simple plugand-play design makes it an easy sell to technicians who want effective solutions without complicated setup.

• Compact and portable: A convenient, space-saving option for shops and garages with limited room for larger heaters.

• Consistent profit opportunity: A practical add-on accessory that appeals to a wide range of customers, ensuring steady sales.

ORIGIN

The idea for the FJC Heater for Electric Blower, No. 62300, came from recognizing a simple but impactful challenge technicians face: working in cold environments. In garages, workshops, and bays — especially during winter months — low temperatures can slow productivity, make work uncomfortable, and even affect the performance of tools and materials. While heating an entire space is costly and inefficient, technicians often need targeted warmth where they’re working most. This product was developed to solve that problem by converting a compatible air blower into a portable space heater. With a simple plug-and-play design, it delivers fast, effective supplemental heat directly where it’s needed, making workspaces warmer, more comfortable, and more productive without unnecessary energy waste.

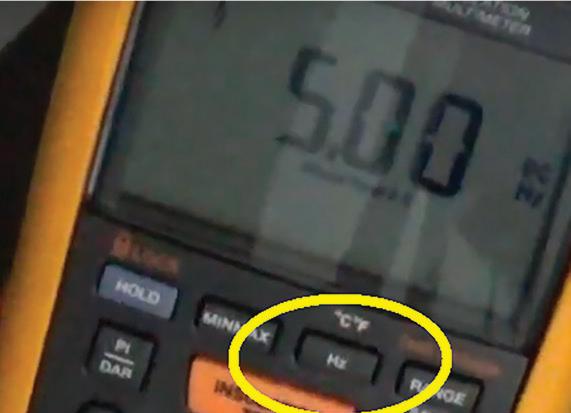

MANUFACTURING SPECS

• Country of origin: Made in China

• Weight: 2.5 lbs

• BTU rating: 5,000 BTU

• Power rating (voltage, current, frequency): 120V, 11A, 60 Hz

• Wattage rating: 1,320W

• Number of phases: 1

• Control type: Switch

• Heat settings: 1 (thermostat non-adjustable)

• Operating temperature: 104°F (40°C)

• Indoor/outdoor use: Indoor only

• Safety features: Overheat shut-off, Tip-over shut-off

• Mounting type: Clip-on

• Dimensions (L x W x H): 8.66” x 4.53” x 3.15”

• Housing material: Steel

• Color/finish: Black painted

• Power cord: 14AWG SJT, grounded plug

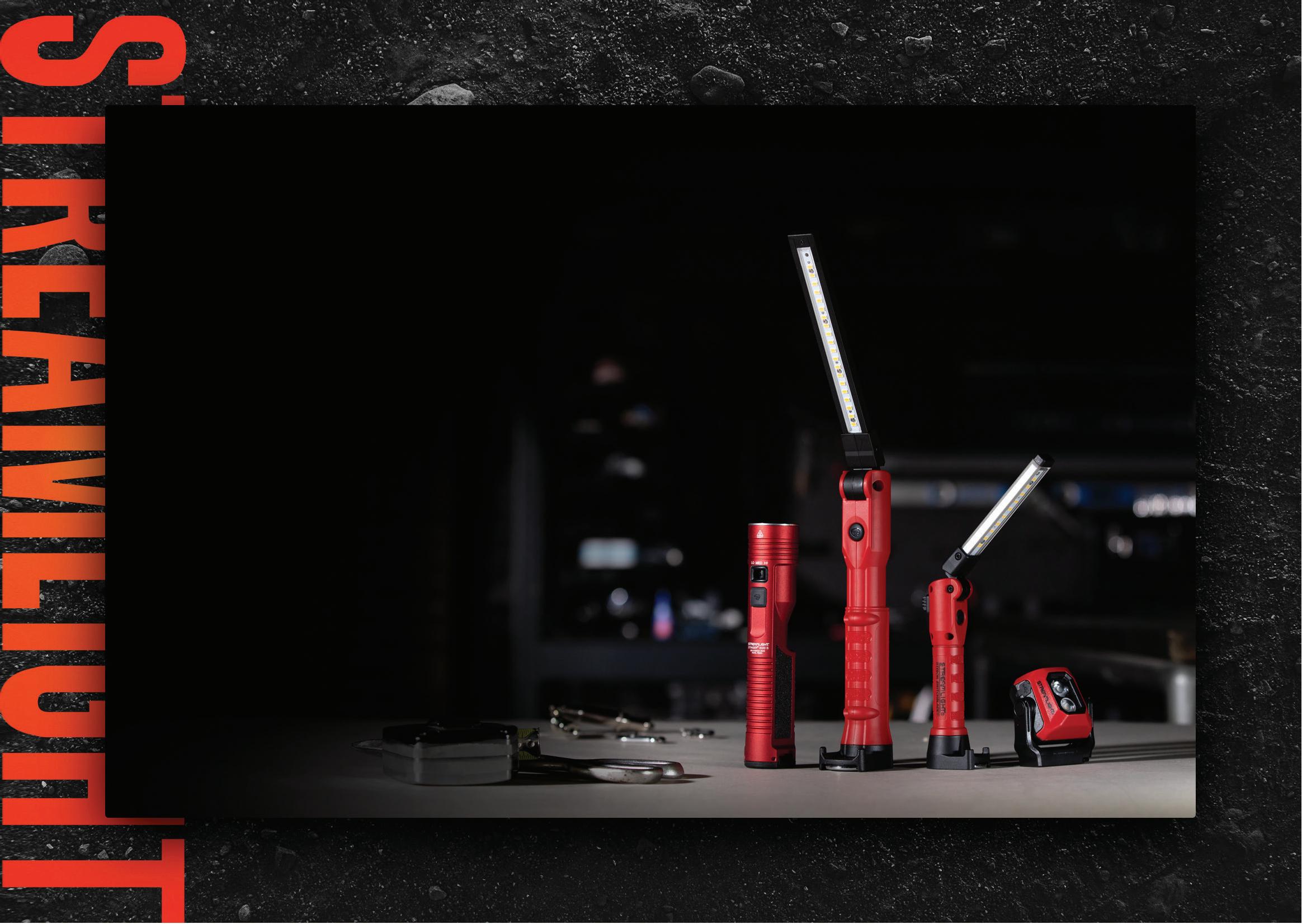

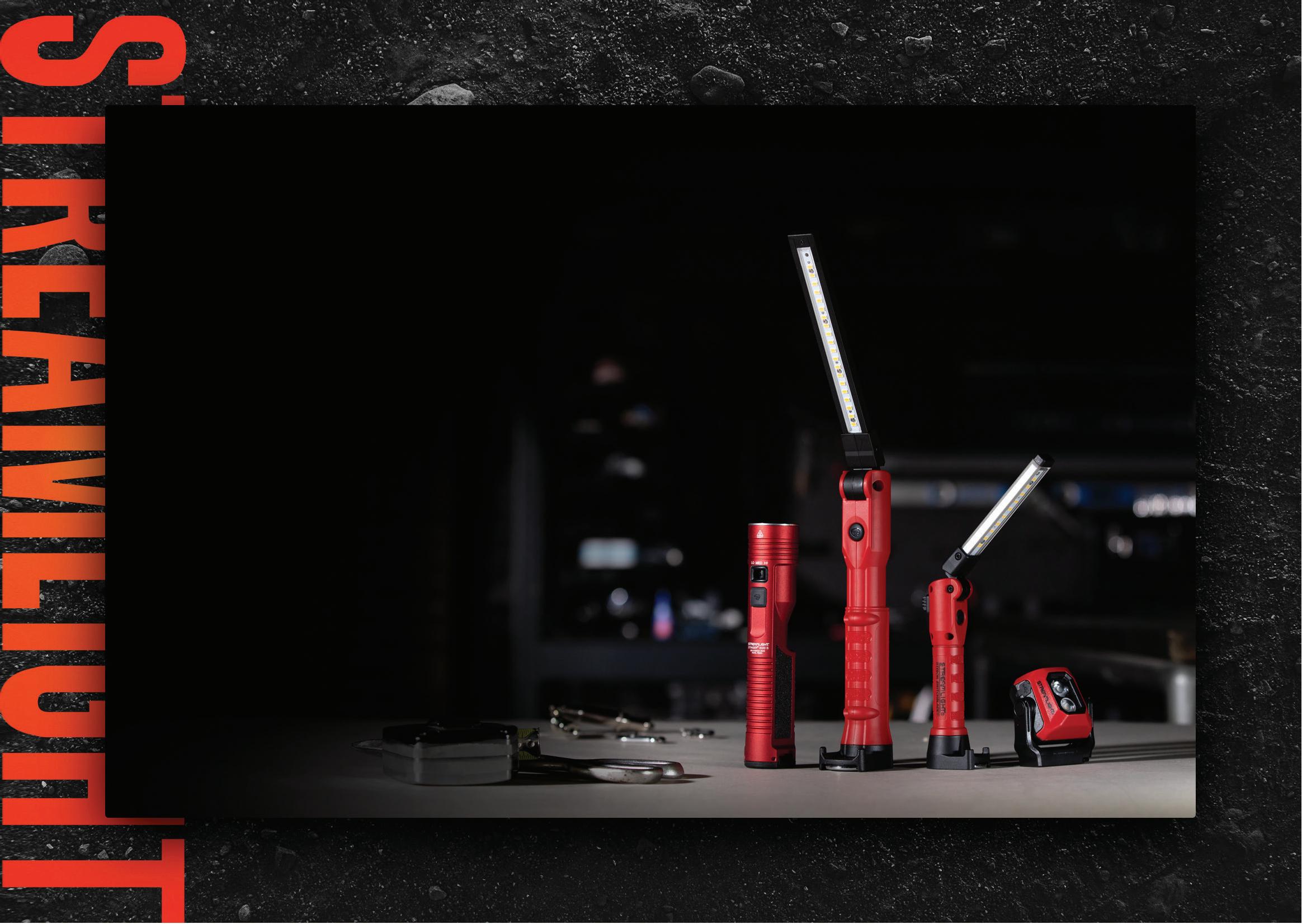

STREAMLIGHT

Wedge SL

Ideal for tight areas where larger flashlights won’t fit or can’t reach.

APPLICATION

The Streamlight Wedge SL is designed for under-hood inspections, interior electrical work, engine bay diagnostics, brake and suspension checks, and undercarriage reviews. Ideal for tight areas where larger flashlights won’t fit and work lights can’t reach.

SELLING POINTS

FEATURES AND BENEFITS

The Wedge SL is built for auto techs who demand performance and portability:

• Ultra-thin profile: Slips effortlessly into your pocket, bag, or toolkit.

MANUFACTURING SPECS

• The Wedge SL is engineered for automotive technicians who need a powerful, ultra-thin inspection light that delivers 50 lm on Low, 100 lm on High, and up to 500 lm on THRO mode, making it a versatile tool for any lighting needs in the shop.

• A sleek, ultra-thin inspection light, the Wedge SL fits easily and securely in your pocket with its stainless-steel, injectionmolded pocket clip.

• A multi-function, tail-mounted tactical switch offers fast, one-handed operation, ideal for tight engine compartments or under-dash work.

• Its USB-C rechargeability, battery status indicator, and deep-carry clip make it perfect for everyday carry on the job.

• With the TEN-TAP programmable switch, you can customize your lighting experience by selecting the output modes to suit your needs.

SUGGESTED RETAIL PRICE

$110

FOR MORE I NFORMATION

Contact Streamlight customer service at 800-523-7488 or email cs@streamlight.com.

• Bright, handsfree illumination: Delivers 100 lm (High), 50 lm (Low), and up to 500 lm (THRO Mode) for focused tasks and wide-area lighting.

• TEN-TAP programmable switch: Lets users select High (factory default) or Low intensity for constant on.

• Rechargeable and efficient: Charges in 4 hours via USB-C with up to 3.5 hours runtime on Low. A four-level LED indicator lets you monitor battery life.

• Multiple finishes: Available in Black, Coyote, and Silver, so techs can easily identify their light on a busy shop floor.

• Durable: Flat, anti-roll design made of MIL-spec anodized aluminum, IPX4-rated for water resistance, and impact-tested to 1 meter.

• Ready for any task: Great for diagnostics, inspection, or any tight-space repairs where reliable lighting is key.

ORIGIN

Automotive professionals asked for a rugged, pocket-sized inspection light that didn’t compromise on brightness or functionality. The Wedge SL was built to meet those needs. It is compact enough to clip into a pocket, but powerful enough to illuminate automotive systems with ease.

• Materials: Type II MIL-spec anodized aluminum body with unbreakable acrylic lens

• Lighting output: 100 lumens (High), 50 lumens (Low), 500 lumens (THRO Mode)

• Run time: Up to 3.5 hours (Low)

• Charging: USB-C rechargeable lithium polymer battery (4 hours to full charge)

• Size: 5.65” L x 0.55” W x 0.28” D without clip/0.41” thick with clip

• Weight: 1.14 oz

• Durability: IPX4 water-resistant; 1-meter impact-tested

STORAGE AND DISPLAY

The Wedge SL is shipped in Streamlightbranded packaging with clear product visibility. It has one unit per package. Its compact design makes it ideal for tool truck countertop displays or clip racks near diagnostic gear. A demo light secured to a dashboard display is highly effective.

To watch a video demonstration of this product, visit: VehicleServicePros.com/55329736

Photos courtesy of Robert Robinson.

Robert Robinson, Mac Tools distributor in Boerne, Texas, credits consistency and clear communication for his success in selling capital equipment.

Making the NEXT BIG SALE

From EV readiness to smarter diagnostics, distributors are redefining what it means to sell capital equipment.

By Nadine Battah, Editor-in-Chief

For tool distributors, few things are more satisfying than closing a big-ticket sale such as a vehicle lift, tire changer, or diagnostic system. These purchases take more than a polished pitch. They depend on timing, trust, and a real understanding of what shop owners need.

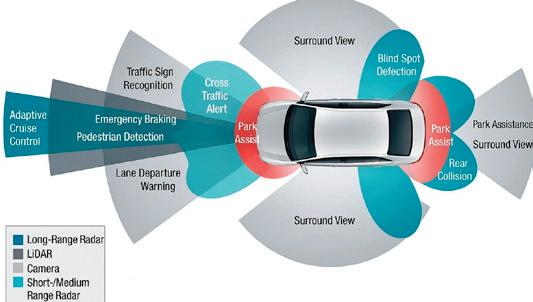

Capital equipment has become both a necessity and a challenge for many repair businesses. Shops are keeping pace with ADAS, hybrids, and EVs while facing rising costs and thinner margins. Every investment must earn its keep through efficiency, reliability, and a clear return.

The right piece of equipment can change how a shop operates. A new lift can add bays and capacity. A diagnostic system can bring outsourced work back in-house. A balancer or aligner can speed up workflow and free technicians to take on more repairs. These are not impulse buys but long-term decisions that affect the bottom line.

Distributors are often the link between that technology and the technicians who depend on it. Their role goes far beyond selling. They help shop owners identify what will keep their business running smoothly and growing. Manufacturers support that process through training and information that help distributors present the full picture of value.

To learn how those efforts come together, we spoke with Robert Robinson, a Mac Tools distributor based in Boerne, Texas; Kevin Keefe, director of marketing for Coats; Denis White, TEXA EDU manager; and Jeff Kritzer, president and CEO of BendPak. Each offers a perspective on how relationships, education, and return-on-investment conversations drive capital equipment sales.

COVER STORY

A DISTRIBUTOR’S PERSPECTIVE

For Robert Robinson, selling major equipment starts with curiosity.

“The general approach, honestly, is don’t be afraid to ask,” Robinson says. “I look for things in a shop that could be running better and make suggestions. It’s about planting the seed. You might not get a yes today, but it grows into a sale later.”

Robinson has spent more than ten years as a mobile tool dealer and two decades as an automotive technician. His customers include independent repair shops, dealerships, and fleet operations throughout the Texas Hill Country near San Antonio. Over the years, he has learned that price is rarely the real hurdle.

“If it’s just an expenditure, then it costs money,” he says. “But if it’s an investment, it’s something they can make money with.”

He often starts by identifying where a shop might be losing revenue. If a technician is sending out ADAS calibrations or diagnostic jobs several times a week, he breaks down what that costs over a year and compares it to the price of owning the equipment.

“When you show them the math, it clicks,” Robinson says. “You’re not pushing them. You’re showing them where it makes sense.”

That practical approach has helped him sell several high-end diagnostic systems and lifts in recent months. But for Robinson, the sale is only the start of the relationship.

“It’s not just getting the sale,” he says. “It’s following up afterward. If something goes wrong down the road, they know they can call me.”

He makes it a point to stay in touch long after delivery, checking that customers are comfortable with the new setup or know where to find support. That extra step, he said, often leads to the next opportunity.

“You have to talk to the managers and owners,” he says. “Help them stay ahead by showing what’s new and how it fits their shop.”

He added that success often builds on itself. A lift sale can lead to a diagnostic tool upgrade, and a diagnostic sale can open the door to an alignment system conversation. “It’s all about helping them grow,” he said. “When their business expands, so does mine.”

ROI OVER SPECS

Once a distributor starts the conversation, manufacturers like Coats

provide the information and resources that help close the deal. Coats’ Keefe says most customers already know a great deal about the products they’re considering.

“By the time a buyer engages a distributor, they’re often 70 to 75 percent through their research,” Keefe says. “They already know what they want. Our job, and the distributors, is to prove the value, not just the features.”

For Coats, that means shifting the discussion from product specs to measurable results. A modern tire

Distributor Robert Robinson walks a customer through a diagnostic tool on his Mac Tools truck, focusing on how each product can support workflow and efficiency.

changer or wheel balancer shortens cycle times, reduces comebacks, and improves technician ergonomics. Each of those outcomes affects profitability.

“A tire changer may not ring the register directly, but it keeps cars moving through the shop,” Keefe says. “Downtime hurts productivity, and that’s what affects profitability.”

Coats helps distributors demonstrate those benefits through digital training and livestream product demos. Visual examples of cycle times and technician workflow make it easier to show how equipment contributes to revenue.

Keefe says many shop owners have also begun planning replacements on a set schedule, often every five to eight years, instead of waiting until equipment fails. That shift creates steady

opportunities for distributors who stay in touch.

“It creates an ongoing partnership,” he says. “We want shops to see their distributor as part of their success plan, not just someone who sells them a machine.”

The partnership model continues to grow as shops balance long-term investments with rapid changes in technology. The distributors who can talk through the numbers and help owners make informed choices tend to earn repeat business.

TRAINING BUILDS CONFIDENCE

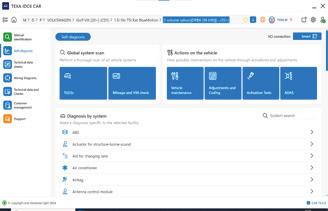

When it comes to diagnostic and ADAS systems, knowledge carries just as much weight as the equipment itself. White from TEXA says that while most

shops understand they need advanced technology, many are still learning how to use it to its full potential.

“ADAS and A/C equipment are not optional anymore,” White says. “They are driven by the technology inside the vehicle. Shops that ignore that are setting themselves up to fall behind.”

White explains that the pace of vehicle innovation has changed how technicians approach diagnostics. Constant updates, changing communication protocols, and complex calibration procedures make ongoing education essential.

TEXA addresses that need through its TEXA EDU program, which offers structured training for distributors and technicians on setup, operation, troubleshooting, and software management.

WORKLIGHTS

INSPECT, IDENTIFY AND REPAIR.

Get the ultimate in brightness and versatility with a broad selection of lights for delivering precise lighting or illuminating large areas. Fewer trip hazards and unlimited portability mean you can work harder for longer. All backed by 50 years of Streamlight’s commitment to the industry.

“You can sell the best diagnostic tool in the world, but if the shop doesn’t know how to use it, they won’t get the value,” White says.

Training also helps distributors feel more confident explaining the technology. When they understand how the systems work, they can better connect features to real-world performance.

White adds that upgrade cycles for diagnostic tools are getting shorter, often around two years. Regular communication keeps customers prepared for updates rather than surprised by them.

“The relationship doesn’t end when the tool is sold,” he says. “It’s about helping shops stay current and confident.”

For White, education is not just support; it’s part of the sales process. “When a technician understands the tool,” he says, “they start to see it as essential, not optional.”

DURABILITY AND ADAPTABILITY

Large-scale shop equipment brings a different kind of decision. Bendpak’s Kritzer says those purchases require planning and foresight.

“Lifts and heavy shop equipment are not impulse buys,” Kritzer says. “They are infrastructure. Shops want confidence that what they buy today will serve them for decades.”

BendPak has seen growing demand for high-capacity and EV-ready lifts as shop owners prepare for a broader range of vehicles. Safety and flexibility remain top priorities.

“A lift might be the biggest purchase a shop ever makes,” he says. “So, we focus on building long-term value into every design.”

To help distributors explain that

value, BendPak provides a range of digital tools. The company’s Fusion dealer portal includes ROI calculators, sales materials, and technical data so that distributors can tailor presentations to each shop’s needs.

“It’s not about handing someone a brochure,” Kritzer says. “It’s about showing them how this investment fits into their business model.”

He noted that even as technology changes, some principles never do. Proper use and maintenance remain critical to safety and longevity. Helping shops understand those details builds confidence in both the product and the distributor who sold it.

“When you tie safety and efficiency together, it clicks for people,” he says. “They see it as part of their success, not just another cost.”

Robinson, left, connects with a long-time customer during a stop on his route. Building trust and maintaining relationships remain key to selling high-ticket tools and equipment.

COMMON GROUND ACROSS THE INDUSTRY

Although each company serves a different segment of the market, their perspectives align closely. Selling capital equipment depends on education, trust, and consistent communication.

Robinson’s route-based, relationship-driven sales style mirrors the training and support strategies used by Coats, TEXA, and BendPak. Whether through live demonstrations, online training, or follow-up calls, the goal remains the same: help shop owners make informed decisions that strengthen their business.

As each manufacturer emphasizes, the goal is not to push a product but to show shop owners how the right investment makes their business stronger and more capable.

Distributors who take that approach often find that large-equipment sales open the door to lasting partnerships rather than one-time transactions.

LOOKING AHEAD

Capital equipment sales aren’t slowing down; they’re shifting. As EVs, ADAS, and automation continue to change the shape of repair work, distributors are being asked to play a bigger role in how shops plan for those changes. The traditional one-time sale has evolved into a consultative process where education and follow-up are just as important as the initial purchase.

Manufacturers say the next few years will bring more connected tools, data-driven diagnostics, and equipment that communicates across systems. Shops will expect their distributors

Jump Starting Made Easy with Jump-N-Carry

Whether it’s lithium or lead acid, shops and technicians know that when they reach for a JNC, it’s going to work. Our lithium units deliver exceptional power, supreme convenience, unsurpassed safety and long unit life.

- Deep cranking reserve - Effective on totally dead (0,0V) batteries - UL2743-certified for safe operation - Quick, efficient and easy recharging - Service Repair Coupon

to understand how these technologies work together, not just how they operate individually. That means keeping up with software updates, knowing which machines integrate best, and explaining how each piece contributes to overall efficiency.

Training will also continue to grow in importance. Both distributors and technicians will need ongoing education to keep pace with new platforms and service procedures. Several manufacturers are already expanding digital learning options so distributors can access information anytime and share it directly with customers.

The distributors who lean into this approach will stay ahead. As Robinson says, “The key is to keep talking to your customers. Find what helps their business and show them why it matters.”

EACH YEAR, WE COMPILE

A LIST OF the most popular products we’ve featured in PTEN This year we featured over 500 products, from the smallest bits and nuts to the biggest lifts and toolboxes. Our goal in sharing this list is to help you stay informed on what your customers are most interested in, what they’re buying, and what can ultimately help your bottom line. These products were pulled based on the number of pageviews they received over the last year on our website Vehicle Service Pros. The next pages showcase the top 25 products of 2025. You can find the full top 100 list by visiting VehicleServicePros.com/2025-top-100-products.

–Elli Carder, Assistant Editor

Cuts hub removal time by up to 80 percent

ProMAXX Tool by Milton Air Hammer-Powered Tommy 475 Wheel Hub Puller, No. PMXTOM475PRO

For more information, visit VehicleServicePros.com/55308401

Drop forged jaws ensure durability

Dynamic Tools

Grip-on 10-pc Essential Locking Pliers Set, No. EK-SET10

For more information, visit VehicleServicePros.com/55294664

Available in 8 different color schemes

Matco Tools

75” x 25” Triple-Bay 2s Series Toolbox, No. 2325TB For more information, visit VehicleServicePros.com/55261998

Displays real-time current readings

Power Probe

PPFUSE Fuse Monitor

For more information, visit VehicleServicePros.com/55267311

2-hour run-time on high Streamlight

MegaStream USB For more information, visit VehicleServicePros.com/55262542

Battery tester for 12V and 24V systems

TOPDON

BT600

For more information, visit VehicleServicePros.com/55288054

Covers more than 7,400 static ADAS procedures

Hunter

Prints health report 3 seconds after scan

Matco Tools

Digital Battery Tester with Printer, No. MDMAX For more information, visit VehicleServicePros.com/55250605

3-Ton Off-Road Floor Jack For more information, visit VehicleServicePros.com/55288050

Features six barrel lock-secured drawers

SUNEX Tools

Tony Squindo “It’s Alive!!” Premium Full Drawer Service Cart, No. SUN8057XTL For more information, visit VehicleServicePros.com/55273286

Ready to jump in 70 seconds

Milwaukee Tool M18 HOTSHOT Jump Starter

Prevents over- and under-tightening CTA Tools

Torque Limit Ratchet Wrench Set, No. 8945 For more information, visit VehicleServicePros.com/55278769

Lifting pucks for car lifts and jacks BendPak AutoPucks

For more information, visit VehicleServicePros.com/55267641

For more information, visit VehicleServicePros.com/55298829 Features maximum charging rate of 120A Clore Automotive PRO-LOGIX 12/24V Flashing Power Supply and HD Battery Charger, No. PL6850 For more information, visit VehicleServicePros.com/55243998

Includes locking mechanism and keys

Matco Tools

Triple-Bay 2s Series Hutch, No. 2325HTC

For more information, visit VehicleServicePros.com/55262001

THE TRUCK STOP

The setup of your truck can have a serious impact on the success of your sales.

Customizing your mobile tool truck: Turning wheels into winning retail space

When customizing your truck, try to think about the needs of your route and display your tools accordingly.

By the LDV Team

For franchisees in the mobile tool sales world, your truck isn’t just transportation — it’s your storefront, showroom, and warehouse rolled into one. The way you set up your truck can make the difference between an average sales call and a memorable retail experience that drives loyalty and repeat business. While every truck generally starts with similar basic features: smart customization, layout, organization, and displays allow you to create a space that feels unique to your business and tailored to your customers’ needs.

THINK RETAIL, NOT JUST STORAGE

Too often, new franchisees view the truck primarily as a rolling

stockroom. Over the past 10 years or so, tool trucks have undergone a dramatic change, shifting from mobile warehouses to mobile retail environments. The most successful mobile operators have learned that the best sales opportunities lie in treating their trucks like retail shops. Customers should feel like they’re stepping into a store designed with them in mind, not just rummaging through shelves of product.

That means considering product placement, flow, and customer comfort. Ask yourself: where do customers’ eyes naturally go when they step in? Are the most profitable items displayed in a way that draws attention? Is there room for a customer to browse without feeling rushed or cramped? By

approaching your truck layout with a retail mindset, you’ll help customers stay longer and buy more.

ORGANIZE AROUND YOUR ROUTE’S NEEDS

No two routes are the same. The technicians, shops, and industries you service influence what your customers want most. A diesel-heavy territory may need prime real estate for larger sockets and torque tools, while an automotive repair route might respond better to specialty diagnostic equipment and hand tools.

Take time to analyze sales patterns and customer requests. Which categories dominate your sales? Which ones are impulse buys? Customizing your truck isn’t about showing everything you carry — it’s about designing what resonates with your audience. Use sales history and feedback to make layout decisions that maximize engagement with your most in-demand products and give you opportunities to feature new and promotional products.

DISPLAY WITH PURPOSE

Good retailing is about more than just putting tools on a shelf. Effective displays help customers visualize value and see tools in context. Integrating these customized displays into your truck gives customers the chance to easily and directly put the product in their hands and demo the tools. Some ideas to consider:

• Hand tools: Pegboard and slat wall make for easy organization and quick access. Group similar items together — pliers, wrenches, and screwdrivers — so customers can compare options quickly. Hand tool displays are a great way to show lots of these tools in a very compact area. Customized slatwall displays also provide great options for displaying your products.

Photos courtesy of LDV

• Power tools: Create a dedicated “power zone.” Use secure mounts or stands to allow hands-on interaction. Tools that can be touched or tested have a higher likelihood of being purchased. Group power tool accessories like batteries, chargers, and bits together to generate addon sales.

• Diagnostics and electronics: These higher-ticket items deserve special attention. Consider eye-level shelving with signage or integrated screens to highlight features. Power the products up so customers can play with them and see them work.

• Promotions and new arrivals: Install a small display area near the entryway or workstation where customers naturally look. Rotating promotions here keeps the space fresh and sparks conversation. Remember: you want to guide the customer’s journey, not overwhelm them with clutter. Displays should spark interest and make it easy to find solutions.

MAXIMIZE SPACE WITHOUT SACRIFICING COMFORT

Space is always at a premium, but there are many ways to stretch it:

• Vertical storage: Take advantage of walls and ceilings. Overhead racks for smaller boxed items or cases free up shelf space below. While certainly not a normal retail concept, many customers shopping on mobile tool stores have been trained to look at the ceiling for product. Take advantage of this unique aspect of your business and utilize that space accordingly.

• Hidden storage: Pull-out drawers or compartments under benches can house overflow stock while keeping the main area clean and focused. Floor drawers are a great spot to store extra product without sacrificing prime retail display space.

At the same time, don’t overcrowd. Customers need space to step in, look around, and engage in conversation. A cramped truck feels overwhelming; a well-planned truck feels inviting.

KEEP IT FRESH AND ENGAGING

Beyond product, your truck can reflect your personality and the culture of your route. Small touches — a branded mat, signage with your name, even music — help customers feel at ease. Think of it as creating a brand identity on wheels.

Some franchisees create themed areas (e.g., “weekly promos” or “tech’s pick of the week”) to spark conversation. Others use digital screens to run product videos or demonstrations. The goal is to make your truck memorable so customers look forward to stepping inside each week.

To further entice your customers, don’t let your truck setup become stagnant. Customer needs evolve, product offerings change, and what works one year might feel stale the next. Periodically step back and evaluate:

• Which displays are driving the most engagement?

• Is there stock taking up prime space without moving?

• Are customers asking for items you don’t have visible?

• Is there a particular area of the

truck that customers just don’t pay attention to?

A regular refresh, even if minor, keeps your truck dynamic and responsive. It also signals to customers that you’re proactive about meeting their needs. LDV’s VersaFlex interior was built with this in mind. Easily adjustable drawers, shelving, and merchandising displays afford the opportunity to refresh your truck quickly and easily, without spending excess time or money on costly refurbishment. This adjustable system lets you reconfigure as product lines shift or seasonal promotions arise, all within the structure of the original build.

FINAL THOUGHTS

Customizing your truck is more than an investment in shelving and displays — it’s an investment in the customer experience. By designing your truck as a retail environment, tailoring displays to your route’s unique demands, and continuously refining based on new products, feedback, and experience, you can turn your mobile workspace into a powerful sales engine.

Remember, the most successful franchisees don’t just sell tools; they create a shopping experience on wheels. With the right layout, organization, and personal touch, your truck becomes more than a store — it becomes a destination.

Get creative with your truck setup, and keep in mind comfortability as you put up your inventory.

A distributor’s worst nightmare

This distributor went through a potentially career-ending collision, but came out unscathed with the help of those close to him.

By Emily Markham, Editor

Earlier this year, Cornwell Quality Tools distributor Jay Hashagen was in what could have been a careerending accident. When another vehicle collided with his truck, though he walked away unscathed, his truck was totaled. For many distributors, this kind of loss is difficult to come back from. Without a truck, doing their job becomes almost or entirely impossible. Not to mention the potential damage a wreck could cause to their inventory.

INDUSTRY SUPPORT

Luckily, this was not the case for Hashagen.

“I called my district manager, [Jim Ledbetter], and said, ‘I was in a wreck. Truck’s totaled. I’m fine, but I need a truck,’” Hashagen says. “By the morning — we had a dealer in our district who had left the tool business — [Ledbetter] had called him, arranged me renting his truck for immediate needs, and contacted Tim [Herr of Herr Display Vans.]

“I got in a wreck on the 18th of June … [and] I ordered my truck the morning of the 19th.”

Between Ledbetter’s quick work finding a replacement truck and Herr having a chassis sitting in stock, seemingly waiting for this moment, Hashagen could not be more grateful to them both for the quick turnaround they helped make happen to get him back on the road.

DESIGNING THE NEW TRUCK

Over his 27 years in the mobile tool business, Hashagen has had 11 tool trucks, with the last five coming from Herr. His totaled truck was a “show truck” displayed at the Cornwell Tool Fair less than a year ago. When discussing what he wanted his latest truck to be, Hashagen told Herr he wanted the same thing as previously, with a couple of tweaks. Herr had the truck ready for him in about six weeks.

“My customers liked my old trucks so much that I didn’t want to do wholesale changes to it,” Hashagen says.

Instead, the distributor made small tweaks to make things more organized and visually appealing. For starters, he adjusted the amount of space he has for diagnostic equipment like scan tools, power probes, and relay testers

and made sure that it’s front and center for customers to see as they walk in the door. He notes that his customers are “always shopping that area” in the truck.

This truck also has wood-looking vinyl flooring, enough curtain and strobe lights on the outside to be seen from outer space (Herr says Hashagen will not get hit on his watch), multicolor LED strip lighting inside around the ceiling, TVs in the front and back, a no-touch liftgate, and dual power tool and beef jerky displays.

Hashagen also plans to add auto chains to the tires and solar panels.

LESS IS MORE

The distributor describes his truck as “hyper-organized.” He used his experience on the rental truck — a much smaller 18’ truck — to guide how he’s currently stocking his 2025 24’ Freightliner.

“In the past, when I switched from truck to truck, I just tried to take everything that was in the last truck and put it in the new truck,” Hashagen says. “I’ve been running this truck for over two months. There’s still inventory in my shop that was on the last truck that is not on this truck yet.”

Hashagen is taking a lighter approach to stocking this truck, only having about one of every product instead of multiples. He likes to take the “grouped” as opposed to the “scattered” organization style — keeping similar types of products together.

“It makes it easy for customers to browse,” Hashagen says, “and honestly, no matter how much they say they don’t like to ‘shop’ on the truck, they love it. It’s like Sephora for men.”

ENDING THE YEAR STRONG

Though he never thought he’d be buying a new tool truck again so soon, Hashagen is just glad it didn’t affect his business.

“By God’s grace and with a lot of good people around me, I went through what could’ve been a career-ending wreck,” he says, “and came out the other side just fine. My numbers didn’t dip. I’ll have the same year I had last year, which is amazing.”

Top Left- After the crash, Tim Herr was able to get Hashagen a showquality truck in just six weeks. Top Right- Hashagen knows that as long as there are people who work with their hands, there will always be a need for mobile tool distributors. Bottom Left- Hashagen tries to keep his tool truck "hyper-organized" because it makes his life easier and the customer's experience smoother. Bottom Right- Hashagen utilizes both a computer and a tablet to manage emails and look up items.

Jay Hashagen

Centralia, Washington

Top photos courtesy of Rebecca Parker Photography; bottom photos courtesy of Jay Hashagen

Selling starts with the tote

By Brian Fahlgren, Contributing

Editor

The humble tote tray might just be the secret weapon your route is missing.

The 52K tray was the metaphor used to describe the metal tote tray when I started in the mobile tool world. Fifty-two was the number of weeks in a year, and “K” was for $1,000. It was based on the fact that the average dealer would sell an additional $200 a day, which equates to $1,000 a week in additional sales. One thousand dollars a week multiplied by 52 weeks makes 52K

Those numbers were based on the average business, some 25-plus years ago. A quick web search of the value of today’s dollar compared to 1998 shows the 1998 dollar

is now worth just shy of $2.00. The dealer who carries tools into shops could realistically see a six-digit increase in annual sales based on today’s dollar value.

STARTING OUT IN THE MOBILE TOOL WORLD

When I first started on a tool truck, I was one of Mac Tools’ mobile distributors. At that the time, my district manager was also my boss. He told me that if he ever came to do a dealer ride along and customers asked me why I wasn’t carrying a tote tray, he’d fire me. I still consider him my mentor, and to this day, he denies telling me that! However, it was good motivation to get me to carry a tote tray.

DISCOVERING THE POWER OF THE TOTE

What I quickly learned was that toting tools actually worked. I nicknamed my tote tray, “the dog and pony show.” One of the first questions I was asked when I entered the shop was, “What’s in the D&P this week?” I’d usually set my tote on a bench or ask permission to set it on a toolbox. If customers wanted to look at the tools, they knew they could without the “What will it take to put you into a new impact gun today?” No one wants to feel pressured into buying tools.

I’d always leave the D&P in the shop while I went with customers back out to the truck. I found that a lot of customers were more comfortable looking at the tools in

the D&P on their own terms, without a tool dealer looking over their shoulder.

It wasn’t unusual to find customers looking at the tools when I walked back into the shop. A lot of times I’d hear, “Put those pliers on my bill,” or “I don’t need those sockets, but that reminded me to ask about a new ratchet.” I had a veteran tech tell me he appreciated seeing the D&P every week. He went on to explain that sometimes, between “waiters” or simply the immediate need to get on to the next car, he wasn’t always able to come out to the truck. He liked the fact that he was still able to see what was on sale, what was new, or even a great deal on a used tool. In all those years, I never had a single item come up “missing” when I returned back into the shop. The main issue I had was forgetting to retrieve the D&P before I drove off. Too many times, I’d need to go back to grab the D&P.

WHY SOME DEALERS AVOID TOTING TOOLS

So why are so many dealers reluctant to tote tools? I think the reluctance starts in the way it’s presented in training as much as simply having items with you. There used to be formulas for what to carry in your tote. I found it didn’t matter as to the mix of the tools as much as simply having items with you. I’d have days where I’d struggle with what to put in the tote next, as the items sold. I’d always use the current sales flyer as the basis of what I promoted. A combination of electronic, hardline, and power tools is a good start. The biggest issue was keeping the tote light enough so you don’t feel like you’re carrying a bowling ball around all day.

THE TOTE AS A SALES DRIVER

The tote focuses the conversation on tools. Yes, it’s nice to talk about the past weekend, sports, and such, but your job is to sell tools! The tote tray will also increase your customer count. I had UPS, FedEx drivers, car sales, and office staff on the books simply because they saw me walk past and wanted to know what was in the tote tray. If you’re a dealer who simply walks into a shop, making the rounds asking, “Is there anything I can do for you today,” expect to walk out without a sale. The old saying, “Bring nothing in, take nothing out,” is still just as relevant today.

BRIAN FAHLGREN started in the tool business in 1998. Falhgren has been an employee dealer, franchised dealer, and district manager for two different flags. In 2018, he returned to the driver’s seat of his own tool truck. Providing premium service and his continuous “close to perfect” attitude, he achieved his goal of being a Top 10 dealer for Cornwell Quality Tools. He and his wife of over 44 years recently retired, moving from Oregon to the endless summers of Beverly Hills, Florida.

Mac distributor Maria Lee demonstrating a scan tool to a customer.

Photo courtesy of Ed & Maria Lee

DRIVING SALES

Under Vehicle Equipment

Under Vehicle Equipment

Under vehicle equipment can range from something as large as vehicle alignment equipment to something as small as a stud and hub cleaner, but regardless of whether it’s a product you keep on the truck at all times or a capital equipment sale you make after speaking with the shop owner, each has its place in your customers’ tool line-up. We’ve gathered the latest under vehicle equipment for you to consider for your next inventory top-up.

BUILT-IN FLOW METER PREVENTS FALSE READINGS

The Lincoln PowerLuber Model 1884 is a dual-battery grease gun featuring a liquid crystal display that provides real-time battery level and grease flow readings. The Model 1884 has a rugged three-point base that provides stability without adding bulk, allowing access to tight spaces. It also includes a built-in LED light for enhanced visibility and a built-in flow meter that detects the loss of prime to prevent false readings.

For more information, visit VehicleServicePros.com/55278190

MOBILE DESIGN ALLOWS FOR QUICK RELOCATION

DESIGNED FOR ONEPERSON OPERATION

DESIGNED FOR HIGHVOLUME TIRE AND REPAIR SHOPS

The ProBalance Diagnostic Wheel Balancer, No. E900, from Coats is designed to be a high performing direct drive wheel balancer with new diagnostics. It’s up to 10 times faster than non-direct drive balancers, and is backed by a 10-year warranty on the motor. The balancer features a touchscreen interface. It utilizes a diagnostic roller and ProMatch feature to measure radial runout and address wheel and tire shap and detect issues before weights are applied. Its maximum tire weight is 160 lbs and maximum diameter for tires is up to 44”.

For more information, visit VehicleServicePros.com/55322048

The Universal Suspension Arm Lever from Pichler Tools is designed to push down the wishbone when removing the drive shaft, changing the axle boots, or before replacing the wheel bearings. The lever is made for one-person operation, allowing the suspension arm to carry out the required work. The tool locks the lower arm down and allows for controlled alignment for reassembly.

For more information, visit VehicleServicePros.com/53096161

The ARI-Hetra WS-MobileAlign is a cutting-edge mobile alignment machine designed to simplify vehicles of all sizes from heavy duty trucks and buses, to motorcoaches and cars. Designed and engineered for flexibility and mobility, the WS-MobileAlign features advanced 3D imaging and HD cameras. Wheel-mounted targets help to ensure precise calculations and alignment results. Works on the ground or on various lift types, including four-post, scissor, and platform lifts, while retaining calibration during elevation. Users can operate the system remotely from any tablet for added conveinece. A secondary monitor enhances visibility when working at ground level. For more information, visit VehicleServicePros.com/55296772

FEATURES SELF-CENTERING QUICK-CHUCK ADAPTER FOR FASTER SET-UP TIMES