TOP TIPS TO IMPROVE YOUR ELECTRICAL TROUBLESHOOTING SKILLS

on pg. 20

on pg. 20

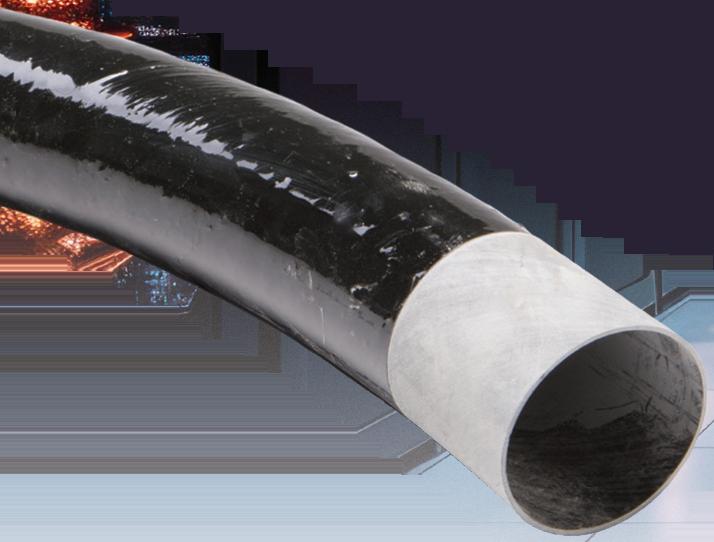

MC Glide® is the only metal clad cable on the market with a patented armor designed to glide through metal studs.

Say goodbye to the struggles of traditional cables – experience smoother, faster, quieter cable pulls with MC Glide®.

Learn more

Scan to learn more about the MC Glide ® product line

these common

The multi-wire branch is here to stay; so is ground fault protection. But we should unite these technologies only when it’s a good match.

With its exclusive online content, ecmweb.com is a valuable source of industry insight for electrical professionals. Here’s a sample of what you can find on our site right now:

10

Gallery A new study compiled data regarding fatal accidents on job sites across various industries to determine the rankings. ecmweb.com/55130269

EC&M TECH TALK — HOW TO USE THE PPE CATEGORY METHOD

Video Randy demonstrates how to use the PPE Category Method to select electrical PPE when the arc flash warning label is not on the equipment. ecmweb.com/55130122

Safety Nearly all of the injuries that occur with this kind of work can be prevented with simple steps. ecmweb.com/55130191

Editorial

Group Editorial Director - Buildings & Construction: Michael Eby, meby@endeavorb2b.com

Editor-in-Chief: Ellen Parson, eparson@endeavorb2b.com

Managing Editor: Ellie Coggins, ecoggins@endeavorb2b.com

Editor: Michael Morris, mmorris@endeavorb2b.com

Art Director: David Eckhart, deckhart@endeavorb2b.com

Consultants and Contributors

NEC Consultant: Mike Holt, mike@mikeholt.com

NEC Consultant: Russ LeBlanc, russ@russleblanc.net

Sales and Marketing

VP/Market Leader - Buildings & Construction: Mike Hellmann, mhellmann@endeavorb2b.com

Regional/Territory Account Manager: David Sevin, dsevin@endeavorb2b.com

Regional/Territory Account Manager: Jay Thompson, jthompson@endeavorb2b.com

Regional/Territory Key Account Manager: Ellyn Fishman, efishman@endeavorb2b.com

Media Account Executive – Classifieds/Inside Sales: Steve Suarez, ssuarez@endeavorb2b.com

Production and Circulation

Production Manager: Josh Troutman, jtroutman@endeavorb2b.com

Ad Services Manager: Deanna O’Byrne, dobyrne@endeavorb2b.com

User Marketing Manager: James Marinaccio, jmarinaccio@endeavorb2b.com

Endeavor Business Media, LLC

CEO: Chris Ferrell President: June Griffin COO: Patrick Rains

CRO: Paul Andrews

Chief Digital Officer: Jacquie Niemiec

Chief Administrative and Legal Officer: Tracy Kane

EVP, Group Publisher – Buildings/Lighting/Digital Infrastructure: Tracy Smith

Electrical Construction & Maintenance (USPS Permit 499-790 , ISSN 1082-295X print, ISSN 2771-6384 online) is published monthly by Endeavor Business Media, LLC. 201 N. Main St 5th Floor, Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI, and additional mailing offices. POSTMASTER: Send address changes to Electrical Construction & Maintenance, PO Box 3257, Northbrook, IL 60065-3257. SUBSCRIPTIONS: Publisher reserves the right to reject non-qualified subscriptions. Subscription prices: U.S. ($68.75 year); Canada/Mexico ($ 112.50); All other countries ($162.50). All subscriptions are payable in U.S. funds. Send subscription inquiries to Electrical Construction & Maintenance, PO Box 3257, Northbrook, IL 60065-3257. Customer service can be reached toll-free at 877-382-9187 or at electricalconstmaint@omeda.com for magazine subscription assistance or questions.

Printed in the USA. Copyright 2024 Endeavor Business Media, LLC. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopies, recordings, or any information storage or retrieval system without permission from the publisher. Endeavor Business Media, LLC does not assume and hereby disclaims any liability to any person or company for any loss or damage caused by errors or omissions in the material herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever. The views and opinions in the articles herein are not to be taken as official expressions of the publishers, unless so stated. The publishers do not warrant either expressly or by implication, the factual accuracy of the articles herein, nor do they so warrant any views or opinions by the authors of said articles.

Reprints: Contact reprints@endeavorb2b.com to purchase custom reprints or e-prints of articles appearing in this publication.

Photocopies: Authorization to photocopy articles for internal corporate, personal, or instructional use may be obtained from the Copyright Clearance Center (CCC) at (978) 750-8400. Obtain further information at www.copyright.com.

Archives and Microform: This magazine is available for research and retrieval of selected archived articles from leading electronic databases and online search services, including Factiva, LexisNexis, and ProQuest.

Privacy Policy: Your privacy is a priority to us. For a detailed policy statement about privacy and information dissemination practices related to Endeavor Business Media products, please visit our website at www.endeavorbusinessmedia.com.

Please Note: The designations “National Electrical Code,” “NE Code,” and “NEC” refer to the National Electrical Code®, which is a registered trademark of the National Fire Protection Association. Corporate

By Ellen Parson, Editor-in-Chief

Every August, we unveil the year’s top three winners (platinum, gold, and silver) for EC&M’s longstanding Product of the Year competition. Launched in 2001 to recognize excellence in new product development in the electrical industry, this prominent awards program is still going strong, showcasing the most innovative products of the past year, recognizing the talent and commitment of those involved with all aspects of new product development, and demonstrating the evolution of electrical equipment technology advancements and capabilities.

It’s hard to believe it’s been more than 20 years since we created this special recognition program (yes, I was around back then). Obviously, so many things have changed during that time, but when you really think about it, so many others have stayed the same. For example, the creativity, innovation, and inventiveness exemplified in the new products electrical manufacturers bring to market year after year are nothing short of remarkable. The desire to ensure electrical professionals can perform their jobs more efficiently, effectively, and safely is also still the driving force behind new product introductions and updates alike. Products eligible for the 2024 competition were those introduced to market between Jan. 1, 2023 and Dec. 31, 2023. Out of 123 product entries we received in 2024 (a total that was 12% higher than the previous year), a panel of 12 independent industry expert judges (representing the electrical engineering, electrical contractor, and plant/facility segments of our audience) narrowed down the field as part of phase one. Ranking each product based on a uniform listing of scoring criteria, the group ranked each entry, ultimately identifying 30 category winners. The top three winners were then determined by an online voting process administered on the EC&M website between May 19 and June 23. Note: Only EC&M print and digital edition subscribers can vote in this competition. To keep the voting objective and make sure winners are selected solely on technical merit, any votes from manufacturers or manufacturers’ reps are thrown out.

I recently had the opportunity to sit down and chat with representatives from all three manufacturers of the winning products for my EC&M On Air podcast. Don’t miss this episode (available at https://www.ecmweb.com/podcasts/ecm-on-air), which will drop toward the end of August — the same time this issue hits the hands of our print subscribers.

First I talked with Tia Willett, product marketing manager for NEMA safety switches at ABB. Winning the silver award in the power distribution equipment (breakers & switches) category, ABB’s Spec Setter Safety Switch definitely answered the industry’s call. “As part of our commitment to continuous improvement, and over the course of just talking and watching and looking at electrical contractors, we saw how difficult it was to install large ampacity safety switches,” Tia said. “We thought there has to be a better way. This is when we developed a new mounted bracket.”

Next, Rebecca Lore, industrial product manager with Lex Products, joined me to discuss its PowerRACK, part of the company’s Load Master Series. Winning the gold award in the power distribution category, this product offers flexibility and convenience for companies that provide temporary power applications where a range of power loads are required and changed frequently. “There’s no rewiring, no changing breakers or gland plates to get the breaker protection that is needed,” Rebecca explained.

Finally, I spoke with Jim Cuzuppe, Eaton’s product line manager – cable tray systems for North America, to go over highlights of this year’s overall platinum winner — the KwikRail Cable Tray System, representing the conduit, raceways, and wireways category. “Our primary design goal with this product is basically to offer an advantage over standard wire basket or conduit systems, and we feel we achieved just that,” he said. “For an award of this nature. We realize the significance, and we’re humbled by it.” In a nutshell, the cable tray system helps contractors improve project speed and simplify installation. “It really offers superior cable management compared to conduit systems, as well as the ability to field modify the system itself for future expansion, and these benefits are achieved in part by Eaton’s innovative tab and lock trapeze system,” he said. “That system actually eliminates the need for hold down hardware, which results in significant time savings when positioning and clamping cable tray supports, and it also requires less hardware compared to traditional strut trapeze solutions.”

Turn to page 16 for more details on all three winners, and don’t forget to catch the Product of the Year podcast, coming soon to ecmweb.com or wherever you listen to podcasts.

By Jim Lucy, Electrical Wholesaling

Have you noticed many of the local electrical supply houses in your market selling to larger companies? It’s part of a national surge in acquisition activity in the electrical wholesaling industry that’s quite possibly the biggest ever. In the past five years, Electrical Wholesaling magazine, EC&M’s sister publication, has counted more than 60 mergers or acquisitions. Combined, these deals represent millions of dollars in sales of electrical products moving from many family-owned independent distributors to a handful of largze national and regional distributors. Many of these deals were done by WESCO Distribution Inc., Pittsburgh; Sonepar North America, North Charleston, S.C.; Graybar Electric Co., St. Louis; Rexel USA, Dallas; and Consolidated Electrical Distributors (CED), Irving, Texas.

These acquisitions have fueled consolidation in the electrical wholesaling industry, and Electrical Wholesaling estimates the 10 largest electrical distributors have enormous clout in the electrical market. Together, they had combined 2023 revenues of more than $75.5 billion. That’s approximately 52% of the $145.3 million in 2023 sales Electrical Wholesaling estimates was sold through U.S. via electrical distributors. If you’re looking for more information, visit www.ewweb.com/55125909 to download this free e-book on them.

Because of all these acquisitions, this year, Electrical Wholesaling had to trim down its annual ranking of the largest distributors in North America from 150 companies to 100 companies. The fifty largest companies are in Table 1, and you can visit

www.ewweb.com/55055225 to see the rest of the rankings.

In the past two years alone, Sonepar or one of its subsidiaries has acquired eight large independent distributors, including most recently Echo Electric, Council Bluffs, Iowa; Electric Supply Center, Burlington, Mass., as well as Madison Electric Co., Warren, Mich.; Standard Electric Co., Saginaw, Mich.; Electrozad, Windsor, Ontario; Billows Supply, Philadelphia; Sunrise Electric Supply, Addison, Ill.; and Electric Supply of Tampa, Tampa, Fla. Other national or super-regional distributors were active acquirers, too, including Rexel, which in 2023 or 2024 bought Electrical Supplies Inc., Miami; Buckles-Smith, Santa Clara, Calif.; Teche Electric, Lafayette, La.; and Talley Inc., Los Angeles, a large VDV specialist.

Graybar Electric, Consolidated Electrical Distributors, and Border States Electric also bought some big distributors. Graybar acquired Shepherd Electric Supply, Baltimore, and Blazer Electric Supply, Colorado Springs, Colo.; CED

bought Parrish-Hare Electrical Supply, Irving, Texas; and Border States Electric acquired Dominion Electric Supply, Arlington, Va., and Winston Engineering, West Hollywood, Calif.

You may or may not see much of a change in your local supply house if one of these large distributors purchases it because these companies very often try to keep local management and employees in place after the acquisition — and being part of a larger company can often give smaller firms access to resources to grow the business that they previously did not have when they were privately owned.

When one of these larger chains moves into town, they can provide some tough competition for the independents still in the market, particularly on pricing. Theoretically, these larger companies can negotiate more lucrative volume purchasing discounts for the products they buy from electrical manufacturers, and then pass some of the savings on to customers. Many of the remaining independent electrical

45

distributors battle this price competition by banding together with other distributors in buying/marketing groups like the recently merged Affiliated Distributors, Wayne, Pa., and IMARK Group, Bowie, Md., to receive better pricing from the electrical vendors in these groups.

Not every remaining independent distributors sees the growth of the largest distributors as an insurmountable obstacle. Some respondents said smaller distributors can still react faster to market opportunities and may have better access to local talent.

At Inline Electric Supply, Huntsville, Ala., Bruce Summerville, president said, “We are one of the last multi-location independent distributors left in our area of the country. My perception is that fact, along with us being a 100% ESOP, gives us an advantage in recruiting new ‘A players’ to our team. The bigger guys that we are competing with are probably going to put a bit of a squeeze on our margins, but overall I am confident that we will be able

to outperform them due to having better and more qualitied people.”

Richard Booth, electrical division manager for Coburn Supply, Beaumont, Texas, says the acquisitions sometimes give larger companies advantages with their vendor relationships. “Big-name companies come into play with stronger vendor relationships than an independent regional has in some cases,” he wrote in his response. “It forces the smaller distributor into corners we have to fight out of. Vendors who promised to work with you as you entered a new market now back out of that agreement when the larger national chain gobbles up the competition.”

Unfortunately for electrical contractors and distributors’ other customers hoping for some relief in the astronomical lead times for switchgear, the situation doesn’t sound like it will improve anytime soon.

Only 8% of the respondents to Electrical Wholesaling’s Top 100 survey thought things would get back to normal by the end of the year, and 59% of Top 100 distributors don’t think lead times for switchgear will improve until 2025.

This year’s companies have seen plenty of challenges. On average, Electrical Wholesaling’s Top 100 distributors are fairly optimistic about the 2024 business climate, but 43% of respondents see business slowing in the second half of 2024. Sixteen percent of respondents said they already saw signs in 2Q 2024 that the economy is contracting. On a positive note, none of the respondents see a recession anytime in 2024.

Many distributors on the 2024 Top 100 list were quite bullish about opportunities in the market because of all

Distributor

Town/City State Involvement with Large Construction Projects

Access Electric Supply Renton WA Two hospitals, numerous data centers

American Electric Supply, Inc. Corona CA Large warehouse buildings to support the Los Angeles and Long Beach port along with health care and mental care facilities.

Border States Fargo ND Data centers, EV-component manufacturing facilities, utility infrastructure, transportation, and chemical processing.

Butler Supply Inc St Louis MO Boeing plant addition

CBT Co. Cincinnati OH New bridge over Ohio River planned to begin construction in 2025

CEEUS Inc.

West Columbia SC Data centers, EV manufacturing and related

Central Supply Co. Indianapolis IN Indiana University Health facility & data centers

D&S Electrical Supply Co. Pocatello ID Bayer facility in Soda Springs, Idaho & Idaho National Lab

Dulles Electric Supply Corp. Sterling VA Data centers

Echo Group, Inc.

Council Bluffs IA Data centers

Eckart Supply Corydon IN Ford’s Blue Oval EV plants & Meta

Electric Supply & Equipment Co.

Greensboro NC Toyota plant, Wolfspeed, Boom Supersonic Jets, VinFast Korean Manufacturer

Facility Solutions Group Austin TX Helix - Health and Life Science Exchange NJ & Lions Gate Studios, N.J.

Franklin Empire St-Laurent QC A hospital, battery plants & Ontario Power Generation

G&G Electric Supply Co., Inc. New York NY JP Morgan tower at 270 Park Ave. project & the Gateway Tunnel project under Hudson River

Gresco Utility Supply Inc. Forsyth GA Electric Cooperatives’ fiber to the home projects.

Hein Electric Supply Co. West Allis WI Microsoft

Independent Electric Supply Billerica MA Bio lab space & college projects

Inline Electric Supply Co. Huntsville Al FBI project and Facebook project in Huntsville, AL

Jackson Electric Supply Jacksonville FL The Four Seasons Resort project in Florida that’s part of the Jacksonville Shipyards redevelopment project.

Loeb Electric Columbus OH Intel microchip plant

LoneStar Electric Supply Houston TX Samsung and Texas Instruments chip plants

Mars Electric Mayfield Village OH Major Cleveland Clinic new construction projects

Metro Wire & Cable Corp. Sterling Heights MI Automotive and solar projects

Nassau National Cable Great Neck NY California High-Speed Rail, Vineyard Wind Project, Chokecherry, and Sierra Madre Wind Energy Project, ongoing data center development.

O’Neil Electric Supply Woodbridge ON Multi-unit high rise condos in the greater Toronto area (Canada) — forecast is for 500 more condos to be added in the next six years.

Schwing Electrical Supply Corp. Farmingdale NY Hospital renovations, Brookhaven National Labs, Amazon Logistic centers, Multi-unit dwellings

Service Electric Supply, Inc. Romulus MI University of Michigan Critical Care Tower

Van Meter Inc. Cedar Rapids IA Data centers

Wesco International Pittsburgh PA

$30-million contract to support an ethylene cracker; a $100-million contract to provide power distribution units, fiber optic cable, cabinets and other data center materials to a large EV manufacturer; and a $125-million, five-year contract to deliver high-voltage breakers for a renewable project.

Table 1. These are the biggest current and upcoming projects that 2024 Top 100 electrical distributors are supplying.

the electrical construction spending related to data centers, semiconductor plants, and electric vehicle (EV) or EV battery factories.

Not every Top 100 distributor is fortunate enough to have one of these mega-projects in their backyard. But the billions of dollars in the electrical spend for these projects now washing over the electrical wholesaling industry is quite impressive. Look at some of the biggest

projects 2024 Top 100 distributors worked on or are currently supplying in Table 2

Although consolidation is changing the ownership of many independent distributors (whether they are independent or owned by global distribution giants), they still must provide stellar service and reasonable pricing to win business from you and other end users

in local markets. In particular, electrical contractors will always command tremendous mind share with these distributors because they very often account for 50% or more of the typical distributor’s business. Large or small, all EW Top 100 distributors want your business, and the smart ones are hustling to get it. As the saying goes in the electrical wholesaling industry, “Whoever is closest to the customer wins.”

By Mark Lamendola, Electrical Consultant

Safety experts often focus on educating people against making common mistakes. They identify the mistake and tell you what to do instead. That’s good because those mistakes have a disproportionate effect on workplace safety compared to uncommon mistakes. But this focus has a downside — namely that uncommon mistakes may be just as deadly, injurious, debilitating, or disfiguring when they occur.

The so-called “freak accident” comes as a surprise, but a skilled observer watching the safety mistakes leading up to it would likely say it was predictable.

Consider the following four examples of uncommon safety mistakes during this motor installation:

• Tim and Brad failed to obtain the correct lifting device for the space they were working in, so their “cherry picker” didn’t have quite enough reach.

• Brad failed to ensure the lifting strap was secure within the lifting eye, and that the load was balanced.

• Tim stood with his left foot directly under the motor.

• Tim and Brad jostled the motor manually to make up for the lack of reach. Each mistake is fairly uncommon. But these added up to a “freak accident”

that sent Tim to the hospital, where most of his left foot was amputated.

Would it have helped for Tim or Brad to have memorized a list of uncommon safety mistakes? Or do you think the problem is something else? If so, what do you think that might be? Consider these three characteristics, which you will find in NFPA 70E:

• Awareness

• Self-discipline

• Being a qualified person

It appears that neither Tim nor Brad received the proper training for using the lifting device. Therefore, neither fit the definition of a “qualified person” [NFPA

70E Sec. 110.6(A)(1)]. Both should have been aware of this when the “cherry picker” didn’t reach as far as they needed it to — and they should have had the self discipline to ask their supervisor about the situation.

Consider this confined entry case. Jake filled out the permit using the information the operators gave him, plus what was on the work order and electrical drawings. He knew there was a possibility that the O2 reading might quickly drop below the minimum level, so he wore extraction gear — and the operations department assigned him an attendant. What he didn’t foresee is the space contains bracing upon which his clothes or the extraction gear can snag. So there was a “freak accident” resulting from the inability of the attendant, who is half Jake’s weight, to pull him out. There is a solution to this — we’ll get to it in a moment.

A “freak accident” is a kind of safety failure that can occur even when safety training does a great job with the expected (e.g., common mistakes), yet does not also address the unexpected (e.g., uncommon mistakes). It’s unrealistic to expect people to memorize long lists of potential mistakes or unexpected safety problems. So what is the alternative?

You can train for the unexpected without defining or even naming the possible dangers during training. Workers must

develop a mindset of methodically looking for mistakes, potential dangers, and unexpected problems.

They must apply this mindset in specific ways so they can protect themselves. Here are four ways people can apply that mindset.

Assess the area. Teach people to pause and assess the area before proceeding into it. A commonly taught method is the “look, listen, smell” method. You pause to visually scan left to right, top to bottom, and ask, “What are the dangers here, and how do I protect myself?” You also listen for unusual sounds (e.g., the hiss of steam) and sniff the air for “red flag” odors (e.g., smoldering plastic, odd chemical smell, smoke).

In Jake’s case, upon entering the confined space, he should have noticed those snag points and then promptly exited. Some discussion should have ensued as to how to deal with those. Cover them with cardboard temporarily? Perhaps a tarp? And why the size difference between Jake and his attendant — isn’t that dangerous?

Use gear correctly. Improperly used safety gear is another cause of uncommon mistakes. Stepping outside the electrical industry for a moment, consider what happened to Marty Hoey, a professional climber, in 1982. She had made thousands of climbs, but on her last one, she didn’t go through the normal safety check climbers perform. She leaned back in her harness, and it opened, allowing her to fall 6,000 ft. Her body was never recovered.

One aspect of using extraction gear correctly is to ensure the extractor has the physical strength to extract the other person. Using the example of Jake, can you think of other mistakes people can make when using the gear required for confined entry? How, for example, do you know your O2 meter is functioning? Do you check the calibration sticker on it and take a reference reading outside the confined space? Or do you just wait until you’re inside before looking at it?

The term “gear” is more inclusive than just personal protective equipment (PPE) or safety gear in general. It includes tools, test equipment, and things like ladders. Never use any gear in a manner that is outside its design parameters or intended purpose. Many people have “saved time” by using a ratchet extension where a punch is required, only to have tool steel shatter in their face (that shaft is hardened for tensile strength, not for impact resistance).

When it comes to test equipment, pay attention to the CAT rating. As a general rule, for example, factory maintenance personnel should use only CAT III or CAT IV test equipment to service production equipment.

Have rote rituals. A ritual is rote when you do it the same way every time. This eliminates a potential source of errors. A rote ritual climbers used for many years was that before each ascent the climber and belayer (person operating the rope) would check the harness “D” clips in an exact sequence to ensure they were fastened. This ritual was rendered obsolete when harness manufacturers eliminated the D clips. But the climber and belayer still check other things. Had Marty performed the simple D clip-checking ritual, she’d probably be alive today.

You’ve never heard a commercial airline pilot say, “Welcome aboard flight 317 to New York. I’ve got 20 years of experience, so we aren’t doing the pre-flight checks before taking off.” But you may have heard an electrician say, “I’ve done lockout/tagout on this circuit many times. I don’t need to use my meter to check that it’s de-energized.” Maybe you have skipped this step when changing a switch or receptacle in your home. Going back to Marty and also to the pilot, now what do you think about skipping this step under any circumstances?

The tool check is another ritual that people might skip to “save time.” They might get away with this for years or even decades, until a “freak accident” occurs when there’s a metallic path between two phases at the time power is restored.

It’s not enough that you don’t skip these safety check rituals. You should also do them the same way every time. If you vary a safety check ritual, you introduce the potential for error. If you always do your voltage check the same way, you don’t have that extra error factor working against you. For tool count, do the same thing.

Don’t be there. Going back to the motor example, what if Tim and Brad had been joined by Gary? He’d have been a person who didn’t have to be there for that job to get done. Had Tim and Brad been “qualified persons” and thus correctly used the correct lifting device, then nobody would have “been there” on the business end of the lifting device.

Once the lifting device acquires the load, human hands and feet have no business being near the load. A similar thing applies when setting the new motor in place. Tim could have used a metal bar or similar tool to nudge the motor an inch or so this way or that, but there was no reason for his foot to be under the motor. And he should have stood well away until the motor was almost done being lowered onto its base.

Often, a thermographer is outsourced and an in-house electrician takes him from panel to panel. When a thermographer is working in an open panel, there is no need for the in-house person to be standing in front of the open panel. Only one person needs to be exposed to that energy.

Ideally, your company’s safety culture would produce a situation in which safety mistakes don’t happen. However, mistakes are inevitable. The trick is to catch them before they catch you. By adopting the mindset of looking for those mistakes, no matter how uncommon or unlikely, and adopting rote safety checks to identify them, you can prevent the “freak accidents” that uncommon mistakes eventually produce.

Mark Lamendola is an electrical consultant based in Merriam, Kan. He can be reached at mark@mindconnection.com.

The KwikRail cable tray system, which meets NEMA 12A and 12B requirements, can be modified on site, reducing labor hours and installed cost.

By Amy Fischbach, Freelance Writer

Cable tray systems have emerged as a popular alternative to electrical conduit systems in the electrical construction market. Their dependability and design flexibility are a good fit for commercial and industrial applications.

“A properly designed and installed cable tray system enables outstanding reliability for a facility’s control, communication, data, instrumentation, and power systems cabling and wiring,” says Jim Cuzzupe, product line manager, cable tray systems (North America) for Eaton.

Eaton, an intelligent power management company, launched its KwikRail cable tray, the 2024 EC&M Platinum Product of the Year award winner, when it identified a gap in the market for a better ladder tray system meeting NEMA 12A and 12B requirements. Over the course of two years, the manufacturer consolidated features from its existing Redi-Rail and KwikSplice cable tray systems into a new product.

“By combining the best aspects of both products, we aimed to provide customers with a best-inclass product that not only offered lower total installed cost but could also be easily modified in the field and seamlessly integrated into various verticals including data centers,” Cuzzupe says.

Eaton designed the system for NEMA 12A and 12B (CSA class C-3 and D-3M) load classes for small power and instrumentation tray cable management in multiple applications including commercial buildings, light industrial, and more.

The team at Eaton designed the KwikRail cable tray system with several major considerations in mind. For example, the product includes I-beam rungs for a high strength-to-weight ratio. In addition, the system features an I-beam side rail splice retention groove allowing installers to easily guide and snap the splice in place with two bolts compared to the four or eight bolts required for traditional solutions.

The KwikRail cable tray system helps contractors improve project speed and simplify installation by requiring up to 80% fewer parts and being up to 75% faster to install. It also offers improved cable management compared to conduit systems and features the ability to field modify for future expansion.

The product, which won the Conduit, Raceways & Wireways category, became commercially available in April 2023 following rigorous lab testing and achieving third-party UL classification and a CSA rating.

In addition, Eaton’s team engineered a tab and lock trapeze hanger design eliminating the need for hold-down hardware, offering time savings compared to traditional strut trapeze systems. To achieve this, the straight sections and fittings feature perforations along the side rail that allow the installers to quickly and easily alter the system. One of the greatest technical challenges of designing the system was figuring out how to incorporate perforations into the side rail, Cuzzupe says.

Eaton engineered the solution to provide customers with the option to choose between welded rungs or bolted rungs. The Add-A-Rung kits enable installers to add an additional rung to either welded or bolted KwikRail configurations using pre-cut rung sections and included attachment hardware.

“This means contractors can quickly adjust the system to prevent cable sagging, providing an extra layer of support without compromising performance,” he says.

The system also facilitates direct dropouts with the use of a waterfall accessory, and a wide range of fittings and accessories are available to accommodate nearly any cable management layout.

Arlington’s heavy-duty Grounding Bridges provide reliable intersystem bonding between power and communication grounding systems. And handle multiple hookups of communications systems: telephone, CATV and satellite.

Our new GB5T is THREADED for threaded conduit or another GB5T – with a SET SCREW for use on EMT or PVC.

Arlington’s zinc and bronze grounding bridges...

• Four termination points; more than required by the NEC

• Meet 2020 NEC bonding requirements for 250.94

• Fast, simple installation indoors or outside

• Textured, paintable plastic cover (except GB5NC)

• Easy access for inspections

“Overall, our primary design goal was to offer an advantage over standard wire basket or conduit systems — and we achieved just that,” he says. “The KwikRail cable tray system meets the cable management demands of today and tomorrow at a lower total installed cost, with the ability to expand alongside evolving needs and be easily modified in the field.”

The cost of the system depends on the project, but Eaton has a savings calculator available for its KwikRail cable tray system at Eaton.com/KwikRail. This calculator demonstrates the total cost differences between the KwikRail cable tray and other cable management methods. It considers material costs, labor costs, and potential support structure cost savings. For example, a 1,000-ft run of KwikRail generates a savings of nearly 50% compared to a wire basket alternative.

“These savings are attributed not only to optimized labor efficiency, but also to material savings,” he says. “Wire baskets support every 5 ft to 8 ft, while KwikRail only needs support every 10 ft to 12 ft, reducing the number of supports needed.”

Splicing hardware is also included in the straights and

fittings for KwikRail, which is not typically included in wire basket solutions. Further, the two-bolt splicing method is quicker and requires fewer parts than a standard wire basket washer splice kit.

Today, the KwikRail system is stocked as part of the company’s Ready, Set, Stock program across Eaton warehouses in North America. So far, the ease of installation and versatility of the system have impressed customers in vertical markets such as data centers, alternative energy sites, government projects, and hospital projects.

“With KwikRail, we are proud to provide an easier and faster-to-install cable management solution that enables significant time and material savings compared to other ladder or wire basket systems,” he says. “We’re extremely proud of our KwikRail cable tray system because it is a perfect demonstration of how we work closely with our customers to understand their day-to-day challenges.”

For more information, visit https://www.eaton.com/us/ en-us/catalog/support-systems/kwikrail-cable-tray.html.

Lex Products’ PowerRACK for Outdoor Use (the Power Distribution Equipment category winner and overall Gold winner) is designed for rough use and harsh environments. The product provides enhanced safety and durability where a range of power loads are required.

The first cULus-listed portable power distribution unit eliminates the need to reconfigure or rewire panels for each job. Fed directly from a power source, these units deliver 800A of 3-phase power to multiple circuits, creating a main power distribution station within the job site. Part of the Load Master Series, these racks feature outputs with electronic 100% rated adjustable circuit breakers. Ranging from 60A to 600A, overcurrent protection is configurable to match specific application loads.

In the Power Distribution Equipment (Breakers & Switches) category, ABB redesigned the 400A to 600A General Duty and Heavy Duty Spec Setter Safety Switch with premium features to improve safety. The product, which won the silver award, includes a wall mounting bracket and securing clips, plus a clear line shield and neutral kit as a standard offering. The viewing window option extends to the heavy-duty product offering. The new wall mounting bracket is designed to ease Safety Switch installation by decreasing installation time and improving installation accuracy. The door latch of the enclosure also comes with a new secure clip, which ensures the latch does not accidentally open. Handles are now level to the product enclosure during the shipping process, resulting in reduced warehouse footprint and decreased packaging material. These 400A-600A General Duty Safety Switches are available in NEMA Type 1 and Type 3R enclosures, fusible and non-fusible with a maximum voltage rating of 240VAC, 250VDC.

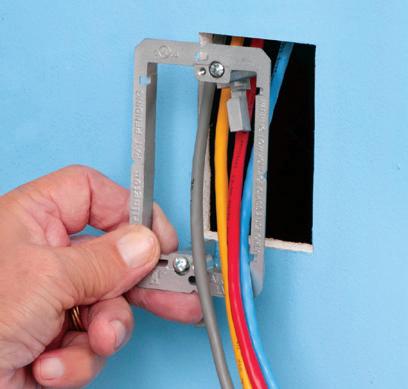

Arlington’s new Furred Wall Box™ kit makes challenging outlet box installations fast and easy!

Versatile mounting options Our high strength FSB series outlet box kits are designed for use with existing 1x2 drywall furring strips – but can also be mounted directly to a concrete block wall between furring strips – so installers can place the box or outlet where it’s needed.

No cable pullout! Accommodates GFCI and USB receptacles. Convenient kits simplify ordering.

Large, pancake-style box with cover

High-strength No breakage in cold weather

Integral Mounting Flanges

and

By Randy Barnett, NTT Training

Avoiding these common mistakes in electrical system evaluation and diagnosis leads to increased efficiency and reduced downtime

Photo 1. A good practice whether troubleshooting or maintenance testing is to clip the black test lead of a digital multimeter onto a common terminal and use the red test lead to “probe” at different points in the circuit to measure voltage as applicable. In this image, X2 is the common from the control power transformer, and the red probe is testing for voltage at terminal 4 —and can be easily moved to the next terminal when ready. The meter is supported by a magnetic strap attached to the panel door.

We’ve all had those long days where you wish you could just find the electrical problem and get to the next job — or go home! The best way to try and avoid these frustrating days is to review prints beforehand, stay abreast of the latest troubleshooting technologies, and understand that some problems are not easily diagnosed but hidden in the distribution system.

Electrical prints may contain more information than you first realize. Choosing the best test tools to locate and diagnose the issue will not only help reduce troubleshooting time but also provide much more detailed information to help solve a problem. In some cases, you may have to dig into the distribution system itself and determine if the power being delivered to loads is of good quality. Reducing downtime is an important business goal, and so is increasing your comfort level with your troubleshooting abilities.

To spend time troubleshooting a control problem only to find out you have been barking up the wrong tree is truly frustrating. Interpreting an electrical diagram is more than just identifying the symbol types and component numbers. First, use the symbols and current flow path to determine the system operation. Pay attention to additional information, such as equipment numbers, and

location. Then, use a systematic and logical approach to trace through the circuit with a digital multimeter (DMM). Typically, you look for the “missing voltage.” That is, if there is no voltage at a component and there should be, then where did it get lost?

Knowing the symbols is a must. If not accompanying the diagram, many resources are available to identify drawing symbols. Though equipment manufacturers may use somewhat different types of layout schemes, the purpose of the electrical schematic is to depict the sequence of operation of the system’s electrical components. Being able to follow this sequence and identify where the system faults are is what troubleshooting is all about. The ladder diagram is one of the most common arrangements for depicting the operation of a circuit and is basic for understanding all types of electrical schematics.

Using Fig. 1 on page 22 as an example, notice the information that is available to reduce troubleshooting time. This system is spread out through a chemical

plant. However, there is information that could send you to the best location to start the troubleshooting process.

• Understand the overall operation of this ladder diagram: Current flows into the circuit from X1 through the 10A fuse, down the power rail on the left, across the 1052 rung of the ladder through the 3612 R1 relay coil, then through the X2 return rail on the right and back to its source at X2.

• The overall operation of the component is evident: The PS-1 pressure switch contacts close to energize the 3612 R1 relay coil.

• The legend identifies not only the meaning of the symbols but also the location of all components in the plant.

• Once at the correct panel, the ladder diagram identifies the individual terminal strip and the terminal number for each specific wire.

• When the coil is energized, the numbers to the right of the ladder rung indicate that the relay contacts operated by the coil are electrically connected in lines 1053 and 1057 of the ladder diagram.

• To check whether a voltage is being applied to the PS-1 pressure switch, you could go into the field, find the switch, and, assuming it is convenient to access, remove the cover and check for the presence of voltage at terminal 1 of the switch. Or you could just (safely) open the main control panel and test for voltage on terminal strip 36P, terminal number 69.

• This ladder diagram is well over 1,000 rungs long. Based on your knowledge of the system, you should decide to start troubleshooting at the most logical point that makes sense for you. The more you know about the system, the quicker you can expect to find the problem.

Photo 1 on page 20 is a practical application of using the DMM for troubleshooting. Tracing through a circuit often goes quite quickly. Time can be saved by using a magnetic strap or other means to place the test instrument in a convenient location. Placing the black test lead (black for conventional purposes only) to the control circuit Common (X2) port, the red test lead can be used to go from terminal to terminal as identified on the print to check for voltage.

Fig. 1. Troubleshoot the ladder diagram just as you would step down from a ladder. Start at the top rung and come down one rung at a time checking for voltage from left to right across each rung. Interpret all of the information on the diagram to facilitate troubleshooting.

The use of IEC prints is common, depending upon the equipment manufacturer. The components and the electricity obviously still work the same, but the symbols are different. Figure 2 on page 24 is a comparison of drawings between a NEMA start-stop circuit and an IEC start-stop circuit for energizing a starting contactor. If you troubleshoot using IEC prints, be sure you are familiar with these symbols. The troubleshooting methodology remains the same.

Safety Tip: While following lockout/ tagout procedures, reading resistance is always the preferred method for troubleshooting — although it’s not always feasible. Most often control circuits must be energized for troubleshooting.

Be sure to follow your electrical safety rules for diagnostic testing when working on energized circuits (see Sidebar below, “Troubleshooting Methods Have Evolved”).

It is said that “experience is the best teacher — as long as it is someone else’s experience.” Case in point: An electrician tested a 3-phase AC induction motor onboard a nuclear submarine. The electrician pronounced the windings were shorted, and the motor needed to be replaced. A hole was cut in the titanium hull to remove and replace the motor. To

diagnose the problem, the electrician disconnected the motor from its source and then measured resistance phase-to-phase at the motor leads. He noticed very low resistance values. Resistance values were consistent between all phase-to-phase measurements. Therefore, the electrician diagnosed that the windings were shorted together due to the low resistance, and the motor needed replacement. By using only a DMM and not understanding the construction of the motor, the electrician jeopardized the success of a mission — and at a significant financial cost. Similar mistakes are no doubt made every day throughout the industry. Training and knowledge of the latest technologies can help prevent such costly errors.

The Good Old Days

Here’s a quote from the 1942 edition of the American Electrician’s Handbook.

“Electricians often test circuits for the presence of voltage by touching the conductors with the fingers.” The handbook then describes the “proper” methods to perform this including “tasting” low voltages. Yikes!

In the 2000 edition of the NFPA 70E, Standard for Electrical Safety in the Workplace, a new section on test equipment stated, “Test instruments and equipment and all associated

test leads, cables, power cords, probes, and connectors shall be visually inspected for external defects and damage before the equipment is used on any shift.” Subsequent editions begin to revise and expand the requirements.

The 2024 edition of the standard requires that only qualified persons may use test equipment and that an inspection must be made “before each use.” Also addressed are rating and design requirements, repairs, and operation verification. The standard requirement is not specific to multimeters but applies to all types of test equipment — from non-contact detectors to surge comparison testers to power quality analyzers.

Arlington’s convenient fan/fixture pan box works with 1/2", and single or double 5/8" drywall –on furring strips or hat channel.

• Easy mounting in new work

•Fan bracket installation screws ship captive until ready for use

•Secure joist-mount installation

•14.4 cu. in. UL/CSA Listed

Product info aifittings.com/catalog/fan-fixture-boxes/fan-fixturemounting-boxes-for-drywall-with-furring-strips-or-hat-channel/FB412

Arlington’s IN/OUT™ fan/fixture boxes adjust up to 1-1/2" to accommodate varying ceiling thicknesses, like single or double FBA426 is Listed for fans up to 70 lbs; fixtures up to 100 lbs. Pre-set for 1/2" ceiling – depth adjustment screw positions the box flush with the ceiling after it’s in place Complies with 2020 NEC, 314.20 for set back boxes

• (4) screws attach box securely to joist in new work • 2-Hour Fire Rating

Fig. 2. IEC prints are prevalent. The components all function the same, just different symbols are used to depict the components. Use the same methodology to troubleshoot both diagrams.

While the DMM is a valuable tool for the first analysis of motor windings, a more detailed test, such as a surge comparison test can accurately diagnose winding issues. The surge comparison tester injects a high-voltage signal into an individual phase winding. As the waveform decays there should be only one waveform present on the screen of the surge comparison tester. The appearance of a second waveform indicates a potential problem. See Fig. 3 for examples.

The lessons learned from such an incident can be applied to all testing and troubleshooting. Here are three tips to improve your maintenance and troubleshooting skills:

• Know your equipment. OSHA, the NEC, and NFPA 70E all require qualified persons to be knowledgeable in the construction and operation of their equipment. Learn to be inquisitive and be open to all learning opportunities.

• Select test tools and methods that give the most complete data to make a decision.

• Know your test equipment and how to interpret the results.

When a load does not operate properly and there are no apparent causes, the quality of the electrical distribution power should be investigated. Just a few short decades ago, power quality issues were relatively unheard of. Other than brownouts and blackouts, the quality of the power delivered to incandescent lamps and motors was of little concern. However, the grid is

(a) Good winding

(b) Short circuit between turns

Fig. 3. The surge comparison test discharges a high voltage into the winding. One decaying waveform (a) on the test equipment screen indicates a good winding. The appearance of a second waveform (b) indicates deteriorating insulation and a short between turns.

no longer loaded with just motors and incandescent lamps.

Electronic loads, such as variablespeed drives, battery chargers, data servers, and electronic ballasts, produce currents that flow back into the facility distribution system. Those currents flow back in at multiples of the primary frequency of 60 Hertz (Hz) — 3 times 60 Hz equals 180 Hz, or the third harmonic; 300 Hz would be the fifth harmonic, etc. The effects of harmful harmonic frequencies include overheated neutrals and transformers, motor inefficiency, and misoperation of electronic equipment. Other power quality issues include voltage transients, sags and swells, and distortion of the primary 60 Hz sine wave.

The use of a power quality analyzer is not difficult (see Photo 2 on page 22). Interpreting the results and comparing them to standard maximum values requires knowledge obtained through training. Analyzing and interpreting power quality data is the first step in

solving some of the more significant power distribution issues.

In summary, increase your trouble shooting skills to become more efficient and reduce downtime. Study electrical diagrams before the problems arise. Know how the system operates, and realize there may be information on the print that can help streamline the troubleshooting pro cess. Select test tools that provide the most complete data to help diagnose problems. Understand that power quality problems do exist and can be isolated and corrected. You may never solve all the world’s electrical problems, but following some basic tips can reduce downtime and satisfactorily get you to your next goal.

Randy Barnett is an NFPA Certified Electrical Safety Professional, a long-time journeyman electrician, instructor, and author with expertise in industrial electrical construction and maintenance. He is Electrical Codes & Safety Manager for NTT Training. He can be reached at electricrb@yahoo.com.

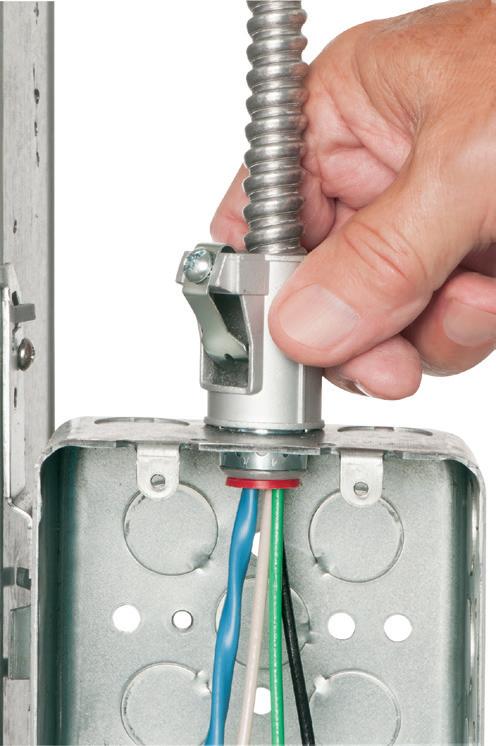

Fully assembled, SNAP2IT® fittings handle the widest variety of MC cable AND THE NEW MC-PCS cables.

Compared to fittings with a locknut and screw, you can’t beat these snap in connectors for time-savings!

LISTED SNAP2IT ® CONNECTORS FOR NEW MC-PCS CABLE ...lighting & low voltage circuits in the same cable

• Fits widest range and variety of MC cable 14/2 to 3/3

AC, MC, HCF, MC continuous corrugated aluminum cable and MCI-A cables (steel and aluminum)...including the new MC-PCS cable that combines power and low voltage in the same MC cable

ANY Snap2It Connectors LISTED for MC cable are also LISTED for MC-PCS cable! These products offer the greatest time-savings.

• Fast, secure snap-on installation

• Easy to remove, reusable connector From cable Loosen screw on top. Remove connector from cable. From box Slip screwdriver under notch in Snap-Tite® Remove connector.

By Mose Ramieh III, CBS Field Services

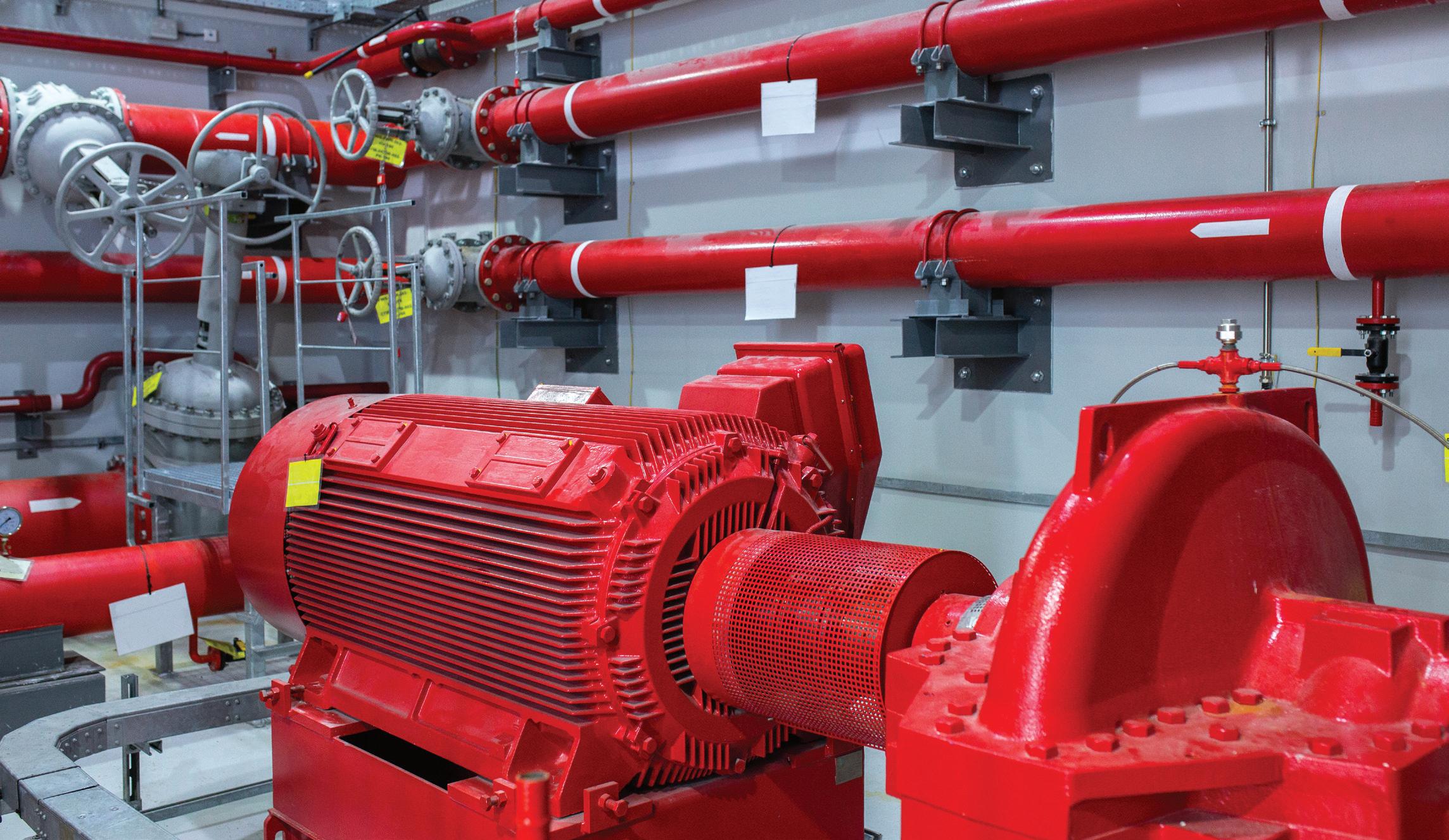

Electrical power systems are often built with crucial auxiliary systems, which are often dependent on each other to ensure these power users have systems that are safe and reliable. The DC battery system might be one of the more significant of these systems.

DC batteries provide power to protective relays, breaker trip circuits, and other vital system-control systems. If these battery systems are not properly maintained and monitored, the safe operation of the entire power system will be placed in jeopardy.

When planning for DC battery system preventive maintenance, reference the ANSI/NETA Standards for Maintenance Testing Specifications for Electrical Equipment and Systems, Section 7.18.1 – 7.18.3. The specifications provide detailed recommended visual/mechanical inspections and electrical tests for batteries, chargers, and rectifiers.

Arlington’s steel SliderBar™ offers the easy, NEAT way to mount single or two-gang boxes between wood or metal studs with non-standard stud cavities.

No more cutting, nailing and fitting extra 2x4s to fill the space! SliderBar saves about 20 minutes per box. Designed for studs spaced 12” to 18” apart, SL18 allows positioning of one or more boxes anywhere in the stud cavity.

• Bending guides on bracket assure proper positioning on studs

• Interlocking tab stop prevents accidental disassembly

• Pre-punched pilot holes on BOTH sides of S for easy attachment of one or two boxes

Electrical Testing Education articles are provided by the InterNational Electrical Testing Association (NETA), www.NETAworld.org. NETA was formed in 1972 to establish uniform testing procedures for electrical equipment and systems. Today the association accredits electrical testing companies; certifies electrical testing technicians; publishes the ANSI/NETA Standards for Acceptance Testing, Maintenance Testing, Commissioning, and the Certification of Electrical Test Technicians; and provides training through its annual conferences (PowerTest and EPIC — Electrical Power Innovations Conference) and its expansive library of educational resources.

Deficient battery string conditions occur most commonly when a battery system is placed behind doors or covers.

One manufacturing facility suffered a catastrophic failure of its switchgear because of a loss of control power — the loss of control power to the medium-voltage switchgear created a situation where the electromechanical protective relays operated during an overcurrent condition in the system, but there was no DC control power to trip the breakers. This inability to trip the breakers allowed the fault to persist, doing more damage, until the fault was finally cleared by the upstream electric utility fuses.

The battery system had been overlooked for years because it was located in the rear of the switchgear behind a bolted cover. Photo 1 on page 26 shows the battery system with the cover removed.

While this is an odd place to locate the battery system, it is not entirely rare. The equipment lineup in Photo 2 also hides a battery system.

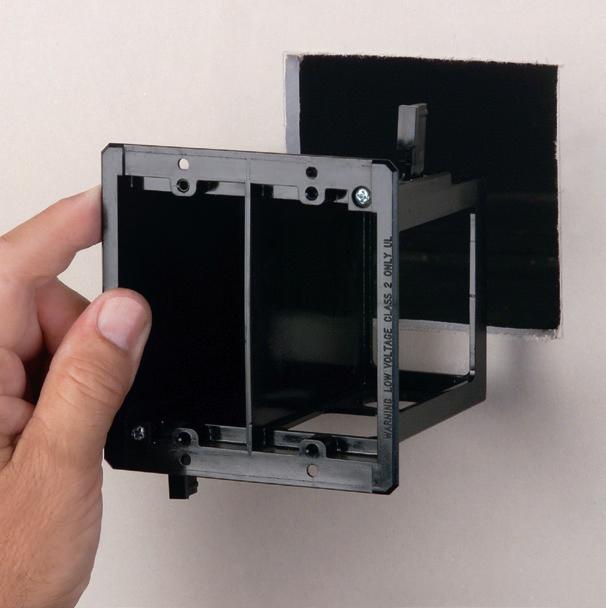

Arlington’s 8X10 TV Box™ with a Plastic or Steel Box offers the ultimate in versatility for installing TVs in new and retrofit projects. There's more room in the box for wires and it installs horizontally or vertically to properly position low voltage connections behind the TV.

• Ideal for home theater systems: multiple connections for sound systems, satellite TV, CATV, DVRs

• Brackets for neater cables, with a 1-1/2" knockout for ENT and other low voltage wiring

• Box mounts to stud in new work; for retrofit, mounting wing screws secure

Arlington’s new duplex diecast couplings save time and easy transitions from 3/4" EMT to 3/8" trade size flexible metal cables – perfect for running MC cable above a drop ceiling and connecting EMT to feed a box or switch.

combination couplings install easily on AC, MCI-A, HCF steel and aluminum cable, flexible metal conduit (steel and aluminum, regular and reduced wall), MCI cable and continuous corrugated aluminum. And offer independent securing of different size cables.

• Tested, LISTED to exceed UL ground fault requirements Compatible with 3/4" EMT

SADDLE GRIP® styles

The best solution is to place battery systems where they are visible during a standard system walk-through. In utility substations, these battery strings are typically located on the floor of the substation control room and are completely visible so that even minor issues can be observed ( Photo 3 on page 28).

Getting back to our failure at a manufacturing facility example, there were visible warning signs that the DC control power had failed. Unfortunately, those responsible for monitoring the power systems were not familiar enough to recognize the warning signs. You might be guilty of this too if you have ever ignored a breaker with a red (breaker closed) light that is not illuminated. This could indicate something as simple as a blown lamp, but it could also be something as critical as a bad trip coil or a complete loss of control power — as was the case in this example.

Photo 4 illustrates the worst case of battery corrosion. This situation clearly indicates the power system was neglected with no service or inspection for many years.

The facility lacked the trained personnel necessary to ensure the system was properly maintained. This neglected system was discovered in response to flood recovery efforts. If not for a flood, this power system’s negligence would have likely continued.

All power system safety and reliability programs start with good housekeeping. When it comes to DC battery systems, a great deal can be learned — and issues can be avoided — from routine visual inspections. These are the items you should focus on:

• General corrosion on battery posts.

• Other cracked or damaged internals such as a cracked internal seal (Photo 5).

• Acid levels not between the high and low marks (Photo 5).

• Damage to plates including positive plate growth.

• Bright lead-sulfate crystals on the negative plates indicate the battery is being undercharged.

Designed for new construction, Arlington’s non-metallic FR series device and fixture boxes mount directly to a flat surface without the need to cut an opening in the substrate. They feature interchangeable backs and extension rings so ONE box works with almost any cladding system – including engineered foam/stucco systems.

Extra-wide flanges prevent water and air-intrusion, helping to meet the International Energy Conservation Code, and eliminating the need for gaskets or caulking.

• FR series boxes ship ready for use with 1-3/8” finish or cladding thickness Depth can be set for custom depth finishes or cladding materials up to 1-7/8"

• Install before or after the weather barrier house wrap - Installation of box before the house wrap at right

• 20 cu inch volume

Inspect the battery (particularly the bottom) for material that could eventually cause a short between plates.

An electric utility was making a system modification that necessitated de-energizing the control power transformer. “No problem, right?” they said. “Our substation doesn’t need AC power except for lighting and air conditioning in the relay control house.” Of course, this also created a loss of AC power to the battery charger.

During a short window — from a few hours to even as much as a couple of days — this is not an issue. However, the lack of a charging current causes the battery string to be slowly depleted. In this particular case, the slow depletion of the batteries created a DC undervoltage condition that led to protective devices tripping and knocking the entire substation offline. This interrupted power to thousands of customers. Recovery efforts included having to bring in a portable generator to power the charger as well as relays to be reset and breakers closed.

Most power system designs include DC battery-voltage monitoring by the protective relays. Those same systems will also trip breakers before the DC control power becomes too low to protect the system from being in a configuration where the breakers wouldn’t be able to trip.

Modern communication technology can be utilized to provide early warning for this type of system issue. In this example, a text message to the substation supervisor would have allowed an intervention to avoid the system tripping itself offline.

Additional inspections and testing that can be performed vary from easy to difficult. Here are some to keep in mind.

1. Note any indicator lights on the battery charger that represent a fault condition and/or error codes on a display. Avoid normalizing deviation and maintain an error code and fault-free system. Positive/negative DC grounds are one example of errors that can be difficult to resolve. Troubleshooting this type of error takes time and the ability to isolate portions of the system to locate and correct the ground.

2. Measure the voltage of the entire battery string with the charger DC output breaker off.

3. Measure the voltage of each half of the battery string. This value should be roughly half of the measurement of the entire string. Any significant variation should be investigated by measuring the voltage of each cell (which is also an option; it just takes longer).

4. Measure the charger output for AC ripple. Excessive AC ripple can shorten battery life by creating a situation where the battery is repeatedly undercharged and discharged.

a. One battery manufacturer recommends that a maximum ripple of 1.5% of the voltage be allowed during the bulk phase of the charging and a maximum of 0.5% voltage ripple during the float phase.

b. Remember to check battery charger manufacture

literature for ripple levels. The nameplate in Photo 6 lists the design ripple as 100mV rms.

5. Float and equalize charger settings. Settings that are too low or too high will damage the batteries and shorten their service life.

6. Check the specific gravity level of the batteries.

7. Perform a load bank test.

Remember to always use the appropriate personal protective equipment (PPE) when working on and around batteries. Ensure that eye wash stations are available and working (the water tank is full and/or water is available to the system). Use insulated tools when working on a battery system. Wrapping a wrench or screwdriver with electrical tape does not make it an insulated tool.

Mose Ramieh III is vice president, business development at CBS Field Services and has been in the electrical testing industry for 26 years. Over the years, he has held various positions including field service technician, operations, sales, business development, and company owner across four companies.

Arlington’s Concrete Pipe Sleeves are the economical way to sleeve through concrete pours in tilt-up construction WALLS – and FLOORS allowing cable and conduit to run easily from one floor to the next.

No costly core drilling – No cutting holes in the form. Plus, you can position the hole prior to pouring the concrete.

• Attaches to form with nails or screws

• Stackable up to 23" h for extra deep pours

• Vents keep wet pipe sleeves from sticking together

• Multiple hole sizes: 1-1/2"

Arlington’s new one-piece RETROFIT SNAP2IT® fittings are easy to use in an OLD WORK installation, and handle the widest variety of cables! They’re ideal for adding additional circuits to a load center. And you get the same labor-savings in a retrofit installation!

Easy snap-in installation - NO TOOLS. Install connector into the knockout in an existing box, pulling cable/conduit through the knockout. Slip the fitting onto the cable, then snap the assembly into the box. That’s it... a secure installation with no pullout

Widest total cable ranges 14/2 to 10/3

Widest variety of cables AC, MC, HCF, MC continuous corrugated aluminum cable, MCI-A cables (steel and aluminum), AC90,

The multi-wire branch is here to stay; so is ground-fault protection. But we should unite these technologies only when it’s a good match.

By Randal Andress, Electrical Engineer (retired from Northrop Grumman)

Ground-fault protection and the multi-wire branch circuit (MWBC) are both common topics in the electrical industry. This article discusses their union — the use of a 2-pole GFCI/GFPE breaker to protect the two 120V legs (L1 and L2) of a 120V/240V split-phase, 3-wire (L1/ L2/N), shared neutral circuit. You may be surprised (as I was) to find that the protection provided is attended with subtle (if not troublesome and problematic) differences from the protection provided by a single-pole breaker on a 2-wire circuit (hot/neutral). The manifestation of these differences in a marine environment is of particular interest and will be highlighted in this piece. Several years ago, I began thinking about the effects of marina basin background current (sometimes called foreign or stray current) on the measurement of AC leakage from boats — as is commonly made by clamping the shore power cord with an ammeter. I concluded that the effect of background current depends on whether it originates from the same or opposite leg (L1/L2) of the distribution source as the current leaking from the boat circuit.

That led to the question of how fault/leaks from different legs of a main or feeder panel would be seen by a 2-pole (L1/L2/N) ground-fault protection breaker. So far, I have been unable to locate a treatment of this subject. (Perhaps readers will be able to provide me with references.) So based on my analysis, simulation, and testing as well as interaction with a few electrical professionals, I have reached preliminary conclusions. They are presented in this article with the expectation that they will elicit

Arlington’s recessed STEEL combination power/low voltage TV BOX™ is the best way to mount an LED or Hi-Def TV flush against a wall.

TV BOX provides power and/or low voltage in one or more of the openings. Plugs and connectors stay inside the box, without extending past the wall.

Designed for use in new or retrofit commercial construction where metal raceway is used, we have a STEEL TV BOX for almost any application!

• Steel box; non-metallic paintable white trim plate

• Easy, secure installation

• Optional covers

ROOF TOPPER® supports raise conduit/raceway 4" or more off the roof surface, allowing contractors to comply with the 2017 NEC® for temperature adjustment for circular conduit.

The heavy-duty base, made of 100% recycled material, sits on the roof deck. There’s no need to mount ROOF TOPPER to the surface with mechanical fasteners.

Offered in a variety of sizes and configurations, ROOF TOPPER supports up to 2000 lbs, and stands up to extreme rooftop conditions protecting and elevating conduit or raceway above the roof deck.

comments, critique, and reader feedback from the EC&M audience.

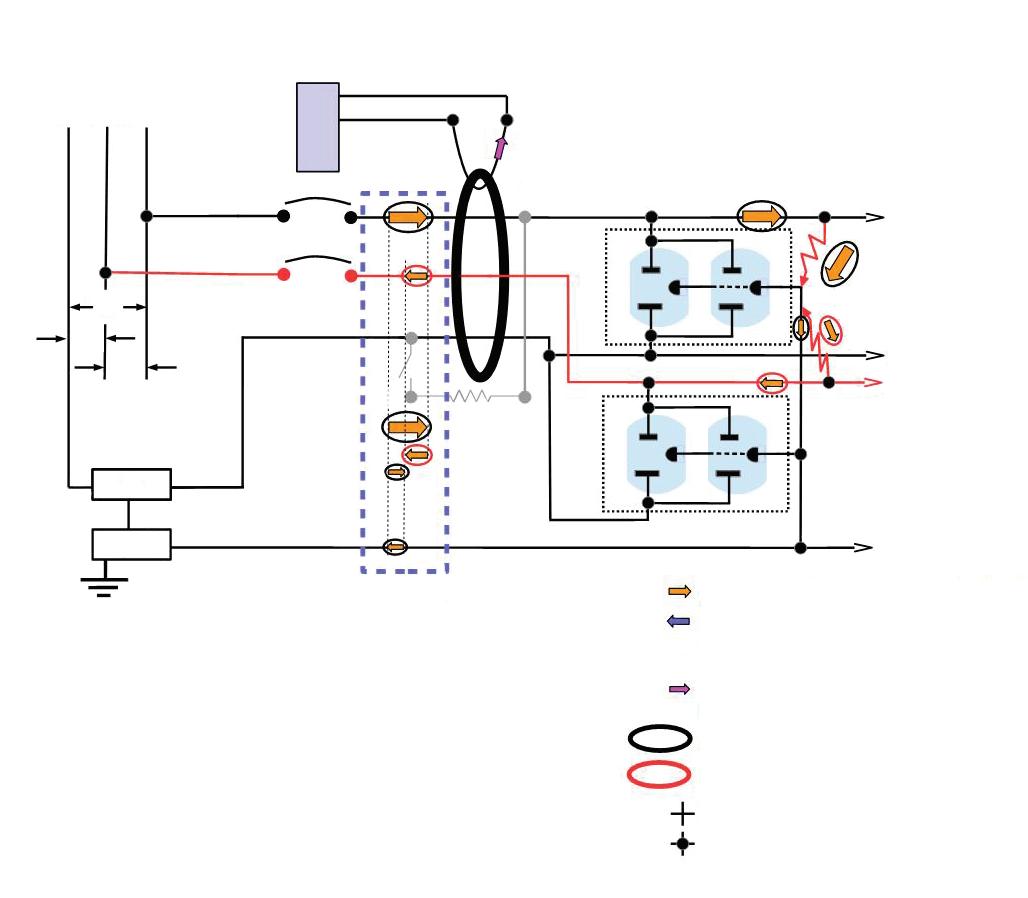

Before considering the 2-pole groundfault protection breaker on an MWBC, let’s look briefly at the single-pole, 2-wire (H/N), GFCI/GFPE breaker (Fig. 1). Its heart is the residual current transformer (CT). The core of the transformer is typically a toroid — a doughnut-shaped ring of magnetic material (the heavy black ring in Fig. 1). Both the hot and neutral conductors are passed through the toroid, making each of these conductors a single-turn primary winding of the CT.

The transformer’s secondary is a multi-turn winding on the toroid that functions as a sensor. It is energized when the sum of the currents in the hot and neutral primaries is non-zero. Consider current flowing through the toroid on the hot or neutral from the source toward the load to have one sign (+ or -) and current flowing in the other direction to have the opposite sign (- or +, respectively). If the current that flows from the source out on the hot wire is equal to that returning through the neutral, then a net-zero primary current results — so no magnetic

field is generated; therefore, no current flows in the secondary winding. This is the case when the circuit has no leaks or faults to ground.

On the other hand, if some of the cur rent returns to the source — not on the neutral but on the safety ground or through some environmental path — (e.g., a person, a building structure, and the earth), then there is a current imbalance. The neutral return current will be less than the hot supply current. These unequal, opposite direction hot and neutral currents do not offset each other. The result is a non-zero net cur rent through the primary windings that produces a magnetic field whose AC dynamics induce a current in the sens ing secondary winding — a current that is proportional to the imbalanced cur rent sum. If the imbalance reaches the trip level for the breaker (e.g., 5mA for a GFCI and 20, 30, or 100mA for a GFPE), then the breaker is tripped by processing circuitry, which opens the hot conduc tor path.

To be able to periodically test its functionality, a GFCI/GFPE breaker is equipped with a manual test circuit. A push-button switch completes a path from the load side hot through a resis tor to the supply side neutral, thereby providing a return path for a test current

• All normal currents flow out on Hot (H) and return on Neutral (N) producing a zero current sum in the CT primary and no current in the sensing secondary.

Fault/leak current flows out on Hot through the current summing transformer and returns on the Gnd without any offsetting current on Neutral.

• This imbalanced net flow in the CT primary (fault/leak current) creates a magentic field which generates a non-zero current in the current summing secondary.

Normal current to load returning on neutral

Fault/leak current returning on ground

Current in CT secondary due to H/N imbalance

No connection

Connection

Fig. 1. Ground-fault protection of a single 120V branch circuit using a single-pole ground fault protection (GFP) breaker.

Perfect for EV Chargers in parking garages, panels, equipment feeds and data center remote power panel feeds, Arlington’s Listed CableStop™ Transition Fittings deliver the efficient, cost-effective way to transition feeder cables to 2-1/2" EMT, IMC and RMC conduit in protective drops, risers and feeds to panels and equipment.

Our new CableStop fittings integrate our patented, versatile and SKU-reducing 8412 series cable fittings, with Arlington conduit fittings, allowing for easy transitions to larger knockout sizes.

Available with set-screw or compression connections into 2-1/2" conduit, they ship with multiple end-stop bushings that vary the size of the opening –along with a to help installers select the right bushing for the cable.

2" Trade Size • 2-1/2" Conduit size

Listed for EMT, IMC, RMC conduit 841516 Set Screw connection

that does not flow through the toroid. The imbalance created simulates an actual fault or leak. Since the resistor is chosen so that the current is just above the trip limit, the breaker trips in the usual way. Typically, this test is to be performed monthly.

Now let’s consider the subject circuit: a 120V/240V multi-wire branch protected by a 2-pole (L1/L2/N) GFCI/ GFPE breaker ( Fig. 2 ). A second ungrounded conductor (red in Fig. 2) is added to the single-pole breaker current transformer as a third primary. This conductor originates on the opposite leg (line or split-phase) of the single-phase service source. It takes a switched path through the breaker and passes through the CT toroid to a loadside connector. From there, it is wired to a separate 120V circuit (L2), but it uses the same neutral as a return path. Normal load current flows out L1 hot or L2 hot to the load and returns on L2 hot or L1 hot, respectively, or on the neutral. The current on the neutral is the difference between the L1 and L2 currents [iN = | iL1 – iL2 |]. An L1 fault or leak to ground (red zigzag in Fig. 2) flows through the current summing transformer (on L1) without any offsetting current in L2 or N. Just as in the single-pole breaker, this imbalanced net flow in the primaries creates a magnetic field that generates a nonzero current in the current summing secondary, and the breaker trips at the designed trip current level.

That explains the case of a fault/leak on one leg (L1) or the other (L2). But suppose there are fault/leaks on both the L1 and the L2 120V branch circuits. First, consider the case of equal fault/leaks (Fig. 3 on page 40).

The current flow for equal fault/leaks is similar to that of equal loads (L1 and L2) — the return current for each uses the opposite leg. Follow the L1 fault/leak current (orange arrow in Fig. 3) from the L1 source through the CT out to the L1 leg fault. It flows to ground through the L1 fault path and then through the L2

•

• L1 Hot fault/leak to ground flows through the CT without any offsetting current in L2 Hot or N.

• This imbalanced net flow in the CT primary (|L1- L2|fault/leak current difference) creates a magnetic field which generates a current in the CT current sum sensing secondary.

Normal load current during 2nd half cycle

Fault current direction during 1st half cycle

Fault current direction during 2nd half cycle

Secondary current generated by primary imbal.

Fault/leak current from L1 Hot

No connection Connection

Fig. 2. Ground-fault protection of a multi-wire branch circuit using a 2-pole GFP breaker when only one leg (L1) has a fault/leak.

fault to L2 and returns on L2 through the CT to the source. So no current returns on the ground or the neutral. The current that flows from L1 returns in L2 and vice versa. The current sum in the CT primaries is zero; therefore, there is no magnetic field, no current in the secondary, and no trip. Note that regardless of the size of the fault/leaks, if they are equal, the breaker will not trip.

But suppose one leak is smaller than the other (Fig. 4 on page 42). Let’s say the 2-pole breaker is a GFPE with a 30mA trip limit. Suppose the appliances connected to L1 have a total fault/leak current of 25mA, and the L2 total is 15mA.

Normal currents (not fault/leaks) flow to and from the load on the L1/ L2/N as usual; therefore, they will flow in equal amounts in both directions through the CT and will not contribute to any current imbalance measured by the secondary. They are being ignored in this analysis.

Let’s trace the fault/leak currents on the positive AC half-cycle (i.e., when the instantaneous L1 voltage is greater than the L2 voltage. See the orange arrows in

Fig. 4). The L1 current, 25mA, travels from the source through the CT to the fault/leaks and then through them to ground. At the ground point, 15mA of the 25mA travels through the L2 fault/ leakage path to the L2 circuit and returns through the CT to the source on the L2 circuit. The remaining 10mA follows the ground path back to the source via the panel ground to neutral bus connection. During the negative half-cycle, the currents all reverse on the same paths and in the same amounts. (The negative halfcycle is not shown in Fig. 4; they would be blue arrows equal in size and head to head with each orange arrow.)

The current imbalance in the CT primaries is: 25mA L1 source to load (+), 15mA L2 load to source (-) and 0mA through the neutral, 25mA + (-15 mA) + 0 = 10mA. The resulting magnetic field induces a current in the secondary indicative of a 10mA imbalance so the breaker will not trip (10mA < the trip level of 30mA).

Let’s look at another case. With L1 still faulting/leaking at 25mA, suppose L2

the cable into the connector and rotate the connector clockwise.

YEARS

Available in 3/8" trade size, both connectors install into a 1/2" knockout, and are Listed for steel and aluminum AC, HCF, MCI and MCI-A cable.

The tinted 40STS has more room inside for easier cable insertion.

for use with AC90 and ACG90 cable.

• Tested to UL 514B and Listed to meet UL ground fault requirements

• Removable Unscrew the connector counterclockwise to remove it from the cable. Remove the connector from the box using a flat blade screw driver. Release the snap tangs from the inside of the box while pulling the connector out of the knockout.

• Packed in heavy-duty, 200-piece boxes

CATALOG NUMBER CABLE RANGES STEEL Snap2It® connectors

38STSC AC, HCF, MCI, MC!-A 14/2 w ground, 14/3, 14/2 12/2 w ground, 12/3, 12/2 • 10/2 w ground, 10/3, 10/2 .405” Dia. Minimum to .605” Dia. Maximum

40STSC AC, HCF, MCI, MC!-A Tinted 12/2 w ground, 12/3, 12/2 • 10/2 w ground, 10/3, 10/2 .480” Dia. Minimum to .605” Dia. Maximum

All normal current (not shown) flows out L1 Hot or L2 Hot and returns on L2 Hot or L1 Hot, respectively, or on the Neutral without creating a CT current imbalance. If equal, L1 and L2 fault/leak currents return through the series connected fault/leak in the opposite leg (not on the Neutral, the Gnd, or the earth).

• The current sum through the CT primary is zero so the magnetic field is zero and the current in CT secondary sensing winding is zero.

Current direction during 1st half cycle

Fault/leak current from L1 Hot

Fault/leak current from L2 Hot

Fig. 3. Failure of a 2-pole GFP breaker to detect equal ground fault/leaks when present on both legs (L1 and L2) of a multi-wire branch circuit.