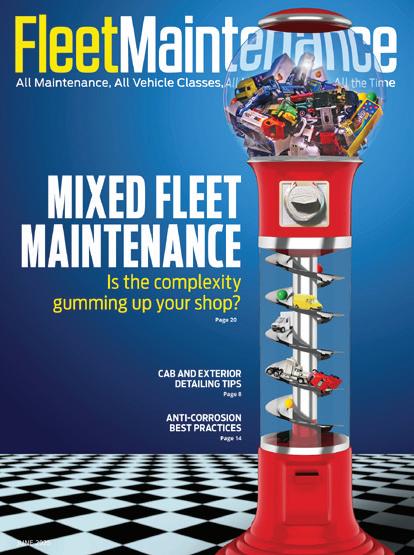

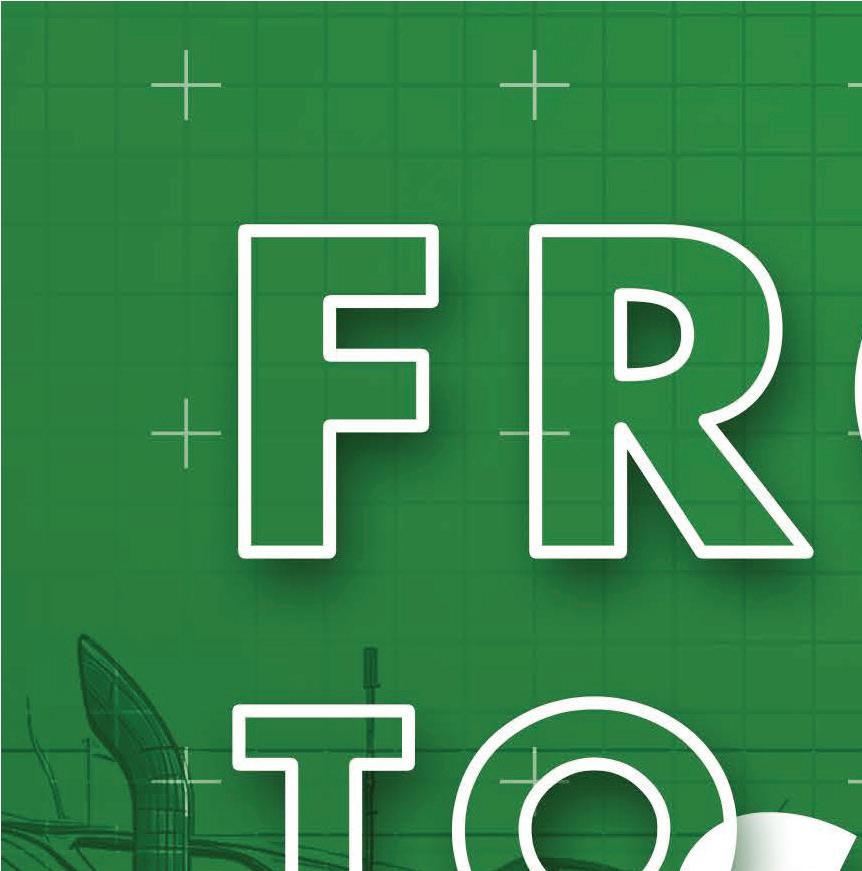

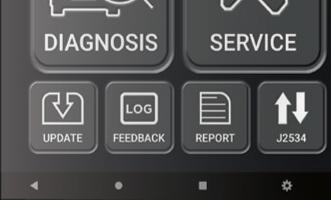

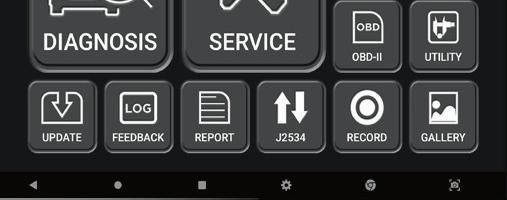

Is the complexity gumming up your shop?

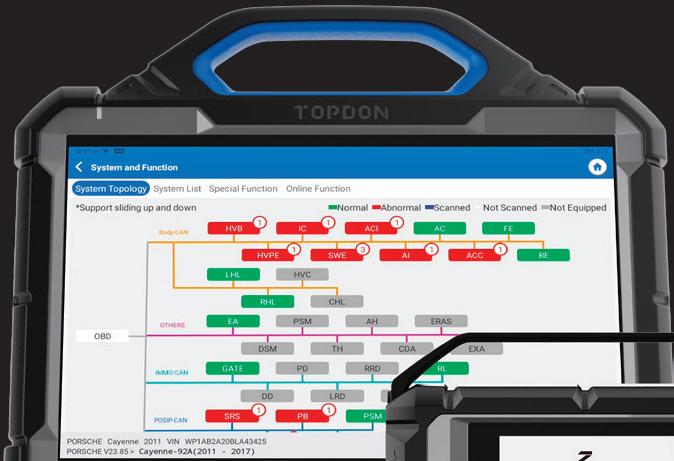

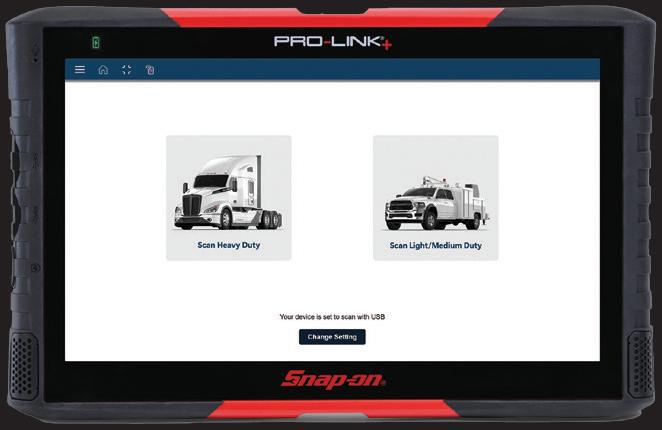

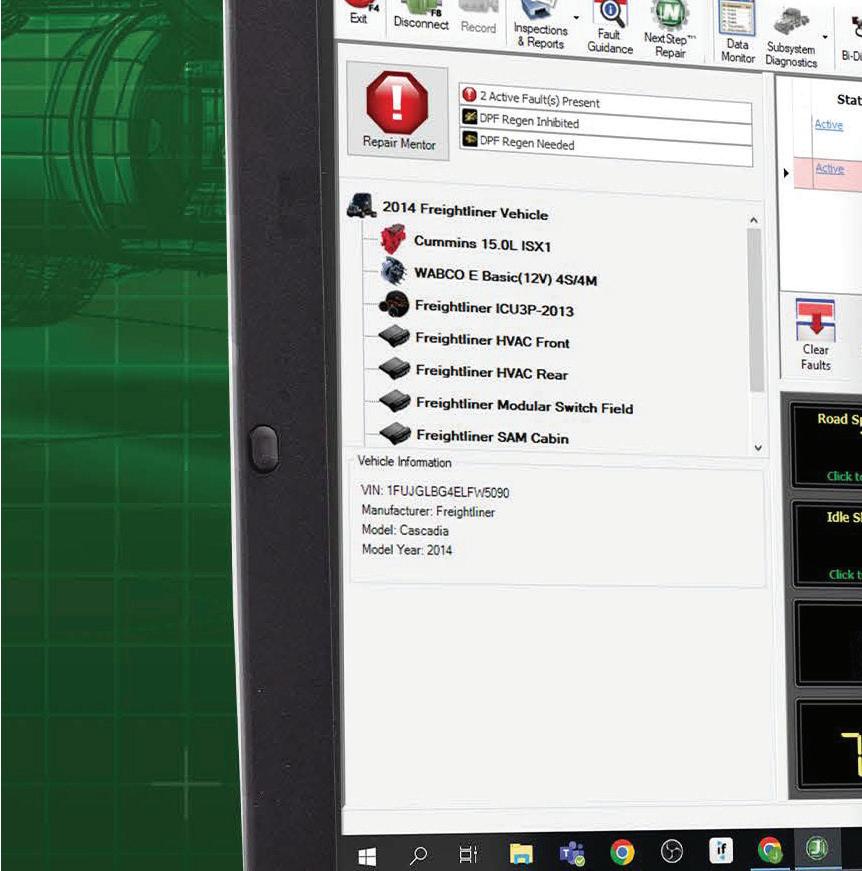

PRO-LINK+, built for servicing a complete range of commercial vehicles, makes Benny more than just a pitstop technician - it makes him an efficiency expert.

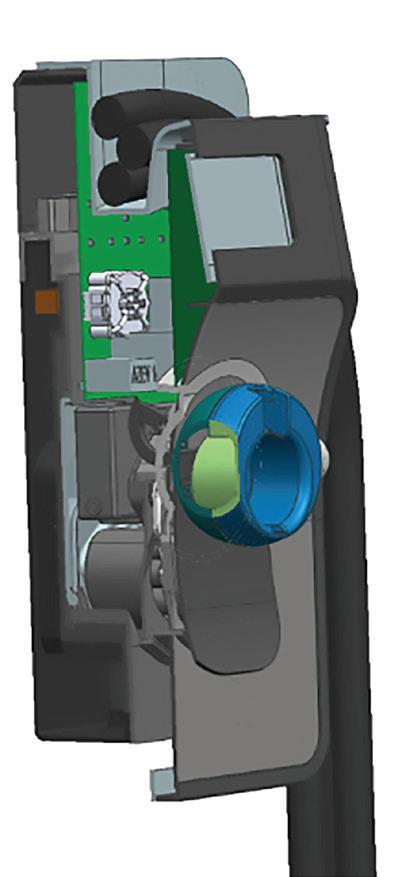

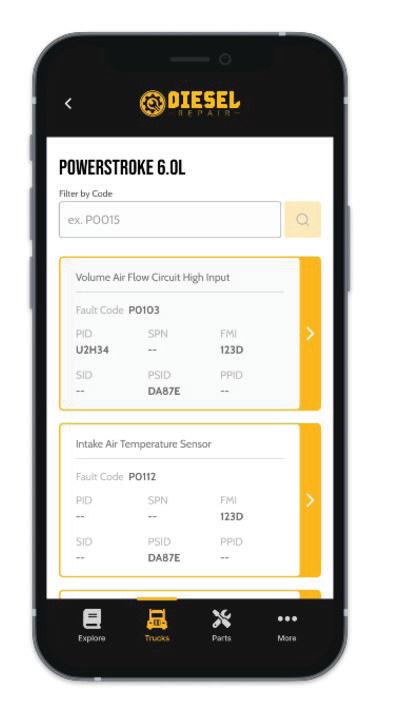

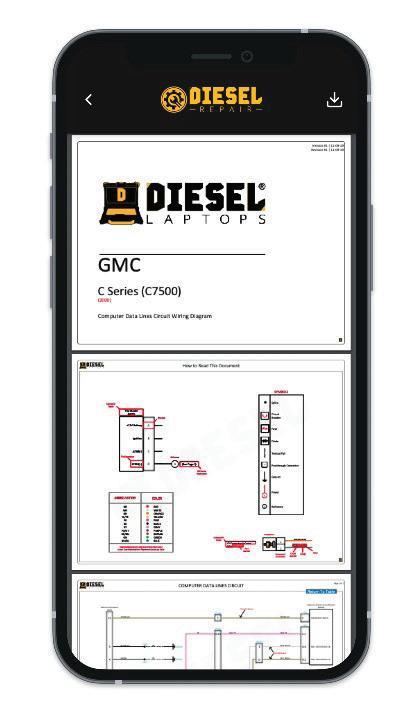

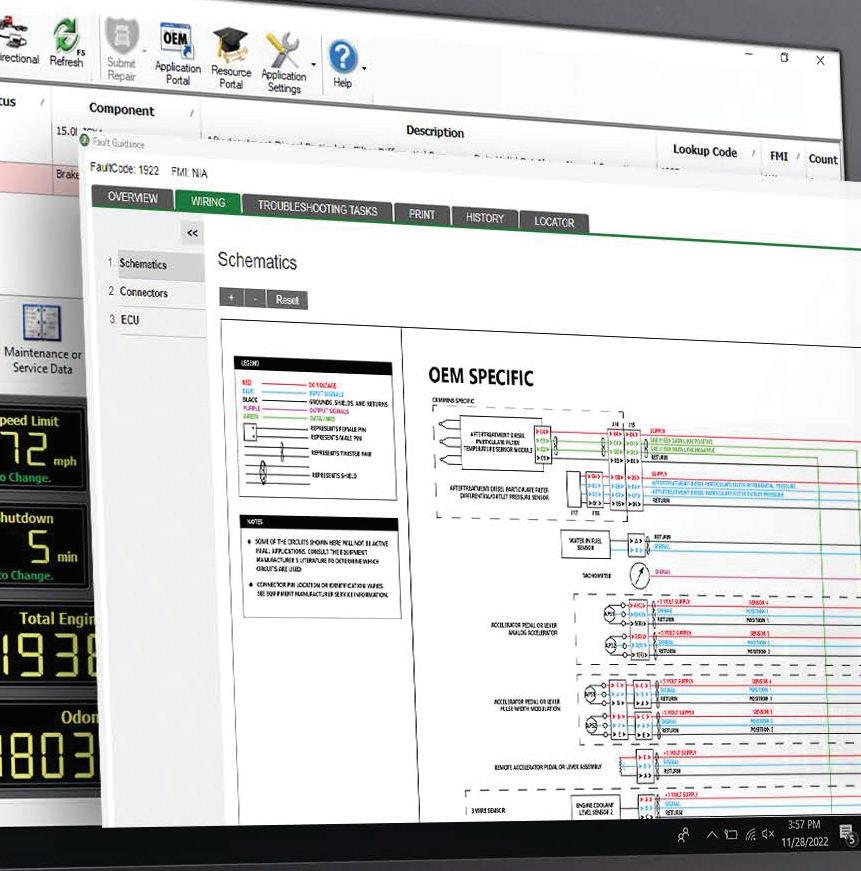

Under the hood, PRO-LINK+ delivers:

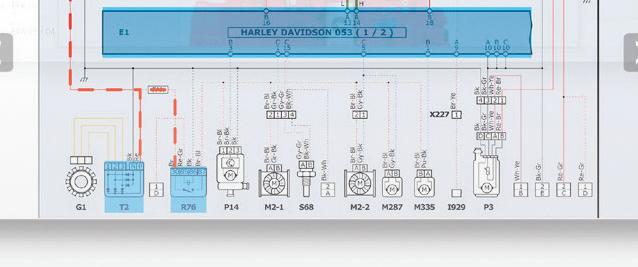

• OEM-specific coverage for engines, transmissions, chassis, and brakes

• Code-specific information with detailed testing procedures, component photos and wiring diagrams

Take control with over 200 special tests and 600 user-configurable parameters. Built tough for medium and heavy-duty trucks, PRO-LINK+ is your essential diagnostic companion.

In The Bay

From pig rig to clean machine

Avoid a tarnished reputation with these cab and exterior detailing tips, which can help clean even the messiest truck.

Busting rust and corrosion

Creating a strong line of defense against corrosion on trucks and trailers starts with proper spec’ing, and the battle continues with a solid PM strategy.

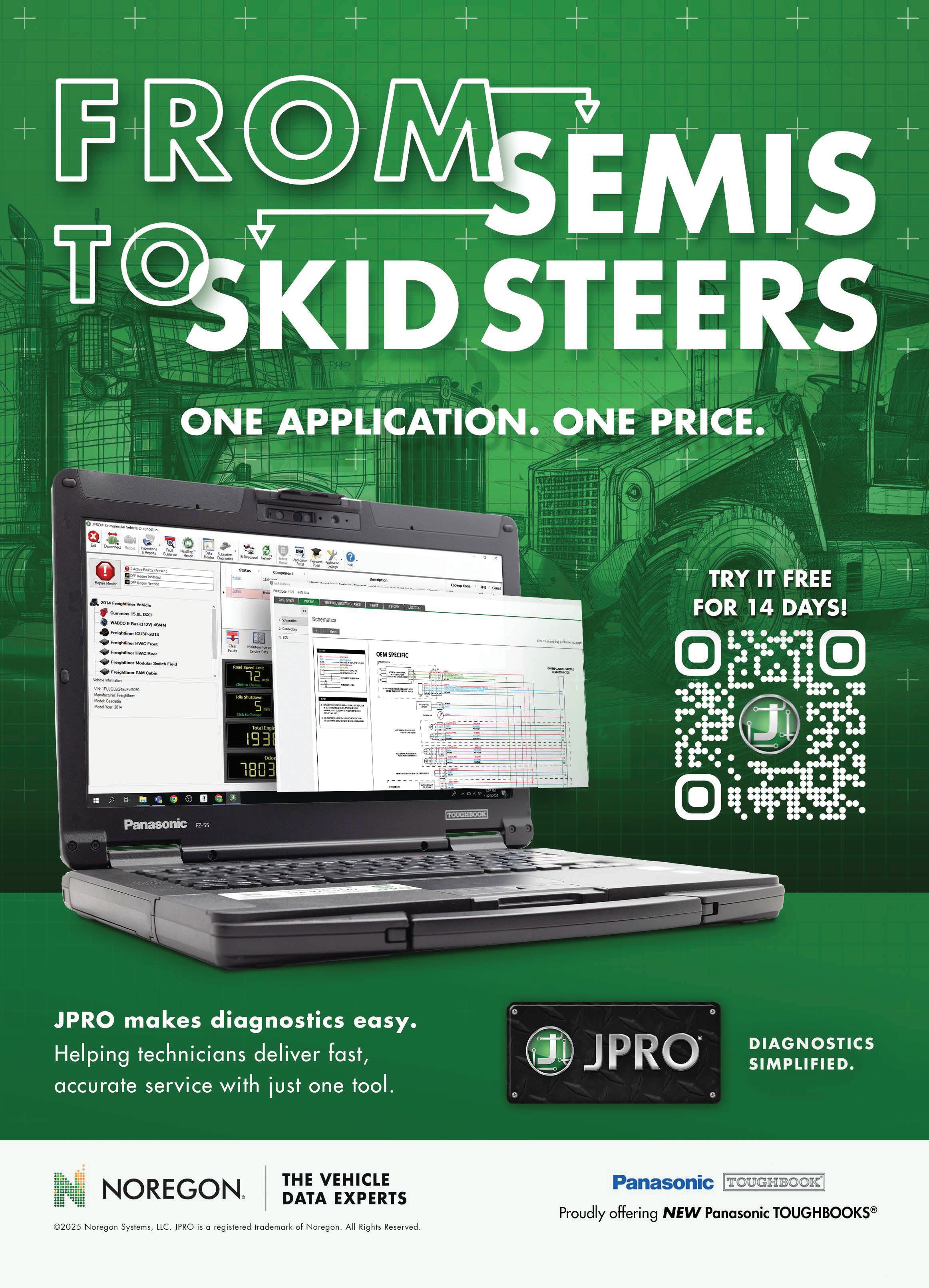

Is mixed fleet maintenance gumming up your shop?

Mixed fleets have many maintenance needs that can burst your uptime bubble, but technology and training can keep you from getting stuck.

Nuclear

AI-powered dashcams can become a strong nuclear verdict deterrent and also improve safety culture with the right adoption strategy.

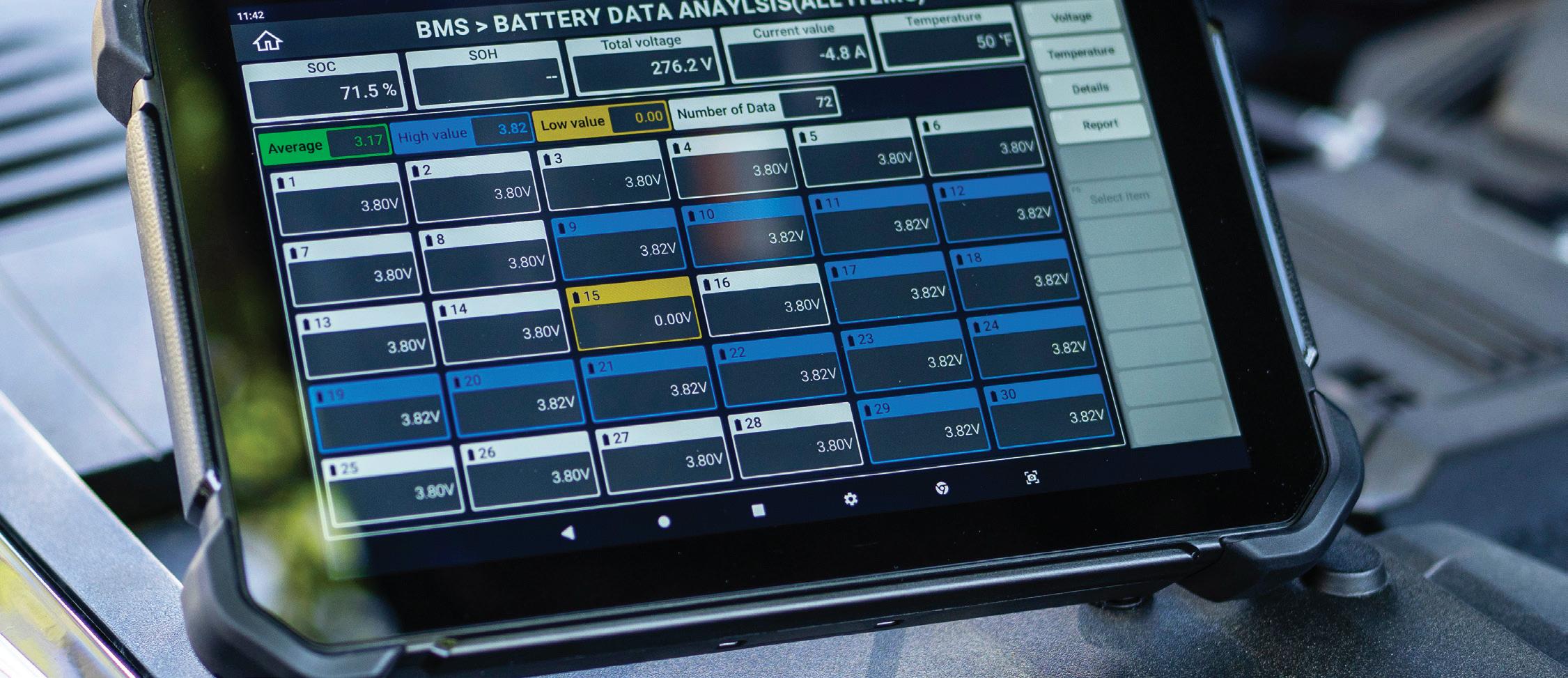

Basics of EV charger diagnostics and maintenance

Building up charging infrastructure can be difficult and costly, but maintaining the chargers afterwards doesn’t have to be.

Cover photo: John Hitch, 859792234, 1461604272 | Getty Images, 37290517, 152404167, 157293066, 157293066 | Dreamstime.com, 1162041847, 2599561255| Shutterstock

Visit the official website of Fleet Maintenance for more information from stories in this issue, plus online exclusives on pertinent topics in the fleet maintenance management industry.

Senate votes to remove California EPA waiver; trucking industry takes victory lap

The Senate has overturned the EPA’s waiver allowing California to enforce its ACT regulation, fulfilling President Trump’s campaign promise to end the EV mandate. FleetMaintenance.com/55292304

Outsourcing offers Turkey Hill a less rocky road to optimal uptime

After switching to a leasing model and turning over maintenance to Ryder, Turkey Hill believes it has ensured more reliable deliveries of its iconic ice cream flavors. FleetMaintenance.com/55291167

READ ANYTIME, ANYWHERE

Read the digital edition online at FleetMaintenance.com/ magazine/78559

Want your own issue? There are two simple steps to get a free subscription: 1. Go online to: FleetMaintenance.com/ subscribe 2. Complete the online subscription form. That’s all there is to it.

Work Truck Roundup: Bucket truck maintenance Electricity has quickly become critical infrastructure for Americans, making the high-flying operators that maintain powerlines, and the trucks that keep them in the sky, important to maintain. FleetMaintenance. com/55287727

Market Leader - Commercial Vehicle Group Dyanna Hurley

| dhurley@fleetmaintenance.com

Editorial Director Kevin Jones kevin@fleetmaintenance.com

Editor-in-Chief John Hitch john@fleetmaintenance.com

Associate Editor Alex Keenan alex@fleetmaintenance.com

Associate Editor Lucas Roberto lucas@fleetmaintenance.com

Contributors Seth Skydel, Gregg Wartgow

Sales Development Representative Sachin Sinha sachin@fleetmaintenance.com

Fleet Maintenance Multimedia Account Executives

Multimedia Account Executive - West Michael Simone 973-713-0094 | michael-s@fleetmaintenance.com

Multimedia Account Executive - Southeast Peter Lovato 231-233-2660 | peter@fleetmaintenance.com

Multimedia Account Executive - Northeast Larry Schlagheck 248-444-1320 | larry@fleetmaintenance.com

Tool & Equipment Multimedia Account Executives

Multimedia Account Executive - Midwest Diane Braden 920-568-8364 | diane@fleetmaintenance.com

Multimedia Account Executive - West Mattie Gorman-Greuel 920-563-1636 | mattie@fleetmaintenance.com

Multimedia Account Executive - East Cortni Jones 920-568-8391 | cortni@fleetmaintenance.com

Production Manager Patricia Brown Ad Services Manager Karen Runion Art

| michael.costantino@infogroup.com

| kevin.collopy@infogroup.com

Breakthrough battery algorithm could double lithium lifecycles, Flux Power says FleetMaintenance. com/55289568

847-559-7598

• Northbrook

60065-3257

Conti HDR 5 19.5" Drive

Conti HSR 5 19.5" Steer

The Conti HSR 5 and Conti HDR 5 tires offer superior durability, traction, and stability for Class 4 and 5 vehicles. Whether navigating city streets, delivering goods, or responding to emergencies, Continental's 19.5" tires ensure you get the job done efficiently and safely. Our tires provide exceptional all-weather performance and longevity with advanced tread compounds and innovative siping. Additionally, these tires come with matching retreads, ensuring consistent performance and extended tire life.

Nuclear verdicts are meant to force faceless corporations into seeing the error of their ways. But justice is blind, so help yourself out by recording your own evidence.

By

It all started in Albuquerque with an English grandma, a McDonald’s drive-thru, and a molten cup of coffee. It was the early ’90s, and 79-year-old Stella Liebeck just wanted to add cream and sugar to her coffee. Sitting in the passenger seat of a parked car, she loosened the lid on the Styrofoam cup, causing the flimsy container to tilt, spilling steaming hot coffee onto her lap. The near-boiling liquid—around 190 degrees F—soaked into Liebeck’s skin, leading to horrific third-degree burns to her thighs and genitalia that would require skin grafts and years of rehab. She died in 2004.

What followed that set-up was a civil case in 1994 and a sensationalized punitive award of nearly $3 million that became a punchline for late-night talk show hosts—and a cautionary tale for how out of control America’s tort system was. How could a woman who spilled coffee on herself deserve that much money?

It should be noted Liebeck’s lawyer attempted to settle for $20,000, but some burger-brained McDonald’s lawyer low-balled her with $800—essentially $100 for every day she was in the hospital. And in court, it was revealed that 700 other people were burned by McDonald’s coffee, which was around 40 degrees hotter than your typical cup of joe. The punitive damages were deemed excessive and reduced to $480,000 by the judge, who noted the “callous” fast-food chain showed no attempt to mitigate the danger.

Since this infamous McDonald’s Coffee Incident, personal injury lawyers have exponentially poured out of every dark recess of the legal system to follow suit. Whatever the accident, and whoever was at fault, if it involved a big recognizable brand, no injury was too small, and no damages were too excessive.

Looking back, this pivotal moment in the New Mexico desert was the Manhattan Project of the nuclear verdict age, kicking off a war that rages on 30 years later, with one of the largest fronts being the trucking industry. In accidents involving commercial vehicles where someone is hurt or killed, fleets and manufacturers alike may be subject to such a verdict, when damages exceed $10 million.

As I discuss in detail on Pg. 26, the data suggests nuclear verdicts are indeed out of control. A study for the U.S. Chamber of Commerce, “Tort Costs in America,” found in 2022 that costs and compensation related to torts exceeded half a trillion dollars. One of the

paper’s authors, David McKnight, a principal at consulting firm The Brattle Group, revealed $58 billion of that involved a commercial vehicle. That same year, 5,936 people were killed in large truck accidents and about 160,000 injured, according to NHTSA. That’s about twice the number that died 10 years earlier.

Now here’s the problem: Punitive damages, as the name suggests, are meant to punish the liable party and force changes to whatever industry practices led to the malfeasant actions. Providing financial justice to the alleged victim is secondary to sticking it to the man. But nuclear verdicts have seen a 10% annual growth rate since 2016, according to McKnight, so if that were true, fatal crashes involving commercial vehicles would go down.

They are not. But how could that be?

My theory is it’s because trucking must abide by a never-ending list of rules and regulations, and lawyers need only to expose and exploit ones that weren’t followed to the letter. Then they use reptile theory to manipulate jurors.

As Rachel York Colangelo, national managing director of jury consulting for Magna Legal Services, explains it, “We all have this reptilian brain… [an] innate need to feel safe and secure in our world and our communities.” And by “inciting fear in the hearts and minds of these jurors,” plaintiff lawyers get the nuclear result they want.

They get paid and everyone else covered by the insurer deals with the fallout. And when trucking insurance goes up, we all pay.

To make matters worse, some lawyers have

even teamed up with disreputable doctors and criminal gangs to stage accidents. One outfit busted up in the New Orleans area specifically targeted tractor-trailers. So what can you do when justice is blind? You can provide a real vision of events with dashcams.

They clearly capture what happened in the case of an accident, and the benefits get even better when using a dual-facing camera enhanced by AI. The forward-facing lens can pick up on posted speed signs, and when the accelerometer senses a speeding event, it can alert the driver, and eventually the fleet if the behavior continues. This is true for lane departure and tailgating, as well.

Inward-facing cameras, meanwhile, can identify drowsy or distracted driving, and again, warn the driver and inform the fleet. Dashcams do three major things to fight those billboard lawyers. First, they provide autonomous coaching to deter unsafe driving in general. Second, both good and bad behaviors can be captured and used for training all drivers. And lastly, the video speaks for itself when an accident occurs. Whether it’s a staged accident or a real one, the video shows what happened.

The video can also help reduce legal costs when the blame lies with your driver.

“Even if it is our fault, we know right away,” explained Jon Somerville, fleet safety manager at Veit. “We can say, ‘Yes, it was our fault in this accident,’ and that can save a long time of litigation, versus the old way, which was it would get litigated out.”

Efforts are being made to enforce stricter federal penalties for staged accidents, and states are in various stages of tort reform, but that is out of your control. The best course of action is to research the myriad dashcams available and find one right for your fleet. And of course, spec braking systems suitable for your application, and keep up with your preventive maintenance and driver and technician training. Lawyers are still gonna’ lawyer, so you might not win every battle. But at least you’ll make progress in the war.

Avoid a tarnished reputation with these cab and exterior detailing tips, which can help clean even the messiest truck.

By Lucas Roberto

If there’s one thing to know about Jim Fraley, owner of J & S Trucking in Arkansas, he likes to keep his trucks clean. He’s so meticulous, in fact, he doesn’t even like having his wife in the truck, because when she brushes her hair, it ends up all over the floor.

“All my guys know how I am—every truck that leaves here, I clean all the windows three or four times a week, inside and out, and I wipe the door panels down,” Fraley explained.

And if you want to know another thing about Fraley, it’s that he’s pretty altruistic. A few years ago, an owner-operator he knew was down on his luck and needed a job. Fraley described him as a “decent lookin’ feller” in his early 40s—and “not a fat slob.” He owned a show-quality Kenworth W900. Fraley recalled it was “very fancy” and “super nice.” (On the outside, at least, he qualified .) Fraley, who operates 13 trucks, wasted no time putting the new driver in a well-kept 2020 Peterbilt Model 579 Ultra Lo . e long-haul driver did tell Fraley that his 30.-lb pet pig would be riding along, but that didn’t bother him or violate the company’s ban on certain pets.

“I don’t like dogs that shed, and I don’t want a cat in the truck because of the hair. Pigs don’t shed,” he reasoned. Fraley was also under the impression it was housebroken.

e fastidious fleet owner would soon regret that decision only a few months a er entrusting the impeccable Pete to this new driver. As he was departing the yard to drive up to the 2023 Mid-America Truck Show, Fraley swung by to check up on the contractor.

He opened the driver’s side door and that’s when it hit him.

“I was knocked o my ass from the smell,” Fraley painfully recalled, equating it to the foulest barnyard your nose can imagine. He started gagging but luckily kept his lunch down.

“Apparently my sni er is very, very good,” Farley o ered.

ere is no literary license taken by calling this cab a pigsty, as that’s exactly what it was. e pig slept on the bottom bunk and used the rest of the cab as its toilet. Fraley had thought it was housebroken, but that may have been Pig #1, which died early into the driver’s tenure with J & S, and was replaced with a rescue.

Regardless, pig pellets, to so en Fraley’s terminology, were “just everywhere, under the seats, in places you can’t get to,” Fraley described. And

despite the truck being a loaner, the pig took every chance to mark its territory. Pig urine was “soaked in and saturated everything.”

e driver, who otherwise had no issues, and his pig were understandably fi red on the spot. Somehow Fraley, whose bacon was really fried at this point, composed himself enough to not end up in police custody. Instead, he went to MATS, dreading the monumental clean-up that awaited him at home.

is is, of course, an extreme example of the messes that fleets must deal with. ere are around 3.6 million CDL holders in the U.S., and we’d wager most drivers don’t turn their trucks into rolling biohazards, but instead do their best to keep a clean, professional-looking cab to represent their fleet in the best way possible. But humans are still mammals that need to eat, sleep, and do all the other natural things mammals do. And if you cram them in a cab for one shi in a day cab or several months in a sleeper, messes happen— some obviously worse than others. But whatever the stain, spill, or scu , fleets have to ensure their trucks are presentable inside and out, considering their company name and DOT number are visible for all to see. It’s an essential part of maintaining the one thing you can’t fi x with tools and replacement parts: your brand reputation. So if you can stomach it, read on to see how Fraley cleaned up his literal pig rig and pick up some detailing tips to keep your machines clean.

» While New Pig didn’t create their PIG Blood, Vomit & Urine Cleanup Kit for situations like the one J&S Trucking dealt with, this product can handle the worst messes imaginable, including actual pig urine.

• Coffee on upholstery: Blot with a dry cloth, then dab with cold water and a bit of dish soap

• Foggy or smeared windshield: Wipe inside glass with glass cleaner and a clean microfiber

• Grease/oil on floor mat: Sprinkle baking soda or cornstarch on stain, then vacuum off

• Gum stuck to fabric: Freeze with an ice cube, then scrape off with a plastic knife

While at MATS in Louisville, Fraley ran into Vann Brown, founder and CEO of Brown Ox Ventures. e inventor behind the BullSnot! cleaning product line has turned a tidy profit selling a wide array of aerosol sprays and detailing products to clean up the trucking masses’ messes. As far as cab horror stories go, Brown has heard them all over the company’s 20 years.

And he had just the thing to help get rid of the pig smell at least: BlastABull Odor Eliminator. Imbued with “Advanced Odor Encapsulation Technology,” the spray traps and removes o ensive scents le from tobacco smoke, pets, and food.

“ e deodorizer, which is a huge seller for me, doesn’t mask the odor; it destroys it on a molecular level,” Brown explained.

It’s the same stu that solved a serious situation between two slip-seat drivers when one of the drivers’ boorish behavior became an all-out assault on his co-worker’s olfactory system. Brown noted this guy had a penchant for stogies and had an incontinent English Bulldog ride shotgun.

e other driver sought Brown’s help because the cab “stunk to high heaven.” Along with aromas of cigar smoke and dog droppings, the driver detected a hint of his cabmate’s body odor. If this miracle spray was strong enough for that situation, it should work on anything.

Fraley le the truck show with the spray and soon returned home to get started on the truck. His wife, who helps him with maintenance and cleaning, had already gotten to work.

e condition was so severe that Fraley contemplated putting in a whole new interior, but he and his wife were able to get it road-ready in a few weeks. ey ripped out the floors and power washed the whole cab. en they replaced the vinyl seats, curtains, side panels, insulation, and mattresses, also installing a new rubber floor.

“We gave the truck a 1,000% deep clean,” Fraley said, estimating the total cost was $3,000. at does not count the labor he put in or the several weeks of downtime.

e good news is that a er everything, the violated 579 is still in use. Fraley was able to get the truck to the point where the next driver, who knew the backstory, used it for a year.

It was a costly lesson, but Fraley now regularly checks every truck’s interior before they depart the yard. His drivers know the penalty for a dirty truck is a pink slip.

“I’ve been a truck driver all my life, but don’t ever tell me you don’t have time to keep the inside of the truck clean,” Fraley concluded.

“Detailing of a unit should happen every three months for the owner-operator and roughly the same for fleet units that are not being slip-seated,” suggested Jhonny Interian, detail shop manager at JLE Truckwash in Washington. Some customers get wipedowns every few weeks to “keep their driver satisfaction at a high level,” he added.

Cleaning the cab is no di erent than any routine maintenance. e more frequently you do it, the less trouble it is. Trucks generate revenue on the

road, though, so you can’t always get all the accumulated crumbs and dirt. Interian recommends using pressurized air to blow out dust and debris and follow up with a vacuum on a weekly basis.

But the longer you wait, the harder it’ll be to clean. Chris Foley, detail manager at Fyda Freightliner in Columbus, Ohio, noted the importance of acting quickly.

“One common mistake we o en see is spills that are not cleaned up quickly enough,” he noted. “Understandably, a driver can’t just stop at any time, but usually spills are le to dry up on their own. A couple of minutes cleaning up a spilled soda can save an hour or more later on.”

And when it comes to odor, sometimes the problem can be right above you instead of under your nose. Zeb Alford, owner of Clean Z’s Mobile Detailing in Raleigh, North Carolina, pointed out that cigarette smoke dri s upwards.

“ I’ve been a truck driver all my life, but don’t ever tell me you don’t have time to keep the inside of the truck clean. ”

Jim Fraley, owner of J & S Trucking, Arkansas

“One of the biggest forgotten things for nasty odors or smoke smells is giving the headliner a deep shampoo,” he said. “ at’s where a lot of smells hang out. It’s a pain because you’re upside down, but the outcome is defi nitely worth it.”

Interian recalled a time a truck rolled into the shop a er sitting for about 18 months.

“ ere was dog hair, rodent droppings, and mold inside the sleeper cab,” he said. “Our team suited up in Hazmat suits and masks to enter the cab.” e team fi rst used air to blow out debris, then vacuumed the interior and removed the mold.

“ e dog hair was removed with painstaking detail using tools that are specifically designed for that purpose,” Interian added.

Considering hazmat suits were needed, the bunk mattress had to be replaced. To get rid of the lingering smell, JLE also ran an ozone machine in the cab for a few days. Ozone, or O3, breaks down smells through oxidation, essentially lending a spare molecule to the stink source to change its chemical makeup.

Interian said this is “the only truly e ective way to remove the lingering smells that can build up in a cab. At times, it will need to run for a few days to remove everything, including smoke.”

Some highly rated versions go for as little as $70 on Amazon.

e bottom line is that, while a full detail is necessary every so o en to make sure a vehicle gets a deep clean, taking care of an interior more regularly will keep its condition under control, even if it’s just a quick cleanup.

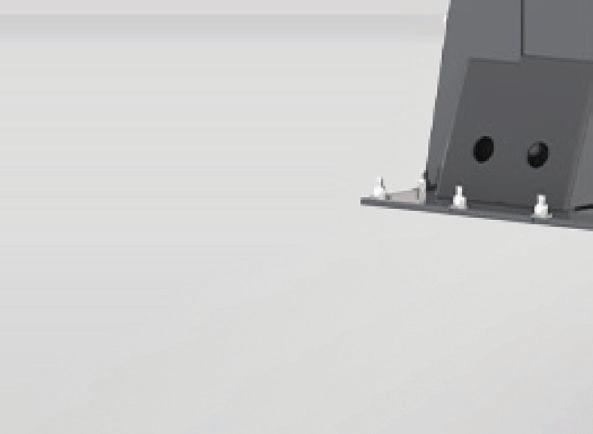

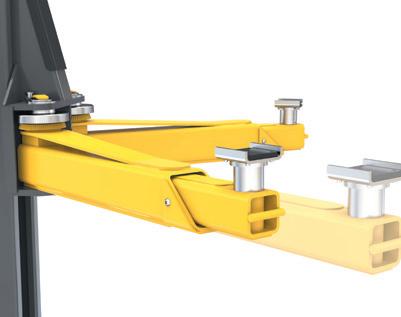

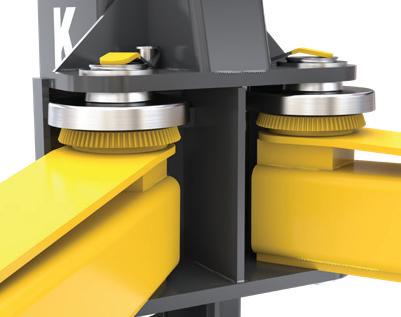

Equalization System

Failsafe mechanical system delivers equal lifting and a stable, level vehicle for operators.

Extended Height

The extended-height top beam on 192 models provides greater clearance.

Hydraulic Cylinders

Dual-drive hydraulic cylinders deliver smooth operation and rise higher than those in comparable lifts.

UHMW Polyethylene Load Bearings

Evenly distribute radial and axial forces during operation.

Column Safety Locks Placed every four inches in the columns and engage automatically when lifting.

A versatile choice for mixed fleets, BendPak’s new 16AP and 20AP

super-duty two-post lifts easily take on Class 1 through 5 vehicles, from passenger cars to commercial trucks and vans. They reach further, lift higher and deliver greater stability than other lifts, all while protecting technicians with unmatched safety systems and ergonomics. With fewer moving parts, they’re easier to maintain, less prone to wear, and more cost-effective to operate. Maximize your uptime and efficiency with BendPak’s super-duty lifts — delivering superior performance and unmatched value. To learn more or to shop now, visit bendpak.com or call us at 1-800-253-2363

Safety Lock Failsafe mechanisms secure the lifting carriages and arm assemblies during operation.

Multi-face Metal Columns Innovative design better withstands twisting and biaxial loading forces to minimize movement for greater stability.

Lift Dampener Precision controls allow operators to manage descent speed.

» BullSnot! offers a variety of aerosol cleaning products, like the ShineABull tire shine and conditioner, which restores tires, bumpers, and trim with a lasting, glossy finish. BullSnot!

» Fyda Freightliner uses a mild wheel acid on the tanks, wheels, and frames to lift the oxidation off. According to detail manager Chris Foley, “the results are much quicker than just pressure washing alone, [but] you must be diligent in properly rinsing it off to get the desired results.” Fyda Freightliner

• Act fast: The longer that scratches or chips are exposed to the elements, the more likely they’ll lead to rust, oxidation, or peeling. Even small imperfections should be addressed quickly.

• Keep the area clean: Gently wash around the damaged spot to remove dirt or contaminants. Dirt can worsen scratches and trap moisture against exposed metal.

• Seal the damage temporarily: Use a quality touch-up paint or protective coatings to seal the area until it can be properly refinished. This will help keep the exposed metal from rusting or oxidizing.

• Avoid harsh chemicals or pressure washers: These can worsen peeling or lift clear coat around scratched areas. Stick with mild soap and hand-washing near the damage.

-Chris Foley, detail manager at Fyda Freightliner

Keeping your truck’s exterior looking good won’t improve fuel e ciency or uptime, but do not discount the intrinsic value. It’s undeniably good for branding and reputation, as a fleet’s trucks have the company name and logo plastered on the sides, making them essentially rolling billboards. A fresh wax job indicates pride in your equipment and dedication to small details, while a dirty, beat-up rig tells customers maintaining a professional appearance is low priority.

“Everyone going down the road notices clean trucks and trailers, and also dirty trucks and trailers,” said Michael Gray, assistant shop manager at K&J Trucking, a Best Fleets to Drive For winning fleet out of Sioux Falls, South Dakota.

Plus, a dirty or poorly maintained truck can signal to Commercial Vehicle Safety Alliance inspectors that a closer look might be warranted. Visual indicators of neglect raise red flags, and can make inspectors question what else you’ve missed. And neglecting fi lth for too long can cause real damage. “If you let any type of particles, dirt, debris, pollen, or contamination sit on the vehicle for too long, the vehicle can actually be damaged beyond repair in terms of cleaning,” Clean Z’s Alford explained.

A clean, polished truck turns heads on the highway, and with the right techniques and wash intervals, it doesn’t need to be a big to do. Most agree that the best practice is to make sure vehicles are simply washed regularly. Good old soap and water will take o most dirt and grime, maintaining the wax coating for longer.

“I don’t think you need to have a wax and polish every time the truck is in, but the wash itself will keep everything clean and shiny without overdoing it,” Gray said. “Start with a good mix of soap and water to get the grime o .”

JLE’s Interian agreed, recommending a wash no less than once per month for most of the year, and at least twice a month in the winter to combat corrosion from chemicals and salt on the roads.

Fyda’s Foley advised a wash every 2 to 4 weeks, depending on usage and road conditions. “For fleet trucks, it’s o en easier to stay on a more frequent schedule since many fleets have access to on-site wash facilities,” he explained. “However, for owner-operators, washing may happen less frequently due to limited access to facilities. In these cases, we recommend washing the truck every 4 to 6 weeks, or sooner if driving through harsh weather or dirty conditions.”

Hand washing is the preferred method of the detailing professionals who responded, as sometimes the tools can be detrimental.

“Brushes will leave swirl marks,” cautioned Brown, explaining that more o en than not, they just push the dirt and grime back and forth over the paint. “You’ve got to be real careful with people using brushes, especially on black paint.”

“Hand washing is the preferred method for deep cleaning,” Interian concurred. “Handheld pressure washing wands with so bristle brushes will get rid of the maximum amount of road

grime that cannot always be removed by automated systems. Automated systems also cannot adequately wash the engine compartment to provide a good visual inspection.”

Another advantage of manual cleaning is the ability to adjust during the process based on the condition of the vehicle and what you notice as you’re washing.

“I feel as if hand washing is always better,” Gray said. “You get a better idea of what’s coming off the truck and can control the pressure of the water and brushes better than a machine.”

There is also the risk of missing spots when using automated washing tools, Brian Warner, owner of One Touch Detailing, pointed out, listing the inside of the rims, wheel wells, the grille, and emblems as places that are hard to reach without using your hands.

When it comes to power washing, be aware of the water pressure, as a high psi could result in the water damaging paint or stripping the clear coat.

According to Clean Z’s Alford, anything under 2,300 psi should be safe for most applications. He uses a 1,800 psi pressure washer to err on the side of caution.

Warner also highlighted the importance of using the correct spigot or nozzle on the washer, referring to attachments that can be used for more aggressive cleaning applications.

“If those things can damage concrete, imagine what it could do to paint,” he pointed out.

Another thing for fleets to keep in mind, especially when using new products, is to simply read the directions.

Brown mentioned having to correct users of his products when they spray and immediately wipe the product right off.

“If you do that, you’re not taking advantage of the technology in the can,” he said, recommending that customers leave it on 15 seconds to let the product do its work.

Scratches can sometimes be handled with a good buffing compound and some elbow grease, but it depends on the severity of the blemish.

“There are many good products on the market that need to be used by commercial vendors with the correct power tools and buffing pads,” cautioned Interian.

Deeper issues with paint are another story, however, and usually need to be fixed professionally.

“For paint chips, you really need to just have that touched up and sealed properly so the paint doesn’t peel off,” warned Gray.

Interian agreed, noting that the best bet is to just take the vehicle to a body shop.

And don’t forget the finishing touches, the details that will make the truck pop and stand out to others on the road.

“On trucks, you’re always going to notice a shiny tailpipe or a door handle,” Alford added. “Make sure those are streak-free.”

K&J’s Gray recommends Blue Magic Metal Polish Cream, a non-abrasive solution that can be used on all metal to remove tarnish and oxidation. The cream can be used with buffers and polishers to create a lasting protective coating.

And while a clean exterior does not impact vehicle performance and uptime, under the hood is another story.

For companies struggling with driver retention, a question to ask is how clean is their fleet?

A pristine truck is a point of pride in this industry, and many drivers spend their downtime polishing and buffing their baby. But fleets should offer assistance where they can, such as enforcing high sanitary standards in slip-seat situations, and making sure when a driver gets in a truck for the first time, it feels and smells like new.

Chris Foley, detail manager at Fyda Freightliner, suggested giving the interior a deep

clean every time drivers are changed out, ensuring each one gets a fresh start.

Emory A. Mills, sr. vp at FTC Transportation, noted the truck is a longhauler’s home away from home and sometimes their only residence.

“To say the equipment they spend weeks at a time in affects their morale is an understatement,” Mills said.

FTC asks new drivers why they left their last company, and “oftentimes we see that the previous company did not maintain their equipment, or the driver was assigned ‘junk,’” she added.

“Keeping salt and grime away from a truck’s important components will increase the lifespan of those parts,” Gray noted. “Minimizing corrosion is also very important where steel and aluminum meet.” [For more on that, check out our corrosion feature on Pg. 14.]

Interian agreed, adding that the time spent cleaning a vehicle can also reveal issues that require additional attention.

“Regular washing of the engine and compartment allows for easy visual inspection for leaks and other worn components,” he explained. “Engine bay washing should be done as a regular

Jhonny Interian, detail shop manager at JLE Truckwash, agreed, saying, “When drivers feel that the company is looking out for their comfort by providing clean places to work, they are more likely to stay with that employer.”

And if you think your truck wash bill is too high, just compare it to your onboarding/ hiring expenses.

“Drivers come to a company because of pay/benefits, but they stay because they are respected and are proud to represent said company,” Mills concluded.

part of the detail services.”

Detailing by its very nature is not a value-add for your fleet, but keeping up appearances with routine cosmetic maintenance benefits every fleet, whether it’s a handful of HVAC vans or dozens of heavy-duty trucks. Because the inverse, ignoring unsightly scuff marks and bug guts on the exterior, or soiled seats and piles of fast-food bags on the inside, imply you cut corners and lack attention to detail. And that’s just pig-headed.

For related content go to FleetMaintenance.com/in-the-bay

Creating a strong line of defense against corrosion on trucks and trailers starts with proper spec’ing, and the battle continues with a solid PM strategy.

By Gregg Wartgow [ PREVENTIVE MAINTENANCE ]

First and foremost, fleets must remain vigilant to keep things clean and protected. Technicians should regularly inspect for rust, pitting, or damage to higher-risk components like wheel ends and brakes, as well as the undercarriage, suspension, and frame. Paint starting to bubble or peel is an obvious sign.

en, well-timed cleaning is essential.

ust—and corrosion overall—can wreak havoc on fleet assets such as trucks and trailers, with the potential to compromise safety and uptime, while also increasing repair and replacement costs. And all it takes to develop is the right material, like untreated carbon steel, placed in the right conditions—outdoors in the rain—over a certain amount of time. is process weakens and ruins whatever it touches, reducing the toughest steel constructs to crumbling reddish-brown flakes. e war against rust has been waged since at least the Iron Age, with each fleet still fighting its own battles to varying levels of success. If you feel like you’re on the losing side, fear not. According to the experts we spoke with, there are plenty of rust-busting weapons fleets and shops can deploy to turn the tide. And they explain in detail how to use those to properly maintain your truck and trailer components, which are most susceptible to rust and corrosion. But fi rst, let’s explain exactly how metal’s mortal enemy works.

Corrosion is the electrochemical process by which certain metals and non-metals deteriorate as a result of oxidation, or when a surface is exposed to air or chemicals. At the molecular level, this oxidation-reduction (redox) reaction steals an electron from the material and gives it to the environment, so it’s kind of like a tax from Mother Nature. Discoloration varies by substance and catalyst. For example, a battery terminal may develop a green or white chalky layer when the sulfuric acid reacts with the copper terminal. If the sulfuric acid is hot, a blue hue may appear. Either way, conductivity diminishes, and you might experience slow cranking, reduced battery life, or possibly total failure.

Rusting is a type of corrosion related to iron oxidation. It occurs in the presence of air and moisture. us, rusting develops as an orangey-brown growth on the surfaces of iron and its alloys. Salts, such as the ones Northern roads are covered in all winter, accelerate the process by essentially supercharging the negative ions as the molecules break down.

In a perfect world, fleets could keep all their trucks, trailers, and shop tools in a perpetually clean, dry environment, and they would never come into contact with moisture or chemicals. In the real world, of course, that isn’t happening. e good news is that there are several ways to slow or stop corrosion, ranging from preventive maintenance and cleaning to coatings and products that thwart rust and corrosion.

“Regularly wash and thoroughly dry vehicles to remove road salts, dirt, and other corrosive substances,” said Scot Reeder, senior product manager at STEMCO. “Apply wax or ceramic coatings to protect the paint and metal surfaces from corrosion. Use anti-corrosion sprays or treatments on vulnerable areas such as the undercarriage and wheel wells. You can also apply rust inhibitors to metal parts to prevent rust formation.”

Fleets can also preemptively strike against rust and other corrosion during the spec’ing stage by choosing truck and trailer bodies and parts, like hitches, made from galvanized steel. Galvanization coats the steel or iron components with zinc. is brave element serves as the sacrificial anode and takes the brunt of moisture and oxygen, and will corrode before the underlying steel does. rough a process called cathodic protection, a zinc patina layer forms.

It can have a huge slowing e ect on corrosion.

e International MY2025 HV Series, for example, uses a double-sided galvanized steel and anti-corrosion coating for its cab. Andy Hanson, International vocational marketing director, noted the fortification allows the cab to withstand 1,000 hours of exposure and the rail 2,000 hours.

Galvanization does add cost, so you may choose other coating options.

If operating in harsh cold-weather environments, you may want to consider adding an underbody coating. is area is regularly splashed with melted snow and ice that’s laden with chloride from deicers.

“Chassis are also less visible and more di cult to clean than the rest of the vehicle, making it more likely that corrosion deterioration could creep up on fleet managers unexpectedly,” said Julie Holmquist, content writer for Cortec, a developer of corrosion-control technologies.

Suspension OEs also o er their own coatings. SAF-Holland has made its anti-corrosion coating, called Black Armour, standard for many years. SAF said the eco-friendly “protective skin” guards against moisture and anti-icing chemicals while not shrinking or peeling.

Hutchens Industries, meanwhile, fights corrosion at the design phase by engineering its 9200 with “C” channel frame rails. This design removes areas on the suspension that would collect salt and rust faster. Hutchens also sells “hot-dipped” galvanized versions.

Fleets that want the convenience and low VOC benefits typical of water-based coatings may opt for something like Cortec’s CorrBarrier. The company also offers VpCI-398, a solvent-based sulphonate version for those who desire heavier-duty protection. VpCI stands for Vapor Phase Corrosion Inhibitor.

Throughout the winter season, it’s important for fleets to regularly wash their vehicles. This seemingly simple step is more scientific than you’d think. According to Holmquist, fleets should consider adding a flash corrosion inhibitor to their detergent for extra protection against flash rust during and shortly after washing.

“VpCI-406 is one phosphate-free cleaner that includes a flash corrosion inhibitor,” Holmquist said. “It can be metered into automatic washes or power wash equipment.”

For vocational trucks, fleets should also consider protecting things like truck beds, snowplows, and other hydraulically powered equipment.

“VpCI-396 is a one-component, corrosion-inhibiting urethane coating with 2H pencil hardness for high scratch resistance,” Holmquist said. “For even longer-lasting durability, it is best to prime the surface with a corrosion-inhibiting epoxy coating such as VpCI-395 first. This creates a stronger coating system with a durable base that continues to protect the metal, even when the topcoat wears away over time and needs to be reapplied.”

Armor Protective Packaging is another company that specializes in rust prevention products. The company’s Dry Coat Rust Preventative is a water-based liquid that creates a clear protective coating and dries to the touch within 30 minutes of application at ambient conditions. It can be a beneficial preventive measure in shops dealing with high humidity.

“Our Dry Coat is best applied in a trigger spray bottle,” said Chris Elias, sales and marketing director at Armor Protective Packaging. “It is safe to use on ferrous metals and stainless steel, and will not harm most elastomers or plastics. It protects for up to one year for items stored indoors.”

Gemplers also offers a suite of rust-combating products. Rust Remover dissolves rust to provide clean, bare metal. Rust Converter converts rust into an inert, protective coating that shields the metal underneath from exposure to moisture, preventing further rusting.

So, which one is the right one for a shop to use?

“Since Rust Converter forms a protective primer coating on treated metal, it isn’t what you want when you are looking for the final finish of the object to be bare metal,” said Devon McWilliams, systems support and product tech specialist at Gemplers. “It also isn’t suited to objects with close-fitting moving parts that might be stuck together as the coating dries. If the item can be taken apart, however, Rust Converter could be applied and then the item reassembled once dry. It is also important to note that Rust Converter

coating is not heat- or chemical-resistant, so it can’t be used on parts like mufflers or inside fuel tanks.”

Concerning Rust Remover, it’s not a practical option for large objects. “That’s because the rusty object must be submerged in Rust Remover for it to work,” McWilliams explained.

It should be noted, McWilliams added, that neither product can restore the structural integrity of severely rusted parts or equipment. But to clean up some tools and parts with a normal level of rust, they can be very effective and easy to use.

Each of the commonly used materials for trailers— stainless steel, galvanized steel, and aluminum— offers varying degrees of corrosion resistance. Even aluminum can corrode under certain conditions, even though it will not rust.

Fleets should think about where their trailers are stored and utilized to determine the level of corrosion resistance they should spec for.

“In some cases, lower corrosion resistance is acceptable if the trailer is not exposed to the aggressive road deicing chemicals seen in colder, harsher climates,” said Tim Schmeits, director of reefer product engineering at Great Dane. On the other hand, exposure to road chemicals could warrant a higher degree of corrosion protection. “Coastal areas may also incur more corrosion due to the proximity to salt water,” Schmeits added. What should fleets be focused on when spec’ing and evaluating trailers?

On aluminum flatbed trailers, there are a few areas that are more susceptible to corrosion.

Mark Sabol, platform product manager at East Trailers, said these include: “the air tanks and brackets, the area between the fifth wheel plate and main beam, the area where suspensions attach to the main beam, and the landing gear mounting area.”

On combo flatbed trailers, which incorporate a combination of steel and aluminum, Sabol said

like Gemplers

provide

corrosion may occur where the floor crossmembers attach to the main beam of the trailer.

“To avoid corrosion, be sure the manufacturer uses a barrier to separate the dissimilar metals,” Sabol said. “This barrier can be paint or another type of isolator that will keep the dissimilar metals from touching. For instance, East Trailers installs an HDPE (High-Density Polyethylene) barrier between all steel and aluminum parts wherever they meet each other.”

When it comes to dry vans and reefers, there are two general categories of corrosion to contend with. One is more worrisome than the other.

“Generally speaking, when you can see surface rust, you can take care of it,” said Brian Hanlon, product manager for dry vans at Wabash. “What we worry about is rust and corrosion in areas you can’t see, especially structural areas.”

When spec’ing dry vans, Hanlon recommends paying close attention to the construction of the “crossmember to base rail connection” and the “coupler to base rail connection”. Those areas can be difficult to inspect unless the trailer is taken apart. Thus, those areas need to not only be stout, but also resistant to corrosion.

“Connections with dissimilar materials are where you’ll see galvanic corrosion,” Hanlon said. “On the crossmember to base rail connection, you typically have an aluminum base rail and carbon steel crossmember. There may also be backing tape, but that’s only good for so much.”

This is one reason why Wabash only uses a steel bolt as a connector. The typical alternative, an aluminum rivet, is susceptible to creating “hidden” problems, according to Hanlon.

“If an aluminum rivet corrodes from within, the head on the outside looks okay, but you don’t know what’s happening on the inside,” Hanlon explained. “Aluminum is also much more reactive than steel. When you use a steel bolt, the most reactive material is the aluminum base rail. That’s very large and easy to see on the outside. You’ll easily see discoloration if corrosion is starting, but it won’t fail. When you’re dealing with an aluminum rivet, on the other hand, you typically won’t see that corrosion and potential failure coming until it’s too late.”

Another area of a dry van to pay close attention to is the kingpin through the upper coupler. This area must maintain its integrity, but it can also be difficult to see.

Hanlon recommends spec’ing for maximum corrosion resistance.

“Some manufacturers galvanize the entire structure, including the kingpin,” Hanlon said. “But galvanizing is a high-heat process that could soften the kingpin, so Wabash galvanizes the entire upper coupler, but not the kingpin. Instead, we weld the kingpin to that galvanized upper coupler and add sacrificial zinc locks inside

the cavity. Zinc is highly reactive, so it will take all the moisture, and any corrosion will happen on those zinc locks, leaving the coupler intact.”

Even when spec’d with the right coatings, trailers need regular maintenance to ensure a less corrosive existence.

“Always inspect areas where dissimilar metals meet,” East Trailers’ Sabol said. “Keep those areas clean and free of road debris. If an isolator or barri-

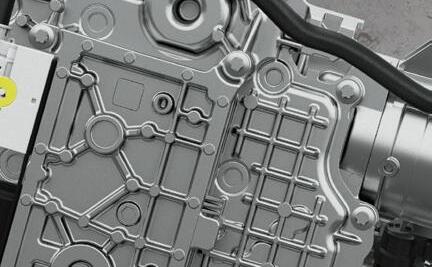

Reliable and ready to work, the Detroit® DT12® Vocational Series transmission is built for everything the job demands. Features like off-road mode, rock-free mode, power launch, and Hill Start Aid (HSA) make it easier than ever to reach peak performance in rough applications and extreme terrains. With the DT12-V powering your truck, the toughest challenge doesn’t stand a chance.

Demand performance. Demand Detroit.

» The Peterson Defender Modular Harness System is designed to provide the strongest defense against moisture damage and corrosion. The system features Maxi-Seal technology that incorporates an integrated moisture barrier, over-molded design of the connector, advanced silicone seals, sealed ring terminals with adhesive-filled heatshrink connectors, dual-isolated grounding, heavy-duty terminals, and other features. Peterson

» ConMet offers both aluminum and iron PreSet Plus hub assemblies. For an added measure of protection, the company applies specialized coatings and lubricant to critical surfaces during the manufacturing process. Then, all designs are validated through extensive testing in cyclical corrosion chambers that simulate repeated salt spray and environmental stress.

» STEMCO Sentinel Hub Caps are highquality diecast aluminum and naturally corrosion-resistant. They also feature a unique filtering system to eliminate contamination from dirt, dust, sand, and water, making it easy to visually monitor lube levels.

er has been damaged or lost, we recommend repairing or replacing it to keep the corrosion at bay.”

As important as timely cleaning is, Hanlon discourages power-washing. ( ey are called dry vans, a er all.)

“Trailers are waterproof, but not watertight,” said Hanlon. “You never want water creeping into little crevices. And if you’re cleaning with chemicals, read the product label because some of those products require a specific dilution. You’re asking for trouble if you introduce acidic materials and can’t control where they go.”

It’s also important to understand the types of products a given trailer is hauling. Some cargo, such as batteries, can o -gas. at could lead to corrosion or rust forming on the inside of the trailer.

“ e good thing is you can see that,” Hanlon said. “You may see corrosion forming on roof bows and logistic strips. If you see any surface rust, you probably need to figure out some better ventilation.”

Here’s some advice regarding some of those items that are typically more susceptible to rust and corrosion.

Wiring & electrical systems

Electrical system connections, typically located in areas like the front of the trailer, the back of the cab, and near the tandem axles, are constantly exposed to road spray and deicing chemicals. “Moisture also travels along the cables and into the connections, compounding the issue,” said Andy Summers, director of fleet sales at Phillips Industries.

When spec’ing electrical system connections, Summers said fleets should opt for:

Ü Over-molded plugs, sockets, and wiring harnesses to block moisture intrusion

Ü Sealed noseboxes and connectors (such as AMP-style connectors)

Ü Dielectric grease (a thin coating, applied on clean surfaces) to protect pins from moisture and corrosion

Ü Concentric jacketing that centers the copper strands in the insulation to reduce the risk of jacket breakage and moisture intrusion

Even though wire harnesses are tucked away, it’s still very di cult to keep them free from water and small debris, and harder to visually detect. ey are also o en routed over, under, or through metal crossmembers or other sharp surfaces. Together, these make a perfect breeding ground for corrosion.

“With vibration over time, the outer coating of a wiring harness can wear through, leaving exposed copper,” said Al Anderson, VP of sales and marketing at Peterson Mfg. “ is is an open invitation for chemicals to enter the system.”

Anderson recommends choosing something with an IP69K rating, which validates a harness’s ability to e ectively seal out moisture and debris. He also suggests working with the truck builder to make sure no terminal is exposed to the atmosphere, particularly the ground terminal.

“In some cases, like with our Peterson Defender harness, there are closed-loop systems where there are no chassis grounds,” Anderson said. “Everything runs clear back to the trailer nosebox,

Fleets face a variety of factors that elevate the risk of corrosion even more, such as:

• Roadway deicing and anti-icing chemicals

• High humidity and wild temperature fluctuations

• Mountainous regions and stop-and-go urban routes under heavy load

• Hot and humid service shops

• Shops and storage yards close to the ocean (salt water)

which eliminates any opportunity for corrosion to enter the system through the ground circuit.”

With lighting system components specifically, fleets should also look for properly sealed, weather-resistant products.

“ e type of wire insulation also matters,” said John Hoover, VP of fleet at Truck-Lite. “Rubber insulation holds up better in high heat and UV exposure, while jacketed options that use GPT are ideal for heavy-duty use.”

For lighting itself, Hoover said to look for designs with potted circuit boards (where the electronics are sealed in epoxy) or conformal coatings, which help protect against moisture and contaminants. Also, make sure the lens and housing materials match the environment. Polycarbonate is great for impact resistance, while acrylic o ers better protection against chemicals.

“It’s also smart to choose components with IP-rated connectors (like IP67 or IP68), which are tested to resist water and dust,” Hoover added. “Corrosion-resistant coatings on terminals and housings, such as anti-corrosive compounds, can also make a big di erence in long-term durability.”

Smart spec’ing is a fleet’s fi rst and most important step in the fight against corrosion. But sometimes corrosion will still happen. By remaining vigilant with inspections and using the right cleaning, prevention, and restoration products, fleets can take corrective action before it’s too late.

Wheel ends are constantly exposed to the elements, but that’s not the only reason they are high risk for rust.

“Wheel ends are also particularly vulnerable to corrosion due to brake pad dust,” STEMCO’s Reeder said. “ e friction between brake pads and discs generates heat and releases iron particles. ese particles can adhere to the wheel ends, promoting corrosion.”

When spec’ing wheel ends, material choice should play a major role.

“Most ferrous materials will need protection against corrosion,” said Je Larson, VP of engineering for core products at ConMet. “ e type of protection will depend on their function and exposure. Alternatively, aluminum is mostly corrosion-resistant, which makes it a better material for guarding against rust in critical components like hubs.”

Another advantage of aluminum is that it doesn’t require any protective coatings like ferrous

metals do. “Those protective measures help initially, but can wear off over time—especially under heavy use,” Larson said.

In addition to aluminum alloys, Reeder also said that stainless steel and composite materials, which optimize strength, weight, and corrosion resistance, can have their place when utilized correctly.

The protective coating is another thing fleets should look at, even when spec’ing aluminum, as different coatings provide additional unique benefits beyond just corrosion protection.

“Electroplating adds a protective layer to the metal surface,” Reeder continued. “However, it may not offer sufficient protection against prolonged exposure to corrosive environments. Powder coating provides a durable finish that resists chipping and scratching. Anodizing is particularly effective for aluminum, as it increases surface hardness. Ceramic coatings offer superior protection against wear.”

One final piece of advice for protecting your electrical systems: Improper troubleshooting and repairs may inadvertently introduce corrosion to your system, which can spread into an army of faults.

“Poking a wire with a test probe leaves a hole in the wire for corrosive chemicals to enter,” Peterson’s Anderson said. “Always check for electrical current at the end of the harness, whether it be where the light is plugged into the harness or where one harness connection connects to another.”

Another repair tip Anderson offered is to avoid splicing a harness, if possible. It’s nearly impossible to make a splice completely waterproof, which can also allow chemicals into the system.

“If a repair is needed, find the closest place where the harness is plugged together and replace the damaged section,” Anderson advised. “Modular systems are more reliable and easier to repair correctly because you can just replace one section of a damaged electrical system.”

Unlike wiring harnesses, electrical system connections are often out in the open. Technicians should take advantage of that.

“Fleets should regularly inspect these components, especially from October to March in northern regions where road chemicals are

used,” added Phillips Industries’ Summers.

Then, as a general rule, fleets should focus on back-of-cab connections, which are rarely unplugged and cleaned, but are the most vulnerable.

“During yard checks or whenever equipment is in for service, unplug the connectors, clean the pins and sockets with stainless steel or brass brushes, or use specialty tools like Phillips’ 4-123 kit for dual pole, and apply fresh dielectric grease,”

Summers advised. “Don’t rely on annual PMs alone; incorporate this into regular maintenance. Also, keep replacement cartridges and sockets (e.g., QCP and 16-724 sockets) in [your]inventory, and treat worn pins and sockets as replaceable wear items.”

For related content go to FleetMaintenance.com/equipment

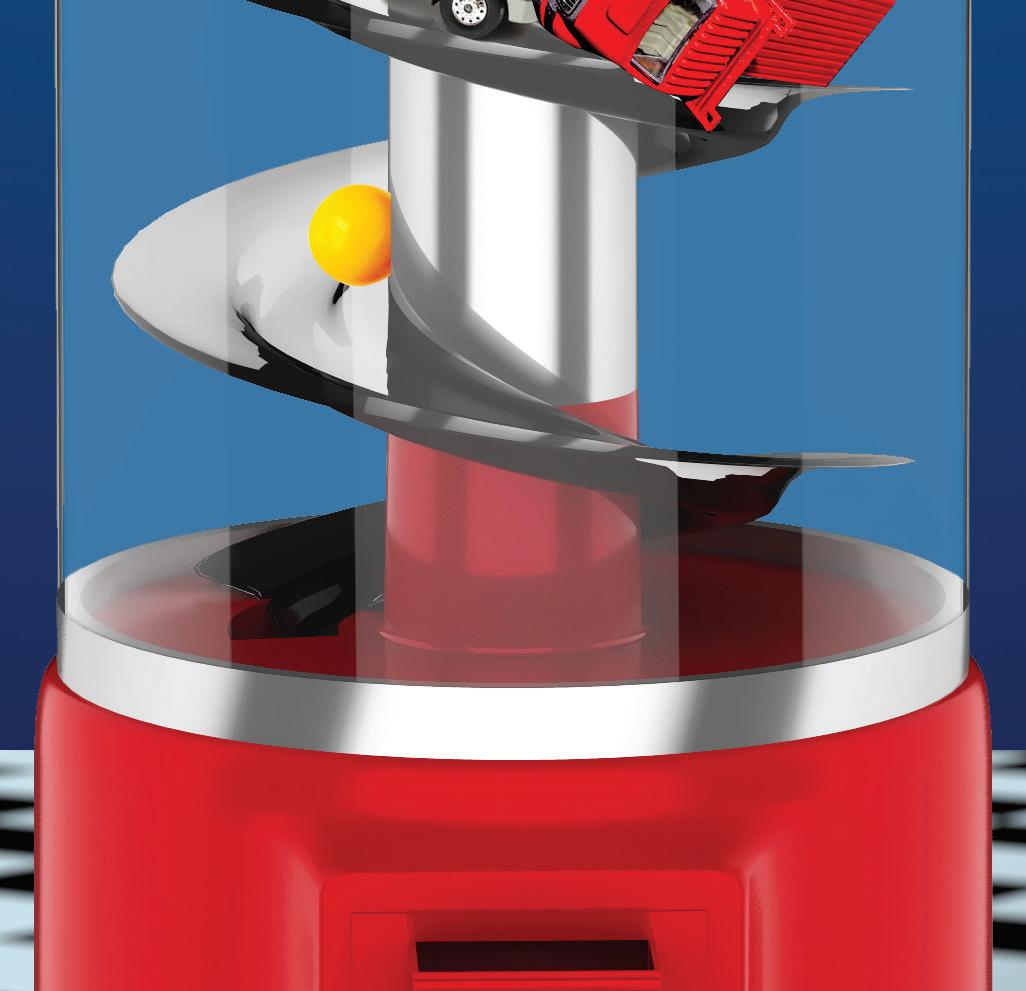

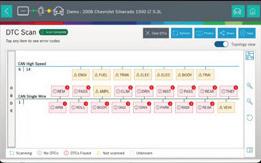

Is mixed fl eet maintenance gumming up your shop? Is mixed fl gumming up your shop? Is mixed gumming up your shop? Is mixed fl eet maintenance up your shop?

Mixed fleets have a diverse range of maintenance needs that can burst your uptime bubble, but the right balance of technology and training can help keep you from getting stuck.

By Seth Skydel

MANAGEMENT ]

he average gumball machine typically contains four or five di erent colors and flavors. And when you drop your quarter in, you’re never sure what you’re going to get.

Now take your average mixed fleet, which can have twice that number of vehicle types, from cargo vans and pickups to box trucks and tractor-trailers, each with their own maintenance needs and nuances. at’s not even counting utility vehicles and yard tractors. is variety grows significantly when operations are fielding equipment from multiple OEMs and model years, and don’t forget to count spec’ing and upfitting di erences. en there’s the growing trend of alt-fuel powertrains. A fleet may have several battery-electric or CNG trucks jumbled in.

And like with a gumball machine, each day, maintenance departments aren’t quite sure what’s in store for them as they cycle between various tools and OEM guidelines.

“Depending on the makeup of your fleet, you could be looking at dozens of di erent PM schedules, which, let’s face it, can get overwhelming,” noted Sunny Chalam, director of product management at Fleetio, a provider of fleet management so ware.

All this adds up to a mound of challenges that, if not managed correctly, can gum up the works.

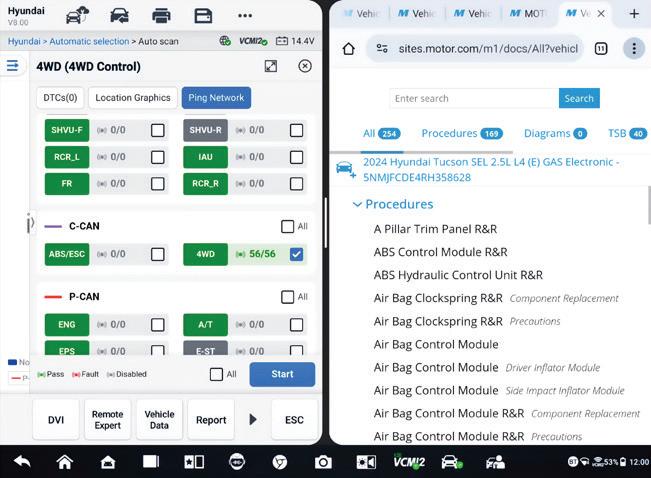

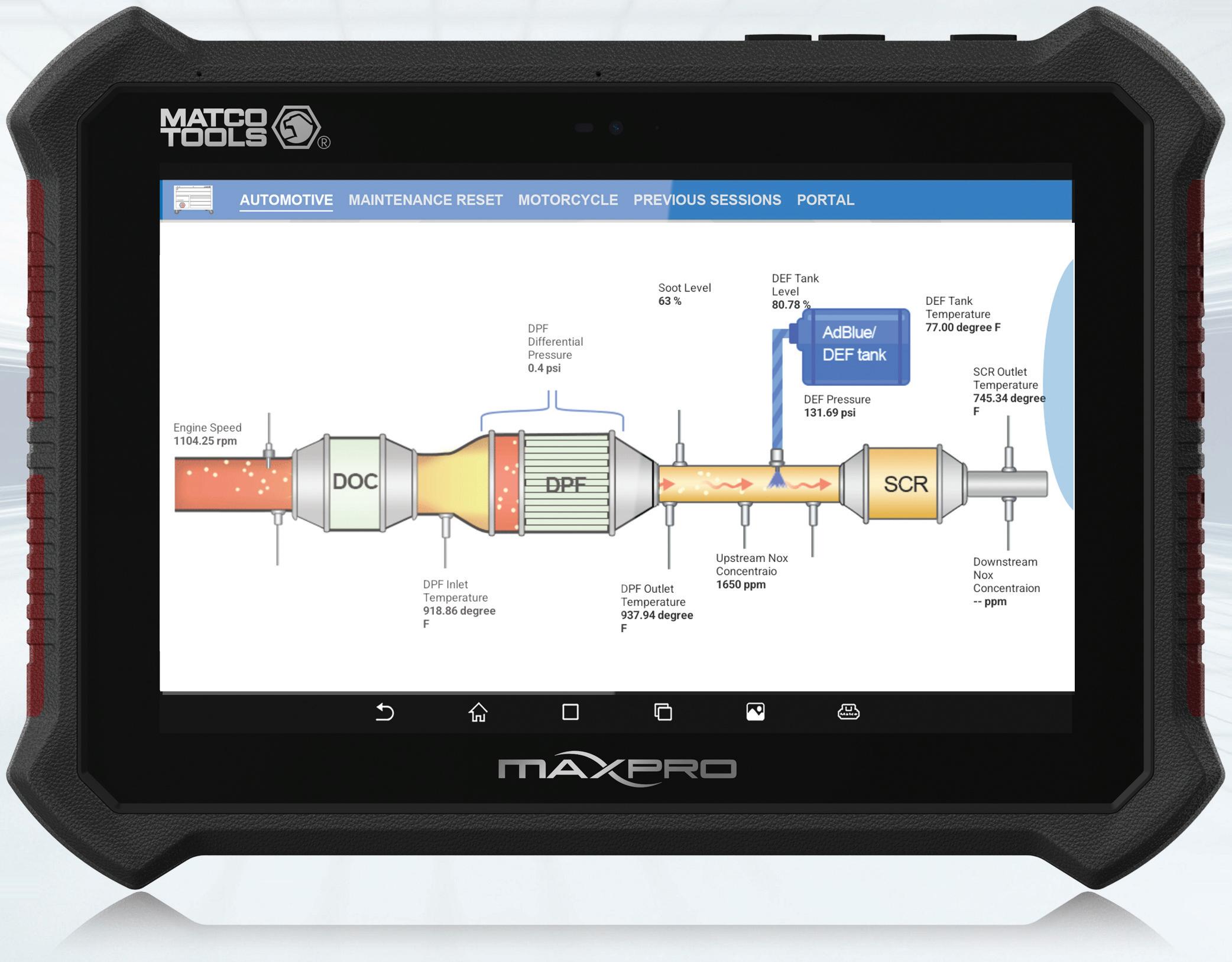

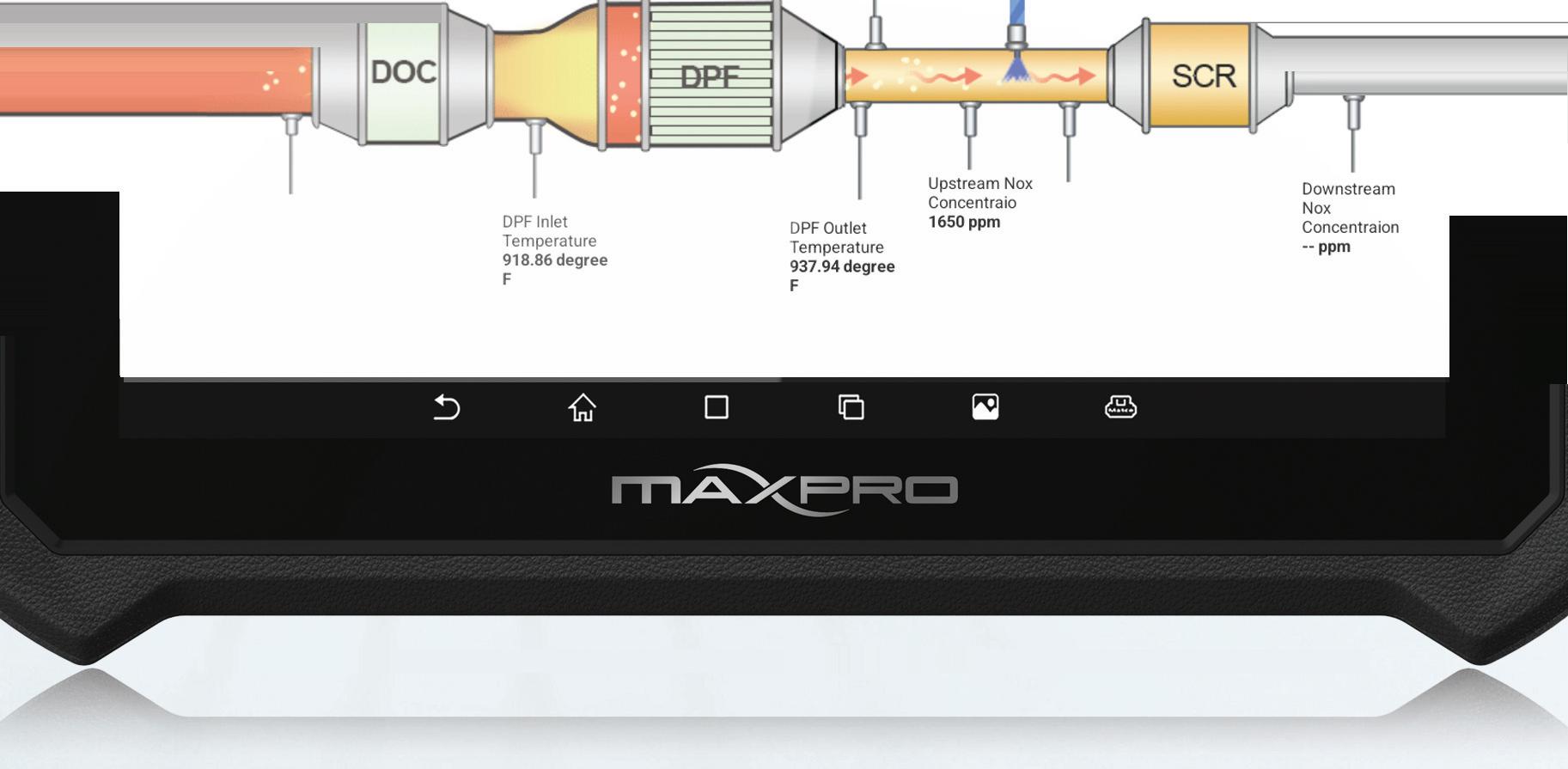

“A mixed fleet introduces complexity—plain and simple,” said Gerry Mead, VP of truck service at TravelCenters of America, who has been maintaining a wide range of assets since the late 1980s, starting with military vehicles for the Marine Corps. “When you have di erent engine platforms, a ertreatment systems, and various technology setups, you have di ering PM schedules. at means technicians need broader training, more diagnostic tools, and parts inventory becomes a real juggling act. e more variety you have, the more chances there are for bottlenecks.”

If this sounds like your fleet, don’t worry. We’ve collected an assortment of colorful expert opinions and strategies to sort things out. You still might not know what to expect with your mixed fleet tomorrow, but at least you’ll be better equipped to get out of sticky situations.

Mixed fleet managers’ free time lasts about as long as a stick of Fruit Stripe gum, so let’s jump right to some quick advice to keep the uptime bubble from bursting.

A good place to start is eliminating the potential for problems, Mead noted. “For example, keep technicians in consistent lanes or service bays, and batch[ing] similar units together so techs aren’t constantly shi ing between asset types is key,” he advised. “If they have to work on a diesel day cab, an electric step van, and a reefer unit all in one shi , that kind of constant switching increases the chance of mistakes.

“But just as important is clear communication,” he said. “It’s not enough to hand over a printed work order—you must ensure every tech understands the priority, sequence, and special considerations before they start.”

Standardization, where possible, is also a valuable approach, Mead noted. “You can standardize PM intervals, inspection sheets, labeling systems, and communication protocols,” he added. “ is not only reduces training complexity, but it also reduces the SKUs needed on the shelf.”

Chalam agreed, o ering that standardizing asset types by OEM gives mixed fleets “a more organized and manageable feel.”

Angelo Cinquegrana, VP of operations for Amerit Fleet Solutions, said there are four main ways to maximize repair and maintenance eciency in a mixed fleet.

e fi rst is knowing your techs’ strengths and weaknesses. For instance, be aware that an ‘A’-level diesel tech can handle light-duty jobs, but that light-duty tech is likely not suited to work on heavy-duty equipment, he said.

When prioritizing who should tackle what, Cinquegrana said, “For most fleets, any DOT items or anything a ecting route readiness is priori-

“ “

It’s not enough to hand over a printed work order—you must ensure every tech understands the priority, sequence, and special considerations before they start.”

Gerry Mead, VP of truck service, TravelCenters of America

ty—and those jobs should get your best people assigned to handle them.”

And make sure those assigned have experience with the particular components and systems due to slight di erences between OEMs. Mead said even oil changes can trip a fleet up if techs don’t know enough about what they’re working on. For instance, some techs may change the oil and fuel fi lter at the same time to save time. For engines that don’t have an electronic fuel injection pump, you have to prime the fuel system fi rst, though.

“If you don’t, you risk running the engine dry of

oil while trying to re-prime fuel, which can lead to significant damage,” Mead warned. “ at kind of failure isn’t immediately obvious—it shows up later as a bearing or top-end issue.”

Secondly, watch your sta scheduling. “It seems fundamental, but we see situations where a tech is scheduled for a day shi for vehicles that are supposed to load out at 6 a.m.,” Cinquegrana said. “Not having a tech scheduled to cover startup leaves the fleet exposed to increased downtime if there is a problem.”

e other two cover parts management and tools. e quick tips here are to “ensure you have min/max levels set for frequently used parts” and always have the right diagnostic equipment available.

“Typically, there are tools that will cover everything, but it’s not cookie-cutter, and every once in a while, there is a situation where a certain diagnostic tool doesn’t connect to a certain type of vehicle,” the Amerit executive explained. “Having all the tools needed for comprehensive maintenance sounds rudimentary, but it is o en overlooked and can cause increases to outside spend and downtime.”

As mentioned, when feasible, standardize what you can, when you can. But when that’s not possible, customize your preventive maintenance programs according to the specific needs of each asset type, where each unit goes, and what it does. is could be based on OEM recommendations or the asset’s service and inspection history.

“For blended fleets with a complex mix of vehicles, we always recommend building a PM program that takes into account the asset class, duty cycle, routes, location, operating conditions, and routine service downtimes for each group of vehicles,” said Bob Brauer, chief commercial ocer at Amerit Fleet Solutions. “Breaking the fleet into these categories allows fleet managers to be more predictive and proactive with their preventive maintenance requirements.”

Using a tiered PM schedule that considers class and usage is also important, noted Ricky Bains, VP at Kooner Fleet Management Solutions. is should not be static, but change based on new real-time health data from the trucks and defects reported by the drivers. Bains noted digital DVIRs and maintenance audits can aid in this respect by helping standardize inspections and stay compliant with FMCSA and DOT regulations, while also catching things you might miss.

“Regular maintenance audits identify trends, reduce downtime, and optimize fleet performance across all asset types,” he explained.

You could try to do this all manually on spreadsheets, but a better modern solution is to utilize a centralized dashboard to consolidate and aggregate vehicle and maintenance data.

And there are so many fleet management platforms available to connect your telematics and maintenance data, that one is bound to fit your fleet size and budget. For PM scheduling alone, they are invaluable tools.

“[Maintenance management platforms] allow you to create custom service reminders based

To manage parts inventories for mixed fleets, Kooner recommends using a centralized system across all vehicle types. “ at maintains accurate records, which allows for demand forecasting to help predict part usage, ensuring the right inventory levels,” said Chris Brooks, operations director at Kooner Fleet Management Solutions. “It can categorize parts by vehicle type for easy access and facilitate collaborating with parts providers. ese strategies improve fleet uptime and inventory management while avoiding excess stock and ensuring the right parts are on hand when needed.”

Consolidating oil and grease products should make things easier in the shop as well, noted Brandon ompson, product manager at CITGO. “ at can help improve inventory tracking by allowing for the ability to have fewer items,” he said. “At the same time, high-quality lubricants across diverse fleets may allow for the extension of drain intervals with oil analysis.” ere’s another very good reason: Eliminating possible mistakes, as TravelCenters’ Mead fi rst advised. He recalled about 20 years ago when the industry transitioned to the PC-10 diesel engine oil designed for the newer emissions systems.

on parameters like mileage or engine hours,” Fleetio’s Chalam said. “Furthermore, data visibility and reporting capabilities o er insights into maintenance costs and downtime and can shine a light on overdue maintenance to help optimize operations.”

Plus, they allow you to utilize your valuable fleet vehicle health and fault code data to get ahead of future problems with predictive maintenance and to schedule PMs based on real-time data, not on general recommendations.

“Data source integration and synchronization, regardless of the number of vehicle types, are critical to ensuring timely diagnosis, repairs, and usage versus schedule-based service management,” explained Jim Gripp, sr. director of product management at Powerfleet.

In short, the ability to analyze your mixed fleet’s real-time health and diagnostics data allows you to flag issues earlier to “ensure timely service, reduce downtime, and extend the life of vehicles across diverse fleets,” according to Mike Quimby, chief operating o cer at Kooner Fleet Management Solutions.

To reiterate, though, e ective service tracking and scheduling requires a comprehensive maintenance plan based on specific vehicle type, application, and location.

“A well-established PM schedule covering inspections, fluid changes, tire rotations, and more can catch issues early,” said Jenn Dixon, VP of maintenance technology at Ryder. “Also consider mobile and on-site maintenance options to ensure consistent performance.”

“I remember fleets mixing old CI-4+ oil with the newer CJ-4 (PC-10), thinking it was no big deal,” he said. “But that misstep caused a ertreatment issues and premature wear, especially in engines designed specifically for the newer spec. at moment drove home how critical it is to educate teams on what’s inside the bottle, not just what’s on the label.”

For mixed fleets overall, e ective parts inventory management ensures uptime and cost control, related Dixon. “Develop and enforce SOPs for purchasing, storing, and tracking parts,” she advised. “Maintain a centralized database of vehicle specs to simplify parts sourcing and long-term planning.

“Use data-driven systems to track parts usage, forecast demand, and automate replenishment,” Dixon continued. “You can also use location-specific parts data to maintain optimal inventory levels and prevent costly delays.”

[Editor’s note: Remember that as dicult as it is to manage all these PMs, it is tougher to complete them. When your vital techs need a few days o this summer, consider using capable mobile techs to fi ll in at the shop. at will help keep uptime stable and show employees you have their back, which goes a long way in retention e orts.]

Managing parts inventories for mixed fleets requires systematic tracking to ensure parts availability while maintaining cost control, or, rather, controlling overhead, noted Chalam. is can include using a fleet solution with inventory management features to set reorder thresholds or using negative inventory reports to catch discrepancies.

ffihffi ffiuffil ffiffiffiffiffiffiffiffi ffiffi ffiffiffiffiffiffiffi® Effigffiffiffi Offils affid thffi hffia ffi-dutffi prffitffiffitffiffiffi ffiffi M stffik® ffirffiasffis arffi a smar t ffiffimbffiffiatffiffiffi tffi sa ffi ffiffiu tffimffi affid mffiffiffiffi Let us pro e it. SOME COMBIN TIONS M KE MORE SENSE TH N OTHERS.

“But the fi rst step is to establish optimal inventory levels, which can be done through inventory movement reports or historical cycle counts for those still tracking inventory manually,” Chalam said. “Knowing how much of what you need, in addition to movement trends, can help inform you of optimal reorder levels so you’re not caught high and dry when an asset goes down.”

“Many fleets also use local parts stores to supply their inventory, which can add a level of insight, such as purchase histories,” Chalam added. “ at information can then be used to spot trends around purchase date, quantity, and price.”

Keeping up with all the ins and outs of a mixed fleet naturally will require a mix of training options that are both scalable and flexible, said Greg Morrison, sr. director of learning & development at Amerit Fleet Solutions.

Various formats to consider include:

Ü Traditional classroom training

Ü modular, self-paced learning/online modules

Ü Assessments

Ü Hands-on

Ü Training from OEMs/vendors

“All of these tools support ongoing professional growth and align with key certification goals, Morrison said. “Ultimately, it’s not about one-size-fits-all; it’s about delivering the right training, in the right format, at the right time.”

And getting the right mix of training will ensure techs have the diverse skills to keep up with fleet demands, Dixon pointed out. Key training elements at Ryder, for example, include OEM-specific training to stay current with diagnostics, tools, and procedures, and providing technicians with access to digital libraries, technical bulletins, service manuals, and diagnostic guides to stay sharp and e cient.

Ryder does use a blended learning model that includes classroom, virtual, and self-paced learning “to ensure technicians build both theoretical and hands-on skills,” Dixon said.

Citgo’s ompson agreed, adding that as the trucks evolve, techs must keep up. “Certification programs can also be used to set a clear baseline for technician skill levels, and training schedules should be recurring to keep pace with new technologies,” he said.

Making time for training not only benefits shop KPIs such as standard repair time and accuracy, but also improves the chances a tech will stay put.

“Industry certifications, like ASE, are valuable not just for training and skill development, but also for employee engagement and career growth, which o en translates to retention,” Fleetio’s Chalam said. “At the same time, open communication fosters feedback and strengthens training outcomes, enhancing technician competence and fleet e ciency.”

Knowing how much of what you need, in addition to movement trends, can help inform you of optimal reorder levels so you’re not caught high and dry when an asset goes down. ”

Sunny Chalam, director of product management, Fleetio

»

Brauer said, “as well as reduce expensive third-party spending, speed communications, and enhance visibility and control. Providers can also go one step further by tailoring services and shi s to suit the fleet and its duty cycles and routine downtimes, ensuring minimal interruption to operations.”

To maintain performance and minimize downtime in mixed fleet operations, a strong PM program is essential, noted Chalam. “Fleet solutions can o en play a pivotal role by enabling compliance tracking and data analysis while providing customized inspections tailored to specific asset types to enhance readiness and, by extension, productivity,” he said. “Another option for fleets with limited shop availability would be balancing in-house and third-party maintenance, which can help fleets address services based on repair priority, ensuring e cient use of resources.”

Kyle Neumann, Foodliner

SOME COMBINATIONS JUST WORK.

When you pair the fuel efficiency of CITGARD® Engine Oils and the heavy-duty protection of Mystik® Greases, you’ve got an unbeatable combination that’s made to make it last. Saving you time. And saving you money. Let us prove it.

e choice of maintenance structure is also key to providing e ective service for mixed fleets. Brauer, for example, noted that if a fleet is selecting a supplier for maintenance services, choosing a single-source provider with national reach will reduce complexity.

“It will also bring standardized practices across your footprint,”

Whatever approach you choose, remember that successfully managing a mixed fleet takes a mixed maintenance strategy— one that combines the right technology, tools, and training. And just like if you’re trying to get a certain flavor of gumball, it might take more than one attempt.

And don’t forget that stable leadership is what will make all the investments in time and money stick together.

“Structure, communication, and visibility are just as vital to the workday as wrenches and sockets,” Mead concluded. “A diverse fleet doesn’t have to be a liability if you bring structure to the chaos.”

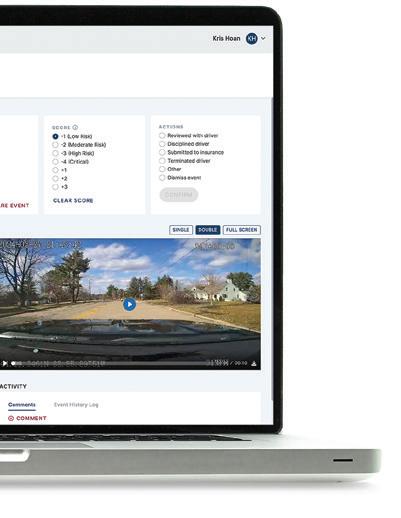

AI-powered dashcams can become a strong nuclear verdict deterrent and also improve safety culture with the right adoption and maintenance strategy.

By John Hitch

In the past 10 years, trucking nuclear verdicts, or judgments above $10 million in civil suits related to crashes, have become a top concern for fleets, as well as their maintenance and manufacturing partners. To put it more frankly, they scare the hell out of the industry. They drive up insurance premiums and legal costs, and, unfortunately, are spreading like a mushroom cloud at a time when fleets need to keep costs down as economic factors such as tariffs threaten to increase equipment and parts prices.

According to David McKnight, a principal at consulting firm The Brattle Group, commercial auto liabilities have experienced an annual growth of 10.1% since 2016.

“This is the highest growth among the segments that we track in our ‘Tort Costs in America’ study and exceeds growth in inflation or GDP over the same period,” McKnight told Fleet Maintenance.

McKnight’s research points to costs and compensation related to the U.S. tort system reaching $529 billion in 2022, more than 2% of the U.S. GDP. And 11%, or $58 billion, was related to commercial vehicles.

“Nobody can deny the fact that our industry is targeted,” asserted Drew Hofley, VP of sales for Phillips Industries. He mentioned a certain personal injury lawyer in Dallas who brags on billboards that he earned a client $27 million for injuries he suffered in a truck accident.

The lawyer’s fee was $21 million. He was also reported to have spent $6 million on his daughter’s quinceañera. It certainly seems things have gotten out of hand.

“For every dollar of revenue that [trucking companies] make, 90 cents of it goes to cover their costs,” he noted. They now must self-insure, shaving their razor-thin profit margins even more.

“Anybody who says it’s not inflationary is delusional,” Hofley opined.

And from 2022 to 2023, the amount of nuclear verdicts overall in the U.S. rose to 89, a 27% YOY increase, Marathon Industries found in the research firm’s Corporate Verdicts Go Thermonuclear report. The median award was $44 million, though the amount of thermonuclear verdicts—those above $100 million—are on the rise. Marathon said these grew by 35% in 2023. Juries from Missouri ($4 billion) and Texas ($3.7 billion) gave out the most nuclear verdicts overall across several industries.

Missouri is the same place where a jury levied $450 million in punitive damages against Wabash because an intoxicated driver sped directly into a nearly stopped 15-year-old trailer’s backend and died, as did his passenger. Judge Christopher McGraugh decided that was “grossly excessive” and lowered it to $108 million, which is still a fairly gross interpretation of justice. Texas, meanwhile, can claim the $100 million verdict against Werner Enterprises and a $160 million decision against Daimler Truck North America.

This report noted Florida dropped from second place to seventh after tort reforms were signed into law by Gov. Ron Desantis.

With the proliferation of nuclear verdicts, fleets cannot wait for other states to reform their tort law, and they certainly cannot “duck and cover,” the recommended practice for actual nuclear explosions. ey must face the threat head on. And while plainti lawyers emotionally manipulate juries to achieve their lucrative payouts, fleets have found technology to strike back.

In the cab itself, this means advanced driver assistance systems, including collision mitigation, lane keep assist, and blind-spot monitoring.

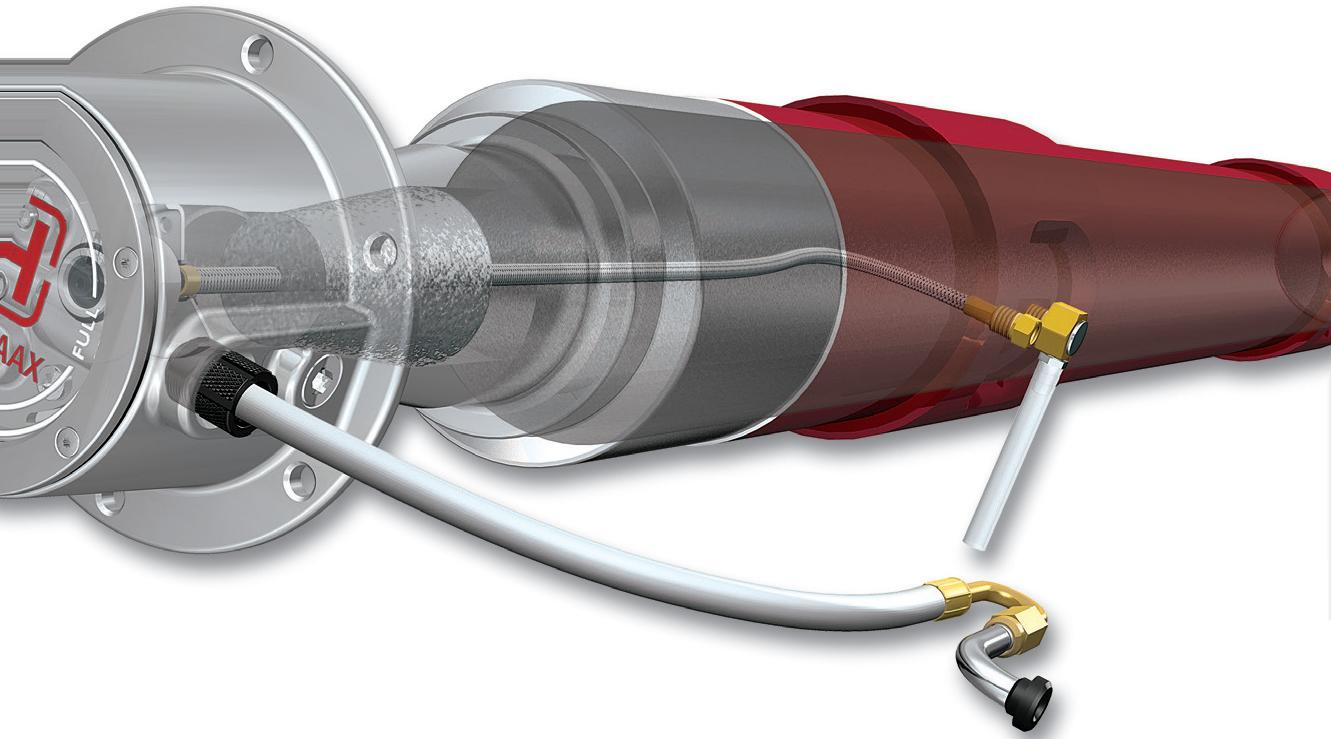

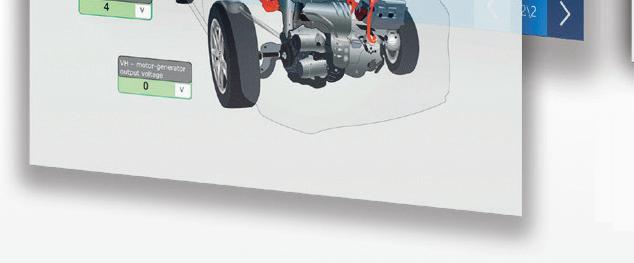

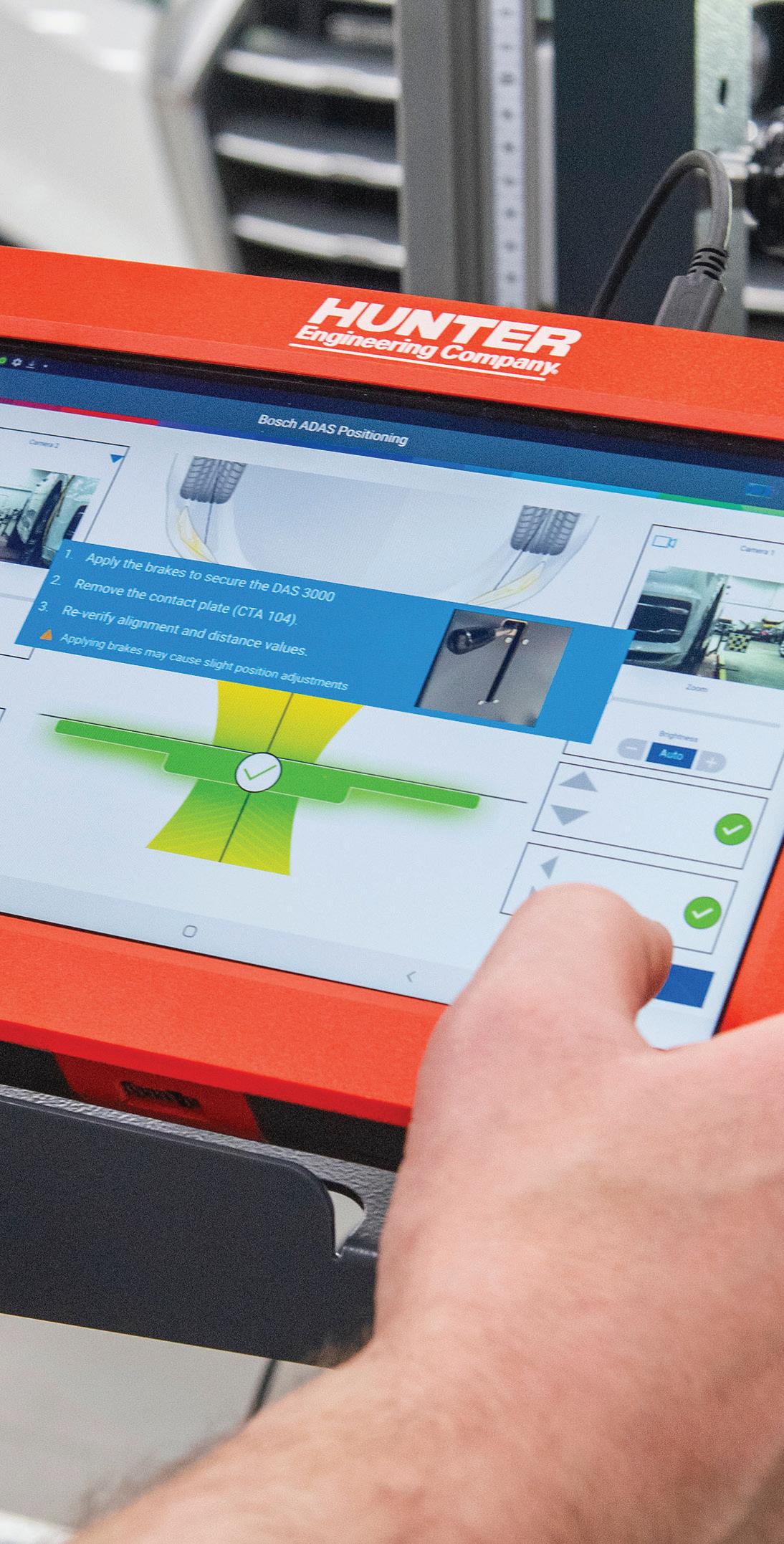

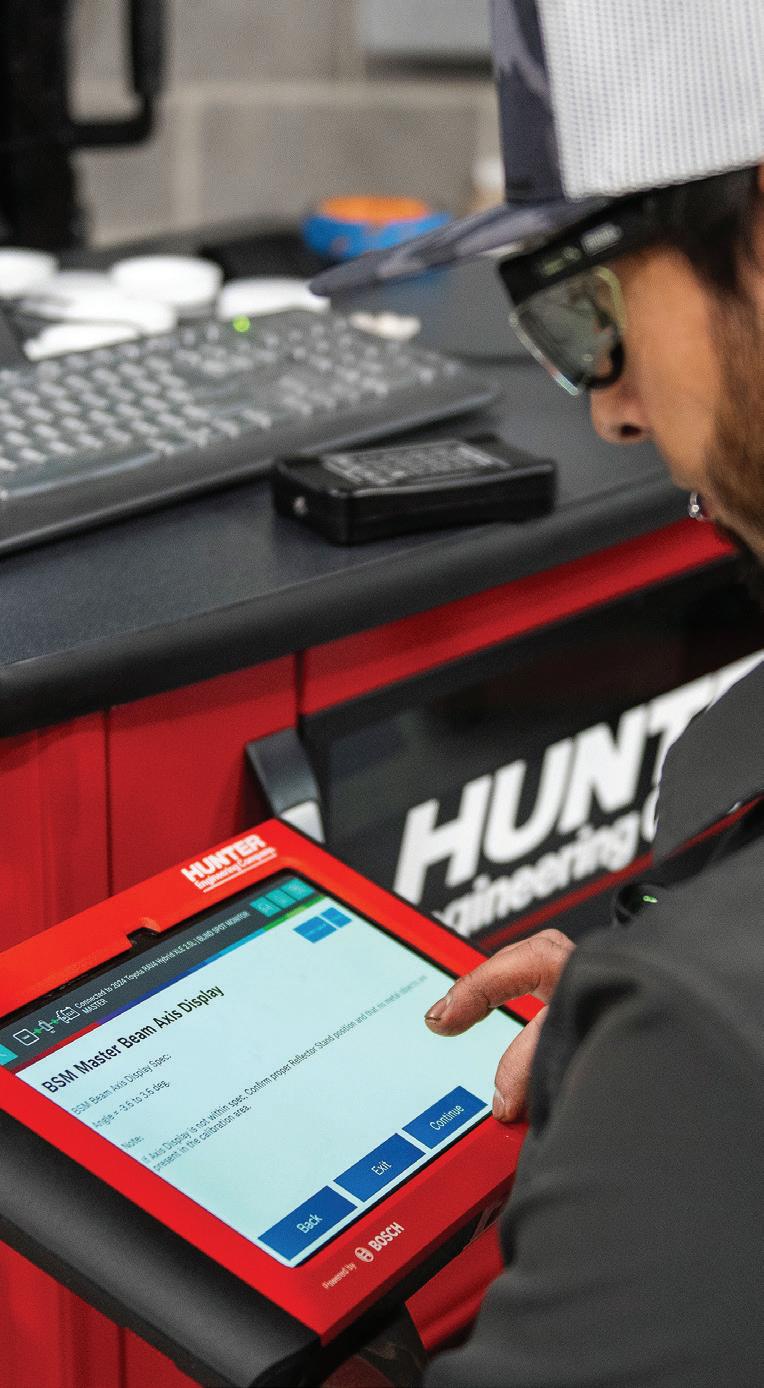

ese are always active and provide surface-level protection. Fleets can go deeper with AI-enhanced dashcams, available facing forward, inward, or both, as well as trailer options. In the event of an accident, they can provide video evidence that may exonerate a fleet. And preventatively, they act as in-cab coaches giving real-time alerts if a driver is speeding (via an accelerometer) or engaging in behavior that would distract them.

Video can also be sent to management to review certain unsafe practices for more in-depth coaching. Positive and negative events can also be used to train other drivers. Some may show how a fleet’s star driver turned certain doom into a near miss, while another can show how a momentary lapse in judgment can create a fatality.

Dashcams combined with ADAS, proper driver training, and of course, following best practices to maintain braking systems and tires, are the best o ense against whatever madness awaits drivers when they leave the terminal.

“ e roadways have never been more unsafe, when you think about the distracted drivers, aggressive drivers, and/or impaired drivers that are out there,” asserted Je Martin, global director of safety at Lytx, a provider of telematics and dashcams. “ e only thing that companies can do, big and small, is put their drivers and field techs in a winning position by giving them the coaching and the technology to promote defensive driving skills.”

e results speak for themselves.