The world's leading synthetic brand - at your service. Learn about our offers at poweredbymobil.com

The world's leading synthetic brand - at your service. Learn about our offers at poweredbymobil.com

More and more drivers want to book ahead—even for quick visits. AutoOps makes that easy—especially for shops that don’t usually take appointments. And it’s built with quick lube in mind, thanks to our collaboration with the Mobil 1™ brand.

We know the unique challenges of quick lube shops. Whether you're a no appointments location or prefer scheduled slots, AutoOps adapts to your workflow.

Online scheduling puts your shop in front of customers actively searching for quick and convenient service.

Make it easy for customers to come back with a booking flow they’ll actually want to use again.

Leverage the power of the Mobil 1 brand to attract customers who value premium service and products.

Help your team stay on task by giving your customers a self-serve scheduling option that just works.

Stay bookable around the clock without lifting a finger—on your site, Google, and more.

*Source: Data provided by Steer Insights

• Includes a 3-Year Warranty*

• Premium starting power and performance

• Built-in protection against temperature extremes

• High reserve capacity for emergency power

• Premium maintenance-free design for maximum convenience

*3-Year Warranty covered by

Reach 65 million AAA members — tap into a massive, loyal customer base.

1 in 4 members need a battery each year — be ready when they do.

On-site battery availability — DEBI ensures immediate access to top-quality AAA-branded batteries.

Offer value-added promotions — NAPA funds consumer rebates during promotional windows, no cost to you.

Last month’s most-read online columns and most listened to podcast episode

ADAS calibration is profitable, but there’s a caveat

The 2025 Ratchet+Wrench Industry Survey Report

Royalty Auto Service fans are so loyal to its YouTube channel that some drive from Delaware—or even stay overnight in a nearby hotel—to get their car repaired at the Southeast Georgia shop.

LEONA SCOTT

An easier way to get repair orders approved

How Curt’s Automotive rebuilt after a shop

Roy Foster’s father opened the shop in 1947, a Chevron station until around 1990. He named the shop after himself and conveniently shares his name with his son and its current owner

BY KACEY FREDERICK

Is it time to adopt industrywide licensing and regulations?

Lead the pack with BG’s professional-use additives, cleaners, and specialty lubricants

Automotive specialists choose premium BG Products and Services to maintain their customers’ vehicles across nine automotive systems, increasing shop efficiency, productivity, and profitability.

BENNETT: Top Strategies for Rethinking Sales Tactics in a Chaotic Economy

Mike Bennett of ATI addresses how auto shops can thrive during economic uncertainty by adapting their sales approach to meet cautious but discerning consumers. He asks shop owners to shift from high-pressure “harvesting” tactics to relationship-building “farming” by offering transparency, empathy, and flexible solutions. Bennett advocates categorizing repairs by urgency (safety-critical, important, preventative), presenting financing options early, and leaving final decisions with the customer, who wants certainty, value, empathy, and convenience.

SCHMIDT: It’s in the Details

Lauralee Schmidt of Schmidt Auto Care urges auto shop owners to prioritize aesthetics and customer experience since car care is a high-dollar, emotiondriven service. She says creating “professional comfort” through thoughtful design choices, proper lighting for safety, cleanliness, and attention to detail are small things customers notice but may not articulate. Schmidt encourages shop owners to view their facilities through their customers’ eyes, making small improvements that build trust and differentiate their business from competitors.

PODCAST: It’s Not What You Say, It’s How You Say It w/Kathleen Callahan

In this episode, Xpertech Auto Repair owner and Ratchet+Wrench columnist Kathleen Callahan talks about the role of strong communication in auto repair businesses. She discusses effective communication strategies with customers, employees, and vendors, highlighting the importance of tone and body language. Callahan reminds listeners that great communication skills directly influence business success and customer relationships.

EDITORIAL

EDITORIAL DIRECTOR

Chris Jones

EDITOR-IN-CHIEF

Chris Jones

ASSISTANT EDITOR

Kacey Frederick

CONTRIBUTING WRITERS

Tess Owings, Leona Scott

EDITORIAL ADVISORY BOARD

Tara Topel, Topel’s Towing and Repair

Andrew Marcotte, American Pride Automotive

J.J. Mont, J.J.’s Auto Service

Rachel Spencer, Spencer’s Auto Repair

Tonnika Haynes, Brown’s Automotive

Lucas Underwood, L&N Performance Auto Repair

SALES

PUBLISHER

Andrew Johnson / ajohnson@endeavorb2b.com

ASSOCIATE SALES DIRECTOR

Mattie Gorman-Greuel / mgorman@endeavorb2b.com

DIRECTOR OF BUSINESS DEVELOPMENT

Cortni Jones / cjones@endeavorb2b.com

ACCOUNT EXECUTIVES

(NATIONAL ACCOUNTS)

Diane Braden / dbraden@endeavorb2b.com

Darrell Bruggink / dbruggink@endeavorb2b.com

Marianne Dyal / mdyal@endeavorb2b.com

Chad Hjellming / chjellming@endeavorb2b.com

Lisa Mend / lmend@endeavorb2b.com

Annette Planey / aplaney@endeavorb2b.com

Kyle Shaw / kshaw@endeavorb2b.com

Sean Thornton / sthornton@endeavorb2b.com

ADMINISTRATIVE ASSISTANT

Ryan McCanna

ART AND PRODUCTION

ART DIRECTOR

Emme Osmonson

PRODUCTION MANAGER

Mariah Straub

AD SERVICES MANAGER

Jen George

ENDEAVOR BUSINESS MEDIA, LLC

CEO

Chris Ferrell

COO

Patrick Rains

CRO

Paul Andrews

CDO

Jacquie Niemiec

CALO

Tracy Kane

CMO

Amanda Landsaw

EVP ENDEAVOR BUSINESS INTELLIGENCE

Paul Mattioli

VEHICLE SERVICE/REPAIR GROUP

AND FLEET AND TRAILER GROUP

Chris Messer

SUBSCRIPTIONS

Send address changes and subscription inquiries to:

Ratchet+Wrench PO Box 3257 Northbrook, IL 60065-3257

SUBSCRIPTION CUSTOMER SERVICE: 877-382-9187 ratchetwrench@omeda.com

LETTERS TO THE EDITOR

editor@ratchetandwrench.com

Opinions expressed in Ratchet+Wrench are not necessarily those of Endeavor Business Media, and Endeavor Business Media does not accept responsibility for advertising content.

Aside from consumer safety, ADAS calibrations open the door to a significant annual profit center for auto repair shops

BY CHRIS JONES

The U.S. Department of Transportation’s National Highway Traffic Safety Administration’s Federal Motor Vehicle Safety Standard No. 127 ruling, which will make automatic emergency braking standard to help reduce rear-end crashes by September 2029, means that auto repair shops need to be more meticulous about advanced driver assistance systems, and do them by the book.

As vehicles with ADAS technology become more prevalent in auto repair shops, Steve Dawson of Hunter Engineering says one of the big challenges today is that calibration systems that were once individual are now intertwined. Adding to the challenge of deciphering ADAS is when cars use these systems to interact natively on the driver’s behalf (e.g., the aforementioned automatic emergency braking).

Systems such as those require properly aligned ADAS components that have travel speeds and direction calibrated accurately, adaptive cruise control functioning to follow cars at a safe distance, and no corrective action needed. If a car is off half a degree from the thrust line, automatic corrective action may be applied unintentionally and could create a serious hazard on the road.

by the Numbers:

• 5 million vehicles require ADAS service in an independent shop in 2023

• $283 million in calibration work outsourced

• 90% of ADAS work is outsourced to mechanical repair shops

• 75% of ADAS calibrations outsourced to collision shops

• 60% of passenger vehicles registered in the U.S. have ADAS components that need calibration of touched, moved, or replaced

All OEMs require ADAS calibration after a collision and on repairs where sensors are engaged. “If we touch this system, if we just align the car, it needs to be recalibrated,” Dawson says. Auto repair shops need to pull up repair procedures for alignments, and if shops are subletting ADAS work, the subcontracting partner, be it another shop, dealership, or mobile technician, should know what has to happen for a proper alignment.

“There are a number of things that have to be verified, and the other shop must know what to do,” Dawson says, adding that in the long run, all auto repair shops should provide ADAS. “I want you to think about it. You’re going to need to be in the ADAS business. You could be subletting 50% of your profits if you don’t do (ADAS) in-house.”

• Collision

• Sensor removal or replacement

• Lift, level, or lower vehicle (change ride height)

• Wheel alignment

• Windshield

• Mirror and underhood work

• Tire/wheel package upgrades (change in overall diameter)

He stressed the need for shops to use the right tools (including OEM tools), have trained technicians who are versed in electrical diagnostics, and access to

OEM websites for files to download firmware to communicate with the car and above all, for the technician performing the calibration to follow OEM procedures and make sure the vehicle is on a level surface.

“When we’re talking about ADAS, it’s about having the right tools to work effectively,” Dawson says. “And it’s critical that we get the training that we need and that we’re doing the most accurate calibrations that we can, and we’re following those OEM procedures.”

Dawson called ADAS calibration a team sport—everyone in the shop needs to be involved, from technicians to the front office. “It’s critical to have a process in place for liability and making sure nothing falls through the cracks,” Dawson says.

For auto repair shops who choose to sublet the work to independent contractors, dealerships, or collision repair facilities, Dawson says to make sure that the party you hire is properly vetted out since all liabilty for the work falls on the

shop and not the subcorntacted partners legally. To that, Dawson says documenting every step matters.

“Your shop is liable for the work of the (repairing partner). All processes must be written down and documented, or they didn’t happen,” Dawson says.

For many shops, ADAS calibrations

open the door to a significant annual profit center. Dawson says auto repair shops offering ADAS can add $140,000 per year of additional revenue by doing ADAS calibrations in-house. As sensors become more complex, the average charge for calibration changes. While equipment cost and space are often a deterrent for many shops, Dawson says most ADAS can be completed within a modest foot-

print that’s well-lit. He recommended shops keep digital documentation showing visually what needs to be done.

“(ADAS calibration) is doable in many of your shops, but it requires that your shop floors are in good shape. Space is different by manufacturer. Use the resources you have before you sublet. You may be able to do a lot of calibrations in the space you have,” Dawson says.

Wayne’s Automotive of Grand Rapids, Minnesota, has partnered with a nonprofit in the state to provide free emissions repairs to low-income individuals, reports Lakeland PBS.

The nonprofit, Environmental Initiative, is working with the shop as part of its Project CAR, where it collaborates with local auto repair businesses to cover the cost of emissions control and exhaust system repair.

Currently, the program hasn’t gone far beyond the Twin Cities, but its partnership with Wayne’s Automotive marks its entrance into greater Minnesota as it seeks to expand its reach. Since the program was launched in 2017, it has helped repair over 800 cars and eliminate 43 tons of emissions.

“It’s an opportunity to help our community with car repair,” said Jordan Cozatt, VP of business development and client services for the shop’s parent company, Victory Auto Services. “Certainly, having a nonprofit like Environmental Initiative help is kind of a two-pronged approach, where we’re helping the environment, of course, and this beautiful country up here, but also if we can help the pocketbook of our customers.”

A recent report from Perceptyx suggests that there is a lack of career opportunities for middle-aged employees, according to Automotive Dive.

The May 7 report examined factors in retaining and engaging employees. Four out of the top five drivers of an employee’s intention to stay were directly related to career growth, with employees who plan to stay being three times more likely to believe they can achieve their career goals, and more than twice as likely to see a clear path forward.

However, this confidence in career opportunities decreases with each passing generation, through baby boomers. Training satisfaction peaked with Gen Z, suggesting that there is a gap in opportunities for those older.

Lisa Sterling, chief people officer at Perceptyx, also added that the uptick

in AI tools may prompt concern from middle-aged and mid-level employees. According to a report earlier this year, nearly half of the employees surveyed by TalentLMS felt AI was advancing faster than their organization could prepare anyone for.

“Career trajectories become much more unpredictable and obscure at middle age,” added Sterling. “These workers, many of whom are managers with a significant scope of influence, have valuable skills and experience but are left wondering what success looks like in this next stage of life.”

New York Auto Shop Faces Hundreds of 311 Complaints— Allegedly, From One Person

A longtime family-owned auto repair shop in Brooklyn, New York, has been the target of excessive 311 complaints over vehicles being parked on the sidewalk, reports the Brooklyn Eagle.

Located at 60 Old Fulton St., New Xcell Auto Repair has been operated by the same family for over 50 years. Eric Han is the current owner, with his grandfather, father, and uncle having first started the business in 1972.

The shop has built a loyal reputation over the years, but has faced a sudden explosion in 311 complaints lodged against it in the past couple of months, specifically ranging between 300 to 400, which take issue with vehicles being moved between the street and the shop’s property.

Han was informally told that these complaints were coming from the same person, which made sense given how diligent the complainants have been. For example, when a vehicle was recently dropped off by a tow truck, it took less than five minutes for an employee to bring it in, but it still led to a 311 complaint being filed.

Another example Han provided was a delivery truck coming to drop off parts, which prompted a 311 complaint over the couple of minutes it took the shop to sign for the delivery. It took police half an hour to investigate the complaint, after the delivery truck was long gone.

“Every time a delivery truck pulls up for five minutes to drop off parts, or someone pulls into my driveway to ask a question, boom, a complaint is

immediately filed. When the police get here 20 minutes later, the delivery truck is gone,” said Han. “This guy probably watches the DOT traffic cam and files a complaint online the second a car is on the sidewalk.”

The problem received even more attention when customers of the shop became aware of what was happening and sent requests for help to Councilmember Lincoln Restler (D-Brooklyn Heights – Greenpoint).

“This is such a shame. New Xcell are good mechanics,” said one local, Marilynn Donini. “I walk by there every weekday and never have trouble navigating the sidewalk. Twice, I’ve even been on crutches. It’s important to keep local businesses like New Xcell in the neighborhood.”

Restler told the Brooklyn Eagle that he and his team will be working with New Xcell to find a solution for the shop.

“New Xcell is a valued small business in our community, and we want to ensure they are able to operate effectively without parking cars on the sidewalk or in the bike lane,” said Restler. “We are committed to working with New Xcell to identify safe alternatives that work well.”

Vehicle, Parts Output Fell in April; Could Face Further Complications from Tariffs

The automotive sector saw a decrease in manufacturing output last month, and could struggle to climb back up due to tariffs, according to Reuters.

Factory output fell by 0.4%, following an upwardly revised 0.4% gain in March. Reuters also polled economists who predicted a 0.2% decline, after having previously estimated a 0.3% rise.

Motor vehicle and parts output had been increasing in the past two months, and in April was up by 1.2% year-overyear, but last month also saw a 1.9% drop in motor vehicle and parts output.

With many tariffs remaining in place—including a 30% tariff on Chinese imports, 10% tariff on nearly all imports, 25% tax on steel and aluminum, and tariffs on motor vehicles and parts—and production heavily relying on imported raw materials, this decline may be difficult for the industry to make up for in the coming months.

We have not just enhanced, but mastered, the concept of car repair. With monthly revenue figures over $1 million, our system guarantees exceptional customer service and unprecedented sales numbers.

In 15 minutes every car gets a full comprehensive inspection on the speed rack. Pictures and videos capture the problems to be presented to the customer.

Full day of learning the new AI tools being used in our shops. This class will elevate your shop to new heights.

P&L Statements

Projections & Forecasting

Management Fraud & Embezzlement Plus so much more!

“This

This year’s Ratchet+Wrench Industry Survey Report adds new data to examine the impact of AI and the effect of tariffs

BY CHRIS JONES

Featuring data collected from nearly 200 auto repair shops across the United States, the 2025 Ratchet+Wrench Industry Survey Report remains your trusted resource year after year for an at-a-glance look at the independent auto repair

owners’ gender, younger owners, and shops earning higher revenues.

In each of its four sections—Industry Overview, KPI, Leadership and Tech+Tools—you’ll get comparative data segmented by category to give you

For the first time, the Ratchet+Wrench Industry Survey Report examines the impact of AI tools in the auto repair shop and the effect of tariffs.

All this and more comes packaged in this 32-page report available to you free at ratchetandwrench.com.

Owner Levi Glover has always been focused on cultivating a recognizable brand name, which he’s achieved through the use of striking colors and an inviting space for all customers

BY KACEY FREDERICK | PHOTOS BY ALAINA LOGAN

Levi Glover first opened Redline Automotive in June 2018. Having been raised by the owner of an auto body shop, he’s been immersed in the industry since he was a child and worked in dealerships—working his way up from advisor to fixed operations manager, and eventually general manager—before deciding to open his shop.

Glover wanted to go for a bold and modern look with the building. It features dark gray walls with black accents, and

bright red doors in reference to the shop’s name.

The side of the building has been used for aesthetic purposes, with a professional artist painting a mural over it entirely. It displays a vintage repair shop and an older model Porsche 911 with bright red colors to help it stand out.

The front entrance also has a Vgroove placed across it so that when customers pull up, they can see where to go.

Customers are greeted with dark gray leather chairs, hardwood floors, and granite countertops. The walls are light gray, with a black ceiling and

HAVE AN OUTSTANDING SHOP? Send a few photos and a brief description to submissions@ratchetandwrench.com and we might feature it here.

Owner: Levi Glover

Location: Thomasville, Georgia

Staff Size: 7

Shop Size: 2,000 square feet

Number of Bays: 6 Average Monthly Car Count: 115 Annual Revenue: $1.2M

recessed lighting. An essential oil diffuser in the waiting area helps maintain a clean, professional environment.

“When you walk in, it doesn’t smell like gear oil or transmission fluid. It smells like lemon basil or whatever we have at that time. It’s a real comfortable, modern atmosphere,” describes Glover. “It still says ‘mechanical, industrial,’ but also very comfortable to where you can send a family member in here.”

The clean and professional feel of the waiting room is far from a facade, though. The shop area has gray epoxy floors with red flake, with the Redline Automotive logo epoxied into the flooring. Similarly to the front of house, the walls are also gray, contrasted by the bright red racks throughout the shop. The area has a spray foam roof painted black, along with UFO LED lights.

The gray-black-red color scheme can be seen throughout the whole shop, along with the Redline logo. It’s the result of a conscious effort by Glover to establish a recognizable brand name that could last for generations.

“Being that we’re in a smaller shop, a lot of people want to name it their last name, or ‘Joe’s Automotive’ or something like that,” explains Glover. “I went with the aspect of doing a brand. So, when I get older, I could either give it to my children or sell a brand versus just somebody’s name.”

Increase customer loyalty by putting these systems to work at your shop

BY KATHLEEN CALLAHAN

Educating clients is at the heart of excellent customer service. Our tools, from digital inspections to customer retention management systems, go beyond improving shop efficiency; they play a pivotal role in fostering customers’ trust. As vehicle systems advance, so should our service standards. It can be overwhelming—and expensive—to keep up with all of the latest tools. So, I’ve listed a few below that are critical to your shop’s continued success.

I was an early DVI adopter, but getting my team on board felt like a monumental task! Today, they all embrace it and are upset when we have hiccups and it doesn’t work (which isn’t often). I created our inspection process by writing down the exact order in which my team did their inspections, and when we all agreed on a uniform order, that became our inspection procedure. Having your team as part of the creation is crucial in gaining their participation. Performing DVIs will take technicians more time in the beginning, which is normal, but that time will decrease once it is part of their routine.

Most demonstrations with DVI providers focus on making more money and increasing profit. Awesome! That is a benefit, but my favorite part is the increased trust with your clients. You’re showing them the condition of their vehicle and helping them make educated decisions about repair and maintenance that align with the client’s budget and schedule. Customers who understand the intricacies of their vehicle systems through clear explanations and digital reports become more receptive to the necessary repairs, even as costs rise. This level of education benefits the client and elevates the reputation of our industry. They’re not coming in for “just an oil change” anymore. They’re having the fluids serviced and a system check on all the expensive components to avoid breakdowns and unexpected expenses. To convert your customers to clients, DVI is a must-have tool.

(Note: Encourage your advisors to em-

brace silence after presenting DVI findings. People process information differently, and allowing them time to reflect ensures they feel confident in their decisions. Silence doesn’t mean no; it’s an opportunity for understanding.)

A CRM is a must-have for improving communication, customer retention, and overall service. These tools let you build and manage email lists for targeted marketing campaigns, like service reminders, special offers, and follow-up messages, making sure your shop stays top-of-mind for customers. Most CRM systems include review management features, so you can easily track feedback and respond to reviews all in one place. This helps you maintain a strong online reputation and makes sure you’re always on top of customer concerns.

Another valuable way to enhance your CRM is with add-ons, like two-way texting and online scheduling. These allow you to communicate with clients in realtime, whether it’s answering questions, giving updates, or sending important information. Online scheduling lets customers book services when it’s convenient for them, including nights and weekends, which helps eliminate wait times and smooths the whole process.

At its basic level, CRM systems ensure follow-ups and service reminders don’t slip through the cracks, offering automated reminders that keep customers engaged and coming back. This also helps clients book deferred services and not forget about them. These features are small shifts that often lead to increased revenue over time and lead to better customer retention, stronger loyalty, and ensure your clients trust you for future repairs and maintenance.

Digital payment options are a fantastic way to elevate the customer experience! When your shop offers a variety of payment methods—from mobile wallets to contactless payments—it becomes easier and more

convenient for customers to pay. Plus, with enhanced security features, digital payments protect both your customers and your business from fraud, giving everyone peace of mind. By embracing additional payment solutions, you’re not only streamlining the checkout process, but you’re also showing your customers that you’re keeping up with the latest technology. This forward-thinking approach builds trust, boosts customer confidence, and keeps them coming back for future services. It’s a win-win!

Another great tool for building stronger customer relationships is a shop management system. You can make future interactions personal and meaningful by using the notes section to log important details about each client: birthdays, anniversaries, children’s names, pets, or upcoming travel

Kathleen Callahan has owned Florida’s Xpertech Auto Repair for 20 years. In 2020, she joined Repair Shop of Tomorrow as a coach to pursue her passion for developing people and creating thriving shop cultures. Callahan is the 2018 Women in Auto Care Shop Owner of the Year, nationally recognized by AAA for three consecutive years, testified for Right to Repair on Capitol Hill, and is vice chair of Women in Auto Care. kathleencallahanfl@gmail.com

5 Ways Royalty Auto Service Grew a YouTube Channel and a Much Broader Customer Base

From TikTok stardom to YouTube success, this Georgia-based father-son shop demonstrates how authentic content builds trust from viewers and customers worldwide

Royalty Auto Service fans are so loyal to its YouTube channel that some drive from Delaware—or even stay overnight in a nearby hotel—to get their car repaired in Southeast Georgia.

That’s not hyperbole. Nestled three minutes off I-95 in St. Marys, Georgia, Royalty Auto Service isn’t just a shop–it’s a destination. Customers traveling from Alabama, the Carolinas, or even on their way to Orlando make it a point to stop and see “the shop from YouTube.” The reason? Trust. Transparency. And a whole lot of heart behind the camera.

In just two years, Sherwood Cooke Jr. and Sherwood Cooke III–also known as S2 and S3–built an impressive YouTube presence that complements their earlier success on TikTok. Their content isn’t flashy or gimmicky. Instead, it’s practical, digestible, and relatable–showing the real-world challenges of diagnosing and repairing complex vehicles, all while demystifying what happens behind the service desk.

Here are five strategies that helped Royalty Auto Service grow a loyal following–and attract the right customers, not just views.

Royalty Auto Service’s first foray into social media came via TikTok around 2021. After several months, Sherwood Jr. found an audience while his son handled the technical side of shooting and editing everything in-house. When their bite-sized videos gained momentum (amassing more than 920,000 TikTok followers), they decided to expand into longer-form content.

“YouTube gave us a platform to go deeper,” says Sherwood III. “We wanted to show what a real diagnostic process looked like, how we use scope testing, and just open the shop doors to the public.”

They launched their YouTube channel on March 1, 2023, with no intention of chasing new business, but the company followed anyway.

The channel strikes a unique balance between educating car owners and engaging professional technicians. By showing actual repairs in process —and

keeping the explanations clear—the Cookes earned global fans from as far away as Australia and South Africa. Still, 73% of their audience is based in the U.S.

“We don’t try to be flashy or fake,” said Sherwood III. “People can see through the fluff. We talk to viewers like they’re right here in the shop.”

Some videos cater to DIYers, like how to reset automatic windows (a surprise hit with more than two million views). Others delve deeper, such as diagnosing a Mercedes steering lock issue or walking through a proper brake job.

The common thread? Clarity. Authenticity. And respect for the viewer’s time and intelligence.

At Royalty, the car comes first. The content comes second, but it’s recorded along the way.

“We’re always creating content,” says Sherwood III. “We film while we’re working on cars, so it’s a real behind-thescenes look. It might take a little longer, but people enjoy watching the process— and for us, it’s worth sharing what we do.”

The behind-the-scenes format helps viewers understand what happens in a diagnostic bay, showing the steps, including false starts, that go into solving challenging automotive problems. It’s not always slick, but that’s what builds trust.

“We’ve had customers say, ‘I’ve been

to five shops and nobody could figure this out. But I saw what you did on YouTube and I knew you were different.’ That’s the kind of customer we want.”

Videos typically take eight to 10 hours to edit per week, and Sherwood III often does it all on his iPhone. That DIY spirit translates into relatable content that’s both high quality and grounded in reality.

In a social media landscape dominated by algorithms, Royalty Auto Service adopts a different approach: consistency, not virality.

“Our goal was never to get more cars in the shop,” says Sherwood III. “It was to attract the right customers—the ones who appreciate diagnostics and understand the value of good work.”

That mindset has is paying off. They are not trying to please the masses, rather they’re building a community centered on values such as transparency, integrity, and craftsmanship. And that’s exactly what their ideal customers are looking for.

Whether it’s showing a transmission flush or discussing fluid maintenance (yes, even controversial opinions on fluids), their videos convey confidence and conviction.

One key piece of advice from Sherwood III: “Before you launch, have 10 to 15 videos in your content bank. That way, you can publish regularly while still making new videos.”

“They see the process. They understand what we’re doing. And when they drive hundreds of miles to see us, they know we’re not just fixing cars— we’re earning their trust every step of the way.”

— Sherwood Cooke III, Royalty Auto Service

While Sherwood Jr. turns the wrenches, Sherwood III keeps the cameras rolling—and they both stay humble about the journey.

“I don’t even like working on cars,” Sherwood III admits. “I did basic maintenance, then went into a service advisor role. But this partnership with my dad works perfectly. He’s the expert under the hood. I help share that with the world.”

Along the way, they’ve made their share of mistakes, but those missteps became valuable lessons. Their advice for other shops starting?

• Start small. Short-form content, such as TikTok or Instagram Reels, can be an easier entry point.

• Don’t rush. Viewers will quickly

spot inaccuracies, especially in diagnostic content.

• Be yourself. Authenticity outperforms polish every time.

• Don’t overthink. Simpler topics often perform best, such as the window reset video.

One of the most rewarding parts?

Being recognized by fellow technicians and shop owners at industry events or airports, who say the Royalty channel helped them become better at their jobs.

What’s next for Royalty Auto Service? In addition to a third shop location on the horizon, the team is developing a training website, set to launch in late 2025.

“We kept going to events like VISION

and STX and seeing the same group of shops,” says Sherwood III. “We wanted to create something from the ground up— training that starts at Day One and helps techs build real diagnostic skills.”

Just like their videos, the training platform will focus on practical skills, presented with clarity and honesty.

Royalty Auto Service didn’t set out to build an empire. However, by sharing their work openly and staying true to themselves, they built a worldwide following—and a local business fueled by customer trust.

“People love the transparency,” said Sherwood III. “They see the process. They understand what we’re doing. And when they drive hundreds of miles to see us, they know we’re not just fixing cars— we’re earning their trust every step of the way.”

Rev Up Your RWMC Experience at the Vendor

Thursday, October 9 • 4:30 – 7:30 PM

Top Industry Vendors

Meet face-to-face with the companies shaping the future of auto repair.

Cutting-Edge Tools & Tech

Explore products and services designed to increase efficiency and profitability.

Live Demos & Expert Insights

Powerful Networking

Get the latest tools, tech, and trends driving the auto repair industry forward. The Vendor Showcase is your all-access pass to hands-on innovation and meaningful connections.

O CTOBER 8-10, 2025

See new solutions in action and get your questions answered by the pros.

Grow your professional circle during the vendor showcase hours and evening reception.

Roy Foster found his fulfillment in the auto repair industry—now, he uses his place as a shop owner to help others thrive

BY KACEY FREDERICK

BY RICHARD BEDNARSKI

Growing up in the industry as a technician, seeing yourself running a shop of your own one day—it’s a common start to many paths of shop ownership. What many don’t see up ahead are the curves and twists that come with overseeing an entire business and expanding into areas that you didn’t previously have to consider.

It’s a journey Roy Foster knows all too well. Since his father opened Roy Foster’s Automotive in Reno, Nevada, over 50 years ago, it’s been through many different periods of growth—and ownership. When it was time for Foster to step in the role of an owner, he was as ready as anyone could be; but there are some lessons you can only learn from first-hand experience.

Foster’s father first opened the shop in 1947, originally as a service station. He named the shop after himself, and conveniently shares his name with his son and current owner.

While Foster was raised around automotive work, his father came from a farming background and was the first in his family to pursue auto service. He got experience fixing up farm equipment and eventually went on to work in service stations. After serving as a Navy man in World War II, he then moved out to Reno to open his service station in the ‘40s.

Foster’s involvement in the business came when he was in junior high. He started helping out around the shop and always saw himself following in his father’s footsteps.

“I’ve always had a passion for the business, and always thought that’s what I would do. In high school, of course, I was thinking what else I might do—but it always just came back to, ‘Yeah, this is in my bloodline,’” recalls Foster.

However, when Foster’s father passed away in 1980, it would be his two older brothers that took over operating the business. There would be a period of growing pains as one brother realized he preferred to work as an employee, and stepped away from an operator role.

The shop was a Chevron station until around 1990, when Chevron reached out to the business and said they wanted to replace its service stations with a

convenience store. Rather than forego the shop’s successful repair business, it would split off into its own separate entity. The existing store was converted into a gas station and convenience store, while the shop’s repair work was moved into another building.

Throughout all of this, Foster remained with the shop, working as a technician. When the business split up, Foster was a natural fit to oversee the repair shop, while his older brother continued to oversee the older location’s operations as a convenience store.

While Foster had plenty of experience working with vehicles as a technician, he would soon discover that it was a whole different playing field as a shop owner. There were now many different aspects of his job competing for his time and energy.

“It’s a whole other area of expertise that you have to learn: what numbers you need to look at, how to do marketing, how to lead employees, how to keep up with the times, reinvesting,” says Foster. “You don’t know what you don’t know, right? People looking at a shop, they see all the cash flow and big repair orders, but what they don’t see is the other side of the business.”

For Foster, seeking out coaching companies has been an invaluable asset to his operations. The guidance he received helped him build a process that can easily be duplicated and carried over for whenever the business is handed to someone else.

Part of that has involved investing in his employees through a myriad of ways. Being a husband and the father to seven children, Foster always valued his family before all else, and integrated a healthy work-life balance into his shop’s culture. All of his employees are provided with benefits that allow them to take care of themselves and family, as well as plenty of paid time off.

Knowing that not only he but his employees are taken care of is part of what reminds Foster why it’s so important to manage a business properly.

“You have to be able to manage and run your business properly in order to accomplish all these things—to reinvest, to keep up with the technology, to have the best talent, to take care of them the best you can, so they can also have their work-

“You have to be able to manage and run your business properly in order to accomplish all these things”

life balance, make a great living, and get paid for the value that they bring.”

The shop also has a NAPA Apprentice Program, which provides both hands-on training and an online curriculum, with students receiving a tool set at the end of their training.

The training and career opportunities his shop has offered people has been one of the most gratifying parts of Foster’s career. His own son even found his calling through the NAPA Apprentice Program, after a potential career in college baseball didn’t turn out how he planned due to the COVID-19 pandemic.

At the same time, he saw how much he could make through a career in auto-

motive repair and decided to pivot from baseball to joining the apprentice program. He saved his money and bought a house, all before his friends were able to finish their college studies.

It’s worked out great for him, but his success is something Foster wants everyone in the field to see. Through efforts like his apprentice program, he hopes to play an active role in recreating that same result for others.

“Last year, he bought a house. He has all his tools. He has no student debt, and he’s well on his way in life making great money,” shares Foster. “It’s a real success story. And we’re going to continue to repeat that, over and over.”

BY ALISON JOHNSON

I can’t afford it. I don’t have time today. I’ll call back later.

Those are by far the top three objections raised by customers facing unexpected car repairs, especially if they are financially stressed.

The way a shop responds can make all the difference, says Samantha SchearerHigdon, marketing manager for Schearer’s Sales & Service, Inc., in Allenton, Pennsylvania. Patience, empathy, flexibility, and education all go a long way.

“Our goal is not to shove anything down people’s throats when they’re feeling uncertain or overwhelmed, but to partner with them to keep their vehicle

safe, reliant, and efficient,” SchearerHigdon says. “If they feel seen and heard, they’re going to trust you much more.”

Here are some tips:

Objection No. 1:

“It’s Too Expensive. I Don’t Have the Money Right Now.”

Solutions: Offer financing options, use exit scheduling, and explain the importance of the job

Auto repair shops can break larger bills into smaller installments by developing in-house payment plans or partnering with external financing companies that

provide loans or credit cards specifically for auto repairs.

Some auto parts suppliers also have plans with deferred interest if a customer pays in full within a certain amount of time, often six months.

Part of a shop’s job is to ensure that customers understand potential fees, Schearer-Higdon says: “Figure out what they can manage financially. If they don’t think they can take care of a bill in six months, for example, a high interest rate might hurt rather than help them. You never want to put anyone in a worse financial position.”

Another route is carefully spacing

out work based on a customer’s situation, rather than tackling everything at once. The key there is to prioritize problems that could affect safety or cause significant damage to a vehicle in the short term, while scheduling less-urgent maintenance jobs for a future date before a customer leaves the shop.

Finally, keep in mind that “too expensive” may not be all about money. Instead, a customer may not fully understand the value of a repair or service.

In that case, discuss details of the fix and why the investment likely will save money and headaches in the long run, as well as why relying on a trained technician is a better guarantee than trying doit-yourself repairs or turning to a friend with a bit of automotive know-how.

“I

Don’t Have Time. I Need My Car Back Today.”

Solutions: Invest in a fleet of loaner cars, and schedule their use wisely

Simply having vehicles for customers to borrow for a day or more isn’t enough.

The trick is to have enough of them in the shop at any given time to accommodate customers who need unanticipated repairs.

Schearer’s Sales & Service has 12 loaner cars but only schedules five or six to be out of the shop per day, which leaves half on hand for last-minute requests.

“For loaners to be an effective ‘objection buster’, you need to have that wiggle room,” Schearer-Higdon notes. “That way, you can not only sympathize with the customer standing right in front of you, saying they don’t have another car and they have all these errands to run— you can actually help them.”

“I’ll Just Do That Next Time.”

Solutions: Use both exit scheduling and calendar reminders for your team

Many people who promise to call back either procrastinate or forget the task due to their busy daily lives. The best move, then, is to book an appointment while the customer is still standing at the service desk.

Driving lubricants innovation for all types of engines

If that doesn’t happen, make a record of the conversation but avoid negative comments about the decision. Instead, set a future calendar alert—via your shop management software—to remind advisors to follow up with that customer by a specific date.

“That holds us accountable to contact people and talk about how we’re aiming to keep their car in the best condition possible,” Schearer-Higdon says. “If a client’s car breaks down, I consider that to be a failure on our part.”

Of course, the best scenario is to avoid objections in the first place, which requires getting to know each customer’s specific needs early on.

Some good questions to ask: How long have you had your car? What do you like about it? What do you use it for the most? How long do you hope to keep it? What is the definition of a “big bill” for you? Is there a tipping point with cost that would make you decide to get a new car?

“What it really comes down to is, don’t treat clients like numbers,” Schearer-Higdon says. “Treat them like part of your family.”

BY

After a fire burned their shop to the ground, this team found a way to come out stronger

BY TESS OWINGS

“One of the most spectacular fireworks displays I’ve ever seen.”

That’s how Eric Newton says his father-in-law, Curt Rock, described the fire that ended in a total loss for his shop, Curt’s Auto Repair.

On December 7, 2007, the family was sitting in a midweek church service when one of their business neighbors in Phoenix ran in looking for Curt because the shop had caught on fire. The fire would burn the shop to the ground, along with a few customers’ cars.

Rather than dwell on their situation, the team pulled together and was able to quickly find a new location and retain almost all of their customers. Newton, the general

manager, outlines what happened and the important business lessons that he’s learned.

Newton married into the Curt’s Auto family when he wed Rock’s eldest daughter. He’s been in the business, which started in 1987, for 25 years.

Newton says that his father-in-law started by doing fleet maintenance, and then, when he got busy enough, he rented a place and started a shop, Curt’s Auto in Phoenix.

On December 7, 2007, the building caught fire and burned to the ground. The fire inspectors said that the cause

of the fire was a short in the wiring of the building, and the breaker wasn’t able to do its job, which melted the wires and caused the total loss of the building. When all was said and done, it was a $300,000 loss. The shop only had $75,000 worth of coverage. That meant that a couple of customers would be able to get their vehicles replaced, and that was it. Curt’s Auto was left without tools, equipment, or a place to call home.

Initially, the team wanted to rebuild at the same location, but they weren’t allowed to because there were already “too many buildings in the area.” So, they started asking

around and looking to see what was available. They ended up finding a location roughly six miles away from their initial location. It was a run-down repair shop that had recently become available because the landlord had to kick the previous tenant out. There was a lot of work to be done, but they knew they could make it work.

During the process of finding a new building, the team never stopped working. They brought in whatever they had from home or could borrow and kept working on the customers’ cars that they had in the parking lot that were not damaged by the fire. Luckily, they had a backup of all of their customers’ information, so they were able to keep in contact with all of the customers and let them know what happened, what the plan was, and keep them updated all throughout the process. The new location opened around the first of 2008, with lightning speed turnaround time.

“We didn’t have a choice,” Newton says of the hard work that was put in to get a new location up and running as soon as possible.

The location that burnt down did between $600,000 and $700,000 per year with a staff of four. The new location is pushing $2 million with a staff of 15. After the fire, Newton estimates that they retained 90% of their customer base at the new location, even though some of those customers suffered personal loss of their own from the fire.

“I would say it’s because we were always good to them, so when things happened, they were willing to be there for us,” Newton says.

TAKEAWAY:

For Newton and the rest of the staff who went through this, one of the biggest lessons was not to take anything for granted.

“You never know what tomorrow will bring,” Newton says.

Newton says that going through something like this has made him somewhat a cynic and made him double-check everything. For example, make sure you’re covered

“YOU

financially in case there’s a total loss. Newton says that at any time, the shop may have up to $1 million worth of equipment and vehicles in the shop, and he can’t cover that for a few thousand dollars worth of insurance.

Also, make sure you’re being diligent about business maintenance, especially if you’re in an older building.

“We preach about maintenance on vehicles, but the building itself needs to be maintained,” Newton says.

Communication, Newton adds, is also key, especially in a time like this. Customers need to be kept in the know, and they will appreciate it in the long run. Cell phones were a

— Eric Newton of Curt’s Auto Repair

newish concept at the time of the fire, but employees made sure to use their personal lines to keep in contact with their customers.

Last, remember that you are a team and you need to work together. At the time, Curt’s had to let a few people go because they couldn’t afford to keep them around, but once the shop had recovered, they were able to get one of those employees back because they maintained a good relationship.

Nobody expects to go through anything as devastating as this, but it can happen to anyone at any time, and it’s important to think ahead, work together, and never take anything for granted.

THE 35,000-FOOT VIEW

A look at why effective regulations in the auto care industry elevate the level of quality, service, and accountability among shops

BY R. “DUTCH” SILVERSTEIN

Soon after closing my shop, I began the mind-numbing task of sorting through decades’ worth of Hot Rod and trade magazines. As I sifted through the contents of countless boxes of magazines, separating those bound for recycling from those I would keep, I found myself stopping to reread columns about the business of auto repair that were written many years ago.

The topics were familiar: adapting to new technology, shifting societal expectations, combating public distrust, employee issues, industry regulation, and economic pressures. These recurring subjects caused me to reflect on the current state of the industry and the need for change. The more I read, the more I noted that shop owners still gripe about these same issues and seem just as unwilling now to create the environment they claim to want to see. To this, the saying “doing the same thing over and over and expecting different results is the definition of insanity” is applicable.

It should come as no surprise to anyone by now that one of the most significant changes in our trade is the rapid advancement of technology. But inasmuch as I am loath to admit it, the technology change requires that we reexamine the need for some manner of regulation. This isn’t your father’s Oldsmobile; we need to get serious about training and safety. It’s time to have an in-depth discussion about licensing. Make no mistake, I’m not a fan of what I consider to be an overreaching governmental intrusion in my life. I don’t want to do this, but if we are to be honest, we must begrudgingly acknowledge that some small amount of government involvement in critical areas of safety is necessary, prudent, and there’s ample precedent for it, too.

The goal of licensing, whether by professional association or government mandate, should be to provide a safeguard for consumers against unethical behavior and substandard repairs. However, the reality is that attempts

at regulation in the U.S. and in Canada have fallen well short of expectations. For instance, lawmakers in Michigan enacted the Motor Vehicle Service and Repair Act in 1974, and yet, after 50 years in existence, complaints are frequently filed each year about deceptive trade practices and the unscrupulous shops that perform them. The punishment for violating the law is a misdemeanor and a fine of up to $1,000 or up to 90 days in jail. If the offense is egregious enough, the shop may lose its ability to legally operate a repair business, which seldom happens.

In Canada, government licensing requirements have also failed to deliver on the promises made. “The Ministry of Government and Consumer Services in Ontario oversees the licensing of automotive technicians and shops. However, a review of the program reveals that it is more focused on administrative tasks, such as license renewals and fees, rather than ensuring shops meet minimum standards of competence and honesty.”

These examples highlight the need for a different approach to program design, enforcement, and regulation. Rather than requiring shops to register or obtain a license, effective regulation should:

• Focus on establishing clear guidelines for industry best practices while ensuring shops adhere to these standards.

• Provide swift enforcement of consequences for non-compliance (something which is currently absent). Regular site inspections, stricter standards for technician training, certification (including skills-based testing), and mandatory continuing education must be present. Guidelines and enforcement alone aren’t enough.

• The public must be made aware of the necessity to have service work performed by qualified professionals and the potentially devastating consequences if they don’t. This public awareness campaign must be funded by the com-

bined efforts of individual repair shops that recognize the necessity of becoming involved in charting a course for the future of our trade.

By taking a more proactive and consumerfocused approach to regulation, the auto repair industry can build trust with the public and demonstrate its genuine commitment to excellence and safety. The time is ripe for lawmakers and regulatory bodies to work with shop owners to create a system that prioritizes consumer safety and satisfaction. By doing so, we can create a fair and transparent system that benefits everyone involved, from consumers to reputable shop owners and their employees. Ultimately, effective regulation, whether through the government or a professional association, is key to driving out unscrupulous shops and promoting a culture of accountability and professionalism within the industry.

R. “Dutch” Silverstein, who earned his Accredited Automotive Manager Certificate from AMI, owns and operates A&M Auto Service, a seven bay, eight lift shop in Pineville, North Carolina. Dutch was a captain for a major airline earning type ratings in a variety of aircraft including the Boeing 767/757, 737, 200, 300 and 400 series, Airbus 319/320/321, McDonnell Douglas MD80/ DC9 and Fokker FK-28 mk 4000 and 1000. After medically retiring, he transitioned his part-time auto repair business into a full-time occupation. dutch@dutchsgarage.com

nformation on wh aintenance for fiv

Information on what systems do and why technicians suggest maintenance for five key vehicle systems: brakes, starting/charging, steering/suspension, engine management, and climate control. at systems do and why technicians e systems: start and climate c

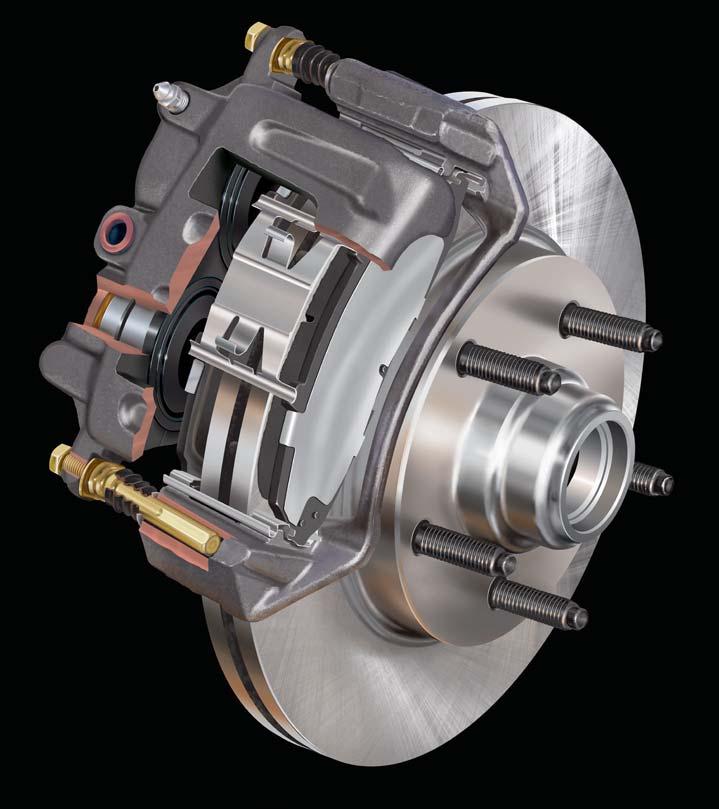

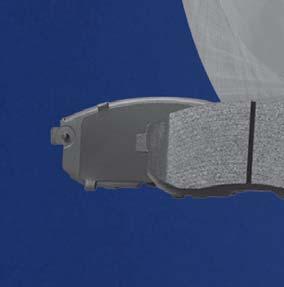

The brake system on a modern vehicle is complex and requires meticulous care to maintain properly. Multiple components ensure your vehicle is safe and roadworthy, and brake system components are at the top of that list. Every piece of the brake system, such as the master cylinder, fluid quality, and brake pad wear, should be checked by a professional automotive technician to ensure the vehicle is meeting the minimum safety standards. Continue reading to expand your knowledge of common braking system components and good practices to preserve the overall braking system. Also, learn potential braking system service items a vehicle may need.

Most modern vehicles are equipped with four-wheel disc brakes. Many components at the wheel need to be maintained for proper brake function. If something at the wheel seizes or fails, issues such as uneven brake pad wear or even brake failure can occur. A brake caliper uses a piston to squeeze the brake pads on a brake rotor to stop the vehicle. Brake calipers contain hardware that helps brake pads slide. In some instances, this hardware can fail due to local climate conditions, ripped rubber boots that cover the slide pins, or going long periods of time without driving the vehicle. The caliper piston may also seize. All these conditions will cause premature and uneven brake pad wear. If you have a brake caliper that needs replacing, it is best to replace them in pairs to ensure even stopping power.

When replacing brake pads, it is also responsible to either resurface or replace the brake rotors. As time goes on, it is becoming more costeffective to replace brake rotors instead of paying to resurface them. Duralast® rotors offer original equipment (OE) or better stopping power to ensure top braking quality. Rotors may also need replacement if a brake pad wears too thin and damages them. Just like brake calipers, rotors should also be replaced in pairs to ensure even wear.

TAPERED LINING

SYMPTOM:

Irregular wear

CAUSE:

Worn or damaged caliper bushings and/or brake hardware

GROOVED LINING

SYMPTOM:

Noise, increased stopping distance

CAUSE:

Rotors that have become scored or damaged

CRACKED OR CHIPPED LINING

SYMPTOM:

Irregular wear

CAUSE:

Calipers not working properly, causing constant friction

OFFSET LINING

SYMPTOM:

Irregular wear

CAUSE:

Caliper or slide not working properly

WORN THROUGH LINING

SYMPTOM:

Noise

CAUSE:

Disc pads worn beyond safe point

STEPPED LINING

SYMPTOM:

Noise, irregular wear

CAUSE:

Worn pads not making full contact with rotor

PAD MATERIAL TRANSFER

SYMPTOM:

Vibration

CAUSE:

Heavy loads/towing; faulty caliper

UNEVEN SURFACE WEAR

SYMPTOM:

Increased stopping distance

CAUSE:

Worn pads/hardware; binding caliper

STEPPED SURFACE

SYMPTOM:

Noise, vibration

CAUSE:

Pads out of position; worn hardware

SCORED/GROOVED SURFACE

SYMPTOM:

Noise, increased stopping distance

CAUSE: Inconsistent pad contact

There are several options when selecting the brake pad material for your vehicle. Normally, this would be based on the OE brake pads that were installed. The two most common compounds available are ceramic and semi-metallic. Ceramic brake pads are very durable and provide a high amount of stopping power at normal temperatures. Semi-metallic brakes can be used in higher-performance applications but tend to wear more quickly than ceramic brakes. Duralast offers a selection of replacement brake pads with material matching OE quality or better. Select the right brake pads for your vehicle and driving habits to ensure safety and optimal performance.

The entire brake system must be inspected to ensure complete vehicle safety. If your brake fluid is found to be contaminated, a system flush is necessary. If your vehicle’s fluid is contaminated with oil, you will need to replace all the rubber components — including brake hoses — on the vehicle due to contamination. Brake hoses that need replacement will have cracks, swelling, or fluid leaking from them.

Many newer model vehicles come equipped with advanced driver assistance systems (ADAS) and emergency braking system (EBS) features. These updates are changing the industry and may require more purchases for further vehicle service, including a recalibration of the cameras for the EBS system. Knowing what ADAS systems your vehicle is equipped with can make the difference when taking it in for service.

Batteries are in every single vehicle on the road, and the technology in them has come a long way in the last 100+ years. It is natural to want to blame a no-start condition on a bad battery, but this isn’t always the case. There is a whole system of components to consider when looking at starting, charging, and battery system issues. Sometimes a simple jump start may be a solution, but modern no-start concerns can, on occasion, take hours for a technician to diagnose in certain situations.

Continue reading to learn about emerging battery technology, battery system service and maintenance, and common charging and starting system problems.

Batteries are more durable and easier to maintain compared to several decades ago. Nofill, no-spill batteries are safer to handle and don’t require the trouble of manually filling with distilled water to balance the acid levels. The evolution of AGM (“Absorbed Glass Mat”) batteries has not only added to this simplicity and peace-of-mind for the consumer, but have harnessed more, longer-lasting power for their vehicles.

With the increasing variety of batteries offered on the market, testing processes have become more complex. The testing procedure for a traditional flooded lead-acid battery will differ from that for an AGM or enhanced flooded battery. No matter what battery a vehicle has, it is always a good idea to have a technician use professional testing equipment to verify the state of the battery.

AGM batteries continue rapid growth in the market. They provide a more stable source of power compared to traditional lead-acid batteries. A saturated glass mat replaces free-flowing liquid acid in AGM batteries. AGM batteries generally have a higher cycling capacity compared to standard “flooded” batteries, which adds longevity when supporting power-hungry vehicles. These batteries have proven themselves to be a worthy alternative to traditional batteries and in many cases are required by specific vehicle manufacturers. Duralast ProPower® AGM batteries meet or exceed OE specifications and are backed by a four-year free replacement warranty. Duralast ProPower AGM Elite batteries provide the highest quality and durability and are backed by a five-year free replacement warranty

The charging system must be intact for the battery to maintain its proper charge. The alternator is the main component of the charging system, managed in many modern vehicles by the electronic control module. If either of these components fails, it can result in the battery not charging and the vehicle not starting. If the battery was already weak to begin with, then it may be necessary to replace it as well as the charging components. Sometimes charging issues can appear as a bad battery, or a battery will degrade so much that it will no longer charge. Keep in mind that sometimes battery issues can be complex, and multiple components may need to be serviced.

Starters and their related components should be considered when discussing battery systems. If a vehicle starter draws too much current, it will wear a battery down quickly or even cause a slow-crank condition, eventually causing the battery to fail. Another aspect of battery service and maintenance is the start/stop system. Many new vehicles are equipped with a second battery to power the starter in a stop/start event. Some vehicles may even be considered mild hybrids and have secondary starting features built into their alternators.

FUNCTION:

• Charges the battery and powers the electrical system while the engine is running

SIGNS OF FAILURE:

• Battery losing its charge

• Poor accessory and light operation

• Erratic engine operation

• Dashboard warning lights illuminating

FUNCTION:

• Activates the vehicle’s main electrical system and starter to start the vehicle

SIGNS OF FAILURE:

• Vehicle does not start

• Starter does not make noise

• Intermittent loss of electrical power

• Inability to turn the key

FUNCTION:

• Protects various electrical circuits within the vehicle

• Prevents damage from overloads and/or short circuits

SIGNS OF FAILURE:

• Total or intermittent power disruption to electrical components

• Visual discoloration or dark spots within transparent casing

FUNCTION:

• Ensure the electrical power from the battery is delivered to the vehicle’s electrical system

SIGNS OF FAILURE:

• Loose or corroded battery cables and terminals The vehicle is not starting

BATTERY

FUNCTION:

• Provides the electrical power needed to start the engine

• Powers the electrical components when the engine is off

SIGNS OF FAILURE:

• Dim headlights, dashboard lights, and interior lights when starting

• The vehicle is not starting

STARTER

FUNCTION:

• Engages the engine flywheel to start the engine

SIGNS OF FAILURE:

• Clicking sound when turning the key

• Slow or labored starting

• Dimming lights when attempting to start

FUNCTION:

• Completes a circuit, sending power to components which require more current than a switch can handle on its own

SIGNS OF FAILURE:

BELT

FUNCTION:

BATTERY WARNING LIGHT

FUNCTION:

• Indicates problems with battery or charging system

• Drives the alternator and other engine accessories

SIGNS OF FAILURE:

• Squealing sound

• Noisy alternator

• Alternator not charging

• A specific, electrical-related system will not function

Ride height and suspension component health can be easily overlooked when considering general vehicle maintenance. Ride height is the level at which your vehicle sits when it is on level pavement. Several suspension-related issues can cause further damage to the vehicle and lead to abnormal tire wear if not addressed.

Learn about the common suspension component failures, how ride height can affect them, and what you can do to avoid unnecessary repairs.

There are many reasons why someone may change their ride height. Natural wear of suspension components and either lowering the suspension for aesthetics or raising a vehicle for off-road use could cause the ride height to change. If the ride height of a vehicle changes, it will be necessary to verify that the suspension alignment hasn’t changed. In most cases, the alignment will need to be readjusted. Failure to fix the alignment can cause abnormal tire wear patterns and extra wear on suspension components. Control arm bushings, ball joints, shock absorbers, and struts are all susceptible to excessive wear from mismatched alignment angles.

Today’s vehicles are equipped with a variety of suspension configurations, each with its own unique features. Most modern passenger cars are equipped with rack-and-pinion steering systems and MacPherson strut-style suspensions. Older vehicles, as well as larger pickup trucks/SUVs, have conventional steering systems and use shock absorbers in their suspension setup.

RACK & PINION STEERING, FWD

OUTER TIE ROD END

STRUT MOUNT

STRUT

COIL SPRING

SWAY BAR BUSHING

RACK & PINION BOOT (BELLOWS)

SWAY BAR

RACK & PINION ASSEMBLY

OUTER CV JOINT/BOOT

RACK MOUNT BUSHINGS

INNER TIE ROD END

INNER CV JOINT/BOOT

CONTROL ARM BUSHING

SWAY BAR END LINK

CONTROL ARM

When driving the vehicle, you can hear indicators of failing suspension parts. A distinct clunk when going over bumps is commonly a sway bar link or ball joint issue, regardless of what suspension configuration is equipped. However, if there are ride quality issues, they may be caused by a failed shock absorber in a conventional suspension or a faulty strut in a modern passenger car. To ensure the overall integrity of the replacement parts, when ball joints of specific designs fail, the entire control arm must be replaced as an assembly per manufacturer recommendations.

Some of the most common suspension issues your vehicle may experience are strut-related failures. Struts are components that help cushion the impact of bumps and imperfections in the road. When a strut fails, the vehicle’s ride quality will begin to suffer greatly. This may be accompanied by noises coming from the corner of the vehicle where the strut has failed. These noises will be most noticeable when driving over a bump or pothole.

When having struts replaced, it is wise to replace them in pairs. This can ensure the vehicle handles the road’s impacts evenly and of the highest quality. Using a Duralast-loaded strut, sometimes called a “quick strut,” ensures original equipment (OE) ride quality or better. Replacing your struts before they fail completely can help prevent further repair costs and restore your vehicle’s suspension to factory specifications.

As vehicles continue to develop and advance, so will the services needed to keep them on the road. Advanced driver assistance systems (ADAS) are becoming the standard for today’s vehicles. These systems include advanced cruise control, lane keep assistance, and emergency braking features. If your vehicle’s ride height is purposely altered, you must have the ADAS system components recalibrated. Make sure you consider the technology your vehicle is equipped with before having the ride control system serviced or altering the ride height.

PROBLEM:

Excessive bounce and harsh ride on rough surfaces

PROBLEM:

Excessive play in steering wheel

PROBLEM:

Excessive lean or sway in turns

PROBLEM:

Rattling, grinding, popping, or clunking noise under vehicle

PROBLEM:

Dips, sways, and dives when braking

UPPER BALL JOINT

PROBLEM:

Steering wheel vibrates

PROBLEM:

Uneven or premature tire wear

PROBLEM: Drifts left or right

PROBLEM: Veers in crosswind

PROBLEM:

Squealing or squeaking when turning

UPPER CONTROL ARM BUSHING

UPPER CONTROL ARM

COIL SPRING

LOWER CONTROL ARM BUSHING

SWAY BAR BUSHING

LOWER CONTROL ARM SWAY BAR

LOWER BALL JOINT

OUTER TIE ROD END

CENTER LINK

PITMAN ARM IDLER ARM

INNER TIE ROD END

SWAY BAR LINK

TIE ROD ADJUSTING SLEEVE

STRUT ROD BUSHING

The main goals of engine management on fuel-injected vehicles are to optimize efficiency and monitor the conditions surrounding the engine. Modern engines are controlled closely by an electronic control module (ECM) to help achieve optimum performance, peak fuel economy and lower emissions output. The ECM calculates optimal operating conditions, such as air/fuel ratio, by using a stream of sensor data. The ECM also operates various actuators, such as the throttle plate or exhaust gas recirculation (EGR) valve.

Read on to learn about engine management sensors and actuators, how the ECM strategizes based on these components, and common engine management issues.

When it comes to actuators, think “action.” Once the sensors have communicated with the ECM, the ECM can better make its decisions. Actuators, also known as outputs, take commands from the ECM and then carry out that specific task. This completes what is called a feedback loop. Electronic throttle plates are an example of a common actuator. In the past, a throttle had to be connected physically to the gas pedal with a cable. As time has progressed, these physical connections have been replaced with electronic throttles that can be actuated. An electronic throttle can be moved with greater precision, resulting in improved control over airflow, smoother cruise control operation, and allowing new technologies such as start/stop technology and hybrid engines to exist.

Engine management sensors can be compared to our five natural senses. Our brains are constantly paying attention to what our bodies perceive through sight, sound, smell, taste, and touch. In a similar way, sensors (sometimes called inputs) report all sorts of data back to the ECM. Sensors such as mass airflow (MAF), manifold absolute pressure (MAP), and electronic coolant temperature (ECT) all help the ECM calculate how much fuel to inject into the engine. Oxygen (O2) sensors help the ECM fine-tune fuel calculations even further. The crankshaft position sensor (CKP) and camshaft position sensor (CMP) monitor the physical timing of the engine. All of these inputs are crucial in ensuring optimal fuel economy and helping the engine run more efficiently.

There are other outputs that must be considered as well. Ignition coils need to be controlled for the air fuel (A/F) mixture to burn properly. The ECM controls how long an ignition coil is charged as well as when it is fired. Variable valve timing (VVT) solenoids are yet another ECM controlled actuator that will vary the engine timing for changes in driver demand and airflow. Other examples of actuators controlled by the ECM would be fuel injectors, EVAP purge and vent solenoids, or an EGR valve.

An engine management issue can present itself in various ways. Whether it’s a check engine light or your vehicle is running rough, the solution is not always cut and dry. There may be multiple steps a technician takes to properly diagnose an engine management fault. Replacement sensors and actuators need to have the same precision and accuracy as the original parts. Duralast offers a wide variety of engine management sensors and actuators of original equipment (OE) quality or better. The Duralast line offers components, such as purge solenoids, that are purposely redesigned to improve on issues found with OE parts. Usually, when sensors or actuators fail, a warning light is displayed. However, in some cases, a technician may need to spend extra time diagnosing the problem. Diagnostic equipment such as scan tools, multimeters, or even specialty tools like an oscilloscope may be used.

FUNCTION:

Provides the electrical current for the plug to spark, which tes fu

FUNCTION:

FUNCTION:

FUNCTION:

Monitors the mass of air entering the engine to balance the amount of fuel needed for engine demand

Detects vibrations in the engine to prevent engine knocking which is a metallic ping or knocking sound caused by uneven fuel combustion in the cylinders

MANIFOLD ABSOLUTE PRESSURE SENSOR (MAP)

Measures pressure in engine intake manifold to calculate the correct air-fuel mixture for optimal engine performance

ENGINE COOLANT TEMPERATURE SENSOR (ECT)

FUNCTION:

Monitors the temperature of the coolant circulating through the engine

FUNCTION:

Controls the timing of the intake and exhaust valves on the camshaft

ABS SENSOR

FUNCTION:

Sends signal to the ABS computer to determine if the system needs to activate

FUNCTION:

Monitors and reports the RPM of the crankshaft to the computer which is used to precisely control fuel injection and ignition timing

FUNCTION:

Measures the camshaft's rotational position which the computer uses to precisely control fuel injection and ignition timing

FUNCTION:

Controls how much air flows into the vehicle's engine which determines how much power the engine produces

TPMS

FUNCTION:

Sends signal to indicate low tire pressure

OXYGEN SENSOR

FUNCTION:

Measures oxygen to notify the computer to increase or reduce fuel supplied to the engine

In an era focused on enhancing the driver’s experience, it’s no surprise that heating, ventilation, and air conditioning (HVAC) issues are among the most common concerns experienced. The integrity of the components in air conditioning (A/C) and cooling systems is important to the climate control operation inside a vehicle.

Learn more about common A/C refrigerant types and services, vital A/C componentry, air distribution necessities, and cooling system maintenance best practices.

All new vehicle models since 2021 are equipped with 1234yf refrigerant. Many vehicles on the road still use 134a refrigerant as well. Regardless of which refrigerant your car needs, it is wise to have it serviced by a certified technician with a professional-grade recovery machine. Technicians can use specialized equipment to identify the type of refrigerant in your vehicle, recover the system contents, and recharge it after the repair is complete. Be aware that simply recovering the refrigerant and recharging it is not a proper repair, and the technician will need to find the cause of the leak prior to recharging the vehicle’s A/C.

In some instances, if debris is found inside the system or an A/C component is being replaced, the accumulator or receiver drier should also be replaced. These components are meant to keep the system free of moisture and collect debris. If debris is found, it is also important to perform any flushing procedures recommended by the manufacturer.

The A/C compressor is one of the most critical parts of the A/C system. It is the main component that moves the refrigerant through the system. When an A/C compressor starts to wear out, you may notice the air conditioning performance suffers inside the cabin. When an A/C compressor is replaced, it is also a good practice to replace the accumulator or receiver drier.

A/C condensers are located at the front of the vehicle and act as a point in the A/C system where the refrigerant can turn from gas to liquid. These are weak points in the system since condensers are mounted on the front of the vehicle and the radiator, where they are very susceptible to collecting debris. This can cause a few problems, such as overheating and underperformance of the vehicle’s A/C. To remedy the issue, a technician must thoroughly clean the condenser and radiator.