Performance driven Tested and designed to meet the highest quality standards

6 ways to search The aftermarket made easy

Performance driven Tested and designed to meet the highest quality standards

6 ways to search The aftermarket made easy

6,000

NAPA Auto Parts stores in the U.S. supported by a nationwide network of distribution centers

Access to an in-house APPRENTICE PROGRAM at no additional cost

NAPA is proud to have America’s largest network of parts and care.

With nearly 6,000 Auto Parts stores and over 18,000 Auto Care centers, from coast to coast, we are one NAPA.

95%

consumer recognition when you co-brand with NAPA Auto Care

NATIONWIDE PEACE OF MIND WARRANTY for your customers, and local labor coverage for you

NAPA Auto Care centers are featured in the national marketing campaign PRIORITY PARTS DELIVERY SERVICE

from your servicing NAPA store

Interested in becoming a NAPA Auto Care center? Scan this QR code to be contacted by a local NAPA sales representative.

November 4–6 • Venetian Expo • Las Vegas

Booth A1457

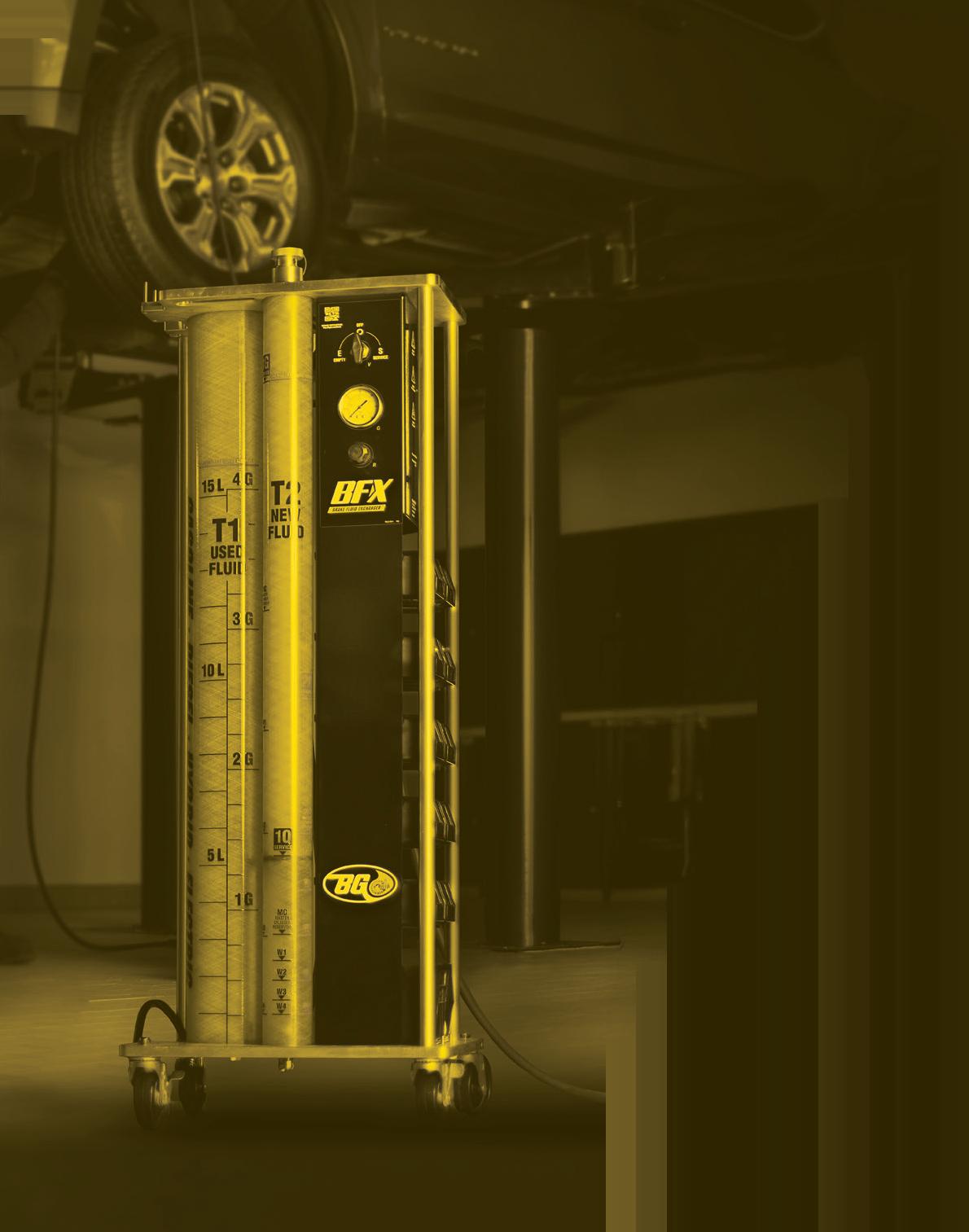

Joe’s Garage, Bay 7

BG Products helps you enhance vehicle performance, extend component life, and drive profitability with innovative products and equipment. Check out our new booth, and stop by Joe’s Garage for live service demos, including the 2025 MOTOR Top 20 award-winning BG BFX Brake Fluid Exchanger.

Learn

New columns focus on finances and why shops struggle to build great teams. Plus: Ratchet+Wrench Management Conference keynote Kinja Dixon ponders the four pillars of success in a podcast episode.

How auto repair shops are navigating tariff turbulence

18 SHOP VIEW

Ironwood Automotive in Richmond, Virginia, is sleek, modern, and inviting

20 MEASURE, MANAGE & MASTER

Tackling the three biggest client hiccups

KATHLEEN CALLAHAN

35 TOOLS + TECHNOLOGY

How to talk to customers about ADAS calibration

39 CASE STUDY

The art of transitioning to a new owner (and other modifications)

42 THE 35,000-FOOT VIEW

From hourly pay to salaried employees, there is more than one way to satisfy the list of demands from employees looking for a stable paycheck. Two shop owners share the strategies on how they remain financially solid and help their employees to do the same. While one utilizes flat-rate plus bonuses and the other leans on hourly pay, the method is not as important as the message they are sending their employees–they want them to thrive and not just survive.

BY ALISON JOHNSON

Involve customers in the DVI process DUTCH SILVERSTEIN

BENNETT: Why Shops Struggle to Build Great Teams

Every leader knows the frustration. The teammate with so much talent yet average to poor production is their norm. They possess the skill, know the processes, and have the experience, yet somehow, they consistently produce lackluster results. They show no initiative, take no ownership, and are content with “good enough.” Then you have another team member, perhaps less experienced or skilled, but they’re asking the right questions, staying late, driven, hungry to learn, and steadily improving. You start asking yourself: “What’s the real difference here?” Mike Bennett delves into the difference between competency and capacity and how to grow a team that uses both to their advantage.

DEMAREST: How to Minimize Taxes After Selling Your Business

Like most business owners, the question of how to pay the IRS less money is not uncommon. While there are plenty of ways to save a buck, the best way to leverage your finances is to plan before ever making the sale. Take advantage of allocating your assets to the four main buckets Hunt Demarest discusses in his most recent column. Although you will still end up paying your fair share to Uncle Sam, you may be able to keep more than you realized.

PODCAST: The Four Pillars of Success

In this Ratchet+Wrench Management Conference teaser episode, Kinja Dixon reveals how his doctor’s orders and a moment of vanity sparked a transformation that led to international sales awards, early retirement at 34, and becoming a sought-after speaker who’s inspired thousands worldwide. Dixon discusses his Four Pillar system (Purpose, Health, Emotions, Knowledge) and why change is happening whether we choose it or not.

RATCHET+WRENCH RADIO

Strategies and inspiration for auto care success.

Catch new episodes every Wednesday featuring thought leaders from across the automotive aftermarket. Scan to subscribe!

EDITORIAL

EDITORIAL DIRECTOR

Chris Jones

EDITOR-IN-CHIEF

Christine Schaffran

ASSISTANT EDITOR

Kacey Frederick

CONTRIBUTING WRITERS

Tess Owings, Leona Scott, Alison Johnson

EDITORIAL ADVISORY BOARD

Tara Topel, Topel’s Towing and Repair

Andrew Marcotte, American Pride Automotive

J.J. Mont, J.J.’s Auto Service

Rachel Spencer, Spencer’s Auto Repair

Tonnika Haynes, Brown’s Automotive

Lucas Underwood, L&N Performance Auto Repair

SALES

PUBLISHER

Andrew Johnson / ajohnson@endeavorb2b.com

ASSOCIATE SALES DIRECTOR

Mattie Gorman-Greuel / mgorman@endeavorb2b.com

DIRECTOR OF BUSINESS DEVELOPMENT

Cortni Jones / cjones@endeavorb2b.com

ACCOUNT EXECUTIVES

(NATIONAL ACCOUNTS)

Diane Braden / dbraden@endeavorb2b.com

Darrell Bruggink / dbruggink@endeavorb2b.com

Marianne Dyal / mdyal@endeavorb2b.com

Chad Hjellming / chjellming@endeavorb2b.com

Lisa Mend / lmend@endeavorb2b.com

Kyle Shaw / kshaw@endeavorb2b.com

Sean Thornton / sthornton@endeavorb2b.com

ART AND PRODUCTION

ART DIRECTOR

Emme Osmonson

PRODUCTION MANAGER

Mariah Straub

AD SERVICES MANAGER

Jen George

ENDEAVOR BUSINESS MEDIA, LLC

CEO Chris Ferrell

COO

Patrick Rains

CRO

Paul Andrews

CDO

Jacquie Niemiec

CALO

Tracy Kane

CMO

Amanda Landsaw

EVP TRANSPORTATION GROUP

Chris Messer

EVP ENDEAVOR BUSINESS INTELLIGENCE

Paul Mattioli

VP OF CONTENT STRATEGY, TRANSPORTATION GROUP

Josh Fisher

SUBSCRIPTIONS

Send address changes and subscription inquiries to:

Ratchet+Wrench PO Box 3257 Northbrook, IL 60065-3257

SUBSCRIPTION CUSTOMER SERVICE: 877-382-9187 ratchetwrench@omeda.com

LETTERS TO THE EDITOR

editor@ratchetandwrench.com

Opinions expressed in Ratchet+Wrench are not necessarily those of Endeavor Business Media, and Endeavor Business Media does not accept responsibility for advertising content.

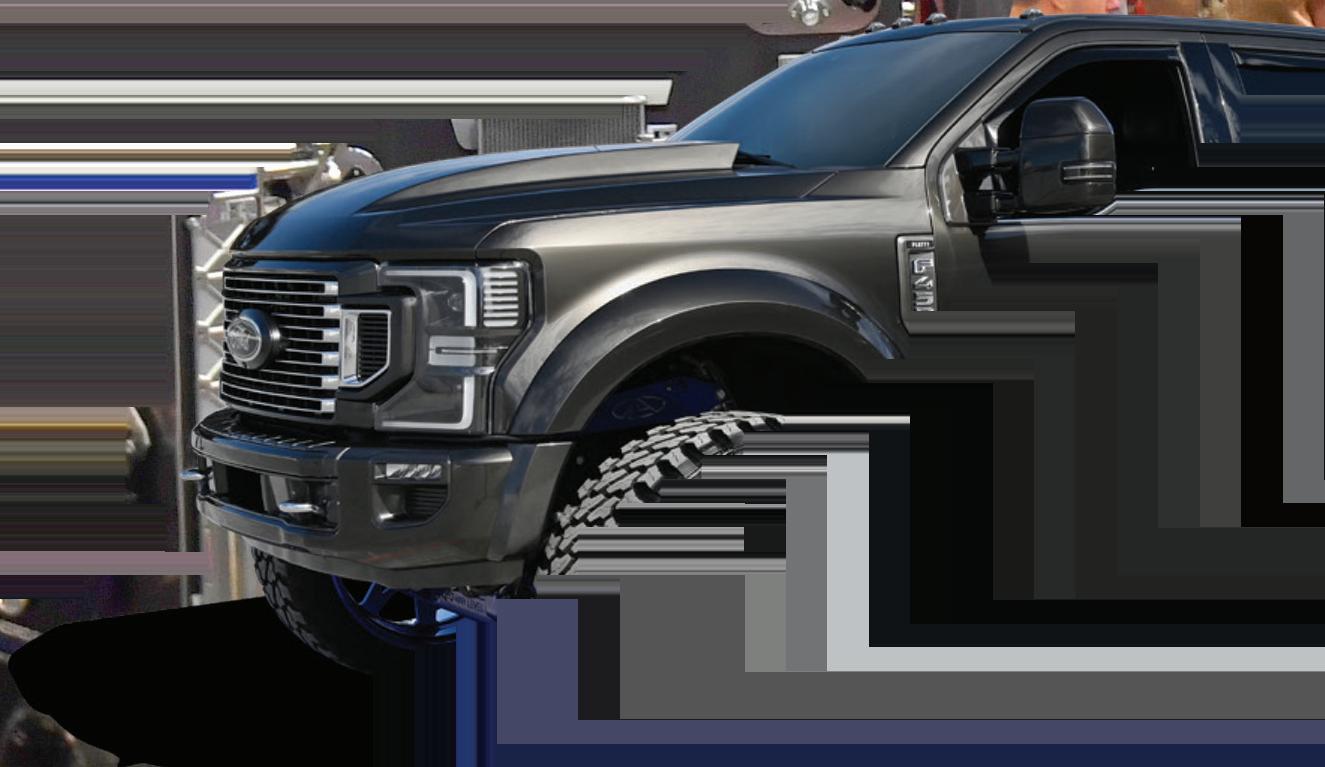

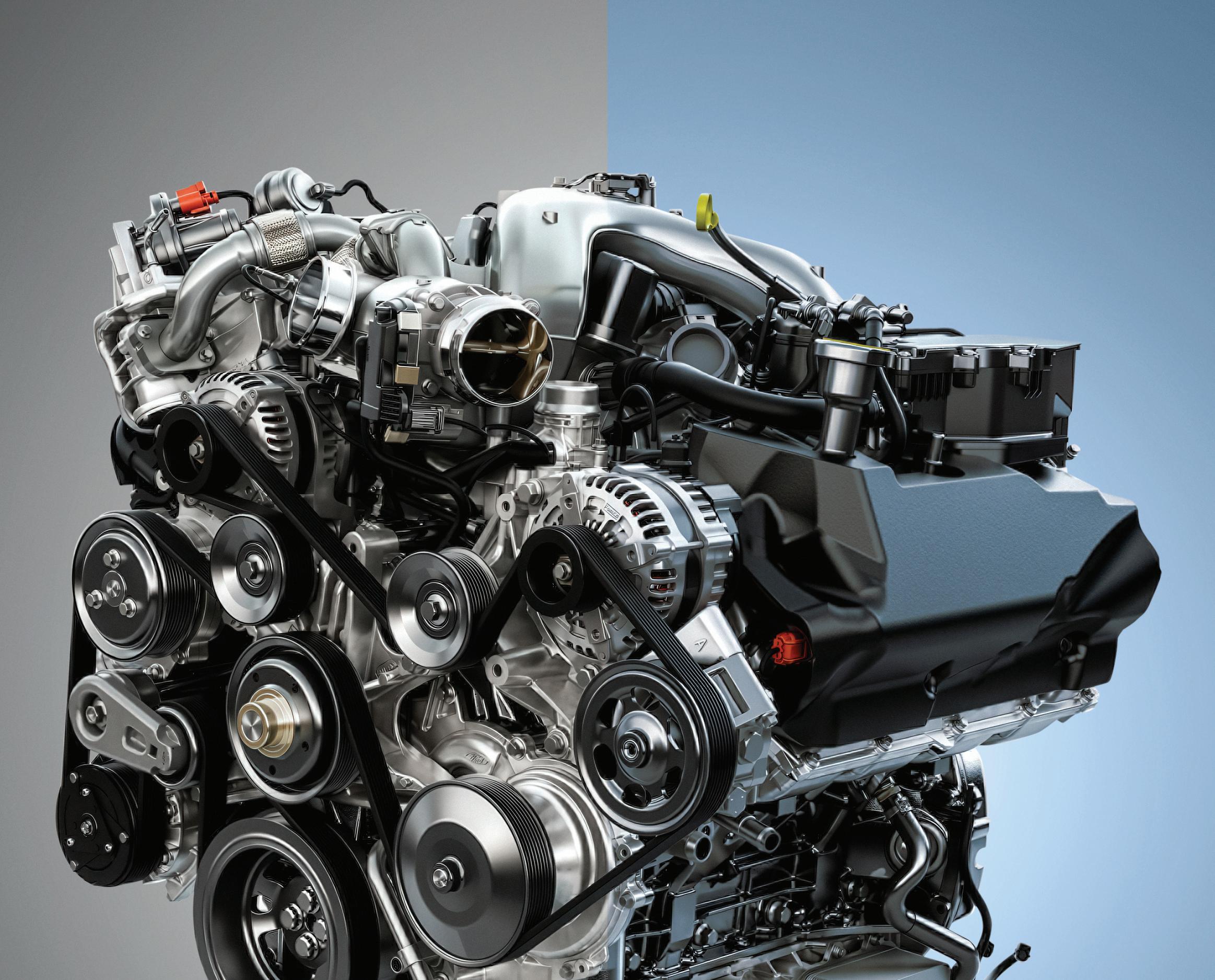

Precision-crafted Ford and Motorcraft® powertrain assemblies are built to all quality standards and OE specifications. They’re specifically engineered to fit and deliver consistently reliable performance and peace of mind: New and remanufactured transmissions and gas engines are covered for three years with unlimited miles, including labor, while diesel engines are supported by a two-year/unlimited-mile warranty (including labor). Plus, there are no exceptions for commercial vehicles. And with our no-risk core return policy, you don’t have to worry about extra charges if your engine or transmission core are damaged.*

Ford and Motorcraft make all the difference — for your customers and your business.

of the extensive support I receive as a local independent shop owner. This support gives our customers access to shops across the country and ensures they will have peace of mind wherever they travel. ”

JOHN WADE

Super Eagle Auto Care

TechNet Member Since 2014

Level up your shop and get access to exclusive business and marketing solutions, including motorist programs like Nationwide Warranty, Roadside Assistance and Road Hazard Tire Protection.

Scan the QR code or visit technetprofessional.com/membership to learn more.

Girlington Garage, a small shop based in South Burlington, Vermont, is doing the work to protect itself and its customers

BY KACEY FREDERICK

2025 has brought many headwinds for the auto repair field—particularly with regard to tariffs. From independent repair shops and suppliers to dealerships and automakers, the entire automotive field has been affected, as well as several other sectors that rely on imported materials and goods. These national decisions are now begin-

ning to impact small, independent operations, like Girlington Garage: an auto repair business in South Burlington, Vermont. Nya Key, the shop’s service manager, spoke with Ratchet+Wrench about the changes shops like theirs are seeing and how they’re supporting their customers while taking care of their own needs.

Girlington Garage began noticing an uptick in prices in March. Since then, one of the biggest challenges has been an inability to stockpile inventory before prices creep up. Even if the shop knows price increases are coming, they just don’t have the space to store excess inventory.

“Especially being a small shop in a small state, when we first started hearing about the possibility of tariffs, we were very scared, because we don’t have the ability to stock up on parts,” explains Key. “We carry oil filters and fluids, but we can’t stock up for average, normal repairs.”

Adding to the struggle are suppliers who do not communicate price changes. Girlington utilizes a website that connects them to dealers for parts—but upon ordering certain components, they found the price was higher when they arrived than was advertised. This created significant obstacles for the shop as it tried to navigate the issue while taking care of their customers. Fortunately, though, the shop has noticed suppliers being more upfront recently, especially on the aftermarket side. They’ve been made aware of upcoming price increases that aren’t quite as steep as they were earlier this year, underscoring the importance of being in close communication with shop vendors and suppliers.

“When my reps come in for our check-ins every month, I am getting more of a warning,” shares Key. “Prices are still changing, but it’s happening at more of a slower (pace) and shorter amount. So, the cost of our brakes just increased by like $10, which is a lot easier to chew than having a price that was two times the amount we quoted.”

As prices continue to fluctuate, there are

measures shops like Girlington are taking to mitigate the impact. For Key, this means staying on top of parts pricing and locking in prices in advance to secure the best deal.

“When we’re ordering parts, or when I have a customer that has an OEM part, I double check parts availability, and I order it right away. So, let’s say the job’s two weeks out; I make sure to lock in that price as fast as I can, just to not have any changes,” explains Key.

Aside from price changes, Girlington has faced difficulty in the availability of parts, particularly for non-domestic manufacturers. Metal components, like exhaust systems and rotors, have been especially difficult for the shop to acquire recently. Meanwhile, brakes are almost entirely OEM right now and are typically on backorder or take several weeks to arrive.

Since Girlington is unable to stockpile components, the shop takes preemptive measures to avoid a surplus of unused parts. For example, parts that require special order necessitate a deposit from the customer that typically sits around 15%, which the shop calls a restocking fee. And for parts that can’t be returned, customers must pay for them upfront. These policies help protect the business from losing out on inventory that is ordered but cannot be used.

“That is kind of how we protect our business, just because we’re so small,” says Key. “Even now, I have a couple of parts that I’ve purchased within the last year that are just

sitting here because I can’t return them, and it really takes a lot of cost to just hold parts that you can’t use.”

Customers are increasingly worried about how and when rising prices will impact them. Girlington has seen more customers coming in asking about when the shop expects prices to change. While Key does her best to stay updated, it’s difficult to know in advance if something will change.

For some customers, this prompts them to request that certain components be replaced when they don’t need to be. At Girlington, they emphasize that it’s always the customer’s choice, and make it clear to each customer what the status of their vehicle is and what it needs—but Key cautions customers from making purchases purely out of fear since no one can predict what changes are in store over the next few months.

“It’s always their choice, but I do try to guide them toward the need of the repair more than the pricing,” says Key. “Because I don’t have proof of when things are going to increase, and the whole point of being in service is to make sure things are done right the first time and that the vehicle is safe. So, I always try to give them the guidance that I have. But since we are not parts manufacturers or suppliers, I’m still guiding in the way that I’ve always guided as an advisor or service manager.”

LEARN THE AUTO SHOP CONCEPT THAT WILL CHANGE YOUR LIFE

Transform Your Business with Advanced Automotive Training

We have not just enhanced, but mastered, the concept of car repair. With monthly revenue figures over $1 million, our system guarantees exceptional customer service and unprecedented sales numbers.

DECEMBER 20-21

JANUARY 17-18

FEBRUARY 21-22

A full day of learning the new AI tools being used in our shops. Spend the day in a deep dive with the industry’s best teachers of AI. This class will elevate your shop to new heights!

ACCOUNTING FIRST & FRAUD PREVENTION

“If you’re not counting your money, someone else is.”

Financial / P&L Statements

Budgeting, Projections & Forecasting

Inventory Management Fraud & Embezzlement Plus so much more!

SCAN TO REGISTER FOR THE NEXT COURSE

A BMW owner recently took to social media to share the high prices he faced for routine maintenance at the local dealership, as recently shared by Car Scoops.

When Reddit user Khalnayak took in his 2021 M3 for routine maintenance, he was met with a total cost of $1,199.85 for his visit.

This included a $399.95 oil change, which takes 7.4 quarts of 0W-30, and $340 for a replacement of the cabin air filter, a component that runs less than $40 at most stores.

Additionally, the customer was charged $179.95 for a Standard Scope, which was likely a scan of the ECU through the OBDII port; and another $279.95 for a “Vehicle Check.”

According to the Reddit user, these charges came right after his complimentary maintenance plan expired. Despite having been a customer, the BMW owner promptly took his business elsewhere, opting instead for DIY work. With the cost of vehicle ownership only continuing to rise, it’s clear customers like Khalnayak need providers who can offer reliable service as well as reasonable prices.

The National Institute for Automotive Service Excellence has partnered with EndeavorB2B and its Motor Age publication to launch a new newsletter: “ASE Certified Tech Edge.” The first issue of the newsletter, a co-branded project between ASE and Motor Age, is scheduled for distribution on Oct. 1.

“We are looking forward to launching the new ASE Certified Tech Edge Newsletter powered by Motor Age. Working with EndeavorB2B, we know it will be an informative and insightful publication,” said Dave Johnson, ASE president and CEO. “ASE strives to provide informative resources to help service professionals perform their jobs effectively and students acquire the knowledge they will need to succeed in the workplace. This newsletter will be a valuable source of information for all our stakeholders.”

The newsletter content will include Motor Age technical articles and news, as well as videos with source content hosted on the Vehicle Service Pros and Motor Age YouTube channels. ASE will provide content that links back to the ASE website, and a

new test question of the week will be featured in each newsletter.

“We are honored to collaborate with the great people at ASE to create this one-ofits-kind newsletter for automotive service professionals,” said Chris Messer, executive vice president for EndeavorB2B. “The ASE Certified Tech Edge newsletter will be dedicated to providing technical content and leading industry resources for the most engaged automotive service professionals, as well as offering guidance for young technicians and support for established repairers.”

Sign up to receive the weekly ASE Certified Tech Edge in September and be entered to win one of 10, $250 Snap-on Tools gift cards. Terms and conditions can be found at ASE.com/legal.

Christian Brothers Automotive has outlined plans for a $12 million technology and training center in Katy, Texas, as well as a systemwide effort to install air conditioning in every service bay by mid-2027, per a recent press release.

The company will soon break ground on its nearly 14,000-square-foot facility, set to open in early 2027. It will serve as a national hub for hands-on training in both technical skills and customer service, equipped with the latest in vehicle lifts, diagnostic equipment, and ADAS tools.

CBA will also be relocating its corporate support center from Houston’s Energy Corridor to the new facility, creating a unified headquarters capable of supporting up to 500 employees.

Additionally, CBA said it will be expanding its shop enhancement initiative through air-conditioned service bays. More than 100 shops have now been retrofitted to feature air-conditioned service bays, and all new shops south of I-70 are now built with A/C included. The brand is also supporting franchisees who opt to retrofit existing shops.

“As we look toward the future of our brand, this new campus and our facility upgrades reinforce our belief that growth and purpose go hand in hand,” said Donnie Carr, president and CEO of Christian Brothers Automotive. “It’s about so much more than building infrastructure. We’re creating an environment where our team members, franchisees, and guests all benefit from a stronger, more united brand experience.”

Longevity of technicians says a lot about a business. What do your numbers say about you?

One of the best indicators of a healthy business is the length of time your team members have had within the shop. The 2025 Ratchet+Wrench Industry Survey Report shows that most operations are not only dedicated to their customers, but also to their employees, as 65% report that their technicians have been with them for 5 years or more. Here’s a look at longevity in shops and a reminder that investing in your technicians is a sure-fire way to bridge the knowledge gap between incoming employees and seasoned veterans.

Is your European oil really European?

TotalEnergies Quartz Engine Oil is born in Europe and available across the US. Trusted by leading OEMs as their first fill with full specifications coverage and proven performance, it is the oil your engine was designed for.

For more information:

This Richmond, Virginia, auto repair shop owned by Kayla and Aaron Williams is sleek, modern, and inviting

BY KACEY FREDERICK | PHOTOS BY EMMICLAIRE PHOTOGRAPHY

Ironwood Automotive first opened in 2019, following Aaron Williams working for 14 years as a technician doing his own side work. During that time, he met Kayla Williams, his wife and co-owner of Ironwood Automotive. After establishing a solid clientele, the two decided to pursue shop ownership, and bought their first building.

The initial shop was small, but since 2022, the business has operated out of a larger, 7,000-square-foot facility. The building was a custom renovation, requiring a seven-figure investment, with significant changes made to the structure and layout.

The black exterior and glass windows create a sleek, modern aesthetic while an outdoor waiting area and patio complete with seating, plants, and seasonal decorations invite customers to pull up a seat and take a breath of fresh air. The business’ sign is made of aluminum and wood, with a laser-cut design that helps it to shine at night.

The inside of the building features concrete floors with a refreshment station that greets customers as soon as they enter placed strategically beneath a high-contrast display of the brand’s logo. There are also plants throughout the shop, accompanied by an essential oil diffuser.

“I’m really big on green and natural influences,” tells Kayla. “I really wanted it to feel like a little spa when you enter the building. I worked in the spa industry, so I kind of pulled from my experiences there, and wanted people to feel really relaxed the minute they walk in.”

The waiting room also features a sprawling mural which depicts illustrations of various automotive components. The Williamses got the idea from architects they worked with when opening the shop, who showed them concept art that sparked the idea.

“They had showed us some concept

images, and we loved the engine cutaways, but they were a lot of domestic, focused parts,” explains Kayla. “We specialize in Honda, Toyota; basically Asian vehicles. So I was like, ‘We need to do something a little bit different that makes more sense for our brand’.”

Owners: Kayla and Aaron Williams

Location: Richmond, Virginia

Send a few photos and a brief description to submissions@ratchetandwrench.com and we might feature it here.

Kayla found an artist online who compiled a couple of different engine schematics and made a brand new design; it was then painted by a local artist who had previously painted the logo on both of Ironwood’s buildings. He used a projector on the wall to outline the design.

Back inside, a glass door opens to a platform that offers customers a bird’s-eye view of what’s going on inside the shop. Raised about two feet off the ground, customers are sometimes taken out to the platform for a closer look.

“We call it our catwalk, and it really

gives a great overview to walk out and show a customer—or maybe those customers have young children, and they think it’s fascinating to see a shop. We will often let people go out there and just take a look,” says Aaron.

Out in the shop, the spotless, white floor helps to reflect light and create a bright space while also helping workers to quickly identify oil spills and other hazards that need to be cleaned.

It’s not always easy to maintain a color scheme when it comes to shop equipment—but the Williamses don’t play around with branding. Whenever possible, Aaron opts for black equipment to maintain their facility’s color scheme. Ultimately, the shop prioritizes efficiency overall, with no lifts in front of each other so technicians can work independently. The shop is also equipped with an inground alignment rack, modular cabinet systems for organizing parts, and an oil distribution bar for convenience.

“We just laid the shop out to be as efficient as possible with the space that we had,” says Aaron. “I wanted the techs to be able to independently pull things out as much as they could and not affect workflow. So we really thought about that.”

How you handle difficult situations speaks volumes about the level of your shop’s professionalism

BY KATHLEEN CALLAHAN

We have talked a lot this year about how to enhance your client’s experience with your shop. This month, let’s address the elephant in the room–difficult clients.

Handling difficult situations is an inevitable part of life. In business, it is essential to remain calm and solution-focused. Many of the skills I’m about to cover will sound familiar if you’re a regular reader, and they are critical when dealing with an upset client. In my experience, most hiccups with clients come from three areas of confusion: price, quality, or communication.

Our industry has had a bad reputation on pricing for years. Customers worry about being overcharged, but here’s the kicker: Half the time, it’s because many shops undervalue themselves! When they undercharge, it makes everyone else look like we’re gouging. Add to that the fact that most people have no idea what a repair should really cost, and it leaves us doing the heavy lifting of showing the true value behind the number.

Quality concerns almost always boil down to lack of trust. Unpleasant previous experiences, cheap parts, or unclear explanations make people doubt the work. If the repair doesn’t meet their expectations, or if they don’t understand the “why” behind it, they assume it’s not good enough.

This is the biggest one! Even if the price is fair and the work is solid, poor communication can sink the whole experience. If clients don’t understand what’s being done, how long it will take, or why it matters, they’ll fill in the blanks themselves, and that is NEVER a good idea! Silence makes people nervous. On the flip side, too much jargon makes them tune out. Clear, timely, and honest communication keeps expectations aligned and stops most problems from blowing up.

Here are a few key strategies to train your staff on (if you read my columns in April and June, these should sound familiar):

1. Remain calm and empathetic.

• Stay composed and don’t get defensive. The client’s anger isn’t a personal attack. Use your active listening skills and allow the client to fully express their concerns without interrupting them.

• Show empathy for their frustration and validate their feelings. Using phrases like, “I understand why you’re upset,” can be incredibly helpful.

• Use nonverbal cues like maintaining eye contact, nodding, and keeping your arms uncrossed all show that you are engaged. Crossed arms sends the message that you are closed off or not interested in what they have to say.

2. Understand and address the issue.

• Ask clarifying questions to ensure you understand their concern.

• Be honest and transparent. We’re all human, and admitting mistakes can actually build trust.

• Explain what needs to be done without drowning them in jargon.

• If you don’t have the answer yet, say so. Then let them know when you will.

3. Find a solution.

• Present a clear path forward, even if it means compromise.

• If the issue is fixable, offer both an immediate fix and a proactive step to prevent future recurrences.

• Keep the client informed by providing regular updates on progress.

• Follow up with the client afterward to ensure they are satisfied.

Learning from what happens, good or bad, is what keeps us from hitting the same wall twice. A friend of mine used to say: the ‘yets’ are fine, but the ‘agains’ are the ones to avoid.

So–write it down, share it, and learn from it–every complaint and how it was resolved. That’s how you spot patterns and improve. Pair that with clear, written procedures, and you’ve got consistency, fairness, and staff who feel empowered to handle problems in real time without waiting for the boss to step in.

Most importantly, train your team! When your staff has the tools and confidence to handle tough situations, everything gets easier. Strong training means fewer fires to put out, happier clients, and better service across the board.

Kathleen Callahan has owned Florida’s Xpertech Auto Repair for 20 years. In 2020, she joined Repair Shop of Tomorrow as a coach to pursue her passion for developing people and creating thriving shop cultures. Callahan is the 2018 Women in Auto Care Shop Owner of the Year, nationally recognized by AAA for three consecutive years, testified for Right to Repair on Capitol Hill, and is vice chair of Women in Auto Care.

kathleencallahanfl@gmail.com

Supercharge Your Supply Chain With

Build Estimates In Seconds.

Wit h N expar t Mult i-S el ler you’re c onne cte d to real-t ime inventor y and whole sale pricing from al l o f your par ts suppl iers. Find par ts, t ires, and more Bui ld detai le d est imates fast!

Backe d by t he most c omprehensive catalo g in t he af termarket . You’l l se e more pro ducts, from more suppl iers, g iving you more c ontrol o f your supply chain.

earn points on every parts order Multi-Seller

Selecting the system that will satisfy technicians’ ability to earn a living and a desire to continue to improve their skills

BY ALISON JOHNSON | DATA SOURCE: 2025 RATCHET+WRENCH INDUSTRY

SURVEY REPORT

A flat-rate-plus-bonus pay structure

Kendall Warnock instituted at A1 Automotive aims to reward those who desire a higher earning potential. Meanwhile, new or inexperienced techs are paid hourly to ensure they can hone their skills through practice and time.

Liz and Keith Perkins opt to pay their techs hourly at Level 1 Automotive to ensure a steady paycheck and to avoid the peaks and valleys of some seasons, such as fall and winter.

TIVE REPAIR

OWNERS THEIR OPINION ON THE BEST PAY STRUCTURE to attract and retain high-quality, productive technicians, and you’re likely to hear 10 different answers. Or at least seven or eight.

With a nationwide shortage of skilled technicians, economic pressures throughout the industry, and changes in the scope of work needed for modern vehicles, the traditional flat-rate payment system has increasingly given way to more hybrid plans.

For owners, of course, the constant challenge is to balance a need to provide technicians with financial stability–in an industry that can’t afford to lose them–while still motivating them to work efficiently and continuously strive to improve their skills and techniques.

Many shops have built a variety of incentives and bonus structures into their flat-rate plans in an effort to reward productivity and training level. Key metrics such as first-time fix rate, return jobs rate, customer retention rate, and even customer satisfaction scores all can be considered in this type of system. Meanwhile, a smaller number of owners have decided that hourly pay is a more effective, fair, and straightforward way to maintain employee morale, prevent frequent turnover, and promote teamwork rather than a “me-first” mentality.

Much less common for independent shops is an annual salary system, despite the advantage of maximizing income predictability and long-term thinking by team members. That’s due to its high cost for shop owners, as well as limited earning growth potential for employees.

Most businesses still only tend to

turn to a salary plan as a reward for highly trained technicians and shop leaders, all of them people who have long proven that they will pay for themselves in terms of output and value to the team.

At a time filled with challenges for owners and general managers–from rising parts and labor costs driven by inflation, to supply-chain disruptions, to expensive technology and diagnostic equipment required to service newer vehicle models–many shops have frequently experimented with and tweaked their pay plans.

Beyond increasing profitability, their reasons have included changes in top leadership, shifting local market conditions, efforts to attract new talent, and incentivization of specific repairs, especially if a business has had gaps in certain service areas.

Here is a look at two successful businesses that have developed–and carefully fine-tuned–two separate approaches on pay.

Years into implementing those plans, each has no regrets.

Kendall Warnock owns two repair shops in Lincoln, Nebraska, where he employs a total of 17 technicians and four service advisors.

During his first eight years in business, Warnock used an hourly payment plan as he worked to build up his customer base. Once his shop got busier, he switched over to paying techs based on a “flag time” for each job, based on predetermined industry standards, regardless of how long the work actually took to complete.

It was only in year 11 of operation,

however, that Warnock finally created a flat-rate-plus-bonus structure that he is confident is a good fit for him and all of his technicians. Today, he views his main role in that system as keeping his shop busy enough to be profitable for everyone, via smart hiring, equipment purchasing, marketing, and advertising.

“First and foremost, we need to adequately reimburse our auto techs to be able to take care of themselves and their families,” he says. “I think that’s a good shift in perspective that has come about in our industry in more recent times.”

“At the same time,” he continues, “there has to be accountability attached to salary in terms of output. If we do things wisely, tactfully, and empathetically, we can all get better together and serve our customers well. That way, everybody wins.”

A1 Automotive’s pay plan is precise and detailed. Each year, Warnock breaks down the number of possible eight-hour work days in a month, factoring in holidays and weekends on the annual calendar. This year, that ranges from 19 days in November to 23 days in October.

Next, the business sets a threshold of turned hours per month that, if exceeded, triggers bonuses of $1 (Level I) or $3 (Level II) an hour. Technicians can reach Level I by reaching 9.5 hours turned per working day; they can get to Level II by hitting 12 hours turned per day.

Take this November as an example: A tech who turns 180.5 or more hours that month would earn a Level I bonus, while one who turned 228-plus hours would qualify for the higher Level II boost.

In October, on the other hand, working 218.5 or more hours equates to a

“There has to be accountability attached to salary in terms of output. If we do things wisely, tactfully, and empathetically, we can all get better together and serve our customers well. That way, everybody wins.”

— Kendall Warnock, Owner, A1 Automotive

“What we’re incentivizing is teamwork. We’re all working toward one goal, which is to do our best work and get the cars back to customers in a timely manner, but without racing the clock or possibly competing with each other.”

— Liz Perkins, Co-Owner, Level 1 Automotive

Level I pay increase, and 276 hours or more to Level II. For both levels, the expectation is no comebacks due to negligence, which prevents any urge to rush through jobs.

Unlike some businesses, Warnock has opted to pay those bonuses on a monthly basis rather than every two weeks. “I like that my techs have a whole month to chase their goals,” he explains. “To me, two weeks feels like too fast a turnaround–too much of a rat race for people. You don’t have to be great every day because no one is. You just have to be great overall.”

The system aims to reward efficiency and improvements in techniques and skills, which in turn creates more earning potential for the most high-performing techs.

As for the potential disadvantages typically cited with flat-rate plans–such as a temptation for techs to cut corners, or the risk of unpredictable income during slower periods–A1 Automotive hasn’t had problems, according to Warnock.

One reason is that Warnock hasn’t entirely given up on hourly pay, which undeniably provides greater stability for more

inexperienced technicians as they practice and learn skills that can only come with education, repetition, and time.

When Warnock hires a new technician, he keeps them on a fixed per-hour payment plan for their first 90 days as they get up to speed on shop protocols and navigate expected bumps in the road. More seasoned hires can still begin on a negotiated flat-rate plan, he noted.

That strategy was based on Warnock’s own rough start as a young technician about 25 years ago, after he had moved to the city of Lincoln from the tiny Omaha Indian Reservation. He was thrown unprepared into a flat-rate system at a major car dealership and, without proper mentoring, struggled to make ends meet despite regularly working eight- to 10-hour days.

“I couldn’t pay my rent and bills. I was mentally exhausted and demoralized,” he recalls. “I still remember how terrible it felt to be in that situation, and I don’t want people here to feel that way. I don’t want them to decide that they hate the entire industry, because we can’t afford to run our young techs out of the building.”

Once a new technician has been employed at one of his shops for about three months, Warnock holds a “90-Day Pit Stop” huddle so they can mutually evaluate and discuss if they’re ready to move on to the flat-rate payment system.

In some cases, Warnock opts to extend their time on hourly pay by another 60 days, as long as he has seen a good work ethic and efforts to improve on their part. Most of the time, however, he has found that a technician is prepared to make the switch.

The system only works with mentorship from more experienced technicians,

of shops offer salary plus commission 13%

of technicians are paid hourly 27%

Warnock adds. And that, he has learned, has again required flexibility in payment systems–one that factors in a more nuanced definition of what “production” means.

Namely: that metric shouldn’t only translate to hours turned working on vehicles, but to time spent serving as a teacher, mentor, and shop leader.

A1 Automotive, for example, has a recently promoted foreman who has agreed to complete 20 hours of billed repair time per week plus another 20 hours of mentorship, which ultimately sharpens everyone’s focus and skill level in the shop.

“It’s a really good blend for him that also adds significant value to the business,” Warnock says. “This is an industry that will beat you up physically, and it takes a lot of effort and knowledge to get to the point where you deserve such a blend–and we should recognize that. It will only benefit us as owners, too.”

Liz and Keith Perkins, the married coowners of the Tulsa, Oklahoma-based shop, run a brick-and-mortar location along with a mobile business, L1 Automotive Diagnostics and Programming LLC, that serves both Tulsa and Oklahoma City. They also have a training company, L1 Automotive Training, that has taken them to shops around the country and world.

The couple, who originally started their mobile business in 2018, have five technicians and a service advisor. And they have never wavered from their belief that fixed hourly pay is the best way to keep income steady for their employees,

Hybrid

Flat rate plus guarantee

Hourly plus bonuses

Flat rate plus bonuses

Multilevel flat rate

Hourly plus bonus for flagged hours

Flat rate plus incentives

even though Liz Perkins estimates that only about 10% of the people she visits as a trainer have made the same decision.

“They do tend to be surprised, but it really works for us,” she says.

Like Warnock, Liz Perkins was influenced by her experience in the industry. In her case, however, it was in her role as a wife to Keith Perkins, an ASE Master Certified L1 Technician who has worked as an engine machinist and assembler, dyno tuner, diagnostic technician, repair technician, and more. The couple has two children.

In previous jobs, Keith was reimbursed based on flag times, and Liz was surprised by how dramatically his paychecks could fluctuate in a single calendar year.

During slower periods such as winters, holidays, and the span of Oklahoma’s popular 10- to 11-day state fairs, Keith would call Liz to warn her that he would be bringing less money home than usual. Late springs and summers were typically much more lucrative.

“We learned that we really had to

save in better months ahead of those down periods, but those calls were still hard on both of us,” she remembers, noting that she has heard about techs taking on second jobs because they were struggling to top minimum wage.

“After I’d been through that myself, I couldn’t have my own techs worried about being able to feed their families. I don’t want them stressed about being able to pay their bills and wondering if they were going to be eating steak or a bunch of ramen noodles that week.”

Even outside of expected annual downtimes, Liz says she realized from first-hand experience that a technician’s income could drop suddenly if a shop didn’t get enough complex, high-value repair jobs such as rebuilding transmissions or replacing head gaskets and engines.

And certain employees, particularly younger techs, tended to lose out on those jobs to longer-tenured team members.

That left some technicians trying to survive on more low-profit work such as time-consuming warranty jobs or routine maintenance tasks such as

oil changes, alignments, and standard brake jobs (although, the counter-argument goes there, a good tech should be able to knock out those latter jobs in a fraction of the hours typically billed).

On the other hand, a difficult diagnostic or repair job could easily exceed flag time and become unprofitable despite a tech’s best efforts, especially if unexpected complications cropped up or a flag time was poorly calculated from the beginning.

Perkins feared that morale would drop quickly for techs without more regularity in their work lives. “I just think that people are going to do their best and stay with us if they have the stability,” she says. “They’re also not feeling pressure to look out for themselves and fight over the ‘better’ jobs, like, ‘He got the engine job last time; when do I get one? What about me?’”

So, she continues: “This way, what we’re incentivizing is teamwork. We’re all working toward one goal, which is to do our best work and get the cars back to customers in a timely manner,

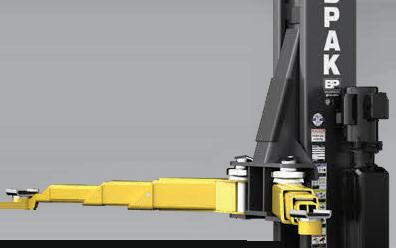

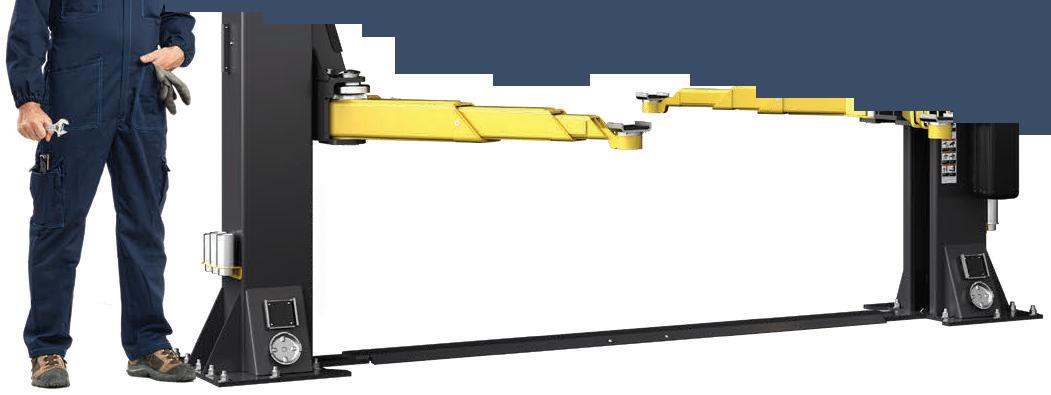

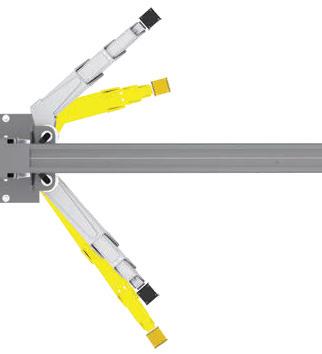

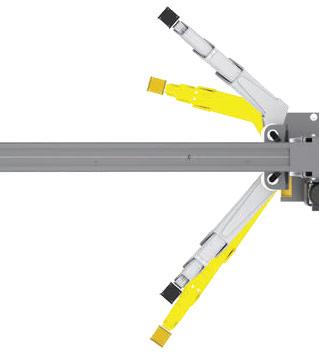

The BendPak 12AP-SRT short-rise two-post lift cost-effectively improves tire shop productivity and efficiency while mitigating risk. With 12,000 pounds rated capacity, massive wingspan that reaches most OEM lifting points, and BI-METRIC™ arms to suit virtually every vehicle lifting requirement – symmetric or asymmetric. The 12AP-SRT can raise 99 percent of cars, SUVs, and trucks to a comfortable working height much faster (and easier) than a set of jacks. Its single-point safety lock system, super-strong automatic arm restraints, and limited max lifting height of 47 inches deliver superior peace of mind. The short 93.5inch columns offer lower product, installation, and maintenance costs, plus a cleaner floorplan. Check out the full line of BendPak lifts at bendpak.com or call us at 1-800-253-2363.

but without racing the clock or possibly competing with each other.” Still, establishing an effective hourly pay system isn’t as easy as simply setting an hourly wage and stepping back, Perkins stresses.

Most important has been scheduling regular staff reviews on all details of the shop’s daily workflow. Those step-bystep plans run from the time of a customer’s initial call through scheduling appointments, collecting information on a vehicle, inspecting the vehicle and diagnosing problems, ordering needed parts, completing and documenting maintenance or repair work, checking customers out, and cleaning up workspaces and outdoor lots. Everyone has to clearly understand their role in that system, as well the procedures for making adjustments if something threw the schedule off–if, for example, a two-hour allotment for diagnostic work stretched into four hours on a complex case.

“There needs to be guidance in place on questions like, ‘What are the next steps? Who, let’s say, will be in charge of

contacting the customer?’” Perkins says. “Everyone has to be held accountable and be on the same page about how to keep things running well. There’s a lot of setup needed to get to that place, but once you get there, everything is easier.”

The shop holds weekly staff meetings on Wednesdays, with a free lunch included, to discuss those issues and any problems, concerns or suggestions that arise. The system requires owners to trust and respect team members, Perkins says, and for techs to reward that regard with consistent hard work.

Level 1 Automotive does regular employee evaluations that can result in hourly raises to recognize experience, quality results, new training and certifications, and/or the acceptance of added shop responsibilities.

All new employees are evaluated after 90 days, six months, and one year, followed by reevaluations that happen at least once a year as long as they stay with the business. “We have given raises multiple times to one person in a single year before,” Perkins notes. “We love

to see people taking initiative and approaching us to ask if they might take on more job roles and tasks, and that can include serving as mentors to newer team members.”

The business did try out a bonus system at one point in the past, she adds, but employees soon reported back that they preferred a higher hourly wage due to its predictability.

In addition, the shop doesn’t only rely on paychecks to help retain technicians. For example, it provides tools, uniforms, and work boots to help technicians avoid going into any debt, especially early in their careers; the company also maintains heated and cooled work spaces year-round and operates on a four-day work week, with 10 hours of labor expected a day.

“A work-life balance has become part of our culture, which I think is happening at more and more shops,” Perkins says. “We need our techs to be happy, enjoy their jobs, and want to please us as owners. If they are, we can be optimistic about our industry’s future.”

VISION’s final night on Saturday is ending on a whole new level of excitement. The ultimate send-off: highenergy racing, games, and celebration at Andretti Indoor Karting & Games!

Tickets available for purchase when registration opens. Group transportation provided.

Saturday, March 7, 2026 6:00 PM - 10:00 PM

Emphasize OEM requirements, safety, and clear communication strategies to improve customer understanding and acceptance

BY LEONA SCOTT

Advanced driver-assistance systems are now routine in repair tickets from a post-collision radar aim to a camera calibration after an alignment or windshield replacement. Yet for many motorists, the line item still reads like an unfamiliar upsell. Two veteran shop leaders —Matt Fanslow, shop manager at Riverside Automotive in Red Wing, Minnesota, and Tom Schearer, owner of Schearer’s Sales & Service, Allentown, Pennsylvania, and Ratchet+Wrench’s 2024 All-Star Award Winner —share how they explain the work, price it confidently, and keep the conversation focused on safety and OEM procedure.

Lead with the OEM, Not Opinions Fanslow’s first principle is simple: the service manual is the script.

“If a manufacturer says, ‘replace this part, then calibrate this sensor,’ we have to do it,” he says. “That doesn’t always mean step-by-step hand-holding in the manual, but the end goal never changes: the targets and equipment must be placed exactly where they need to be, accurately.”

He keeps it concrete by showing customers the published procedure or position statements. It shifts the dialog from “our recommendation” to “the vehicle maker’s requirement,” which also reframes price questions. “The equipment, the targets, the annual updates there’s real cost and maintenance behind doing this right,” Fanslow notes. “Like any business expense, you have to recoup it—and yes, make a profit.”

Schearer has learned that making ADAS sound exotic can backfire. “We present calibration just like any other needed service,” he says. “Along with your four-wheel alignment, we’ll calibrate the vehicle’s cameras for your safety systems. Then we move on.”

When customers do ask why calibration costs more than an alignment, he keeps the answer short and specific: adjustments change reference points; today’s vehicles use cameras and radar that must be recalibrated to those new reference points; that takes time, space, tooling, and precision. “We’re upfront and transparent, but we don’t dramatize it,” Schearer says.

the

Pushback typically stems from an education gap. Many motorists don’t realize their car even has ADAS, Schearer says. His team bridges that gap by naming familiar features:

• Adaptive cruise that slows in traffic

• Lane warnings (beeps or steering wheel feedback) at the yellow line

• Forward collision/automatic braking alerts.

Once customers connect those experiences to the sensors you’re calibrating,

the need makes sense. Fanslow adds a vivid mental model: a camera that’s off by a fraction of a degree may be “inches off” a few feet ahead —but feet off hundreds of yards down the road, potentially reading the wrong target. That framing sticks.

Both leaders use visuals to keep explanations tight and clear.

• Printed/OEM excerpts: A snippet of the procedure that ties the calibration to the repair performed (e.g., alignment with thrust angle change).

• Short animations: Schearer’s team attaches MotoVisuals clips to estimates —what an alignment does, why calibration is required afterward.

• Screens/photos: Images of the target setup or a quick scan report add credibility without overwhelming the customer.

Fanslow also shares third-party resources when helpful (vendor explainer videos; safety organization overviews). “People may not like the price,” he says, “but once they understand it’s safetycritical, they don’t hesitate.”

A concrete case study can be the turning point. Schearer recalls an Audi whose driver felt intermittent brake pulsing and saw a brief “front assist limited” message. A windshield had been replaced a week earlier, and the customer had been told the camera would “recalibrate as you drive.”

On a road test, the team verified the pulsing, scanned the vehicle, and performed a proper static calibration. The symptoms were resolved. “When she connected the timing to the glass work, it clicked,” Schearer says. “It’s a reminder to trace recent work and verify OEM steps were actually followed.”

Fanslow shares the opposite scenario: a driver who refused calibration after a repair despite clear documentation that it was required. His shop had the customer sign the RO and towed

the vehicle home at the shop’s expense—a line-in-the-sand decision based on safety and liability. “If we let them drive out, it could imply the car is safe,” he says. “In today’s litigious environment, we couldn’t take that chance.”

Train Advisors

Human Service advisors don’t need to be techs, but they do need to be fluent in the why, able to translate technician notes into customer language, and consistent from counter to counter. Schearer builds that consistency through Shift Point Training Academy (founded by his daughter, Samantha, the 2024 AAPEX Service Advisor of the Year), plus lunch-and-learns, “in-the-moment” coaching, and tight tech-advisor feedback loops. “Every client should get a similar, confident explanation of what’s needed and why,” he says.

Fanslow points advisors to equipment-maker resources (Autel, Hunter, Bosch, Snap-on, Launch) and emphasizes linking the calibration to the operation performed. Example: “We completed your alignment; the manual says if thrust angle changes, we must calibrate the forward camera for the safety systems to function properly.”

Both owners stress pricing discipline. Calibrations require space, targets, specialized tooling, software subscriptions, and ongoing updates. “Remember your worth,” Schearer says. “Don’t devalue the work—or the industry —by discounting or treating it as an afterthought.”

Fanslow agrees: document the OEM requirement, perform the calibration to spec and retain proof of completion.

Treat ADAS calibration as standard of care, not a debate. Normalize it in estimates. Tie it to the OEM requirement and the customer’s real-world safety. Use visuals to keep explanations short. Train advisors to be consistent and confident. Price and document the work like the critical procedure it is.

Do that, and most customers will move from skeptical to satisfied —because they understand what they’re buying and why it matters on the road.

Equip your front-of-house with a concise script they can make their own:

1. State the need plainly. “Because we adjusted your vehicle’s geometry, the manufacturer requires a camera/radar calibration, so your safety systems work properly.”

2. Anchor to the OEM. “Here’s the procedure that ties calibration to this repair.”

3. Connect to lived experience. “This is what enables your adaptive cruise/ lane keep/automatic braking to behave correctly.”

4. Set the expectation. “It takes precise setup, targets, and software to do this to spec. We’ll handle it end-toend and document the results.”

5. Invite questions—briefly. Use an animation or photo if needed; avoid a tech lecture.

In this business, timing is everything. Since 1945, we’ve been your family-owned source for OE parts, training, and creative business solutions. Get in touch to discover how we can customize a program that keeps your business firing on all cylinders.

Whether it’s a change in logo, owners, or procedures, adjustments and modifications can be tricky. Here’s how one operator mastered them

BY TESS OWINGS

Bill Snow still remembers a customer he encountered the first day he officially took over as owner of his shop in Wickliffe, Ohio, from the Maher Brothers.

“She stopped dead in her tracks,” Snow recalls of the woman. She came in–maybe only two feet or so–into the repair shop, looked around and said, “Who are you? Where is everyone?” The woman had known the shop as Maher Brothers Automotive and was surprised to see it under new ownership with Snow at the helm, and a new name: Rad Air Complete Car Care. “She then said, ‘I don’t know what to do, I might have to leave’,” Snow chuckles. He assured her that although the name on the door and a few faces had changed, the core values and the care that the Maher Brothers had extended to the community were still there and that she was in good hands.

Taking over a shop is never easy, particularly if it’s well regarded in the community. Snow knew that he was in for a challenge, especially because the shop was switching over to a franchise. Here’s how he was able to handle the transition and carve out his own spot in the community’s heart.

Snow came from corporate America and had some interest in starting his own business. In 2012, he and his wife were on a trip in North Carolina when his wife’s car broke down because the repair shop that they had visited used the wrong antifreeze. He remembers sitting

on the beach telling his wife, “If it’s happening to us, it’s happening to other people.” It was then that they began contemplating opening their own repair shop.

Snow began looking for shops for sale, but nothing came to fruition until Rad Air Complete Car Care

reached out to him with an opportunity. Two brothers were interested in being bought out, and Rad Air needed to find someone to take on the shop. Initially, Snow wasn’t interested in becoming a franchise owner because he viewed it as cookie-cutter approach to starting a

business and he wasn’t thrilled about the idea of someone else helping him launch his ideas. It took a few sit downs with Rad Air representatives, but Snow quickly realized the brand would provide a lot of flexibility and the ability to tailor it to his vision.

The Maher brothers had built a nice business in the neighborhood and with new ownership, there was bound to be some growing pains. Since employees and customers aren’t always receptive to change, Snow had to figure out a way to get everyone on board with a new name and a new leader.

The previous owners—Corey and Daryl Maher—were the reason that the business ran so smoothly. Snow says that each brother had their own role. Corey was on the business side while Daryl was more hands on. According to Snow, Corey was the reason that he agreed to the deal. He says the way he led his shop and the core values of the business were major selling points for him. Meanwhile, Daryl expressed an interest in

staying as a technician, which turned out to be a great fit as he and Snow developed a good relationship and shared a lot of the same ideas. Snow adds having him at the shop for a few years was huge so people could see a friendly face. Before Snow officially took over, Corey introduced him to people in the community, including Chamber of Commerce representatives as well as a local networking organization. He also called his top 100 customers to explain what was happening so by the time the official announcement was made, everyone knew that Snow was the person that the Mahers chose to take over. In the shop’s windows, caricatures of the brothers depicted the two with their arms extended and when the new ownership took over, they playfully added the Rad Air logo in their arms as if they were presenting it to the community. For Snow’s part, he made sure to get to know the staff and customers by hanging out in the shop for a few weeks, even going as far as to wear a Maher Brothers sweatshirt. Snow says although employees can be apprehensive of new ownership, it went

Originally, Bill Snow hadn’t considered being a part of a franchise because he didn’t think he needed anyone’s help in running his own business. It took a few meetings before he was sold on the concept. Although franchises aren’t for everyone, it can be a great option for some business owners. Here are some of the benefits of being a Rad Air Complete Car Care shop, according to Snow.

• More flexibility than expected

• Recommendations on equipment

• Business support

• Large marketing reach

• Name recognition

much better than he anticipated. He says that spending that time in the shop paid off because his team could sense that he was a good guy. The only real obstacle the team had with the new ownership was that Rad Air had a different inspection process than Maher Brothers did. Although the team was initially frustrated, Snow assured them that they could tweak it to find a solution that worked for them and eventually they found their groove.

Snow estimates that he was able to keep roughly 75% of the customers that Maher Brothers Automotive had, along with picking up new customers. He says that revenue has tripled in 12 years, and the staff has doubled.

For any shop owner that’s considering repositioning itself—either through new ownership, a name change, or even a new phone-answering process—Snow says to think it through and decide if it’s really what you want. Ask yourself whether a refresh will really move the needle and make a difference; otherwise, it’s not worth it. Snow cautions that such moves are expensive, so first make sure that it will pay off.

He also urges shop owners to see ideas all the way through. He says he’s seen many shops toy with introducing a new logo or a new name and then only put it up on a few social platforms but it’s not consistent throughout, so rather than making a difference, people are just confused. Perhaps the most important piece of advice he has is that if there is something you are thinking about to improve your business, you need to take action.

“If you leave that plan in your notebook, it’s never executed,” Snow says.

Although some people want an idea or a plan to be flawless before it’s executed, it will never be perfect. If you want to change something in your business and think it will make a difference, you need to really go for it.

THE 35,000-FOOT VIEW

Involving them

in

the DVI process means listening to what is most important when it comes to service

BY R. “DUTCH” SILVERSTEIN

Having written a previous column on utilizing the 300% rule while performing a digital vehicle inspection there was an aspect of the process that I felt required more detail but the word count limitations interfered. So, I figured now would be a good time to address an issue that is seldom discussed–specifically respecting an individual’s agency.

Agency is defined as “a fundamental principle of interpersonal relationships and ethical behavior. It acknowledges and honors the inherent right of individuals to make decisions about their own lives, bodies, and experiences.” Although it seems simple enough, in transactions where conflict of interest is present, respecting an individual’s agency is often subordinated to the urgency of making a sale. Add to this the knowledge that we live in an extremely litigious society where business owners are frequently accused of being greedy or unfeeling by an uneducated public and what the consumer wants often takes a back seat to what we as service providers recommend.

In best-case scenarios, we interview the vehicle owner and ask detailed questions about their plans and their goals for their property. We then tailor the services that we provide according to their wishes as long as they are legal, ethical, and comport with what we believe will be best practice in accordance with that plan. This is where the DVI process can shine as long as we provide meaningful education about what is being shown in that DVI and how that relates to their goals. When used this way, the DVI is a tool that can be used to promote education and understanding.

But in my experience in reviewing hundreds of DVI reports from other shops, the educational aspect of the DVI process is frequently exploited to threaten and in the worst case–frighten–prospects and customers into making unnecessary repairs while providing no meaningful benefit. At my shop, we emphasized creating legitimate, trusting relationships built on empathy and a genuine need to understand what our clients wanted. We

soon gained a reputation for being the shop where people brought their vehicle if someone wanted a “second opinion.” When we would “interview” that prospective customer on the phone (often following up on a text or email request for service) we’d ask them to bring any paperwork and electronic links to their inspection report or DVI. Comparing those services that others deemed necessary against that which we noted while the vehicle was in our service bay was far too frequently eye opening and was nearly always distressing.

Over time, I began noting some patterns: most of these recommendations occurred in volume-based big box stores (frequently national chains or facilities that modeled themselves after them), and dealerships where the technicians were paid on straight flat rate and the service writers were commissionbased. Examples of such services included but were not limited to:

• Replacing brake pads whose friction material thickness exceeded 6mm and were without defect.

• Replacing oxygen sensors and suspension components not based on the lack of verifiable performance but on what was an arbitrary standard.

• Applying chemical treatments that had no empirical evidence of efficacy as verified by independent testing.

Daily/weekly revenue and production hour quotas were the key performance indicators used for making recommendations and it was appalling.

How can we use DVI as a learning tool and not just as a sales tool? How do we respect our customers’ agency? The answer is relatively simple and is decidedly old school. Show customers through your actions that you are on their side. Allocate time to ask what their goals are for their vehicle. And really listen to what you’re being told. Find out what is important to them about their

vehicle. Take notes and follow up by repeating what they said back to them. Don’t allow distractions to interfere. Is the telephone ringing? Let someone else answer it or allow it to go to voicemail. Carefully explain your DVI process and allow time for questions. Involve them in the process by presenting them with options that align with their stated goals. Let them know that they are being heard and that their concerns about cost, or time or both can be valid. A common adage is that while people may not remember what you said, they will remember how you made them feel. Making them feel respected and valued is a foundational principle of understanding agency.

R. “Dutch” Silverstein, who earned his Accredited Automotive Manager Certificate from AMI, owns and operates A&M Auto Service, a seven bay, eight lift shop in Pineville, North Carolina. Dutch was a captain for a major airline earning type ratings in a variety of aircraft including the Boeing 767/757, 737, 200, 300 and 400 series, Airbus 319/320/321, McDonnell Douglas MD80/DC9 and Fokker FK-28 mk 4000 and 1000. After medically retiring, he transitioned his parttime auto repair business into a full-time occupation.

dutch@dutchsgarage.com