Atkore manufactures PVC & HDPE Conduit right here in the U.S.A. From Allendale, South Carolina to Eugene, Oregon, our regional plant locations make it convenient to source plastic conduit from coast to coast.

Finding the right parts shouldn’t be one of them. Save money and time when you order online. Shop for your next job at SupplyHouse.com

At SupplyHouse, we’re making it easier than ever to get all the gear you need for a job, all from one convenient place. You’ll find products, parts, and tools from the top brands. And once you place an order, we pack it right and ship it fast, so you get it on schedule. The only thing you won’t find at SupplyHouse? Challenges. 50K+ Electrical Products | Exceptional Customer Service | Leviton, Blackburn, & more

With its exclusive online content, ecmweb.com is a valuable source of industry insight for electrical professionals. Here’s a sample of what you can find on our site right now:

MEMBERS ONLY

TOP OSHA VIOLATIONS OF 2024

Quiz Test your knowledge on the top OSHA violations of 2024 and enter for a chance to win a $25 gift card to Amazon! ecmweb.com/55297896

DATA CENTER CONSTRUCTION CONTINUES TO GROW Construction Trend pumps up stats for office sector that’s been in the doldrums ecmweb.com/55301300

MOVING VIOLATIONS VIDEO NO. 338: POOLSIDE PROBLEMS

Video Check out the latest installment of Moving Violations with NEC Expert Russ LeBlanc. ecmweb.com/55301178

Editorial

Group Editorial Director - Buildings & Construction: Michael Eby, meby@endeavorb2b.com

Editor-in-Chief: Ellen Parson, eparson@endeavorb2b.com

Managing Editor: Ellie Coggins, ecoggins@endeavorb2b.com

Editor: Michael Morris, mmorris@endeavorb2b.com

Art Director: David Eckhart, deckhart@endeavorb2b.com

Consultants and Contributors

NEC Consultant: Mike Holt, mike@mikeholt.com

NEC Consultant: Russ LeBlanc, russ@russleblanc.net

Sales and Marketing

VP/Market Leader - Buildings & Construction: Mike Hellmann, mhellmann@endeavorb2b.com

Regional/Territory Account Manager: David Sevin, dsevin@endeavorb2b.com

Regional/Territory Account Manager: Jay Thompson, jthompson@endeavorb2b.com

Regional/Territory Key Account Manager: Ellyn Fishman, efishman@endeavorb2b.com

Media Account Executive – Classifieds/Inside Sales: Steve Suarez, ssuarez@endeavorb2b.com

Production and Circulation

Production Manager: Josh Troutman, jtroutman@endeavorb2b.com

Ad Services Manager: Deanna O’Byrne, dobyrne@endeavorb2b.com

User Marketing Manager: James Marinaccio, jmarinaccio@endeavorb2b.com

Endeavor Business Media, LLC

CEO: Chris Ferrell

CDO: Jacquie Niemiec

COO: Patrick Rains CRO: Paul Andrews

CMO: Amanda Landsaw CALO: Tracy Kane

EVP Building, Energy and Water Group: Mike Christian

Electrical Construction & Maintenance (USPS Permit 499-790, ISSN 1082-295X print, ISSN 2771-6384 online) is published monthly by Endeavor Business Media, LLC. 201 N. Main St 5th Floor, Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI, and additional mailing offices. POSTMASTER: Send address changes to Electrical Construction & Maintenance, PO Box 3257, Northbrook, IL 60065-3257. SUBSCRIPTIONS: Publisher reserves the right to reject non-qualified subscriptions. Subscription prices: U.S. ($68.75 year); Canada/Mexico ($ 112.50); All other countries ($162.50). All subscriptions are payable in U.S. funds. Send subscription inquiries to Electrical Construction & Maintenance, PO Box 3257, Northbrook, IL 60065-3257. Customer service can be reached toll-free at 877-382-9187 or at electricalconstmaint@omeda.com for magazine subscription assistance or questions.

Printed in the USA. Copyright 2025 Endeavor Business Media, LLC. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopies, recordings, or any information storage or retrieval system without permission from the publisher. Endeavor Business Media, LLC does not assume and hereby disclaims any liability to any person or company for any loss or damage caused by errors or omissions in the material herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever. The views and opinions in the articles herein are not to be taken as official expressions of the publishers, unless so stated. The publishers do not warrant either expressly or by implication, the factual accuracy of the articles herein, nor do they so warrant any views or opinions by the authors of said articles.

Reprints: Contact reprints@endeavorb2b.com to purchase custom reprints or e-prints of articles appearing in this publication.

Photocopies: Authorization to photocopy articles for internal corporate, personal, or instructional use may be obtained from the Copyright Clearance Center (CCC) at (978) 750-8400. Obtain further information at www.copyright.com.

Archives and Microform: This magazine is available for research and retrieval of selected archived articles from leading electronic databases and online search services, including Factiva, LexisNexis, and ProQuest.

Privacy Policy: Your privacy is a priority to us. For a detailed policy statement about privacy and information dissemination practices related to Endeavor Business Media products, please visit our website at www.endeavorbusinessmedia.com.

Please Note: The designations “National Electrical Code,” “NE Code,” and “NEC” refer to the National Electrical Code®, which is a registered trademark of the National Fire Protection Association.

Corporate Office: Endeavor Business Media, LLC,

Assemble Conduit Above TrenchNo Workers BelowPrevents Injuries and Deaths. Also Allows Digging a Narrower Trench for Less: Excavation, Concrete, Slurry, Backfill & Shoring.

By Ellen Parson, Editor-in-Chief

When we surveyed leading electrical firms across the country for our annual Top 40 Electrical Design Firms project in March and our Top 50 Electrical Contractors in June, there was certainly a consensus on one key point: the ongoing skilled labor shortage. When asked “which factor is having the most negative impact on the growth of your business,” 62% of electrical design firm respondents cited “difficulty finding and retaining quality employees” as their No. 1 concern followed closely by 57% of their electrical contractor counterparts. Also on par with last year’s results, the number of Top 40 respondents who said they were experiencing “staffing issues” remained high at 89%. For the fifth year in a row, “project engineer” earned the title of “most difficult job title to fill” followed by “supervising engineer” and “design engineer.” Down from 86% last year, the vast majority (74%) of Top 50 electrical contractors indicated they continue to experience worker shortages. “Electrician” bumped “electrical foreman,” moving into the top spot for most challenging title to fill. It’s no secret that, like many other markets, the electrical industry continues to face a critical skilled labor shortage that is only poised to intensify over the next decade. According to a 2023 report by Boston Consulting Group (BCG), one in three engineering roles in the nation currently goes unfilled — with “electrical engineering” identified as one of the leading fields contributing to this gap. The report estimates the nation will need about 400,000 new engineers annually through 2030 to meet demand, yet the pipeline of workers with next-generation skills, such as AI integration, automation, and digital system design, remains insufficient. The situation seems to be even more daunting among electricians. The Bureau of Labor Statistics projects an 11% growth in employment for electricians from 2023 to 2033 (in order to fill approximately 802,000 positions), also outpacing the average for all jobs. This translates to about 80,200 new job openings per year.

Despite these very real hiring challenges, electrical design firms and contractors are making intentional investments in recruiting and retaining top-tier talent — efforts clearly reflected in the record-breaking volume and quality of nominations received for EC&M’s 30 Under 30 program. By recognizing and empowering young professionals who are driving innovation through technology, these companies are not only filling critical roles but also cultivating the next generation of leaders and redefining the future of the electrical industry. Now in its eighth year, our 30 Under 30 Electrical All Stars recognition program has become one of our brand’s most popular and impactful initiatives. Since its launch in 2018, this special report spotlights exceptional individuals under the age of 30 who consistently go above and beyond the call of duty, all while demonstrating leadership, creativity, and a forward-thinking approach to their work. One of the characteristics that sets this generation apart is how seamlessly they’re embracing cutting-edge technologies, using tools like AI, automation, and advanced software to optimize job-site efficiency, improve safety, and solve complex challenges in real time.

This year’s program broke previous records for both volume and caliber of nominations, showcasing a remarkable pool of candidates from across the industry, representing electrical contracting companies, electrical design firms, and facility/plant maintenance teams. By sharing the following personal profiles (starting on page 30), we not only celebrate the individual achievements and companies developing this top talent, but also hope to inspire the next generation of electrical professionals. Take the time to read these 30 outstanding young people’s stories and experience the electrical industry through their fresh eyes. They aren’t just keeping pace with industry changes — they’re driving them.

By Thomas Sandri, Vector Power

Atime domain reflectometer (TDR) measures reflections along a cable. It is similar in principle to radar. To measure those reflections, the TDR transmits an incident signal into the cable and watches for its reflections (Fig. 1 on page 12). If the cable has a uniform impedance and is properly terminated, there will be no reflections — and the remaining incident signal will be absorbed by the termination at the far end. However, if impedance variations exist, some of the incident signals will be reflected to the source.

Two side-by-side conductors separated by an insulator (as in a cable) will show characteristic impedance between them. If the distance between the conductors does not change, the impedance does not change. If the distance between them increases, the impedance goes up.

This technician is using a time domain reflectometer (TDR) to measure reflections on power cables that serve a building.

If the distance between them decreases, the impedance goes down. Time domain reflectometers (TDRs) use simple

Electrical Testing Education articles are provided by the InterNational Electrical Testing Association (NETA), www.NETAworld.org. NETA was formed in 1972 to establish uniform testing procedures for electrical equipment and systems. Today the association accredits electrical testing companies; certifies electrical testing technicians; publishes the ANSI/NETA Standards for Acceptance Testing, Maintenance Testing, Commissioning, and the Certification of Electrical Test Technicians; and provides training through its annual conferences (PowerTest and EPIC — Electrical Power Innovations Conference) and its expansive library of educational resources.

transmission-line theory and pulsereflection principles to detect these impedance changes along a cable. The TDR transmits high-frequency electrical pulses that travel through the cable until a change in characteristic impedance is encountered (Fig. 2 on page 12). Depending on the nature of the impedance change, all or part of the transmitted pulse will reflect to the TDR.

A change in a cable’s characteristic impedance will cause one of two types of reflections: positive or negative.

• Positive reflections are caused by increases in impedance (Fig. 3 on page 14). This will occur if the longitudinal resistance were to increase or if the

If you’re an engineer, commercial or industrial facility manager, or electric utility employee concerned about the quality and reliability of power delivery, this e-newsletter (sent out monthly) is for you.

Topics covered include:

• Power quality

• Voltage sags & swells

• Transients

• Harmonics

• Power factor

• Test & measurement techniques

See all of our EC&M e-newsletters at www.ecmweb.com

R = Longitudinal resistance

L = Inductance

G = Conductivity

C = Capacitance

conductors go farther apart, causing an inductive change.

• Negative reflections are caused by decreases in impedance (Fig. 4 on page 14). This will occur if the conductance and/or capacitance change as the conductors get closer together, causing a capacitive change.

A TDR translates reflections into traces that can be interpreted to indicate events, such as open circuits, short circuits, and splices in the cable circuit. All traces follow the two basic rules of impedance changes.

Let’s review the TDR pattern for a common cable splice (Fig. 5 on page 14). As the TDR pulse enters the splice and the conductor and metallic shield are separated, an inductive change in the characteristic impedance is seen. This results in a small positive reflection. As

the TDR pulse exits the splice, the conductor and metallic shield come back to their natural separation, resulting in a capacitive change. This transition results in a small negative reflection.

Reading a TDR signature is like reading a map. Before reading a map, however, you must learn what the symbols mean. Before reading a TDR trace, you must first understand the reflection patterns.

Understanding the basics is beneficial, but to be helpful, you also need to know the location of these changes in the cable. A TDR sends pulses along the cable that are reflected when they encounter a change in impedance. The TDR notes how long it takes for the transmitted pulse to travel along the

cable and for the reflections to return to the unit. If the TDR knows how long the pulse has been gone and how long it has been traveling, it can determine the distance.

TDRs are like an arithmetic word problem that asks: “If you leave Dallas and travel for two and a half hours at 50 miles per hour, how far have you gone?” Because the TDR knows how long the pulse has been gone, if we can tell it how fast these pulses and their reflections travel along the cable, it will be able to calculate the distance from the TDR to the impedance change. We can do this. But to complicate the situation, the TDR’s pulse travels at different speeds in different types of cables.

The transmitted pulses travel at different velocities on different cables — much like a ball travels at different velocities through liquids with different viscosities. The velocity of propagation changes according to these factors:

• Impedance

• Dielectric materials (e.g., XLPE, PVC, PILC, EPR)

• Age of the cable

• Temperature

• Moisture content (i.e., water inside the cable)

• Wire position inside the cable (e.g., communication type cables)

• Cable manufacturer (composition of insulation material and additives)

Fortunately, we can tell the TDR how fast the pulses and their reflections travel in various cables. This speed is usually stated as a ratio of the speed of the pulse in the cable divided by the speed of light in a vacuum. This ratio is called the velocity of propagation (VoP). If the VoP is 0.50, the speed of the pulse is 50% of the speed of light in a vacuum or 0.5 x 186,000 miles per second. Examples of VoPs by cable type are shown in the Table below.

Typical velocity factors for various types of power and communications cables.

If velocity is not known, the velocity of a cable can easily be determined by connecting it to a sample cable of known length. If we can see the length markings or measure it, we can work backward with a TDR and calculate the VoP.

The TDR now has enough information to calculate the location of the event. Like our trip from Dallas, it knows how long the pulse and its reflection traveled, and it knows how fast that pulse was going. The TDR must merely do the arithmetic.

If neither the velocity nor the length of the cable is known, an accurate location can be accomplished by measuring the distance to the fault from both ends of the cable. If an error exists in the velocity setting, the TDR will over-measure or undermeasure from both ends of the cable. The fault will be between the two measurements.

• A TDR will not work on a single conductor. The TDR relies on the impedance model of two conductors in parallel.

• TDR pulses do not travel down the conductor and return on the neutral. TDR pulses travel down the conductors and reflect in those conductors.

Think of the TDR pulse as a train and the cable as train tracks. The train requires two tracks (rails) to function; the TDR pulse requires two conductors. If one rail is missing, the train must stop; if one conductor becomes open, the TDR pulse cannot travel any farther. If a rail is missing, the train may need to return to the station and will take the same path, but travel backward; if a conductor is open, the TDR pulse cannot continue and will reflect to the source.

Communication cable

For telephone and CATV applications, water can seep through the insulation of a twisted-pair cable at multiple points. In these situations, testing the cable from both ends and recording the distance to a fault provides the tester with an accurate assessment of the severity of the water issue (Fig. 6) or confirms that

the anomaly that was initially spotted is correct.

Electrical cable

Illegal electrical service taps are a major problem for many electric companies throughout the world. An illegal tap occurs when an individual connects to the power cable before it reaches the meter. If you bypass a meter, you’re stealing electricity from the utility. Millions of dollars are lost due to theft of service. A TDR can be useful in identifying the location of illegal taps (Fig. 7) and removing them from the system.

Low-voltage electrical cable

The best methods for locating a fault on

a low-voltage electrical circuit involve a good vs. bad comparison (Fig. 8 on page 18). A healthy TDR trace produced by a complex network shows many reflections caused by the service connection taps and the ends of these cables. Even a gross fault down the network will be masked by other features of the network. In many cases, comparison and differential techniques are the only option.

The arc reflection method of pre-locating a fault on medium-voltage electrical cables combines the use of a TDR and a surge generator (i.e., “thumper”). By using an arc reflection filter, a low-voltage

This twice-a-month e-newsletter tracks the development, design, installation, and safe operation of electric vehicle supply equipment and systems.

Topics covered include:

• Applying NEC requirements

• Industry news and trends

• New products

• Federal investment allocation

• National EV charging infrastructure buildout development

See all of our EC&M e-newsletters at www.ecmweb.com

Before HV Surge

After HV Surge

9. This arc reflection test reveals the cable termination point and fault location detected during an HV surge (red).

TDR and a high-voltage surge generator connected to the faulted cable, the TDR can look down the cable while surging (i.e., thumping). The filter protects the TDR from the surge generator’s highvoltage pulses and routes the low-voltage pulses down the cable. When an arc is created at the fault location, its resistance is reduced to a very low value (less than 200 ohms), which will reflect TDR pulses. The arc location will appear as a downward reflection — a short circuit — on the TDR cable trace (Fig. 9).

The TDR is a versatile, low-voltage device that can be used on almost any cable structure, provided two

conductors are traveling in parallel. The TDR creates a map of the cable displaying impedance changes or events that occur along the transmission path. Distances to events can be determined by knowing the travel time between the launch of the incident pulse and any reflected pulses, and the speed or velocity at which the pulses are traveling. Pulse width settings determine how far pulses can travel and reflect along a cable. They also identify a dead zone or closely spaced events.

Thomas Sandri is the Director of Workforce Development at Vector Power, where his responsibilities include designing and developing learning courses.

Arlington’s new Furred Wall Box™ kit makes challenging outlet box installations fast and easy!

Versatile mounting options Our high strength FSB series outlet box kits are designed for use with existing 1x2 drywall furring strips – but can also be mounted directly to a concrete block wall between furring strips. Place the box or outlet where it’s needed.

Integral cable securement – No pullout! Accommodates GFCI and USB receptacles. Convenient kits simplify ordering of FSB1 and FSB2.

High-strength No breakage in cold weather

Integral Mounting Flanges

NEW FSB12 * FSB22

ADD OUR BOX EXTENDERS to BROADEN APPLICATION and USE

Furring strip flange Mounting Bracket

Block wall flange Mounting Bracket

FSB22 Two-gang

Our NEW Low Profile single and two-gang Furred Wall Box™ base assemblies have 1/2" raised ring for use with standard wall plates.

They combine with Arlington’s Box Extenders to deliver installation solutions for wall thicknesses from 1/2" to 1-1/2" and varying device depths

One-gang FSB12

• Integral cable securement – No pullout!

• For standard and GFCI devicesUses standard wall plates

• Single gang FSB12 - 17.0 cu. in. Two-gang FSB22 - 20.5 cu. in.

Add our BOX EXTENDERS for these specific conditions...

1 if Total Wall Layer Thickness is GREATER than 1/2" (up to 1-1/2") Add BE1 or BE2

+ BE1

if Using a Deep Depth Device with 1/2" Wall Thickness

Add BES1 or BES2

or Dimmer

The largest electrical distributors in Electrical Wholesaling annual ranking continue to invest in their businesses in a big way despite an uncertain economic outlook for 2025.

By Jim Lucy, Electrical Wholesaling

Notes: In most cases, if revenue data is marked “NA,” it means the company elected to provide 2024 sales data confidentially and for placement only. EW’s editors estimate electrical sales for placement of some companies if updated data is unavailable.

Electrical Wholesaling (EW) has been ranking the electrical wholesaling industry’s largest distributors for more than 40 years, but its editors can’t remember a time when distributors’ revenue forecasts, year-over-year (YOY) revenue growth, and expectations for the health of the overall U.S. economy showed such a wide disparity.

For example, of the 37 distributors that provided a revenue forecast, an impressive 40.5% of respondents expect growth of 10% or better — but the same percentage of distributors see growth in a rather pedestrian range of 1% to 5%. Roughly 14% of distributor respondents are gunning for 2025 revenue growth in the 6% to 9% range, which is fairly close to the electrical wholesaling industry’s historical growth range of 4% to 8%. And when asked about the chances of a U.S. recession in the next 12 months, 69% of the 42 Top 100 distributor execs who answered the question said recession chances are 50/50, and another 11.9% said chances were very likely.

This same disparity surfaced in answers to the Top 100 survey’s question about 2024 sales change from 2023. An impressive 40.5% saw revenues grow 10% or better — but 48.6% of

respondents saw growth either flat or topping out at 5% YOY growth.

You will find a listing of Electrical Wholesaling’s Top 50 Distributors in the Table on page 24. A complete listing of all 100 distributors in the ranking is available at www.ewweb.com.

It’s tough to pinpoint exactly why the largest electrical distributors are all over the map with their economic expectations, especially when outside of the uncertainty over tariffs and concern over the size of the national debt, the overall U.S. economy is still growing at a steady if unspectacular rate. Unemployment is currently not growing at a dangerous rate, inflation has not hit the

danger zone, and while the expected real GDP growth rate of less than 2% for Q2 2025 will elicit plenty of yawns, it’s still expected to land on the positive side of the ledger for this quarter.

EW’s editors think the most likely reasons for the widespread differences of opinion over 2025’s economic prospects may be linked to two market drivers.

Tariffs and rising product pricing are very much on the minds of the biggest distributors, and, when asked about which economic, technological, or demographic factors will have the most impact on their

Arlington’s Low Voltage Mounting Brackets are the solution for fast and easy cut-in installation and mounting of Class 2 communications, computer and cable TV wiring and connections.

Introducing METAL low voltage mounting brackets for EXISTING or RETROFIT construction...

LV1M and LV2M COMMERCIAL GRADE

• Extra rigidity and stability where performance and visibility are important or critical

• Threaded holes for easy, fast device installation

• Adjustable bracket for 1/4" to 1" wall board thicknesses

Our LV1S and LV2S PLATED STEEL bracket design, provide excellent stability and secure installation of low voltage devices in 1/4" to 1-1/4" walls - without an electrical box.

50

Perfect for commercial or residential applications, Arlington’s time-saving non-metallic CableAble® Support Brackets are the ONE BRACKET designed for horizontal runs of cable or conduit, commercial or residential applications, power or low voltage wiring, and plenum* or non-plenum ceilings.

• Versatile four- and eight-hole L or T style Brackets mount horizontally or vertically to wood or steel studs, and unistrut, and horizontally to all thread and beam clamps

• Multiple mounting options, secure support for EMT or flexible metal conduit, power MC and NM cables, and low voltage cables

• Load Rated for various mounting options

• For Environmental Air Handling Spaces per NEC 300.22 (c)

businesses, tariffs and rising product pricing were ranked No. 1 and No. 2 as having the most impact — with 25.8% of the 63 respondents expecting tariffs to have the most impact on their businesses and 21.3% worried about product pricing.

Evidence of rising electrical product prices surfaced in the April 2025 data in Electrical Marketing’s monthly Electrical Price Index, the first since tariffs were announced in early April. The April data was up 1.5% over March 2025 and +4% over April 2024. These increases were up significantly over the EPI’s historical averages of 0.21% monthly increases and 2.6% YOY increases.

Right place/right time and right products/right service package for the right project. The Top 50 distributors are working on an impressive array of large construction projects with data centers, semiconductor plants, hospitals, airports, and public works projects being the most common in this year’s survey results. But if a company doesn’t have some of these large projects underway or in the pipeline in their geographic market, it may be hard to enjoy a stellar growth year.

For some distributor specialists, their product and service expertise is matching the need of some very large construction projects. For instance, C.N. Robinson Lighting, Baltimore, Md., is expecting double-digit growth this year, based in part on servicing three larger projects Maryland — the expansion of the Fort Meade East Campus Building in Fort Meade, Md.; the renovation of the Pimilco Racetrack in Baltimore; and a project at the Johns Hopkins medical center in Baltimore.

Shikha Gupta, marketing manager, Nassau National Cable, Great Neck, N.Y., says the company is supplying wire and cable products to a diverse array of large construction projects, including power cable for a utility-scale offshore wind farm in Virginia; cabling products for a Meta data center in Wisconsin; and the Greenlink West Transmission Line (a large utility project in Nevada) with “huge demand” for aluminum and copper building wire.

For other distributors, growth is linked to tremendous opportunities in servicing mega-projects in their own backyard. For example, Jackson Electric Supply Co., Jacksonville, Fla., enjoyed 34% YOY growth in 2024 and expects 2025 growth of 15%. While Larry Swink, company president, said some of his company’s 2024 growth could be attributed to gaining additional market share

from customers and the easing of leadtime issues with switchgear and some other products, he said the Jacksonville market is also enjoying “unprecedented growth driven by transformative devel opments across downtown revitalization, health care, infrastructure, defense, and public utilities.”

These construction projects include a $1.4-billion renovation of the NFL’s Jack sonville Jaguars’ EverBank Stadium that will include a translucent roof, expanded concourses, and upgraded amenities. The project will also include a development by team owner Shad Khan’s Iguana Invest ments featuring a Four Seasons Hotel & Residences; condominiums; and a new six-story Jaguars HQ adjacent to the stadium. Other big projects in the Jack sonville market include more than $600 million in renovations to the U.S. Navy’s Kings Bay Naval Submarine Base; two wastewater reclamation projects topping $100 million; a $190-million expansion of the Baptist Medical Center; and several large interstate construction projects.

“Jackson Electric Supply is actively involved in many of these high-impact initiatives, and their scale and momen tum are already shaping our future,” Swink wrote in his Top 100 response. “These projects are expected to signifi cantly accelerate our progress toward surpassing key revenue milestones within our five-year plan, potentially reaching those goals two-to-three years ahead of schedule.”

Other mega-projects the largest distributors worked on include the Indiana University Hospital, India napolis; Dana-Farber Cancer Institute, Boston; Northeastern University and Boston University student housing, also in Boston; JFK Airport, Queens, N.Y.; a $15-billion Micron facility expansion in Boise, Idaho; and the Paul, Weiss, Rifkind, Wharton & Garrison office tower renovation in New York.

Over the past 18 months, more than a dozen distributors that were previously ranked on EW’s annual listing of the largest distributors were acquired. Sonepar North America, Charleston, S.C., was once again the most active acquirer, with seven large acquisitions in the

17SAVE seconds

Fully assembled, SNAP2IT® fittings handle the widest variety of MC cable AND THE NEW MC-PCS cables.

Compared to fittings with a locknut and screw, you can’t beat these snap in connectors for time-savings!

LISTED SNAP2IT ® CONNECTORS FOR NEW MC-PCS CABLE ...lighting & low voltage circuits in the same cable

• Fits widest range and variety of MC cable 14/2 to 3/3

AC, MC, HCF, MC continuous corrugated aluminum cable and MCI-A cables (steel and aluminum)...including the new MC-PCS cable that combines power and low voltage in the same MC cable

ANY Snap2It Connectors LISTED for MC cable are also LISTED for MC-PCS cable! These products offer the greatest time-savings.

• Fast, secure snap-on installation

• Easy to remove, reusable connector From cable Loosen screw on top. Remove connector from cable. From box Slip screwdriver under notch in Snap-Tite® Remove connector.

United States or Canada, but the other national distributors (WESCO, Graybar, Rexel, and Consolidated Electrical Distributors) were active as well, and all acquired major distributors previously ranked in EW’s listings.

Companies that were acquired include Blazer Electric Supply, Colorado Springs, Colo.; Desert Electric Supply, Palm Springs, Calif.; Dominion Electric Supply, Arlington, Va.; Electric Supply Center (ESC), Burlington, Mass.; Electrical Supplies Inc., Miami; Kovalsky-Carr Electric Co., Rochester, N.Y.; Madison Electric Co., Warren, Mich.; Parrish-Hare Electrical Supply, Irving, Texas; Standard Electric Co., Saginaw, Mich.; and Summit Electric Supply, Albuquerque, N.M.. So far in 2025, three Top 100 electrical distributors have been acquired — Schwing Electrical Supply Corp., Farmingdale, N.Y.; and Swift Electric Supply, Teterboro, N.J.; and Warshauer Electric Supply, Tinton Falls, N.J.

While it wasn’t uncommon for the largest electrical distributors to invest in new branches or regional distribution centers, manage an executive succession plan, refine their ERP computer operating system, or make acquisitions, Border States, Fargo, N.D., has been involved with all of these initiatives in 2024 and 2025.

In addition to acquiring Dominion Electric Supply, Arlington, Va., and adding more than 300 employee-owners in 10 locations to service government, commercial, residential and data centers in Virginia, Maryland, and Washington, D.C., the company embarked on several major initiatives, including the appointment of Jason Seger as president and CEO, following the retirement of David White in March 2024.

The company is building several new distribution centers and is working on a new corporate operating model, Thomas Nelson, the company’s communications director, said in his survey response, “Border States introduced a new operating model, which places greater emphasis on providing a customer-centric, streamlined experience at branches across the country, and aligns with the company’s commitment to

supporting their customers’ unstoppable businesses,” he wrote. “The new model focuses on two key areas of Border States’ business — growing and fulfilling customer relationships. With this shift, leadership at Border States also realigned to best support the needs of customers, vendors, and employee-owners.

“A key strategy to support the new operating model is the implementation of distribution centers to enhance Border States’ network of 131 locations. Branches and distribution centers will work together to scale for optimization, while still allowing for customization and delivering cost-effective and unique experiences for customers.”

The 2025 Top 100 distributors do a combined total of $108.5 billion in revenues — 73% of estimated 2024 industry sales of $148 billion.

Despite the mix of 2025 revenue growth forecasts from the largest distributors — and the fact that their customers are buying more products online than ever from their websites and other sources, they also enjoy the convenience of shopping at local branches, judging from the number of new branches electrical supply houses opened up over the past year. Distributors on Electrical Wholesaling’s list now operate at least 8,000 local branches. They have recently opened up dozens of new branches. For example, City Electric Supply, Dallas, opened up more than 30 new locations in 2024 and plans to open more this year. Elliott Electric Supply, Nacogdoches, Texas, has relied on new branches to fuel growth for many years, but the past 18 months have been particularly busy for the company on this front, with new locations

in Doraville, Ga.; Yukon, Okla.; Laredo, Texas; Fort Collins, Colo.; Jacksonville, Fla.; Charlotte, N.C.; Kansas City, Mo.; Durant, Okla.; El Paso, Texas; Cookeville, Tenn.; Prescott Valley, Ariz.; Jonesboro, Ark.; Centennial, Colo.; and Colorado Springs, Colo. Elliott Electric Supply’s new branches in Jacksonville and Charlotte are its first locations in those states. In addition to building new RDCs in the Charlotte, N.C., and Fargo, N.D., markets. Border States opened a new branch in Tampa, Fla., to service the utility market. Other companies opening new branches over the past year include Atlantic Coast Electric Supply, Summerville, S.C.; Coburn Supply Co., Beaumont, Texas; D&S Electrical Supply Co., Pocatello, Idaho; Dakota Supply Group, Fargo, N.D.; Dulles Electric Supply Corp., Sterling, Va.; Facility Solutions Group, Austin, Texas; Inline Electric Supply Co., Huntsville, Ala.; K/E Electric Supply Co., Mt. Clemens, Mich.; Lonestar Electric Supply, Houston; Main Electric Supply Co., Santa Ana, Calif.; Rural Electric Supply Cooperative (RESCO), Middleton, and CEEUS, West Columbia, S.C. (Glenn Allen, Va.).

The 2025 Top 100 distributors do a combined total of $108.5 billion in revenues — 73% of estimated 2024 industry sales of $148 billion. The 10 largest distributors on this year’s list do an estimated $77.6 billion in sales for a 52% share of total industry sales. At least 19 distributors on this list do at least $1 billion in annual revenues — and, in total, companies on this year’s list employ at least 151,887 workers (counting Grainger and Fastenal), or at least 102,180 employees if you just count full-line distributors and electrical product specialists.

Although the largest distributors in Electrical Wholesaling’s annual ranking have some differences of opinion on the short-term business prospects in the electrical construction industry, the scale of the investment in their businesses shows proof they are bullish on longer-term growth potential of this market and will continue to be the primary electrical supply option for electrical contractors, facility maintenance personnel, and other electrical professionals for years to come.

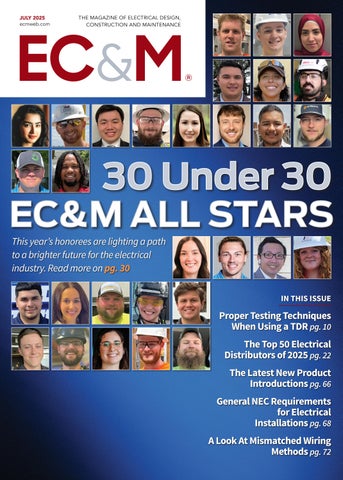

This year’s honorees are lighting a path to a brighter future for the electrical industry.

By Amy Fischbach, Freelance Writer

Today’s young electrical professionals are igniting a spark in the industry with their passion, persistence, and burning desire to make a difference.

To honor those who rise above and beyond their peers, EC&M shines the spotlight on a select few — the 30 Under 30 Electrical All Stars.

Over the last eight years, EC&M has accepted nominations for this special recognition from electrical contractors, electrical engineering firms, and plants/facilities for electrical professionals 30 years old or younger. To make the cut, they must demonstrate innovation, efficiency, and creativity, while incorporating technology into their jobs.

Carlie Cook, site manager for Rosendin, said she is honored and grateful to be selected for the 30 Under 30 honor.

“Growing up, I never imagined myself in the electrical construction industry, let alone thriving as a young woman in the field,” Cook said. “I’m so thankful to have found this career path and hope it inspires other young professionals to pursue opportunities in this industry as well.”

This year, a record number of nominations flooded in for the 2025 EC&M 30 Under 30. Our select group of Electrical All Stars, who are shining brightly at their companies, are helping to shape the electrical industry.

For example, Sophia Pike, electrical engineer III for Syska Hennessy Group, enjoys walking around Boston, knowing that she helped to change and develop the city’s iconic skyline.

“It’s really cool to see something tangible when I spend so much time looking at floor plans on a computer screen,” she said.

Like others in our 30 Under 30, she also enjoys serving as a mentor to the younger engineers. Nicholas Burge, superintendent for Eldeco, agreed, saying his favorite part of his role is being able to watch people excel in their careers.

“There is nothing more rewarding than giving someone encouragement and watching them take off running,” he said.

To make their mark, many of the engineers, electricians, project managers, and business owners in this year’s group are embracing the latest tools and technologies and going above and beyond to improve productivity and safety for their workforce.

Nada Abdelfattah, electrical engineer III at Mott MacDonald, said technology is critical for today’s electrical firms and drives efficiency, innovation, and competitive advantage in an increasingly complex industry landscape.

“Advanced design software, building information modeling, and analytical tools not only streamline workflows but also enable the development of more sophisticated, sustainable, and optimized electrical systems,” Abdelfattah said.

Katie Green, assistant project manager for Encore Electric, said staying up to date with technology is very important, especially with projects getting more complex and fast-paced.

“Tools like BIM, digital collaboration platforms, and field-tracking software help us stay organized, work more efficiently, and keep everything moving smoothly,” Green said.

While the 30 Under 30 have diverse educational backgrounds, training experiences, and work responsibilities, one common theme that emerged is that the electrical industry is fast-paced and moving quickly into the future. Eric Laub, the great-grandson of the founder of Cache Valley Electric, said opportunities in the electrical industry are abundant right now.

“Anyone who has a great attitude and work ethic has a tremendous opportunity to succeed,” Laub said.

The following profiles explore the educational and training backgrounds of these 30 young electrical professionals and reveal how they are continuing to make a lasting impact on their companies and communities.

Amy Fischbach (amyfischbach@gmail.com) is a freelance writer and editor based in Overland Park, Kan.

Job Title: Electrical Engineer III

Company: Mott MacDonald

Location: Iselin, N.J.

Age: 27; Years on the Job: 4

Interests: Community service and volunteer work for the Women2Women America International Leadership Program, the ISEF Science and Engineering Fair, and MSU Breakaway in San Francisco

As she was taking final exams at a STEM boarding school in Egypt, a city-wide power outage sparked a transformative ex perience for Nada Abdelfattah. This pivotal moment shaped her vision for transforming power infrastructure globally, revealing how system vulnerabilities shape communities.

“Rather than being influenced by family connections in the trade, my passion grew from witnessing firsthand the critical importance of reliable electrical systems,” she said. “My formative years in Egypt shaped my perspective on infrastructure challenges in developing regions, giving me unique insights that continue to influence my professional approach.”

energy efficiency while ensuring compliance with stringent industry standards in her role at Mott MacDonald.

also earned a lean six sigma green belt certification and participated in specialized training programs at Mott MacDonald.

After participating in the Women2Women leadership conference in Boston, she pursued a bachelor’s degree in electrical engineering with a minor in mathematics at Montana State University through the USAID Scholarships program. This marked the beginning of her journey.

Following the completion of her master’s degree in electrical engineering, she obtained her professional engineering license in electrical and computer power, Certified Associate in Project Management (CAPM), and LEED AP BD+C certification. She

“These ongoing learning opportunities ensure I stay at the forefront of industry developments while building the business acumen needed for my leadership aspirations,” she said.

As an electrical engineer III, she develops comprehensive lighting and low-voltage designs for complex transportation infrastructure projects across North America. In her role, she enjoys developing sustainable energy solutions, collaborating with multidisciplinary teams, and giving back by mentoring early career professionals through her leadership positions.

Job Title: Project Manager

Company: Weifield Group Contracting

Location: Centennial, Colo.

Age: 25; Years on the Job: 6

Interests: Motor sports like motocross and golfing with friends

A family friend brought Kyle Acdal into Weifield Group Contracting as a shipping and receiving manager in 2019. From here, his interest grew, and he wanted to learn more about the business and how the industry operated.

After graduating from the IEC Rocky Mountain Electrical Apprenticeship, he was nominated for IEC’s Emerging

Leader program, which helped him to develop his people and leadership skills.

“I continue to learn from my peers at work and am not afraid to take on new challenges that can help me improve and learn,” he said.

As a project manager, he coordinates with the field team to ensure they have the correct equipment and materials at hand to successfully complete the scheduled milestones. He’s also responsible for maintaining documentation, reviewing the budget, and handling financial reporting.

“Monitoring progress and tracking efficiencies are a huge help to the field team so you can maintain transparency throughout the process,” he said.

His favorite parts of his job are learning the ins and outs of how a company operates and the different strategies to maximize growth. A challenging part of his position, however, is having crucial conversations and understanding the effectiveness of planning.

Currently, his company is working on a wide range of projects across many industry verticals. For example, he is managing risks and developing plans and schedules for a project to develop new workspaces and facilities for the United States Air Force.

As a project manager, he believes technology will play a pivotal role in how companies develop processes and become more intelligent on how they manage the performance of work. When looking into the future, he hopes to be part of the senior management team.

“I want to be part of the leadership team and help to develop the next generation of colleagues,” he said.

Arlington’s non-metallic Split Wall Plates provide a simple and effective way to accommodate pre-connectorized low voltage cable(s) of varying size and quantity or pre-existing low voltage cables.

Multiple split grommets are provided with our single- and two-gang wall plates for increased versatility in effectively sizing and covering the hole/opening.

Use as shipped, or with one of the supplied bushings to alter the size of the opening.

• Single-gang CESP1 w/ 1-1/2" opening, bushings for .312" • .500" • 1" openings

• Two-gang CESP2 w/ 2" opening, bushings for .750" • 1.250" openings

Product info aifittings.com/landing/split-hole-plates

Arlington’s recessed STEEL combination power/low voltage TV BOX™ is the best way to mount an LED or Hi-Def TV flush against a wall.

TV BOX provides power and/or low voltage in one or more of the openings. Plugs and connectors stay inside the box, without extending past the wall.

Designed for use in new or retrofit commercial construction where metal raceway is used, we have a STEEL TV BOX for almost any application!

• Steel box; non-metallic paintable white trim plate

• Easy, secure installation

• Optional covers

DYLAN BUI

Job Title: Electrical Engineer and Associate Vice President

Company: Salas O’Brien

Location: Tustin, Calif.

Age: 29; Years on the Job: 7

Interests: Reading science fiction, keeping up with space technology development, and tweaking his smart home deployment

As the son of an electrical engineer, Dylan Bui was inspired to follow in his father’s footsteps. Talented in math and physics, he knew he was destined to study engineering or programming. Once he got to college, he discovered the engineering classes were both interesting and fulfilling, making the decision an easy one.

“It is truly gratifying to design systems that people can count on every single day,” he said.

Born and raised in Orange County, Calif., he graduated from the University of California-San Diego with a bachelor’s degree in electrical engineering with a focus on power engineering. He also took classes in renewable energy and microgrid technology, which became important for his work.

The registered professional electrical engineer was recently promoted to associate vice president. In this role, he is responsible for managing multiple projects, handling BIM support, and developing the DC platform. His company designs medical office buildings and hospitals with DC lighting instead of running

Emerging professionals like Dylan Bui are key to shaping the future of our team and the vital work we do for clients in the healthcare, life sciences, and mission-critical sectors.

Congratulations, Dylan, on being named to this year’s EC&M 30 Under 30 All Stars!

conduit, which has led to cost savings in the millions of dollars for clients. He also meets with his team to ensure the projects are running smoothly, and he answers any questions.

“My favorite part is being able to work side-by-side every day with my team, figuring out answers to complex questions and providing input to help grow and learn,” he said.

He says technology has helped his company to improve efficiency tremendously. For example, he is working with a coworker on developing a custom software add-in that can increase collaboration between disciplines.

“What once took us weeks now only takes us a day or two at most — with even less manpower required,” he said. “AI is here to stay, and companies that do not adapt or integrate some form of automation or assistive intelligence will fall behind very quickly.”

Down the road, he sees himself as a vice president or a managing principal in charge of hundreds of employees. “To keep up with the high demand, I would ensure that I am leading the company in innovation and technology, keeping us at the cutting edge of development,” he said.

Dylan Bui PE AVP, ELECTRICAL ENGINEER

Arlington’s heavy-duty Grounding Bridges provide reliable intersystem bonding between power and communication grounding systems. And handle multiple hookups of communications systems: telephone, CATV and satellite.

Our new GB5T is THREADED for threaded conduit or another GB5T – with a SET SCREW for use on EMT or PVC.

Arlington’s zinc and bronze grounding bridges...

• Four termination points; more than required by the NEC

• Meet 2020 NEC bonding requirements for 250.94

• Fast, simple installation indoors or outside

• Textured, paintable plastic cover (except GB5NC)

• Easy access for inspections

Job Title: Project Superintendent

Company: Interstate Electrical Services Corporation

Location: North Billerica, Mass.

Age: 28; Years on the Job: 10

Interests: Spending time outdoors hiking with his dog, fishing, and his favorite hobby — going on motorcycle rides with his wife

As a child, Mason Brunelle admired all the moving parts and advanced knowledge that went into the projects his dad was working on. When he grew older, he knew he wanted to work in the field.

His dream became a reality when he got the opportunity to work for Interstate Electrical Services immediately following his high school graduation. He completed his four-year ap prenticeship through Greater Lawrence Technical School at night while also working full-time in the field gaining valuable hands-on experience. After topping out as a journeyman and working for three years, he advanced his skill set at Interstate as a project superintendent.

“This position has allowed me to continue growing not only as an electrician, but also to gain vast knowledge about the other moving parts within the construction industry,” he said. “I’ve learned how all of the trades need to work cooperatively to complete a common goal.”

In addition, Brunelle is required to complete continuing education hours, code updates, OSHA certifications, and other licensures/certifications as required by the state of Massachusetts, the job site, or Interstate.

Interests:

their cat and dogs; cooking smoked chicken wings; playing video games; and hunting, fishing, hiking, or going to an outdoor range

While he was growing up, nearly all of Nicholas Burge’s male family members worked in the construction trade as iron

the experience I have to inspire future generations and projects,” he said. “It is a privilege to be able to continue to work in such a growing trade.”

workers, carpenters, bridge builders, and jacks of all trades. When he was looking for a job fresh out of college, his father, who worked as an iron worker turned millwright, told him: “Well, I know every project manager and superintendent on site. Pick a trade, and I’ll put you in it.”

Burge always had an interest in the electrical field, and he had a small amount of knowledge from working on residential projects with his family.

“On my first day as a green helper, I remember thinking to myself, ‘you know nothing,’” he said. “I grew obsessed with learning everything I could as fast as possible, and I haven’t stopped learning since.”

He attended trade programs related to construction while in high school, but the majority of his education is through field experience. “The training and experience I gained coming up through the field has helped me immensely in my role as a superintendent,” he said. “On all the projects I’ve had a part in, I always had ideas of how I would do things. Now, I get to implement them.”

Today, some of his key responsibilities are creating a schedule for the weeks ahead, ordering material for the scheduled tasks, reviewing time entries, and putting the right people in the right places.

In the future, he would like to move into a role that requires less travel and be more involved in the development and evolution of the company. “I have never seen myself as the ‘office’ type until I realized the experience I gained by coming up through the field is just as valuable as guys with degrees,” he said. “I don’t want to be on the road forever, but I am sure that I want to be an influential part of this industry.”

Perfect for data center remote power panel feeds, panels, equipment feeds and EV Chargers in parking garages, Arlington’s Listed CableStop™ Transition Fittings deliver the efficient, cost-effective way to transition feeder cables to 1.25", 2.5", 3" and 3.5" EMT, IMC and RMC conduit in protective drops, risers and feeds to panels and equipment. Our new CableStop fittings integrate our patented, versatile and SKU-reducing 8412 series cable fittings, with Arlington conduit fittings, allowing for easy transitions to larger knockout sizes.

Available with set-screw or compression connections into 1.25", 2.5", 3" and 3.5" conduit, they ship with multiple end stop bushings that vary the size of the opening – along with a free template select the right bushing for the cable.

Job Title: Senior Project Manager

Company: Sturgeon Electric Company, Inc.

Location: Henderson, Colo.

Age: 28; Years on the Job: 6

Interests: Spending time outdoors with his 16-month-old son and his fiancée, building custom epoxy tables and entertainment centers, and doing other woodworking projects

J.D. Chenoweth embarked on a non-traditional path into the world of electrical construction. After earning his bachelor’s degree in business administration with an emphasis in energy management on a full-ride scholarship from Western State Colorado University, he was unable to land a job in the oil and gas industry due to market conditions.

A position opened, however, as an assistant project manager for PAR Electrical Contractors, a transmission and distribution company in Nevada, and he jumped at the opportunity. During his time with the company, he gained vast amounts of experience regarding estimating, running several jobs, time management, scheduling, resources management, and the transmission and distribution industry.

In 2020, he transitioned to the commercial and industrial market when he took the position with Sturgeon Electric. Through working on projects, he has learned about document control and the importance of being organized, managing several scopes of work, and handling billing and estimating.

Born and raised in a small farming and ranching community in southeastern Colorado, J.D. had various hands-on opportunities to learn and grow relating to construction before he even graduated from high school. “I always had an interest in electrical construction as I grew up on a farm and ranch, and I assisted with electrical installs growing up,” he said.

He recently stepped into a new role as a senior project manager, where he is currently overseeing three large projects, all of which are at different phases — the NWC Livestock Center, Adams County Midway, and a large data center. He said what sets himself apart in the electrical trade is his passion for electrical construction. “I am willing to put the work in — not only for the paycheck, but ultimately, because I am fascinated with the industry, and I am eager to continuously improve.”

shows that you don’t need a family background or deep prior knowledge to find success here — you just need curiosity, drive, and the willingness to learn.”

A proud native of Tulsa, Okla., she attended the University of Nebraska at Omaha, where she played Division I soccer and earned her degree in civil engineering. After graduation, she pursued her MBA at the University of Louisville while working full-time. Once she completed her MBA, she accepted a position with Rosendin in Arizona, which launched her career in the electrical construction industry.

“My engineering degree taught me how to problem-solve, ask the right questions, and think innovatively,” she said. “My MBA strengthened my skills in presenting and understanding financial information.”

She’s currently a site manager on a large data center project. In this role, she is responsible for the site’s overall performance, including budget, schedule, team management, and client relationships. Since starting as an assistant project manager six years ago, her role has grown significantly. She now oversees a much larger scope and leads an entire team, which has been a big but rewarding shift over the years.

She is currently managing a large mission-critical project and is on-site daily to ensure its success. She also supports efforts to win new work and help position her team for future projects. In the future, she’d like to continue to grow with Rosendin and take on greater leadership responsibilities while also focusing on building a family and maintaining a strong work-life balance. “I plan to reach these goals by staying committed to learning, taking on new challenges, and mentoring others as I grow,” she said.

Arlington’s variety of cULus Listed Box Extenders extend set back electrical boxes up to 1-1/2".

Made of heavy-duty, 105°C continuous use 94V0 rated, flame retardant plastic, they level and support wiring devices, while protecting wires against damage and stripping.

Choose the one that’s right for you!

BE1, BE2, BE3, BE4...Single-, two-, three- and four-gang, and BE1R for round or octagonal boxes...

Box Extenders

device support in oversized or mis-cut wall openings, available in single-, two-, three- and four-gang, (patented BE1X, BE2X, BE3X, BE4X.)

Our new heavy duty, COMMERCIAL-GRADE steel support plate! As shipped, single and two-gang BE1XLS and BE2XLS work with maxi cover plates, but they’re and standard plates. Convenient. Saves time. Great for poorly cut drywall.

For all standard devices, switches and GFCIs, our box extenders comply with NEC Article 314.20 for set back boxes.

Job Title: Electrical Safety Advisor

Company: The Happy Outlet

Location: Carson City, Nev.

Age: 24; Years on the Job: 6

Interests: Fishing, coaching soccer, and hunting

When Brett Daywalt asked his father, the trades operations manager at USC College, about a career in the trades, he rec ommended HVAC or electrical. He decided to go the electrical route, and, after two years of an IEC program in Carson City, Nev., he is now working for the Happy Outlet. Twice a week, he receives one hour of skills and customer service training.

“My schooling and training helped me to troubleshoot any problem that comes my way if it’s an electrical issue or customer challenge,” said Daywalt, who was born in San Diego but lived in Los Angeles and South Carolina before moving to Nevada.

He said while he is a good electrician, his people skills help him to have a competitive edge.

“Anyone can work on an electrical system with a couple years of training,” he said. “The hard part is dealing with cus tomers and making them feel comfortable. Time management and attention to details are both very important aspects to this role, and I love helping people.”

He started out as an apprentice, moved to an installer, and then to a lead installer, electrical safety advisor, and now a lead electrical safety advisor. He takes about three

especially in the Adirondacks

panels and researching energy systems.

Throughout college, he interned at CHA Consulting and at GlobalFoundries. After completing his master’s degree, he began working at CDM Smith.“I was trained on the job and quickly pulled into a variety of projects all over the country,” said DeGennaro, who recently passed the PE electrical

His company is designing microgrid systems, piloting utility thermal energy networks, leading fleet vehicle and building electrification initiatives, and designing municipal water/ wastewater upgrades nationwide. While most of his projects are in the Northeast, he’s had opportunities to work on projects across the country and even internationally.“I am excited to be involved in so many projects that are reshaping communities through improved water and energy infrastructure,” he said.

“The variety keeps my day-to-day exciting and pushes me to constantly learn and sharpen my skill set as an engineer.”

With a mom as a teacher and a dad as a structural engineer, Danny DeGennaro was encouraged from a young age to ask technical questions and seek out explanations for how things work. When he was in high school, his dad introduced

As an electrical engineer in the infrastructure services group at CDM Smith, he conducts site visits, oversees the design process, reviews submittals, and responds to RFIs. In the future, he’d like to lead innovative power systems projects and continue to navigate the rapidly changing world of energy technologies.

“I aspire to one day be a team leader who is actively involved in hands-on design, while also mentoring others and driving strategic initiatives,” he said.

(SEE ABOVE)

• Easy snap-in cable installation Save time over 90° 2-screw MC Connectors at same cost per connector

• Handles widest range & variety of cables: 14/2 to 10/2 AC, MC, HCF, MC continuous corrugated aluminum cable, MCI-A cables (steel & aluminum), AC90 and ACG90

• Fast, secure installation...No pullout

• Easy to remove from box...reusable

Job Title: General Foreman

Company: Trinity Electric

Location: North Sioux City, S.D.

Age: 28; Years on the Job: 8

Interests: Fishing, spending time with friends and family, and playing competitive card games

Tanner Ehlers spent his whole life around the construction industry. Whenever he had time, he helped his father, who ran a construction company.

“Growing up around it, I was always interested in how the electricians made all the things I use on a daily basis like lights and outlets work,” he said. “That’s what sparked my interest in the electrical field.”

Born and raised in Sioux City, S.D., he attended the Joint Apprenticeship Training Committee from 2017 through 2022 for electrical construction and maintenance. Since then, he has attended various leadership training programs such as Dale Carnegie’s Leadership Course.

Through the apprenticeship program, he had five years of schooling along with five years of on-the-job hands-on experience.

“This gave me an opportunity to apply what I learned in class directly to the job site,” he said. “It also gave me the chance to work under individuals who have extensive experience in the trade and learn everything I could from them.”

As the general foreman in charge of 16 employees, his day starts at 6:30 a.m. with a morning safety meeting followed by a meeting with the customer.

Company: TC Electric

Location: Great Neck, N.Y.

Age: 28; Years on the Job: 5

Interests: Playing guitar, serving as a volunteer firefighter, and going to his lake house in Pennsylvania to go fishing and ride his new dirt bike

Following high school graduation, Paul Giovanni trained to become an electrician so he could work with his hands.

ent trades because I had a curiosity about electricity and how it works, and I thought it would be more interesting and fulfilling.”

As the first electrician in his family, he was born and raised in Hillsdale, N.J., and he still lives in this town, which is close to his work location. He learned most of his skills from on-the-job training, and he considers it the best way to learn any trade.

After attending night school technical education courses, he joined the apprenticeship program for USWU Local 363, where he was able to learn on the job while also attending classes twice a week.

“My training helped prepare me for my current position by learning how to complete a job from start to finish,” he said. “I am always learning new skills every day by doing things I have never done before. This is a great way to keep growing as a professional electrician.”

As a fifth-year apprentice for TC Electric, a typical day consists of pipe running/bending and terminating/installing electrical wire and cables. Following a safety briefing, a foreman assigns daily tasks, and, over time, he has gotten more responsibilities.

He enjoys working on projects for New York’s Metropolitan Transportation Authority (MTA), particularly those involving work on subway tracks.

“These jobs require extra concentration and attention paid to safety,” he said.

One day, he hopes to become a foreman or even run his own company.

“I plan to reach these goals by coming to work with a positive attitude and learning new things every day,” he said.

Super-secure installation!

Our lowest cost, L-shaped fan/fixture box mounts to single or double joists with a captive center screw. No loose parts!

screws ship captive, ready to install box and bracket.

•

This convenient combo box has power and low voltage openings in the same box for a neat, time-saving installation.

The box adjusts to fit wall thicknesses from 1/4" to 1-1/2". Mounting wing screws hold it securely in place.

• 2-Hour Fire Rating

• Low voltage side has a combo 1/2" and 3/4" KO for raceway

• Includes NM cable connector (power side)

Arlington’s Concrete Pipe Sleeves are the economical way to sleeve through concrete pours in tilt-up construction WALLS – and FLOORS allowing cable and conduit to run easily from one floor to the next.

No costly core drilling – No cutting holes in the form. Plus, you can position the hole prior to pouring the concrete.

• Attaches to form with nails or screws

• Stackable up to 23" h for extra deep pours

• Vents keep wet pipe sleeves from sticking together

• Multiple hole sizes: 1-1/2"

Job Title: Assistant Project Manager

Company: Encore Electric

Location: Belgrade, Mont.

Age: 28; Years on the Job: 2.5

Interests: Spending time with her dog and paddleboarding on a quiet lake, hiking through scenic trails, or spending a weekend camping under the stars in Montana

Katie Green didn’t originally plan to work in the electrical industry, and she doesn’t have any family members in the trade. While searching for a project engineer position, a role in the electrical field happened to be available. What started as a practical next step quickly turned into something she enjoys.

“I’ve come to really value the complexity of the work and the collaboration it requires,” she said. “It’s also incredibly satisfying to see the work I’ve managed come to life. It’s been rewarding to grow into a career I hadn’t expected, but now truly appreciate.”

Born and raised in Auburn, Wash., she earned her bachelor’s degree in chemical engineering from Montana State University. After working for a few years in the industry, she realized that the aspects of her work she enjoyed most — problem solving, coordinating, and seeing projects through concept to completion — aligned more closely with project engineering.

“With the guidance of some incredible mentors, I made a successful transition into this new path,” she said. “Their support has been instrumental in helping me grow and succeed in this field.”

Her engineering background gave her a strong foundation in problem solving, technical communication, and atten-

tion to detail, all of which have been essential in managing construction projects with many moving parts, she said.

As an assistant project manager, she manages project schedules, coordinates with other trades, processes change orders, and makes sure everything stays on time and within budget.

“I really enjoy the fast-paced, team-oriented environment and the sense of accomplishment that comes with seeing a project evolve from just drawings to a fully functional system,” she said.

When she becomes a project manager one day, she’d like to lead larger projects and take on more responsibility in both the planning and execution phases.

wired a shed with his stepbrother, and this experience

inspired him to apply to a trade school for the electrical trades — C-TEC of Licking County.

After being hired full-time by Claypool Electric, he enrolled in the company’s apprenticeship program at the main headquarters. Upon graduating, he completed NCCER’s Instructor Certification Training Program, which allowed him to assist with new hire classes. He later took over teaching the company’s second-year apprenticeship class.

“Throughout my time in the field, I consistently took on additional responsibilities to expand my knowledge and skills,” he said.

He then embraced opportunities to work as a service tech, safety manager, and an apprenticeship coordinator, following in the footsteps of Jesse Mitchell, who was also part of the EC&M 30 Under 30 in 2023.

He is now responsible for visiting local trade schools, creating and maintaining the schedule for the apprenticeship program, and supporting the team of instructors. He also recruits and organizes new hire training sessions, coordinates and develops advanced training courses for journeymen and foremen, and monitors and tracks the progress of apprentices enrolled in the program.

“I enjoy the dynamic nature of the role and the opportunity it gives me to contribute directly to the future of our workforce,” he said.

Currently, his company is completing a significant number of water and wastewater treatment plant projects. To support these efforts, he coordinates vendor-led training sessions and ensures new hires can correctly and efficiently bend conduit. He hopes to continue growing and strengthening the apprenticeship program by showing up every day with a positive attitude, a commitment to learning, and a drive to keep improving.

Job Title: Street Lighting Engineering Associate

Company: Bureau of Street Lighting, City of Los Angeles

Location: Los Angeles

Age: 29; Years on the Job: 5

Interests: Advocating STEM subjects, making home improvements, investing in collectibles, and going to the movies

Prime Hein’s interest in engineering began at a very young age, but when he got shocked during a high school project, he discovered he wanted to pursue electrical engineering.

Born and raised in Yangon, Myanmar, he came to the United States at the age of 15, and he struggled to adapt to the culture and contend with the language barrier. Fast forward to 2018, and he graduated from California State University-Los Angeles with bachelor’s and master’s degrees in electrical engineering. He then completed the Engineer-in-Training exam while in school and then became a professional engineer.

“Education provides you with knowledge, and training impacts you with life-long lessons,” he said. “I’m blessed to receive both as I embark along my journey.”

As part of the Metro Transit Division, a typical work day consists of prioritizing tasks, meeting with the project team to provide updates, and reviewing technical drawings to prepare comments. He also attends meetings to look at the schedule/budget and creates spreadsheets, and reports for management.

“Every day is different and interesting,” he said. “As a supervisor overseeing engineering and drafting staff, I become responsible not just for delivering results with quality but also improving the team as a whole.”

With strong technical expertise, leadership, and dedication to improving the city, he aims to make a significant impact on the lives of Angelenos and visitors to the City of Angels. For example, the Metro Transit Division at the Bureau of Street Lighting is working with the Metropolitan Transportation Authority to deliver 28 projects by the 2028 Olympics, which involves street lighting improvements near and at the bus and rail stations.

“I supervise at least half, which are multi-million-dollar projects from conceptual to construction phase,” he said.

When he was in high school, Adrian Hernandez went to work for a commercial contracting company. This experience sparked his interest in the electrical trade.

“Being able to see the drawings, the wire pulling, and the installation of conduit all just clicked to me,” said Hernandez, who is the first one in his family to work as an electrician.

Born and raised in Texas, he was involved in a welding competition, which involved electrical work, during his junior and senior year of high school.

“I was mainly in charge of the electrical side of the project, which got me to learn and understand more of how electrical works,” he said.

After he graduated from high school, he is currently taking college classes for his NCCER for electrical, and he’s also employed as an electrical apprentice full-time. As an electrician, he works with wiring, runs conduit, and troubleshoots mistakes that have been made in the field. He arrives on the job site 15 minutes early to set up the fabrication area. He then completes the daily tasks, makes sure everyone has the necessary tools, and then cleans up the job site at the end of the day.

Currently, his company is handling multiple jobs, but he is working at the Dow work site in Clute, Texas. Moving forward, he said he wants to take on every challenge he can and is proud to be part of the 2025 EC&M 30 Under 30.

“I am truly grateful to be recognized, especially at this stage in my career and at my age. It’s an honor that motivates me to continue growing and striving for excellence,” he said.

* Aluminum & Steel Flexible Metal Conduits

ONE trade size fits SEVERAL cable types and sizes, plus flexible metal conduit for super convenience and cost-savings! Reduces inventory and material handling too.

Patented

Conductor Size CSA TECK90 Conductor Size # of Conductors* # of Conductors* (AWG/KCMIL) (AWG/KCMIL/ACWU) 6/3, 6/4, 4-3, 4-4, 8/3, 8/4, 6/3

2-3, 2-4, 1-3

2-3, 2-4, 1-3, 1-4, 6/3, 6/4, 4/3, 4/4, 3/3, 1/0-3, 1/0-4, 2/0-3, 3/4, 2/3, 2/4

2/0-4, 3/0-3

2/0-4, 3/0-3, 3/0-4, 2/4, 1/3, 1/4, 1/0-3 4/0-3, 4/0-4, 250-3, 250-4 1/0-4, 2/0-3 250-4, 300-4, 350-3, 2/0-3, 2/0-4, 3/0-3, 3/0-4, 350-4, 500-3 4/0-3, 4/0-4, 250-3 500-3, 500-4, 600-3 4/0-4, 250-3, 250-4, 300-3 600-4, 750-3 300-4, 350-3, 350-4, 500-3 600-4, 750-3, 750-4 350-4, 500-3, 500-4 750-3, 750-4, 1000-4 750-3, 750-4, 1000-3

SHREENITHI LAKSHMI NARASIMHAN

Job Title: Founder and Renewable Energy Leader

Company: Global Climate Collective

Location: New York City

Age: 28; Years on the Job: 6

Interests: Mentoring young professionals through IEEE and Student Energy, writing for climate publications, and taking long walks while listening to global affairs podcasts. She is also passionate about cultural storytelling and youth engagement.

Shreenithi Lakshmi Narasimhan’s interest in the electrical industry began during her teenage years in rural India, where she spent most of her summer vacations. In the semi-rural regions nearby her hometown of Chennai, India, energy access challenges became very personal to her.

“Experiencing frequent power outages shaped my fascination for resilient energy systems and inspired me to explore sustainable solutions,” she said. “Although no one in my family worked in the trade, these early experiences motivated me to pursue electrical and energy engineering, and eventually specialize in renewable energy and grid resilience.”

She earned her bachelor’s degree in electrical engineering and her master’s degree in energy engineering from the University of Illinois-Chicago. She’s also received certifications in solar PV layout design, sustainable energy engineering, and energy policy.

“My academic and professional training helped build a strong foundation in system design, energy modeling, and decarbonization strategy,” she said.

She brings a cross-disciplinary approach to solving energy challenges, merging technical expertise with systems

continuously stays updated through industry conferences, IEEE memberships, mentorship, and policy advisory engagements with international entities like the United Nations, International Renewable Energy Agency, and

“Success in this industry today requires not just technical skills, but a bold vision, adaptability, and collaboration across Technology is fundamental for advancing today’s electrical

tion to grid-edge AI, I help bring cutting-edge tools into practice,

aspect of the work. For the last three years, he has been enrolled in Edgewood Electric’s apprenticeship program — Edgewood University — while working full-time as an electrician in his hometown. “The program has helped prepare me for the rigors of the electrical industry and keeps me aware of the hazards that are associated with the trade,” he said.