The responsibility for complete, safe, and quality repairs rests with all collision repair industry stakeholders.

THE BEST REPAIR Planner/Estimator Award, as I've written about before, came about to help highlight the need for complete, safe, and quality repairs. (Nominations are still open; go to fenderbender.com/ awards for more information.) It's a theme that was repeated throughout the I-CAR National Conference, covered elsewhere in this issue. As any stakeholder goes through his or her day, speakers urged, they need to consider every action they take that affect their ability to deliver a safe repair to protect the consumer.

Collision Advice's Mike Anderson, whose team will help judge the estimate exercise portion of the award selection process, was one of those speakers. He recalled the 1986 Space Shuttle Challenger disaster, which was determined to be caused by faulty o-rings in the solid-fuel rocket boosters, as a failure of everyone who knew the o-rings could be a problem at low temperatures not speaking up and scrubbing the launch on that cold day.

"I understand in this industry, we have to look at the KPIs like cycle time and severity," he said. "But cycle time and severity should never, ever trump human lives. And again, so ladies and gentlemen, when you look at this, if you do any research, you find that it was the culture of NASA that led to the deaths of these astronauts. There was a culture that said, 'We've got to launch on time, and we can't go over budget."

A culture of committing to safe repairs can be taught, he said, just as if our parents taught us to wash our hands after we use the restroom, or to brush our teeth before we go to bed.

"Once that's ingrained in you, when someone comes along and tells you you don't have to do that anymore, you can't deviate from that once you know it's right. Every single person here should be focused to ensure the quality standards are basically the quality in the way we take care of the consumer, right, our customer experience, the way we greet them, the way we answer the phone and the cleanliness of our facilities; it should be the quality of the repair plan, that we only bill for what is truly needed on that vehicle… nothing more, nothing less. We have quality documentation, and a quality repair."

JAY SICHT EDITOR-IN-CHIEF jsicht@endeavorb2b.com

Chris Jones Group Editorial Director

Jay Sicht Editor-in-Chief

Peter Spotts Associate Editor

Kacey Frederick Assistant Editor

Emily Kline Special Projects Editor

Leah Marxhausen Special Projects Editor

Drew Bryant Contributing Writer

Tiffany Menefee Contributing Writer

Greg Lobsiger Contributing Writer

Noah Brown Contributing Writer

Lindsey Gainer Contributing Writer

Todd Kortemeier Contributing Writer

Darrell Amberson Contributing Writer

Abdulla Gaafarelkhalifa Contributing Writer

Steve Trapp Contributing Writer

EDITORIAL ADVISORY BOARD

Jordan Beshears Steve’s Auto Body

Sheryl Driggers Collision Advice

Frank Rinaudo Industry Consultant

Jason Mundy Mundy’s Collision Center

Stan Medina Certified Collision Works

Chris Messer VP/Market Leader - Vehicle Repair Group

Andrew Johnson Associate Publisher ajohnson@endeavorb2b.com

Mattie Gorman-Greuel Associate Sales Director

Cortni Jones Director of Business Development

Diane Braden Account Executive (National Accounts) dbraden@endeavorb2b.com

Marianne Dyal Account Executive (National Accounts) mdyal@endeavorb2b.com

Chad Hjellming Account Executive (National Accounts) chjellming@endeavorb2b.com

Lisa Mend Account Executive (National Accounts) lmend@endeavorb2b.com

Annette Planey Account Executive (National Accounts) aplaney@endeavorb2b.com

Kyle Shaw Account Executive (National Accounts) kshaw@endeavorb2b.com

Sean Thornton Account Executive (National Accounts) sthornton@endeavorb2b.com

Ryan McCanna Sales Support Specialist

Mariah Straub Production Manager

Jen George Ad Services Manager

Mitch Bradford Art Director

CEO Chris Ferrell

COO Patrick Rains

CRO Paul Andrews

CDO Jacquie Niemiec

CALO Tracy Kane

CMO Amanda Landsaw

EVP Transportation Kylie Hirko

EVP Endeavor Business Intelligence Paul Mattioli

SUBSCRIPTIONS

Send address changes and subscription inquiries to:

FenderBender PO Box 3257 Northbrook, IL 60065-3257

Subscription Customer Service: 877.382.9187 fenderbender@omeda.com

LETTERS TO THE EDITOR

editor@fenderbender.com

Opinions expressed in FenderBender are not necessarily those of Endeavor Business Media, and Endeavor Business Media does not accept responsibility for advertising content.

• Abrasives

• Aerosols

• Bed Liners

• Body Fillers & Putties

• Buffing

• Clears & Primers

• Cleaners & Solvents

• Compounds & Polishes

• Detailing

• Masking

• Painting Supplies

• Safety & PPE Products

• Sealers & Adhesives

• Clothes, Wipes & Rags

• Tools & Equipment

FEDERAL AGENCIES are investigating multiple fires at Tesla facilities in Missouri and Nevada for possible arson and terrorism.

Five Tesla vehicles were damaged by fire and bullets early morning at a Tesla Collision Center on West Badura Avenue in Las Vegas on Tuesday, March 18, according to the Las Vegas Metropolitan Police Department.

“As officers arrived, they located several vehicles fully engulfed in flames and the word ‘Resist’ spray painted on the building,” the LVMPD statement said. “The Clark County Fire Department responded, and firefighters were able to quickly extinguish the fire.”

The suspect reportedly wore all black and used Molotov cocktails to set two vehicles ablaze. The LVMPD recovered an undetonated device inside one of the vehicles. The suspect reportedly fired three rounds from a firearm into the vehicles. The attack was “targeted,” said LVMPD Assistant Sheriff Dori Koren during a news conference. The LVMPD also shared a video of the incident.

The LVMPD investigation is ongoing in collaboration with the Clark County Fire Department and the FBI.

Anyone with any information about this incident should contact the Southern Nevada Counter Terrorism Center at 702-828-7777 or at https://www.snctc.org. To remain anonymous, contact Crime Stoppers by phone at 702-385-5555, or at https:// crimestoppersofnv.com.

Two more Tesla vehicles were damaged by fire on Monday, March 17. Shortly before midnight, a Kansas City Police Department officer reported a fire at the Tesla Store and Service Center on State Line Road in Kansas City, Missouri, according to a news article from local news station KMBC.

As KCFD Firefighters responded to the scene, the fire spread to a second Cybertruck before it was put out. The KCPD Bomb and Arson Unit also assisted. The FBI and ATF describe the fire as “suspicious in nature.”

The police department is working with the FBI and ATF to investigate the cause of the fire. The FBI and ATF are working with federal, state, and local law enforcement to investigate similar incidents across several states, according to a statement by the FBI’s Kansas City field office.

The two fires are the latest incidents for Tesla, which has faced protests and vandalism across the U.S. and the world after Elon Musk’s prominent role in President Donald Trump’s administration.

Anyone who sees suspicious activity or has information about potential threats should contact their local FBI or ATF field offices or tip lines at 1-800-CALL-FBI or 1-888-ATF-TIPS.

FenderBender.com/news for daily updates from around the collision repair industry.

The list of accomplishments since the organization’s 1979 founding is long.

By JAY SICHT

I-CAR’S 2025 NATIONAL CONFERENCE Feb. 28-March 2 in downtown Houston celebrated innovation and industry leadership with engaging keynote speakers and a comprehensive look at the latest I-CAR initiatives, including in breakout sessions, bringing together professionals who share a commitment to learning education and safety.

Kicking off the conference, Jeff Peevy, vice president of industry relations, spoke on the importance of I-CAR’s commitment to complete, safe, and quality repairs. He recalled how he first placed “the empty chair,” now on the stage at all Collision Industry Conferences, at his first meeting as chairman.

”The chair represented the consumer, the families that entrusted their lives and their well-being in our industry’s hands when we repair their car,” he said. “You all know that education, the role that all of us play, plays a huge part in our ability to perform a complete, safe, and quality repair. Every decision that we make, regardless

of the segment that we’re in, we need to always consider those who entrust us with their lives.”

Mike Anderson of Collision Advice later echoed Peevy’s sentiments, pointing to his father’s life-changing injury as a paratrooper in Vietnam. In having a consumer sign an authorization form, writing a repair plan, or researching repair procedures, he urged all stakeholders to ask themselves if they are “packing the parachute properly.” Anderson was recognized at the conference with the Chairman’s Award, presented by Chair Jennifer Goforth.

CEO and President John Van Alstyne spoke of some of I-CAR’s accomplishments since

its 1979 founding and during the past 15 years he’s been at the helm. (He will retire at the end of the year.) During the welcome reception, he was recognized with the True North Visionary Award.

“A lot has changed in our industry since 1979,” he said. “Repairs today are more advanced in nature than ever before, and ICAR has responded over the years with innovations in our curriculum, credentialing, standards, or what we refer to as protocols, and related technical services.”

From 2010, he said, the organization has quadrupled the number of course offerings (now 467) to perform complete, safe, and quality repairs, including introducing vehicle-specific curriculum in 2016.

In 2014, the Repairability Technical Support platform was introduced,

followed by the RTS app in 2024, which was runner-up for the Best New Collision Repair Product at the SEMA Show. The Academy won the SEMA Best New collision Repair product award

Out of approximately 1,000 school programs, 656 schools were using the previous I-CAR curriculum, and 456, or about

70%, have transitioned to the new I-CAR Academy, with more set to transition this year. Also, 94 shops are using the Academy, which launched in late 2024.

And this year for the first time, there are 10,000 Gold Class-recognized shops, the first of many milestones Van Alstyne predicted for the program.

Master diagnostics and key programming with one powerful tool. Whether you're a seasoned technician or a locksmith looking to expand your offerings, the UltraDiag equips you with pro-level capabilities in one compact device. Diagnose faster, fix smarter, and elevate your services today.

Comprehensive Vehicle Diagnostics:

• Full-System Scans for more than 100+ car brands

• Bi-directional Control Test and activate components like fuel injectors, windows, and coolant pumps.

• 30 Reset Functions

• Pro-Level OBD2 Capabilities

• AutoVIN & AutoScan

• Advanced Key Programming for Asian & Domestic Vehicles

• All Keys Lost Solution

• Smart Repair Assistance + DTC Repair Guide

• Wireless Bluetooth Diagnostics + Magnetic VCI

• Long-Lasting 10000mah Battery, Android 11, and Expanded Storage Options

• Optional Battery Testing Pair with BT Mobile ProS analyzers for advanced battery health insights.

Retired NASCAR Crew Chief and Fox Racing commentator Larry McReynolds spoke in part on the importance of communication in building a winning team, recalling a number of talented drivers who, once they were no longer paired with the crew chief with whom they “clicked,” found further success difficult to achieve.

“Bad communication, or a lack of communication, Is like a vibration in a race car. If that driver ever came on the radio and told me, ‘Larry, I’ve got a bad vibration,’ I could have said, ‘10-4; it’ll be OK.’ Well, the next thing that’s probably going to happen is we

were going to be the next caution and we were going to blow a tire and hit the wall.”

José Hernández had dreams of becoming an astronaut as a child. The son of migrant farm workers from Mexico, the family worked the fields months at a time each year from southern to northern California. After being rejected 11 times by NASA, he was accepted into the astronaut program. And after 18 months of rigorous training, he was selected to be a flight engineer on the 14-day STS 128 Discovery mission, the second-to-last mission for the Space Shuttle.

He wrote a book (given to attendees) about his experience, Reaching for the Stars: The Inspiring Story of a Migrant Farmworker Turned Astronaut. It was also turned into the Amazon movie A Million Miles Away.

He recalled to the audience that he’d met the minimum requirements. But after his sixth rejection, his wife pushed him to take a look at what the successful applicants had that he didn’t. It’s what led him to earn his pilot’s license and learn to SCUBA-dive, both skills he noticed in successful applicants.

“So compare yourself with successful people. Ask yourself what they have that you don’t.”

See how Caliber is continuing to combat the tech shortage with transitioning active-duty service members.

By ABDULLA GAAFARELKHALIFA

THE BRAVERY AND SACRIFICES exhibited by active service members are truly admirable and often overlooked, reduced to the blanket phrase, “Thank you for your service.”

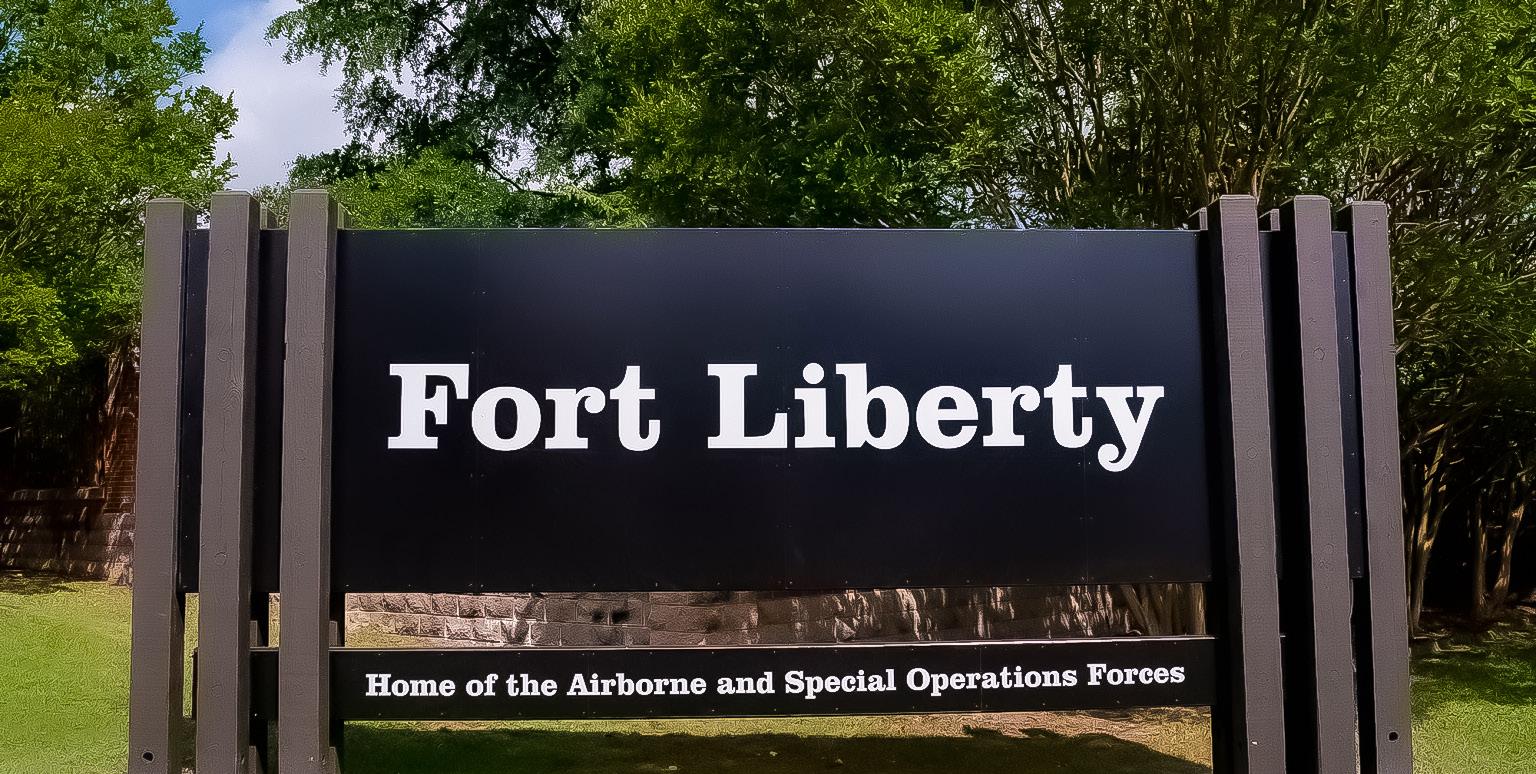

Caliber Collision has taken a significant extra step by helping service members transition from military to civilian life while working in the collision repair industry, providing a pathway to a career in collision repair. This initiative, called Changing Lanes, addresses both the tech shortage and the need for post-military careers. Changing Lanes, which started in 2016 through the Department of Defense’s SkillBridge program, recently celebrated the graduation of its 60th cohort.

What is SkillBridge?

SkillBridge allows service members to gain

valuable civilian work experience through industry training, apprenticeships, or internships during their last 180 days of service. This program connects transitioning service members with industry partners of any trade, providing real-world job experiences while they continue to receive their military compensation and benefits. It offers opportunities for service members to work and learn in civilian career areas, easing their transition from military to civilian life. The program also benefits any participating industry partner by giving them access to a highly trained and motivated workforce at no cost.

In a search for the SkillBridge program on its website, service members can find training opportunities in sectors such as healthcare, transportation, data processing,

and even in careers at NASA. There’s another sector/option that service members can explore, and you probably already guessed it: collision repair.

“Skilled trades, such as becoming a body technician, are in high demand,” Andrew Vaccaro, director of apprenticeships at Caliber Collision, told FenderBender in an interview. “Those trades are really in high demand, and the earning potential and career advancement opportunities really are endless.”

They’re in high demand due to a nationwide tech shortage that is impacting not only collision repair but all blue-collar trades.

According to a 2023 TechForce Foundation report, there are over 30,000 unfilled collision repair technician positions, which is often blamed on a lack of interest by younger generations. A 2019 research study by Education Next states that between 1990 and 2009, as the average number of academic credits high school students earned increased, the number of vocational credits dropped by 14 percent, or roughly twothirds of a year of vocational studies.

Luckily, there is a rebound taking place because, according to a study by the National Student Clearinghouse Research Center, public two-year colleges with a strong focus on vocational programs experienced

a 13.6% growth for the second consecutive year. These schools now make up 19.5% of all public two-year college enrollments, up from 15.3% in 2019.

There can still be more than one solution for a single problem, and that’s where Changing Lanes comes in, because it provides activeduty service members with the skills and training needed to become body technicians. Over 15 weeks at Caliber Academy, participants gain hands-on experience and certifications before transitioning into Caliber’s Technician Apprenticeship Program (TAP) for further training and development.

Vaccaro said Changing Lanes began and continues to take place in Fayetteville, North Carolina. Participants are offered housing in nearby Fort Liberty. The program was born out of a desire to support service members transitioning to civilian life, a mission close to Vaccaro’s heart, given his father’s military

background. “If I can help support our servicemen and women who sacrifice so much, it’s very important to me to be part of this program,” Vaccaro said.

Service members interested in the program work with their transition assistance offices to find opportunities with Caliber. Once accepted, they relocate to Fayetteville for the 15-week training period, where they receive hands-on training from experienced instructors, some of whom are veterans themselves. Upon completion, participants can be placed in any of the 39 states where Caliber operates, ensuring broad accessibility and support.

“I actually found out that one of our Changing Lanes graduates became a general manager at a center,” Vaccaro said. “So there’s opportunity, there’s upward mobility at Caliber.” Of course, the skills obtained through Changing Lanes, as well as TAP, are transferable to any collision repair center or body shop. TAP

was created with the purpose of tackling the nationwide tech shortage after all.

Caliber provided a testimony about the program by a recent Changing Lanes graduate and current Caliber Body Technician:“I wanted to learn helpful life skills that could benefit myself and others, and to go into a civilian career field to produce work that I can be proud of. What I enjoy the most is fine-tuning the little details that make the product the best it can be. Caliber has been a great place to learn and to make personal growth through experience and great teamwork and management. My time with Caliber has been the best I’ve had with my employment history by far and I can see myself doing this job with Caliber for a long time.”

“We’ve invested one and a half million dollars in the last 18 months into the Changing Lanes program directly and invested $2 million over the next couple of years,” Vaccaro said. Since Changing Lanes’ inception, Caliber has invested over $5 million into the program.

The company is also expanding the program to include new locations and additional training opportunities, such as a formal glass program at Camp Pendleton in California.

The program has already seen remarkable success, with over 100 graduates securing full-time jobs at Caliber in the last 18 months alone.

FenderBender covered TAP last year as the program has been instrumental in addressing the industry’s skill gap and providing career opportunities for many aspiring technicians who often start off with very little knowledge about auto body repair. Veterans can be seen as more appealing to attract into the industry.

“These are high-skilled positions that are only becoming more high-skilled,” Vaccaro added. “As you know, the industry becomes more advanced, and technology continues to develop. Active-duty service members are highly skilled people that are perfect for these positions.”

Being part of the Abra network means having a community of support that helps you grow and thrive.

As an independent operator, it can be tough to navigate the challenges alone, but with Abra, I can focus on building relationships locally, while they handle the bigger picture. The community here is all about collaboration, whether it’s with insurance partners, marketing, or training, and that support keeps me motivated and inspired to push forward.

– Jeremy Buller, owner of Abra Bismarck, Mandan,

and Minot

Quality Collision Group has expanded its footprint by acquiring Eveland Bros. Collision Repair Center in Johnson County, Kansas, according to a press release.

The release notes the acquisition marks QCG’s entry into its 12th state, growing its network and commitment to providing high-quality collision repair services nationwide.

Eveland Bros. Collision Repair Center was founded in 1978 by brothers Bill and Mark Eveland, serving the greater Kansas City metro area since. It has 12 original equipment manufacturer certifications from brands including Porsche, Rivian, Tesla, Mercedes-Benz, and Jaguar/Land Rover. With the acquisition of the single-location Eveland Bros. Collision, QCG now holds more than 360 manufacturer certifications across all of its locations.

“We are extremely excited to bring Eveland Bros. Collision into the Quality Collision Group team,” said Blake Farley, executive VP of Operations at QCG. “The shop has an extremely reputable name within their community, and we look forward to leveraging their insight regarding OEM certifications in the collision space.”

Bill and Mark Eveland built a reputable name for themselves with their OEM-centric collision repair, an elevated statndard, and highly regarded customer service.

“It has been amazing to see Quality Collision Group’s impact on our industry,” Bill and Mark Eveland said. “It is an honor to join QCG’s network, and we know that our shop is only going to continue its growth with them.”

Eveland Bros. Collision is QCG’s first shop located in Kansas, with close proximity to the 14 Schaefer Autobody Centers locations in Missouri and Illinois.

The Insurance Institute for Highway Safety requires better protection for second-row occupants for the 2025 Top Safety Pick and Top Safety Pick+ awards. Automakers need to make advanced seat belt technology and other safety innovations the norm in the back seat, according to IIHS.

As a result, only 48 models qualify for 2025 awards so far, compared to 71 at this time last year. Thiry-six of the 2025 winners earn Top Safety Pick+ and 12 earn Top Safety Pick.

“We’re once again challenging automakers to make their new models even safer than those they were building a year ago,” said IIHS President David Harkey. “Every vehicle that earns a 2025 award offers a high level of safety in both the front seat and the second row.”

The Institute’s updated moderate overlap front test adds a second dummy seated behind the driver and emphasizes back seat safety. Last year, an acceptable or good rating in the updated test was a requirement for the Top Safety Pick+ award. A good rating in the original test was enough to earn the base award.

This year, vehicles must earn an acceptable rating in the updated test to qualify for Top Safety Pick, while a good rating is required for Top Safety Pick+. The original test has been phased out completely.

AkzoNobel announced a strategic collaboration with Collision Vision to connect a collision shop from a compliance standpoint with all relevant industry providers, according to a press release.

For example, Collison Vision gives a holistic understanding of the health of one’s collision shop at a moment’s glance as it pertains to OEM training and certifications status, tool availability, and compliance, health, safety, and environmental services.

“We are excited to collaborate with AkzoNobel to bring Collision Vision to market,” said Andrew Suggs, the vice president of Collision Vision. “The positive reception of Collision Vision across all segments of the industry has been encouraging. Together with AkzoNobel, we will deliver impactful solutions to thousands of new users worldwide.”

Integrating Collision Vision’s platform with AkzoNobel’s value-added tools can make collision repair shops more efficient. The collaboration can reduce the time shops spend managing certifications, training, equipment, and preventative maintenance.

“Partnering with Collision Vision in bringing this innovative software to market is a strategic move for AkzoNobel as we enhance our commitment to delivering value to our clients,” said Tony Mahon, business services manager at AkzoNobel. “We believe this alliance offers comprehensive solutions that simplify complex and redundant processes within the collision repair industry, ultimately increasing productivity.”

To learn more, visit the Collision Vision website.

Elmer’s Body Shop is celebrating 100 years this year, according to a press release. Since its founding in 1925 by Elmer Steffen, the family-owned business has remained a trusted name in collision repair and a cornerstone of downtown Elkhart, Indiana.

The business continues to evolve across four generations while staying true to its commitment to craftsmanship, community, and customer satisfaction.

Elmer’s began as a small auto body shop in the heart of Elkhart and grew into a local institution. It’s recognized for its attention to detail and dedication to quality. Through economic shifts, technological advancements, and generations of leadership, Elmer’s mission is to provide expert craftsmanship and customer care.

Today, Elmer’s continues its legacy under the ownership of Wes Steffen.

“At Elmer’s, we don’t just fix cars — we bring them back to life, one detail at a time,” Wes Steffen said. “This milestone is a testament to the passion of our team, the loyalty of our customers, and the strong ties within our Elkhart community.”

The journey began when Elmer Steffen, a body seam sealer at the Crow Elkhart Manufacturing Plant, opened his own shop in 1925. He recognized that auto body repair was as much an art as it was a skill. His entrepreneurial spirit led to significant expansions in 1935 and 1948, despite the challenges of the Great Depression and World War II.

IDENTIFY & CALIBRATE ADAS WITH OEM DATA GET PAID FASTER WITH CLEAR, INSURER FRIENDLY REPORTS

GENERATE DETAILED DOCUMENTATION EFFORTLESSLY

ELITEK ADAS MAP ENSURES ACCURACY, EFFICIENCY, AND COMPLIANCE SO YOU CAN FOCUS ON REPAIRS WITH CONFIDENCE.

Automated Estimate Analysis: Identifies ADAS components and necessary calibrations quickly.

Extensive ADAS Database: Access up-to-date calibration procedures for most vehicle makes and models.

Seamless Integration: Works with CCC and ALLDATA for smooth workflow integration.

Enhanced Repair Accuracy: Restore vehicles to optimal safety standards.

Increased Efficiency: Reduce research time and focus on repairs.

Revenue Boost: Streamline ADAS repairs for better reimbursement.

Compliance: Stay aligned with OEM standards and position statements.

UPGRADE YOUR SHOP TODAY! Contact us today to learn how to receive ADAS MAP for Free when utilizing our Remote Programming & Scanning Device for scans!

REPAIRABLE EV CLAIMS continue to rise, according to Mitchell's Plugged-in report (mitchell.com). That's despite an increase in overall total loss frequency, which Ryan Mandell, Mitchell's director of claims performance, attributes to "the continued overall decline in vehicle values and surge in catastrophic claims activity in the second half of 2024."

The report shows claims frequency for repairable battery electric vehicles rose to 2.71%, a 38% increase from last year, while claims frequency for mild hybrid EVs and plug-in hybrid EVs rose by 7% in the U.S. Repairable BEVs in the U.S. had an average claims severity of $6,236, a 3% decrease, while MHEV and PHEV severity ranged from $4,726 to $5,583. These figures are from Mitchell's Plugged-in report.

By ABDULLA GAAFARELKHALIFA Photos: PAINTWORX COLLISION CENTER

DAVE STUMPF, the owner of Paintworx Collision Center, has built his business from the ground up with a clear vision and relentless determination. Paintworx stands out not just for its quality repairs but for the unique approach Stumpf brings to the industry.

“I had $3,000 in the bank. That’s all I had,” Stumpf said, recalling the early days of his business venture. His first major purchase was a $5,000 Kansas Jack frame machine, which he found on Craigslist. This initial investment paid for itself with the first job, setting the stage for the growth of Paintworx.

Today, Paintworx boasts top-of-theline equipment, including Car-O-Liner frame machines and Accudraft paint booths. Stumpf’s pride in his tools is evident, especially in his admiration for the Accudraft paint booths. “My dream of mine was to have an Accudraft paint booth. And to finally get it was surreal,” he said.

Stumpf’s artistic side is also a significant part of Paintworks’ identity. Known for his custom paint jobs, Stumpf used to sign his work, a practice that has carried over into the branding of Paintworx. His signature is now part of the company logo, symbolizing the personal touch and quality for which Paintworx is known.

The shop is meticulously organized, with a clear separation between the paint shop

and the body shop. This division ensures a clean and efficient workflow. Stumpf has implemented a system where all cars are backed into their spots to prevent accidents, and the entire shop is lined up with precision.

One of the standouts features of Paintworks is the integration of technology. Screens are placed throughout the shop, displaying real-time updates on the status of each vehicle. This system, developed by Stumpf and his son Anthony, ensures that every technician is on the same page, enhancing communication and efficiency.

“We have a main screen that we screen from our computer to the main screen so the guys can actually look at the inventory list of cars that have to leave,” Stumpf said.

Stumpf emphasizes the importance of treating employees well and maintaining a positive work environment. Motivational quotes and the motto “Decide, Commit, Succeed” are displayed throughout the shop, reflecting Stumpf’s philosophy. “I’m a big pusher of just staying positive,” he said.

Looking ahead, Stumpf is in talks to purchase the property he has been leasing for 16 years, which includes a towing company. It’s a poetic start to this new chapter if he succeeds, because he had to work out a deal with the landlord to be able to start operations at his shop.

“I hope I can give back what they gave me,” Stumpf said. “My whole goal was just a better collision center.”

Winning sports teams don’t require a roster full of only superstars, and neither do you.

Last month, we looked at when is the right time to add employees, when we should downsize, and customers to avoid. This month, we are going to look at how we can learn to control payroll costs by looking at professional sport teams.

If we research the NFL (National Football League), NHL (National Hockey League), NBA (National Basketball Association), MLB (Major League Baseball) etc., we find all have one form or another of salary caps. Otherwise, they can only spend a certain amount of money on their players. If this were not so, the team with the deepest pockets would be able to hire the best players in their respective league then win every game over and over.

First off, we need to find out how much we are spending in our shop currently for payroll. Let’s take an example of a similar shop we had in last month’s column of $3,000,000 in gross sales and a 10% net profit or $300,000. Let’s break down their profit & loss statement: parts, paint, and sublet: 36% ($1,080,000), technician wages: 20% ($600,000), admin wages: 8% ($540,000), and overhead costs: 16% ($480,000), for a total of 90% ($2,700,000) in cost to run the business with a 10% ($300,000) net profit. What did this example shop spend on payroll wages? $600,000 + $540,000 = $1,140,000

In the above shop example, they’re paying 20% + 18% = 38% of their income on employees’ payroll! Let’s say to improve their low net margin, this shop only looked at cutting their high cost of payroll. A 10% net profit = $300,000, and a 20% net profit = $600,000 (a $300,000 increase). In this shop scenario, they need to drop their payroll from $1,140,000 - $300,000 = $840,000 is what is available for wages. How do you think your employees would respond to taking a 25% pay cut? As we know, it would fly over like a lead balloon.

What is one to do? How can a shop doing $3,000,000 in gross sales do it now with only a $840,000 payroll budget? Well, if you have been in the U.S. for any amount of time, you’ve likely heard of the football team the New England Patriots and their former head coach Bill Belichick. From 2002-2019 the Patriots under Belichick’s leadership, they won six Superbowls and eleven AFC championships. How can this be possible with every team in the NFL having the exact same

salary cap? Belichick had the ability to maximize his payroll dollars for high productivity. Take their quarterback at the time, Tom Brady. If they wouldn’t have good linemen on offense to protect him, he would have been flattened like a pancake. They also needed a wide receiver to catch the ball, defense, a kicker, etc. What is one to do that is different from all the other teams?

Belichick had a sixth sense when it came to managing his roster. As an example, let’s take a veteran all pro free safety who had won even Superbowls with the Patriots. Belichick would not re-sign the player at the end of his contract, even though he was at the peak of his career. He would then be quickly picked up by another team for possibly even more money. Then Belichick would find a young free safety in the NFL draft, train and teach him well, and within half the season they were back where they started, with nearly 80-90% SAVINGS.

“Wait a minute, Greg,” you’re thinking. “This is collision repair were talking about here, not football!” Tom Brady was to Belichick what our head body tech or painter is to our shops. We only need one or two “A” body techs or painters. Let’s go back to our $3,000,000 shop. Why would they need four expensive “A” body techs? A top tech is just like the lead heart surgeon in a hospital. The doctor comes into the operating room, and the patient is prepped by lower paid subordinates. The surgery is performed, and the doctor is on to the next operating room.

In my shop, I have one primary (“doctor”) body tech and head painter and we’re projecting $5M in gross sales this year. Granted, I have others who are cross-trained for when the “doctors” are on vacation. We have hired four apprentices in the last three years and have a career path for each. We have no detailers, no porters, no janitors, etc. Every employee in my shop rotates through a bathroom-cleaning schedule, and this includes me, the owner. It’s funny how clean the bathroom stays!

If you get a chance, watch the movie “Moneyball” with Brad Pitt. It tells the strategy of how the Oakland As achieved great success with the smallest payroll budget at the time of any other MLB team. With these types of concepts, a 20%+ net profit can be achieved!

GREG LOBSIGER

Greg Lobsiger has owned Loren’s Body Shop in Bluffton, Indiana, for over 23 years. He has been a member of Mike Anderson’s groups for ten years and had extensive lean manufacturing training.

EMAIL: greg@lorensbodyshop.com

ARCHIVE: fenderbender.com/lobsiger

With a waterborne basecoat that’s easy to mix, match and apply and that uses the same coat flash application you’ve already perfected, Cromax® EZ makes an exceptional finish feel effortless. Discover how easy an outstanding finish can be.

axalta.us/ez

STRATEGIES & INSPIRATION FOR MSO SUCCESS

Mr. Dent Collision grew from PDR to full collision repair by attracting and hiring the highest level of talent.

By Lindsey Gainer | Photos: Julie Stoecker, Stoecker Media

T“A QUALITY SHOP, WITH QUALITY PEOPLE, THAT DOES QUALITY WORK.”

“I CAN’T GIVE THIS PLACE MORE THAN 5 STARS, BUT THEY DESERVE 100.”

hose five-star Google reviews sum up Mr. Dent Collision to a tee, and they’re just two of hundreds the shop has amassed, all praising the excellent customer service, highquality repairs, and friendly, helpful staff customers find at all the company’s shops.

Started by Brent Martin and his wife Kim in 1993, Mr. Dent Collision is still a familyowned-and-operated business, and now includes Brent and Kim’s son, Logan, and his wife, Larissa, who co-own and operate the business as 50/50 partners.

Together, the foursome is growing the business across southern Missouri, currently operating three locations — the original in West Plains, a shop in Seymour, and a newly constructed shop in Ozark, right outside Springfield — and there are no plans to stop there.

While the Martins don’t aspire to be a “great big MSO,” Brent says, the intent is to continue growing the business. “We want to stay relatively small, because we want

to do a very good job of taking care of our customers and doing quality work. That’s our primary focus.”

“A lot of times there can be strife when families work together, but we’re super fortunate that we don’t have that,” adds Logan, which he credits to the confidence he and his father share in one another to make wise decisions and give 100% effort to the business every day. “We make a great team.”

“When people ask me how long I’ve been working on cars, I tell them I cut my teeth on a 3/8 ratchet; I’ve been around it my whole life,” says Brent, whose father was a rebuilder with his own business in which Brent grew up and worked from 1983 to 1991.

In 1991, with the realization that the rebuilder world was “dying,” and with the encouragement of his father, Brent decided to enter the paintless dent repair (PDR) business, going to work for a shop in Springfield, Missouri. In 1993, he moved

The original building had to be added onto twice to accommodate the influx of work, before Brent constructed the current shop in 2010 (which has also had two additions).

“The business really took off after we built that new shop,” he reminisced.

Then came an unexpected development — Logan decided he wanted to join the business, after going to college to become an accountant.

Logan coming along and being interested definitely helped me find another gear.”

With new wind in the sails, Mr. Dent Collision grew from one shop to two, with Logan joining his parents as partner and co-owner of Mr. Dent Collision’s Seymour location in 2017. He then married his wife, Larissa, in 2019; shortly thereafter, the family acquired a shop in Ozark in 2021.

back to West Plains and opened Mr. Dent, in space rented from his father. That same year, Brent married his wife, Kim.

“She’s been with me every step of the way from the beginning, my partner in the business from day one,” he says, adding that Kim is still heavily involved in the financial side of the business to this day.

By 1994, Mr. Dent had outgrown its rented space, leading Brent to build his first shop in West Plains. Initially most of the work was PDR, with rebuilding and insurance jobs sprinkled in through the winter. Eventually, however, that side of the business grew to the point that he needed to hire help, and things kept escalating from there. All the money Brent made “chasing hail” was invested directly back into the body work side of the business, and eventually Mr. Dent morphed into a full-blown body shop — Mr. Dent Collision.

“Growing up in the industry, I thought I wanted to do something different,” he admits. “But after I did something different, I realized I missed the shop environment and everything that comes along with it. I love the camaraderie. The sales component. The repairs. It’s a rewarding industry, and I missed it.”

His affinity for numbers is a huge boon to the business, praised Brent, who says Logan’s strength in the front office is the perfect complement to his own strengths on the shop floor.

Not only that, his return motivated Brent to grow the business — without Logan’s involvement, he says, it’s likely he’d still be content with one shop.

“I knew from an early age I wanted to work on cars,” Brent says. “But did I ever dream of owning multiple shops? No. I just wanted to have a retail body shop, that was my goal.

After just three short years, the business had once again grown to the point of necessitating an expansion — which resulted in the construction of the brand-new, state-of-theart shop the team just moved into in Ozark. The 22,800 sq. ft. building has 35 bays, including two paint booths and three prep stations, positioning them to take the business to yet another level.

“The efficiency we’re going to gain, that’s what I’m looking forward to most,” says Brent, whose operations were split between three separate buildings at the previous Ozark shop. “We’re really excited about the workflow aspect.”

Even though Brent had prior experience building in West Plains, this new shop, he said, was a different beast. The project took a little over two years from start to finish and came with its share of challenges, given that Ozark is a much larger market with “more hoops to jump through.” But, he says, it was

a great learning experience that will speed the process of building up in the future.

And while an acquisition would be the ideal scenario for a fourth location, according to Logan, they’re open to brownfield or greenfield projects as well. “We’ll likely do a combination of all three moving forward.”

Whatever they decide, they’ll do it as a family…just as they always have.

“We pride ourselves on being a family business,” says Brent, who adds that everyone is actively involved and takes a hands-on approach. “We don’t stand back and point — we’re in there, in the mix, getting things done. That’s the only way I’ve ever known, and it’s the way Logan’s been taught. To gain the respect of your employees they have to see that you’re willing to get in the trenches with them and help them solve problems.”

Both father and son readily agree that the “secret sauce” to their success is simple: great employees.

“A lot of it, for us, just comes down to our people,” Logan says. “We believe you win with people. We can have the best shop, processes, and equipment…but if you don’t put the best people in there, you’re not going to win.”

With nearly 100 miles between each location, Brent and Logan rely heavily

on their team and managers to carry out daily operations independently. And with around 50 employees now, it’s more important than ever that processes be kept tight and aligned with the business’ goals, to ensure “everyone is pulling the rope in the same direction.”

A great deal of effort goes into “getting the right people through the door the first time,” the duo says, and ensuring they’re offering the training, benefits, and work environment that attracts the highest level of talent.

“Nine times out of ten you’re better off hiring the high-level employee who ‘costs’ more,” Logan says, “because that person will more than make up for the value they bring to the table.”

And the father/son team is always on the lookout for people eager to learn — that’s a non-negotiable prerequisite to work at Mr. Dent Collision, where all the shops are ICAR Gold Class.

“We firmly believe the best people want to be taught; they want to be trained,” Logan continues. “We have people flying somewhere all the time for training,” Brent says. “We’re not afraid to invest in our people.”

The shop’s training is largely driven by the duo’s commitment to OEM certifications, of which there are currently 16 between the three shops. Certifications, Brent says, make the company better…plain and simple.

“We like to have certifications that have some teeth to them,” he explained, noting that they pursue certs that have substantial, beneficial training components, and will satisfy the needs of a shop’s market and dealerships. The Ozark shop, for example, recently acquired the Mercedes-Benz Elite certification at the request of the local dealer.

Up-and-coming technology will also play a role in selecting certifications in the future, added Logan, pointing to the GM and Mercedes-Benz collision assistance programs as examples. In addition to guiding a driver through the proper steps of documenting and reporting an accident, the apps also help a driver find a certified repair facility.

“How will these OEMs help us drive revenue and drive work?” Logan wonders. Time will tell, but he’s “excited to see what the OEMs will keep coming out with.”

In keeping with their commitment to high-quality repairs, they even have their own calibration company and do mechanical work to keep as much in-house as possible.

“Not only do we control our quality and deadlines that way, we keep the profit inhouse, too,” Brent says.

“Learning how to manage people — going from just Kim and me to over 50 employees in three locations — there’s been some definite

learning curves,” says Brent, who believes investing in the human side of the business is of the utmost importance.

“Fixing cars is always a focus, of course, and it’s something we work on every day…but that’s nuts and bolts, reading, studying, educating. Managing people, on the other hand, is a fluid deal. Every person working for you is different, and taking the time to understand them and listen to them, that’s essential.”

There are two things Brent believes you must know about every employee: what motivates them and what triggers them. Knowing that, he says, will go a long way toward creating a happy, cohesive work environment, and solving problems in a way that satisfies everyone.

Effective communication is also something they “preach a lot,” added Logan.

“No matter what role someone is in, we believe 95% of every problem, if you look at the root cause, comes down to some form of breakdown in communication.”

Remaining flexible, listening to your team, and taking feedback to heart is imperative, too, continued Brent. “We want the whole team involved — that’s how we design processes.”

Both Brent and Logan are humble men, and that’s a character quality they expect their managers and shop workers to embody as well…especially in customerfacing situations.

“We want to be truly helpful to people in their time of crisis — we want to embody that spirit of help in people’s time of need and take care of them.”

They’re certainly achieving that goal, according to their customers.

“ In a world where genuine customer service is becoming a rarity, the team at Mr. Dent Collision shines brightly,” says another five-star Google reviewer. “I wholeheartedly recommend their services to anyone seeking superior quality auto body work. A heartfelt thank you to Brent Martin and the entire Mr. Dent team. They have restored my faith in quality craftsmanship and excellent customer service.”

Helping people and building relationships with customers and employees is Brent’s favorite part of the job, and Logan also enjoys the human relations side of

the business most…particularly developing employees. Both men love seeing their team grow, professionally and personally, and find that to be an incredibly rewarding part of ownership.

“To know that the decisions we make directly affect our employees, and that they trust us to steer the ship in the right direction…that’s a huge deal to us,” Brent says.

“The sky is the limit for us right now, and it’s up to us to follow through and execute,” Logan adds. “We have some big goals and, hopefully, we can achieve them.”

No doubt they will.

“Pulling the Rope in the Same Direction” Mr. Dent’s Owner/ operators say they offer training, benefits, and the work environment that attracts the highest level of talent.

Selecting a buyer that fits into the right niche can make all the difference in the world for you and your staff.

Imagine that you own or manage a regional MSO that performs well and has an excellent reputation. You are probably contacted regularly by various consolidators, brokers, paint companies, private equity (PE) companies, and more, about your possible interest in selling. When you go to industry events, there are always some of these people who want to be your new friend. At times, you feel like “the prettiest girl at the dance.” (When using this analogy with a consolidator suitor, I was once told that I was “smokin’ hot!.” I assure you that my physical attributes have never caused anyone to describe me that way.) Everyone wants to capture your attention and be close. Perhaps you even get invitations to various sporting events with these suitors. If you are inclined to consider a sale, how does one categorize and consider all the suitors? For this fun, hypothetical exercise, we will just consider the consolidators, not the PE companies or other entities. You care about your business and all its people. Price isn’t the only consideration. You will be aligned, at least to some extent, for a long time. Your legacy is at stake. You are metaphorically putting your baby up for adoption and you want it to go to a good new home. And you want the buyer to succeed for the good of all parties involved, including your staff and customers and vendors. It will likely be a tenant in your buildings. With whom do you wish to go through this experience with and have a (probably) longstanding relationship?

I asked a good industry friend, Madeleine Roberts Rich, of Focus Advisors Automotive M&A, how she would categorize consolidators. She answered as follows:

“Our firm likes to describe the consolidators in three categories:

1. Consolidators (“The Big Five). These are the five largest collision repair consolidators in the US (and Canada, in the case of Gerber). They have mature financing from private equity, and the Boyd Group is public. The Big Five are: Caliber, Gerber, Crash Champions, Classic Collision, and Joe Hudson’s.

2. Fully Launched. These are the four consolidators that have PE sponsors but are not quite at the level of the Big Five. Each of them has between 50 and around 115 shops at present. These four consolidators are Quality Collision Group, CollisionRight, Kaizen Collision, and VIVE Collision. They have clearer geographic concentrations and defined strategies. Quality Collision Group, for example, focuses on well-regarded and highly OEMcertified shops in strong markets.

3. Newly Launched. These are the platforms that were just getting started a few years ago (or even more recently) by getting a Private Equity sponsor. We consider these earlystage platforms that are adding on additional shops and streamlining operations to realize economies of scale. There are a few of them: Puget Collision, OpenRoad Collision, BrightPoint Auto Body, and (as of November), Driving Force Collision, and Authentic Auto Body. There are many private equity firms looking to get into the collision repair industry, so there are likely more of these “newly launched” to come.

Good answer. It breaks them down by size and (to some extent) by stature.

There are many attributes that could be used to further categorize consolidators. I’ll toss a few out.

There are some that truly have a national presence and some are regional.

There are some that focus more on larger shops versus small- to medium-sized.

While there aren’t many, there are some consolidators that are still familyowned/operated, such as B Street Collision and G&C Auto Body. Some of these represent longstanding second generation family businesses.

There are some, such as Driven Brands, that offer solutions for franchises or acquisitions.

Over the years, there have been some large companies, such as Ford and Allstate, who got into our industry, acquiring and operating a number of shops. Both Ford and Allstate later sold off these shops, in some cases to the previous owners.

Keep in mind that consolidation in our industry is not immune to failures. A couple of examples include CARA and M2. Both collapsed about 2001-2005, probably due to growing too fast for their own abilities and resources.

While most consolidators only purchase businesses, some will also purchase real estate.

Consolidation has been in our industry long enough that there are some current consolidator executive management people who were key people within other consolidators in the past. Many of those learned how to do things, some properly, and some improperly, leading to their desire for better performance in their next venture.

While most consolidators focus strictly on collision repair, there is an increasing segment that embraces non-collision work such as glass, ADAS, PDR, clear guard, or

mechanical work. And some are embracing medium- or heavy-duty collision work. By far, the majority of consolidators have built their businesses around insurance DRPs. Some are embracing original equipment manufacturer (OEM) certification programs. It’s not that the two can’t coexist, but there is often some element of conflict due to the different expectations of insurers and OEMs. Some consolidators will implement OEM certifications in areas based upon demand and demographics. These can be suggested by insurers, again based on their needs. Parts purchasing restrictions can drive some of these, as in some cases shops can’t purchase critical parts without certification.

This leads to an area I’ve been living in. I’ve worked for LaMettry’s Collision for many years. It’s a regional MSO with many OEM certifications and close dealer relationships. We’ve evolved away from most DRPs and instead prioritized the customers’ safety and satisfaction over

the expectations of a DRP (We are not anti-insurer nor anti-DRP. But DRPs came with many requirements and expectations, many evolving around KPIs that are based on keeping costs contained. Too often, a shop is caught between frustrating an insurer or providing a compromised repair.) The LaMettry’s family, after a lot of soul-searching, decided to sell. The new owner is the Quality Collision Group (QCG), which is a great choice because of their similar philosophies.

As far as I know, QCG is the only large consolidator with this model. They focus on buying high-performing shops, especially ones with OEM certifications. They are all about putting the consumer first, including an emphasis on OEM parts, OEM repair procedures, safety, and overall doing the right thing. They are not anti-insurer, but they are not focused on growing their business through DRP relationships like other consolidators. They have many close and growing relationships with the OEMs. They typically maintain the brand of the larger MSO in a particular market.

For example, in the Minneapolis/St. Paul area, the LaMettry’s brand will continue to be used.

I know that being part of a leadership team experiencing a transition of ownership can be very challenging and stressful. Selecting a buyer that fits into the right niche, with the right characteristics and philosophies, can make all the difference in the world for you and your staff.

I wish to also thank John Walcher of Veritas Advisors, whose input helped me write this article.

DARRELL AMBERSON

Darrell Amberson is the president of operations for LaMettry’s Collision, a 10-location multi-shop operator in the Minneapolis area purchased by Quality Collision Group November 2024. Amberson has more than 40 years of collision industry experience, and served as chairman of the Collision Industry Conference for the 2021-2022 term as well as interim chairman for the first two CIC meetings of 2024.

ARCHIVE: fenderbender.com/Amberson

EMAIL: d.amberson@frontier.com

Consolidation is happening rapidly. Understand private equity investment and the market forces behind it so you can not only compete but thrive.

By MADELEINE ROBERTS RICH

OPERATORS IN THE U.S. collision repair industry know there are many different kinds of players in the industry. Within one geographical area, there are collision repair enterprises with highly distinctive styles, reputations, work cultures, and owners. That’s how it’s always been, although the increasing complexity of cars in recent years has necessitated even more specialization by shops. What’s a relatively new dynamic is the rip-roaring pace of consolidation – either by regional rivals in a

market or by the biggest names in the industry. Here at Focus Advisors, a mergers and acquisitions firm that focuses on collision repair, we often hear from owners, “so and so sold to Caliber” or “so and so signed up with CARSTAR.” And increasingly, we’re hearing, “this private equity firm gave me a call and offered me X. Do you know them?”

For some historical context, up until a few decades ago, the collision repair industry was comprised of many tens of thousands of one- to two-shop operations. Occasionally, there was larger enterprise than that – one of the early independent MSOs. Back in 2012, over 92% of collision repair locations throughout the US were doing less than $10M in annual sales, per the Romans Report. Those operators (sub$10M in sales) comprised 32,500 shops across the US. By 2023, the number of enterprises doing less than $10M in annual sales declined by 23% to a count of 25,000. A large part of this can be explained by the growth of the U.S. collision industry, which – during that same timeframe of 2012 to 2013 – grew from $30B per year to $50B per year. Cars became more advanced and costs went up, driving up annual sales per shop. However, the Romans Report also illustrates that most of the gains in the market size flowed to enterprises doing north of $20 M of sales annually. That means that the very large operators – those

enterprises clearing upwards of $20 M in sales – gained significant market share in the last 13 years.

What these statistics demonstrate is that the collision industry has consolidated, and the large players are getting larger. We estimate that by the end of 2024, the largest operators had one-third of the collision repair market share. While there is still room for the small independent shops and independent MSOs to compete, they need to invest in management, techs, and specialization. They also need to know who the large players are and a little about their playbooks. This article will explore that.

In 2023, we at Focus Advisors introduced the “Fish Scale,” which mapped out the various enterprises into different strata. At the top end of the fish scale are the “Whales” and the “Sharks.”

What we dubbed the “Whales” are the five largest collision repair consolidators, also known as “the Big Five.” In order of their market share, they are: Caliber, Gerber, Crash Champions, Classic Collision, and Joe Hudson’s. Gerber is the lone public company among the consolidators; the remaining four are backed by private equity investors. These consolidators have grown their footprints through acquisitions, and

increasingly, real estate developments in the last few years.

While the two smallest of the Big Five, Classic Collision and Joe Hudson’s, grew by north of 22% in 2024, Caliber, Gerber, and Crash Champions grew by about a third of that pace. Collectively, at the end of 2024, the Big Five controlled 3,839 locations, comprising over $15.5 B of annual revenue.

Then there are the “Sharks.” These are smaller enterprises that have also been backed by private equity sponsors, although they are at an earlier stage of their maturation than the “Big Five.”

As background, private equity firms looking to enter the collision repair space will seek out an existing enterprise and entrepreneur with enough market share to form a “platform.” They will often pay a competitive price for this first platform, from which they will then launch a multi-year strategy of single-shop add-on acquisitions, often geography adjacent to their original platform. Over time, they will add shops through acquisitions, while also aiming those shops’ total sales and profit, as measured by EBITDA. After a few years, having grown total EBITDA, they then sell the enterprise — now substantially larger — to another buyer. This is a playbook that is otherwise known as a “rollup.” It is behind private equity-backed consolidation in industries as diverse as HVAC and dental practices, and now to collision

repair. It was what was behind the Big Five’s growth and now the seven “sharks.”

Leading the seven sharks is Quality Collision Group, backed by Susquehanna Capital. They grew their shop footprint by 35 locations, or 70% growth, in 2024. They closed on the two largest transactions in 2024 – that of Cascade, a nine-shop platform in Utah, and LaMettry’s, with 11 locations in Minneapolis. Their strategy is to focus on highly regarded local enterprises that have many OEM certifications.

Second to Quality Collision in terms of market share, there is CollisionRight, based in Dublin, Ohio. They were acquired by Summit Partners at the start of 2024, which gave them deep pockets to grow quickly throughout the year to a total of 101 locations.

Following CollisionRight is Kaizen (owned by Kinderhook) and VIVE Collision (owned by Greenbriar). They each closed the year with around 50 locations. Kaizen is located in several key markets on the west coast, whereas VIVE has come to be a driving force of consolidation in the Northeastern states.

The fifth shark is Puget Collision, which has expanded to over 52 locations throughout the Pacific Northwest. They have focused on acquiring franchise organizations through Driven Brands, such as Carstar and Fix Auto. They now have locations in Washington, Oregon, southern

California, and Colorado. Collectively, these five largest “sharks” comprise almost $1.4 B in annual revenue, or 2.5% market share.

There are two more – OpenRoad and BrightPoint – which are much more nascent platforms, but which did see significant growth throughout 2024. All in all, there are seven “fully-launched collision repair platforms.”

Given the background above, it’s clear that in recent years, there’s been a lot of talk about PE firms entering collision. Our firm, for instance, has been approached by over 130 PE firms looking to get a foothold in this industry. They’re attracted to industry’s resilience to recessionary pressures, its nature as a hedge against inflation, and its economies of scale across multiple locations, among other aspects. Many PE firms launched their platforms right around the time COVID started, as the Federal Reserve cut rates, capital was abundant, and the cost of capital was low.

But how did the low cost of capital translate to collision consolidation? Let’s start with the big picture. Private equity firms raise individual funds – getting capital commitments from institutional investors, family offices, accredited investors, et cetera. These investors are betting on the PE firm’s track record, but also their fund thesis, which commits to a certain strategy,

risk/return profile, and target investment return over the course of the fund’s life cycle (typically around 10 years).

Once the capital is committed from those investors and the fund is “subscribed,” the PE firm immediately begins looking for investments to make based on its underlying thesis (while also charging management fees, I might add). Acquisitions they make are through a specific entity they create for that purpose and funded mostly with debt. In the case of collision repair, PE starts a new collision repair enterprise by paying up for a “platform,” a larger MSO acquisition, through which they typically keep the management on board to grow this platform to the next level in a few years. The goal here is to aggregate more sales and improve the profitability of the business. In four to seven years, they’ll aim to exit their investment and pay back their investors, so they hope to sell the enterprise to another PE firm – this time with more EBITDA and a higher EBITDA multiple.

This playbook has been executed several times since the collision industry began consolidating. Between November 2023 and May 2024, for instance, $9 B of capital came into the industry, providing the “Sharks” and the “Whales” with deeper pockets and mandates to grow – and grow fast.

While historically PE firms have looked for large platforms from which to launch, it became evident that those large transactions

—Madeleine Roberts Rich, Senior Associate, Focus Advisors Automotive M&A

(let’s call them MSOs of at least six shops) were far and few between. When enterprises of that scale did transact, however, existing consolidators often had the leg up. So, being one of many dozen PE firms looking to get the deal was extremely competitive.

So starting in 2024, PE firms began approaching entrepreneurs much further upstream in the company life cycle, approaching energetic and capable collision entrepreneurs when they’re one- to three-shop enterprises. This became clear in November 2024, when TRP Capital launched a platform called Driving Force Collision by buying a three-shop MSO in Long Island, and Envest Capital Partners concurrently launched a platform called Authentic Auto Body by acquiring a single shop in Massachusetts.

These days, our firm hears of emerging platforms almost on a weekly basis, so this is a dynamic that is growing at a rapid clip.

While the Whales and the Sharks now control a third of the collision repair market share, that means two-thirds of the industry is still owned by independent collision repair providers. In the vast majority of cases, these are family-owned enterprises that have never raised outside capital. The “Independents,” as we like to call them, span an enormous range of sizes. Most independents are longstanding single-shop operations. But at the very top end, there are MSOs with over 20 locations. The largest independent MSO, by way of example, is G&C in Northern California, with 45 shops at the time of writing.

Each of these independent collision repair enterprises has a different business model. Some have DRPs in the enterprise’s DNA; others focus instead on OEM certifications. Some are franchisees with Driven Brands,

for instance, and are able to scale that model well. There are some of the many ways independents have remained competitive in the face of significant consolidation. However, what’s become clear is that both cars and the collision repair industry are becoming increasingly sophisticated and require much more strategy on the part of owners.

For most owners, 2024 was a difficult year. Claims counts were down, and more of the cars that came into the shops were totaling. These headwinds really began in the second quarter of the year, and experts have cited many factors: a mild winter, economic uncertainty, an older car parc, or fear about getting dropped by an insurer for submitting a claim. Some of the larger independents, however, saw the down year as their opportunity to acquire at attractive prices. Texas Collision Group, G&C Auto Body, and Manders Collision and Glass are just three examples of independent MSOs that capitalized on the down-year by acquiring or even building new shops. There are many more.

It’s critical to understand the composition of this industry and the different players within it. With only one public company in the entire industry (Gerber), there is still a lot of opacity in this industry, which makes it difficult to see how different enterprises are competing. What’s important to note, though, is that this is a growing industry, and two-thirds of it is still held by independent operators. Competition from consolidators and large independent players will intensify, especially as conditions normalize back toward pre-COVID levels. Operators looking to keep their footing in their markets must enhance: (i) enhance their understanding of their real-time financials, (ii) incentivize their management toward those financials, (iii) understand

their valuation and its drivers, (iv) figure out ways to get repairable vehicles in the door at a consistent pace, (v) maintain their bench of technicians, and lastly, (vi) plan for growth. It’s a tall order. While more capital in the industry necessitates this, the good news is that it presents many new options for visionary collision entrepreneurs.

Focus Advisors (www.focusadvisors.com), M&A advisory firm to the collision industry, partners with MSOs between $10-100M in annual revenue, helping owners achieve maximum value through strategic growth and exits. Unlike traditional business brokers or large investment banks, Focus Advisors specializes exclusively in collision repair — giving owners unparalleled insight into value, interest, and opportunity timing. With over 25 years in the industry, Managing Director David Roberts has led more than 40 transactions totaling over $500 million in transaction value and more than 325 collision repair shops, including Tripp’s Collision, Pride Auto Body, Quanz Auto Body, Mills Body Shops, and Master Collision Group. For a confidential discussion about your future, your value, and the benefits of having an experienced advisor on your side, visit https://focusadvisors. com/contact/ or email Madeleine Roberts Rich at madeleine.rich@focusadvisors. com or call (510) 414-7707.

Investment Banking Services and Securities offered through Independent Investment Bankers Corp. a broker-dealer, member FINRA/SIPC. Focus Advisors is not affiliated with Independent Investment Bankers Corp.

*Chart data and statistics on industry shop counts and acquisition volumes represent our best estimates from available public information, not statements of absolute fact.

body shop near me

THE SOP

The Google Business Profile is a free yet powerful tool for reaching online customers.

IT IS UNDERSTANDABLE WHY a business owner may be hesitant when it comes to marketing dollars. A marketing budget can seem like a black hole — without the right strategy, money goes out the door and never comes back. But what if there was a marketing strategy that cost you nothing but time? And it comes on a platform that most of your customers are already using.

You already know your customers are using Google to find your business. But what exactly they find is fed from your Google Business Profile. When a customer searches for a business on Google Maps, for instance, they’ll find not only where it’s located but also other basic info, such as hours, services, customer reviews, and more. By optimizing your Google Business Profile, you can help make that first (virtual) impression as positive as possible.

“The industry is a need-based industry,” says Daniel Burkholder, founder of Body Shop Marketing. “So our strategy needs to be a little bit different. That’s where the search becomes such a strong play.”

Marketing professionals like Burkholder can assist a business with all their marketing needs. But he cites the Google Business Profile as one of the most powerful tools available to business owners, provided they optimize it correctly.

As told to TODD KORTEMEIER

When somebody needs an auto body shop, there’s a few places they go. They might ask their dad, they might ask a friend, or their insurance may direct them to a certain shop. But the younger generation is finding a lot of their answers on Google. So that is one place that you want to be, and obviously you want to be the No. 1 shop when they’re searching, because statistically, the No. 1 shop gets 40% of the calls and clicks. And especially the Google Map

results, because that’s getting the largest portion of real estate. Whether you’re on desktop or mobile, the Google Maps search is getting the highest, most real estate.

The more consistent activity you can have going on at your Google Business Profile is sending—I use the word “signals” — it’s just sending those signals to Google, “Hey, this is an active profile.” New photos are getting uploaded every now and then, updated photos. They’re not having pictures that look like they come from the 1980s; we are in 2025, so you want to keep putting some new pictures there showing what’s going on.

Reviews are a great strategy. I like to tell people it is part of the puzzle. A large portion of consumers that leave reviews like to see a response within 24 hours. So if you can leave a nice, thoughtful response within 24 hours, that’s great. And here’s another little side note — Google doesn’t tell us this, but there’s some thought that even including keyword phrases in your reply, saying things like, “Hey, thanks for choosing (shop name) as your auto body repair shop” can be helpful. And obviously, replying to the negative reviews is huge. Honestly, for myself as a consumer, I like to see how the owner or management replies to those bad reviews. It tells me a lot about them.

In the admin side of your Google Business Profile — and this gets displayed publicly then as well — under Business Information

is the Business Category. And what I see happening is collision repair shops will have their main business category as “auto repair shop.” Well, to Google, an auto repair shop is a mechanic shop. So you can see the conflict there. You don’t want to rank for auto repair shop. You don’t want to be ranking when people are searching for “transmission repair near me” or “engine repair near me.” Google has a business category that is “auto body shop.” So that is what you want as your primary category. Now, Google does give you the option to select secondary categories. That’s where I would say go in and select all those secondary services that you provide, whether it’s glass replacement, detailing, etc. You’d have to look through what Google has there and what matches up with your secondary services.

I would say you should probably have at least two to three activities going on there on your Google Business Profile per week. That could be a review response, or adding some new photos, or doing a post. Some shops are using the post update section for before and after photos, photos of things going on inside the facility. Google gives you a nice little area there where you can write a post. It’s pretty much like a social media platform at that level, and it’s a great way to send signals here, again, to Google that there’s activity going on there at the website.

If you’re interested in learning more, on my Body Shop Marketing YouTube channel we’ve got all kinds of webinars that we’ve done in the past, talking about these kinds of things. Also, I’m happy to walk through it with a shop owner, I’m happy to review it with them and kind of tell them, “Hey, here’s some things that you could be doing.” Above all, don’t sleep on this opportunity that Google is giving you. The Google Business Profile is a free tool. And it has lots of cool tools inside of it that you can be utilizing. So definitely make sure it’s optimized, and keeping it up to date and maintaining it is really key for ranking high in the local search results.

Working on dealership loaner vehicles can be a headache. Learn the three ways to effectively handle these vehicles.

By NOAH BROWN

WORKING WITH A DEALERSHIP can bring in steady work for your shop, but it can also bring in a constant stream of headaches.

One of the main sources of work your shop can expect when working with a dealership is a fleet of loaner vehicles. Andrew Batenhorst, body shop manager of Pacific BMW in Glendale, California, says working on those will present its own set of unique challenges.

Over the years, his shop has developed a method to help increase the efficiency of handling these requests and to reduce the overall hassle when dealing with them.

Though there are many issues that can come up while dealing with a damaged loaner vehicle, Batenhorst says the issues usually start with the coverage investigation process.

“Since this is typically a temporary vehicle provided for a service customer, you have a separate contract. Not every dealership is going to have the same contract,” Batenhorst says. “When the claim originates, the person in the dealership who is trying to gather that info may not have all the facts of what happened.”

When the person you’re working with at the dealership doesn’t have all the facts, that can create confusion. Batenhorst says his shop has sometimes found out that there’s an exclusion and a particular carrier doesn’t cover a temporary vehicle when it gets in an accident. In addition, most dealerships are not self-insuring these vehicles, and they want to avoid their own insurance as much as possible.

“Most shops won’t begin working on a car until they know the coverage on that claim is going to be good,” Batenhorst says. “You need to have a good understanding of how that’s going to be handled.”

Batenhorst says, unfortunately, there’s no one-size-fits-all solution to dealing with loaner vehicles. Still, his shop has developed a method to maximize the productivity and profit from working on loaners.

The first step is to figure out what the best-case scenario is for a car. Typically, most dealerships will want to sell a loaner vehicle. However, after an accident that may not be feasible.

“If that car has structural damage or airbags deployed, now the dealership can’t sell that as a certified pre-owned,” Batenhorst says. “As a shop, you have to have a good conversation with someone in the sales department at that dealership to figure out the best thing for that car.”

Batenhorst says in his shop, his team then writes a preliminary estimate without disassembly or full diagnostics and then presents it to the dealership.

“We ask what the desired outcome is. They may wholesale it, they may total it, or they may want to fix it. Those are the three main routes to go,” he says. “The decision-making process involves multiple people from the dealership, and you should have those conversations early so you don’t end up wasting time.”

He says a “good, hour-long meeting” with everyone who’s involved with the decision-making process for loaner vehicles on the dealership side before beginning repairs essential. He also says you need to create a standard process for how those vehicles are handled.