With more than 750,000 parts from over a thousand brands, AutoZone is here to help you get exactly what you need, exactly how you need it. That way, you can get more bays turned, faster. And more customers on their way, happier.

6,000

NAPA Auto Parts stores in the U.S. supported by a nationwide network of distribution centers

Access to an in-house APPRENTICE PROGRAM at no additional cost

NAPA is proud to have America’s largest network of parts and care.

With nearly 6,000 Auto Parts stores and over 17,000 Auto Care centers, from coast to coast, we are one NAPA.

95%

consumer recognition when you co-brand with NAPA Auto Care

NATIONWIDE PEACE OF MIND WARRANTY for your customers, and local labor coverage for you

NAPA Auto Care centers are featured in the national marketing campaign PRIORITY PARTS DELIVERY SERVICE

from your servicing NAPA store

Interested in becoming a NAPA Auto Care center? Scan this QR code to be contacted by a local NAPA sales representative.

For Nichole Bennecoff of Empower Automotive and the Rocha siblings at Rocha’s Auto Service, specialized service has been a sustainable model for decades. Are they now ready for change?

BY NOAH BROWN

When shop owner and technician Jason LaBonte saw a gap in in-house training opportunities for techs, he took action to create change.

BY KACEY FREDERICK

How The Auto Shop chased a dream of becoming a top shop

Knowing when and how to fire an employee

Grow your business, not your fears KATHLEEN CALLAHAN

Handling a discrimination complaint

Moving customers from deferred to scheduled

Does fear of failure affect your decision-making? DUTCH SILVERSTEIN

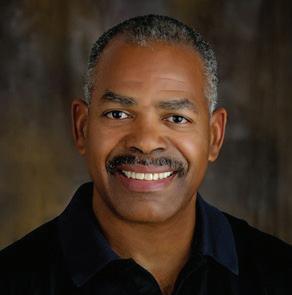

Nichole Bennecoff of Empower Automotive, photographed by Grace Hudson Photography.

Knowing your customers and your purpose is paramount to staying focused and finding success

BY CHRIS JONES

I have long admired the people who sell Mary Kay, and whenever I see a pale pink Cadillac, I know whoever drives it hustled hard for it. To succeed in multilevel marketing, you have an unwavering tenacity and passion for and belief in the business you represent and the product you sell. And in the case of Mary Kay, that’s a singular product line. Mary Kay reps don’t sell Bobbi Brown. They don’t sell Bare Minerals. They sell one cosmetic brand to their customers—wash, rinse, and repeat—for the life of their relationship with the company. So, yes, that Mary Kay Pink Pearl Cadillac is earned. This isn’t an endorsement for MLM practices or strategies, just an observation that when you know your clientele, you can find the riches in the niches.

In this issue, we look inside the businesses of niche shops. For Nichole Bennecoff of Empower Automotive, and Ronnie, Yamil, and Andrea Rocha of Rocha’s Auto, succeeding in the auto care industry while servicing individual makes or select vehicle types is a testimony of the hard work and dedication it takes to say ‘no’ to other work. In “Primed to Specialize” (p. 22), Bennecoff, who specializes in Subarus, talks about how her shop chose the automaker as its focus and how today, while it remains the lion’s share of her clientele, she’s started to repair other Japanese makes since the shop now has command of the market.

On the note of market share and competition, Dutch Silverstein asks a pointed question to shop owners that older millennials can appreciate: “Do you have FOMO?” (fear of missing out, if you’re not hip to the lingo).

Silverstein discusses in his column,

“Motivation: What Gets Your Motor Running?” (p. 34), a growing trend in the auto care industry of auto repair shop owners not operating from their business plan, but instead operating out of fear. They don’t want to miss out by not doing what shop owners around them are doing. He warns that this strategy can lead to fear-based leadership and poor decision-making.

Niching in and going against the grain aren’t easy ways to run a business, but as you’ll learn in this issue, those willing have been met with success. You can be, too. Stay the course.

CHRIS JONES, EDITOR CHRISTOPHERJ@ENDEAVORB2B.COM

EDITORIAL

EDITORIAL DIRECTOR / EDITOR-IN-CHIEF

Chris Jones

ASSISTANT EDITOR

Kacey Frederick

CONTRIBUTING WRITERS

Tess Owings, Nolan O’Hara, Noah Brown

EDITORIAL ADVISORY BOARD

Tara Topel, Topel’s Towing and Repair

Andrew Marcotte, American Pride Automotive

J.J. Mont, J.J.’s Auto Service

Rachel Spencer, Spencer’s Auto Repair

Bruce Howes, Atlantic Motorcar

Lucas Underwood, L&N Performance Auto Repair

SALES

ASSOCIATE PUBLISHER

Andrew Johnson / ajohnson@endeavorb2b.com

ASSOCIATE SALES DIRECTOR

Mattie Gorman-Greuel / mgorman@endeavorb2b.com

DIRECTOR OF BUSINESS DEVELOPMENT

Cortni Jones / cjones@endeavorb2b.com

ACCOUNT EXECUTIVES (NATIONAL ACCOUNTS)

Diane Braden / dbraden@endeavorb2b.com

Darrell Bruggink / dbruggink@endeavorb2b.com

Marianne Dyal / mdyal@endeavorb2b.com

Chad Hjellming / chjellming@endeavorb2b.com

Lisa Mend / lmend@endeavorb2b.com

Martha Severson / mseverson@endeavorb2b.com

Kyle Shaw / kshaw@endeavorb2b.com

Sean Thornton / sthornton@endeavorb2b.com

SENIOR ACCOUNT EXECUTIVE (REGIONAL ACCOUNTS)

Melody Todd / mtodd@endeavorb2b.com

ACCOUNT EXECUTIVE (REGIONAL ACCOUNTS)

Tim Hill / thill@endeavorb2b.com

CUSTOMER SUCCESS REPRESENTATIVE (REGIONAL ACCOUNTS)

Autumn Morey / amorey@endeavorb2b.com

ADMINISTRATIVE ASSISTANT

Ryan McCanna

ART AND PRODUCTION

ART DIRECTOR

Emme Osmonson

PRODUCTION MANAGER

Mariah Straub

AD SERVICES MANAGER

Jen George

ENDEAVOR BUSINESS MEDIA, LLC

CEO Chris Ferrell

PRESIDENT

June Griffin

COO

Patrick Rains

CRO

Paul Andrews

CHIEF DIGITAL OFFICER

Jacquie Niemiec

CHIEF ADMINISTRATIVE AND LEGAL OFFICER

Tracy Kane

EVP ENDEAVOR BUSINESS INTELLIGENCE

Paul Mattioli

EVP TRANSPORTATION

Kylie Hirko

VICE PRESIDENT - VEHICLE REPAIR GROUP

Chris Messer

HOW TO REACH US

ENDEAVOR BUSINESS MEDIA

571 Snelling Avenue North, St. Paul, MN 55104 tel 651.224.6207 fax 651.224.6212

web endeavorbusinessmedia.com

LETTERS TO THE EDITOR

editor@ratchetandwrench.com

Opinions expressed in Ratchet+Wrench are not necessarily those of Endeavor Business Media, and Endeavor Business Media does not accept responsibility for advertising content.

• Speaker lineup featuring the best of the best sharing their insights and best practices in

• Over 30 strategy sessions focused on improving your business

• New event format and networking events to enhance learning and networking opportunities

• Exhibitor & Sponsor Showcase to provide dedicated time to see the latest equipment, products, technologies and services first-hand from top vendors

• New location in the exciting city of Orlando!

• Closing “Margaritaville” Social Celebration guaranteed to bring on the fun!

• And more!

2024 MWACA Best Places to Work winners Danny and Kelley Crawford share why industry events matter

BY KACEY FREDERICK

Industry events like VISION are something many are familiar with, and those who attend receive insight into how to make their businesses even better. For Danny and Kelley Crawford, owners of The Auto Shop in Jefferson City, Missouri, it wasn’t until they attended VISION in person that they saw the potential it had to help their entire staff. The husband-and-wife owners tell why

they now close up shop each year to bring their entire staff to VISION, and how the changes they experienced from such events helped them become the 2024 MWACA Best Places to Work winner.

It all started in 2010 when the Crawfords first opened their shop. It wasn’t unfamiliar

territory for Danny, who had been near the automotive field since he was 10 years old helping in his father’s shop.

Danny acquired 15 years of experience at a Honda/Hyundai dealership as a service manager. Later, after opening his shop, he wanted to find resources offered to other small businesses like his. That alongside encouragement from their parts vendors led

the shop to join TechNet, doing quarterly training with Carquest, and getting involved with the Midwest Auto Care Alliance.

It wasn’t long before the Crawfords began hearing about VISION, and they became interested in the opportunity for networking and expanding their industry knowledge. So, Kelley and Danny went on their own to scope it out, attending classes offered on management and finances.

Upon seeing other teams of shops and their staff walking around at the event, in t-shirts showcasing their brands, Danny and Kelley immediately knew they were not the only ones who could benefit from being there.

“We were just blown away,” remembers Danny. “We were like, ‘Oh my gosh; how can we afford to bring our employees back?’”

After returning the next year with a couple of their staff members, the Crawfords closed the shop each year after to bring their entire team to VISION because there’s insight for everyone—from shop owners to managers and technicians.

By meeting other techs in the field,

Kelley saw an opportunity for their team to collaborate outside the event and share knowledge.

“When do they ever get to speak to other technicians? They’re always down in the car,” explains Kelley. “It was a really good opportunity for all of them to kind of set their sights a little higher than where they thought they might go; it gives them all kinds of opportunities.”

For the Crawfords, their team’s experience at VISION is crucial. Each night of their stay, the Crawfords do something with their staff—whether it be taking them somewhere fun for dinner or going out to an arcade for game night, each year it marks a memorable bonding time for the entire shop.

Using insight gained from the event, the Crawfords have improved their shop’s culture and organization. Much of the conversations they have with other shop owners as VISION revolves around how to encourage positivity and productiveness in the workplace, and the weekly meetings held with The Auto Shop staff is something Kelley credits with why they were named the Best Places to Work winner.

“We sit down with them, one on one, and say, ‘What can we do better as owners? What resources do you need? What’s going on in your personal life? How can we help you with that? What resources can we give you?’” tells Kelley. “Instead of a negative thing, it turned it into a positive thing.”

The speakers at VISION have been effective at challenging mindsets and asking shop owners to view things from other perspectives: to understand what motivates your employees, and that seeing change in your staff starts with making changes in yourself and management.

“We had such good instructors that kind of wake you up from the wrong way of thinking or your lazy way of thinking—they just wake you up, and they do a really good job of finding all the right people (to speak at VISION),” says Kelley.

Not just VISION, but other groups they’ve been involved with, such as MWACA, have offered them a look into what others in the industry are doing, sparking ideas for improvement they may not

have had otherwise. It helps the Crawfords and their staff know what obstacles others are facing and how they’re handling them. Especially when it comes to rapidly changing vehicle technology, it can be tremendously helpful to know what others are doing to adapt to the change.

“I think it reassures how complicated our industry is. How the manufacturers change the cars constantly, and the expectations of the clients on how the car reacts or doesn’t, especially with ADAS stuff,” said Danny. “I think being able to talk to other shop owners about that, and technicians, just makes you feel good.”

Industry groups are what introduced Danny and Kelley to amazing networking opportunities like VISION, and they encourage others to seek out any resources they can find that will help them get more involved with others in the auto repair field. Coaching companies are a great first step for those looking for a place to start. The Midwest Auto Care Alliance has chapters across the nation as well, representing other regions like the Mid-Atlantic and Northwest, and larger states like Florida and Texas.

Taking the leap and attending industry networking events can be a commitment, and may even seem daunting, but the benefits a business owner can yield from it are tremendous. Having been named MWACA’s 2024 Best Places to Work winner, The Auto Shop is proof of that—and Kelley can’t help but

feel moved by how they’ve truly seen a vision they had for themselves become reality.

“The first time we went, we saw all these teams walking around with the shirts on, and we’re like, ‘Gosh, one day, maybe that could be us.’ And not to get choked up, but that was us this year,” tells Kelley.

The fossil fuel-less carriage has arrived…

352 Innovation is HERE to HELP!

Roadmap to the Clean Vehicle World

How to Prepare Your Shop to Offer Clean Vehicle Service

• Web-based Subscription Service

• 11 Sections including…

▶ Major Components: Operation | Service Needs

▶ Electrical & Hydrogen: Safety | Tools | Infrastructure | Regulations

▶ Shops & Technicians: Training Locations | Resources

• Updated Quarterly

• Discounts, Referral & Affiliate Programs Available!

“Roadmap … has helped me make well informed decisions to transition into the clean energy arena.”

-Dirk

-

“The Roadmap, designed by 352 Innovation, is simply ingenious. It provides pivotal information for automotive shop owners to adapt to the rapidly changing environment of adhering to clean energy standards while becoming more efficient with working on electric and hydrogen vehicles”

Automotive Aftermarket Charitable Foundation Executive Director Joel Ayres

Joel Ayres, the Automotive Aftermarket Charitable Foundation’s first executive director, has announced his retirement in a recent press release.

Following nearly a decade of working in AACF, Ayres’ retirement took effect on April 30. Having been the first executive director appointed to the organization, he has been credited with playing a role in much of its success. With the launch of AACF’s Awareness Partner Program

that Ayres oversaw, the number of its partner companies doubled.

Ayres’ experience in the automotive aftermarket stretches beyond just AACF, having served as a sales manager, general manager, national marketing director, and VP of sales and marketing for several different manufacturers. Additionally, Ayres held a role on the SEMA Board of Directors, where he spearheaded its charitable arm, SEMA Cares, and chaired the SEMA Memorial Scholarship Committee.

Having a passion for charity work, Ayres has also been involved with the Sacramento Heart Gallery, Big Brothers of Northeastern Indiana, Adam Petty Victory Junction Camp, Child Help Village, Newcomers High School, and Camp Ukandu.

He’s earned a myriad of titles for the work he’s done, including the JBPCO Chairman’s Award, Northwood University Leadership Award, LTAA Chairman’s Award, SBN Athena Award, PRO Jim Borré Lifetime Achievement Award, SEMA Hall of Fame induction, SEMA Person of the Year recognition, Heart Gallery Dedicated Service Award, and most recently has been inducted into the TORA Hall of Fame.

“I was honored to have been chosen as the first executive director of AACF. I was blessed with a fantastic Board of Trustees to work with these past nine-plus years,” said Ayres. “I am proud of the work we were able to accomplish, and I love the mission of the Foundation. Outside of the limelight, we help many individuals and families through kindness and support. I

will be forever grateful for the opportunity to serve and help my brothers and sisters in the Automotive Aftermarket.”

Repairify recently donated more than $180,000 in diagnostic repair tools to the Automotive Technology program at Collin College Technical Campus in Allen, Texas, according to a press release.

With the program providing students with training and certifications in automotive repair, receiving this donation will help the program expand to offering hands-on training with diagnostic equipment.

In addition, any tools left over from the donation will be distributed from Collin College to high school automotive programs throughout the state.

According to Repairify Vice President of Training and Organizational Development Chris Chesney, several of the company’s current employees are alumni of the school, having made it a good fit for the donation.

“I am a big believer in sharing the wealth, and with these donations, we’ll be able to make an impact not only on our students but also throughout the DFW metro area and beyond,” told Elias Alba, director of automotive and collision technology at Collin College. “We are thankful to Repairify for their support of our program and the automotive industry at large.”

This year’s report contains new segments on technician learning, service advisors’ impact on shops, and online scheduling data

BY CHRIS JONES

Featuring data collected from nearly 400 auto repair shops across the United States, the 2024 Ratchet+Wrench Industry Survey Report remains your trusted resource year after year for an at-a-glance look at the independent auto repair industry as reported by your peers.

Notable trends highlighted in this year’s report include labor rate by region, the impact of knowledge gaps and learn-

ing loss on technicians, the effect advisors have on shop revenue, and how online scheduling increases business.

In each of its four sections—Industry Overview, KPI, Leadership, and Tech+Tools—you’ll get comparative data segmented by category to give you benchmarks that help you visualize how your operations align with auto repair shops the same size and scope as yours.

For a second year, the Ratchet+Wrench Industry Survey Report examines the operational and leadership style of womanowned auto repair shops, plus you’ll get a closer look at the correlation between shops actively engaged in marketing and their customer acquisition.

All this and more comes packaged in this 33-page report available to you free at ratchetandwrench.com.

BY ANDY TIRADO & CHRIS JONES

You’re going through interviews and resumes trying to pick that needle in the haystack, the person who has the credentials to get the job done. As a shop owner, you’re also trying to be sure that person has the knowledge and character to be the right fit with the team to be a value-added hire to help shift your company and your team to the next level. But what happens when they don’t live up to the hype?

Andy Tirado, founder of Andy Tirado LLC, a leadership-driven consulting firm specializing in business and employee development, has worked with shop owners and collaborated with some of the industry’s top coaching and consulting companies. In this month’s edition of The SOP, Tirado talks about what happens when a shop owner needs to fire an employee who showed a lot of promise.

As told to Chris Jones

You see the signs, but there’s an absolute sense of denial where you don’t want to see them and you don’t want to accept them. At this point, you’re already in the deep end, and then that’s where you start getting this sour taste in your mouth and, as a responsible leader and responsible owner,

you start wondering, “Is it something that is happening internally? Is it something that can be controlled? Are we lacking the support for that particular person?” Those are your first evaluations. We don’t want to say, “Oh, this person just isn’t a fit” immediately. We go and analyze: “Did we

provide the person the correct amount of training or support? Or giving them the tools they need? What can we do to try to help this person stay with us because it’s a hard task to hire any person, let alone the right person?”

Good workers are hard to find, so there needs to be another strategy before terminating an employee. Is there anywhere else in the shop where the person might be a better fit? If you hired them as a technician, can they be a service advisor instead? Could they be a customer service liaison? Try them out elsewhere and once you’ve pulled every single card out of your deck and nothing seems to fit, then there is nothing more you can do than to start the

exit strategy. By this point, you’ve had the conversations, you’re provided the coaching, you’re documenting it, and the warnings are dated and timestamped. The next step is to make that call; you have to pull that trigger. Remember that even though you’re firing somebody and they may have not been a good fit for your shop, that doesn’t make them a bad person. That’s something to keep in mind. You never know if that person will come around later and if you have a different role, you may end up calling that person back. In this industry, I’ve seen that. It’s a common event. They end up either working back with you or working with another company you have a good relationship with. Now, if the person was an absolute disaster, did nothing for the shop, and only put more risk

into the company, that’s cut and dry—let go, eliminate all communication, and wish them the best of luck.

We always give the first 90 days, which is industry standard, but we have to talk beyond those. In the first 90 days, if you’re getting signs and feeling that denial, this means the person needs drastic and heavy help. From my experience, (performance) doesn’t tend to be as big of an issue in the first 90 days. It’s after those days where you have to pay attention. The new hire gets comfortable, so have a monthly engagement to see where they’re at, making sure that they’re hitting the numbers. See where the productivity is and use a CRM or shop management system to show you documented and quantifiable data. Now, from the time that you’ve identified the problem to where you want a resolution, I wouldn’t want to see more than 30 to 60 days tops, depending on the situation. It’s a two-way street. If you’re going to give them training, give them support, and give them the payroll, the exchange is their productivity. Termination-wise, if there is no change after that period, it’s time to accept the loss and start searching. Here, you want to be sure to not do what a lot of shops are doing, which is terminating that employee and then start looking (for their replacement). You want to start putting the probes out early on when you sense the problem may not be correctable. When I interview for a position, I always have three other candidates—my top three. So, I have my selected one and two other candidates. I keep those two close by so I can reach out in case it doesn’t work out with my new hire. Since I’ve already gone through the interviews with them, I have people ready instead of starting from scratch. The worst thing you can do as a shop owner is wait until termination to restart the whole process.

When it’s time to terminate, you want to make sure that you’re doing a faceto-face dismissal. It shouldn’t be in an email, it shouldn’t be in text. You should be scheduling a meeting. One thing to mention: if you’re providing this person uniforms or equipment that belong to the company, that needs to be returned and that needs to be written down.

Always have documentation during the termination process that is written and endorsed by that now former employee that any type of equipment or any uniform needs to be returned within 15 days. I know a lot of companies don’t request the uniform back. I always request the uniform back because the last thing I want is for that person to impersonate my company as a non-employee. They can create a negative image of your shop by continuing to have and wear your uniform. You also don’t want your uniform to end up on the Goodwill rack. You don’t want to have some random stranger wearing your uniform. The average consumer doesn’t understand that this is a random person wearing your uniform. And what if they don’t behave well while wearing it? Their consumer’s first thought is, “Well, that’s what this company supports. That’s the type of people they hire.” So, when it comes to uniforms, always ask for them back. Never reassign that uniform to a person, just destroy them; turn them rags. Just make sure that your uniform isn’t out there being misrepresented after you’ve let a person go.

Tirado is the owner and founder of Andy Tirado LLC, a leadership-driven consulting firm specializing in business and employee development. With extensive experience in education, training, and development, Andy is dedicated to helping organizations create a motivated, empowered, and forward-thinking workplace. andy.t@andytirado.com

“This

Don’t

Slow times happen and economic uncertainty is cyclical. Use this time to check your processes and prepare for growth

BY KATHLEEN CALLAHAN

I don’t know about you, but I have been hearing so many people talk from a place of fear lately. Big-picture fears include the uncertainty of political outcomes, the potential for war, and the ever-present looming recession. Closer to home (or shop) fears include car count being down, bays being open, and interest rates being high.

I have been a shop owner for over 20 years, and it seems we have this happen every four years. Many forget that the economy is cyclical, and “slower” times allow us to refine processes. You have all heard the saying, “If you have time to lean, you have time to clean!” Well, this may be that time for you! It’s time to examine your progress compared to your goals. A few KPIs (key performance indicators) you should calculate are:

• Shop/Technician Productivity

• Shop/Technician Efficiency

• Hours per Repair Order (HRO)

Shop/Technician Productivity can be easily calculated by taking the number of hours physically in the building and dividing it by the number of hours flagged. The goal for this number is 100% or greater.

Shop/Technician Efficiency is the number of hours flagged divided by the number of hours spent on the cars. This is challenging to measure without a time clock system where you track the technician’s time of singular focus on the vehicle, not setting a machine and walking away, actual hands-on time. I use labor profit management for this, and I know many SMSs also offer a way to track within their system. The goal for efficiency is 125% or more.

Finally, calculating Hours per Repair Order is simple. Take your total flagged hours and divide by the number of repair orders. The goal for this KPI varies by the shop. Anything under two hours per car creates a hectic pace in any shop and can leave your staff exhausted or lead to burnout.

If you are not able to meet the percentages above, here are some things to consider: Is your shop management system programmed with the proper hours for canned jobs like fluid changes, inspections, tire rotations, or alignments? No matter how you pay your staff, you will not see a clear picture if

you are not correctly flagging hours in your system. Additionally, how do you measure the performance of team members without keeping track of their productivity?

Is your car count too low?

Take a look at your marketing.

How are your phones being answered? Are you saying “yes” to business or scheduling too far out causing people to go elsewhere? What are your 911 services (bring in now!)?

Are your inspections thorough enough? Inspections are how we locate current and future repair and maintenance opportunities. Oil changes are opportunities, not burdens. It is crucial to create a thorough inspection process and ensure it is followed every time by every technician. Make every car count!

Estimate all findings. Clients look to us as their professional guide when caring for their vehicles. We do not need to sell everything today, but we do need to inform them of the current state of their cars. Putting declined work into future recommended services will allow your customer retention management system to remind them at a future date of the services they were not able to perform today and is a silent salesman for your shop.

Are you asking for the sale?

Service advisors estimate all the findings and don’t ask the client for the sale. Ensuring your staff isn’t judging with their wallet is critical. You never know what a vehicle owner will invest in their car, so don’t guess, ask!

The presentation is an excellent opportunity for the advisor to build value by creating a maintenance plan with your client that fits within their budget today and over the next year of service. Harvest, don’t hunt!

Is your staff adequately equipped?

Are all shop tools and equipment properly working, or do they need maintenance or repairs? Broken tools can’t make you money and can be a safety risk.

Are your shop tools located in a convenient and efficient place? Ask your technicians. If dragging a flush machine to their bay is too tricky, they are less likely to recommend that service. Like water, we mostly follow the path of least resistance.

Do you offer to send your technicians and advisors to training? Our industry is advancing at lightning speed! If you do not keep your staff trained on the new technology, it will leave you behind. Your advisors need training as well!

Have you reviewed your spending to see if you can renegotiate any of your bills? Many things we leave on autopilot can be looked at to save costs, like telephone, internet, uniforms, rags, and cleaning supplies, to name a few. Many owners begin with advertising or payroll to cut costs, but these are not the places to start. These are the two places that bring in cars and profit.

Once you have turned the scope inward and done this analysis, the next thing to look at is “time wasters” in your shop. Stay tuned for a future column on those, as those production and profit killers warrant a column all to themselves.

Kathleen Callahan has owned Florida’s Xpertech Auto Repair for 20 years. In 2020, she joined Repair Shop of Tomorrow as a coach to pursue her passion for developing people and creating thriving shop cultures. Callahan is the 2018 Women in Auto Care Shop Owner of the Year, nationally recognized by AAA for three consecutive years, testified for Right to Repair on Capitol Hill, and is vice chair of Women in Auto Care.

kathleencallahanfl@gmail.com

BY MICHAEL DORRINGTON, SVP SALES AND MARKETING, AMAROK

As the economic climate in the U.S. continues to struggle, vehicle theft is surging. Your automotive repair center is at greater risk of a break-in and vehicle theft than ever before. Will a traditional security system be enough to keep you safe? Before crime pulls up at your repair shop, you’ll want to read these six steps.

Cars left for repairs are prime targets for theft of valuable, easily removed parts like catalytic converters. In addition, an unsecured site puts your parts, inventory, tools, and machinery at risk. This loss can cripple your ability to make repairs, damage your reputation, and in turn, disrupt your income stream — one bad review can cost you dozens of new customers. Plus, most insurance providers do not cover theft or vandalism and if they do, your premium will be affected.

COULD YOUR AUTO REPAIR BUSINESS BE A TARGET FOR THEFT?

Yes! Depending on the location and the types of vehicles you are repairing, servicing or storing, the greater your risk for theft or vandalism.

Vehicle theft isn’t the only threat. Other forms of theft can also impact your business, operations and reputation, such as:

• Tool and Equipment Theft : Thieves target valuable tools in mechanic and auto body shops.

• Vehicle Parts Theft: The high demand for auto parts makes them lucrative for thieves.

• Catalytic Converter Theft: These are easily stolen and the cost to replace one catalytic converter can cost you up to $1500 each.

• Personal Belongings Theft : Theft of customer belongings such as license plates, registrations, personal information, etc., can damage your reputation resulting in lost revenue.

• Fuel Theft: Rising gas prices make fuel storage tanks attractive targets.

• Vandalism : This can include actions such as keying the paint, breaking windows, slashing tires, graffiti, smashing headlights or taillights, and damaging mirrors.

Don’t wait for thieves to target your auto services shop. Implement these security measures to protect your vehicles, employees, profits and reputation.

1 Install Security Cameras

Act as a deterrent and provide critical evidence. Ensure coverage of key areas such as doors, windows and gates.

2 Enhance Lighting

Proper lighting deters theft and makes it easier to spot suspicious activity.

3 Arm Your Alarm

Essential for immediate alerts to law enforcement and security personnel.

4 Lock Up Your Keys Prevent opportunistic thefts by keeping keys secure and implementing a sign-in / sign-out system.

5

Conduct Regular Security Audits Regular checks and upgrades ensure your security systems are always effective. AMAROK can help assess your center to determine where weaknesses may be in your current security solution.

6 Take a Layered Approach

A multi-layered approach is the only solution effective at deterring criminals. This can include measures such as high fences, wires, steel poles, cameras, lights, alarms, electric fences, and physical shock deterrents. While one layer may be defeated, the remaining layers continue to offer protection.

AMAROK RECOMMENDS TAKING A MULTI-LAYERED APPROACH

Protect your property with multiple forms of defense on your side, starting with our full-perimeter, solar-powered Electric Guard Dog ™ Fence. This powerful and intimidating barrier delivers peace of mind with three powerful layers of defense:

PHYSICAL DETERRENT

Fenced barrier with multilingual warning signs

SHOCK DETERRENT

Pulsed electricity delivers a safe but memorable shock

ALARM DETERRENT

Silent or audible, with 24-hr monitoring

ONE BAD CUSTOMER REVIEW CAN COST YOUR AUTO REPAIR SHOP AN ANNUAL AVERAGE OF $40K IN LOST REVENUE IS YOUR AUTO CENTER PROPERLY PROTECTED?

Contact AMAROK to request a site visit. SCAN

HOW

BY NOAH BROWN | PHOTOS BY GRACE HUDSON PHOTOGRAPHY

In photography, there are two basic categories of camera lenses: prime and zoom.

Zoom lenses do exactly what it sounds like they do—they can change focal length to capture a wide range of images. For example, an 18-200mm lens can capture everything from a super-wide angle landscape shot to a close-up of a football player running down the sideline while the photographer is standing 20 yards away.

Prime lenses, however, are a fixed focal length. A 20mm lens will only be good for capturing wide shots, a 50mm for medium portrait-style shots, a 400mm for closeups of nature or action in sports, and so on.

On the surface, it may seem like going with a zoom lens is a no-brainer because it can cover all your bases decently well. Why, then, do most professional photographers tend to have a collection of several prime lenses instead of one wide-ranging zoom lens that covers all the focal lengths? It’s because those prime lenses, though slightly less flexible, can be specialized for specific functions and genres of photography. Prime lenses tend to have sharper image quality and other characteristics that lead to higher-quality photos.

Knowing what you’re best at and figuring out ways to harness and focus can be a powerful tool. Whether you’re a pho-

tographer figuring out what lens will best fit your subject or an auto repair shop deciding what kinds of vehicles to work on, knowing what you do best and specializing in that niche can be key in helping you stand out from the rest and raise the overall quality of work.

A photographer should choose a lens that best fits the kind of genres and subjects they want to capture. So, naturally, the first step for anyone getting into photography is to decide what genre and subjects they want to take photos of.

It’s the same for auto repair shops looking to specialize in a certain make or type of vehicle. Nichole Bennecoff, owner of Empower Automotive in Traverse City, Michigan, says specialization for her shop has come in the form of focusing primarily on Subarus. Her dad started the shop around 25 years ago and was an avid Subaru driver. His love of those vehicles, plus a large emphasis on outdoor culture in their community, made the decision to specialize easy.

“My dad noticed there was a wide need for Subaru repair, so he decided to specialize,” Bennecoff says, “and he’s the type that once he makes a decision, that’s it and he dives in.”

Over on the West Coast, Rocha’s Auto Service in California has specialized in repairing hybrid vehicles for almost 15 years. Ronnie Rocha, along with siblings Yamil and Andrea, took over the business from their dad about five years ago.

“Our dad was non-stop, and he was always looking for something new to learn,” says Yamil, who heads up the repair team at Rocha’s. “He saw hybrids as an opportunity, and we thought it was a great idea. It’s worked out really well for us.”

For both shops, finding their niche was a combination of proactive planning and reactive observation. At Rocha’s, there were already hybrids coming into the shop, which means there was already a sizeable customer pool. They saw hybrids not only as a future customer base to prepare for, but also one that already in need of service and that could sustain an operation.

“Most people can work on hybrids now, but we were one of the first ones to jump on them as soon as we saw them coming down the pipeline,” Yamil says. “When you’re the first, you have time to train and learn. That can set you apart.”

In Bennecoff’s case, being in a rural area with a strong nature-focused culture meant that her shop’s customer base was naturally going to be drawn to vehicles that could handle outdoor adventures.

“Our area lends itself to those kinds of vehicles,” she says. “Subaru culture permeates throughout our shop.”

It doesn’t matter how good a lens is, if the photographer has no idea how to use it and maximize its strengths, the final photos aren’t going to look that good.

Once your shop decides to specialize, it’s time to invest in training to make sure that not only can you do the work, but to ensure that you can be the best at it in your area. Following their decision to focus on hybrids, Ronnie says his brother immediately got to work researching and learning as much as he could.

“Training was a big part. If you wait until you’re totally ready for it, you’re never going to do it,” Ronnie says. “You

just have to do it and do it all the way. Commit. That’s something our dad always taught us.”

Yamil says he is constantly training to stay on top of new hybrid technology, participating in classes, conferences, and anything else he can find to keep learning. Whatever he learns he takes back to his team and those who want to are given the opportunity to go to training.

Getting their team involved early and allowing them to play a role helped in the transition to specializing in hybrids. Andrea, who oversees Rocha’s finances, says emphasizing on hybrid repair has given the shop’s techs an opportunity to learn and become experts in their field, which gives them a leg up over other shops in terms of hiring and retention.

“When we started hybrids, there

weren’t any shops near us that were even touching hybrids, and that was something exciting for employees to be a part of,” Andrea says.

Andrea says they also reached out to shops that were repairing hybrids and asked about what they should be doing, which proved to big help as they navigated the switch.

“That’s what dad does with any new venture,” she says. “He finds the top shop doing something and reaches out to them.”

Throughout the whole process, Ronnie says that dedication to innovating and providing a service that was completely untouched in their area helped them become the leaders they are today.

“We’ve never been scared to work on hybrids,” Ronnie says. “When we started, we were another option to the dealer. As

we learned and progressed, we became the option.”

Even though a photographer may have one strength they rely on for a majority of their work, very rarely will they only ever need just one lens. Someone who captures primarily sports photos might also freelance as a wedding photographer, and the lens they use for football games won’t work for close-ups of the bride and groom.

Very rarely is total specialization a viable option. Keeping other lenses in your toolkit and being able to repair other types of vehicles is essential to staying relevant. Recently, Bennecoff says that her shop had almost reached the point of total market saturation with Subarus.

“We’re trying to grow and expand our business,” she says, “and we expanded our mailing radius, but there aren’t that many more Subarus in our area. If want to grow more, there’s not that available pool to draw from.”

Because of that, her shop has recently undergone a branding and philosophy change. Though they still get around 92% of their total business from Subaru repairs, Empower now also works on other Asian makes, such as Honda and Toyota. Bennecoff says the expansion of service is striking a balance between staying loyal to the shop’s current customers while also meeting new needs.

“We wanted to keep similar clientele,” she says, “but we also wanted to be able to service our clients’ other vehicles.”

For the Rochas, hybrids only make up around 25% of their total workload. Andrea says their expertise in hybrid repair makes them a destination for hybrid drivers, but the shop is always trying to innovate and provide new services for their community to keep people coming back.

“In our small town, we tried to bring a lot of things that already existed but weren’t available here,” she says. “Whether that’s working on hybrids or doing digital multi-point inspections, we’re not just providing our customers extra value but also for our employees, too.”

Having a specialty can help set your shop apart and become known as the prime provider for that niche, but your shop must always be constantly evolving to stay relevant and complete picture-perfect repairs for your customers.

Jason LaBonte learned how to use the resources he had to offer free training to every auto tech in his community. Now, he works with other shop owners so they can do the same

BY KACEY FREDERICK | PHOTOS CONTRIBUTED

It’s one thing to enter an industry, but what impact will you leave behind for those who come after you? It’s a question that’s driven many to innovate groundbreaking concepts, and it was no different for Jason LaBonte: a lifetime enthusiast of auto repair who has only continued to let his passion for the industry inspire ways he can improve it.

The journey toward mastering your craft is an eternal one, and what you invest into it, you’ll see return tenfold. Early in his automotive career, LaBonte was guided by mentors who underscored the value of honing your skills, namely, gaining certifications that prove you’ve trained for and understand the work you’re doing.

LaBonte discusses with Ratchet+ Wrench how this philosophy led him to establish the Free Automotive Service and Technician Training (FASTT) group, which brings high-quality, advanced training from around the country straight to shops for local techs to learn from at no cost to them.

For LaBonte, working on cars is all he’s ever known. He grew up in Massachusetts, surrounded by a family of gearheads with an affinity for motorcycles and hot rods. By the time he was in high school, he gained his first job at a local independent repair shop, where fuel was only added to his passion.

At the age when many kids were beginning to decide what careers they wanted, LaBonte wasn’t as sure of his path until he started working at the shop. He took pride in his identity as a repair technician and decided to embrace it.

“The only thing I’ve ever done for a living my entire life was work on automotive: automobiles, trucks, motorcycles, things like that. It’s all I’ve ever done, it’s all I’ve ever known, it’s all I’ve ever trained for,” tells LaBonte. “I’m not even into sports and things like that. I’m a pretty simple guy.”

After high school, LaBonte worked at a shop in New Hampshire called Importech, where he and owner Jason Stretch would create a bond—particularly over their dislike of the region’s climate.

“It was kind of a dream to get away

from the inclement weather,” LaBonte explains. “So we thought, ‘Why can’t we just take the processes, procedures, and customer satisfaction rate that we have, and move to Southwest Florida and just kind of flourish in a different state, with beautiful weather?’”

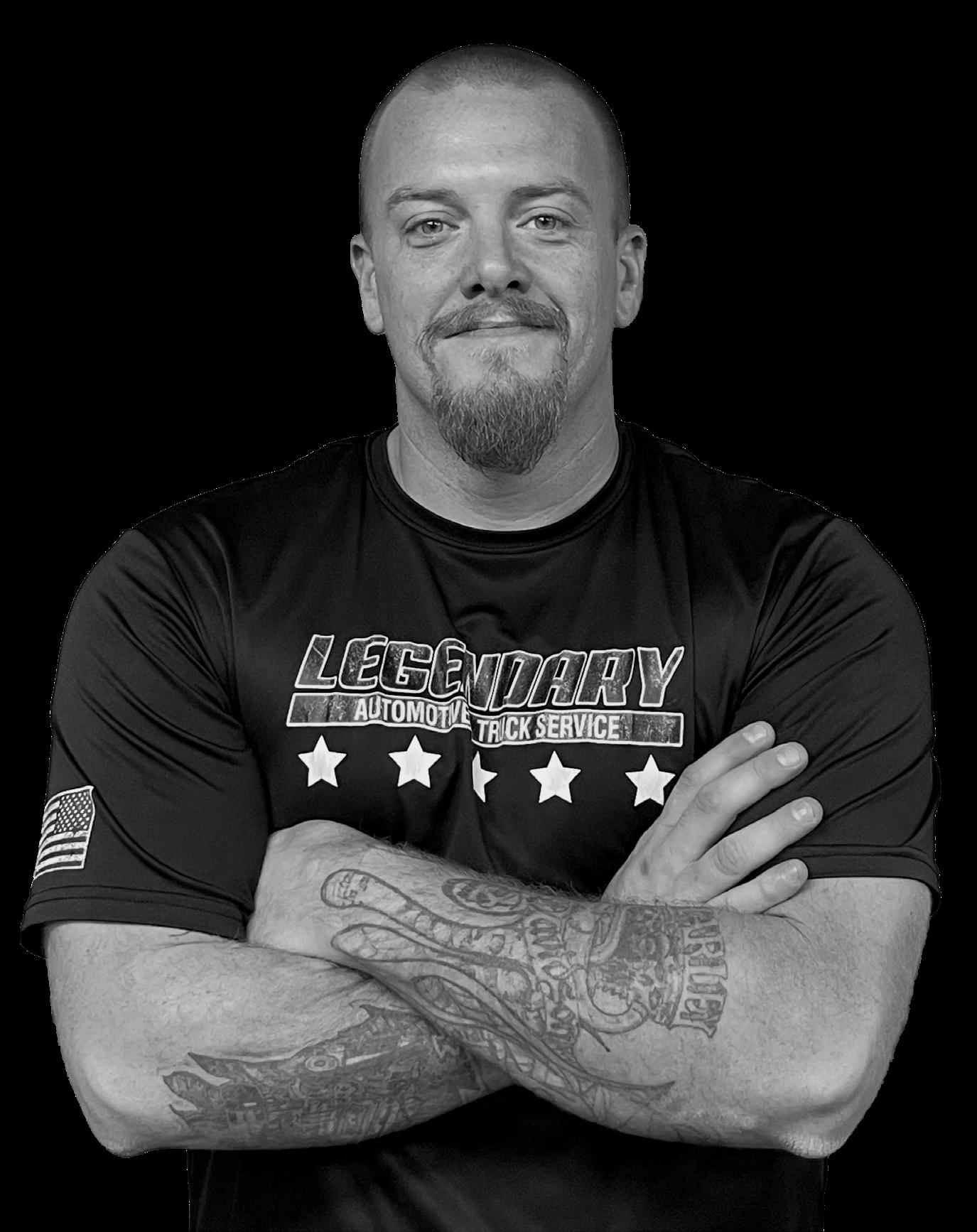

The two made it a reality, with Stretch purchasing an existing repair shop in Fort Myers, Florida, and establishing Legendary Automotive, with LaBonte as a part owner of the business.

Being an ASE Master Technician, LaBonte places a lot of value in training. Though he wanted to send his staff to attend informative events like VISION, it would have required the entire shop to shut down for a week and wasn’t feasible. He wondered what it would look like to bring that high-quality training to them, rather than them going to it.

Using his industry connections, LaBonte reached out to trainers he thought may be interested in traveling to Florida and holding a training session in his shop—open to not only Legendary Automotive but any technicians in the area— leading to the formation of FASTT.

The group provides shop owners with a formula for organizing training events at their own facilities and to be part of a network of other local shops that will offer similar events too. Though it does cost the shop, FASTT helps them figure out ways to alleviate the cost, such as having parts vendors pitch in to cover lunch for attendees and even travel expenses for trainers.

“Now, is it going to be 100% free for the shop owner? Probably not. But training doesn’t cost, it pays. I believe Jim Morton said that and it really stuck with me,” says LaBonte. “So if you can get the shop owner to pay the trainer, and then show him the formula of using his resources locally—like his local parts vendors and things like that to supply breakfast and lunch—it really takes the edge off, and it really takes a lot of the cost out of putting on these events.”

Besides the opportunity to involve an entire team of techs without the need for travel, one of the biggest benefits

of the training events is the hands-on experience they can have in an actual shop, as opposed to sitting through a seminar. The environment also allows shops in the community to share problems they’re having with one another and develop solutions.

LaBonte has always maintained a close relationship with other auto shops in the area, viewing connections with them as a chance for collaboration rather than competition. Being in Southwest Florida, there’s plenty of business to go around, and he’s much more interested in helping the repair industry as a whole.

A shop’s techs will already likely feel obligated to attend training events funded in part by their boss, but FASTT does all it can to make the experience enjoyable for them. Rather than having them stay late after a workday, the training events are typically done on Saturdays, with breakfast and lunch offered to the techs. Not all who are invited show up, but those who do reveal to a business owner who is committed to their career.

Throughout his career, the value of training is something LaBonte has regarded highly. He doesn’t believe in

doing anything halfway and views the time put into training as a commitment and investment in something you care about. With FASTT now having expanded to both the states of Utah and Washington, the only satisfaction he gains from his work is the impact he’ll be leaving behind on the industry.

Being a father, part of LaBonte’s motivation lies in setting an admirable example for his kids. Alongside enforcing industry standards, the community outreach LaBonte has done—such as veteran fundraisers and car care clinics for women—is all part of a motivation to show the world that the auto industry is a place for innovation and help.

“When my kids get older, I want them to be proud to see their father doing so much for their community, when 35 or 40 years ago, what did everybody think about the mechanics, right?—the grease monkey, the guy that was trying to rip you off. Women didn’t feel comfortable going to their facilities,” says LaBonte. “I’m just really trying to get rid of that old-fashioned stigma that has followed mechanics around for so many years.”

When a customer feels they’ve been singled out or mistreated, follow these steps

BY NOLAN O’HARA

As a shop owner, you might have a range of emotions if a customer complains of discrimination at your business. Obviously, you don’t want your customers to feel mistreated. You might get defensive about the situation. And the prospect of potentially dealing with

a discrimination lawsuit down the road can be pretty intimidating.

But if you find yourself in this unfortunate predicament, take a breath, stay level-headed, and be sure to take the complaint seriously. It’s not ideal, and it’s a difficult situation to deal with, no

doubt, but there are plenty of steps you can take to address the situation and limit any potential damage.

“Remain calm. I know a lot of people, their first reaction to something like this is to get very defensive; avoid your instincts to do that,” says Ryan Byers, an

attorney at Rammelkamp Bradney in Jacksonville, Illinois.

Instead, take the complaint seriously, talk with the customer, figure out what happened, be clear and direct with communication and determine a course of action. Should you find yourself dealing with a discrimination complaint at your shop, here are some steps you can take to properly address the situation.

The first step in the process is simply finding out what occurred. Not every discrimination complaint is created equal, so much of the process is dictated by the situation. But in all cases, talk to the customer and take their complaint seriously. Tell them you’ll look into the situation and follow up with them. Be sure you’re true to your word.

If anyone else witnessed the event, talk to them as well. If a specific employee or employees were the focus of the complaint, talk with them to understand their view of what happened. You can’t begin to address the complaint until you have a firm grasp of what occurred.

“You just need more information to be able to get to the bottom of it,” says Allison Harrison, the founder of AHL Law Group in Columbus, Ohio. “And maybe you can do something about it, maybe you can’t. But at least if you’re listening and trying to really dial in on it, it shows that you care.”

The end goal of the investigation should be to determine exactly what happened, whether you feel the complaint was founded or unfounded, and you should understand the severity of the complaint being leveled—you need to understand if you’re dealing with illegal discrimination, such as discrimination based on race, gender or sexual orientation.

Once you know what happened, whether the complaint was founded or not, and understand the severity of said complaint, then you can determine a course of action.

There’s no one-size-fits-all approach you can take to determine a course of action. What you do will depend on what the complaint entails and whether you’ve determined something improper

has occurred. But if it’s at all reassuring, most complaints will be dealt with directly from person to person and without litigation.

“I think the odds are in favor of it being resolved before there’s formal legal action, and even if there’s a suit filed, the odds are very high it will get settled short of trial,” Byers says.

So let’s say you found the customer’s complaint to be unfounded. In that case, you should still be respectful but communicate to the customer that you’ve investigated, you haven’t found improper conduct, and you don’t intend to take further action.

But if you believe the case to be founded and want to make things right with that particular customer, you can choose a course of action you deem best. Maybe it’s giving them a discount or covering their repairs entirely. Maybe it’s an apology. Whatever you determine is the best way to make things right with that customer.

“Some people who are upset by a situation will give you a lot more grace, and maybe the situation will fully resolve if they just feel like they’ve been heard, so hear them out in a non-defensive manner,” Byers says.

If you do go this route, it could open you up to legal action. Apologies or anything of the sort are information that could be uncovered if the complaint resulted in mediation or a lawsuit. But that isn’t a reason to avoid making things right if you do feel the customer was mistreated, Byers says.

“If you’re really concerned about that coming back and biting you later, the thing to do is get in touch with your attorney and possibly get them to draw up an agreement that would indicate that, ‘Hey, we’re going to do this for you, whatever the accommodation is, but when we do that, it’s going to be in satisfaction of whatever claims that you think you have,’” Byers says.

At that point, you’re already in unlikely territory. Most complaints won’t result in any sort of legal action. But that does remain a possibility. So when is it time to talk to lawyers?

Well, that’s also going to depend on the circumstances. If the complaint is alleging illegal discrimination, for example, you should talk to lawyers immediately. But if you’re dealing with a smaller complaint, say a customer felt they were

overcharged $20 for repairs, you may not need to get attorneys involved.

However, if you are worried about the complaint, it never hurts to play it safe and reach out to your lawyer early and often. It’s always better to be safe than sorry.

“I don’t think it’s ever too soon. It’s often too late. Just because it gets more expensive, not because they can’t help you,” Harrison says.

All in all, how you approach a complaint will entirely depend on the situation and what’s being alleged. But as you attempt to deal with the situation, just be clear and direct in your communication with the customer, follow your best judgment to approach the situation, and don’t hesitate to reach out to your attorney.

For those who have the means, Byers recommends putting your employees through some sort of discrimination or implicit bias training. That not only helps with prevention of these types of discrimination complaints, but it also can be something you could point to should the complaint advance to some form of litigation.

“In a lot of situations where we’re talking about lawsuits, be it a claim for discrimination or really any other type of claim, is a situation where an ounce of prevention is worth a pound of cure,” Byers says.

That doesn’t mean discrimination or bias training will be 100% effective in preventing discrimination. It doesn’t mean you won’t be liable if discrimination does occur. But it can be something that helps you when it comes to punitive damages, which are the damages awarded in civil cases if the defendant shows a disregard for the rights or safety of others.

“If you’ve taken all the right steps and you’ve tried your best, you did training once a month and every time there was a complaint, you have this rigorous investigation period, they’re not going to have as much of a deterrent penalty,” Harrison says.

But again, that’s getting to the worstcase scenario. In most cases, you won’t even get to litigation. Just be clear and direct, take the customer’s complaint seriously, and take the necessary steps to address it. The end results should be just fine.

When it comes to deferred work, getting to ‘Yes’ may be easier than you think

BY TESS OWINGS

Stop thinking of deferred work as failing. It’s an opportunity.

That’s the way Frank Leutz sees it. The owner of Desert Car Care of Cave Creek in Arizona knows that deferred work is inevitable. Not every person who comes through your shop doors will get all of the recommended work done on their vehicle. That’s unrealistic. Leutz estimates that the average amount of work that was declined throughout his career was roughly 30%. That may not be the same for your shop, depending largely on your customer base, but your number definitely isn’t zero.

So, how do you handle this? Accept it and move on? Nope. Do what Leutz

does—face the challenge head-on and figure out how to get that customer back into your shop.

BACKSTORY:

Leutz has over three decades of experience operating repair shops and is no stranger to the problems plaguing the industry, including deferred work. His experience has taught him a thing or two, one being that when it comes to a “no” from a customer, it’s not always black and white.

PROBLEM:

Around 2003, Leutz realized that his

team’s approach to presenting work to be done on a vehicle was too cut and dry.

“We didn’t have bedside manner,” Leutz says. “It was, ‘Hey, this is the work on your car.’ The intent was there, but the delivery and identifying how to partner up wasn’t there.”

Leutz examined how his team was approaching work that was being declined and he decided to pivot.

SOLUTION:

Figure out how to connect with the customer and then get them back in the door.

“It’s deeper than telling them that they

need A,B,C,D done. You need to connect with your audience,” Leutz says.

When the work is being presented, there are levels. First, there are safety issues, which are at a different level and the easiest work to convey. Then, it’s addressing some issues today that can cause bigger problems and more money down the road; and there’s maintenance—this is where a lot of deferred work comes in.

For any work that is deferred, Leutz’s team is trained to say something along the lines of:

“We realize today is not going to work. We’ll document it and let’s schedule a courtesy follow-up visit while you wait to reexamine to see how it’s going.”

It’s a low-pressure approach that allows the customer time to digest and also know that the team is there for them and not out to get their money. Making it a courtesy check makes a huge difference.

“It gets folks back into the garage,” Leutz says of his revamped approach. “They know that it needs money to be done but we guide them and hold their hand.”

Getting them to come back is just one step. The other step is figuring out who the customer is and what they use their vehicle for.

AFTERMATH:

Leutz says offering courtesy followups has given him a much better rate of return and that out of his estimated 30% of deferred work, he can get 75% of those customers back within three to nine months.

TAKEAWAY:

Find a way to get your customer back into the shop, even if it’s for a courtesy check. For those who think he’s throwing time and money out the door by doing this, Leutz says it’s definitely not the case. Everyone is nervous about taking their vehicles in and nobody is looking forward to spending money, so be prepared for “no.” You may get a lot of initial pushback on recommended work, but Leutz says if you make an effort to understand where they are in their life and the way they use their vehicle, you may have a better chance to earn their business again somewhere down the line.

The most important step to handling deferred work is to know your customer. Leutz says the best way to get his customers is to understand where they’re in life and what they use their vehicles for.

“Get down to what their goals are with the vehicle,” Leutz says. When customers come into Leutz’s shop, he says his team will say, “You’re new to us and we don’t have a history. What are the goals of your vehicle today? How are you driving the vehicle?” Some questions he says your team can ask to get to know the answers to this are:

1. How are you driving your vehicle?

2. How long do you plan on keeping it?

3. What are your short- and long-term goals for the vehicle?

The answers to these questions can help you and your team understand how to approach recommended work. A customer who is planning on selling the vehicle in the next few months will be a much tougher close than a customer who is planning on keeping their vehicle long-term.

35,000-FOOT

Is your business motivated by an internal desire to succeed, or a fear of failure and falling behind?

BY R. “DUTCH” SILVERSTEIN

There are many opinions about the types of motivation that people experience. At its most basic level, motivational influence can be reduced to simple forms: External (known as extrinsic) and internal (known as intrinsic). External motivation can be awards, bonuses, gifts, promotions, and prizes. It’s something outside of a person that is usually, but not always, accompanied by some action. An external influence that seeks to get people to behave in a certain way. Examples include a coach, mentor, or at an extreme, a drill sergeant. Intrinsic motivation is personal and comes from an internal desire. Studies show it’s usually more successful. It’s that inner voice you hear that drives you. It can be manifested in personal satisfaction resulting from growth, achievement, and connecting with coworkers. So, why bring this up now?

I’m seeing a resurgence of fear-based motivation in online discussions (not uncommon for an election year). People are worried about the economy and its effects on business. According to a new Guardian/ Harris poll, 56% of respondents believe our country is in a recession. In a previous column, I posed some questions shop owners should ask themselves about whether they were truly transparent in their business. This time, I’m going to ask you to consider if you run a fear-based business and to evaluate what that means and what can be done to change. Are you afraid your business will suffer and may ultimately fail if:

1. you charge more than your competitors?

2. you don’t install customer-supplied parts?

3. you charge more than dealer list price for parts?

4. you perform a multi-point inspection of a car because you may be accused by its owner of “fishing for business” or worse, up-selling.

5. a customer threatens to leave a bad online review.

6. you don’t offer discounts (e.g., fleet,

teacher, police, firefighter, military).

7. you tell a customer, “No, I won’t do that.”

8. you don’t provide estimates via email or telephone without first evaluating the car at your shop.

9. you don’t adopt the ‘Just say, yes’ strategy of always taking more work in, irrespective of your commitments to your customers and the work already in the shop.

10. you don’t open early and stay late (extended hours) because your competitors have extended hours.

11. you are not open on Saturdays because your competitors are open.

12. you don’t give your customers your cell phone number or forward the shop phone to your cell to be answered whenever they call.

13. you discipline an employee because he or she will likely quit and leave you short-staffed.

14. you fire a technician that you will not be able to hire another because of the tech shortage.

I respectfully submit that if you answered many of these questions with a “yes,” you may be running a fear-based business where fear of failure may compromise your ability to make the best decisions for your business. Fear of failure can be a doubleedged sword. On one hand, fear of failure and its consequences can drive us to work hard and push ourselves to go above and beyond our competition. It can cause us to increase concentration and our focus on attention to detail. This is the beneficial side of fear as a motivational tool. On the flip side, fear can lead to analysis paralysis where nothing is accomplished for fear of making a mistake. It can cause anxiety, selfdoubt, stress, and health issues. It can lead to creative tunnel vision preventing us from seeing new ideas and techniques. So, what can be done? First, recognize that you are not alone. Others have been in your shoes. Find a mentor with the same business

model as you and ask for their help. Check your area for a chapter or S.C.O.R.E (the Service Corps of Retired Executives) at score.org. It’s a free resource. Recognize, too, that most of your fears aren’t grounded in reality but in your imagination. While it’s important to acknowledge our fear of failure we should always remember that it’s a tool in our ‘toolbox, one of many to be used in a secondary role. We must first remember to focus on the positive things we can control and always remember to set our course on growth and an affirmation of success.

R. “Dutch” Silverstein, who earned his Accredited Automotive Manager Certificate from AMI, owns and operates A&M Auto Service, a seven bay, eight lift shop in Pineville, North Carolina. Dutch was a captain for a major airline earning type ratings in a variety of aircraft including the Boeing 767/757, 737, 200, 300 and 400 series, Airbus 319/320/321, McDonnell Douglas MD80/DC9 and Fokker FK-28 mk 4000 and 1000. After medically retiring, he transitioned his parttime auto repair business into a full-time occupation.

dutch@dutchsgarage.com

A top-shelf solution that fuels your bottom line

Serve up more sales and higher customer satisfaction add BG Platinum® 44K® Fuel System Cleaner to every oil service. This convenient, high-quality pour-in efficiently cleans the entire fuel system, including fuel injectors, fuel filters, and combustion chambers.

Find a BG Distributor to get 44K® in your shop. bgfor.me/distributor

Evolve your technical skills for the future with training from Worldpac Training Institute® .